High Precision Bulk Metal

®

Foil Surface Mount Voltage Divider,

TCR Tracking of < 0.5 ppm/°C, Tolerance Match of 0.01 %

and Stability of ± 0.005 % (50 ppm)

DSM

Vishay Foil Resistors

Document Number: 63088

For any questions, contact:

foil@vishaypg.com

www.vishayfoilresistors.com

Revision: 22-Apr-2013

1

INTRODUCTION

Bulk Metal

®

Foil (BMF) technology out-performs all other

resistor technologies available today for applications that

require high precision and high stability.

This technology has been invented, patented and pioneered

by Vishay Foil Resistors (VFR). Products based on this

technology are the most suitable for a wide range of

appilcations.

BMF technology allows the production of customer oriented

products designed to satisfy challenging and specific

technical requirements. Model DSM offers low TCR (both

absolute and tracking), excellent load life stability, tight

tolerance, excellent ratio stability, and low current noise, all in

one package.

The DSM surface mount divider provides a matched pair of

Bulk Metal

®

Foil resistors in a small epoxy molded package.

The electrical specification of this integrated construction

offers improved performance and better real estate utilization

over discrete resistors and matched pairs.

VFR’s application engineering department is available to

advise and make recommendations. For non-standard

technical requirements and special applications, please

contact

foil@vishaypg.com

.

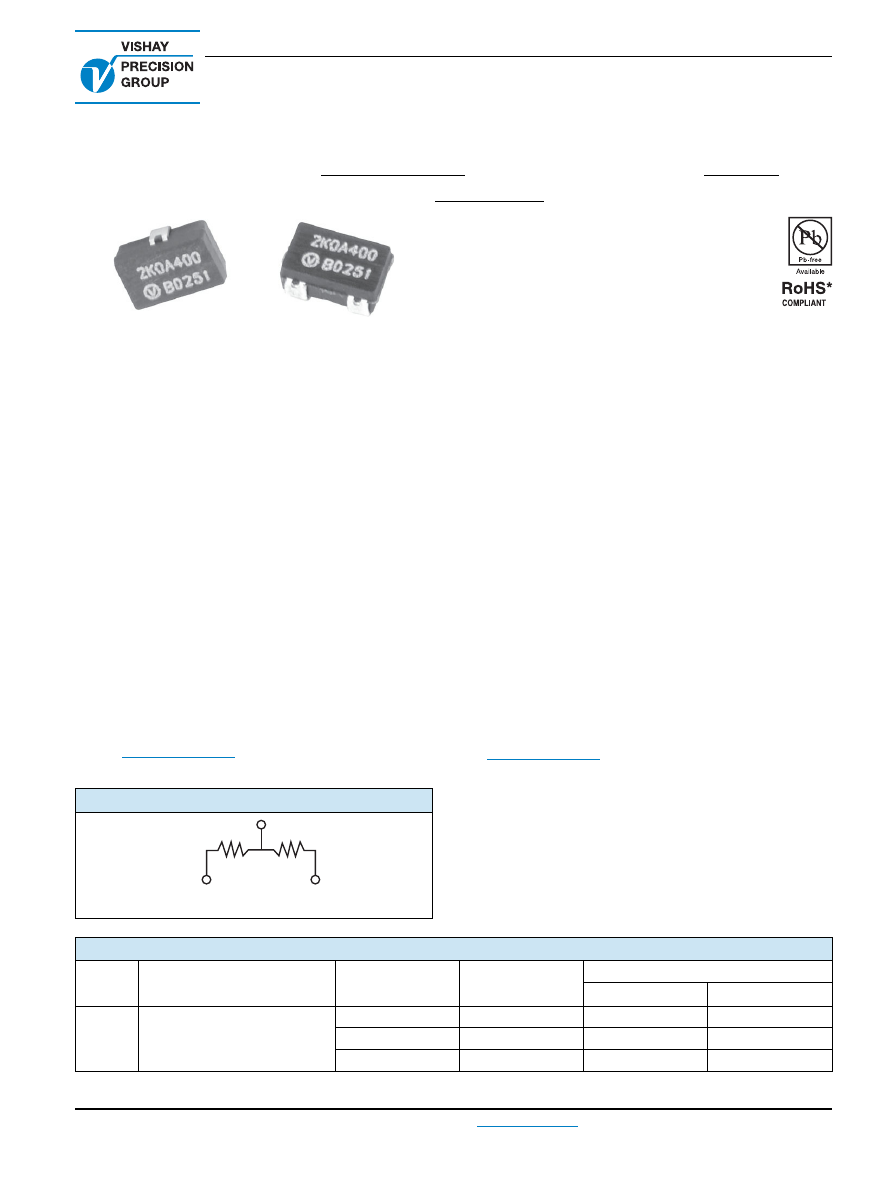

FIGURE 1 - SCHEMATIC

OPTION 1

SAME OHMIC VALUE,

SAME ABSOLUTE TOLERANCE

R

1

OPTION 2

RESISTOR PAIR

R

1

/R

2

- DIFFERENT VALUES

R

2

FEATURES

Temperature coefficient of resistance (TCR):

Absolute: 2 ppm/°C typical

(- 55 °C to + 125 °C, + 25 °C ref.)

Tracking: 0.5 ppm/°C typical

Tolerance: absolute: ± 0.02 %; match: 0.01 %

Power rating: to 70 °C: entire package: 0.1 W

each resistor: 0.05 W

Ratio stability: 0.005 % (0.05 W at 70 °C, 2000 h)

Resistance range: 100

to 12 k

per resistor

Large variety of resistance ratios: 1:120

Vishay Foil resistors are not restricted to standard

values/ratios; specific “as required” values/ratios can be

supplied at no extra cost or delivery (e.g. 1K234/2K345 vs.

1K/2K)

Thermal stabilization time < 1 s (nominal value achieved

within 10 ppm of steady state value)

Electrostatic discharge (ESD) at least to 25kV

Short time overload: 0.005 %

Non inductive, non capacitive design

Rise time: 1 ns effectively no ringing

Current noise: < 0.010 µV

RMS

/V of applied voltage

( - 40 dB)

Voltage coefficient: 0.1 ppm/V

Non inductive: 0.08 µH

Non hot spot design

Terminals: silver coated copper alloy (see Table 5)

Compliant to RoHS directive 2002/95/EC

Prototype quantities available in just 5 working days

or sooner. For more information, please contact

foil@vishaypg.com

For better performances, please see DSMZ datasheet

(Z-Foil)

TABLE 1 - MODEL DSM SPECIFICATIONS

MODEL

ABSOLUTE TCR

(- 55 °C TO + 125 °C, + 25 °C REF.)

TYPICAL + MAX. SPREAD

RESISTANCE

RATIO

TCR TRACKING

TOLERANCE

ABSOLUTE

MATCH

DSM

± 2 ppm/°C ± 3 ppm/°C

R1/R2 = 1

1.0 ppm/°C

± 0.02 %

0.01 %

1 < R1/R2

10

2.0 ppm/°C

± 0.05 %

0.02 %

10 < R1/R2

120

3.0 ppm/°C

± 0.1 %

0.05 %

* Pb containing terminations are not RoHS compliant, exemptions may apply