ASJ PTE LTD

14

CF

Carbon Film Resistors

INTRODUCTION

The Carbon Film Resistors are highly reliable. These resistors are pyrolytically deposited and

manufactured in streamlined automated assembly facilities under strict quality control procedures.

The stable performance is achieved with the technology of film deposition onto a ceramic core with

excellent thermal conductivity, mechanical strength and good electrical properties. Together with

multi layers of epoxy coatings, the Carbon Film Resistors offer stability with long term reliability.

FEATURES

• Small size with high power ratings.

• Excellent long term stability.

• Wide Resistance Range.

• Lead Free

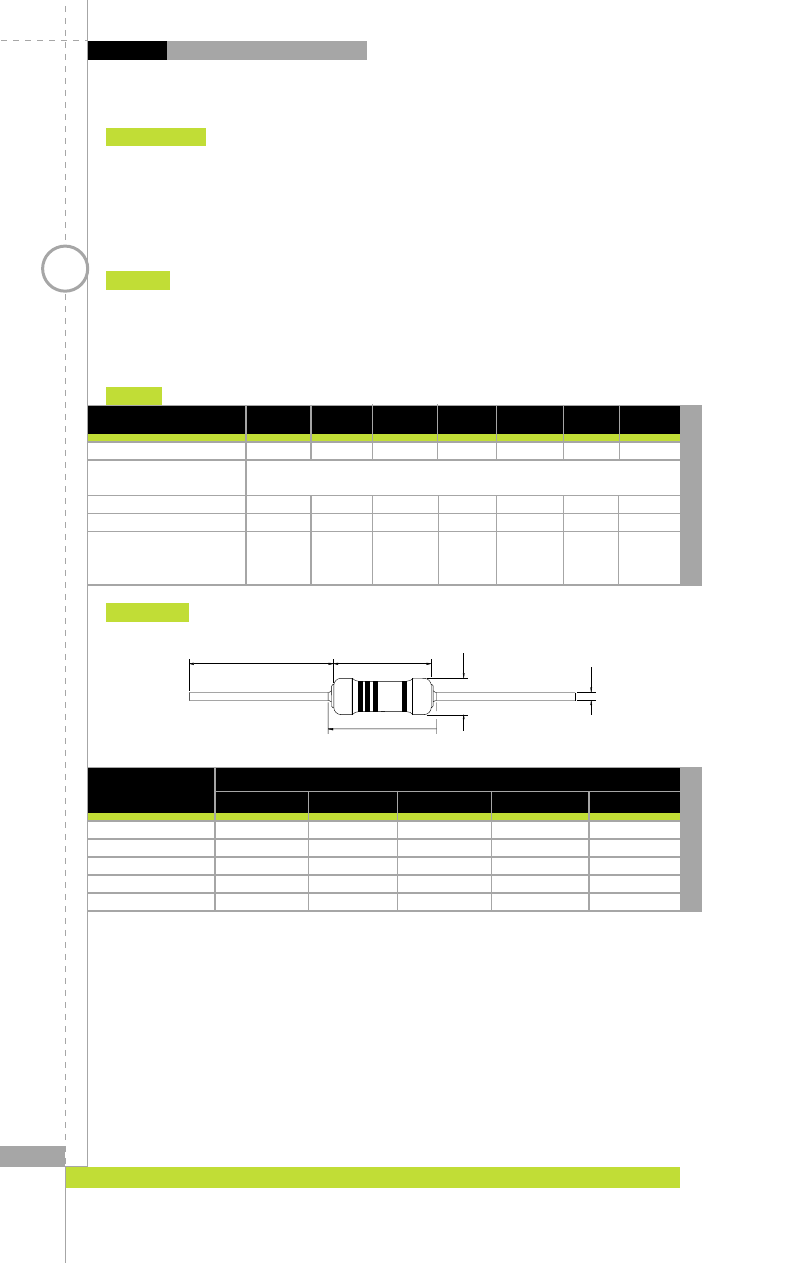

DIMENSIONS

Type

DIMENSIONS

L

C

D

l

d

CF1/6 / CF1/4SS

3.00

±

0.4

3.5 Max

1.70

±

0.2

28.0

±

3.0

0.45

±

0.05

CF1/4 / CF1/2SS

6.35

±

0.5

7.1 Max

2.30

±

0.3

28.0

±

3.0

0.60

±

0.05

CF1/2

9.00

±

0.5

11.8 Max

3.20

±

0.5

28.0

±

3.0

0.60

±

0.05

CF 1

12.00

±

1.0

15.0 Max

4.50

±

0.5

35.0

±

3.0

0.80

±

0.05

CF 2

16.00

±

1.0

22.0 Max

5.00

±

0.5

35.0

±

3.0

0.80

±

0.05

(Millimeters)

ød

øD

l

L

C

RATINGS

Type

CF 1/6 CF 1/4 CF1/4SS CF 1/2 CF1/2SS CF 1 CF 2

Power Rating @ 70ºC

1/6W 1/4W 1/4W 1/2W

1/2W 1W 2W

Operating Temp. Range

-55ºC to +155ºC

Derated to 0 Load at

+155ºC

Maximum Working Voltage

200V 250V 250V 350V

350V 500V 500V

Maximum Overload Voltage

400V 500V 500V 700V

700V 700V 1000V

Resistance Range

2%, E-24

10

Ω

-1M

Ω

10

Ω

-1M

Ω

10

Ω

-1M

Ω

10

Ω

-1M

Ω

10

Ω

-1M

Ω

10

Ω

-1M

Ω

10

Ω

-1M

Ω

5%, E-24

1

Ω

-22M

Ω

1

Ω

-22M

Ω

1

Ω

-22M

Ω

1

Ω

-22M

Ω

1

Ω

-22M

Ω

1

Ω

-22M

Ω

1

Ω

-22M

Ω