PTC Thermistors

Temperature Sensors for Motor

Protection and Electronics

(temperature-sensitive resistors)

FEATURES

– rapid response protection for electrical machines

– compact size for easy assembly into windings

– silvered copper leads

PTC-Ther

mistors

02-02-02

1000-Y

-180

Microtherm International Cooperation

YD

1

YG

1

YD

3

YG

3

EF

1

YGM 1

YGM 3

TKA 1

TKA 2

DESCRIPTION

PTC thermistors act as thermal protection for electrical machines, and

are well known particularly as motor-protectors. They are available with

or without insulating sleeve and have flexible connecting leads.

PTC thermistors have a non-linear resistance/temperature response,

and at a specified temperature the resistance changes rapidly to a very

high value.

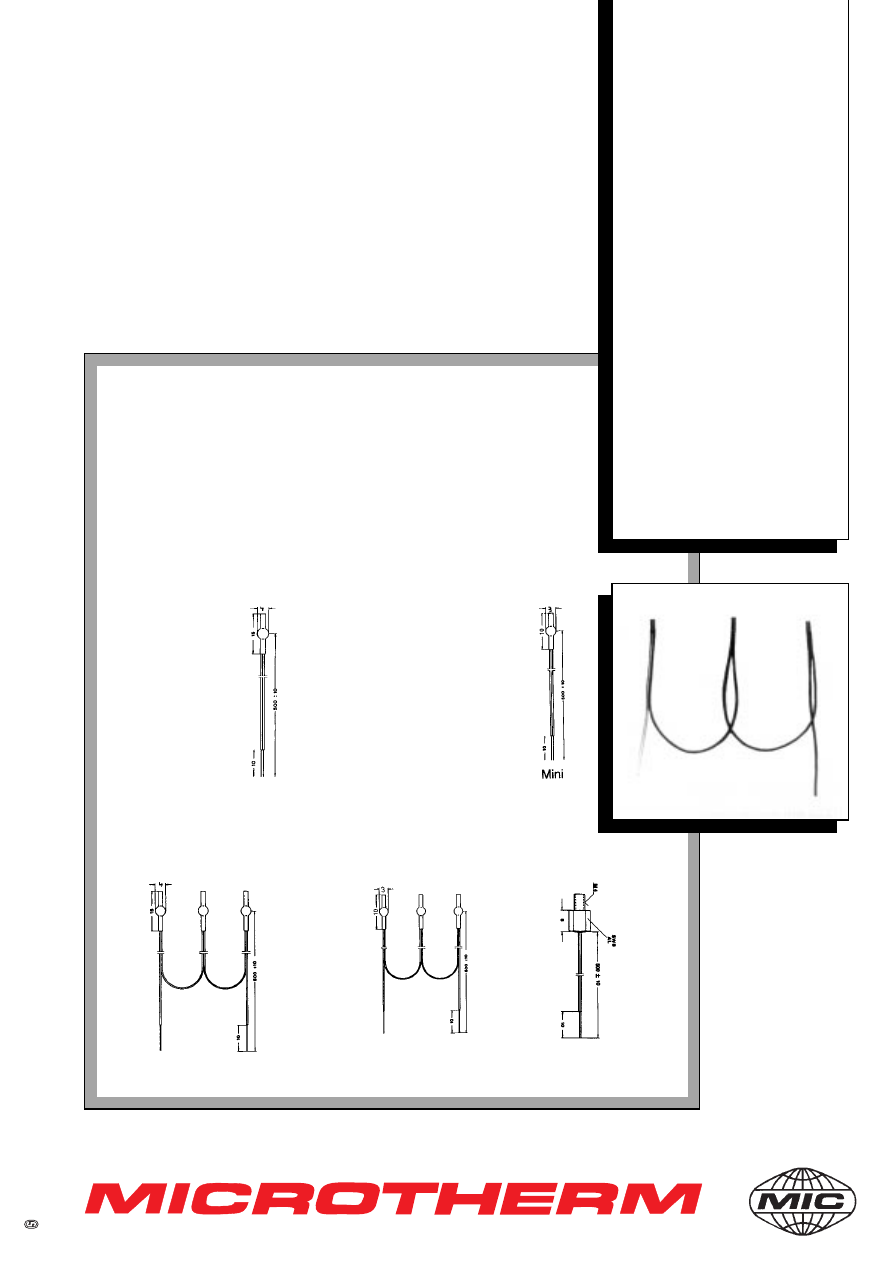

DIMENSIONS

YD 1

Single thermistor

with shrunk-sleeve

YGM 1

Mini-version

with shrunk-sleeve

YD 3

Triplet version (in series)

YGM 3

Mini-version

EF 1

Sensor

Standard

mini

threaded