Selection Guide

Thermal Management For LED Applications

Selection Guide

Thermal Management For LED Applications

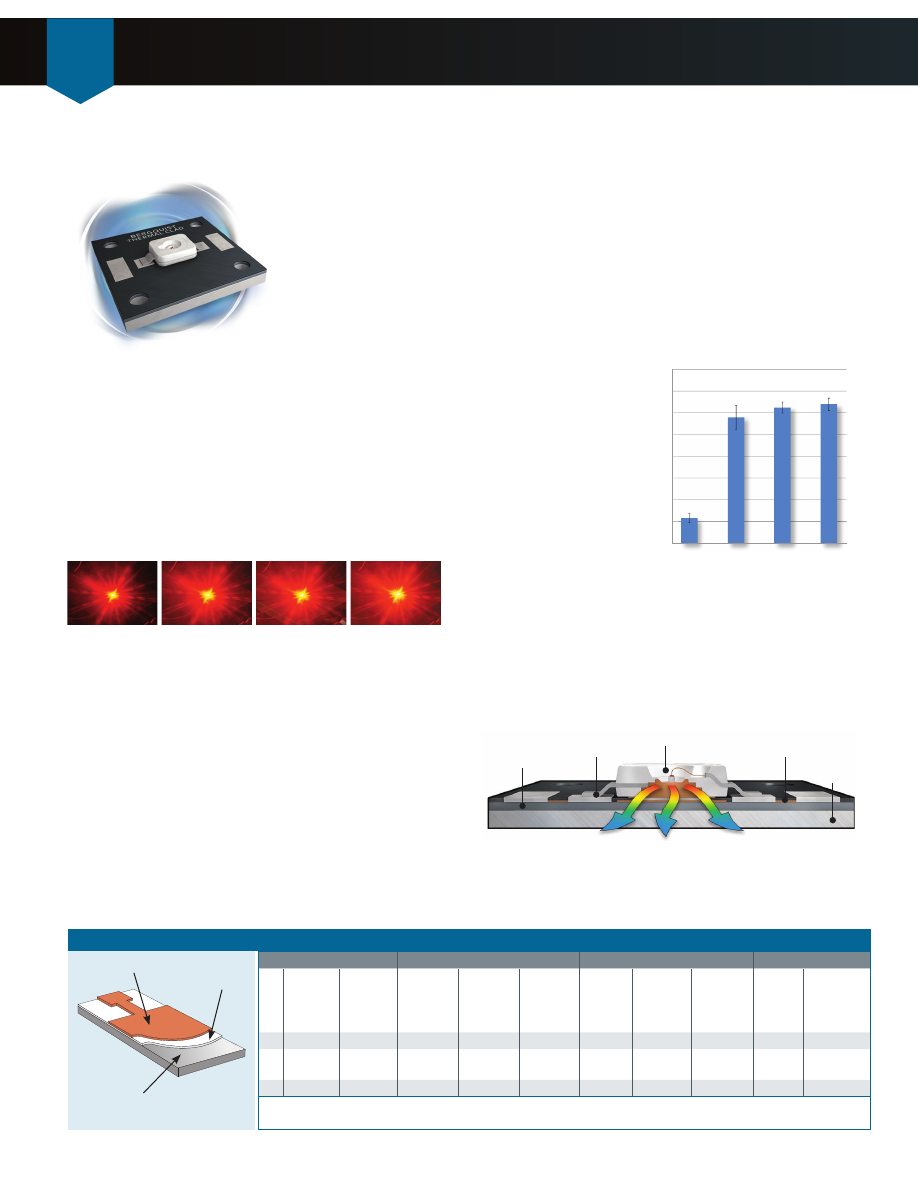

THERMAL CLAD

®

Conductive

Dielectric Layer

Copper

Circuit Layer

Aluminum

Base

Solder or

Adhesive

LED Base

The Effect of Temperature

The LED’s color, or wavelength, will change with temperature. As the

die temperature increases, the wavelength of the color increases.

This is particularly important with white light. The human eye can

differentiate small color changes in white light. When Power LEDs

are populated in an array, consistent thermal resistance from one die

to the next assures consistent color. Because of the comparatively

low thermal resistance THERMAL CLAD offers versus FR‑4, die

temperature is less affected by slight variances in the junction‑to‑case

thermal resistance that occurs with eutectic or epoxy‑die mounting

techniques. It is also possible to pack the die more closely in an

assembly that utilizes good thermal management techniques, thereby

reducing the effects of temperature.

Generally, a 30‑50 percent drop in light output for a constant‑forward

current indicates end‑of‑life for Power LEDs. Power LED lifetimes have

been extrapolated to over 50,000 hours.

Cost of Heat Summary

Better thermal management allows more forward current to be applied

to the LED, which means more light and possibly reducing the number of

LEDs required for the desired light output. Maintaining a cooler assembly

at an equivalent power equates to more light per die.

Circuit Board Comparison

Metal core PCB and standard FR‑4 are commonly used circuit board

materials in conjunction with Power LEDs. BERGQUIST’s THERMAL CLAD

dielectric is a thin, thermally conductive layer bonded to an aluminum

or copper substrate for heat dissipation (see illustration below). The key

to THERMAL CLAD’s superior performance lies in its dielectric layer.

This layer offers electrical

isolation with high thermal

conductivity and bonds the

base metal and circuit foil

together. Other manufacturers

use standard prepreg as

the dielectric layer, but

prepreg doesn’t provide the

high thermal conductivity

and resulting thermal

performance required to help

assure the lowest possible

operating temperatures and

brightest light output for

high‑intensity LEDs. THERMAL CLAD circuit board materials are

available from The Bergquist Company in three different thermal

conductivities, High Power Lighting (HPL), High Temperature (HT),

and Multi‑Purpose (MP).

Packaging Conclusion

There are several options available for thermal management of

Power LEDs. The most critical thermal path in the stack is the one with

the highest thermal resistance. Good practice suggests that you reduce

the thermal resistance of that layer with THERMAL CLAD dielectric

instead of FR‑4.

Henkel’s BERGQUIST brand Thermal Solutions Ensure Color Consistency And

Maximum Lifecycles For Your LEDs.

Thermal Solutions For Long‑Term Reliability Of Power LEDs

Light Emitting Diodes (LEDs)

have been around for years,

primarily concentrated in such

markets as cell phones, PDAs

and other consumer electronics.

Since most of these products

have relatively short lifecycles,

protecting LEDs wasn’t a primary

concern because the product

would fail or become obsolete

long before the LED failed. Today,

as technological advancements

in LED design and processes are continually boosting light output

to rival incandescent, fluorescent, and even halogen light sources,

the need to protect the LEDs against heat build‑up is greater than

ever before. Three and five‑watt LEDs are now commonplace, and

industry experts are predicting 10‑watt LED availability in the next

few years. Power LEDs of greater than one‑watt are almost always

surface mounted devices. This is because the axial leads to the die

in a leaded package do not conduct enough heat away from the

LED. Chip‑on‑board (COB), ceramic submounts and other thermally

efficient packages are emerging as the standard thermal management

packaging solution for Power LEDs.

Bergquist TCLAD in a typical

leaded Power LED package.

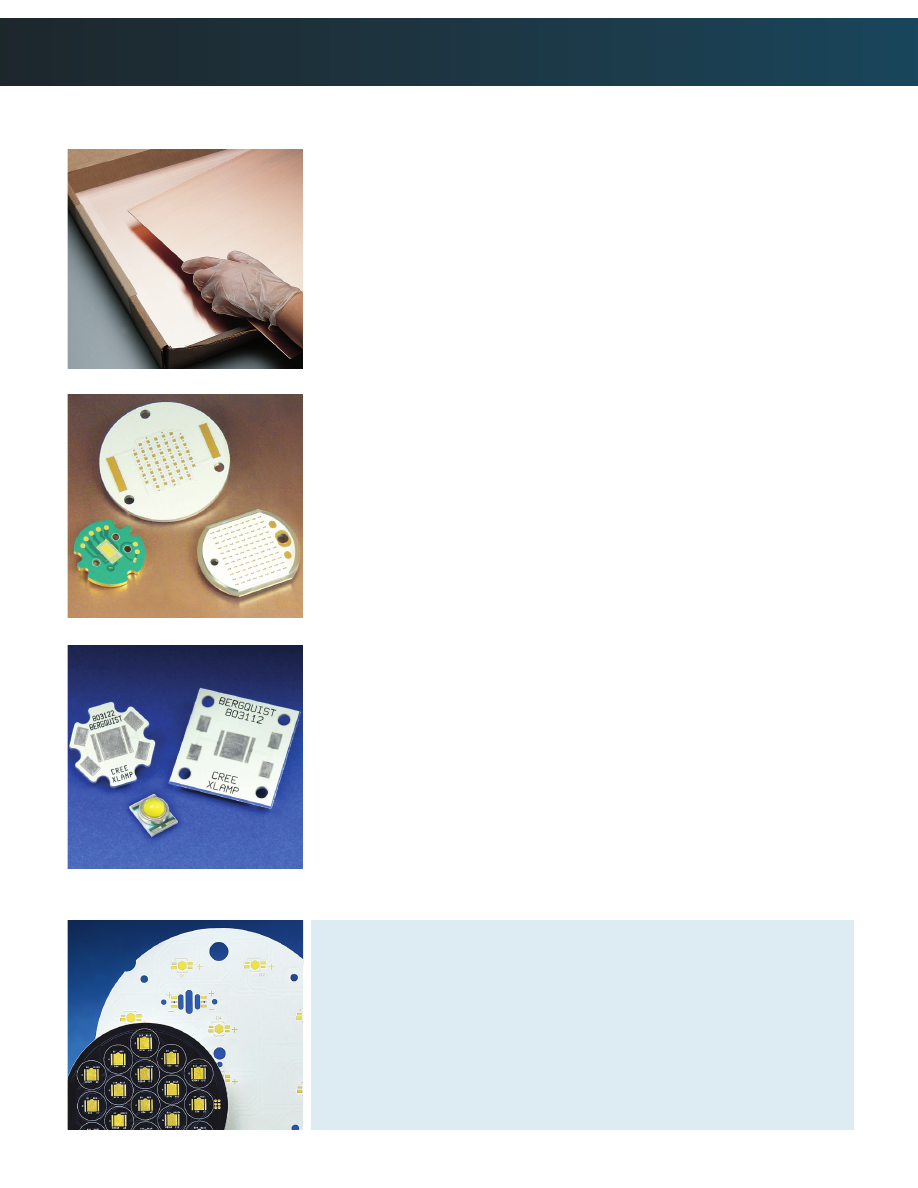

Light output of the same LED die on different circuit board materials at a

maintained die temperature of 80ºC.

FR-4

110 Lumens

IMS HPL

630 Lumens

IMS HT

620 Lumens

IMS MP

580 Lumens

Light Output

Peak Output (Lumens

)

FR4

MP

HT

HPL

Luminus Devices SST-50 star board driven at 9.5 W

800

700

600

500

400

300

200

100

0

A Power LED’s light output and life expectancy are directly attributed to how well

the LED is managed thermally. As the LED generates heat, the dielectric of the

BERGQUIST THERMAL CLAD metal core PCB quickly transfers it to the aluminum

base, significantly improving the LED’s performance.

Circuit Layer

Dielectric Layer

( HPL, HT, MP )

Base Layer

Copper or Aluminum

PRODUCT FAMILY

PRODUCT PERFORMANCE

DIELECTRIC PERFORMANCE

OTHER

Part

Number

(1)

Thickness

(.000''/µm)

(2)

Thermal

Performance

(ºC/W)

(3)

Impedance

(ºC in

2

/W) /

(ºC cm

2

/W)

(2)

Conductivity

(W/m‑K)

(5)

Breakdown

(kVAC)

(6)

Permittivity

(Dielectric

Constant)

(4)

Dielectric

Conductivity

(W/m‑K)

(7)

Glass

Transition

(°C)

(8)

Peel Strength

(lbs/in) /

(N/mm)

HPL

HPL‑03015

1.5/38

0.30

0.02/0.13

7.5

5.0

6

3.0

185

5/0.9

HT

HT‑04503

HT‑07006

3/76

6/152

0.45

0.70

0.05/0.32

0.11/0.71

4.1

4.1

8.5

11.0

7

7

2.2

2.2

150

150

6/1.1

6/1.1

MP

MP‑06503

3/76

0.65

0.09/0.58

2.4

8.5

6

1.3

90

9/1.6

Method Description: 1‑Optical 2‑MET‑5.4‑01‑40000‑Test Thermal Performance of Insulated Metal Substrates (IMS)

3‑Calculation from ASTM 5470 4‑Extended ASTM 5470 5‑ASTM D149 6‑ASTM D150 7‑MET‑5.4‑01‑7800 7‑ASTM D2861

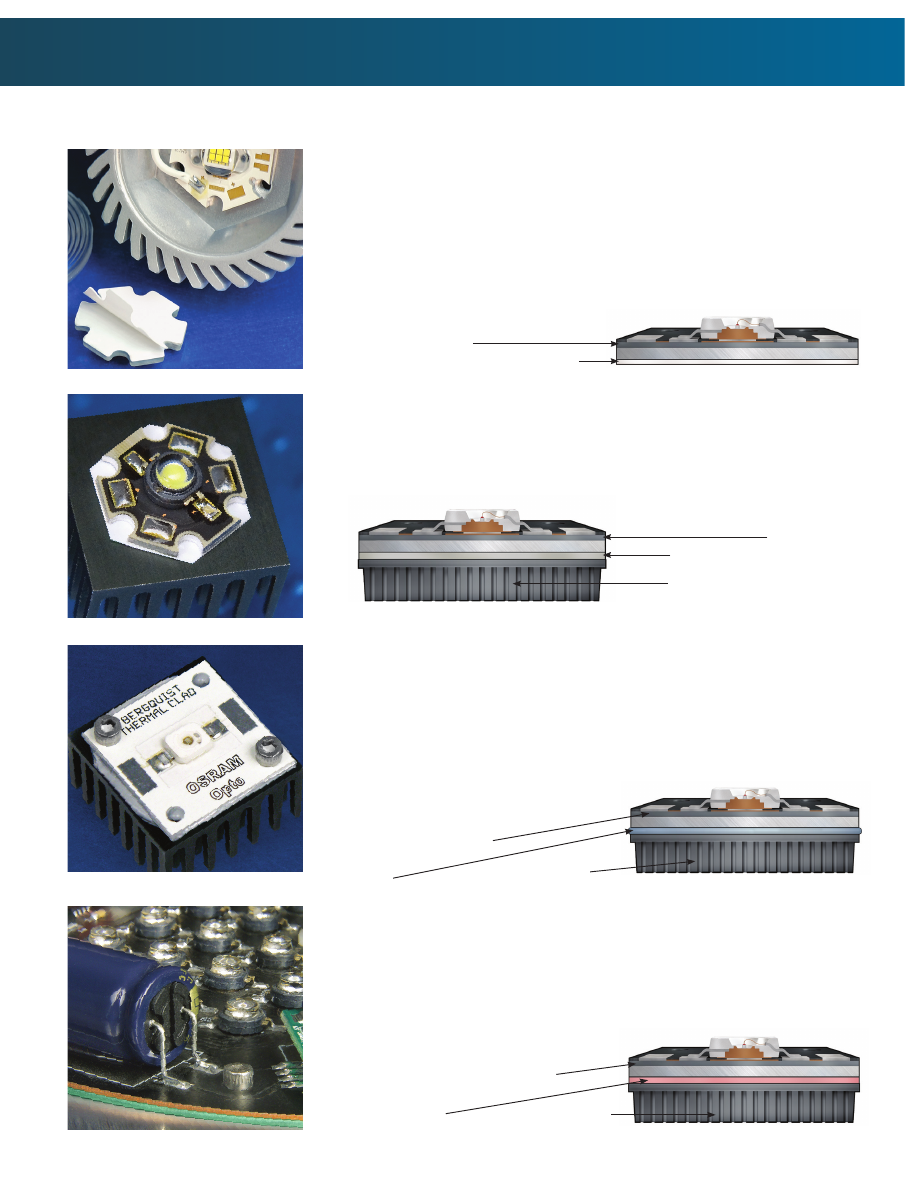

Anatomy of a THERMAL CLAD Board

THERMAL CLAD

®

Metal Core PCB

THERMAL CLAD

®

Printed Circuit Boards (PCB)

THERMAL CLAD circuit boards are the answer

for designers wanting the best of both worlds.

Power LED light output and lifecycles are directly

attributed to how well the package is managed

thermally. A THERMAL CLAD PCB offers superior

heat transfer. As a metal based material,

THERMAL CLAD can be configured for shapes,

bends and thicknesses allowing installation in

virtually any application. With a THERMAL CLAD

PCB you’re assured of the lowest operating

temperature, maximum LED color consistency

and life.

•

Circuit layer ‑ 35µm to 350µm

•

Dielectric layer ‑ HPL, HT, MP

•

Base plate available in:

Copper 0.020''‑0.125''

(0.51mm‑3.18mm)

Aluminum 0.020''‑0.190''

(0.51mm‑4.83mm)

THERMAL CLAD

®

Standard Configurations

THERMAL CLAD Standard Configurations are

specifically designed to help jump‑start your

design. Available in different LED footprints,

they give you the freedom to select the LED

component’s color, brightness and power

necessary to fit your needs.

Provided in star or square footprints, they can be

ordered in single, strip or array configurations.

Optimize the prototyping process with the lowest

possible operating temperatures and the brightest

light output for your next Power LED application.

•

Circuit layer ‑ 35µm (1 oz.)

copper circuit foil

•

Dielectric layer ‑ .076mm

(3 mil) MP

•

Base plate ‑ Aluminum 5052

1.57mm (0.062'')

•

Surface Finish ‑ White solder

mask, Pb‑free HASL solder pads

(RoHS compliant)

•

Choose numerous footprints

from such LED manufacturers

as Osram, Cree, Lite‑On

®

,

Lumileds

™

, Seoul, Avago, Nichia

and Lumex

THERMAL CLAD

®

Metal Core PCB

THERMAL CLAD is a dielectric (ceramic‑polymer

blend) coated metal base with a bonded copper

circuit layer. Improved reliability, processing

advantages and exceptional cost performance makes

THERMAL CLAD a superior alternative to traditional

FR4 and non‑thermally conductive constructions.

THERMAL CLAD panels are available in a variety of

thicknesses depending on the base metal and circuit

foil thickness. Standard sheet sizes are 18'' x 24'',

18'' x 25'' and 20'' x 24''. Material selection should be

based on thermal, dielectric and mechanical

application requirements.

•

Circuit layer ‑ 35µm to 350µm

•

Dielectric layer ‑ HPL, HT, MP

•

Base plate available in:

Copper 0.020''‑0.125''

(0.51mm‑3.18mm)

Aluminum 0.020''‑0.190''

(0.51mm‑4.83mm)

THERMAL CLAD

®

Dielectric Options

THERMAL CLAD panels and PCBs are available in four dielectric types meeting

the unique thermal and mechanical requirements of various LED applications.

THERMAL CLAD dielectrics are named to describe their typical application.

MP (Multi‑Purpose), twenty plus years industry proven dielectric for a multitude of

applications including LEDs, HT (High Temperature) a dielectric resistant to degradation

from high temperature exposure and features high dielectric breakdown characteristics,

HPL (High Power Lighting) meeting the increased thermal performance requirements

of Power LEDs.

Available as:

•

Panels

•

Printed circuit boards (PCB)

Silicone or Silicone‑Free GAP PAD

™

and Gap Filler

GAP PAD and Gap Filler are cost‑effective, filled,

thermally conductive interface materials. With

shock dampening abilities, the GAP PAD line

is recommended for applications that require

a minimum amount of pressure between

components. For sensitive applications that do

not allow silicone, such as underwater pools

and automotive lighting, they are available in a

silicone‑free form.

•

Exceptional thermal conductivity

•

Electrically isolating

•

Highly conformable, low hardness

•

Efficient gap filling material for

minimizing component stress

•

Silicone‑free options available

Thermally Conductive Adhesives, Compounds and Fillers

THERMAL CLAD

®

PA (Pre‑applied) Substrates

THERMAL CLAD

®

Conductive

Dielectric Layer

BOND-PLY

®

450 PA

BOND-PLY

®

Adhesive

Traditional Heat Sink

or Metal Casing

THERMAL CLAD

®

Conductive

Dielectric Layer

BOND-PLY

®

or

GAP PAD

™

TIC

®

Thermal Interface Compound and HI-FLOW

®

TIC

®

or

BOND-PLY

®

or

GAP PAD

™

THERMAL CLAD

®

Conductive Dielectric Layer

Traditional Heat Sink

or Metal Casing

THERMAL CLAD

®

Conductive Dielectric Layer

GAP PAD

™

or

Gap Filler

or

BOND-PLY

®

Traditional Heat Sink

or Metal Casing

BERGQUIST’s THERMAL CLAD PA substrates

include pre‑applied BOND-PLY

®

450. This allows

you to adhere your mounted LEDs to a variety

of heatsinks and surfaces while thermally

optimizing your application. This version of

“peel and place” THERMAL CLAD can withstand

the high temperatures of solder reflow during

LED assembly and then be positioned in the

lighting application using its strong thermally

conductive adhesive.

•

Circuit layer ‑ 35µm to 350µm

Dielectric layer ‑ HPL, HT, MP

•

Base plate copper or aluminum

0.020''‑0.125'' (0.51mm‑3.18mm)

•

Pre‑applied exclusively on

BERGQUIST THERMAL CLAD PCBs

•

Withstands the heat of solder reflow

•

Good thermal performance

•

Immediately bonds to target

surface

•

Eliminates need for mechanical

fasteners or screws

•

Alternative to heat‑cure adhesives

TIC is a high performing, thermally conductive

grease designed for use as a thermal interface

between an aluminum base and a heat sink

or metal casing. The compound wets‑out the

thermal surfaces and flows to produce the lowest

impedance for your LED application. HI-FLOW is a

thermally conductive phase change material that

changes from a solid at specific temperatures and

flows to assure wet‑out of the interface without

the overflow. Comparable to grease, without

the mess.

•

High thermal performance

•

Good thermal conductivity

•

Can be screened

•

No post “cure” required

•

Room temperature storage

•

Exceptional value

BOND-PLY is a thermally conductive, pressure

sensitive adhesive tape, available in either

fiberglass reinforced or unreinforced. With

its ability to have a high bond strength, it can

eliminate the need for screws, clipmounts

or fasteners.

The Power Factor Evolves

With the era of brighter and more powerful LEDs, we are

witnessing the world of lighting changing forever. Power LEDs

are entering nearly every market niche as the light source

of choice. Advancements in LED technology has led to a

cost‑effective alternative to incandescent, fluorescent and

halogen lighting. With these bring significant opportunities

to LED manufacturers and integrators.

Power LED packaging has evolved to adapt to higher power

dissipation demands. For these Power LED packages, the lowest

possible thermal resistance packaging is paramount to a long

and reliable service life. By combining BERGQUIST thermal

management materials with this new and innovative packaging,

progress in both light output and light quality can be achieved.

Henkel has established itself as one of the world’s foremost

leaders in thermal management solutions. From innovative new

products to global support, BERGQUIST is your total thermal

management supplier. With the depth of our product portfolio,

Bergquist promises to make these challenging new thermal

hurdles less daunting. Whether you’re a manufacturer, an

integrator or a company that procures the final package,

you’ll benefit from a BERGQUIST solution.

Typical Types of LED Packages

A Bright New Chapter Unfolds

Now that Power LEDs are capable of unprecedented levels

of white LED brightness and luminous efficacy, they are

being used in many products that are part of our daily lives.

Although today the initial cost of Power LEDs is higher, many

applications have demonstrated LED lighting as the most cost

or energy efficient solution for future installations. Equipment

manufacturers worldwide are making devices with Power LEDs

for both the commercial and consumer segments.

With smaller footprints, our products lead the way in reducing

the buildup of heat and maximize the LED’s potential benefits.

Bergquist provides critical thermal management support for

a myriad of Power LED applications that include: medical,

signage, signal, transportation, aircraft, automotive, security,

portable, theatrical, commercial, residential and street lighting.

Whether indoors or outdoors, the range of uses for Power LEDs

is ever expanding. Leading automotive manufacturers have

not only begun to move Power LEDs into interiors and signals,

but forward LED lighting is now available on an ever increasing

number of vehicles. BERGQUIST’s silicone‑free materials

are an excellent choice for automotive and submersible

applications. By using copper based THERMAL CLAD, along

with Silicone‑Free GAP PAD, unique agency requirements for

UL approval in underwater lighting applications, such as pools,

can be met. As a one‑source supplier, this right combination of

thermal interface and substrate materials allows customers to

quickly meet their objectives.

Easing The Thermal Issues Ahead

Be confident specifying your Power LEDs at their maximum

power levels by partnering with an expert in thermal

management. Our vast experience in the thermal field, coupled

with our solid customer‑focused solutions, makes us the best

choice for thermal design choices. Rely on Henkel’s BERGQUIST

brand to stay on top of Power LED packaging and continue to

innovate and market thermal material solutions for this rapidly

expanding technology. Extend performance, durability and

reliability by including us in your Power LED equation.

A complete thermal

package lets you reap the

benefits of today’s new

Power LED’s.

Thermal Management for Today’s Power LEDs

Automotive

Signage

Consumer

Street Lighting

Henkel’s BERGQUIST brand of thermal products are hard at work keeping

the world’s best known products reliably cool.

Dome Die

Recessed Die

Thermally Optimized

Standard Chip-On-Board (COB)

Printed Circuit Board (Substrate)

Epoxy Dome Lens

Printed Circuit Board (Substrate)

Gold Wire

LED Chip

Anode

Cathode

Substrate

Solder

Phosphorus-Doped Epoxy

Cathode

Reflective Layer

Solder

Blue-Emitting LED Chip

Anode

Printed Circuit Board (Substrate)

Epoxy Dome Lens

Cathode

Gold Wire

LED Chip

Conductive Paste

Anode

Printed Circuit Board (Substrate)

USA

Henkel Electronics Materials, LLC.

18930 W. 78th Street

Chanhassen, MN 55317 USA

Toll-Free: (800) 347-4572

All marks used are trademarks and/or registered trademarks of Henkel and its affiliates in the U.S. and elsewhere.

® = registered in the U.S. Patent and Trademark Office. © 2016 Henkel Corporation. All rights reserved. 14919/LT-8151 (02/16)

www.henkel-adhesives.com/thermal