Catalog

2017

Schneider Electric

Legacy Time Delay

and Sensor Relays

Catalog

2017

Schneider Electric

Legacy Time Delay

and Sensor Relays

2

Contents

Legacy Time Delay and

Sensor Relays

Series Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

820 Series Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

831 Series Voltage Sensing Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

841 Series Current Sensing Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

800 Series Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TDR782 Series Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TDR782 Series Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TDRPRO Series Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TDRPRO Series Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Website Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3

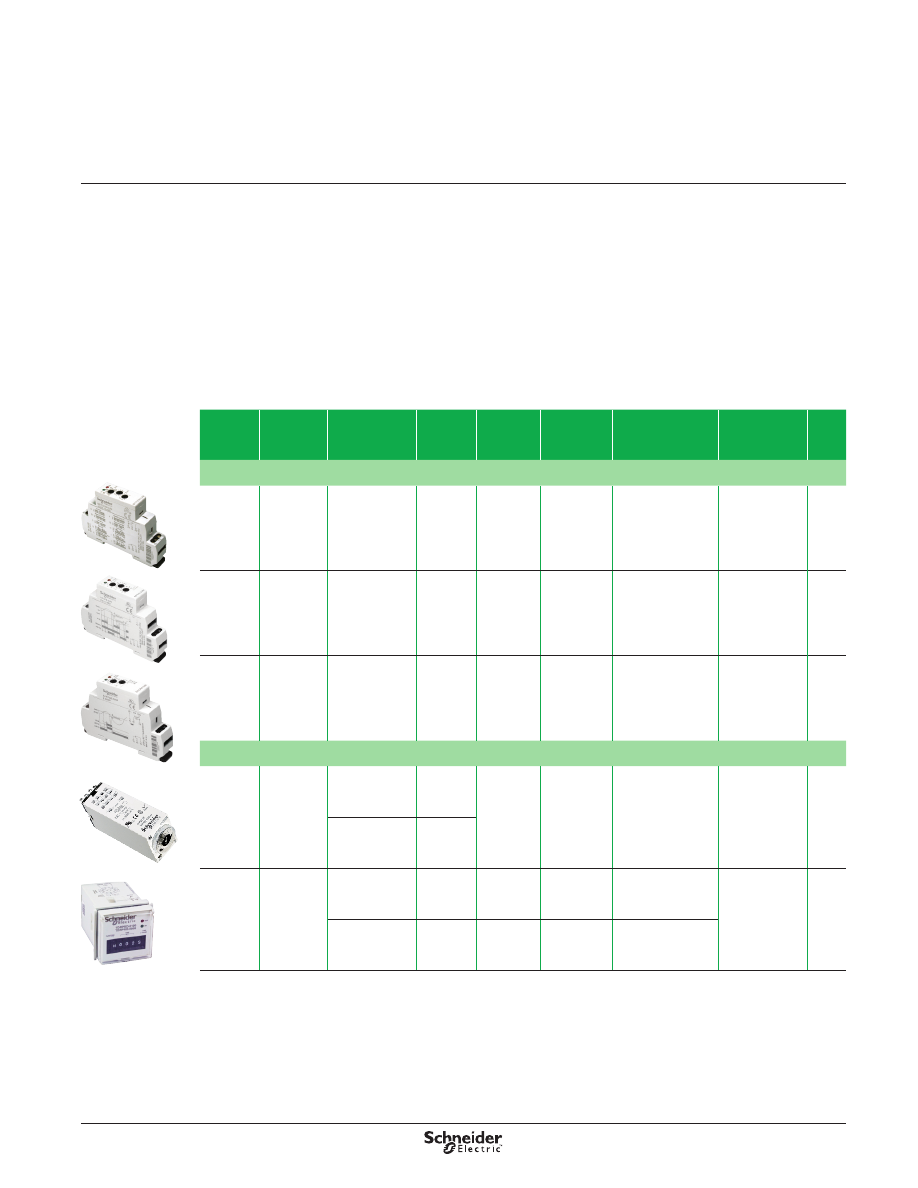

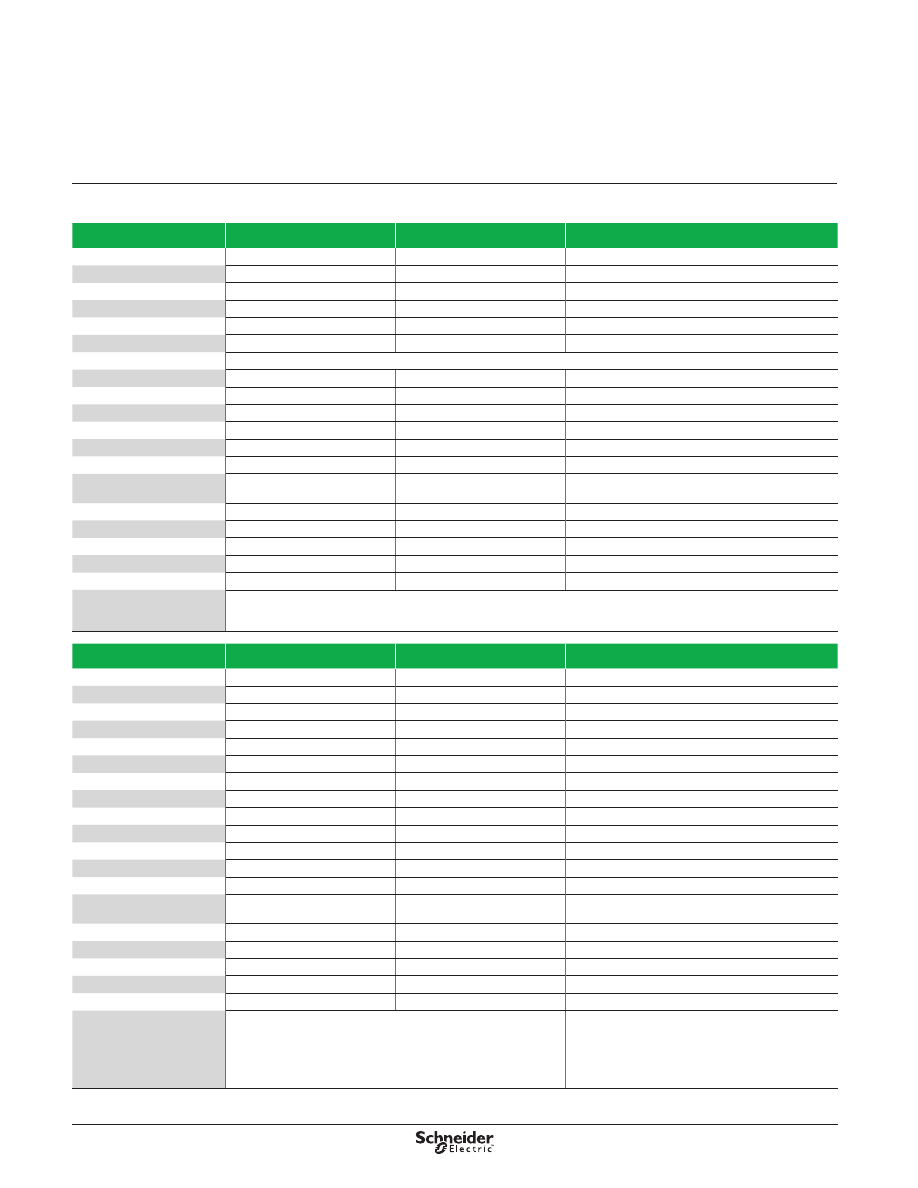

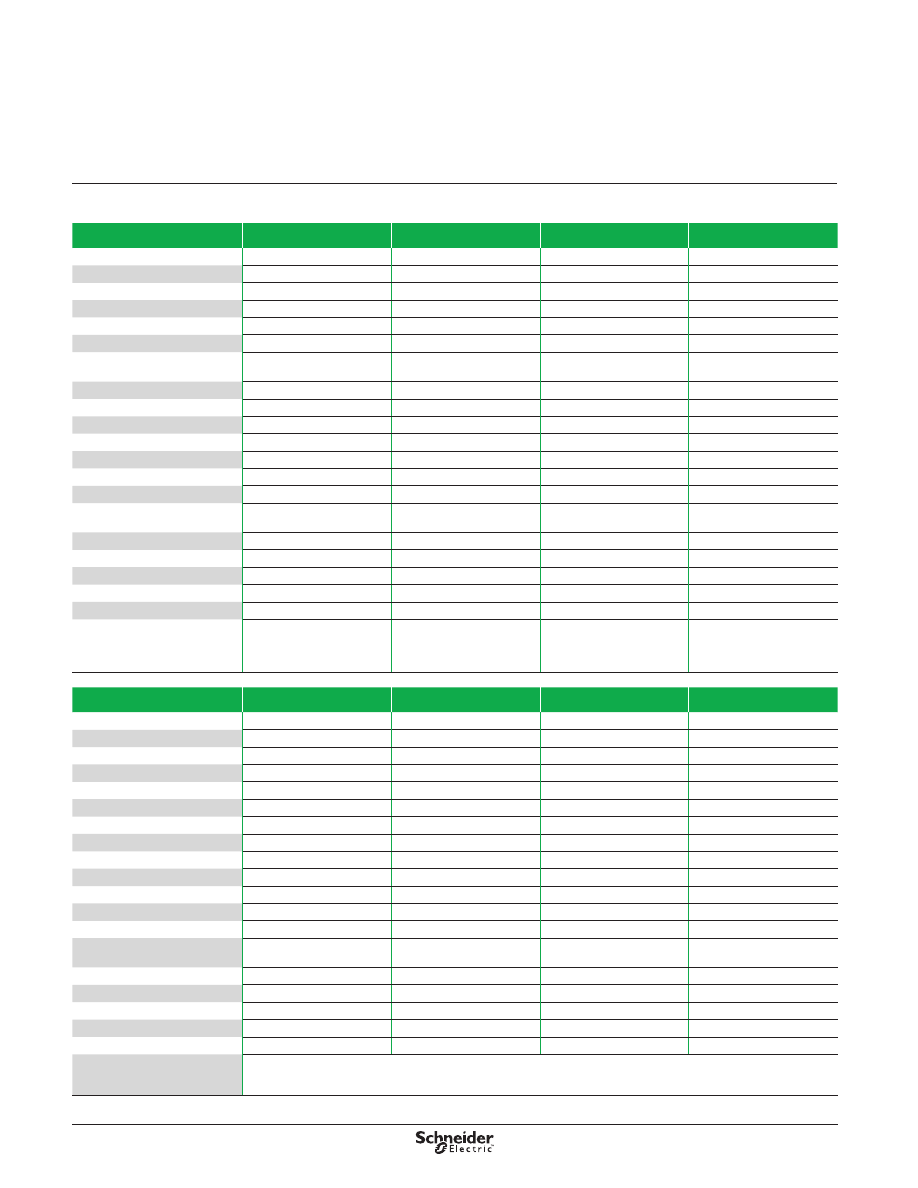

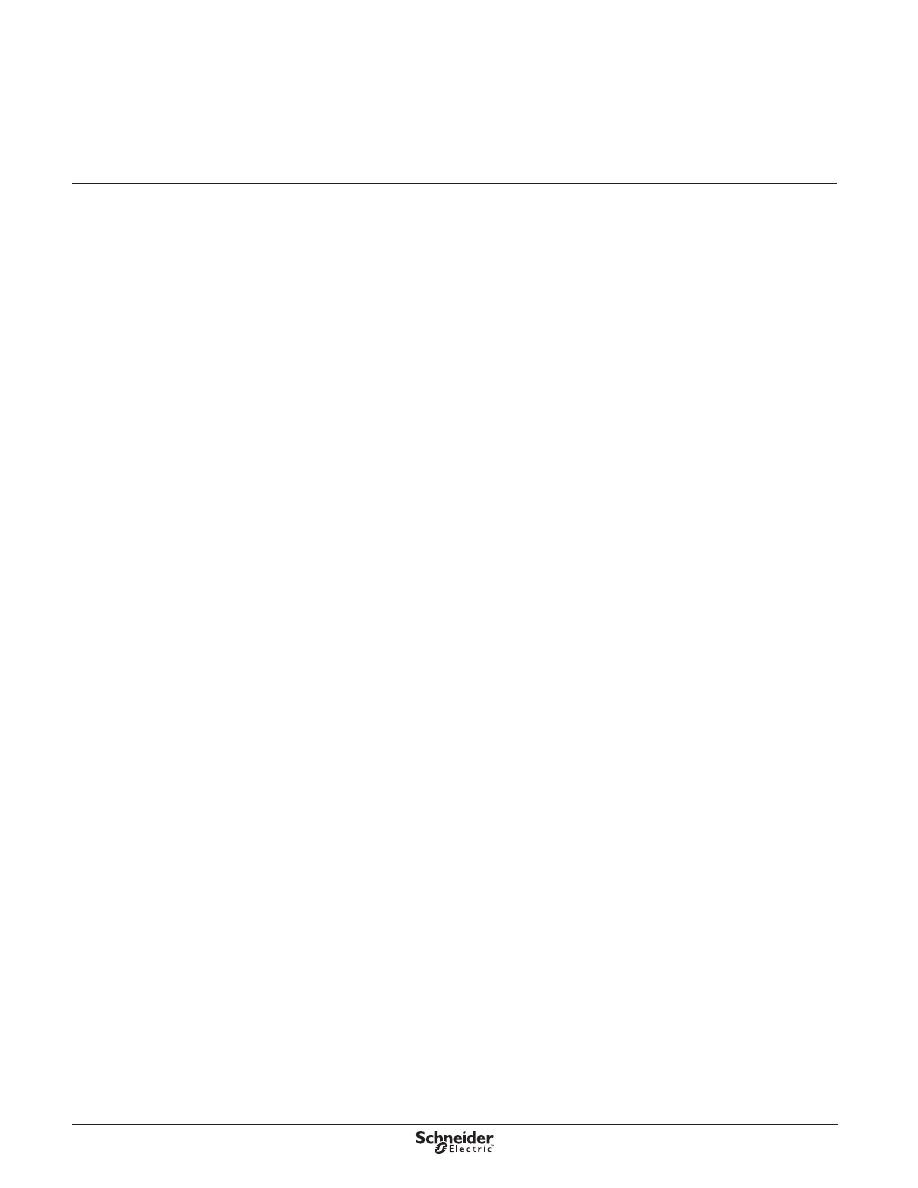

Series

Style

Contact

Configuration

Rated

Current

Load (A)

Timing

Range

Number of

Functions Function Type

Input Voltage

Range

Page

DIN Mounting

820

Relays

Time

delay

relay

SPST

DPDT

15

100 ms to

10 days

10

All

12–240

Vac/Vdc

831

Voltage

Sensing

Relays

Voltage

sensing

relay

SPDT

15

100 ms to

10 s

1

On-Delay

120, 240 Vac;

24 Vdc

841

Current

Sensing

Relays

Current

sensing

relay

SPDT

15

100 ms to

10 s

1

On-Delay

24–240 Vac

Plug-in Mounting

TDR782

Relays

Time delay

relay with

dial

DPDT

5

100 ms to

100 hr

1

On-Delay

12, 24 Vdc;

24, 110, 230 Vac 14

4PDT

3

TDRPRO

Relays

Time delay

relay with

5-digit

thumb-wheel

SPDT

12

100 ms to

9990 hr

10

All

12–240

Vac/Vdc

DPDT

12

100 ms to

9990 hr

3

On-Delay / Repeat

Cycle / On Interval

Legacy Schneider Electric™ time delay and sensor relays provide cost effective

solutions for your industrial timing and sensing needs . Available in a wide array

of forms, fits, and functions, these timers offer the ultimate in flexibility and

performance . Accurate adjustments, legible wiring diagrams, and an interactive timer

demo make selection quick and easy .

Key Features

Multiple timing functions

Wide input voltage range

Wide timing range

DIN, panel, or plug-in mounting styles

Conforms to international standards including UL, CSA, RoHS, and CE IEC

Series Overview

Legacy Time Delay and

Sensor Relays

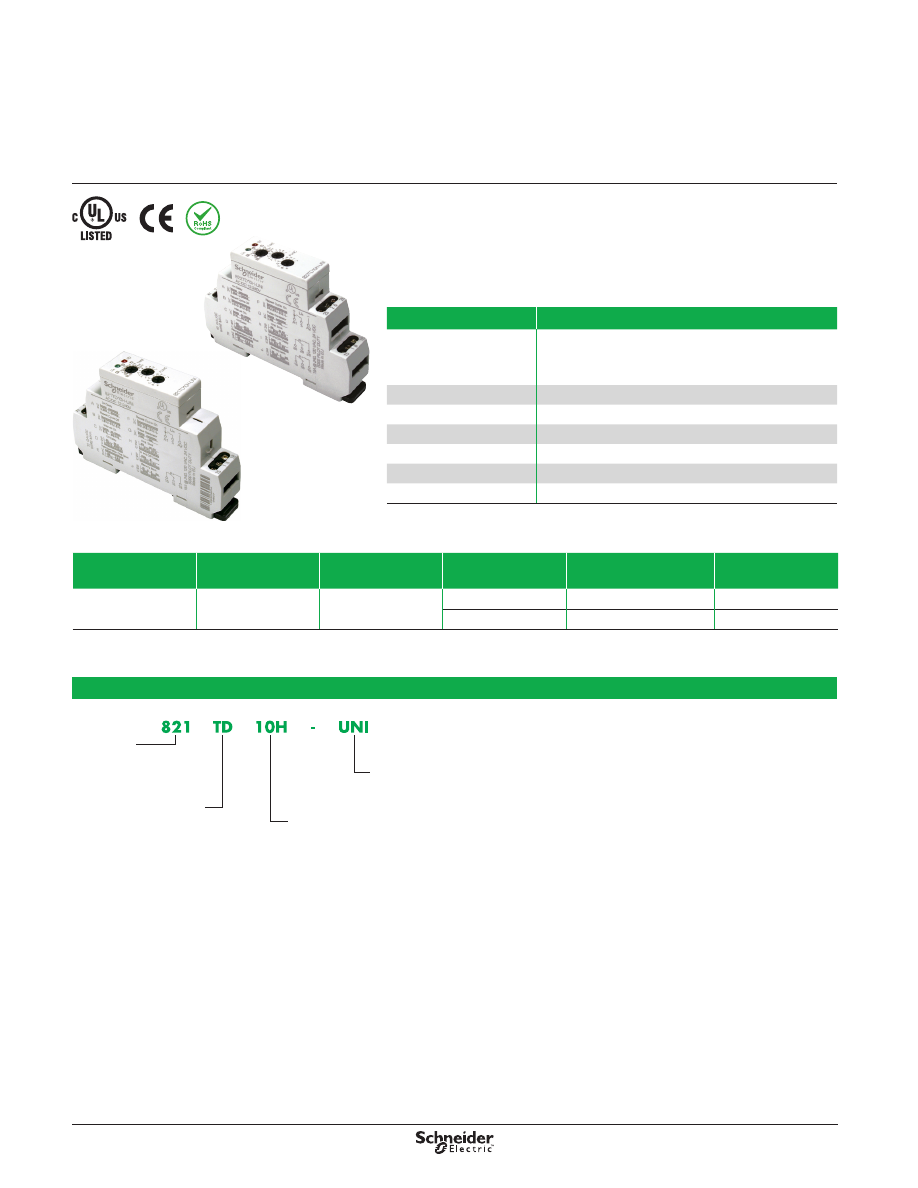

4

Description

The 820 Series time delay relays are 35-mm DIN-rail mountable products offering ten

different timing functions, ultra-wide timing range (10 ms to 10 days), and a universal

voltage input (12–240 Vac/Vdc), all in a slim 17 .5 mm (0 .69 in .) modular package .

Input Voltage

Functions

Available

(1)

Timing Range

Contact

Configuration

Rated Current

Standard

Part Number

12–240 Vac/Vdc

A,B,C,D,E,F,G,H,I,J

10 ms to 10 days

SPDT

15 A

821TD10H-UNI

DPDT

15 A (2 pairs of contacts)

822TD10H-UNI

(1) For function descriptions, see page 31.

Part Number Explanation

Series:

821 =

SPDT

822 =

DPDT

Relay Style:

TD =

Time Delay

Input Voltage:

UNI =

12–240 Vac/Vdc

Number of Functions:

10H =

10 Functions

Feature

Benefit

Up to 10 functions

■ 5 timing functions controlled via supply voltage

■ 4 timing functions controlled via trigger input

■ 1 memory latching function

Meets most timing requirements

Contact configuration

SPDT or DPDT

Universal power supply

12–240 Vac/Vdc

2 LED status indicators

Shows status at a glance

Only 17 .5 mm (0 .69 in .) wide Ideal for tight spaces

DIN-rail mountable

Easy installation (screwdriver required)

RoHS compliant

Environmentally friendly

Description

Legacy Time Delay and

Sensor Relays

820 Series

SPDT, 15 A; DPDT, 15 A

821 Relay

822 Relay

5

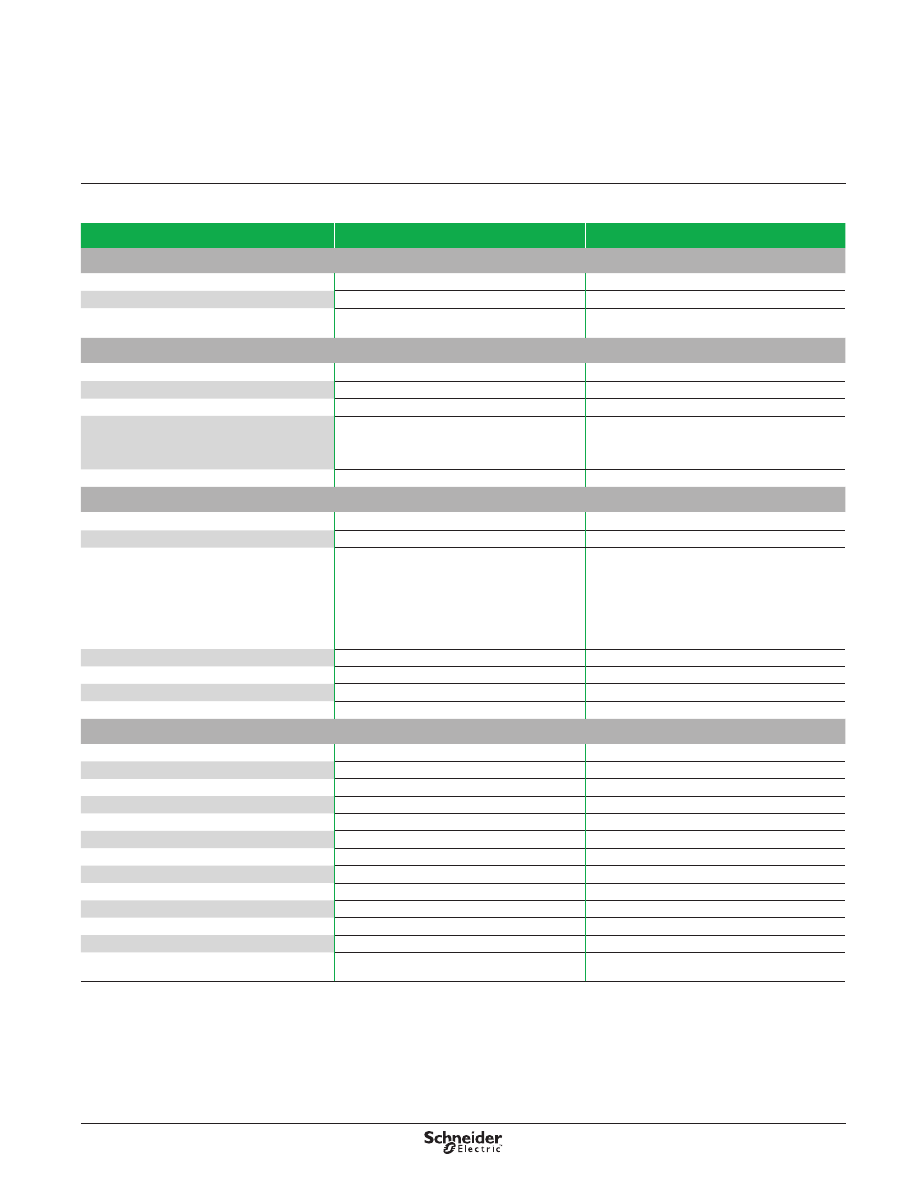

Specifications

Part Number

821TD10H-UNI

822TD10H-UNI

Input Characteristics

Input Voltage Range

12–240 Vac/Vdc

12–240 Vac/Vdc

Operating Voltage (% of Nominal)

85% of 12 V to 110% of 240 V

85% of 12 V to 110% of 240 V

Maximum Power Consumption

3 VA

1 .7 W

3 VA

1 .7 W

Output Characteristics

Contact Configuration

SPDT

DPDT

Output Current Rating

15 A

15 A

Contact Material

Silver alloy

Silver alloy

Switching Capability

15 A @ 240 Vac, 50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac, 50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

Minimum Switching Requirement

100 mA

100 mA

Timing Characteristics

Functions Available

(1)

Multifunction

Multifunction

Time Scales

8

8

Time Ranges

100 ms to 1 s

1 s to 10 s

0 .1 min to 1 min

1 min to 10 min

0 .1 hr to 1 hr

1 hr to 10 hr

0 .1 day to 1 day

1 day to 10 days

100 ms to 1 s

1 s to 10 s

0 .1 min to 1 min

1 min to 10 min

0 .1 hr to 1 hr

1 hr to 10 hr

0 .1 day to 1 day

1 day to 10 days

Tolerance

5% of mechanical setting

5% of mechanical setting

Repeatability at Constant Voltage and Temperature

0 .2%

0 .2%

Reset Time

150 ms maximum

150 ms maximum

Trigger Pulse Length

50 ms minimum

50 ms minimum

General Characteristics

Electrical Life (Operations at Rated Current)

(2)

70,000 operations

70,000 operations

Mechanical Life (Unpowered)

(2)

10,000,000 operations

10,000,000 operations

Dielectric Strength (Input to Contacts)

2500 Vac

2500 Vac

Dielectric Strength (Between Open Contacts)

1600 Vac

1600 Vac

Storage Temperature Range

−30 to +70 °C (−22 to +158 °F)

−30 to +70 °C (−22 to +158 °F)

Operating Temperature Range

−20 to +55 °C (−4 to +131 °F)

−20 to +55 °C (−4 to +131 °F)

Terminal Wire Capacity (Input and Output)

14 AWG (2 .1 mm²) maximum

14 AWG (2 .1 mm²) maximum

Terminal Screw Torque

7 .1 lb-in (0 .8 N•m) maximum

7 .1 lb-in (0 .8 N•m) maximum

Weight

55 g (1 .9 oz)

70 g (2 .5 oz)

Input Indication

Green LED

Green LED

Output Indication (Blinking = Timing; On = Energized)

Red LED

Red LED

Enclosure Rating (according to IEC 60529 IP rating) IP20

IP20

Approvals

cULus (File: E234203, CCN: NKCR, NKCR7),

CE 61810-1, RoHS

cULus (File: E234203, CCN: NKCR, NKCR7),

CE 61810-1, RoHS

(1) For function descriptions, see page 31.

(2) Actual product life varies based on electrical load, duty cycle, application, and environmental conditions.

Specifications

Legacy Time Delay and

Sensor Relays

820 Series

SPDT, 15 A; DPDT, 15 A

6

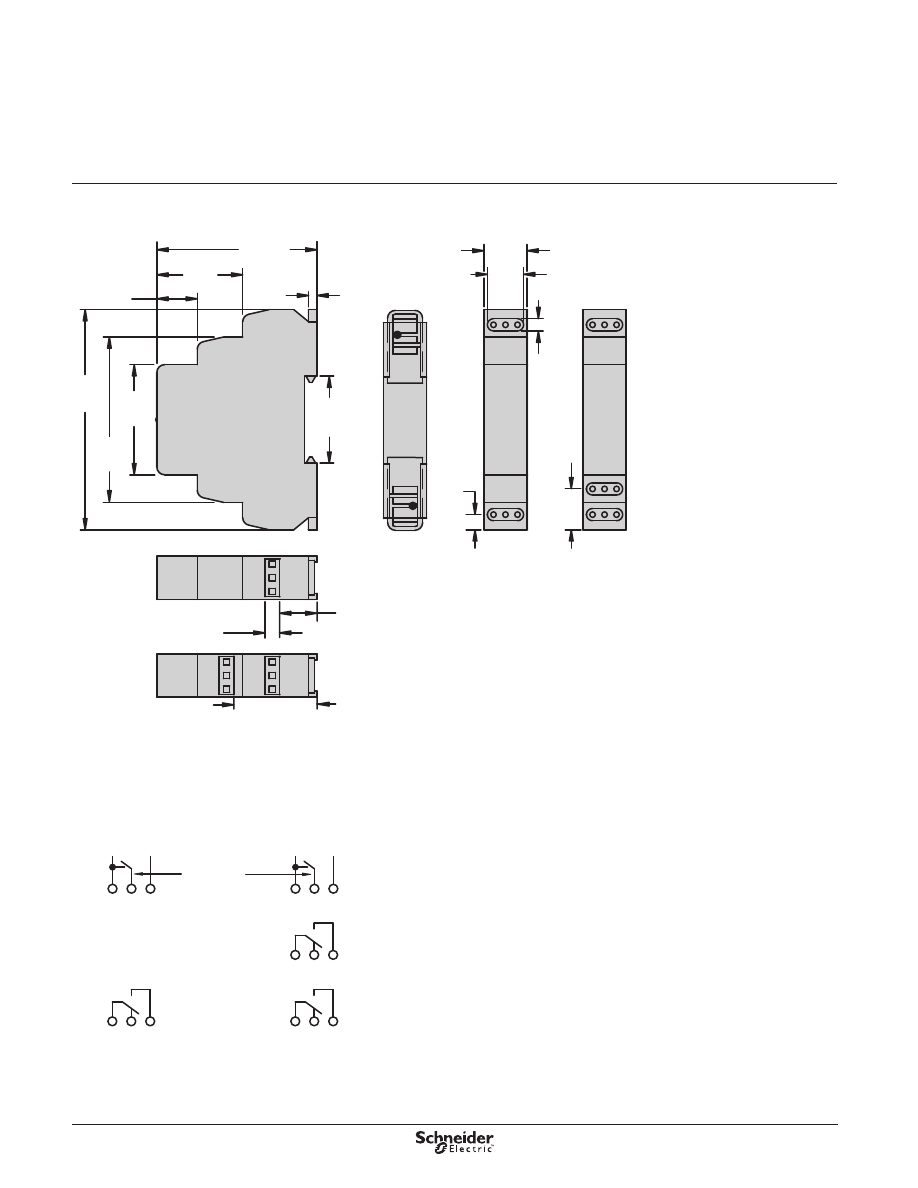

Wiring Diagram

Dimensions—in. (mm)

R

16

15

18

U

n

R

28

25 26

+

−

S

A1

A2

R

16

15

18

U

n

+

−

S

A1

A2

821TD10H-UNI

822TD10H-UNI

Input

Voltage

External

Control

Switch

(Dry Switch

Only)

15

—

Common

16

—Normally Closed

18

—Normally Open

26

—Normally Closed

28

—Normally Open

25

—Common

Input

Voltage

(7.4)

0.3

0.7

(17.6)

0.6

(14.2)

(5)

0.2

(65)

(16)

(45.3)

1.8

0.63

(67.5)

2.7

(90)

3.5

1.4

2.6

(34.2)

1.35

(3.4)

0.13

(35)

0.6

(16)

0.236

(6)

(16.71)

0.7

1.3

(34)

Dimensions,

Wiring Diagram

Legacy Time Delay and

Sensor Relays

820 Series

SPDT, 15 A; DPDT, 15 A

7

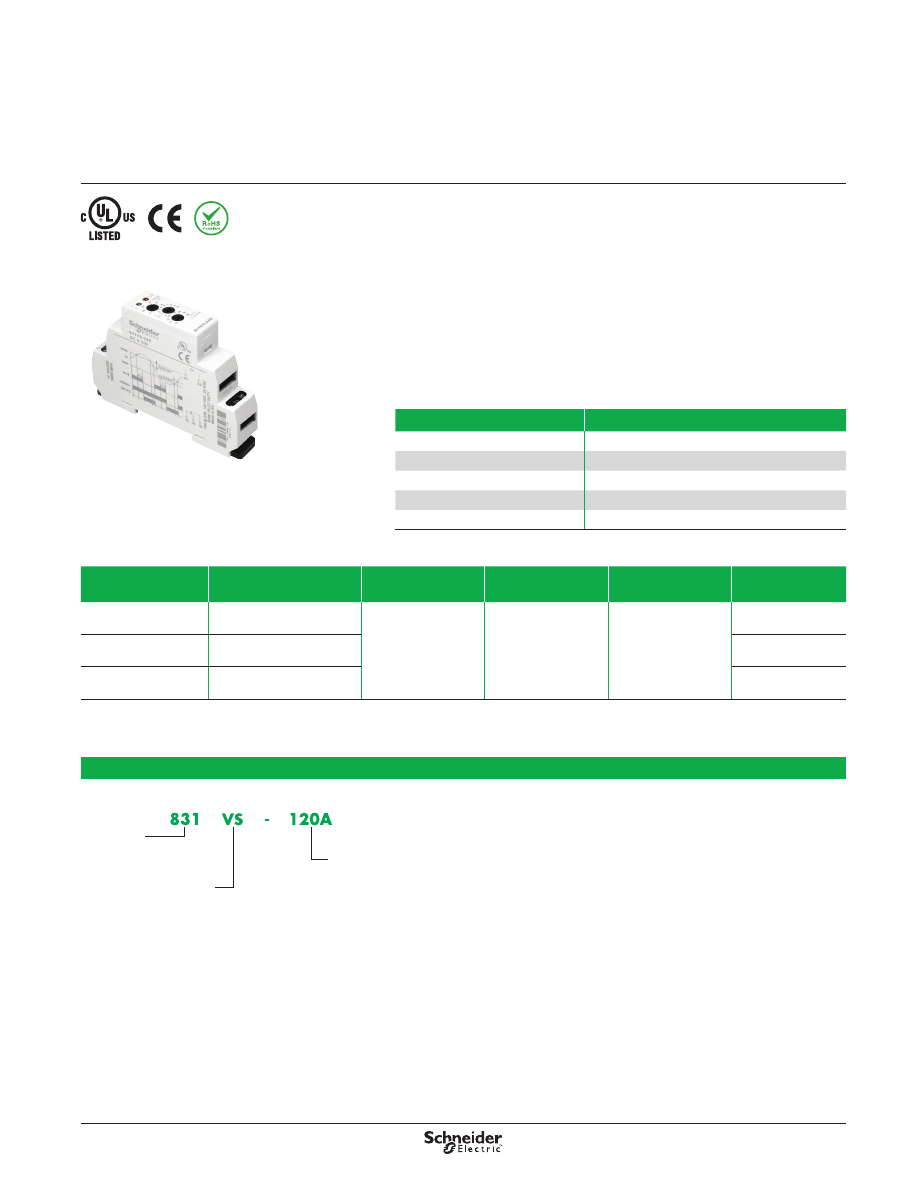

Description

Legacy Time Delay and

Sensor Relays

831 Series

SPDT, 15 A

Description

The 831 voltage sensor is a single-phase AC voltage sensing device capable of

monitoring and reacting to overvoltage and undervoltage conditions . This product is

designed to be wired across terminals A1 and A2 with the voltage being monitored .

The two LED lamps indicate when the input voltage is present (green LED) and

when the output is energized (red LED) .

The Umax dial is used to set the upper trip-point for the voltage sensor . The Umin

dial is a percentage of the Umax dial and is used to set the lower trip-point for the

voltage sensor . The timing dial is used to delay the transfer of the contacts, from

0–10 s, when a set point has been violated .

Nominal

Input Voltage

Sensing

Voltage Range

Timing Range

Contact

Configuration

Rated Current

Standard

Part Number

120 Vac

Upper: 85–150 Vac

Lower: 30–99% of upper

0–10 s

SPDT

15 A

831VS-120A

240 Vac

Upper: 160–276 Vac

Lower: 30–99% of upper

831VS-240A

24 Vdc

Upper: 18–30 V

Lower: 30–99% of upper

831VS-24D

Part Number Explanation

Series:

831 =

SPDT

Relay Style:

VS =

Voltage Sensor

Nominal Input Voltage:

120A =

120 Vac

240A =

240 Vac

24D =

24 Vdc

Feature

Benefit

Three-state indication LEDs

Indicate normal state and two types of faulted states

Timing dial

Adjustable delay 0–10 s

DIN mounting capability

Mounts directly on a 35 mm DIN rail

Current rating: 15 A @ 240 Vac, 24 Vdc High switching capacity

Narrow width: 17 .5 mm (0 .69 in .)

Ideal for tight spaces

831 Relay

8

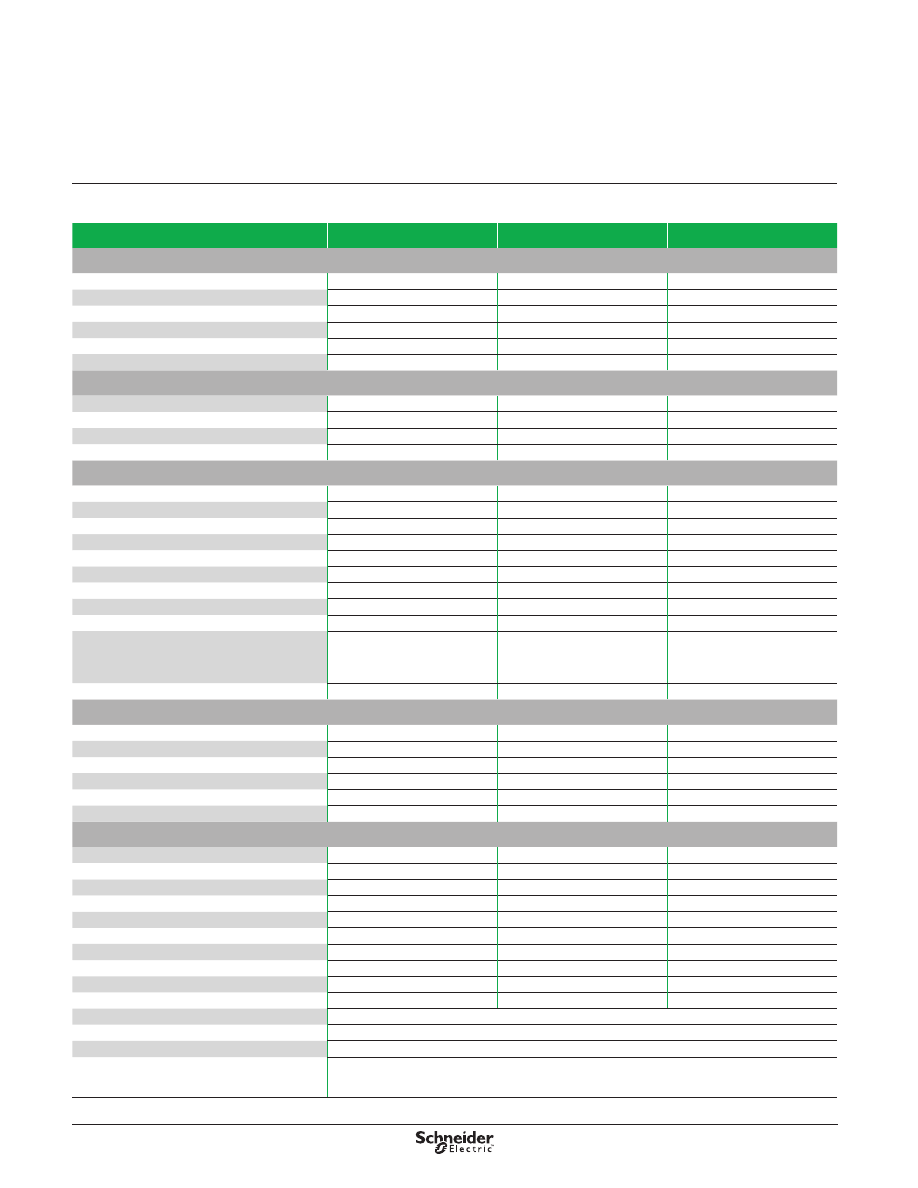

Specifications

Legacy Time Delay and

Sensor Relays

831 Series

SPDT, 15 A

Specifications

Part Number

831VS-120A

831VS-240A

831VS-24D

Input Characteristics

Nominal Input Voltage

120 Vac

240 Vac

24 Vdc

Absolute Input Voltage Maximum

200 Vac

280 Vac

35 Vdc

Upper Supply Voltage Range

85–150 Vac

160–276 Vac

18–30 Vdc

Lower Supply Voltage Range

30–99% of upper preset

30–99% of upper preset

30–99% of upper preset

Maximum Power Consumption

1 .2 VA

1 .2 VA

1 .2 W

Time Delay

adjustable, 0–10 s

adjustable, 0–10 s

adjustable, 0–10 s

Accuracy

Mechanical Setting

5%

5%

5%

Repeat Accuracy

<1%

<1%

<1%

Temperature Variation

<1% / ºC

<1% / ºC

<1% / ºC

Hysteresis (from fault to normal)

2–6% of adjusted value

2–6% of adjusted value

2–6% of adjusted value

Output Characteristics

Contact Configuration

SPDT

SPDT

SPDT

Output Current Rating

15 A @ 120, 240 Vac, 24 Vdc

15 A @ 120, 240 Vac, 24 Vdc

15 A @ 120, 240 Vac, 24 Vdc

Breaking Capacity

4000 VA/AC1, 384 W/DC

4000 VA/AC1, 384 W/DC

4000 VA/AC1, 384 W/DC

Inrush Current

30 A / <3 s

30 A / <3 s

30 A / <3 s

Maximum Switching Voltage

250 Vac / 24 Vdc

250 Vac / 24 Vdc

250 Vac / 24 Vdc

Minimum Breaking Capacity DC

500 mW

500 mW

500 mW

Mechanical Life

(1)

10,000,000 operations

10,000,000 operations

10,000,000 operations

Electrical Life

(1)

70,000 operations

70,000 operations

70,000 operations

Contact Material

Silver alloy

Silver alloy

Silver alloy

Switching Capability

15 A @ 240 Vac, 50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac, 50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac, 50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

Minimum Switching Requirement

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

Timing/Sensing Characteristics

Time Scales

1

1

1

Time Ranges

0–10 s

0–10 s

0–10 s

Tolerance

5% of mechanical setting

5% of mechanical setting

5% of mechanical setting

Repeatability at Constant Voltage and Temperature

1%

1%

1%

Upper Sensing Voltage Range

85–150 Vac

160–276 Vac

18–30 Vdc

Lower Sensing Voltage Range

30–99% of upper preset

30–99% of upper preset

30–99% of upper preset

General Characteristics

Dielectric Strength (Input to Contacts)

2500 Vac

2500 Vac

2500 Vac

Dielectric Strength (Between Open Contacts)

1600 Vac

1600 Vac

1600 Vac

Mounting Position

Any, 35 mm DIN rail EN 50022

Any, 35 mm DIN rail EN 50022

Any, 35 mm DIN rail EN 50022

Overvoltage Category

III

III

III

Pollution Degree

2

2

2

Storage Temperature Range

−30 to +70 °C (−22 to +158 °F)

−30 to +70 °C (−22 to +158 °F)

−30 to +55 °C (−22 to +131 °F)

Operating Temperature Range

−20 to +55 °C (−4 to +131 °F)

−20 to +55 °C (−4 to +131 °F)

−20 to +55 °C (−4 to +131 °F)

Terminal Wire Capacity (Input and Output)

14 AWG (2 .5 mm²) maximum

14 AWG (2 .5 mm²) maximum

14 AWG (2 .5 mm²) maximum

Terminal Screw Torque

7 .1 lb-in (0 .8 N•m) maximum

7 .1 lb-in (0 .8 N•m) maximum

7 .1 lb-in (0 .8 N•m) maximum

Weight

62 g (2 .19 oz)

62 g (2 .19 oz)

88 g (3 .10 oz)

Input Indication

Green LED

Output Indication (Blinking = Timing; On = Energized)

Red LED

Enclosure Rating (according to IEC 60529 IP rating) IP40

Approvals

UL (E234203, CCN: NKCR, NKCR7),

CE (IEC 60947-1, 61000-4),

RoHS

(1) Actual product life varies based on electrical load, duty cycle, application, and environmental conditions.

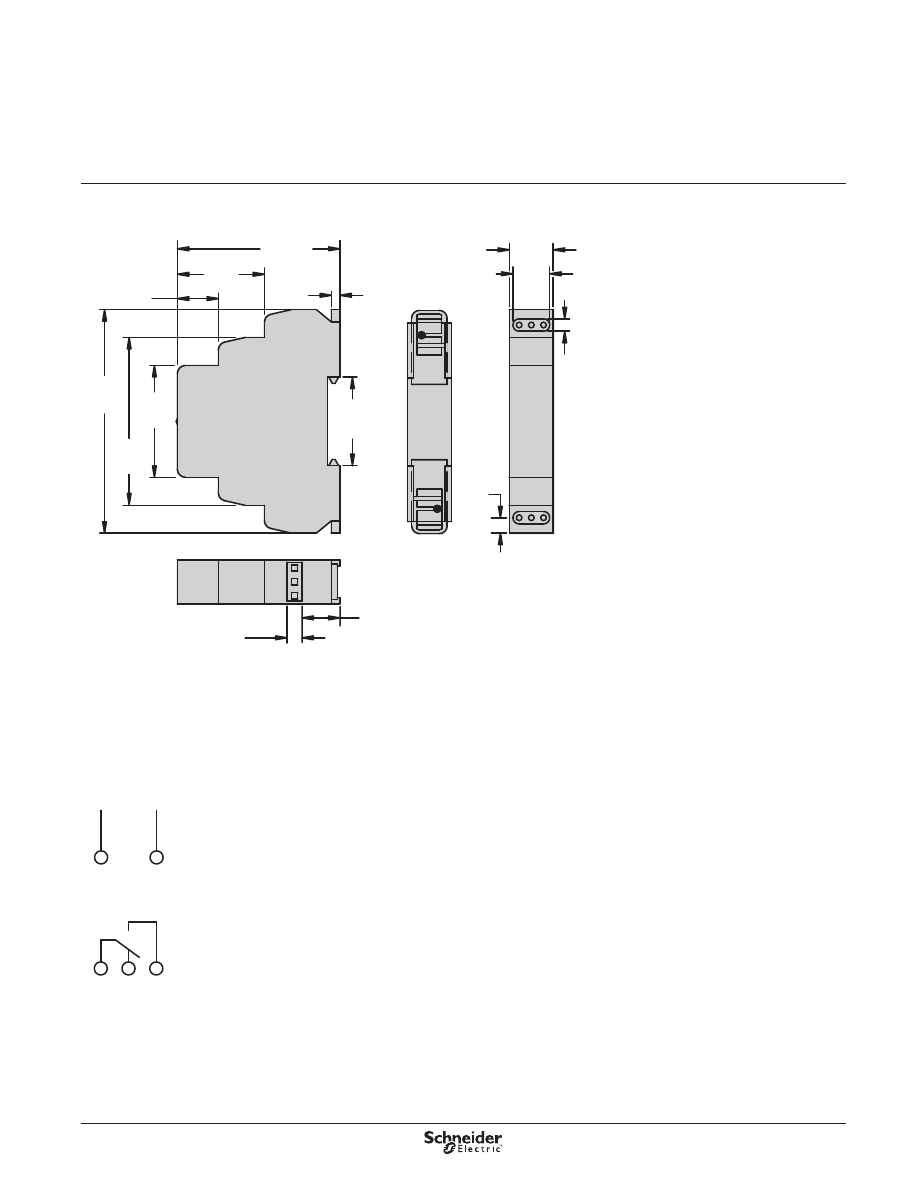

9

Dimensions—in. (mm)

Wiring Diagram

16

15

18

U

n

+

–

A1

A2

Input

Voltage

15

—Common

16

—Normally Closed

18

—Normally Open

(7.4)

0.3

0.7

(17.6)

0.6

(14.2)

(5)

0.2

(65)

(16)

(45.3)

1.8

0.63

(67.5)

2.7

(90)

3.5

1.4

2.6

(34.2)

1.35

(3.4)

0.13

(35)

0.6

(16)

0.236

(6)

Dimensions,

Wiring Diagram

Legacy Time Delay and

Sensor Relays

831 Series

SPDT, 15 A

10

Description

Legacy Time Delay and

Sensor Relays

841 Series

SPDT, 15 A

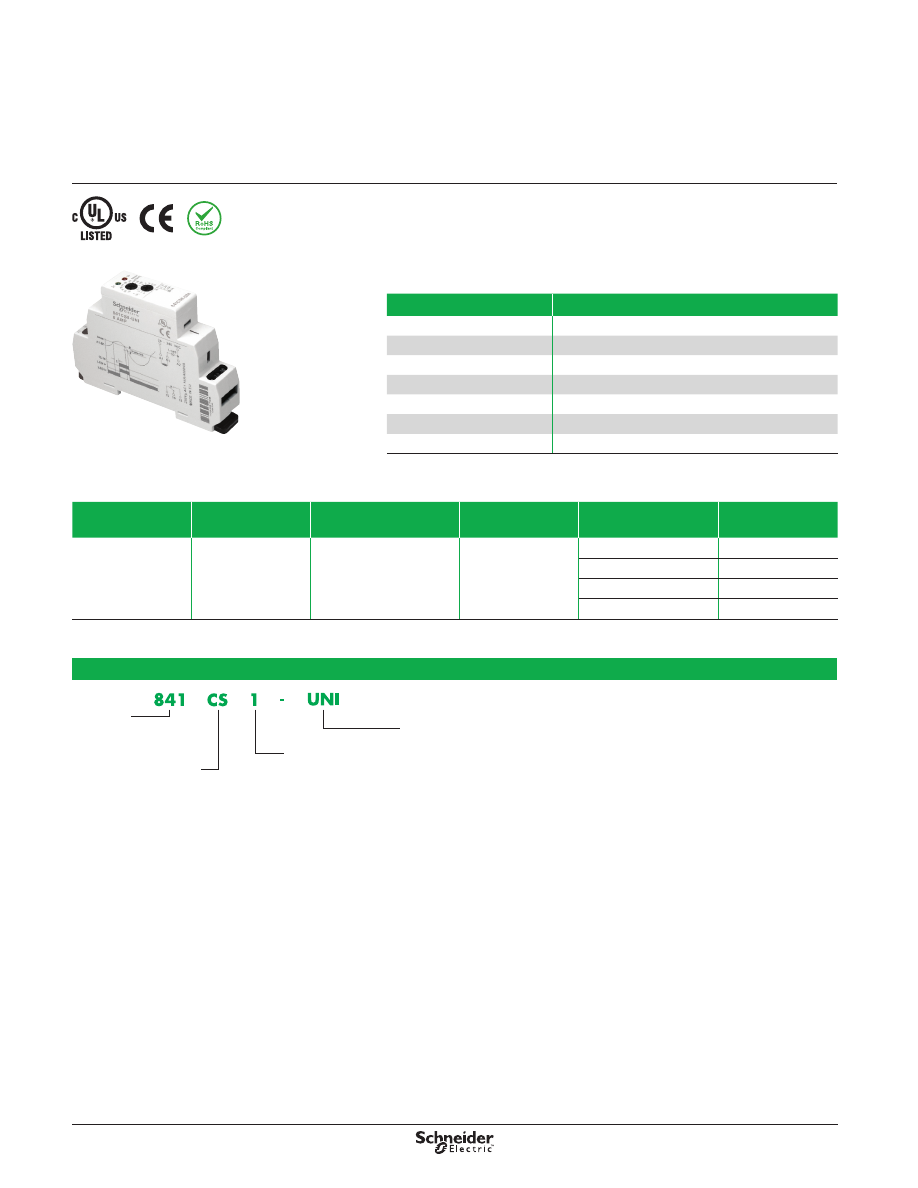

Description

This current sensing relay allows you to monitor the current of one circuit (1–8 A) and

switch another circuit in case of an overcurrent condition . The relays are modular and

finger protected (according to IEC 60529 IP rating) .

Input Voltage

Timing Range

Contact Configuration

Output (A)

Sensing

Current Range (AC)

Standard

Part Number

24–240 Vac

100 ms to 10 s

SPDT

15

100 mA to 1 A

841CS1-UNI

200 mA to 2 A

841CS2-UNI

500 mA to 5 A

841CS5-UNI

800 mA to 8 A

841CS8-UNI

Part Number Explanation

Series:

841 = SPDT

Relay Style:

CS = Current Sensor

Sensing Range:

1 = 100 mA to 1 A

2 = 200 mA to 2 A

5 = 500 mA to 5 A

8 = 800 mA to 8 A

Nominal Input Voltage:

UNI = 24–240 Vac

Feature

Benefit

Current-sensing adjustment knob Sense from 10–100% of the rated sensing current

Input/ouput terminals

Accepts wire up to 14 AWG

Solid-state circuitry

Used for precise sensing and timing control

Input/output indication

Shows status at a glance

DIN rail mounting capability

Mounts directly on a DIN Rail

Narrow width: 17 .5 mm (0 .69 in .) Ideal for tight spaces

Wide input range

Works with common AC voltages

841 Relay

11

Specifications

Legacy Time Delay and

Sensor Relays

841 Series

SPDT, 15 A

Specifications

Part Number

841CS1-UNI

841CS2-UNI

841CS5-UNI

841CS8-UNI

Input Characteristics

Input Voltage Range

24–240 Vac

24–240 Vac

24–240 Vac

24–240 Vac

Maximum Power Consumption

1 .2 VA

1 .2 VA

1 .2 VA

1 .2 VA

Output Characteristics

Contact Configuration

SPDT

SPDT

SPDT

SPDT

Output Current Rating

15 A

15 A

15 A

15 A

Contact Material

Silver alloy

Silver alloy

Silver alloy

Silver alloy

Switching Capability

15 A @ 240 Vac,

50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac,

50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac,

50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

15 A @ 240 Vac,

50/60 Hz, 24 Vdc

1/2 hp @ 120 Vac

1 hp @ 240 Vac

Pilot duty B300

Minimum Switching Requirement

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

Timing/Sensing Characteristics

Time Scales

1

1

1

1

Time Ranges

0–10 s

0–10 s

0–10 s

0–10 s

Tolerance

5% of mechanical setting 5% of mechanical setting 5% of mechanical setting 5% of mechanical setting

Repeatability at Constant Voltage and Temperature

1%

1%

1%

1%

Sensing Range

100 mA to 1 A

200 mA to 2 A

500 mA to 5 A

800 mA to 8 A

General Characteristics

Electrical Life (Operations at Rated Current)

(1)

70,000 operations

Mechanical Life (Unpowered)

(1)

10,000,000 operations

Dielectric Strength (Input to Contacts)

2500 Vac

Dielectric Strength (Between Open Contacts)

1600 Vac

Storage Temperature Range

−30 to +70 °C (−22 to +158 °F)

Operating Temperature Range

−20 to +55 °C (−4 to +131 °F)

Terminal Wire Capacity (Input and Output)

14 AWG (2 .1 mm²) maximum

Terminal Screw Torque

7 .1 lb-in (0 .8 N•m) maximum

Weight

60 g (2 .12 oz)

Input Indication

Green LED

Output Indication (Blinking = Timing; On = Energized)

Red LED

Enclosure Rating (according to IEC 60529 IP rating) IP20

Approvals

cULus (File: E234203, CCN: NKCR, NKCR7),

CE 61810-1, RoHS

(1) Actual product life varies based on electrical load, duty cycle, application, and environmental conditions.

12

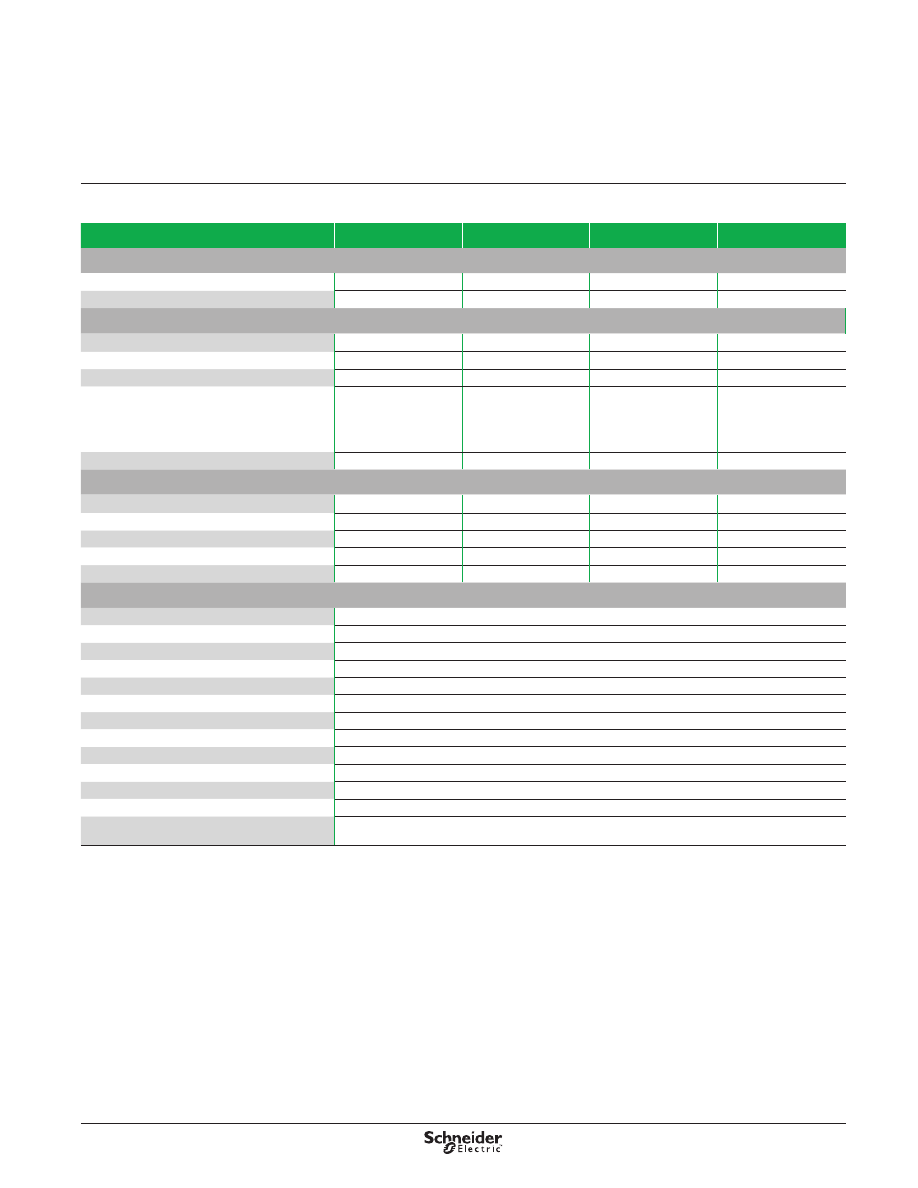

Dimensions—in. (mm)

Wiring Diagram

(7.4)

0.3

0.7

(17.6)

0.6

(14.2)

(5)

0.2

(65)

(16)

(45.3)

1.8

0.63

(67.5)

2.7

(90)

3.5

1.4

2.6

(34.2)

1.35

(3.4)

0.13

(35)

0.6

(16)

0.236

(6)

A1

A2

Input

Voltage

B1

Sensing

Circuit

16

15

18

15

—Common

16

—Normally Closed

18

—Normally Open

Direct current sensing

16

15

18

A1

A2

Input

Voltage

B1

Current sensing through a current transformer

Ip

Is

Input

Voltage

Current

Transformer

Ip:

Primary Current

Is:

Secondary Current

Inner

Shunt

Inner

Shunt

Dimensions,

Wiring Diagram

Legacy Time Delay and

Sensor Relays

841 Series

SPDT, 15 A

13

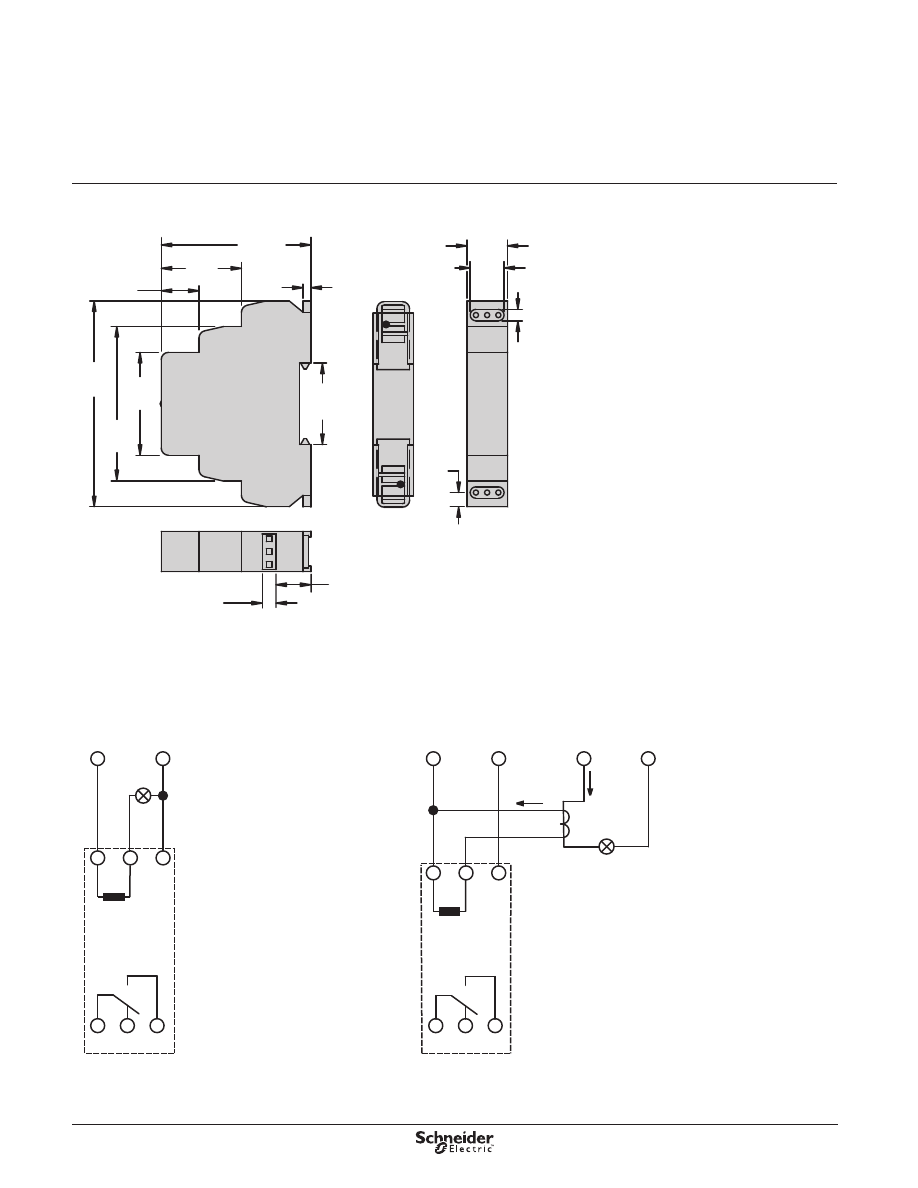

Accessories

Legacy Time Delay and

Sensor Relays

800 Series Accessories

Description

The 16-700DIN DIN rail provides for quick removal and installation of most sockets,

while the 16-788C1 panel adapter provides a panel mounting option .

Description

Function

For Use With Relays

Packaging Quantities

Standard Part Number

Metal DIN Rail

39 .3 in . (1 m) .

Quick installation and removal

821, 822, 831, 841

10

16-700DIN

DIN Rail End Clip

Holds sockets firmly in place on the DIN rail

—

16-DCLIP-1

Panel Adapter

Provides additional panel mounting option

821, 822, 831, 841

16-788C1

16-700DIN DIN Rail,

16-DCLIP-1 DIN Rail

End Clip

Shown with an 821 Relay

Shown with an 831 Relay

16-788C1 Panel Adapter

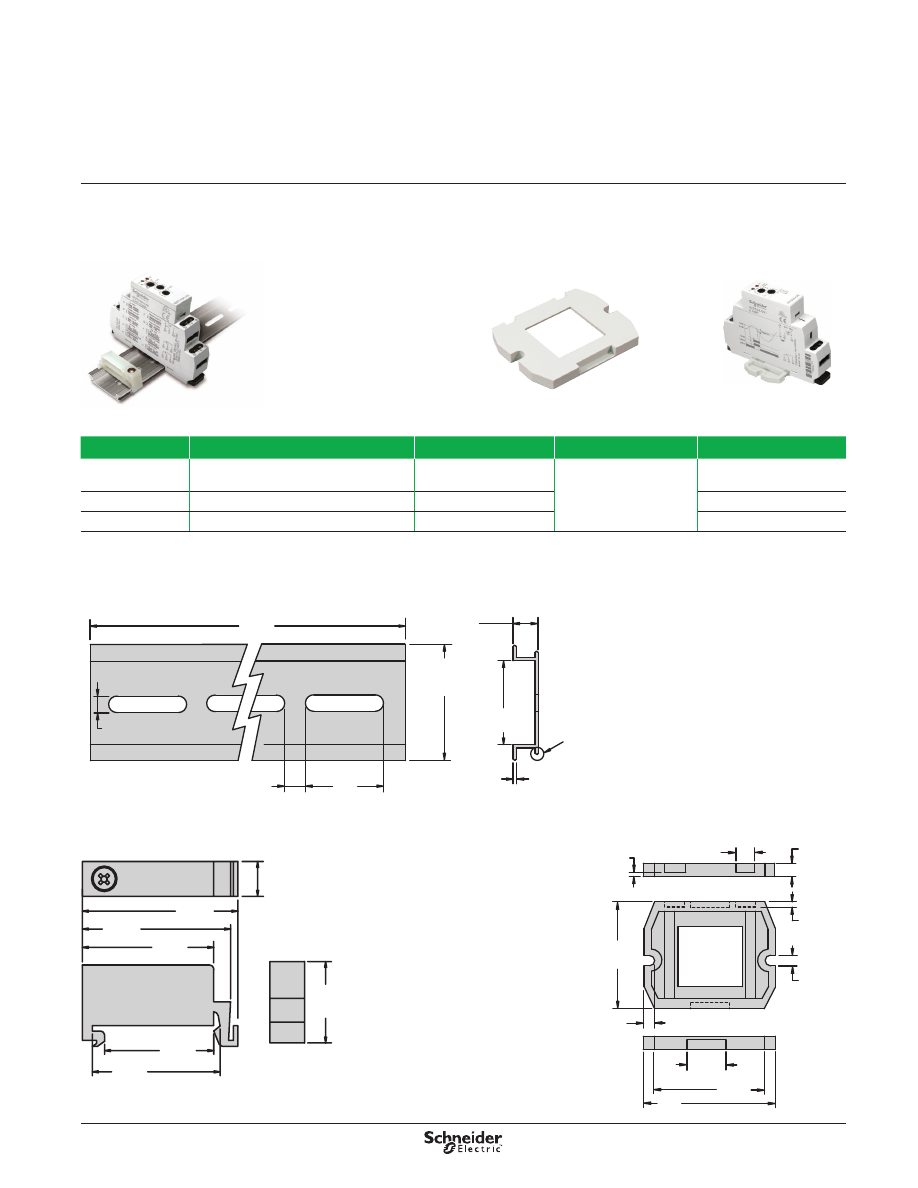

Dimensions—in. (mm)

Note

: The lips at the

base of the DIN rail may

or may not be present

on DIN rail extrusions .

16-700DIN Metal DIN Rail

(5)

0.19

1.377

+0.011 / −0.007

(35 ± 0.3)

0.99

(10)

0.39

(25)

(1 ± 0.04)

0.039

(25.5)

1.0

39.3

(1000)

0.3

(7.5 +0.0 / −0.4)

0.165 TYP

(4.19)

1.39 Max.

(35.3)

0.06 TYP

(1.4)

16-788C1 Panel Adapter

1.7

(43.18)

1.4 Max.

(35.5)

0.585

(14.95)

0.17 TYP

(4.31)

0.165

(4.19)

0.256

(6.5)

0.12

(3.04)

0.37

(9.4)

1.39

(35.5)

1.55

(39.5)

1.65

(42.0)

1.37

(34.7)

1.17

(29.7)

0.86

(22.0)

14

Description

Legacy Time Delay and

Sensor Relays

TDR782 Series

DPDT, 5 A; 4PDT, 3 A

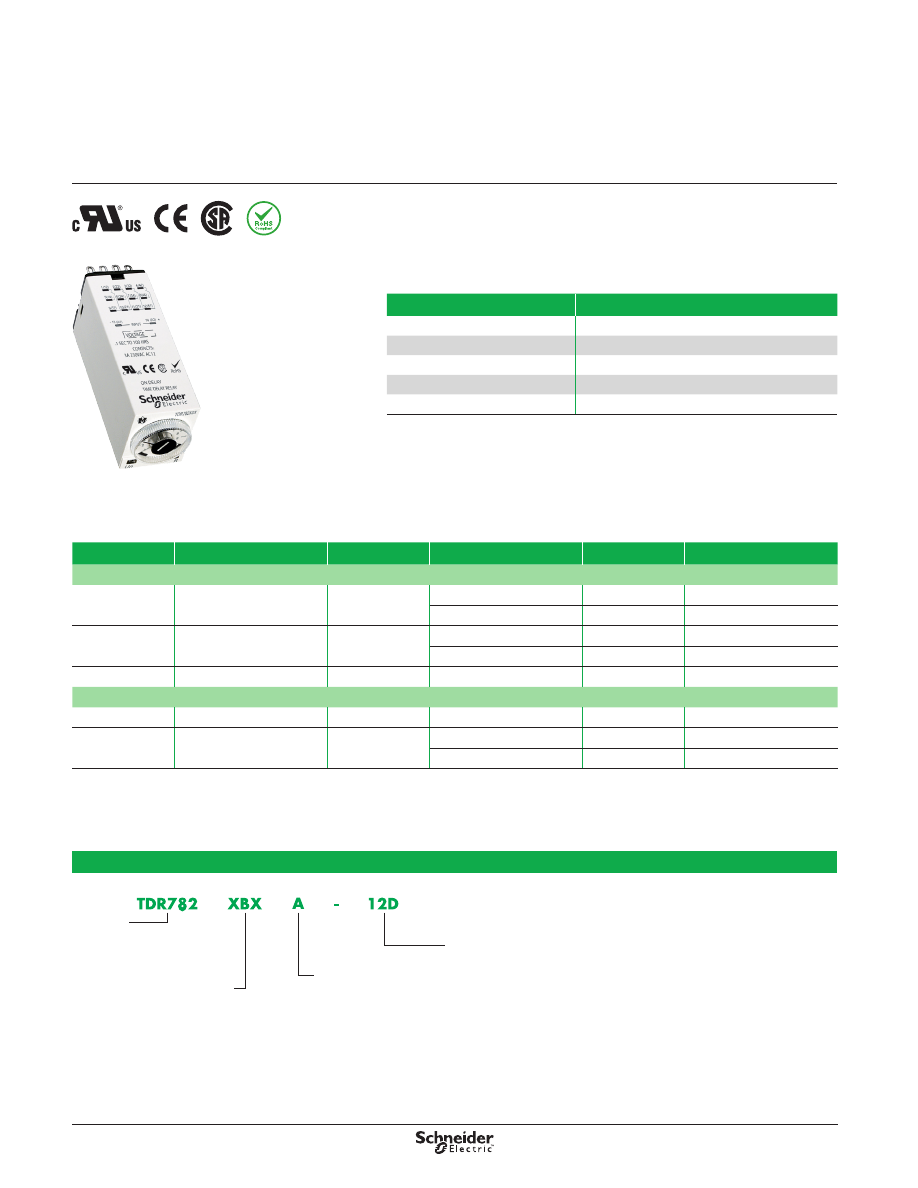

Description

Miniature time delay relay that is single-function, single-voltage, and socket-

compatible . Ideal for tight spaces .

Input Voltage

Functions Available

(1)

Timing Range

Contact Configuration

Rated Current

Standard Part Number

AC

24 Vac

A (On-Delay)

100 ms to 100 hr

4PDT

3 A

TDR782XDXA-24A

DPDT

5 A

TDR782XBXA-24A

110 Vac

A (On-Delay)

100 ms to 100 hr

4PDT

3 A

TDR782XDXA-110A

DPDT

5 A

TDR782XBXA-110A

230 Vac

A (On-Delay)

100 ms to 100 hr

4PDT

3 A

TDR782XDXA-230A

DC

12 Vdc

A (On-Delay)

100 ms to 100 hr

4PDT

3 A

TDR782XDXA-12D

24 Vdc

A (On-Delay)

100 ms to 100 hr

4PDT

3 A

TDR782XDXA-24D

DPDT

5 A

TDR782XBXA-24D

(1) For function descriptions, see page 31.

Part Number Explanation

Series:

TDR782 =

782 Miniature

Timer

Contact Configuration:

XBX =

DPDT

XDX =

4PDT

Functions:

A =

On Delay

Input

V

oltage:

12D =

12 Vdc

24D =

24 Vdc

24A =

24 Vac

110A =

110/120 Vac

230A =

230/240 Vac

Feature

Benefit

Time setting

Selects between 7 different time scales

Socket compatible

Mounts directly to DIN rail or panel

Input/output indication

Shows status at a glance

Time adjustment dial

Fine-tunes the time setting

IEC and NEMA terminal numbering

Allows numbering compatibility

TDR782 Relay

15

Specifications

Legacy Time Delay and

Sensor Relays

TDR782 Series

DPDT, 5 A; 4PDT, 3 A

Specifications

Part Number

TDR782XBX

TDR782XDX

Input Characteristics

Input Voltage Range

24, 110/120, 230/240 Vac

12, 24 Vdc

24, 110/120, 230/240 Vac

12, 24 Vdc

Operating Voltage

Vac

85–115% of nominal

85–115% of nominal

Vdc

90–110% of nominal

90–110% of nominal

Maximum Power Consumption

1 .7 VA @ 24 Vac

2 .6 VA @ 120 Vac

3 VA @ 230 Vac

1 .5 W @ 12 Vdc

1 .2 W @ 24 Vdc

1 .7 VA @ 24 Vac

2 .6 VA @ 120 Vac

3 VA @ 230 Vac

1 .5 W @ 12 Vdc

1 .2 W @ 24 Vdc

Output Characteristics

Contact Configuration

DPDT

4PDT

Output Current Rating

5 A

3 A

Contact Material

Silver alloy

Silver alloy

Maximum Inrush Current

10 A @ < 100 ms

10 A @ < 100 ms

Minimum Switching Requirement

100 mA at 5 Vac/Vdc

100 mA at 5 Vac/Vdc

Timing Characteristics

Functions Available

(1)

A (On-Delay)

A (On-Delay)

Time Scales

7

7

Time Ranges

100 ms to 1 s

1 s to 10 s

0 .1 min to 1 min

1 min to 10 min

0 .1 hr to 1 hr

1 hr to 10 hr

10 hr to 100 hr

100 ms to 1 s

1 s to 10 s

0 .1 min to 1 min

1 min to 10 min

0 .1 hr to 1 hr

1 hr to 10 hr

10 hr to 100 hr

Tolerance

5% of mechanical setting

5% of mechanical setting

Repeatability at Constant Voltage and Temperature

0 .5%

0 .5%

Reset Time

50 ms maximum

50 ms maximum

Temperature Drift

0.05% / °C

0.05 % / °C

General Characteristics

Electrical Life (Operations at Rated Current)

(2)

100,000 operations

Mechanical Life (Unpowered)

(2)

10,000,000 operations

Dielectric Strength (Input to Contacts)

2000 Vrms

Storage Temperature Range

−40 to +70 °C (−40 to +158 °F)

Operating Temperature Range

−20 to +60 °C (−4 to +140 °F)

Weight

43 g (1 .52 oz)

Input Indication

Green LED

Output Indication (On = Energized)

Amber LED

Enclosure Rating (According to IEC 60529 IP Rating) IP50

Approvals

cURus (File: E191122, CCN: NRNT2, NRNT8),

CSA (File No . 254373),

CE 61810-1, RoHS

(1) For function descriptions, see page 31.

(2) Actual product life varies based on electrical load, duty cycle, application, and environmental conditions.

16

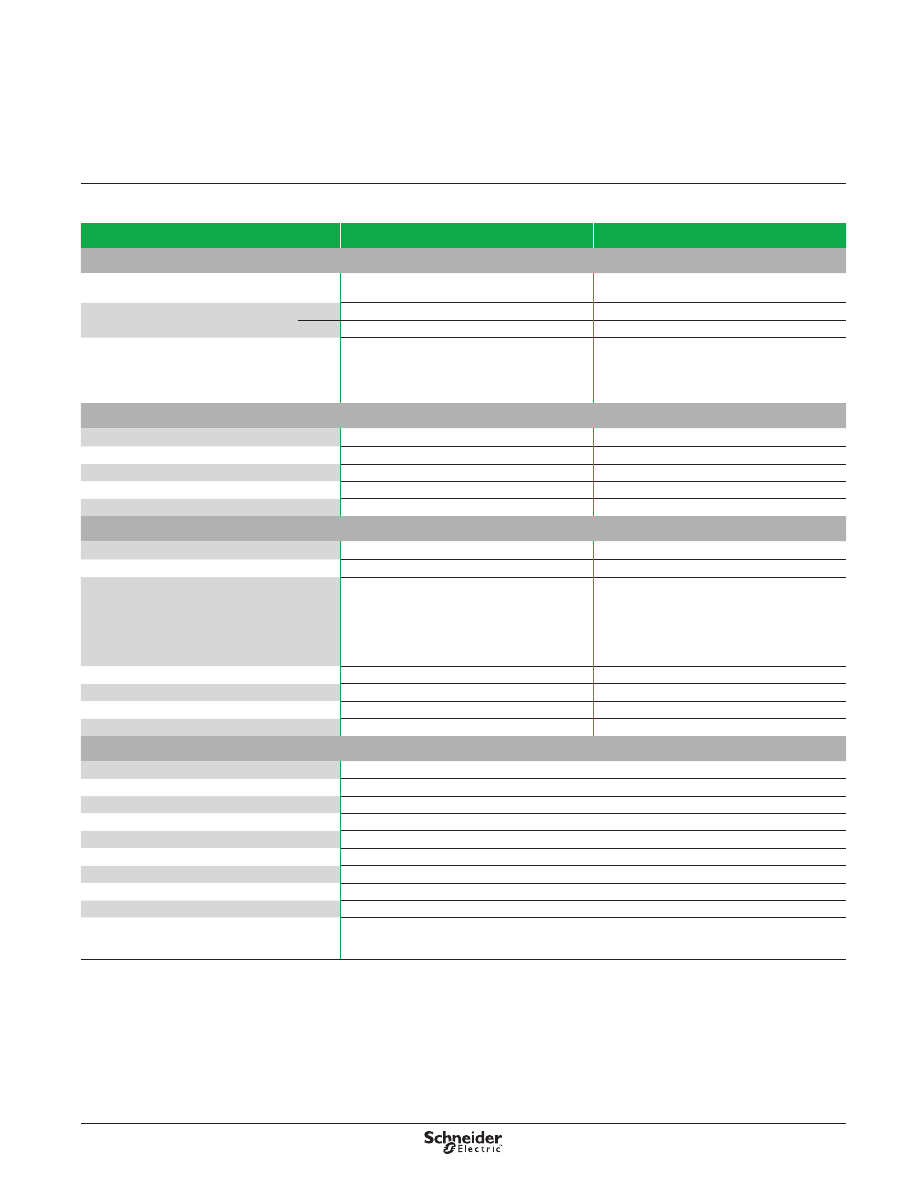

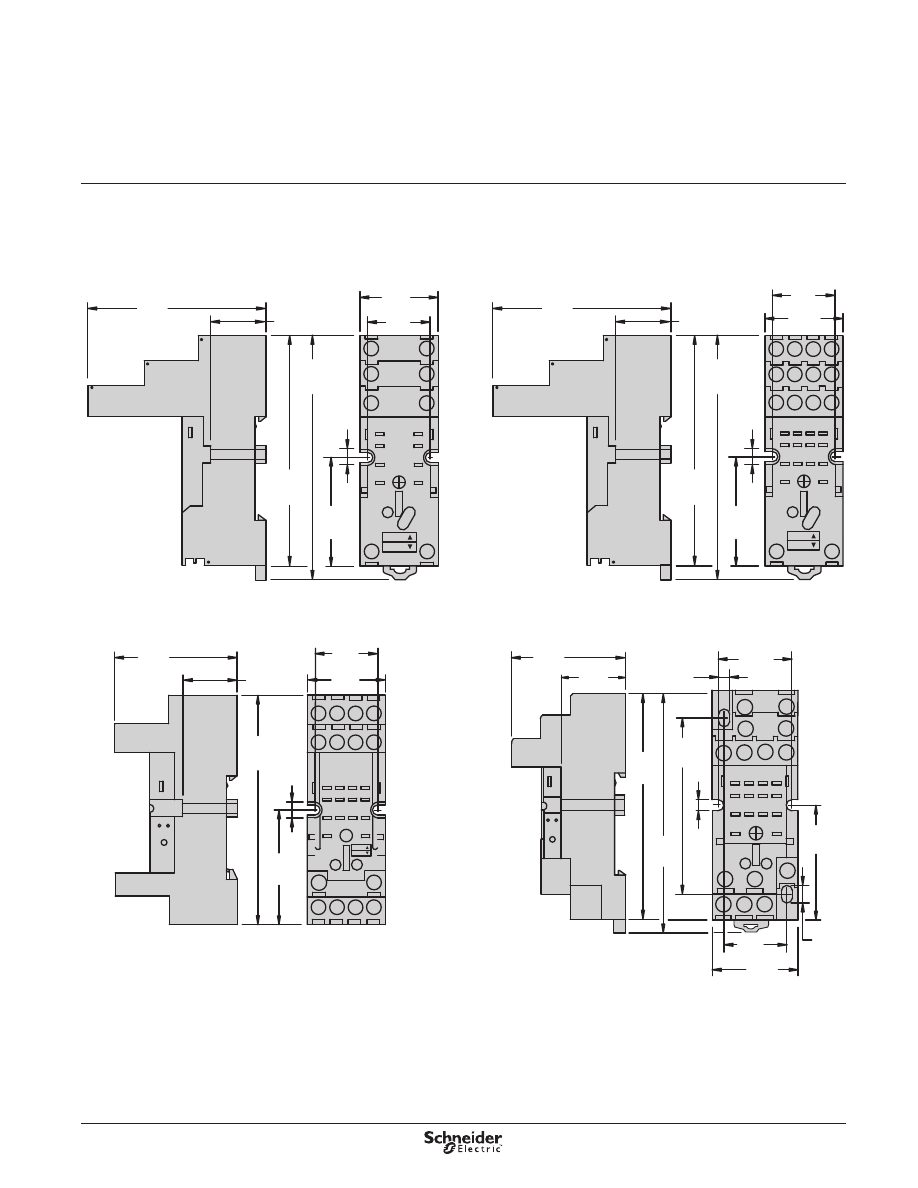

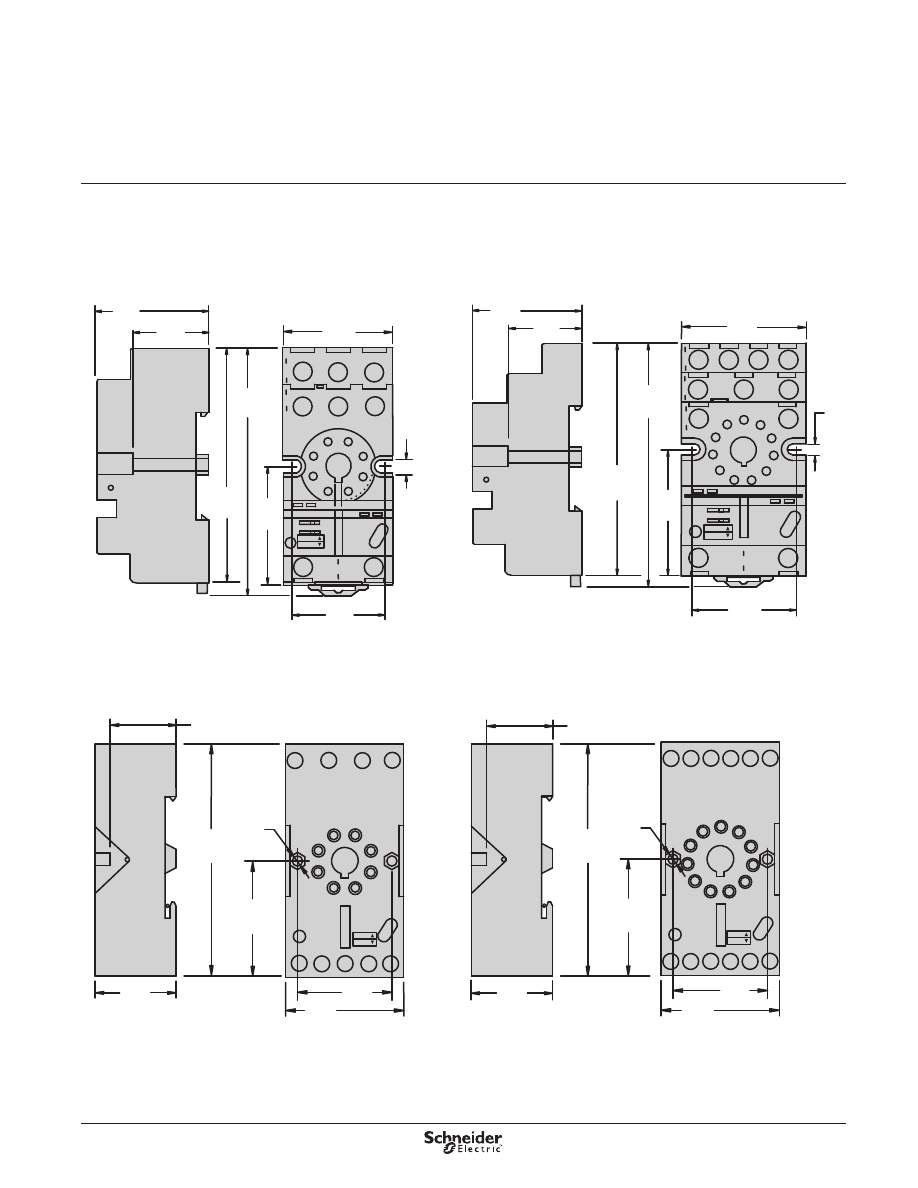

Dimensions—in. (mm)

Wiring Diagram

0.8

(21)

1.0

(27)

0.14

(3.5)

2.3

(59.4)

2.57

(65.28)

0.02

(0.48)

13

5

9

1

14

6

10

2

8

7

11

12

3

4

8

5

13

9

14

12

1

4

SPDT

NEMA

DPDT

NEMA

Dimensions,

Wiring Diagram

Legacy Time Delay and

Sensor Relays

TDR782 Series

DPDT, 5 A; 4PDT, 3 A

17

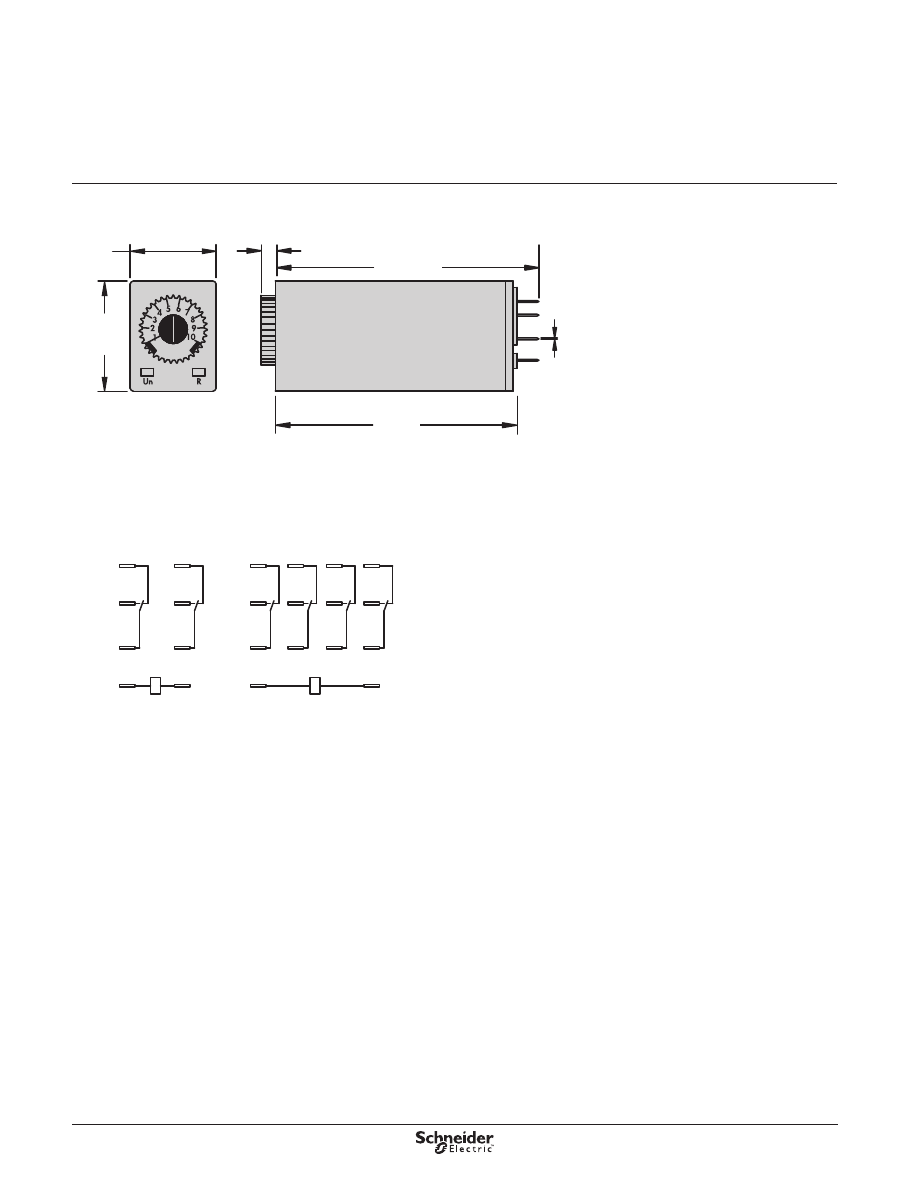

Description

Legacy Time Delay and

Sensor Relays

TDR782 Series Accessories

Description

The TDR782 accessories create a complete system solution for all your application

needs .

The 70-782EL socket offers an alternate installation option for plug-in models .

The 16-TDR782SC retention clip holds the relay securely in place while allowing

quick and efficient installation and maintenance .

Relay Accessories

Description

Function

For Use

With Relays

Packaging

Quantities

Standard

Part Number

Socket

Mounts directly to the DIN rail or panel

TDR782XBX

10

70-782EL8-1

TDR782XBX

TDR782XDX

10

70-782EL14-1

DIN or panel mounting with rising elevator box terminals

TDR782XBX

TDR782XDX

10

70-782E14-1

DIN or panel mounting with screw terminals and clamping

plates

TDR782XBX

TDR782XDX

10

70-782D14-1

TDR782XBX

TDR782XDX

10

70-461-1

Solder terminals for chassis mounting

TDR782XBX

TDR782XDX

10

70-378-1

Printed circuit terminals

TDR782XBX

TDR782XDX

10

70-379-1

Metal Retention Clip

Helps secure the relay in the socket

TDR782●●

(1)

10

16-TDR782SC

(1)

Replace the bullets (

●●) with the the part number suffix. See page

14 .

70-782EL8-1 Socket

70-782E14-1 Socket

16-TDR782SC Retention Clip

Socket Accessories

Description

Function

For Use

With Sockets

Packaging

Quantities

Standard

Part Number

Metal DIN Rail, 1 m (39 .3 in .)

Quick installation and removal of sockets

See table above

10

16-700DIN

DIN Rail End Clip

Holds sockets firmly in place on the DIN rail

—

10

16-DCLIP-1

ID Tags

Allows for identification of circuits in multi-relay applications

70-782EL8-1

70-782EL14-1

70-782E14-1

10

16-782FT-1

18

Specifications

Legacy Time Delay and

Sensor Relays

TDR782 Series Accessories

Specifications

Part Number

70-782EL8-1

70-782EL14-1

70-782E14-1

Contact Configuration

DPDT

4PDT

4PDT

Number of Terminals

8

14

14

Mounting Style

Panel or DIN Rail

Panel or DIN Rail

Panel or DIN Rail

Current Rating

12 A

10 A

10 A

Nominal Voltage Rating

300 V

300 V

300 V

Storage Temperature Range

−40 to +105 °C (−40 to +221 °F)

−40 to +105 °C (−40 to +221 °F)

−40 to +105 °C (−40 to +221 °F)

Protection Category

IP20 (Finger Protection)

Internal Metal Tracks

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Screw Terminals

Steel, Zinc Plated

Steel, Zinc Plated

Steel, Zinc Plated

Screw Style

Combination Head

Combination Head

Combination Head

Screw Size

M3

M3

M3

Terminal Connection

Elevator

Elevator

Elevator

Terminal Layout

Logic

Logic

Non-Logic

Wire Size Capacity

Solid or Stranded Cu:

Two 14–16 AWG (1 .5–2 .5 mm²)

Solid or Stranded Cu:

Two 14–16 AWG (1 .5–2 .5 mm²)

Solid or Stranded Cu:

Two 14–16 AWG (1 .5–2 .5 mm²)

DIN Rail Mounting, EN 60715

35 mm (1 .38 in)

35 mm (1 .38 in)

35 mm (1 .38 in)

Maximum Screw Torque

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

Flammability Rating

UL94 Class V-0

UL94 Class V-0

UL94 Class V-0

Body Color

Light Gray

Light Gray

Light Gray

DIN Locking Method

Red Plastic Locking Clip

Red Plastic Locking Clip

Metal Compression Spring

Product Certifications

cURus (File: E70550, CCN: SWIV2, SWIV8),

CSA (File: 40787, Class: 3211 07),

CE 60947-1, RoHS

Part Number

70-379-1

70-378-1

70-461-1, 70-782D14-1

Contact Configuration

4PDT

4PDT

4PDT

Number of Terminals

14

14

14

Mounting Style

PCB

Chassis

Panel or DIN Rail

Current Rating

5 A

5 A

10 A

Nominal Voltage Rating

300 V

300 V

300 V

Storage Temperature Range

−40 to +105 °C (−40 to +221 °F)

−40 to +105 °C (−40 to +221 °F)

−40 to +105 °C (−40 to +221 °F)

Protection Category

–

–

70-782D14-1

: IP20 (Finger Protection)

Internal Metal Tracks

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Screw Terminals

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Steel, Zinc Plated

Screw Style

–

–

Combination Head

Screw Size

–

–

M3 mm

Terminal Connection

PCB

Solder

Screw Clamping

Terminal Layout

Non-Logic

Non-Logic

Non-Logic

Wire Size Capacity

–

Solid or Stranded Cu:

Two 14–16 AWG (1 .5–2 .5 mm²)

Solid or Stranded Cu:

Two 14–16 AWG (1 .5–2 .5 mm²)

DIN Rail Mounting, EN 60715

–

–

35 mm (1 .38 in)

Maximum Screw Torque

–

–

7 lb-in (0 .8 N•m)

Flammability Rating

UL94 Class V-0

UL94 Class V-0

UL94 Class V-0

Body Color

Light Gray

Light Gray

Light Gray

DIN Locking Method

–

–

Red Plastic Locking Clip

Product Certifications

cURus (File: E70550, CCN: SWIV2, SWIV8),

CSA (File: 40787 Class: 3211 07),

CE 60947-1, RoHS

70-461-1:

cURus (File: E70550, CCN: SWIV2, SWIV8),

CSA (File: 40787 Class: 3211 07),

CE 60947-1, RoHS

70-782D14-1:

cURus (File: E70550),

CSA (File: 40787 Class: 3211 07),

CE 60947-1, RoHS

19

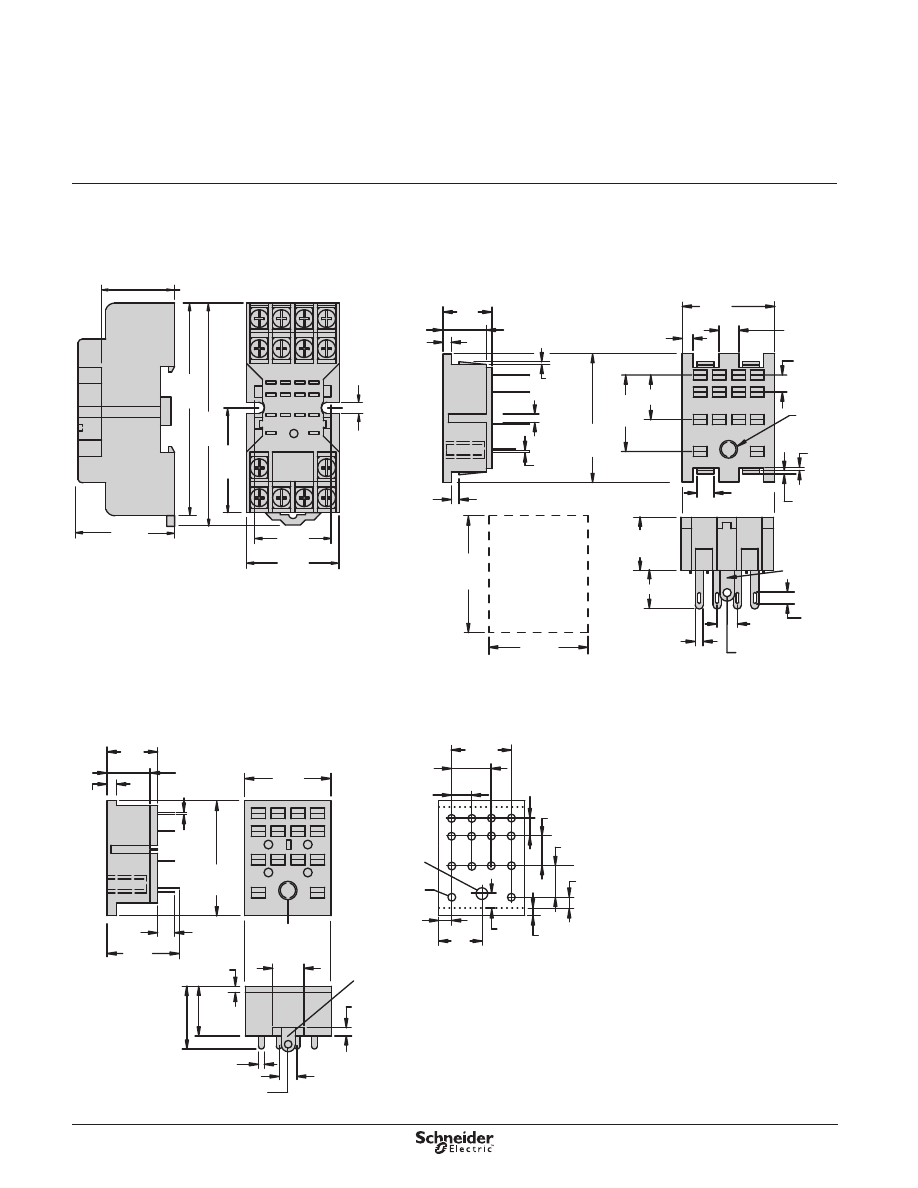

Dimensions—in. (mm)

1.06

(26.9)

A1

INPUT

A2

14

13

12

5

9

11

14

4

1

8

12

42

41

44

NEMA:

IEC:

70-782EL8-1

Mounts Directly to the DIN Rail or Panel

0.9

(22)

(19.0)

(61.0)

2.4

0.74

3.11

(79.0)

(85.0)

3.34

(38.0)

1.49

0.2

(5.6)

Dimensions

Legacy Time Delay and

Sensor Relays

TDR782 Series Accessories

70-782EL14-1

Mounts Directly to the DIN Rail or Panel

0.9

(22)

1.06

(25.4)

(19.0)

(61.0)

2.4

0.74

3.11

(79.0)

(85.0)

3.34

(38.0)

1.49

0.2

(5.6)

1

A1

12

5

9

11

14

INPUT

A2

14

3

4

7

8

11

12

32

42

41

31

34

44

13

2

6

10

22

21

24

NEMA:

IEC:

70-782E14-1

DIN or Panel Mounting with Rising Elevator Box Terminals

10

12

11

9

21

41

31

11

INPUT

14

13

A1

A2

6

8

7

5

24

44 34

14

12

1

42

3

22

2

4

32

(26.9)

(22.0)

(43.0)

(79.0)

(17.0)

(3.0)

(40.0)

1.69

3.12

0.67

1.57

0.12

0.86

1.06

NEMA:

IEC:

70-782D14-1

DIN or Panel Mounting with Screw Terminals and Clamping Plates

(3.8)

(30.0)

(21.0)

(84.0)

(79.0)

(6.4)

(39.5)

(61.0)

(40.0)

(3.8)

(25.5)

0.14

1.0

1.55

0.25

0.82

0.14

3.3

3.11

1.57

2.4

1.18

44 14

11

12

10

INPUT

INPUT

31

14

A2

41

13

9

A1

21

11

3

4

2

1

8

32

42

5

22

12

34

7

24

6

0.74

(19.0)

20

Dimensions

(continued)

Legacy Time Delay and

Sensor Relays

TDR782 Series Accessories

70-378-1

Solder Terminals for Chassis Mount

0.105

(2.67)

(17.7)

0.07

(28.5)

1.14

(2.59)

0.102

(9.52)

0.375

(11.1)

0.44

Ground

Lug

(3.17)

(3.81)

0.15

(1.77)

0.07 Dia.

0.125

(4.06)

0.16

0.05

(1.27)

(1.27)

0.05

(16.5)

0.65

(9.9)

0.39

0.16 Dia.

(4.06)

(1.98)

0.078

0.10

0.145

(3.68)

(2.54)

(21.8)

0.86

(4.57)

0.18

(2.54)

(0.381)

0.015

0.44

(11.1)

0.375

(9.52)

0.10

Recommended

Chassis Cutout

Top View

(25.7)

1.01

(21.5)

0.86

Dimensions—in. (mm)

70-379-1

Printed Circuit Terminals

0.625

(15.8)

0.30

(1.54)

0.061

(11.1)

0.44

(1.52)

0.06

(7.82)

Ground

Lug

0.07 Dia. (1.77)

(3.81)

0.15

(2.03)

0.08

(25.4)

1.0

0.16 Dia.

(4.06)

0.75

(19.0)

(2.66)

0.105

0.674

(17.0)

(4.76)

0.1875

0.375

(9.52)

(11.17)

0.44

Recommended

Circuit Board Layout

Top View

0.015

(0.381)

0.16

(2.4)

0.095

(6.35)

0.25

(6.35)

0.25

(4.06)

0.175

(4.44)

(2.6)

0.102

0.35

(8.89)

0.525

(13.3)

0.10

(2.5)

0.12

(3.04)

(9.5)

0.375

0.07 (1.78) Dia.

14 Places

0.145 (3.68) Dia.

70-461-1

DIN or Panel Mounting with Screw Terminals and Clamping Plates

2.71

(69.0)

(64.0)

2.51

(25.4)

1.0

9

5

1

4

8

3

7

6

2

1

1

4

1

2

1

3

1

0

1

(22.7)

0.89

0.17

(4.32)

Dia.

Typ.

(30.7)

1.2

1.25

(32.0)

0.708 (18)

21

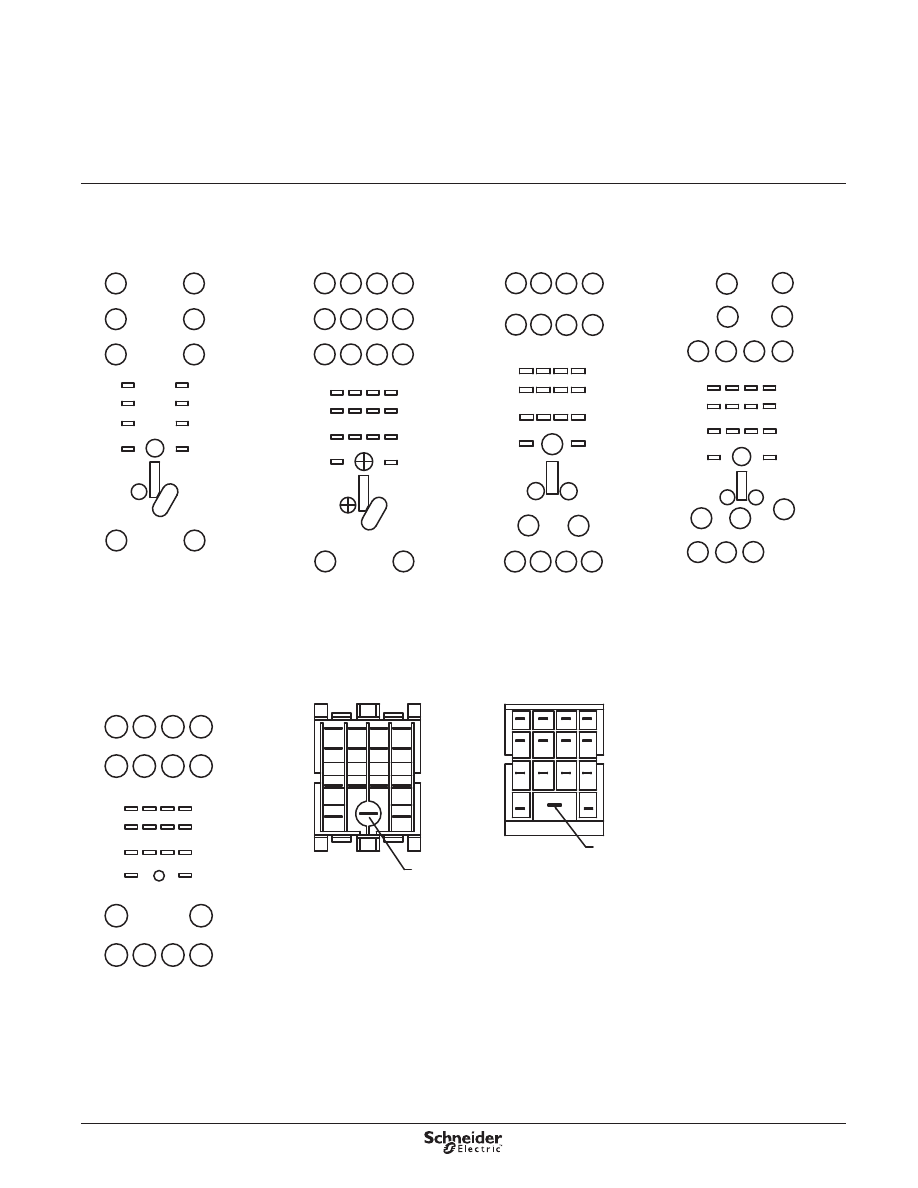

Wiring Diagrams

Legacy Time Delay and

Sensor Relays

TDR782 Series Accessories

Wiring Diagrams

70-782EL14-1

A2

14

13

INPUT

A1

44

41

42

4

8

12

2

32

3

22 12

1

14

6

34

7

24

5

21

10

31

11

11

9

1

2

3

4

5

6

7

8

9

10

11

12

14

13

MODULE

INPUT

COM

INPUT

N.O.

N.C.

IEC

NEMA

70-782EL8-1

1

A1

12

5

9

11

14

INPUT

A2

14

4

8

12

42

41

44

13

N.O.

INPUT

COM

N.C.

4

1

5

8

9

12

14

13

MODULE

INPUT

IEC

NEMA

70-378-1

11

10

9

13

5

7

6

12

14

8

1

3

2

4

N.O.

N.C.

COM

INPUT

12

22

32

42

14

24

34

44

11

21

31

41

A1

A2

GROUND

LUG

IEC

NEMA

70-379-1

INPUT

COM

N.C.

N.O.

2

3

4

5

6

7

8

9

10

11

12

13

14

22

32

42

14

24

34

44

11

21

31

41

A1

A2

GROUND

LUG

IEC

NEMA

1

12

70-461-1

8

4

7

5

6

3

1

2

10

11

12

14

13

9

41 31 21 11

A2

A1

42 32 22 12

44 34 24 14

N.C.

N.O.

COM

INPUT

8 7 6 5

4 3 2 1

14

13

9

10

11

12

IEC

NEMA

INPUT

70-782D14-1

A2

14

12

41

9

A1

13

11 10

31 21

11

4

42

1

2

3

24

34

14

6

7

44

12

22

32

5

8

INPUT

COM

N.O.

N.C.

4 3 2 1

5

8

6

7

12 11 10

14

13

9

MODULE

INPUT

IEC

NEMA

INPUT

70-782E14-1

N.O.

INPUT

COM

N.C.

1

12

2

22

3

32

4

42

5

14

6

24

7

34

8

44

A1

13

A2

14

11

9

21

10

31

11

41

12

13

14

8 7 6 5

3

4

2 1

12 11 10 9

IEC

NEMA

MODULE

INPUT

INPUT

22

Description

Legacy Time Delay and

Sensor Relays

TDRPRO Series

SPDT, 12 A; DPDT, 12 A

Description

Time delay relays that are programmable, multifunction, multi-voltage, and socket-

compatible—offering the ultimate in design flexibility . The thumb-wheel adjustment

dials result in no mechanical deviation for supreme accuracy .

Input Voltage

Timing Range

Functions

Available

(1)

Contact

Configuration

Rated Current

Standard

Part Number

12–240 Vac/Vdc

100 ms to 9990 hr

A,B,C,D,E,F,G,H,I,J

DPDT

12 A

TDRPRO-5100

A,B,C,D,E,F,G,H,I,J

SPDT

12 A

TDRPRO-5101

A,B,C

DPDT

12 A

TDRPRO-5102

(1) For function descriptions, see page 31.

Part Number Explanation

Series:

TDRPRO =

48 x 48 mm

Time Delay Relay

Contact Configuration and Number of Functions:

5100 =

DPDT, 10 Functions

5101 =

SPDT, 10 Functions

5102 =

DPDT, 3 Functions

Feature

Benefit

Up to 10 functions

5 timing functions controlled via supply voltage

4 timing functions controlled via trigger input

1 memory latching function

Broad timing range

0 .1 s to 9990 hr

Panel-mounting adapter

Panel mountable

Dust cover

Retains settings and keeps dust out

Universal power supply

12–240 Vac/Vdc

Thumb-wheel adjustment for

function / timing

Helps ensure accuracy and reduces timing deviations

2 LED status indicators

Indicate coil power, timing out, and output state

RoHS compliant

Environmentally friendly

TDRPRO Relay

23

Specifications

Legacy Time Delay and

Sensor Relays

TDRPRO Series

SPDT, 12 A; DPDT, 12 A

Specifications

Part Number

TDRPRO-5100

TDRPRO-5101

TDRPRO-5102

Input Characteristics

Input Voltage Range

12–240 Vac/Vdc

12–240 Vac/Vdc

12–240 Vac/Vdc

Operating Voltage

85–115% of nominal

85–115% of nominal

85–115% of nominal

Maximum Power Consumption (AC)

2 .5 VA

2 .5 VA

2 .5 VA

Maximum Power Consumption (DC)

2 W

2 W

2 W

Output Characteristics

Contact Configuration

DPDT

SPDT

DPDT

Output Current Rating

12 A

12 A

12 A

Contact Material

Silver alloy

Silver alloy

Silver alloy

Switching Capabilties

12 A, 240 Vac, 50/60 Hz, 30 Vdc

1/3 hp @ 120 Vac

1/2 hp @ 240 Vac

Pilot duty B300

12 A, 240 Vac, 50/60 Hz, 30 Vdc

1/3 hp @ 120 Vac

1/2 hp @ 240 Vac

Pilot duty B300

12 A, 240 Vac, 50/60 Hz, 30 Vdc

1/3 hp @ 120 Vac

1/2 hp @ 240 Vac

Pilot duty B300

Minimum Switching Requirement

100 mA

100 mA

100 mA

Timing Characteristics

Functions Available

(1)

A,B,C,D,E,F,G,H,I,J

A,B,C,D,E,F,G,H,I,J

A,B,C

Time Scales

7

7

7

Time Ranges

0–999 by 0 .1 s

0–999 by 1 s

0–999 by 0 .1 min

0–999 by 1 min

0–999 by 0 .1 hr

0–999 by 1 hr

0–999 by 10 hr

0–999 by 0 .1 s

0–999 by 1 s

0–999 by 0 .1 min

0–999 by 1 min

0–999 by 0 .1 hr

0–999 by 1 hr

0–999 by 10 hr

0–999 by 0 .1 s

0–999 by 1 s

0–999 by 0 .1 min

0–999 by 1 min

0–999 by 0 .1 hr

0–999 by 1 hr

0–999 by 10 hr

Repeatability of the Time Delay

at Constant Voltage and Temperature

0 .1%

0 .1%

0 .1%

Reset Time

150 ms

150 ms

150 ms

Operate Time

(3)

25 ms maximum

25 ms maximum

25 ms maximum

Release Time

(3)

25 ms maximum

25 ms maximum

25 ms maximum

General Characteristics

Electrical Life (Operations at Rated Current)

(2)

100,000 operations

100,000 operations

100,000 operations

Mechanical Life (Unpowered)

(2)

10,000,000 operations

10,000,000 operations

10,000,000 operations

Dielectric Strength (Input to Contacts)

2500 Vrms

2500 Vrms

2500 Vrms

Storage Temperature Range

−30 to +70 °C (−22 to +158 °F)

−30 to +70 °C (−22 to +158 °F)

−30 to +70 °C (−22 to +158 °F)

Operating Temperature Range

−20 to +60 °C (−4 to +140 °F)

−20 to +60 °C (−4 to +140 °F)

−20 to +60 °C (−4 to +140 °F)

Weight

133 g (4 .69 oz)

133 g (4 .69 oz)

133 g (4 .69 oz)

Input Indication

Green LED

Green LED

Green LED

Output Indication (Blinking = Timing; On = Energized)

Red LED

Red LED

Red LED

Enclosure Rating (according to IEC 60529 IP rating)

IP40

IP40

IP40

Approvals

cURus (File: E43641, CCN:

NLDX2), CE 61810-1, RoHS,

cULus (File: E43641, CCN:

NLDX2, UL Listed when used

with Schneider Electric socket

70-465)

cURus (File: E43641, CCN:

NLDX2), CE 61810-1, RoHS,

cULus (File: E43641, CCN:

NLDX2, UL Listed when used

with Schneider Electric socket

70-464)

cURus (File: E43641, CCN:

NLDX2), CE 61810-1, RoHS,

cULus (File: E43641, CCN:

NLDX2, UL Listed when used

with Schneider Electric socket

70-464)

(1) For function descriptions, see page 31.

(2) Actual product life varies based on electrical load, duty cycle, application, and environmental conditions.

(3) After the time delay period expires, or upon application of the trigger signal (depending on the selected function).

24

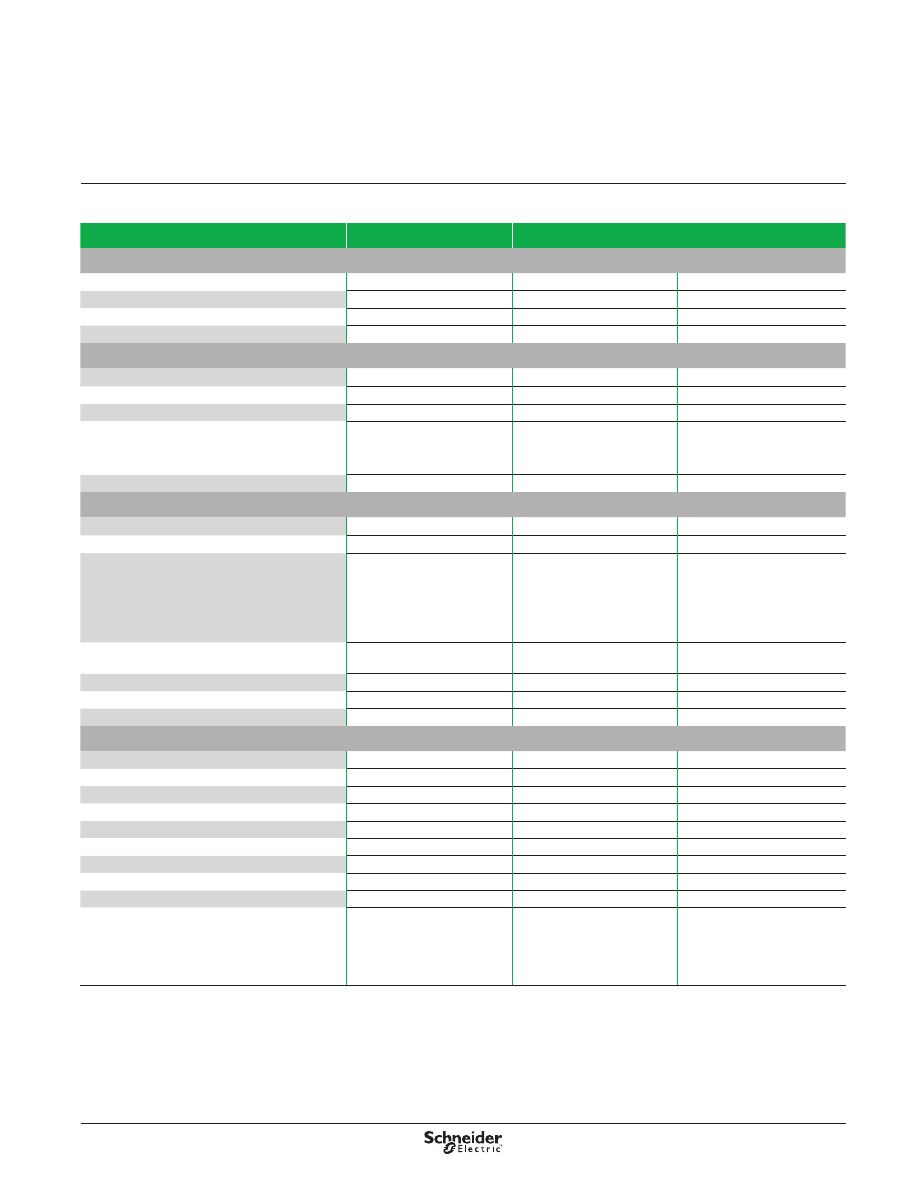

Dimensions—in. (mm)

Wiring Diagrams

(48)

1.9

(48)

1.9

(6)

0.23

0.06

(1.52)

(72)

2.8

3.15

(80.0)

(6.35)

0.25

Input

3

2

1

6

7

8

4

5

Input

2

1

4

3

7

8

5

6

3

2

1

4

9

10

11

8

6

5

7

Input

TDRPRO-5100

TDRPRO-5101

TDRPRO-5102

External

Control

Switch

(Dry Switch

Only)

External

Control

Switch

(Dry Switch

Only)

Dimensions,

Wiring Diagrams

Legacy Time Delay and

Sensor Relays

TDRPRO Series

SPDT, 12 A; DPDT, 12 A

25

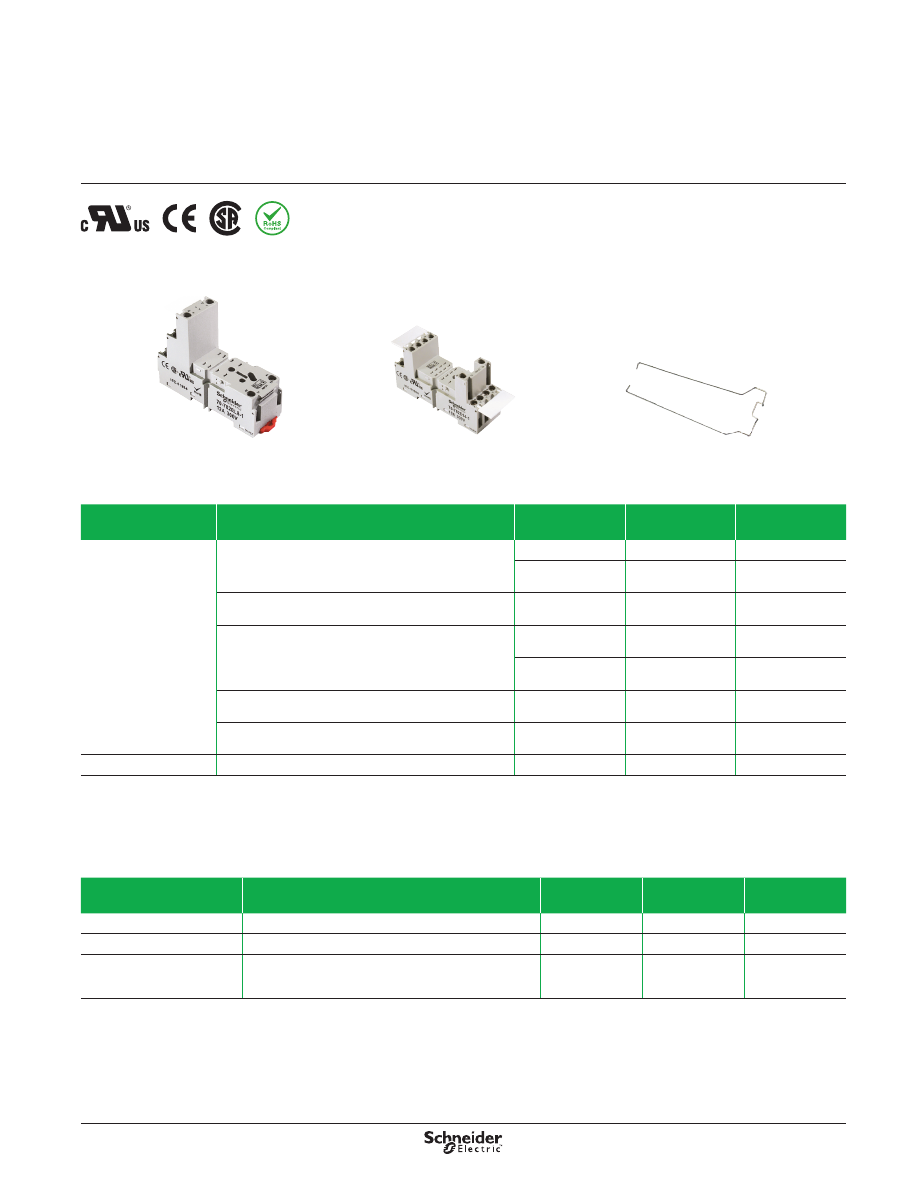

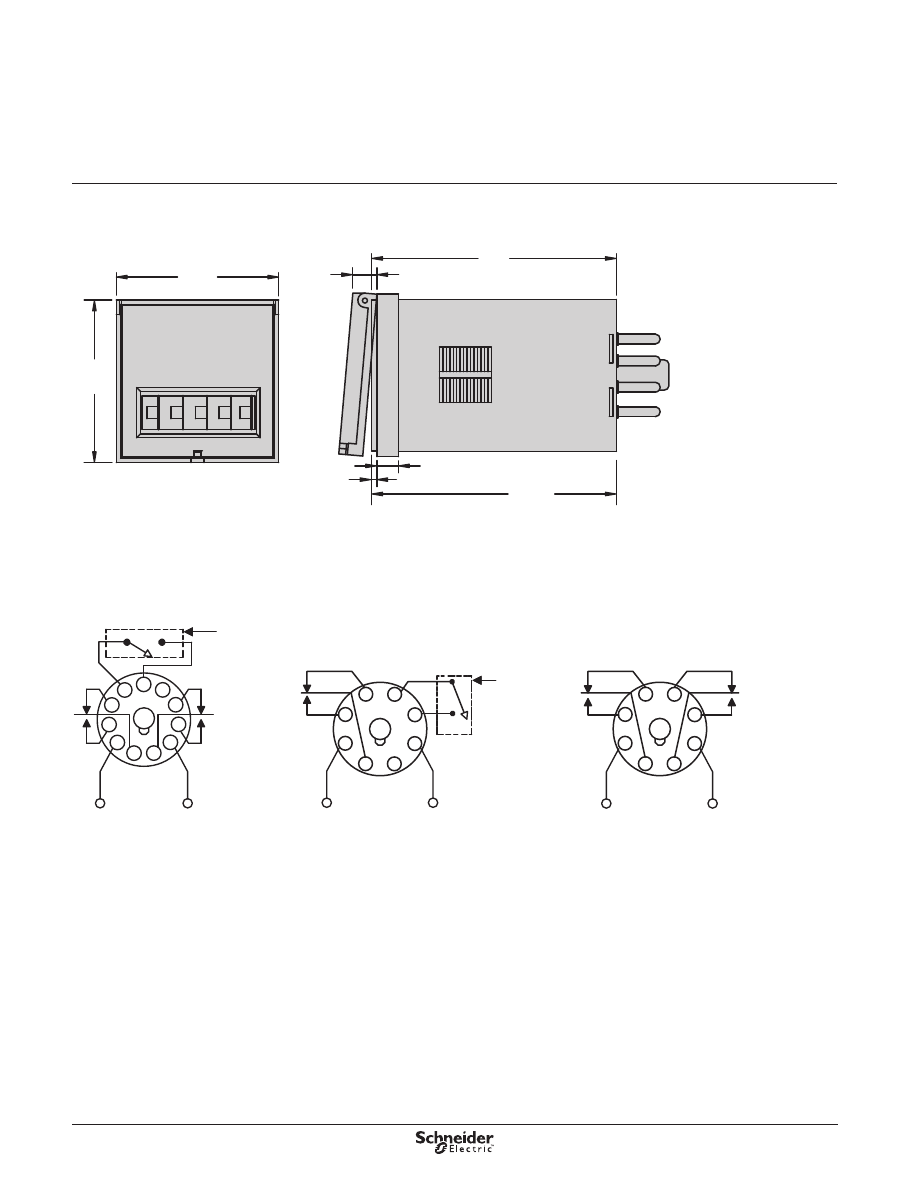

Description

Legacy Time Delay and

Sensor Relays

TDRPRO Series Accessories

Description

The TDRPRO accessories create a complete system solution for your application

needs . The 70-750DL socket offers an alternative installation option for plug-in

models . The 16-TDRPROSC retention clip holds the relay securely in place while

allowing quick and efficient installation and maintenance .

Relay Accessories

Description Function

For Use With Relays

Packaging

Quantities

Standard Part

Number

Socket

Mounting directly to DIN Rail or Panel

TDRPRO-5101,

TDRPRO-5102

10

70-750DL8-1

Panel Mounting with Screw Terminals and Clamping Plates

10

70-169-1

DIN or Panel Mounting with Elevator Terminals

TDRPRO-5101

10

70-750E8-1

DIN or Panel Mounting with Screw Terminals and Clamping Plates

10

70-464-1

Mounting directly to DIN Rail or Panel

TDRPRO-5100

10

70-750DL11-1

DIN or Panel Mounting with Elevator Terminals

10

70-750E11-1

DIN or Panel Mounting with Screw Terminals and Clamping Plates

10

70-465-1

Panel Mounting with Screw Terminals and Clamping Plates

10

70-170-1

Metal

Retention Clip Helping secure the relay in the socket

TDRPRO

10

16-TDRPROSC

70-750DL8-1 Socket

70-750E8-1 Socket

16-TDRPROSC Retention Clip

0.37

(9.4)

1.39

(35.5)

1.55

(39.5)

1.65

(42.0)

1.37

(34.7)

1.17

(29.7)

0.86

(22.0)

16-DCLIP-1 DIN Rail End Clip

Socket Accessories

Description

Function

For Use With Sockets

Packaging

Quantities

Standard

Part Number

Metal DIN Rail, 1 m (39 .3 in .)

Quick installation and removal of sockets

Compatible with all sockets

listed in the table above .

10

16-700DIN

DIN Rail End Clip

Holding sockets firmly in place on the DIN rail

10

16-DCLIP-1

ID Tags

Identification of circuits in multi-relay applications

70-750E8-1, 70-750EL8-1,

70-750DL8-1, 70-750E11-1,

70-750EL11, 70-750DL11-1

10

16-750/782FT-1

Insulated Coil Bus Jumper System Wireless socket connection

10

16-750/788CBJ-1

26

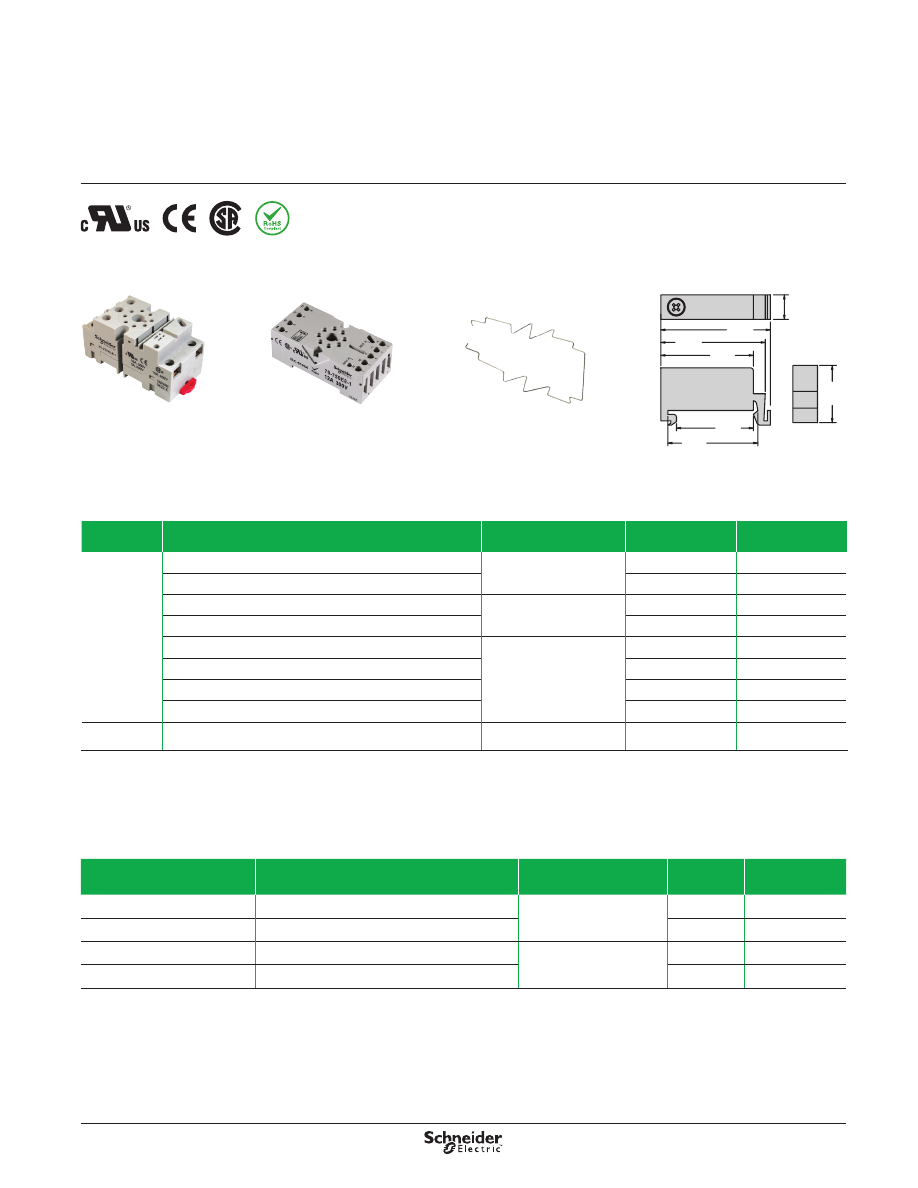

Specifications

Legacy Time Delay and

Sensor Relays

TDRPRO Series Accessories

Specifications

Part Number

70-750DL8-1

70-750DL11-1

70-750E8-1

70-750E11-1

Contact Configuration

DPDT

3PDT

DPDT

3PDT

Number of Terminals

8

11

8

11

Mounting Style

Panel or DIN rail

Panel or DIN rail

Panel or DIN rail

Panel or DIN rail

Current Rating

16 A

5 A

12 A

12 A

Nominal Voltage Rating

300 V

600 V

600 V

300 V

Storage Temperature Range

−40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F)

Protection Category according to

IEC 60529 IP rating (finger protection)

IP20

IP20

IP20

IP20

Internal Metal Tracks

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Screw Terminals

Steel, Zinc Plated

Steel, Zinc Plated

Steel, Zinc Plated

Steel, Zinc Plated

Screw Style

Combination Head

Combination Head

Combination Head

Combination Head

Screw Size

M3 .5 mm

M3 .5 mm

M3 .5 mm

M3 .5 mm

Maximum Screw Torque

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

Terminal Connection

Screw Clamping

Screw Clamping

Elevator

Elevator

Terminal Layout

Logic

Logic

Non-Logic

Non-Logic

Maximum Wire Size

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

DIN Rail Mounting, EN 60715

35 mm (1 .38 in)

35 mm (1 .38 in)

35 mm (1 .38 in)

35 mm (1 .38 in)

Chassis Mounting Screw Torque

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

Flammability Rating

94V-0 Class

94V-0 Class

94V-0 Class

94V-0 Class

Body Color

Light Gray

Light Gray

Light Gray

Light Gray

DIN Locking Method

Red Plastic Locking Clip

Red Plastic Locking Clip

Red Plastic Locking Clip

Red Plastic Locking Clip

Agency Approvals

cURus (File: E70550, CCN:

SWIV2, SWIV8), CSA (File:

40787, Class: 3211 07), CE

60947-1, RoHS

cURus (File: E70550, CCN:

SWIV2, SWIV8), CSA (File:

40787, Class: 3211 07), CE

60947-1, RoHS

cURus (File: E70550, CCN:

SWIV2, SWIV8), CSA (File:

40787, Class: 3211 07), CE

60947-1, RoHS

cURus (File: E70550, CCN:

SWIV2, SWIV8), CSA (File:

40787, Class: 3211 07), CE

60947-1, RoHS

Part Number

70-169-1

70-170-1

70-464-1

70-465-1

Contact Configuration

DPDT

3PDT

DPDT

3PDT

Number of Terminals

8

11

8

11

Mounting Style

Panel

Panel

Panel or DIN rail

Panel or DIN rail

Current Rating

15 A

15 A

15/10 A

15/5 A

Nominal Voltage Rating

300 V

600 V

300/600 V

300/600 V

Temperature Storage Range

−40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F) −40 to +105 °C (−40 to +221 °F)

Internal Metal Tracks

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Copper Alloy, Zinc Plated

Screw Terminals

Steel, Zinc Plated

Steel, Zinc Plated

Steel, Zinc Plated

Steel, Zinc Plated

Screw Style

Combination Head

Combination Head

Combination Head

Combination Head

Screw Size

M3 .5 mm

M3 .5 mm

M3 .5 mm

M3 .5 mm

Maximum Screw Torque

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

9 lb-in (1 .0 N•m)

Terminal Connection

Screw Clamping

Screw Clamping

Screw Clamping

Screw Clamping

Terminal Layout

Non-Logic

Non-Logic

Non-Logic

Non-Logic

Maximum Wire Size

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

Solid or Stranded Cu:

two 12–14 AWG (2 .5–4 mm²)

DIN Rail Mounting, EN 60715

35 mm (1 .38 in)

35 mm (1 .38 in)

35 mm (1 .38 in)

35 mm (1 .38 in)

Chassis Mount Screw Torque

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

7 lb-in (0 .8 N•m)

Flammability Rating

94 V-0 Class

94 V-0 Class

94 V-0 Class

94 V-0 Class

Body Color

Light Gray

Light Gray

Light Gray

Light Gray

DIN Locking Method

–

–

Red Plastic Locking Clip

Red Plastic Locking Clip

Product Certifications

cURus (File: E70550, CCN: SWIV2, SWIV8),

CSA (File: 40787, Class: 3211 07),

CE 60947-1, RoHS

27

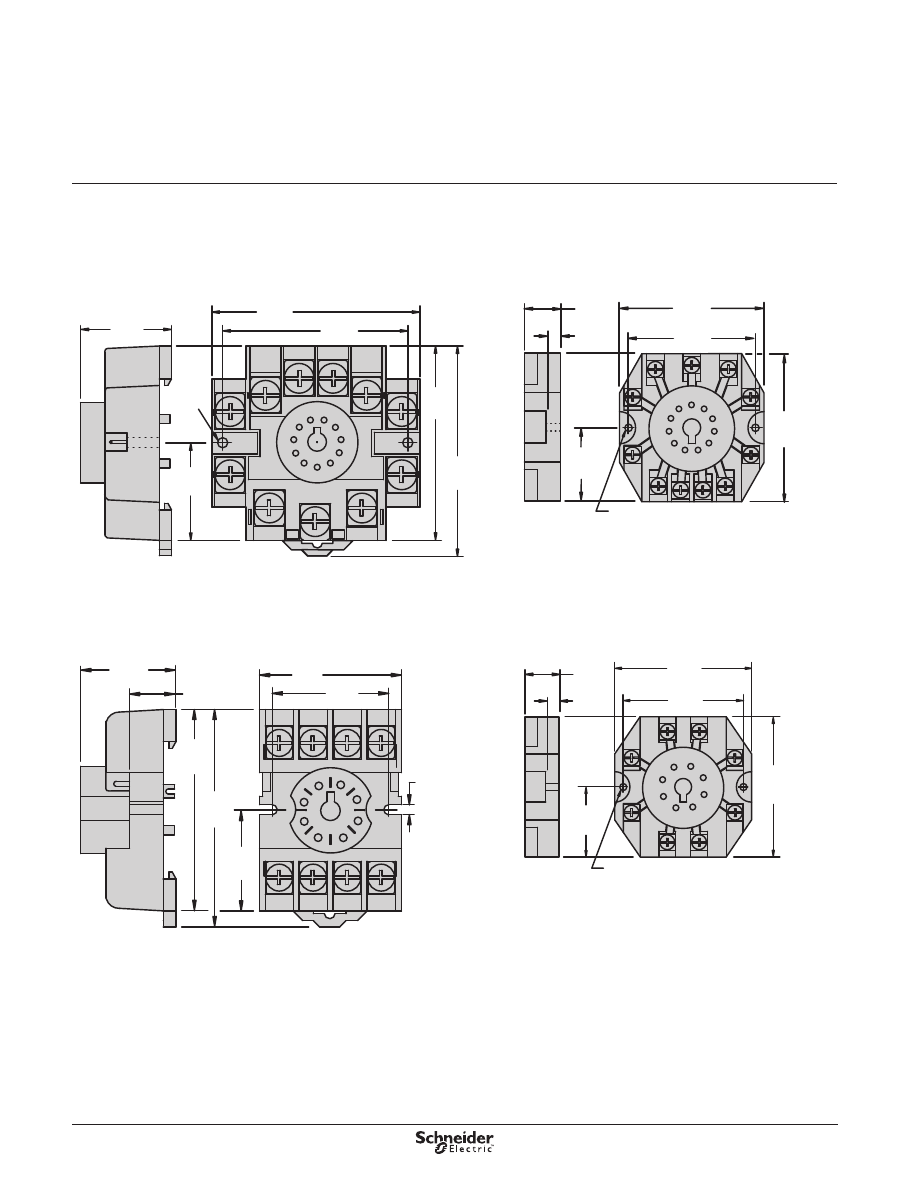

Dimensions—in. (mm)

Dimensions

Legacy Time Delay and

Sensor Relays

TDRPRO Series Accessories

70-750DL11-1

Mounts Directly to the DIN Rail or Panel

(38)

1.5

(3.8)

0.15

(76.8)

3.02

(37)

1.45

(81)

3.19

(40)

1.58

(34.2)

1.35

11

4

1

12

14

3

A2

10

5

22

21

24

6

7

A1

2

INPUT

INPUT

34

9

31

11

32

8

1.1

(27.9)

NEMA:

IEC:

70-750DL8-1

Mounts Directly to the DIN Rail or Panel

(36)

1.42

(3.8)

0.15

1.1

(27.9)

11

4

1

12

14

3

A2

7

5

22

21

24

6

8

A1

2

(72.7)

2.86

(36)

1.42

INPUT

INPUT

(77.5)

3.0

(40)

1.58

(30)

1.2

NEMA:

IEC:

70-750E11-1

DIN or Panel Mounting with Elevator Terminals

INPUT A1

10

INPUT A2

2

A1

A2 A2 31 21 11

10

11

10

6

1

2

14

34

24

32

22

12

9

7

8

4

3

5

2.95

(22)

0.86

(27)

1.06

1.45

1.49

0.12

(75)

(37)

(30)

(38)

NEMA:

IEC:

(3.1)

0.12

70-750E8-1

DIN or Panel Mounting with Elevator Terminals

11

7

7

INPUT A1

INPUT A2

A2

7

A2

8

21

2

1

A1

12

5

6

24

4

22

3

14

2

(3.1)

2.95

1.45

0.12

1.49

0.12

0.86

(22)

(27)

1.06

(75)

(30)

(38)

(37)

NEMA:

IEC:

28

Dimensions

(continued)

Legacy Time Delay and

Sensor Relays

TDRPRO Series Accessories

Dimensions—in. (mm)

70-169-1

Panel Mounting with Screw Terminals and Clamping Plates

7

6

8

1

2

3

5

4

0.17 DIA. (4.3)

0.25

(6.3)

0.625

(16)

2.0

(50)

1.68

(42.8)

2.25

(57)

1.12

(28)

70-464-1

DIN Mounting with Screw Terminals and Clamping Plates

3

5

4

6

8

2

1

(4.2)

0.16

7

(33)

1.29

(40)

1.6

(54)

2.12

2.02

(51)

(24.6)

0.97

(25.6)

1.01

0.59

(15)

70-465-1

DIN Mounting with Screw Terminals and Clamping Plates

3

4

5

6

7

11

2

1

10

8

9

(59)

(52)

2.06

2.32

(54.8)

2.16

2.05

(52)

(24.6)

0.97

(40)

1.6 DIA.

1.02

(25)

70-170-1

Panel Mounting with Screw Terminals and Clamping Plates

0.17 DIA. (4.3)

7

6

11

9

8

10

1

2

3

5

4

2.5

(64)

2.2

(56)

2.59

(65)

1.29

(32)

0.25

(6.3)

0.629

(16)

29

Wiring Diagrams

(continued)

Legacy Time Delay and

Sensor Relays

TDRPRO Series Accessories

Wiring Diagrams

70-169-1

3

4

2

1

6

5

8

7

24

A2

14

12

22

A1

11

1

2

5

4

3

7

6

21

8

INPUT

INPUT

IEC

NEMA

70-170-1

5

11

1

3

9

10

2

4

8

6

7

4

3

8

9

14

34

12

5

7

6

22

24

21

32

2

10

1

11

A1

A2

11

31

INPUT

INPUT

IEC

NEMA

70-464-1

3

4

2

1

6

5

8

7

14

12

22

24

A1

11

21

A2

3

4

2

1

6

5

8

7

INPUT

INPUT

IEC

NEMA

70-465-1

5

4

5

7

6

3

2

10

1

11

8

9

14

A1

A2

11

31

34

12

22

24

21

32

11

1

3

9

10

2

4

8

6

7

INPUT

INPUT

IEC

NEMA

70-750DL11-1

5

34

14

9

3

31

11

6

21

5

7

8

32

22

24

1

11

4

12

11

1

3

9

10

2

4

8

6

7

A1

A2

10

Coil Bus

Jumper

2

Module

Input

INPUT

IEC

NEMA

70-750DL8-1

2

7

Coil Bus

Jumper

A1

A2

5

4

7

8

1

2

6

3

21

14

24

6

3

8

11

12

22

5

1

4

Module

Input

INPUT

IEC

NEMA

70-750E11-1

10

1

11

6

2

11

A2

31 21

A1

14

34

24 22

12

3

9

7

5

4

10

8

32

A2

4

3

9

8

7

5

6

1

10

11

2

INPUT

INPUT

Module

Input

IEC

NEMA

70-750E8-1

10

1

11

6

2

11

A2

31 21

A1

14

34

24 22

12

3

9

7

5

4

10

8

32

A2

4

3

9

8

7

5

6

1

10

11

2

INPUT

INPUT

Module

Input

IEC

NEMA

30

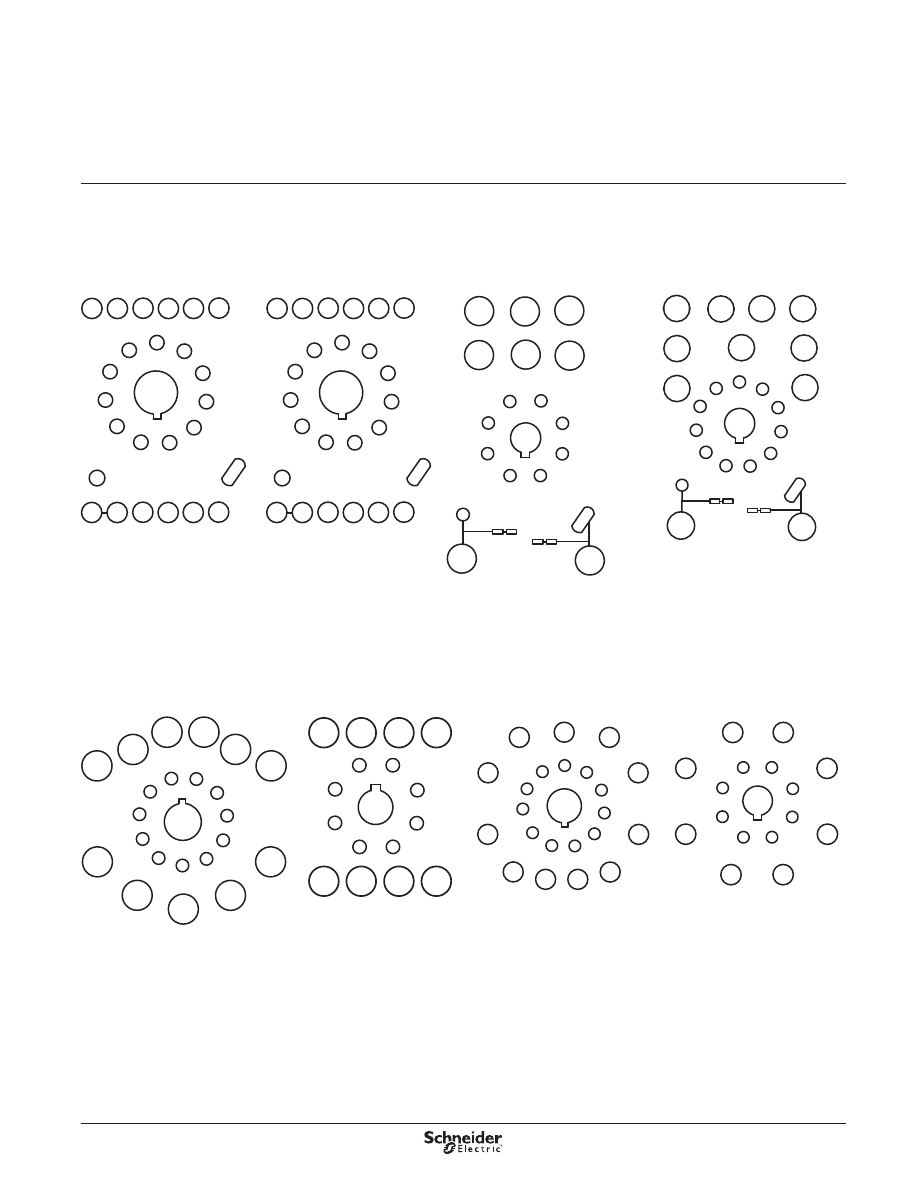

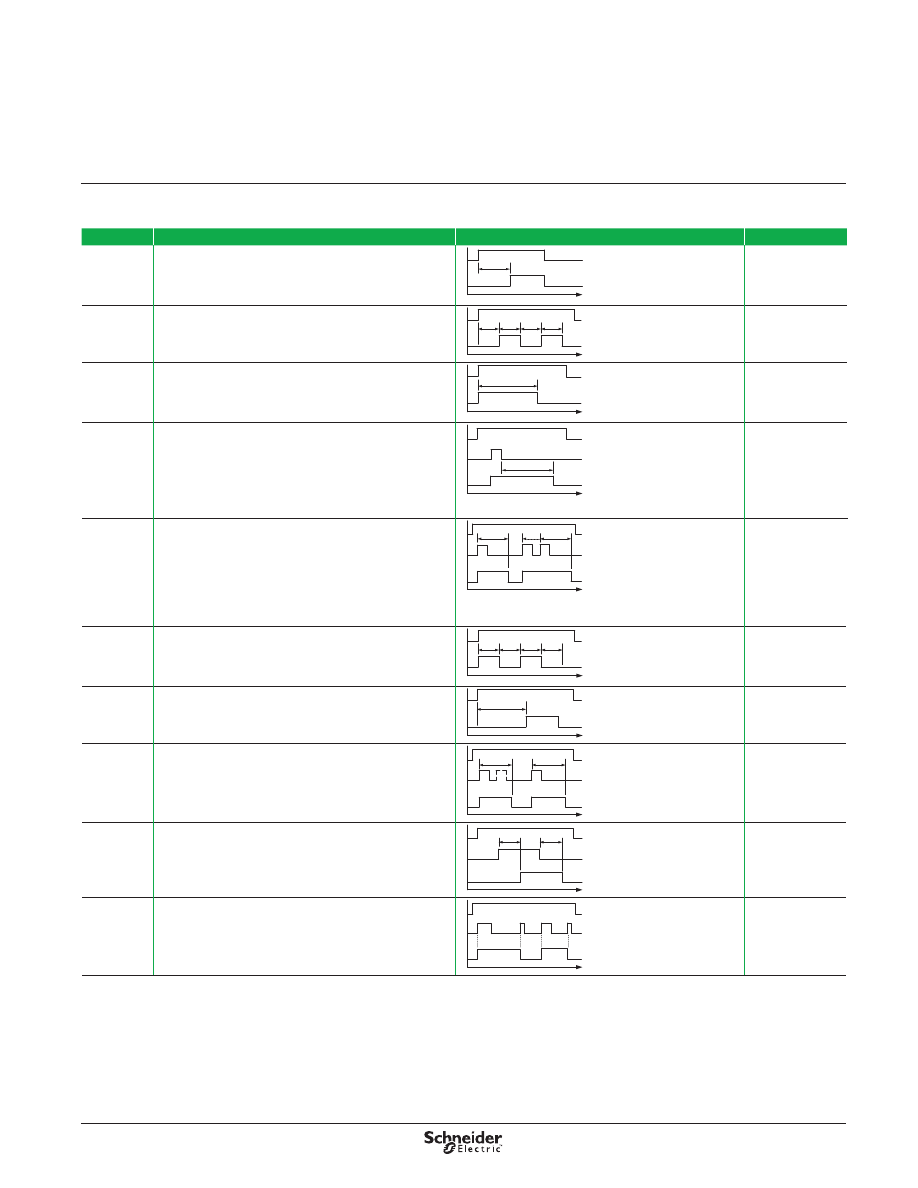

Application Data

Legacy Time Delay and

Sensor Relays

Definition

A time delay is a controlled period between the functioning of two events . A time

delay relay combines an electromechanical output relay and a control circuit . The

control circuit is composed of solid-state components that control the operation of

the relay and the timing range .

Typical time delay functions include:

On-Delay

Repeat Cycle (Starting Off)

Interval

Off-Delay

Retriggerable One-Shot

Repeat Cycle (Starting On)

Pulse Generator

One-Shot

On- and Off-Delay

Memory Latch

Each function is explained in the table on page 31 . Time delay relays offer a broad

choice of timing ranges from less than one second to many days . There are many

choices of timing adjustments from calibrated external knobs, DIP switches, thumb-

wheel switches, or a recessed potentiometer .

Principle of Operation

Time delay relays are simply control relays with a time delay built in . Their purpose

is to control an event based on time . The difference between relays and time delay

relays is

when

the output contacts open and close:

on a control relay, contacts change state when voltage is applied and removed

from the coil

on time delay relays, contacts change state before or after a pre-selected, timed

interval

Typically, time delay relays are initiated or triggered by one of two methods:

application of input voltage (On-Delay, Interval On, Flasher, Repeat Cycle,

Delayed Interval, and Interval/Flasher)

opening or closing of a trigger signal (Off-Delay, Single Shot, and Watchdog)

These trigger signals can be one of two designs:

a control switch (dry contact)—for example, limit switch, push button, float switch

voltage (commonly known as a power trigger)

Definitions

:

Input Voltage:

Control voltage applied to the input terminals (see the wiring

diagrams on page 31) . Depending on the function, input voltage either initiates

the unit or readies it to initiate when a trigger signal is applied .

Trigger Signal:

On certain timing functions, a trigger signal initiates the unit after

input voltage has been applied . As noted above, this trigger signal can either be a

control switch (dry contact switch) or a power trigger (voltage) .

Output (Load):

A time delay relay has an internal relay (usually mechanical) with

contacts that open and close to control the load . The contacts are represented by

the dotted lines in the wiring diagrams .

NOTE

: For the time delay relay to operate properly, voltage must be applied to

power the load being switched by the relay’s output contacts.

31

Application Data

(continued)

Legacy Time Delay and

Sensor Relays

Time Delay Relay Functions

Function

Description

Timing Chart

Relays

On-Delay

(A)

When the input voltage U is applied, time delay T begins . Relay

contact(s) R change state after the time delay is complete .

Contacts R return to their shelf state when input voltage U is

removed . A trigger switch is not used in this function .

time

U

R

T

821, 822, TDR782,

TDRPRO-5100,

TDRPRO-5101,

TDRPRO-5102,

831, 841

Repeat Cycle:

Starting Open

(B)

When input voltage U is applied, time delay T begins . When

time delay T is complete, relay contact(s) R change state

for time delay T . This cycle repeats until input voltage U is

removed . A trigger switch is not used in this function .

time

U

R

T

T

T

T

Off On Off On

821, 822,

TDRPRO-5100,

TDRPRO-5101,

TDRPRO-5102

Interval

(C)

When input voltage U is applied, relay contact(s) R change

state immediately and the timing cycle begins . When time

delay T is complete, contacts return to shelf state . When input

voltage U is removed, contacts also return to their shelf state . A

trigger switch is not used in this function .

time

U

R

T

821, 822,

TDRPRO-5100,

TDRPRO-5101,

TDRPRO-5102

Off-Delay,

with

Switch Trigger

(D)

Input voltage U must be applied continuously . When trigger

switch S is closed, relay contacts R change state . When trigger

switch S is opened, delay T begins . When delay T is complete,

contacts R return to their shelf state . If trigger switch S is closed

before time delay T is complete, then time is reset . When trigger

switch S is opened, the delay begins again, and relay contacts

R remain in their energized state . If input voltage U is removed,

then relay contacts R return to their shelf state .

time

U

S

R

T

821, 822,

TDRPRO-5100,

TDRPRO-5101,

TDRPRO-5102

Retriggerable

One-Shot

with

Switch Trigger

(E)

Upon application of input voltage U, the relay is ready to accept

trigger signal S . Upon application of trigger signal S, relay

contacts R transfer, and preset time T begins . At the end of

preset time T, relay contacts R return to their normal condition—

unless trigger switch S is opened and closed before before

preset time T elapses . Continuous cycling of trigger switch S

at a rate faster than preset time T causes relay contacts R to

remain closed . If input voltage U is removed, relay contacts R

return to their shelf state .

time

U

S

R

T

T

821, 822,

TDRPRO-5100,

TDRPRO-5101,

TDRPRO-5102

Repeat Cycle:

Starting

Closed

(F)

When input voltage U is applied, relay contacts R change state

immediately and time delay T begins . When time delay T is

complete, contacts return to their shelf state for time delay T .

This cycle repeats until input voltage U is removed . A trigger

switch is not used in this function .

time

U

R

T

T

T

T

On

Off

On

Off

821, 822,

TDRPRO-5100,

TDRPRO-5101

Pulse

Generator

(G)

Upon application of input voltage U, a single output pulse of

0 .5 s is delivered to the relay after time delay T . Power must be

removed and reapplied to repeat the pulse . A trigger switch is

not used in this function .

time

U

R

T

Pulse

821, 822,

TDRPRO-5100,

TDRPRO-5101

One-Shot with

Switch Trigger

(H)

Upon application of input voltage U, the relay is ready to accept

trigger signal S . Upon application of trigger signal S, relay

contacts R transfer, and preset time T begins . During time-out,

trigger signal S is ignored .

The relay is reset by applying trigger switch S when the relay is

not energized .

time

U

S

R

T

T

821, 822,

TDRPRO-5100,

TDRPRO-5101

On- and Off-

Delay with

Switch Trigger

(I)

Input voltage U must be applied continuously . When trigger

switch S is closed, time delay T begins . When time delay

T is complete, relay contacts R change state and remain

transferred until trigger switch S is opened . If input voltage U is

removed, relay contacts R return to their shelf state .

time

U

S

R

T

T

821, 822,

TDRPRO-5100,

TDRPRO-5101

Memory Latch

with Switch

Trigger

(J)

Input voltage U must be applied continuously . The output

changes state with every closure of trigger switch S . If input

voltage U is removed, relay contacts R return to their shelf

state .

time

U

S

R

821, 822,

TDRPRO-5100,

TDRPRO-5101

Note

: G = Gate . R = Relay contacts or outputs . S = Switch trigger . Y1 = Control contact . T = Time delay setting . U = Input voltage (power supply) .

32

Applications

Legacy Schneider Electric time delay and sensor relays provide cost effective

solutions for your industrial timing and sensing needs . Available in a wide array of

forms, fits, and functions, these timers offer flexibility and performance for process

control and industrial building applications .

Application Data

(continued)

Legacy Time Delay and

Sensor Relays

Automation Panels

Process controls, motor controls,

emergency lighting

Power Supplies

Universal power supplies, battery backup

systems

Appliances

Air conditioners, water heaters, portable

heaters, spa controls, water pumps

Packaging Machinery

Conveyor motors, food processors,

product/shrink wrap, solenoid controls

Material Handling

Motor control, conveyor controls

HVAC & Refrigeration

Anti-condensation equipment, compressor

controls, blower controls, motorized

duct/vent controls

Lighting Control

Traffic signal systems, motorway information

systems, theatrical lighting, ballast lighting

Food & Beverage

Commercial/industrial cooking equipment,

filtration systems, bottling, chillers,

convection ovens

Typical Examples of Timer Applications

33

The Schneider Electric Relays website

(www.serelays.com)

helps you to easily

find the proper relay to fit your design requirements, and to simplify and shorten

workflow .

Easily find the proper relay to fit your design

requirements

Online Catalog

Find the right product by choosing specifications, compare products side-by-

side, and view technical specifications, 2D and 3D drawings, and associated

accessories .

Cross-Reference Search

Search our comprehensive database to identify products by manufacturer and

part number, and link directly to part specifications .

3D CAD Library

View, email, download, or insert a file directly into your open CAD software .

You can choose from 18 different file formats .

Order Free Samples

Schneider Electric offers free samples as a courtesy to individuals and

companies evaluating our products for their designs and applications . Sample

orders are subject to approval .

Simplify and shorten workflow

Interactive Tools

View interactive demonstrations, such as our Time Delay Relay Interactive Demo

(left), which visually demonstrates the ten different timing functions offered on

legacy Schneider Electric time delay relays .

Distributor Inventory Search

Search authorized distributors’ current Schneider Electric inventory and buy

online .

(Buy online is not available for all distributors .)

Website Guide

Legacy Time Delay and

Sensor Relays

Time Delay Relay Demo

3D Models

34

Index

Legacy Time Delay and

Sensor Relays

16-700DIN

16-750/782FT-1

16-782FT-1

16-788C1

16-DCLIP-1

16-TDR782SC

16-TDRPROSC

70-169-1

70-170-1

70-378-1

70-379-1

70-461-1

70-464-1

70-465-1

70-750DL8-1

70-750DL11-1

70-750E8-1

70-750E11-1

70-782D14-1

70-782E14-1

70-782EL8-1

70-782EL14-1

821TD10H-UNI

822TD10H-UNI

831VS-24D

831VS-120A

831VS-240A

841CS1-UNI

841CS2-UNI

841CS5-UNI

841CS8-UNI

TDR782XBX

TDR782XDX

TDRPRO-5100

TDRPRO-5101

TDRPRO-5102

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel . No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material .

© 2012–2017 Schneider Electric . All Rights Reserved .

Schneider Electric is a trademark and the property of Schneider Electric SE, its subsidiaries and

affiliated companies. All other trademarks are the property of their respective owners.

8501CT1104R01/17, 06/2017

Replaces 8501CT1104R05/15 dated 02/2016

Schneider Electric USA, Inc.

200 N . Martingale Road

Schaumburg, IL 60173

Tel: 847-441-2540

www .serelays .com