Fenghua Advanced Technology (holding) Co., Ltd

- 1 -

LOW-OHMIC THICK FILM CHIP FIXED RESISTOR

■

Features

●

Resistance Values from 0.5 to 1000m ohms

●

Lowest TCR is

±

50

PPM/

℃

●

Suit for re-flow and wave flow soldering

●

Stable electrical capability, high reliability

●

Low assembly cost, suit for automatic SMT

equipment

●

Superior mechanical and frequency

characteristics

●

Compliant with RoHS Directive

■

Applications

Switching Power Supply

、

Over Current Protection in Audio Application

、

Voltage Regulation Module(VRM)

、

DC-DC Converter

、

Charger

、

Automotive Engine Control

、

Portable Devices etc.

■

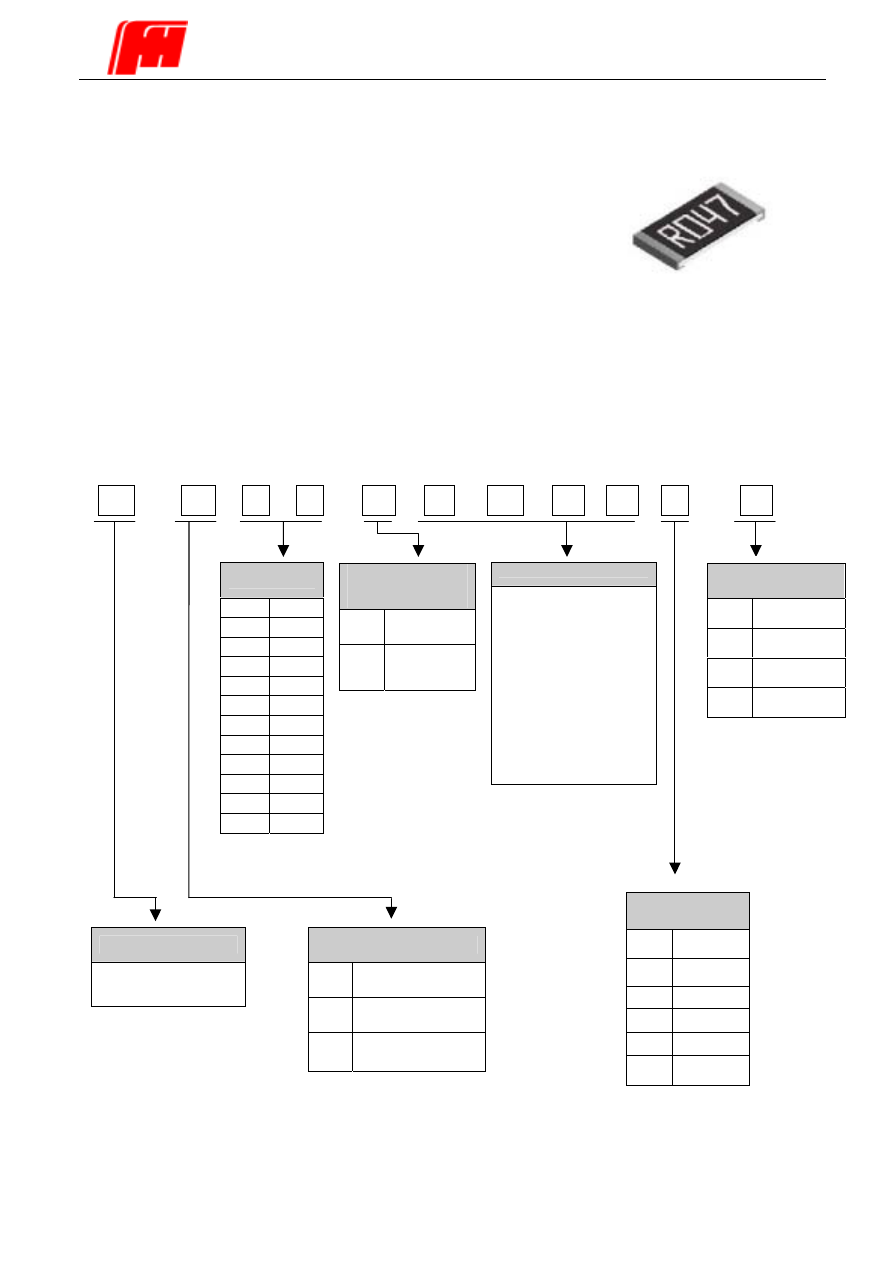

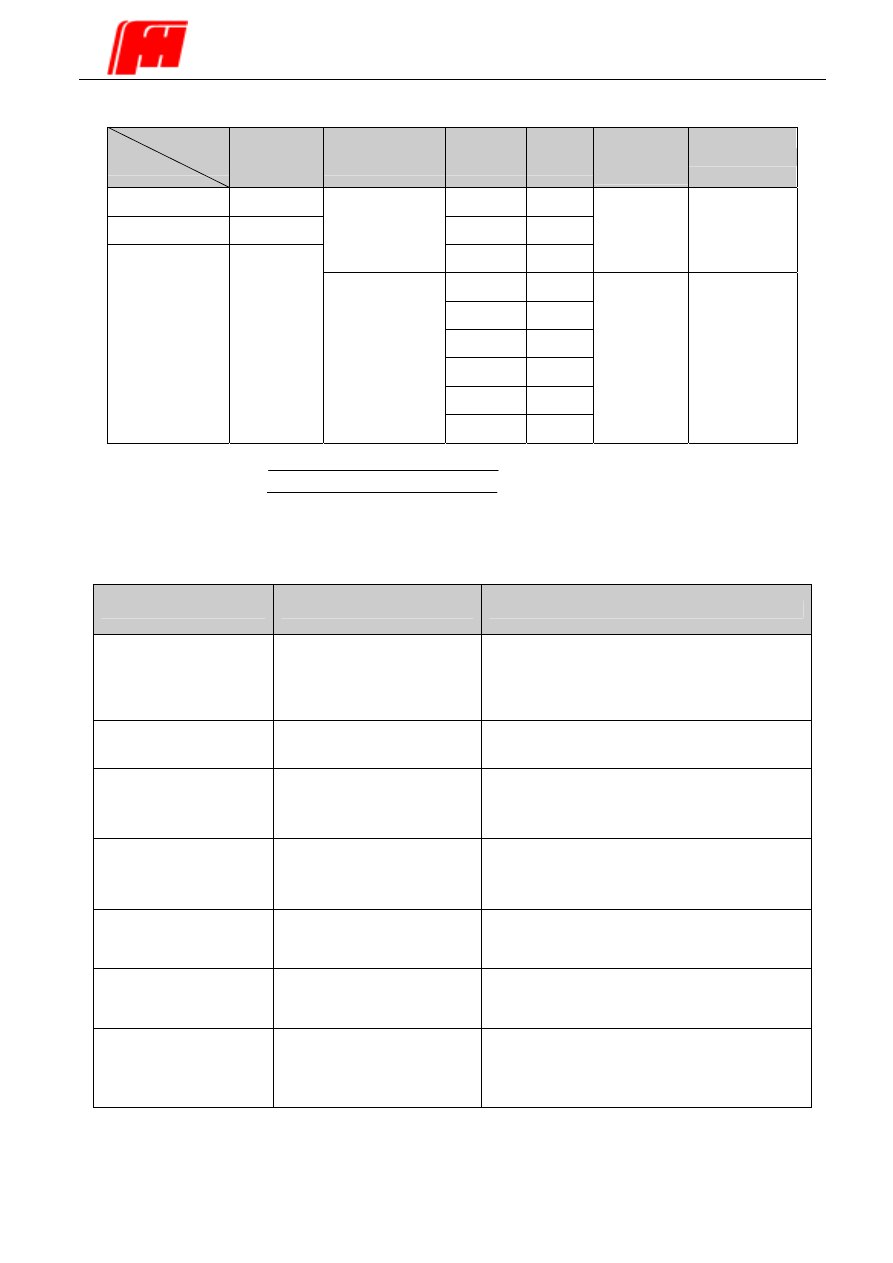

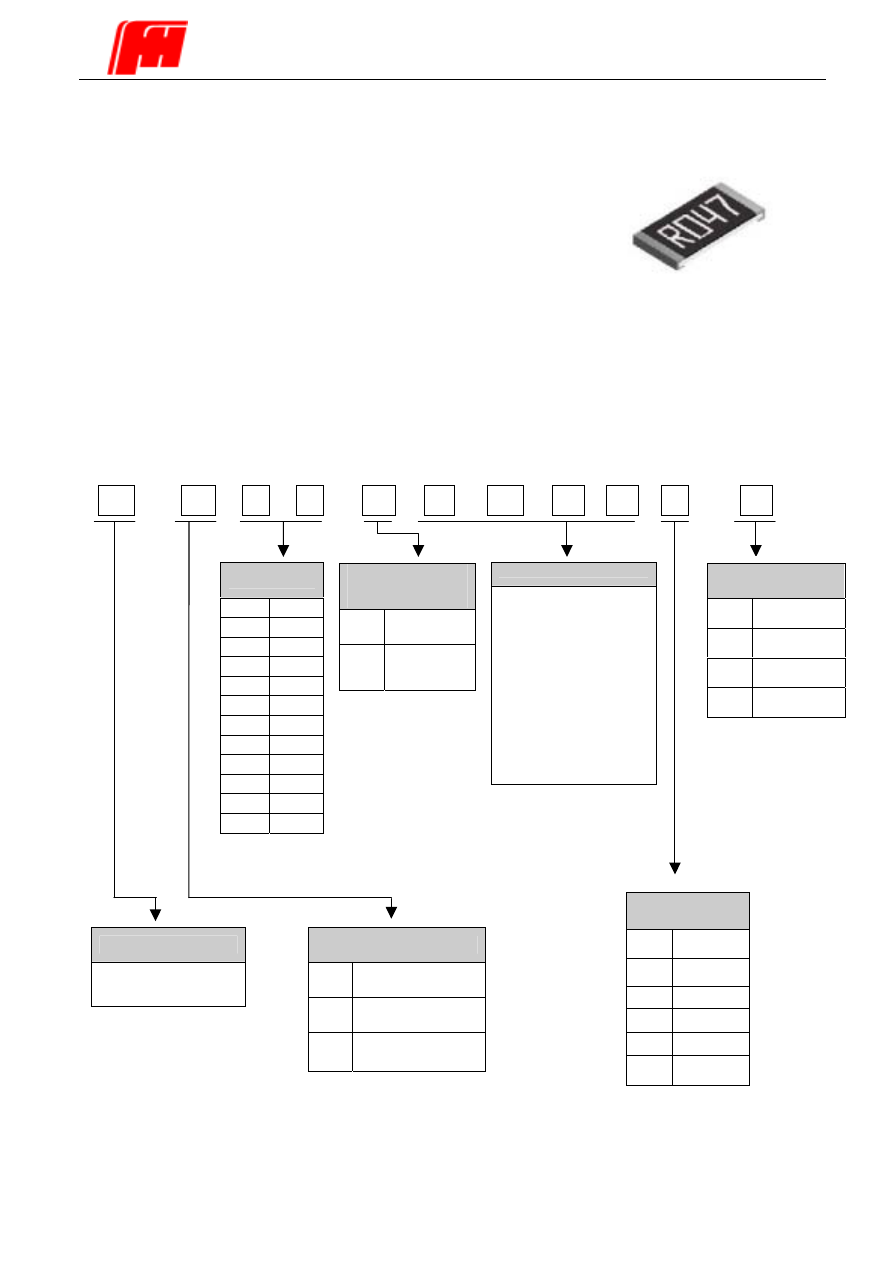

Type Designation

R

C 0

3

M

R

0 4

7

F

T

Product Code

Thick film chip fixed

resistor

Resistance

Temperature

Coefficient Code

Code

T.C.R

M

±

50

~

±

600PPM/

℃

Type Code

Code Type

02 0402

03 0603

05 0805

06 1206

1210 1210

1812 1812

10 2010

12 2512

1225 1225

3720 3720

7520 7520

Resistance Value Code

The precision of resistance

above m

Ω

:decimal point

should be expressed by

“

R

”

;

“

Ω

”

as the unit.

The precision of resistance

below m

Ω

:Decimal point

should be expressed by

“

M

”

;

“

m

Ω

”

as the unit.

Example

:

R220=0.22

Ω

(220m

Ω

)

R047=0.047

Ω

(47m

Ω

)

R005=0.001

Ω

(1m

Ω

)

M500=0.50m

Ω

2M50=2.50m

Ω

Resistance

Tolerance

Code

Code

Tolerance

F

±

1%

G

±

2%

H

±

3%

J

±

5%

K

±

10%

Packing Style Code

Code

Packing Style

T

Tape & Reel

B

Bulk Case

C

Case

Power Rating

Series Code

Code

Power rating

series

C

Normal Power Series

S

Upgraded Power

Series

Fenghua Advanced Technology (holding) Co., Ltd

- 2 -

■

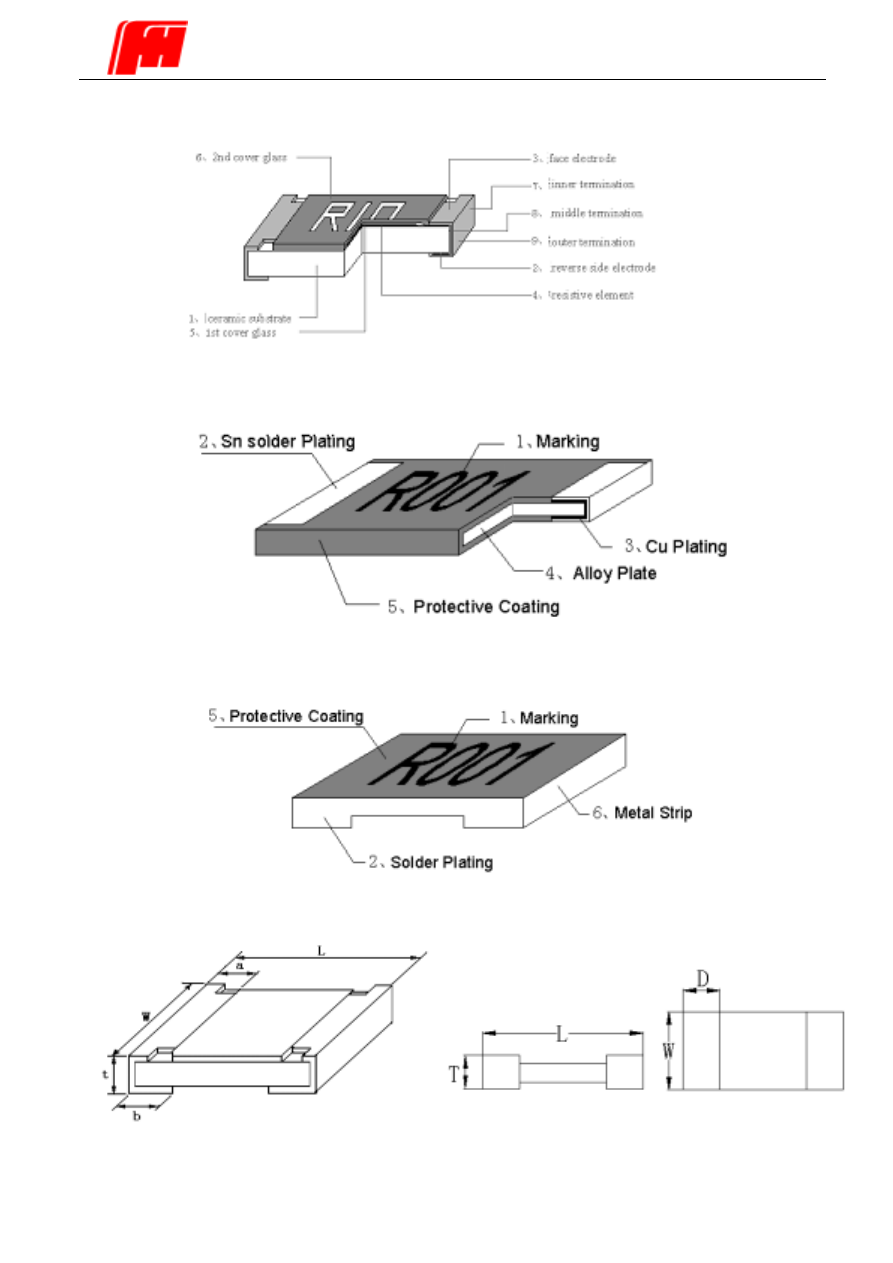

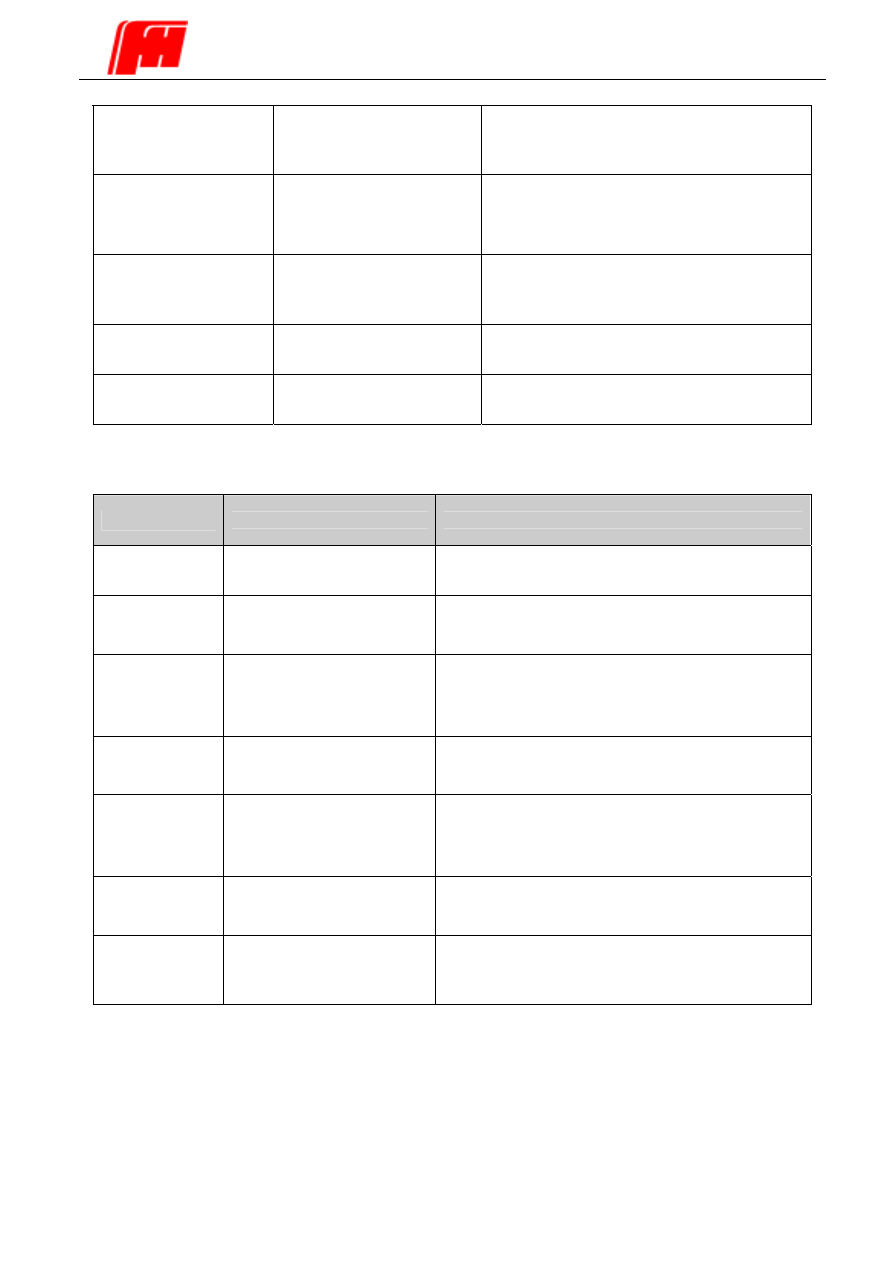

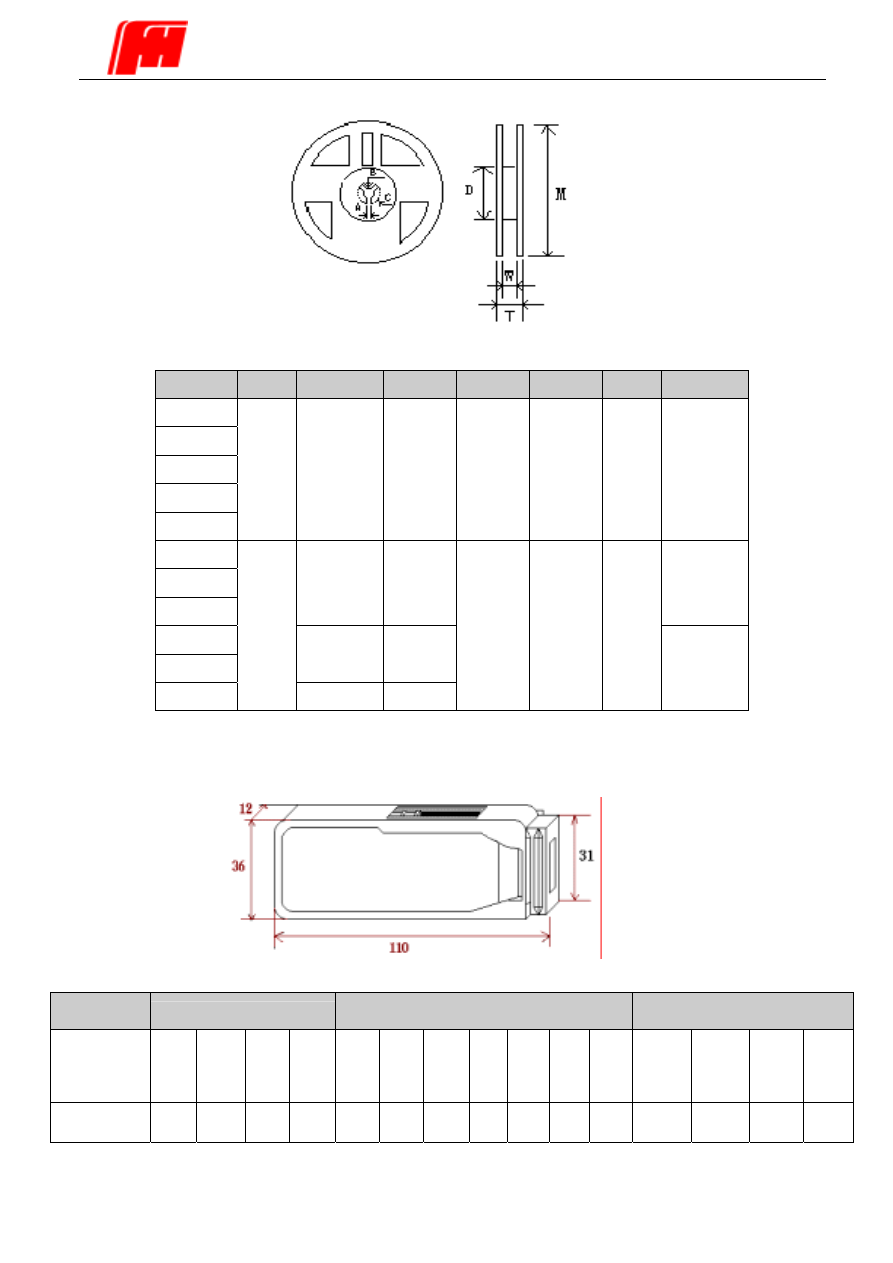

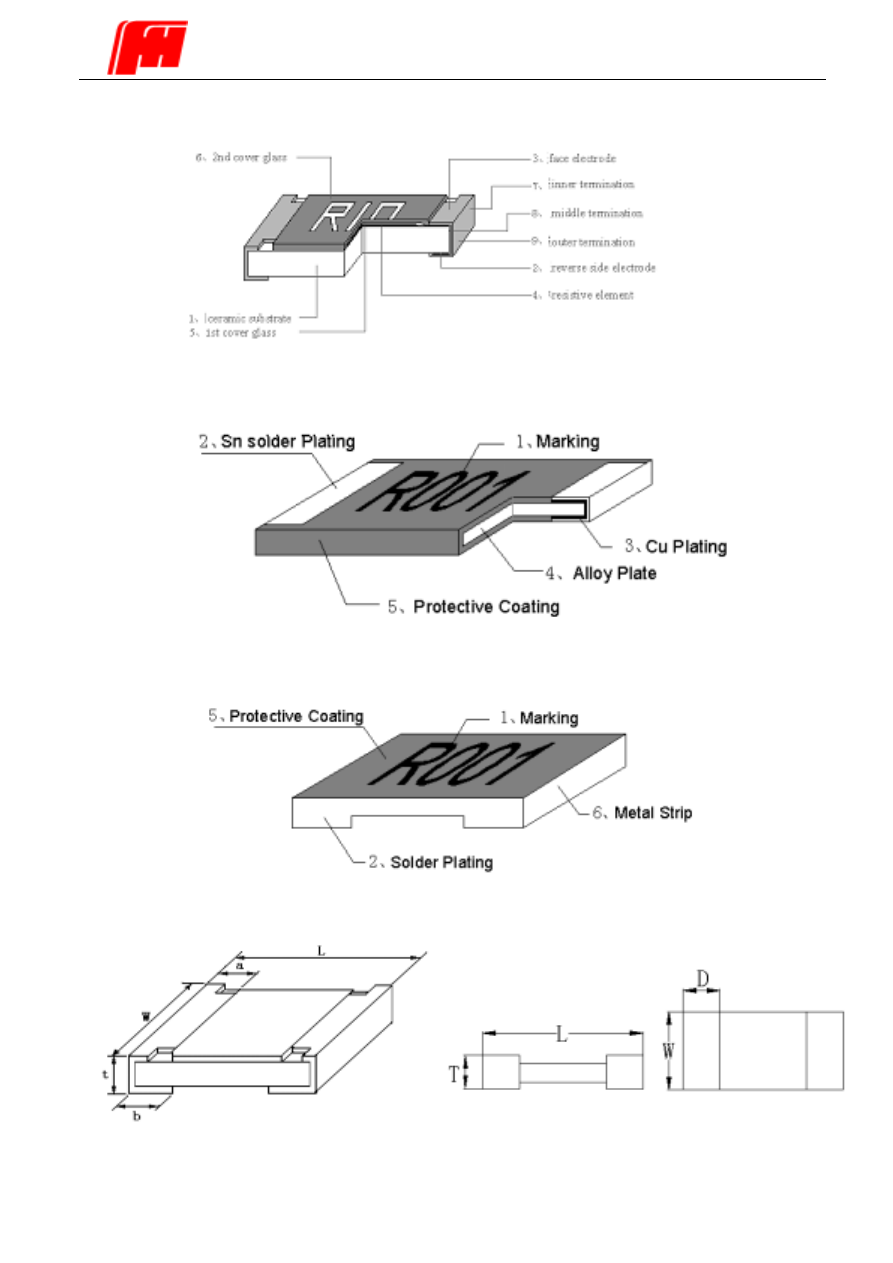

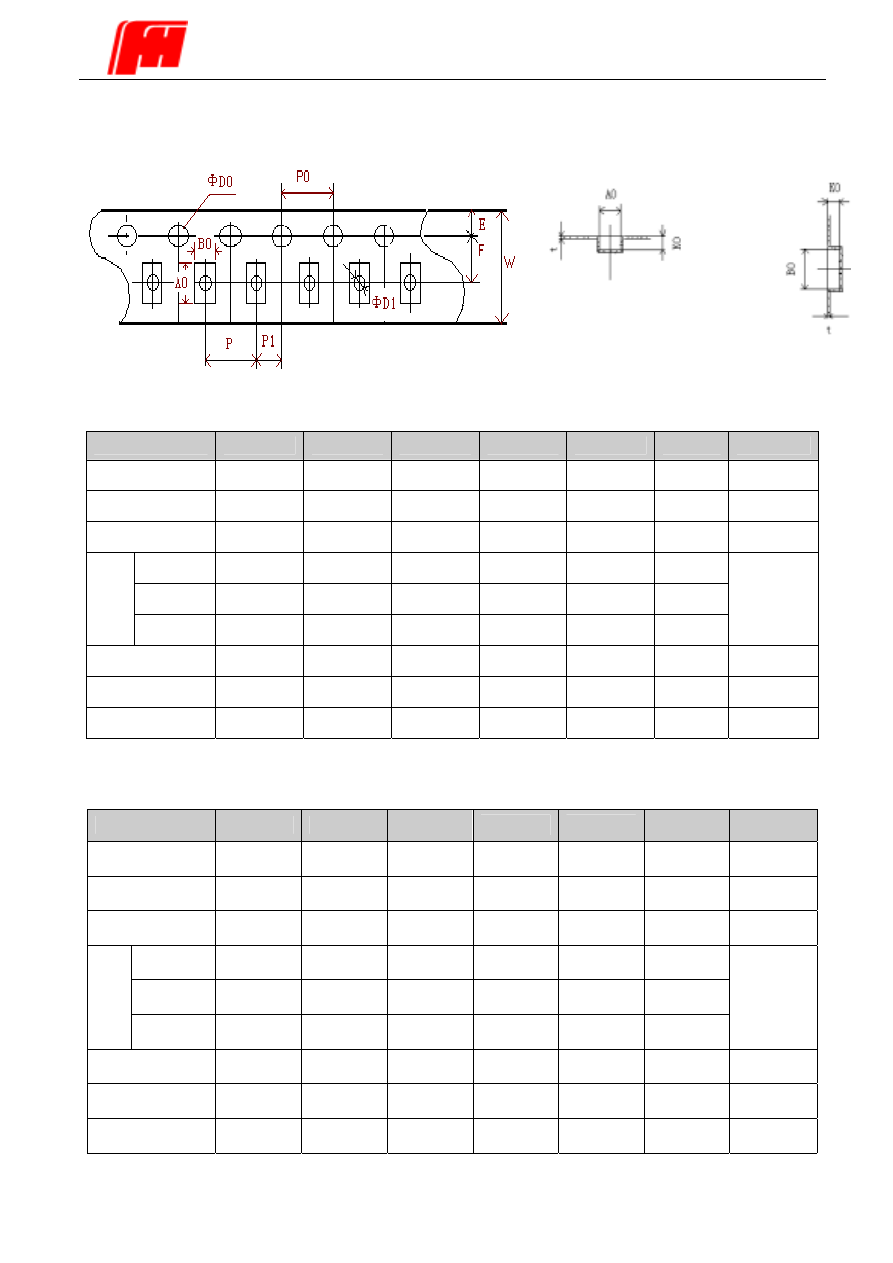

Construction and dimension

Fig1: Part Figure for Construction 1

Fig2:

Part Figure for Construction 2

Fig3:

Part Figure for Construction 3

:Ω

Decimal point should be expressed by “R”

;

Fig4:

Dimension Figure for Construction 1

Fig5:

Dimension Figure for Construction 2

、

3

Fenghua Advanced Technology (holding) Co., Ltd

- 3 -

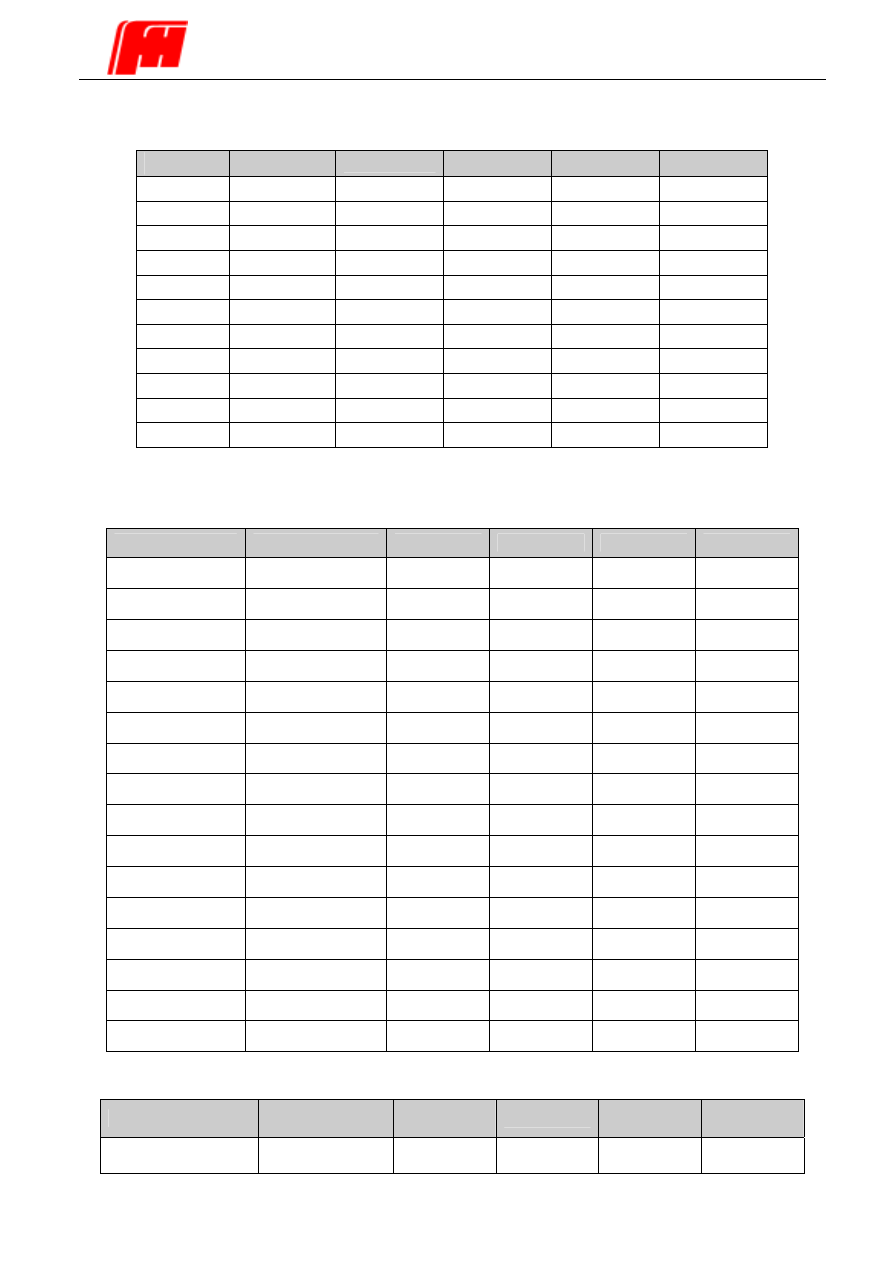

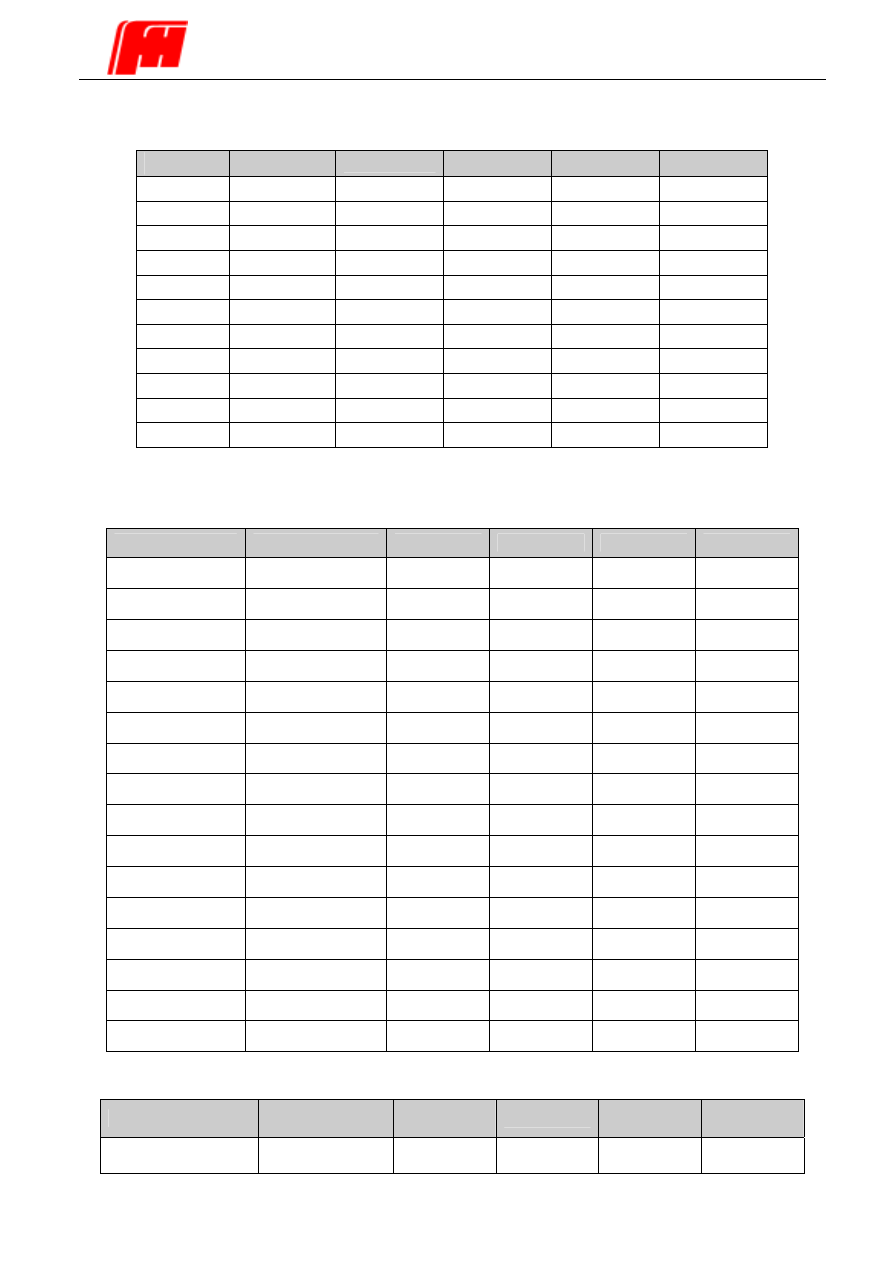

1

、

Dimensions for

Construction

1

Type

L

(

mm

)

W(mm)

t

(

mm

)

a

(

mm

)

b

(

mm

)

0402 1.00

±

0.10 0.50

±

0.10 0.30

±

0.10 0.20

±

0.10 0.25

±

0.10

0603 1.60

±

0.15 0.80

±

0.15 0.40

±

0.10 0.30

±

0.20 0.30

±

0.20

0805 2.00

±

0.20 1.25

±

0.15 0.50

±

0.10 0.40

±

0.20 0.40

±

0.20

1206 3.20

±

0.20 1.60

±

0.15 0.55

±

0.10 0.50

±

0.20 0.50

±

0.20

1210 3.20

±

0.20 2.50

±

0.20 0.55

±

0.10 0.50

±

0.20 0.50

±

0.20

1812 4.50

±

0.20 3.20

±

0.20 0.55

±

0.10 0.50

±

0.20 0.50

±

0.20

2010 5.00

±

0.20 2.50

±

0.20 0.55

±

0.10 0.60

±

0.20 0.60

±

0.20

2512 6.40

±

0.20 3.20

±

0.20 0.55

±

0.10 0.60

±

0.20 0.60

±

0.20

1225 3.10

±

0.15 6.30

±

0.15 0.90

±

0.15 0.60

±

0.30 0.55

±

0.25

3720 2.00

±

0.20 3.75

±

0.20 0.60

±

0.10 0.40

±

0.20 0.40

±

0.20

7520 2.00

±

0.20 7.50

±

0.30 0.60

±

0.10 0.40

±

0.20 0.40

±

0.20

2

、

Dimensions for

Construction

2

Type

Resistance(m

Ω)

L

(

mm

)

W(mm)

T

(

mm

)

D

(

mm

)

RC12

□

M50

□

0.50

6.35

±

0.25

3.18

±

0.25

1.40

±

0.20 1.30

±

0.30

RC12

□

M75

□

0.75

6.35

±

0.25

3.18

±

0.25

1.00

±

0.20 1.30

±

0.30

RC12

□

R001

□

1.00 6.35

±

0.25

3.18

±

0.25

0.80

±

0.20 1.30

±

0.30

RC12

□

1M50

□

1.50 6.35

±

0.25

3.18

±

0.25

0.65

±

0.20 1.30

±

0.30

RC12

□

R002

□

2.00 6.35

±

0.25

3.18

±

0.25

0.50

±

0.20 1.30

±

0.30

RC12

□

2M50

□

2.50 6.35

±

0.25

3.18

±

0.25

1.00

±

0.20 1.30

±

0.30

RC12

□

R003

□

3.00 6.35

±

0.25

3.18

±

0.25

0.70

±

0.20 1.30

±

0.30

RC12

□

3M50

□

3.50 6.35

±

0.25

3.18

±

0.25

0.71

±

0.20 1.30

±

0.30

RC12

□

R004

□

4.00 6.35

±

0.25

3.18

±

0.25

0.60

±

0.20 1.30

±

0.30

RC12

□

4M50

□

4.50 6.35

±

0.25

3.18

±

0.25

0.58

±

0.20 1.30

±

0.30

RC12

□

R005

□

5.00 6.35

±

0.25

3.18

±

0.25

0.50

±

0.20 1.30

±

0.30

RC12

□

5M50

□

5.50

6.35

±

0.25

3.18

±

0.25

0.47

±

0.20 1.30

±

0.30

RC12

□

R006

□

6.00 6.35

±

0.25

3.18

±

0.25

0.50

±

0.20 1.30

±

0.30

RC12

□

6M50

□

6.50 6.35

±

0.25

3.18

±

0.25

0.47

±

0.20 1.30

±

0.30

RC12

□

R007

□

7.00 6.35

±

0.25

3.18

±

0.25

0.45

±

0.20 1.30

±

0.30

RC12

□

R010

□

10.0 6.50

±

0.25

3.20

±

0.25

0.80

±

0.20 1.90

±

0.30

3

、

Dimensions for

Construction

3

Type

Resistance(m

Ω)

L

(

mm

)

W(mm)

T

(

mm

)

D

(

mm

)

RC12

□□□□□□

11

~

20 6.35

±

0.25

3.18

±

0.35

0.60

±

0.20 1.93

±

0.75

Fenghua Advanced Technology (holding) Co., Ltd

- 4 -

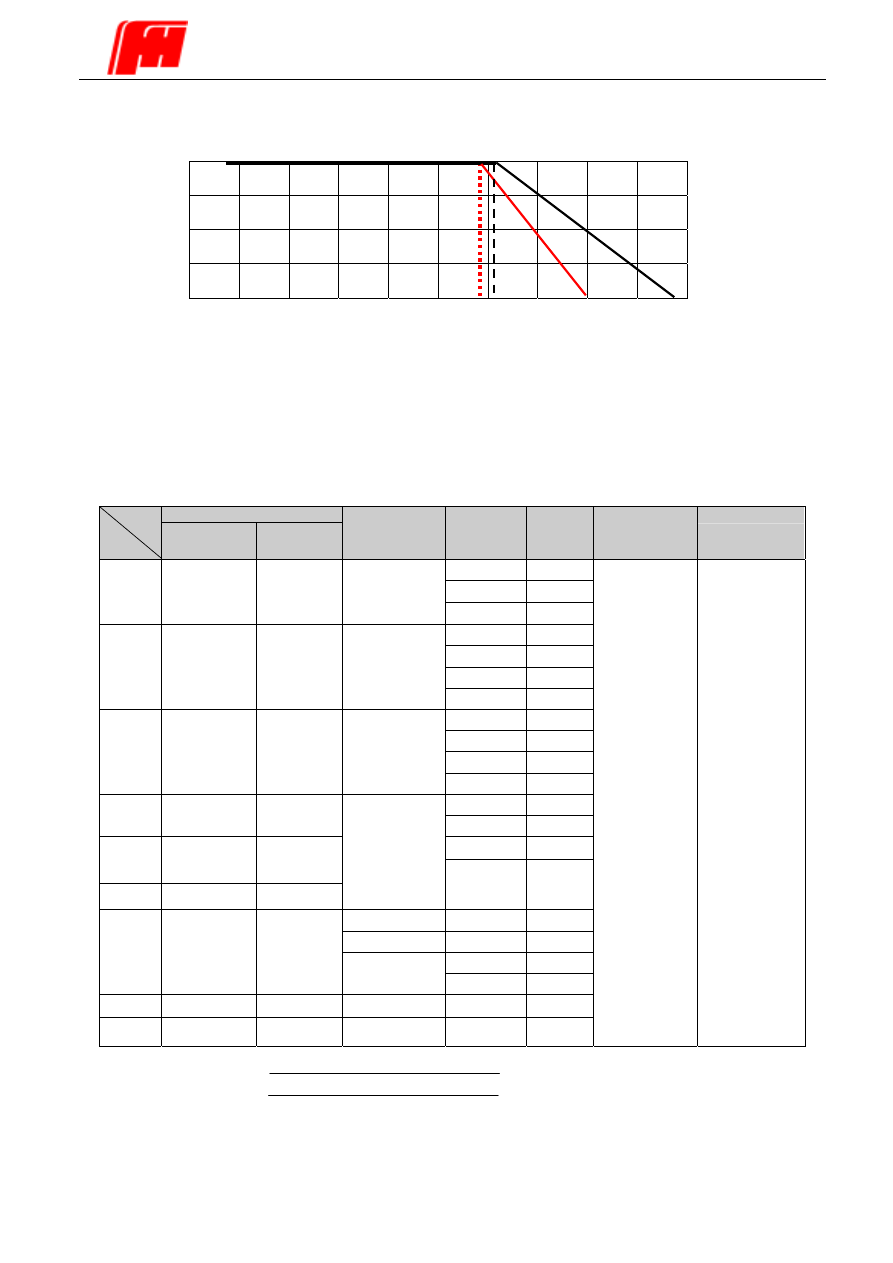

■

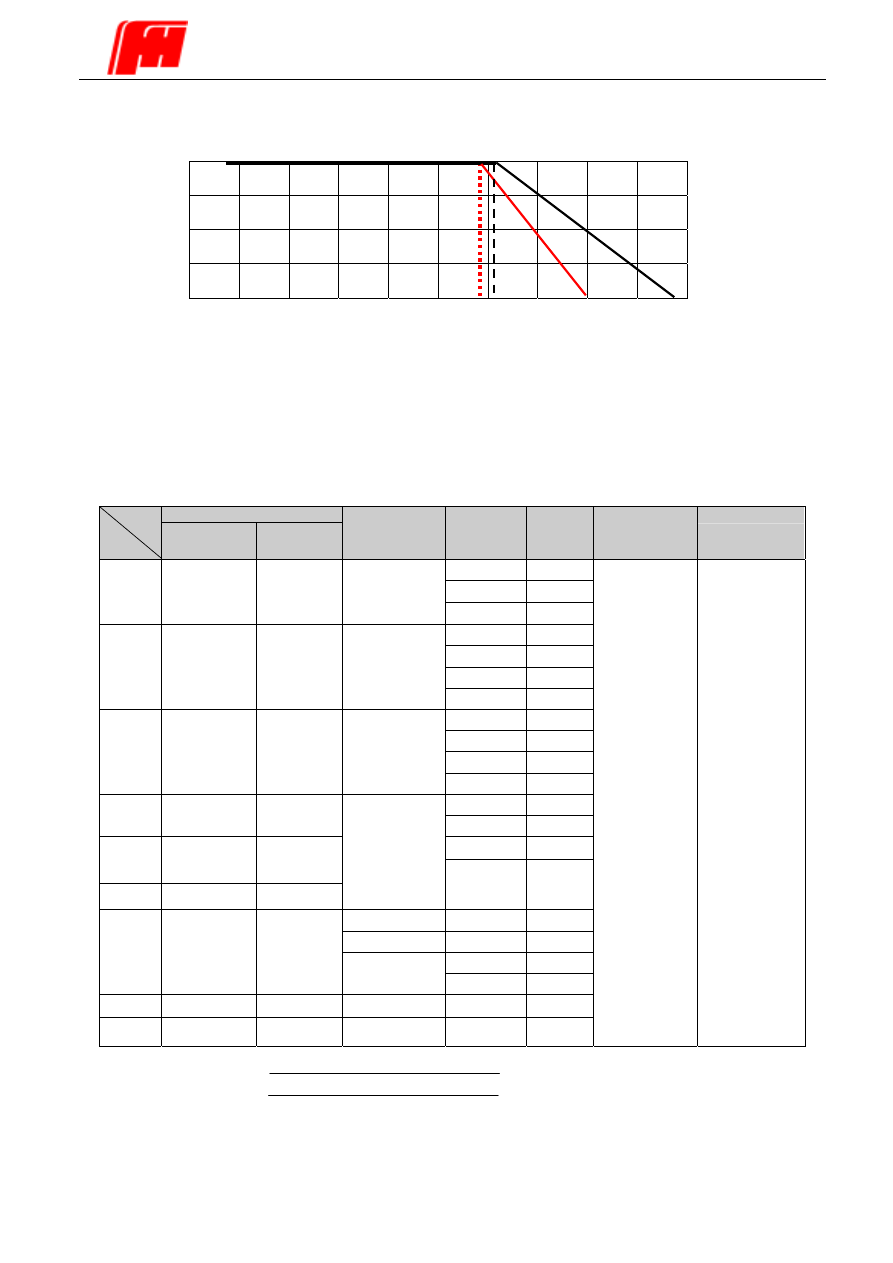

Derating Curve

-55

℃

70

℃

①

②

100

75

50

25

Operating

Temperature

Range

:

①

-55

℃~

125

℃

②

-55

℃~

170

℃

-75 -50 -25 0 25 50 75 80 100 125 155 180

Pe

rc

en

t ra

te

d loa

d

Ambient temperature

(

℃

)

For resistors operated in ambient over 70

℃

/80

℃

,rated load (power rating) shall be derated in accordance with

the above figure.

Curve

①

is suitable for the product of

Construction 1

Curve

②

is suitable for the product of

Construction 2

、

3

■

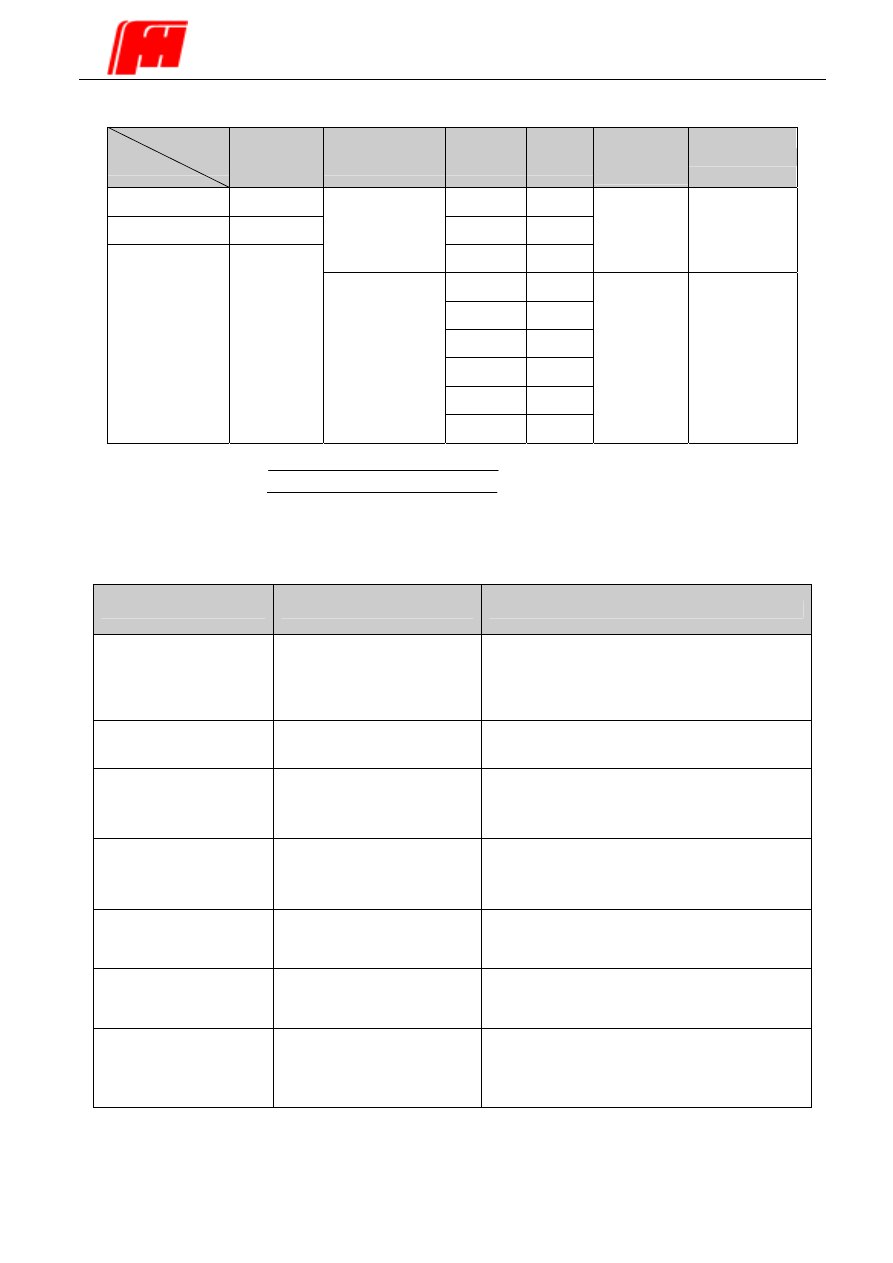

Ratings

Power Rating

Item

Type

Normal Power

Series

Upgraded

Power Series

Resistance

Tolerance

Resistance

(m

Ω

)

TCR

(PPM/

℃

)

Operating

Temperature Rang

Remark

50~100

±

400

101~500

±

300

0402

1/16W

\

±

1%,

±

2%,

±

5%

501~976

±

200

20~50

±

600

51~100

±

400

101~500

±

300

0603

1/16W 1/10W

±

1%,

±

2%,

±

5%

501~976

±

200

20~50

±

600

51~100

±

400

101~500

±

300

0805

1/10W 1/8W

±

1%,

±

2%,

±

5%

501~976

±

200

10~20

±

600

1206

1/8W 1/4W

21~50

±

400

51~500

±

300

2010

1/2W

\

2512

1W

\

±

1%,

±

2%,

±

5%

501~976

±

200

±

5%

3~5

±

600

±

2%,

6~9

±

600

10~49

±

600

1225

\

3W

±

1%,

±

2%,

±

5%

50~200

±

200

3720

\

1W

±

1%,

±

2%,

±

5%

10

~500

±

300

7520

\

2W

±

1%,

±

2%,

±

5%

1~500

±

300

-55

℃

~+125

℃

product

characteristics

are refer to

Characteristics 1

Note

:

Rating

Voltage V=

√

Power Rating

×

Resistance Value

,

Rating

Current I=

√

Power Rating

/Resistance Value

Fenghua Advanced Technology (holding) Co., Ltd

- 5 -

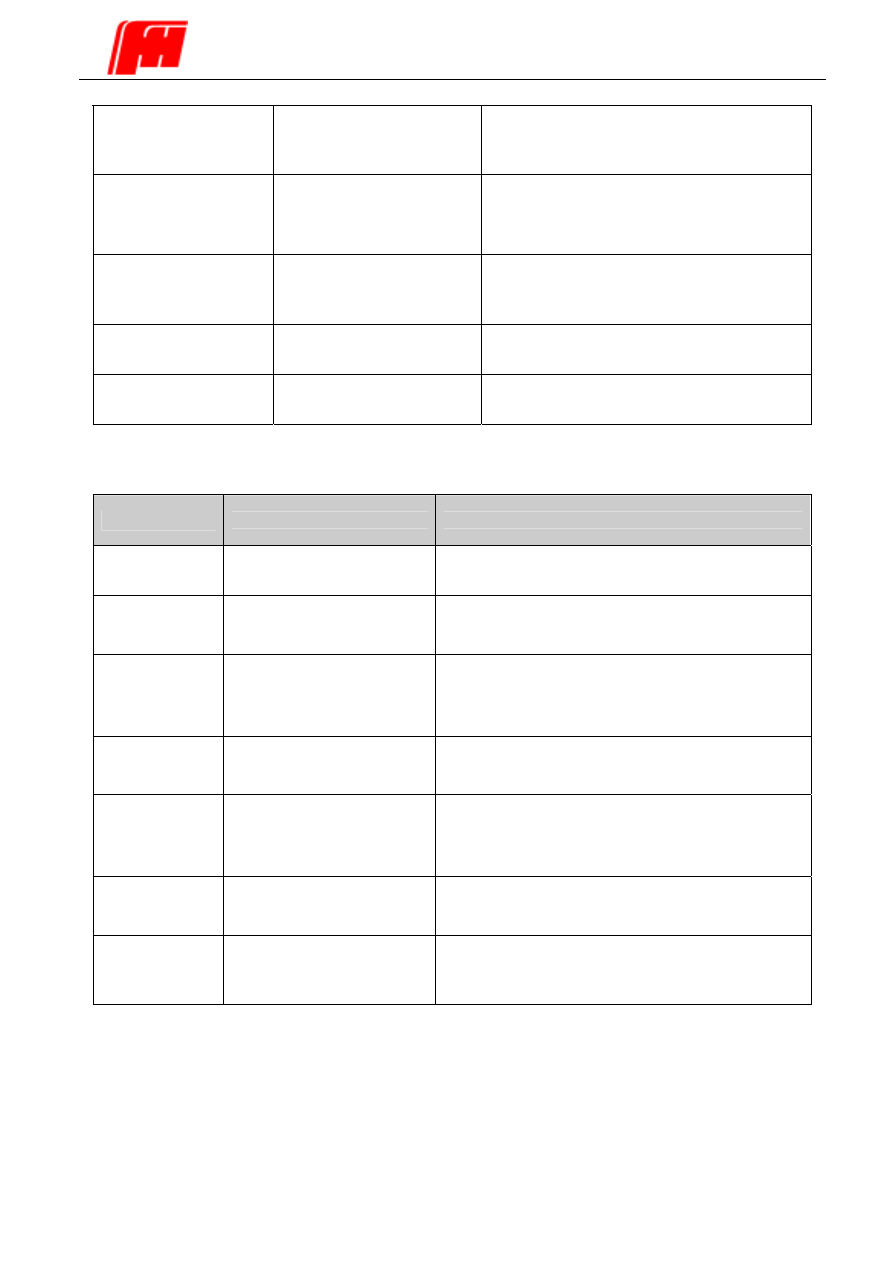

■

Low TCR Series Ratings

Item

Type

Power Rating

at 80

℃

Resistance

Tolerance

Resistance

(m

Ω

)

TCR

(PPM/

℃

)

Operating

Temperature

Rang

remark

RS06K

□□□□

1/4W 100~1000

±

100

RS10K

□□□□

1/2W 100~1000

±

100

±

1%,

±

2%,

±

5%

100~1000

±

100

-55

℃

~+125

℃

product

characteristics

are refer to

Characteristics 1

0.5~2.0 50

2.5~3.0 150

4.0~5.5 100

6.0~7.0 75

10 100

RC12K

□□□□

1W

±

1%,

±

3%,

±

5%

11~20 50

-55

℃

~+170

℃

product

characteristics

are refer to

Characteristics 2

Note

:

Rating

Voltage V=

√

Power Rating

×

Resistance Value

,

Rating

Current I=

√

Power Rating

/Resistance Value

■

Characteristics 1

Item

Specifications

Test Methods (JIS C 5202)

Bending Strength

No mechanical damage

△

R

≤±(

1.0%R+0.005

Ω)

Duration:10s

±

1s

Bending Distance:

0402

、

0603

、

0805

、

1206

、

1210

、

1225

:

3mm

;

1812

、

2010

、

2512

、

3720

、

2520

:

1mm

T.C.R

within

specified

T.C.R

Measure between

-55

℃

~+125

℃

Temperature Cycling

No mechanical damage

△

R

≤±(

1.0%R+0.005

Ω)

-55

℃(

30min

)

~normal temperature

(

5min

)

~125

℃(

30min

)

5 cycles

Short Time Overload

No mechanical damage

△

R

≤±(

2.0%R+0.005

Ω)

2.5

×

Rated Current for

5 seconds

Steady state humidity

No mechanical damage

△

R

≤±(

3.0%R+0.005

Ω)

40

℃±

2

℃

90

~95%RH 1000h

Load Life

o mechanical damage

△

R

≤±(

3.0%R+0.005

Ω)

70

℃±

2

℃,

1000h

,

Rated voltage

1.5h on/0.5h

off

Endurance at upper

temperature

No mechanical damage

△

R

≤±(

3.0%R+0.005

Ω)

125

℃±

2

℃

1000h

Fenghua Advanced Technology (holding) Co., Ltd

- 6 -

Continue to the former list

:

Resistance to Solvent

No mechanical damage

△

R

≤±(

1.0%R+0.005

Ω)

Dip in chloroethylene for 10h

±

1h

.

Insulation Resistance

1000M

Ω

Min

Apply DC 100V between substrate and

termination for 1 minute, then check

insulation resistance .

Resistance to

Soldering Heat

No mechanical damage

△

R

≤±(

1.0%R+0.005

Ω)

270

℃±

5

℃

10s

±

1s

Solder-ability

95% Cover Min

240

℃±

5

℃

2s

±

0.5s

Adhesion

No mechanical damage

Applying 5N 10s

±

1s

■

Characteristics 2

Item

Specifications

(

Low TCR

)

Test Methods

T.C.R

within

specified

T.C.R -55

℃

~+125

℃(

MLT-STD-202F-Method

)

Thermal Shock

No mechanical damage

△

R

≤±(

1.0%R+0.5m

Ω)

-55

℃

~150

℃

100cycles

Short Time

Overload

No mechanical damage

△

R

≤±(

1.0%R+0.5m

Ω)

)

2.5

×

Rated Current or Max Overload Current

,

whichever is lower

,

for

5 seconds

(

JIS C 5202

)

Resistance to

Soldering Heat

No mechanical damage

△

R

≤±(

1.0%R+0.5m

Ω)

260

℃±

5

℃

10s

±

1s

(

MLT-STD-202F-Method

)

Load Life

No mechanical damage

△

R

≤±(

1.0%R+0.5m

Ω)

70

℃±

2

℃

1000h

Rated voltage

1.5h on/0.5h off

(

MLT-STD-202F-Method

)

Solder-ability

95% Cover Min

235

℃±

5

℃

2s

±

0.5s

(

MLT-STD-202F-Method

)

Resistance to Dry

Heat

No mechanical damage

△

R

≤±(

1.0%R+0.5m

Ω)

+155

℃,

96h

(

JIS C 5202

)

Fenghua Advanced Technology (holding) Co., Ltd

- 7 -

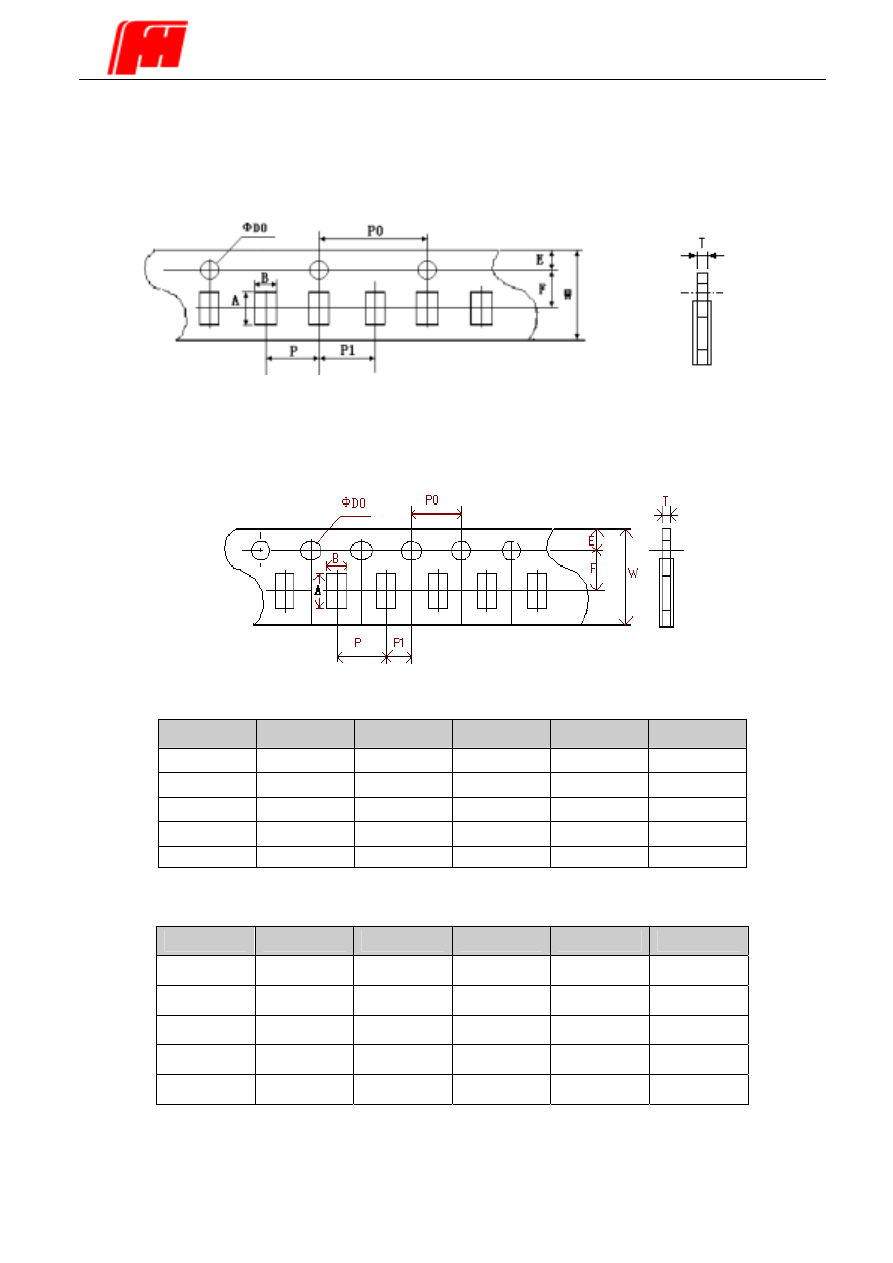

■

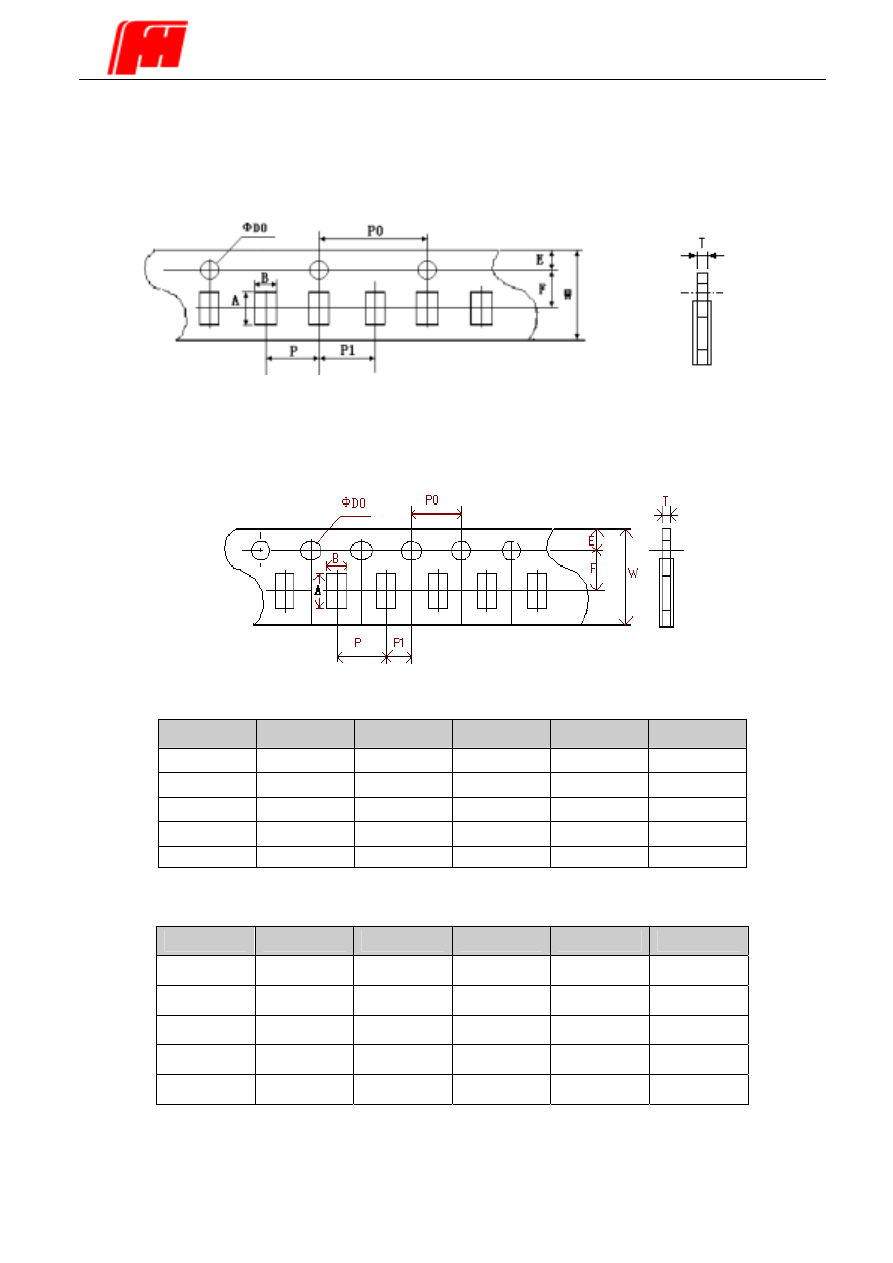

Packaging

●

Tape and reel

* Paper taping

0402

:

0603

、

0805

、

1206

、

1210

:

unit: mm

Type

A

B

W

F

E

0402 1.20

±

0.1 0.70

±

0.1

8.0

±

0.20

3.5

±

0.05 1.75

±

0.1

0603 1.85

±

0.1 1.10

±

0.1

8.0

±

0.20

3.5

±

0.05 1.75

±

0.1

0805 2.35

±

0.1 1.65

±

0.1

8.0

±

0.20

3.5

±

0.05 1.75

±

0.1

1206 3.50

±

0.2 1.90

±

0.2

8.0

±

0.20

3.5

±

0.05 1.75

±

0.1

1210 3.50

±

0.2 2.80

±

0.2

8.0

±

0.20

3.5

±

0.05 1.75

±

0.1

unit: mm

Type

P

P0

P1

Ф

D0

T

0402 2.0

±

0.05 4.0

±

0.1 2.0

±

0.05 1.5

±

0.1 0.6Max

0603 4.0

±

0.1 4.0

±

0.1 2.0

±

0.05 1.5

±

0.1 0.60

±

0.1

0805 4.0

±

0.1 4.0

±

0.1 2.0

±

0.05 1.5

±

0.1 0.75

±

0.1

1206 4.0

±

0.1 4.0

±

0.1 2.0

±

0.05 1.5

±

0.1 0.75

±

0.1

1210 4.0

±

0.1 4.0

±

0.1 2.0

±

0.05 1.5

±

0.1 0.75

±

0.1

Fenghua Advanced Technology (holding) Co., Ltd

- 8 -

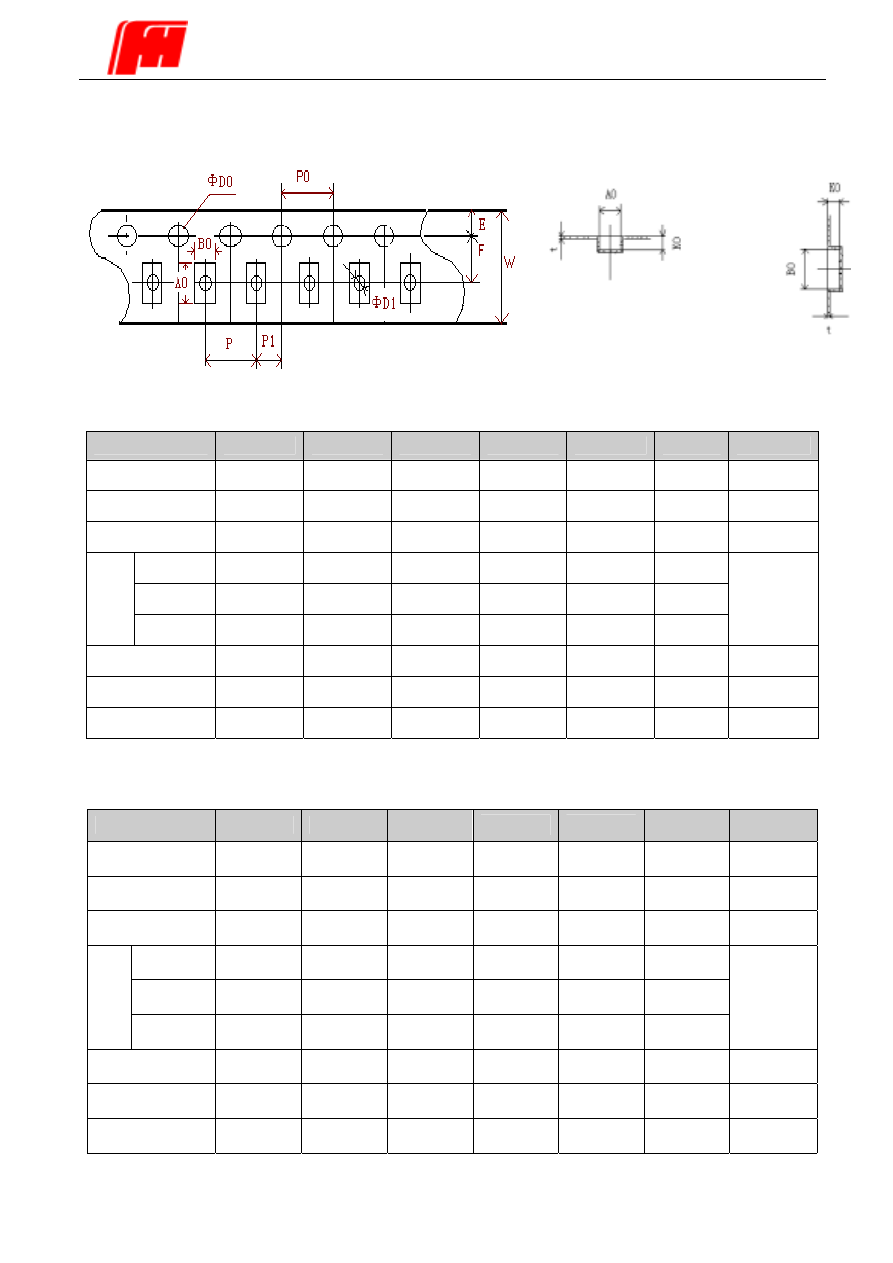

Embossed taping

1812

、

2010

、

2512

、

1225

、

3720

、

7520

unit: mm

Type

A0

B0

W

F

E

t

remark

1812

4.80

±

0.10 3.40

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10 0.25

±

0.05

2010

5.45

±

0.10 2.77

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10 0.24

±

0.05

2512

6.73

±

0.10 3.40

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10 0.24

±

0.05

Construction 1

0.50m

Ω

6.70

±

0.10 3.40

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10

\

0.75m

Ω

6.80

±

0.20 3.50

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10

\

2512

1

~

20m

Ω

6.70

±

0.10 3.40

±

0.10 12.00

±

0.10 5.50

±

0.10 1.75

±

0.10

\

Construction 2

、

3

1225

6.68

±

0.10 3.38

±

0.10 12.00

±

0.30 5.50

±

0.10 1.75

±

0.10

\

3720

4.45

±

0.20 2.50

±

0.20 12.00

±

0.30 5.50

±

0.05 1.75

±

0.01

\

7520

8.30

±

0.20 2.50

±

0.20 16.00

±

0.30 7.80

±

0.05 1.75

±

0.01

\

unit: mm

Type

P

P0

P1

Ф

D0

Ф

D1

K0

remark

1812

4.00

±

0.10 4.00

±

0.10 2.00

±

0.05 1.55

±

0.10 1.50

±

0.10 1.00

±

0.10

2010

4.00

±

0.10 4.00

±

0.10 2.00

±

0.05

1.50+0.10/-0

1.50

±

0.10 0.84

±

0.10

2512

4.00

±

0.10 4.00

±

0.10 2.00

±

0.05

1.50+0.10/-0

1.50

±

0.10 0.81

±

0.10

Construction 1

0.50m

Ω

4.00

±

0.10 4.00

±

0.05 2.00

±

0.05 1.50

±

0.10

1.40 Min

1.40

±

0.10

0.75m

Ω

4.00

±

0.10 4.00

±

0.05 2.00

±

0.05 1.50

±

0.10

1.40 Min

1.35

±

0.10

2512

1

~

20m

Ω

4.00

±

0.10 4.00

±

0.05 2.00

±

0.05 1.50

±

0.10

1.40 Min

0.80

±

0.10

Construction 2

、

3

1225

4.00

±

0.10 4.00

±

0.10 2.00

±

0.05

1.55+0.05 1.40

Min 1.45

±

0.20

3720

4.00

±

0.10 4.00

±

0.05 2.00

±

0.05

1.50+0.10 1.40

Min 1.50

±

0.10

7520

4.00

±

0.10 4.00

±

0.05 2.00

±

0.05

1.50+0.10 1.40

Min 1.50

±

0.10

Fenghua Advanced Technology (holding) Co., Ltd

- 9 -

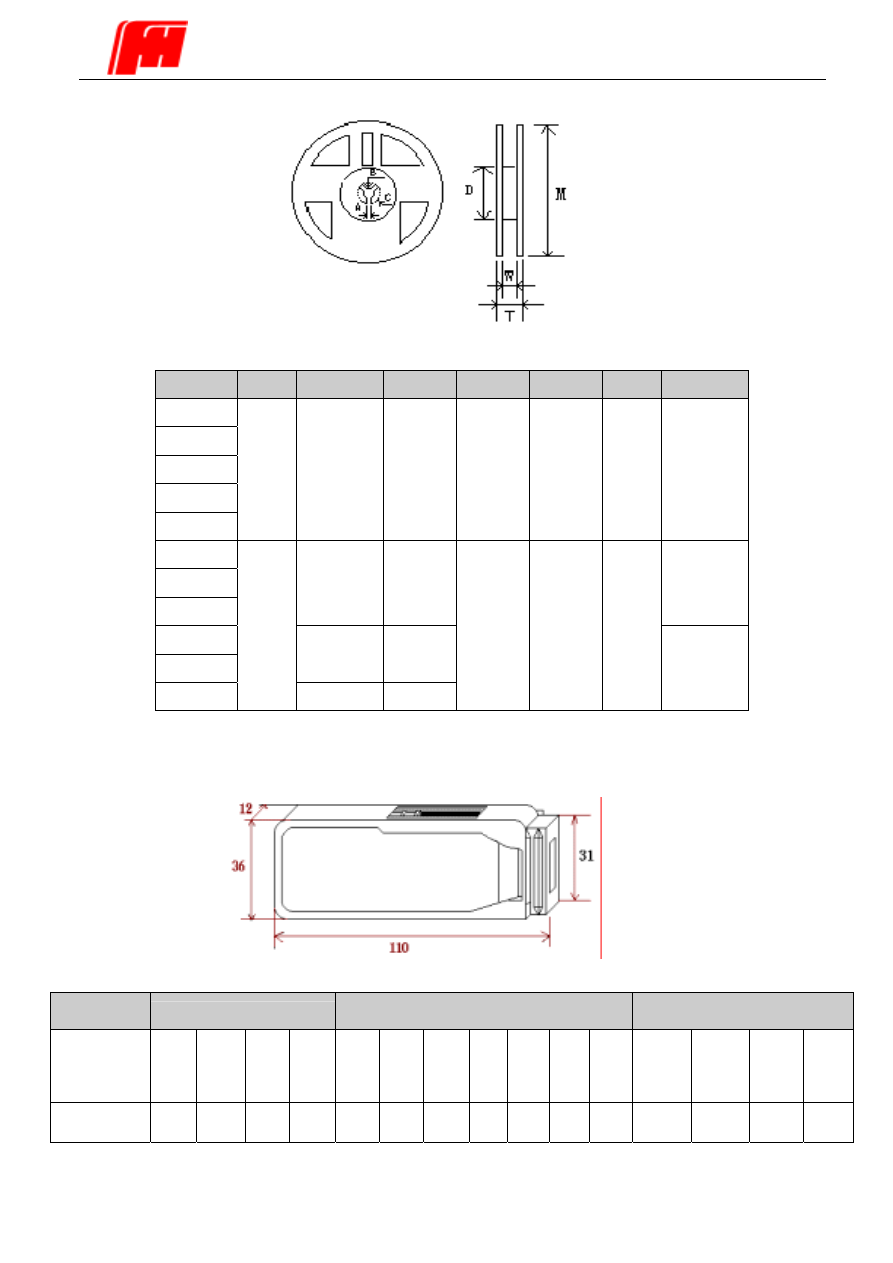

* Reel

unit: mm

Type

M

W

T

A

B

C

D

0402

0603

0805

1206

1210

178

±

2.0

9.5

±

1.0

12.5

±

1.5

2.0

±

0.5

13.0

±

0.5

21.0

±

0.5

58.0

±

2.0

1812

2010

2512

13.0

±

0.5

15.5

±

1.5

57.0

±

2.0

1225

3720

13.2

±

1.5 16.0

±

0.2

7520

178

±

2.0

17.0

±

0.5 19.0

±

1.0

2.0

±

0.5

13.0

±

0.5

21.0

±

0.5

60.2

±

0.5

●

Bulk case

unit:mm

●

Packaging quantity

Packaging

style

Tape and reel

Bulk case

Bulk

Type 0402

0603

0805

1206

1210

1812

2010

2512

1225

3720

7520

0402 0603 0805 1206

1210

2010

1812

2512

1225

3720

7520

0402

0603

0805

1206

1210

1812

2010

2512

1225

3720

7520

Quantity

(

PCS

)

10000 5000 4000 2000 50000 25000 10000 5000 1500 1000 500

≤

50000

≤

10000

≤

4000

≤

1

000