Isolation Switches 911/912/913-...

www.e-t-a.com

Issue B

4

- 65

4

Description

Typical applications

Technical data

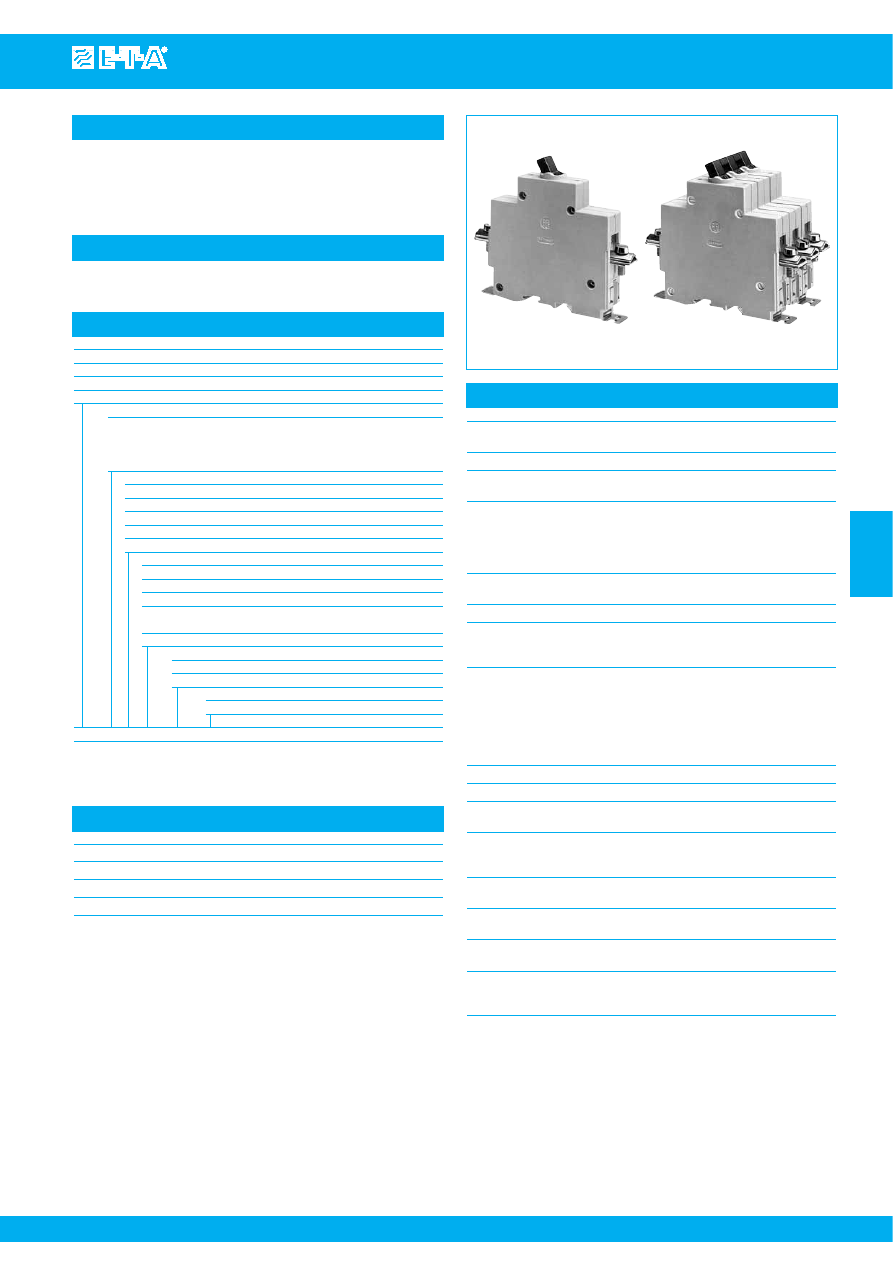

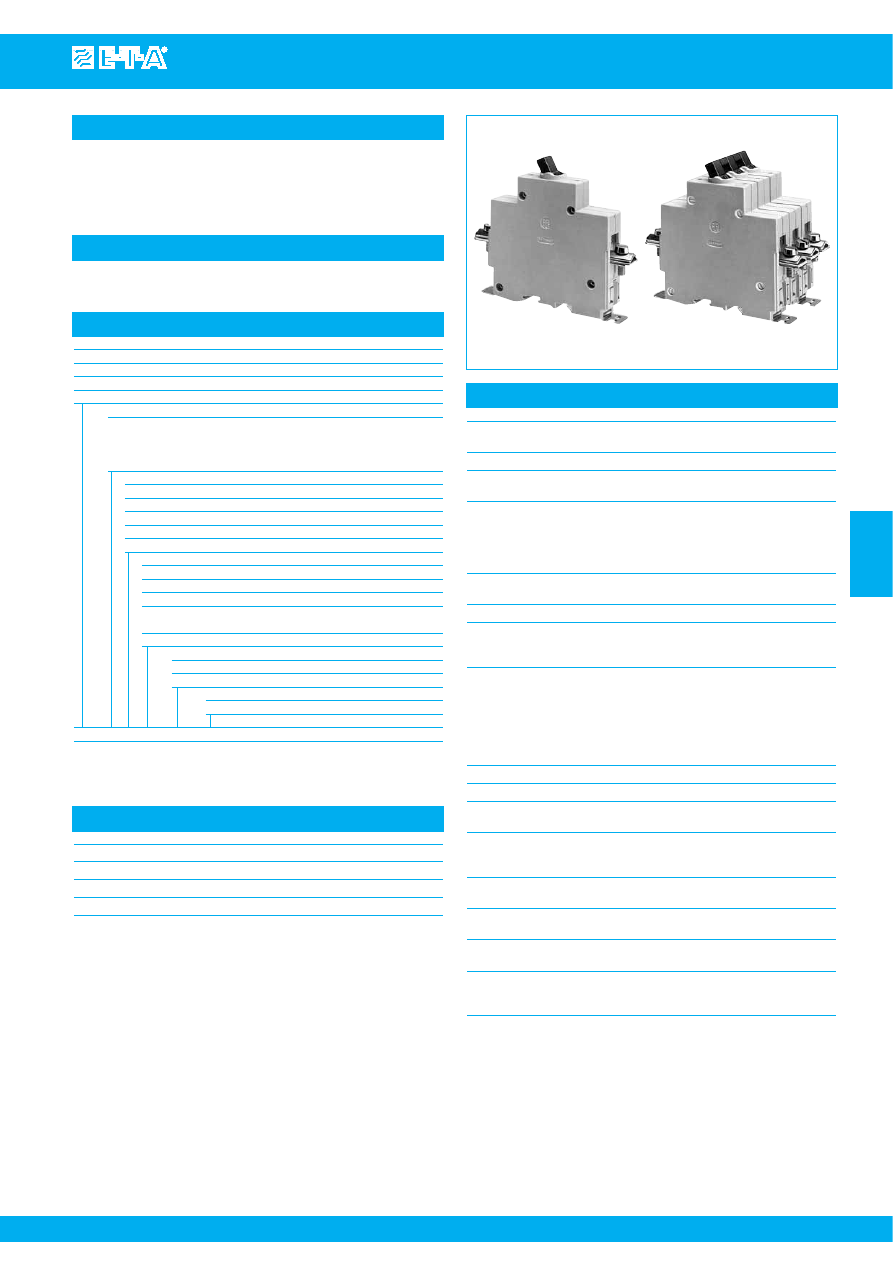

Single, two and three pole isolators to EN 60947 / IEC 60947 with toggle

actuation. Designed for rail, panel or surface mounting. Options include

auxiliary contacts and remote electrical disconnection.

For circuit breaker versions see types 410, 520, 530.

Control systems, industrial equipment.

911-K

913-K

Voltage rating

AC 240 V; 3 AC 415 A; 3 AC 500 V;

DC 110 V

Current rating range

32 A, 63 A, 125 A

Auxiliary contact rating

6 A at AC 240 V or DC 28 V;

1 A at DC 110 V

Electrical remote disconnection (FA)

operating voltage

DC 12 V or DC 24 V

operating current

approx. 18 A or 12 A

max. pulse time

10 ms < t

ON

< 20 ms /t

OFF

> 10 s

switching time

< 20 msec

Typical life

10,000 operations at I

N

20,000 operations mechanical

Ambient temperature -40...+75 °C (-40...+167 °F)

Insulation co-ordination rated impulse

pollution

(IEC 60664 and 60664A)

withstand voltage

degree

6 kV

3

Dielectric strength

(IEC 60664 and 60664A)

test voltage

operating area

AC 3,300 V

pole/pole

AC 3,300 V

main to aux. circuit

AC 2,200 V

aux. circuit 11-12

to 13-14

AC 1,000 V

Insulation resistance

> 100 MΩ (DC 500 V)

Short-circuit protection

back up fuse max. 125 A

Degree of protection

operating area IP40

(IEC 60529/DIN 40050)

terminal area IP00

Vibration

5 g (57-200 Hz), ± 0.38 mm (10-57 Hz)

to IEC 60068-2-6, test Fc

10 frequency cycles/axis

Shock

25 g (11 ms)

to IEC 60068-2-27, test Ea

Corrosion

96 hours at 5 % salt mist

to IEC 60068-2-11, test Ka

Humidty

240 hours at 95 % RH

to IEC 60068-2-3, test Ca

Mass

approx. 220 g single pole

approx. 440 g double pole

approx. 660 g three pole

Standard current ratings and typical internal resistance values

Current rating (A)

Internal resistance (

Ω

)

32

≤ 0.002 per pole

63

≤ 0.002 per pole

125

≤ 0.002 per pole

Ordering information

Type No.

911

single pole switch

912

double pole switch

913

three pole switch

Terminal design

K

main terminal

up to 32 A: pressure plate B5-DIN 46288

up to 63 A: pressure plate B6-DIN 46288

up to 125 A: terminal screws DIN 46206, sheet 2, form 1, thread M6

Mounting

1

surface mounting

2

rail or panel mounting (rail DIN EN 50022-35x7.5)

3

rail or panel mounting (rail DIN EN 50035-G32)

4

panel mounting only

5

mounting brackets – surface mounting

Auxiliary contacts (terminals M3.5 or blade terminals (-FA)

Si

one each N/O and N/C (not for 911-FA)

Si1

one N/C (11,12) (not for 911-FA)

Si2

one N/O (13,14)

2Si

two each N/O and N/C – types 912, 913 only

(not for 912-FA)

3Si

three each N/O and N/C – type 913 only (not for 913-FA)

Remote trip (optional)

FA 12

remote disconnection, for DC 12 V

FA 24

remote disconnection, for DC 24 V

Current ratings

32, 63, 125 A

911 - K - 1- Si -

... - 63 A

ordering example

The exact part number required can be built up from the table of choices shown

above. Ordering references for optional features should be omitted if not required.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

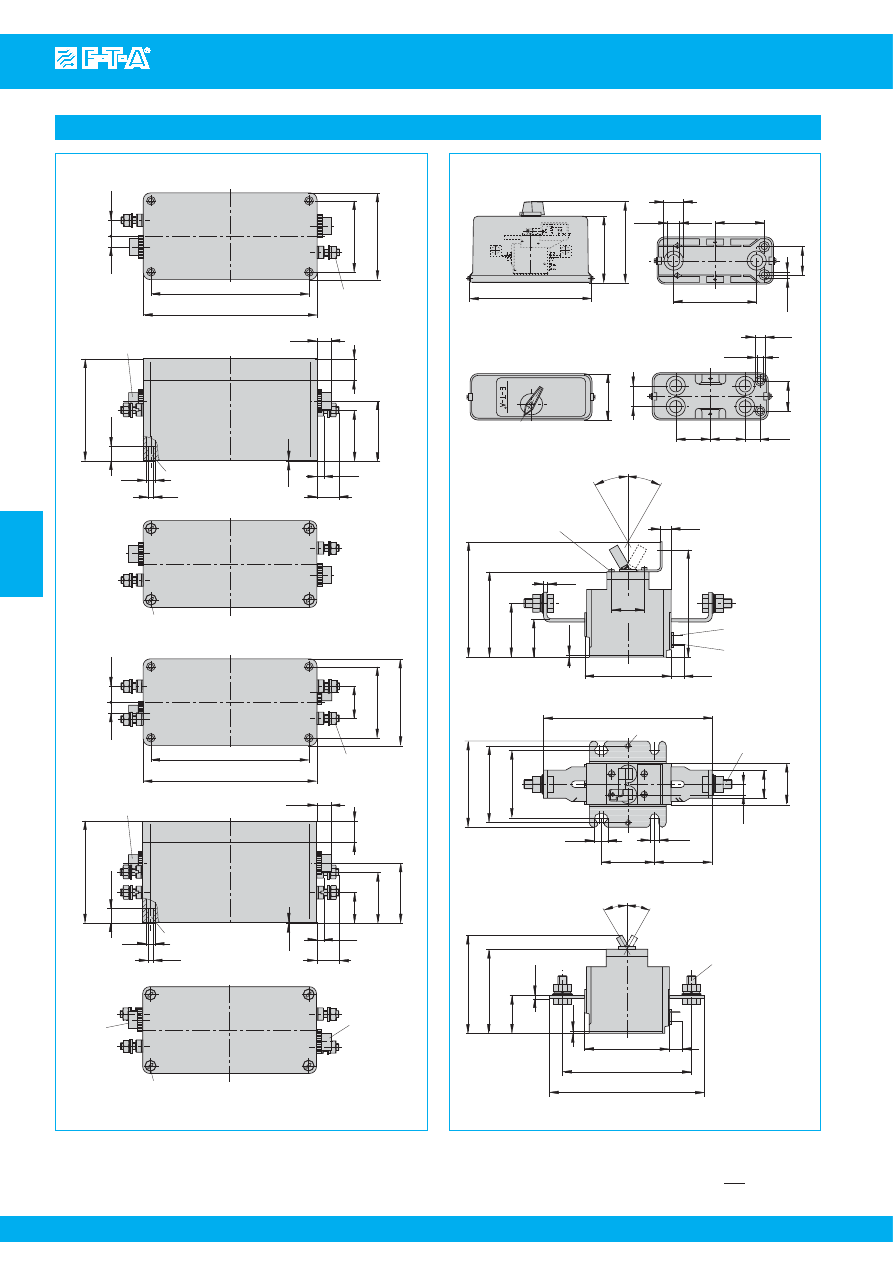

2.84

2

8.7

14

9

92

72

83.5

M5

57

10

.551

.354

.394

2.24

3.62

3.29

.343

.079

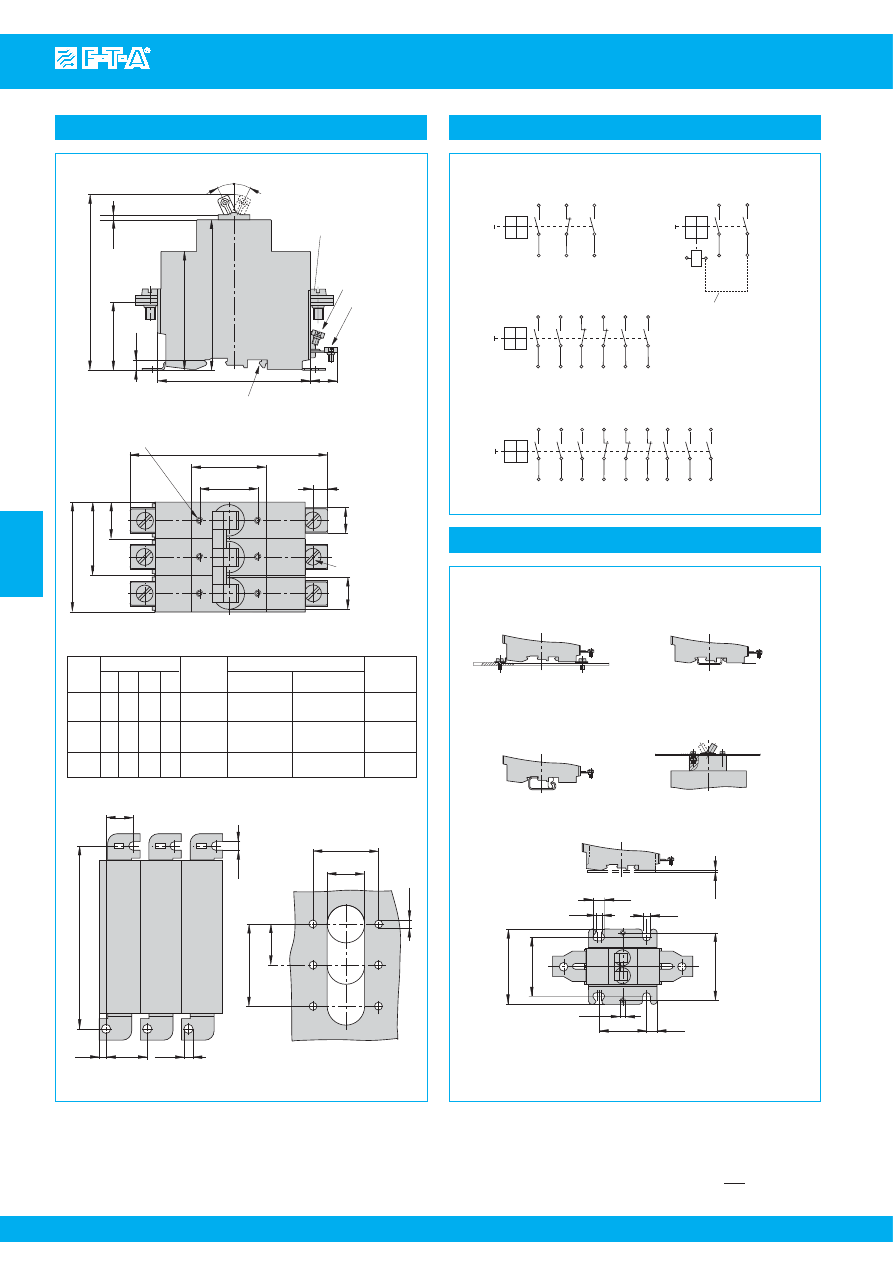

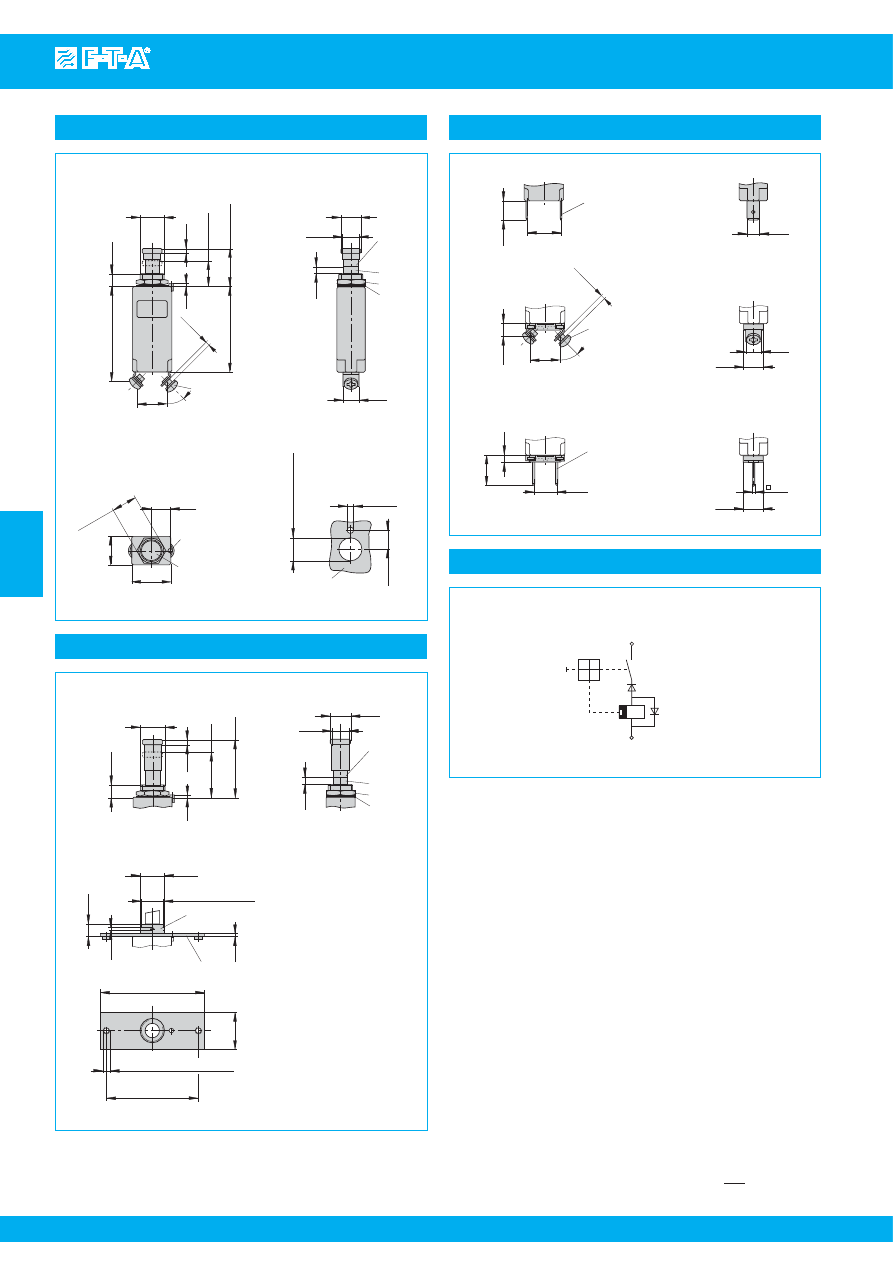

S

urface mounting

s

uffi

x

: -1

Rail mounting

(EN 50035-G32)

s

uffi

x

: -3

Mounting bracket

s

-

s

urface mounting

s

uffi

x

: -5

Rail mounting

(EN 50022-35

x

7.5)

s

uffi

x

: -2

Panel mounting

s

uffi

x

: -4

Cover

s

, label

s

,

s

ealing

s

crew

s

etc. can be fitted on the

front of the hou

s

ing.

www.e-t-a.com

Issue B

4

- 66

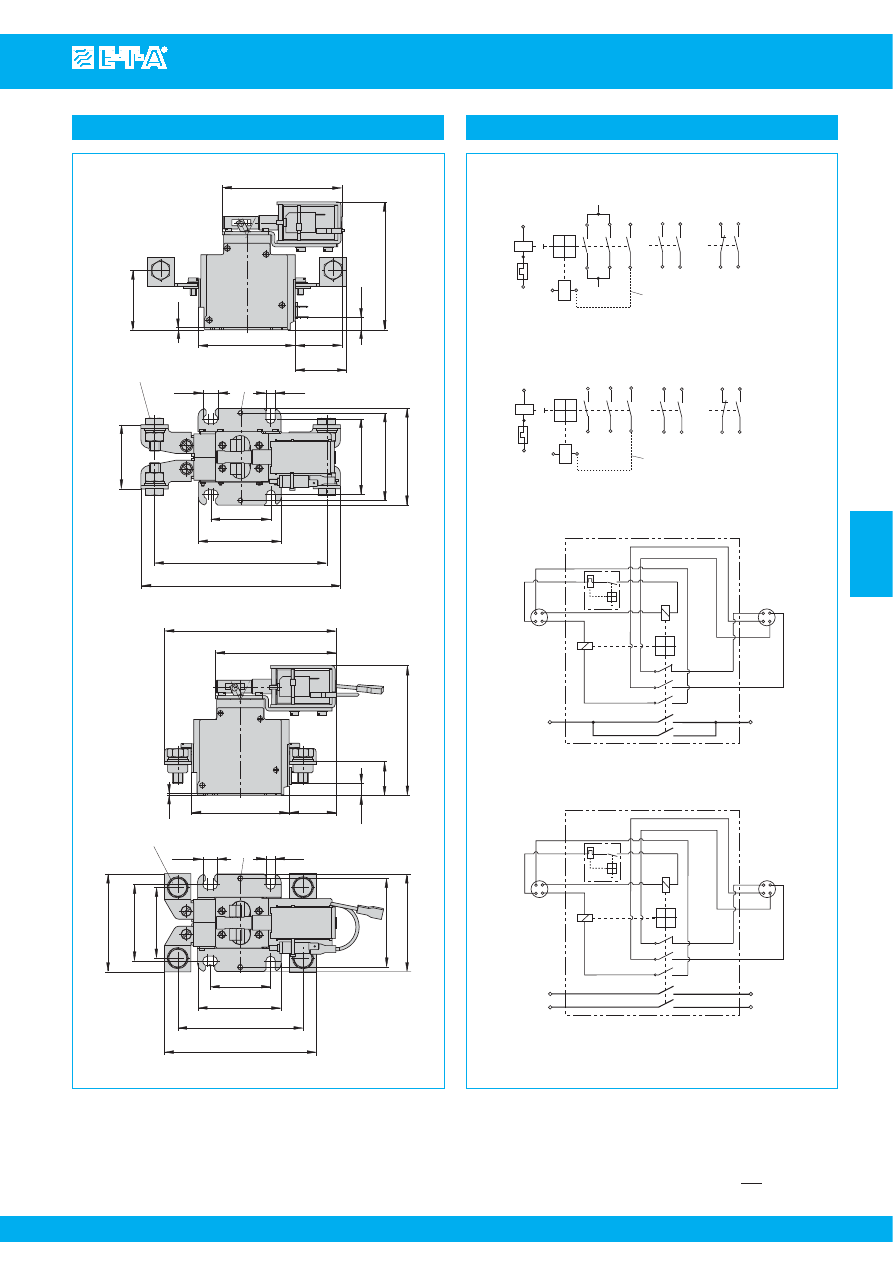

Isolation Switches 911/912/913-...

4

1

line

3

1

5

3

2

FA

13

14

13

21

11

12

4

22

23

24

14

1

2

S

i

13

21

11

12

4

22

23

24

14

2

3

S

i

6

31

32

33

34

11

13

2

12

14

2

911

911-…-FA

912-K

913-K

line 1

recommended lin

k

for FA coil protection

pre-wired at the factory

line

line

Internal connection diagrams

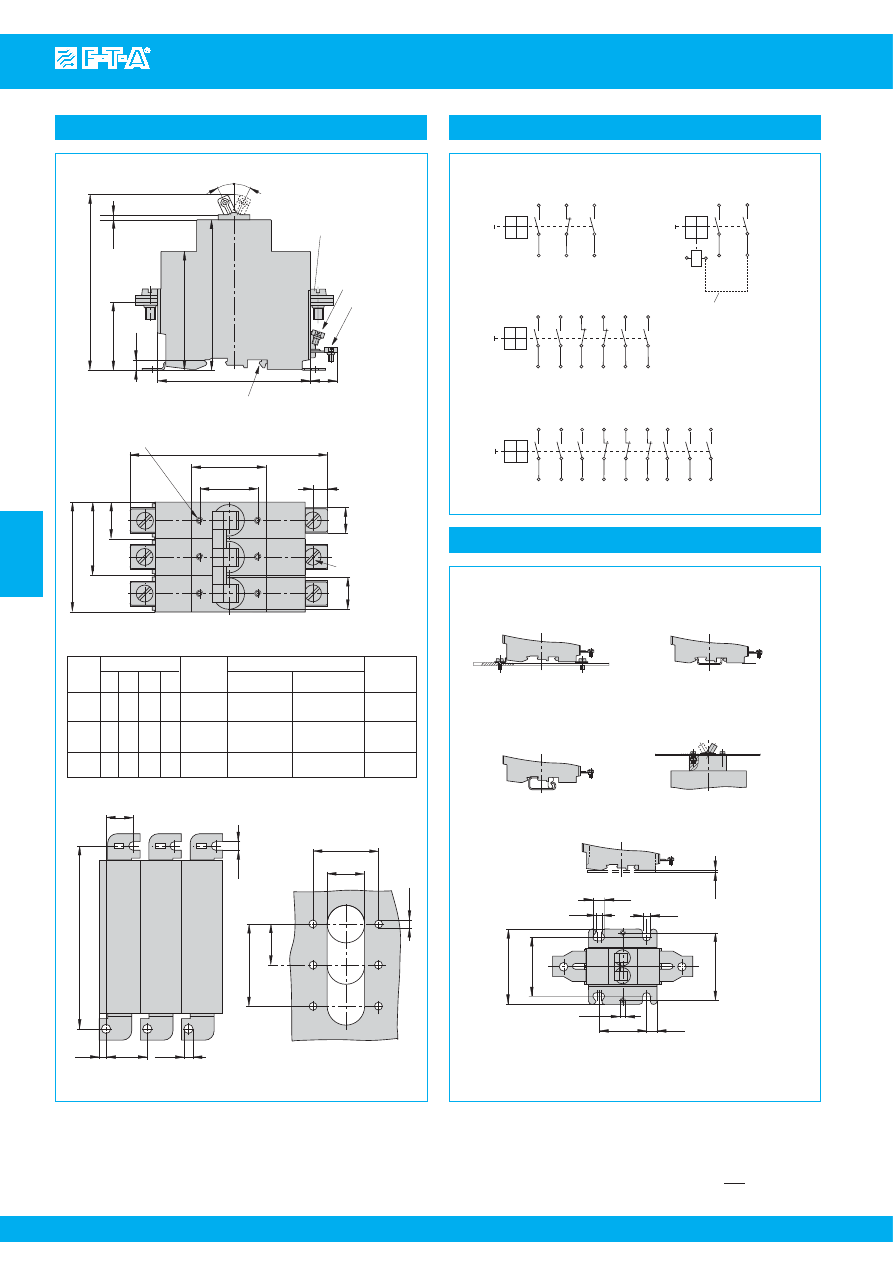

Dimensions

13

.512

15.4

.606

15.4

.606

114

4.49

120

4.72

120

4.72

7

.276

9

.354

9

.354

Max.

tightening

tor

q

ue

≤

32 A

≤

63 A

≤

125 A

Dimen

s

ion

s

mm/in. Terminal

B

pre

ss

ure

plate B5

DIN 46288

pre

ss

ure

plate B6

DIN 46288

terminal

s

crew

97

3.7

22

ø4.6

4.6

14.6

s

urface mounting

35

ø20

ø4

22

+0,5

44

+1

monting hole

s

26

°

26

°

106

90.5

71.5

41

6

92

16

s

ymmetrical rail DIN EN 50022-35x7.5

G

profile rail DIN EN 50035-

G

32 (not

s

hown)

D

45

35

66

44

22

E

B

C

S

i terminal

s

M3.5*

1 N/C (

S

i1) or FA

coil (pole 1 only)

OFF

ON

M3.5 - thread max. 9 mm (.354 in.) deep

tightening tor

q

ue max. 0.55 Nm

3

pole 1

pole 2

pole 3

1N/O (

S

i2)

Current

rating

Cro

ss

s

ection (

s

ee DIN 46288)

with 1 or 2 e

q

ual

conductor

s

with 2 different

conductor

s

M5

M6

M6

C

D

E

2.0 Nm

2.5 Nm

2.5 Nm

2.5 mm

2

to

10 mm

2

2.5 mm

2

to

10 mm

2

4 mm

2

to

16 mm

2

4 mm

2

and 6 mm

2

or

6 mm

2

to 16 mm

2

.236

3.56

1.64

4.17

.118

2.82

3.62

.630

1.77

1.38

.866

1.73

2.60

19

.748

.575

.181

3.82

.146

.181

.866

.787

1.38

.157

.866

1.73

+.020

+.039

tightening tor

q

ue

max. 4 Nm

tightening tor

q

ue

max. 0.8 Nm

Mounting method

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

Isolation Switches 911/912/913-...

www.e-t-a.com

Issue B

4

- 67

4

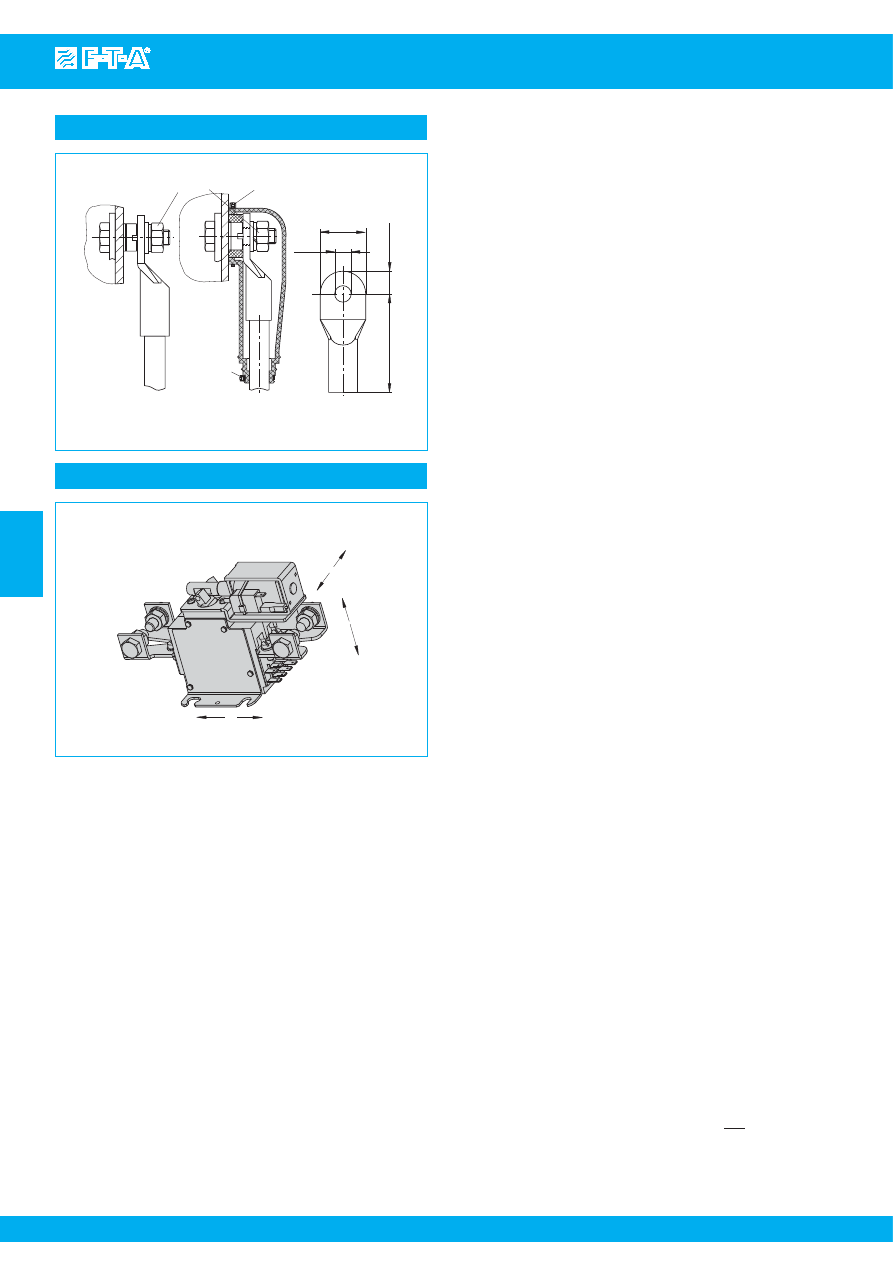

mounting hole

s

1.2

38

max. 4

24.5

53

62

59

59

+0.3

35

22

ø4

.047

25

+0.3

21

2.07

2.44

1.50

.827

.965

max .157

.984

+.012

.157

2.32

+.012

1.38

2.32

.827

.047

1.2

44

53

40

40

35

25

+0.3

+0.3

ø4

38

21

max. 4

24.5

mounting hole

2.07

1.73

1.50

.827

.965

max .157

.984

+.012

.157

1.58

+.012

1.38

1.58

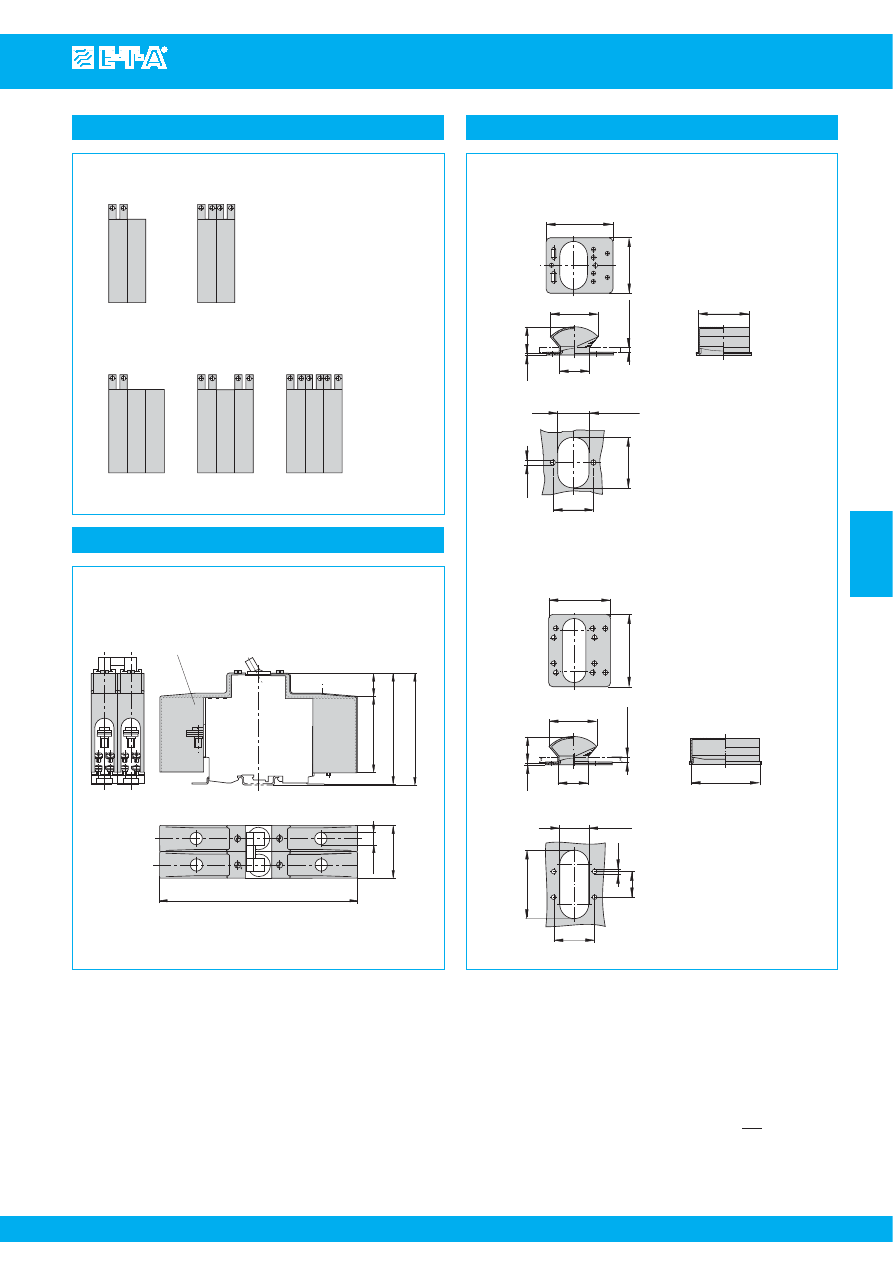

For

s

erie

s

911

≤

125 A

Water

s

pla

s

h cover tran

s

lucent with fi

x

ing plate

and

s

crew

s

(IP54)

X 211 118 01

For

s

erie

s

911 - 240 A and 912

Water

s

pla

s

h cover tran

s

lucent with fi

x

ing plate

and

s

crew

s

(IP54)

X 211 119 01

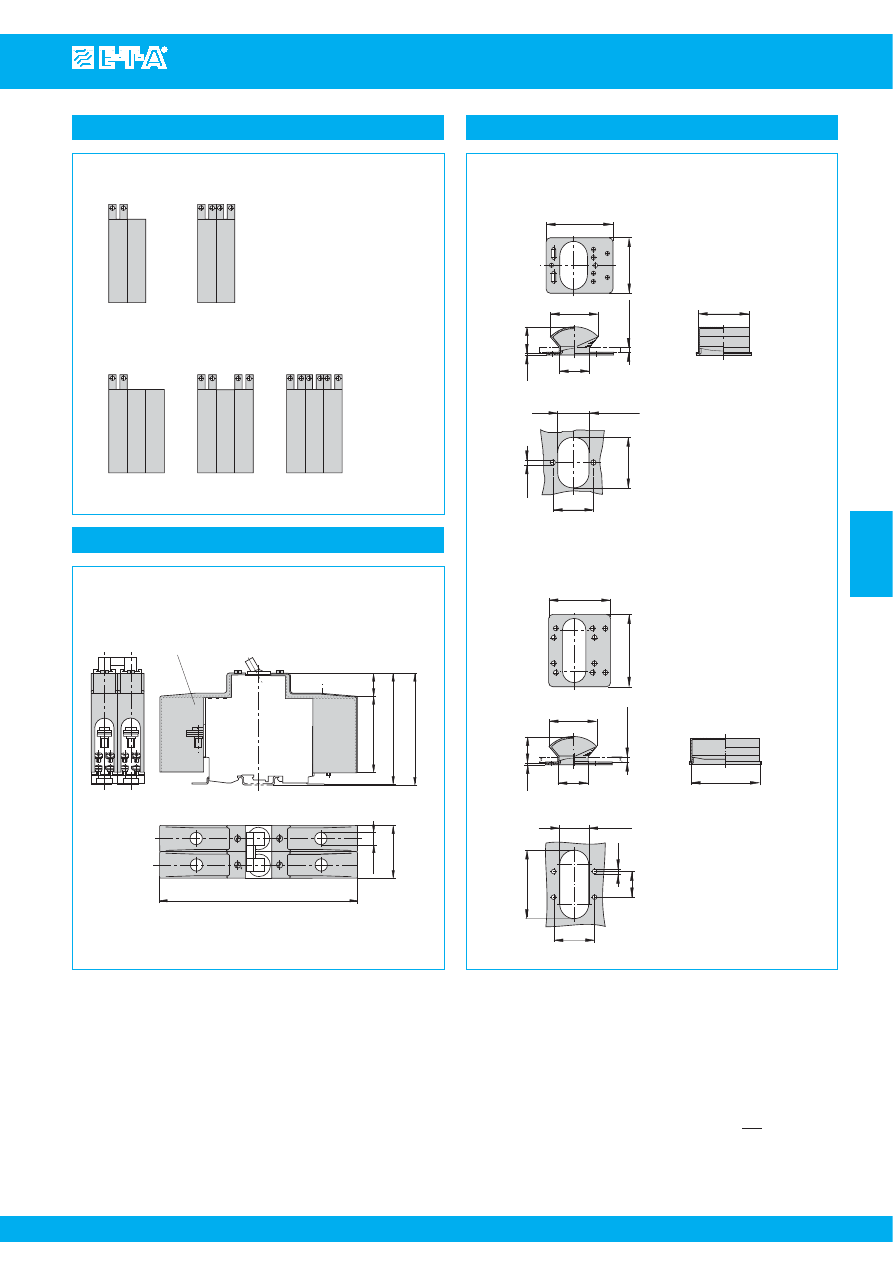

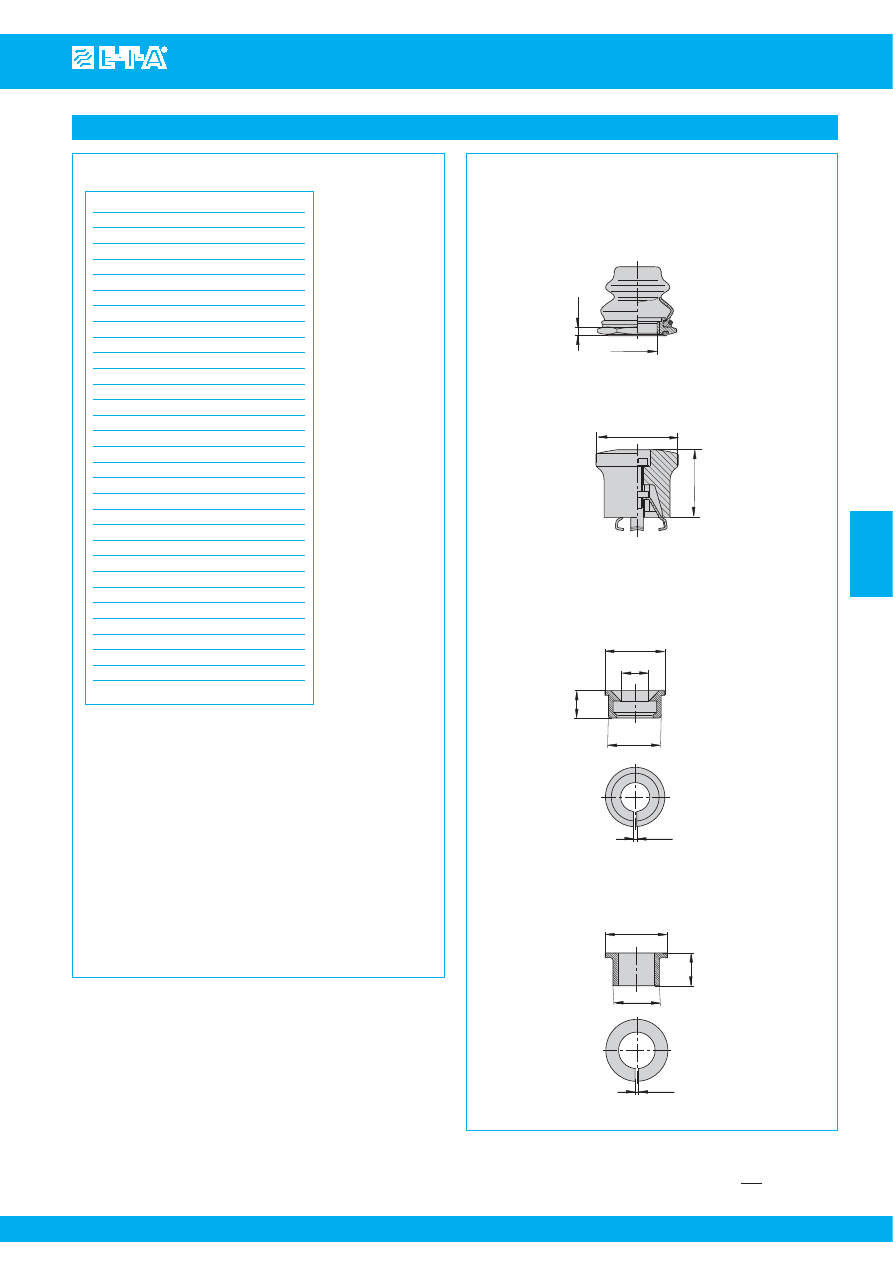

Accessories

Accessories

protected again

s

t bru

s

h contact *

165

ø10

44

64

19

92

94

protected again

s

t bru

s

h contact *

* to DIN 57106T100/VDE 0106 T100

6.50

.748

2.52

3.62

3.70

.394

1.73

Terminal in

s

ulation cover

X 211 705 01

(1

s

et = 2 pc

s

per pole)

Auxiliary contact arrangement with multipole switches

S

i

2

S

i

S

i

2

S

i

3

S

i

double pole device

s

three pole device

s

This is a metric design and millimeter dimensions take precedence ( mm )

inch

All dimensions without tolerances are for reference only. In the interest of improved design,

performance and cost effectiveness the right to make changes in these specifications

without notice is reserved.Product markings may not be exactly as the ordering codes.

Errors and omissions excepted.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

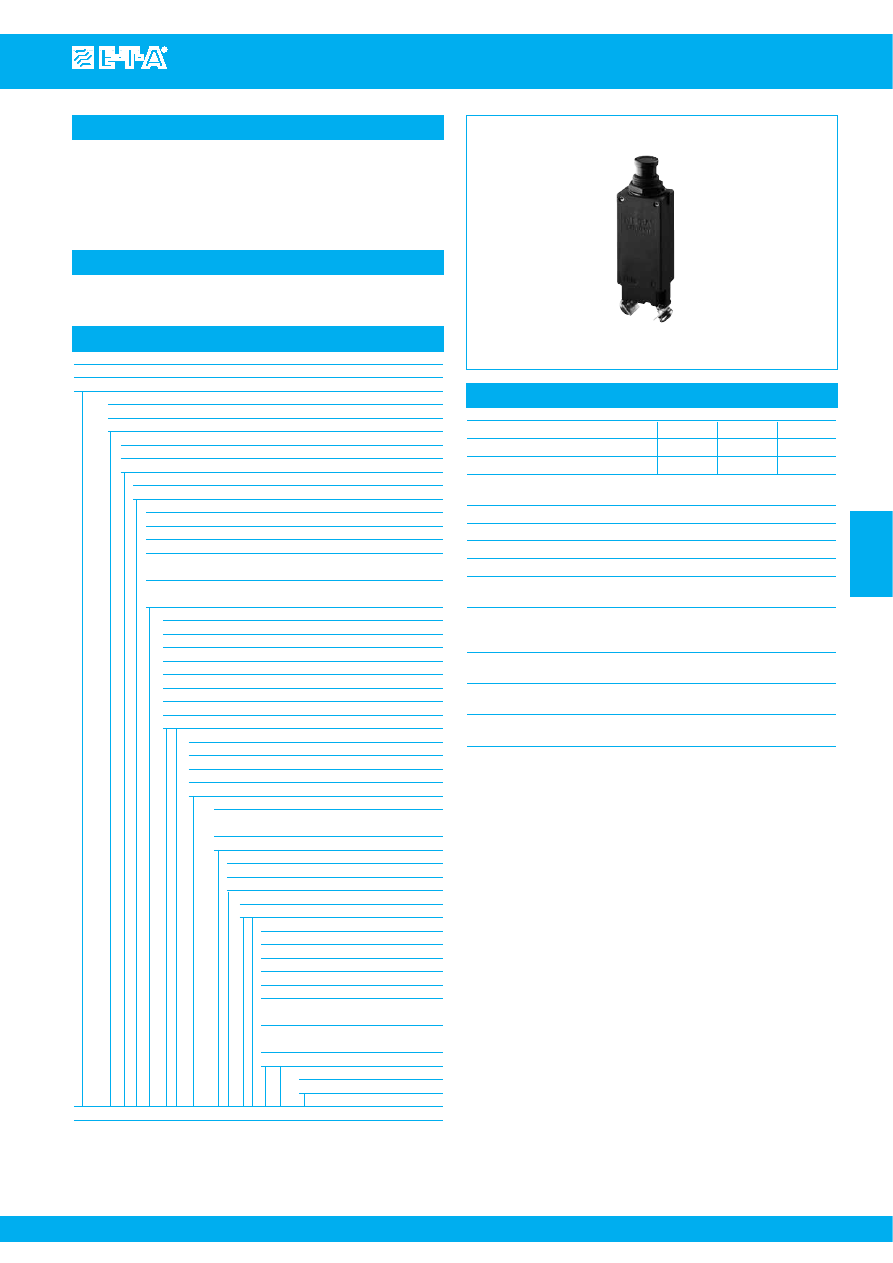

Battery Isolation Switches 921/922

www.e-t-a.com

Issue B

4

- 69

4

Description

Typical applications

Ordering information

Technical data

Single or two pole isolation switches to IEC 60947/EN 60947 with toggle

actuation. Options include auxiliary contacts, a moulded flame retardant

enclosure for added environmental protection (with or without rotary

action external operating knob), and remote operation - disconnection

only, or disconnection and re-connection. A version for use in hazardous

areas (e.g. petroleum and chemical tankers) is available to special order.

Vehicles of all types (including tankers), boats, battery powered systems.

921 922

single pole double pole

Type No.

921

single pole switch

922

double pole switch

Enclosure design (optional)

B3

without external operating knob, for use only with single pole devices

B31

with external operating knob, for use only with single pole devices

B32

without external operating knob, for use only with double pole devices

B33

with external operating knob, for use with double pole devices

B34

with external operating knob, for use only with double pole devices

with remote-re-connection facility

B35

with external operating knob, for use only with single pole devices

with remote-re-connection facility

C3

without external operating knob, 1-pole, IP65

C32

without external operating knob, 2-pole, IP65

Terminal design

K12

for single pole version, enclosures B3, B31, B35

K60

for single pole version

K61

for double pole version

K62

for double pole version

K71

compulsory and only for C3 housing

K72

for double pole version, enclosures B32, B33, B34

K76

compulsory and only for C32 housing

Mounting

2

compulsory and only for C3 and C32 housing

5

mounting brackets - surface mounting

Auxiliary contacts (blade terminals 6.3x0.8)

Si2

one N/O

Si01

one N/C, two N/O

2Si2

two N/O

Si10

one each N/O and N/C

Remote operation

FA

remote disconnection

FC

electrical remote disconnection (FA)

and re-connection (FE)

BC-FA

electrical remote disconnection and

manual remote re-connection

(not for enclosure -B.. or -C..)

Coil voltage

12

AC/DC 12 V

24

AC/DC 24 V

Current ratings

240 A

type 921

120 A

type 922

921 - ... - K60 - 5 - Si2 - FA

24 - 240 A

ordering example

The exact part number required can be built up from the table of choices shown

above. Ordering references for optional features should be omitted if not required.

Voltage rating

DC 12 V; DC 24 V

Current rating range

240 A type 921, single pole

120 A type 922, double pole

Auxiliary contact rating

6 A at DC 24 V

1 A at DC 110 V

Electrical remote disconnection (-FA):

operating voltage

DC 12 V or DC 24 V

operating current

approx. 18 A or approx. 12 A

max. pulse time

10 ms < t

ON

< 20 ms /t

OFF

> 10 s

switching time

< 20 ms

Electrical remote re-connection (-FE):

operating voltage

DC 12 V or DC 24 V

operating current

approx. 30 A or approx. 15 A

max. pulse time

0.1 s < t

ON

< 1.2 s /t

OFF

> 60 s

switching time

< 100 ms

Typical life

10,000 operations at I

N

20,000 operations mechanical

Ambient temperature -40...+75 °C (-40...+167 °F)

Insulation co-ordination rated impulse

pollution

(IEC 60664 and 60664A)

withstand voltage degree

6 kV

3

Dielectric strength

(IEC 60664 and 60664A) test voltage

operating area

AC 3,300 V

pole/pole

AC 3,300 V

main to aux. circuit

AC 2,200 V

aux. circuits 11-12

to 13-14

AC 1,000 V

Insulation resistance

> 100 MΩ (DC 500 V)

Switching capacity

Type 921

Type 922

2,500A for 1s at +23°C

1,500A for 1s at +23°C

600A for 1min at +23°C

600A for 30s at +23°C

600A for 2min at -23°C

600A for 1min at -23°C

600A for 90s at 0°C

600A for 45s at 0°C

Degree of protection

operating area IP40

(IEC 529/DIN 40050)

terminal area IP00

IP54 with enclosure -B..

IP65 with enclosure -C..

Vibration

5 g (57-200 Hz), ± 0.38 mm (10-57 Hz)

to IEC 60068-2-6, test Fc

10 frequency cycles/axis

Shock

25 g (11 ms), to IEC 60068-2-27, test Ea

Corrosion

96 hours at 5 % salt mist

to IEC 60068-2-11, test Ka

Humidity

240 hours at 95 % RH,

to IEC 60068-2-3, test Ca

Mass

approx. 900 g base unit

+ approx. 400 g remote disconnection

+ approx. 100 g remote re-connection

+ approx. 750 g B housing

+ approx. 1,000 g C housing

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

www.e-t-a.com

Issue B

4

- 70

Battery Isolation Switches 921/922

4

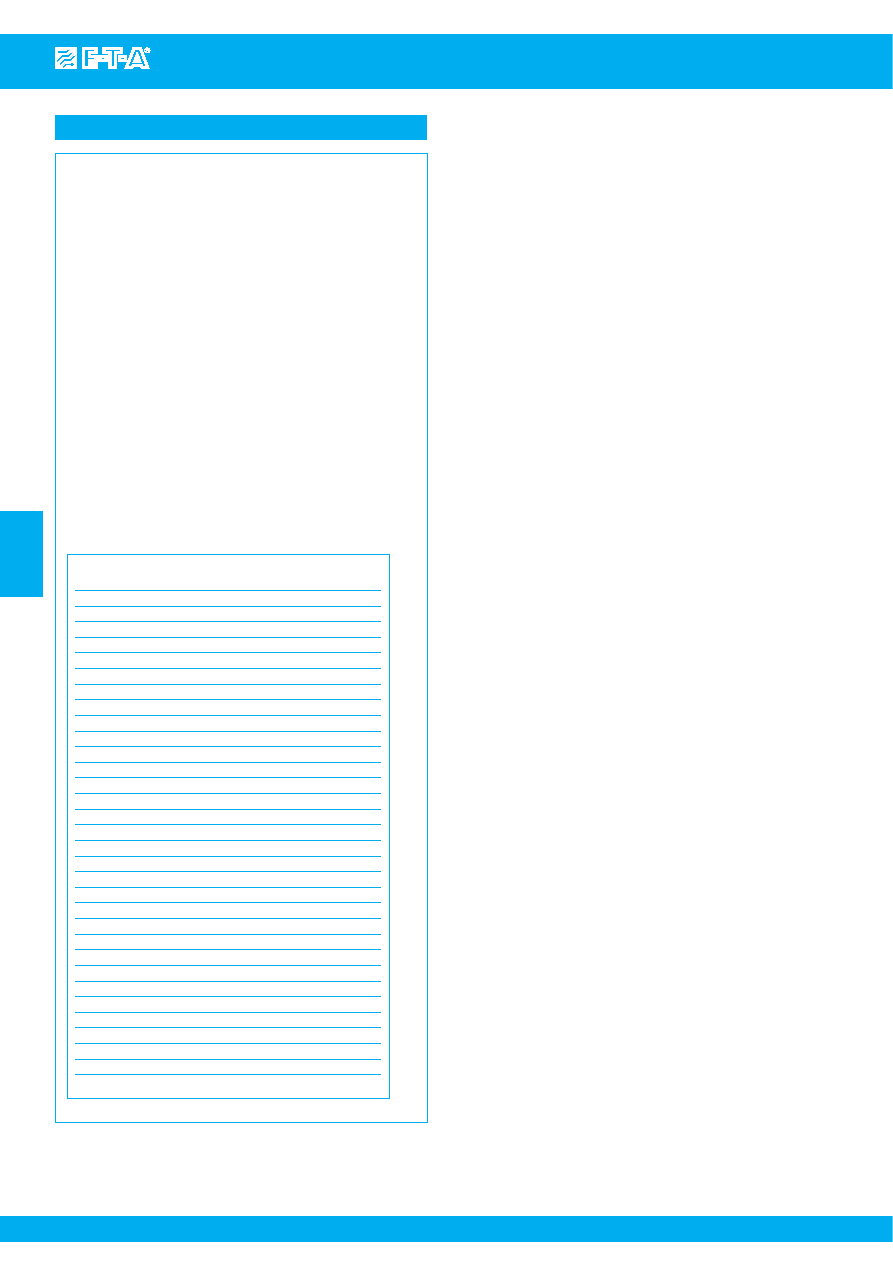

Dimensions

3.62

116

288

155

192

0

I

M3.5x10

tightening tor

q

ue

max. 0.55 Nm

123

91

61

45

4

2

35

11.5

114.5

92

13

26

°

26

°

180

83.5

M5

M10x25

tightening tor

q

ue

max. 4 Nm

72

92

14

9

57

61.5

11

30

26

°

26

°

106

91

45

4

2

92

13

M10x25

tightening tor

q

ue max. 4 Nm

72

ø26

ø15.3

49

82.5

82.5

35

70

44

N/C or FA

N/O

ø16.5

116

196

141

1

2

167.5

1-pole

2-pole

921-K12-5-…-BC-FA..

921-K60-…-FA

ø28.5

ø47

1.85

1.12

4.57

7.72

7.56

6.10

11.34

2.84

.650

4.57

2.76

1.02

.602

1.38

3.25

3.25

1.93

.453

4.51

1.38

.512

3.62

.079

.157

1.77

2.40

3.58

4.84

7.09

3.29

2.84

.433

1.18

1.73

.551

.354

2.24

2.42

5.55

6.59

.512

3.62

.079

.157

1.77

3.58

4.17

Moulded enclo

s

ure IP54 -B3

8.74

222

AUX.

CONTACT

S

+ BATTERY

REMOTE

CONTROL

- LOAD

102

222

244

31

9.5

s

lot for mounting

s

crew M6

20

M10 tightening tor

q

ue

max. 20 Nm

21

ø11

ø7

AUX.

CONTACT

S

BATTERY

REMOTE

CONTROL

LOAD

s

lotted

s

crew plug, tightening tor

q

ue 2 Nm

±

0,2 Nm

124

30

connector

to DIN 72585

146

15

23

73

86

+ LOAD

- BATTERY

46

43

Moulded enclo

s

ure IP 65 -C3

Moulded enclo

s

ure IP 65 -C32

.591

.906

8.74

9.61

4.02

4.88

.787

1

1.18

2.87

3.39

.827

5.75

.433

.276

.039

.374

1.22

102

244

M10 tightening tor

q

ue

max. 20 Nm

124

15

23

.591

.906

4.02

4.88

9.61

1.81

31

9.5

s

lot for mounting

s

crew M6

20

21

ø11

ø7

30

connector

to DIN 72585

146

73

86

.787

1

1.18

2.87

3.39

.827

5.75

.433

.276

.039

.374

1.22

1.69

s

lotted

s

crew plug, tightening tor

q

ue 2 Nm

±

0,2 Nm

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

Battery Isolation Switches 921/922

www.e-t-a.com

Issue B

4

- 71

4

Dimensions types 922

2.24

114

0

I

122

11

45

92

49

57

2

M10x25

tightening tor

q

ue max. 4 Nm

M5

9

72

83.5

92

79

164

190

57

61

14

162

114

M10x25

tightening tor

q

ue max. 4 Nm

2

92

45

32

122

M5

922-K72-5-…-FC

922-K61-5-…-FC

118

143

72

67.5

93

4.49

4.80

.433

2.24

.079

3.62

1.77

1.93

.354

.551

2.84

3.29

3.62

2.24

3.11

6.46

7.48

2.40

11

4.49

4.80

.433

3.66

.079

3.62

1.77

6.38

1.26

9

79

57

14

.354

.551

3.11

4.65

5.63

83.5

92

3.29

3.62

2.66

2.84

Internal connection diagrams

connector acc.

to DIN 72582

REMOTE CONTROL

BATT

LOAD

AUX. CONTACT

S

BATT

LOAD

REMOTE CONTROL

13

14

S

i2

FE

load 2

FA

battery +

13

14

S

i2

23

24

13

14

2

S

i2

13

14

11

12

S

i10

FE

load

1

FA

2

4

3

1

921

922

3

1

2

4

FA

3

1

2

4

11

13

12

14

FE

921-C3-…

922-C32-…

3

1

2

4

FA

3

1

2

4

11

13

12

14

FE

connector acc.

to DIN 72582

connector acc.

to DIN 72582

AUX. CONTACT

S

recommended lin

k

for FA coil protection

pre-wired at the factory

battery +

recommended lin

k

for FA coil protection

pre-wired at the factory

connector acc.

to DIN 72582

23

24

13

14

2

S

i2

13

14

11

12

S

i10

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

www.e-t-a.com

Issue B

4

- 72

Battery Isolation Switches 921/922

4

4

3

5

6

1

2

Terminals with housing C3.

Shoc

k

directions

max. 30

IP00

IP54

T

max

= 20 Nm

max. 65

max. 15

ø 11.5

cable fa

s

tener

cable fa

s

tener

Rubber cap

s

and cable fa

s

tener

s

are

s

upplied with the product.

.453

max. 1.18

max .591

max. 2.56

This is a metric design and millimeter dimensions take precedence ( mm )

inch

All dimensions without tolerances are for reference only. In the interest of improved design,

performance and cost effectiveness the right to make changes in these specifications

without notice is reserved.Product markings may not be exactly as the ordering codes.

Errors and omissions excepted.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

4

- 73

4

Description

Typical applications

Ordering information

Technical data

Single pole, miniaturised aircraft simulator switch with extremely fast

magnetic trip time. Blade, screw and wire wrap terminals. Aircraft style

threadneck and push/pull button with white trip indicator ring. Current

rating marked on the push button according to customer’s request by

adhesive labels or marking inserts.

Simulators.

9510-...

Type No.

9510

switch with magnetic instantaneous trip for flight simulators

Mounting method and style

G

threadneck mounting with standard push button

L

threadneck mounting with long push button

Threadnec

k

design

1

M12x1x6.3

2

7/16-32UNx6.3

Number of poles

1

single pole

Accessories for threadnec

k

0

without accessories

1

hex nut M12x1, aluminium, lock washer ø12/ ø15 (crinkle) fitted

2

hex nut M12x1, aluminium, serrated lock washer ø12.1/ø17.2, fitted

3

hex nut 7/16-32UN, aluminium, toothed washer

ø11.3/ø14.9, fitted (MS 3533-141)

9

front plate with mounting thread 6-32UNC-2B for

threadneck 7/16-32 UN, threaded sleeve 7/16-32 UN

Terminal configuration

J

screw terminals with inch thread

1

6-32UNC-2B, silver plated bent 45° inwards

3

6-32UNC-2B, silver plated, with socket, bent 45° inwards

P

blade terminals

1

A6.3x0.8 DIN 46244, silver plated

W

wire wrap terminal

4

pin size 1.2x1.2 EN 60352-1, gold plated, with socket

Z 0

without terminals

Rated voltage

F0

DC 24 V

F1

DC 28 V

F2

DC 48 V

F4

DC 12 V

Accessories (terminal screws)

B

Phillips screw 6-32UNC-2Ax4.8 fitted

(MS 51957-25)

Z

without accessories

Accessories (terminal washers)

0

without accessories

2

3.6 split washer fitted (MS 35338-136)

Internal circuit

R2

with logic diode, contacts gold plated

Colour of the push button

S

black

G

green

A

green, for marking insert

B

black, for marking insert

0

without marking

1

hot-stamped marking, can be

read when locating pin is above

2

hot-stamped marking, can be read

when locating pin is at the bottom

9

without marking insert

Current ratings

0.5...150 A

9510 -

G

1 1 1 - J 1 F1 - B 0 R 2 S 0 - 10 A

ordering example

Voltage rating

DC 12 V

DC 24 V

DC 28 V

DC 48 V

Trip current

< 450 mA < 160 mA < 200 mA < 340 mA

Trip time

< 25 ms

< 25 ms

< 25 ms

< 20 ms

Min. switching voltage

at +23 °C/+73.4 °F DC 25 V

at +60 °C/+140 °F

DC 28 V

Internal resistance

157 Ω

Typical life

10,000 operations at DC 24, 28 or 48 V

Temperature range

-30...+60 °C (-22...+140 °F)

Insulation resistance

> 100 MΩ (DC 500 V)

Degree of protection

operating area IP40

(IEC 60529)

terminal area IP00

Vibration (sinusoidal) 3 g (57-500 Hz), ± 0.23 mm (10-57 Hz)

to DIN IEC 60068-2-6, test Fc

10 cycles/frequency axis

Shock

5 g (11 ms),

to DIN IEC 60068-2-27, test Ea

Humidity

240 hours at 95 % RH, 40 °C

to DIN IEC 60068-2-3, test Ca

Mass

23 g without hardware

26 g with hardware

Simulator switch, magnetic operation 9510-...

Issue B

www.e-t-a.com

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

www.e-t-a.com

Issue B

4

- 74

Simulator switch, magnetic operation 9510-...

4

2

-

line I

+

internal circuit R 2

Dimensions

Other main terminal designs

Internal connection diagram

15

+0.15

9.5

±

0.2

45

°

2

tightening tor

q

ue max. 3.5 Nm

M12x1 or

7/16-32UN-2A THD

18.5 OFF

I LINE

m

ax

. 2

1.5

2.5

13 ON

42.7

terminal

s

crew

6-32UNC-2A x 4.8/.189

(M

S

51957-25)

with loc

k

wa

s

her (M

S

35338-136)

plug-in terminal

s

tightening tor

q

ue:

0.8 Nm factory mounted

0.4 Nm mounted by cu

s

tomer

47.5

ø10

blac

k

or

green

white

hex nut

loc

k

wa

s

he

ø8.4

3.5

8

mounting hole

s

ø3.2

thic

k

ne

ss

1.5 … 3

.059 … .118

S

W

14

(M12x1)

S

W12.7(7/16-32)

9.5

locating pin

current rating in A

14.2

19.5

6.35

+0.2

(M12x1)

(7/16-32)

+0.2

ø12.5

ø11.5

.250

1.87

.059

.098

m

ax .079

.512

.728

1.68

.591

.315

.138

.331

.394

.374

.559

.768

.374

±

.008

.126

+.006

+.008

(M12x1)

(7/16-32)

+.008

.492

.453

9510-G…-J1..-B2....

m

ax

. 2

m

ax .079

15

45

°

.591

8

.315

.248

17

9.5

blade terminal

DIN 46244-A6.3-0.8 (QC .250)

plug-in terminal

s

.374

.669

-P1…

6.3

.268

6.8

-J3…

1.2

12.7

.614

wire wrap pin 1.2 x 1.2 /.047 x .047

EN 60352-1

plug-in/pull-out terminal

module (max. 25 time

s

)

15.6

3.6

.142

.500

.047

-W4…

terminal

s

crew

6-32UNC-2A x 4.8/.189

(M

S

51957-25)

with loc

k

wa

s

her

(M

S

35338-136)

plug-in/pull-out terminal

module

(max. 25 time

s

)

tightening tor

q

ue 1 Nm

10

.394

10

.394

Other threadnec

k

designs

6-32UNC-2B in

s

ertion nut

s

M12x1 or

7/16-32UN-2A THD

28

1.5

2.5

22.5

6.35

.250

.059

.098

.886

1.10

ON

OFF

blac

k

or

green

ø10

white

hex nut

loc

k

wa

s

her

ø8.4

3.5

.138

.331

.394

-G219

-L219

-L…

.250

7/16-32UN-2. THD

1.5

.059

6.35

1.6

.063

ø12

.472

52.1

2.05

18.5

.728

46

1.81

(

s

elf loc

k

ing)

threaded

s

leeve

front plate

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

4

- 75

4

Plug-in screw terminal,

bent at 45° inwards (2 pcs needed per unit)

Y 307 187 02

terminal silver plated

Y 304 508 02

Phillips screw 6-32 UNC-2Ax4.8 (MS 51957-25)

Y 304 509 01

split washer (MS 35338-36)

Plug-in blade terminal

(2 pcs needed per unit)

Y 307 202 02

P10 terminal silver plated

Plug-in/pull-out screw terminals with soc

k

et,

bent at 45° inwards

X 222 173 11

terminals silver plated

Plug-in/pull-out wire wrap terminals with soc

k

et

X 222 174 12

terminals gold plated

Part number

Rated current (A)

Y 307 082 01

0.5

Y 307 082 02

1/2

Y 307 082 03

1

Y 307 082 04

1.5

Y 307 082 05

1 1/2

Y 307 082 06

2

Y 307 082 07

3

Y 307 082 08

5

Y 307 082 09

7.5

Y 307 082 10

7 1/2

Y 307 082 11

10

Y 307 082 12

15

Y 307 082 13

20

Y 307 082 14

25

Y 307 082 15

30

Y 307 082 16

35

Y 307 082 17

6

Y 307 082 18

40

Y 307 082 19

50

Y 307 082 20

60

Y 307 082 21

70

Y 307 082 22

75

Y 307 082 23

80

Y 307 082 24

90

Y 307 082 25

100

Y 307 082 26

120

Y 307 082 27

125

Y 307 082 28

150

Y 307 082 29

2.5

Y 307 082 30

2 1/2

Y 307 082 31

7

Label (blac

k

) for push/pull button (S0 or

G

0)

S

pla

s

h cover/he

x

nut a

ss

embly with O ring

(IP66 and IP67)

(approved to V

G

95345, part 23)

X 200 801 03

matt black fini

s

h nut M12

x

1

x

1.8, black cover

X 200 801 08

nickel plated nut M12

x

1

x

1.8, tran

s

parent cover

X 200 801 09

matt black fini

s

h nut

7/16-32

x

1

x

1.8,

black cover

X 200 801 10

matt black fini

s

h nut

7/16-32

x

1

x

1.8,

tran

s

parent cover

M12x1 or

.071

7/16-32

1.8

Actuator e

x

ten

s

ion

(blac

k

) to be fitted on the pu

s

h button

(approved to V

G

95345, T23)

X 200 803 01

ø20

17

ø.787

.669

Identification collar

to be

s

napped on the pu

s

h button

Y 307 004 01

black

Y 307 004 02

white

Y 307 004 03

red

Y 307 004 04

green

Y 307 004 05

blue

6.4

ø6.85

ø12.35

ø14

.270

.551

.486

.252

0.65

.026

Lock out ring

to bloc

k

the pu

s

h button in OFF po

s

ition

Y 307 005 01

red

Y 307 005 02

black

0.8

.031

ø10.9

ø14.6

.575

.429

7.7

.303

Accessories

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Issue B

www.e-t-a.com

Simulator switch, magnetic operation 9510-...

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

4

- 76

4

Hex nut M12x1

Y 300 116 04

Hex nut 7/16-32

Y 304 506 03

Loc

k

washer Ø12 / Ø15

Y 300 118 03

Serrated loc

k

washer Ø12.1 / Ø17.2

Y 302 911 01

Toothed washer Ø11.3 / Ø14.9 (MS 35333-141)

Y 304 507 01

Front plate with mounting thread 6-32UNC-2B

for threadnec

k

7/16-32UN

Y 301 516 21

Threaded sleeve

Y 307 281 02

Extracting tool of mar

k

ing insert

Y 307 301 01

Mar

k

ing inserts (push button configuration A or B)

Accessories

hot stamped

current rating

blac

k

green

(A)

Y 307 280 01

Y 307 280 02

without

X 222 175 01

X 222 176 01

0.5

X 222 175 02

X 222 176 02

1/2

X 222 175 03

X 222 176 03

1

X 222 175 04

X 222 176 04

1.5

X 222 175 05

X 222 176 05

1 1/2

X 222 175 06

X 222 176 06

2

X 222 175 07

X 222 176 07

3

X 222 175 08

X 222 176 08

5

X 222 175 09

X 222 176 09

7.5

X 222 175 10

X 222 176 10

7 1/2

X 222 175 11

X 222 176 11

10

X 222 175 12

X 222 176 12

15

X 222 175 13

X 222 176 13

20

X 222 175 14

X 222 176 14

25

X 222 175 15

X 222 176 15

30

X 222 175 16

X 222 176 16

35

X 222 175 17

X 222 176 17

6

X 222 175 18

X 222 176 18

40

X 222 175 19

X 222 176 19

50

X 222 175 20

X 222 176 20

60

X 222 175 21

X 222 176 21

70

X 222 175 22

X 222 176 22

75

X 222 175 23

X 222 176 23

80

X 222 175 24

X 222 176 24

90

X 222 175 25

X 222 176 25

100

X 222 175 26

X 222 176 26

120

X 222 175 27

X 222 176 27

125

X 222 175 28

X 222 176 28

150

X 222 175 29

X 222 176 29

2.5

X 222 175 30

X 222 176 30

2 1/2

X 222 175 31

X 222 176 31

7

All dimensions without tolerances are for reference only. In the interest of improved design,

performance and cost effectiveness the right to make changes in these specifications

without notice is reserved.Product markings may not be exactly as the ordering codes.

Errors and omissions excepted.

Simulator switch, magnetic operation 9510-...

Issue B

www.e-t-a.com

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

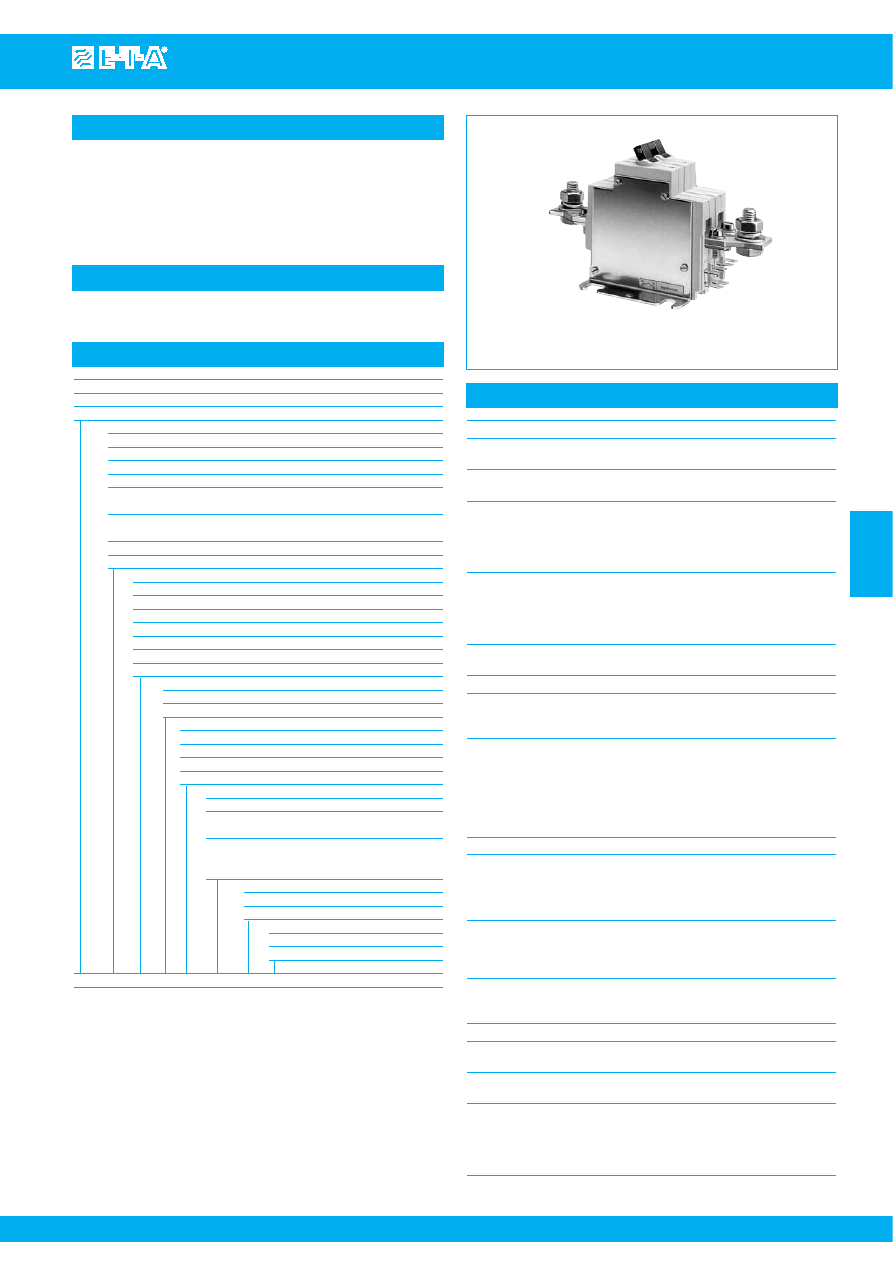

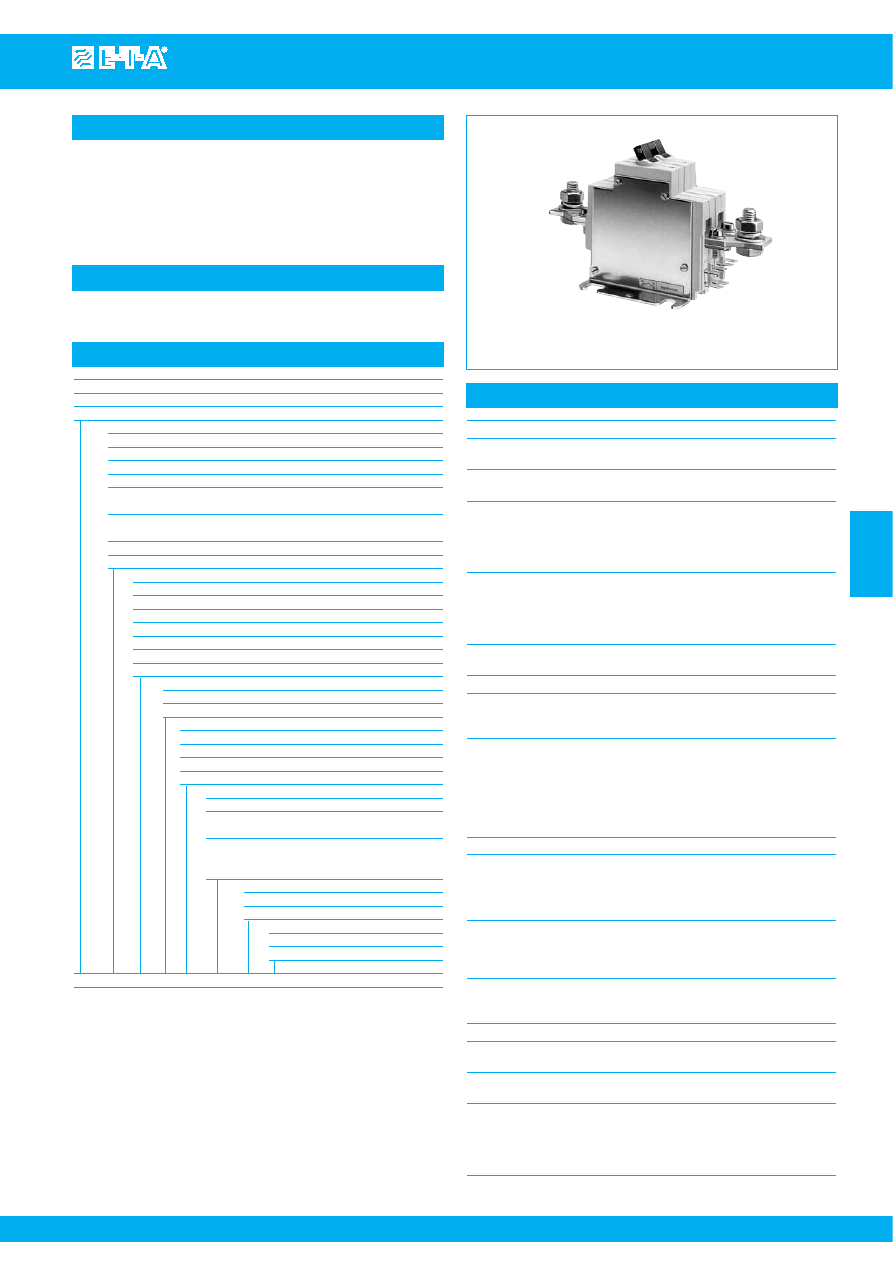

Battery Master Switch E-1032-...

www.e-t-a.com

Issue B

4

- 77

4

Description

Typical applications

Ordering information

Technical data

The battery master switch E-1032-... allows remotely controlled

connection and disconnection of the battery. In the event of reverse

connection the battery will be disconnected from the vehicle electrical

system.

Commercial vehicles

E-1032

Type No.

E-1032

Version

NA1

single pole

NA2

double pole

Enclosure

C

with moulded enclosure IP65

Isolation switch

921

single pole switch

922

double pole switch

Voltage rating

DC 24 V

DC 12 V

Variant No.

e.g. special versions, mounting plate.

Designation determined by

manufacturer

E-1032 - NA1 - C 921 - DC 24 V - ...

ordering example

Voltage rating

DC 24 V

DC 12 V

Voltage rang

ON

18 - 32 V

9 - 16 V

OFF 15 - 32 V

8.5 - 16 V

The switching function is no longer ensured

when the voltage falls below the minimum

values. The switch will not change its

position when the voltage falls down to 0 V

(automatic locking).

Current ratings

240 A single pole

120 A double pole

Overload capacity

2,500 A for 1 s at 23 °C, single pole

1,500 A for 1 s at 23 °C, double pole

Current consumption

≤ 15 mA

of the electronics

(with the control circuit connected)

Switching current at U

N

DC 24 V:

DC 12 V:

ON

approx. 15A/100 ms approx. 20A/100 ms

OFF

approx. 12A/100 ms approx. 10A/100

ms

Control circuit

4 - 6 mA ON

Control switch

with coding resistance

(accessory)

DC 24 V: 1 kΩ

DC 12 V: 330 Ω

without coding resistance to ADR for

external actuation

Temperature range

-40...+75 °C (-40...+167 °F)

Reverse polarity

If polarized incorrectly, the Master Switch

protection

will switch off immediately, disconnecting

the entire vehicle electrical system. After

approx. 30 s the circuit breaker of the ON

coil will trip.

Resettability

When the Battery Master Switch is

mechanically switched off, it will be reset

immediately by the electronics.

Typical life

10,000 operations at I

N

20,000 operations, mechanical

Degree of protection

housing IP65

IEC 60529/DIN40050)

terminal studs with rubber cap IP54

Vibration

5 g (57-200 Hz), ± 0.38 mm (10-57 Hz)

to IEC 60068-2-6, test Fc,

10 frequency cycles/axis

Shock

25 g (11 ms) direction 1, 2, 3, 4

15 g (11 ms) direction 5, 6

to IEC 60068-2-27, test Ea

Corrosion

96 h at 5 % salt mist,

to IEC 60068-2-11, test Ka

Humidity

240 h at 95 % RH,

to IEC 60068-2-78, test Cab

Terminals

Main terminals

blade terminals with cable lugs for M10

terminal studs

Control cable

connector to DIN 72585

Technical data

Auxiliary contact

max. 6 A

for auxiliary relay

(circuit not protected)

Mass single pole:

approx. 3,500 g with enclosure,

double pole:

approx. 3,700 g with enclosure,

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

www.e-t-a.com

Issue B

4

- 78

Battery Master Switch E-1032-...

4

max. 30

IP00

IP54

T

max

= 20 Nm

max. 65

max. 15

ø 11.5

cable fa

s

tener

cable fa

s

tener

Rubber cap

s

and cable fa

s

tener

s

are

s

upplied with the product.

.453

max. 1.18

max .591

max. 2.56

Rubber cap

Dimensions

E-1032-NA1-…

1 pole

E-1032-NA2-…

2 pole

8.74

222

+ BATTERY

POWER

S

UPPLY

- LOAD

BATTERY

POWER

S

UPPLY

LOAD

s

lotted

s

crew plug, tightening tor

q

ue 2 Nm

±

0,2 Nm

+ LOAD

- BATTERY

46

43

102

244

M10 tightening tor

q

ue

max. 20 Nm

124

15

23

.591

.906

4.02

4.88

9.61

1.81

31

9.5

s

lot for mounting

s

crew M6

20

21

ø11

ø7

30

connector

to DIN 72585

146

73

86

.787

1

1.18

2.87

3.39

.827

5.75

.433

.276

.039

.374

1.22

1.69

s

lotted

s

crew plug, tightening tor

q

ue 2 Nm

±

0,2 Nm

102

222

244

M10 tightening tor

q

ue

max. 20 Nm

124

15

23

.591

.906

8.74

9.61

4.02

4.88

31

9.5

s

lot for mounting

s

crew M6

20

21

ø11

ø7

30

connector

to DIN 72585

146

73

86

.787

1

1.18

2.87

3.39

.827

5.75

.433

.276

.039

.374

1.22

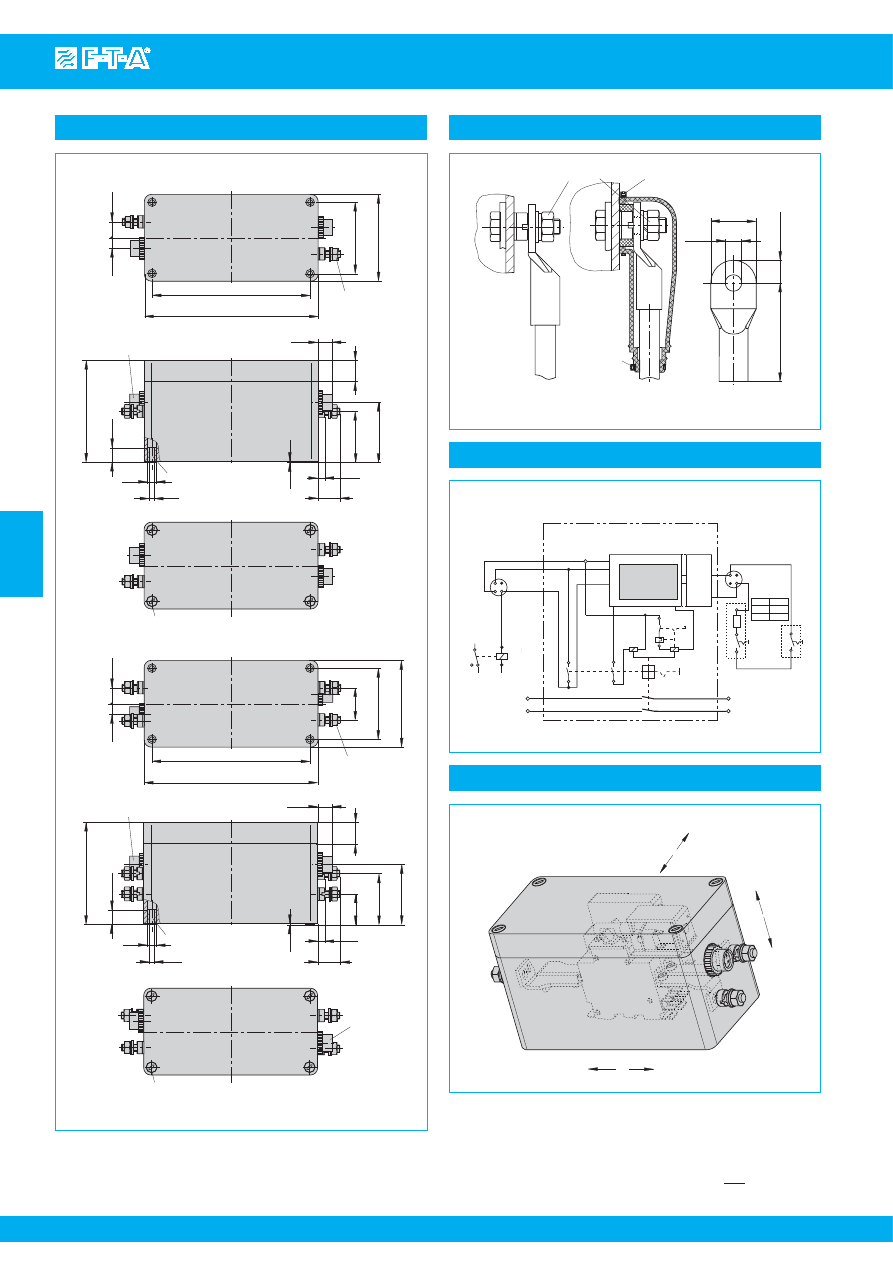

Internal connection diagrams

connector acc.

to DIN 72582

3 pole

OFF

2(-)

connector acc.

to DIN 72582

2 pole

- rel.85

87a

E-1032-

Electronic

R1

BATT

(D+)

generator D+

85

86

87

30

15

31

LOAD

ON

circuit

brea

k

er

ON 4…6 mA

3

(+)

1

(-)

2

1

(+)

batt +

batt -

1

2

3

2

3

Power connection

R1

12 V

24 V

UB

330

Ω

1

k

Ω

contr

ol

cir

cuit

Shock directions

4

3

5

6

1

2

Please follow the instructions for installation

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

Battery Master Switch E-1032-...

www.e-t-a.com

Issue B

4

- 79

4

5. 90

°

cover for

corrugated conduit NW10

Y 306 499 01

ø25.8

42

ø25.8

33

6. 90

°

cover for

s

heathed cable

Y 306 499 02

47.5

ø25.8

4. 180

°

cover for

s

heathed cable

Y 306 500 01

1. Female connector

S

W

X 221 378 02

2-way

X 221 378 01

3-way

X 221 378 03

4-way

ø5.9

7.8

3.

S

eal

Y 306 502 01

31

ø18.3

ø32.8

2. Jac

k

for female connector

Y 306 501 01

20.7

jac

k

for female

connector

female connector

1

2

3

4

5 or 6

180

°

cover for

s

heathed cable

90

°

cover

Manufacturer: AMP

s

eal

1.22

.720

1.29

.307

.232

.815

1.87

1.02

1.02

1.30

1.02

1.65

Accessories

.126

mounting hole

s

(with pin wa

s

her)

9.3

ø3.2

ø12.4

ADR

s

witch with

s

afety cover

0Z223Z000141

12 V

0Z223Z000142

24 V

mounting hole

s

(with pin wa

s

her)

9.3

ø3.2

ø12.4

ADR

s

witch without rubber boot

0Z223Z000143

ADR

s

witch with rubber boot

(IP54 in operating area)

0Z223Z000144

max.16

max.16

35

max. 29

max. 50

max. 52

6.5

max.16

35

max. 29

17

°

17

°

12

6.5

73.5

35

max. 29

6.5

.366

.126

.488

max .630

max. 1.97

max. 2.05

1.38

.256

max. 1.14

max .630

max .630

.472

2.89

1.38

.256

max. 1.14

max. 1.14

.366

.488

1.38

.256

Standard connector set OZ112Z000179,

comprising:

(AMP-parts) suitable for single/double pole Battery Master Switch

E-1032-..., DC 12 V and DC 24 V

Quantity

Designation

Ref. No.

1

female connector, 3-pole

X 221 378 01

1

female connector, 2-pole

X 221 378 02

5+1 replacem.

jack for female connector

Y 306 501 01

5+1 replacem.

seal

Y 306 502 01

2

90 ° cover

Y 306 499 01

corrugated conduit NW 10

This is a metric design and millimeter dimensions take precedence ( mm )

inch

All dimensions without tolerances are for reference only. In the interest of improved design,

performance and cost effectiveness the right to make changes in these specifications

without notice is reserved.Product markings may not be exactly as the ordering codes.

Errors and omissions excepted.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

Battery Isolation Switches E-1073-437 and E-1073-921/-922

www.e-t-a.com

Issue B

4

- 81

4

Description

Typical applications

Ordering information

Technical data – Electronic module

Single pole circuit breaker type 437 or single/two pole isolation switches

types 921/922 featuring an additional electronic function module which

limits the duration of the supply to the remote disconnect and re-

connect coils, avoiding damage in the event of unusual operating

circumstances. Available with undervoltage monitoring option to

protect batteries from the effects of deep discharge, status output for

undervoltage, auto reset feature.

Battery and cable protection for all types of vehicle (including electric),

battery powered systems.

E-1073-437

Type No.

E-1073

control unit for types 921/922 and 437 with remote control

Voltage rating

0

DC 12 V

1

DC 24 V

Control mode

1

ON/OFF control input

00

without additional function

02

with undervoltage protection and status output

12

with autoreset, undervoltage protection and status output

(921/922 only)

2

ON and OFF buttons

33

with control current supply and ON/OFF test input

Circuit Breaker/Isolation Switch

437

single pole circuit breaker (2-pole upon request)

921

single pole battery isolation switch

922

double pole battery isolation switch

Enclosure design (optional)

blank = without housing

B3

moulded housing, for use with single pole devices

B32

moulded housing, for use with double pole device

B34

moulded housing, external operating knob, for use

with double pole devices (not with auto reset)

B35

moulded housing, external operating knob, for use

with single pole devices (not with auto reset)

Terminal design

K12

flat screw terminals angled 90°,

for single pole version

K60

straight flat screw terminals,

for single pole version, without housing

K72

flat screw terminals angled 90°,

for double pole version

Characteristic curve (type 437 only)

06

fast magnetic trip

07

delayed magnetic trip (standard)

Auxiliary contacts

Si01

one N/C, two N/O

(one N/C, one N/O with

autoreset option)

Current ratings

437:

40, 50, 63, 80, 100,

120, 160, 200, 240A

921:

240 A

922:

120 A

E-1073 - 1 1 02 - 437 - B3 - K12 - 07 - Si01 - 240 A

ordering example

The exact part number required can be built up from the table of choices shown

above. Ordering references for optional features should be omitted if not required.

Voltage rating

DC 12 V

DC 24 V

Voltage rating range

ON 10.3 - 16 V

18 - 32 V

OFF 9 - 16 V

16 - 32 V

Correct switching performance is not

guaranteed if the voltage falls below the

minimum value.

Temperature range

electronic control unit -40...+80 °C (-40...+176 °F)

Operating current

ON

approx. 30 A approx. 15 A

OFF

approx. 10 A approx. 20 A

Excitation time

ON

typically 100 ms

OFF

typically 20 ms

Switching frequency

0.1 Hz max.

Power consumption typically < 1 mA

of electronic control unit (when switched off or button operated)

Control inputs

E-1073-.1..:

»E/A« (ON/OFF), »U-AUS«

(undervoltage protection OFF), »A-W« (auto reset)

E-1073-.2..:

»T-EIN« (button ON), »T-AUS« (button OFF)

voltage

max. 32 V

ON (high)

> 8 V

OFF (low)

< 3 V

power consumption DC 12 V: typically 1 mA

DC 24 V: typically 5 mA

EMC

according to DIN 40839/ISO 7637

Reverse polarity

If polarized incorrectly, the Battery Isolation

protection Switch will operate immediately. The

circuit breaker will trip after a few seconds.

Undervoltage protection

optional with E-1073-.1..

switching thresholds DC 12 V: 11.0 V ± 0.2 V

DC 24 V: 22.8 V ± 0.2 V

hysteresis

typically 0.5 V

trip time

typically 40 sec

Undervoltage status output »UST«, optional with E-1073-.1..

transistor output minus switching

current load

corresponding to 2 W lamp load, short-

circuit proof

Automatic reset »A-W«,

(optional with E-1073-.1.., with series 921/922 only)

Reset after mechanical disconnection is

provided by the integral electronic

control after approx. 100 ms.

Control current supply »+US2«, with E-1073-.2.. for T-EIN/T-AUS

May be connected to 20 control inputs.

Noise-voltage proof, short-circuit proof

Terminals

control terminals

blade terminals 6.3x0.8 mm

Mass, with circuit breaker approx. 2,000 g without enclosure

or isolation switch approx. 2,500 g with enclosure

Technical data of switch or circuit breaker

see types 437, 921 or 922

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

www.e-t-a.com

Issue B

4

- 82

Battery Isolation Switches E-1073-437 and E-1073-921/-922

4

Features

●

Multiple functions in one unit

●

High performance circuit breaker providing battery and cable

protection from overloads and short-circuits.

●

Master switch for ON/OFF operation

●

Electrical remote control

●

Undervoltage protection with status output

●

Auxiliary contacts (e.g. for generator disconnection)

●

Active reverse polarity protection of the entire vehicle electrical

system

●

Current ratings to 240 A (higher voltage ratings to special order)

●

Closed-circuit current consumption < 1 mA

Technical description

E-T-A circuit breaker/battery isolation switches combined with electronic

control unit E-1073 will meet a wide range of requirements.

Circuit breaker/battery isolation switches

The main switching contacts will open the plus, the minus or both

poles according to model and application.

●

Series E-1073-....437

Single pole thermal-magnetic circuit breaker for current ratings up

to 240 A, to protect the vehicle electrical system from overloads

and short circuits.

●

Series E-1073-...-921

Single pole battery isolation switch for current ratings up to 240 A.

●

Series E-1073-...922

Double pole battery isolation switch for current ratings up to 120 A.

Electronic control unit

An electronic control unit enables the basic on/off function and two

additional functions. The system voltage is connected across terminals

+UB/-UB to provide the supply to the control unit and a feed is taken

from +US1 for the remotely sited operating switch(es). The quiescent

current drain is typically less than 1 mA, with a short duration excursion

during excitation of the ON/OFF coils.

Basic function

Switch ON/OFF

Operation of the ON control switch will energise the switch-on coil for

approximately 100 ms causing the main switching contacts to latch

closed. Operation of the OFF control switch will cause the disconnect

coil to trigger the release of the switching mechanism within

approximately 20 ms. Both coil circuits are current limited to prevent

damage through overheating.

Manual operation

An optional external operating knob is available to provide manual

control in addition to electrical ON/OFF operation.

Reverse polarity protection

In the event of reverse polarity connection, the electronic control unit

will immediately operate the battery switch to isolate the entire

electrical system. The circuit breaker will trip after a short delay to

protect the operating coils and must be re-set once the fault has been

corrected.

Control functions

Type 1 E-1073-.1.. with ON/OFF switch

ON/OFF control switch input (»E/A«)

The battery isolation switch can be operated on or off by an external

control switch to plus.

Undervoltage protection (optional)

This optional feature protects the battery from deep discharge

should electrical loads be left on.

The battery is automatically disconnected whenever the voltage

falls below a critical value for more than 40 s. The unit is reset by

operation of the control switch. Sustained undervoltage after

reconnection causes the unit to disconnect again after approx. 40 s.

Overriding the undervoltage protection (»U-AUS«)

Undervoltage protection may be overridden if required by

connecting control output »U-AUS« to plus terminal or terminal 15.

Undervoltage status output (»UST«)

Undervoltage is signalled immediately via the minus-switching,

short-circuit proof transistor output (2 W lamp load).

Auto reset (»A-W«), optional with series 921 and 922

Immediate reset after unwanted mechanical disconnection (e.g.

upon excessive vibration) is provided by the integral electronic

control.

Type 2 E-1073-.2.. with ON/OFF button

ON/OFF control inputs (»T-ON/T-OFF«)

ON/OFF function is provided by two external switches with a

central control function, i.e. several systems can be operated

simultaneously.

Additional control current supply (»+US2«)

If several circuit breakers/battery isolation switches are operated

in parallel, switches can be supplied with control current from any

of the electronic control units available. This power source is

short-circuit proof, protected from noise voltages and will operate

for 20 inputs.

Additional control input »ON/OFF Test« (»E/A«)

This control input can be used for maintenance purposes. The

battery isolation switch is switched on when plus voltage is applied,

and switched off when plus voltage is removed.

Note

The circuit breaker should be in the OFF condition when connecting or

replacing the battery.

Observe instructions for installation!

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

Battery Isolation Switches E-1073-437 and E-1073-921/-922

www.e-t-a.com

Issue B

4

- 83

4

300

288

155

67

ø15.3

116

57

ø28.5

47

116

155

192

116

cylinder head

s

crew

I

S

O 1207 M6x16-4.8

72

196

300

-B3,

s

ingle pole

-B35,

s

ingle pole with operating

k

nob

-B32, double pole

-B34, double pole with operating

k

nob

11.34

11.81

.354

ø9

4.57

1.12

6.10

2.84

1.85

2.24

7.72

.602

2.64

4.57

4.57

70

ø26

ø15.3

49

82.5

82.5

35

1.93

3.25

3.25

1.38

.602

1.02

2.76

11.81

6.10

7.56

Dimensions – Enclosures

Dimensions

92

2.84

72

94

3.70

3.62

57

9

M10x25

tightening tor

q

ue max. 4 Nm

2.24

.354

92

2.84

M5

30

23

13

11 12

14

a

b

24

FE

CB

180

122

61

terminal

s

trip

1

10

II

I

5

6

4

2

57

M5

23

13

11 12

14

a

b

24

72

FE

CB

141

5

6

45

4

167

9

57

M5

61

M10x25

tightening tor

q

ue max. 4 Nm

190

164

E-1073-…-437/-921-…-K12-…

E-1073-…-437/-921-…-K60-…

E-1073-…-922-…-K72-…

7.48

2.40

2.24

.354

6.46

CB

122

57

2

.079

2.24

4.80

23

13

11 12

14

a

b

24

72

92

FE

5

6

94

3.70

3.62

2.84

9

M10x25

tightening tor

q

ue max. 4 Nm

2.24

.354

122

2

.079

4.80

94

3.70

3.62

5.55

6.58

.157

1.77

45

4

.079

.157

1.77

4.80

2.40

1.18

7.09

Connection diagrams

E-1073-.1…-437/-921/-922 control function ON/OFF

s

witch

ON / OFF

s

witch

s

erie

s

921/922

s

erie

s

437

(only with

s

erie

s

437)

Electronic control unit

I >

FE

load

A-W

II

11

23

13

FA

b

a

FE

3

4

L13

brown

L15

blac

k

-

red

L12

brown

L11

green

FA

ON/OFF

L4 gr

ey

L5 gr

ey

L6 yellow

L2 gr

ey

battery

I

12

1

2

3

4

5

6

7

8

9

10

24

14

L3 br

own

+U

S

1

L7 orange

L8 white

U-OFF U

S

T.

CB

6

5

L1 red

+UB

-UB

L10 blac

k

-UB

+

+

UVP OFF

unde

s

rvoltage

s

tatu

s

max. 2 W

L14 grey

ON/OFF

+U

S

1

U-OFF

U

S

T.

terminal

s

trip

double

contact

≥

125 A

Aux. contact 23-24 pr

e-wir

ed with option

“autor

e

s

et” and/or hou

s

ing B35.

power

s

upply

2

main contact

s

with

s

erie

s

922

E-1073-.2…-437/-921/-922 control function ON/OFF button

terminal

s

trip

battery

double

contact

≥

125 A

+U

S

2

ON / OFF

te

s

t

s

erie

s

921/922

s

erie

s

437

Electronic conrol unit

I >

FE

load

II

11

23

13

FA

b

a

FE

3

4

L13

brown

L12

brown

L11

green

FA

ON/OFF

L4 gr

ey

L5 gr

ey

L6 yellow

L2 gr

ey

I

12

1

2

3

4

5

6

7

8

9

10

24

14

L3 br

own

+U

S

1

L7 orange

L8 white

T-OFF

T-ON

CB

6

5

L1 red

+UB

-UB

L10 blac

k

-UB

ON/OFF

+U

S

1

T-OFF

+U

S

2

+U

S

2

T-ON

L9 violet

(only with

s

erie

s

437)

power

s

upply

2

main contact

s

with

s

erie

s

922

OFF

button

ON

button

This is a metric design and millimeter dimensions take precedence ( mm )

inch

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

87BATSW-html.html

For road vehicles, e.g. buses and coaches

Series E-1073-1102-437-B3-K12-07-Si01-240 A

In this application, the E-T-A combined battery switch/circuit

breaker has several functions:

●

High performance circuit breaker rated at 240 A, providing

battery and cable protection from overloads and short circuits.

●

Isolation switch, for ON/OFF operation (e.g. for main system

disconnection).

●

Remote control via external, low-current circuit.

●

Undervoltage protection from battery deep discharge should

electrical loads be left on.

●

Early under voltage signalisation via a warning lamp

(undervoltage status output), located as required.

●

Undervoltage operation can be overridden if required.

●

Auxiliary contact to disconnect the generator field.

●

Reverse polarity protection through immediate disconnection

of the entire vehicle electrical system if the battery is

incorrectly connected.

These functions allow the number of components and cables

required to be reduced, with significant space and weight saving

benefits.

www.e-t-a.com

Issue B

4

- 84

Battery Isolation Switches E-1073-437 and E-1073-921/-922

4

E-T-A E- 1073-1233-437-

control

battery

ON/OFF

T-OFF

T-ON

+U

S

2

battery + E- 1073-1233-437-

underground carriage

load

load cir

cuit

ON/OFF te

s

t

OFF

ON

contr

ol cir

cuit

contr

ol cable “ON”

contr

ol cable “OFF”

II

I

3

4

5

6/7

8

9

10

+UB

-UB

+U

S

1

+

–

+U

S

2

I >

+

–

+

+

–

E-T-A E- 1073-1233-437-

control

II

battery

I

3

4

5

6/7

8

9

10

+UB

-UB

ON/OFF

+U

S

1

T-OFF

+

–

T-ON

+U

S

2

I >

battery + E- 1073-1233-437-

underground carriage

+

–

load

+

load cir

cuit

+

–

ON/OFF te

s

t

OFF

ON

contr

ol cir

cuit

contr

ol cable “ON”

contr

ol cable “OFF”

(External power

s

upply not

s

hown)

Typical applications

ON / OFF

button

s

erie

s

437

Electronic control unit

I >

FE

vehicle electrical

s

y

s

tem

II

11

23

13

FA

b

a

FE

3

4

L13

brown

L12

brown

L11

green

FA

ON/OFF

L4 gr

ey

L5 gr

ey

L6 yellow

L2 gr

ey

battery

I

12

1

2

3

4

5

6

7

8

9

10

24

14

L3 br

own

+U

S

1

L7 orange

L8 white

U-OFF U

S

T.

CB

6

5

L1 red

+UB

-UB

L10 blac

k

-UB

+

+

UVP OFF

undervoltage

s

tatu

s

max. 2 W

ON/OFF

+U

S

1

U-OFF

U

S

T.

terminal

s

trip

double

contact

≥

125 A

generator field

di

s

connection

85

86

generator D+

30

87

87a

31

K

l. 15

+

-

K

l. 15

For rail vehicles, e.g. underground carriages

Series E-1073-1233-437-K60-06-Si01-200 A

In this application, the E-T-A combined battery switch/circuit

breaker has two functions:

●

High performance circuit breaker providing battery and cable

protection from overloads and short circuits.

●

Isolation switch between battery and loads.

In this application, an ON/OFF remote control switch can be provided

in both the first and last carriages. This will enable all batteries to be

disconnected from the power distribution system by the operation

of one control, irrespective of its location. In the same way, all

batteries can be re-connected by the operation of a single control

switch.

This is extremely helpful during coupling/de-coupling of carriages

for example. In addition the E/A test input permits the operation of

individual battery switch/circuit breakers during maintenance.

This is a metric design and millimeter dimensions take precedence ( mm )

inch

All dimensions without tolerances are for reference only. In the interest of improved design,

performance and cost effectiveness the right to make changes in these specifications

without notice is reserved.Product markings may not be exactly as the ordering codes.

Errors and omissions excepted.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com