www.e-t-a.com

1

- 15

Thermal Overcurrent Circuit Breakers 104/105/106-...

Issue B

1

Current

Internal

Current

Internal

rating (A)

resistance (Ω)

rating (A)

resistance (Ω)

0.05

285

1.8

0.28

0.08

134

2

0.25

0.1

81

2.5

0.18

0.2

22

3

0.11

0.3

8.7

3.5

0.076

0.4

5.5

4

0.067

0.5

3.3

4.5

0.051

0.6

2.45

5

≤ 0.05

0.7

1.6

6

≤ 0.05

0.8

1.45

7

≤ 0.05

1

0.9

8

≤ 0.05

1.2

0.6

10

≤ 0.05

1.5

0.4

Description

Typical applications

Ordering information

Approvals

Technical data

Miniaturised single pole thermal circuit breaker with push-to-reset,

tease- free, trip-free, snap action mechanism (R-type TO CBE to EN

60934). Available in versions for PCB or panel mounting, snap-in or

threadneck, or as an integral type. Manual release facility optional for

type 105.

Approved to CBE standard EN 60934 (IEC 60934). For higher current

ratings see type 1140.

Motors, transformers, solenoids, printed circuit boards, hand-held

machines and appliances, marine applications, caravans.

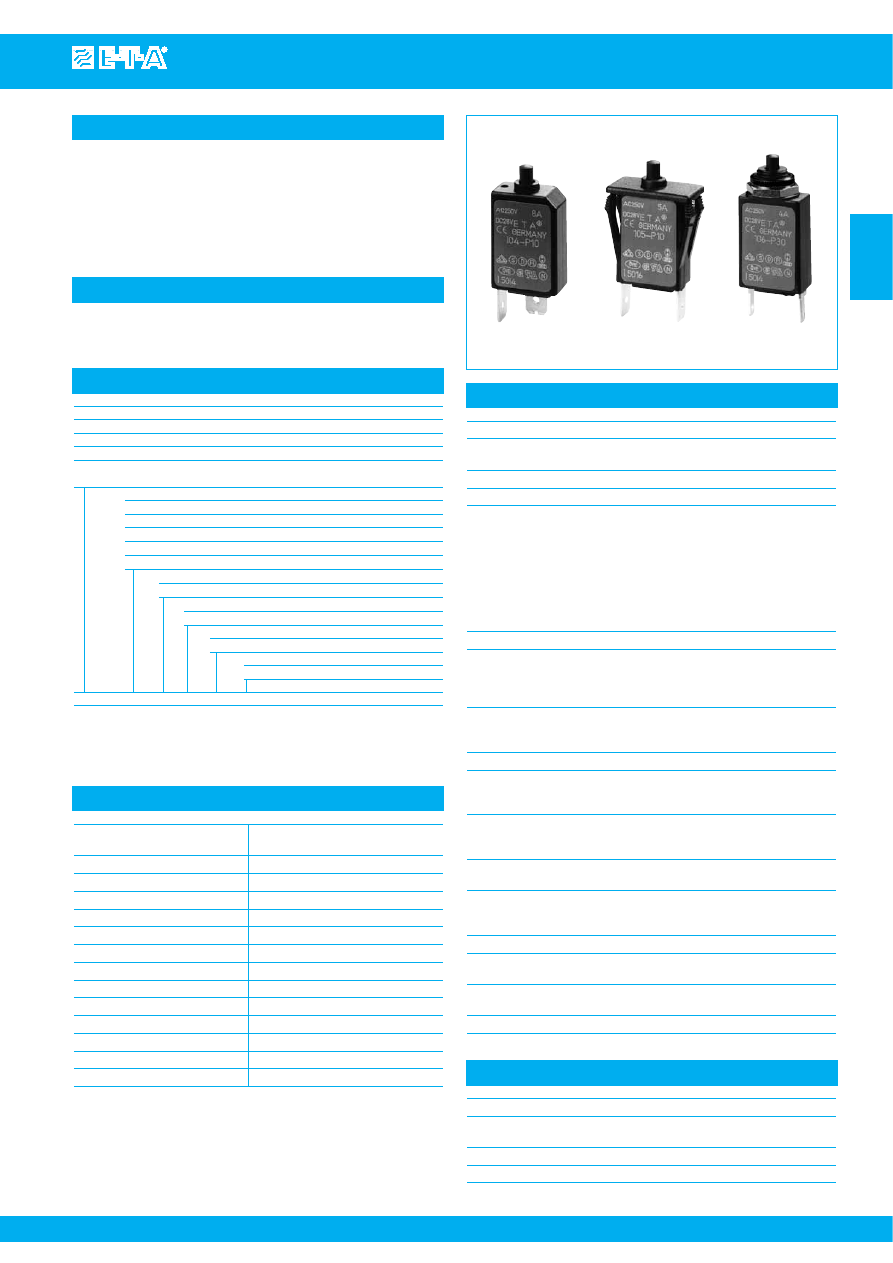

104-... 105-...

106-...

For further details please see chapter: Technical Information

Voltage rating

AC 240 V; DC 48 V

(UL: AC 250 V; DC 48 V)

Current ratings

0.05...10 A

Auxiliary circuit

0.5 A, AC 240 V, DC 28 V

Typical life

AC 240 V

0.05...8 A

2,000 operations at 1 x I

N

, inductive

0.05...5 A

3,000 operations at 2 x I

N

, inductive

6...8 A: 500 operations at 2 x I

N

, inductive

DC 48 V

0.05...8 A

2,000 operations at 1 x I

N

, inductive

0.05...5 A

3,000 operations at 2 x I

N

, inductive

6...8 A: 500 operations at 2 x I

N

, inductive

10 A

200 operations at 1 x I

N

, inductive

10 A 50 operations at 2 x I

N

, inductive

Ambient temperature -20...+60 °C (-4...+140 °F) T 60

Insulation co-ordination rated impulse

pollution

(IEC 60664 and 60664 A) withstand voltage

degree

2.5 kV

2

reinforced insulation in operating area

Dielectric strength

test voltage

(IEC 60664 and 60664A)

operating area

AC 3,000 V

Insulation resistance

> 100 MΩ (DC 500 V)

Interrupting capacity I

cn

0.05...8 A

6 x I

N

AC

> 8...10 A

5 x I

N

AC

0.05...10 A

6 x I

N

DC

Interrupting capacity

I

N

U

N

(UL 1077)

0.05...10 A

AC 250 V

2,000 A

0.05...10 A

DC 48 V

200 A

Degree of protection

operating area IP40

(IEC 60529/DIN 40050) terminal area IP00

Vibration

10 g (57-500 Hz) ± 0.76 mm (10-57 Hz),

to IEC 60068-2-6, test Fc,

10 frequency cycles/axis

Shock

25 g (11 ms) to IEC 60068-2-27, test Ea

Corrosion

96 hours at 5 % salt mist,

to IEC 60068-2-11, test Ka

Humidity

240 hours at 95 % RH,

to IEC 60068-2-78, test Cab

Mass

approx. 10 g

Authority

Voltage ratings

Current ratings

VDE, SEV,

AC 240 V

0.05...8 A

Kema (EN 60934)

DC 48 V

0.05...10 A

CSA, UL

AC 250 V; DC 48 V

0.05...10 A

Circuit breakers with -Si51 not approved

Standard current ratings and typical internal resistance values

Type No.

104

PCB mounting type (-PR), or integral type (-P30/P10)

105

snap-in panel mounting

106

threadneck panel mounting with hex and knurled nut*

106-M2

threadneck panel mounting 3/8-27UNS with collar, hex nut and

knurled nut*

Terminal design

P10

blade terminals A6.3-0.8 (QC .250)

P30

blade terminals A2.8-0.8 (QC .110)

PR

solder terminal pins for PCB mounting (type 104 only)

PR2

PCB mounting (vertical), type 104 only up to 6 A

PR3

PCB mounting (vertical), type 104 only

Shunt terminal (optional)

A3

same as main terminals (up to I

N

6 A/3 A max. load)

Manual release facility (optional)

H

only with type 105

Auxiliary contacts (optional)

Si51

type 104 only

Current ratings

0.05...10 A

106 -

P30 - .. - .. -

.. - 5 A

= ordering example

The exact part number required can be built up from the table of choices shown

above. Ordering references for optional features should be omitted if not required.

* mounting hardware bulk shipped

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com