POWDER CORES

Molypermalloy | High Flux | Kool Mµ

®

| XF

lux

®

| Kool Mµ

®

MAX

POWDER CORES

Molypermalloy | High Flux | Kool Mµ

®

| XF

lux

®

| Kool Mµ

®

MAX

We offer the confidence of over sixty years of expertise in the

research, design, manufacture and support of high quality magnetic

materials and components.

A major manufacturer of the highest performance materials in the

industry including: MPP, High Flux, Kool Mµ®, Kool Mµ® MAX,

XFlux®, power ferrites, high permeability ferrites and strip wound

cores, Magnetics’ products set the standard for providing consistent

and reliable electrical properties for a comprehensive range of core

materials and geometries. Magnetics is the best choice for a variety

of applications ranging from simple chokes and transformers used

in telecommunications equipment to sophisticated devices for

aerospace electronics.

Magnetics backs it products with unsurpassed technical expertise

and customer service. Magnetics’ Sales Engineers offer the

experience necessary to assist the designer from the initial design

phase through prototype approval. Knowledgeable Sales Managers

provide dedicated account management. Skilled Customer Service

Representatives are easily accessible to provide exceptional sales

support. This support, combined with a global presence via a

worldwide distribution network, including a Hong Kong distribution

center, makes Magnetics a superior supplier to the international

electronics industry.

www.mag-inc.com

1

Contents

Contents

Core Locator by Part Number

Core Index and Unit Pack Quantities . . . . . . . 2

General Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Applications and Materials . . . . . . . . . . . . . . 9

Material Properties . . . . . . . . . . . . . . . . . . . 10

Core Weights and Unit Conversions . . . . . . 11

Core Identification . . . . . . . . . . . . . . . . . . . . 12

Inductance and Grading . . . . . . . . . . . . . . . 13

Core Coating . . . . . . . . . . . . . . . . . . . . . . . 14

Core Selection

Inductor Core Selection Procedure . . . . . . . 15

Core Selection Example . . . . . . . . . . . . . . . 16

Toroid Winding . . . . . . . . . . . . . . . . . . . . . . 17

Powder Core Loss Calculation . . . . . . . . . . 18

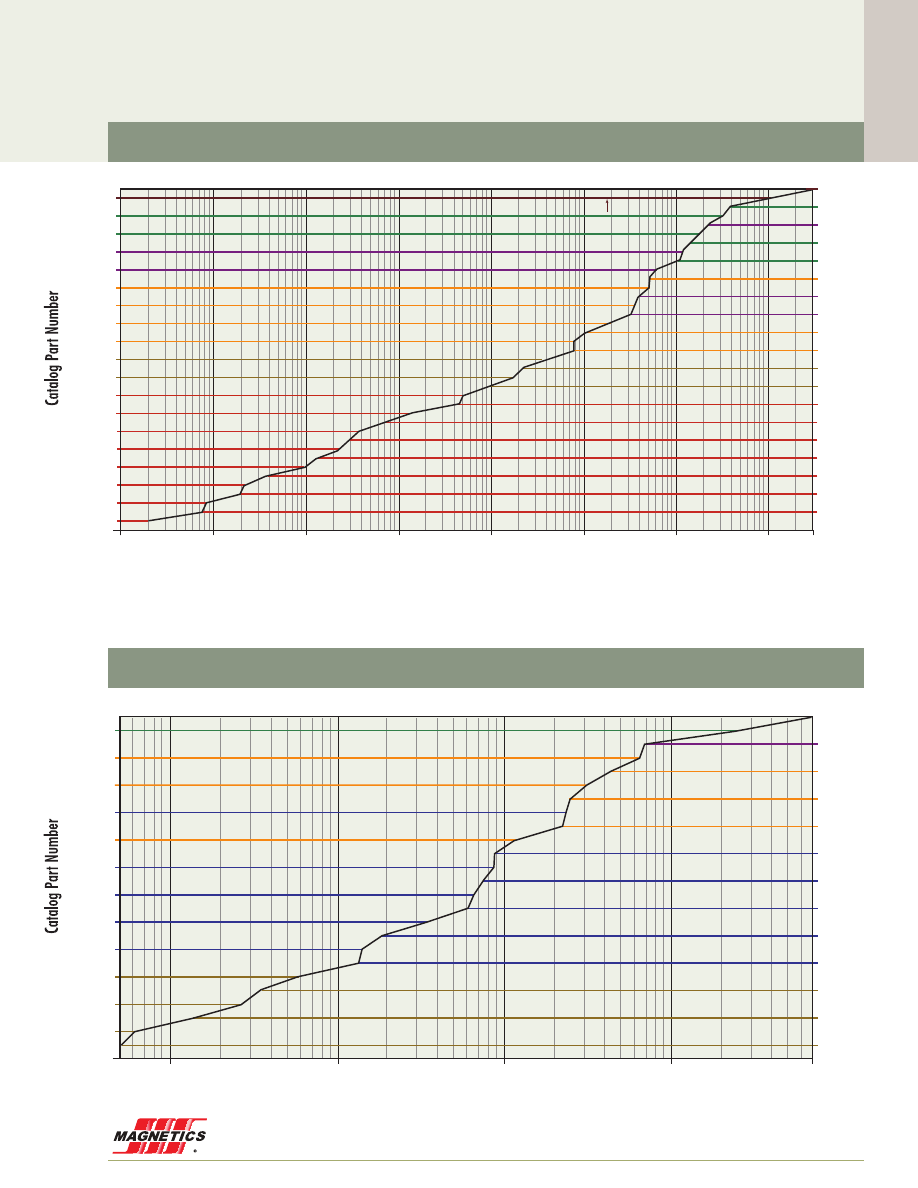

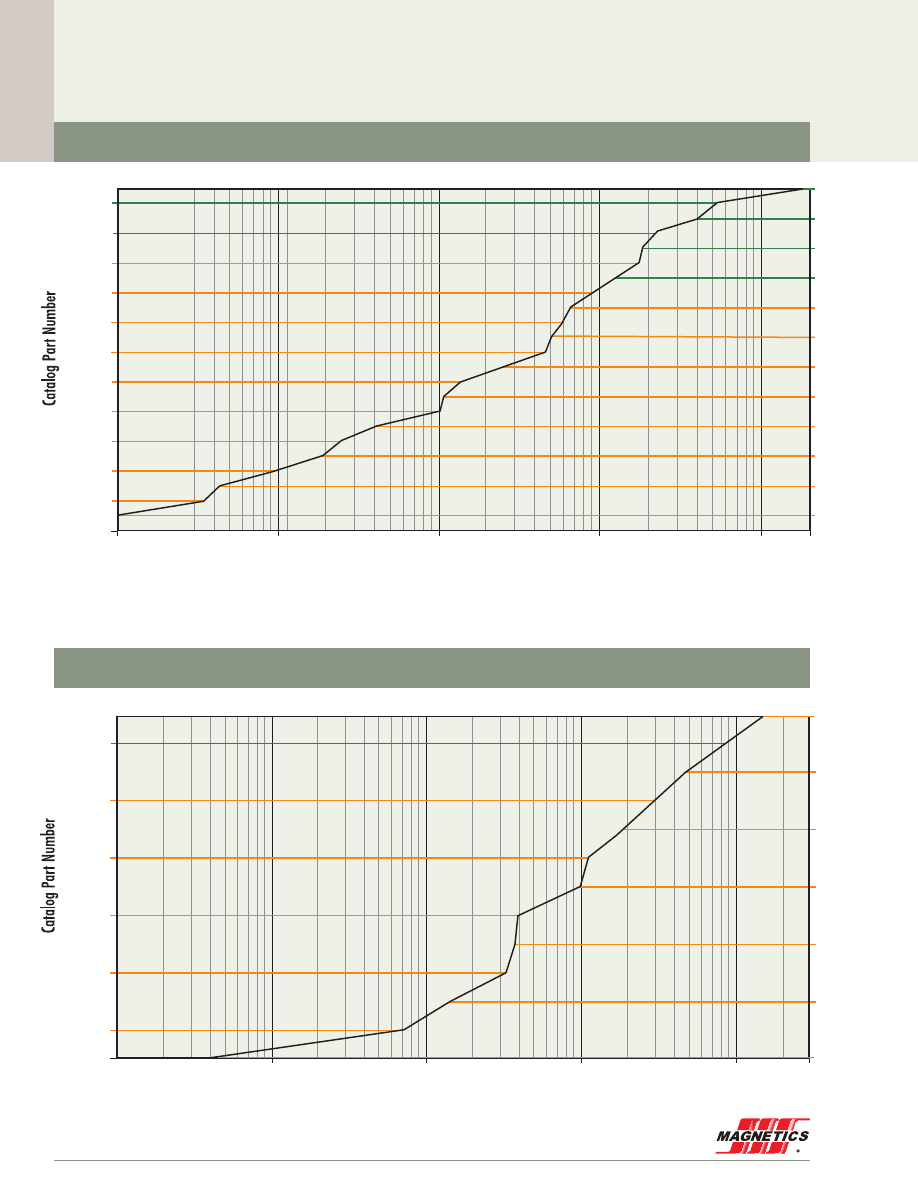

Core Selector Charts . . . . . . . . . . . . . . . . . 23

Wire Table . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Material Data

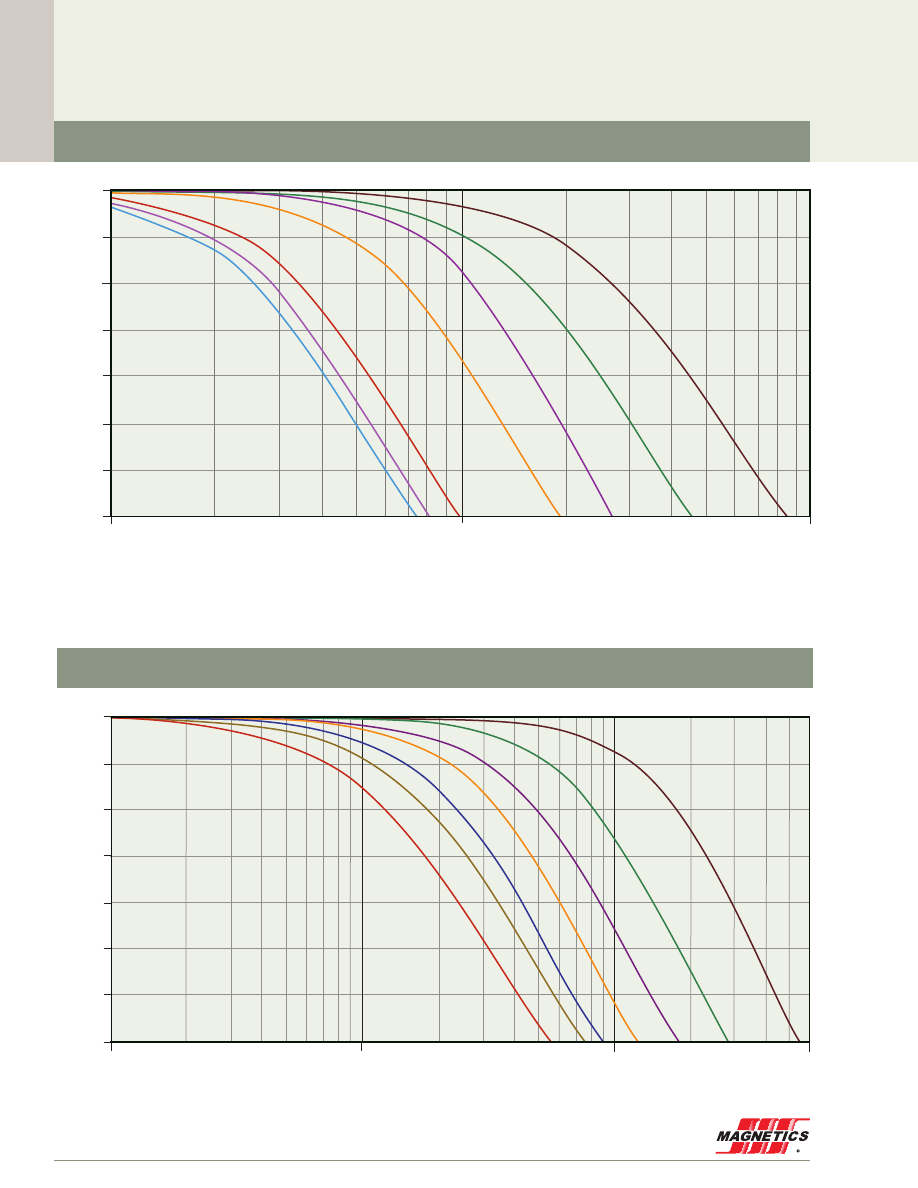

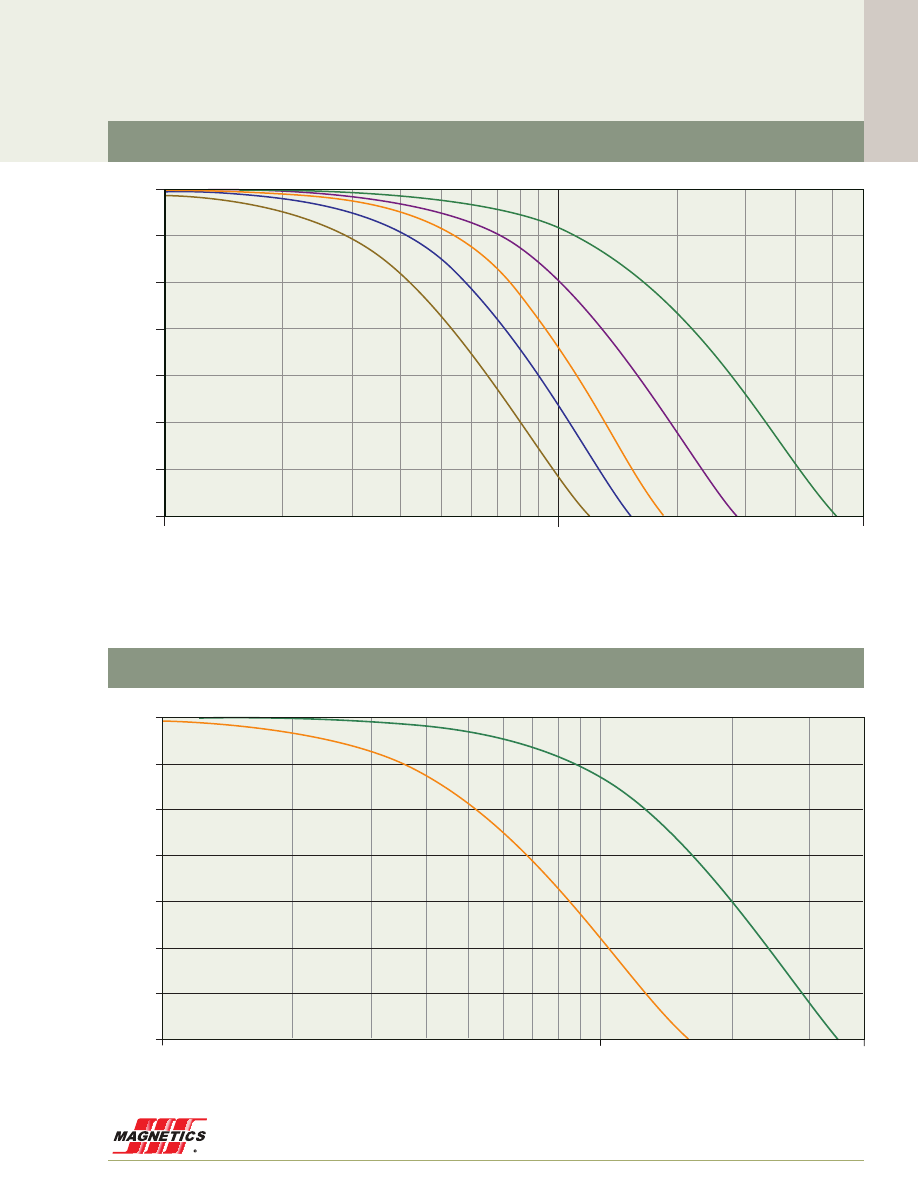

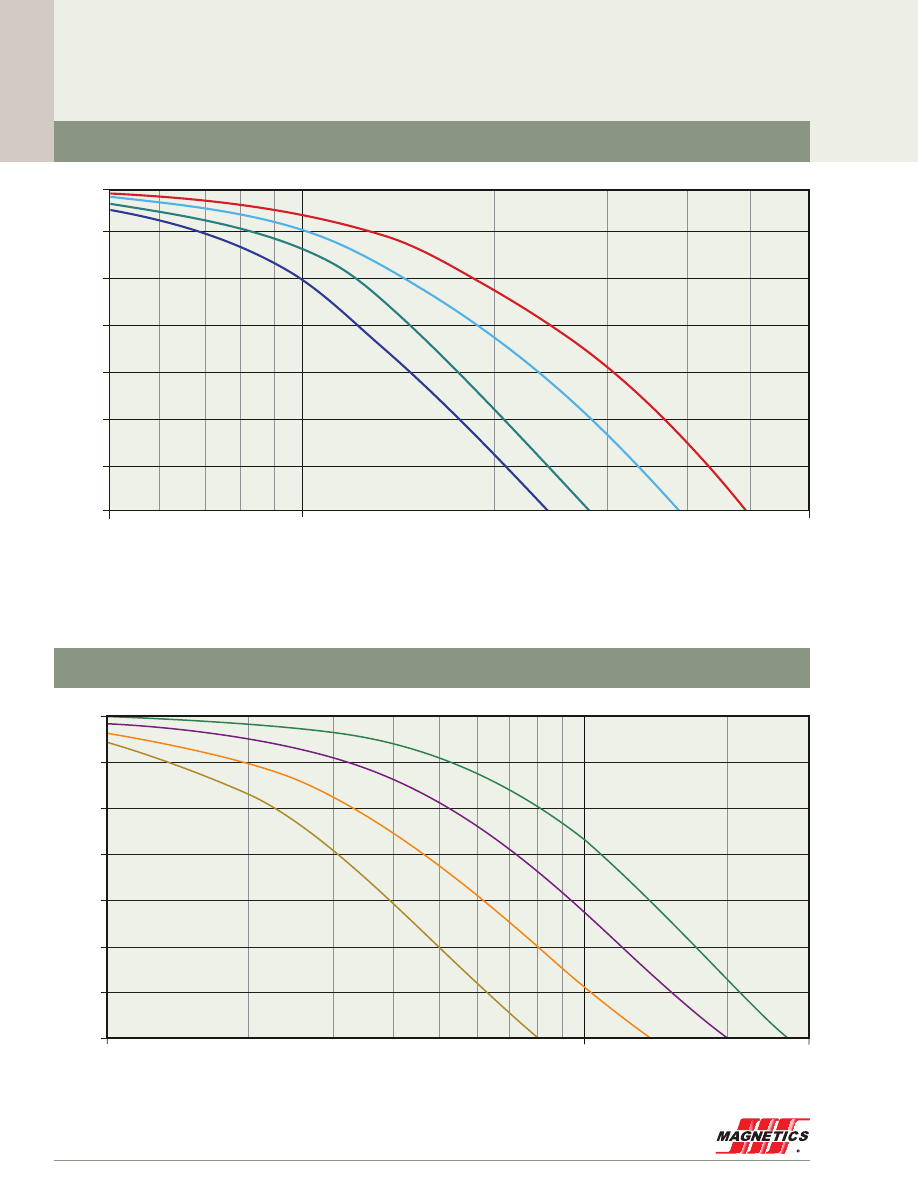

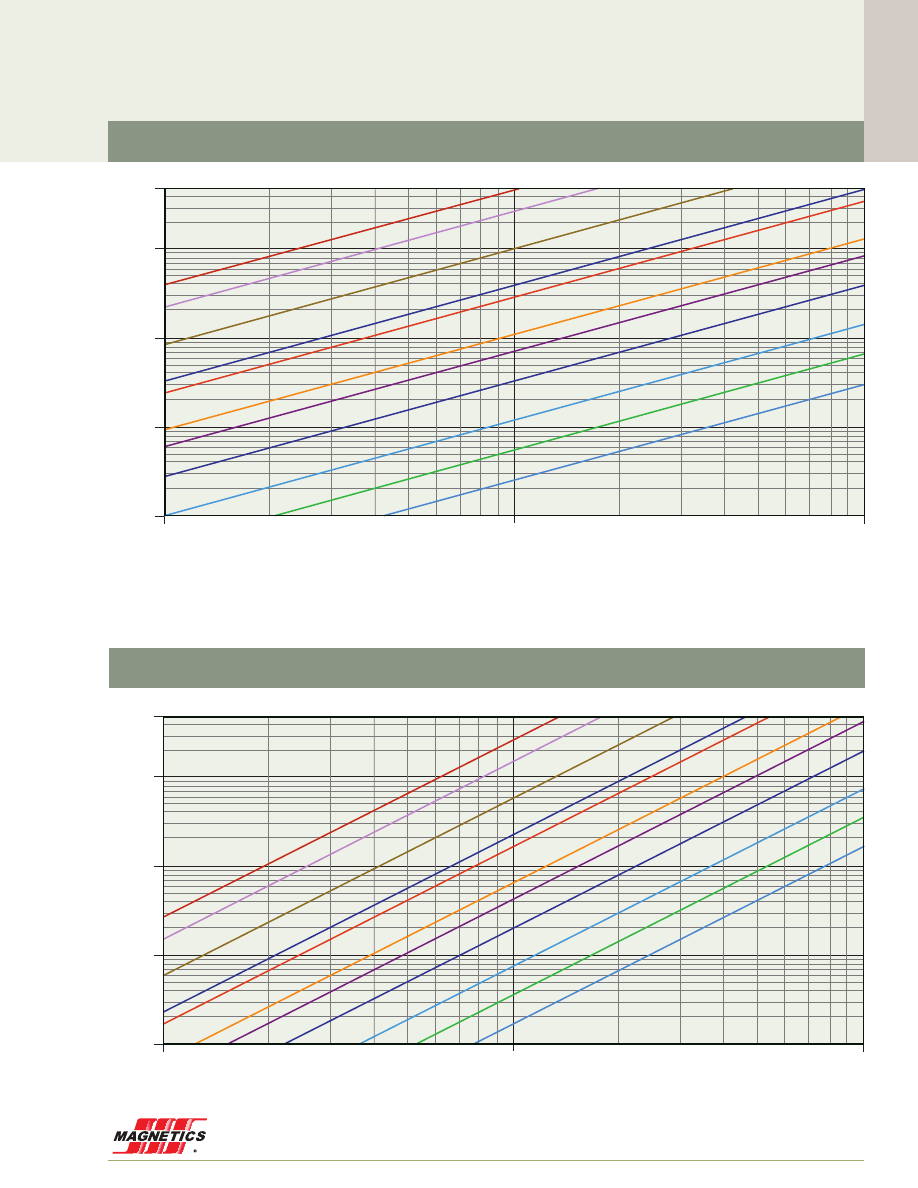

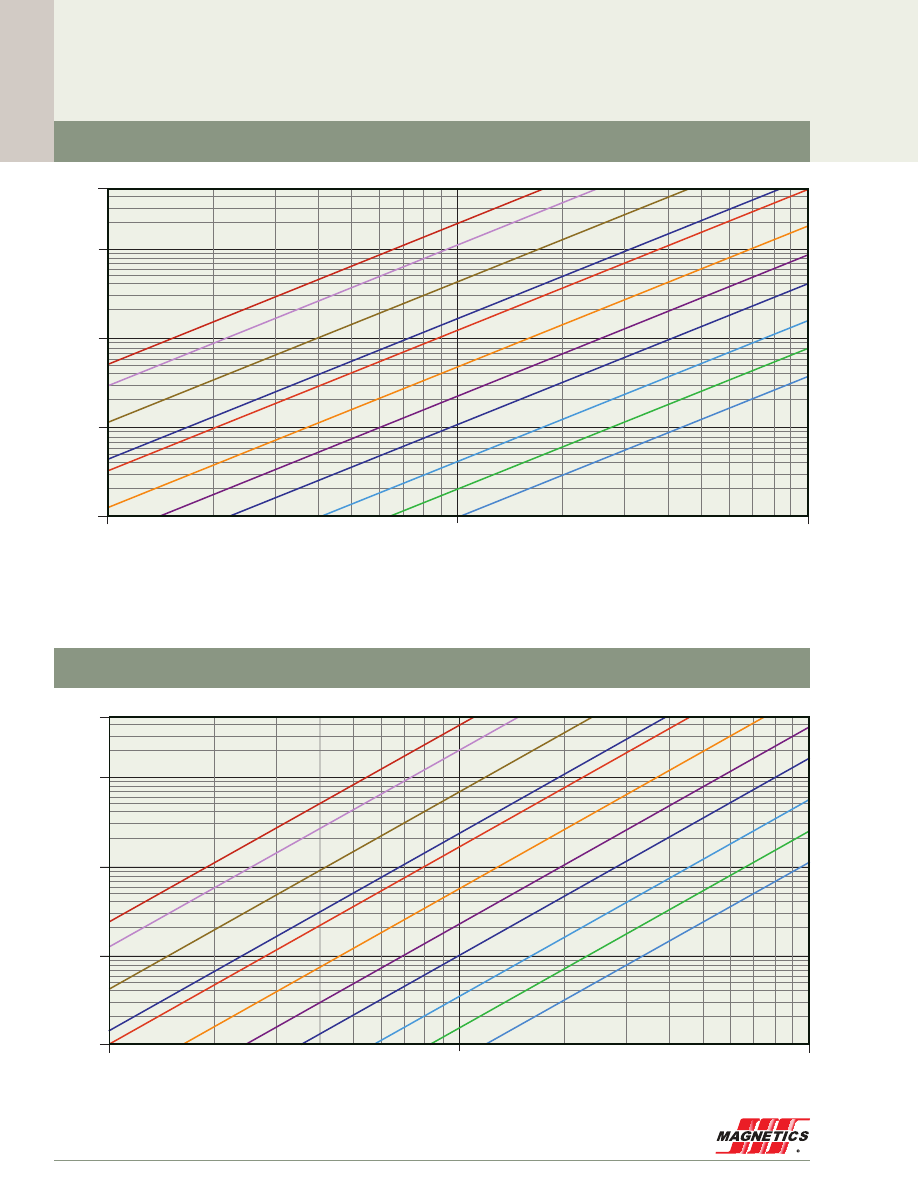

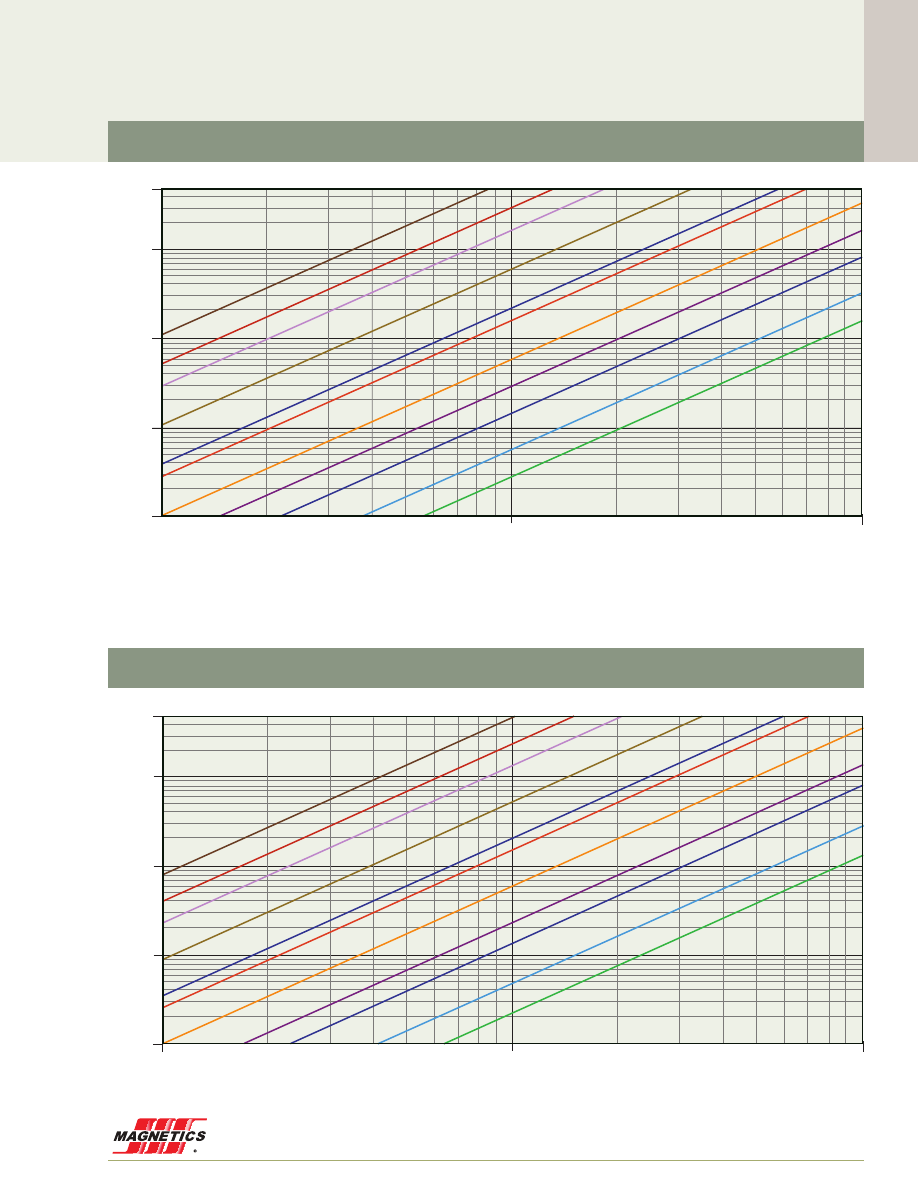

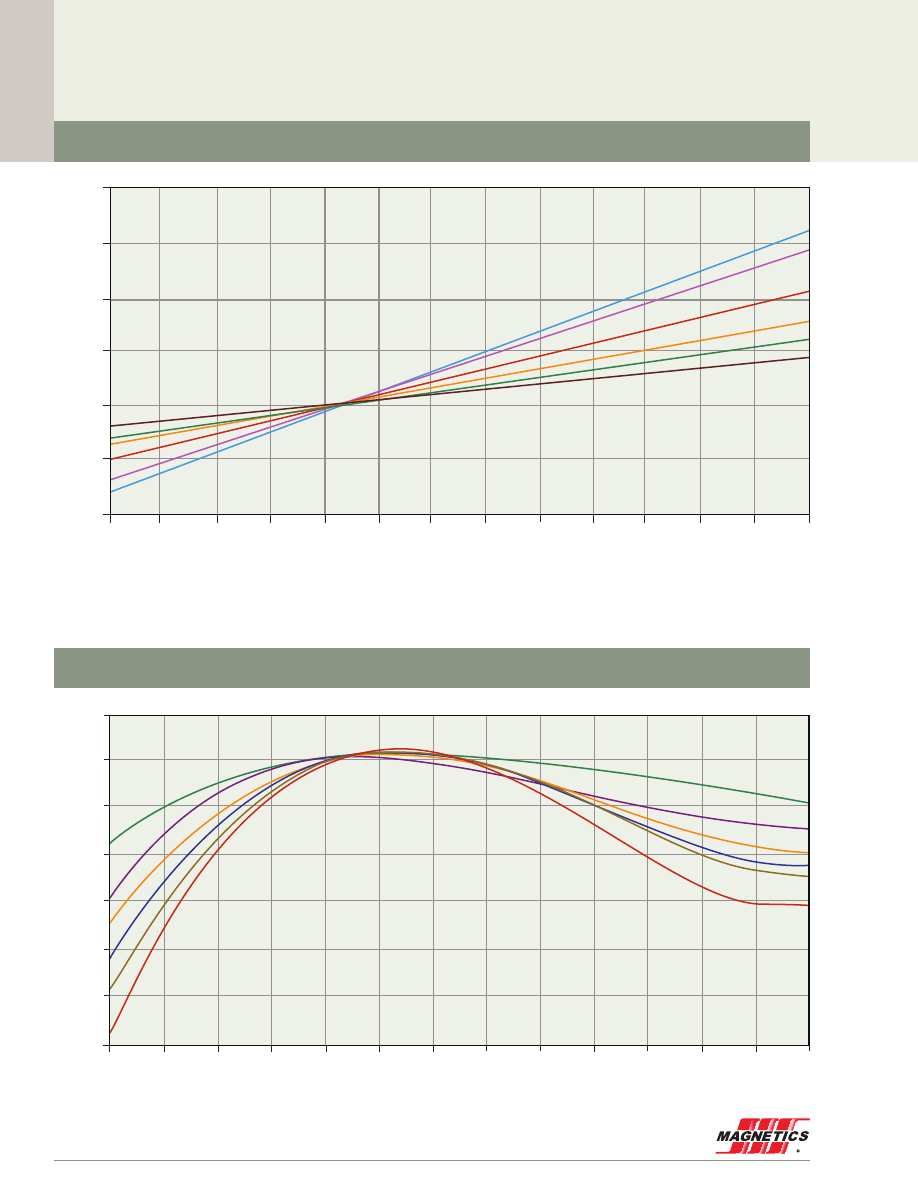

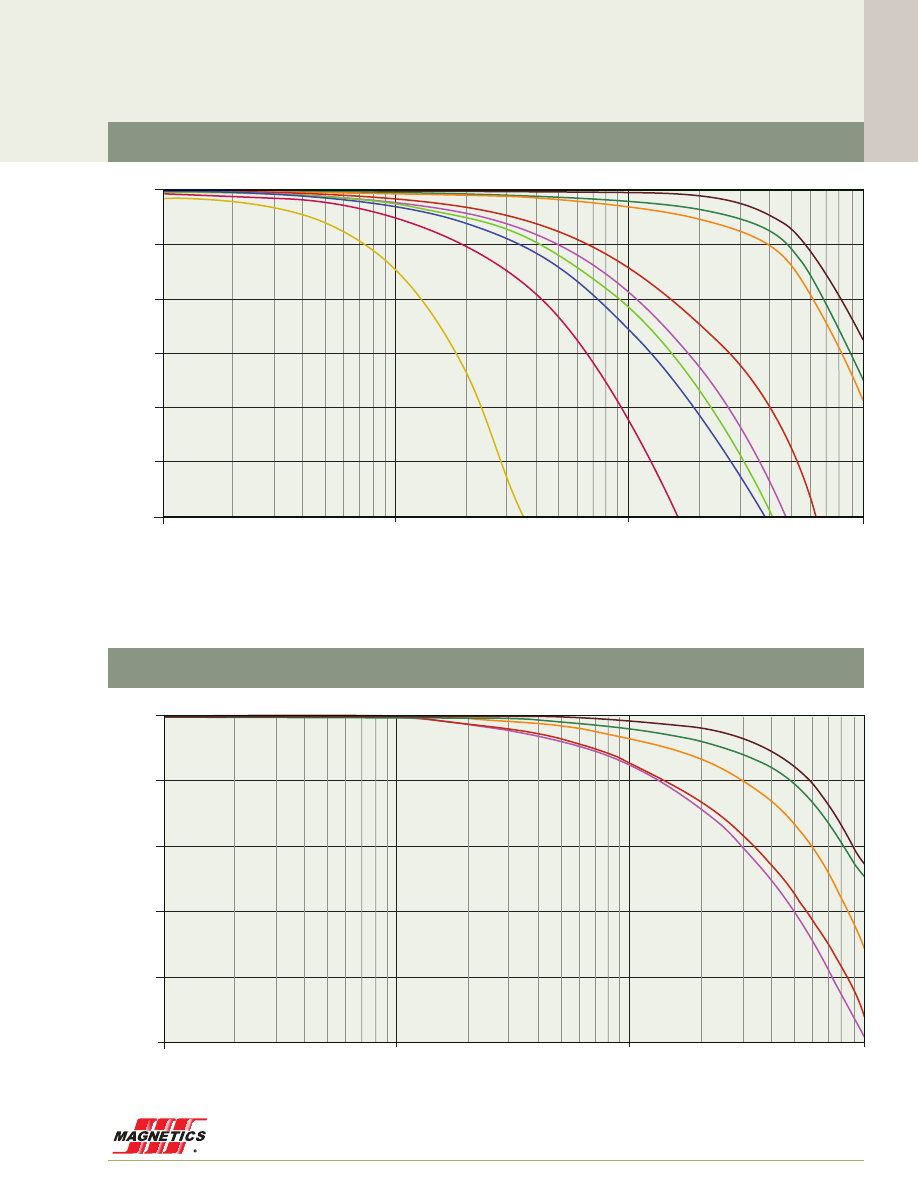

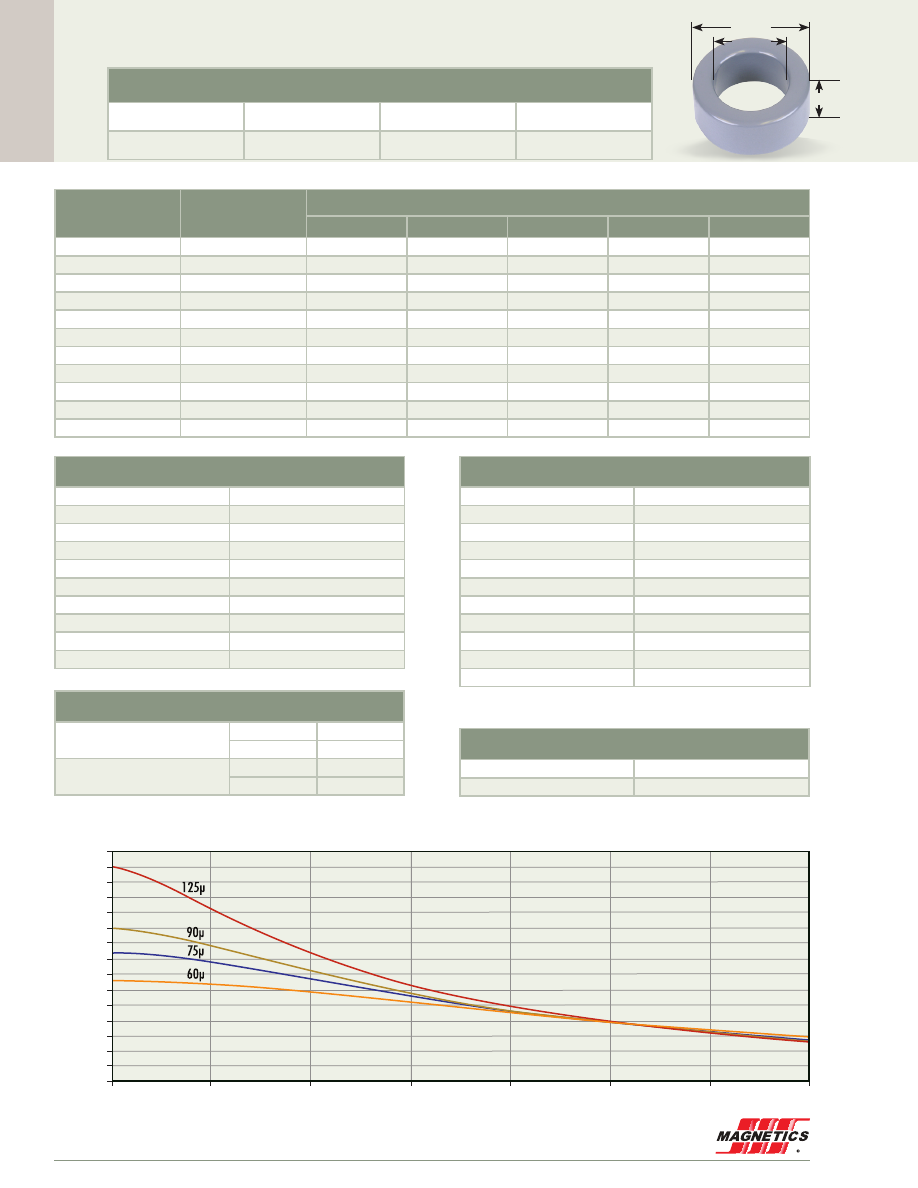

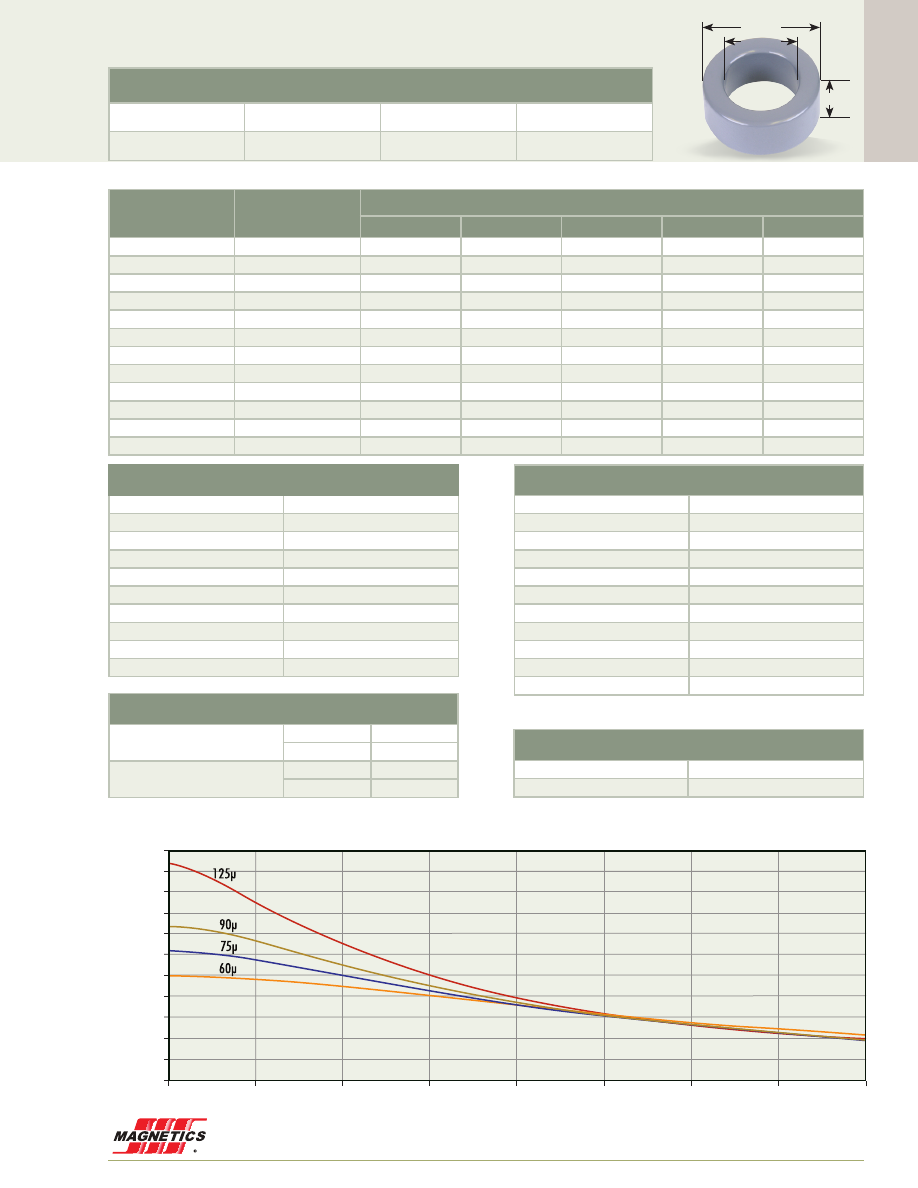

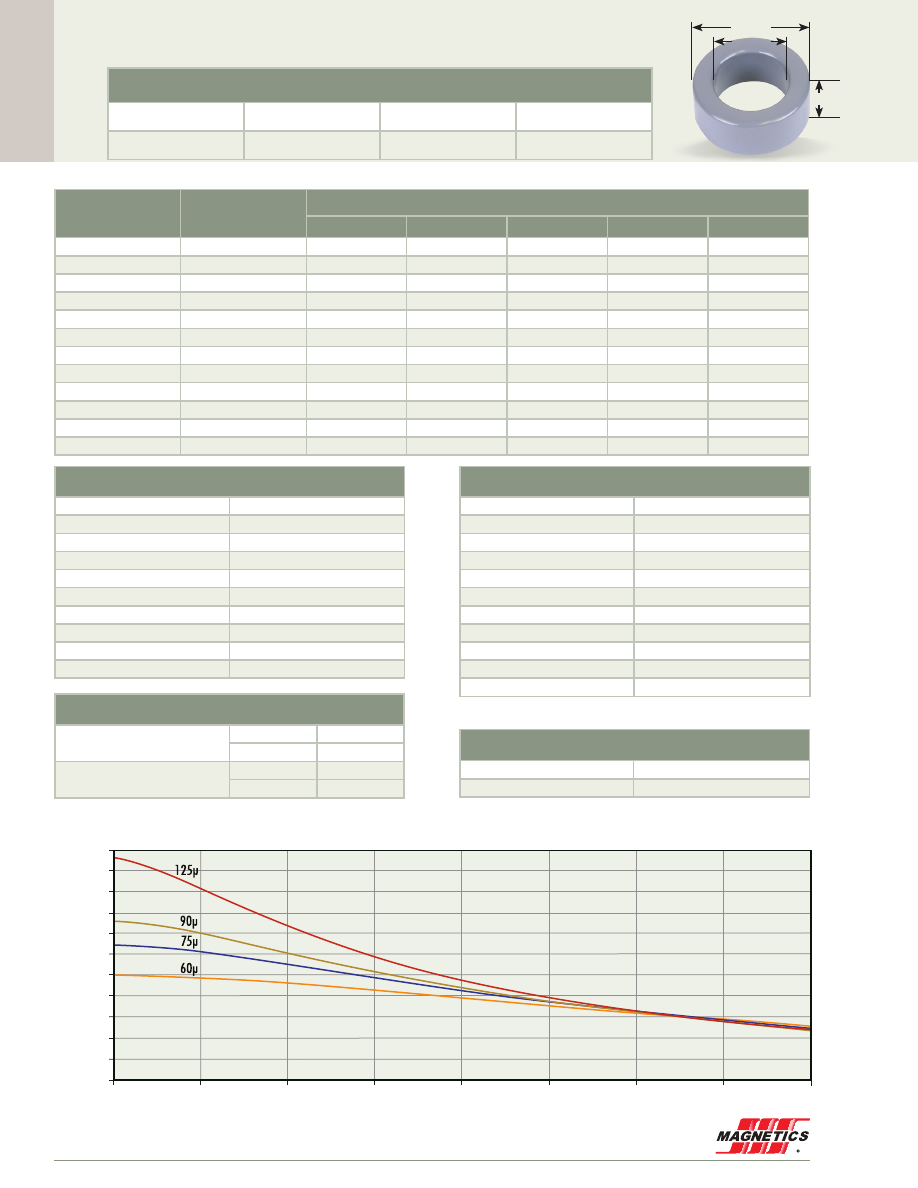

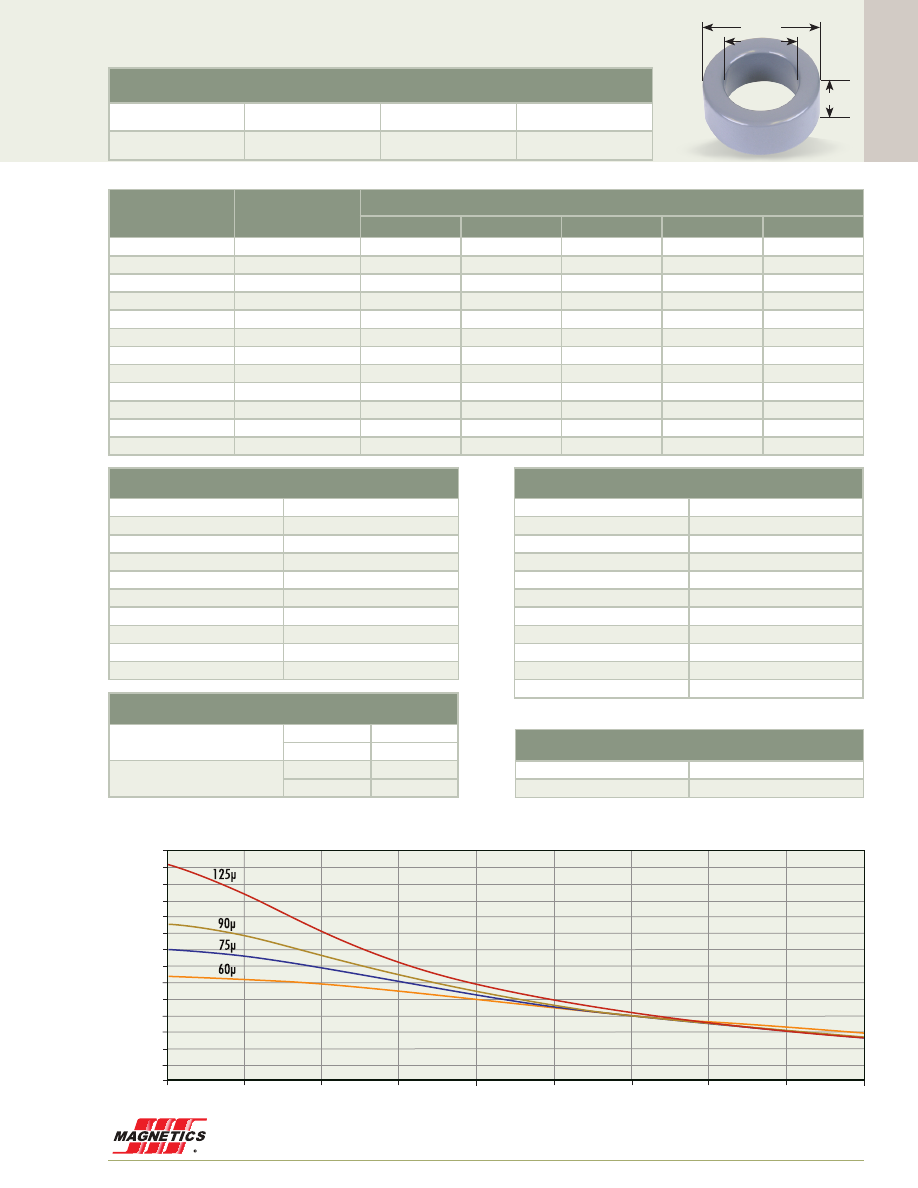

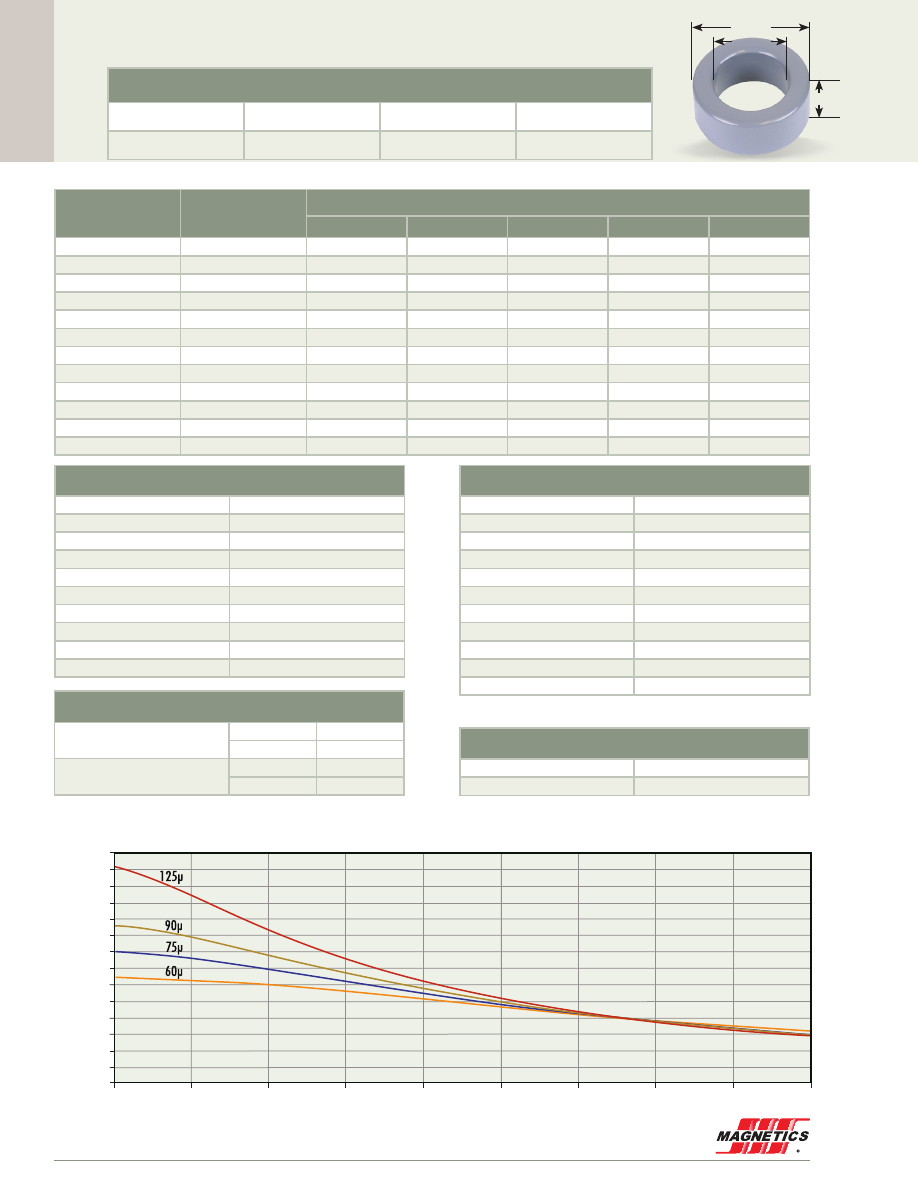

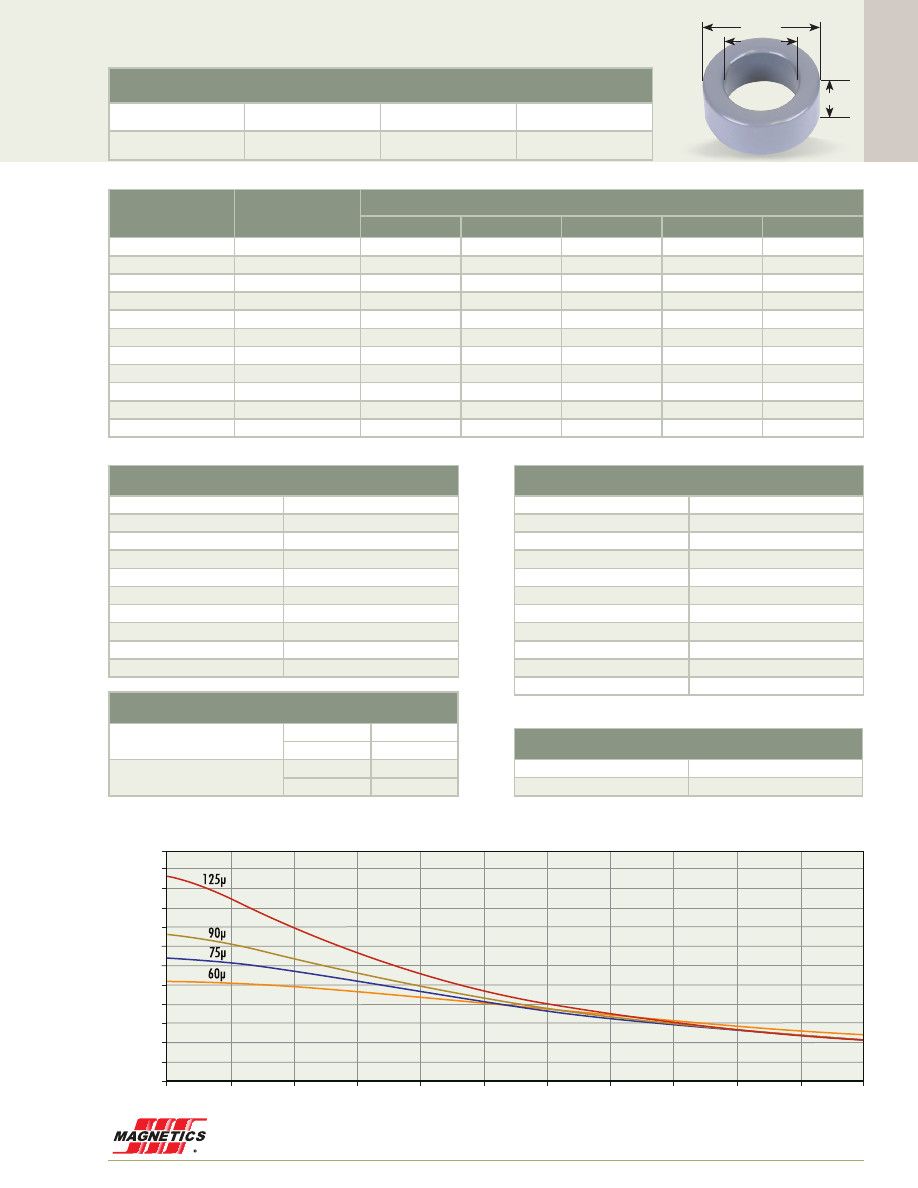

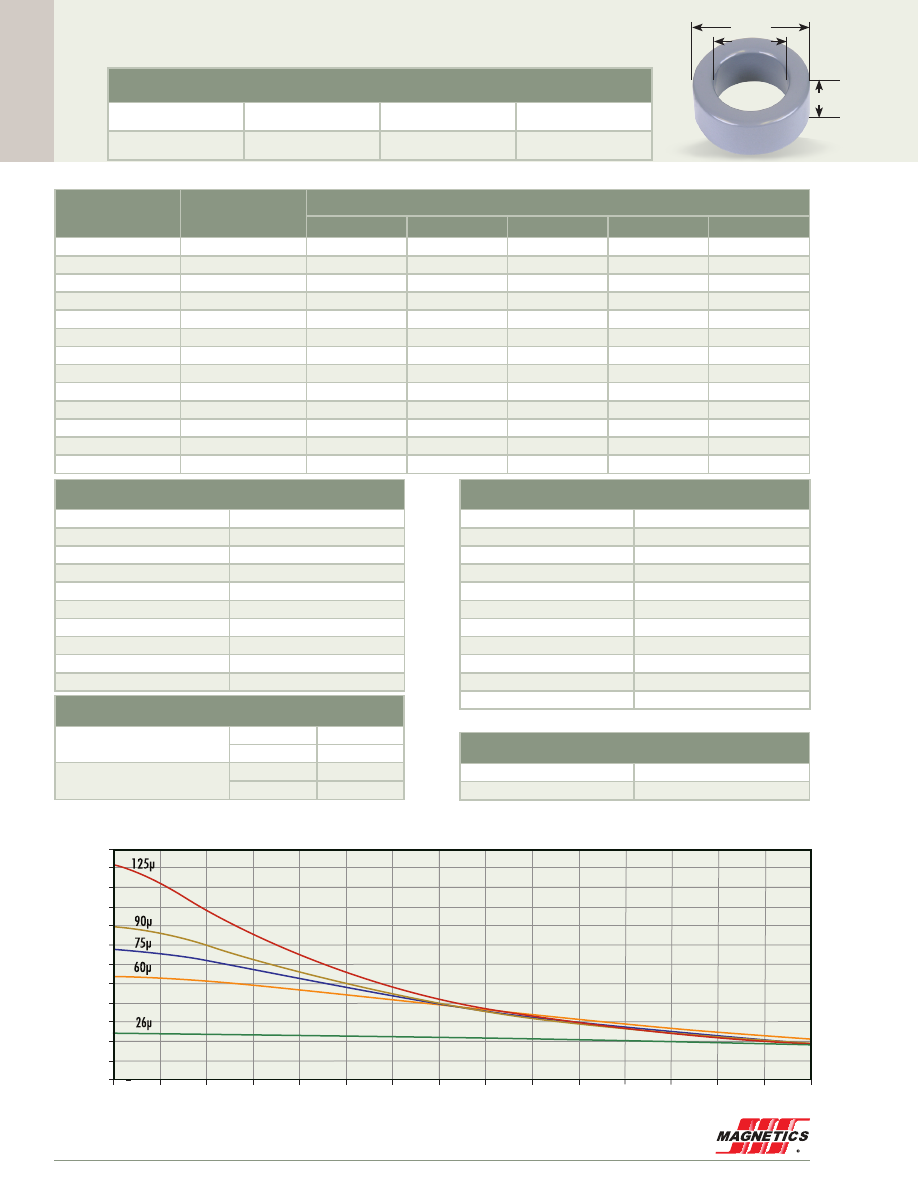

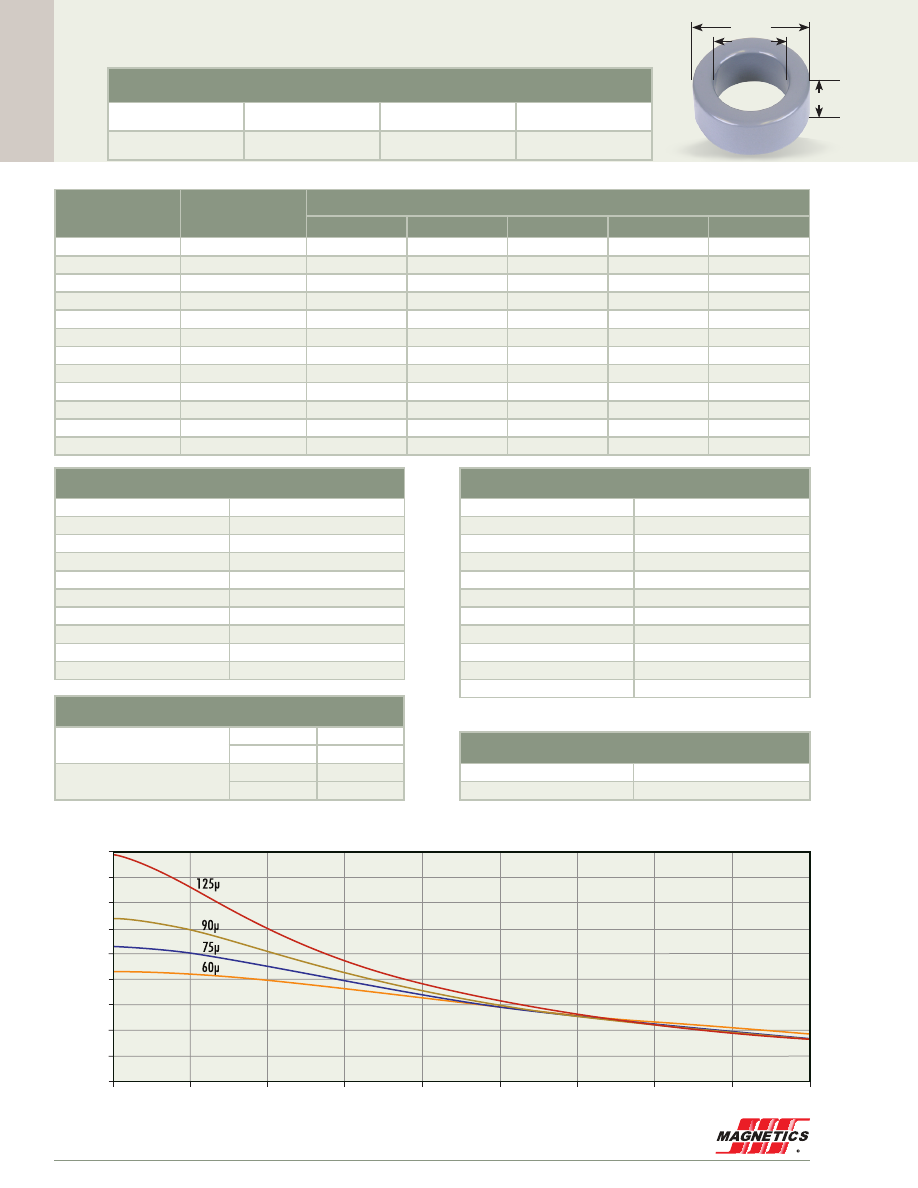

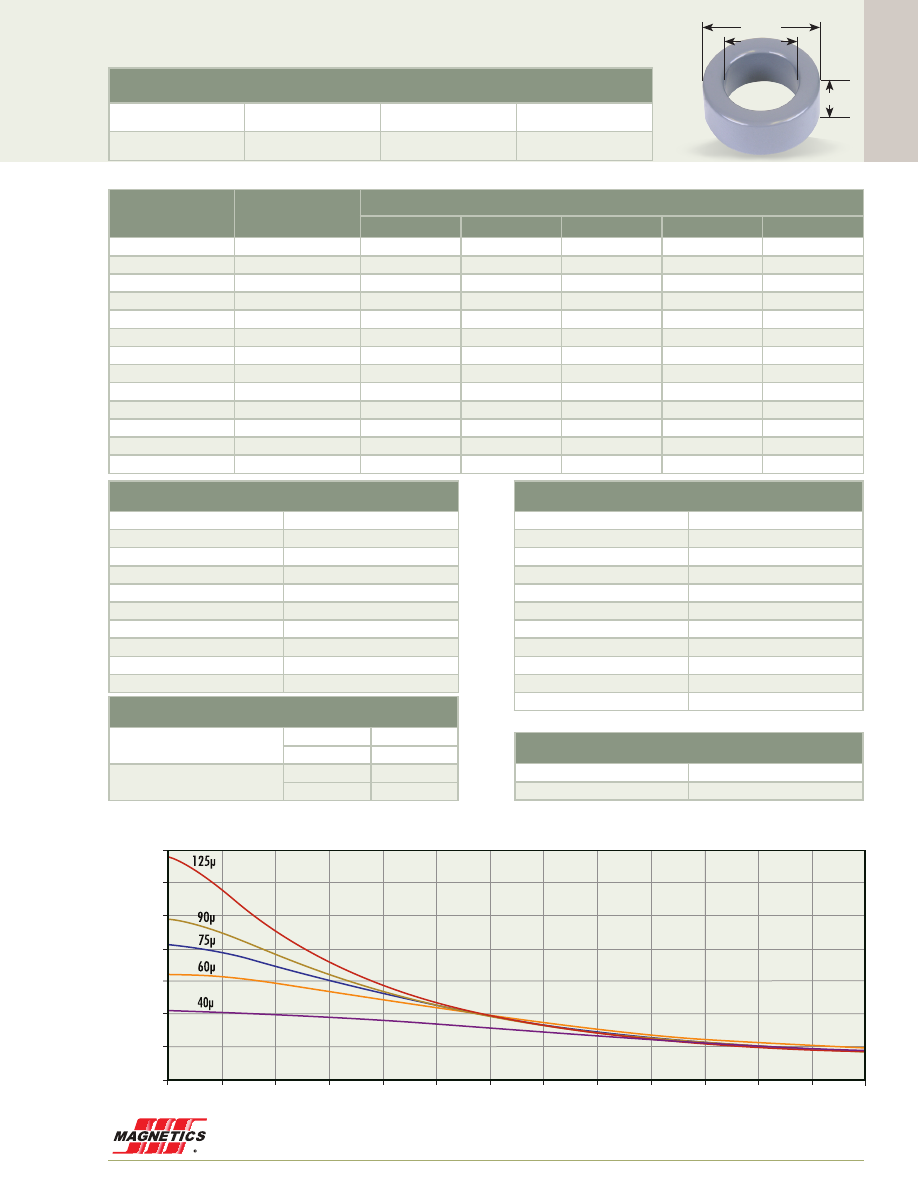

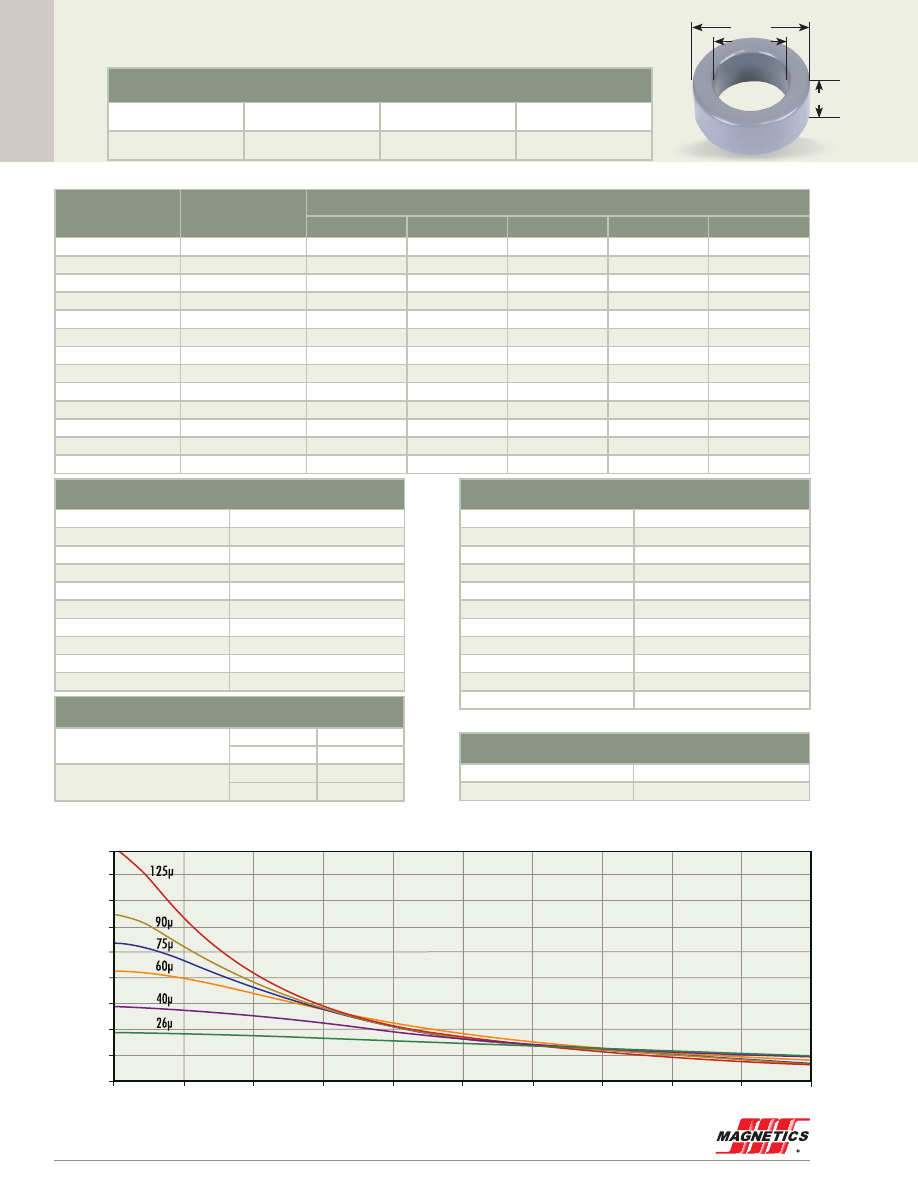

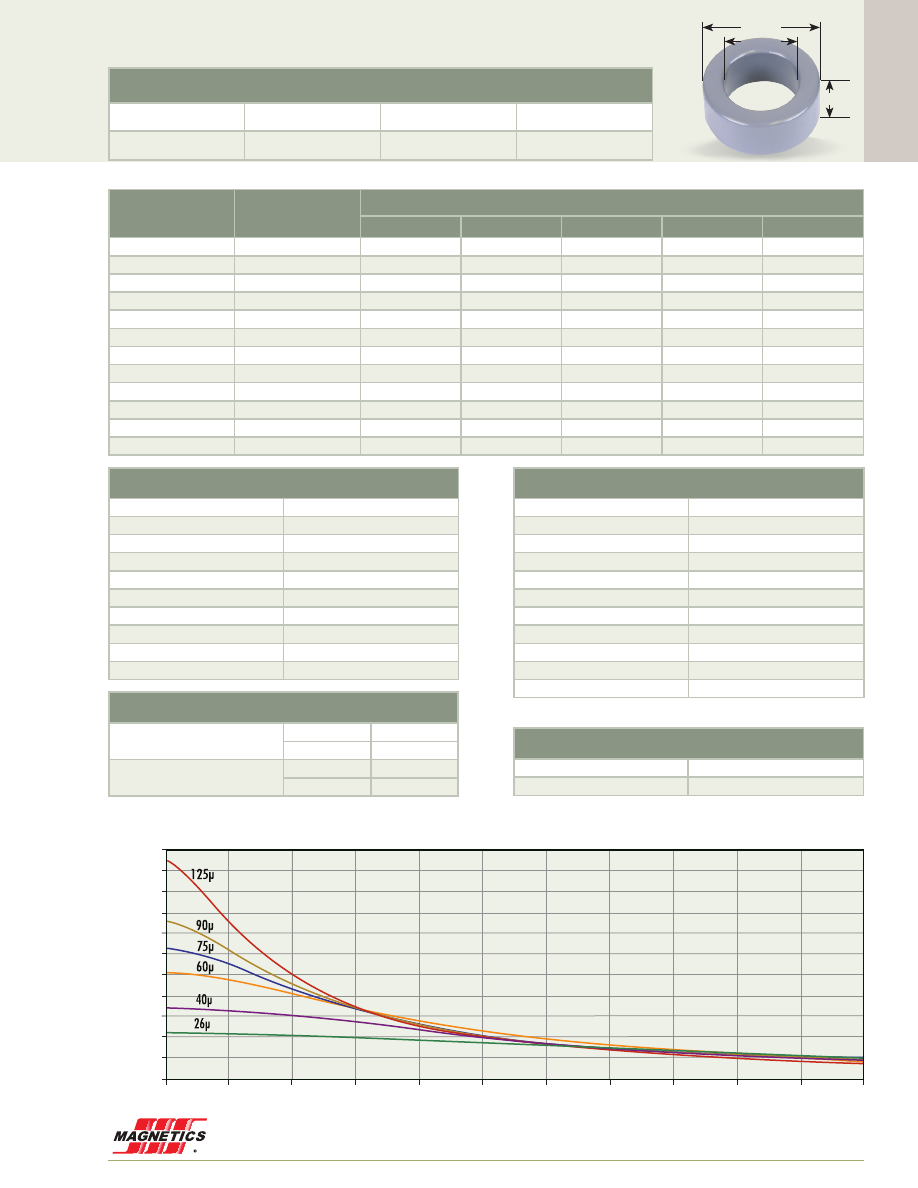

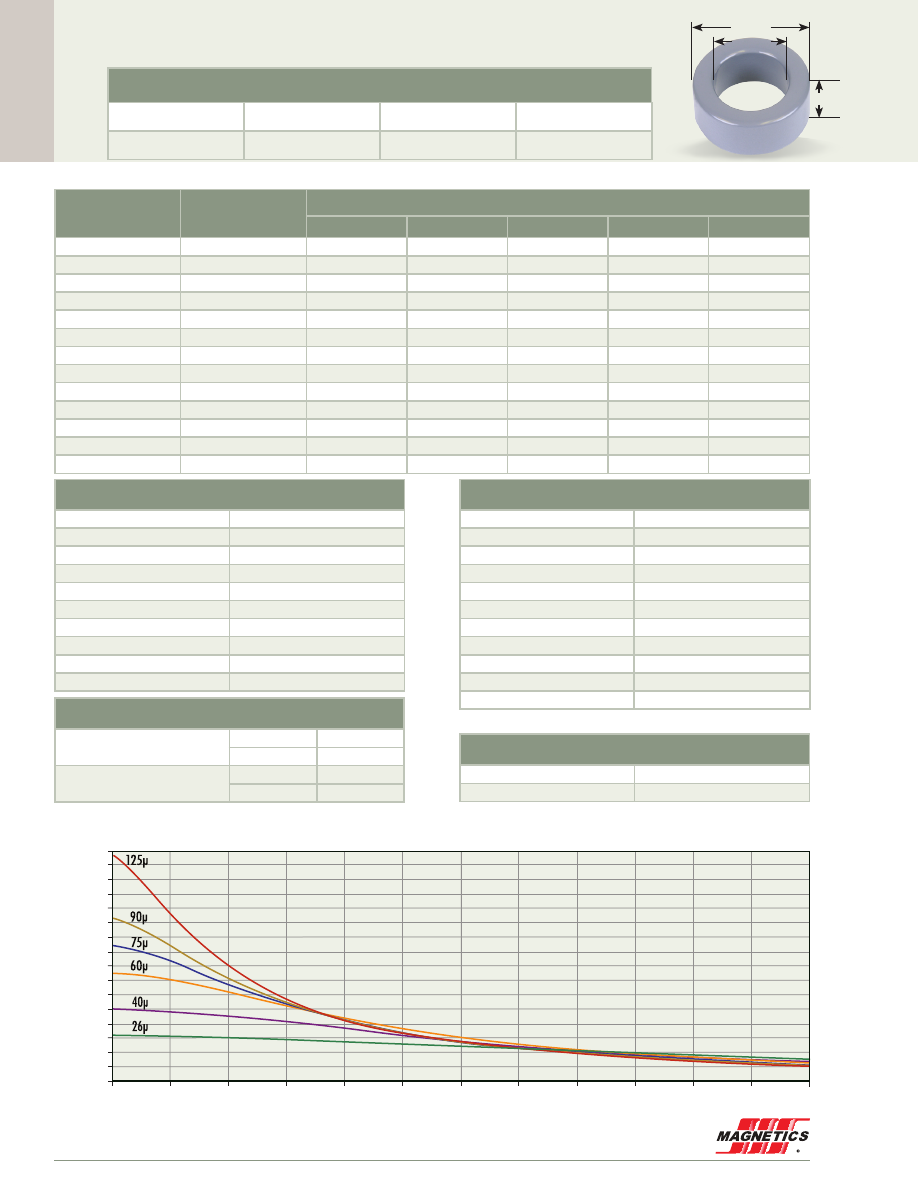

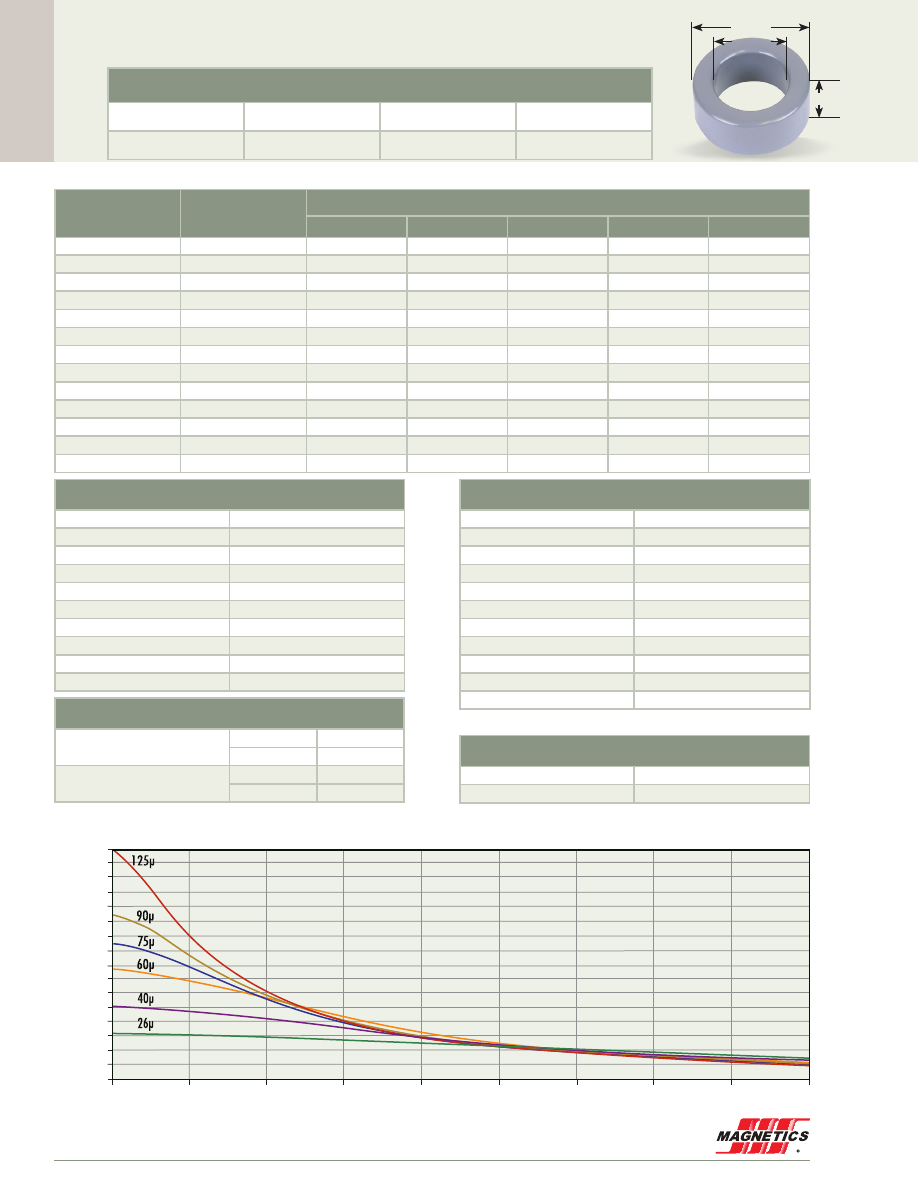

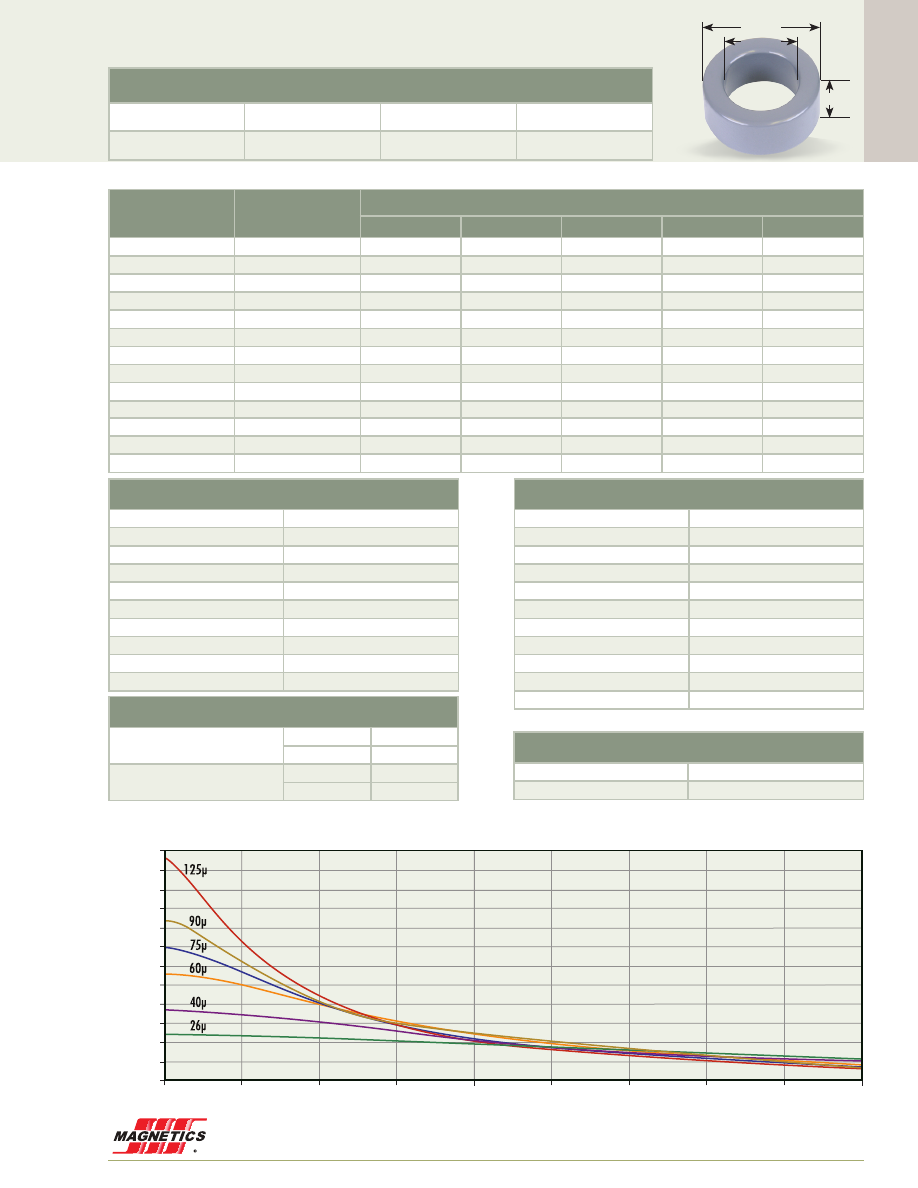

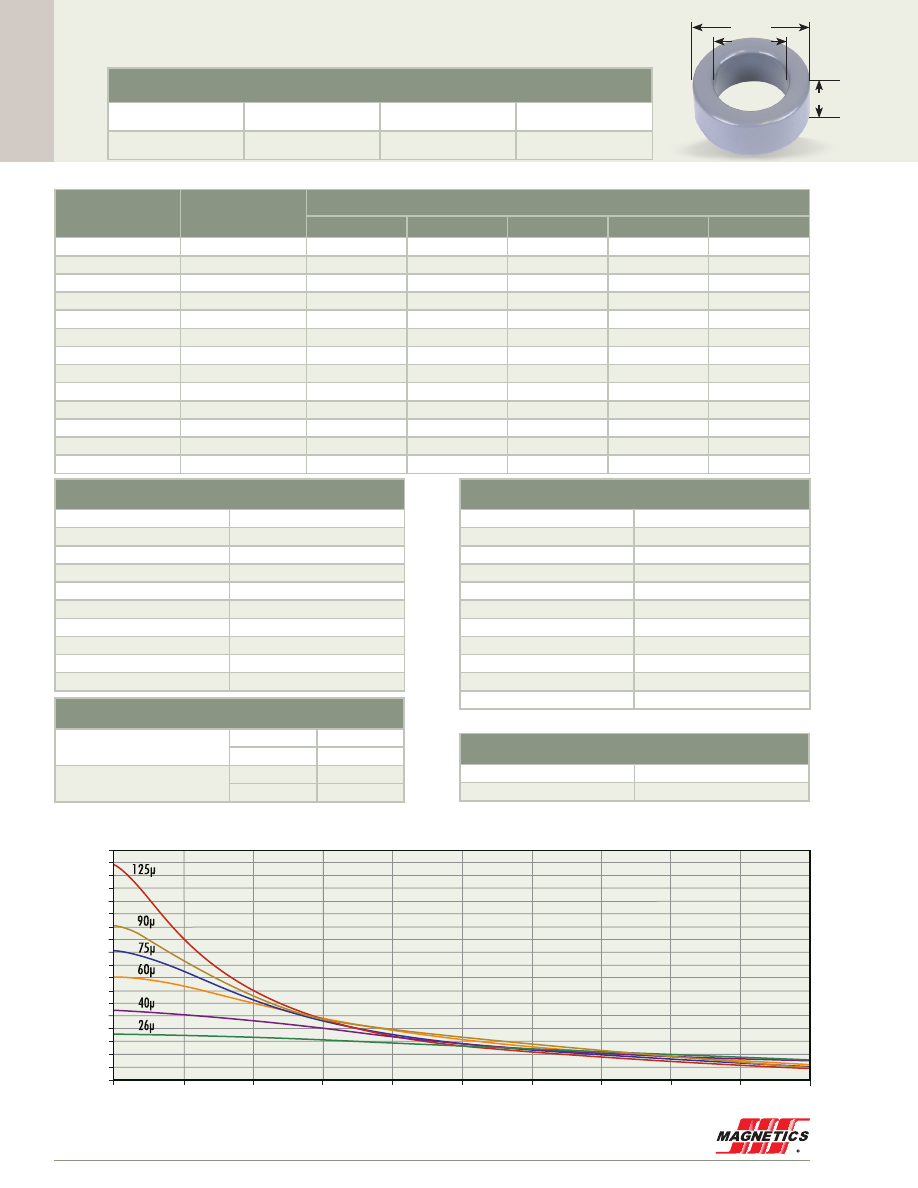

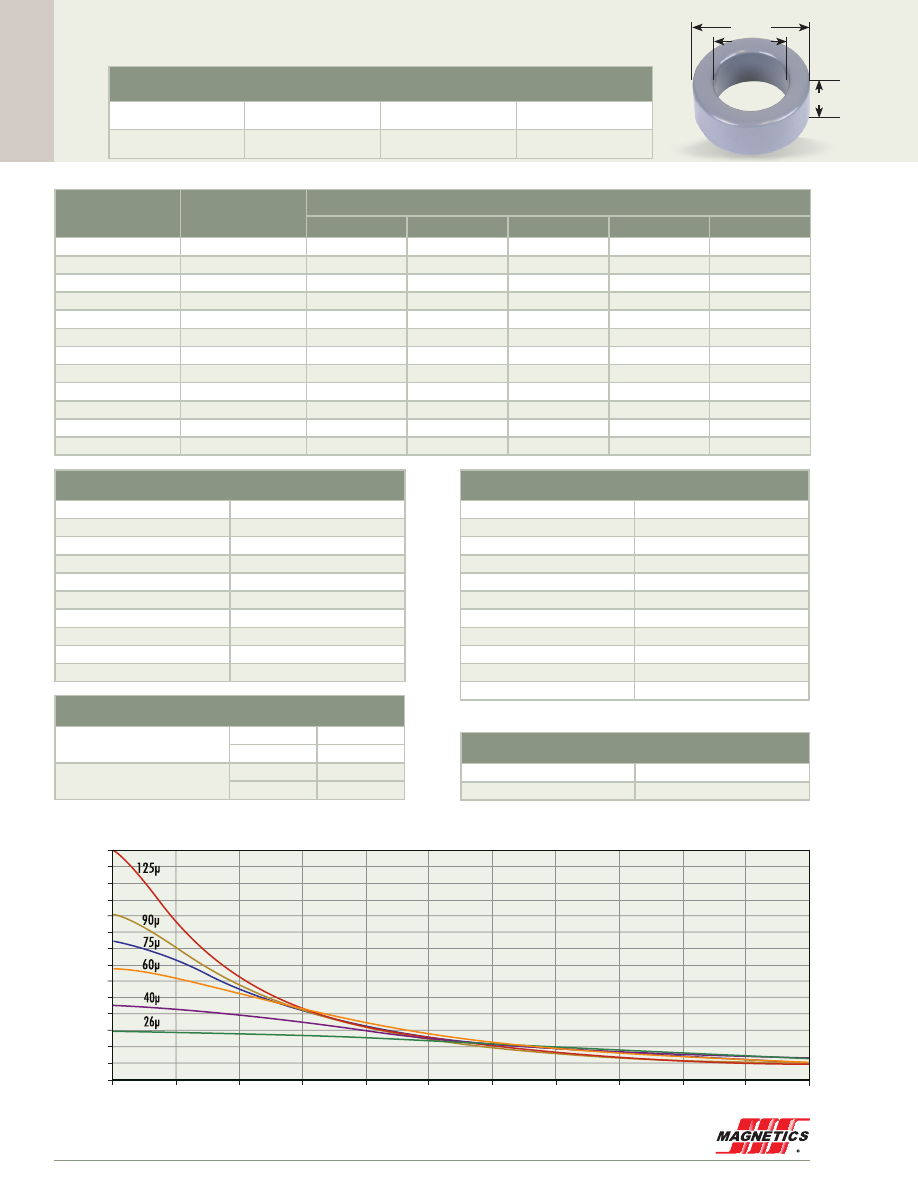

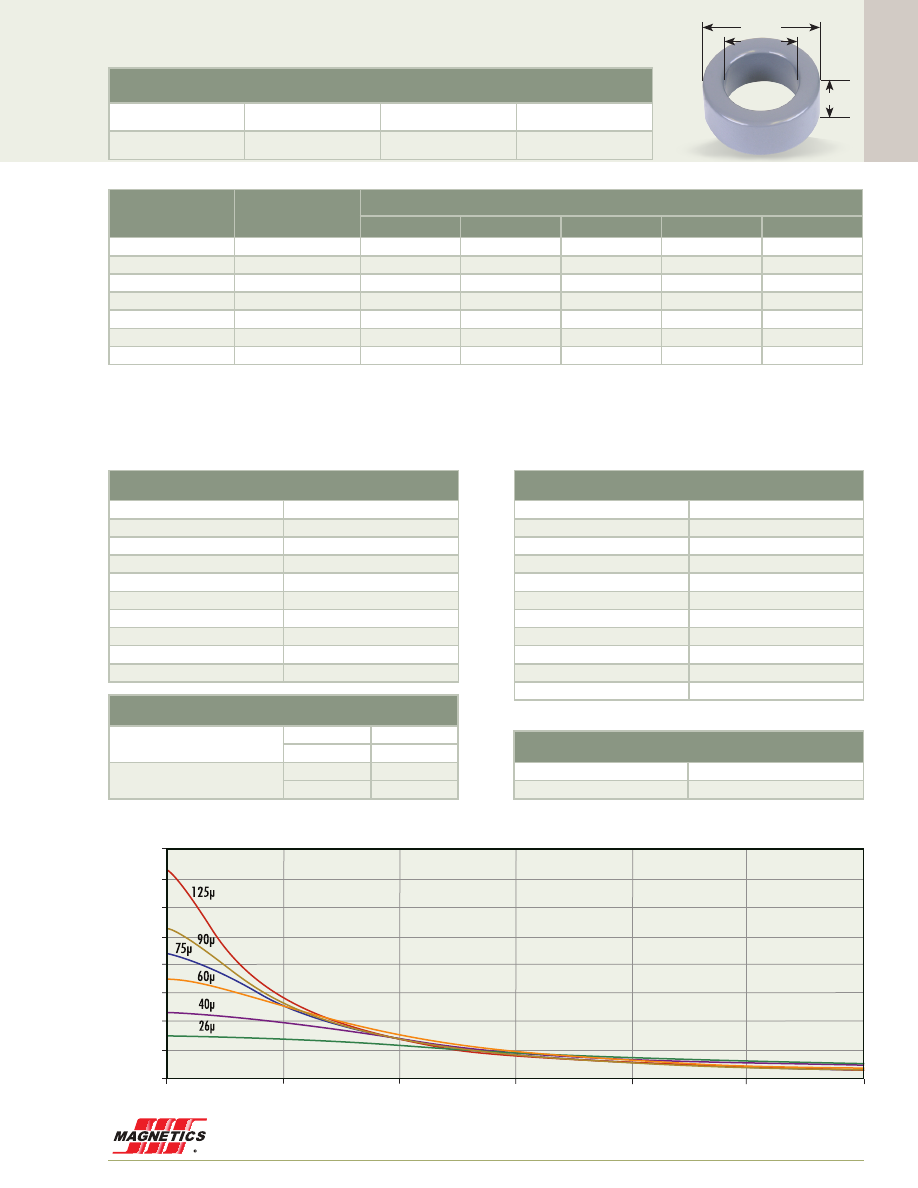

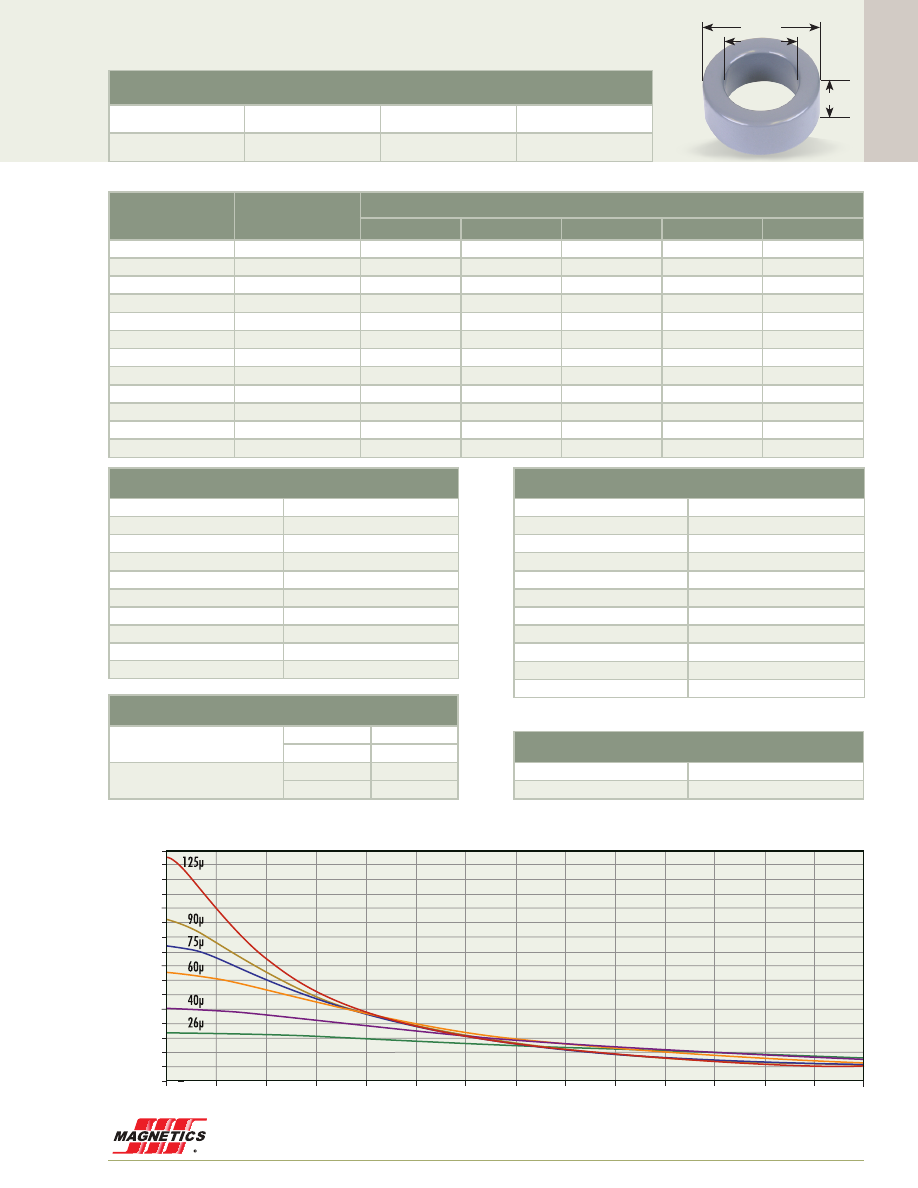

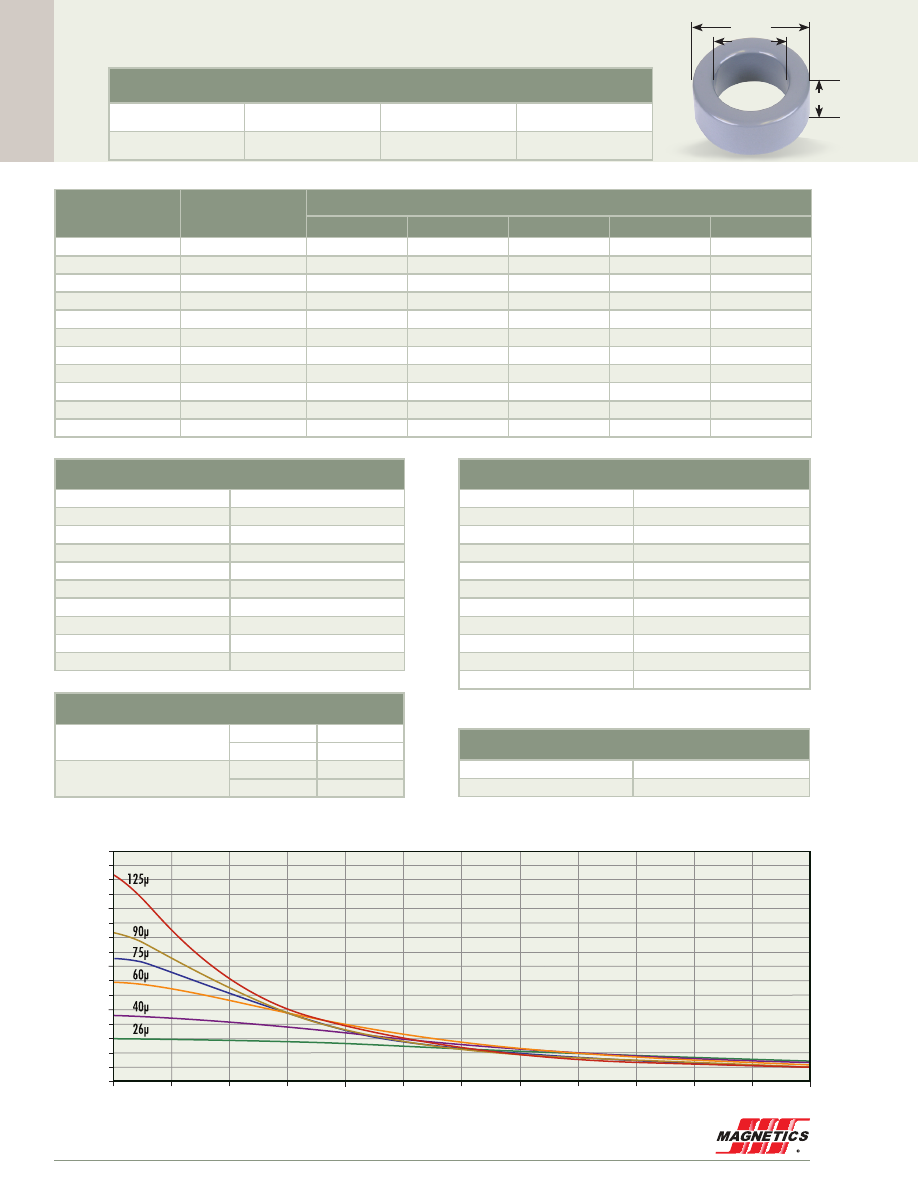

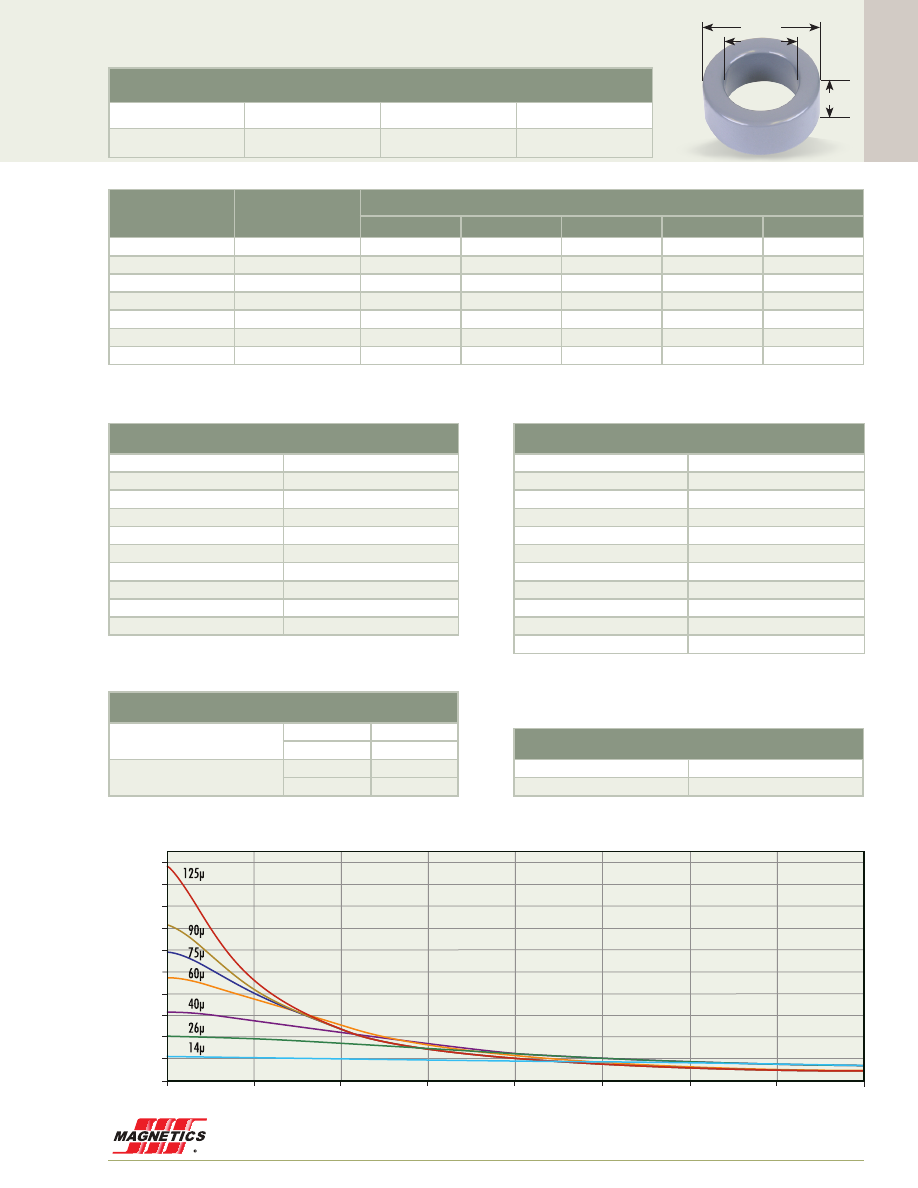

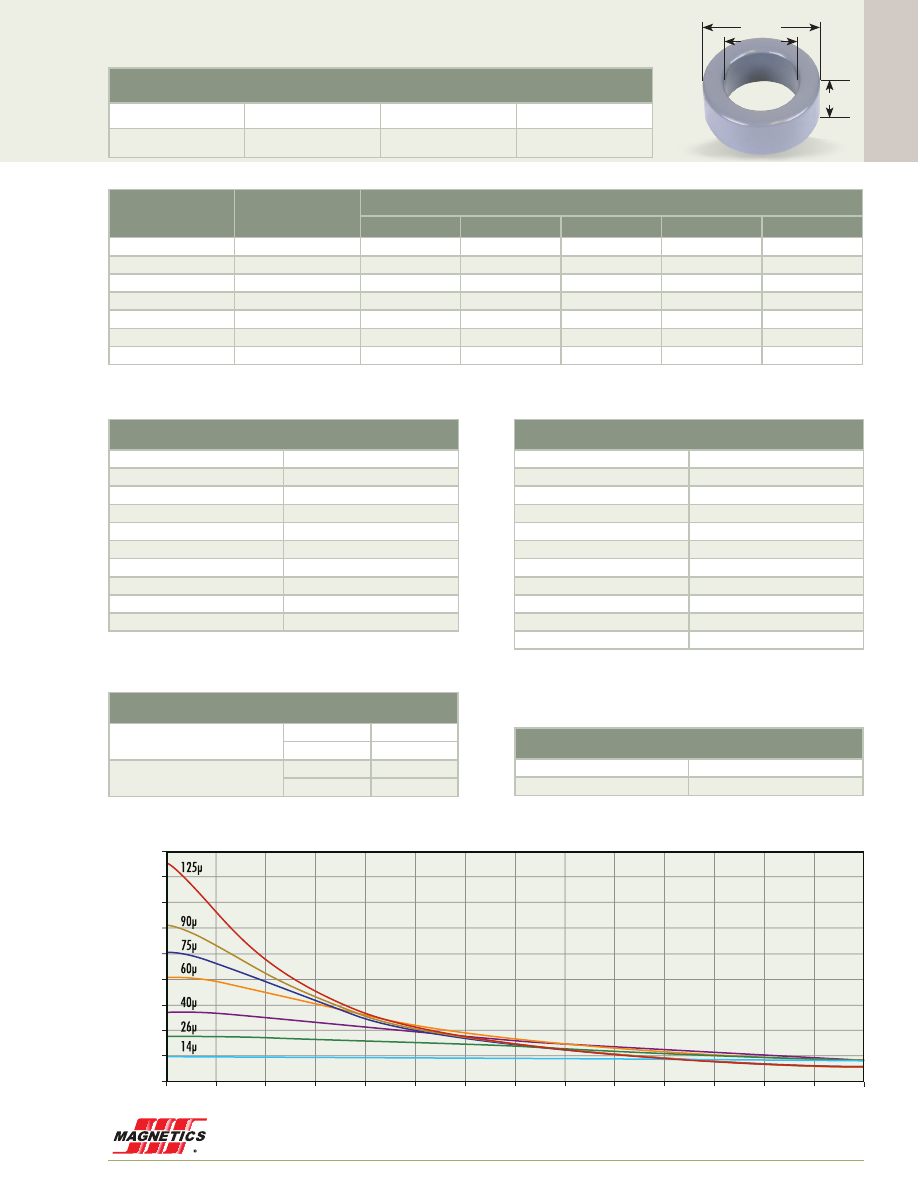

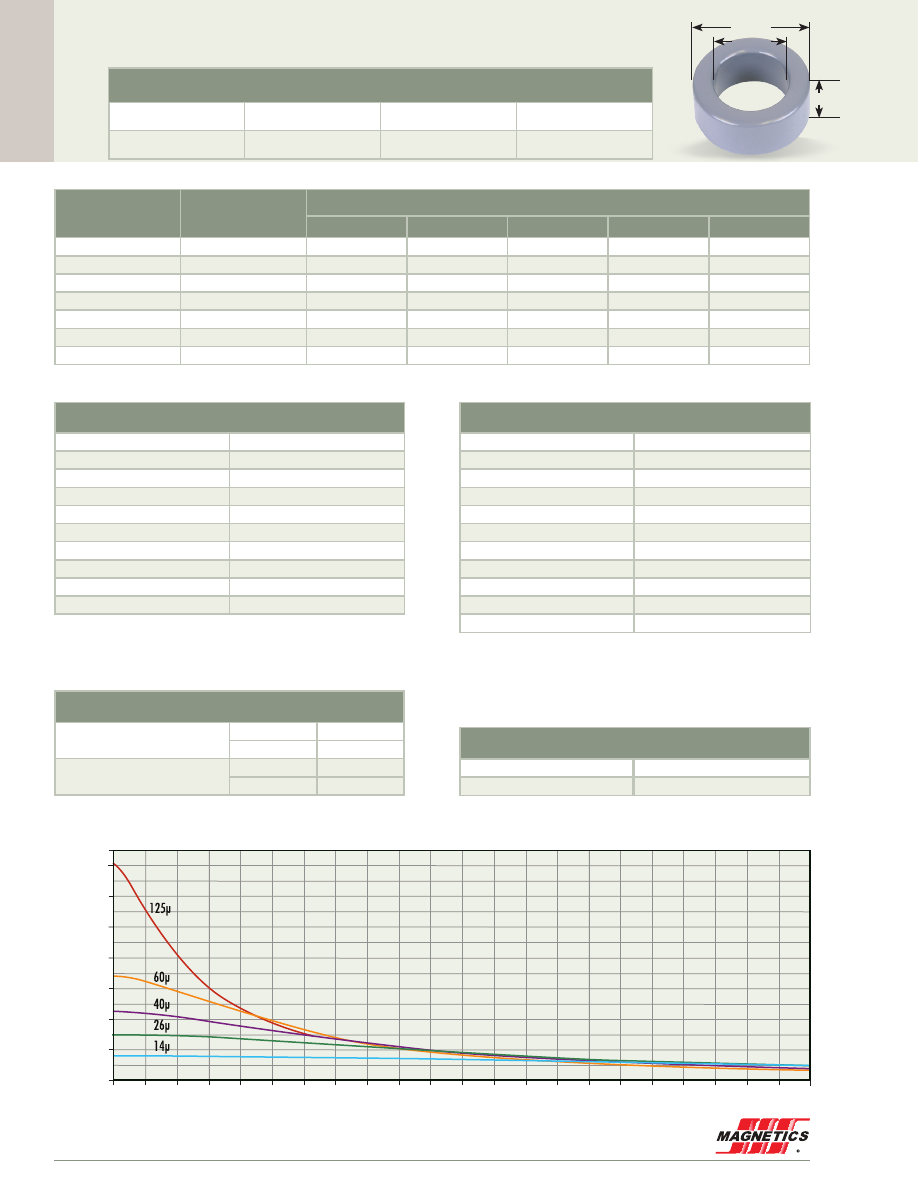

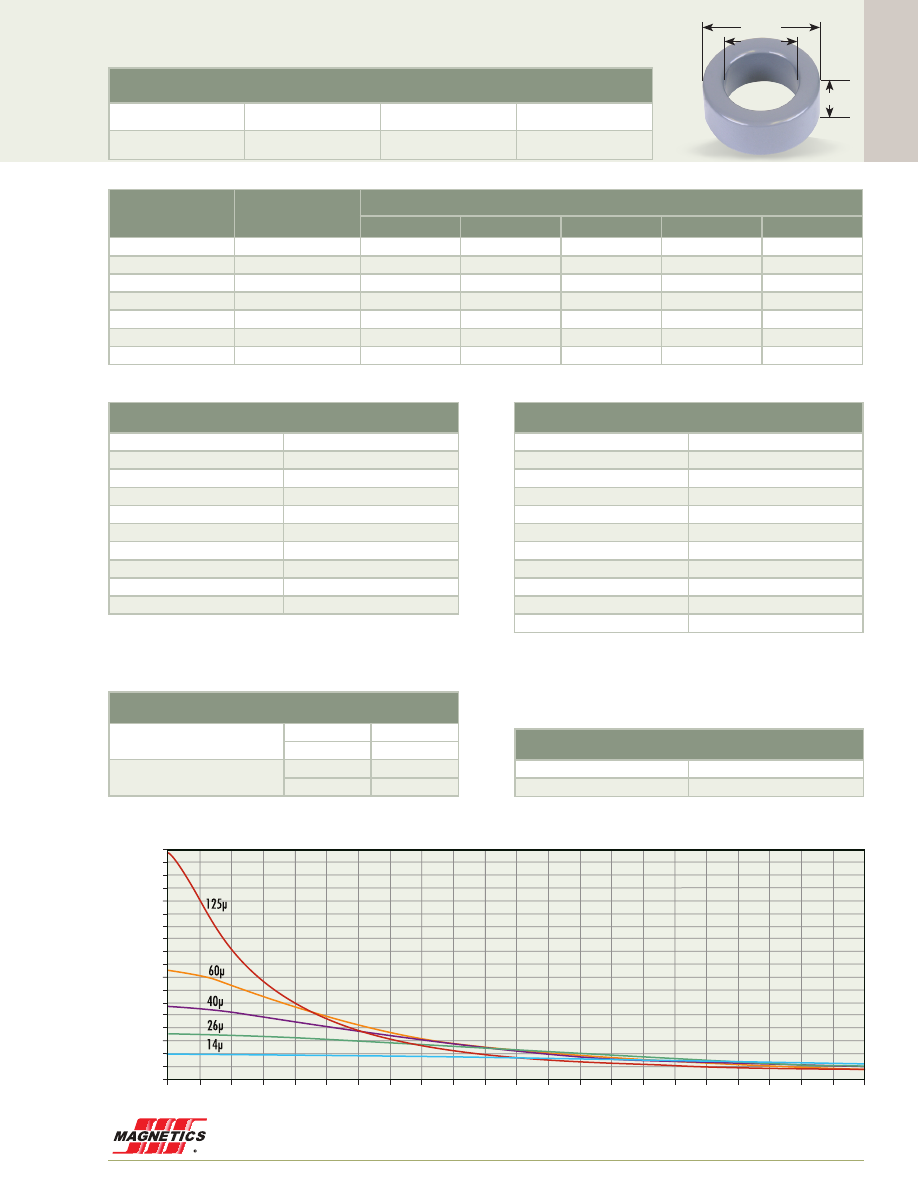

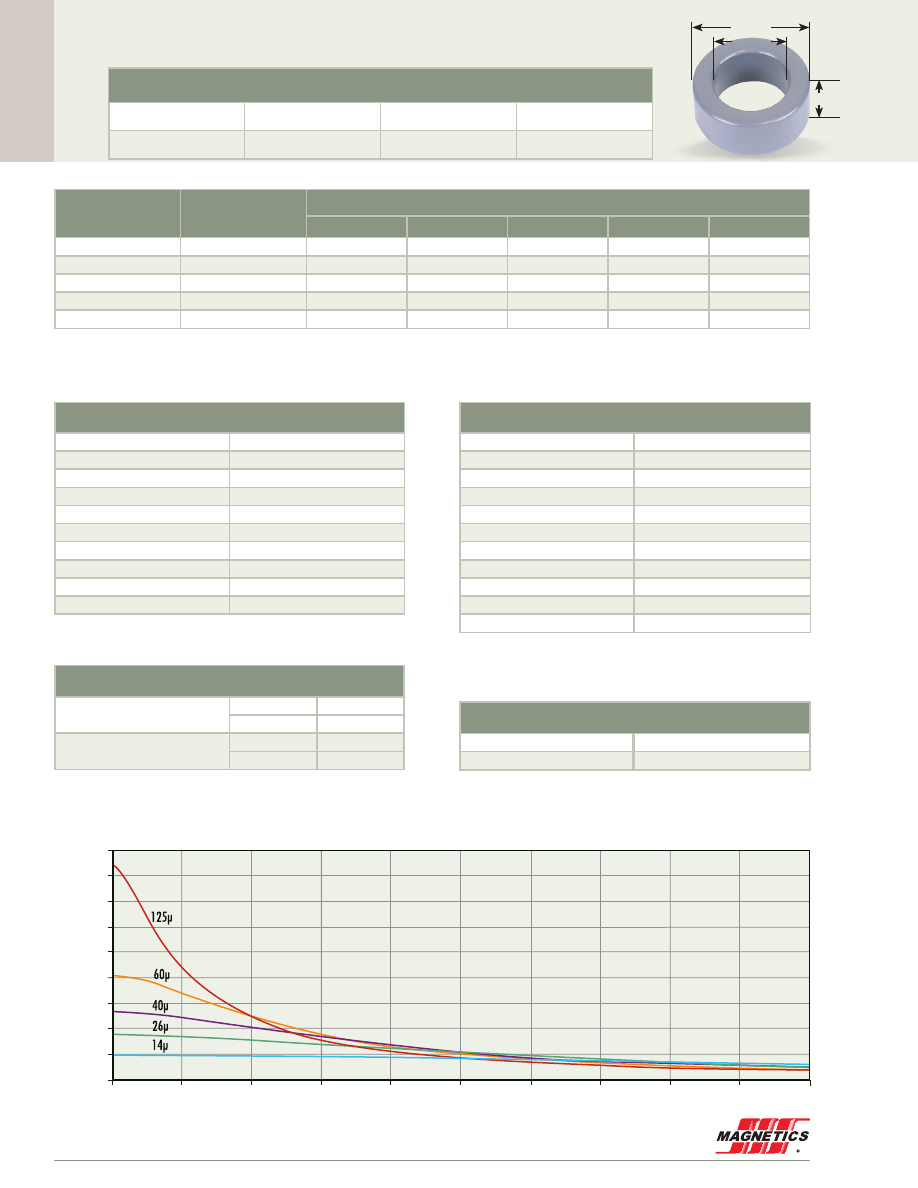

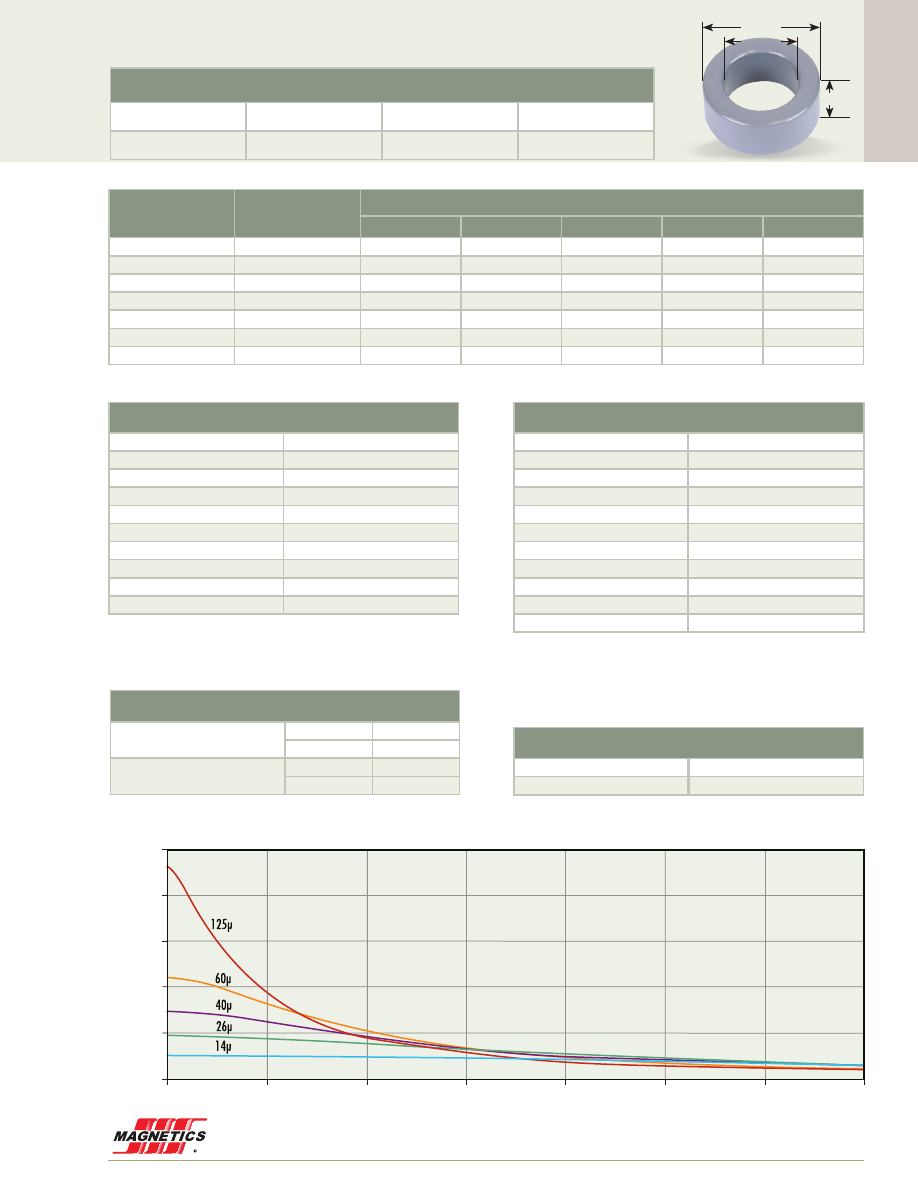

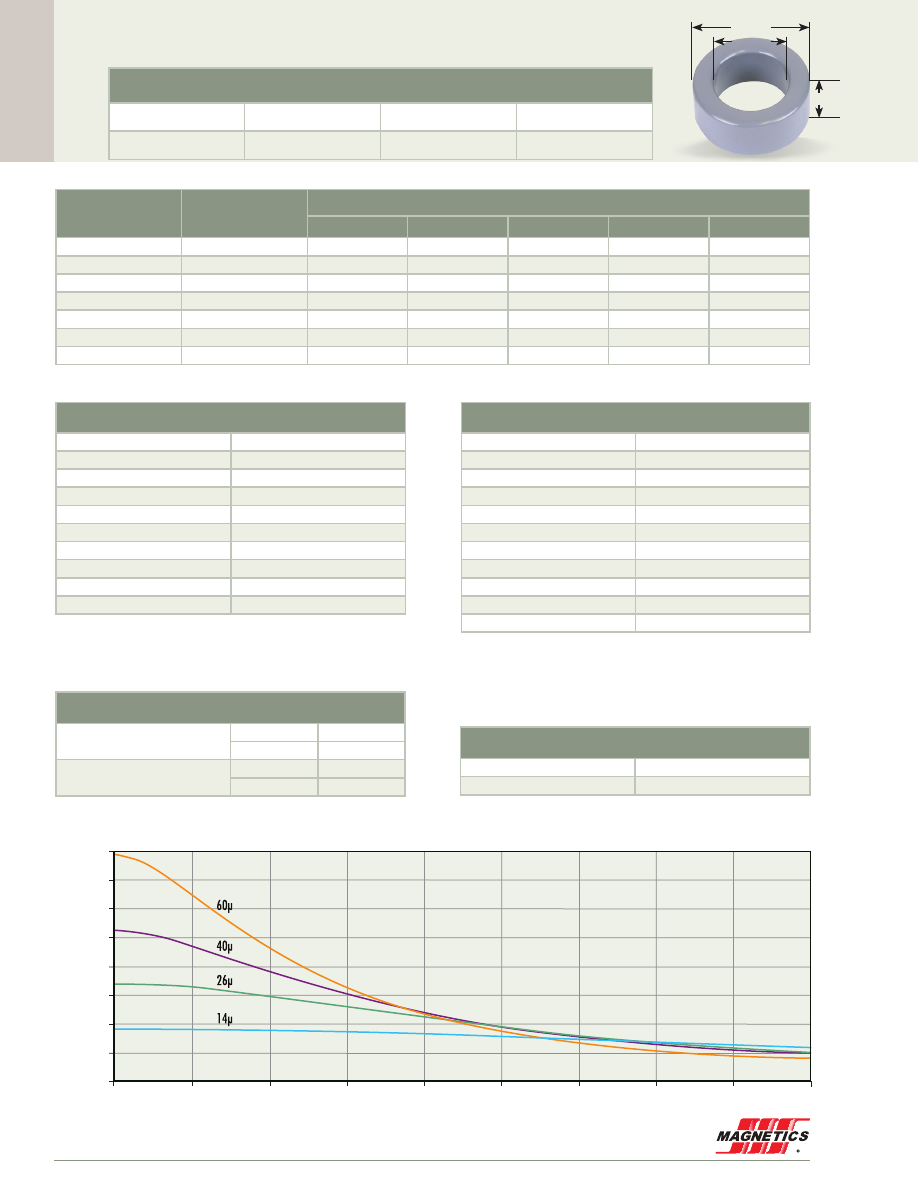

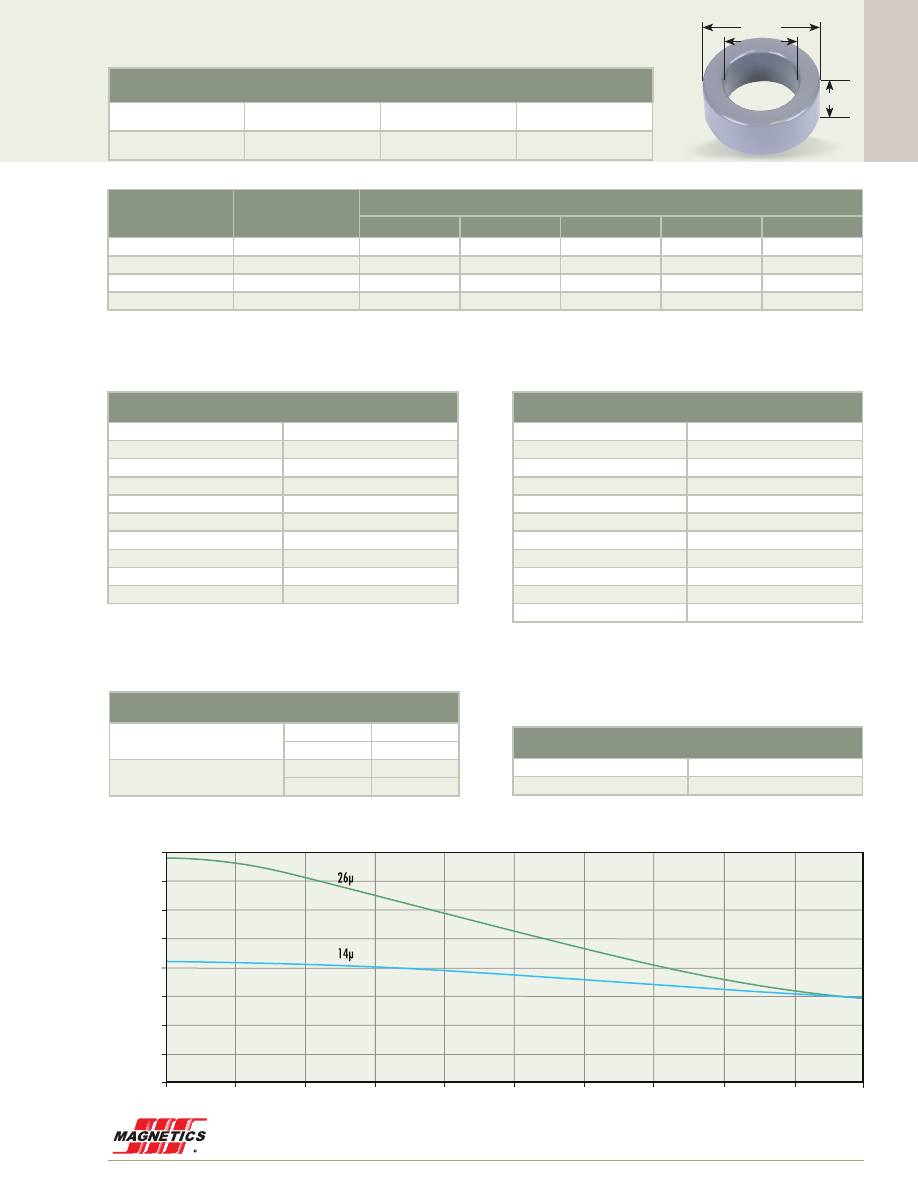

Permeability versus DC Bias Curves . . . . . . 29

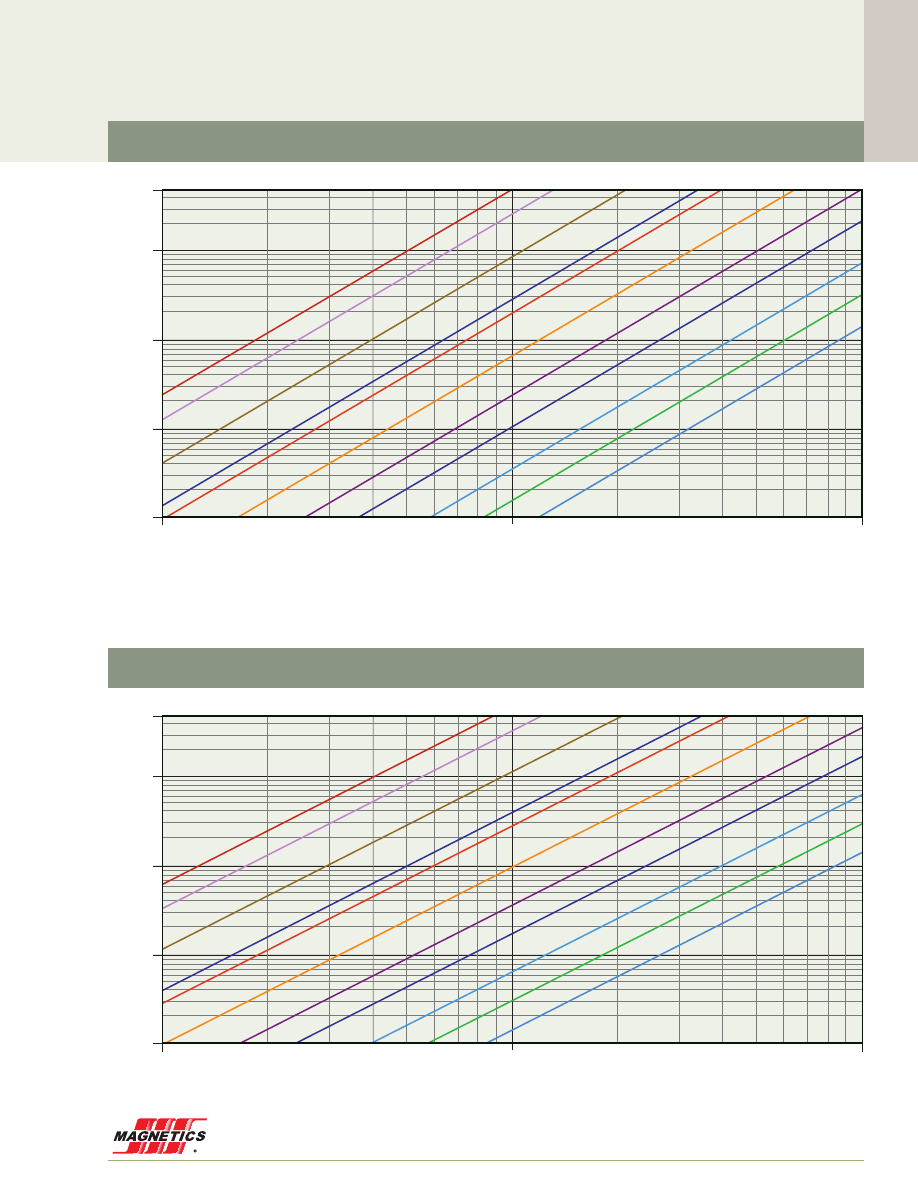

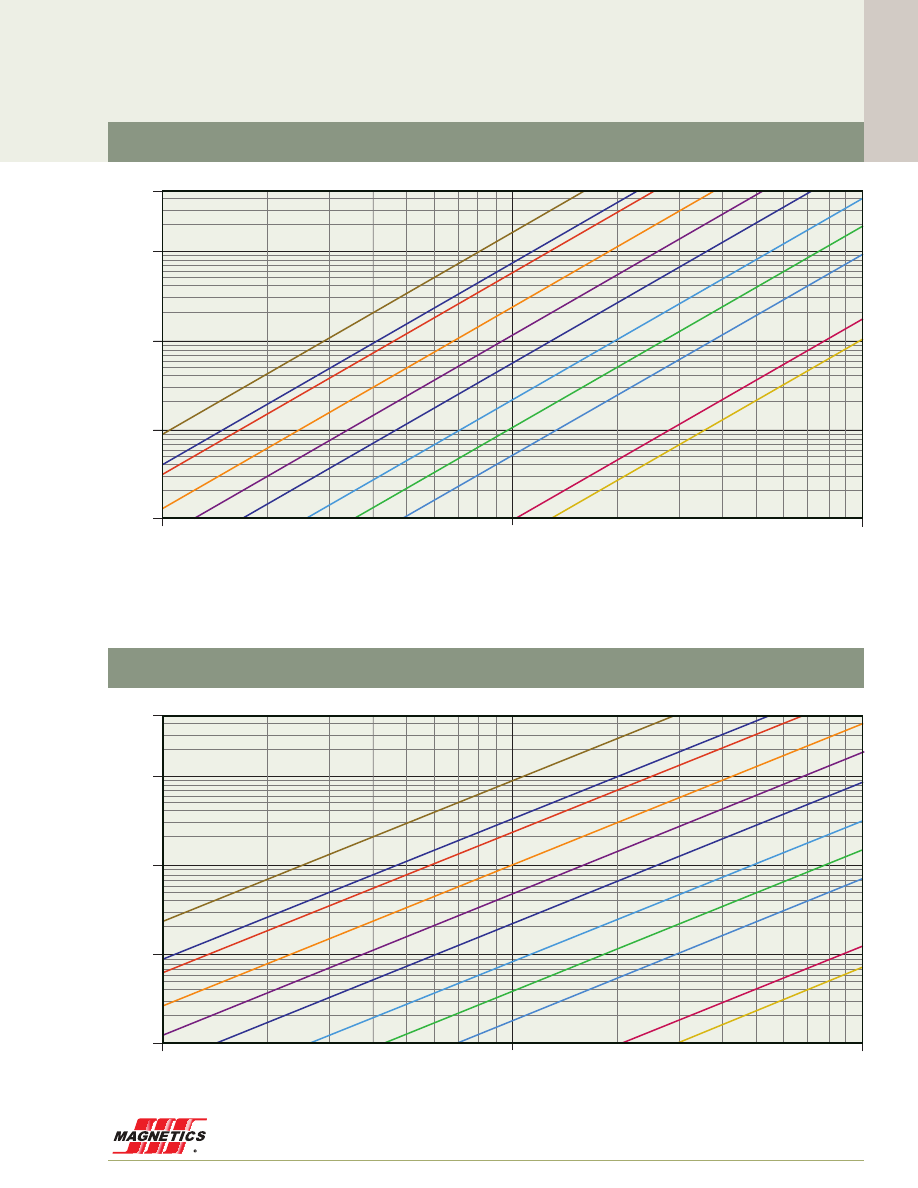

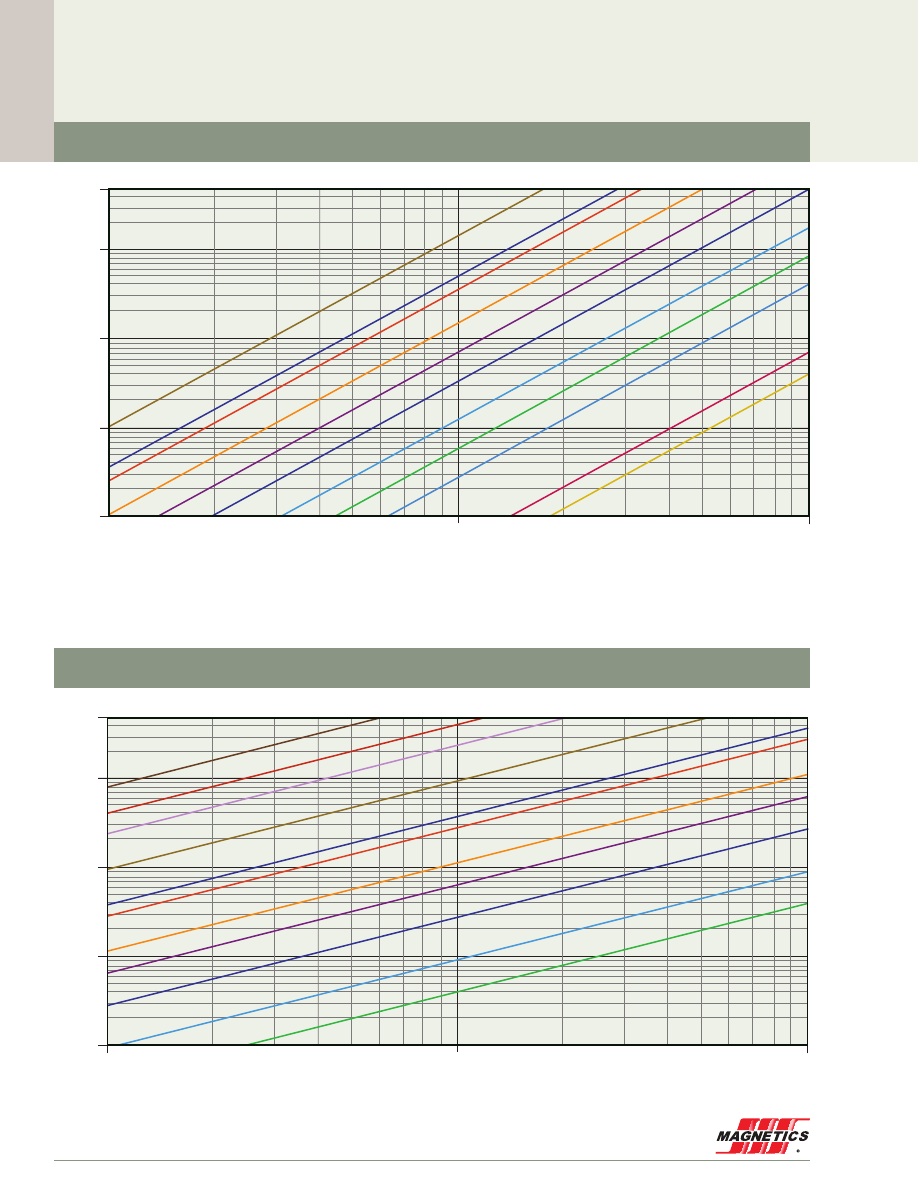

Core Loss Density Curves . . . . . . . . . . . . . . 35

DC Magnetization Curves . . . . . . . . . . . . . . 47

Permeability versus Temperature Curves . . . 51

Permeability versus Frequency Curves . . . . 55

Core Data

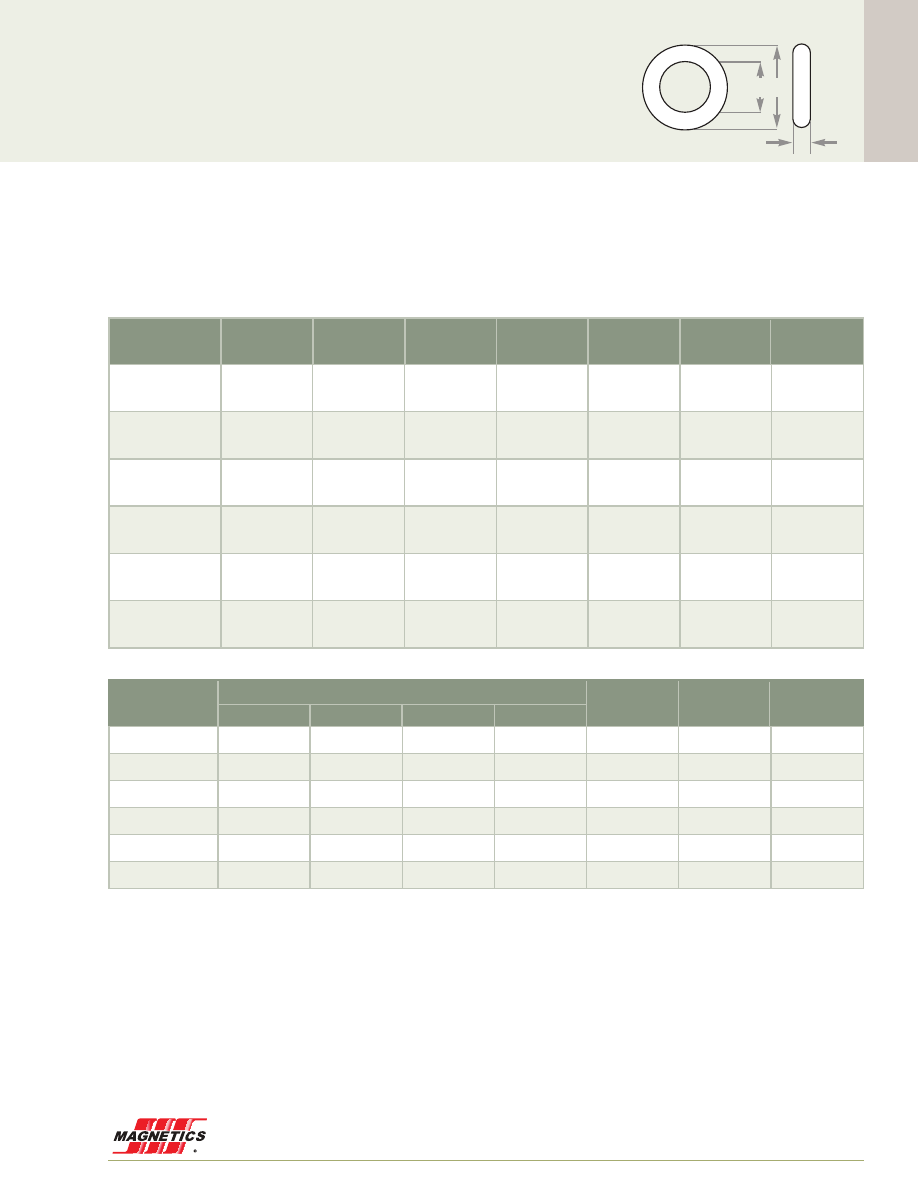

Toroid Data . . . . . . . . . . . . . . . . . . . . . . . . . 58

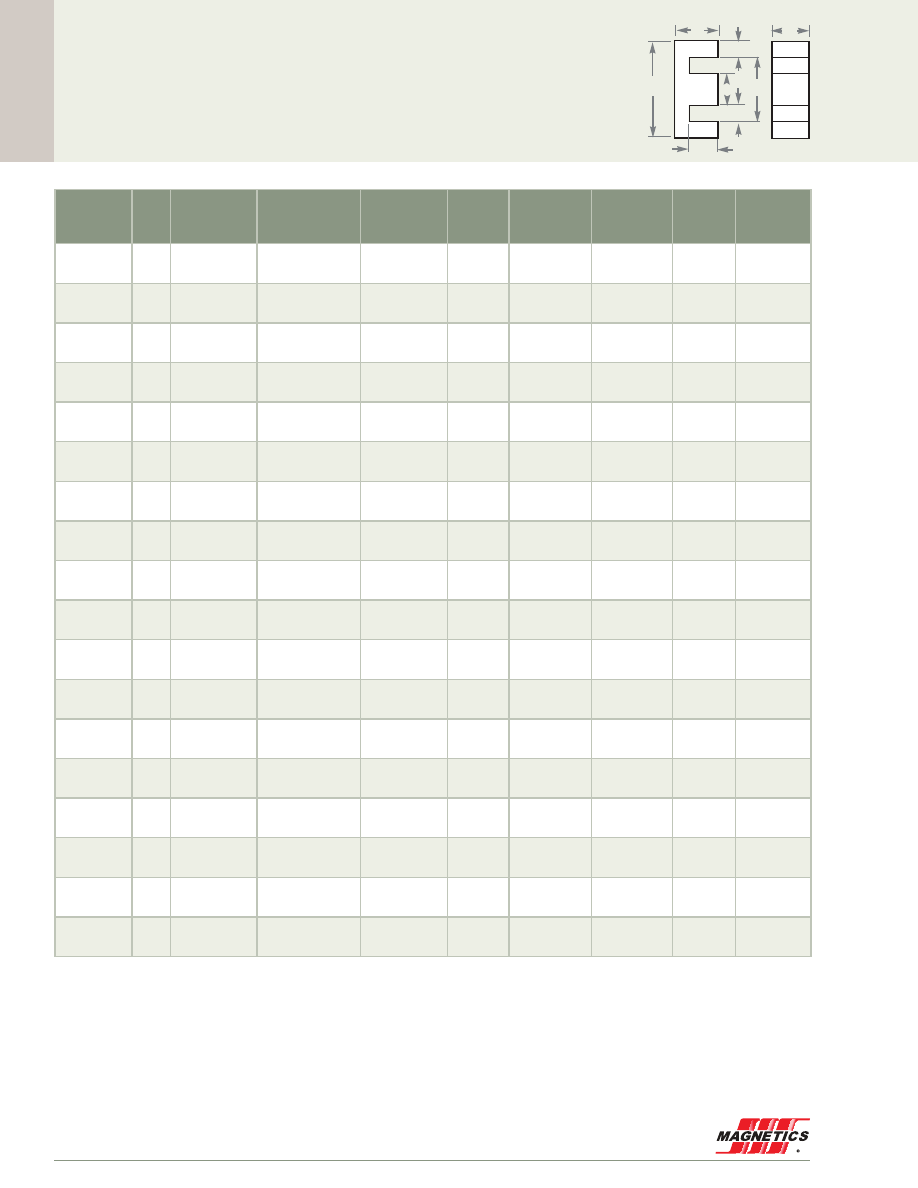

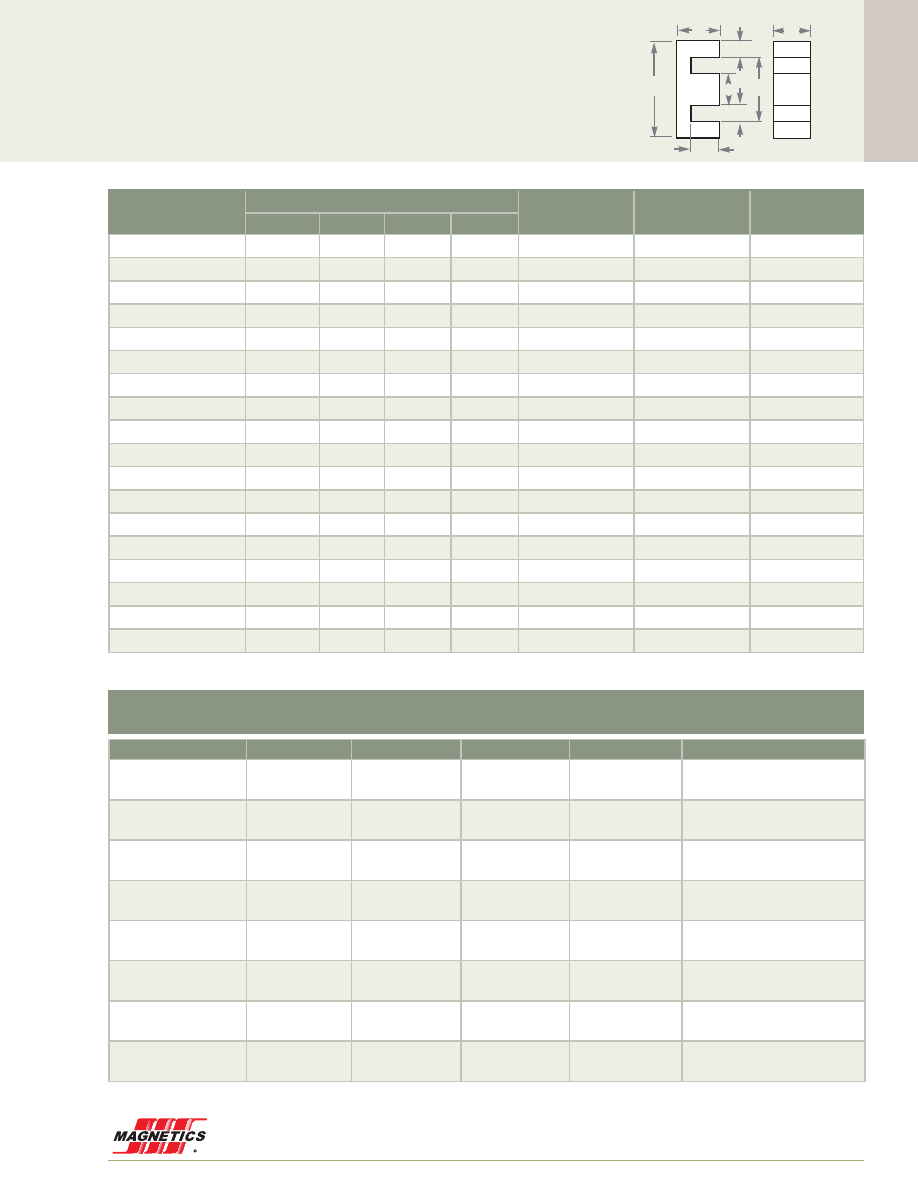

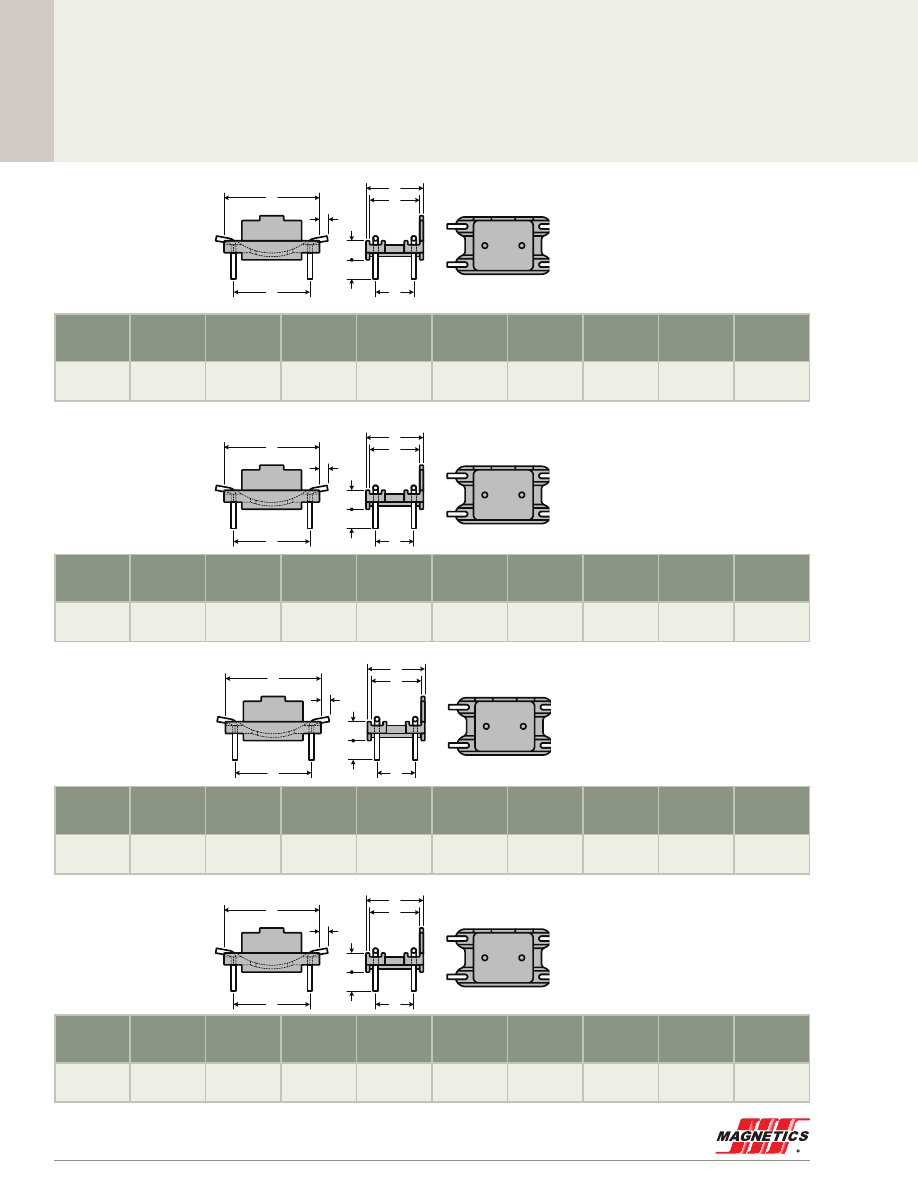

E Core Data . . . . . . . . . . . . . . . . . . . . . . . . 96

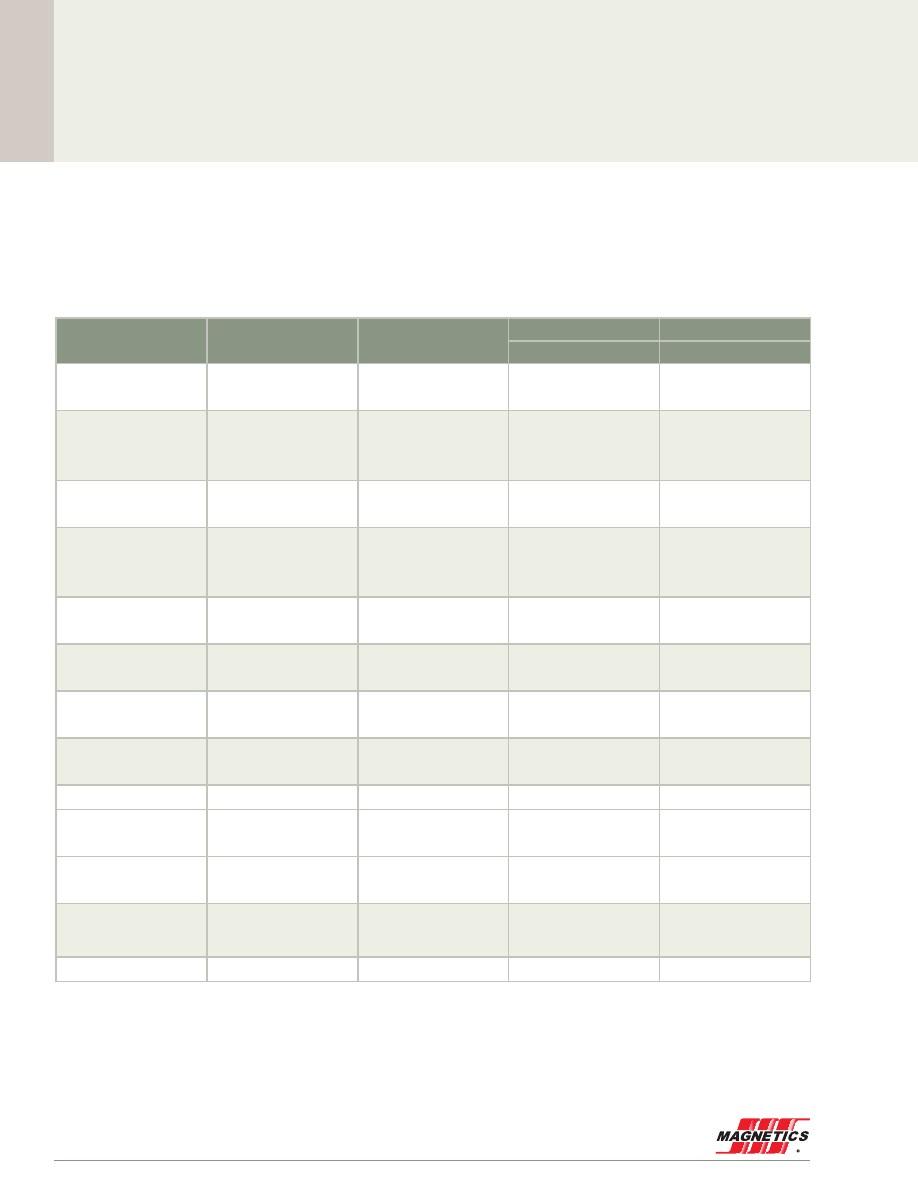

Block Data . . . . . . . . . . . . . . . . . . . . . . . . . 97

U Core Data . . . . . . . . . . . . . . . . . . . . . . . . 98

MPP THINZ

Data . . . . . . . . . . . . . . . . . . . . 99

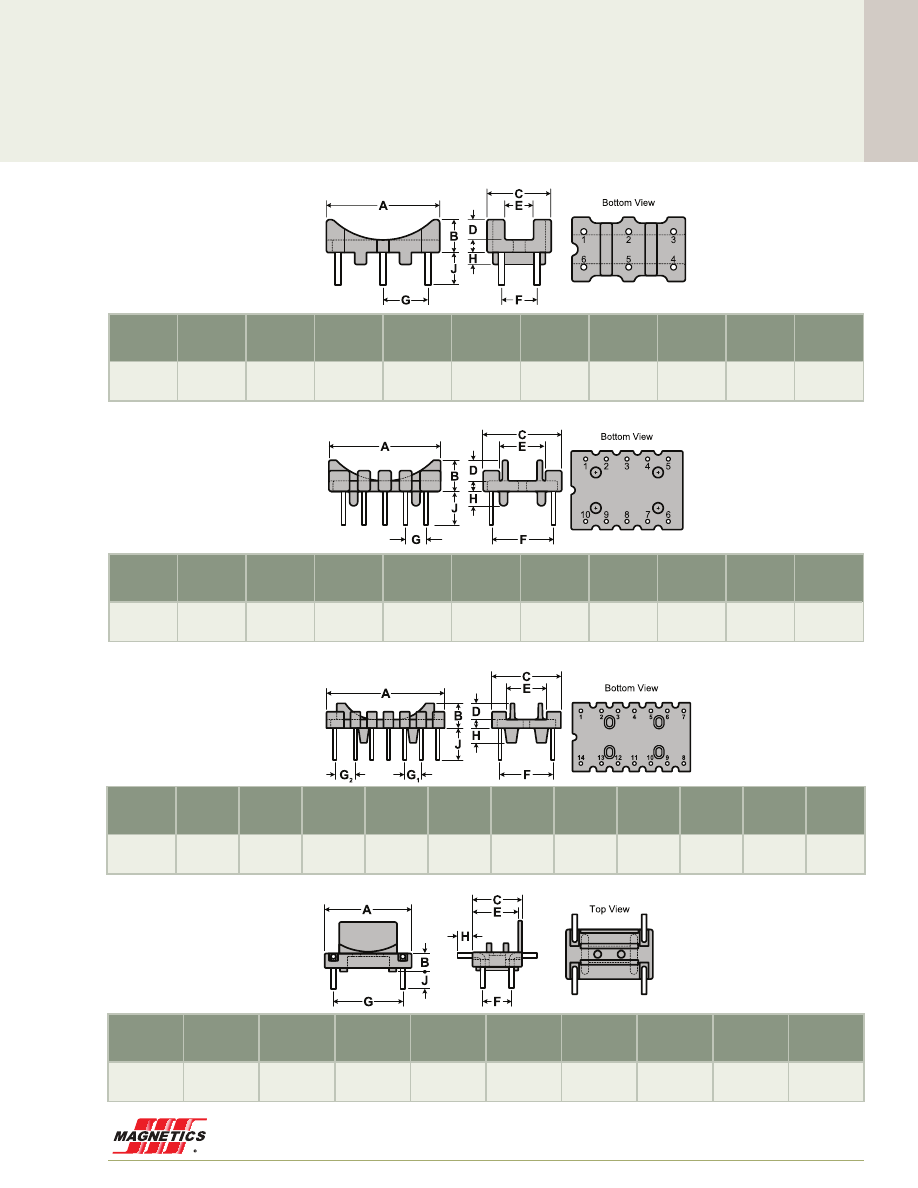

Hardware

E Core Hardware . . . . . . . . . . . . . . . . . . . 100

Toroid Hardware . . . . . . . . . . . . . . . . . . . . 101

Winding Tables

Winding Tables . . . . . . . . . . . . . . . . . . . . . 103

Index

< Click the page name

or page number to go

directly to the page

www.mag-inc.com

3

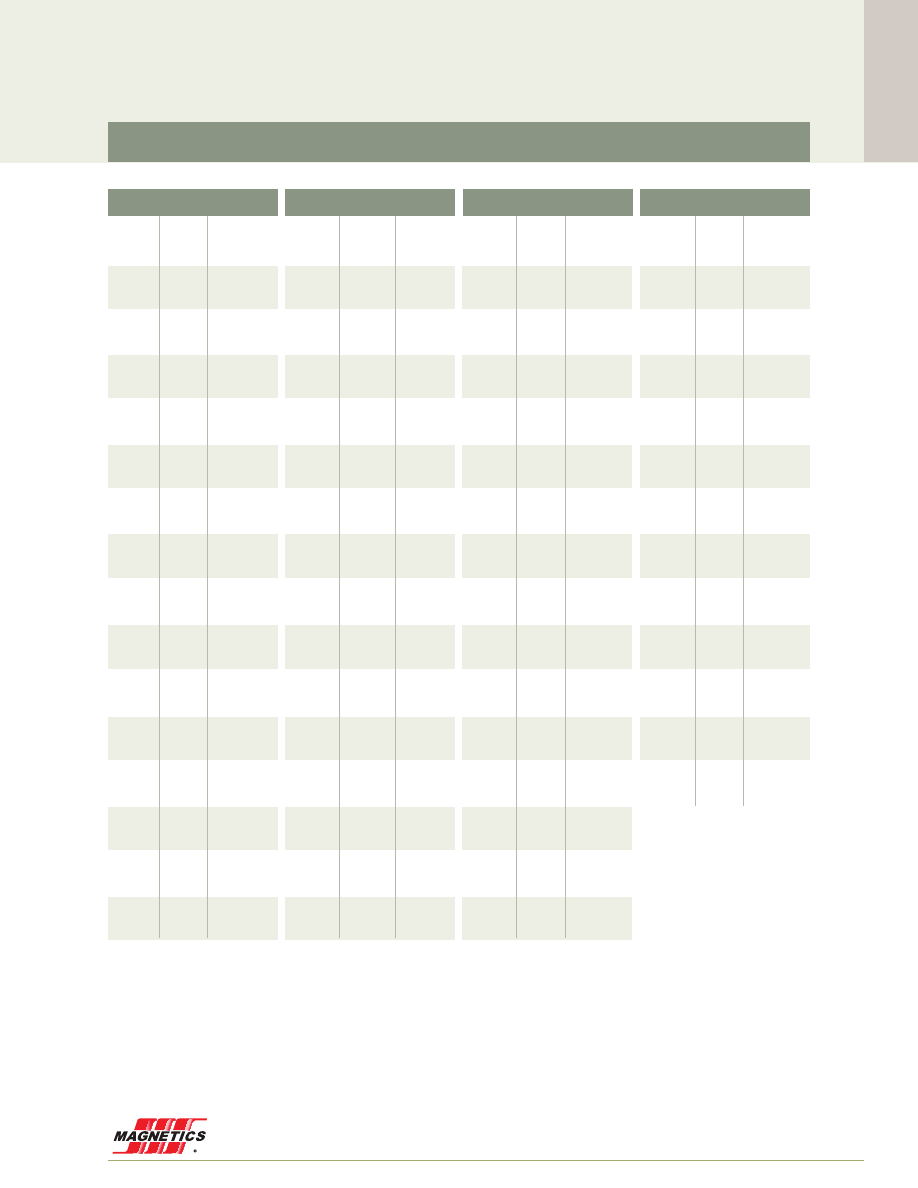

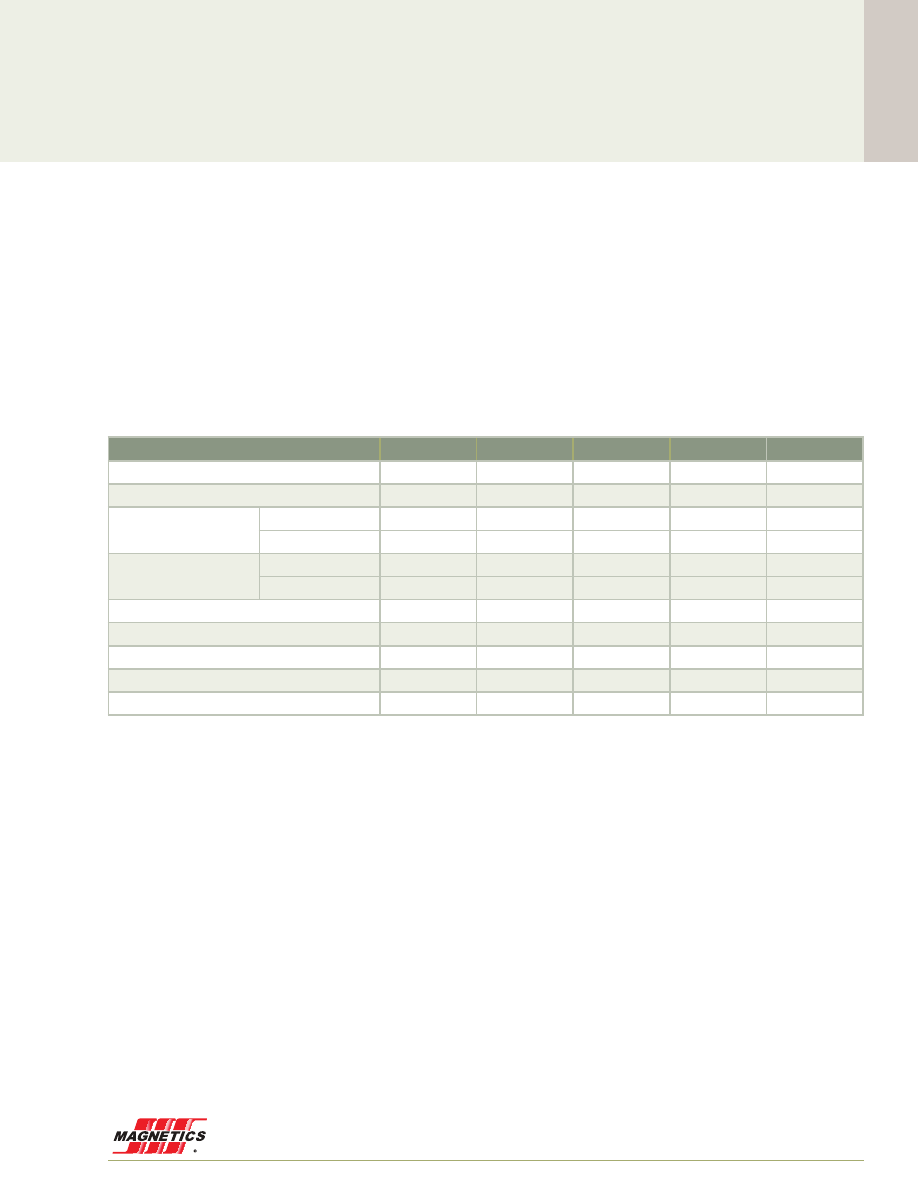

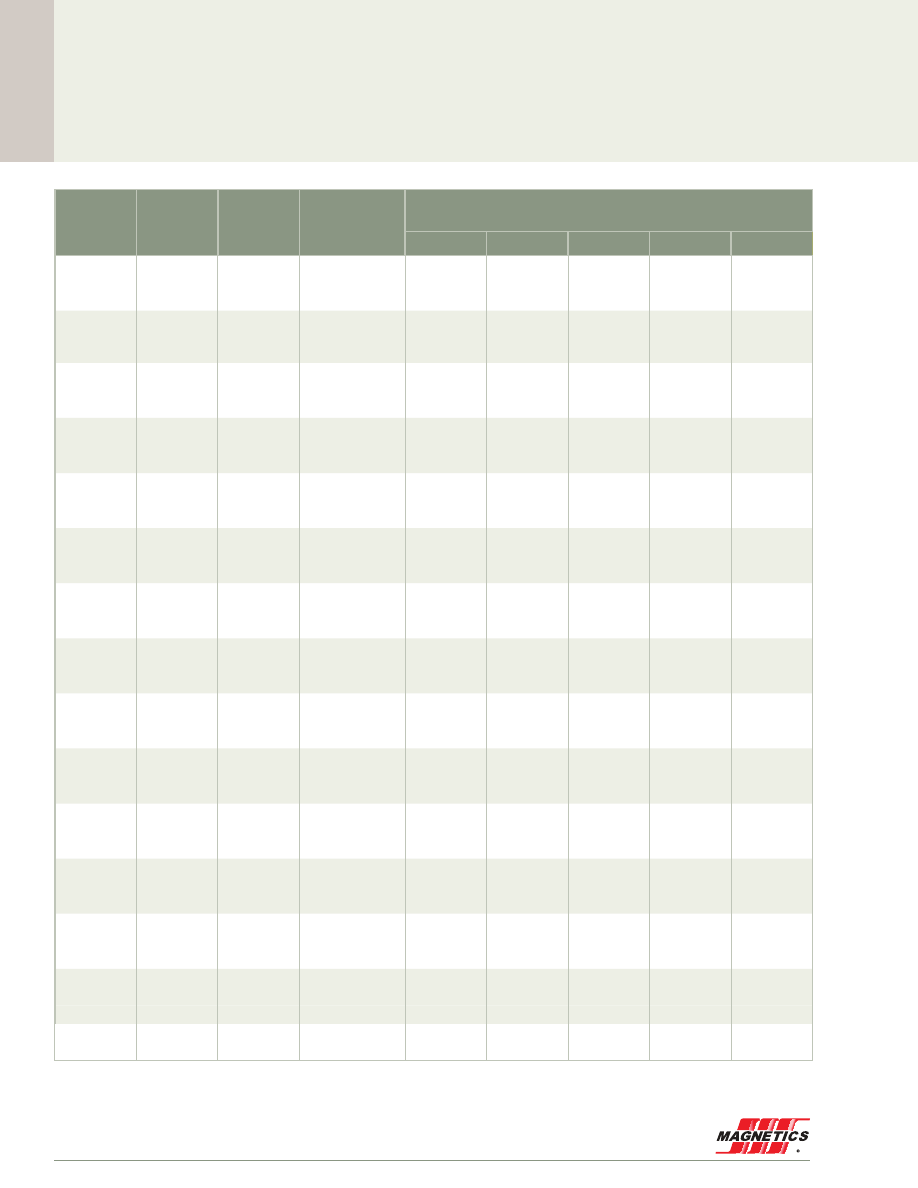

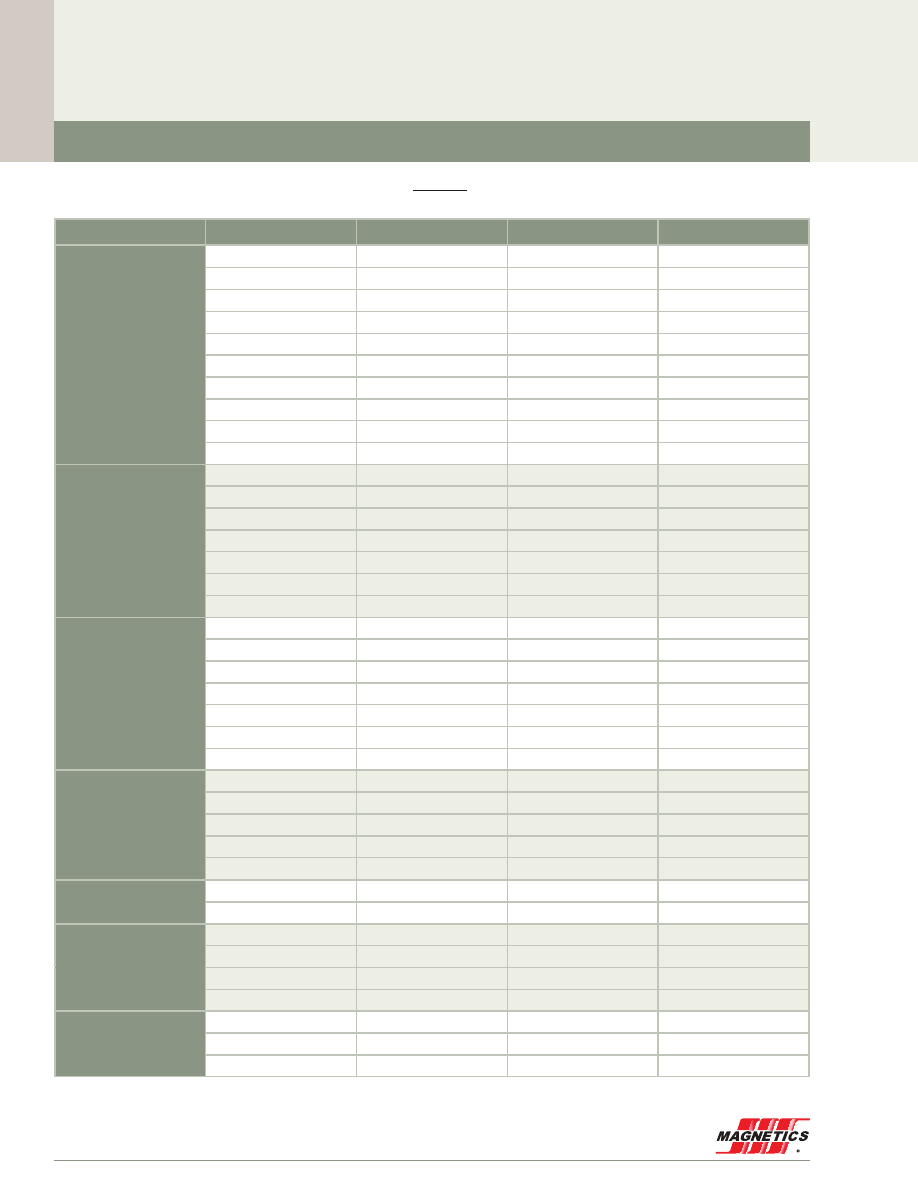

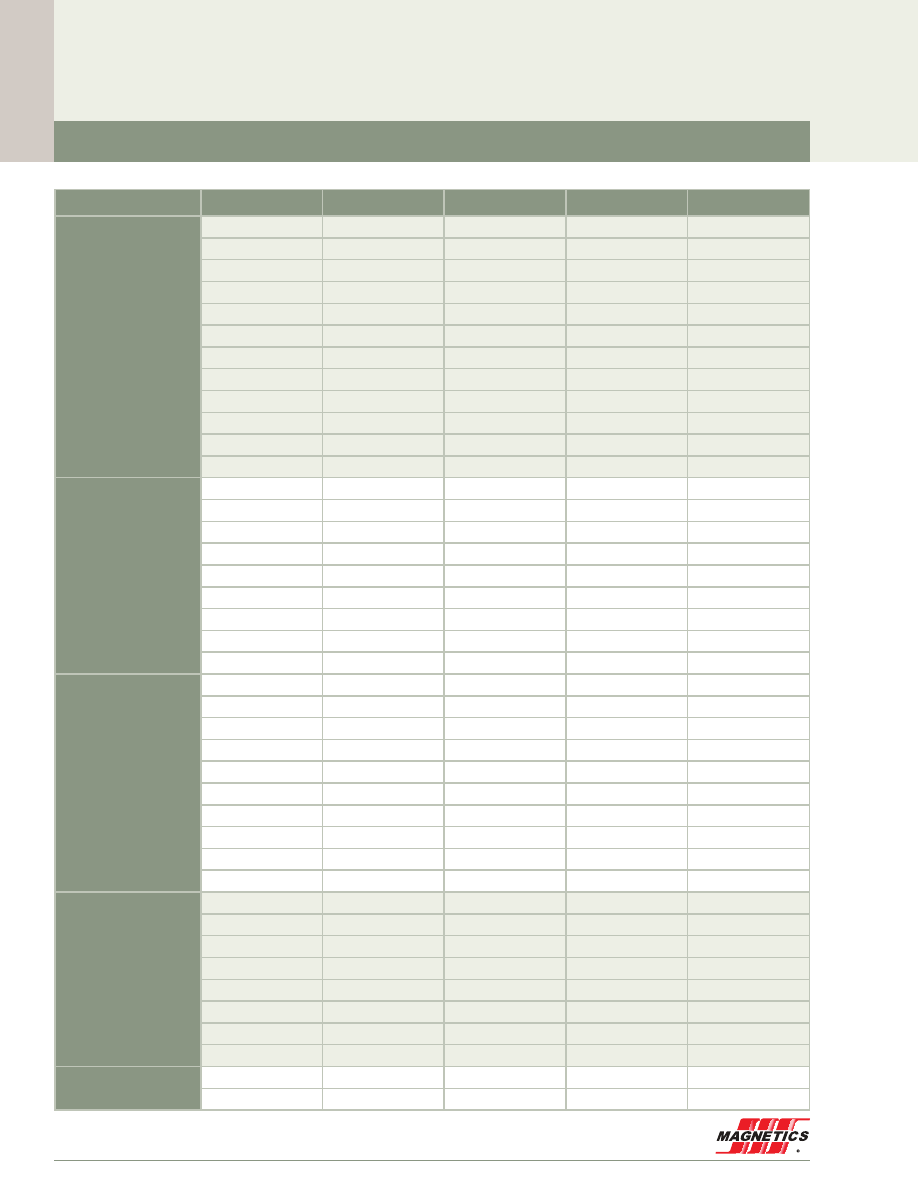

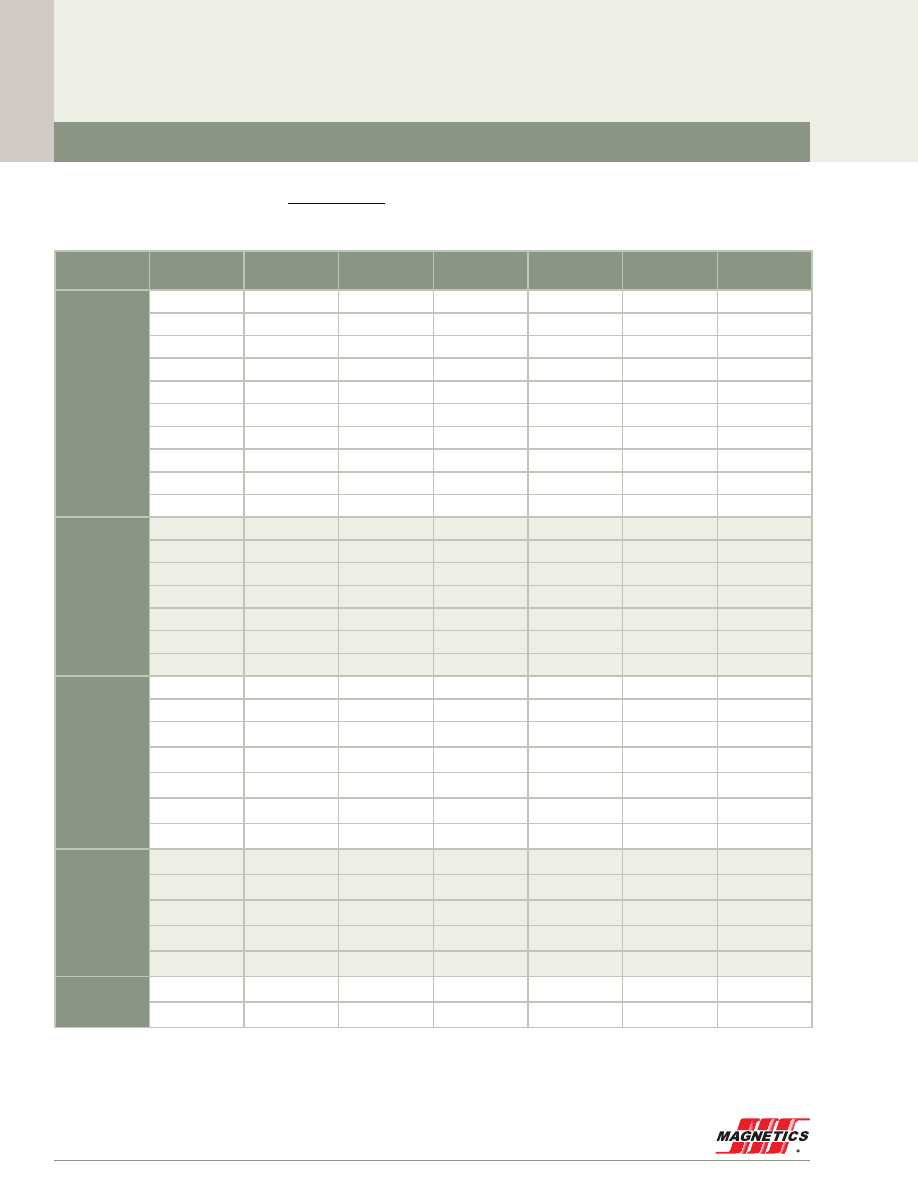

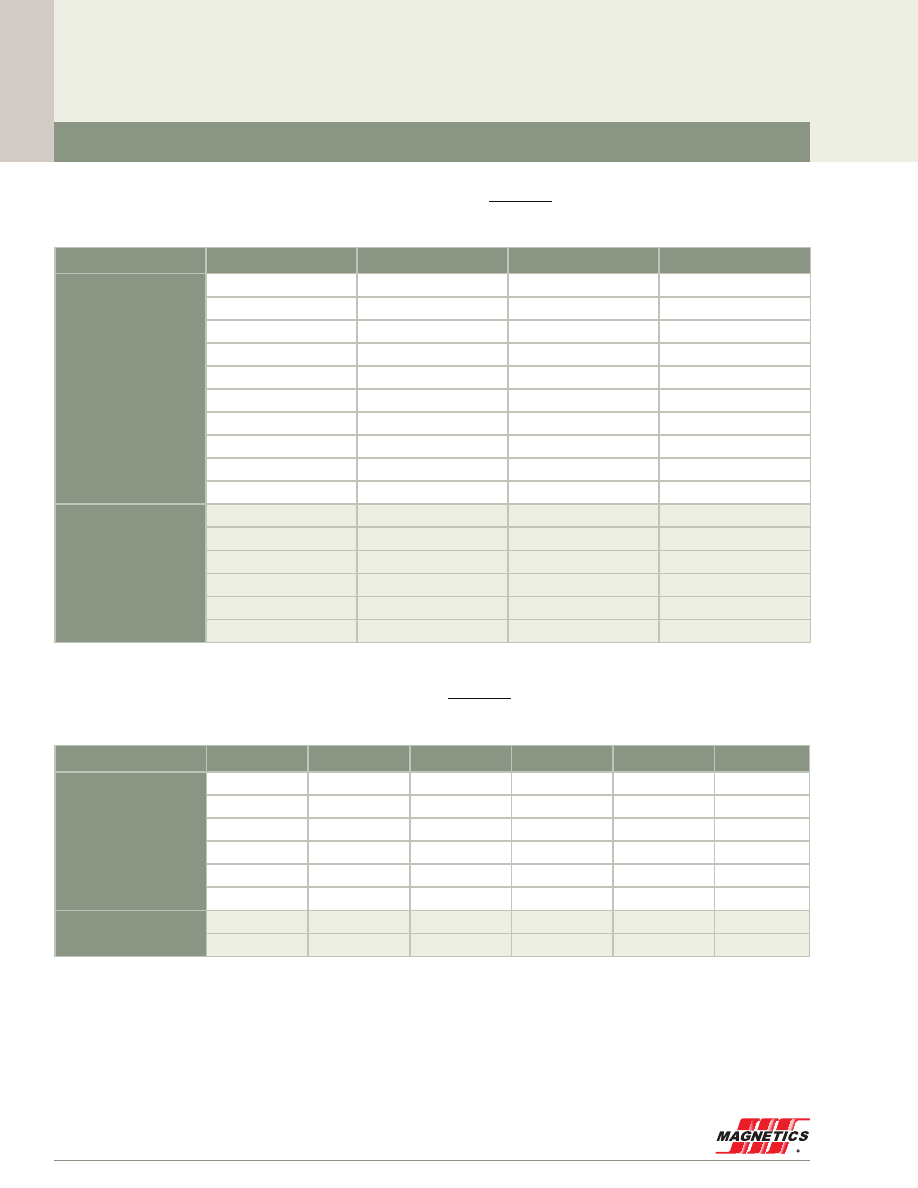

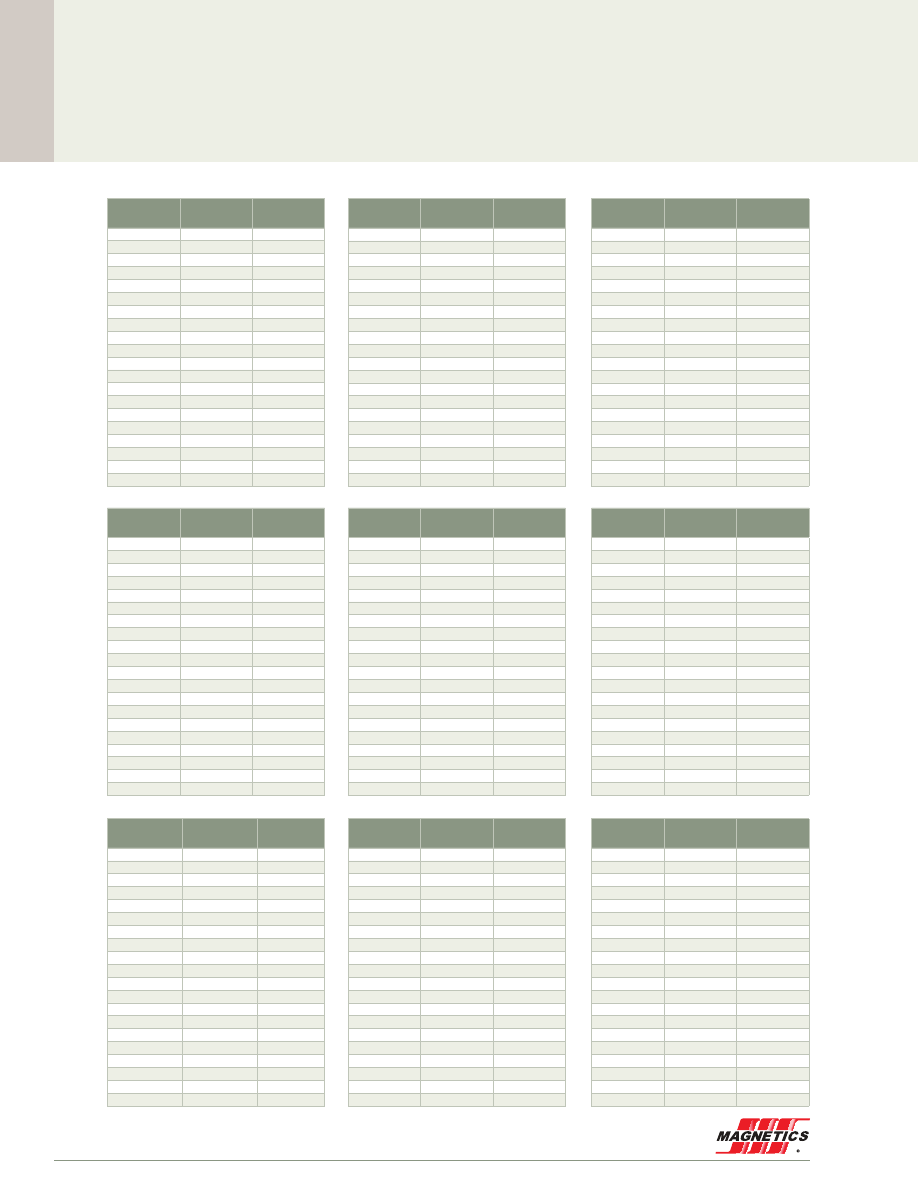

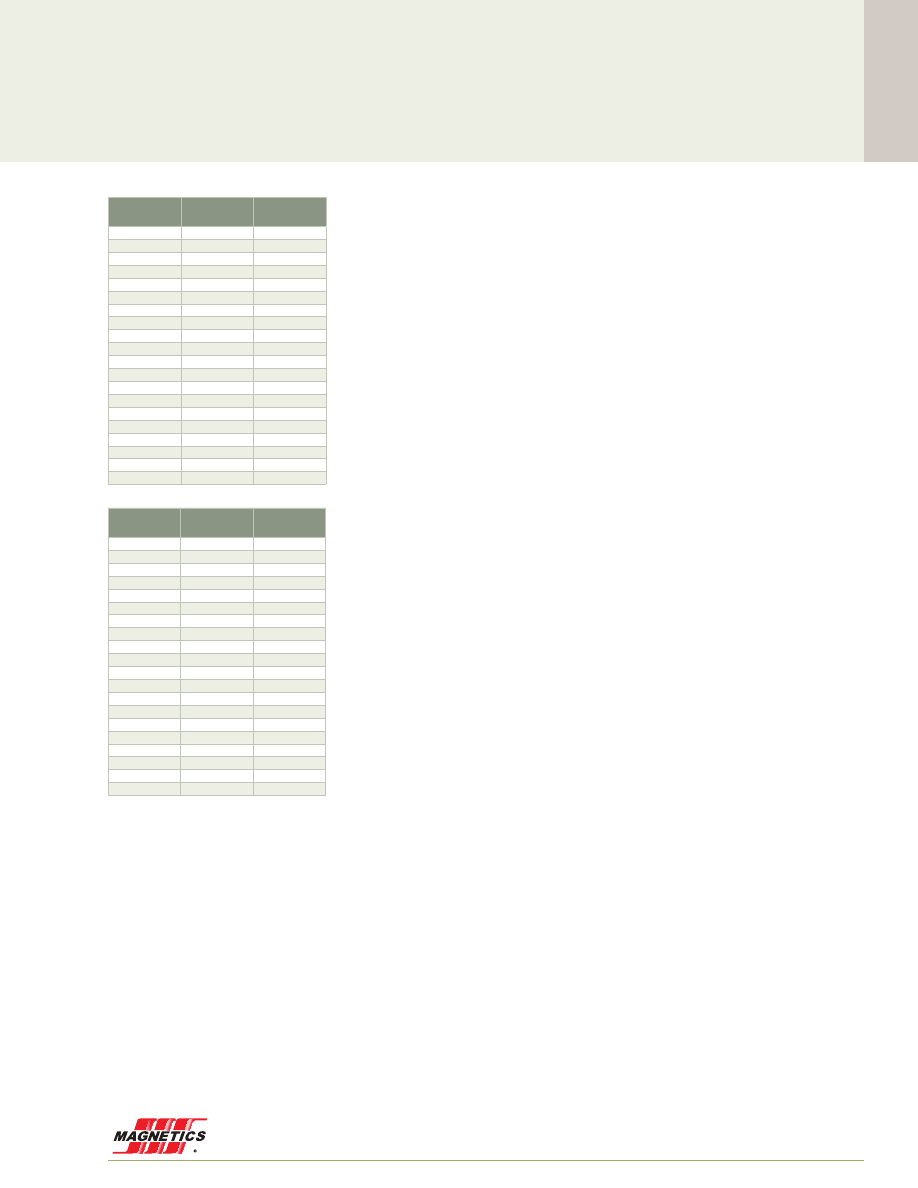

Core Locator & Unit Pack Quantity

High Flux Toroids

Index

P/N PAGE BOX QTY

P/N PAGE BOX QTY

P/N PAGE BOX QTY

P/N PAGE BOX QTY

58018

61

10,000

58019

61

10,000

58020

61

10,000

58021

61

10,000

58022

61

10,000

58023

61

10,000

58028

65

10,000

58029

65

10,000

58030

65

10,000

58031

65

10,000

58032

65

10,000

58033

65

10,000

58038

68

8,000

58039

68

8,000

58040

68

8,000

58041

68

8,000

58042

68

8,000

58043

68

8,000

58048

70

5,000

58049

70

5,000

58050

70

5,000

58051

70

5,000

58052

70

5,000

58053

70

5,000

58059

74

1,000

58070 88

35

58071

77

250

58072

88

35

58073

88

35

58074

88

35

58075

88

35

58076

79

220

58083

80

180

58089

81

120

58090

81

120

58091

81

120

58092

81

120

58099

93

25

58100

93

25

58101

93

25

58102

93

25

58109

85

90

58110

85

90

58111

85

90

58112

85

90

58118

71

2,000

58119

71

2,000

58120

71

2,000

58121

71

2,000

58122

71

2,000

58123

71

2,000

58128

69

6,000

58129

69

6,000

58130

69

6,000

58131

69

6,000

58132

69

6,000

58133

69

6,000

58164

95

6

58165

95

6

58190

86

80

58191

86

80

58192

86

80

58195

86

80

58204

73

1,600

58205

73

1,600

58206

73

1,600

58208

73

1,600

58209

73

1,600

58238

62

10,000

58239

62

10,000

58240

62

10,000

58241

62

10,000

58242

62

10,000

58243

62

10,000

58252

80

180

58253

80

180

58254

80

180

58256

80

180

58257

80

180

58268

63

10,000

58269

63

10,000

58270

63

10,000

58271

63

10,000

58272

63

10,000

58273

63

10,000

58278

66

8,000

58279

66

8,000

58280

66

8,000

58281

66

8,000

58282

66

8,000

58283

66

8,000

58288

67

8,000

58289

67

8,000

58290

67

8,000

58291

67

8,000

58292

67

8,000

58293

67

8,000

58308

74

1,000

58309

74

1,000

58310

74

1,000

58312

74

1,000

58313

74

1,000

58322

79

220

58323

79

220

58324

79

220

58326

79

220

58327

79

220

58336

94

16

58337

94

16

58338

94

16

58339

94

16

58348

75

720

58349

75

720

58350

75

720

58351

75

720

58352

75

720

58353

75

720

58378

72

2,000

58379

72

2,000

58380

72

2,000

58381

72

2,000

58382

72

2,000

58383

72

2,000

58408

64

10,000

58409

64

10,000

58410

64

10,000

58411

64

10,000

58412

64

10,000

58413

64

10,000

58437

82

105

58438

82

105

58439

82

105

58440

82

105

58441

82

105

58546

77

250

58547

77

250

58548

77

250

58550

77

250

58551

77

250

58583

78

300

58584

78

300

58585

78

300

58586

78

300

58587

78

300

58588

78

300

58614

87

45

58615

87

45

58616

87

45

58617

87

45

58620

87

45

58714

84

90

58715

84

90

58716

84

90

58717

84

90

58718

84

90

58725 83

70

58726

83

70

58727

83

70

58728

83

70

58734

89

24

58735

89

24

58736

89

24

58737

89

24

58774

92

20

58775

92

20

58776

92

20

58777

92

20

58778

92

20

58848

73

1,600

58866

90

45

58867

90

45

58868

90

45

58869

90

45

58894

76

400

58906

91

40

58907

91

40

58908

91

40

58909

91

40

58928

76

400

58929

76

400

58930

76

400

58932

76

400

58933

76

400

MAGNETICS

4

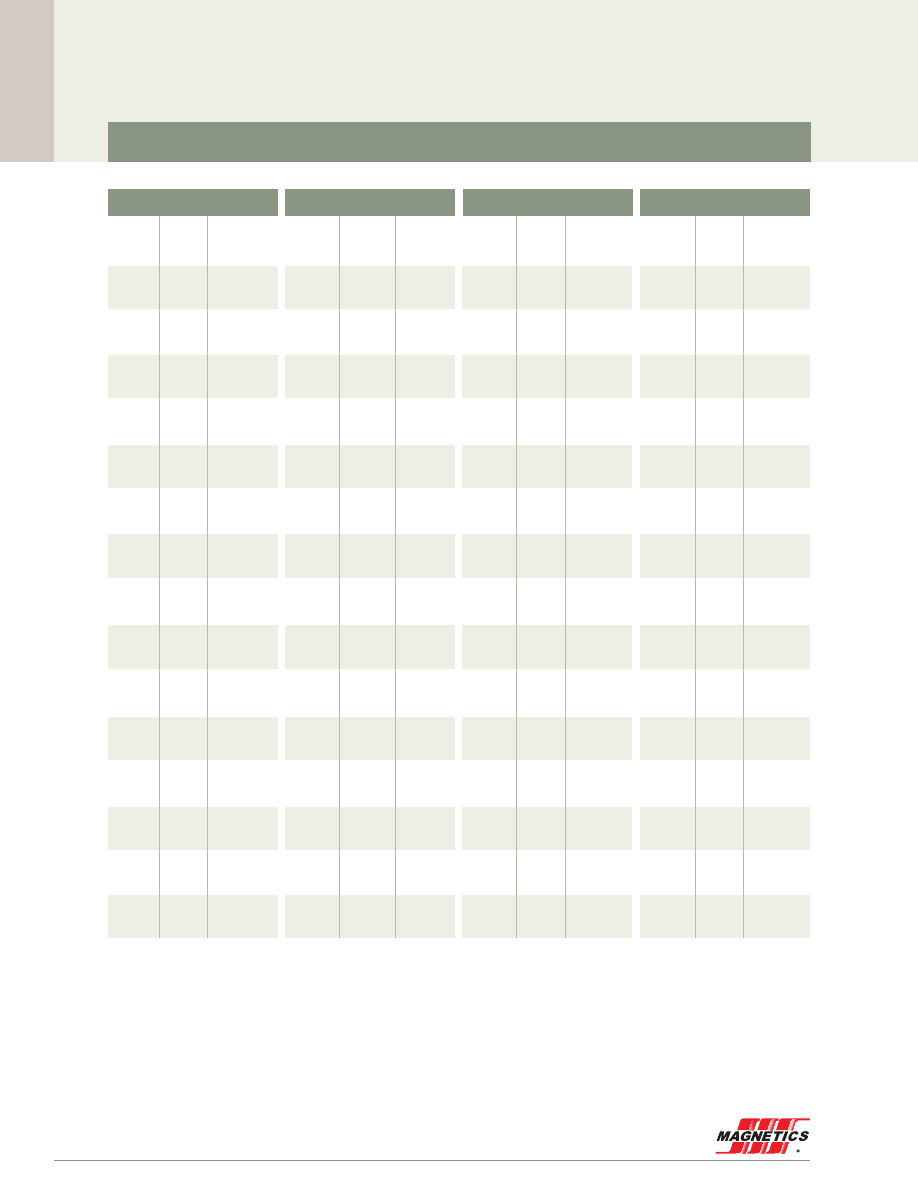

P/N PAGE BOX QTY

P/N PAGE BOX QTY

P/N PAGE BOX QTY

P/N PAGE BOX QTY

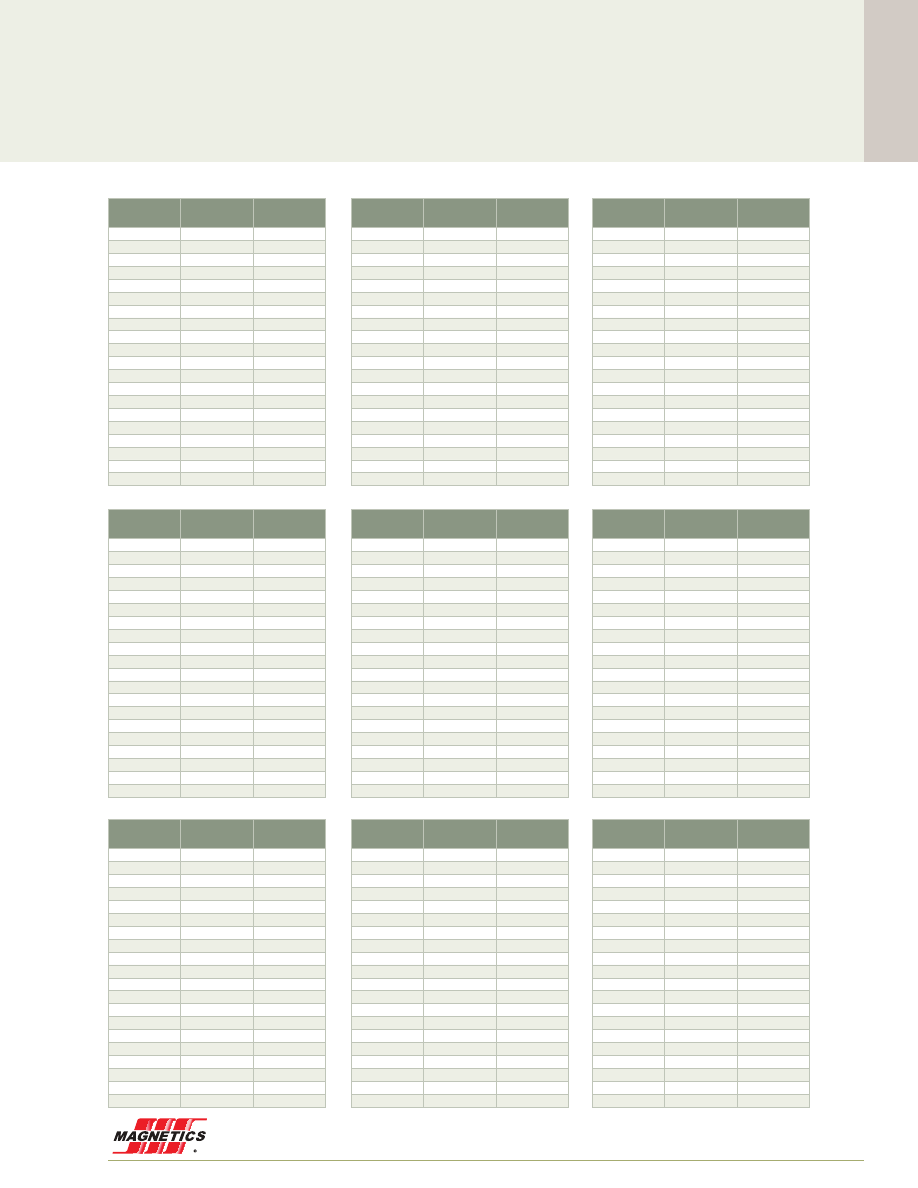

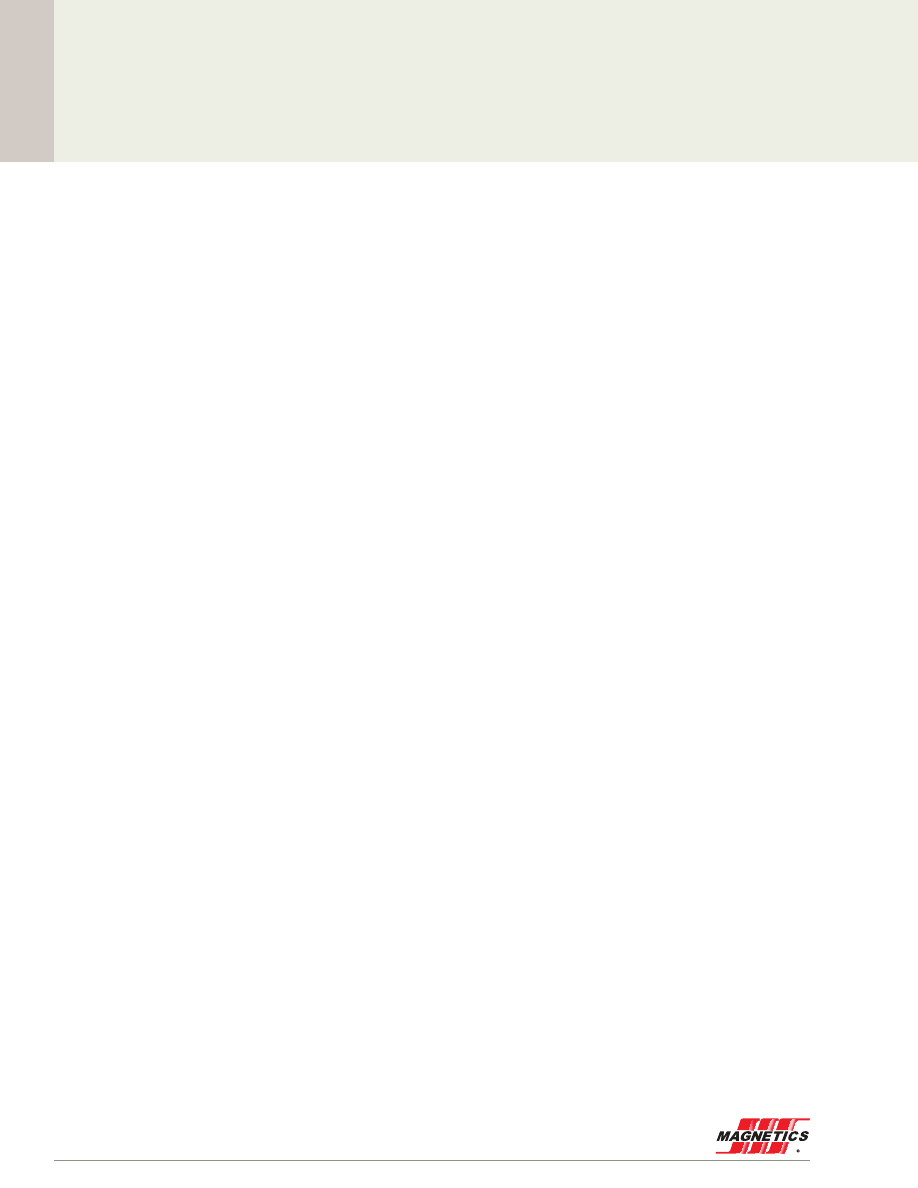

Core Locator & Unit Pack Quantity

Kool Mµ

®

Toroids

77020

61

10,000

77021

61

10,000

77030

65

10,000

77031

65

10,000

77040

68

8,000

77041

68

8,000

77050

70

5,000

77051

70

5,000

77052

70

5,000

77054

70

5,000

77055

70

5,000

77059

74

1,000

77068 88

35

77069

88

35

77070

88

35

77071

77

250

77072

88

35

77073

88

35

77074

88

35

77075

88

35

77076

79

220

77083

80

180

77089

81

120

77090

81

120

77091

81

120

77093

81

120

77094

81

120

77095

81

120

77098

93

25

77099

93

25

77100

93

25

77101

93

25

77102

93

25

77109

85

90

77110

85

90

77111

85

90

77120

71

2,000

77121

71

2,000

77130

69

6,000

77131

69

6,000

77140

58

7,500

77141

58

7,500

77150

59

7,500

77151

59

7,500

77154

59

7,500

77155

59

7,500

77164

95

6

77165

95

6

77180

60

5,000

77181

60

5,000

77184

60

5,000

77185

60

5,000

77189

86

80

77191

86

80

77192

86

80

77193

86

80

77194

86

80

77195

86

80

77206

73

1,600

77210

73

1,600

77211

73

1,600

77212

85

90

77213

85

90

77214

85

90

77224

71

2,000

77225

71

2,000

77240

62

10,000

77241

62

10,000

77244

62

10,000

77245

62

10,000

77254

80

180

77256

80

180

77258

80

180

77259

80

180

77260

80

180

77270

63

10,000

77271

63

10,000

77280

66

8,000

77281

66

8,000

77290

67

8,000

77291

67

8,000

77294

67

8,000

77295

67

8,000

77310

74

1,000

77312

74

1,000

77314

74

1,000

77315

74

1,000

77316

74

1,000

77324

79

220

77326

79

220

77328

79

220

77329

79

220

77330

79

220

77334

69

6,000

77335

69

6,000

77336

94

16

77337

94

16

77338

94

16

77339

94

16

77350

75

720

77351

75

720

77352

75

720

77354

75

720

77355

75

720

77356

75

720

77380

72

2,000

77381

72

2,000

77384

72

2,000

77385

72

2,000

77410

64

10,000

77411

64

10,000

77414

64

10,000

77415

64

10,000

77431

82

105

77438

82

105

77439

82

105

77440

82

105

77442

82

105

77443

82

105

77444

58

7,500

77445

58

7,500

77548

77

250

77550

77

250

77552

77

250

77553

77

250

77555

77

250

77585

78

300

77586

78

300

77587

78

300

77589

78

300

77590

78

300

77591

78

300

77614

87

45

77615

87

45

77616

87

45

77617

87

45

77618

87

45

77619

87

45

77620

87

45

77715

84

90

77716

84

90

77717

84

90

77719

84

90

77720

84

90

77721

84

90

77725

83

70

77726

83

70

77727

83

70

77729

83

70

77730

83

70

77733

83

70

77734

89

24

77735

89

24

77736

89

24

77737

89

24

77738

89

24

77739

89

24

77740

89

24

77774

92

20

77775

92

20

77776

92

20

77777

92

20

77778

92

20

77824

61

10,000

77825

61

10,000

77834

65

10,000

77835

65

10,000

77844

68

8,000

77845

68

8,000

77847

73

1,600

77848

73

1,600

77866

90

45

77867

90

45

77868

90

45

77869

90

45

77872

90

45

77874

63

10,000

77875

63

10,000

77884

66

8,000

77885

66

8,000

77894

76

400

77906

91

40

77907

91

40

77908

91

40

77909

91

40

77912

91

40

77930

76

400

77932

76

400

77934

76

400

77935

76

400

77936

76

400

Index

www.mag-inc.com

5

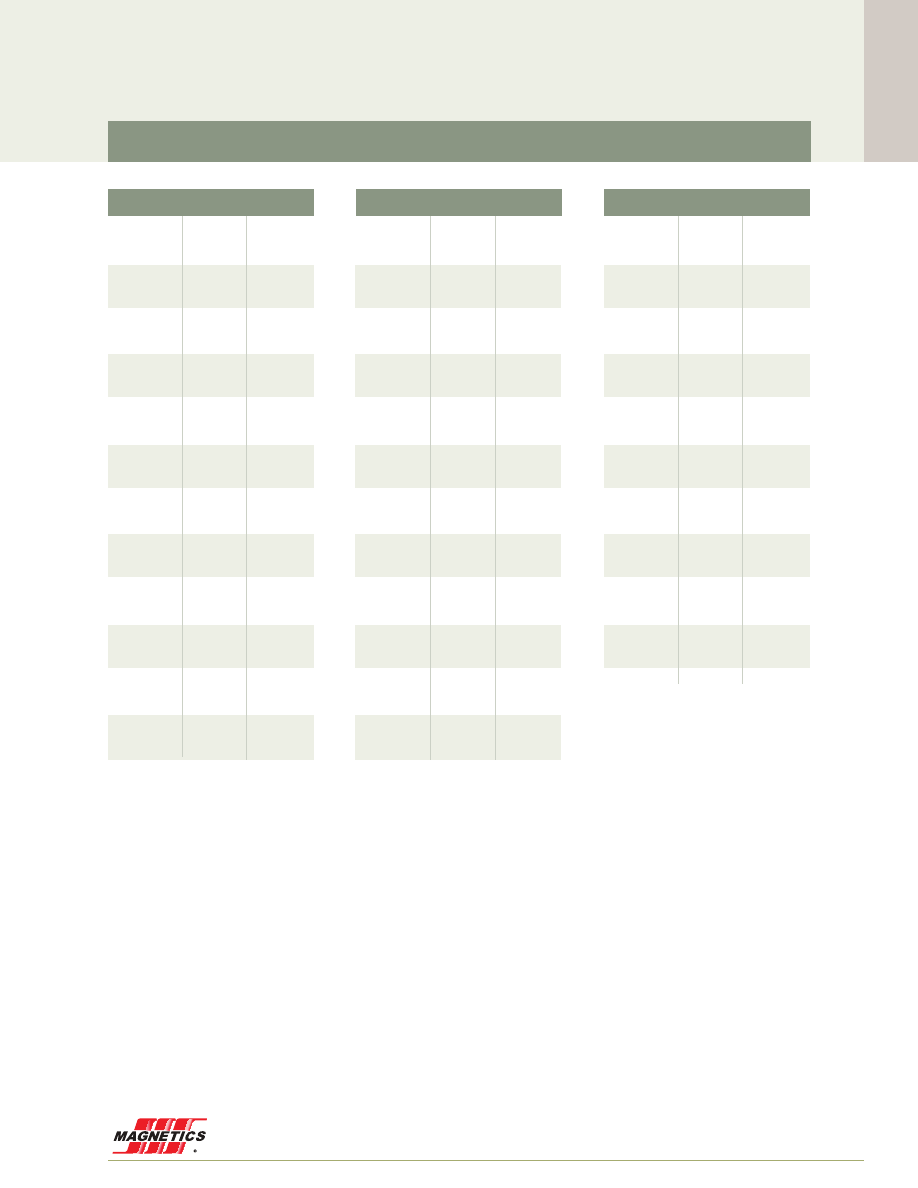

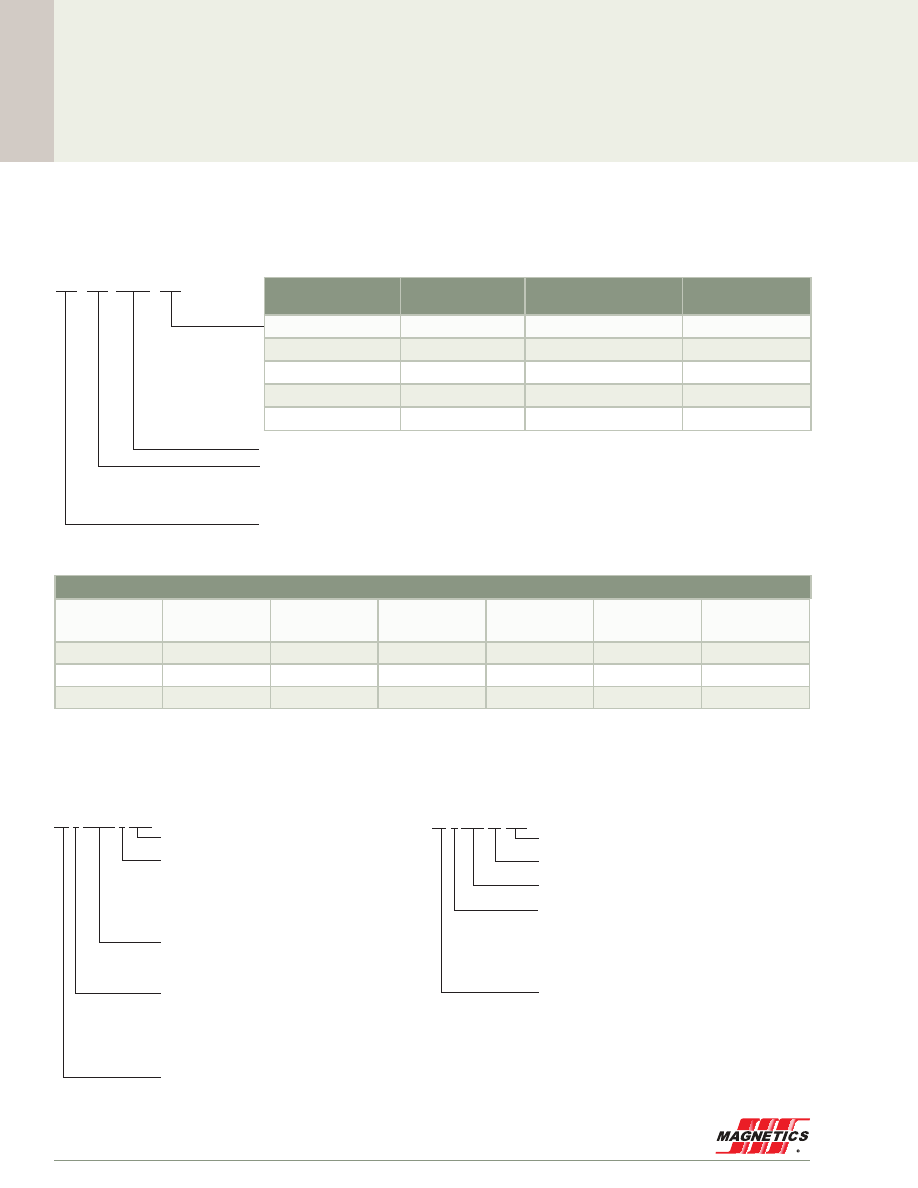

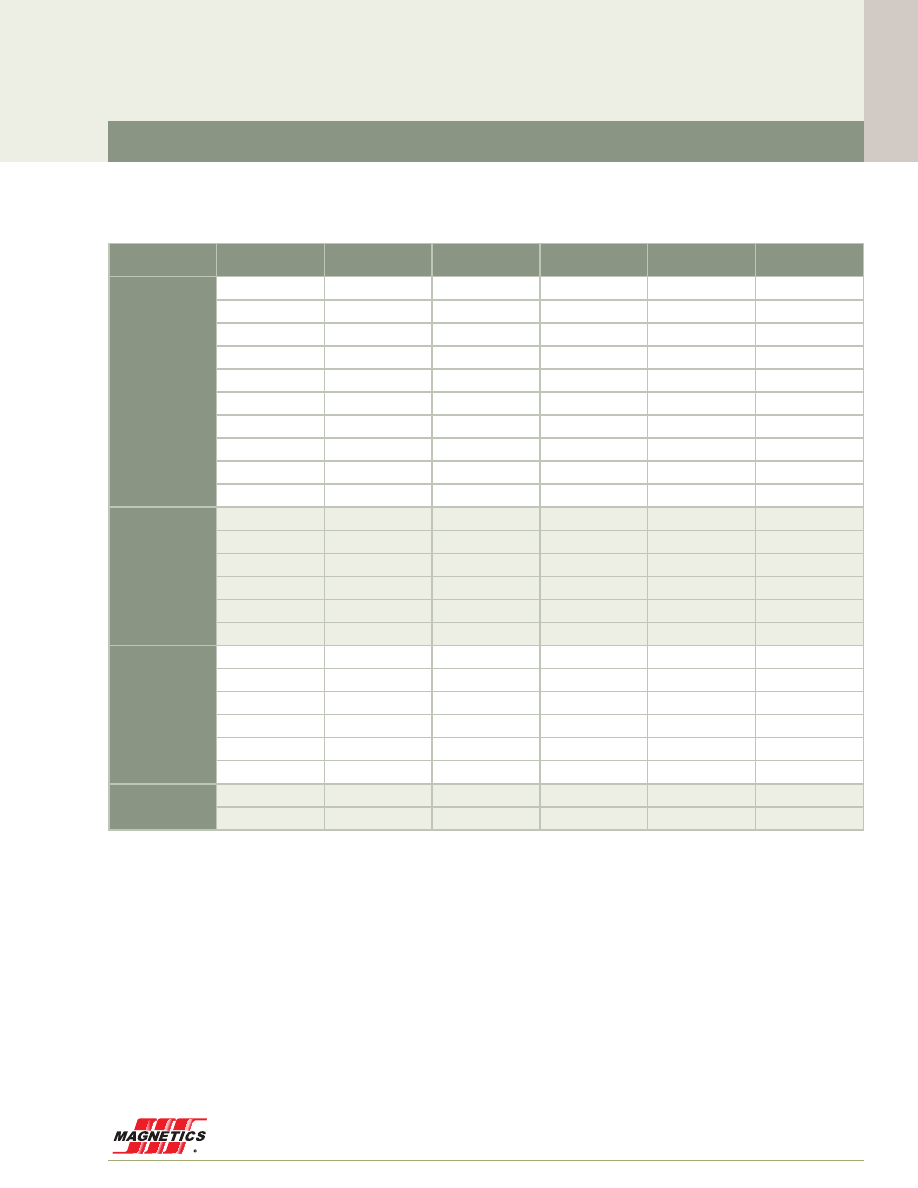

Core Locator & Unit Pack Quantity

K114LE026

96

18

K114LE040

96

18

K114LE060

96

18

K130LE026

96

12

K130LE040

96

12

K130LE060

96

12

K160LE026

96

16

K160LE040

96

16

K160LE060

96

16

K1808E026

96

2,880

K1808E040

96

2,880

K1808E060

96

2,880

K1808E090

96

2,880

K2510E026

96

1,728

K2510E040

96

1,728

K2510E060

96

1,728

K2510E090

96

1,728

K3007E026

96

720

K3007E040

96

720

K3007E060

96

720

K3007E090

96

720

K3112U040

98

672

K3112U060

98

672

K3112U090

98

672

K3515E026

96

720

K3515E040

96

720

K3515E060

96

720

K3515E090

96

720

K4017E026

96

264

K4017E040

96

264

K4017E060

96

264

K4017E090

96

264

K4020E026

96

192

K4020E040

96

192

K4020E060

96

192

K4020E090

96

192

K4022E026

96

168

K4022E040

96

168

K4022E060

96

168

K4022E090

96

168

K4110U040

98

480

K4110U060

98

480

K4110U090

98

480

K4111U040

98

480

K4111U060

98

480

K4111U090

98

480

K4119U040

98

240

K4119U060

98

240

K4119U090

98

240

K4317E026

96

270

K4317E040

96

270

K4317E060

96

270

K4317E090

96

270

K4741B026

97

48

K4741B040

97

48

K4741B060

97

48

K5030B026

97

64

K5030B040

97

64

K5030B060

97

64

K5527U026

98

128

K5528B026

97

112

K5528B040

97

112

K5528B060

97

112

K5528E026

96

112

K5528E040

96

112

K5528E060

96

112

K5529U026

98

96

K5530E026

96

96

K5530E040

96

96

K5530E060

96

96

K6030B026

97

80

K6030B040

97

80

K6030B060

97

80

K6527E026

96

54

K6527E040

96

54

K6527E060

96

54

K6527U026

98

54

K6533U026

98

54

K7020B026

97

90

K7020B040

97

90

K7020B060

97

90

K7030B026

97

60

K7030B040

97

60

K7030B060

97

60

K7228E026

96

84

K7228E040

96

84

K7228E060

96

84

K7236U026

98

60

K8020E026

96

63

K8020E040

96

63

K8020E060

96

63

K8020U026

98

63

K8024E026

96

45

K8024E040

96

45

K8024E060

96

45

K8030B026

97

48

K8030B040

97

48

K8030B060

97

48

K8038U026

98

63

K8044E026

96

63

K8044E040

96

63

K8044E060

96

63

K9541B026

97

30

Kool Mµ

®

Blocks, E Cores, and U Cores

P/N

PAGE BOX QTY

P/N

PAGE BOX QTY

P/N

PAGE BOX QTY

Index

www.mag-inc.com

7

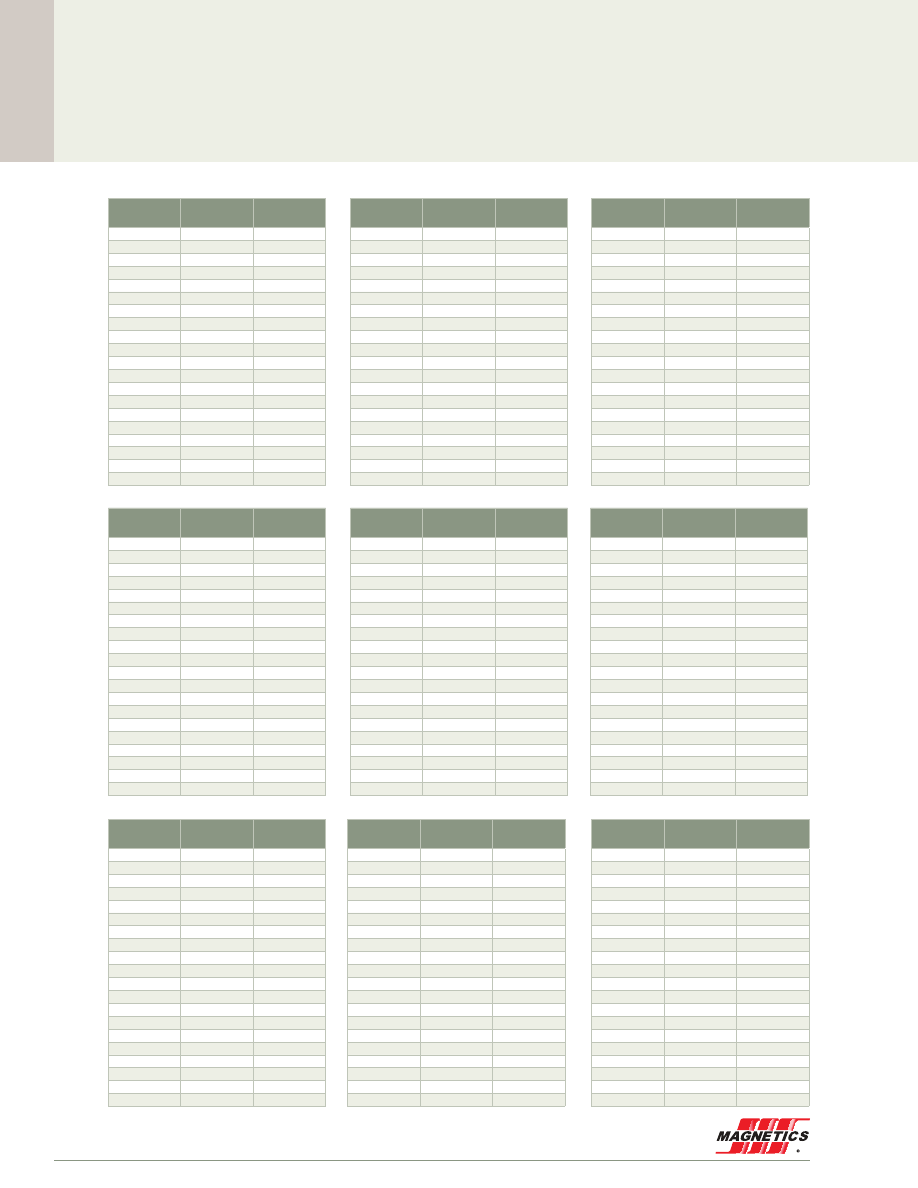

Core Locator & Unit Pack Quantity

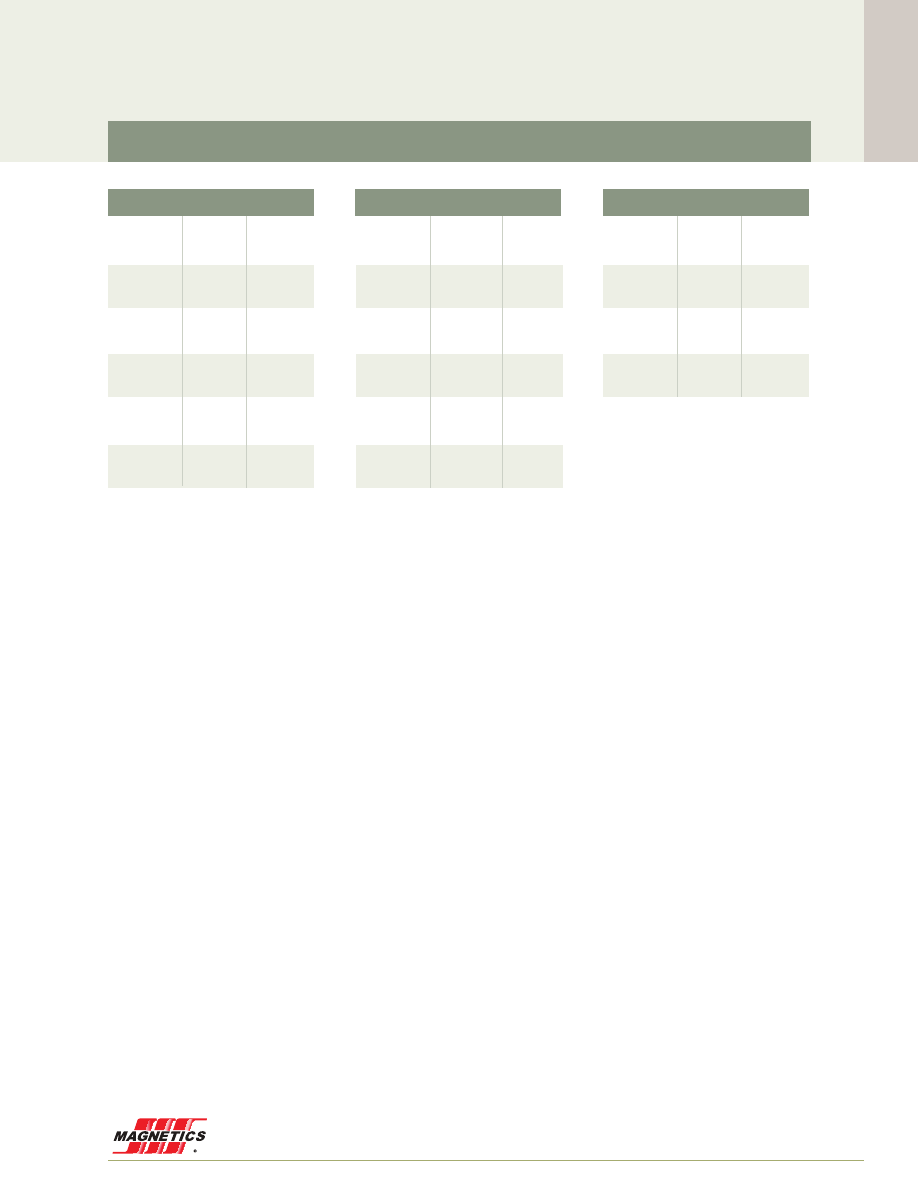

79051

70

5,000

79052

70

5,000

79059

74

1,000

79071

77

250

79072

88

35

79074

88

35

79076

79

220

79083

80

180

79090

81

120

79091

81

120

79099

93

25

79102

93

25

79110

85

90

79111

85

90

79121

71

2,000

79122

71

2,000

79191

86

80

79192

86

80

79208

73

1,600

79256

80

180

79312

74

1,000

79326

79

220

79337

94

16

79351

75

720

79352

75

720

79381

72

2,000

79382

72

2,000

79439

82

105

79440

82

105

79550

77

250

79586

78

300

79587

78

300

79615

87

45

79617

87

45

79716

84

90

79717

84

90

79726

83

70

79727

83

70

79735

89

24

79737

89

24

79848

73

1,600

79867

90

45

79868

90

45

79894

76

400

79907

91

40

79908

91

40

79932

76

400

Kool Mµ

®

MAX Toroids

P/N

PAGE BOX QTY

P/N

PAGE BOX QTY

P/N

PAGE BOX QTY

Index

Magnetics Molypermalloy Powder (MPP)

, or washer cores, put the premium

powder cores are distributed air

cores . Frequently, High Flux allows the designer to

reduce the size of an inductive component compared with

MPP, powdered iron, or ferrite .

powder cores are distributed air

distributed air gap cores are made from

6 .5% silicon iron powder . XF

powdered iron cores and superior DC bias performance .

The soft saturation of XF

cores are ideal for low and medium

frequency chokes where inductance at peak load is critical .

www.mag-inc.com

9

General Information

can be a lower cost alternative

to High Flux, in situations where the higher core losses and

more limited permeability availability of XF

more information on cylinders or custom shapes, please

contact Magnetics.

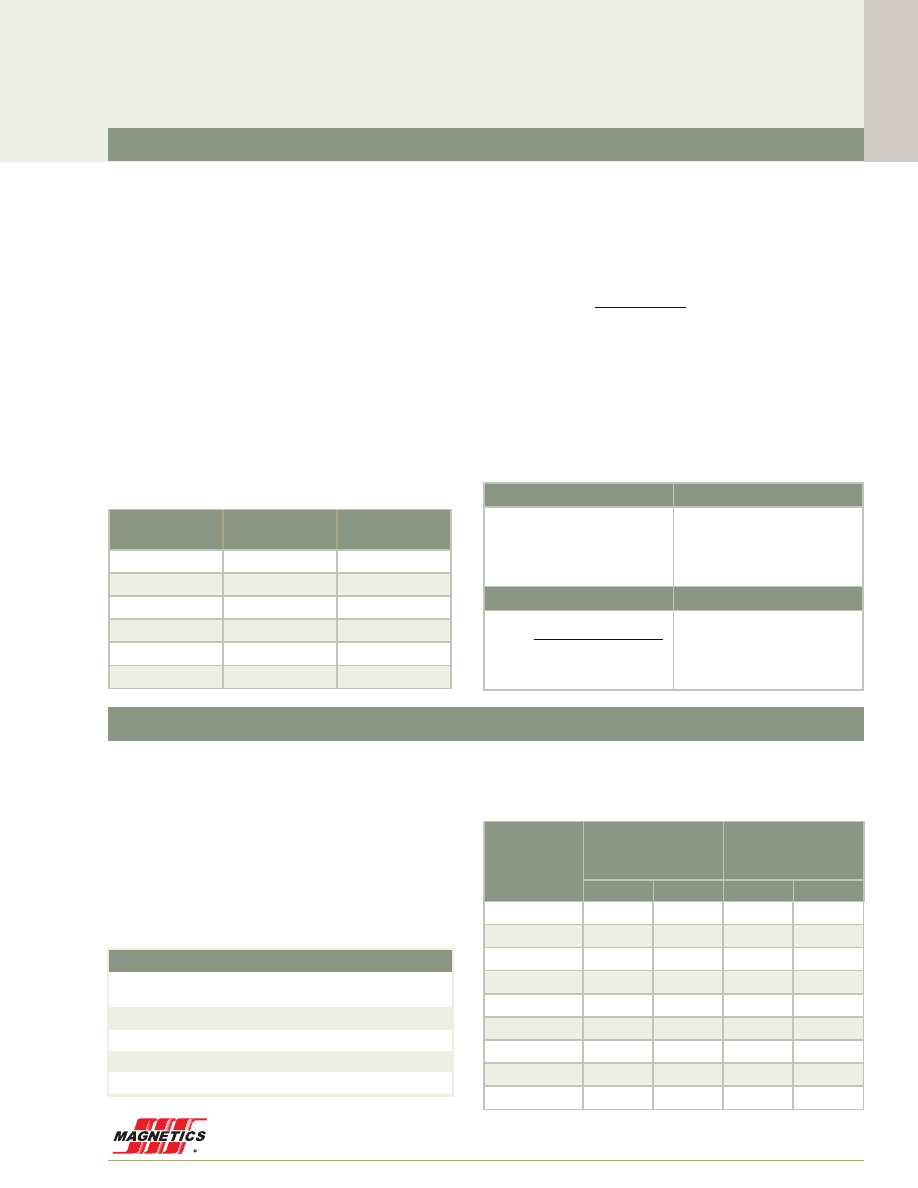

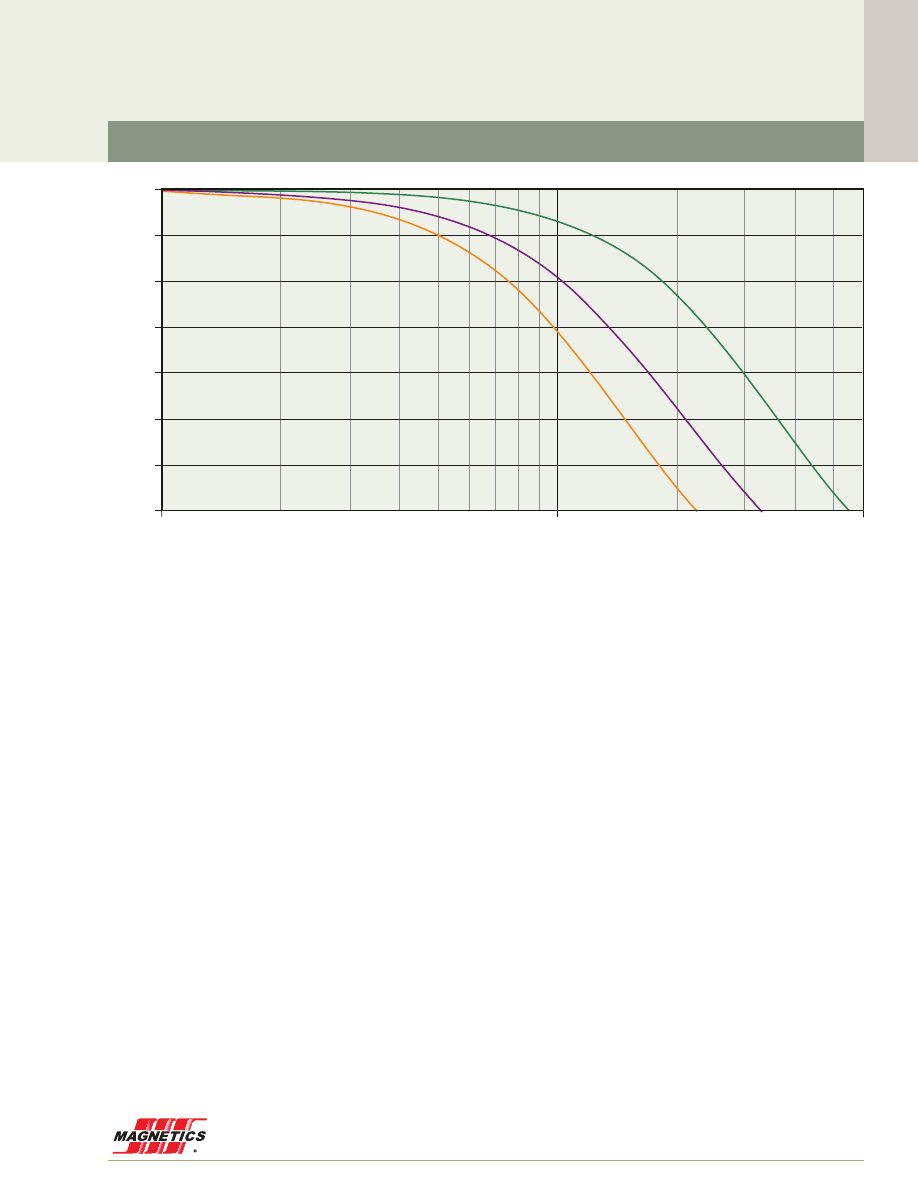

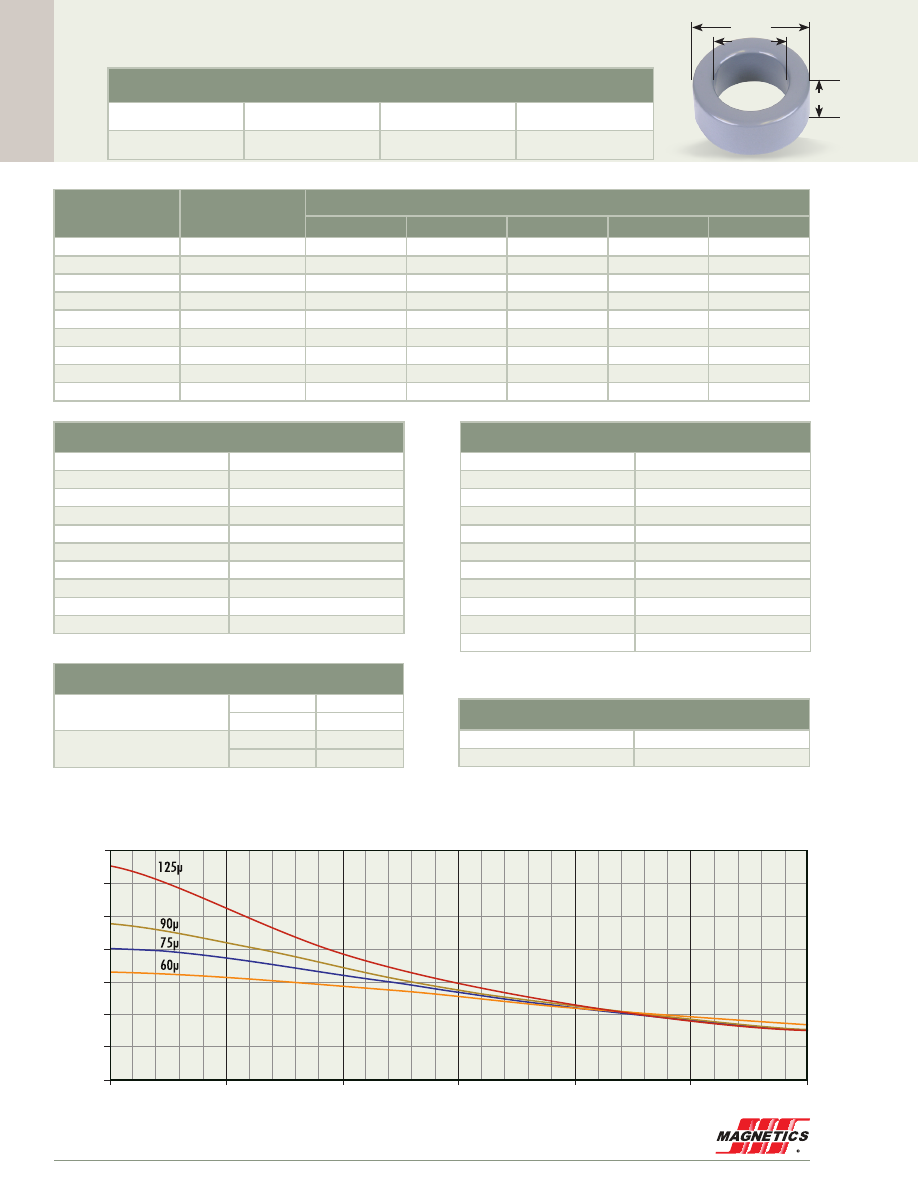

Perm vs. DC Bias - 60µ (AT/cm)

60µ Temperature Stability - Typical % shift from -60 to 200°C

Saturation Flux Density (Tesla)

Catalog Number (designates size and permeability)

Material Code . . . . 55 = MPP

Grading Code . . . . . CO = Graded into 2% inductance bands – OD <4.65 mm, 5% bands

• No voltage breakdown min for A2 or A7 with OD

• A2 and A7 voltage breakdown is 1000 V

• AY finish not available for 550µ MPP

Permeability Code ... Permeability, e.g. 060 for 60µ

Shape Code . . . . . . E = E Core

Size Code . . . . . . . First two digits equal approximate length

or OD in mm / Last two digits equal

approximate height or ID in mm

Material Code . . . . . K = Kool Mµ

Grading Code . . . . . 00 = Not graded

• Full part number and shop order

number are marked on all shapes

Permeability Code . . Permeability, e.g. 026 for 26µ

Shape Code . . . . . . LE = Large E Core

Material Code . . . . . M = MPP*

Grading Code . . . . . 00 = Not graded

• Full part number and shop order

number are marked on all shapes

Powder Core Toroid Marking Summary

• Inductance Code is only marked on MPP and High Flux toroids with C0 grading code

• Cores with OD < 6.35 mm are not marked

• Shop order number identifies the product batch, ensuring traceability of every

core through the entire manufacturing process, back to raw materials

(Inductance factor) is given for each core in this catalog .

Inductance for blocks is tested in standard picture frame

arrangements . Units for A

, in µH) by the number of turns, N .

Example: C055930A2 with 25 turns (p . 76)

Example : C055930A2 (26 .9 mm, 125µ, p . 76)

• 14µ and 26µ cores • MPP THINZ

The following toroid OD sizes:

Core Inductance Tolerance and Grading

Measured vs. Calculated Inductance

= leakage induc tan ce adder (µH)

= core magnetic path length (mm)

Est Measured Induc tan ce

L = L

= leakage induc tan ce adder (µH)

= core magnetic path length (mm)

Est Measured Induc tan ce

L = L

= leakage induc tan ce adder (µH)

= core magnetic path length (mm)

Est Measured Induc tan ce

L = L

= leakage induc tan ce adder (µH)

= core magnetic path length (mm)

Est Measured Induc tan ce

L = L

9 - old1 - 4?or5

= leakage induc tan ce adder (µH)

= core magnetic path length (mm)

Est Measured Induc tan ce

L = L

= leakage inductance adder (µH)

= core magnetic path length (mm)

*THINZ and Kool Mµ cores with OD < 12 .7 mm have wider tolerances .

Higher minimum breakdown coatings can be applied upon

request for cores larger than 4 .65 mm .

materials can be operated continuously at 200°C with no

aging or damage .

www.mag-inc.com

15

Cor

e Selection

Inductor Core Selection Procedure

Only two parameters of the design application must be

known to select a core for a current-limited inductor; in-

ductance required with DC bias and the DC current . Use

the following procedure to determine the core size and

number of turns .

1 .

Compute the product of LI

2

where:

L = inductance required with DC bias (mH)

I = DC current (A)

2 .

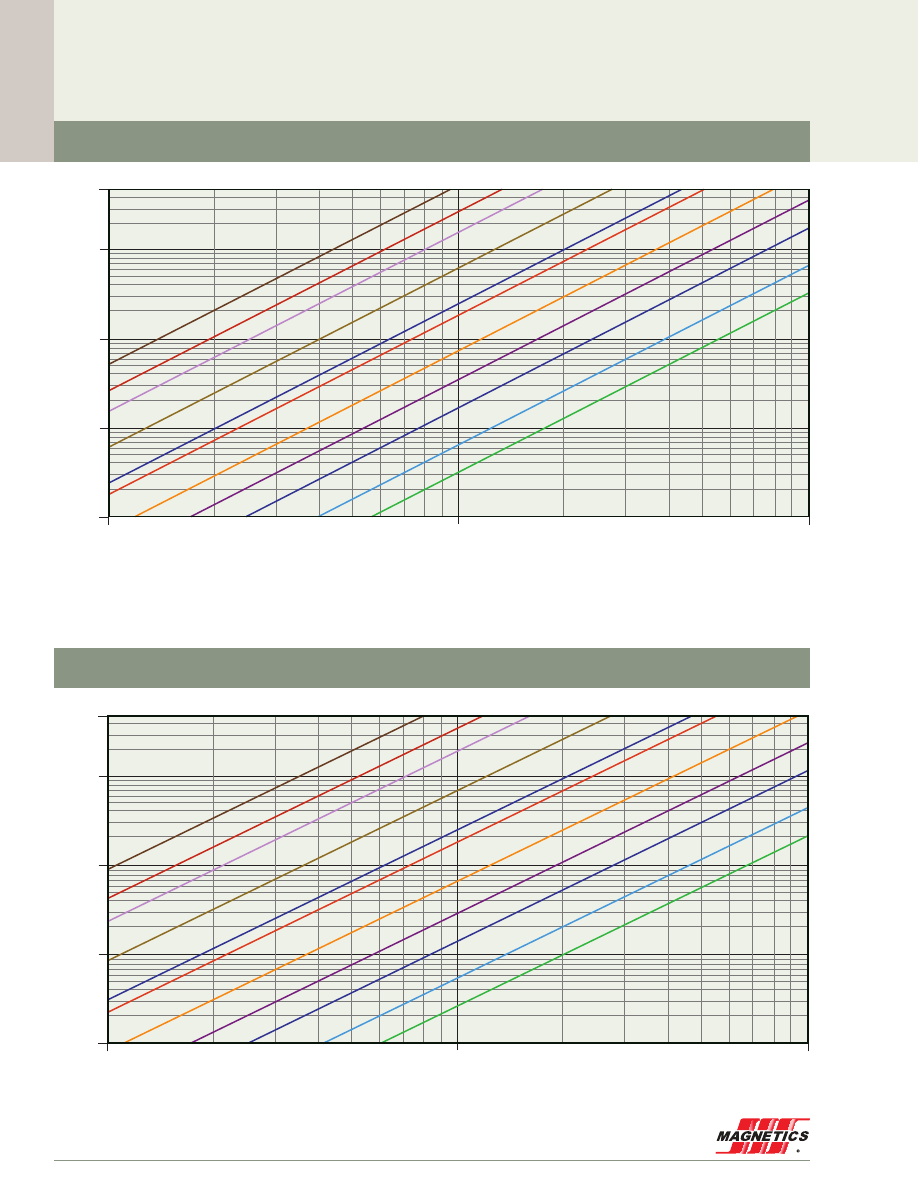

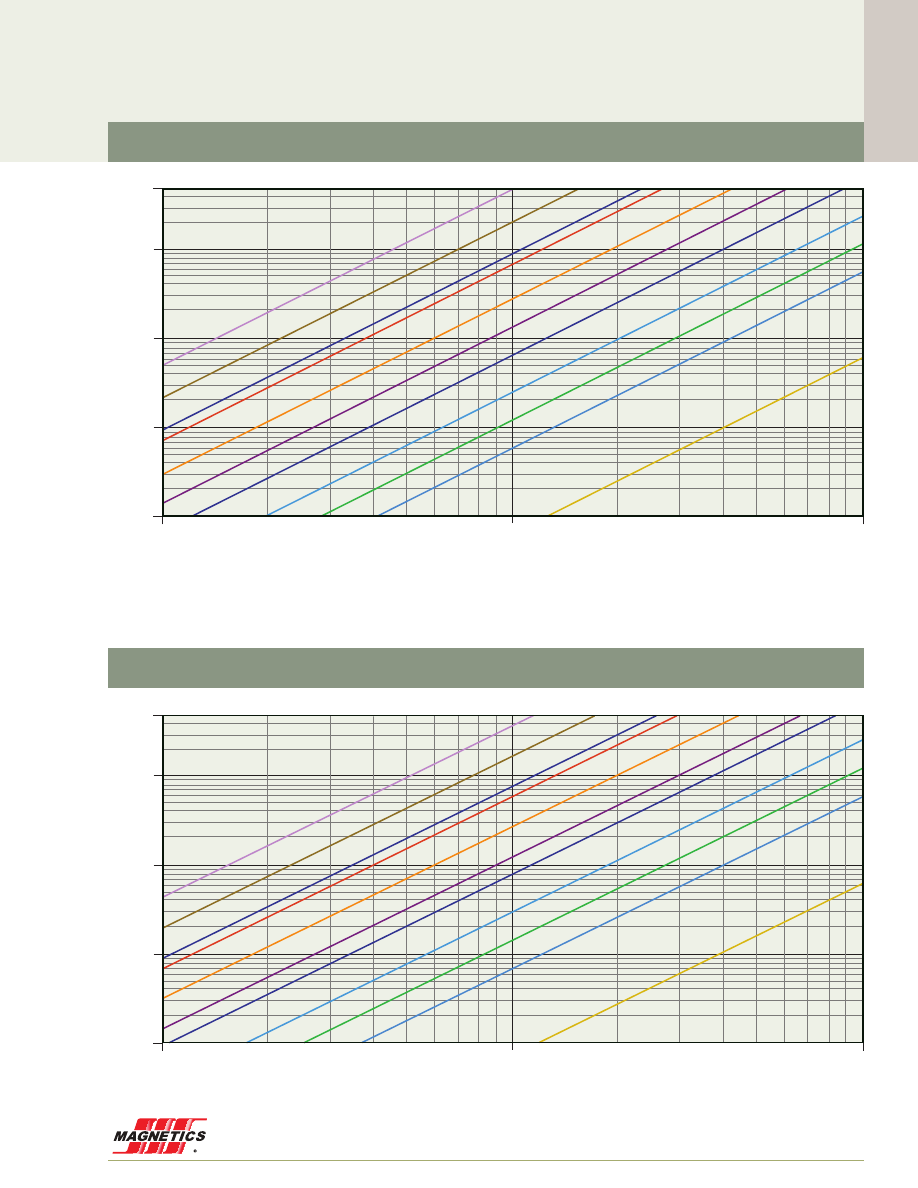

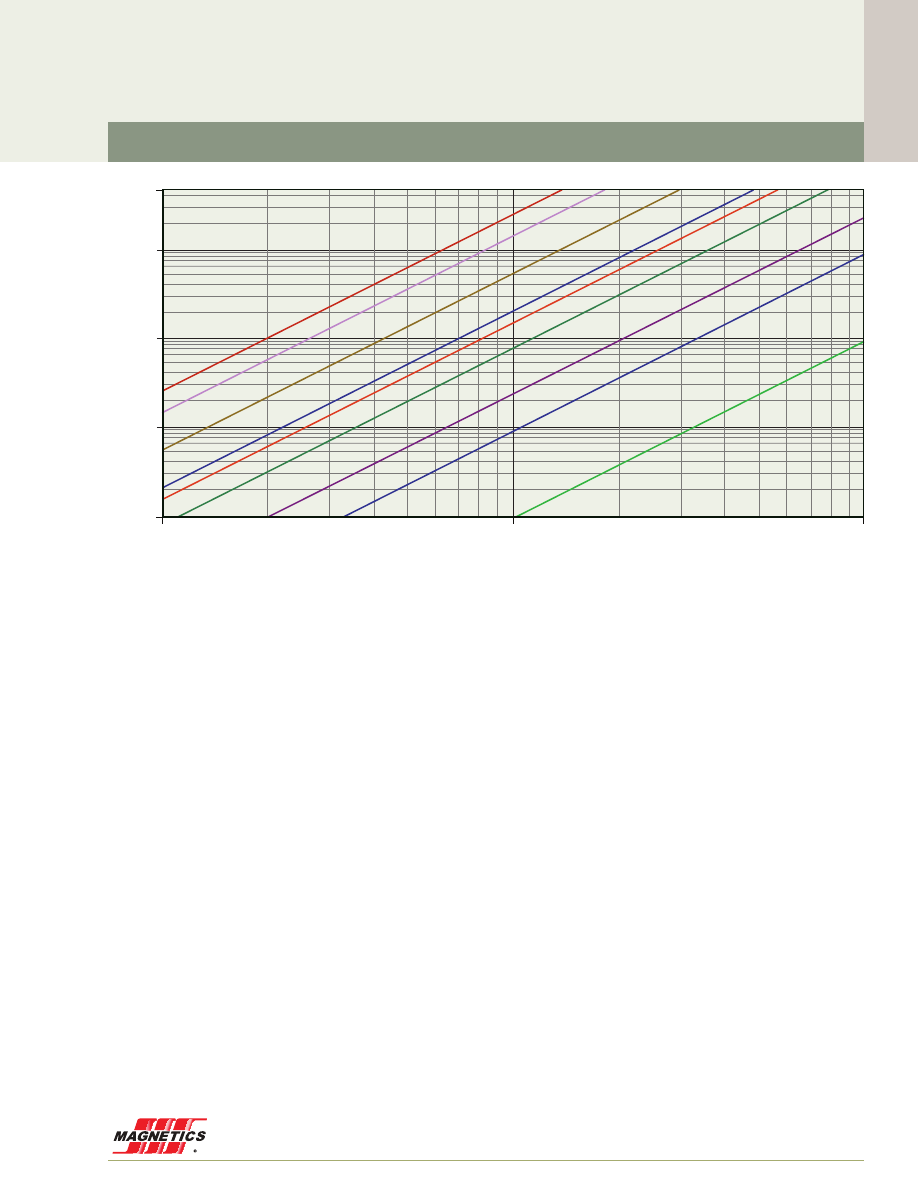

Locate the LI

2

value on the Core Selector Chart

(pgs . 24 - 27) . Follow this coordinate to the inter-

section with the first core size that lies above the

diagonal permeability line . This is the smallest core

size that can be used .

3 .

The permeability line is sectioned into standard

available core permeabilities . Selecting the core

listed on the graph will tend to be the best tradeoff

between A

L

and DC bias .

4 .

Inductance, core size, and permeability are now

known . Calculate the number of turns by using the

following procedure:

(a) The inductance factor (A

L

in nH/T

2

) for the

core is obtained from the core data sheet .

Determine the minimum A

L

by using the worst

case negative tolerance (generally -8%) . With

this information, calculate the number of turns

needed to obtain the required inductance

from:

11old 2 - 1

N =

A

L

L 10

3

H =

l

e

NI

3

T (˚C) =

Component Surface Area (cm

2

)

Total Losses (mW)

U

Z

0 .833

Where L is required inductance (µH)

(b) Calculate the bias in A·T/cm from:

11old 2 - 1

N =

A

L

L 10

3

H =

l

e

NI

3

T (˚C) =

Component Surface Area (cm

2

)

Total Losses (mW)

U

Z

0 .833

(c) From the Permeability vs . DC Bias curves

(pgs . 29 - 33), determine the rolloff percentage

of initial permeability for the previously calculat-

ed bias level . Curve fit equations shown in the

catalog can simplify this step . They are also

available to use on Magnetics website: http://

www .mag-inc .com/design/design-guides/

Curve-Fit-Equation-Tool

(d) Multiply the required inductance by the per-

centage rolloff to find the inductance with bias

current applied .

(e) Increase the number of turns by dividing the

initial number of turns (from step 4(a)) by the

percentage rolloff . This will yield an inductance

close to the required value after steps 4 (b), (c)

and (d) are repeated .

(f) Iterate steps 4 (b), (c) and (d) if needed to adjust

turns up or down until the biased inductance is

satisfactorily close to the target .

5 . Choose a suitable wire size using the Wire Table (p .

28) . Duty cycles below 100% allow smaller wire

sizes and lower winding factors, but do not allow

smaller core sizes .

6 .

Design Checks

(a)

Winding Factor

. See p .17 for notes on checking

the coil design .

(b)

Copper Losses

.

See p .17 for notes on calculat-

ing conductor resistance and losses .

(c)

Core Losses

. See p .18 for notes on calculating

AC core losses . If AC losses result in too much

heating or low efficiency, then the inductor may

be loss-limited rather than current-limited . Design

alternatives for this case include using a larger

core or a lower permeability core to reduce the

AC flux density; or using a lower loss material

such as MPP or Kool Mµ MAX in place of Kool

Mµ, or High Flux in place of XF

lux

.

(d)

Temperature Rise

. Dissipation of the heat gener-

ated by conductor and core losses is influenced

by many factors . This means there is no simple

way to predict temperature rise (

%

T) precisely .

But the following equation is known to give a

useful approximation for a component in still air .

Surface areas for cores wound to 40% fill are

given with the core data in this catalog .

11old 2 - 1

N =

A

L

L 10

3

H =

l

e

NI

3

T (˚C) =

Component Surface Area (cm

2

)

Total Losses (mW)

U

Z

0 .833

0.00 mm O.D.

Cor

e Selection

MAGNETICS

16

Core Selection Example

Determine core size and number of turns to meet the

following requirement:

(a) Minimum inductance with DC bias of

0 .6 mH (600 µH)

(b) DC current of 5 .0 A

1 . LI

2

= (0 .6)(5 .0)

2

=15 .0 mH·A

2

2 . Using the Kool Mµ Toroids LI

2

chart found on p .

25, locate 15 mH·A

2

on the bottom axis . Following

this coordinate vertically results in the selection of

0077083A7 as an appropriate core for the above

requirements .

3 . From the 0077083A7 core data p . 80, the inductance

factor (A

L

) of this core is 81 nH/T

2

± 8% . The minimum

A

L

of this core is 74 .6 nH/T

2

.

4 . The number of turns needed to obtain 600 µH at no

load is 90 turns . To calculate the number of turns

required at full load, determine the DC bias level:

H= N·I/

l

e

where

l

e

is the path length in cm . The DC bias

is 45 .7 A·T/cm, yielding 71% of initial permeability from

the 60µ Kool Mµ DC bias curve on p . 30 .The adjusted

turns are 90/0 .71 =127 Turns .

5 . Re-calculate the DC bias level . The permeability versus

DC bias curve shows 57% of initial permeability at

64 .5 A·T/cm .

6 . Multiply the minimum A

L

74 .6 nH/T

2

by 0 .57 to yield

effective A

L

= 42 .5 nH/T

2

. The inductance of this core

with 127 turns and with 64 .5 A·T/cm will be 685 µH

minimum . The inductance requirement has been met .

7 . The wire table indicates that 17 AWG is needed to

carry 5 .0 A with a current density of 500 A/cm

2

.

127 turns of 17 AWG (wire area = 1 .177 mm

2

) equals

a total wire area of 149 .5 mm

2

. The window area of a

0077083A7 is 427 mm

2

. Calculating window fill,

149 .5 mm

2

/427 mm

2

corresponds to an approximate

35% winding factor . A 0077083A7 with 127 turns of

17 AWG is a manufacturable design .

Cor

e Selection

0.00 mm O.D.

www.mag-inc.com

17

Cor

e Selection

4

Toroid Winding

Winding Factor

Winding factor, also called fill factor, is the ratio of total

conductor cross section (usually copper cross section) to

the area of the core window . In other words, in a toroid,

winding factor is given by:

N

•

A

W

/W

A

N = Number of turns

where:

A

W

= Area of the wire

W

A

= Window Area of the core

p

·

ID

2

Toroid Core Winding factors can vary from 20-60%, a typical

value in many applications being 35-40% .

In practice, several approaches to toroid winding are used:

-

Single layer: The number of turns is limited by

the inside circumference of the core divided by

the wire diameter . Advantages are lower winding

capacitance, more repeatable parasitics, good

cooling, and low cost . Disadvantages are reduced

power handling and higher flux leakage .

-

Low fill: For manufacturing ease and reduced

capacitance, winding factor between single layer

and 30% may be used .

-

Full winding: Factors between 30% and 45%

are normally a reasonable trade off between fully

utilizing the space available for a given core size,

while avoiding excessive manufacturing cost .

-

High fill: Winding factors up to about 65%

are achievable, but generally only with special

expensive measures, such as completing each coil

by hand after the residual hole becomes too small

to fit the winding shuttle .

Estimating Wound Coil Dimensions

For each core size, wound coil dimensions are given for

40% winding factor, since this is a typical, practical value .

Worst case package dimensions for coils wound completely

full are also shown . These are max expected OD and max

expected HT .

To estimate dimensions for other winding factors, use:

Rv 7 - 17

OD

x%

=

40%

X% OD

40%

2

- OD

core

2

Q

V

+ OD

core

2

HT

x%

=ID

core

+ HT

core

-

60%

100%- X% ID

core

+ HT

core

- HT

40%

Q

V

2 - 8

H

ACmax

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

2 - 9

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .44T

2 - 11

B

pk

= 0 .5 µ

0

Q V

%µ

i

Q V

µ

i

Q V

3

H

where

3

H

=

I

e

N

%

I

Where: X% is the new winding factor;

OD

40%

and HT

40%

are the coil dimensions shown on

the core data page;

OD

core

and HT

core

are the maximum core dimensions

after finish .

Cor

e Selection

MLT and DCR

MLT (Mean Length of Turn) is given for a range of winding

factors for each core size . To estimate DCR, first, calculate

the winding factor for the core, wire gauge, and number of

turns selected . On the wire table look up resistance per

unit of length for the gauge selected . On the data page for

the core selected, consult the Winding Turn Length chart .

Unless the winding factor is exactly one of the values listed,

interpolate to find the MLT . Then,

DCR = (MLT)(N) (

Q

/Length) .

For single layer winding, MLT is the 0% fill value on each

core data page . Even easier, DCRs for single layer windings

for a range of wire gauges are given in the winding tables on

pgs . 103 - 107 .

Wire Loss

DC copper loss is calculated directly as I

2

R . Naturally, for

aluminum conductors, a suitable wire table must be used .

Also, the increase of wire resistance with temperature

should be considered .

AC copper loss can be significant for large ripple and for

high frequency . Unfortunately, calculation of AC copper loss

is not a straight-forward matter . Estimates are typically used .

Cor

e Selection

MAGNETICS

18

Powder Core Loss Calculation

Magnetizing Force (A·T/cm)

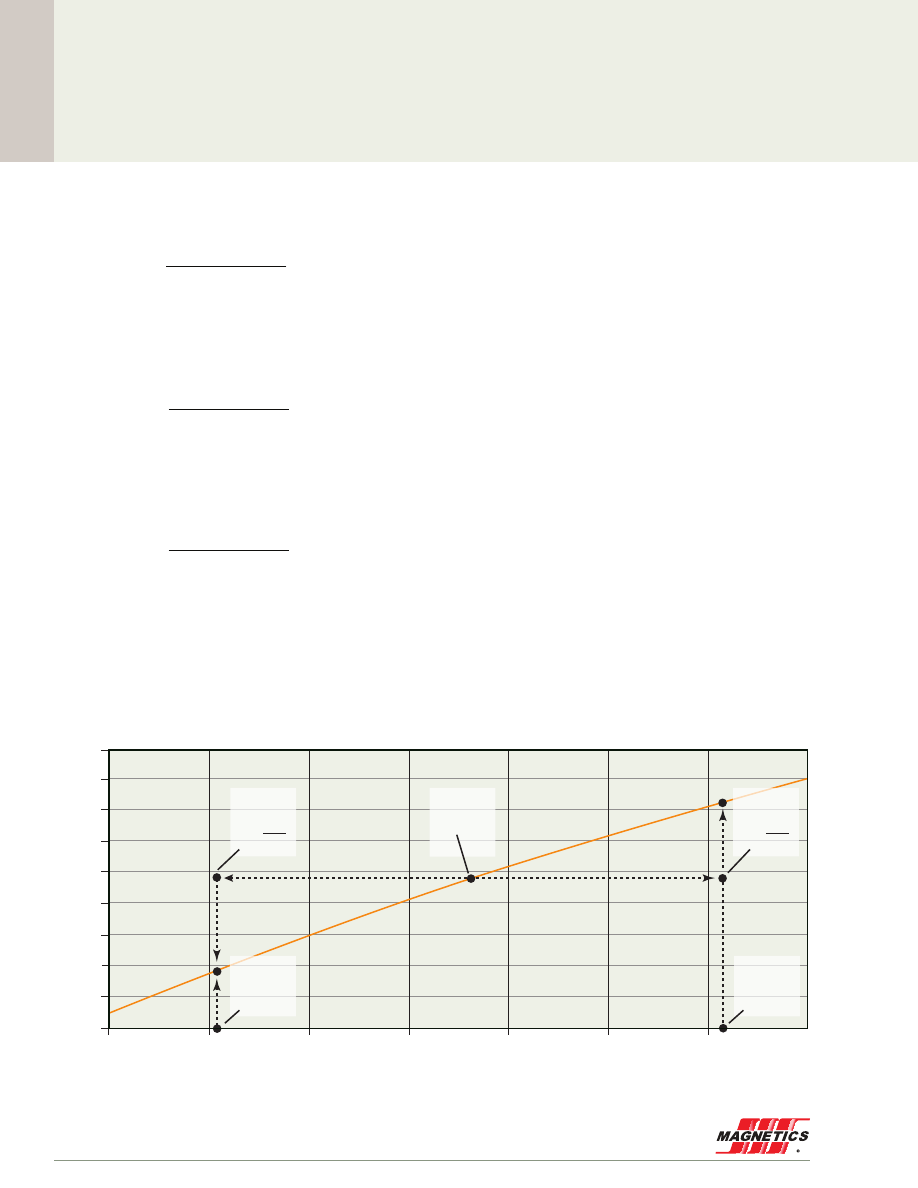

60µ Kool Mµ DC Magnetization (Example 2)

1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

10

100

Flux Density (T

esla)

160

147

125

90

75

60

40

26

14

173

200

250

300

550

500

550µ

160µ

H

AC min

H

AC max

B

AC max

B

AC min

B

H

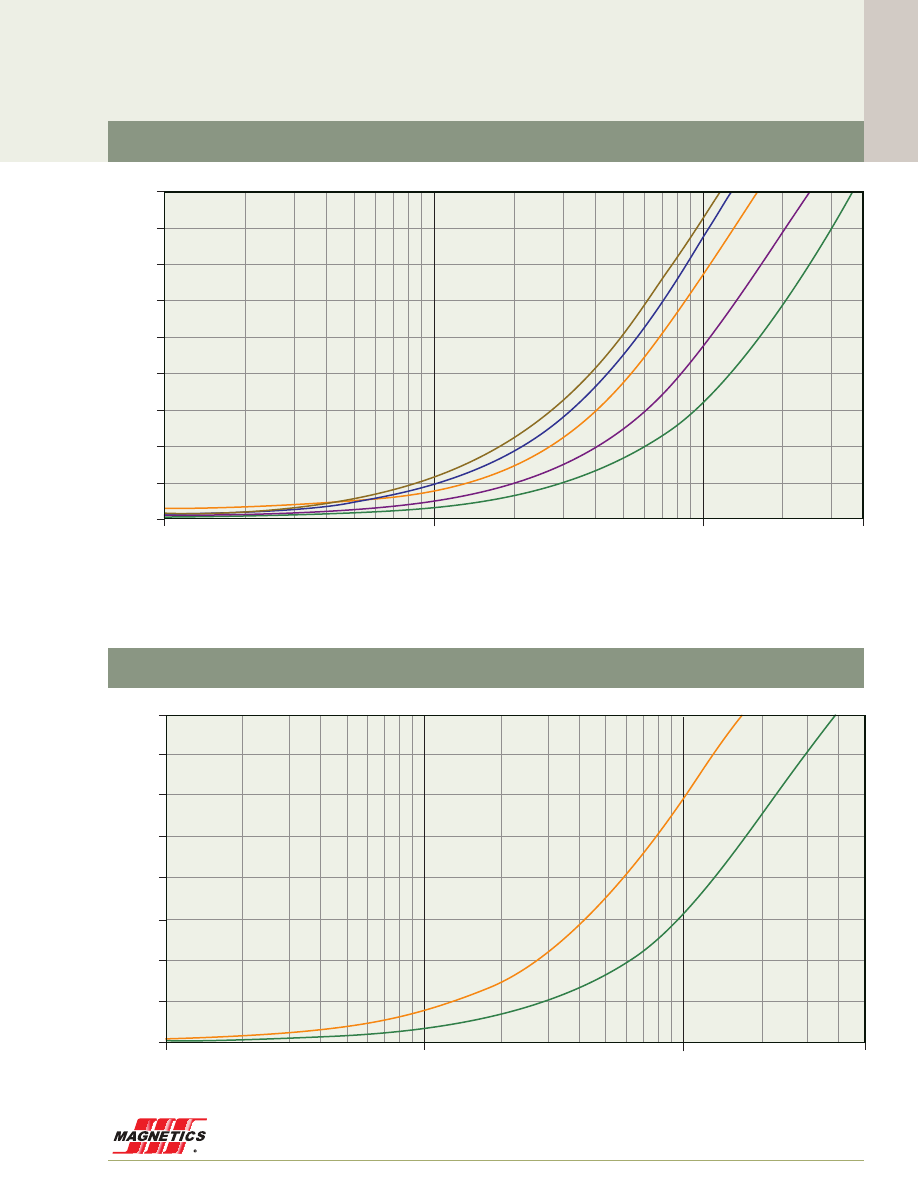

Core loss is generated by the changing magnetic flux

field within a material, since no magnetic materials exhibit

perfectly efficient magnetic response . Core loss density (PL)

is a function of half of the AC flux swing (½ B=B

pk

) and

frequency (

f

) . It can be approximated from core loss charts

or the curve fit loss equation:

14 - old 2 - 8

PL = aB

pk

b

f

c

B

pk

= 2

%

B =

2

B

AC max

- B

AC min

H

AC max

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

H

AC min

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

where a, b, c are constants determined from curve fitting,

and B

pk

is defined as half of the AC flux swing:

14 - old 2 - 8

PL = aB

pk

b

f

c

B

pk

= 2

%

B =

2

B

AC max

- B

AC min

H

AC max

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

H

AC min

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

Units typically used are (mW/cm

3

) for PL; Tesla (T) for B

pk

;

and (kHz) for

f

.

The task of core loss calculation is to determine B

pk

from

known design parameters .

Example 1 - AC current is 10% of DC current:

Approximate the core loss of an inductor with 20 turns wound on Kool Mµ p/n 77894A7 p . 76 (60µ,

l

e

=6 .35 cm, A

e

=0 .654 cm

2

,

A

L

=75 nH/T

2

) . Inductor current is 20 Amps DC with ripple of 2 Amps peak-peak at 100kHz .

1 .) Calculate

H

and determine

B

from BH curve (p . 48) or curve fit equation (p . 50):

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

2 .) Determine Core Loss density from chart or calculate from loss equation p . 46:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

3 .) Calculate core loss:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

Method 1 – Determine B

pk

from DC

Magnetization Curve . B

pk

=

f(

H

)

Flux density (B) is a non-linear function of magnetizing field (H),

which in turn is a function of winding number of turns (N), current

(I), and magnetic path length (

l

e

) . The value of B

pk

can typically be

determined by first calculating

H

at each AC extreme:

14 - old 2 - 8

PL = aB

pk

b

f

c

B

pk

= 2

%

B =

2

B

ACmax

- B

ACmin

H

ACmax

=

I

e

N I

DC

+ 2

3

I

S

X

#

&

H

ACmin

=

I

e

N I

DC

- 2

3

I

S

X

#

&

Units typically used are (A·T/cm) for H .

From H

AC max

, H

AC min

, and the BH curve or equation (listed as

DC Magnetization, pgs . 47 - 50) B

AC max

, B

AC min

and therefore

B

pk

can be determined .

www.mag-inc.com

19

Cor

e Selection

Powder Core Loss Calculation

Example 2 - AC current is 40% of DC current:

Approximate the core loss for the same 20-turn inductor, with same inductor current of 20 Amps DC but ripple of 8 Amps peak-

peak at 100kHz .

1 .) Calculate

H

and determine

B

from BH curve fit equation p . 50:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

2 .) Determine Core Loss density from chart or calculate from loss equation p . 46:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

3 .) Calculate core loss:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

Note: Core losses result only from AC excitation . DC bias applied to any core does not cause any core losses, regardless of the

magnitude of the bias .

Example 3 – pure AC, no DC:

Approximate the core loss for the same 20-turn inductor, now with 0 Amps DC and 8 Amps peak-peak at 100kHz .

1 .) Calculate H and determine B from BH curve fit equation p . 50:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

Note: Curve fit equations are not valid for negative values of B . Evaluate for the absolute value of B, then reverse the sign of the

resulting H value .

2 .) Determine Core Loss density from chart or calculate from loss equation p . 46 .

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

3 .) Calculate core loss:

1415 - old 2 - 9 & 10

H

ACmax

= 6 .35

20

20 + 2

2

S

X

= 66 .14

A

$

T

cm

"

B

ACmax

b

0 .40T

H

ACmin

= 6 .35

20

20 - 2

2

S

X

= 59 .84

A

$

T

cm

"

B

ACmin

b

0 .37T

"

B

pk

= 2

%

B =

2

0 .40 - 0 .37 =0 .015T

PL = (62 .65) (0 .015

1 .781

)(100

1 .36

)

,

18 .5 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) ~ (18 .5)(6 .35)(0 .654)

b

77mW

H

ACmax

= 6 .35

20

20 + 2

8

S

X

= 75 .59

A

$

T

cm

"

B

ACmax

b

0 .44T

H

ACmin

= 6 .35

20

20 - 2

8

S

X

= 50 .39

A

$

T

cm

"

B

ACmin

b

0 .33T

"

B

pk

= 2

%

B =

2

0 .44 - 0 .33 =0 .055T

PL = (62 .65) (0 .055

1 .781

) (100

1 .36

)

,

188 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (188)(6 .35)(0 .654)

,

781mW

H

ACmax

= 6 .35

20

+ 2

8

S

X

= 12 .60

A

$

T

cm

"

B

ACmax

b

0 .092T

H

ACmin

= 6 .35

20

- 2

8

S X

= - 12 .60

A

$

T

cm

"

B

ACmin

b

-0 .092T

"

B

pk

= 2

%

B ~0 .092T

PL = (62 .65) (0 .092

1 .781

) (100

1 .36

)

,

470 cm

3

mW

P

fe

= (PL) (

l

e

) (A

e

) = (470)(6 .35)(0 .654)

,

1 .95W

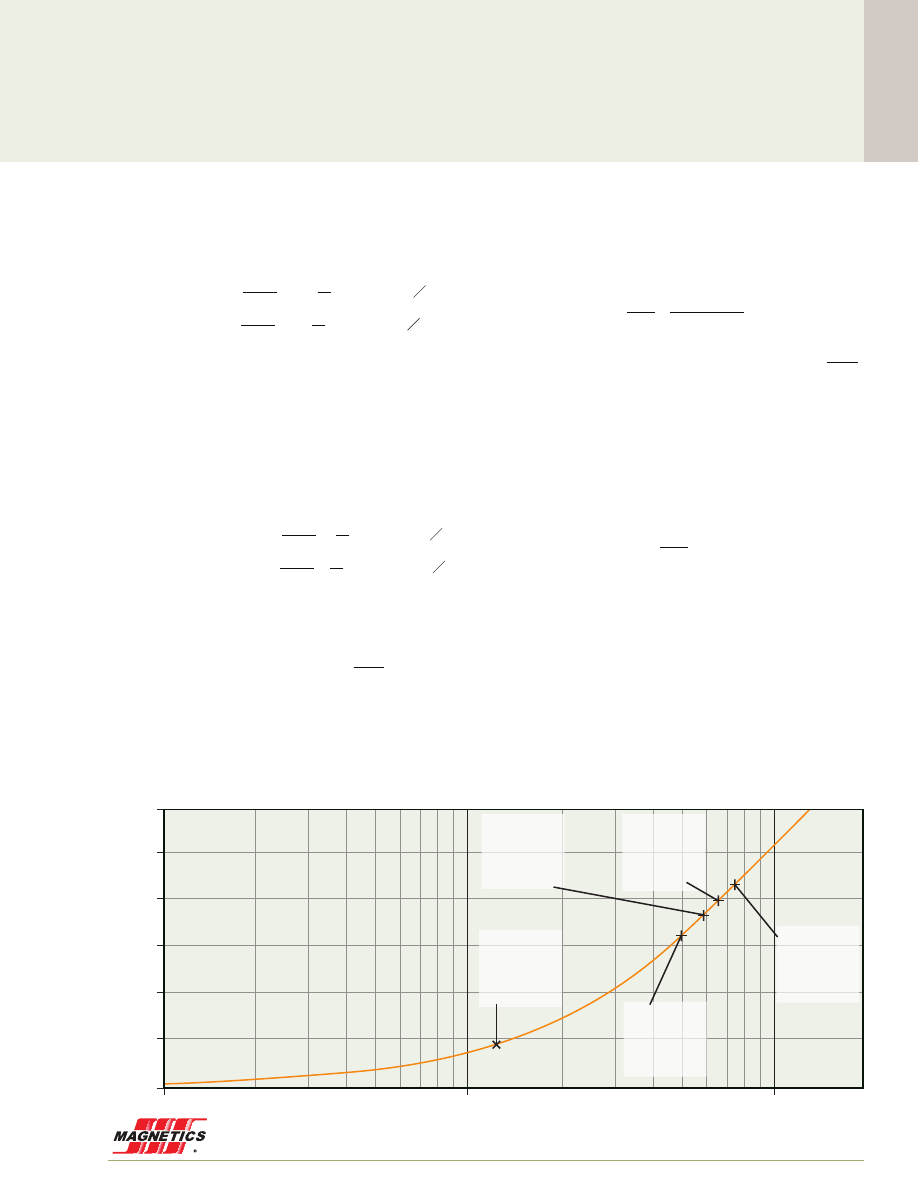

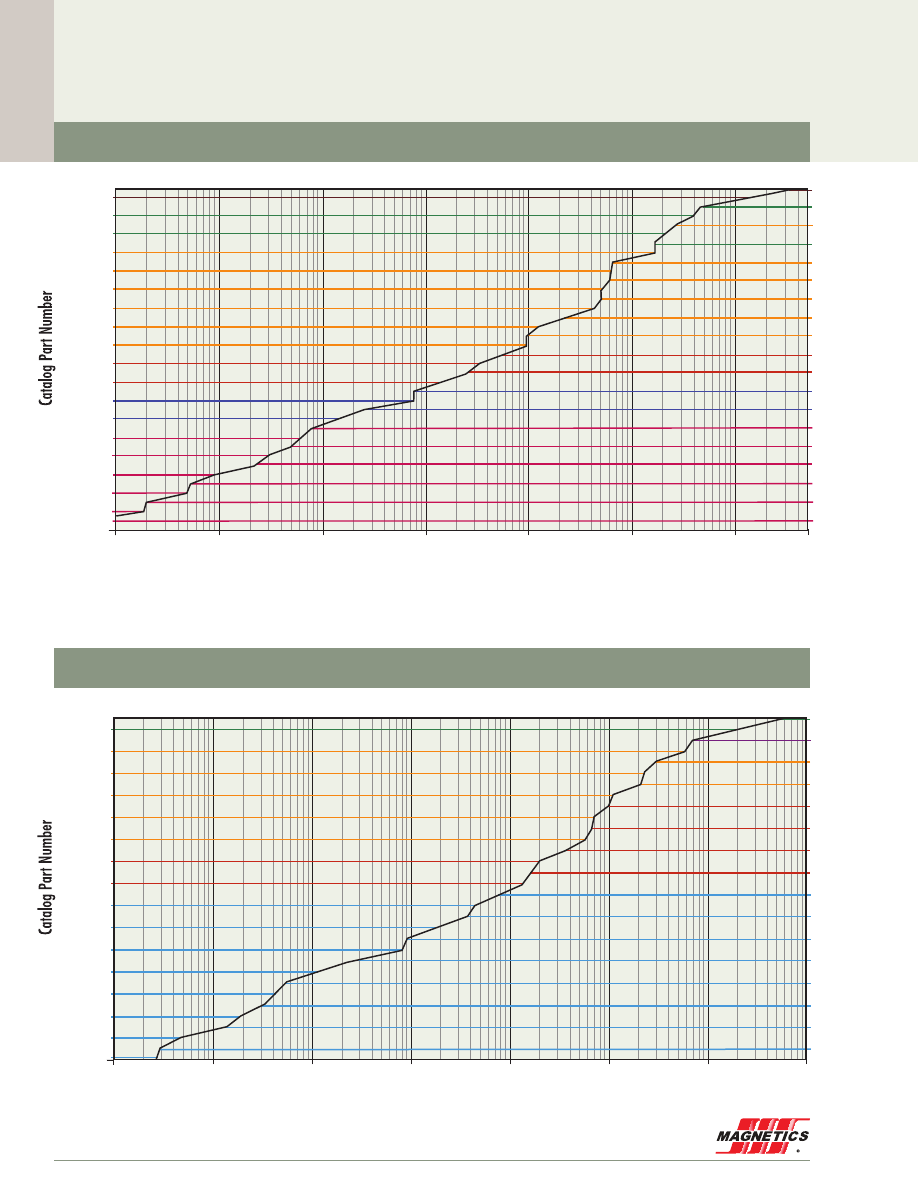

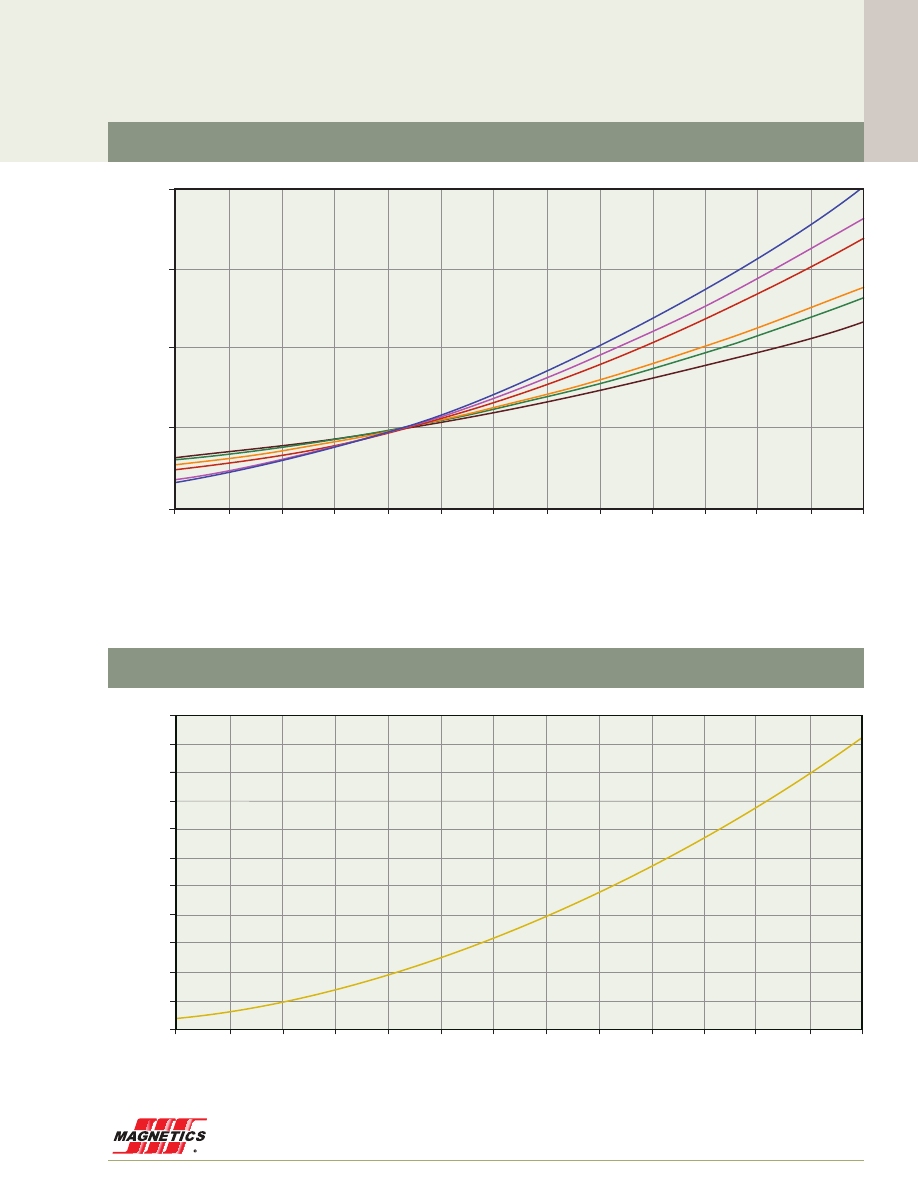

Plotted below are the operating ranges for each of the three examples .

Note the significant influence of DC bias on core loss, comparing Example 3 with Example 2 . Lower permeability results in less B

pk

,

even if the current ripple is the same . This effect can be achieved with DC bias, or by selecting a lower permeability material .

Magnetizing Force (A·T/cm)

60µ Kool Mµ DC Magnetization

1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

10

100

Flux Density (T

esla)

160

147

125

90

75

60

40

26

14

173

200

250

300

550

500

550µ

160µ

H

AC min

H

AC max

B

AC max

B

AC min

B

H

Example 1

H

AC max

=66.14

B

AC max

=0.4

Example 3

H

AC max

=12.6

B

AC max

=0.092

Example 2

H

AC max

=75.59

B

AC max

=0.44

Example 1

H

AC min

= 59.84

B

AC min

= 0.37

Example 2

H

AC min

= 50.39

B

AC min

= 0.33

Cor

e Selection

MAGNETICS

20

Method 2, for small H, approximate B

pk

from effective perm with DC bias .

B

pk

= f(

µ

e

, H)

The instantaneous slope of the BH curve is defined as the absolute permeability, which is the product of permeability of free space

(µ

0

=4

p

x10

-7

) and the material permeability (µ), which varies along the BH curve . For small AC, this slope can be modeled as a

constant throughout AC excitation, with µ approximated as the effective perm at DC bias (µ

e

):

16 - old 2 - 11

ppp

dH

dB =

µ

0

µ

e

"

%

H

%

B =

µ

0

µ

e

"

%

B =

µ

0

µ

e

%

H B

pk

= 2

%

B = 0 .5

Q V

µ

0

µ

e

%

H

B

pk

= 0 .5

Q V

µ

0

Q V

%µ

i

Q V

µ

i

Q V

100

Q V

%

H

Q V

where

%

H =

l

e

N

%

I

H

DC

= 6 .35

20 20

Q V

#

&

= 63

A

$

T

cm

"

from curve or curve fit equation,

%µ

i

= 0 .58

µ

i

= 60

%

H =

l

e

N

%

I =

6 .35

20(2)

= 6 .3

A

$

T

cm

B

pk

= 0 .5(4

r

x 10

-7

)(0 .58)(60)(100)(6 .3)

b

0 .014T

(this compares to 0 .015T using Method1)

The effective perm with DC bias is shown in this catalog as % of initial perm and can be obtained from the DC bias curve or curve

fit equation, pgs 29 - 34

16 - old 2 - 11

ppp

dH

dB =

µ

0

µ

e

"

%

H

%

B =

µ

0

µ

e

"

%

B =

µ

0

µ

e

%

H B

pk

= 2

%

B = 0 .5

Q V

µ

0

µ

e

%

H

B

pk

= 0 .5

Q V

µ

0

Q V

%µ

i

Q V

µ

i

Q V

100

Q V

%

H

Q V

where

%

H =

l

e

N

%

I

H

DC

= 6 .35

20 20

Q V

#

&

= 63

A

$

T

cm

"

from curve or curve fit equation,

%µ

i

= 0 .58

µ

i

= 60

%

H =

l

e

N

%

I =

6 .35

20(2)

= 6 .3

A

$

T

cm

B

pk

= 0 .5(4

r

x 10

-7

)(0 .58)(60)(100)(6 .3)

b

0 .014T

(this compares to 0 .015T using Method1)

H is multiplied by 100 because

l

e

is expressed in cm, while B

pk

units include m .

Reworking Example 1

(20 Amps DC, 2 Amps pk-pk)

16 - old 2 - 11

ppp

dH

dB =

µ

0

µ

e

"

%

H

%

B =

µ

0

µ

e

"

%

B =

µ

0

µ

e

%

H B

pk

= 2

%

B = 0 .5

Q V

µ

0

µ

e

%

H

B

pk

= 0 .5

Q V

µ

0

Q V

%µ

i

Q V

µ

i

Q V

100

Q V

%

H

Q V

where

%

H =

l

e

N

%

I

H

DC

= 6 .35

20 20

Q V

#

&

= 63

A

$

T

cm

"

from curve or curve fit equation,

%µ

i

= 0 .58

µ

i

= 60

%

H =

l

e

N

%

I =

6 .35

20(2)

= 6 .3

A

$

T

cm

B

pk

= 0 .5(4

r

x 10

-7

)(0 .58)(60)(100)(6 .3)

b

0 .014T

(this compares to 0 .015T using Method1)

Reworking Example 2

(20 Amps DC, 8 Amps pk-pk)

From example 1,

H

DC

= 63

A

$

T

cm

,

%µ

i

= 0 .58;

µ

i

= 60

%

H =

l

e

N

%

I =

6 .35

20(8)

= 25 .2

A

$

T

cm

B

pk

= 0 .5(4

r

x 10

-7

) (0 .58) (60) (100) (25 .2) = 0 .055T

(this compares to 0 .055T usingMethod 1)

%

H = 25 .20

A

$

T

cm

H

DC

= 0

A

$

T

cm

%µ

i

= 1

B

pk

= 0 .5(4

r

x 10

-7

) (1) (60) (100) (25 .2) = 0 .095T

(this compares to 0 .092T usingMethod 1)

Reworking Example 3

(0 Amps DC, 8 Amps pk-pk)

From example 2,

H

DC

= 63

A

$

T

cm

,

%µ

i

= 0 .58;

µ

i

= 60

%

H =

l

e

N

%

I =

6 .35

20(8)

= 25 .2

A

$

T

cm

B

pk

= 0 .5(4

r

x 10

-7

) (0 .58) (60) (100) (25 .2) = 0 .055T

(this compares to 0 .055T usingMethod 1)

%

H = 25 .20

A

$

T

cm

H

DC

= 0

A

$

T

cm

%µ

i

= 1

B

pk

= 0 .5(4

r

x 10

-7

) (1) (60) (100) (25 .2) = 0 .095T

(this compares to 0 .092T usingMethod 1)

Powder Core Loss Calculation

www.mag-inc.com

21

Cor

e Selection

Powder Core Loss Calculation

Method 3, for small H, determine B

pk

from biased inductance . B

pk=

=

f

(L,I)

B can be rewritten in terms of inductance by considering Faraday’s equation and its effect on inductor current:

17 - old 2 - 12

V

L

=NA dt

dB =L

dt

dl

"

dB = NA

L dl

%

B = NA

L

DC

%

I

"

B

pk

= 2NA

e

L

DC

%

I

"

dH

dB =

NA

L

dH

dl

"

dH

dB =

N

2

A

e

L

I

e

%

H

%

B =

N

2

A

e

L

DC

I

e

"

%

B = N

2

A

e

L

DC

l

e

%

H= NA

e

L

DC

%

I

"

%

B

pk

= 2NA

e

L

DC

%

I

L varies non-linearly with I . For small AC, L can be assumed constant throughout AC excitation and is approximated by the biased

inductance (L

DC

) .

17 - old 2 - 12

V

L

=NA dt

dB =L

dt

dl

"

dB = NA

L dl

%

B = NA

L

DC

%

I

"

B

pk

= 2NA

e

L

DC

%

I

"

dH

dB =

NA

L

dH

dl

"

dH

dB =

N

2

A

e

L

I

e

%

H

%

B =

N

2

A

e

L

DC

I

e

"

%

B = N

2

A

e

L

DC

l

e

%

H= NA

e

L

DC

%

I

"

%

B

pk

= 2NA

e

L

DC

%

I

Another way of looking at this is by rewriting the relationship between B and L as:

17 - old 2 - 12

V

L

=NA dt

dB =L

dt

dl

"

dB = NA

L dl

%

B = NA

L

DC

%

I

"

B

pk

= 2NA

e

L

DC

%

I

"

dH

dB =

NA

L

dH

dl

"

dH

dB =

N

2

A

e

L

I

e

%

H

%

B =

N

2

A

e

L

DC

I

e

"

%