Catalog 43

131 Radio Circle, Mount Kisco, NY 10549

800.882.8020

n

914.666.2911

n

Fax: 914.666.0216

Made in USA

001.914.666.2911

www.zierick.com

3

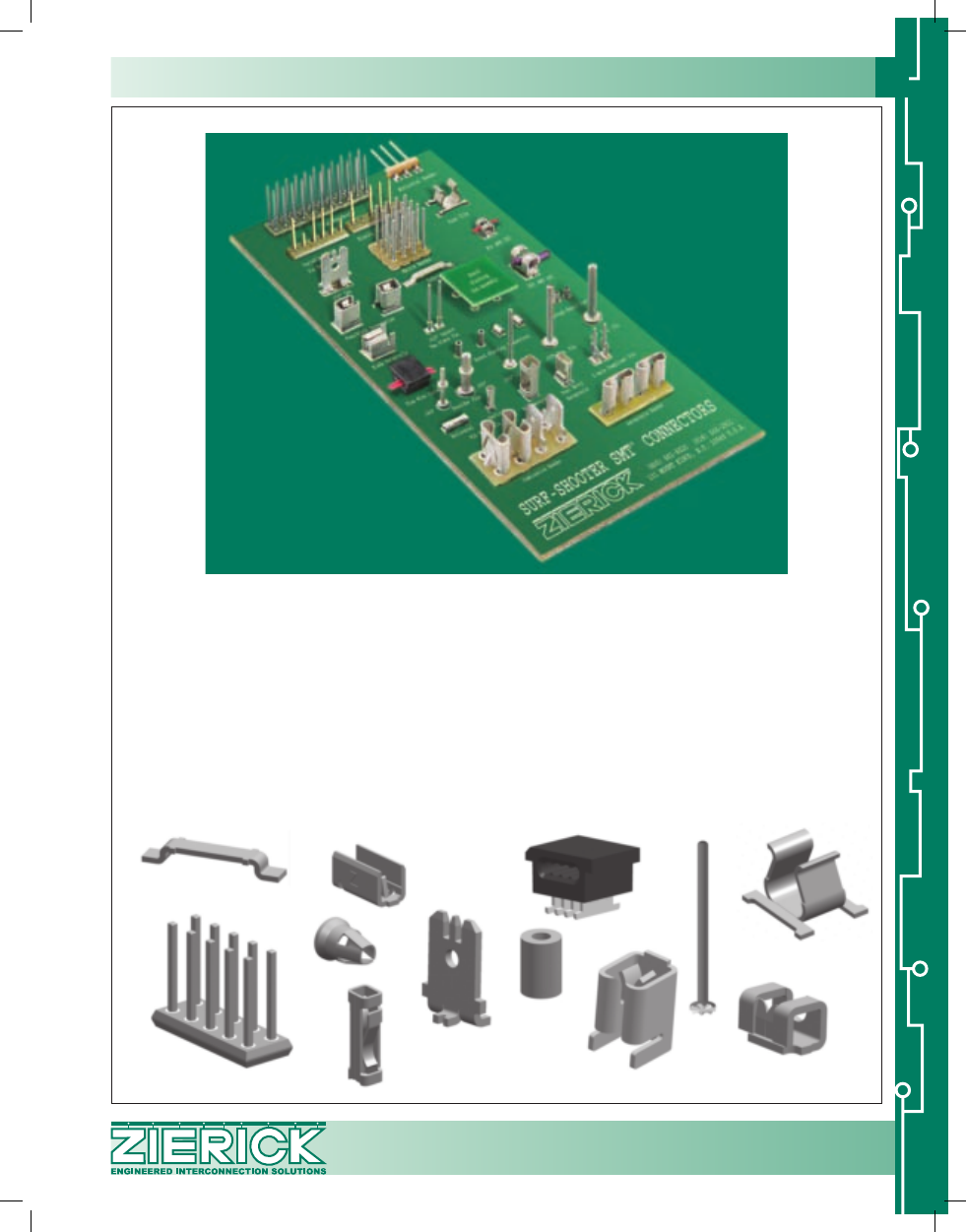

Surface Mount Connectors

As the industry’s first surface-

mountable connectors to be

supplied on a continuous reel,

our surface mount connectors are

designed to be used as part

of Zierick’s

Surf-Shooter SMT™

(

Surface Mount Technology

) assembly

system to simplify and reduce the

cost of surface mount assembly.

The complete

Surf-Shooter SMT™

system (

consisting of connectors

supplied on a continuous reel and

a special feeder

) feeds, separates, and

presents the continuous format,

surface-mountable connectors to

the pick-up head of the customer’s

existing placement system.

The continuous format design

of the stamped SMT connectors

eliminates the need for hand

placement or prepackaging that

is typically used for surface mount

connectors. It eliminates the need

for putting the Zierick component

in tape and reel, which costs

more than the price of the

component itself. Even odd-form

components can be fed to the

customer’s placement system on

continuous reels, eliminating

hand assembly.

63259 Zierick Cat.indd 3

10/30/12 1:33 PM