CATALOG

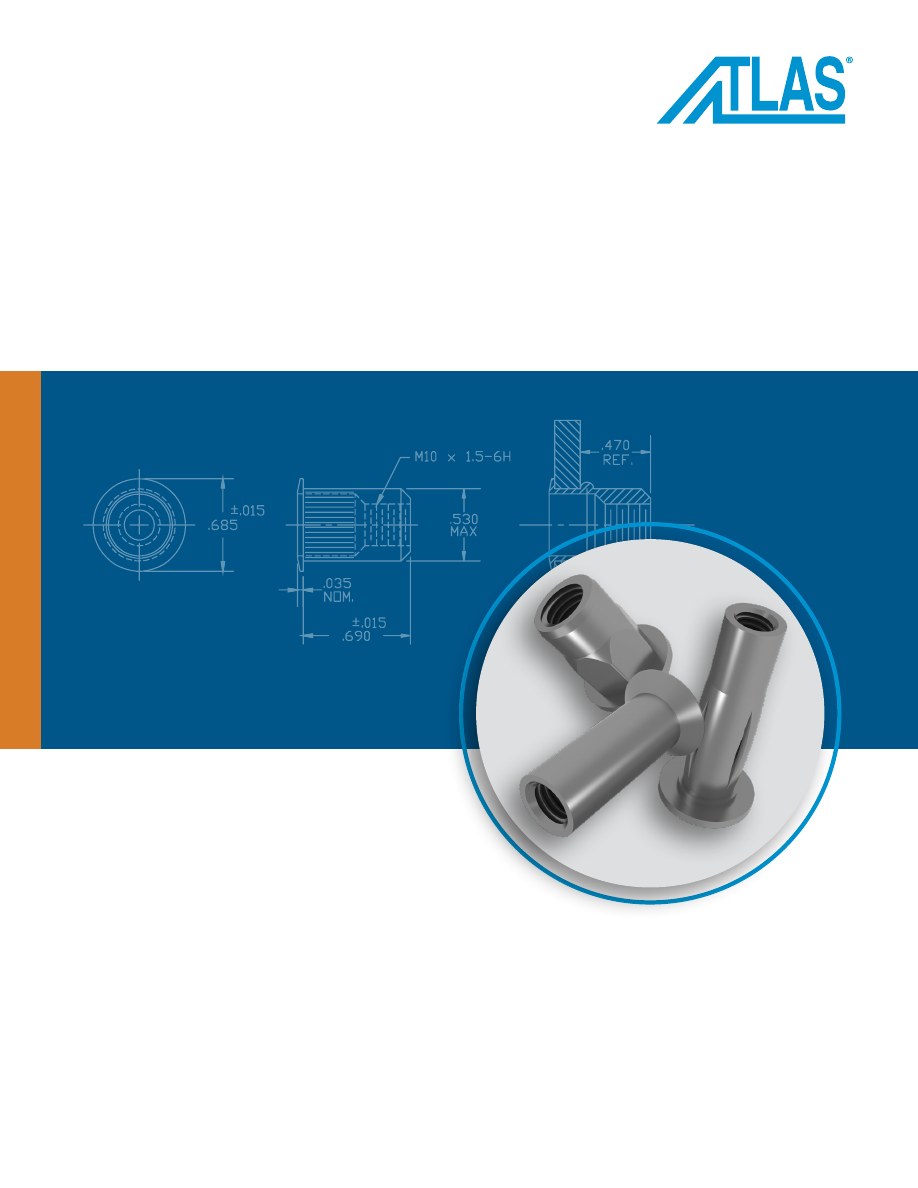

ATLAS® BLIND

THREADED INSERTS

ATLAS® brand blind threaded inserts

provide strong and reusable permanent

threads in sheet materials where only one

side is accessible for hardware installation.

CATALOG

ATLAS® BLIND

THREADED INSERTS

ATLAS® brand blind threaded inserts

provide strong and reusable permanent

threads in sheet materials where only one

side is accessible for hardware installation.