135

S

ur

fa

ce

M

ou

nt

R

es

is

to

rs

S

ur

fa

ce

M

ou

nt

Surface Mount

R

es

is

to

rs

Resistors

Part Number

E-24 Series

E-96 Series

Thick Film Chip Resistors

Type MCR Series

∆

How to Order

∆

Resistance Marking

473

1542

0C2

ex. 473: 47x10^3 = 47K

Ω

105: 10x10^5 = 1M

Ω

1R5: 15x10^-1 = 1.5

Ω

0: 0

Ω

3 digit marking for E24

1R00

ex. 1R00: 1

Ω

R470 470m

Ω

R010 10m

Ω

4 digit marking for E241:

Ω

~10m

Ω

ex. 1542: 154x10^2 = 15K4

Ω

4 digit marking for E96

ex.

0C2 (see table)

102x10^2 = 10K2

Ω

3 digit marking for E96 - 0603

• Small size and lightweight with size range per int’l standard.

• Highly stable in auto-placement surface mounting application.

• Compatible with flow and reflow soldering.

∆

Features

• Suitable for lead free soldering.

∆

Applications

• Consumer electronics

• Automotive, industry

• Computer

∆

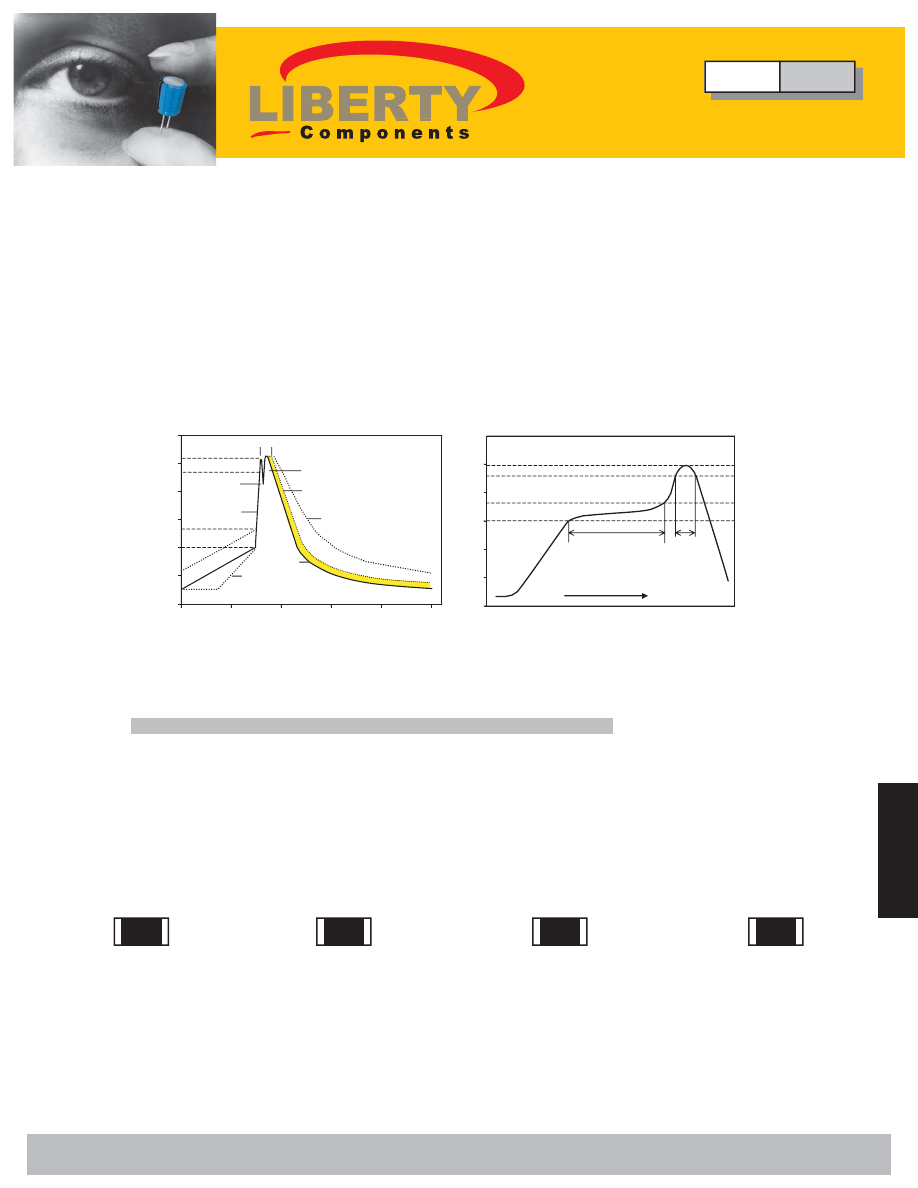

Soldering Temperature Curve

Typical values (solid line).

Process limits (dotted line).

WAVE soldering.

IR Reflow Soldering

Peak : Less than 245

˚

C

230

˚

C

180

˚

C Pre Heating Zone

150

˚

C

Soldering Zone

0

t (s)

T

(

˚

C

)

90±30s

10 ~ 15s

Heating time

50

250

200

150

100

second wave

0

0

t (s)

200 K/s

2 K/s

200

250

150

100

50

50

100

150

200

2 K/s

5 K/s

250

T

(

˚

C

)

first wave

forced

cooling

10s

235

˚

C to 260

˚

C

100

˚

C to 130

˚

C

Example

MCR

0603

Type

Size

MCR

0201

T: Tape

B: ±0.1%

123 = 12x10^3 LF = Lead Free

0402

C: ±0.25%

= 12k

Ω

0603

D: ±0.5%

0805

F: ±1%

1206

G: ±2%

1210

J: ±5%

2010

2512

LF

123

Resistance Value

Packing

Tolerance

T

J

• Medical equipment

• Telecom equipment

Type

MCR

Thick Film Chip Resistors

Liberty Bell Components, Inc. 11631 Seaboard Circle, Stanton, CA 90680 (888)820-8885

Fax: (888)820-8884 email: sales@libertycomponents.com website: www.libertycomponents.com