Carlisle Interconnect Technologies

/ 7911 S. 188th St., Kent, WA 98032

Toll Free - 800.227.5953 / Fax - 425.251.8826 /

www.CarlisleIT.com

Carlisle Interconnect Technologies’ (CarlisleIT) light-weight

series D-sub Backshells are designed to minimize weight

and maximize internal space and EMI shielding. Our D-sub

backshells are an ideal solution for high end commercial and

aviation cables where weight and/or EMI shielding are critical.

The light weight series backshells also feature a number of

unique features that improve the ease of assembly and overall

system stability.

»

Straight, 45° and 90° exit

»

60% lighter than comparable industry

standard products

»

Compact and efficient design maximizes

internal space

»

Front panel mount capability

»

Slots for mounting stability

INTRODUCTION

FEATURES

Compact D-Sub Backshells

»

Tapped body style

»

Accommodates conventional and moisture proof

MIL-STD-24308 D-sub connectors

»

Designed for ease of manufacturing and rework in

the field

»

High precision manufacturing results in a minimal air gap

»

Very effective EMI shielding

»

RoHS and ELV compliant

»

Special mounting features for mechanical mounting

stability that maximizes cable strain relief strength. This

subsequently prevents potential damage to individual

wires and electrical contacts.

»

Readily available engineering support for shield

termination methods that optimize the mechanical

and electrical system performances.

»

Custom designs are available to suit special application

requirements such as tight space limitations or bending

radai.

KEY CHARACTERISTICS

BENEFITS

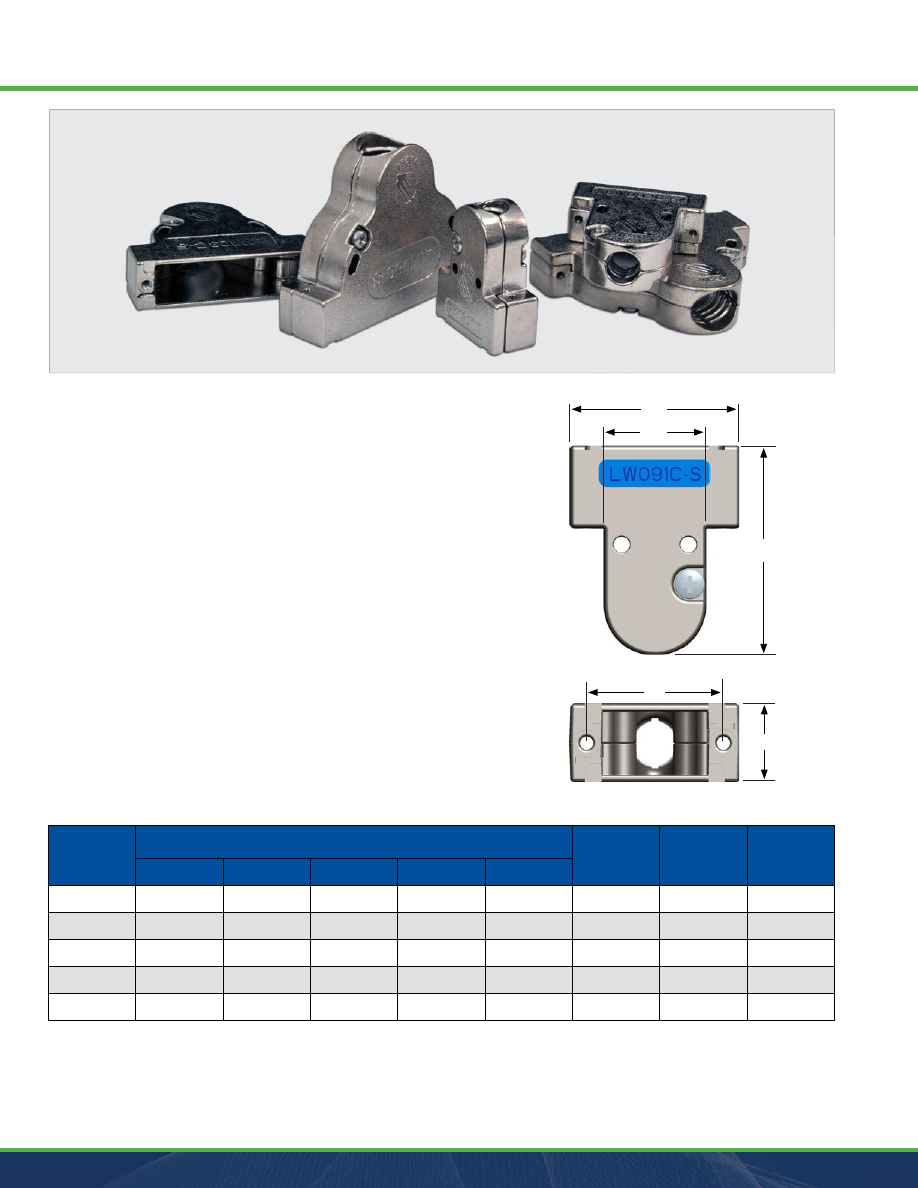

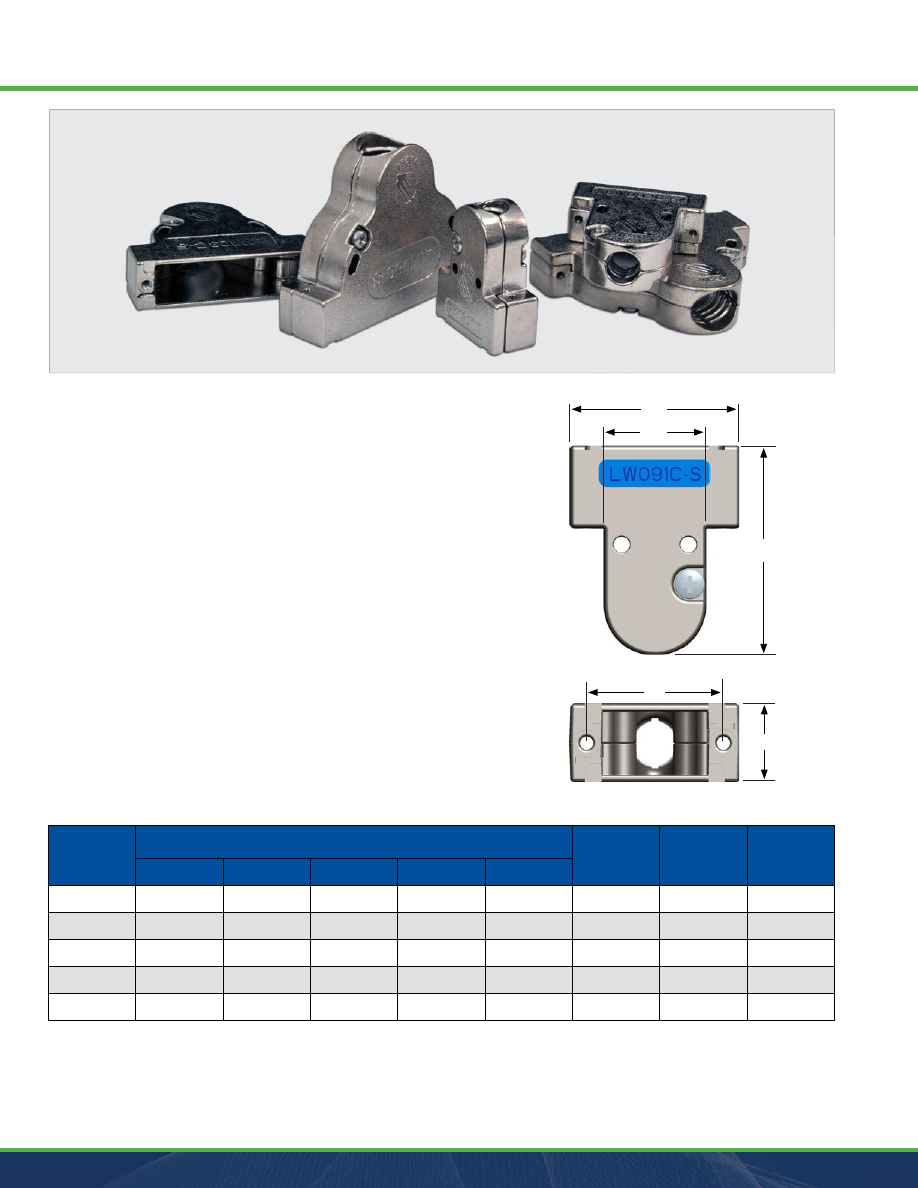

Straight Exit Angle Backshell

Features

»

Straight cable exit

»

Unique front panel mount feature

»

Slots for 4-40 screw or tie strap to provide more mounting stability

Ideal Applications

»

Aerospace video and Ethernet

»

EMI protection

»

Weight sensitive

Kit Contents

»

2 shell halves

»

2 screws (MS51957)

Standard Material

»

Shell - aluminum alloy with electroless nickel plating

»

4-40 pan head screws - stainless steel

Optional Material

»

Zinc alloy or metalized plastic

»

Additional plating upon customers’ request

Straight exit angle backshells

Shell Size

Dimensions in Inches

Cable DIA

(Min-Max)

in Inches

Weight

(Grams)

CarlisleIT

P/N

A

B

C

D

E

1/E

1.230

1.500

0.740

0.984

0.560

0.1 - 0.3

18.0

LW091C-S

2/A

1.550

1.800

1.000

1.312

0.580

0.1 - 0.3

25.0

LW092C-S

3/B

2.100

1.800

1.475

1.852

0.580

0.2 - 0.4

28.5

LW123C-S

4/C

2..750

2.000

2.155

2.500

0.580

0.3 - 0.6

36.0

LW154C-S

5/D

2.650

2.000

2.085

2.406

0.680

0.3 - 0.6

38.0

LW165C-S

Notes:

1. The parts shown in the above table are standard items, other strain relief diameters can be available upon request.

2. Parts are packaged unassembled.

D

E

A

B

C

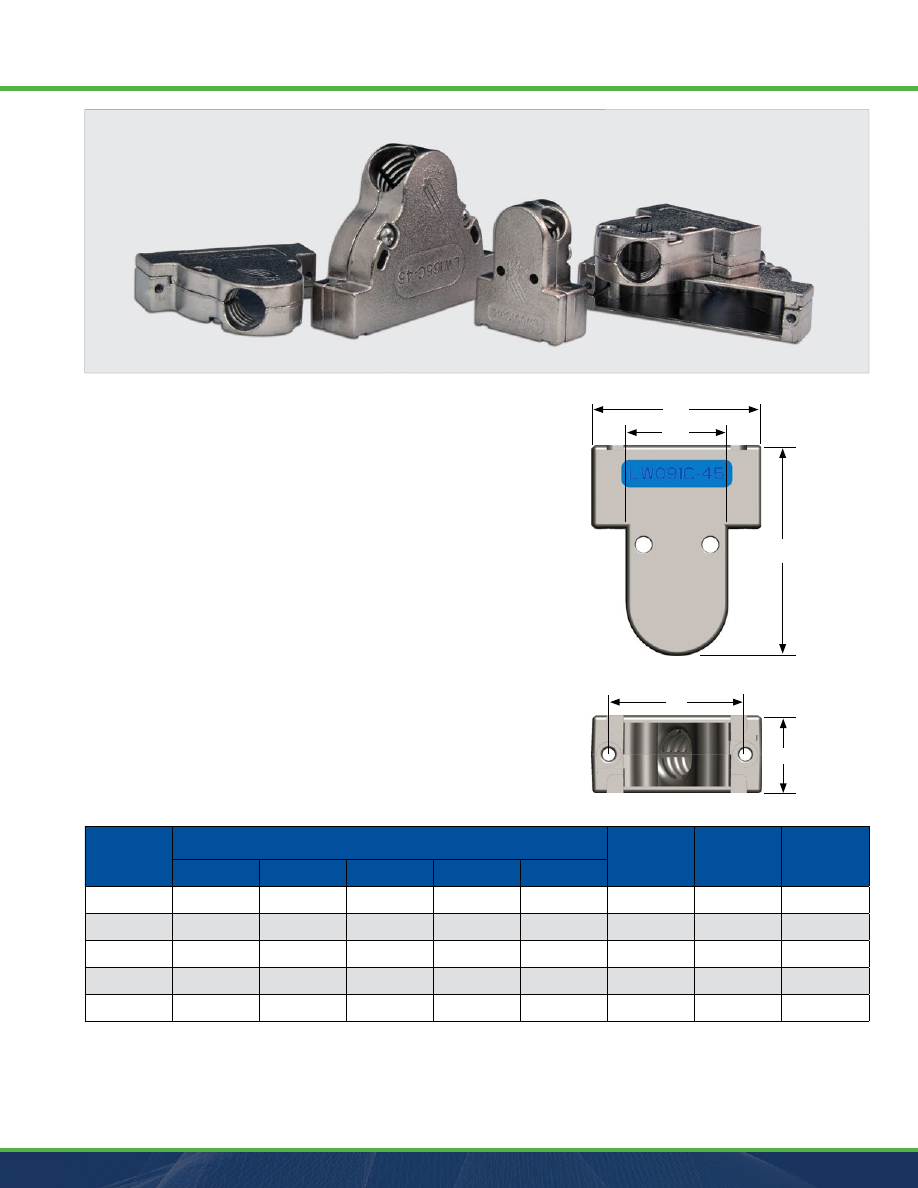

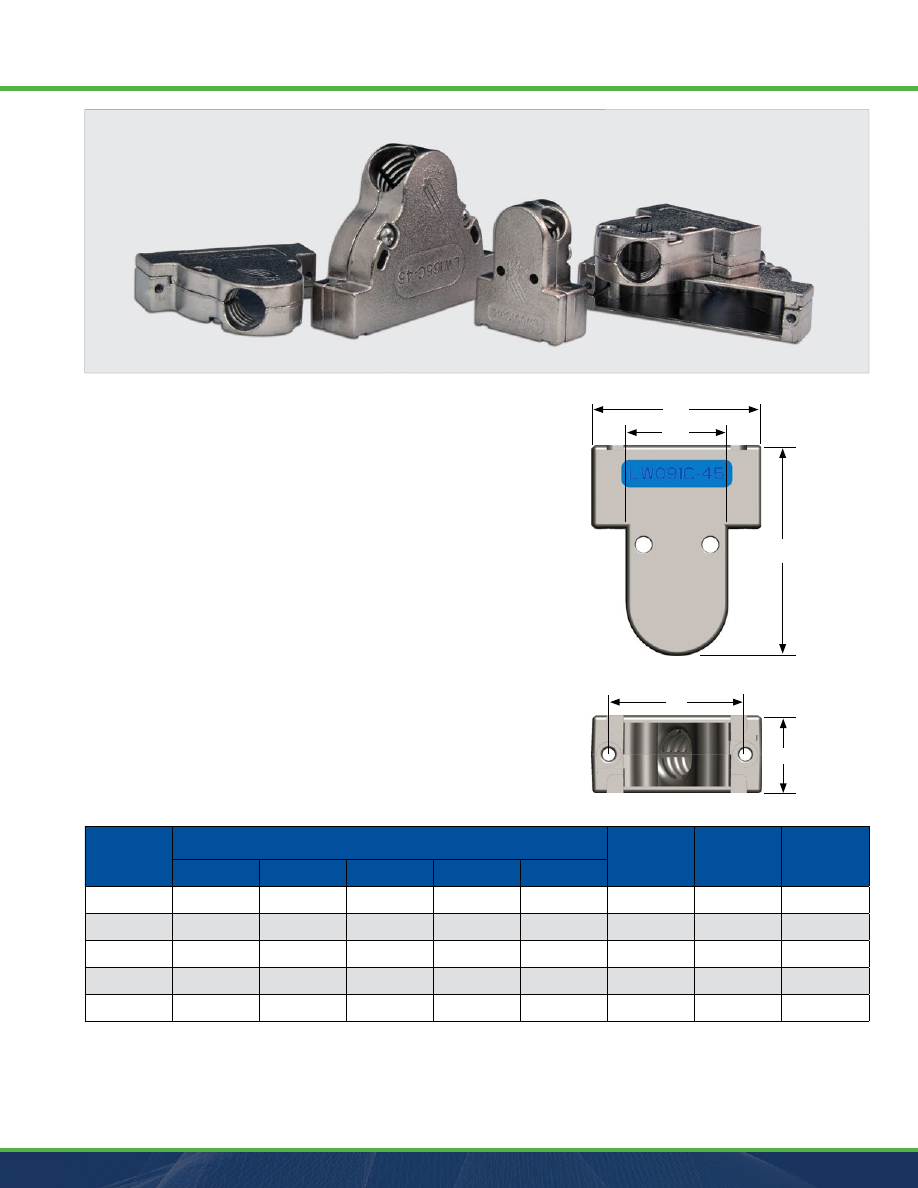

45° Exit Angle Backshell

Features

»

45° cable exit

»

Unique front panel mount feature

»

Slots for 4-40 screw or tie strap to provide more mounting stability

Ideal Applications

»

Aerospace video and Ethernet

»

EMI protection

»

Weight sensitive

Kit Contents

»

2 shell halves

»

2 screws (MS51957)

Standard Material

»

Shell - aluminum alloy with electroless nickel plating

»

4-40 pan head screws - stainless steel

Optional Material

»

Zinc alloy or metalized plastic

»

Additional plating upon customers’ request

45° exit angle backshells

Shell Size

Dimensions in Inches

Cable DIA

(Min-Max)

in Inches

Weight

(Grams)

CarlisleIT

P/N

A

B

C

D

E

1/E

1.230

1.500

0.740

0.984

0.560

0.1 - 0.3

18.0

LW091C-45

2/A

1.550

1.800

1.000

1.312

0.590

0.2 - 0.48

25.0

LW122C-45

3/B

2.100

1.800

1.475

1.852

0.580

0.2 - 0.4

28.5

LW123C-45

4/C

2..750

2.000

2.155

2.500

0.580

0.3 - 0.5

35.0

LW154C-45

5/D

2.650

2.000

2.085

2.406

0.690

0.3 - 0.6

38.0

LW165C-45

Notes:

1. The parts shown in the above table are standard items, other strain relief diameters can be available upon request.

2. Parts are packaged unassembled.

A

B

C

D

E

Carlisle Interconnect Technologies

/ 7911 S. 188th St., Kent, WA 98032

Toll Free - 800.227.5953 / Fax - 425.251.8826 /

www.CarlisleIT.com

© Carlisle Interconnect Technologies, 2015. All trademarks, service marks and trade names are property of their respective holding companies. All Rights Reserved.

Rev. 010115-POD

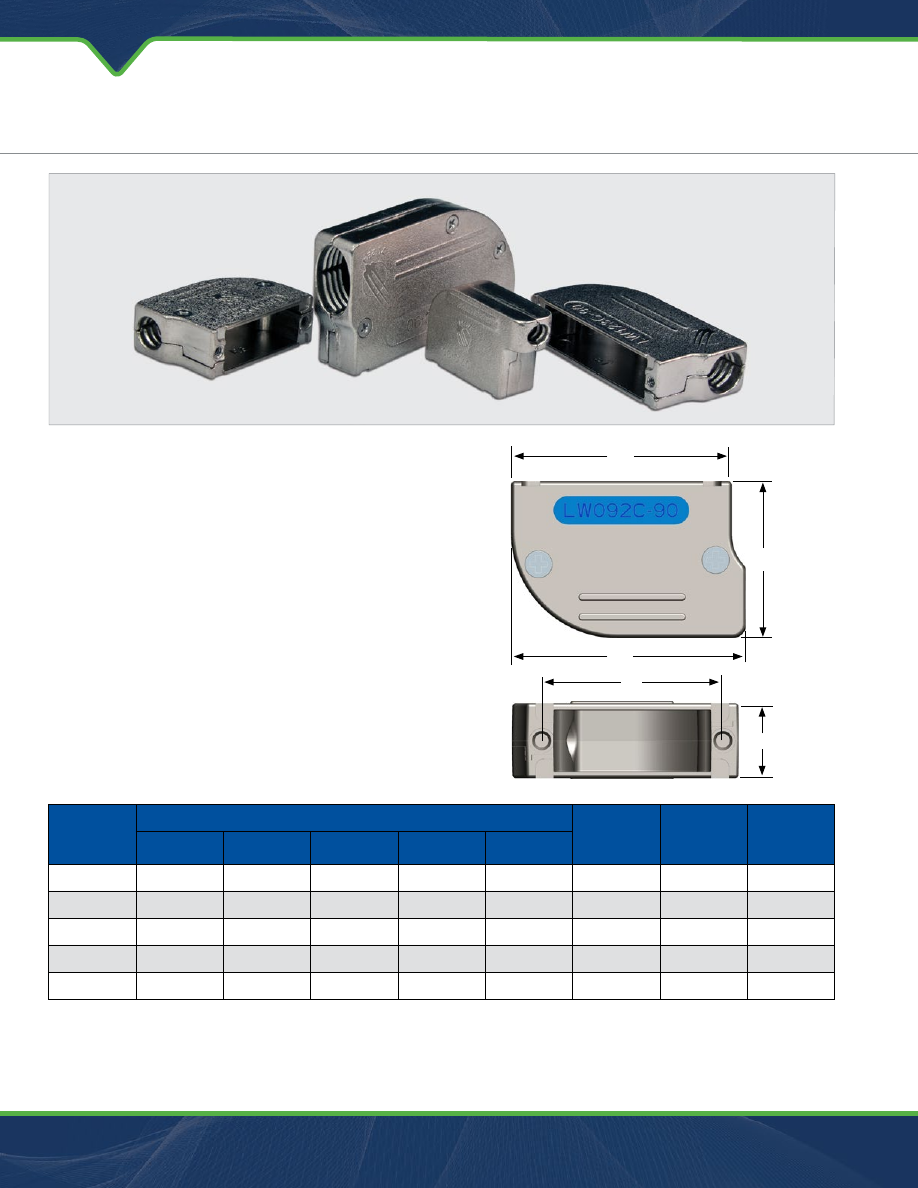

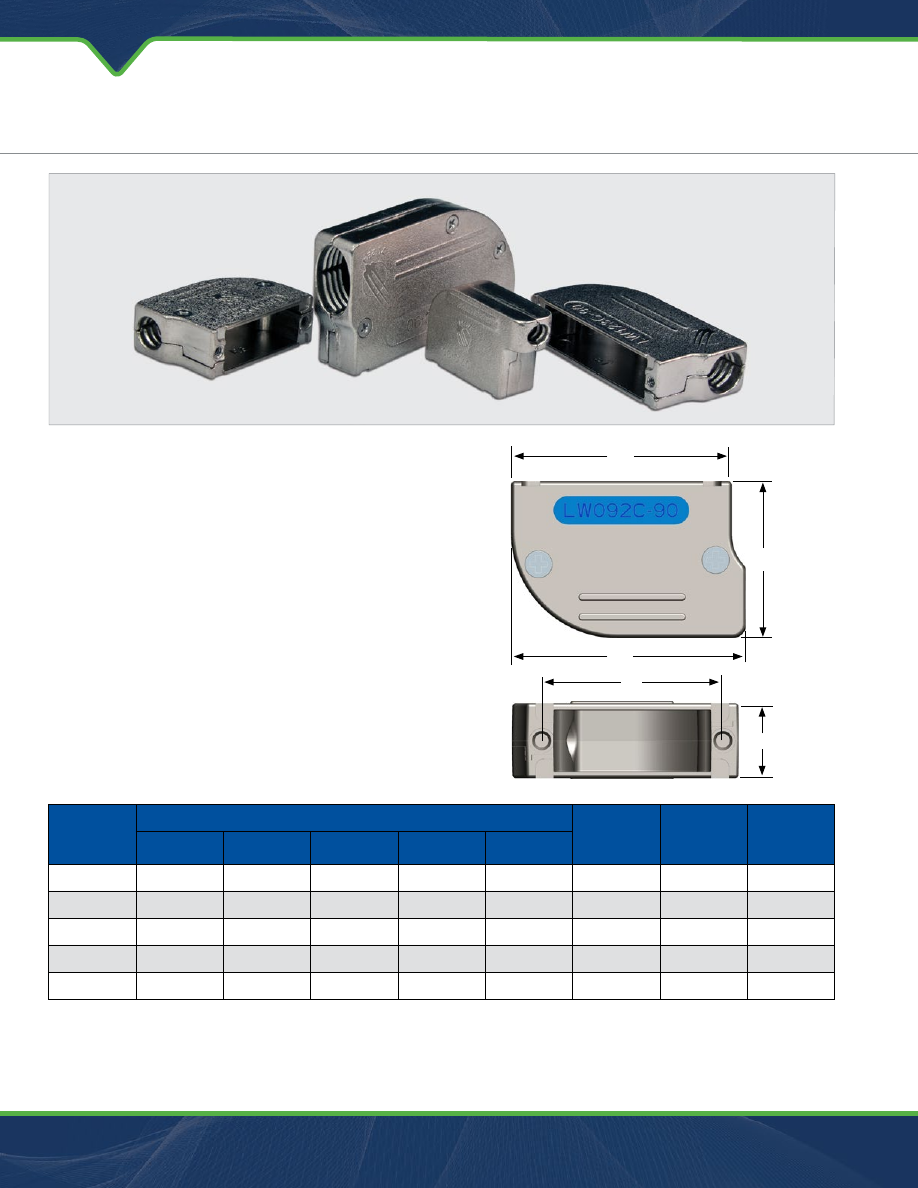

90° Exit Angle Backshell

Features

»

90° cable exit

Ideal Applications

»

Aerospace video and Ethernet

»

EMI protection

»

Weight sensitive

Kit Contents

»

2 shell halves

»

2 screws

Standard Material

»

Shell - cast aluminum alloy with electroless nickel plating

»

Flat head screws - stainless steel

Optional Material

»

Zinc alloy or metalized plastic

»

Additional plating upon customers’ request

Shell Size

Dimensions in Inches

Cable DIA

(Min-Max)

in Inches

Weight

(Grams)

CarlisleIT

P/N

A

B

C

D

E

1/E

1.230

1.330

0.95

0.984

0.540

0.10 - 0.25

12.0

LW071C-90

2/A

1.550

1.650

1.10

1.312

0.540

0.15 - 0.35

15.0

LW092C-90

3/B

2.100

2.200

1.20

1.852

0.540

0.20 - 0.40

18

LW123C-90

4/C

2..750

2.850

1.50

2.500

0.540

0.30 - 0.60

30

LW164C-90

5/D

2.650

2.750

1.50

2.406

0.680

0.35 - 0.65

34

LW165C-90*

*Design in development only.

Notes:

1. The parts shown in the above table are standard items unless otherwise noted, other strain relief diameters can be

available upon request.

2. Parts are packaged unassembled.

90° exit angle backshells

D

E

A

C

B