Cat.No.C49E-15

Murata

Manufacturing Co., Ltd.

Radial Lead Type

Monolithic Ceramic

Capacitors

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

CONTENTS

Recycled Paper

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Part Numbering

2

Radial Lead Type Monolithic Ceramic Capacitors

3

Marking

4

Temperature Compensating Type, C0G Characteristics

5

High Dielectric Constant Type, X7R Characteristics

8

High Dielectric Constant Type, Z5U Characteristics

10

High Dielectric Constant Type, Y5V Characteristics

11

Small Size, Temperature Compensating Type, C0G Characteristics

12

Small Size, High Dielectric Constant Type, X7R Characteristics

13

Small Size, High Dielectric Constant Type, Z5U Characteristics

14

Small Size, High Dielectric Constant Type, Y5V Characteristics

14

Specifications and Test Methods

15

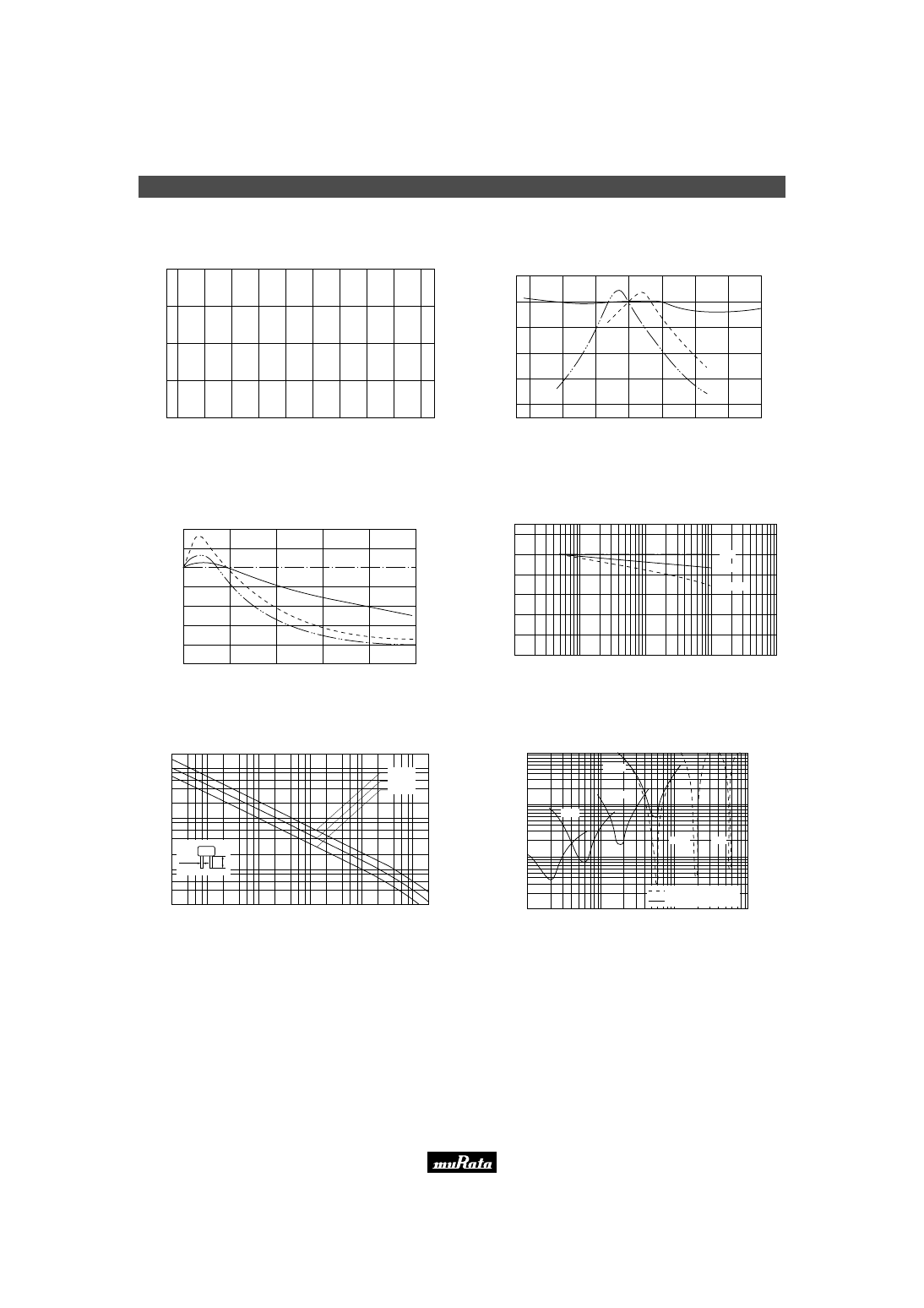

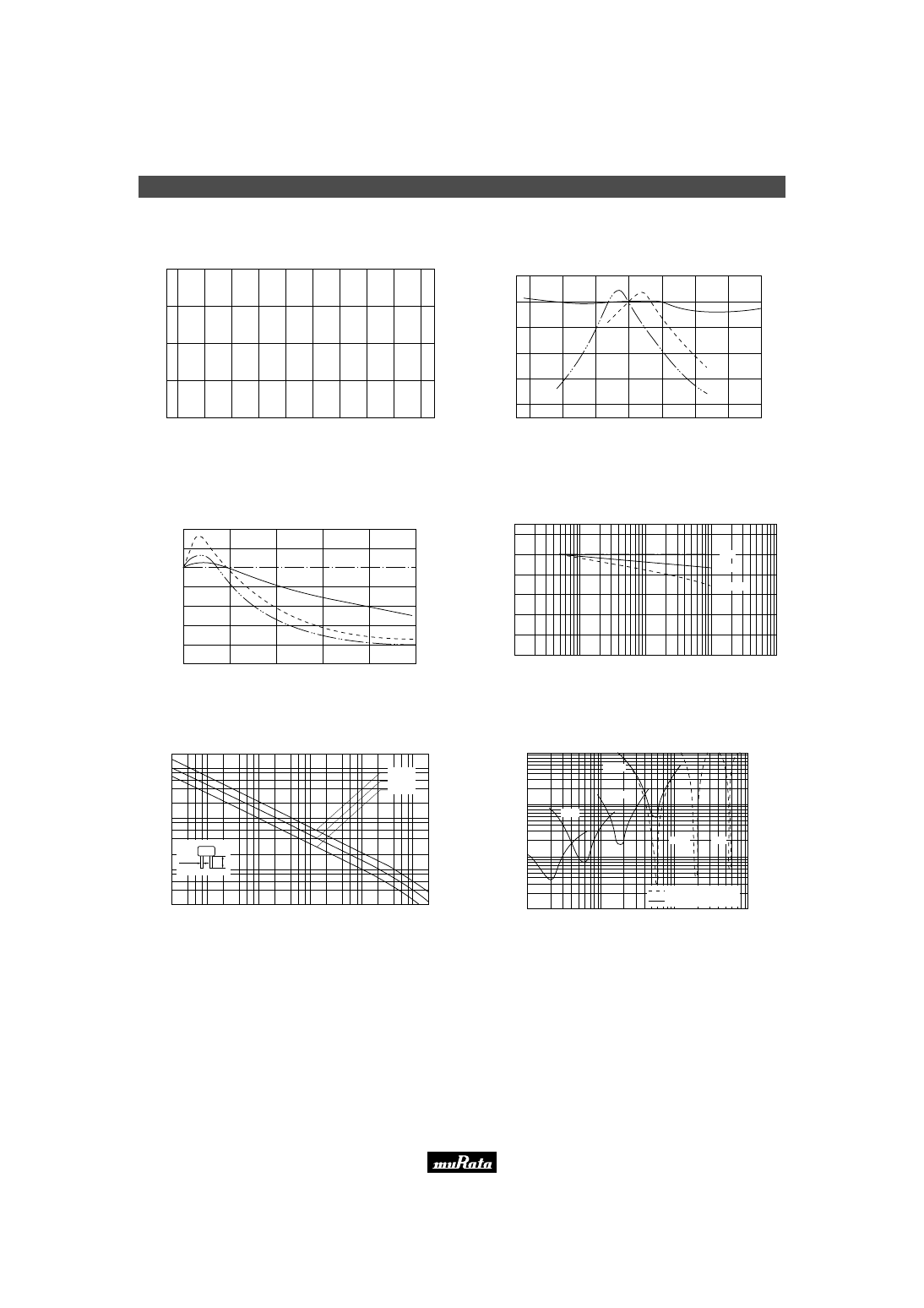

Characteristics Data (Typical Example)

18

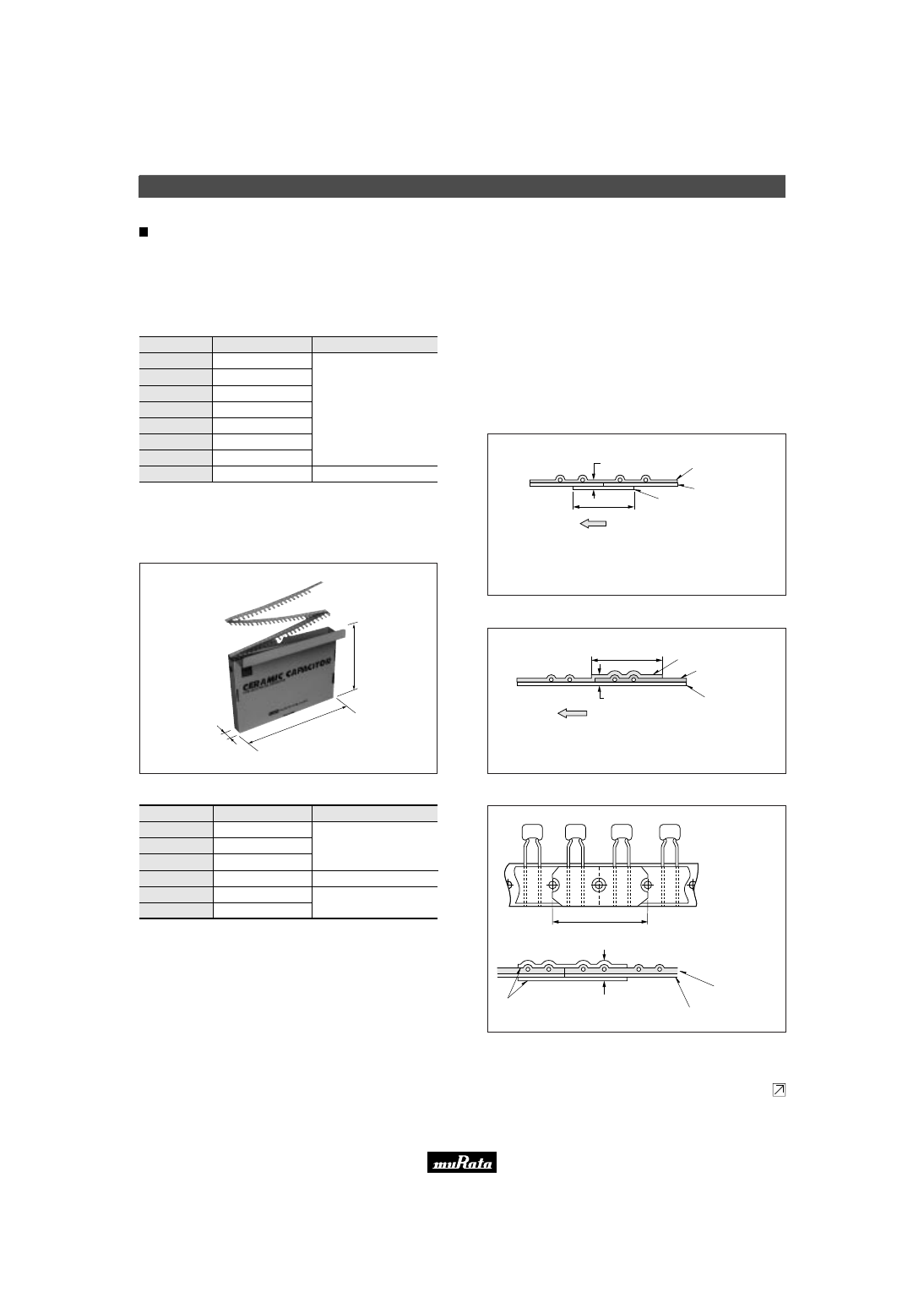

Packaging

19

!

Caution

21

Notice/QS9000 Certification

24

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

2

o

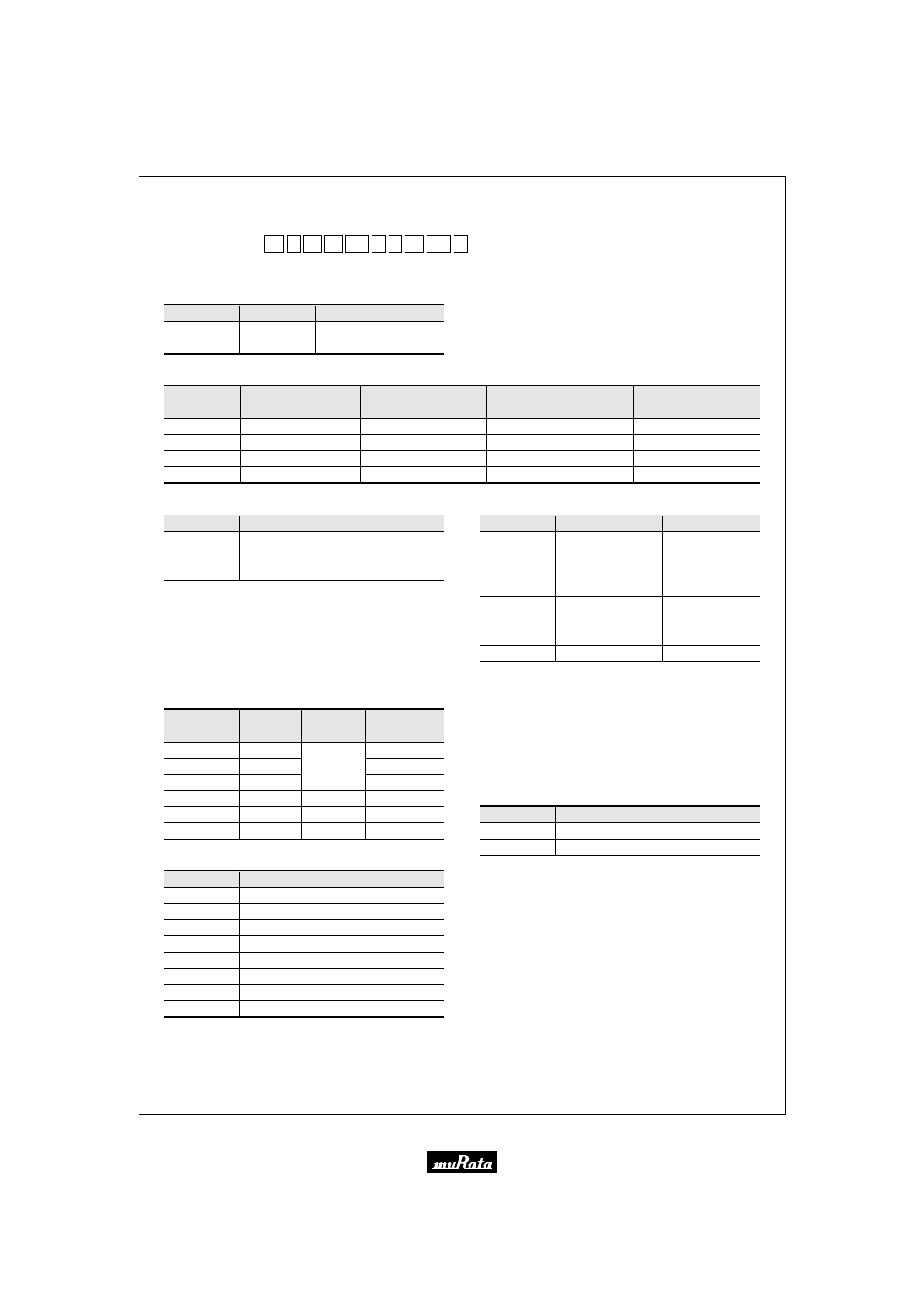

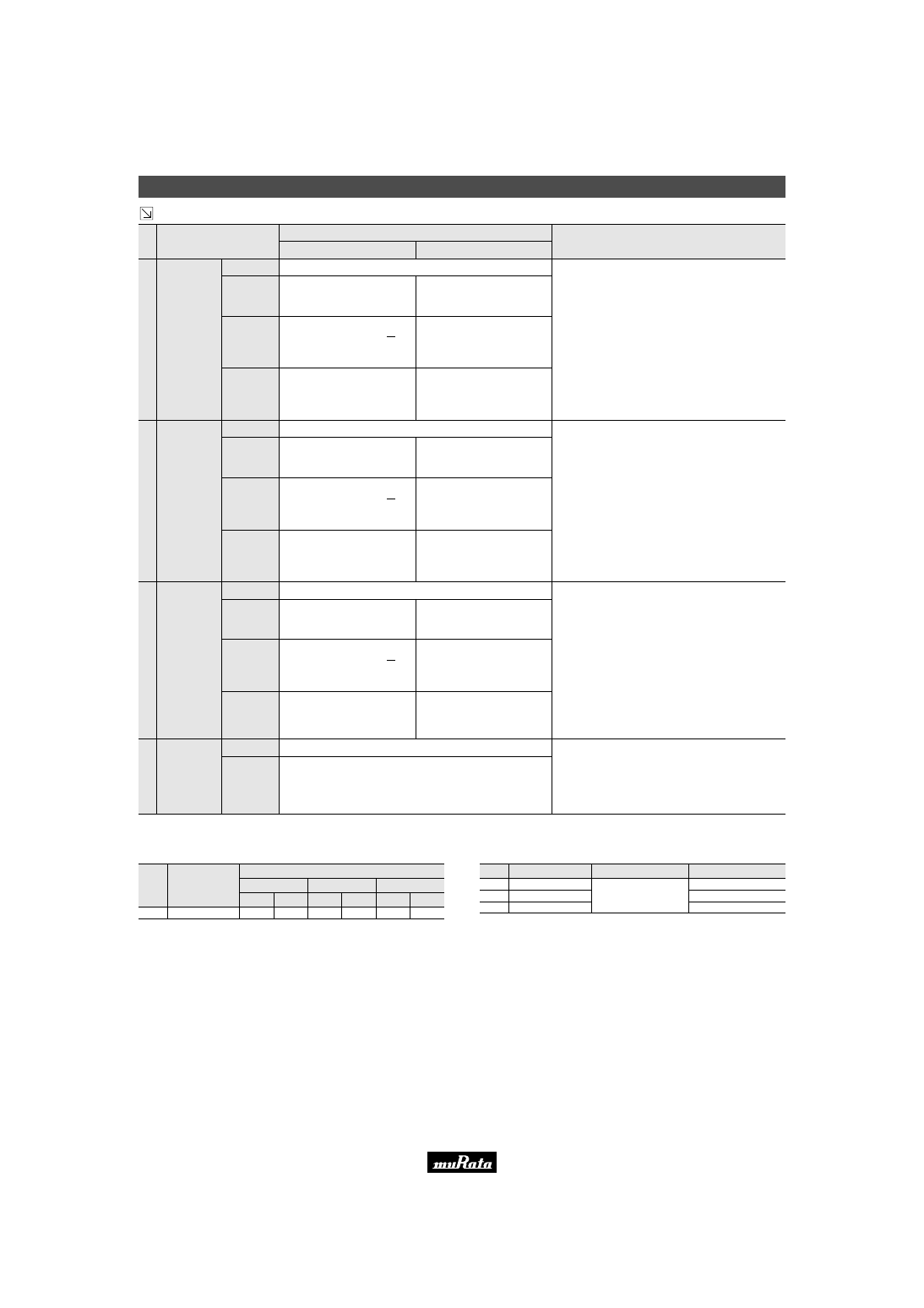

Part Numbering

(Part Number)

w

q

Product ID

w

Series/Terminal

RP

E

Radial Lead Type Monolithic

Ceramic Capacitors

Product ID

Series/Terminal

RP

q

E

e

R7

r

1H

t

104

u

2

i

M1

y

K

o

A03

!0

A

t

Capacitance

Expressed by three figures. The unit is pico-farad (pF). The first

and second figures are significant digits, and the third figure

expresses the number of zeros which follow the two numbers.

If there is a decimal point, it is expressed by the capital letter "

R

".

In this case, all figures are significant digits.

o

Individual Specification Code

Expressed by three figures

y

Capacitance Tolerance

Code

C

D

J

K

M

Z

C0G

X7R

Z5U

Y5V

Radial Lead Type Monolithic Ceramic Capacitors

e

Temperature Characteristics

Code

25 to 125

°

C

10 to 85

°

C

-30 to 85

°

C

-55 to 125

°

C

Temperature

Range

0

±

30ppm/

°

C

+22, -56%

+22, -82%

±

15%

Capacitance Change or

Temperature Coefficient

-55 to 125

°

C

10 to 85

°

C

-30 to 85

°

C

-55 to 125

°

C

Operating

Temperature Range

C0G

Z5U

Y5V

X7R

Temperature

Characteristics

5C

E4

F5

R7

r

Rated Voltage

Code

1E

1H

2A

DC25V

DC50V

DC100V

Rated Voltage

u

Dimensions (LxW)

Code

1

2

3

4

5

6

7

8

3.5

g

3.0mm

5.0

g

3.5mm

5.0

g

4.5mm

7.5

g

5.0mm

7.5

g

7.5mm

10.0

g

10.0mm

12.5

g

12.5mm

7.5

g

5.5mm

Temperature

Characteristics

V

5pF : 1pF Step

6 to 9pF : 1pF Step

U

10 : E12 Series

E6 Series

E3 Series

E3 Series

Capacitance

Step

±

0.25pF

±

0.5pF

±

5%

±

10%

±

20%

+80%, -20%

Capacitance

Tolerance

i

Lead Style

Code

Lead Style

Lead Spacing

A1

B1

C1

E1

/

E2

K1

M1

/

M2

P1

S1

/

S2

F=2.5mm

F=5.0mm

other than above

F=5.0mm

F=5.0mm

F=5.0mm

F=2.5mm

F=2.5mm

Straight Long

Straight Long

Straight Long

Straight Taping

Inside Crimp

Inside Crimp Taping

Outside Crimp

Outside Crimp Taping

Dimensions (LxW)

Lead distance between reference and bottom planes.

M1, S1 : H

0

= 16.0

±

0.5mm

M2, S2 : H

0

= 20.0

±

0.5mm

E1 : H = 17.5

±

0.5mm

E2 : H = 20.0

±

0.5mm

!0

Packaging

Code

A

B

Ammo Pack

Bulk

Packaging

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

3

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

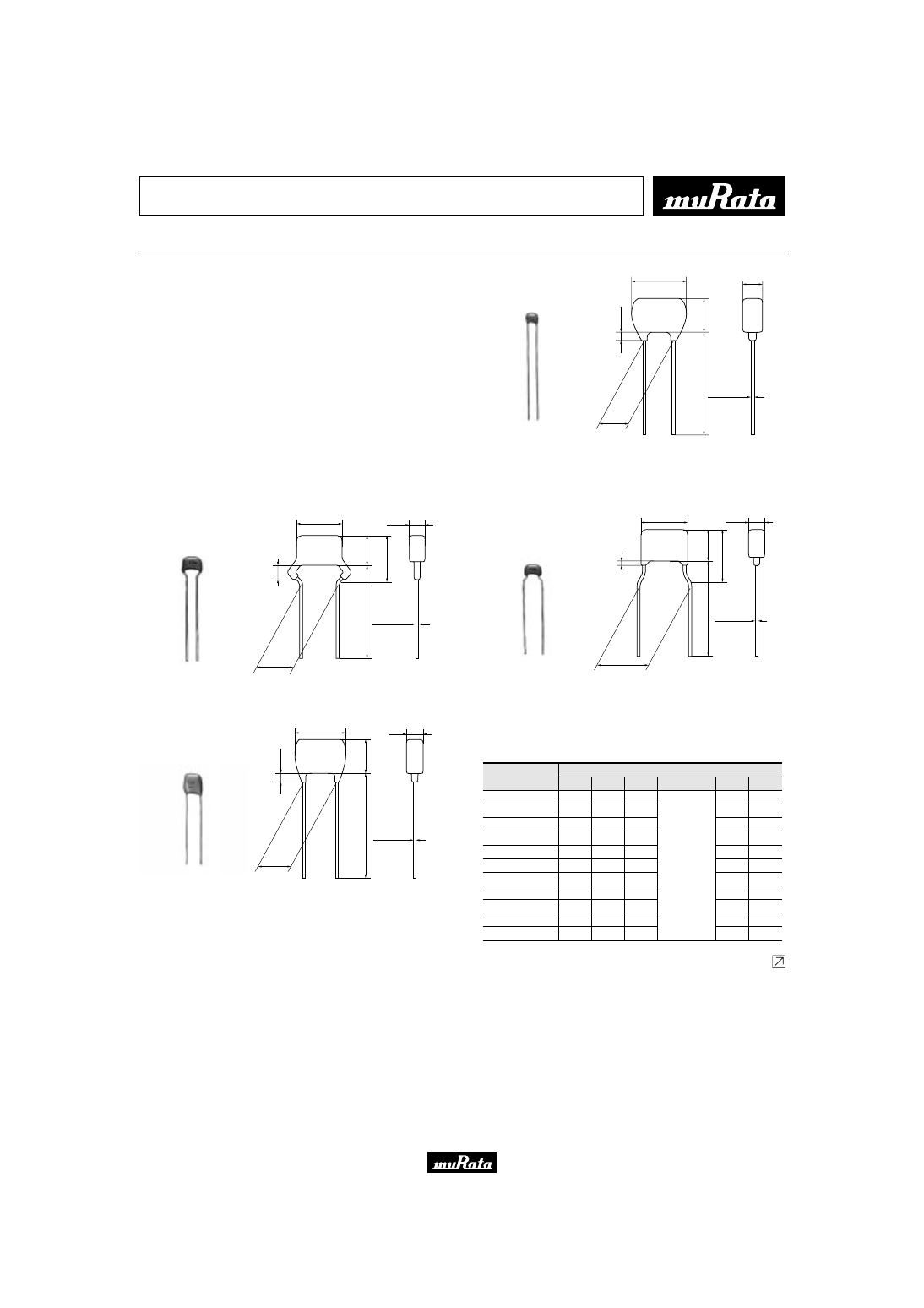

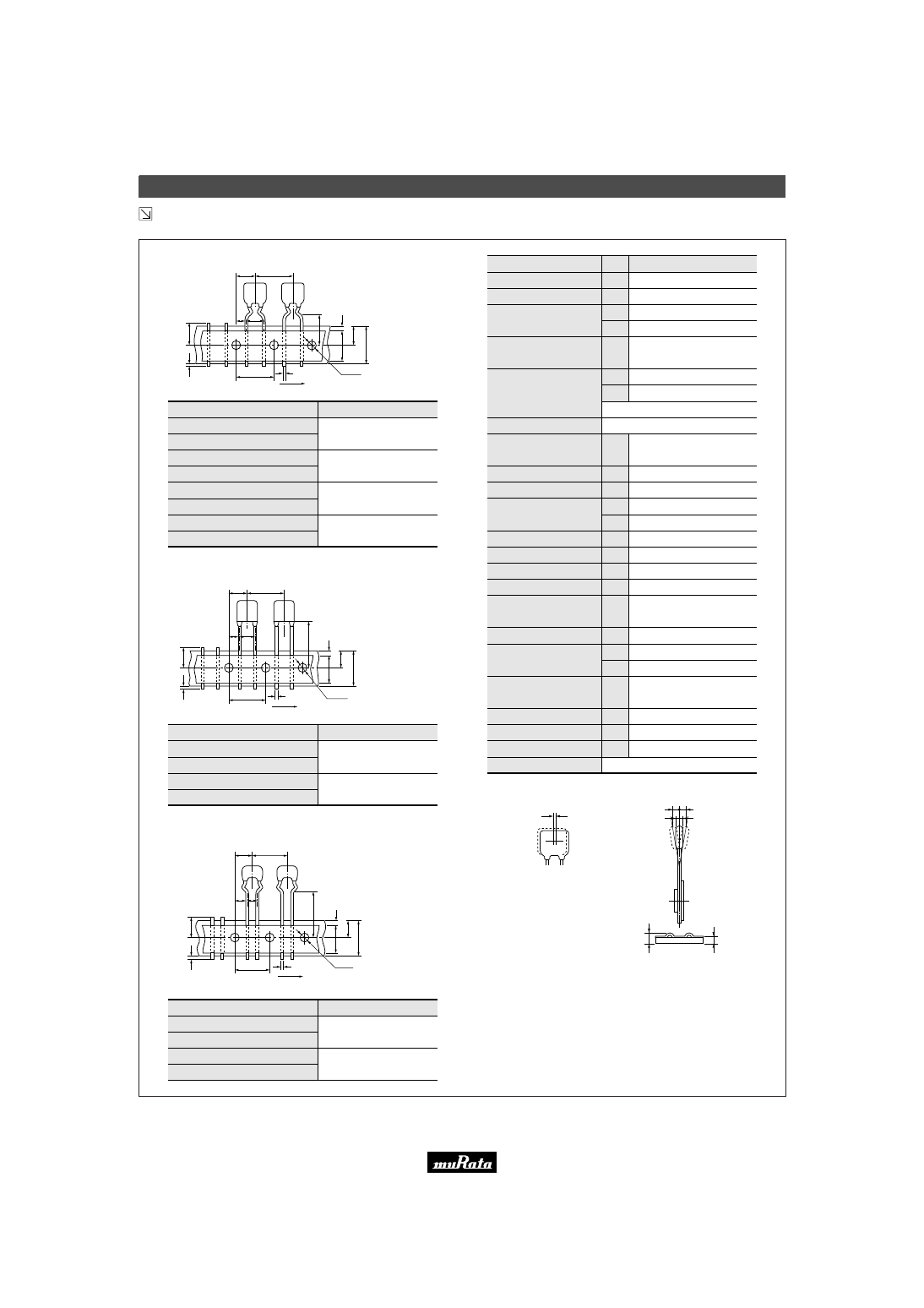

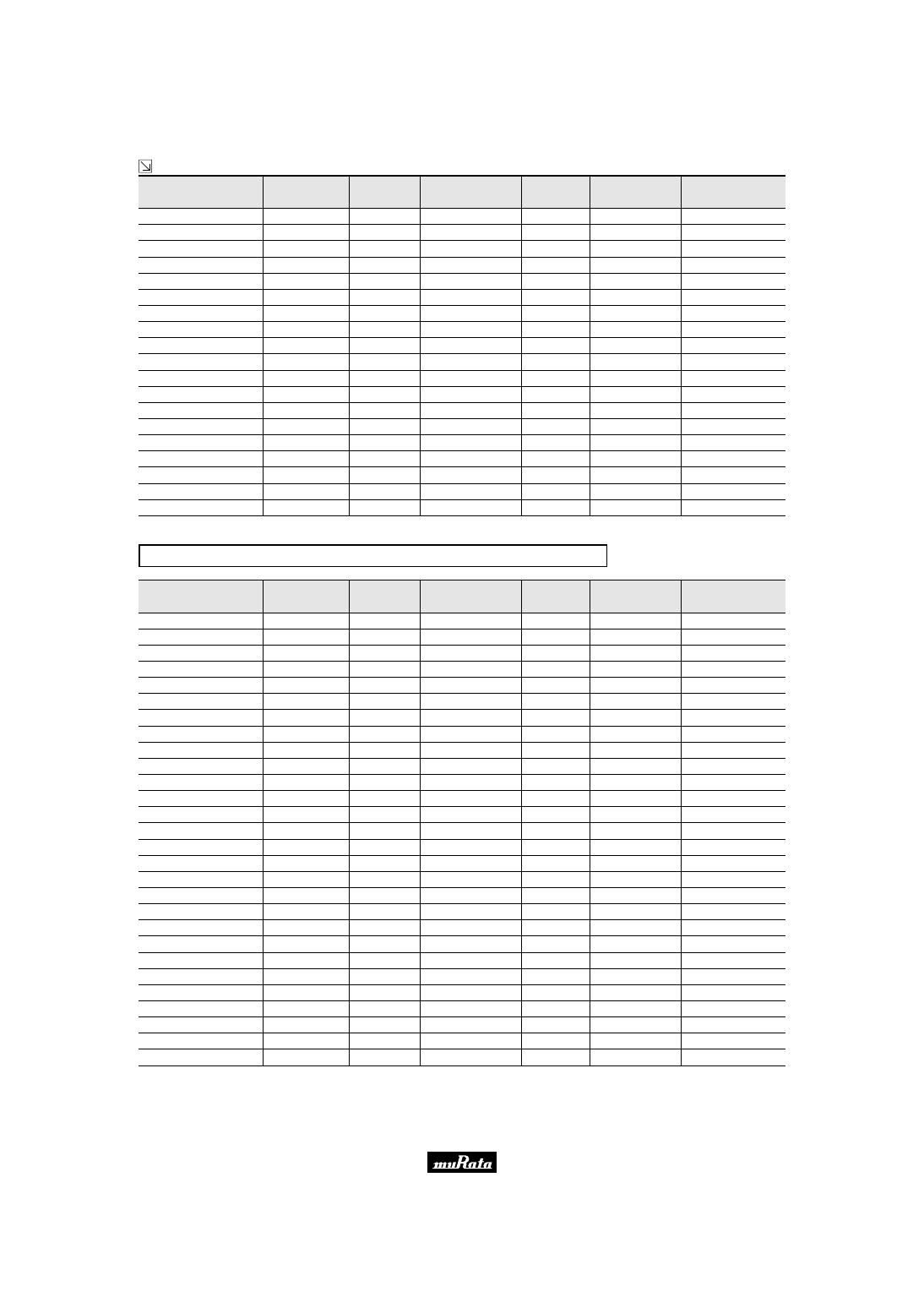

Radial Lead Type Monolithic Ceramic Capacitors

Radial Lead Type Monolithic Ceramic Capacitors

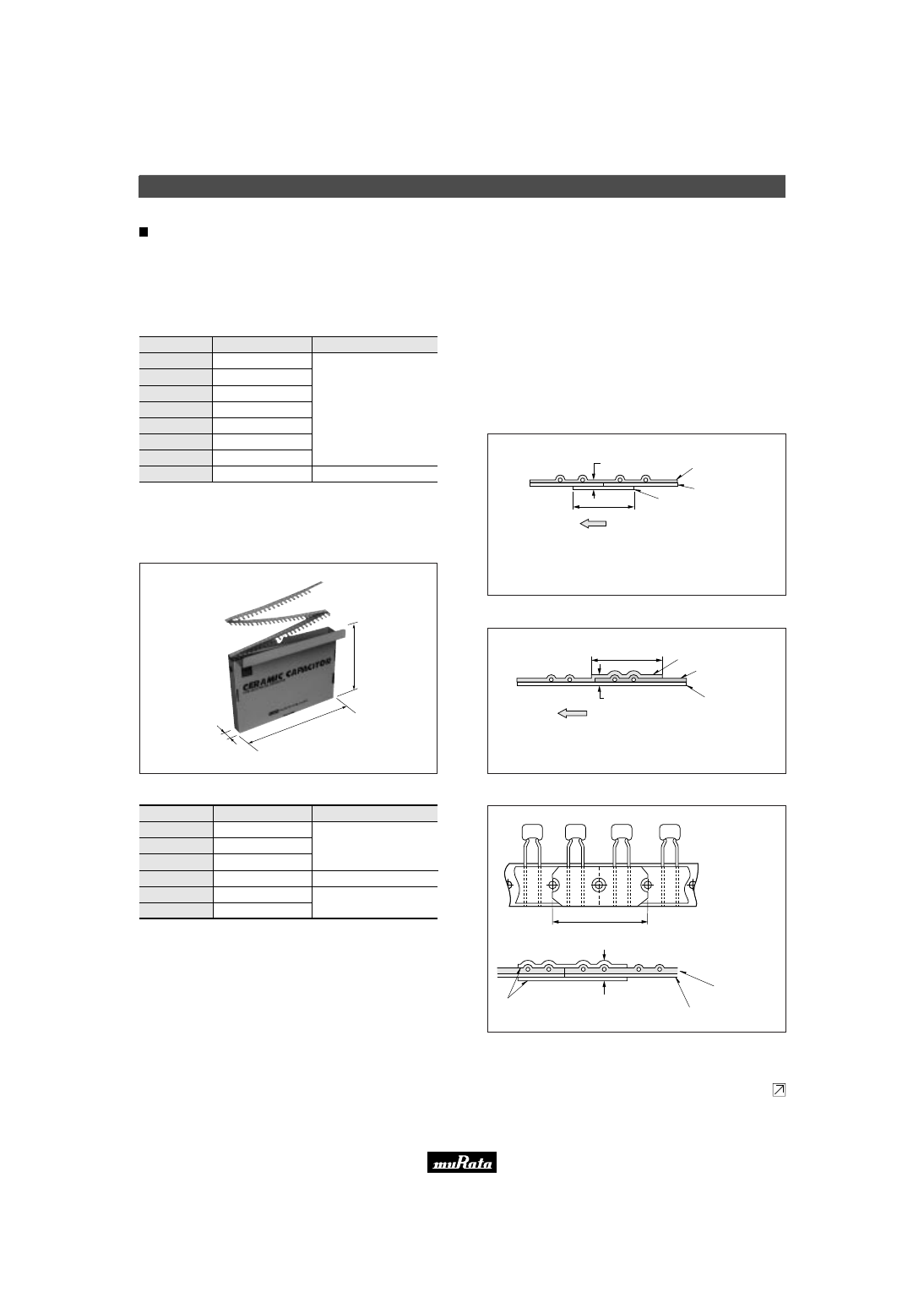

■

Features

1. The RPE series capacitors have small dimensions,

large capacitance, and a capacity volume ratio of

10 micro F/cm cube, close to that of electrolytic

capacitors. These do not have polarity.

2. These have excellent frequency characteristics and

due to these small internal inductance are suitable

for high frequencies.

3. These are not coated with wax so there is no change

in their exterior appearance due to the outflow of

wax during soldering or solvent during cleansing.

4. These are highly inflammable, having

characteristics equivalent to the UL94V-0 standard.

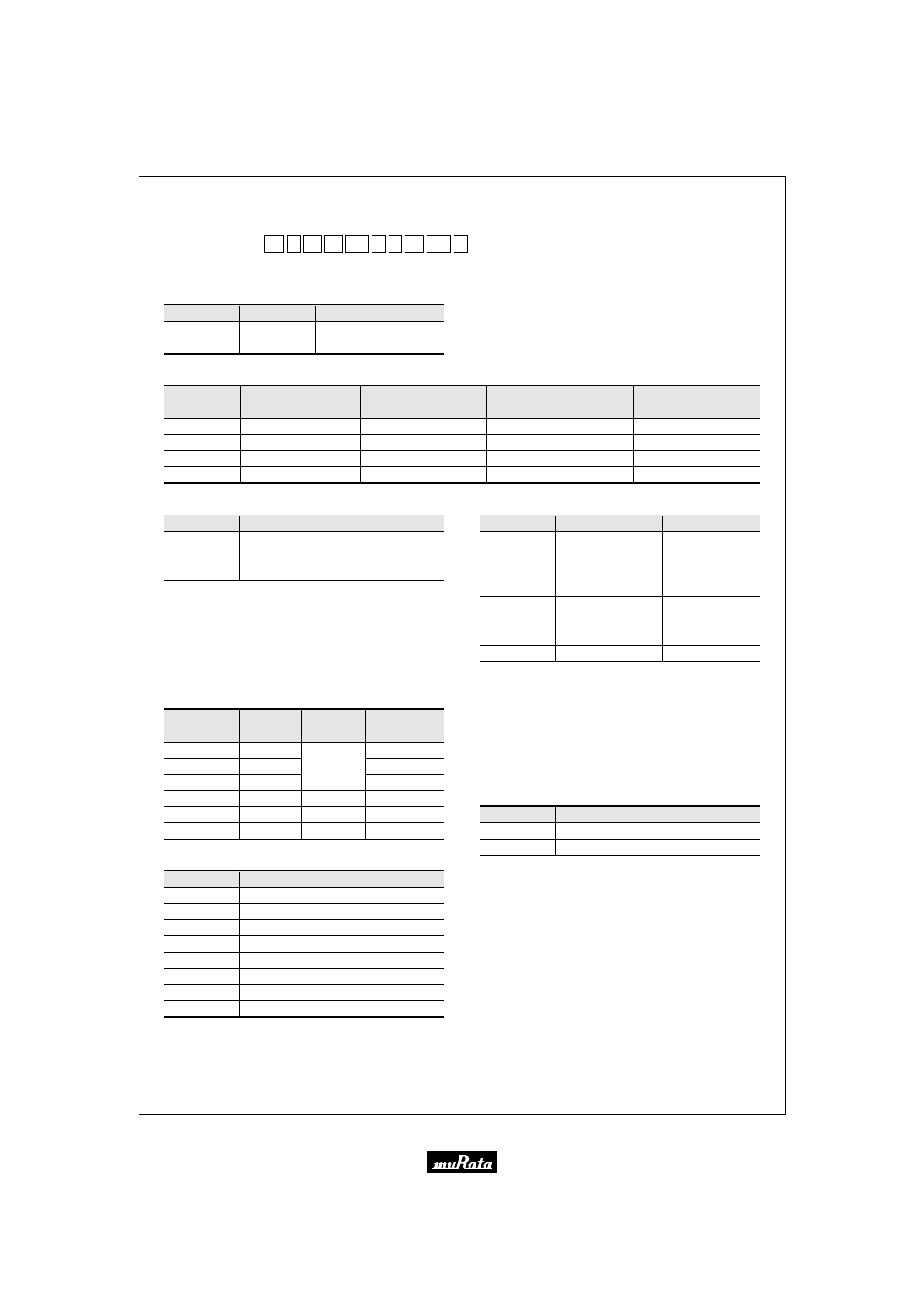

(in mm)

L max.

1.5 max.

F : 2.5

±

0.8

T max.

W max.

25.0 min. ød : 0.4

±

0.05

· Lead Wire : Solder Coated Copper Wire or

Solder Coated CP Wire

Dimensions code: 1

Lead style code: A1

(in mm)

L max.

ød : 0.5

±

0.05

T max.

W max.

25.0 min.

W1 max.

F : 2.5

±

0.8

∗

∗

Coating extension does not exceed the end of the lead bend.

· Lead Wire : Solder Coated Copper Wire or

Solder Coated CP Wire

Dimensions code: 2/3

Lead style code: P1

(in mm)

∗

Coating extension does not exceed the end of the lead bend.

· Lead Wire : Solder Coated Copper Wire or

Solder Coated CP Wire

ød : 0.5

±

0.05

T max.

L max.

W max.

25.0 min.

W1 max.

F : 5.0

±

0.8

∗

Dimensions code: 2/3/4/8

Lead style code: K1

(in mm)

T max.

L max.

ød : 0.5

±

0.05

W max.

25.0 min.

1.5 max.

F

±

0.8

· Lead Wire : Solder Coated Copper Wire or

Solder Coated CP Wire

Dimensions code: 5/6/7

Lead style code: B1/C1

■

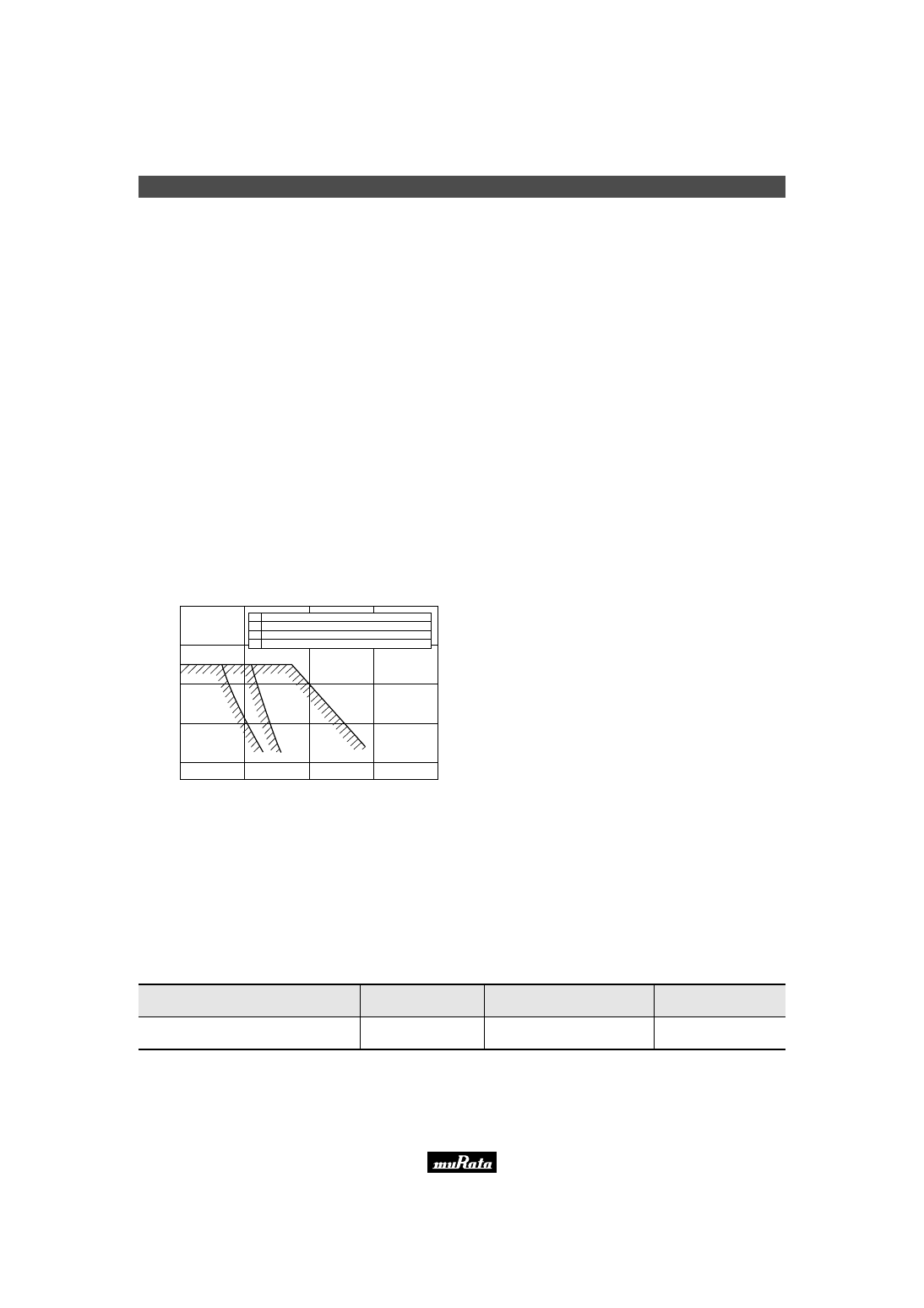

Dimensions

Dimensions and

Lead style code

Dimensions (mm)

L

W

W1

T

F

d

1A1

2P1/2S1/2S2

2K1/2M1/2M2

3P1/3S1/3S2

3K1/3M1/3M2

4K1/4M1/4M2

5B1/5E1/5E2

6B1/6E1/6E2

7C1

TB1/TE1/TE2

0.4

2.5

-

3.0

3.5

0.5

2.5

5.0

3.5

5.0

0.5

5.0

5.0

3.5

5.0

0.5

2.5

6.3

See

the individual

product

specification

4.5

5.0

0.5

5.0

6.3

4.5

5.0

0.5

5.0

7.0

5.0

7.5

0.5

5.0

-

7.5

7.5

0.5

5.0

-

10.0

10.0

0.5

10.0

-

12.5

12.5

8K1/8M1/8M2

0.5

5.0

8.0

5.5

7.5

0.5

5.0

-

8.5

10.0

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

4

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

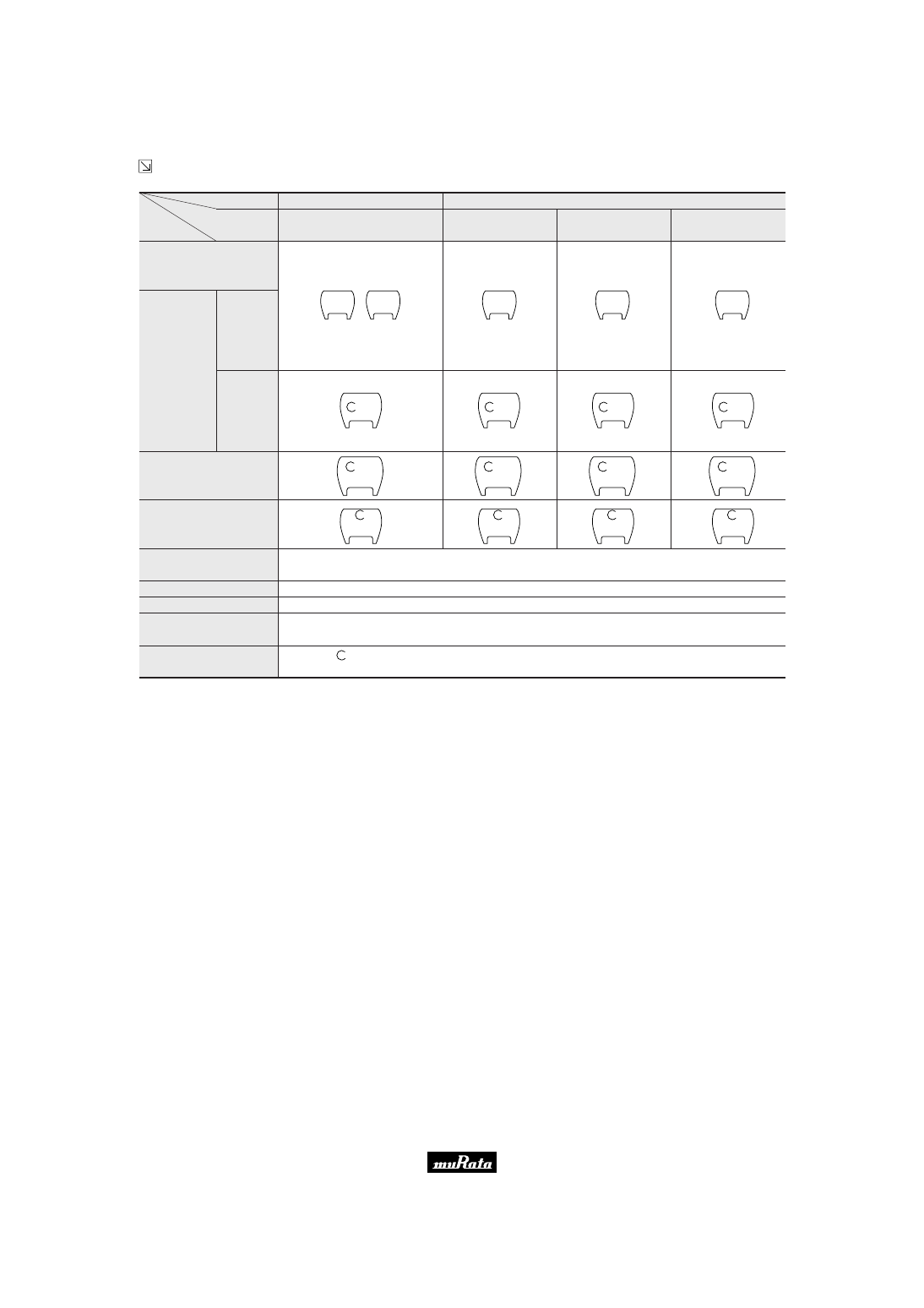

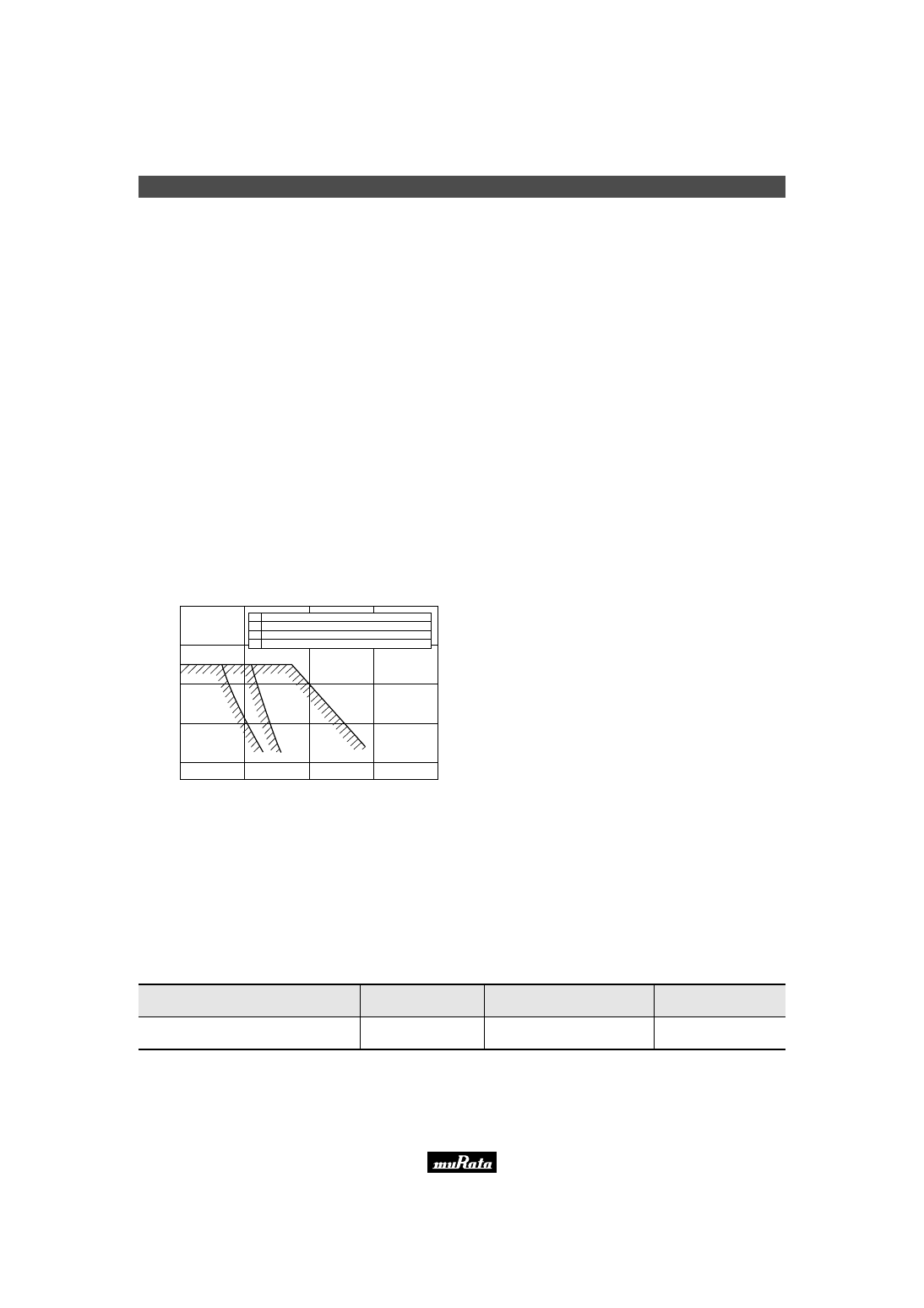

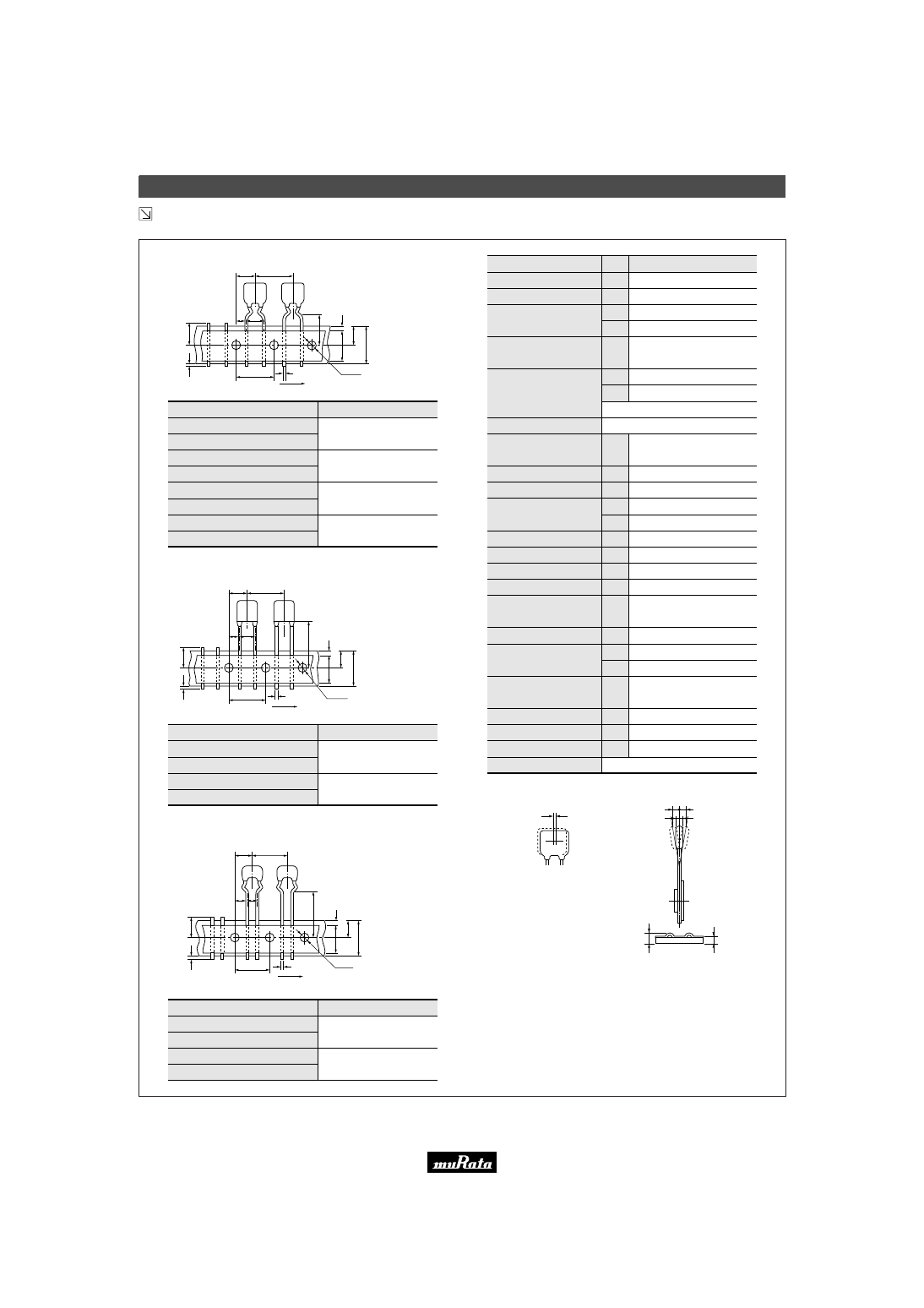

Continued from the preceding page.

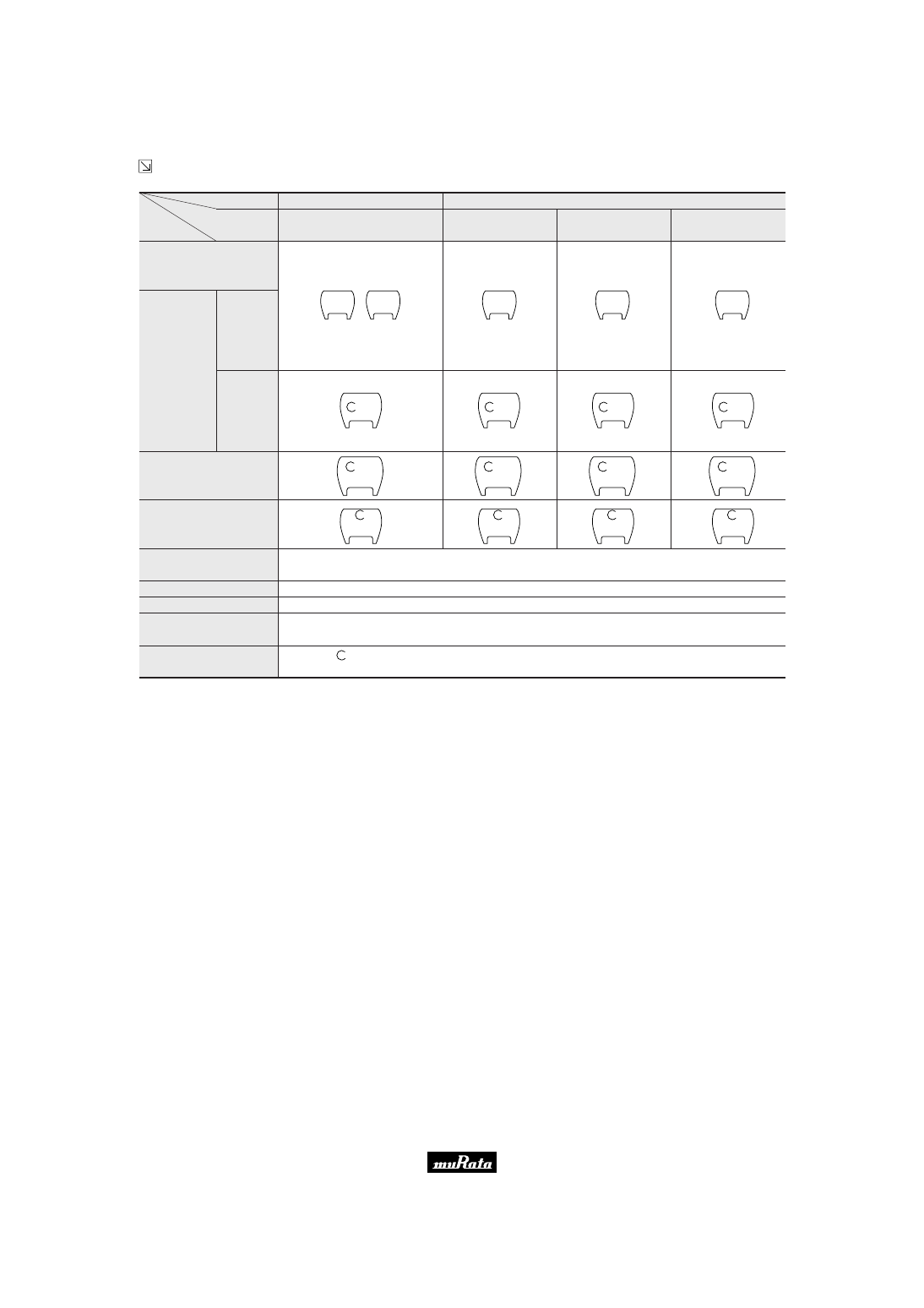

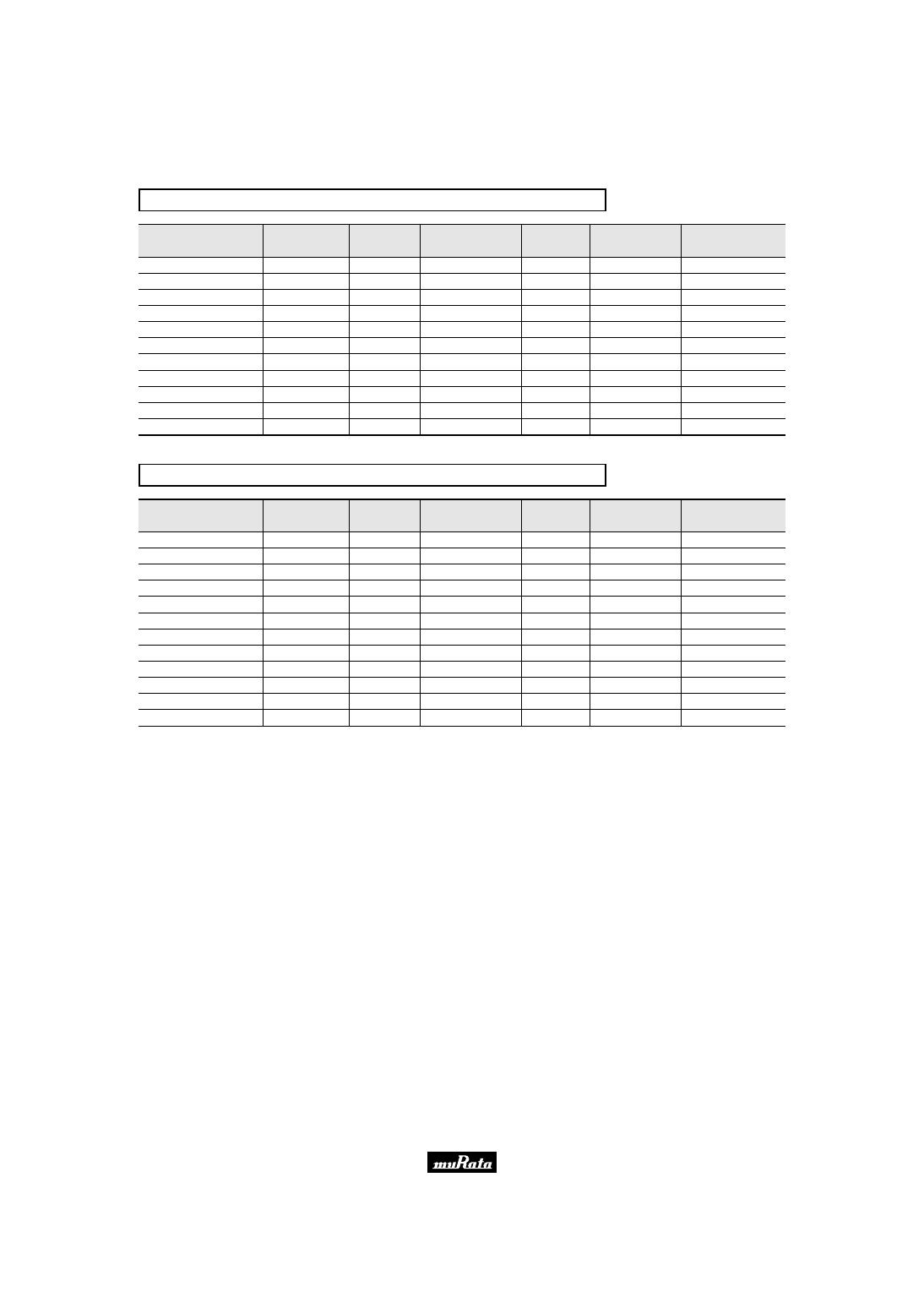

■

Marking

Type

Temp. Char.

Individual

Specification

Code

A

pp

B

pp

Z

pp

Individual

Specification

Code

Except

A

pp

B

pp

Z

pp

Dimensions

Code

1

3, 4, 8

5, 6, 7

Temperature Characteristics

Nominal Capacitance

Capacitance Tolerance

Rated Voltage

Manufacturer's Identification

2

Temperature Compensating Type

High Dielectric Constant Type

C0G

X7R

Z5U

Y5V

102J

222K

222M

224Z

5A

682

J5A

333

J5A

103

J5A

M

M

M

M

224

K5C

225

K5C

684

K5C

M

M

M

224

M5E

225

M5E

105

M5E

M

M

M

474

Z5F

225

Z5F

105

Z5F

M

M

M

Under 100pF: Actual value 100pF and over: marked with 3 figures

Marked with code

Marked with code (C0G char.: A, X7R char.: C, Z5U char.: E, Y5V char.: F)

A part is omitted (Please refer marking example)

Marked with code (DC25V: 2, DC50V: 5, DC100V: 1)

A part is omitted (Please refer marking example)

Marked with

A part is omitted (Please refer marking example)

Marked on both sides

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

5

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

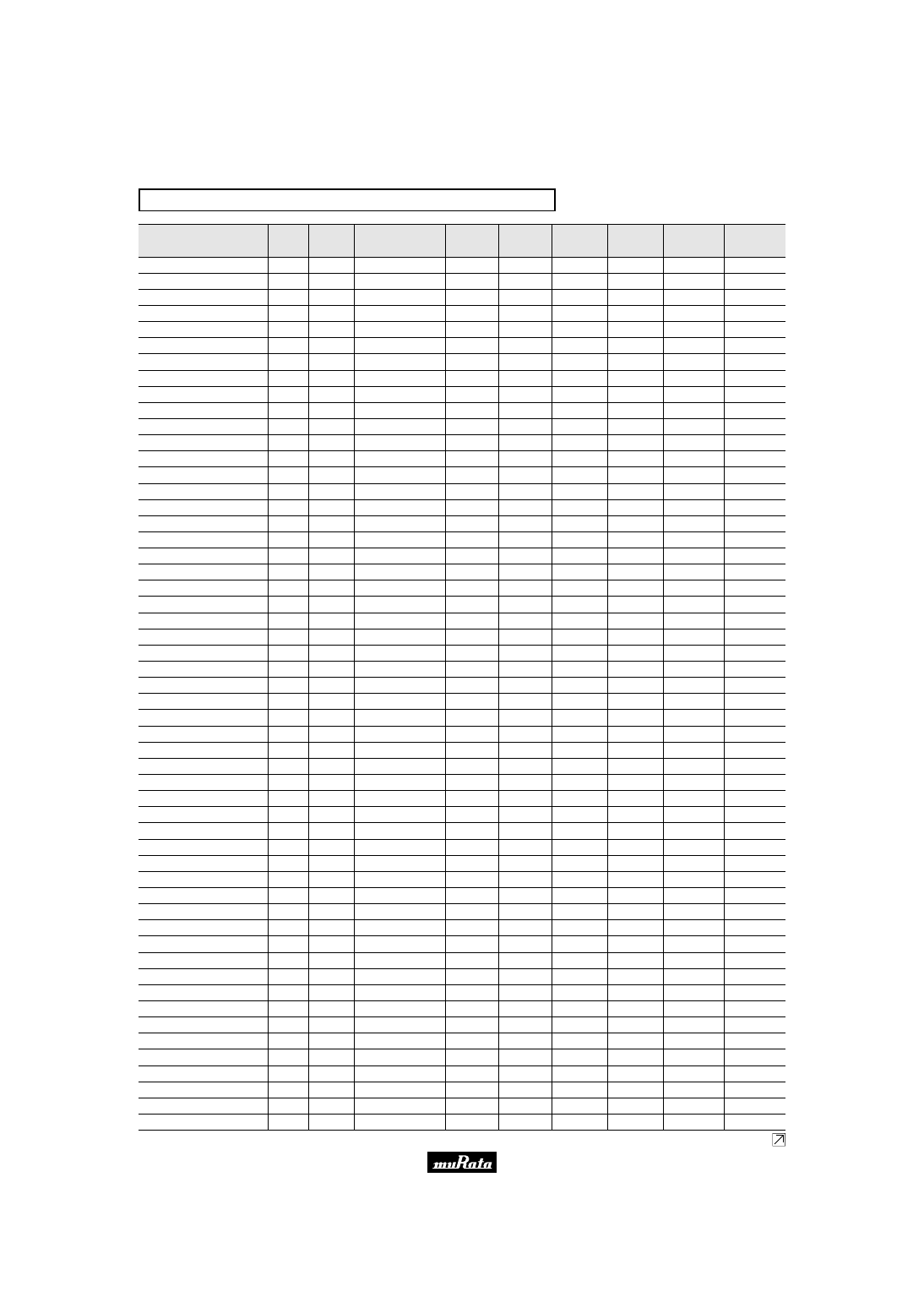

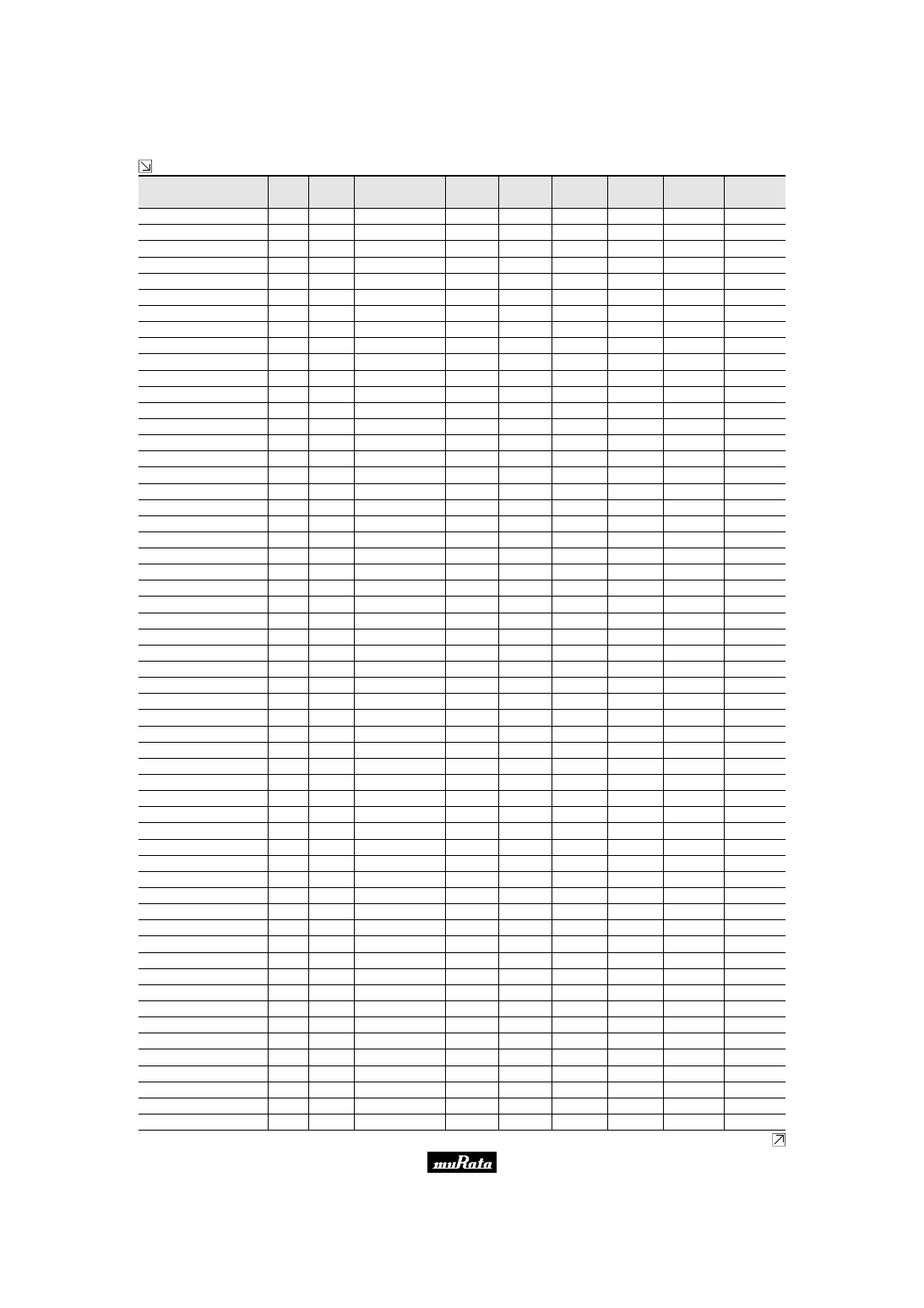

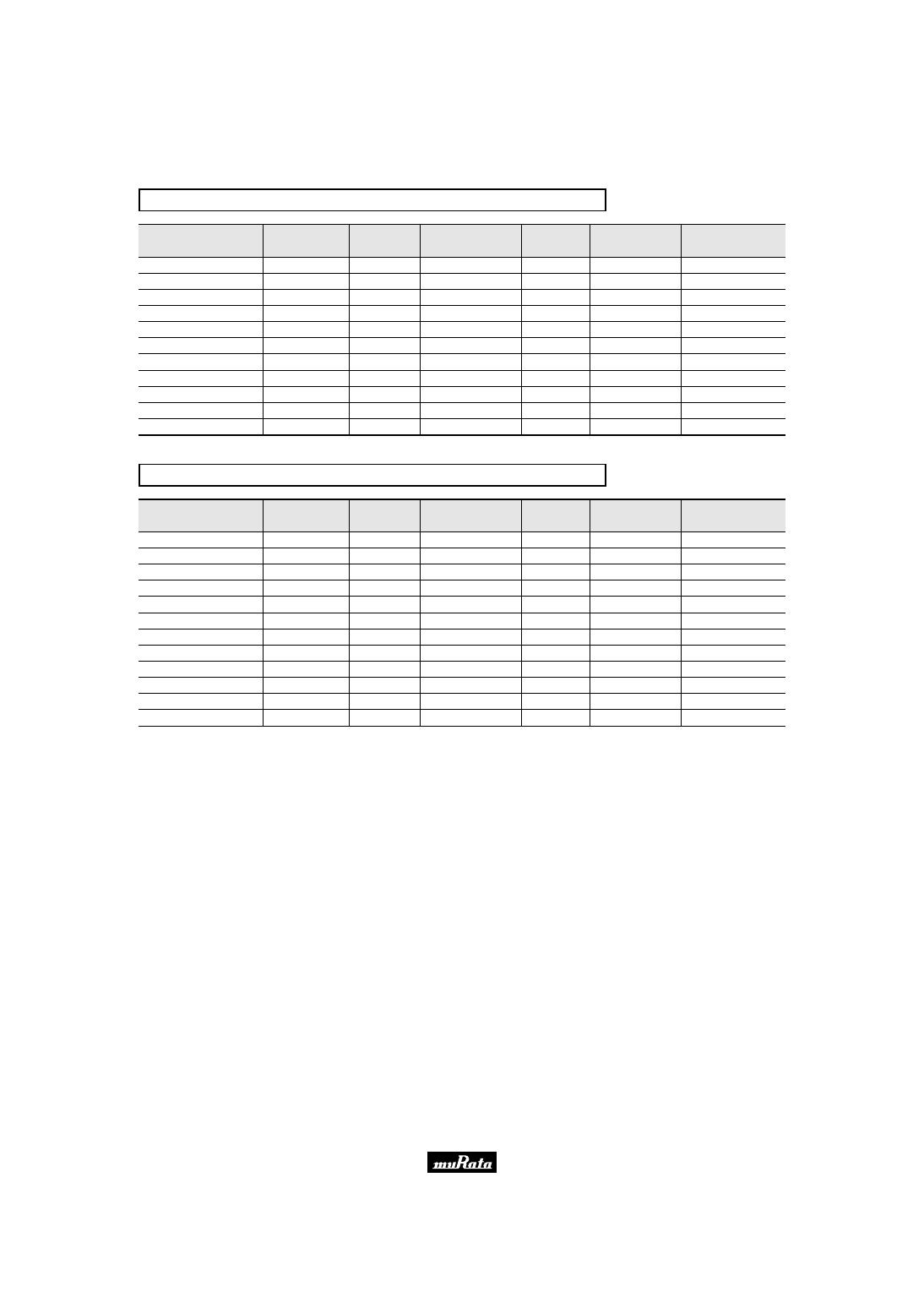

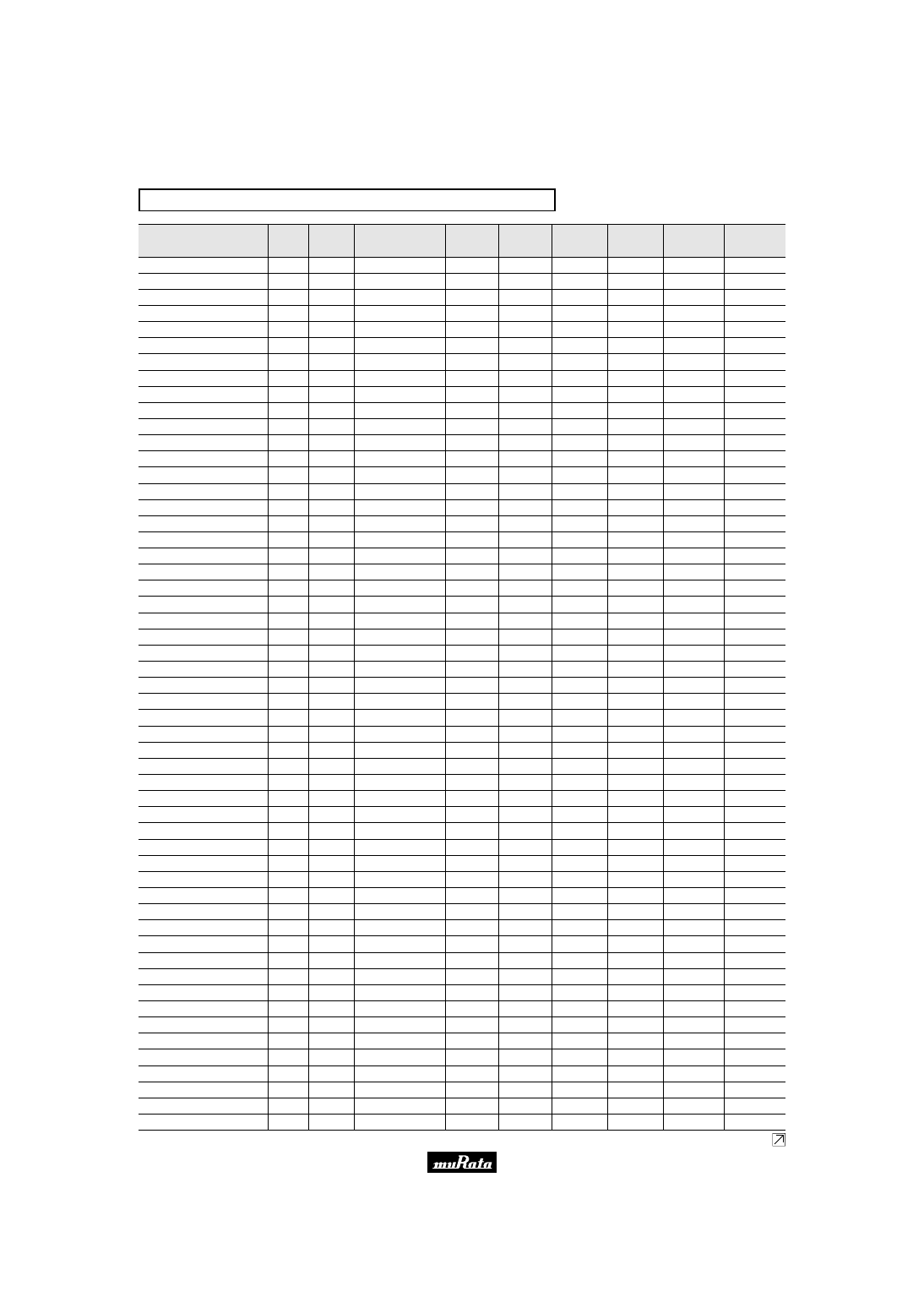

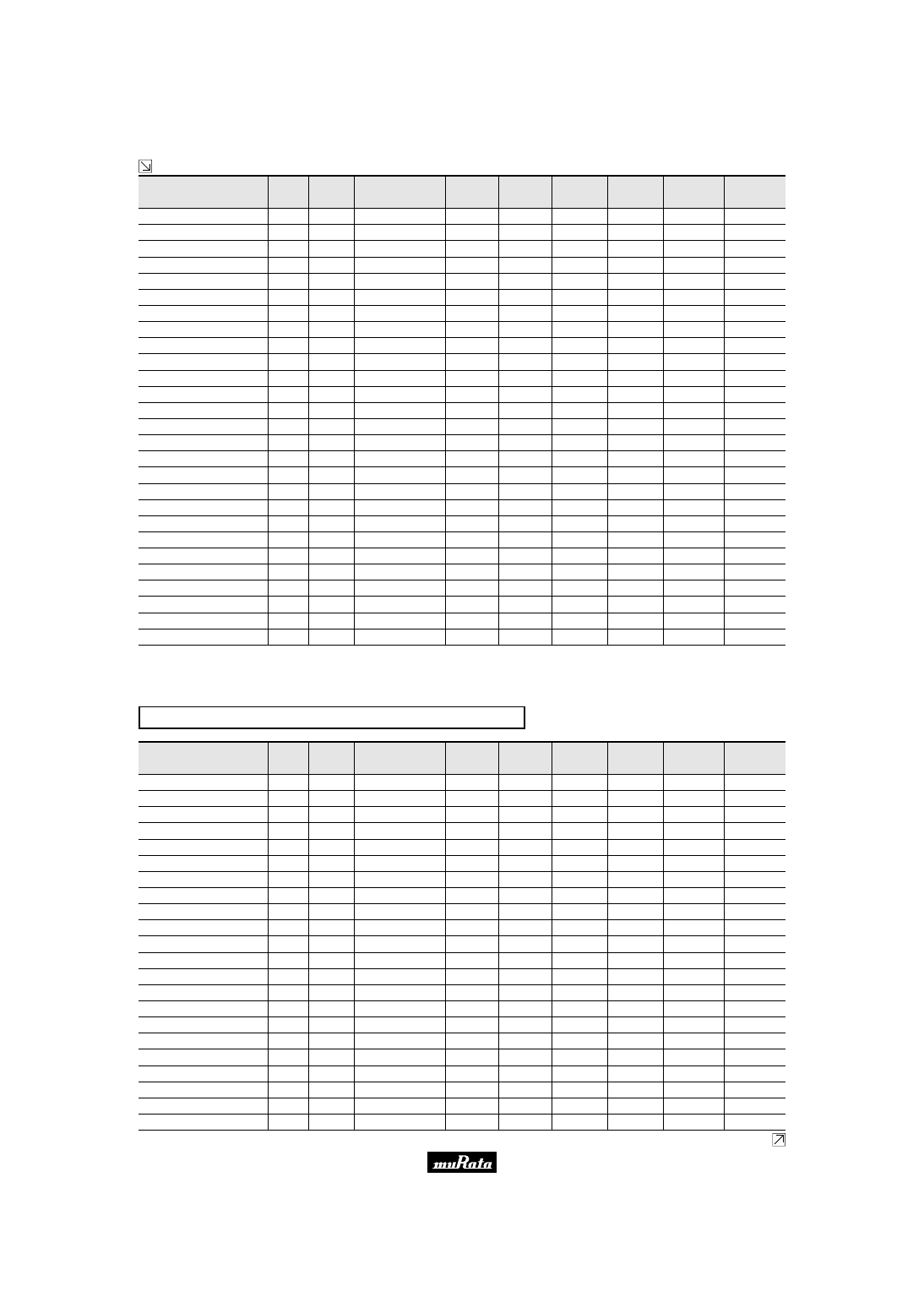

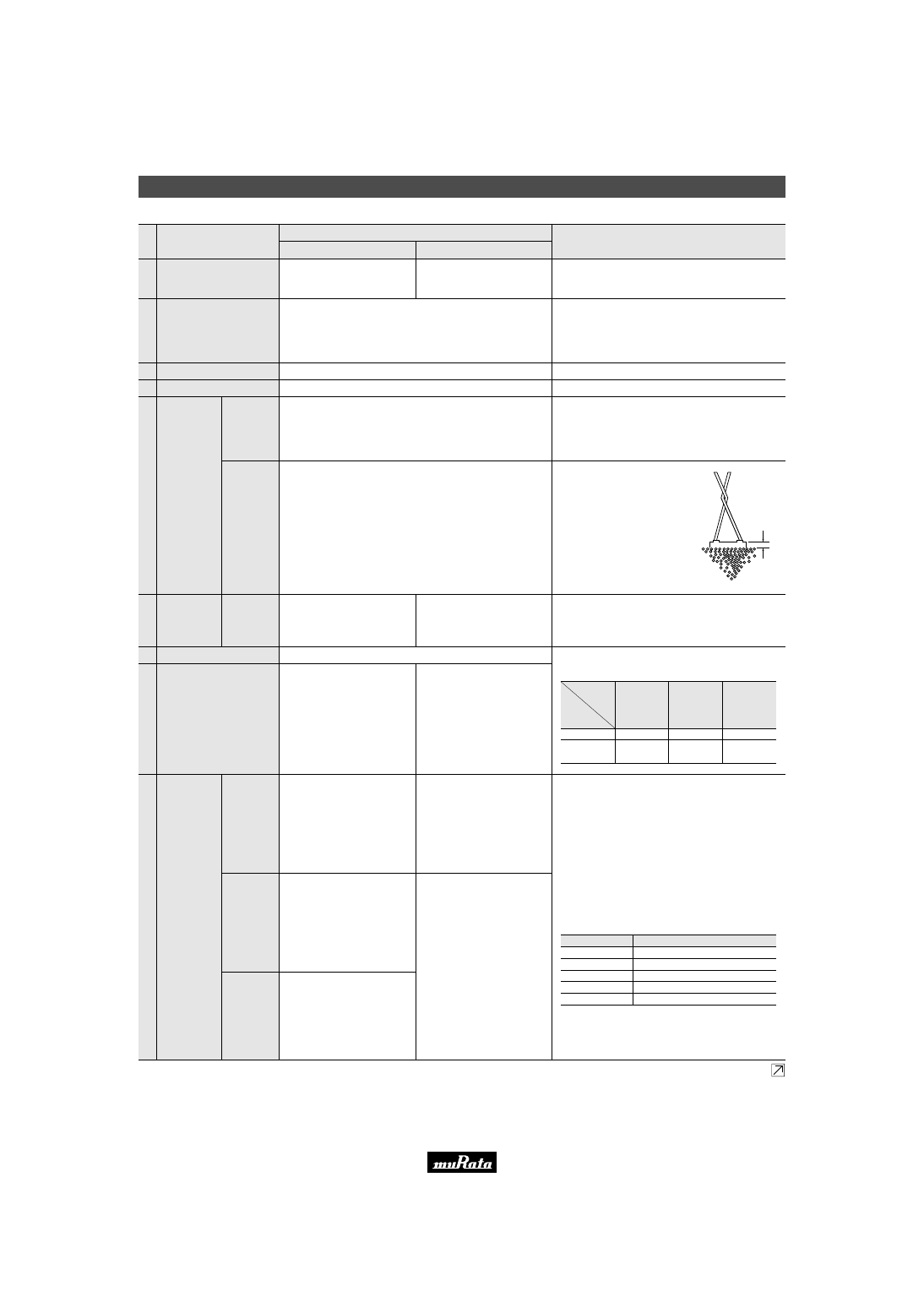

Temperature Compensating Type, C0G Characteristics

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

(pF)

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

RPE5C1H1R0C2

pp

B03

p

C0G

50

1.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H1R0C2

pp

B03

p

C0G

50

1.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H2R0C2

pp

B03

p

C0G

50

2.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H2R0C2

pp

B03

p

C0G

50

2.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H3R0C2

pp

B03

p

C0G

50

3.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H3R0C2

pp

B03

p

C0G

50

3.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H4R0C2

pp

B03

p

C0G

50

4.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H4R0C2

pp

B03

p

C0G

50

4.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H5R0C2

pp

B03

p

C0G

50

5.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H5R0C2

pp

B03

p

C0G

50

5.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H6R0D2

pp

B03

p

C0G

50

6.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H6R0D2

pp

B03

p

C0G

50

6.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H7R0D2

pp

Z03

p

C0G

50

7.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H7R0D2

pp

Z03

p

C0G

50

7.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H8R0D2

pp

Z03

p

C0G

50

8.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H8R0D2

pp

Z03

p

C0G

50

8.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H9R0D2

pp

Z03

p

C0G

50

9.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H9R0D2

pp

Z03

p

C0G

50

9.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H100J2

pp

Z03

p

C0G

50

10

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H100J2

pp

Z03

p

C0G

50

10

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H120J2

pp

Z03

p

C0G

50

12

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H120J2

pp

Z03

p

C0G

50

12

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H150J2

pp

Z03

p

C0G

50

15

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H150J2

pp

Z03

p

C0G

50

15

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H180J2

pp

Z03

p

C0G

50

18

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H180J2

pp

Z03

p

C0G

50

18

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H220J2

pp

Z03

p

C0G

50

22

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H220J2

pp

Z03

p

C0G

50

22

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H270J2

pp

Z03

p

C0G

50

27

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H270J2

pp

Z03

p

C0G

50

27

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H330J2

pp

Z03

p

C0G

50

33

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H330J2

pp

Z03

p

C0G

50

33

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H390J2

pp

Z03

p

C0G

50

39

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H390J2

pp

Z03

p

C0G

50

39

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H470J2

pp

Z03

p

C0G

50

47

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H470J2

pp

Z03

p

C0G

50

47

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H560J2

pp

Z03

p

C0G

50

56

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H560J2

pp

Z03

p

C0G

50

56

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H680J2

pp

Z03

p

C0G

50

68

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H680J2

pp

Z03

p

C0G

50

68

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H820J2

pp

Z03

p

C0G

50

82

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H820J2

pp

Z03

p

C0G

50

82

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H101J2

pp

A03

p

C0G

50

100

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H101J2

pp

A03

p

C0G

50

100

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H121J2

pp

A03

p

C0G

50

120

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H121J2

pp

A03

p

C0G

50

120

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H151J2

pp

A03

p

C0G

50

150

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H151J2

pp

A03

p

C0G

50

150

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H181J2

pp

A03

p

C0G

50

180

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H181J2

pp

A03

p

C0G

50

180

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H221J2

pp

A03

p

C0G

50

220

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H221J2

pp

A03

p

C0G

50

220

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H271J2

pp

A03

p

C0G

50

270

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H271J2

pp

A03

p

C0G

50

270

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

6

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

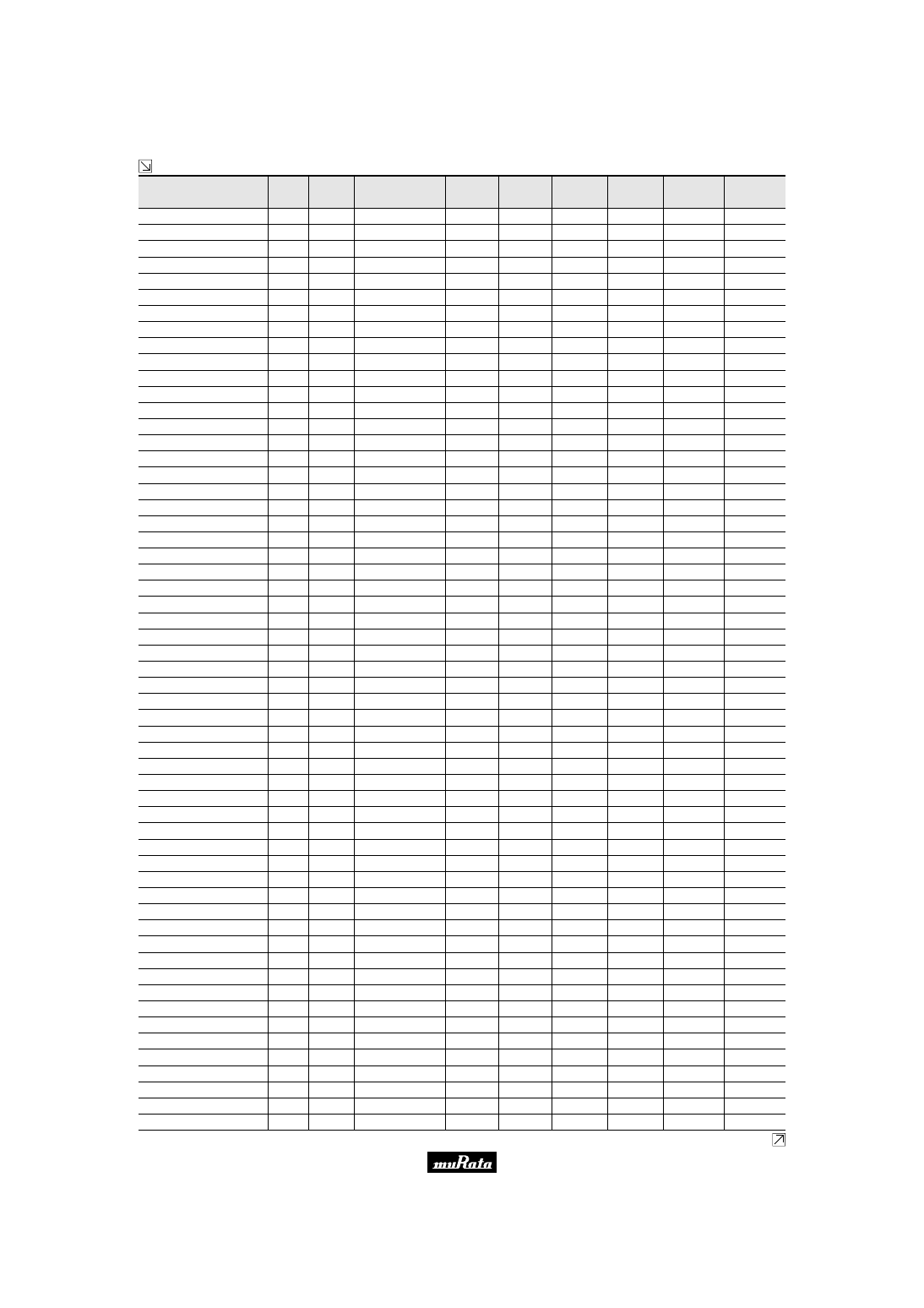

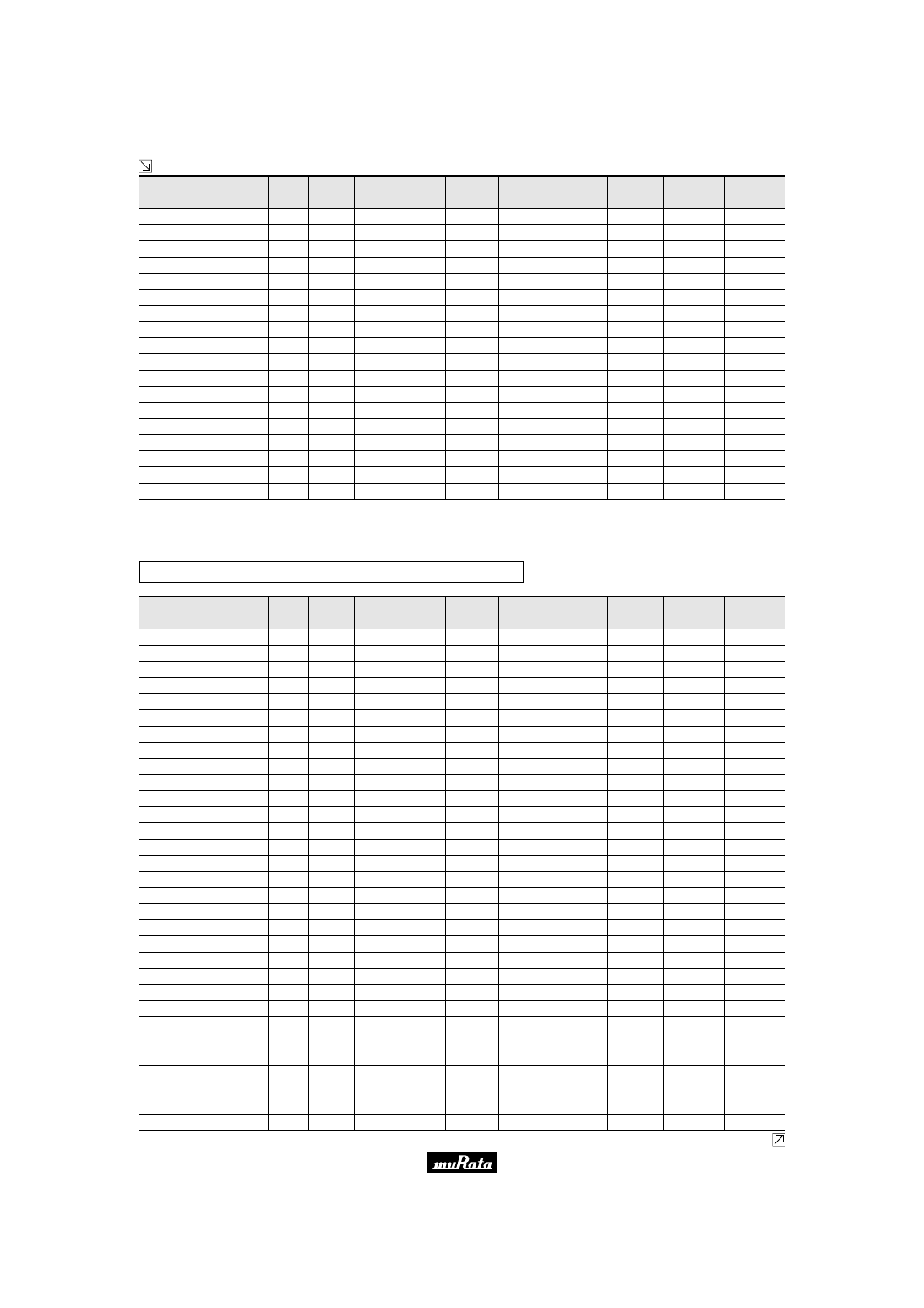

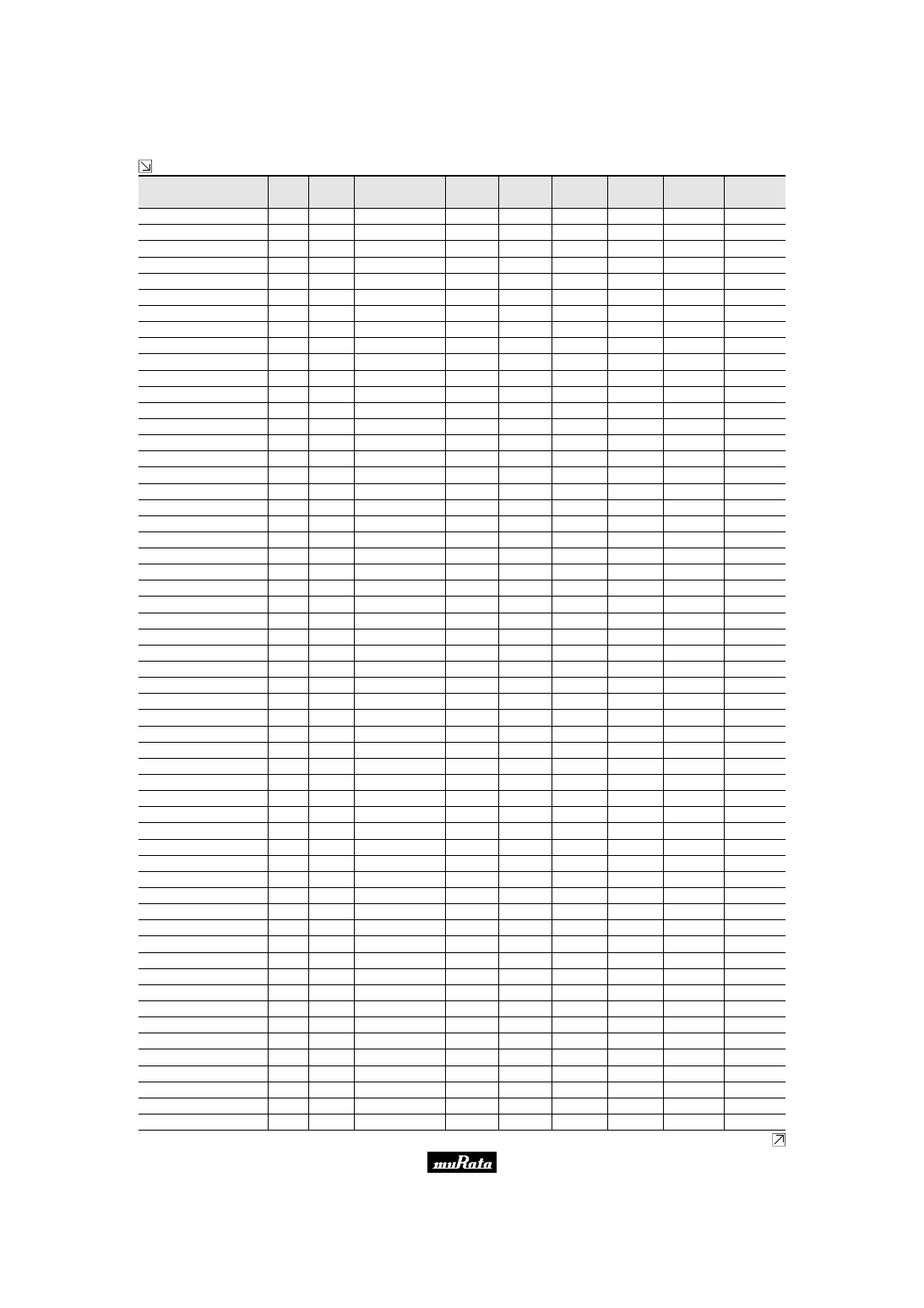

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

(pF)

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPE5C1H331J2

pp

A03

p

C0G

50

330

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H331J2

pp

A03

p

C0G

50

330

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H391J2

pp

A03

p

C0G

50

390

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H391J2

pp

A03

p

C0G

50

390

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H471J2

pp

A03

p

C0G

50

470

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H471J2

pp

A03

p

C0G

50

470

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H561J2

pp

A03

p

C0G

50

560

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H561J2

pp

A03

p

C0G

50

560

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H681J2

pp

A03

p

C0G

50

680

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H681J2

pp

A03

p

C0G

50

680

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H821J2

pp

A03

p

C0G

50

820

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H821J2

pp

A03

p

C0G

50

820

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H102J2

pp

A03

p

C0G

50

1000

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C1H102J2

pp

A03

p

C0G

50

1000

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C1H122J2

pp

A03

p

C0G

50

1200

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H122J2

pp

A03

p

C0G

50

1200

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H152J2

pp

A03

p

C0G

50

1500

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H152J2

pp

A03

p

C0G

50

1500

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H182J2

pp

C03

p

C0G

50

1800

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H182J2

pp

A03

p

C0G

50

1800

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H222J2

pp

C03

p

C0G

50

2200

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H222J2

pp

A03

p

C0G

50

2200

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H272J2

pp

C03

p

C0G

50

2700

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H272J2

pp

A03

p

C0G

50

2700

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H332J2

pp

C03

p

C0G

50

3300

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H332J2

pp

A03

p

C0G

50

3300

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H392J2

pp

C03

p

C0G

50

3900

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H392J2

pp

A03

p

C0G

50

3900

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H472J2

pp

C03

p

C0G

50

4700

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H472J2

pp

A03

p

C0G

50

4700

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H562J2

pp

C03

p

C0G

50

5600

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C1H562J2

pp

A03

p

C0G

50

5600

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H682J2

pp

C03

p

C0G

50

6800

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H822J2

pp

C03

p

C0G

50

8200

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H103J2

pp

C03

p

C0G

50

10000

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C1H123J4

pp

F03

p

C0G

50

12000

±

5%

7.5 x 5.0

3.15

5.0

K1

M1

M2

RPE5C1H153J4

pp

F03

p

C0G

50

15000

±

5%

7.5 x 5.0

3.15

5.0

K1

M1

M2

RPE5C1H183J5

pp

X03

p

C0G

50

18000

±

5%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPE5C1H223J6

pp

F12

p

C0G

50

22000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C1H273J6

pp

F12

p

C0G

50

27000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C1H333J6

pp

F03

p

C0G

50

33000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C1H393J6

pp

F03

p

C0G

50

39000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C1H473J7

pp

F03

p

C0G

50

47000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

RPE5C1H563J7

pp

F03

p

C0G

50

56000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

RPE5C1H683J7

pp

F03

p

C0G

50

68000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

RPE5C2A1R0C2

pp

B03

p

C0G

100

1.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A1R0C2

pp

B03

p

C0G

100

1.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A2R0C2

pp

B03

p

C0G

100

2.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A2R0C2

pp

B03

p

C0G

100

2.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A3R0C2

pp

B03

p

C0G

100

3.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A3R0C2

pp

B03

p

C0G

100

3.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A4R0C2

pp

B03

p

C0G

100

4.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A4R0C2

pp

B03

p

C0G

100

4.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A5R0C2

pp

B03

p

C0G

100

5.0

±

0.25pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A5R0C2

pp

B03

p

C0G

100

5.0

±

0.25pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A6R0D2

pp

B03

p

C0G

100

6.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A6R0D2

pp

B03

p

C0G

100

6.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

7

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

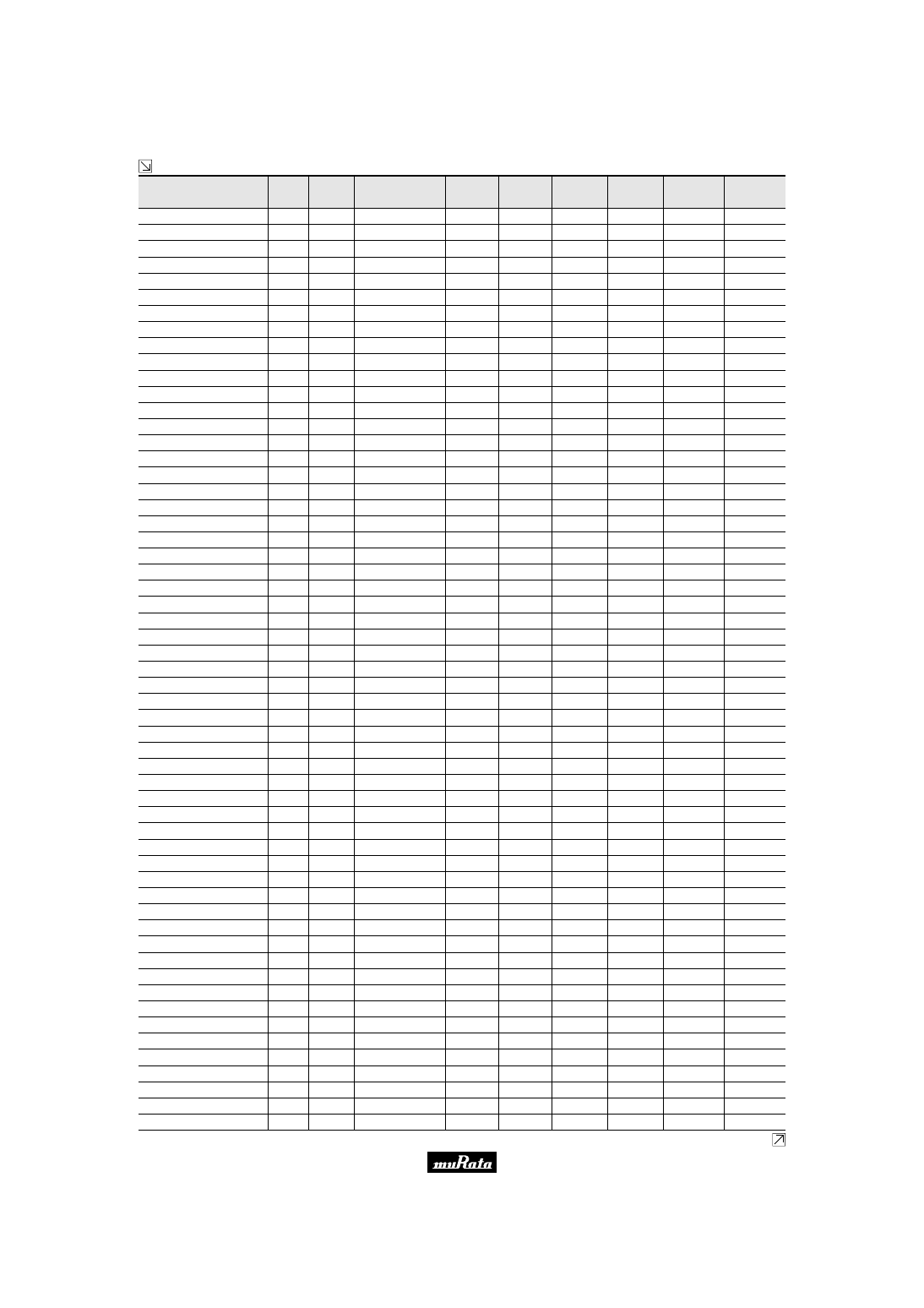

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

(pF)

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPE5C2A7R0D2

pp

Z03

p

C0G

100

7.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A7R0D2

pp

Z03

p

C0G

100

7.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A8R0D2

pp

Z03

p

C0G

100

8.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A8R0D2

pp

Z03

p

C0G

100

8.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A9R0D2

pp

Z03

p

C0G

100

9.0

±

0.5pF

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A9R0D2

pp

Z03

p

C0G

100

9.0

±

0.5pF

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A100J2

pp

Z03

p

C0G

100

10

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A100J2

pp

Z03

p

C0G

100

10

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A120J2

pp

Z03

p

C0G

100

12

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A120J2

pp

Z03

p

C0G

100

12

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A150J2

pp

Z03

p

C0G

100

15

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A150J2

pp

Z03

p

C0G

100

15

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A180J2

pp

Z03

p

C0G

100

18

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A180J2

pp

Z03

p

C0G

100

18

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A220J2

pp

Z03

p

C0G

100

22

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A220J2

pp

Z03

p

C0G

100

22

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A270J2

pp

Z03

p

C0G

100

27

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A270J2

pp

Z03

p

C0G

100

27

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A330J2

pp

Z03

p

C0G

100

33

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A330J2

pp

Z03

p

C0G

100

33

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A390J2

pp

Z03

p

C0G

100

39

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A390J2

pp

Z03

p

C0G

100

39

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A470J2

pp

Z03

p

C0G

100

47

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A470J2

pp

Z03

p

C0G

100

47

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A560J2

pp

Z03

p

C0G

100

56

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A560J2

pp

Z03

p

C0G

100

56

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A680J2

pp

Z03

p

C0G

100

68

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A680J2

pp

Z03

p

C0G

100

68

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A820J2

pp

Z03

p

C0G

100

82

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A820J2

pp

Z03

p

C0G

100

82

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A101J2

pp

Z03

p

C0G

100

100

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A101J2

pp

Z03

p

C0G

100

100

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A121J2

pp

Z03

p

C0G

100

120

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A121J2

pp

Z03

p

C0G

100

120

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A151J2

pp

Z03

p

C0G

100

150

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A151J2

pp

Z03

p

C0G

100

150

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A181J2

pp

Z03

p

C0G

100

180

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A181J2

pp

Z03

p

C0G

100

180

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A221J2

pp

Z03

p

C0G

100

220

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A221J2

pp

Z03

p

C0G

100

220

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A271J2

pp

Z03

p

C0G

100

270

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A271J2

pp

Z03

p

C0G

100

270

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A331J2

pp

Z03

p

C0G

100

330

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A331J2

pp

Z03

p

C0G

100

330

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A391J2

pp

Z03

p

C0G

100

390

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A391J2

pp

Z03

p

C0G

100

390

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A471J2

pp

Z03

p

C0G

100

470

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A471J2

pp

Z03

p

C0G

100

470

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A561J2

pp

B03

p

C0G

100

560

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A561J2

pp

B03

p

C0G

100

560

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A681J2

pp

B03

p

C0G

100

680

±

5%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPE5C2A681J2

pp

B03

p

C0G

100

680

±

5%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPE5C2A821J2

pp

B03

p

C0G

100

820

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C2A821J2

pp

B03

p

C0G

100

820

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A102J2

pp

B03

p

C0G

100

1000

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C2A102J2

pp

B03

p

C0G

100

1000

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A122J2

pp

D03

p

C0G

100

1200

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

8

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

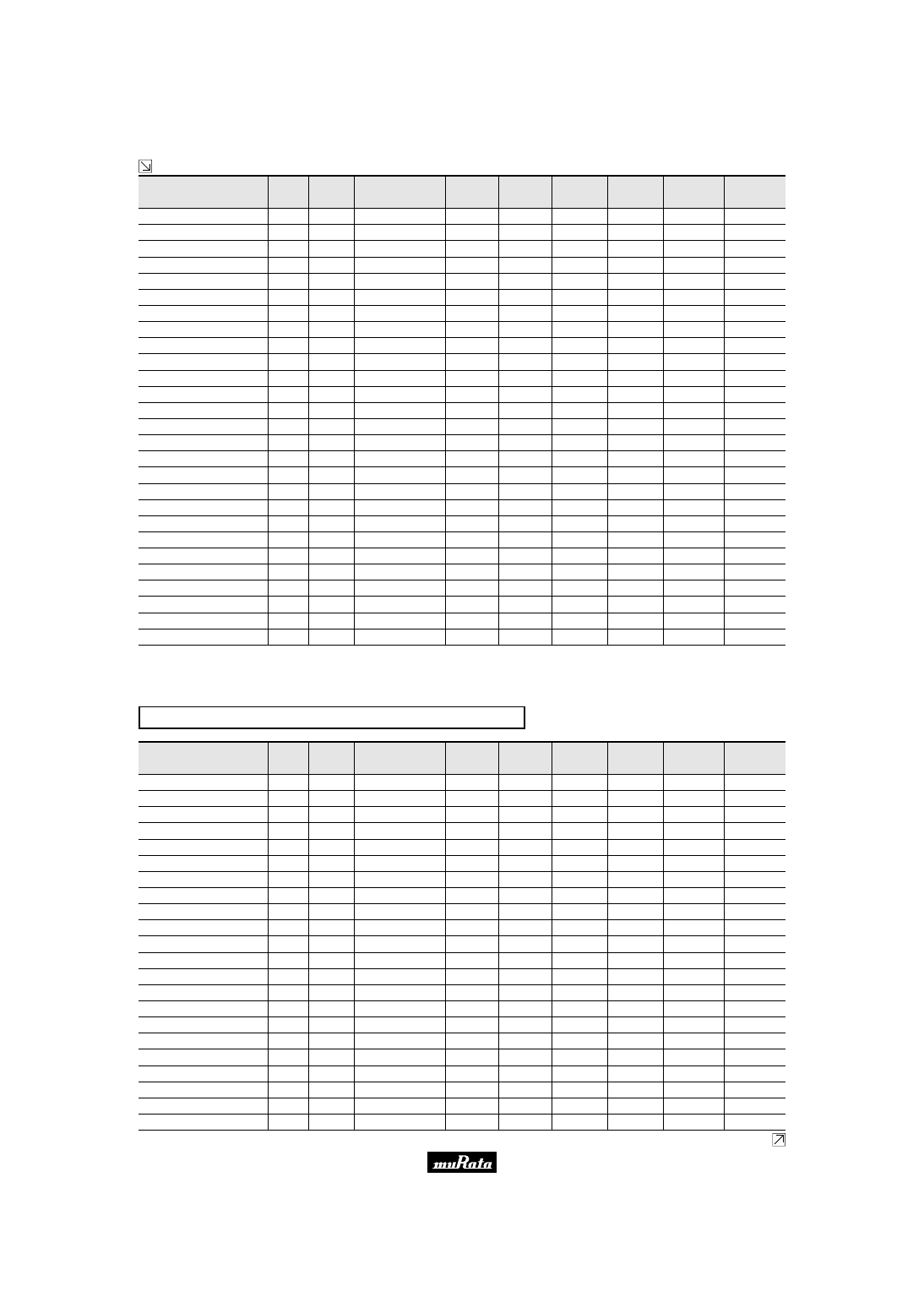

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

(pF)

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPE5C2A122J2

pp

D03

p

C0G

100

1200

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A152J2

pp

D03

p

C0G

100

1500

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C2A152J2

pp

D03

p

C0G

100

1500

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A182J2

pp

D03

p

C0G

100

1800

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C2A182J2

pp

D03

p

C0G

100

1800

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A222J2

pp

D03

p

C0G

100

2200

±

5%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPE5C2A222J2

pp

D03

p

C0G

100

2200

±

5%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPE5C2A272J3

pp

D03

p

C0G

100

2700

±

5%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPE5C2A272J3

pp

D03

p

C0G

100

2700

±

5%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPE5C2A332J3

pp

D03

p

C0G

100

3300

±

5%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPE5C2A332J3

pp

D03

p

C0G

100

3300

±

5%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPE5C2A392J3

pp

D03

p

C0G

100

3900

±

5%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPE5C2A392J3

pp

D03

p

C0G

100

3900

±

5%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPE5C2A472J4

pp

X03

p

C0G

100

4700

±

5%

7.5 x 5.0

2.5

5.0

K1

M1

M2

RPE5C2A562J4

pp

F03

p

C0G

100

5600

±

5%

7.5 x 5.0

3.15

5.0

K1

M1

M2

RPE5C2A682J4

pp

F03

p

C0G

100

6800

±

5%

7.5 x 5.0

3.15

5.0

K1

M1

M2

RPE5C2A822J5

pp

X03

p

C0G

100

8200

±

5%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPE5C2A103J5

pp

X03

p

C0G

100

10000

±

5%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPE5C2A123J5

pp

X03

p

C0G

100

12000

±

5%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPE5C2A153J6

pp

X13

p

C0G

100

15000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C2A183J6

pp

X13

p

C0G

100

18000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C2A223J6

pp

X03

p

C0G

100

22000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C2A273J6

pp

X03

p

C0G

100

27000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C2A333J6

pp

F03

p

C0G

100

33000

±

5%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPE5C2A393J7

pp

X03

p

C0G

100

39000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

RPE5C2A473J7

pp

F03

p

C0G

100

47000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

RPE5C2A563J7

pp

F03

p

C0G

100

56000

±

5%

12.5 x 12.5

5.0

10.0

C1

-

-

Two blank columns are filled with the lead style code. Please refer to the 3 columns on the right for the appropriate code.

The last blank column is filled with the packaging code. (B: bulk, A: ammo pack)

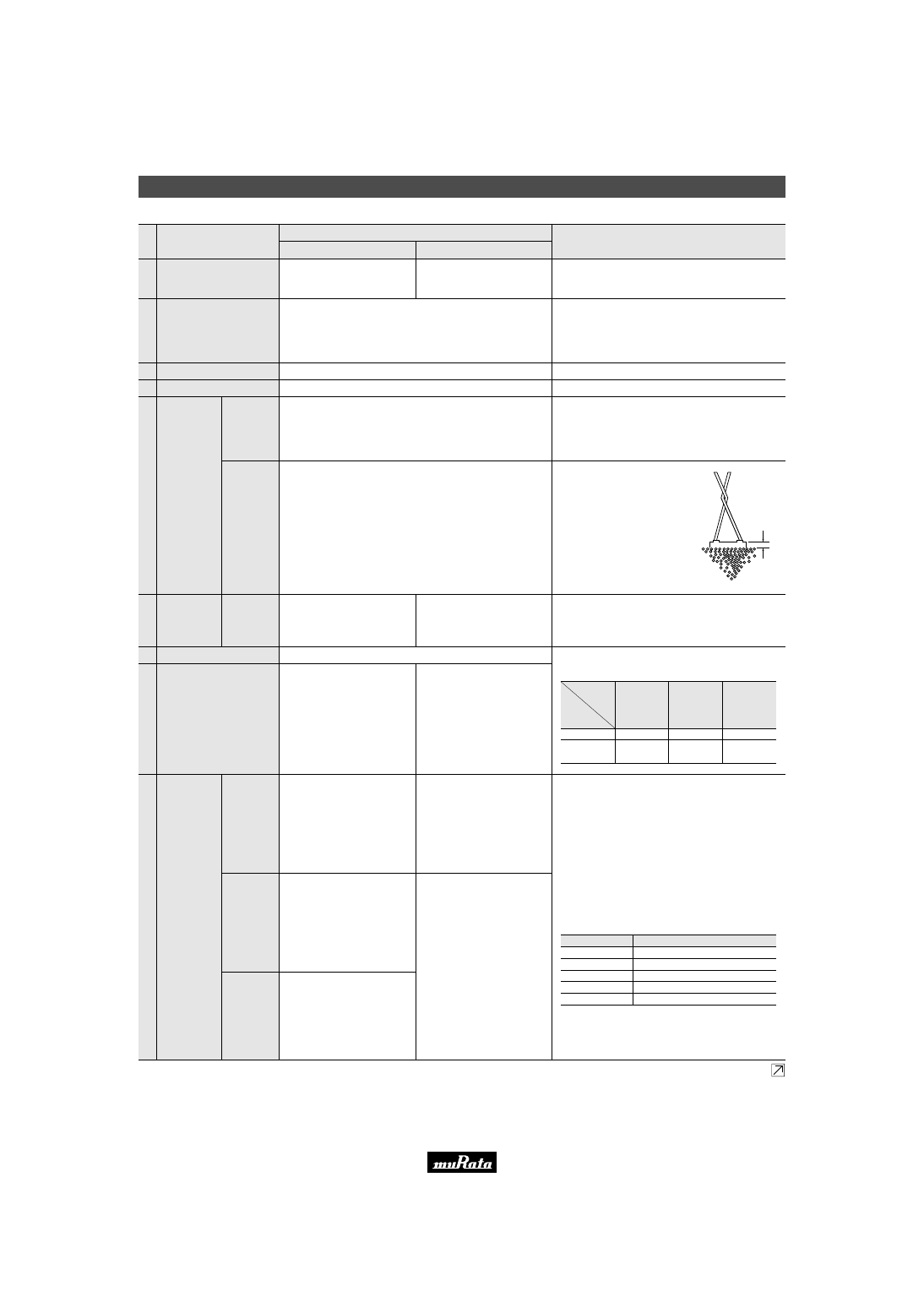

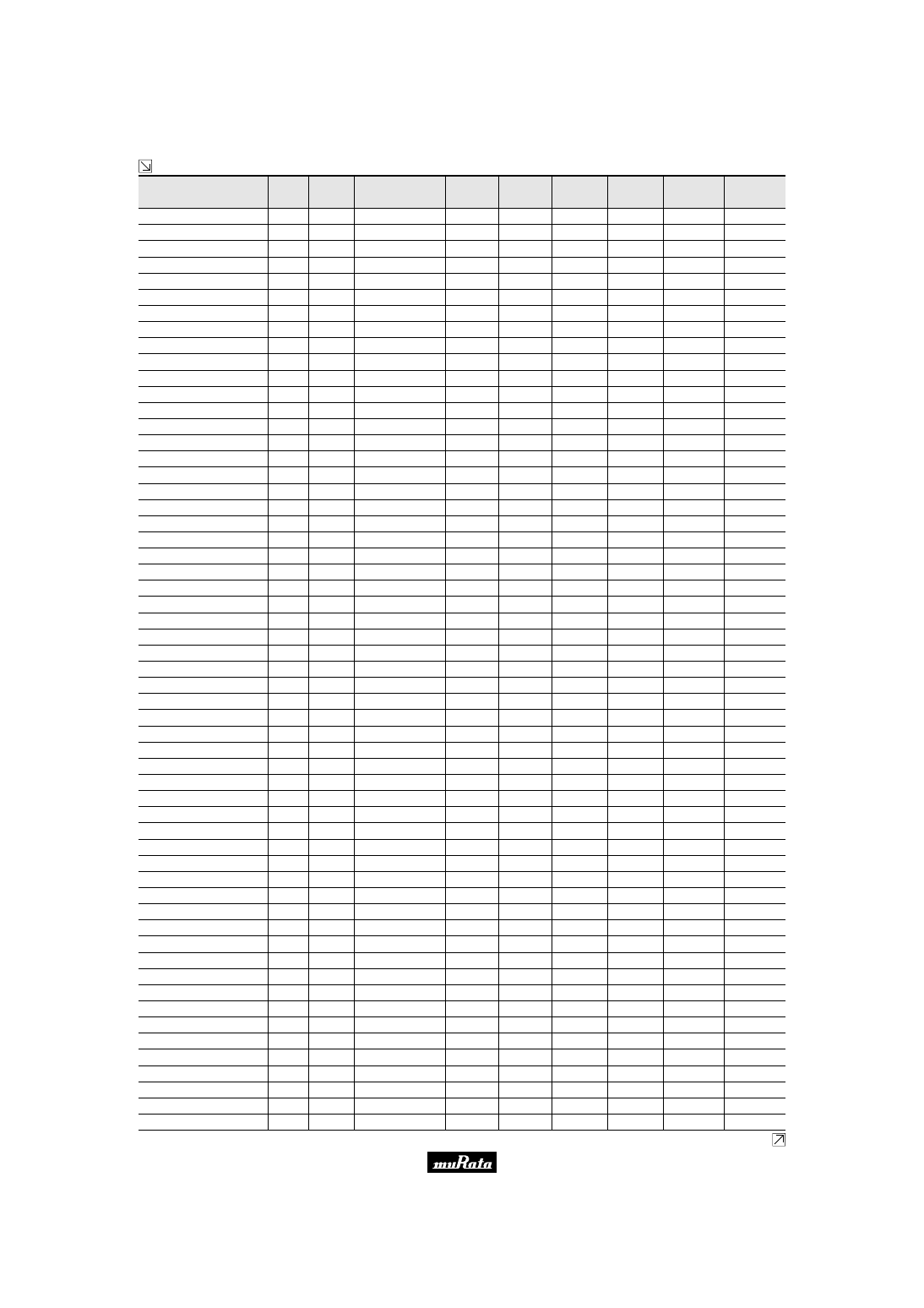

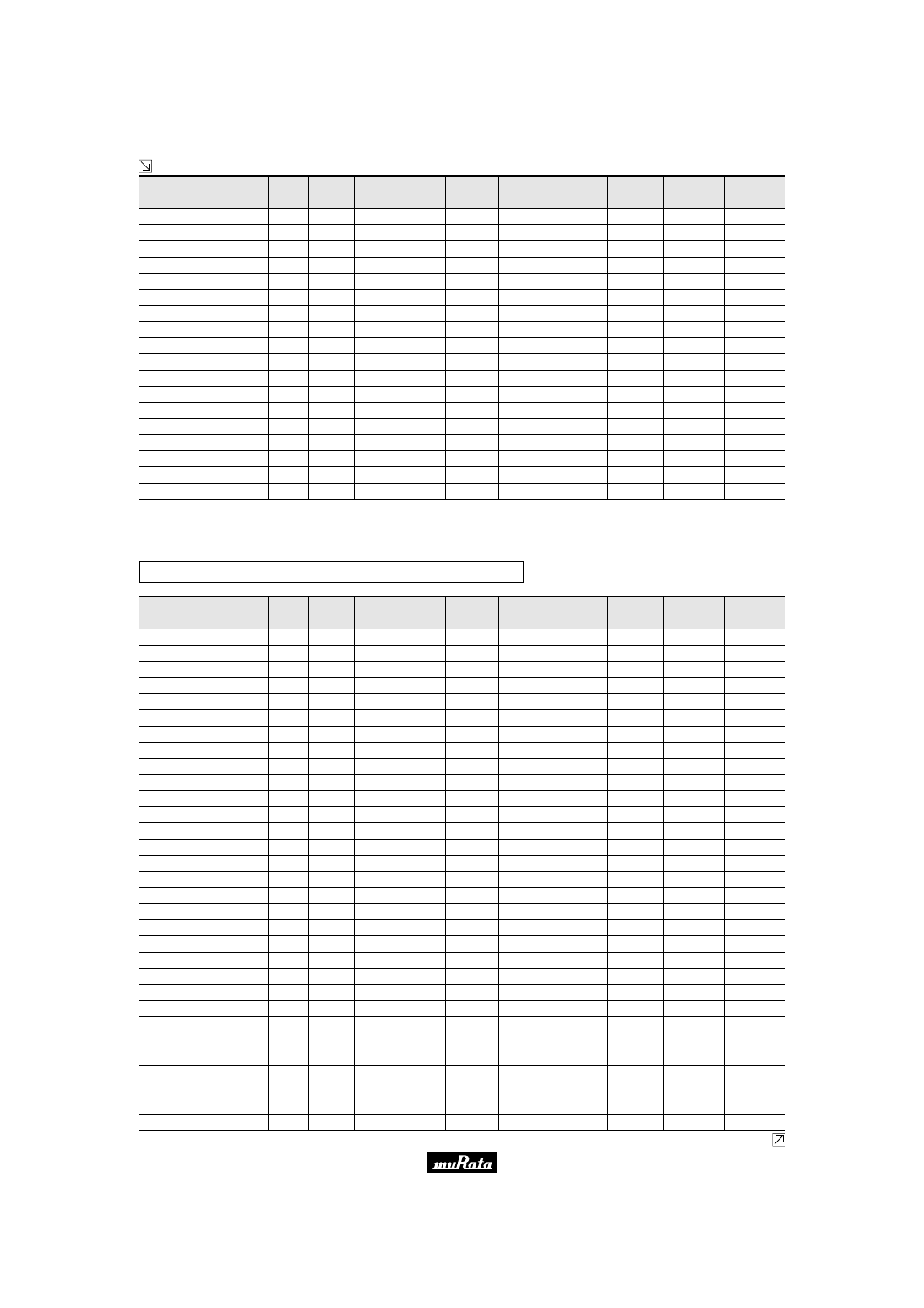

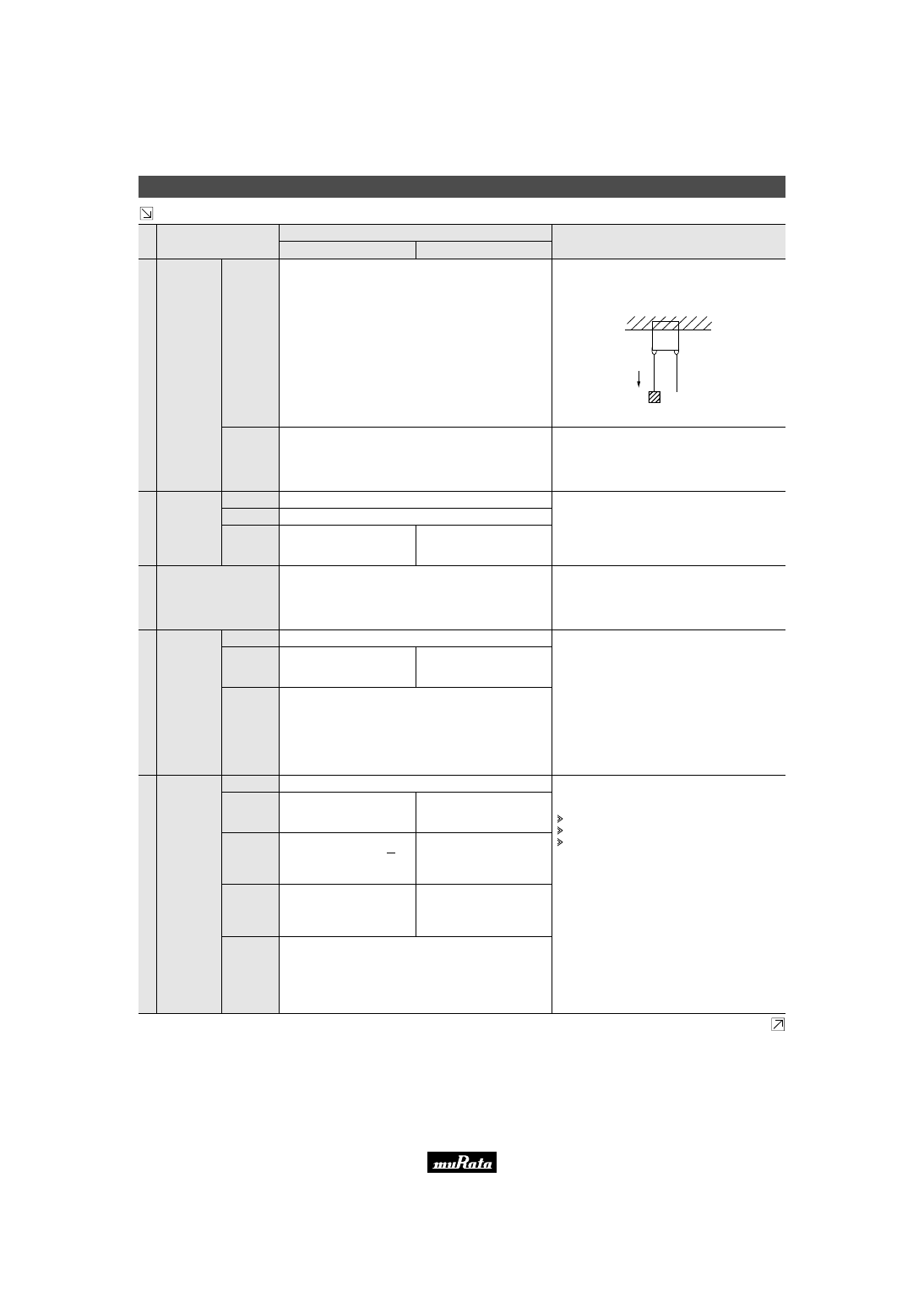

High Dielectric Constant Type, X7R Characteristics

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

RPER71E474K2

pp

A03

p

X7R

25

0.47

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71E684K2

pp

C03

p

X7R

25

0.68

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71E105K2

pp

C03

p

X7R

25

1.0

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71E155K3

pp

C07

p

X7R

25

1.5

µ

F

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER71E225K3

pp

C07

p

X7R

25

2.2

µ

F

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER71H221K2

pp

A03

p

X7R

50

220pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H221K2

pp

A03

p

X7R

50

220pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H331K2

pp

A03

p

X7R

50

330pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H331K2

pp

A03

p

X7R

50

330pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H471K2

pp

A03

p

X7R

50

470pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H471K2

pp

A03

p

X7R

50

470pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H681K2

pp

A03

p

X7R

50

680pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H681K2

pp

A03

p

X7R

50

680pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H102K2

pp

A03

p

X7R

50

1000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H102K2

pp

A03

p

X7R

50

1000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H152K2

pp

A03

p

X7R

50

1500pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H152K2

pp

A03

p

X7R

50

1500pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H222K2

pp

A03

p

X7R

50

2200pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H222K2

pp

A03

p

X7R

50

2200pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H332K2

pp

A03

p

X7R

50

3300pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H332K2

pp

A03

p

X7R

50

3300pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H472K2

pp

A03

p

X7R

50

4700pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

9

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPER71H472K2

pp

A03

p

X7R

50

4700pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H682K2

pp

A03

p

X7R

50

6800pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H682K2

pp

A03

p

X7R

50

6800pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H103K2

pp

A03

p

X7R

50

10000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H103K2

pp

A03

p

X7R

50

10000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H153K2

pp

A03

p

X7R

50

15000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H153K2

pp

A03

p

X7R

50

15000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H223K2

pp

A03

p

X7R

50

22000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H223K2

pp

A03

p

X7R

50

22000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H333K2

pp

A03

p

X7R

50

33000pF

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H333K2

pp

A03

p

X7R

50

33000pF

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H473K2

pp

A03

p

X7R

50

47000pF

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H473K2

pp

A03

p

X7R

50

47000pF

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H683K2

pp

A03

p

X7R

50

68000pF

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H683K2

pp

A03

p

X7R

50

68000pF

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H104K2

pp

A03

p

X7R

50

0.10

µ

F

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H104K2

pp

A03

p

X7R

50

0.10

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H154K2

pp

C03

p

X7R

50

0.15

µ

F

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H154K2

pp

C03

p

X7R

50

0.15

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H224K2

pp

C03

p

X7R

50

0.22

µ

F

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H224K2

pp

C03

p

X7R

50

0.22

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H334K2

pp

C03

p

X7R

50

0.33

µ

F

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER71H334K2

pp

C03

p

X7R

50

0.33

µ

F

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER71H474K2

pp

C03

p

X7R

50

0.47

µ

F

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER71H474K2

pp

C03

p

X7R

50

0.47

µ

F

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER71H684K3

pp

C03

p

X7R

50

0.68

µ

F

±

10%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPER71H684K3

pp

C03

p

X7R

50

0.68

µ

F

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER71H105K3

pp

C07

p

X7R

50

1.0

µ

F

±

10%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPER71H105K3

pp

C07

p

X7R

50

1.0

µ

F

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER71H155K8

pp

C03

p

X7R

50

1.5

µ

F

±

10%

7.5 x 5.5

4.0

5.0

K1

M1

M2

RPER71H225K8

pp

C03

p

X7R

50

2.2

µ

F

±

10%

7.5 x 5.5

4.0

5.0

K1

M1

M2

RPER71H335K5

pp

C03

p

X7R

50

3.3

µ

F

±

10%

7.5 x 7.5

5.0

5.0

B1

E1

E2

RPER71H475K5

pp

C03

p

X7R

50

4.7

µ

F

±

10%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPER72A221K2

pp

B03

p

X7R

100

220pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A221K2

pp

B03

p

X7R

100

220pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A331K2

pp

B03

p

X7R

100

330pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A331K2

pp

B03

p

X7R

100

330pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A471K2

pp

B03

p

X7R

100

470pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A471K2

pp

B03

p

X7R

100

470pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A681K2

pp

B03

p

X7R

100

680pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A681K2

pp

B03

p

X7R

100

680pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A102K2

pp

A03

p

X7R

100

1000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A102K2

pp

A03

p

X7R

100

1000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A152K2

pp

A03

p

X7R

100

1500pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A152K2

pp

A03

p

X7R

100

1500pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A222K2

pp

A03

p

X7R

100

2200pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A222K2

pp

A03

p

X7R

100

2200pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A332K2

pp

A03

p

X7R

100

3300pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A332K2

pp

A03

p

X7R

100

3300pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A472K2

pp

A03

p

X7R

100

4700pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A472K2

pp

A03

p

X7R

100

4700pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A682K2

pp

A03

p

X7R

100

6800pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A682K2

pp

A03

p

X7R

100

6800pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A103K2

pp

A03

p

X7R

100

10000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A103K2

pp

A03

p

X7R

100

10000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPER72A153K2

pp

A03

p

X7R

100

15000pF

±

10%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPER72A153K2

pp

A03

p

X7R

100

15000pF

±

10%

5.0 x 3.5

2.5

5.0

K1

M1

M2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

10

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPER72A223K2

pp

A03

p

X7R

100

22000pF

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER72A223K2

pp

A03

p

X7R

100

22000pF

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER72A333K2

pp

C03

p

X7R

100

33000pF

±

10%

5.0 x 3.5

3.15

2.5

P1

S1

S2

RPER72A333K2

pp

C03

p

X7R

100

33000pF

±

10%

5.0 x 3.5

3.15

5.0

K1

M1

M2

RPER72A473K3

pp

C07

p

X7R

100

47000pF

±

10%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPER72A473K3

pp

C07

p

X7R

100

47000pF

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER72A683K3

pp

C07

p

X7R

100

68000pF

±

10%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPER72A683K3

pp

C07

p

X7R

100

68000pF

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER72A104K3

pp

C07

p

X7R

100

0.10

µ

F

±

10%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPER72A104K3

pp

C07

p

X7R

100

0.10

µ

F

±

10%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPER72A154K8

pp

C03

p

X7R

100

0.15

µ

F

±

10%

7.5 x 5.5

4.0

5.0

K1

M1

M2

RPER72A224K8

pp

C03

p

X7R

100

0.22

µ

F

±

10%

7.5 x 5.5

4.0

5.0

K1

M1

M2

RPER72A334K5

pp

C03

p

X7R

100

0.33

µ

F

±

10%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPER72A474K8

pp

C03

p

X7R

100

0.47

µ

F

±

10%

7.5 x 5.5

4.0

5.0

K1

M1

M2

RPER72A684K6

pp

F14

p

X7R

100

0.68

µ

F

±

10%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPER72A105K5

pp

C03

p

X7R

100

1.0

µ

F

±

10%

7.5 x 7.5

4.0

5.0

B1

E1

E2

RPER72A155K7

pp

F03

p

X7R

100

1.5

µ

F

±

10%

12.5 x 12.5

5.0

10.0

C1

-

-

RPER72A225K7

pp

F03

p

X7R

100

2.2

µ

F

±

10%

12.5 x 12.5

5.0

10.0

C1

-

-

Two blank columns are filled with the lead style code. Please refer to the 3 columns on the right for the appropriate code.

The last blank column is filled with the packaging code. (B: bulk, A: ammo pack)

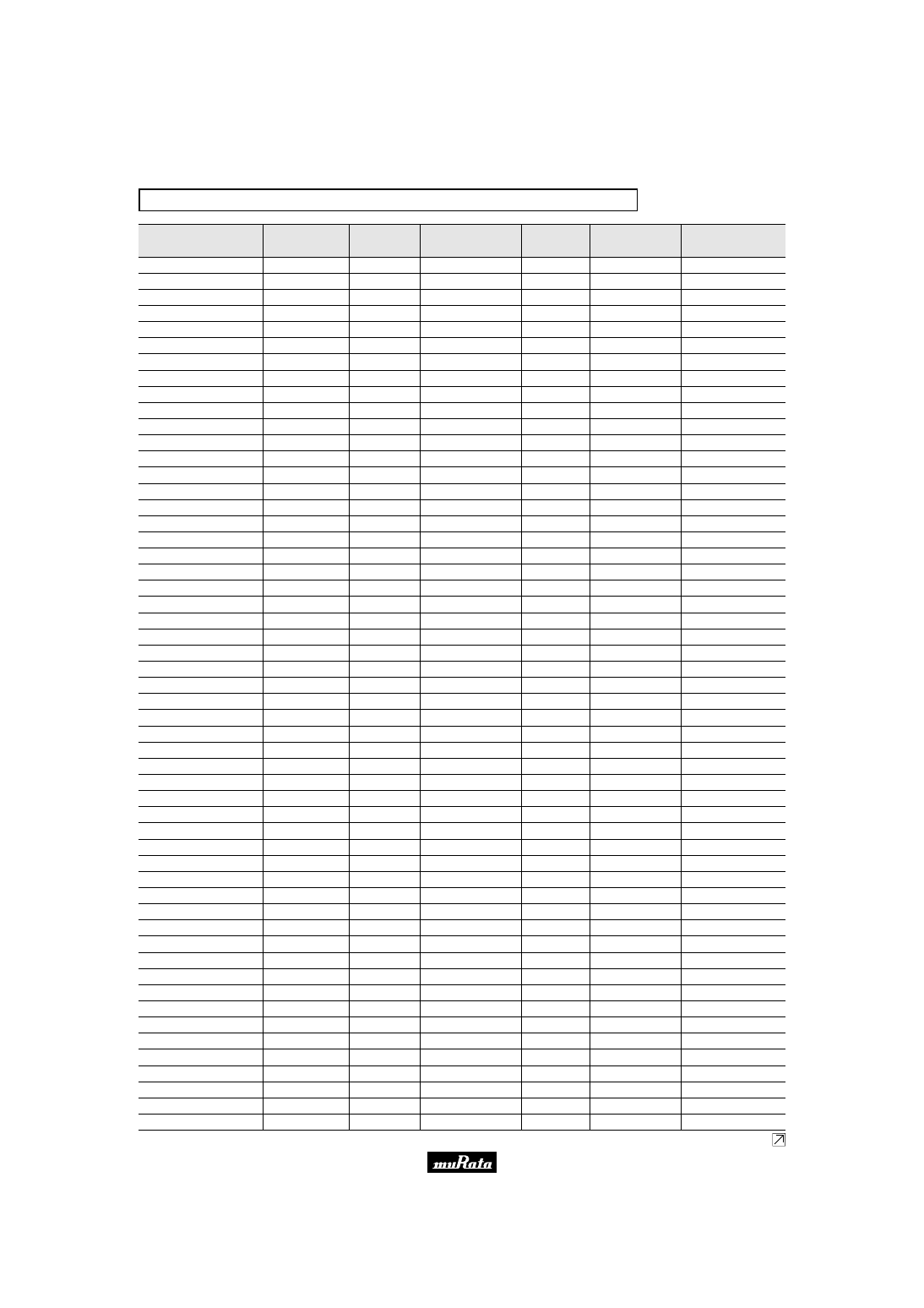

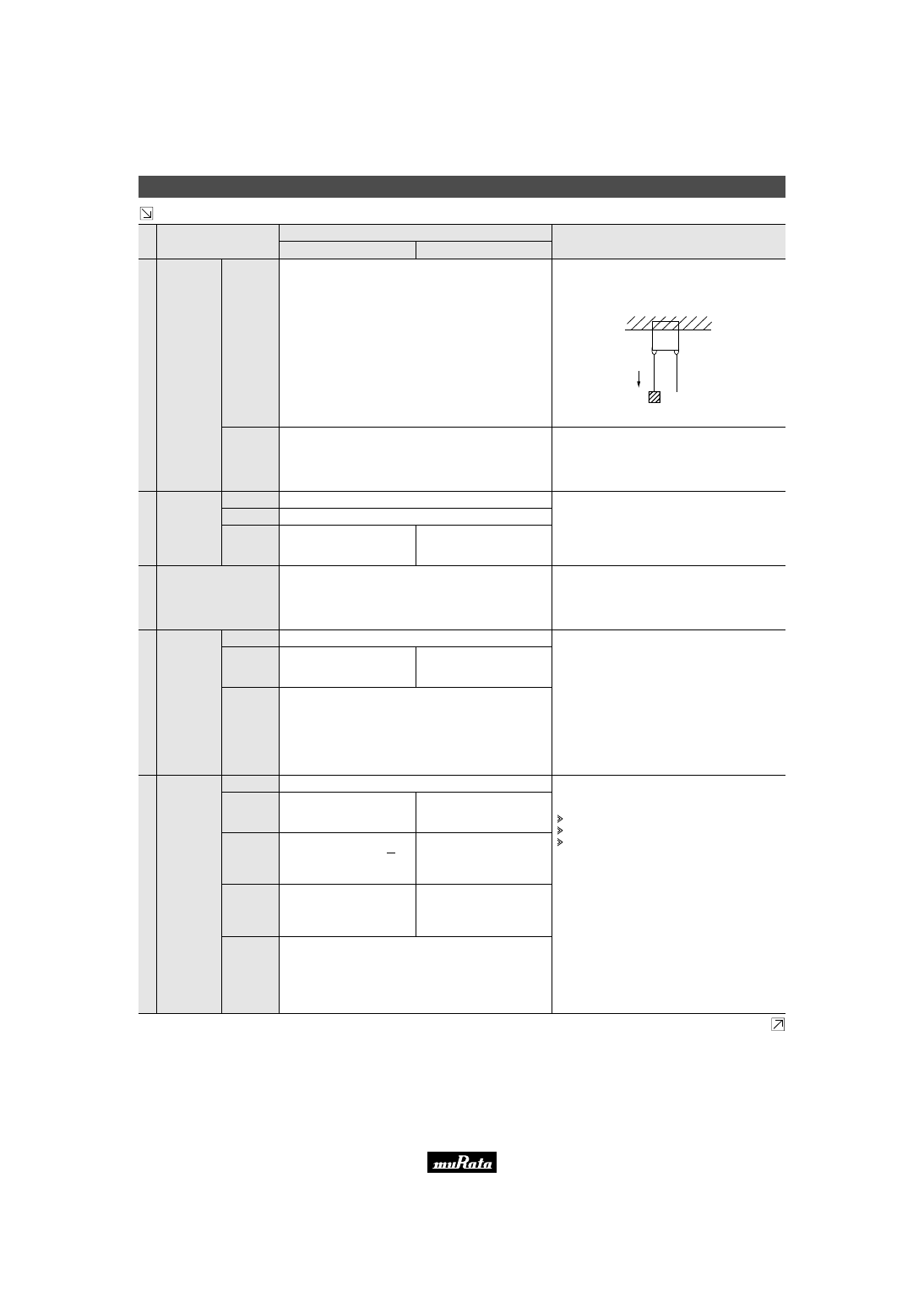

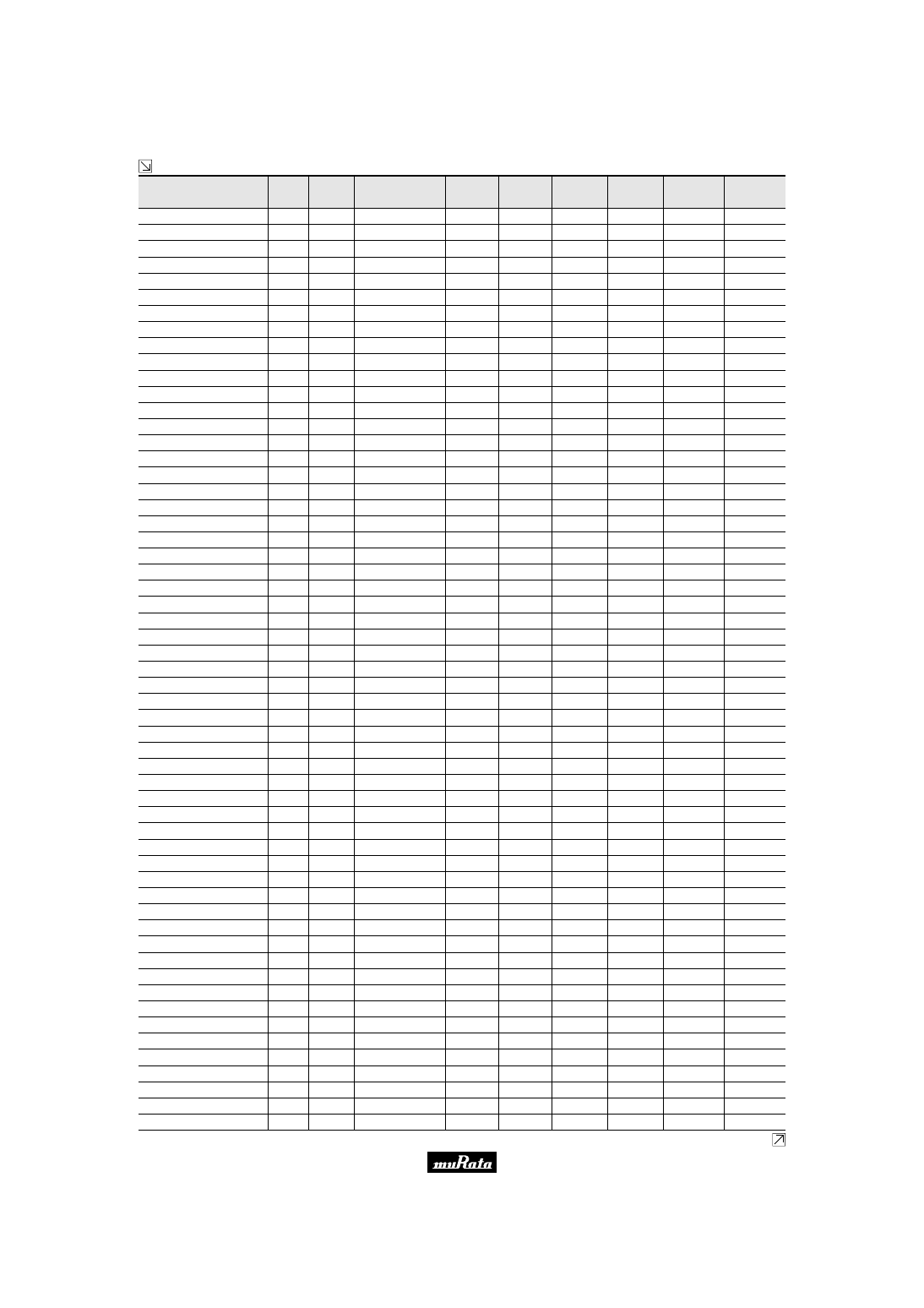

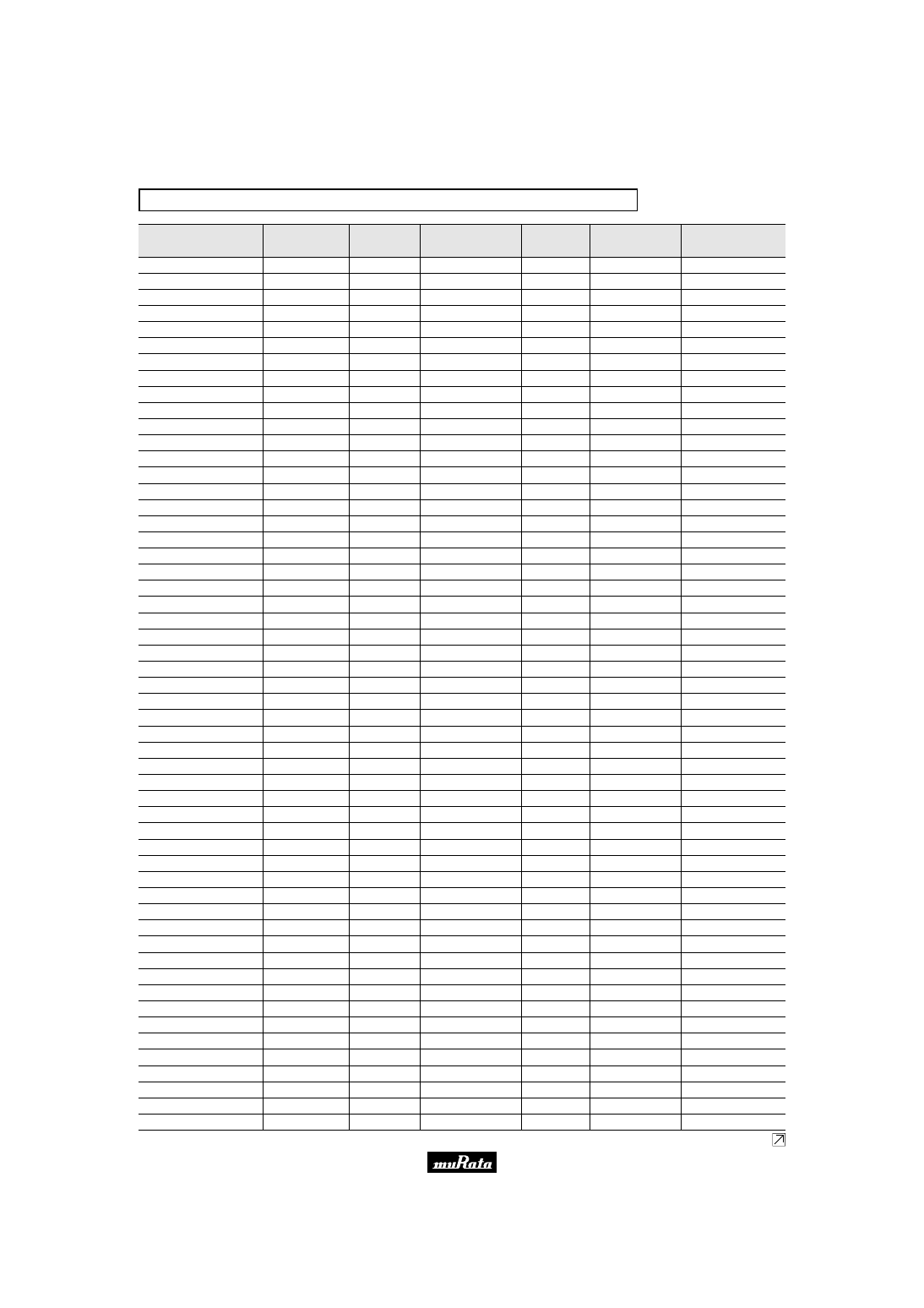

High Dielectric Constant Type, Z5U Characteristics

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

RPEE41E105M3

pp

C03

p

Z5U

25

1.0

µ

F

±

20%

5.0 x 4.5

2.5

2.5

P1

S1

S2

RPEE41E105M3

pp

C03

p

Z5U

25

1.0

µ

F

±

20%

5.0 x 4.5

2.5

5.0

K1

M1

M2

RPEE41H102M2

pp

A03

p

Z5U

50

1000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H102M2

pp

A03

p

Z5U

50

1000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H222M2

pp

A03

p

Z5U

50

2200pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H222M2

pp

A03

p

Z5U

50

2200pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H472M2

pp

A03

p

Z5U

50

4700pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H472M2

pp

A03

p

Z5U

50

4700pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H103M2

pp

A03

p

Z5U

50

10000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H103M2

pp

A03

p

Z5U

50

10000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H223M2

pp

A03

p

Z5U

50

22000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H223M2

pp

A03

p

Z5U

50

22000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H473M2

pp

A03

p

Z5U

50

47000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H473M2

pp

A03

p

Z5U

50

47000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H104M2

pp

A03

p

Z5U

50

0.10

µ

F

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE41H104M2

pp

A03

p

Z5U

50

0.10

µ

F

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE41H224M3

pp

C03

p

Z5U

50

0.22

µ

F

±

20%

5.0 x 4.5

2.5

2.5

P1

S1

S2

RPEE41H224M3

pp

C03

p

Z5U

50

0.22

µ

F

±

20%

5.0 x 4.5

2.5

5.0

K1

M1

M2

RPEE41H474M3

pp

C03

p

Z5U

50

0.47

µ

F

±

20%

5.0 x 4.5

3.15

2.5

P1

S1

S2

RPEE41H474M3

pp

C03

p

Z5U

50

0.47

µ

F

±

20%

5.0 x 4.5

3.15

5.0

K1

M1

M2

RPEE41H105M4

pp

E12

p

Z5U

50

1.0

µ

F

±

20%

7.5 x 5.0

3.15

5.0

K1

M1

M2

RPEE41H225M6

pp

F14

p

Z5U

50

2.2

µ

F

±

20%

10.0 x 10.0

4.0

5.0

B1

E1

E2

RPEE41H475M7

pp

F03

p

Z5U

50

4.7

µ

F

±

20%

12.5 x 12.5

5.0

10.0

C1

-

-

RPEE42A102M2

pp

B03

p

Z5U

100

1000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE42A102M2

pp

B03

p

Z5U

100

1000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE42A222M2

pp

B03

p

Z5U

100

2200pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE42A222M2

pp

B03

p

Z5U

100

2200pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE42A472M2

pp

B03

p

Z5U

100

4700pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE42A472M2

pp

B03

p

Z5U

100

4700pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

RPEE42A103M2

pp

B03

p

Z5U

100

10000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE42A103M2

pp

B03

p

Z5U

100

10000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1

M2

Continued on the following page.

Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this PDF catalog to prevent smoking and/or burning, etc.

This catalog has only typical specifications. Therefore, you are requested to approve our product specifications or to transact the approval sheet for product specifications before ordering.

!

Note

C49E15.pdf 04.12.29

Murata_Monolithic_Ceramic_Capacitors_Lead_Type-html.html

11

1

!

Note

• Please read rating and

!

CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

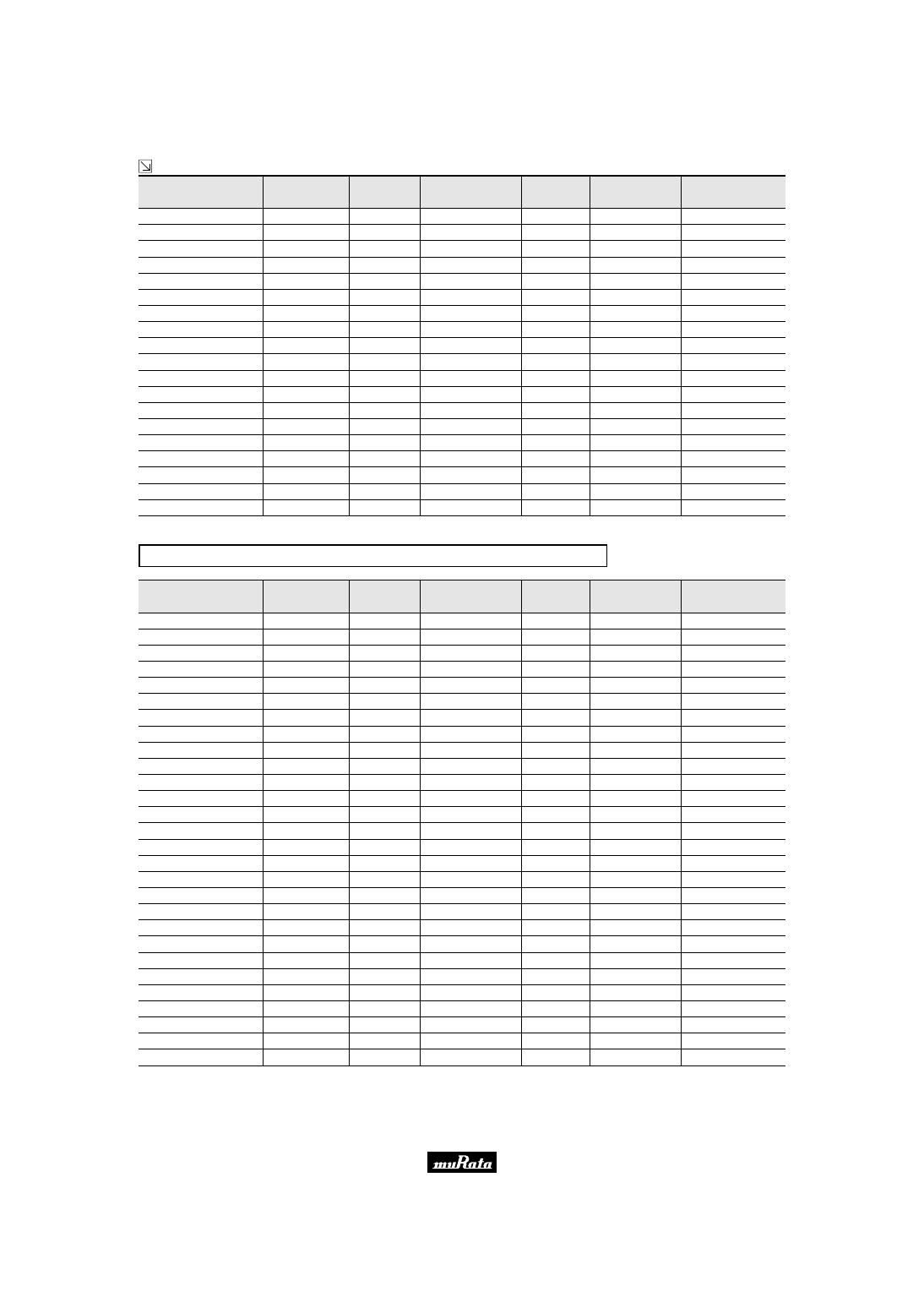

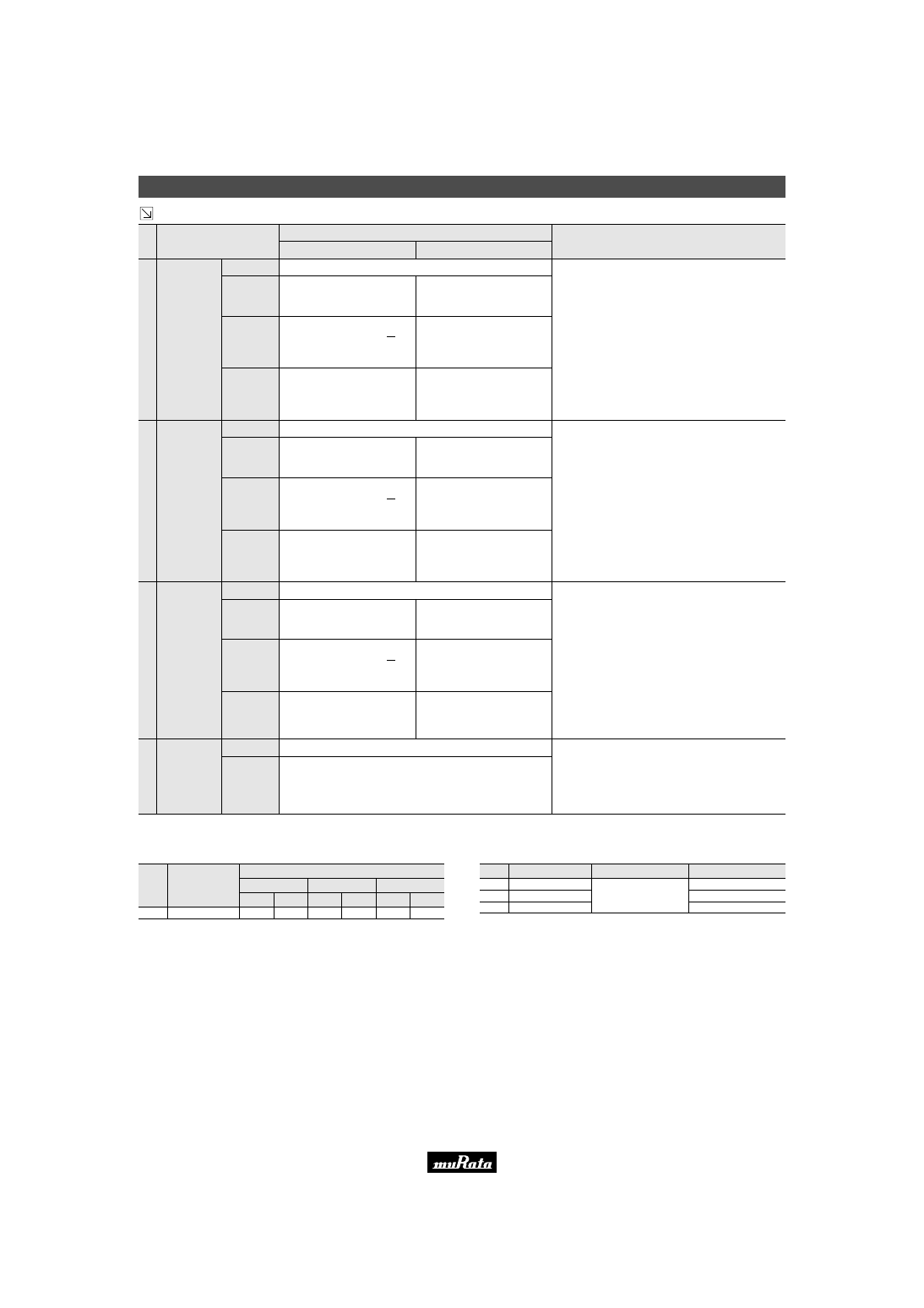

Part Number

Temp.

Char.

Rated

Voltage

(Vdc)

Capacitance

Dimensions

LxW

(mm)

Dimension

T

(mm)

Lead

Space F

(mm)

Lead Style

Code

Bulk

Lead Style

Code

Taping (1)

Lead Style

Code

Taping (2)

Continued from the preceding page.

RPEE42A223M2

pp

D03

p

Z5U

100

22000pF

±

20%

5.0 x 3.5

2.5

2.5

P1

S1

S2

RPEE42A223M2

pp

D03

p

Z5U

100

22000pF

±

20%

5.0 x 3.5

2.5

5.0

K1

M1