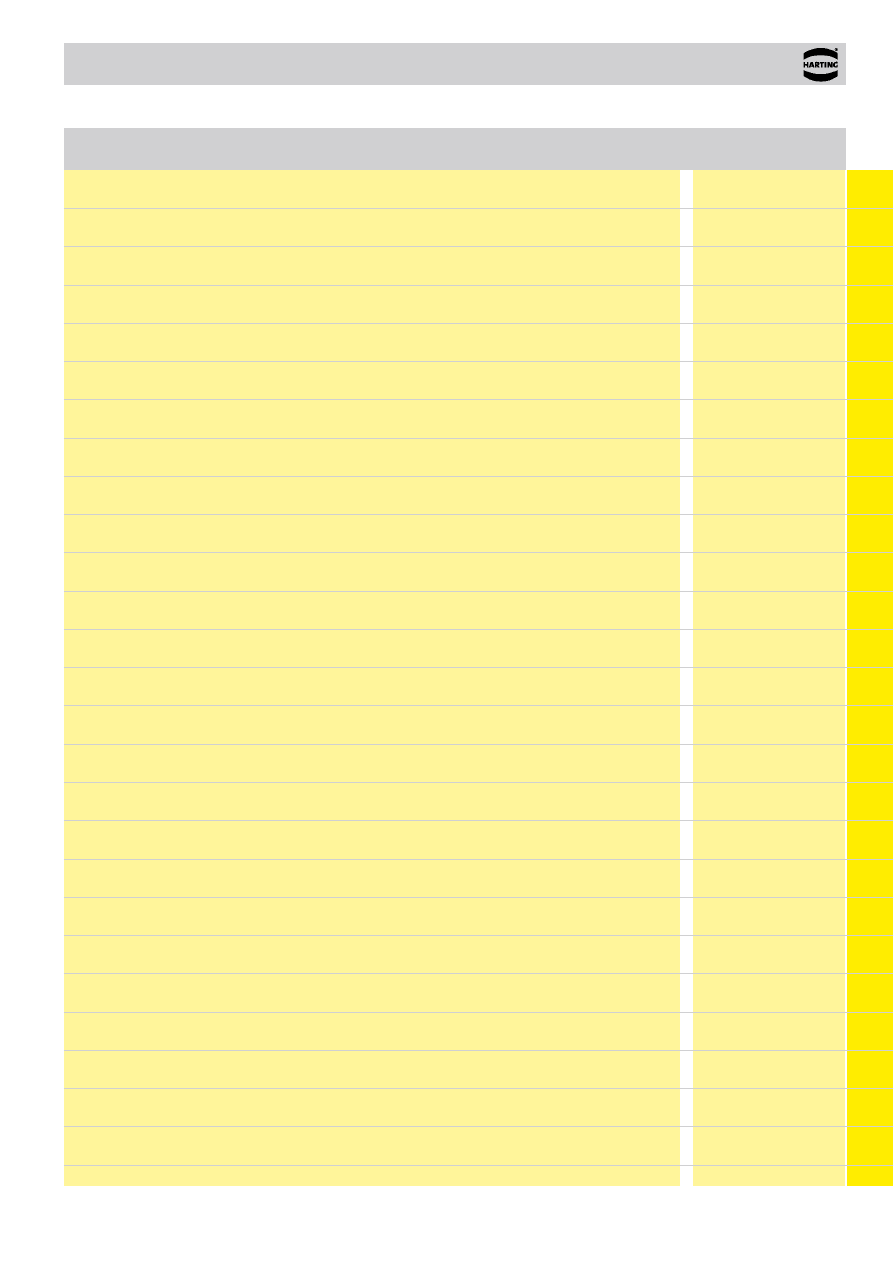

Chapter

Contents

Industrial Connectors Han

®

– Series Summary

Industrial Connectors Han

®

. . . . . . . . . . . . . . . . . . .

Technical Characteristics

00

Slim Construction Size

(up to 16 amperes) . . . . . . . . . . . . . . . . . . . . . . .

Han A

®

01

High pin count connectors

up to 216 contacts . . . . . . . . . . . . . .

Han D

®

/ DD

®

02

for 16 amperes –

Connectors

. . . . . . . . .

Han E

®

/ Han

®

ES/ESS/EE/EEE

03

proven and reliable

Connectors

for higher voltages . . . . . . . . . . . . . . . . . .

Han Hv E

®

/ Han

®

Hv ES

04

Combination Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han-Com

®

05

Modular Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han-Modular

®

06

Connectors

for higher currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han

®

HsB

07

Terminal Block Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han

®

AV

08

Connectors

for low voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Staf

®

09

Circular Connectors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

R 15

10

Connectors

for the use in switch cabinets . . . . . . . . . . . . . . . . . . . . . .

Han-Snap

®

11

Interface

for power and signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han-Port

®

12

Connectors

(not only for drives) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han

®

Q

13

High Current Connectors

. . . . . . . . . . .

Han

®

K 3/0, K 3/2

/

Han

®

HC-Modular

14

Energy Bus Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han-Power

®

15

Industrial Bus Interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han-Brid

®

19

Han

®

PCB-Adapter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

for shielding, for harsh environments

Han

®

Hoods and Housings

with Pg entries

30

with various locking systems

for shielding, for harsh environments

Han

®

Hoods and Housings

with metric thread

31

with various locking systems

Accessories

for Hoods and Housings / Han

®

Inserts . . . . . . . . . . . . . . . . . . . . . . . .

40

Han

®

Thermocouple

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

Han

®

GND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

Tools

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

99

Application Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Part-Numbers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Han

Han

A

Han

D / DD

Han

E / EE

Part No.

Han

HvE

Han

Com

Han

Modular

Han

HsB

Han

AV

Staf

R 15

Han

Snap

Han-

Port

Han

Q

Han HC-

Modular

Power

Distribution

Han-

Brid

PCB-

Adapter

Han Hoods

Housings

Han Hoods

Housings

Accessories

Thermo-

couple

Han

GND

Tools

Applica-

tions