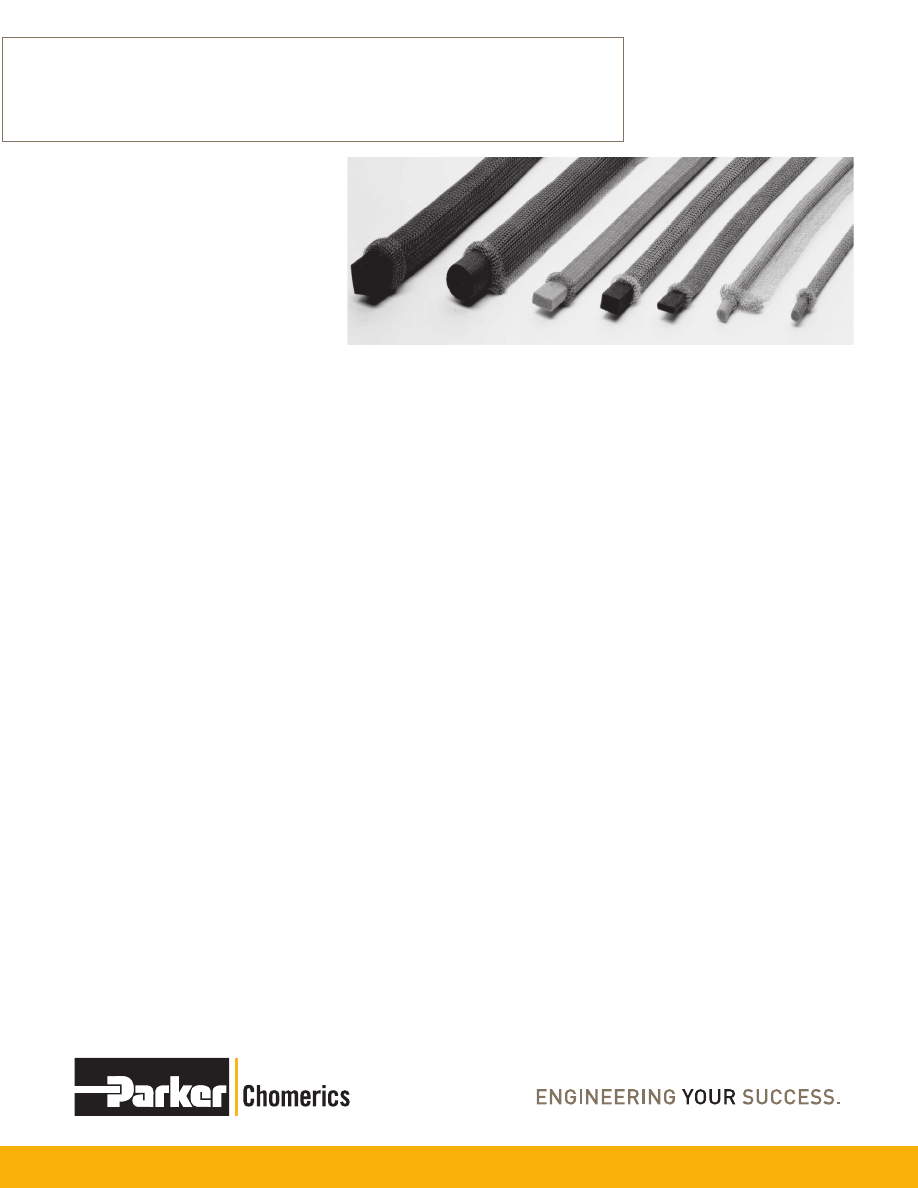

MESH STRIP

®

with Elastomer Core EMI Gasketing

Contact Information:

Parker Hannifin Corporation

Chomerics Division

77 Dragon Court

Woburn, MA 01801

phone 781 935 4850

fax 781 933 4318

chomailbox@parker.com

www.chomerics.com

www.parker.com/chomerics

Customer Value Proposition:

MESH STRIP gaskets with elastomer

core are cost effective, resilient,

highly conductive, knitted wire over

an elastomer core used to provide

electromagnetic interference (EMI)

shielding, electromagnetic pulse (EMP)

shielding and electrical grounding at the

joints and seams of a variety of enclosure

applications.

The presence of an elastomer core

improves compression set characteristics

as compared to traditional all-mesh

gasket offerings. This results in higher

performance over a longer lifespan,

reducing replacement costs and other

factors associated with the total cost of

gasket ownership.

To reduce application design time,

tooling charges and lead time, MESH

STRIP with elastomer core gaskets

are produced in a variety of standard

cross sectional geometries, wire mesh

alloys and elastomer choices to meet a

wide array of performance criteria. For

unique application requirements, custom

materials and profile geometries are

available upon request.

To ensure quick and easy integration

into any manufacturing environment,

without the need for additional capital

expenditures, material can be provided in

spooled, cut-to-length, or spliced gasket

forms and attached utilizing adhesive

spot-bonding or riveting.

Features:

• Monel, Ferrex* and aluminum are

standard alloy choices, with

customs available upon request

• Standard elastomer choices are

sponge or solid silicone or solid

neoprene, with custom elastomers

available upon request

• Rectangular, round and round with

fin are standard cross sectional

geometries, with customs

available upon request

• High metal content

• Knit construction

• Multiple gasket form-factors and

installation options

• Foreign object debris (FOD) free

version available upon request

Benefits:

• Various metal alloy offerings allow for

optimized performance variables such

as galvanic corrosion, EMI / EMP

attenuation, electrical conductivity and

temperature range

• Various elastomer offerings allow

for optimized performance variables

such as compression set, compressive

force versus deflection, fluid resistance,

temperature range and durability

• Numerous standard geometric offerings

ensure easy gasket integration into

existing applications, thereby eliminating

the need for redesign

• High metal content gaskets are highly

durable, making them an excellent

choice for applications with cut-through

or tear resistance requirements

• Knitted wire construction results in a

light-weight product offering for

applications with weight restriction

requirements.

• Multiple gasket form factors and

attachment methods allow for easy

incorporation into existing

manufacturing installation environments

without the need for capital expenditures

• Encapsulated ends ensure the

elimination of foreign object debris and

associated rework costs

* Ferrex is Parker Chomerics tradename or tin-plated,

copper-clad steel wire per ASTM B-520, ASTM

(QQ-W-343) tin-plated, 2-3% by weight; ASTM B-227

copper-cladding 30-40% by weight; SAE 1010 steel

wire, balance by weight and is the same as Tecknit

Su/Cu/Fe which it replaces.