Sales and Corporate Office

1717 Chicago Avenue

Riverside, California 92507-2364

Phone: (951) 788-1700

Fax: (951) 369-1151

Applications Engineering

17271 North Umpqua Hwy.

Roseburg, Oregon 97470-9422

Phone: (541) 496-0700

Fax: (541) 496-0408

e-mail: caddock@caddock.com • web: www.caddock.com

For Caddock Distributors listed by country see caddock.com/contact/dist.html

© 2004 Caddock Electronics, Inc.

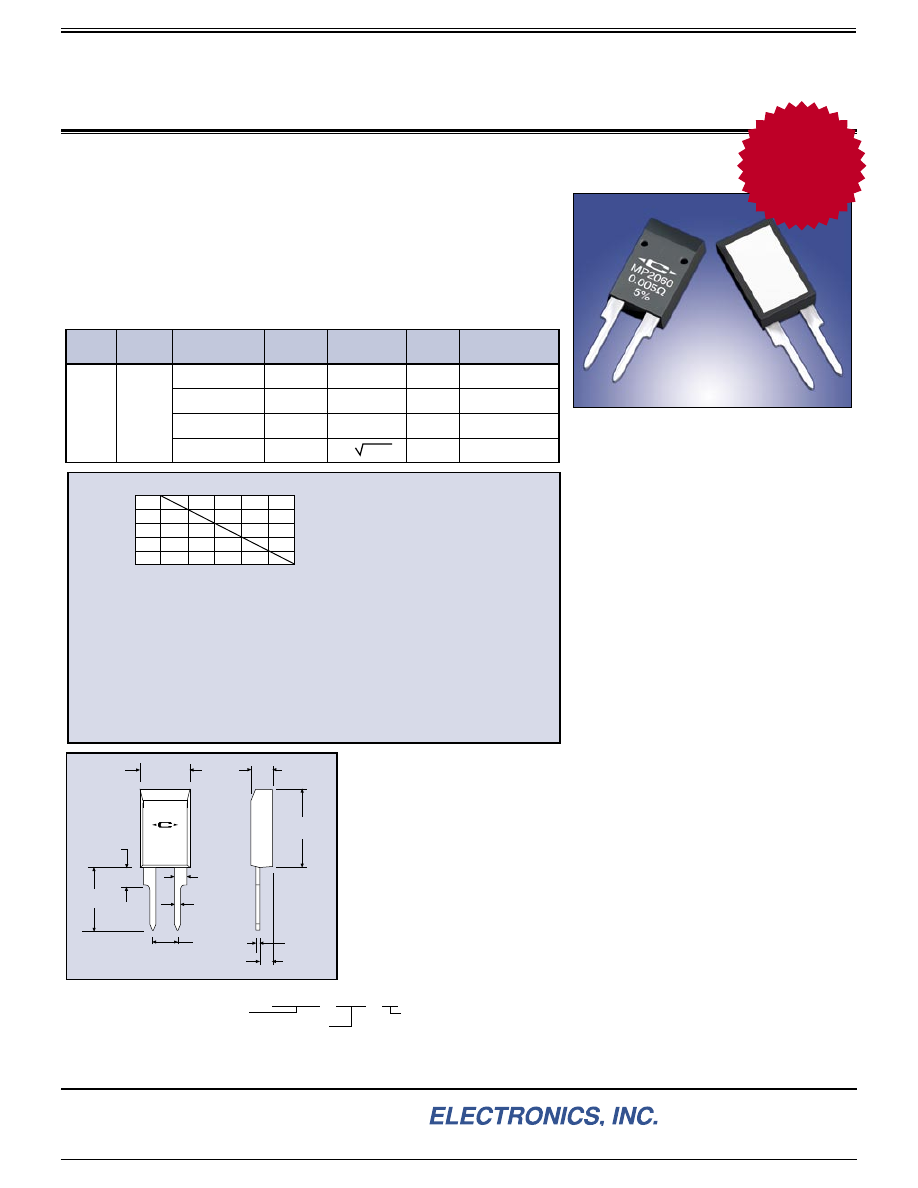

CAD

K

DOC

0.410

±

0.010

(10.41

±

0.26)

0.150

±

0.030

(3.81

±

0.76)

0.500

±

0.050

(12.70

±

1.27)

0.035

±

0.007

(0.89

±

0.18)

0.175

±

0.010

(4.45

±

0.26)

0.105

±

0.010

(2.67

±

0.26)

0.100

±

0.020

(2.54

±

0.51)

0.050

±

0.007

(1.27

±

0.18)

0.200

±

0.010

(5.08

±

0.26)

0.640

±

0.010

(16.26

±

0.26)

MP2060

50.0

1%

MP2060 - 0.050 - 1%

Model Number:

Resistor Value:

Tolerance

0.015

Ω

Current

Limited

0.005

Ω

MP2060

Model

Thermal Resistance

R

θ

JC

Film (

J

) to Case (

C

)

Resistance

Max.

Voltage

0.020

Ω

to 1.00K

Package

TO-220

Style

Current

Limited

250 V

rms

6.94

°

C/Watt

2.31

°

C/Watt

2.08

°

C/Watt

60 A

rms

Max. Current

Rating (Amps)

60 A

rms

Power

Rating

18 Watts

*

60 Watts

*

I = P/R

Current

Limited

0.010

Ω

3.47

°

C/Watt

60 A

rms

36 Watts

*

54 Watts

*

MP2060 Kool-Pak

®

Clip Mount

Power Film Resistor

25

100

150

CASE TEMPERATURE,

°

C

0

20

40

100

80

60

RA

TED POWER

%

All power and associated overload ratings are

derated based upon case temperature using the

derating curve. The case temperature is mea-

sured at the center of the ceramic mounting sur-

face, with the part properly mounted and under

electrical load. Without a heat sink, when in free

air at +25°C, the MP2060 is rated for 2.5 watts.

The thermal design should satisfy the following equation:

Case Temperature (Tc) + [Thermal Resistance (R

θ

JC

) x power applied (Watts)] ≤ 150°C, considering the full

operating temperature range of the application.

Mounting Note:

Mount on a smooth, clean and flat heat sink surface with a thermal interface material, such as

thermal grease. The entire exposed ceramic portion must be in contact with the heat sink. When using a

spring clip, it is recommended that a mounting force of 8 to 30 pounds (35 to 130 N) be applied to the center of

the package. The clip should be round or smooth in the contact area to avoid concentrating the load on a small

point of the plastic body of the package. Another mounting option is to use a pressure bar method which can

achieve a greater mounting force with a greater contact area.

For additional applications information regarding mounting and pulse handling see the Caddock Ap-

plications Notes at caddock.com or contact Applications Engineering.

*

Derating Using Case Temperature (TC):

Derating Curve

0.005

Ω

5%

0.010

Ω

2%

0.015

Ω

2%

0.020

Ω

0.025

Ω

0.030

Ω

0.033

Ω

0.040

Ω

0.050

Ω

0.075

Ω

0.10

Ω

0.15

Ω

0.20

Ω

0.25

Ω

0.30

Ω

0.33

Ω

0.40

Ω

0.50

Ω

0.75

Ω

1.00

Ω

1.50

Ω

2.00

Ω

2.50

Ω

3.00

Ω

3.30

Ω

4.00

Ω

5.00

Ω

7.50

Ω

8.00

Ω

10.0

Ω

12.0

Ω

15.0

Ω

20.0

Ω

25.0

Ω

27.0

Ω

30.0

Ω

33.0

Ω

40.0

Ω

47.0

Ω

50.0

Ω

56.0

Ω

75.0

Ω

100

Ω

120

Ω

150

Ω

200

Ω

250

Ω

300

Ω

330

Ω

400

Ω

470

Ω

500

Ω

560

Ω

750

Ω

1.00 K

Standard Resistance Values:

Tolerance: 1% Standard (except as noted)

For custom values and tolerances contact

Applications Engineering

Ordering Information:

DIMENSIONS IN INCHES AND (MILLIMETERS)

Specifications:

Temperature Coefficient:

TC referenced to +25°C,

Δ

R taken at +150°C

0.50 ohm and above, -20 to +80 ppm/°C

0.050 ohm to 0.49 ohm, 0 to +100 ppm/°C

0.015 ohm to 0.049 ohm, 0 to +200 ppm/°C

0.005 ohm to 0.014 ohm, 0 to +300 ppm/°C

Operating Temperature:

-55°C to +150°C

Inductance:

10 nH typical in series when

measured at the shoulder of the lead.

Capacitance:

<1 pf typical without heat sink.

DWV:

1500 V

rms

AC isolation to the mounting

surface or a clip in contact with the top surface.

Insulation Resistance:

10,000 Megohms, min.

The resistor element is electrically isolated from the

mounting surface.

Momentary Overload:

1.5 times rated power for

5 seconds,

Δ

R ±(0.5 percent + 0.0005 ohm) max.

Load Stability:

2000 hours at rated power

Δ

R less than ±(1 percent +0.0005 ohm).

Moisture Resistance:

Mil-Std-202, Method 106,

Δ

R ±(0.5 percent + 0.0005 ohm) max.

Thermal Shock:

Mil-Std-202, Method 107,

Cond. F,

Δ

R ±(0.5 percent + 0.0005 ohm) max.

Shock:

100G, Mil-Std-202, Method 213,

Cond. I,

Δ

R ±(0.4 percent + 0.0005 ohm) max.

Vibration, High Frequency:

Mil-Std 202,

Method 204, Condition D,

Δ

R ±(0.4 percent

+ 0.0005 ohm) max.

Terminal Strength:

Mil-Std-202, Method 211,

Cond. A (Pull Test) 5 lbs.,

Δ

R ±(0.2 percent

+ 0.0005 ohm) max.

Terminal Material:

Solderable

Measurement Note:

Resistance measurements

shall be made at 0.2 inch (5.08 mm) from the

resistor body.

These products are covered by one or more

patents, also patents pending.

• Up to 60 Watts continuous power at +25°C case temperature, 0.020

Ω

and above.

• Up to 60 Amps continuous current at +25°C case temperature, 0.015

Ω

and below.

• TO-220 Style package utilizes proven power semiconductor thermal solutions.

• Equivalent to UL94 V-0 flammability rating.

• Excellent pulse/surge performance.

• Non-inductive design for high speed switching, snubbers and rf applications.

• Operation up to +150°C case temperature.

• Electrically isolated case.

TO-220 Style Power Resistor Designed for Clip Mounting -

Non-Inductive

Packaging Information:

MP2060 resistors are packaged in plastic shipping tubes, 50 pieces

per tube. These resistors are available in a 50 piece minimum quantity and in full tube

quantity increments (i.e. 50, 100, 150, etc.).

New

Clip M

ount

Values to

0.005

Ω

28_IL128.1004