• 1 W to 17 W

• R025 to 82K

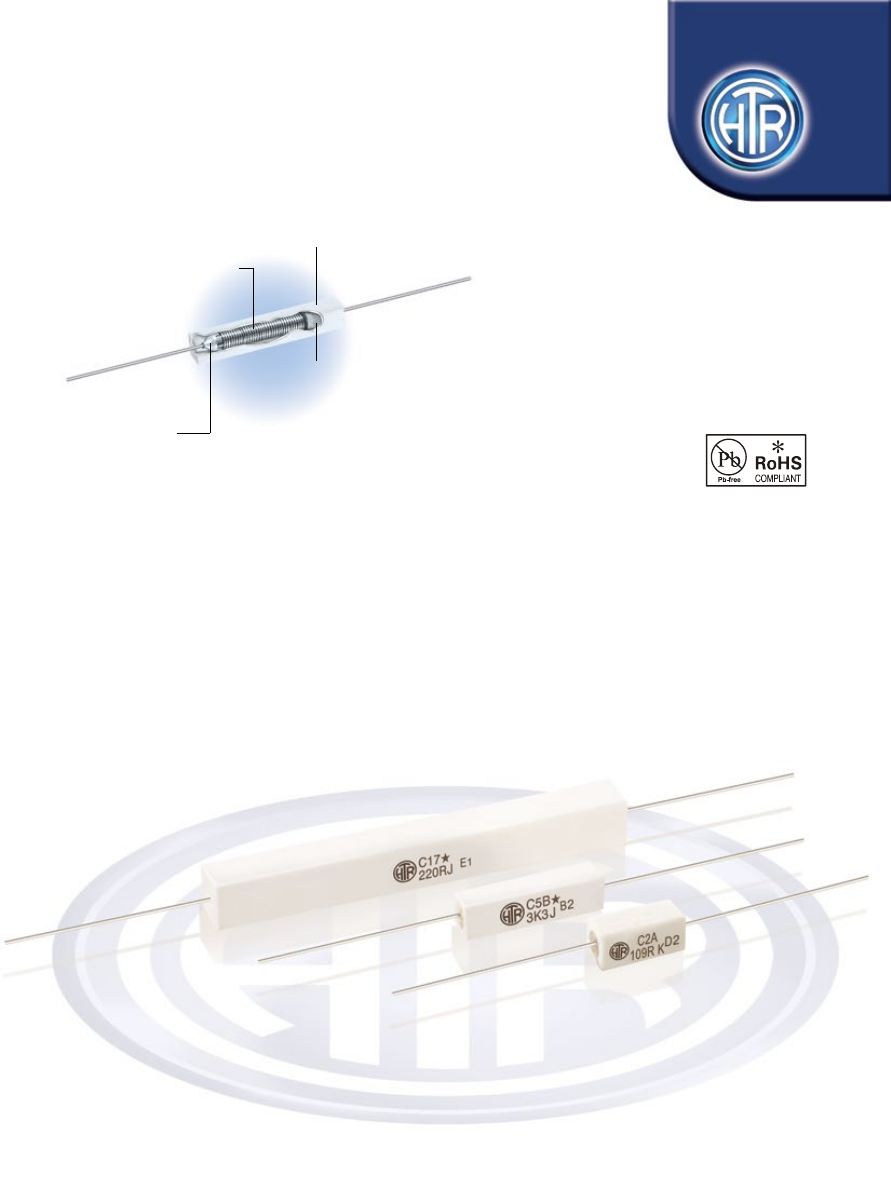

• Non Inductive Aryton-Perry

style available upto 1K0

Alloy Wire Wound Element

On Heat Conducting

Ceramic / Fibre Glass Substrate

Quartz Silica

Powder

Fire Proof Ceramic

Housing

Mechanically

Crimped

Termination

Assembly

WIRE WOUND RESISTORS

CERAMIC ENCASED TYPE

HEA

SERIES

EUROPEAN STYLE

Power Ceramic Encased

Wire Wound

www.htr-india.com

e : info@htr-india.com