Description

Details

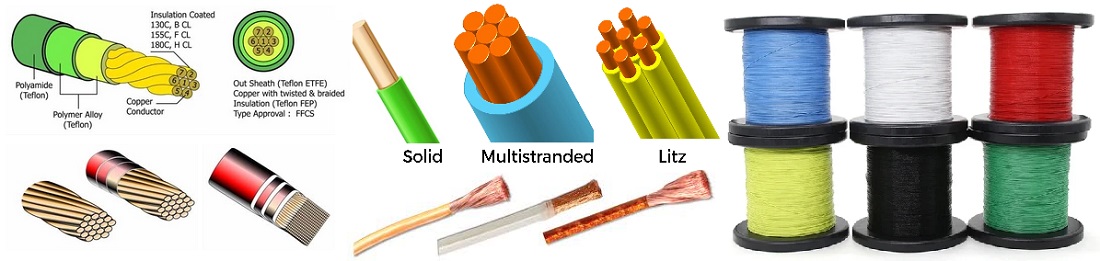

Litz wires, composed of multiple bunched, individually insulated wires, are ideal for applications demanding flexibility and high-frequency performance. In response to growing customer demand for innovative, high-quality products, Rubadue began supplying a wide range of high-frequency litz wires.

Given the diverse applications, Rubadue offers several types of litz wires to meet various requirements.

In the early 20th century, litz wire usage was aligned with the technological advancements of the time. For instance, in 1923, litz wires enabled the first medium-frequency radio broadcast. In the 1940s, they were crucial in developing the first ultrasonic diagnostic systems and basic RFID technology. By the 1950s, litz wire was used in USW chokes. As electronic components rapidly advanced in the latter half of the century, the use of litz wire expanded significantly.

Litz wire mitigates losses due to skin and proximity effects at high frequencies while offering greater mechanical flexibility than single-wire alternatives.

Rubadue Bare Litz Wire

Common Applications:

- Electric Vehicles and Charging Stations

- Wireless Charging

- Switch Mode Power Supplies

- Induction Heating

- Solar Inverters

- Renewable Energy

- Linear Motors & Motion Control

- Medical Power Supplies

Rubadue Bare Round Litz Wires

Product Specifications:

- Individual Wire Size Range: 50 AWG (0.02mm) to 12 AWG (2.05mm)

- Total Number of Wires: From 2 to over 10,000

- Total Conductor Diameter: Up to 0.350″ (8.9mm)

- Temperature Class: 155°C to 240°C

Optional Coatings:

- Nylon Serve (Single or Double Layer)

- Extruded Insulations: ETFE, FEP, PFA

- Custom options available upon request

Agency Approvals:

- UL Recognized Component (OBMW2 File #: E190291)

- RoHS Compliant

- Approved for use in various Electrical Insulation Systems

Since 1977, Rubadue Wire has been synonymous with quality and innovation. Founded in Southern California, Rubadue was the pioneer in designing and manufacturing Triple Insulated Wire, maximizing the use of the winding window from one bobbin wall to the other. With expertise in insulated litz, multi-layer winding wires, and our branded Coilbond product, Rubadue Wire delivers the solutions you need with the quality you demand.

LITZ WIRE TYPES

Loveland, CO — At APEC 2019, Rubadue is showcasing its extensive range of Litz wire products. As design engineers across various industries strive for more energy-efficient designs in smaller, lighter packages, Litz wire has become an essential component.

Rubadue’s Litz wire conductors are specifically engineered for use in electronic components rated up to 464°F (240°C) and are UL and VDE approved for applications up to 1,500 Vpk with the appropriate insulation. These conductors are widely used in applications ranging from electric vehicles and medical devices to consumer electronics and solar inverters.

Rubadue’s Litz wire is compatible with many UL-approved electrical insulation systems and has been approved by leading OEMs for use in their products worldwide.

| Type | Basic | Taped | Extruded | Profiled | Served | With strain relief | |||||||||||||||||||

| Diameter of Magnet Wire | 0.010 – 0.500 mm | 0.040 – 0.500 mm | 0.032 – 0.500 mm | 0.200 – 0.500 mm | 0.020 – 0.300 mm | 0.032 – 0.500 mm | 0.030 – 0.300 mm | ||||||||||||||||||

| No. of wires | 2 – 25.000 strands | max. 25.000 strands | max. 700 strands | max. 25.000 strands | 2 – 23.000 strands | max. 500 strands | max. 23.000 strands | ||||||||||||||||||

| Total outer diameter | 0.095 – 15.0 mm | 1.0 – 10.0 mm | 0.4 – 1.2 mm | max. 10.0 mm |

|

0.4 – 1.2 mm | 0.5 – 5.0 mm | ||||||||||||||||||

| Total copper cross section | 80 mm² | 36 mm² | 0.5 mm² | 36 mm² |

|

0.38 mm² | up to 10.6 mm² | ||||||||||||||||||

| Outer coating | PET (Thermal class A-F) PEN (Thermal class B-H) PI (Thermal class H-C) |

Polyamide Polyester Polyurethane |

optional with/out serving

|

Natural silk Nylon Polyester |

|

|

|||||||||||||||||||

| Additional options |

|

Wallthickness overcoat: 0.1 – 0.4 mm |

|

No. of layers (max.): 2 |

|

Taping construction: 3 layers (min.) | |||||||||||||||||||

| Characteristics | Flexible optimization of construction and conductor material possible acc.:

|

|

|

|

|

|

|

||||||||||||||||||

| Typical applications | Transformers, Chokes, RF-tranducers, medical applications, sensors, electronic ballasts, switching power supplies, heating applications | Inverter, RF-transformers, RF-transducers, RF-chokes, Inductive charger | Heating applications, Smart Textiles, Patient Comfort | Induction cooking hobs, RF-transformers, RF-chokes, E-motors | Inverter, RF-transformers, RF-transducers, RF-chokes, Inductive charger | Automotive industry, industrial applications, medical applications, Smart Textiles, special applications for technical textiles, sports equipment | Inverter, RF-transformers, RF-transducers, RF-chokes, Inductive charger |