Installation and Programming Instructions

KSC-2

High-Performance Signal Conditioner for Kulite

Sensor Products

October 25, 2015

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

One Willow Tree Road

Leonia, New Jersey 07605

www.kulite.com

Installation and Programming Instructions

KSC-2

High-Performance Signal Conditioner for Kulite

Sensor Products

October 25, 2015

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

One Willow Tree Road

Leonia, New Jersey 07605

www.kulite.com

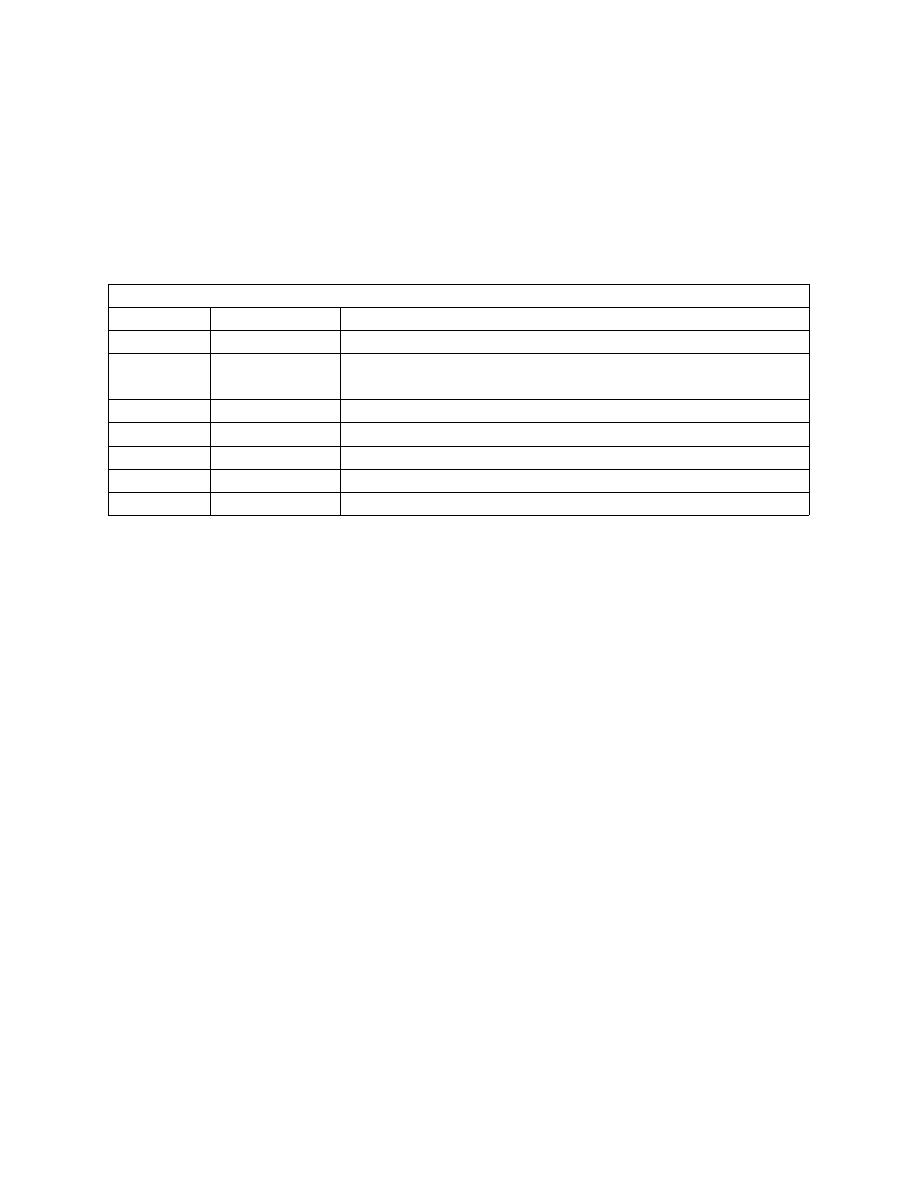

Revision Record

Rev Level

Date

Description of Change

-

7/30/2015

Initial release

A

10/25/2015

Corrected Notes about CAL mode; Corrected recommended COM port

Flow Control setting in Troubleshooting section

Software Copyright Information

Kulite KSC-2 System Control Software Copyright © 2015 Kulite Semiconductor

Products, Inc. All Rights Reserved.

Trademark Information

The following terms and names are trademarks of Kulite Semiconductor Products,

Inc., in the United States and/or other countries.

•

Rezcomp and the Rezcomp logo

The following trademarks from other companies that may be used in this manual are

listed below:

•

Adobe, the Adobe logo, Acrobat and Reader are registered trademarks or trade-

marks of Adobe Systems Incorporated in the United States and/or other countries.

•

Microsoft, Windows, Excel and the Windows logo are trademarks of Microsoft

Corporation in the United States, other countries, or both.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Safety Guidelines

Page

i

Safety Guidelines

This document describes how to use the KSC-2 Signal Conditioner and includes

product information, installation and programming instructions, and contact informa-

tion for support and service.

The safety guidelines and product information in this document are specific to the

KSC-2 Signal Conditioner. The other components in your system might not meet the

same safety rating and specifications. Please read and understand the documentation

for each component in your system to determine the safety rating and specifications

of the entire system.

CAUTION

A CAUTION statement describes a hazard. It calls attention to a

procedure, practice, or condition that, if not correctly performed

or adhered to, could result in damage to the product or loss of

data. Do not proceed beyond a CAUTION statement until the

conditions are fully understood and met.

Safety Information

General

Do not use this product in any manner not specified by the manufacturer. The protec

-

tive features of this product may be impaired if it is used in a manner not specified in

this document. Do not install substitute parts or perform any unauthorized modifica

-

tion to the product.

Return the product for service and repair to ensure that safety features are maintained.

See Section 7 of this manual,

Support and Service

, for information on how to contact

Kulite Semiconductor Products, Inc.

KSC-2 Safety Guidelines

Page ii

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

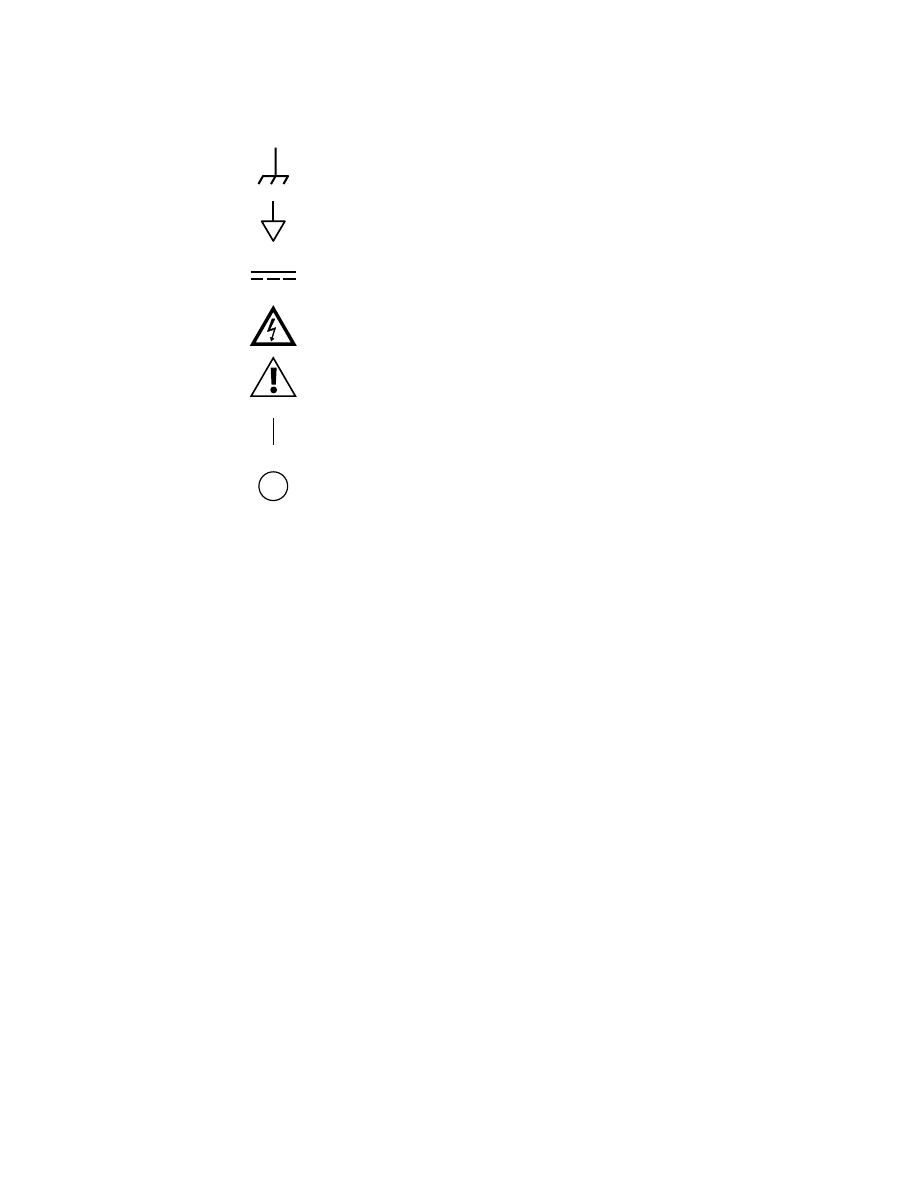

Safety Symbols

Chassis Ground

Signal Ground

Direct Current

Risk of Electric Shock

Refer to Manual for Additional Safety Information

On Supply

Off Supply

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Table of Contents

Page

iii

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Excitation Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Input Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Input Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Input Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Flat/Pulse Low-Pass Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Flat Mode Low-Pass Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pulse Mode Low-Pass Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Anti-Aliasing Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

REZCOMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Distributed Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Overload Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

KSC-2 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Constant Voltage Excitation Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Input Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Optional KSC-2 Transducer Compensator (C3) Characteristics . . . . . . . . . . . . . . . . . . . .12

Filter Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Output Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

General Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

ISO/IEC Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

KSC-2 Table of Contents

Page iv

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Storage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Transport Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Shipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Vertically Mounting Two or More Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Horizontally Mounting Two or More Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Horizontal Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

KSC-2 Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Input Cabling and Input Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

KSC-2 Full-Bridge 4-Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

KSC-2 Full-Bridge 6-Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Other Bridge Input Configurations Using External Completion Resistors . . . . . .26

Voltage Input Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

CAL Input Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5th Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Communication USB 2.0 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Output Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Signal Ground Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bank Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Applying Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Autobalance Indicators and Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Overload Indicators and Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Table of Contents

Page

v

Antivirus Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Installing the KSC-2 Control GUI Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Uninstalling the KSC-2 Control GUI Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Starting the KSC-2 Control GUI Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connecting Multiple KSC-2 Units to the Control GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Save. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Save As . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

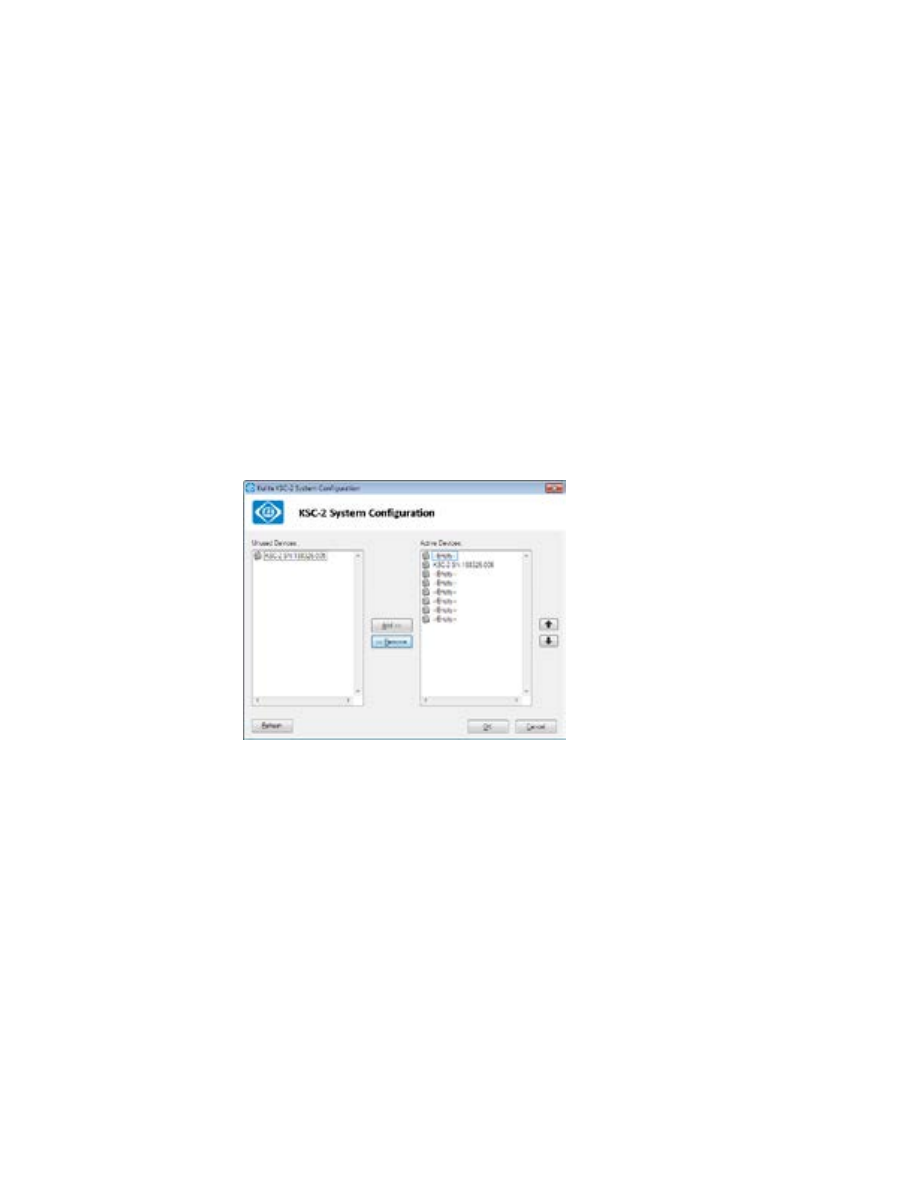

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Compensation Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

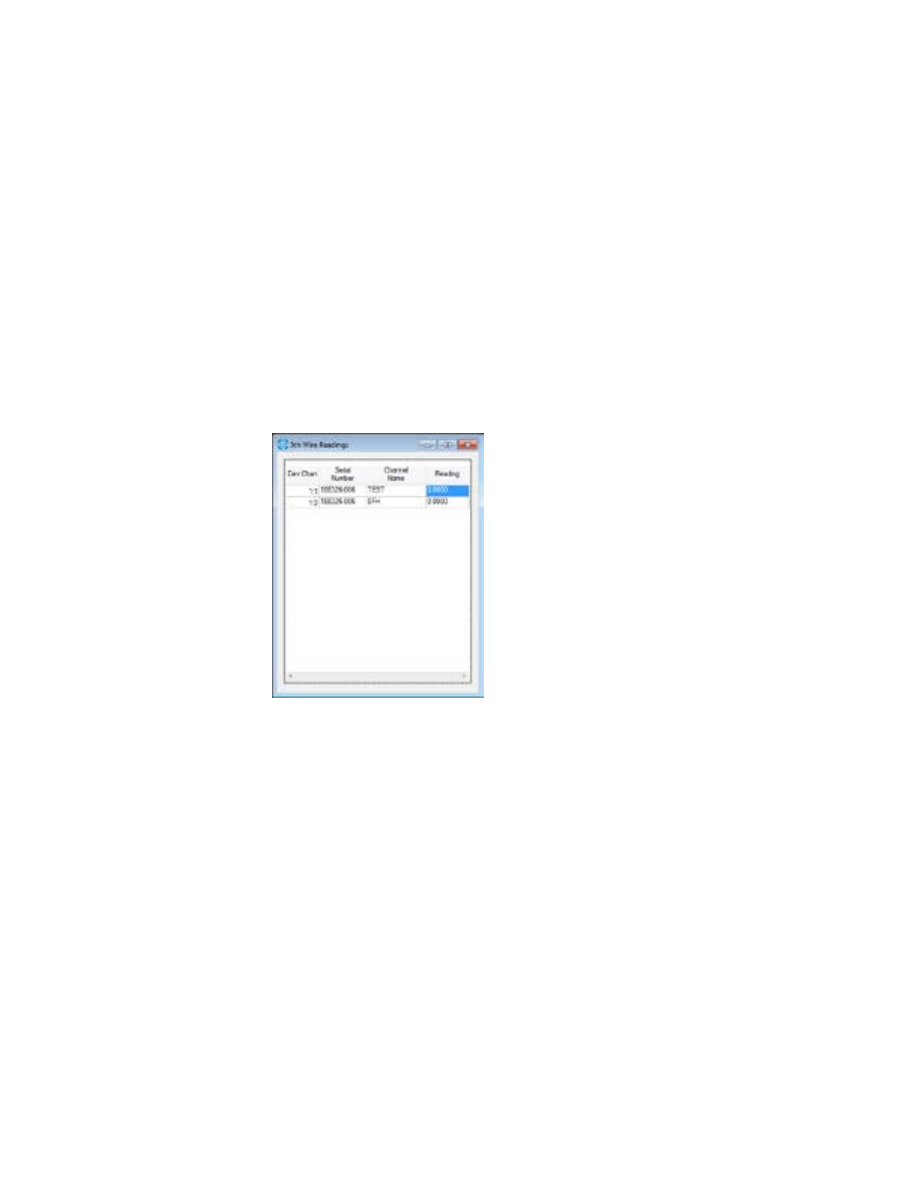

5th-Wire Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

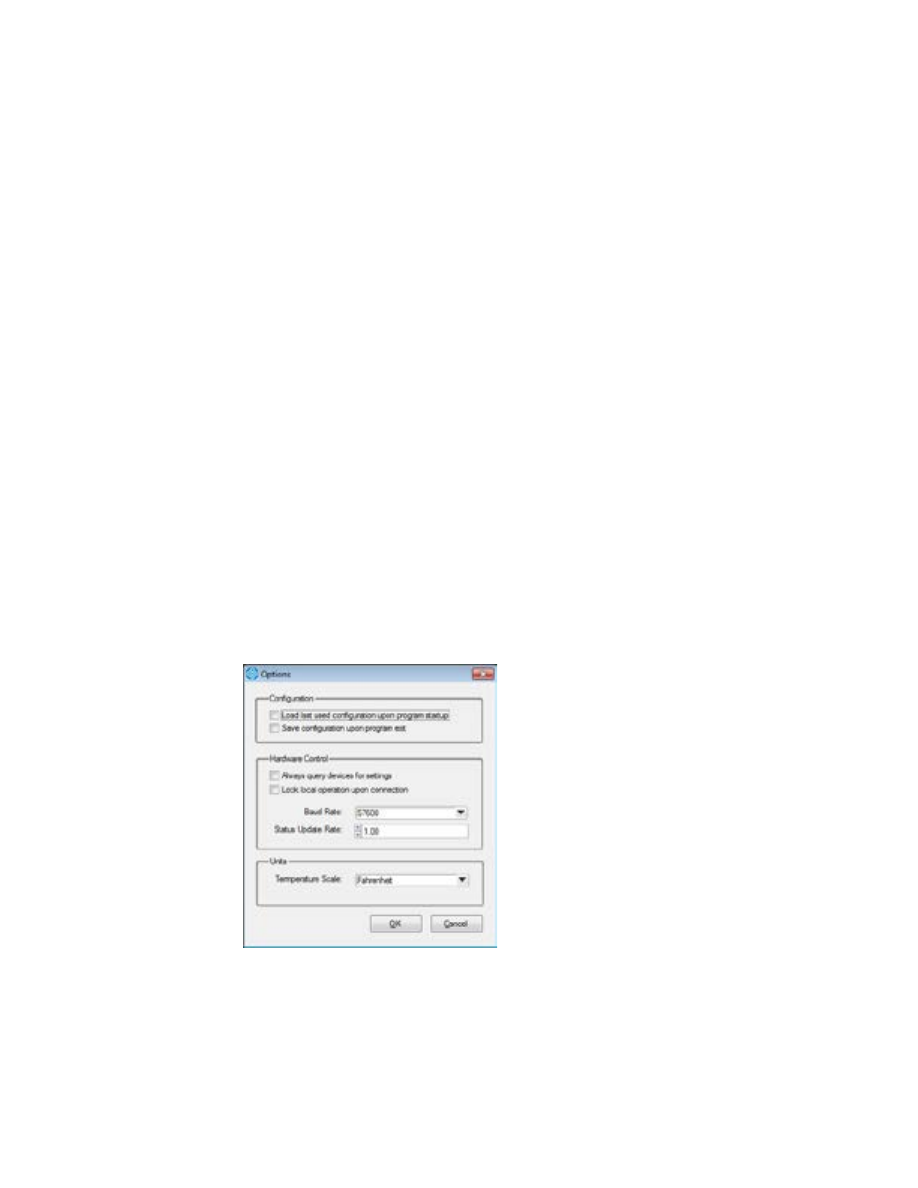

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Re-sync Device Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Device:Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Channel Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Excitation Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Excitation Value (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Excitation Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Sense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Balance Voltage (mV). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Autobalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

KSC-2 Table of Contents

Page vi

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Overload Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pregain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Filter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Filter Cutoff (Hz). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Resonance Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Postgain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Output Overload (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Overloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

KSC-2 High-Level Command Set 51

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Communication Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Excitation Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Input Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Filter Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Output Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Offset Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Overload Detector Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Bridge Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

KSC-2 Does Not Turn On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

KSC-2 GUI Does Not Recognize the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Overload Indicators Are Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

KSC-2 Unit LEDs Are Out of Sync with the GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

1

1

KSC-2 General Information

1.1 Introduction

This manual,

KSC-2 Installation and Programming Instructions

, contains informa-

tion specific to the configuration, installation, and programming of the KSC-2 signal

conditioner. Refer to this document and to the documentation supplied with each

component in your system to understand how to operate your entire system safely and

correctly.

The

KSC-2 Installation and Programming Instructions

manual comprises the

following chapters and supplement:

KSC-2 General Information

(this chapter) provides an overview and specifications of

the KSC-2 system, along with environmental requirements, ISO/IEC conformity, and

available accessories

.

KSC-2 Installation and Operation

contains location and power requirements,

installation instructions, cable connections, and operating instructions.

KSC-2 Control Software Programming Instructions

describes how to install and

operate the stand-alone KSC-2 Control Graphical User Interface (GUI) software.

KSC-2 High-Level Command Set

describes the high-level commands that can control

the KSC-2 unit using the command interface via USB 2.0.

KCS-2 Troubleshooting

offers steps to deal with common problems, such as when the

unit does not turn on or when the GUI fails to recognize the system.

Support and Service

tells you where to get technical support and how to obtain

service or repair.

KSC-2 General Information

Page 2

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.2 Description

The KSC-2 is a compact, rugged dual-channel high precision filter/amplifier with

programmable constant voltage excitation optimized for conditioning Kulite pres

-

sure sensors and microphone products. Fully programmable bipolar excitation with

remote sense provides voltage for bridge-type sensors, and a unipolar excitation

mode is supplied to condition sensors that have internal regulation. The unit supports

automatic and manual balance modes.

A low-noise, high common mode rejection balanced differential input is supplied with

programmable AC/DC input coupling. Sharp, programmable precision low-pass filters

support two response characteristics, which are optimized for making time- domain

or frequency-domain measurements. Amplification is distributed as pre- and post-

filter gain, allowing for elimination of out-of-band energy such as transducer resonant

peaking, which can cause nonlinearities due to clipping of the amplifier. Overload

detectors alert the user to output overloads as well as prefilter overloads that may be

masked by the low-pass filter.

The KSC-2 features optional, patent-pending REZCOMP

TM

transducer resonant

compensation technology, which extends the usable frequency response of sensors

with recess mounting, device packaging, or seismic resonances. Based on a charac

-

terization of the sensor Q and resonant frequency, the REZCOMP technique extends

the usable sensor bandwidth to as much as 80% of the sensor resonant frequency or, in

some cases, even beyond the sensor resonant frequency.

A high-level command interface can control the KSC-2 via USB 2.0. In addition, a

spreadsheet-style graphical user interface is supplied to control up to eight KSC-2

units as a single system. Configurations may be saved and recalled from the host

computer. Settings may be saved to nonvolatile memory for field deployment without

a host computer. Front-panel LED indicators alert the user to overloads, excitation

faults, and auto balance status. In addition, autobalance can be initiated via a momen

-

tary switch on the front panel. The KSC-2 is supplied with an external AC-to-DC

universal supply or may be powered using an external 10 to 30 VDC input.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

3

1.3 Features

1.3.1 Excitation Type

The KSC-2 may be configured for bipolar or unipolar excitation operation. Bridge-

type pressure transducers without internal amplification will generally be interfaced

to the KSC-2 in bipolar mode. The bipolar excitation voltage is fully programmable

from 0 to 12.5 Vdc in 1.25 mV steps. The excitation supply is connected across to the

sensor +/− excitation leads, and the KSC-2 differential amplifier signal leads measure

the sensor output. A four-wire connection to the bridge may be used when precise reg

-

ulation of the excitation voltage at the transducer is not critical. The excitation sense

leads can be run to the bridge (6-wire connection) for precise regulation of the excita

-

tion supply at the transducer load; these should be connected as close to the sensor as

is practical.

Unipolar excitation mode is intended for use with internally amplified sensors. The

unipolar excitation supply is 14 Vdc.

1.3.2 Input Stage

The KSC-2 features an ultra low-noise, low-drift, high common mode rejection

differential input stage for making low-level AC and DC measurements. In bipolar

excitation mode, a fully automatic bridge balance circuit is used to zero the sensor DC

output for zero measurand.

For unipolar excitation mode, the zero suppress mode may be used to zero the initial

sensor DC output. When only the dynamic portion of the signal is to be measured,

the programmable AC input coupling feature of the KSC-2 is useful to block any DC

voltages on the input in order to emphasize the low-level AC portion of the signal by

applying programmable gain.

1.3.3 Input Shield

The KSC-2 has a programmable input shield termination for each channel. The shield

may be terminated in ground, float (AC terminated in 0.1 uF), or driven. In general, it

is recommended that the cable shield be terminated at only one end of the cable to pre

-

vent ground loop pickup. A driven shield may be employed to guard the differential

amplifier input leads (± SIG) to enhance common mode rejection at low frequencies.

KSC-2 General Information

Page 4

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.3.4 Input Modes

The KSC-2 amplifier stage input is software configurable to facilitate

in situ

calibration or diagnostics. Three input modes are available:

•

OPERATE is the normal operating mode. It connects the sensor signal input pins

to the amplifier input.

•

SHORT mode disconnects the sensor and internally shorts the amplifier inputs to

signal ground. This is a useful diagnostic test mode to measure and document the

DC offset and noise contribution of the KSC-2 internal circuitry.

Note:

Any DC voltage injected to execute an automatic or manual bridge balance

is temporarily removed while in SHORT mode.

•

CAL mode disconnects the sensor input and internally connects the KSC-2 ampli

-

fier to the CAL INPUT on the KSC-2 front panel. CAL mode is a useful feature to

accurately measure the AC or DC gain of the KSC-2 amplifier.

Note:

The signal on the KSC-2 CAL input can be distorted if the prefilter gain

stage is driven into heavy saturation by the test signal. This could corrupt a

calibration reading on a second channel connected to the same CAL signal. To

prevent false calibrations, the KSC-2 GUI allows multiple channels to be in CAL

mode only if all channels have the same prefilter gain setting. To further safe

-

guard against false calibrations, the KSC-2 GUI does not allow changes to pre-

filter gain while in CAL input mode.

1.3.5 Flat/Pulse Low-Pass Filters

The KSC-2 has a flexible, high-performance 6-pole low-pass filter characteristic that

can be optimized for time- or frequency-domain measurements. Simply program the

filter characteristic to match your measurement requirements.

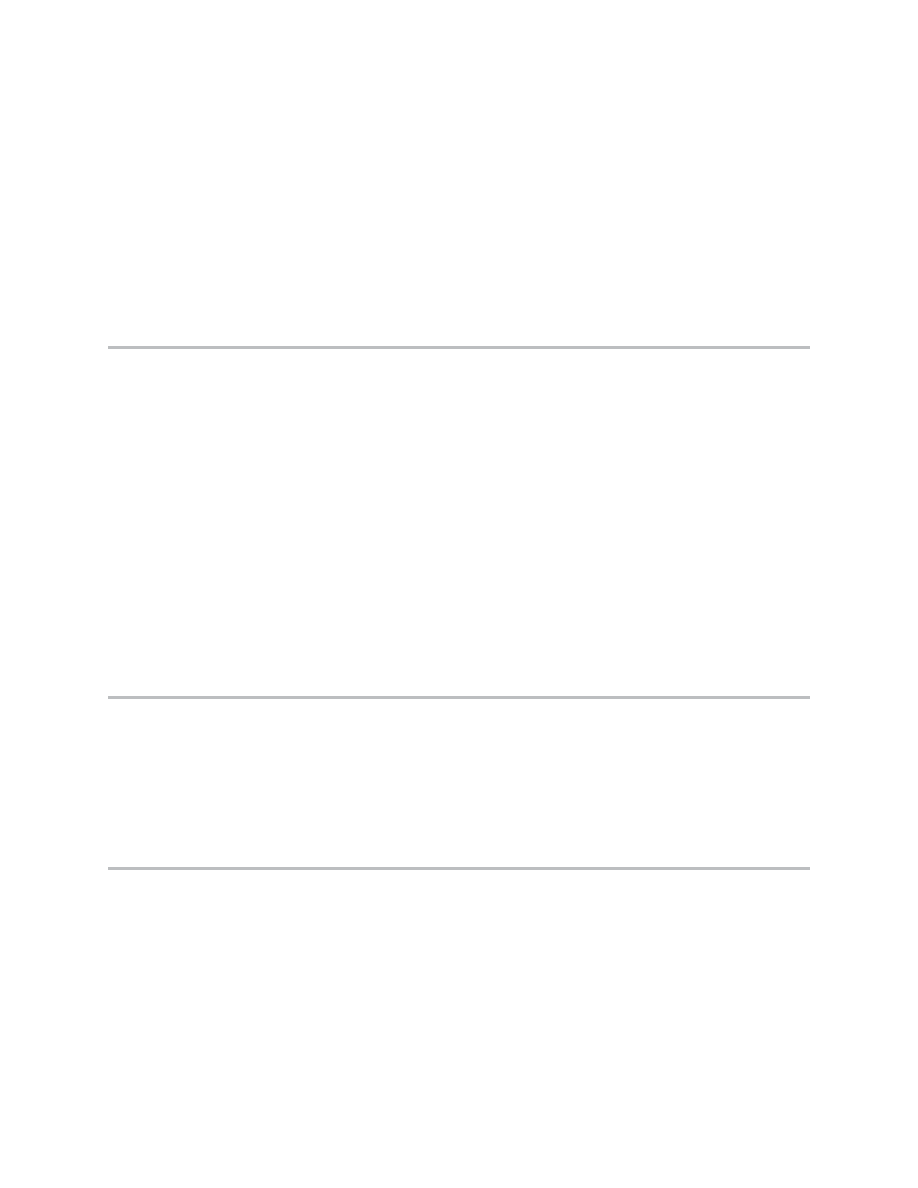

Gain (dB)

Normalized Frequency (f/Fc)

LP6F and LP6P Amplitude Response

0

–15

–30

–45

–60

–75

–90

–105

0.1

0.2

0.7

0.4

10

1

2

4

7

LP6F

–80dB

LP6P

Figure 1

LP6F and LP6P Amplitude Response

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

5

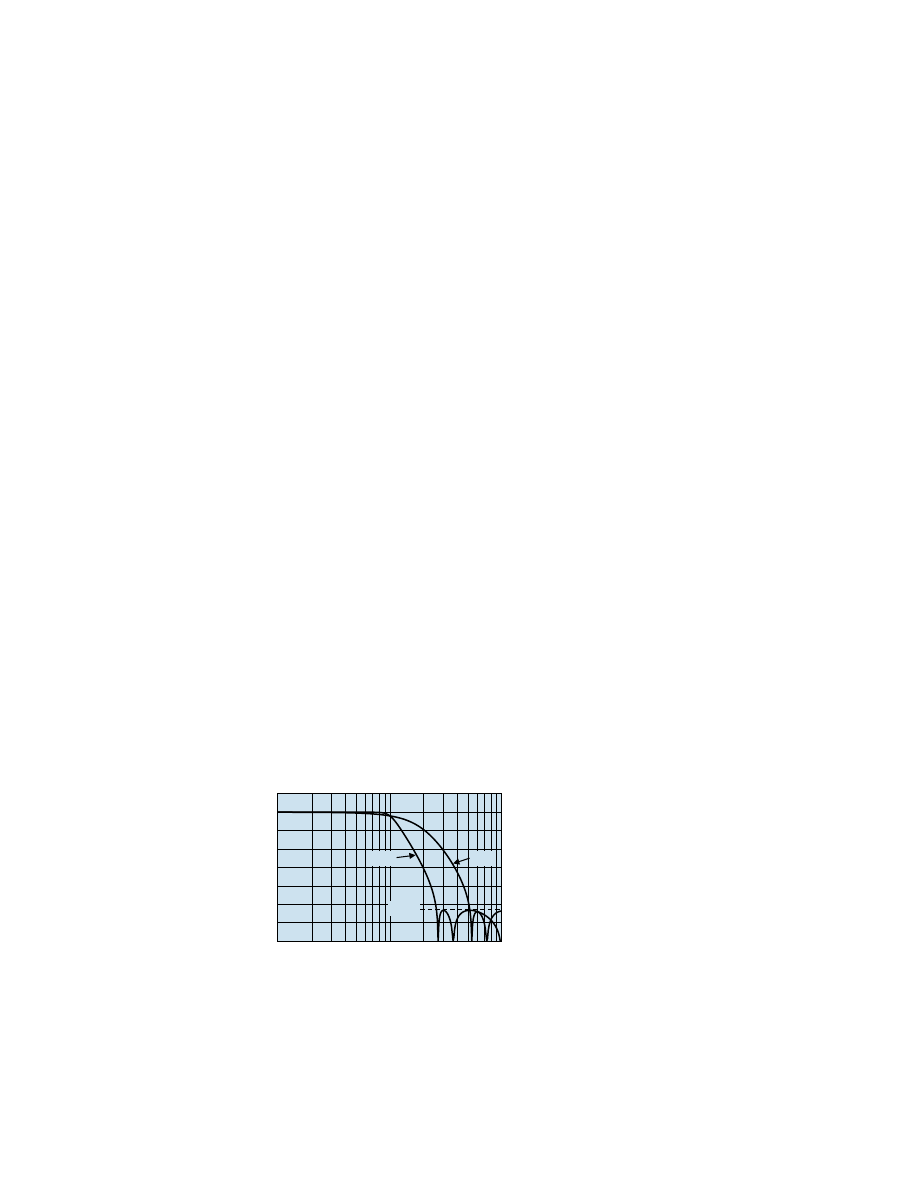

Flat Mode Low-Pass Filters

The LP6F FLAT mode characteristic has a pass-band amplitude response nearly iden

-

tical to the 6-pole Butterworth filter, yet with much sharper roll-off characteristics,

as shown in Figure 2. This makes the LP6F a good choice for spectral analysis or for

anti-aliasing applications.

Gain (dB)

Normalized Frequency (f/Fc)

LP6F vs. 6-Pole Butterworth Amplitude Response

0

–10

–20

–30

–40

–50

–70

–60

–80

0.1

0.2

0.7

0.4

10

1

2

4

7

LP6F

6-Pole

Butterworth

Figure 2

LP6F vs. 6-Pole Butterworth Amplitude

Response

Like the Butterworth low-pass filter, the LP6F has a nonlinear phase response with 60

degrees of phase distortion at the cutoff frequency. See Figure 3.

The nonlinear phase characteristics of the LP6F result in an input-to-output time

delay that is not constant versus frequency. Filters with linear phase, such as the LP6P,

have constant delay for all frequencies in the pass-band, as shown in Figure 4.

Phase

Distortion

Phase

Response

LP6F Phase Response and Phase Distortion

Phase Distor

tion (Deg

rees)

–45

0

–90

Phase (Deg

rees)

–45

–90

–135

–180

–225

–270

–315

–360

Normalized Frequency (f/Fc)

0

0.1

0.3

0.2

0.8 0.9 1.0

0.4 0.5 0.6 0.7

0

Figure 3

LP6F Phase Response and Phase

Distortion

LP6F & LP6P Phase Delay

Phase Dela

y x F

c (Sec x Hz)

0.7

0.8

0.6

0.5

0.4

0.3

0.2

0.1

0

Normalized Frequency (f/Fc)

0

0.4 0.6

0.2

1.6 1.8 2.0

0.8 1.0 1.2 1.4

LP6P

LP6F

Figure 4

LP6F and LP6P Phase Delay

KSC-2 General Information

Page 6

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

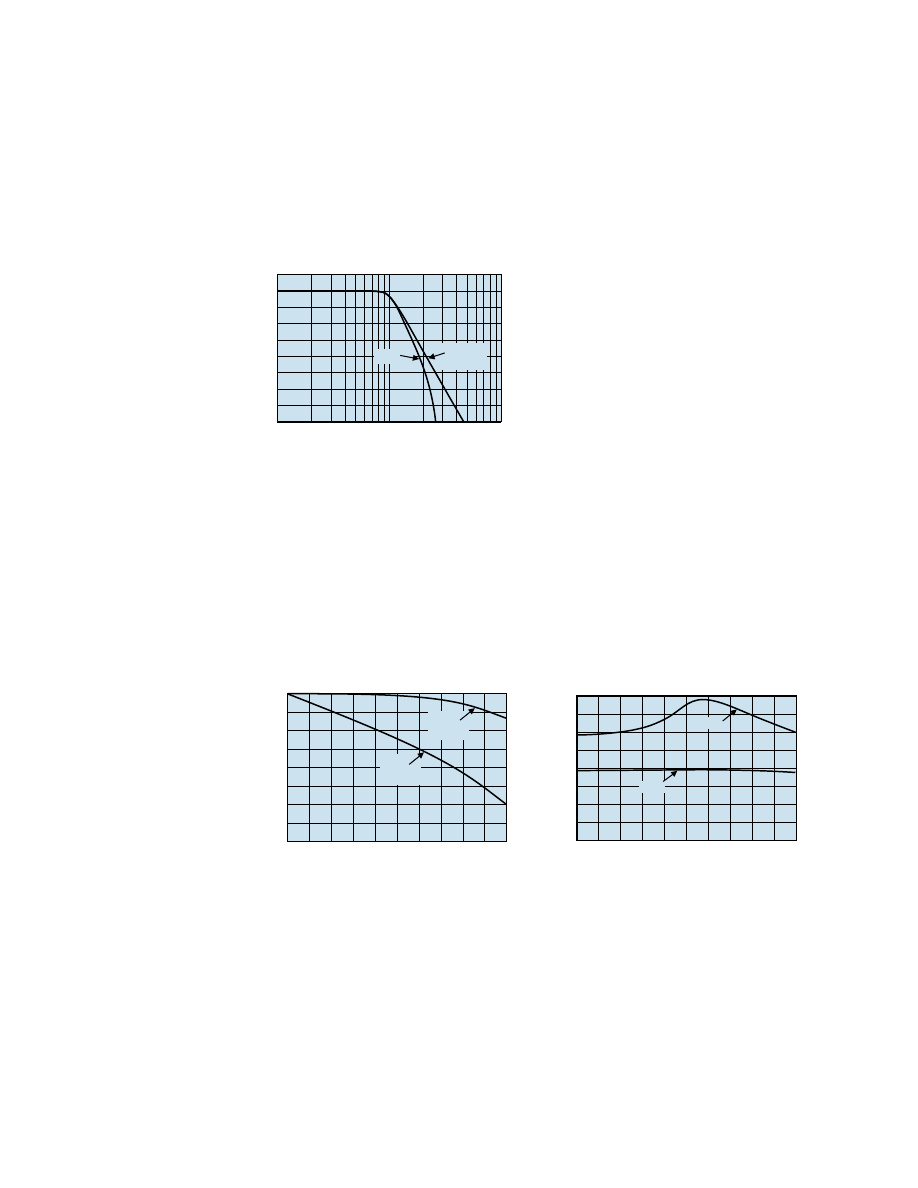

Pulse Mode Low-Pass Filters

For the time domain, the LP6P PULSE mode low-pass filter has excellent transient

response and phase linearity required for time-domain applications such as transient

(shock) measurements and time-domain waveform analysis.

A quantitative measure of a filter's transient behavior to evaluate the response to a unit

step function input in the time domain. As Figure 5 shows, the LP4F step response

exhibits under damped characteristics with 16% overshoot and notable ring-down as

the output decays to its final value. In contrast, the LP4P is nearly critically damped

and thus exhibits little overshoot and fast settling time in response to a step input.

When compared to a 6-pole Bessel filter, the LP6P has similar pass-band characteris

-

tics, yet with a much sharper transition slope from pass-band to stop-band (Figure 6).

LP6F & LP6P Step Response

Response/Final V

alue

1.2

1.0

0.8

0.6

0.4

0.2

0

Settling Time x Fc (Sec-Hz)

0.0 0.5

1.5

1.0

5.0

2.0 2.5 3.0 3.5

4.5

4.0

LP6F

LP6P

10-90% Rise (Sec)

50% Delay (Sec)

% Overshoot

10% Error (Sec)

5% Error (Sec)

1% Error (Sec)

0.5% Error (Sec)

LP6F

0.501/Fc

0.639/Fc

15.8%

1.26/Fc

1.52/Fc

2.80/Fc

3.31/Fc

LP6P

0.350/Fc

0.385/Fc

1.1%

0.57/Fc

0.61/Fc

0.84/Fc

0.93/Fc

Figure 5

LP6F and LP6P Step Response

Gain (dB)

Normalized Frequency (f/Fc)

LP6P vs. 6-Pole Bessel Amplitude Response

0

–10

–20

–30

–40

–50

–70

–60

–80

0.1

0.2

0.7

0.4

10

1

2

4

7

LP6P

6-Pole

Bessel

Figure 6

LP6P vs. 6-Pole Bessel Amplitude

Response

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

7

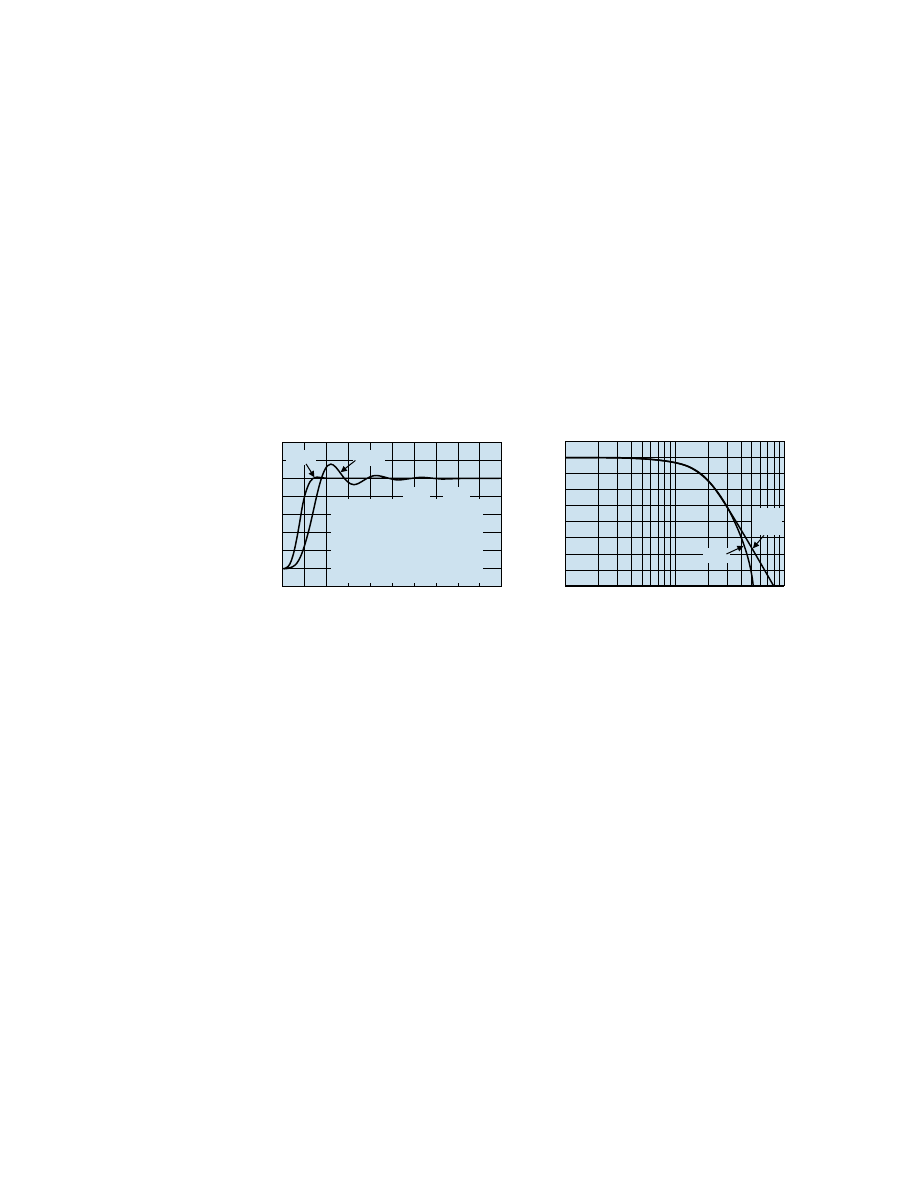

Anti-Aliasing Applications

When used for anti-aliasing applications, the LP6F provides more usable bandwidth

for a given sampling frequency. In exchange for linear phase and excellent transient

response, the LP6P is less selective and thus requires a higher sampling frequency

than the LP6F.

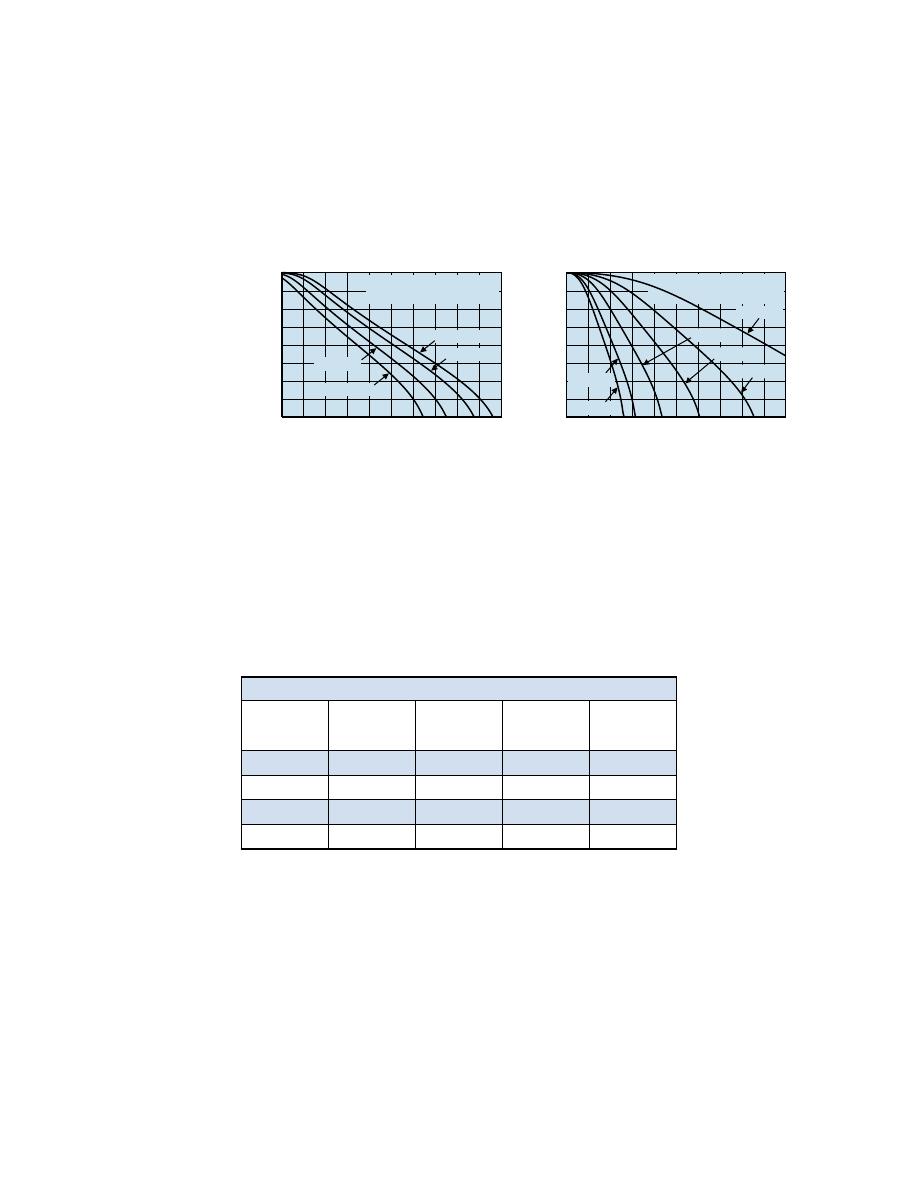

LP6F Attenuation of Aliases vs Sampling Frequency

Minim

um Atten

uation of Aliases (dB)

–10

0

–20

–30

–40

–50

–60

–70

–80

Sampling Frequency/Fh

2.00

2.50 2.75

2.25

4.00 4.25 4.50

3.00 3.25 3.50 3.75

α

= 3.01 dB

α

= 1.0 dB

α

= 0.1 dB

α

= 0.25 dB

Fh = Highest Frequency of Interest

α

= Attenuation at Fh

Figure 7

LP6F Attenuation of Aliases vs.

Sampling Frequency

LP6P Attenuation of Aliases vs Sampling Frequency

Minim

um Atten

uation of Aliases (dB)

–10

0

–20

–30

–40

–50

–60

–70

–80

Sampling Frequency/Fh

1

5

7

3

17

19

21

9

11

13

15

α

= 3.01 dB

α

= 2.0 dB

α

= 0.1 dB

α

= 0.25 dB

α

= 0.5 dB

α

= 1.0 dB

Fh = Highest Frequency of Interest

α

= Attenuation at Fh

Figure 8

LP6P Attenuation of Aliases vs.

Sampling Frequency

Table 1 compares attenuation of aliases versus sampling frequency for the LP6P,

6-pole Bessel (BE6), LP6F, and the 6-pole Butterworth (BU6). The table shows that

much lower sampling frequencies are required for the KSC-2 LP6P and LP6F than for

traditional filter characteristics.

Table 1 Sampling Frequency for −3.01 dB Attenuation at Fh

Alias Attn.

BE6

LP6P

BU6

LP6F

20

3.4Fc

3.4Fc

2.5Fc

2.4Fc

40

4.6Fc

4.5Fc

3.2Fc

2.9Fc

60

6.4Fc

5.5Fc

4.2Fc

3.3Fc

80

9.0Fc

6.2Fc

5.6Fc

3.6Fc

KSC-2 General Information

Page 8

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.3.6 REZCOMP

The frequency response of a pressure transducer is influenced by numerous factors:

•

Natural resonance of the sensor structure

•

Spatial resolution of the sensor due to its diaphragm size

•

Sensor packaging

•

Signal conditioning

•

Mounting at the measurement location

In particular, the resonance of the sensor and aerodynamically driven resonances

related to sensor packaging and/or mounting can distort dynamic pressure measure

-

ments within the range of greatest interest (10 Hz–20 kHz). This typically results in

erroneous amplification. Unknown resonant frequencies and damping factors (quality

factors) make such errors hard to quantify, so correcting for these errors within the

frequency response of a pressure transducer or measurement system can be a chal

-

lenge. However, with the ability to fully characterize resonant frequencies that lie

within 10 Hz–50 kHz using Kulite’s proprietary dynamic pressure characterization

methodology or other methods, it is possible to apply electrical filtering to substan

-

tially extend the flat (0 ± 2 dB) frequency response of a transducer before any digital

signal conversion.

REZCOMP, optional with the KSC-2, is a real-time frequency response compensation

scheme that uses electrical filtering to correct for aerodynamically driven packaging-

or mounting-related resonances while preventing signal distortion caused by sensor

resonances. The compensation extends the usable, flat amplitude bandwidth of the

transducer while correcting the phase response to maintain constant time delay over

the extended bandwidth.

1.3.7 Distributed Gain

Amplifier gain of the KSC-2 is distributed as pre- and postfilter gain. Gain may be

apportioned around the compensator and filter to provide headroom for out-band

signals that would otherwise clip against the internal ±10 V supply rails of the KSC-2.

After removal of the out-band energy by the KSC-2 filters, the postfilter gain is used

to achieve the desired full-scale output.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

9

1.3.8 Overload Detectors

Input overload detectors alert the user to an out-band overvoltage condition that would

clip against the internal ±10 V supply rails of the KSC-2 and could be masked by the

filter.

An output overload detector is provided with a programmable threshold. This is useful

for providing visibility to output signals approaching the full-scale capability of the

attached recording device.

1.3.9 KSC-2 Control

Remote Interface

The KSC-2 unit has a USB 2.0 type B interface that uses a high-level command set

protocol. Section 5 of this manual,

KSC-2 High-Level Command Set

, discusses these

commands and how to use them.

Nonvolatile Memory

The KSC-2 module’s programmed state can be saved to nonvolatile memory to retain

settings through the power cycle or to deploy in the field without a control computer

attached.

To save settings to nonvolatile memory, use the Tool menu’s Save All command (see

Section 4.4.4,

Tools

).

KSC-2 Control Software

The KSC-2 comes with spreadsheet-style software for use with Windows OS. Using

the GUI, you can control up to eight KSC-2 units as a system. Configurations can be

saved to and retrieved from the control computer. Section 4 of this manual,

KSC-2

Control Software Programming Instructions,

explains how to use the GUI Control

software.

Front Panel Controls and Indicators

Each channel has LEDs to monitor the following conditions:

•

Input or output overload

•

Excitation fault (short or overvoltage)

•

Balance mode status

Momentary switches let you clear overload detectors in latching mode and initiate

a balance/suppress operation. A successful balance or suppress operation turns the

front-panel AUTO BALANCE light green. Remote commands or the GUI control

panel allows you to lock the front-panel switches.

KSC-2 General Information

Page 10

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.4 Specifications

1.4.1 Input Wiring

Input Connector:

9-pin female D-sub at front panel (2 each)

Channel Input Wires:

±SIG (2); ±EXC (2); ±SEN (2); SHLD (1); GND; 5

th

wire sensor temperature output (1)

1.4.2 Constant Voltage Excitation Supply

Type:

Programmable constant voltage excitation

Mode:

Programmable bipolar or unipolar

Bipolar Mode:

Level:

0 to 12.5 V in 1.25 mV steps

Accuracy:

±0.1% of setting ±5 mV

Current:

30 mA, short circuit protected

Noise:

100 μVrms, 3 Hz to 100 kHz

Drift:

±0.0025%/ºC of setting or ±50 μV/ºC

Stability:

±0.005% or ±250 μV for 8 hours

Load Regulation:

±0.03% or ±200 μV, whichever is greater, no load to full load

Sense:

Programmable local or remote. Sense boost limited to 3 V above programmed

setting.

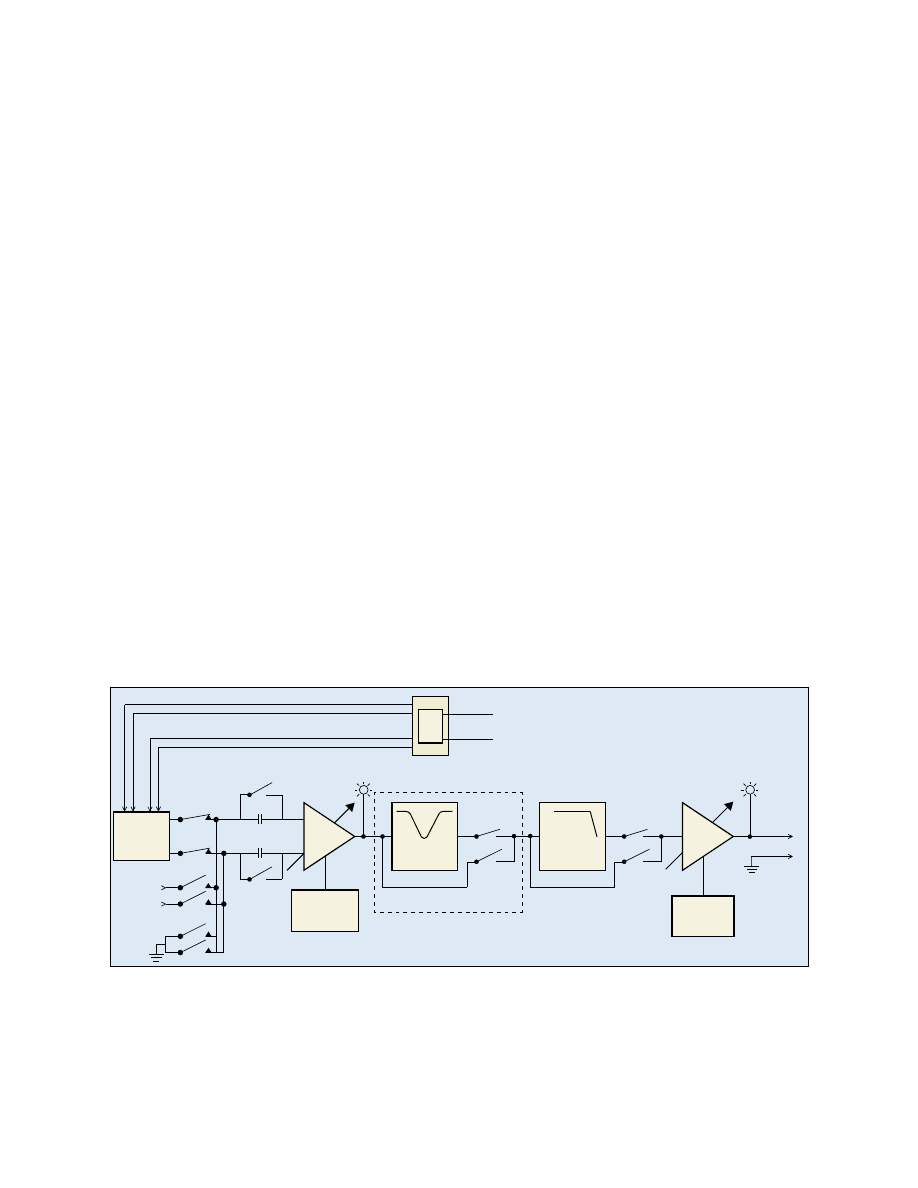

Option C3

Compensator

In

Compensator

Out

Post-Filter Gain

AC/DC Coupling

Resonance

Compensator

Prog.

Buffered

Amp

Cal

Input

Pre-Filter

Gain

Power

Reg

Bipolar \ Unipolar Excitation Supply

Auto Calibrate

Gain & Offset

Auto Balance/

Zero Suppress

LP6F or

LP6P

Filter In

Filter Out

Programmable

6-Pole

Input

Overload

Output

Overload

Input

2-6 Wire

w/Shield

Output

Figure 9

KSC-2 Channel Block Diagram

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

11

Autobalance (Bipolar EXC Mode Only):

On command, bridge DC output is automatically balanced using voltage

insertion at amplifier input.

Modes:

Automatic or manual entry

Range (RTI):

Prefilter Gain ≥16:

±32 mV/V with 1 µV/V resolution

Prefilter Gain <16:

±512 mV/V with 16 µV/V resolution

Unipolar Mode:

Level:

14 Vdc ±5%

Current:

30 mA, short circuit protected

Suppress (Unipolar EXC Mode Only):

Transducer DC output is automatically suppressed using voltage insertion at

the amplifier input.

Modes:

Automatic or manual entry

Range (RTI):

Prefilter Gain ≥16:

±320 mV with 10 µV resolution

Prefilter Gain <16:

±5.12 V with 160 µV resolution

1.4.3 Input Characteristics

Type:

Balanced differential input with programmable AC/DC coupling

Maximum Input Level:

±10 Vpk (common mode and normal mode signals)

Level vs. Frequency:

±10 Vpk for f ≤ 127.5 kHz; ±10 Vpk x (127.5 kHz/f) for f >127.5 kHz

Input Impedance:

10 MΩ per side

Drift:

1 µV/°C, RTI

CMRR (input gain >x16):

110 dB, DC to 1000 Hz

Spectral Noise:

7 nV/ √Hz at 1 kHz and prefilter gain >64

Programmable AC Coupling Frequency:

0.25 Hz (−3.01 dB), 2-pole

Input Protection:

24 V continuous

KSC-2 General Information

Page 12

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.4.4 Optional KSC-2 Transducer Compensator (C3) Characteristics

Transducer Cavity Resonance Compensator:

Patent-pending transducer cavity resonance compensation for sensor as

characterized by Q and resonant frequency (Fr)

Compensation Q:

1 to 20 in 0.1 steps; 20 to 50 in 0.5 steps

Compensation Frequencies (Fr):

Low Range:

10 Hz to 2.55 kHz in 10 Hz steps

Mid Range:

2.6 kHz to 51 kHz in 200 Hz steps

High Range:

52 kHz to 255 kHz in 1 kHz steps

Accuracy:

Low Range:

±0.1 dB DC to 0.8 Fr; 1.25 Fr

≤

f

≤

10 kHz

Q

≤

10: ±0.2 dB; 0.8 Fr < f < 1.25 Fr

Q > 10: ±0.02 dB * Q; 0.8 Fr < f < 1.25 Fr

Mid Range:

±0.15 dB DC to 0.8 Fr; 1.25 Fr

≤

f

≤

100 kHz

Q

≤

10: ±0.25 dB; 0.8 Fr < f < 1.25 Fr

Q > 10: ±0.025 dB * Q; 0.8 Fr < f < 1.25 Fr

High Range:

±0.2 dB; DC to 0.6 Fr;

±0.5 dB; 1.7 Fr

≤

f

≤

255 kHz

Q

≤

10: ±1.25 dB; 0.6 Fr < f < 1.7 Fr or 255 kHz, whichever is less

Q > 10: ±0.125 dB * Q; 0.6 Fr < f < 1.7 Fr or 255 kHz, whichever is less

Phase Match:

±2°, DC to 0.8 Fr low and mid ranges;

DC to 0.6 Fr high range

Amplitude Match:

±0.2 dB, DC to 0.8 Fr low and mid ranges; DC to 0.6 Fr high range

Compensator Off:

Compensator may be removed from the signal path.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

13

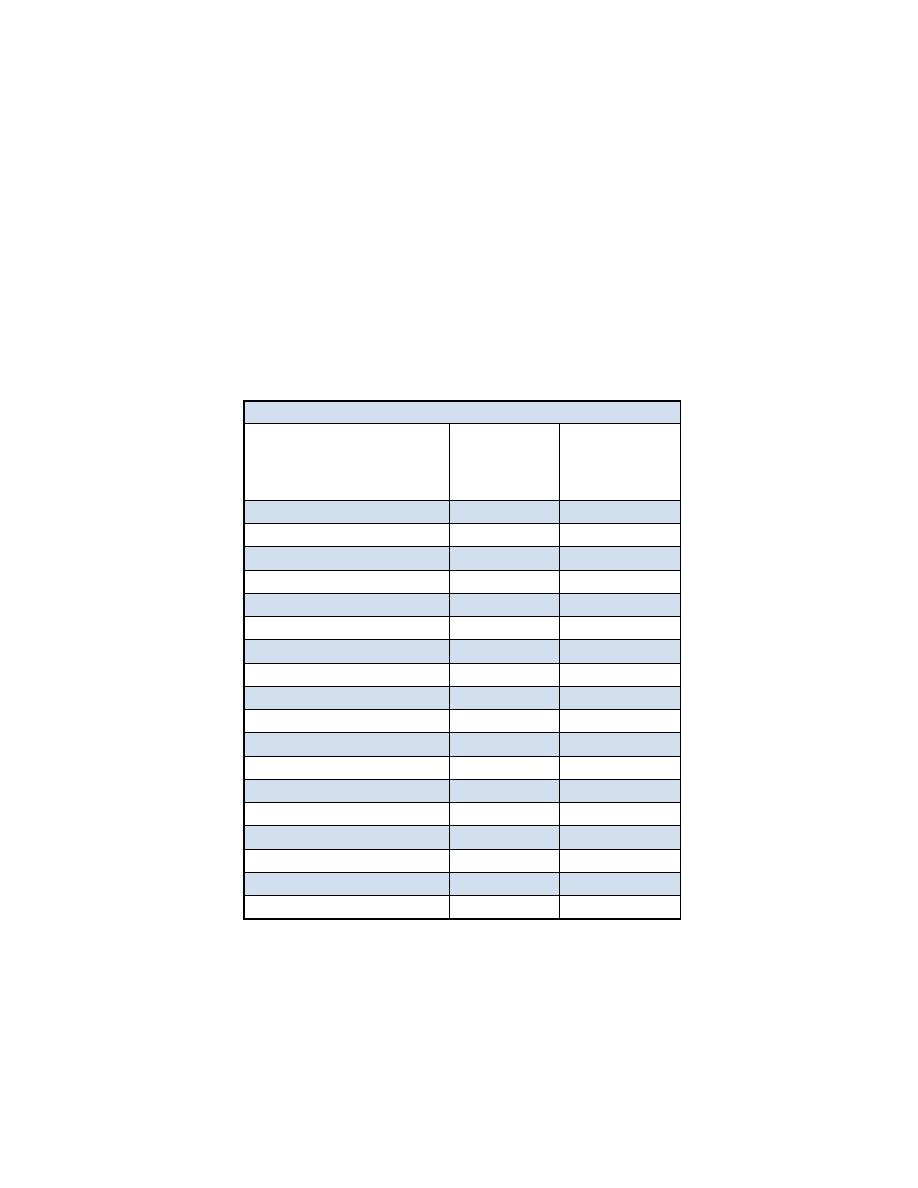

1.4.5 Filter Characteristics

Type:

Programmable flat/pulse low-pass 6-pole, 6-zero low-pass filter. See Table 2.

Programmable for maximally flat pass-band (LP6F) or linear phase (LP6P)

Cutoff Frequencies:

500 Hz to 127.5 kHz in 500 Hz steps

Pass-Band Accuracy:

±0.2 dB maximum to 0.8 Fc

Amplitude Match:

±0.2 dB maximum to 0.8 Fc

Phase Match:

±2° maximum to 0.8 Fc

Wideband Mode:

Filter may be removed from the signal path, resulting in 3-pole Butterworth

wideband amplifier frequency response with nominal –3 dB frequency at 500 kHz.

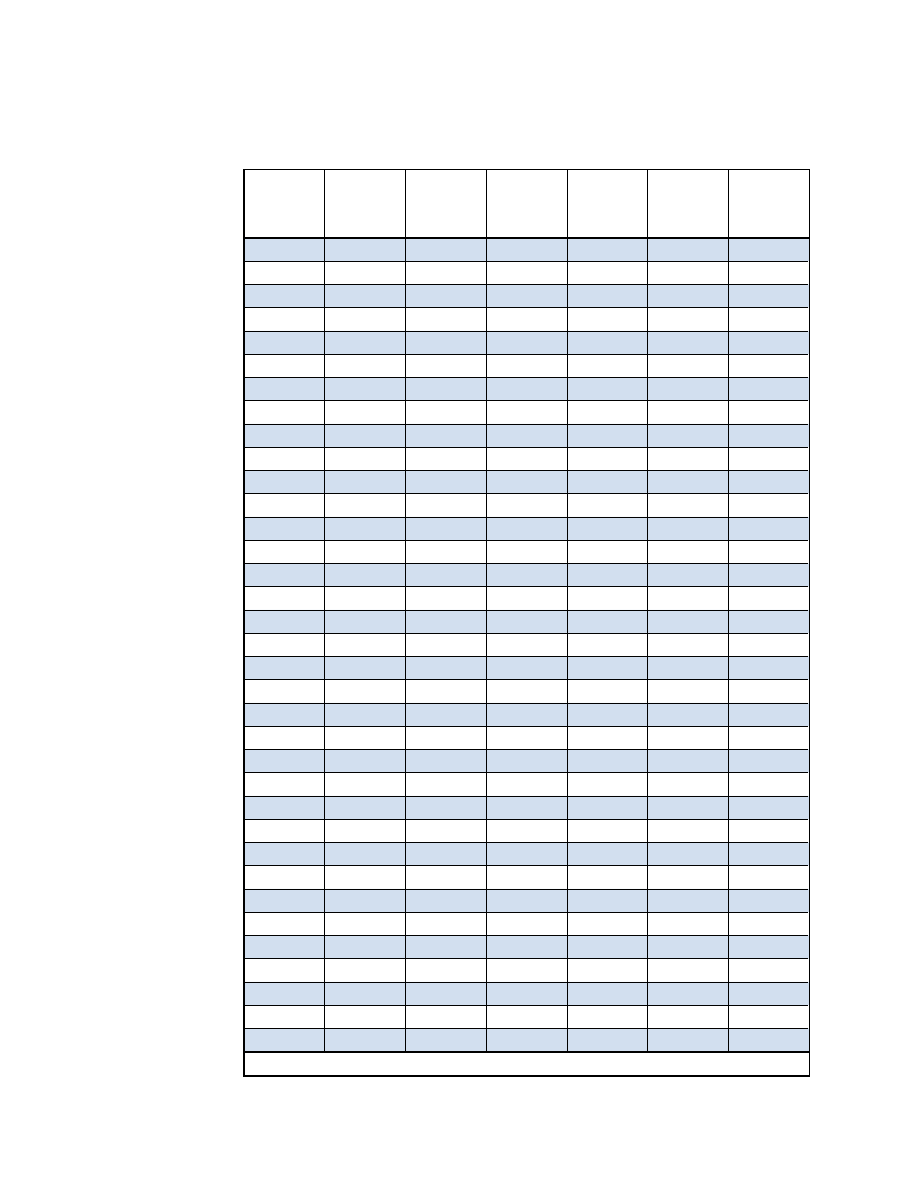

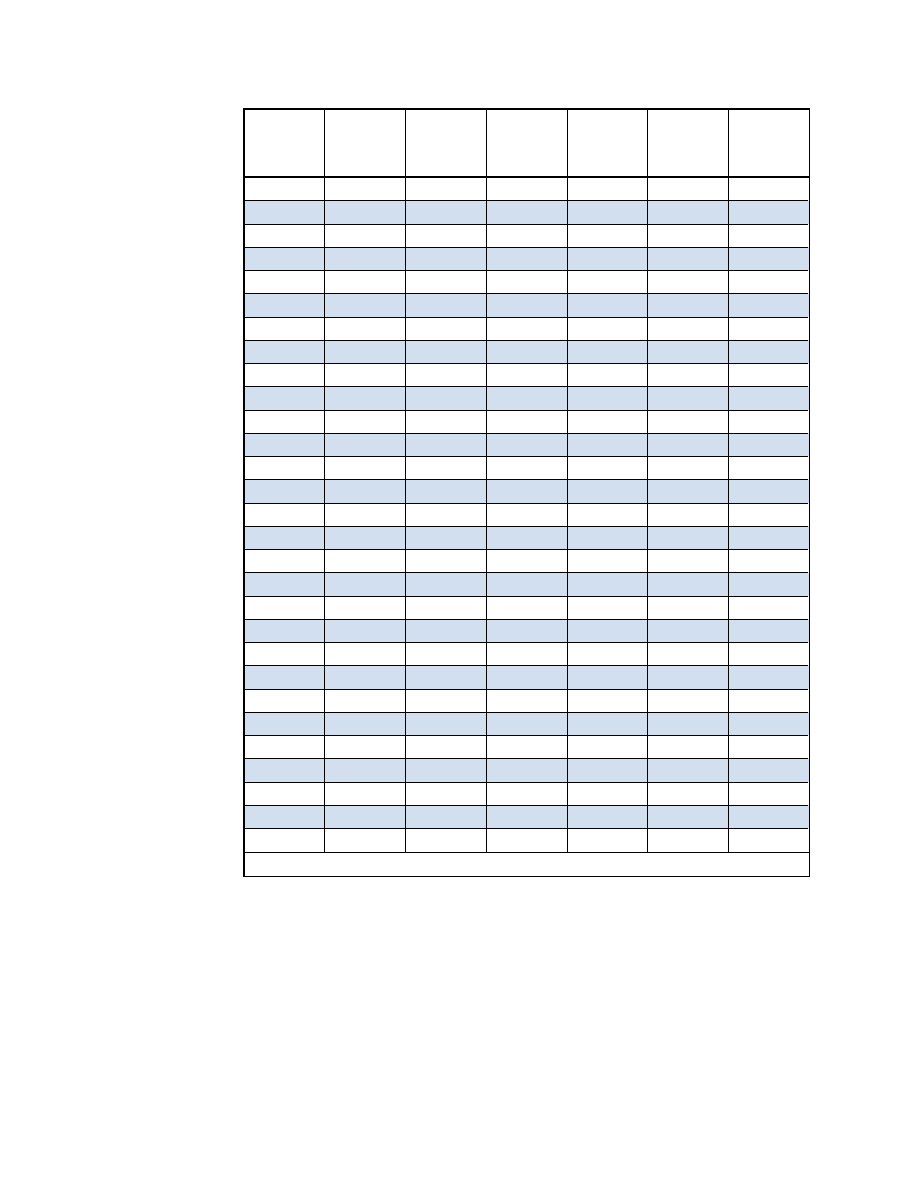

Table 2 LP6F vs. LP6P Filter Characteristics

Specification

LP6F 6-Pole

Maximally

Flat Low-Pass

Filter

LP6P 6-Pole

Constant Time

Delay Low-Pass

Filter

Cutoff Frequency Amplitude

–3.01 dB

–3.01 dB

DC Gain

0.00 dB

0.00 dB

Pass-Band Ripple

0.00 dB

0.00 dB

Stop-Band Frequency

2.6113 Fc

5.1923 Fc

Cutoff Frequency Phase

–270.0 deg

–140.3 deg

Phase Distortion (DC to Fc)

< 60 deg

< 1.45 deg

Zero Frequency Group Delay

0.5834/Fc

0.3924/Fc

Percent Overshoot

15.8%

1.1%

1% Settling Time

2.80/Fc

0.84/Fc

0.1 % Settling Time

4.36/Fc

1.02/Fc

–0.1 dB Frequency

0.766 Fc

0.193 Fc

–1 dB Frequency

0.9080 Fc

0.5983 Fc

–2 dB Frequency

0.9624 Fc

0.8293 Fc

–3.01 dB Frequency

1.0000 Fc

1.0000 Fc

–20 dB Frequency

1.3822 Fc

2.3616 Fc

–40 dB Frequency

1.8546 Fc

3.5115 Fc

–60 dB Frequency

2.3206 Fc

4.5462 Fc

–80 dB Frequency

2.6113 Fc

5.1923 Fc

KSC-2 General Information

Page 14

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.4.6 Output Characteristics

Type:

DC coupled, single-ended output, short circuit protected

Impedance:

10 Ω

Max Output:

±10 Vpk, ±25 mA pk

Offset:

< 5 mV after auto-adjust at any gain setting

Offset Drift:

1 µV/°C, RTI + 150 µV /°C RTO, typical

Noise:

2.8 µV rms RTI + 60 µV rms RTO, 3 Hz to 100 kHz

Crosstalk:

–80 dB, DC to 100 kHz

1.4.7 General Characteristics

Size:

12.5 x 8.6 x 1.75 inches (L x W x H)

Weight:

3.5 lb. net

Temperature:

0°C to 55°C (operating); –20°C to 85°C (storage)

Humidity:

10% to 90% noncondensing

Input Connectors:

2 each 9-pin D-sub on front panel

Output Connectors:

2 each isolated BNC on rear panel

Cal Input Connector:

Isolated BNC on front panel

Ground:

Signal ground post at rear panel. Slider switch connects chassis ground to signal

ground or isolates signal ground to accommodate external ground reference.

Chassis ground is referenced to ground pin on power input connector.

Power Entry Connector:

Mini DIN

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 General Information

Page

15

1.5 ISO/IEC Conformity

Product Category:

Electrical equipment for measurement, control, and laboratory use conforms to the

directives and standards listed below.

Council Directive 2004/108/EC, Electromagnetic Compatibility,

IEC 61326-1:2005

Emission, group 1 equipment measured on a test site:

• CISPR 11:2010 Conducted emissions: Class B, 150 kHz to 30 MHz.

• CISPR 11:2010 Radiated emissions: Class B, 30 MHz to 1 GHz.

• 61000-3-2:2009 Harmonics

• 61000-3-3:2008 Flicker

Immunity, equipment intended for use in industrial locations:

• IEC 61000-4-2:2009 Electrostatic discharge: Performance Criteria B, 4 kV

by contact, 8 kV by air discharge

• IEC 61000-4-3:2010 Radiated immunity: Performance Criteria B, 10 V/m,

80 MHz to 2.7 GHz, 80% AM with 1 kHz sine wave modulation, 200 Hz pulsed

modulation

• IEC 61000-4-4:2011 Electrical fast transient/burst: Performance Criteria B,

1 kV to AC power line, Ethernet communication line, signal lines

• IEC 61000-4-5:2005 Surge: Performance Criteria B, 1 kV line to line/2 kV line to

ground for AC power port, 1 kV for I/O signal/control lines, including functional earth

lines

• IEC 61000-4-6:2008 Conducted immunity: Performance Criteria B, 10 V,

150 kHz to 80 MHz

• IEC 61000-4-11:2004 Voltage dips: Performance Criteria B, AC power port,

0% during half cycle, 0% during 1 cycle, 70% during 25 cycles for 50 Hz test, 70%

during 30 cycles for 60 Hz test

• IEC 61000-4-11:2004 Voltage interrupts: Performance Criteria C, AC power port, 0%

during 25 cycles for 50 Hz test, 0% during 30 cycles for 60 Hz test

Council Directive 2006/95/EC, Low-Voltage Safety

• IEC 61010-1:2010 Product meets the essential requirements for low-voltage safety.

KSC-2 General Information

Page 16

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

1.6 Accessories

200-B-84801

Link kit for joining two KSC-2 units

200-B-84802

Rack mount ear kit

910-A-84803

Spare external AC/DC power supply (one included with KSC-2 unit)

908-A-84792

Mating power entry connector for KSC-2

220-A-84804

9-pin mating input connector with metal backshell and gold-plated screw

machined crimp contacts

220-A-84805

9-pin mating input connector with metal backshell and gold-plated screw

machined solder cup contacts

908-A-84797

9-pin mating input connector with metal backshell and screw terminal

connections

910-A-84798

Locking USB cable accessory (72")

Standard (nonlocking) type A USB connector for host computer to locking type B

USB connector for KSC-2

910-A-84799

USB Cable Accessory (36”)

High-speed, double-shielded type A USB connector for host computer to type B

USB connector for KSC-2 (one included with KSC-2 unit)

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

17

2

KSC-2 Installation and Operation

2.1 Introduction

This section contains instructions for installing and operating the KSC-2 signal

conditioner: unpacking, location and power requirements, mounting options,

connecting cables, and basic operation.

Before installing the system, read the complete procedure to become familiar with the

steps. After installation, the system must be configured using the system configura

-

tion instructions in Section 4 of this manual,

KSC-2 Control Software Programming

Instructions

.

2.2 Site Preparation

This section describes the preparations that are necessary before you install the

system.

2.2.1 Power Requirements

The KSC-2 unit includes one external AC/DC power supply. The input power

connector is located on the left side of the rear panel.

The KSC-2 requires input power of 10–30 VDC, 25 W maximum, applied at the rear

panel POWER IN connector. Mating power entry connectors (KPPX-4P-30) and spare

external AC/DC power supplies (KSC-2-ACPS) are available.

2.2.2 Location Requirements

KSC-2 units must be installed and operated in an area that meets and can maintain the

environmental specifications listed below:

•

Maximum temperature: 55°C (131°F)

•

Minimum temperature: 0°C (32°F)

•

Relative humidity: 10% to 90% (noncondensing)

2.2.3 Physical Requirements

The KSC-2 unit weighs 3.5 lb. net. The frame can be bench or rack mounted. The unit

is 12.5 inches long by 8.6 inches wide by 1.75 inches high. Provide adequate room

behind the unit for connecting cables to the rear panel.

KSC-2 Installation

Page 18

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

CAUTION

Use only the supplied flat-head Phillips screws when installing the

mounting ears. Longer screws will damage the system hardware.

2.3 Unpacking

Before shipment, this KSC-2 unit was free of electrical and mechanical defects. It was

fully tested and burned in.

2.3.1 Shipping Container

Inspect shipping containers immediately upon receipt for evidence of mishandling

during transit. If a shipping container has been damaged in any way, have the carrier’s

agent present when the equipment is unpacked.

If the equipment is damaged, file a claim with the carrier and forward a copy to

Kulite. Kulite will notify you of the disposition of the equipment and will arrange for

repair or replacement without waiting for a settlement of the claim against the carrier.

Retain the shipping container and packing material for the carrier’s inspection or for

reuse.

NOTE: Need Kulite’s procedure for this.

2.3.2 Chassis Inspection

Make a visual check of the unit’s exterior to ensure that there are no broken controls

or connectors and that the panel surfaces are free of dents and scratches.

2.4 Storage, Transport, and Shipment

The following environmental conditions must be maintained during storage, trans-

port, or shipment of KSC-2 units:

•

Maximum temperature: 85°C (185°F)

•

Minimum temperature: −20°C (−4°F)

•

Relative humidity: 10% to 90% (noncondensing)

2.4.1 Storage Requirements

The unit can be stored or remain in an equipment rack. For prolonged storage, protect

the unit with a cover to prevent dust accumulation. The storage area should be free of

dust and must meet the environmental conditions described in Section 2.4.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

19

2.4.2 Transport Requirements

The unit may be transported over a short distance if vibration and shock are held to

an absolute minimum. Before transport, remove cables. The environmental conditions

described in Section 2.4 must be maintained.

2.4.3 Shipment Requirements

Always use the original packaging materials to ship system components. A new

container can be purchased from Kulite. The environmental conditions described in

Section 2.4 must be maintained.

KSC-2 Installation

Page 20

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

2.5 Mounting the KSC-2

The KSC-2 can be mounted individually on a desk or counter. It has four nonskid feet

for stability. In addition, KSC-2 units can be connected vertically or horizontally or

mounted to a rack, as described in the following sections.

For optimal performance, maintain airflow around the KSC-2 to allow adequate

cooling. For example:

•

When multiple units are stacked on a bench, the units’ sides should remain

unobstructed to facilitate airflow between the boxes.

•

If a unit’s side is obstructed, the top panel should remain open to airflow.

•

When an array of KSC-2 units are rack mounted, the top, bottom, and side of the

array should allow for airflow.

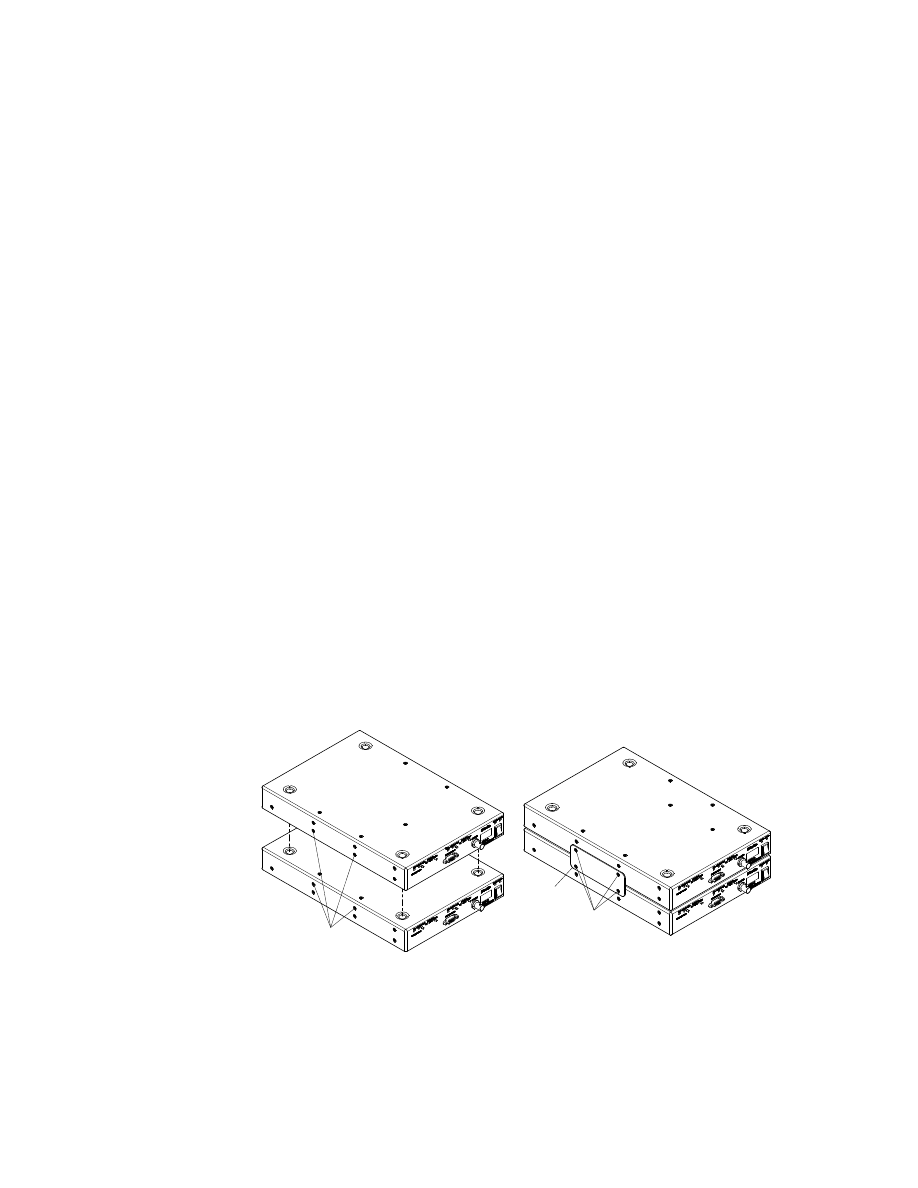

2.5.1 Vertically Mounting Two or More Units

The top panel of each KSC-2 unit contains four dimples, one near each corner, that

correspond to the positions of the unit’s feet. These dimples allow the units to fit

together snugly when stacked vertically. The KSC-2 link kit (KSC-2-LINK) consists

of two plates, each with four holes. The KSC-2 chassis side panels come with eight

preinstalled flat-head Phillips screws to secure the plates.

To mount two KSC-2 units vertically, remove the preinstalled mounting screws. Place

one unit on top of another, aligning the upper unit’s feet with the dimples on the top

panel of the lower unit. See Figure 10. Align a link plate with the side panels’ pre-

drilled holes and secure the plate with the supplied installation screws (Figure 11).

Install the second plate on the units’ other side in the same manner.

Mounting

Screws

Mounting

Screws

Link Plate

Figure 10

Vertically Mounting Two KSC-2 Units

Figure 11

Vertical Mounting: Attaching the

Link Plate

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

21

CAUTION

Use only the preinstalled flat-head Phillips screws when installing

the link plates. Other screws may damage the system hardware.

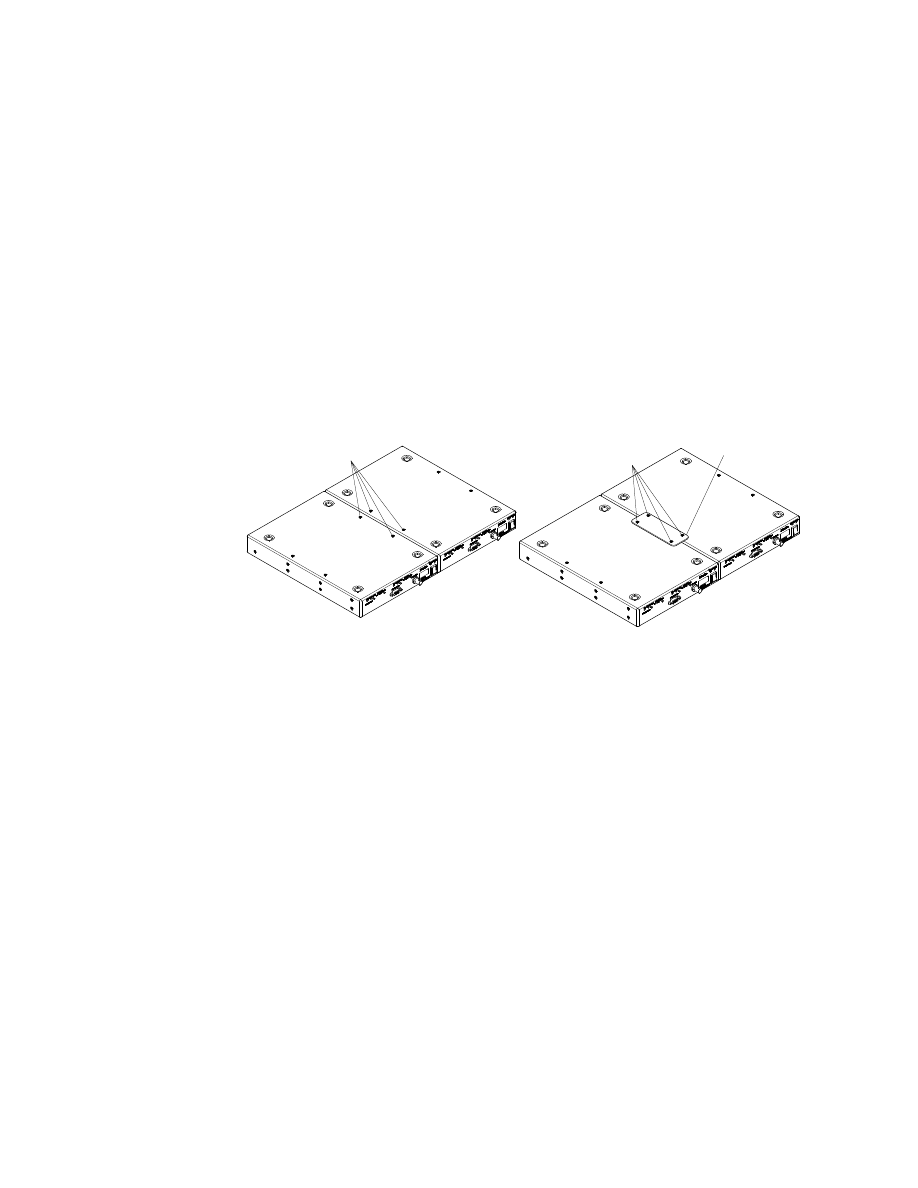

2.5.2 Horizontally Mounting Two or More Units

Two or more KSC-2 units can be connected side by side. The KSC-2 link kit (KSC-

2-LINK) consists of two plates, each with four holes. The KSC-2 frame’s top and

bottom panels come with eight preinstalled screws for attaching the plates.

To mount two KSC-2 units side by side, remove the preinstalled mounting screws and

place the units beside each other. See Figure 12. Align a link plate with the top panels’

predrilled holes and secure the plate with four of the supplied installation screws (Fig-

ure 13). Install the second plate on the units’ bottom panels in the same manner.

Mounting

Screws

Mounting

Screws

Link Plate

Figure 12

Horizontally Mounting Two KSC-2

Units

Figure 13

Horizontal Mounting: Attaching the

Link Plate

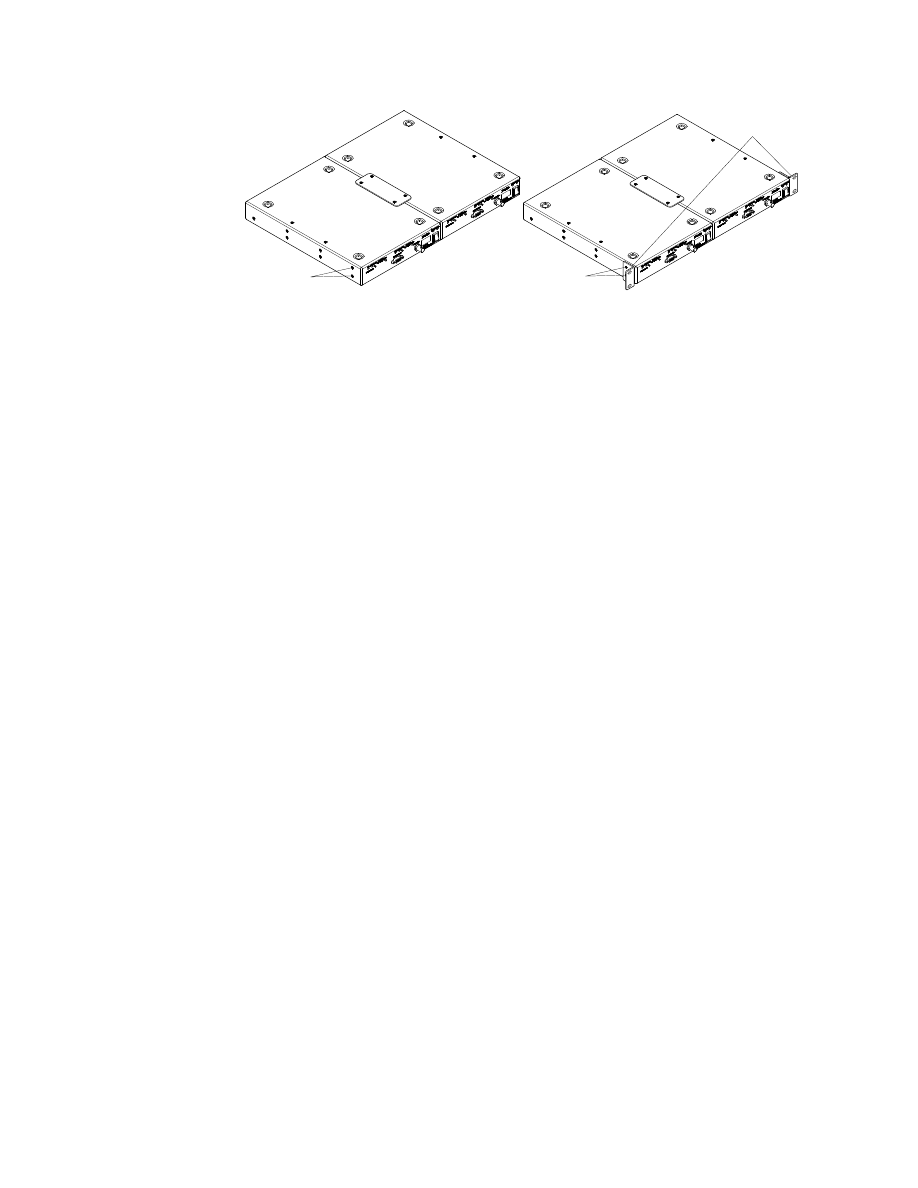

2.5.3 Horizontal Rack Mounting

The KSC-2 rack mount kit (KSC-2-RM) consists of a pair of mounting ears. The

KSC-2 chassis side panels come with four preinstalled flat-head Phillips screws to

secure the mounting ears.

To rack mount two KSC-2 units, connect two units horizontally as described in the

previous section. Remove the preinstalled screws on the exposed side panels (see

Figure 14 for the locations). Align the rack mounting ears with the holes and secure

the ears with the supplied installation screws (Figure 15). Attach the mounting ears to

the rack.

KSC-2 Installation

Page 22

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Mounting

Screws

Mounting

Screws

Rack

Mounting Ears

Figure 14

Rack-Mounting Two KSC-2 Units

Figure 15

Installing Rack Mounting Ears

CAUTION

Use only the preinstalled flat-head Phillips screws when installing

the link plates. Other screws may damage the system hardware.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

23

2.6 Install Cables

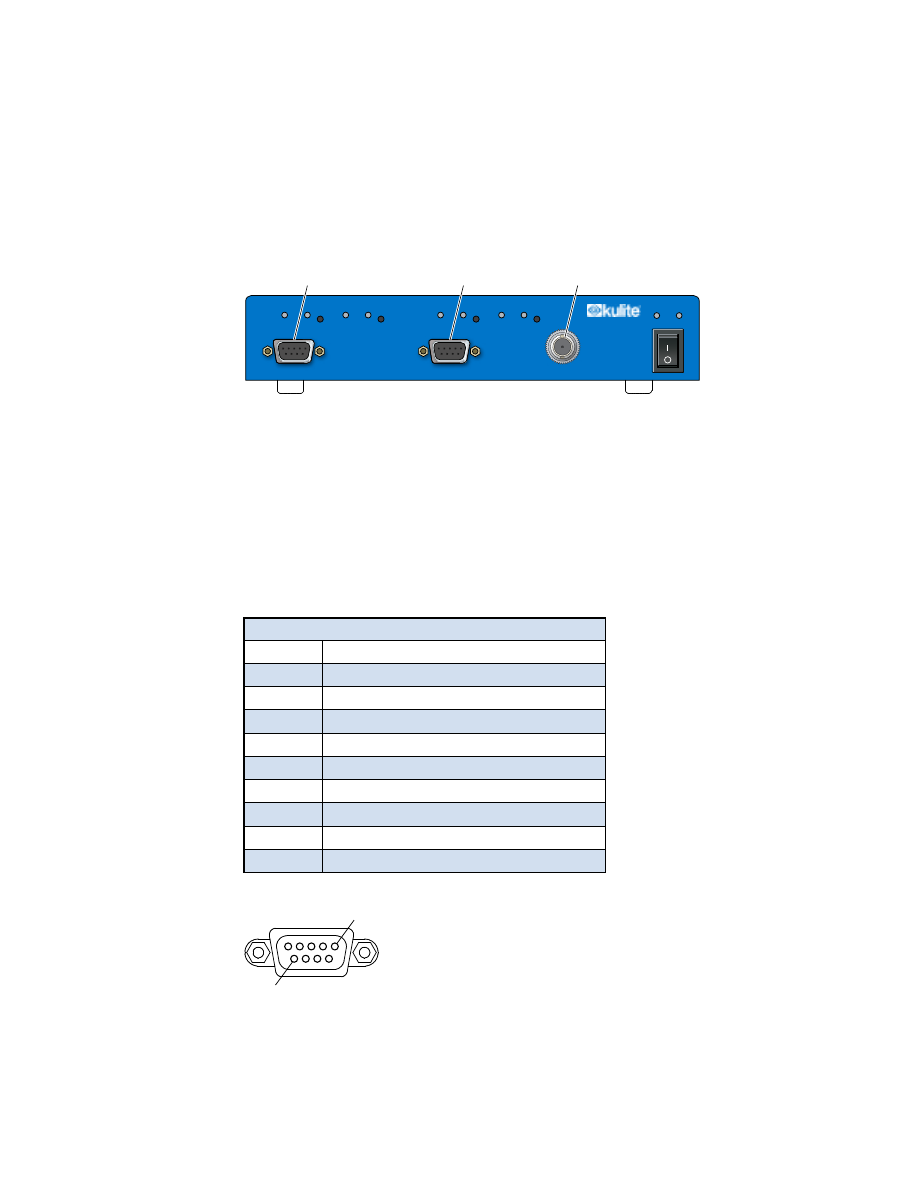

2.6.1 Front-Panel Input Connections

This section provides information about installing the input signal cables for KSC-2

units. Figure 16 shows the front-panel input connectors.

AUTO BALANCE

IN

INPUT CHANNEL 2

INPUT CHANNEL 1

OUT

IN

OUT

STATUS POWER

CAL INPUT

EXC

OVERLOAD

AUTO BALANCE

EXC

RESET

OVERLOAD RESET

Input Connector

Channel 1

Input Connector

Channel 2

Calibation Input

Connector

KSC-2

Signal Conditioner

Figure 16

KSC-2 Front Panel

KSC-2 Input Connectors

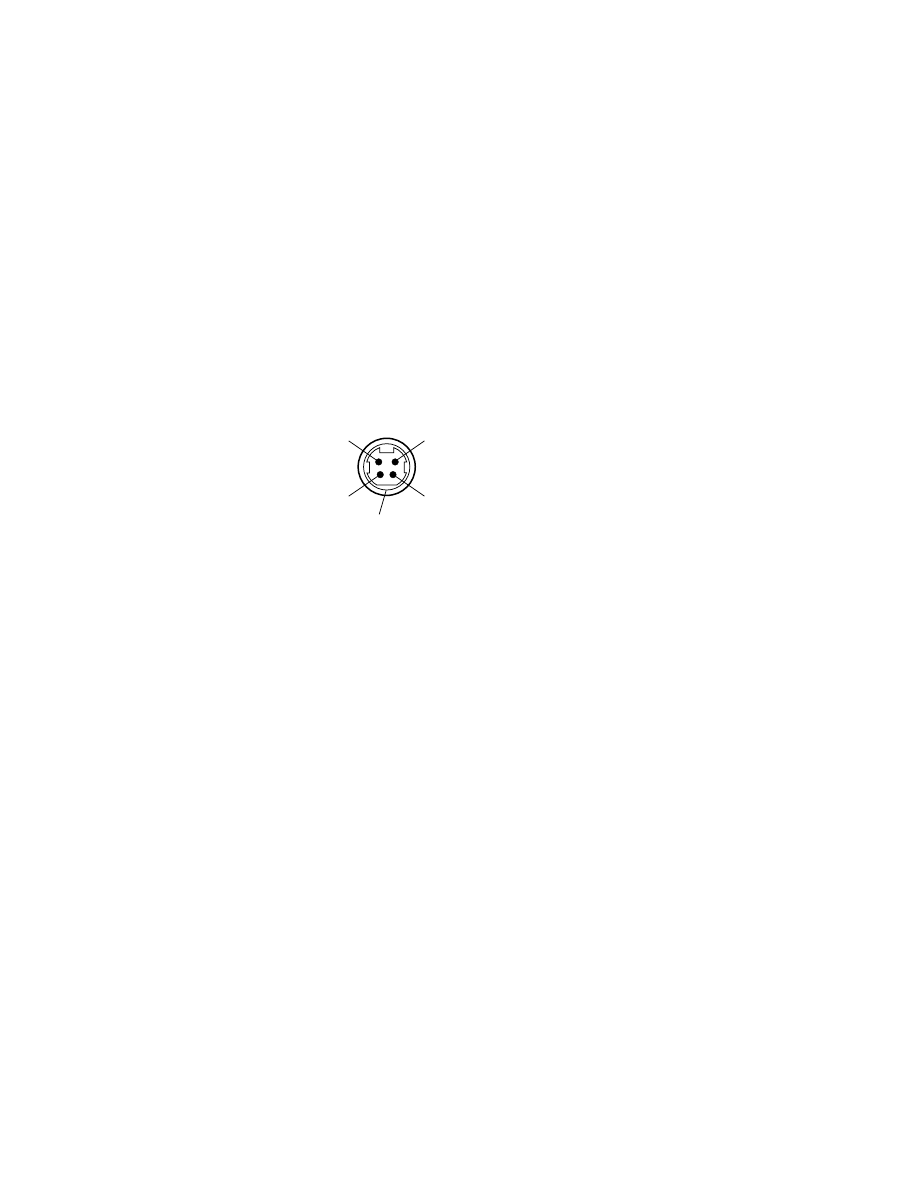

The KSC-2 provides two conditioning channels, labeled INPUT CHANNEL 1 and

INPUT CHANNEL 2. Two industry-standard DB-9 female input connectors, shown

in Figure 17, extend through openings on the front panel of the chassis. Table 3 lists

the input connector pin assignments.

Table 3 Input Connector Pin Assignments

Pin

Description

1

Excitation +

2

In +

3

Sense –

4

Signal Ground

5

5th Wire

6

Sense +

7

In –

8

Excitation –

9

Shield

Pin 1

Pin 9

Figure 17

Input Connector Pin Assignments

KSC-2 Installation

Page 24

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Input Cabling and Input Shielding

Twisted and shielded cable should be used for all signal inputs (In+, In−), especially in

high-noise environments. The shield should be connected at one end only (i.e., either

at the transducer or at the instrument) but not at both ends.

Avoid running signal leads near—or especially in parallel with—current-carrying

power cables. In situations where twisted/shielded cable cannot be used, exercise care

to avoid any large loop area (separation) in the input wiring pairs.

Twisted and shielded cable is preferred for + and – excitation and for + and – sense

lines to minimize noise pickup. If the bridge configuration is physically unbalanced,

noise pickup in the excitation or sense leads can degrade signal-to-noise ratio.

CAUTION

It is necessary to provide a high-quality instrument ground to the

KSC-2 system. The KSC-2 input is rated for operation at a signal-

plus-common-mode level of 10 V and is protected for a signal-

plus-common-mode level of 24 V relative to instrument ground.

Note:

The upcoming section “Signal Ground Selection” explains how to optimize

signal ground quality.

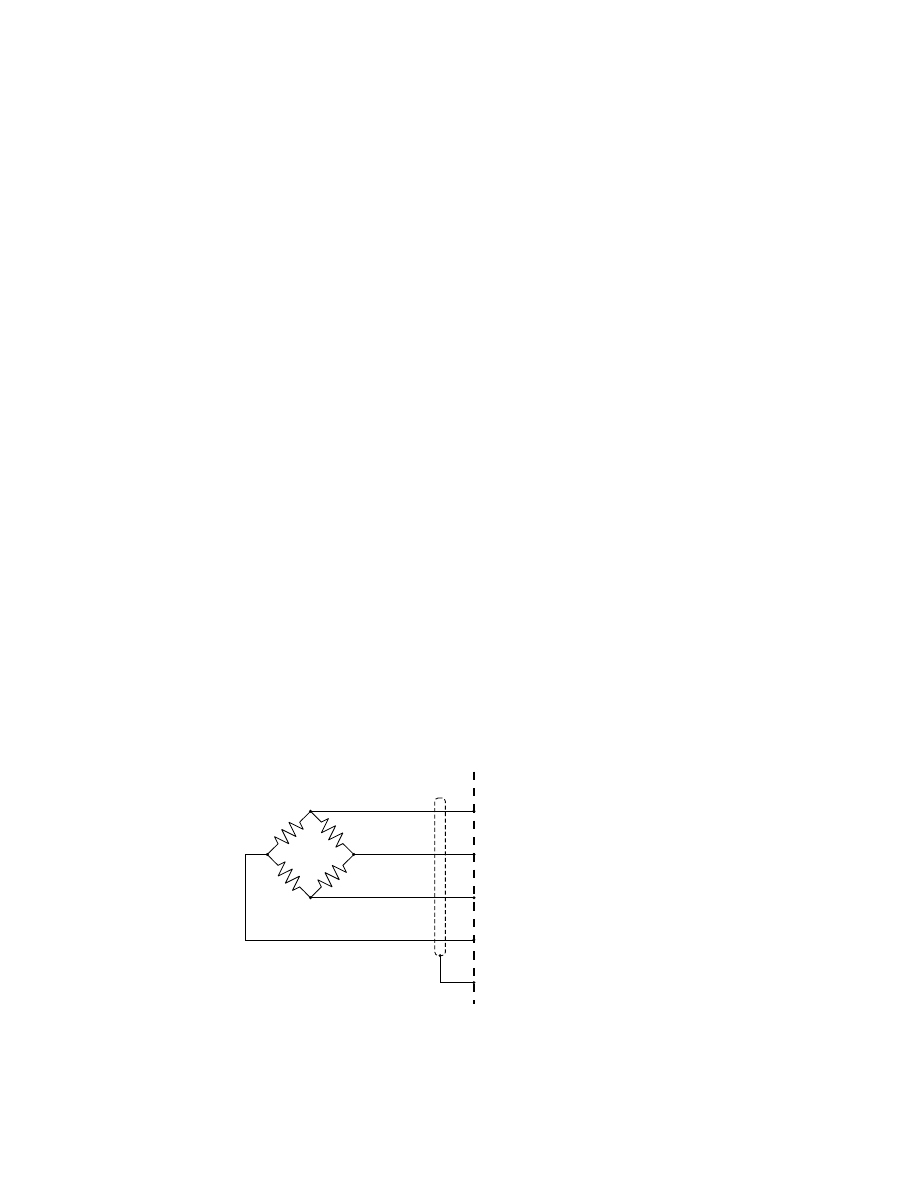

KSC-2 Full-Bridge 4-Wire Connections

For full-bridge measurements using a 4-wire configuration, the KSC-2 connections

should be made as shown in Figure 18. To set up the KSC-2 for 4-wire full bridge

measurements, the excitation sense must be set to Local in the GUI or via remote

command.

In +

Excitation +

In –

Excitation –

Shield

Amplifier

1

2

8

7

9

Figure 18

KSC-2 Full Bridge with Local Sense (4-Wire + Shield)

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

25

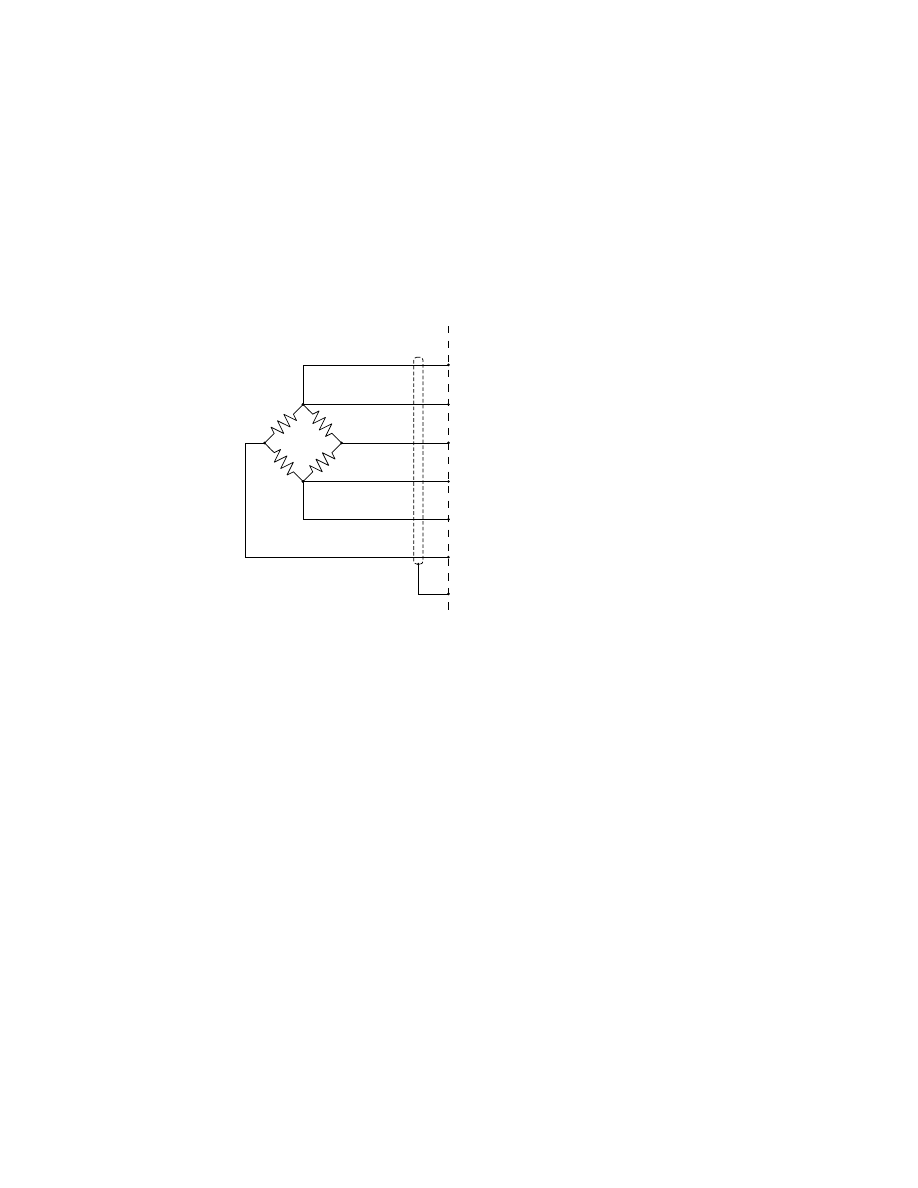

KSC-2 Full-Bridge 6-Wire Connections

Resistance in the excitation leads produces error in excitation delivered to the bridge.

Remote excitation sense leads may be used to sense the excitation at the bridge in

order to correct for the lead resistance drops.

Figure 19 shows the 6-wire configuration that uses the + and – SENSE leads. To set

up the KSC-2 for 6-wire full-bridge measurements, the excitation sense must be set to

Remote in the GUI or via remote command.

Sense +

IN +

Excitation +

Sense –

In –

Excitation –

Shield

Amplifier

6

1

2

8

3

7

9

Figure 19

KSC-2 Full Bridge with Local Sense (6-Wire +

Shield)

KSC-2 Installation

Page 26

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

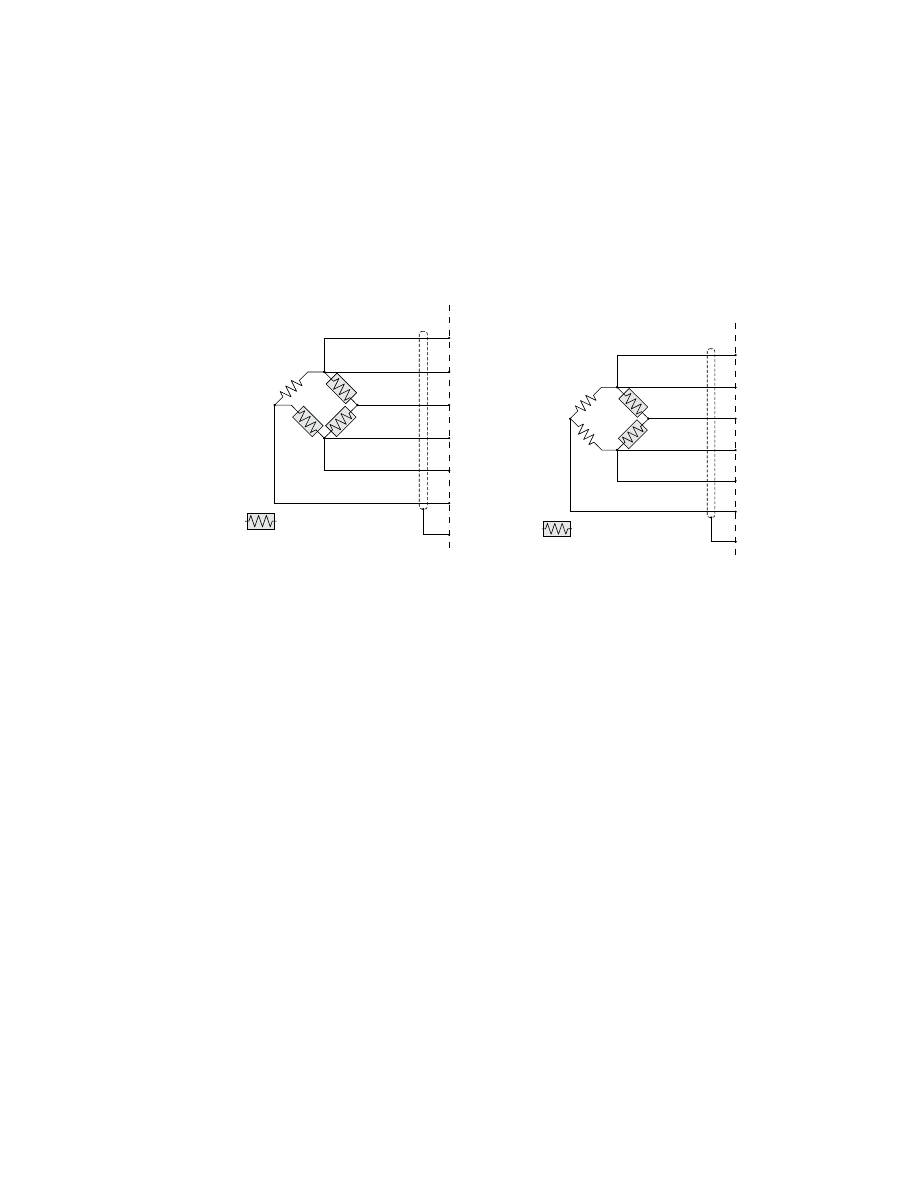

Other Bridge Input Configurations Using External Completion Resistors

The KSC-2 does not provide bridge completion; however, the user may wish to

provide external completion resistors for quarter- and half-bridge configurations.

The completion resistors should be located as close to the active gage as possible to

keep the circuit physically balanced and minimize interfering noise sources. Figure

20 shows a typical configurations for a quarter bridge. Figure 21 shows a typical

configuration for a half bridge.

Sense +

In +

Excitation +

Sense –

In –

Excitation –

Shield

Amplifier

= User supplied

completion resistors

R

GAGE

6

1

2

8

3

7

9

Sense +

In +

Excitation +

Sense –

In –

Excitation –

Shield

Amplifier

= User supplied

completion resistors

R

GAGE 2

or

Dummy

R

GAGE 1

6

1

2

8

3

7

9

Figure 20

KSC-2 Quarter Bridge with

Remote Sense & User-Supplied

Completion Resistors

Figure 21

KSC-2 Half Bridge with

Remote Sense & User-Supplied

Completion Resistors

Voltage Input Configuration

The KSC-2 may be used as a low-noise voltage filter/amplifier by connecting a voltage

output device to the + and − SIGNAL inputs.

CAL Input Connector

The KSC-2’s front panel has an isolated BNC calibration input connector labeled CAL

INPUT.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

27

5th Wire

The Kulite 5th wire transducer was developed to allow customers to obtain data

about the bridge temperature of the pressure transducer in order to compensate the

sensor for thermal errors. Using this temperature signal correctly can result in a very

accurate pressure measurement—even over a wide temperature range.

The Kulite 5th wire voltage is proportional to the temperature of the silicon die.

The output is approximately 5 V at room temperature and increases by 2 mV/°F

nominal. Refer to Kulite application note

Kulite 5th Wire Combination Pressure and

Temperature Transducers

for more details.

The KSC-2 features a 5th wire input that allows measurement of the 5th wire voltage

with an internal analog-to-digital converter.

2.6.2 Rear-Panel Connections

The rear panel contains output connectors, a port for a type B locking USB connector,

and a power-in connector. It also has the KSC-2’s ground configuration switch. See

Power In

Connector

Locking Type B

USB Connector

Ground Configuration

Switch

Output Connector

Channel 2

Output Connector

Channel 1

Signal

Gound Post

CHASSIS GROUND

ISOLATED

SIGNAL

GROUND

OUTPUT CHANNEL 2

OUTPUT CHANNEL 1

!

POWER IN

10 – 30 VDC

25 W MAX

KSC-2 Signal Conditioner

Figure 22

KSC-2 Rear Panel

Before operating the KSC-2 unit, connect the external power supply to the rear panel.

Use the supplied USB cable to connect the unit to the host computer. Insert the Type B

USB connector into the KSC-2 unit’s rear-panel USB port. Insert the standard Type A

connector into the desired USB port of the host computer.

KSC-2 Installation

Page 28

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Communication USB 2.0 Connector

For protection against accidental cable disconnection, Kulite offers an accessory cable

with a locking type B USB connector (Kulite P/N 910-A-84798). The USB-A/B-6

locking USB cable accessory is a 72-inch cable with a standard (nonlocking) type A

connector for the host computer and a locking type B USB connector for the KSC-2.

Output Connectors

Two isolated BNC connectors are labeled OUTPUT CHANNEL 1 and OUTPUT

CHANNEL 2. The KSC-2 has a single-ended output stage with 10

Ω

output imped-

ance. The rear-panel BNC shell is connected to signal ground.

Signal Ground Selection

For optimal data quality, it is important to provide a low-noise, low-impedance, earth

ground reference to internal amplifier circuitry. As shown in Figure 22, the KSC-2 has

rear-panel features to optimize the signal ground used for internal circuits. As shipped

from the factory, the amplifier signal ground is connected to the KSC-2 chassis

(switch in left position). This provides a convenient ground connection through the

attached KSC-2 input power cord to earth ground via the third wire earth ground at

the wall outlet.

If the chassis ground connection is found to be unsuitable due to excessive noise on fa-

cility earth ground connection, the KSC-2 signal ground can be isolated from chassis

ground by moving the rear-panel ground configuration switch to the ISOLATED

(right) position and using the rear-panel ground post to connect to a more suitable

ground connection. For optimal performance, this ground post should be connected to

a quality ground source with a low-impedance connection directly to earth ground.

Bank Isolation

The KSC-2’s ISOLATED mode can be used to reference both channels to a remote

reference other than earth ground. Called bank isolation, this can be useful if a distant

ground causes the common source (to both channels) to be at some potential beyond

the ±10 V input range allowable by the KSC-2 amplifier.

If you are using bank isolation in this manner, follow these rules:

•

The remote ground potential must not be more than 20 V from the chassis ground

of the KSC-2.

•

The input signals to each of the two channels must not differ by more than ±10 V

from the remote ground reference.

•

Any recording device connected to the KSC-2 outputs must also have sufficient

isolation capability.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

29

•

If input cabling connects the overall cable shield to the shell of the DB9 input

connector, this will connect the shield to the remote ground potential through the

chassis connection. To prevent ground loop currents, do not terminate the cable

shield at the sensor end.

Power Connector

One KSC-2-ACPS external AC/DC power supply is provided with each KSC-2

system. The input power connector (Figure 23) is located on the left side of the unit’s

rear panel.

The KSC-2 requires input power of 10–30 VDC, 25 W maximum, applied at the rear

panel POWER IN connector. Mating power entry connectors (KPPX-4P-30) and spare

external AC/DC power supplies (KSC-2-ACPS) are available.

Pin 1: +12 V

Pin 3: Shell (GND)

Pin 2: +12 V Return

Pin 4: N/C

Ground

Figure 23

KSC-2 Power Connector

KSC-2 Installation

Page 30

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

2.7 KSC-2 Front-Panel Operation

Figure 24 illustrates the front-panel indicators and switches used during KSC-2 oper-

ation.

AUTO BALANCE

IN

INPUT CHANNEL 2

INPUT CHANNEL 1

OUT

IN

OUT

STATUS POWER

CAL INPUT

EXC

OVERLOAD

AUTO BALANCE

EXC

RESET

OVERLOAD RESET

Excitation

Fault

LED

Auto Balance

Status LED

Auto Balance

Operation

Switch

Channel 1

LED Indicators and Switch

Overload

Reset

Switch

Input

Overload

LED

Output Overload LED

Overload

Reset

Switch

Input

Overload

LED

Output Overload LED

Excitation

Fault

LED

Auto Balance

Status LED

Auto Balance

Operation

Switch

Power

LED

Power

Switch

Status

LED

Channel 2

LED Indicators and Switches

Channel 1 Overload

LED Indicators and Switch

Channel 2 Overload

LED Indicators and Switch

KSC-2

Signal Conditioner

Figure 24

KSC-2 Front Panel Switches and Indicators

2.7.1 Applying Power

To apply power, be sure that the external power supply is connected to the rear panel

and plugged in. On the front panel, move the right-hand power switch to the On posi-

tion (|). The upper-right POWER light turns green. The green STATUS light indicates

that the KSC-2 unit has initialized.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Installation

Page

31

2.7.2 Autobalance Indicators and Reset Button

The KSC-2’s autobalance function measures any imbalance inherent in the bridge and

provides appropriate compensation to the circuit. Front-panel LEDs for each channel

indicate the channel’s balance mode status: in progress (yellow), successful (green), or

failed (red).

To initiate a balance/suppress operation for a channel, press the momentary switch

to the right of the channel’s AUTO BALANCE LED. You can also initiate an auto-

balance from the KSC-2 Control GUI (see Section 4.5.9) or via remote commands (see

Section 5.4.7).

Note:

Autobalance is disabled when the KSC-2 unit is AC coupled.

The front-panel switches may be locked out using the Options panel in the GUI (see

Tools

in Section 4) or remote commands (see

Device Control and Information

in

Section 5).

2.7.3 Overload Indicators and Reset Button

For each channel, front-panel LEDs indicate input or output overload and excitation

faults (short or overvoltage). Overload indicators, labeled IN and OUT to show input

and output overloads, respectively, turn red in an overload condition:

•

The IN overload detection circuit is located following the prefilter gain stage and

prior to the filter stage.

•

The OUT overload detection circuit is located following the postfilter gain stage.

To clear the overload detectors while in Latching mode, press the RESET switch for

the desired channel. For more information about Latching and Continuous modes, see

Section 4.5.13.

When an excitation fault is detected, the EXC indicator turns red. The LED remains

lit until the excitation fault is corrected.

The front-panel switches may be locked out via a control panel in the GUI (see

Tools

in Section 4

) or remote commands (see

Device Control and Information

in Section 5).

KSC-2 Installation

Page 32

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

This page intentionally left blank.

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Control Software Programming Instructions

Page

33

3

KSC-2 Control Software Programming

Instructions

3.1 Introduction

The KSC-2 Control Graphical User Interface (GUI) provides an easy-to-use

spreadsheet-style interface for control and configuration of the KSC-2 signal

conditioner. The GUI can control up to eight KSC-2 units as a system. This section

describes how to install the GUI on a Windows OS computer and use it to operate

KSC-2 units.

3.2 GUI Installation

This section contains instructions for installing the KSC-2 Control GUI software on a

Windows-based host computer.

3.2.1 Antivirus Software

All software is routinely scanned for computer viruses using the latest antivirus soft

-

ware and has been found to be free of viruses and malicious software.

If your antivirus program is reporting a problem and blocking the installation of the

KSC-2 Control GUI software, disable the antivirus program and retry the installation.

3.2.2 Installing the KSC-2 Control GUI Software

The KSC-2 Control GUI software is distributed on the KSC-2 Signal Conditioner

Software Distribution CD. Install and run the GUI program as described in this

section.

Note:

It is strongly recommended that you exit all programs before you run

the KSC-2 Control installer. Applications that run in the background, such as

virus-scanning utilities, could lengthen the amount of time required for the

installation.

KSC-2 Control Software Programming Instructions

Page 34

KSC-2 Signal Conditioner Installation and Programming Instructions

Rev. A

KULITE SEMICONDUCTOR PRODUCTS, INC.

Step 1

Insert the CD into a Windows-compatible computer, open the

KSC-2 GUI

folder and then open the

Installer

folder.

Double-click the

setup.exe

file to start the GUI software installer.

The start-up panel briefly displays while the installer initializes.

Step 2

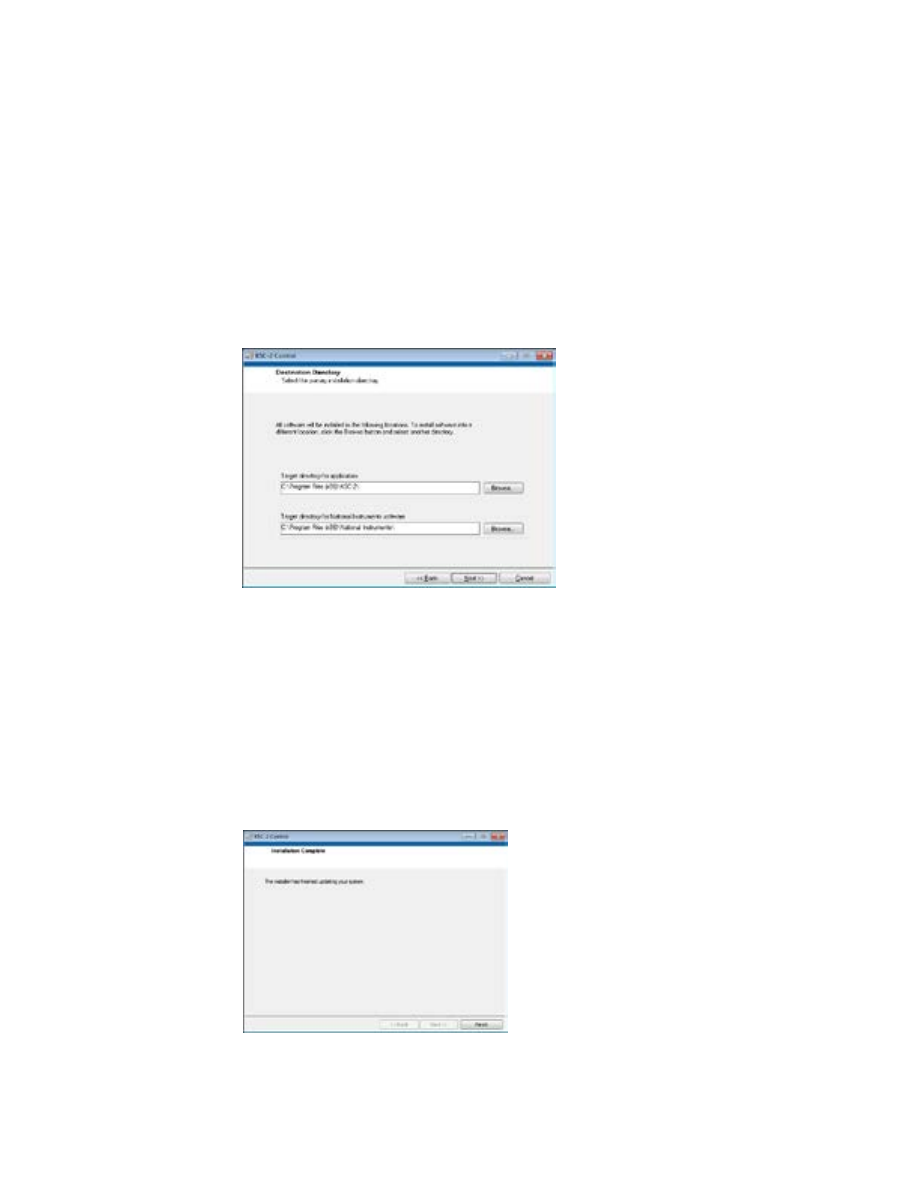

In the Destination Directory panel, shown in Figure 25, select the

destination folder for the software program.

The default destination for the KSC-2 GUI is

C:\Program Files\KSC-2\

.

Click Next to continue.

Figure 25

Destination Directory Panel

Step 3

Review the License Agreement in the License Agreement pane. Select “I

accept the License Agreement” and click Next.

Step 4

Review the Start Installation summary panel and click Next.

The Progress panel displays, showing the installation’s progress.

Step 5

When you see the Installation Complete panel (Figure 26), click Finish.

Step 6

You must restart your computer to finish the installation. Click the Restart

button on the Restart panel.

Figure 26

Installation Complete Panel

Rev. A

KSC-2 Signal Conditioner Installation and Programming Instructions

KULITE SEMICONDUCTOR PRODUCTS, INC.

KSC-2 Control Software Programming Instructions

Page

35

3.2.3 Uninstalling the KSC-2 Control GUI Software

Uninstall the KSC-2 Control GUI software through the Windows Control Panel.

Click the Start button and select Control Panel. In the Control Panel’s list of programs,

find and select

KSC-2 Control

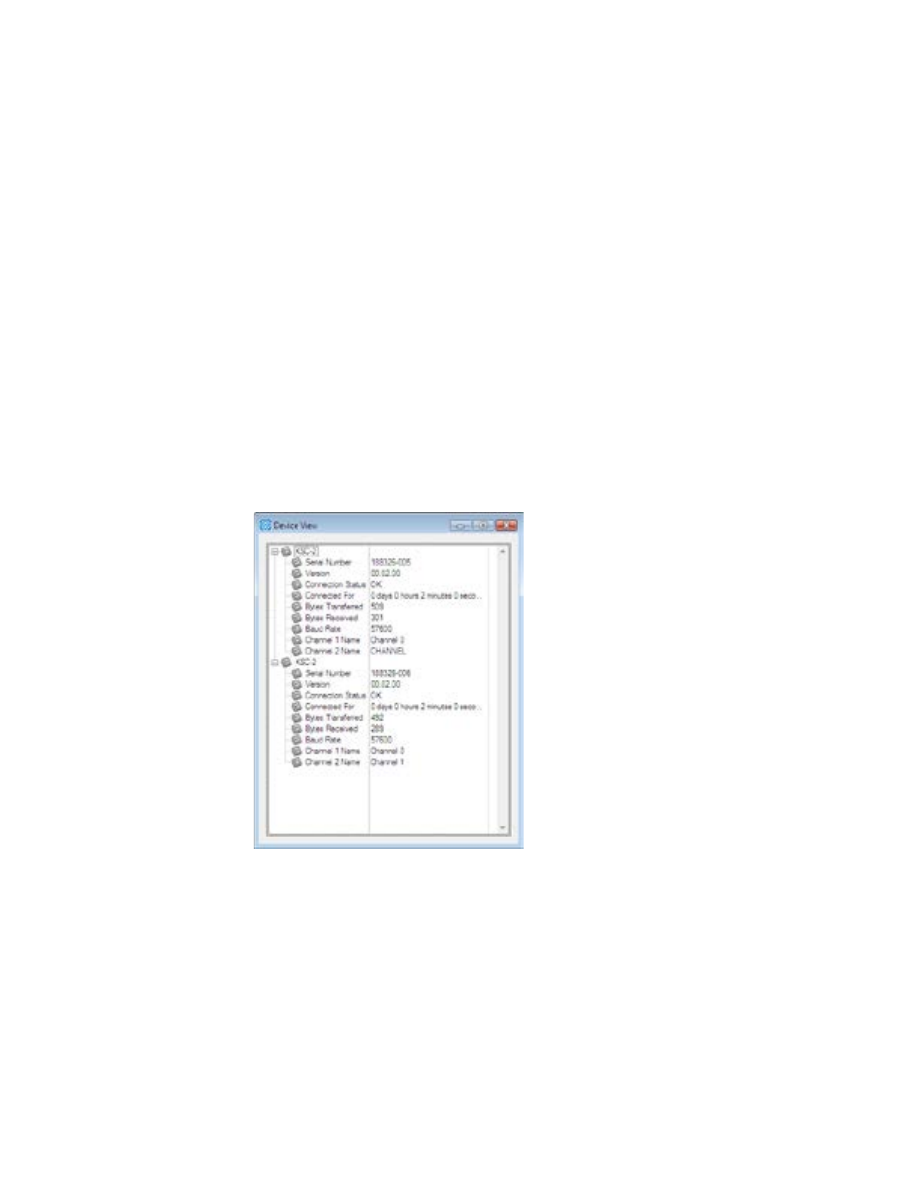

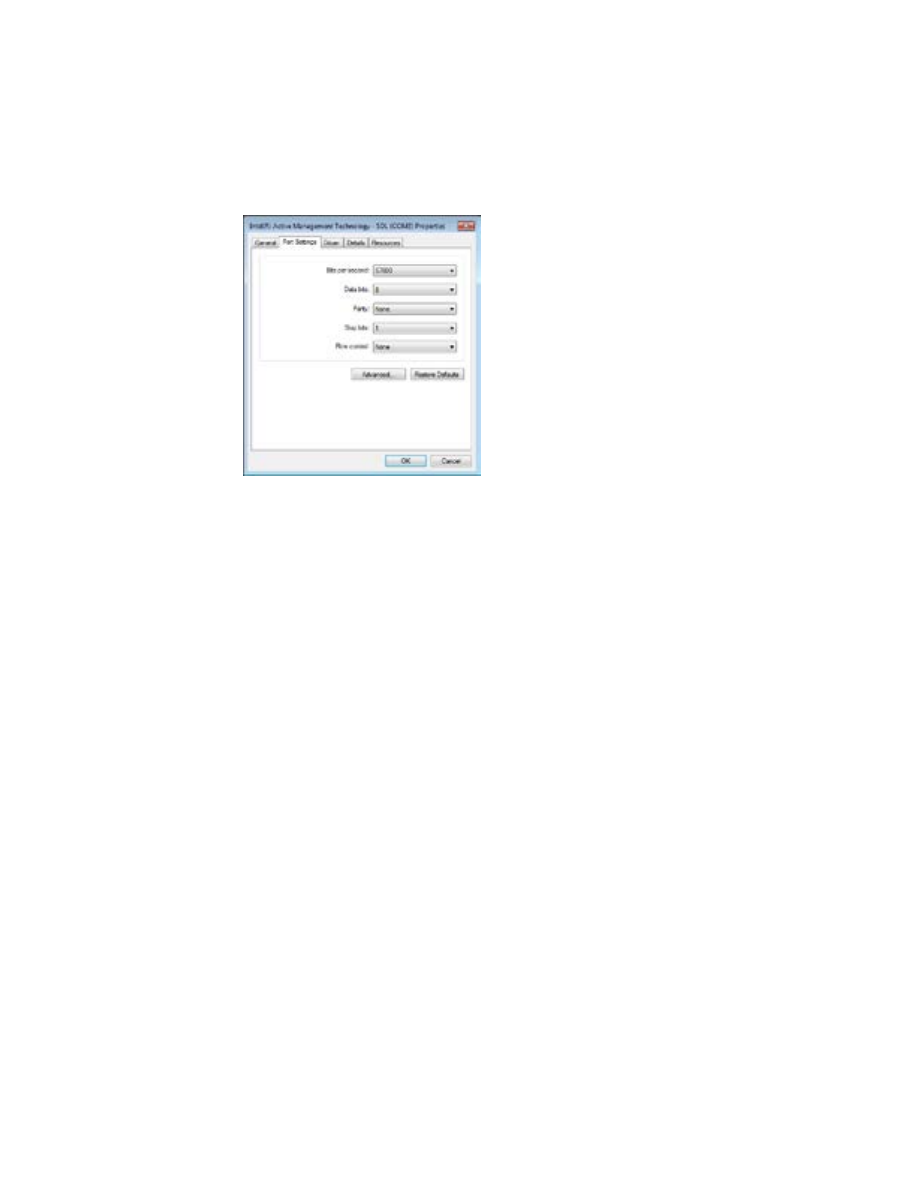

. Click Uninstall/Change. Confirm that you want to