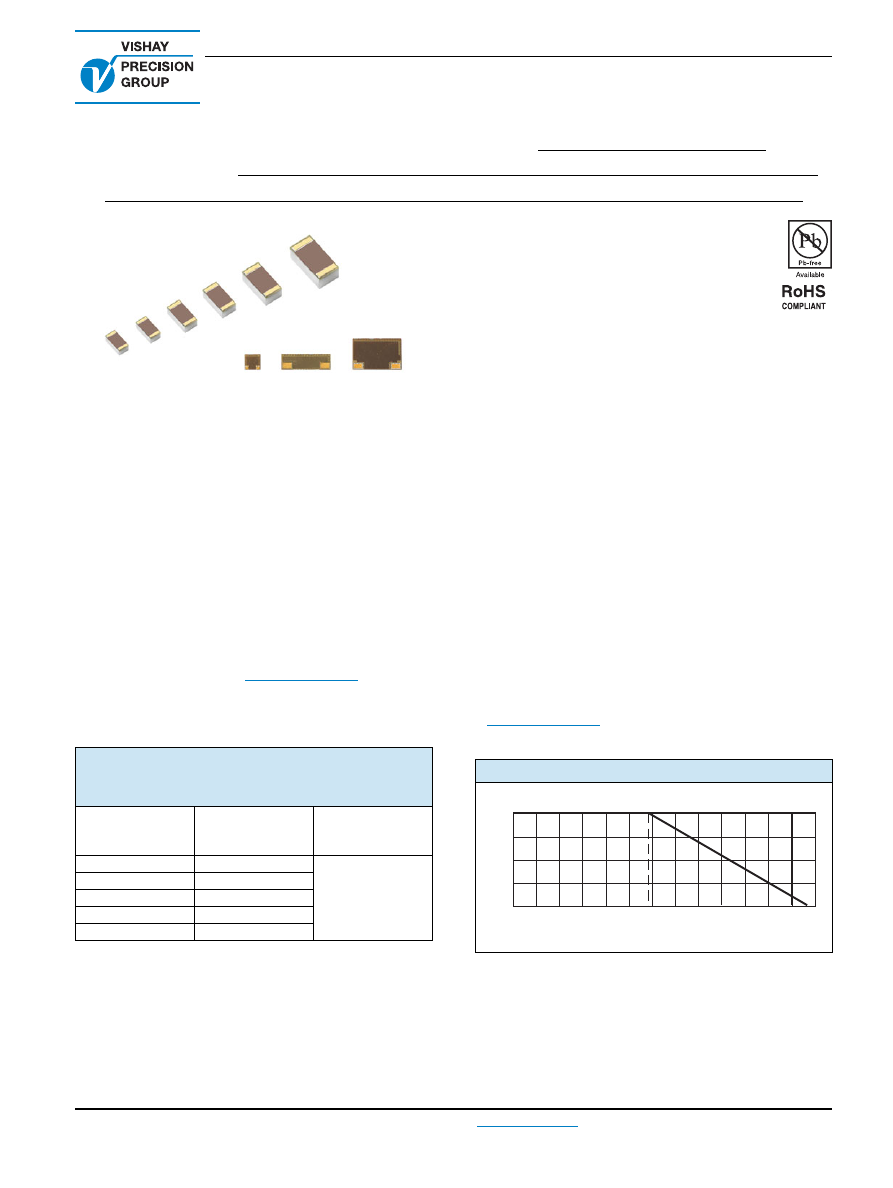

Ultra High Precision Z1-Foil Technology Gold Wire Bondable Chip

Resistor for Hybrid Circuits for High Temperature Applications

up to +240°C, Long Term Stability of 0.05%,TCR to ± 1ppm/°C

HTHG* (Z1-Foil)

Vishay Foil Resistors

Document Number: 63221

For any questions, contact:

foil@vishaypg.com

www.vishayfoilresistors.com

Revision: 13-Dec-12

1

INTRODUCTION

Vishay Foil Resistors (VFR) introduces a new line of Ultra

Precision Bulk Metal

®

Z1-Foil technology: hybrid chip

resistors, connected using gold wire bonding. The HTHG

series features two different layouts of chip designs

according to the sizes (see figure 3 and table 4). These new

types of hybrid chips were especially designed for high

temperature applications up to + 240°C

(1)

(working power: to

150mW at + 220°C), and include gold plated terminals.

The HTHG series is available in any value within the

specified resistance range. VFR's application engineering

department is available to advise and make

recommendations.

For non-standard technical requirements and special

applications, please contact

foil@vishaypg.com

.

TABLE 1 - TOLERANCE AND TCR VS.

RESISTANCE VALUE

(1)(2)

(- 55 °C to + 220 °C, + 25 °C Ref.)

RESISTANCE

VALUE

(

)

TOLERANCE

(%)

TCR Typical

(ppm/°C)

100

to 125K

± 0.02

± 2.5

50

to < 100

± 0.05

25

to < 50

± 0.1

10

to < 25

± 0.25

5

to 10

± 0.5

Notes

(1)

Performances obtained with ceramic PCB.

(2)

For tighter performances or non-standard values up to 150 k

,

please contact VFR's application engineering department by

sending an e-mail to the address in the footer below.

FEATURES

Temperature coefficient of resistance (TCR):

±1 ppm/°C typical (- 55 °C to + 125 °C, + 25 °C ref.)

±2.5 ppm/°C typical (- 55 °C to + 220 °C, + 25 °C

ref.)

Resistance range: 5

to 125 k

(for higher

or lower values, please contact VFR's application

engineering department)

Resistance tolerance: to ± 0.02 %

Connection method: gold wire bonding

Working power: to 150mW at + 220°C

Long term stability: to ± 0.05 % at + 240°C for 2000h, no

power

Load life stability: to 0.05% at + 220°C for 2000h at

working power

Vishay Foil resistors are not restricted to standard values;

specific "as required" values can be supplied at no extra

cost or delivery (e.g. 1K2345 vs. 1K)

Thermal stabilization time < 1 s (nominal value achieved

within 10 ppm of steady state value)

Electrostatic discharge (ESD) at least to 25 kV

Non inductive, non capacitive design

Rise time: 1 ns effectively no ringing

Current noise: 0.010 µV (RMS)/Volt of applied voltage

(< - 40 dB)

Voltage coefficient: < 0.1 ppm/V

Non inductive: < 0.08 µH

Non hot spot design

Terminal finish available: gold plated (lead (Pb)-free alloy)

Prototype quantities available in just 5 working days

or sooner. For more information, please contact

foil@vishaypg.com

FIGURE 1 - POWER DERATING CURVE

100

75

50

25

0

-75

-50

-25

0

+25

+50

+75

+100 +125 +150

+200 +225 +250

+175

Ambient Temperature (°C)

Percent of Rated Power

+70°C

-55°C

+240

* HTHG was previously named HTH