ECM SERVICE GUIDE

A Regal Brand

©2014 Regal-Beloit Corporation

REG9971_ECM_Service_Guide_4-10-14.indd 1

4/10/14 10:48 AM

ECM SERVICE GUIDE

A Regal Brand

©2014 Regal-Beloit Corporation

REG9971_ECM_Service_Guide_4-10-14.indd 1

4/10/14 10:48 AM

WA R N I N G

Working on the motor with power connected may

result in electrical shock or other conditions that may

cause personal injury, death or property damage.

On models 2.0/ 2.3/ 2.5/ Eon/ X13/ 3.0 always

disconnect the power from the HVAC system and

wait at least 5 minutes before opening the motor, i.e.

removing the two bolts from the motor control (end

bell) and disconnecting the 3-pin plug to the motor.

This is to allow the capacitors to dissipate for safety.

WA R N I N G

Always disconnect the power from the HVAC system before

removing or replacing connectors, servicing the motor,

removing the high voltage plug, and before reconnecting.

WA R N I N G

Disconnect AC power from the system and make

sure the blower wheel or fan blade has come to a

complete stop before servicing the motor.

WA R N I N G

Do not operate motor without blower wheel or fan

blade attached. Such operation will cause the motor

to oscillate up and down.

WA R N I N G

You must have the correct replacement module

and/or motor from the manufacturer that is a direct

replacement for the failed module and/or motor.

USING THE WRONG MODULE AND/OR MOTOR

VOIDS ALL PRODUCT WARRANTIES AND MAY

PRODUCE UNEXPECTED RESULTS.

WA R N I N G

WA R N I N G

Genteq does not condone the repair of any individual

components in the motor control or motor of their

ECM products. This practice is unsafe and may cause

personal injury, death, or property damage.

REG9971_ECM_Service_Guide_4-10-14.indd 2

4/10/14 10:48 AM

TABLE OF CONTENTS

Using the ECM Service Guide

Motor Diagnostics & Replacement

ECM SERVICE GUIDE

About the Company

Start Here:

Using the ECM Service Guide

HVAC System Troubleshooting Basics

Tech Tips

Motor Identification Chart

1

3

4

6

7

10

26

37

50

53

Variable Speed Motors

Premium ECM Motor Diagnostics

X13 Motor

Standard ECM Motor Diagnostics

Evergreen Replacement Motors or Retrofit

Retrofit Motor Diagnostics

Outdoor Motors

Motor Identification Chart

Final Checks

REG9971_ECM_Service_Guide_4-10-14.indd 3

4/10/14 10:48 AM

1

Introduction

The ECM Service Guide provided by Genteq

®

is a troubleshooting tool like no other. It covers

over 20 years worth of OEM (Original Equipment

Manufacturer) and aftermarket residential HVAC

ECM motors including the Variable Speed indoor

blower motor models 2.0, 2.3, Eon, and 3.0,

Constant Torque indoor blower motor model

X13, Constant Speed outdoor fan motor model

142 and 142R, and the Constant Torque indoor

blower motor Evergreen. Genteq motors have

been used almost exclusively in OEM equipment

including fossil fuel furnaces, electric air handlers,

geothermal and package systems. Regardless

of the manufacturer of the appliance, this

guide will help troubleshoot the Genteq ECM

motor driving it. It is our hope that this guide

will provide a simple and accurate process for

troubleshooting all of our motors.

About the Company

In 1987 General Electric introduced ECM

technology to the residential HVAC industry.

This technology is predominantly used in variable

speed indoor blower motors, constant speed

induced draft motors and condensing fan motors.

These innovative motors changed the industry by

providing unmatched efficiency as well as comfort

options not possible with PSC induction motors.

In 2004 the Regal Beloit Corporation acquired

General Electric’s Commercial and HVACR

Motors and Capacitors businesses with the

right to use the GE brand through 2009. These

divisions were named GE ECM by Regal Beloit,

GE Commercial Motors by Regal Beloit and GE

Capacitors by Regal Beloit.

In 2009, Regal Beloit announced the rebranding

of those GE branded businesses under the name

Genteq, for markets that include residential and

REG9971_ECM_Service_Guide_4-10-14.indd 4

4/10/14 10:48 AM

2

commercial HVAC equipment and electrical

applications that utilize capacitors. With this

rebranding, the Genteq logo took the place

of GE ECM, GE Commercial Motors and GE

Capacitors logos on all branded products,

sales and marketing materials, Web sites,

communications documents, signage and other

related items.

This rebranding reflects the company’s reputation

for innovation and speaks to the future. We want

to assure customers that this rebranding is an

exciting, progressive step. Genteq continues

providing unparalleled service and developing

the progressive, innovative HVACR solutions for

which this company has always been known. Even

if you are not familiar with the name Regal Beloit,

you are most likely familiar with one or more of

the motor brands they own such as Marathon,

Lincoln, Leeson and Fasco. Regal Beloit is

a leading manufacturer of mechanical and

electrical motion control and power generation

products serving markets throughout the world.

Regal Beloit is headquartered in Beloit, Wis., and

has manufacturing, sales, and service facilities

throughout the United States, Canada, Mexico,

Europe and Asia.

Genteq will continue to create innovative,

premium comfort and electrical components.

Our proven reputation for high quality,

highly reliable products and strong customer

relationships make us the preferred brand

throughout the industry.

For more information on our company, Please

visit our Web site at jointhegeneration.com. For

technical information and training on our OEM

products please visit theDealerToolbox.com.

For information and training on Evergreen visit

EvergreenDealer.com. And for information on

homeowner benefits and tax rebates please

visit genteqcomfort.com.

REG9971_ECM_Service_Guide_4-10-14.indd 5

4/10/14 10:48 AM

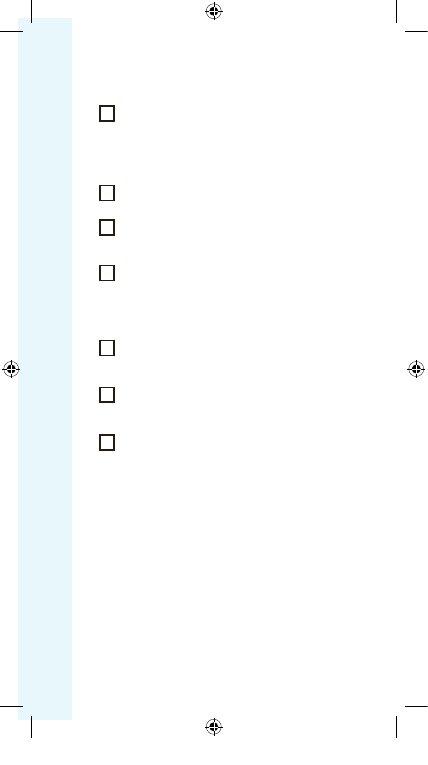

The purpose of this guide is to help you

accurately and efficiently troubleshoot

Genteq ECM-driven systems. For ease of

troubleshooting and to avoid misdiagnosis, it is

strongly recommended that each step of this

guide be used in the following order:

START HERE:

Using the ECM Service Guide

Read this section before using

Motor Diagnostics & Replacement

Using the ECM Service Guide

Begin with the “HVAC System

Troubleshooting Basics” section on the

opposite page.

If the answer to the problem is not solved

there, read all of the Tech Tips on page 6.

After reading all of the Tech Tips, go to the

“Motor ID” section of this guide on page 7 to

be sure you use the procedures for the

correct motor.

After determining which motor you are

working on from the “Motor ID” chart on

page 7, go to the section in this guide for the

motor model you are working on and follow

the instructions listed there.

1.

2.

3.

4.

3

REG9971_ECM_Service_Guide_4-10-14.indd 6

4/10/14 10:48 AM

ST

AR

T HERE

Before troubleshooting the ECM motor, check

these system basics if applicable:

HVAC System

Troubleshooting Basics

Confirm that the correct thermostat input

and ONLY the correct input voltage is

present at the interface or main control

board on the furnace/air handler or outdoor

unit. Loose or broken low-voltage wires are

also potential problem areas and can cause

intermittent problems.

For the heating and/or cooling systems,

use the manufacturers guide to confirm

proper demands (heat or cool), especially

on multi-stage systems. Use the “Sequence

of Operation” charts and the “Thermostat

Wiring Diagrams,” found in these guides to

confirm proper wiring and operation.

When checking low-voltage connections,

always use the C terminal on the board,

never ground.

Check the setting of the jumper pins

or switches or menu selections on the

manufacturer’s control board or system

interface. Do not assume they are correct;

use the manufacturer’s guide to select the

proper airflow, delays, and profiles.

Always

disconnect the main power to the unit

when making these adjustments, unless

required for interface operation.

1.

2.

3.

4

REG9971_ECM_Service_Guide_4-10-14.indd 7

4/10/14 10:48 AM

Check all terminal/plug connections both

at the furnace/air-handler or outdoor unit

control board and at the motor.

Always

disconnect power to the system before

disconnecting and reconnecting plugs

.

Look for:

Loose plugs and/or loose pin connections

in the plug.

Burnt, bent or loose pins or seats.

Confirm there are no limits, rollouts or

safeties tripped. Also check for any fault

codes present on the furnace/air-handler or

outdoor unit control boards.

If fault codes are present, follow the

manufacturer’s recommendations to resolve

the problem.

If these checks do not solve the problem, or if

a fault code reveals a motor problem, read the

Tech Tips on page 6, and go to the “Motor ID”

section on page 7 to identify the motor. Then

go to the corresponding motor section in this

guide for additional diagnostics.

4.

5.

6.

5

REG9971_ECM_Service_Guide_4-10-14.indd 8

4/10/14 10:48 AM

TE

CH TIP

S

Tech Tips

Do not automatically assume the ECM motor

has failed

. Follow this guide completely before

replacing it.

When it is necessary to disconnect the power

from the HVAC system, it is always good

practice to

verify that voltage has been

disconnected

with a voltmeter.

A True- RMS meter is not needed to check high

voltage or low voltage (communication voltage)

to the motor.

Always pull on the connector and not the

wires.

Most connectors are also keyed.

Reconnecting a connector the wrong way could

damage the motor.

When checking any plug connector, the meter

leads are most likely larger than the terminals

or socket. Using thin leads will prevent the

terminals from being damaged by voltage

checks. Thinner leads are also available in a 90º

angle as needed. Go to

thedealertoolbox.com

for part numbers and ordering information if

needed.

TECH TIP #1

TECH TIP #2

TECH TIP #3

TECH TIP #4

TECH TIP #5

6

REG9971_ECM_Service_Guide_4-10-14.indd 9

4/10/14 10:48 AM

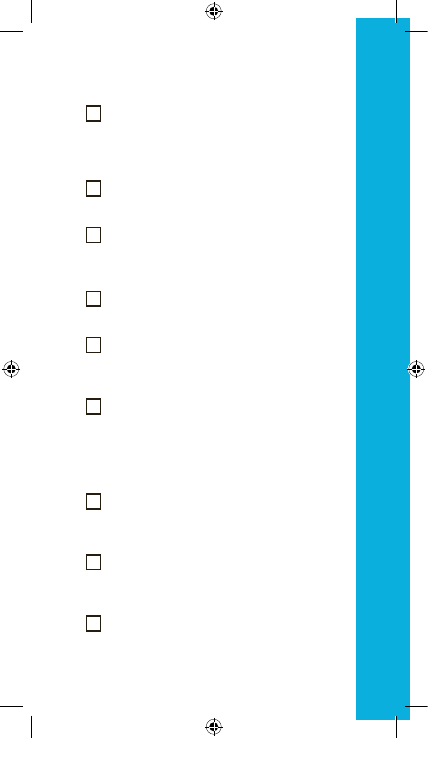

ECM X13

OEM Constant Torque Indoor Blower Motor

Evergreen Aftermarket Constant Torque Indoor Blower Motor

Identification

Sticker

Heat sink

Speed taps

All Evergreen Motors are aftermarket replacements

All Evergreen Motors are Painted Green

Evergreen CM, AH & EM

have a missing

wire upper plug

Evergreen IM

has a white or yellow voltage jumper

All Evergreen Motors have a heat sink here

OEM Constant Speed Outdoor Fan Motor

Sha down application

rounded end of control up

Sha up application

remote located control

Cover plate over

open end of control

Umbilical cord from motor

shell to cover plate

ECM 142 Control

ECM 142 Control

R

Sha up application

rounded end of control up

Cover plate over open

end of control

Umbilical cord from motor

shell to cover plate

ECM 142

R

C L G N

1 2 3 4 5

7

Motor Identification Chart

REG9971_ECM_Service_Guide_4-10-14.indd 10

4/10/14 10:48 AM

MO

TOR

ID

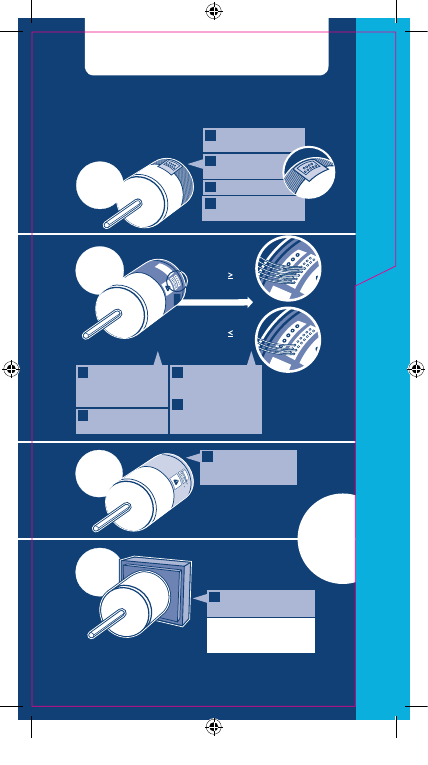

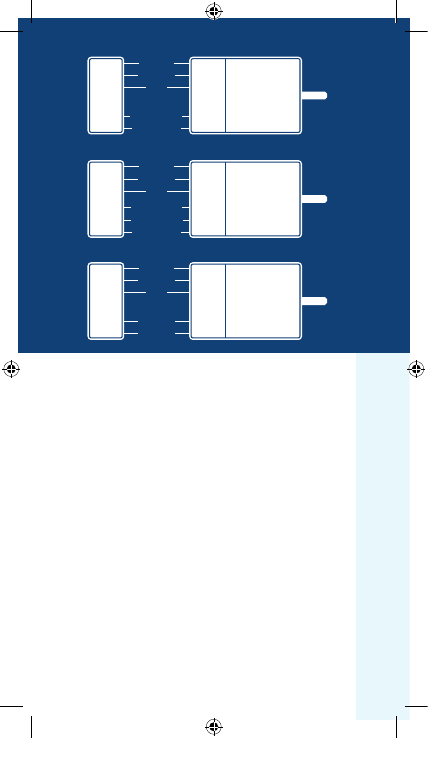

ECM 3.0

& Eon

ECM

2.3/2.5

2.3

6

wires

2.5

5

wires

Identification

Sticker

Heat sink

3.0 uses 4-pin

connector

Eon uses 16-pin

connector

Identification

Sticker

2.3

- 6 or more

wires in the

16-pin connector

2.5

- 5 or less

wires in the

16-pin connector

Painted, steel

motor control

Unpainted,

cast aluminum

motor control

Square motor

control

NOTE: Early models do not

have indentification stickers.

NOTE: ECM

1.0, 2.0,

2.3 & 2.5

motors are

no longer in

production

NOTE: See HVAC

manufacturer’s service guide

for 1.0 motor diagnostics.

ECM 2.0

ECM 1.0

OEM Variable Speed Indoor Blower Motor

8

Motor Identification Chart

REG9971_ECM_Service_Guide_4-10-14.indd 11

4/10/14 10:48 AM

9

WA R N I N G

Working on the motor with power connected may

result in electrical shock or other conditions that may

cause personal injury, death or property damage.

On models 2.0/ 2.3/ 2.5/ Eon/ 3.0 always disconnect

the power from the HVAC system and wait at least

5 minutes before opening the motor, i.e. removing

the two bolts from the motor control (end bell) and

disconnecting the 3-pin plug to the motor. This is to

allow the capacitors to dissipate for safety.

WA R N I N G

Always disconnect the power from the HVAC system before

removing or replacing connectors, servicing the motor,

removing the high voltage plug, and before reconnecting.

WA R N I N G

Disconnect AC power from the system and make

sure the blower wheel or fan blade has come to a

complete stop before servicing the motor.

WA R N I N G

Do not operate motor without blower wheel or fan

blade attached. Such operation will cause the motor

to oscillate up and down.

WA R N I N G

You must have the correct replacement module and/

or motor from the HVAC unit manufacturer that

is a direct replacement for the failed module and/

or motor. USING THE WRONG MODULE AND/OR

MOTOR VOIDS ALL PRODUCT WARRANTIES AND

MAY PRODUCE UNEXPECTED RESULTS.

WA R N I N G

WA R N I N G

Genteq does not condone the repair of any individual

components in the motor control or motor of their

ECM products. This practice is unsafe and may cause

personal injury, death, or property damage.

REG9971_ECM_Service_Guide_4-10-14.indd 12

4/10/14 10:48 AM

10

VARIABLE SPEED

M

OTO

RS

11

15

16

19

24

Models 2.0 / 2.3 / 2.5 / Eon / 3.0

Premium ECM Motor Diagnostics

TECINspect

TECINspect Usage Chart

Troubleshooting with the TECINspect

Module Replacement

ECM Control Module

ECM Motor Module

Variable Speed

Models 2.0 / 2.3 / 2.5 / Eon / 3.0

Premium ECM Motors

See the Motor ID Chart on page 8 if needed.

REG9971_ECM_Service_Guide_4-10-14.indd 13

4/10/14 10:48 AM

It is normal for the motor to rock back and

forth on start up. Do not replace the motor

if this is the only symptom identified.

If the system is excessively noisy, does not

appear to change speeds in response to a

demand (Heat or Cool), or is having symptoms

during the cycle such as a tripping limit or

freezing coil, check the following:

Wait for programmed delays to time out. If

delays are too long, then reset them using the

manufacturer’s charts.

Ensure the airflow settings are correct for

the installed system using the manufacturer’s

charts. Remember that the change in airflow

between continuous-fan speed and low stages

of operation may be very slight depending

on the size of the system. If the system is

operating normally in each stage, then there is

no problem.

Remove the filter and check that all of the

dampers, registers, and grills are open and

free flowing. If removing the filter corrects

the problem, clean or replace with a less

restrictive filter. Also check and clean as

needed the blower wheel, secondary heat

exchanger (if applicable) and evaporator coil

(if applicable).

If this does not correct the problem then:

Check the external static pressure. If it is

higher than the manufacturer’s recommendations,

correct the airflow restriction.

Models 2.0 / 2.3 / 2.5 / Eon / 3.0

Premium ECM Motor Diagnostics

IF THE MOTOR IS RUNNING

11

1.

2.

REG9971_ECM_Service_Guide_4-10-14.indd 14

4/10/14 10:48 AM

If the motor does not shut off at the end of

the cycle, check the delay times and wait for

the delays to time out. Also, make sure that

there is no call for “Continuous fan” on the

“G” terminal. This motor may take a while to

come to a complete stop with selected delays

and the normal ramp down.

If the 2.0 / 2.3 / Eon / 3.0 motor

has

proper high voltage and ground at the 5-pin

connector, go to the “Troubleshooting with

the TECINspect” section on page 16. If

the 2.5 motor has proper high voltage and

ground at the 5-pin connector, the equipment

manufacturer’s checks, located in their service

manuals, must be referenced. This guide

cannot troubleshoot the communication

to the 2.5 motor. The TECINspect is not

designed for use on the 2.5 motor.

Checking the high voltage on the 5-pin

connector is outlined in step 1 on page 13.

12

3.

4.

REG9971_ECM_Service_Guide_4-10-14.indd 15

4/10/14 10:48 AM

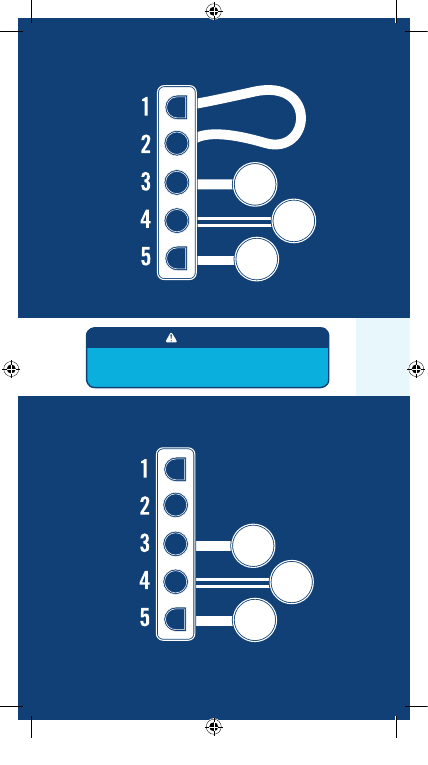

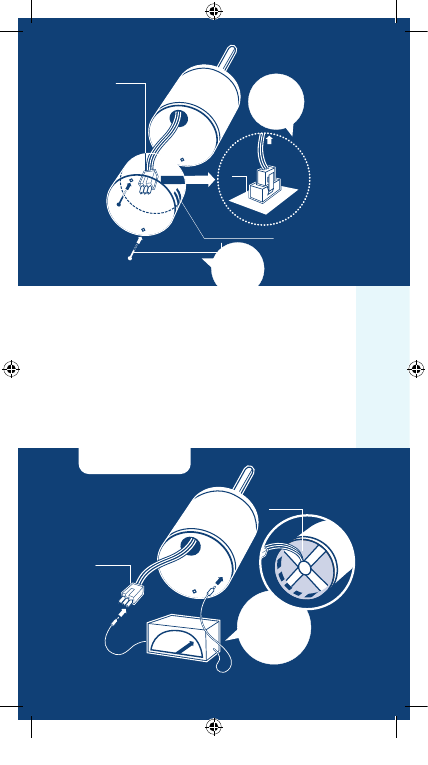

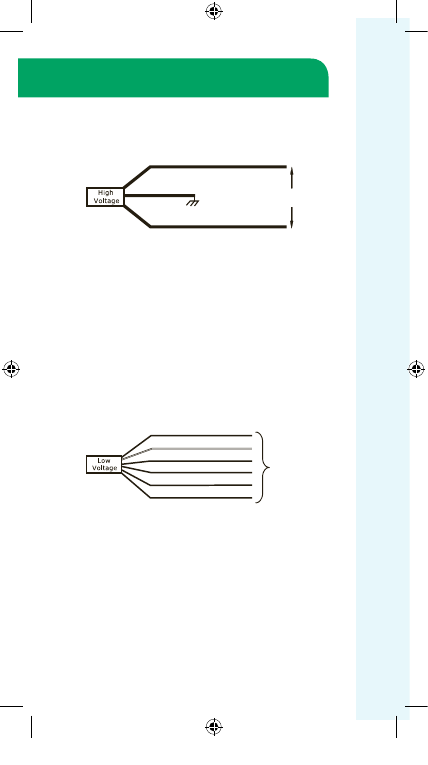

IF THE MOTOR IS NOT RUNNING

Check for proper high voltage and ground

at the 5-pin connector at the motor. Correct

any voltage issues before proceeding to the

next step. These are dual voltage motors

capable of operating in 120 or 240VAC

systems. On 120VAC systems there should

be a jumper between terminals 1 and 2 (see

Figure 1). On 240VAC systems the jumper

should be removed (see Figure 2). If a motor

is operating at 240VAC with the jumper

in place, the motor will be permanently

damaged. Input voltage within plus or minus

10% of the nominal 120VAC or 240VAC is

acceptable.

If the 2.0 / 2.3 / Eon / 3.0 motor has

proper high voltage and ground at the

5-pin connector, go to the “Troubleshooting

with the TECINspect” section on page 16.

If the 2.5 motor has proper high voltage

and ground at the 5-pin connector, the

equipment manufacturer’s checks, located in

their service manuals, must be referenced.

This guide cannot troubleshoot the

communication to the 2.5 motor.

The TECINspect is not designed for use on

the 2.5 motor.

If further troubleshooting identifies a failed

control module, go to “Replacing the ECM

Control Module” section on page 24 of this

guide for replacement steps.

1.

2.

3.

13

REG9971_ECM_Service_Guide_4-10-14.indd 16

4/10/14 10:48 AM

GROUND

120VAC

LINE 1

120VAC

LINE 2

GROUND

NEUTRAL

120VAC

LINE 1

Figure 1

Models 2.0 / 2.3 / 2.5 / Eon / 3.0

120VAC SYSTEM

Figure 2

240VAC SYSTEM

14

Always disconnect the power from the system before

removing the high voltage plug, and before reconnecting.

WA R N I N G

Models 2.0 / 2.3 / 2.5 / Eon / 3.0

REG9971_ECM_Service_Guide_4-10-14.indd 17

4/10/14 10:48 AM

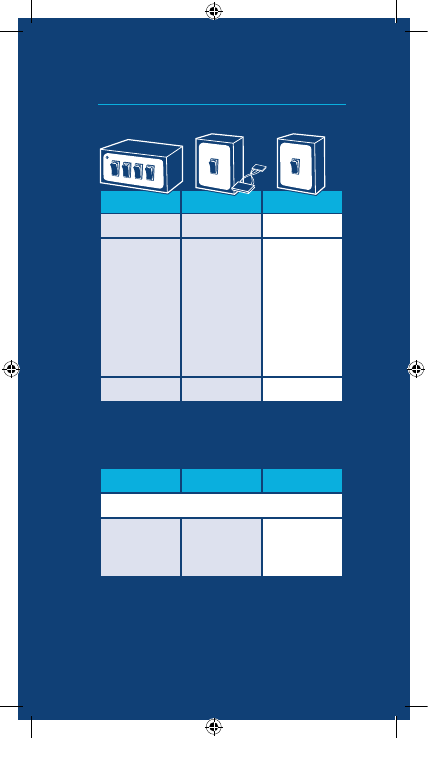

15

TECINspect

USAGE CHART

TECMate XL

TECMate PRO

TECINspect

4 Switches

1 Switch

1 Switch

16-pin connector

1st Generation

16-pin connector

2nd Generation

16-pin connector

with supplied 16-4

pin adapter

3rd Generation

16 & 4 pin

connector harness

16&4 pin

connector harness

No change from

TECMate PRO

3rd generation

Out of Production

Out of Production

Current Model

In 2013 the TECMate Pro service tool was rebranded to TECINspect.

TECINspect Service Tool Generational Growth

Applicable Motors

2.0, 2.3, EON, 3.0

Model 3.0

diagnostics require a

16-4 pin adaptor

1 , 2

Model 3.0

diagnostics may

require a 16-4 pin

adaptor

1

TECMate XL

TECMate PRO

TECINspect

TECINspect Application Chart

These service tools will properly diagnose applicable Genteq indoor

blower motors in all HVAC OEM equipment.

The TECINspect service tools are not designed for use on Genteq

models 1.0, 2.5, X13 or Evergreen. The TECINspect service tools are

not designed for use on Genteq outdoor fan motors.

1

The 16-4 pin adapter can be ordered from thedealertoolbox.com

2

The TECMate XL may not accuratly troubleshoot Carrier/Bryant 2.0/2.3 models.

REG9971_ECM_Service_Guide_4-10-14.indd 18

4/10/14 10:48 AM

Troubleshooting with the TECINspect

(Models 2.0 / 2.3 / Eon / 3.0 only)

See Motor ID Chart on page 8, if needed.

See the Usage Chart on the opposite page for

motors applicable to the TECINspect.

The TECINspect is capable of identifying a

motor control failure versus another HVAC

system controller or wiring failures.

Connect the TECINspect to the

communication plug on the motor

On Models 2.0/2.3/Eon remove the 5-pin

AC power connector first to make accessing

the 16-pin communication connector locking

tab easier. Remove the 16-pin connector

from the motor, and connect the 16-pin

connector from the TECINspect to the motor.

Reconnect the 5-pin AC power connector.

On Model 3.0 remove the 4-pin connector

from the motor (do not remove the 5-pin

ACpower connector). Connect the 4-pin

connector from the TECINspect to the motor.

Use the 16-4 pin adaptor (p15) with early model

TECMate tools.

1.

(see below).

16

4-pin

16-pin

4-pin

16-pin

Disconnect AC power from the system and make

sure the blower wheel has come to a complete stop

before servicing the motor.

WA R N I N G

Do not operate motor without blower wheel

attached. Such operation will cause the motor to

oscillate up and down.

WA R N I N G

REG9971_ECM_Service_Guide_4-10-14.indd 19

4/10/14 10:48 AM

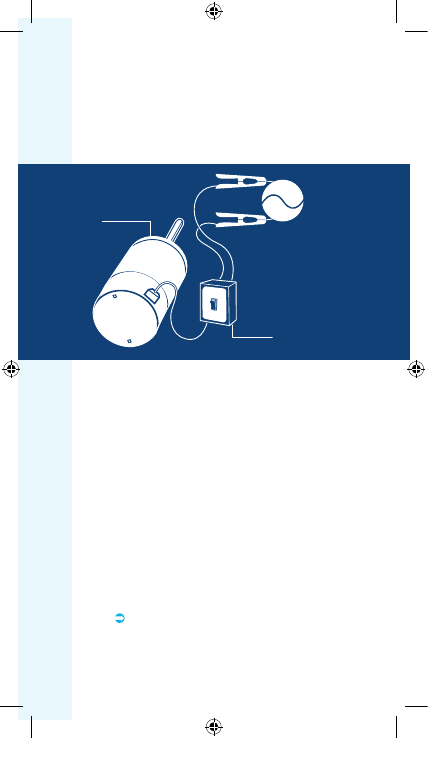

ECM MOTOR

TECINspect

24VAC

Connect the two alligator clips from the

TECINspect to a constant 24VAC

(24VAC

terminal and Common terminal)

source

such as the transformer low-voltage terminals

or terminal strip on the manufacturer’s

control board (see Figure 3 below). These

connections are not polarity sensitive.

Figure 3

NOTE: The high voltage

5-Pin connector must be

connected to the motor for

TECINspect tests.

Place the TECINspect switch(es) in the

OFF position.

Reconnect the AC power to the system. The

green LED light on the TECINspect should

be on when connected properly to 24VAC.

If the green LED light is not on, there is no

power to the TECINspect or the TECINspect

has failed. Do not continue until the green

LED is on by correcting low voltage issue/

connections or replacing the TECINspect.

Refer to the table on the back of the

TECINspect for operation guidelines.

Observe the motor for a minimum of 15

seconds.

If using a TECMate XL on Models

2.0/2.3/Eon,

make sure to set the switches

according to the instructions on the back for

each demand test to eliminate misdiagnosing

the problem.

2.

3.

4.

17

REG9971_ECM_Service_Guide_4-10-14.indd 20

4/10/14 10:48 AM

If using a TECMate XL on Model 3.0

, the

only switch necessary to test the motor is the

furthest switch to the right (labeled BK/PWM

on the XL or DH on the Troubleshooter).

When testing is finished, place the TECINspect

switch(es) in the OFF position and wait for

the motor to completely stop. (Based on the

manufacturer’s program, the motor may not

shut off immediately after a test; this is normal).

If the motor operates using TECINspect,

both the control module and the motor

module are ok.

The motor may operate at a

reduced speed during the TECINspect test, this

is normal. Turn off the power to the unit, remove

the 16-pin or 4-pin communication harness

from both the motor and the manufacturer’s

control board. Perform a continuity check

on each individual wire of the harness. Some

manufacturers use a different style connector

on the control board side of the harness. Follow

the wires to be sure of checking the proper

pins. Replace the communication harness if

any wires fail the continuity check, if any of the

pins are bent beyond rapair or damaged and

check the system operation again. If the harness

is good or a new harness does not solve the

problem, troubleshoot the communication out

of the manufacturer’s control board with their

troubleshooting guide. Always troubleshoot the

communication at the motor end of the harness.

If the motor does not operate with the

TECINspect,

confirm high voltage (pages

13-14) is present before replacing the control

module. Follow the next section on “Replacing

the ECM Control Module” on page 19.

5.

18

REG9971_ECM_Service_Guide_4-10-14.indd 21

4/10/14 10:48 AM

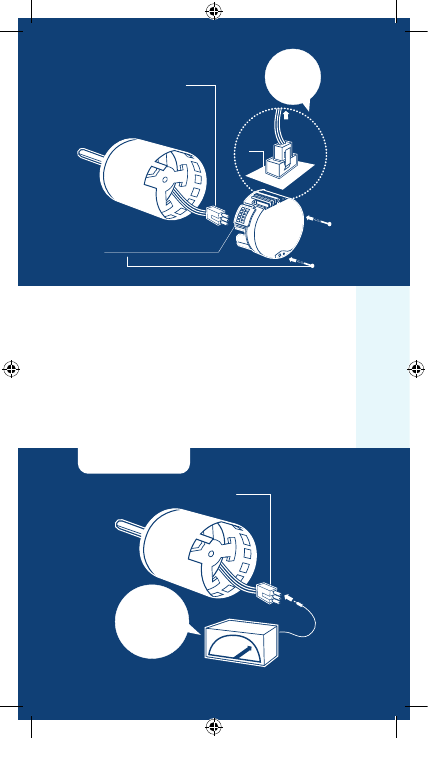

Before replacing the electronic-control module,

you must test the motor module to ensure it

is not also damaged. Installing a new control

on a failed motor will result in no operation,

improper operation and/or potential failure

of the new control. Procedures for testing the

motor module are included below.

Replacing the

ECM Control Module

(Models 2.0/ 2.3/ 2.5/ Eon/ 3.0 Only)

Disconnect AC power from the HVAC system.

Unplug the 16-pin or 4-pin communication

connector and the 5-pin connector from the

motor control.

Remove the blower assembly from the HVAC

system if needed.

ONLY after the system AC power has been

off for 5 minutes

, remove the two (2) hex-

head screws from the back of the control.

Unplug the 3-pin connector from the inside

of the control by squeezing the latch and

gently pulling on the connector (see Figure 4

on the next page). Now you’re ready to

test the motor.

19

Disconnect AC power from the system and make

sure the blower wheel has come to a complete

stop before servicing the motor.

WA R N I N G

You must have the correct replacement module

and/or motor from the manufacturer that is a direct

replacement for the failed module and/or motor.

USING THE WRONG MODULE AND/OR MOTOR

VOIDS ALL PRODUCT WARRANTIES AND MAY

PRODUCE UNEXPECTED RESULTS.

WA R N I N G

1.

2.

3.

4.

REG9971_ECM_Service_Guide_4-10-14.indd 22

4/10/14 10:48 AM

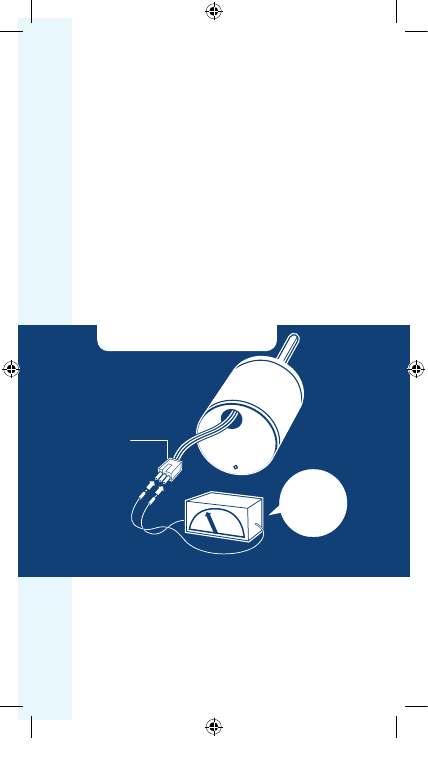

MOTOR MODULE TESTS

A.

The Winding Test (see Figure 5)

Set ohm meter to the highest possible setting

and measure resistance between each of the

three motor leads to the unpainted part of

the end shield (or x-brace on model Eon &

3.0). The motor passes the test if the meter

indicates greater than 100k ohms.

MOTOR CONNECTOR

(3-PIN)

16-PIN & 5-PIN CONNECTORS

FROM

MOTOR

CIRCUIT

BOARD

HEX HEAD SCREWS

Push until latch

seats over ramp

Only remove

Hex Head Bolts

Figure 4

MOTOR CONNECTOR

(3-PIN)

WINDING

TEST

MOTOR

OK

WHEN

R

>

100k ohm

Figure 5

20

X-BRACE

REG9971_ECM_Service_Guide_4-10-14.indd 23

4/10/14 10:48 AM

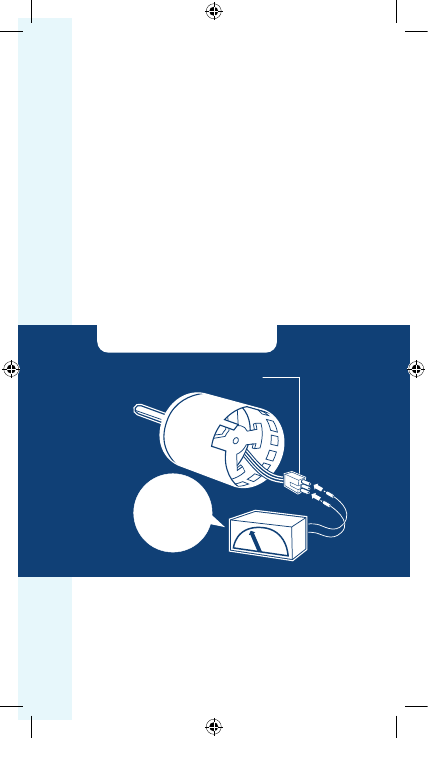

B.

The Phase-to-Phase Test

(see Figure 6 below)

Set ohm meter to lowest possible setting

and measure the motor phase to phase

resistance by checking these combinations

of the 3-pin motor connector with an

ohm meter:

Lead 1 to lead 2

Lead 1 to lead 3

Lead 2 to lead 3

For the purpose of this test, either end of the

3-pin plug is lead 1. Resistance values should

be less than 20 ohms and each of the three

values should be the same (plus or minus

10%). If the measured resistance is outside of

these parameters, the motor fails the test.

MOTOR CONNECTOR

(3-PIN)

PHASE - TO - PHASE

TEST

MOTOR

OK

WHEN

R

<

20 ohm

(lead to lead)

Figure 6

21

C.

If the motor passes both of these tests

and the shaft spins freely when rotated

by hand,

then the motor is ok and only the

control must be replaced. Continue with

replacing the ECM control module in step 5.

REG9971_ECM_Service_Guide_4-10-14.indd 24

4/10/14 10:48 AM

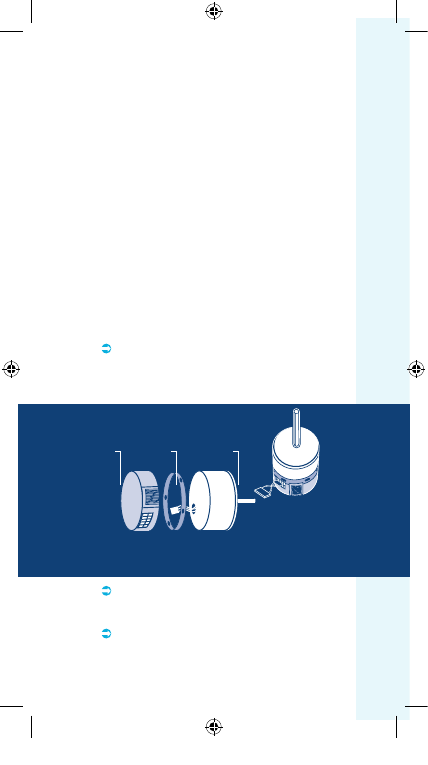

D.

If the motor fails either of these tests

or does not spin freely when rotated by

hand,

replace the motor and control module

following the guidelines on page 24.

Insert the 3-pin connector back into the new

control module. A slight click will be heard

when inserted properly. This connector is

keyed for proper connection.

Attach the new control module with the plug

connections oriented down (see figure 7,

page 23), insert the appropriate bolts and

tighten. Due to model replacements, some

motors may need to be rotated in their

mount to orient the plug connectors properly.

See below for model specific notes and/or

follow any OEM instructions included with

the new control.

Model 2.0 & 2.3 - These models are no

longer available and can only be replaced

with an OEM Eon kit that includes a motor

adapter ring (see below).

Model Eon - This model can only be

replaced with with an OEM Eon.

Model 2.5 - This model is no longer in

production. It can only be replaced with an

OEM 3.0 kit that includes a 16-4 pin wiring

adapter and a motor adapter ring.

5.

6.

22

16-4 Pin Adapter

Completed Assembly

Adapter Ring

Eon Control

Model 2.0 or

2.3 Motor

REG9971_ECM_Service_Guide_4-10-14.indd 25

4/10/14 10:48 AM

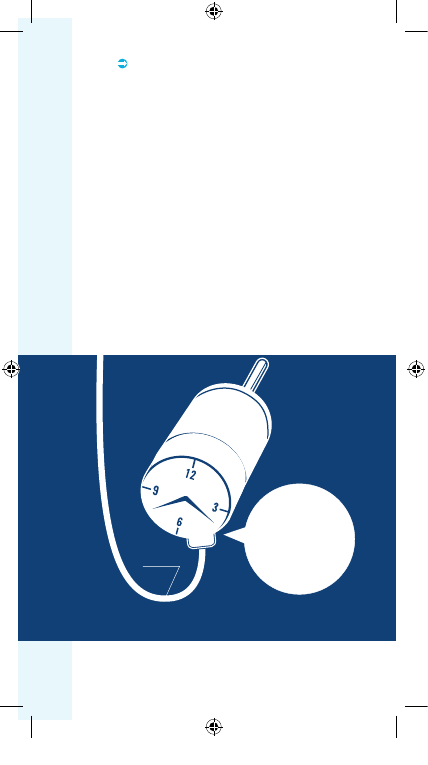

DRIP LOOP

DRIP LOOP

Connection Orientation

Between 4 and 8 o’clock

Model 3.0 - This model can only be

replaced with an OEM 3.0.

Reinstall the blower/motor assembly

into the HVAC system by following the

manufacturer’s guidelines.

Plug the 16-pin or 4-pin communication

connector and the 5-pin connector back

into the motor. The connectors are keyed.

Observe proper orientation.

Be certain to form a drip loop so that water

cannot enter the motor by draining down the

cables (see Figure 7 below).

Go to the “Final Installation Checks” on

pages 53-54.

Figure 7

7.

8.

9.

10.

23

REG9971_ECM_Service_Guide_4-10-14.indd 26

4/10/14 10:48 AM

Replacing the

ECM Motor and Control Modules

(Models 2.0 / 2.3 / 2.5 / Eon / 3.0)

28

The most efficient way to install the motor is to

have the control already attached.

If the new motor and control are not already

bolted together use the OEM instructions or

steps 5 and 6 on page 22.

Make sure the belly band mount is on the

motor module only and is not covering any of

the motor shell holes. Typically the belly band

is located between the two sets of motor

shell holes.

Before tightening down the belly band, rotate

the motor until the connectors in the control

are facing down or at least between the 4 and

8 o’clock position in the blower housing, as it

will mount into the HVAC system (see figure

7 page 23).

Center the blower wheel in the blower housing

and tighten the blower wheel hub bolt on the

flat portion of the motor shaft.

Reinstall the blower/motor assembly into the

HVAC system by following the

manufacturer’s guidelines.

Plug the 16-pin or 4-pin communication

connector and the 5-pin connector back into

the motor. The connectors are keyed. Observe

proper orientation.

Be certain to form a drip loop so that water

cannot enter the motor by draining down the

cables (see figure 7 page 23).

Go to the “Final Installation Checks” on

pages 53-54.

24

1.

2.

3.

4.

5.

6.

7.

8.

REG9971_ECM_Service_Guide_4-10-14.indd 27

4/10/14 10:48 AM

25

WA R N I N G

Working on the motor with power connected may

result in electrical shock or other conditions that may

cause personal injury, death or property damage.

Always disconnect the power from the HVAC system before

removing or replacing connectors, servicing the motor,

removing the high voltage plug, and before reconnecting.

WA R N I N G

Disconnect AC power from the system and make

sure the blower wheel has come to a complete stop

before servicing the motor.

WA R N I N G

Do not operate motor without blower wheel

attached. Such operation will cause the motor to

oscillate up and down.

WA R N I N G

You must have the correct replacement motor from

the manufacturer that is a direct replacement for

the failed motor. USING THE WRONG MOTOR

VOIDS ALL PRODUCT WARRANTIES AND MAY

PRODUCE UNEXPECTED RESULTS.

WA R N I N G

Always disconnect the power from the HVAC

system and wait at least 5 minutes before opening

the motor, i.e. removing the two bolts from the

motor control (end bell) and disconnecting the 3-pin

plug to the motor. This is to allow the capacitors to

dissipate for safety.

WA R N I N G

WA R N I N G

Genteq does not condone the repair of any individual

components in the motor control or motor of their

ECM products. This practice is unsafe and may cause

personal injury, death, or property damage.

REG9971_ECM_Service_Guide_4-10-14.indd 28

4/10/14 10:48 AM

X13 MO

TOR

Model X13

Standard ECM Motor Diagnostics

See the Motor ID Chart on page 7 if needed.

It is normal for the motor to rock back and

forth on start up. Do not replace the motor

if this is the only problem identified.

If the system is excessively noisy, does

not appear to change speeds in response

to a demand (Heat or Cool), or is having

symptoms during the cycle such as a tripping

limit or freezing coil, check the following:

Wait for programmed delays to time out.

If delays are too long, reset them using the

manufacturer’s charts.

Ensure the airflow settings are correct for

the installed system using the manufacturer’s

charts. If the system is operating normally in

each mode, there is no problem.

Remove the filter and check that all of the

dampers, registers, and grills are open and

free flowing. If removing the filter corrects

the problem, clean or replace with a less

restrictive filter. Also check and clean as

needed the blower wheel, secondary heat

exchanger (if applicable) and evaporator coil

(if applicable).

If this does not correct the problem then:

Check the external static pressure.

If it is higher than the manufacturer’s

recommendations, correct the airflow

restriction.

IF THE MOTOR IS RUNNING

26

1.

2.

REG9971_ECM_Service_Guide_4-10-14.indd 29

4/10/14 10:48 AM

If the motor does not shut off at the end of

the cycle, check the delay times and wait for

the delays to time out. Also make sure that

there is no call for “Continuous fan” on the “G”

terminal. This motor may take a while to come

to a complete stop with selected delays.

If the above diagnostics do not solve the

problem, confirm the voltage checks in

the next section below, then continue

diagnostics in the section, “Model X13

Standard ECM Motor Communication

Diagnostics.” The TECINspect is not

designed for use on this motor.

IF THE MOTOR IS NOT RUNNING

Check for proper high voltage and ground

at the (L)(G)(N) connections at the motor

(see Figure 8 on the next page). Correct any

voltage issues before proceeding to the next

step. The X13 motor is voltage specific. Only

the correct voltage should be applied to the

proper motor. Input voltage within plus or

minus 10% of the nominal 115VAC, 230VAC,

277VAC or 460VAC is acceptable.

Always disconnect the power from the system before

removing the high voltage plug, and before reconnecting.

WA R N I N G

27

1.

3.

4.

The TECINspect is not needed for use

on this motor. If the motor has proper

high voltage and ground at the (L)(G)(N)

connections, continue diagnostics in the next

section, “Model X13 Standard ECM Motor

Communication Diagnostics.”

2.

REG9971_ECM_Service_Guide_4-10-14.indd 30

4/10/14 10:48 AM

115VAC MOTOR

NEUTRAL

GROUND

115VAC

LINE 1

C L G N

1 2 3 4 5

230VAC MOTOR

115VAC

LINE 1

115VAC

LINE 2

C L G N

1 2 3 4 5

GROUND

460VAC MOTOR

GROUND

277VAC

LINE 1

277VAC

LINE 2

C L G N

1 2 3 4 5

277VAC MOTOR

GROUND

277VAC

LINE 1

NEUTRAL

C L G N

1 2 3 4 5

Figure 8

28

REG9971_ECM_Service_Guide_4-10-14.indd 31

4/10/14 10:48 AM

Model X13

Standard ECM

Motor Communication Diagnostics

Start with the manufacturer’s literature to

confirm proper set-up, connections and

voltage. It is not required that all terminals

on the motor have a program. If the low-

voltage communication is applied to an

unprogrammed terminal, the motor will not

operate, which is normal.

Initiate a demand from the thermostat and

check the voltage between the common and

the appropriate motor terminal 1- 5. Confirm

the meter is set to the voltage identified

from the manufacturer’s literature (see

Figures 9 and 10 on the next page).

If the low voltage communication is

not present, check the demand from the

thermostat. Also check the output terminal

and wire(s) from the manufacturer’s control

board or relays to the motor.

If the motor has proper high voltage as

identified in the previous section, and proper

low voltage to a programmed terminal, and

is not operating, follow the next section on

“Replacing the ECM Control Module” on

page 31.

The X13 motor can be communicated through

AC or DC low voltage. AC voltage is typically

24VAC and DC voltage can be between

9-23VDC (see Figures 9 and 10 on the next page).

29

1.

2.

Figure 4

REG9971_ECM_Service_Guide_4-10-14.indd 32

4/10/14 10:48 AM

30

AC

VOLTAGE

CONTROL

INPUTS

AC VOLTS

V

COM

24 VAC

C L G N

1 2 3 4 5

DC

VOLTAGE

CONTROL

INPUTS

DC VOLTS

V

COM

9-23 VAC

C L G N

1 2 3 4 5

Figure 9

Figure 10

REG9971_ECM_Service_Guide_4-10-14.indd 33

4/10/14 10:48 AM

Before replacing the electronic-control module,

you must test the motor module to ensure it

is not also damaged. Installing a new control

on a failed motor will result in no operation,

improper operation and/or potential failure

of the new control. Procedures for testing the

motor module are included below.

Replacing the

ECM Control Module

(Model X13)

Disconnect AC power from the HVAC

system. Unplug all wires and/or connectors.

Note tap position of all individual wires from

the motor control.

Remove the blower assembly from the HVAC

system if needed.

ONLY after the system AC power has been

off for 5 minutes

, remove the two (2) hex-

head screws from the back of the control.

Unplug the 3-pin connector from the inside

of the control by squeezing the latch and

gently pulling on the connector (see Figure 11

on the next page). Now you’re ready to

test the motor.

31

Disconnect AC power from the system and make

sure the blower wheel has come to a complete

stop before servicing the motor.

WA R N I N G

You must have the correct replacement module

and/or motor from the manufacturer that is a direct

replacement for the failed module and/or motor.

USING THE WRONG MODULE AND/OR MOTOR

VOIDS ALL PRODUCT WARRANTIES AND MAY

PRODUCE UNEXPECTED RESULTS.

WA R N I N G

1.

2.

3.

4.

REG9971_ECM_Service_Guide_4-10-14.indd 34

4/10/14 10:48 AM

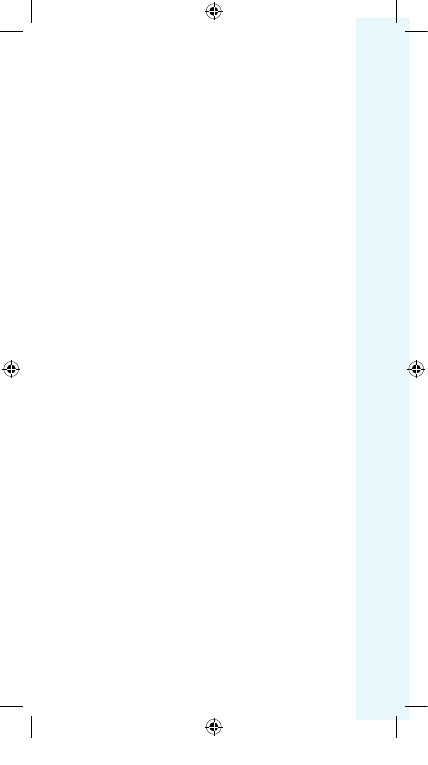

MOTOR MODULE TESTS

A.

The Winding Test (see Figure 12)

Set ohm meter to the highest possible setting

and measure resistance between each of the

three motor leads to the unpainted part of

the x-brace. The motor passes the test if the

meter indicates greater than 100k ohms.

MOTOR CONNECTOR

(3-PIN)

4-PIN & 5-PIN CONNECTORS

HEX HEAD SCREWS

FROM

MOTOR

CIRCUIT

BOARD

Push until latch

seats over ramp

Figure 11

MOTOR CONNECTOR

(3-PIN)

WINDING

TEST

MOTOR

OK

WHEN

R

>

100k ohm

Figure 12

32

REG9971_ECM_Service_Guide_4-10-14.indd 35

4/10/14 10:48 AM

B.

The Phase-to-Phase Test

(see Figure 13 below)

Set ohm meter to lowest possible setting

and measure the motor phase to phase

resistance by checking these combinations

of the 3-pin motor connector with an

ohm meter:

Lead 1 to lead 2

Lead 1 to lead 3

Lead 2 to lead 3

For the purpose of this test, either end of the

3-pin plug is lead 1. Resistance values should

be less than 20 ohms and each of the three

values should be the same (plus or minus

10%). If the measured resistance is outside of

these parameters, the motor fails the test.

PHASE - TO - PHASE

TEST

MOTOR CONNECTOR

(3-PIN)

MOTOR

OK

WHEN

R

<

20 ohm

(lead to lead)

Figure 13

33

C.

If the motor passes both of these tests

and the shaft spins freely when rotated

by hand,

then the motor is ok and only the

control must be replaced. Continue with

replacing the ECM control module in step 5.

REG9971_ECM_Service_Guide_4-10-14.indd 36

4/10/14 10:48 AM

D.

If the motor fails either of these tests

or does not spin freely when rotated by

hand,

replace the motor and control modules

following the guidelines on page 36.

Insert the 3-pin connector back into the new

control module. A slight click will be heard

when inserted properly. This connector is

keyed for proper connection.

Attach the new control module with the plug

connections oriented down (see figure 14,

page 35), insert the appropriate bolts and

tighten.

Reinstall the blower/motor assembly into the

HVAC system by following the manufacturer’s

guidelines.

Reconnect all wires and/or connectors. Make

sure individual wires are connected to proper

taps.

Be certain to form a drip loop so that water

cannot enter the motor by draining down the

cables (see Figure 14 below).

Go to the “Final Installation Checks” on

pages 53-54.

5.

6.

34

7.

8.

9.

10.

REG9971_ECM_Service_Guide_4-10-14.indd 37

4/10/14 10:48 AM

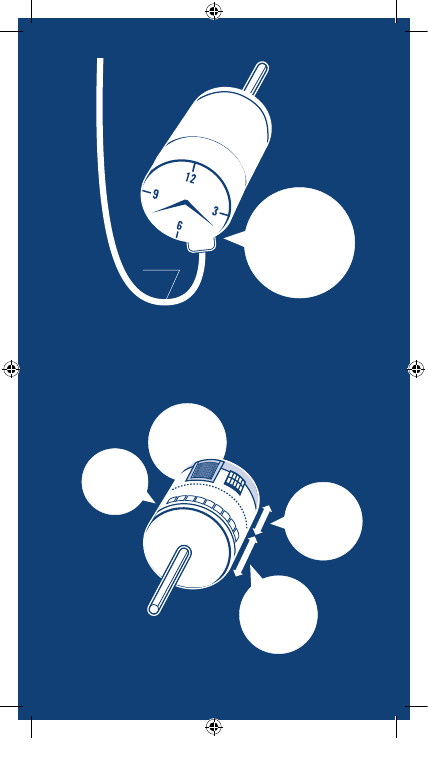

ECM X13

2.75” BELLYBAND

KEEP OUT AREA

RECOMMENDED

BELLYBAND AREA

DO NOT

COVER VENTS

DRIP LOOP

DRIP LOOP

Connection Orientation

Between 4 and 8 o’clock

Figure 14

35

Figure 15

REG9971_ECM_Service_Guide_4-10-14.indd 38

4/10/14 10:48 AM

Replacing the

ECM Motor and Control Modules

(Model X13)

The most efficient way to install the motor is to

have the control already attached.

If the new motor and control are not already

bolted together use the OEM instructions or

steps 5 and 6 on page 34.

When replacing the X13 motor with a belly

band for mounting, the band should not be

located in the area identified in Figure 15.

Before tightening down the belly band, rotate

the motor until the connectors in the control

are facing down or at least between the 4 and

8 o’clock position in the blower housing, as it

will mount into the HVAC system (see figure

14 page 35).

Center the blower wheel in the blower housing

and tighten the blower wheel hub bolt on the

flat portion of the motor shaft.

Reinstall the blower/motor assembly into the

HVAC system by following the manufacturer’s

guidelines.

Reconnect all wires and/or connectors.

Make sure individual wires are connected to

proper taps.

Be certain to form a drip loop so that water

cannot enter the motor by draining down the

cables (see figure 14 page 35).

Go to the “Final Installation Checks” on

pages 53-54.

36

1.

2.

3.

4.

5.

6.

7.

8.

REG9971_ECM_Service_Guide_4-10-14.indd 39

4/10/14 10:48 AM

37

Introduction:

Evergreen is an ECM designed as an

aftermarket replacement of existing PSC

(Permanent Split Capacitor), direct drive,

indoor blower motors for the purpose of

increasing efficiency and comfort. For more

information on this motor please visit www.

thedealertoolbox.com. There you will also find

the complete installation manual, training

videos and other valuable information.

Evergreen motors are not approved to replace

existing ECM Variable Speed or X13 motors,

should not be used on twinned systems and

should not be used on belt drive systems.

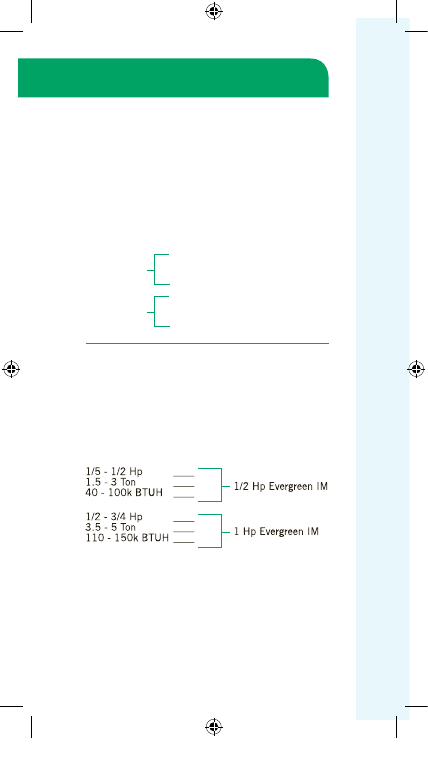

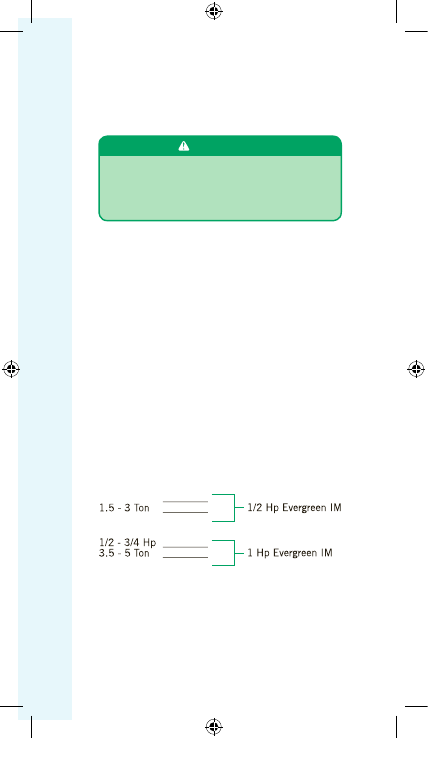

There are two Evergreen Models. Please make sure

to use the appropriate troubleshooting information.

See the Motor ID chart on page 7 if needed.

Evergreen IM (page 38)

This motor is dual voltage 120-240VAC,

reversible, multi-horsepower, and designed for

all residential HVAC systems less than 5 ton of

cooling and 150k BTUh of heating.

Evergreen AH (page 45)

This motor is 208-230VAC only, non reversible,

and designed for any air handler application

including package systems that do not

incorporate fossil fuel.

Evergreen

Indoor Blower Motor Diagnostics

See the Motor ID Chart on page 7 if needed.

REG9971_ECM_Service_Guide_4-10-14.indd 40

4/10/14 10:48 AM

Evergreen • IM Diagnostics

Note: Please read the introduction on page 37

before using these diagnostics

IMPORTANT NOTE:

There must be proper voltage at the

High

Voltage POWER and High Voltage SIGNAL

connections for the motor to operate. Skipping

any of the troubleshooting in this section

could result in misdiagnosis of the motor and/

or HVAC system.

W A R N I N G

ALWAYS DISCONNECT MAIN HVAC SYSTEM

POWER BEFORE DIS-CONNECTING OR

RE-CONNECTING ANY WIRES OR

CONNECTORS TO THE EVERGREEN MOTOR.

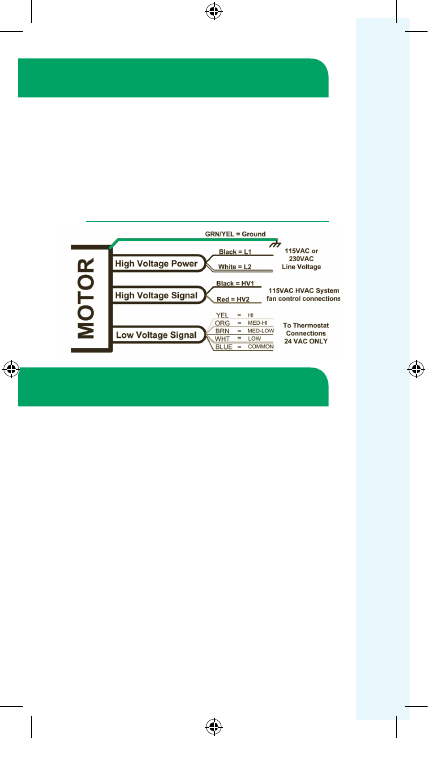

Check that the proper Line Voltage jumper

is installed.

For 230VAC systems the yellow jumper

should be installed. For 115VAC systems the

white jumper should be installed.

NOTE:

If

the motor was powered with 230VAC while the

white jumper was installed, the motor may be

permanently damaged and need to be replaced.

Continue troubleshooting here after proper

jumper is installed.

38

230VAC

115VAC

Yellow Jumper

White Jumper

IF THE MOTOR IS NOT RUNNING

REG9971_ECM_Service_Guide_4-10-14.indd 41

4/10/14 10:48 AM

39

Confirm proper system line voltage is

connected. Measure the voltage at the

High

Voltage POWER connections L1 (black) and L2

(white). On 115VAC systems, Neutral should

be connected to L2. The power connected to

these taps should be continuous un-switched

line voltage.

This voltage alone will not operate

the motor. If proper voltage is not present,

troubleshoot the HVAC system. Continue

troubleshooting here after proper voltage has

been confirmed.

Confirm there is a 115VAC demand on

any one or all of the

High Voltage SIGNAL

connections. The High Voltage SIGNAL

connections of the motor should only be

connected to the HVAC Systems 115VAC

fan controls (fan relay or circuit

board) connections.

On 230VAC systems, the voltage switched

by the fan controls must be the same line

voltage that is connected to the L1 High

Voltage POWER connection.

If 115VAC L1 and Neutral or 230VAC L1

and L2 was powered to these connections, the

motor may be permanently damaged and need

to be replaced.

If proper voltage is not present, troubleshoot

the HVAC System.

IF THE MOTOR IS NOT RUNNING

(continued)

REG9971_ECM_Service_Guide_4-10-14.indd 42

4/10/14 10:48 AM

40

IF THE MOTOR IS NOT RUNNING

(continued)

Final Diagnosis – If there is a 115VAC demand

on one or more of the High Voltage SIGNAL

connections, the correct Line Voltage Jumper

is installed, there is proper voltage on the High

Voltage POWER connections and the motor is

not operating, replace the motor.

Sequence of Operation

A

Low Voltage SIGNAL demand from the HVAC

Systems thermostat connection alone will

not operate the motor. The motor will turn

on when it receives its

High Voltage SIGNAL

demand from the HVAC Systems fan controls

(fan relay or circuit board) connections. The

High Voltage POWER connections must be

powered continuously from the proper line

voltage. Constant fan operation does not

require a Low Voltage SIGNAL demand. The

special low constant fan speed will operate

with a High Voltage SIGNAL demand alone.

REG9971_ECM_Service_Guide_4-10-14.indd 43

4/10/14 10:48 AM

41

IF THE MOTOR IS RUNNING

If the motor is running but there is an

airflow issue causing improper performance,

undesired comfort or HVAC System failure,

check the following:

Confirm the proper HVAC System 24VAC

thermostat demand is connected to a

Low

Voltage SIGNAL (speed) tap. Any voltage above

30VAC could permanently damage the motor.

This voltage alone will not operate the motor

(See the Sequence of Operation section on

page 40). Confirm there is proper 24VAC

between the selected Low Voltage SIGNAL

(speed) tap and the BLUE Common tap on the

motor. (see schematic on page 40) If more or

less airflow is required, change this connection

to a higher or lower speed tap. If the highest or

lowest speed tap does not achieve the required

airflow, the horse power (Hp) selection may

need to be adjusted. If proper 24VAC is not

present, troubleshoot the HVAC System.

Continue troubleshooting here if this does not

solve the problem.

CAUTION:

Adjusting the Horse Power (Hp) selection will

change the airflow value of all Low Voltage

SIGNAL (speed) taps. If the Hp selection is

changed, airflow in all demands will need to be

checked and adjusted as needed.

REG9971_ECM_Service_Guide_4-10-14.indd 44

4/10/14 10:48 AM

42

IF THE MOTOR IS RUNNING

(continued)

To achieve the proper horse power (Hp) the

High Voltage SIGNAL connections must be

connected to the HVAC Systems fan controls

according to the diagrams on page 43. When

the motor was installed it should have been

configured to match the Hp of the replaced

motor. To increase or decrease the Hp

selection, see the chart below.

HV1 & HV2 = 1/2 - 1/3 Hp operation

1/2 Hp Motor

HV1

= 1/3 - 1/4 Hp operation

HV2

= 1/4 - 1/5 Hp operation

HV1 & HV2 = 3/4 Hp operation

1 Hp Motor

HV1

= 3/4 – 1/2 Hp operation

HV2

= 1/2 Hp operation

If the highest or lowest Hp setting does not

achieve the required airflow, the motor size

may be incorrect. This motor is designed to

replace multiple motors based on Hp and

system sizing. If the sizing of the motor is in

question, see the selection chart below.

REG9971_ECM_Service_Guide_4-10-14.indd 45

4/10/14 10:48 AM

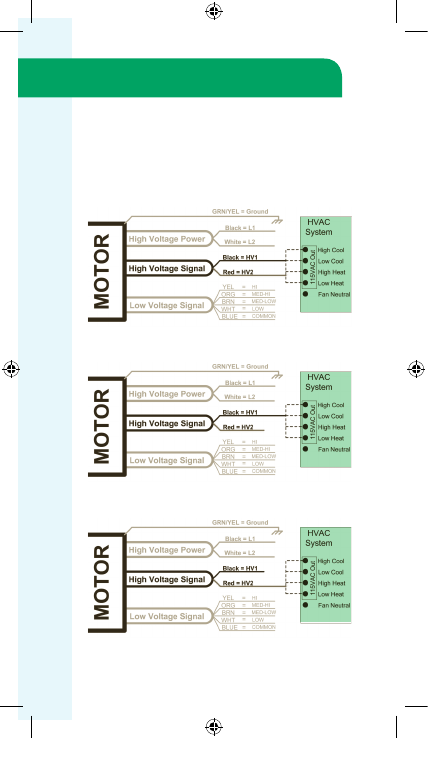

The

High Voltage SIGNAL connections are

connected together with all the 115VAC fan

outputs from the HVAC Systems controls to

communicate to the motor when to turn on

and at what horse power to operate at.

43

IF THE MOTOR IS RUNNING

(continued)

REG9971_ECM_Service_Guide_4-10-14.indd 46

4/10/14 10:48 AM

44

Airflow restrictions can be caused by any one

or more of the following:

Dirty filters

Dirty blower wheel, secondary heat

exchanger and/or evaporator

Too many registers, grilles and/or

balancing dampers are closed.

Dirty, damaged, or poorly constructed

ductwork.

All of these issues can be solved by visual

inspection and cleaning. If this does not solve

the problem check the Total External Static

Pressure (TESP). If the TESP is above .8,

there is an issue with the ductwork or filter

sizing that must be corrected. After correcting

one or more airflow restrictions, it may be

necessary to adjust the speed selection and/or

horse power selection.

If the diagnostics provided here do not solve

your problem, please go to

thedealertoolbox.com

and download

the full installation manual for further support.

Technical Support is also available on the

Evergreen Hotline at 1-866-503-8566.

IF THE MOTOR IS RUNNING

(continued)

•

•

•

•

REG9971_ECM_Service_Guide_4-10-14.indd 47

4/10/14 10:48 AM

45

Evergreen • AH Diagnostics

Note: Please read the introduction on page 37

before using these diagnostics

W A R N I N G

ALWAYS DISCONNECT MAIN HVAC SYSTEM

POWER BEFORE DIS-CONNECTING OR

RE-CONNECTING ANY WIRES OR

CONNECTORS TO THE EVERGREEN MOTOR.

Evergreen • AH Selection Data

Check the HVAC systems existing PSC motor

horse power (Hp) and tonnage of the outdoor

unit to determine the Evergreen sizing. If only

one checkmark falls in each Evergreen sizing

use the larger motor.

1/6 - 1/2 Hp

IMPORTANT NOTE:

There must be proper voltage at the

High

Voltage POWER and the Low Voltage (Speed

Tap) connections for the motor to operate.

Skipping any of the troubleshooting in this

section could result in misdiagnosis of the

motor and/or HVAC system.

REG9971_ECM_Service_Guide_4-10-14.indd 48

4/10/14 10:48 AM

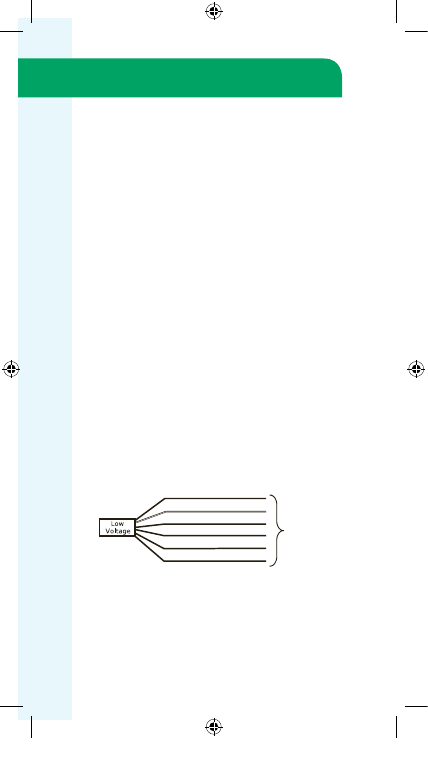

IF THE MOTOR IS NOT RUNNING

Step 1.

Confirm 208-240 VAC between the

two black leads of the motor.

If there is not proper voltage at these leads,

correct the problem before the motor. If the

motor still does not operate after this step has

been corrected, go to

Step 2.

If there is proper voltage at these leads,

go to

Step 2.

Step 2.

Confirm 24 VAC between any one of

the speed taps (Green, Orange, Brown, White

or Yellow) and the Blue lead (24 VAC common

connection)

If there is not proper voltage at one or all of

these leads during proper system demand,

correct the problem before the motor. The

motor should operate with 24 VAC supplied

to any of its speed taps, with proper 24 VAC

common supplied to the blue lead of the

motor. If the motor still does not operate

after this has been corrected, replace the

motor.

46

YEL

HIGH

BRN

MED -LOW

ORN

LOW

GRN

CONST FAN

BLU

24V COM

WHT

MED

-HI

To thermos tat

connections

24 V AC O NL Y

GRN w / Y EL

BLK

BLK

L 1

L 2

G round

208 - 240 V AC

REG9971_ECM_Service_Guide_4-10-14.indd 49

4/10/14 10:48 AM

Symptom:

47

IF THE MOTOR IS RUNNING

If the motor is running but there is an airflow

issue causing improper performance,

undesired comfort or HVAC System failure,

check the following:

Step 1.

Check all of the airside components

such as registers, diffusers, grilles, filters,

blower wheel, and indoor coil for dirt or other

restrictions. Check filter sizing, especially

aftermarket filters.

Clean any dirt or debris on the airside

components. Open and clear all registers,

diffusers and grilles. Replace filters with

proper size according to manufacturer specs.

Aftermarket filters may need to be larger than

the original specs. If this does not correct the

problem go to step 2.

Step 2.

Confirm that the proper speed tap has

been selected for the proper demand by checking

the airflow using one of the methods covered in

the “Airflow Tests” section of the Evergreen

AH manual. This manual can be downloaded

from thedealertoolbox.com.

If the airflow needs to be increased or

decreased, select the speed tap that produces

the proper airflow for the system tonnage.

YEL

HIGH

BRN

MED -LOW

ORN

LOW

GRN

CONST FAN

BLU

24V COM

WHT

MED

-HI

To thermos tat

connections

24 V AC O NL Y

REG9971_ECM_Service_Guide_4-10-14.indd 50

4/10/14 10:48 AM

48

IF THE MOTOR IS RUNNING

(continued)

If the LOW speed is too much airflow or HIGH

speed is not enough airflow, check the motor

sizing using the selection chart on page 45.

Install the correct size motor if needed and

repeat step 2.

(See note below first) If this

does not correct the problem go to Step 3.

NOTE:

Do not oversize the motor to correct airflow

problems. If the motor installed matches the

motor selection chart recommendation, select

the speed that produces the best possible

airflow and proceed to Step 3.

Step 3.

Check the system’s Total External

Static Pressure (Total ESP).

If the total ESP is higher than the system

manufacturer recommends, the problem is

most likely a restricted or undersized duct

system. Correct the duct issues.

If the Total ESP is lower than the system

manufacturer recommends, the problem

is most likely a disconnected or improper

opening in the duct system. Correct the

duct issues.

If the diagnostics provided here do not solve

your problem, please go to

thedealertoolbox.com

and download

the full installation manual for further support.

Technical Support is also available on the

Evergreen Hotline at 1-866-503-8566.

REG9971_ECM_Service_Guide_4-10-14.indd 51

4/10/14 10:48 AM

29

49

WA R N I N G

Working on the motor with power connected may

result in electrical shock or other conditions that may

cause personal injury, death or property damage.

Always disconnect the power from the HVAC system before

removing or replacing connectors, servicing the motor,

removing the high voltage plug, and before reconnecting.

WA R N I N G

Disconnect AC power from the system and make

sure the fan blade has come to a complete stop

before servicing the motor.

WA R N I N G

Do not operate motor without fan blade attached.

Such operation will cause the motor to oscillate

up and down.

WA R N I N G

You must have the correct replacement motor from

the manufacturer that is a direct replacement for

the failed motor.

USING THE WRONG MOTOR VOIDS ALL

PRODUCT WARRANTIES AND MAY PRODUCE

UNEXPECTED RESULTS.

WA R N I N G

WA R N I N G

Genteq does not condone the repair of any individual

components in the motor control or motor of their

ECM products. This practice is unsafe and may cause

personal injury, death, or property damage.

REG9971_ECM_Service_Guide_4-10-14.indd 52

4/10/14 10:48 AM

OUTDOOR

M

OTO

R

It is normal for the motor to rock back and

forth on start up. Do not replace the motor if

this is the only symptom identified.

If the system is working properly but the

motor appears to run slower than it should,

the motor is good. High efficiency systems,

especially those with optimized fan blades,

will run the motor slower to decrease noise.

If the system is noisy, freezing up, running

a high head pressure, tripping the high

pressure switch or the compressor overload,

check the following:

Clean the condensing coil and any

shrouds thoroughly including in between

two pass coils (this may require some unit

disassembly) following the manufacturer’s

recommendations. This motor will not

compensate for lack of airflow through

dirty coils.

Confirm all fan blades are shaped the

same, in good condition and not rubbing

on the shroud. Also confirm the fan blade

hub bolt is secure on the motor shaft. Also

confirm the motor is secure in its mount and

the mount legs are secure to the unit.

Use the next section “If the motor is not

running” for voltage checks to determine if

the motor is getting the proper inputs.

If the motor does not appear to be running

at the proper speed or does not shut off,

refer to the next section for voltage checks

to determine if the motor is getting the

proper inputs.

1.

2.

3.

4.

Models 142 and 142R ECM

Outdoor Fan Motor Diagnostics

See the Motor ID chart on page 7 if needed.

IF THE MOTOR IS RUNNING

50

REG9971_ECM_Service_Guide_4-10-14.indd 53

4/10/14 10:48 AM

Check for proper high voltage and ground.

Using the OEM schematics, locate the L1,

L2, and Ground connections and confirm

voltage is 208-230 10%. Correct any voltage

issues, worn or broken connections.

This motor is energized and de-energized

with communication inputs. Model variations

include Single Speed 24VAC communication,

Multi-speed 24VAC communication and

Single or Multi-speed PWM communication.

See example figures on p52. Using the OEM

schematic, identify the communication type

and check for proper voltage. PWM taps are

diagnosed with DC voltage specified by the

HVAC unit OEM.

If the motor IS NOT receiving any

communication,

troubleshoot the

communication issue using the manufacturer’s

troubleshooting guides. The control board in

the outdoor unit will need the proper demand

call (low voltage or communication) from

the indoor controls to provide the proper

communication to the motor. Confirm these

demand(s) are there before checking the

communication to the motor.

If the motor IS receiving proper

communication

(and proper high voltage

power) and is not running, proceed to the

next section on Motor Replacement.

1.

2.

IF THE MOTOR IS NOT RUNNING

This motor uses a 5 or 6 wire harness with wire

colors specified by the OEM. Therefore the

OEM schematic for the particular unit you are

working on will be necessary to identify motor

connections on the system controls.

51

REG9971_ECM_Service_Guide_4-10-14.indd 54

4/10/14 10:48 AM

Replacing the Motor

This motor is replaced in one piece. The control

cannot be replaced separately from the motor.

Even if the control is remotely located, the

replacement part will be a new control with

harness and new motor.

You must have the correct replacement

motor from the manufacturer that is a direct

replacement for the failed motor. USING THE

WRONG MOTOR VOIDS ALL PRODUCT

WARRANTIES AND MAY PRODUCE

UNEXPECTED RESULTS.

Always mount the replacement motor and

control (if mounted separately) according to the

manufacturer’s specifications using all required

hardware to reduce vibration. Make sure all

wires are free of the fan blade and not pinched

in mountings or cabinet through points.

52

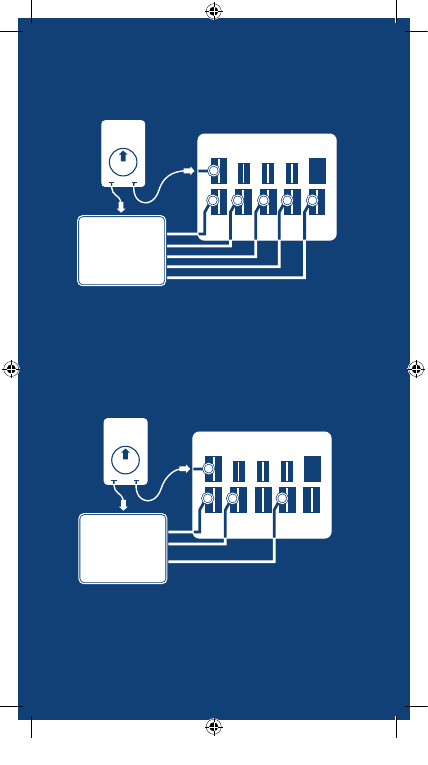

OEM

CONTROL

L1 (115VAC)

L2 (115VAC)

Ground

Speed Tap (24VAC)

Common (24VAC)

OEM

CONTROL

OEM

CONTROL

24VAC Communicated

Single Speed Models

142 & 142

R

24VAC Communicated

Multi-Speed Models

142 & 142

R

PWM Communicated

Models 142 & 142

R

L1 (115VAC)

L2 (115VAC)

Ground

Speed Tap(24VAC)

Speed Tap(24VAC)

Common (24VAC)

L1 (115VAC)

L2 (115VAC)

Ground

PWM (VDC)

PWM (VDC)

REG9971_ECM_Service_Guide_4-10-14.indd 55

4/10/14 10:48 AM

Indoor Motor

Final Installation Checks

Check all wiring and connections,

especially those removed while servicing.

Clear all condensate drain and traps.

Check and plug leaks in return ducts and

equipment cabinet.

Verify that the system is running quietly

and smoothly, producing proper air flow in

all modes (heating, cooling, and continuous

fan) and all stages (if applicable).

Return all thermostat settings to the

customer’s preference.

If any evidence of moisture, then correct

the issue.

If the area is subject to high amounts of

lightning strikes, then use of additional

transient protection may be helpful.

53

Ensure the system is set up as follows:

REG9971_ECM_Service_Guide_4-10-14.indd 56

4/10/14 10:48 AM

FINAL

CHE

CK

S

Good Practices:

Outdoor Motor

Final Installation Checks

54

Before energizing the HVAC system,

confirm the fan blade is free of all

obstructions, including the system shroud

and compressor.

Check all wiring and connections,

especially those removed while servicing.

Verify the system is running quietly and

smoothing in all modes and stages if

applicable.

Check the refrigerant level only after

confirming proper indoor airflow as well.

Bent coil fins restrict airflow; correct if

possible without damaging the coil or

other fins.

Return all thermostat settings to the

customer’s preference.

Finish all service calls by checking all

safeties, and perform a visual inspection of

the overall job to prevent call-backs.

Check the level of Carbon Monoxide (CO)

in the vent(s) and living spaces of all homes

with fossil-fuel appliances.

Recommend annual maintenance.

REG9971_ECM_Service_Guide_4-10-14.indd 57

4/10/14 10:48 AM

1946 WEST COOK ROAD

:

FORT WAYNE, IN 46818

ph :

260 416 5400

fx :

260 416 5499

GTQ-8001 Version 3.0

©2014

Regal-Beloit Corporation

thedealertoolbox.com

Visit

to learn more

A Regal Brand

©2014 Regal-Beloit Corporation

REG9971_ECM_Service_Guide_4-10-14.indd 58

4/10/14 10:48 AM