HCL

S E R I E S

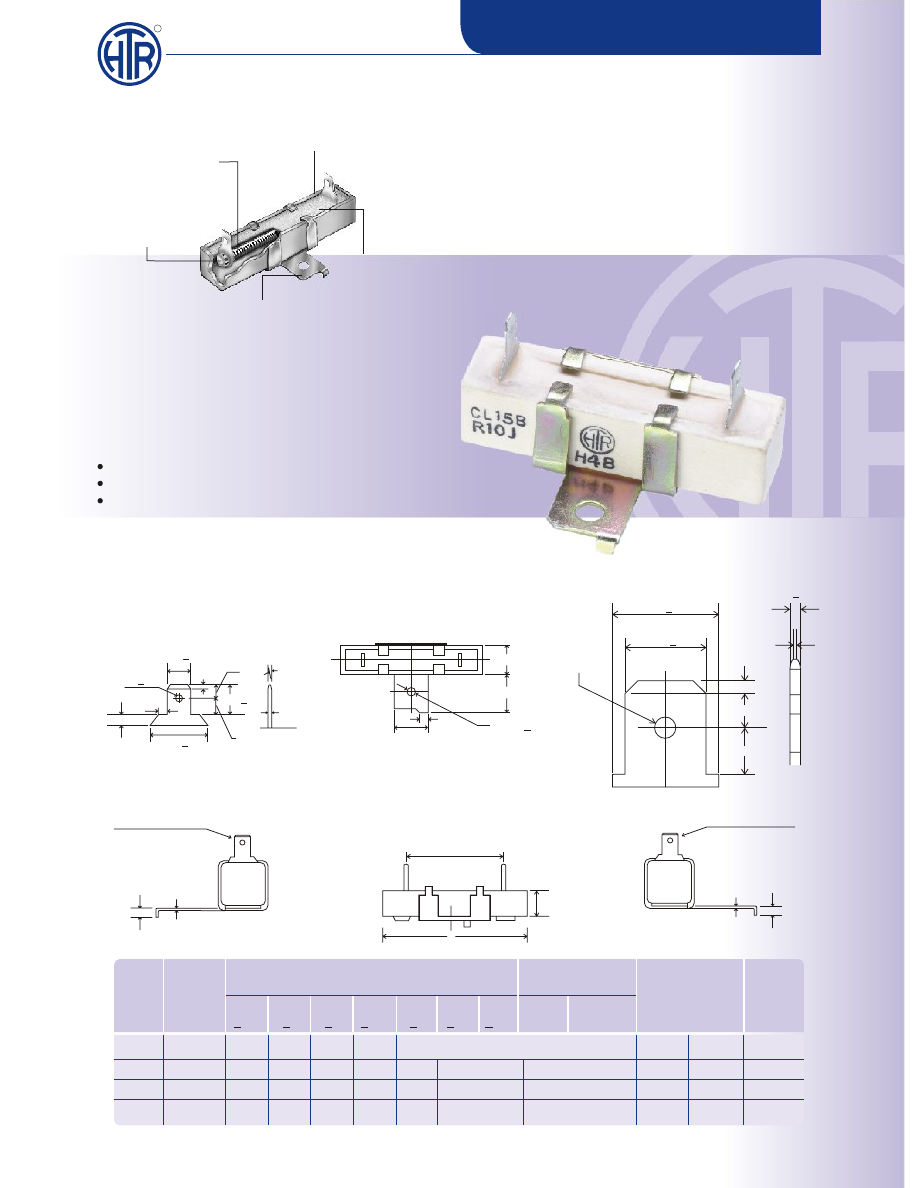

Ceramic Encased Wire Wounds

Industrial Applications

HI POWER TYPE

WIRE WOUND RESISTORS

CERAMIC ENCASED TYPE

10 W to 40 W

Can be supplied with mounting brackets.

Choice of terminals available.

TM

Alloy Wire Wound Element

On Fibre Glass/Ceramic

Substrate

Mechanically Crimped,

Tin / Nickel Plated,

Lug Type Termination

Flame Proof

High Temperature

Ceramic Housing

Inorganic Fire

Retardant

Encapsulant

Duplex Plated

Mounting Bracket

Profile

MOUNTING

BRACKET

DIMENSIONS (mm)

HTR

TYPE

POWER

RATING

at 25 C

°

L

+1.5

W

+1

H

+1

P

+1.5

S1

+1

S2

+0.5

S3

+0.5

RESISTANCE

RANGE

min max

TYPICAL

WT

PER PC

(gms)

Elevation

(70 C)

CL-10 10W

48.0

9.5

9.5

35.0

No

Mounting Bracket

A/B

R10

47K

14.5

CL-15 15W

48.0

12.5

12.5

35.0

14.0

12.0

3.0

B

A/B

R10

47K

24.3

CL-20 20W

63.0

12.5

12.5

48.0

14.0

12.0

3.0

B

A/B

R15

56K

29.1

CL-40 40W

90.0

19.0

19.0

71.0

16.5

18.0

3.0

B

A/B

1R0

68K

87.5

°

ELEVATION - B

0.8

AMP 250 Compatible

3

PROFILES

P

H

L

ELEVATION - A

0.8

AMP F 187 Compatible

3

PHYSICAL CONFIGURATION

0.5

O

10

+

10.95 0.5

0.65

6.35+0.3

2.3

0.9

3.17

3.18

+0.3-0.1

+

f

1.4 0.3

S

1

W

S

3

f

4.2 (+0.2)

S

2

0.4

f

1.65+0.2

0.9+0.1

3.1+0.2-0

4.4+0.2-0.1

6.25+0.1

4.75+0.3

9.3+0.2

0.8+0.05