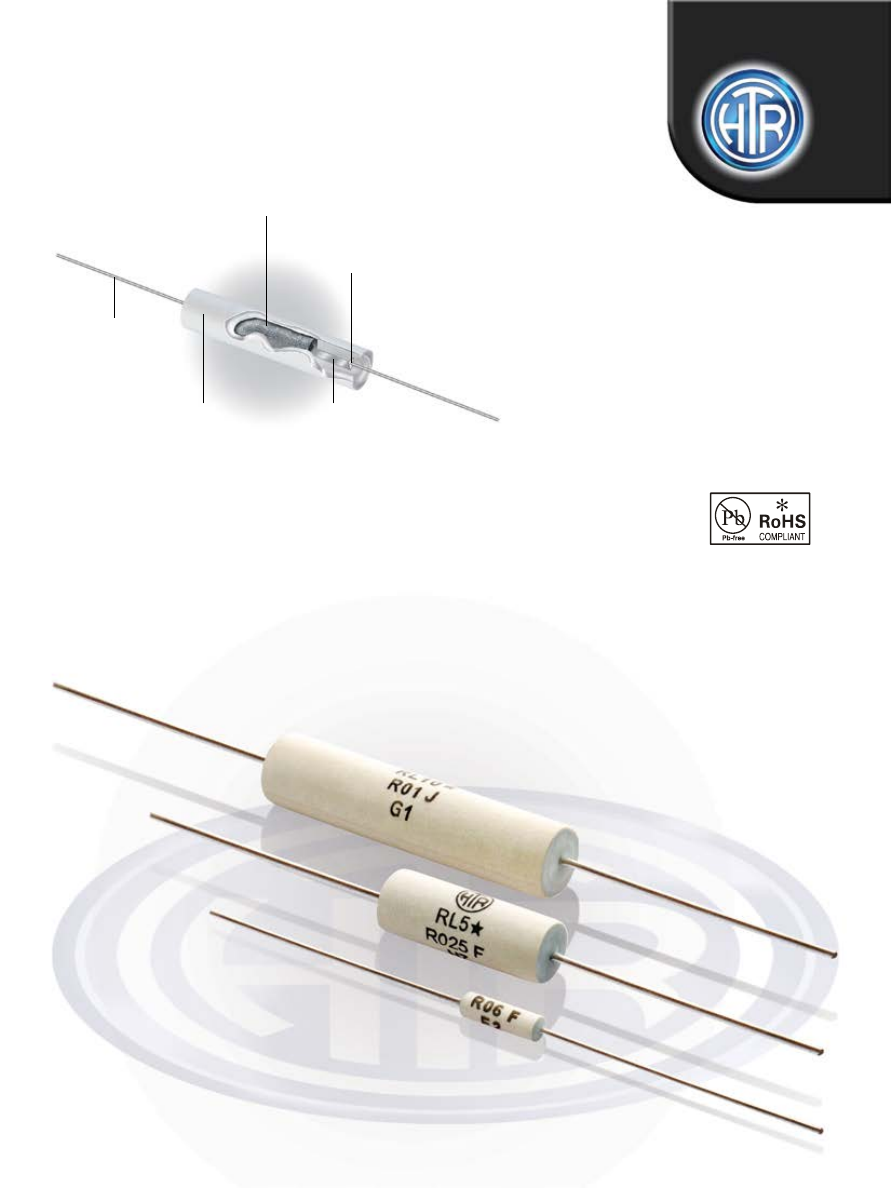

Quartz Silica

Powder

Fire Proof

Ceramic Housing

Alloy Electrical

Resistance Ribbon

All Welded

Construction

Tinned Copper

Terminals

CURRENT SENSE / LOW OHM

CERAMIC ENCASED TYPE

RL

SERIES

LOW OHM / LOW INDUCTANCE

Power Ceramic Encased Resistors

Industrial Applications

• Superior alternative

to replace moulded device of identical size

• Negligible inductance

• Highly thermal efficient power to size ratio

• Any resistance value possible within

resistance range given

• 0.5W to 10W

• R0015 to R 80

e : info@htr-india.com

www.htr-india.com