SafeSite

®

LED Area Light - UL844

for Indoor and Outdoor Industrial Applications

SafeSite

®

LED Area Light - UL844

for Indoor and Outdoor Industrial Applications

2

www.dialight.com

| MDTFHZHAZX001_S

On when it

counts.

Products and solutions that

protect your business

www.dialight.com

| MDTFHZHAZX001_S

3

Application

The SafeSite

®

LED area light represents

the future of energy efficient facility

illumination for hazardous locations

worldwide. The LED Area Light fixture

consumes at least 50% less energy

compared to traditional HID light

sources, while reducing maintenance

and carbon emissions. This light

incorporates both cutting edge LED

technology along with proprietary optics

to achieve area lighting comparable

with other traditional light sources.

Features & Benefits

•

L70 rated for >100,000 hours @ 25°C

•

5 year full performance warranty

•

Instant on/off operation

•

Superior color rendition index

compared to HPS, LPS, MV

•

Mercury free

•

Resistant to shock and vibration

•

Temperature compensation technology

for longer life

•

Factory sealed

•

Low T-rating compared to traditional

fixtures

4

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

Division

Presence of Hazardous Material

Division 1

The substance referred to by class is present during normal conditions.

Division 2

The substance referred to by class is present only in abnormal conditions, such as a container failure or system breakdown.

Groups

The group defines the hazardous material in the surrounding atmosphere.

Group

Hazardous Material in Surrounding Atmosphere

Group A

Acetylene

Group B

Hydrogen, fuel and combustible process gases containing more than 30% hydrogen by volume or gases of equivalent hazard such as

butadiene, ethylene, oxide, propylene oxide and acrolein.

Group C

Carbon monoxide, ether, hydrogen sulfide, morphline, cyclopropane, ethyl and ethylene or gases of equivalent hazard.

Group D

Gasoline, acetone, ammonia, benzene, butane, cyclopropane, ethanol, hexane, methanol, methane, vinyl chloride, natural gas, naphtha,

propane or gases of equivalent hazard.

Group E

Combustible metal dusts, including aluminum, magnesium and their commercial alloys or other combustible dusts whose particle size,

abrasiveness and conductivity present similar hazards in connection with electrical equipment.

Group F

Carbonaceous dusts, carbon black, coal black, charcoal, coal or coke dusts that have more than 8% total entrapped volatiles or dusts

that have been sesitized by other material so they present an explosion hazard.

Group G

Flour dust, grain dust, flour, starch, sugar, wood, plastic and chemicals.

Reference:

http://www.engineeringtoolbox.com/hazardous-areas-classification-d_347.html

Hazardous Locations Ratings

Classes

The classes define the general nature of hazardous material in the surrounding atmosphere.

Class

Hazardous Material in Surrounding Atmosphere

Class I

Hazardous because flammable gases or vapors are present in the air in quantities sufficient to produce explosive or ignitable mixtures.

Class II

Hazardous because combustible or conductive dusts are present.

Class III

Hazardous because ignitable fibers or flying’s are present, but not likely to be in suspension in sufficient quantities to produce ignitable

mixtures. Typical wood chips, cotton, flax and nylon. Group classifications are not applied to this class.

Divisions

The division defines the probability of hazardous material being present in an ignitable concentration in the surrounding

atmosphere.

Fixed and portable fixtures for installation and use in hazardous (classified) locations Class I, Divisions 1 and 2,

Groups A, B, C, and D; Class II, Division 1, Groups E, F, and G; Class II, Division 2, Groups F and G; and Class III,

Divisions 1 and 2, in accordance with the National Electrical Code, NFPA 70

www.dialight.com

| MDTFHZHAZX001_S

5

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL844

Innovative Mounting Options

Unique hinge-style design

Featuring a unique hinge-style design, the Area Light brackets simplify the

installation of fixtures in wall and stanchion mounting applications.

Ease of Installation

The hinge-style brackets come pre-installed on each fixture to eliminate time

consuming bracket assembly in the field. Installers simply mount the bracket

to the wall or stanchion, and the fixture portion hangs in place on the bracket,

leaving the installer’s hands free to make electrical connections.

Specifications

Dialight’s wall mounted Area Light brackets feature a die-cast copper free

aluminum housing with 3/4’’ NPT threaded entries. The 45° stanchion bracket

fits 2” NPT and comes with a reducer to accumulated 1 1/2” NPT as well.

The unique design also encloses all wiring connections inside the mounting

bracket for maximum protection from the environment. With the easy access

to the wiring compartment, installing your fixture becomes incredibly quick

and efficient.

Retrofit to Existing HID Fixtures (not for CID1 applications)

GE Lighting Solutions – Filtr-Gard™

HZXTHGE

Holophane

®

Petrolux II, III

HZXTHP3

Thomas & Betts Hazlux

®

HZXTHTB

Appleton

®

Mercmaster III

HZXTHAP

Appleton

®

Mercmaster II

HZXTHM2

Killark

®

Certilite

®

& Certilite

®

V

HZXTHKL

Eaton’s Crouse-Hinds – Champ

®

HZXTHCH

6

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

SafeSite

®

LED Area Light - UL 844

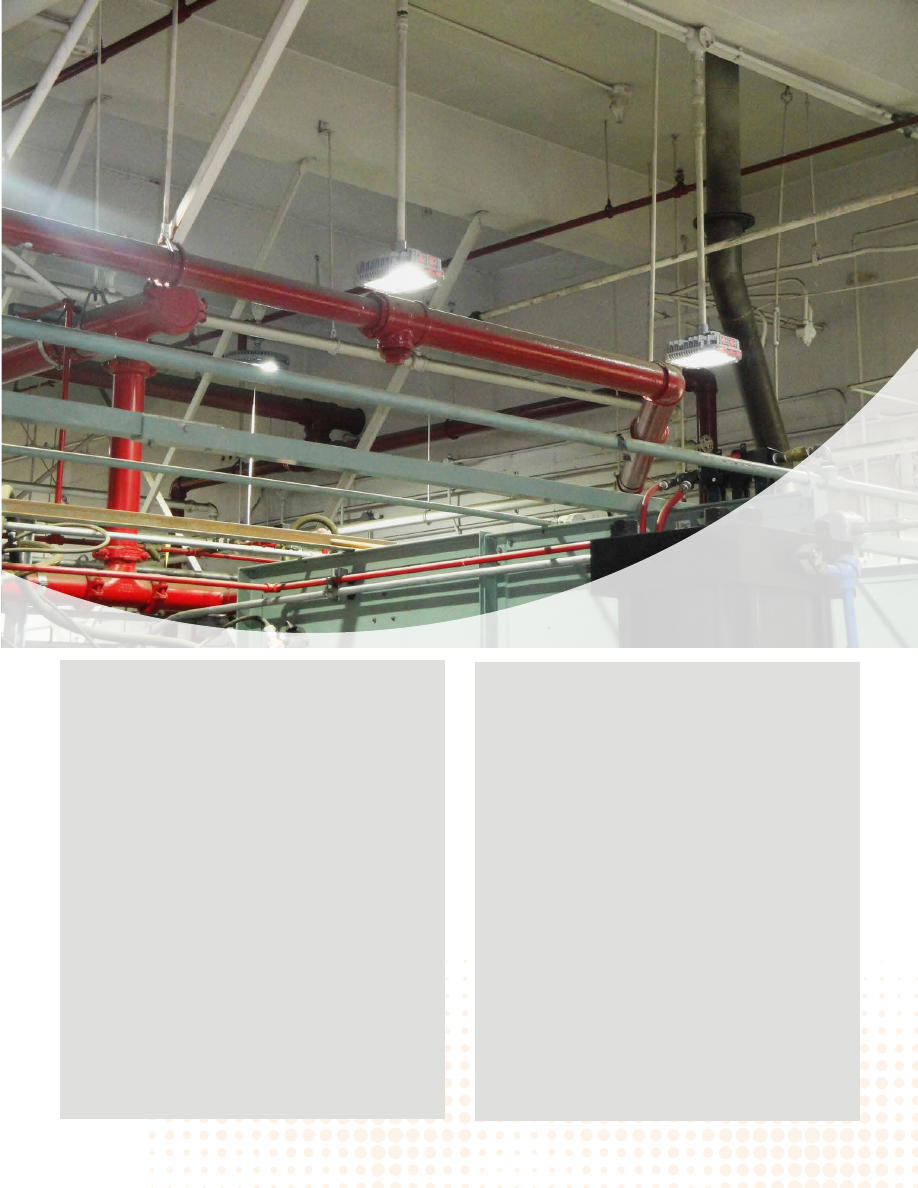

Standard Models- Class I, Div 2 / Class II, Div 1 / Class II, Div 2 / Class III

Mechanical Information:

Fixture weight:

10 lbs (4.5 kg) - Polycarbonate lens

12 lbs (5.5 kg) - Glass lens

Shipping weight:

12 lbs (6.5 kg) - Polycarbonate lens

13 lbs (7.5 kg) - Glass lens

Mounting:

1 Threaded 3/4” NPT rear

(Units with retrofit adapters available)

Cabling:

10’ (3.5m) SOOW Power Cord

(Except when ordered with mounting

brackets)

Electrical Specifications:

Operating voltage:

100 - 277V AC, 50/60 Hz

347 - 480V AC, 50/60 Hz

24 - 48V DC

Total system power

consumption:

See table

Operating temperature:

-40°F to +149°F (-40°C to +65°C)

Harmonics:

IEC 61000-3-2

Noise requirement /EMC:

FCC Title 47, Subpart B, Section 15,

class A device. RF Immunity;

10V/m, 80MHz-1GHz

Transient protection:

100 - 277V AC 50/60Hz:

1 kV line to line, 2 kV line to ground

347 - 480V AC 50/60Hz:

6 kV line to line, 6 kV line to ground

THD:

<20%

Power factor:

> 0.9

Construction:

Housing:

Copper free aluminum

Finish:

Superior dual coat finish

- Sealed polyester topcoat

- Chemical-resistant epoxy primer

Lens

1

:

HZD - polycarbonate (or glass)

HZF - anti-static coated polycarbonate

(or glass)

Photometric Information:

CRI:

75

CCT:

5000K (cool white)

4000K (neutral white)

Optics:

180° forward throw

360° circular pattern

Wide pattern

All values typical unless otherwise stated (tolerance +/- 10%)

1

For information on chemical compatibility, please follow this link to

reference Dialight’s Chemical Compatibility Guide:

www.dialight.com/pubs/MDTFCHEMRFLX001.PDF

Certifications & Ratings

• Class I, Div 2, Groups A, B, C, D

• Class II, Div 1, Groups E, F, G

• Class II, Div 2, Groups F and G

• Class III

• UL 844*

• UL 1598/A*

• CSA 22.2 No. 137-M1981*

• ABS Design Assessed: #

12-HS942957-PDA

• IP66 / 67

• NEMA 4X

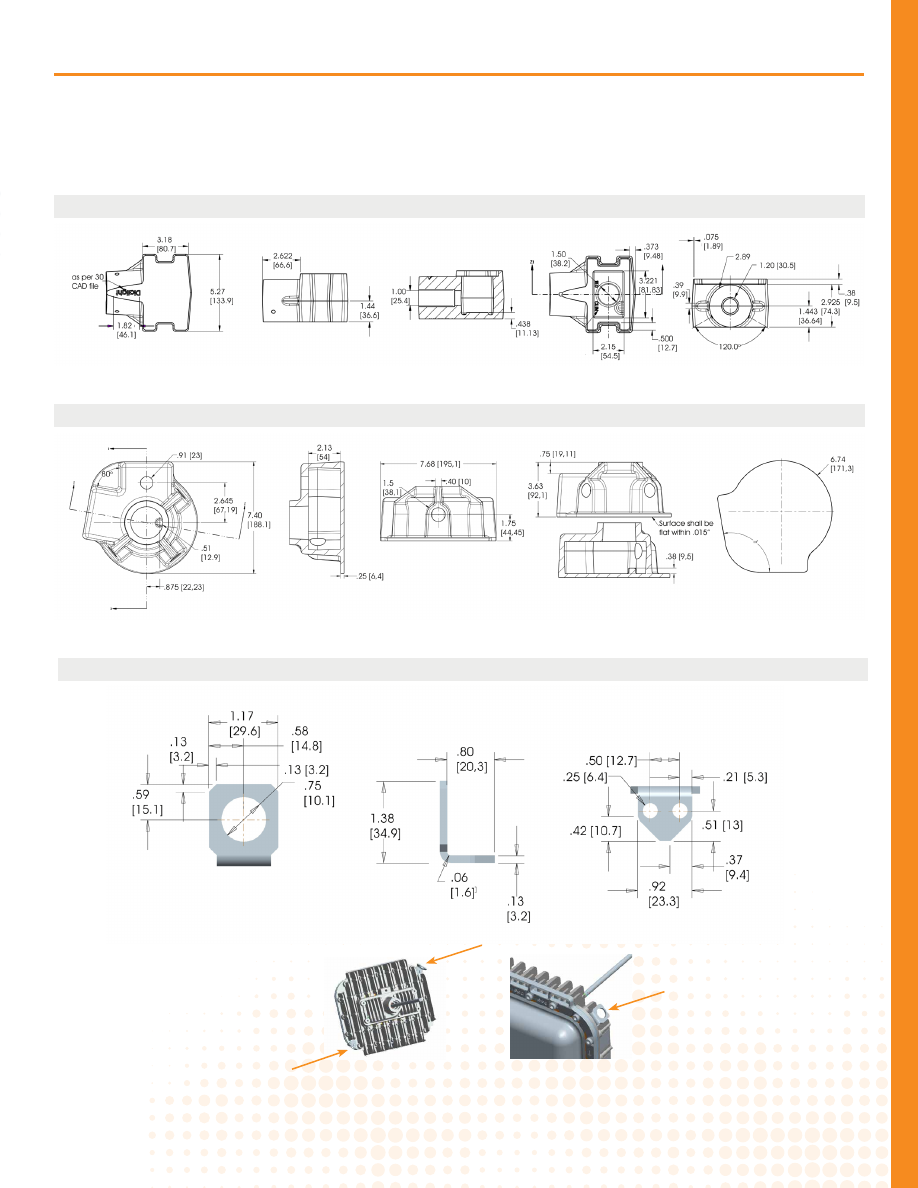

Dimensions in inches [mm]

Temperature Ratings

Ambient Temperature Range T4A

Ambient Temperature Range T5

-40°F to +149°F (-40°C to +65°C)

-40°F to +113°F (-40°C to +45°C)

*ETL listed

www.dialight.com

| MDTFHZHAZX001_S

7

SafeSite

Hazardous Applications | Area Light

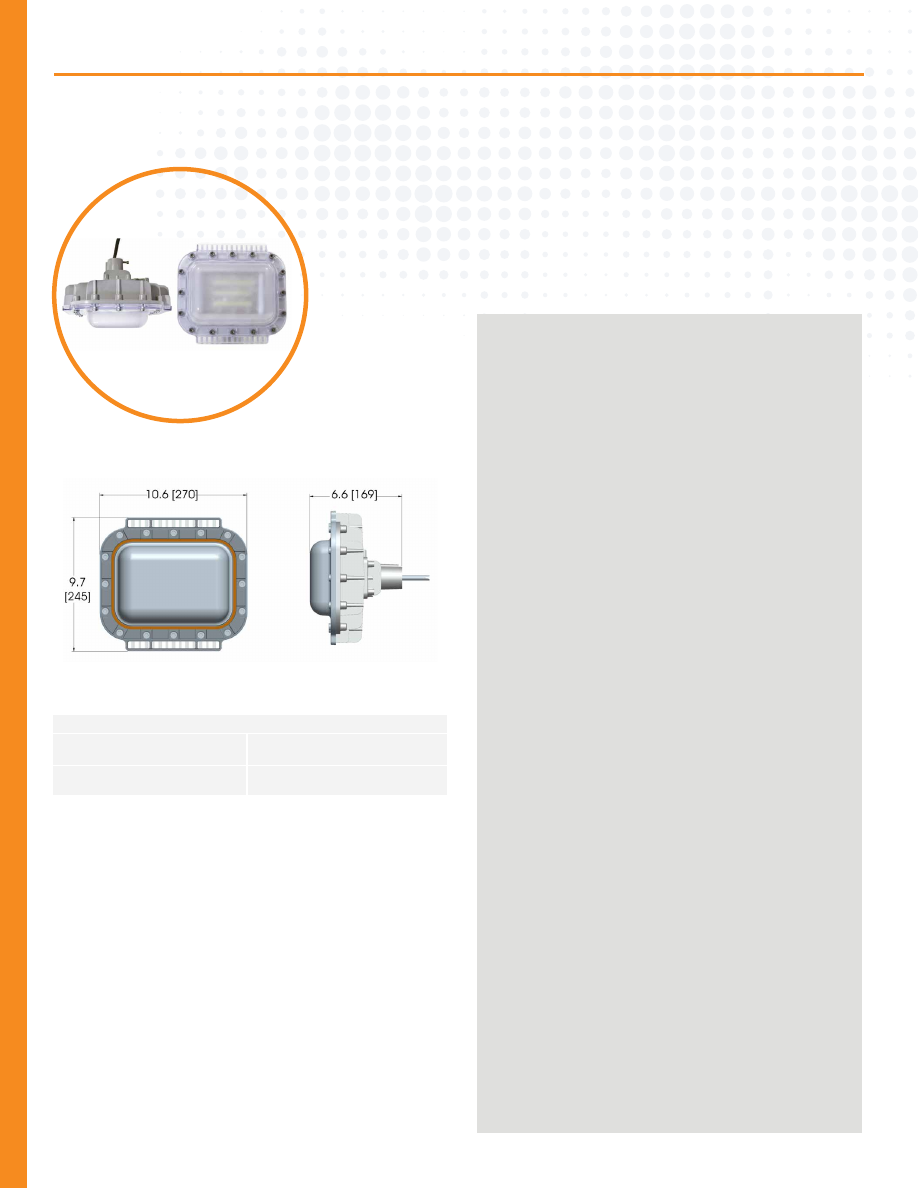

45

o

Stanchion Mount Models

45

o

Wall Mount Models

Wall Mount Models

SafeSite

®

LED Area Light - UL 844

Mounting Models - Class I, Div 2 / Class II, Div 1 / Class II, Div 2 / Class III

Mechanical Information:

Fixture weight:

Wall mount models:

15 lbs (6.8 kg) - Polycarbonate lens

18 lbs (8.2 kg) - Glass lens

45

o

Wall mount models:

14 lbs (6.4 kg) - Polycarbonate lens

17 lbs (7.8 kg) - Glass lens

45

o

Stanchion mount models: 15 lbs (6.7 kg) - Polycarbonate lens

18 lbs (8.1 kg) - Glass lens

Shipping weight:

Wall mount models:

17 lbs (8.8 kg) - Polycarbonate lens

20 lbs (10.2 kg) - Glass lens

45

o

Wall mount models:

16 lbs (8.4 kg) - Polycarbonate lens

19 lbs (9.8 kg) - Glass lens

45

o

Stanchion mount models: 17 lbs (8.7 kg) - Polycarbonate lens

20 lbs (10.1 kg) - Glass lens

Mounting:

(1) Threaded 3/4” NPT rear

Electrical Specifications:

Operating voltage:

100 - 277V AC, 50/60 Hz

347 - 480V AC, 50/60 Hz

24 - 48V DC

Total system power

consumption:

See table

Operating temperature:

-40°F to +149°F (-40°C to +65°C)

Harmonics:

IEC 61000-3-2

Noise requirement /EMC:

FCC Title 47, Subpart B, Section 15,

class A device. RF Immunity;

10V/m, 80MHz-1GHz

Transient protection:

100 - 277V AC 50/60Hz:

1 kV line to line, 2 kV line to ground

347 - 480V AC 50/60Hz:

6 kV line to line, 6 kV line to ground

THD:

<20%

Power factor:

> 0.9

Construction:

Housing:

Copper free aluminum

Finish:

Superior dual coat finish

- Sealed polyester topcoat

- Chemical-resistant epoxy primer

Lens

1

:

HZD - polycarbonate (or glass)

HZF - anti-static coated polycarbonate

(or glass)

Photometric Information:

CRI:

75

CCT:

5000K (cool white)

4000K (neutral white)

Optics:

180° forward throw

360° circular pattern

Wide pattern

All values typical unless otherwise stated (tolerance +/- 10%)

1

For information on chemical compatibility, please follow this link to

reference Dialight’s Chemical Compatibility Guide:

www.dialight.com/pubs/MDTFCHEMRFLX001.PDF

Certifications & Ratings

• Class I, Div 2, Groups A, B, C, D

• Class II, Div 1, Groups E, F, G

• Class II, Div 2, Groups F and G

• Class III

• UL 844*

• UL 1598/A*

• CSA 22.2 No. 137-M1981*

• ABS Design Assessed: #

12-HS942957-PDA

• IP66 / 67

• NEMA 4X

Temperature Ratings

Ambient Temperature Range T4A

Ambient Temperature Range T5

-40°F to +149°F (-40°C to +65°C)

-40°F to +113°F (-40°C to +45°C)

All dimensions in inches [mm]

*ETL listed

8

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

SafeSite

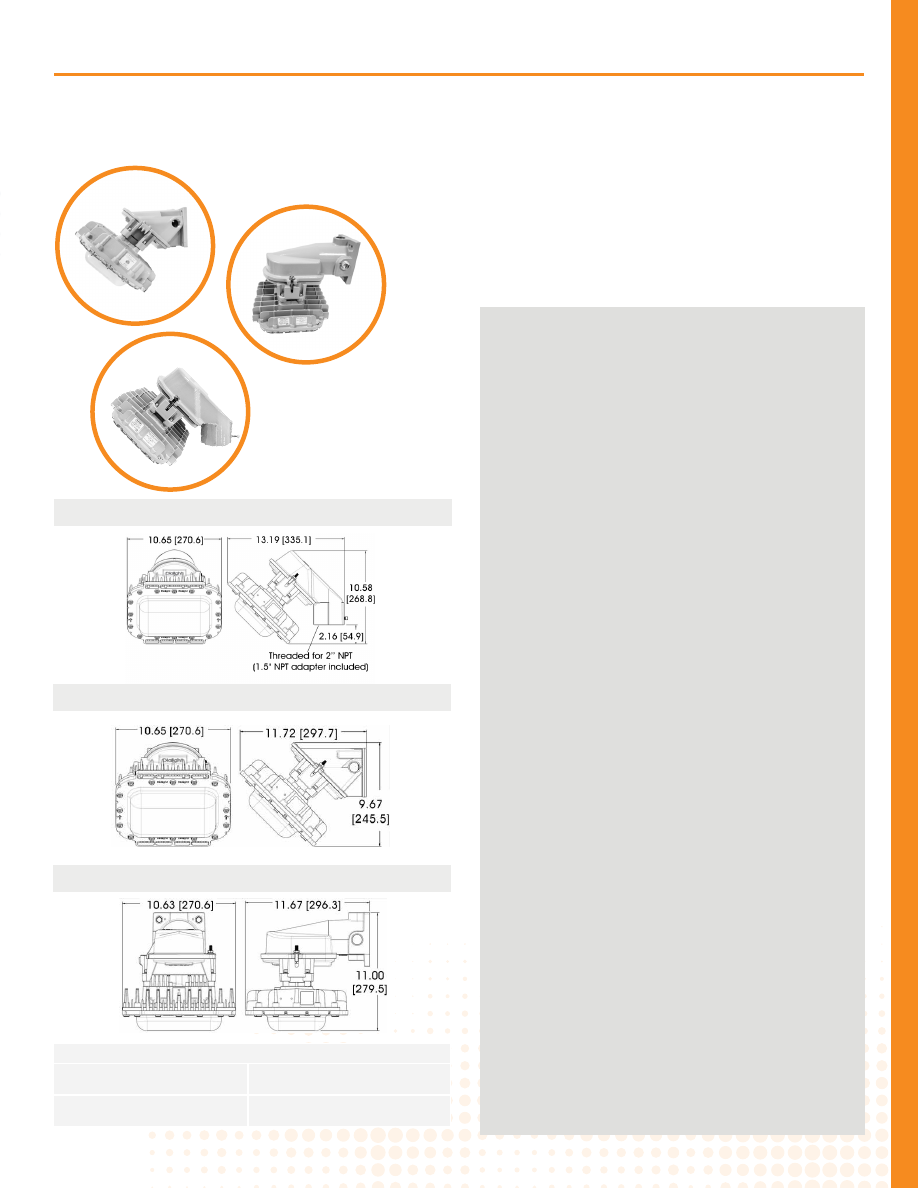

®

LED Area Light - UL 844

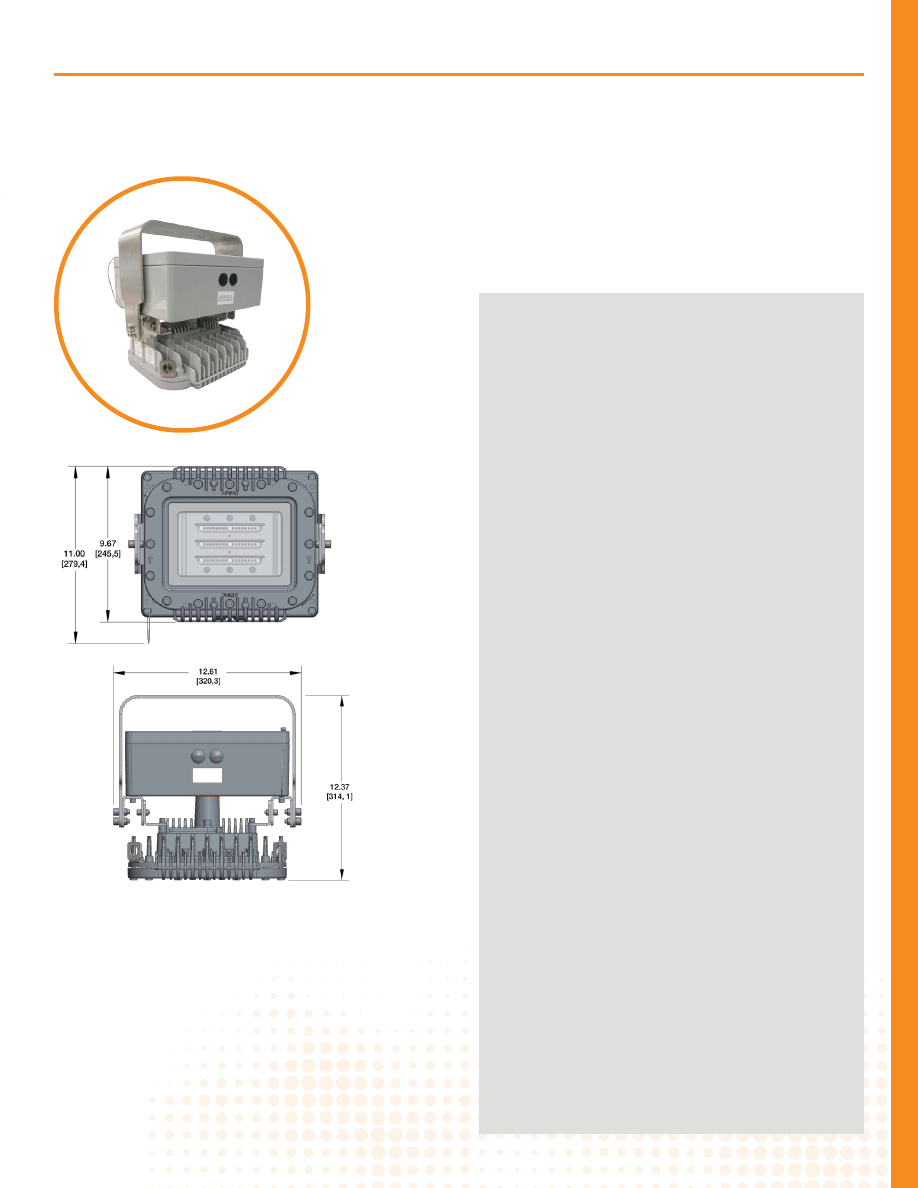

Standard Models - Class I Div. 1 / Class II Div. 1

Mechanical Information:

Fixture weight:

14.5 lbs (5.5 kg)

Shipping weight:

16.5 lbs (7.5 kg)

Mounting:

1) Threaded 3/4” NPT rear

Cabling:

10’ (3.5m) SOOW Power Cord

Electrical Specifications:

Operating voltage:

100 - 277V AC, 50/60 Hz

347 - 480V AC, 50/60 Hz

24 - 48V DC

Total system power

consumption:

See table

Operating temperature:

-40°F to +149°F (-40°C to +65°C)

Harmonics:

IEC 61000-3-2

Noise requirement /EMC:

FCC Title 47, Subpart B, Section 15,

class A device. RF Immunity;

10V/m, 80MHz-1GHz

Transient protection:

100 - 277V AC 50/60Hz:

1 kV line to line, 2 kV line to ground

347 - 480V AC 50/60Hz:

6 kV line to line, 6 kV line to ground

THD:

< 20%

Power factor:

> 0.9

Construction:

Housing:

Copper free aluminum

Finish:

Superior dual coat finish

- Sealed polyester topcoat

- Chemical-resistant epoxy primer

Lens

1

:

Glass

Photometric Information:

CRI:

75

CCT:

5000K (cool white)

4000K (neutral white)

Optics:

180° forward throw

360° circular pattern

All values typical unless otherwise stated (tolerance +/- 10%)

1

For information on chemical compatibility, please follow this link to

reference Dialight’s Chemical Compatibility Guide:

www.dialight.com/pubs/MDTFCHEMRFLX001.PDF

Certifications & Ratings

• Class I, Div 1, Groups B, C, D

• Class II, Div 1, Groups E, F, G

• UL 844*

• UL 1598/A*

• CSA 22.2 No. 137-M1981*

• CSA 22.2 No. 25-1966*

• ABS Design Assessed: #

12-HS942957-PDA

• IP66

• NEMA 4X

Temperature Ratings

Ambient Temperature Range T4A

Ambient Temperature Range T5

-40°F to +149°F (-40°C to +65°C)

-40°F to +113°F (-40°C to +45°C)

Dimensions in inches [mm]

*ETL listed

www.dialight.com

| MDTFHZHAZX001_S

9

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

Battery Backup Model

Mechanical Information:

Fixture weight:

37 lbs (16.78 kg) - Glass lens

35 lbs (15.88 kg) - Polycarbonate lens

Shipping weight:

39 lbs (17.7 kg) - Glass lens

37 lbs (16.8 kg) - Polycarbonate lens

Mounting:

Adjustable bracket

Electrical Specifications:

Operating voltage:

100 - 277V AC, 50/60 Hz

Total system power

consumption:

86W

Operating temperature:

-4°F to +149°F (-20°C to +65°C)

Battery:

10Ah NiMH

Expected battery life:

4 years

Battery duration:

> 3 hours

Battery mode output:

2,000lm

Noise requirement/EMC:

FCC Titel 47, Subpart B, Section 15,

class A device. RF Immunity; 10V/m,

80MHz-1GHz

Surge protection:

1 kV line to line

2 kV line to ground

THD:

< 20%

Power factor:

> 0.9

Construction:

Housing:

Copper free aluminum

Finish:

Superior dual coat finish

- Sealed polyester topcoat

- Chemical-resistant epoxy primer

Body:

Powder coated aluminum

Lens

1

:

HZD - Polycarbonate (or glass)

Photometric Information:

CRI:

75

CCT:

5000K (cool white)

4000K (neutral white)

Optics:

180° forward throw

360° circular pattern

All values typical unless otherwise stated (tolerance +/- 10%)

1

For information on chemical compatibility, please follow this link to

reference Dialight’s Chemical Compatibility Guide:

www.dialight.com/pubs/MDTFCHEMRFLX001.PDF

Dimensions in inches [mm]

Certifications & Ratings

• Class I, Div. 2 Groups A, B, C, D

• Class III

• UL 844*

• UL 1598/A*

• CSA 22.2 No. 137*

• IP66

*ETL listed

10

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

SafeSite

®

LED Area Light - UL 844

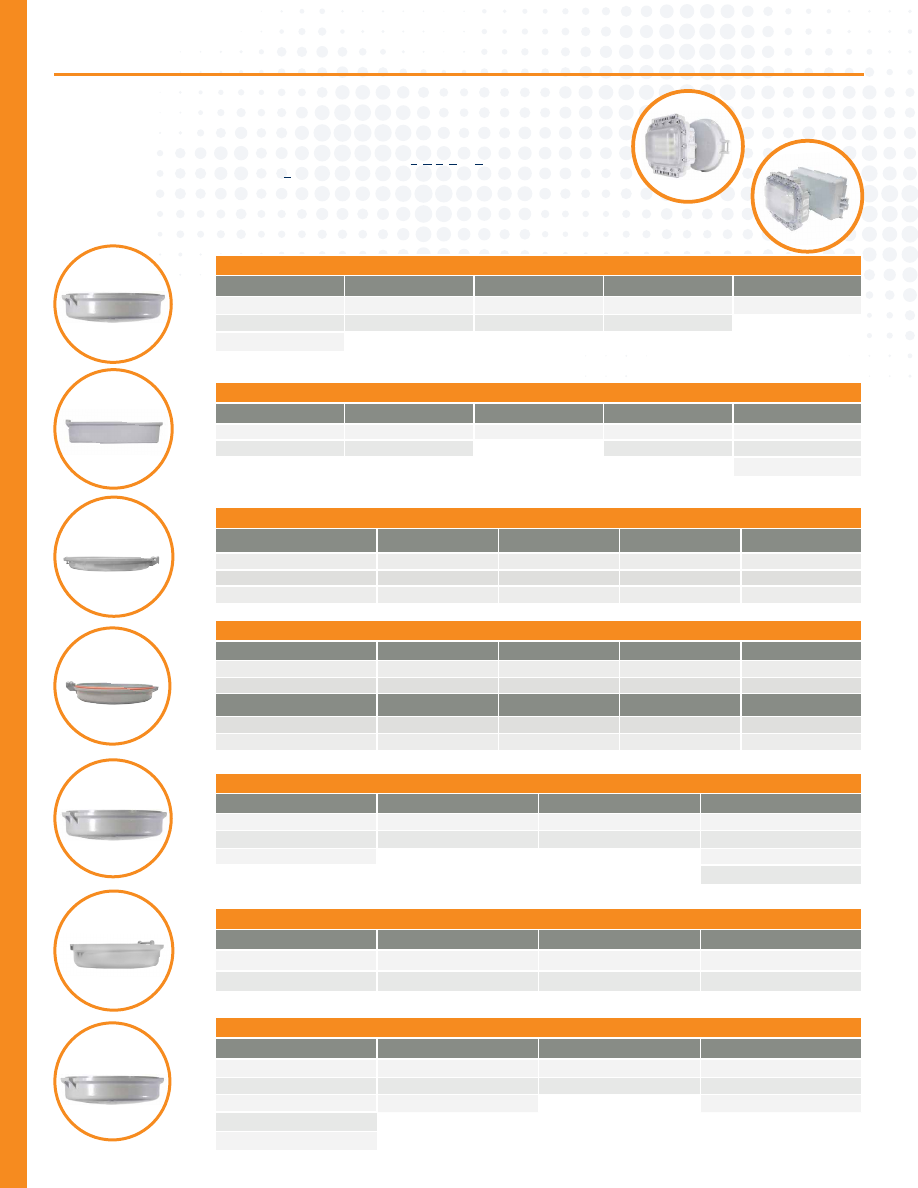

Retrofit Options Overview

HZDXXXX models can be ordered with factory installed retrofit adapter by adding K, A, C, G, or M to the end of the part num-

ber. For example, STW8C2NC becomes STW8C2NC. Please consult factory when ordering.

C

= Eaton’s Crouse-Hinds – Champ

®

A

= Appleton

®

Mercmaster III

M

= Appleton

®

Mercmaster II

Petrolux adapter available as a standalonne accessory only

T

= Thomas & Betts Hazlux

®

K

= Killark

®

Certilite

®

& Certilite

®

V

G

= GE Lighting Solutions – Filtr-Gard™

Eaton’s Crouse-Hinds – Champ

®

- HZXTHCH

Pendant

Ceiling

Wall

Stanchion

Quad Mount

APM2

CM2

TWM2

JM5

QM25

APM3

CM3

TWM3

PM5

HPM2

Killark

®

Certilite

®

& Certilite

®

V - HZXTHKL

Pendant

Ceiling

Wall

Stanchion

VMA2B & VMA-2

VMX2B & VMX-2

VMB2B & VMB-2

VMD4B

VMA3B & VMA-3

VMX3B & VMX-3

VMB3B & VMB-3

VMD5B

VMC2B & VMC-2

VMX6B, 7B, 8B, 9B

VMS5B

VMC3B & VMC-3

VMF2B, 3B

GE Lighting Solutions – Filtr-Gard™ - HZXTHGE

Pendant

Ceiling

Wall

Stanchion

Quad Mount

3P

3F

3C

3W

5S

4P

4F

4W

6S

5J, 6J

Thomas & Betts Hazlux

®

- HZXTHTB

Pendant

Pendant Cone

Flexible Pendant

Ceiling

Wall

VP2

VA2

VF2

VC2

VB2

VP3

VA3

VF3

VC3

VB3

Wall

25° Angle Stanchion 25° AngleStanchion

Straight Stanchion

Straight Stanchion

VB2-VIB

VS4

VS4-VIB

VL4

VL4-VIB

VB3-VIB

VS5

VS5-VIB

VL5

VL5-VIB

Holophane

®

Petrolux II, III - HZXTHP3

Pendant

Universal

Stanchion

Ceiling

Wall

PD

UN

SA

CD

WL

GH

ST

CE

W

P

A

B, C, D

Appleton

®

Mercmaster III - HZXTHAP

Pendant

Ceiling

Wall

Stanchion

KPA- 75, 100

KPC-75

KPWB-75

KPS-125

KPAF-75, 100

KPC-100

KPWB-100

KPS-150

KPCH-75, 100

KPST-125

KPST-150

Appleton

®

Mercmaster II - HZXTHM2

Pendant

Ceiling

Wall

Stanchion

LPA-75

LPC-75

LPWB-75

LPS-125

LPA-100

LPC-100

LPWB-100

LPS-150

www.dialight.com

| MDTFHZHAZX001_S

11

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

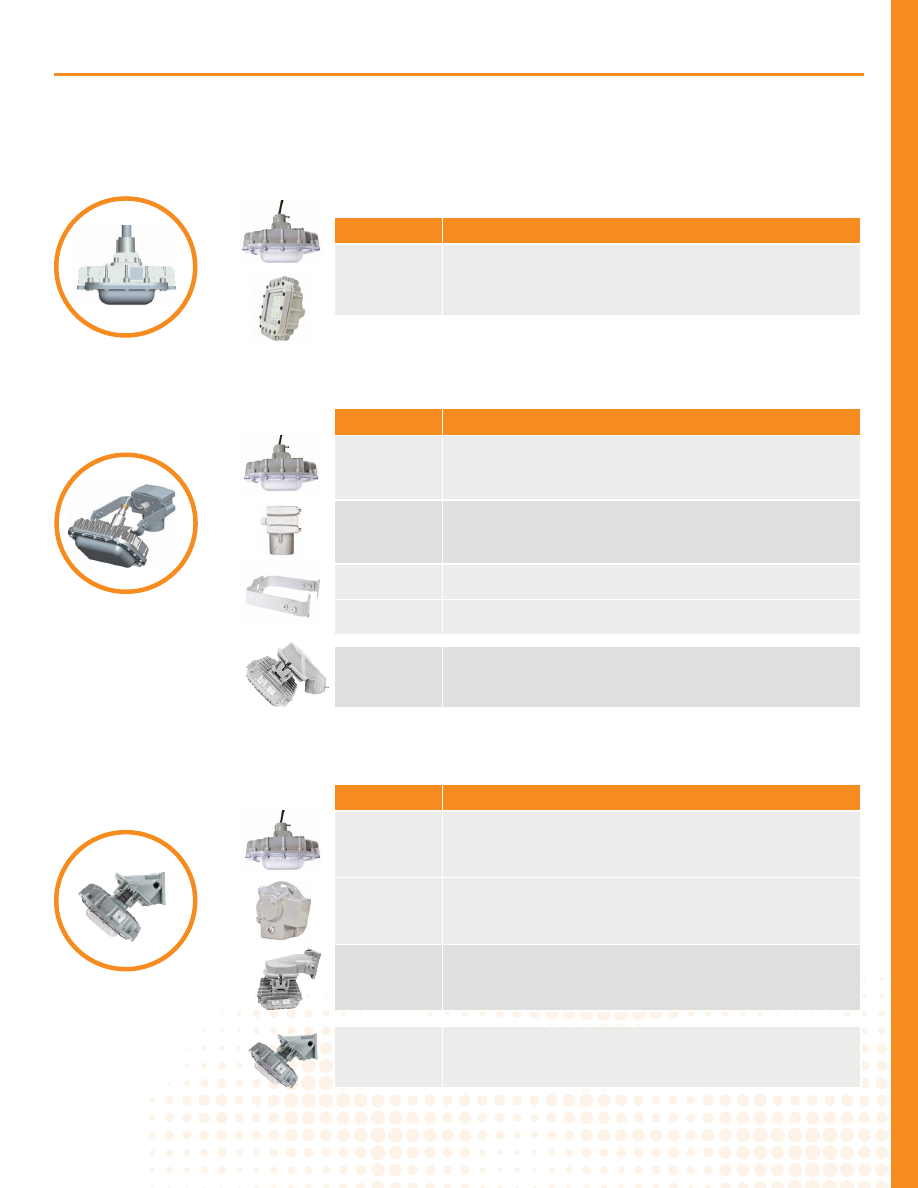

Mounting Overview

Part Number

Description

HZxxxxx

Glass or polycarbonate lens

180° / 360° / wide distribution

3/4” NPT Pendant & Conduit Mount

Part Number

Description

HZxxxxx

Glass or polycarbonate lens

180° / 360° / wide throw optics

HZXSTANxxxx

1.00” - 2.00’ Slip-fit or NPT stanchion mount junction box

HZXW3

Stainless steel mounting brackets

0°, 45°, 90° angles

HZXW7

Aluminum mounting brackets

0°, 45°, 90° angles

Stanchion & Pole Mounting

Part Number

Description

HZxxxxx

Glass or polycarbonate lens

180° / 360° / wide distribution

HZXJBxxx

0.75” - 1.05” ceiling / wall / pole mount junction box

HZDxxxxW01

HZFxxxxW01

Area Light with 0° wall mount bracket included

Glass or polycarbonate lens

180° distribution

Ceiling & Wall Mounting

HZDxxxxS45

HZFxxxxS45

Area Light with 45° stanchion mount bracket included

Glass or polycarbonate lens

180° optics / wide distribution

HZDxxxxW45

HZFxxxxW45

Area Light with 45° wall mount bracket included

Glass or polycarbonate lens

360° / wide distribution

12

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

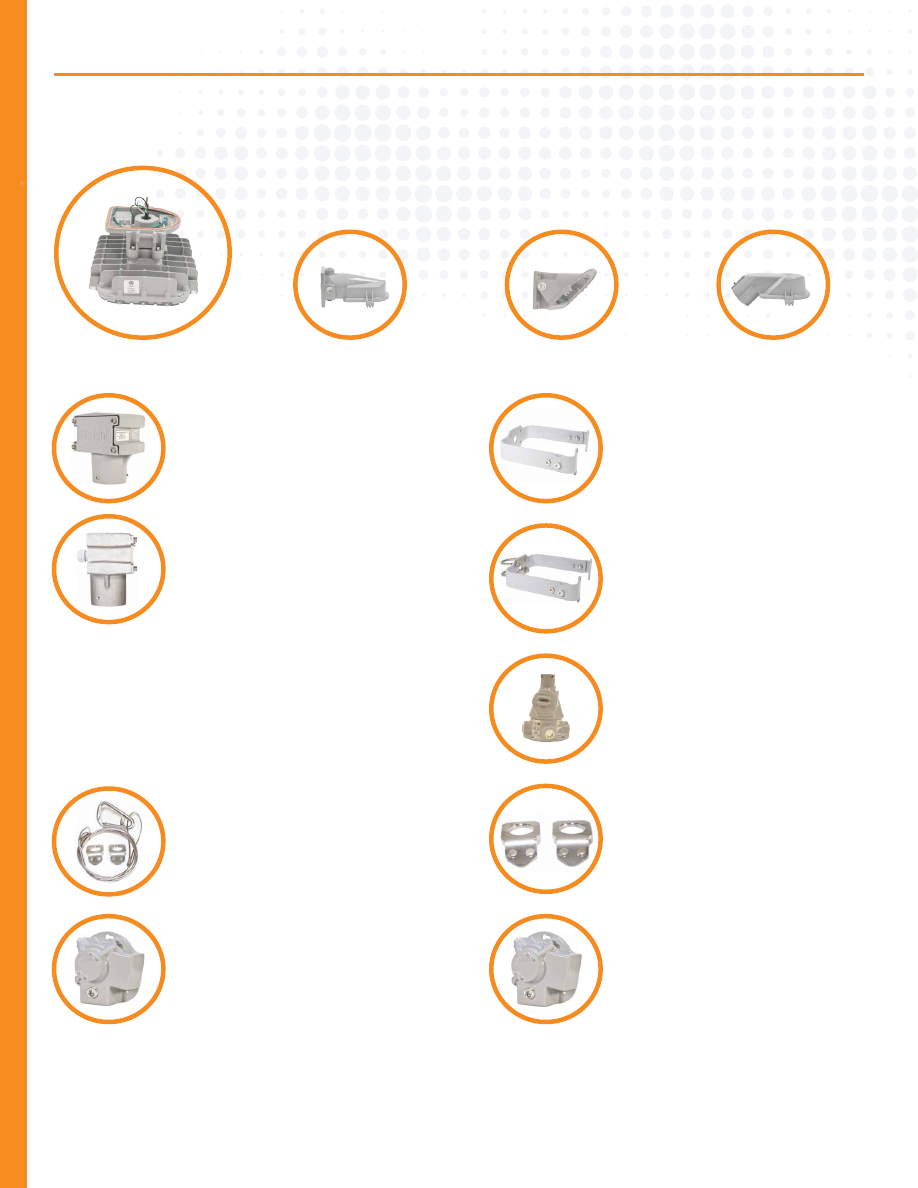

HZXW3

• Stainless steel bracket

HZXW7

• Aluminum bracket

HZXSAFETABS

• Safety tabs

HZXSTAN100S

• 1.00” (1.315” Pole OD) Slip-fit stanchion mount

HZXSTAN125S

• 1.25” (1.660” Pole OD) Slip-fit stanchion mount

HZXSTAN150S

• 1.50” (1.900” Pole OD) Slip-fit stanchion mount

HZXSTAN200S

• 2.00” (2.375” Pole OD) Slip-fit stanchion mount

HZXSTAN100T

• 1.00” (1.315” Pole OD) NPT threaded stanchion mount

HZXSTAN125T

• 1.25” (1.660” Pole OD) NPT threaded stanchion mount

HZXSTAN150T

• 1.50” (1.900” Pole OD) NPT threaded stanchion mount

HZXSTAN200T

• 2.00” (2.375” Pole OD) NPT threaded stanchion mount

HZXW4

• Stainless steel bracket with pipe clamp

HZXW8

• Aluminum bracket with pipe clamp

HZXSAFEKIT

• Safety cable kit

SafeSite

®

LED Area Light - UL 844

Mounting Accessories

Suitable for:

CID2

•

CIID1

•

CIID2

Suitable for:

CID2

•

CIID1

•

CIID2

Suitable for:

CID2

•

CIID1

•

CIID2

Suitable for:

CID2

•

CIID1

•

CIID2

Suitable for:

CID2

•

CIID1

•

CIID2

Certified to:

UL 50E

•

CSA C22.2 No. 94.2-07

HZXJB075

• 0.75” Ceiling / Wall / Pole mount junction box

HZXJB100

• 1.00” Ceiling / Wall / Pole mount junction box

HZXJB125

• 1.25” Ceiling / Wall / Pole mount junction box

HZXJB150

• 1.50” Ceiling / Wall / Pole mount junction box

HZXJB075PC1

• 0.75” Junction box with photocell

HZXJB100PC1

• 1.00” Junction box with photocell

HZXJB125PC1

• 1.25” Junction box with photocell

HZXJB150PC1

• 1.50” Junction box with photocell

Suitable for:

CID2

Suitable for:

CID2

Certified to:

UL 50E

•

CSA C22.2 No. 94.2-07

Certified to:

UL 50E

•

CSA C22.2 No. 94.2-07

HBXC1

• 0.75” NPT Ceiling mount

Suitable for:

CID1

Certified to:

UL 50E

•

UL 1203

ISA 12.12.01

•

CSA C22.2 No. 94.2-07

STWxxxx, HZDxxxx, and HZFxxxx fixtures are now available with a universal mounting adapter factory installed by

adding UMA to the end of the part number. Th choose from one of the three available mounting options:

Wall Mount - HZXW01

45° Wall Mount - HZXW45

45° Stanchion Mount - HZXS45

STWxxxxUMA

www.dialight.com

| MDTFHZHAZX001_S

13

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

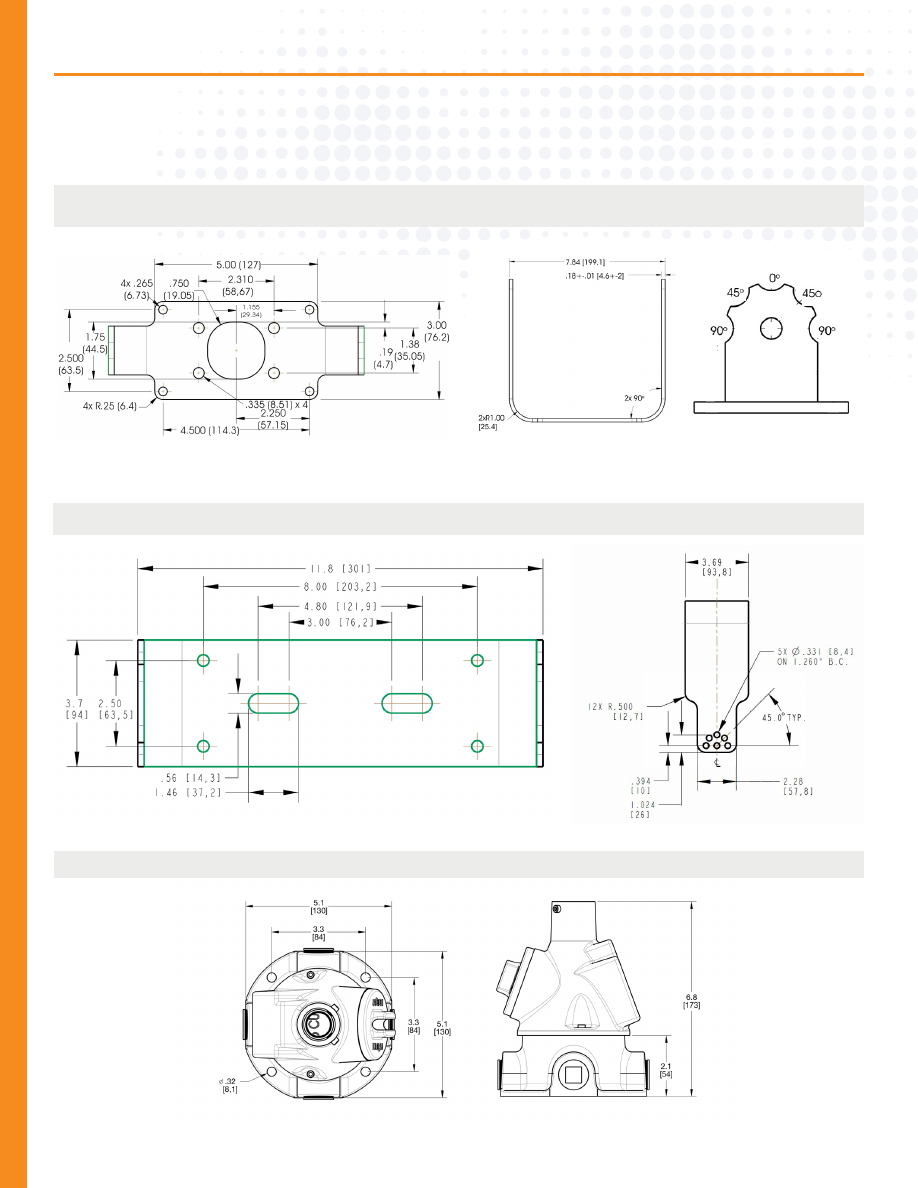

Mounting Bracket Dimensions

HZXSTANXXXX

HZXJBXXX and HZXJBXXXXXX

HZXSAFEKIT and HZXSAFETABS

Dimensions in inches [mm]

Dimensions in inches [mm]

Dimensions in inches [mm]

14

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

SafeSite

®

LED Area Light - UL 844

Mounting Bracket Dimensions

HBXC1 / HBXW1

HZXW3, HZXW4, HZXW7, AND HZXW8

.25” thick; HZXW4 and HZWX8 will mount to 1.5” conduit and comes with pipe mount clamps.

Dimensions in inches [mm]

Battery Backup model bracket

Dimensions in inches [mm]

www.dialight.com

| MDTFHZHAZX001_S

15

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

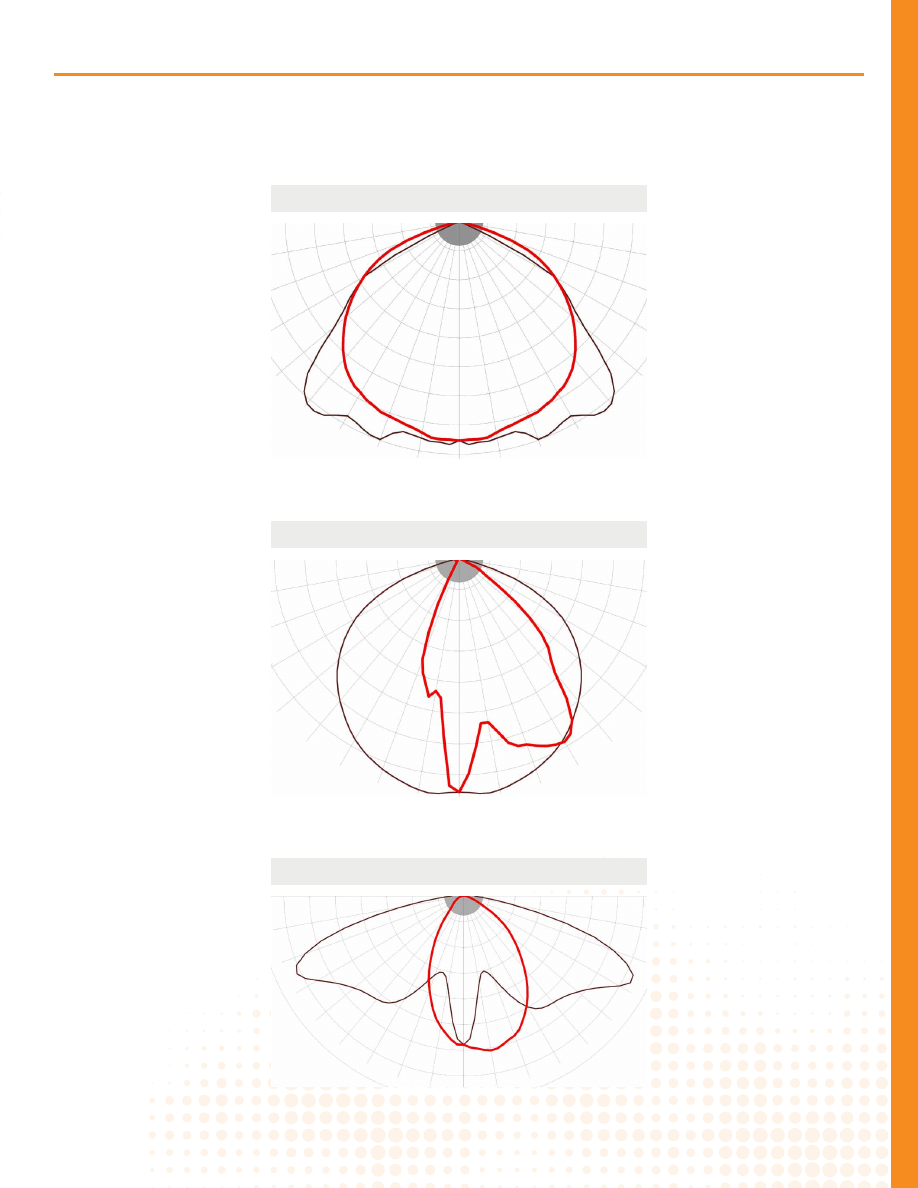

Optical Patterns

360

°

Optical Pattern

180

°

Optical Pattern

Wide Throw Optical Pattern

180° optical pattern models are optimized for a 45° mounting angle

16

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

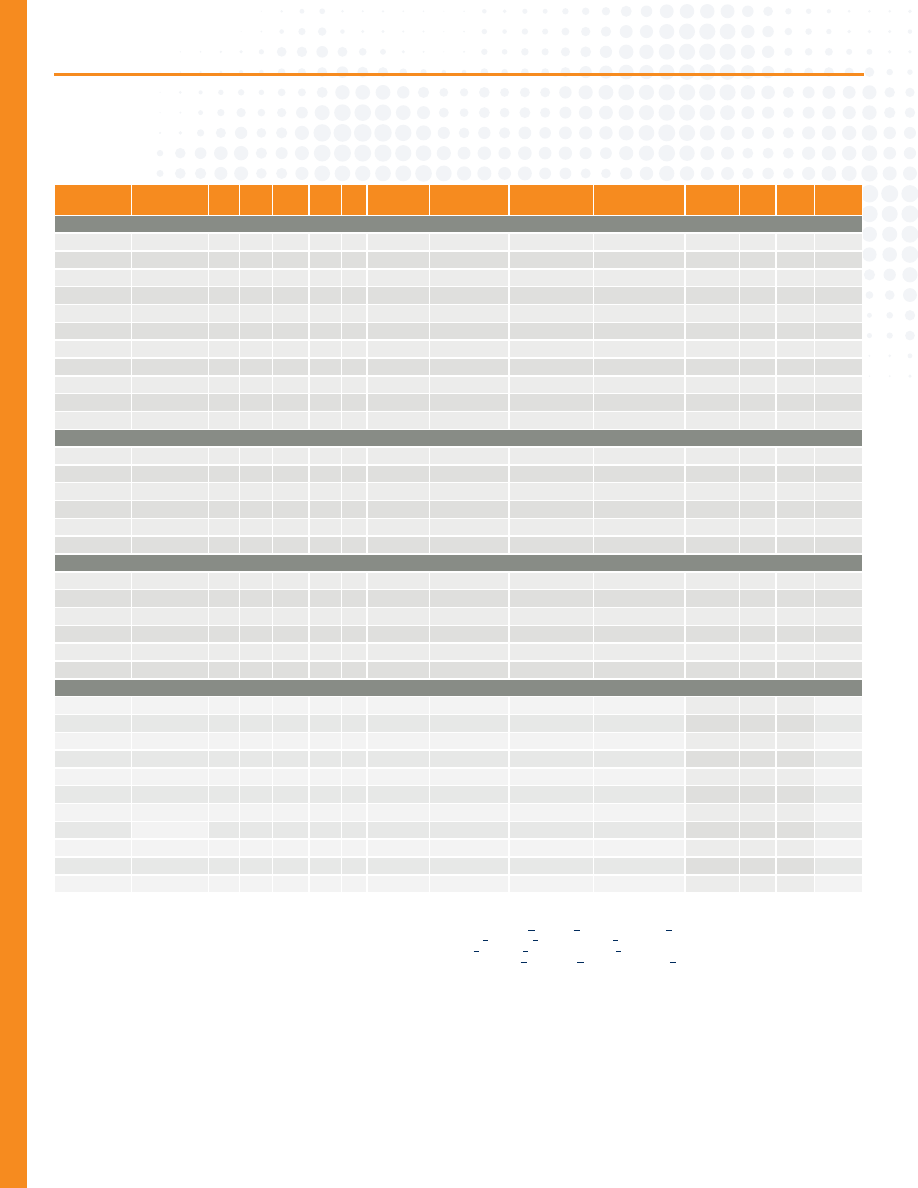

Part Number

Mounting

CID1 CID2 CIID1 CIID2 CIII

Group B

(Hydrogen)

Voltage

Lens

CCT

Fixture

Lumens

Watt

LPW

Optical

Pattern

Class I, Div. 2 - 3/4” NPT Models - 100-277V AC

HZDFC2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZDEC2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

7,000

69

101

180

HZD9C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZD8C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

180

HZD5C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

5,250

47

112

360

HZD4C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

5,000

47

106

180

HZD3C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

360

HZD2C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

180

HZD1C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

360

HZD0C2G

3/4" NPT

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

180

HZDWC2N

3/4" NPT

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 - 3/4” NPT Models - 24 - 48V DC

HZDFC8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

7,250

71

102

360

HZDEC8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

7,000

71

99

180

HZD5C8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

5,000

49

102

360

HZD4C8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

5,000

49

102

180

HZD1C8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

5,000

49

102

360

HZD0C8G

3/4" NPT

•

24 - 48V DC

Tempered glass 5000K (cool white)

3,000

27

111

180

Class I, Div. 2 - Wall Mount Models - 100 - 277V AC

HZDFC2GW01

Wall Mount

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZD9C2GW01

Wall Mount

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZD5C2GW01

Wall Mount

•

100 - 277V AC Tempered glass 5000K (cool white)

5,250

47

112

360

HZD3C2GW01

Wall Mount

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

360

HZD1C2GW01

Wall Mount

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

360

HZDWC2NW01

Wall Mount

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 - 45

º

Wall Mount Models - 100 - 277V AC

HZDFC2GW45 45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZDEC2GW45

45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

7,000

69

101

180

HZD9C2GW45

45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZD8C2GW45 45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

180

HZD5C2GW45

45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

5,250

47

112

360

HZD4C2GW45 45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

5,000

47

106

180

HZD3C2GW45

45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

360

HZD2C2GW45 45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

180

HZD1C2GW45

45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

360

HZD0C2GW45 45

o

wall mount

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

180

HZDWC2NW45 45

o

wall mount

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

SafeSite

®

LED Area Light - UL 844

Class I, Div. 2 - Ordering Information

Classifications:

CID2 A, B, C, D

All values typical unless otherwise stated, Lumen values are typical (tolerance +/- 10%).

180° optical pattern models are optimized for a 45° mounting angle

Part numbers listed in the above table are 5000K (cool white). For 4000K (neutral white) model replace the 5th character with

N

Ex: HZD2

C

2Nxxx becomes HZD2

N

2Nxxx.

Part numbers listed in the above table are 100-277V AC. For 347-480V AC model replace the 6th character with

9

Ex: HZDFC

2

G becomes HZDFC

9

G.

Part numbers listed in the above table are 100-277V AC. For 24-48V DC model replace the 6th character with

8

Ex: HZDFC

2

Gxxx becomes HZDFC

8

Gxxx.

Part numbers listed in the above table come with a glass lens. For polycarbonate lens model replace the 7th character with

N

Ex: HZD8C2

G

xxx becomes HZD8N2

N

xxx.

Wide optical pattern models are available with polycarbonate lens only.

www.dialight.com

| MDTFHZHAZX001_S

17

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

Class I, Div. 2 - Ordering Information

Classifications:

CID2 A, B, C, D

Part Number

Mounting

CID1 CID2 CIID1 CIID2 CIII

Group B

(Hydrogen)

Voltage

Lens

CCT

Fixture

Lumens

Watt

LPW

Optical

Pattern

Class I, Div. 2 - 45

º

Stanchion Mount Models - 100 - 277V AC

HZDFC2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZDEC2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

7,000

69

101

180

HZD9C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZD8C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

180

HZD5C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

5,250

47

112

360

HZD4C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

5,000

47

106

180

HZD3C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

360

HZD2C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

4,000

38

105

180

HZD1C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

360

HZD0C2GS45

45º Stanchion

•

100 - 277V AC Tempered glass 5000K (cool white)

2,250

21

107

180

HZDWC2NS45

45º Stanchion

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 - Battery Backup Models

HZDFCEG

Bracket

•

100 - 277V AC Tempered glass 5000K (cool white)

7,500

85

88

360

HZDECEG

Bracket

•

100 - 277V AC Tempered glass 5000K (cool white)

7,500

85

88

180

All values typical unless otherwise stated, Lumen values are typical (tolerance +/- 10%).

180° optical pattern models are optimized for a 45° mounting angle

Part numbers listed in the above table are 5000K (cool white). For 4000K (neutral white) model replace the 5th character with

N

Ex: HZD2

C

2Nxxx becomes HZD2

N

2Nxxx.

Part numbers listed in the above table are 100-277V AC. For 347-480V AC model replace the 6th character with

9

Ex: HZDFC

2

Gxxx becomes HZDFC

9

Gxxx.

Part numbers listed in the above table are 100-277V AC. For 24-48V DC model replace the 6th character with

8

Ex: HZDFC

2

Gxxx becomes HZDFC

8

Gxxx.

Part numbers listed in the above table come with a glass lens. For polycarbonate lens model replace the 7th character with

N

Ex: HZD8C2

G

xxx becomes HZD8N2

N

xxx.

Wide optical pattern models are available with polycarbonate lens only.

18

www.dialight.com

| MDTFHZHAZX001_S

Hazardous Applications | Area Light

SafeSite

SafeSite

®

LED Area Light - UL 844

Class I, Div. 2 / Class II / Class III - Ordering Information

Classifications:

CID2 A, B, C, D

•

CIID1 E, F, G

•

CIID2 F, G

•

CIII

All values typical unless otherwise stated, Lumen values are typical (tolerance +/- 10%).

Part Number

Mounting

CID1 CID2 CIID1 CIID2 CIII

Group B

(Hydrogen)

Voltage

Lens

CCT

Fixture

Lumens

Watt

LPW

Optical

Pattern

Class I, Div. 2 / Class II / Class III - 3/4” NPT Models - 100-277V AC

HZFFC2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,250

69

105

360

HZFEC2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,000

69

101

180

HZF9C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

360

HZF8C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

180

HZF5C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,250

47

112

360

HZF4C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,000

47

106

180

HZF3C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

360

HZF2C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

180

HZF1C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

360

HZF0C2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

180

HZFWC2N

3/4" NPT

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 / Class II / Class III - Wall Mount Models - 100 - 277V AC

HZFFC2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,250

69

105

360

HZF9C2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

360

HZF5C2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,250

47

112

360

HZF3C2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

360

HZF1C2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

360

HZFWC2NW01

Wall Mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 / Class II / Class III - 45

º

Wall Mount Models - 100 - 277V AC

HZFFC2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,250

69

105

360

HZFEC2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,000

69

101

180

HZF9C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

360

HZF8C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

180

HZF5C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,250

47

112

360

HZF4C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,000

47

106

180

HZF3C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

360

HZF2C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

180

HZF1C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

360

HZF0C2NW45

45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

180

HZFWC2NW45 45

o

wall mount

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Class I, Div. 2 / Class II / Class III - 45

º

Wall Mount Models - 24 - 48V DC

HZFFC8NW45

45

o

wall mount

•

•

•

•

24 - 48V DC

Polycarbonate

5000K (cool white)

7,250

71

102

360

HZFEC8NW45

45

o

wall mount

•

•

•

•

24 - 48V DC

Polycarbonate

5000K (cool white)

7,000

71

99

180

Part numbers listed in the above table are 5000K (cool white). For 4000K (neutral white) model replace the 5th character with

N

Ex: HZD2

C

2Nxxx becomes HZD2

N

2Nxxx.

Part numbers listed in the above table are 100-277V AC. For 347-480V AC model replace the 6th character with

9

Ex: HZDFC

2

G becomes HZDFC

9

G.

Part numbers listed in the above table are 100-277V AC. For 24-48V DC model replace the 6th character with

8

Ex: HZDFC

2

Gxxx becomes HZDFC

8

Gxxx.

Part numbers listed in the above table come with a glass lens. For polycarbonate lens model replace the 7th character with

N

Ex: HZD8C2

G

xxx becomes HZD8N2

N

xxx.

Wide optical pattern models are available with polycarbonate lens only.

www.dialight.com

| MDTFHZHAZX001_S

19

SafeSite

Hazardous Applications | Area Light

SafeSite

®

LED Area Light - UL 844

Class I, Div. 2 / Class II / Class III - Ordering Information

Part Number

Mounting

CID1 CID2 CIID1 CIID2 CIII

Group B

(Hydrogen)

Voltage

Lens

CCT

Fixture

Lumens

Watt

LPW

Optical

Pattern

Class I, Div. 2 / Class II / Class III- 45

º

Stanchion Mount Models - 100 - 277V AC

HZFFC2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,250

69

105

360

HZFEC2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

7,000

69

101

180

HZF9C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

360

HZF8C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

6,000

57

105

180

HZF5C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,250

47

112

360

HZF4C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

5,000

47

106

180

HZF3C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

360

HZF2C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,000

38

105

180

HZF1C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

360

HZF0C2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

2,250

21

107

180

HZFWC2NS45

45º Stanchion

•

•

•

•

100 - 277V AC

Polycarbonate

5000K (cool white)

4,200

58

72

Wide

Classifications:

CID2 A, B, C, D

•

CIID1 E, F, G

•

CIID2 F, G

•

CIII

Class I, Div. 1 - 3/4” NPT Models - 100 - 277V AC

HZCFC2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZCEC2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,750

69

98

180

HZC9C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZC8C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

180

HZC5C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

5,200

47

111

360

HZC4C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

4,700

47

100

180

HZC3C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

4,100

38

108

360

HZC2C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

3,700

38

97

180

HZC1C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

2,200

21

105

360

HZC0C2N

3/4" NPT

•

•

100 - 277V AC Tempered glass 5000K (cool white)

2,200

21

105

180

Class I, Div. 1 - 3/4” NPT Models - Hydrogen group B - 100 - 277V AC

HZPFC2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

7,250

69

105

360

HZPEC2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,750

69

98

180

HZP9C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

360

HZP8C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

6,000

57

105

180

HZP5C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

5,200

47

111

360

HZP4C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

4,700

47

100

180

HZP3C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

4,100

38

108

360

HZP2C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

3,700

38

97

180

HZP0C2N

3/4" NPT

•

•

•

100 - 277V AC Tempered glass 5000K (cool white)

2,200

21

105

180

Classifications:

CID1 B, C, D

•

CID2 A, B, C, D

•

CIID1 E, F, G

•

CIID2 F, G

•

CIII

Class I, Div. 1 - Ordering Information

All values typical unless otherwise stated, Lumen values are typical (tolerance +/- 10%).

Part numbers listed in the above table are 5000K (cool white). For 4000K (neutral white) model replace the 5th character with

N

Ex: HZD2

C

2Nxxx becomes HZD2

N

2Nxxx.

Part numbers listed in the above table are 100-277V AC. For 347-480V AC model replace the 6th character with

9

Ex: HZDFC

2

G becomes HZDFC

9

G.

Part numbers listed in the above table are 100-277V AC. For 24-48V DC model replace the 6th character with

8

Ex: HZDFC

2

Gxxx becomes HZDFC

8

Gxxx.

Part numbers listed in the above table come with a glass lens. For polycarbonate lens model replace the 7th character with

N

Ex: HZD8C2

G

xxx becomes HZD8N2

N

xxx.

Class I, Div. 1 models available with glass lens only.

Wide optical pattern models are available with polycarbonate lens only.

MDTFHZHAZX001_S

Dialight reserves the right to make changes at any time in order to supply the best product possible. The most current

version of this document will always be available at:

www.dialight.com/Assets/Brochures_And_Catalogs/Illumination/MDTFHZHAZX001.pdf

Warranty Statement: EXCEPT FOR THE WARRANTY EXPRESSLY PROVIDED FOR [HEREIN/ABOVE/BELOW], DIALIGHT

DISCLAIMS ANY AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, AND NONINFRINGEMENT.

North American HQ

1501 Route 34 South

Farmingdale, NJ 07727

Tel: 732-919-3119

info@dialight.com

EMEA

Exning Road, Newmarket

Suffolk, England, CB8 0AX

Tel: +44 (0) 1638 665161

Australia office

38 O’Malley St

Osborne Park WA 6017

Tel: +61 (0) 8 9244 7600

Fax: +61 (0) 8 9244 7601

Brazil

Av. Joao Antonio Meccatti,

1601 – Galpao 07 – Jd Planalto

Jundiai – SP – 13211-223

Tel: +55 (11) 4431-4300

Email:vendas.brasil@dialight.com

Copenhagen

Ejby Industrivej 91 B

2600 Glostrup

Tel: +45 8877 4400

E-mail:Info-dk@dialight.com

Houston office

16830 Barker Springs Rd Ste 407

Houston, TX 77084

Tel: 732 -919 - 3119

info@dialight.com

Middle East office

Level 42

Emirates Towers (Office Tower)

Sheikh Zayed Road

Dubai, United Arab Emirates

Tel: +971(0)4319 7686

Southeast Asia office

240 Macpherson Road

#07-05 Pines Industrial Building

Singapore 348574