Automotive

Leading technologies for automotive applications

Automotive

Leading technologies for automotive applications

2

Contents

4 Our customers and products

6 Technologies

8 12V battery management systems

10 HV battery management systems

14 Motor control

18 Charging systems

22 Contact

3

Leading the world in

electrical measurement

A leading company in electrical

measurement, LEM engineers

the best solutions for energy

and mobility, ensuring that

our customers’ systems are

optimized, reliable and safe.

Our 1,500 employees in more

than 15 countries transform

technology potential into

powerful answers. We develop

and recruit the best global

talents, working at the forefront

of mega trends such as

renewable energy, mobility,

automation and digitization.

With innovative electrical

solutions, we are helping

our customers and society

accelerate the transition

to a sustainable future.

4

LEM partners with leading vehicle

manufacturers and Tier 1 suppliers on

powertrain electrification and autonomous

driving applications by providing sensors that

meet high standards of functional safety (ASIL).

LEM offers its customers a broad portfolio of

products tailored to a wide range of technical

requirements. LEM also prides itself on

providing leading engineering services for

customer-specific solutions.

Automotive

Our customers and products

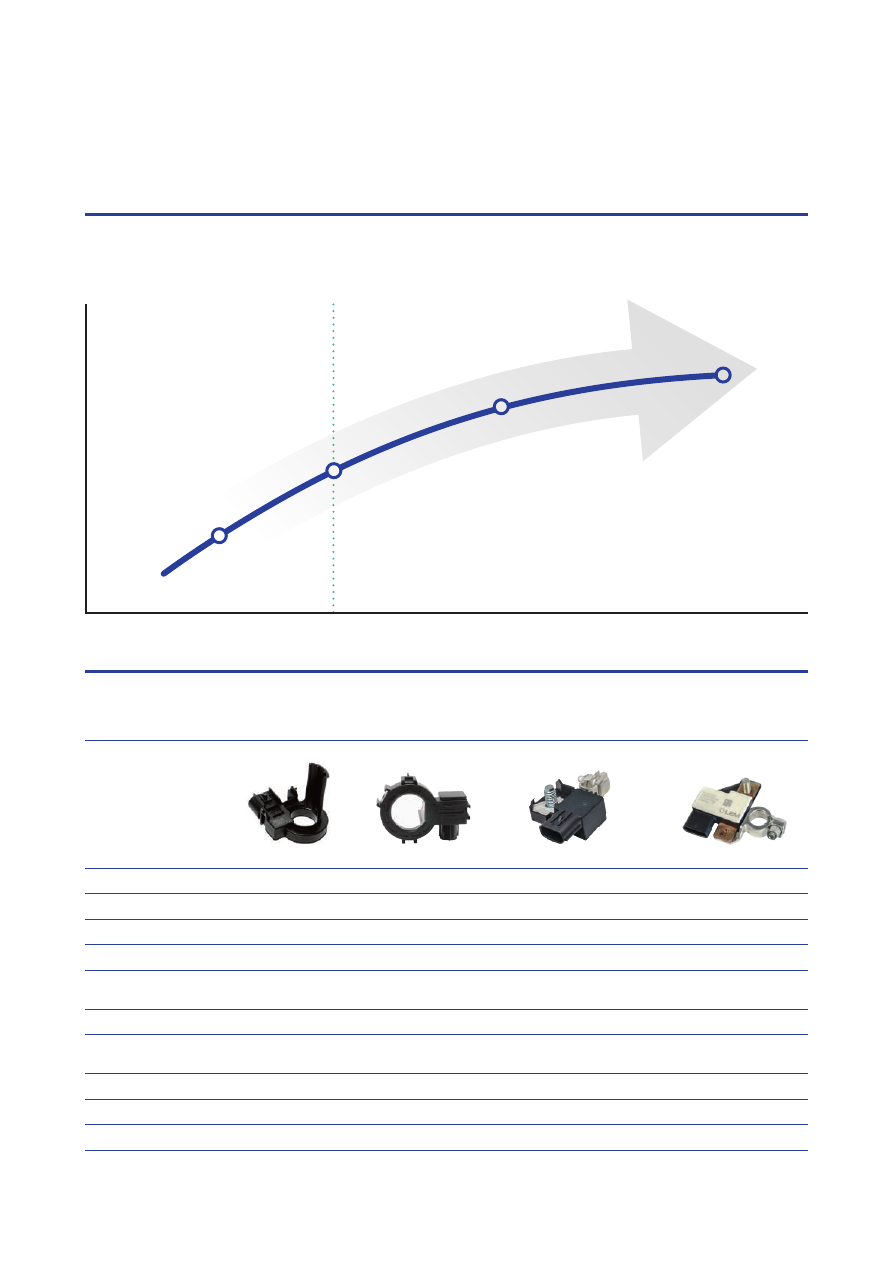

Battery management

For start-stop vehicle architectures, we offer intelligent battery sensors

combining a unique expertise in current sensing with more than 20 years

experience in lead acid battery technologies.

In high voltage battery management (BMS HV), the CAB series brings the LEM

expertise of the fluxgate technology to our customers.

The CAB series offer best-in-class accuracy and a high level of functional

safety (ASIL) which avoids the installation of a redundant sensor.

We offer a broad range of single-phase Hall open loop sensors for high

compactness, fitted with an integrated busbar for cost effectiveness.

LEM developed dual range sensors with a dedicated low range to drastically

improve offset performance while delivering very high accuracy.

5

Motor control

The LEM sensors dedicated to power inverter applications provide flexible

design to Original Equipment Manufacturers (OEMs) and Tier 1 suppliers as well

as solutions compatible with various subsystems: printed circuit design (PCD)

boards, power modules, integrated busbars, and standard busbar mountings.

Charging systems

LEM's newest product range brings technologies tailored to power

management systems from AC to DC and DC to DC for high and low voltage

applications. Future solutions dedicated to current leakage detection will meet

the technical requirements for bi-directional on-board charging (OBC) and

vehicle-to-grid/load (V2G & V2L). Our solutions will be ranging from 5mA to

300mA and guarantee high levels of safety for end-users, sanctioned by the

ISO26262 ASIL certification, and the option to increase power density by

removing reinforced insulation.

Battery

management

Motor

control

Charging

systems

6

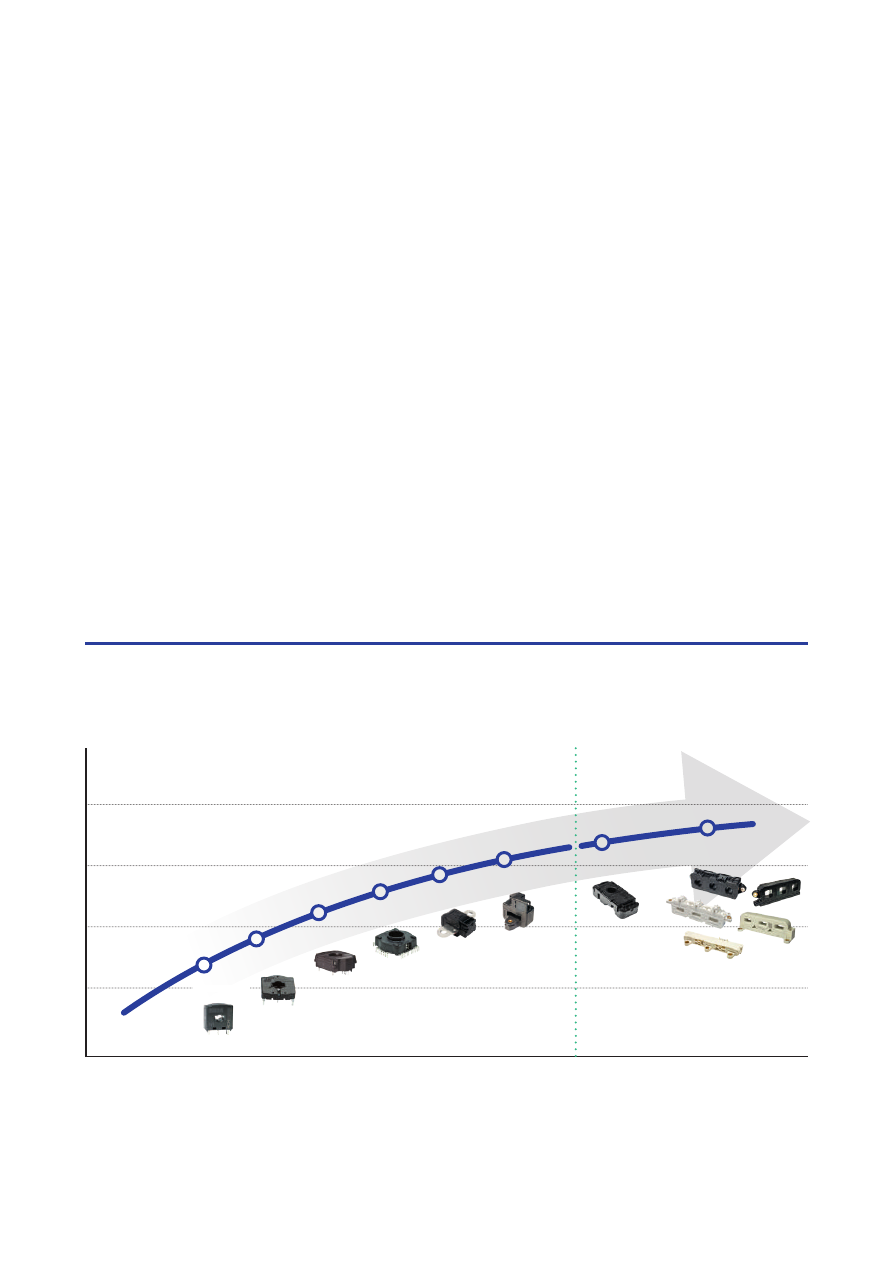

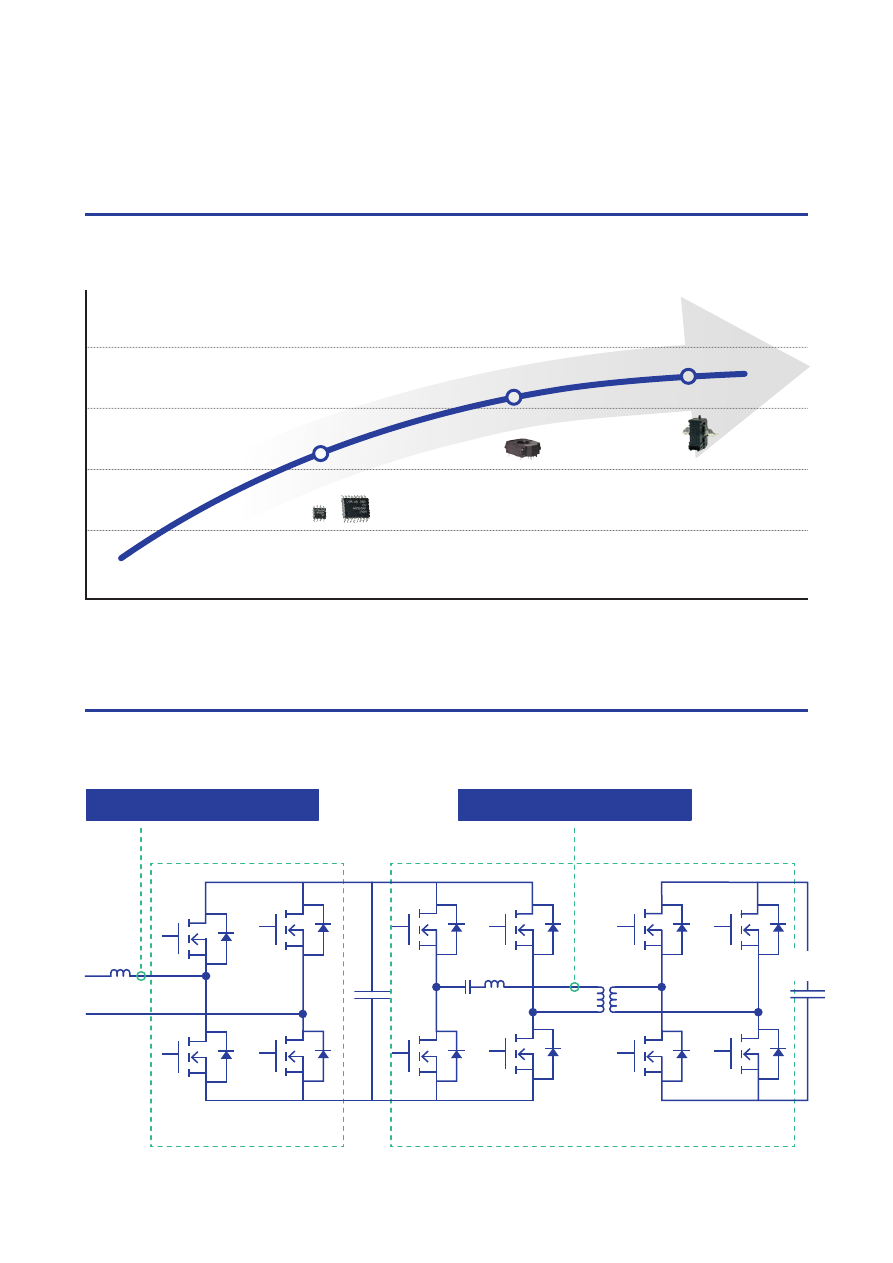

LEM is committed to retaining technology

leadership, continuously investing in R&D

to deliver innovative products and solutions to

customers, leveraging proven and cutting-edge

technologies.

Automotive

Technologies

LEM sensors

Our current and voltage sensors are used in a wide range of applications:

battery management and start-stop applications for conventional cars,

electrical motor controls, battery pack management and charging systems for

hybrid and electric vehicles.

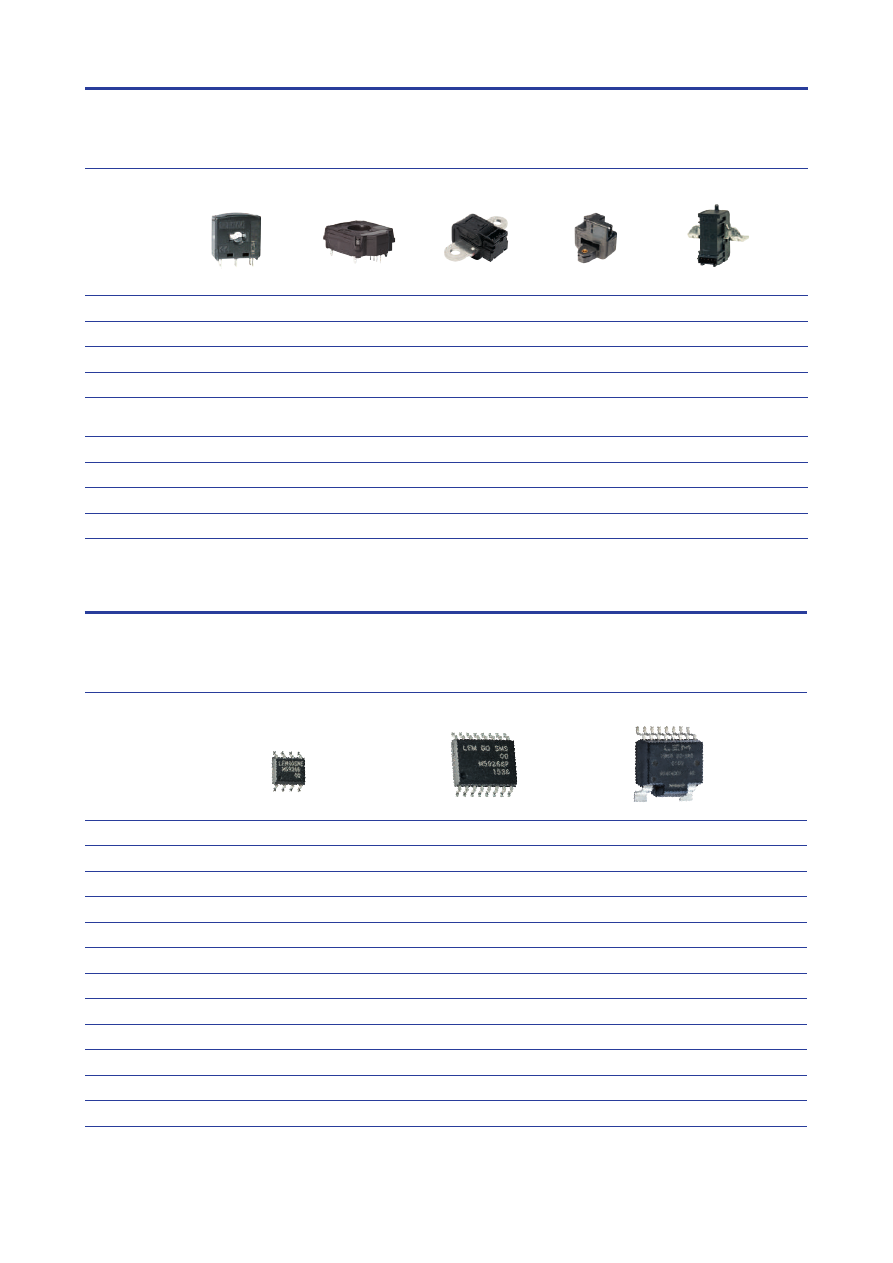

Surface-mounted IC sensors

Power density is a critical factor for increasing performance, as space

constraints are prevalent in virtually every automotive application.

Ever increasing power densities are driving the emergence of new current

sensing technologies. Surface-mounted integrated circuit (IC) sensors

measure high currents in a very compact footprint and therefore have

become the technology of choice.

Smarter sensors

Smart grid and autonomous driving are major disruptions caused by the digital

revolution leading to smarter, greener and more efficient ecosystems. LEM is

at the forefront of these megatrends, developing smart sensors equipped with

data processing capabilities that insure higher safety levels thanks to

self-diagnostic features. The LEM sensors feature embedded software that

provides real time information to the on-board system, offering customers

high-value and versatile solutions.

7

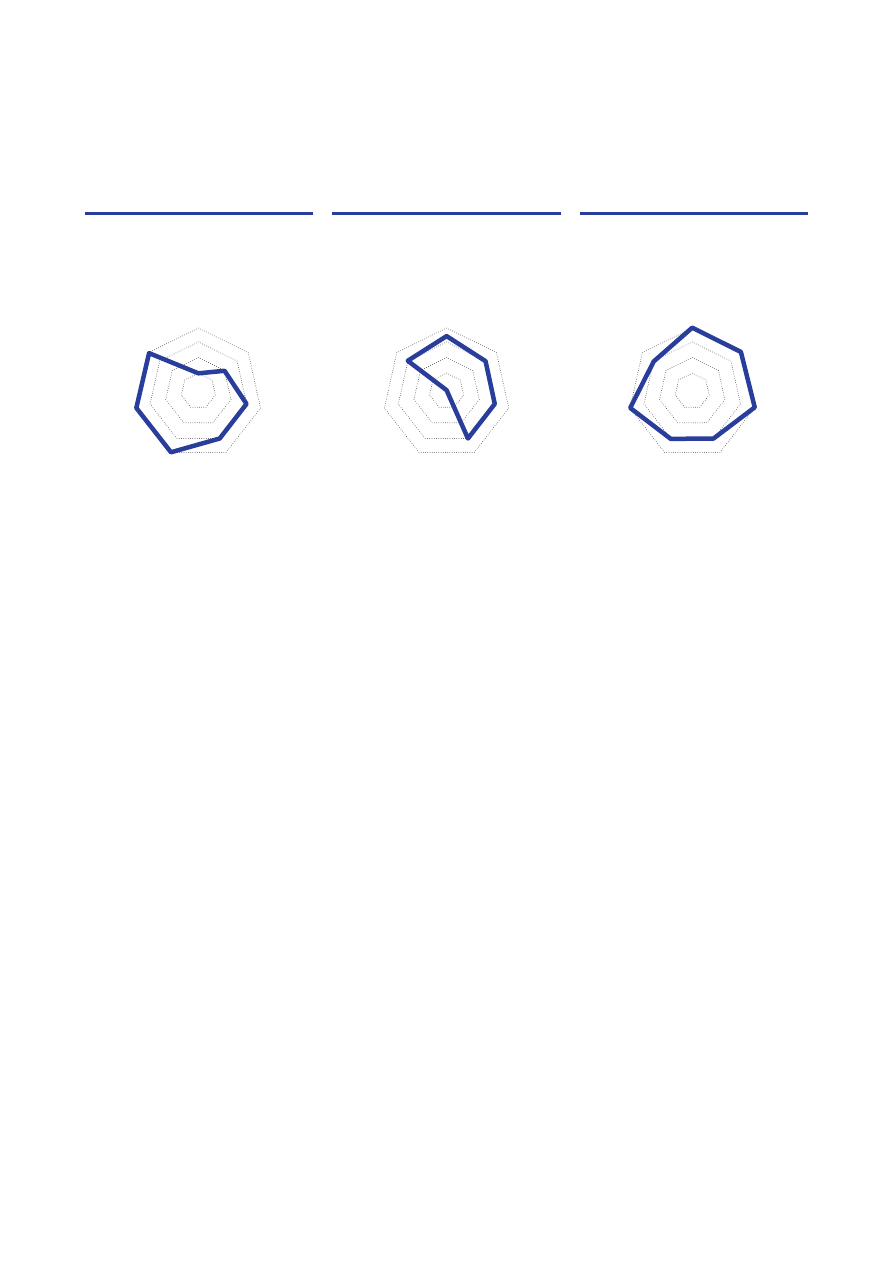

Open loop technology

Open loop sensors use a Hall effect integrated circuit. The magnetic density,

contributing to the rise of the Hall voltage, is generated by the primary current

to be measured, which is supplied by a current source such as a battery or

generator. HEV and EV include battery monitoring, starter generators,

converters, electrical power steering, and motor drive applications.

Shunt technology

LEM shunt sensors, based on Ohm’s Law with voltage drop across the shunt

proportional to its current flow, measure both alternating currents (AC) and

direct currents (DC). Low cost and high reliability, low resistance shunt sensors

are a popular choice for current measurement. Smart shunt technology offers

mechanical and electrical design suitable for both light and heavy duty

applications with multiple batteries.

Fluxgate technology

LEM’s fluxgate sensing head is made of an induction coil with particular

characteristics. The core material has very high permeability and low

remanence (Hc), enabling very fast transition between linear and saturated

state. Energizing the coil with an alternative voltage makes the core go through

a complete hysteresis loop. With a primary current flowing through the coil,

the hysteresis loop is shifted. The measurement of this shift represents the

primary current.

Accuracy OA

offset

Accuracy OA

offset

Accuracy OA

offset

Accuracy

Ipmax

Accuracy

Ipmax

Accuracy

Ipmax

Price

Price

Price

Resolution

Resolution

Resolution

Non-

intrusive

Non-

intrusive

Non-

intrusive

Bandwidth

Bandwidth

Bandwidth

Power

consumption

Power

consumption

Power

consumption

Hall open loop

Shunt

Fluxgate

8

Automotive

12V battery management systems

LEM develops galvanically-isolated current

sensors dedicated to 12V battery management

for standard internal combustion engines (ICE)

and smart BMS for start-stop powertrains.

Solutions for ICE vehicles

LEM brings more than two decades of experience in 12V BMS for lead acid

batteries and offers a leading product portfolio for standard ICE powertrains.

Solutions for start-stop vehicles

LEM offers a range of intelligent battery sensors that combine unique expertise

in current sensing technologies with the experience acquired over the years in

lead acid battery technologies.

12V battery sensor in vehicles

Wheels

Alternator

DC 12V

power net

Battery

12V

Main ECU

Power

management

Starter

Engine

Fuel

Current

sensor

9

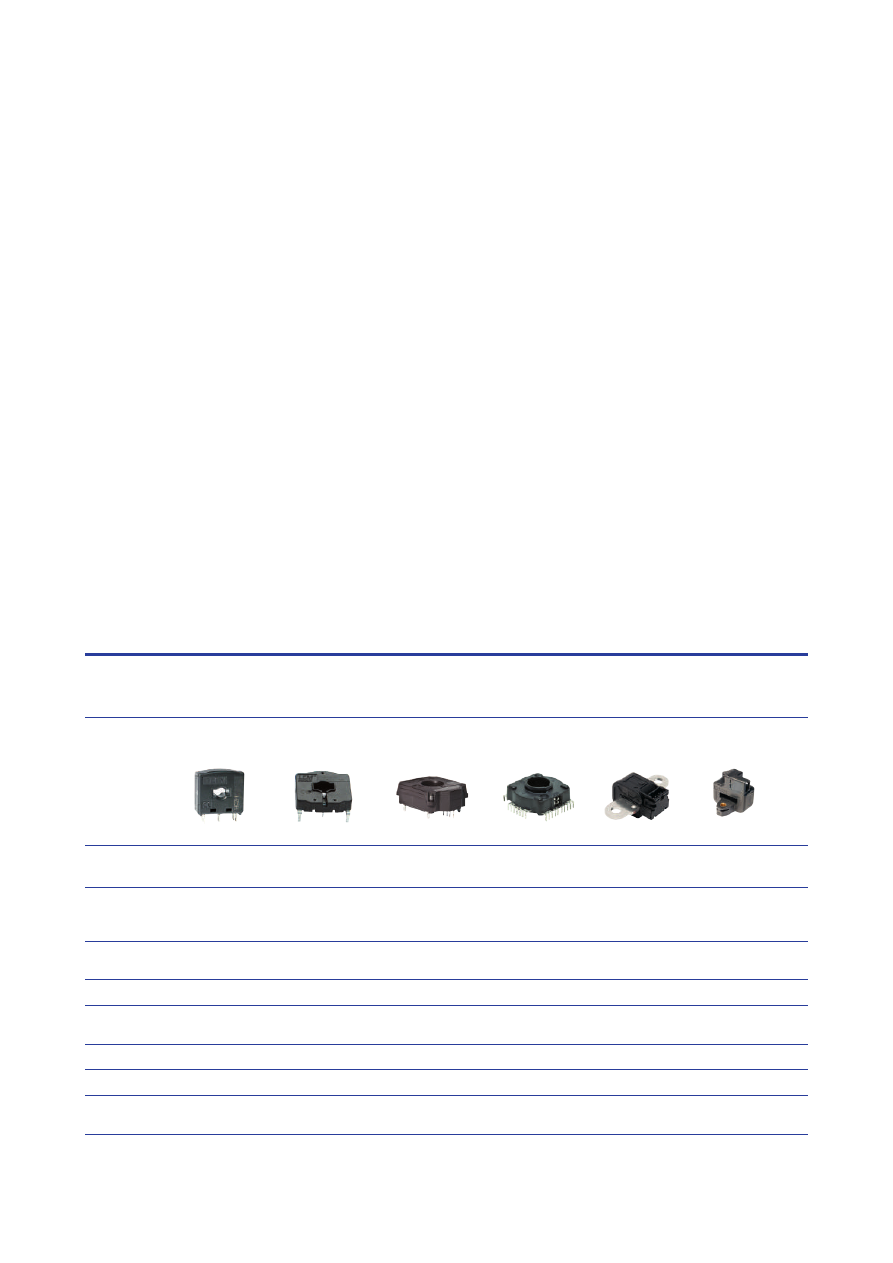

Sensor

HAB

HABT

HBCT

SSVT

Technology

Open loop

Open loop + temp

Open loop + temp

Smart shunt

Current range max

+/- 400A

+/- 120A

+/- 250A

+/- 1500A

Output

Voltage/PWM

Voltage/PWM

Voltage

CAN/LIN SoX status

Global error @25°C

0,8%

0,8%

0,8%

0,5%

Overall accuracy

(over T°C)

3,75%

3,6%

3,75%

1,5%

Offset current

+/- 200 mA

+/- 200 mA

+/- 350 mA

+/- 20 mA

Bandwidth

(programmable)

1.1 kHz

1.1 kHz

1.1 kHz

1.1 kHz

Mounting type

Cable

Cable

Clamp

Clamp

Input voltage

+5V

+5V

+5V

+12V/+24V

Consumption

7 mA

7 mA

10 mA

12 mA

Features

HAB

Analog Hall effect

HABT

Analog Hall + temp

+/- 120A

Temperature at 1%

HBCT

Analog Hall + temp

+/- 250A

Temperature at 1%

SSVT

Smart shunts

SoX status

CAN/LIN transceiver

Applications

12V BMS sensor portfolio

12V BMS specifications

BMS standard ICE

BMS start-stop

10

LEM high voltage battery pack BMS for

hybrid and electric vehicles

Fluxgate technology

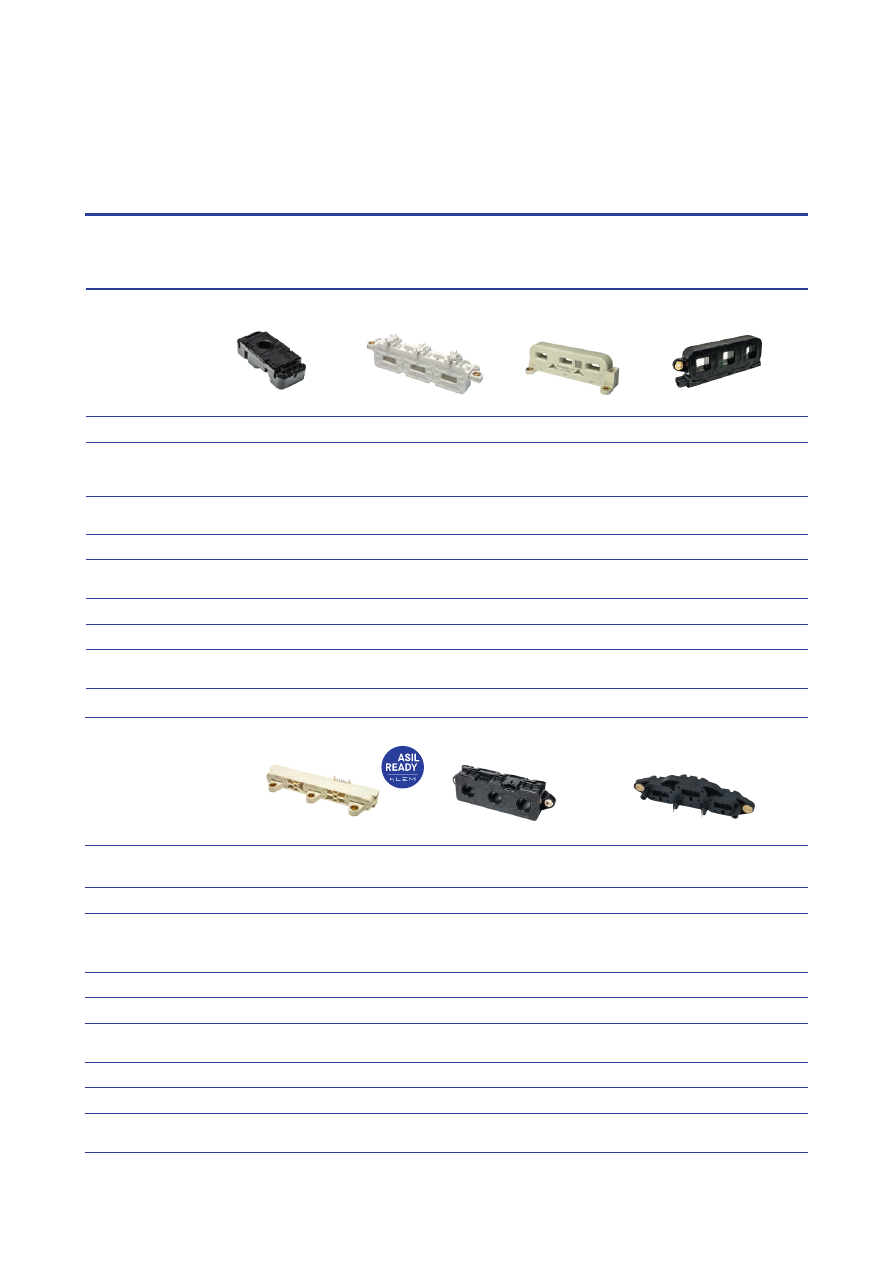

LEM brings a unique capability in fluxgate, the leading technology for high

performance battery management that offers contactless solutions.

The CAB series offers best-in-class accuracy (up to 0.1% and at

I

P

max), an

offset at 0A measurement as well as ASIL readiness which avoids the

installation of a redundant sensor.

The CAB fluxgate products are embedded in the battery disconnection unit

(BDU) or the battery pack of vehicles with electrified powertrains (xEV).

Hall open loop technology

LEM's broad portfolio of single range sensors combines high compactness and

an integrated busbar design for cost effectiveness. LEM developed a high

accuracy dual range sensor with a dedicated low range to drastically improve

offset performances.

The LEM Hall-based products are suitable for the electronic measure of current

in high power and low voltage applications with galvanic separation between

the primary circuit (high power) and the secondary circuit (electronic circuit).

LEM offers the choice between different ranges of current measure in the

same housing while providing excellent accuracy and very good linearity, with

low thermal offset and thermal sensitivity drifts.

Automotive

HV battery management systems

11

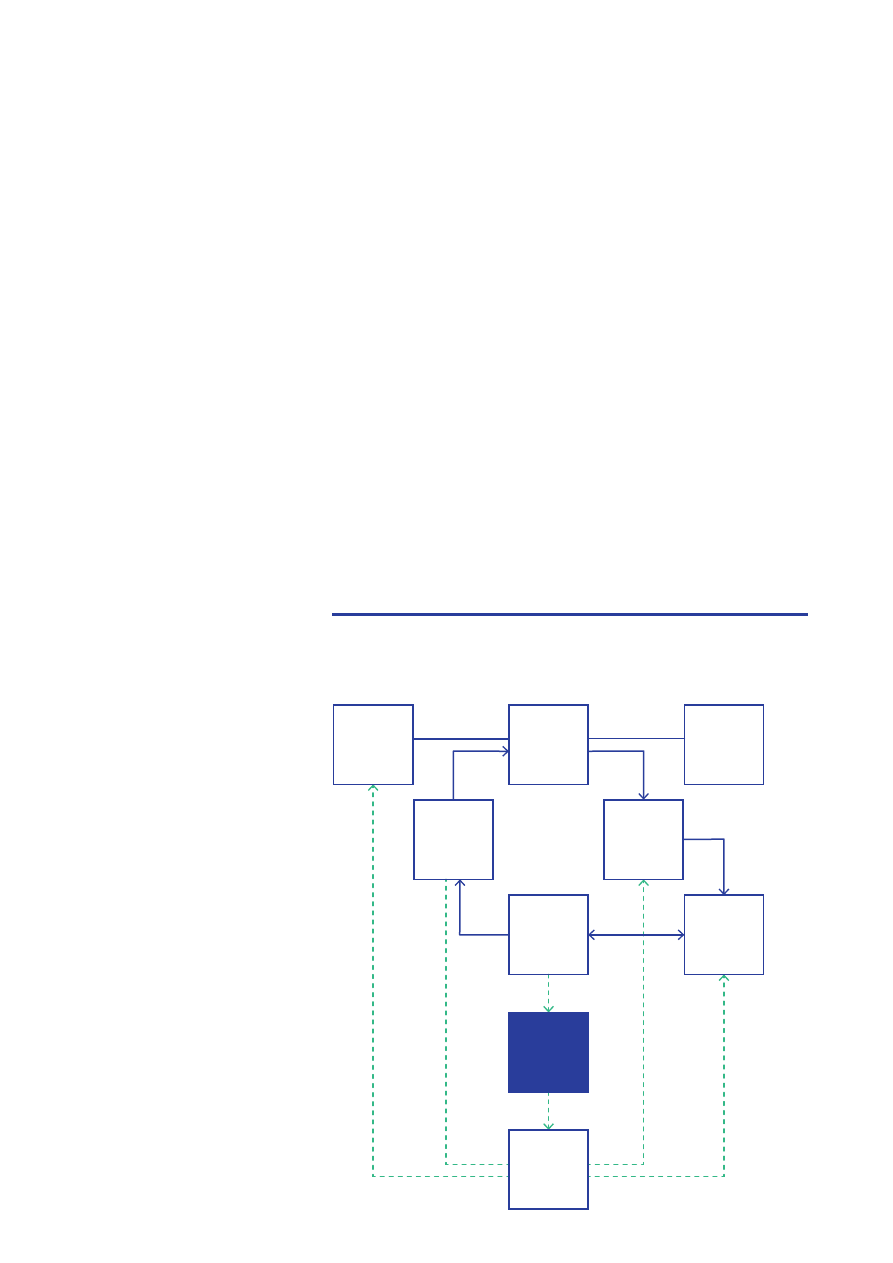

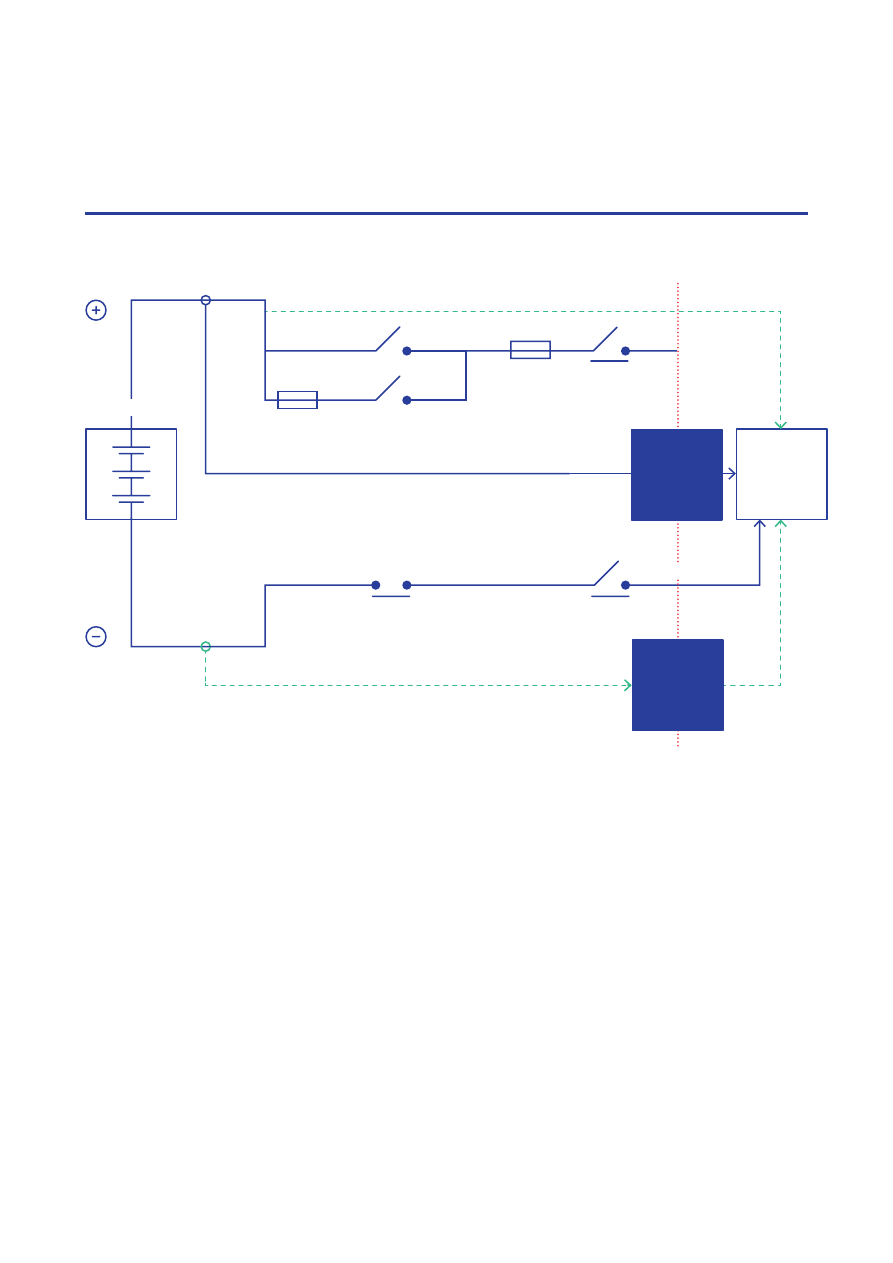

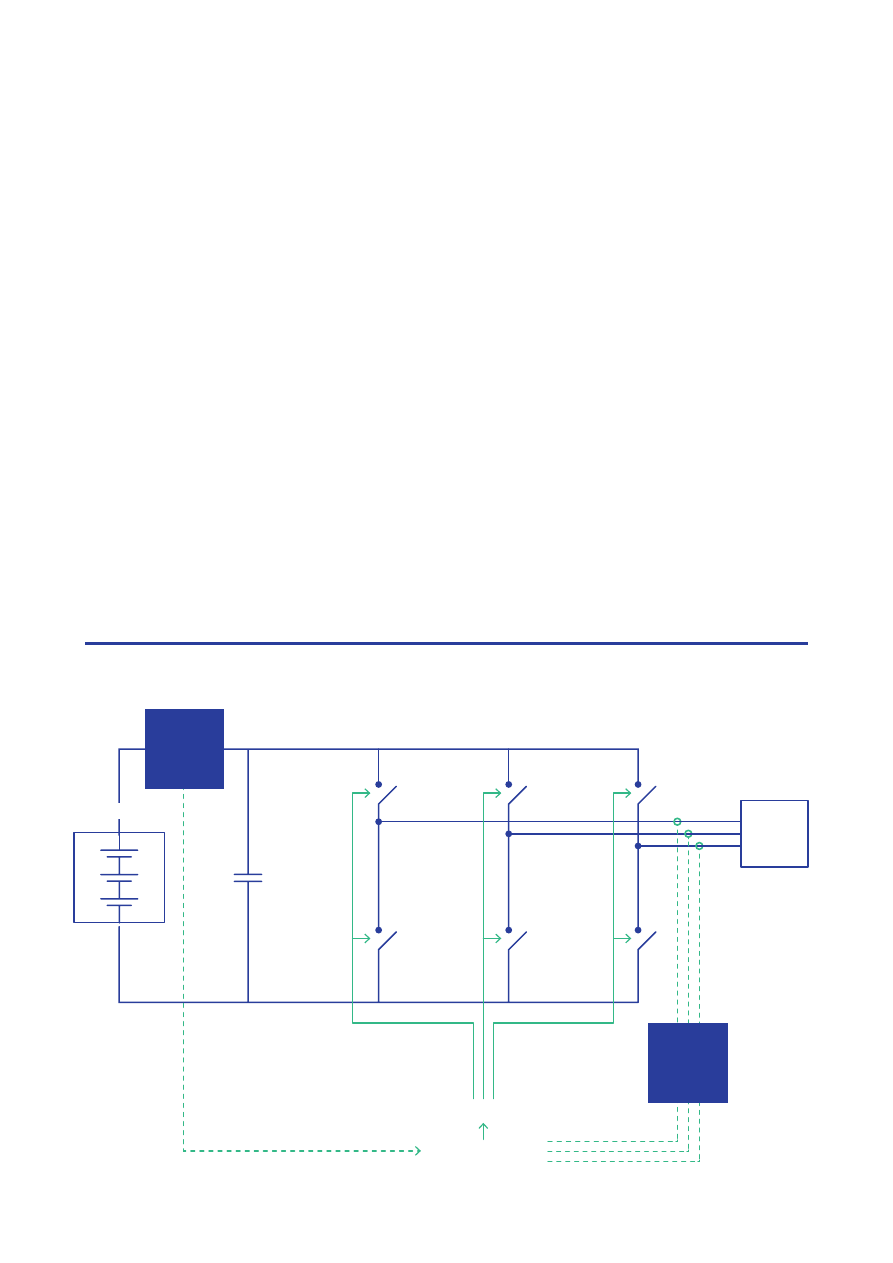

Battery disconnecting unit architecture

BMS master

control unit

Redundant

current

sensor

(optional *)

LV side

HV side

Battery

HV (pack voltage measurement)

Main relay

Main relay

Relay

Fuse

Precharge

relay

Precharge

resistor

Connector status

HV (pack voltage measurement)

* In case of ASIL ready sensor

Isolation barrier

Primary

current

sensor

ASIL ready

12

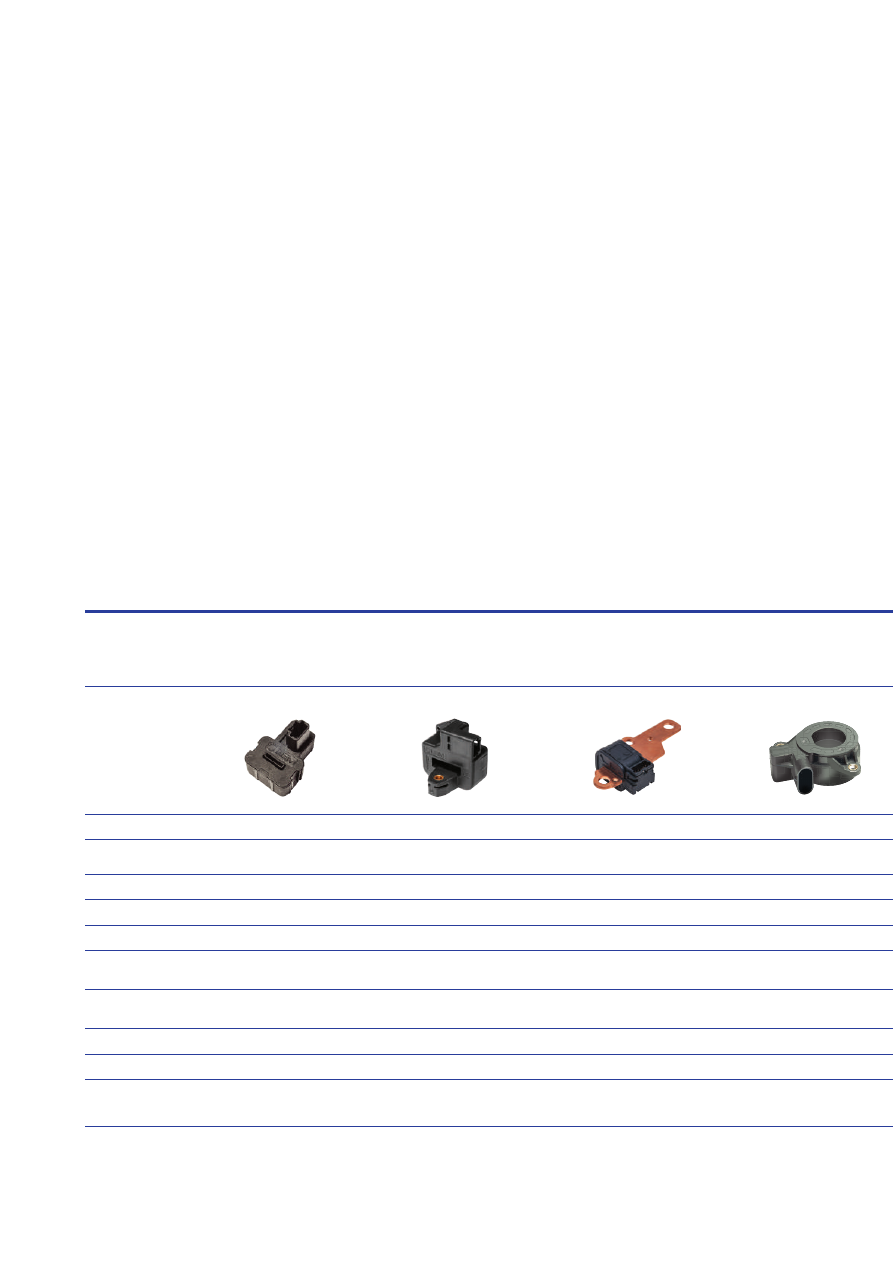

LEM high voltage battery pack BMS for

hybrid and electric vehicles

From mid power to ASIL ready performance

LEM provides a portfolio of solutions featuring a wide range of power levels

that complies with the highest requirements of performance and safety.

Automotive

HV battery management systems

Sensor

HSW

HAH1BVW

HSNBV

DHAB

CAB 500

CAB 1500

CAB 500 SF

CAB 1500 SF

Technology

Open loop

Open loop

Open loop dual range

Open loop dual range

Fluxgate

Fluxgate

Fluxgate

Fluxgate

Current range max

+/- 1000A

+/- 1200A

+/- x00A

+/- 1000A

+/- x00A

+/- 1000A

+/- 500A

+/- 1500A

+/- 500A

+/- 1500A

ASIL readiness

–

–

–

–

–

–

ASIL B

ASIL C

Output

Voltage single

Voltage single/dual

Voltage single/dual

Voltage dual

CAN/LIN

CAN/LIN

CAN/LIN

CAN/LIN

Global error @25°C

0,5%

0,8%

0,5% (single)

0,8% (single)

0,1%

0,1%

0,1%

0,1%

Overall accuracy

(over T°C)

2,0%

2,0%

2,0%

2,8%

0,5%

0,5%

0,5%

0,5%

Bandwidth

(programmable)

1,1 kHz

1,1 kHz

1,1 kHz

1,1 kHz

100 Hz

100 Hz

100 Hz

100 Hz

Mounting type

Busbar

Busbar

Integrated busbar

Cable/Busbar

Cable/Busbar

Busbar

Cable/Busbar

Busbar

Input voltage

+5V

+5V

+5V

+5V

+12V

+12V

+12V

+12V

Consumption

7 mA

8/16 mA

Single 7 mA

Dual 14 mA

16 mA

40 mA (0A)

130 mA

(@500A)

40 mA (0A)

500 mA

(@1500A)

40 mA (0A)

130 mA

(@500A)

40 mA (0A)

500 mA

(@1500A)

HV BMS sensor specifications

13

Performance/Power

Mid power xEV

High performance BMS

1500A

100A low

1000A high

1200A peak

1000A peak

250A rms

Applications

HAH1BVW

Busbar mounting

DHAB

Cable/Busbar

mounting

Mid power xEV

High range, low range channel

Suitable for redundancy

Low offset

High power xEV

High range, low range channel

Coulomb counting

Very low offset

High power

Very high performance

Coulomb counting

ASIL level/CAN bus output

Zero offset

Hall open loop

Single core

Dual core

Fluxgate

HSW

Busbar mounting

HSNBV

Integrated busbar

CAB series

(CAB 500, 1500)

HV BMS sensor portfolio

Sensor

HSW

HAH1BVW

HSNBV

DHAB

CAB 500

CAB 1500

CAB 500 SF

CAB 1500 SF

Technology

Open loop

Open loop

Open loop dual range

Open loop dual range

Fluxgate

Fluxgate

Fluxgate

Fluxgate

Current range max

+/- 1000A

+/- 1200A

+/- x00A

+/- 1000A

+/- x00A

+/- 1000A

+/- 500A

+/- 1500A

+/- 500A

+/- 1500A

ASIL readiness

–

–

–

–

–

–

ASIL B

ASIL C

Output

Voltage single

Voltage single/dual

Voltage single/dual

Voltage dual

CAN/LIN

CAN/LIN

CAN/LIN

CAN/LIN

Global error @25°C

0,5%

0,8%

0,5% (single)

0,8% (single)

0,1%

0,1%

0,1%

0,1%

Overall accuracy

(over T°C)

2,0%

2,0%

2,0%

2,8%

0,5%

0,5%

0,5%

0,5%

Bandwidth

(programmable)

1,1 kHz

1,1 kHz

1,1 kHz

1,1 kHz

100 Hz

100 Hz

100 Hz

100 Hz

Mounting type

Busbar

Busbar

Integrated busbar

Cable/Busbar

Cable/Busbar

Busbar

Cable/Busbar

Busbar

Input voltage

+5V

+5V

+5V

+5V

+12V

+12V

+12V

+12V

Consumption

7 mA

8/16 mA

Single 7 mA

Dual 14 mA

16 mA

40 mA (0A)

130 mA

(@500A)

40 mA (0A)

500 mA

(@1500A)

40 mA (0A)

130 mA

(@500A)

40 mA (0A)

500 mA

(@1500A)

HV BMS sensor specifications

14

LEM provides a broad, versatile range of sensors that enable flexible design

for various systems: gate driver boards, power modules, integrated busbar

and standard busbar mounting.

Electric and hybrid vehicle power motors (few kW to hundreds kW) use

multiphase inverters to drive the traction and generator motors with a high

degree of precision and reliability.

LEM offers standard and customized solutions to fit specific mechatronic

requirements.

Maximum flexibility for power inverter

applications

Gate driver

Micro controller

DC link

Motor

Motor inverter architecture

Automotive

Motor control

IGBT stage

Current

sensors

Current

sensors

Battery

15

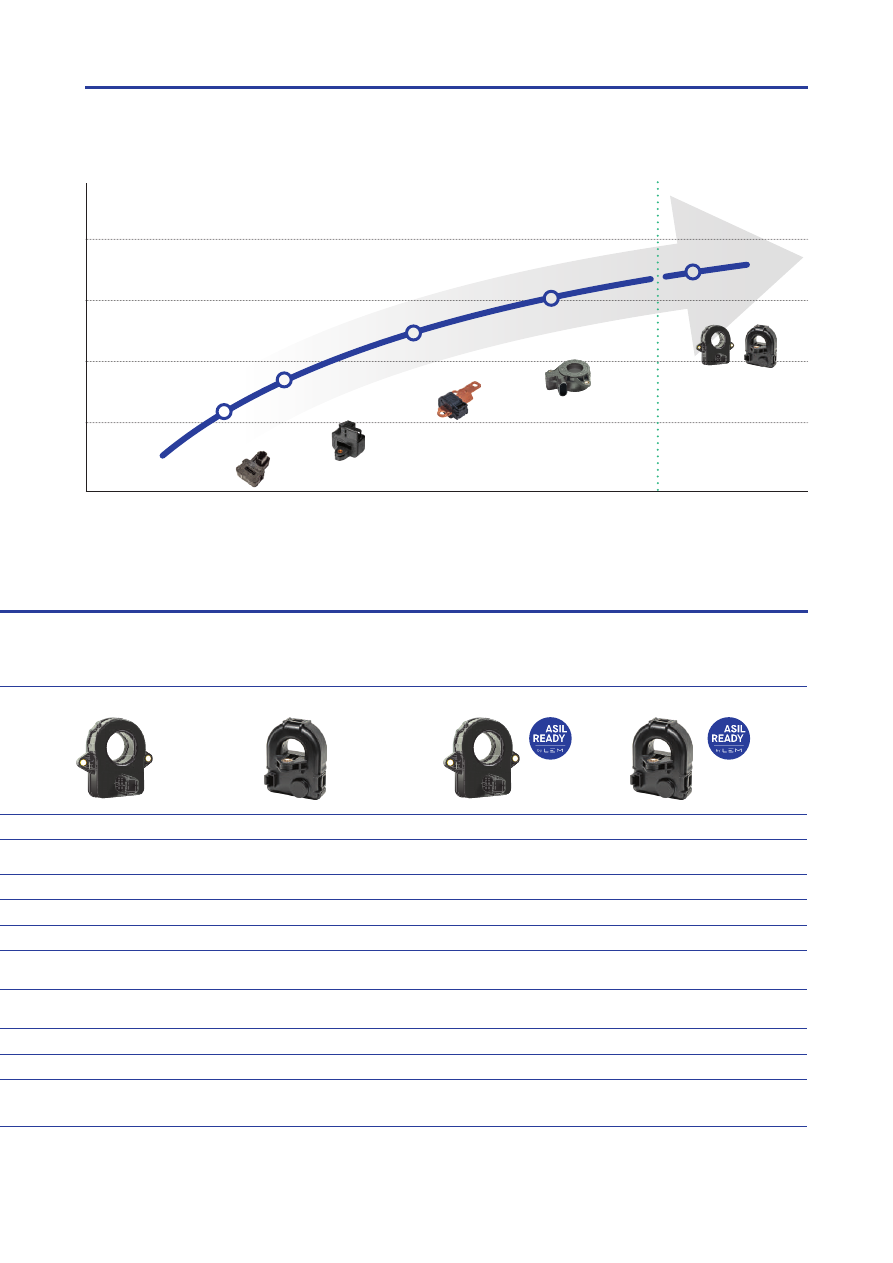

For low to high power inverters (MHEV to BEV)

• Integrated current sensing technologies and PCB mounted sensors

For mid to high power inverters (HEV to BEV)

• Single busbar mounted sensor legacy family

• Integrated busbar sensor for compactness, improved performance and

easy assembly

For high power inverters (BEV)

• Multiphase sensors to improve system integration

• ASIL ready features

Performance/Power

1500A

1000A

800A

250A

Applications

HC6 F/H

HC5FW

HC16FW

HAH3DR series

HSNDR

HAH1DRW

Low power mild hybrid

Mid power xEV

High power xEV

High power multiphase sensor

Single-phase

Multiphase

HAH2DR

HC2 F/H

Motor control sensor portfolio

16

Single-phase and multiphase sensors

Sensor

HC2F/H

HC6F/H

HC5FW

HC16FW

HSNDR

HAH1DRW

Current range

max

1 phase +/- 250A

1 phase +/- 800A

1 phase +/- 900A

1 phase +/- 1600A

1 phase +/- 1200A

1 phase +/- 1500A

Aperture type

(size,

compatibility)

Busbar

(7,2 x 2,5 mm)

ø 4,6 mm

Busbar

(10,5 x 4,2 mm)

ø 7,5 mm

Busbar

ø 12,5 mm

Busbar

(20,5 x 6 mm)

Integrated busbar

(customization)

Busbar

(20,5 x 6 mm)

Output type

Through-hole PCB

voltage

Through-hole PCB

voltage

Through-hole PCB

voltage

SMD or Through-

hole PCB Voltage

Molex connector

voltage

Tyco connector

voltage

Accuracy @25°C

1,2%

1,2%

1,2%

1,2%

1,25%

2%

Overall accuracy

(over T°C)

3,25%

3,25%

3,25%

3,25%

3,2%

3,75%

Bandwidth

50 kHz

50 kHz

50 kHz

50 kHz

50 kHz

50 kHz

Input voltage

+5V

+5V

+5V

+5V

+5V

+5V

Consumption

typical

15 mA

15 mA

15 mA

30 mA

15 mA

15 mA

Single-phase sensor specifications

Automotive

Motor control

LEM offers a wide range of solutions for all inverters

• PCB mounted sensors

• Busbar mounted

• Integrated busbar

• Multiphase sensors

• Reference design sensors *

* Infineon hybrid pack HAH3DR S07 Series

17

Sensor

HAH3DR S07 SPx

HAH3DR S0A

HAH3DR S0C

Current range max

3 phases +/- 1200A

3 phases

+/- 1500A

2-3 phases

+/- 800A

ASIL readiness

ASIL B/C

–

–

Aperture type

(size, pitch,

compatibility)

Infineon hybrid pack

long/short tab

(14,5 x 1,5 mm)

Pitch 47 mm

Busbar

(ø 14,5 mm)

Pitch 34 mm

Busbar

(14,5 x 5,5 mm)

Pitch 30 mm

Output type

Voltage pressfit

Voltage Molex connector

Voltage pin soldering

Accuracy @25°C

2%

1,2%

1,25%

Overall accuracy

(over T°C)

3,2%

3,25%

3,25%

Bandwidth

50 kHz

50 kHz

50 kHz

Input voltage

+5V

+5V

+5V

Consumption

typical

15 mA/phase

15 mA/phase

15 mA/phase

Sensor

HAH2DR

HAH3DR S00

HAH3DR S03 SPx

HAH3DR S06

Current range max

2 phases +/- 650A

3 phases +/- 900A

3 phases +/- 900A

3 phases +/- 900A

Aperture type

(size, pitch,

compatibility)

Busbar

(13,8 x 2,3 mm)

Pitch 44 mm

Busbar

(14,5 x 5,5 mm)

Pitch 30 mm

Busbar

(15,5 x 7,5 mm)

Pitch 38,5 mm

Busbar

(15,5 x 5,5 mm)

Pitch 38,5 mm

Output type

Voltage

JAM connector

Voltage

PCB mounted

Voltage

Hirose connector

Voltage

Molex connector

Accuracy @25°C

2%

2%

2%

2,5%

Overall accuracy

(over T°C)

3,2%

3,5%

3,5%

4,25%

Bandwidth

50 kHz

50 kHz

50 kHz

50 kHz

Input voltage

+5V

+5V

+5V

+5V

Consumption

typical

15 mA/phase

15 mA/phase

15 mA/phase

15 mA/phase

Multiphase sensor specifications

18

Low current applications

LEM has semiconductor based solutions for low current applications from

10A to 200A

rms

. Developed with cutting edge coreless technology, these

products offer isolated high performance sensing in semiconductor packages.

Easy to use and integrate, they are convenient for applications requiring high

power density or very low footprint on current sensing function such as OBC,

DCDC, EPS, BSG.

LEM offers dedicated technologies for

charging systems to support transfer energy

subsystems from AC to DC and DC to DC

with high and low voltage applications.

Automotive

Charging systems

19

Bi-directional LLC

Power/Current

250-1000A

200-500A

10-200A

6 mA

Applications

Busbar mounted

PCB mounted

Integrated current sensor (ICS)

Leakage current

Residual current detection

On-board charger

DC/DC primary

On-board charger

DC/DC secondary

Power DCDC fuel cell

DC/DC secondary

Charging systems sensor portfolio

Current measurement PFC

Current measurement LLC tank

Bidirectional on-board charger architecture

Battery

vehicle

Totem pole PFC

AC

Grid

20

High efficiency power management is key to more

efficient systems and longer driving range.

With increase of accuracy and bandwidth lead by system

power density increase, LEM supports a wide range of sensors

for all applications:

Integrated Current Sensors (ICS)

Hall based SMD sensors for low to mid current

(below 200A peak)

PCB mounted sensors

For busbar current measurements for mid to high current

(200A to 2000A peak)

Busbar mounted sensors

For high power applications

Automotive

Charging systems

21

Sensor

GO SME

GO SMS

HMSR

Current range RMS

10-20A rms

10-30A rms

10-30A rms

Peak current

50A peak

75A peak

75A peak

Isolation

2,5kV

3kV

4,9kV

Accuracy (25°C - over T°C)

1,3% - 3%

1,3% - 3%

1% - 2%

Output type

Analog

Analog

Analog

Vref/Ratiometric

Vref

Vref

Ratio/Vref

Temp. range

-40°C to 125°C

-40°C to 125°C

-40°C to 150°C

Bandwidth

300 kHz

300 kHz

300 kHz

Supply voltage

3,3V/5V

3,3V/5V

3,3V/5V

AECQ100

Yes

Yes

Yes

Target applications

OBC primary, DCDC

OBC primary, DCDC

OBC, DCDC

Package

SOIC 8

SOIC 16

SOIC 16 (footprint compatible)

Sensor

HC2 F/H

HC5FW

HSNDR

HAH1DRW

HAM

Technology

Open loop

Open loop

Open loop

Open loop

Open loop

Current range max

+/- 250A

+/- 900A

+/- 1200A

+/- 1500A

+/- 300A

Output

Voltage

Voltage

Voltage

Voltage

Voltage

Accuracy @25°C

1,2%

1,2%

1,25%

2%

2%

Overall accuracy

(over T°C)

3,25%

3,25%

3,25%

3,75%

3,2%

Bandwidth

50 kHz

50 kHz

50 kHz

50 kHz

500 kHz

Mounting type

Through-hole PCB

Through-hole PCB

Integrated busbar

Busbar

Integrated busbar

Input voltage

+5V

+5V

+5V

+5V

+5V

Consumption

15 mA

15 mA

15 mA

15 mA

15 mA

Integrated current sensor specifications

PCB and busbar mounted sensor specifications

22

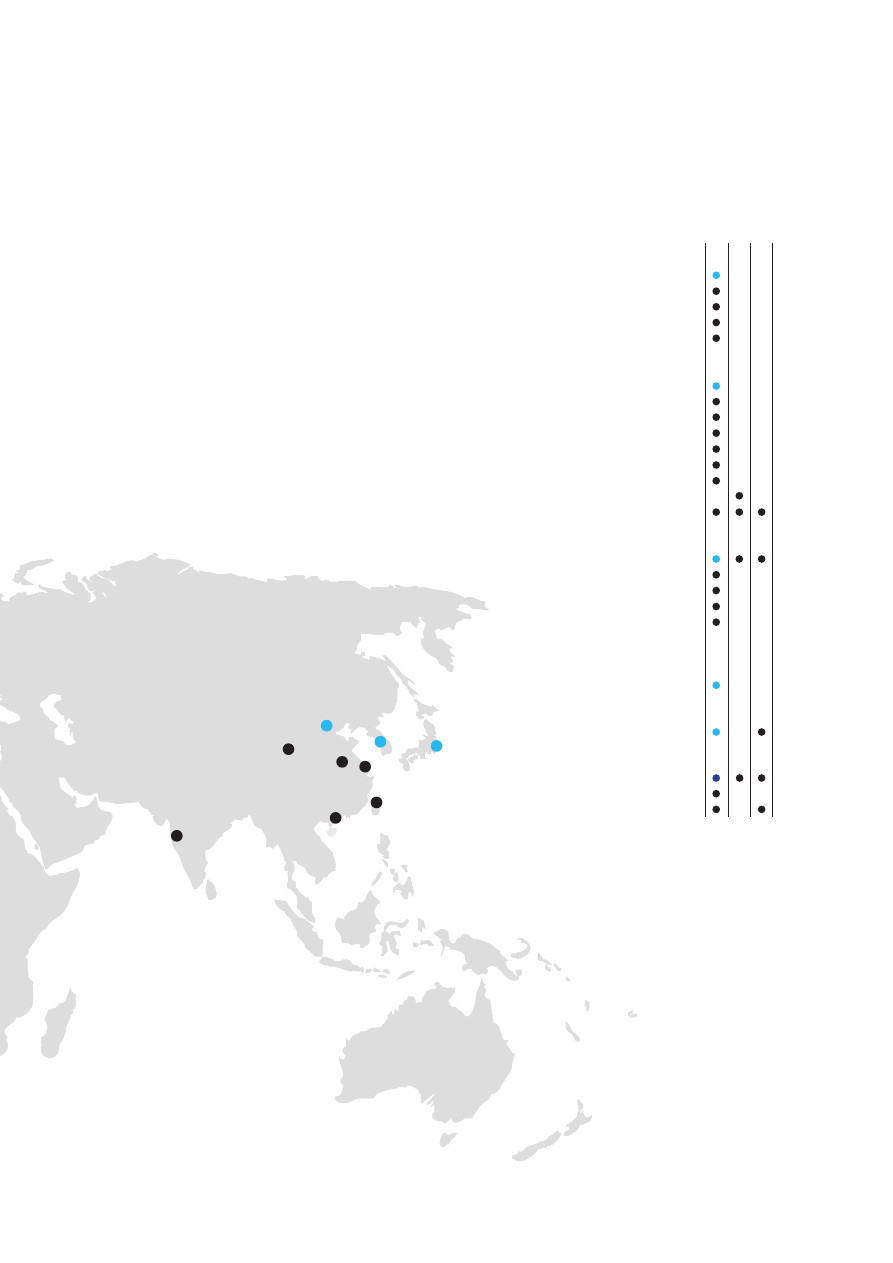

LEM headquarters

Geneva, Switzerland

Automotive

Contact

North America

LEM USA inc. (Detroit)

28221 Beck Road, Suite A4

Wixom, MI 48393

USA

Tel. +1 248 324 0395

Fax +1 248 324 0397

autosales-na@lem.com

Europe

LEM Europe GmbH

Frankfurter Strasse 74

64521 Gross-Gerau

Germany

Tel. +49 6152 930 10

Fax +49 6152 846 61

leu-de@lem.com

China

LEM Electronics (China) co. Ltd.

No. 28, Linhe str. Linhe

Industrial development zone

Shunyi district, Beijing

China

Post code: 101300

Tel. +86 10 89 45 52 88

Fax +86 10 80 48 43 03

+86 10 80 48 31 20

autosales-china@lem.com

South Korea

LEM Management Services Sàrl,

Branch Korea

(Seocho-dong, Wonil Bldg)

1-3F(311) 10

Nambushuhwan-ro 333-gil

Seocho-gu

Seoul, Korea

autosales-korea@lem.com

Japan

LEM Japan k.K.

2-1-2 Nakamachi

Machida-Tokyo 194-0021

Japan

Tel. +81 42 725 81 51

Fax +81 42 728 81 19

autosales-japan@lem.com

Rest of the world

LEM International SA

8, Chemin des Aulx

1228 Plan-les-Ouates

Switzerland

Tel. +41 22 706 13 92

Fax +41 22 706 13 28

automotive_sales@lem.com

23

Sale

s

R&D Produc

tion

North America

Detroit MI

Milwaukee WI

Columbus OH

Amherst MA

Los Angeles CA

Europe

Frankfurt, Germany

Vienna, Austria

Brussels, Belgium

Randers, Denmark

Paris, France

Padova, Italy

Skelmersdale, UK

Lyon, France

Sofia, Bulgaria

China

Beijing

Shanghai

Shenzhen

Xian

Hefei

Taipei, Taiwan

South Korea

Seoul, South Korea

Japan

Tokyo, Japan

Rest of world

Geneva, Switzerland

Pune, India

Tver, Russia

www.lem.com