UNION TECHNOLOGY CORP.

M u l t i l a y e r

C e r a m i c C h i p

C a p a c i t o r s

UNION TECHNOLOGY CORP.

M u l t i l a y e r

C e r a m i c C h i p

C a p a c i t o r s

OVERVIEW

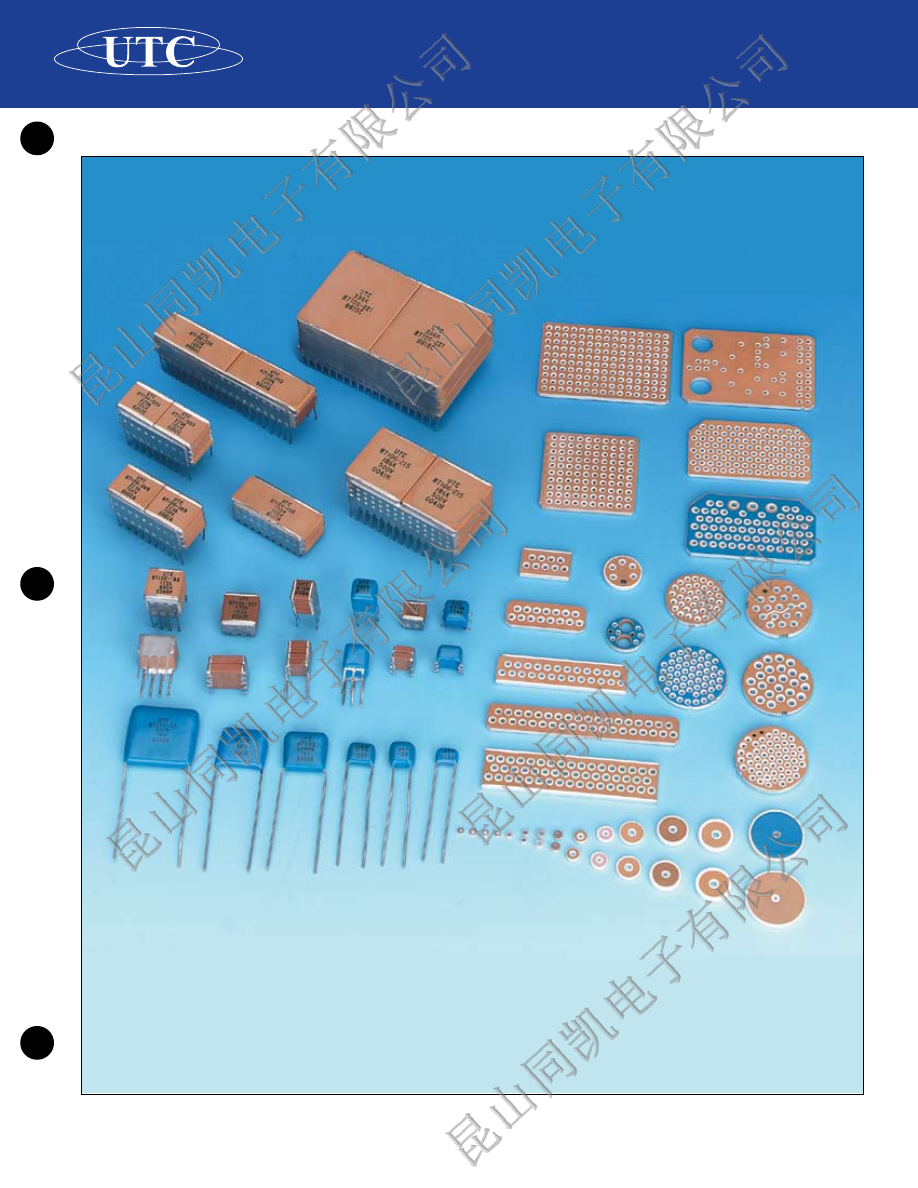

Union Technology Corp. (UTC) is a global provider for the design and manufacture of multilayer ceramic capacitors

for use in: commercial, industrial and high reliability applications.

Product offering:

• SMT multilayer ceramic chips

• Radial Leaded High Voltage Capacitors

• SMT High Voltage MLCC

• Switch Mode Power Supply Capacitors (SMPS)

• SMT Large Body Size MLCC

• Planar Arrays & Discoidal Capacitors

QUALITY

UTC integrates quality throughout its supply chain system by building quality into our designs and manufacturing

process. Supplier control systems ensure the highest quality materials and service to our customers. Our manufacturing

facility is ISO 9001:2000 certified and MIL-STD-790 approved.

UTC is equipped for performing testing in accordance with MIL-PRF-39014, MIL-PRF-20, and MIL-PRF-55681

as required by some customers. Our quality assurance system and procedures are based upon the requirements of

MIL-I-45208 and MIL-STD-790, with the calibration program in accordance with MIL-STD-45662A.

OPERATIONS

Established in 1991, UTC is a Corporation headquartered in Monterey Park, California. Within this 25,000 square

foot facility, UTC houses its technology center, manufacturing operations along with the sales and customer

support staff. UTC also maintains a fully staffed, highly qualified engineering department to support customer

applications, product design, and new product development.

UTC’s global network of sales representatives and distributors are prepared to assist you with designing our

products to meet your application requirements.

ENVIROMENT

UTC is fully committed to helping the cause of achieving and maintaining a clean environment. The complete

UTC offering of commercial ceramic chips within this catalog are designed and produced to be lead-free and are

fully RoHS compliant.

ISO 9001: 2000

C E R T I F I E D

COMPANY OVERVIEW

1

PRODUCT OVERVIEW

Union Technology Corp. is a global supplier of ceramic chip capacitors and other specialty multilayer ceramic

(MLC) products used by electronic manufacturers.

UTC formulates the materials used in the manufacture of its MLCs, including ceramic dielectric powders, electrode

materials, resins, and inks. Precise raw material characterization and tight process control maintains UTC’s quality

reputation as a state-of-the-art manufacturer of ceramic capacitor products.

UTC offers the full range of standard popular EIA sizes from a 0402 up to 2225. They are available in; NPO, X7R,

X5R, and Y5V dielectrics from 6.3 volts up to ratings of 5,000 volts.

In addition to our standard chip products UTC does support many custom application specific designs which

include capacitors that have voltage ratings up to 10 KV and chip sizes as large as 6560. Our Advanced Products

Group is staffed and equipped to assist customers with developing these MLC solutions for their specific

applications requiring cost effective, volumetric efficient designs.

TABLE OF CONTENTS

Company Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SMT MULTILAYER CERAMIC CAPACITORS

Packaging Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

NPO Dielectric Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

X7R Dielectric Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

X5R / Y5V Dielectric Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Certified Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

High Voltage Chips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Soldering Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MILITARY & CUSTOM PRODUCTS

Switch Mode Power Supply Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

High Voltage Radial Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Feed-Through Discoidal Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Planar Capacitor Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TABLE OF CONTENTS

2

3

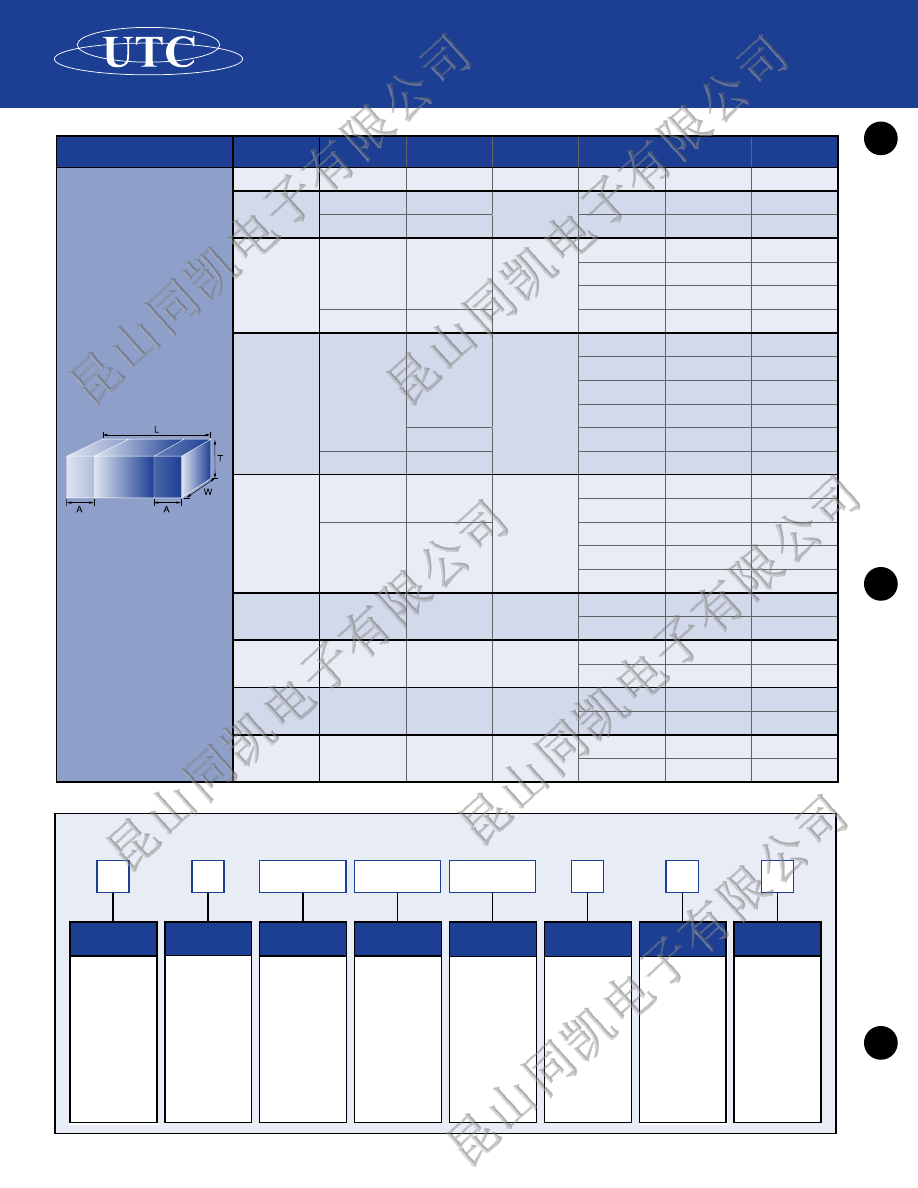

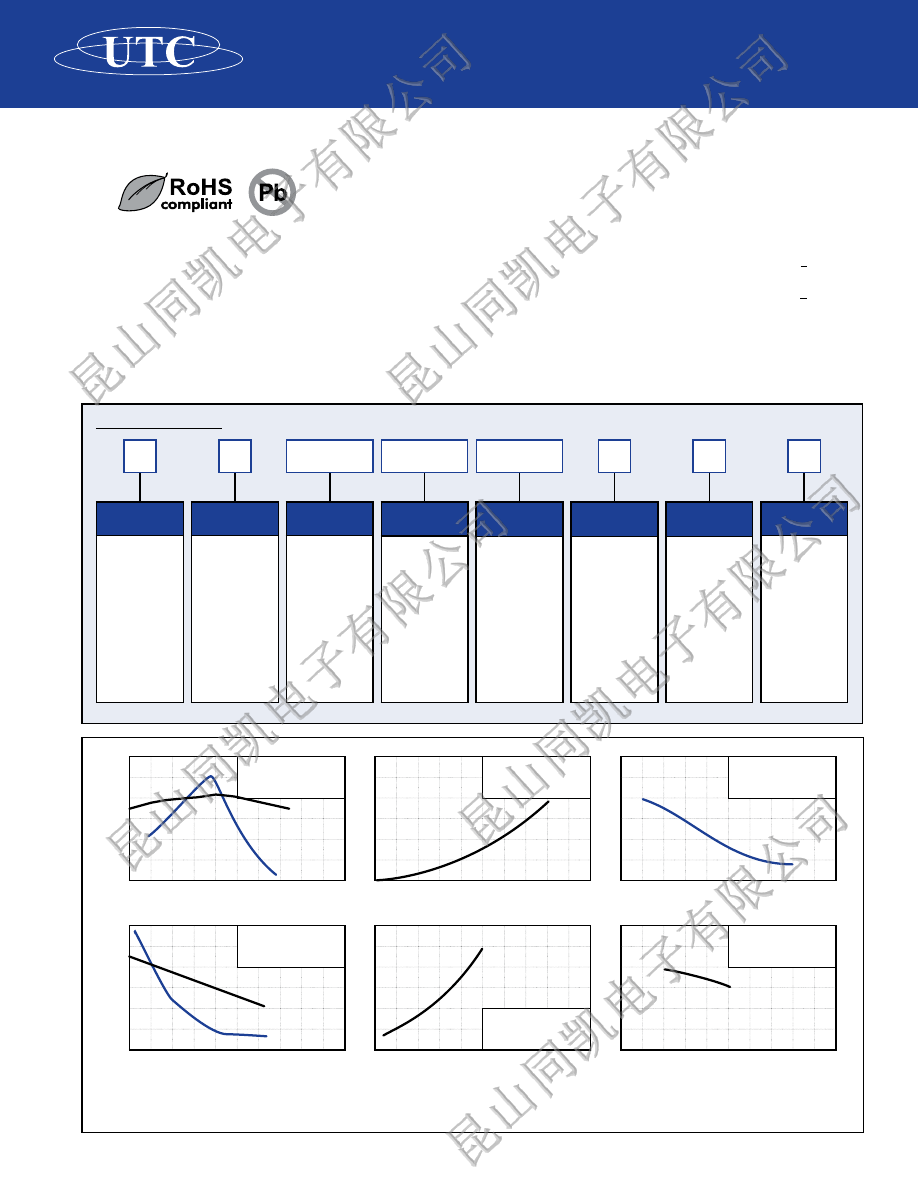

UTC P/N

STYLE

C = MLCC CHIP

S = MLCC SAFETY

CERTIFIED CHIP

C

105

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

L

VOLTAGE

A = 6.3V

C = 10V

E = 16V

L = 25V

G = 50V

B = 100V

R = 200V

H = 250V

J = 300V

N = 400V

S = 500V

K = 600V

K = 630V

T = 1000V

W = 2000V

X = 3000V

Y = 4000V

Z = 5000V

0805

BODY SIZE

0402

0603

0805

1206

1210

1808

1812

1825

2220

2225

3530

4040

5550

K

TOLERANCE

F = 1%

G = 2%

J = 5%

K = 10%

M = 20%

Z = -20% / +80%

*Cap values < 10pF

B = +/-0.10pF

C = +/-0.25pF

D = +/-0.50pF

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

B = Soft

Termination

[consult factory]

T

PACKAGE

STYLE

T = Tape & Reel

X5R

TEMPERATURE

COEFFICIENT

NPO

X7R

X5R

Y5V

HOW TO ORDER

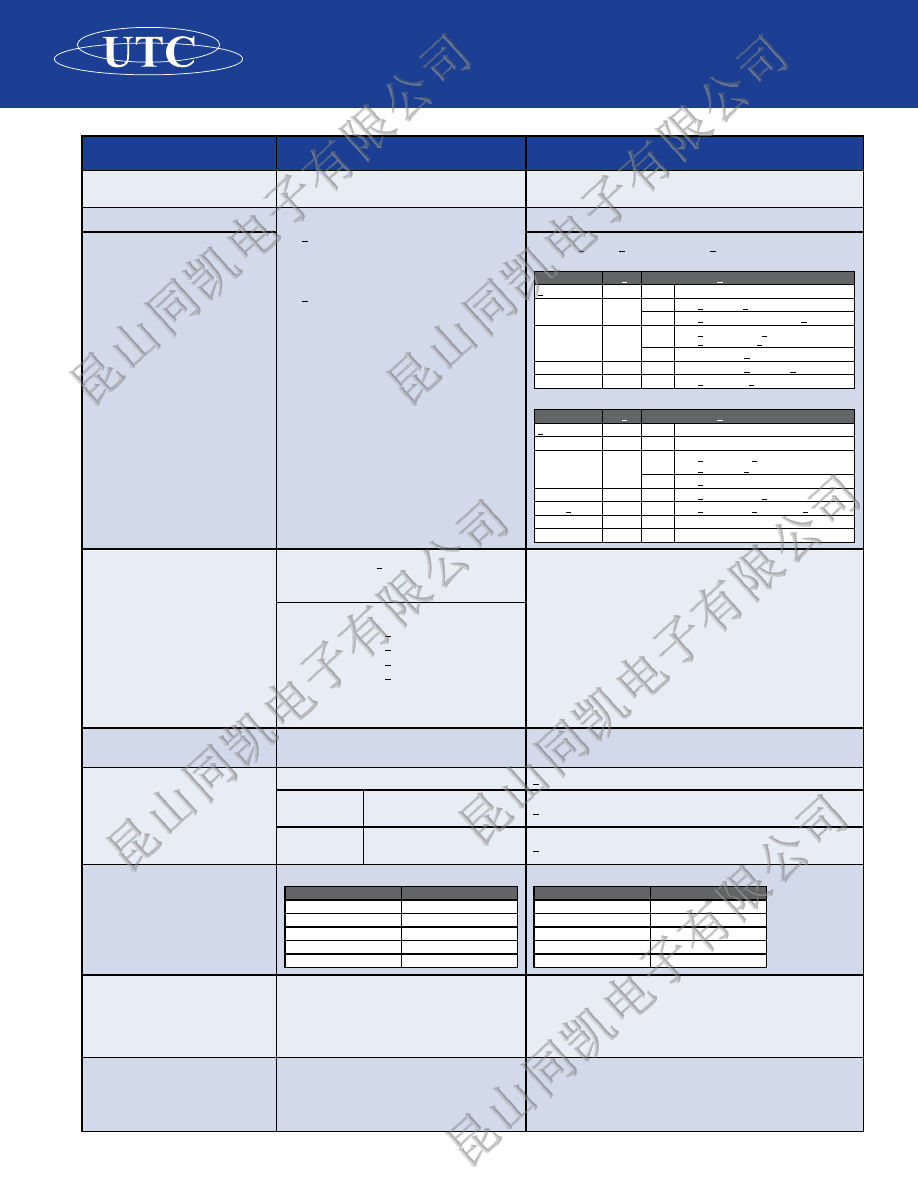

Outline

Size

Inch (mm)

Length

L (mm)

Width

W (mm)

Termination

A (mm)

Thickness Designation

T (mm)/Symbol

Packaging

Qty/Reel

0402 (1005)

1.00±0.05

0.50±0.05

0.25+0.05/-0.10

N

0.50±0.05

10,000

0603 (1608)

1.60±0.10

0.80±0.10

0.40±0.15

S

0.80±0.07

4,000

1.60+0.15/-0.10

0.80+0.15/-0.10

X

0.80+0.15/-0.10

4,000

0805 (2012)

2.00±0.15

1.25±0.10

0.50±0.20

A

0.60±0.10

4,000

B

0.80±0.10

4,000

D

1.25±0.10

3,000

2.00±0.20

1.25±0.20

I

1.25±0.20

3,000

1206 (3216)

3.20±0.15

1.60±0.15

0.60±0.20

B

0.80±0.10

4,000

C

0.95±0.10

3,000

J

1.15±0.15

3,000

D

1.25±0.10

3,000

1.60±0.20

G

1.60±0.20

2,000

3.20+0.30/-0.10

1.60+0.30/-0.10

P

1.60+0.30/-0.10

2,000

1210 (3225)

3.20±0.30

2.50±0.20

0.75±0.25

C

0.95±0.10

3,000

D

1.25±0.10

3,000

3.20±0.40

2.50±0.30

G

1.60±0.20

2,000

K

2.00±0.20

1,000

M

2.50±0.30

1,000

1808 (4520)

4.50±0.40

2.03±0.25

0.75±0.25

D

1.25±0.10

2,000

K

2.00±0.20

1,000

1812 (4532)

4.50±0.40

3.20±0.30

0.75±0.25*

D

1.25±0.10

1,000

K

2.00±0.20

1,000

2220

5.70±

4.50±

.50±

D

2.50±

1,000

K

2.50±

1,000

2225

5.70±

6.35±

.50±

D

3.05±

1,000

K

3.05±

1,000

MECHANICAL DIMENSIONS &

PACKAGING SPECIFICATIONS

3

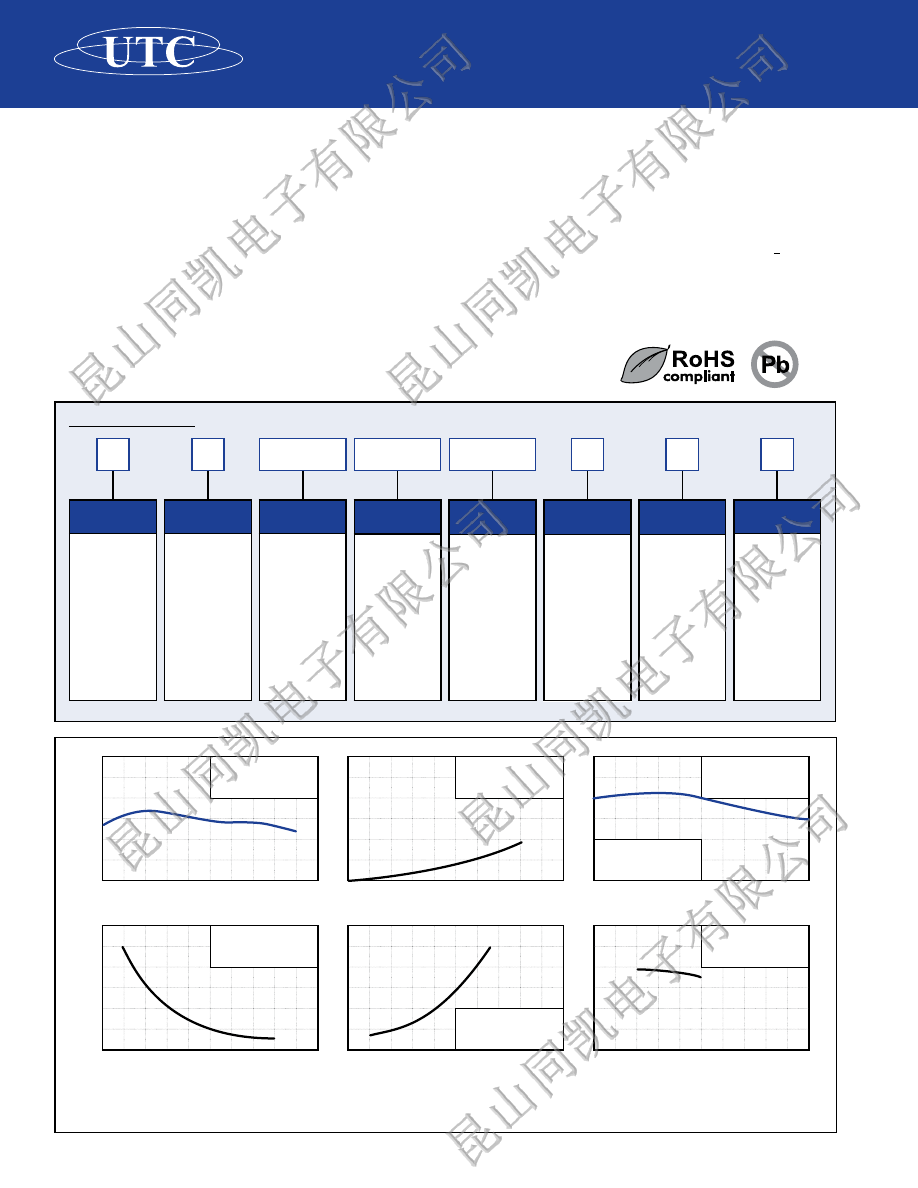

Temperature Coefficient:

< 30 ppm/

o

C, -55

o

C to 125

o

C.

Dissipation Factor:

< 0.1 % @ 1 MHz, 25

o

C.

Insulation Resistance:

1000ΩF or 100GΩ, whichever is less @ rated volt

-

age 25°C. At 125

o

C IR is 10% of 25°C value.

Dielectric Strength:

2.5 times rated voltage D.C.

1.5 times rated voltage for 500V devices.

Quality Factor:

> 1000 @ MHz 25°C.

Test Parameters:

Cap

<

100pF 1.0±0.2Vrms, 1MHz±10%

Cap>100pF 1.0±0.2Vrms, 1KHz±10%

Capacitance Tolerances

Available:

B, C, D, F, G, J, K, M

APPLICATION

Suited for precision circuits, requiring stable capacitor characteristics. No aging effects, low dielectric loss.

PERFORMANCE SPECIFICATIONS

44

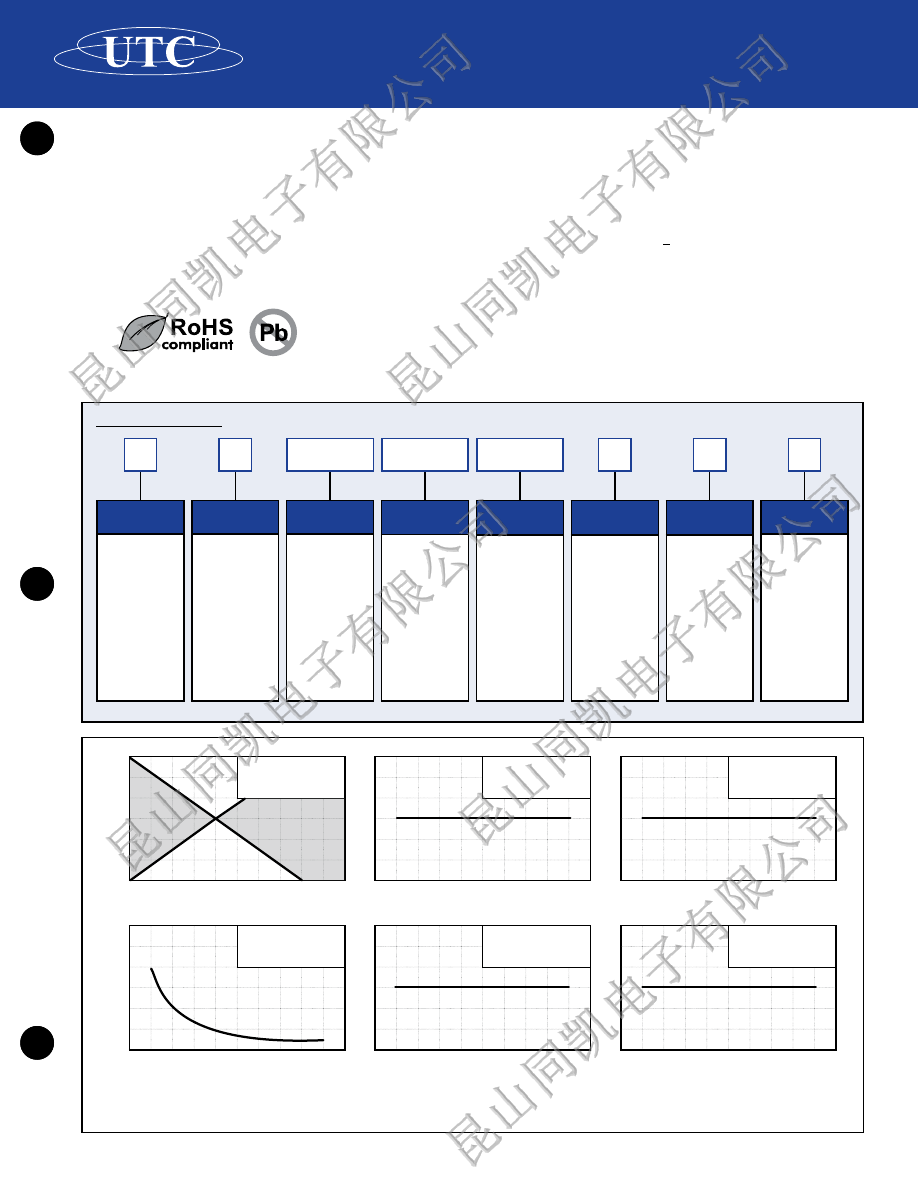

UTC P/N

STYLE

C = MLCC CHIP

C

101

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

B

VOLTAGE

E = 16V

L = 25V

G = 50V

B = 100V

R = 200V

H = 250V

0805

BODY SIZE

0402

0603

0805

1206

1210

1808

1812

2220

2225

K

TOLERANCE

F = 1%

G = 2%

J = 5%

K = 10%

M = 20%

*Cap values < 10pF

B = +/-0.10pF

C = +/-0.25pF

D = +/-0.50pF

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

B = Soft

Termination

[consult factory]

T

PACKAGE

STYLE

T = Tape & Reel

NPO

TEMPERATURE

COEFFICIENT

NPO

HOW TO ORDER

NPO-COG DIELECTRIC

MONOLITHIC CERAMIC CAPACITORS

4

3

Capacitance Change (%)

vs. Temperature (°C)

2

0

-2

-3

-5.0 -25

0

25

50

75 100 125

°C

.0006

Dissipation Factor

vs. Temperature (°C)

.0005

.0004

.0003

.0002

.0001

-5.0 -25

0

25

50

75 100 125

°C

Capacitance Change (%)

vs. RMS Volts

10

5

0

-5

10

0

2

4

6

8

10

12

14

16

RMS Volts

Dissipation Factor (%)

vs. RMS Volts

.01

.001

.0001

0

2

4

6

8

10

12

14

16

RMS Volts

Capacitance Change (%)

vs. D.C. Volts

10

5

0

-5

10

0

2

4

6

8

10

12

14

16

D.C. Volts

Dissipation Factor

vs. Frequency (Hz)

2

1

0

-1

-2

.01

.1

1.0

10

100

Hz

These typical curves are for 50 volt parts.

5

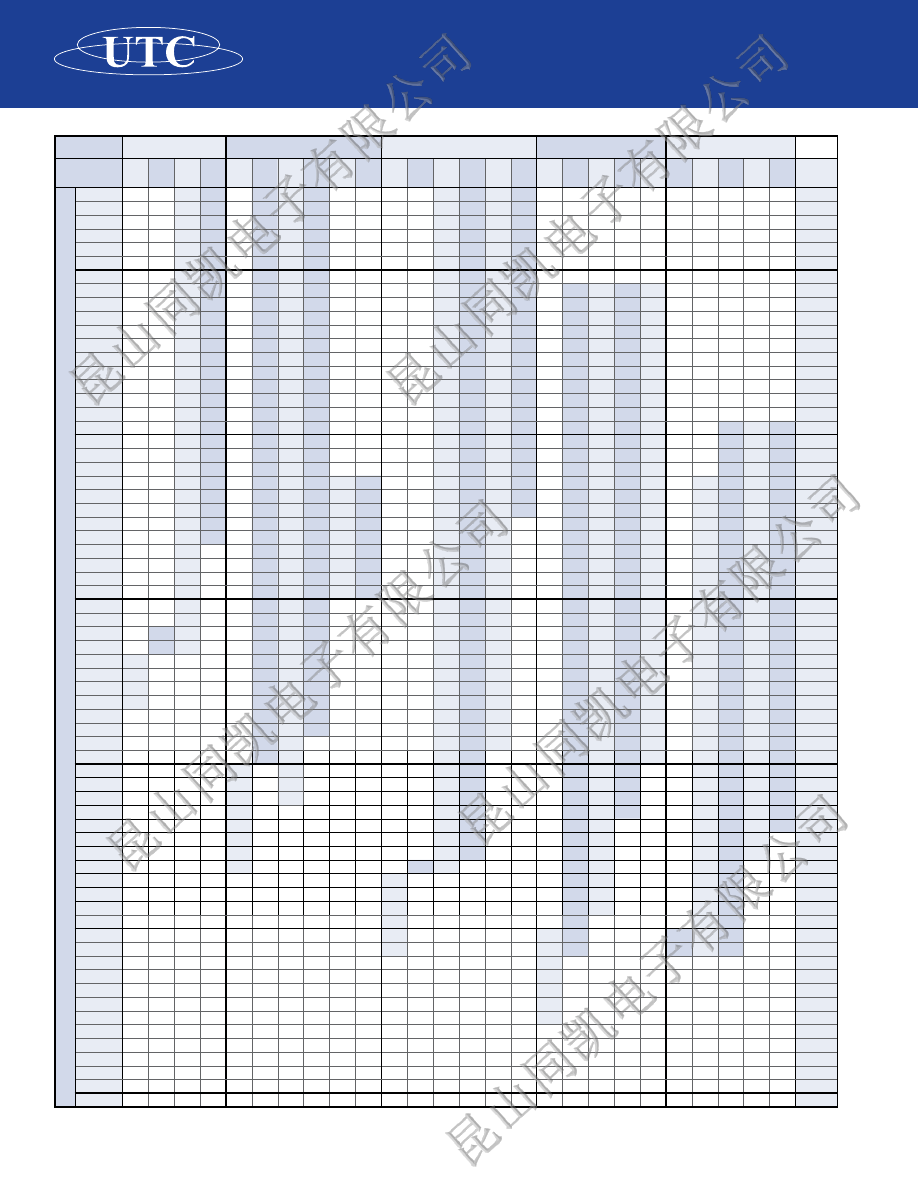

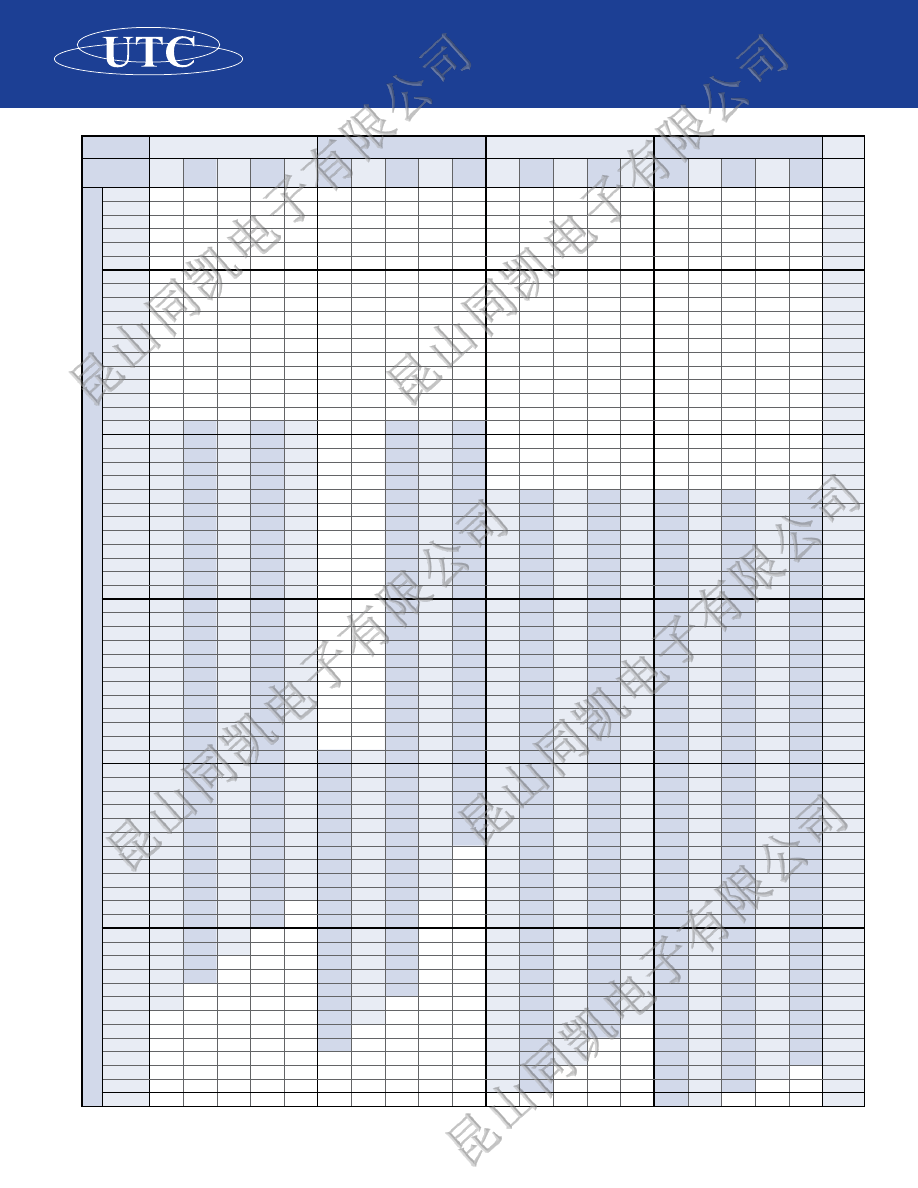

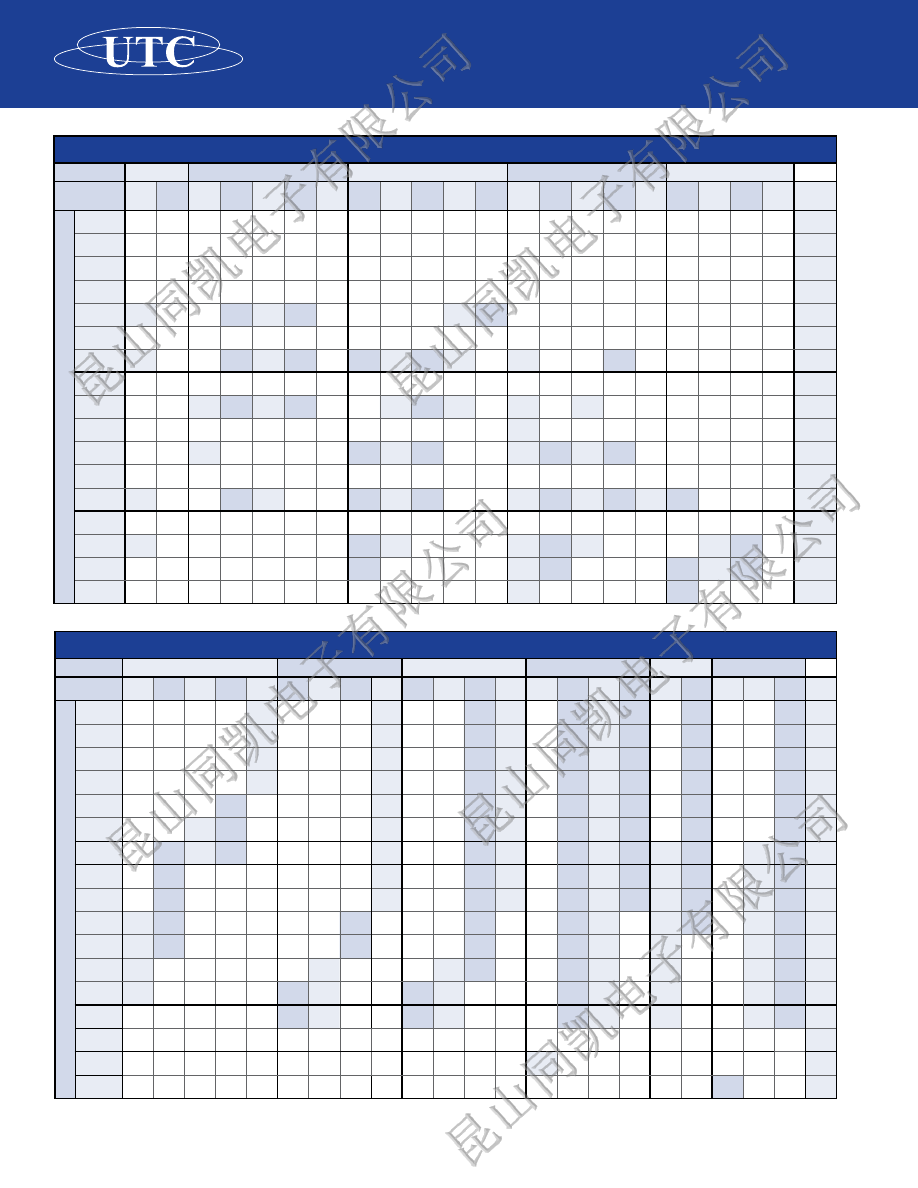

Size

0402

0603

0805

1206

1210

Rated Voltage

(VDC)

16V 25V 50V 100V 16V 25V 50V 100V 200V 250V 16V 25V 50V 100V 200V 250V 16V 50V 100V 200V 250V 16V 50V 100V 200V 250V

EIA

Code

Ca

pacitance

0.5pF

N

N

S

S

S

A

A

A

A

(0R5)

0.6pF

N

N

S

S

S

A

A

A

A

(0R6)

0.7pF

N

N

S

S

S

A

A

A

A

(0R7)

0.8pF

N

N

S

S

S

A

A

A

A

(0R8)

0.9pF

N

N

S

S

S

A

A

A

A

(0R9)

1.0pF

N

N

S

S

S

A

A

A

A

(1R0)

1.2pF

N

N

S

S

S

A

A

A

A

(1R2)

1.5pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(1R5)

1.8pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(1R8)

2.2pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(2R2)

2.7pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(2R7)

3.3pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(3R3)

3.9pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(3R9)

4.7pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(4R7)

5.6pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(5R6)

6.8pF

N

N

S

S

S

A

A

A

A

B

B

B

B

(6R8)

8.2pF

N

N

S

S

S

A

A

A

B

B

B

B

B

(8R2)

10pF

N

N

S

S

S

A

A

A

B

B

B

B

B

C

C

C

100

12pF

N

N

S

S

S

A

A

A

D

B

B

B

B

C

C

C

120

15pF

N

N

S

S

S

A

A

A

D

B

B

B

B

C

C

C

150

18pF

N

N

S

S

S

A

A

A

D

B

B

B

B

C

C

C

180

22pF

N

N

S

S

S

S

S

A

A

A

D

B

B

B

B

C

C

C

C

220

27pF

N

N

S

S

S

S

S

A

A

A

D

B

B

B

B

C

C

C

C

270

33pF

N

N

S

S

S

S

S

A

A

A

D

B

B

B

B

C

C

C

C

330

39pF

N

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

390

47pF

N

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

470

56pF

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

560

68pF

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

680

82pF

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

820

100pF

N

S

S

S

S

S

A

A

A

B

B

B

B

C

C

C

C

101

120pF

N

S

S

S

A

A

A

B

B

B

B

C

C

C

C

121

150pF

N

S

S

S

A

A

A

B

B

B

B

C

C

C

C

151

180pF

N

N

S

S

S

A

A

A

B

B

B

B

C

C

C

C

181

220pF

N

N

S

S

S

A

A

A

B

B

B

B

C

C

C

C

221

270pF

N

S

S

S

A

A

A

B

B

B

C

C

C

C

C

271

330pF

N

S

S

S

A

A

A

B

B

B

C

C

C

C

C

331

390pF

N

S

S

S

A

A

A

B

B

B

C

C

C

C

C

391

470pF

N

S

S

S

A

A

B

B

B

C

C

C

C

C

C

471

560pF

S

S

S

A

A

B

B

B

C

C

C

C

C

C

561

680pF

S

S

S

A

A

D

B

B

C

C

C

C

C

C

681

820pF

S

S

A

A

D

B

B

C

D

C

C

C

C

821

1000pF

S

S

A

A

B

B

C

G

C

C

C

C

102

1200pF

S

S

B

B

B

B

C

C

C

D

D

122

1500pF

S

S

B

B

B

B

C

C

C

D

D

152

1800pF

S

S

B

B

B

B

D

C

C

D

D

182

2200pF

S

B

B

B

B

D

C

C

D

D

222

2700pF

S

D

D

B

B

C

C

D

D

272

3300pF

S

D

D

B

B

C

C

D

332

3900pF

S

D

D

B

B

C

C

D

392

4700pF

S

D

D

B

B

C

C

472

5600pF

D

B

B

C

C

562

6800pF

D

C

C

C

C

682

8200pF

D

C

C

C

C

822

0.010µF

D

D

C

C

103

0.012µF

D

D

P

C

D

D

123

0.015µF

D

D

P

C

D

D

153

0.018µF

D

183

0.022µF

D

223

0.027µF

D

273

0.033µF

D

333

0.039µF

D

393

0.047µF

473

0.056µF

683

0.068µF

563

0.082µF

823

0.010µF

104

0.012µF

124

NPO-COG DIELECTRIC

5

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

6

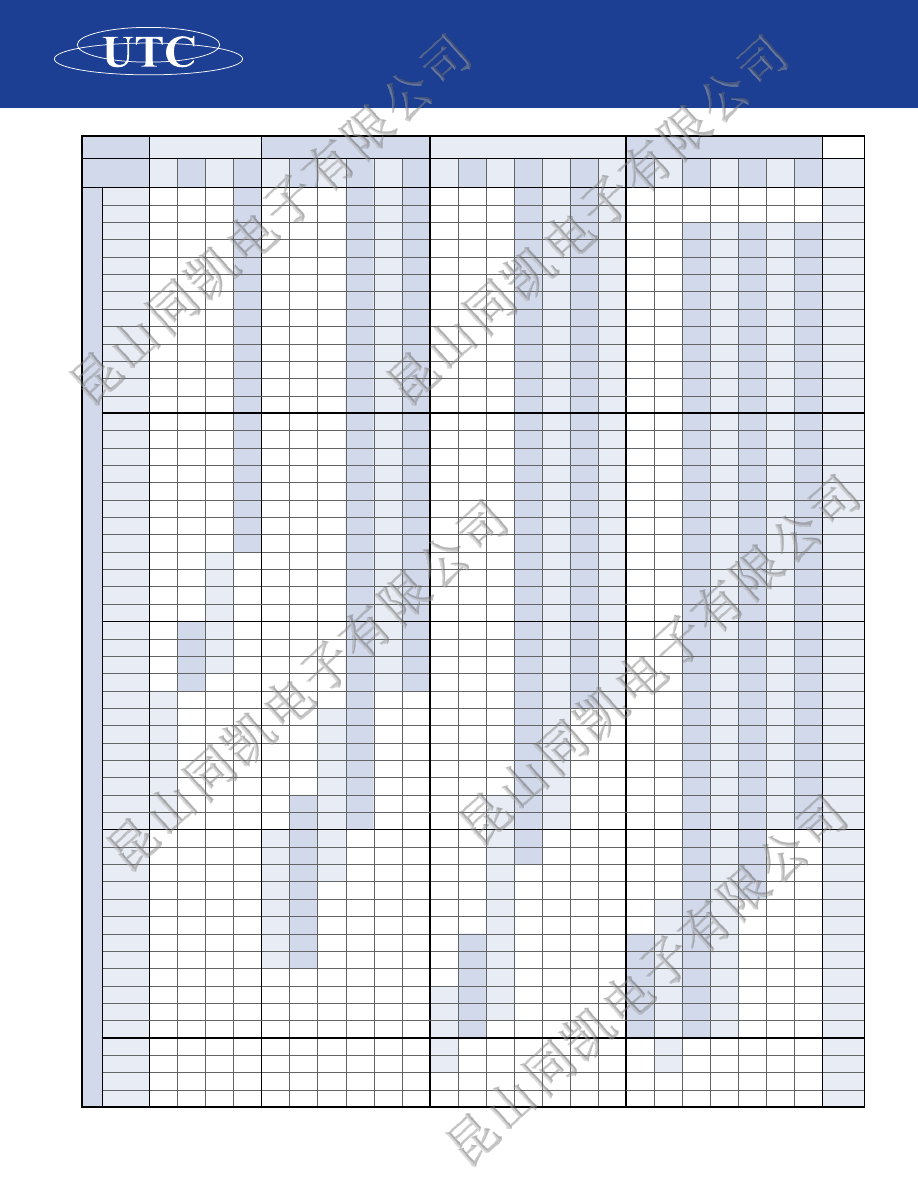

Size

1808

1812

2220

2225

Rated Voltage

(VDC)

25V

50V

100V

200V 250V

25V

50V

100V

200V 250V

25V

50V

100V

200V 250V

25V

50V

100V

200V 250V

EIA

Code

Ca

pacitance

0.5pF

(0R5)

0.6pF

(0R6)

0.7pF

(0R7)

0.8pF

(0R8)

0.9pF

(0R9)

1.0pF

(1R0)

1.2pF

(1R2)

1.5pF

(1R5)

1.8pF

(1R8)

2.2pF

(2R2)

2.7pF

(2R7)

3.3pF

(3R3)

3.9pF

(3R9)

4.7pF

(4R7)

5.6pF

(5R6)

6.8pF

(6R8)

8.2pF

(8R2)

10pF

D

D

D

D

D

D

D

D

100

12pF

D

D

D

D

D

D

D

D

120

15pF

D

D

D

D

D

D

D

D

150

18pF

D

D

D

D

D

D

D

D

180

22pF

D

D

D

D

D

D

D

D

220

27pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

270

33pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

330

39pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

390

47pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

470

56pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

560

68pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

680

82pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

820

100pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

101

120pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

121

150pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

151

180pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

181

220pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

221

270pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

271

330pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

331

390pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

391

470pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

471

560pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

561

680pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

681

820pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

821

1000pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

102

1200pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

122

1500pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

152

1800pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

182

2200pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

222

2700pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

272

3300pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

332

3900pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

392

4700pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

472

5600pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

562

6800pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

682

8200pF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

822

0.010µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

103

0.012µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

123

0.015µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

153

0.018µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

183

0.022µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

223

0.027µF

D

D

D

D

D

D

D

D

D

D

D

D

D

D

273

0.033µF

D

D

D

D

D

D

D

D

D

D

D

D

D

333

0.039µF

D

D

D

D

D

D

D

D

D

D

D

D

393

0.047µF

D

D

D

D

D

D

D

D

D

D

473

0.056µF

D

D

D

D

D

D

D

D

D

563

0.068µF

D

D

D

D

D

D

D

D

683

0.082µF

D

D

D

D

D

D

823

0.10µF

D

D

D

D

D

104

0.12µF

D

D

124

NPO-COG DIELECTRIC

6

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

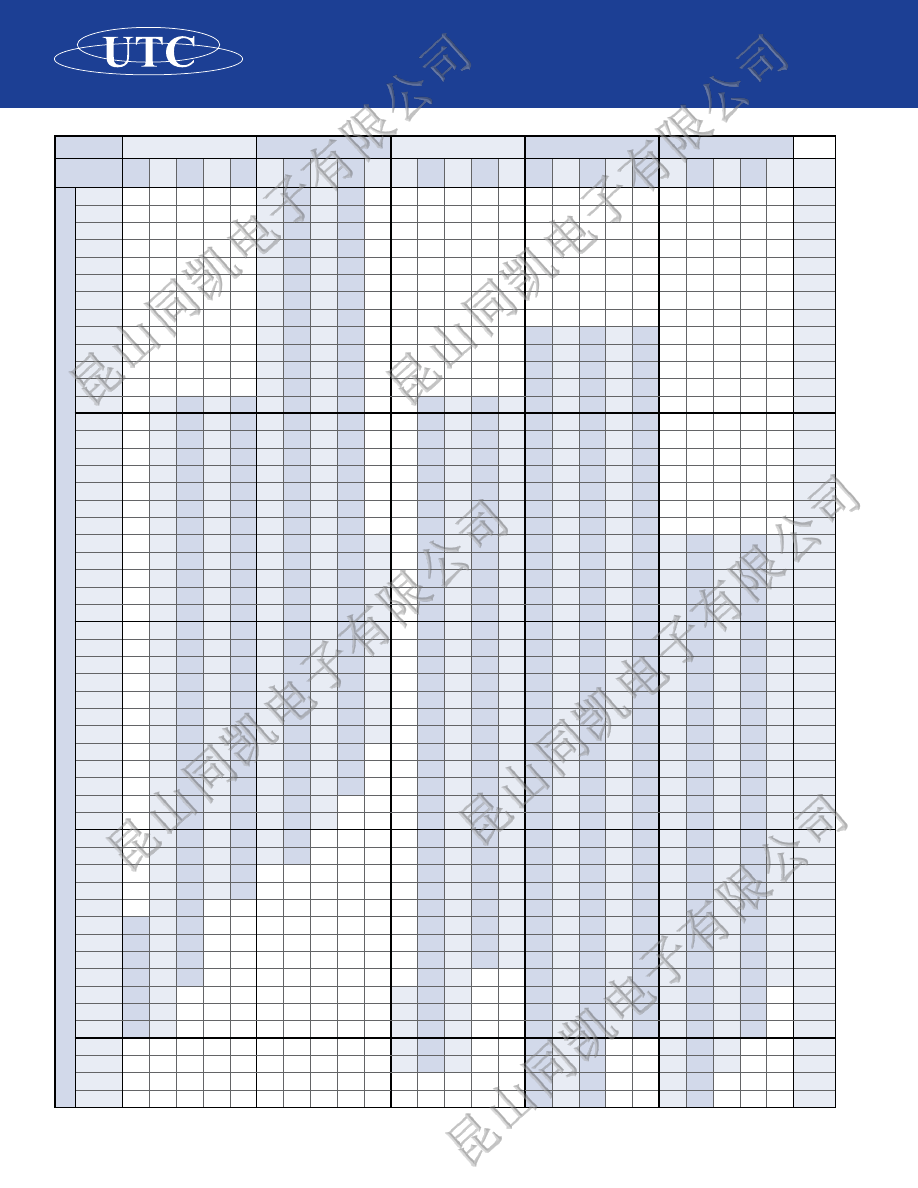

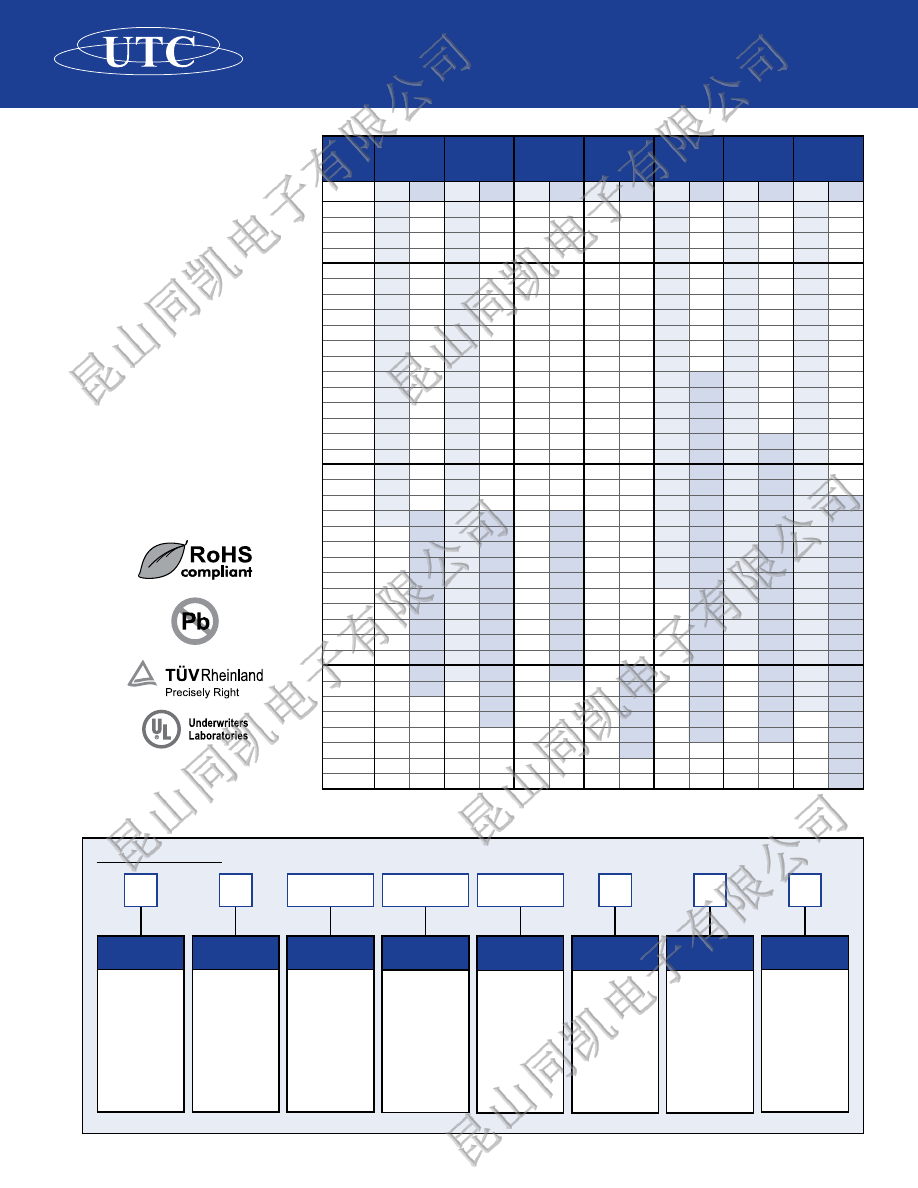

Temperature Coefficient:

±15% ∆C, -55°C to 125°C.

maximum -55 to 125° at WVdc.

Dissipation Factor:

Maximum DF; 25V - 3.5%

Maximum DF; 50V - 2.5%

Maximum DF; 100V - 2.5%

Maximum DF; 250V - 2.5%

Insulation Resistance:

1000ΩF or 100GΩ, whichever is less @ rated

voltage 25°C. At 125°C IR is 10% of 25°C value.

Dielectric Strength:

2.5 times rated voltage D.C.

1.5 times rated voltage for 500V devices.

Aging:

Maximum 2% per decade hour, for X7R.

Test Parameters:

1 kHz and 1 vms if capacitance

< 10

µF

120 Hz and 0.5 vms if capacitance > 10µF

Capacitance Tolerances

Available:

J, K, M

APPLICATION

Suited for By-Pass and Coupling Application, Filtering, D.C. Blocking and Transient Suppression.

PERFORMANCE SPECIFICATIONS

X7R DIELECTRIC

MONOLITHIC CERAMIC CAPACITORS

7

UTC P/N

STYLE

C = MLCC CHIP

C

104

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

B

VOLTAGE

C = 10V

E = 16V

L = 25V

G = 50V

B = 100V

R = 200V

H = 250V

0805

BODY SIZE

0402

0603

0805

1206

1210

1812

2220

K

TOLERANCE

J = 5%

K = 10%

M = 20%

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

B = Soft

Termination

[consult factory]

T

PACKAGE

STYLE

T = Tape & Reel

X7R

TEMPERATURE

COEFFICIENT

X7R

HOW TO ORDER

Capacitance Change (%)

vs. Temperature (°C)

10

0

-10

-20

-40 -20

0

20

40

60

80 100 120 140

°C

Dissipation Factor

vs. Temperature (°C)

5

4

3

2

1

-50 -25

0

25

50

75 100 125

°C

Capacitance Change (%)

vs. RMS Volts

50

40

30

20

10

0

5

10

15

20

RMS Volts

0.1

.08

.06

.04

Dissipation Factor (%)

vs. RMS Volts

.02

0

1

2

3

4

5

6

7

RMS Volts

Capacitance Change (%)

vs. D.C. Volts

0

20

40

Due 10 voltage effects (pg 4), higher

voltage rating have different curves.

Consult factory for typical curves.

60

5

10

15

20

25

30

35

40

45

50

D.C. Volts

Dissipation Factor

vs. Frequency (Hz)

0

-10

-20

-30

10

3

10

4

10

5

10

6

Hz

These typical curves are for 50 volt parts.

-60

0

X7R

0VDC X7R

Size

0402

0603

0805

1206

Rated Voltage

(VDC)

10V 16V 25V 50V

10V 16V 25V 50V 100V 200V 10V 16V 25V 50V 100V 200V 250V 10V 16V 25V 50V 100V 200V 250V

EIA

Code

Ca

pacitance

100pF

N

S

S

S

B

B

B

B

101

120pF

N

S

S

S

B

B

B

B

121

150pF

N

S

S

S

B

B

B

B

B

B

B

B

B

151

180pF

N

S

S

S

B

B

B

B

B

B

B

B

B

181

220pF

N

S

S

S

B

B

B

B

B

B

B

B

B

221

270pF

N

S

S

S

B

B

B

B

B

B

B

B

B

271

330pF

N

S

S

S

B

B

B

B

B

B

B

B

B

331

390pF

N

S

S

S

B

B

B

B

B

B

B

B

B

391

470pF

N

S

S

S

B

B

B

B

B

B

B

B

B

471

560pF

N

S

S

S

B

B

B

B

B

B

B

B

B

561

680pF

N

S

S

S

B

B

B

B

B

B

B

B

B

681

820pF

N

S

S

S

B

B

B

B

B

B

B

B

B

821

1000pF

N

S

S

S

B

B

B

B

B

B

B

B

B

102

1200pF

N

S

S

S

B

B

B

B

B

B

B

B

B

122

1500pF

N

S

S

S

B

B

B

B

B

B

B

B

B

152

1800pF

N

S

S

S

B

B

B

B

B

B

B

B

B

182

2200pF

N

S

S

S

B

B

B

B

B

B

B

B

B

222

2700pF

N

S

S

S

B

B

B

B

B

B

B

B

B

272

3300pF

N

S

S

S

B

B

B

B

B

B

B

B

B

332

3900pF

N

S

S

S

B

B

B

B

B

B

B

B

B

392

4700pF

N

S

S

S

B

B

B

B

B

B

B

B

B

472

5600pF

N

S

S

X

B

B

D

D

B

B

B

B

B

562

6800pF

N

S

S

X

B

B

D

D

B

B

B

B

B

682

8200pF

N

S

S

X

B

B

D

D

B

B

B

B

B

822

0.010µF

N

S

S

X

B

B

D

D

B

B

B

B

B

103

0.012µF

N

N

S

X

X

B

B

D

D

B

B

B

B

B

123

0.015µF

N

N

S

X

X

B

B

D

D

B

B

B

C

C

153

0.018µF

N

N

S

X

X

B

B

D

D

B

B

B

C

C

183

0.022µF

N

S

X

X

B

B

D

D

B

B

B

C

C

223

0.027µF

N

S

B

D

D

D

B

B

B

C

C

273

0.033µF

N

S

X

B

D

B

B

B

C

C

333

0.039µF

N

S

X

B

D

B

B

B

C

C

393

0.047µF

N

S

X

B

D

B

B

B

C

C

473

0.056µF

N

S

X

B

D

B

B

B

C

C

563

0.068µF

N

S

X

B

D

B

B

B

C

C

683

0.082µF

N

S

S

X

B

B

D

B

B

D

C

C

823

0.10µF

N

S

S

X

B

B

D

B

B

D

C

C

104

0.12µF

S

S

S

B

D

B

B

D

124

0.15µF

S

S

S

D

D

C

C

G

154

0.18µF

S

S

S

D

C

C

G

184

0.22µF

S

S

D

C

C

G

224

0.27µF

X

X

D

C

D

D

274

0.33µF

X

X

D

C

D

D

334

0.39µF

X

X

D

D

C

J

P

P

394

0.47µF

X

X

D

D

J

J

P

P

474

0.56µF

D

D

J

J

P

P

564

0.68µF

D

D

D

J

J

P

P

684

0.82µF

D

D

D

J

J

P

P

824

1.0µF

D

D

J

J

P

P

105

1.5µF

D

G

155

2.2µF

D

P

225

3.3µF

335

4.7µF

475

X7R DIELECTRIC

8

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

Size

1210

1808

1812

2220

2225

Rated Voltage

(VDC)

25V 50V 100V 200V 250V 25V 50V 100V 200V 250V 25V 50V 100V 200V 250V 25V 50V 100V 200V 250V 25V 50V 100V 200V 250V

EIA

Code

Ca

pacitance

100pF

D

D

D

D

101

120pF

D

D

D

D

121

150pF

D

D

D

D

151

180pF

D

D

D

D

181

220pF

D

D

D

D

221

270pF

D

D

D

D

271

330pF

D

D

D

D

331

390pF

D

D

D

D

391

470pF

D

D

D

D

D

D

D

D

D

471

560pF

D

D

D

D

D

D

D

D

D

561

680pF

D

D

D

D

D

D

D

D

D

681

820pF

D

D

D

D

D

D

D

D

D

821

1000pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

102

1200pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

122

1500pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

152

1800pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

182

2200pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

222

2700pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

272

3300pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

332

3900pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

392

4700pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

472

5600pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

562

6800pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

682

8200pF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

822

0.010µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

103

0.012µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

123

0.015µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

153

0.018µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

183

0.022µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

223

0.027µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

273

0.033µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

333

0.039µF

C

C

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

393

0.047µF

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

473

0.056µF

C

C

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

563

0.068µF

C

C

G

G

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

683

0.082µF

C

C

G

G

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

823

0.10µF

C

C

G

G

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

104

0.12µF

C

C

G

G

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

124

0.15µF

C

D

M

M

D

D

D

D

K

K

D

D

D

D

D

D

D

D

D

D

154

0.18µF

C

D

M

M

D

D

K

K

D

D

D

D

D

D

D

D

D

D

184

0.22µF

C

D

M

M

D

D

K

K

D

D

D

D

D

D

D

D

D

D

224

0.27µF

C

G

D

D

K

K

D

D

D

D

D

D

D

D

D

D

274

0.33µF

C

D

G

D

D

K

K

D

D

D

D

D

D

D

D

D

D

334

0.39µF

C

D

M

D

D

K

K

D

D

D

D

D

D

D

D

D

D

394

0.47µF

C

D

M

D

K

K

K

D

D

D

D

D

D

D

D

D

D

474

0.56µF

D

D

M

D

K

D

D

D

D

D

D

D

D

D

D

564

0.68µF

D

D

D

K

K

D

D

D

D

K

D

D

D

D

684

0.82µF

D

D

D

K

K

D

D

D

K

K

D

D

D

D

824

1.0µF

D

D

D

K

K

D

D

D

K

K

D

D

D

D

105

1.5µF

K

K

K

D

D

D

D

D

D

155

2.2µF

K

K

K

D

D

D

D

D

D

225

3.3µF

D

D

D

D

D

335

4.7µF

D

D

D

D

D

475

9

X7R DIELECTRIC

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

Temperature Coefficient:

X5R +15% -15% ∆C, -55°C to 85°C

Y5V +22% -82% ∆C, -30°C to 85°C

Dissipation Factor:

Insulation Resistance:

100ΩF or 10GΩ, whichever is less @ Rated

Voltage 25°C.

Dielectric Strength:

2.5 times rated voltage D.C.

Aging:

X5R Maximum 2.5% per decade hour.

Y5V Maximum 7% per decade hour.

Test parameters:

(X5R)

1 kHz and 1 vms if capacitance

< 10

µF

120 Hz and 0.5 vms if capacitance > 10µF

(Y5V)

1 kHz and 1 vms if capacitance

< 10

µF

120 Hz and 0.5 vms if capacitance > 10µF

1 kHz and 1 vms

Capacitance Tolerance

Available:

M, Z

APPLICATION

Hi-K Dielectric suited for applications where PCB real estate is at a premium and usage is at near room temperature with low DC bias.

PERFORMANCE SPECIFICATIONS

X5R/Y5V DIELECTRIC

MONOLITHIC CERAMIC CAPACITORS

10

UTC P/N

STYLE

C = MLCC CHIP

C

105

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

L

VOLTAGE

A = 6.3V

C = 10V

E = 16V

L = 25V

G = 50V

B = 100V

0805

BODY SIZE

0402

0603

0805

1206

1210

1812

K

TOLERANCE

K = 10%

M = 20%

Z = -20% / +80%

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

B = Soft

Termination

[consult factory]

T

PACKAGE

STYLE

T = Tape & Reel

X5R

TEMPERATURE

COEFFICIENT

X5R

Y5V

HOW TO ORDER

X5R

Maximum DF;

6.3V~10V - 3.5%

16V~25V - 3.5%

50V - 2.5%

Y5V

Maximum DF;

6.3V~10V - 10%

16V~25V - 7%

50V~100V - 5%

Capacitance Change (%)

vs. Temperature (°C)

20

0

-20

-40

-60

-80

-40 -20

0

20

40

60

80 100 120 140

°C

Dissipation Factor

vs. Temperature (°C)

5

4

3

2

1

-50 -25

0

25

50

75 100 125

°C

Capacitance Change (%)

vs. RMS Volts

50

40

30

20

10

0

5

10

15

20

RMS Volts

0.1

.08

.06

.04

Dissipation Factor

vs.RMS Volts

.02

0

1

2

3

4

5

6

7

RMS Volts

Capacitance Change (%)

vs. D.C. Volts

0

20

40

60

5

10

15

20

25

30

35

40

45

50

D.C. Volts

Dissipation Factor

vs. Frequency (Hz)

0

-10

-20

-30

10

3

10

4

10

5

10

6

Hz

These typical curves are for 50 volt parts.

Y5V

-60

0

Y5V

X5R

Y5V

X5R

Y5V

Size

0402

0603

0805

1206

1210

1812

Rated Voltage

(VDC)

6.3V

10V

16V

25V

50V

10V

16V

25V

50V

16V

25V

50V 100V

10V

25V

50V 100V

50V 100V

10V

50V 100V

EIA

Code

Ca

pacitance

0.010µF

N

S

A

B

B

B

B

C

D

103

0.015µF

N

S

A

B

B

B

B

C

D

153

0.022µF

N

S

A

B

B

B

B

C

D

223

0.033µF

N

S

A

B

B

B

B

C

D

333

0.047µF

N

S

A

B

B

B

B

C

D

473

0.068µF

N

N

S

A

B

B

B

B

C

D

683

0.10µF

N

N

N

S

A

B

B

B

B

C

C

D

D

104

0.15µF

N

S

A

B

B

B

C

C

C

D

D

154

0.22µF

N

S

A

B

B

B

C

C

C

D

D

224

0.33µF

N

N

S

A

B

B

C

C

D

D

334

0.47µF

N

N

S

B

B

B

C

D

D

474

0.68µF

N

S

B

B

B

B

C

D

D

684

1.0µF

N

S

X

B

D

B

B

C

D

D

105

3.3µF

S

X

B

D

C

C

C

D

D

335

10µF

106

22µF

P

226

47µF

K

476

X5R

Size

0402

0603

0805

1206

1210

Rated Voltage

(VDC)

6.3V

10V

6.3V

10V

16V

25V

50V

6.3V

10V

16V

25V

50V

6.3V

10V

16V

25V

50V

6.3V

10V

16V

25V

EIA

Code

Ca

pacitance

0.010µF

103

0.015µF

153

0.022µF

223

0.033µF

333

0.047µF

N

S

S

S

D

D

473

0.068µF

683

1.0µF

N

S

S

S

D

D

D

D

G

P

105

1.5µF

155

2.2µF

S

S

S

S

D

D

D

G

P

225

3.3µF

G

335

4.7µF

S

D

D

D

P

P

P

P

475

6.8µF

685

10µF

N

S

S

D

D

D

P

P

P

P

P

K

106

15µF

156

22µF

N

D

D

P

P

P

K

K

226

47µF

D

P

P

K

K

K

476

100µF

P

K

107

X5R/Y5V DIELECTRIC

11

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

SAFETY CERTIFIED CHIPS

The “S” Series X2/Y3 & X1/Y2

safety capacitors are designed for

applications in; modem, facsimile,

and various other electronic

communication equipment. They

are also well suited for use in

lighting, surge protection, and EMI

filter isolation circuits.

Features & Applications:

• Small size & high cap values

• Surface mountable

• Safety standard approved by

EN132400+A4:01 & UL60950

• RoHS Compliant

• Lead Free

Cap

Value

1808

X1 / Y2

1808

X2 / Y3

1812

X1 / Y2

1812

X2 / Y3

2208

X1 / Y2

2211

X1 / Y2

2220

X1 / Y2

NPO X7R NPO X7R NPO X7R NPO X7R NPO X7R NPO X7R NPO X7R

2R0pF

D

D

D

D

D

5R0pF

D

D

D

D

D

6R8pF

D

D

D

D

D

8R2pF

D

D

D

D

D

100pF

D

D

D

D

D

120pF

D

D

D

D

D

150pF

D

D

D

D

D

180pF

D

D

D

D

D

220pF

D

D

D

D

D

270pF

D

D

D

D

D

330pF

D

D

D

D

D

360pF

D

D

D

D

D

D

390pF

D

D

D

D

D

D

470pF

D

D

D

D

D

D

560pF

D

D

D

D

D

D

680pF

D

D

D

D

D

D

D

820pF

D

D

D

D

D

D

D

101pF

D

D

D

D

D

D

D

121pF

D

D

D

D

D

D

D

131pF

D

D

D

D

D

D

D

D

151pF

D

D

D

D

D

D

D

D

D

D

D

181pF

D

D

D

D

D

D

D

D

D

D

221pF

D

D

D

D

D

D

D

D

D

D

271pF

D

D

D

D

D

D

D

D

D

D

331pF

D

D

D

D

D

D

D

D

D

D

391pF

D

D

D

D

D

D

D

D

D

471pF

D

D

D

D

D

D

D

D

D

561pF

D

D

D

D

D

D

D

D

D

681pF

D

D

D

D

D

D

D

D

D

821pF

D

D

D

D

D

D

D

D

102pF

D

D

D

D

D

D

D

D

D

122pF

D

D

D

D

D

D

D

152pF

D

D

D

D

D

D

182pF

D

D

D

D

D

222pF

D

D

D

D

272pF

D

D

332pF

D

472pF

D

12

Note: Please refer to the chart on page 3 for the corresponding thickness designation.

UTC P/N

STYLE

S = MLCC SAFETY

CERTIFIED CHIP

S

102

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

X

VOLTAGE

X = X2/Y3

Z = X1/Y2

1808

BODY SIZE

1808

1812

2208

2211

2220

K

TOLERANCE

J = 5%

K = 10%

M = 20%

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

T

PACKAGE

STYLE

T = Tape & Reel

X7R

TEMPERATURE

COEFFICIENT

NPO

X7R

HOW TO ORDER

HIGH VOLTAGE CHIP CAPACITORS

500VDC TO 5000VDC

Dimension

Size

1206

1210

1808

1812

1825

2220

2225

3530

4040

5550

Min Cap

10pF

10pF

10pF

10pF

47pF

47pF

47pF

47pF

47pF

100pF

500V

NPO

1500pF

1800pF

3300pF

.01µF

.022µF

.022µF

.027µF

.068µF

.1µF

.18µF

X7R

.039µF

.047µF

.047µF

.1µF

.33µF

.27µF

.33µF

1.0µF

1.8µF

2.2µF

1000V

NPO

1000pF

2200pF

2200pF

4700pF

.01µF

.01µF

.015µF

.027µF

.056µF

.1µF

X7R

4700pF

.033µF

.01µF

.027µF

.1µF

.1µF

.1µF

.33µF

.56µF

1.0µF

2000V

NPO

220pF

560pF

330pF

1800pF

2700pF

2700pF

3900pF

.015µF

.027µF

.047µF

X7R

1000pF

1800pF

2200pF

4700pF

.012µF

.01µF

.015µF

.068µF

.15µF

.27µF

3000V

NPO

39pF

220pF

1000pF

820pF

1200pF

1200pF

1800pF

.01µF

.018µF

.033µF

X7R

1800pF

1500pF

4700pF

4700pF

5600pF

.027µF

.068µF

.12µF

4000V

NPO

220pF

470pF

680pF

680pF

1000pF

5600pF

.012µF

.018µF

X7R

330pF

680pF

1500pF

1500pF

1500pF

.015µF

.022µF

.047µF

5000V

NPO

390pF

151pF

560pF

3300pF

6800pF

.012µF

X7R

820pF

820pF

1000pF

.01µF

.012µF

.033µF

* TOLERANCE +-.010 or 7% WHICHEVER IS GREATER.

UTC offers a wide variety of sizes, voltages, and capacitance values in our series of High Voltage Ceramic Chips.

Features & Applications:

• Specialized internal electrode designs offer an enhanced product performance.

• Ideally, suited for telecommunication devices in LAN interface (IEEE 802.3) products.

• Performs well as a ballast capacitor for backlighting inverter applications.

• UTC also supports many applications for both custom sizes and voltages beyond those listed.

• RoHS Compliant

• Lead Free

13

UTC P/N

STYLE

C = MLCC CHIP

C

102

CAPACITANCE

CODE

2 significant

digits are used

plus the third

character then

represents

the number of

zeros to follow

T

VOLTAGE

S = 500V

K = 600V

K = 630V

T = 1,000V

W = 2,000V

X = 3,000V

Y = 4,000V

Z = 5,000V

1812

BODY SIZE

1206

1210

1808

1812

1825

2220

2225

3530

4040

5550

K

TOLERANCE

J = 5%

K = 10%

M = 20%

W

TERMINATION

W = 100%

tin termination

& RoHS - Lead

Free compliant

product

B = Soft

Termination

[consult factory]

T

PACKAGE

STYLE

T = Tape & Reel

X7R

TEMPERATURE

COEFFICIENT

NPO

X7R

HOW TO ORDER

Item

Test Condition

Requirements

Visual and Mechanical

---

• No remarkable defect.

• Dimensions to confirm to individual specification sheet

Capacitance

Class I: NPO

Cap

<

100pF 1.0±0.2Vrms, 1MHz±10%

Cap>100pF 1.0±0.2Vrms, 1KHz±10%

Class II: X7R, X5R, Y5R

Cap

<

10µF, 1.0±0.2Vrms, 1KHz±10%

Cap>10µF, 0.5±0.2Vrms, 120Hz±20%

• Shall not exceed the limits given in the detailed spec.

Q/ D.F.

(Dissipation Factor)

NPO:

Cap

>

30pF, Q

>

1000; Cap<30pF, Q

>

400+20C

X7R, X5R:

Rated Voltage D.F.<

Exception of D.F.<

>50V

5.0%

---

---

25V

3.5%

5.0%

0805>1µF, 1210>10µF

7.0%

0603>0.33µF; TT series & Cap>1µF

16V

3.5%

5.0%

0402>0.033µF; 0603>0.15µF;

0805>0.68µF; 1206>2.2µF

10%

TT Series & Cap>1µF

10V

5.0%

10.0% TT Series & Cap>1µF; 0805>10µF

6.3V

10.0%

15.0% 0805>22µF; 1210>100µF

Y5V:

Rated Voltage D.F.<

Exception of D.F.<

>50V

5.0%

---

---

35V

7.0%

---

---

25V

5.0%

7.0%

0603>0.1µF; 0805>µF;

1206>1µF; 1210>4.7µF

9.0%

0402>0.068µF

16V (C<1.0µF) 7.0%

9.0%

0402>0.068µF; 0603>0.68µF

16V (C<1.0µF) 9.0%

12.5% 0805>4.7µF; 1206>10µF; 1210>22µF

10V

12.5%

---

---

6.3V

20.0%

---

---

Dielectric Strength

•

To apply voltage:

(

<

50V) 250%.

•

Duration:

1 to 5 sec.

• Charge & discharge current less than 50mA.

• No evidence of damage or flash over during test.

•

To apply voltage:

100V

>

3 times V DC

200V ~ 300V

>

2 times V DC

500V ~ 999V

>

1.5 times V DC

1000V ~ 5000V

>

1.2 times V DC

• Cut-off, set at 10mA

• TEST= 15 sec.

• RAMP= 0

Dielectric Strength

(for X1/Y2 & X2/Y3)

• To apply 1500 VAC voltage.

•

Duration:

60 sec.

• No evidence of damage or flash over during test.

Insulation Resistance

To apply rated voltage for max. 120 sec.

>

10GΩ or RxC>500 Ω-F whichever is smaller.

Rated Voltage:

100

~ 500V

To apply rated voltage for 60 sec.

>

10GΩ

Rated Voltage:

> 500V

To apply 500V for 60 sec.

>

10GΩ

Temperature Coefficient

With no electrical load.

T.C.

Operating Temp

NPO (COG)

-55~125°C at 25°C

NPO (COJ)

-55~125°C at 25°C

X7R

-55~125°C at 25°C

X5R

-55~85°C at 25°C

Y5V

-55~85°C at 20°C

T.C.

Capacitance Change

NPO (COG)

Within ± 30ppm/°C

NPO (COJ)

Within ± 120ppm/°C

X7R

Within ± 15%

X5R

Within ± 15%

Y5V

Within +30%/-80%

Adhesive Strength

of Termination

•

Pressurizing force:

0402 & 0603:

5N

>0603:

10N

•

Test time:

10±1 sec.

• No remarkable damage or removal of the terminations.

Vibration Resistance

• Vibration frequency: 10~55 Hz/min.

• Total amplitude: 1.5mm

• Test time: 6 hrs. (Two hrs each in three mutually

perpendicular directions.)

• No remarkable damage.

•

Cap change and Q/D.F.:

To meet initial spec.

SPECIFICATIONS &

RELIABILITY TESTS

14

Item

Test Condition

Requirements

Solderability

•

Solder temperature:

235±5°C

•

Dipping time:

2±0.5 sec.

95% min. coverage of all metalized area.

Bending Test

• The middle part of substrate shall be pressurized

by means of the presurrizing rod at a rate of about

1 mm per second until the deflection becomes 1

mm and then the pressure shall be maintained for

5±1 sec.

• Measurement to be made after keeping at room

temp. for 24±2 hrs.

• No remarkable damage.

• Cap change:

NPO:

within ±5.0% or ±0.5pF whichever is larger.

X7R, X5R:

within ±12.5%

Y5V:

within ±30%

(The capacitance change is measured under specified flexture of the

substrate, versus the capacitance measured before the test).

Resistance to

Soldering Heat

•

Solder temperature:

270±5°C

•

Dipping time:

10±1 sec.

•

Preheating:

120 to 150°C for 1 minute before

immerse the capacitor in a eutectic solder.

•

Before intial measurement (Class II only):

Perform 150+0/-10°C for 1 hr and then set for 48±4

hrs at room temp.

• Measurement to be made after keeping at room

temp. for 24±2 hrs. (Class I) or 48±4 hrs. (Class II).

• No remarkable damage.

• Cap change:

NPO:

within ±2.5% or ±0.25pF whichever is larger.

X7R, X5R:

within ±7.5%

Y5V:

within ±20%

•

Q/D.F., I.R. and dielectric strength:

To meet initial requirements.

Temperature Cycle

• Conduct the five cycles according to the temperatures

and time.

Step Temp. (°C)

Time (min.)

1

Min. operating temp. +0/-3

30±3

2

Room temo.

2

~3

3

Max. operating temp. +3/-0

30±3

4

Room temp.

2

~3

• Before initial measurement (Class II only):

Perform 150+0/-10°C for 1 hr and then set for 48±4

hrs at room temp.

• Measurement to be made after keeping at room

temp. for 24±2 hrs. (Class I) or 48±4 hrs. (Class II).

• No remarkable damage.

•

Cap change:

NPO:

within ±2.5% or ±0.25pF whichever is larger.

X7R, X5R:

within ±7.5%

Y5V:

within ±20%

•

Q/D.F., I.R. and dielectric strength:

To meet initial requirements.

Humidity (Steady State)

•

Test temp.:

40±2°C

•

Humidity:

90~95% RH

•

Test time:

500+24/-0 hrs.

• Measurement to be made after keeping at room

temp. for 24±2 hrs. (Class I) or 48±4 hrs. (Class II).

• No remarkable damage.

•

Cap change:

NPO:

within ±5.0% or ±0.5pF whichever is larger.

X7R, X5R:

>

10V, within ±12.5%

6.3V, within ±25%

Y5V:

within ±30%

•

Q/D.F. Value:

NPO:

Cap

>

30pF, Q

>

350; 10pF

<

Cap<30pF, Q

>

275±2.5C.

Cap<10pF; Q

>

200+10C

X7R, X5R:

Rated Voltage D.F.<

Exception of D.F.<

>50V

3.0%

6.0%

0603>0.047µF; 0805>0.18µF;

1206>0.047µF

25V

5.0%

10.0% 0805>1µF, 1210>10µF

14.0% 0603>0.33µF

16V

5.0%

10.0% 0402>0.033µF; 0603>0.15µF;

0805>0.68µF; 1206>2.2µF

10V

7.5%

15.0%

0402>0.033µF; 0603>0.15µF;

0805>0.68µF; 1206>2.2µF,

TT Series & Cap>1µF

6.3V

15.0%

30.0% 0805>10µF; 1210>100µF

Y5V:

Rated Voltage D.F.<

Exception of D.F.<

>50V

7.5%

---

---

35V

10.0%

---

---

25V

7.5%

<10.0% 0603>0.1µF; 0805>0.33µF;

1206>1µF; 1210>4.7µF

<12.5% 0402>0.068µF

16V (C<1.0µF) 10.0%

<12.5% 0402>0.068µF; 0603>0.68µF

16V (C<1.0µF) 12.5%

---

---

10V

15.0%

---

---

6.3V

30.0%

---

---

• I.R.:

>

10V 1GΩ or 50Ω~F whichever is smaller. 6.3V, 10Ω~F

SPECIFICATIONS &

RELIABILITY TESTS

15

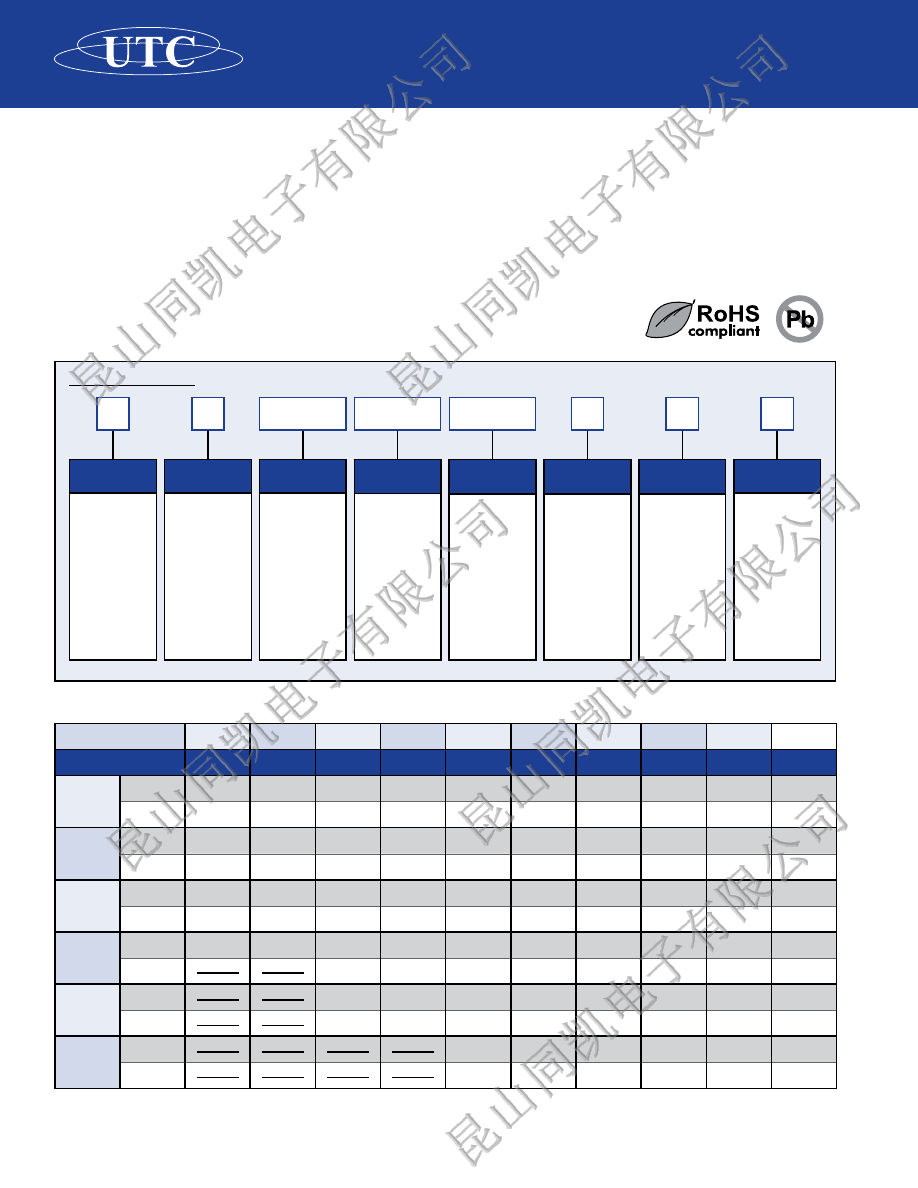

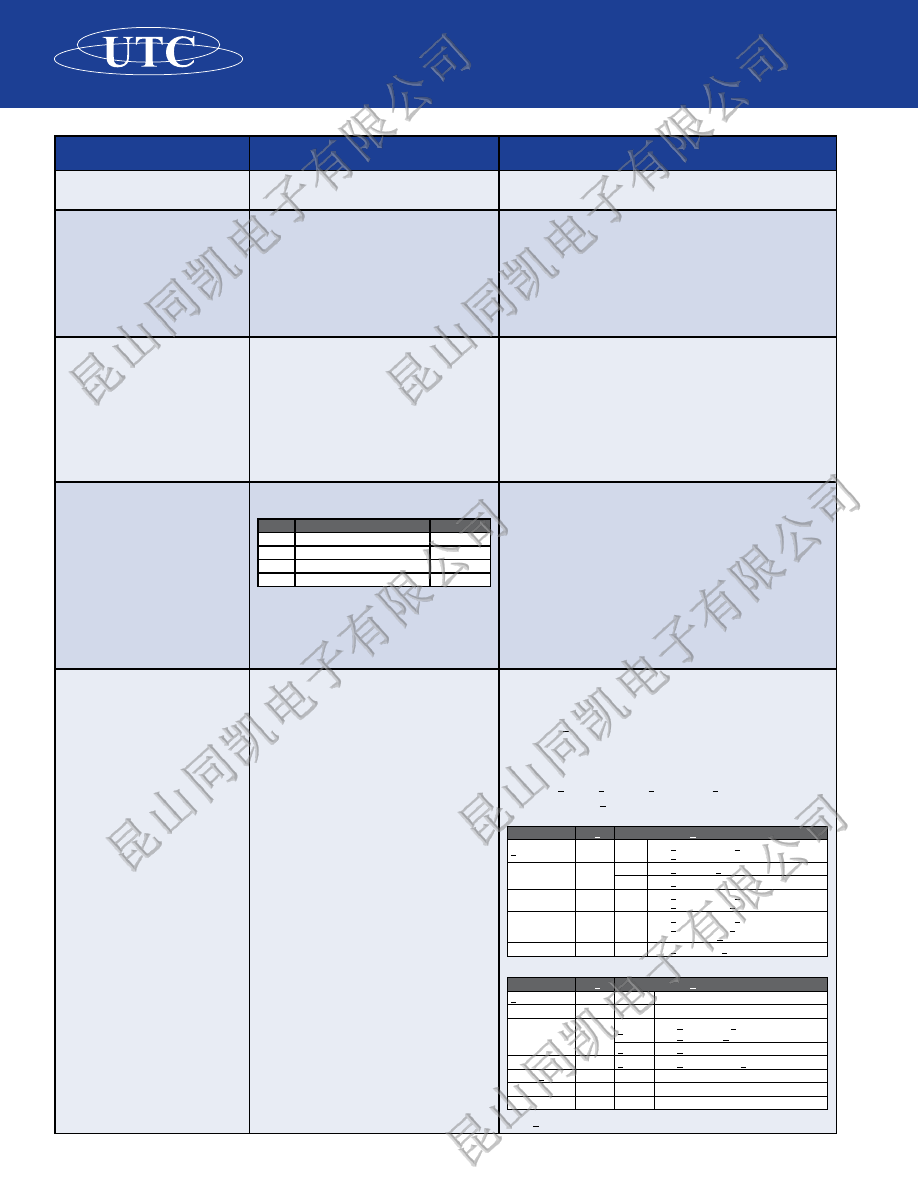

SOLDERING–

ROHS/PB FREE COMPONENTS

The UTC RoHS compliant ceramic chips incorporate

termination bands which are compatible with Pb

Free soldering systems.

PREHEAT CYCLE

The preheat cycle is performed to gradually increase

the component to the higher reflow or wave

solder temperature by minimizing the temperature

differential the component is being exposed to prior

to the reflow cycle beginning.

A higher preheat cycle temperature with wave

soldering can help to reduce thermal shock issues

and can further help if they are preheated from the

bottom side of the board.

REFLOW SOLDER PROFILE

The recommended heating rate will depend on the

body size of each component; however it should not

exceed 3°C / second. While in the reflow phase the

maximum recommended time should not exceed;

40 second time rates @ 230°C. Lastly, the reflow

peak temperature should also not exceed 260°

maximum / 10 seconds. Please refer to the reflow

solder chart for assistance.

WAVE SOLDER PROFILE

Most components that are wave soldered use a

solder at 230°C up to 250°C

Please refer to the charts for guidelines.

COOL DOWN CYCLE

Natural cooling in ambient air is recommended. If

the chips are dipped into a solvent for cleaning,

the temperature difference between the solvent

and the chips must be less than 100°C. This phase

should not be forced, and we recommend a rate

< 6°C / second.

RECOMMENDED

SOLDERING PROFILE

16

25

50

75

100

125

150

175

200

225

250

275

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420

Component Temperature / C°

Time/secs

Preheat

Reflow

Cool Down

Preheat

Reflow

Cool Down

Preheat

Wave

Cool Down

Preheat

Wave

Cool Down

Recommended Pb-Free Reflow

Recommended Soldering

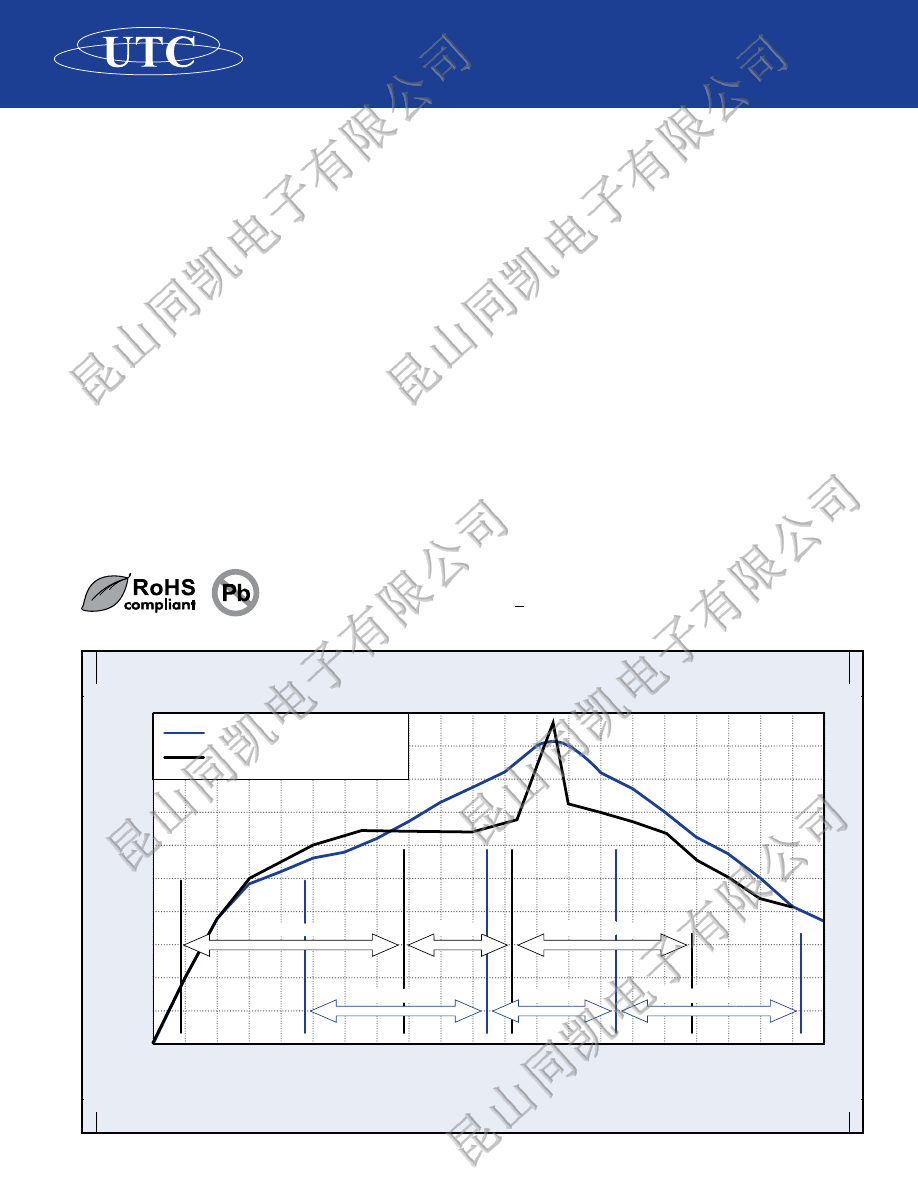

SMPS (Switch Mode Power Supply) Capacitors

Manufactured in accordance with military series DSCC Drawing 87106, 88011, and MIL-PRF-49470 • Standard

capacitance range of .056uF to 270uF • Voltages of 50VDC to 500VDC • Case sizes 1, 2, 3, 4, 5, and 6 with

lead styles N, J, and L

High Voltage Radial Capacitors

Manufactured in accordance with military series DSCC Drawings 87046, 87043, 87040, 87114, 87047, 87076,

87044, 87077, 87070 and 87081 • Standard capacitance range of 10pF-0.47uF • Voltages of 1KV to 10KV

Feed-through Discoidal Capacitors

Manufactured in Outside Diameter (OD) sizes of .070” to .600” • Voltages of 50VDC to 3KV • Please contact

factory for other variations, which include size, voltage, termination, dielectric, or special configuration

Planar Capacitor Array

Manufactured in accordance with MIL-STD-1554, MIL-STD-1560A, MIL-STD-1669 • Style SUB-D, Microstyle

SUB-D in accordance with MIL-C-24308

For more information on these products, contact the factory or visit the UTC website at:

http://www.uniontechcorp.com

MILITARY & CUSTOM PRODUCTS

17

Ordering Terminology

Product Family

Voltage

Physical Size

(See DATA Sheet)

Temperature Characteristic

Capacitance

Tolerance

Testing Level

for SMPS and H.V. Radial Capacitors

P

B

4N1

BX

825

K

B

Termination

for Discoidal and Planar Array

Discoidal:

OD & ID (See DATA Sheet)

Array:

Hole Layout per MIL-STD

Note:

This chart outlines the additional UTC product part numbering but please refer to the specific literature for complete information.

Product Family

P = SMPS Capacitors

H = High Voltage

Radial Capacitors

D = Discoidal

A = Planar Array

Voltage

G = 50V

B = 100V

R = 200V

S = 500V

T = 1000V

W = 2000V

X = 3000V

Y = 4000V

Z = 5000V

Temperature

Characteristic

DSCC

EIA

BX

BR

BG

BP

X7R

X7R

X7R

NPO

(COG)

Tolerance

J = ±5 %

K = ±10%

M = ±20%

V = GMV

Z = +80/-20%

Testing Level

A = Electrical

Screening Only

B = MIL-PRF-39014

Group A

C = MIL-PRF-39014

Group B

Termination

P =

Platinum Silver

MILITARY & CUSTOM PRODUCTS

18

UNION TECHNOLOGY CORP.

718 MONTEREY PASS RD., MONTEREY PARK, CA 91754

TEL: (323) 266-6603 FAX: (323) 266-7890

Email: info@uniontechcorp.com

http://www.uniontechcorp.com

Printed in U.S.A.

Catalog 1004