Why Cooltron Heat Sinks

for High Power LED Lighting?

By Steven Chiang

Why Cooltron Heat Sinks

for High Power LED Lighting?

By Steven Chiang

2

- Cooltron Worldwide Business Partners

- Cooltron Full Line Heat Sink Assembly Products

- Design & CFD Simulation Capabilities

- Custom Design & Build Capabilities

- Extensive Thermal Product Design and Manufacturing

Experiences

- Industry Leading Heat Sink Technologies

- Industry’s Most Complete Manufacturing Facilities

- Custom Solutions & Total Solutions Provider

- Cooltron’s Focused LED Lighting Heat Sink Markets

- Cooltron’s Other Heat Sink Application Markets

Table of Contents

3

Why Cooltron? (1/8) – World Class Supply Chain Partners

4

•

LED High Bay Lights (20’ High+): 70W/100W/150W/200W

•

LED Flood Lights: 100W/200W/300W/400W/500W

•

LED Grow Lights: 100W/300W/400W/500W/600W

•

Modular LED Street/Area Lights: 30W/50W per unit module

Cooltron Full Line LED Lighting Heat Sink Assembly

Why Cooltron? (2/8) – Cooltron Full Line Heat Sink Assembly Products

5

Why Cooltron? (3/8) – Design & CFD Simulation Capabilities

100W COB LED High Bay Light Heat Pipes Module (Cold-Forged Heat Sink + Heat Pipes)

100W/160W/240W SMD LED High Bay Light (Stamped Heat Sink + Die-Casted LED Driver Case

6

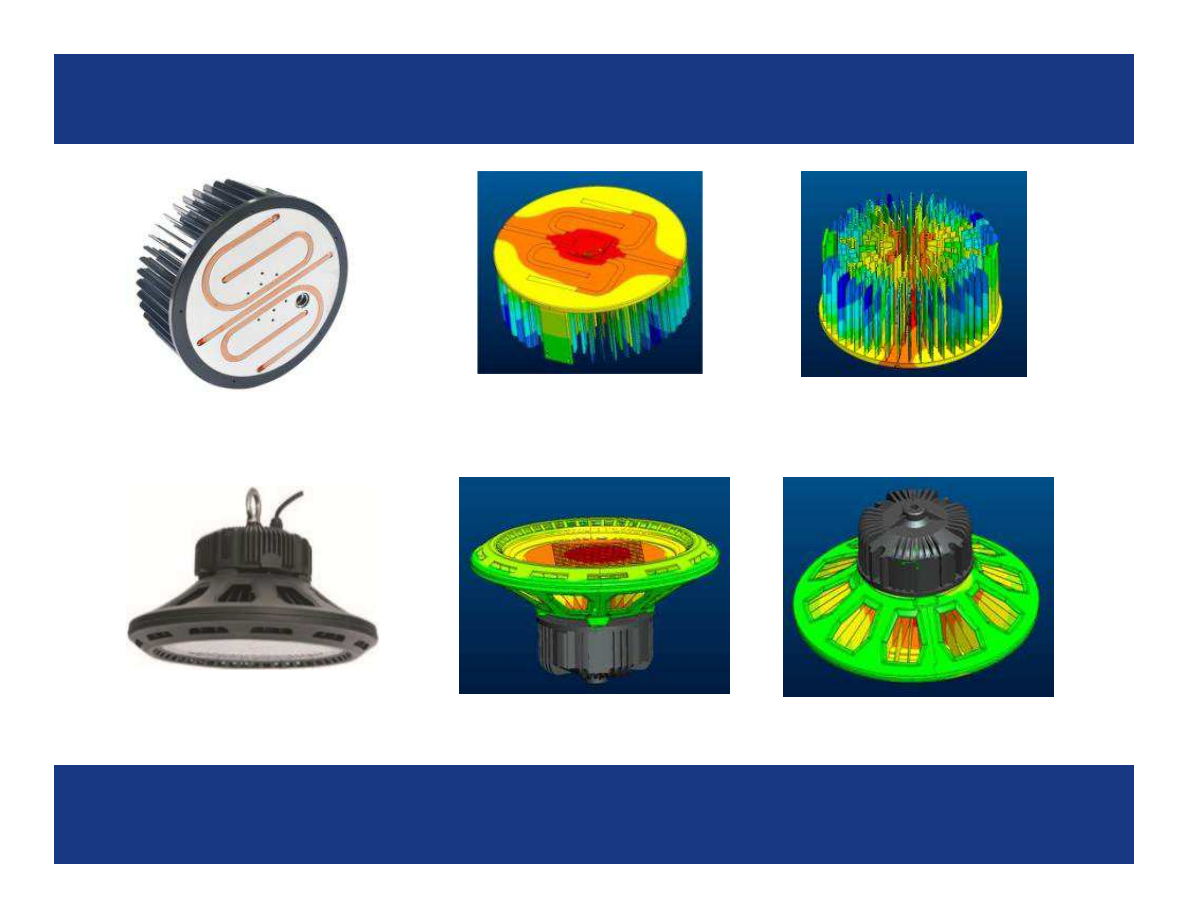

Why Cooltron? (4/8) – Custom Design and Build Capabilities

Cooltron’s

600W

Grow Light PCB Temperature

15

0

C Lower

Than Other Brand’s 300W

7

Why Cooltron? (5/8) – Extensive Application Design & Manufacturing Experiences (a)

•

Telecom: Cellular Phone Tower Power Amplifier

Chassis & Thermal Solution

8

Why Cooltron? (5/8) – Extensive Application Design & Manufacturing Experiences (b)

•

Audio Power Amplifier Chassis & Thermal Solution

9

Why Cooltron? (6/8) – Industry-leading Heat Sink Technologies

Patented Flat & Tight Heat Pipes Embedding Technologies

•

Over

150 Heat Pipes Patents

registered in USA, Germany, Japan, Taiwan

and China

•

Patented

Flat & Tight Heat Pipes Embedding, Riveting, Engaging

Technologies Reduce Thermal Resistance to Minimum

for Best Heat Dissipation Effects

Telecom VGA Graphic

LED Grow Light

COB LED Light

10

Why Cooltron? (7/8) – Industry’s Most Complete Heat Sink Manufacturing Facilities (a)

Extrusion

Progressive Stamping

Forging Machines (300 tons ~ 5000 tons)

Skiving Machines

11

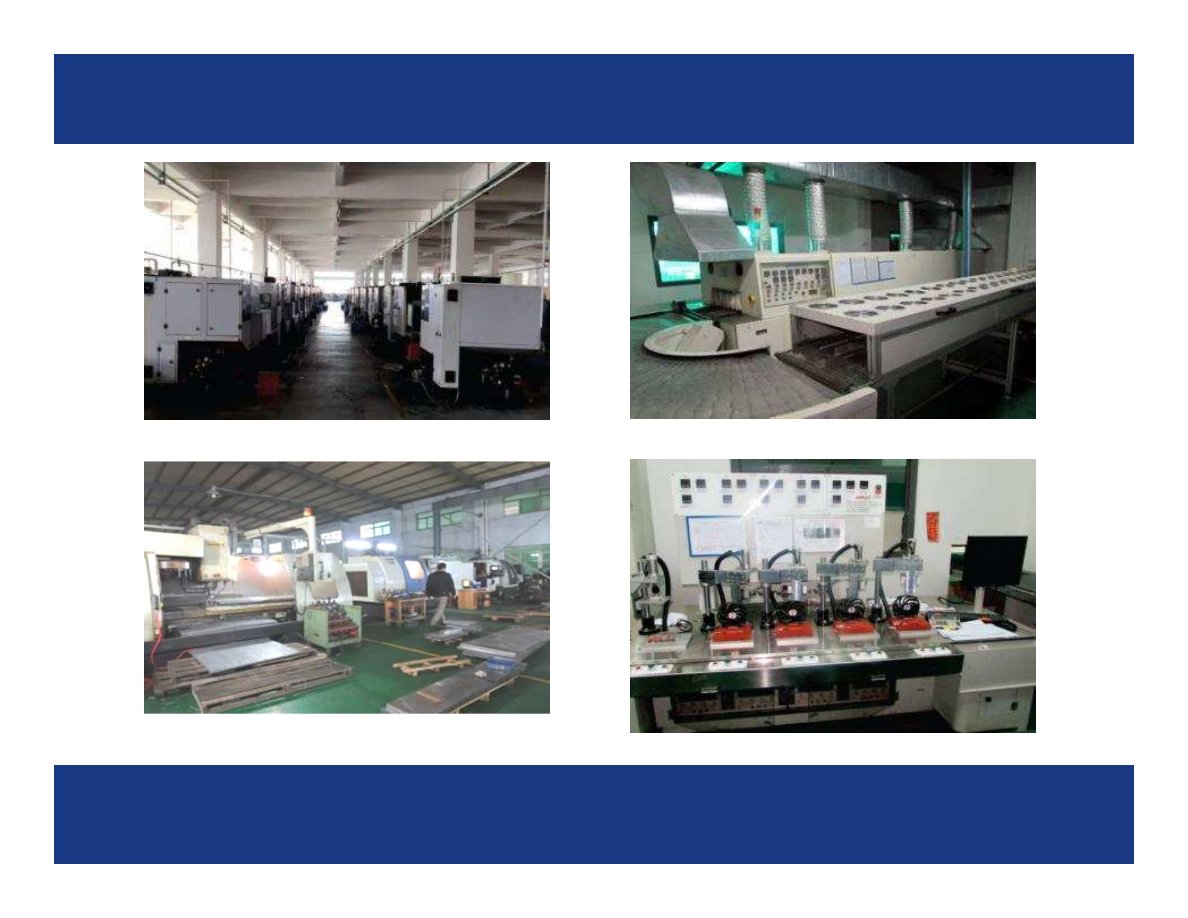

Why Cooltron? (7/8) – Industry’s Most Complete Heat Sink Manufacturing Facilities (b)

CNC Machines

Bonding Machine

Surface Treatment

Thermal Resistance Tester

12

Why Cooltron? (8/8) – Custom Solutions & Total Solutions Provider

•

Custom Solutions & Total Solutions Provider

-

Cooltron is one of very few providers in industry able to provide

customization and total heat sink solutions, starting from market &

product positioning, custom designs, simulation, till manufacturing

•

Industry-Leading Tomorrow Technologies

-

Cooltron’s patented technologies, such as phase-change super-

heat-conductor, and cold-forging, heat pipes embedding, and etc.,

help customers stay ahead of market competition

•

World Class Customers OEM/ODM Manufacturing

Experiences

-

Cooltron assures the products quality for its many years of OEM/ODM

manufacturing experiences with World Class customers in industry and

EMS/CM channel as well

13

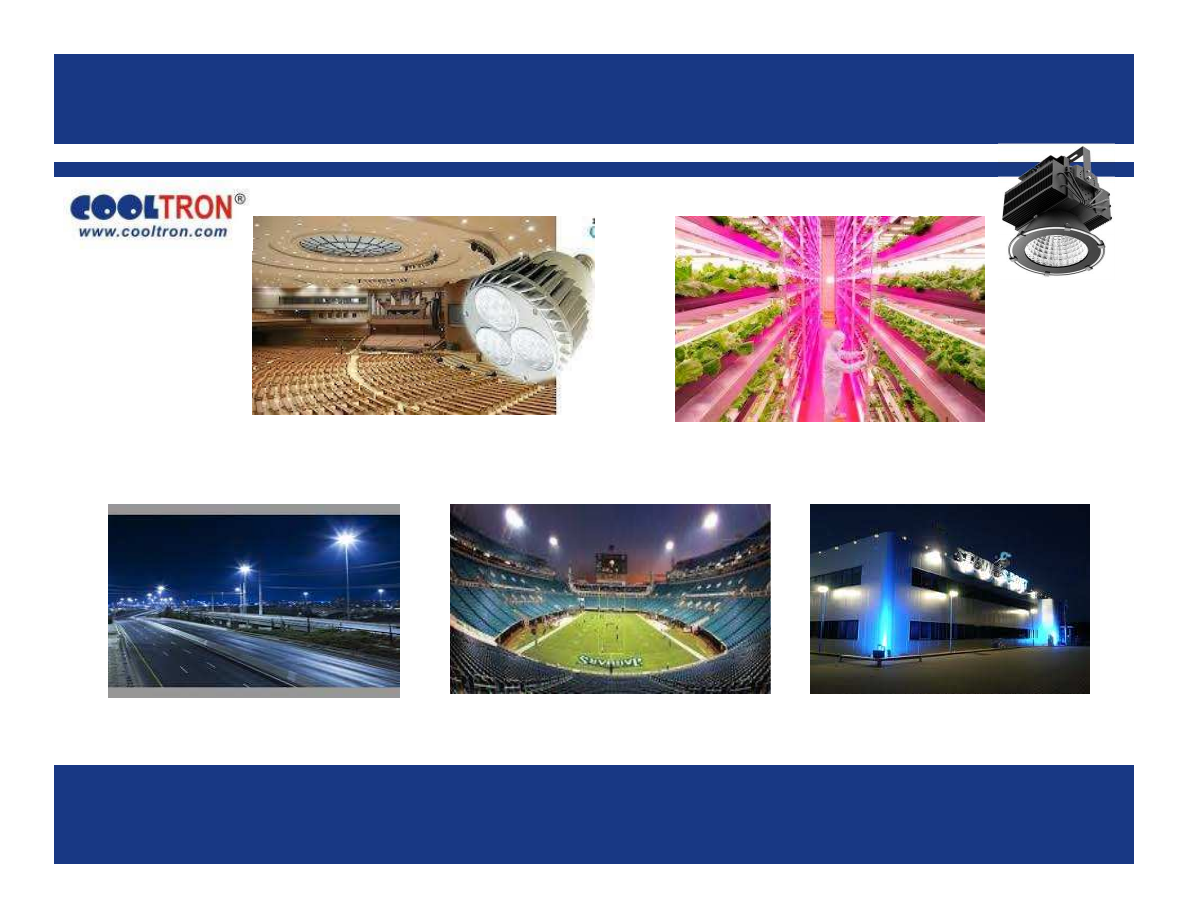

Cooltron Focused LED Lighting Heat Sink Markets

#3 Agricultural LED Grow Light

#1 Commercial LED Lighting

#2 High Power LED Lighting

14

Cooltron Other Heat Sink Application Markets

Networking

Power Supply

Solar Power Inverter

Medical Device

Telecom

15

Let’s achieve win-win!

+

You

=

Success