Customer Value Proposition:

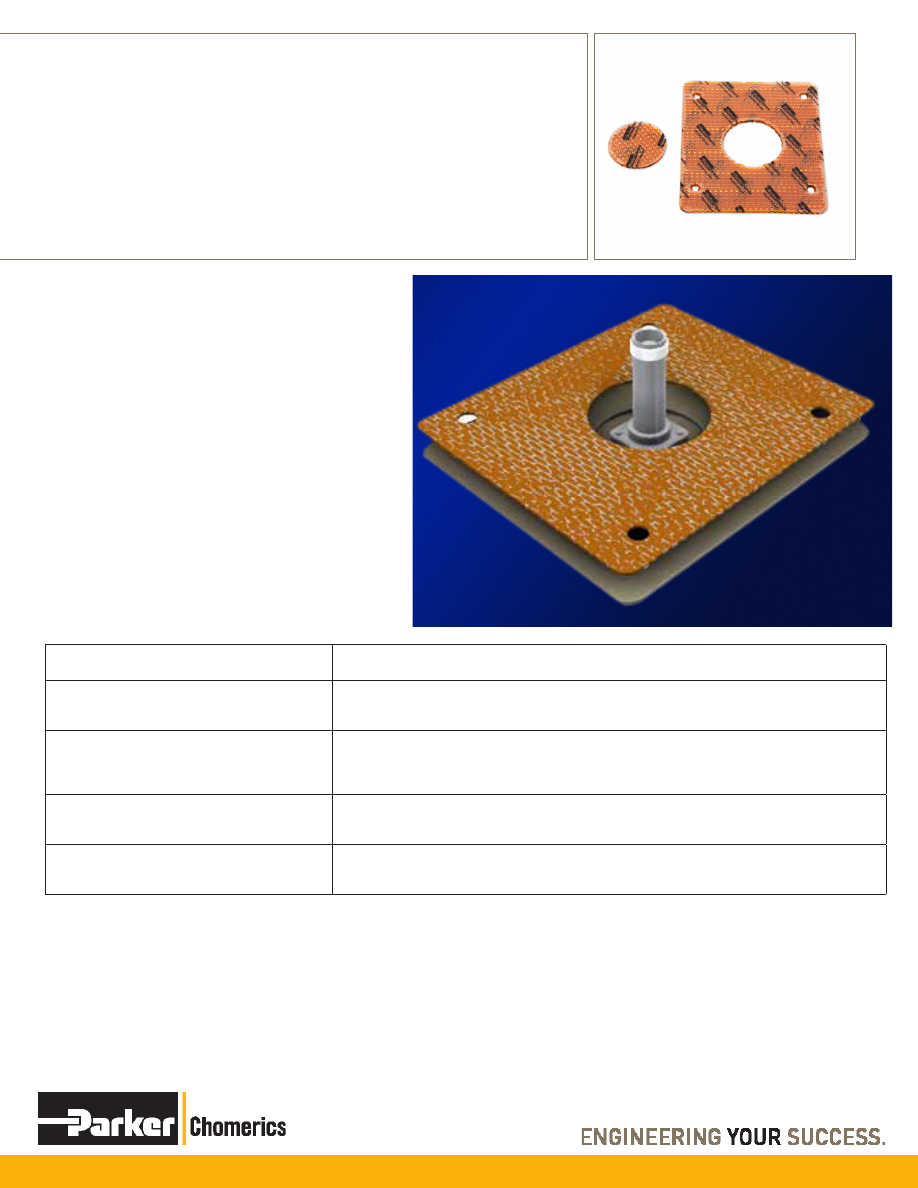

Parker Chomerics urethane filled expanded aluminum gaskets

provide a soft, electrically conductive fluid and pressure sealing

solution for a variety of flange to flange assemblies. Developed

to minimize galvanic corrosion of interfacing surfaces that

require electrical bonding, these fully-cured gaskets are an

effective solution in applications requiring lightning strike

grounding or EMI shielding. With numerous performance

improvements when compared to traditional gasketing

alternatives, customers can expect a 30% lower total cost of

ownership from various contributing factors including the

avoidance of assembly rework and material replacement.

With successful adoption across numerous military and

commercial applications, common usages include:

• Exterior mounted device bases

(antennas, radars, lighting, etc.)

• Access panel assemblies

(electronics bays and hatches)

• Connector / waveguide assemblies

Contact Information:

Parker Hannifin Corporation

Chomerics Division

77 Dragon Court

Woburn, MA 01801

phone 781 935 4850

fax 781 933 4318

chomailbox@parker.com

www.parker.com/chomerics

Features and Benefits:

Conformable, high surface affinity urethane

provides superior fluid sealing

Superior fluid sealing results in corrosion reductions up to 300% when compared to traditional sealing

alternatives, resulting in rework cost reductions of up to 50%.

Soft urethane requires low deflective forces

Low deflective forces allow for increased design freedom for the interfacing assembly, resulting in

cost optimization through reductions in fastener quantities, flange thickness, assembly tolerances and

weight.

Wave-formed aluminum provides electrical

continuity at gasket deflection as low as 15%

Electrical continuity at gasket deflection as low as 15% promotes full surface electrical contact

between gasketing and mating surfaces in highly variable applications where deflection is commonly

localized around fasteners. This promotes optimized electrical performance and minimized system

failures and associated rework costs.

Expanded aluminum promotes uniform distribution

of fastener loads

Uniform distribution of fastener loads eliminates harmful pitting and scoring commonly found with

woven-wire based gasketing solutions due to point-stress created by wire overlap locations. Lower

stress concentrations reduce the associated rework costs of flange cracking due to stress fatigue.

Expanded aluminum promotes optimized electrical

performance

Optimized electrical performance is gained through the elimination of point-to-point contact

resistance associated with woven wire gasketing technologies. Improved electrical efficiency promotes

minimized system failures and resulting rework costs.

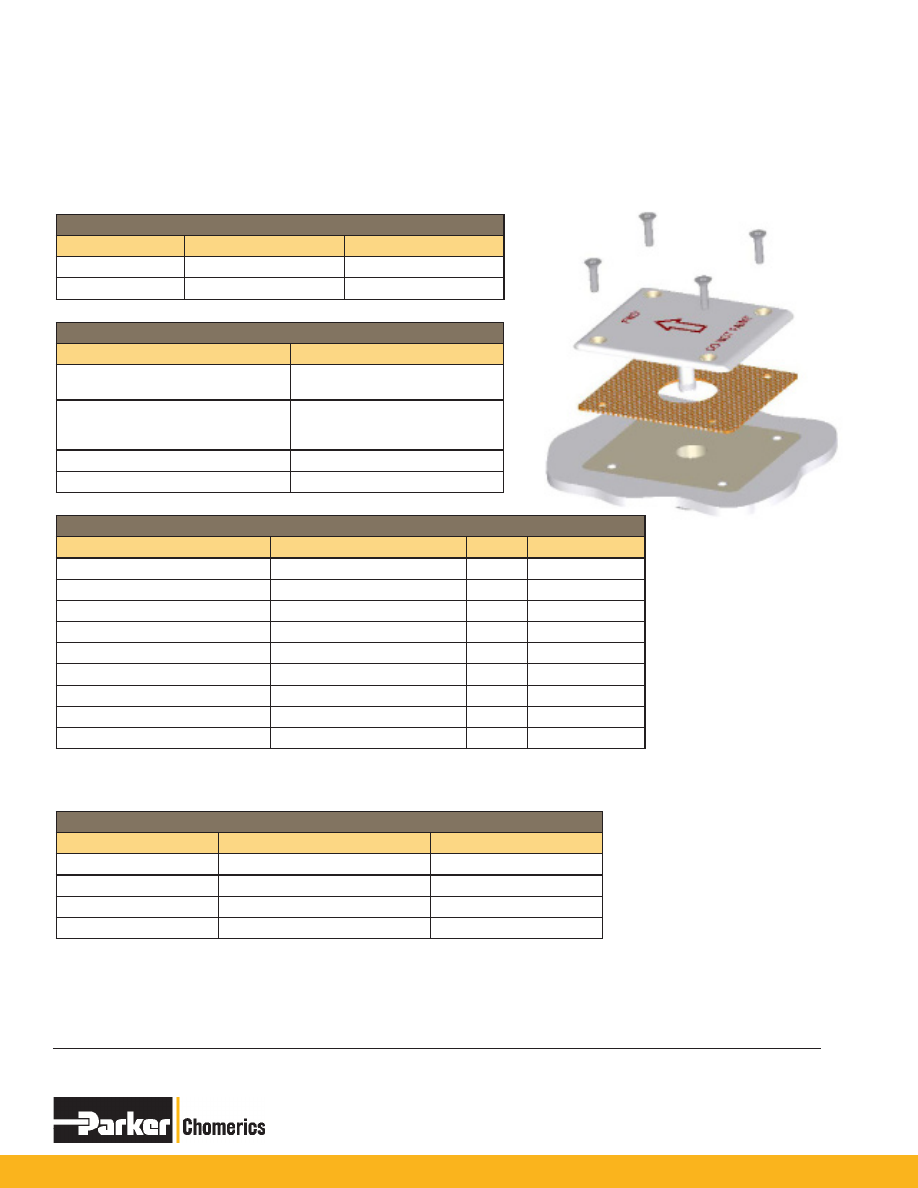

Urethane Filled Expanded Aluminum

Gasketing

METALASTIC

TM

EXP-URE