Sales and Corporate Office

1717 Chicago Avenue

Riverside, California 92507-2364

Phone: (951) 788-1700

Fax: (951) 369-1151

Applications Engineering

17271 North Umpqua Hwy.

Roseburg, Oregon 97470-9422

Phone: (541) 496-0700

Fax: (541) 496-0408

e-mail: caddock@caddock.com • web: www.caddock.com

For Caddock Distributors listed by country see caddock.com/contact/dist.html

© 2004 Caddock Electronics, Inc.

CAD

K

DOC

CC1512FC Standard Resistance Values:

Tolerance CC1512FC ±1% Standard (except as noted).

CC2015FC Standard Resistance Values:

Tolerance CC2015FC ±1% Standard (except as noted).

CC2520FC Standard Resistance Values:

0.010

Ω

5%

0.015

Ω

5%

0.020

Ω

5%

0.025

Ω

5%

0.030

Ω

5%

Tolerance CC2520FC ±1% Standard (except as noted).

0.033

Ω

5%

0.040

Ω

5%

0.050

Ω

2%

0.075

Ω

2%

0.10

Ω

0.15

Ω

0.20

Ω

0.25

Ω

0.30

Ω

0.33

Ω

0.40

Ω

0.50

Ω

0.75

Ω

1.00

Ω

1.50

Ω

2.00

Ω

2.50

Ω

3.00

Ω

0.010

Ω

5%

0.015

Ω

5%

0.020

Ω

5%

0.025

Ω

5%

0.030

Ω

5%

0.033

Ω

5%

0.040

Ω

5%

0.050

Ω

2%

0.075

Ω

2%

0.10

Ω

0.15

Ω

0.20

Ω

0.25

Ω

0.30

Ω

0.33

Ω

0.40

Ω

0.50

Ω

0.75

Ω

1.00

Ω

1.50

Ω

2.00

Ω

2.50

Ω

3.00

Ω

0.020

Ω

5%

0.025

Ω

5%

0.030

Ω

5%

0.033

Ω

5%

0.040

Ω

5%

0.050

Ω

2%

0.075

Ω

2%

0.10

Ω

0.15

Ω

0.20

Ω

0.25

Ω

0.30

Ω

0.33

Ω

0.40

Ω

0.50

Ω

0.75

Ω

1.00

Ω

1.50

Ω

2.00

Ω

2.50

Ω

3.00

Ω

3.30

Ω

4.00

Ω

5.00

Ω

7.50

Ω

8.00

Ω

10.0

Ω

Custom resistance values and non-standard tolerances

can be manufactured for high quantity applications.

Please contact Caddock Applications Engineering.

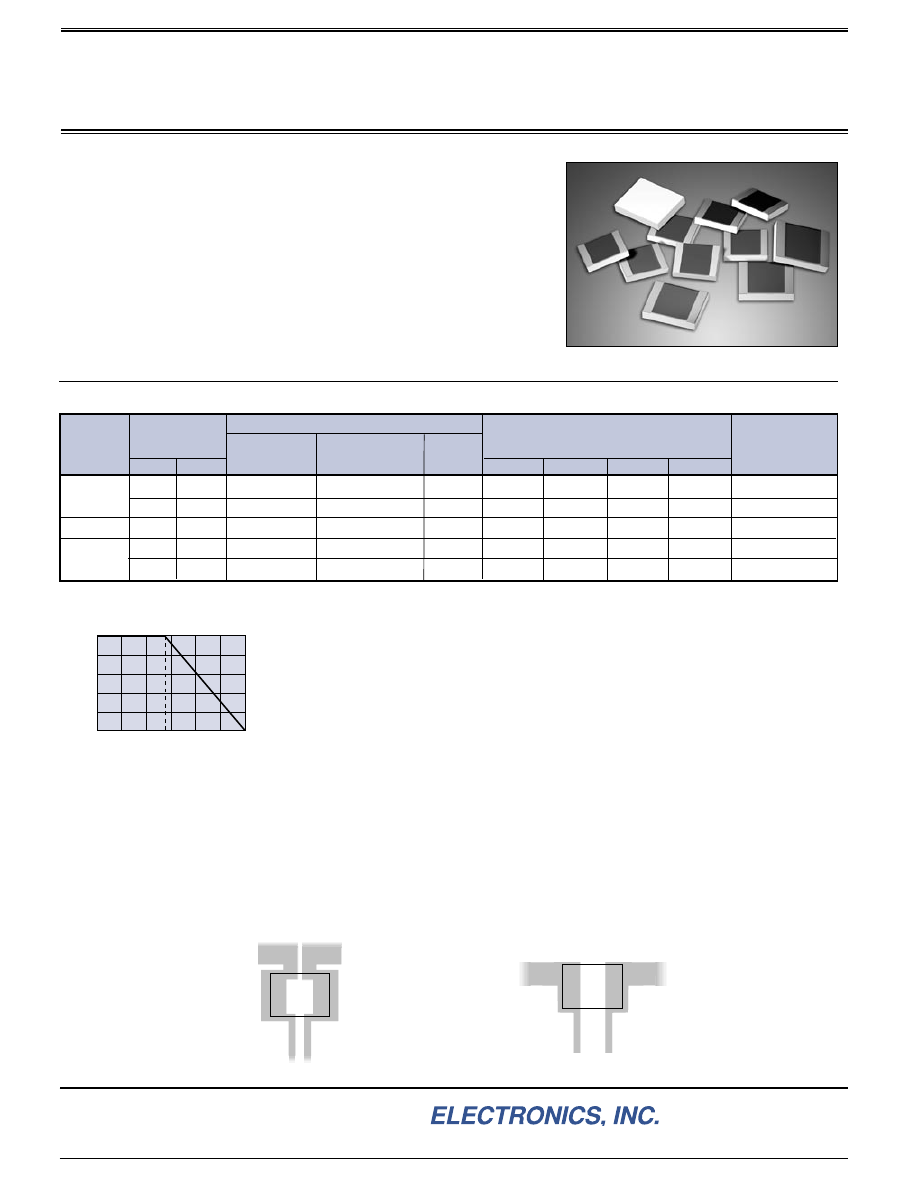

Recommended Circuit Board Layout

(current and sense connections):

Fig. 1A:

Kelvin layout recom-

mended for values below 0.20

Ω

Fig. 1B:

Kelvin layout

recommended for higher

resistance values.

Type CC Low Resistance Precision Chip Resistors

Style FC - Flip Chip Version

is a surface mount version with solderable pads for

flip chip

soldering.

Note 1: General Applications -

The power rating

for general applications is based upon 0.5 sq. in.

(300 mm

2

) of termination pad or trace area (2 oz.

copper) connected to each end of the resistor.

Maximum chip temperature is 150°C. Use Derating

Curve to derate appropriately for the maximum

ambient temperature and for the temperature

limitations of the adjacent materials.

Note 2: Thermal Resistance -

In High Power Applications where the circuit board

material provides high heat sinking benefits (such as IMS, Alumina, or other) the thermal

resistance of the chip resistor is useful to establish the maximum power capability of the

chip resistor in the application. The film temperature is measured at the center of the

resistor element and the solder pad temperature is measured at the center of the

termination pad (point X in the recommended circuit layouts shown below). Maximum

temperature of the chip resistor (at the center of chip) should not exceed 150°C through

the temperature range of the application

.

Style FC Derating Curve For General Applications

3.30

Ω

4.00

Ω

5.00

Ω

7.50

Ω

8.00

Ω

10.0

Ω

3.30

Ω

4.00

Ω

5.00

Ω

7.50

Ω

8.00

Ω

10.0

Ω

S S

X

X

C

C

C

X

X

S

S

C

C

C = Current connection

S = Sense connection

Note: Actual width of current trace is based on magnitude of current. Point of connection should be in the area shown.

0.015

Ω

0.010

Ω

Model

Resistance

Min.

Max.

Power Capability Information

CC1512FC

CC2015FC

CC2520FC

10.0

Ω

0.020

Ω

10.0

Ω

0.020

Ω

10.0

Ω

0.020

Ω

0.010

Ω

0.025

Ω

150

°

C

0.75 Watt

Max. Chip

Temperature

General Applications High Power Applications

Thermal Resistance -

R

θ

JC

Film (J) to Solder Pad (C)

(see note 2)

22.7

°

C/Watt

Power Rating

at 70

°

C

(see note 1)

22.7

°

C/Watt

16.0

°

C/Watt

13.0

°

C/Watt

11.5

°

C/Watt

150

°

C

150

°

C

150

°

C

150

°

C

Dimensions in inches and (millimeters)

.150

±

.007

(3.81

±

.18)

A

B

D

.120

±

.007

(3.05

±

.18)

.035 min.

(0.89 min.)

C

.027

±

.005

(.69

±

.13)

.250

±

.007

(6.35

±

.18)

.200

±

.007

(5.08

±

.18)

.065 min.

(1.66 min.)

.032

±

.005

(.81

±

.13)

.250

±

.007

(6.35

±

.18)

.200

±

.007

(5.08

±

.18)

.040 min.

(1.02 min.)

.041

±

.004

(1.04

±

.10)

.200

±

.007

(5.08

±

.18)

.150

±

.007

(3.81

±

.18)

.050 min.

(1.27 min.)

.027

±

.003

(.69

±

.08)

.150

±

.007

(3.81

±

.18)

.120

±

.007

(3.05

±

.18)

.035 min.

(0.89 min.)

.022

±

.003

(.56

±

.08)

Comments

Solder Coated Pads

Solderable Pads

Solderable Pads

Solder Coated Pads

Solderable Pads

0.75 Watt

1.0 Watt

1.5 Watts

1.5 Watts

AMBIENT TEMPERATURE, C

RA

TED LOAD, %

o

100

80

60

40

20

0

25

100

150

70

•

Style FC

- Flip Chip version for surface mount applications.

Style WB

- Wire Bond version for hybrid applications with metallized back

surface for solder down heat sinking of the chip, includes bondable termination

pads to receive aluminum wire bonds.

• Thermal resistance is provided to optimize high power designs when utilizing

higher thermal conductivity circuit board substrates such as IMS or Alumina.

• Resistance range down to 0.010 ohm at ±5%, 0.050 ohm at ±2%,

and 0.10 ohm at ±1%.

• Low inductance provides excellent high frequency and pulse response.

• High pulse handling and overload capability.

• Best choice for switching power supplies, motor speed controls, and high

current sensing applications.

Page 1 of 2

28_IL106.1004