Terminals

A1

For service and technical support, call 800-777-3300

or visit www.panduit.com.

PANDUIT

Termination Solutions

Success

Depends on the

Crimp.

A proper crimp is the key element

of an overall wire termination

assembly that unfortunately is all

too often overlooked.

Proper terminal selection, application and crimping are critical factors to

the safety, performance and reliability of an electrical connection.When

selected and installed properly, the function of a terminal is transparent

in the overall operation of a product; however, when selected or installed

improperly, it can result in rework, recalls and downtime, which could

result in loss of productivity and profitability.

To produce a high-quality crimp you can rely upon to resist failure, you

need the right terminal, right tool and right technique.

The purpose of the Technical Reference Guide is to give you the

necessary tools to:

•

Select the right terminal for a specific application

•

Select the right tool for the terminal and the application

•

Produce a high-quality crimp

PANDUIT Termination Solutions-html.html

Terminals

A2

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

1. Select the proper

PANDUIT terminal for the application and

wire size used

• Ring terminals are used

for high vibration and

grounding applications

• Fork terminals are used for static

(non-vibration) applications

• Disconnects are used for

applications that require quick

connection of wires without the use of tools

• Splices and wire joints are used to join wires together

•

PANDUIT product

packaging label

• Packaging

instructions

included with the

PANDUIT product

• Or if no packaging

instructions are

available, plan your strip length so that 1/32 of an inch of

wire can be seen protruding through the tongue end of

the terminal barrel

2. Strip wire to the proper length as specified on:

• Use crimping tools that provide a UL Listed and/or CSA

Certified electrical termination, to assure a safe and

reliable connection

•

PANDUIT terminals are UL Listed and CSA Certified when

crimped with

PANDUIT plier type crimping tool or with the

preferred

C

ONTOUR

C

RIMP

™

Controlled Cycle Crimping Tool

specified on the packaging label

3. Select the proper crimp tool to be used

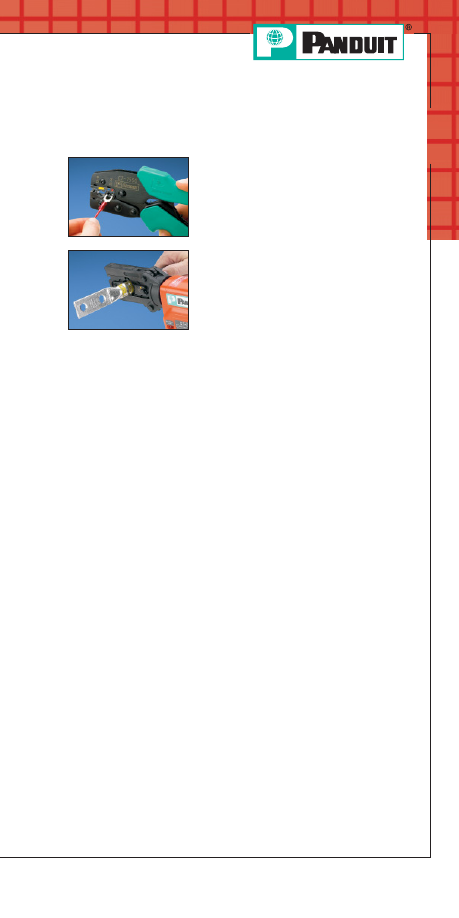

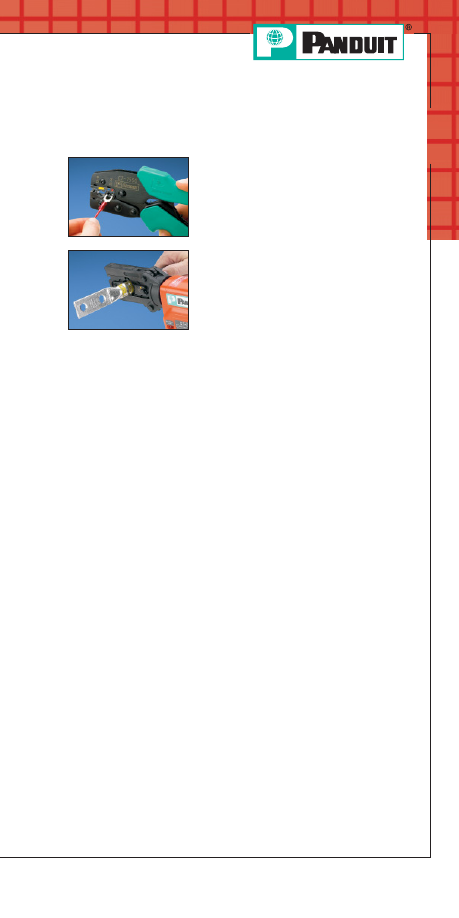

Plier Type

Crimping Tool

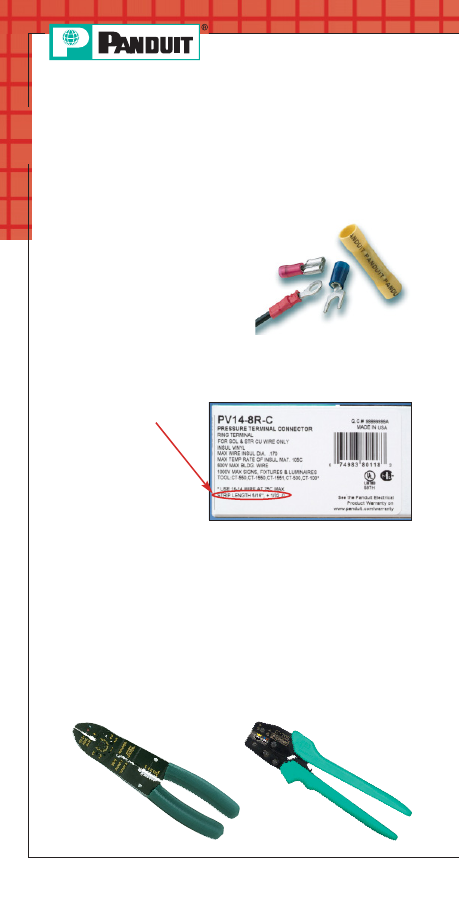

C

ONTOUR

C

RIMP

™

Controlled Cycle

Crimping Tool

PANDUIT Termination Solutions-html.html

Terminals

A3

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

(continued)

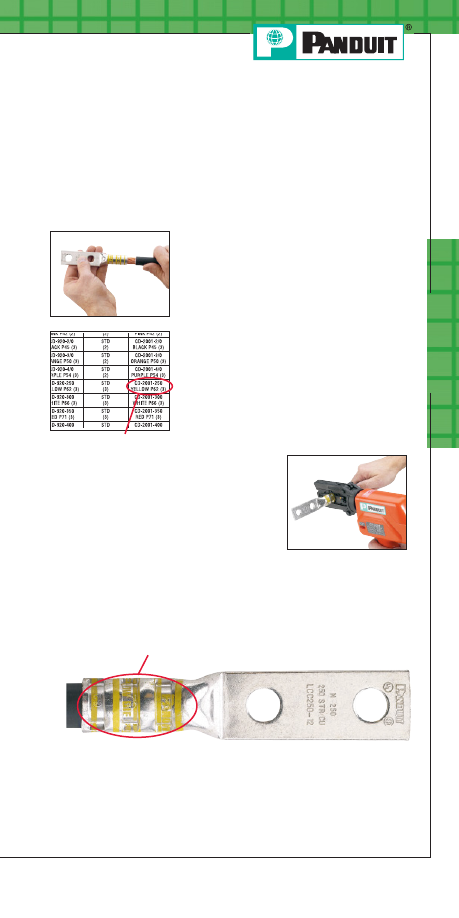

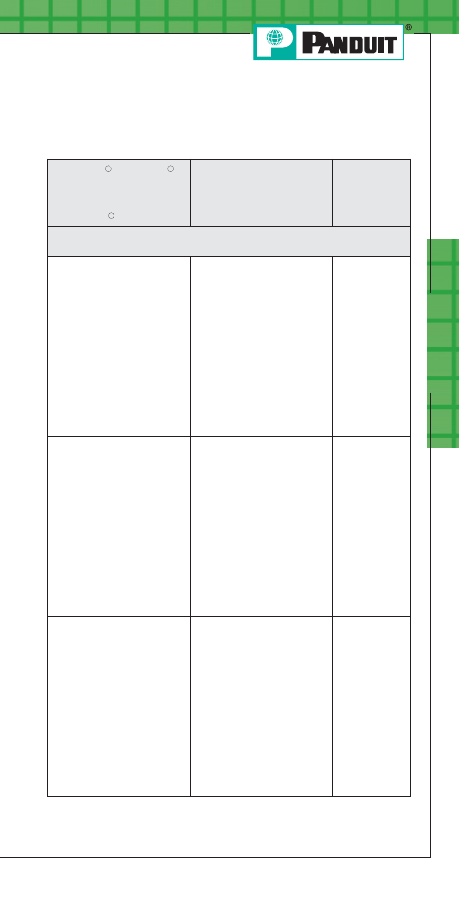

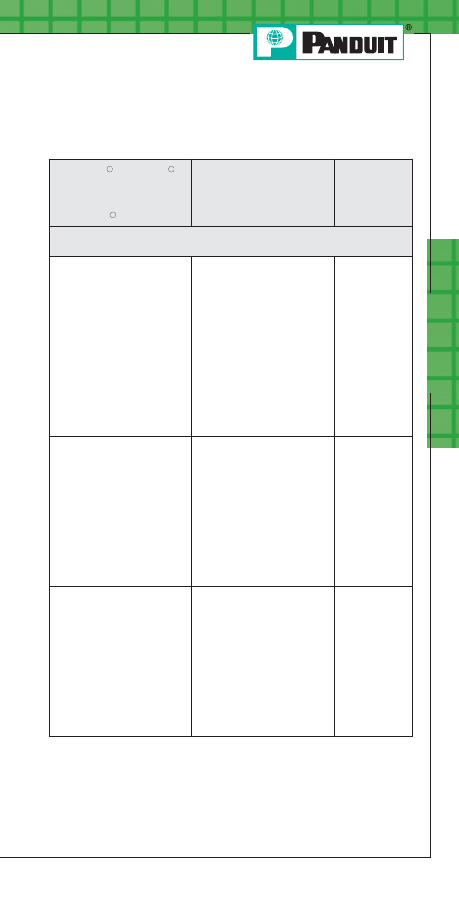

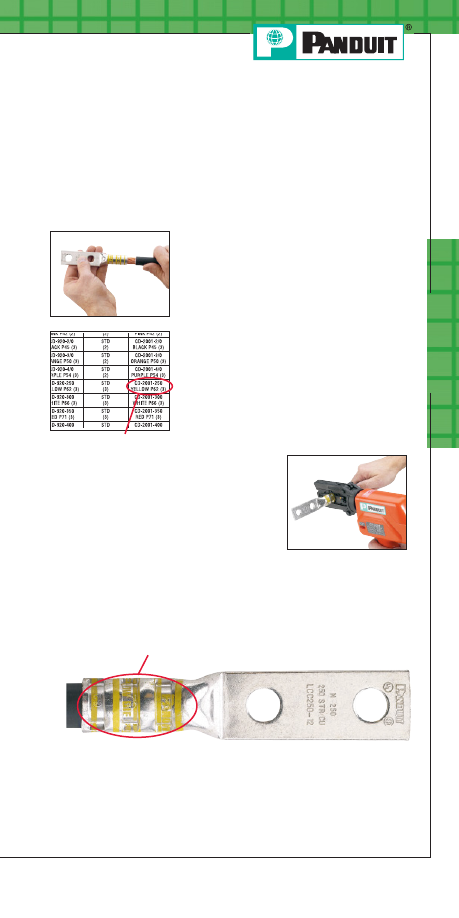

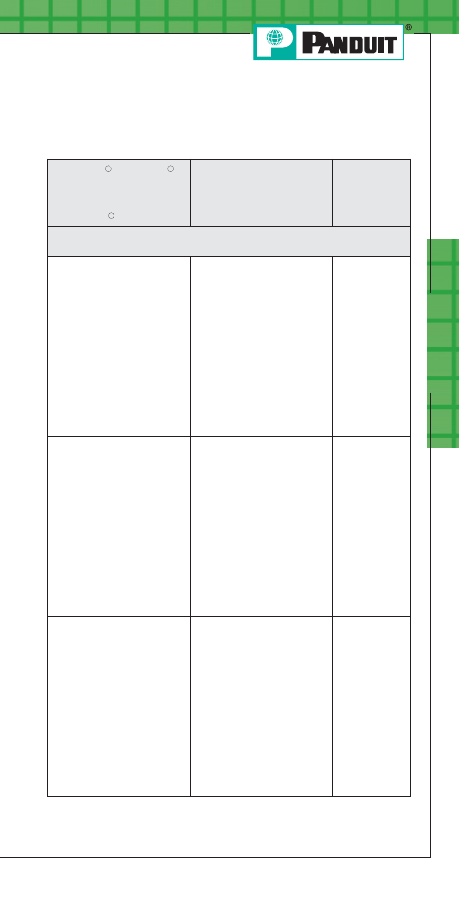

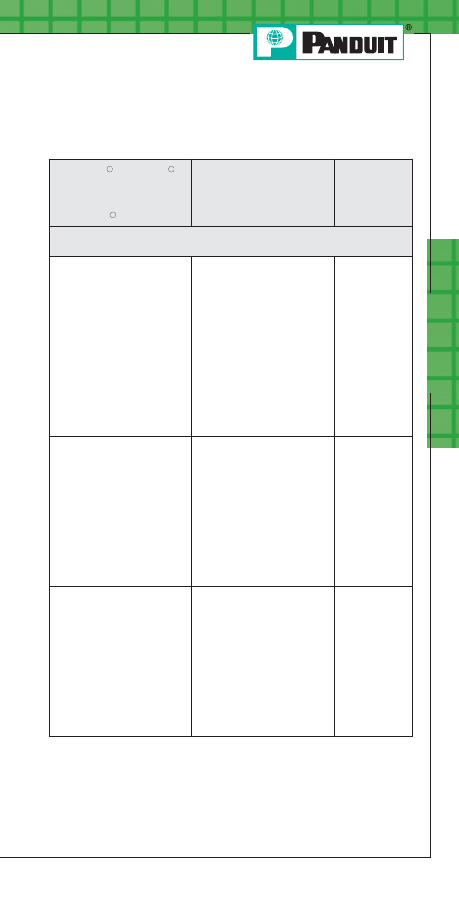

Insulated Terminals and Disconnects

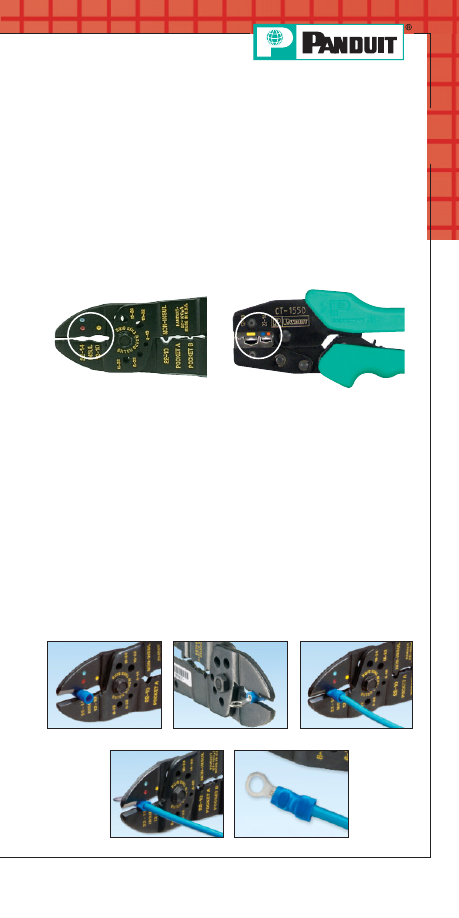

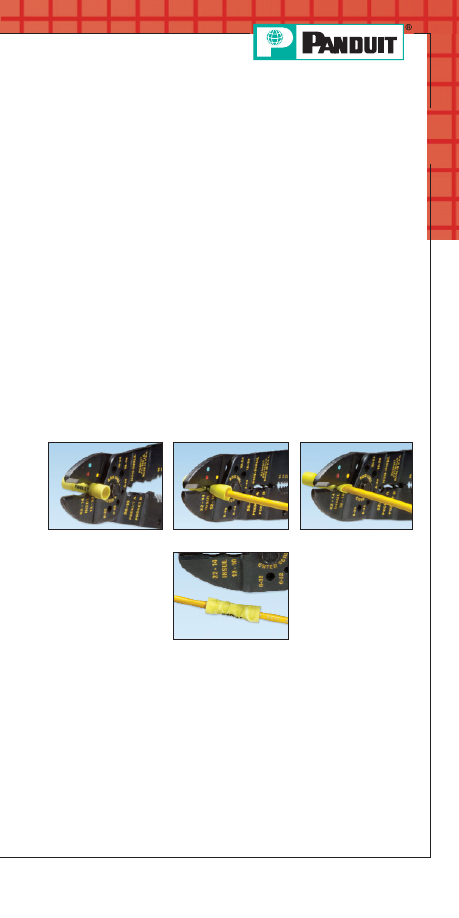

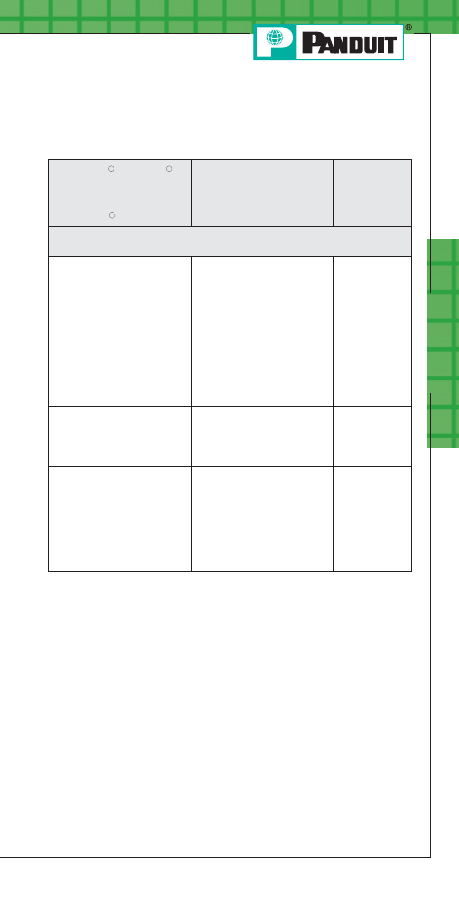

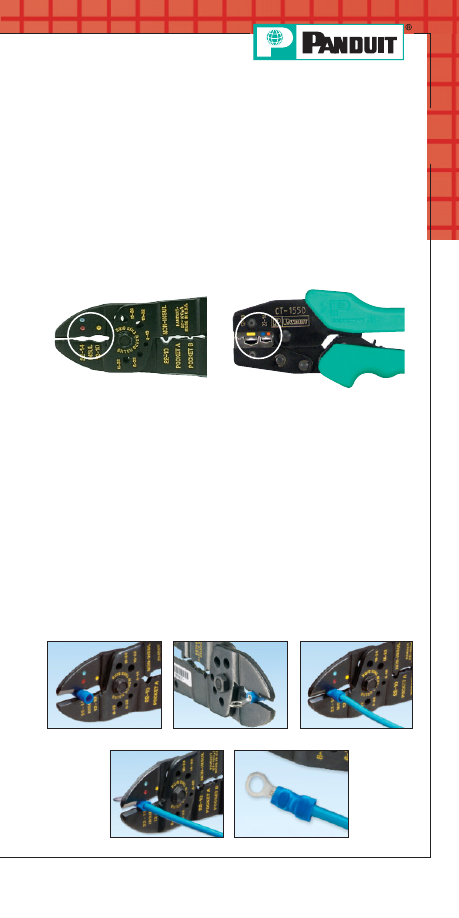

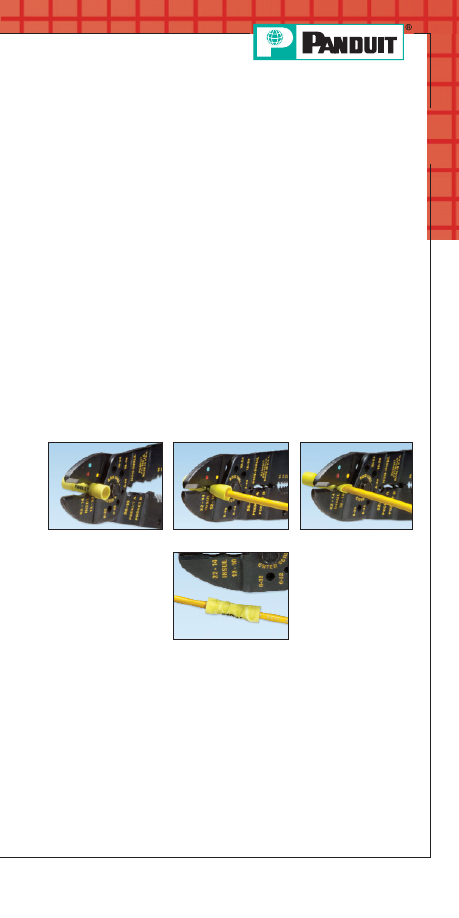

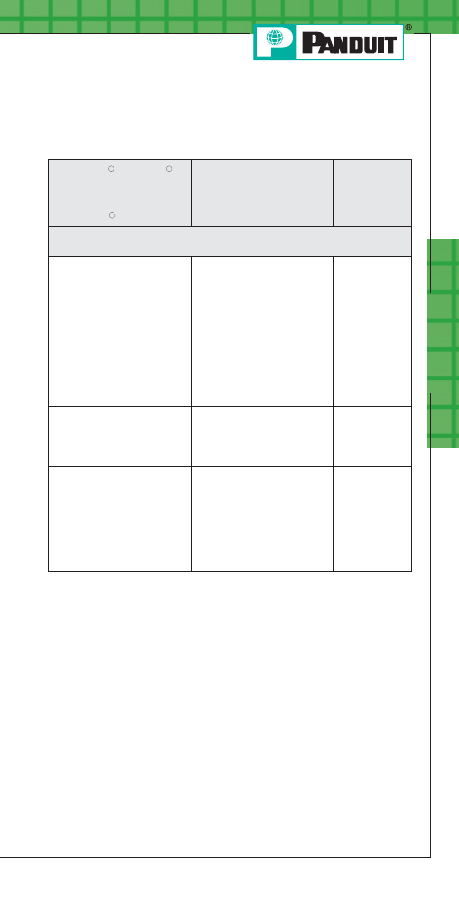

4. Select the proper crimp pocket for the terminals and wire

size you are using

•

PANDUIT crimping tools simplify this process with color

coded crimp pockets. The yellow, blue and red pockets

are specifically designed for the industry standard barrel

sizes, each with a specific color code.

A. Locate terminal in appropriate size color-coded crimp die pocket

with tool centered on insulation sleeve.

(See Note 1 page A6)

B. Rotate terminal so tongue is level with crimp die.

C. Insert properly stripped wire into terminal until a minimum of

1/32" of wire extends beyond the terminal barrel.

D. Squeeze tool handles firmly to perform the electrical crimp.

(See Note 2 page A6)

E. Provide second crimp on the flared portion of the insulation

housing to close the insulation as shown. Caution: when using

plier type crimping tools, do not squeeze as firmly as you did

for the electrical crimp.

(See Note 3 page A6)

Step A

Step B

Complete Crimp

Steps C & D

Step E

5. Perform the electrical crimp

For the plier type tool

PANDUIT Termination Solutions-html.html

Terminals

A4

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

(continued)

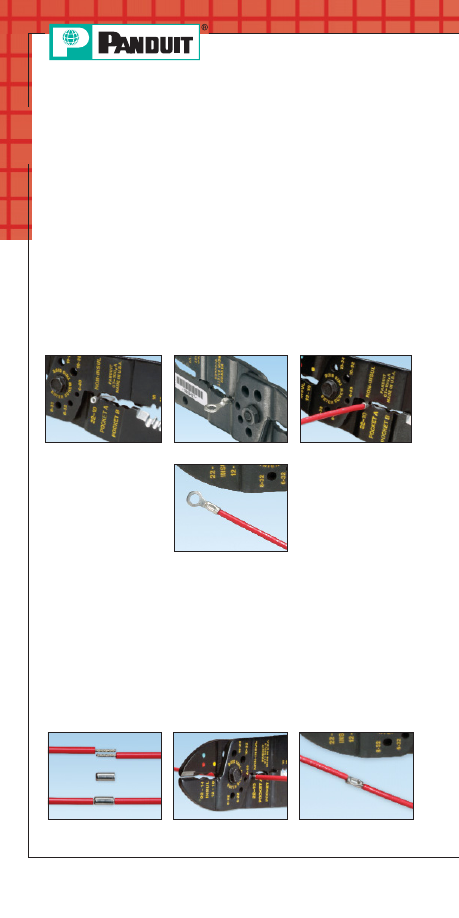

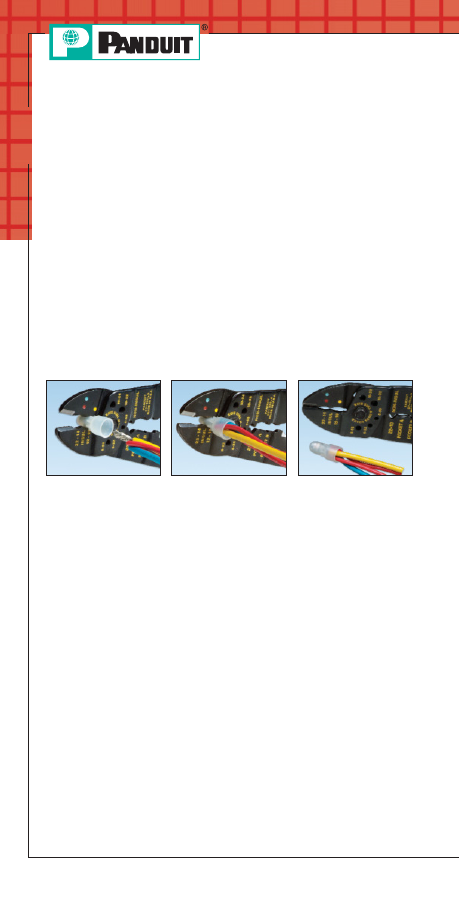

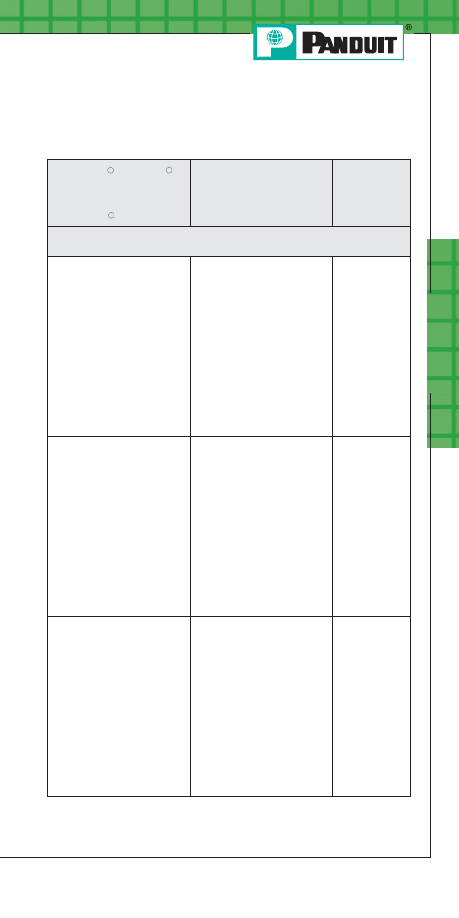

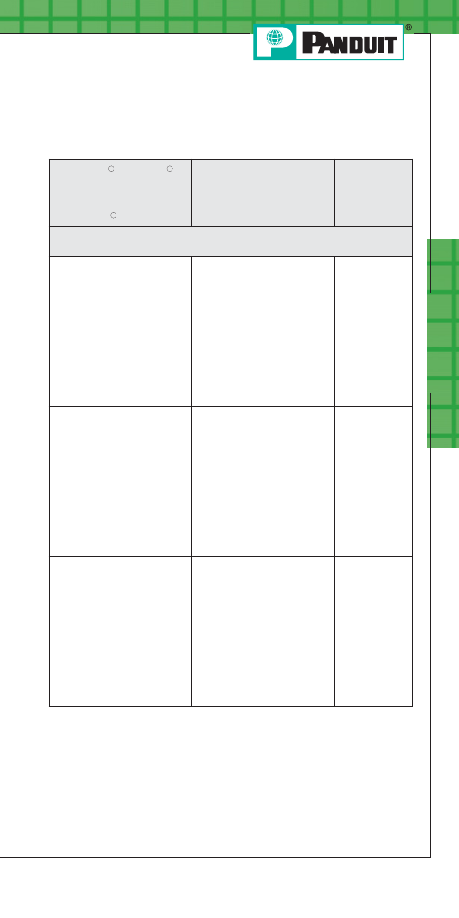

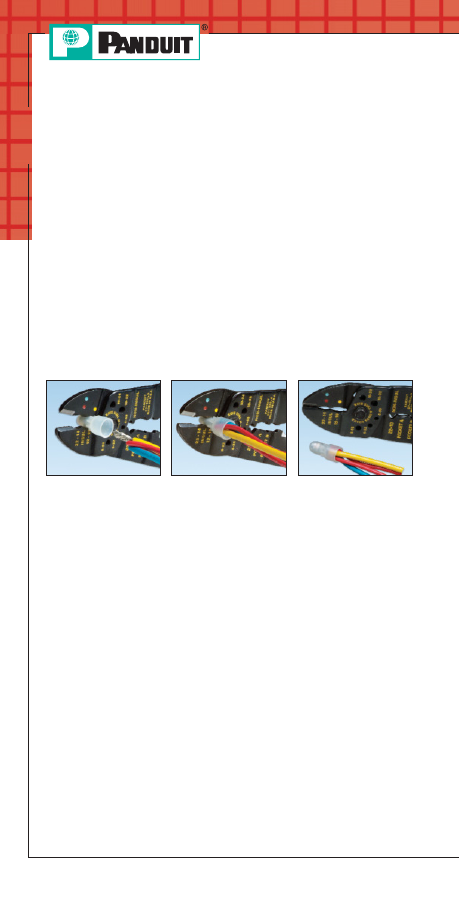

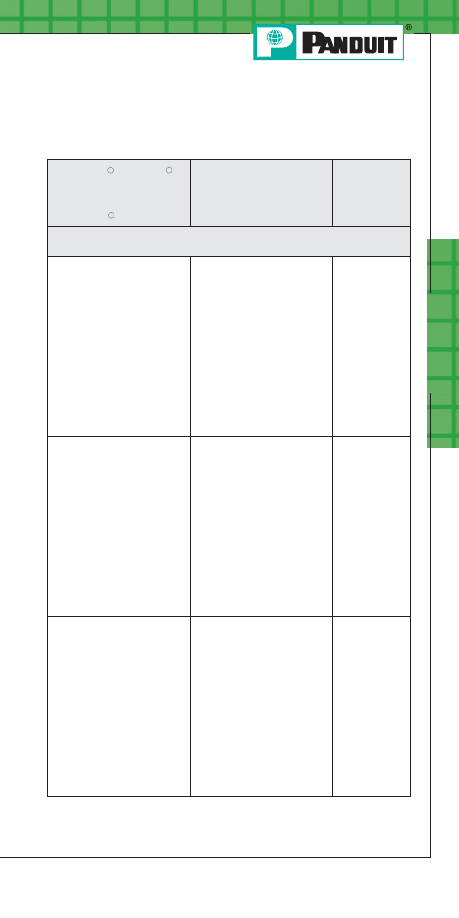

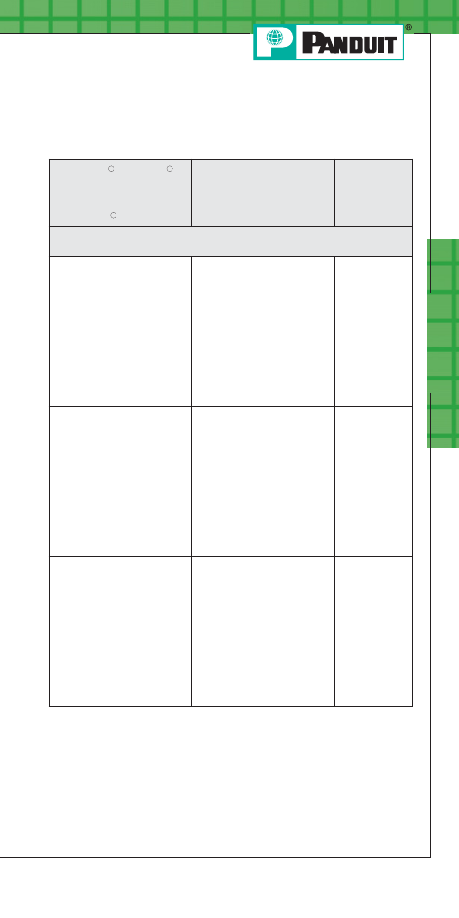

Non-Insulated Terminals and Disconnects

Insulated and Non-Insulated Parallel Splices

A. Locate terminal in appropriate wire gauge crimp die pocket

with indenter centered on barrel seam.

B. Rotate terminal so tongue is level with crimp die.

C. Insert properly stripped wire (based on recommendations on

package label) into terminal until a minimum of 1/32" of wire

extends beyond the terminal barrel.

D. Squeeze tool handles firmly to perform the electrical crimp.

(See Note 2 page A6)

Step A

Step B

Steps C & D

Complete Crimp

A. Locate parallel splice in appropriate wire gauge crimping die

pocket and position tool on the center of the splice.

B. Insert properly stripped wire (based on recommendations

on package label) into each end of the parallel splice.

C. Squeeze tool handles firmly.

(See Note 2 page A6)

D. An insulation crimp is not required on an insulated

parallel splice.

Steps A & B

Steps C & D

Complete Crimp

PANDUIT Termination Solutions-html.html

Terminals

A5

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Insulated and Non-Insulated Butt Splices

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

(continued)

A. Locate butt splice in appropriate color-coded crimp die pocket

and position crimp halfway between the wire stop (center

of splice) and the end of the insulation crimp area.

(See

Note 4 page A6)

B. Insert properly stripped wire (based on recommendations on

package label) into one end of butt splice.

C. Squeeze tool handles firmly to perform the electrical crimp.

(See Note 2 page A6)

D. Provide second crimp on the flared portion of the insulation

housing to close the insulation. Caution: When using plier

type crimping tools, do not squeeze as firmly as you did for

the electrical crimp.

(See Note 3 page A6)

E. Repeat steps one to four for opposite end of butt splice.

Steps A & B

Steps C

Complete Crimp

Step D & E

PANDUIT Termination Solutions-html.html

Terminals

A6

Insulated and Non-Insulated Wire Joints

NOTES for Crimping with the preferred Hand Operated

Controlled Cycle Crimping Tools:

A. Properly strip wires per manufacturer’s recommendations

on product package label.

B. Twist stripped wire ends together, and insert wires into

wire joint.

C. Locate wire joint in appropriate wire gauge crimp die pocket

and position crimp in the center of the metal insert.

D. Squeeze tool handles firmly to perform the electrical crimp.

(See Note 2 below)

Note: an insulation crimp is not required on an insulated

wire joint.

Steps 1 & 2

Steps 3 & 4

Complete Crimp

1.

PANDUIT controlled cycle crimping tools properly locate rings, forks,

and barrel insulated disconnects, pins, and blades. No further

positioning is required.

2. When using the preferred controlled cycle tool, once a crimp has been

started, the ratchet device of controlled cycle tools will not release until

the crimp is complete, independent of operator expertise.

3. Controlled cycle tools provide the electrical crimp and the insulation

closure in a single cycle of the tool.

4. When using controlled cycle tooling, insulated butt splices must be

inserted from the back of the tool to ensure that the electrical and

insulation closure crimp pockets are properly aligned with the splice.

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

(continued)

PANDUIT Termination Solutions-html.html

Terminals

A7

For service and technical support, call 800-777-3300

or visit www.panduit.com.

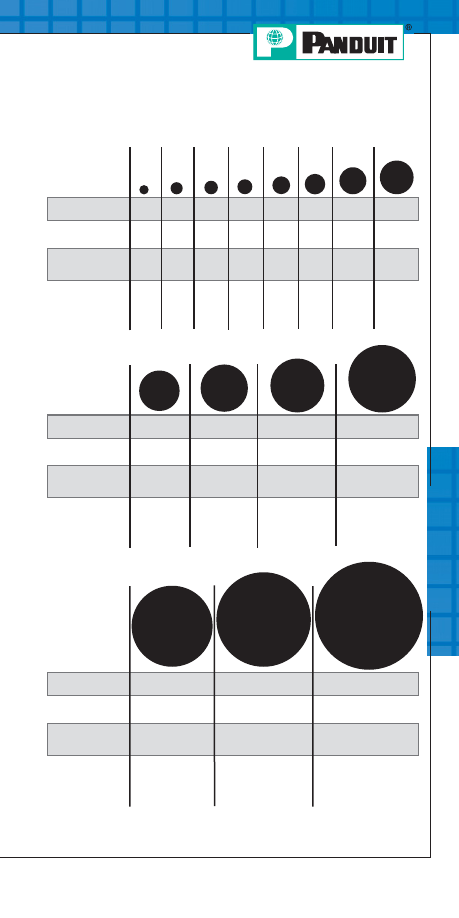

Bent Back Strands

Over Crimp

Rotated Crimp

Crimping Guidelines for

PANDUIT

®

P

AN

-T

ERM

®

Terminals,Disconnects,Splices and Wire Joints

(continued)

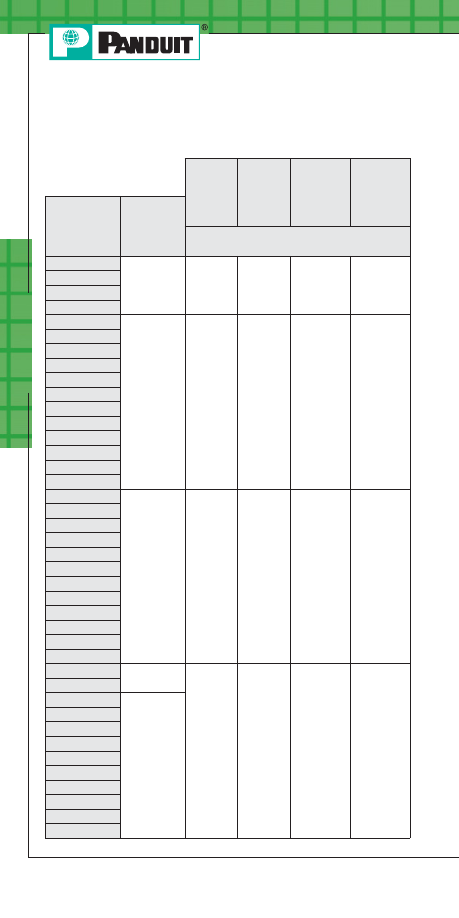

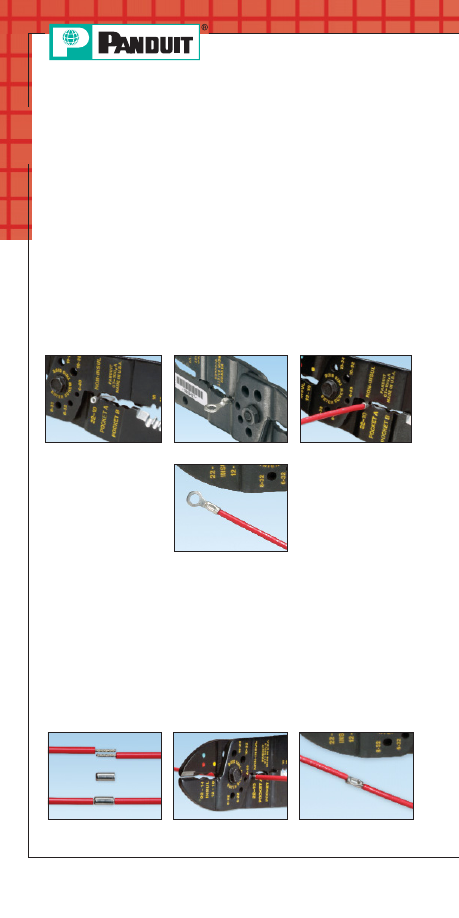

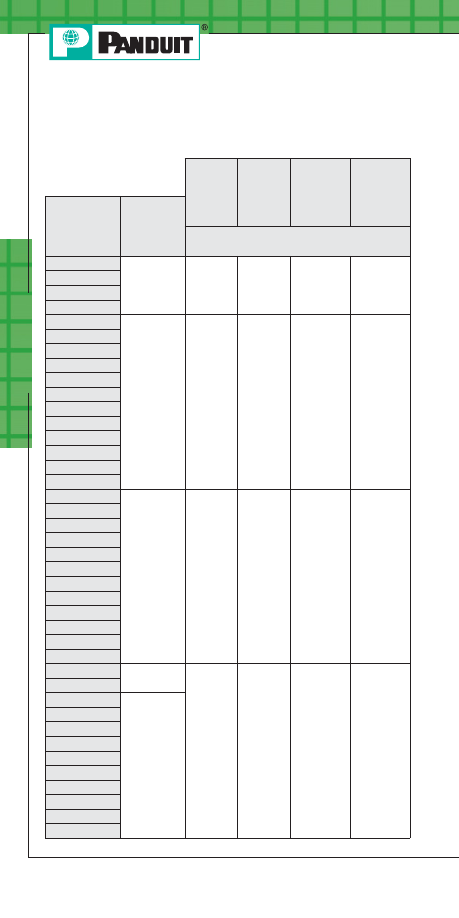

A. Make sure the terminal barrel is centered correctly in the

right die pocket by using the product locator on the backside

of the tool.

B. Determine the correct die pocket to use based on the color

code of the terminal.

C. Squeeze the handles of the tool until one click is heard; this

click indicates the terminal is now held in place securely to

insert the wire.

D. Insert the wire and complete cycle to perform the electrical

and insulation crimp simultaneously.

E. Crimp complete.

Note: If your crimp looks like any of the examples shown below,

cut off the terminal and recrimp. These crimps would

provide a poor connection!

5. Perform the electrical crimp

using the preferred controlled cycle tool

6. Inspect the crimp

Step A

Step B

Complete Crimp

Step C

Step D

PANDUIT Termination Solutions-html.html

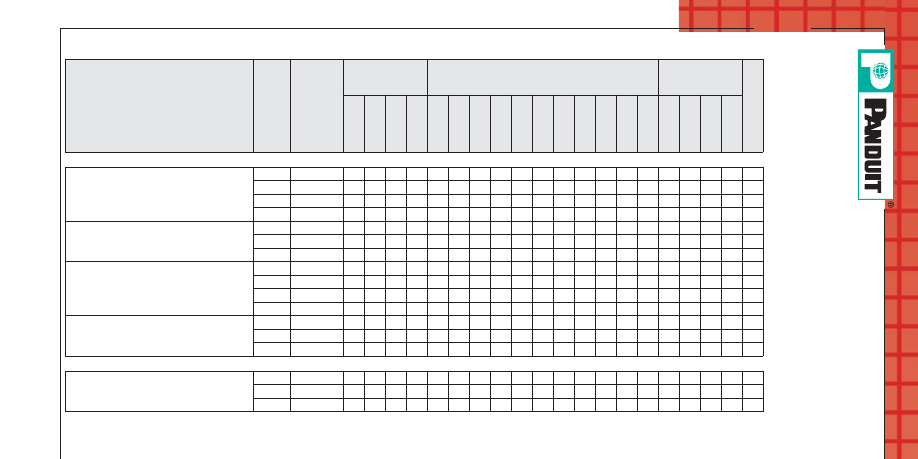

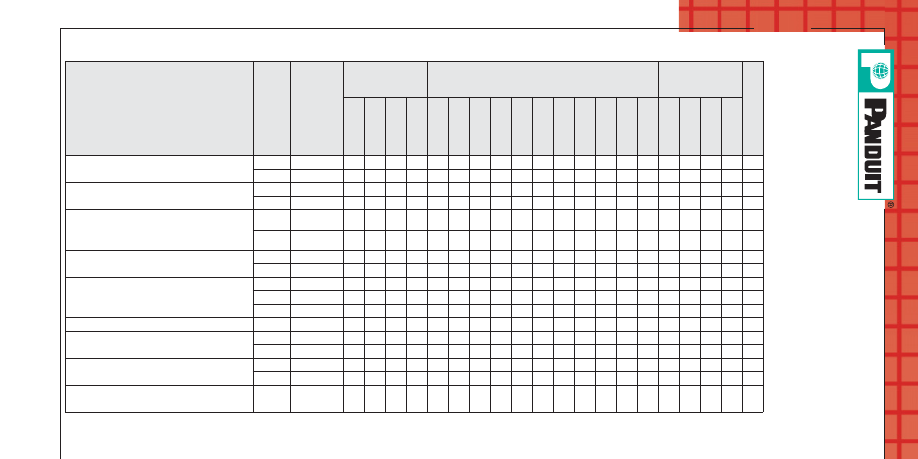

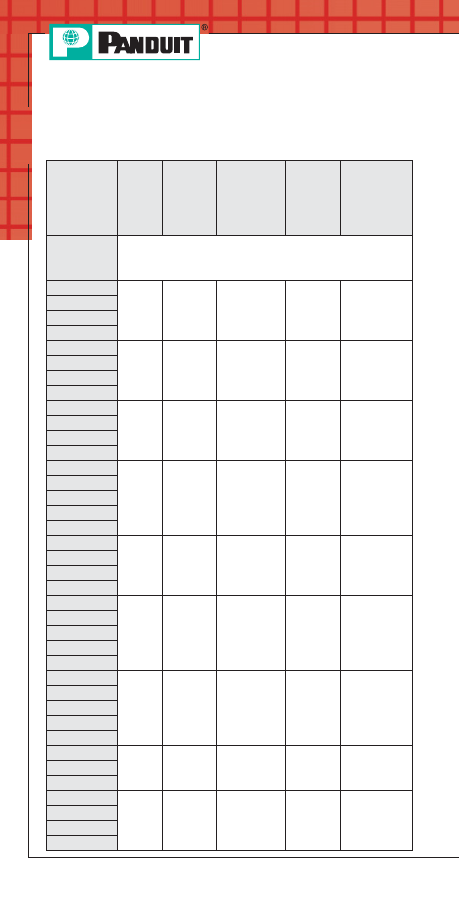

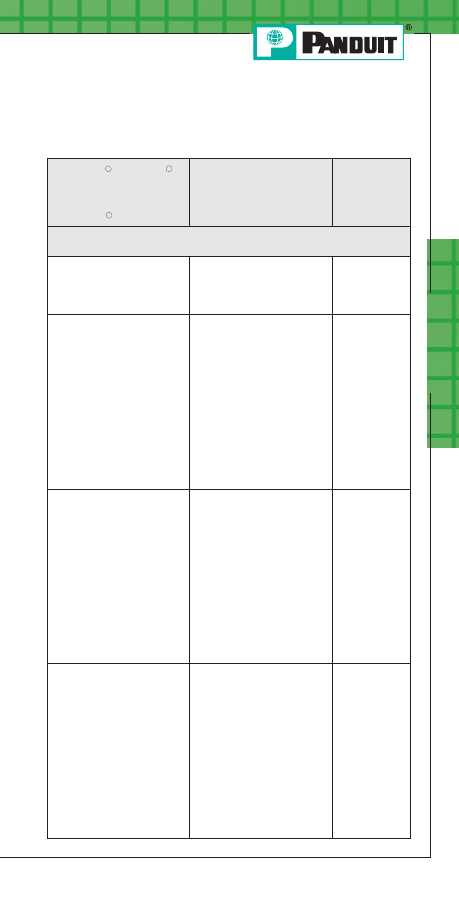

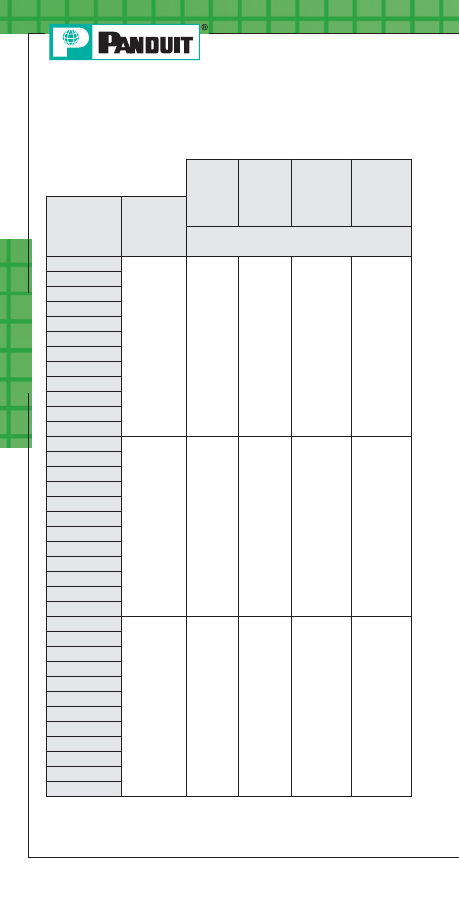

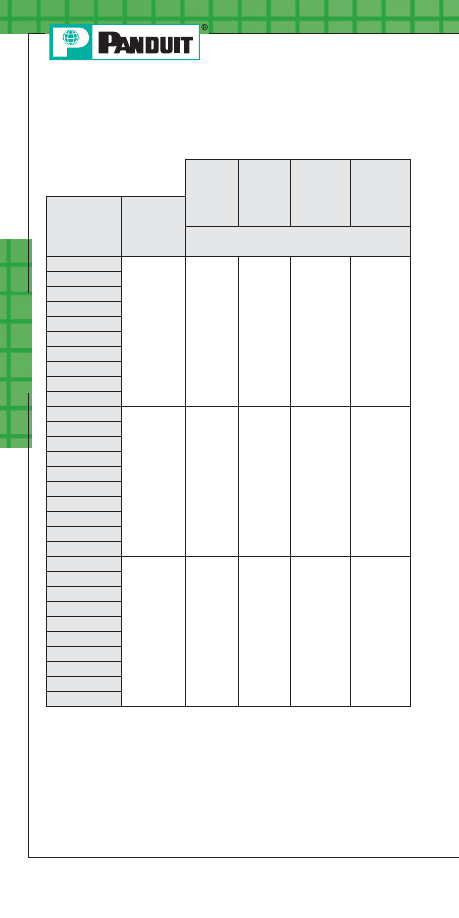

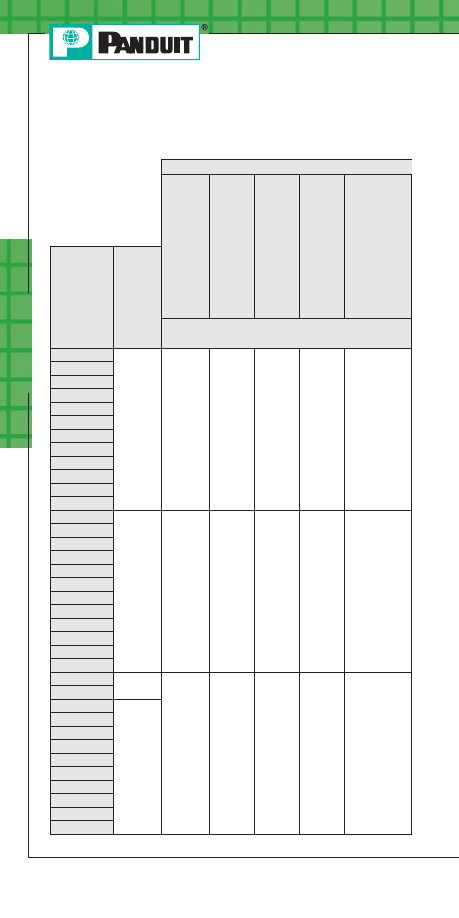

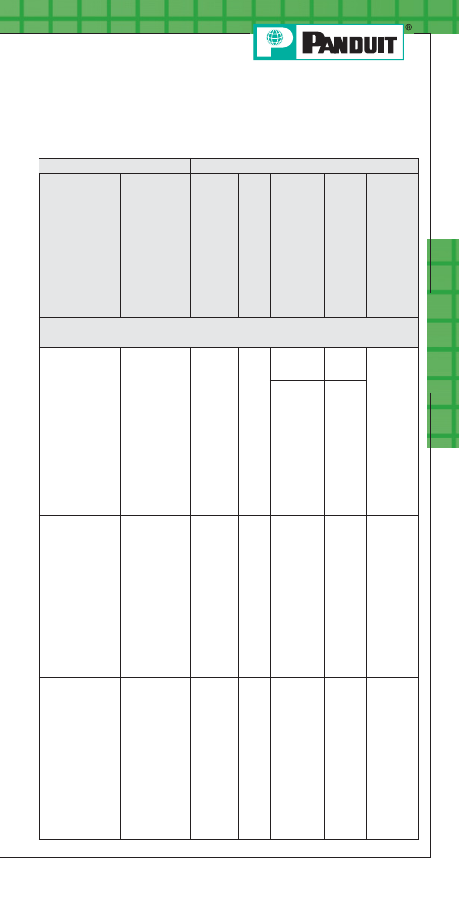

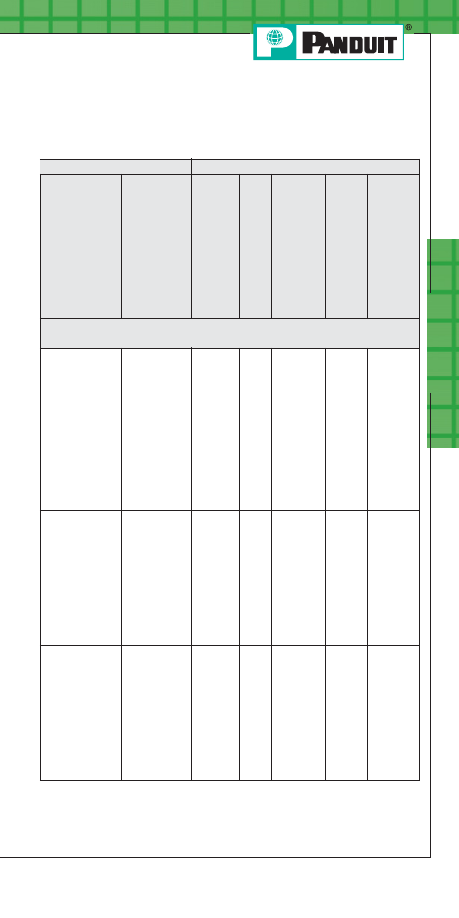

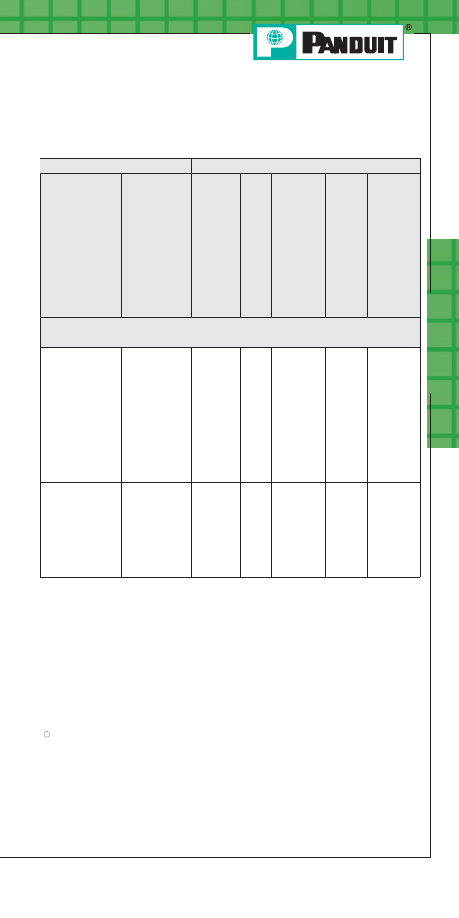

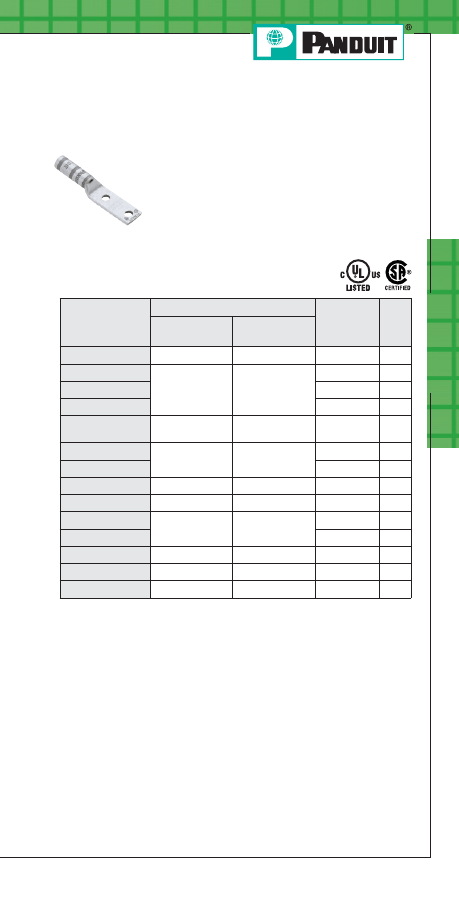

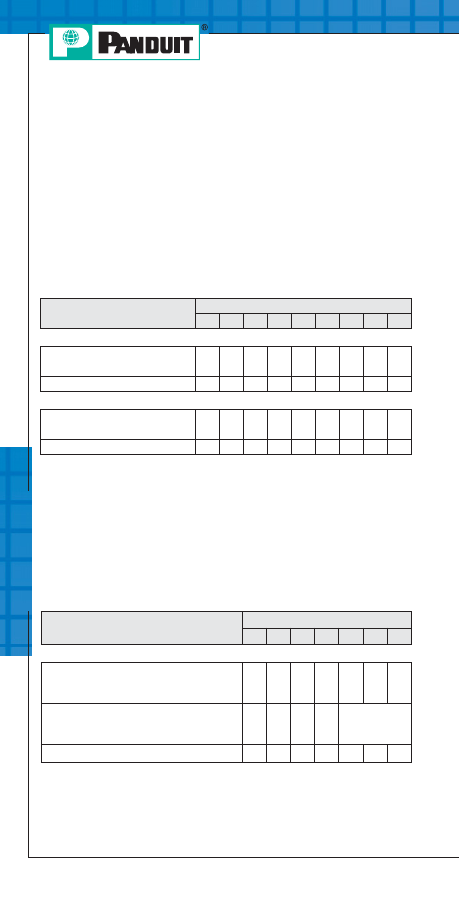

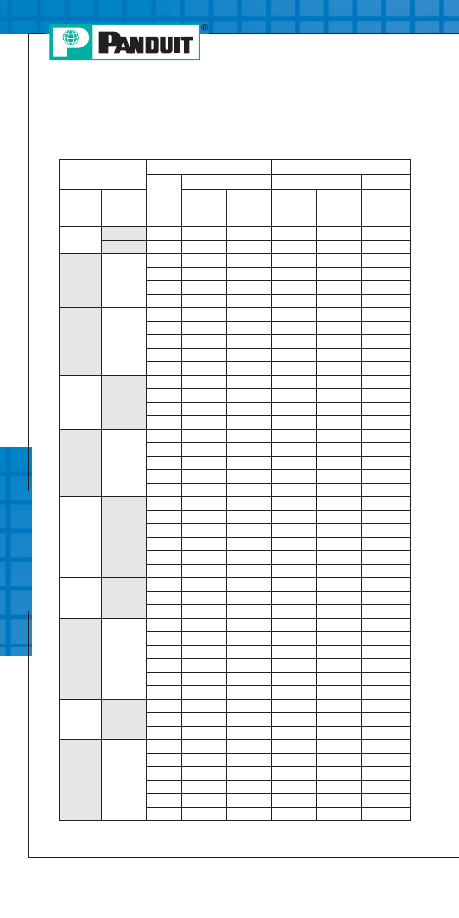

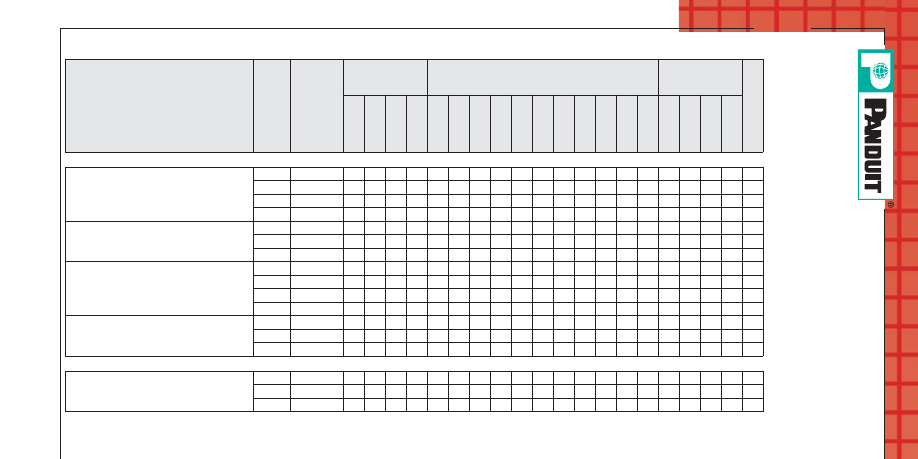

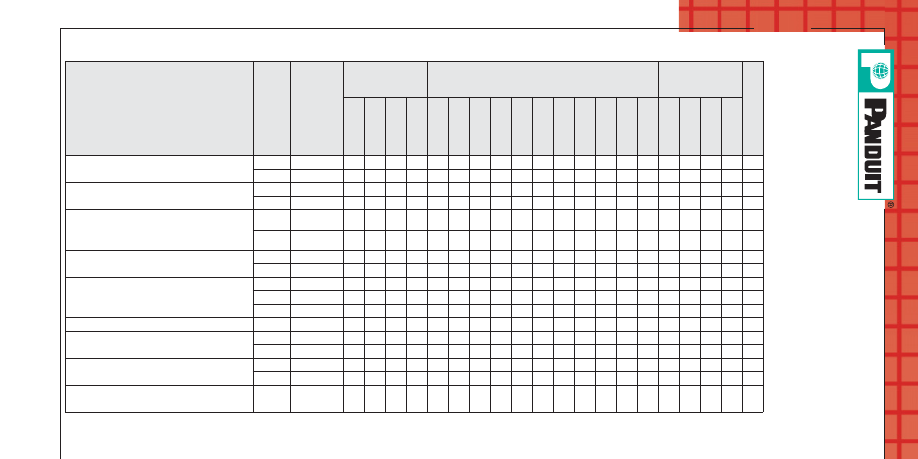

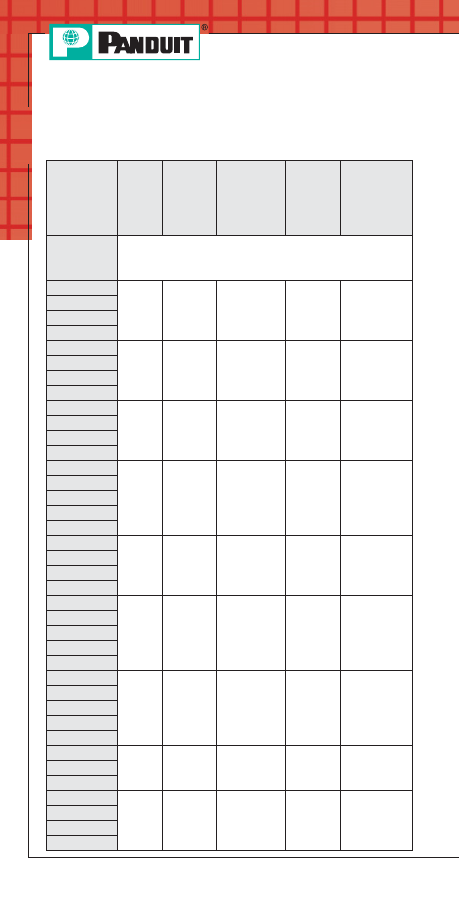

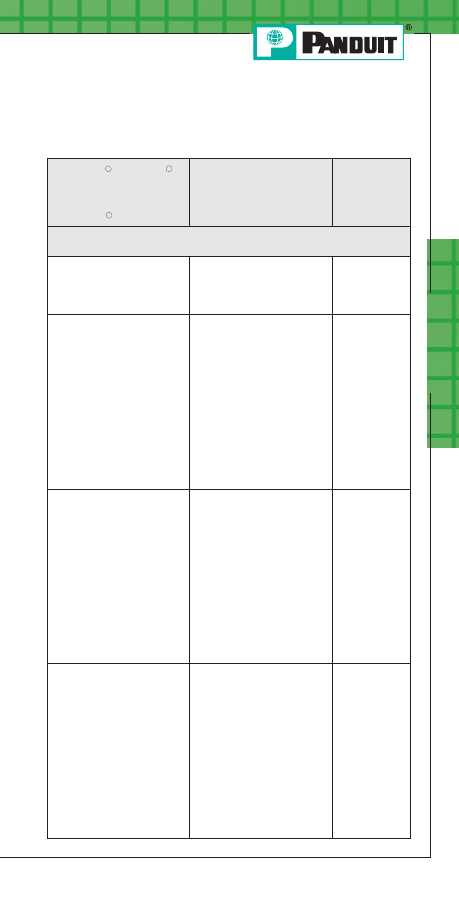

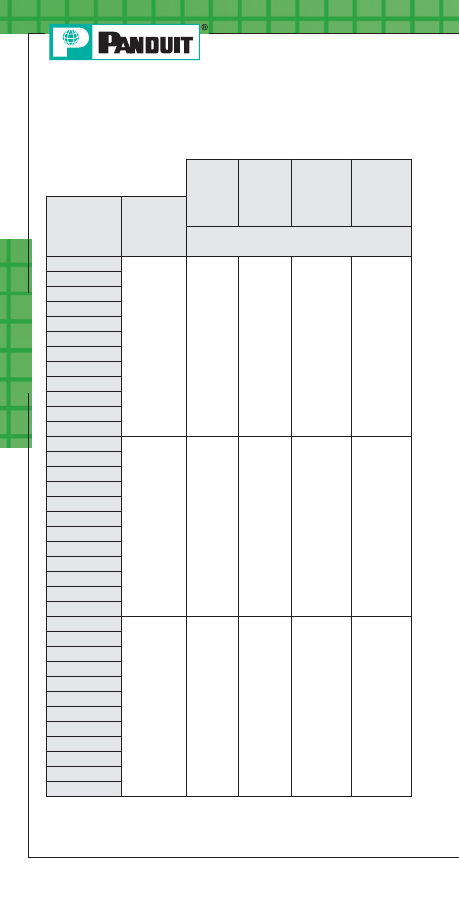

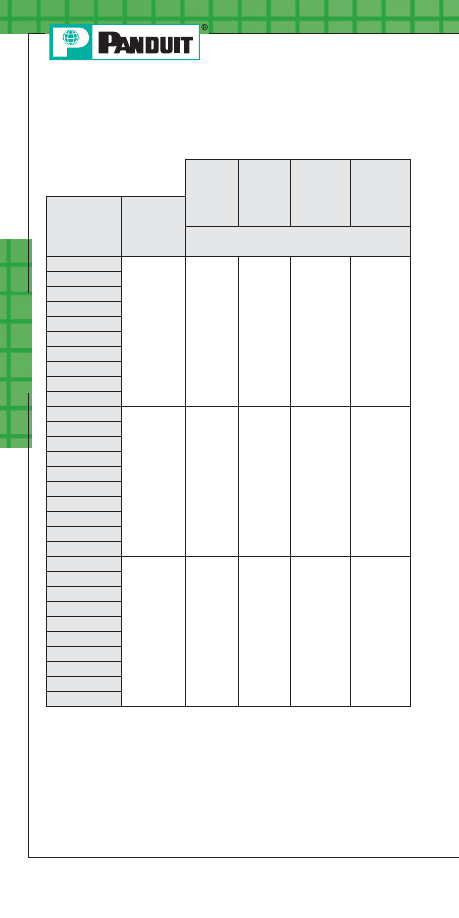

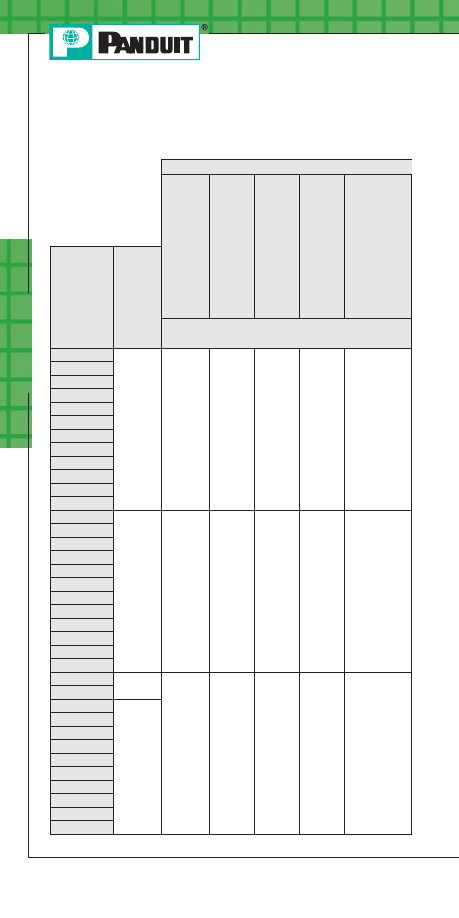

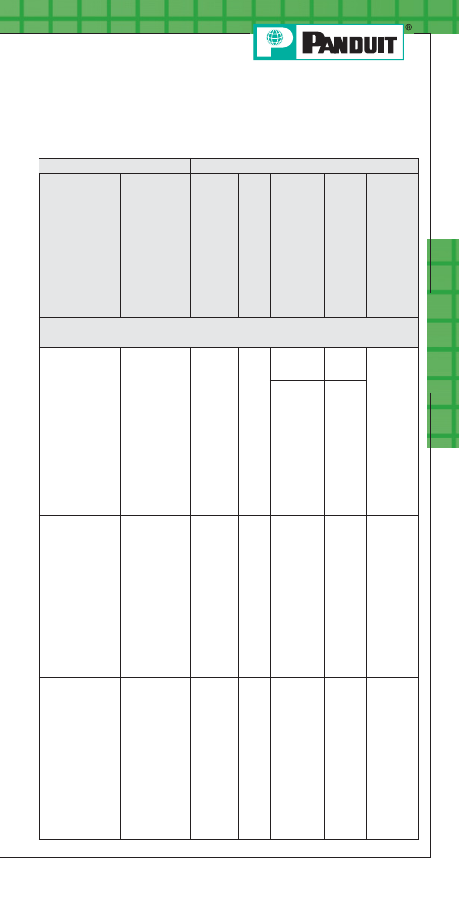

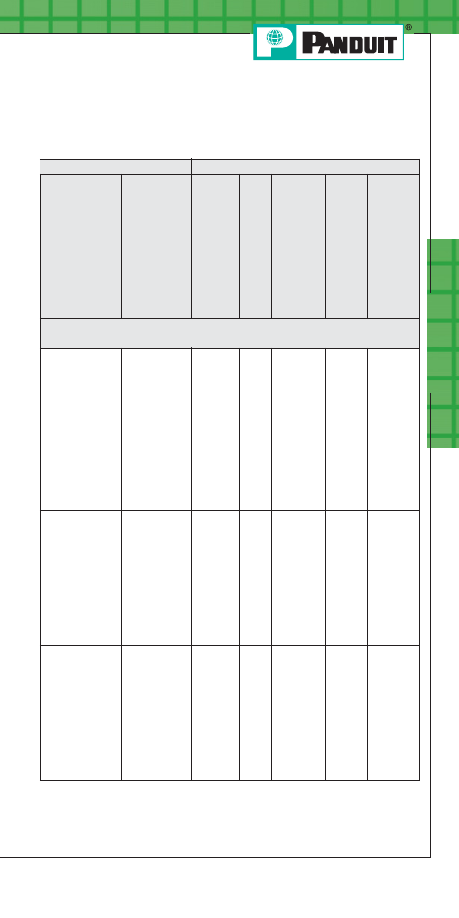

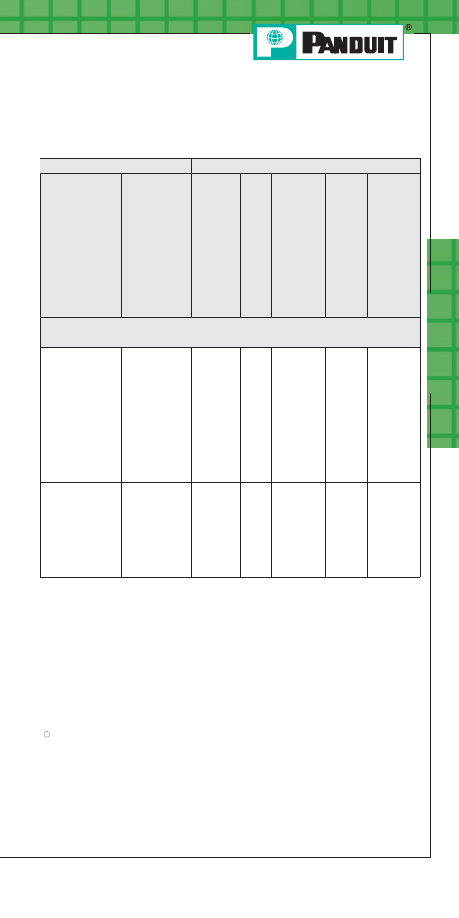

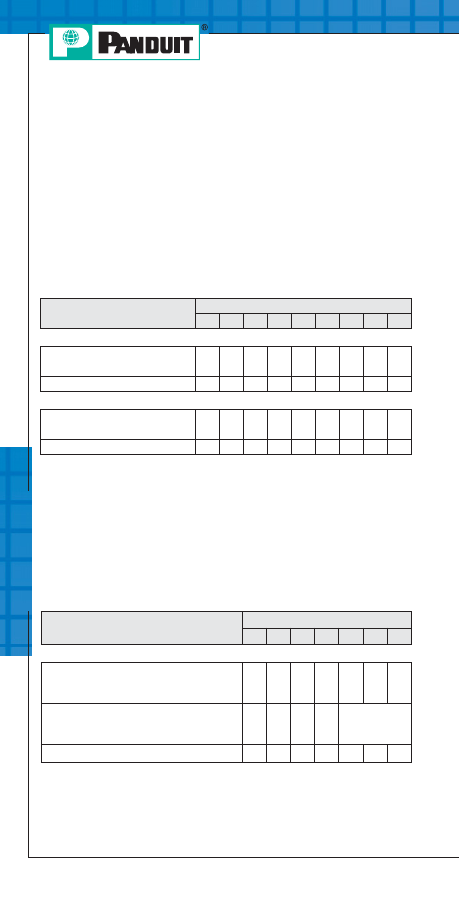

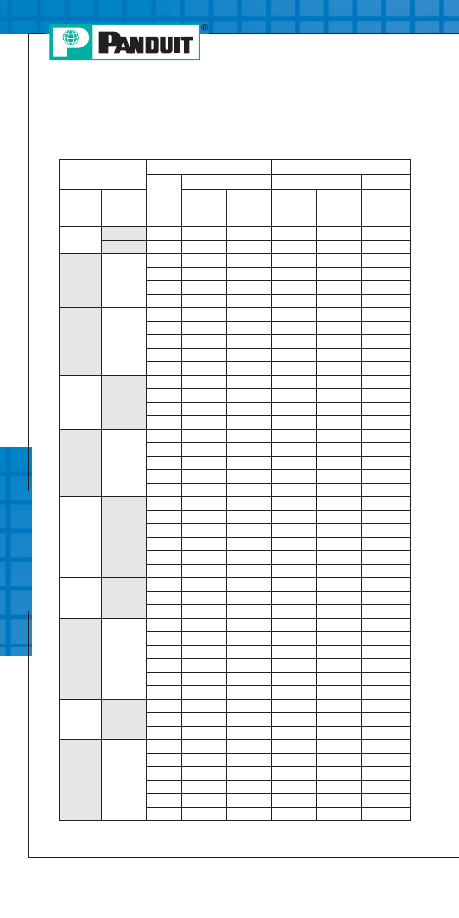

Terminal Series

Std.

Wire

Range

(AWG)

Wire

Strip

Length

(In.)

[+1/32;-0]

Plier Tools

Controlled Cycle Hand Tools

Crimp Heads

for Pneumatic

CT-600 Tool

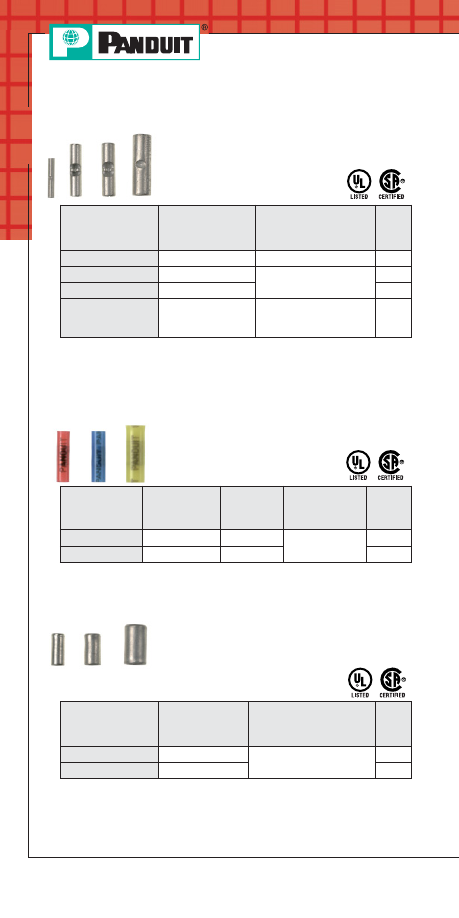

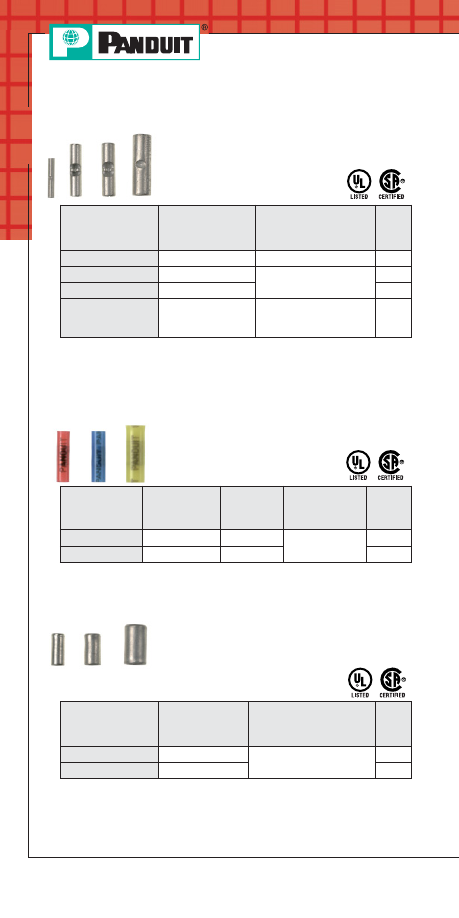

Butt Splices

BS – Non-Insulated Butt Splices

26-22

1/4

X

X

22-18

9/32

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

BSH – Heat Shrink

22-18

5/16

X

16-14

5/16

X

12-10

5/16

X

BSN – Nylon Insulated

26-22

1/4

X

X

X

22-18

9/32

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

BSV – Vinyl Insulated

22-18

5/16

X

X

X

X

X

X

X

X

16-14

5/16

X

X

X

X

X

X

X

X

X

12-10

5/16

X

X

X

X

X

X

X

Disconnects

D, DR – Non-Insulated, Sleeve Barrel

(Includes Right Angle)

22-18

9/32

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

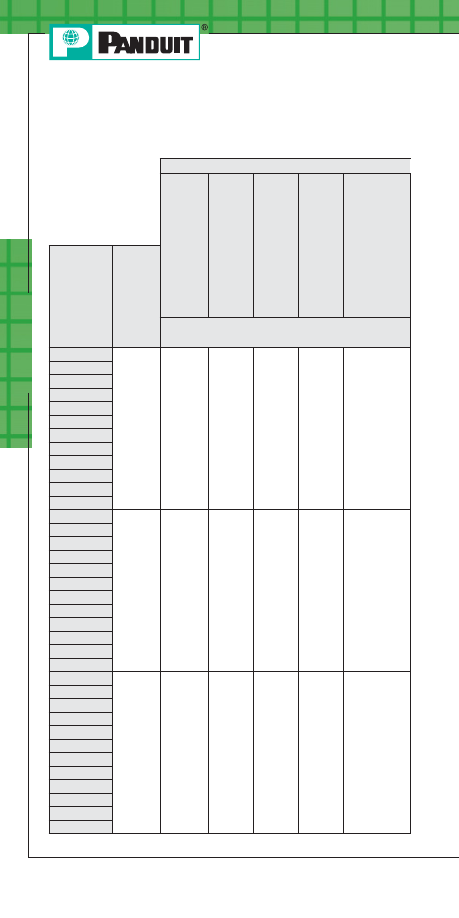

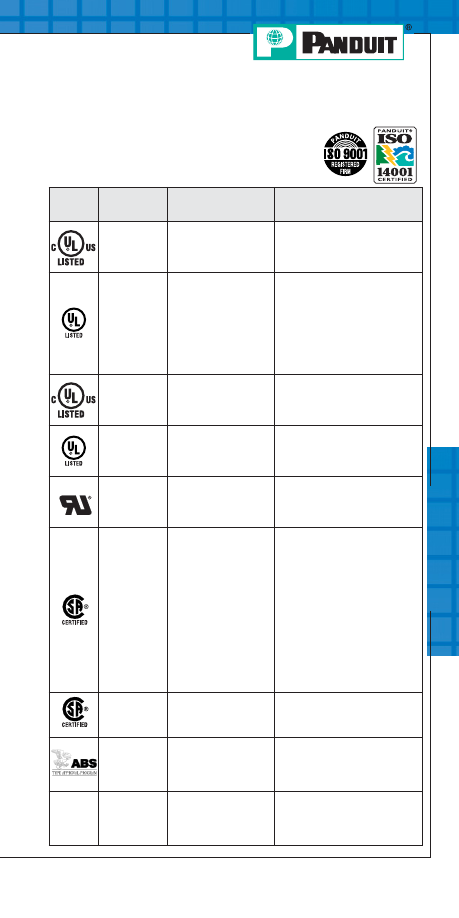

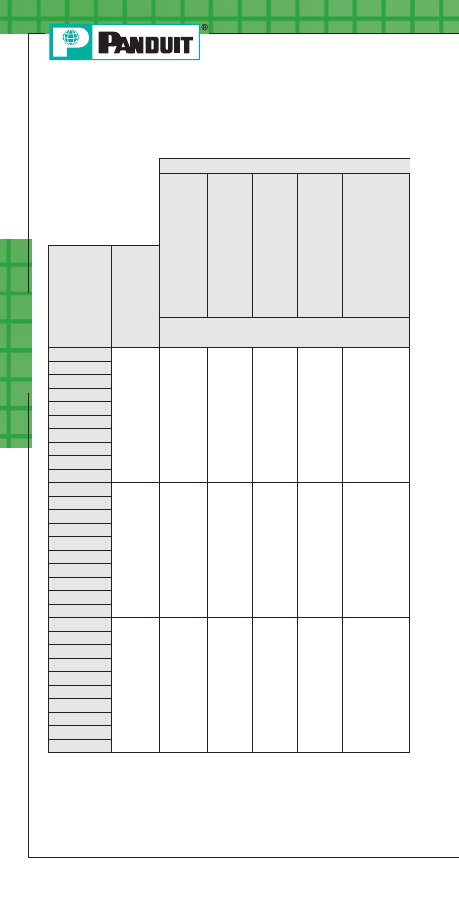

Terminals

A8

PANDUIT

Installa

tion T

ooling

for T

erminals

,

Disconnec

ts and S

plices

CT

-100

CT

-160

CT

-200

CT

-260

CT

-300-1

CT

-310

CT

-400

CT

-460

CT

-1014

CT

-1015

CT

-1525

CT

-1550

CT

-1551

CT

-1570

CT

-1701

CT

-500CH

CT

-520CH

CT

-550CH

CT

-570CH

CT

-720 Mec

hanical

PANDUIT Termination Solutions-html.html

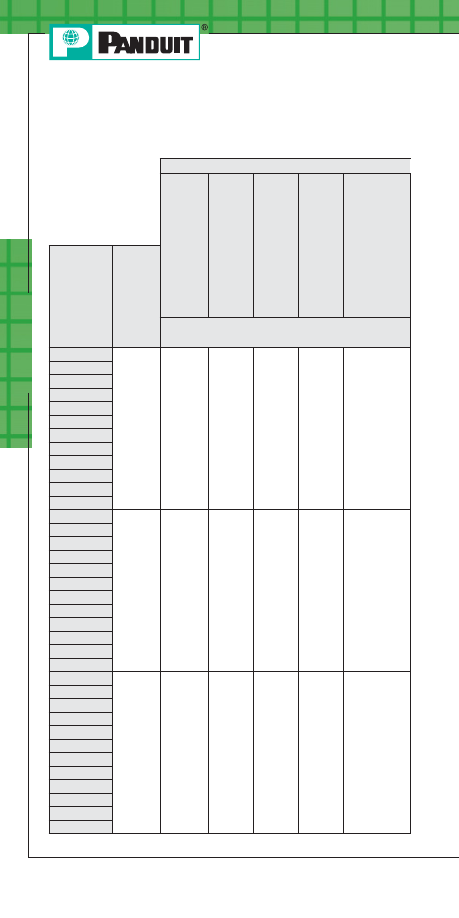

Terminals

A9

F

o

r ser

v

ice and technical suppor

t, call 800-777-3300

or visit www

.panduit.com.

PANDUIT

Installa

tion T

ooling

for T

erminals

,

Disconnec

ts and S

plices (continued)

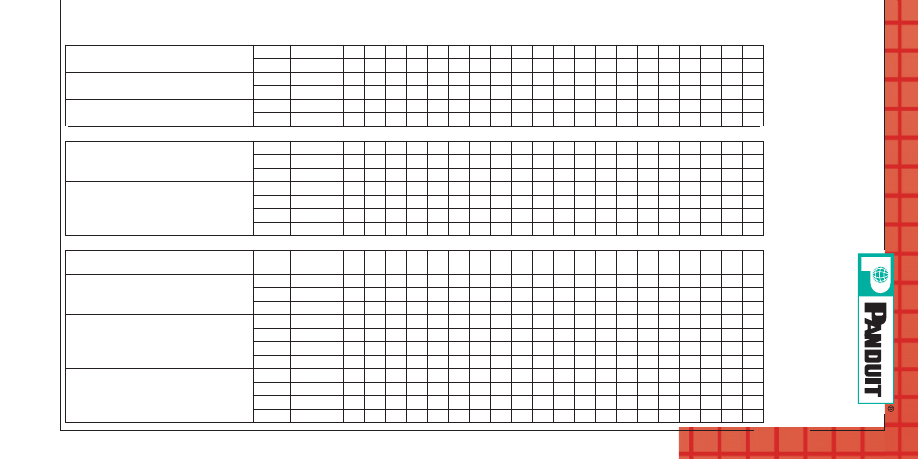

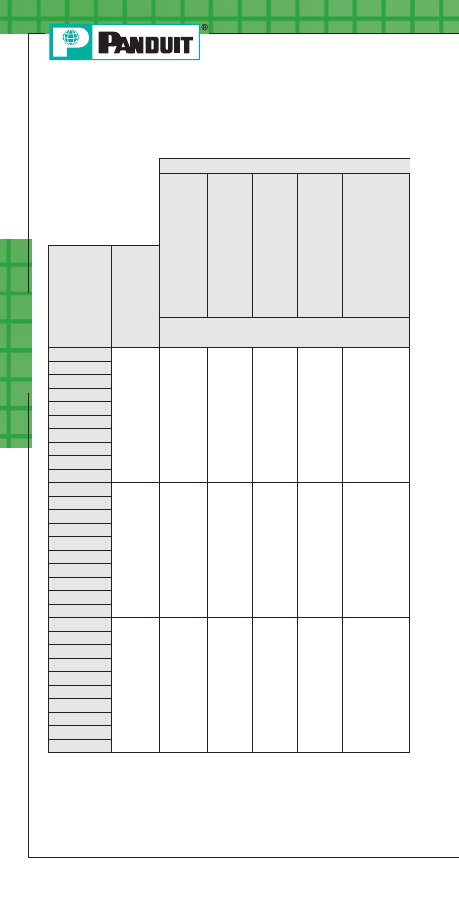

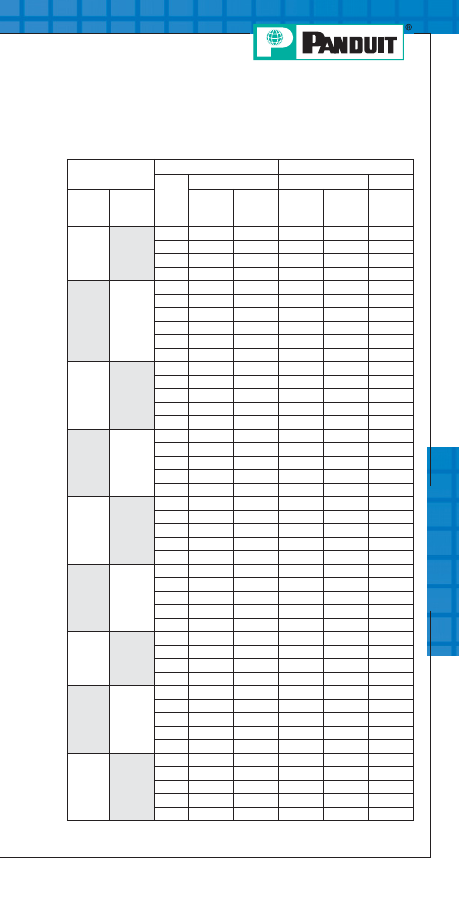

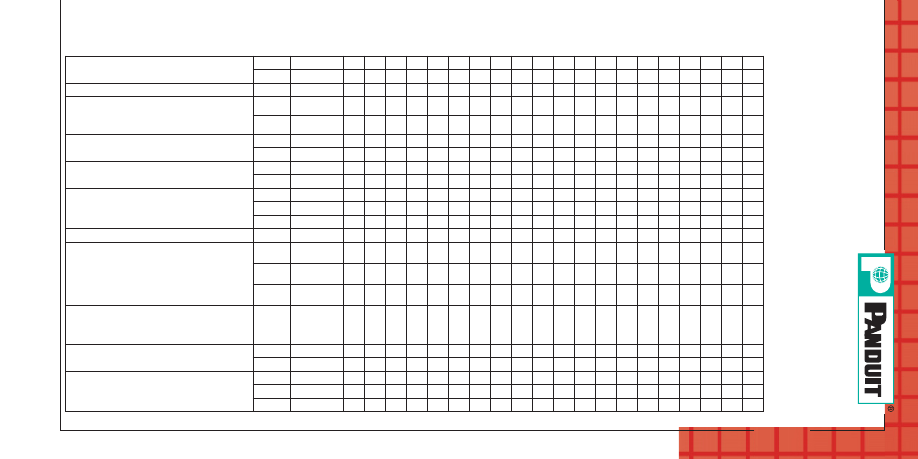

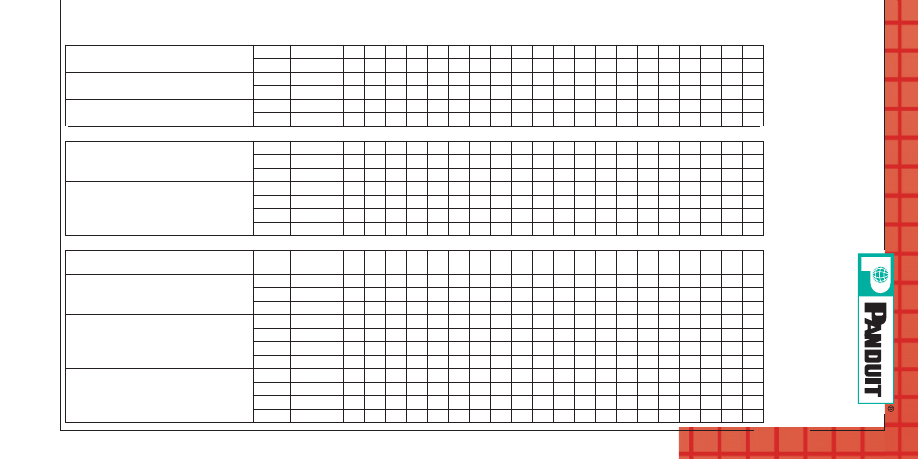

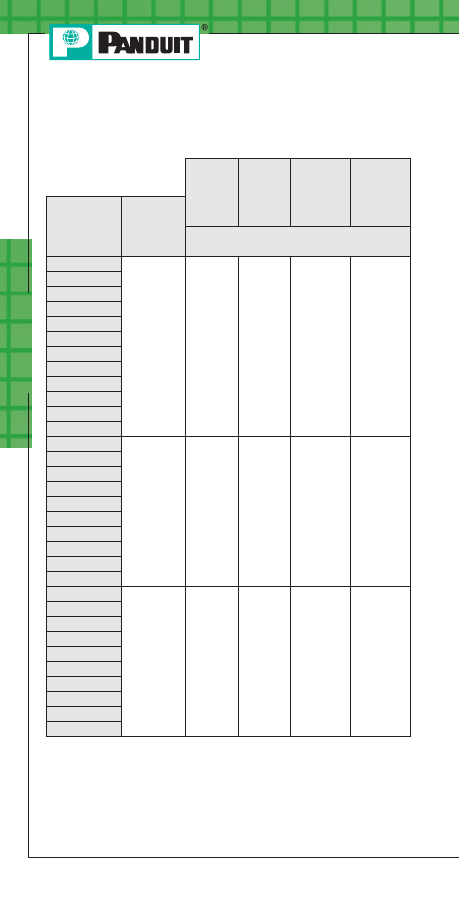

D-M – Non-Insulated Male Blade

Adapters

22-18

9/32

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

D-M – Non-Insulated Male

12-10

9/32

X

X

X

X

X

X

D-MB, DR-B – Non-Insulated Right

Angle Female & Non-Insulated Male

Butted Seam

22-18

9/32

X

X

X

X

16-14

9/32

X

X

X

X

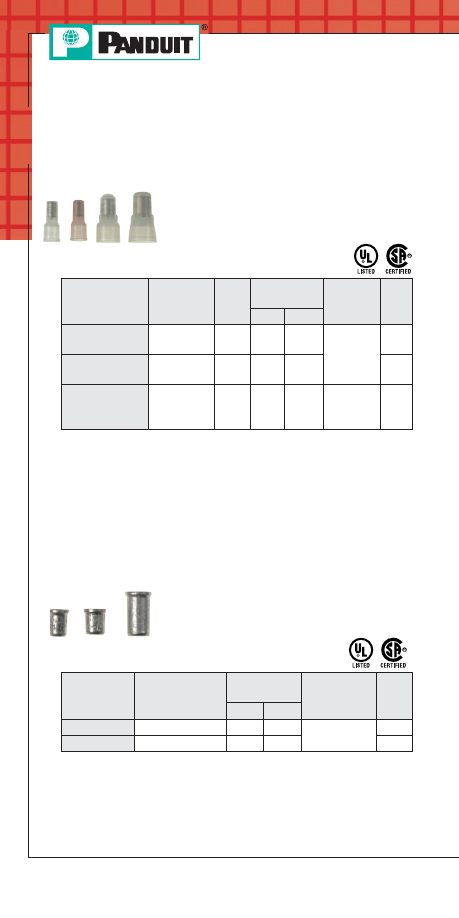

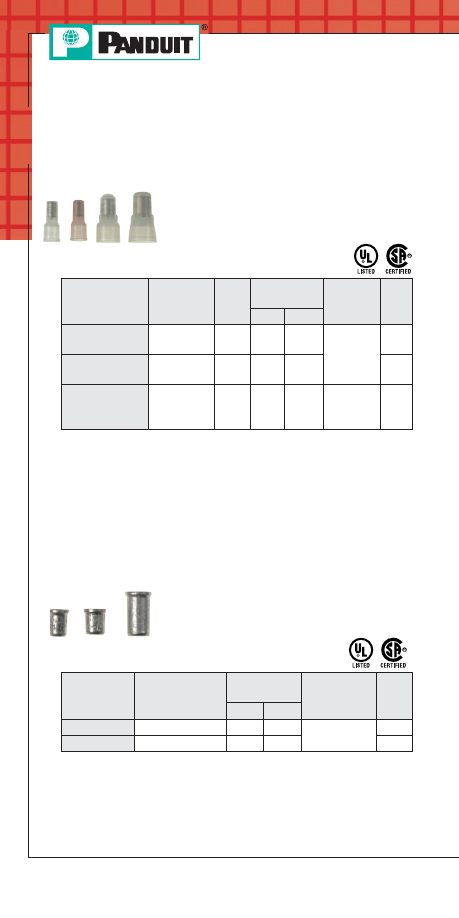

DNF – Nylon, Funnel Entry, Barrel

Insulated (not .110/.111)

22-18

9/32

X

X

X

X

16-14

9/32

X

X

X

X

X

X

X

X

DNF-110, DNF-111 – Nylon, Funnel

Entry Barrel Insulated .110/.111 Tab Size

22-18

7/32

X

X

X

X

16-14

9/32

X

X

X

DNF-FI – Nylon, Fully Insulated

22-18

9/32

X

X

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

X

12-10

3/8

X

X

X

X

X

X

X

DPF-FI – Premium Nylon, Fully Insulated 12-10

3/8

X

X

X

X

X

X

X

DNF-FIB, DNF-FIM, DNF-FIMB,

DPF-FIB, DPF-FIMB, DNF-LPB,

DPF-LPB – Nylon & Premium Grade

Nylon, Fully Insulated, Funnel Entry,

Male/Female Couplers (not .110/.111)

22-18

9/32

X

X

X

16-14

9/32

X

X

X

12-10

3/8

X

DMF-FIB, DPF-FIB – Nylon Premium

Grade Nylon, Fully Insulated, Funnel

Entry, .110/.111 Tab Size

22-18

7/32

X

X

X

DNF-FIBX – Nylon, Expanded Wire

Entry, Fully Insulated

22-18

9/32

X

16-14

9/32

X

DNF-M – Nylon Insulated, Funnel

Entry, Barrel Insulated, Male

22-18

9/32

X

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

PANDUIT Termination Solutions-html.html

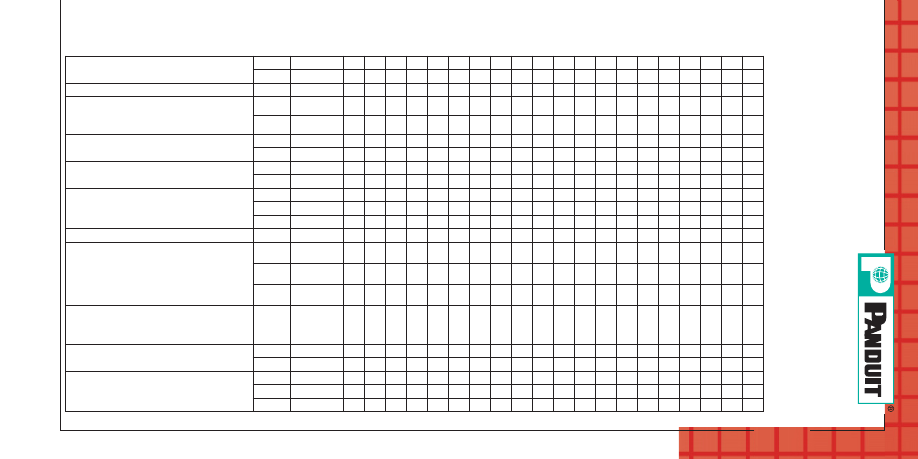

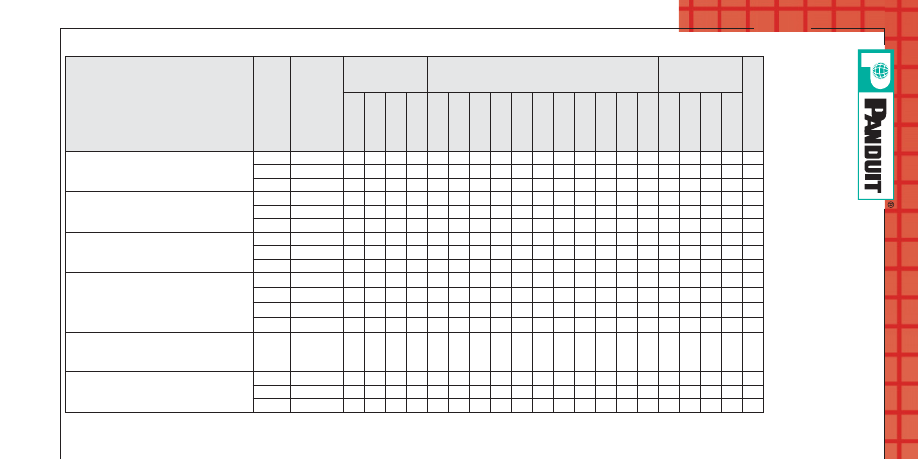

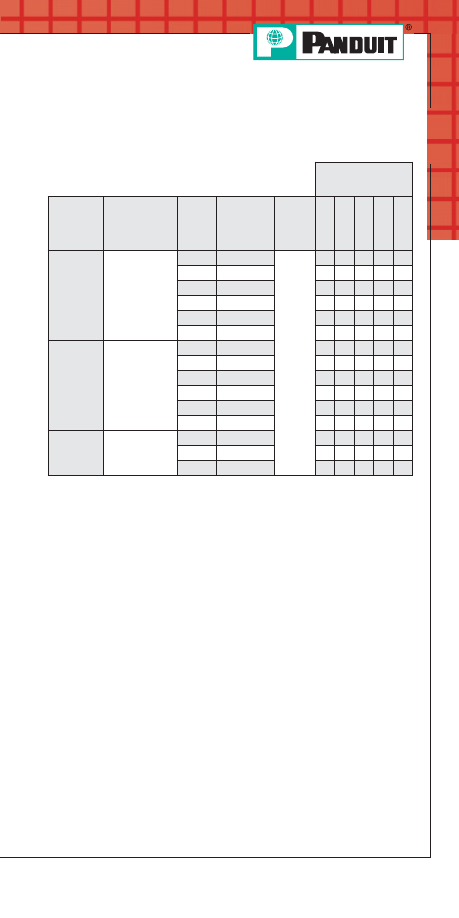

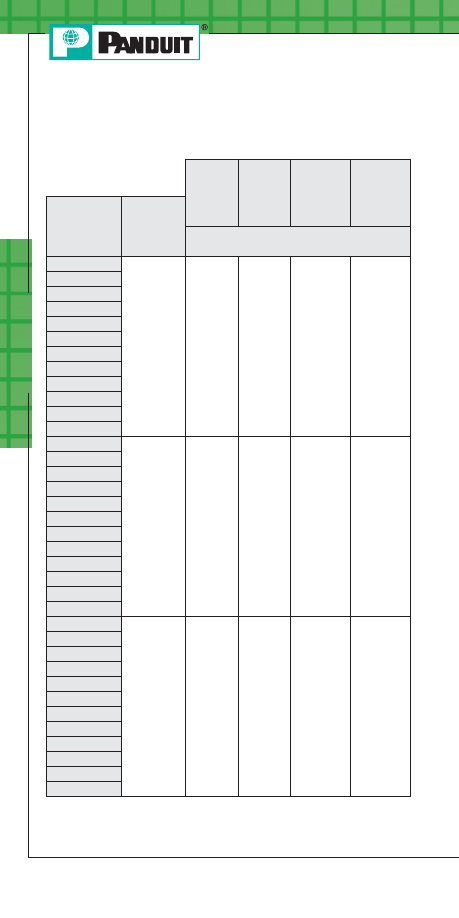

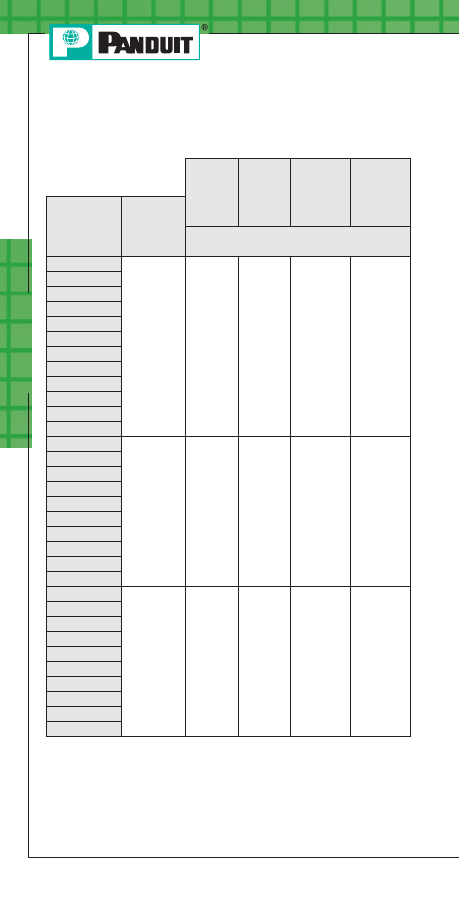

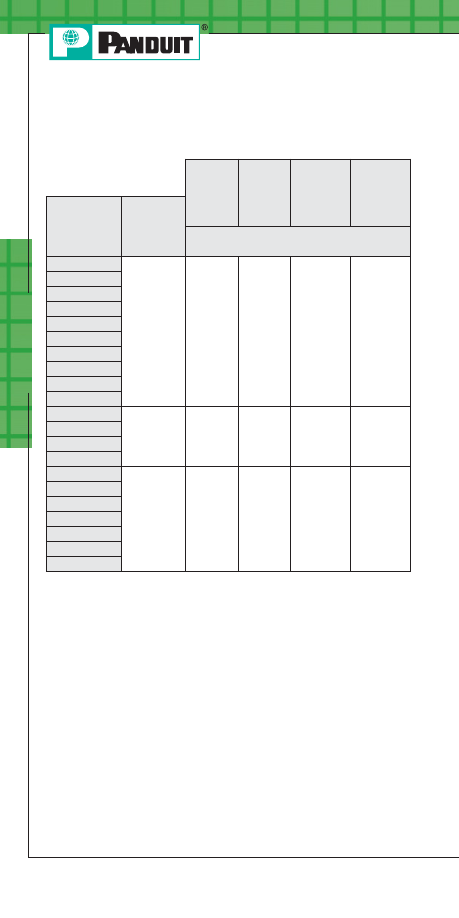

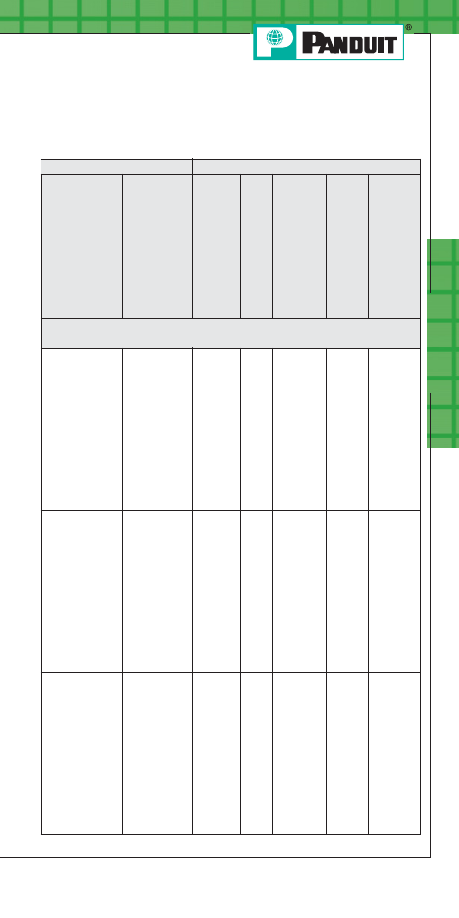

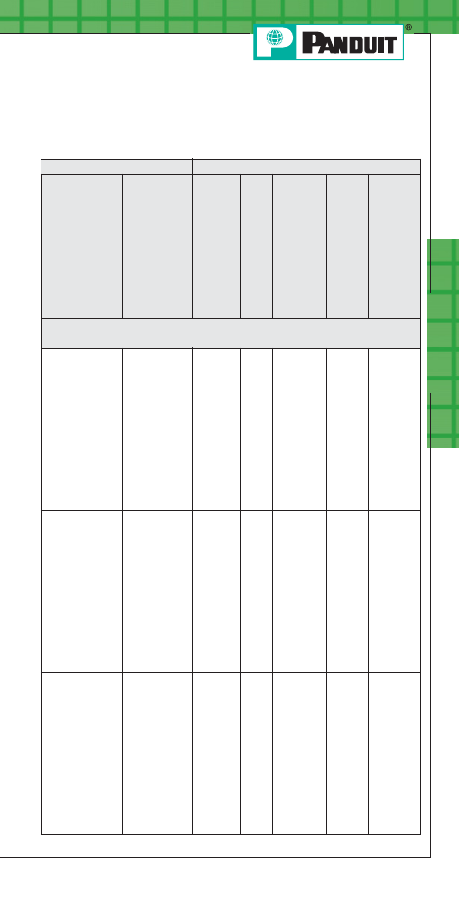

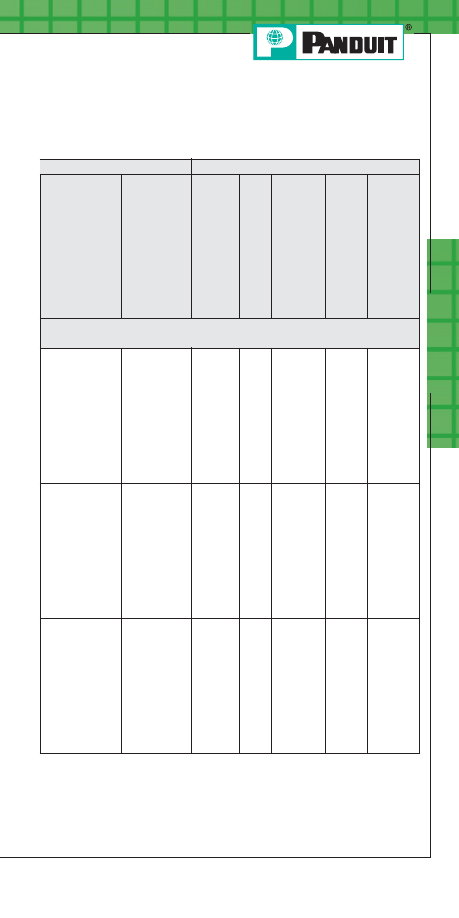

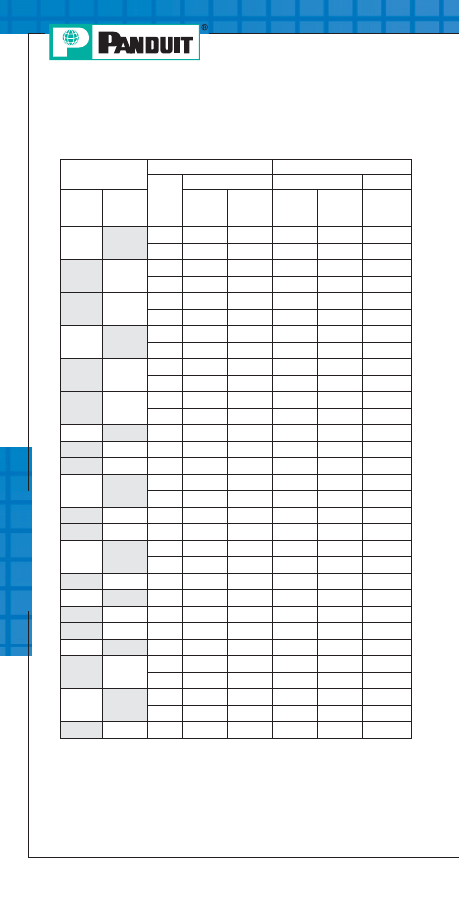

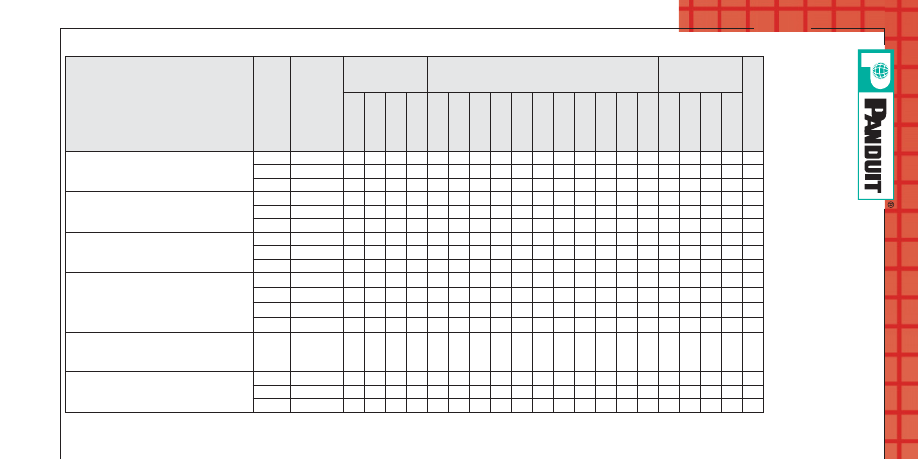

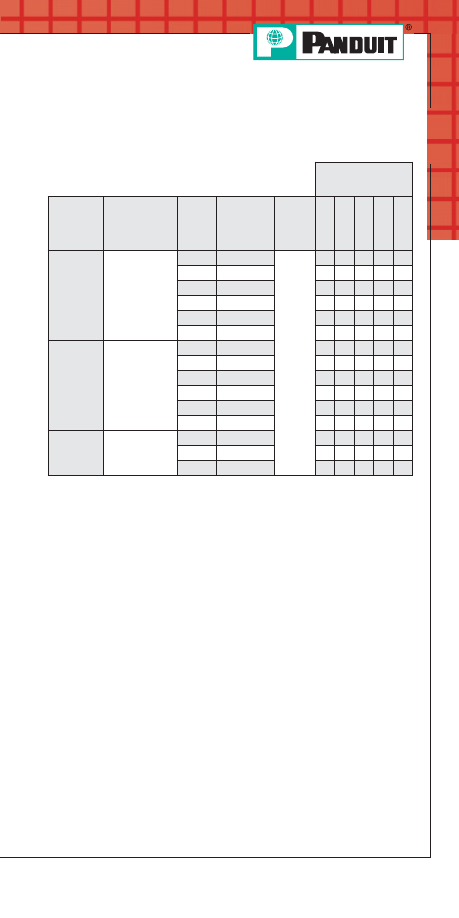

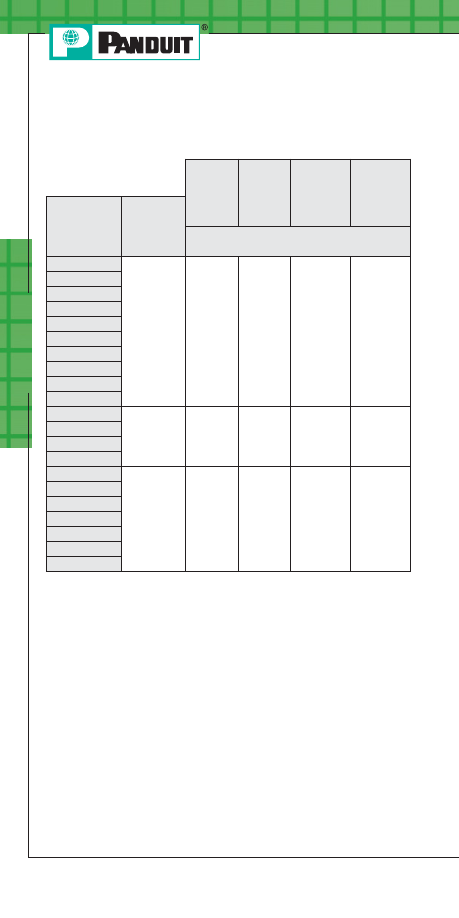

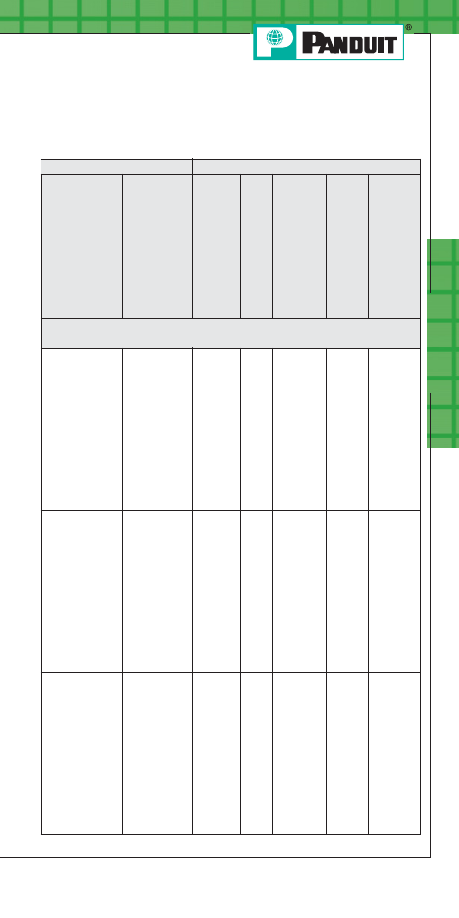

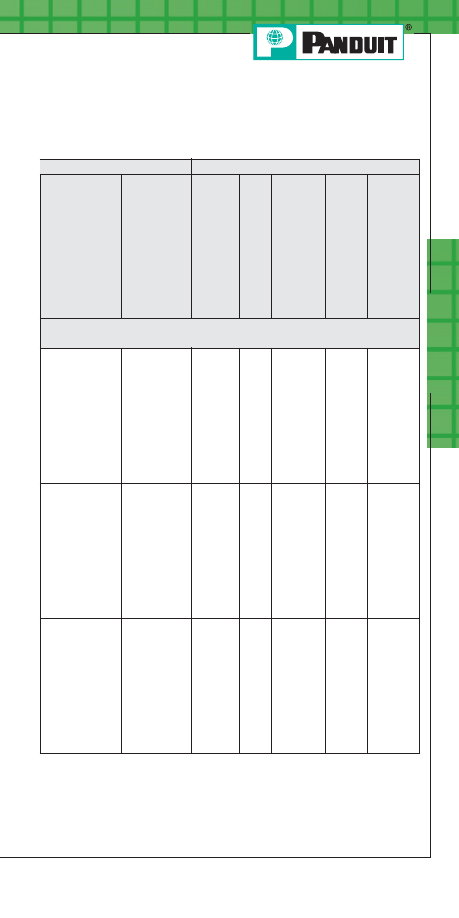

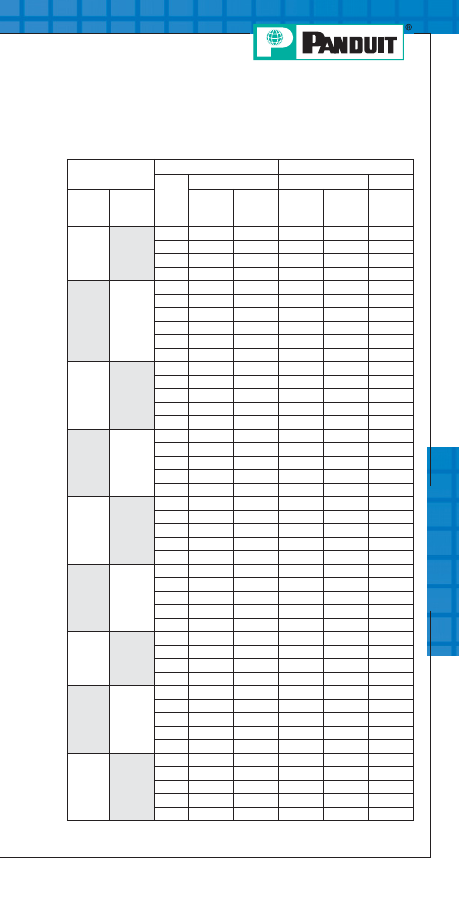

Terminal Series

Std.

Wire

Range

(AWG)

Wire

Strip

Length

(In.)

+1/32;-0]

Plier Tools

Controlled Cycle Hand Tools

Crimp Heads

for Pneumatic

CT-600 Tool

DNFR-B – Nylon Pre-Insulated,

Right Angle

22-18

9/32

X

X

16-14

9/32

X

X

DNFR-FIB – Nylon Butted Seam,

Right Angle

22-18

11/32

X

16-14

11/32

X

DNG-FB – Supra Grip Nylon Fully

Insulated (Except DNG14-187FB &

DNG14-188FB)

22-18

1/4

X

16-14

1/4

X

DNG-FL – Disco-Lok Nylon, Fully

Insulated

22-18

1/4

X

16-14

1/4

X

DNH – Heat Shrink

22-18

5/16

X

16-14

5/16

X

12-10

5/16

X

DV – Vinyl Barrel Insulated Sleeve

12-10

9/32

X

X

X

X

DV-B – Vinyl Insulated, Butted Seam

22-18

1/4

X

X

X

16-14

1/4

X

X

X

DV-M – Non-Insulated Male Blade

Adapters

22-18

9/32

X

X

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

X

X

X

DV-M – Non-Insulated Male

Disconnects

12-10

9/32

X

X

X

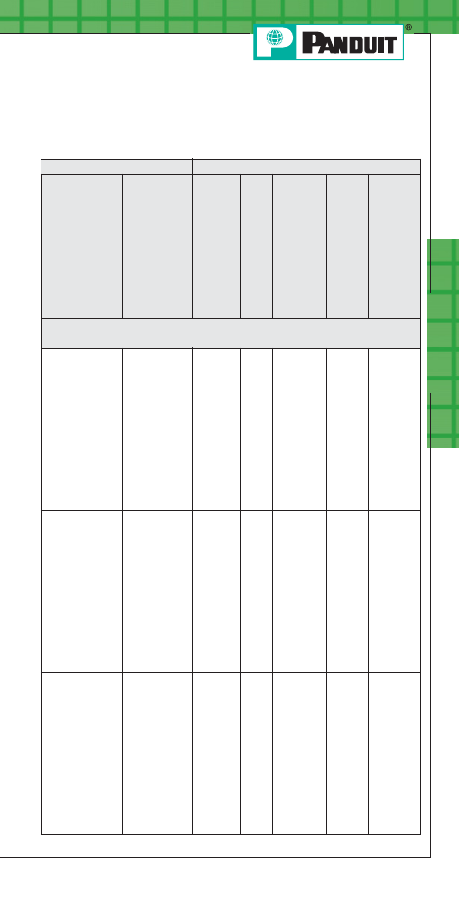

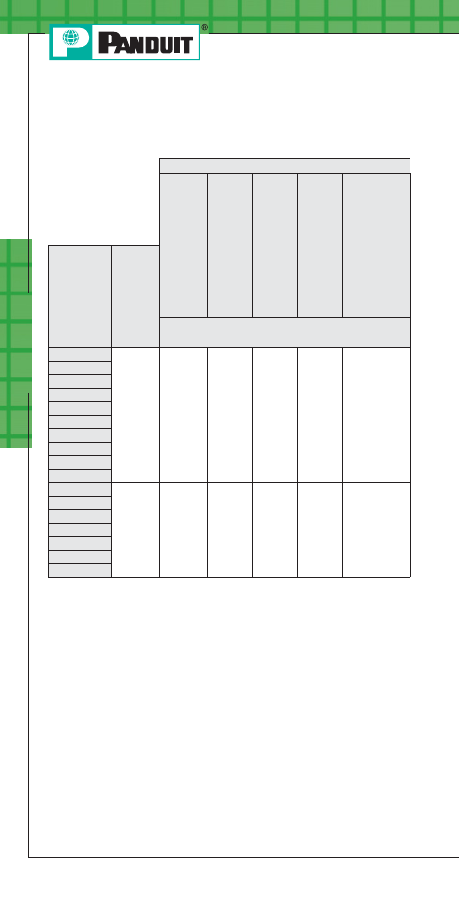

Terminals

A10

CT

-100

CT

-160

CT

-200

CT

-260

CT

-300-1

CT

-310

CT

-400

CT

-460

CT

-1014

CT

-1015

CT

-1525

CT

-1550

CT

-1551

CT

-1570

CT

-1701

CT

-500CH

CT

-520CH

CT

-550CH

CT

-570CH

CT

-720 Mec

hanical

PANDUIT

Installa

tion T

ooling

for T

erminals

,

Disconnec

ts and S

plices (continued)

PANDUIT Termination Solutions-html.html

Terminals

A11

F

o

r ser

v

ice and technical suppor

t, call 800-777-3300

or visit www

.panduit.com.

PANDUIT

Installa

tion T

ooling

for T

erminals

,

Disconnec

ts and S

plices (continued)

DV-MB – Vinyl Insulated Butted Seam

Male Disconnects

22-18

9/32

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

DV-P – Vinyl Insulated Piggyback

Disconnects

22-18

1/4

X

X

X

X

X

X

X

16-14

1/4

X

X

X

X

X

X

X

DVF – Vinyl Funnel Entry Barrel

Insulated Female Disconnect

22-18

9/32

X

X

X

X

16-14

9/32

X

X

X

X

Wire Joints

J – Non-Insulated J214-312,

J318-412,

J216-410

18-12

1/2

X

X

18-12

1/2

X

X

16-10

3/4

X

JN – Nylon Insulated JN224-318,

JN218-216,

JN418-212,

JN314-212

24-16

7/16

X

X

X

X

X

X

X

X

22-14

7/16

X

X

X

X

X

X

X

18-12

1/2

X

X

X

X

X

X

14-12

5/8

X

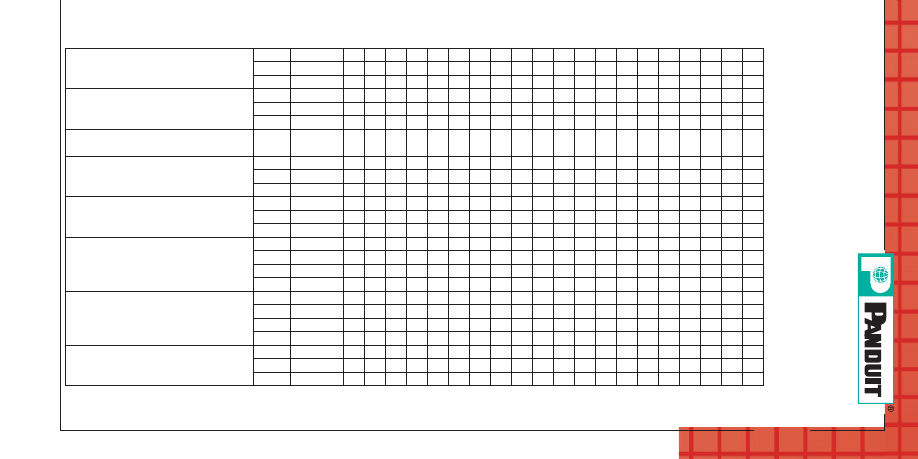

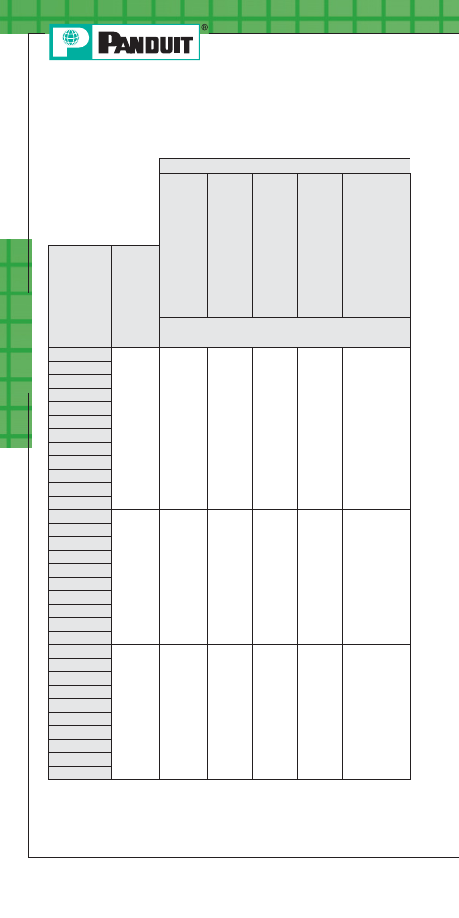

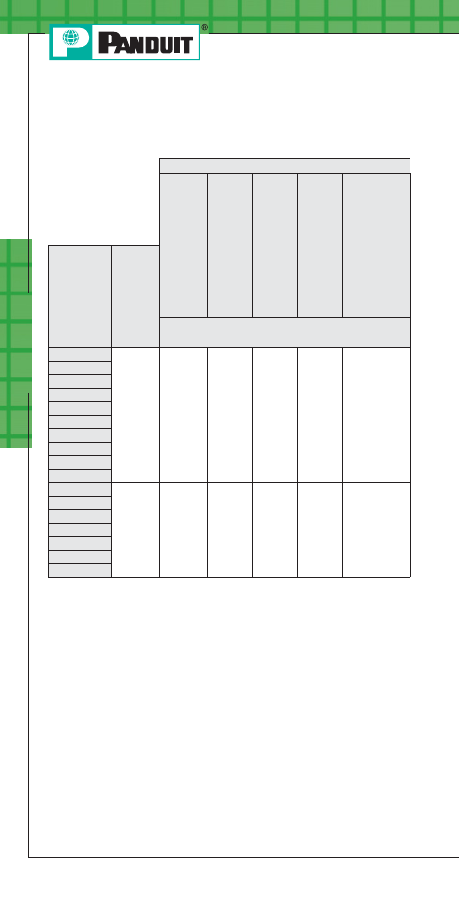

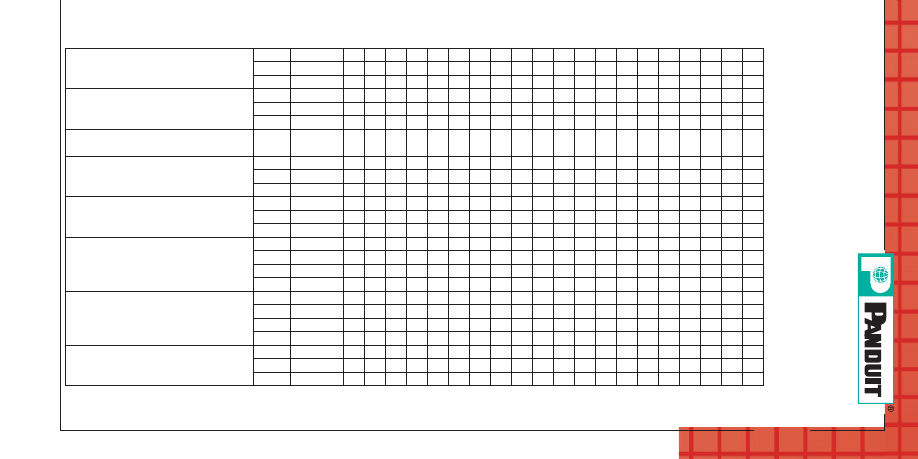

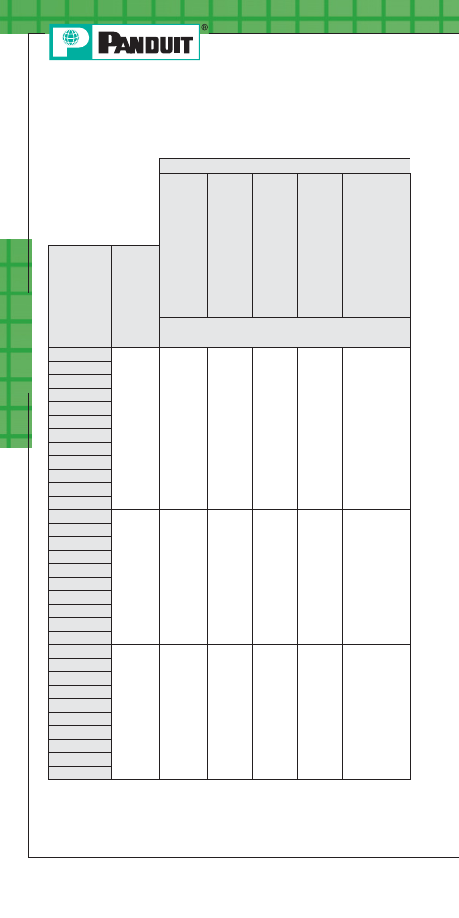

Terminals

P-HDR – Non-Insulated Heavy

Duty Rings

16-12

9/32

X

X

X

X

X

X

X

P-P – Non-Insulated Pin Terminals

22-18

9/32

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

P-R – Non-Insulated Large Ring

Terminals

8

3/8

X

6

7/16

X

4

1/2

X

2

1/2

X

P-R, P-R, P-LF, P-SLF, P-FF –

Non-Insulated Rings, Forks, Locking

Forks, Short Locking Forks, Flanged

Forks

22-26

3/16

X

X

X

22-18

7/32

X

X

X

X

X

X

16-14

7/32

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

PANDUIT Termination Solutions-html.html

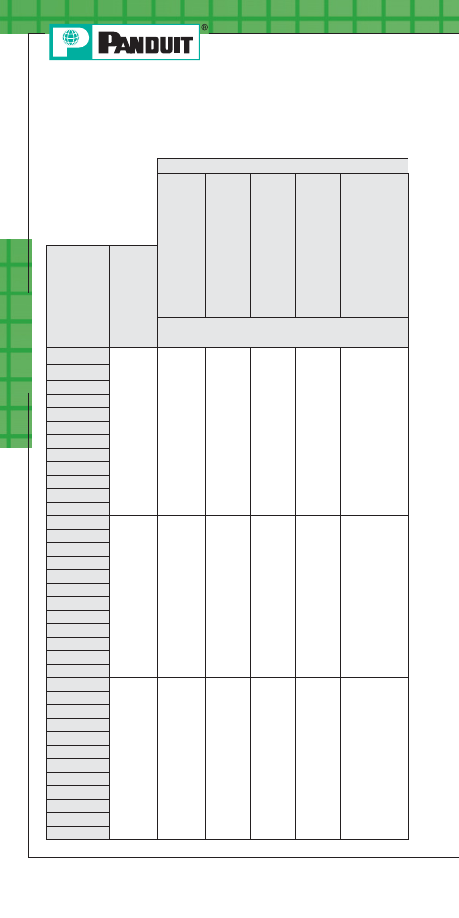

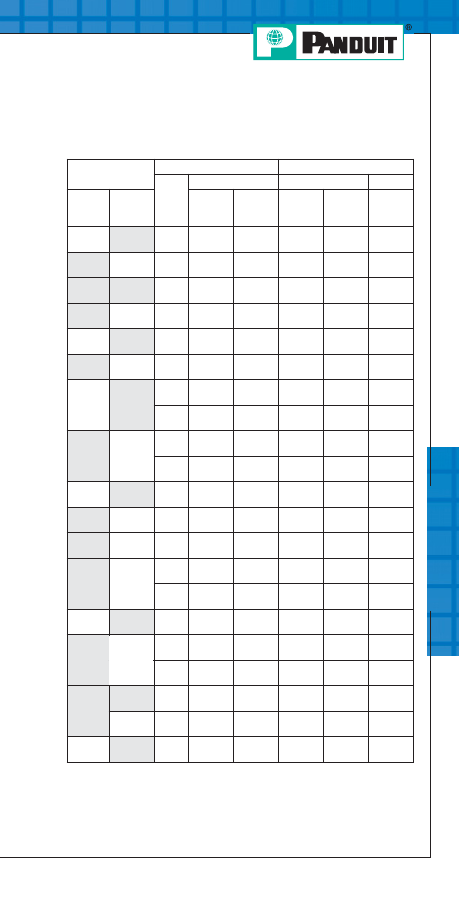

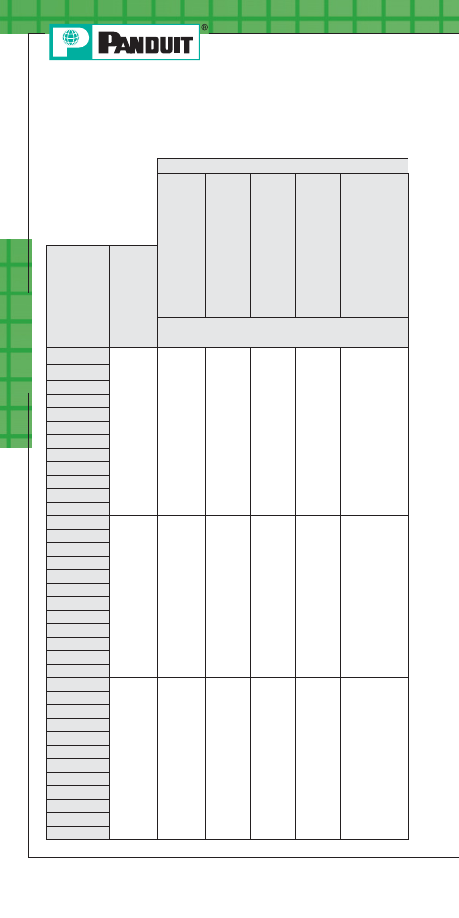

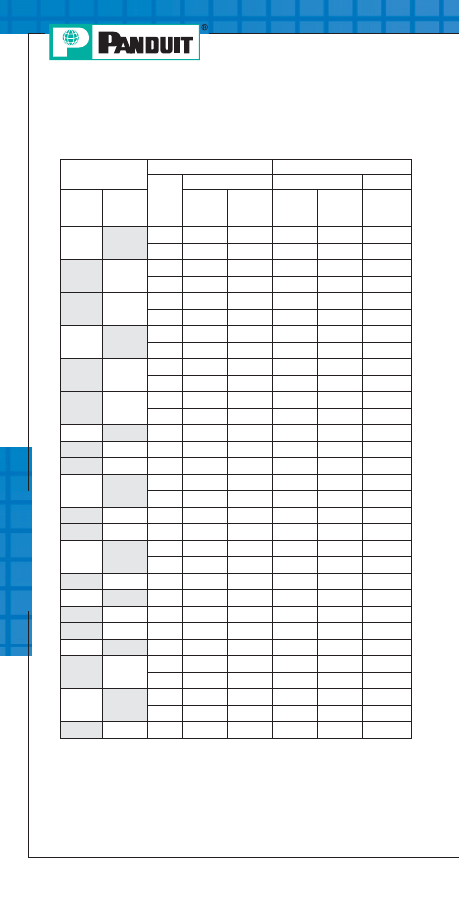

Terminal Series

Std.

Wire

Range

(AWG)

Wire

Strip

Length

(In.)

[+1/32;-0]

Plier Tools

Controlled Cycle Hand Tools

Crimp Heads

for Pneumatic

CT-600 Tool

P-RHT6 – High Temperature Rings

22-18

9/32

X

X

X

X

X

X

16-14

9/32

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

X

X

PH – Heat Shrink Terminals

22-18

5/16

X

16-14

5/16

X

12-10

5/16

X

PK-R – KYNAR* Rings

22-18

7/32

X

X

X

X

X

16-14

7/32

X

X

X

X

X

12-10

9/32

X

X

X

X

PN-R, PN-RX, PN-F, PN-LF, PN-FF,

PNF-R, PNF-F, PNF-LF – Nylon &

Nylon Funnel Entry Forks, Locking

Forks, Flanged Forks (Includes

Expanded Insulated)

26-22

3/16

X

X

X

22-18

7/32

X

X

X

X

X

X

16-14

7/32

X

X

X

X

X

X

X

12-10

9/32

X

X

X

X

X

PN-HDR, PN-HDRX – Nylon Insulated

Heavy Duty & Nylon Expanded

Insulated Heavy Duty Rings

16-12

9/32

X

X

X

X

PN-SLF, PNF-SLF – Nylon Insulated

Short Locking Forks

22-18

7/32

X

X

X

X

16-14

7/32

X

X

X

X

X

12-10

9/32

X

X

X

X

Terminals

A12

PANDUIT

Installa

tion T

ooling

for T

erminals

,

Disconnec

ts and S

plices (continued)

CT

-100

CT

-160

CT

-200

CT

-260

CT

-300-1

CT

-310

CT

-400

CT

-460

CT

-1014

CT

-1015

CT

-1525

CT

-1550

CT

-1551

CT

-1570

CT

-1701

CT

-500CH

CT

-520CH

CT

-550CH

CT

-570CH

CT

-720 Mec

hanical

PANDUIT Termination Solutions-html.html

Terminals

A13

F

o

r ser

v

ice and technical suppor

t, call 800-777-3300

or visit www

.panduit.com.

PANDUIT

Installa

tion T

ooling

for

Te

rminals

,

Disconnec

ts and S

plices (continued)

*KYNAR is a registered trademark of Atofina Chemicals, Inc.

‡Use Die CD-700P-8-2

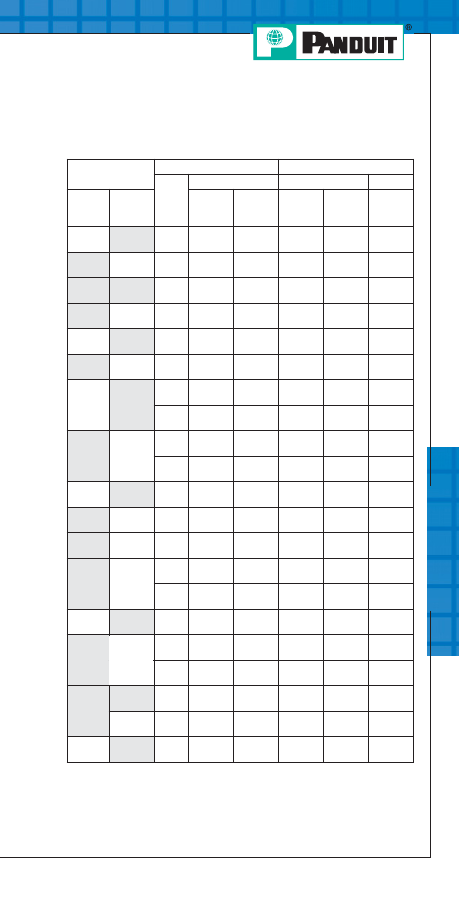

PS – Non-Insulated Parallel Splices

22-18

5/16

X

X

X

20-16

5/16

X

X

X

14-12

7/16

X

X

X

PSN – Nylon Insulated Parallel

Splices

22-18

5/16

X

20-16

5/16

X

X

X

X

14-12

7/16

X

PV-HDR, PV-HDRX – Vinyl Insulated

Heavy Duty Rings

16-12

5/16

X

X

X

X

PV-LF, PV-LFX – Vinyl Insulated

Locking Forks (includes Expanded

Insulation)

22-18

5/16

X

X

X

X

X

X

X

16-14

5/16

X

X

X

X

X

X

X

12-10

5/16

X

X

X

X

X

X

PV-P – Vinyl Insulated Pin Terminals

22-18

5/16

X

X

X

X

X

X

X

16-14

5/16

X

X

X

X

X

X

X

12-10

5/16

X

X

X

X

X

X

PV-R, PV-F, PV-FF, PV-RX,

PV-FX – Vinyl Insulated Rings & Forks

(includes Expanded Insulation)

26-22

3/16

X

X

X

22-18

5/16

X

X

X

X

X

X

X

X

16-14

5/16

X

X

X

X

X

X

X

X

X

12-10

5/16

X

X

X

X

X

X

X

PV-R, PV-RX – Vinyl Insulated Large

Ring Terminals

8

3/8

X

‡

6

7/16

X

‡

4

1/2

X

‡

2

1/2

X

‡

PV-SLF – Vinyl Insulated Short

Locking Forks

22-18

5/16

X

X

X

X

X

16-14

5/16

X

X

X

X

X

X

12-10

5/16

X

X

X

X

PANDUIT Termination Solutions-html.html

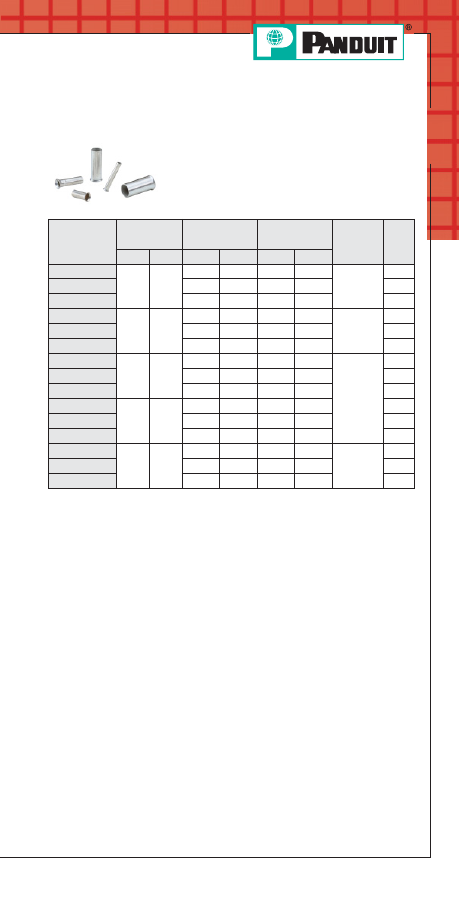

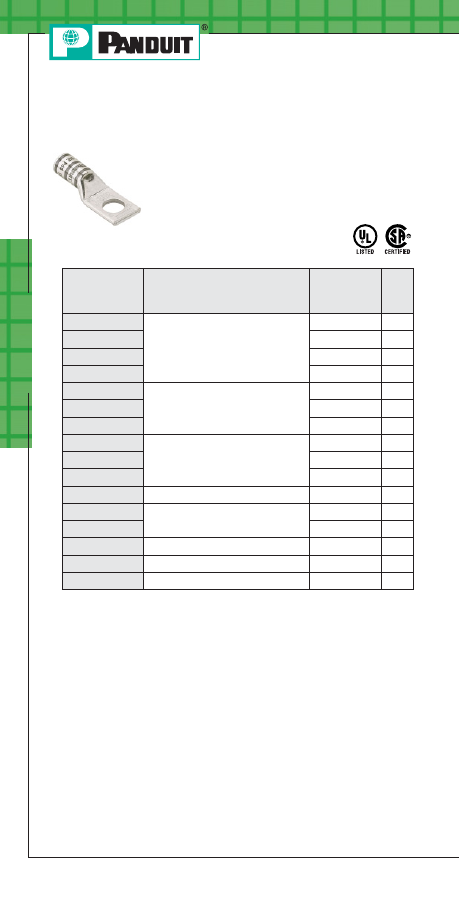

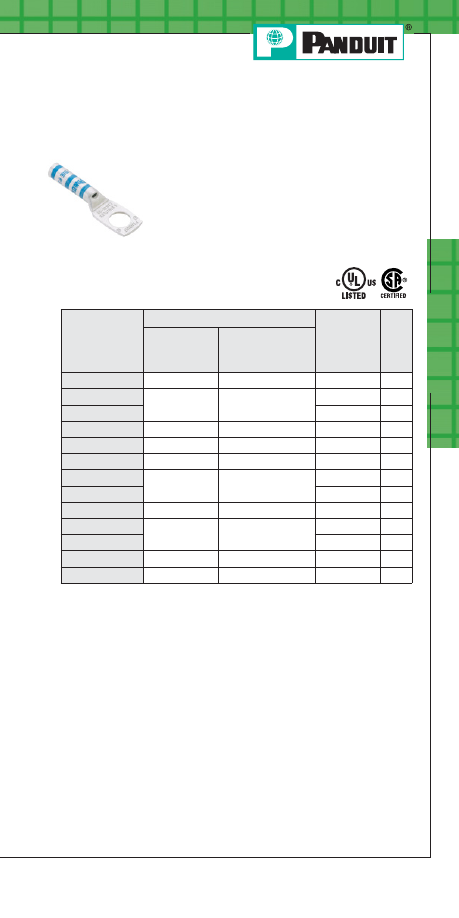

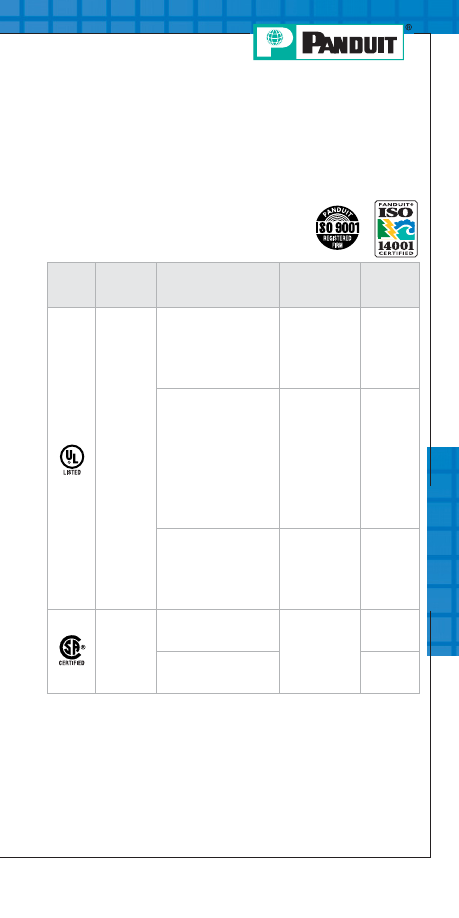

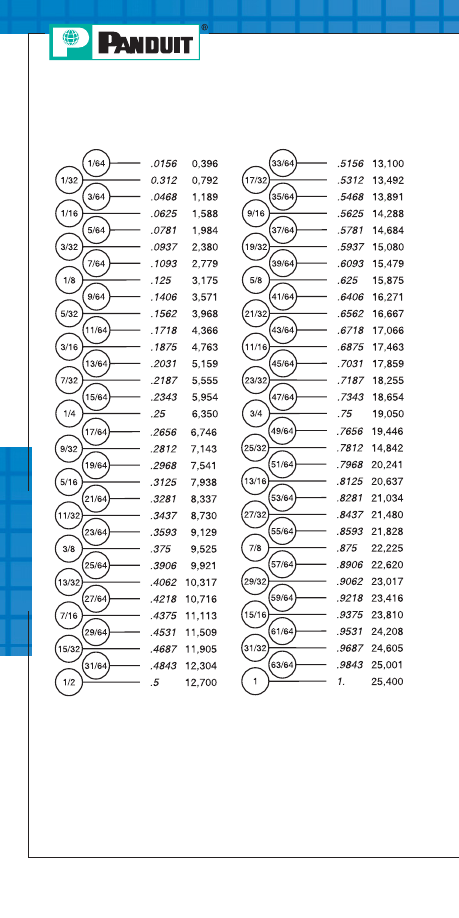

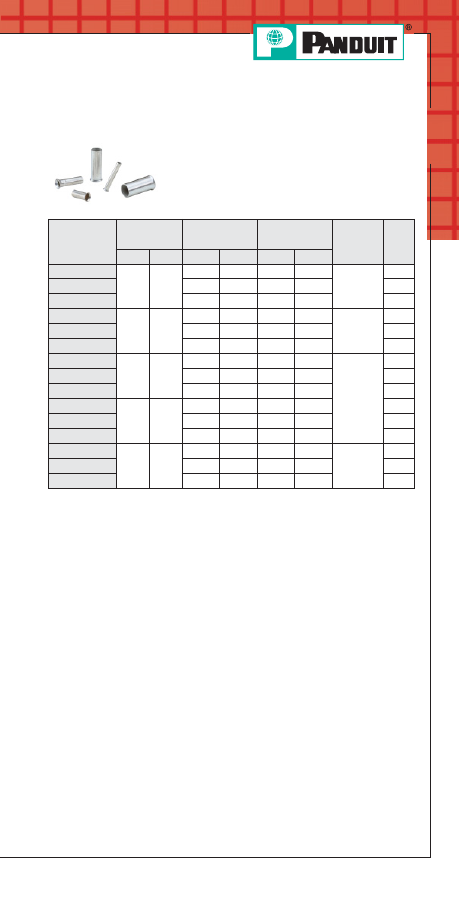

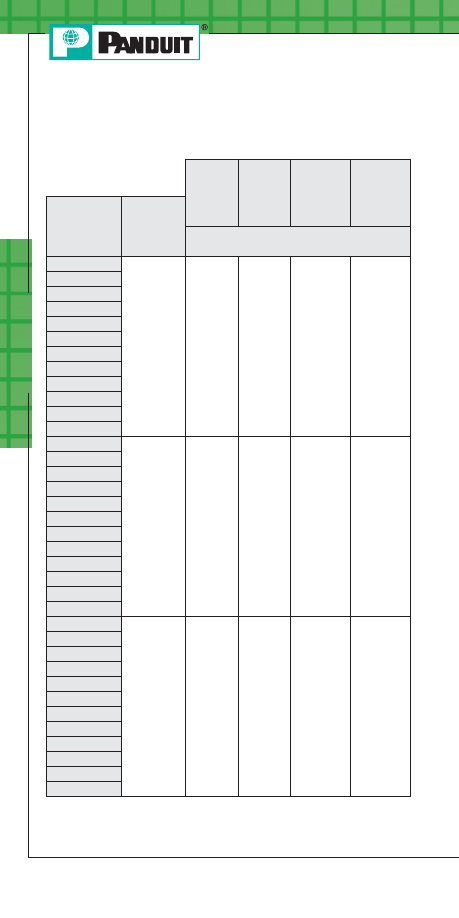

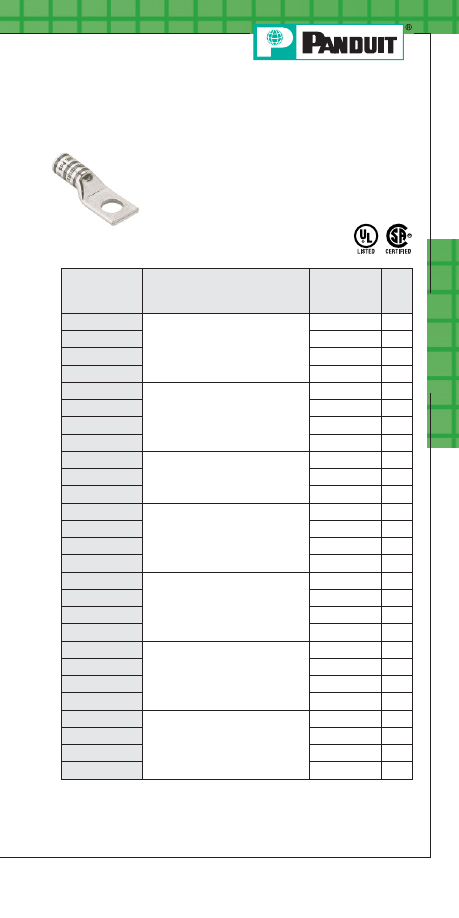

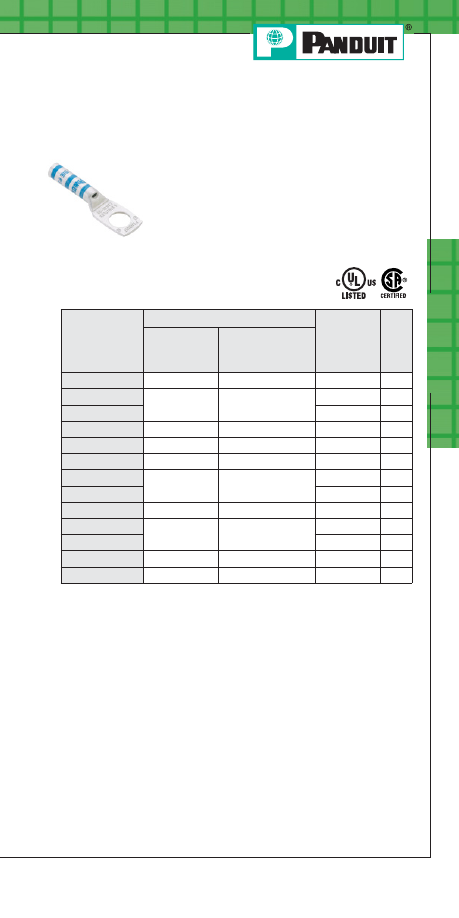

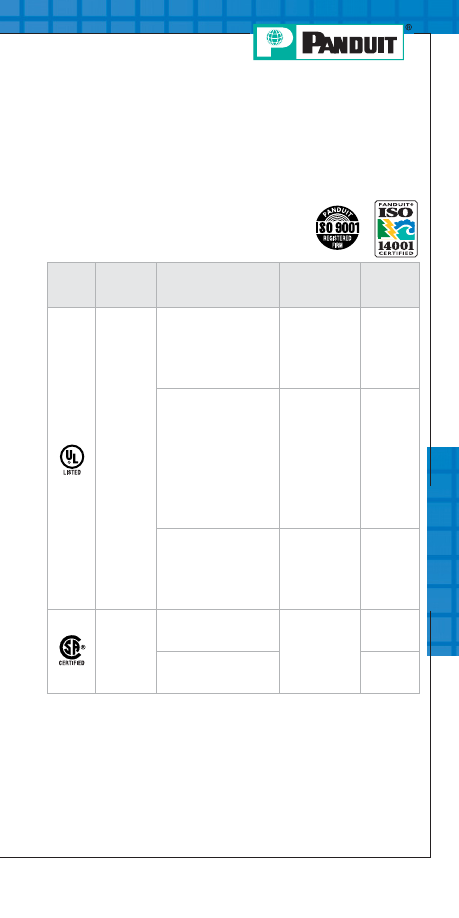

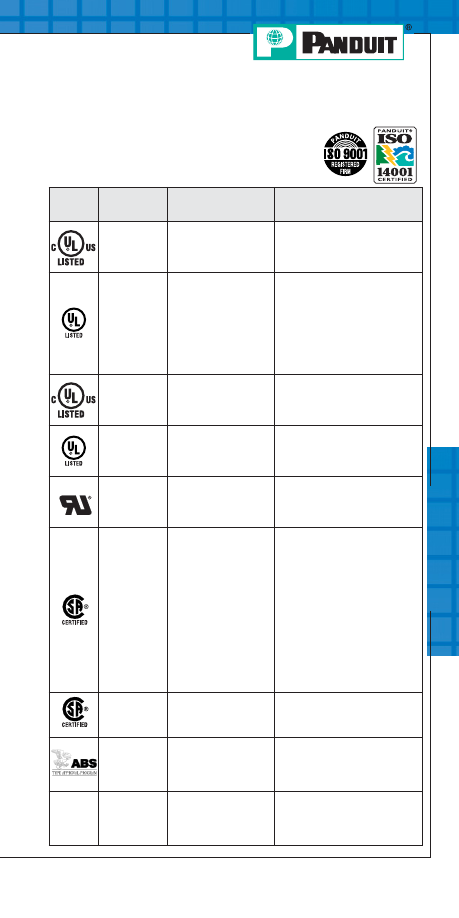

A14

Tooling

CT-1700

CT-720

CT-930,

CT-930CH,

CT-920,

CT-920CH,

CT-2920,

CT-940CH

CT-980,

CT-980CH,

CT-2950,

CT-2980

CT-2001

PANDUIT

®

Part Number

PANDUIT

®

Die Part Number

Die Index Number

(Number of Crimps)

S8-10R-Q

P21

(2)

CD-720-1

P21

(1)

CD-920-8

P21

(1)

—

CD-2001-8

P21

(1)

S8-14R-Q

S8-56R-Q

S8-38R-Q

S6-10R-E

P24

(2)

CD-720-1

P24

(1)

CD-920-6

P24

(1)

—

CD-2001-6

P24

(1)

S6-14R-E

S6-56R-E

S6-38R-E

S4-10R-E

P29

(2)

CD-720-1

P29

(1)

CD-920-4

P28

(1)

STD

(1)

CD-2001-4

P29

(1)

S4-14R-E

S4-56R-E

S4-38R-E

S2-10R-X

P37

(3)

CD-720-2

P37

(1)

CD-920-1

P37

(1)

STD

(1)

CD-2001-1

P37

(1)

S2-14R-X

S2-56R-X

S2-38R-X

S2-12R-X

S1/0-14R-X

—

CD-720-2

P42

(1)

CD-920-1/0

P42

(1)

STD

(1)

CD-2001-1/0

P42

(1)

S1/0-56R-X

S1/0-38R-X

S1/0-12R-X

S2/0-14R-X

—

CD-720-2

P45

(2)

CD-920-2/0

P45

(1)

STD

(1)

CD-2001-2/0

P45

(2)

S2/0-56R-X

S2/0-38R-X

S2/0-76R-X

S2/0-12R-X

S3/0-14R-5

—

CD-720-2

P50

(2)

CD-920-3/0

P50

(1)

STD

(1)

CD-2001-3/0

P50

(2)

S3/0-56R-5

S3/0-38R-5

S3/0-76R-5

S3/0-12R-5

S4/0-38R-5

—

CD-720-3

P54

(2)

CD-920-4/0

P54

(1)

STD

(1)

CD-2001-4/0

P54

(2)

S4/0-76R-5

S4/012R-5

S250-56R-5

—

CD-720-3

P62

(2)

CD-920-250

P62

(1)

STD

(1)

CD-2001-250

P62

(2)

S250-38R-5

S250-76R-5

S250-12R-5

Terminals

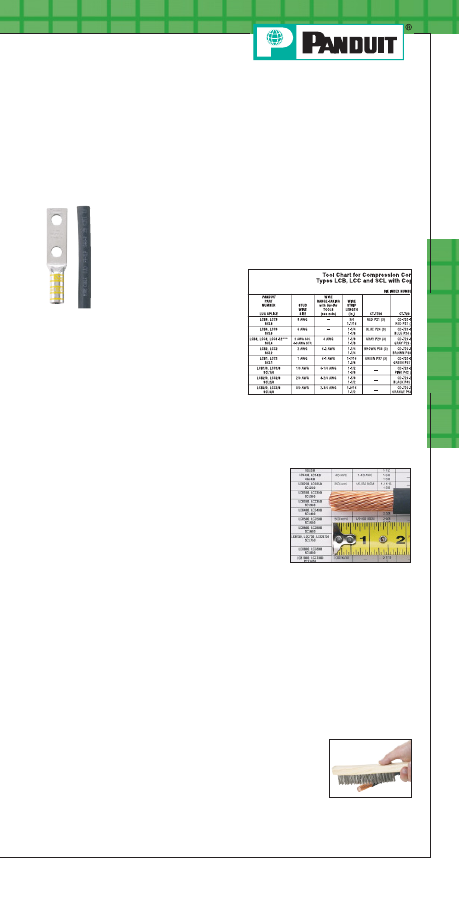

PANDUIT

Installation Tooling for Tubular

Ring Terminals

PANDUIT Termination Solutions-html.html

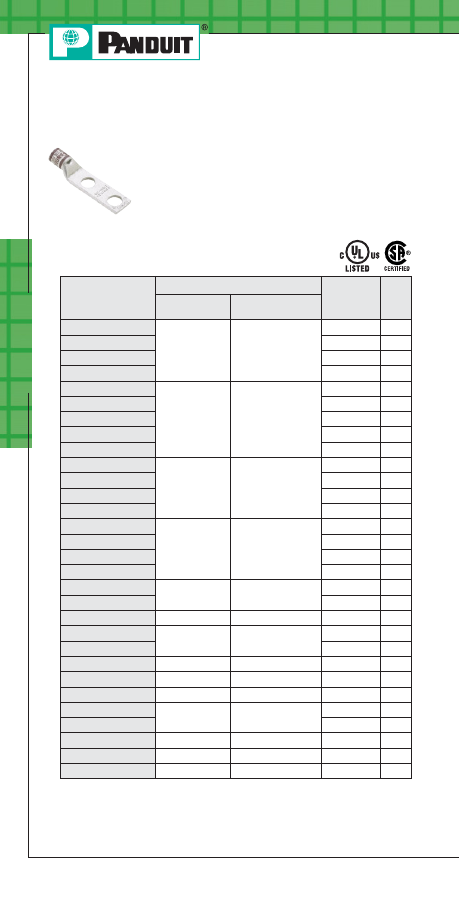

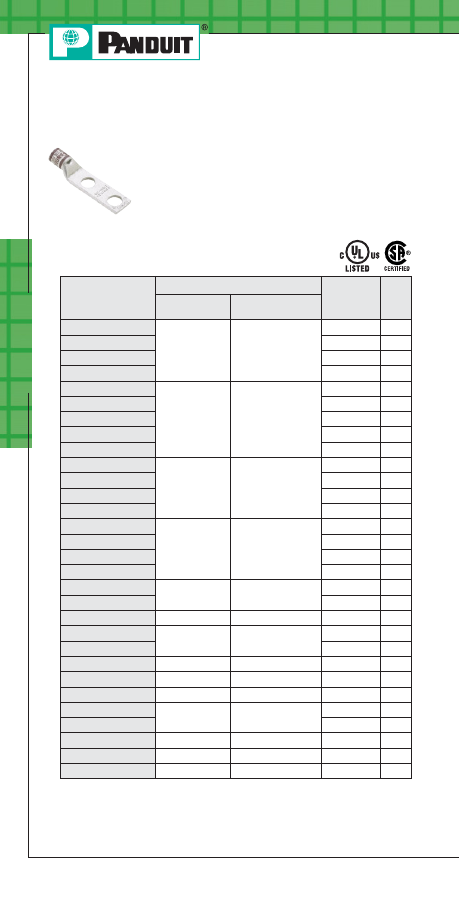

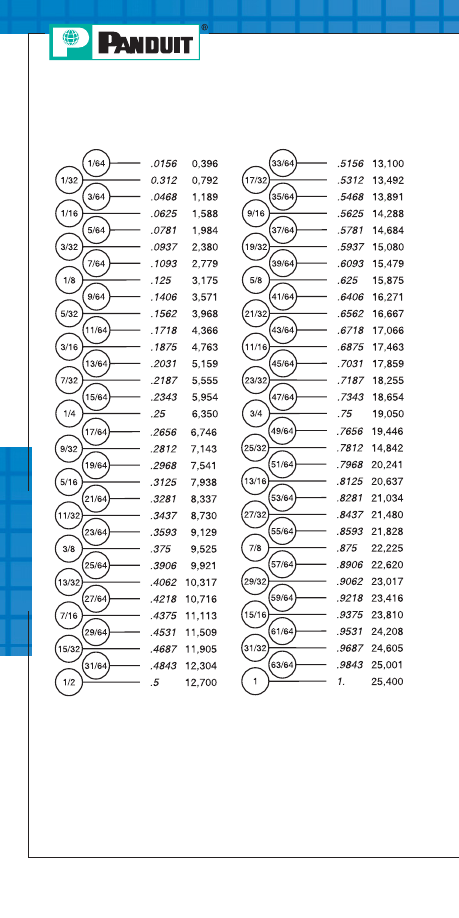

Terminals

A15

For service and technical support, call 800-777-3300

or visit www.panduit.com.

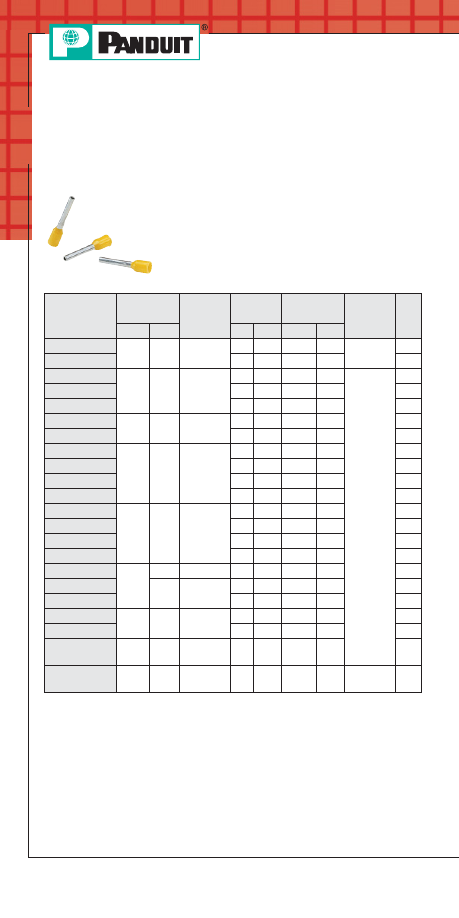

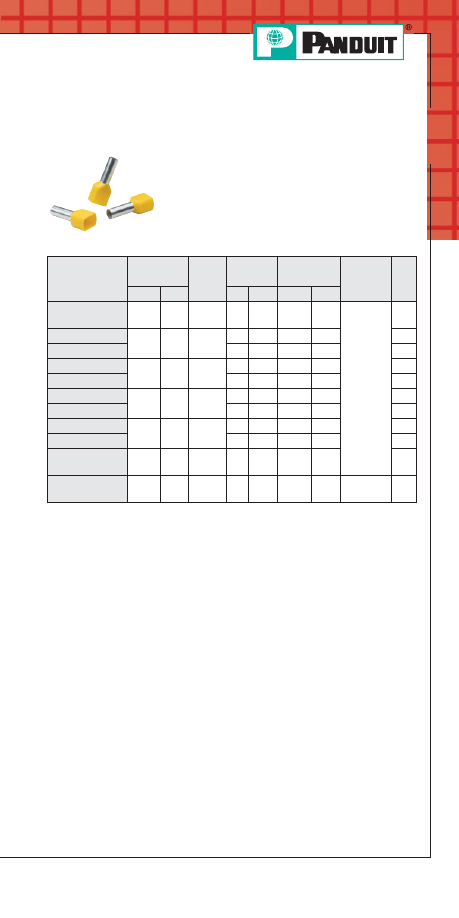

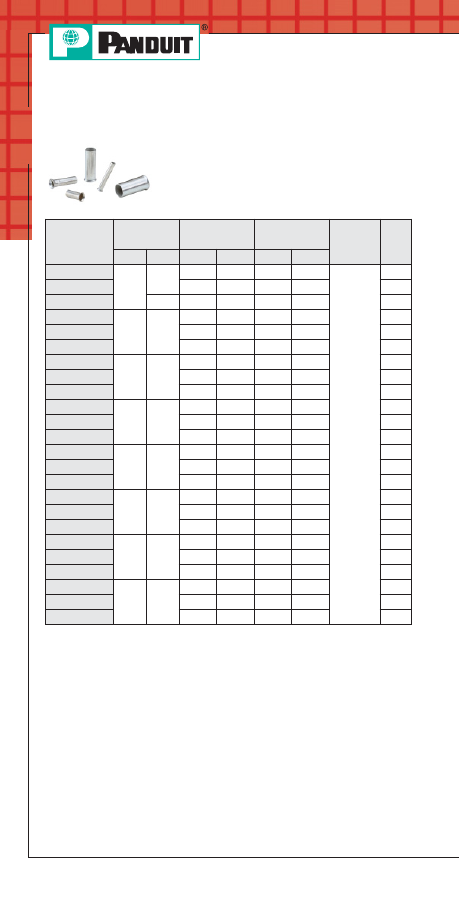

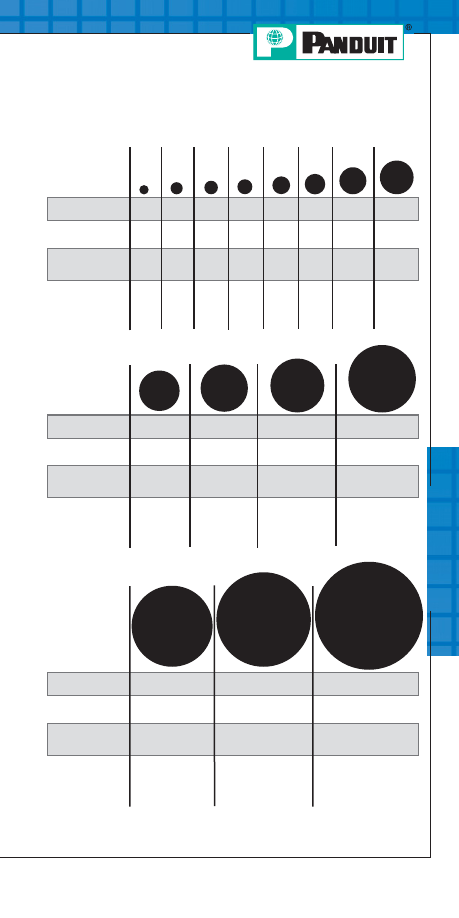

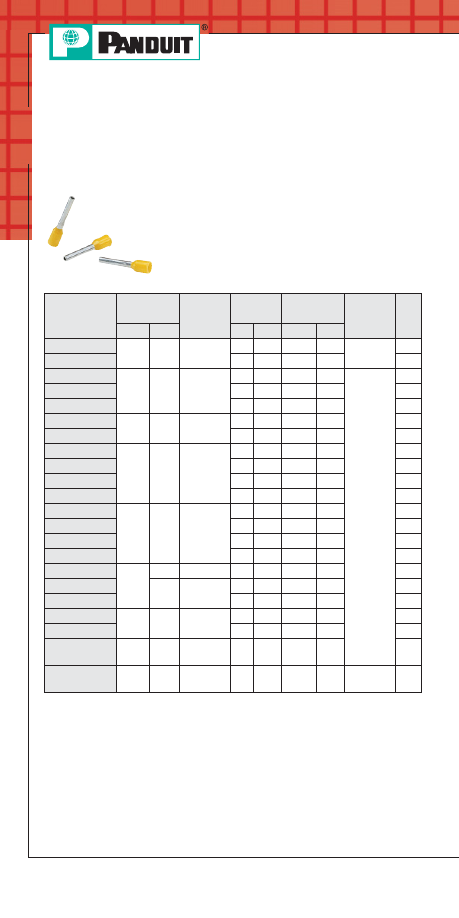

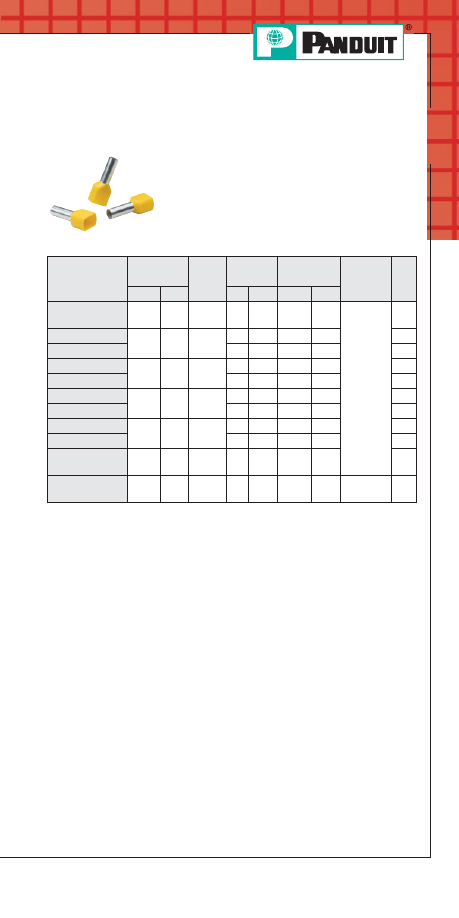

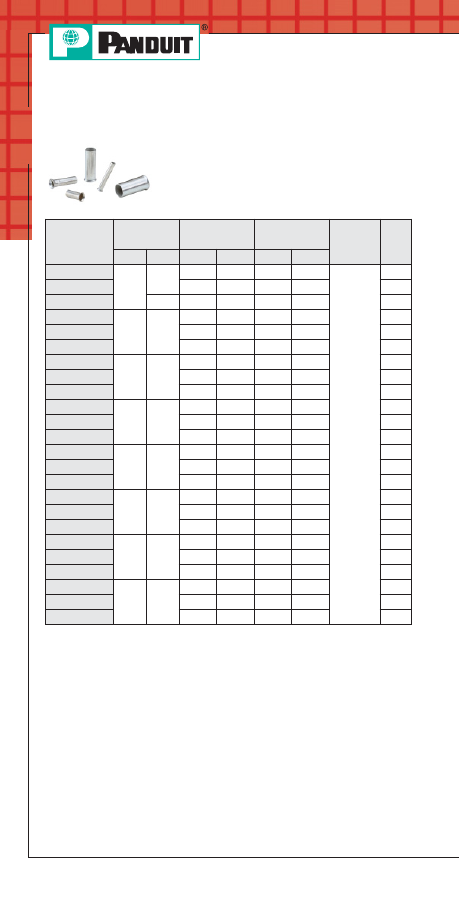

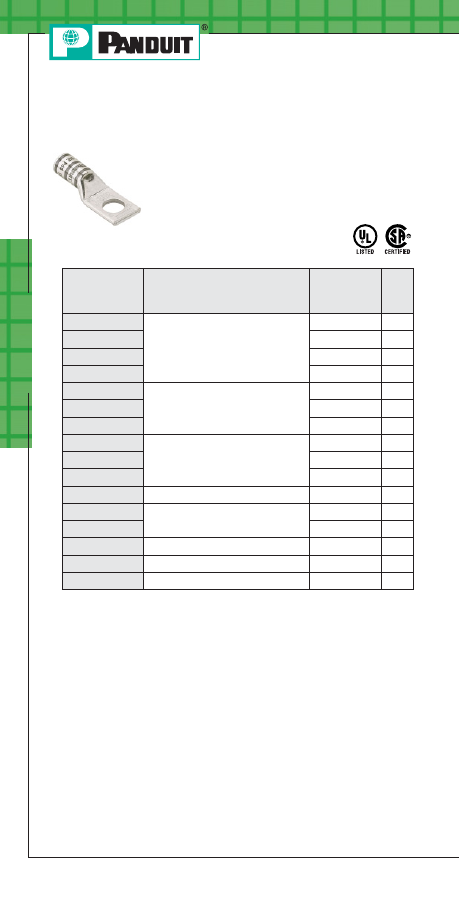

Controlled Cycle

Hand Tools

PANDUIT

Ferrule

Series

Ferrule

Description

Wire

Range

(AWG)

Wire

Range

(mm²)

Wire

Strip

Length

F

Non-Insulated

Ferrules

24-18

.25-1.00

Varies

X

X

16-14

1.50-2.00

X

X

12-10

4.00-6.00

X

X

8-6

10.0-16.0

X

X

4-2

25.0-35.0

X

1

50.0

X

FSD, FSF Insulated

Single Wire

Ferrules (DIN

or French

color code)

26-18

.41-1.00

X

X

16-14

1.50-2.00

X

X

12-10

4.00-6.00

X

X

8-6

10.0-16.0

X

X

4-2

25.0-35.0

X

1

50.0

X

FTD

Insulated

Twin Wire

Ferrules

22-18

.50-1.00

X

X

16-14

1.50-2.00

X

X

12-10

4.00-6.00

X

X

CT

-1002

CT

-1003

CT

-1004

CT

-1005

CT

-1006

PANDUIT

Installation Tooling for Ferrules

PANDUIT Termination Solutions-html.html

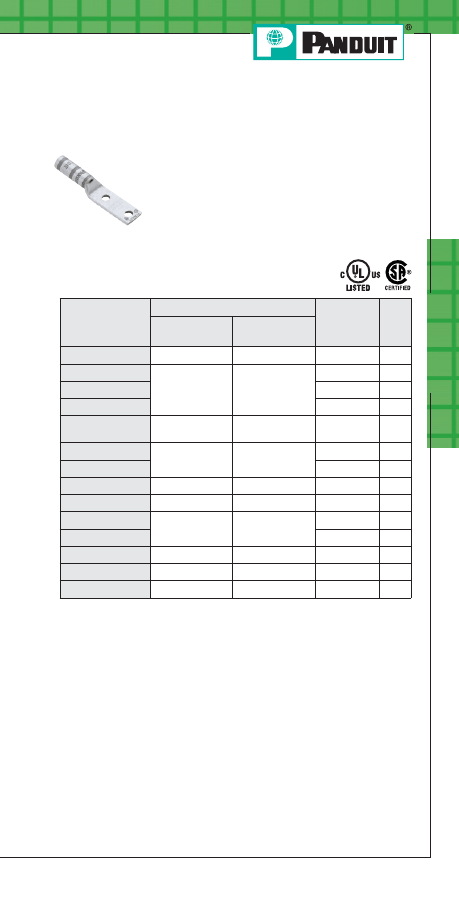

Terminals

A16

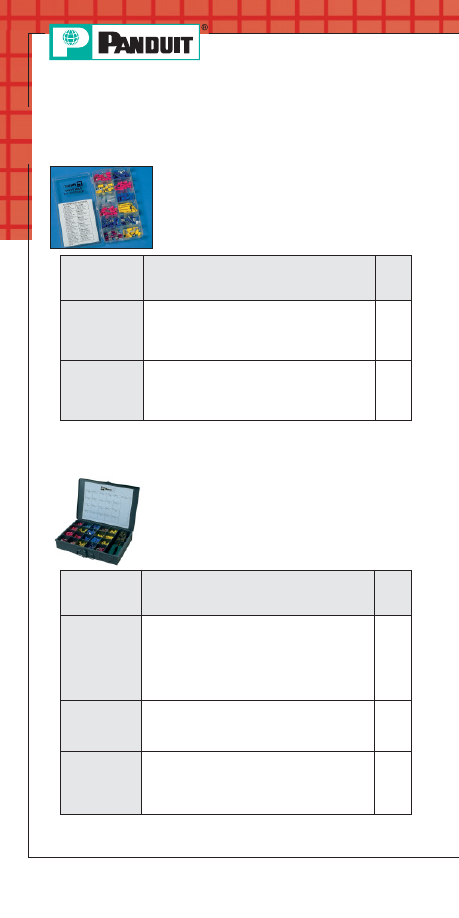

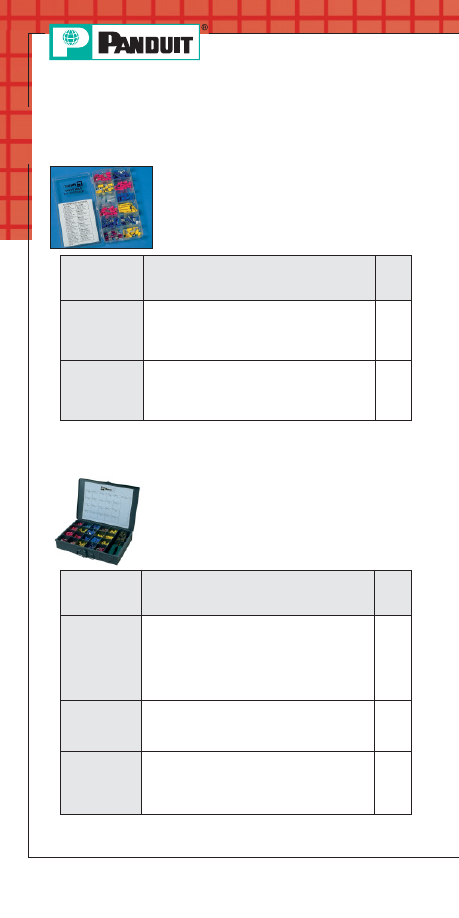

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

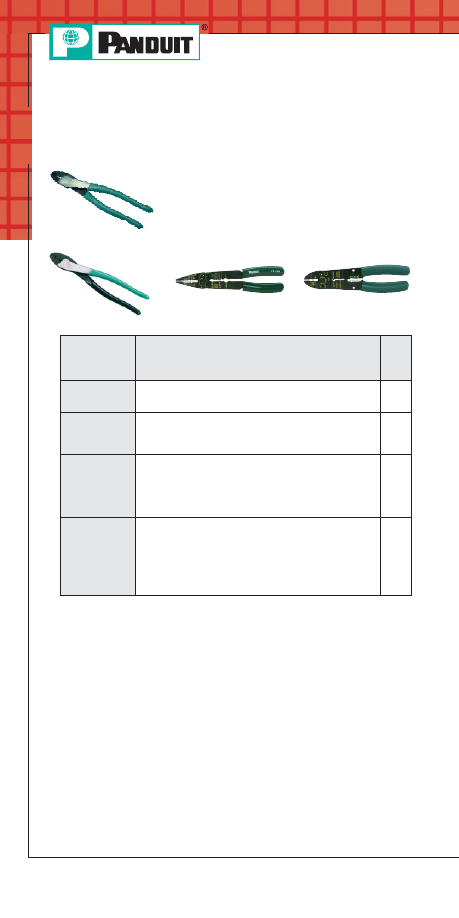

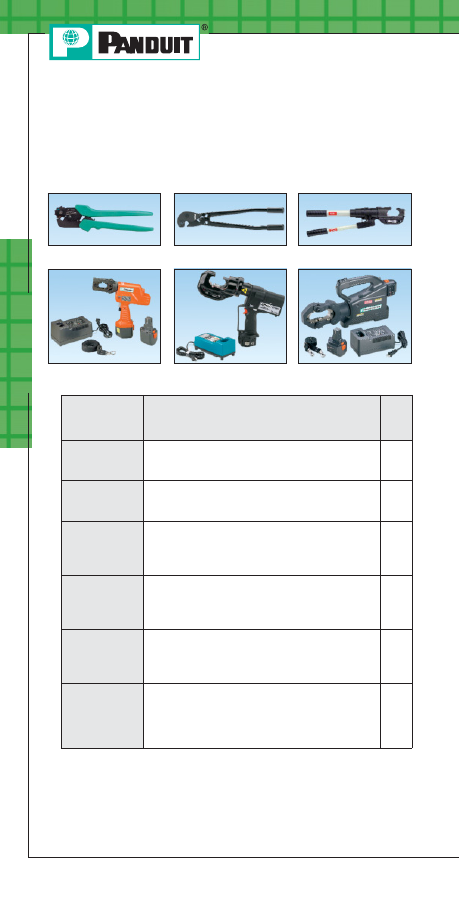

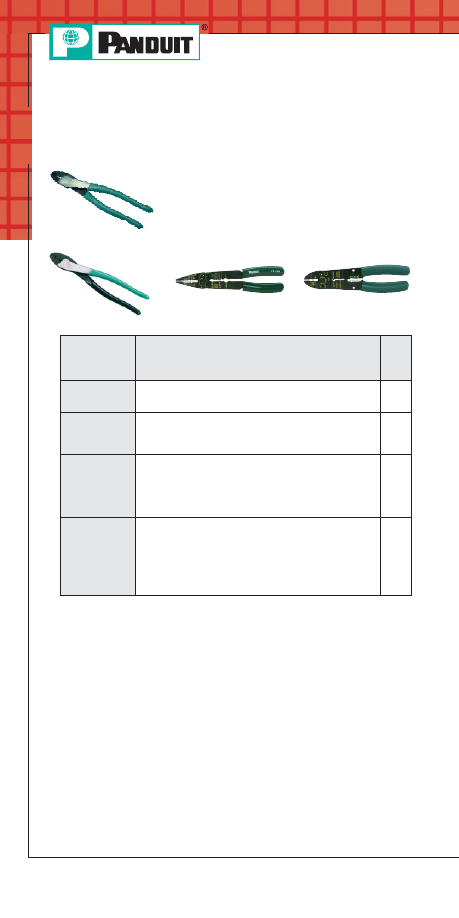

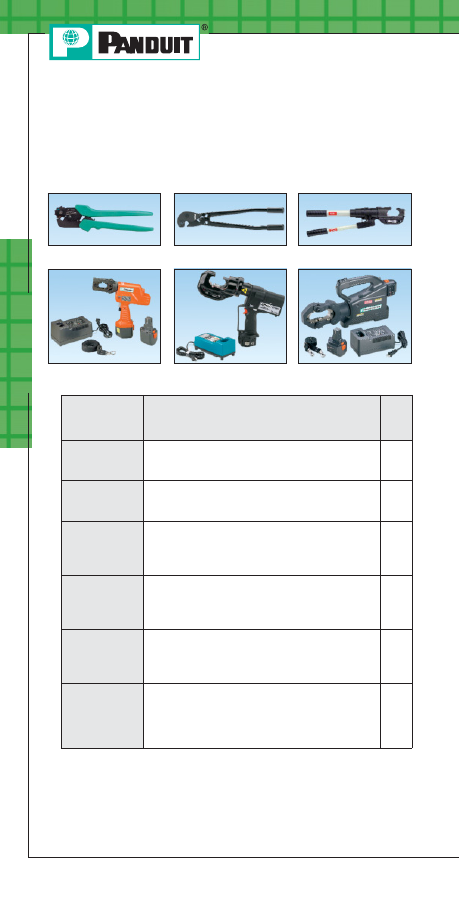

Hand Operated Plier Type Tools

• Installer controlled crimp

• General purpose

• Plier type crimp for #22 thru #10 insulated

and non-insulated terminal products

CT-260

CT-200

CT-160

CT-100

Termination Tooling

Part Number

Part Description

Std.

Pkg.

Qty.

CT-260

Crimps insulated and non-insulated terminals.

Forged steel tool. Cuts wire.

1

CT-200

Crimps most

PANDUIT #18 – #10 AWG

non-insulated terminals, disconnects and splices.

Forged steel tool. Cuts wire.

1

CT-160

Crimps most

PANDUIT #26 – #10 AWG insulated

and non-insulated terminals, disconnects and

splices. Cuts three U.S. and three Metric

screw sizes. Cuts and strips wire. Has insulation

closure pocket.

1

CT-100

Crimps most

PANDUIT #26 – #10 AWG insulated

and non-insulated terminals, disconnects and

splices. Cuts #4, #6, #8 and #10 screw sizes. Cuts

and strips wire. Excellent all-around application

tool of heat treated finished steel with comfortable

cushioned plastic grip handles.

1

PANDUIT Termination Solutions-html.html

Terminals

A17

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

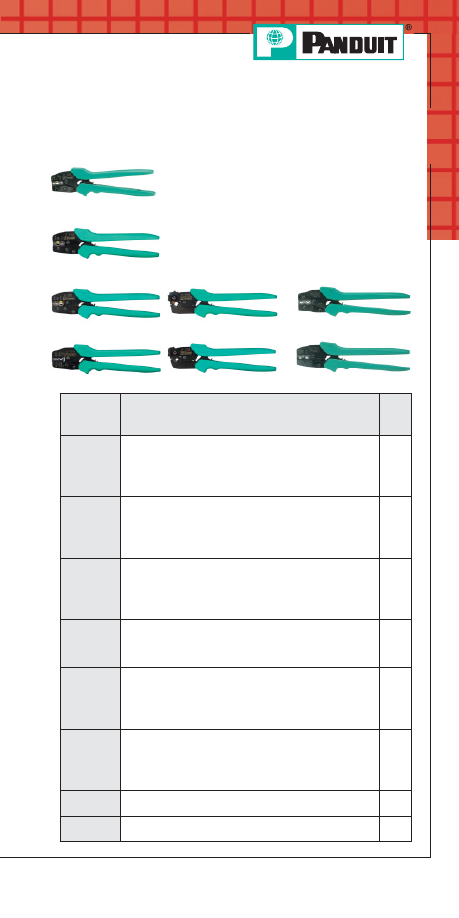

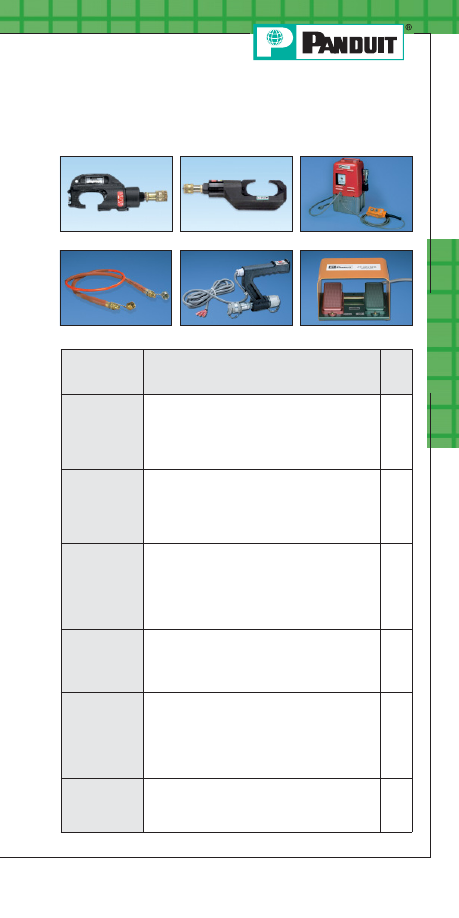

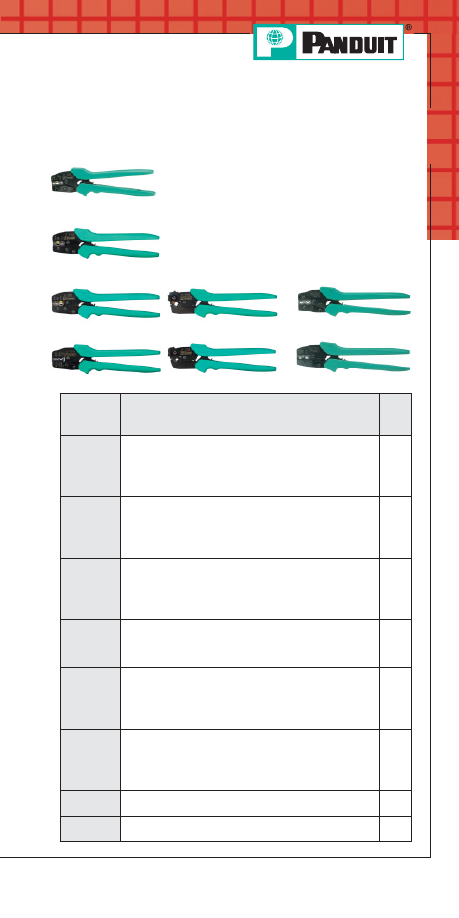

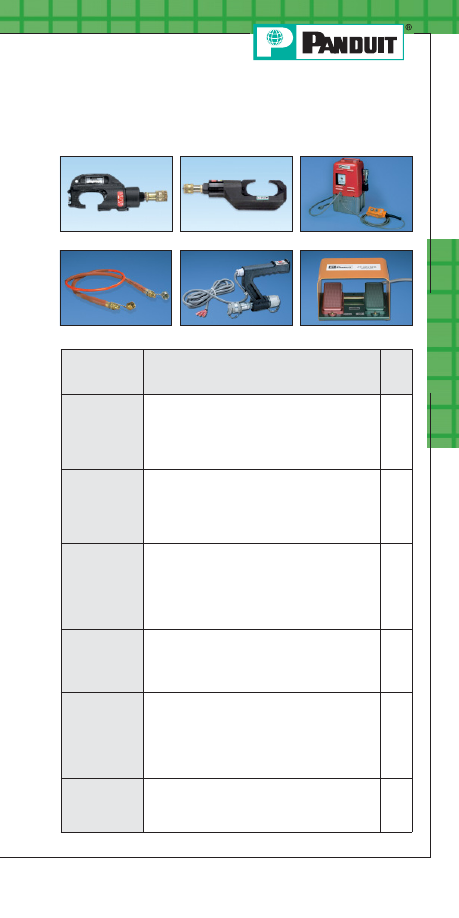

C

ONTOUR

C

RIMP

™

Controlled Cycle Tools

• Specifically designed for the installation of

P

AN

-T

ERM

®

terminals, disconnects and splices

• Controlled cycle mechanism assures high

quality, consistent terminations

• Ergonomic tool design assures operator

comfort, safety, and performance

• Polypropylene handles provide chemical

resistance and a cushioned, non-slip grip

• Multi-position locator facilitates a high quality

repeatable crimp

CT-1525

CT-1550

CT-1551

CT-1570

CT- 1700

CT-1701

CT-1014

CT-1015

Part

Number

Part Description

Std.

Pkg.

Qty.

CT-1525

Crimps

PANDUIT #26 – #22 AWG insulated

terminals and splices, #22 – #10 AWG fully

insulated disconnects and insulated parallel splices.

Crimps

PANDUIT #22 – #14 AWG barrel

insulated disconnects.

1

CT-1550

Crimps most

P

AN

-T

ERM

®

#22 – #10 AWG nylon and

vinyl insulated terminals, splices and disconnects.

The CT-1550 has the red/blue pocket closest to the

pivot which provides a reduced crimp effort for those

who make red/blue terminations.

1

CT-1551

Crimps most

P

AN

-T

ERM

®

#22 – #10 AWG nylon and

vinyl insulated terminals, splices and disconnects.

The CT-1551 has the yellow pocket closest to the

pivot which provides a reduced crimp effort for those

who make yellow terminations.

1

CT-1570

Crimps most

P

AN

-T

ERM

®

#22 – #10 AWG and

.5 – 6.0mm non-insulated terminals and disconnects.

Crimps

PANDUIT #22 – #10 AWG and .5 – 6.0mm

non-insulated splices, and #10 AWG compression lugs.

1

CT-1700

Crimps

PANDUIT #8 – #2 AWG non-insulated tubular

terminals (S series), #8 – #1 AWG copper lugs and

splices, #6 – #4 AWG aluminum lugs and splices and

CTAPF copper taps for #14 – #3 AWG. Includes five

position, color coded rotating die.

1

CT-1701

Crimps

PANDUIT #10 – #2 AWG non-insulated large

gauge ring terminal (P series). Crimps #8 – #1 AWG

copper lugs and splices, and #6 – #4 AWG aluminum

lugs and splices, and #14 – #3 AWG CTAPF copper

taps. Includes 5 position rotating die.

1

CT-1014

Crimps

PANDUIT #22 – #14 AWG loose piece

D

ISCO

-L

OK

™

disconnects.

1

CT-1015

Crimps

PANDUIT #22 – #14 AWG loose piece

S

UPRA

-G

RIP

™

disconnects.

1

PANDUIT Termination Solutions-html.html

Terminals

A18

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

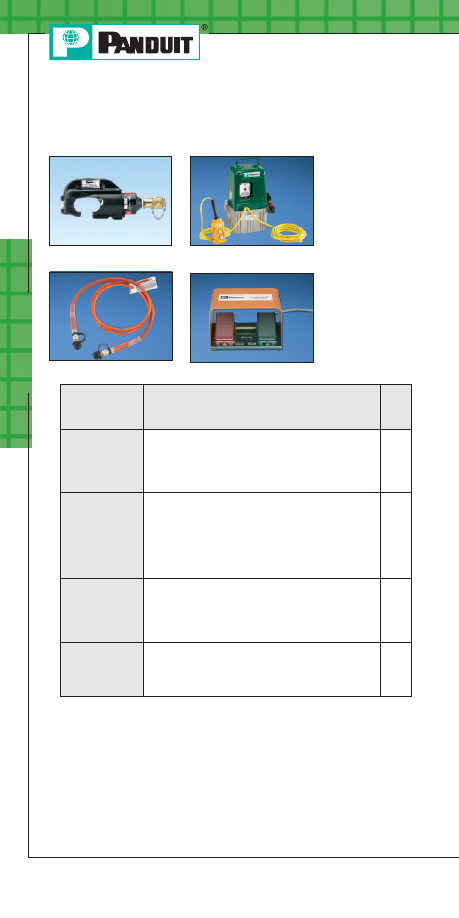

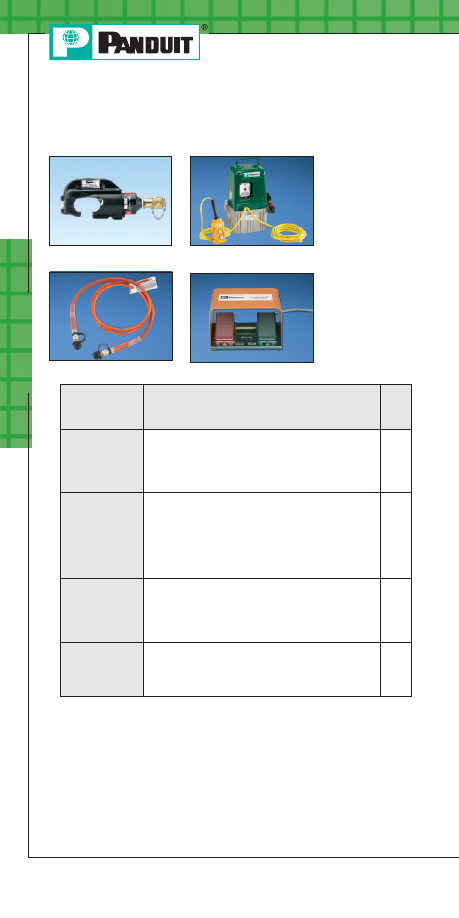

Controlled Cycle Crimping Tools

Ferrule End Sleeve Crimping Tools

• Speciality crimping tools for fully

insulated right angle disconnects and

heat shrink insulated terminals,

disconnects, and splices.

Part

Number

Part Description

Std.

Pkg.

Qty.

CT-300-1

Crimps

PANDUIT #22 – #14 AWG fully insulated

right angle disconnects. (DNFR-FIB series).

1

Part

Number

Part Description

Std.

Pkg.

Qty.

CT-1002

Crimps

PANDUIT #26 – #10 AWG single vinyl

insulated ferrules (DIN). #26 – #10 AWG single

wire insulated ferrules (French).

#22 – #12 AWG vinyl insulated dual-wire ferrules

(DIN). #24 – #10 AWG non-insulated ferrules.

1

CT-1003

Crimps

PANDUIT #22 – #8 AWG single wire

insulated ferrules (DIN). #22 – #8 AWG single wire

vinyl insulated ferrules (French). #22 – #10 AWG

vinyl insulated dual-wire (DIN) ferrules. #22 – #10

AWG non-insulated ferrules.

1

CT-1004

Crimps

PANDUIT #8 – #6 AWG single wire vinyl

insulated ferrule (DIN). #8 – #6 AWG single wire

vinyl insulated ferrules (French).

#10 AWG vinyl insulated dual-wire (DIN) ferrule.

#8 – #6 AWG non-insulated ferrules.

1

CT-1005

Crimps

PANDUIT #4 – #2 AWG single wire vinyl

insulated ferrule (DIN). #4 – #2 AWG single wire

vinyl insulated ferrules (French).

#4 – #2 AWG non-insulated ferrules.

1

CT-1006

Crimps

PANDUIT #1 AWG single wire vinyl

insulated ferrule (DIN) and (French). #1 AWG

non-insulated ferrules.

1

• Specifically designed for the installation of

P

AN

-T

ERM

®

ferrules

• Controlled cycle mechanism assures high

quality, consistent terminations

• Ergonomic tool design assures operator

comfort, safety and performance

• Multi-position locator facilitates a high

quality repeatable crimp

CT-1002

CT-1003

CT-1004

CT-1005

CT-1006

PANDUIT Termination Solutions-html.html

Terminals

A19

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Cable Stripping Tools for Small

Cable Sizes

• Strips and cuts 10 – 20 AWG wire

• Lightweight and durable for comfortable

long use

• Rust resistant coating included to improve

durability of tool

Cable Stripping Tool for Large Cable Sizes

• Cutting blade provides circular, spiral and

in-line insulation cutting

• Cutting blade easily adjusts to proper

height to cut insulation without nicking

conductor strands

• Unique blade profile for long life, low friction

stripping of difficult insulations like rubber

and silicon

• Ergonomic shape for safe comfortable use

• Compact design

CST101

CST115

Part

Number

Part Description

Std.

Pkg.

Qty.

CST101

V notch wire stripper.

1

CST115

Plier nose wire stripper.

1

Item

Part Description

Std.

Pkg.

Qty.

CST114-157 Cable stripping tool for stripping insulation from

cables 3/16" to 1 9/16" diameter. Includes

replacement cutting blade. Warranty: 90 days

1

PANDUIT Termination Solutions-html.html

Terminals

A20

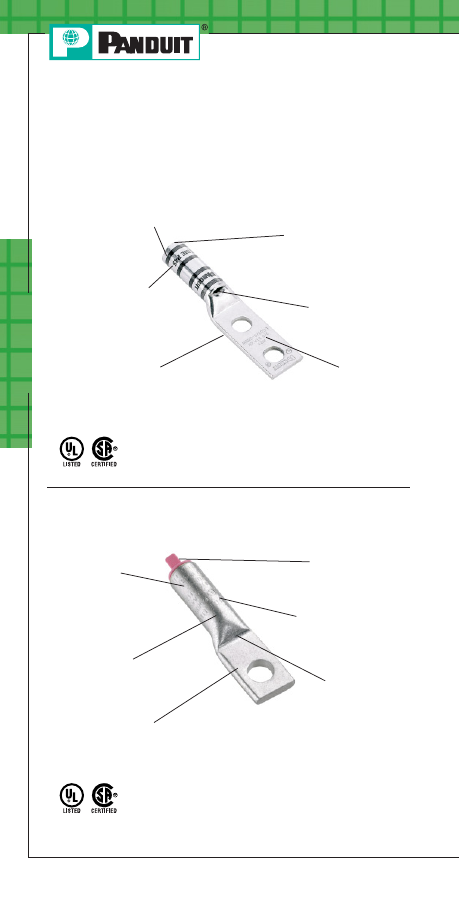

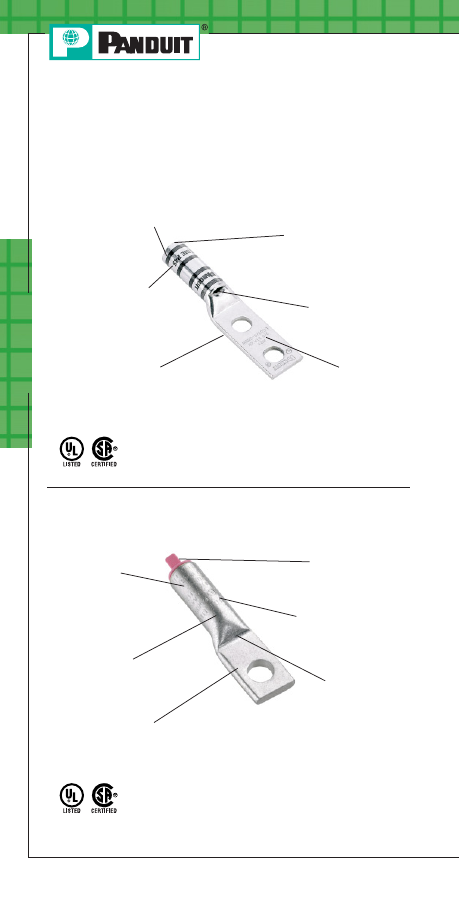

Features and Benefits –

P

AN

-T

ERM

®

Terminals

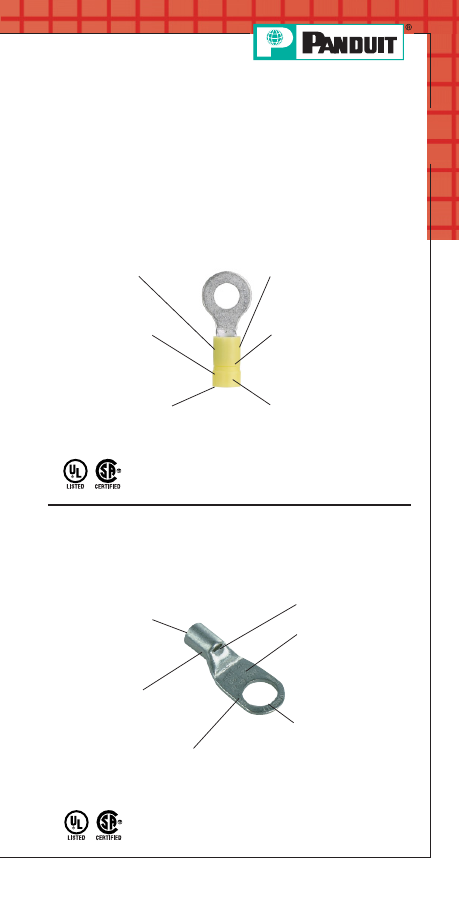

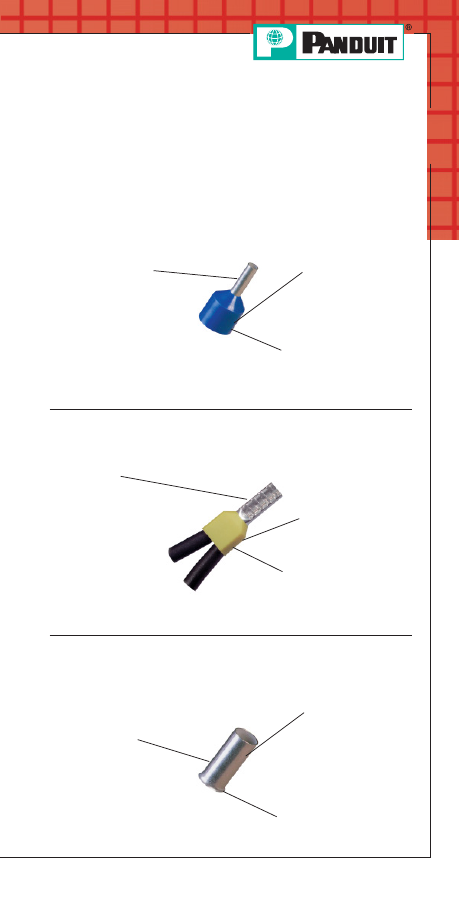

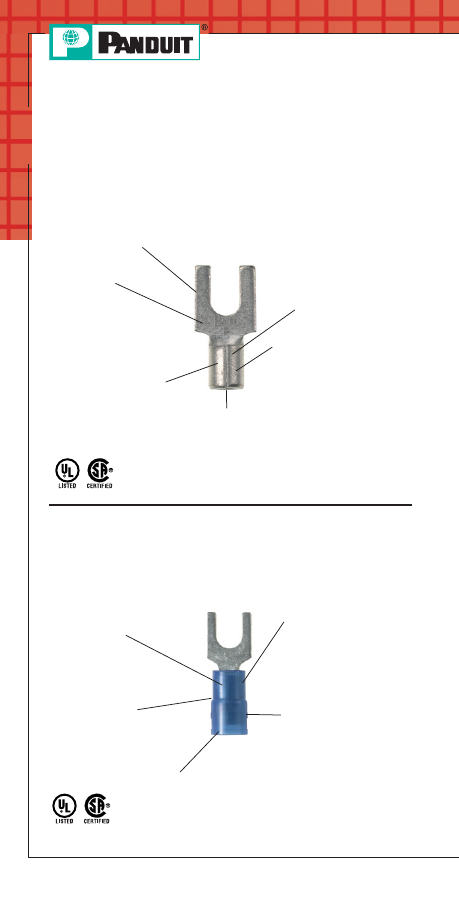

Non-Insulated Terminals

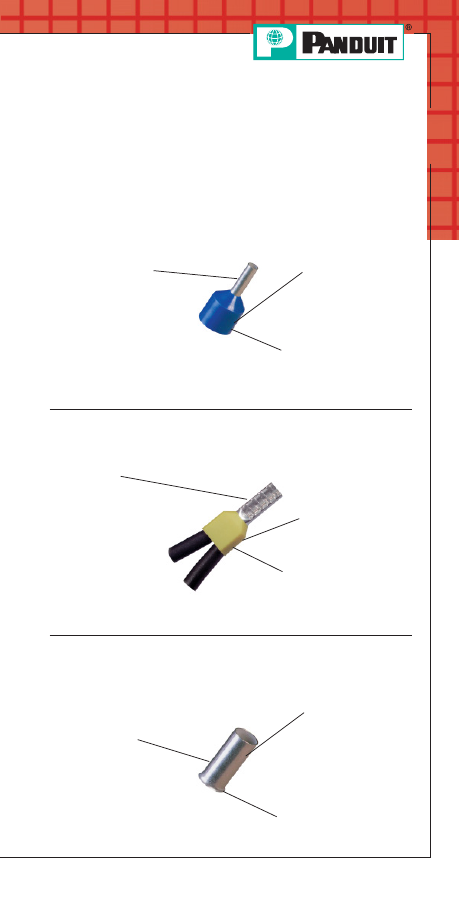

Type P

Maximum recommended

operating temperature 150°C (302°F)

Extended barrel length

assures a good quality

crimp and makes

crimping easier

Product

markings

provide easy

identification of

wire size

Brazed seam

assures crimp reliability

Internally beveled

barrel for quick easy

wire insertion

Internal barrel serrations

assure good wire

contact and maximum

tensile strength

UL and CSA rated up to 2000V per UL486A.

Nickel plated terminals rated up to 343°C (650°F)

maximum operating temperature.

All

PANDUIT Terminals feature high quality materials made with

electrolytic copper for high conductivity and are tin plated for

corrosion resistance.

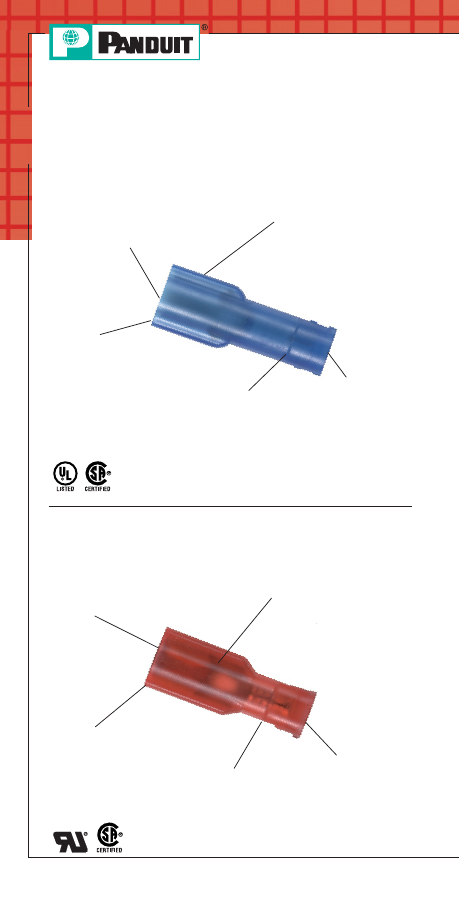

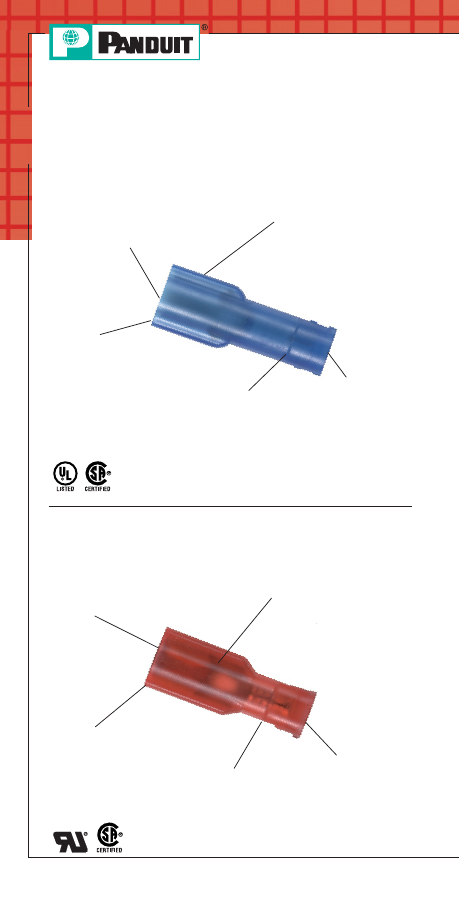

Nylon Insulated Terminals With

Insulation Grip Sleeve

Type PN or PNF

UL and CSA rated up to 600V per UL486.

Flammability – UL94V-2/HB.

Proprietary blend of UL94V-2 and UL94HB

flammability rated materials.

Internal barrel

serrations assure

good wire contact

and maximum

tensile strength

Maximum

insulation

temperature

105°C (221°F)

Color coded

insulation identifies

wire range

Funnel entry for

faster insertion and

lower installed cost

Insulation grip sleeve

provides a superior

insulation crimp for high

vibration and high strain

relief applications

PANDUIT Termination Solutions-html.html

Terminals

A21

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Features and Benefits –

P

AN

-T

ERM

®

Terminals

(continued)

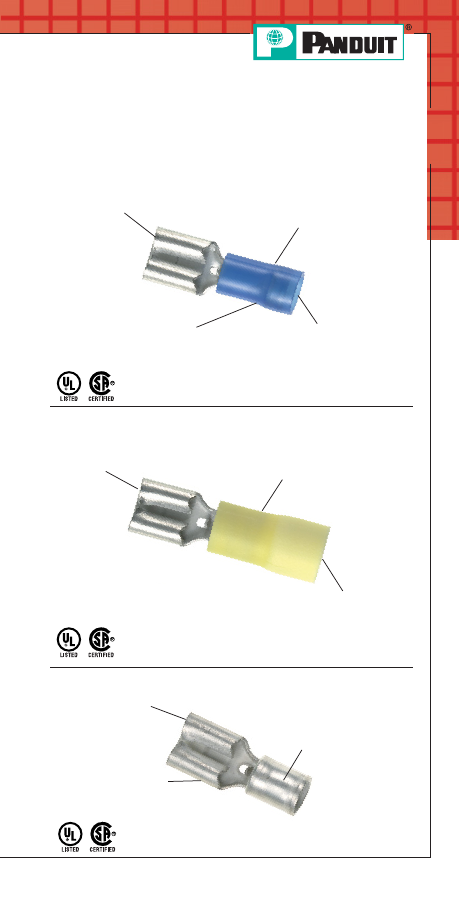

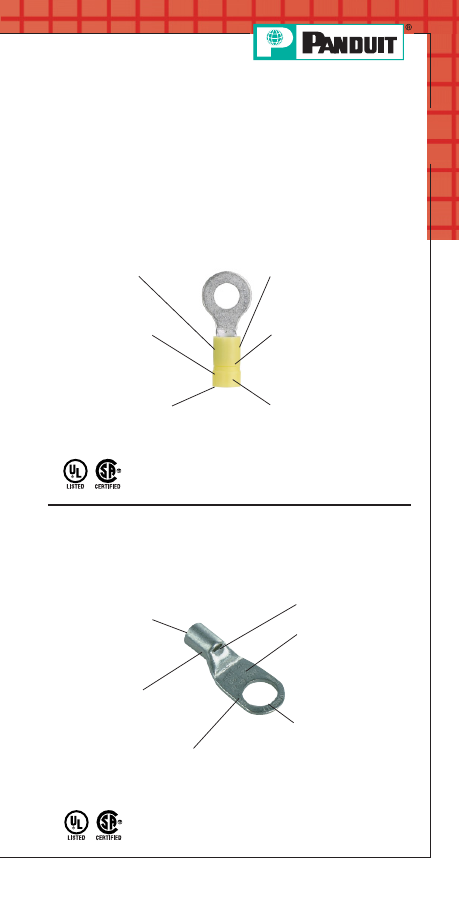

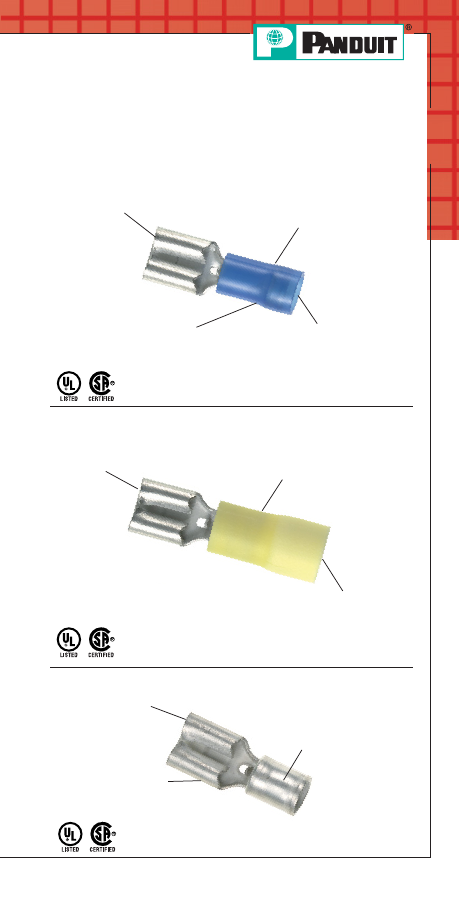

Vinyl Insulated Terminals With

Insulation Support

Type PV

Funnel entry for faster

insertion and lower

installed cost

Brazed seam assures

crimp reliability

Internal barrel

serrations assure

good wire contact

and maximum

tensile strength

Insulation crimp

provides insulation

support to protect

electrical crimp

Color coded insulation

identifies wire range

Maximum insulation

temperature 105°C (221°F)

UL and CSA rated up to 600V per UL486.

Flammability – UL94V-0.

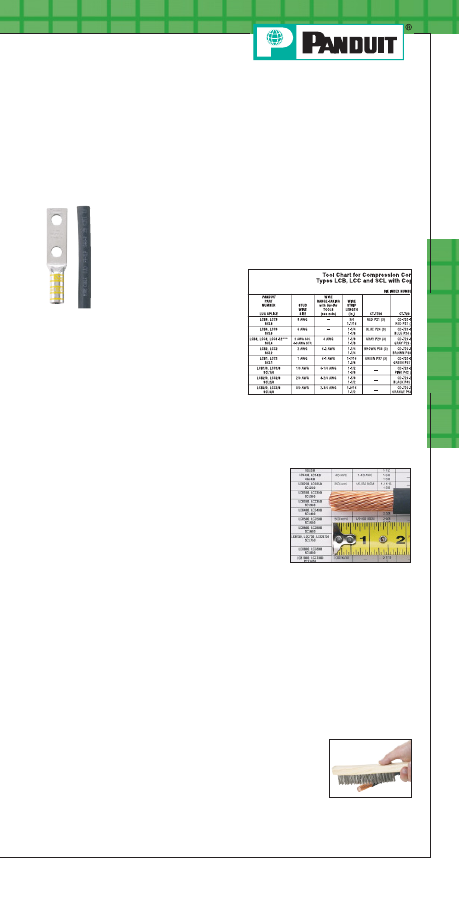

Non-Insulated Seamless Tubular Terminals

Type S

UL and CSA rated up to 2000V per UL486A.

Internally beveled

barrel for quick

easy wire insertion

Maximum recommended

operating temperature

150°C (302°F)

Double thickness

provides a strong

ring tongue

Product markings

provide easy

identification of

wire sizes

Inspection hole allows

visual inspection for

proper wire insertion

Seamless tubular

barrel provides

consistent, high

performance,

quality crimps

PANDUIT Termination Solutions-html.html

Terminals

A22

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

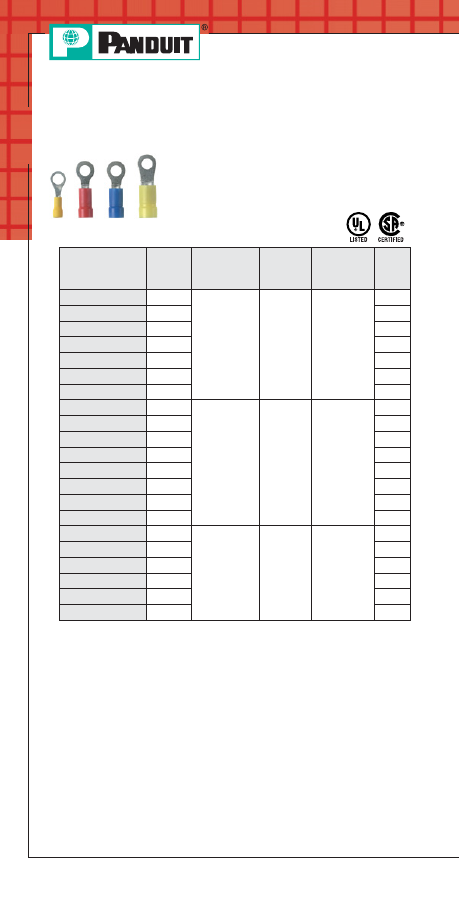

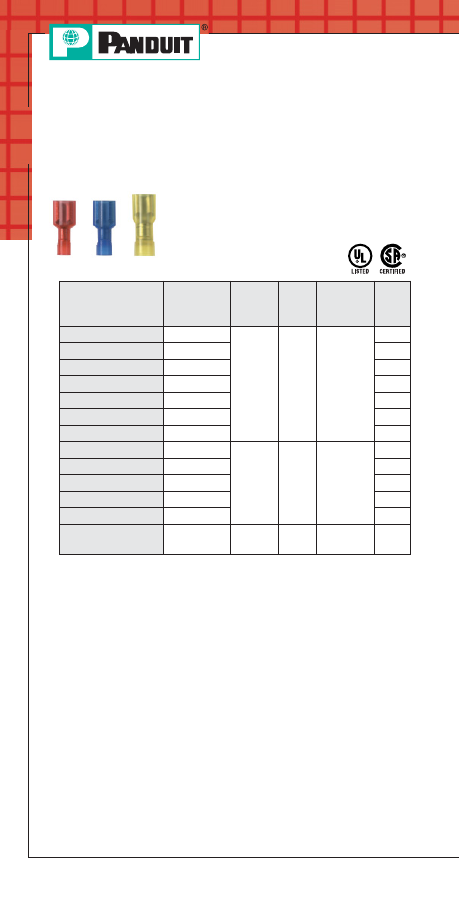

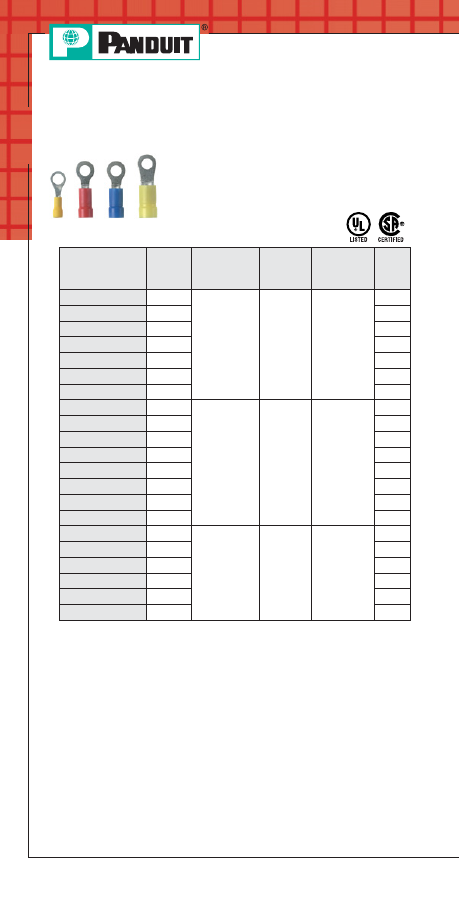

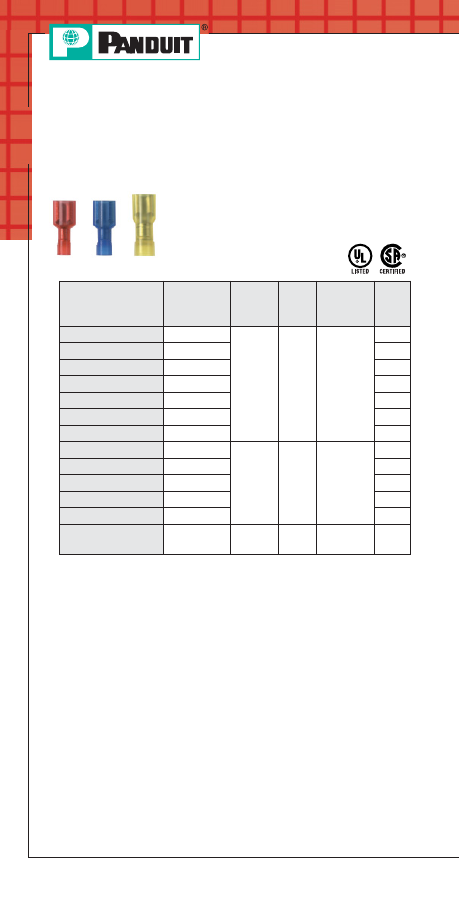

Ring Terminal, Vinyl Insulated –

Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications to provide

a reliable connection

• Brazed seam protects terminal barrel

from splitting during the

crimp process

**To order in bulk, replace -C or -CY in the part number with -M or -MY for

a bulk package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SAC-ELCB03 at www.panduit.com

Part Number

Stud

Size

Wire Range

Color

Code

Tool

Std.

Pkg.

Qty.**

PV18-4R-CY

#4

22 – 18

AWG

Red

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV18-6R-CY

#6

100

PV18-8R-CY

#8

100

PV18-10R-CY

#10

100

PV18-14R-CY

1/4"

100

PV18-56R-CY

5/16"

100

PV18-38R-CY

3/8"

100

PV14-4R-C

#4

16 – 14

AWG

Blue

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV14-6RN-C

#6

100

PV14-6R-C

#6

100

PV14-8R-C

#8

100

PV14-10R-C

#10

100

PV14-14R-C

1/4"

100

PV14-56R-C

5/16"

100

PV14-38R-L

3/8"

50

PV10-6R-L

#6

12 – 10

AWG

Yellow

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

50

PV10-8R-L

#8

50

PV10-10R-L

#10

50

PV10-14R-L

1/4"

50

PV10-56R-L

5/16"

50

PV10-38R-L

3/8"

50

PANDUIT Termination Solutions-html.html

A23

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

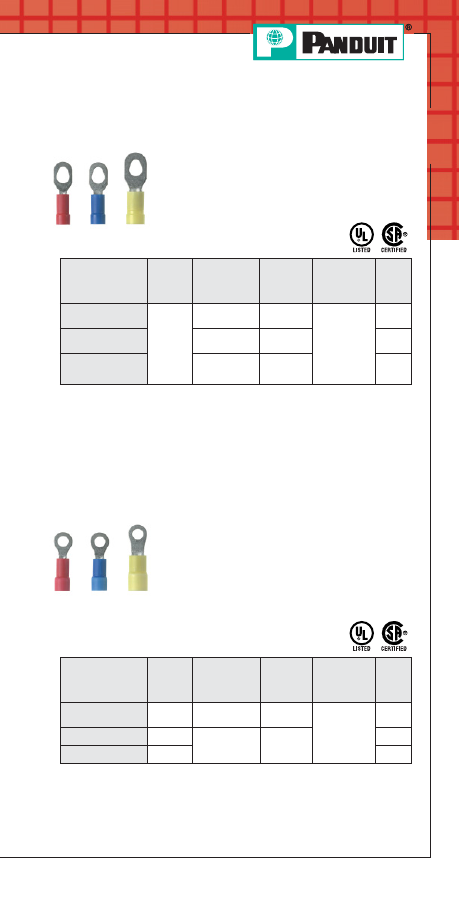

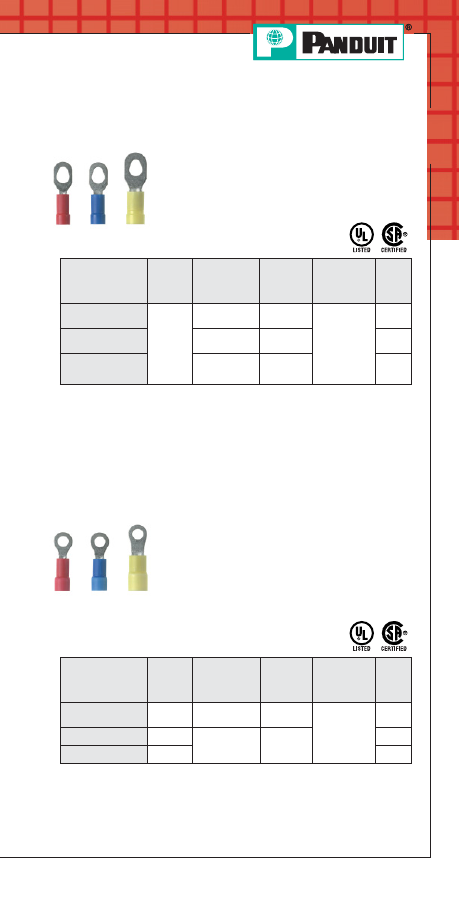

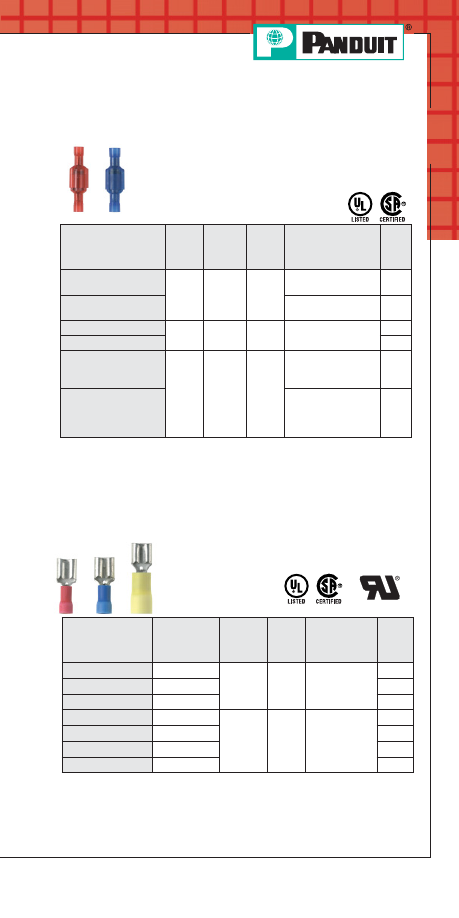

Multiple Stud Terminal, Vinyl Insulated –

Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications for a

reliable connection

• Brazed seam protects terminal barrel

from splitting during the

crimp process

**To order in bulk, replace -C or -CY in the part number with -M or -MY for

a bulk package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Ring Terminal, Vinyl Expanded Insulation

• Insulation support helps to prevent wire

damage in bending applications

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Expanded funnel entry designed to

accommodate wire with a larger than

standard outside diameter insulation

Part Number

Stud

Size

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

PV14-10RX-C

#10

16 – 14

AWG

Blue

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV10-10RX-L

#10

12 – 10

AWG

Yellow

50

PV10-14RX-L

1/4"

50

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Stud

Size

Wire Range

Color

Code

Tool

Std.

Pkg.

Qty.**

PV18-610R-CY

#6, #8,

#10

22 – 18

AWG

Red

CT-100,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV14-610R-C

16 – 14

AWG

Blue

100

PV10-610R-L

12 – 10

AWG

Yellow

50

PANDUIT Termination Solutions-html.html

A24

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

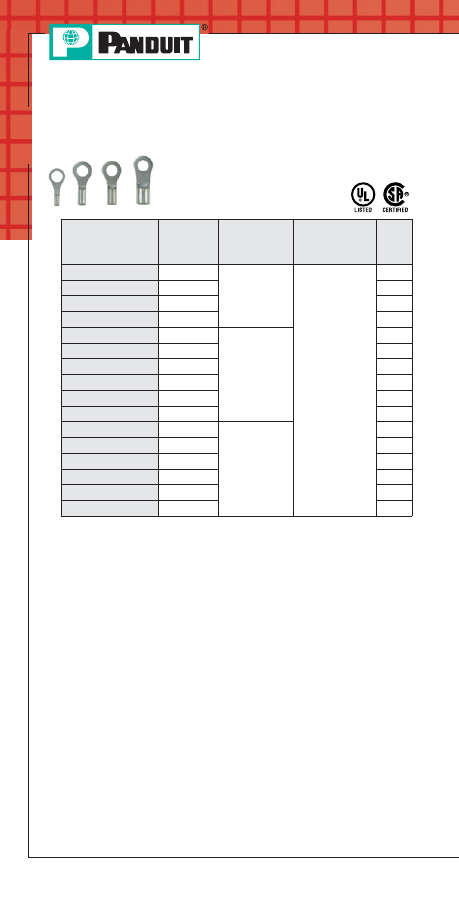

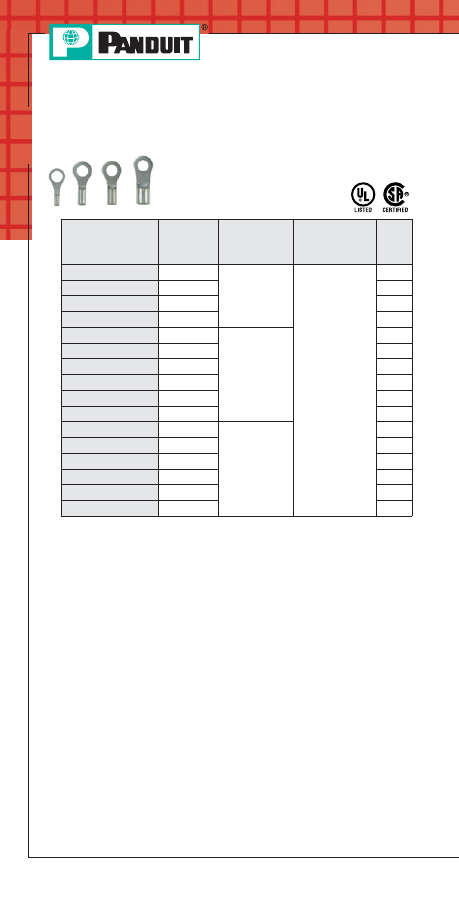

Ring Terminal, Non-Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Barrel of terminal internally beveled to

provide quick and easy

wire insertion

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Stud

Size

Wire

Range

Tool

Std.

Pkg.

Qty.**

P18-6R-C

#6

22 – 18 AWG

CT-100‡,

CT-200‡,

CT-600‡,

CT-1570‡

100

P18-8R-C

#8

100

P18-10R-C

#10

100

P18-14R-C

1/4"

100

P14-6R-C

#6

16 – 14 AWG

100

P14-8R-C

#8

100

P14-10R-C

#10

100

P14-14R-C

1/4"

100

P14-56R-C

5/16"

100

P14-38R-C

3/8"

100

P10-6R-L

#6

12 – 10 AWG

50

P10-8R-L

#8

50

P10-10R-L

#10

50

P10-14R-L

1/4"

50

P10-56R-L

5/16"

50

P10-38R-L

3/8"

50

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

PANDUIT Termination Solutions-html.html

A25

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

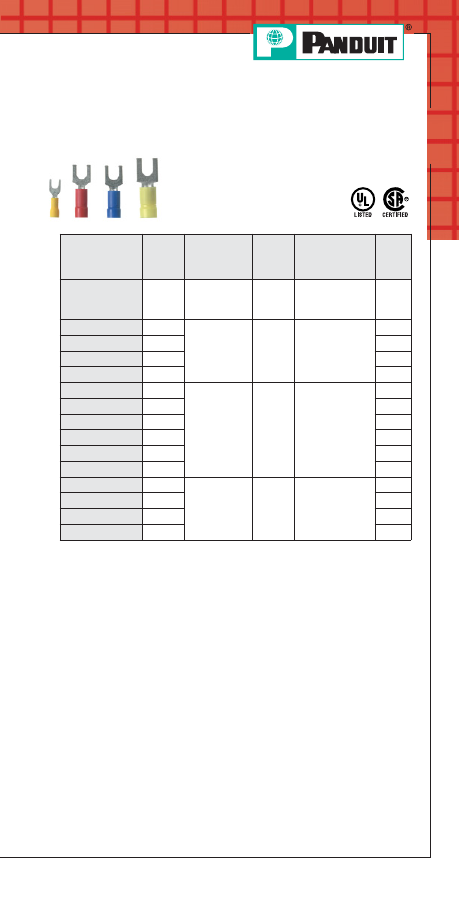

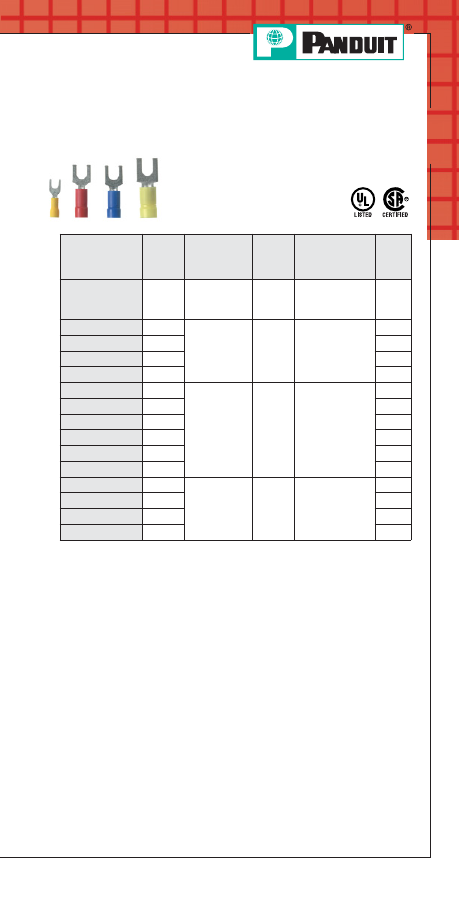

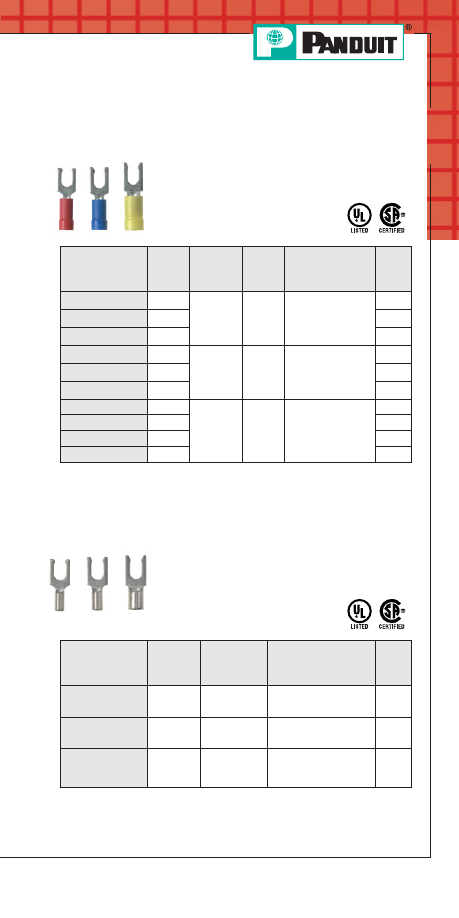

Fork Terminal, Vinyl Insulated –

Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Brazed seam protects terminal

barrel from splitting during the

crimp process

*Not UL Listed or CSA Certified.

**To order in bulk, replace -C or -CY in the part number with -M or -MY

for a bulk package of 1000 and replace -L with -D for a bulk package

of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Stud

Size

Wire Range

Color

Code

Tool

Std.

Pkg.

Qty.**

PV22-6F-C*

#6

26 – 22

AWG

Yellow

CT-100,

CT-600,

CT-1525

100

PV18-6FN-CY

#6

22 – 18

AWG

Red

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV18-6F-CY

#6

100

PV18-8F-CY

#8

100

PV18-10F-CY

#10

100

PV14-6FN-C

#6

16 – 14

AWG

Blue

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV14-6F-C

#6

100

PV14-8F-C

#8

100

PV14-10FN-C

#10

100

PV14-10F-C

#10

100

PV14-14F-C

1/4"

100

PV10-6F-L

#6

12 – 10

AWG

Yellow

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

50

PV10-8F-L

#8

50

PV10-10F-L

#10

50

PV10-14F-L

1/4"

50

PANDUIT Termination Solutions-html.html

A26

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

*Not UL Listed or CSA Certified.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

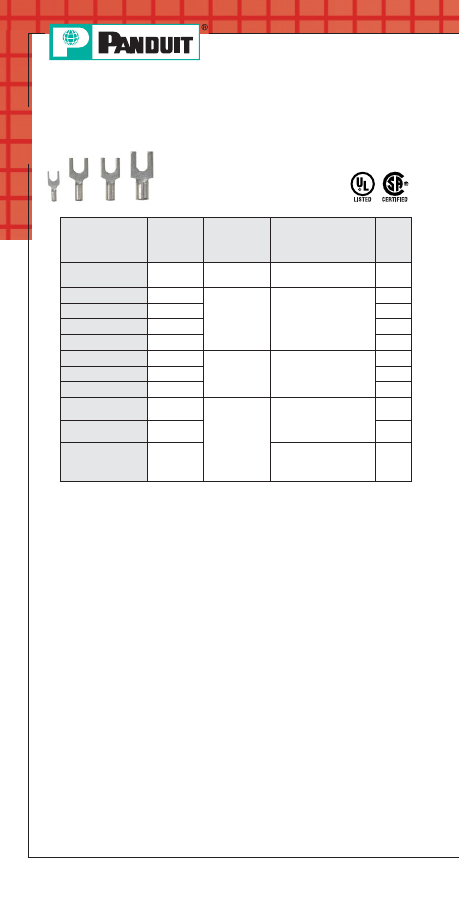

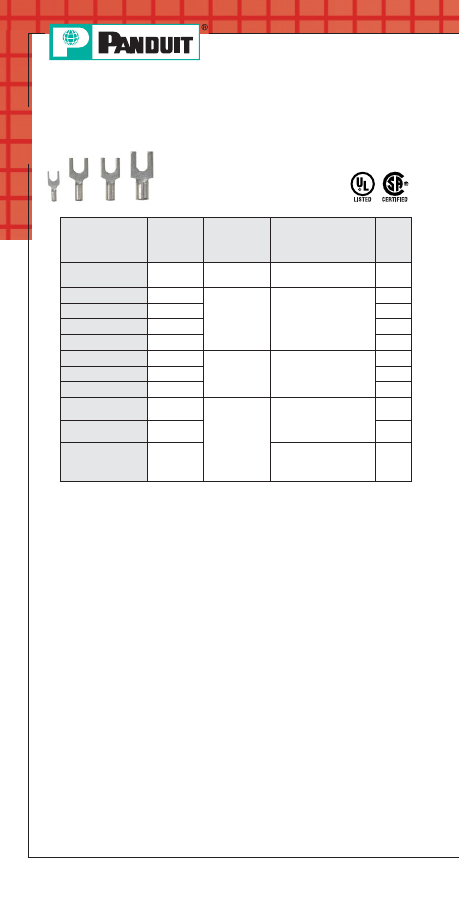

Fork Terminal, Non-Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Barrel of terminal internally

beveled to provide quick and

easy wire insertion

Part Number

Stud

Size

Wire

Range

Tool

Std.

Pkg.

Qty.**

P22-4F-C*

#4

26 – 22

AWG

CT-100, CT-200

100

P18-6FN-C

#6

22 – 18

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡

100

P18-6F-C

#6

100

P18-8F-C

#8

100

P18-10F-C

#10

100

P14-6F-C

#6

16 – 14

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡

100

P14-8F-C

#8

100

P14-10F-C

#10

100

P10-6F-L

#6

12 – 10

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡,

CT-1701‡

50

P10-8F-L

#8

50

P10-10F-L

#10

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡,

CT-1701‡

50

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

PANDUIT Termination Solutions-html.html

A27

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

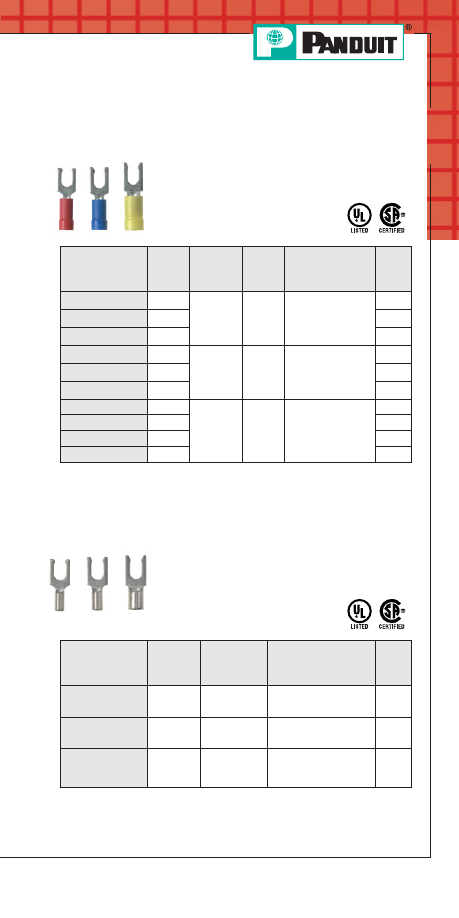

Locking Fork Terminal, Vinyl Insulated –

Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Brazed seam protects terminal

barrel from splitting during the

crimp process

**To order in bulk, replace -C or -CY in the part number with -M or -MY

for a bulk package of 1000 and replace -L with -D for a bulk package

of 500.

‡UL and CSA approved tooling/product combinations.

Locking Fork Terminal, Non-Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Barrel of terminal internally

beveled to provide quick and

easy wire insertion

Part Number

Stud

Size

Wire

Range

Tool

Std.

Pkg.

Qty.**

P18-6LF-C

#6

22 – 18

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡

100

P14-6LF-C

#6

16 – 14

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡

100

P10-10LF-L

#10

12 – 10

AWG

CT-100‡, CT-200‡,

CT-600‡, CT-1570‡,

CT-1701‡

50

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Stud

Size

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.

PV18-6LF-CY

#6

22 – 18

AWG

Red

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV18-8LF-CY

#8

100

PV18-10LF-CY

#10

100

PV14-6LF-C

#6

16 – 14

AWG

Blue

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

100

PV14-8LF-C

#8

100

PV14-10LF-C

#10

100

PV10-6LF-L

#6

12 – 10

AWG

Yellow

CT-100‡,

CT-600‡,

CT-1550‡,

CT-1551‡

50

PV10-8LF-L

#8

50

PV10-10LF-L

#10

50

PV10-14LF-L

1/4"

50

PANDUIT Termination Solutions-html.html

A28

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

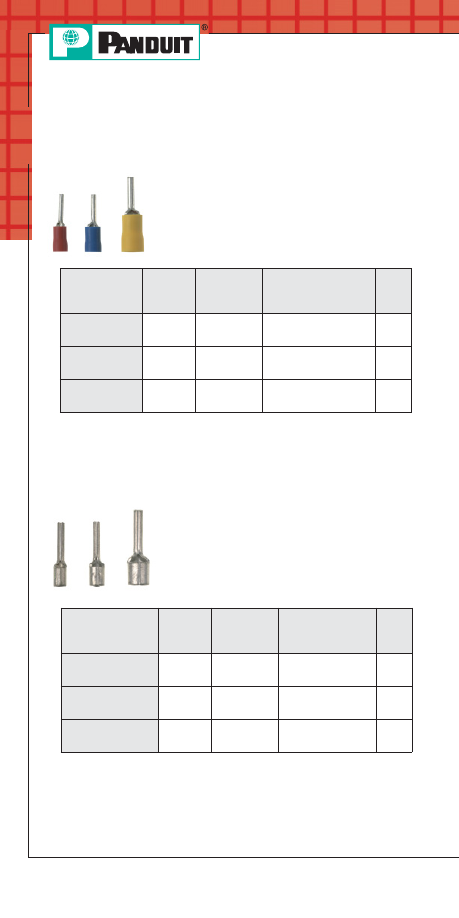

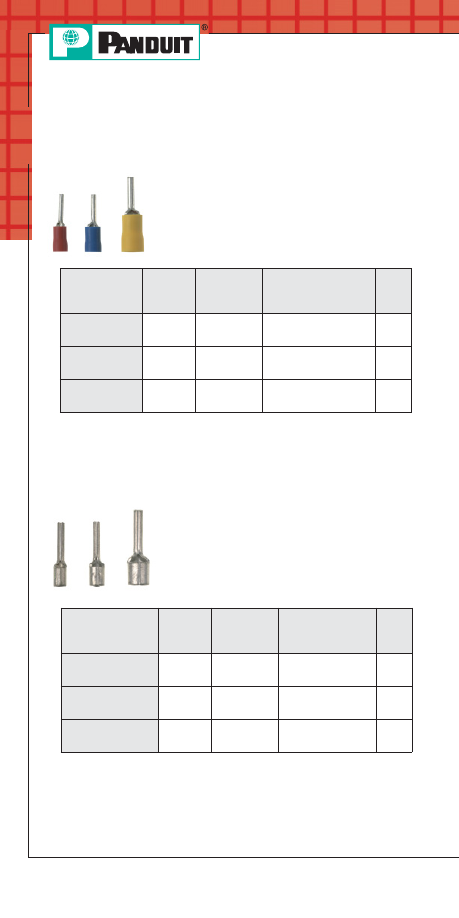

Pin Terminal, Vinyl Insulated –

Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications for a

reliable connection

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Solid pin designed to prevent damage to

the wire from over tightening, resulting in a

reliable electrical connection

**To order in bulk, replace -C or -CY in the part number with -M or -MY

for a bulk package of 1000 and replace -L with -D for a bulk package

of 500.

Pin Terminal, Non-Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Barrel of terminal internally beveled to

provide quick and easy wire insertion

• Solid pin designed to prevent damage to

the wire from over tightening, resulting in a

reliable electrical connection

Part Number

Stud

Size

Wire

Range

Tool

Std.

Pkg.

Qty.**

P18-P47-C

—

22 – 18

AWG

CT-100, CT-200,

CT-260, CT-1570

100

P14-P47-C

—

16 – 14

AWG

CT-100, CT-200,

CT-260, CT-1570

100

P10-P55-L

—

12 – 10

AWG

CT-100, CT-200,

CT-260, CT-1570

50

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

Part Number

Stud Size Wire Range

Tool

Std.

Pkg.

Qty.

PV18-P47-CY

—

22 – 18

AWG

CT-100, CT-260,

CT-1550, CT-1551

100

PV14-P47-C

—

16 – 14

AWG

CT-100, CT-260,

CT-1550, CT-1551

100

PV10-P55-L

—

12 – 10

AWG

CT-100, CT-260,

CT-1550, CT-1551

50

PANDUIT Termination Solutions-html.html

A29

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Features and Benefits –

P

AN

-T

ERM

®

Disconnects

P

AN

-T

ERM

®

disconnects are fabricated from brass and are

electro-tin plated for a long, corrosion resistant operating life.

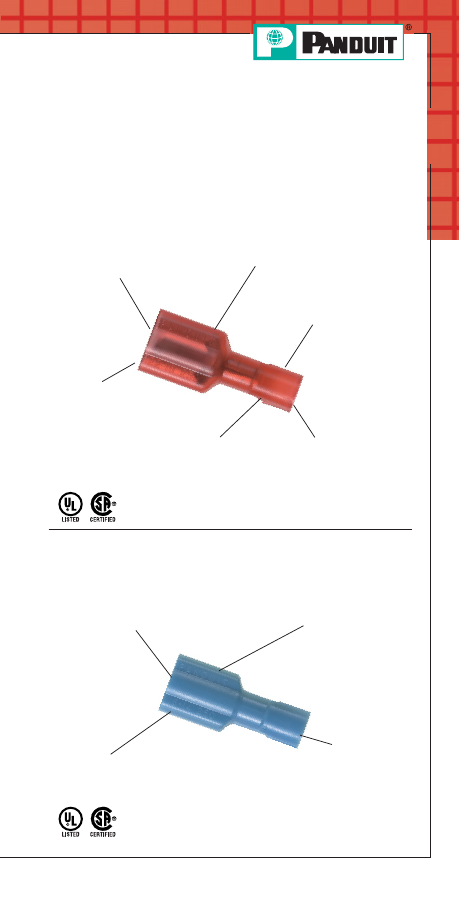

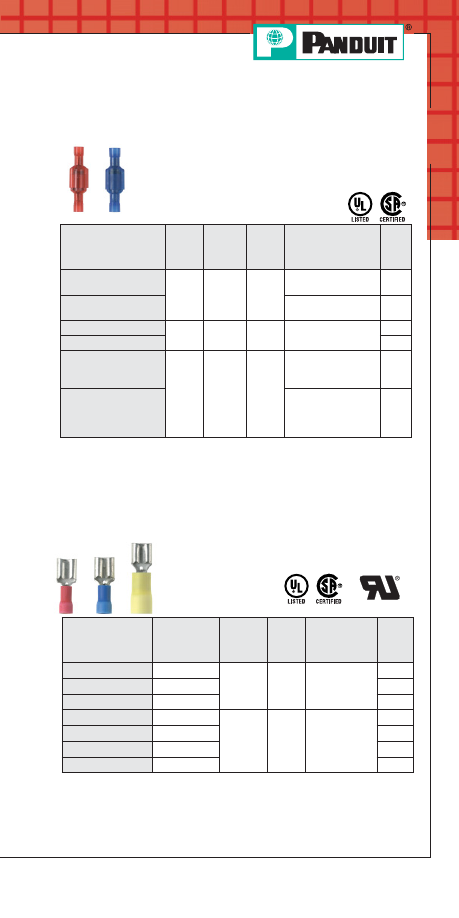

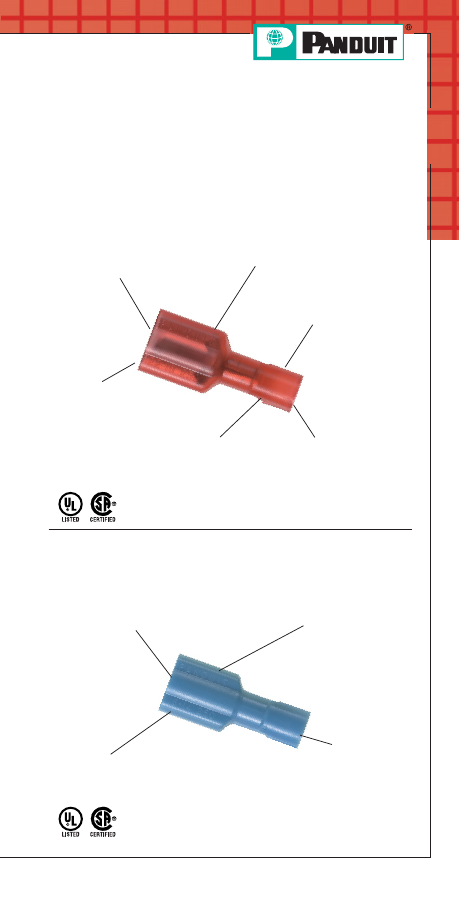

Nylon Fully Insulated

Female Receptacles and Male Tabs

Type DNF-FIB

Maximum

insulation

temperature

105°C (221°F)

Insulation support

restricts excessive wire

movement to minimize

stress on crimp joint

UL and CSA rated up to 600V per UL310.

Funnel entry for

faster wire insertion

and lower installed cost

Expanded wire entry

(on select sizes)

accommodates

large insulation or

multiple wires

Available in tab

sizes to

accommodate

.110", .187", .205"

or .250" tabs

Fully insulated

design provides

protection from

electrical shorts

D

ISCO

-G

RIP

™

Premium Nylon Fully Insulated

Female Receptacles and Male Tabs

Type DNF and DPF

Maximum

insulation

temperature

105°C (221°F)

UL and CSA rated up to 600V per UL310.

Male products available .250" width in standard

and oversized housing configurations.

Funnel entry

for faster

wire insertion

and lower

installed cost

Available in tab

sizes to

accommodate

.250" tabs

Fully insulated

design provides

protection from

electrical shorts

PANDUIT Termination Solutions-html.html

A30

Terminals

S

UPRA

-G

RIP

™

Nylon Fully

Insulated Female Disconnects

Type DNG-FB

Maximum

insulation

temperature

105°C (221°F)

Fully integrated metal

insulation grip for high

vibration, high strain

relief, and double

crimp requirements

Funnel entry

for faster

wire insertion

and lower

installed cost

Available in tab sizes

to accommodate

.187" or .250" tabs

Fully insulated

design provides

protection from

electrical shorts

UL and CSA rated up to 600V per UL310.

D

ISCO

-L

OK

™

Nylon Fully Insulated

Locking Female Disconnects

Type DNG-FL

Maximum

insulation

temperature

105°C (221°F)

Insulation grip sleeve

provides a superior insulation

crimp for high vibration and

high strain relief applications

UL and CSA rated up to 300V.

Funnel entry for

faster wire insertion

and lower installed cost

Available in tab sizes

to accommodate

250" tabs

Unique locking mechanism

allows for low insertion forces

(mating) and positive locking

for secure connections

Features and Benefits –

P

AN

-T

ERM

®

Disconnects

(continued)

PANDUIT Termination Solutions-html.html

A31

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Nylon Barrel Insulated

Female Receptacles and Male Tabs

Type DNF

Insulation grip sleeve provides

a superior insulation crimp for

high vibration and high strain

relief applications

Funnel entry

for faster

wire insertion

and lower

installed cost

Available in tab

sizes to

accommodate

.110", .187",

.205" or

.250" tabs

UL and CSA rated up to 300V.

Male products available .250" width.

Maximum insulation

temperature 105°C (221°F)

Vinyl Barrel Insulated

Female Receptacles and Male Tabs

Type DV and DVF

Insulation support to

protect electrical crimp

Available in

tab sizes to

accommodate

.187", .205"

or .250" tabs

UL and CSA rated up to 600V.

Male products available .250" width.

Flammability – UL94V-0.

Maximum insulation

temperature 105°C (221°F)

Non-Insulated Female Receptacles and Male Tabs

Type D

Male products available .250" width.

Available in tab sizes

to accommodate

.187" or .250" tabs

Sleeved barrel assures

crimp reliability

Maximum recommended

operating temperature

150°C (302°F)

Features and Benefits –

P

AN

-T

ERM

®

Disconnects

(continued)

PANDUIT Termination Solutions-html.html

A32

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

Female Disconnect Nylon Fully

Pre-Insulated – Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Internal wire stop assures proper length of

insertion into terminal barrel

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DNF18-110FIB-C

.110 x .032

22 – 18

AWG

Red

CT-100,

CT-600,

CT-1525‡

100

DNF18-111FIB-C

.110 x .020

100

DNF18-187FIB-C

.187 x .032

100

DNF18-188FIB-C

.187 x .020

100

DNF18-205FIB-C

.205 x .032

100

DNF18-206FIB-C

.205 x .020

100

DNF18-250FIB-C

.250 x .032

100

DNF14-187FIB-C

.187 x .032

16 – 14

AWG

Blue

CT-100,

CT-600,

CT-1525‡

100

DNF14-188FIB-C

.187 x .020

100

DNF14-205FIB-C

.205 x .032

100

DNF14-206FIB-C

.205 x .020

100

DNF14-250FIB-C

.250 x .032

100

DNF10-250FIB-L

.250 x .032

12 – 10

AWG

Yellow

CT-1525‡

50

P

AN

-T

ERM

®

Disconnects

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

PANDUIT Termination Solutions-html.html

A33

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Male /Female Coupler, Nylon Fully

Pre-Insulated – Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Internal wire stop assures proper

length of insertion into

terminal barrel

*UL Listed only.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Female Disconnect, Vinyl Barrel

Insulated – Butted Seam

• Insulation support helps to prevent wire

damage in bending applications

*UL Recognized and CSA approved.

**To order in bulk, replace -C or -CY in the part number with -M or -MY for

a bulk package of 1000.

^CSA approved tooling/product combinations.

‡UL and CSA approved tooling/product combinations.

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DNF18-250FIM-C

.250 x

.032

22 – 18

AWG

Red

CT-100‡, CT-600,

CT-1525‡

100

DNF18-250FIB-C

CT-100, CT-600,

CT-1525‡

100

DNF14-250FIM-C

.250 x

.032

16 – 14

AWG

Blue

CT-600,

CT-1525‡

100

DNF14-250FIMB-L

50

DNF10-250FIMB-L

*

.250 x

.032

12 – 10

AWG

Yellow

CT-600‡,

CT-1550‡,

CT-1551‡

50

DNF10-250FI-L

CT-100‡, CT-460‡,

CT-550‡, CT-600‡,

CT-1550‡,

CT-1551‡

50

*Recognized

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DV18-187B-CY

.187 x .032

22 – 18

AWG

Red

CT-1525‡

100

DV18-188B-CY

.187 x .020

100

DV18-250B-CY

.250 x .032

100

DV14-187B-C*

.187 x .032

16 – 14

AWG

Blue

CT-1525^

100

DV14-188B-C*

.187 x .020

100

DV14-205B-C*

.205 x .032

100

DV14-250B-C*

.250 x .032

100

PANDUIT Termination Solutions-html.html

A34

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

Female Disconnect, Non-Insulated –

Butted Seam

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

Piggyback Disconnect, Vinyl Insulated

• Metal insulation grip sleeve crimps to wire

insulation providing protection to the crimp

joint during high vibration applications

• Combination of female disconnect and male

tab allows versatility in points of connection

• Multiple connection points allow additional

circuits to be added to existing

equipment without

expensive rework

**To order in bulk, replace -C or -CY in the part number with -M or -MY

for a bulk package of 1000.

Disconnect Adapter, Non-Insulated

• Converts one male tab to two male tabs,

allowing two female disconnects to be

connected to the same circuit

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

Part Number

Tab

Size

(In.)

Wire

Range

Tool

Std

Pkg.

Qty.**

D14-250B-C

.250 x .032

16 – 14 AWG

CT-100

100

Part Number

Tab

Size

(In.)

Wire

Range

Std.

Pkg.

Qty.**

D-250A-C

.250 x .032

—

100

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

• Non-insulated barrel can be used to

provide an economical termination when

insulation is not required

Part Number

Tab

Size

(In.)

Wire Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DV18-250P-CY

.250 x

.032

22 – 18

AWG

Red

CT-100,

CT-260,

CT-1550,

CT-1551

100

DV14-250P-C

16 – 14

AWG

Blue

100

PANDUIT Termination Solutions-html.html

A35

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Right Angle Female Disconnect, Nylon

Fully Insulated – Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Right angle design allows low

profile routing of wire in limited

application space

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DNFR18-250FIB-C

.250 x .032

22 – 18

AWG

Red

CT-300-1

100

DNFR14-250FIB-C

.250 x .032

16 – 14

AWG

Blue

CT-300-1

100

Right Angle Female Disconnect, Nylon

Insulated – Funnel Entry

• Insulation support helps to prevent wire

damage in bending applications

• Right angle design allows low profile

routing of wire in limited

application space

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

‡UL and CSA approved tooling/product combinations.

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DNFR18-250B-C

.250 x .032

22 – 18

AWG

Red

CT-1525‡

100

DNFR14-250B-C

.250 x .032

16 – 14

AWG

Blue

CT-1525‡

100

PANDUIT Termination Solutions-html.html

A36

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

Right Angle Female Disconnect,

Non-Insulated – Metal Sleeve

• Sleeved barrel helps to facilitate high

mechanical and electrical performance

when crimping in any orientation

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Right Angle Female Disconnect

Non-Insulated

• Serrated barrel helps to facilitate high

mechanical and electrical performance

when crimping in any orientation

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

*Recognized

Part Number

Tab

Size

(In.)

Wire

Range

Tool

Std.

Pkg.

Qty.**

DR14-250-C*

.250 x .032

16 – 14

AWG

CT-100‡, CT-200‡,

CT-600‡,

CT-1570‡

100

DR10-250-L

.250 x .032

12 – 10

AWG

CT-100‡, CT-200‡,

CT-600‡,

CT-1570‡,

CT-1701‡

50

Part Number

Tab

Size

(In.)

Wire

Range

Tool

Std.

Pkg.

Qty.**

DR14-250B-C

.250 x .032

16 – 14

AWG

CT-100, CT-200

100

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

PANDUIT Termination Solutions-html.html

A37

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Male Disconnect, Nylon Barrel

Insulated – Funnel Entry

• Metal insulation grip sleeve crimps to wire

insulation providing protection to the crimp

joint during high vibration applications

*Not CSA Certified.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

Part Number

Tab

Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

DNF18-250M-C

.250 x .032

22 – 18

AWG

Red

CT-1550,

CT-1551

100

DNF14-250M-C

.250 x .032

16 – 14

AWG

Blue

100

DNF10-250M-L*

.250 x .032

12 – 10

AWG

Yellow

50

Male Disconnect, Vinyl Barrel

Insulated – Funnel Entry

**To order in bulk, replace -C or -CY in the part number with -M or -MY for

a bulk package of 1000.

• Butted seam offers an economical solution

for less demanding applications

Part Number

Tab Size

(In.)

Wire

Range

Color

Code

Tool

Std

Pkg.

Qty.**

DV18-250MB-CY

.250 x

.032

22 – 18

AWG

Red

CT-1550,

CT-1551

100

DV14-250MB-C

.250 x

.032

16 – 14

AWG

Blue

100

PANDUIT Termination Solutions-html.html

A38

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

Male Disconnect, Non-Insulated –

Butted Seam

Part Number

Tab

Size

(In.)

Wire

Range

Tool

Std.

Pkg.

Qty.**

D14-250MB-C

.250 x .032

16 – 14

AWG

CT-100

100

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

Male Blade Adapter, Vinyl Insulated –

Funnel Entry

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Flat blade design to prevent damage to

the wire from over tightening, resulting in a

reliable electrical connection

• Designed specifically for blade-type

terminal blocks

• Insulation support helps to prevent

wire damage in

bending applications

**To order in bulk, replace -C or -CY in the part number with -M or -MY for

a bulk package of 1000.

‡UL and CSA approved tooling/product combinations.

*Recognized

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

• Butted seam offers an economical

solution for less demanding applications

Part Number

Tab Size

(In.)

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.

DV18-145M-CY

.145 x .032

22 – 18

AWG

Red

CT-600,

CT-1550‡,

CT-1551‡

100

DV14-145M-C

.145 x .032

16 – 14

AWG

Blue

100

PANDUIT Termination Solutions-html.html

A39

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Features and Benefits –

P

AN

-T

ERM

®

Splices

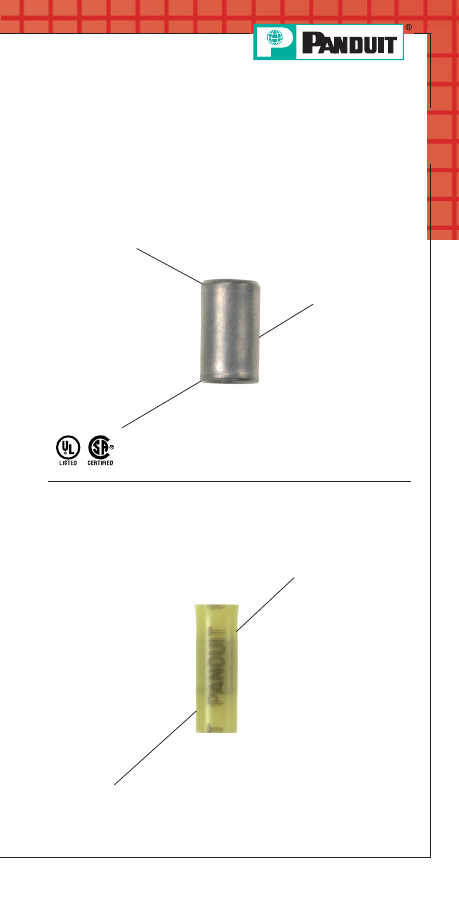

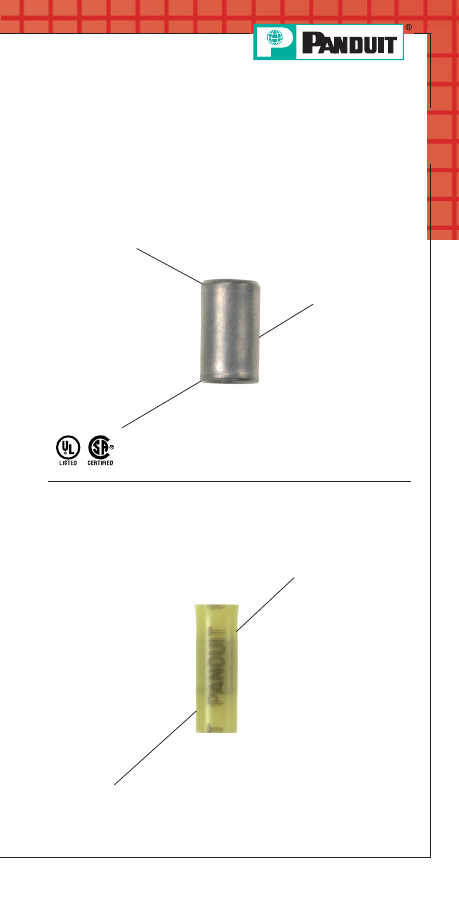

Non-Insulated Parallel Splices

Type PS

Nylon Parallel Splices

Type PSN

Maximum

recommended

operating

temperature

150°C (302°F)

Seamless

tubular barrel

provides

consistent high

performance

quality crimps

UL and CSA rated up to 300V.

Only one crimp

needed to

complete splice

Only one

crimp needed

to complete

splice

Maximum insulation

temperature 105°C

(221°F)

PANDUIT Termination Solutions-html.html

A40

Terminals

Features and Benefits –

P

AN

-T

ERM

®

Splices

(continued)

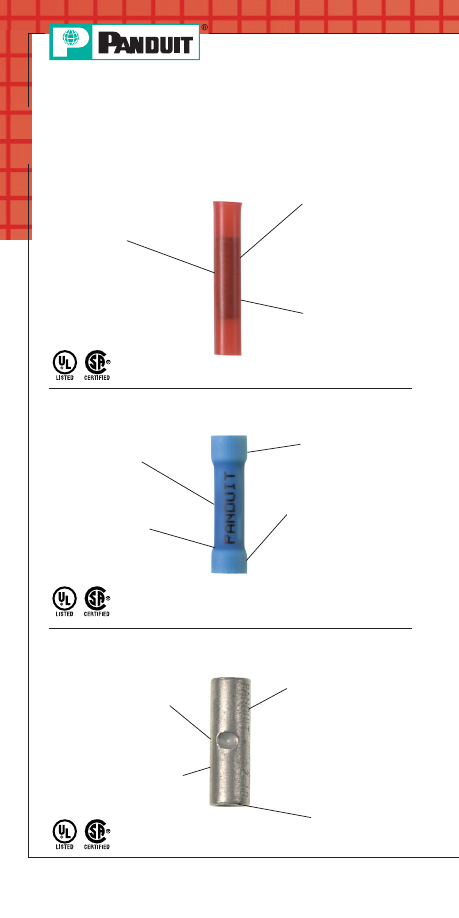

Internal wire

stops assure

proper insertion

length

Maximum insulation

temperature 105°C

(221°F)

Brazed seam

assures crimp

reliability

UL and CSA rated up to 600V.

Maximum insulation

temperature 105°C

(221°F)

Internal wire

stops assure

proper

insertion

length

Expanded

wire entry

accommodates

larger insulation

UL and CSA rated up to 600V.

Flammability – UL94V-0.

Metric versions available.

Brazed seam

assures crimp

reliability

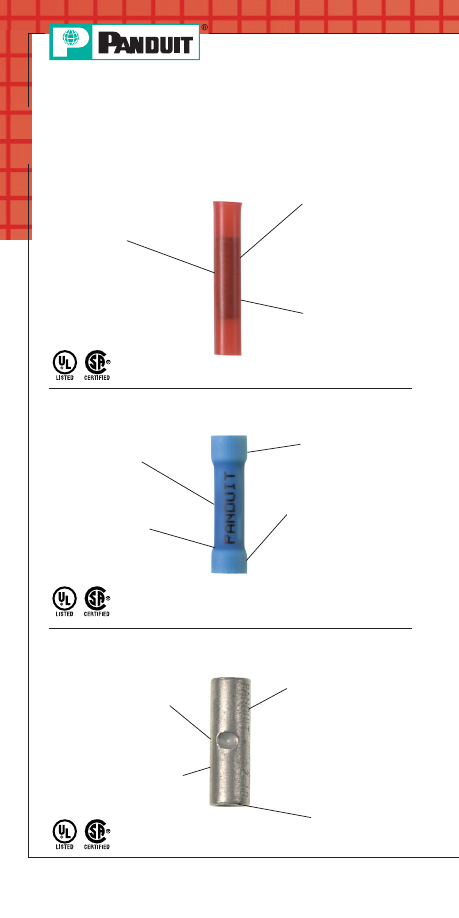

Nylon Butt Splices

Type BSN

Vinyl Butt Splices

Type BSV

Non-Insulated Butt Splices

Type BS

Internally beveled

barrel for quick easy

wire insertion

Internal wire stops

assure proper

insertion length

UL and CSA rated up to 600V.

Metric versions available.

Brazed seam

assures crimp

reliability

Maximum recommended

operating temperature

150°C (302°F)

PANDUIT Termination Solutions-html.html

A41

Prime items appear in BOLD.

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

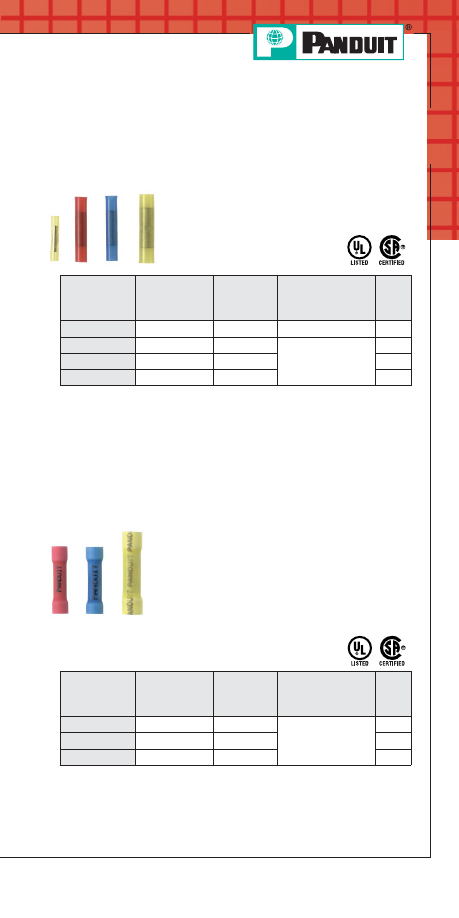

Butt Splice, Nylon Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Internal wire stop assures proper length of

insertion into terminal barrel

*Not UL Listed.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

Part Number

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

BSN22-C

*

26 – 22 AWG

Yellow

CT-100, CT-1525

100

BSN18-C

22 – 18 AWG

Red

CT-100, CT-600,

CT-1550, CT-1551

100

BSN14-C

16 – 14 AWG

Blue

100

BSN10-L

12 – 10 AWG

Yellow

50

P

AN

-T

ERM

®

Splices

Butt Splice, Vinyl Insulated

• Expanded funnel entry designed to

accommodate wire with a larger than

standard outside diameter insulation

• Insulation support helps to prevent wire

damage in bending applications

• Internal wire stop assures proper length of

insertion into terminal barrel

**To order in bulk, replace -C or -CY in the part number with -M or -MY

for a bulk package of 1000 and replace -L with -D for a bulk package

of 500.

Part Number

Wire Range

Color Code

Tool

Std.

Pkg.

Qty.

BSV18X-CY

22 – 18 AWG

Red

CT-100, CT-600,

CT-1550, CT-1551

100

BSV14X-C

16 – 14 AWG

Blue

100

BSV10X-L

12 – 10 AWG

Yellow

50

PANDUIT Termination Solutions-html.html

A42

Prime items appear in BOLD.

Order number of pieces required, in multiples of Standard Package Quantity.

Terminals

Butt Splice, Non-Insulated

• Brazed seam protects terminal barrel from

splitting during the crimp process

• Internal wire stop assures

proper length of insertion into

terminal barrel

*Not UL Listed.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

‡UL and CSA approved tooling/product combinations.

Part Number

Wire

Range

Tool

Std.

Pkg.

Qty.**

BS22-C*

26 – 22 AWG

CT-100

100

BS18-C

22 – 18 AWG

CT-100, CT-200,

CT-600, CT-1570

100

BS14-C

16 – 14 AWG

100

BS10-L

12 – 10 AWG

CT-100, CT-200,

CT-600, CT-1570,

CT-1701‡

50

Parallel Splice, Nylon Insulated

• Parallel design results in only one crimp

required to combine two wires

Parallel Splice, Non-Insulated

• Parallel design results in only one crimp

required to combine two wires

• Non-insulated barrel can be used to provide

an economical termination

when insulation is not required

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000.

**To order in bulk, replace -C in the part number with -M for a bulk

package of 1000 and replace -L with -D for a bulk package of 500.

Part Number

Wire

Range

Tool

Std.

Pkg.

Qty.**

PS16-C

20 – 16 AWG

CT-100, CT-200

100

PS12-L

14 – 12 AWG

50

◆

For a complete line of terminal products, see the

PANDUIT Electrical

Solutions Catalog, SA-ELCB03 at www.panduit.com

Part Number

Wire

Range

Color

Code

Tool

Std.

Pkg.

Qty.**

PSN18-C

22 – 18 AWG

Red

CT-100,

CT-1525

100

PSN16-C

20 – 16 AWG

Blue

100

PANDUIT Termination Solutions-html.html

A43

For service and technical support, call 800-777-3300

or visit www.panduit.com.

Terminals

Features and Benefits –

P

AN

-T

ERM

®

Wire Joints

Non-Insulated Wire Joints

Type J

Nylon Wire Joints

Type JN

Internally

beveled barrel

for quick easy

wire insertion

UL and CSA rated up to 600V.

Maximum

recommended

operating

temperature

150°C (302°F)

Only one crimp

needed to

complete splice

Maximum insulation

temperature 105°C

(221°F)

Deep skirt to

accommodate

multiple variations of

wire combinations

Only one

crimp needed

to complete

splice

UL and CSA rated up to 600V