3111 N. Deer Run Road, Suite 4

Carson City, NV USA 89701

800-808-2434 / 775-884-2434

Fax 775-884-0670 / www.ametherm.com

Circuit Protection Thermistors

Ametherm’s MegaSurge™ Inrush Current Limiter is an economical and space saving way to limit

high inrush current. MegaSurge’s rugged high temperature construction allows safe operation at

high continuous currents. It is specially designed to withstand up to 50 amperes of continuous

current and 900 joules of input energy.

The MegaSurge Inrush Current Limiter is useful in:

➤

AC Motors

➤

Power Supplies

➤

Motor Drives

➤

Audio Amplifiers

➤

Battery Chargers

The MegaSurge Inrush Current Limiter absorbs high amounts of inrush current when electrical

equipment is turned on by offering a high resistance to current and quickly decreasing in

resistance once steady state current begins to flow through the thermistor. In a switching power

supply, the instantaneous surge energy is caused by the large input filter capacitors and

AC input voltage.

During the absorption of energy, the initial high resistance of the thermistor drops within

milliseconds to a negligible resistance in preparation of allowing high levels of steady state

current to flow with a minimal loss of power through the circuit. The MegaSurge Inrush Current

Limiter will absorb up to 900 joules of input energy and carry 50 amperes of steady state current.

➤

Use the maximum allowable inrush

current and Ohm’s Law to determine

the least allowable resistance at

turn on for your application.

➤

Using the formula J=

1

/

2

CV

2

,

determine how much input energy

the thermistor will absorb when the

device is turned on.

➤

Determine the maximum steady state

current that will flow through

the Inrush Current Limiter.

➤

Select the Ametherm Inrush

Current Limiter that will work for

your application.

How does the

MegaSurge

Inrush Current

Limiter work?

Specify the right

MegaSurge

Inrush Current Limiter

for your application.

Ametherm’s new Inrush Current Limiter

provides big protection.

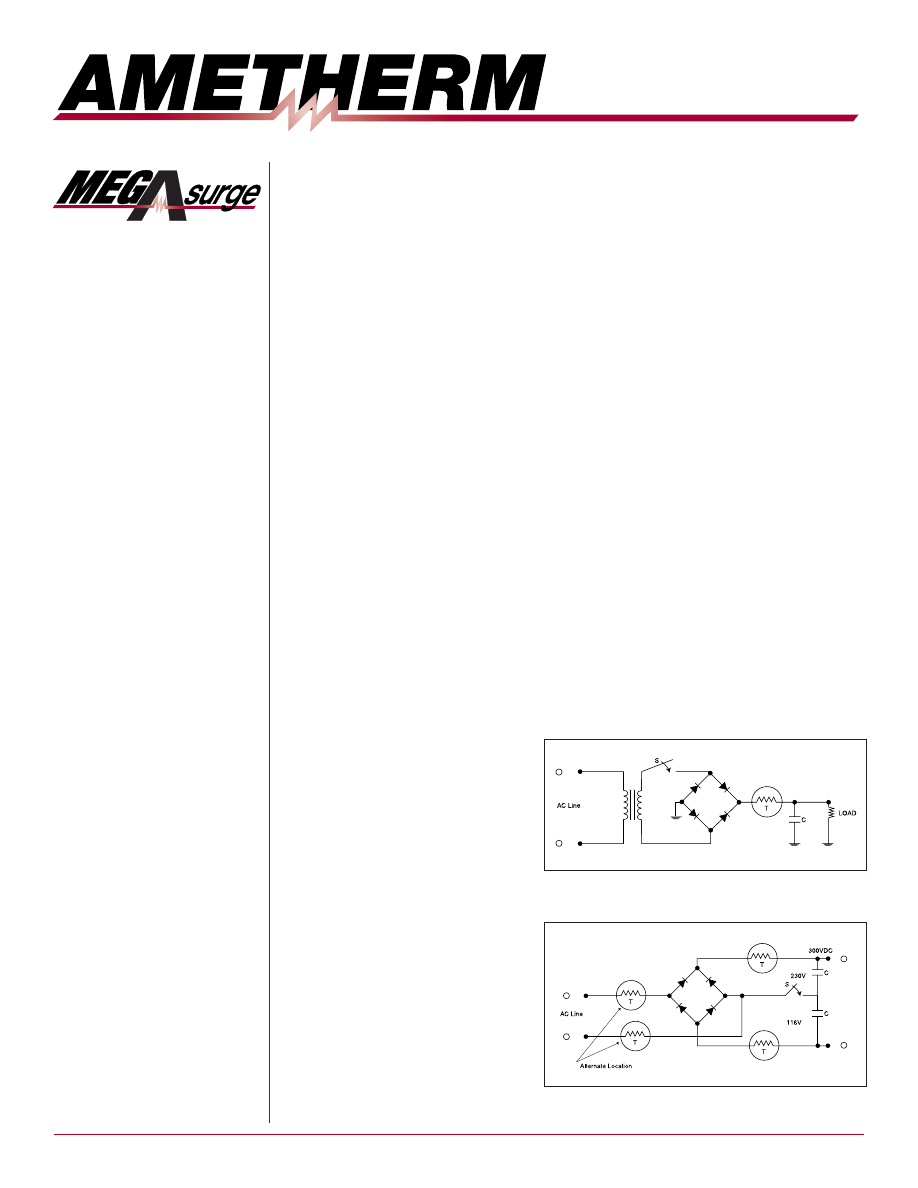

One example of a typical circuit for limiting

inrush current.

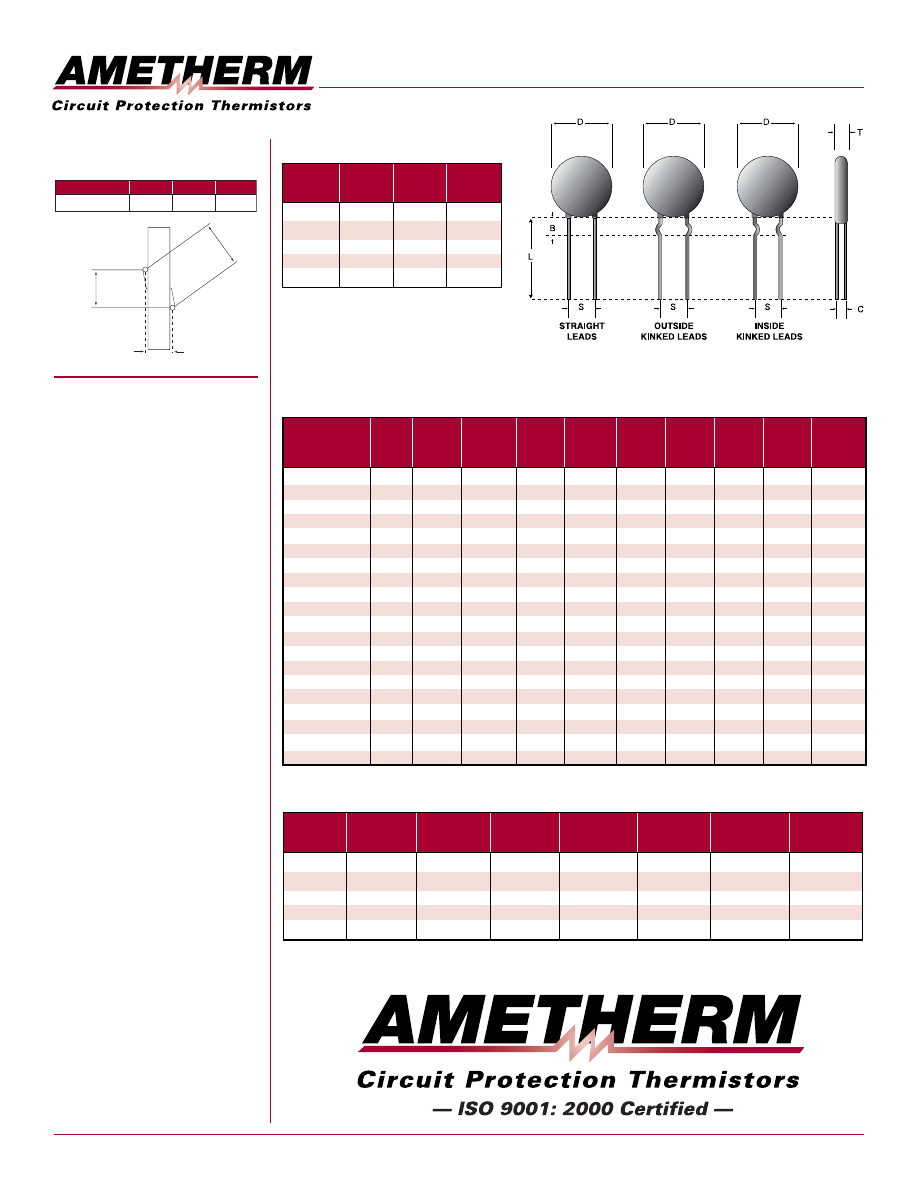

Another example of a typical circuit for limiting

inrush current.

➤

Frequency Generators

➤

Plasma Cutting Tools

➤

MRI Machines

➤

Toroidal Transformers up to 4.0KVA

➤

Other equipment that can be improved with

inrush current protection

Copyright ® Ametherm 2003. All rights reserved.

Made in the U.S.A.

www.ametherm.com

Ametherm – USA

Corporate Headquarters

3111 N. Deer Run Rd., Suite 4

Carson City, NV 89701

U.S.A.

800-808-2434

Tel: 775-884-2434

Fax: 775-884-0670

Ametherm – Europe

Thomatronik

Brückenstrasse 1

D83022 Rosenheim

GERMANY

Tel: +49 8031-2175-10

Fax: +49 8031-2175-30

Ametherm – Europe

Sequoia Technology Ltd.

Basingstoke Road

Spencers Wood, Reading

Berks

ENGLAND RG71PW

Tel: +44 1883-7228-22

Fax: +44 1189-7690-20

Ametherm – Asia

Cost Effective Solutions

Ltd.

Rm. 1034,10/F Nan Fung Centre

264-298 Castle Peak Road

Tsuen Wan, New Territories

HONG KONG

Tel: +852 241-11998

Fax: +852 241-10278

Ametherm –

Middle East

RAPAC Electronics Ltd.

60 Amal Street, PO Box 4127

Kiryat Arie, Petach Tikva

ISRAEL 49130

Tel: +972 3-9203-456

Fax: +972 3-9203-443

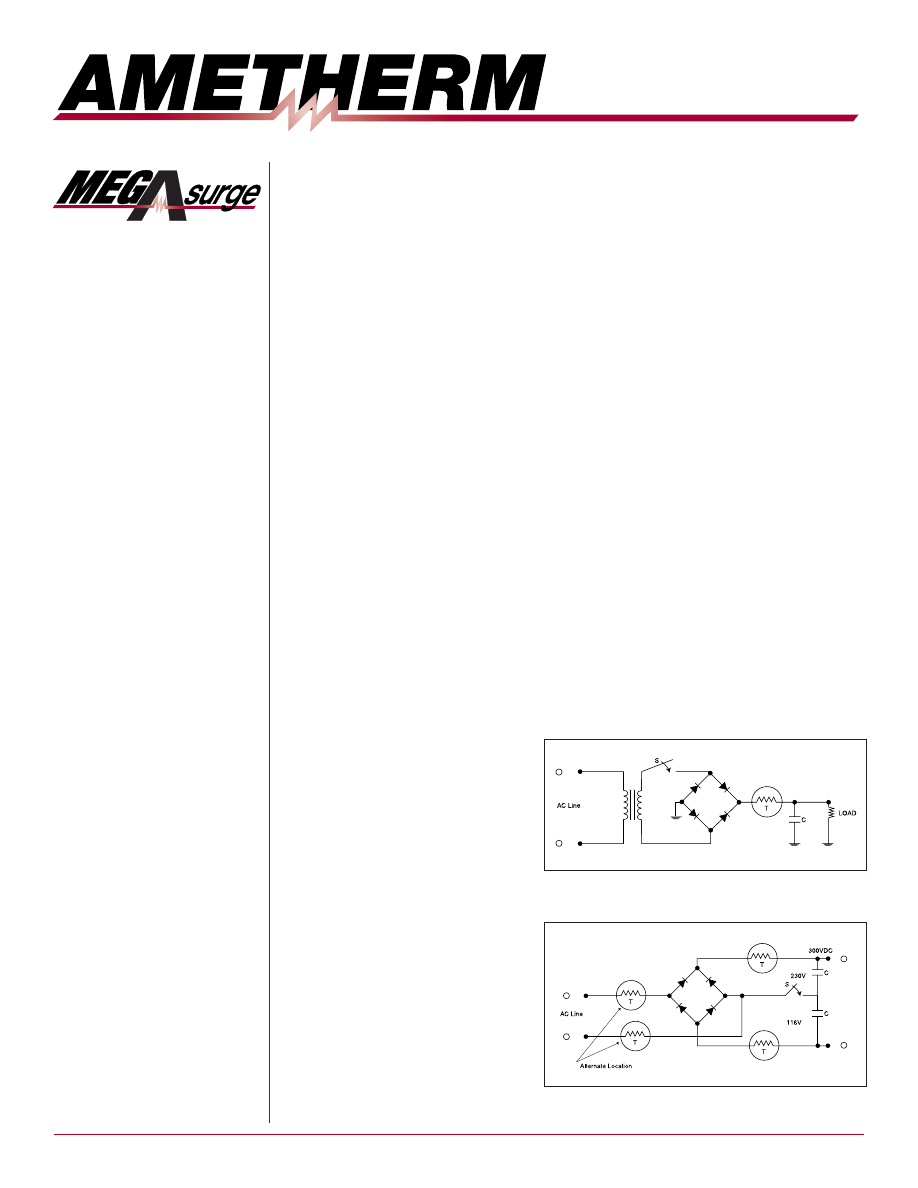

MegaSurge Inrush Current Limiter Specifications

Mechanical Specifications

Part

Series

D

(mm)

S

(mm)

L

(mm)

B

(mm)

C

(mm)

T

(mm)

Lead Dia

(mm)

MS12

12.0 Nom

9.0 Nom

1.3 Nom

7.80 Nom

38.0 Nom

6.35 Nom

6.70 Nom

MS15

15.0 Nom

9.0 Nom

1.3 Nom

7.80 Nom

38.0 Nom

6.30 Nom

6.70 Nom

MS22

22.0 Nom

9.0 Nom

1.3 Nom

7.80 Nom

38.0 Nom

7.60 Nom

6.70 Nom

MS32

32.0 Nom

9.0 Nom

1.3 Nom

7.80 Nom

38.0 Nom

7.60 Nom

6.70 Nom

MS35

35.0 Nom

9.0 Nom

2.5 Nom

19.0 Nom

39.0 Nom

9.80 Nom

7.50 Nom

Part

Series

Straight

Inside

Kink

Outside

Kink

MS12

✔

✔

✔

MS15

✔

✔

✔

MS22

✔

✔

✔

MS32

✔

✔

MS35

✔

Available Lead Configurations

MegaSurge Footprint

Specifications

C

A

B

Component shown

without coating

Tolerance: +/- .5mm

Part Number

A

B

C

MS32 10015

7.8mm

9.6mm

5.6mm

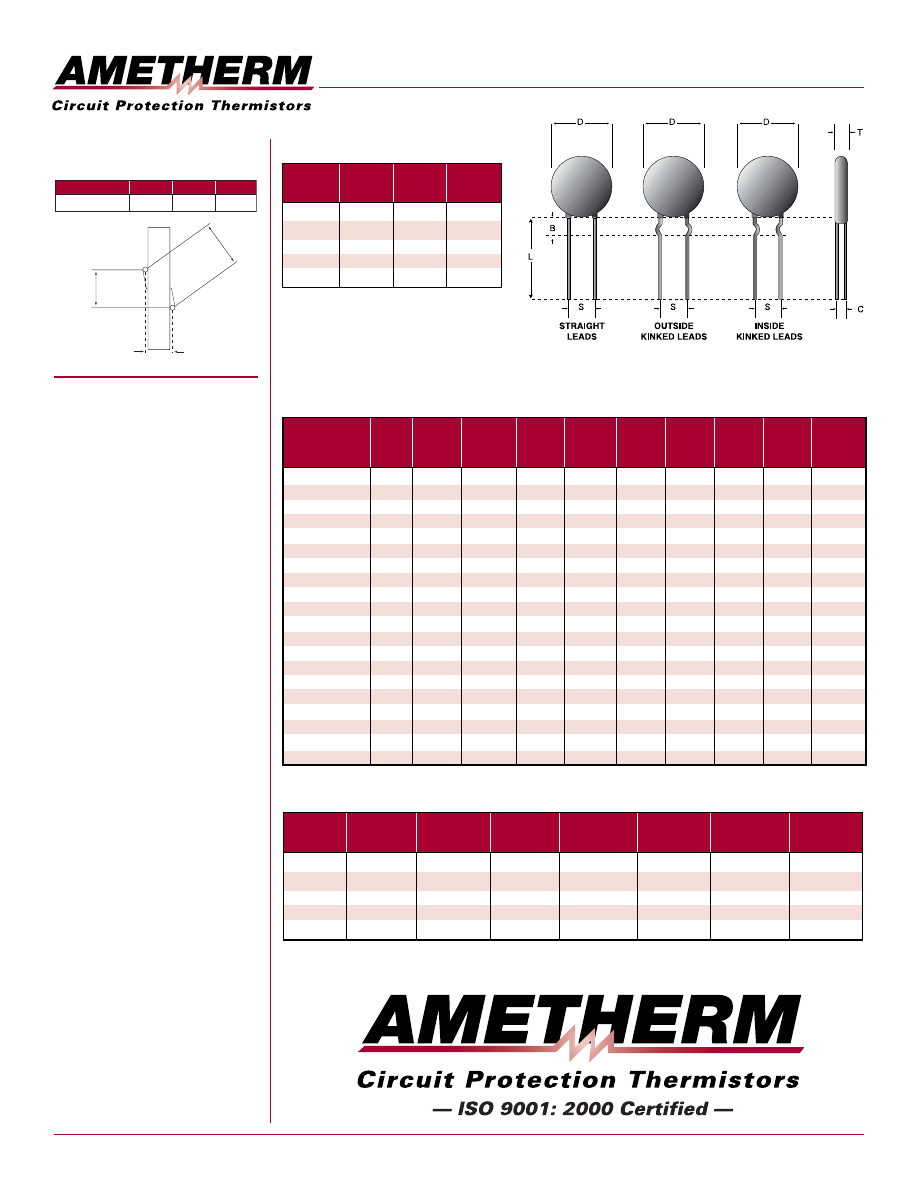

Part

Number

Material

Type

R @

25

°

C

(

Ω

)

Max

SSI

(Amp)

Max

Voltage

(Volts)

Max Cap

@ Max

Voltage

(

µ

F)

Max

Energy

(Joules)

Rhot @

100%

SSI

Rhot @

75%

SSI

Rhot @

50%

SSI

Rhot @

25%

SSI

MS32 1R036-L

1

36

300

440

1500

0.012

0.015

0.030

0.070

B

MS32 2R025

2

25

350

440

1500

0.020

0.032

0.060

0.160

C

MS32 5R020

5

20

325

440

1250

0.035

0.060

0.100

0.300

G

MS32 10015

10

15

250

440

1250

0.060

0.100

0.190

0.500

H

MS32 20008

20

8

220

440

1250

0.200

0.330

0.570

1.360

I

MS22 20005

20

5

150

440

1000

0.320

0.500

0.720

2.000

H

MS15 40004

40

4

135

440

700

0.400

0.623

0.960

2.500

I

MS22 50004

50

4

240

440

1200

0.400

0.625

1.100

3.150

I

MS15 66003

66

3.5

125

440

600

0.400

0.824

1.730

2.950

H

MS22 75004

75

4

240

440

1200

0.500

0.770

1.350

3.540

M

MS22 12103

120

3

220

440

1100

0.950

1.400

2.500

6.400

M

MS12 15102

150

2

110

440

560

1.050

1.900

2.710

3.840

I

MS22 22103

220

3

100

440

775

1.000

1.670

3.000

8.000

L

MS35 0R550

0.5

50

900

680

2000

0.008

0.013

0.020

0.050

B

MS35 1R040

1

40

800

680

1700

0.012

0.020

0.030

0.080

B

MS35 2R035

2

35

750

680

1600

0.020

0.027

0.040

0.102

C

MS35 3R030

3

30

750

680

1250

0.030

0.052

0.080

0.200

G

MS35 5R025

5

25

600

680

1000

0.050

0.100

0.150

0.400

H

MS35 10018

10

18

500

680

1000

0.100

0.320

0.480

1.250

I

MS35 20010

20

10

500

680

1600

0.030

0.040

0.065

0.155

I