Pressure Switches:

The SQ range of compact pressure switches are manufactured with quality in mind, unlike many other manufacturers who’s products mechanical life

is 1 million cycles the SQ range has a mechanical lifetime of 1.5 million cycles when operated below a pressure of 50bar. Pressures from 0.2bar to

100bar can be accommodated with either factory fixed or adjustable pressure ranges. With a choice of Diaphragm materials the switches can cope

with a variety of chemicals including compressed air, hydraulic oil, engine oil, heating oil and water.

Features:

- Robust in any severe application

- Customised body housing (Steel, 316SS, Brass)

- Selectable contact (Gold or Silver Contact)

- Screw / push on terminal contact

- Cost effective yet high quality

- Easily adjustable pressure range setting

Pressure Switch Part Numbers

Pressure switch

Hex size

Body material

Contact type

Diaphragm material

Connection fitting

Screw thread

Pressure rating

Example SQ24B-ANC-2A1

Pressure switch

SQ Series

Hex length

24mm

27mm

Body material

B = Brass

S = Stainless Steel grade 316

Z = Zinc plated steel

Contact type

A = Normally open contacts

B = Normally closed contacts

S = Single pole double throw (SQ 27 only)

Diaphragm material

N = Nitrile (standard)

V = VITON

E = EPDM (ethylene propylene diene Monomer)

Connection fitting

S = Screw terminals

T = Tag (spade terminal)

C = DIN Cap

Screw thread

1 = M10X1 (tap 1°)

2 = M10X1

3 = M12X1.5

4 =

⅛

" PT

5 = ¼" PT

6 =

⅛

" G

7 = ¼" G

8 =

⅛

" NPT

9 = ¼" NPT

Pressure rating fixed

F1 = 0.2 Bar

F2 = 1.1 Bar

F3 = 5 Bar

F4 = 50 Bar

Adjustable

A1 = 0.2-1 Bar

A2 = 1-19 Bar

A3 = 20-50 Bar

A4 = 51-100 Bar

Optional Socket Type

D = DT04-2P

A = 250 Type

Socket wiring

1 = 3mm PVC (2P)

Add (XX) to end

2 = 3mm PVC (2P) with wrap up sheath

3 = 6.4mm PE Cable

4 = 3mm PVC (2P) with heat shrink sheath

Cap only part numbers

SQA-1130

The Comus International group of companies consists of:

Comus International

454 Allwood Road

Clifton

New Jersey 07012

U.S.A

Tel: (1)973 - 777 - 6900

Fax:(1)973 - 777 - 8405

email: info@comus-intl.com

internet: http://www.comus-intl.com

Assemtech Europe Limited

Unit 7, Rice Bridge Industrial Estate

Thorpe - Le - Soken

Essex

England

CO16 0HL

Tel: +44 (0)1255 862236

Fax: +44 (0)1255 862014

email: sales@assemtech.co.uk

internet: http://www.assemtech.co.uk

Comus Belgium BVBA

Overhaamlaan 40

B-3700 Tongeren

Belgium

Tel: +32 (0)12 390400

Fax: +32 (0)12 235754

email: info@comus.be

internet: http://www.comus.be

Switching Technologies Gunther

B-9, B-10, & C-1 Special Economic Zone (MEPZ)

Kadapperi

Tambaram

Chennai 600 045

India

Comus Electronics and Technologies

India Private Limited

No 3. Kamaraj Nagar 2nd Street

Tambaram Sanatorium

Chennai 600045

India

Tel: +91 44 43219090

Fax: +91 44 22628198

email: P.Ramesh@stg-india.com

chudan@comus-intl.com

Website:http://www.comusindia.com

We also have a large network of worldwide agents. These can be found on any of our websites, or on our company profile brochure.

Com/19/jan11/Iss.1

Our Switch Ranges:

We now have a comprehensive range of switches including: Reed Switches, Tilt Switches, Proximity Switches and Magnets,

Electronic Proximity Switches, Non Mercury Tilt, Tip Over and Acceleration Switches, Float Switches, Glass Mercury and Mercury

Switches.

How a Pressure switch works:

A pressure switch works by a rubber disc (the diaphragm) changing it’s shape when subjected to

pressure from either a fluid or a gas. This deflection of the diaphragm in turn pushes a small rod

or piston which connects to a set of contacts via a spring. When the pressure is enough to over-

come the tension of the spring the contacts will either open or close depending on the set up thus

making or breaking the connection. This action can be utilised in many applications such as alerting

when pressure drops in medical equipment, cutting of power to machines in the event of a fault,

warning and controlling of air or oil pressure and detection of leaks in pressurised systems.

$IAPHRAGM

#ONTACTS

0ISTON

!DJUSTING3CREW

3PRING

ISO 9001:2008

CERTIFICATE NO: FM 21080

ISO 9001:2008

CERTIFICATE NO: 03-12314

Comus Technologies BV

Jan Campertstraat 11

6416 SG Heerlen,

The Netherlands

Tel: +31 (0) 45 5439345

Fax: +31 (0) 45 5427216

email: jperez@comus-intl.com (USA, Canada)

G.Kemper@comus.be (Europe, Asia)

Please scan this quick response code

with your QR enabled smartphone

PRESSURE

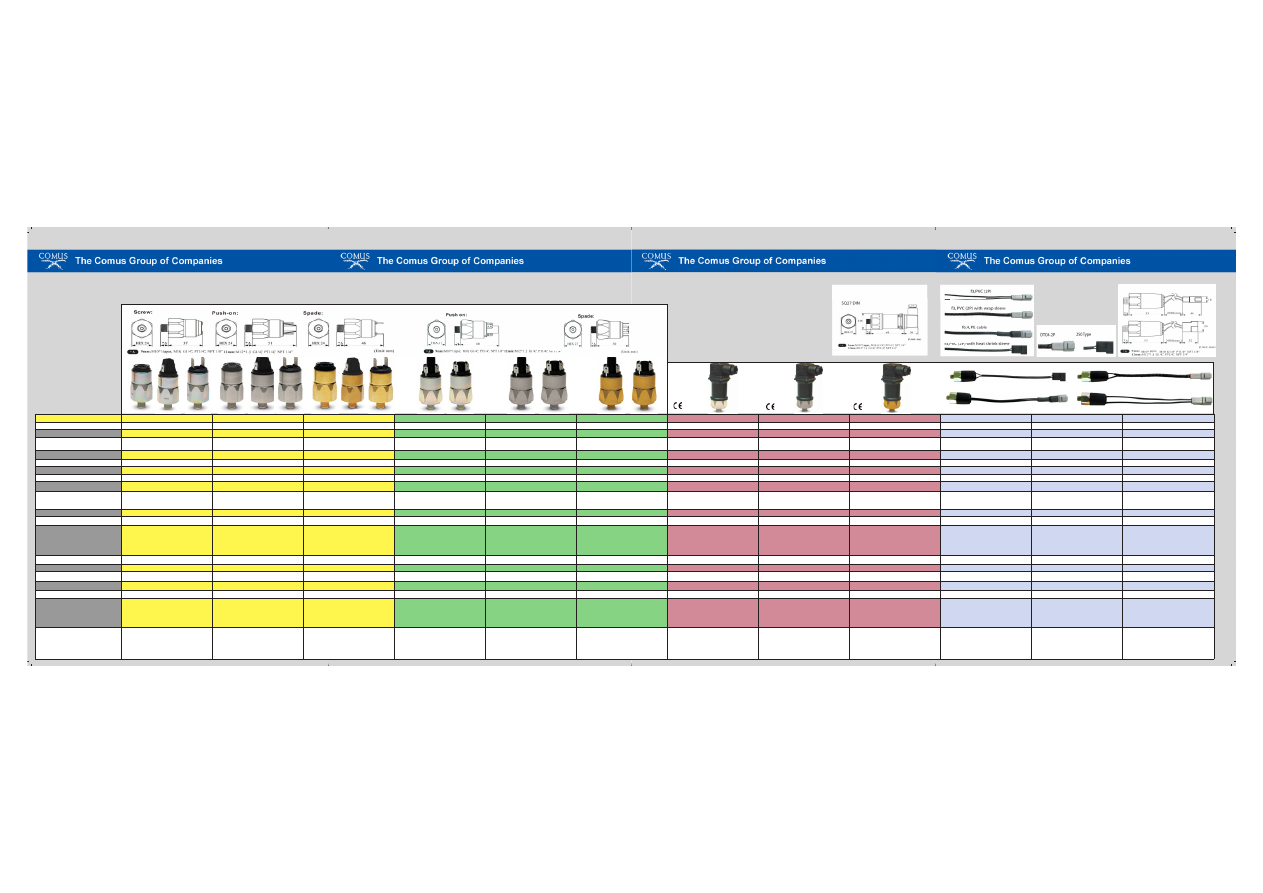

SWITCHES

TYPE

SQ24Z

SQ24S

SQ24B

SQ27Z

SQ27S

SQ27B

SQ27Z

SQ27S

SQ27B

SQ24Z

SQ24S

SQ24B

Hex Length

24mm

24mm

24mm

27mm

27mm

27mm

27mm

27mm

27mm

24mm

24mm

24mm

Body Material

Zinc Plated Steel

316 Grade Stainless Steel

Brass

Zinc Plated Steel

316 Grade Stainless Steel

Brass

Zinc Plated Steel

316 Grade Stainless Steel

Brass

Zinc Plated Steel

316 Grade Stainless Steel

Brass

Wiring

Screw / Push on

Spade Terminal

Screw / Push on

Spade Terminal

Screw / Push on

Spade Terminal

Screw /

Spade Terminal

Screw /

Spade Terminal

Screw /

Spade Terminal

Push on

Spade Terminal

Push on

Spade Terminal

Push on

Spade Terminal

DT04-2P

250 Type

DT04-2P

250 Type

DT04-2P

250 Type

Contact rating (Max)

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

4A/42Vdc,4A 240Vac

Response Frequency

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

2Hz

Max Voltage Peak

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

1.5KV (IEC60947-2)

Electric Insulation

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

100MΩ (IEC60092-54)

Operation Temperature

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

-10°C~100°C

Membrane Materials

NBR(Stnd)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

NBR(Standard)-30°C~100°C

VITON-15°C~120°C

EPDM-30°C~120°C

Pressure Range

0.2~100bar

0.2~100bar

0.2~100bar

0.3~100bar

0.3~100bar

0.3~100bar

0.3~100bar

0.3~100bar

0.3~100bar

0.2~100bar

0.2~100bar

0.2~100bar

Pressure Acting Variation

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

±5% of set point@20°C

Piping Selection

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

M10*1(TAP1°)

M10*1, M12*1.5

PT1/8”,PT1/4”

NPT1/8”, NPT1/4”

Contact Model

NO,NC

NO,NC

NO,NC

SPDT

SPDT

SPDT

SPDT

SPDT

SPDT

NO,NC

NO,NC

NO,NC

Body Protection

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

IP00 (EIC60529)

Protection

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

IP67 (EIC60529)

Mechanical Life

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

1.5Million cycles<50bar

Screw Torque

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

<0.35Nm

Shock Resistance

ISO / IEC 17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

ISO / IEC17025, Half sine wave,

Acceleration:30G@14ms ±X ±Y ±Z axis

Vibration Resistance

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

ISO / IEC 17025, Sine wave 5-200Hz, Acceleration 10G,

Displacement :16mm, sweeping rate :1 Oct/min, test direc-

tion X,Y,Z axis, Test time: 1hr for each

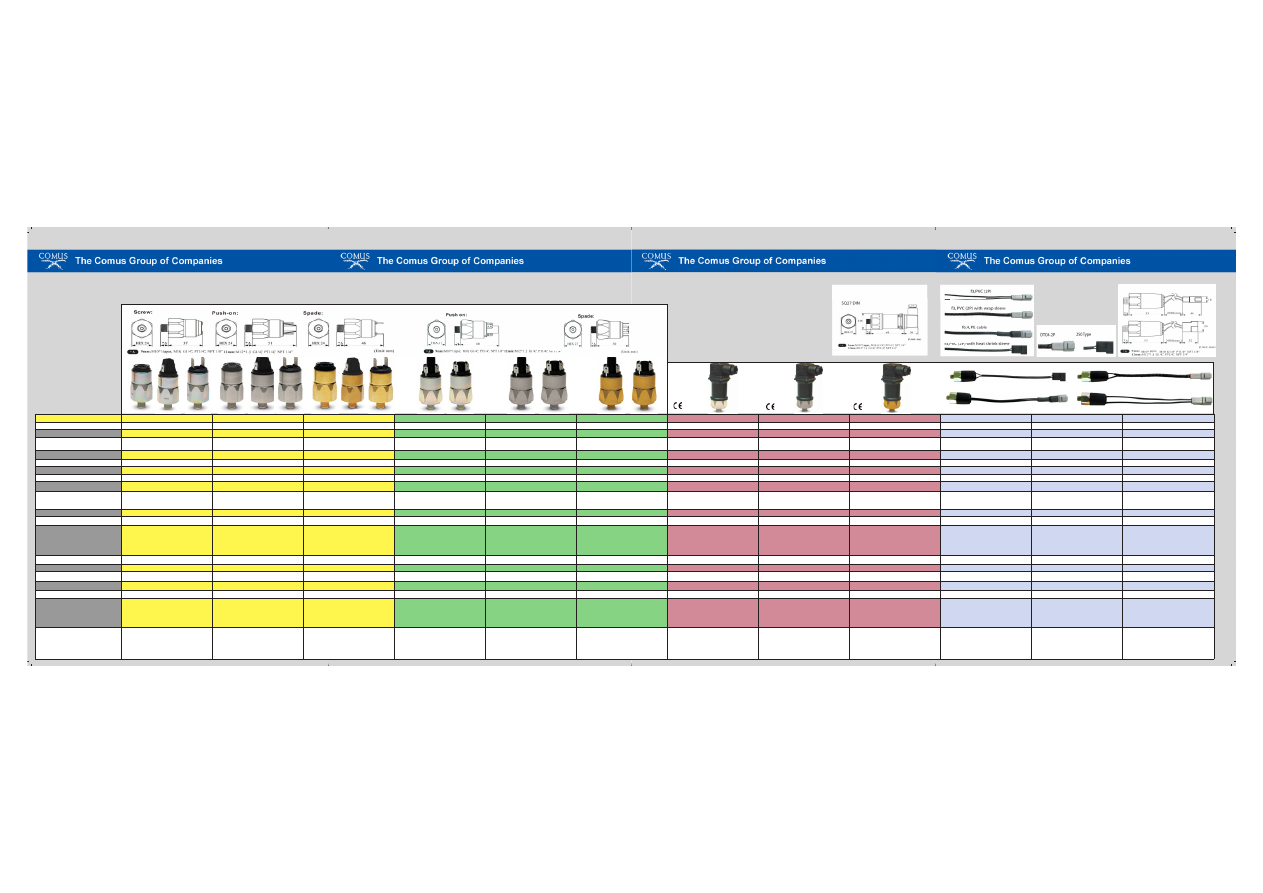

The line of mPm DIN connectors is designed to

reduce the number of components making them

easier to assemble and with fewer parts to stock.

They provide repeatable, unsurpassed IP67 sealing

performance using an external nut over the cable.

The external nut accepts a wider range of cables

from 4mm to 9mm, reducing the number of parts

from 3 to 1.

Custom made to your Requirements.

Deutsch type connectors available as

standard. Please enquire if you have any

special requirements

SQ24 Dimensions

SQ27 Dimensions

Dimensions

Dimensions