How to Extend the Service Life of LED Outdoor Lighting

By Gary Chan and Henning von Lepel*

can often cause the air inside the LED luminaire to rapidly heat

up, with the resulting higher pressure putting positive pressure

on the seals. As temperatures drop again at night, the internal

air contracts and creates a gentle vacuum, which draws the seals

inward. A quick drop in temperature can create a vacuum of up

to 150 mbar inside the luminaire, while a 30 °C change in

temperature creates approximately 10 percent of volumetric flow

of air in or out in a non-hermetically sealed enclosure.

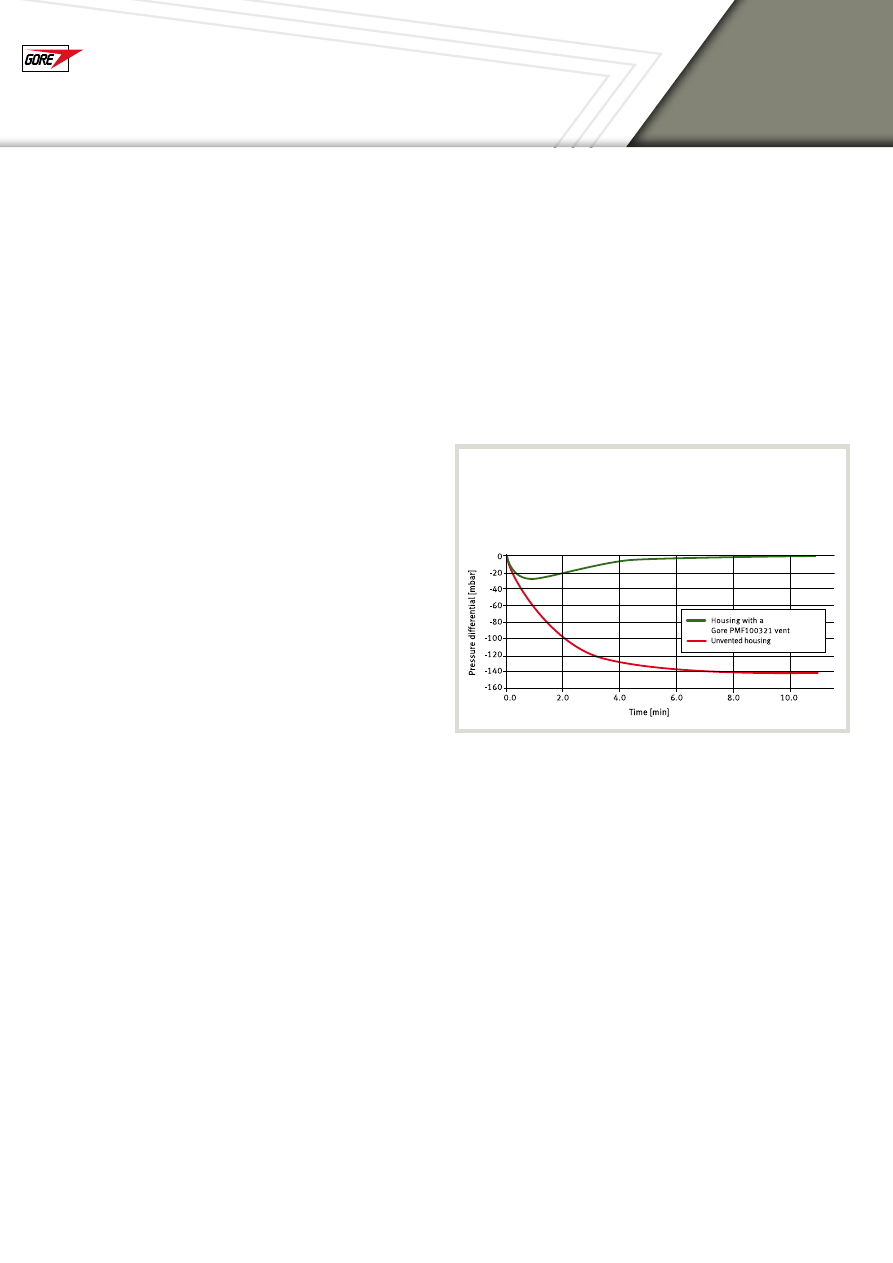

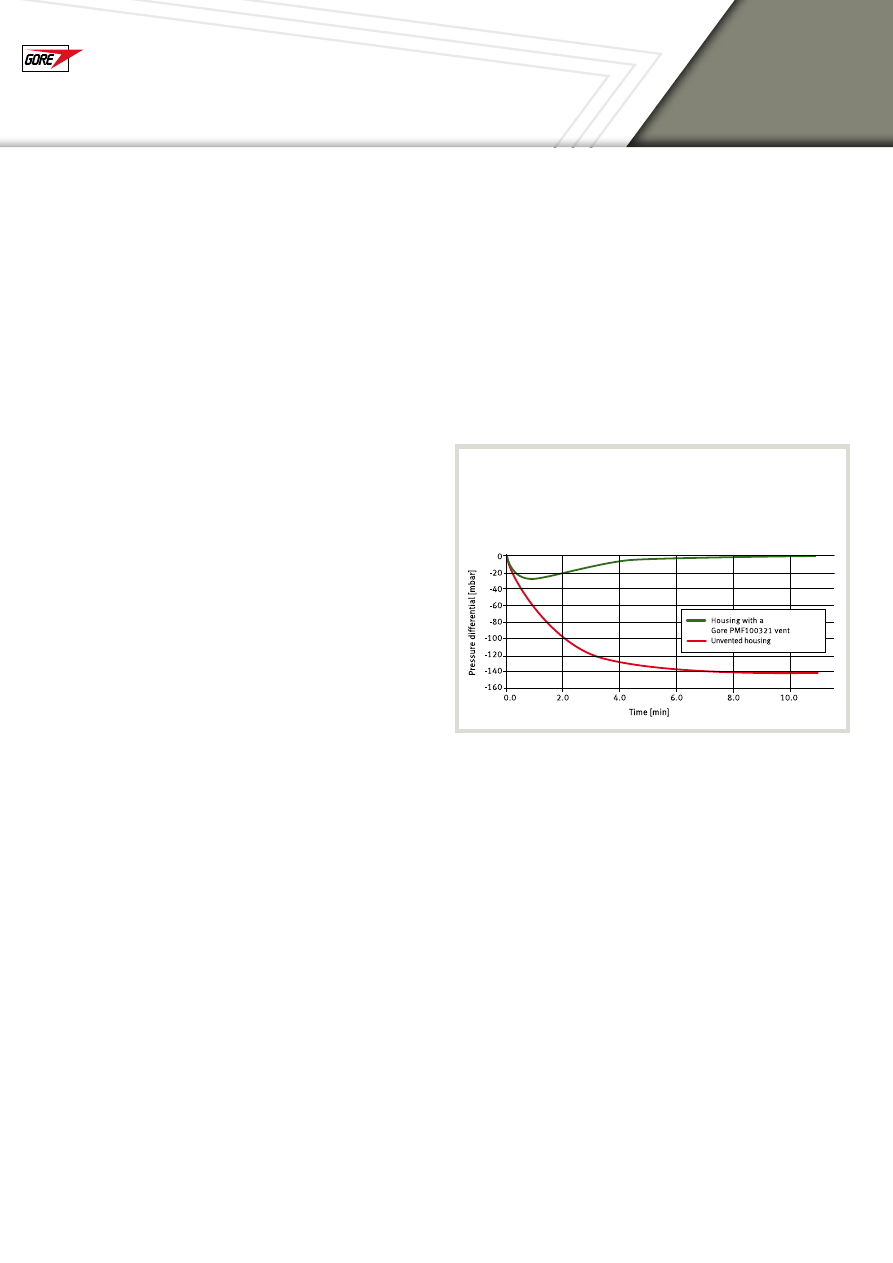

Figure: Typical calculation of pressure differentials in a housing

Temperature Changes within LED Luminaires

Although LEDs do not get as hot as incandescent lamps,

switching a luminaire on and off nonetheless results in significant

temperature fluctuations. These are at their strongest immediately

after switching, which means that switching luminaires on and

off repeatedly puts not only the electronics but also the seals

under considerable strain.

Altitude Changes

When LED luminaires are shipped by air from their manufacturing

sites, the lamps will be subject to major changes in altitude, even

several times when the shipment involves intermediate stops.

This means LED luminaires are exposed to the difference in

pressure between a little over 1,000 mbar at ground level and

800 to 850 mbar in the aircraft.

Thermal Shock

A thermal shock occurs when a hot LED luminaire is sprayed

with cold water from a garden hose, for instance, or when a cold

luminaire is washed with hot water. It can also arise when a

luminaire encounters snowfall.

LED luminaires in outdoor use need to be protected from harsh

environmental conditions. The most significant stress factor

for the sealings of luminaire housings are pressure differences

caused by everyday temperature changes. In order to protect

the sensitive electronics inside, pressure variations have to be

equalized while preventing water and dust to enter the housing.

The most effective solution is a “smart venting element” with

a membrane that protects electronic housings against con-

tamination and fluids and provides air exchange and pressure

equalization at the same time.

For both commercial and residential applications standard

neon tubes and energy-saving lamps are increasingly replaced

by LED (light-emitting diodes) luminaires. The advantages of

LED lightings are numerous:

• They are fully RoHS-compliant (Restriction of Hazardous

Substances).

• They provide up to 85 percent energy savings in comparison

to conventional lamps.

• They can generate as much as 50,000 hours of light.

• They are one of the most environmentally friendly and reliable

solutions for outdoor lighting applications.

However, the service life of a LED is subject to the reliability

of the electronic components and power supply drivers, which

altogether make up the lighting system itself. This poses a

major challenge on LED systems for outdoor use. The housings

of the LED luminaires must be able to withstand the harsh

environmental conditions. To achieve this goal, the housing

of an LED lamp is sealed against the ingress of water and

contaminants. However, changes in outdoor temperature

cause the air pressure within the housing to fluctuate constantly,

which in turn puts either positive or negative pressure on

the seals and compromises their functionality. Over time,

seals begin to allow water and contaminants to enter the

housing, which can lead to corrosion, shorts, and potential

failure of the electronics. In addition, condensation on the

inside of the luminaire can impact the quality of its light.

Causes for Pressure Differentials

Temperature Fluctuations

Changes in outdoor temperature are one of the most common

causes of pressure differentials. These changes can be sudden,

for instance a strong thunderstorm on a hot summer day, or more

gradual over the course of the day or of the year. Either way, they

put significant stress on the seals. What is more, direct sunlight

White Paper

Typical Calculation

Pressure differential in a housing with 5 liters of free air

volume caused by a temperature drop from 65 °C to 15 °C

in 11 minutes.

Protective Vents

adhesive vents

Gore-PTV-WhitePaper-Service-Life-LED-US-html.html

Challenge: Equalizing Pressure

For maintaining constant pressure inside a luminaire it is crucial

to allow air to flow freely in and out of the luminaire. The challenge

is to block water and contaminants in doing so. Most types of

seals to achieve this goal have multiple drawbacks as explained

below:

• Labyrinth seals are completely permeable to particles,

insects, and water.

• Rugged seals, additional bolts, thicker housings or potting

compounds for hermetically sealing the device require

the use of non-permeable materials and is relatively

expensive. Moreover, it makes the device heavier,

extremely difficult to open under negative pressure and

repair almost impossible.

• Felt elements and sintered vents address the pressure

differentials, but they can become blocked by water

and contaminants.

• A mechanical valve is a one-way solution from inside to

outside, which means it cannot prevent a vacuum.

Solution: “Breathing” Luminaire Housings

Gore has developed a solution: a vent made of expanded polytetra-

fluoroethylene (ePTFE). A two-way breathable membrane continu-

ously equalizes pressure inside the luminaire housing while also

preventing the ingress of water and contaminants. Equalizing

pressure using an ePTFE vent reduces the potential for moisture

vapor to condense on lenses and reflectors, and increases the

service life of seals. The microporous membrane can be coated

to provide oleophobicity. ePTFE’s node-and-fibril microstructure

is open enough to allow gas molecules and vapor to pass through

it easily, but the openings are so small that liquid and other

particulates are repelled. Also, hydrogen sulphide is expelled

this way.

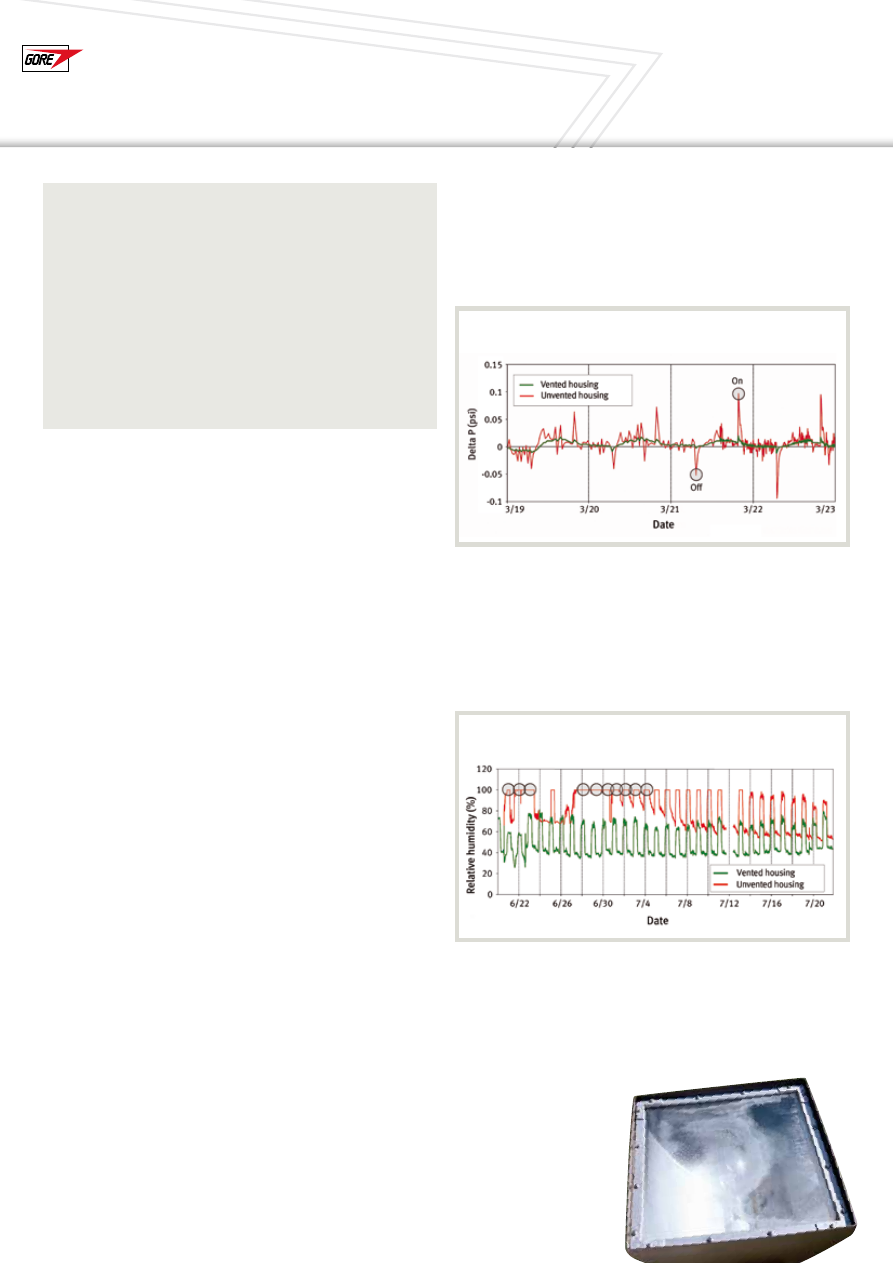

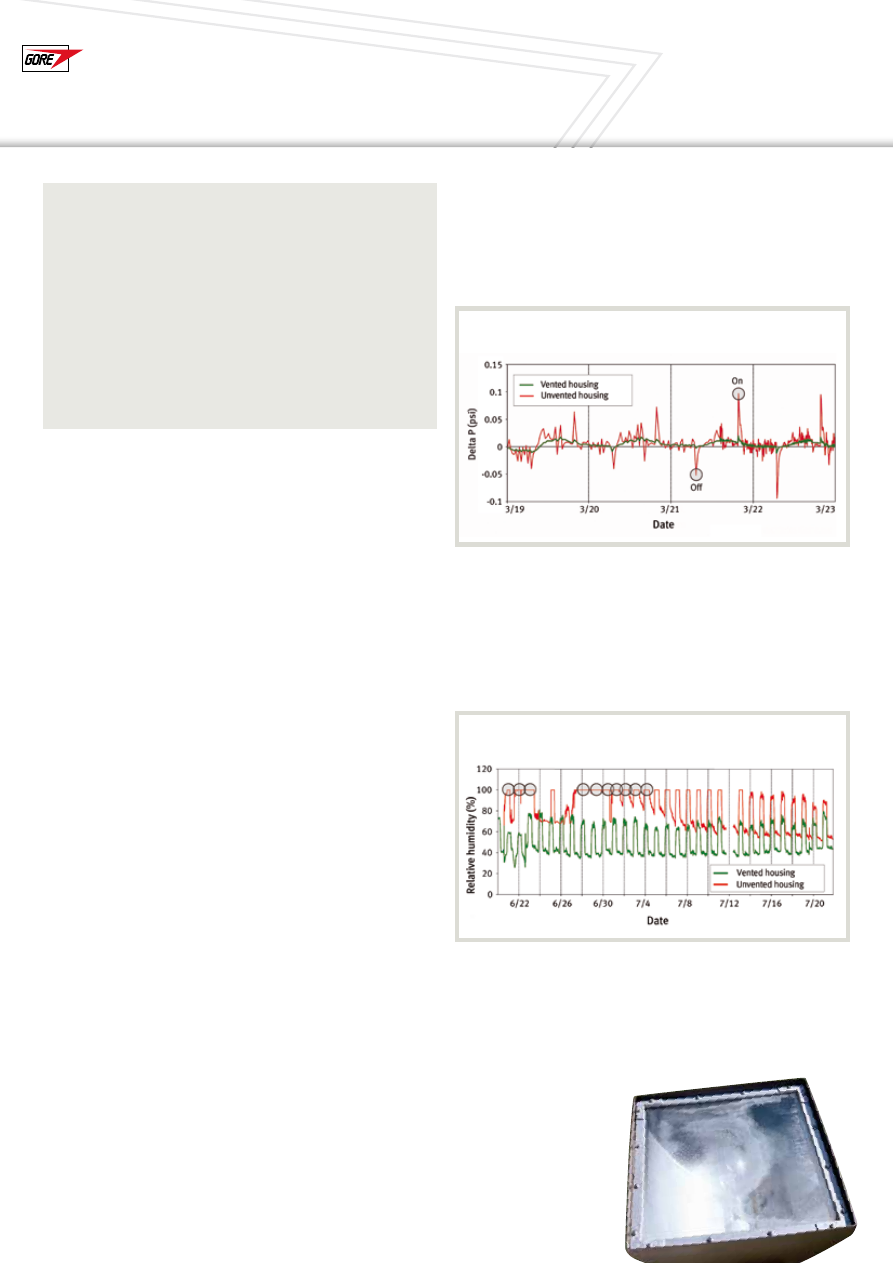

Proper pressure equalization and water tightness have been

demonstrated by thorough testing to compare two commercially

available LED luminaires, one conventionally sealed unit and

one with an ePTFE vent. Although the on/off cycle of both

luminaires caused temperatures to rise and fall, the amount

of pressure placed on the seals is significantly different. In the

sealed luminaire, the pressure spiked by 6.2 mbar when the light

was switched on and dipped -6.9 mbar when switched off. However,

the vented luminaire showed a change of only ±0.69 mbar.

Figure: Impact of pressure on vented and unvented housings.

Comparing the relative humidity inside the LED luminaires after

a standard IPX5 water ingress test demonstrates the significance

of pressure differentials. The relative humidity in the sealed

luminaire was significantly higher than in the vented luminaire.

Over the course of ten days, the relative humidity in the sealed

luminaire almost always remained at around 100 percent.

Figure: The unvented housing shows relative humidity of 100%, indicating

condensation.

This indicated condensation inside the luminaire caused by water

entering during the test. Although the relative humidity in the vented

luminaire rose immediately after the shock test, it decreased again

relatively quickly and there was no evidence of condensation.

Figure:

Luminaire with condensation

Important Consideration: Hydrogen Sulfide

Not only constant pressure is important for a long service

life of an LED luminaire. Hydrogen sulfide is given off

especially by inexpensive EPDM seals produced using

sulfur vulcanization where not all the sulfur atoms were

one-hundred per cent cross-linked. Sulfur vulcanized nitrile

butadiene rubber (NBR) or other components containing

sulfur can also give off hydrogen sulfide. This substance

corrosion in luminaire components such as silver-plated

leadframes, which could impact electrical contacts with

the wire bond or die bond.

Impact of pressure on vented and unvented housings.

Relative humidity in vented and unvented housings.

White Paper

Protective Vents

adhesive vents

Gore-PTV-WhitePaper-Service-Life-LED-US-html.html

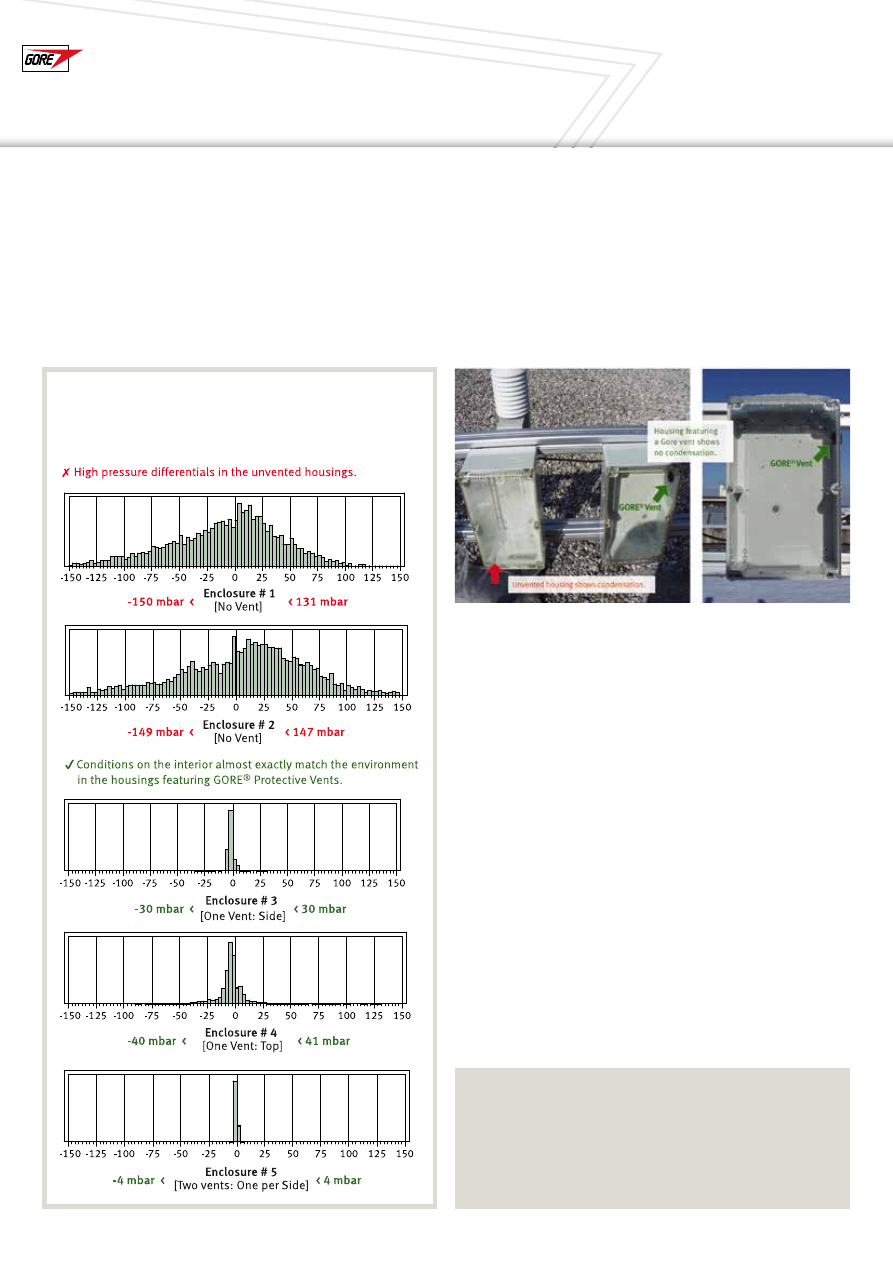

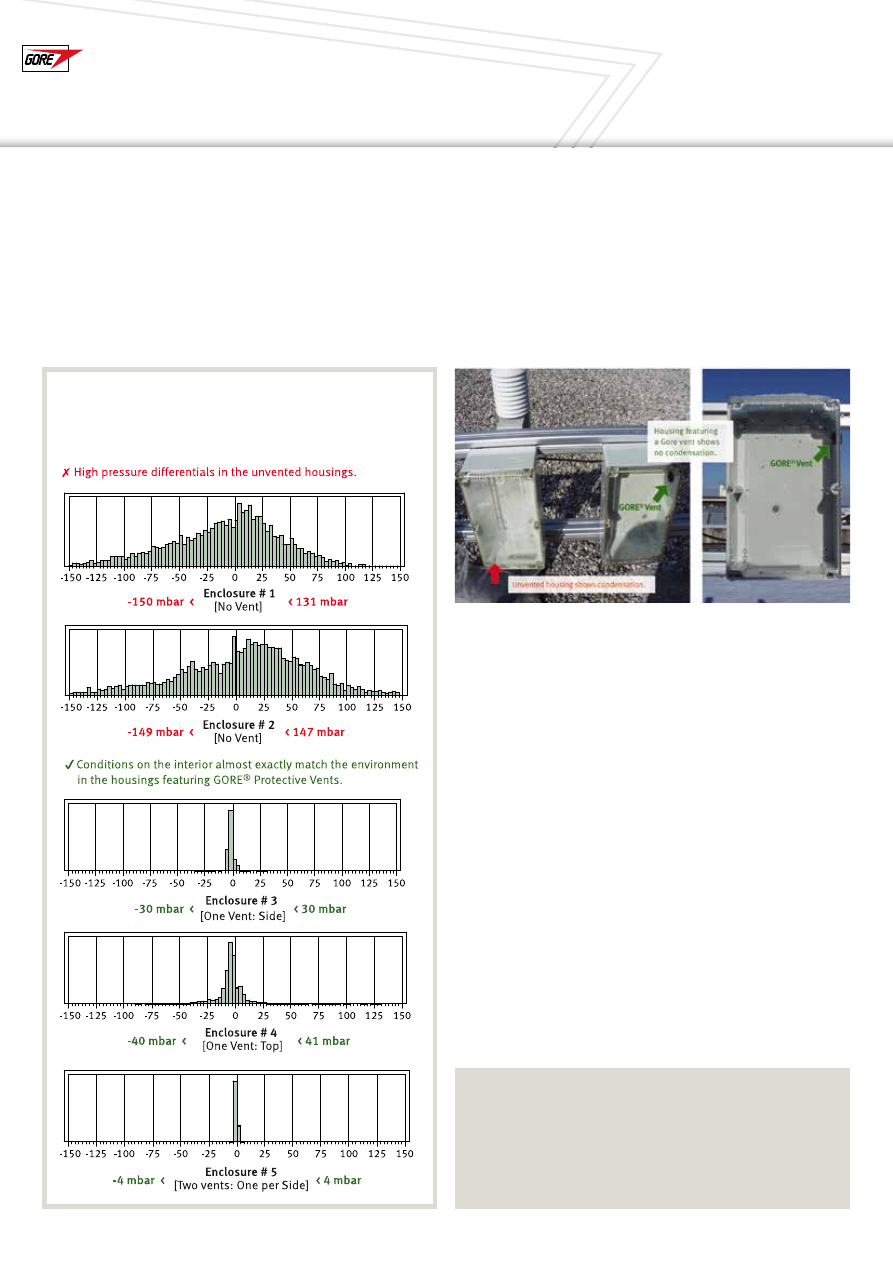

Comparison Test Proves

Long-Term Protection

A further test, conducted outdoors over a period of five years south

of Munich, demonstrated the longer service life of vented enclosures.

Five units were tested: two with no vents, one with a side vent, one

with a top vent, and one with two vents (one on each side). The

testing showed that the pressure differential in the unvented units

ranged from -150 mbar in both to 131 and 147 mbar respectively.

Figure: Long-term study of pressure differentials in electronics housings

A significant amount of condensation was also detected.

In the vented units, the maximum pressure measurements fell

to ±40 mbar with a top vent, ±30 mbar with a side vent, and

just ±4 mbar with both vents. This is an impressive demonstration

of how effective these venting systems are at equalizing pres-

sure. In addition, no condensation was detected, and neither

was the ingress of water or dust. Further testing showed that

the vents were fully functional even after five years of outdoor

operation.

Figure: Long-term study of pressure differentials in electronics housings

Roundup: Venting Solutions Extend the

Service Life of Outdoor LED Luminaires

Pressure differentials compromise housing seals. Not taking

this into account when designing LED luminaires can reduce

the service life of LEDs, power supply drivers and other

electronics. The ingress of water through damaged seals also

leads to condensation on lenses and reflectors that can

decrease light efficiency and the aesthetic quality of the

luminaire. As demonstrated through the IPX5 test, integrating

an ePTFE vent into the housing equalizes pressure by allowing

continuous airflow in both directions and preventing the ingress

of water. What’s more, the vent reduces condensation because

moisture vapor is able to escape from the luminaire before

condensing.

* Gary Chan and Henning von Lepel are Application Engineers

at W. L. Gore & Associates

Long-term study of pressure differentials

in electronics housings

Over a period of five years, pressure differentials were recorded

in five housings.

Long-term study

You will find more information on this topic in the long-term

study “Life Time Study of GORE

®

Protective Vents installed

in Enclosures in Outdoor Environments”, which you can

download from

www.gore.com/5-year-study

.

White Paper

Protective Vents

adhesive vents

Gore-PTV-WhitePaper-Service-Life-LED-US-html.html

PT

V-115-

WHP-EN-A

UG14

FOR INDUSTRIAL USE ONLY. Not for use in food, drug, cosmetic or

medical device manufacturing, processing, or packaging operations.

All technical information and recommendations given here are based on Gore’s previous experiences and/or test

results. Gore gives this information to the best of its knowledge, but assumes no legal responsibility. Customers

should check the suitability and usability in the specific application, since the performance of the product can

only be judged when all necessary operating data are available. The above information is subject to change and

is not to be used for specification purposes.

Gore’s terms and conditions of sale apply to the sale of the products by Gore.

GORE, GORE-TEX and designs are trademarks of W. L. Gore & Associates.

© 2014 W. L. Gore & Associates GmbH

Please Contact Gore to

Learn About the Right

GORE

®

Protective Vent for

your Unique Application

International Contacts

W. L. Gore & Associates GmbH

Wernher-von-Braun-Str. 18 • 85640 Putzbrunn • Germany

Tel.: +49 89 4612 2211 • Fax: +49 89 4612 2302

E-mail: protectivevents@wlgore.com

gore.com/protectivevents

About W. L. Gore & Associates

Gore is a technology-driven company focused on discovery and product

innovation. Well known for waterproof, breathable GORE-TEX

®

fabric,

the company’s portfolio includes everything from high-performance

fabrics and implantable medical devices to industrial manufacturing

components and aerospace electronics. Gore products have remained

at the forefront of creative solutions because they are engineered

specifically for challenging applications requiring durable performance

where other products fail.

For almost thirty years, Gore has delivered venting solutions for a

variety of applications working in rugged environments throughout the

world — applications for heavy-duty equipment and the automotive

industry; electronic housings for the solar, lighting, security and

telecommunication market; mobile electronic devices; and chemical

and agricultural packaging. Engineered with the latest materials and

technology, Gore’s vents are backed by years of research and testing

to help extend product life and enhance reliable performance — all

to ensure that these venting products can meet the challenging

environments and application demands of today’s technology.

Headquartered in the United States, Gore employs approximately

10,000 associates in 30 countries worldwide. In Europe, Gore started

its first business operations only a few years after the Enterprise’s

founding in 1958.

Learn more at gore.com/protectivevents

.

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

Brazil

+55 11 5502 7800

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South Africa

+27 11 080 6150

South America +55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

Turkey

+90 216 3935749

United Kingdom +44 1506 460123

USA

+1 410 392 4440

White Paper

Protective Vents

adhesive vents