PennEngineering has enjoyed a sustained history as a global leader in the fastening industry since our founding in 1942. PEM®, the company’s leading brand has been recognized as the premier product in the thin sheet fastening industry for over 75 years. Today, our expanding portfolio of fastener designs and technologies continues to keep pace with the challenges presented by an ever-evolving marketplace.

PEM® Self-clinching fasteners

Concealed-head self-clinching studs and standoffs

Fasteners for use with pc boards

Penn Engineering Self-clinching fastener handbook

penneginering self clinching nuts

penneginering short-form catalog

Self-clinching standoffs bulletin

Penn Engineering

PEM® Fasteners

PennEngineering is a prominent brand known for its engineering-focused approach. The company prioritizes direct interaction between its engineers and customers. While the concept of how products are held together might not be at the forefront of your mind, it is the sole focus of PennEngineering. They firmly believe that small components can have a significant impact, and their dedication lies in creating enduring connections.

PennEngineering is a prominent brand known for its engineering-focused approach. The company prioritizes direct interaction between its engineers and customers. While the concept of how products are held together might not be at the forefront of your mind, it is the sole focus of PennEngineering. They firmly believe that small components can have a significant impact, and their dedication lies in creating enduring connections.

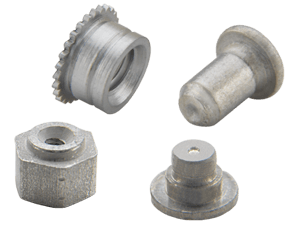

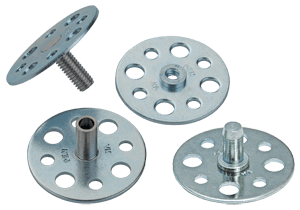

What is a PEM Fastener? PEM fasteners, designed and manufactured by PennEngineering, utilize self-clinching technology for attaching to thin sheet metal. A self-clinching fastener is any device, usually threaded, that when pressed into ductile metal, displaces the host material around the mounting hole, causing it to cold flow into a specially designed annular recess in the shank or pilot of the fastener.

PEM® brand fasteners utilize self clinching, broaching, flaring, surface mount, or weld technology to provide strong, reusable, and permanent threads and mounting points in thin sheet metal, P.C. board materials, and other ductile or non-ductile thin material. ![]()

PEM® brand fasteners, offered by PennEngineering, employ various technologies such as self-clinching, broaching, flaring, surface mount, or weld methods. These fasteners are designed to establish robust, reusable, and permanent threads and mounting points in thin sheet metal or P.C. board materials. For compact electronics, microPEM fasteners are particularly suitable, catering to applications such as smartwatches, laptops, notebooks, tablets, smartphones, and handheld devices.

Nuts For Sheet Metal

- Floating – A4, AS, AC, LA4, LAC, LAS

- Blind – B, BS

- Standard – CLA, CLS, CLSS, H, HN, S, SS, SMPP, SMPS, SP

- Flush – F, F4

- Miniature – FE, FEO, FEOX, FEX, U, UL

- All Metal, Locking Thread – FE, FEO, HNL, LA4, LK, LKA, LKS, SL, UL

- Nylon Insert, Locking Thread- CFN, PL, PLC

- Right Angle, R’ANGLE® – RAA, RAS

- Installing Into Stainless – A4, LA4, SP

- Spinning Flare Nut – SFN™

- Hard Panel Nut – SH™

Studs and Pins For Sheet Metal

- Concealed Head – CFHA, CFHC, CHA, CHC

- Flush-Head – FH, FH4, FHA, FHP, FHS

- Flush-Head Stud with X-Press™ Threads- FHX

- Flush-Head, Low Displacement – FHL, FHLS

- Heavy Duty, Non Flush – HFH, HFHB, HFE, HFHS, THFE

- Hard Panel Stud – HFLH™

- High Tensile Strength, Non Flush – HF109, HFG8

- Thin Sheet, Non Flush – TFH, TFHS

- Unthreaded Pins, Flush – TP4, TPS, TPXS

- Installing Into Stainless – FH4, FHP, TP4

- microPEM®, Self-Clinching- MPP

- Swaging Collar Studs, Non Flush – SGPC

- microPEM® TackSert® Pins – TKA, TK4

Standoffs For Sheet Metal

- Concealed-Head – CSOS, CSS

- Keyhole® – SKC

- Blind, Threaded – BSO, BSO4, BSOA, BSOS

- Thru-hole, Threaded and Unthreaded – SO, SO4, SOA, SOS

- For Installing Into Stainless – BSO4, SO4, TSO4

- Thin Sheet, Thru-hole Standoffs – TSO, TSOA, TSOS

- Snap-Top® – SSA, SSC, SSS

- Grounding – SOAG, SOSG

- Close-To-Edge – DSO, DSOS

- microPEM®, Self-Clinching – MSO4

- Thin Sheet, Thru-hole Standoffs for Installation into Stainless Steel- TSO4

Captive Panel Screws And Hardware

- Large Knob, Spring-Loaded – PF11, PF11M, PF11MF, PF11MW, PF12, PF12M, PF12MF, PEM C.A.P.S®, PF12MW

- Low Profile Knob, Spring-Loaded – PF30, PF31, PF32, PF50, PF60,

- Screw Head, Spring-Loaded – PFC2, PFS2, PF7M, PF7MF

- Screw Head, No Spring – PFHV

- Tool Only, Non Flush, Spring-Loaded – PFC2P, PFC4

- Tool Only, Flush Mounted, No Spring – N10, PR10, PS10

- Tool Only, Spinning Clinch Bolt, No Spring – SCB, SCBJ

- Tool Only, Spinning Clinch Bolt, With Spring – SCBR

- For Installing Into Stainless – PFC4, PF11MF, PF12MF, PF11MW, PF12MW, PF7MF

- Locating Pin, Spring-Loaded – PSL2, PTL2

- Heat Sink Mounting Fastener System – HSCB, HSR, HSL

Sheet-To-Sheet Attachment

- Metal To Metal, SpotFast® – SF, SFP

- Metal To Metal Hinging With Washer, SpotFast® – SFW

- Metal To Plastic, SpotFast® – SFK

- Panel To Panel, KEYHOLE® Style – SKC-F

- Metal To Metal, For Installing Into Stainless, SpotFast® – SFP

- microPEM®, Self-Clinching TackPin® – Type T

- microPEM® TackScrew™ Fasteners – TS4

Cable Tie-Mounts And Hooks For Sheet Metal

- Standard Tie-Mount, TY-D® – TD

- Hook Style Tie-Mount, TY-D® – TDO

For Mounting Into Printed Circuit Boards

- Captive Screws, Broaching – PFK

- Captive Screws, Surface Mount – SMTPR, PSHP

- Captive Screws, Other – PF11MF, PF11MW, PF12MF, PF12MW

- Nuts, Broaching – KF2, KFS2

- Nuts And Spacers/Standoffs, Surface Mount – SMTSO

- Tin Plated Brass Nuts And Spacers/Standoffs, Surface Mount – SMTSOB

- microPEM® Nuts/Standoffs, Surface Mount – SMTSO

- Standoffs, Broaching – KFE, KFSE

- Standoffs, SNAPTOP® – KSSB

- Standoffs, Flare Mount – KFB3

- Studs, Broaching – KFH

- Nuts, R’ANGLE® – SMTRA

- Heat Sink Mounting Fastener System – HSCB, HSR, HSL

microPEM® Fasteners

- microPEM®, Self-Clinching Pins – MPP

- microPEM®, Self-Clinching Standoffs – MSO4

- microPEM®, Self-Clinching TackPin® – TA, T4

- microPEM®, Surface Mount Nuts/Standoffs – SMTSO

- microPEM®, Thru-Threaded Inserts For Plastic- MSI

- microPEM® TackSert® Pins – TKA, TK4

- microPEM® TackScrew™ Fasteners – TS4

Weld Nuts

- Weld Nuts – WN, WNS

VariMount® Bonding Fasteners

- Base plate provides generous footprint for surface bonding or mold-in mounting.

- Multiple radial holes in base plates encapsulate adhesives or molded plastics.

- Radial holes accept standard sized rivet diameters.

- Radial holes accept standard sized self-clinching fasteners.

- Assemblies can be mounted on front or through back of panels.

- Proven PEM self-clinching fastener technology permanently holds fastener to base plate.

- Variety of fasteners available.

PEM® Self-clinching Fasteners

Concealed-head self-clinching Studs and Standoffs

Fasteners for use with PC Boards

Penn Engineering Self-clinching Fastener Handbook

Penneginering Self Clinching Nuts

penneginering Short-form catalog

In addition to fasteners, PennEngineering encompasses Haeger®, a manufacturer of hardware insertion machines. They are recognized worldwide for their innovative solutions in fastener insertion technology. PEMSERTER® presses, also part of PennEngineering, are specifically designed to provide safe, reliable, accurate, and efficient installation of PEM fasteners.

For sheet materials where only one side is accessible, the ATLAS® brand offers rivet nuts and tools. These products provide durable and reusable permanent threads. Lastly, PennEngineering’s SI® brand inserts utilize press-in, molded-in, or heat/ultrasonic installation methods to establish strong, reusable, and permanent threads in plastic materials.

Product Categories

PEM® Brand Fasteners for Metal Sheets and Panels

ATLAS® Brand Rivet Nuts

PEM® Brand Fasteners for PC Boards and other Non Ductile Materials

SI® Brand Insert for Plastics

PEM® Brand VariMount® Bonding Fasteners

Fastener Installation Equipment

PROFIL® Brand Fasteners for Metal Sheets and Panel

Self-Clinching Roller Bearing Fasteners – PFTRC

Self-Clinching Roller Bearing Fasteners – PFTRF

PennEngineering’s diverse range of products and technologies showcases their expertise in providing effective solutions for joining and fastening applications across various industries.