AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

AAVID

THERMALLOY

Corporate Office: 80 Commercial Street • Concord, NH 03301

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

This condensed catalog features the more popular devices and configurations that Aavid

Thermalloy produces today to cool high speed microprocessors and other commonly used semi

conductors. We offer a broad range of products and consulting services.These are the most popular

parts and we are adding new ones on a regular basis. Contact Aavid’s application engineering for the

latest designs.

More information is also available 24 hours a day by using our FastFacts™ System, fax retrieval system

at 603 223-1750, or see our web-site, http://www.aavid.com.

A-Dux™, Kon-Dux™, A- Pli™, In-Sil-8™, Sil-Free™, AavGard™, Kool Klips™,Ther-O-Bond™,Ther-A-Grip™,Ther-O-Link™,Wave-on™,

and Shur-Lock™ are trademarks of Aavid Thermalloy, LLC

PLEASE NOTE: Our customers are reminded that they bear the responsibility for testing Aavid Thermalloy products for proposed use. Any

information furnished by Aavid is believed to be accurate and reliable, but our customers must bear all responsibility for use and applications

of Aavid products.

AAVID MAKES NO WARRANTIES EXPRESSED OR IMPLIED, AS TO THE FITNESS, MERCHANT ABILITY, OR SUITABILITY OF ANY

AAVID PRODUCTS FOR ANY SPECIFIC OR GENERAL USES. AAVID SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUEN-

TIAL DAMAGES OF ANY KIND.

All Aavid products are sold pursuant to the Aavid Domestic Terms and Conditions of Sale in effect from time to time, a copy of which shall

be furnished upon request (8911A).

Copyright©Aavid Thermalloy, LLC December 1997 (Revision 1.0) All icons, drawings, illustrations, and trademarks are the property

of Aavid Thermalloy, LLC and may not be reproduced without express written permission. All rights reserved.

Pentium® is a registered trademark of Intel Corporation. Softface™ is a registered trademark of the Bergquist Company.

Corporate Office: 80 Commercial Street • Concord, NH 03301

1

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

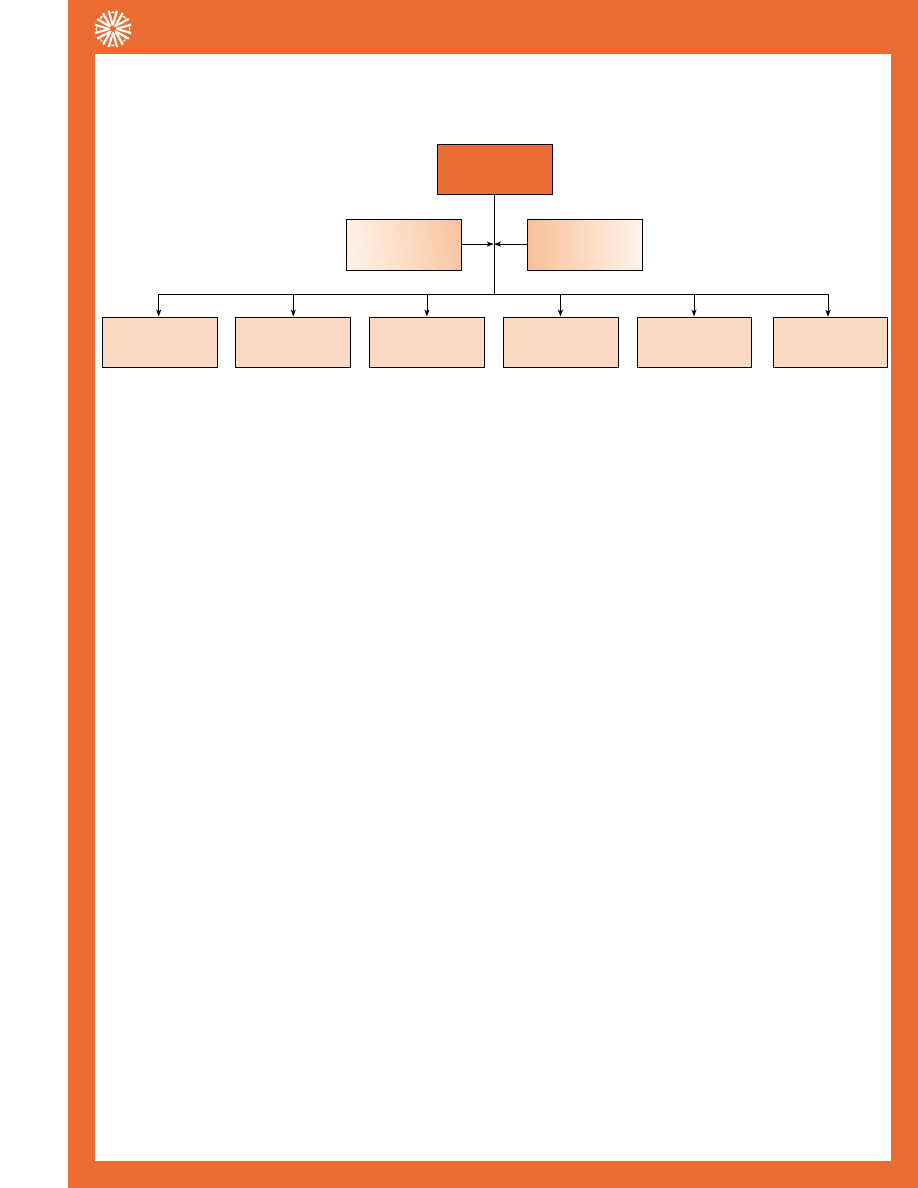

AAVID AROUND THE WORLD: COMPLETE COOLING SOLUTIONS

Aavid Thermal Technologies, Inc. is the global leader in advanced thermal management products, engineering services, and

design analysis software. Aavid has been developing and delivering cutting-edge thermal management products for more than

30 years. As a result of this unfailing dedication, Aavid ranks as the leader in providing totally integrated cooling solutions for

an ever expanding array of multi-national blue chip companies.

Aavid provides complete cooling solutions for a wide variety of customers including the computer, consumer entertainment,

communications, medical, power supply, controls, instrumentation, and transporation industries.

Applications that use Aavid designed thermal solutions range from cooling discrete semiconductors and microprocessors to

diesel-electric locomotives and from motor drives to wireless cellular base stations.

Aavid Thermal Technologies, Inc. is comprised of 3 separate operating companies working together to solve complex thermal

problems.

Aavid Thermalloy, an ISO certified manufacturing company is recognized worldwide for the exceptional quality of its cutting-

edge thermal management products offered in a vast selection of standard and custom shapes, sizes, and options to fit any

thermal challenge.

Aavid provides not only original designs for heat sinks, fan heat sinks, heat exchangers, attachment features, interface materials,

and liquid cold plate devices, but also comprehensive applications engineering services.

With over 8 factories strategically located worldwide, Aavid can supply you locally, wherever you are.

Applied Thermal Technologies, located in the heart of Silicon Valley, California, provides consulting design and analytical ser-

vices to augment your in-house thermal engineering expertise by developing problem-solution concepts and first article proto-

types. Using sophisticated computer design tools Applied's consultants become members of your design team to reduce time

to market while minimizing costs.

Fluent Incorporated is the world's leader in sophisticated computational fluid dynamic (CFD) software used to provide

complete, highly accurate system and component heat sink analysis. Fluent's unique analysis capabilities allows designers to

examine alternative designs for airflow, heat transfer and mass flow without the expense of building exact physical models.

Aavid's complete thermal solutions are reinforced by a global network of sales, manufacturing, distribution, and customer sup-

port services in North America, Europe, India, and the Pacific Rim.

With all this in place, Aavid is ready to work with you anytime, anywhere. Please call us so we can start creating cool new

options for your next generation products.

For more information on how to put our strengths to work for you, contact your local sales representative:

http://www.aavid.com/atp/globalSalesRep/globalSales.html or a distributor near you:

http://www.aavid.com/atp/globalDistrib/globalDistrib.html

for technical assistance, or placing an order.

Global offices: http://www.aavid.com

AAVID

THERMALLOY

Corporate Office: 80 Commercial Street • Concord, NH 03301

2

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

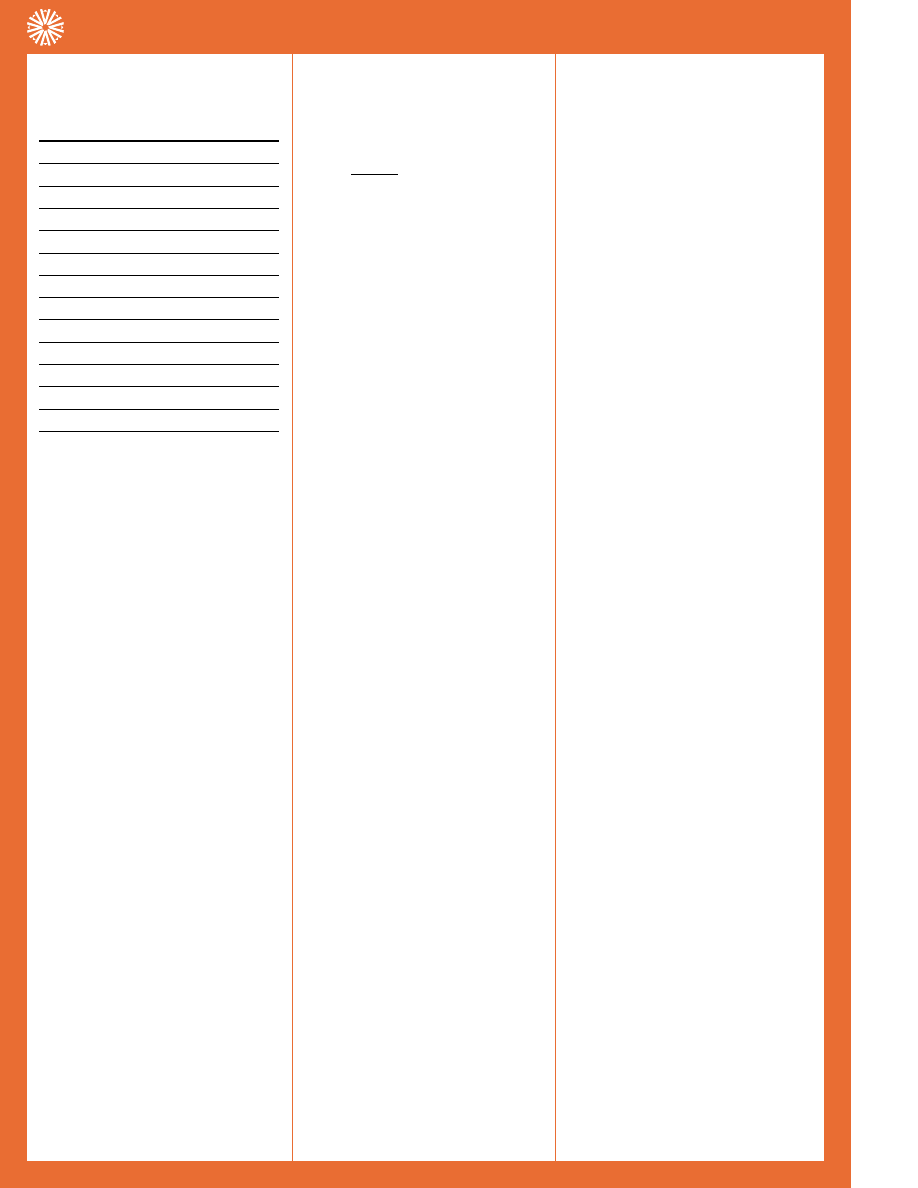

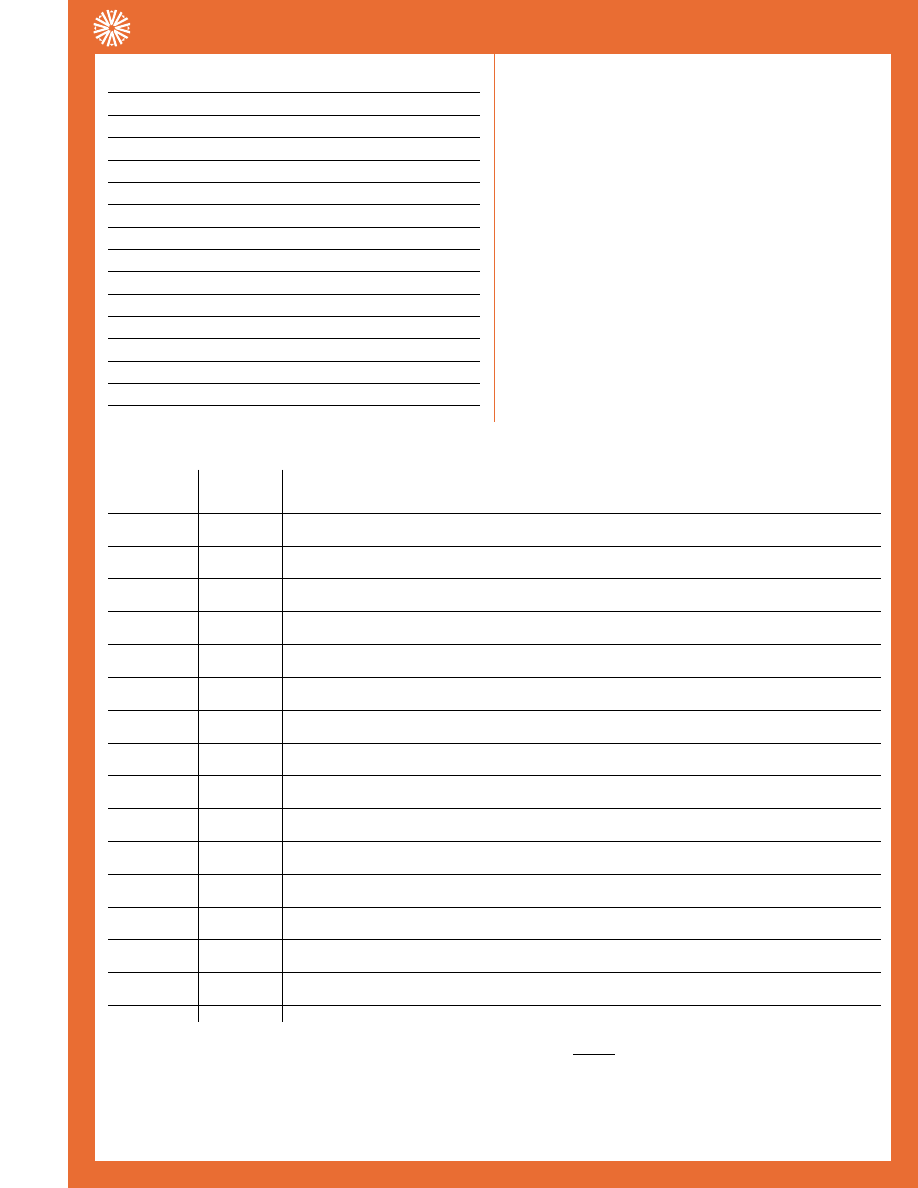

CONTENTS

Corporate Profile

Aavid Around the World . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Select a Heat Sink

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Introduction

PC Board Level Heat Sinks, Options and Accessories . . . . . . . . . . . . . . . . . . . . 5

Fabricated Extrusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ordering Information

For Standard Heat Sinks - Part Numbers, Options,

and Attachment Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Options

Thermal Interface Materials:

Chart, Descriptions, and Technical Information . . . . . . . . . . . . . . . . . . . . . . 7-10

PC Board Level Heat Sinks

Part Number Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Heat Sinks for TO-3s,TO-5s,TO-126s,TO-127s,TO-202s,TO-218s,TO-220s,

DIPs, SIPs, Multiwatt BGA/OptiPin, Digital, DC-DC,

and Surface Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Thermal Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-25

Power Device and Systems Level Extrusions, Fabricated Extrusions

Part Number Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

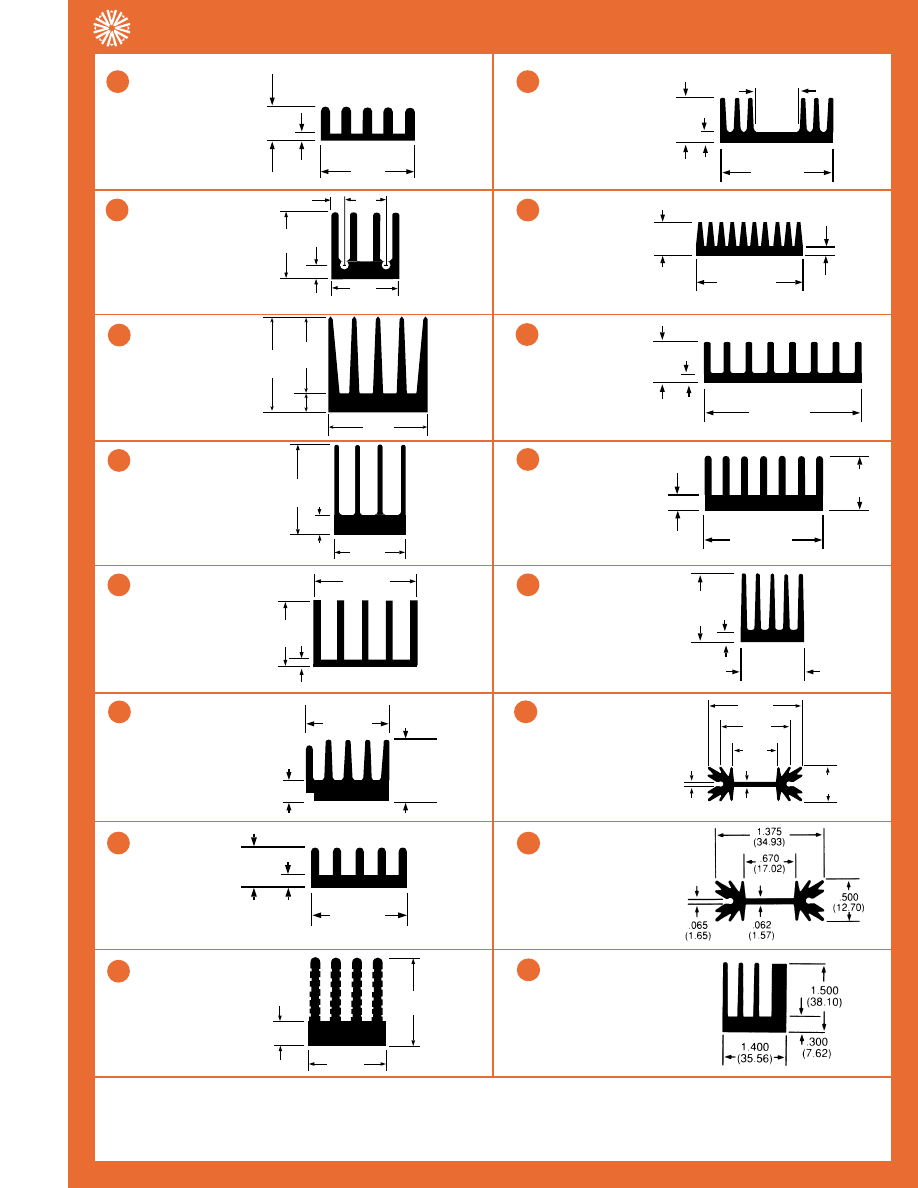

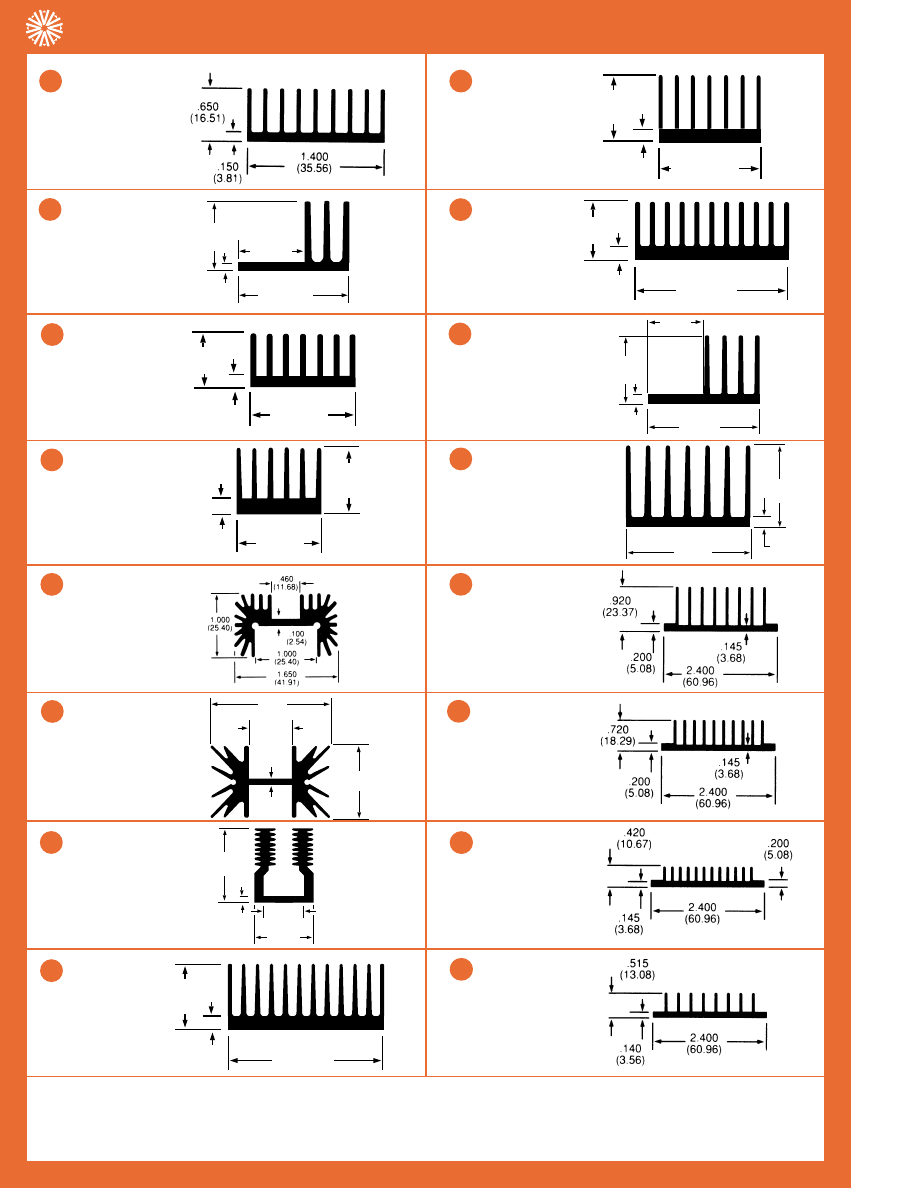

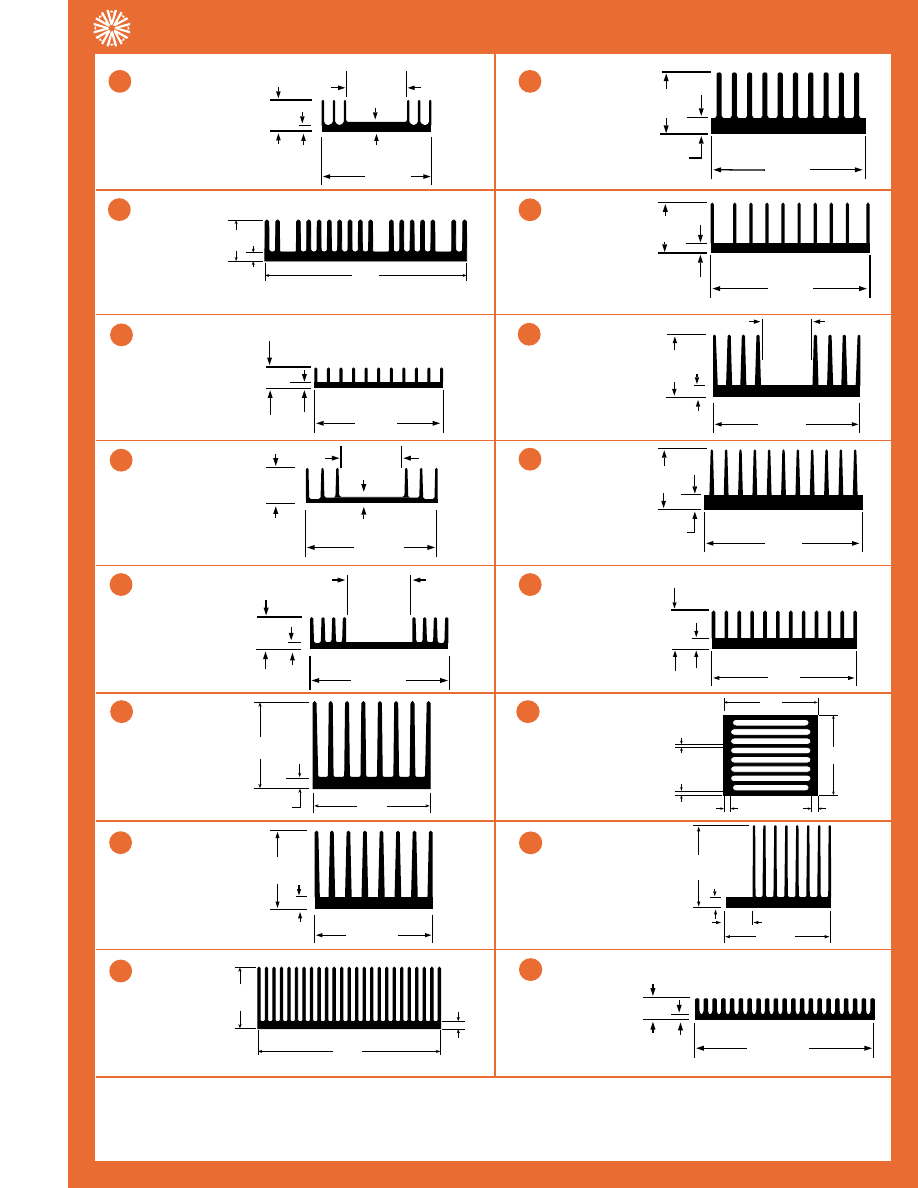

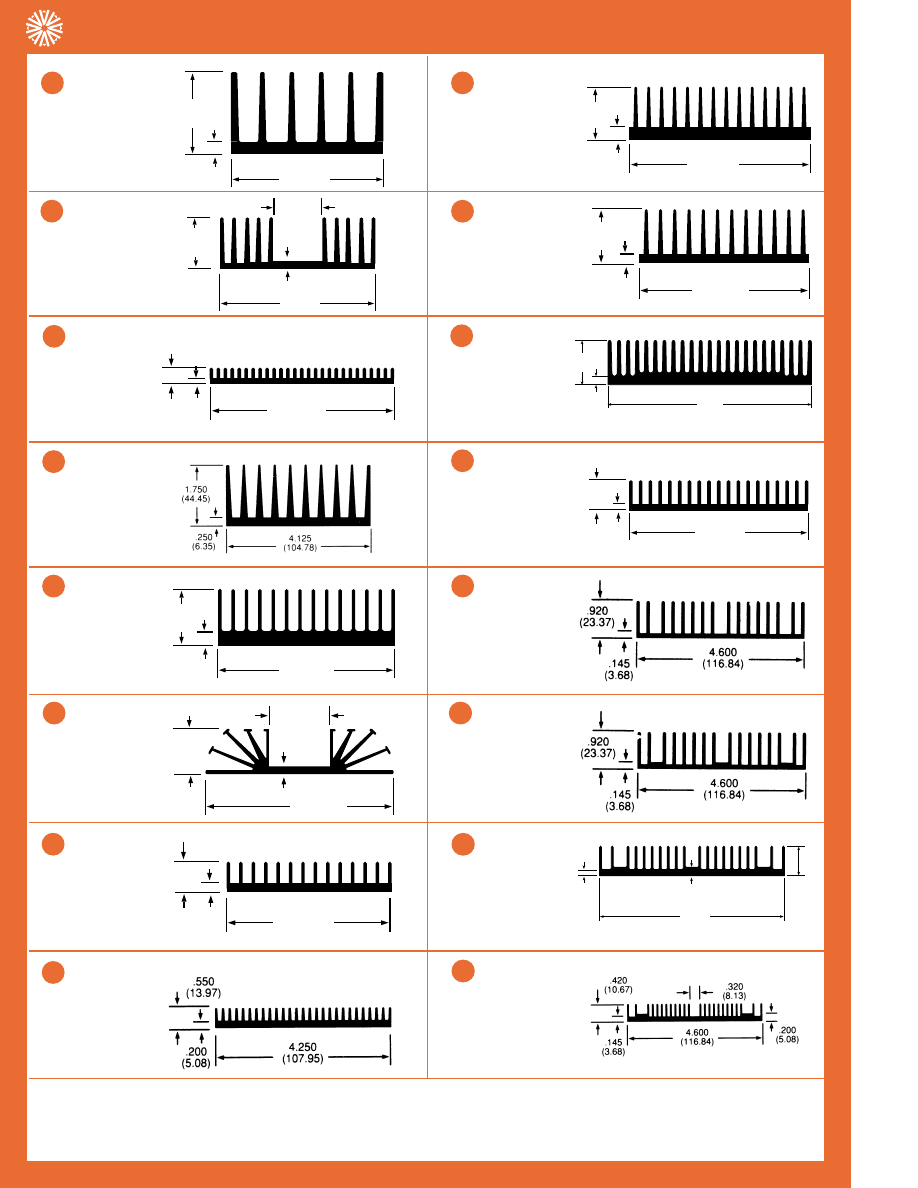

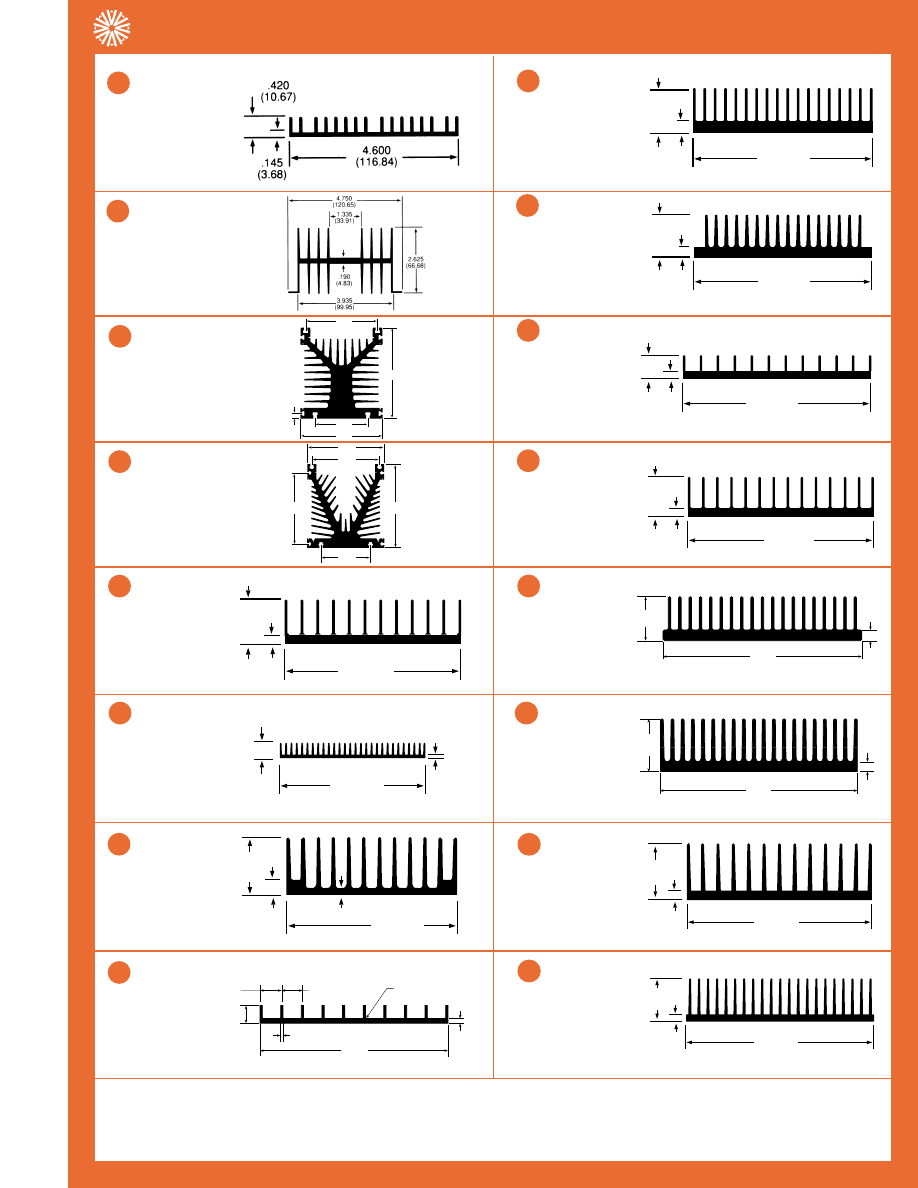

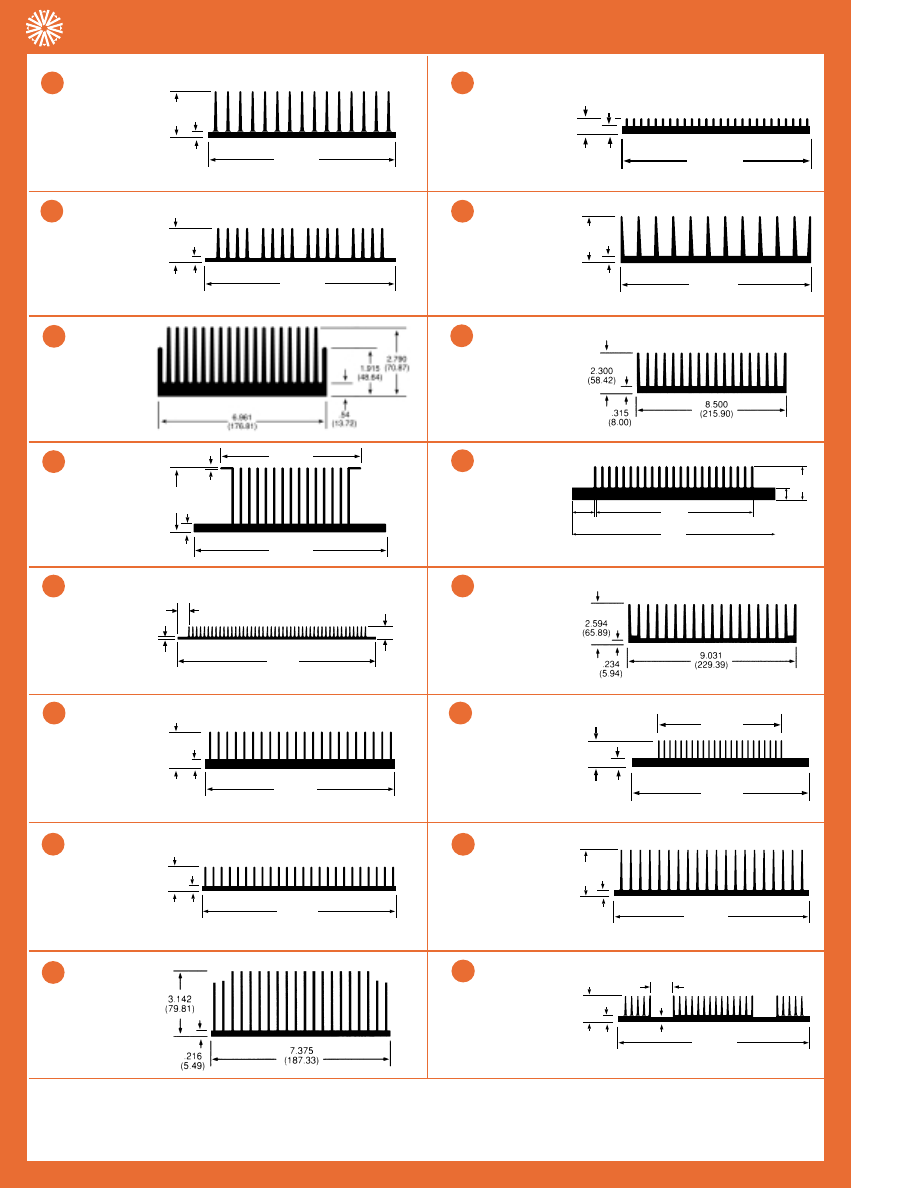

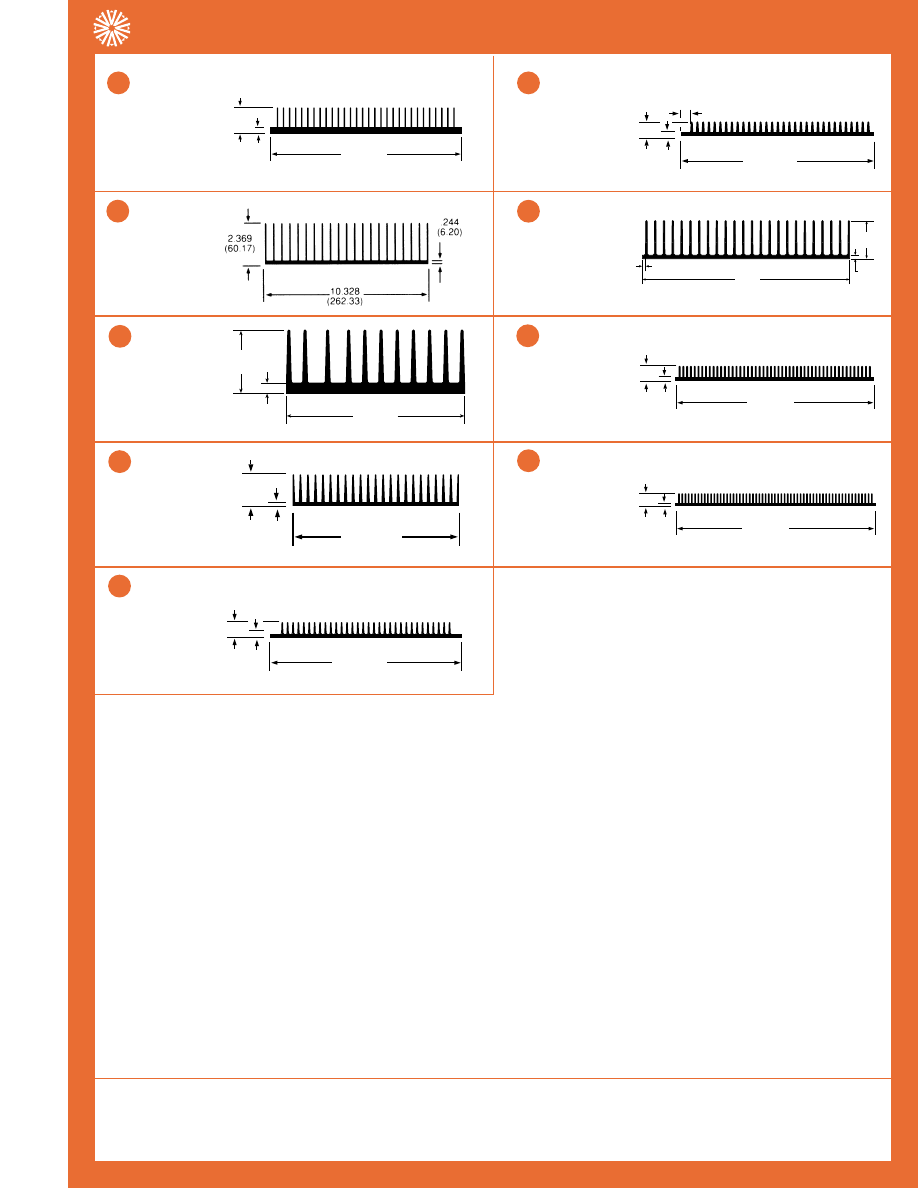

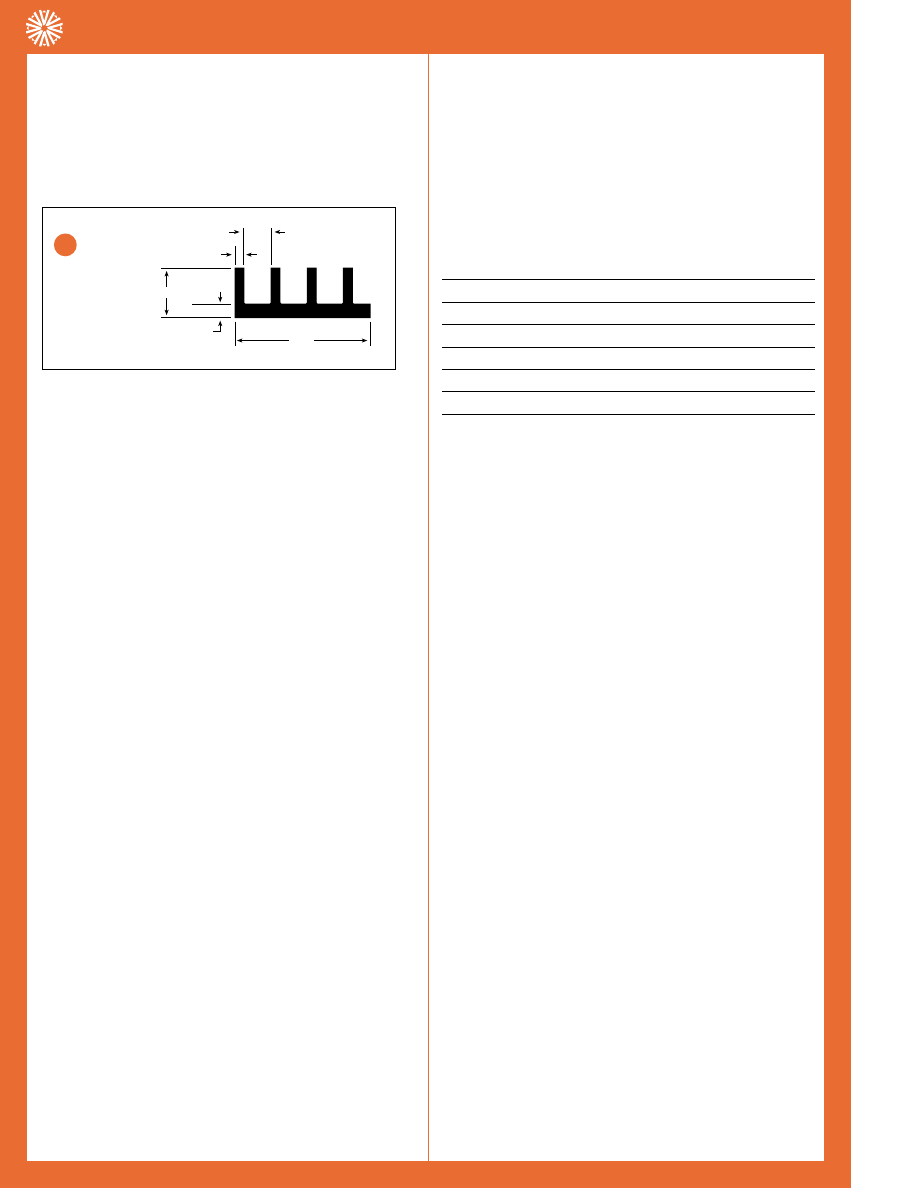

Extrusion Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-33

Thermal Information:

How to Use Published Data for Extrusion Profiles. . . . . . . . . . . . . . . . . . . . . 34

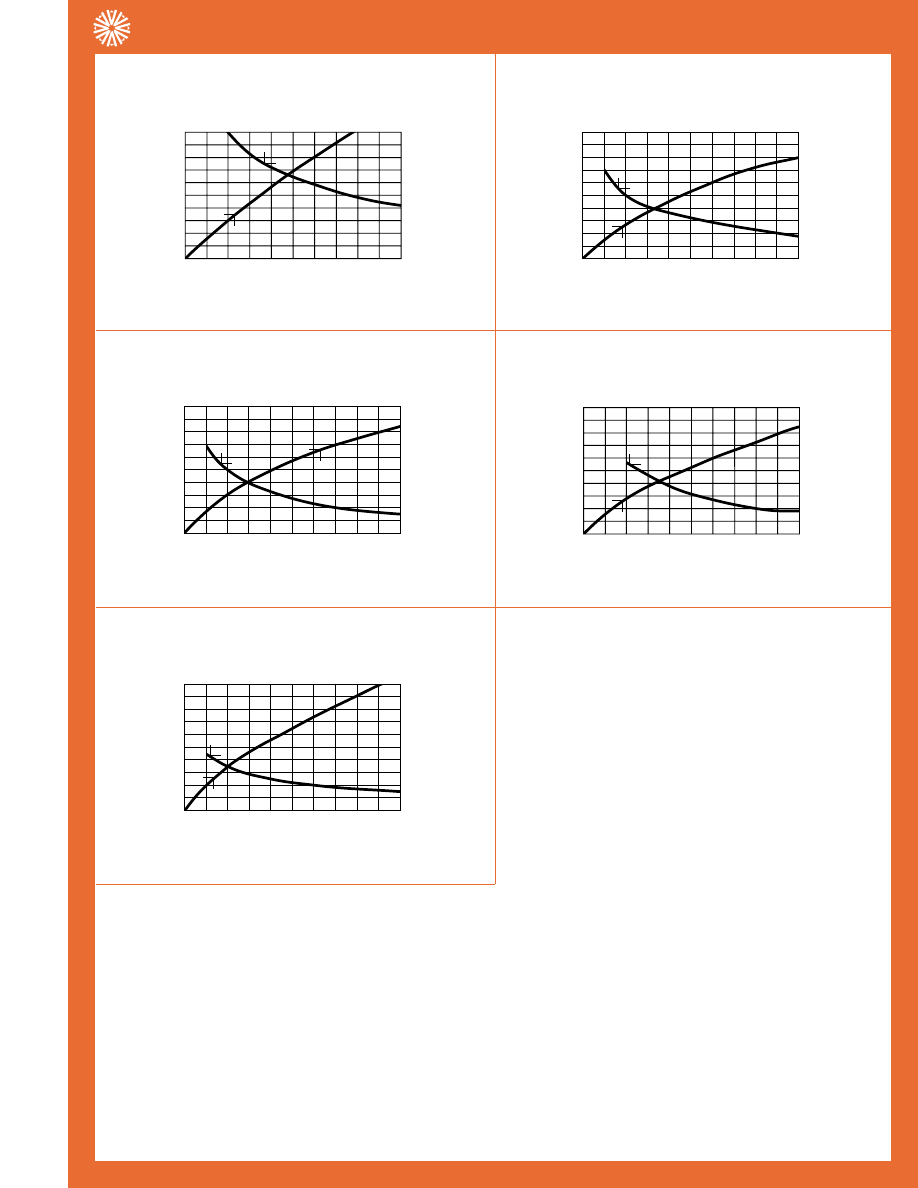

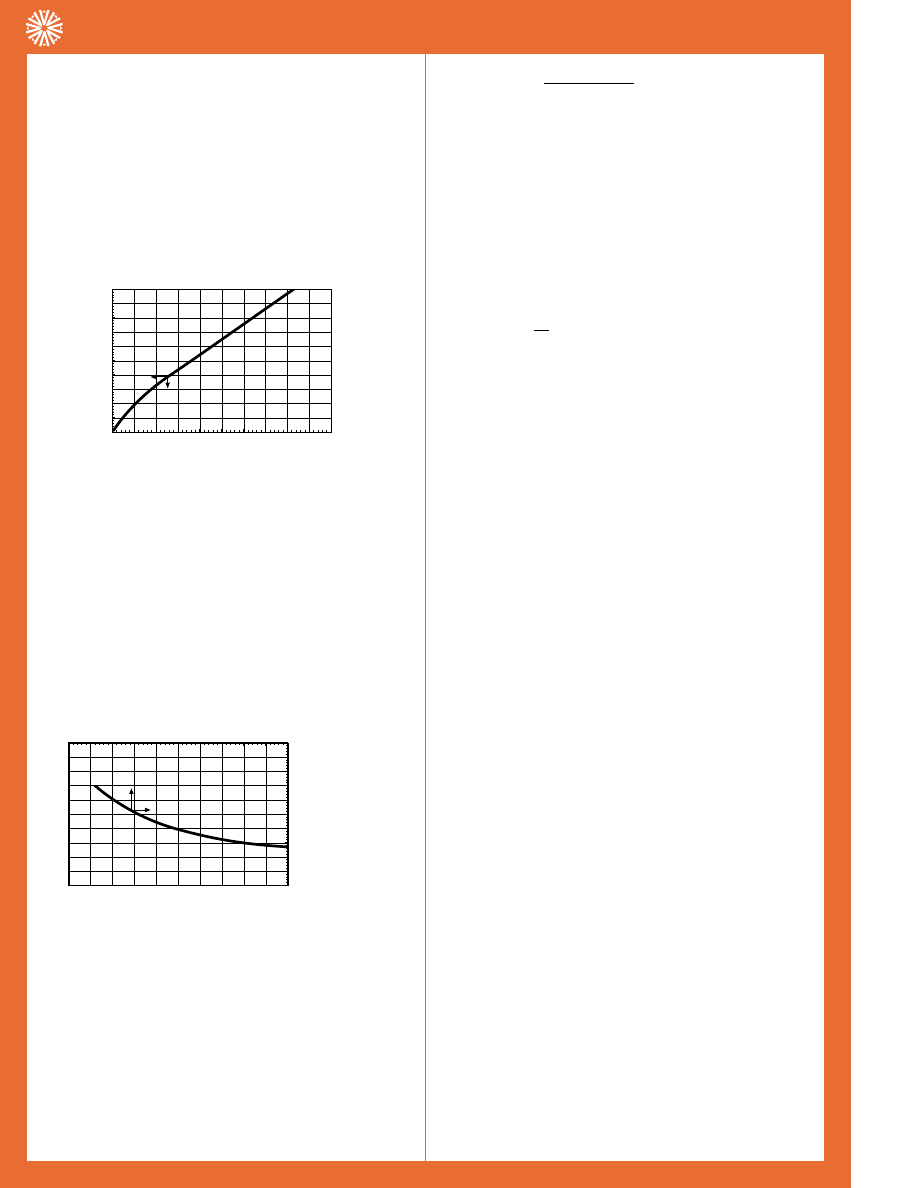

Reading a Thermal Performance Graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

For more information on how to put our strengths to work for you, contact your

local sales representative: http://www.aavid.com/atp/globalSalesRep/globalSales.html

or a distributor near you: http://www.aavid.com/atp/globalDistrib/globalDistrib.html

for technical assistance, or placing an order.

Global offices: http://www.aavid.com

AAVID

THERMALLOY

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE

Condensed

HOW TO SELECT A

HEAT SINK

Heat sinks reduce and maintain device

temperature below the maximum

allowable temperature of the device

in its normal operating environment.

In selecting a heat sink to achieve this

goal, four fundamental parameters

must be known about the application:

• The amount of heat, Q, being gener-

ated by the semiconductor device

in watts (W).

• The maximum allowable junction

temperature,Tj, of the device in

degrees Celsius (°C): this informa-

tion is available from the semicon-

ductor manufacturer’s data book

or fact sheet.

• The maximum temperature of the

ambient cooling air,Ta, in °C.

• The type of convection cooling in the

area of the device: is it natural or

forced? If it is forced convection, the

air flow velocity, in linear feet per

minute, must be known.

BASIC FORMULAS:

Heat is a form of energy that flows

from a higher temperature location (i.e.

the semiconductor junction at Tj) to a

lower temperature location (i.e. the

surrounding ambient air at Ta). In semi-

conductor devices, heat will flow from

the device to ultimately the ambient air

through many paths, each of which rep-

resents resistance to the heat flow.This

resistance is called thermal resistance,

denoted as

θ

in °C/W, and is defined as

the ratio between the amount of total

heat being transferred and the temper-

ature difference that drives the heat

flow.The total thermal resistance of a

system for a given device can therefore

be expressed as

where

θ

is the thermal resistance in

degrees C per watt, where the subscript

ja represents junction-to-ambient.

Thermal resistance is a measure of rela-

tive performance: a low thermal resis-

tance represents better performance

than a high thermal resistance. A sys-

tem that has a lower thermal resistance

can either dissipate more heat for a

given temperature difference or dissi-

pate a given amount of heat with a

smaller temperature difference.

In cooling electronic devices, heat sinks

lower the overall junction to ambient

thermal resistance.The actual thermal

path runs through the heat sink when

it is mounted on the device by means

of an attachment mechanism. In this

case, the total thermal resistance,

θ

ja, is

the sum of all the individual resist-

ances which represent the physical

aspect of the thermal path.There are

three thermal resistances that are

commonly used to express the total

resistance: 1) the junction-to-case

resistance,

θ

jc, to account for the ther-

mal path across the internal structure

of the device, 2) the case-to-sink resis-

tance,

θ

cs, which is also called the

interface resistance, to account for the

path across the interface between the

device and the heat sink, and 3) the

sink-to-ambient resistance,

θ

sa, to

account for the thermal path between

θ

ja

Tj –

Q

Ta

the base of the heat sink to the ambi-

ent air. It follows that

θ

ja

θ

jc +

θ

cs +

θ

sa

Realistically, a typical thermal designer

has no access to the internal structure

of the device, and can only control two

resistances outside of the device:

θ

cs

and

θ

sa.Therefore, for a device with a

known

θ

jc obtained from the device

manufacturer’s data book, these

become the main design variables in

selecting a heat sink.

Thermal interface between the case

and the heat sink is controlled in a

variety of manners, with different heat

conducting materials.The interface

resistance associated with Aavid stan-

dard interface materials can be found

on pages 8-10 of this catalog. However,

when standard materials are not used,

the following information is useful:The

interface resistance between the case

and heat sink is dependent on three

variables: the thermal resistivity of the

interface material (

ρ

, °C/W•inch), the

average material thickness (t, inches)

and the area of the thermal contact

footprint (A, inch

2

).

The interface thermal resistance

is then expressed as:

NOTE:The thermal resistivity (

ρ

), of

any material, is the reciprocal of its

thermal conductivity (k).Therefore, if

the conductivity is known, its resistivity

can be calculated.The expression is:

when k is in units of

B

h

t

r

u

.

.

ft

2

in

.°

ch

F

ρ

273

k

.2

θ

cs

ρ

.

A

t

Corporate Office: 80 Commercial Street • Concord, NH 03301

3

Tel. (603) 224-9988 • Fax (603) 223-1790

Corporate Office: 80 Commercial Street • Concord, NH 03301

4

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PC BOARD LEVEL HEAT SINKS, OPTIONS & ACCESSORIES

TYPICAL VALUES FOR

THERMAL RESISTIVITY

ρ

(°C/W•INCH):

copper (pure)

0.10

aluminum (1100 series)

0.19

aluminum (5000 series)

0.28

aluminum (6000 series)

0.17

beryllium oxide

0.32

carbon steel

0.84

alumina

1.15

anodized finish

5.60

silicon rubber

81.00

mica

66.00

mylar

236.00

silicone grease

204.00

dead air

1200.00

Once the

θ

cs is calculated, the

required thermal resistance from the

sink to ambient (

θ

sa) is easily calculat-

ed by the following equation:

The above information will allow you

to use the catalog’s performance

graphs in choosing a standard, ready to

use, heat sink to meet your require-

ments.When your heat sink application

requires a custom fabricated extrusion,

the thermal resistance (

θ

sa) of any

profile can be calculated by using the

performance factors shown in table on

page 35.The heat sink’s performance

factor (PF) is determined by its expect-

ed length and air flow conditions.Then,

θ

sa is obtained using the PF and the

extrusion profile’s perimeter.

In conclusion, the lower the thermal

resistance, the better the cooling, and

the larger the overall surface area (or

perimeter), the better the cooling.

θ

sa

Tj –

Q

Ta –(

θ

jc +

θ

cs)

Example

A TO-220 to dissipate 13 watts:

Tj max = 150°C

Ta max = 50°C

θ

jc = 3.0°C/W

Air Velocity = 400 ft/min

Find a suitable heat sink.

Assume the use of a Kon-Dux™ pad

with a torque of 2 in-lb. From Aavid

data for this type of semiconductor, we

know that

θ

cs = 0.5°C/W.

Aavid 504222 has a thermal resistance

of 4.0°C/watt at an air velocity of 400

ft/min and therefore complies with the

requirements.

Corporate Office: 80 Commercial Street • Concord, NH 03301

5

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PC BOARD LEVEL HEAT SINKS, OPTIONS & ACCESSORIES

INTRODUCTION

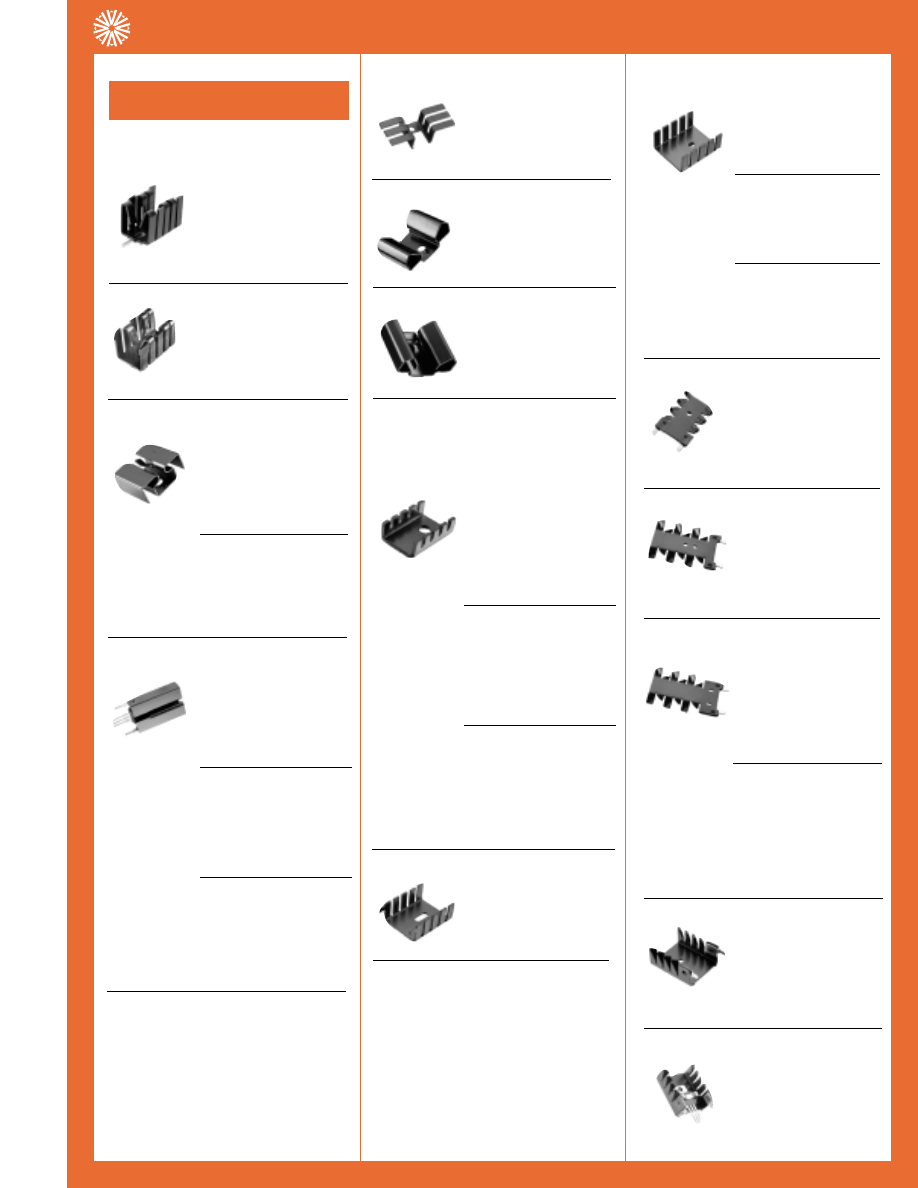

AAVID’S CORE/70

®

PC BOARD LEVEL STANDARD PRODUCTS

With ever-increasing demands to shorten time-to market, Aavid’s highly responsive distribution network makes readily available

to its global audience of PC board level designers CORE/70 - a proven, versatile core of more than seventy of Aavid’s most

sought after standard PC board level products.

A full array of Aavid’s most popular installation options, including a variety of tabs, pins, interface materials, mounts and clips

are part of the CORE/70 product offering to enhance manufacturability in your applications.

To quickly find the exact answers you need now, simply consult this condensed catalog.The CORE/70 ordering system is quick

and easy to use. Remember, for thermal problem-solving at its fastest and most dependable, ask your distributor for Aavid’s

CORE/70 solutions - a flexible system of products and options designed to keep you in the lead.

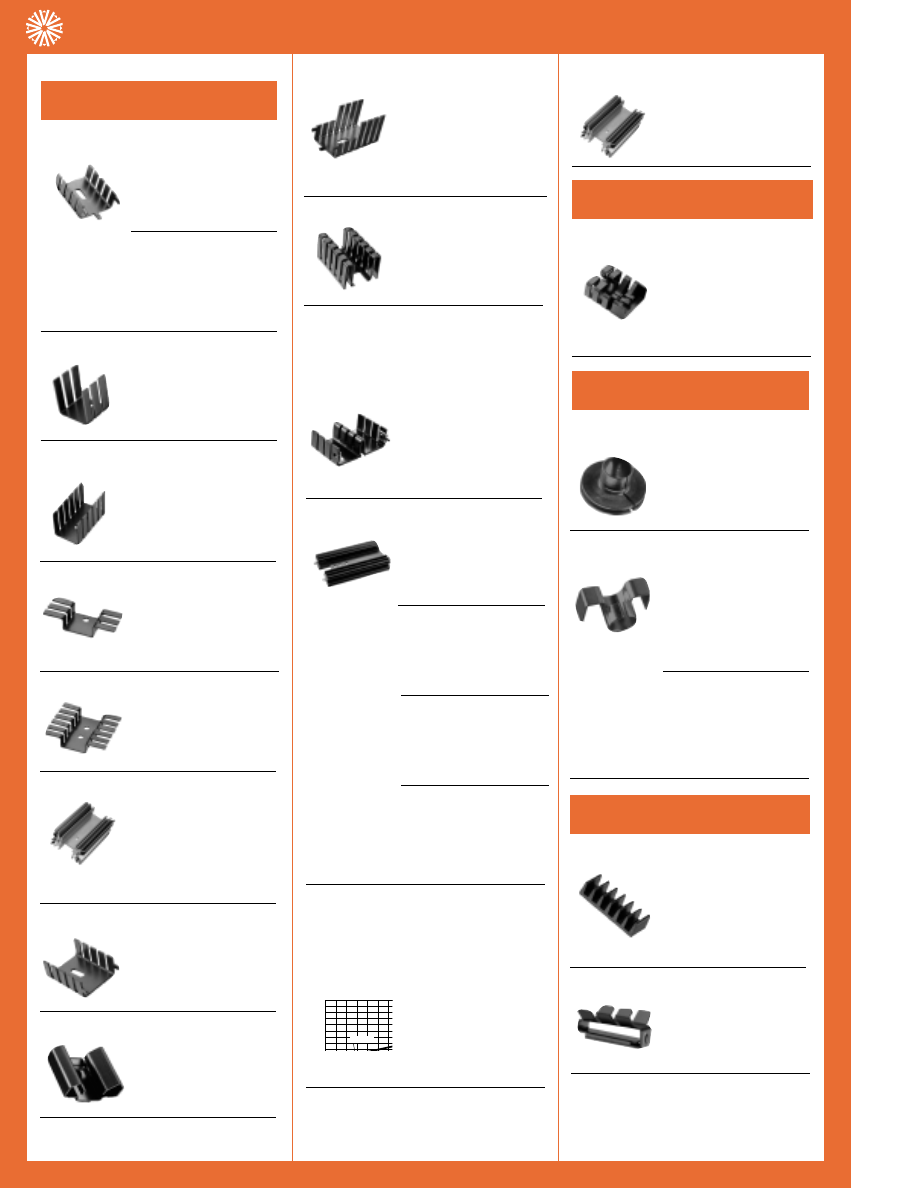

AAVID’S EXTRUSION BASICS GET YOU UP AND RUNNING IN RECORD TIME

When your thermal design solutions call for the highest quality extruded parts, call for Aavid immediately. Aavid has assembled

for easy reference and rapid response a core of approximately 150 extrusions - a virtual guarantee that you will find the

answer you need in stock.

These are all popular extrusions that Aavid constantly maintains in stock for rapid response.There’s no long development

process to factor in, no design surprises; and small minimum orders - only the assurance that Aavid can deliver exactly what you

want, now.

Keep in mind too, these extrusions are just the tip of the Aavid cooling solution iceberg.The current family of Aavid extru-

sions expands far beyond the 3,000 mark, and Aavid is constantly adding new, innovative items to the list. Aavid truly is one

cool idea after another. We built our worldwide reputation on it, now let us help build yours.

AAVID

THERMALLOY

Finish (

DIGIT

7)

CODE

DESCRIPTION

B

Black Anodize

C

Gold Chromate

D

Tin Plated

S

AavGard

Corrosion Protection

L

Clear Chromate

N

Clear Anodize

T

Dielectric Coated

with Tin Plated Tabs

U

Unfinished

PC Board Mounting (

DIGITS

9, 10)

Tinned Staked on **Tabs™

CODE

PART#

28

Shur-Lock™ Tab

(.130 for .062” PC Boards)

30

Vertical triangular

(.093O/.125 L)

31

Centered horizontal

(.050 W x .130 L)

32

Centered vertical

(.062 W x .125 L)

33

Centered vertical

(.062 W x .340 L)

34

Vertical pair L & R

(.075 W x .170 L)

35

Vertical pair L & R

(.097 W x .200 L )

36

Centered vertical

(.095 W x .150 L )

37

Centered step

(.062 W x .250 L

with .125 wide step)

38

Centered horizontal

(.032 W x .130 L )

39

Centered vertical

(.050 W x .340 L )

40

Centered vertical

(.050 W x .220 L )

**See individual parts for tab code

Device Mounting (

DIGITS

11, 12)

to PCB Semiconductor Mounts

CODE

PART#

DESCRIPTION

01

n/a

#6-32 female

02

n/a

#4-40 female

03

n/a

3mm female

04

n/a

#6-32 male

05

n/a

#4-40 male

Kool-Klips™

CODE

PART#

50

115000

51

115100

52

115200

53

115300

54

115400

For Rail

Extrusions

TO Case

CODE PART#

DEVICE

SIDES

55

115500

TO-220

tapered

PC Board Mounting (

DIGITS

9, 10)

Heat Sink to Board Mounting

Tinned Wave-On™ Mounts

CODE STAND-OFF

THREAD

01

.100”

#6-32

02

.100”

#4-40

03

.045”

#4-40

04*

.100”

#6-32

05

.045”

#6-32

07

.100”

3.5mm

08*

.100”

3.5mm

09

.200”

#6-32

Tinned Steel Solder Pins

for Board Mounted Extrusions

25

.093” dia. x.156” exposed

* .090 PCB (Others .062”)

Device Type (

DIGITS

5, 6)

CODE

DEVICE

00

Blank

01

TO-218

02

TO-220,TO-216,TO-217

03

TO-3

04

TO-202

05

TO-5,TO-39

06

TO-66

08

TO-247

Pads (

DIGIT

8)

Interface Heat Sink to Device

CODE

DESCRIPTION

0

None

1

One Kon-Dux™ Pad

2

Two Kon-Dux™Pads

3

One In-Sil-8™ Pad

4

Two In-Sil-8™ Pad

5

One A-Dux™ Pad

Kon-Dux™ is both thermally and

electrically conductive.

In-Sil-8™ and A-Dux™ are thermally

conducting and electrically isolating.

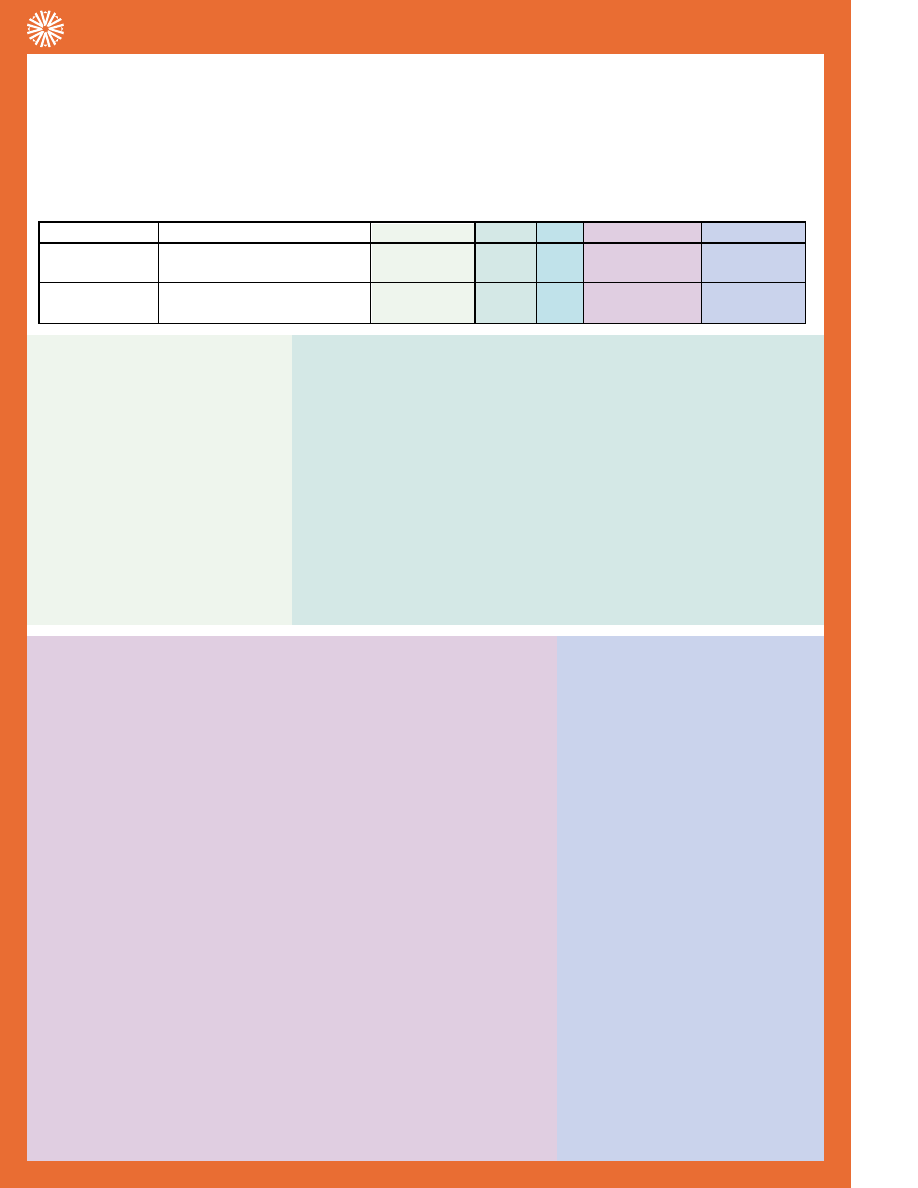

ORDERING INFORMATION

Ordering by Part Number - A twelve digit part number defines Aavid’s standard parts.

To order a part from this catalog, you need to construct a 12 digit ordering code/part number using the following options.

Digits 1 through 4 are the part numbers listed on the catalog pages. Digits 5, and 6, designate the type of device. The 7th digit is

for the finish, the 8th digit is for the interface material, the 9th and 10th digits indicate the type of mounting and the 11th digit

defines the method of attachment to the device.

Many of the parts in the catalog show their most popular options. If you require an option not listed here, contact our

applications engineering group at any of our worldwide offices.

DIGIT #

1

2

3

4

5

6

7

8

9

10

11

12

Ordering

5

7

6

8

0

2

B

0

0

0

0

0

Codes

DESIGNATION

Basic Device

PC

Board

Device

Part #

Type

Finish

Pads

Mounting

Mounting

Corporate Office: 80 Commercial Street • Concord, NH 03301

6

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

Corporate Office: 80 Commercial Street • Concord, NH 03301

7

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

Interface

Materials

Interface

Materials

Electrically

Conductive

Electrical

Insulation

Thermal

Greases

Thermal

Adhesives

Thin Films

Gap Fillers

Double-Sided

Tapes

Insulating

Elastomeric

Reinforced Pads

Mechanical Aspects of Thermal Materials

• Ther-A-Grip™ 1050

• Ther-A-Grip™ 1070

• Sil-Free™

•Ther-O-Link™

• Ther-O-Bond™

1500

•Ther-O-Bond™

1600 & 2000

• A-Pli™ Series

• In-Sil-8™

• Softface™

• Kon-Dux™

• A-Dux™

A-Dux, when you need thermal conductivity but electrical isolation is important too, A-Dux fits the bill.With the perfor-

mance of a grease, A-Dux has a breakdown voltage of 250 volts/mil of thickness.This material significantly enhances thermal

conductivity between semiconductor packages and heat sinks, and withstands aqueous washing that may occur during the man-

ufacturing process. For faster manufacturing time, have Aavid pre-install A-Dux on your heat sink.

A-Pli Gap Filler, when you need to transfer heat across an irregular opening, the A-Pli series fills the gap.The flexible, elastic

nature of A-Pli allows it to blanket extremely uneven surfaces, either individually or as a group. A-Pli conducts heat away from

the individual components, or an entire PCB, into metal covers, frames, or spreader plates.

The size of the gap that can be filled depends upon the amount of mounting pressure used. Aavid offers a range of A-Pli prod-

ucts with different compression rates to solve your thermal needs.

This low durometer product comes with a slightly tacky surface (A-Pli 200), or a very tacky surface (A-Pli 200S).

There are A-Pli products to meet your requirements when your gap filler needs specific electric properties, too. A-Pli 274 sili-

cone elastomer materials conform to irregular gaps with good thermal conductivity, while providing electrical insulation (A-Pli

274T) or electrical conductivity (A-Pli 274A).

In-Sil-8 Pads, when you need thermal conductance and electrical isolation in one package, In-Sil-8 Pads offer you the best of

both.These silicone-based insulators come with thermally conductive fillers to isolate up to 6000 volts. In-Sil-8 pads withstand

the rigors of assembly, harsh environments, and aging under continuous use.You'll save time with these cost-effective pads too:

installation is 4 times faster than mica and grease, and they won't contaminate solder baths. Order In-Sil-8 Pads with or with-

out pressure-sensitive adhesive, and in standard or custom shapes.

Kon-Dux interface pads are a cost-effective alternative to thermally conductive grease compounds. Aavid pre-applies Kon-Dux

to your heat sink to enhance heat conductance from the semiconductor case and speed your manufacturing process. Kon-Dux

pads are the equivalent of Softface™ for low-volume applications.This material is ideal for use with small, discrete semiconductors.

Sil-Free Grease, when you need to enhance heat transfer between a semiconductor case and a heat sink without the

migration or contamination associated with silicone-based products, Sil-Free Grease offers an easy-to-apply solution.This

metal-oxide filled, synthetic grease reduces dry interface thermal resistance by 50% to 70% with proper application. Sil-Free

will not dry out, harden, melt, or run, even after long-term, continuous exposure to temperatures up to 200° C. Even in

a vacuum atmosphere (24 hours at 5-10 Torr and 100° C), Sil-Free exhibits virtually no "bleed" or evaporation.

Softface™ is a cost-effective alternative to thermally conductive grease compounds. Once applied to a heat sink, Softface™

speeds installation of the semiconductor device. Applied with commercial hot-stamping equipment, Softface™ yields excellent

thermal performance with no need for adhesive. For the best value of any interface material, allow Aavid to pre-apply

Softface™ to your heat sink at any one of its worldwide locations.

THERMAL INTERFACE MATERIALS

Corporate Office: 80 Commercial Street • Concord, NH 03301

8

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

Ther-O-Bond Adhesives, when you need a thermally conductive adhesive,Ther-O-Bond Adhesives offer excellent heat

transfer and high voltage isolation.Ther-O-Bond 1500 and 1600 series epoxy adhesives offer low shrinkage, and coefficients of

thermal expansion comparable to copper or aluminum.They bond readily to metals, glass, ceramics, and most plastics.Ther-O-

Bond 1500 is ideal for large-scale applications, providing excellent heat transfer with dimensional stability over a wide tempera-

ture range. For smaller applications,Ther-O-Bond 1600 produces a strong, durable, high-impact bond, with good heat transfer

characteristics.

Ther-O-Bond 2000 Acrylic Adhesive cures rapidly at room temperature, while providing a repairable, thermally conductive

bond.

Ther-A-Grip 1050 and 1070, when you need to attach a heat sink to an electrical package, consider Ther-A-Grip double-

sided tape.Ther-A-Grip 1050 uses a thin, Kapton MT-filled, polydimide film coated on both sides with pressure-sensitive, acrylic

adhesive loaded with aluminum oxide for good thermal performance and excellent electrical isolation.Ther-A-Grip 1070 con-

sists of a thin aluminum foil coated with aluminum oxide-filled, acrylic adhesive for electrical conductivity and enhanced thermal

conductivity.

These easy-to-install tapes reduce the need for mechanical fasteners or messy epoxy adhesives.When Aavid pre-installs the

tape on your heat sink, you benefit with faster production time.With low cost and quick assembly combined with reparability,

Ther-A-Grip saves you time and money.

Ther-O-Link is a silicone-based thermal compound that cost effectively enhances the heat transfer between a semiconductor

case and a heat sink. Easy to apply,Ther-O-Link substantially reduces dry interface thermal resistance, while providing long life

under a variety of conditions.

TECHNICAL INFORMATION

Softface™

Thickness:

0.005 inch

(ASTM D374)

Color:

Black

Thermal Conductivity:

3.5 watt/m-°C

(ASTM D5470)

Thermal Impedance:

0.06 °C-in2/watt

(ASTM D5470)

Filler:

Graphite

Volume Resistivity:

10 Ohm-Cm

(ASTM D4496)

Dielectric Constant:

Non-Insulating

Dielectric Strength:

N/A

Storage Life:

1 year (min) @ 25°C

Cleanability:

Water and/or Isopropyl Alcohol (IPA)

Liner:

None

Kon-Dux

Thickness:

0.005 inch

Color:

Black (Metallic)

Thermal Impedance:

0.08 °C-in2/watt

Electrical Resistivity:

15 x 10

-6

Ohms

Compression Strength:

580 psi

for 10% reduction in thickness

Tensile Strength:

650 psi

Ultimate Compression

Strength:

12500 psi

Service Temperature:

-240 to +300 °C

Liner:

None

A-Dux

Color:

Gray

Thickness:

0.004 inch

Thermal Impedance:

0.16 °C-in2/watt

Electrical Resistivity:

1 x 10

-14

Ohm-cm

Tensile Strength:

700 psi

Service Temperature:

-50 to +200 °C

Liner:

Clear Mylar

Corporate Office: 80 Commercial Street • Concord, NH 03301

9

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

A-Pli Gap Filler

A-Pli 210

A-Pli 220

A-Pli 260

Color:

Pink

Blue

White

Thickness:

0.010 inch

0.020 inch

0.060 inch

Thickness Tolerance:

+/- 0.001 inch

+/- 0.002 inch

+/- 0.010 inch

Filler:

Boron Nitride

Boron Nitride

Boron Nitride

Thermal Impedance

.12

.14

.28

(@ 10 psi min.) °C-in2/watt

Thermal Conductivity

6 Watt/(m-C)

8 Watt/(m-C)

10 Watt/(m-C)

Dielectric Strength

2000 Volts

4000 Volts

4000 Volts

Density

1.28 g/cc

1.28 g/cc

1.28 g/cc

Hardness (Shore A)

10

10

6

Liner:

Clear Mylar

Clear Mylar

Clear Mylar

Ther-A-Grip 1050 and 1070

Ther-A-Grip 1050

Ther-A-Grip 1070

Electrical Function:

Insulating

Conductive

Color:

Beige

White

Thickness:

0.005 inch

0.006 inch

Carrier:

Kapton

Aluminum

Thermal Impedance

0.58°C/watt

0.54°C/watt

Breakdown Voltage

5570 VAC

N/A

Volume Resistivity

3 x 10

14

Ohm-cm

N/A

UL Flammability

94V-O

94V-O

Rating

U.L. 94

U.L. 94

Lap Shear Adhesion

124 psi

134 psi

Die Shear Adhesion

Aluminum 25°C

130 psi

125 psi

Aluminum 150°C

50 psi

55 psi

Alum. Oxide 25°C

170 psi

145 psi

Alum. Oxide 150°C

50 psi

60 psi

Creep Adhesion

25°C @ 12 psi

> 50 days

> 50 days

150°C @ 12 psi

> 10 days

> 10 days

Ther-A-Grip passes the following Environmental testing:

• High Temperature / Humidity Resistance:

1000 hours @ 66°C, 85% relative humidity

• High Humidity: 1000 hours, 25°C, 95% relative humidity

• Conformal Coating Compatibility

• Heat Aging: 1000 hours, 150°C

• Mechanical Shock

• Potting Compound Compatibility

• Salt Spray

• Solvent Exposure

• Thermal Shock:

-60°C to 150°C for 10 cycles and 100 cycles

• Heat Aging,Vibration @ 25°C,Vibration @ 150°C

• Temperature Cycling: -50°C to 150°C, 1000 cycles

• Long Term Storage

143 North Main Street • Suite 206 • Concord, NH 03301

10

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PC BOARD LEVEL HEAT SINKS, OPTIONS & ACCESSORIES

Sil-Free Grease

Color:

White

Thermal Conductivity:

0.79 watt/(m-C)

Operating Temperature Range:

-40°C to 200°C

Volume Resistivity:

2.3 x 10

12

Ohm-cm

Dielectric Strength:

225 Volts/mil

Consistency:

Paste

Bleed (% after 24hr @ 200°C):

0.09 max

Specific Gravity

2.8

Shelf Life:

Indefinite (unopened)

Ther-O-Link

Color:

White

Thermal Conductivity:

0.73 watt/(m-K)

Operating Temperature Range:-

-40°C to 200°C

Volume Resistivity:

1.0 x 10

15

Ohm-cm

Dielectric Strength:

250 Volts/mil

Consistency:

Paste

Bleed (% after 24hr @ 200°C):

0.6 max

Specific Gravity

2.8

Shelf Life:

Indefinite

Ther-O-Bond Adhesives

2000

1599

1600

Color:

White

Black

Blue

Thermal Conductivity watt/(m-C):

0.48

1.26

0.85

C.T.E. (ppm/(C):

25

25

25

Tensile Strength (@25) :

2360 psi

9200 psi

9200 psi

Dielectric Strength (volts/mil):

220

800

500

Shelf Life:

12 months

12 months

12 months

In-Sil-8 Pads

1896

1897

1898

1899

Color:

Grey

Rust

Grey

Grey

Thickness (in):

0.006

0.009

0.007

0.009

Thermal Res. (C/watt)

TO-3

0.40

0.21

0.33

0.50

TO-220

1.40

0.63

1.25

1.50

TO-218

0.93

0.49

0.77

1.16

Breakdown Voltage

6000

5000

4000

5000

Dielectric Constant

5.5

4.5

5.5

5.5

143 North Main Street • Suite 206 • Concord, NH 03301

11

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

Part #

Page

533002

14

534202

13

534302

13

551002

14

563002

14

566010

14

569003

15

573100

16

573300

16

573400

16

574004

15

574102

13

574204

15

574402

13

574502

13

574602

13

574902

13

575002

13

575102

13

576602

14

576802

13

577002

13

577102

13

577202

13

577304

15

577404

15

577500

15

578205

14

578305

14

Part #

Page

578622

14

579302

13

579402

14

579704

15

580200

14

590102

14

591302

13

592502

13

593002

13

593202

13

594302

13

D-PAK, D

2

, D

3

16

1" Morrlong

16

1.25” Morrison 16

Morrlong/

Morrison Clip

16

PC BOARD LEVEL

HEAT SINKS, OPTIONS &

ACCESSORIES PART

NUMBER INDEX

Part #

Page

022938

16

025417

16

026205

16

026350

16

026437

16

322505

14

364424

15

501200

14

501503

15

501603

15

504102

14

504222

14

507002

14

507102

13

507222

14

507302

15

523002

14

529801

15

529802

14

530002

14

530101

15

530102

15

530162

15

530613

13

530614

13

530714

13

531002

14

531102

14

531202

14

531302

14

TO-220

Part #

Page

551002

14

563002

14

574102

13

574402

13

574502

13

574602

13

574902

13

575002

13

575102

13

576602

14

576802

13

577002

13

577102

13

577202

13

578622

14

579302

13

579402

14

590102

14

591302

13

592502

13

593002

13

593202

13

594302

13

TO-220 and TO-218

530002

14

533002

14

TO-220 or TO-218

530101

15

530102

15

530162

15

DIPs and SIPs

Part #

Page

501200

14

580200

14

Multiwatt

566010

14

OptiPin™ for BGAs

364424

15

Digital

1" Morrlong

16

1.25” Morrison 16

Clip

16

025417

16

026437

16

Surface Mount

573100

16

(D-PAK/TO-252)

573300

16

(D2PAK/TO-263)

573400

16

(D3PAK/TO-268)

PC BOARD LEVEL

HEAT SINKS PART NUM-

BER INDEX BY SEMICON-

DUCTOR TYPE

TO-3

Part #

Page

501503

15

501603

15

569003

15

TO-5

322505

14

578205

14

578305

14

TO-126

and TO-127

507302

15

577500

15

TO-202

574004

15

574204

15

577304

15

577404

15

579704

15

TO-218

529801

15

TO-220

504102

14

504222

14

507002

14

507102

13

507222

14

523002

14

529802

14

530613

13

530614

13

530714

13

531002

14

531102

14

531202

14

531302

14

534202

13

534302

13

Corporate Office: 80 Commercial Street • Concord, NH 03301

12

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

143 North Main Street • Suite 206 • Concord, NH 03301

13

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

†

5These products have been patented by Aavid Thermal

Technologies, Inc.

With Sure-Lock

™

TabsforVert.Mounting.

With Solderable Tabs for Horiz.Mounting.

With Solderable Tab for Vert.Mounting:

577202B00000

0.500

24.4°C/W @2.5W

Ordering

Code:

Height:

θ

:

574102B00000

0.750

23.2°C/W @2.5W

Ordering

Code:

Height:

θ

:

574402B03200

0.395

23.2°C/W @2.5W

574402

†

, 574102

†

Ordering

Code:

Height:

θ

:

592502B03400

1.250

22.0°C/W @2.5W

592502

Ordering

Code:

Height:

θ

:

576802B04000

0.750

18.8°C/W @2.5W

576802

†

Ordering

Code:

Height:

θ

:

575102B00000

0.750

16.8°C/W @2.5W

575102

Ordering

Code:

Height:

θ

:

579302B00000

0.750

16.8°C/W @2.5W

579302

†

Ordering

Code:

Height:

θ

:

574902B03300

1.375

16.0°C/W @2.5W

Ordering

Code:

Height:

θ

:

591302B02800

0.790

26.8°C/W @2.8W

591302

†

Ordering

Code:

Height:

θ

:

530613B00000

0.500

16.7°C/W @4.5W

530613, 530614, 530714

Ordering

Code:

Height:

θ

:

530614B00000

0.500

16.7°C/W @4.5W

530614

†

Ordering

Code:

Height:

θ

:

575002B00000

1.180

13.6°C/W @5.0W

575002

Ordering

Code:

Height:

θ

:

SELF-LOCKING

With Solderable Tab for Vert.Mounting:

577202B04000

With Solderable Tabs for Vert. Mounting

With Solderable Tab for Horiz.Mounting:

576802B03100

507102B00000

.700

15.6ºC/W

507102

Ordering

Code:

Height:

θ

:

TO-220

With Solderable Tabs for Vert.Mounting.

574602B03300

0.690

21.6°C/W @2.5W

Ordering

Code:

Height:

θ

:

With Solderable Tab for Vert.Mounting.

MANUAL ATTACHMENT

574502B03300

0.750

21.2°C/W @2.5W

574502

†

, 574602

†

, 574902

†

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

577002B00000

0.250

32.0°C/W @2.5W

577002, 577102, 577202

Ordering

Code:

Height:

θ

:

577002B04000

577102B00000

0.380

25.9°C/W @2.9W

Ordering

Code:

Height:

θ

:

With Solderable Tab for Vert.Mounting:

577102B04000

534302B03553

2.000

10.4°C/W @5.0W

534302, 594302

†

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

593202B03500

2.000

10.0°C/W @5.0W

593202

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

530714B00000

0.500

20.3°C/W @3.7W

530714

†

Ordering

Code:

Height:

θ

:

594302B02853

2.000

8.8°C/W @8.5W

Ordering

Code:

Height:

θ

:

With Sure-Lock

™

Tabs and Kool-Klip

™

#115330 for Vert.Mounting.

534202B03453

1.180

13.0°C/W @5.0W

534202

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting:

593002B03400

1.180

13.4°C/W @5.0W

593002

Ordering

Code:

Height:

θ

:

With Sure-Lock

™

Tabs for Vert.Mounting:

593002B02800

1.Thermal resistance has been evaluated in

natural convection, at the power level which

results in a 75°C temperature rise above

ambient.

2. Height (in inches) designation is by refer-

ence to the part size, oriented to the board

in its most common configuration.

AAVID

THERMALLOY

Corporate Office: 80 Commercial Street • Concord, NH 03301

14

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

†

5These products have been patented by Aavid Thermal

Technologies, Inc.

580200B00000

.410

38ºC/W @0.8W

580200

Ordering

Code:

Height:

θ

:

507222B00000

0.375

9.6°C/W @5.0W

507222

Ordering

Code:

Height:

θ

:

TO-220 Continued

507002B00000

0.375

15.6°C/W @5.0W

507002

Ordering

Code:

Height:

θ

:

563002B00000

1.180

13.0°C/W @5.0W

563002, 576602

Ordering

Code:

Height:

θ

:

504102B00000

0.850

15.6°C/W @5.0W

504102

Ordering

Code:

Height:

θ

:

523002B00000

1.180

13.6

523002

Ordering

Code:

Height:

θ

:

579402B00000

0.750

16.8

579402

Ordering

Code:

Height:

θ

:

504222B00000

1.450

6.4°C/W @11.8W

504222

Ordering

Code:

Height:

θ

:

529802B02500

1.500

3.7°C/W @20.0W

529802

Ordering

Code:

Height:

θ

:

With Solderable Pins for Vert.Mounting.

590102B03600

1.680

10.0°C/W @7.5W

590102

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

551002B00000

0.787

12.4°C/W @5.0W

551002

Ordering

Code:

Height:

θ

:

578622B03200

1.030

13.2°C/W @2.5W

578622

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

531002B02500

1.000

13.4°C/W @5.6W

531002, 531102, 531202, 531302

Ordering

Code:

Height:

θ

:

531102B02500

1.500

10.4°C/W @7.2W

531102

Ordering

Code:

Height:

θ

:

531202B02500

2.000

8.3°C/W @9.0W

531202

Ordering

Code:

Height:

θ

:

576602B00000

0.950

16.6°C/W @5.0W

576602

Ordering

Code:

Height:

θ

:

Multiwatt

566010B03400

1.220

11.5°C/W @6.5W

566010

Ordering

Code:

Height:

θ

:

With Sure-Lock

™

TabsforVert.Mounting:

566010B02800

531302B02500

2.500

8.0°C/W @5.0W

531302

Ordering

Code:

Height:

θ

:

DUAL MOUNTING

DIPs and SIPs

501200B00000

0.250

62.5°C/W @1.2W

501200

Ordering

Code:

Height:

θ

:

For 14 or 16 Pin DIPs

TO-5

322505B00000

0.400

56.0°C/W @1.25W

322505

Ordering

Code:

Height:

θ

:

578205B00000

0.500

38.0

578205, 578305

Ordering

Code:

Height:

θ

:

578305B00000

0.750

35.0°C/W @1.0W

Ordering

Code:

Height:

θ

:

†

5These products have been patented by

Aavid Thermal Technologies, Inc.

HIGH PERFORMANCE

AIR VELOCITY (FEET PER

OUNTING SURF

ACE TEMP

SE ABO

VE AMBIENT–(

°

C)

600

400

200

0

100

80

60

40

20

WITH FAN ON

533002B02551

1.000

13.0°C/W @5.0W

533002

†

Ordering

Code:

Height:

θ

:

With Solderable Pins and Kool-Klip

™

#115100 for Vert.Mounting.

530002B02500

2.500

3.8°C/W @10.0W

530002

†

Ordering

Code:

Height:

θ

:

AAVID

THERMALLOY

143 North Main Street • Suite 206 • Concord, NH 03301

15

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

†

5These products have been patented by Aavid Thermal

Technologies, Inc.

574204

577500B00000

0.520

26.0°C/W @2.5W

577500

Ordering

Code:

Height:

θ

:

For TO-126.

TO-202

579704B03300

0.900

24.0°C/W @2.5W

579704

†

Ordering

Code:

Height:

θ

:

With Solderable Tabs for Vert.Mounting.

574004B00000

0.580

28.0°C/W @2.5W

574004

†

Ordering

Code:

Height:

θ

:

574204B00000

0.900

16.8

Ordering

Code:

Height:

θ

:

577404B00000

0.500

24.0°C/W @2.5W

577404

Ordering

Code:

Height:

θ

:

TO-3

501503B00000

1.000

6.3°C/W @12.0W

501503. 501603

Ordering

Code:

Height:

θ

:

501603B00000

1.250

5.4°C/W @14.0W

501603

Ordering

Code:

Height:

θ

:

TO-218

529801B02500

1.500

3.7°C/W @20.0W

529801

Ordering

Code:

Height:

θ

:

569003B00000

1.310

5.4°C/W @10.0W

569003

Ordering

Code:

Height:

θ

:

577304B00000

0.375

27.2°C/W @2.5W

577304, 577404

Ordering

Code:

Height:

θ

:

This condensed catalog

features the more popular

devices and configurations.

For other devices and

configurations, contact Aavid

Applications Engineering

to receive our full

Product Selection Guide.

More information is also

available 24 hours a day by

using our FastFacts System,

603 223-1750, or see our

web-site,

http://www.aavid.com.

530162B00162

1.750

4.4°C/W @17.0W

530162

†

Ordering

Code:

Height:

θ

:

With Solderable Mounts and Two Kool-Klips

™

#116200 for Vert.Mounting.

for Two TO-220s

TO-220/TO-218

for One TO-218

530101B00150

1.750

6.3°C/W@12.0W

530101

†

Ordering

Code:

Height:

θ

:

With Solderable Mounts and Kool-Klip

™

#115000 for Vert.Mounting.

530102B00150

1.750

6.3°C/W@12.0W

530102

†

Ordering

Code:

Height:

θ

:

With Solderable Mounts and Kool-Klip

™

#115000 for Vert.Mounting.

for One TO-220

364424B00032

.450

10.7°C/W

364424

Ordering

Code:

Height:

θ

:

OptiPin Heat Sinks for

BGA Devices

TO-126 and TO-127

507302B00000

0.375

24.0°C/W @2.5W

507302

Ordering

Code:

Height:

θ

:

For TO-126 & TO-127.

With preinstalled 1070 tape

364424B00000 without tape

AAVID

THERMALLOY

Corporate Office: 80 Commercial Street • Concord, NH 03301

16

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks, Options & Accessories

†

5These products have been patented by Aavid Thermal

Technologies, Inc.

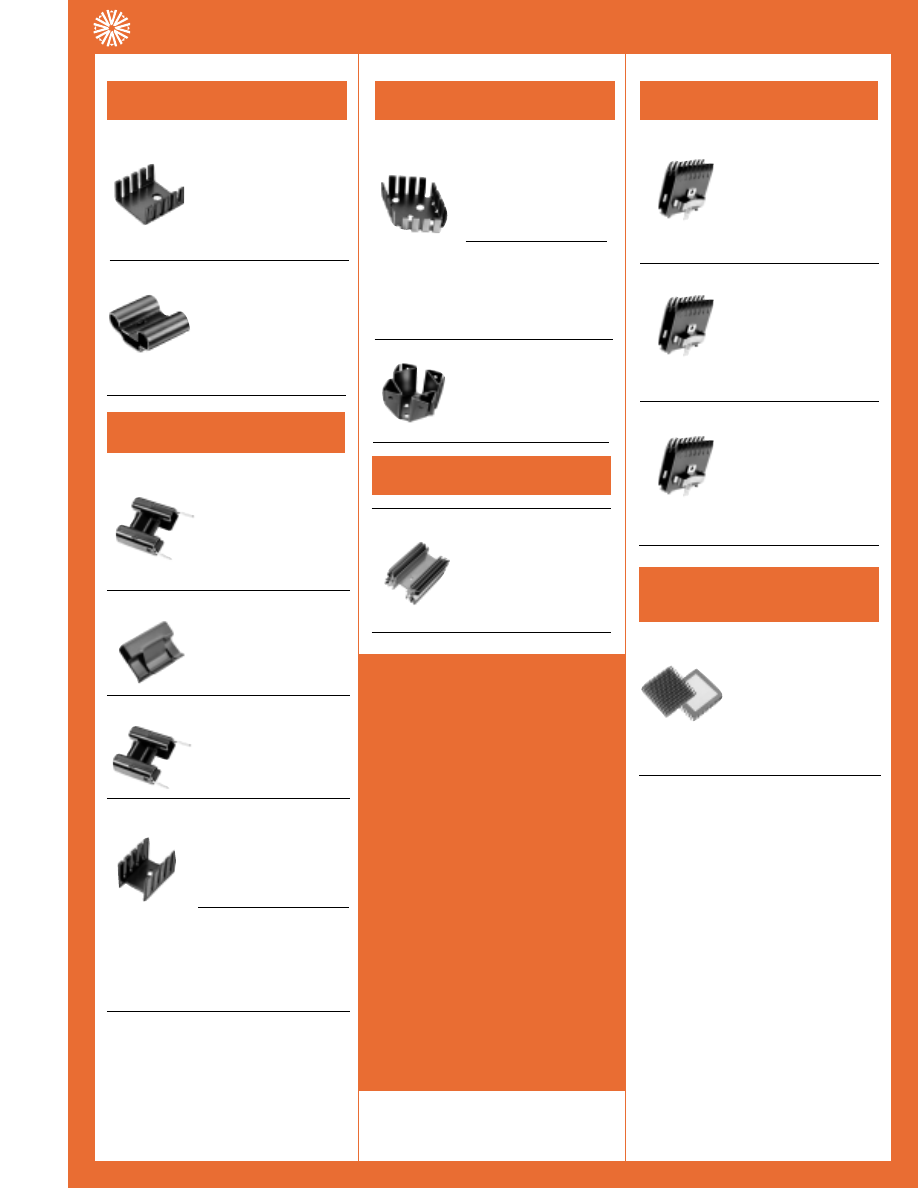

D-PAK/T0-252

D

2

PAK/T0-263

D

3

PAK/T0-268

Bulk

Pkg.:

Bulk

Pkg.:

Bulk

Pkg.:

Surface Mount Components

Hot solder dipped coating

over highly conductive

copper for maximum heat

transfer in surface mount

applications. Tape and reel

packaged per EIA-481,

compatible with automatic

SMT placement. 250 pieces

per reel.

573400D00010

.400

14ºC/W

573300D00010

.400

18ºC/W

573100D00010

.400

26ºC/W

Ordering

Code:

Height:

θ

:

Ordering

Code:

Height:

θ

:

Ordering

Code:

Height:

θ

:

573100D00000

573100D00000

573400D00000

Digital

026205

1.000

3°C/W

1” Morrlong

Ordering

Code:

Height:

θ

:

026350

1.250

2.7°C/W

1.25” Morrison

Ordering

Code:

Height:

θ

:

022938

1.250

2.7°C/W

Morrlong/Morrison Clip

Ordering

Code:

Height:

θ

:

025417

1.250 0.68°C/W

Fan Heat Sinks for Pentium® MMX

Ordering

Code:

Height:

θ

:

025417

1.250

0.68°C/W

Ordering

Code:

Height:

θ

:

Fan Heat Sinks for AMD and Cyrix CPU’s

026437

1.200

0.66°C/W

Ordering

Code:

Height:

θ

:

573100, 573300, 573400

DC-DC Converters

Heat Sink

Call us for our latest offering:

Chris Soule (603) 223-1722

or email soule@aavid.com

AAVID

THERMALLOY

143 North Main Street • Suite 206 • Concord, NH 03301

17

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks,Thermal Information

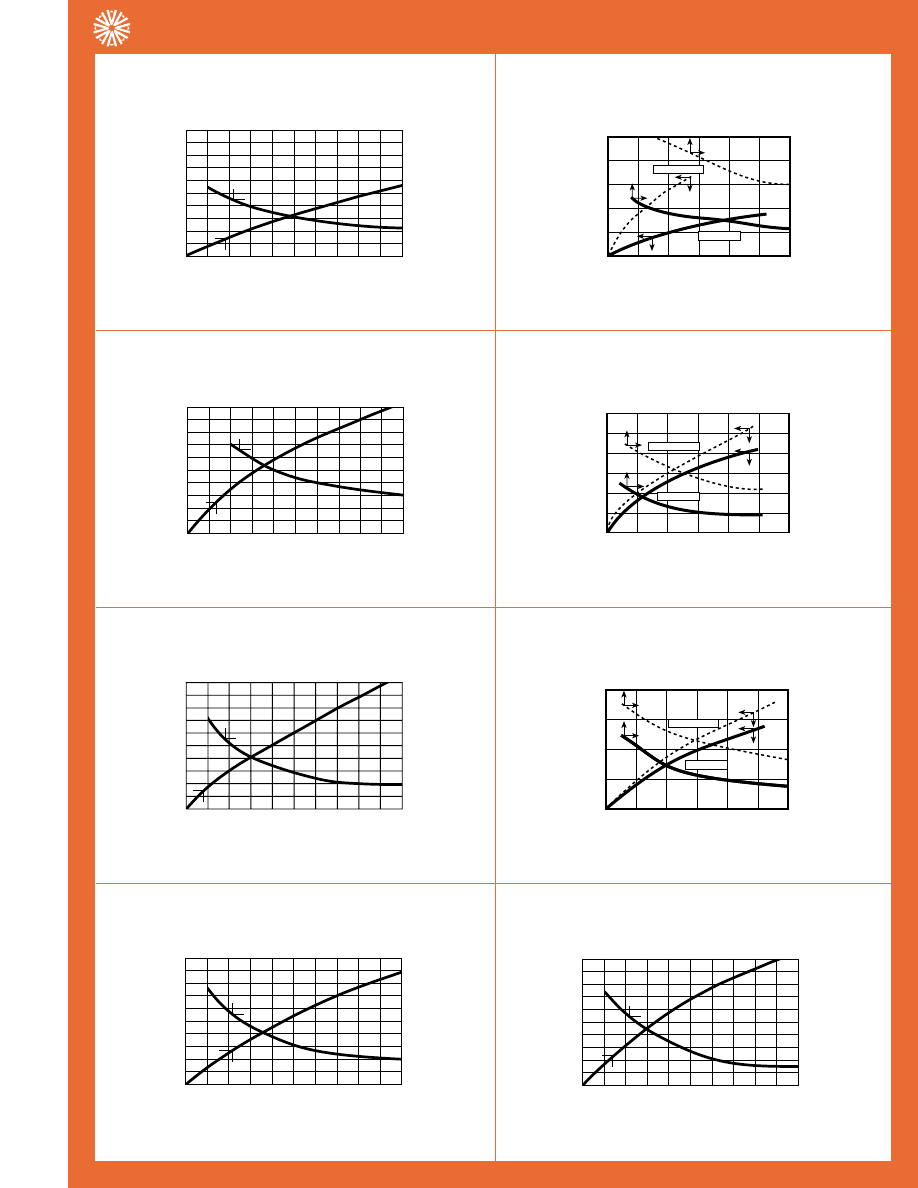

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT

°

C/W

AT

T

AIR VELOCITY (FEET PER MINUTE)

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–(

°

C)

HEAT DISSIPATED (WATTS)

800

1,000

600

400

200

0

100

80

60

40

20

0

5

10

25

15

20

1.0

2.0

3.0

4.0

5.0

0

0

026205

P OW E R ( w a t t )

A I R F L OW ( f t / m i n )

TEMPERA

TURE

RISE ABO

VE AMBIENT

(

°

C)

THERMAL RESIST

ANCE C-A (

°

C/watt)

0

20

20

40

60

80

100

1

0

2

3

4

5

6

7

8

9

0

200

400

600

4

0

8

12

3364424

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT

°

C/W

AT

T

AIR VELOCITY (FEET PER MINUTE)

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–(

°

C)

HEAT DISSIPATED (WATTS)

800

1,000

600

400

200

0

100

80

60

40

20

0

5

10

25

15

20

1.0

2.0

3.0

4.0

5.0

0

0

026350

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

0.4

0.8

1.2

1.6

2.0

0

20

40

60

80

100

0

20

40

60

80

100

▲

▲

501200

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT

°

C/W

AT

T

AIR VELOCITY (FEET PER MINUTE)

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–(

°

C)

HEAT DISSIPATED (WATTS)

800

1,000

600

400

200

0

100

80

60

40

20

0

5

10

25

15

20

1.0

2.0

3.0

4.0

5.0

0

0

WITH FAN ON

026437

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

▲

▲

501503

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT

°

C/W

AT

T

AIR VELOCITY (FEET PER MINUTE)

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–(

°

C)

HEAT DISSIPATED (WATTS)

800

1,000

600

400

200

0

100

80

60

40

20

0

5

10

25

15

20

1.0

2.0

3.0

4.0

5.0

0

0

WITH FAN ON

025417

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

0.5

1.0

1.5

2.0

2.5

0

20

40

60

80

100

0

10

20

30

40

50

▲

▲

322505

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

504102

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

507222

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

504222

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

▲

▲

▲

▲

507302

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

507002

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

523002

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

▲

▲

501603

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

2

4

6

8

10

507102

Corporate Office: 80 Commercial Street • Concord, NH 03301

18

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

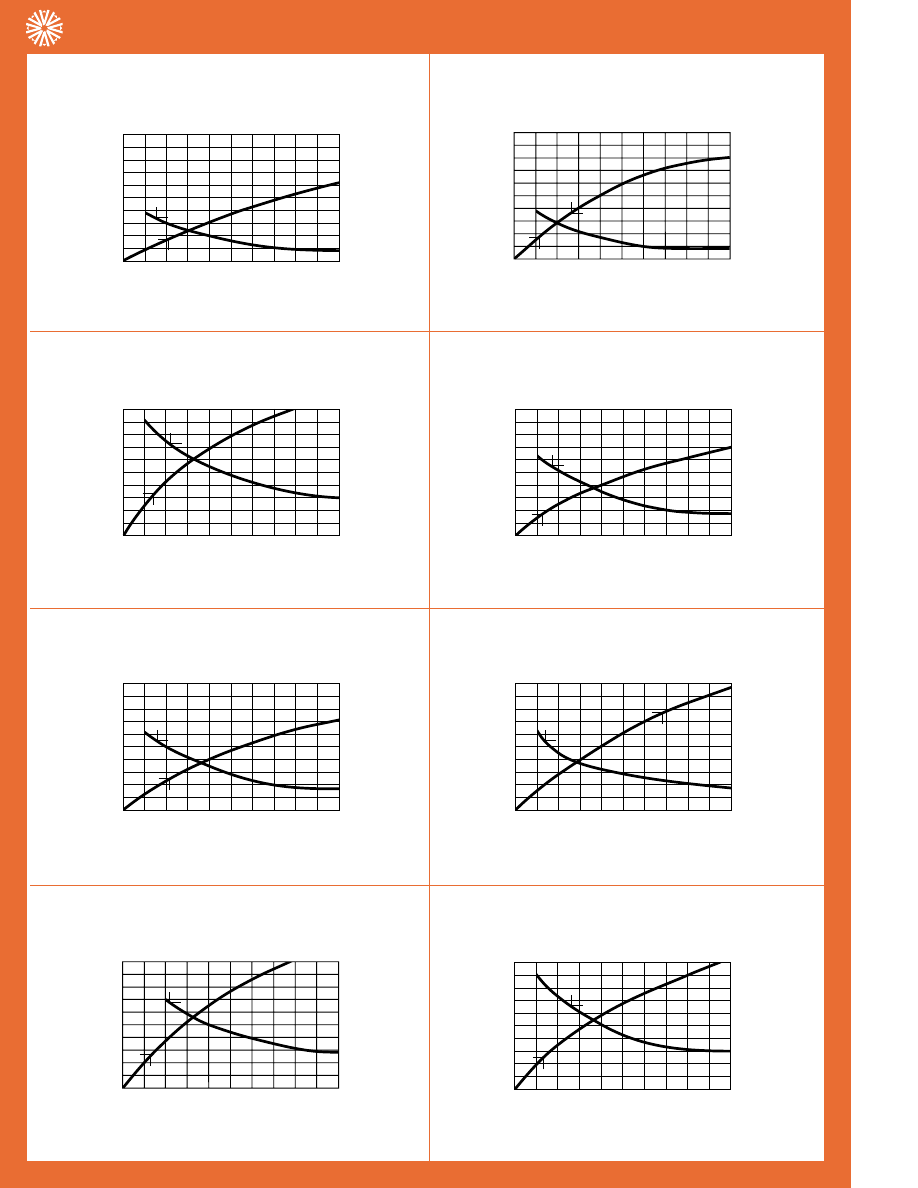

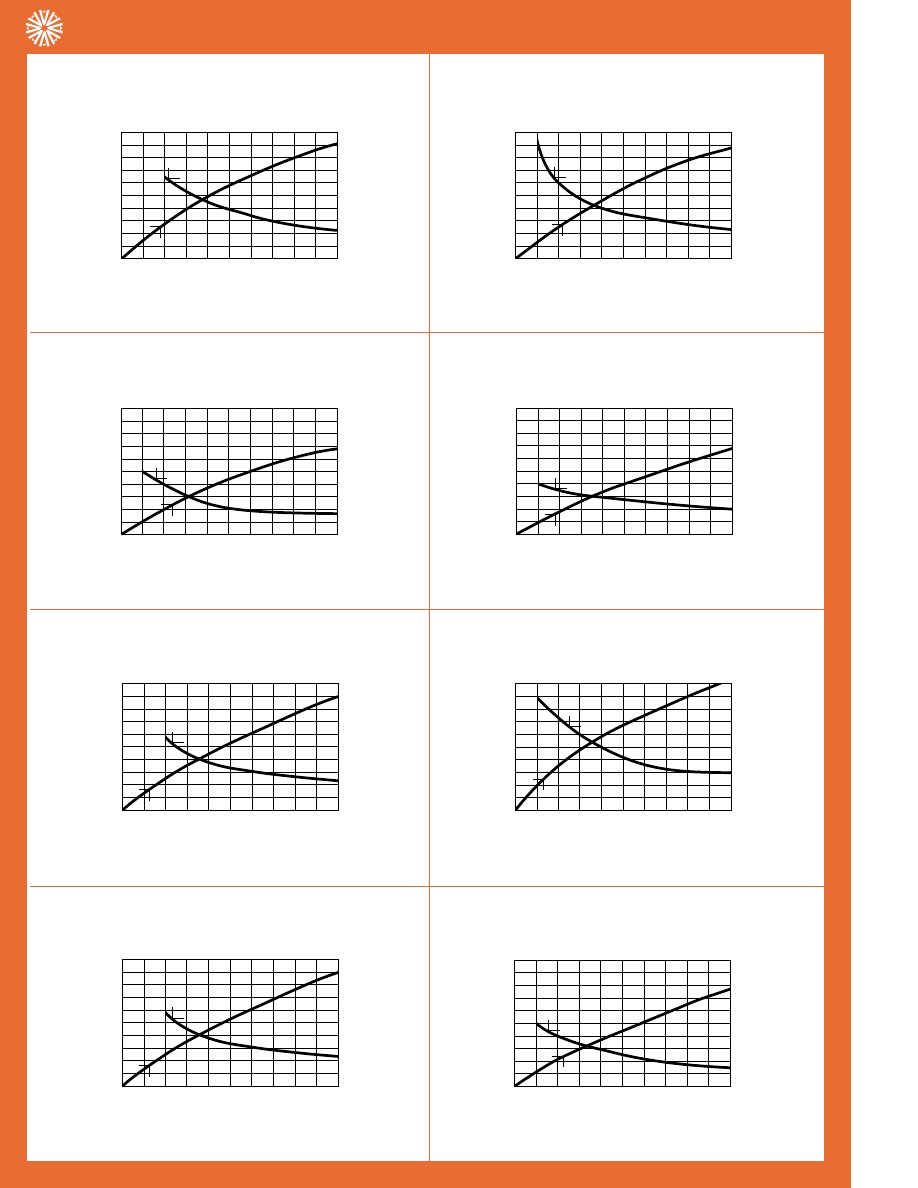

PC Board Level Heat Sinks,Thermal Information

143 North Main Street • Suite 206 • Concord, NH 03301

19

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks,Thermal Information

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

529802

530162

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

530002

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

▲

▲

▲

▲

530613

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

530101

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

▲

▲

▲

▲

530614

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

529801

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

530102

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

531002

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

533002

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

531102

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

534202

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

531202

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

534302

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

▲

▲

▲

▲

530714

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

531302

Corporate Office: 80 Commercial Street • Concord, NH 03301

20

Tel. (603) 224-9988 • Fax (603) 223-1790

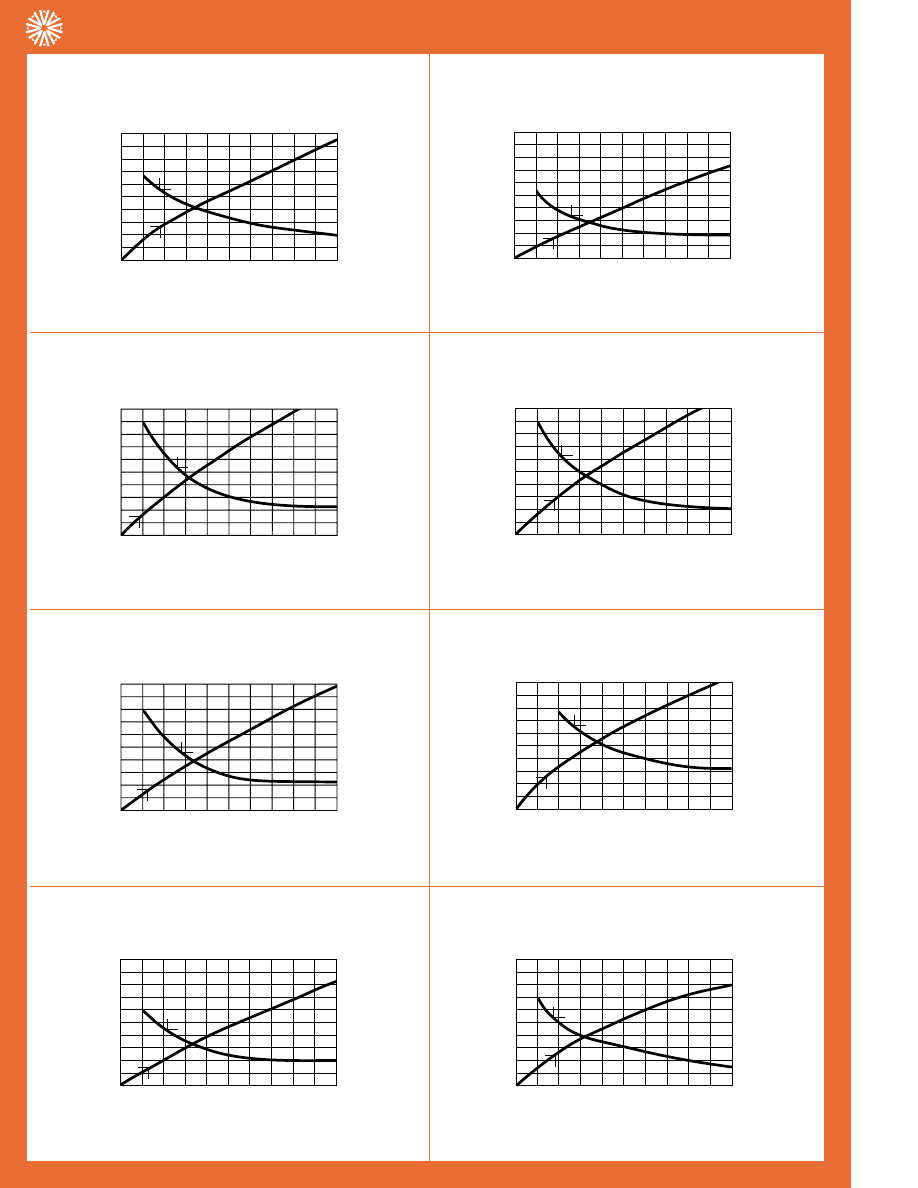

AAVID

THERMALLOY

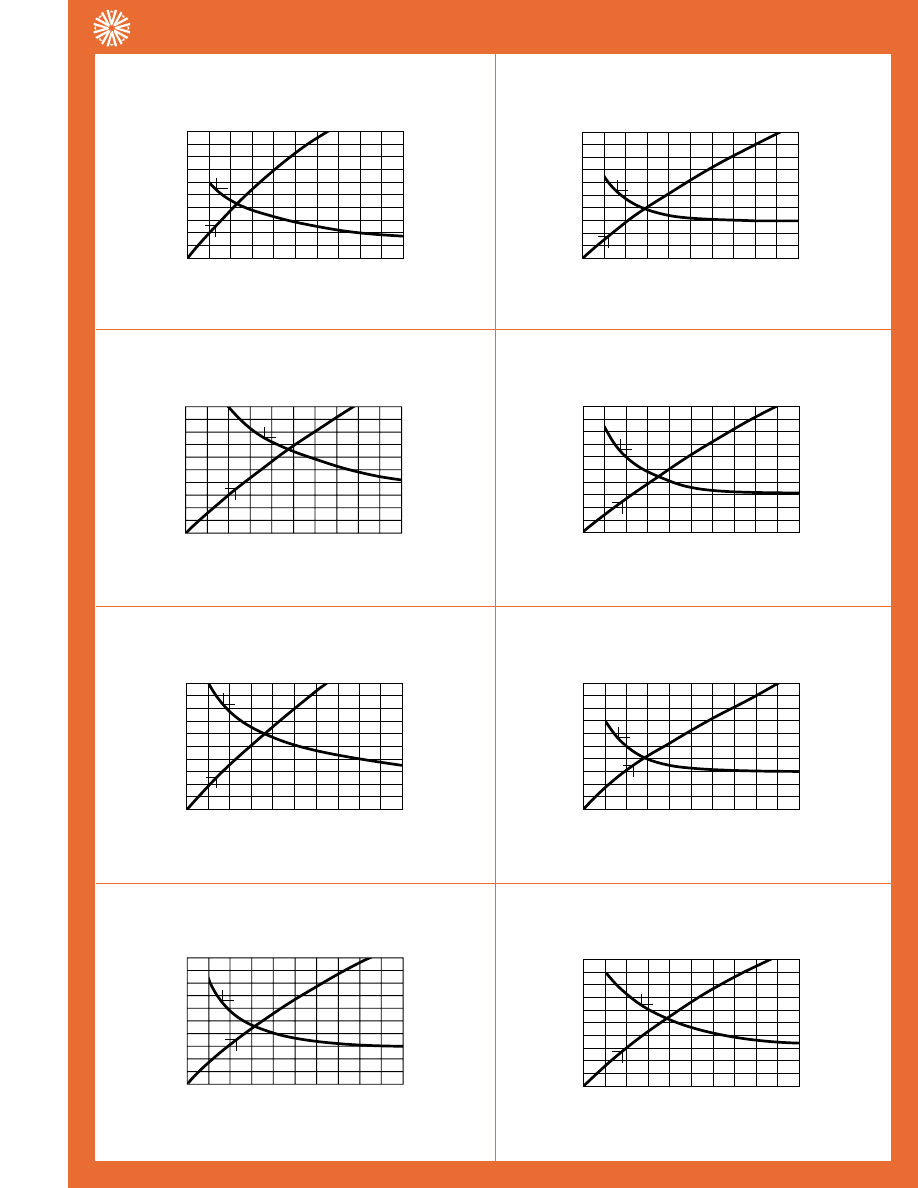

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks,Thermal Information

143 North Main Street • Suite 206 • Concord, NH 03301

21

Tel. (603) 224-9988 • Fax (603) 223-1790

AAVID

THERMALLOY

PRODUCT SELECTION GUIDE, Condensed

PC Board Level Heat Sinks,Thermal Information

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

563002

10

20

30

40

60

0

0.5

1.0

1.5

2.5

3.0

2.0

0

5

10

15

20

25

30

0

400

800

1,200

0

50

S M T D

2

PA K W E B - D E S I G N

TEMPERA

TURE

RISE ABO

VE AMBIENT

(Øca)

P OW E R ( WAT T S )

A I R F L OW ( L F M )

WITH HEAT SINK

WITHOUT HEAT SINK

THERMAL RESIST

ANCE CASE-AMBIENT (C/W)

573300

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

2

4

6

8

10

0

20

40

60

80

100

0

2

4

6

8

10

566010

566010

15

45

0

0.5

1.0

1.5

2.5

3.0

2.0

0

15

20

100

450

5

10

0

25

35

800

THERMAL RESIST

ANCE CASE-AMBIENT (C/W)

TEMPERA

TURE

RISE ABO

VE AMBIENT

(Øca)

S M T D

3

PA K W E B - D E S I G N

P OW E R ( WAT T S )

A I R F L OW ( L F M )

WITH HEAT SINK

WITHOUT HEAT SINK

THERMAL RESIST

ANCE CASE-AMBIENT (C/W)

TEMPERA

TURE

RISE ABO

VE AMBIENT

(Øca)

S M T D

3

PA K W E B - D E S I G N

P OW E R ( WAT T S )

A I R F L OW ( L F M )

WITHOUT HEAT SINK

THERMAL RESIST

ANCE CASE-AMBIENT (C/W)

P OW E R ( WAT T S )

WITHOUT HEAT SINK

573400

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

4

8

12

16

20

0

20

40

60

80

100

0

1

2

3

4

5

▲

▲

569003

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

574004

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

2

4

6

8

10

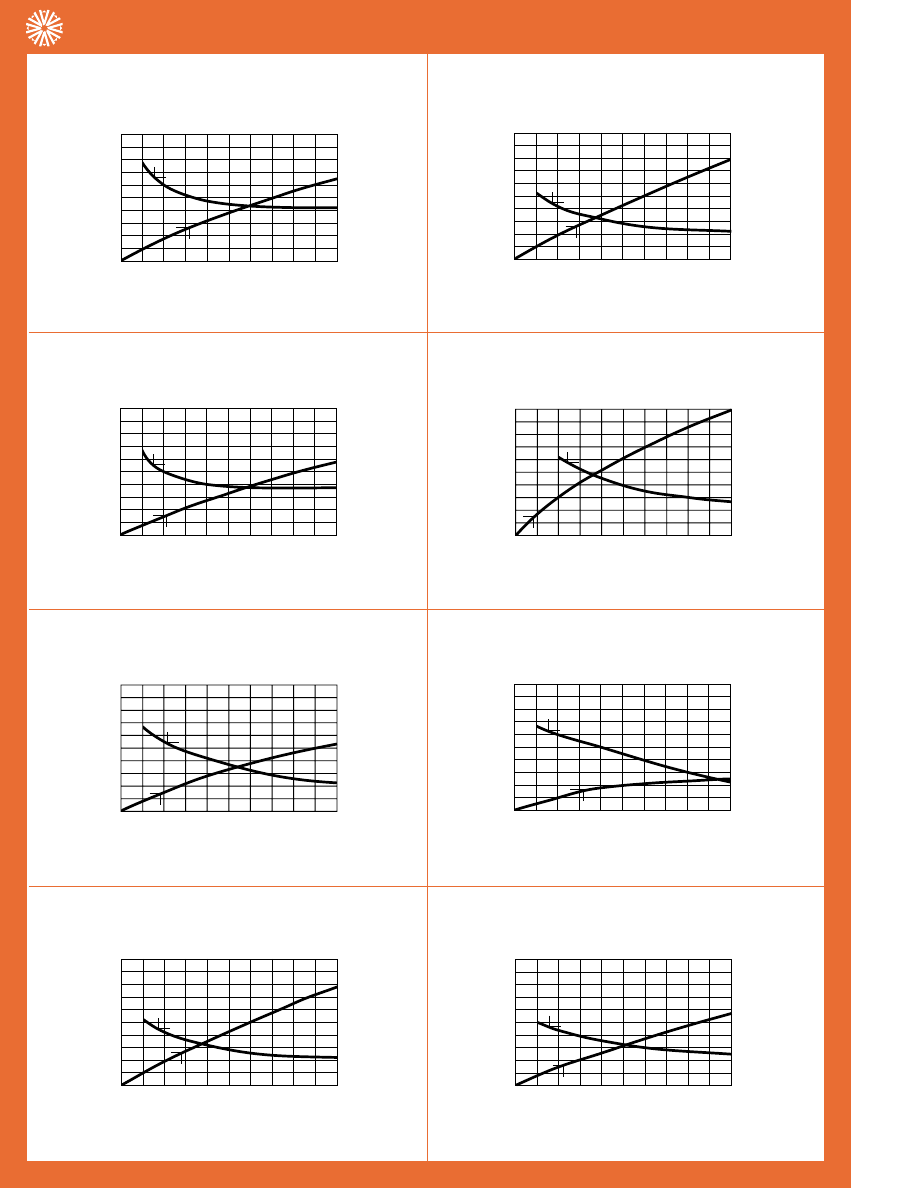

551002

40

80

160

200

0

0.5

1.0

1.5

2.5

3.0

2.0

0

10

30

40

50

0

400

20

0

120

800

THERMAL RESIST

ANCE CASE-AMBIENT (C/W)

TEMPERA

TURE

RISE ABO

VE AMBIENT

(Øca)

S M T D PA K W E B - D E S I G N

P OW E R ( WAT T S )

A I R F L OW ( L F M )

WITH HEAT SINK

WITHOUT HEAT SINK

573100

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

4

8

12

16

20

574204

▲

▲

▲

▲

THERMAL RESIST

ANCE FROM MTG

SURF

ACE T

O

AMBIENT–

˚

C/W

AT

T

MOUNTING SURF

ACE TEMP

RISE ABO

VE AMBIENT–

˚

C

0

200

400

600

800

1000

AIR VELOCITY–FEET PER MINUTE

HEAT DISSIPATED–WATTS

0

1

2

3

4

5

0

20

40

60

80

100

0

2

4

6

8

10

574902

▲