THERMAL CIRCUIT BREAKERS

THERMAL CIRCUIT BREAKERS

KLIXON® thermal circuit breakers are

compact, lightweight, protective devices

designed to repeatedly interrupt short circuits

or extended overloads in applications which

require precise, dependable operation plus

high resistance to shock and vibration. To

avoid nuisance tripping caused by harmless

transient or momentary overloads, these

circuit breakers feature an inherent thermal

time-lag characteristic. This enables

equipment to operate at maximum limits with

complete safety.

The heart of the thermal circuit breaker is the

KLIXON® metal disc. At a predetermined

overload, the heat caused by current passing

through the disc causes the disc to reverse its

curvature, or snap. This snapping action

separates the electrical contacts and opens

the circuit.

Trip curves provide the approximate time vs

current characteristics based on the ambient

“room” temperature of 77°F (25°C). Should

your application require performance

characteristics beyond the ambient “room”

temperature of 77°F (25°C), derating curves

provide additional data for ambient

temperatures significantly higher or lower than

standard room temperature.

KLIXON® thermal circuit breakers are

available in automatic reset and manual reset.

Some manual reset devices offer a switchable

feature whereby the contacts can be manually

opened to de-energize the circuit. For the

automatic reset device, the circuit stays open

until the disc cools and returns to its original

curvature, completing the circuit. For the

trip-free manual reset device, the contacts will

remain open until the device’s pushbutton is

depressed to reset the device and complete

the circuit.

KLIXON®

Thermal Circuit Breakers

“With over 90 years of experience in a myriad

of industries and mission-critical applications,

Sensata Technologies is one of the world’s

leading suppliers of sensing, electrical

protection, control and power management

solutions.

Motors, machines, equipment and vehicles in

the industrial, heating, ventilation, air

conditioning, appliance, automotive,

recreational, mobile work, data and

telecommunications industries operate safely

and efficiently thanks to reliable and robust

Sensata circuit protectors, switches, and

sensors. Our products sense and monitor

position, temperature and pressure, provide

power protection and help manage challenging

DC-to-AC power conversions.

From design to manufacturing and every

business process in between, our people strive

not just to meet standards of excellence but to

set them. Serving you is mission-critical to us.”

Tom Wroe

,

Chairman of the Board and Chief

Executive Officer, Sensata Technologies

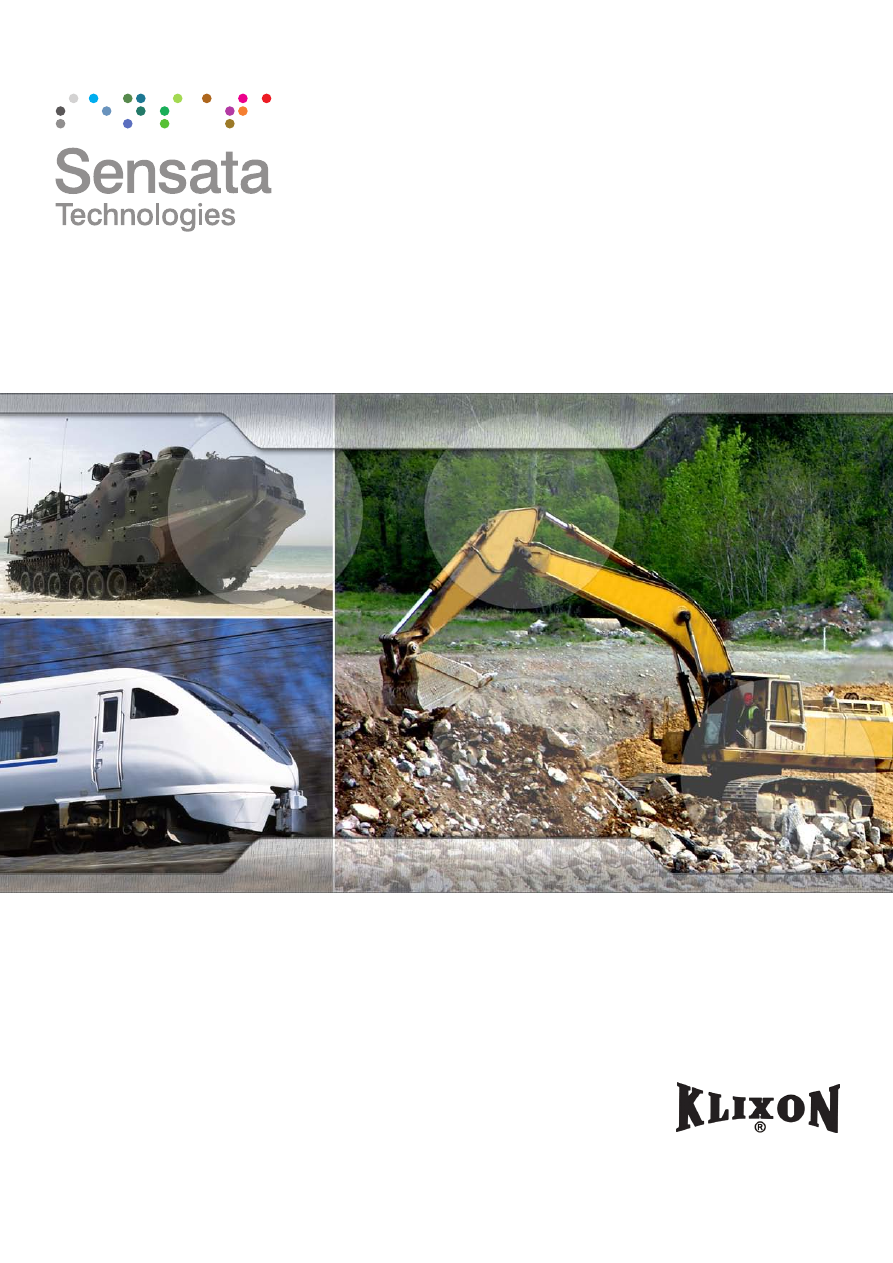

Cross Reference for KLIXON® Thermal Circuit Breakers

SERIES

PAGE

AUTOMA

TIC

MANUAL

OPEN

COVERED

STUD

SCREW

UL

CID AA55571

2 Amps

3 Amps

4 Amps

5 Amps

6 Amps

8 Amps

10 Amps

12.5 Amps

15 Amps

CM

6

•

•

•

•

•

•

•

•

•

•

•

•

•

CA

6

•

•

•

•

•

•

•

•

•

•

•

•

•

CDM

6

•

•

•

•

•

•

•

•

•

•

•

•

•

CDA

6

•

•

•

•

•

•

•

•

•

•

•

•

•

7851

8

•

•

•

•

•

•

7854

8

•

•

•

•

•

•

FDLM

10

•

•

•

FDLA

10

•

•

•

FDLS

10

•

•

•

FDLT

10

•

•

•

SDLM

12

•

•

•

•

SDLA

12

•

•

•

•

SLA

12

•

•

•

•

6766-19

14

•

•

•

7855-6

16

•

•

•

•

/ 03

7855-7

16

•

•

•

•

/ 08

PDM

18

•

•

•

•

•

•

•

•

•

•

•

•

•

PDA

18

•

•

•

•

•

•

•

•

•

•

•

•

•

PDLM

20

•

•

•

/ 04

PDLA

20

•

•

•

/ 07

PSM

22

•

•

•

•

/ 06

•

•

•

•

•

•

•

•

•

PSA

22

•

•

•

•

/ 05

•

•

•

•

•

•

•

•

•

PSM-N

24

•

•

•

•

•

•

•

•

•

•

•

•

9115-5

26

•

•

•

•

/ 01

•

9115-6

26

•

•

•

•

/ 02

•

MAXI

28

•

•

•

•

EXT 200

29

•

•

•

•

•

Cross Reference for KLIXON® Thermal Circuit Breakers

17.5 Amps

20 Amps

25 Amps

30 Amps

35 Amps

40 Amps

45 Amps

50 Amps

60 Amps

70 Amps

80 Amps

90 Amps

100 Amps

105 Amps

120 Amps

135 Amps

150 Amps

175 Amps

200 Amps

PAGE

SERIES

TYPE

•

•

•

•

•

•

6

CM

COMMERCIAL

•

•

•

•

•

•

6

CA

•

•

•

•

•

•

6

CDM

•

•

•

•

•

•

6

CDA

•

•

•

•

•

•

•

•

8

7851

•

•

•

•

•

•

•

•

8

7854

•

•

•

•

•

•

•

•

•

•

•

•

•

10

FDLM

•

•

•

•

•

•

•

•

•

•

•

•

•

10

FDLA

•

•

•

•

•

•

•

•

•

•

•

•

•

10

FDLS

•

•

•

•

•

•

•

•

•

•

•

•

•

10

FDLT

•

•

•

•

•

•

•

•

•

•

•

•

•

12

SDLM

•

•

•

•

•

•

•

•

•

•

•

•

•

12

SDLA

•

•

•

•

•

•

•

•

•

•

•

•

•

12

SLA

•

•

•

•

•

•

•

•

•

•

•

•

•

14

6766-19

•

•

16

7855-6

PRECISION

•

•

16

7855-7

•

•

•

•

•

•

18

PDM

•

•

•

•

•

•

18

PDA

•

•

•

•

•

•

•

•

•

•

•

•

20

PDLM

•

•

•

•

•

•

•

•

•

•

•

•

20

PDLA

•

•

•

•

22

PSM

•

•

•

•

22

PSA

•

•

•

•

24

PSM-N

•

•

•

26

9115-5

•

•

•

26

9115-6

•

•

•

•

•

•

28

MAXI

MINI

•

•

•

29

EXT 200

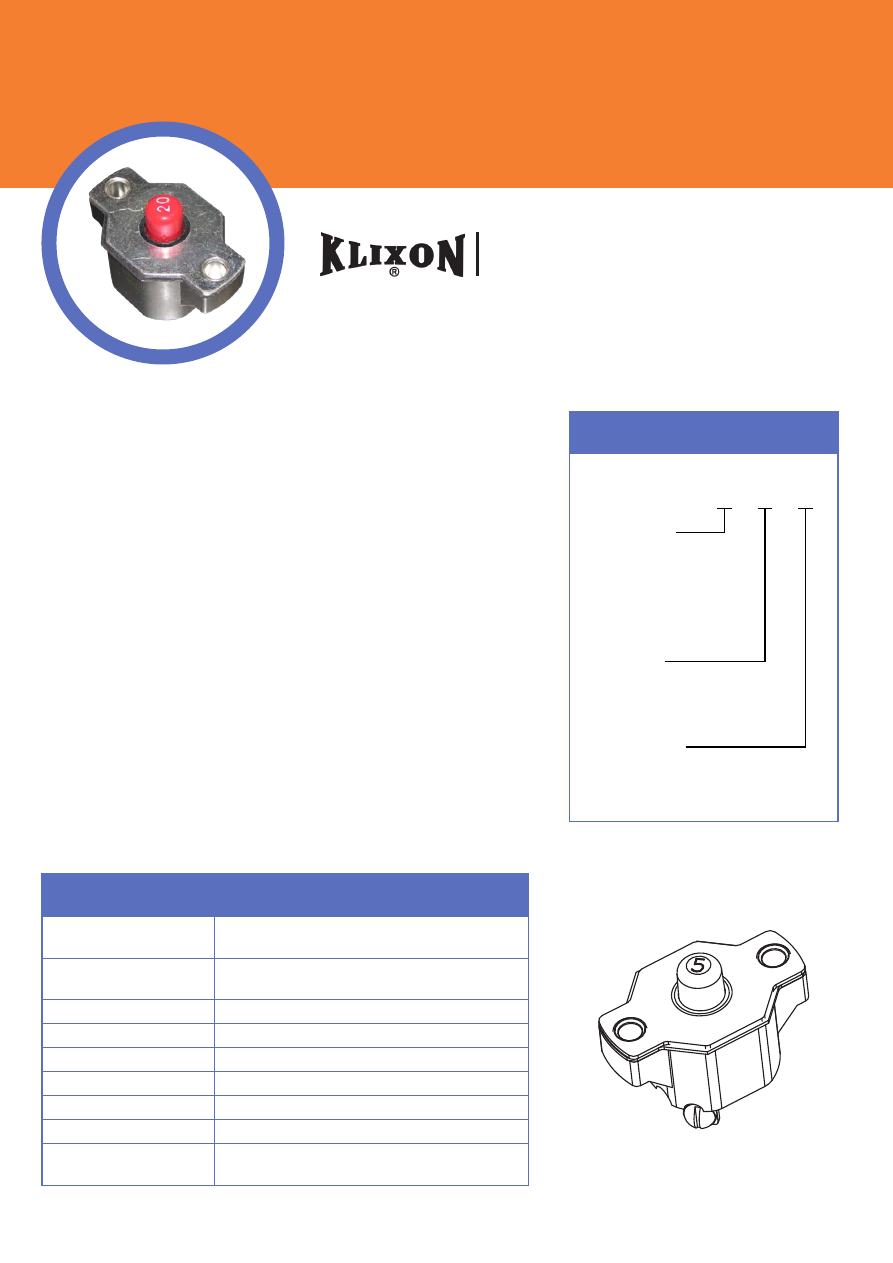

ORDERING INFORMATION

FEATURES

• 30VDC or 120VAC, 2 to 40 Amps

• Open and closed construction

• Automatic and manual reset options

• Ignition protected SAE J1171

• Weatherproof SAE J553

• UL Recognized E36869

DESCRIPTION

The KLIXON® C series thermal breakers are designed to protect wiring

and meet the harshest environmental requirements. The C series closed

construction circuit breakers are weatherproof sealed for protection

against moisture, dust, grease, fuel vapors and other harsh environments.

The C series breakers are compact, lightweight and designed to interrupt

short circuits or overloads, and combine trip-free protection with fast

response time. Typical applications are protection of wire cable of

accessory circuits, equipment and battery protection in construction

and off-road equipment, marine, recreational vehicles (RV’s), mining,

agricultural equipment and electric (hybrid) vehicles.

C Series (CM, CA, CDM, CDA)

2 to 40 Amp Commercial Thermal Circuit Breaker

Configuration

CA = Auto, open unit

CM = Manual, open unit

CDM = Manual, sealed unit

CDA = Auto, sealed unit

X − X − X

Amp Rating

(2, 3, 4, 5, 6, 8, 10, 12.5, 15

17.5, 20, 25, 30, 35, 40)

Mounting Nuts

= leave blank for none

I

= include optional mounting nuts

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated

current, 77°F (25°C)

2 to 10 amps : 20 to 150 seconds

12.5 to 40 amps : 5 to 55 seconds

Ultimate Trip at

77°F (25°C) Must hold 100%, Must trip 135%

Endurance Per SAE J553

Interrupt Current Capacity Per SAE J553 and ABYC E-11

Vibration 10G MIL-STD-202 Method 204, Condition A

Salt Spray MIL-STD-202 Method 101D (sealed only)

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B, 100 M

Ω

min

Weight (with mounting

nuts)

CDM: 48 grams max CDA: 41 grams max

CM : 37 grams max CA : 32 grams max

R

Se

ns

at

a

Te

ch

no

lo

gi

es

2.0)

SEE NOTE 1

(

R

Se

ns

at

a

Te

ch

no

lo

gi

es

3

2

M

A

D

E

IN

M

EX

IC

O

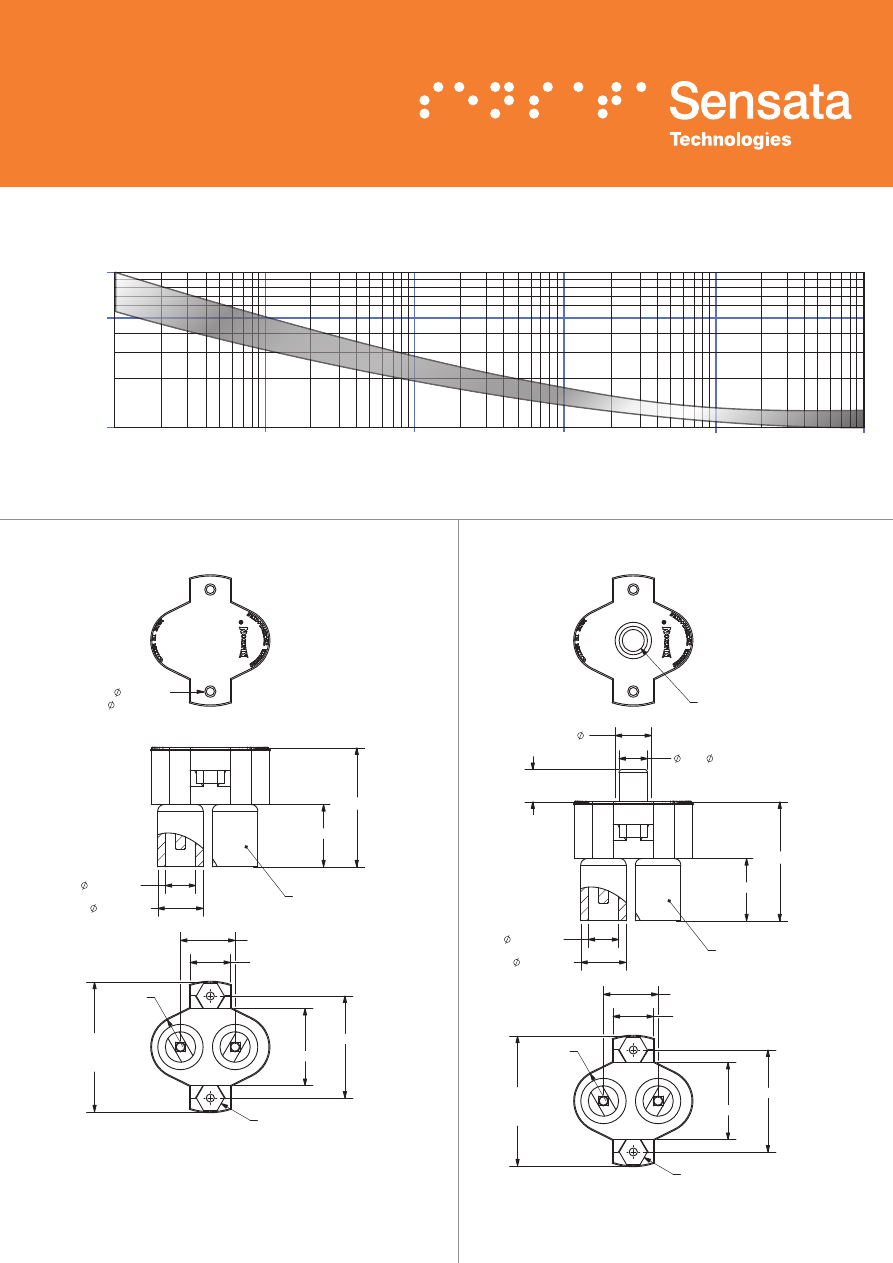

BOTTOM VIEW FOR 2 AMP THRU 10 AMP

FIG. #1

1

.641

.312

ROUND HEAD SCREW

(2 PLACES)

.250 LONG #8-32 UNC-2A

(2 PLACES)

LOCKWASHER

.047 REF. THK.

A

PART NUMBER

AND DATE CODE

LOCATION

.430

1.145

.562

MIN. PANEL HOLE DIA.

.380

OPTIONAL

#8-32 UNC-2B THREADED LOCKING

MOUNTING BUSHING FURNISHED ONLY

WHEN SPECIFIED ON ORDER. (2 PLACES)

DETAIL A

NOTES:

1. DIMENSION DOES NOT INCLUDE SEALING GASKET.

1.586

1.562

SEE NOTE 1

(1.221 / 1.159)

3

1

M

A

D

E

IN

M

EX

IC

O

BOTTOM VIEW FOR 12½ AMP THRU 40 AMP

EYELET FOR #10 SCREW

(2 PLACES)

FIG. #2

2

.906

C

A

V

0

2

1

/

C

D

V

0

3

G

N

IT

A

R

E

G

A

T

L

O

V

200% OVERLOAD

S

D

N

O

C

E

S

0

5

1

-

0

2

S

P

M

A

0

1

-

2

S

D

N

O

C

E

S

5

5

-

5

S

P

M

A

0

4

-

5

.

2

1

ULTIMATE TRIP % AT 77° F RATED CURRENT

%

0

0

1

M

U

M

I

N

I

M

%

5

3

1

M

U

M

I

X

A

M

1

1

E

-

C

Y

B

A

D

N

A

3

5

5

J

E

A

S

Y

TI

C

A

P

A

C

T

P

U

R

R

E

T

N

I

3

5

5

J

E

A

S

H

TI

W

S

E

I

L

P

M

O

C

E

C

N

A

R

U

D

N

E

3

5

5

J

E

A

S

P

M

A

0

4

-

5

.

2

1

P

O

R

D

E

G

A

T

L

O

V

M

U

M

I

N

I

M

C

A

V

0

0

5

1

H

T

G

N

E

R

T

S

C

I

R

T

C

E

L

E

I

D

M

0

0

1

E

C

N

A

T

S

I

S

E

R

N

O

IT

A

L

U

S

N

I

Ω

MINIMUM

A

N

O

IT

I

D

N

O

C

4

0

2

D

O

H

T

E

M

2

0

2

-

D

T

S

-

L

I

M

G

0

1

E

C

N

A

T

S

I

S

E

R

N

O

IT

A

R

B

I

V

MECHANICAL SHOCK RESISTANCE

100G

D

1

0

1

D

O

H

T

E

M

2

0

2

-

D

T

S

-

L

I

M

Y

A

R

P

S

T

L

A

S

1

7

1

1

J

E

A

S

D

E

T

C

E

T

O

R

P

N

O

IT

I

N

G

I

3

5

5

J

E

A

S

F

O

O

R

P

R

E

H

T

A

E

W

.

X

A

M

S

M

A

R

G

8

4

S

T

R

E

S

N

I

H

TI

W

:

T

H

G

I

E

W

9

6

8

6

3

E

D

E

T

S

I

L

L

U

PERFORMANCE CHARACTERISTICS

CDM-40

40

2

CDM-40-I

CDM-35

35

2

CDM-35-I

CDM-30

30

2

CDM-30-

CDM-25

25

2

CDM-25-I

CDM-20

20

2

CDM-20-I

CDM-17½

17½

2

CDM-17½-I

CDM-15

15

2

CDM-15-I

CDM-12½

12½

2

CDM-12½-I

CDM-10

10

1

CDM-10-I

CDM-8

8

1

CDM-8-I

CDM-6

6

1

CDM-6-I

CDM-5

5

1

CDM-5-I

CDM-4

4

1

CDM-4-I

CDM-3

3

1

CDM-3-I

CDM-2

2

1

CDM-2-I

PART NO.

AMP RATING

FIGURE NO.

PART NO. WITH THREADED INSERTS

6

.250 [6.35] LONG

#8-32 UNC-2A ROUND

HEAD SCREW (2 PLACES)

LOCKWASHER (2 PLACES)

.047 [1.19] REF. THK.

.430 [10.92]

1.145 [29.08]

MIN. PANEL HOLE DIA.

2.0 [ 50.8]

.562 [ 14.27]

SEE NOTE 1

INCHES [MM]

1.586 [40.28]

1.562 [39.67]

1.221 [31.01]

1.159 [29.44]

(DOES NOT INCLUDE SEALING GASKET)

R

Se

ns

at

a

Te

ch

no

lo

gi

es

3

2

M

A

DE

IN

M

EX

IC

O

BOTTOM VIEW

2 AMP THRU 10 AMP

1

.641 [16.28]

.312 [7.93]

R

Se

ns

at

a

Te

ch

no

lo

gi

es

3

1

M

A

DE

IN

M

EX

IC

O

BOTTOM VIEW

12½ AMP THRU 40 AMP

EYELET FOR

#10 SCREW

(2 PLACES)

2

.906 [23.01]

.380 [9.65]

OPTIONAL #8-32 UNC-2B

MOUNTING NUT

(2 PLACES)

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

40

60

80

Ultimate Trip in % Rated Load

Ambient T

emperature in °F

, °C

100

120

140

160

180

3

4

1

2

77°F, 25°C

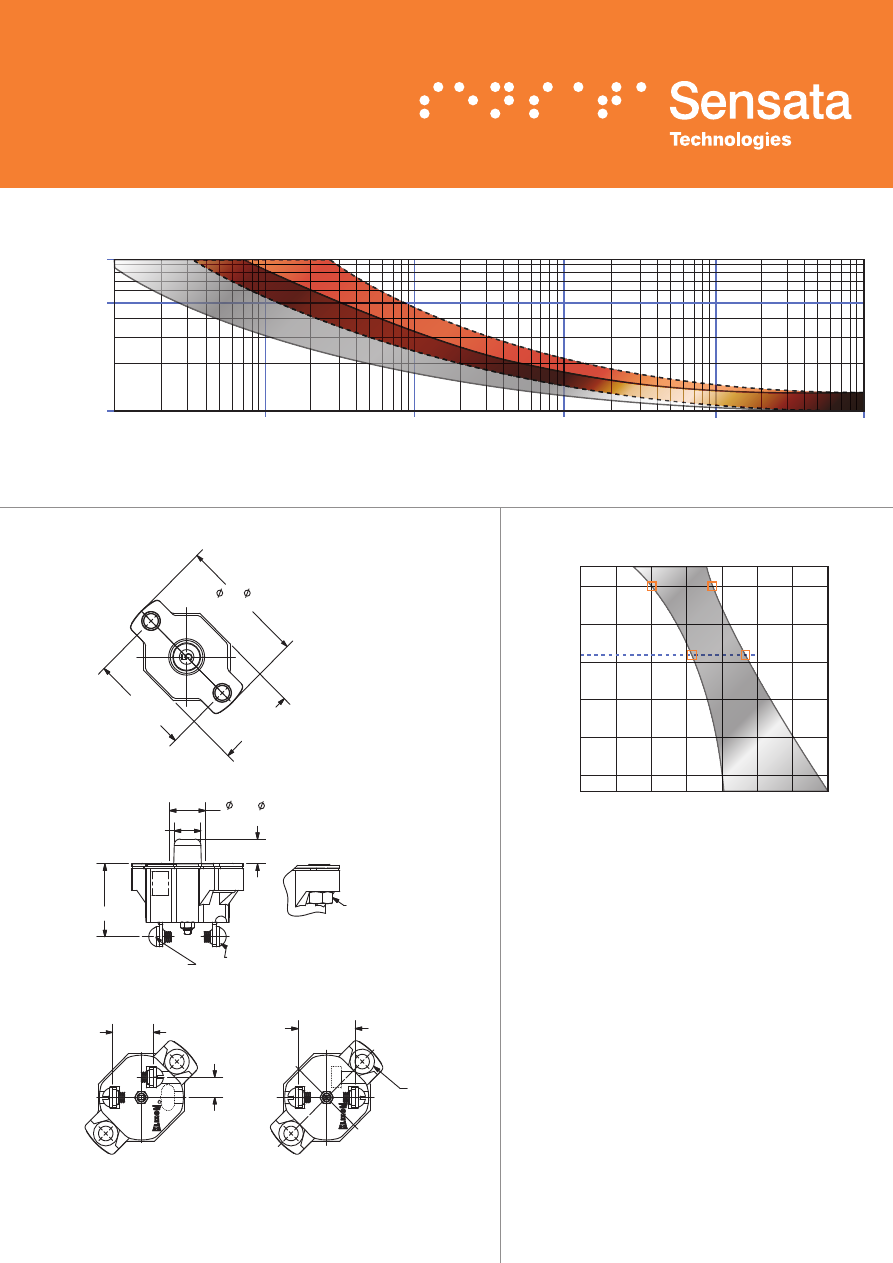

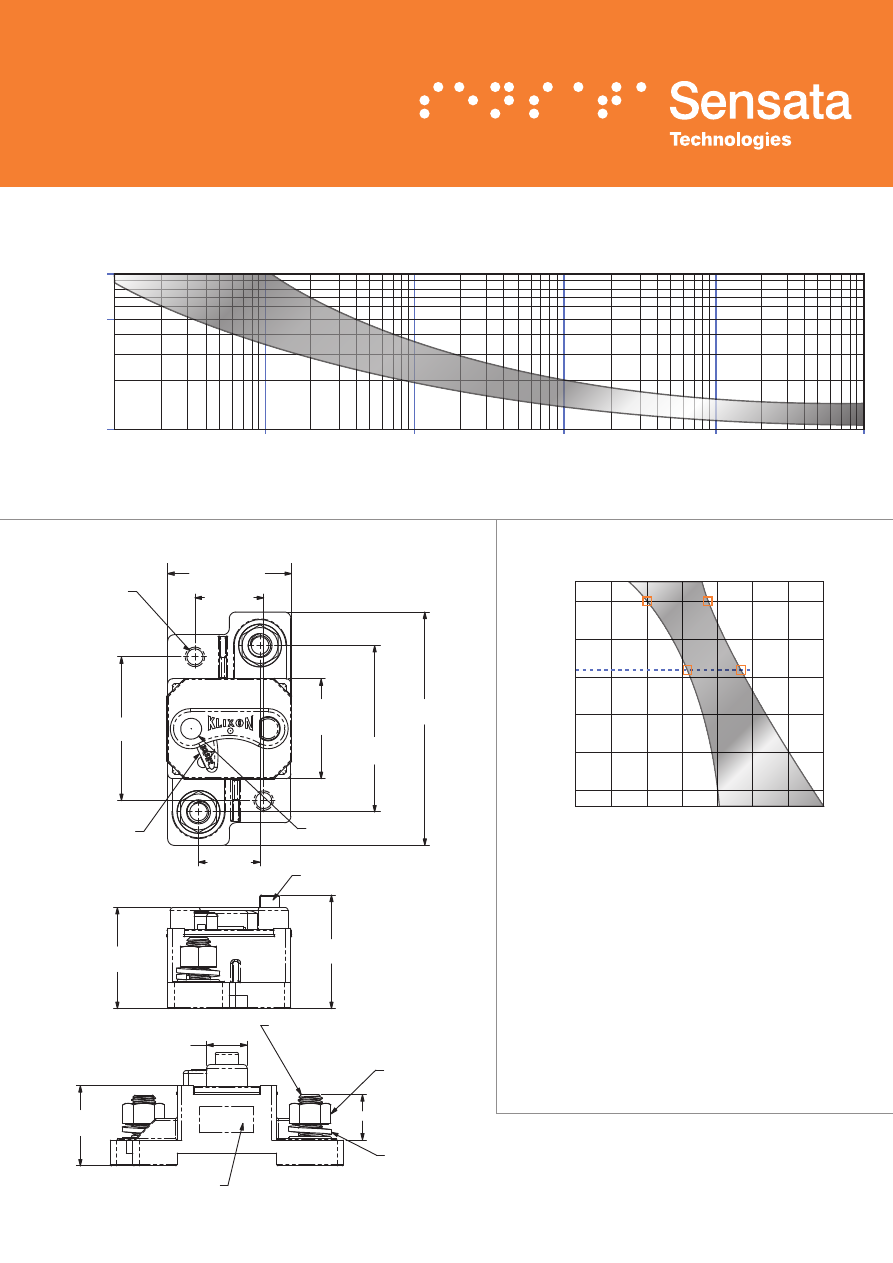

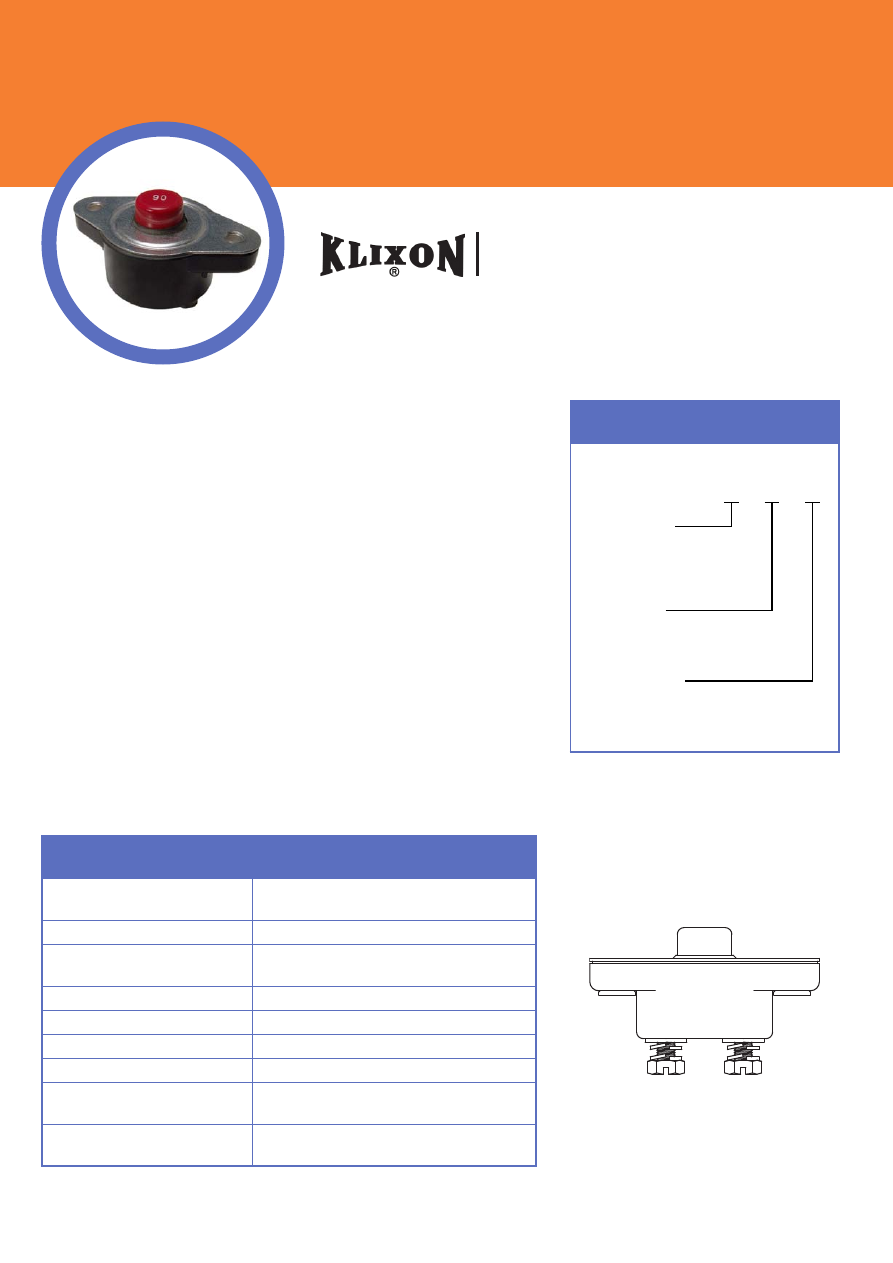

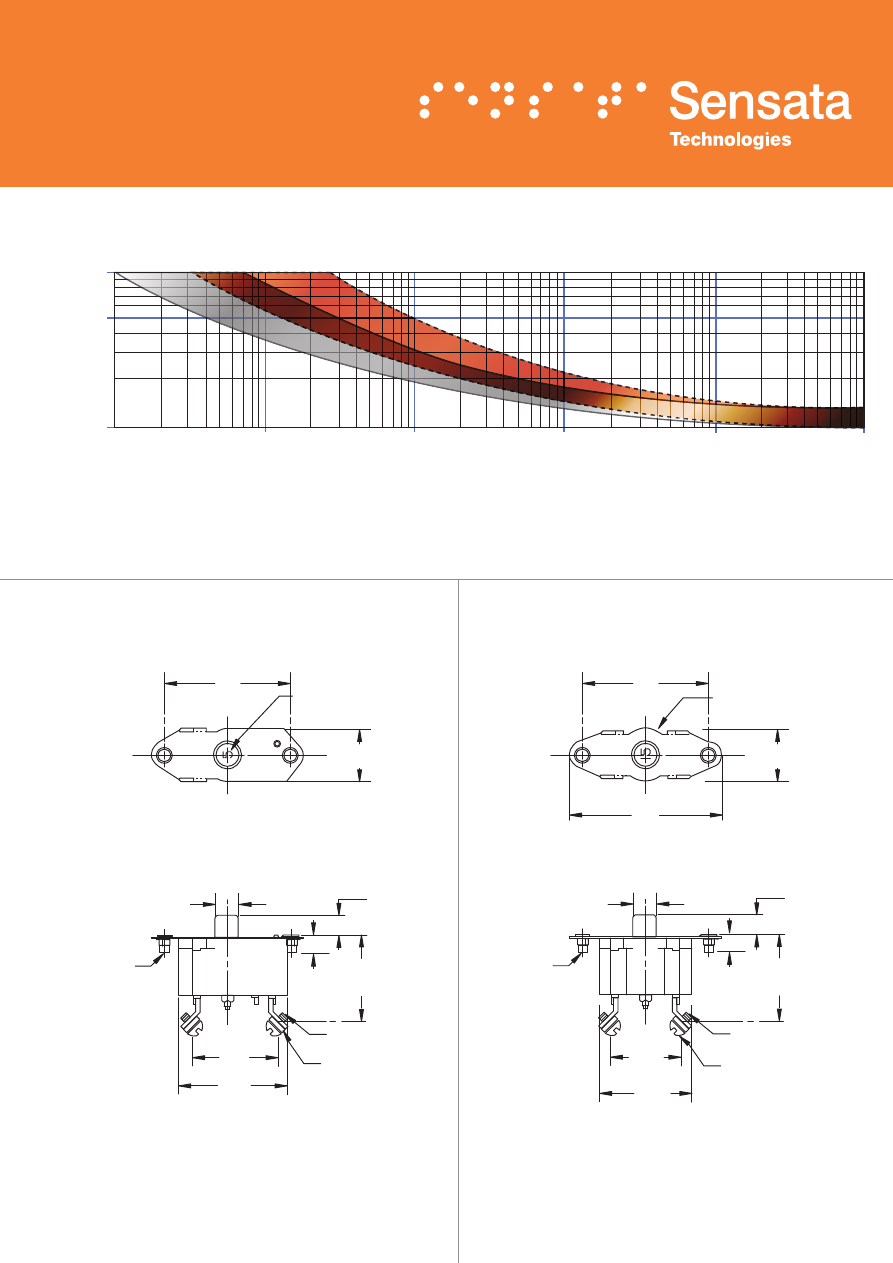

DERATING CURVE

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 100% of rated current (1) and trip at 135% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 78% of rated current (3), and trip at

approximately 115% of rated current (4).

Dotted Lines:

10 amps or below

Solid Lines:

Above

10 amps

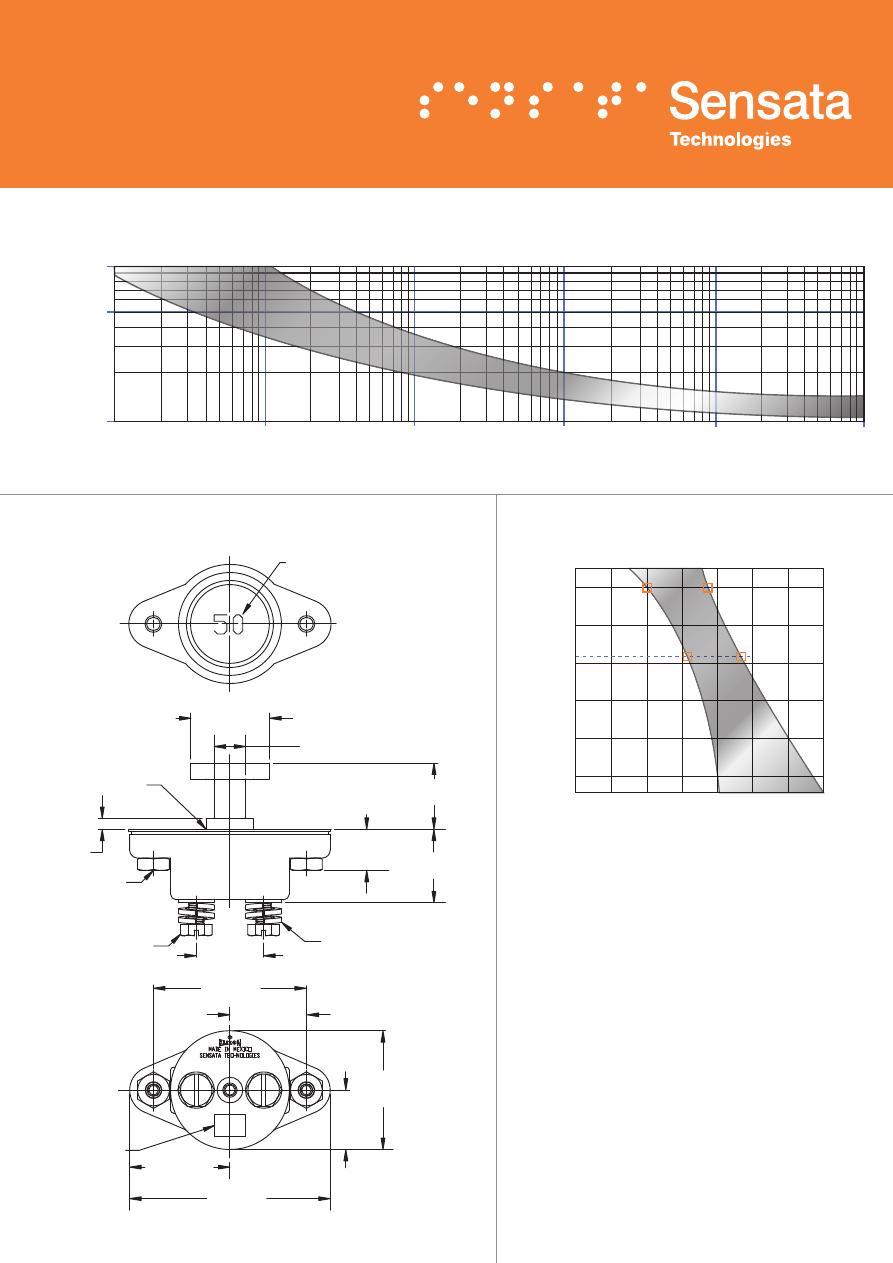

DIMENSIONS -

CDM

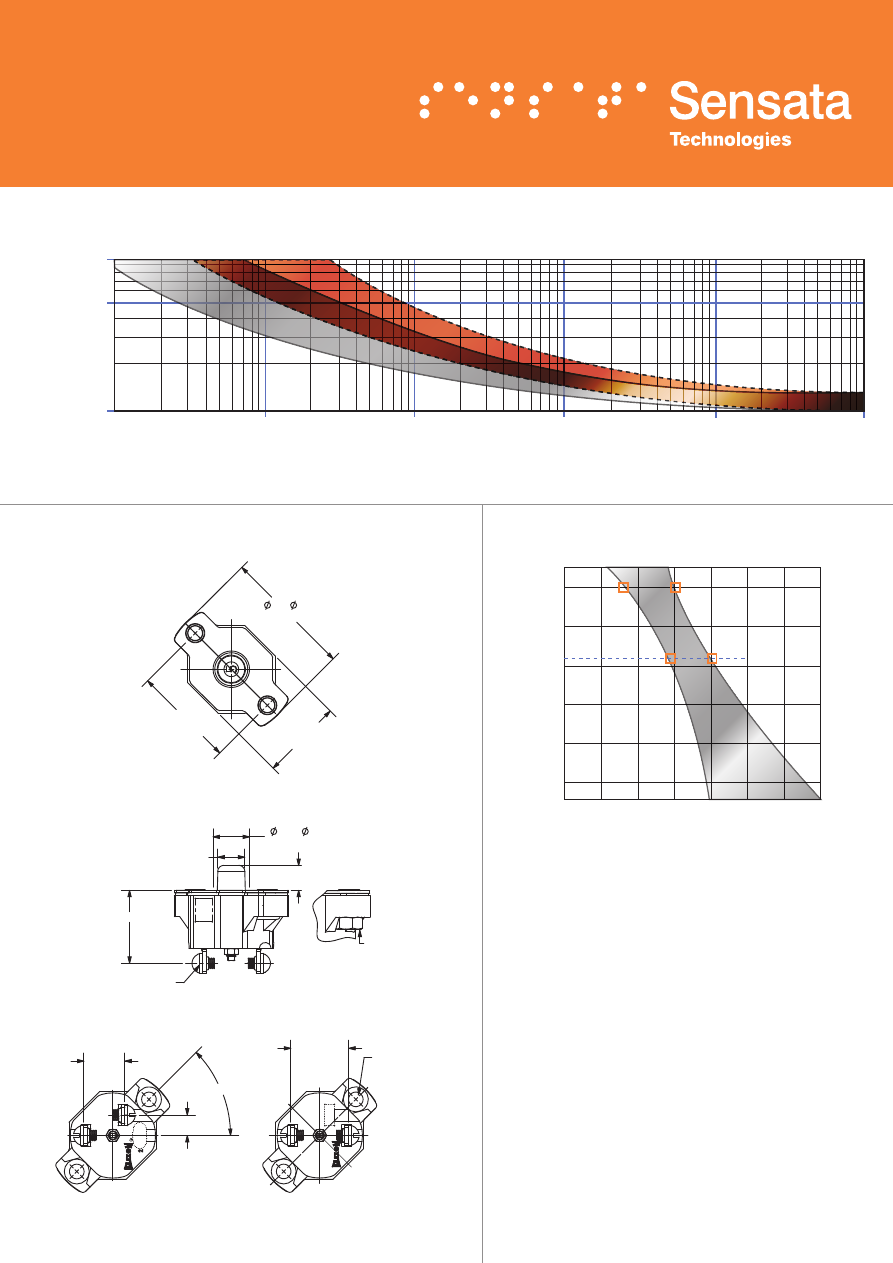

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

7

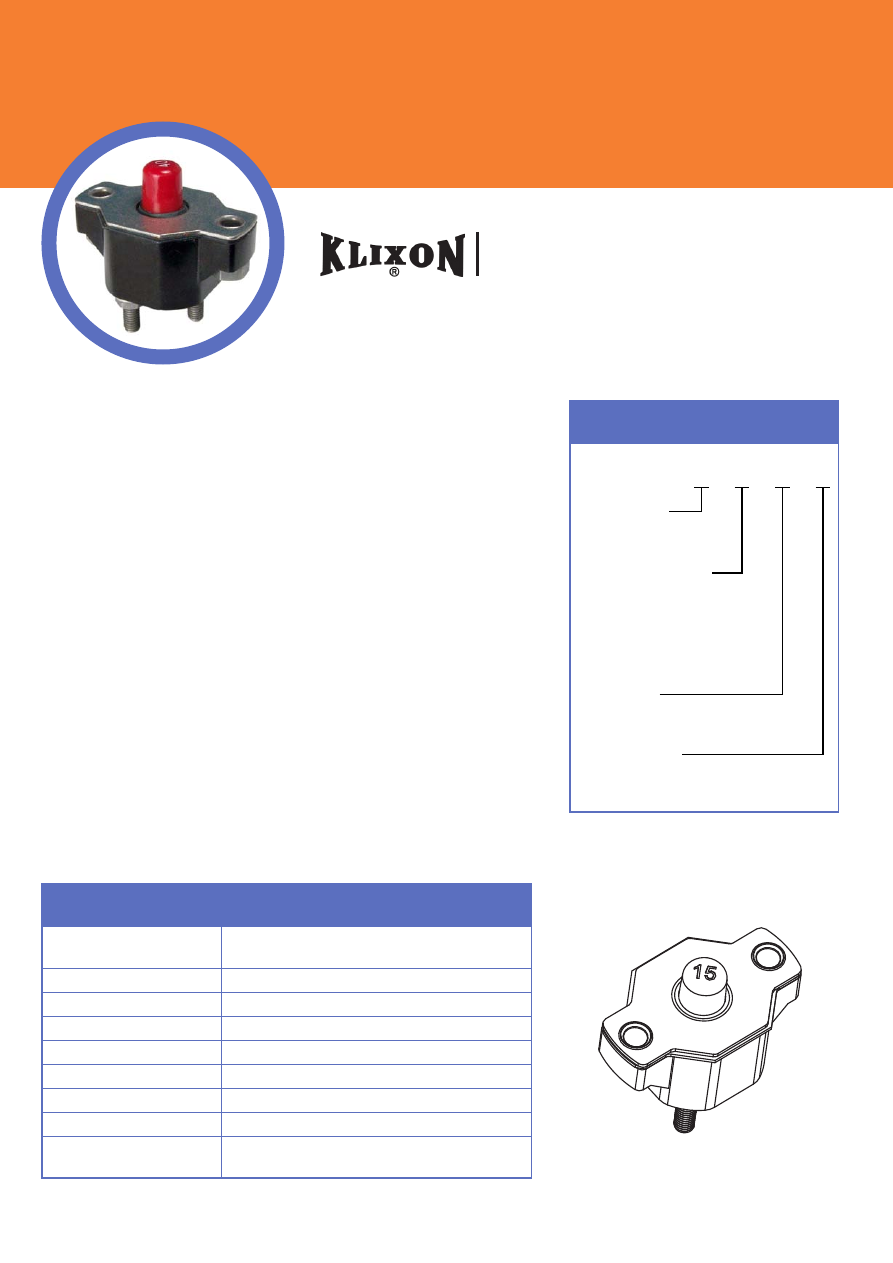

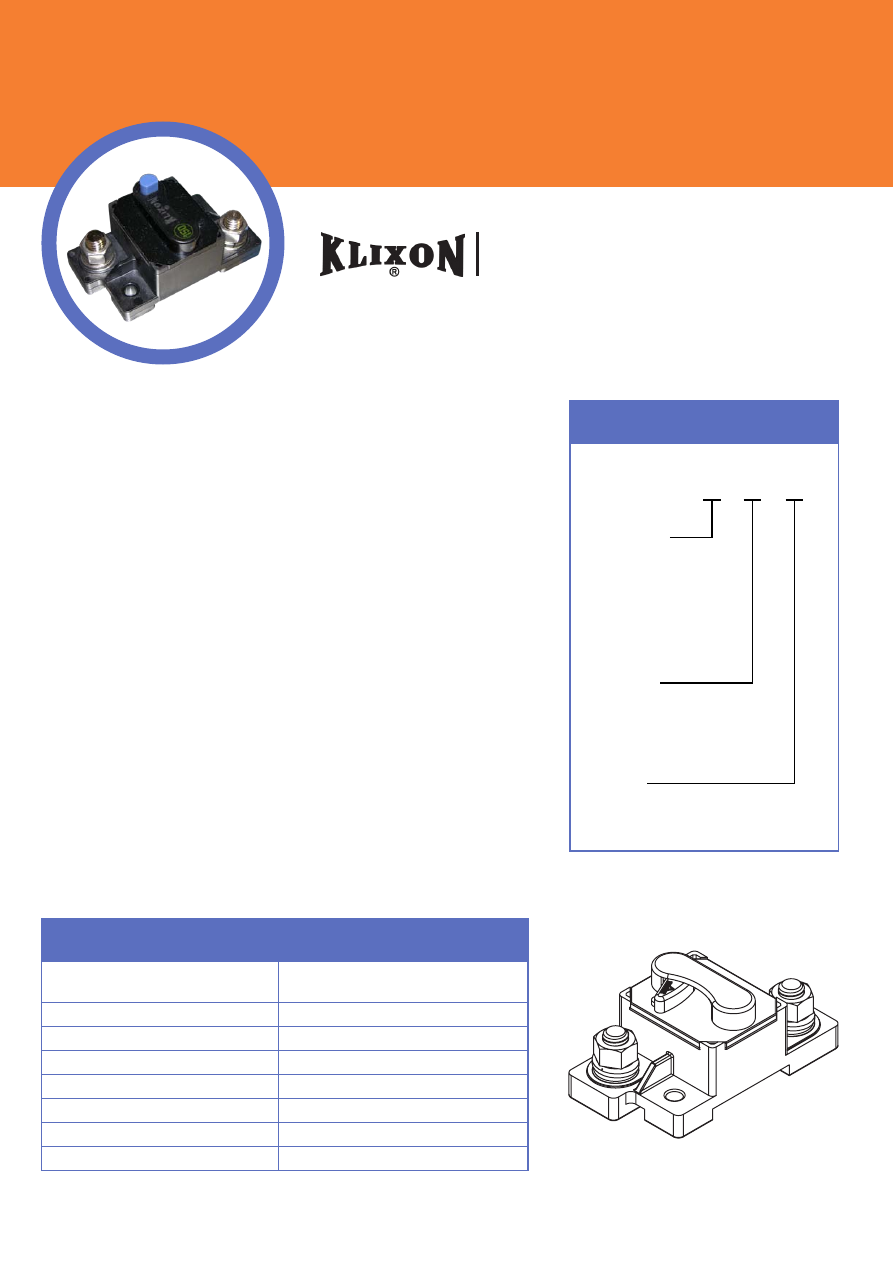

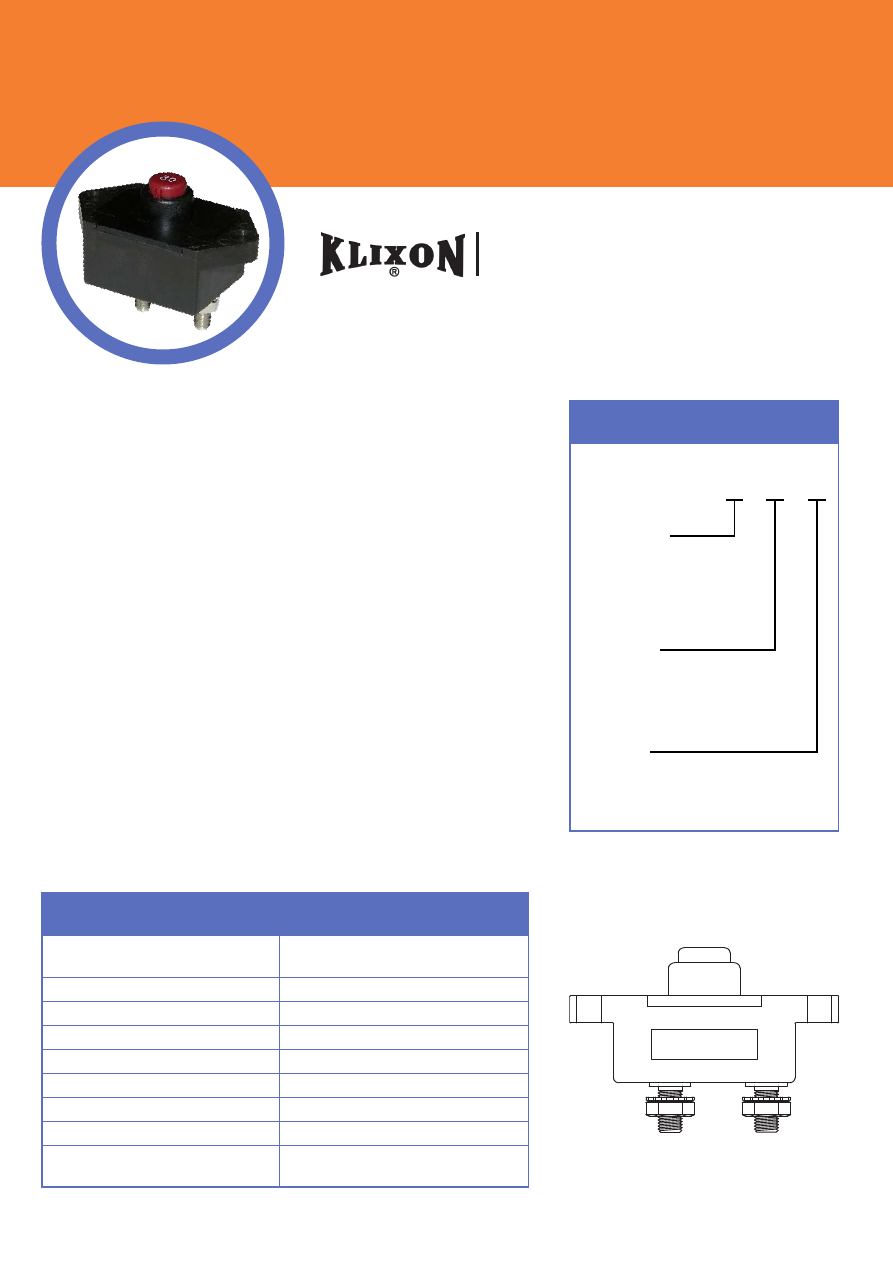

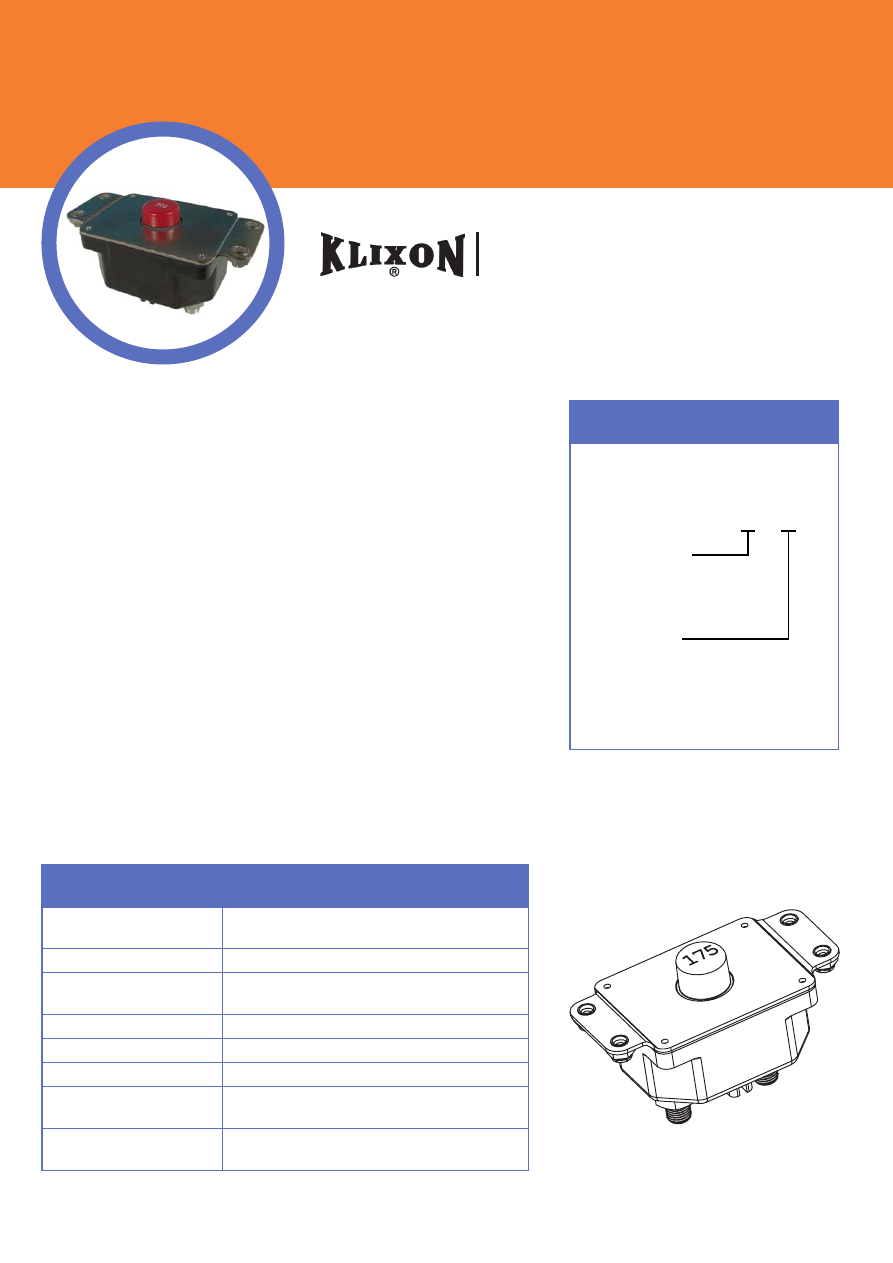

ORDERING INFORMATION

FEATURES

• 30VDC or 120VAC, 12.5 to 60 Amps

• Sealed assemblies, manual and automatic reset options

• Ignition protected SAE J1171

• Weatherproof SAE J553

• UL Recognized E36869

DESCRIPTION

The KLIXON® 7851 and 7854 series thermal breakers were designed

to protect wiring and meet the harshest environmental requirements.

The 7851 and 7854 series closed construction circuit breakers are

weatherproof sealed for protection against moisture, dust, grease, fuel

vapors and other harsh environments. The 7851 and 7854 series breakers

are compact, lightweight and designed to interrupt short circuits or

overloads, and combine trip-free protection with fast response time.

Typical applications are protection of wire cable of accessory circuits,

equipment and battery protection in construction and off-road equipment,

marine, recreational vehicles (RV’s), mining, agricultural equipment and

electric (hybrid) vehicles.

7851 & 7854 Series

12.5 to 60 Amp Commercial Thermal Circuit Breaker

Configuration

7851 = Manual, sealed

7854 = Auto, sealed

X − X − X − X

Stud Length (approx)

18 = 0.310” for 7851 & 7854

37 = 0.455” for 7851

26 = 0.455” for 7854

13 = 0.610” for 7851

15 = 0.610” for 7854

Amp Rating

(12.5, 15, 17.5, 20, 25, 30

35, 40, 50, 60)

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated

current, 77°F (25°C) 12.5 to 60 amps : 5 to 55 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 135%

Endurance Per SAE J553

Interrupt Current Capacity Per SAE J553 and ABYC E-11

Vibration 10G MIL-STD-202 Method 204, Condition A

Salt Spray MIL-STD-202 Method 101D

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B, 100M

Ω

min

Weight (with mounting nuts) 7851 : 54 grams max

7854 : 49 grams max

Mounting Nuts

= leave blank for none

I

= optional mounting nuts

8

x2 WASHER FOR #10 SCREW (2 PLACES)

#10-32 UNF - 2A TERMINAL (2 PLACES)

# 10-32 UNF - 2B NUT (2 PLACES)

(2 PLACES)

STYCAST SEAL

.430 [10.92]

1.531 [38.89]

1.469 [37.31]

.484 [12.29]

MIN. PANEL HOLE DIA.

.562 [ 14.27]

.637 [16.18]

2.0 [ 50.8]

SEE NOTE 1

1.586 [40.28]

1.562 [39.67]

(DOES NOT INCLUDE SEALING GASKET)

1.221 [31.01]

1.159 [29.44]

Sensata

Technologies

R

MADE IN MEXICO

EYELET FOR #10 SCREW (2 PLACES)

.729 [18.52]

.791 [20.09]

(45°)

INCHES [MM]

OPTIONAL #8-32 UNC-2B

MOUNTING NUT

(2 PLACES)

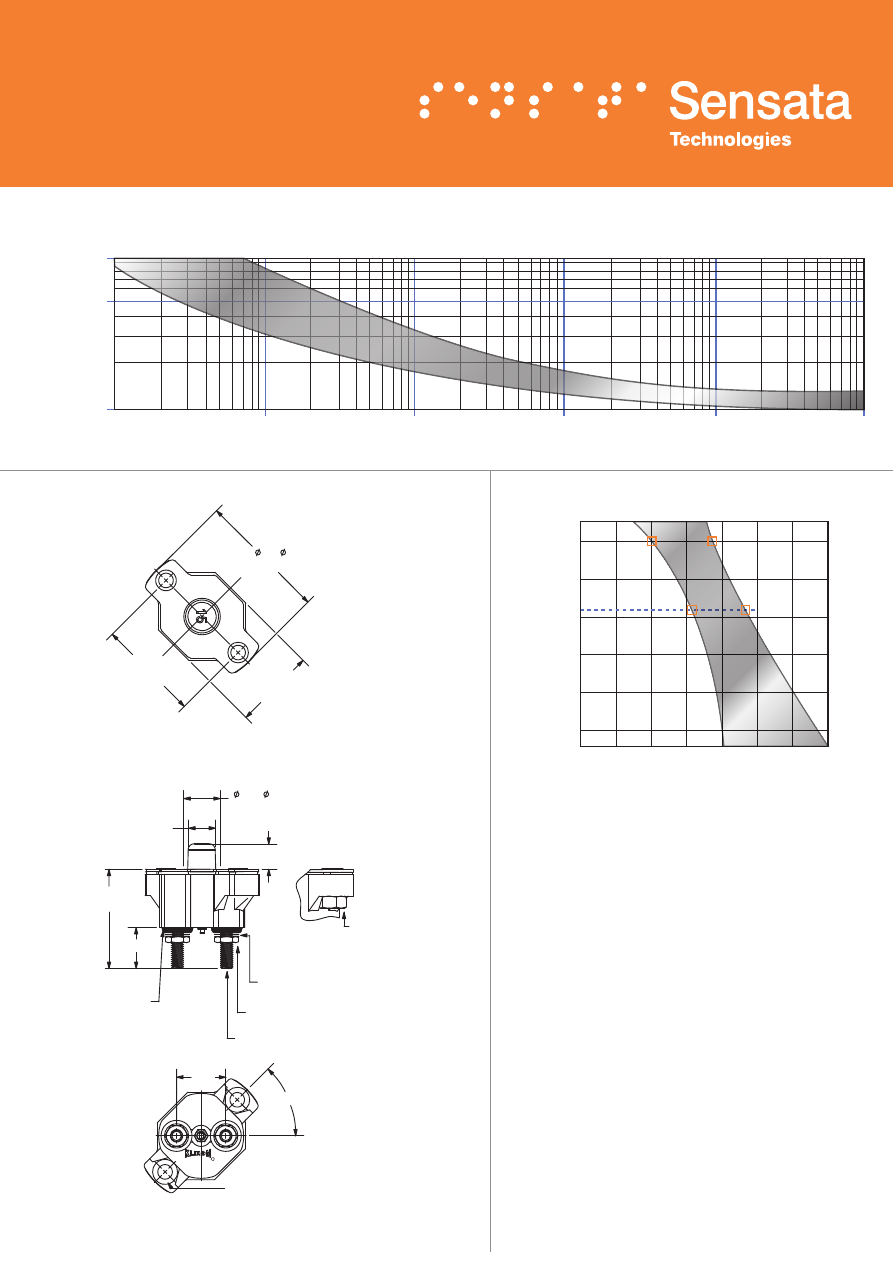

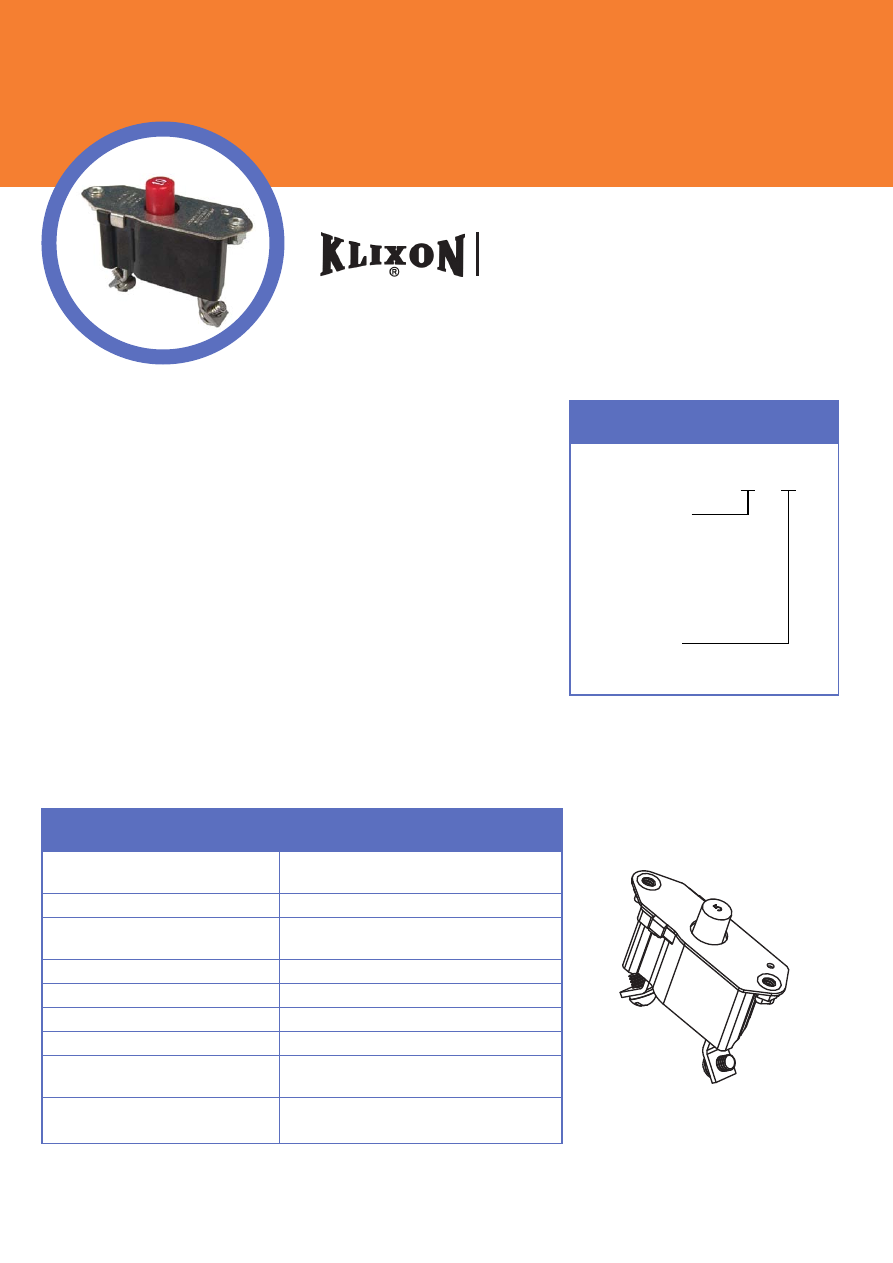

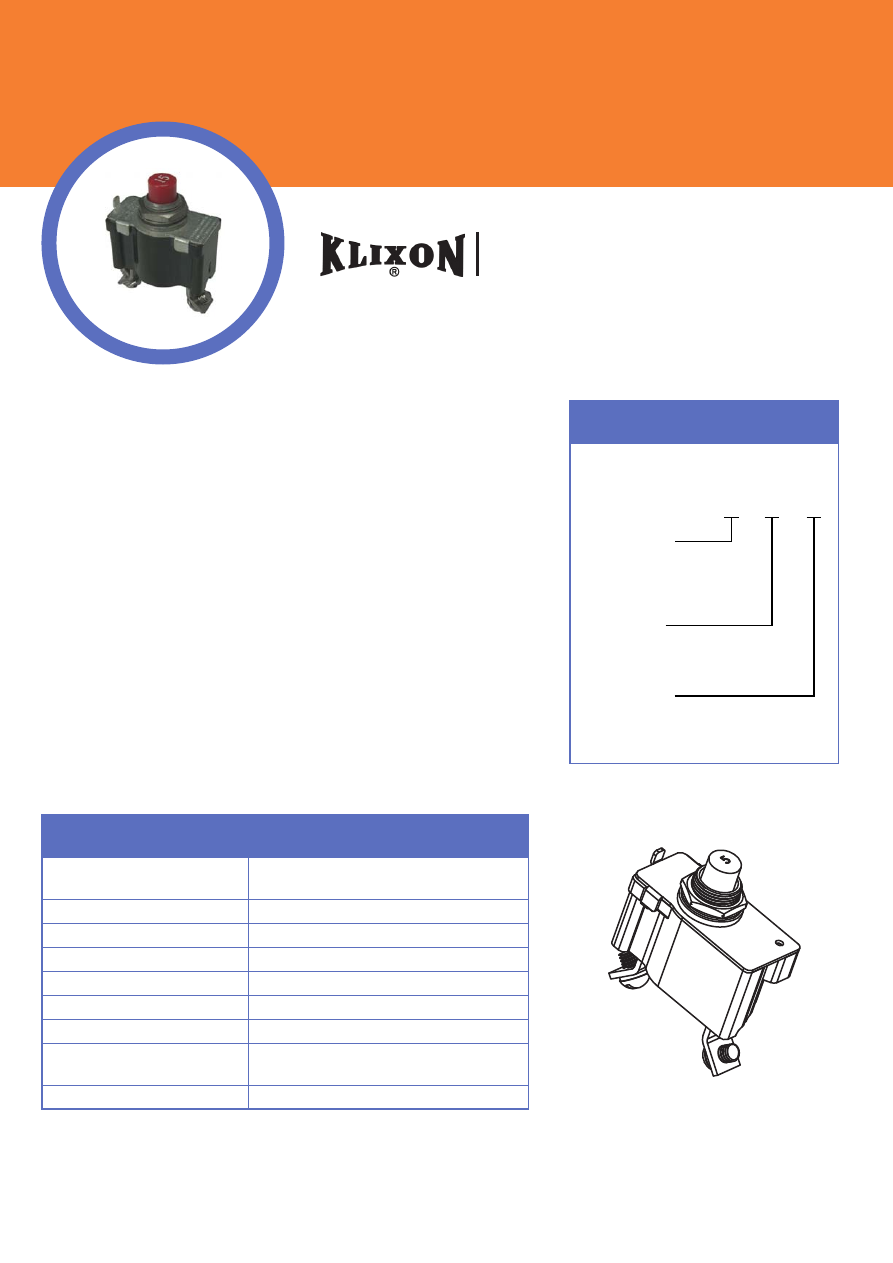

DERATING CURVE

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 100% of rated current (1) and trip at 135% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 78% of rated current (3), and trip at

approximately 115% of rated current (4).

DIMENSIONS -

7851

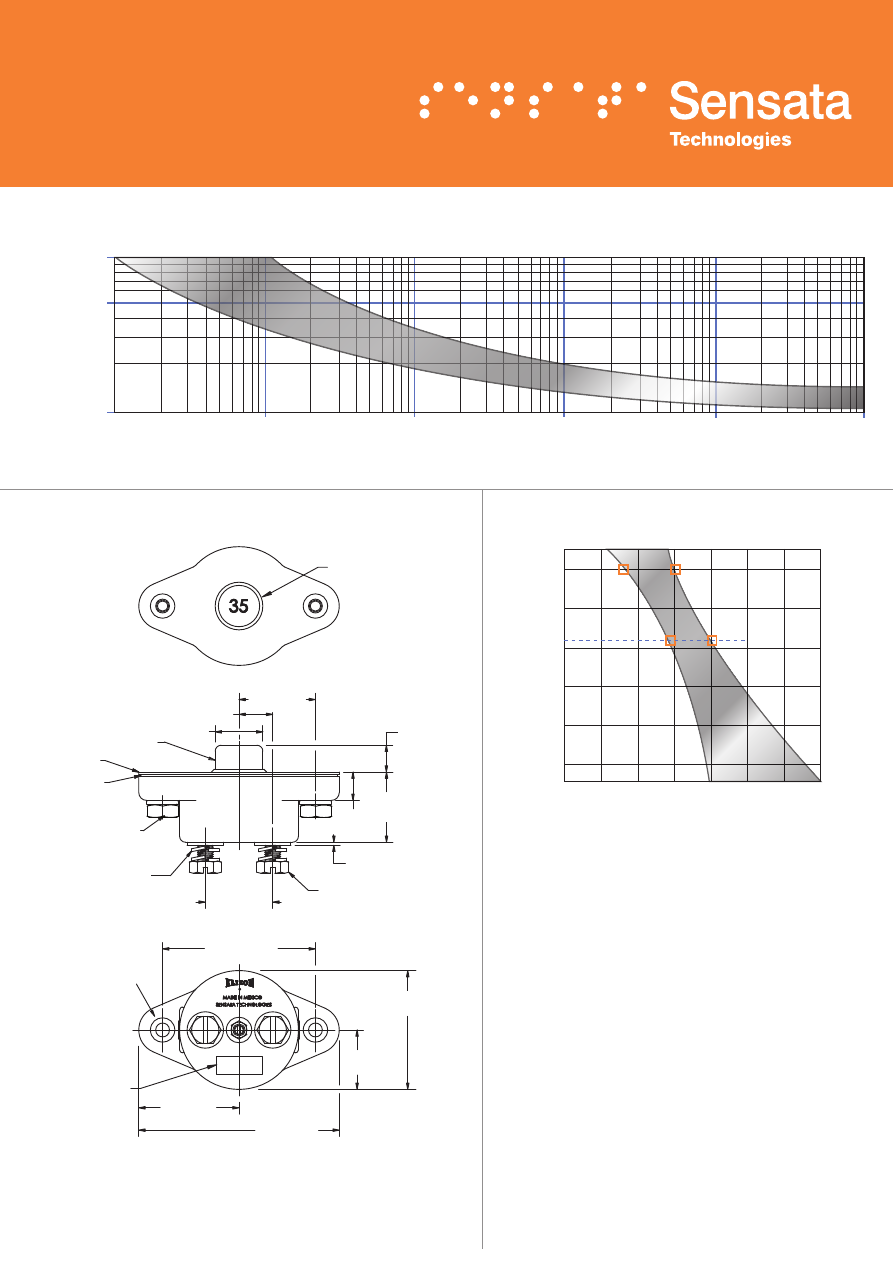

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

9

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

40

60

80

Ultimate Trip in % Rated Load

Ambient T

emperature in °F

, °C

100

120

140

160

180

3

4

1

2

77°F, 25°C

ORDERING INFORMATION

F Series (FDLM, FDLA, FDLS, FDLT)

35 to 150 Amp Surface Mounted Thermal Circuit Breaker

Configuration

A = Auto

M = Manual

S = Manual Reset / Switch

T = Trip Lever

FDL X − X − X

Amp Rating

(35, 40, 45, 50, 60, 70, 80, 90, 100,

105, 120, 135, 150)

Terminals

1 = 1/4-28 UNF-2A

2 = 3/8-16 UNC-2A

FEATURES

• 30VDC, 35 to 150 Amps

• Weatherproof, ignition protected, trip-free design

• Stronger housing material for increased robustness

• Ability to accommodate heavy gauge wire lugs across terminal studs

• SAE J1625 surface vehicles circuit breaker standards

• SAE J1171 marine circuit breaker standards

• Meets 5000 amps @ 12VDC for interrupt capacity per ABYC E-11,

DC electrical systems of boats

DESCRIPTION

The KLIXON® F series thermal breaker series are designed for surface

mount applications and are available with automatic trip, manual reset,

trip indication, and a switchable option in a single device. The internal

components are enclosed in a vibration resistant, weatherproof, robust

casing to provide protection in the harshest environments found in

heavy truck, off-road, marine and construction applications. The F series

thermal breakers are designed to combine trip-free protection with fast

response time. Terminal studs are available in 1/4” or a larger 3/8” option

to allow higher torque connections and provide wider spacing for heavy

gauge wire lugs.

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C) 35 to 150 Amps : 8 to 100 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 135%

Endurance Per SAE J1625

Interrupt Current Capacity Per SAE J1625 and ABYC E-11

Mechanical Vibration Per SAE J1455, 4G’s 10-2K Hz

Voltage Breakdown Per SAE J1625 500VAC

Salt Spray Per SAE J1455, 96 hours

Weight 150 grams max

10

3.800 [96.52]

MAX.

(2 PLACES)

LOCKWASHER

1.260 [32.00]

REF.

.650 [16.51]

REF.

'B' REF.

PUSHBUTTON

(BLUE)

1.900 [48.26]

REF.

1.600 [40.64]

REF.

135

MOUNTING HOLE

FOR 1/4" SCREW

2 PLACES

RESET LEVER

(RED)

AMP RATING

(FOR EXAMPLE: 135A)

2.242 [56.95]

2.600 [66.04]

REF.

.950 [24.13]

REF.

SEE NOTE 1

1.085 [27.56]

1.560 [39.62]

REF.

1.035 [26.29]

2.192 [55.68]

SEE NOTE 1

2.100 [53.34] MAX

R

HEX NUT

(2 PLACES)

PART NUMBER AND DATE CODE

1/4 - 28 UNF - 2A ('B' = 0.55 [13.97] REF) OR

TERMINAL STUDS 2 PLACES

3/8 -16 UNC - 2A ('B' = 0.65 [16.51] REF)

INCHES [MM]

DERATING CURVE

DIMENSIONS -

FDLS

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 100% of rated current (1) and trip at 135% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 78% of rated current (3), and trip at

approximately 115% of rated current (4).

Notes:

1. Dimension does not include sealing gasket.

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

11

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

40

60

80

Ultimate Trip in % Rated Load

Ambient T

emperature in °F

, °C

100

120

140

160

180

3

4

1

2

77°F, 25°C

S Series (SDLM, SDLA, SLA)

35 to 150 Amp Commercial Thermal Circuit Breaker

FEATURES

• 30VDC, 35 to 150 Amps

• Open and sealed assemblies, manual and automatic reset options

• Ignition protected

• UL Recognized E69772

DESCRIPTION

The KLIXON® S series thermal breakers are designed to protect wiring

and meet the harshest environmental requirements. The sealed circuit

breakers are weatherproof for protection against moisture, dust, grease,

fuel vapors and other harsh environments. The S series breakers are

lightweight and designed to interrupt short circuits or overloads and

combine trip-free protection with fast response time. Typical applications

are protection of wire and cable of accessory circuits, equipment and

battery protection on heavy trucks, buses, construction equipment, off-

road vehicles, marine, recreational vehicles (RVs) and electric (hybrid)

vehicles, and battery chargers.

The S series is available in both open and sealed body configurations with

manual and automatic reset options.

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C) 35 to 150 Amps : 8 to 100 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 135%

Endurance Per SAE J1625

Interrupt Current Capacity Per SAE J1625 and ABYC E-11

Mechanical Vibration Per SAE J1455, 4G’s, 10-2K Hz

Voltage Breakdown Per SAE J1625 500VAC

Salt Spray Per SAE J1625, 96 hours

Voltage Drop Per SAE J1625

Weight (with mounting nuts) SDLM (A) : 75 grams (71 grams) max

SLA : 62 grams max

ORDERING INFORMATION

Configuration

SLA = Auto, open unit

SDLM = Manual, sealed unit

SDLA = Auto, sealed unit

X − X − X

Amp Rating

(35, 40, 45, 50, 60, 70, 80, 90, 100,

105, 120, 135, 150)

Terminals

1 = 1/4-28 UNF-2A

with optional mounting nuts

12

AMP RATING

FOR ILLUSTRATION

PUSH BUTTON

(RED)

2.930 [74.42]

MAX

150

1.650 [41.91]

MAX

.580 [14.73]

.750 [19.05]

.540 [13.72]

.590 [14.99]

2X THREADED STUD

1/4-28 UNF-2A

2.429 [61.70]

2.399 [60.93]

1.550 [39.37]

MAX

(SEE NOTE 1)

2X PRE-ASM NUT

2X (

Ø .261 [Ø 6.63])

MOUNTING HOLE

10-32-UNF-2B

MOUNTING NUTS

FURNISHED WHEN

SPECIFIED

1.009 [25.63]

.284 [7.21]

INCHES [MM]

DERATING CURVE

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 100% of rated current (1) and trip at 135% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 78% of rated current (3), and trip at

approximately 115% of rated current (4).

DIMENSIONS -

SDLM

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

13

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

40

60

80

Ultimate Trip in % Rated Load

Ambient T

emperature in °F

, °C

100

120

140

160

180

3

4

1

2

77°F, 25°C

ORDERING INFORMATION

6766-19 Series

35 to 150 Amp Commercial Thermal Circuit Breaker

FEATURES

• 30VDC, 35 to 150 Amps

• Manual reset

• Weatherproof SAE J1625 and ideally suited for rugged applications

• Ignition protected SAE J1171

DESCRIPTION

The KLIXON® 6766-19 series is a manually switchable thermal

circuit breaker that is designed to meet the harshest environmental

requirements. The 6766-19 series breakers are weatherproof for

protection against moisture, dust, grease, fuel vapors, and other harsh

environments. The 6766-19 series of breakers is suited for rugged

applications, where a robust switchable breaker is required for

accessory, equipment and battery protection on heavy trucks, buses,

construction equipment, off-road vehicles, marine, recreational vehicles

(RVs) and electric (hybrid) vehicles.

Configuration

6766-19 = Manual, sealed

X − X

Amp Rating

(35, 40, 45, 50, 60, 70, 80,

90 105, 120, 135, 150)

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C) 35 to 150 Amps : 8 to 100 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 135%

Endurance Per SAE J1625

Interrupt Current Capacity Per SAE J1625 and ABYC E-11

Vibration Per SAE J1455, 4G’s, 10-2K Hz

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B,

100 M

Ω

min

Weight (with mounting nuts) 6766-19 : 129 grams max

14

AMP RATING

FOR ILLUSTRATION

Ø

1.250 [31.75]

1.230 [31.24]

Ø

.531 [13.49]

.469 [11.91]

Ø

.750 MIN PANEL HOLE

.202

.140

1.072 [27.23]

1.052 [26.72]

.687 [17.45]

.625 [15.88] 1.187 [30.15]

1.125 [28.58]

1.043 [26.49] MAX OPEN

.872 [22.15] MIN CLOSE

2X #10-32 UNC-2B

LOCKNUTS

2X 1/4-28UNF-2 HEX

HEAD CAP SCREW

4X SPLIT LOCKWASHER

2.416 [61.37]

2.396 [60.86]

1.208 [30.68]

1.198 [30.43]

1.906 [48.41]

1.844 [46.84]

SEE NOTE 1

.958 [24.33]

.922 [23.42]

3.187 [80.95]

3.125 [79.38]

(DOES NOT INCLUDE SEALING GASKET)

1.594 [40.49]

1.562 [39.67]

PART NO. AND

DATE CODE

LOCATION

INCHES [MM]

DERATING CURVE

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 100% of rated current (1) and trip at 135% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 78% of rated current (3), and trip at

approximately 115% of rated current (4).

DIMENSIONS -

6766-19

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

15

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

40

60

80

Ultimate Trip in % Rated Load

Ambient T

emperature in °F

, °C

100

120

140

160

180

3

4

1

2

77°F, 25°C

ORDERING INFORMATION

7855 Series

175 to 200 Amp Commercial Thermal Circuit Breaker

FEATURES

• 30VDC, 175 to 200 Amps

• Sealed assemblies, manual and automatic reset options

• Ignition protected

• 7855-6 meets CID A-A-55571/03 specifications

• 7855-7 meets CID A-A-55571/08 specifications

DESCRIPTION

The KLIXON® 7855 series thermal breaker are designed to meet the

harshest environmental requirements. The 7855 series breakers are

weatherproof for protection against moisture, dust, grease, fuel vapors

and other harsh environments. The 7855 series breakers are designed to

interrupt short circuits or overloads and combine trip free protection with

fast response time.

The 7855 series of breakers typical applications are protection of wire and

cable of accessory circuits, military vehicles, lift gates, and recreational

vehicles.

Configuration

7855-6 = Manual, sealed

7855-7 = Auto, sealed

X − X

Amp Rating

(175, 200)

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated

current, 77°F (25°C) 8 to 100 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 138%

Endurance Manual 500 cycles @ 200%

Automatic 2000 cycles @ 200%

Interrupt Current Capacity Per SAE J1625, 900A

Vibration 10G MIL-STD-202 Method 204, Condition A

Dielectric Strength MIL-STD-202, Method 301, 1500VAC min

Insulation Resistance MIL-STD-202, Method 302, Condition B, 100 M

Ω

min

Weight 7855-6 : 241 grams max

7855-7 : 237 grams max

16

4 MTG HOLES

Ø

.218 [

Ø 5.54]

MOUNTING NUTS

SUPPLIED FOR

7855-6

BOTTOM VIEW

.78 [19.81]

Ø

.875 [22.23] MIN CLEARANCE

HOLE FOR PUSH BUTTON

REQ’D FOR MOUNTING

.062 [1.58]

1.47 [37.34]

.500 ± .015 [12.700 ± .381]

1.500 ± .015

[38.100 ± .381]

LOCK WASHER x2

HEX NUT x2

3/8 - 24 UNF - 2B

THREAD

2.75 [69.85]

3.500 [88.9]

4.000 [101.6]

2.12 [53.85]

1.000

[25.4]

.500

[12.7]

1.50

[38.1]

INCHES [MM]

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

60

80

100

Ultimate Trip in % Rated Load

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

Ambient T

emperature in °F

, °C

120

140

160

180

200

3

4

1

2

77°F, 25°C

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

32˚F

DERATING CURVE

DIMENSIONS -

7855-6

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for

ambient temperatures significantly higher or lower than

standard room temperature.

Example:

At 77°F (25°C) the device is calibrated to hold

at 110% of rated current (1) and trip at 138% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 92% of rated current (3), and trip at

approximately 120% of rated current (4).

17

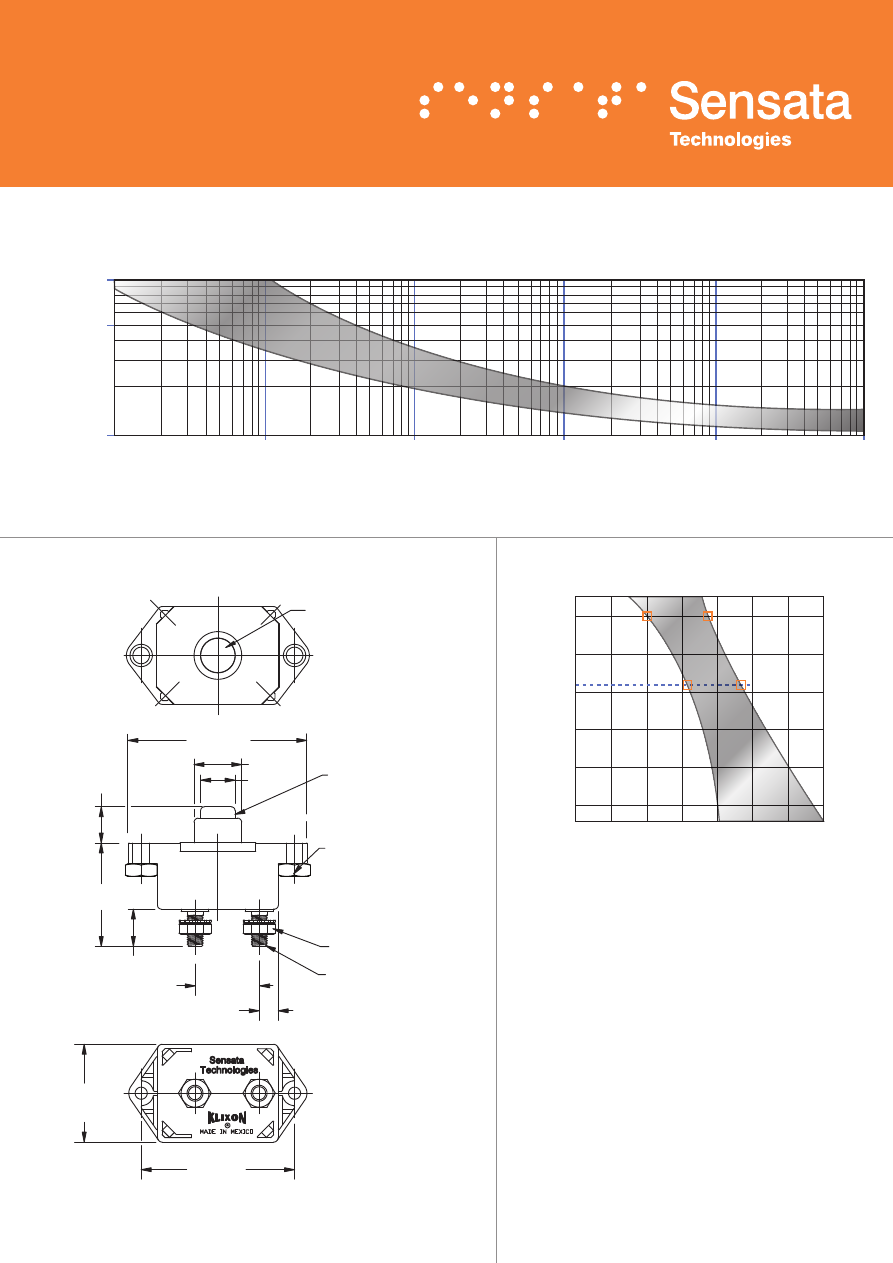

ORDERING INFORMATION

Small Frame PD Series (PDM, PDA)

2 to 40 Amp Precision Thermal Circuit Breaker

FEATURES

• 30VDC or 120VAC, 2 to 40 Amps

• Sealed assemblies, available in manual and automatic reset options

• Ignition protected

• UL Recognized E36869

DESCRIPTION

The KLIXON® PD series thermal breakers are designed to protect wiring

and meet the harshest environmental requirements. The PD series are

weatherproof sealed for protection against moisture, dust, grease,

fuel vapors and other harsh environments. The PD series breakers

are compact, lightweight and designed to interrupt short circuits or

overloads, and combine trip-free protection with fast response time.

Typical applications are protection of wire and cable of accessory circuits,

equipment and battery protection in construction and off-road equipment,

marine, recreational vehicles (RV’s), mining, agricultural equipment and

electric (hybrid) vehicles.

The PD series is used in commercial and military applications.

Configuration

PDM = Manual, sealed

PDA = Auto, sealed

X − X − X

Amp Rating

(2, 3, 4, 5, 6, 8, 10, 12.5, 15

17.5, 20, 25, 30, 35, 40)

Mounting Nuts

= leave blank for none

I

= include optional mounting nuts

PERFORMANCE CHARACTERISTICS

Calibration :

200% rated current, 77°F (25°C)

2 to 10 amps : 20 to 150 seconds

12.5 to 40 amps : 8 to 50 seconds

Ultimate Trip at 77°F (25°C) Must hold 110%, must trip 138%

Endurance Per SAE J553

Interrupt Current Capacity Per SAE J553 and ABYC E-11

Vibration 10G MIL-STD-202 Method 204, Condition A

Mechanical Shock MIL-STD-202 Method 213, Condition C, 100G

Salt Spray MIL-STD-202 Method 101D

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B,

100 M

Ω

min

Weight (with mounting nuts) PDM : 48 grams max

PDA : 41 grams max

18

ROUND HEAD SCREW

2X .250 [6.35] LONG #8-32 UNC-2A

2X (.047 [1.1938]) THK.

LOCKWASHER

.430 [10.92]

.562 [ 14.28]

MIN. PANEL HOLE DIA.

1.145 [29.08]

.380 [9.65]

2.0 [ 50.8]

SEE NOTE 1

1.586 [40.28]

1.562 [39.68]

(DOES NOT INCLUDE SEALING GASKET)

1.221 [31.01]

1.159 [29.44]

R

Se

ns

at

a

Te

ch

no

lo

gi

es

3

2

M

AD

E

IN

M

EX

IC

O

1

Se

ns

at

a

Te

ch

no

lo

gi

es

R

1

3

M

AD

E

IN

M

EX

IC

O

2

BOTTOM VIEW

FOR 2 AMP THRU 10 AMP

.312 [7.93]

.641

[16.28]

(45°)

BOTTOM VIEW

FOR 12½ AMP THRU 40 AMP

2X EYELET

FOR #10 SCREW

.906 [23.01]

INCHES [MM]

2X #8-32 UNC-2B

MOUNTING NUTS

FURNISHED WHEN

SPECIFIED

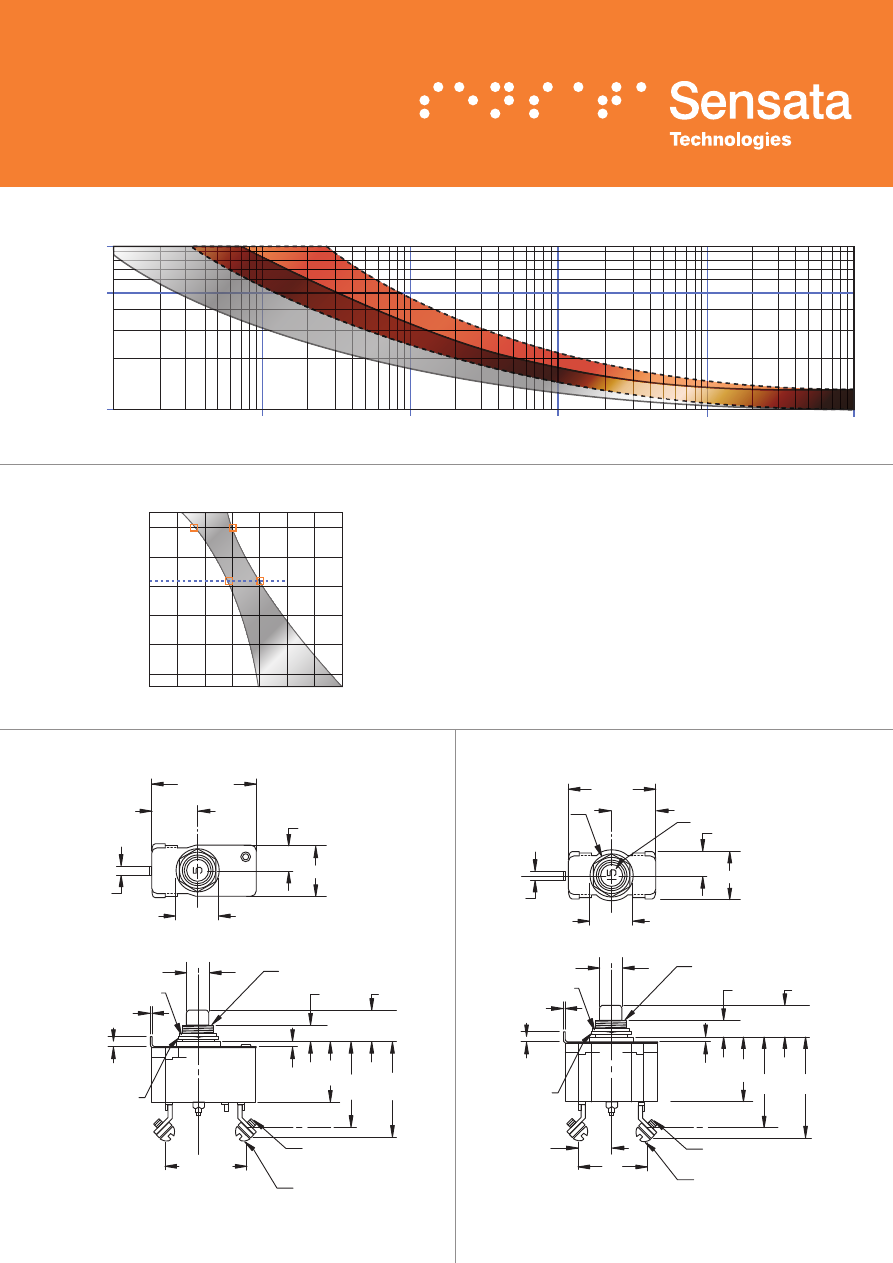

DERATING CURVE

DIMENSIONS -

PDM

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for ambient

temperatures significantly higher or lower than standard

room temperature.

Example: At 77°F (25°C) the device is calibrated to hold

at 110% of rated current (1) and trip at 138% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 92% of rated current (3), and trip at

approximately 120% of rated current (4).

Dotted Lines:

10 amps or below

Solid Lines:

Above

10 amps

0

60

80

100

Ultimate Trip in % Rated Load

120

140

160

180

200

3

4

1

2

77°F, 25°C

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

Ambient T

emperature in °F

, °C

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

19

ORDERING INFORMATION

Large Frame PDL Series (PDLM, PDLA)

35 to 150 Amp Precision Thermal Circuit Breaker

FEATURES

• 30VDC, 35 to 150 Amps

• Sealed assemblies, available in manual and automatic reset options

• Ignition protected & CCC certified

• PDLM meets CID A-A-55571/04 specifications

• PDLA meets CID A-A-55571/07 specifications

DESCRIPTION

The KLIXON® PDL series thermal breakers are designed to meet the

harshest environmental requirements. The PDL series breakers are

weatherproof for protection against moisture, dust, grease, fuel vapors,

and other harsh environments. The PDL series of breakers are designed

to interrupt short circuits or overloads and combine trip-free protection

with fast response time. The PDL series of breakers can be used in

commercial and military vehicles and equipment where more precise

ultimate trip characteristics are required.

Configuration

PDLM = Manual, sealed

PDLA = Auto, sealed

X − X − X

Amp Rating

(35, 40, 45, 50, 60, 70, 80, 90,

105, 120, 135, 150)

Mounting Nuts

= leave blank for none

I

= include optional mounting nuts

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C) 8 to 100 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 138%

Endurance Automatic: 2,000 cycles @ 200% rated current

Manual: 500 cycles @ 200% rated current

Interrupt Current Capacity Per SAE J1625 and ABYC E-11

Vibration 10G MIL-STD-202 Method 204, Condition A

Mechanical Shock 100G MIL-STD-202 Method 213, Condition C

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B,

100 M

Ω

min

Weight (with mounting nuts) PDLM : 129 grams max

PDLA : 116 grams max

20

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

AMP RATING

ILLUSTRATION

1.213 [30.81]

1.193 [30.30]

.536 [13.61]

.526 [13.36]

.422

[10.72]

.781 [19.84]

MAX

PUSHBUTTON (RED)

.875 [22.23]

MIN PANEL HOLE

COVER

GASKET

4X LOCKWASHER

.469 [11.91]

.437 [11.10]

1.140 [28.96]

1.078 [27.38]

.063 [1.60]

.031 [.78]

1.072 [27.23]

1.052 [26.72]

2x 1/4-28 x 1/2” LG.

HEX HEAD CAP SCREWS

1.891 [48.03]

1.859 [47.22]

.954 [24.23]

.922 [23.42]

2.416 [61.37]

2.396 [60.86]

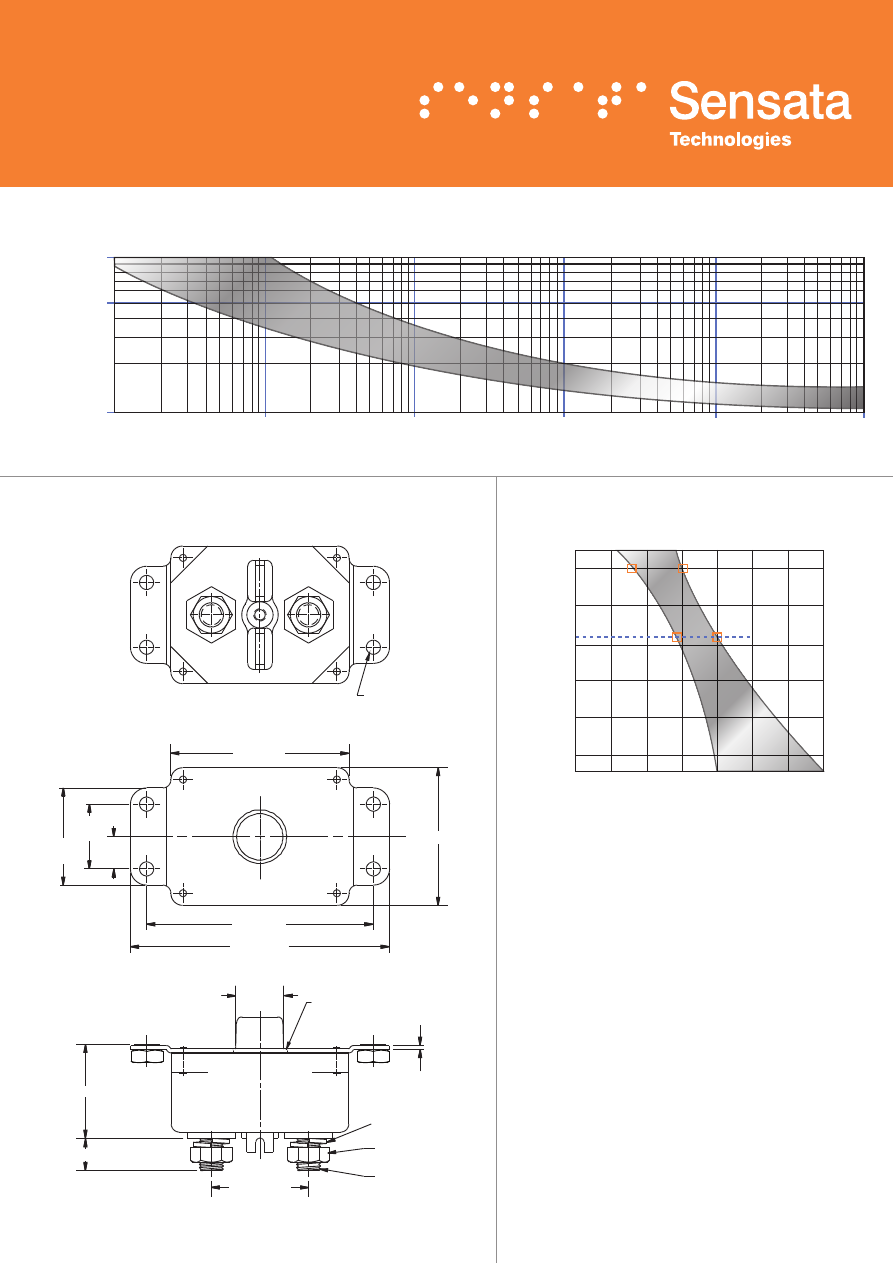

DIMENSIONS

DO NOT INCLUDE

SEALING GASKET

3.187 [80.95]

3.125 [79.38]

1.594 [40.49]

1.562 [39.68]

PART NO.

AND DATE CODE

LOCATION

2X EYELET FOR #10

SCREW

(SEE NOTE 1)

INCHES [MM]

MOUNTING NUTS

FURNISHED WHEN

SPECIFIED

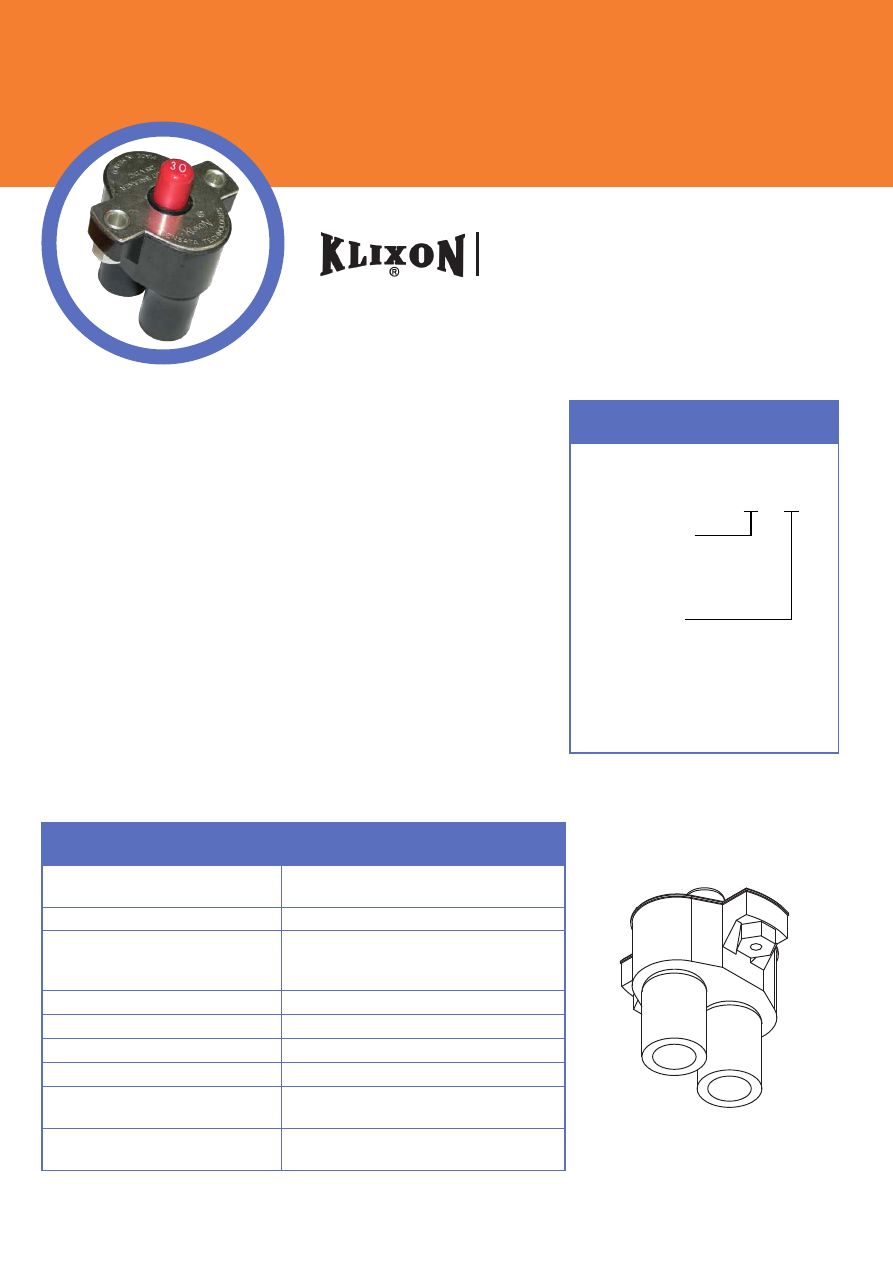

DERATING CURVE

DIMENSIONS -

PDLM

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for ambient

temperatures significantly higher or lower than standard

room temperature.

Example: At 77°F (25°C) the device is calibrated to hold

at 110% of rated current (1) and trip at 138% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 92% of rated current (3), and trip at

approximately 120% of rated current (4).

0

60

80

100

Ultimate Trip in % Rated Load

120

140

160

180

200

3

4

1

2

77°F, 25°C

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

Ambient T

emperature in °F

, °C

21

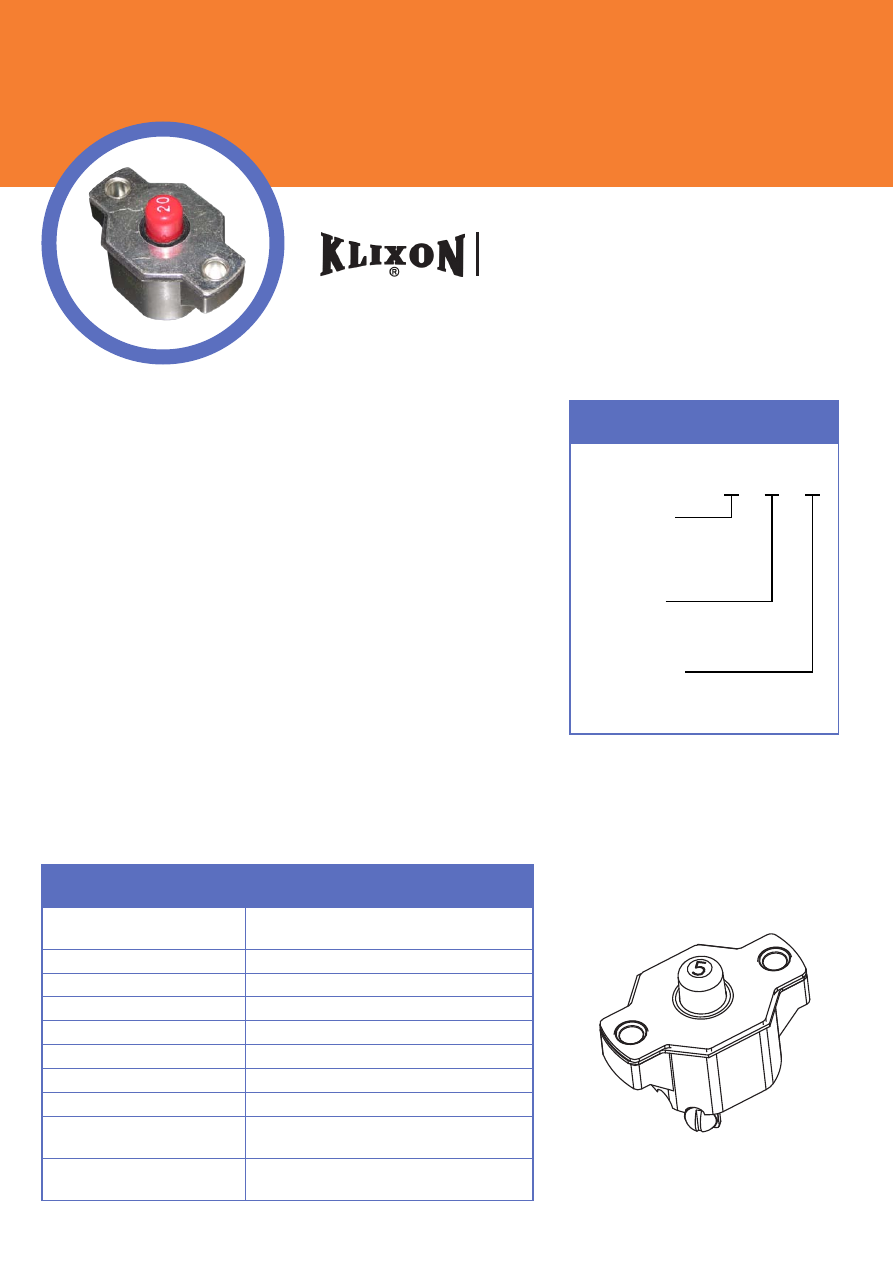

ORDERING INFORMATION

PS Series (PSM, PSA)

2 to 35 Amp Precision Thermal Circuit Breaker

FEATURES

• 30VDC, 2 to 35 Amps

• Available in manual and automatic reset options

• PSM meets CID A-A-55571/06 specifications

• PSA meets CID A-A-55571/05 specifications

• UL Recognized E36869

DESCRIPTION

The KLIXON® PS series of breakers are designed to interrupt

short circuits or overloads and combines trip-free protection with

fast response time. The PS series thermal breaker is ideal for

commercial and military vehicle equipment where precise ultimate trip

characteristics are required.

Configuration

PSM = Manual

PSA = Automatic

X − X

Amp Rating

(2, 3, 4, 5, 6, 8, 10, 12.5, 15

20, 25, 30, 35)

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C)

≤

10A for 20 to 150 seconds

>

10A for 8 to 50 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 138%

Endurance Automatic: 2,000 cycles @ 200% rated current

Manual: 500 cycles @ 200% rated current

Interrupt Current Capacity Per SAE J553, 600A

Vibration 10G MIL-STD-202 Method 204, Condition A

Mechanical Shock 100G MIL-STD-202 Method 213, Condition C

Dielectric Strength MIL-STD-202, Method 301, 1500VAC min

Insulation Resistance MIL-STD-202, Method 302, Condition B,

100 M

Ω

min

Weight PSA : 30 grams max

PSM : 32 grams max

22

AMP RATING

FOR ILLUSTRATION

1.812

[46.02]

1.234

[31.34]

1.57

[39.88]

.760

[19.30]

2X #6-32 UNC-2B

MOUNTING NUTS

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X LOCK WASHER

.338

[8.59]

REF

REF

1.234

[31.34]

.315

[8.00]

.250

[6.35]

1.031

[26.19]

2X #6-32 UNC-2B

MOUNTING NUTS

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X LOCK WASHER

R .375 [9.53]

1.812

[46.02]

2.19

[55.63]

.750

[19.05]

.338

[8.59]

REF

REF

.280

[7.11]

.250

[6.35]

1.234

[31.34]

1.313

[33.35]

DIMENSIONS -

PSM (10 amps or less)

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

Dotted Lines:

10 amps or below

Solid Lines:

Above

10 amps

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

DIMENSIONS -

PSM (over 10 amps)

23

AMP RATING

FOR ILLUSTRATION

1.812

[46.02]

1.234

[31.34]

1.57

[39.88]

.760

[19.30]

2X #6-32 UNC-2B

MOUNTING NUTS

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X LOCK WASHER

.338

[8.59]

REF

REF

1.234

[31.34]

.315

[8.00]

.250

[6.35]

1.031

[26.19]

2X #6-32 UNC-2B

MOUNTING NUTS

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X LOCK WASHER

R .375 [9.53]

1.812

[46.02]

2.19

[55.63]

.750

[19.05]

.338

[8.59]

REF

REF

.280

[7.11]

.250

[6.35]

1.234

[31.34]

1.313

[33.35]

ORDERING INFORMATION

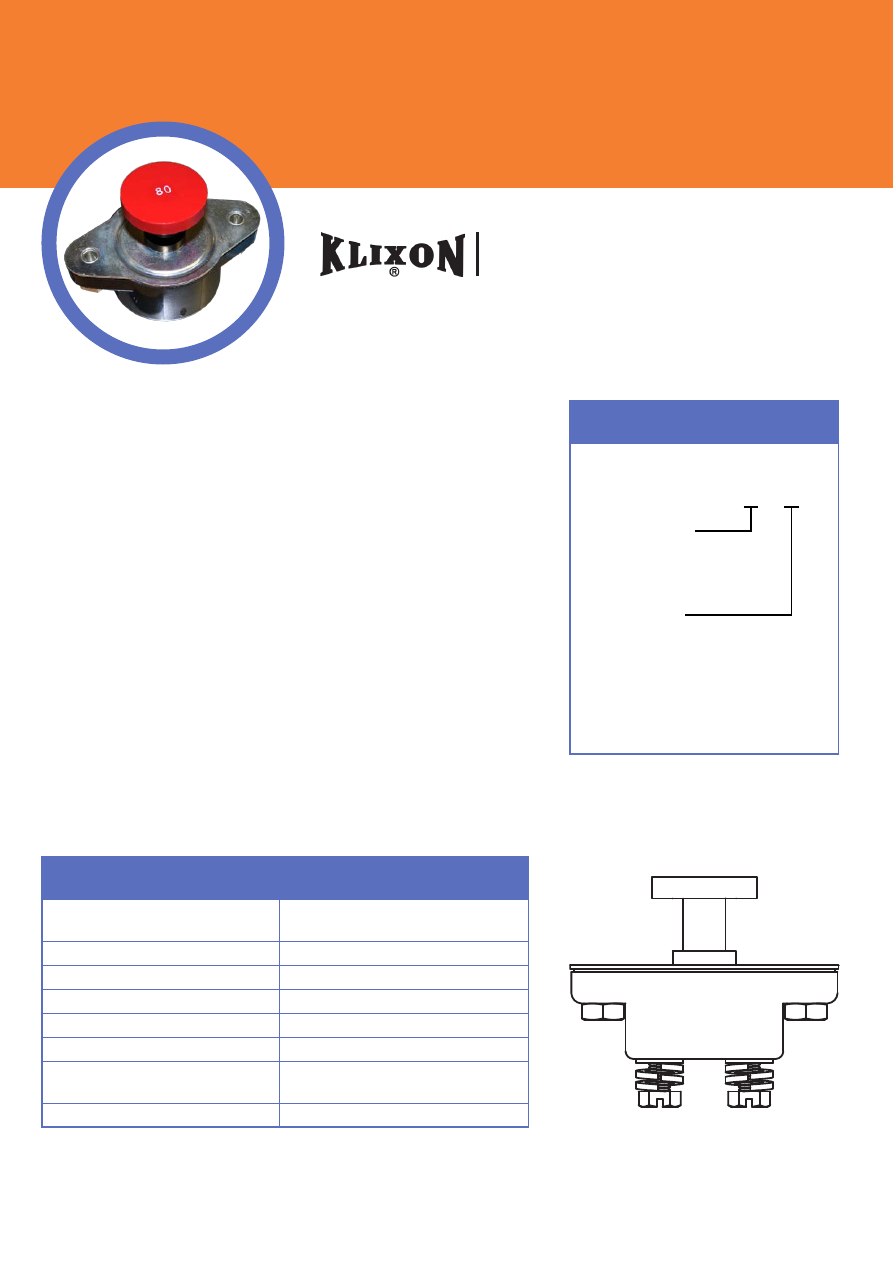

PS Neck Mounting Series (PSM-XX-N)

2 to 35 Amp Precision Thermal Circuit Breaker

FEATURES

• 30VDC, 2 to 35 Amps

• Manual reset neck mount circuit breaker

DESCRIPTION

The KLIXON® PSM-XX-N series of breakers are designed to interrupt

short circuits or overloads and combines trip-free protection with

fast response time. The PSM-XX-N series thermal breaker is ideal for

commercial and military vehicle equipment where precise ultimate trip

characteristics are required.

Configuration

PSM = Manual, sealed

X − X − N

Amp Rating

(2, 3, 4, 5, 6, 8, 10, 12.5, 15

17.5, 20, 25, 30, 35)

Neck Mount

N = neck mount

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated

current, 77°F (25°C)

2 to 10 amps : 20 to 150 seconds

12.5 to 35 amps : 8 to 50 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 138%

Endurance Per SAE J553, 500 cycles @ 200%

Interrupt Current Capacity Per SAE J553

Vibration 10G MIL-STD-202 Method 204, Condition A

Mechanical Shock MIL-STD-202, Method 213, Condition C, 100G

Dielectric Strength MIL-STD-202, Method 301, 1500VAC min

Insulation Resistance MIL-STD 202, Method 302, Condition B,

100 M

Ω

min

Weight PSM-N : 35 grams max

24

DERATING CURVE

DIMENSIONS -

PSM-XX-N (10 amps and less)

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

Performance characteristics are based on room

temperature (77°F, 25°C). Consult Derating curve for ambient

temperatures significantly higher or lower than standard

room temperature.

Example: At 77°F (25°C) the device is calibrated to hold

at 110% of rated current (1) and trip at 138% of rated

current (2). At 140°F (60°C), the same device will hold

at approximately 92% of rated current (3), and trip at

approximately 120% of rated current (4).

Dotted Lines:

10 amps or below

Solid Lines:

Above

10 amps

0

60

80

100

Ultimate Trip in % Rated Load

120

140

160

180

200

3

4

1

2

77°F, 25°C

100˚F

140˚F

160˚F

70˚F

-60˚F

-40˚F

0˚F

32˚F

38˚C

60˚C

71˚C

21˚C

-51˚C

-40˚C

-18˚C

0˚C

Ambient T

emperature in °F

, °C

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

1.566 [39.78]

.688 [17.48]

Ø .625

[15.88]

.125 [3.18]

.75 [19.05]

.375 [9.53]

1.234 [31.34]

NASM 35333-136

INTERNAL TOOTH

LOCK WASHER

MS 25082-C21 NUT

.030 [.762]

15/32 - 32UNS-2 THREAD

2X .250 [6.35] LONG

#8-32 UNC-2A ROUND HEAD

SCREW

2X LOCK WASHER

.338 [8.59]

1.282

[32.56]

1.390

[35.31]

.908

[23.06]

.060

[1.52]

.49 [12.45]

.25 [6.35]

.125 [3.175]

1.032

.516

INTERNAL

TOOTH LOCK

WASHER

CLINCH NUT

.032

15/32 - 32UNS-2 THREAD

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X .047 THICK

LOCK WASHER

.344

REF

1.282

1.391

.907

.063

.469

.25

.125

AMP RATING

FOR ILLUSTRATION

1.313

.688

.563

.125

.704

.375

0.375 RADIUS

INCHES [MM]

25

DIMENSIONS -

PSM-XX-N (over 10 amps)

1.566 [39.78]

.688 [17.48]

Ø .625

[15.88]

.125 [3.18]

.75 [19.05]

.375 [9.53]

1.234 [31.34]

NASM 35333-136

INTERNAL TOOTH

LOCK WASHER

MS 25082-C21 NUT

.030 [.762]

15/32 - 32UNS-2 THREAD

2X .250 [6.35] LONG

#8-32 UNC-2A ROUND HEAD

SCREW

2X LOCK WASHER

.338 [8.59]

1.282

[32.56]

1.390

[35.31]

.908

[23.06]

.060

[1.52]

.49 [12.45]

.25 [6.35]

.125 [3.175]

1.032

.516

INTERNAL

TOOTH LOCK

WASHER

CLINCH NUT

.032

15/32 - 32UNS-2 THREAD

2X .250 LONG #8-32 UNC-2A

ROUND HEAD SCREW

2X .047 THICK

LOCK WASHER

.344

REF

1.282

1.391

.907

.063

.469

.25

.125

AMP RATING

FOR ILLUSTRATION

1.313

.688

.563

.125

.704

.375

0.375 RADIUS

INCHES [MM]

PERFORMANCE CHARACTERISTICS

Calibration : 200% rated current,

77°F (25°C) 8 to 50 seconds

Ultimate Trip At 77°F (25°C) Must hold 100%, Must trip 138%

Endurance

Per SAE J553:

Automatic: 2,000 cycles @ 200% rated current

Manual: 500 cycles @ 200% rated current

Interrupt Current Capacity Per SAE J553, 600A

Vibration 10G MIL-STD-202 Method 204, Condition A

Mechanical Shock 100G MIL-STD-202 Method 213, Condition C

Dielectric Strength MIL-STD-202 Method 301, 1500VAC min

Insulation Resistance MIL-STD-202 Method 302, Condition B,

100 M

Ω

min

Weight 9115-5 : 65 grams max

9115-6 : 76 grams max

ORDERING INFORMATION

9115 Series

15 to 30 Amp Precision Thermal Circuit Breaker

FEATURES

• 30VDC, 15 to 30 Amps

• Sealed assemblies, available in manual and automatic reset options

• Ignition protected SAE J1171 & CCC certified

• 9115-5 meets CID A-A-55571/01 specifications

• 9115-6 meets CID A-A-55571/02 specifications

• UL Recognized E36869

DESCRIPTION

The KLIXON® 9115 series of circuit breakers was designed for

waterproof electrical systems of ordnance vehicles. The 9115 series is

recommended for other mobile military and ground equipment, including

trucks, tractors, graders, earth movers, fuel units, and amphibious as well

as commercial vehicles. In addition to a complete sealed thermal element

this series of thermal breakers has molded in terminals and are supplied

with rubber connectors (shells).

Configuration

9115-5 = Auto, sealed

9115-6 = Manual, sealed

X − X

Amp Rating

(15, 20, 25, 30)

26

Notes:

1. Shell female MS33800 mates with MS27143 or MS27144.

28

V

D

C

CI

R

CUI

T

B

R

E

A

K

E

R

2.000±.032 [50.8±.813]

DOES NOT INCLUDE

SEALING GASKET

2X #8-32 MOUNTING NUTS

1.187

1.574

± .032 [15.88 ± .813]

±.032

.485

[12.32]

.625

2X R

±.008

.843 ± .032 [21.41 ± .813]

SHELL, FEMALE

MS33800

2X( .700 [17.78])

.960 [24.4]

.470 [11.94])

2X (

1.875 [47.63] MAX.

AMP RATING SHOWN

FOR ILLUSTRATION

INCHES [MM]

.174 ± .002

2X

[4.42 ± .051]

MTG. HOLE

2X

DIMENSIONS -

9115-5

TRIP CURVE -

Approximate Time, Current Characteristics At 77°F (25°C)

1000

500

100

.10

1

10

Trip Time in Seconds

Current in % Rated Load

100

1000

10,000

15

28

V

D

C

CI

R

CUI

T

B

R

E

A

K

E

R

2.000±.032 [50.8±.813]

DOES NOT INCLUDE

SEALING GASKET

2X #8-32 MOUNTING NUTS

1.187

1.574

± .032 [15.88 ± .813]

±.032

.485

[12.32]

.625

2X R

±.008

.843 ± .032 [21.41 ± .813]

SHELL, FEMALE

MS33800

.562 [14.27]

MIN. PANEL HOLE

2X(

.440 [ 11.18]

.700 [17.78])

.960 [24.4]

.470 [11.94])

2X (

.500 [12.7]

1.875 [47.63] MAX.

AMP RATING SHOWN

FOR ILLUSTRATION

INCHES [MM]

DIMENSIONS -

9115-6

27

28

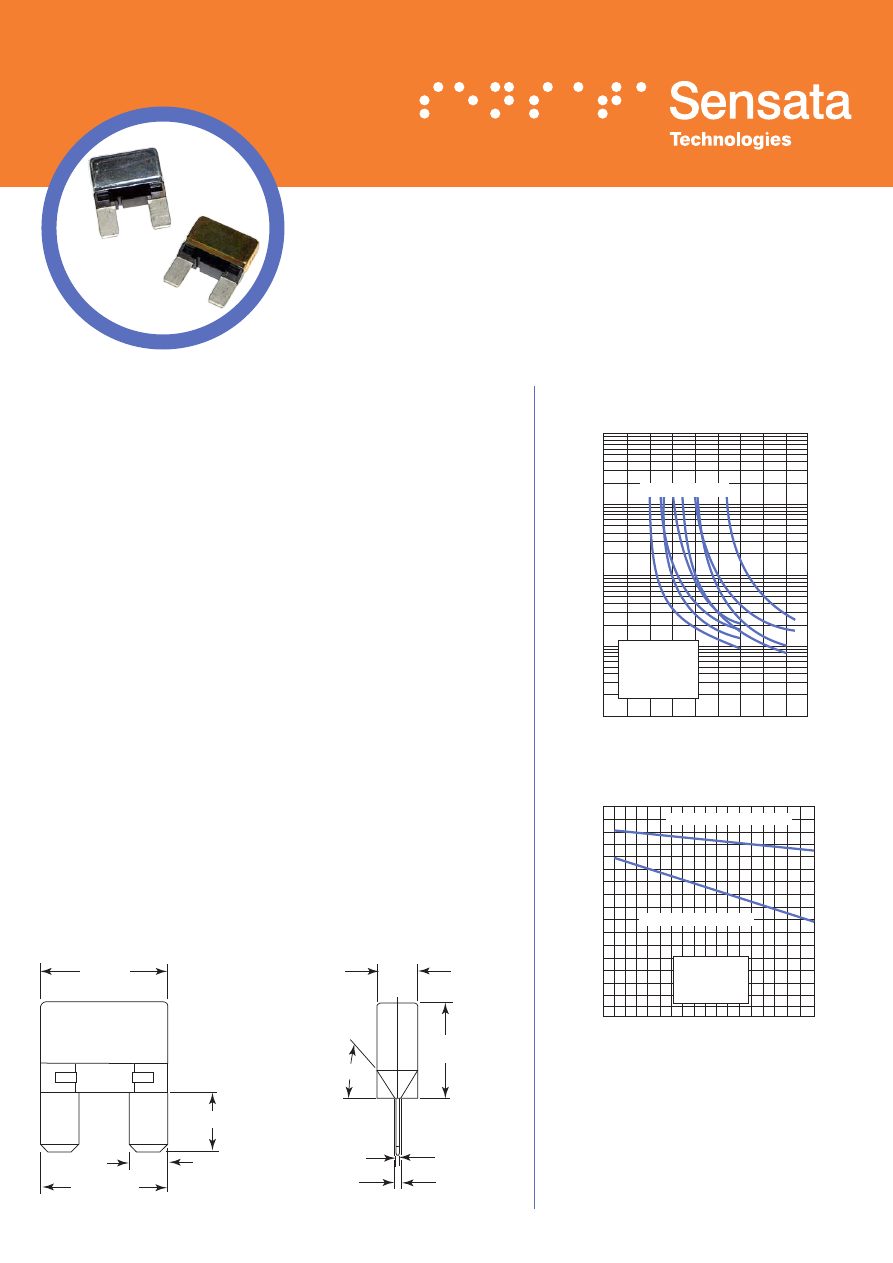

MAXI BREAKER® Series

Miniature Circuit Breakers

FEATURES

• Available in SAE Type 1 (cycling) and SAE Type 2 (non-cycling)

• Multiple bimetallic resistivities available

• Heater wire wrapped around the bimetal keeps the protector open

until power is removed (Type 2 only)

DESCRIPTION

The MAXI BREAKER® series of circuit protectors are rated for use

up to 125ºC. This patented device is available both as a cycling (SAE

Type 1) and non-cycling (SAE Type 2) device. Typical placement

of the MAXI BREAKER® is under the hood fuse blocks or other

areas of the vehicle that house a MAXI™ Blade Fuse*. The MAXI

BREAKER® protects against momentary overloads and eliminates

the need for fuse replacement.

SPECIFICATIONS

• Nominal Operating Voltage: 14 Volts DC

• Typicale Voltage Drop at Operating Current: 200 mV max

• Current Rating: 10 to 50 amps @ 25ºC (in 5 amp increments)

• Typical Ambient Temperature Range: -40ºC to 125ºC

DIMENSIONS, mm (inches)

29.21

(1.150)

29.21

(1.150)

12.70 (.500)

8.9

(.350)

60.0º

21.60 (.850)

.82 (.032)

2.54 (.100)

10000

8000

6000

4000

2000

1000

800

600

400

200

100

80

60

40

20

10

8

6

4

2

1

Trip T

ime in Seconds

0 10 20 30 40 50 60 70 80 90

Current in Amperes

Typical

Maxi Breaker

Trip Time Curves

at 25ºC

160

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

-50 -30 -10 10 30 50 70 90 110 130

Temperature in ºCelsius

Percent of Rated Current

Typical

Maxi Breaker

Derating Curves

All breakers will trip in this area

All breakers hold in this area

20A 25A 30A 40A

These curves are to be used only as a guide in

selecting a protector for a particular application.

Factors such as distance from the heat

source and the method of mounting should be

considered in selecting a protector. Final trip

times are dependent upon terminal configuration

and mounting in the application.

* MAXI™ Blade Fuse is a trademark of Littelfuse®

CURVES

10000

8000

6000

4000

2000

1000

800

600

400

200

100

80

60

40

20

10

8

6

4

2

1

Trip T

ime in Seconds

0 10 20 30 40 50 60 70 80 90

Current in Amperes

Typical

Maxi Breaker

Trip Time Curves

at 25ºC

160

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

-50 -30 -10 10 30 50 70 90 110 130

Temperature in ºCelsius

Percent of Rated Current

Typical

Maxi Breaker

Derating Curves

All breakers will trip in this area

All breakers hold in this area

20A 25A 30A 40A

29

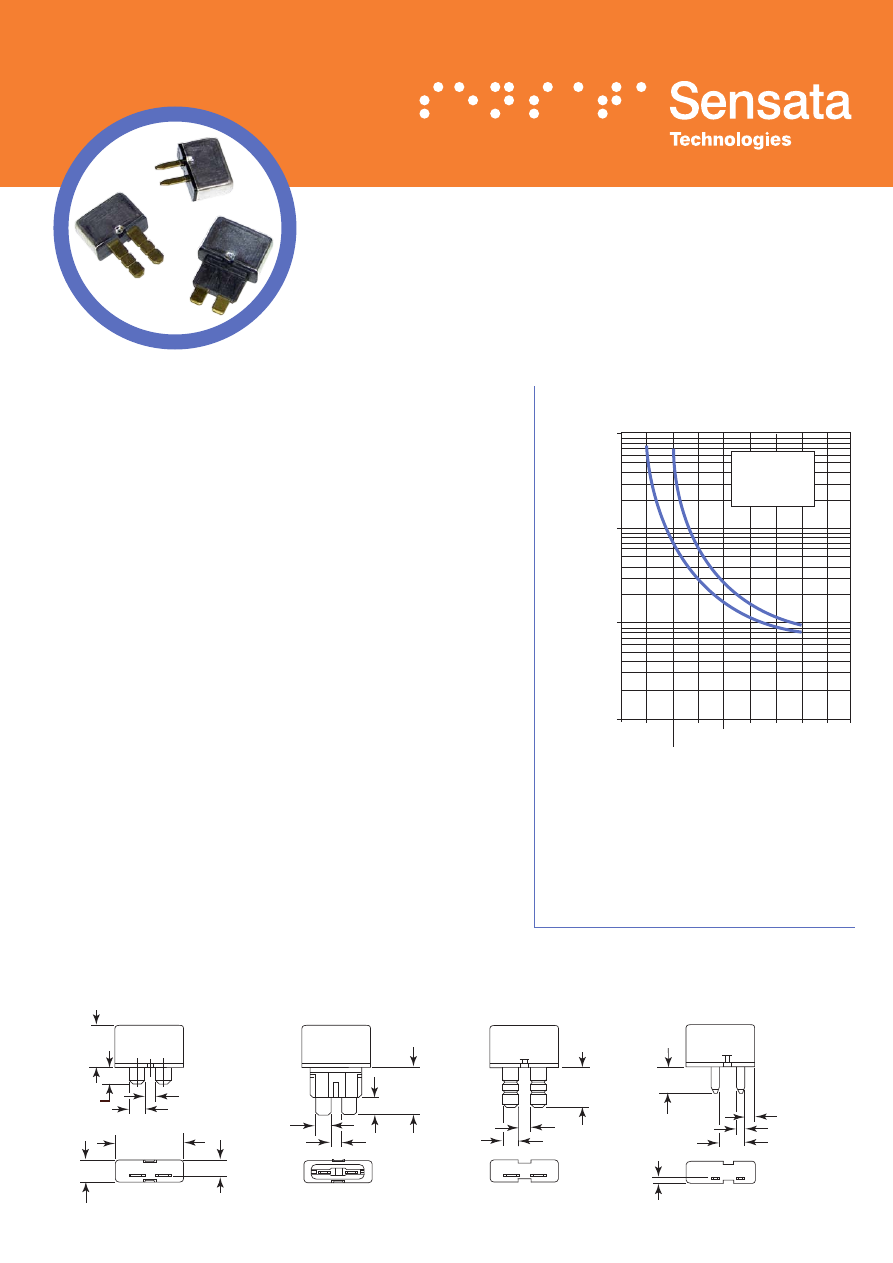

EXT 200 Series

Miniature Circuit Breakers

FEATURES

• SAE Type 2 (non-cycling) device

• Multiple bimetallic resistivities available

• Multiple terminal configurations available

• Metal encased

DESCRIPTION

The EXT 200 Series of mini remote reset circuit breakers are

commonly designed for 12 Volt DC wiring harness protection. The

device is ideal for the protection of circuits that may experience

momentary overloads and is often chosen as an alternative to

fuses, where nuisance replacement can be an inconvenience. The

EXT 200 can be mounted in the fuse block or elsewhere within the

wiring harness. This bimetallic device is sensitive to both over-

current and over-temperature fault conditions.

SPECIFICATIONS

• Nominal Operating Voltage: 12 Volts DC

• Typicale Voltage Drop at Operating Current: 200 mV max

• Current Rating: 5 to 35 amps @ 25ºC (in 5 amp increments)

• Typical Ambient Temperature Range: -40ºC to 85ºC

DIMENSIONS, mm (inches)

These curves are to be used only as a guide in

selecting a protector for a particular application.

Factors such as distance from the heat

source and the method of mounting should be

considered in selecting a protector. Final trip

times are dependent upon terminal configuration

and mounting in the application.

CURVES

Typical

EXT 200

Trip Time Curve

at 25ºC

1000

800

600

400

200

100

80

60

40

20

10

8

6

4

2

0

Trip T

ime in Seconds

Rated

Current

200% Rated

Current

Test Current

135% Rated

Current

7.3 (.29)

EXT 221

EXT 234

EXT 229

EXT 232

17.8 (.70)

5.4 (.21)

4.45 (.175)

25.1 (.99)

9.9 (.39)

7.8 (.31)

19.7 (.78)

5.2 (.20)

4.2 (.17)

12.3 (.48)

6.6 (.26)

5.2 (.20)

4.0 (.16)

11.0 (.43)

2.8 (.11)

3.8 (.15)

10.9 (.43)

2.25 (.88)

30

Amp Rating

The nominal electrical current in amperes

that the breaker will carry at room

temperature without tripping

Automatic

Reset

A device that opens by a combination of

overcurrent and elevated temperature,

with a design feature that allows the

breaker to cycle or continuously self reset.

Circuit

Breaker

A device designed to carry a specific value

of current and automatically open a circuit

upon overloads or short circuits.

Dielectric

Strength

A device’s ability to withstand a deliberate

application of pre–determined over–

voltage for a specified time.

Dielectric

Withstanding

Voltage

The maximum voltage that a switch can

withstand between specified points

without leaking current exceeding a

specified value.

Endurance

Refers to the longevity cycling of a circuit

breaker under less than direct short

conditions

Insulation

Resistance

The resistance offered by the insulating

members of a component part to direct

voltage tending to produce a leakage

current through or on the surface of these

members. Insulation resistance should

not be considered the equivalence of

dielectric withstanding voltage. Also:

Measures the resistance of the insulating

member of the device to a target voltage.

Manual Reset

A device that opens by a combination of

overcurrent and elevated temperature,

and remain open until manually reset into a

conducting state.

Maximum

Ultimate Trip

Current rating at which breaker must trip

within a certain period (usually 1 hour) at a

specified temperature.

GLOSSARY OF TERMS

Minimum

Ultimate Trip

Current rating at which breaker will not

trip within a certain period (usually 1 hour)

at a specified temperature.

Switchable

A design feature that allows a switchable

circuit breaker to function as a

conventional manual reset circuit breaker

and also has a mechanism, which when

exercised at the discretion of the user,

permits opening of the breaker internal

circuit to stop current flow. The breaker is

reset to its normal condition by the manual

rest function, whether tripped unattended

by a real fault condition or by the user.

Thermal

Circuit

Breaker

A circuit breaker that senses a current

overload based on thermal heating of the

sensing element.

Thermal

Derating

The effect of ambient temperature on

the trip characteristics of the breaker.

For example, as ambient temperature

increases, the amount of current required

to trip the breaker decreases.

Time-Current

Curve

An approximate graph showing the

minimum and maximum time a specific

breaker will trip at various degrees of

overload.

Trip Free

A design feature that makes it impossible

to hold the breaker closed against an

overload.

UL

Underwriters Laboratory

Voltage Drop

The voltage decrease across the breaker

due to internal resistance of the device.

Weatherproof

Circuit breakers designed such that

if immersed or submerged in fluid (for

example, water) no fluid shall infiltrate the

internal cavities or workings of the circuit

breaker.

ABOUT SENSATA TECHNOLOGIES

Sensata Technologies provides leaders in the automotive, appliance, aircraft, industrial,

HVAC/R, over-the-road truck, heavy vehicle, bus, RV, marine, telecom and datacom global

markets with sensing, protection and control solutions. Our mission is to improve safety,

efficiency and environmental protection for millions of people worldwide.

Sensata Technologies is headquartered in Attleboro, Massachusetts in the United States

and has business and manufacturing centers and sales offices throughout the world.

THE SUPPLIER YOU WANT. THE PARTNER YOU NEED.

At Sensata Technologies we do all we can to ensure your satisfaction. We apply our

unsurpassed experience and expertise to focus on your needs. We adhere to the highest

technical, manufacturing and testing standards. Our experts work with you to ensure the

quality and precision it takes to meet the most demanding application requirements. No

wonder a world of businesses relies on the more than 1 billion sensor, protection and

control devices we manufacture each year to optimize our customers’ own leading-edge

technologies.

WE DO IT ALL FOR YOU.

We are dedicated to being our customers’ first choice – no matter where in the world you

are located. We do this by:

• Offering rugged designs and in-house testing facilities to ensure consistent quality

• Locating business centers close to your markets in every region of the world

• Consolidating manufacturing in large Make sites in cost-effective locations

• Partnering with those setting the latest standards in industrial and automotive system

performance, safety and emission control

SAFETY, PERFORMANCE, RELIABILITY

You will find Sensata products wherever increased safety, performance and reliability are

required and where improved machine productivity and efficiency are desired. You will

find our products in an endless number of applications including HVAC and refrigeration,

transportation, aircraft, trucks, buses, trains, datacom and telecom, construction, mining,

agriculture, boats, recreational vehicles and material handling equipment. Our products

are also found in compressors, pumps, hydraulics, pneumatics, process control and factory

automation equipment, alternative fuel systems, communication towers and much more.

MANUFACTURING PRODUCTS TO THE HIGHEST STANDARDS.

Sensata’s manufacturing and technology

centers are ISO / TS16949 and ISO 14001

certified throughout the world.

2455009003 | Printed In USA, October, 2008

Important Notice: Sensata Technologies (Sensata) reserves the right

to make changes to or discontinue any product or service identified in

this publication without notice. Sensata advises its customers to obtain

the latest version of the relevant information to verify, before placing

any orders, that the information being relied upon is current. Sensata

assumes no responsibility for infringement of patents or rights of others

based on Sensata applications assistance or product specifications since

Sensata does not possess full access concerning the use or application

of customers’ products. Sensata also assumes no responsibility for

customers’ product designs.

www.sensata.com

OTHER SENSATA CATALOGS THAT MAY INTEREST YOU:

Airpax™ Power Protection Catalog

Literature PN 2455005000

Klixon™ Aircraft Circuit Breakers

Literature PN 2455009002

Dimensions™ DC to AC Inverters

Literature PN 2455008000

BUSINESS CENTERS

Sensata Technologies Inc.

529 Pleasant Street

Attleboro, MA 02703, USA

Phone: +1 508-236-3287

Brands: Klixon™, Sensata Technologies™

Sensata Technologies

807 Woods Road

Cambridge, MD 21613, USA

Phone: +1 410-228-1500

Brands: Airpax™

Sensata Technologies

4467 White Bear Lake Parkway

St. Paul, MN 55110, USA

Phone: +1 800-553-6418

Brands: Dimensions™

Sensata Technologies Holland B.V.

Kolthofsingel 8

7602 EM Almelo, The Netherslands

Phone: +31 546 87 95 55

Brands: Klixon™, Sensata Technologies™

Sensata Technologies China Co., Ltd.

Novel Plaza, 8th Floor

128 Nanjing Road West

Shaghai, 20003

People’s Republic of China

Phone: +86 21 23061500

Brands: Klixon™, Sensata Technologies™

Sensata Technologies Korea Ltd.

29F, Trade Tower

159-1 SamSung-Dong, KangNam-Ku, Seoul

135-729, Korea

Phone: +81-2-551-2918

Brands: Klixon™, Sensata Technologies™

Sensata Technologies Japan Ltd.

305, Tanagashira

Oyama-cho, Sunto-gun, Shizuoka-ken

Japan, 410-1396

Phone: +81 550 78 1211

Brands: Klixon™, Sensata Technologies™

Sensata Technologies Nihon-Airpax

6-3, Chi Yoda 5 Chome

Saitama-Ken

Japan, 350-0214

Phone: +81 492 83 7575

Brands: Airpax™