Selection Guide

Fuse Characteristics, Terms

and Consideration Factors

Selection Guide

Fuse Characteristics, Terms

and Consideration Factors

FUSEOLOGY

Selection Guide

Fuse Characteristics,

Terms and Consideration

Factors

Table of Contents

Page

Fuse Characteristics, Terms and Consideration Factors

2–4

Fuse Selection Checklist

5–7

PTC Characteristics and Terms

8–9

PTC Product Applications

10

Typical PTC Circuit Protection Designs

11

Standards

12–14

PTC Selection Worksheet

15

Fuse and PTC Products Selection Guide

16–18

Packaging and Part Numbering

19

Legal Disclaimers

20

About this guide

Fuses are current-sensitive devices that provide reliable protection for discrete components

or circuits by melting under current overload conditions. Choosing the right fuse for your

application can be an overwhelming, time-consuming process, even for a seasoned

electronics design engineer. This user-friendly Fuseology Selection Guide makes the fuse

selection process quick and easy-helping you optimize the reliability and performance of

the application.

Specifications descriptions and illustrative material in this literature are as accurate as known at the time of publication,

but are subject to changes without notice. Visit

littelfuse.com

for more information.

© 2014 Littelfuse, Inc.

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

The purpose of this introductory section is to promote

a better understanding of both fuses and common

application details within circuit design.

The fuses to be considered are current sensitive devices

designed to serve as the intentional weak link in the

electrical circuit. Their function is to provide protection of

discrete components, or of complete circuits, by reliably

melting under current overload conditions. This section

will cover some important facts about fuses, selection

considerations and standards.

The application guidelines and product data in this guide

are intended to provide technical information that will

help with application design.

The fuse parameters and

application concepts presented should be well understood

in order to properly select a fuse for a given application.

Since these are only a few of the contributing parameters,

application testing is strongly recommended and should be

used to verify performance in the circuit / application.

Littelfuse reserves the right to make changes in product

design, processes, manufacturing location and information

without notice. For current Littelfuse product infomation,

please visit our web site at

www.littelfuse.com

.

AMBIENT TEMPERATURE:

Refers to the temperature

of the air immediately surrounding the fuse and is not to

be confused with “room temperature.” The fuse ambient

temperature is appreciably higher in many cases, because

it is enclosed (as in a panel mount fuseholder) or mounted

near other heat producing components, such as resistors,

transformers, etc.

BREAKING CAPACITY:

Also known as interrupting rating

or short circuit rating, this is the maximum approved

current which the fuse can safely break at rated voltage.

Please refer to the INTERRUPTING RATING definition of

this section for additional information.

CURRENT RATING:

The nominal amperage value of the

fuse. It is established by the manufacturer as a value of

current which the fuse can carry, based on a controlled set

of test conditions (See RERATING section).

Catalog Fuse part numbers include series identification

and amperage ratings. Refer to the FUSE SELECTION

CHECKLIST section for guidance on making the proper

choice.

RERATING:

For 25ºC ambient temperatures, it is

recommended that fuses be operated at no more than

75% of the nominal current rating established using the

controlled test conditions. These test conditions are part of

UL/CSA/ANCE (Mexico) 248-14 “Fuses for Supplementary

Overcurrent Protection,” whose primary objective is

to specify common test standards necessary for the

continued control of manufactured items intended for

protection against fire, etc. Some common variations of

these standards include: fully enclosed fuseholders, high

contact resistances, air movement, transient spikes, and

changes in connecting cablesize (diameter and length).

Fuses are essentially temperature-sensitive devices. Even

small variations from the controlled test conditions can

greatly affect the predicted life of a fuse when it is loaded

to its nominal value, usually expressed as 100% of rating.

The circuit design engineer should clearly understand

that the purpose of these controlled test conditions is to

enable fuse manufacturers to maintain unified performance

standards for their products, and he must account for

the variable conditions of his application. To compensate

for these variables, the circuit design engineer who is

designing for trouble-free, long-life fuse protection in his

equipment generally loads his fuse not more than 75%

of the nominal rating listed by the manufacturer,keeping

in mind that overload and short circuit protection must be

adequately provided for.

The fuses under discussion are temperature-sensitive

devices whose ratings have been established in a 25ºC

ambient. The fuse temperature generated by the current

passing through the fuse increases or decreases with

ambient temperature change.

The ambient temperature chart in the FUSE SELECTION

CHECKLIST section illustrates the effect that ambient

temperature has on the nominal current rating of a fuse.

Most traditional Slo-Blo

®

Fuse designs use lower melting

temperature materials and are, therefore, more sensitive to

ambient temperature changes.

DIMENSIONS:

Unless otherwise specified, dimensions

are in inches.

The fuses in this catalog range in size from the approx.

0402 chip size (.041”L×.020”W×.012”H) up to the 5

AG, also commonly known as a”MIDGET” fuse (13/32”

Dia.×11/2” Length). As new products were developed

throughout the years, fuse sizes evolved to fill the various

electrical circuit protection needs.

The first fuses were simple, open-wire devices, followed

in the 1890’s by Edison’s enclosure of thin wire in a lamp

base to make the first plug fuse. By 1904, Underwriters

Laboratories had established size and rating specifications

to meet safety standards. The renewable type fuses and

automotive fuses appeared in 1914, and in 1927 Littelfuse

started making very low amperage fuses for the budding

electronics industry.

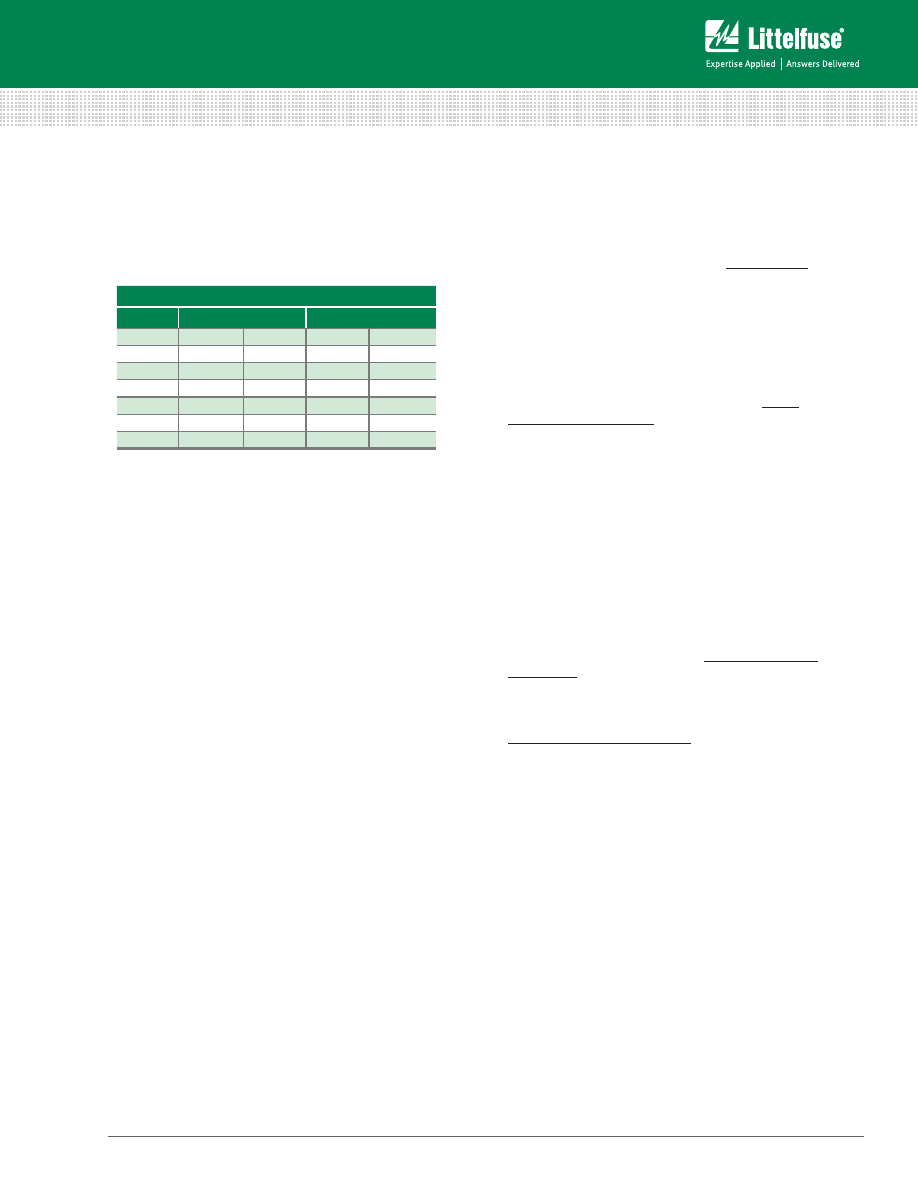

The fuse sizes in following chart began with the early

“Automobile Glass” fuses, thus the term “AG”. The

numbers were applied chronologically as different

manufacturers started making a new size: “3AG,” for

example, was the third size placed on the market. Other

non-glass fuse sizes and constructions were determined by

functional requirements, but they still retained the length

or diameter dimensions of the glass fuses. Their

Fuse Characteristics, terms and Consideration Factors

2

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

designation was modified to AB in place of AG, indicating

that the outer tube was constructed from Bakelite, fibre,

ceramic, or a similar material other than glass. The largest

size fuse shown in the chart is the 5AG, or “MIDGET,”

a name adopted from its use by the electrical industry

and the National Electrical Code range which normally

recognizes fuses of 9/16”× 2” as the smallest standard

fuse in use.

FUSE SIZES

SIZE

DIAMETER (Inches)

LENGTH (Inches)

1AG

1/4

.250

5/8

.625

2AG

–

.177

–

.588

3AG

1/4

.250

1¼

1.25

4AG

9/32

.281

1¼

1.25

5AG

13/32

.406

1½

1.50

7AG

1/4

.250

7⁄8

.875

8AG

1/4

.250

1

1

TOLERANCES:

The dimensions shown in this catalog

are nominal. Unless otherwise specified, tolerances are

applied as follows. Tolerances do not apply to lead lengths:

± .010” for dimensions to 2 decimal places.

± .005” for dimensions to 3 decimal places.

Contact Littelfuse should you have questions regarding

metric system and fractional tolerances.

FUSE CHARACTERISTICS:

This characteristic of a fuse

design refers to how rapidly it responds to various current

overloads. Fuse characteristics can be classified into three

general categories: very fast-acting, fast-acting, or Slo-Blo

®

Fuse. The distinguishing feature of Slo-Blo

®

fuses is that

these fuses have additional thermal inertia designed to

tolerate normal initial or start-up overload pulses.

FUSE CONSTRUCTION:

Internal construction may vary

depending on ampere rating. Fuse photos in this catalog

show typical construction of a particular ampere rating

within the fuse series.

FUSEHOLDERS:

In many applications, fuses are

installed in fuseholders. These fuses and their associated

fuseholders are not intended for operation as a “switch”

for turning power “on” and “off “.

INTERRUPTING RATING:

Also known as breaking

capacity or short circuit rating, the interrupting rating is

the maximum approved current which the fuse can safely

interrupt at rated voltage. During a fault or short circuit

condition, a fuse may receive an instantaneous overload

current many times greater than its normal operating

current. Safe operation requires that the fuse remain intact

(no explosion or body rupture) and clear the circuit.

Interrupting ratings may vary with fuse design and range

from 35 amperes for some 250VAC metric size (5×20mm)

fuses up to 200,000 amperes for the 600VAC KLK series.

Information on other fuse series can be obtained from the

Littelfuse.

Fuses listed in accordance with UL/CSA/ANCE 248 are

required to have an interrupting rating of 10,000 amperes

at 125V, with some exceptions (See STANDARDS section)

which, in many applications, provides a safety factor far in

excess of the short circuit currents available.

NUISANCE OPENING:

Nuisance opening is most often

caused by an incomplete analysis of the circuit under

consideration.

Of all the “Selection Factors” listed in the FUSE

SELECTION CHECKLIST, special attention must be given

to items 1, 3, and 6, namely, normal operating current,

ambient temperature, and pulses.

For example, one prevalent cause of nuisance opening in

conventional power supplies is the failure to adequately

consider the fuse’s nominal melting I

2

t rating. The fuse

cannot be selected solely on the basis of normal operating

current and ambient temperature. In this application, the

fuse’s nominal melting I

2

t rating must also meet the inrush

current requirements created by the input capacitor of the

power supply’s smoothing filter.

The procedure for converting various waveforms into

I

2

t circuit demand is given in the FUSE SELECTION

CHECKLIST. For trouble-free, long-life fuse protection, it is

good design practice to select a fuse such that the I

2

t of

the waveform is no more than 20% of the nominal melting

I

2

t rating of the fuse. Refer to the section on PULSES in the

FUSE SELECTION CHECKLIST.

RESISTANCE:

The resistance of a fuse is usually an

insignificant part of the total circuit resistance. Since the

resistance of fractional amperage fuses can be several

ohms, this fact should be considered when using them

in low-voltage circuits. Actual values can be obtained by

contacting Littelfuse.

Most fuses are manufactured from materials which have

positive temperature coefficients, and, therefore, it is

common to refer to cold resistance and hot resistance

(voltage drop at rated current), with actual operation being

somewhere in between.

Cold resistance is the resistance obtained using a

measuring current of no more than 10% of the fuse’s

nominal rated current. Values shown in this publication for

cold resistance are nominal and representative. The factory

should be consulted if this parameter is critical to the

design analysis.

Hot resistance is the resistance calculated from the

Fuse Characteristics, terms and Consideration Factors (continued)

3

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

stabilized voltage drop across the fuse, with current equal

to the nominal rated current flowing through it. Resistance

data on all Littelfuse products are available on request.

Fuses can be supplied to specified controlled resistance

tolerances at additional cost.

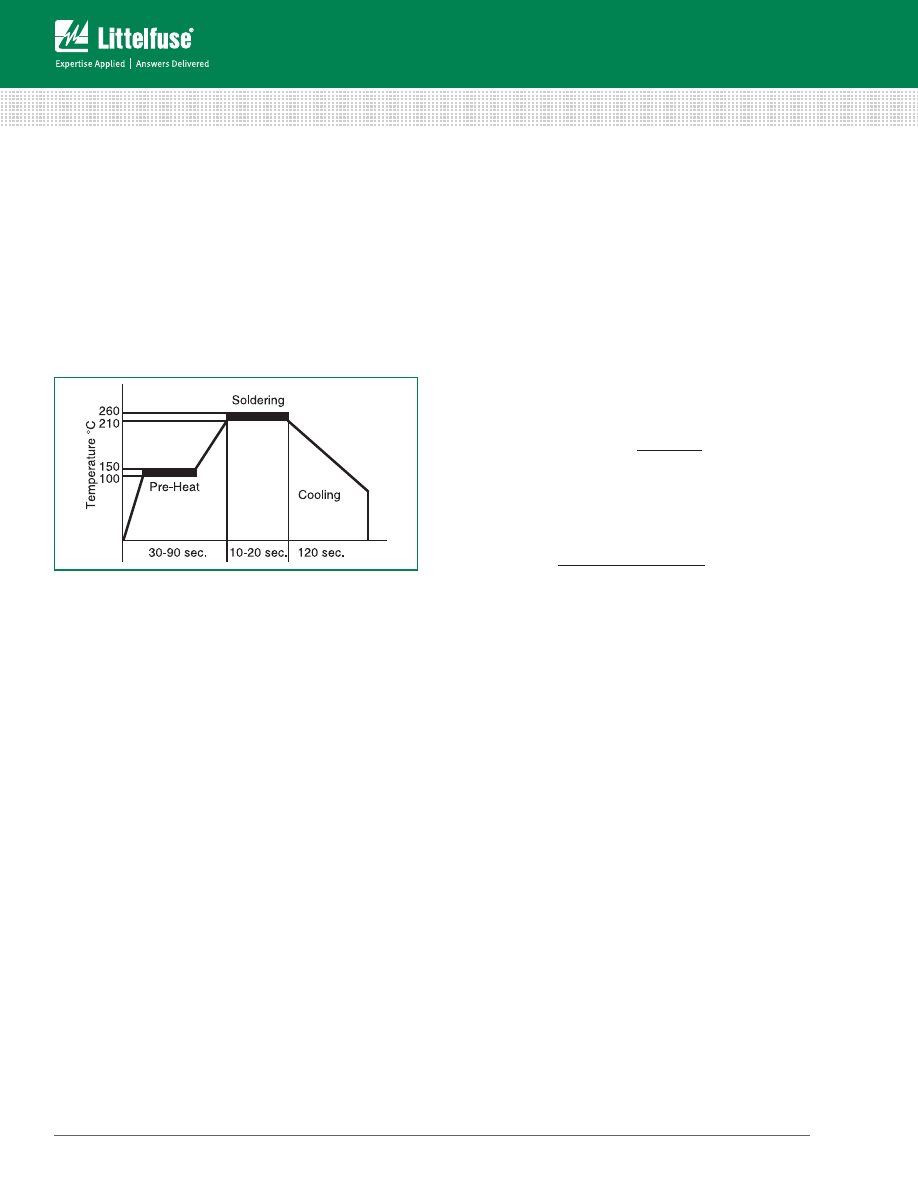

SOLDERING RECOMMENDATIONS:

Since most fuse

constructions incorporate soldered connections, caution

should be used when installing those fuses intended to

be soldered in place. The application of excessive heat can

reflow the solder within the fuse and change its rating.

Fuses are heat-sensitive components similar to semi-

conductors, and the use of heat sinks during soldering is

often recommended.

Lead-Free Soldering Parameters (most instances):

Wave Solder — 260ºC, 10 seconds max

Reflow Solder — 260ºC, 30 seconds max

TEST SAMPLING PLAN:

Because compliance with certain

specifications requires destructive testing, these tests are

selected on a statistical basis for each lot manufactured.

TIME-CURRENT CURVE:

The graphical presentation of

the fusing characteristic, time-current curves are generally

average curves which are presented as a design aid but

are not generally considered part of the fuse specification.

Time-current curves are extremely useful in defining

a fuse, since fuses with the same current rating can

be represented by considerably different time-current

curves. The fuse specification typically will include a life

requirement at 100% of rating and maximum opening

times at overload points (usually 135% and 200% of rating

depending on fuse standard characteristics). A time-current

curve represents average data for the design; how ever,

there may be some differences in the values for any one

given production lot. Samples should be tested to verify

performance, once the fuse has been selected.

UNDERWRITERS LABORATORIES:

Reference to “Listed

by Underwriters Laboratories” signifies that the fuses

meet the requirements of UL/CSA/ANCE 248-14 “Fuses

for Supplementary Overcurrent Protection”. Some 32

volt fuses (automotive) in this catalog are listed under

UL Standard 275. Reference to “Recognized under the

Component Program of Underwriters Laboratories”

signifies that the item is recognized under the component

program of Underwriters Laboratories and application

approval is required.

VOLTAGE RATING:

The voltage rating, as marked on a

fuse, indicates that the fuse can be relied upon to safely

interrupt its rated short circuit current in a circuit where the

voltage is equal to, or less than, its rated voltage.

This system of voltage rating is covered by N.E.C.

regulations and is a requirement of Underwriters

Laboratories as a protection against fire risk. The standard

voltage ratings used by fuse manufacturers for most small-

dimension and midget fuses are 32, 63, 125, 250 and 600.

In electronic equipment with relatively low output power

supplies, with circuit impedance limiting short circuit

currents to values of less than ten times the current rating

of the fuse, it is common practice to specify fuses with

125 or 250 volt ratings for secondary circuit protection of

500 volts or higher.

As mentioned previously (See RERATING section), fuses

are sensitive to changes in current, not voltage, maintaining

their “status quo” at any voltage up to the maximum rating

of the fuse. It is not until the fuse element melts and

arcing occurs that the circuit voltage and available power

become an issue. The safe interruption of the circuit, as it

relates to circuit voltage and available power, is discussed

in the section on INTERRUPTING RATING.

To summarize, a fuse may be used at any voltage that is

less than its voltage rating without detriment to its fusing

characteristics. Please contact the factory for applications

at voltages greater than the voltage rating.

DERIVATION OF NOMINAL MELTING I

2

t:

Laboratory

tests are conducted on each fuse design to determine the

amount of energy required to melt the fusing element. This

energy is described as nominal melting I

2

t and is expressed

as “Ampere Squared Seconds” (A

2

sec.).

A pulse of current is applied to the fuse, and a time

measurement is taken for melting to occur. If melting

does not occur within a short duration of about 8

milliseconds (0.008 seconds) or less, the level of pulse

current is increased. This test procedure is repeated until

melting of the fuse element is confined to within about 8

milliseconds.

The purpose of this procedure is to assure that the heat

created has insufficient time to thermally conduct away

from the fuse element. That is, all of the heat energy (I

2

t)

is used, to cause melting. Once the measurements of

current (I) and time (t) are determined, it is a simple matter

to calculate melting I

2

t. When the melting phase reaches

completion, an electrical arc occurs immediately prior to

the “opening” of the fuse element.

Clearing I

2

t = Melting I

2

t + arcing I

2

t

The nominal I

2

t values given in this publication pertain to

the melting phase portion of the “clearing” or “opening”.

Alternatively the time can be measured at 10 times of the

rated current and the I

2

t value is calculated like above.

Fuse Characteristics, terms and Consideration Factors (continued)

4

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

Fuse selection Checklist

The application guidelines and product data in this guide

are intended to provide technical information that will help

with application design. Since these are only a few of the

contributing parameters, application testing is strongly

recommended and should be used to verify performance in

the circuit/application.

Many of the factors involved with fuse selection are listed

below. For additional assistance with choosing fuses

appropriate to you requirements, contact your Littelfuse

products reprentative.

Selection Factors

1. Normal operating current

2. Application voltage (AC or DC)

3. Ambient temperature

4. Overload current and length of time in which the

fuse must open

5. Maximum available fault current

6. Pulses, Surge Currents, Inrush Currents, Start-up

Currents, and Circuit Transients

7. Physical size limitations, such as length, diameter,

or height

8. Agency Approvals required, such as UL, CSA, VDE,

METI, MITI or Military

9. Fuse features (mounting type/form factor, ease of

removal, axial leads, visual indication, etc.)

10. Fuseholder features, if applicable and associated

rerating (clips, mounting block, panel mount, PC

board mount, R.F.I. shielded, etc.)

11. Application testing and verification prior to

production

1. NORMAL OPERATING CURRENT:

The current rating

of a fuse is typically derated 25% for operation at 25ºC to

avoid nuisance blowing. For example, a fuse with a current

rating of 10A is not usually recommended for operation at

more than 7.5A in a 25ºC ambient. For additional details,

see RERATING in the previous section and AMBIENT

TEMPERATURE below.

2. APPLICATION VOLTAGE:

The voltage rating of the

fuse must be equal to, or greater than, the available circuit

voltage. For exceptions, see VOLTAGE RATING.

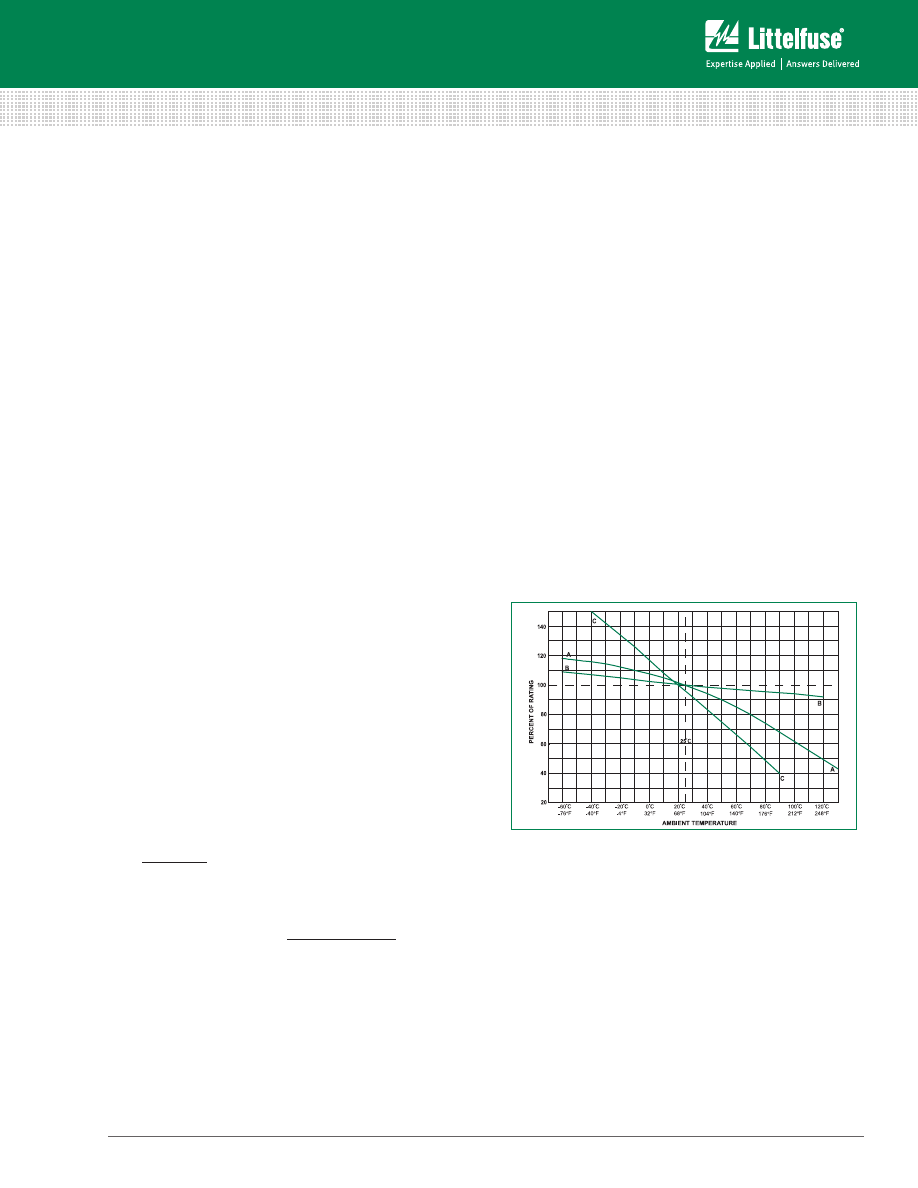

3. AMBIENT TEMPERATURE:

The current carrying

capacity tests of fuses are performed at 25ºC and will be

affected by changes in ambient temperature. The higher

the ambient temperature, the hotter the fuse will operate,

and the shorter its life. Conversely, operating at a lower

temperature will prolong fuse life. A fuse also runs hotter

as the normal operating current approaches or exceeds the

rating of the selected fuse. Practical experience indicates

fuses at

room temperature

should last indefinitely, if

operated at no more than 75% of catalog fuse rating.

Ambient temperature effects are in addition to the

normal re-rating, see example. Example: Given a normal

operating current of 1.5 amperes in an application using

a traditional Slo-Blo

®

fuse at room temperature, then:

Normal Operating Current

Catalog Fuse Rating = ——————————————————

0.75

- or -

1.5 Amperes

——————— = 2.0 Amp Fuse (at 25ºC)

0.75

Similarly, if that same fuse were operated at a very high

ambient temperature of 70°C, additional derating would

be necessary. Curve "A" (Traditional Slo-Blo

®

Fuse) of

that ambient temperature chart shows the maximum

operating "Percent of Rating" at 70°C to be 80%, in

which case;

Normal Operating Current

Catalog Fuse Rating = ——————————————————

0.75 x Percent of Rating

- or -

1.5 Amperes

——————— = 2.5 Amp Fuse (at 70ºC)

0.75 x 0.80

This charts shows typical ambient temperature effects on

current carrying capacity of Littelfuse products. For specific

re-rating information, please consult the product data sheet

at

www.littelfuse.com

or contact a Littelfuse representative.

Curve A: Thin-Film Fuses and 313 Series (.010 to .150A)

Curve B: FLAT-PAK

®

, TeleLink

®

, Nano

2®

, PICO

®

, Blade

Terminal and other leaded and catridge fuses

Curve C: Resettable PTC’s

5

Fuseology Selection Guide

©

2015 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

4. OVERLOAD CURRENT CONDITION:

The current level

for which protection is required. Fault conditions may be

specified, either in terms of current or, in terms of both

current and maximum time the fault can be tolerated

before damage occurs. Time-current curves should be

consulted to try to match the fuse characteristic to the

circuit needs, while keeping in mind that the curves are

based on average data.

5. MAXIMUM FAULT CURRENT:

The Interrupting Rating

of a fuse must meet or exceed the Maximum Fault Current

of the circuit.

6. PULSES:

The general term “pulses” is used in this

context to describe the broad category of wave shapes

referred to as “surge currents”, “start-up currents”, “inrush

currents”, and “transients”. Electrical pulse conditions can

vary considerably from one application to another. Different

fuse constructions may not react the same to a given

pulse condition. Electrical pulses produce thermal cycling

and possible mechanical fatigue that could affect the life

of the fuse. Initial or start-up pulses are normal for some

applications and require the characteristic of a Slo-Blo

®

fuse. Slo-Blo

®

fuses incorporate a thermal delay design

to enable them to survive normal start-up pulses and still

provide protection against prolonged overloads. The start-

up pulse should be defined and then compared to the time-

current curve and I

2

t rating for the fuse. Application testing

is recommended to establish the ability of the fuse design

to withstand the pulse conditions.

Nominal melting I

2

t is a measure of the energy required

to melt the fusing element and is expressed as “Ampere

Squared Seconds” (A

2

Sec.). This nominal melting I

2

t,

and the energy it represents (within a time duration of

8 milliseconds [0.008 second] or less and 1 millisecond

[0.001 second]or less for thin film fuses), is a value that is

constant for each different fusing element. Because every

fuse type and rating, as well as its corresponding part

number, has a different fusing element, it is necessary to

determine the I

2

t for each. This I

2

t value is a parameter of

the fuse itself and is controlled by the element material

and the configuration of the fuse element. In addition

to selecting fuses on the basis of “Normal Operating

Currents”, “Rerating”, and “Ambient Temperature” as

discussed earlier, it is also necessary to apply the I

2

t

design approach. This nominal melting I

2

t is not only a

constant value for each fuse element design, but it is also

independent of temperature and voltage. Most often, the

nominal melting I

2

t method of fuse selection is applied to

those applications in which the fuse must sustain large

current pulses of a short duration. These high-energy

currents are common in many applications and are critical

to the design analysis.

The following example should assist in providing a better

understanding of the application of I

2

t.

EXAMPLE:

Select a 125V, very fast-acting PICO

®

II fuse that

is capable of withstanding 100,000 pulses of current (I) of

the pulse waveform shown in Figure 1.

The normal operating current is 0.75 ampere at an ambient

temperature of 25ºC.

Step 1

— Refer to Chart 1 and select the appropriate

pulsewaveform, which is waveform (E) in this example.

Place the applicable value for peak pulse current (i

p

) and

time (t) into the corresponding formula for waveshape (E),

and calculate the result, as shown:

1

I

2

t = — (i

P

)

2

t

5

1

= —×8

2

×.004 = 0.0512 A

2

Sec.

5

This value is referred to as the “Pulse I

2

t”.

Step 2

— Determine the required value of Nominal Melting

I

2

t by referring to Chart 2. A figure of 22% is shown in

Chart II for 100,000 occurrences of the Pulse I

2

t calculated

in Step 1. This Pulse I

2

t is converted to its required value of

Nominal Melting I

2

t as follows:

Nom. Melt I

2

t = Pulse I

2

t/.22

0.0512/.22 = 0.2327 A

2

Sec.

Step 3

— Examine the I

2

t rating data for the PICO

®

II, 125V,

very fast-acting fuse. The part number 251001, 1 ampere

design is rated at 0.256 A

2

Sec., which is the minimum

fuse rating that will accommodate the 0.2327 A

2

Sec.

value calculated in Step 2. This 1 ampere fuse will also

accommodate the specified 0.75 ampere normal operating

current, when a 25% derating factor is applied to the 1

ampere rating, as previously described.

7. PHYSICAL SIZE LIMITATIONS:

Please refer to the

product dimensions presented in current Littelfuse product

data sheets for specific information.

8. AGENCY APPROVALS:

For background information

about common standards, please consult the STANDARDS

section of this guide or visit our Design Support web site

at

www.littelfuse.com/design-support.html

. For specific

agency approval information for each Littelfuse product,

please refer to the data sheets within this catalog and

information presented on

www.littelfuse.com

. As agency

approvals and standards may change, please rely on the

information presented on

www.littelfuse.com

as current

information.

9. FUSE FEATURES:

Please consult the specific product

features presented within this catalog and on our web

site at

www.littelfuse.com

. For additional information and

support contact your Littelfuse product representative.

Fuse Selection Checklist (continued)

6

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

.001

.002

.003

.004 .005

.006

Time (Seconds)

Cur

rent (Amperes)

Figure 1

2

4

6

8

10

Normal Operating Current

l t

Pulse

Energy

2

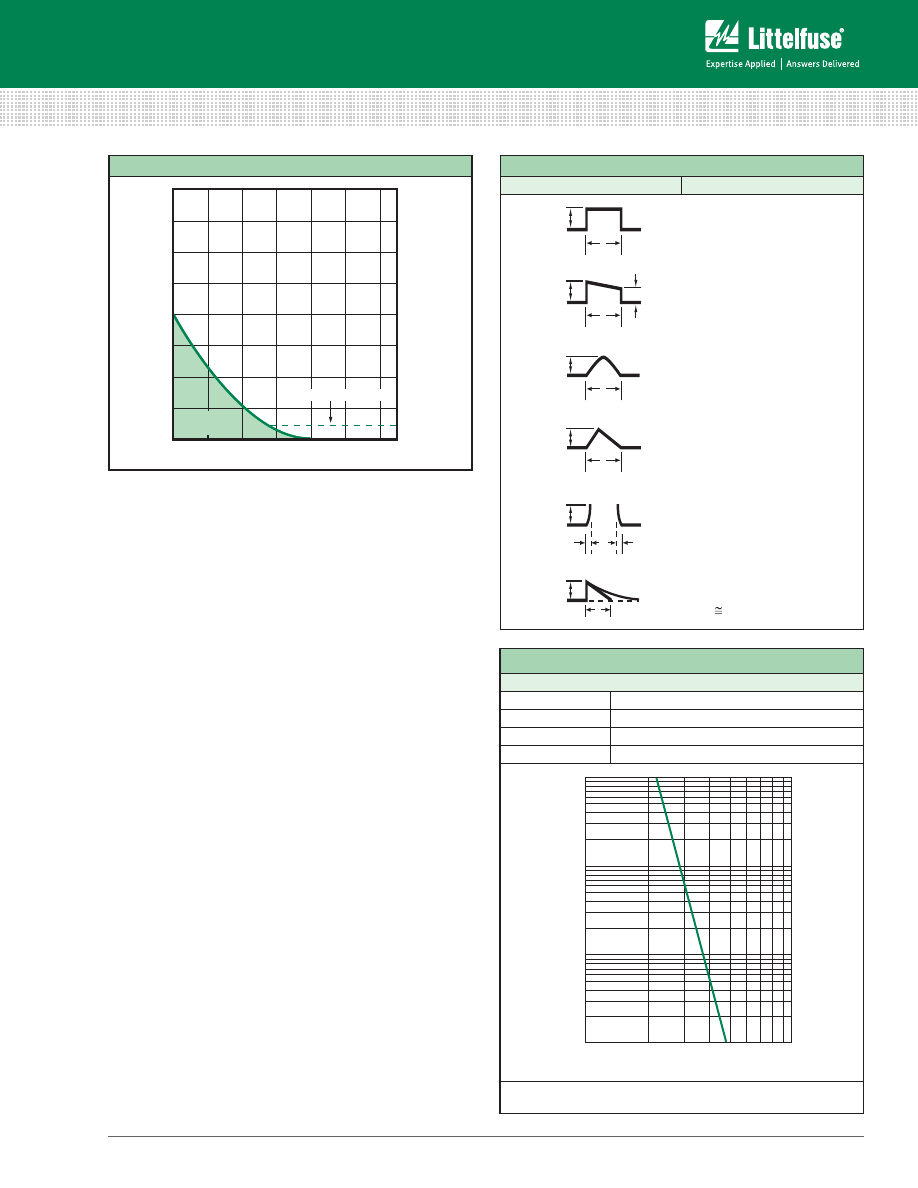

CHART 1

WAVESHAPES

FORMULAS

t

t

t

1

i

p

i

p

i

p

i

p

i

p

i

b

i

p

F

E

D

C

B

A

OR

t

t

t

t

i = k

I

2

t = i

p

2

t

i = i

p

-kt

I

2

t = (1/3)(i

p

2

+ i

p

i

b

+ i

b

2

) t

i = i

p

sin t

I

2

t = (1/2) i

p

2

t

I

2

t = (1/3) i

p

2

t

i = kt

2

OR i = i

p

(1-kt)

2

I

2

t = (1/5) i

p

2

t

i = i

p

e

–kt

)

I

2

t (1/2) i

p

2

t

1

CHART 2

PULSE CYCLE WITHSTAND CAPABILITY

100,000 Pulses

Pulse I

2

t = 22% of Nominal Melting I

2

t

10,000 Pulses

Pulse I

2

t = 29% of Nominal Melting I

2

t

1,000 Pulses

Pulse I

2

t = 38% of Nominal Melting I

2

t

100 Pulses

Pulse I

2

t = 48% of Nominal Melting I

2

t

100000

10000

1000

100

10%

100%

Number of P

ulses

Pulse I

2

t / Average Melting I

2

t

Note: Adequate time (10 seconds) must exist between pulse events

to allow heat from the previous event to dissipate.

10. FUSEHOLDER FEATURES AND RERATING:

For

information about the range of Littelfuse fuseholders and

specific features and characteristics, please consult with

a Littelfuse products representative or visit our web site

(

www.littelfuse.com

).

For 25ºC ambient temperatures, it is recommended that

fuseholders be operated at no more than 60% of the

nominal current rating established using the controlled test

conditions specified by Underwriters Laboratories. The

primary objective of these UL test conditions is to specify

common test standards necessary for the continued

control of manufactured items intended for protection

against fire, etc. A copper dummy fuse is inserted in

the fuseholder by Underwriters Laboratories, and then

the current is increased until a certain temperature rise

occurs. The majority of the heat is produced by the contact

resistance of the fuseholder clips. This value of current

is considered to be the rated current of the fuseholder,

expressed as 100% of rating. Some of the more common,

everyday applications may differ from these UL test

conditions as follows: fully enclosed fuseholders, high

contact resistance,air movement, transient spikes, and

changes in connecting cable size (diameter and length).

Even small variations from the controlled test conditions

can greatly affect the ratings of the fuse-holder. For

this reason, it is recommended that fuseholders be

derated by 40% (operated at no more than 60% of the

nominal current rating established using the Underwriter

Laboratories test conditions, as previously stated).

11. TESTING:

The factors presented here should be

considered in selecting a fuse for a given application. The

next step is to verify the selection by requesting samples

for testing in the actual circuit. Before evaluating the

samples, make sure the fuse is properly mounted with

good electrical connections, using adequately sized wires

or traces. The testing should include life tests under normal

conditions and overload tests Under fault conditions, to

ensure that the fuse will operate properly in the circuit.

FIGURE 1

Fuse selection Checklist (continued)

7

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Overcurrent circuit protection can be accomplished

with the use of either a traditional fuse or PTC (positive

temperature coefficient) device.

PTCs are typically used in a wide variety of telecom,

computer, consumer electronics, battery and medical

electronics product applications where overcurrent events

are common and automatic resettability desired.

Littelfuse offers PTCs with the following general forms and

features, and come in a variety of sizes and capacities:

Surface Mount Devices:

• A full range of compact footprints

• Low hold current

• Very fast trip time

• Low resistance

Radial Leaded Series:

• Protection devices up to 600Vdc

• A very high hold current

• Low trip-to-hold current ratio

• Low resistance.

Battery Strap Devices:

• A narrow low profile design

• A weldable band Nickel terminal

• Low resistance–for extended battery run time

If your application requirements fall outside of our product

range, in certain instances we can offer customized

solutions. Please contact Littelfuse for more information.

Traditional Fuses Vs. PTCs

Fuses and PTCs are both overcurrent protection

devices, though each offer their own unique operating

characteristics and benefits. Understanding the differences

between the two technologies should make the choice in

selection easier, depending on the application.

The most obvious difference is that PTCs are automatically

resettable whereas traditional Fuses need to be replaced

after they they are tripped. Whereas a fuse will completely

stop the flow of current (which may be desired in critical

applications) after most similar overcurrent event, PTCs

continue to enable the equiment to function, except in

extreme cases.

Because they reset automatically, many circuit designers

choose PTCs in instances where overcurrent events are

expected to occur often, and where maintaining low

warranty and service costs, constant system uptime, and/

or user transparency are at a premium. They are also often

chosen in circuits that are difficult to access or in remote

locations, were fuse replacement would be difficult.

There are several other operating characteristics to be

considered that distinguish PTCs and fuses, and it is also

best to test and verify device performance before use

within the end application.

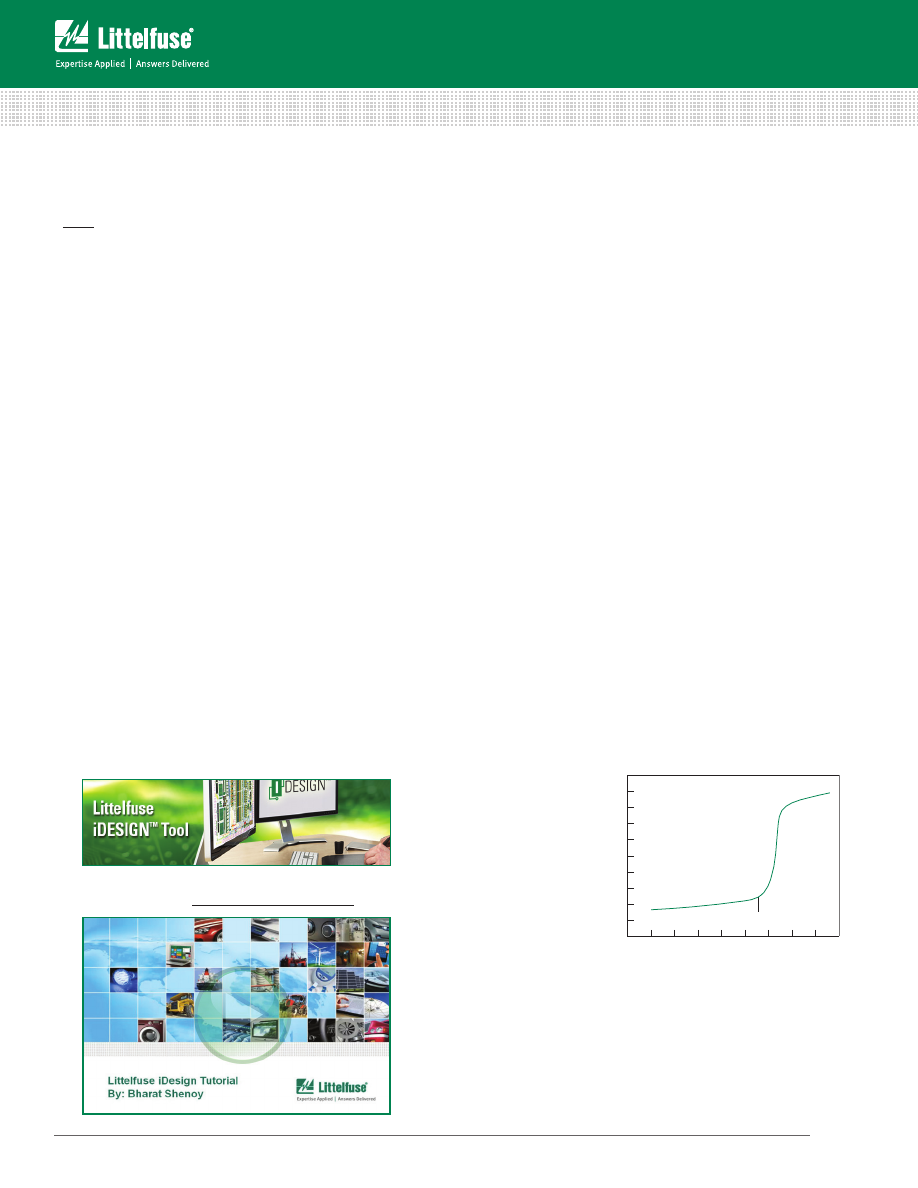

Littelfuse PTC Characteristics

Both Polymeric (Positive Temperature Coefficient) PTC

and traditional Fuse devices react to heat generated by

the excessive current flow in a circuit. A fuse melts open,

interrupting the current flow whereas a PTC limits current

flow as it rises in temperature, changing from low to high

resistance state. In both

cases this condition is

called "tripping." The

graph at right shows the

typical response of a

PTC to temperature.

Littelfuse Polymer PTCs

are made chiefly of high

density polyethylene

mixed with graphite.

During an overcurrent

event, a Polymer PTC

will heat and expand, which in turn causes the conducting

particles to break contact and stop the current.

The general procedure for resetting the device after an

overload has occurred is to remove power and allow the

device to cool down.

Log resistance (ohms)

Temperature (C)

Trip Point

PtC Characteristics and terms

To view a short online tutorial on using the Littelfuse

iDesign tool, visit: http://vimeo.com/90118164

Littelfuse iDesign

TM

Online Fuse Design

and Selection Tool

8

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

Leakage Current:

When a PTC is in a "tripped state" it

protects the circuitry by limiting the current flow to a low

leakage level. Leakage current can range from less than

a hundred milliamps (mA) at rated voltage up to a few

hundred milliamps (mA) at lower voltages. Fuses on the

other hand completely interrupt the current flow when

tripped, and this open circuit results in no leakage current

when subjected to an overload current.

Interrupting Rating:

PTCs are rated for a maximum

short circuit current at rated voltage also known as

"breaking capacity" or Imax. This fault current level is the

maximum current that the device can withstand safely,

keeping in mind that the PTC will not actually interrupt

the current flow (see Leakage Current above). A typical

Littelfuse PTC short circuit rating is 40A; or for the battery

strap PTCs, this value can reach 100A. Fuses do in fact

interrupt the current flow in response to the overload

and the range of interrupting ratings, vary from tens of

amperes (A) up to 10,000 (A) amperes at rated

voltage.

Operating Voltage Rating:

General use

Littelfuse PTCs are not rated above 60V while

fuses are rated up to 600V.

Hold Current Rating:

The hold (operating)

current rating for PTCs can be up to 14A, while

the maximum level for fuses can exceed 30A.

Resistance

:

Reviewing product

specifications indicates that similarly rated

PTCs have about twice (sometimes more) the

resistance of fuses.

Agency Approvals:

Littelfuse PTCs

are Recognized under the Component Program of

Underwriters Laboratories to UL Standard 1434 for

Thermistors. The devices have also been certified under

the CSA Component Acceptance Program.

Time-Current Characteristic

:

Comparing the time-

current curves of PTCs to time-current curves of fuses

show that the speed of response for a PTC is similar to the

time delay of a Littelfuse Slo-Blo® fuse.

Temperature Rerating:

The useful upper limit for a

PTC is generally 85ºC, while the maximum operating

temperature for fuses is 125ºC.

Ambient temperature effects are in addition to the normal

rerating. PTCs hold and trip rating must be rerated when

applied at conditions other than room ambient. For

example, any rise in ambient temperature will decrease the

hold current rating as well as the trip current. A reduction in

ambient temperature will increase the trip current as well

as the hold current.

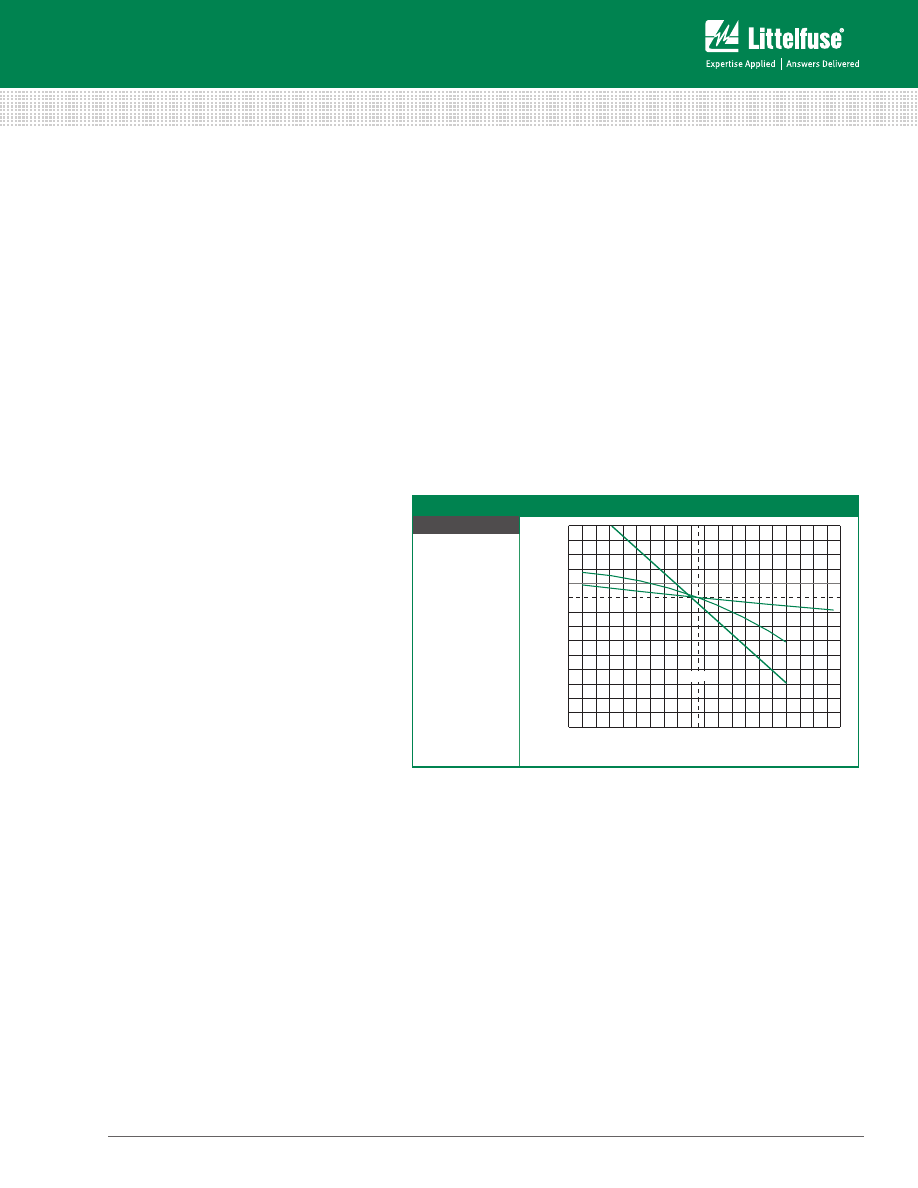

The temperature rerating curves in the table below

compare PTCs to fuses and illustrate that more rerating is

required for a PTC at a given temperature.

Temperature Rerating Curves Comparing PTCs to Fuses

Chart Key

Curve A

Thin-Film Fuses and 313

Series (.010 to .150A)

Curve B

FLAT-PAK

®

, Nano

2®

,

PICO

®

, Blade Terminal,

Special Purpose and

other leaded and

cartridge fuses

(except 313.010 – .150A)

Curve C

Resettable PTCs

-60°C

-76°F

20

40

60

80

100

120

140

-40°C

-40°F

-20°C

-4°F

25°C

C

C

A

B

AMBIENT TEMPERATURE

PERCENT OF RA

TING

A

B

0°C

32°F

20°C

68°F

40°C

104°F

60°C

140°F

80°C

176°F

100°C

212°F

120°C

248°F

PtC Characteristics and terms (continued)

9

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

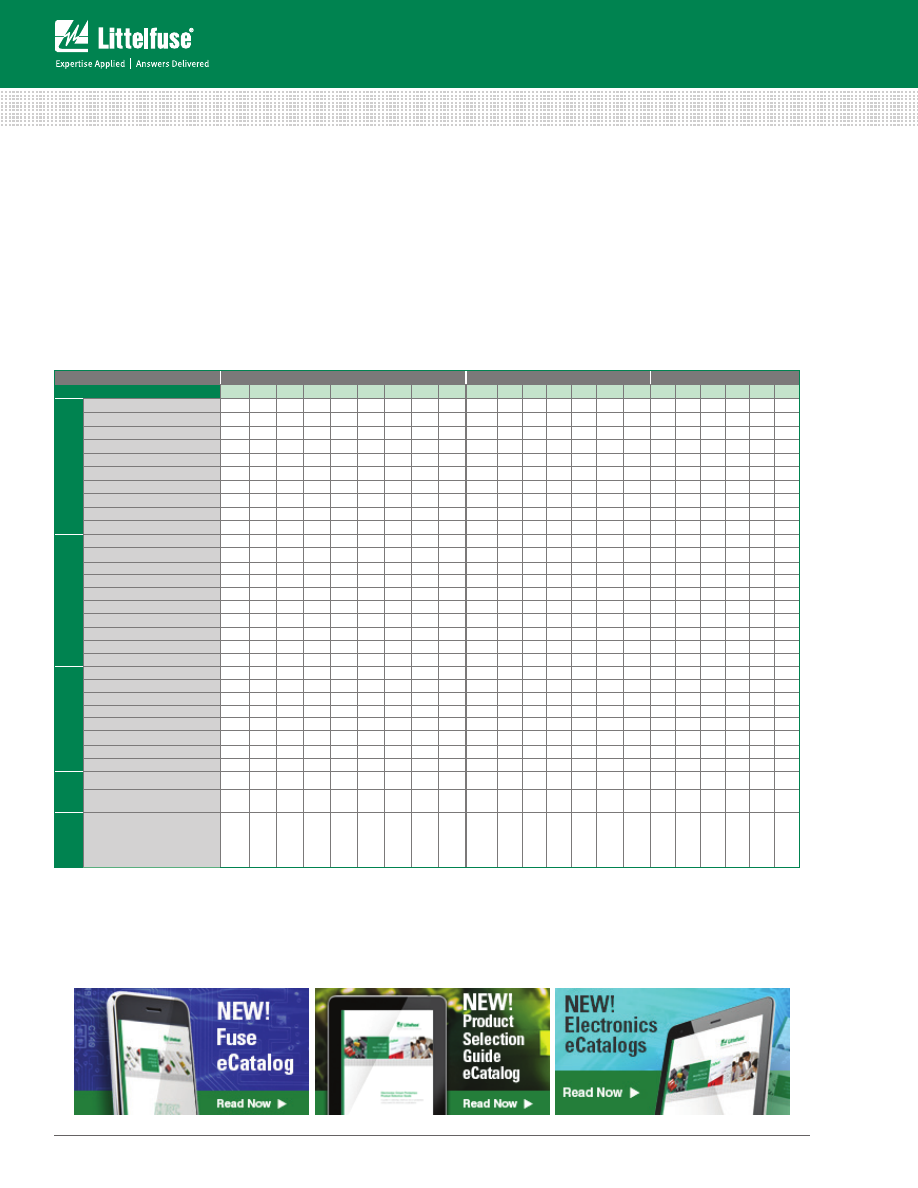

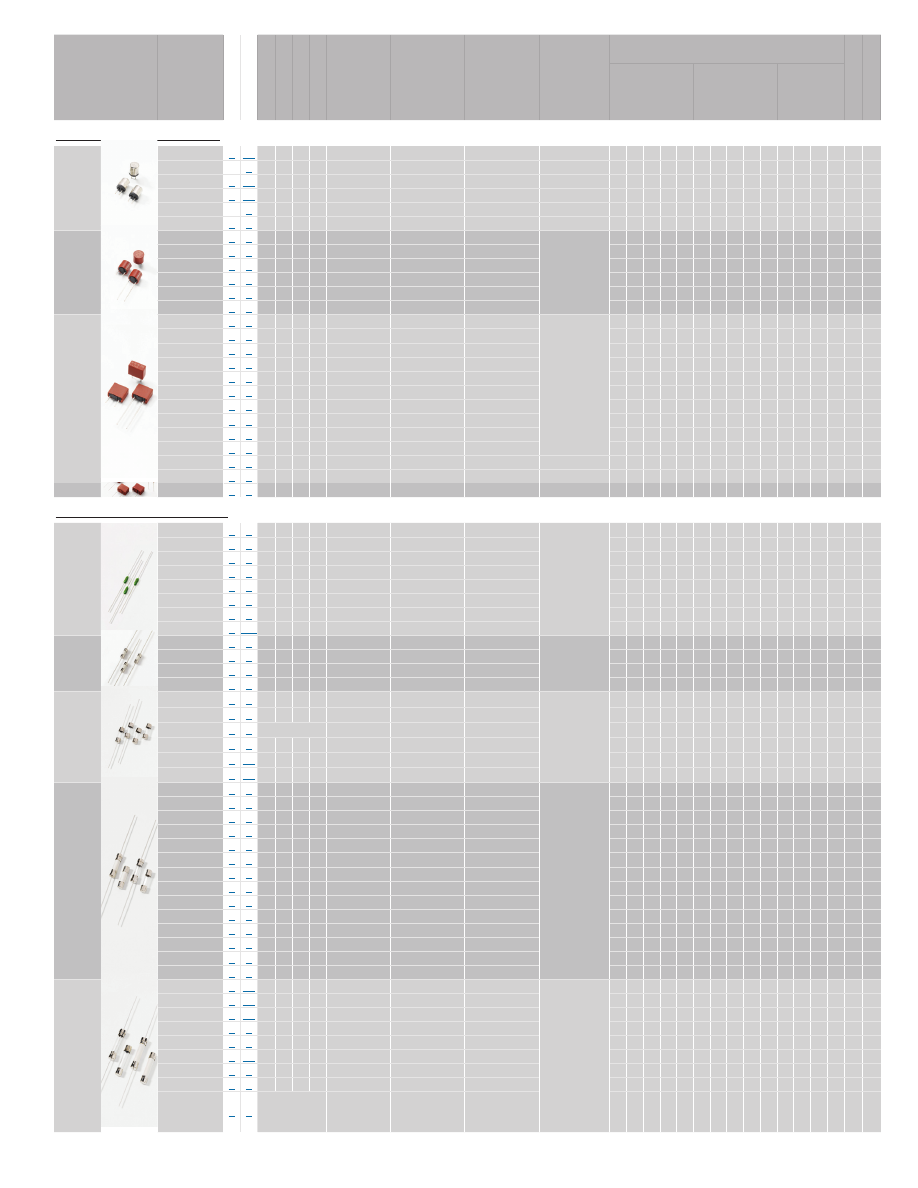

Surface Mount

raDIaL LeaDeD

Battery Strap

Series name

LoRho 0603L 0805L 1206L 1210L 1812L 2016L 2920L 250s usbR

16R

30R

60R

72R

250R 600R

LR

LR

Lt

st

VL

Vt

Telecom

application

ul60950 ,tiA-968-A, gR-1089 Req’s

X

X

X

itu-t Recoomendations

X

X

X

CPe (Customer Premises equipment)

X

X

X

Analog Line Card

X

X

X

t1/e1/J1 And hdsL

X

X

X

isdN

X

X

X

AdsL

X

X

X

Cable telephony

X

X

X

PbX/Kts And Key telephone system

X

X

X

Comput

er

CPu

X

X

X

usb

X

X

X

X

X

X

X

X

ieee1284 Parallel data bus

X

X

X

X

X

ieee 802.3

X

X

X

X

ieee 1394

X

X

X

i/o Ports

X

X

X

X

X

X

X

PC Card

X

X

X

X

X

X

X

X

X

sCsi

X

X

X

X

X

X

Video Port

X

X

X

X

X

X

LCd Monitor

X

X

X

X

X

X

X

X

Consumer

Electr

onics

set top box

X

X

X

X

Loudspeaker

X

smart Card Reader

X

Mobile Phone

X

X

X

X

X

Linear AC/dC Adapter

X

X

X

X

X

X

X

X

X

X

Portable electronic input Port

X

X

X

X

X

X

X

electromagnetic Loads, Motor

X

X

X

X

X

solenoid Protection

X

X

X

X

X

Bat

tery

Lithium Cell

X

X

X

X

X

X

battery Pack

X

X

X

X

X

X

Medical

electr

onic

Voltage / Current input terminal

X

X

Note: the application summary is for reference only. determination of suitability for a specific application is the responsibility of the customer.

PTCs are typically used as circuit protection in applications

where sensitive components are at constant risk of

damage from overcurrent conditions. The ability of PTCs to

reset themselves after exposure to a fault current makes

them ideal within circuits that are not easily accessible to a

user or technician or where constant uptime is required.

Typical applications include port protection on personal

computers (USB, Firewire, keyboard/mouse, and serial

ports), peripherals (hard drives, video cards, and hubs), cell

phone, battery packs, industrial controls, lighting ballast

and motor controls.

The chart below is meant as a quick guide in narrowing to

a Littelfuse PTC device that may be appropriate to certain

end applications.

For detailed application assistance please contact a

Littelfuse product specialist or visit our new reference

design center at

www.littelfuse.com/designcenter

.

For detailed product specifications, please consult the

Littelfuse PTC datasheets within this catalog or visit

www.littelfuse.com/PTCs.

PtC Product Applications

Littelfuse Electronics eCatalogs includes the latest standards, products, diagrams and videos in a new interactive

format. View the eBook on your mobile device, tablet or desktop for easy access to Littelfuse products, technologies

and technical resources. Quickly order free product samples, request more information and download datasheets all

within the new user-friendly design.

10

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

Outside

Wo

rl

d

D+

D -

VBU

Signal

Ground

Shield

Ground

(2) V0402MHS03

1206L150

USB Port

USB Controller

V5.5MLA0603

PTC

Cell Phone

Battery -

Control

Battery +

Signal

Ground

Shield

Ground

Battery Connector

Battery Controller IC

(3) V5.5MLA0402

(Multilayer

Varistor)

PTC

Outside

Wo

rl

d

D+

D -

VBUS

Signal

Ground

Shield

Ground

1206L150

USB Port

USB Controller

V5.5MLA063

(2) PGB1010603

(PulseGuard

®

ESD Suppressor)

PTC

Telco

Tip

Signal

Ground

RJ11 Connector

Tx/Rx Circuits

SMD/leaded

SIDACtor

®

Device

Ring

PTC

600R Series

250R Series

Outside W

orld

TPA+

TPA-

VBU

Signal

Ground

Shield

Ground

1812L110/33

1394 Port

1394 Controller

V33MLA1206

(4) PGB1010603

(PulseGuard

®

ESD Suppressor)

TPB+

TPB-

PTC

Data Pair

Data Pair

Data Pair

Data Pair

Power Source

Equipment

(PSE)

Powered

Device

(PD)

Switch/Hub

Powered End Station

PTC

POWER OVER ETHERNET

LI-ION BATTERY PACK

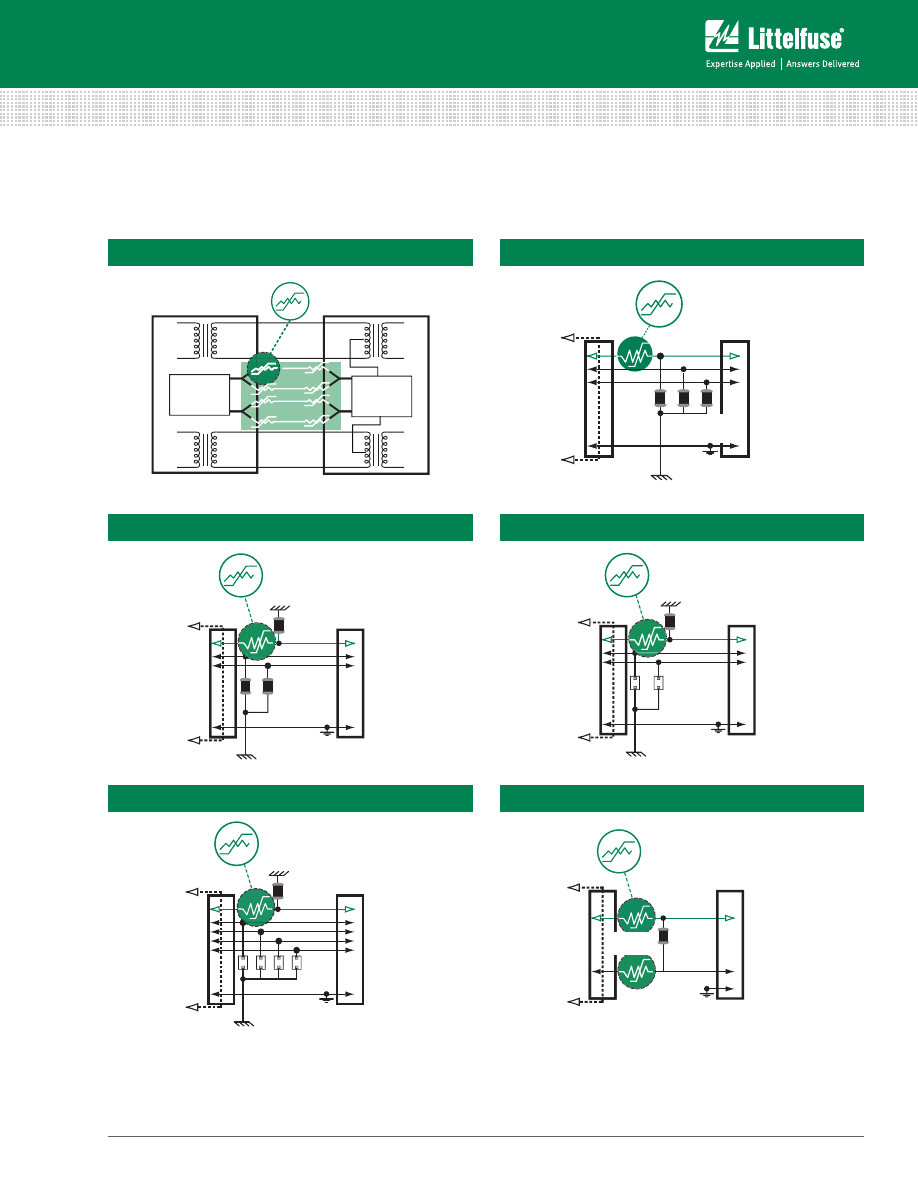

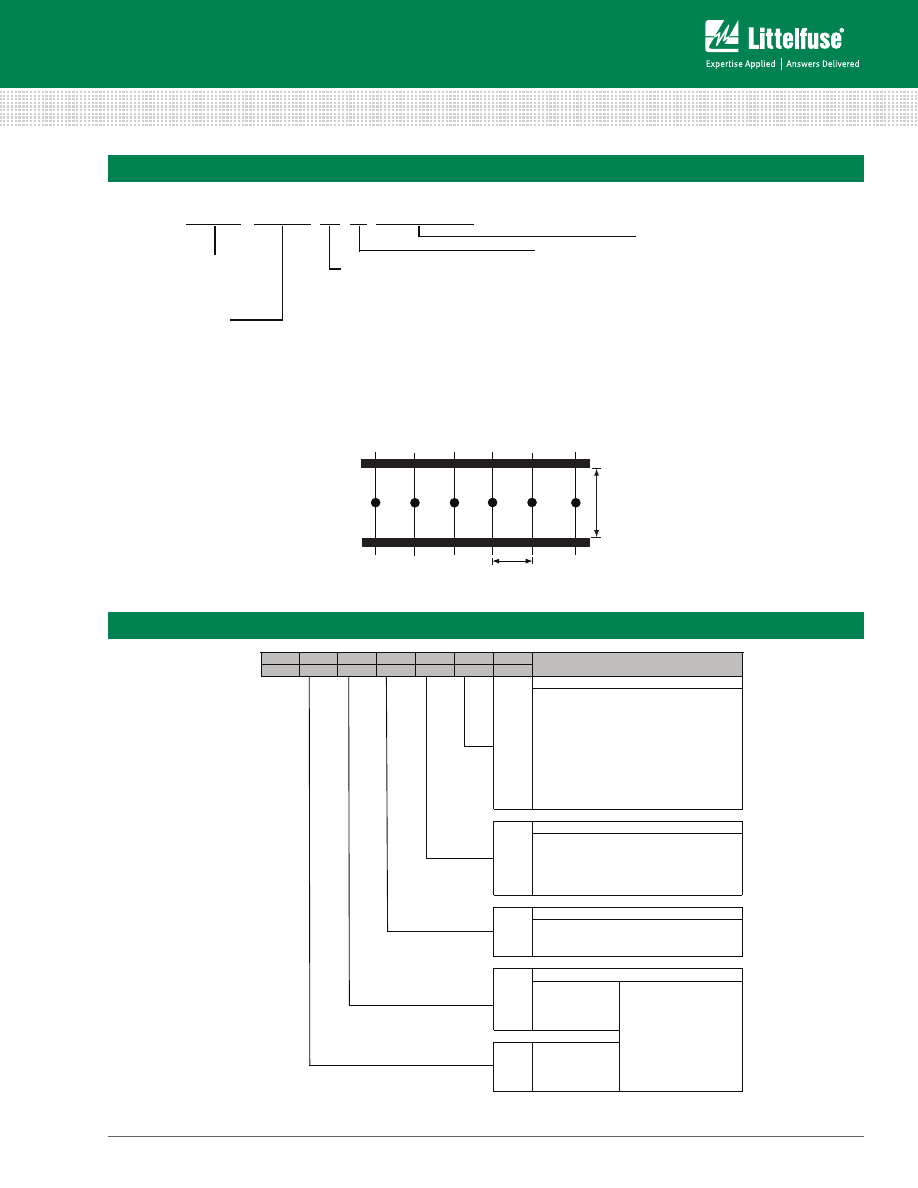

The following are examples of typical circuits using

Littelfuse PTCs in combination with other Littelfuse circuit

protection devices to provide a comprehensive protection

solution. Contact a Littelfuse application expert for design

assistance or visit

www.littelfuse.com/designcenter

or

www.littelfuse.com/PTCs

for additional information.

Be sure to to veryify specifications and test device

performance before use in the end application.

USB 1.1

USB 2.0

IEEE 1394 - FIREWIRE

TIP/RING CIRCUIT - METALLIC

typical PtC Circuit Protection designs

11

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Littelfuse is at your service to help solve your electrical

protection problems. When contacting Littelfuse sales

engineers, please have all the requirements of your

applications available. Requests for quotes or assistance

in designing or selecting special types of circuit protection

components for your particular applications are also

welcome. In the absence of special requirements,

Littelfuse reserves the right to make appropriate changes

in design, process, and manufacturing location without

prior notice.

Fuse ratings and other performance criteria are evaluated

under laboratory conditions and accptance criteria, as

defined in one or more of the various fuse standards. It is

important to understand these standards so that the fuse

can be properly applied to circuit protection applications.

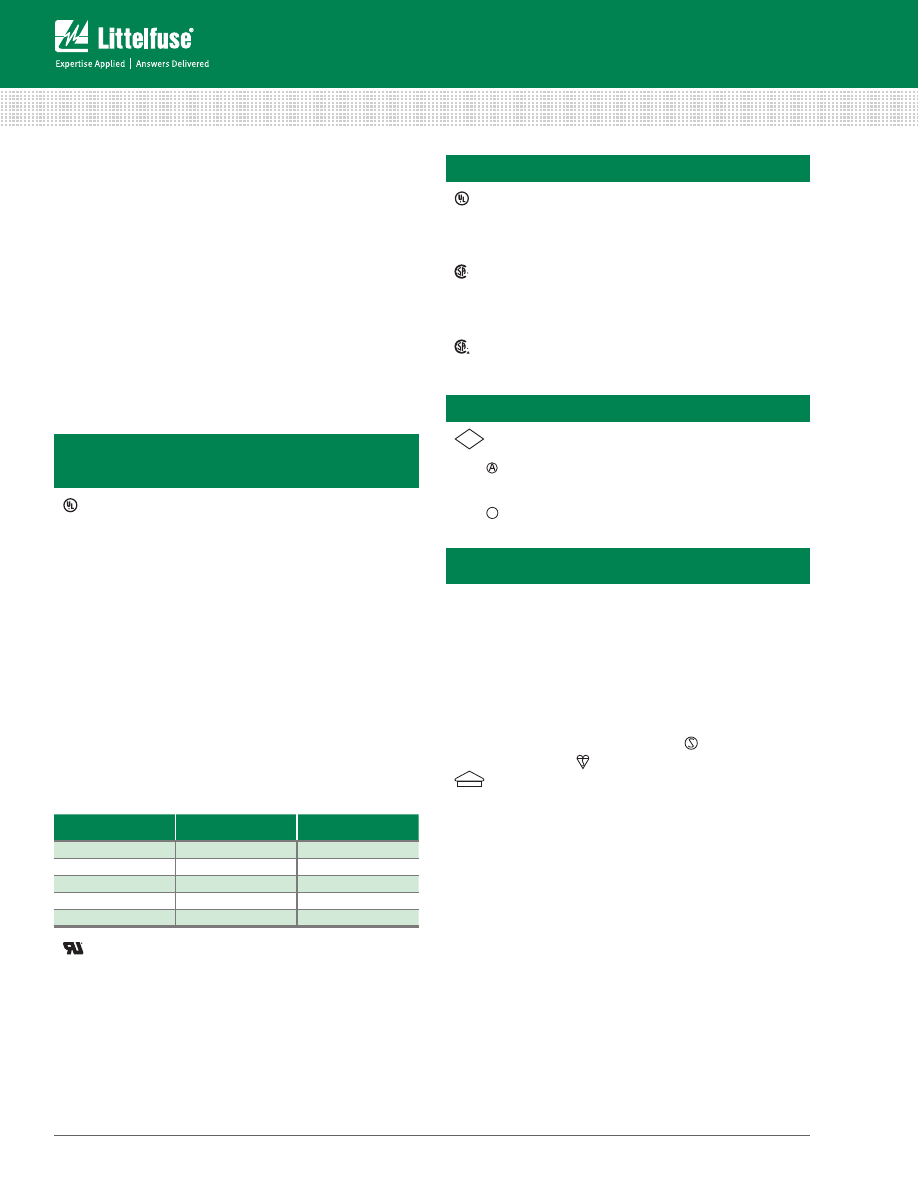

UL/CSA/ANCE (Mexico) 248-14 FUSES FOR

SUPPLEMENTARY OVERCURRENT PROTECTION (600 Volts,

Maximum) (Previously UL 198G and CSA C22.2, No. 59)

UL LISTED

A UL Listed fuse meets all the requirements of the UL/

CSA/ANCE 248-14 Standard. Following are some of the

requirements. UL ampere rating tests are conducted at

100%, 135%, and 200% of rated current. The fuse must

carry 100% of its ampere rating and must stabilize at a

temperature that does not exceed a 75ºC rise.

The fuse must open at 135% of rated current within one

hour. It also must open at 200% of rated current within 2

minutes for 0-30 ampere ratings and 4 minutes for 35-60

ampere ratings.

The interrupting rating of a UL Listed fuse is 10,000

amperes AC minimum at 125 volts. Fuses rated at 250

volts may be listed as interrupting 10,000 amperes at 125

volts and, at least, the minimum values shown below at

250 volts.

Ampere Rating of

Fuse

Interrupting Rating

In Amperes

Voltage Rating

0 to 1

35

250 VAC

1.1 to 3.5

100

250 VAC

3.6 to 10

200

250 VAC

0.1 to 15

750

250 VAC

15.1 to 30

1500

250 VAC

Recognized Under the Component Program of

Underwriters Laboratories

The Recognized Components Program of UL is different

from UL Listing. UL will test a fuse to a specification

requested by the manufacturer. The test points can be

different from the UL Listed requirements if the fuse

has been designed for a specific application. Application

approval is required by UL for fuses recognized under the

Component Program.

standards

UL 275 AUTOMOTIVE GLASS TUBE FUSES (32 Volts)

UL LISTED

UL ampere ratings tests are conducted at 110%, 135%,

and 200%. Interrupting rating tests are not required.

CSA Certification

CSA Certification in Canada is equivalent to UL Listing in

the United States.

The Component Acceptance Program of CSA is

equivalent to the Recognition Program at UL.

METI (Japan Ministry of Economy, Trade and Industry)

PS

E

METI APPROVAL

METI approval in Japan is similar to UL Recognition in the

United States.

METI

B

has its own design standard and characteristics.

INTERNATIONAL ELECTROTECHNICAL

COMMISSION (IEC)

Publication 60127, Parts 1, 2, 3, 4, 6

The IEC organization is different from UL and CSA, since

IEC only writes specifications and does not certify. UL

and CSA write the specifications, and are responsible for

testing and certification.

Certification to IEC specifications are given by such

organizations as SEMKO (Swedish Institute of Testing

and Approvals of Electrical Equipment) , BSI (British

Standards Institute) and VDE (German Standard Insitute)

E

D

V

, as well as UL and CSA.

IEC Publication 60127 defines three breaking capacity

levels (interrupting rating). Low breaking capacity fuses

must pass a test of 35 amperes or ten times rated current,

whichever is greater, while enhanced breaking capacity

fuses must pass a test of 150 amperes and high breaking

capacity fuses must pass a test of 1500 amperes.

60127 Part 2

Sheet 1

— Type F Quick Acting, High Breaking Capacity

Sheet 2

— Type F Quick Acting, Low Breaking Capacity

Sheet 3

— Type T Time Lag, Low Breaking Capacity

Sheet 4

— Style Fuses 1/4×1 1/4

Sheet 5

— Type T Time Lag, High Breaking Capacity

Sheet 6

— Type T Time Lag, Enhanced Breaking Capacity

The letters ‘F’ and ‘T’ represent the time-current

characteristic

of the fast-acting and time delay fuses. One

of these letters will be marked on the end cap of the fuse.

12

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

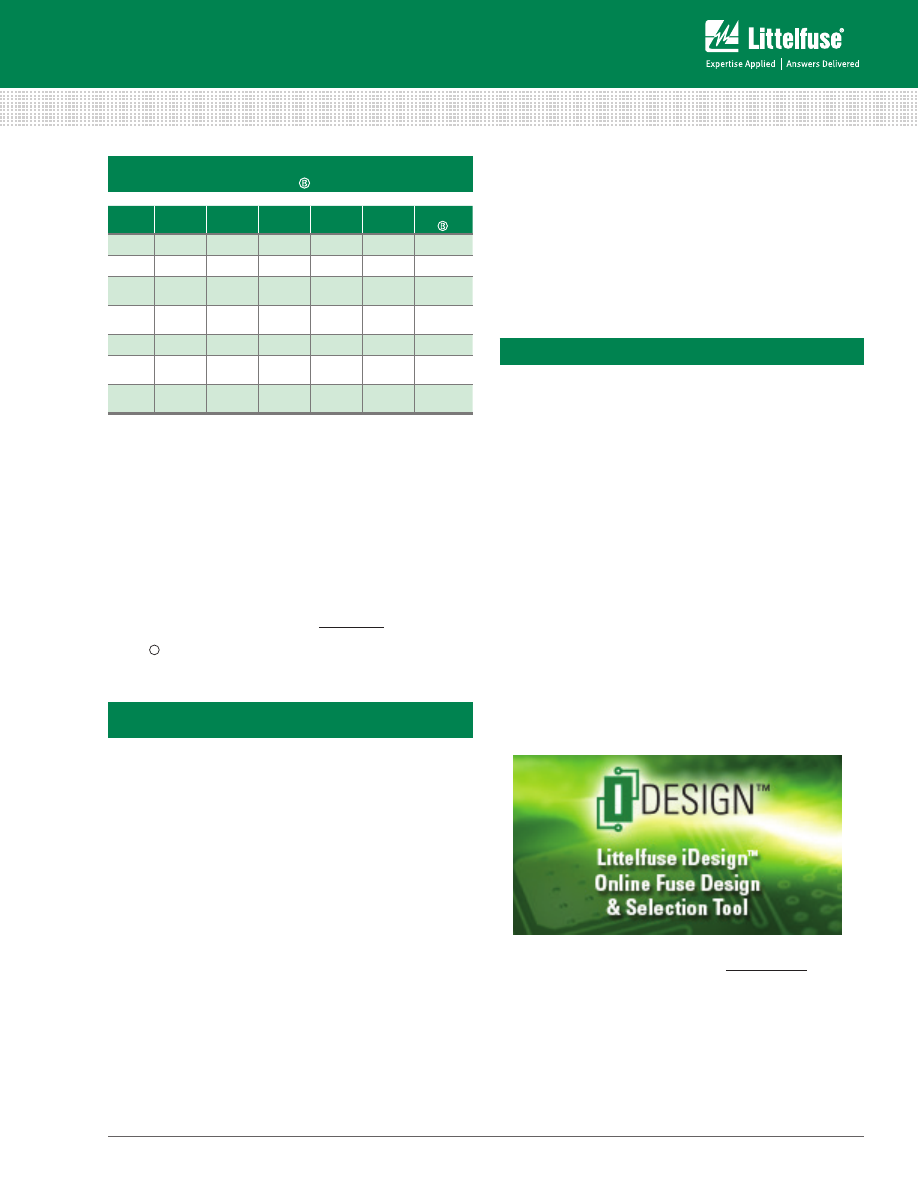

UL/CSA/ANCE (Mexico) 248-14 vs. IEC 60127 Part 2 FUSE

OPENING TIMES vs. METI/MITI

Percent of

Rating

uL & CsA

std 248-14

ieC tYPe F

sheet 1 (*)

ieC tYPe F

sheet 2 (*)

ieC tYPe t

sheet 3 (*)

ieC tYPe t

sheet 5 (*)

Meti/Miti

100

4Hr.Min.

—

—

—

—

130

—

—

—

—

—

1Hr.Min.

135

60 Minutes

Max.

—

—

—

—

150

—

60 Minutes

Min.

60 Minutes

Min.

60 Minutes

Min.

60 Minutes

Min.

160

—

—

—

—

—

1Hr.Max.

200

2 Minutes

Max.

—

—

—

—

2 Minutes

Max.

210

—

30 Minutes

Max.

30 Minutes

Max.

2 Minutes

Max.

30 Minutes

Max.

(*) Note: The IEC Specification is written up to

10.0A. Any components above these ratings are

not recognized by the IEC (although the fuses

may have similar opening characteristics).

IEC also has opening time requirements at 275%, 400%

and 1000%; however, the chart is used to show that

fuses with the same ampere rating made to different

specifications are not interchangeable. According to the

IEC 60127 Standard, a one ampere-rated fuse can be

operated at one ampere. A one ampere-rated fuse made to

UL/CSA/ANCE 248-14 should not be operated at more than

.75 ampere (25% derated — See RERATING section).

METI

B

does not differentiate between fast acting and time

delay characteristics.

Publication IEC 60127-4 (Universal Modular Fuse-Links

[UMF])

This part of IEC 60127-4 covers both PCB through-hole

and surface mount fuses. This standard covers fuses rated

32, 63, 125, and 250 volts. This standard will be accepted

by UL/CSA making it the first global fuse standard. This

specification uses different fusing gates than IEC 60127-2;

the gates used here are 125%, 200%, and 1000%.

The fuses must not open in less than one hour at 125%

of rated current and open within two minutes at 200% of

rated current. The 1000% overload is used to determine

the fuse characteristic. The opening time for each rating is

listed below.

Type FF : Less than 0.001 sec.

Type F : From 0.001 - 0.01 sec.

Type T : From 0.01 - 0.1 sec.

Type TT : From 0.1 - 1.00 sec.

These characteristics correlate to the terminology used in

IEC 60127-1.

Breaking capacity (interrupting rating) varies based on

voltage rating. Parts rated at 32 & 63 volts must pass a

test of 35 amperes or ten times rated current, whichever

is greater. Parts rated at 125 volts must pass a test of 50

amperes or ten times rated current, whichever is greater.

Parts rated at 250 volts are further defined as either low,

intermediate or high breaking. The low breaking capacity

fuses must pass a test of 100 amperes rated current, while

intermediate breaking capacity fuses must pass a test of

500 amperes and high breaking capacity fuses must pass a

test of 1500 amperes.

MILITARY/FEDERAL STANDARDS

MIL-PRF-15160 and MIL-PRF-23419

These specifications govern the construction and

performance of fuses suitable primarily for military

electronic applications.

MIL-PRF-19207

This specification governs the construction and

performance of fuseholders suitable for military

applications.

DSSC Drawing #87108

This drawing governs the construction and performance

of .177” × .570” (2AG size) cartridge fuses and axial lead

versions suitable for military applications. DSSC #87108

designation is included in the fuse end cap marking.

standards (continued)

A robust web-based tool to help circuit designers

identify the optimal electronic fuses for their products.

To use the Littelfuse iDesign tool, simply register to

create a free online account at the iDesign Login.

13

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

MILITARY/FEDERAL STANDARDS

FEDERAL SPECIFICATION W-F-1814

This specification governs the construction and

performance of fuses with high interrupting ratings that are

approved for federal applications. Fuses approved to these

specifications are on the Federal Qualified Products List.

Write to the following agencies for additional information

on standards, approvals, or copies of the specifications.

Underwriters Laboratories Inc. (UL)

333 Pfingsten Road

Northbrook, Illinois, USA 60062-2096

Canadian Standards Association (CSA)

5060 Spectrum Way, Suite 100

Mississauga, Ontario, Canada L4W 5N6

International Electrotechnical Commission (IEC)

3, Rue de Varembe

1211 Geneva 20, Switzerland

Naval Publications and Military StandardsForm

Center (for Military and Federal Standards)

5801 Tabor Avenue

Philadelphia, Pennsylvania, USA 19120

Defense Supply Center Columbus (DSCC)

3990 East Broad Street

Columbus, Ohio, USA 43218-3990

Ministry of Economy Trade and Industry (METI)

1-3-1 Kasumigaseki

Chiyouda-ku, Tokyo 100-8901, Japan

standards (continued)

14

© 2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuseology Selection Guide

1. Define the circuit operating parameters.

Normal operating current in amperes:

....................................................................................................

Normal operating voltage in volts:

....................................................................................................

Maximum interrupt current:

....................................................................................................

Ambient

temperature: ....................................................................................................

Typical overload current:

....................................................................................................

Required opening time at specified overload:

....................................................................................................

Transient pulses expected:

....................................................................................................

Agency

approvals:

....................................................................................................

Mounting type/form factor:

....................................................................................................

Typical resistance (in circuit):

....................................................................................................

2. Select the proper circuit protection component.

(

Refer to Table on Page 3 and specifications with Data Sheets

)

3. Determine the opening time at fault.

Consult the Time-Current (T-C) Curve of each PTC series to determine if the

selected part will operate within the constraints of your application.

If the device opens too soon, the application may experience nuisance

operation. If the device does not open soon enough, the overcurrent may

damage downstream components.

To determine the opening time for the chosen device, locate the overload

current on the X-axis of the appropriate T-C Curve and follow its line up to its

intersection with the curve. At this point read the time tested on the Y-axis.

This is the average opening time for that device.

If your overload current falls to the right of the curve the device will open.

If the overload current is to the left of the curve, the device will not operate.

4. Verify ambient operating parameters.

Ensure that the application voltage is less than or equal to the device’s rated

voltage and that the operating temperature limits are within those specified

by the device.

5. Verify the device’s dimensions.

Compare the maximum dimensions of the device to the space available in

the application. The dimension of each product is included within each data

sheets on the following pages.

6. Test the selected product in an actual application.

PtC selection Worksheet

A robust web-based tool to help circuit designers

identify the optimal electronic fuses for their products.

Littelfuse iDesign

TM

Online Fuse Design and Selection Tool

15

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

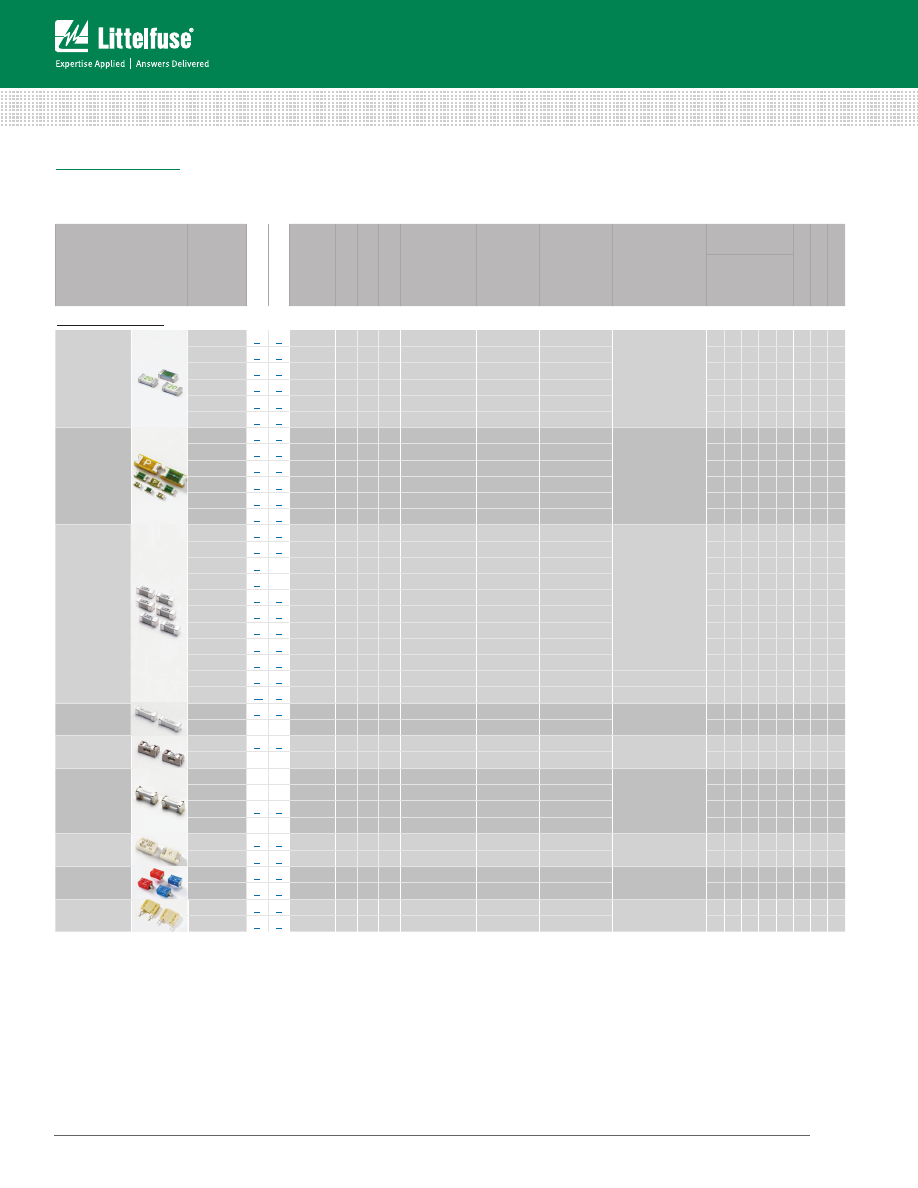

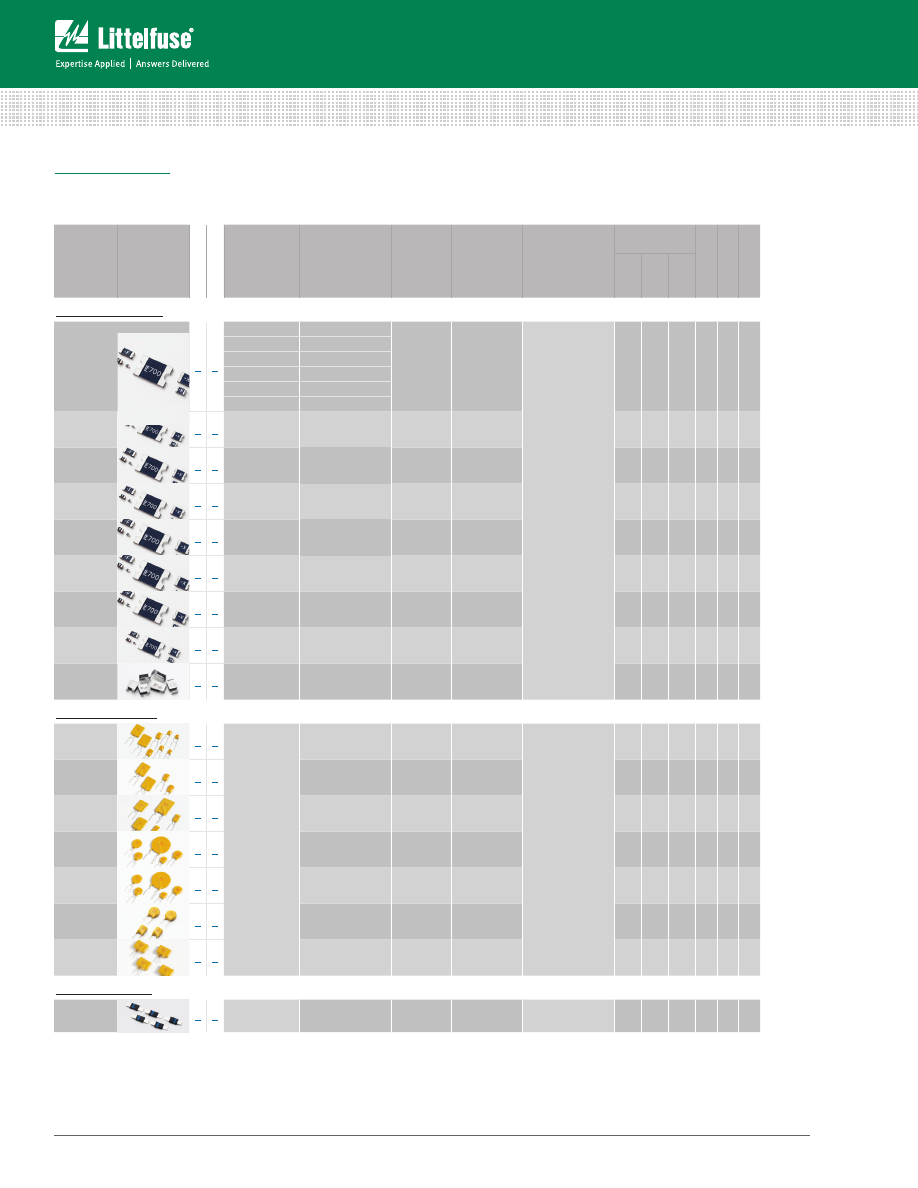

Fuse and PtC Products selection guide

Fuse PRoduCts

Fuses provide protection by completely stopping the flow of energy to sensitive circuits. If current exceeds the fuse’s operating range, the metal

wire or strip melts safely within an enclosure. Littelfuse offers the most extensive range of fuses available, and for easy replacement of cartridge

fuses Littelfuse offers a wide selection of fuseholders including panel mount, in-line, and surface and thru-hole circuit board mount devices.

Series

Name

1

Vie

w Dat

asheet

Order Samples

Size

2

Time Lag

Fast A

cting

Ver

y

Fast A

cting

Device Range

3

(Operating

Current Options

in Amps)

Max. Voltage

Rating

3

(Volts)

Interrupting

Rating at

Max. Voltage

Rating

3

(Amps)

Operating

Temperature

Range

Agency

Approvals

3

Halogen F

ree

R

oHS Compliant

Lead F

ree

UL

UR

C

SA

PSE

UMF

Surface Mount:

Ceramic Chip

437

•

•

1206

•

0.25 - 8

125 / 63 / 32

50

-55°C to +150°C

•

• • •

438

•

•

0603

•

0.25 - 6

32 / 24

50

•

• • •

440

•

•

1206

•

1.75 - 8

32

50

• •

• • •

441

•

•

0603

•

2 - 6

32

50

• •

• • •

469

•

•

1206

•

1 - 8

24 / 32

24 - 63

• •

• • •

501

•

•

1206

•

10, 12, 15, 20

32

150

•

• • •

Thin Film

466

•

•

1206

•

0.125 - 5

125 / 63 / 32

50

-55°C to +90°C

• •

• •

429

•

•

1206

•

7

24

35

• •

• •

468

•

•

1206

•

0.5 - 3

63 / 32

35 - 50

• •

• • •

467

•

•

0603

•

0.25 - 5

32

35 - 50

• •

• • •

494

•

•

0603

•

0.25 - 5

32

35 - 50

• •

• • •

435

•

•

0402

•

0.25 - 5

32

35

• •

• • •

Nano

2®

Fuse

448

•

•

2410

•

0.062 - 15

125 / 65

35 - 50

-55°C to +125°C

• • •

• •

449

•

•

2410

•

0.375 - 5

125

50

• • •

• •

451 / 453

•

2410

•

0.062 - 15

125 / 65

35 - 50

• • • •

• •

452 / 454

•

2410

•

0.375 - 12

125 / 72

50

• • •

• •

456

•

•

4012

•

20, 25, 30, 40

125

100

•

• •

458

•

•

1206

•

1.0 - 10

75 / 63

50

•

• •

443

•

•

4012

•

0.5 - 5

250

50

•

• •

464

•

•

4818

•

0.5 - 6.3

250

100

• • • •

465

•

•

4818

•

1 - 6.3

250

100

• • • •

462

•

•

4118

•

0.500 - 5

350

100

-40°C to +80°C

•

•

•

485

•

•

4818

•

0.500 - 3.15

600

100

-55°C to +125°C

•

• •

Telelink

®

Fuse

461

•

•

4012

0.5 - 2.0

600

60

-55°C to +125°C

• •

• •

461E

4012

1.25

600

60

•

• •

OMNI-BLOK

®

Fuseholder

154

•

•

*

•

0.062 - 10.0

125

35 - 50

-55°C to +125°C

•

• •

154T

*

•

0.375 - 5

125

50

•

• •

Fuse and Clip

Assemblies

157

*

•

0.062 - 10

125

35 - 50

-55°C to +125°C

•

• •

157T

*

•

0.375 - 5

125

50

•

• •

159

•

•

*

0.5 - 2

600

60

•

• •

160

*

•

0.5 - 5

250

50

•

• •

PICO

®

SMF

Fuse

459

•

•

*

•

0.062 - 5

125

50 - 300

-55°C to +125°C

• •

460

•

•

*

•

0.5 - 5

125

50

• •

Flat Pak

202

•

•

*

•

0.062 - 5

250

50

-55°C to +125°C

• •

203

•

•

*

•

0.25 - 5

250

50

• •

EBF

446

•

•

*

•

2.0 - 10.0

350

100

-40°C to +125°C

• •

447

•

•

*

•

2.0 - 10.0

350

100

• •

tAbLe CoNtiNues oN NeXt PAge

(1) Detailed information about most product series listed here can be found on our web site.

(2) Size for these surface mount items refers to common industry length and width dimensions of the device surface area. Example: 0402 = .04” x .02”

(3) In some cases for these categories the ratings, agency approvals and specifications vary by part number and are presented here as ranges representing the whole series.

Please refer to product data on www.littelfuse.com and in our data sheets for detailed information by part number.

* Please refer to data sheet for detailed specifications.

16

Series

Name

1

View Datasheet

Order Samples

Time Lag

Medium Acting

Fast Acting

Very Fast Acting

Device

Range

3

(Operating

Current

Options in

Amps)

Max. Voltage

Rating

3

(Volts)

Interrupting

Rating at

Max Voltage

Rating

3

(Amps)

Operating

Temperature

Range

Agency Approvals

3

RoHS Compliant

Lead Free

Americas

Europe

Asia

UL

UR

CSA

QPL

UMF

CE

VDE

TUV

BSI

Semko

PSE

K

CCC

CQC

Radial Leaded / Socket:

Micro

™

Fuse /

TR3 Fuse

262/268

• ••

•

0.002 - 5

125

10,000

-55°C to +125°C

• •

•

269

•

•

0.002 - 5

125

10,000

-55°C to +125°C

• • •

•

272/278

• ••

•

0.002 - 5

125

10,000

-55°C to +125°C

• •

•

273/279

• ••

•

0.002 - 5

125

10,000

-55°C to +85°C

• •

•

274

•

•

0.002 - 5

125

10,000

-55°C to +85°C

•

•

303

• •

•

0.5 - 5

125

50

-55°C to +70°C •

•

•

• •

TR5

®

Fuse

370

• •

•

0.4 - 6.3

250

35 - 50

-40°C to +85°C

•

• •

• •

•

• •

372

• •

•

0.4 - 6.3

250

35 - 50

•

• •

• • • • • • •

373

• •

•

0.5 - 10

250

50

•

•

•

• •

374

• •

•

0.5 - 10

250

50

•

•

•

• •

382

• •

•

1 - 10

250

100

•

• •

• • • • • • •

383

• •

•

1 - 10

300

50 - 100

•

• •

•

• •

TE5

369

• •

•

1 - 6.3

300

50

-40°C to +85°C

•

•

•

• •

385

• •

•

0.35 - 1.5

125

50

•

•

• •

391

• •

•

0.125 - 4

65

50

•

•

• •

392

• •

•

0.8 - 6.3

250

25 - 63

•

• •

• • •

• • •

395

• •

•

0.05 - 6.3

125

100

•

•

•

•

396

• •

•

0.05 - 6.3

125

100

•

•

•

• •

397

• •

•

0.35 - 1.5

125

50

•

•

• •

398

• •

•

0.125 - 4

65

50

•

•

• •

399

• •

•

0.125 - 4

65

50

•

•

• •

400

• •

•

0.5 - 6.3

250

130

•

• •

•

• •

804

• •

•

0.8 - 6.3

250

150

-40°C to +125°C

• • •

• •

• • •

808

• •

•

2 - 5

250

100

-40°C to +85°C

•

•

• •

TE7

807

• •

•

0.8 - 6.3

300

100

-40°C to +125°C • • •

•

• •

• •

Axial Leaded / Cartridge:

PICO

®

Fuse /

PICO

®

II

Fuse Axial

251

• •

•

0.062 - 15

125

300DC / 50AC

-55°C to +125°C

• •

•

•

•

•

253

• •

•

0.062 - 15

125

300DC / 50AC

•

•

•

•

•

275

• •

•

20 - 30

32

300DC / 50AC

• •

•

263

• •

•

0.062 - 5

250

50

• •

•

•

•

471

• •

•

0.5 - 5

125

50

• •

•

•

•

472

• •

•

0.5 - 5

125

50

•

•

•

473

• •

•

0.375 - 7

125

50

• •

•

•

•

265/266/267

• •••

•

0.062 - 15

125

300DC / 50AC

• • •

•

•

3.6x10 mm

874

• •

•

0.1 - 10

250

50

-55°C to +125°C

•

•

• •

875

• •

•

0.1 - 10

250

50

•

•

• •

876

• •

•

0.125 - 5

250

35 - 50

•

• •

• •

877

• •

•

2 - 6.3

250

35 - 63

•

• •

• •

4.5x14.5

mm

(2AG)

208

• •

•

0.125 - 10

350

100

-55°C to +125°C

•

•

•

•

• •

209

• •

•

0.25 - 7

350

100

•

•

•

•

• •

220

• •

Special Fuse

0.3 - 7

250 / 300 / 350

35 - 100

• • •

•

•

• •

2205

• •

•

0.25 - 2.5

250

35

• •

•

• •

224/225

• ••

•

0.375 - 10

250 / 125

35 - 500

• • •

•

•

• •

229/230

• ••

•

0.25 - 7

250 / 125

35 - 400

• • •

•

•

• •

5x20

mm

217

• •

•

0.032 - 15

250

35 - 150

-55°C to +125°C

• •

• •

• • • • •

• •

218

• •

•

0.032 - 16

250

35 - 100

• •

• •

• • • • •

• •

213

• •

•

0.2 - 6.3

250

35 - 63

• •

• •

• • •

•

• •

219XA

• •

•

0.04 - 6.3

250

150

• •

• •

• • •

•

• •

216

• •

•

0.05 - 16

250

750 - 1500

• •

• •

• • • • •

• •

215

• •

•

0.125 - 20

250

400 / 1500

• •

• •

• • • • •

• •

232

• •

•

1 - 10

250 / 125

300 / 10,000

•

• •

• •

235

• •

•

0.1 - 7

250 / 125

35 - 10,000

•

•

•

• •

• •

233

• •

•

1 - 10

125

10,000

•

•

•

• •

• •

234

• •

•

1 - 10

250

100 - 200

•

•

•

• •

• •

239

• •

•

0.08 - 7

250 / 125

35 - 10,000

•

•

•

• •

• •

285

• •

•

0.125 - 20

250

400 - 1500

•

•

• •

477

• •

•

0.5 - 16

400DC / 500AC

100 - 1500

• •

•

• •

• •

977

• •

•

0.5 - 16

450DC / 500AC

200 / 100

•

• •

• •

6.3x32 mm

(3AG/3AB)

312/318

• ••

•

0.062 - 35

250 / 32

35 - 300

-55°C to +125°C

• • •

•

• •

• •

313/315

• ••

•

0.01 - 30

250 / 125 / 32

35 - 300

• • •

•

• •

• •

314/324

• ••

•

0.375 - 40

250

35 - 1000

• • •

•

• •

• •

322

• •

•

12 - 30

65

200 - 1000

•

•

•

•

332

• •

•

1- 10

250

100 / 200

• •

•

•

• •

325/326

• ••

•

0.01 - 30

250

100 - 600

• • •

•

• •

• •

505

• •

•

10 - 30

450 / 500

20,000 - 50,000

• •

•

• •

506

• •

•

15 - 20

600DC

10,000

• •

•

• •

508

• •

1000VAC / DC

High Voltage

Fuse

0.315 - 1

1000

10,000

• •

•

• •

Fuseology Selection Guide

©

2014 Littelfuse • Fuseology Selection Guide

www.littelfuse.com

Fuse and PtC Products selection guide (continued)

PtC PRoduCts

PTCs (positive temperature coefficient) increase resistance as temperature increases. They are designed to prevent unsafe levels of current

while allowing constant safe current levels, and their resistance will “reset” automatically when the current and temperature returns to a

safe level. PTCs are typically used in applications where automatic reset is desired.

Series Name

1

Vie

w Dat

asheet

Order Samples

Size

2

Hold Current (I

HOLD

)

Max Voltage

(V

MAX

)

Max Fault

current (I

MAX

)

Operating

Temperature

Range

Agency Approvals

Halogen Free

RoHS