Bulletin No

I02 EB0

(Jul,2000)

K DIC218

SANKEN ELECTRIC COMPANY LTD.

1-11-1 Nishi -Ikebukuro,Toshima-ku, Tokyo

PHONE: 03-3986-6164

FAX: 03-3986-8637

TELEX: 0272-2323(SANKEN J)

Overseas Sales Offices

●

Asia

SANKEN ELECTRIC SINGAPORE PTE LTD.

150 Beach Road #14-03,

The Gateway, West Singapore 0718, Singapore

PHONE: 291-4755

FAX: 297-1744

SANKEN ELECTRIC HONG KONG COMPANY LTD.

1018 Ocean Centre, Canton Road,

Kowloon, Hong Kong

PHONE: 2735-5262

FAX: 2735-5494

TELEX: 45498 (SANKEN HX)

SANKEN ELECTRIC KOREA COMPANY LTD.

SK Life B/D 6F,

168 Kongduk-dong, Mapo-ku, Seoul, 121-705, Korea

PHONE: 82-2-714-3700

FAX: 82-2-3272-2145

●

North America

ALLEGRO MICROSYSTEMS, INC.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615, U.S.A.

PHONE: (508)853-5000

FAX: (508)853-7861

●

Europe

ALLEGRO MICROSYSTEMS EUROPE LTD.

Balfour House, Churchfield Road,

Walton-on-Thames, Surrey KT12 2TD, U.K.

PHONE: 01932-253355

FAX: 01932-246622

PRINTED in JAPAN H1-I02EB0-0007020ND

Motor Driver ICs

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

1

Contents

Contents

Motor Driver ICs

Selection Guide

........................................................................................................................................ 2

Product Index by Part Number .....................................................................................

3

Notes on SLA7000/SMA7000 Series

Features/Applications/Handling Precautions/Constant Current Chopper Method .............................. 4

2-Phase Stepper Motor Unipolar Driver ICs

2-Phase Excitation

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M ............................................................................... 5

SMA7036M ............................................................................................................................................. 12

2-Phase/1-2 Phase Excitation

SLA7027MU/SLA7024M/SLA7026M .................................................................................................... 20

SLA7032M/SLA7033M .......................................................................................................................... 28

SDK03M ................................................................................................................................................. 36

UCN5804B ............................................................................................................................................. 42

2W1-2 Phase Excitation/Micro-step Support

SLA7042M/SLA7044M .......................................................................................................................... 44

Serial Signal Generator IC for SLA7042M and SLA7044M

PG001M ................................................................................................................................................. 48

2-Phase Stepper Motor Bipolar Driver ICs

2-Phase/1-2 Phase Excitation

A3966SA/SLB ........................................................................................................................................ 54

A3964SLB .............................................................................................................................................. 58

A3953SB/SLB ........................................................................................................................................ 60

A2918SW ............................................................................................................................................... 68

A3952SB/SLB/SW ................................................................................................................................. 70

2-Phase/1-2 Phase/W1-2 Phase Excitation

UDN2916B/LB ....................................................................................................................................... 78

UDN2917EB ........................................................................................................................................... 84

2W1-2 Phase Excitation/Micro-step Support

A3955SB/SLB ........................................................................................................................................ 88

4W1-2 Phase Excitation/Micro-step Support

A3957SLB .............................................................................................................................................. 94

3-Phase Stepper Motor Driver ICs

Star Connection/Delta Connection

SI-7600/SI-7600D ................................................................................................................................... 98

5-Phase Stepper Motor Driver ICs

Pentagon Connection

SI-7502

(SLA5011/SLA6503)

................................................................................................................... 104

List of Discontinued Products

....................................................................................................... 110

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

2

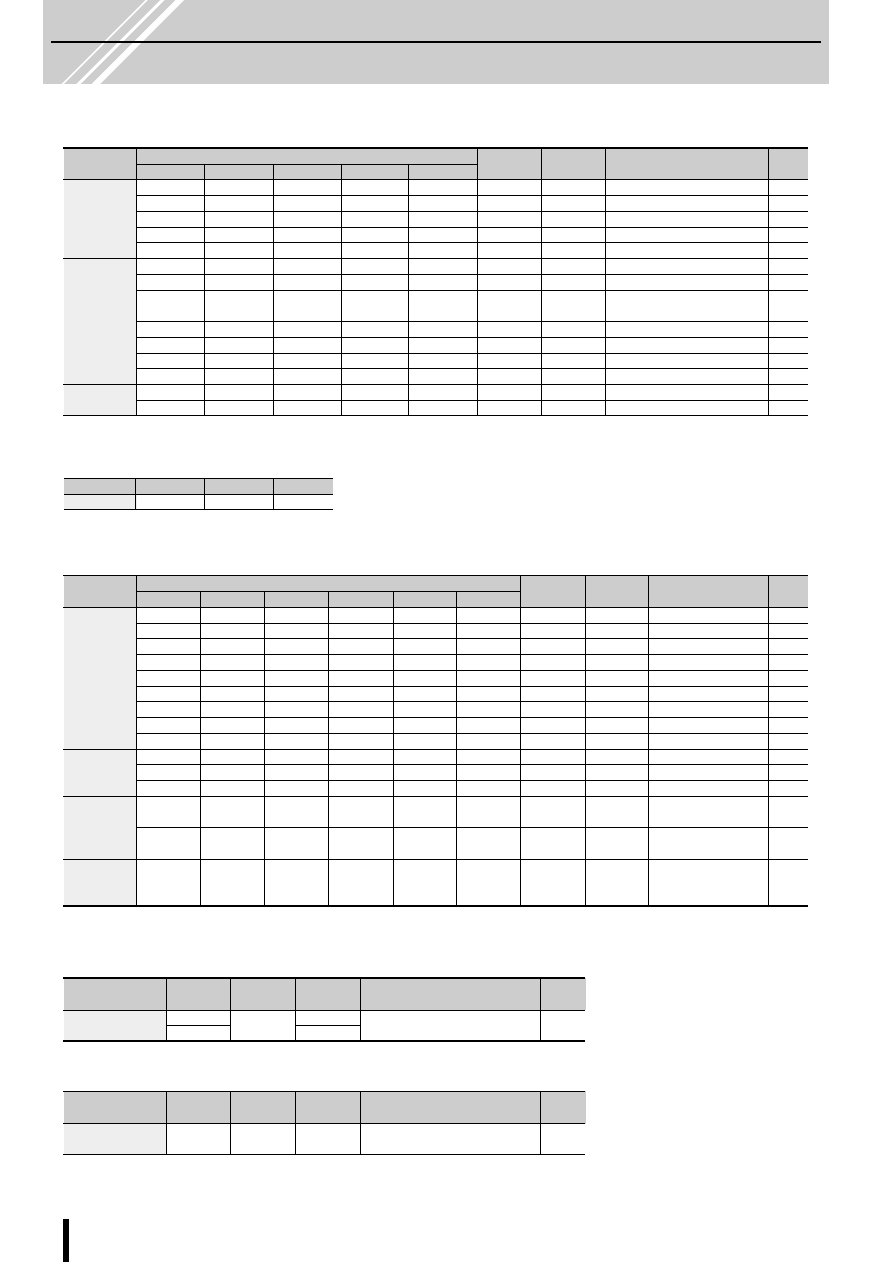

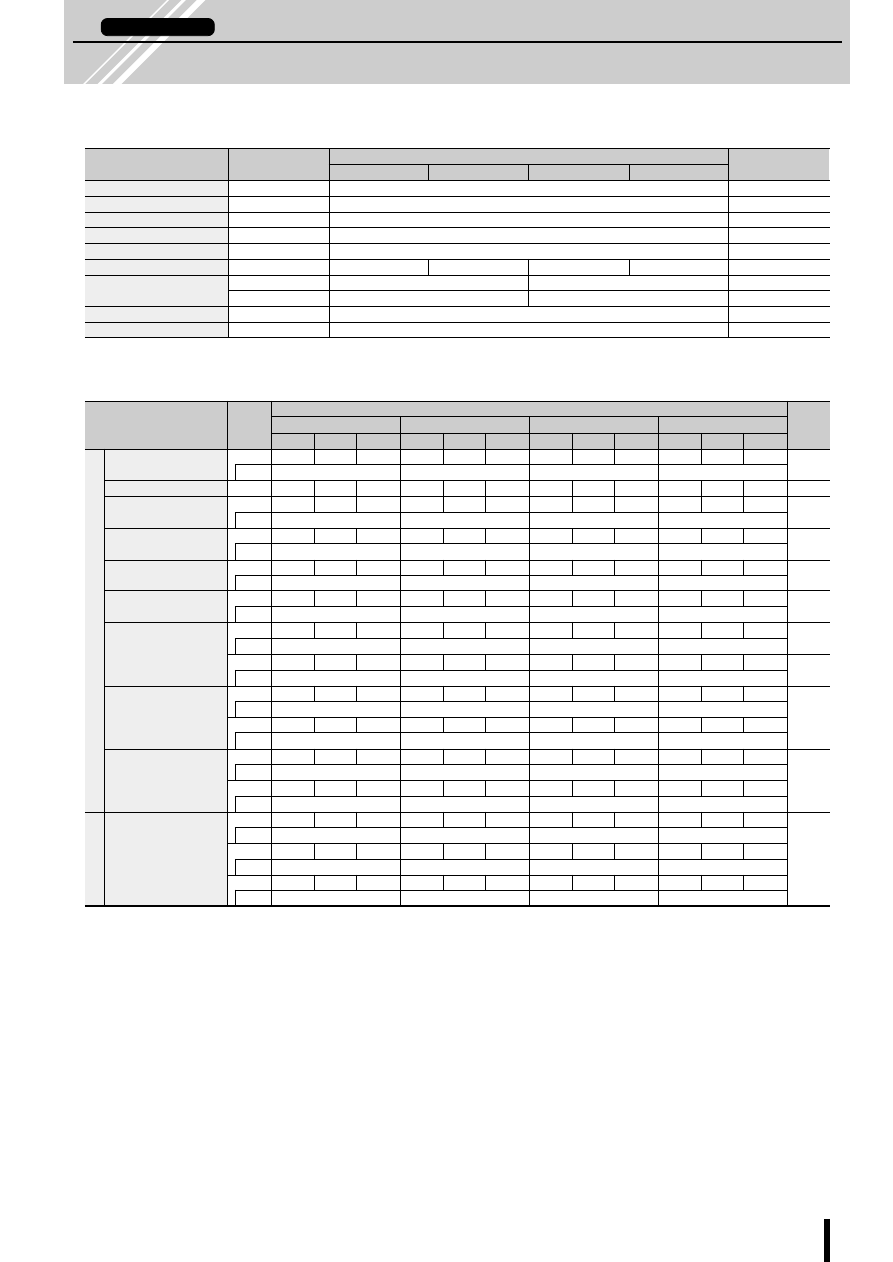

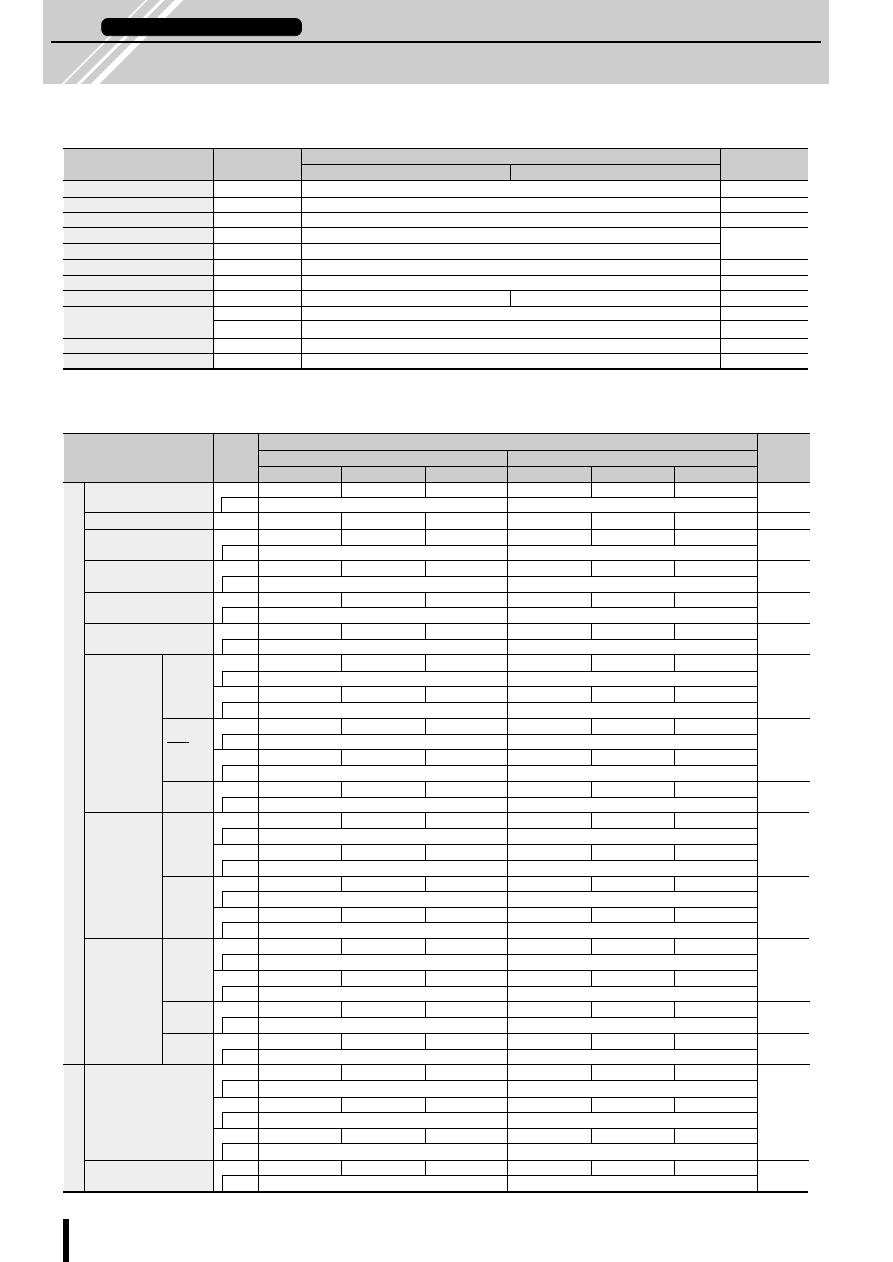

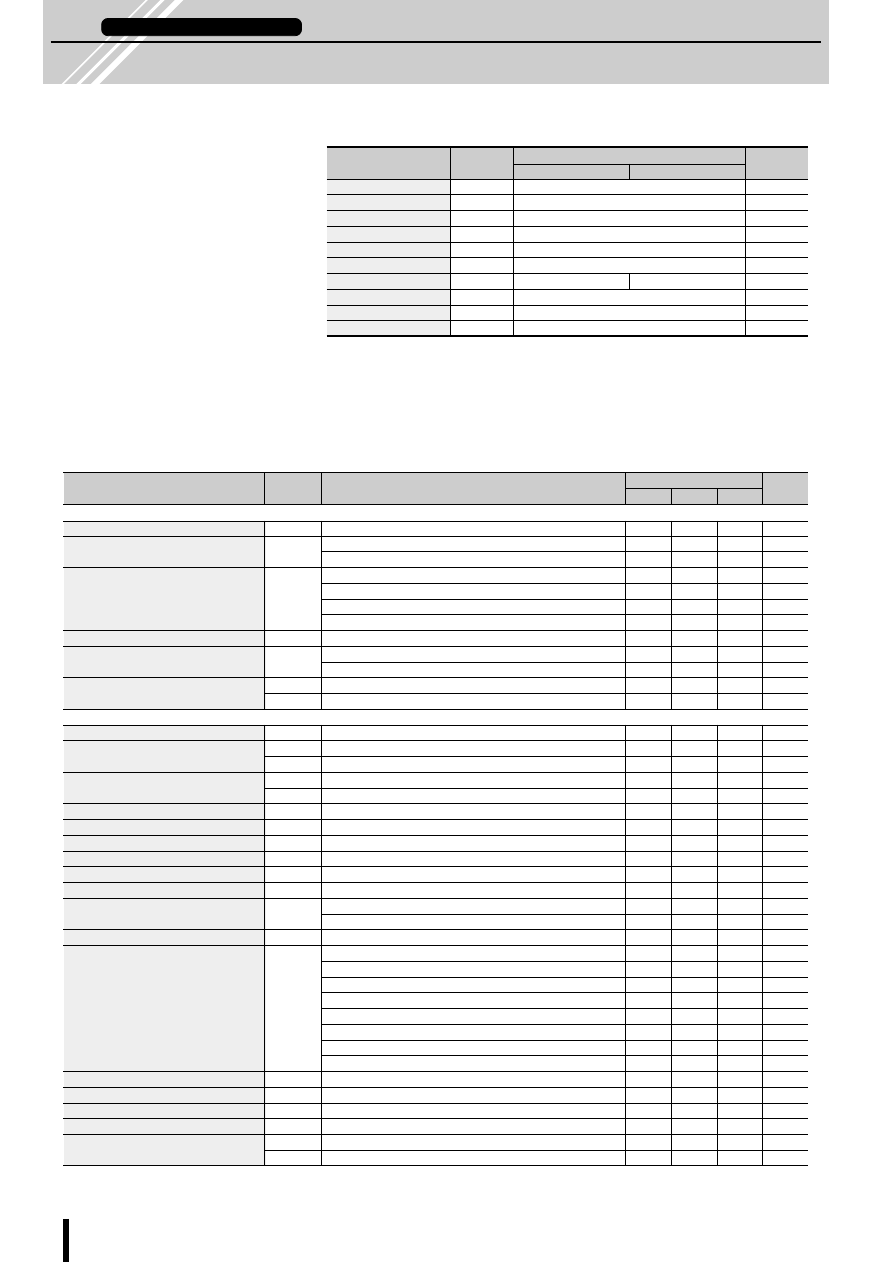

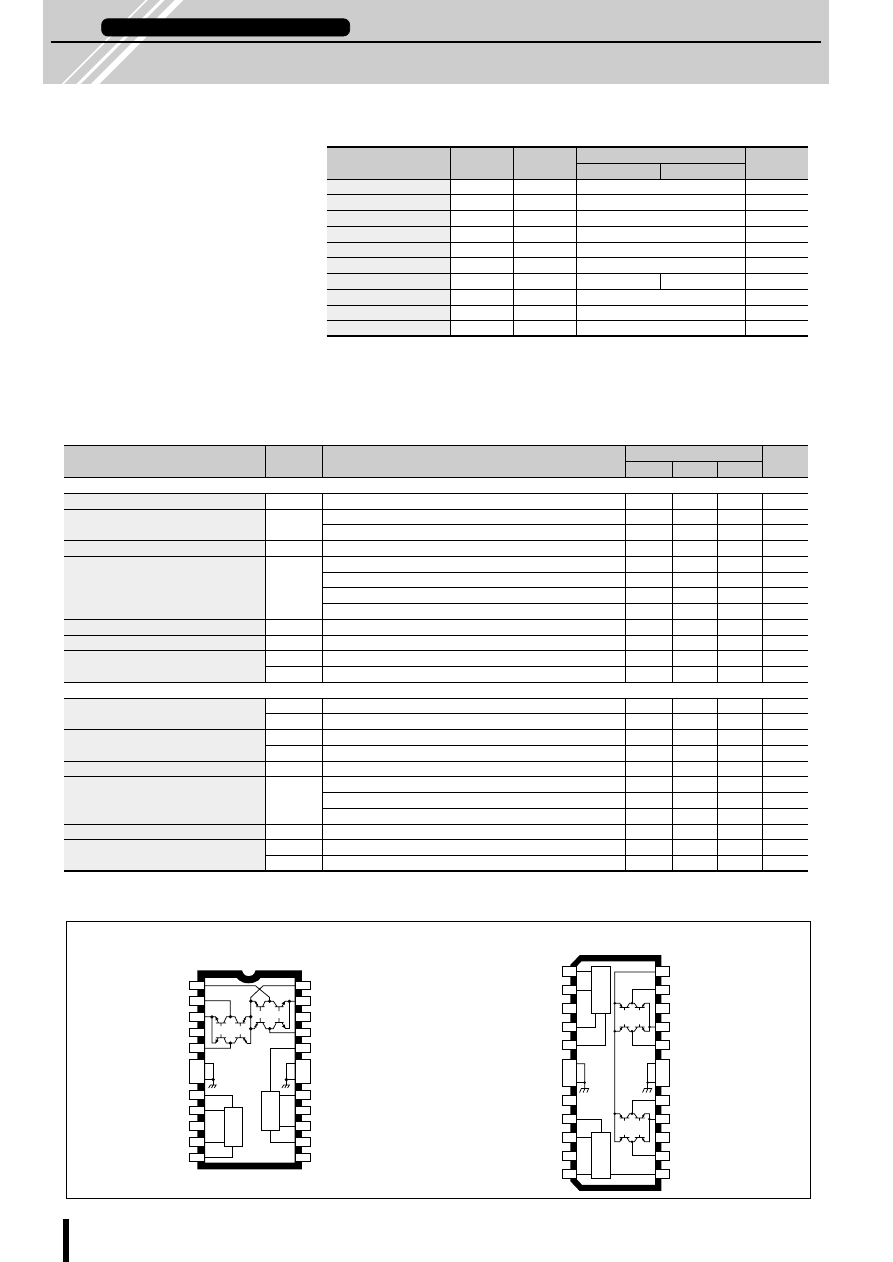

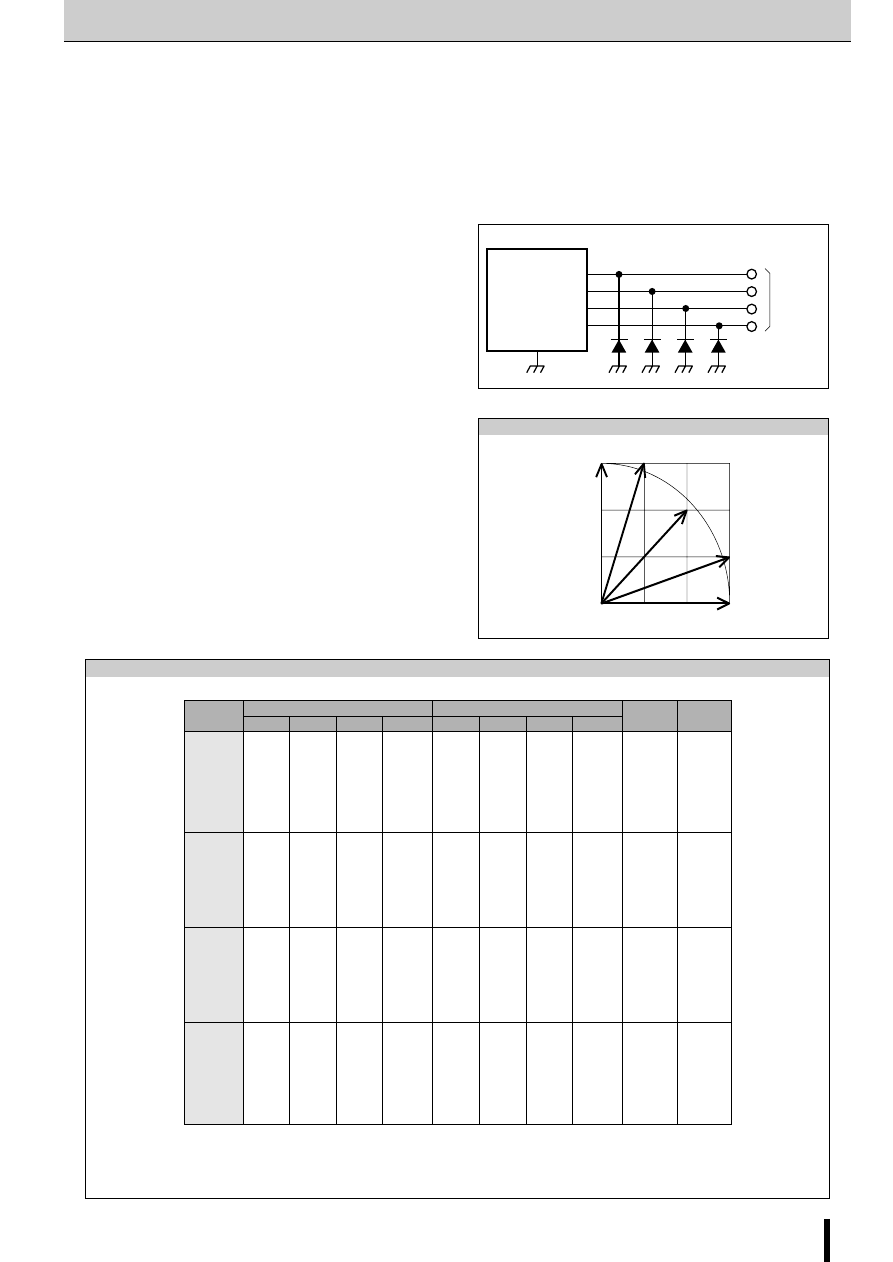

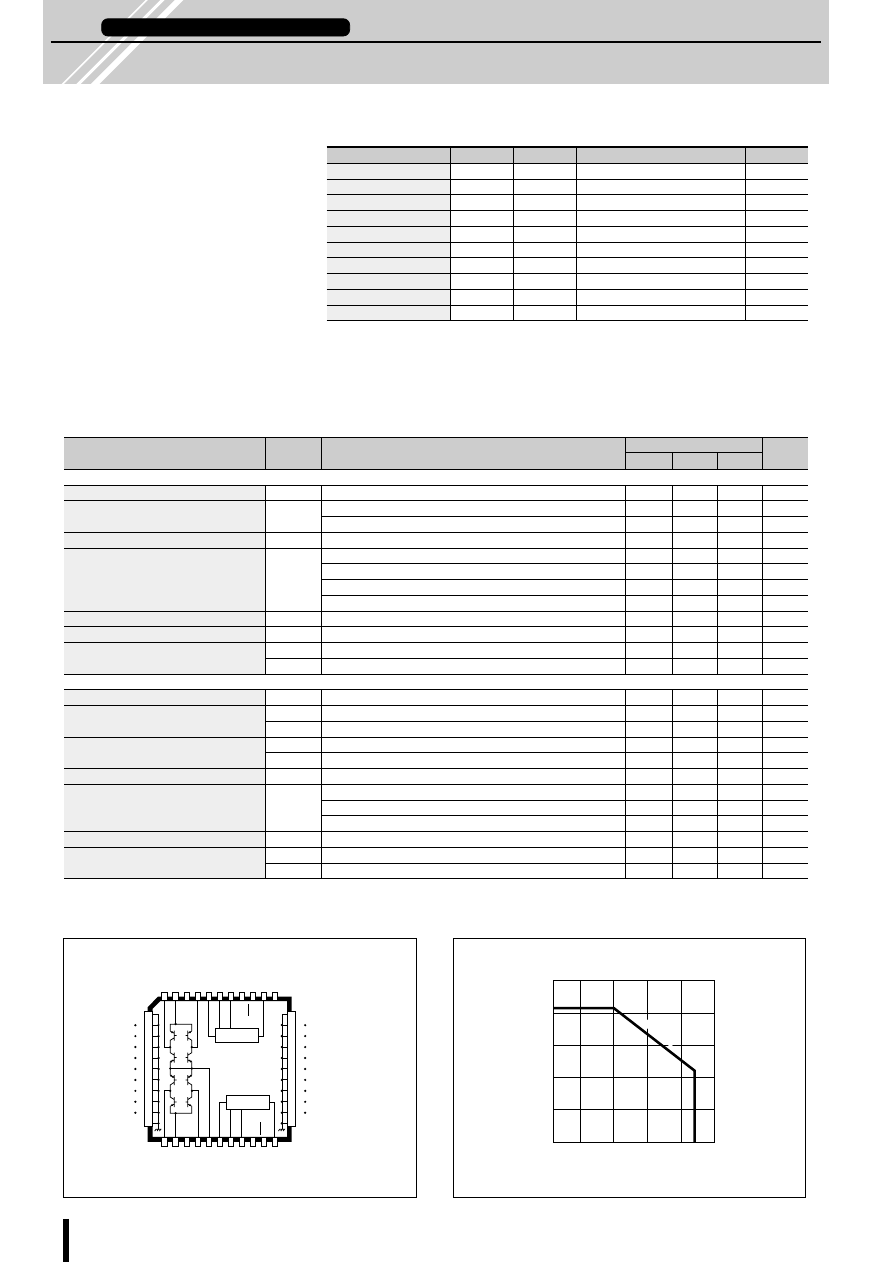

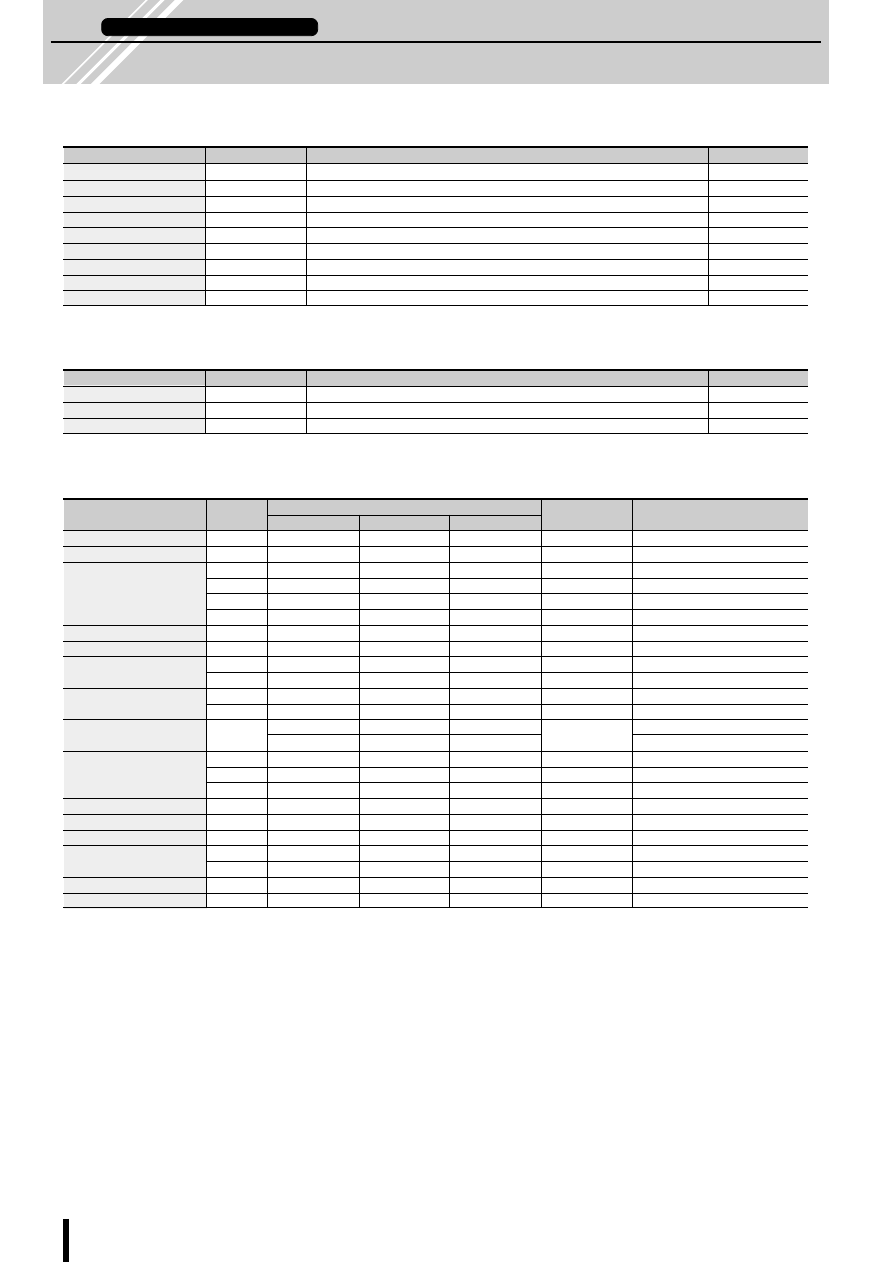

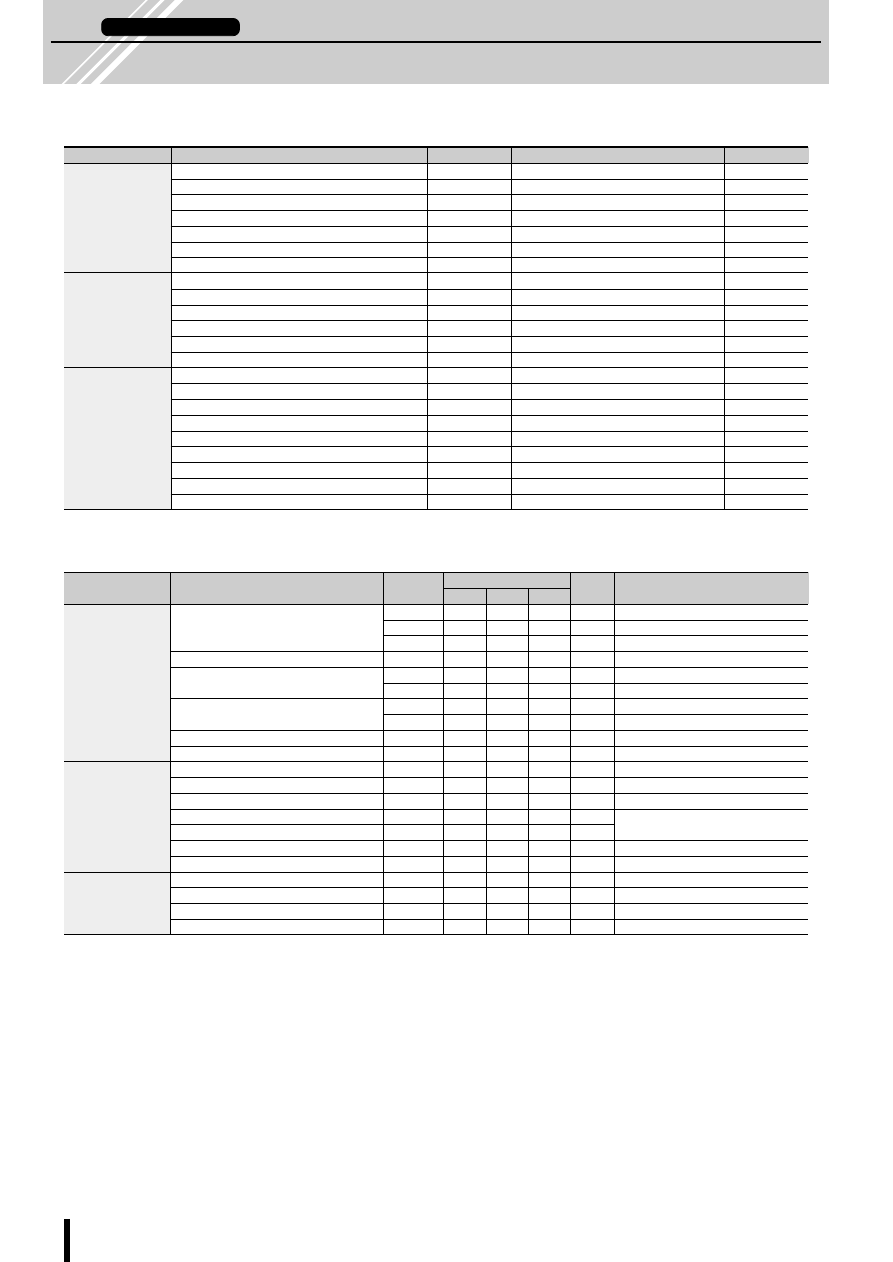

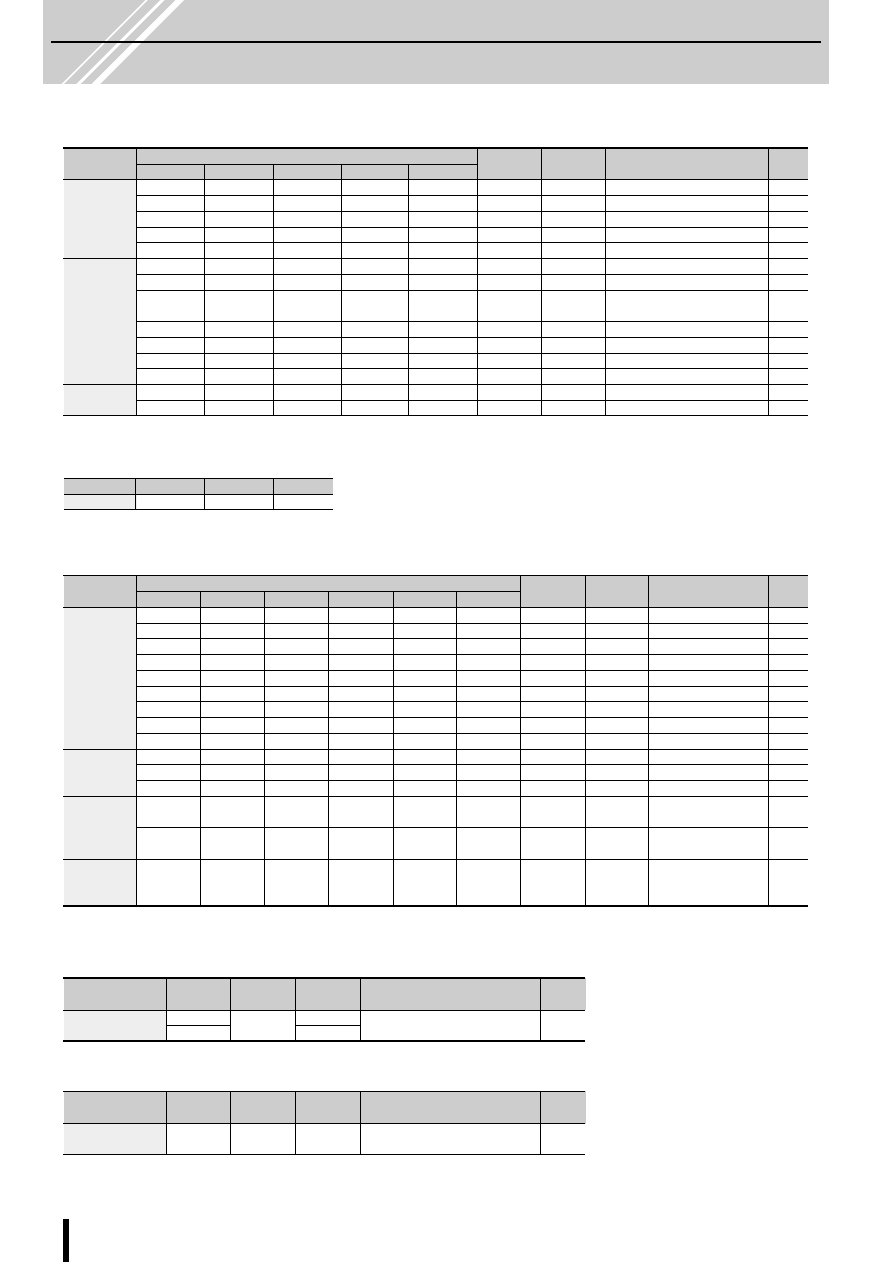

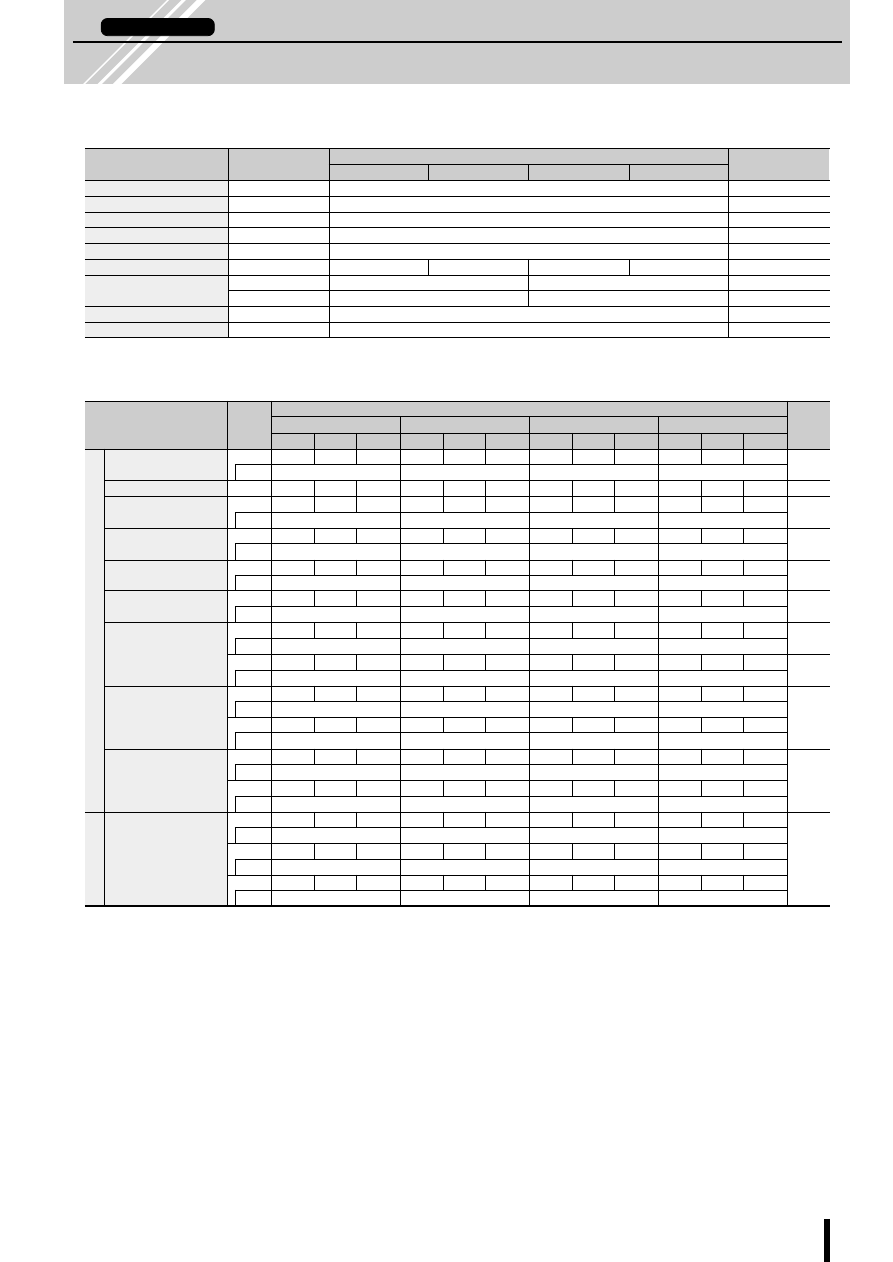

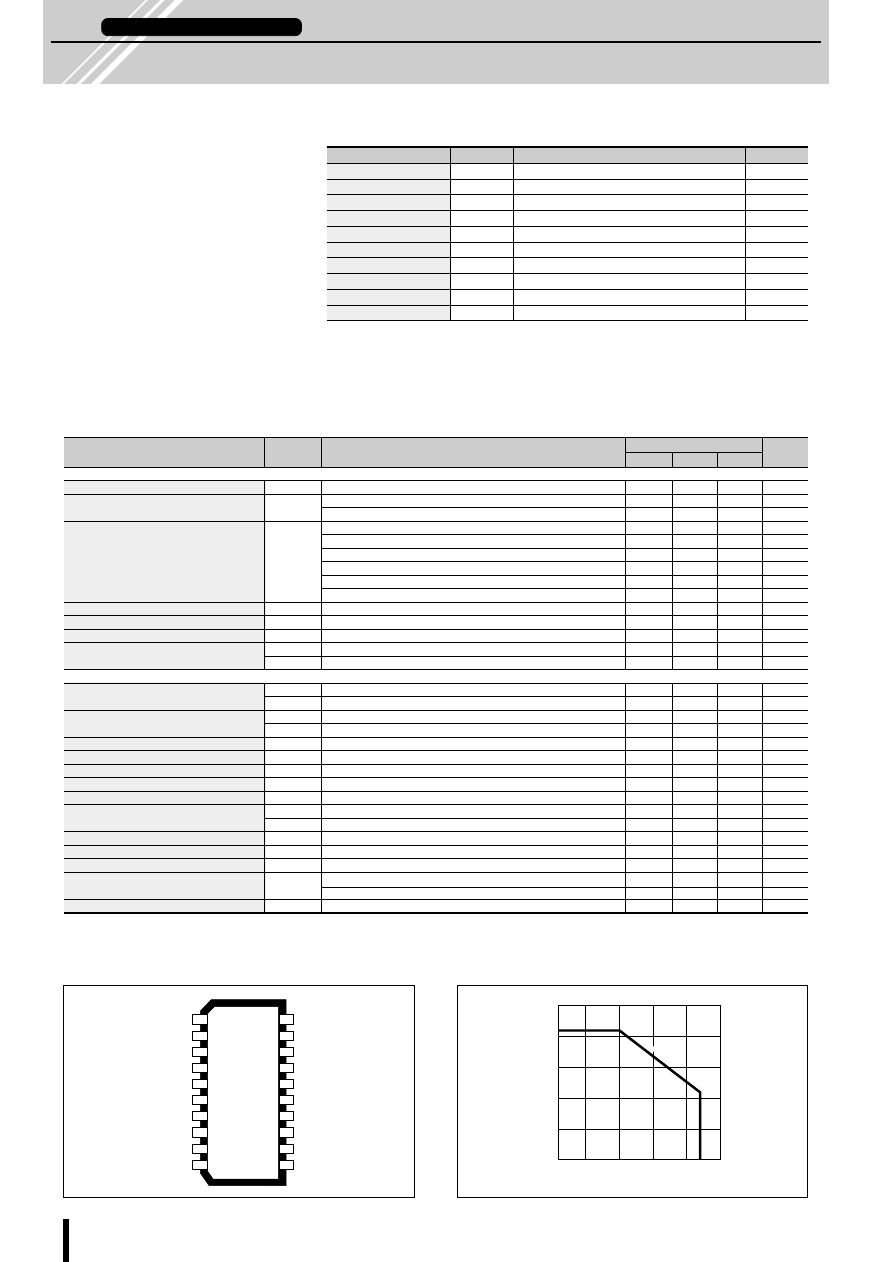

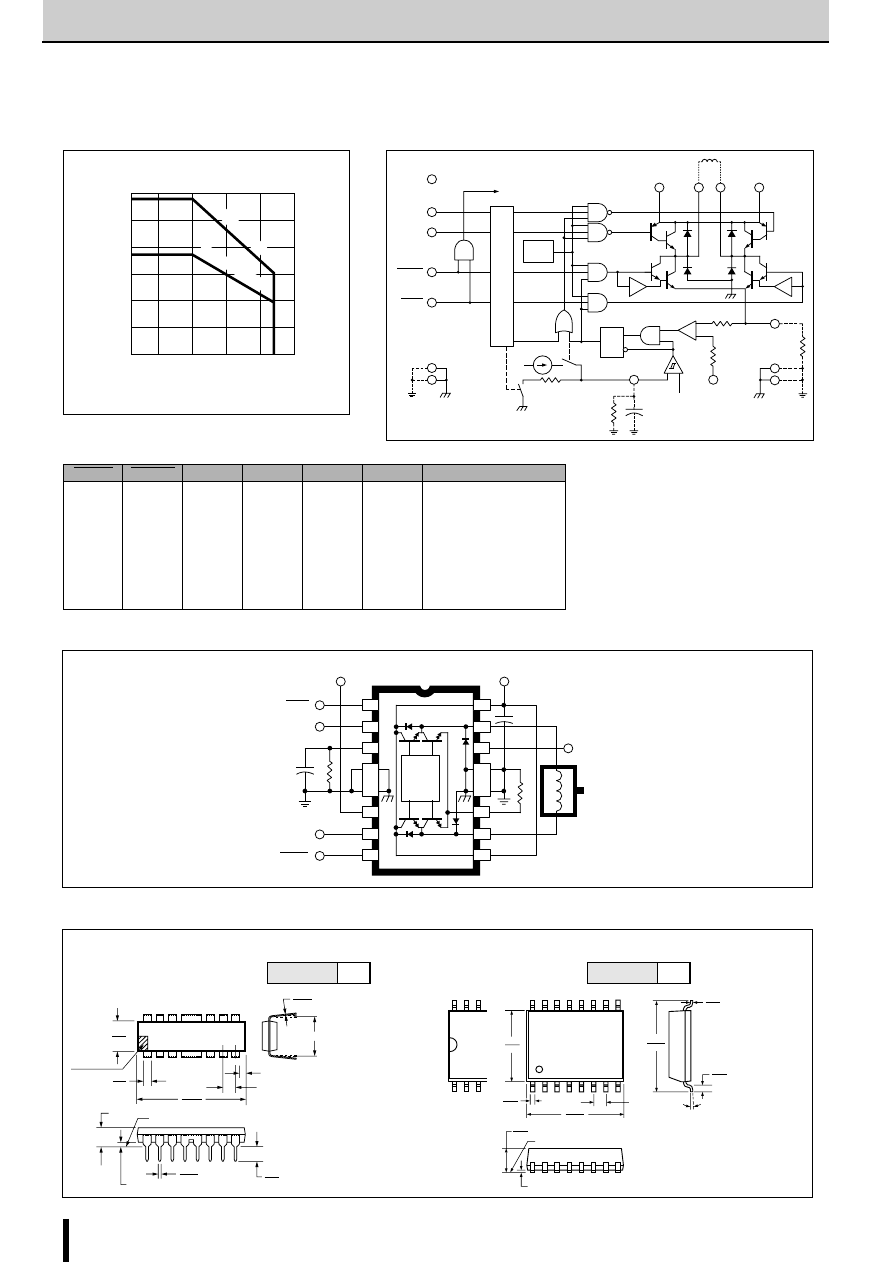

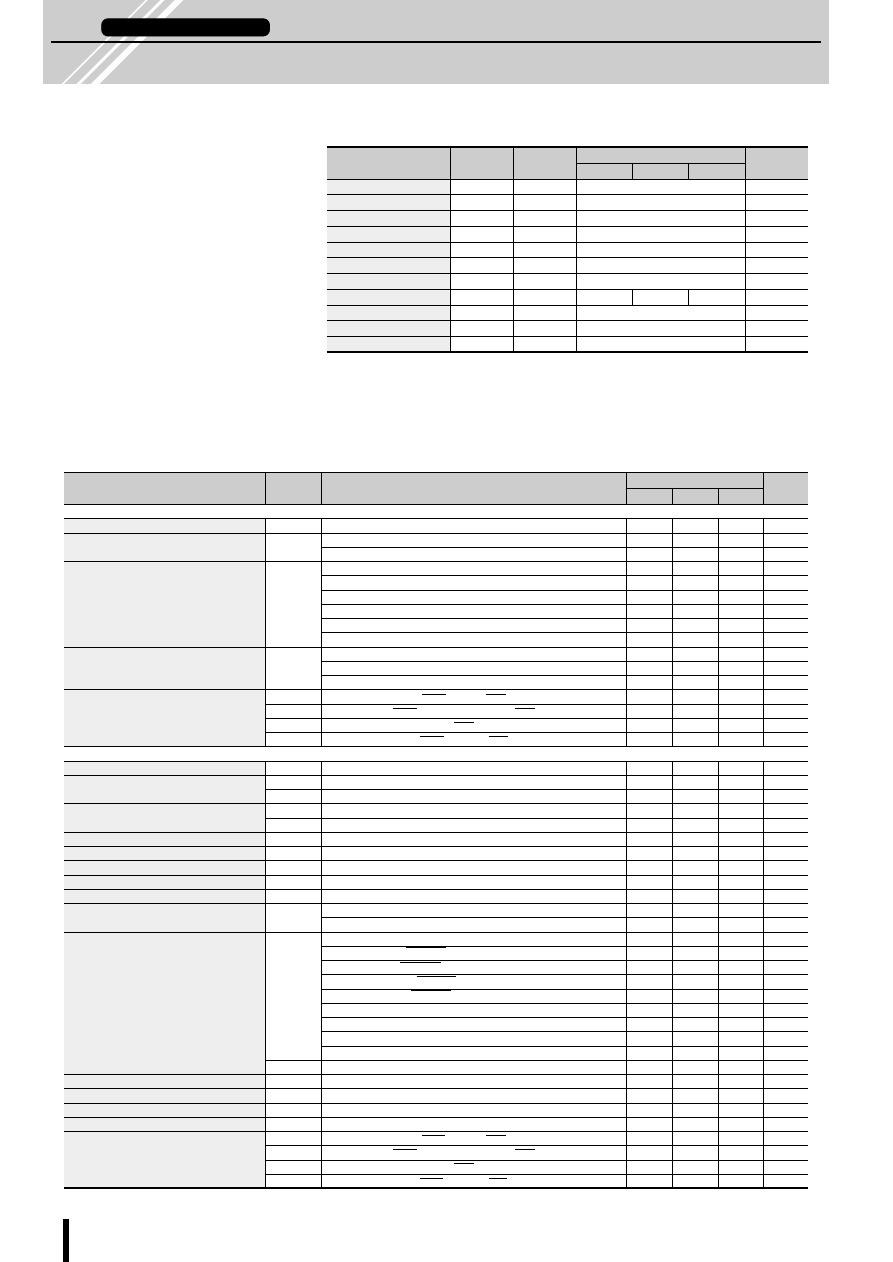

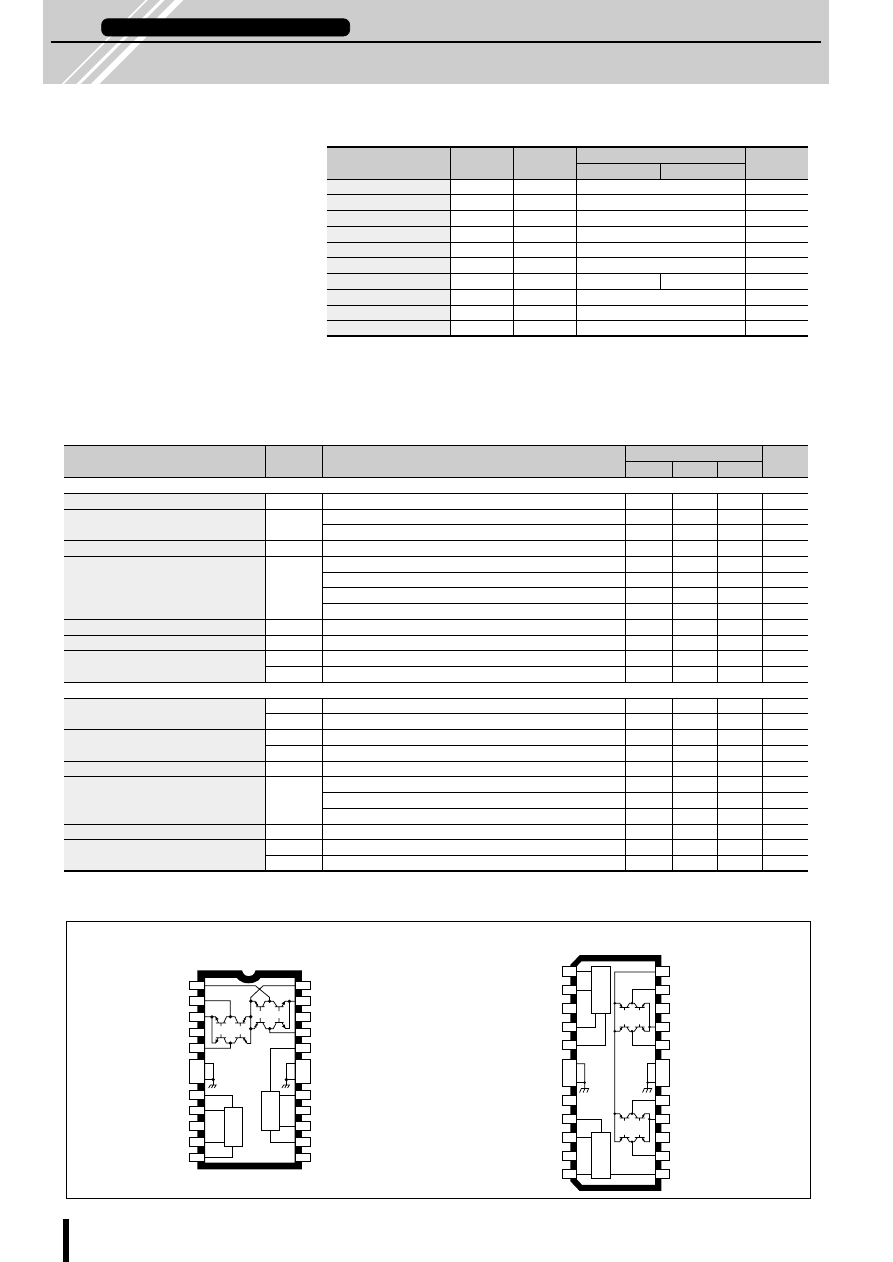

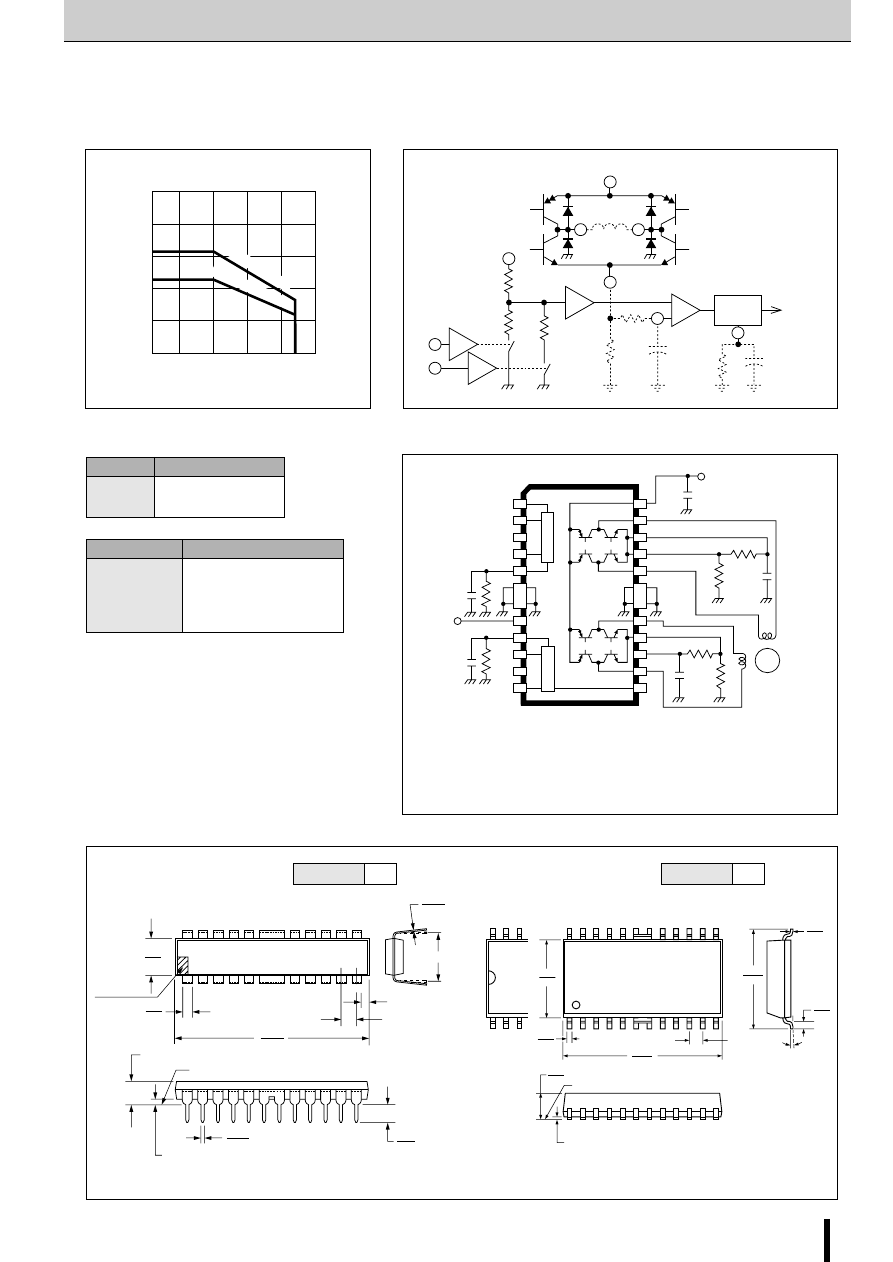

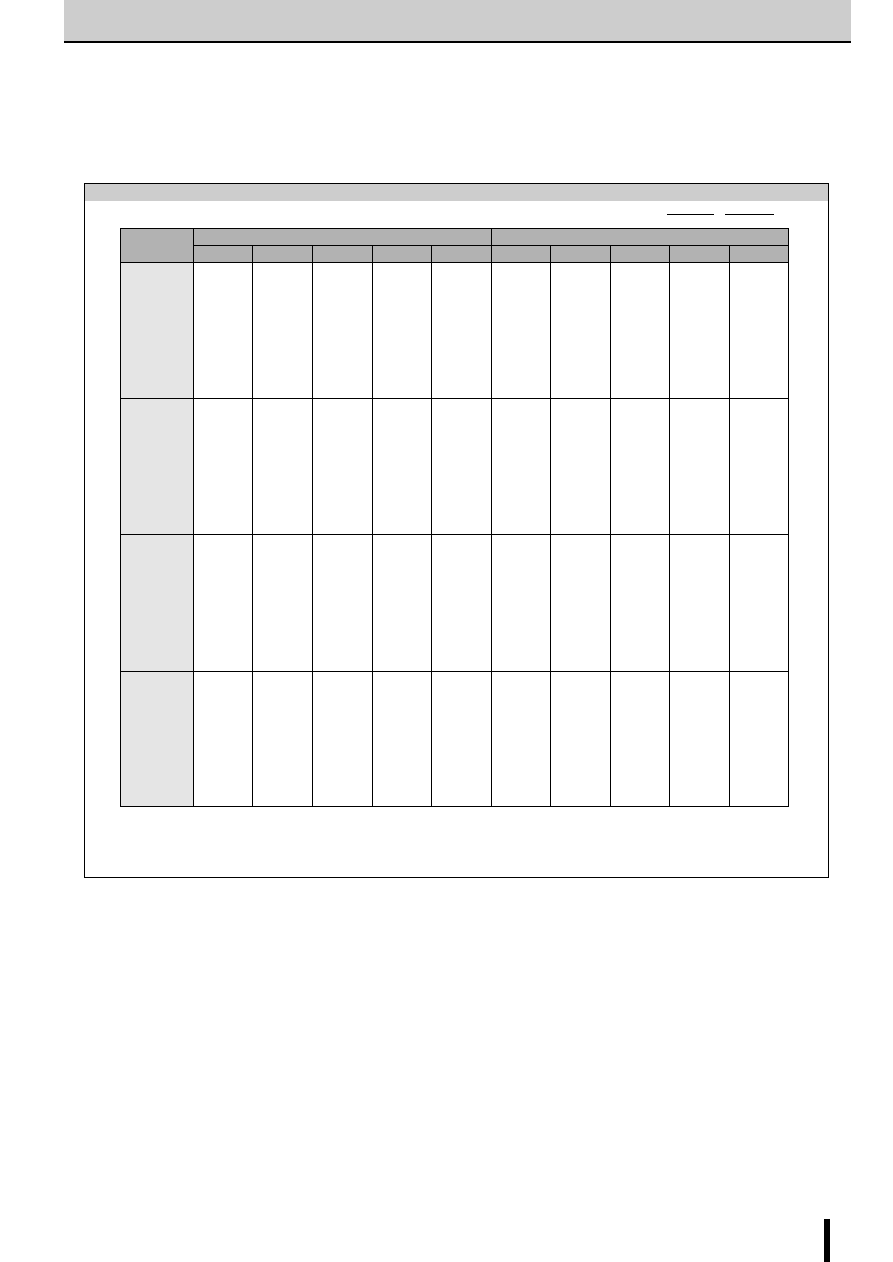

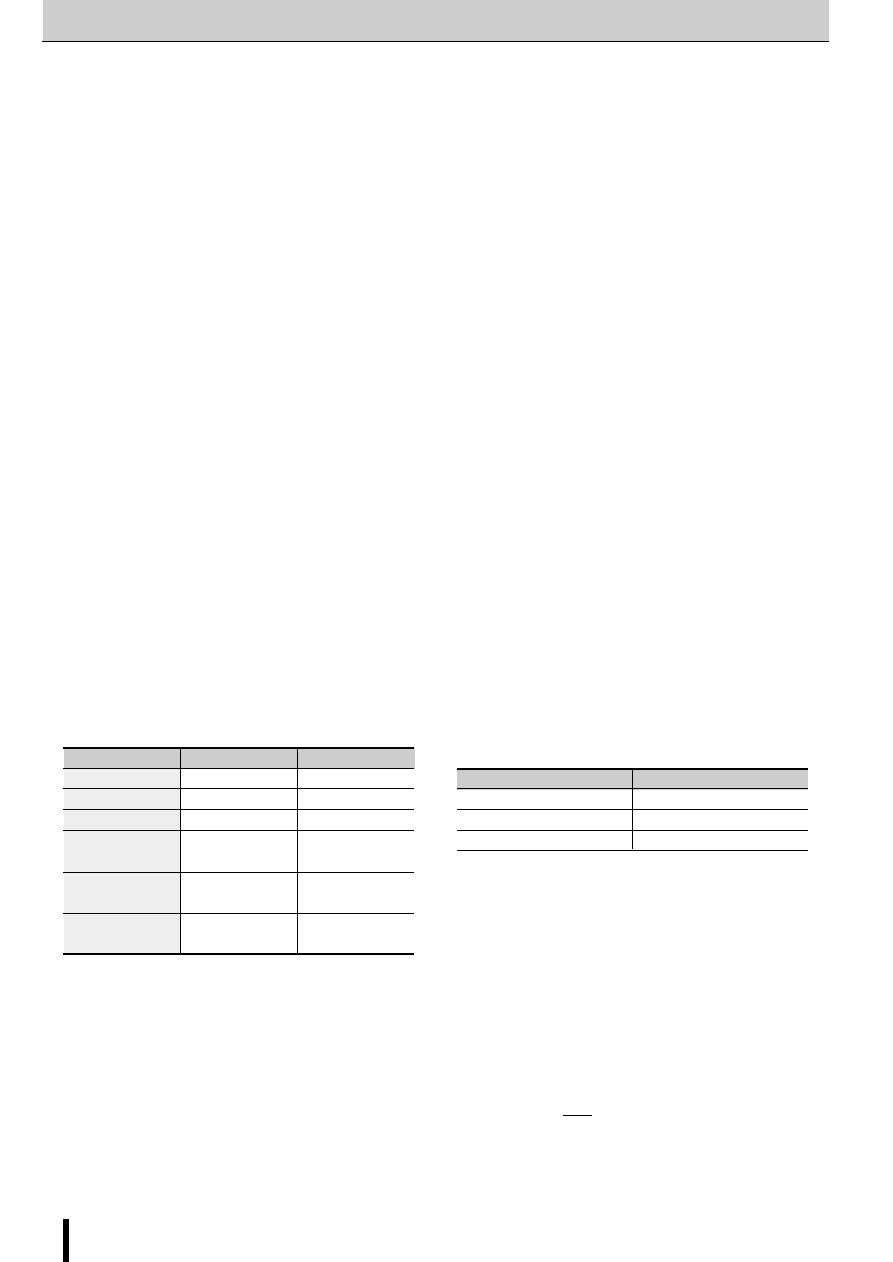

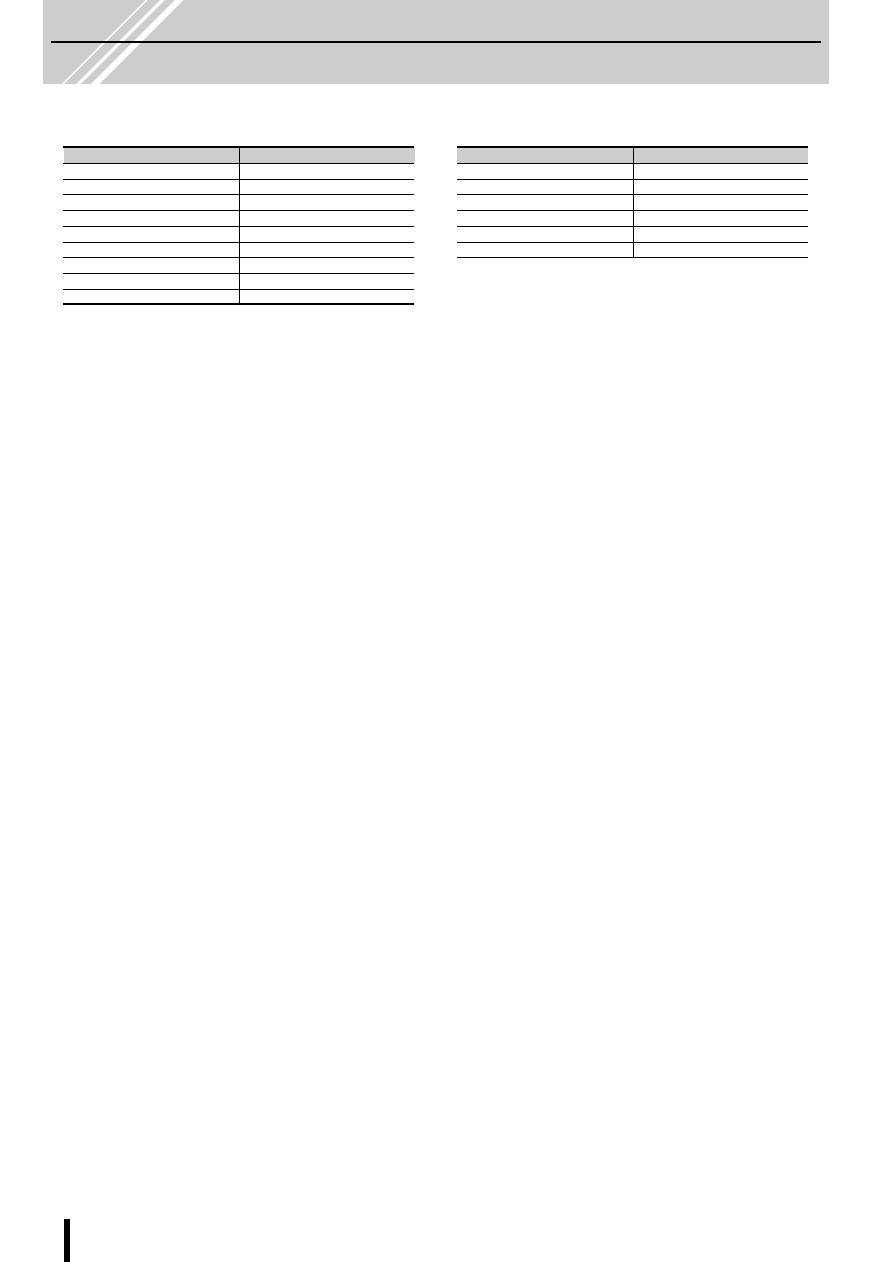

Excitation

Output current (A)

Motor supply

Package

Remarks

Page

method

1

1.2

1.25

1.5

3

voltage (V)

SLA7022MU

to 46

ZIP15Pin

5

SMA7022MU

to 46

ZIP15Pin

5

SLA7029M

to 46

ZIP15Pin

5

SMA7029M

to 46

ZIP15Pin

5

SMA7036M

to 46

ZIP15Pin

12

SDK03M

to 46

SMD16Pin 1 motor driven by 2 packages

36

SLA7027MU

to 46

ZIP18Pin

20

UCN5804B

to 35

DIP16Pin

Internal sequencer,

42

constant voltage driver

SLA7024M

to 46

ZIP18Pin

20

SLA7032M

to 46

ZIP18Pin

28

SLA7026M

to 46

ZIP18Pin

20

SLA7033M

to 46

ZIP18Pin

28

SLA7042M

to 46

ZIP18Pin

44

SLA7044M

to 46

ZIP18Pin

44

2-phase

excitation

2-phase/

1-2 phase

excitation

2W1-2 phase

Micro-step support

■

2-Phase Stepper Motor Unipolar Driver ICs

Supply voltage (V)

Package

page

PG001M

4.5 to 5.5

DIP16Pin

48

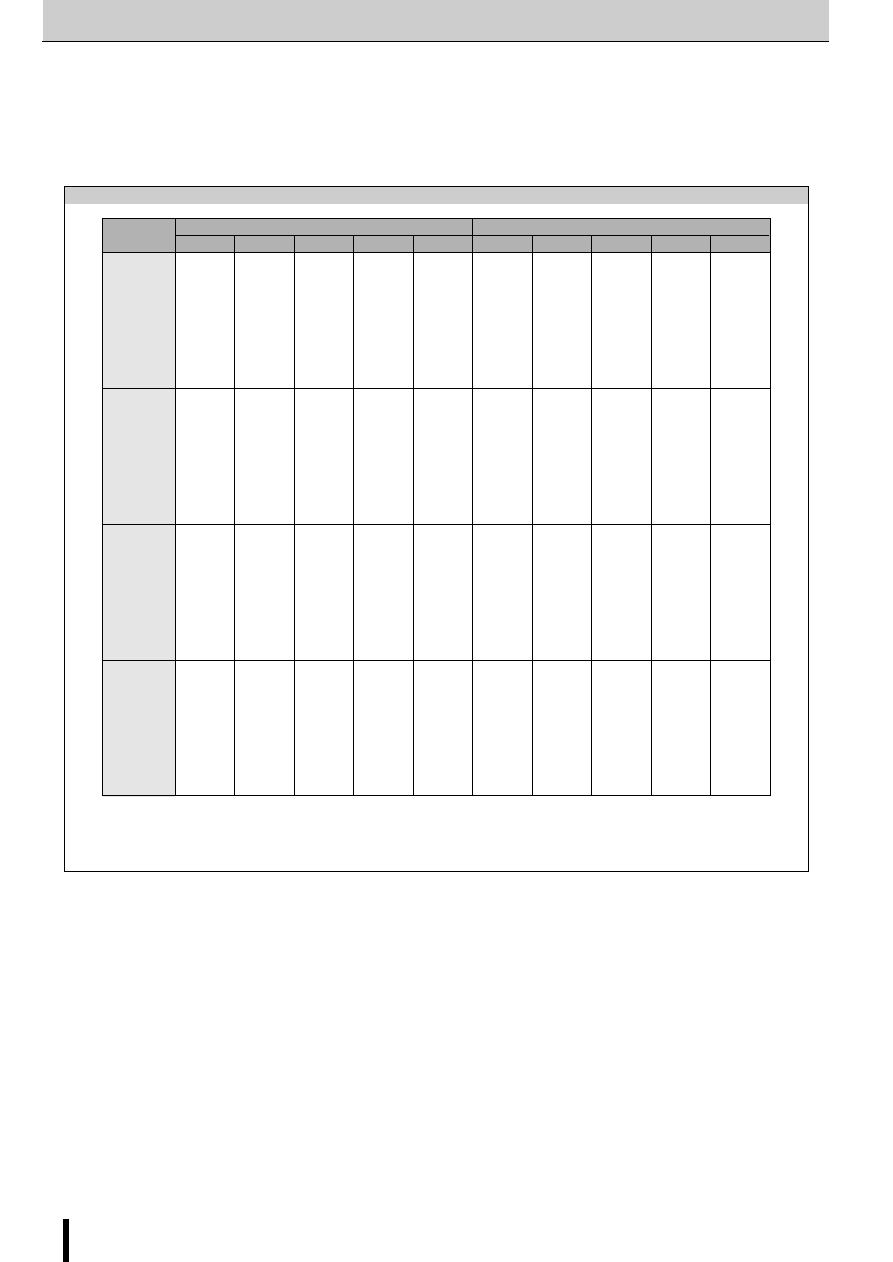

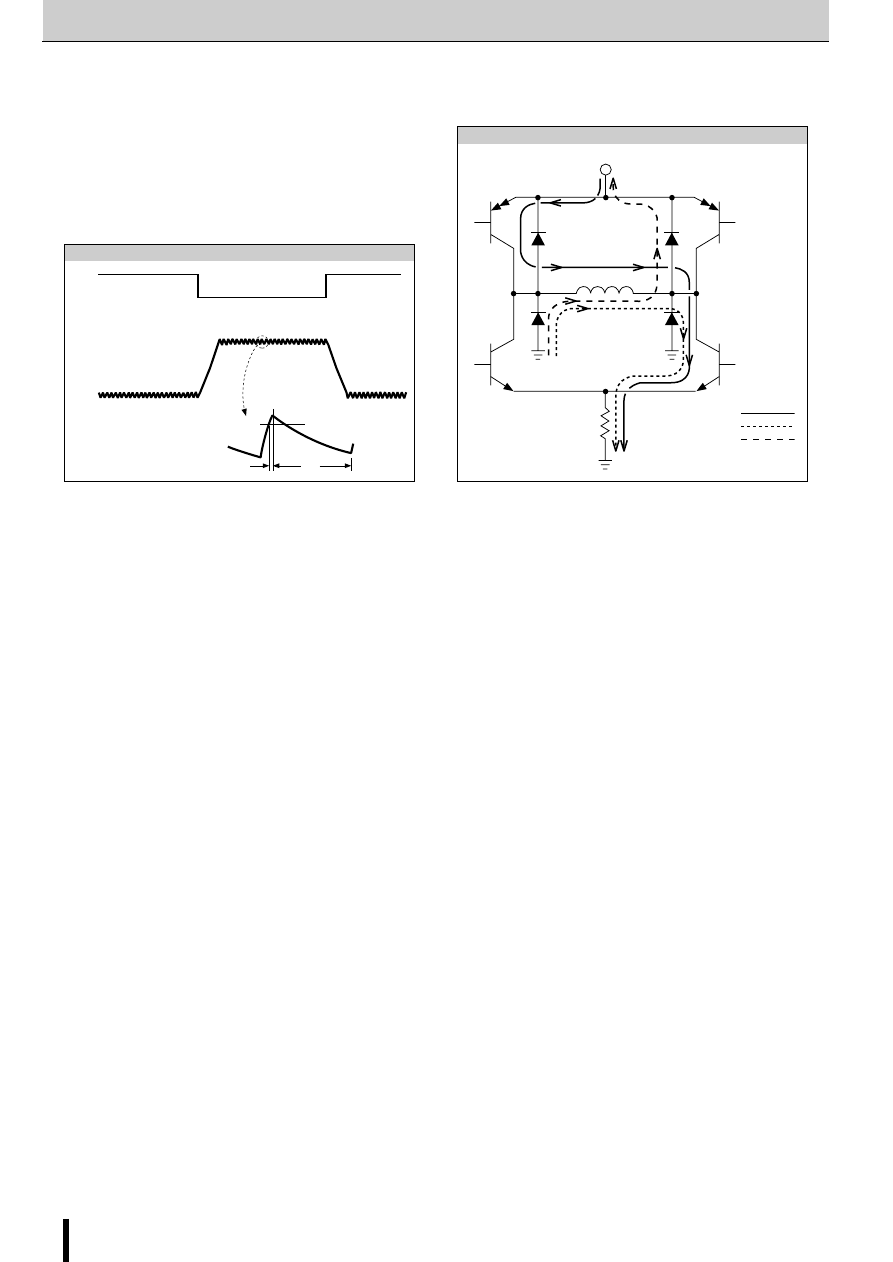

Excitation

Output current (A)

Motor supply

Package

Remarks

Page

method

0.65

0.75

0.8

1.3

1.5

2

voltage (V)

A3966SA

Vcc to 30

DIP16Pin

54

A3966SLB

Vcc to 30

SOP16Pin

54

A3964SLB

Vcc to 30

SOP20Pin

58

A3953SB

Vcc to 50

DIP16Pin

One motor driven by 2 ICs

60

A3953SLB

Vcc to 50

SOP16Pin One motor driven by 2 ICs

60

A2918SW

10 to 45

ZIP18Pin

68

A3952SB

Vcc to 50

DIP16Pin

One motor driven by 2 ICs

70

A3952SLB

Vcc to 50

SOP16Pin One motor driven by 2 ICs

70

A3952SW

Vcc to 50

SIP12Pin

One motor driven by 2 ICs

70

UDN2916B

10 to 45

DIP24Pin

78

UDN2916LB

10 to 45

SOP24Pin

78

UDN2917EB

10 to 45

PLCC44Pin

84

A3955SB

Vcc to 50

DIP16Pin

One motor driven by 2 ICs

88

A3955SLB

Vcc to 50

SOP16Pin One motor driven by 2 ICs

88

A3957SLB

Vcc to 50

SOP24Pin One motor driven by 2 ICs

94

2-phase/

1-2 phase

excitation

2-phase/1-2

phase/W1-2

phase excitation

2W1-2 phase

excitation/

micro-step

support

4W1-2 phase

excitation/micro-

step support

■

2-Phase Stepper Motor Bipolar Driver ICs

■

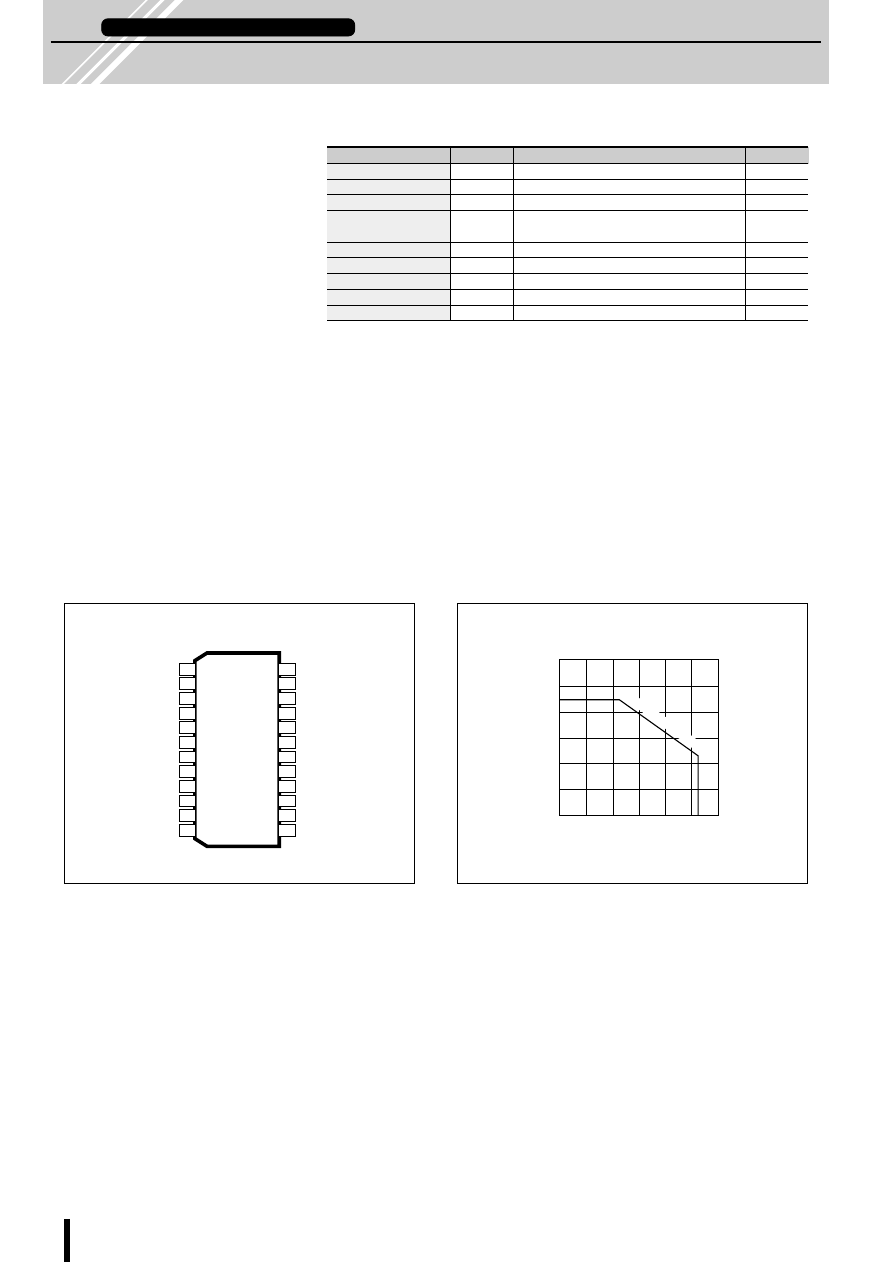

3-Phase Stepper Motor Driver Control ICs

Excitation method

Part No.

Motor supply

Package

Remarks

Page

voltage (V)

2-phase/

SI-7600

15 to 45

SOP20Pin

Use with SLA5017 or others

98

2-3 phase excitation

SI-7600D

DIP20Pin

■

5-Phase Stepper Motor Driver Control ICs

Drive method

Part No.

Motor supply

Package

Remarks

Page

voltage (V)

Pentagon

SI-7502

15 to 42

Powder

Use with SLA6503 and SLA5011

104

connection

coating 27 pin

Selection Guide

Selection Guide

Motor Driver ICs

■

Serial Signal Generator IC for SLA704xM

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

3

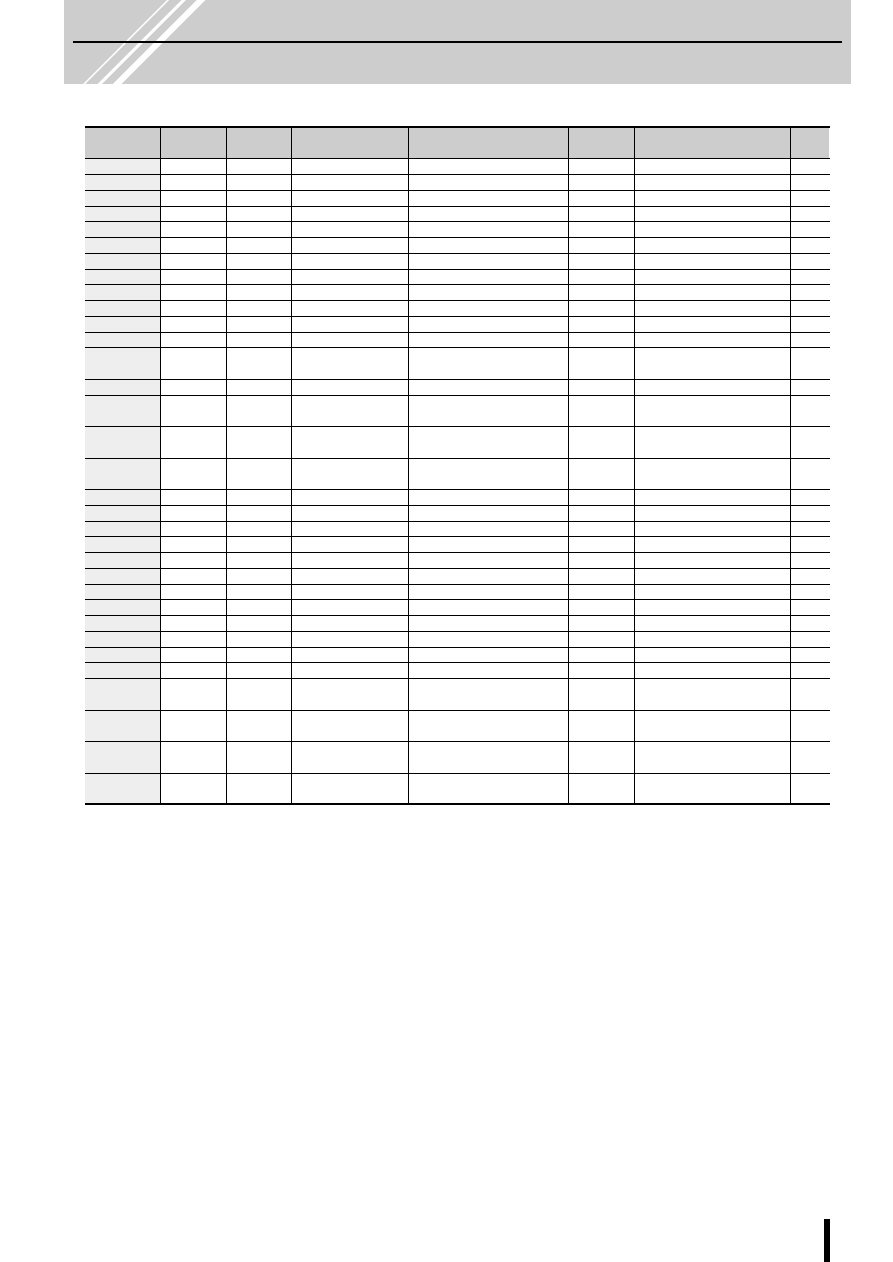

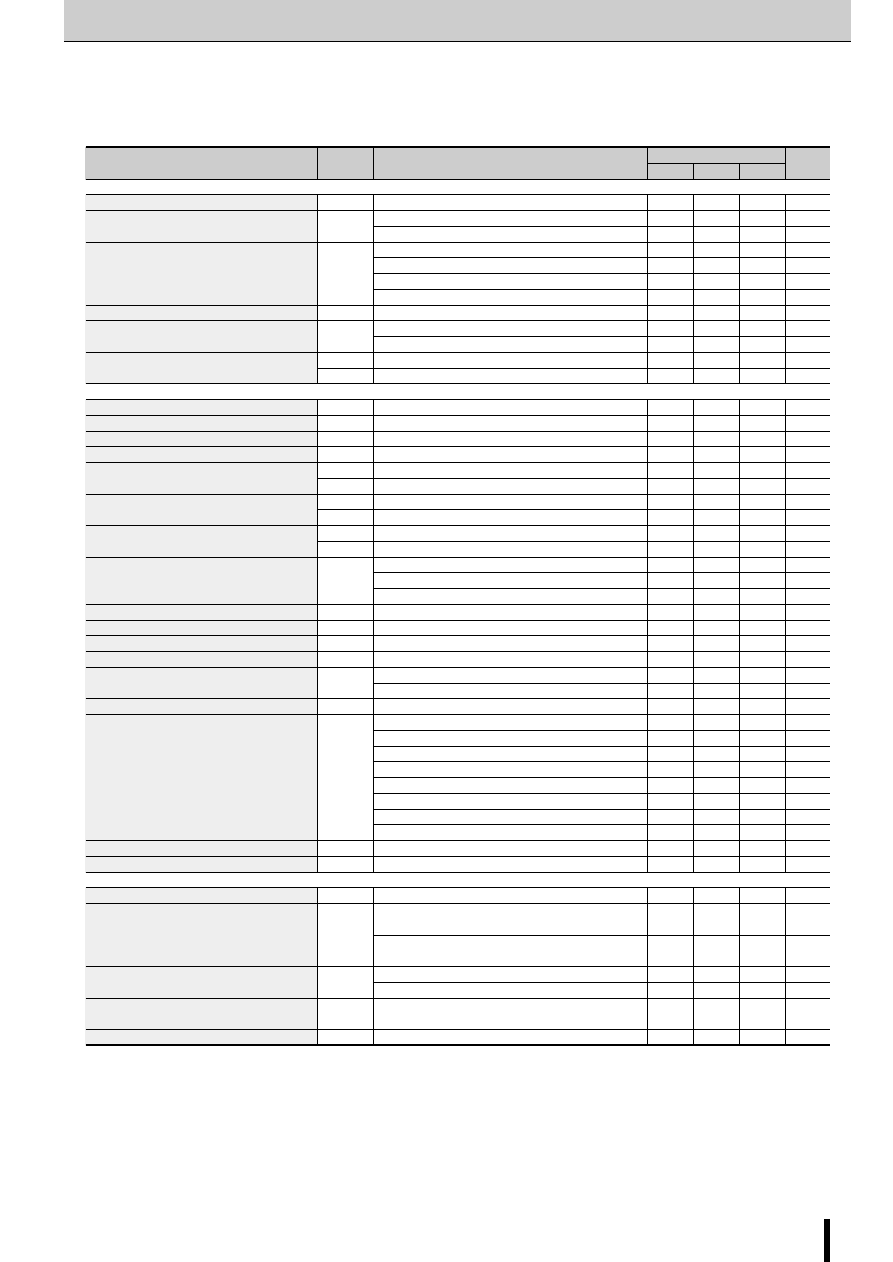

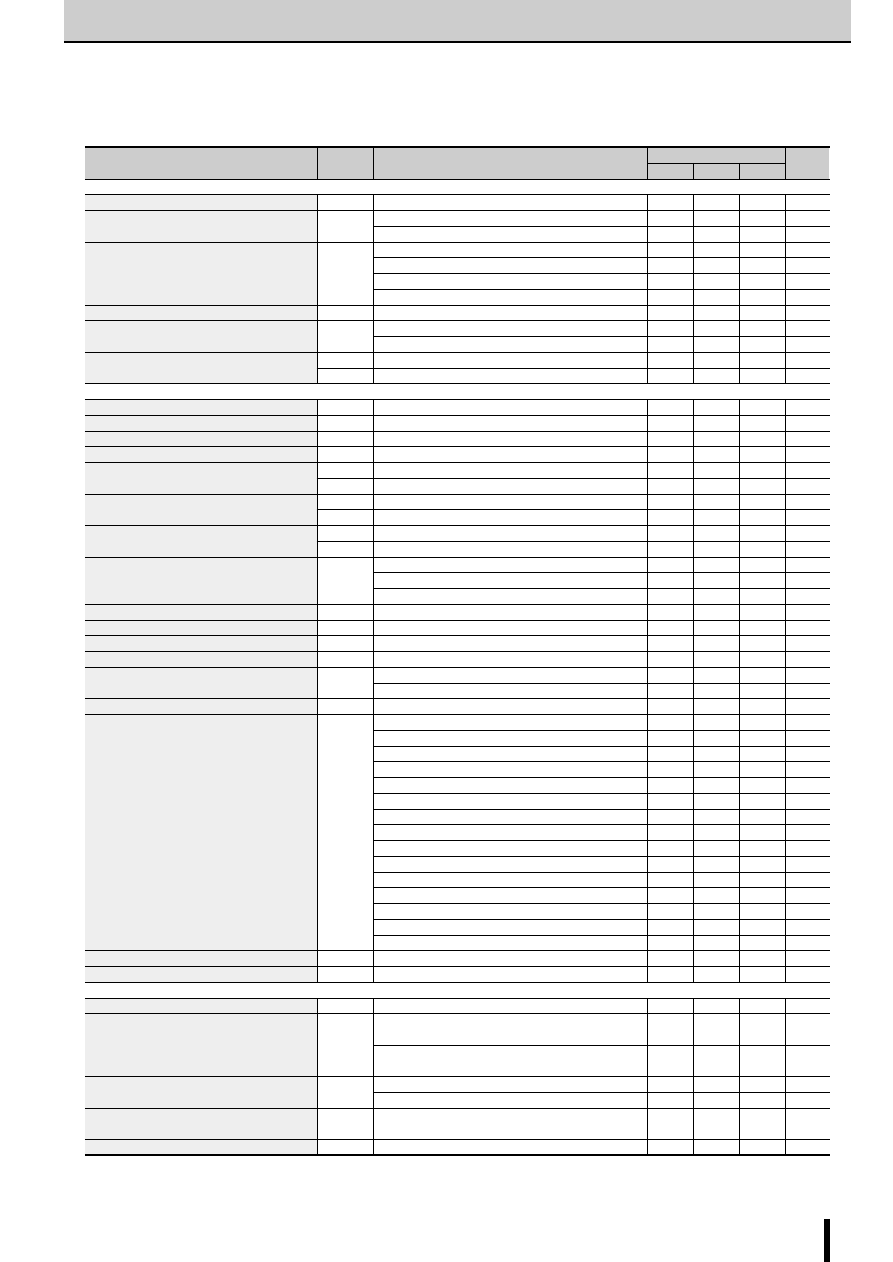

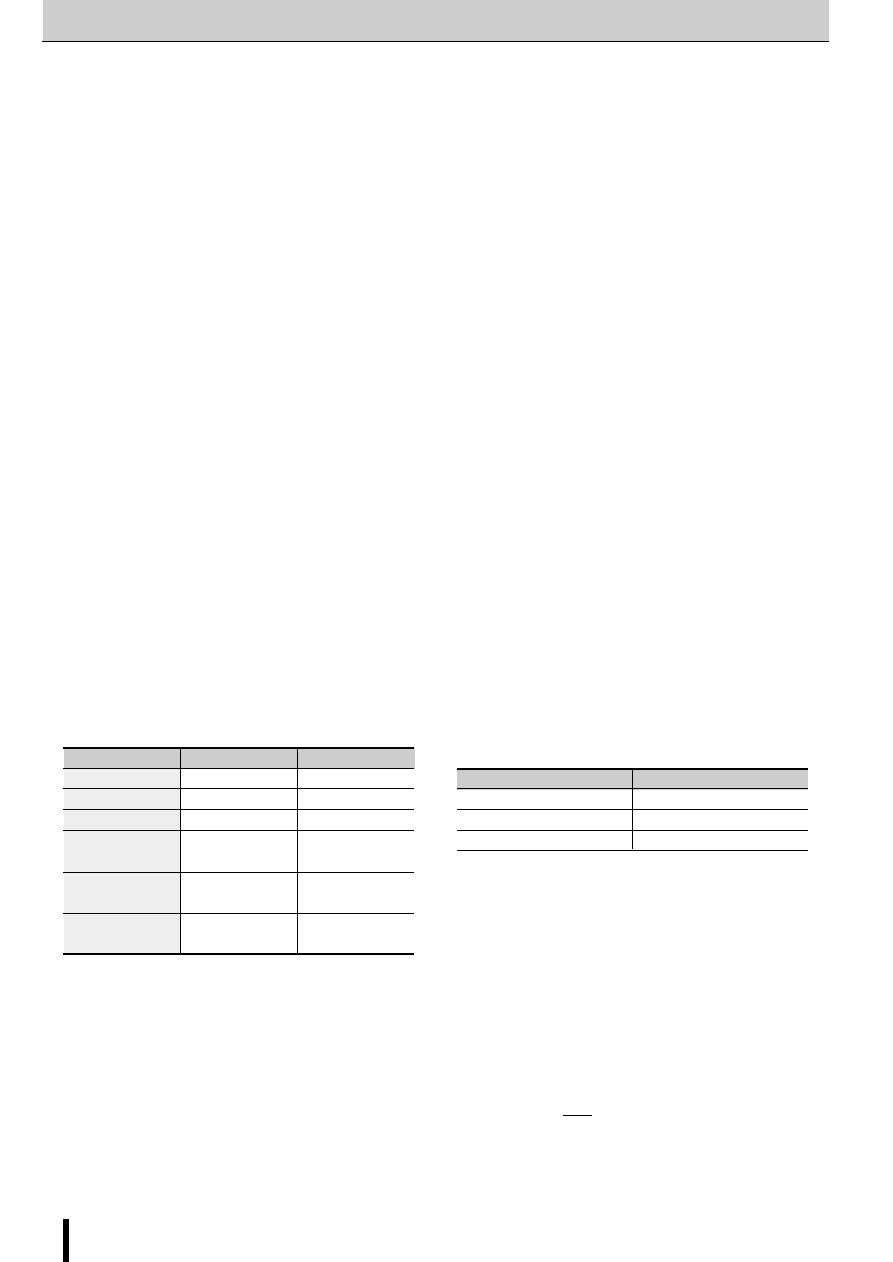

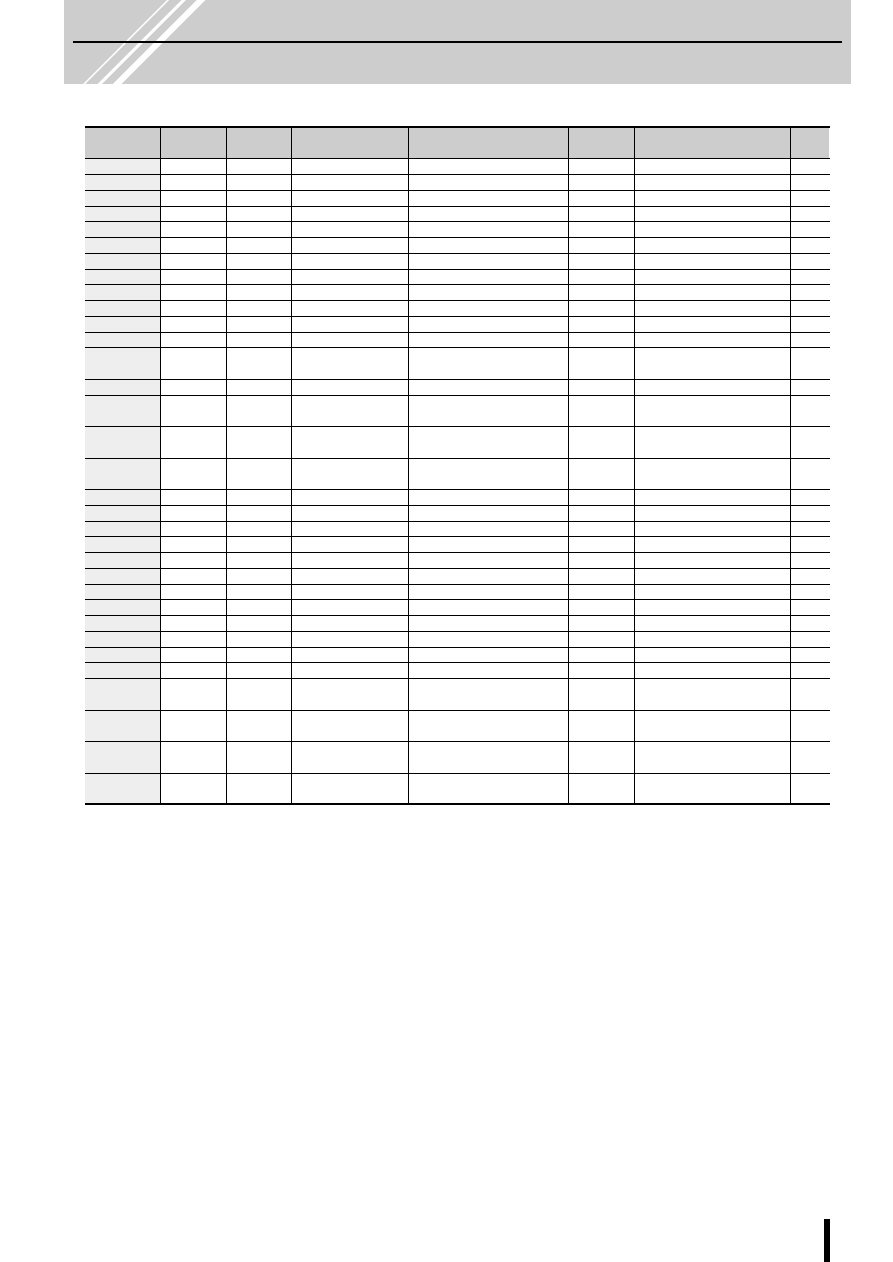

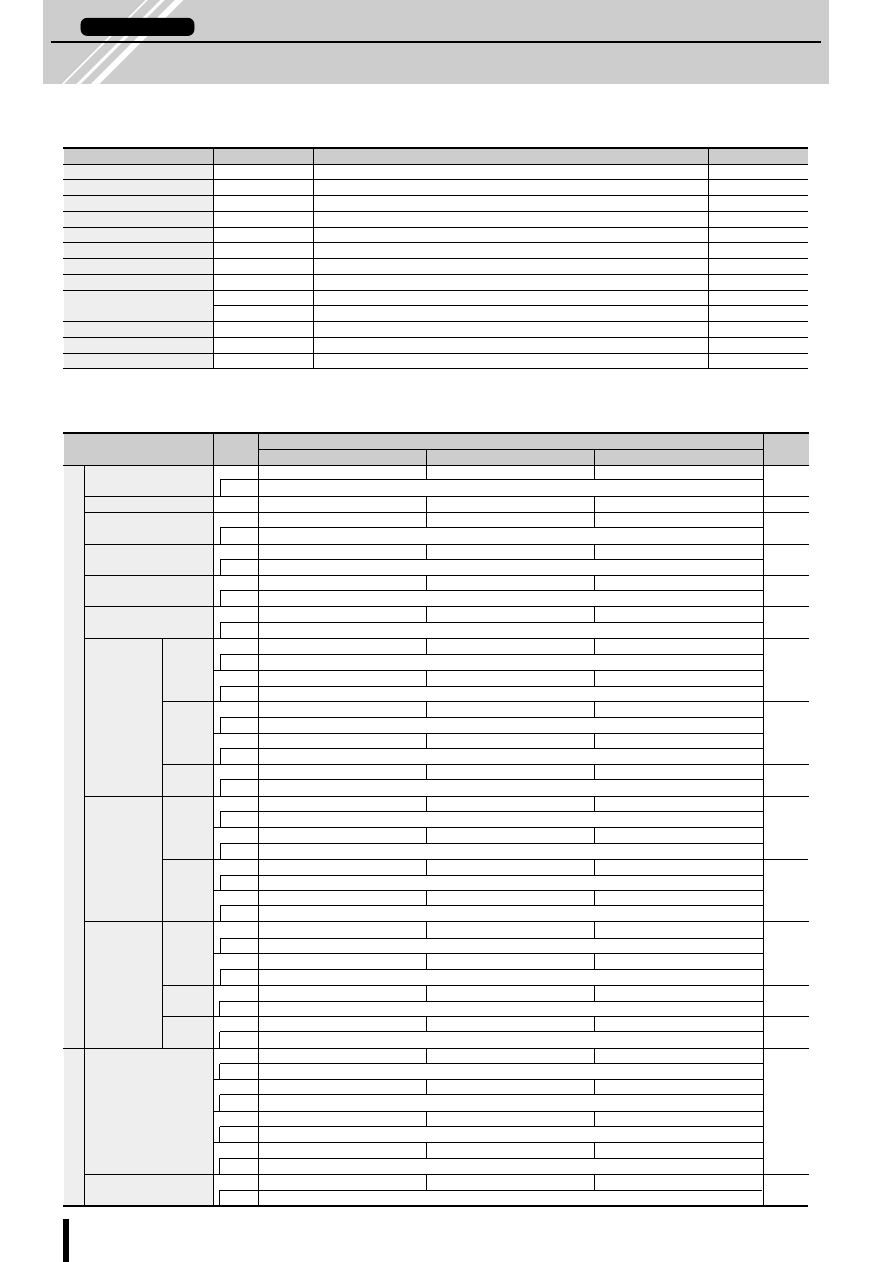

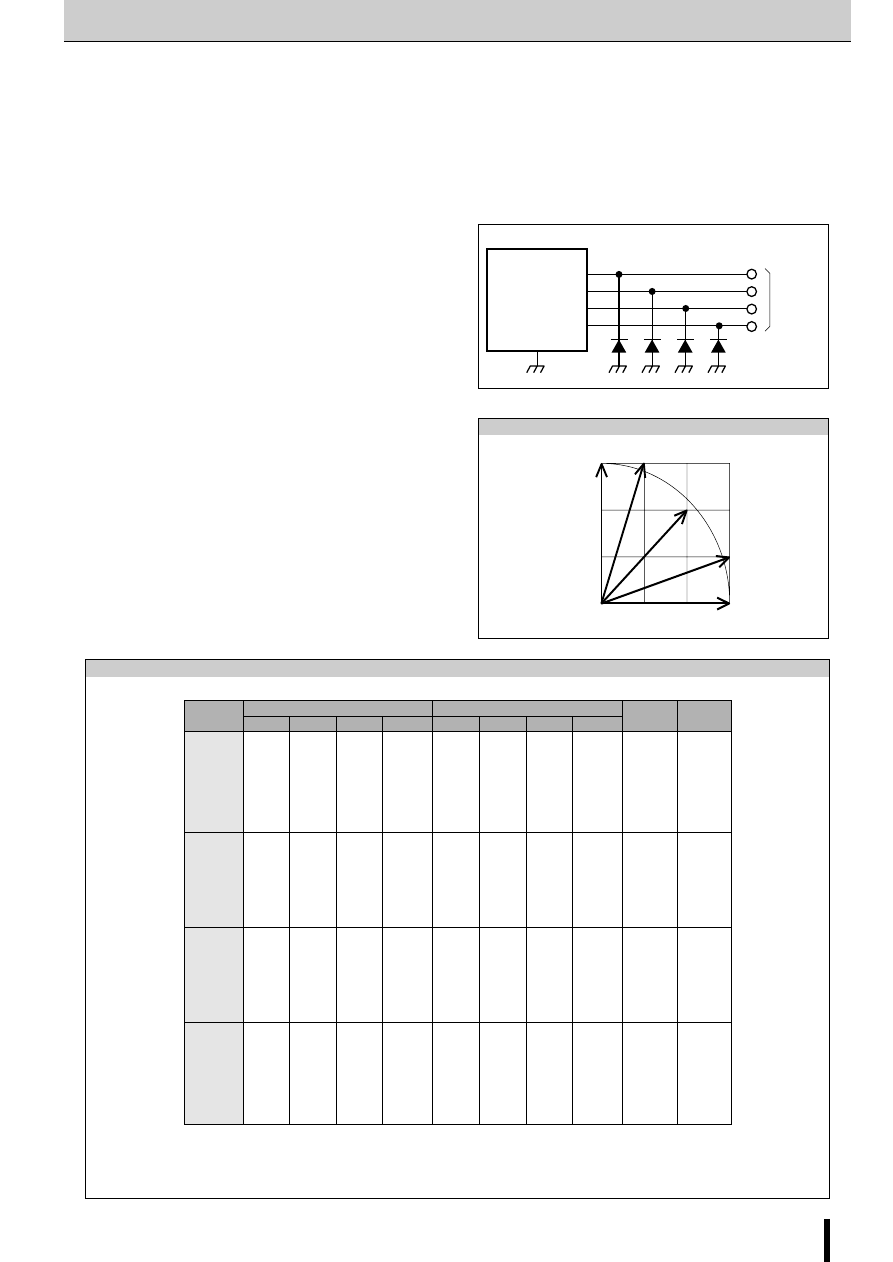

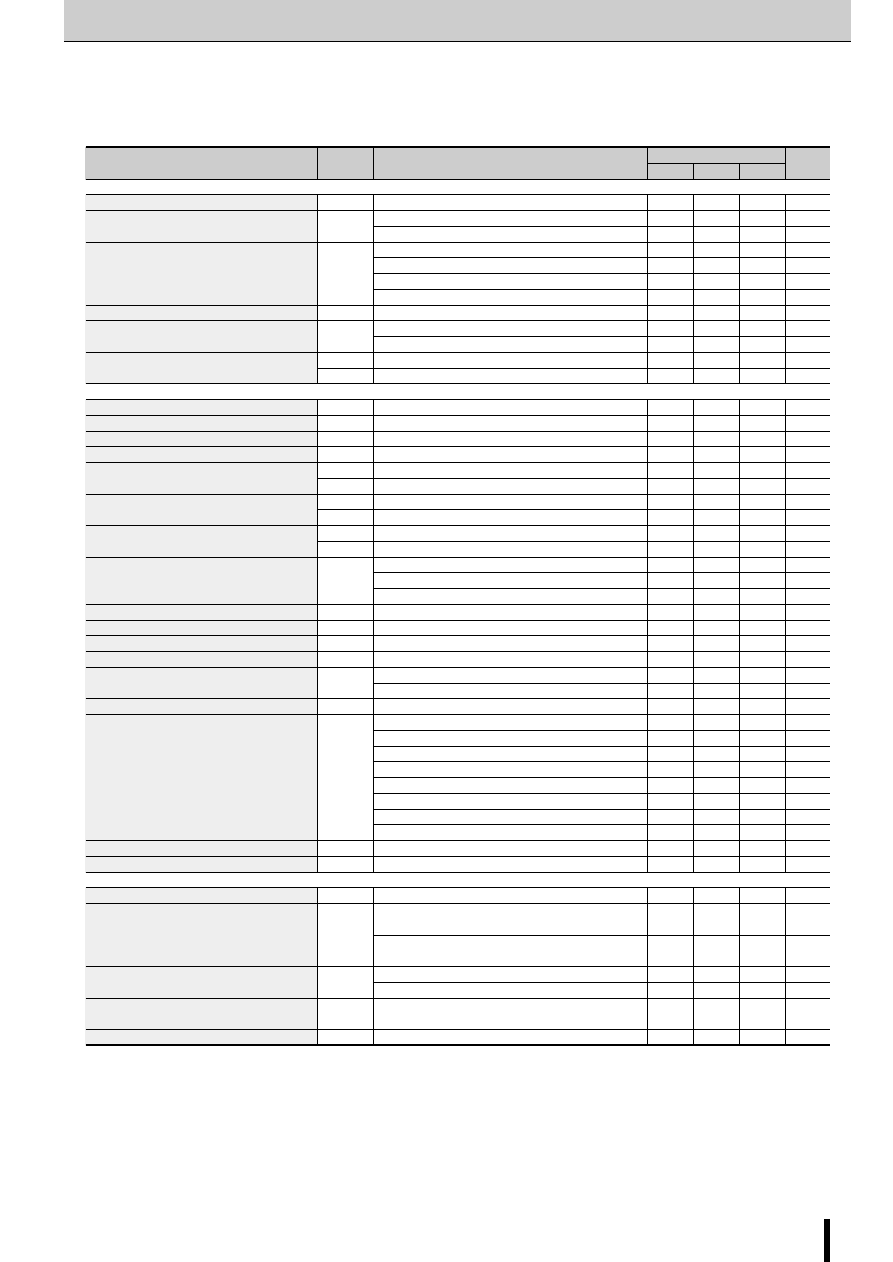

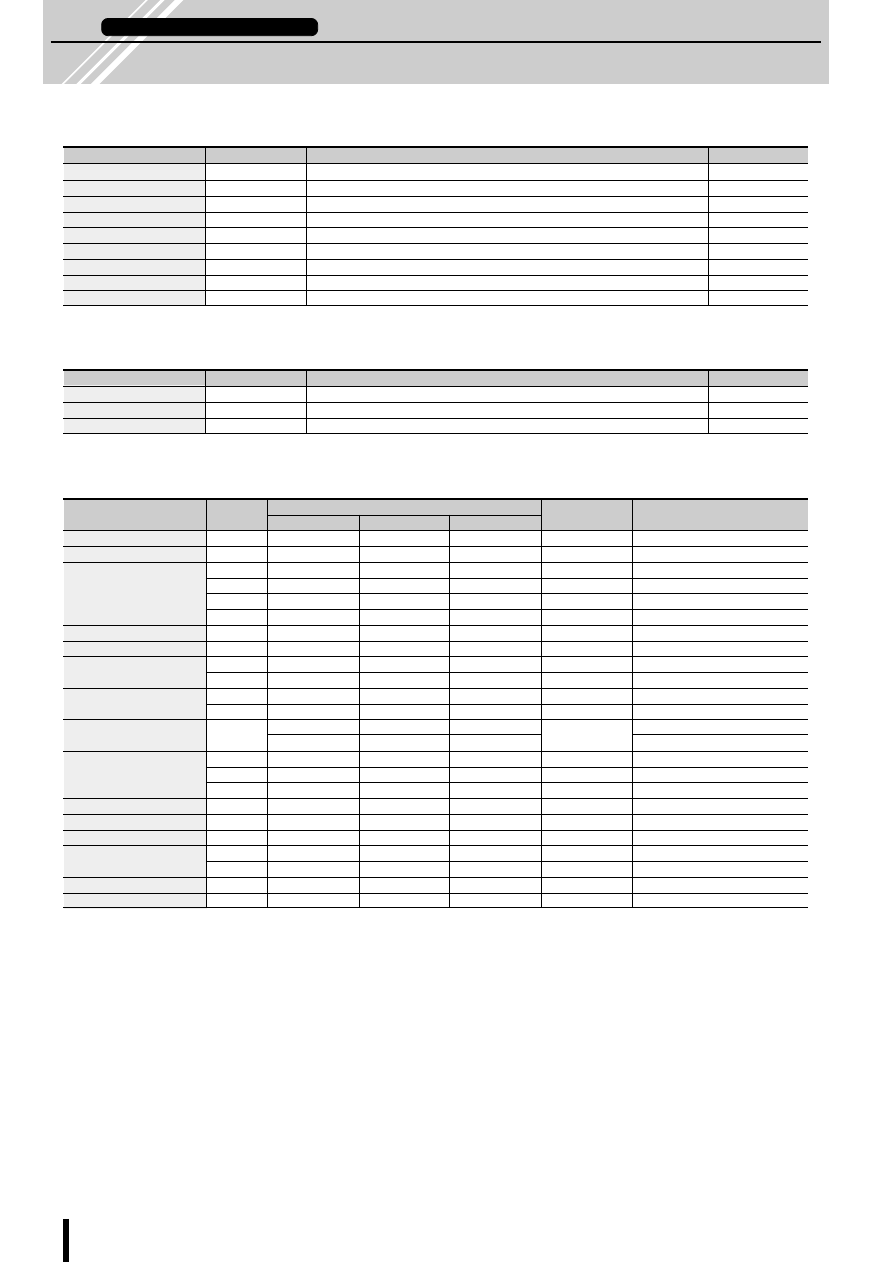

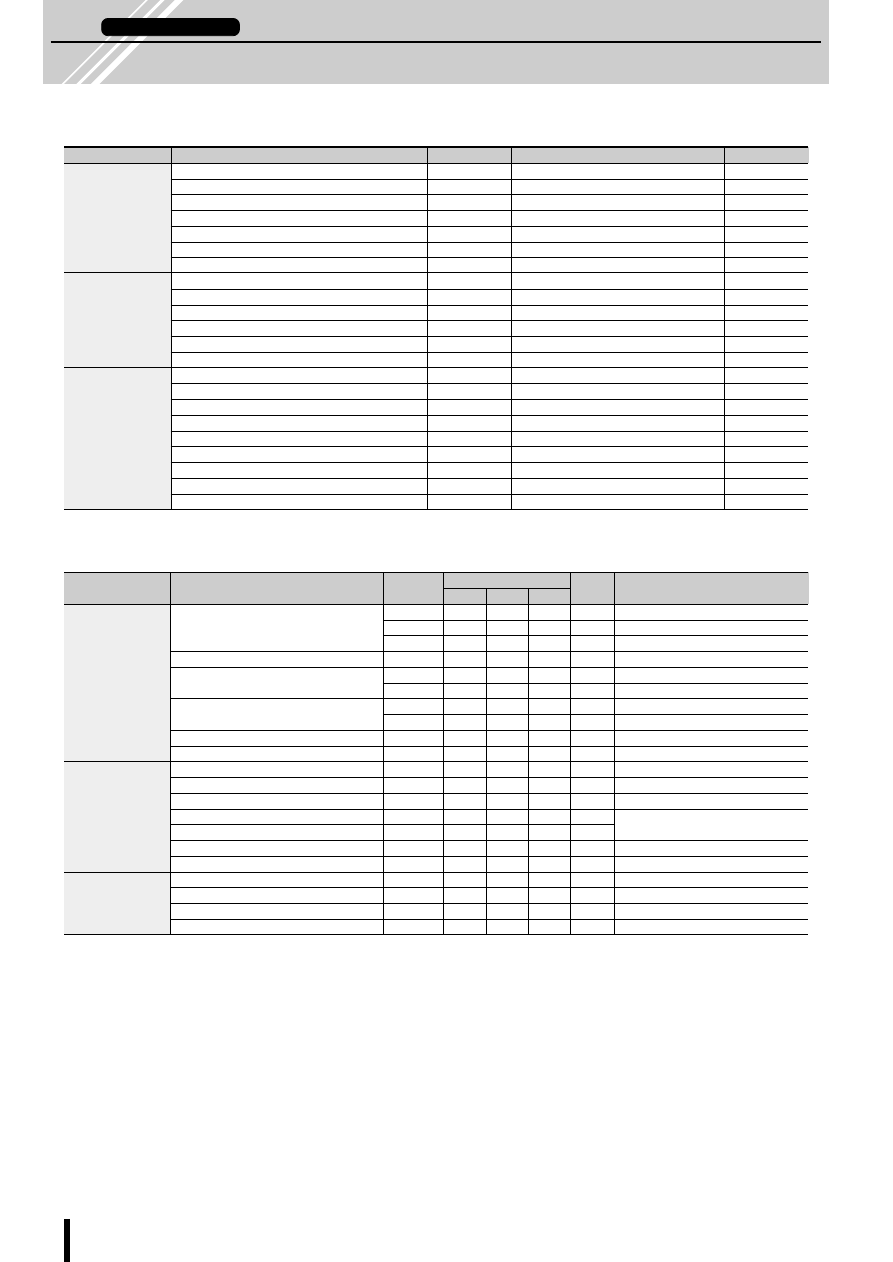

Part No.

Output current Supply voltage

Drive method

Excitation method

Package

Remarks

Page

(A)

(V)

A2918SW

1.5

10 to 45

Bipolar

2-phase/1-2 phase excitation

ZIP18pin

68

A3952SB

2

V

CC

to 50

Bipolar

2-phase/1-2 phase excitation

DIP16pin

One motor driven by 2 ICs

70

A3952SLB

2

V

CC

to 50

Bipolar

2-phase/1-2 phase excitation

SOP16pin

One motor driven by 2 ICs

70

A3952SW

2

V

CC

to 50

Bipolar

2-phase/1-2 phase excitation

SIP12pin

One motor driven by 2 ICs

70

A3953SB

1.3

V

CC

to 50

Bipolar

2-phase/1-2 phase excitation

DIP16pin

One motor driven by 2 ICs

60

A3953SLB

1.3

V

CC

to 50

Bipolar

2-phase/1-2 phase excitation

SOP16pin

One motor driven by 2 ICs

60

A3955SB

1.5

V

CC

to 50

Bipolar

2W/1-2 phase micro-step support

DIP16pin

One motor driven by 2 ICs

88

A3955SLB

1.5

V

CC

to 50

Bipolar

2W/1-2 phase micro-step support

SOP16pin

One motor driven by 2 ICs

88

A3957SLB

1.5

V

CC

to 50

Bipolar

4W/1-2 phase micro-step support

SOP24pin

One motor driven by 2 ICs

94

A3964SLB

0.8

V

CC

to 30

Bipolar

2-phase/1-2 phase excitation

SOP20pin

58

A3966SA

0.65

V

CC

to 30

Bipolar

2-phase/1-2 phase excitation

DIP16pin

54

A3966SLB

0.65

V

CC

to 30

Bipolar

2-phase/1-2 phase excitation

SOP16pin

54

PG001M

−

4.5 to 5.5

−

−

DIP16pin

Serial signal generator IC for

48

SLA704xM

SDK03M

1

to 46

Unipolar

2-phase/1-2 phase excitation

SMD16pin

One motor driven by 2 ICs

36

SI-7502

−

15 to 42

Pentagon connection

5-phase excitation

Powder coat

Control IC

104

27pin

SI-7600

−

15 to 45

Star connection/

2-phase/2-3 phase excitation

SOP20pin

Control IC

98

delta connection

SI-7600D

−

15 to 45

Star connection/

2-phase/2-3 phase excitation

DIP20pin

Control IC

98

delta connection

SLA7022MU

1

to 46

Unipolar

2-phase excitation

ZIP15pin

5

SLA7024M

1.5

to 46

Unipolar

2-phase/1-2 phase excitation

ZIP18pin

20

SLA7026M

3

to 46

Unipolar

2-phase/1-2 phase excitation

ZIP18pin

20

SLA7027MU

1

to 46

Unipolar

2-phase/1-2 phase excitation

ZIP18pin

20

SLA7029M

1.5

to 46

Unipolar

2-phase excitation

ZIP15pin

5

SLA7032M

1.5

to 46

Unipolar

2-phase/1-2 phase excitation

ZIP18pin

SLA7024M equivalent

28

SLA7033M

3

to 46

Unipolar

2-phase/1-2 phase excitation

ZIP18pin

SLA7026M equivalent

28

SLA7042M

1.2

to 46

Unipolar

2W/1-2 phase micro-step support

ZIP18pin

44

SLA7044M

3

to 46

Unipolar

2W/1-2 phase micro-step support

ZIP18pin

44

SMA7022MU

1

to 46

Unipolar

2-phase excitation

ZIP15pin

5

SMA7029M

1.5

to 46

Unipolar

2-phase excitation

ZIP15pin

5

SMA7036M

1.5

to 46

Unipolar

2-phase excitation

ZIP15pin

SMA7029M equivalent

12

UCN5804B

1.25

to 35

Unipolar

2-phase/1-2 phase excitation

DIP16pin

Internal sequencer, constant

42

voltage driver

UDN2916B

0.75

10 to 45

Bipolar

2-phase/1-2 phase/W1-2 phase

DIP24pin

78

excitation

UDN2916LB

0.75

10 to 45

Bipolar

2-phase/1-2 phase/W1-2 phase

SOP24pin

78

excitation

UDN2917EB

1.5

10 to 45

Bipolar

2-phase/1-2 phase/W1-2 phase

PLCC44pin

84

excitation

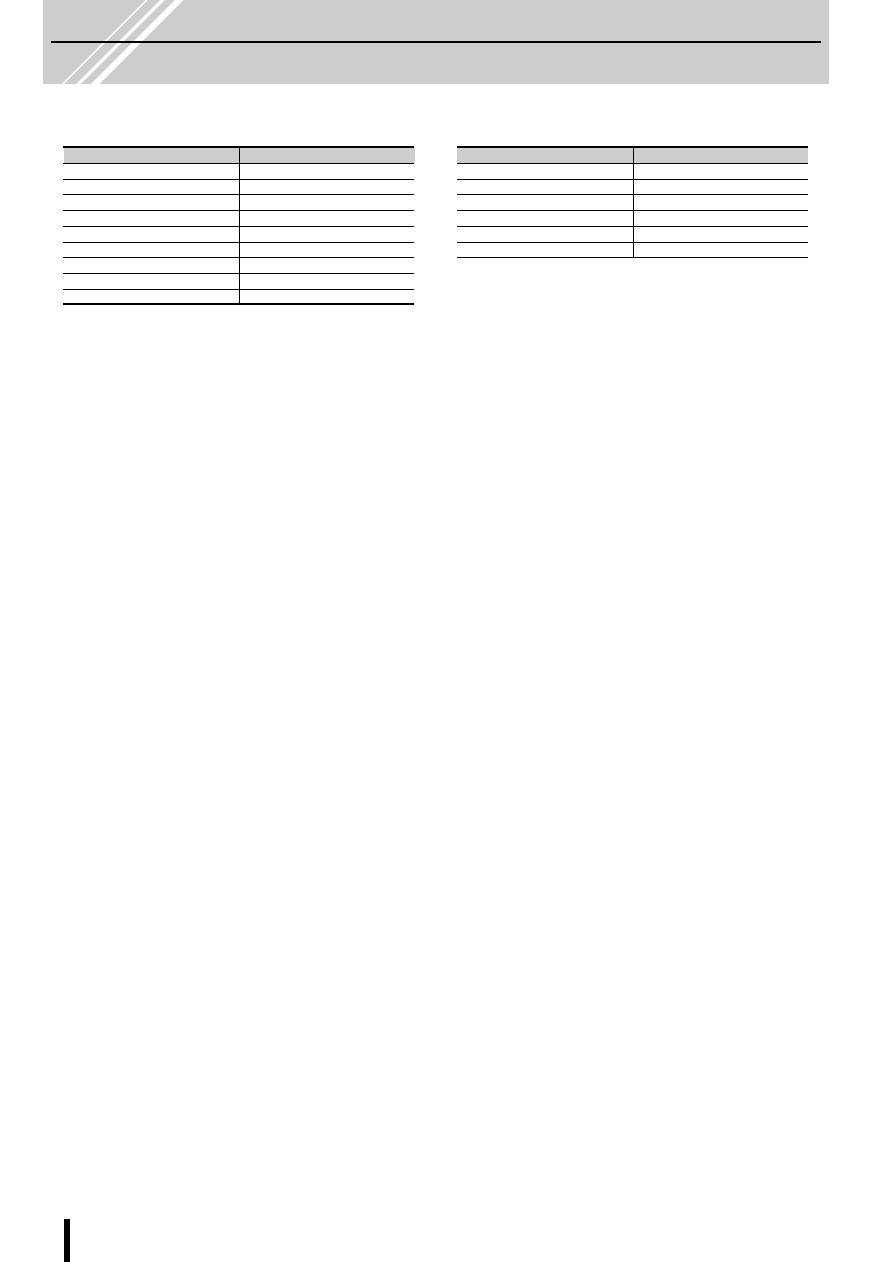

Product Index by Part Number

Product Index by Part Number

Motor Driver ICs

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

4

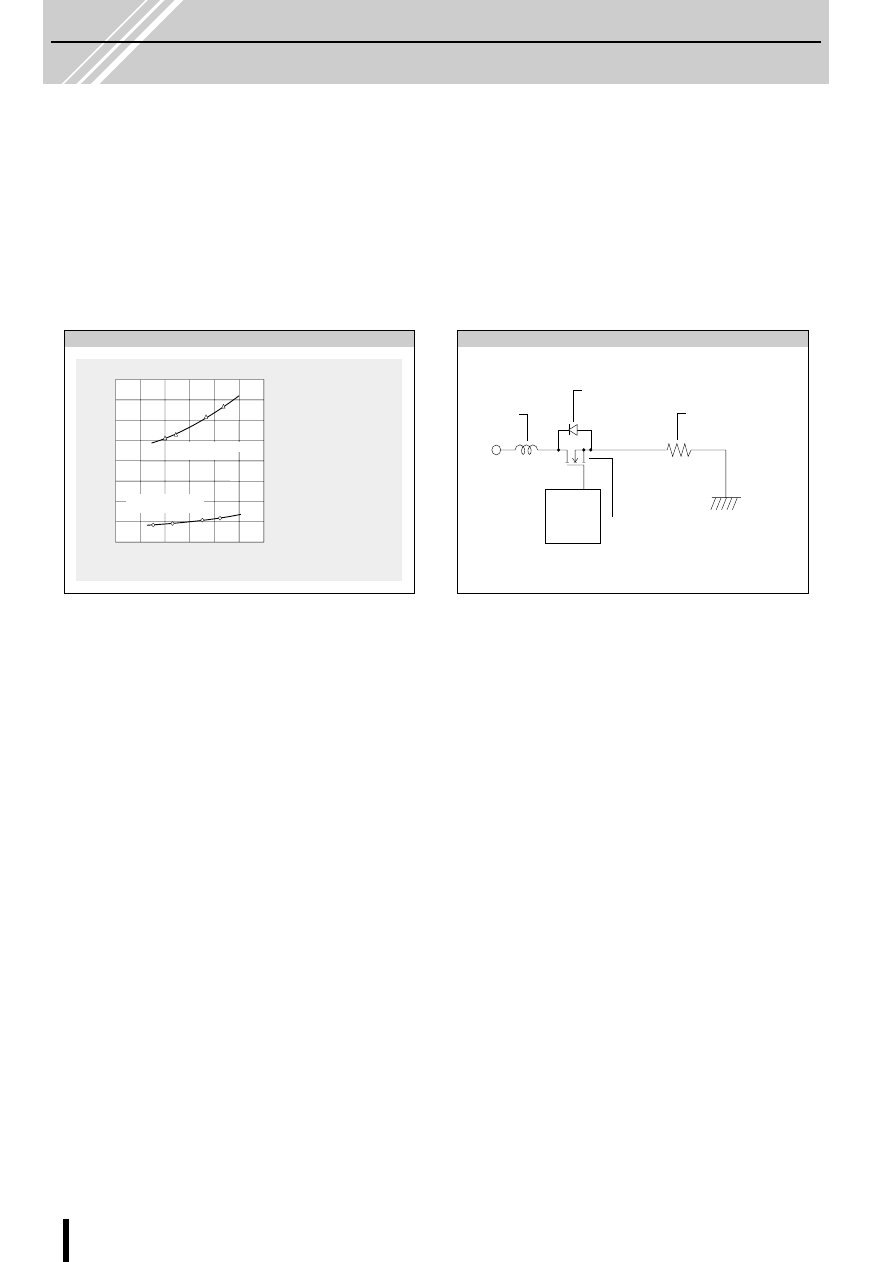

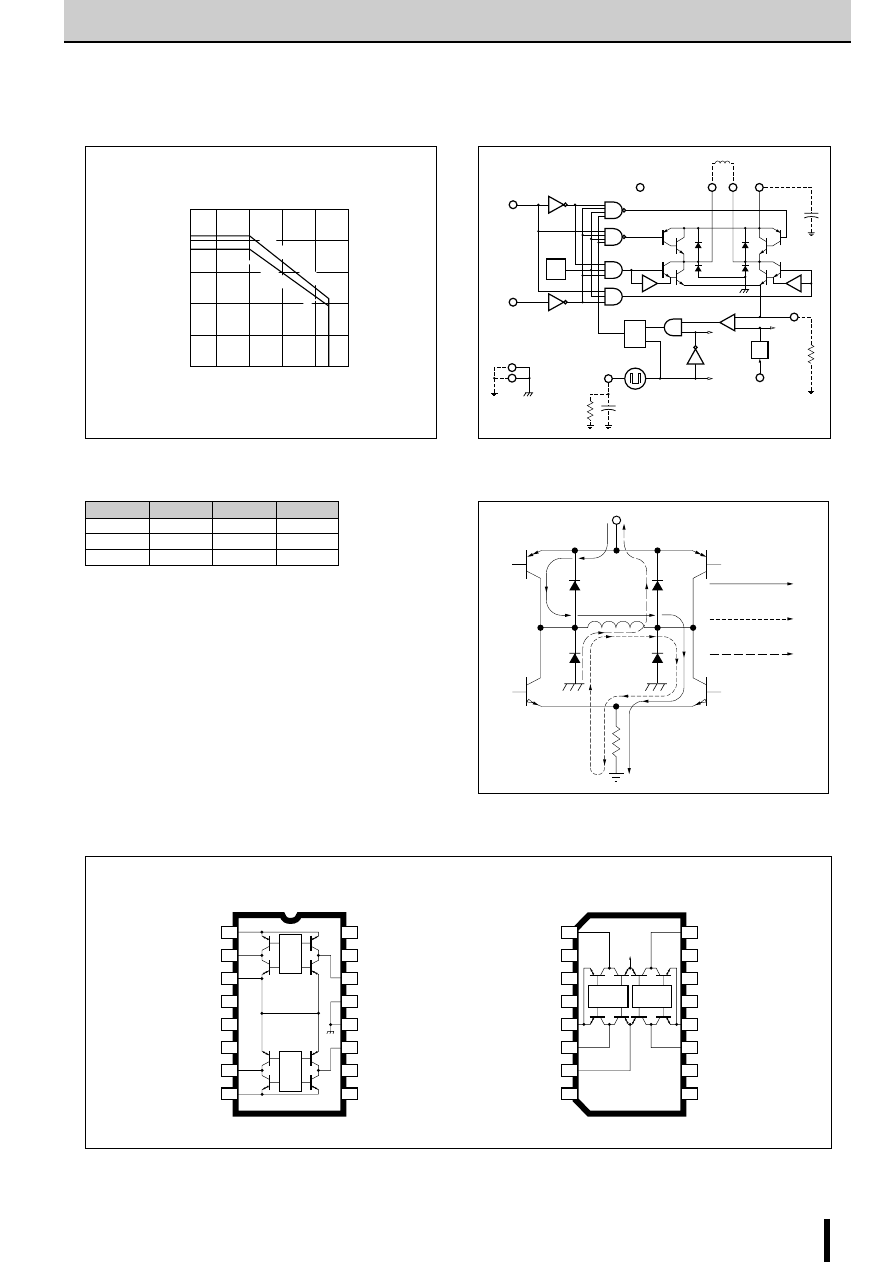

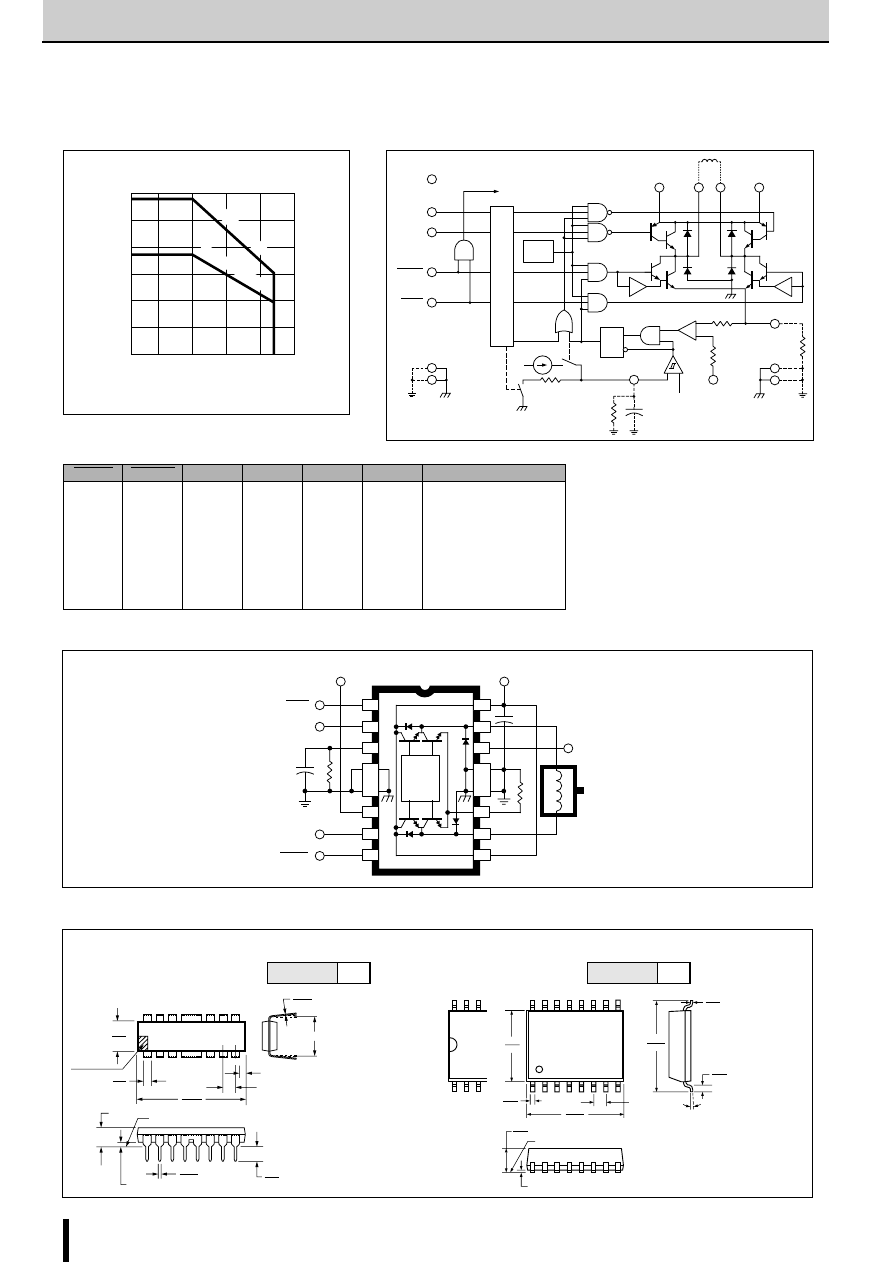

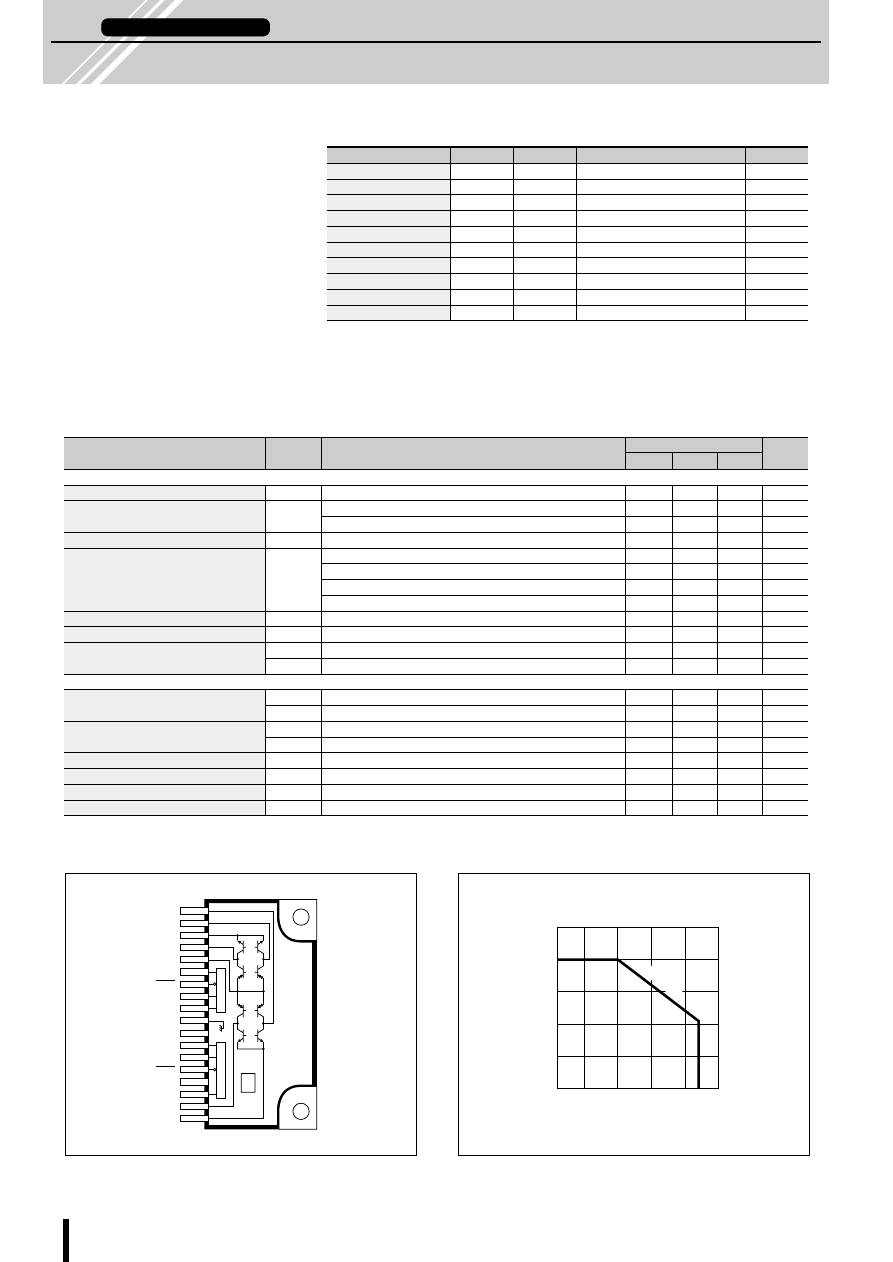

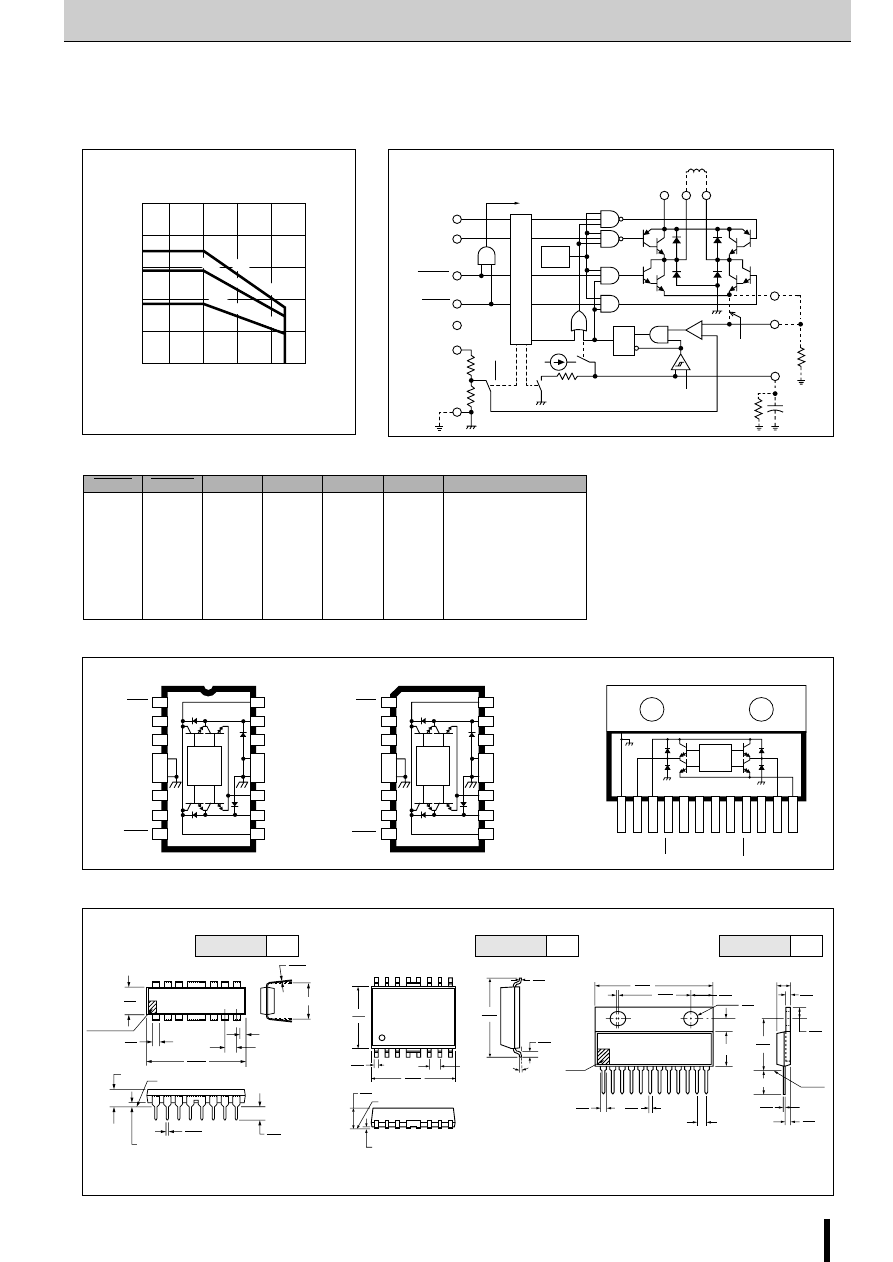

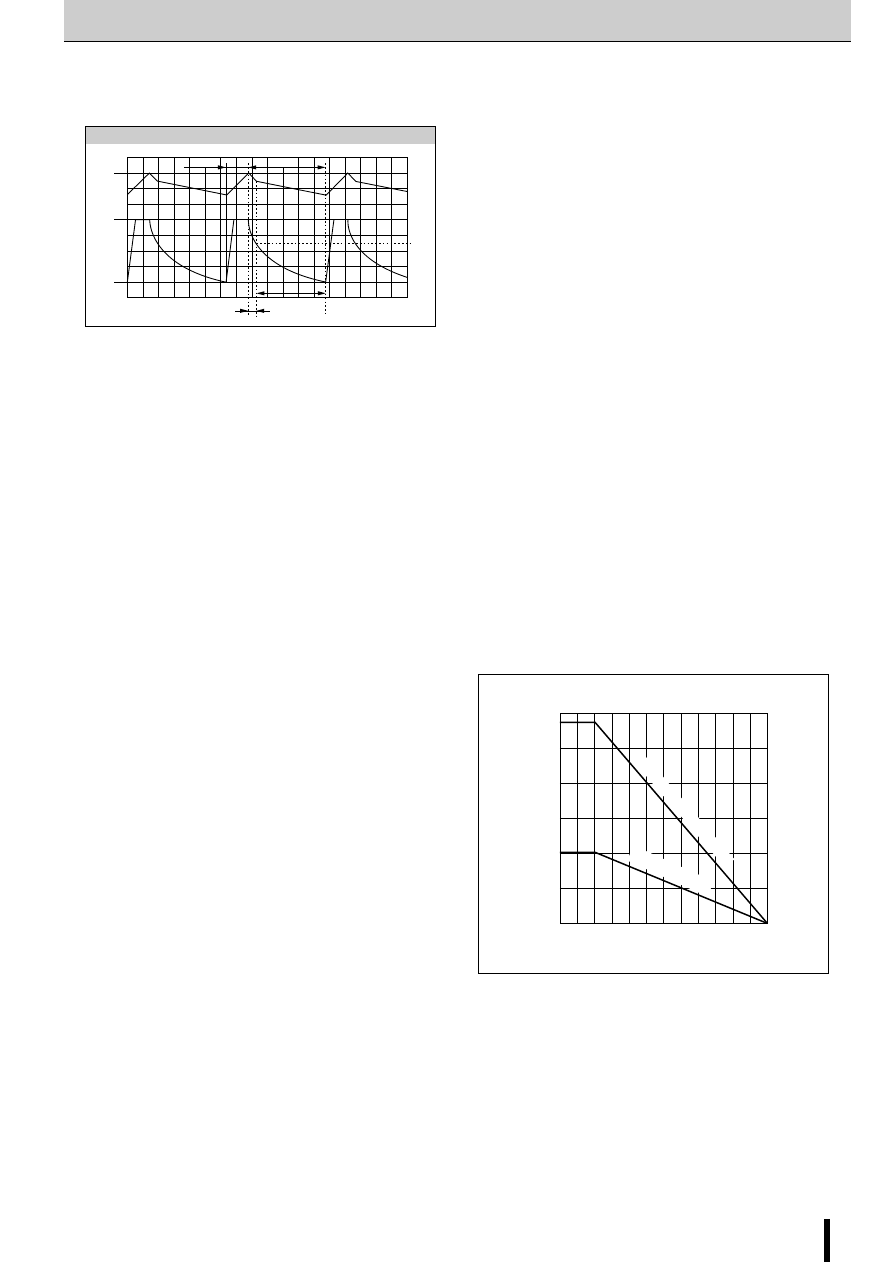

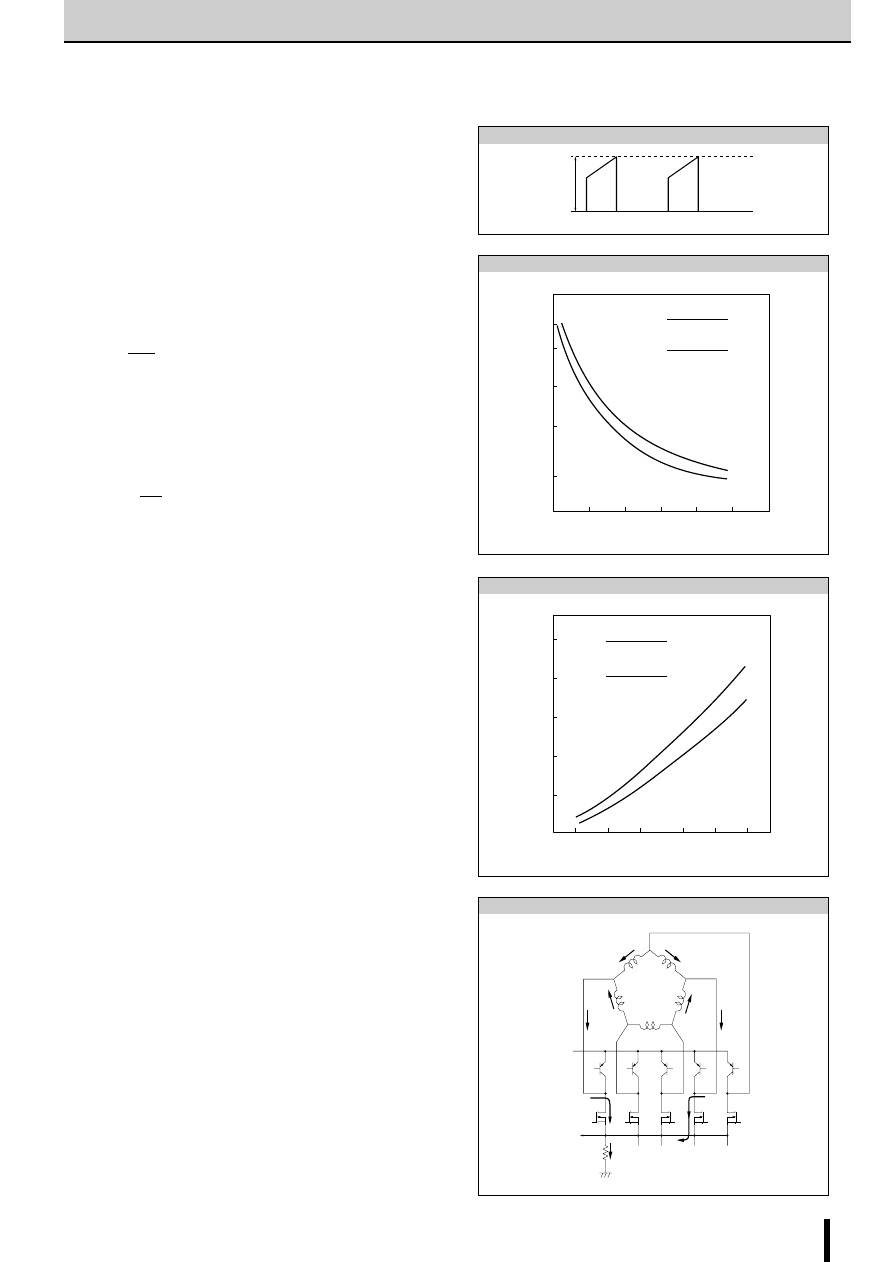

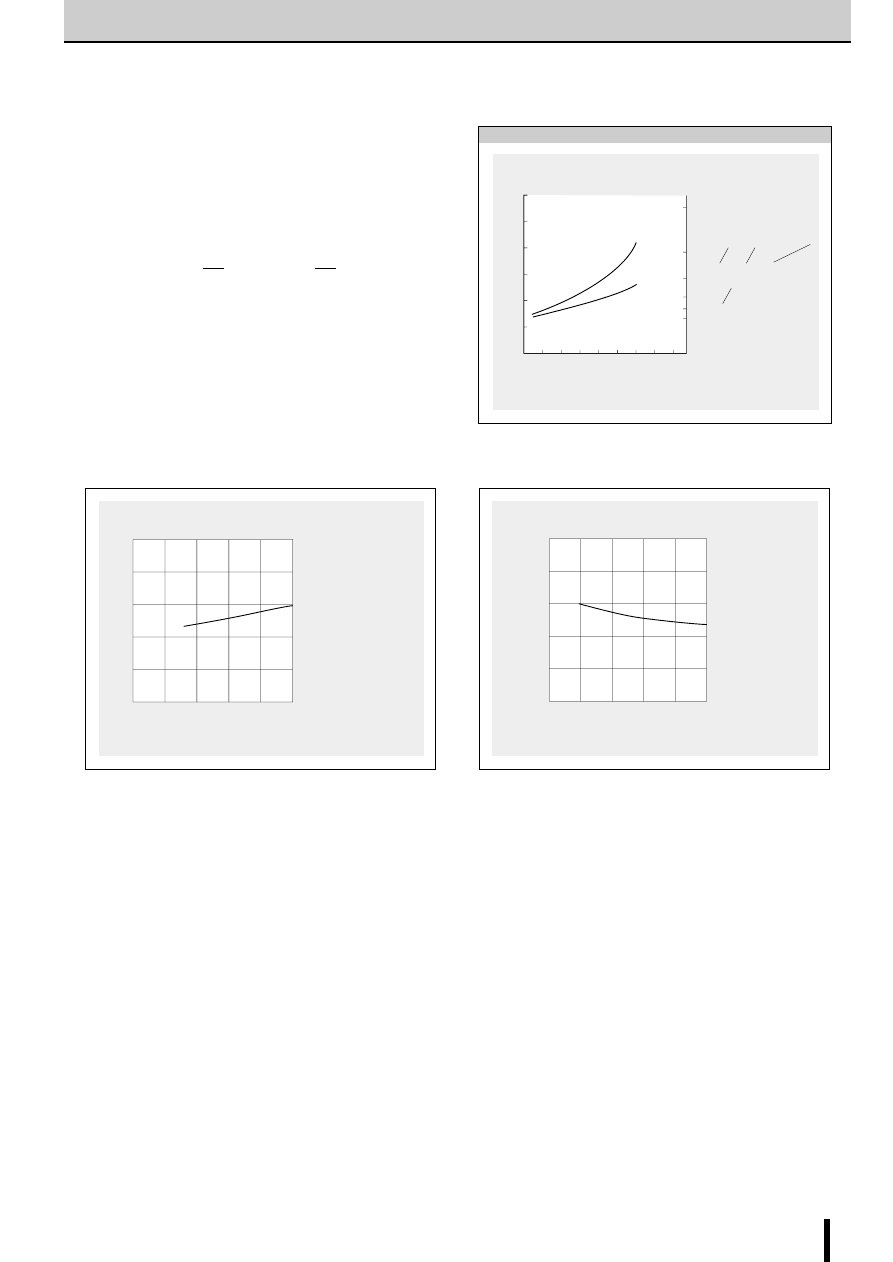

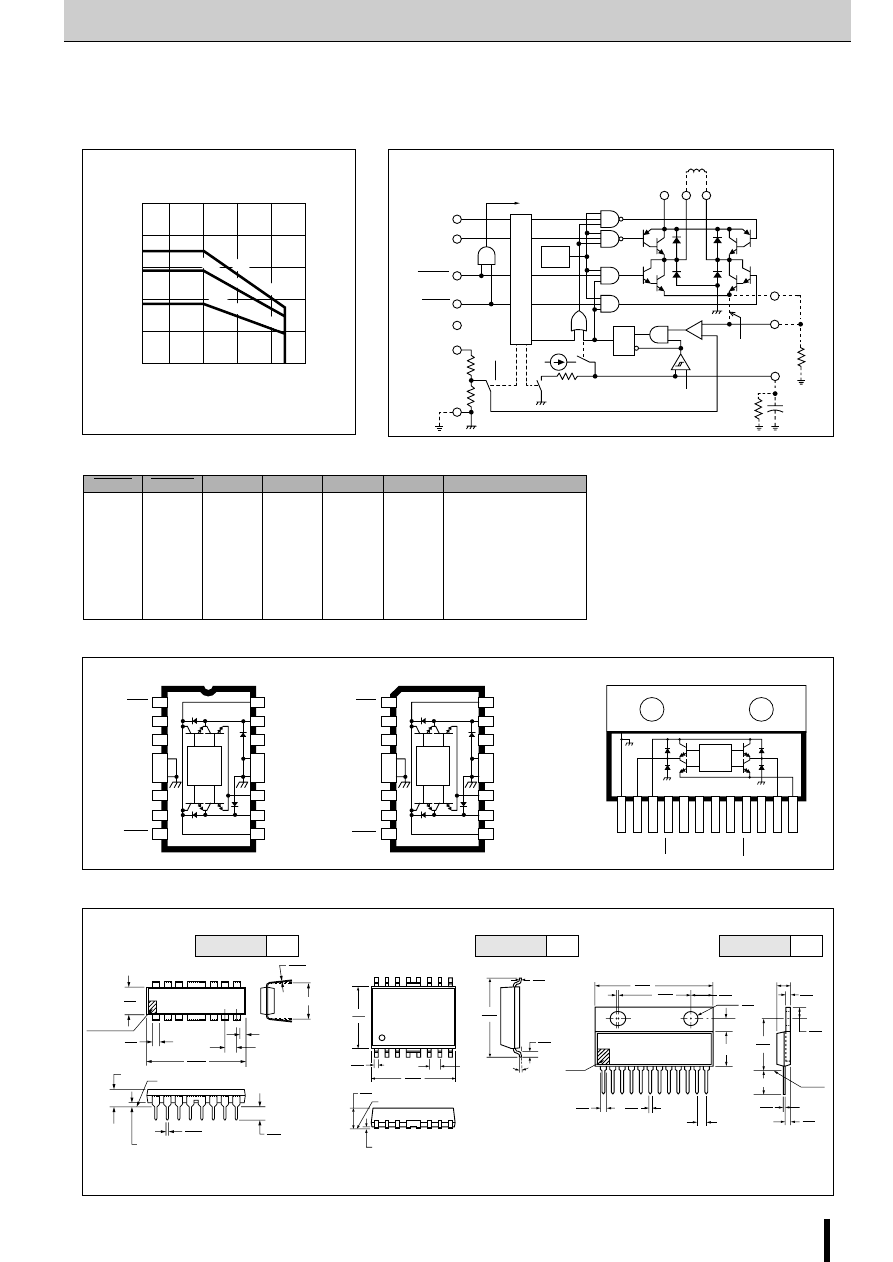

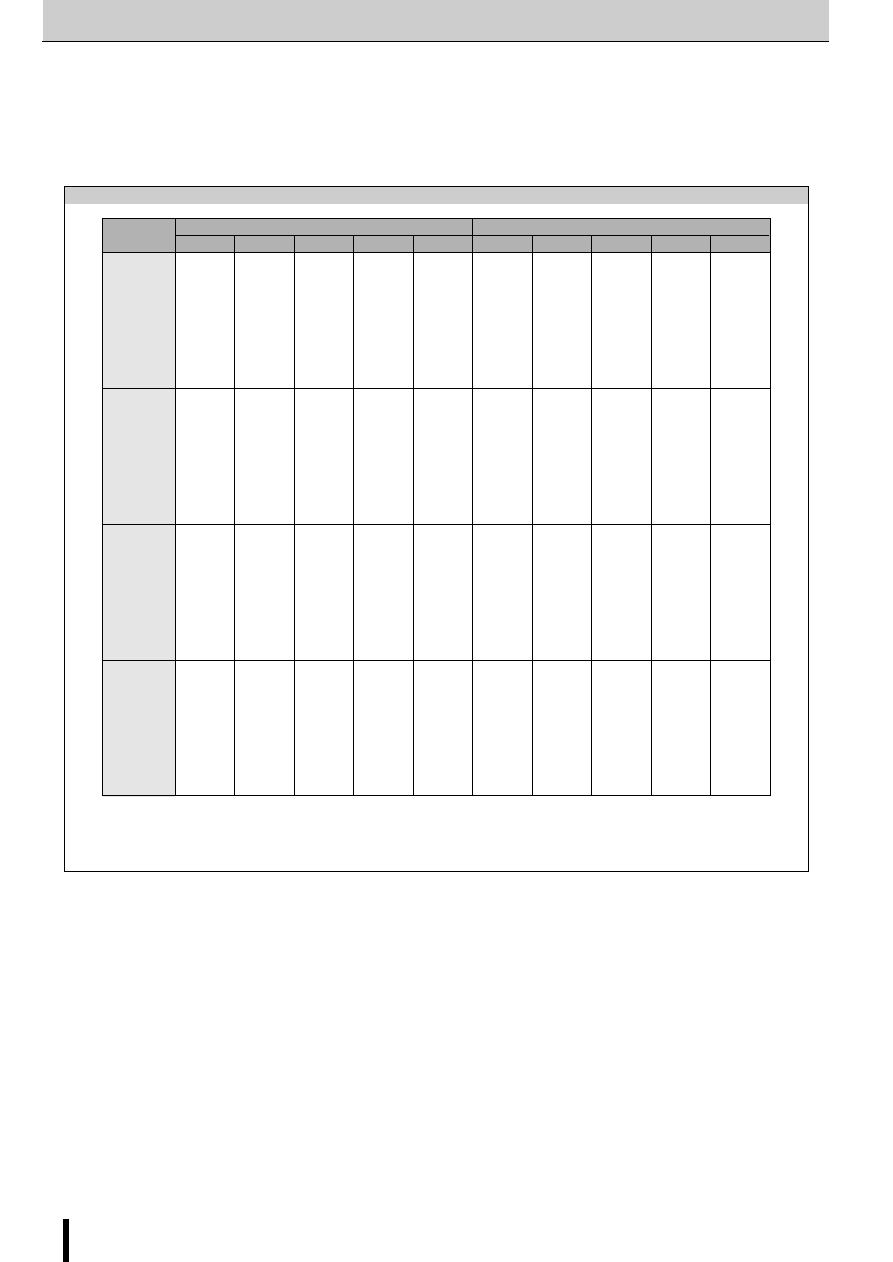

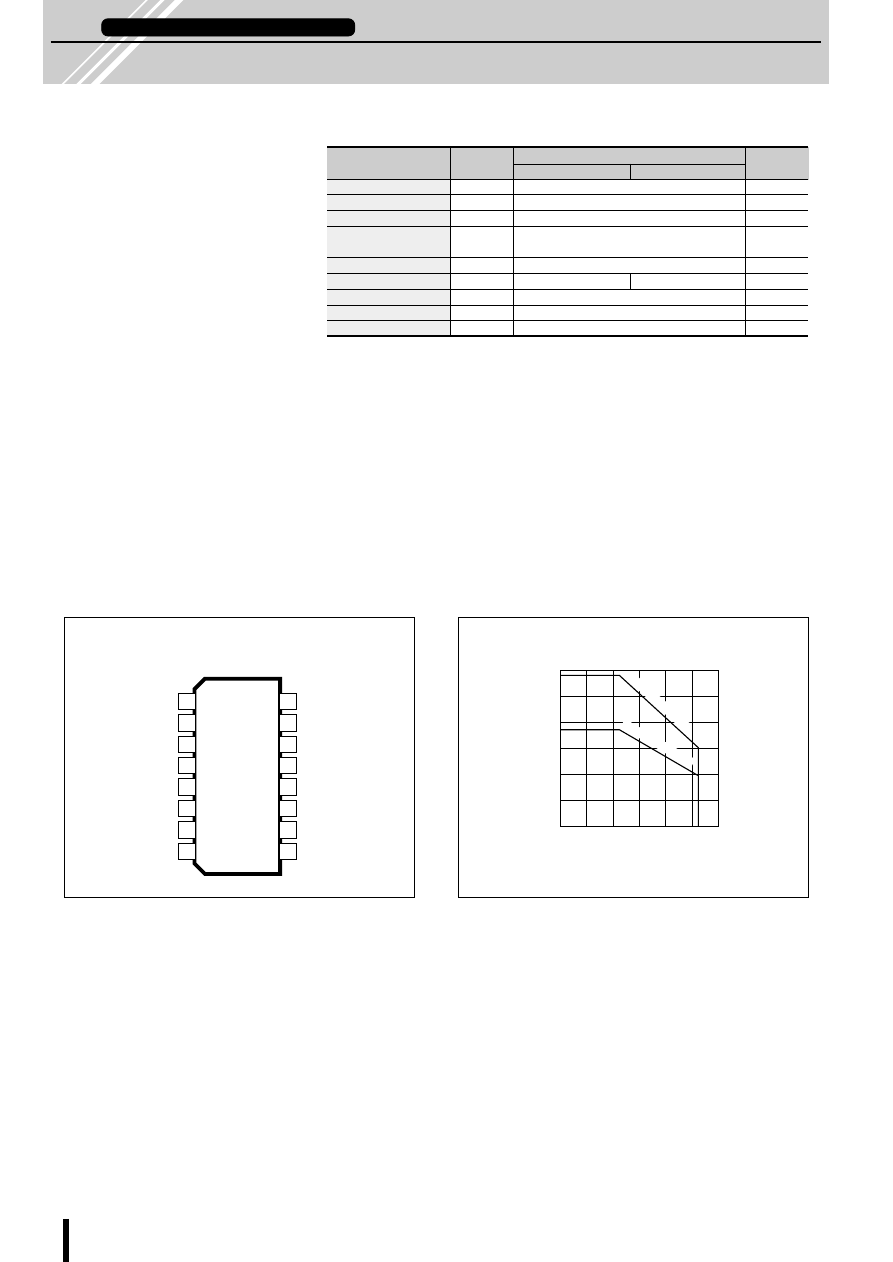

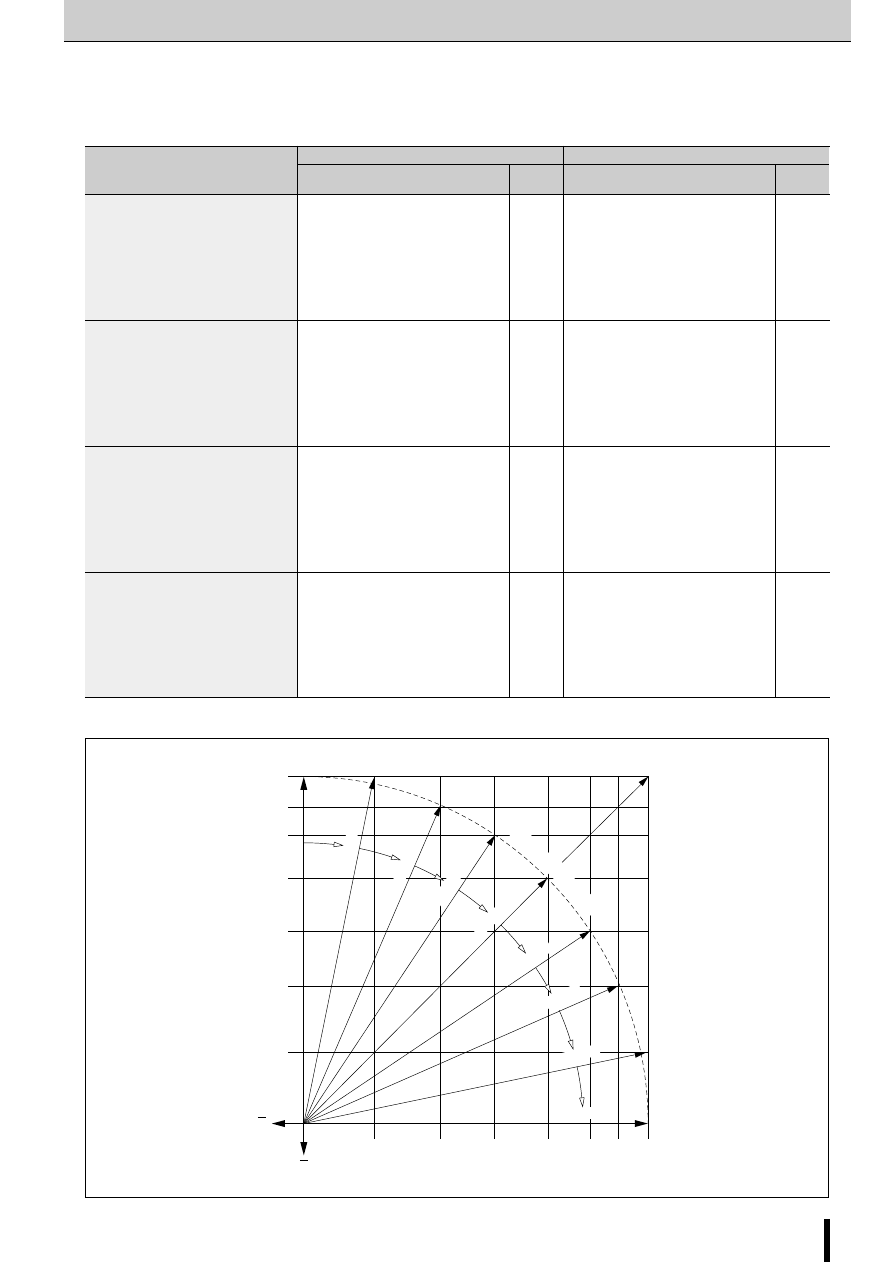

Notes on SLA7000/SMA7000 Series

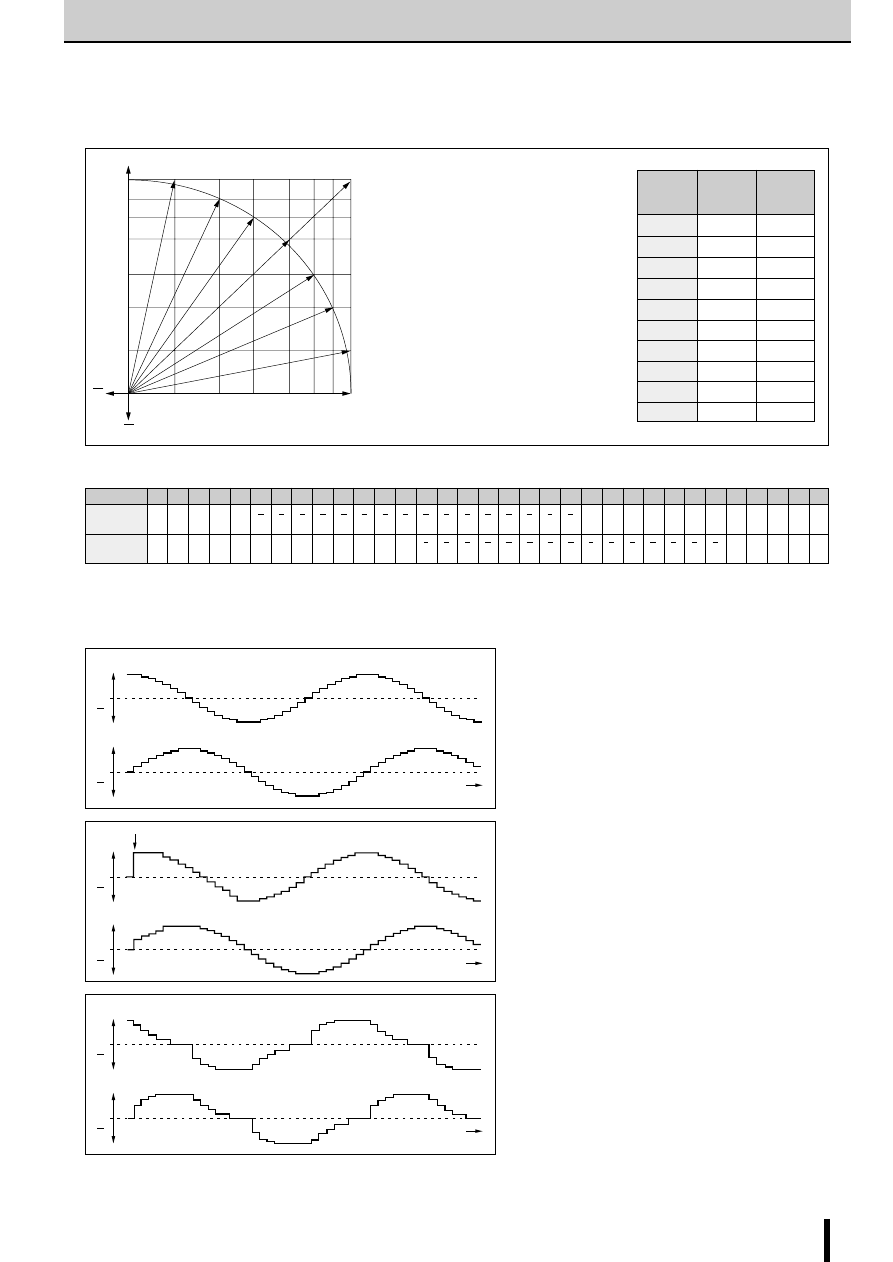

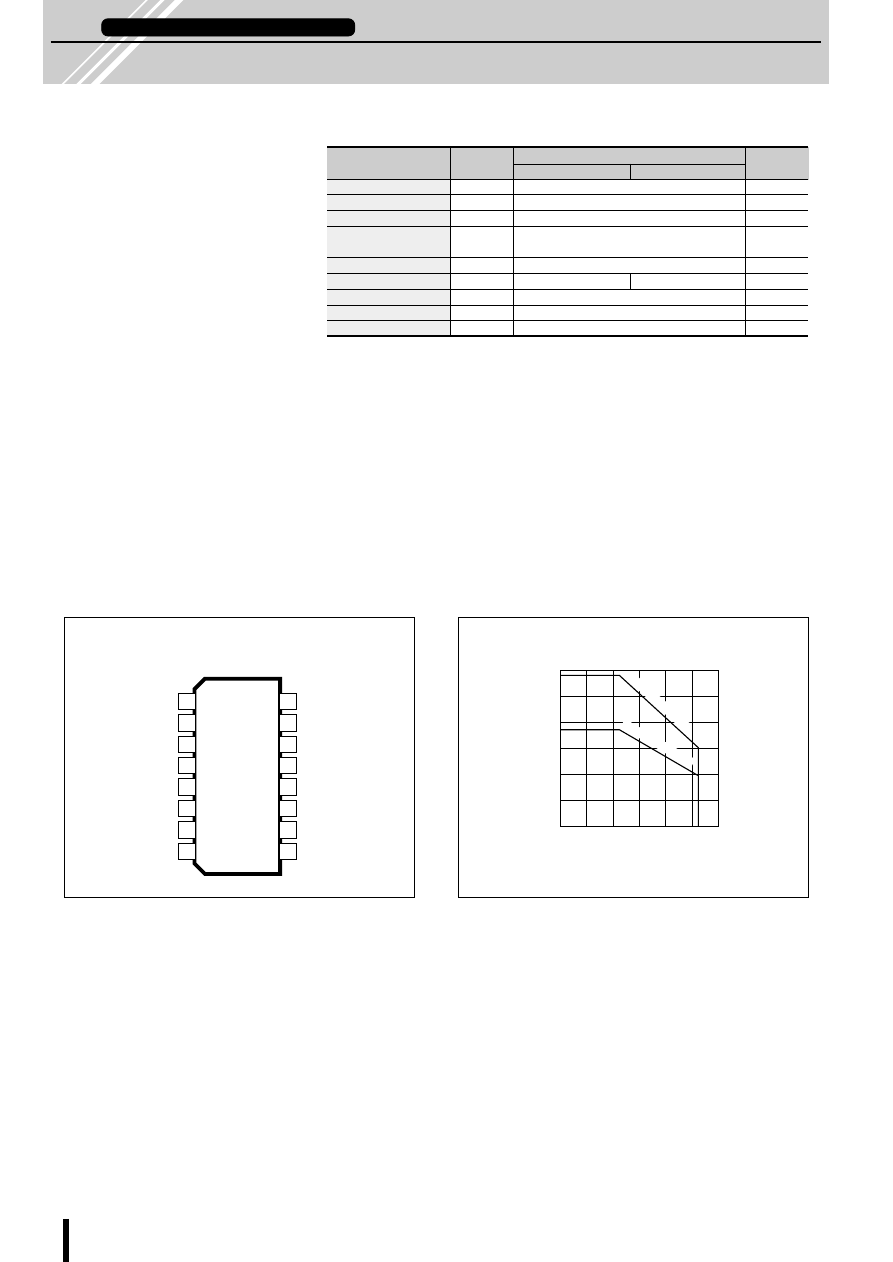

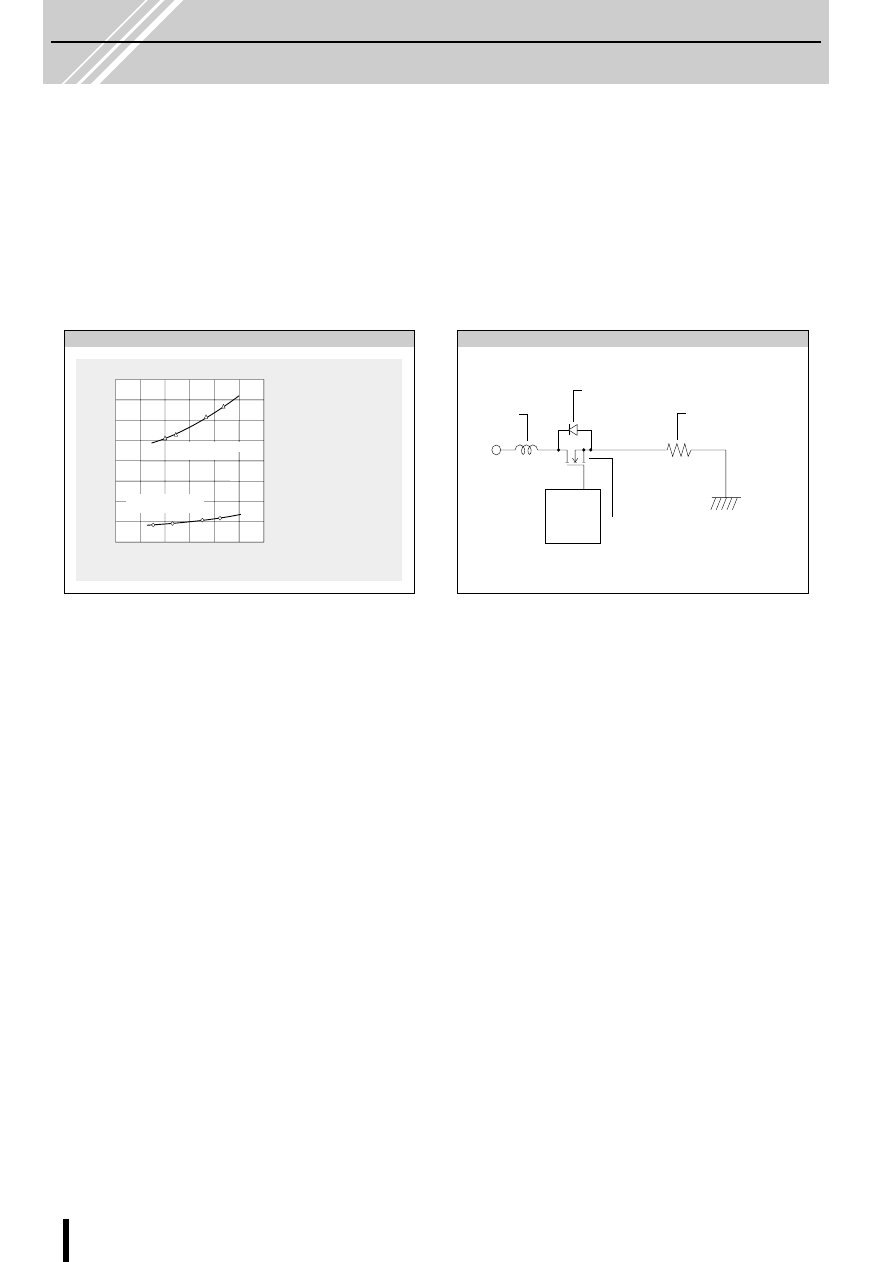

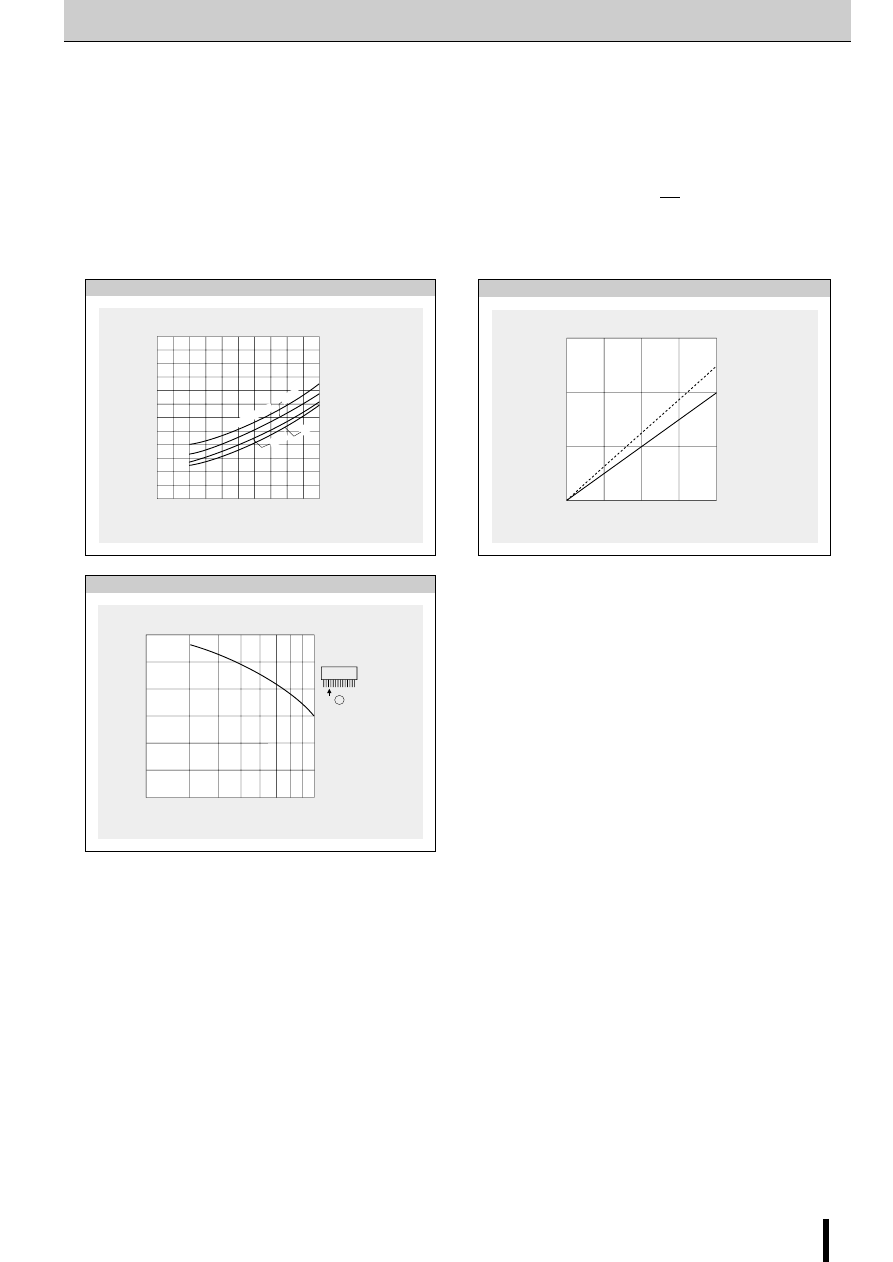

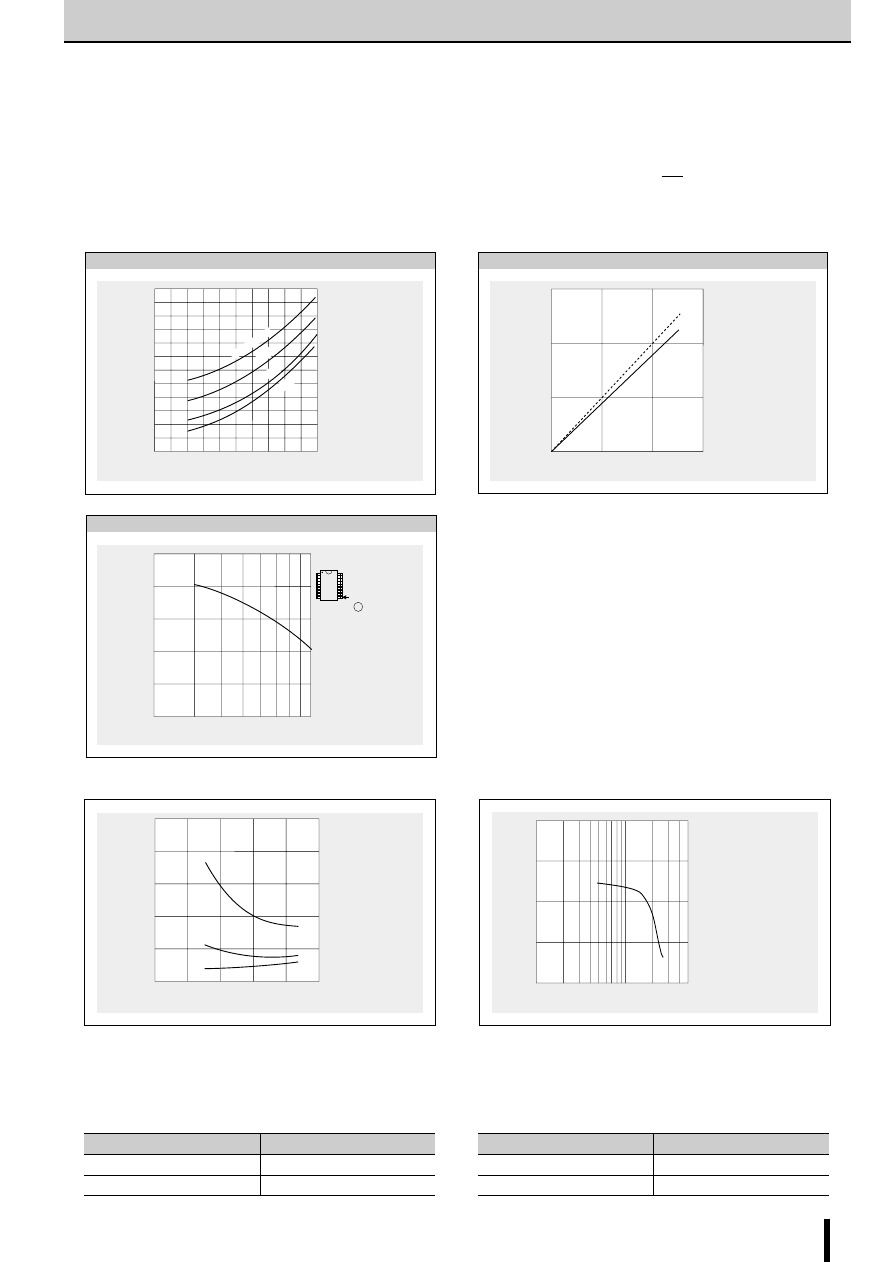

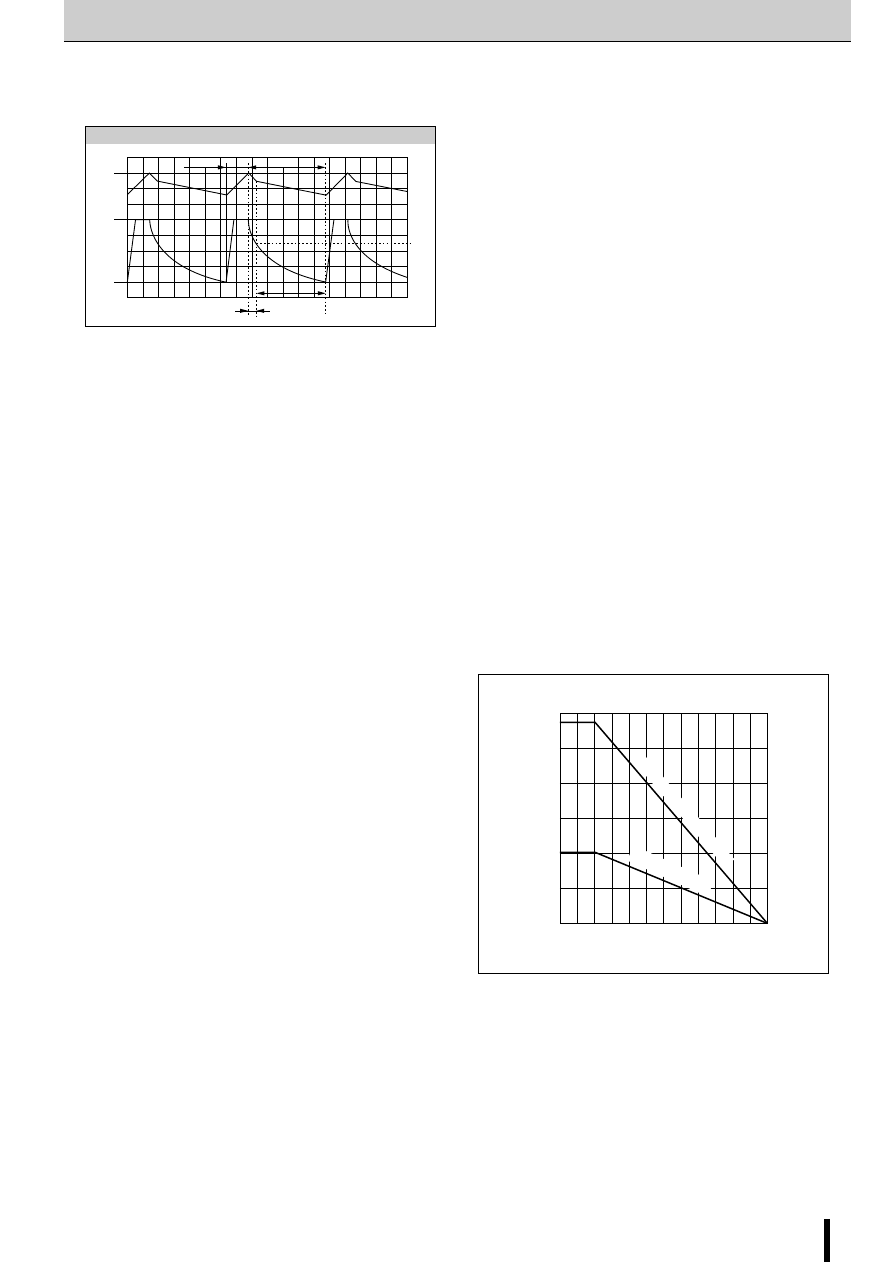

0

P

o

w

er dissipation

P

H

(W)

Supply voltage V

CC

(V)

8

7

6

5

4

3

2

1

0

10

20

30

40

50

Motor : 23LM-C202

I

O

: Output current

2-phase excitation, holding mode

I

O

=1A

I

O

=1A

SLA7024M, SLA7029M

SMA7029M

Sanken product: SI-7300A

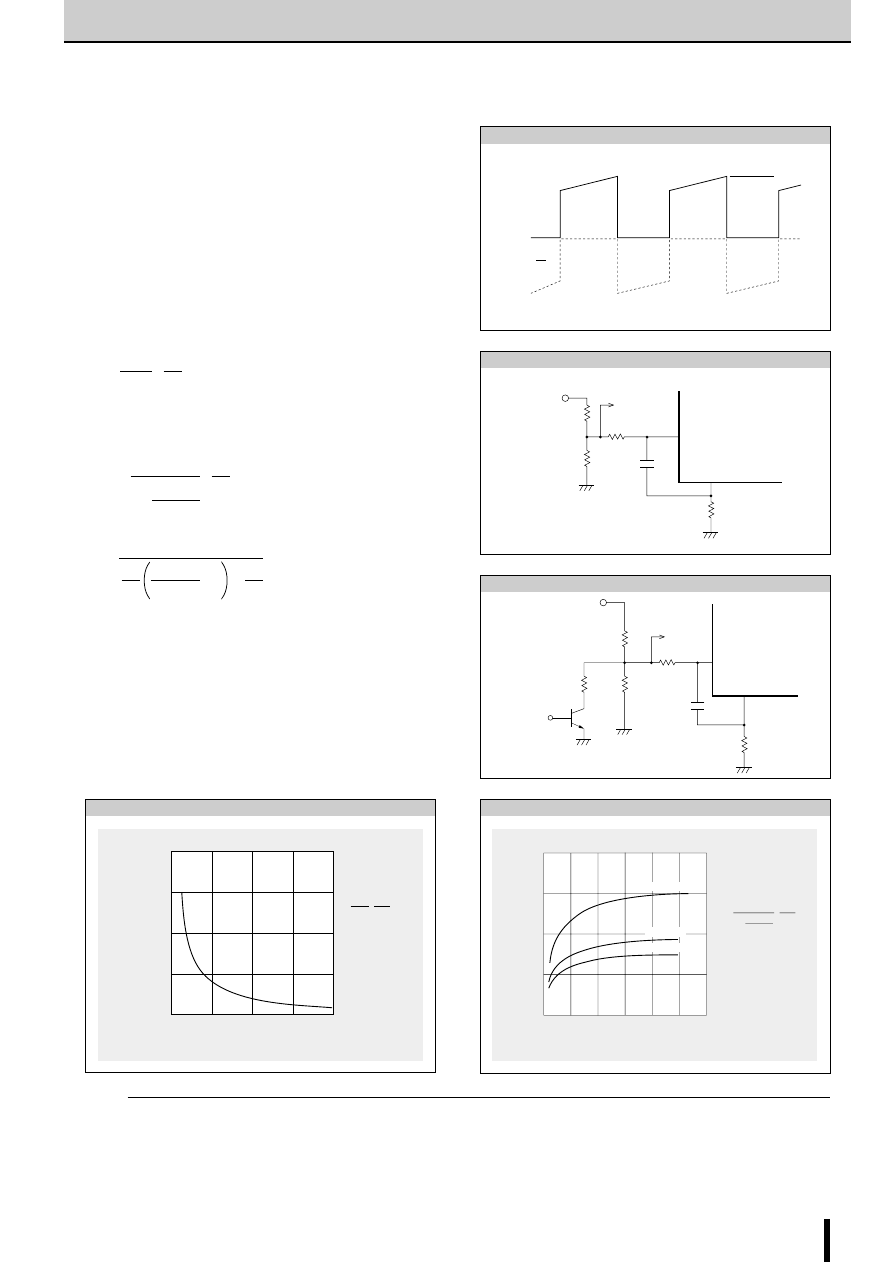

Comparison of power dissipation.

■

Features

●

Employs a constant-current chopper control method.

●

Integrates power MOSFETs and monolithic chip control cir-

cuitry in a single package.

●

One-fifth the size and one-fourth the power dissipation com-

pared with conventional SANKEN ICs

■

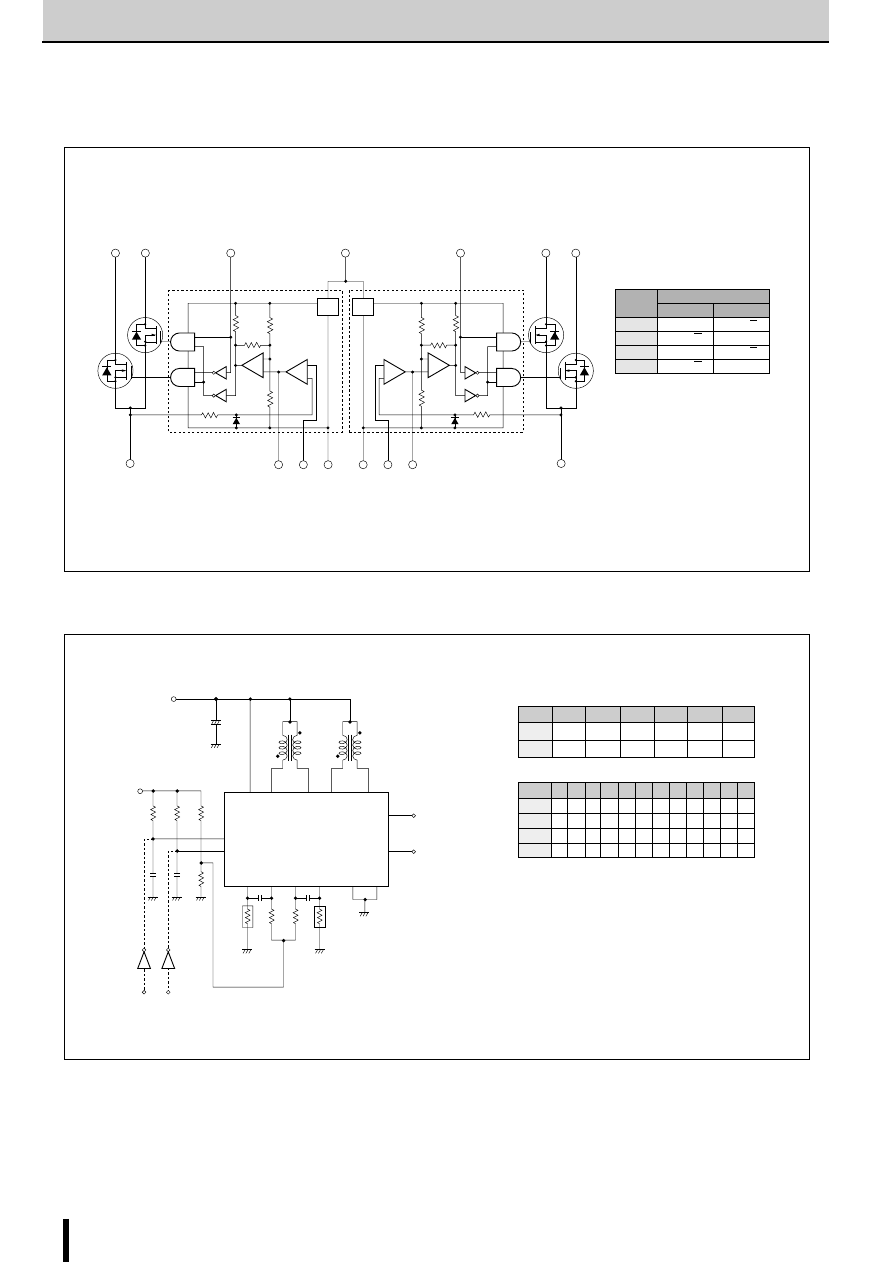

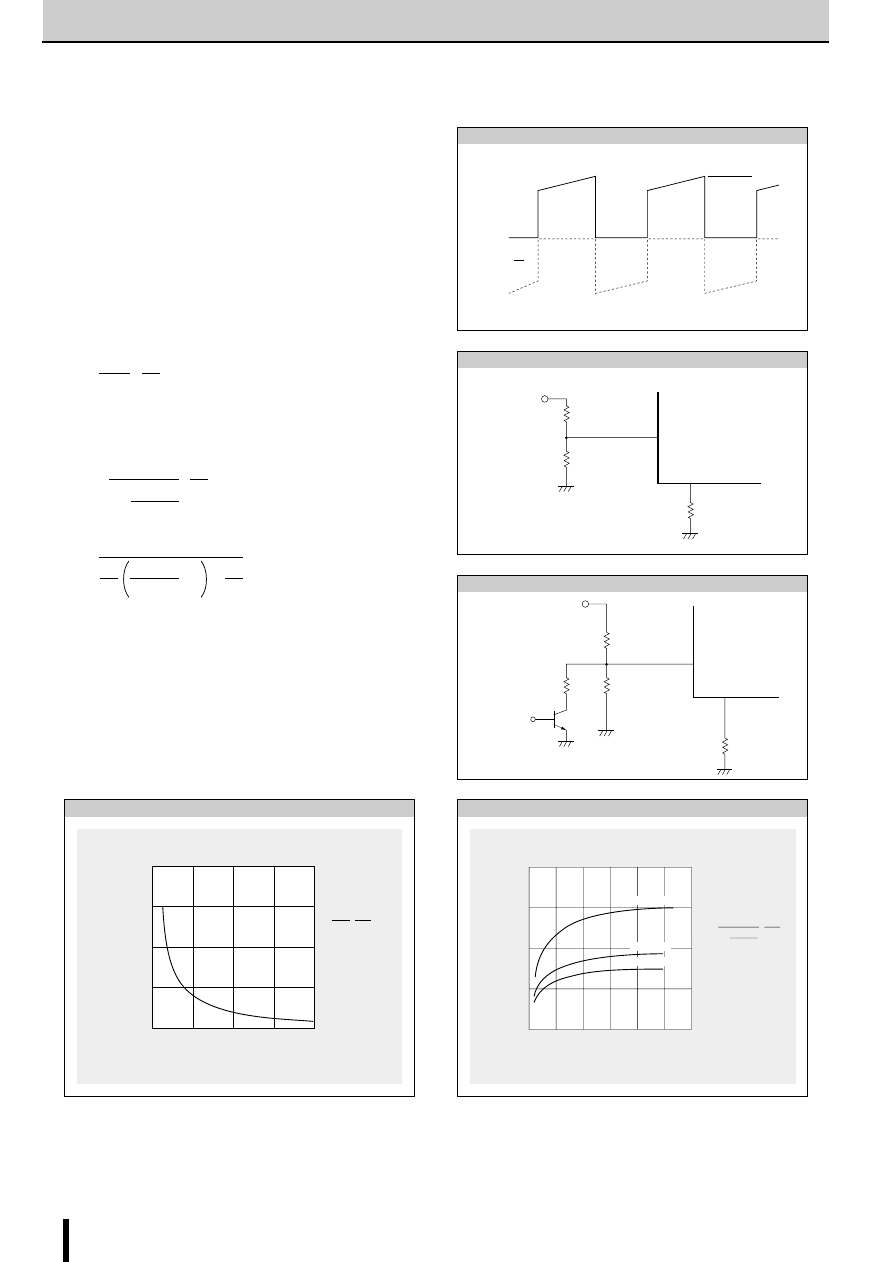

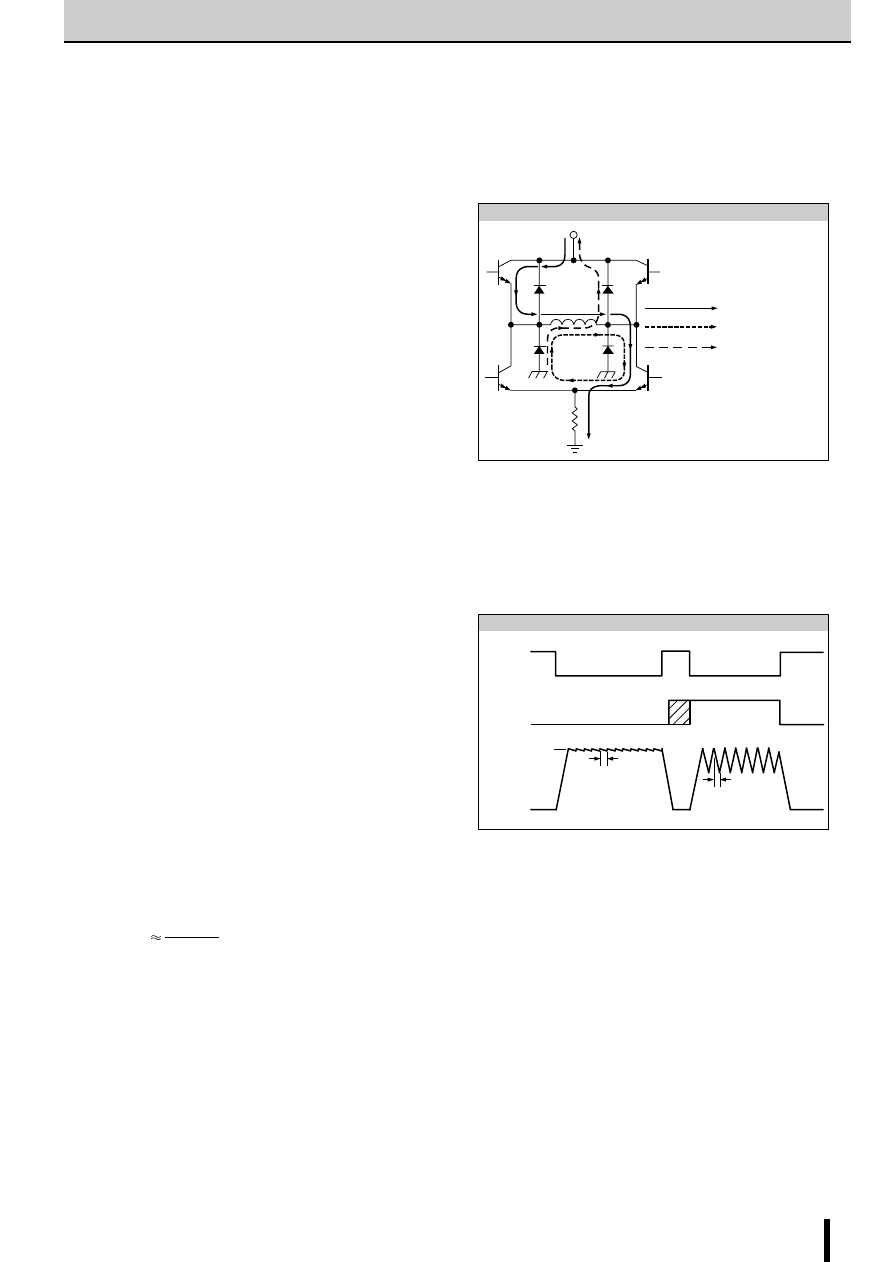

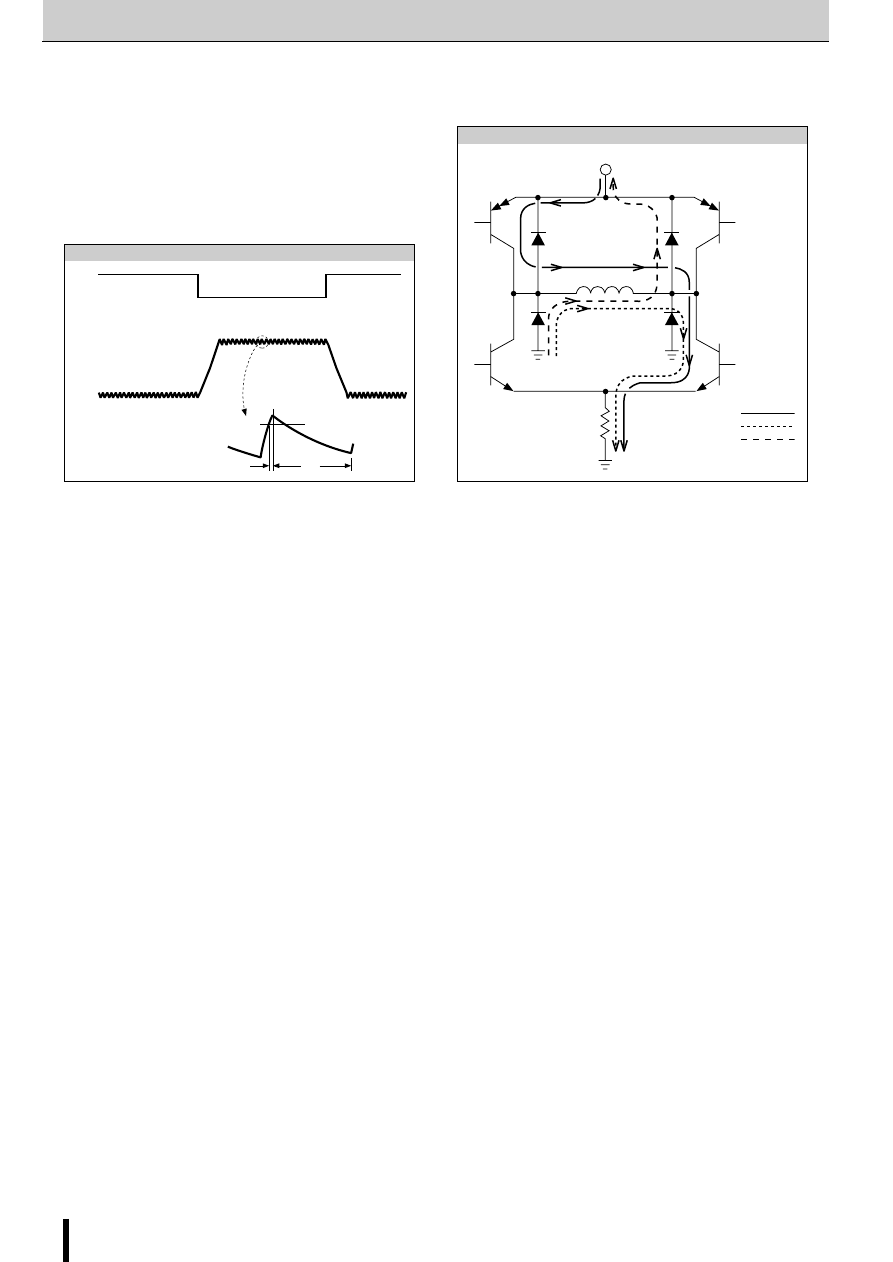

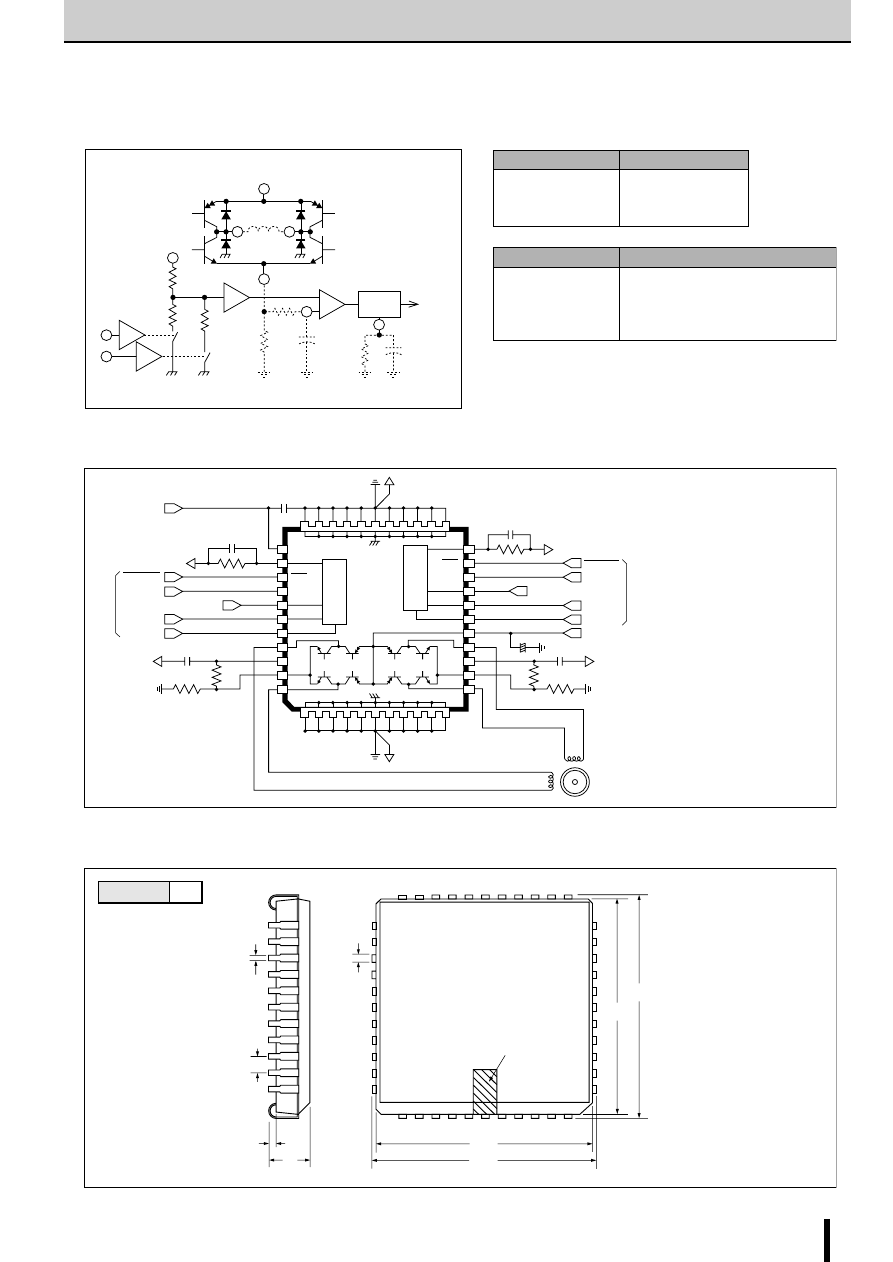

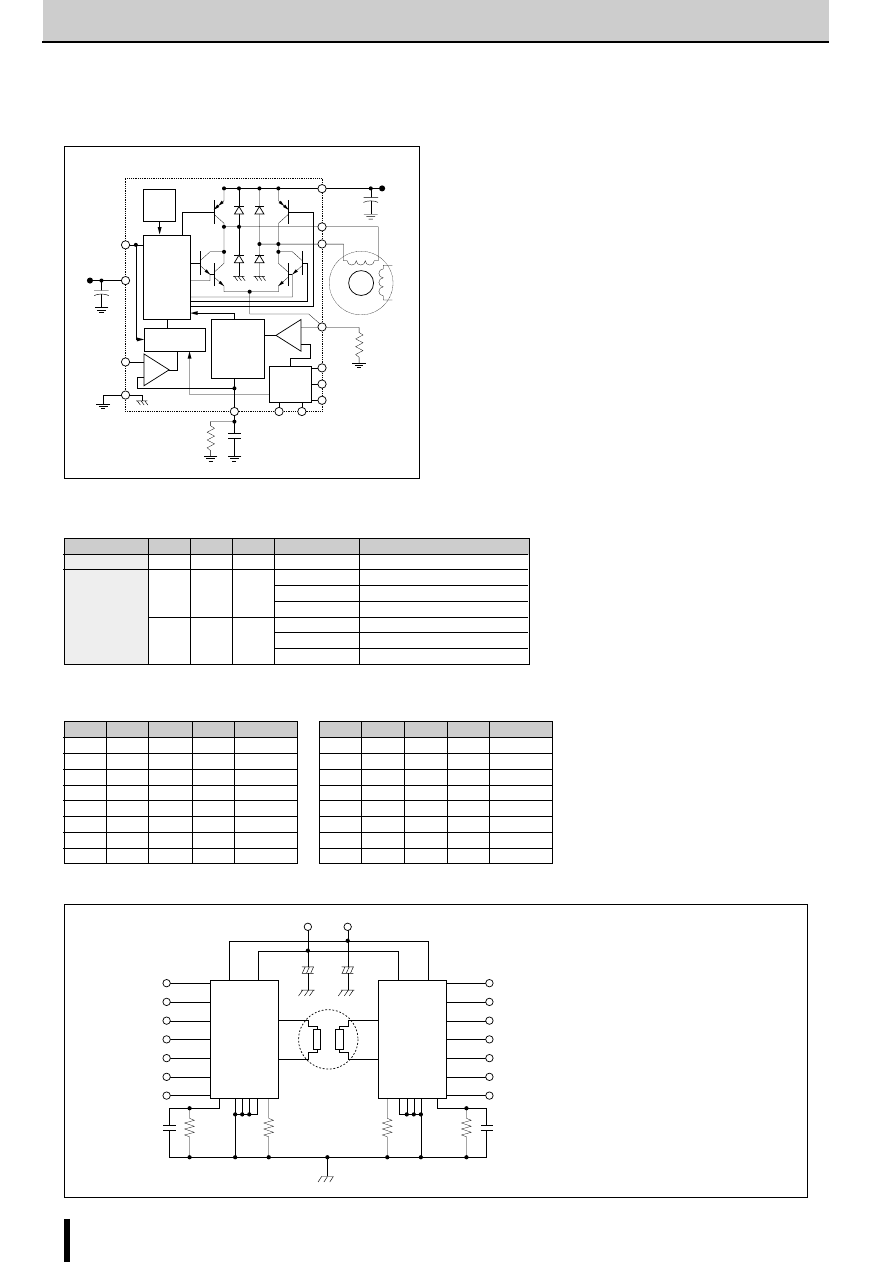

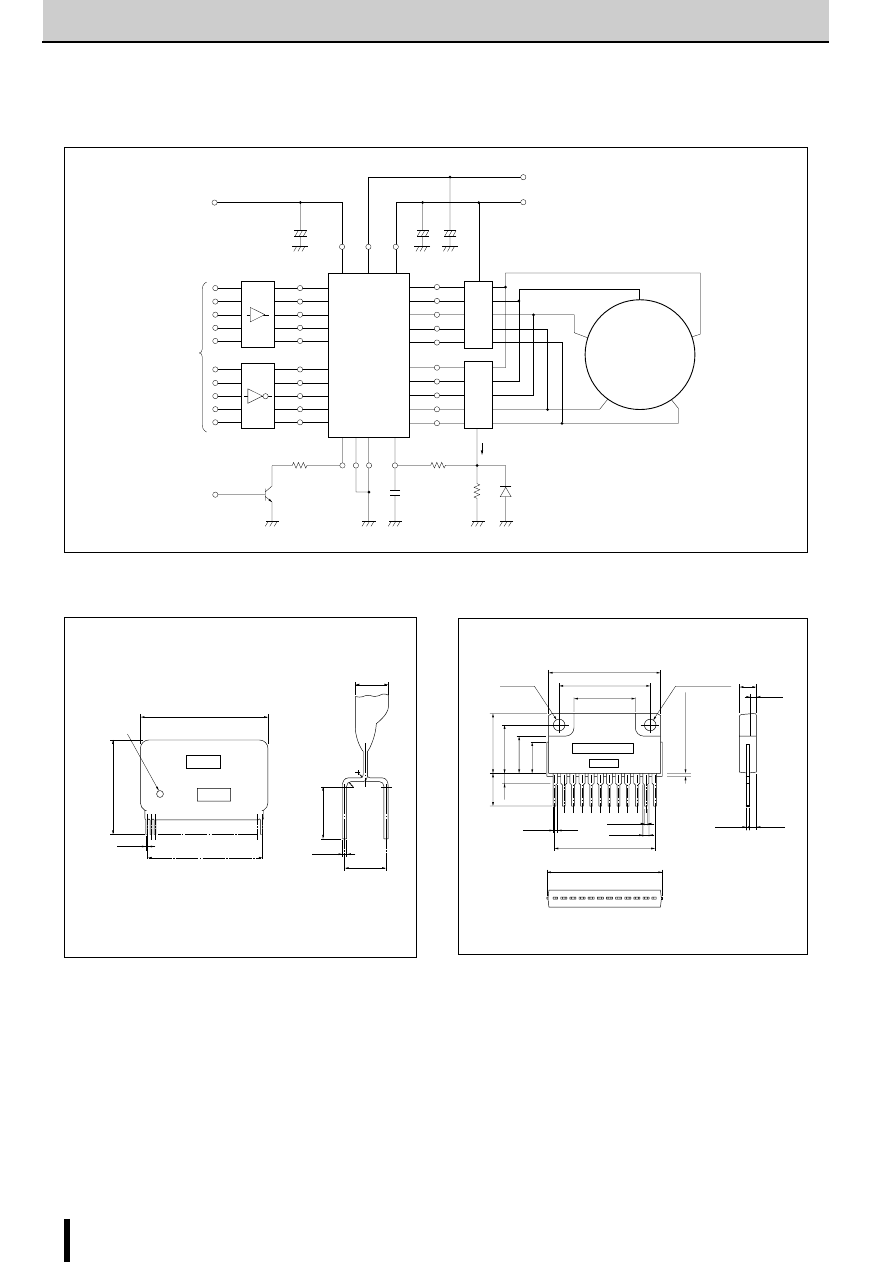

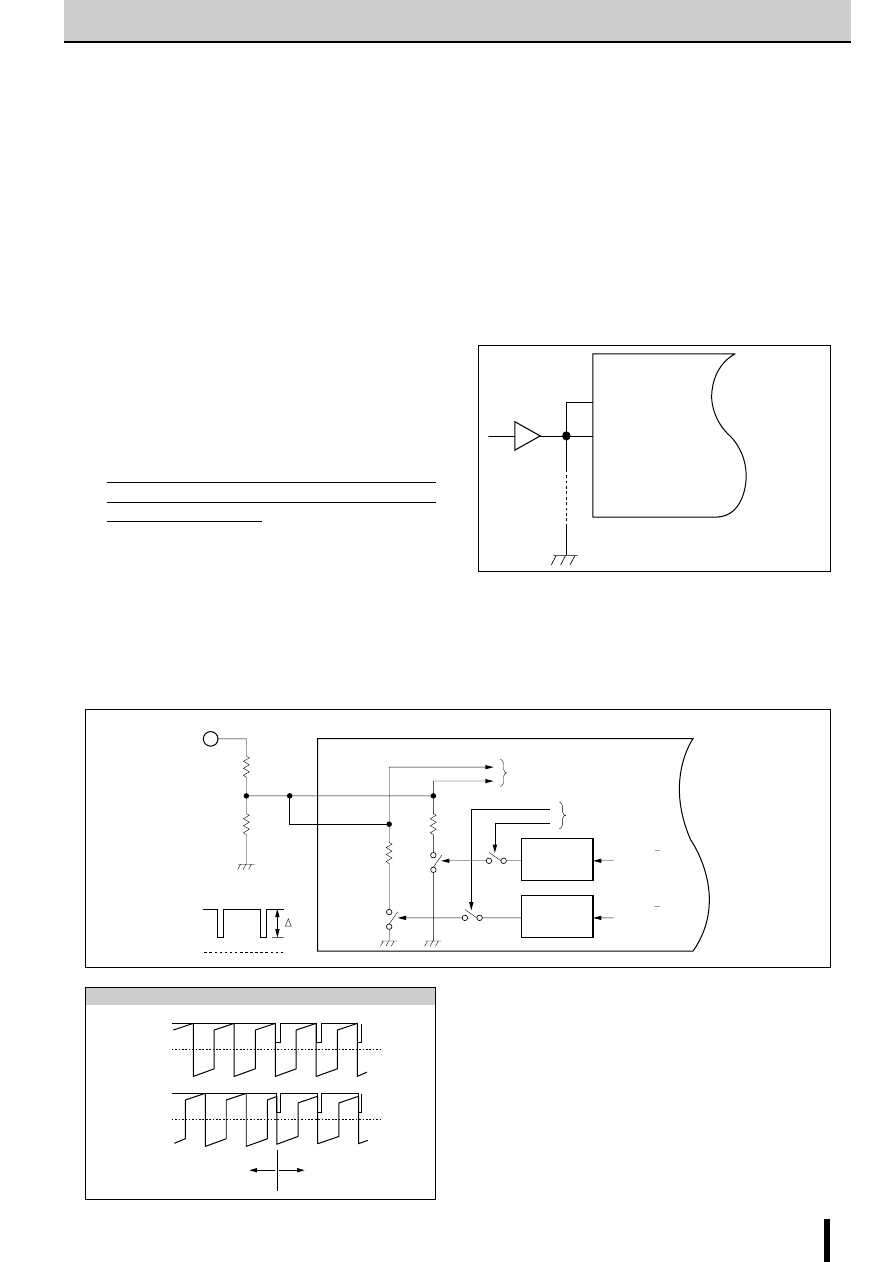

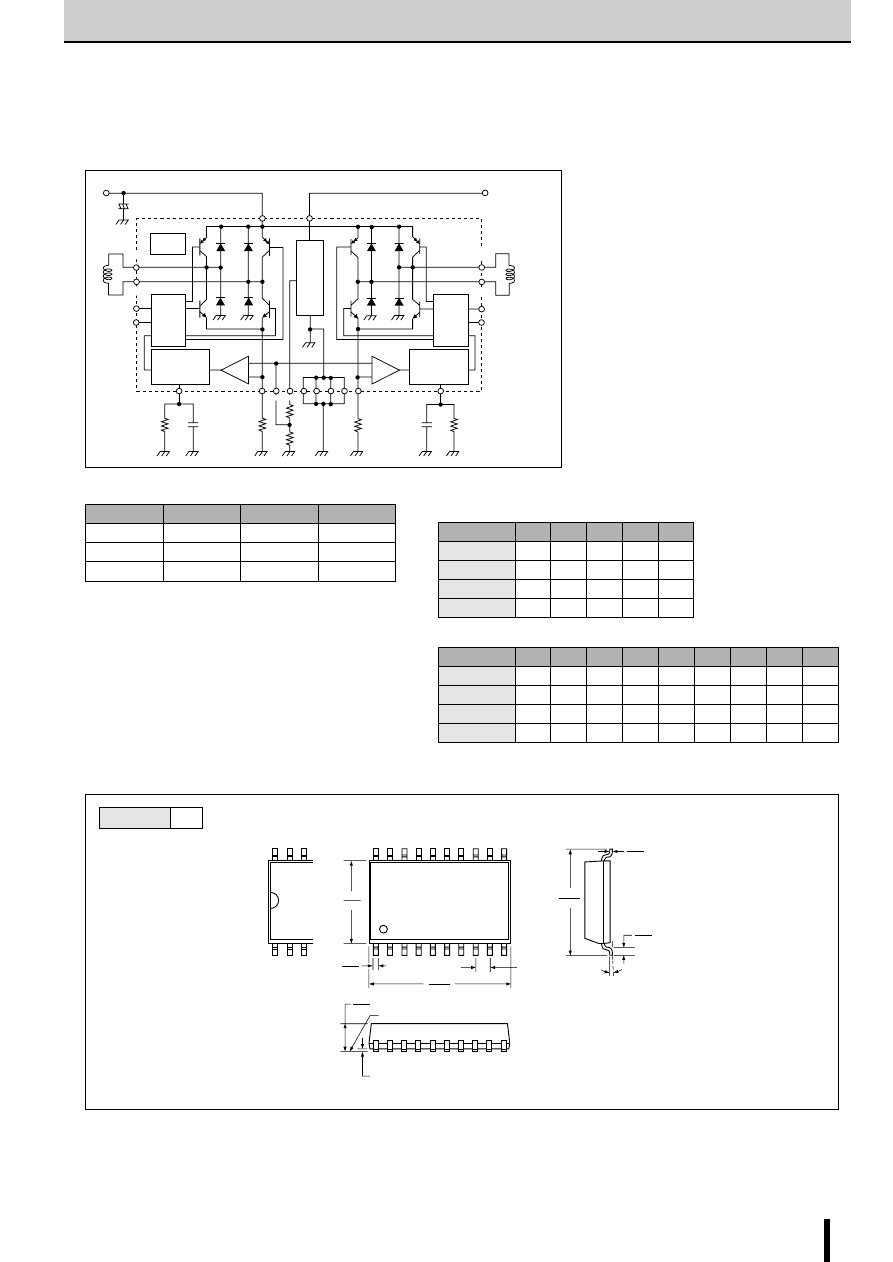

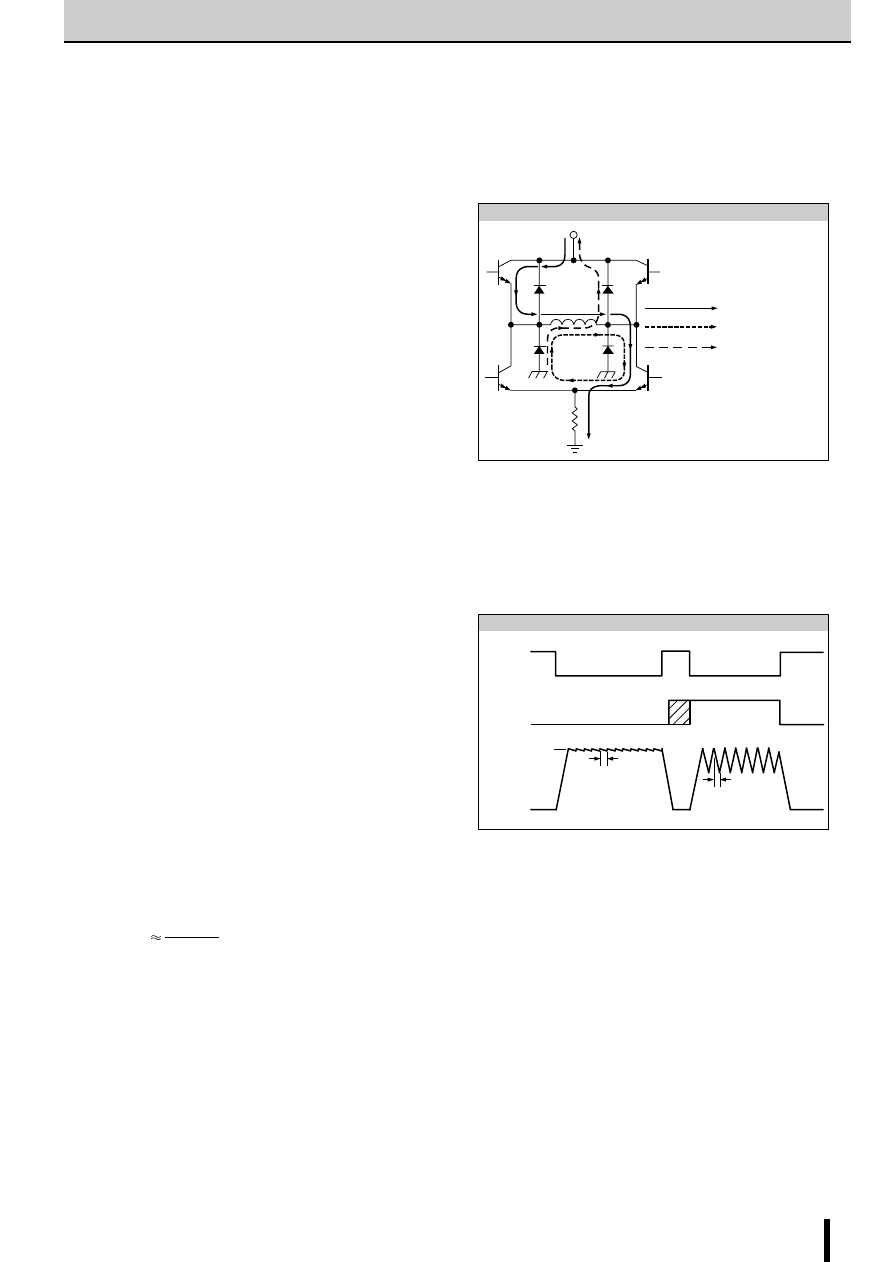

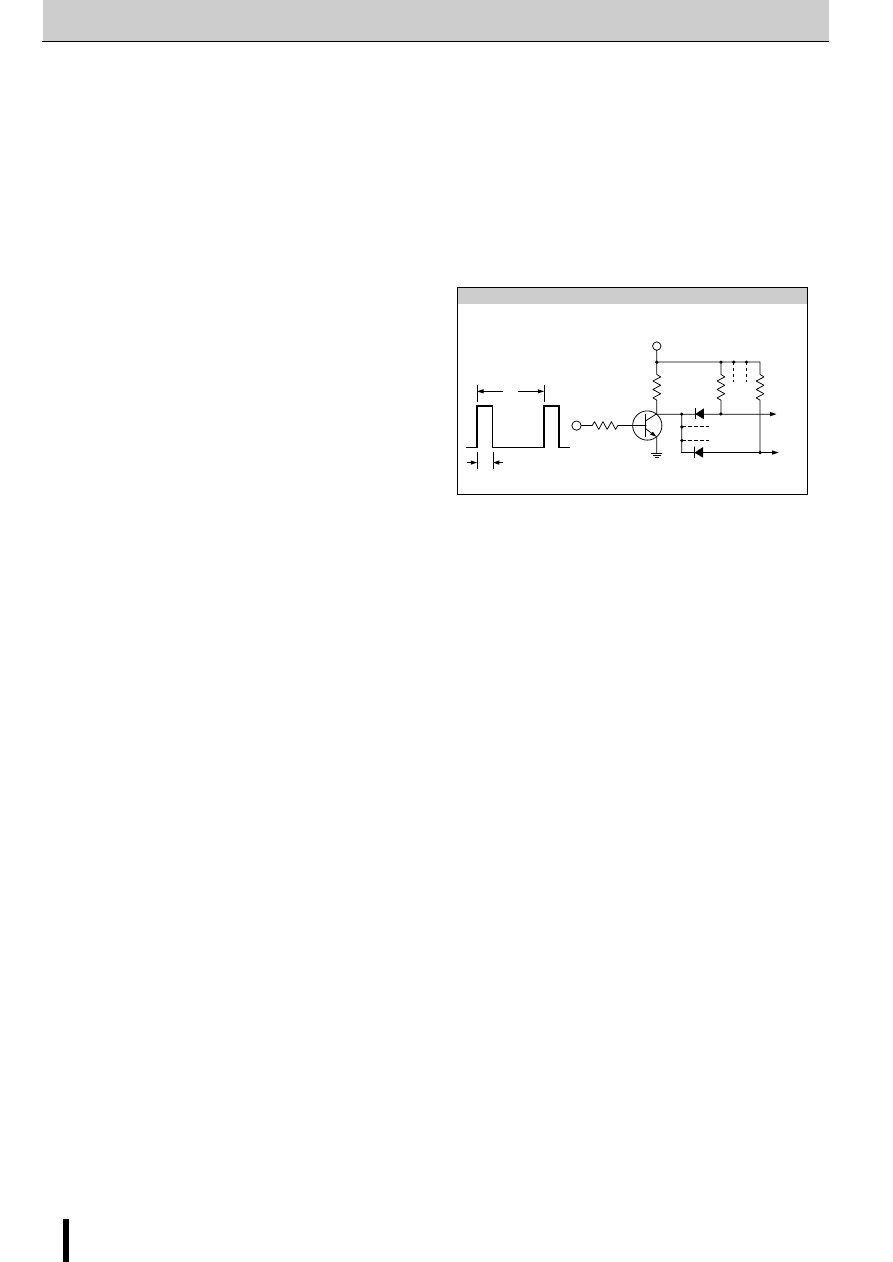

Constant Current Chopper Method

In the constant current chopper method, a voltage higher than

the rated voltage of the motor is applied and when the current

rises, the chopper transistor is switched on thereby shortening

the current rise time. After the current rises, the coil current is

held by the PWM chopper to a constant current level deter-

mined by the current sense resistor. This method has the ad-

vantage of improving the motor's high frequency response and

the efficiency response and efficiency of the driver circuitry.

●

Eliminates the need for heatsink thereby decreasing part-in-

sertion workload and increasing flexibility in mounting.

●

Reduces the size of power supplies required.

●

Lineup: 2-phase excitation, 2-phase/1-2 phase excitation,

2W1-2 phase micro-step support ICs

■

Applications

The SLA7000 and SMA7000 series are ideal for the following

applications.

●

Sheet feeders and carriage drivers in printers.

●

Sheet feeders for PPC and facsimile machines.

●

Numeric control equipment.

●

Industrial robots.

■

Handling Precautions

●

Recommended screw torque

0.588 to 0.784 [N

•

m](6.0 to 8.0 [kgf

•

cm])

●

Recommended silicon grease

Shin-Etsu Chemical Co., Ltd.: G746

GE Toshiba Silicone Co., Ltd.: YG-6260

Dow Corning Toray Silicone Co., Ltd.: SC102

Please be careful when selecting silicone grease since the oil

in some grease may penetrate the product, which will result

in an extremely short product life.

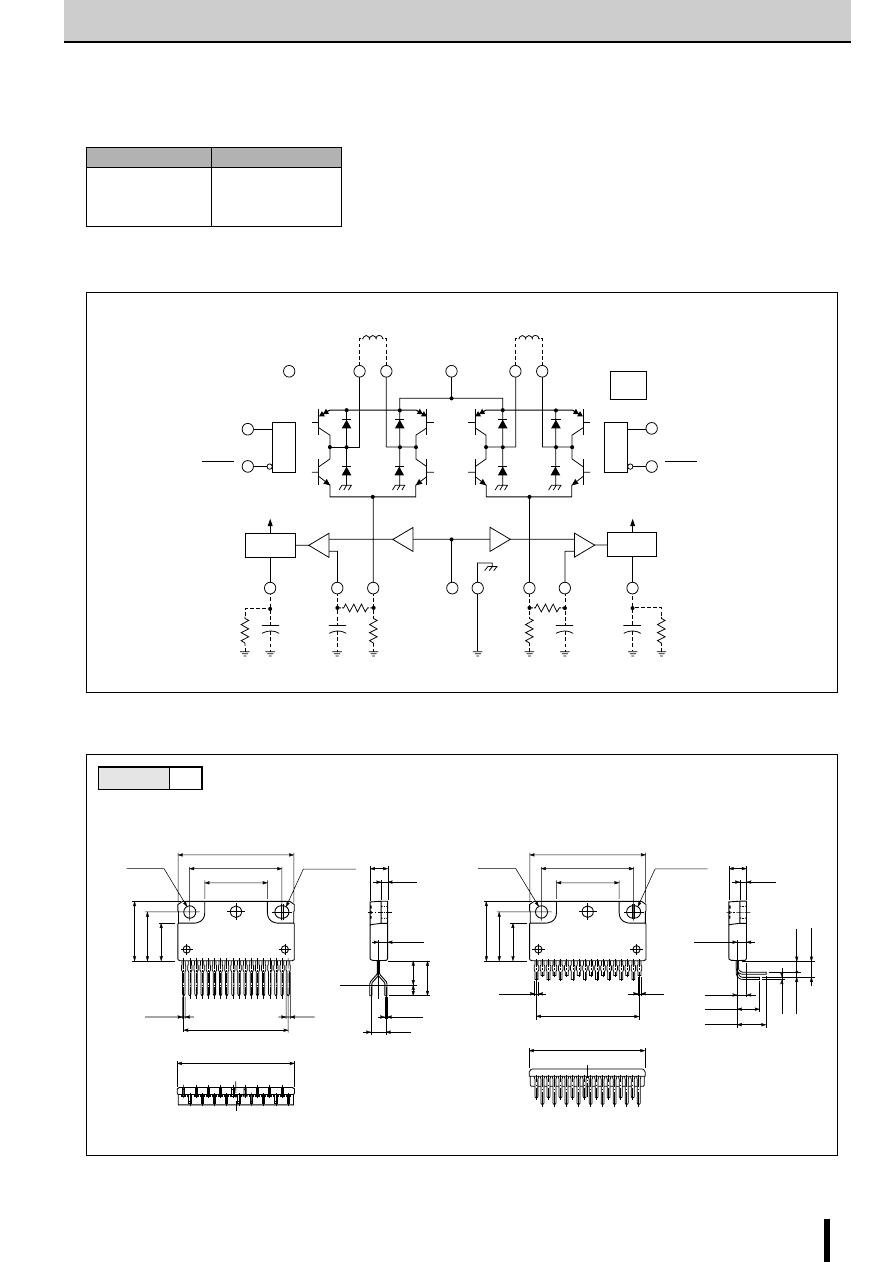

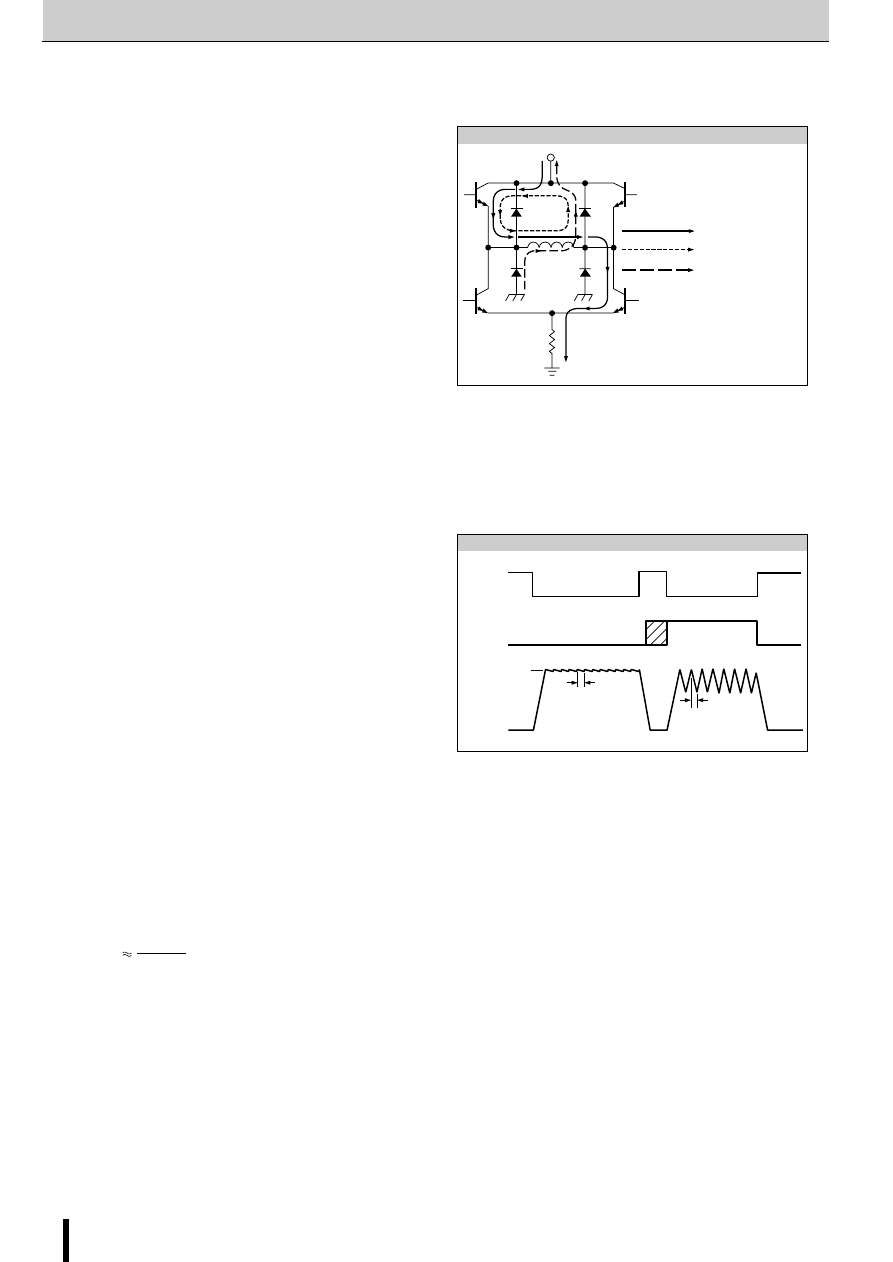

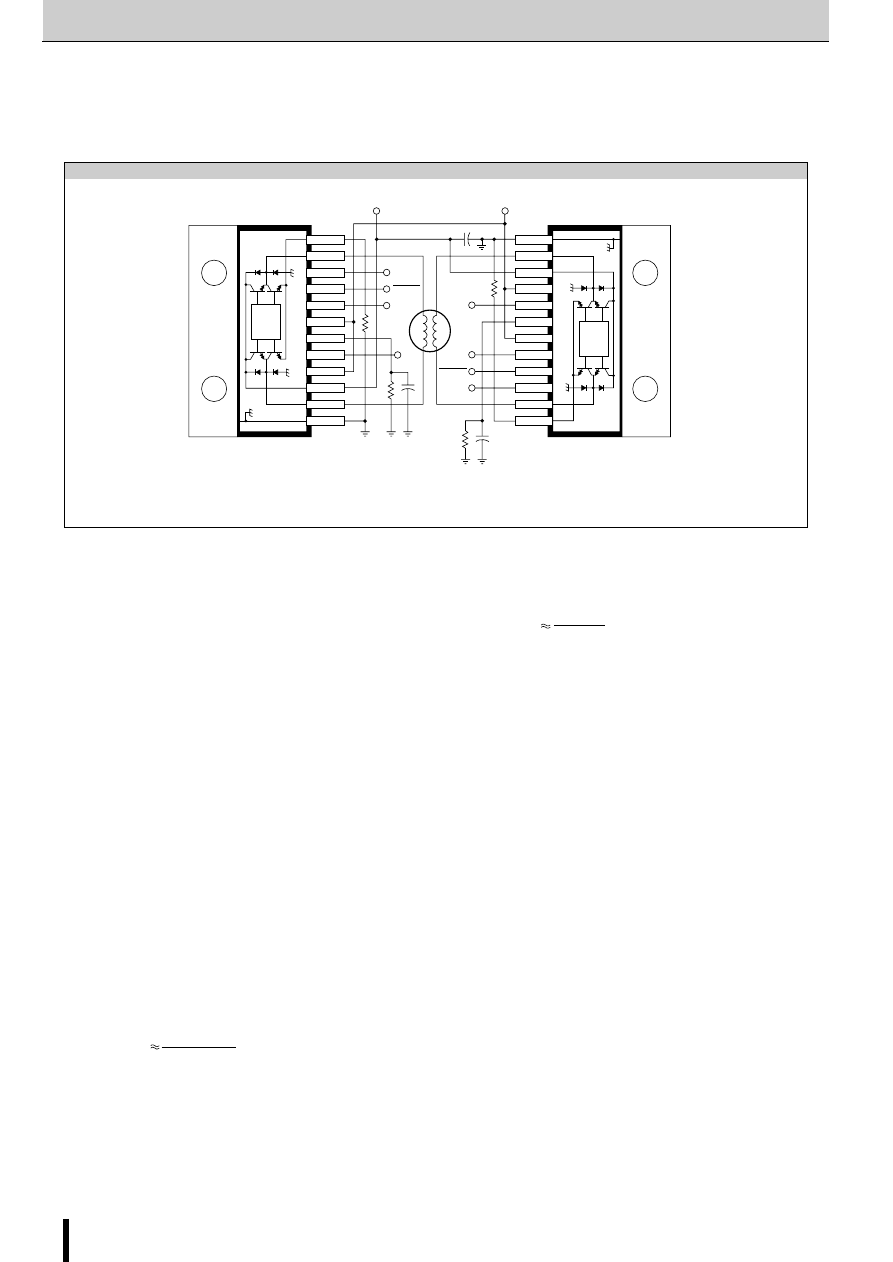

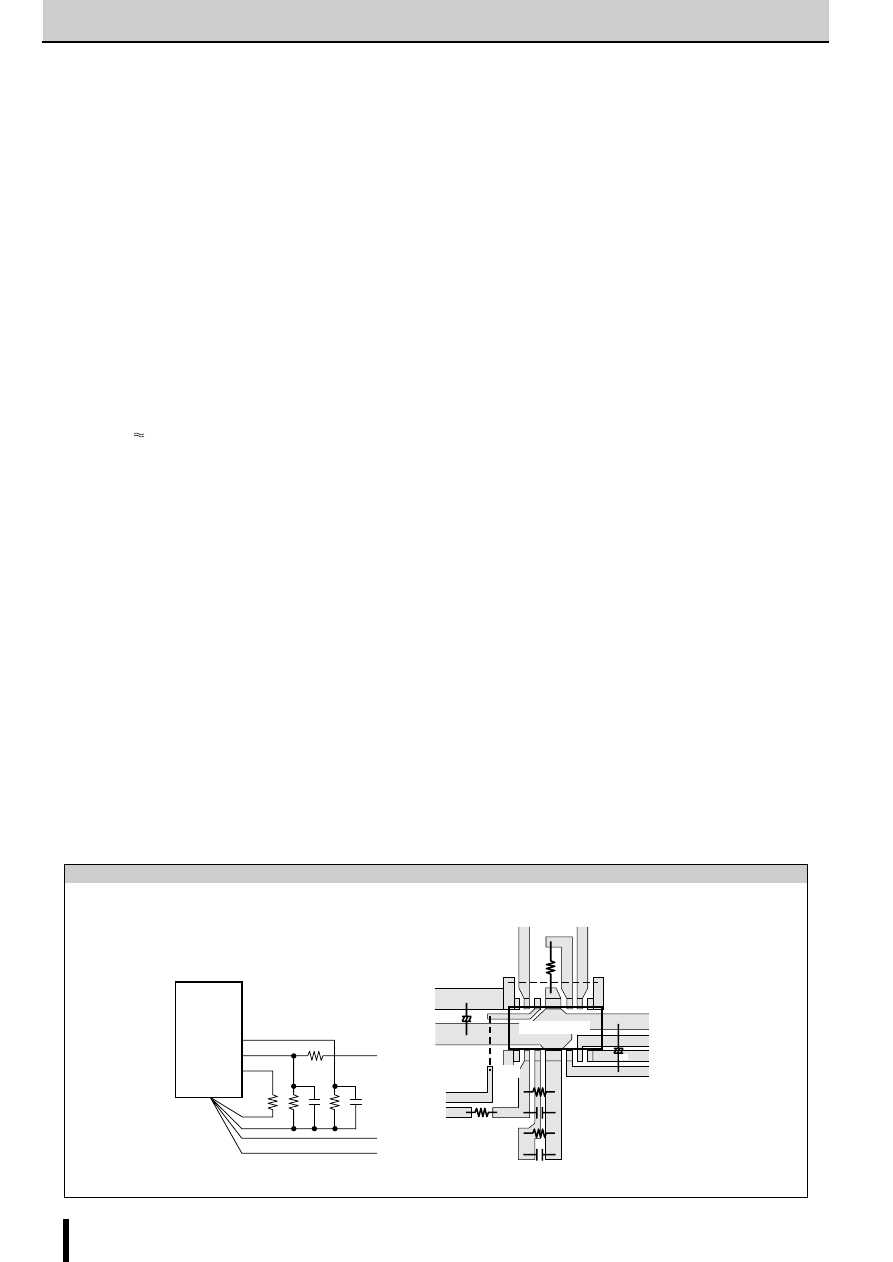

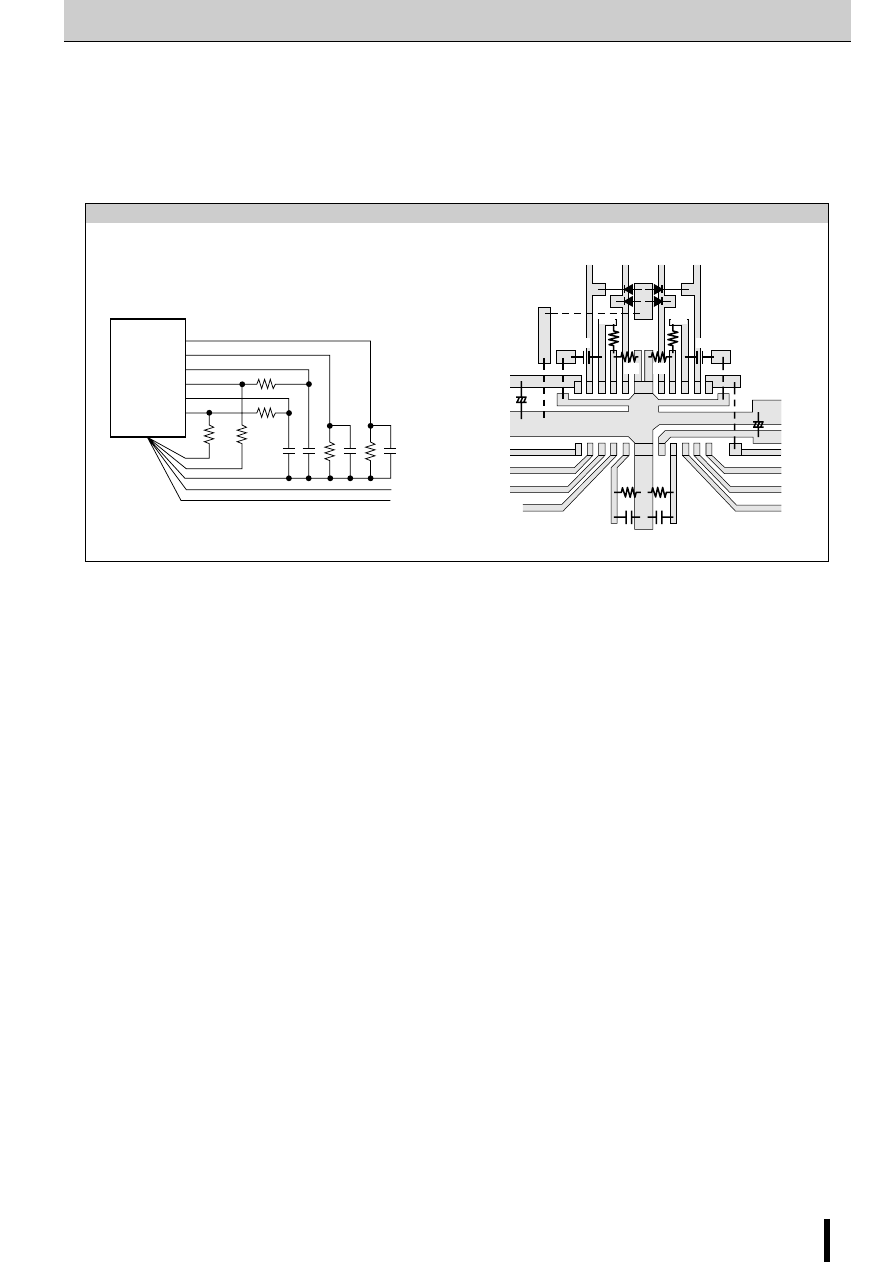

Current sense resistor

Motor coil

Transient-suppression diode

PWM control

and phase

switching

control

V

CC

Used as both chopper

MOSFET and phase

switching MOSFET

Basic constant current chopper circuitry

Notes on SLA7000/SMA7000 Series

Motor Driver ICs

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

5

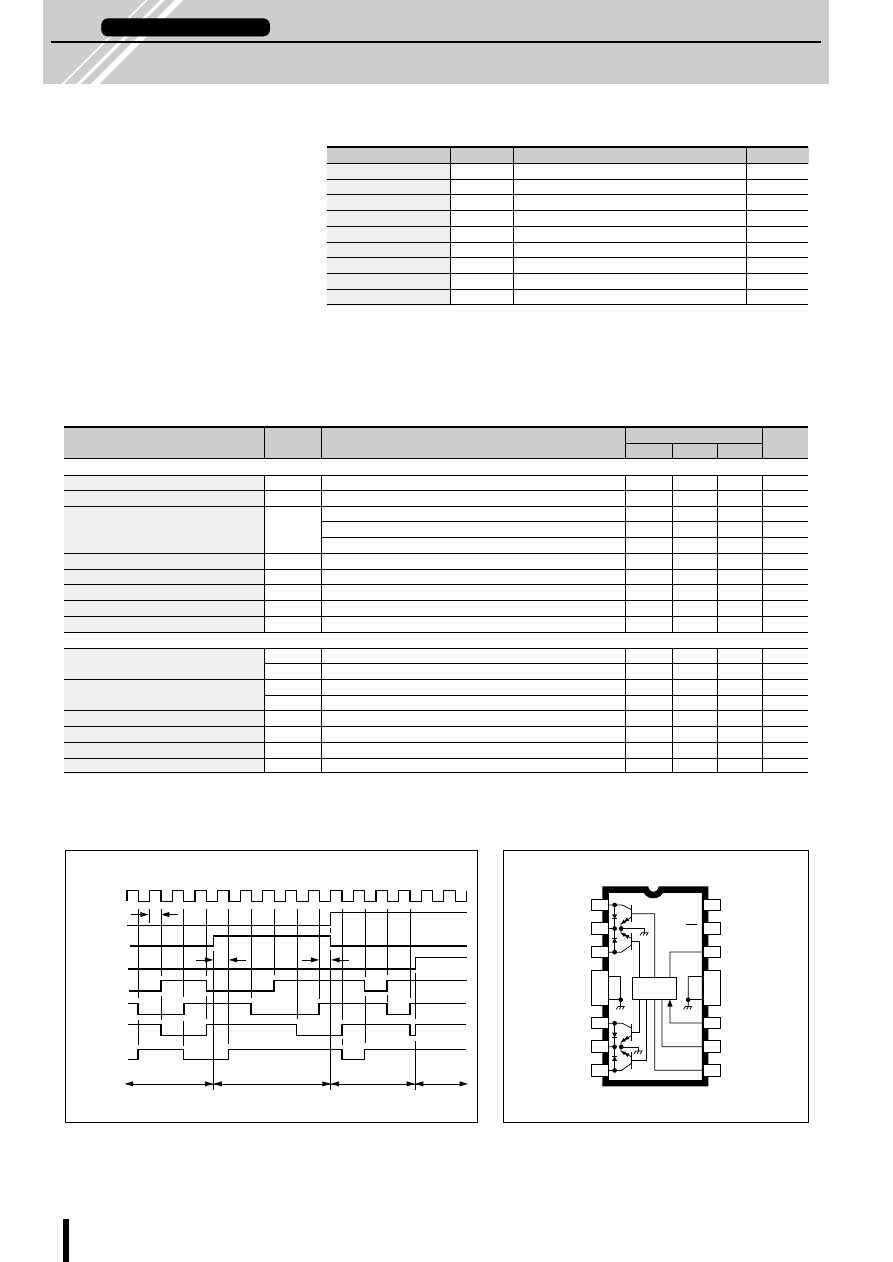

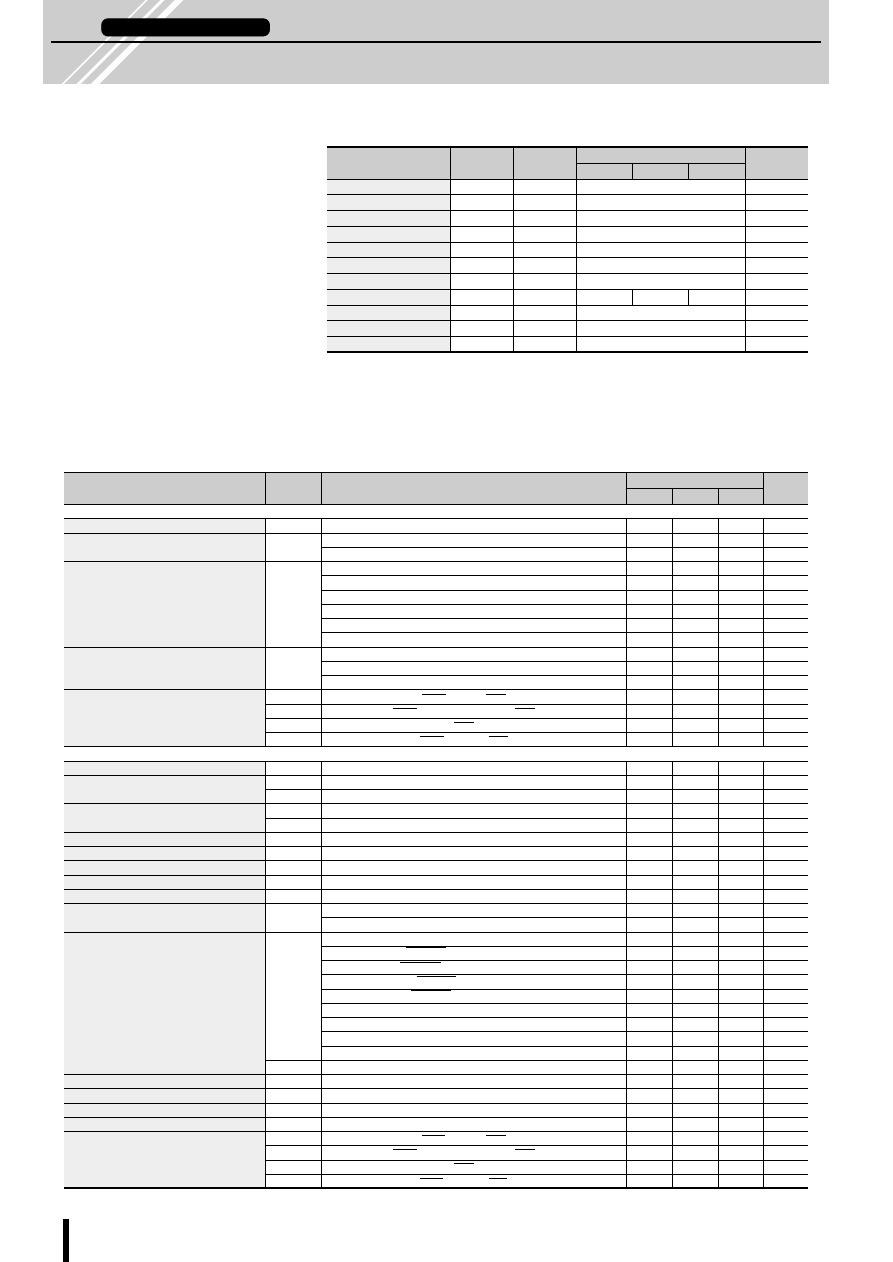

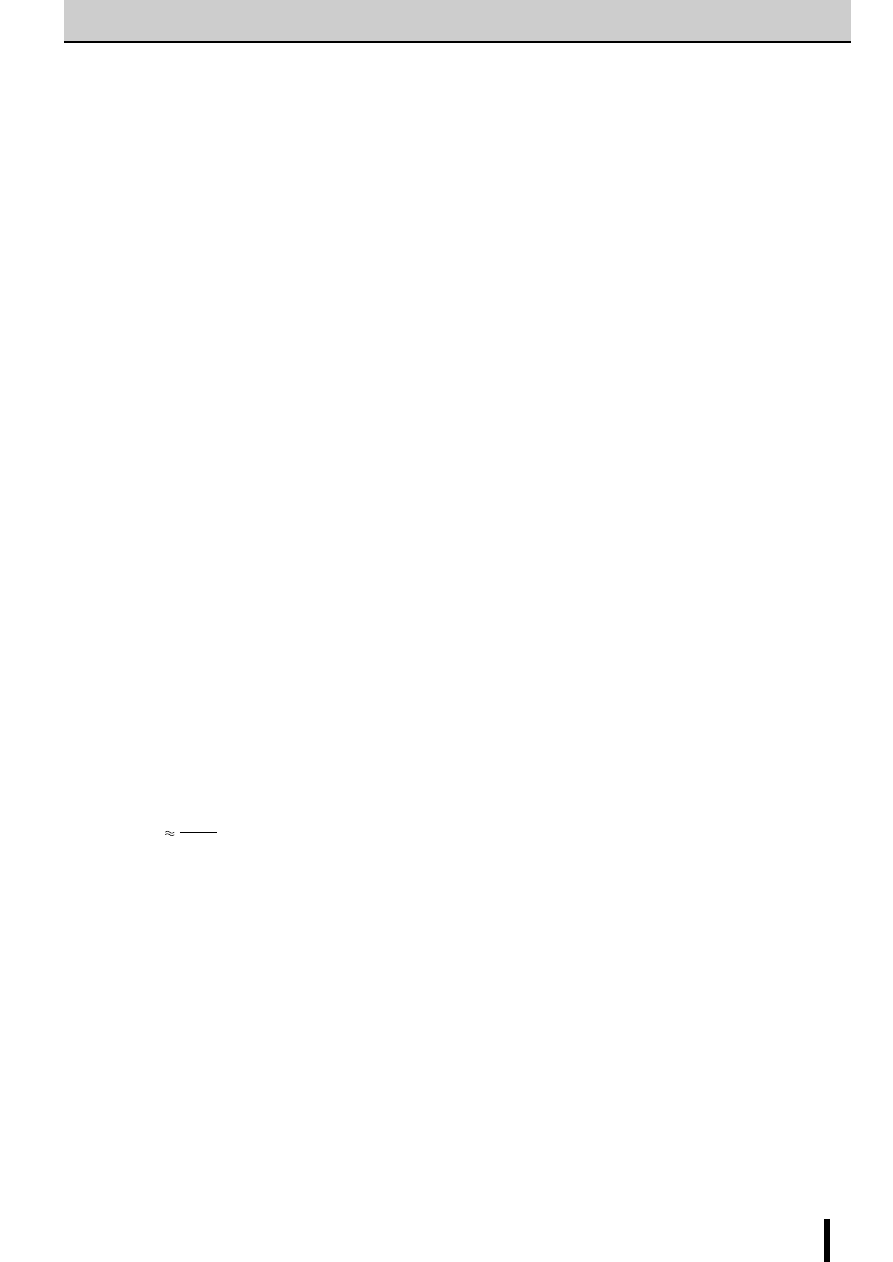

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

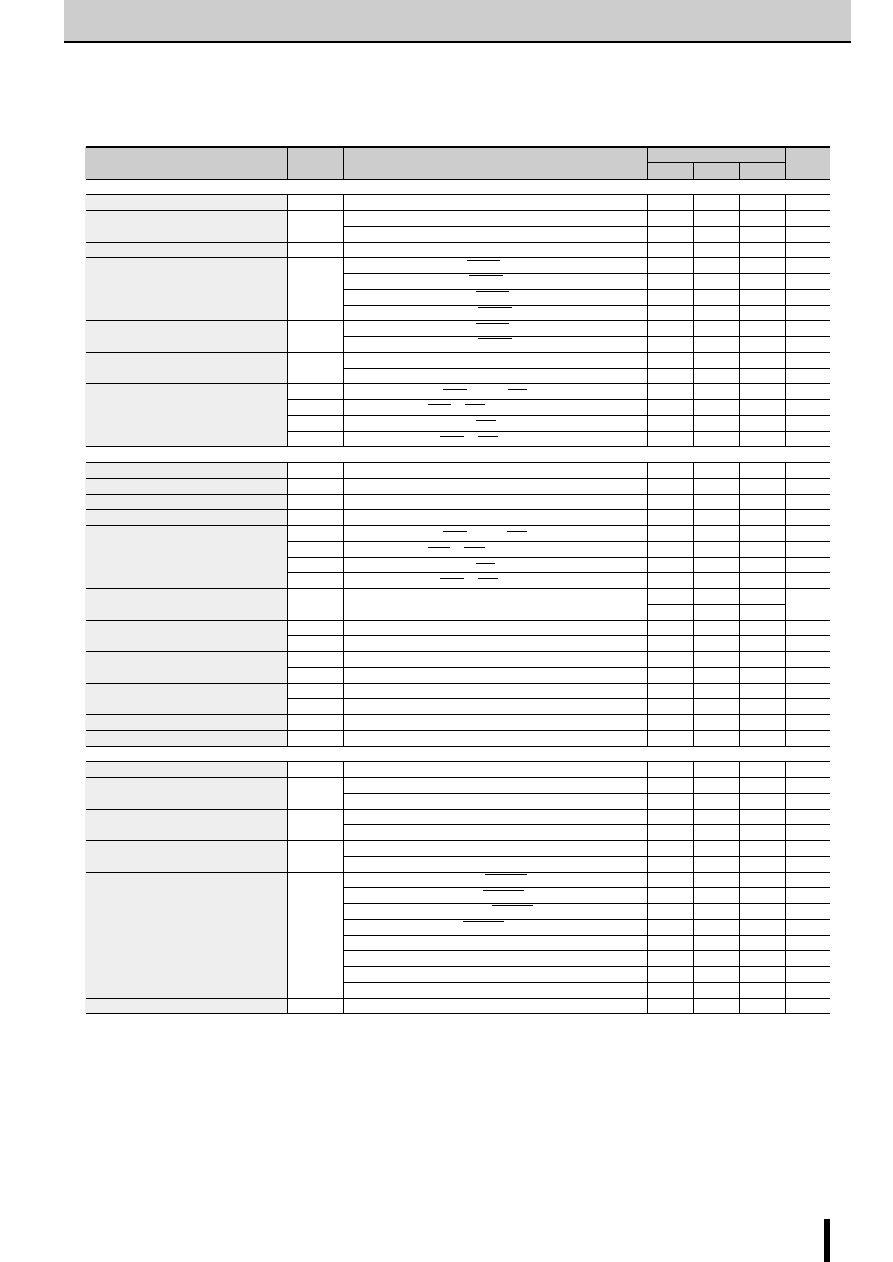

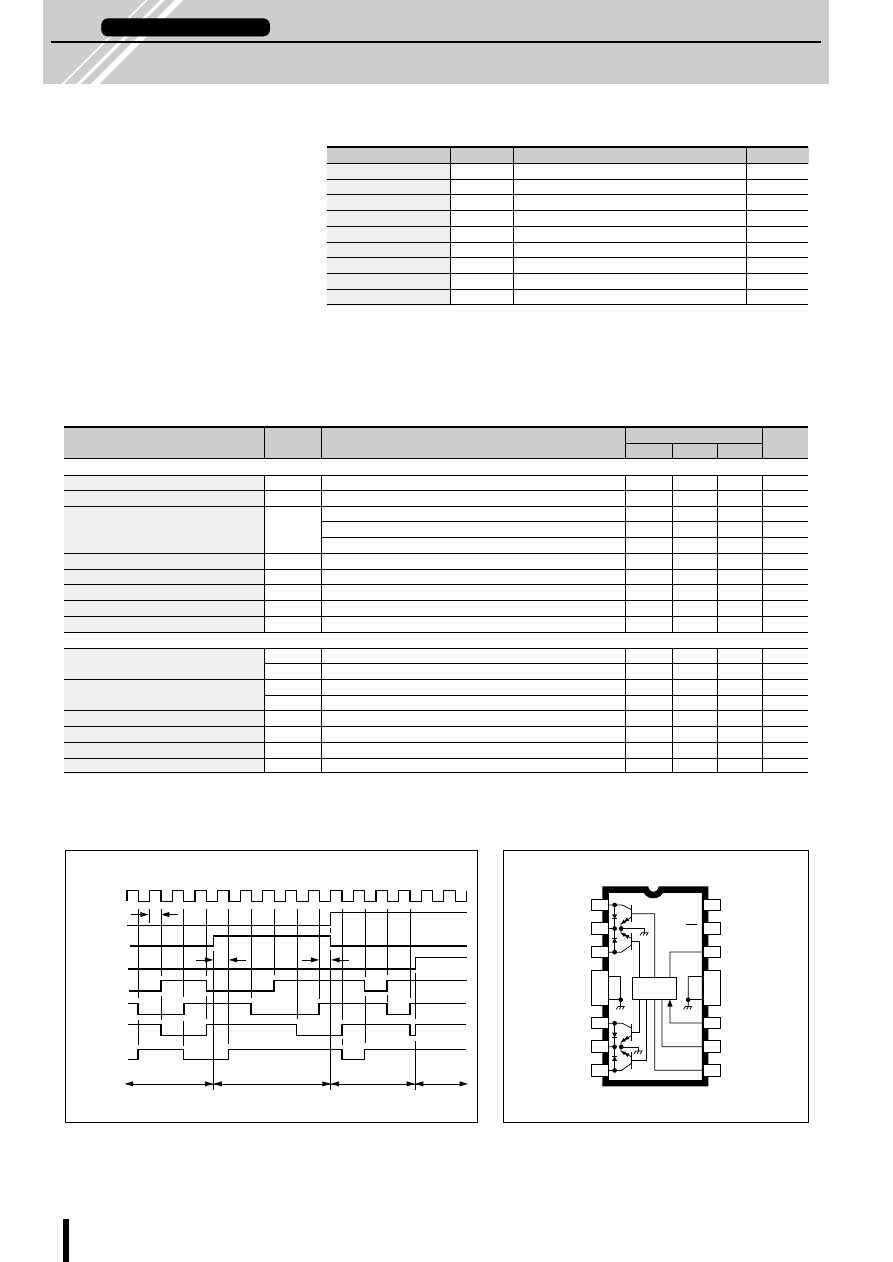

Parameter

Symbol

Ratings

Units

SLA7022MU

SLA7029M

SMA7022MU

SMA7029M

Motor supply voltage

V

CC

46

V

FET Drain-Source voltage

V

DSS

100

V

Control supply voltage

V

S

46

V

TTL input voltage

V

IN

7

V

Reference voltage

V

REF

2

V

Output current

I

O

1

1.5

1

1.5

A

Power dissipation

P

D1

4.5 (Without Heatsink)

4.0 (Without Heatsink)

W

P

D2

35 (T

C

=25

°

C)

28(T

C

=25

°

C)

W

Channel temperature

T

ch

+150

°

C

Storage temperature

T

stg

−

40 to +150

°

C

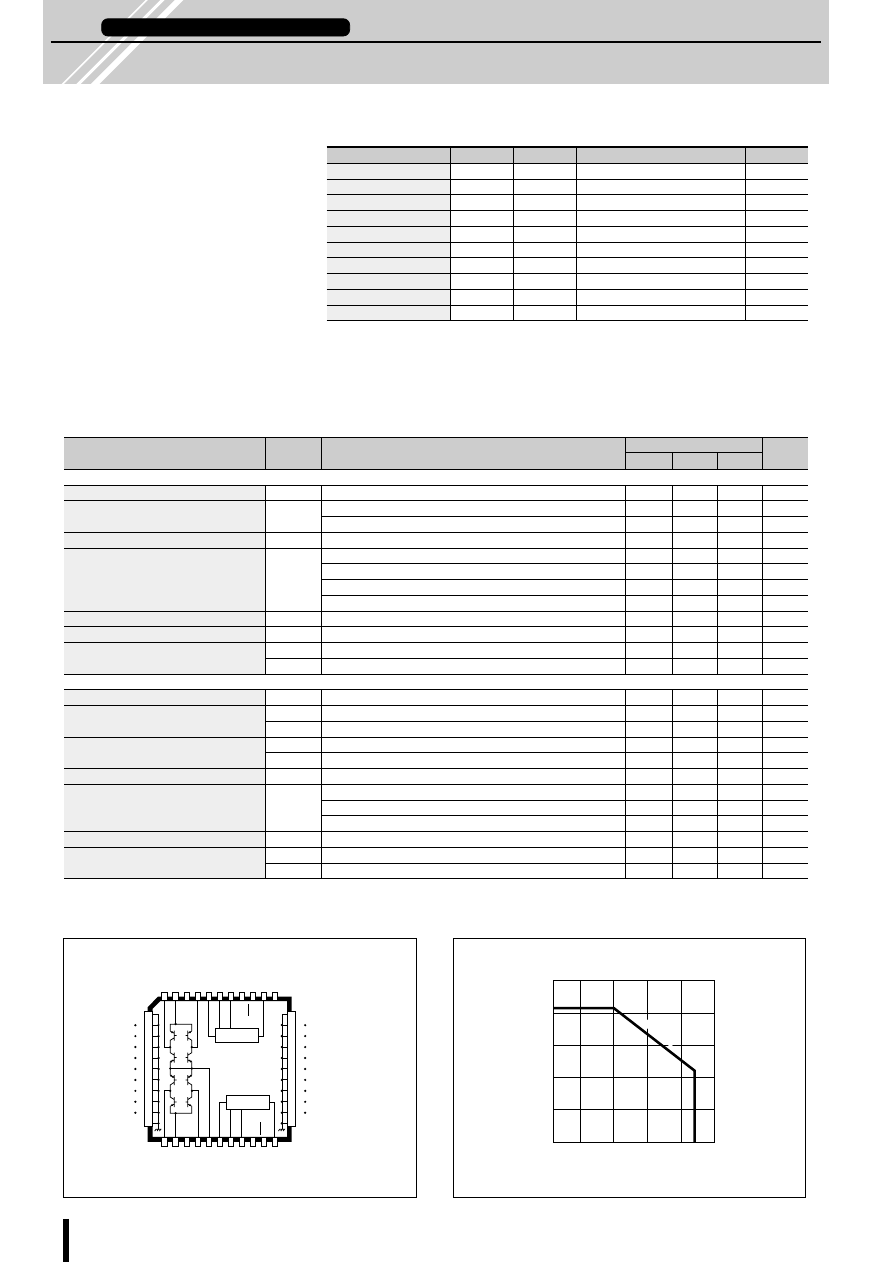

■

Absolute Maximum Ratings

2-Phase Stepper Motor Unipolar Driver ICs

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Excitation

(T

a

=25

°

C)

Ratings

Parameter

Symbol

SLA7022MU

SLA7029M

SMA7022MU

SMA7029M

Units

min

typ

max

min

typ

max

min

typ

max

min

typ

max

Control supply current

I

S

10

15

10

15

10

15

10

15

mA

Condition

V

S

=44V

V

S

=44V

V

S

=44V

V

S

=44V

Control supply voltage

V

S

10

24

44

10

24

44

10

24

44

10

24

44

V

FET Drain-Source

V

DSS

100

100

100

100

V

voltage

Condition

V

S

=44V, I

DSS

=250

µ

A

V

S

=44V, I

DSS

=250

µ

A

V

S

=44V, I

DSS

=250

µ

A

V

S

=44V, I

DSS

=250

µ

A

FET ON voltage

V

DS

0.85

0.6

0.85

0.6

V

Condition

I

D

=1A, V

S

=14V

I

D

=1A, V

S

=14V

I

D

=1A, V

S

=14V

I

D

=1A, V

S

=14V

FET drain leakage current

I

DSS

4

4

4

4

mA

Condition

V

DSS

=100V, V

S

=44V

V

DSS

=100V, V

S

=44V

V

DSS

=100V, V

S

=44V

V

DSS

=100V, V

S

=44V

FET diode forward

V

SD

1.2

1.1

1.2

1.1

V

voltage

Condition

I

D

=1A

I

D

=1A

I

D

=1A

I

D

=1A

I

IH

40

40

40

40

µ

A

TTL input current

Condition

V

IH

=2.4V, V

S

=44V

V

IH

=2.4V, V

S

=44V

V

IH

=2.4V, V

S

=44V

V

IH

=2.4V, V

S

=44V

I

IL

−

0.8

−

0.8

−

0.8

−

0.8

mA

Condition

V

IL

=0.4V, V

S

=44V

V

IL

=0.4V, V

S

=44V

V

IL

=0.4V, V

S

=44V

V

IL

=0.4V, V

S

=44V

V

IH

2

2

2

2

TTL input voltage

Condition

I

D

=1A

I

D

=1A

I

D

=1A

I

D

=1A

V

(Active High)

V

IL

0.8

0.8

0.8

0.8

Condition

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

IH

2

2

2

2

TTL input voltage

Condition

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

(Active Low)

V

IL

0.8

0.8

0.8

0.8

Condition

I

D

=1A

I

D

=1A

I

D

=1A

I

D

=1A

T

r

0.5

0.5

0.5

0.5

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

Switching time

T

stg

0.7

0.7

0.7

0.7

µ

s

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

T

f

0.1

0.1

0.1

0.1

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

■

Electrical Characteristics

(T

a

=25

°

C)

DC characteristics

AC characteristics

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

6

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

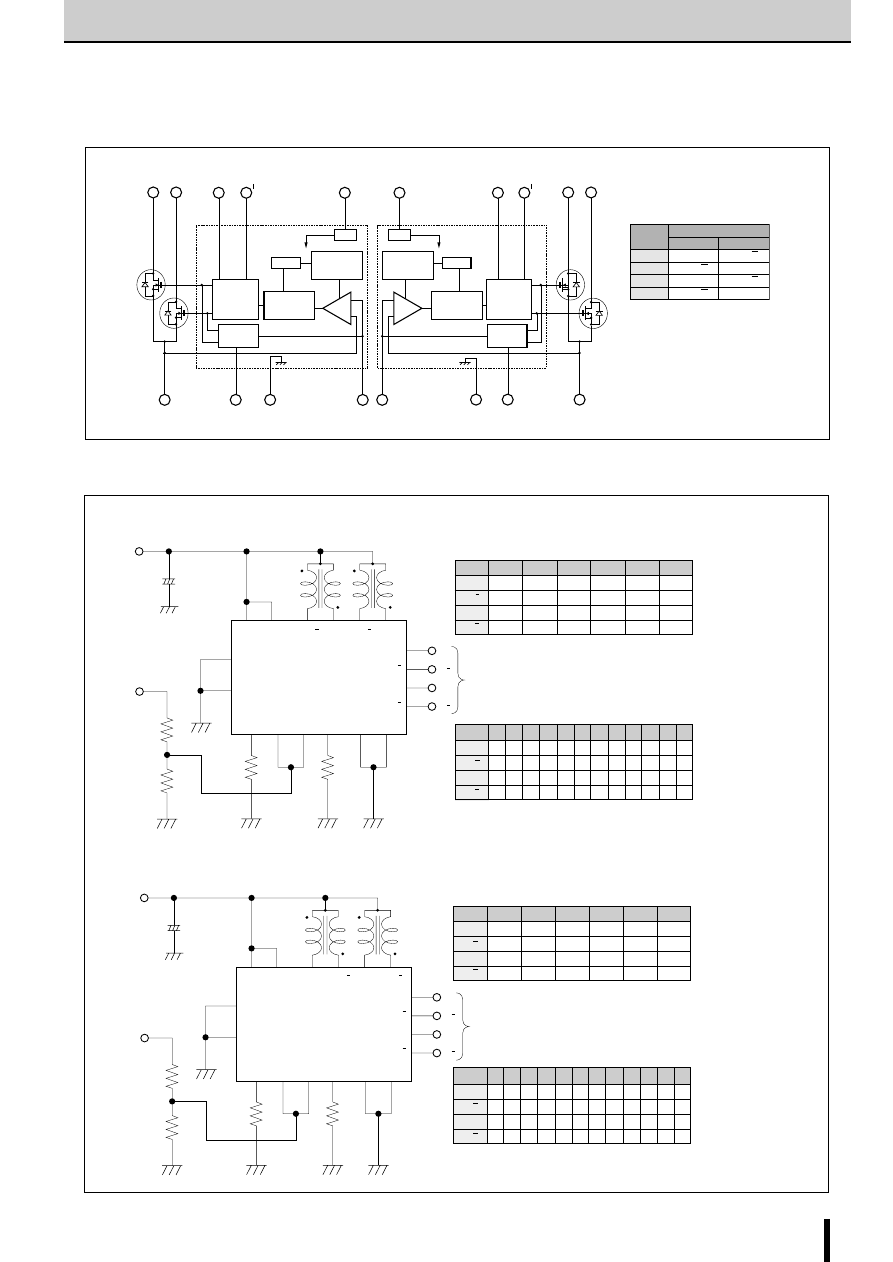

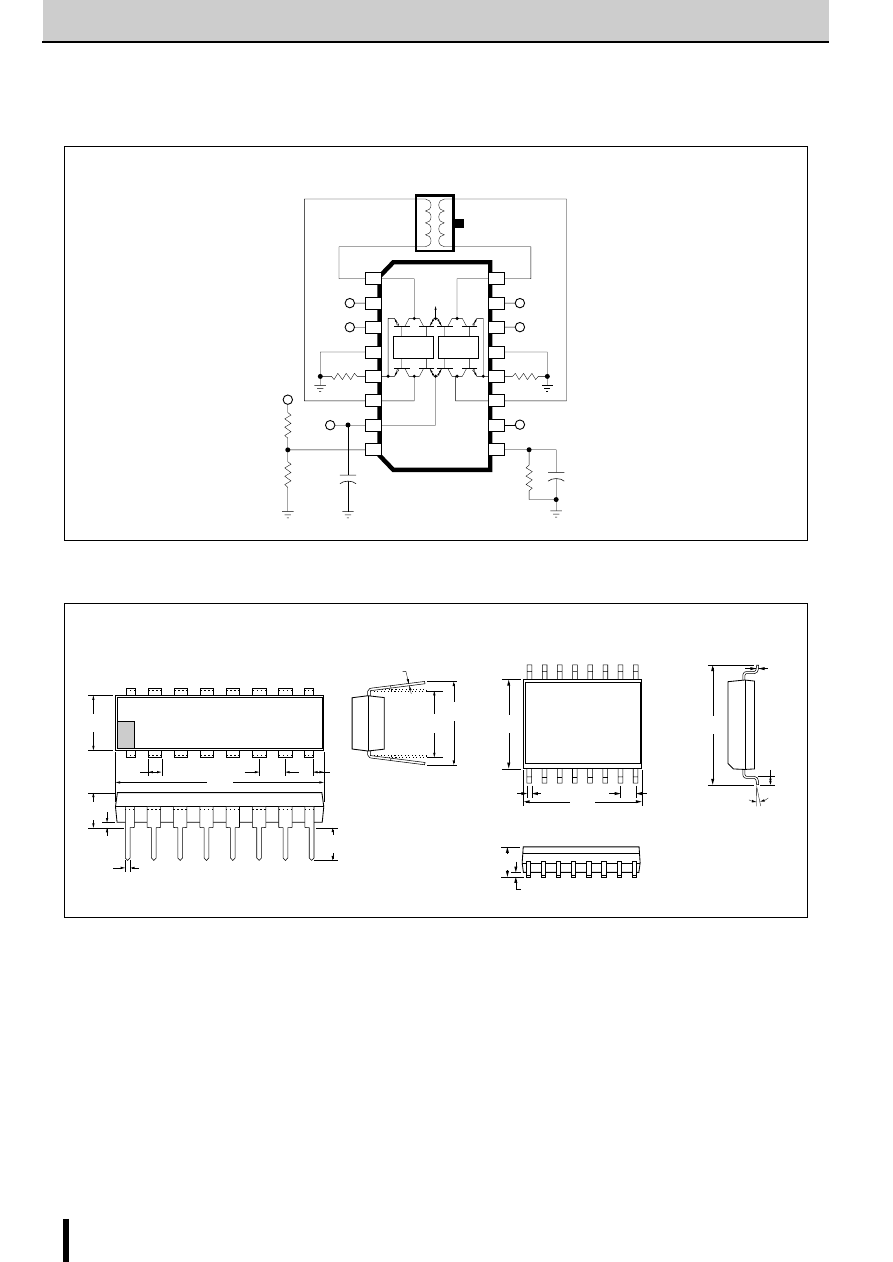

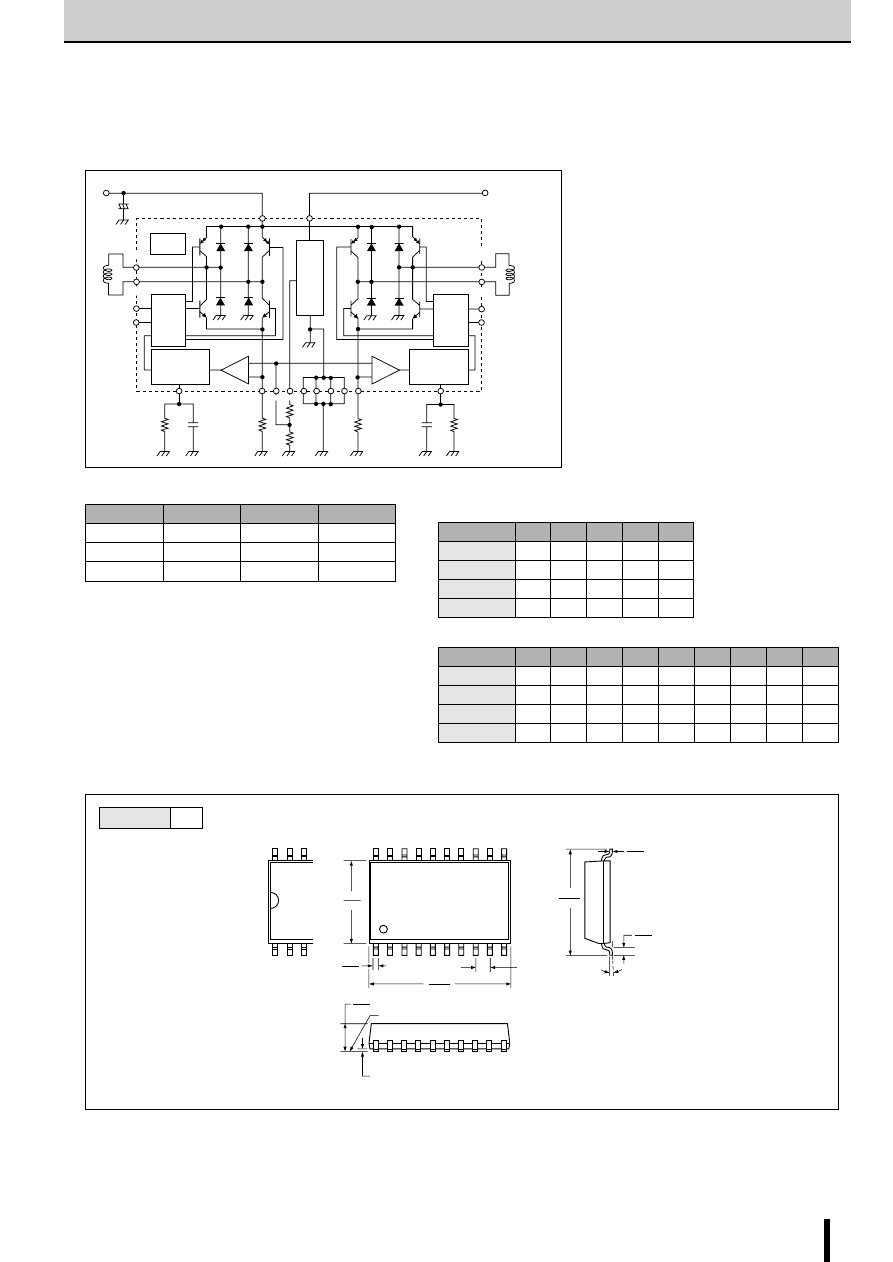

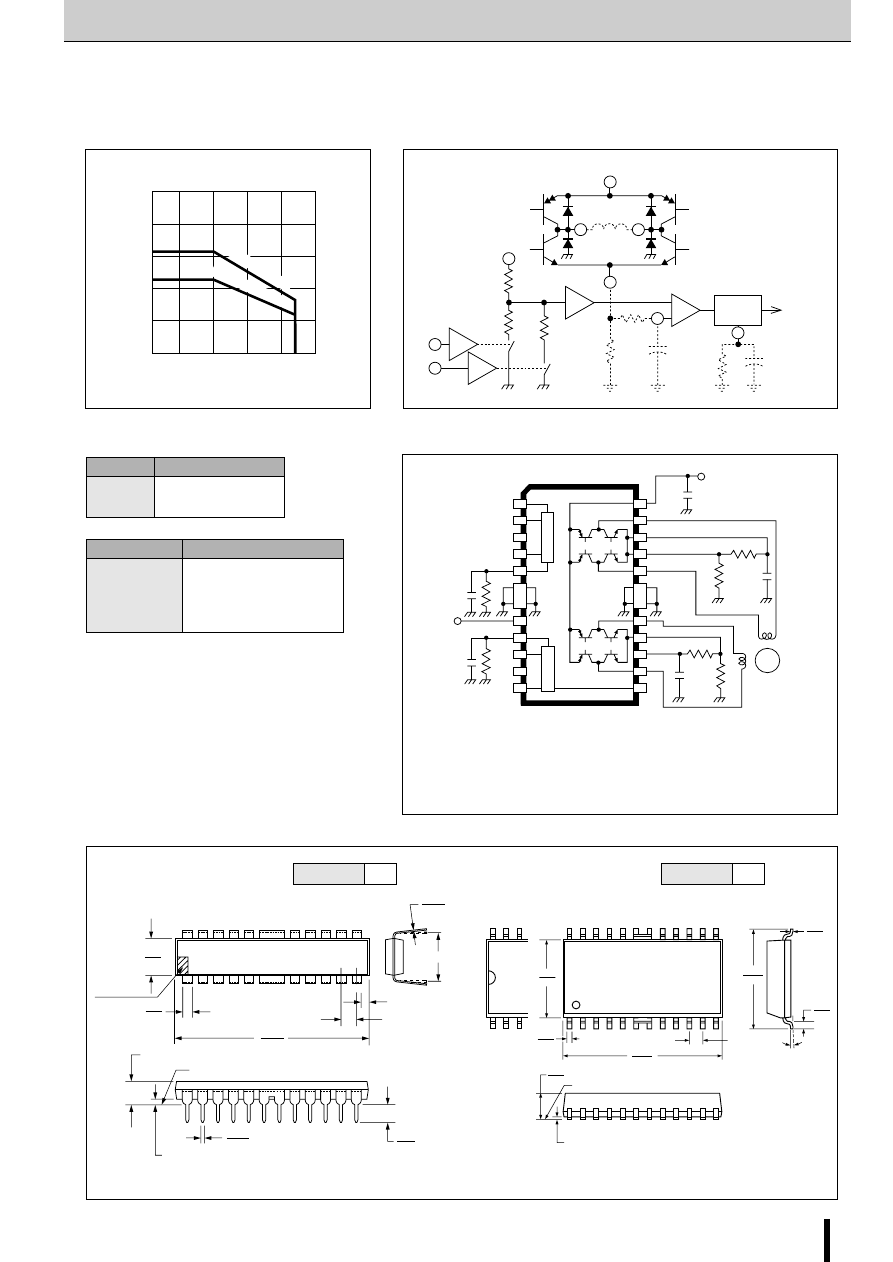

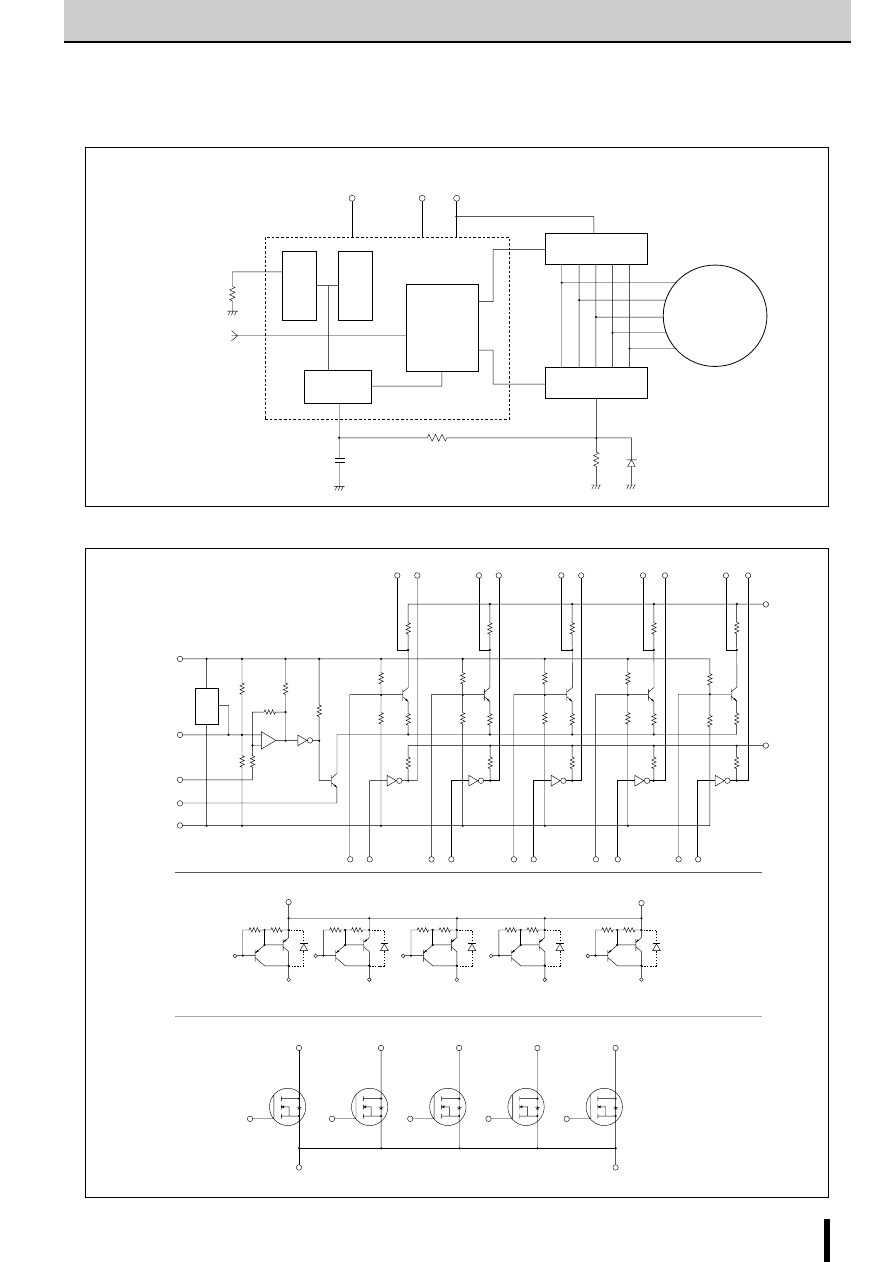

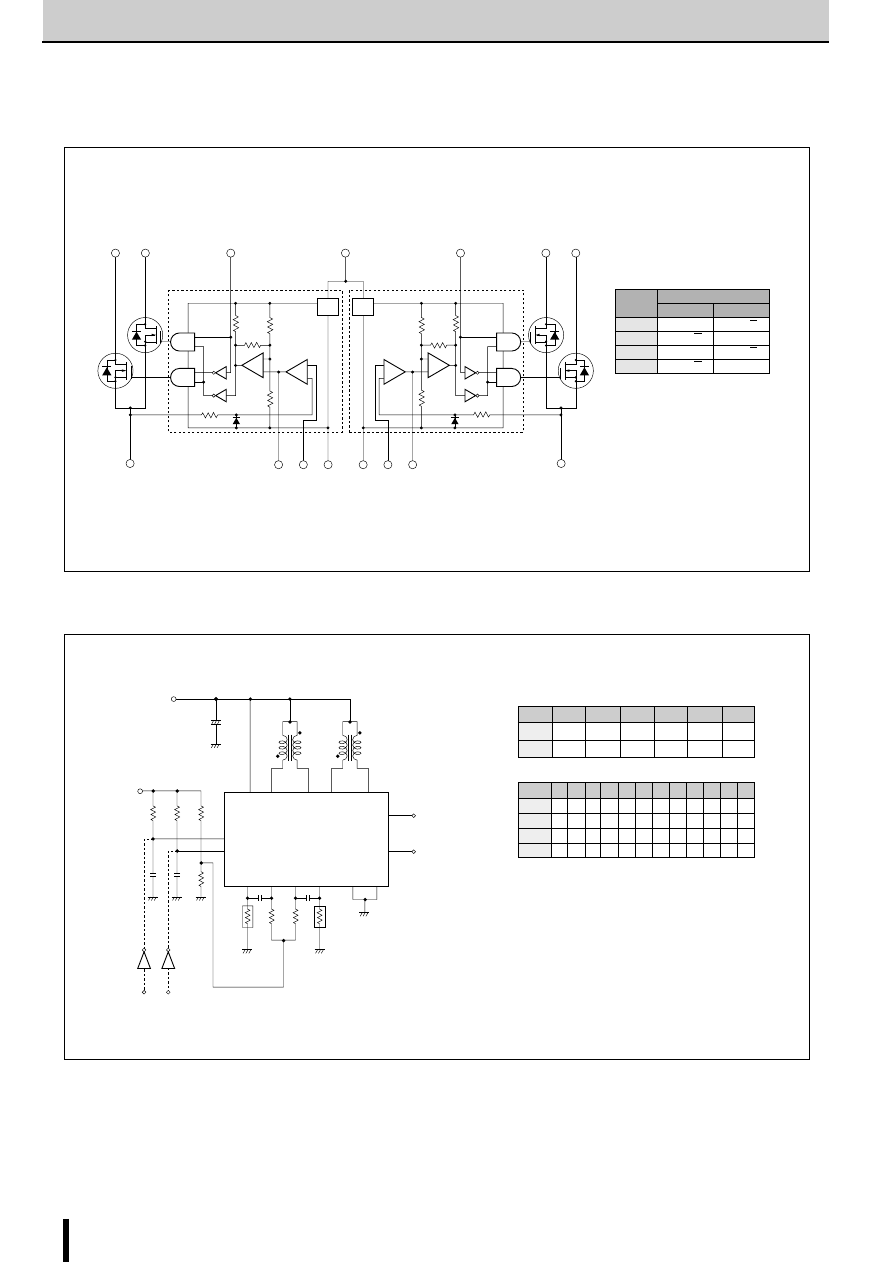

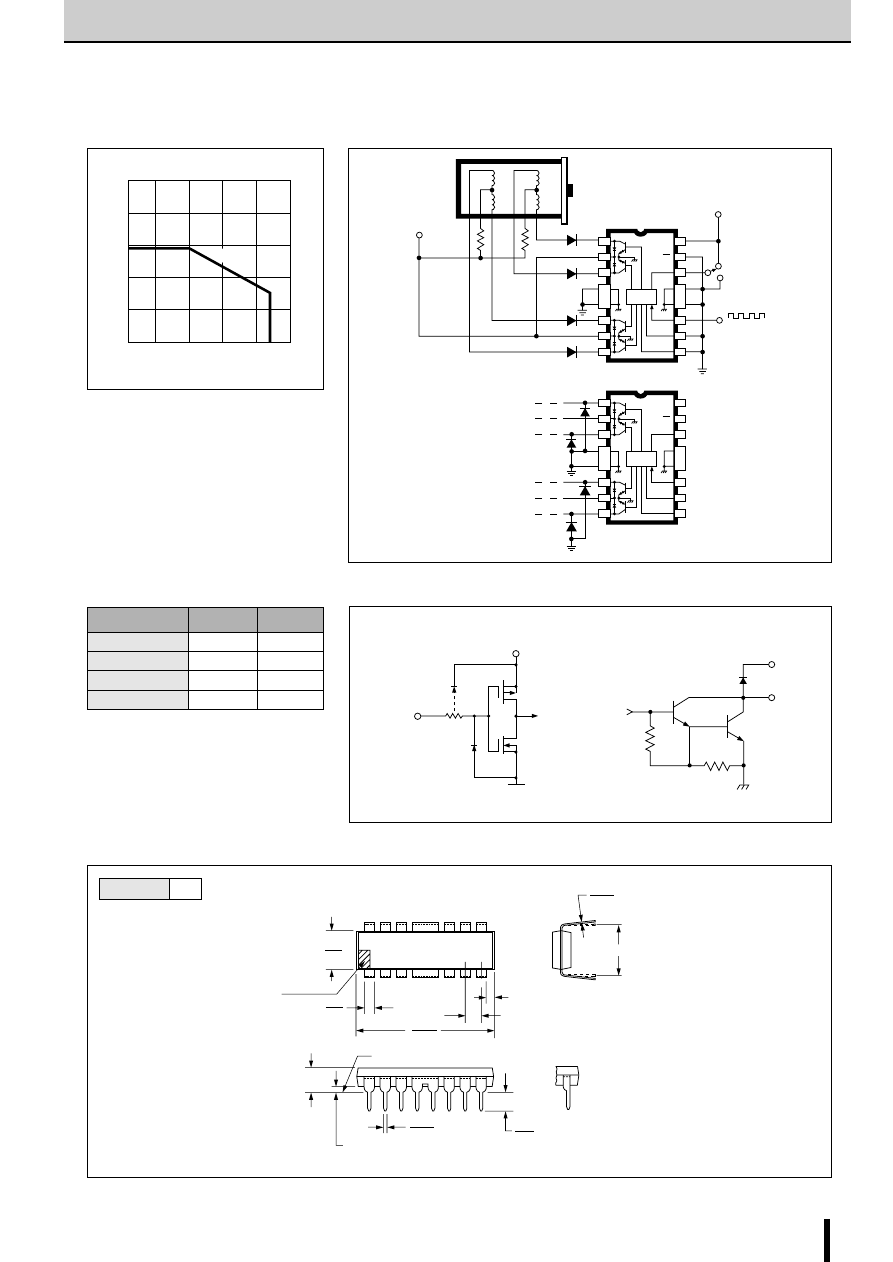

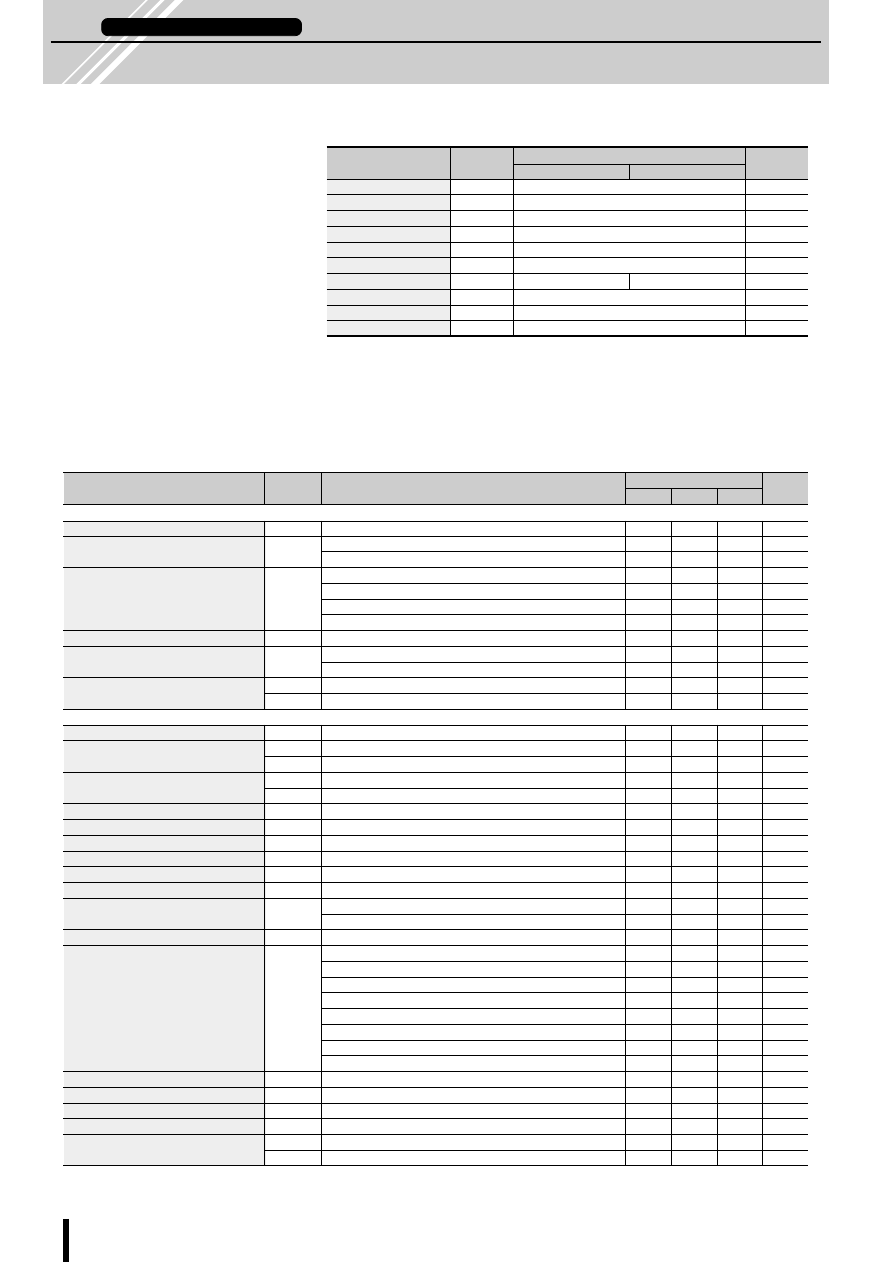

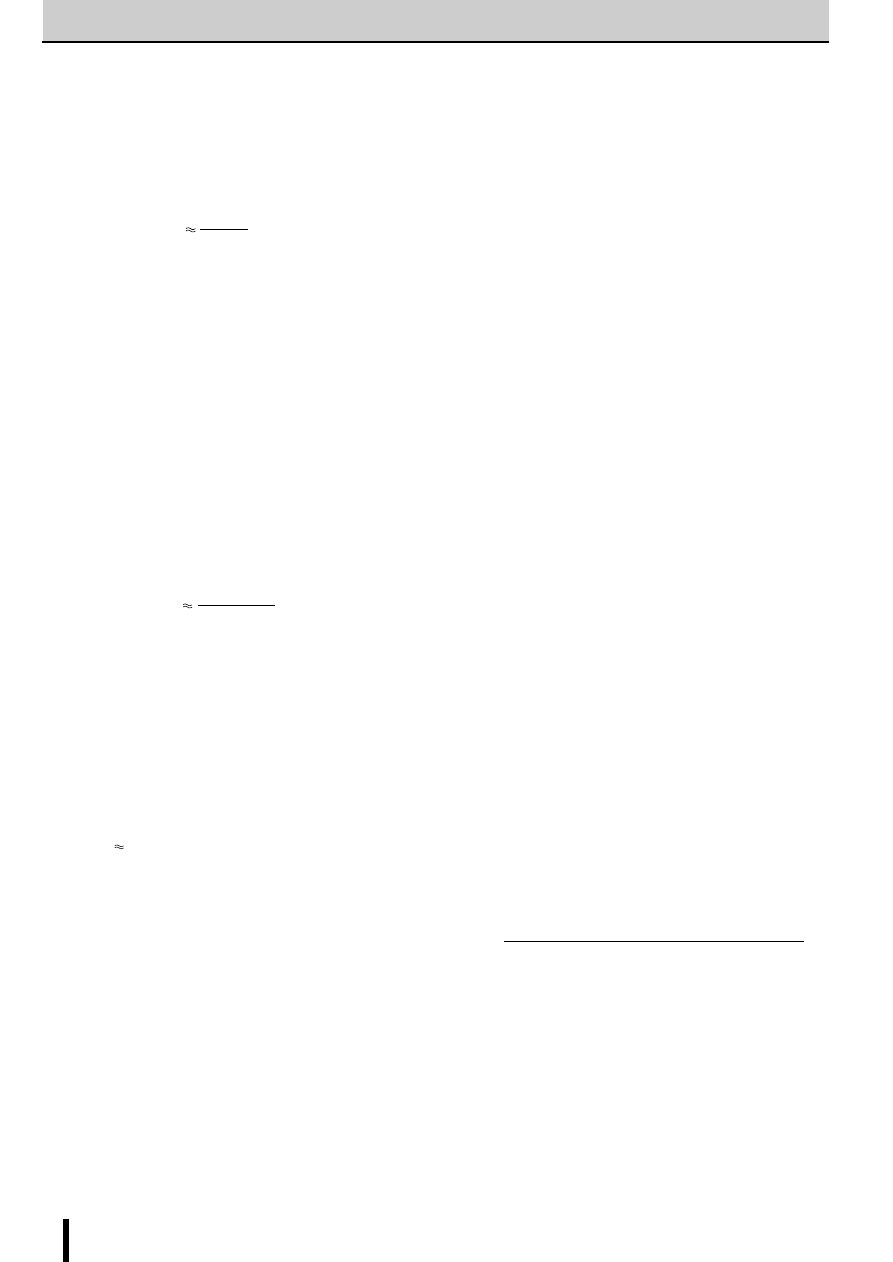

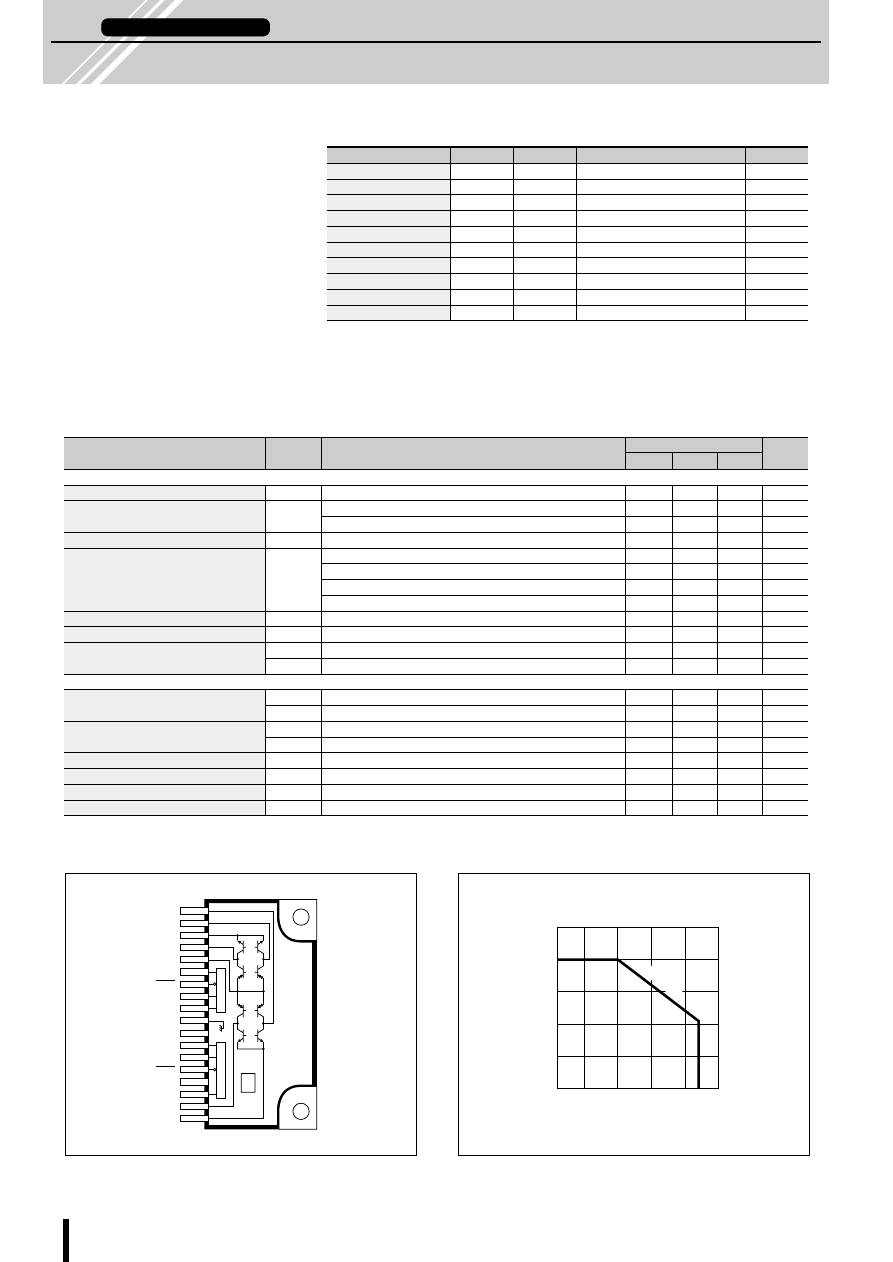

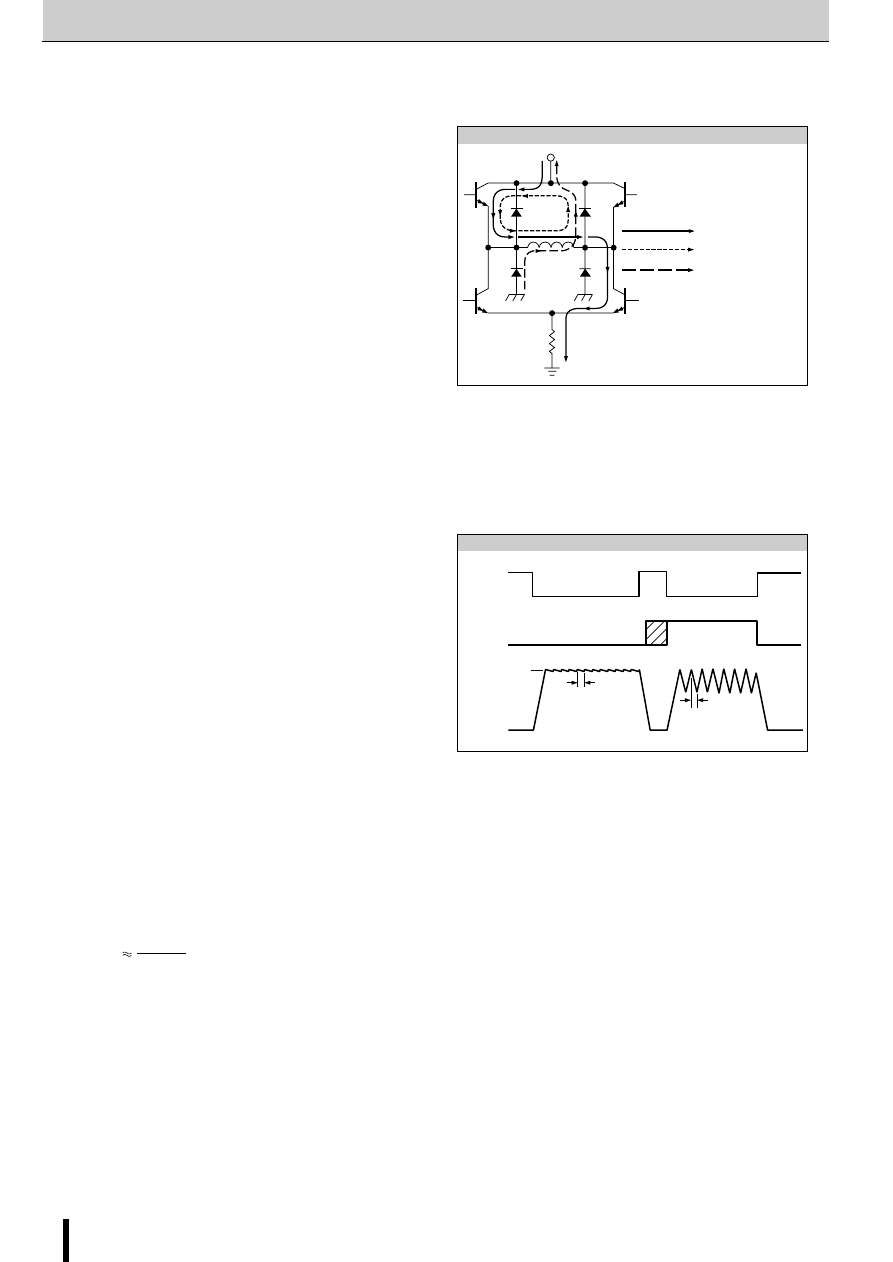

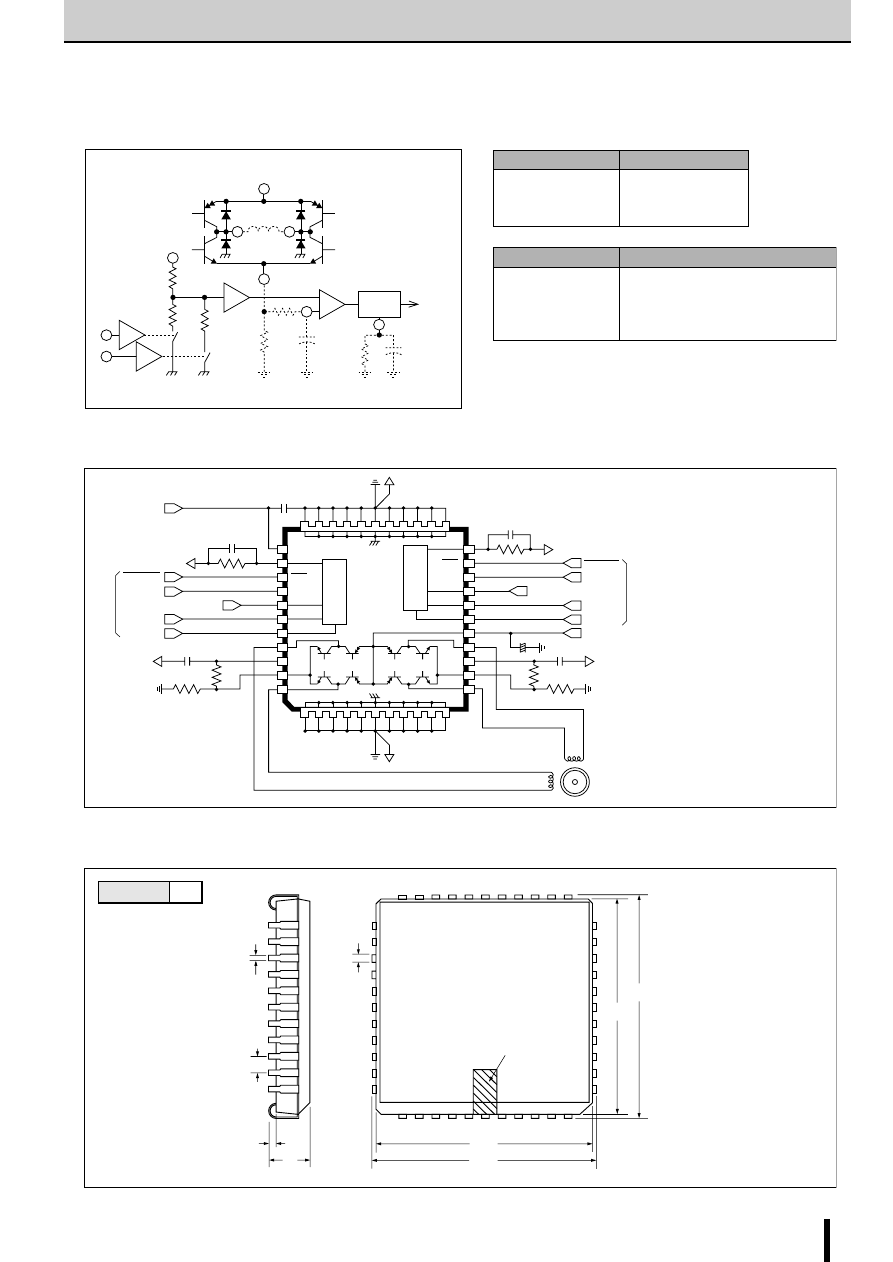

■

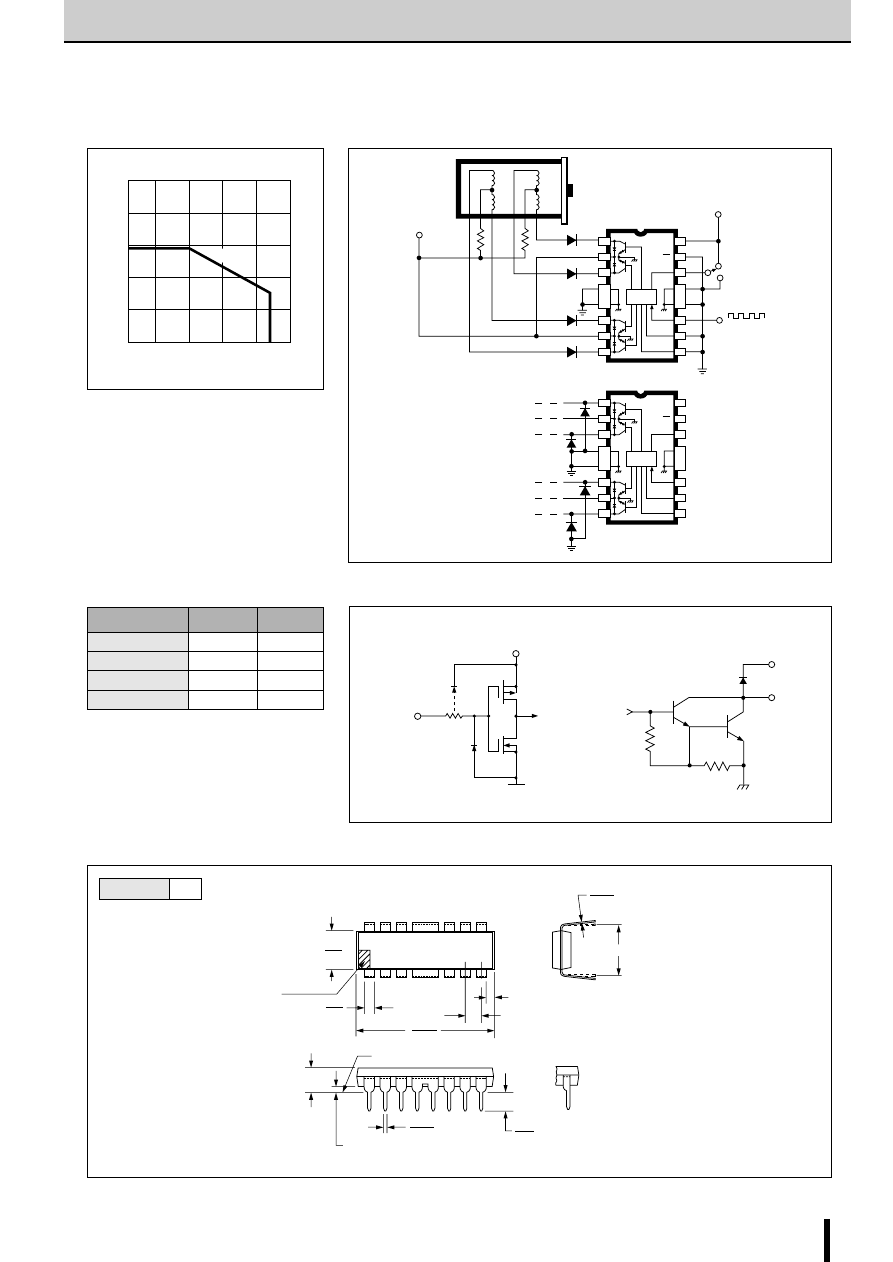

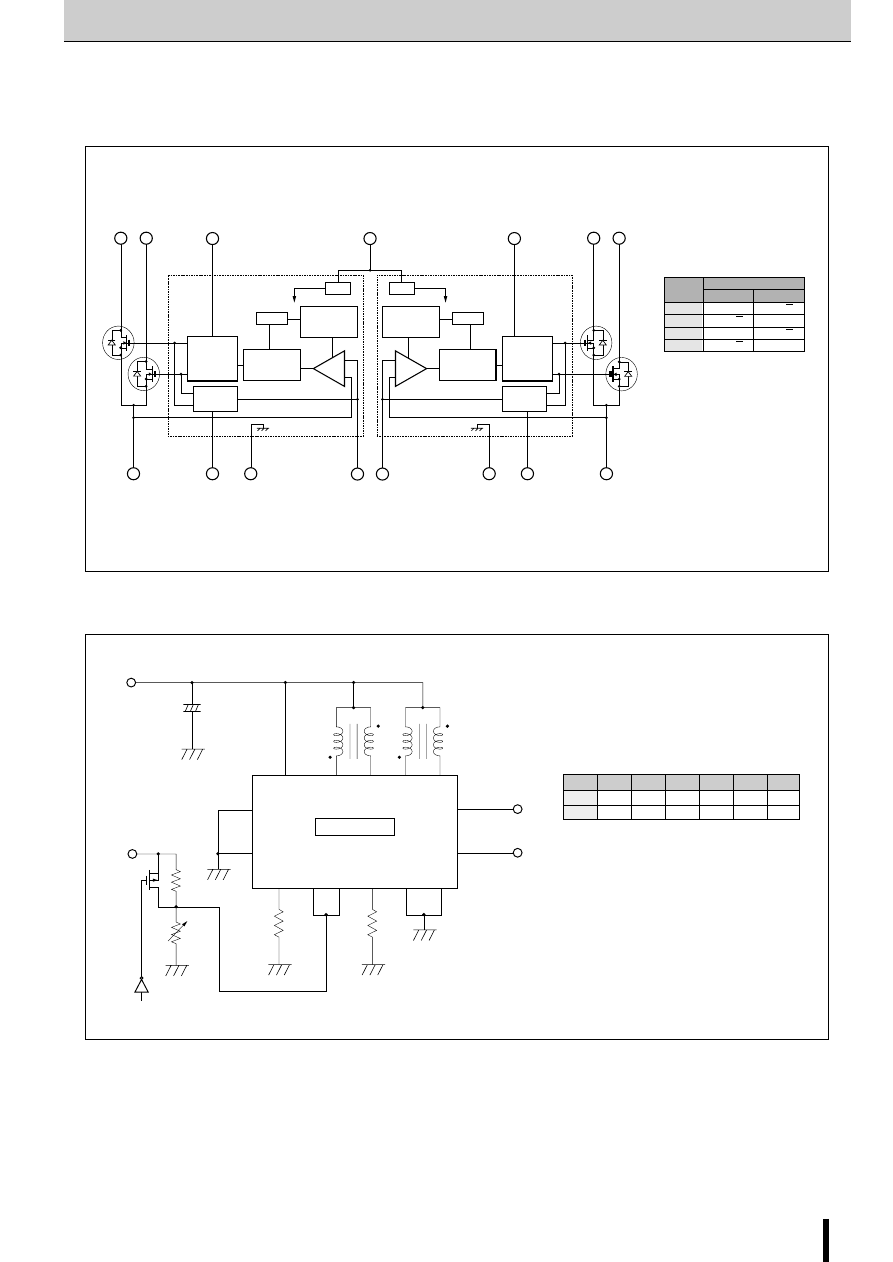

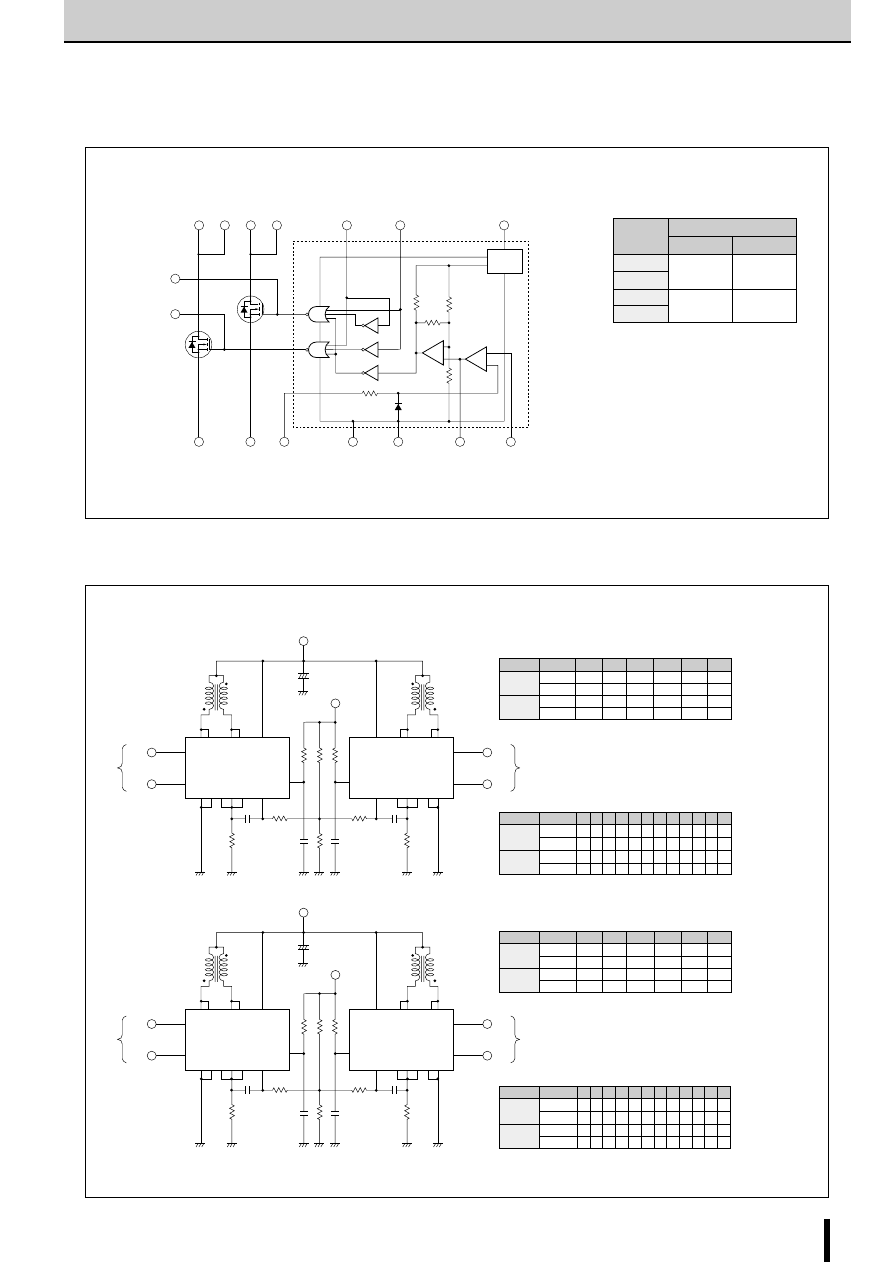

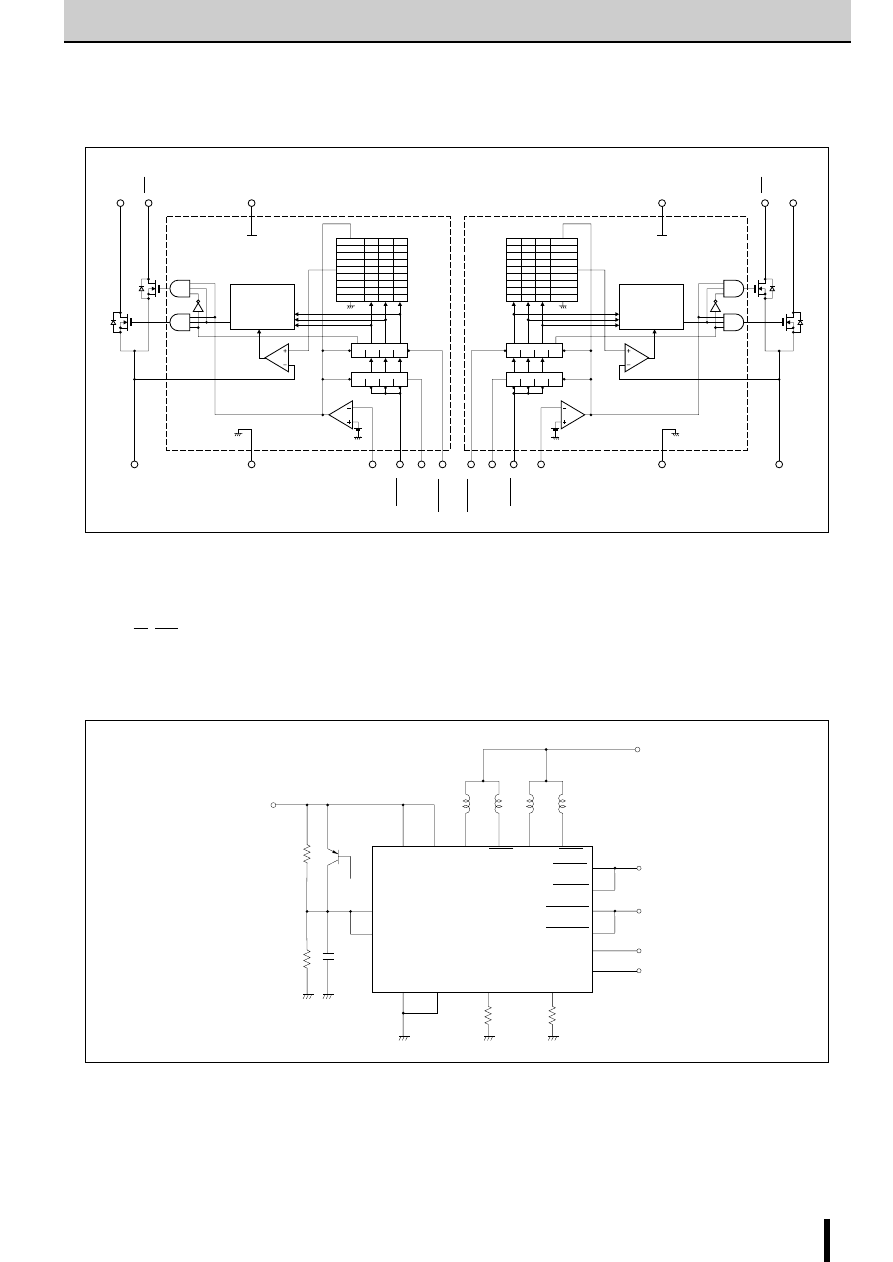

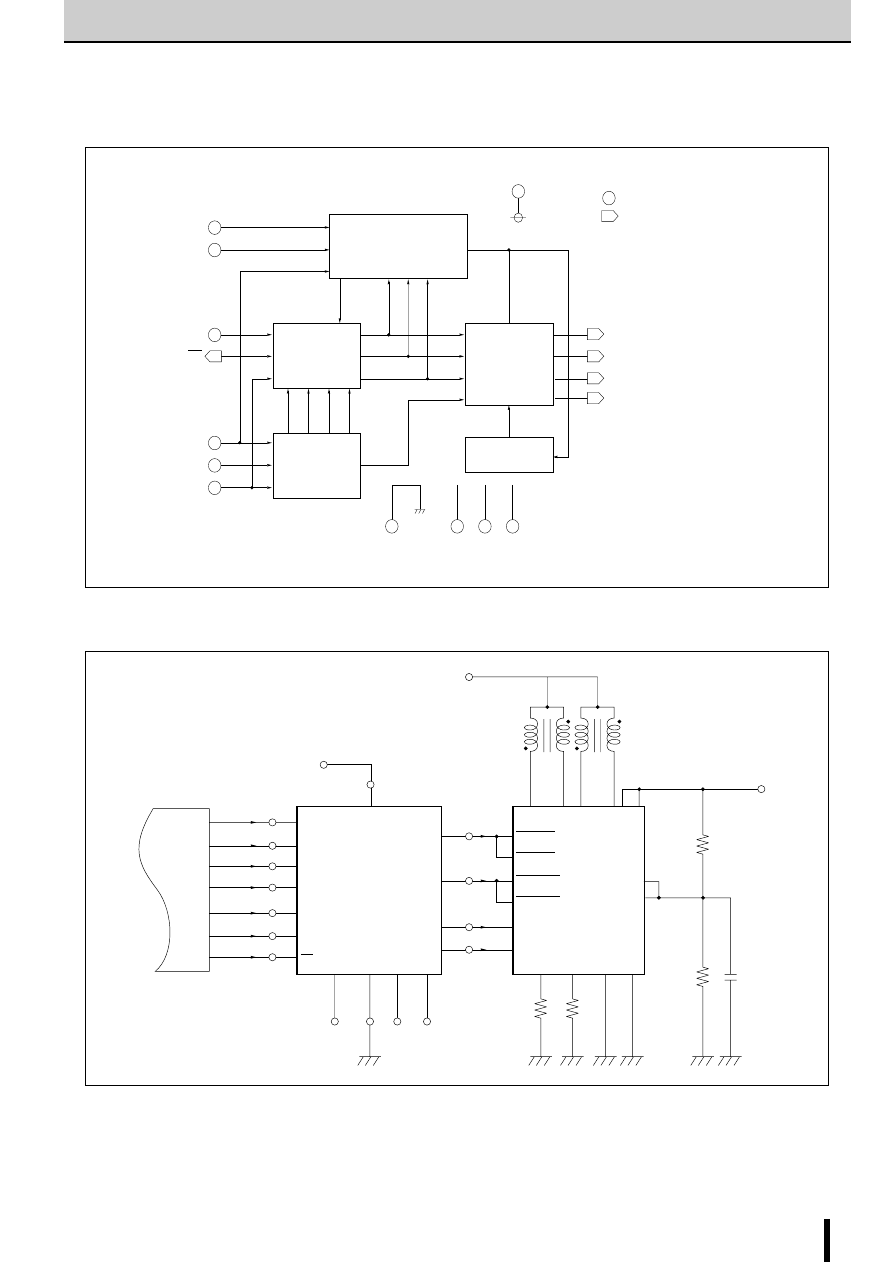

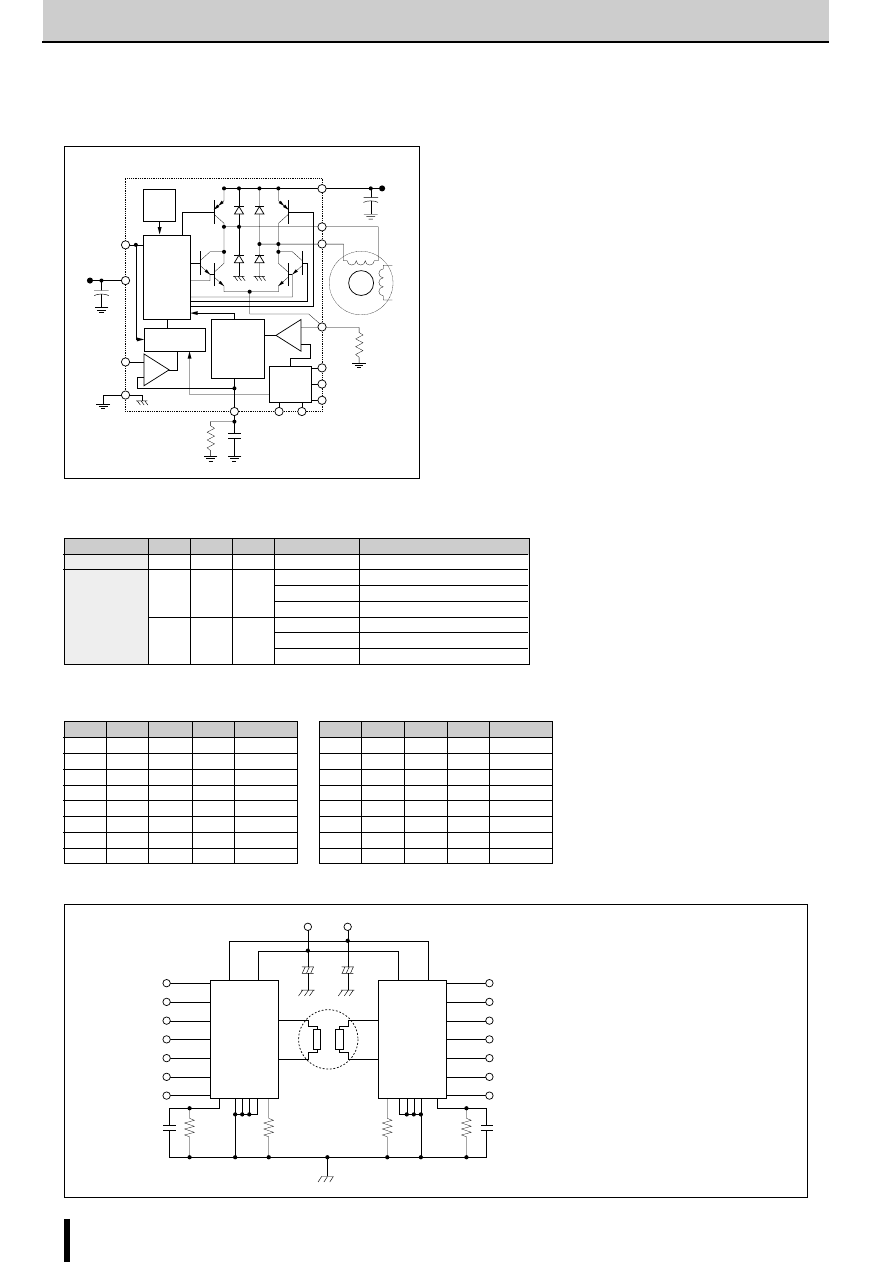

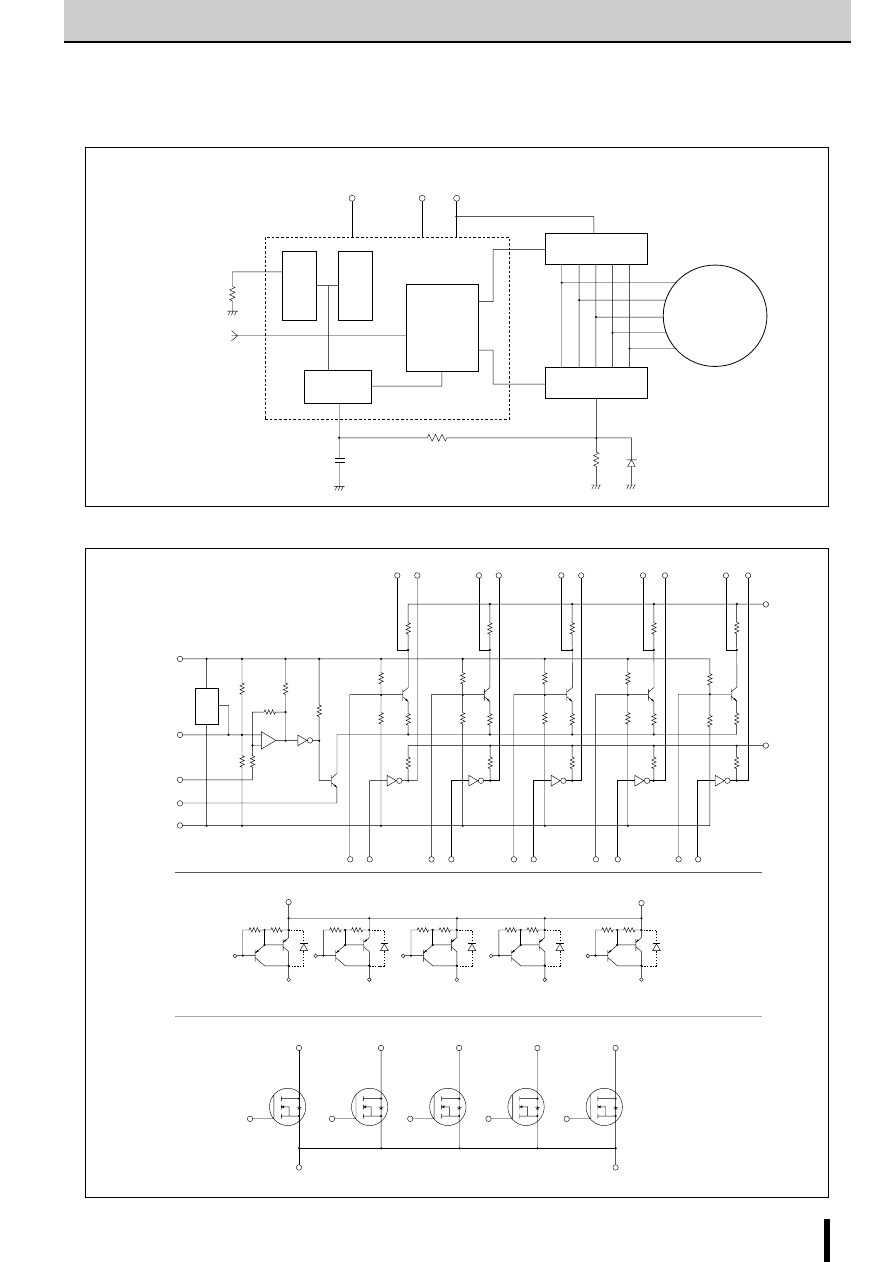

Internal Block Diagram

■

Diagram of Standard External Circuit (Recommended Circuit Constants)

6

Reg

Reg

1

5

8

V

S

14

IN

B

IN

A

7

R

SA

2

3

4

12

13

11

T

DA

REF

A

GND

A

GND

B

REF

B

T

DB

R

SB

9

10

15

+

–

+

–

+

–

+

–

1, 6, 10, 15pin

Description of pins

Excitation input

Active H

OUT A

OUT A

OUT B

OUT B

1pin

6pin

10pin

15pin

Active L

OUT A

OUT A

OUT B

OUT B

8

1

6

10

15

V

S

R

SA

REF

A

REF

B

R

SB

G

A

G

B

7

3 13

9

4

12

C

4

r

6

r

5

r

2

r

1

r

4

r

3

C

1

C

2

T

dA

T

dB

IN

A

IN

B

IN

A

IN

B

5

14

+

V

CC

(46V max)

V

b

(5V)

Rs

Rs

C

3

11

2

Open

collector

t

dA

t

dB

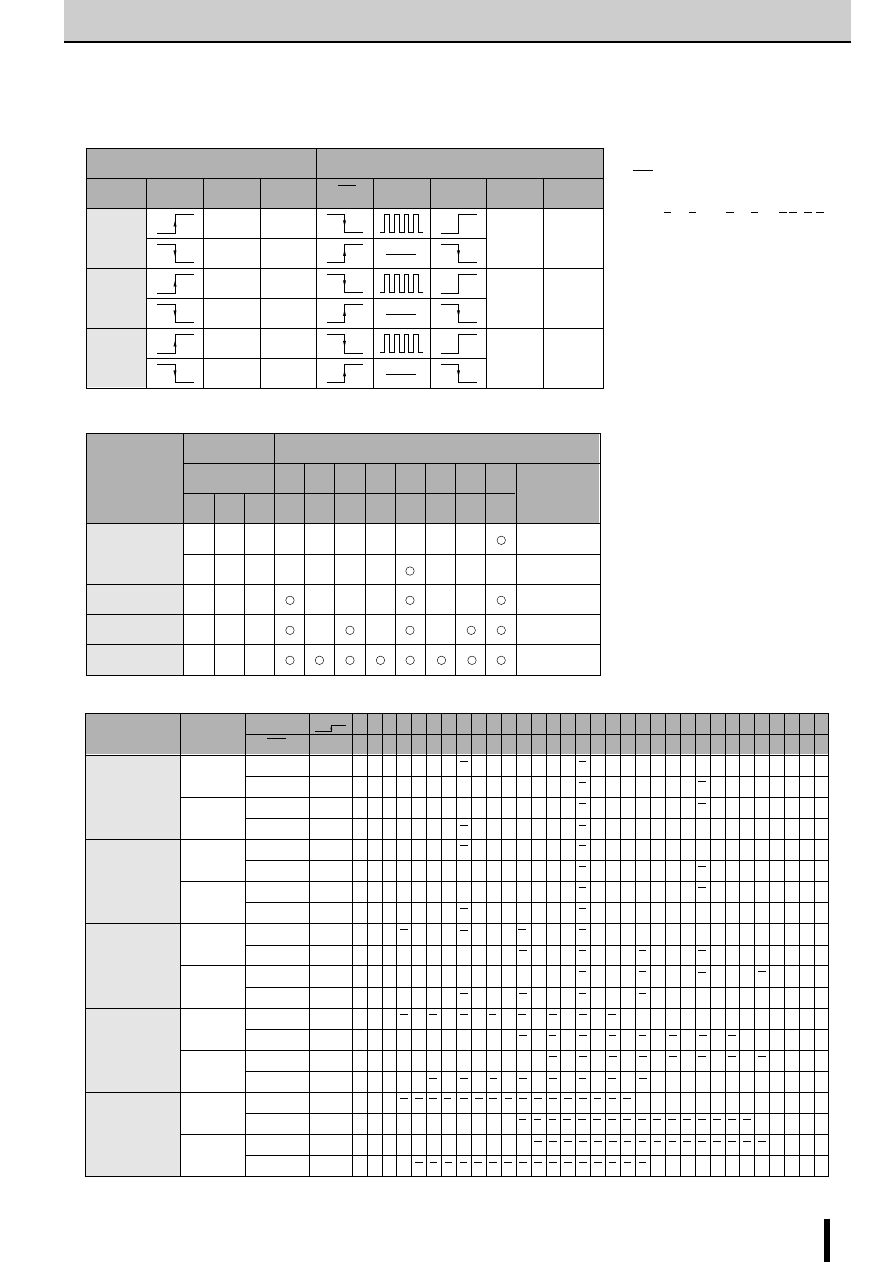

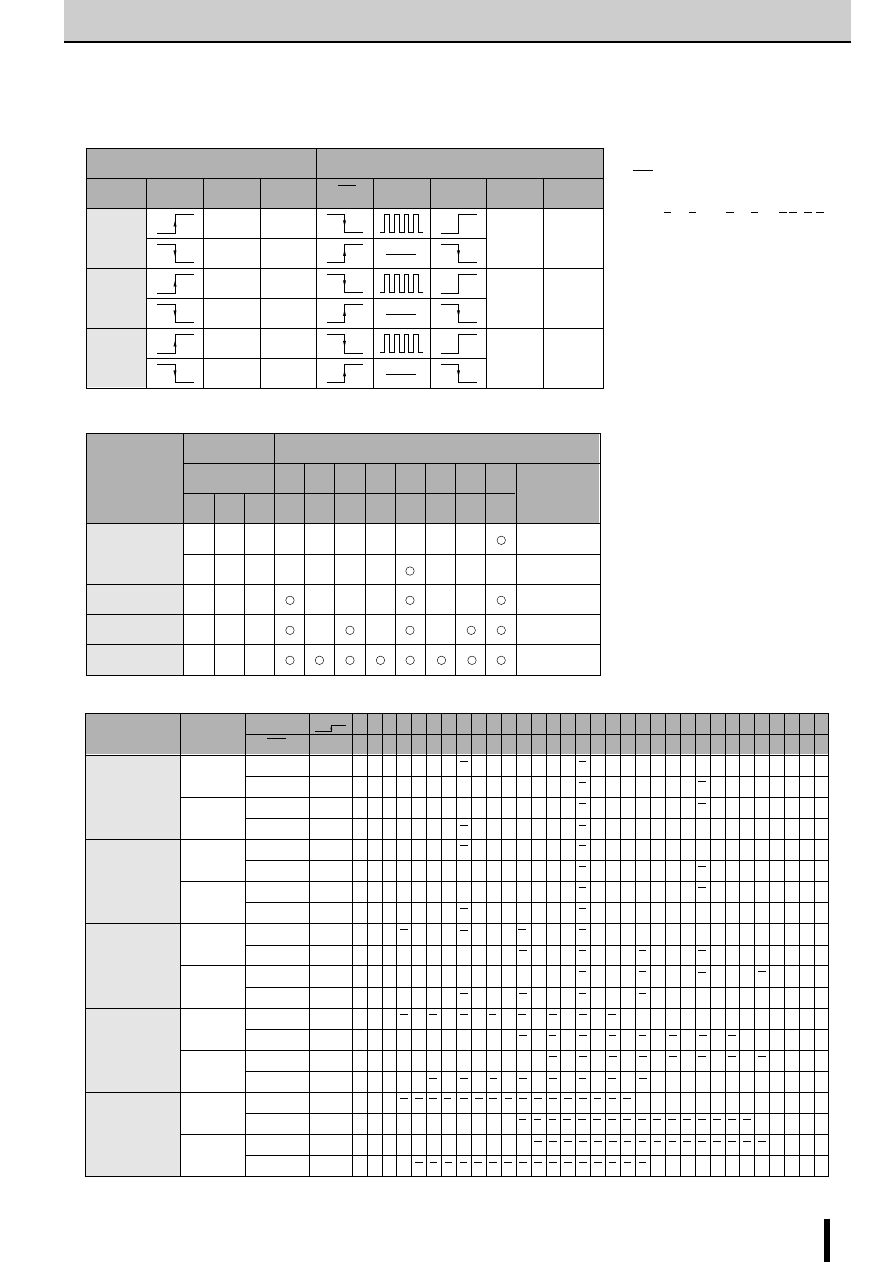

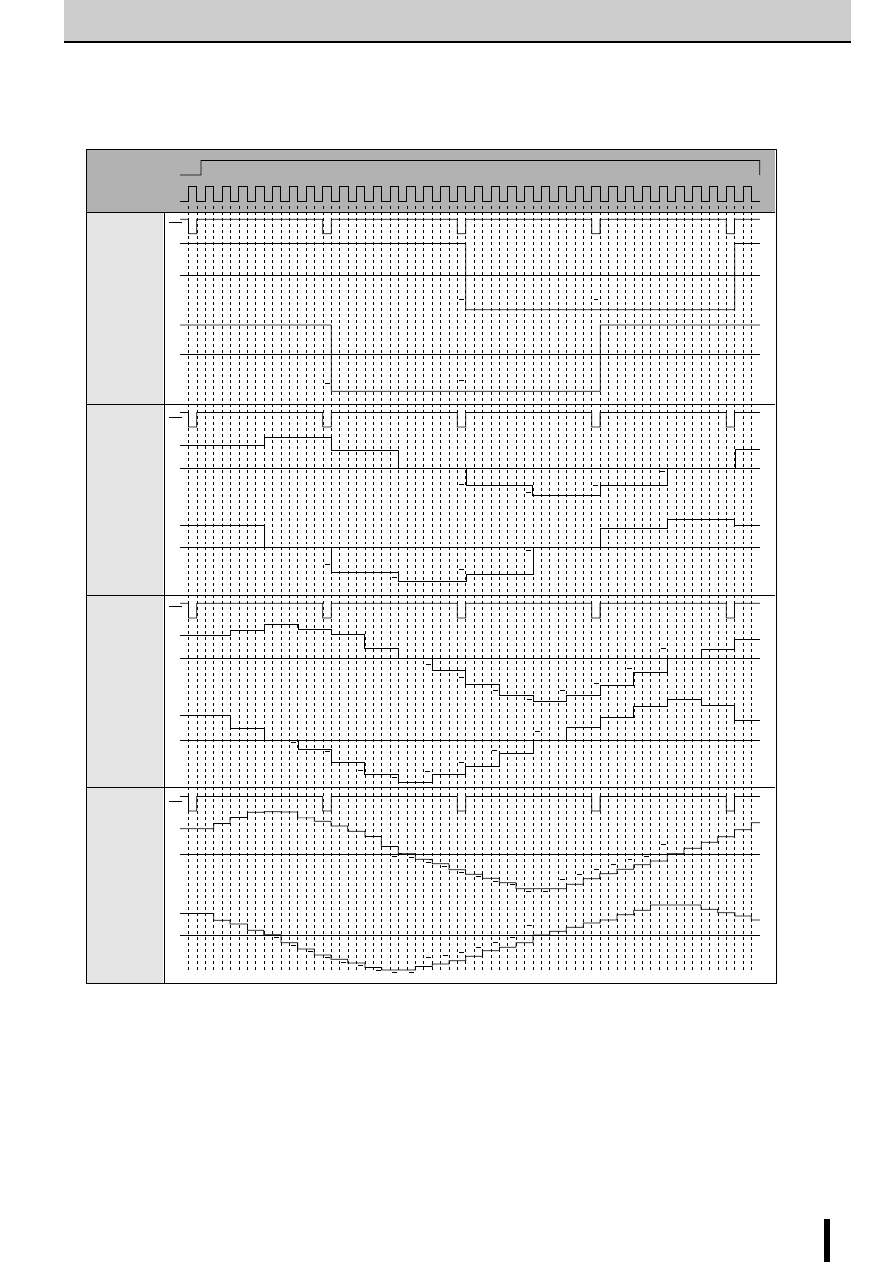

Excitation signal time chart

2-phase excitation

clock

0

1

2

3

0

1

IN

A

H

H

L

L

H

H

IN

B

L

H

H

L

L

H

1-2 phase excitation

clock 0

1

2

3

4

5

6

7

0

1

2 3

IN

A

H H H H

L

L

L

L

H H H H

td

A

L

L

L

H

L

L

L

H L

L

L

H

IN

B

L

L

H H H H

L

L

L

L

H

H

td

B

L H L

L

L

H

L

L

L

H

L

L

●

tdA and tdB are signals before the inverter stage.

r

1

: 510

Ω

r

2

: 100

Ω

(VR)

r

3

: 47k

Ω

r

4

: 47k

Ω

r

5

: 2.4k

Ω

r

6

: 2.4k

Ω

C

1

: 330 to 500pF

C

2

: 330 to 500pF

C

3

: 2200pF

C

4

: 2200pF

R

s

: 1.8

Ω

typ(7022MU)

1

Ω

typ(7029M)

(1 to 2W)

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

7

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

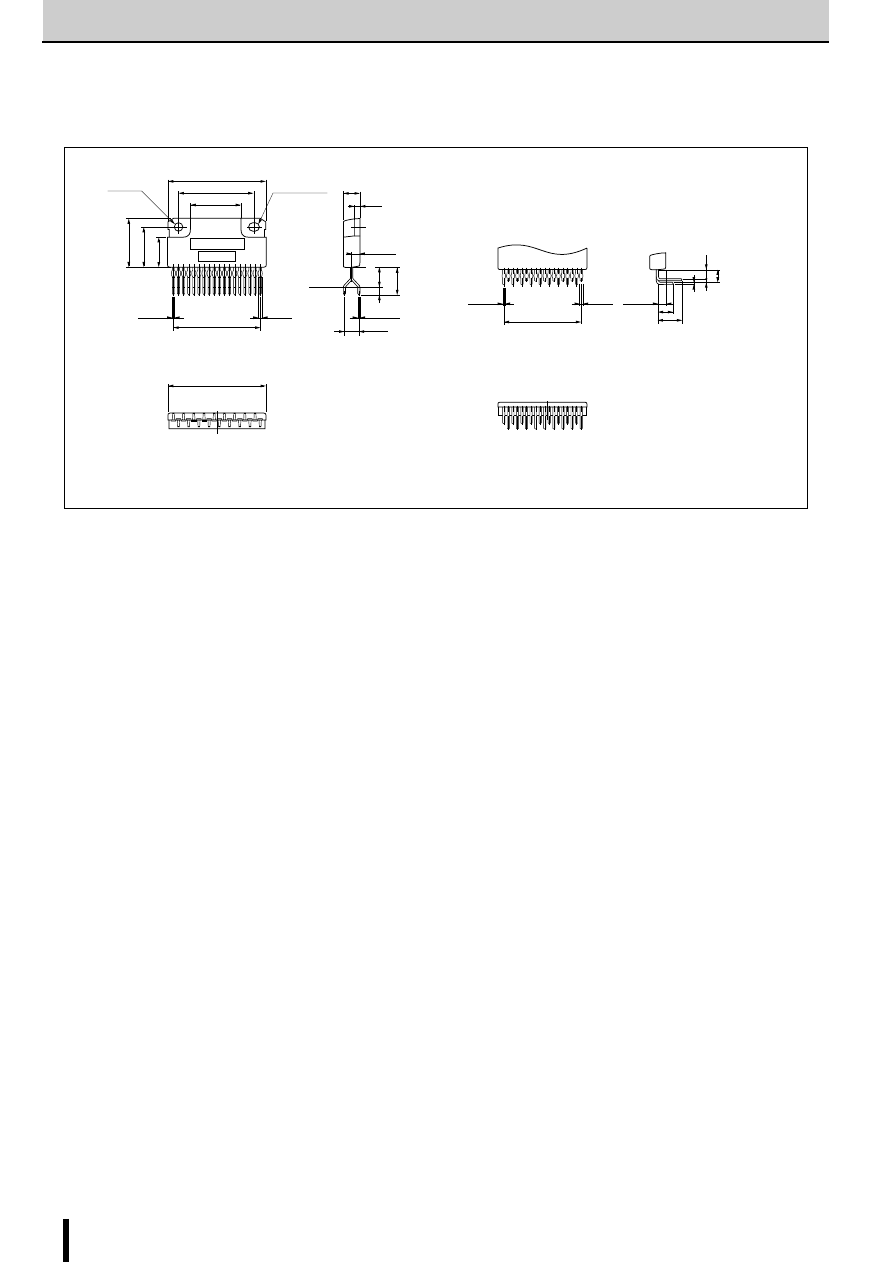

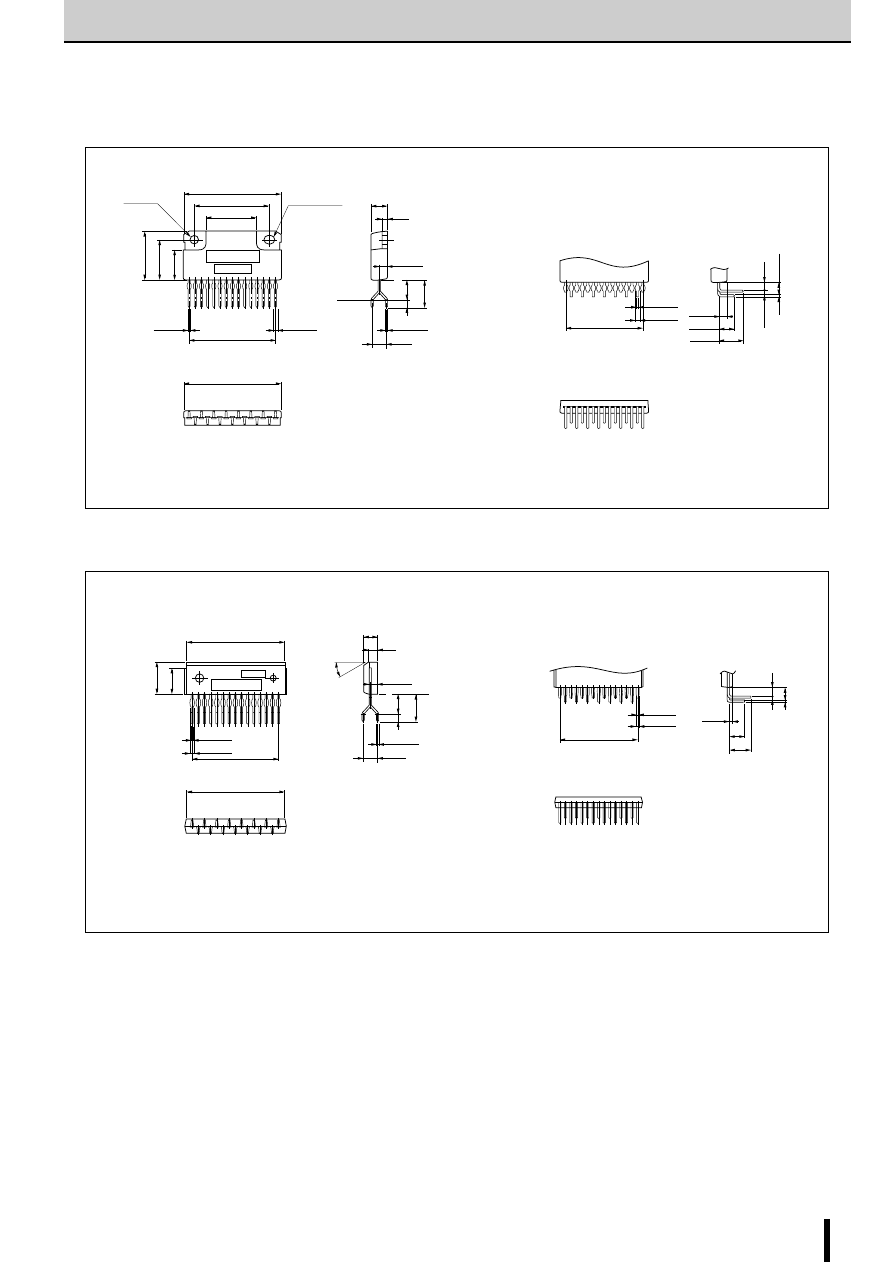

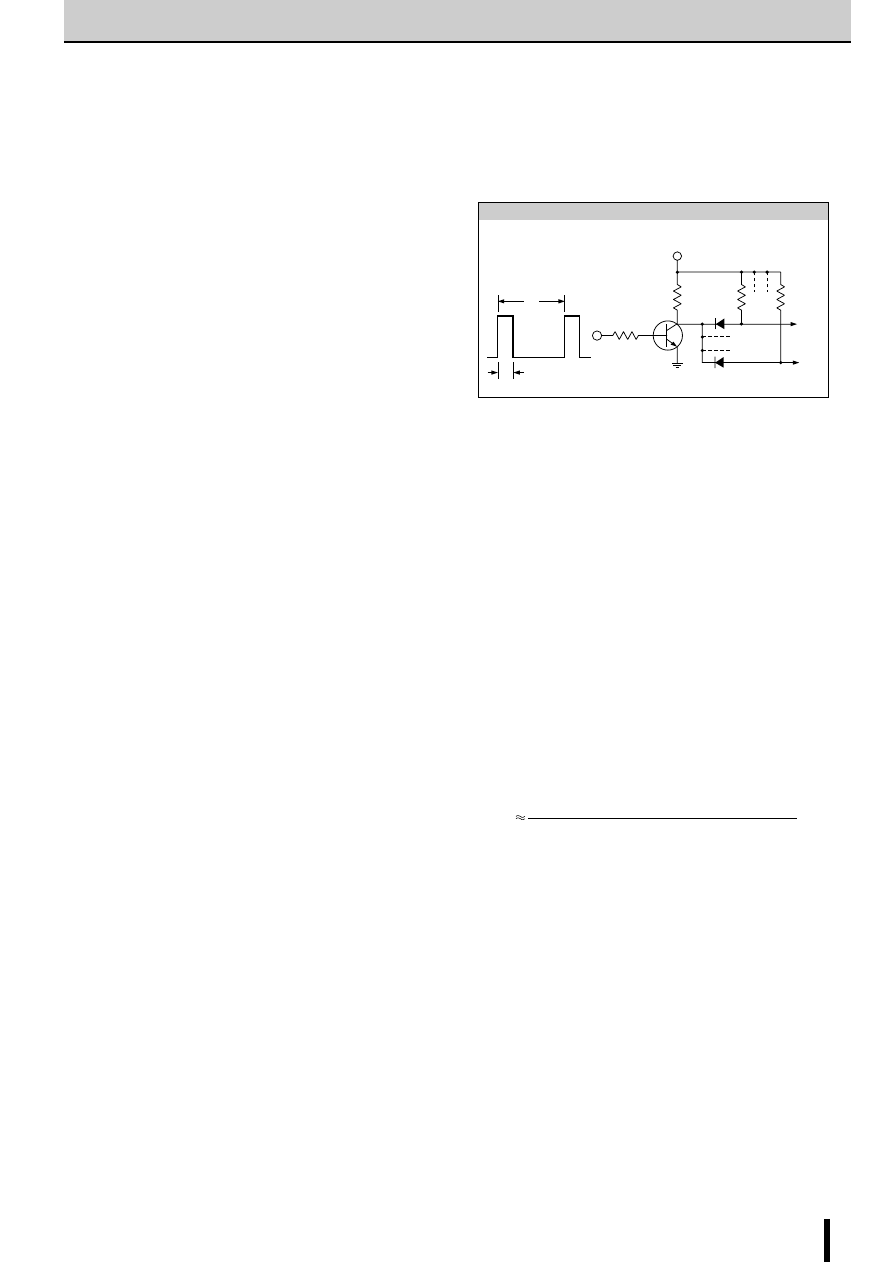

■

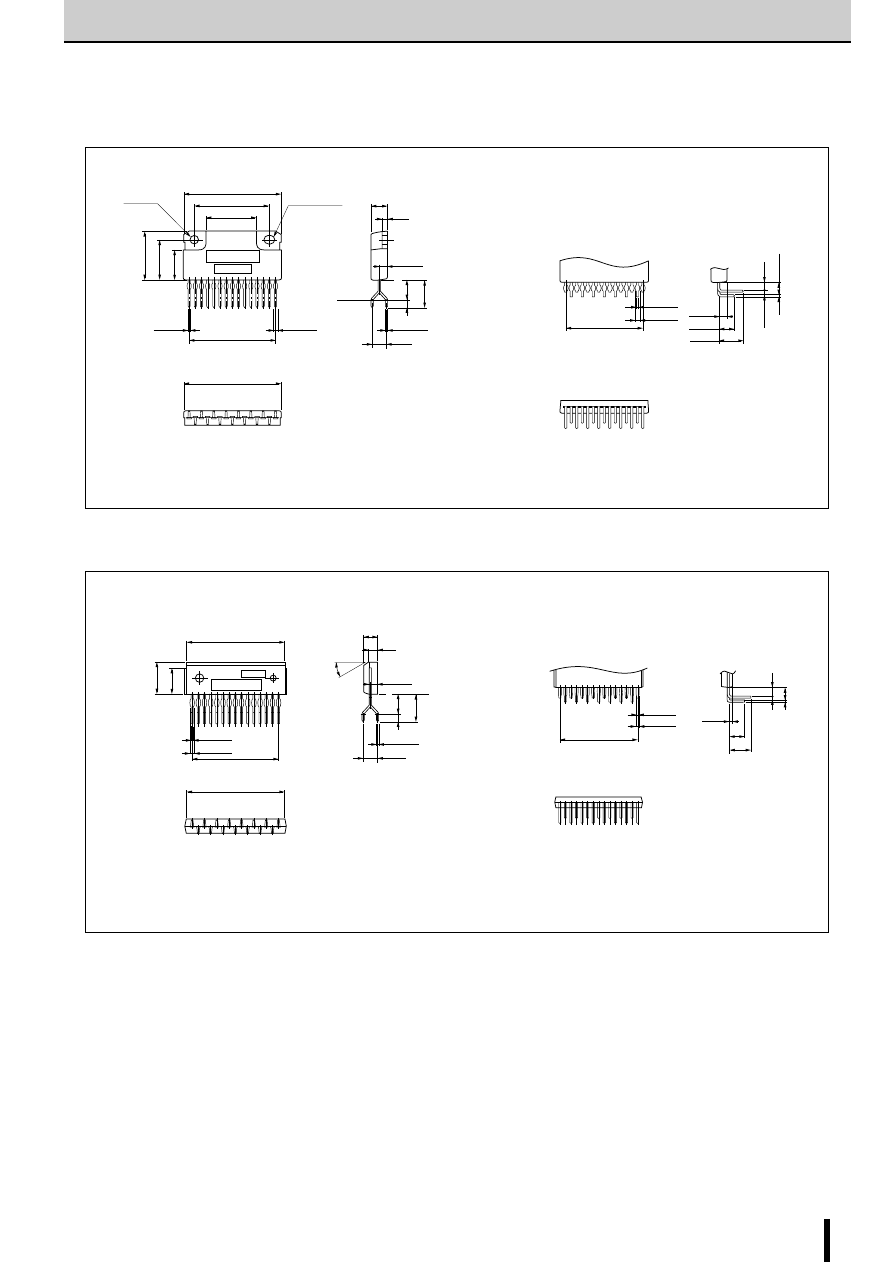

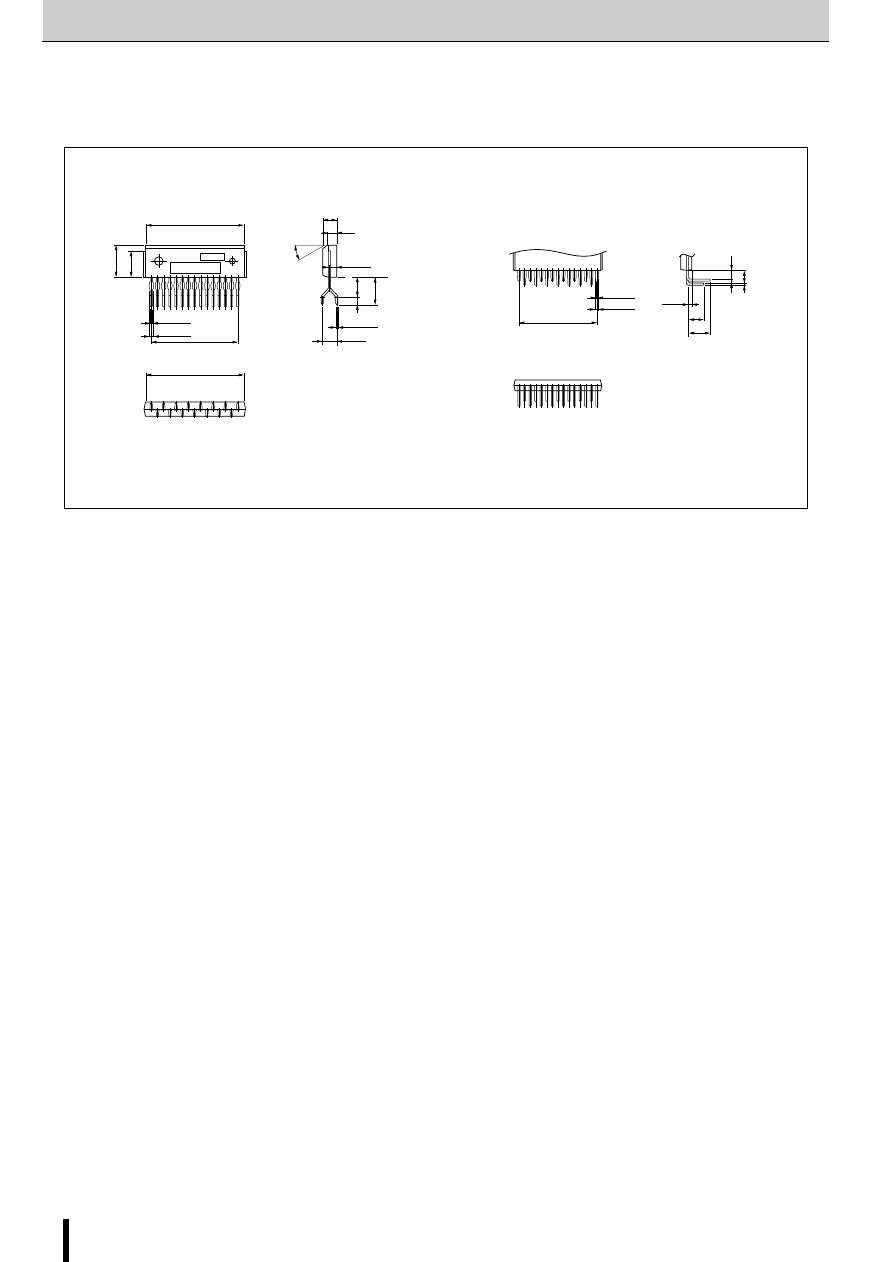

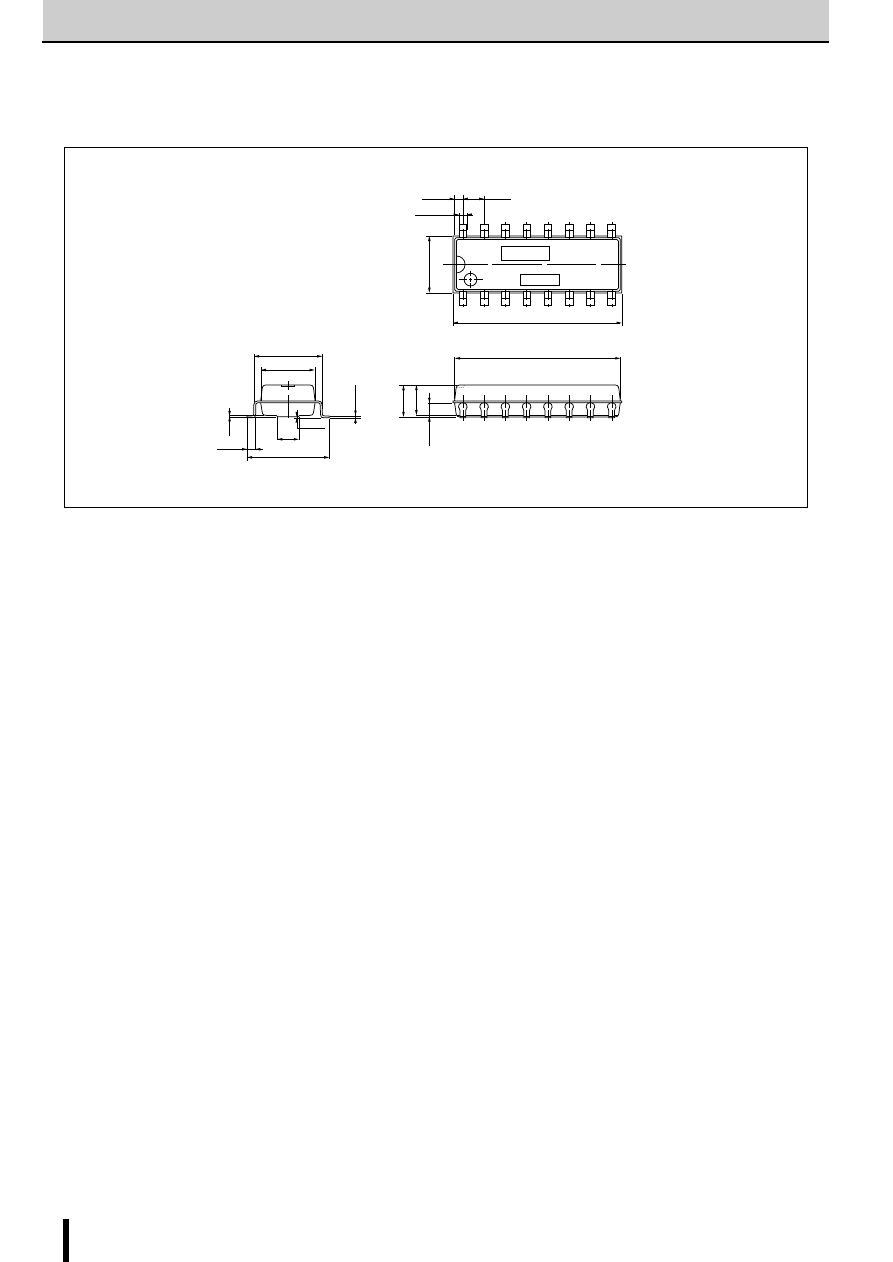

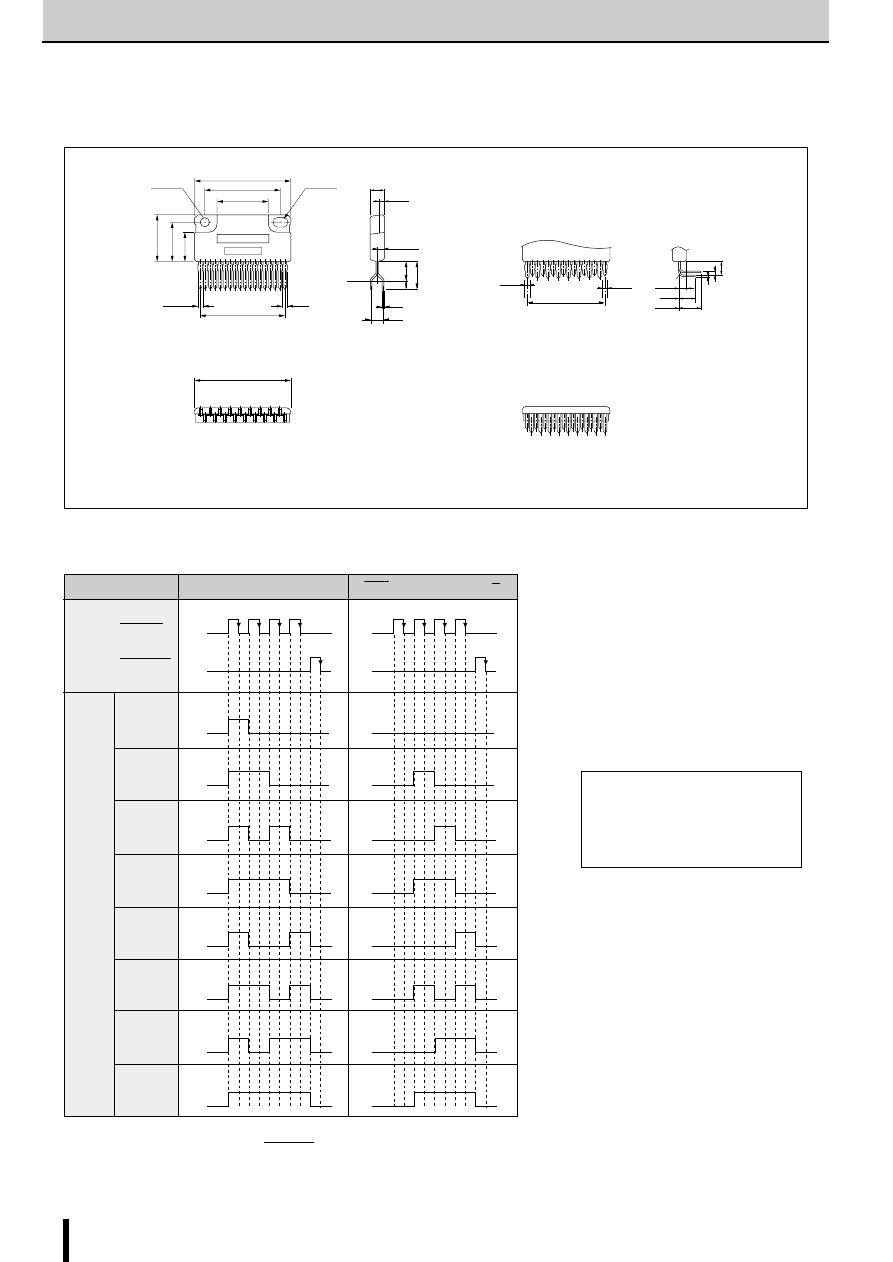

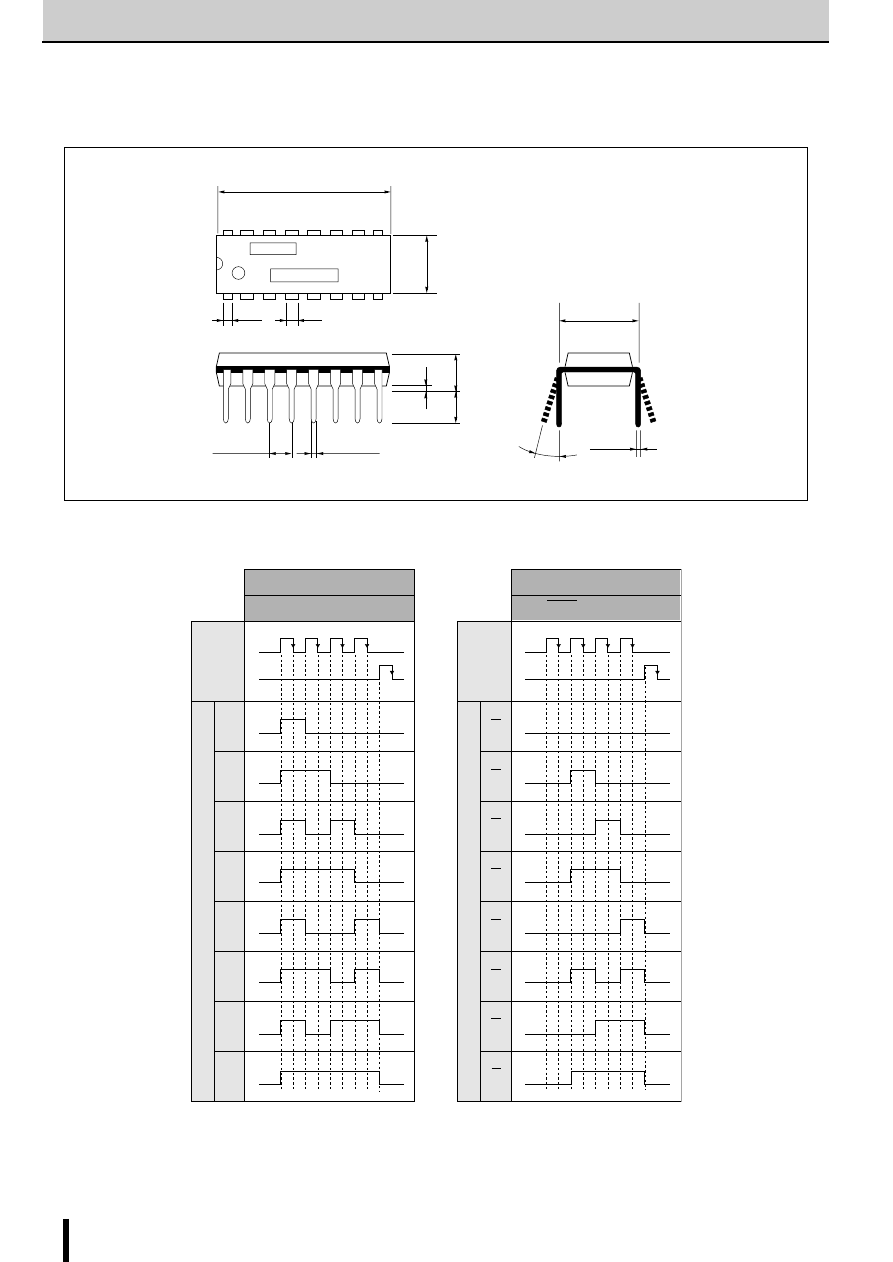

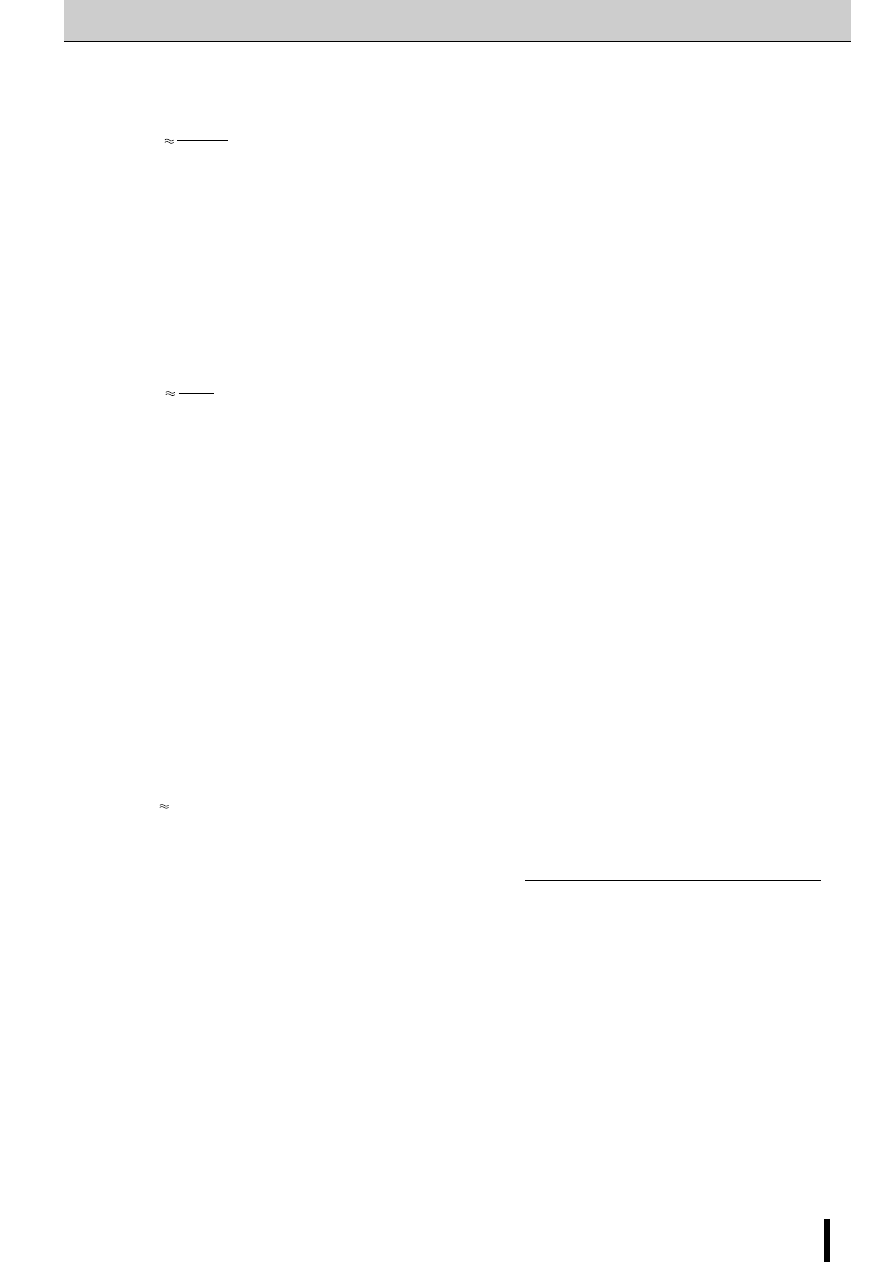

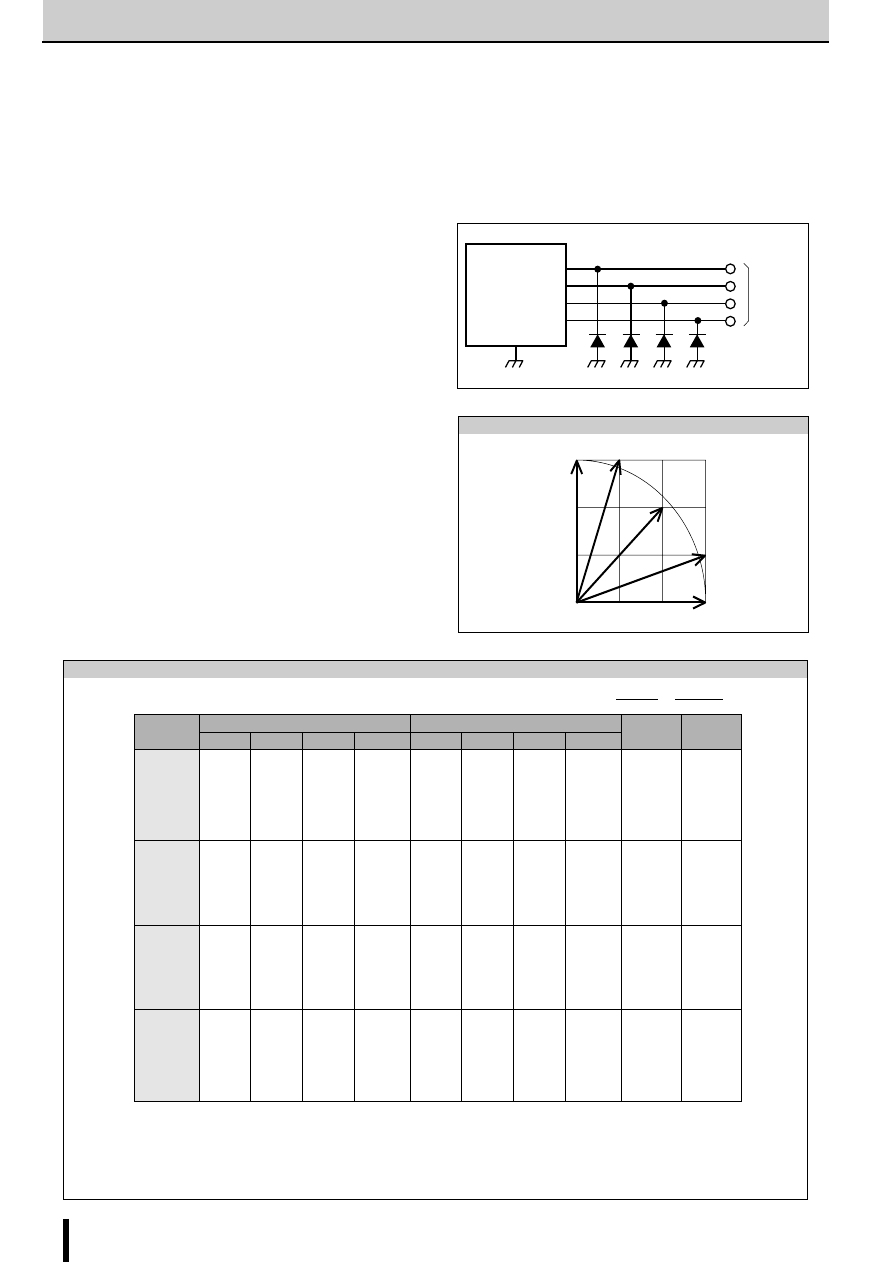

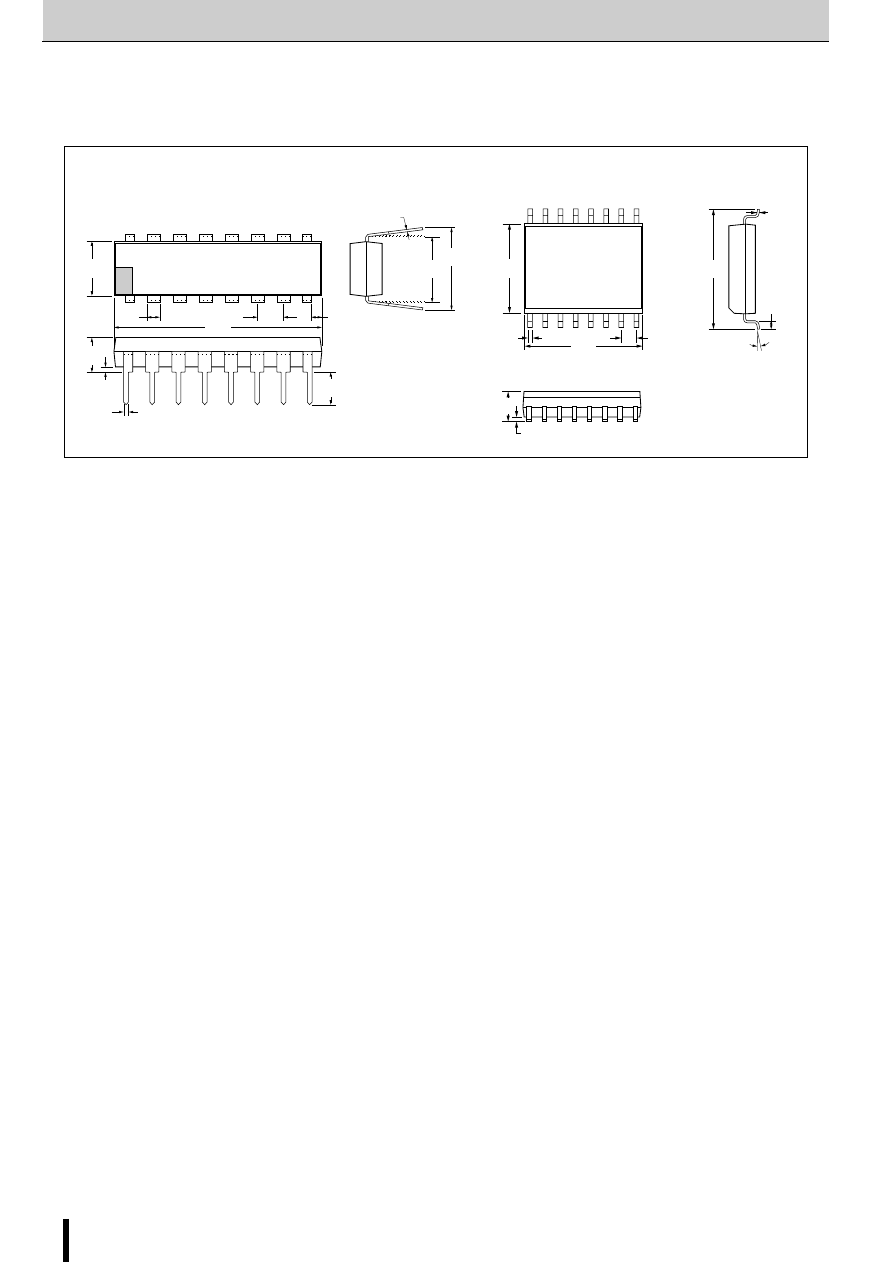

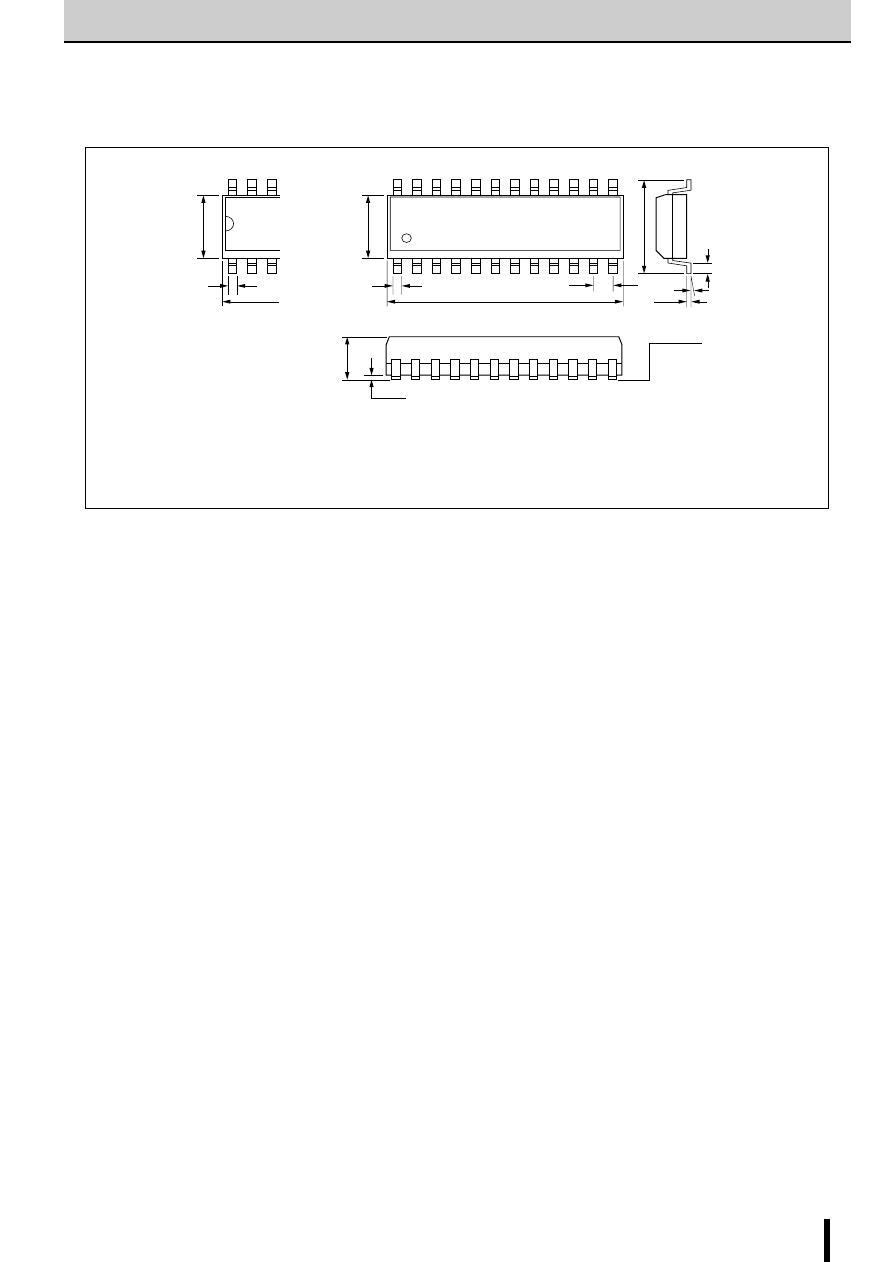

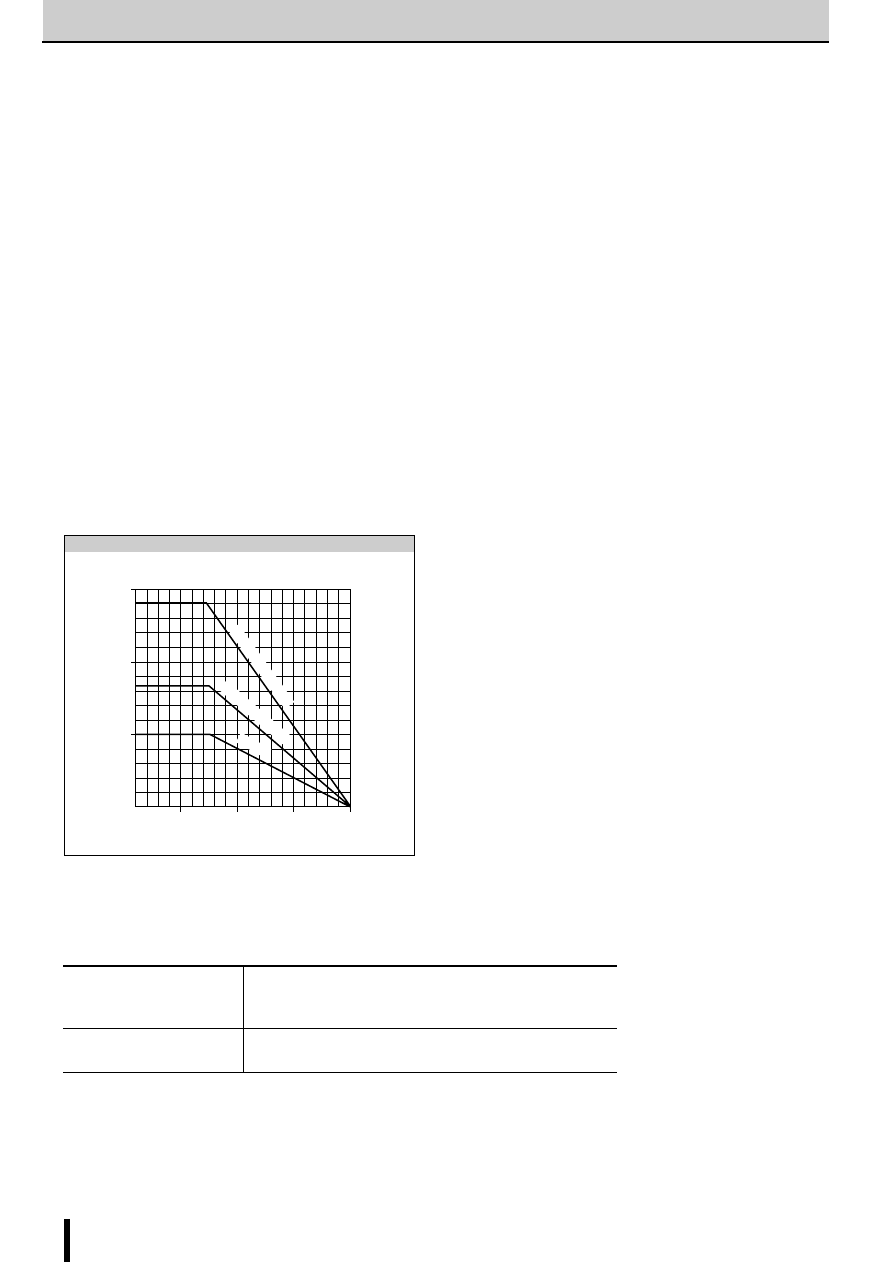

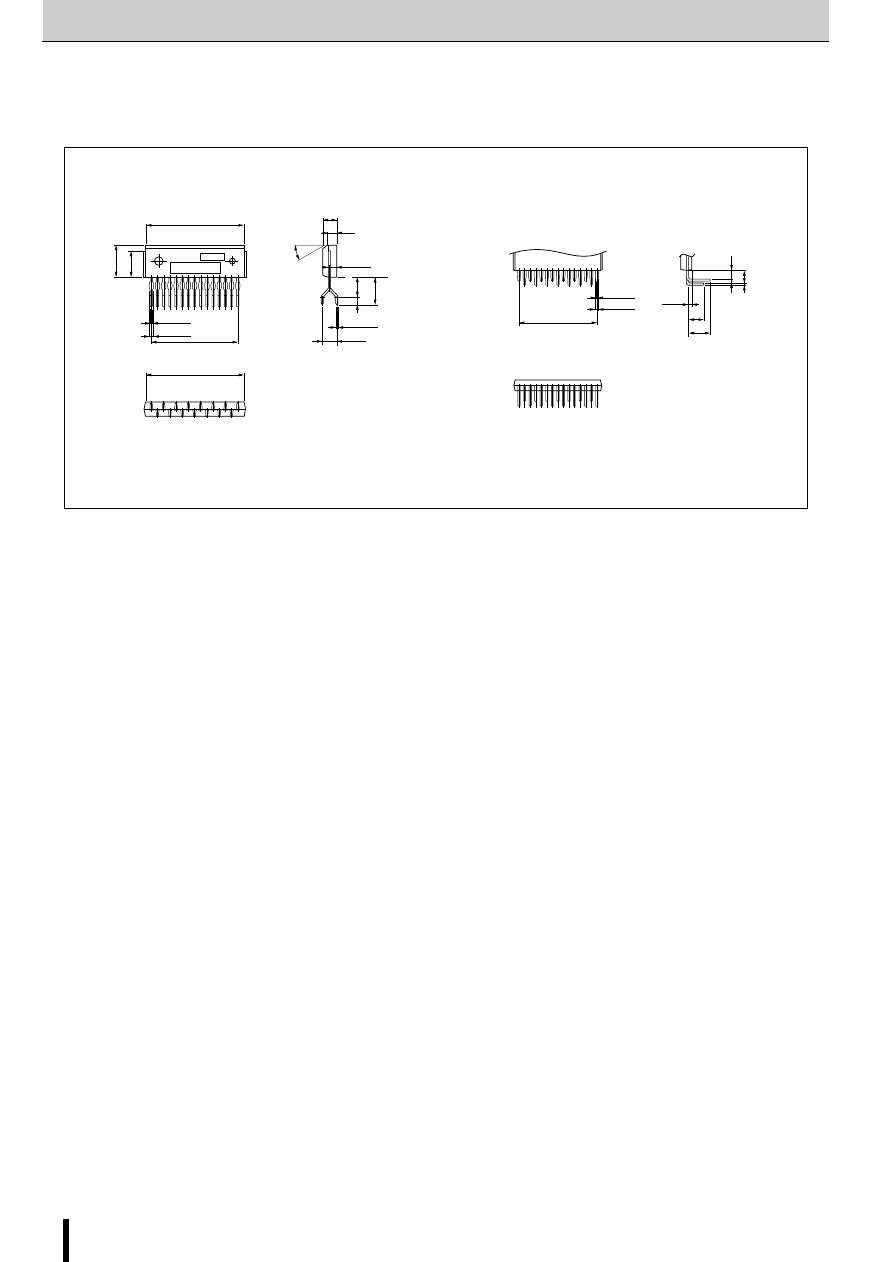

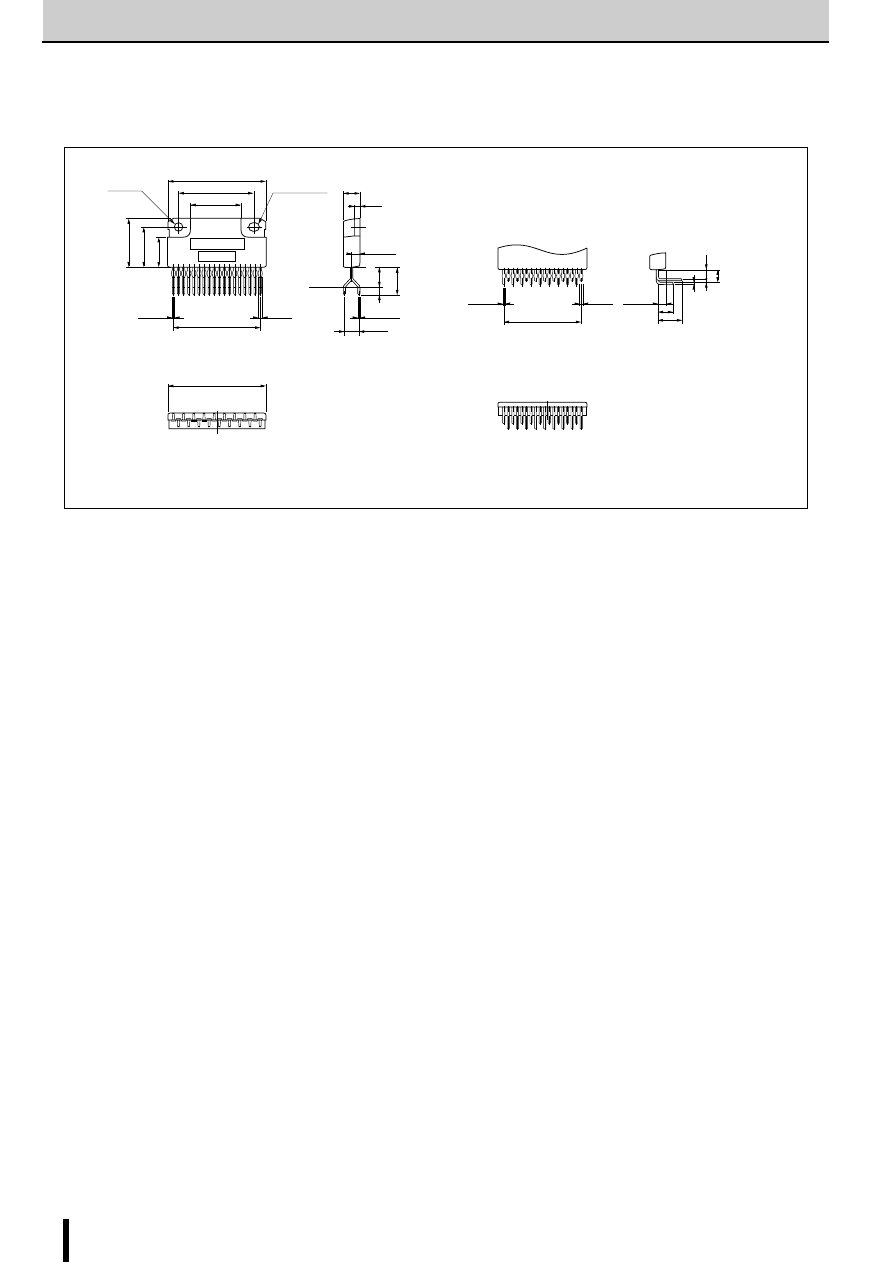

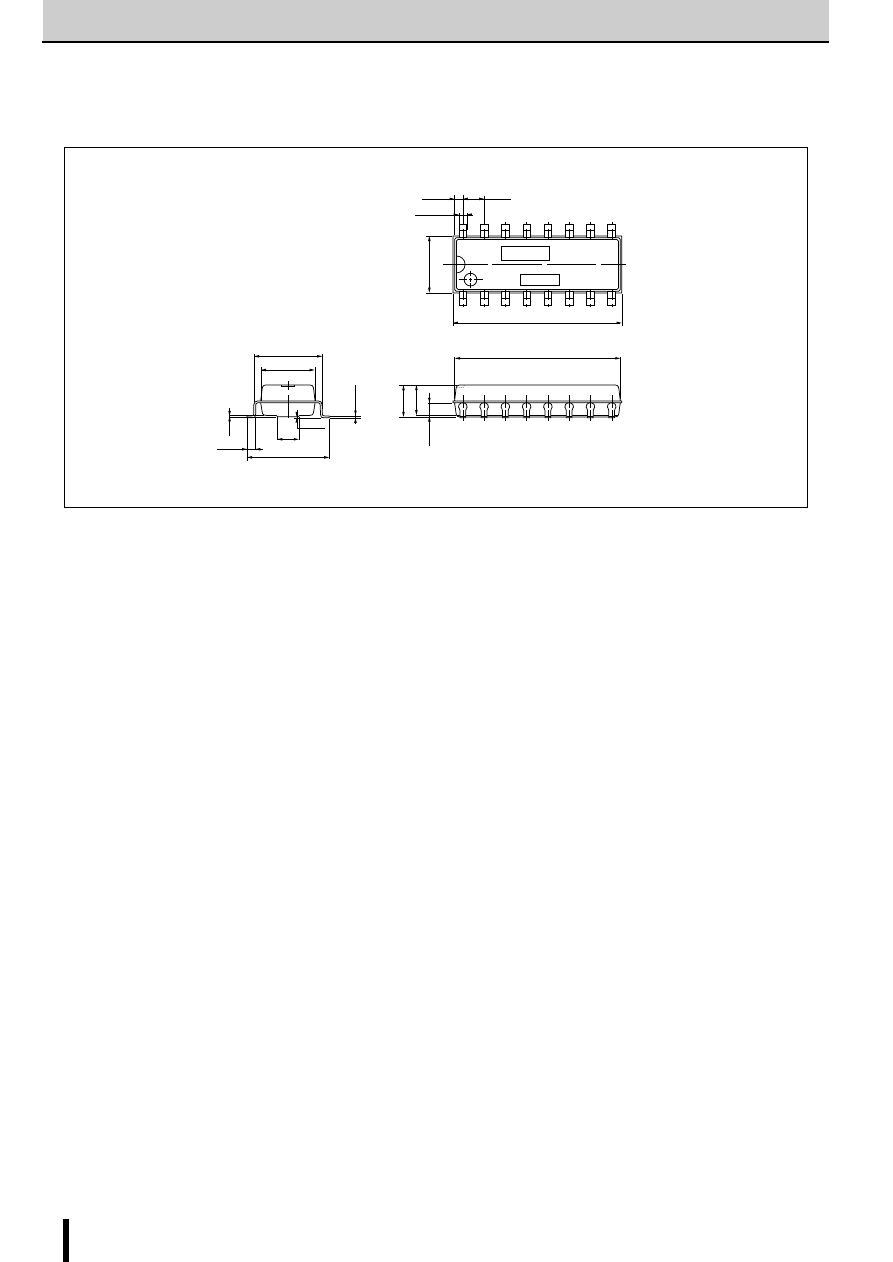

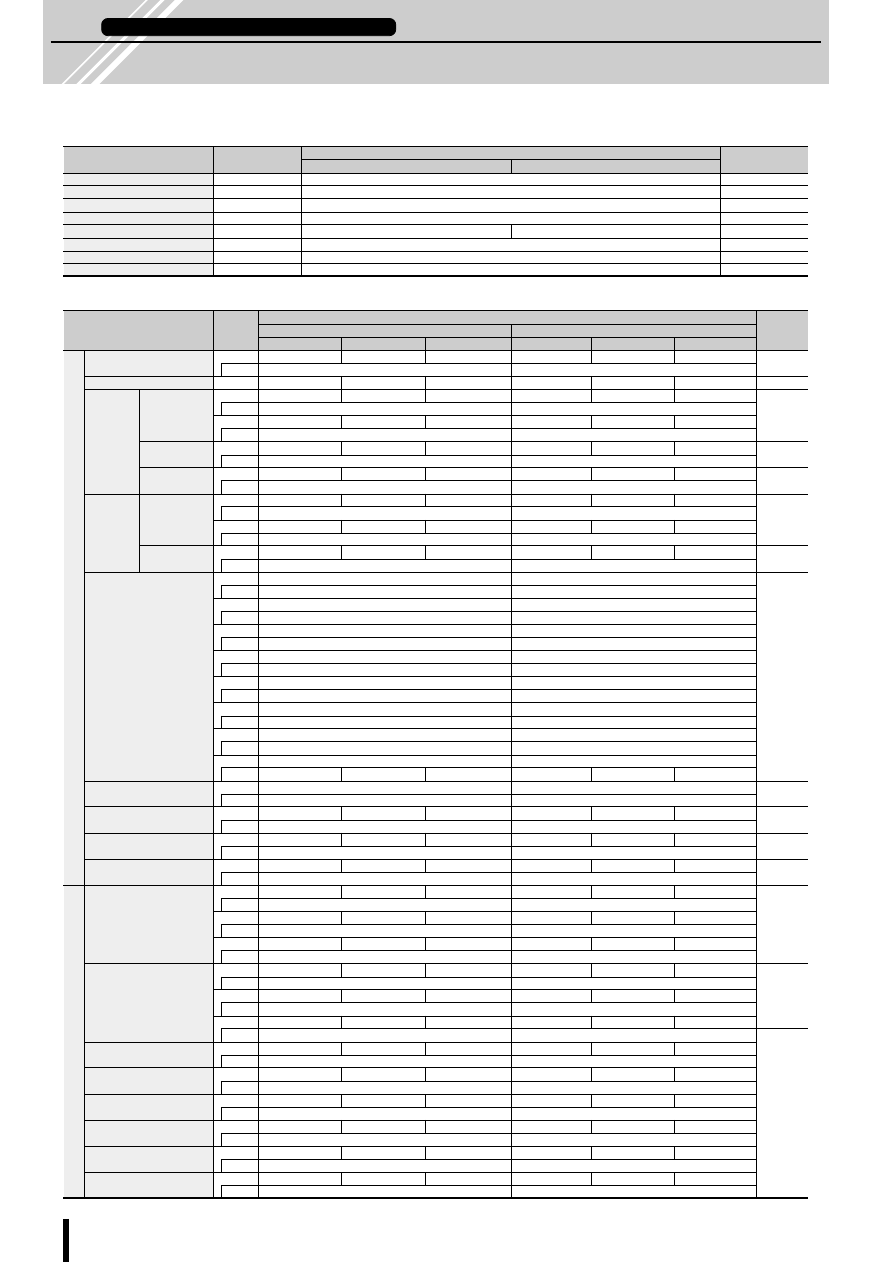

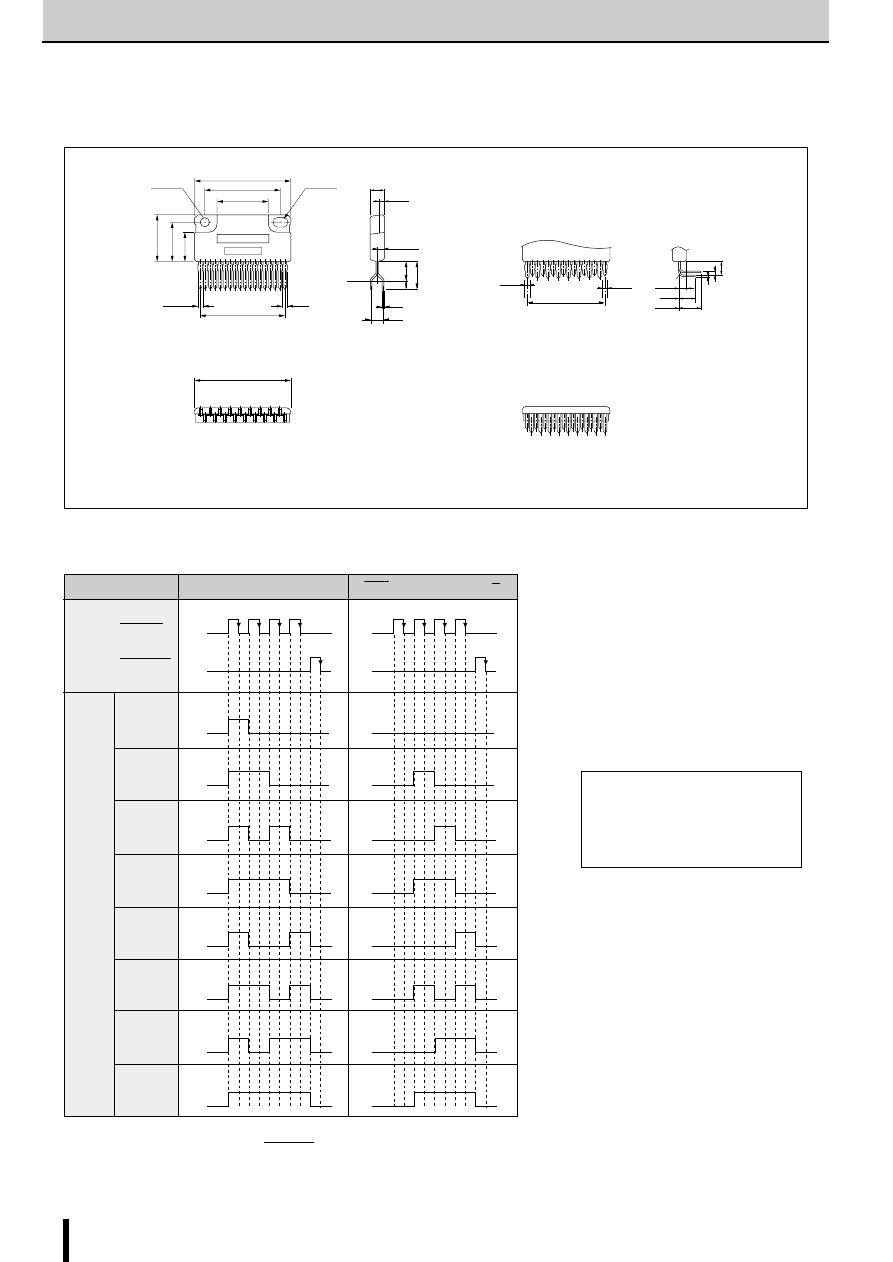

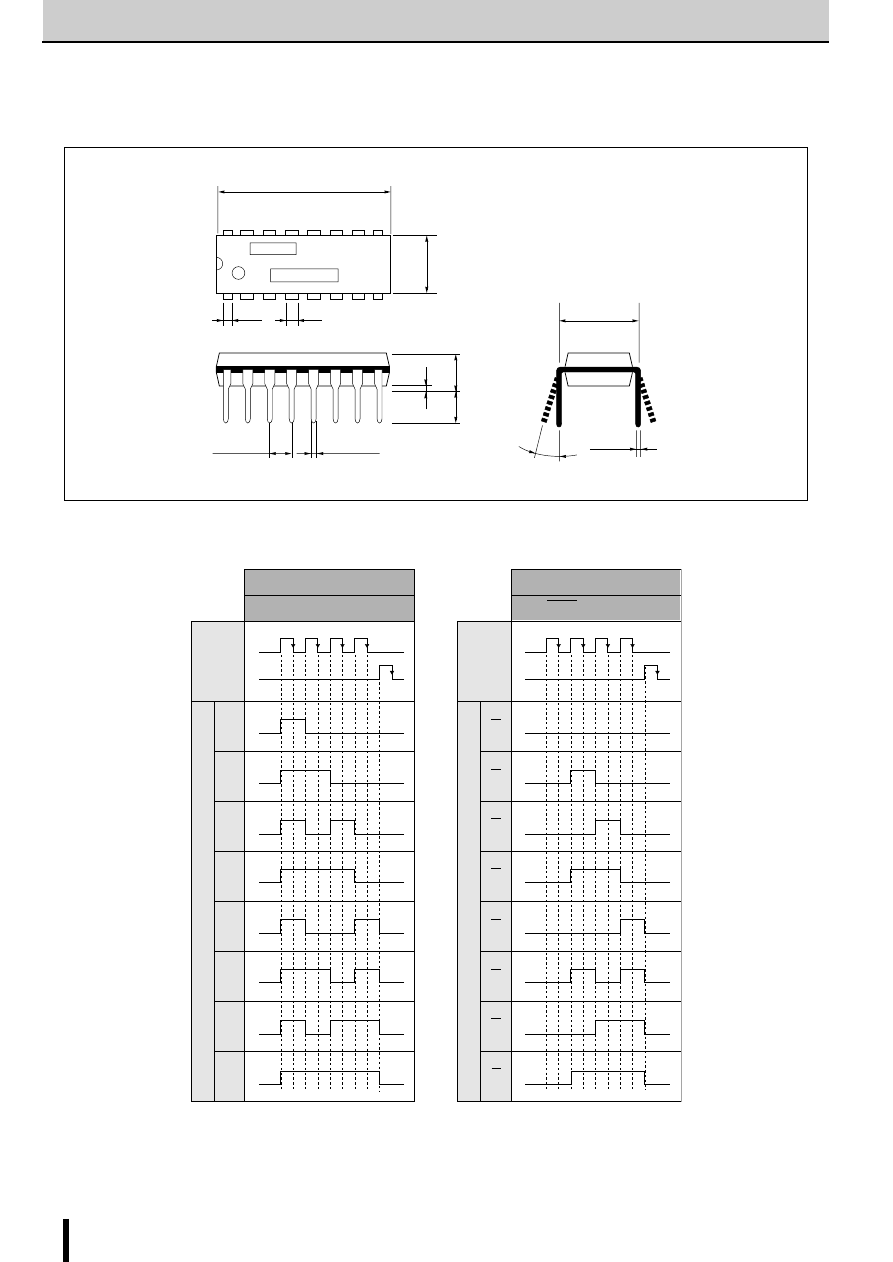

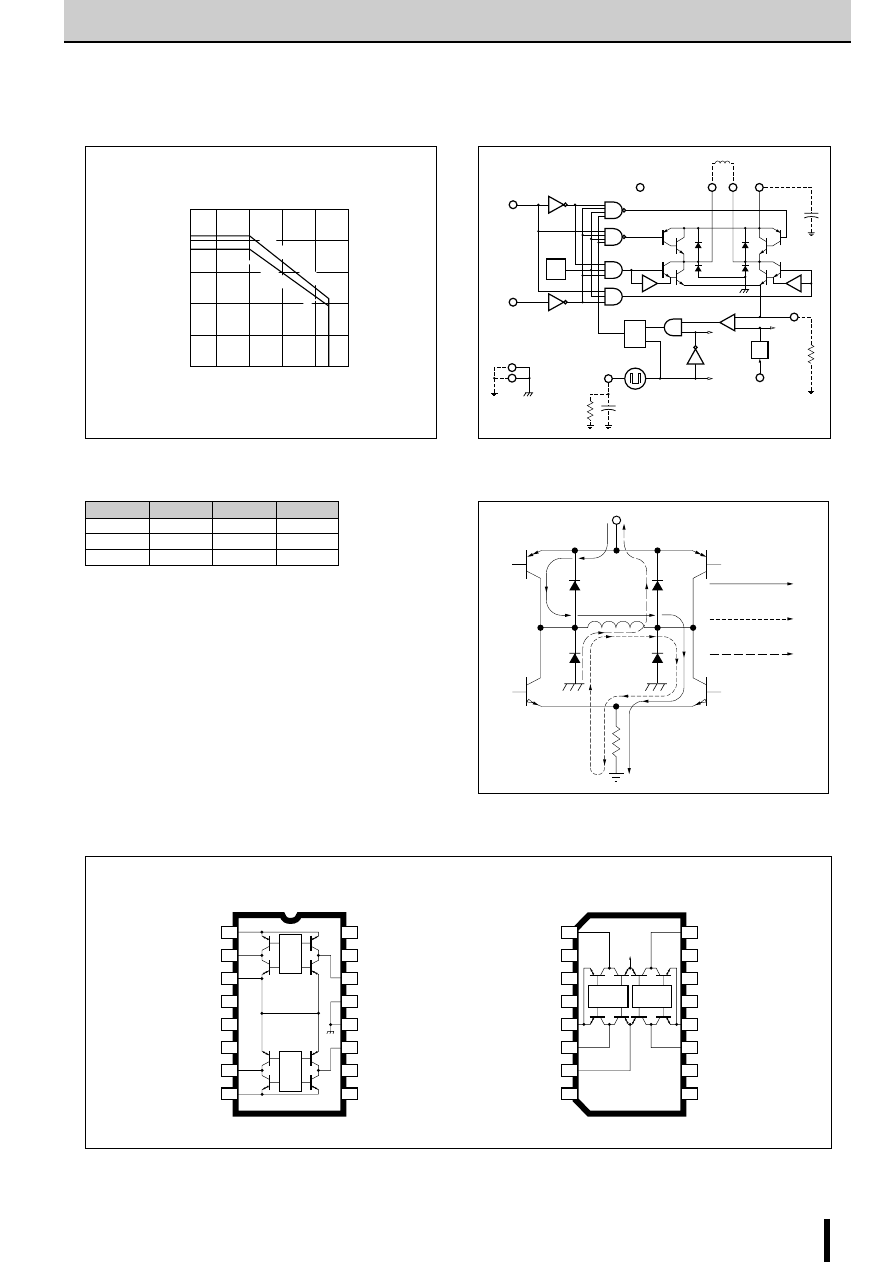

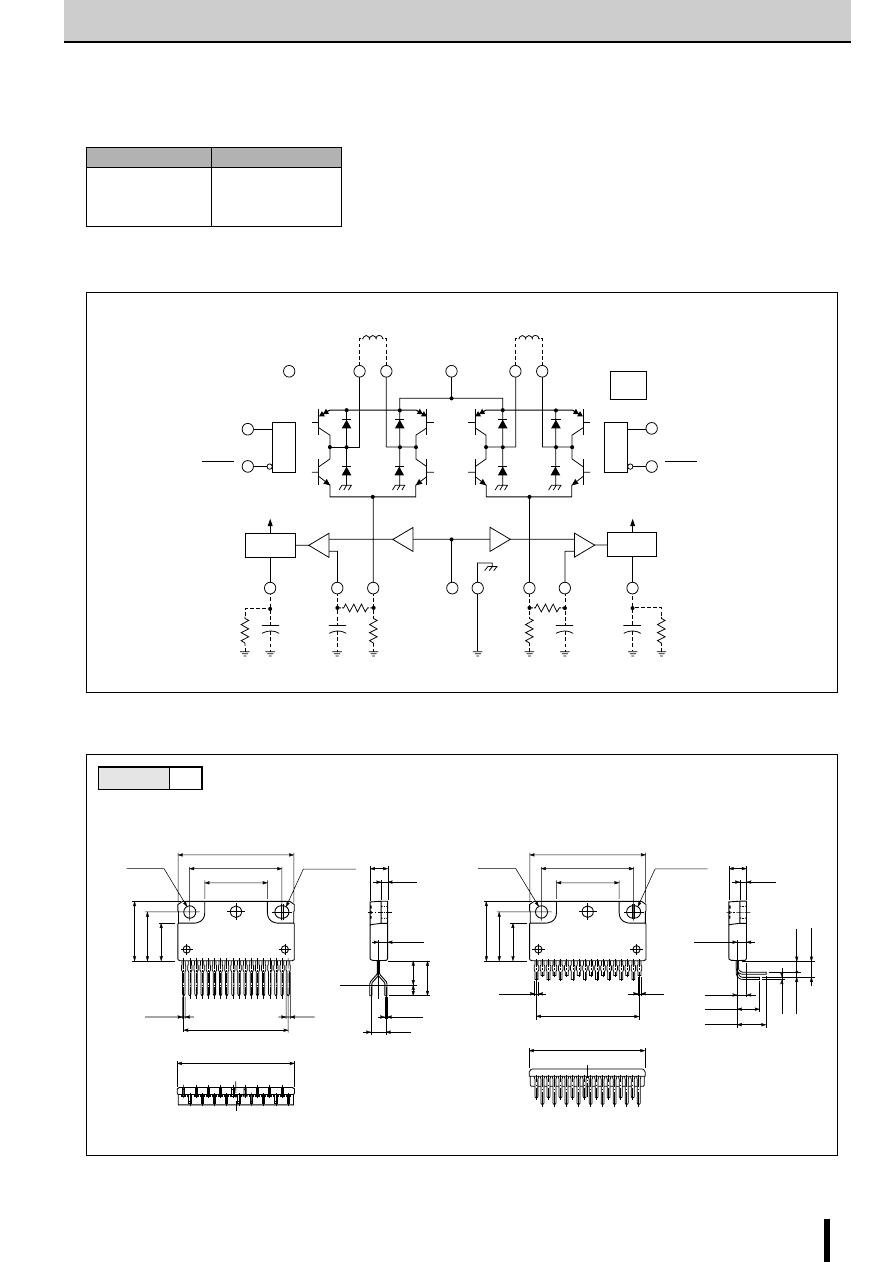

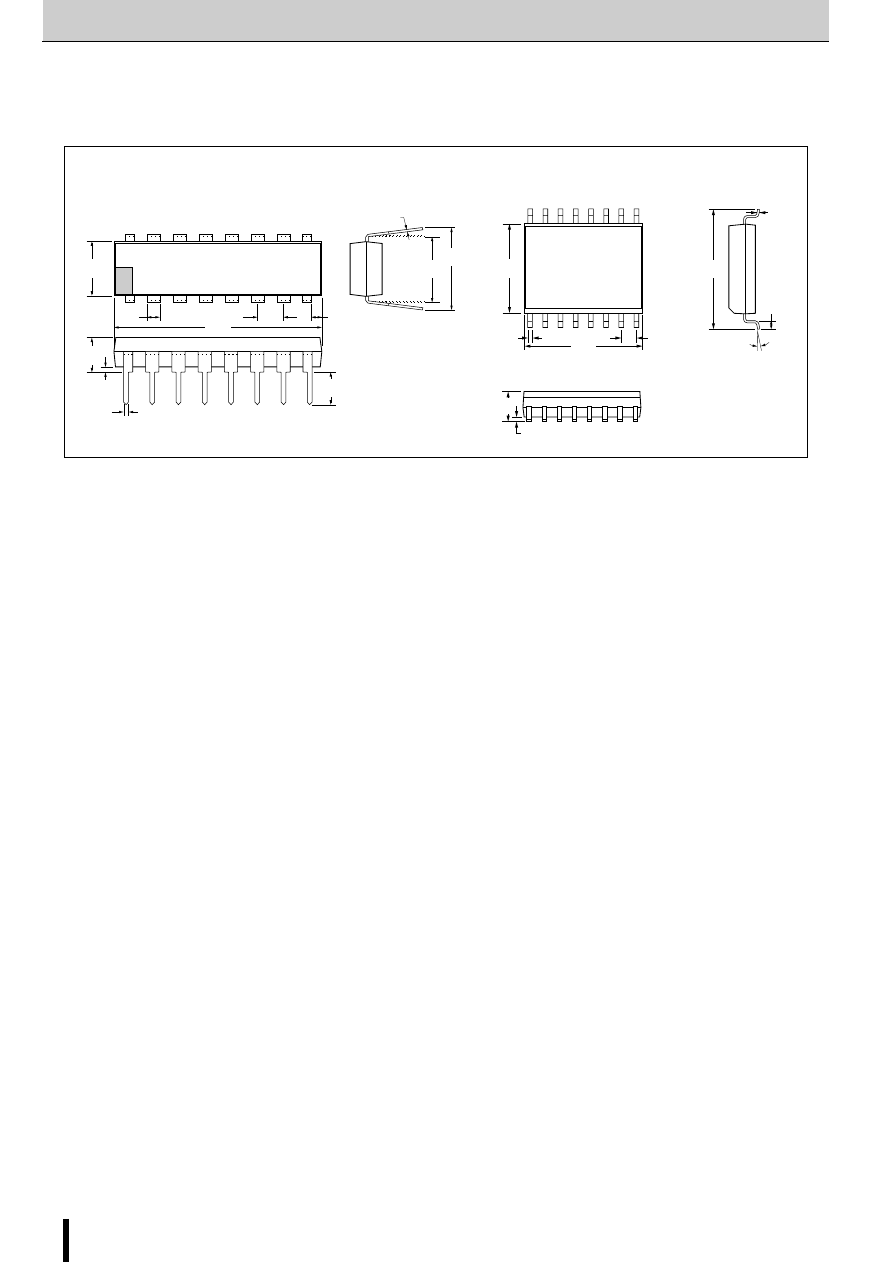

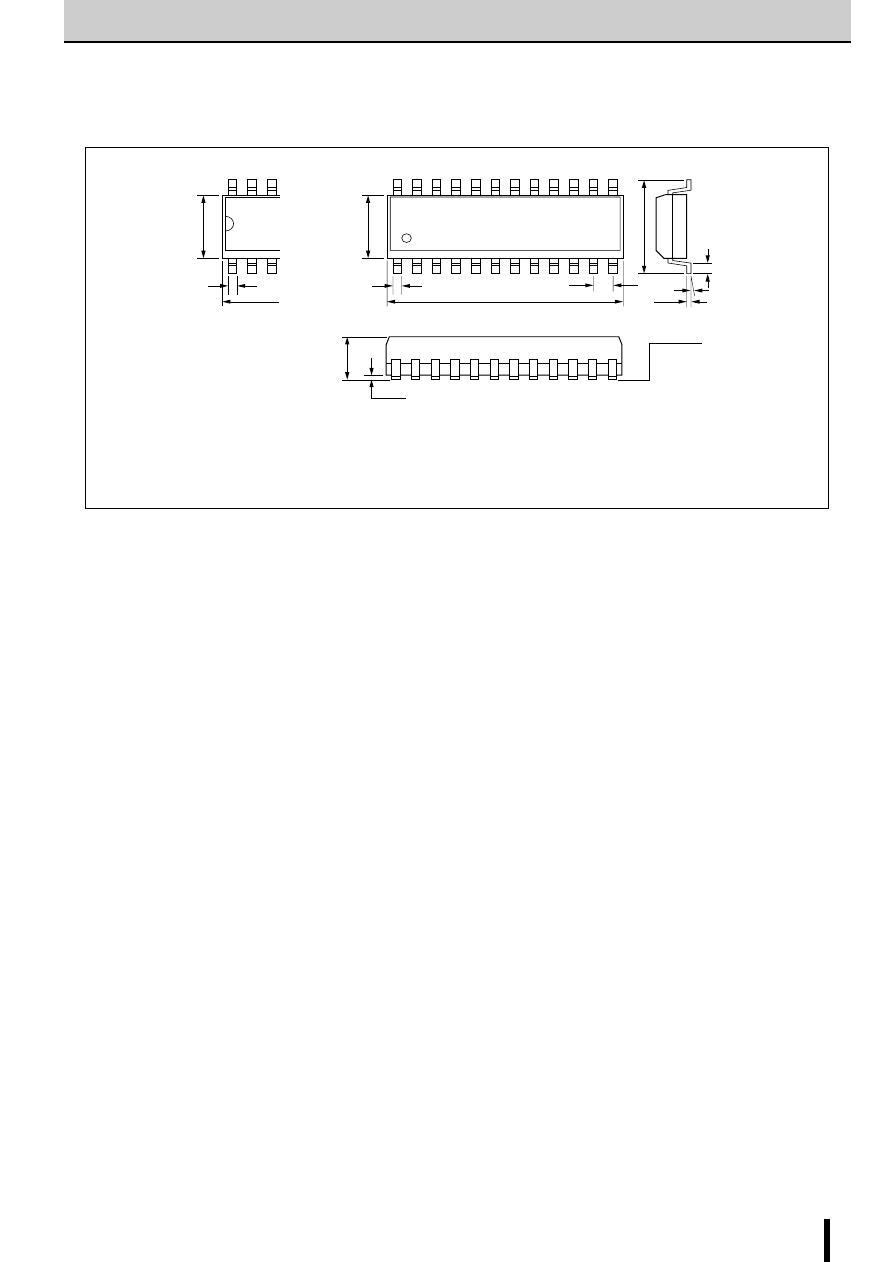

External Dimensions SLA7022MU/SLA7029M

(Unit: mm)

31

±

0.2

24.4

±

0.2

16.4

±

0.2

3.2

±

0.15

φ

16

±

0.2

13

±

0.2

9.9

±

0.2

Part No.

Lot No.

3.2

±

0.15

×

3.8

φ

4.8

±

0.2

1.7

±

0.1

2.45

±

0.2

R-End

6.7

±

0.5

9.7

+1 –

0.5

(3)

0.55

+0.2

–0.1

4

±

0.7

1.15

+0.2

–0.1

14

×

P2.03

±

0.7

=28.42

±

1.0

0.65

+0.2

–0.1

31.3

±

0.2

Forming No. No.853

1 2 3 · · · · · · · 15

12 3 · · · · · · · 15

Forming No. No.855

14

×

P2.03

±

0.4

=28.42

±

0.8

0.65

+0.2

–0.1

3

±

0.6

0.55

+0.2 –

0.1

2.2

±

0.4

6.3

±

0.6

7.5

±

0.6

4.6

±

0.6

1.6

±

0.6

Epoxy resin package

1.15

+0.2

–0.1

(Unit: mm)

■

External Dimensions SMA7022MU/SMA7029MA

Forming No. No.1054

31

±

0.2

Part No.

Lot No.

4

±

0.2

2.5

±

0.2

1.45

±

0.15

6.7

±

0.5

(9.7)

(3)

0.55

+0.2

–0.1

4

±

0.7

P2.03

±

0.1

×

14=28.42

0.65

+0.2

–0.1

1 2 3 · · · · · · · 15

12 3 · · · · · · · 15

P2.03

±

0.1

×

14=28.42

1.16

±

0.15

3

±

0.6

0.55

+0.2 –

0.1

1.2

±

0.1

(5.9)

(4.6)

1.6

±

0.6

1.16

+0.2

–0.1

30

°

0.62

±

0.1

(7.5)

Epoxy resin package

8.5ma

x

10.2

±

0.2

31.3

+0.2

Forming No. No.1055

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

8

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

■

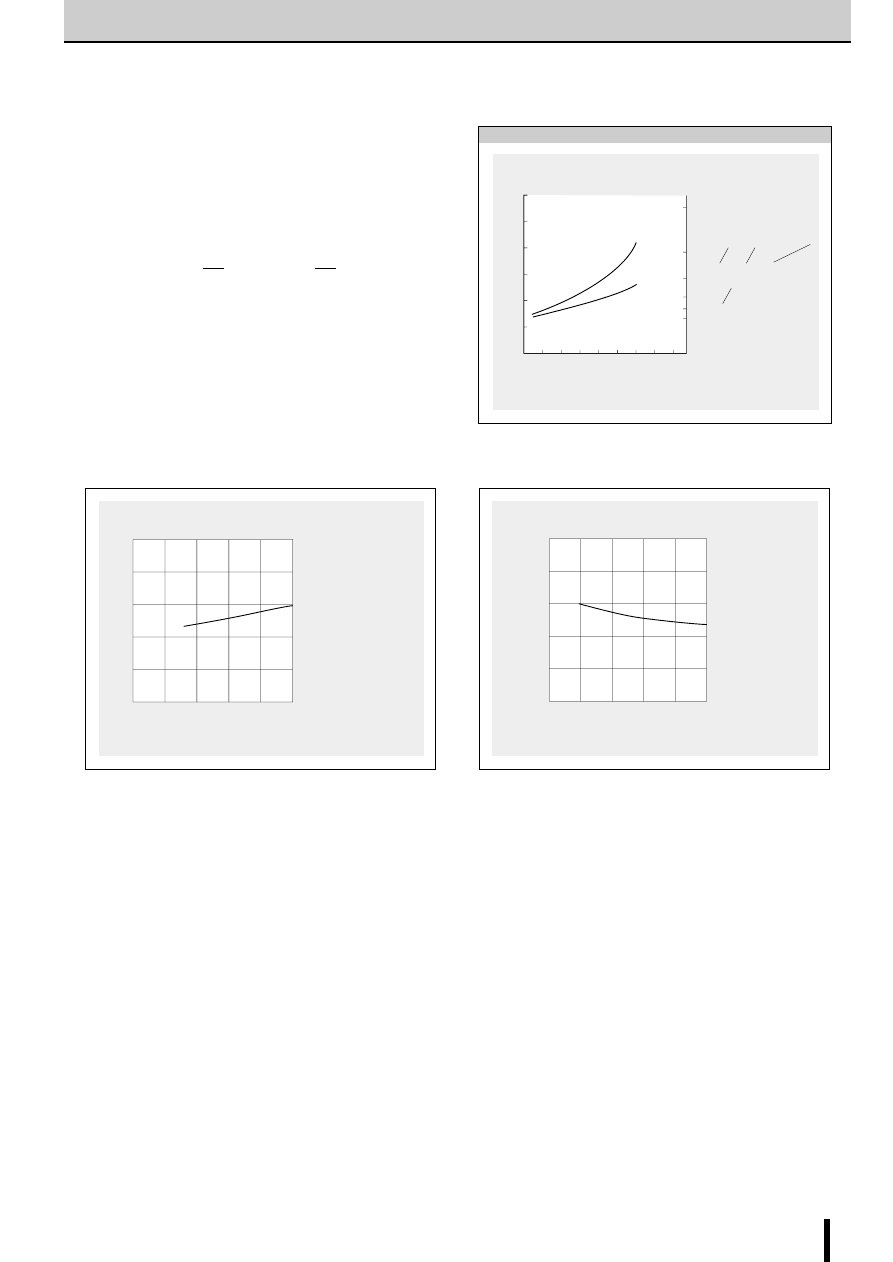

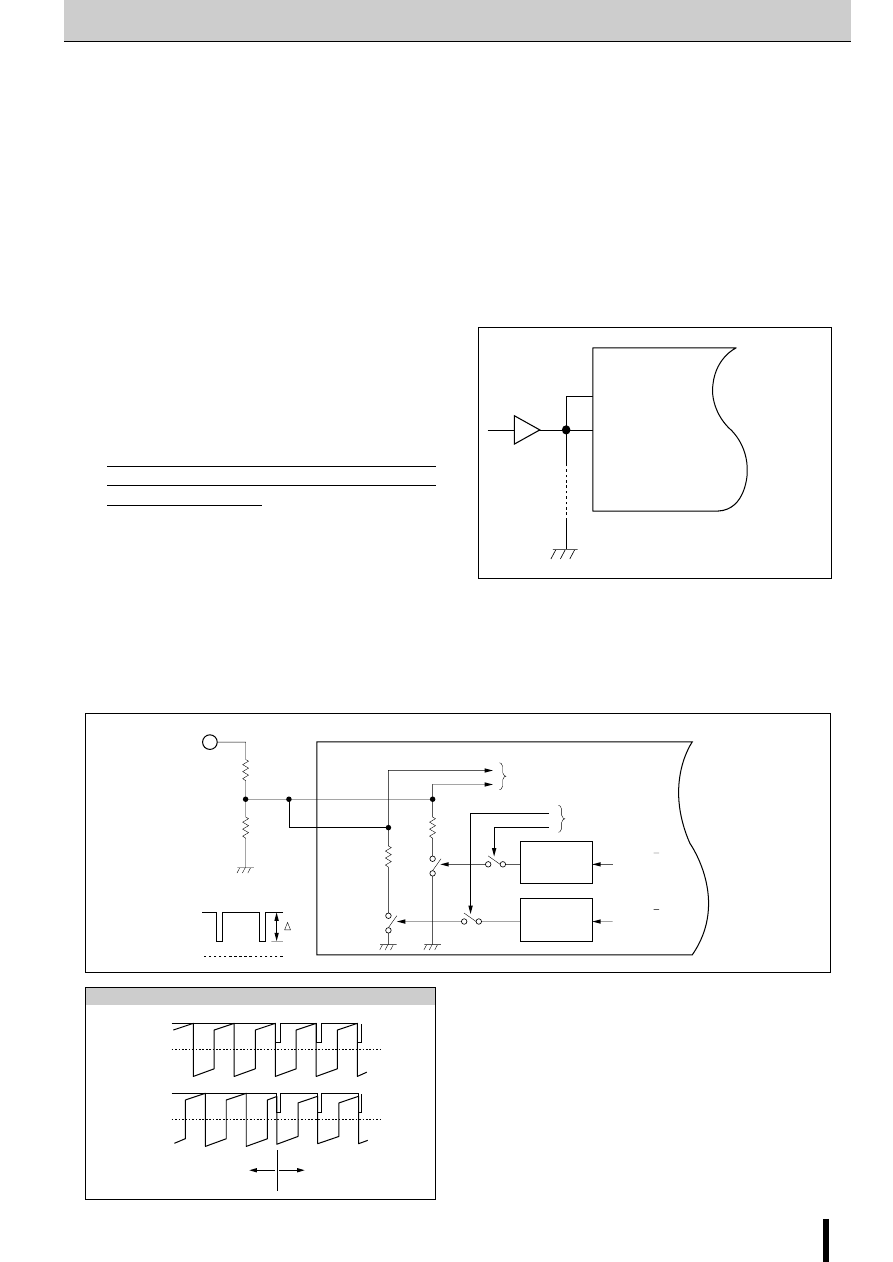

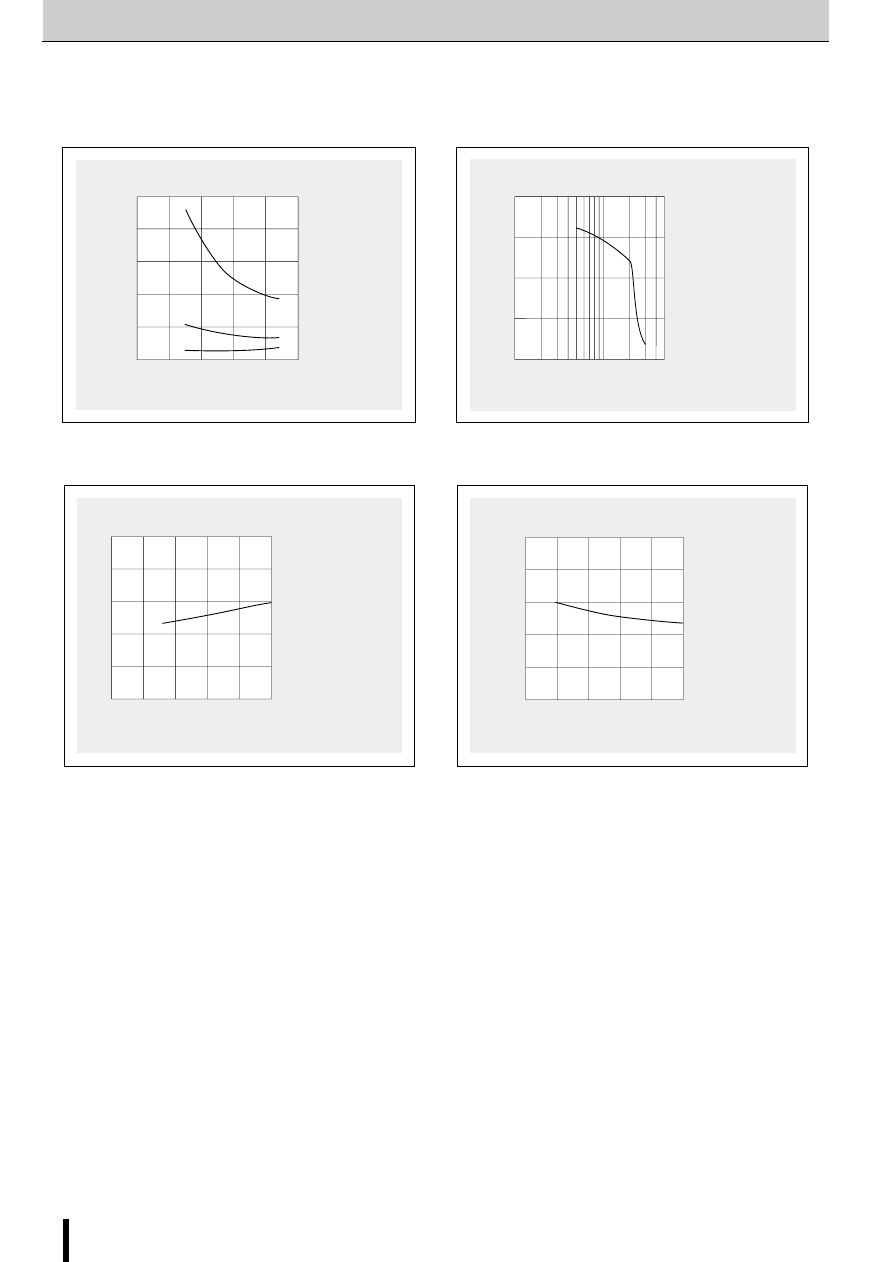

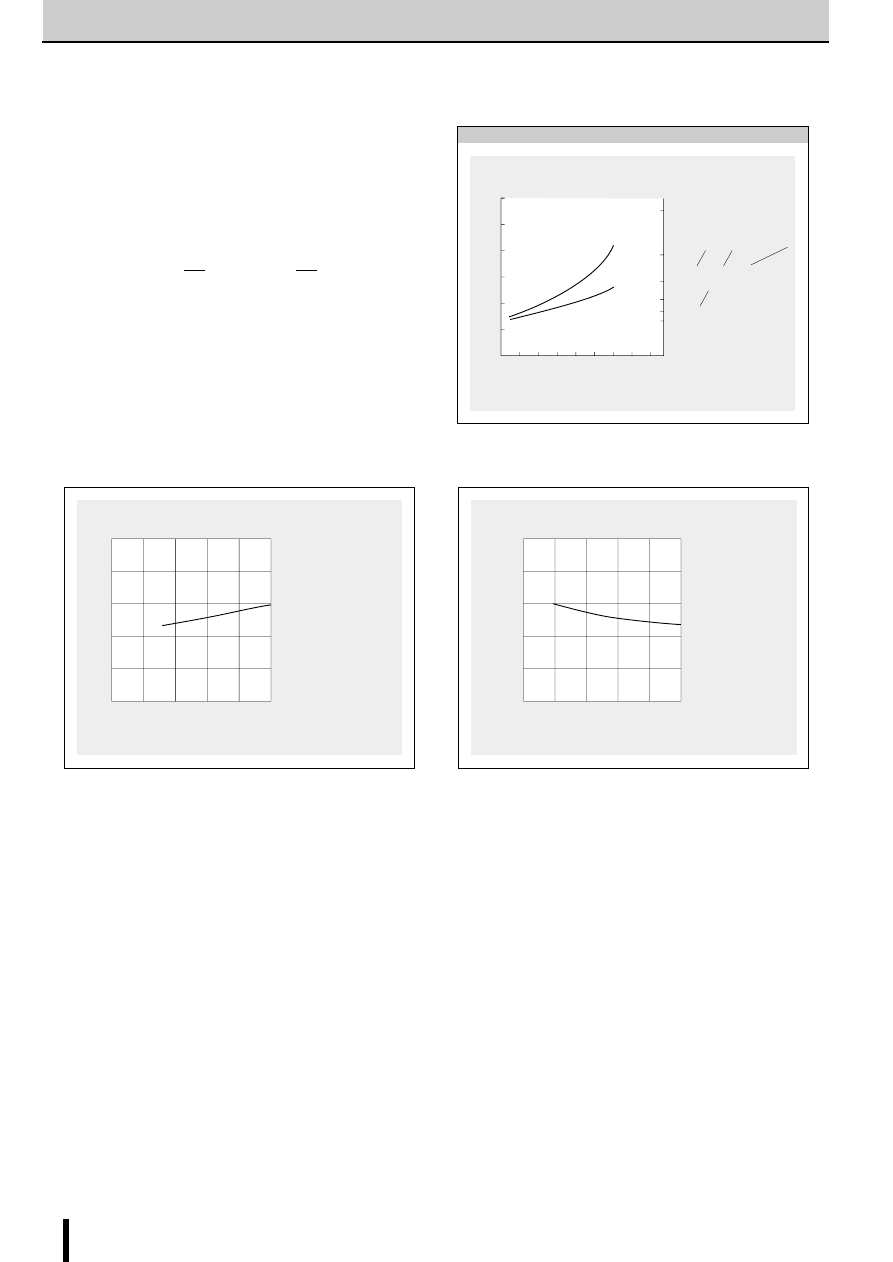

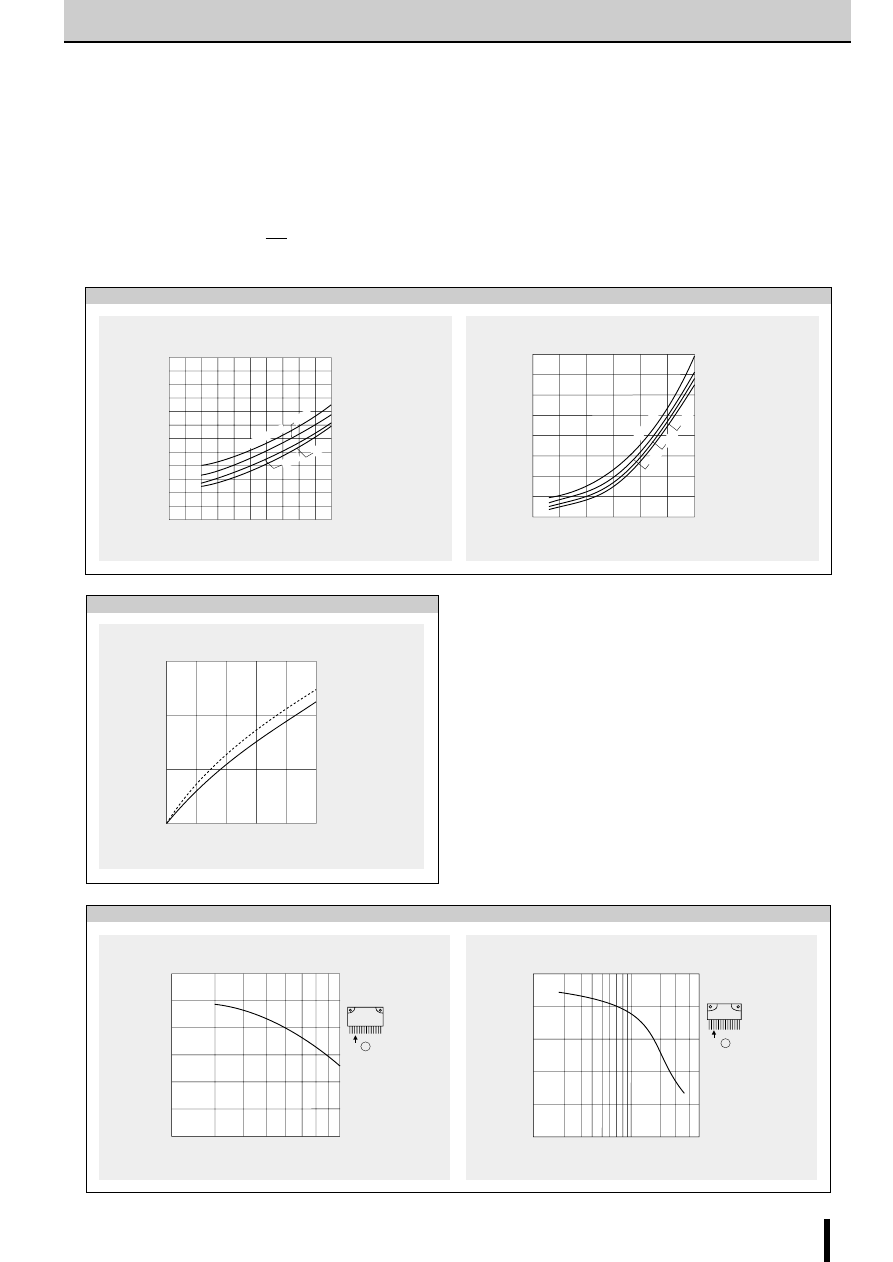

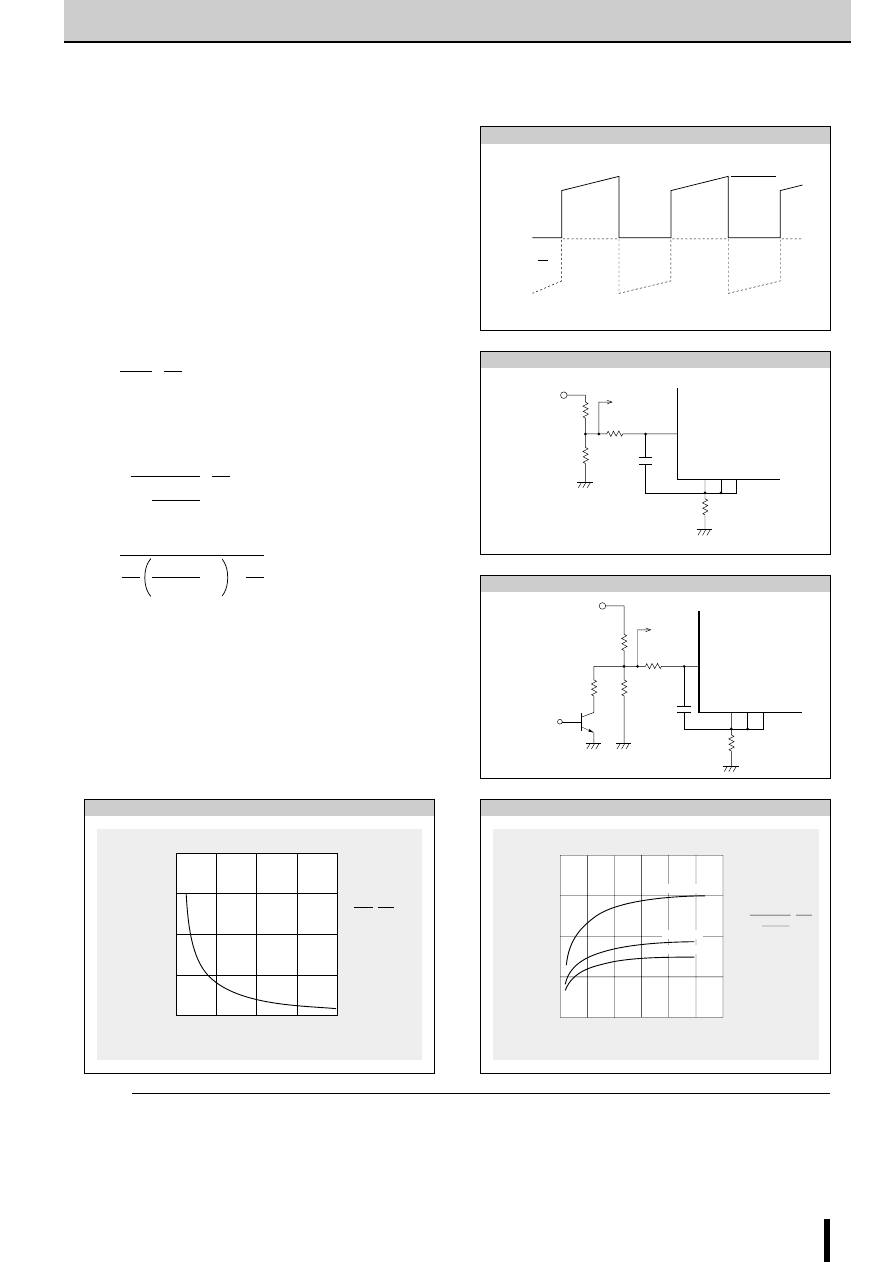

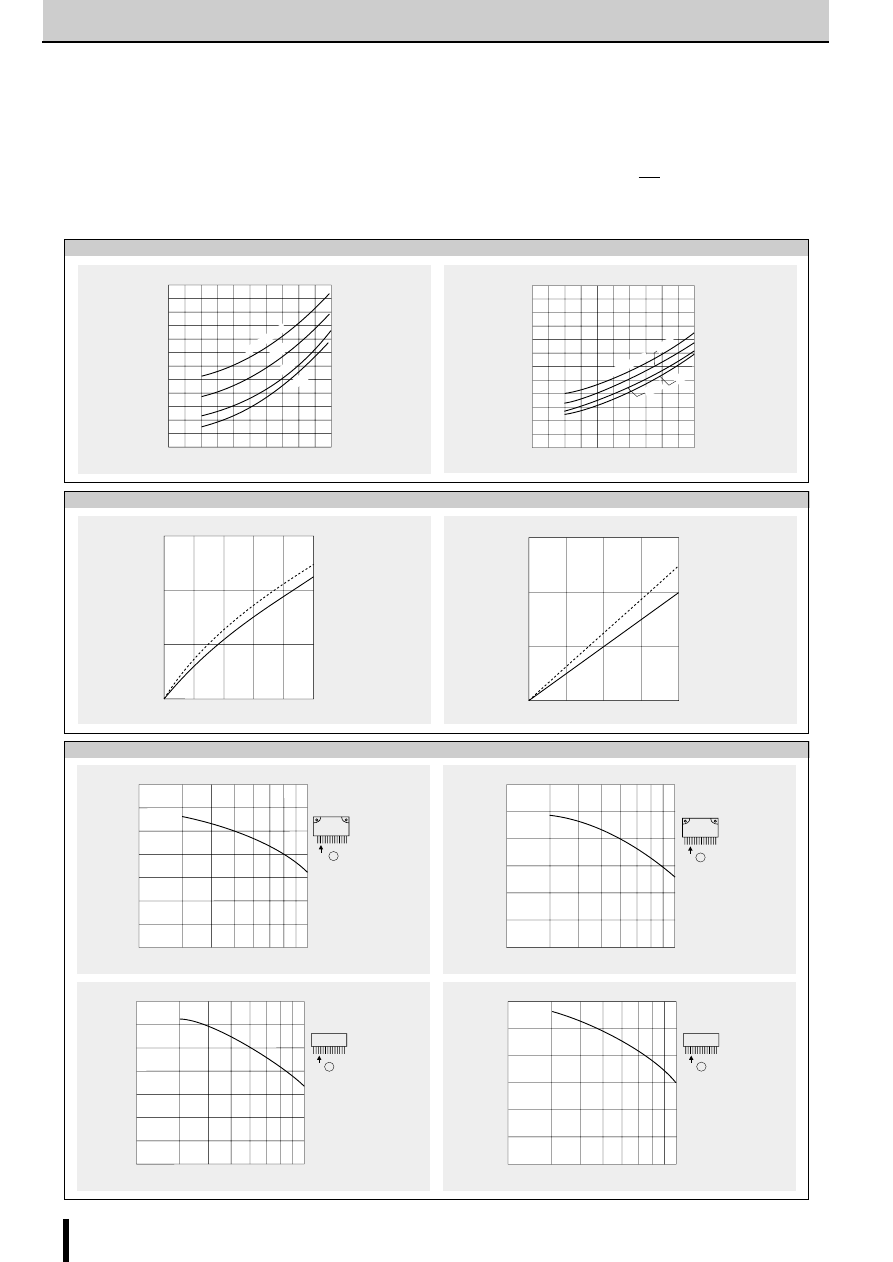

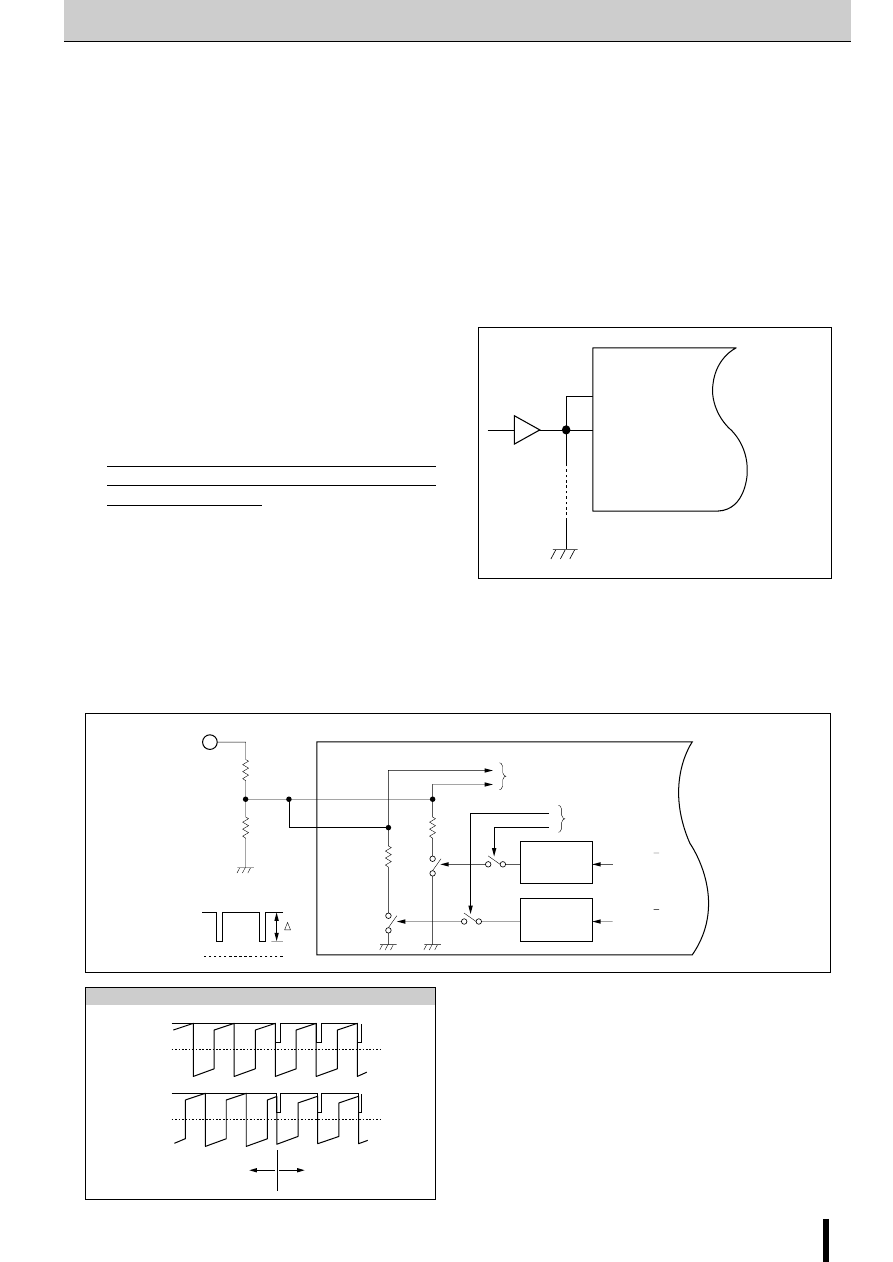

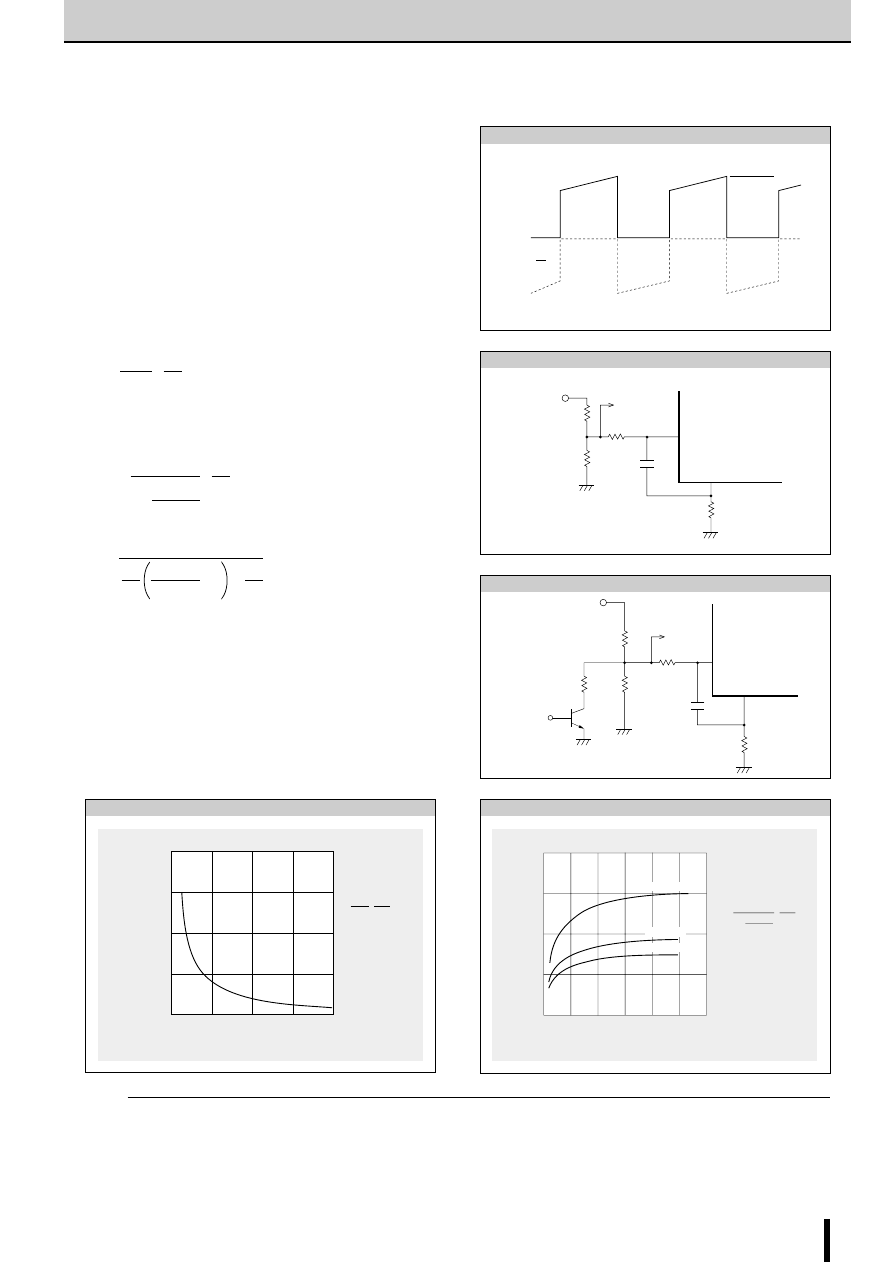

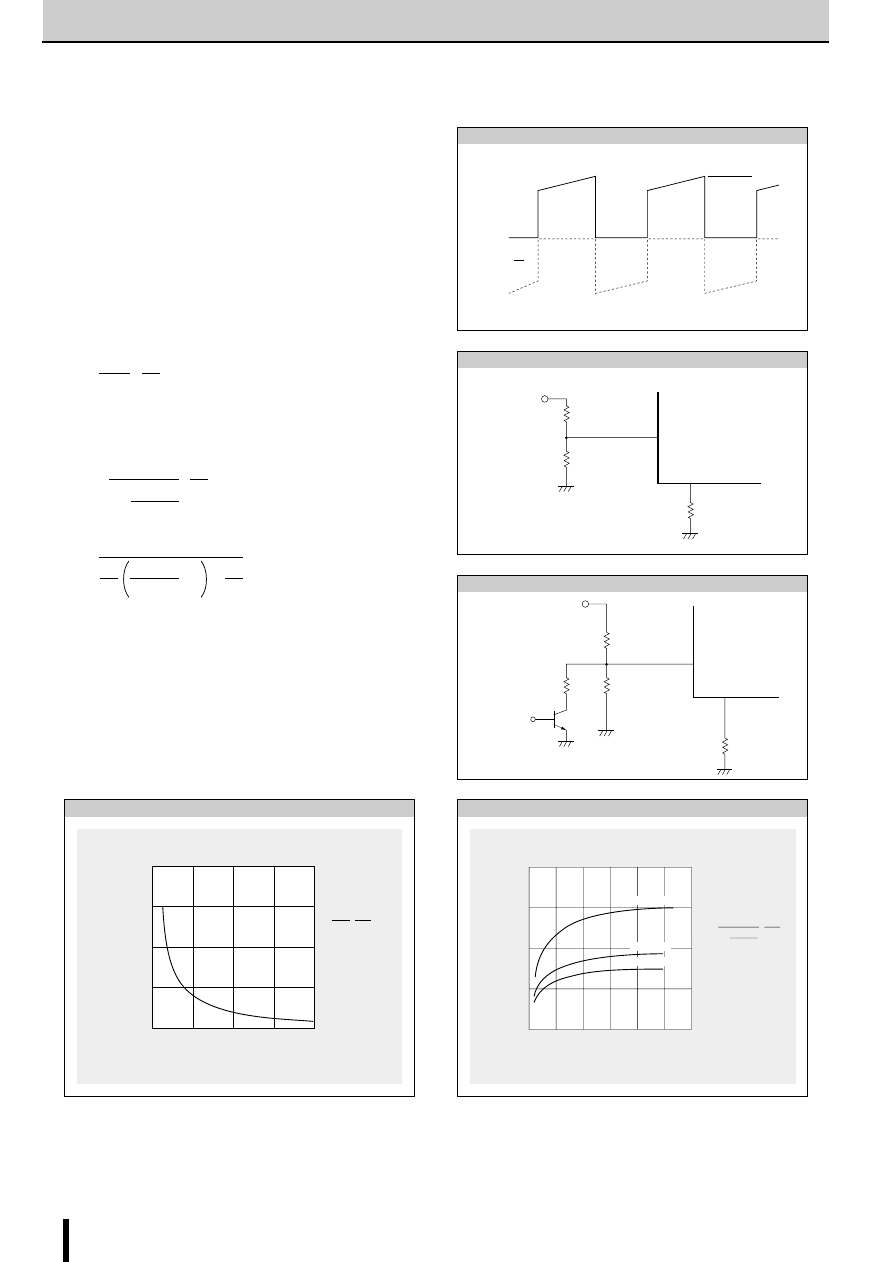

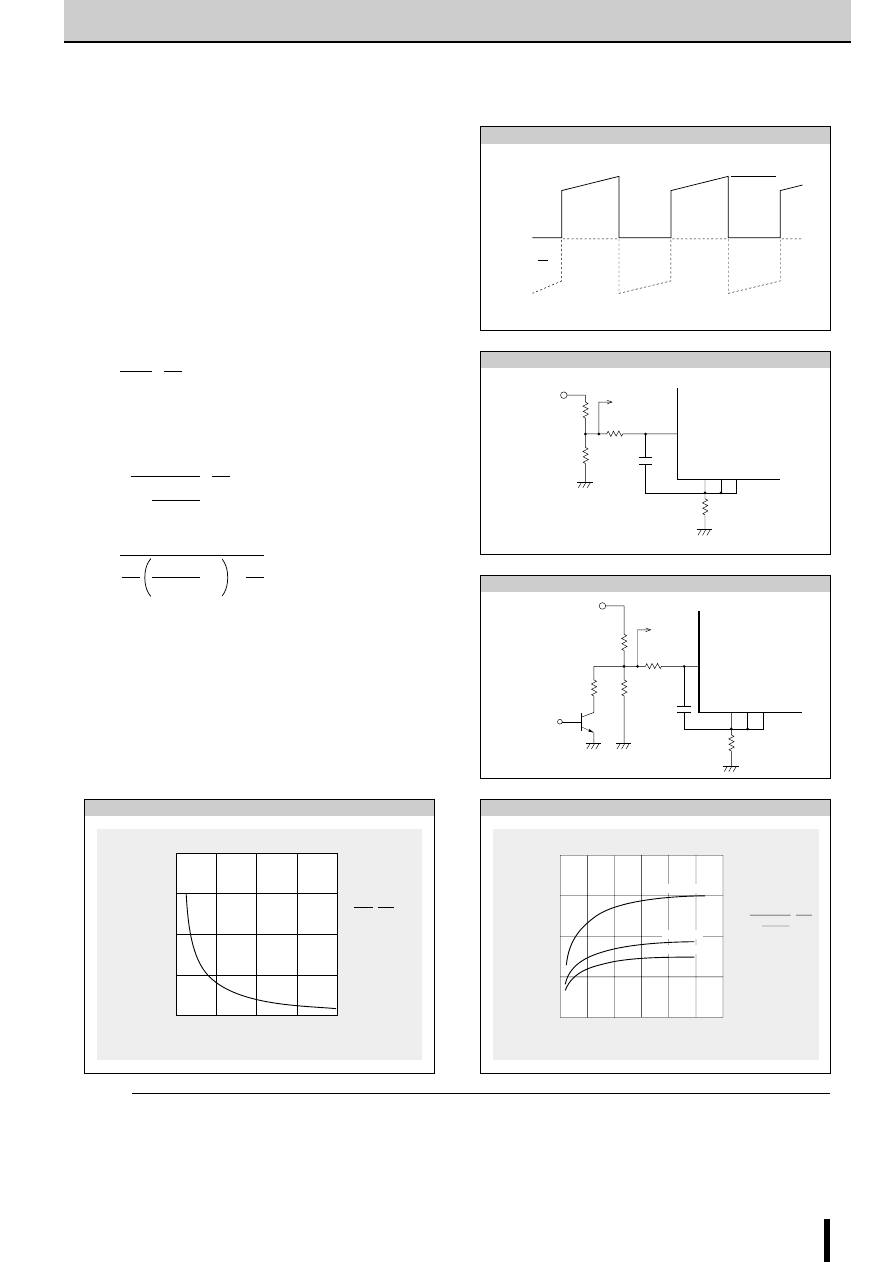

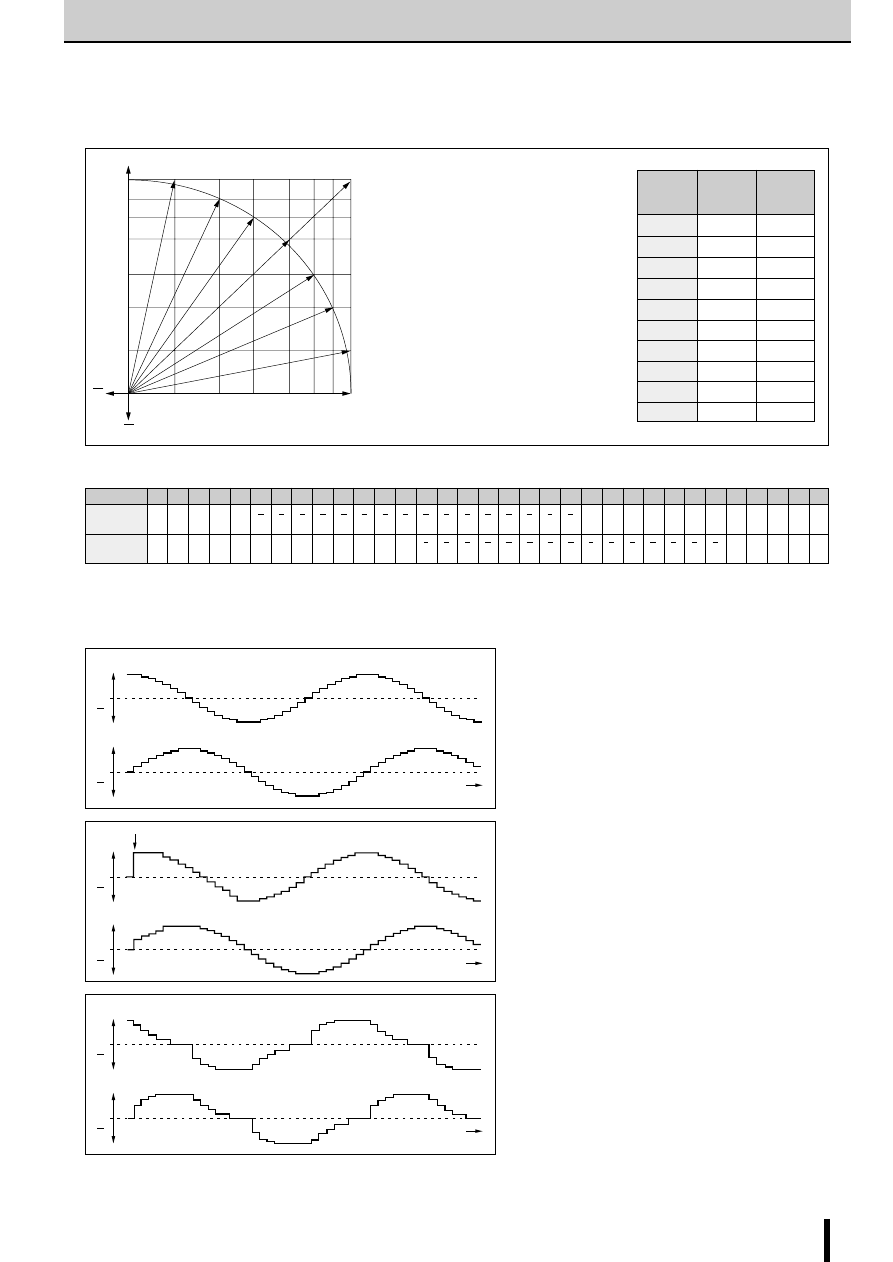

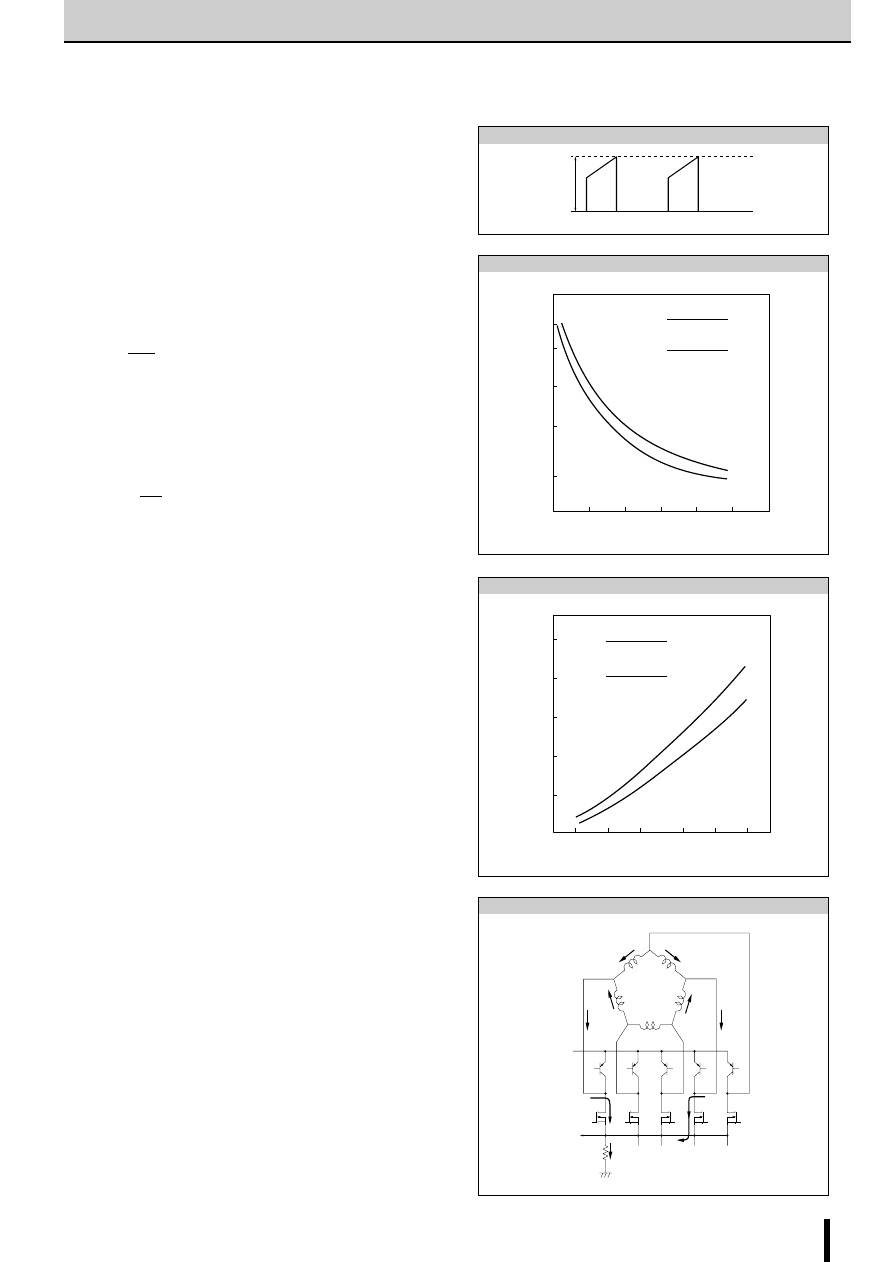

Determining the Output Current

Fig. 1 shows the waveform of the output current (motor coil cur-

rent). The method of determining the peak value of the output

current (I

O

) based on this waveform is shown below.

(Parameters for determining the output current I

O

)

V

b

: Reference supply voltage

r

1

,r

2

: Voltage-divider resistors for the reference supply voltage

R

S

: Current sense resistor

(1) Normal rotation mode

I

O

is determined as follows when current flows at the maximum

level during motor rotation. (See Fig.2.)

(2) Power down mode

The circuit in Fig.3 (rx and Tr) is added in order to decrease the

coil current. I

O

is then determined as follows.

Equation (2) can be modified to obtain equation to determine rx.

Fig. 4 and 5 show the graphs of equations (1) and (2) respec-

tively.

(NOTE)

Ringing noise is produced in the current sense resistor R

S

when

the MOSFET is switched ON and OFF by chopping. This noise

is also generated in feedback signals from R

S

which may there-

fore cause the comparator to malfunction. To prevent chopping

malfunctions, r

5

(r

6

) and C

3

(C

4

) are added to act as a noise filter.

R

S

C

3

r

2

r

1

r

6

r

5

V

b

(5

V

)

7,(9)

3,(13)

Fig. 2 Normal mode

0

Phase A

Phase A

I

O

Fig. 1 Waveform of coil current (Phase A excitation ON)

R

S

C

3

r

2

r

1

r

6

r

5

V

b

(5

V

)

7,(9)

3,(13)

r

x

T

r

Power down

signal

Fig. 3 Power down mode

4

3

2

1

0

0

1

2

3

4

Current sense resistor R

S

(

Ω

)

Output current I

O

(A)

I

O

=

r

1

+r

2

R

S

r

1

=510

Ω

r

2

=100

Ω

r

x

=

∞

V

b

=5V

r

2

·

V

b

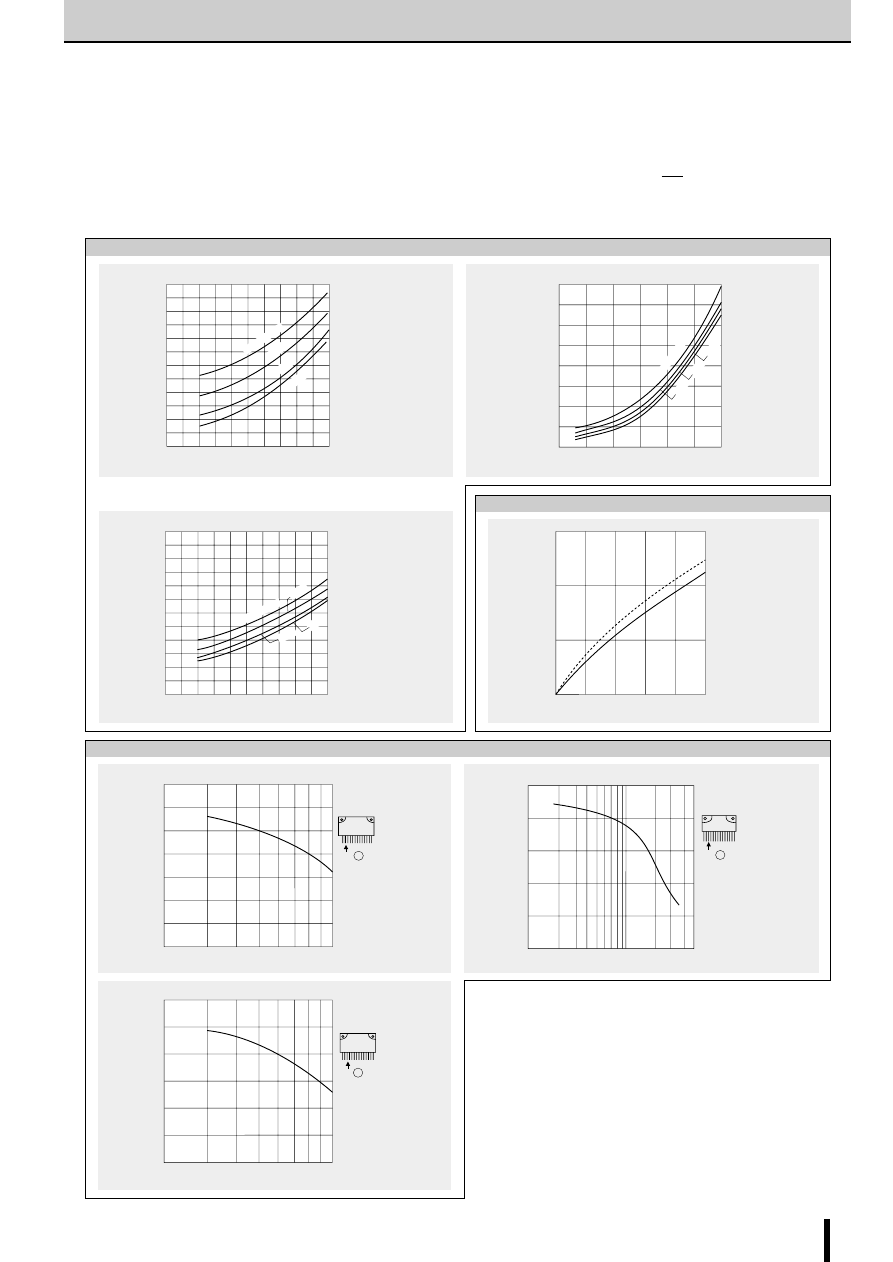

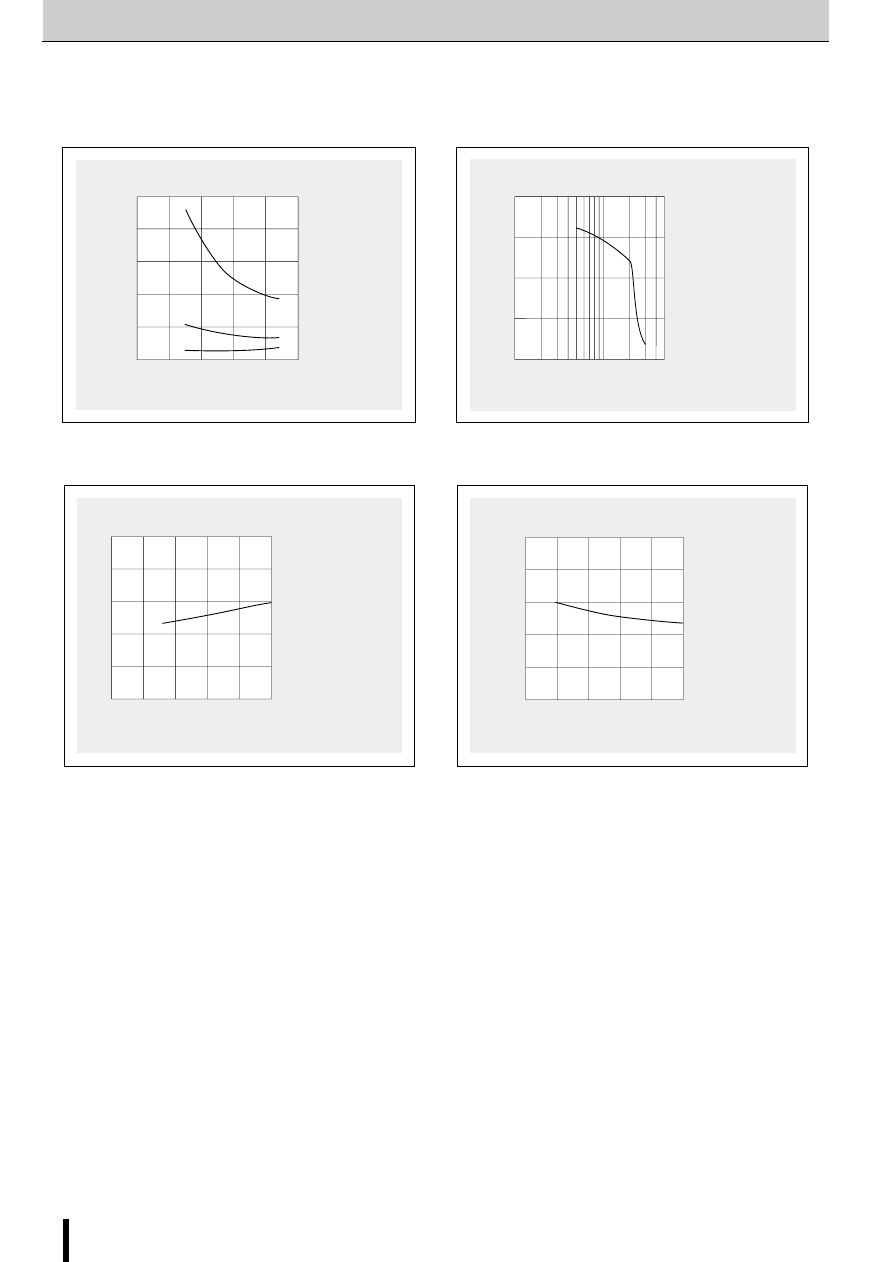

Fig. 4 Output current I

O

vs. Current sense resistor R

S

Fig. 5 Output current I

OPD

vs. Variable current sense resistor rx

2.0

1.5

1.0

0.5

00

200

400

600

800

Variable current sense resistor r

X

(

Ω

)

Output current I

OPD

(A)

1000

1200

R

S

=0.5

Ω

R

S

=0.8

Ω

R

S

=1

Ω

I

OPD

=

1+ R

S

r

1

=510

Ω

r

2

=100

Ω

V

b

=5V

1

·

V

b

r

1

(r

2+

r

X

)

r

2 ·

r

X

Application Notes

However, when the values of these constants are increased,

the response from R

S

to the comparator becomes slow. Hence

the value of the output current I

O

is somewhat higher than the

calculated value.

r

X

=

1

V

b

R

s

•

I

OPD

1

r

1

−

1

−

1

r

2

................................................................ (1)

I

O

≅

•

r

2

r

1

+r

2

V

b

R

S

......................................................... (2)

I

OPD

≅

•

1

r

1

(r

2

+r

X

)

r

2

•

r

X

V

b

R

S

1+

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

9

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

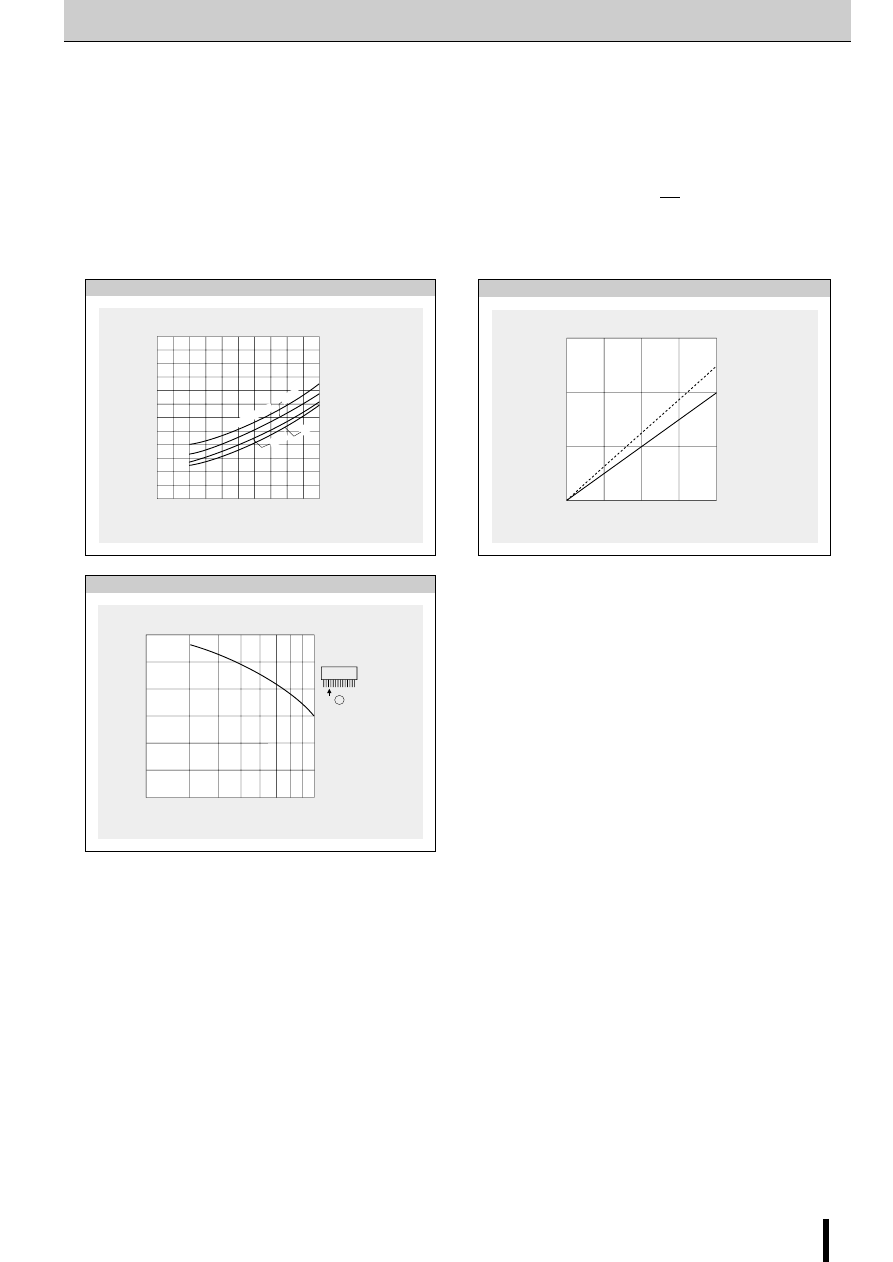

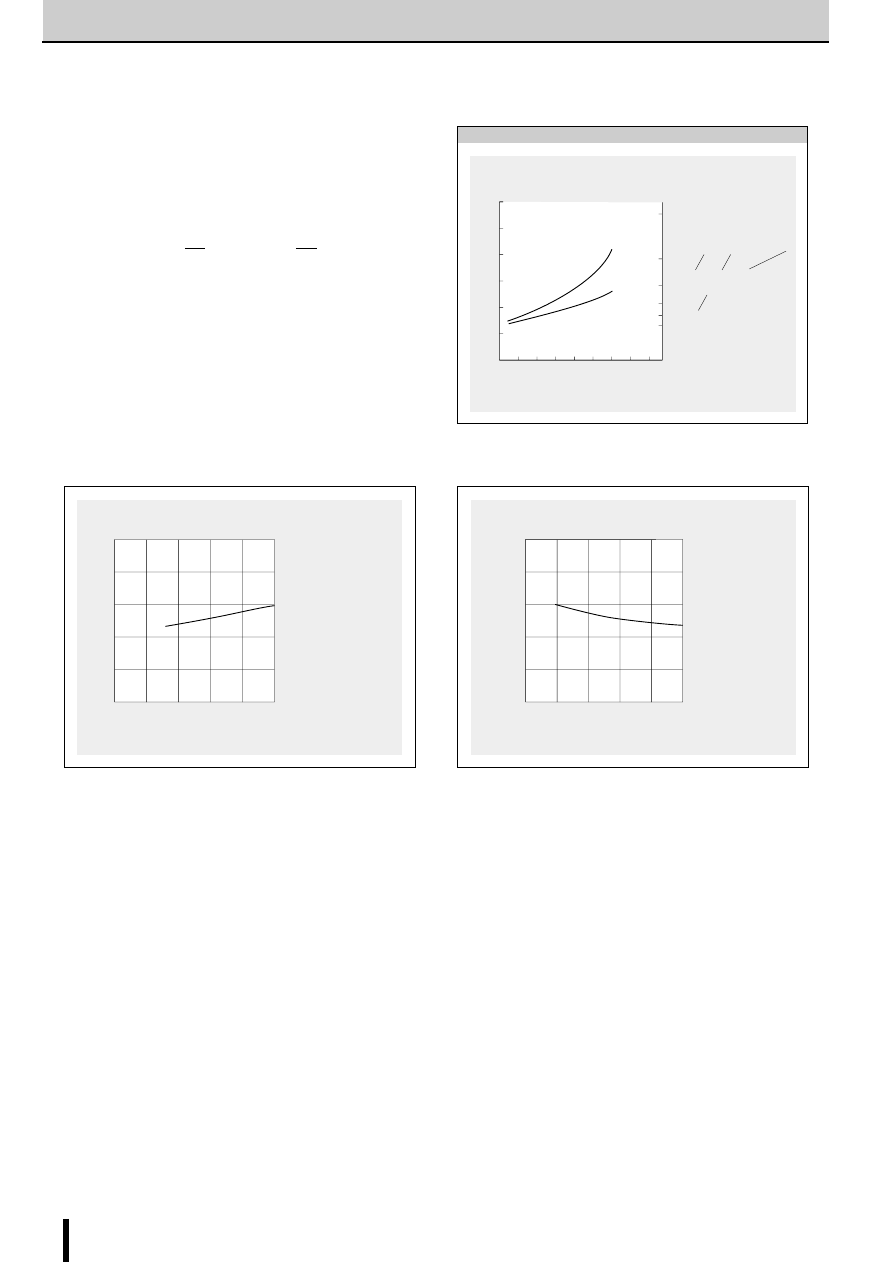

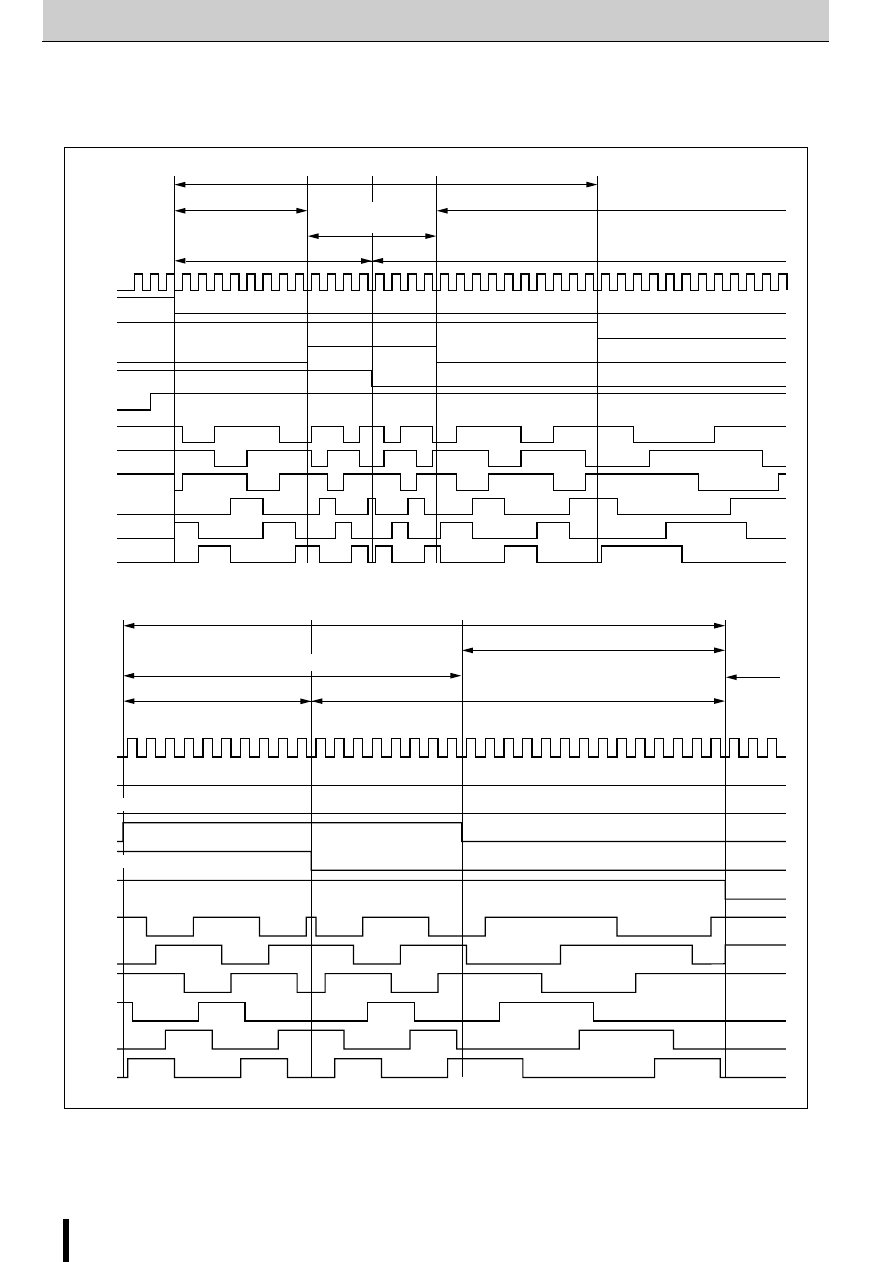

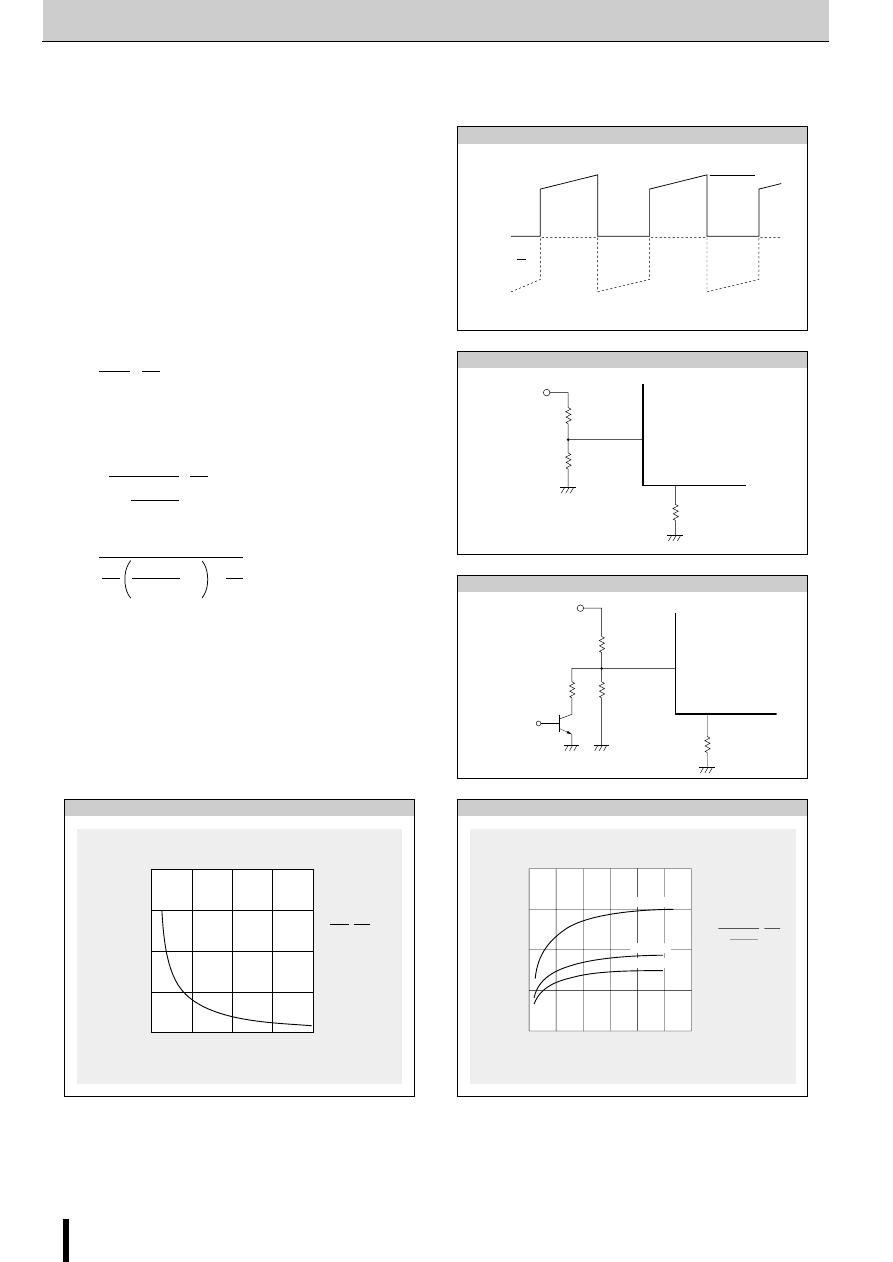

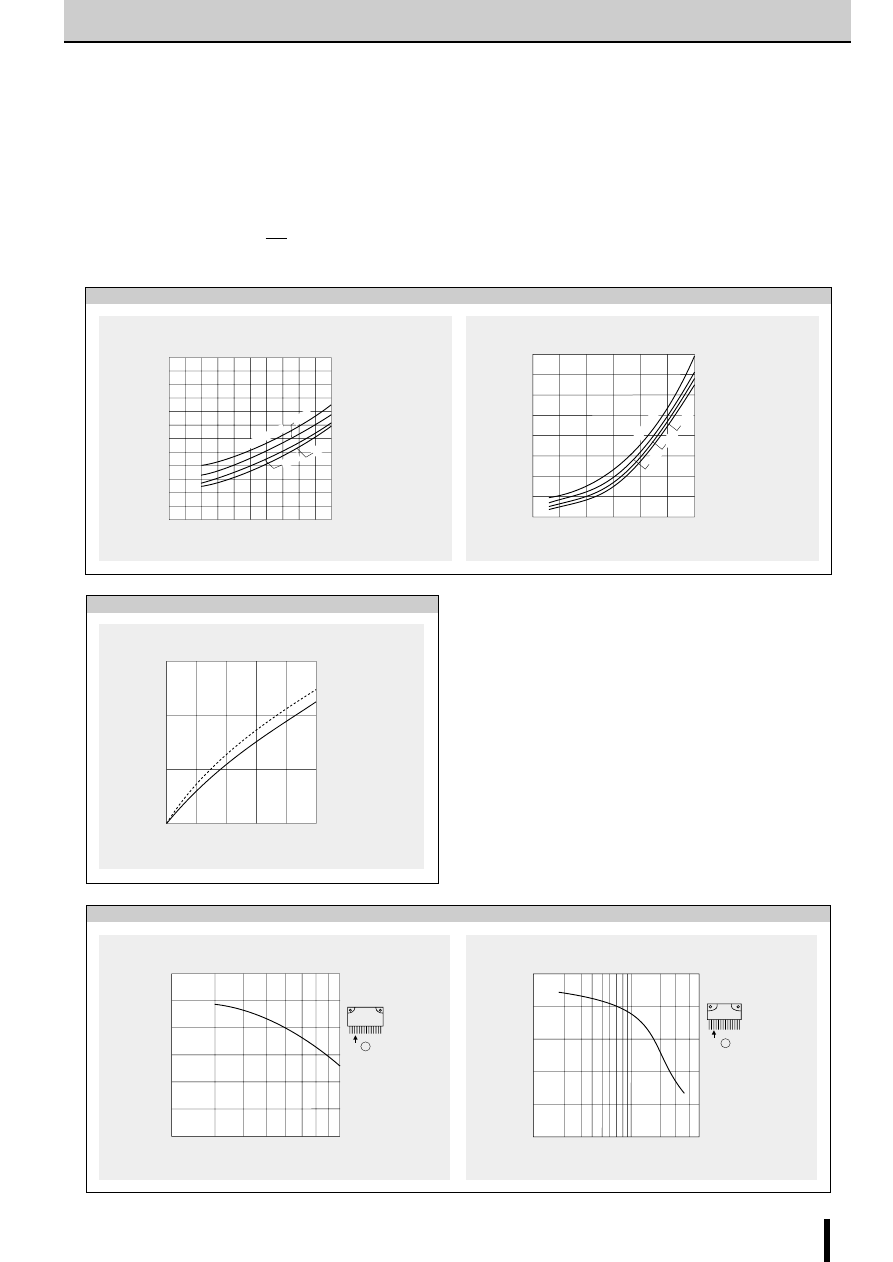

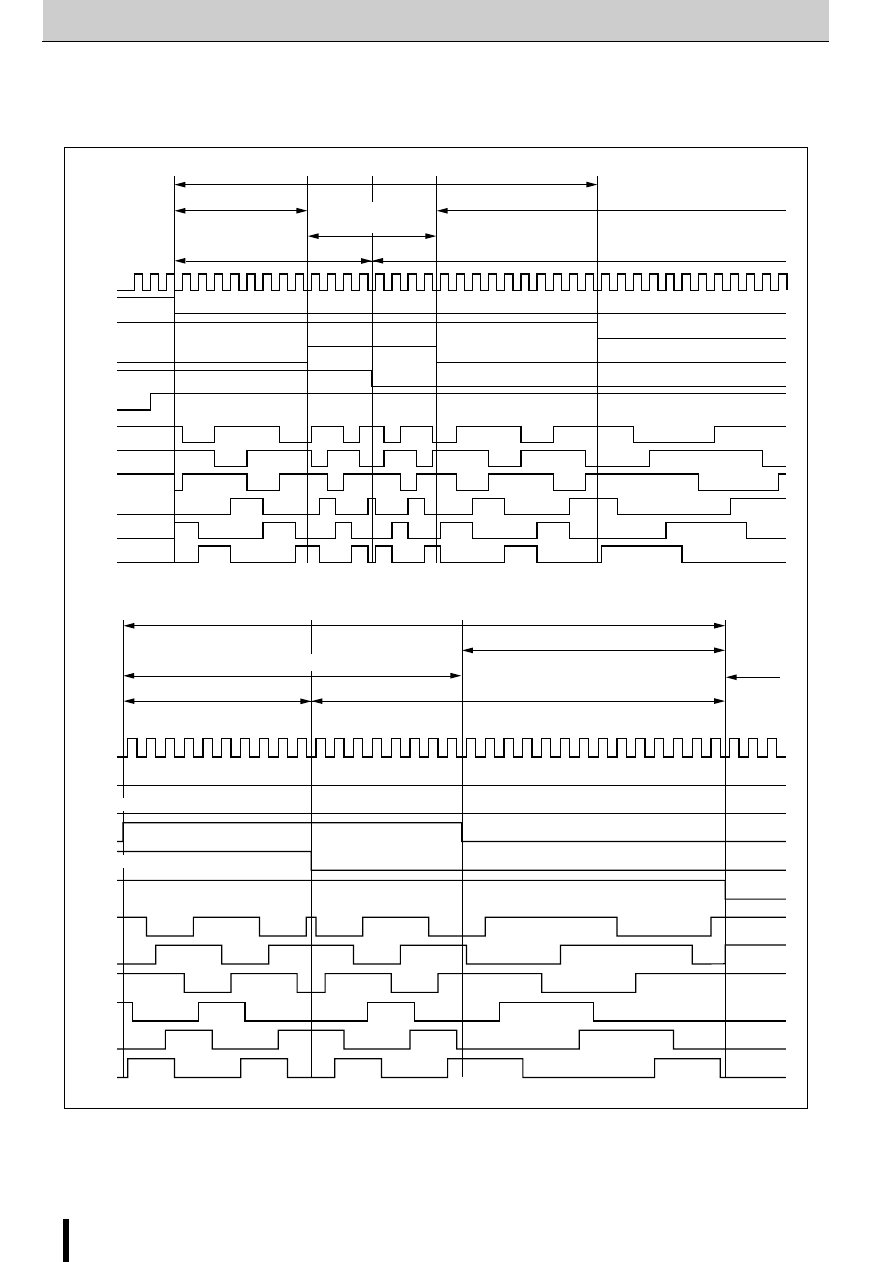

■

Determining the chopper frequency

Determining T

OFF

The SLA7000M and SMA7000M series are self-excited chop-

pers. The chopping OFF time T

OFF

is fixed by r

3

/C

1

and r

4

/C

2

connected to terminal Td.

T

OFF

can be calculated using the following formula:

The circuit constants and the T

OFF

value shown below are rec-

ommended.

T

OFF

= 12

µ

s at r

3

=47k

Ω

, C

1

=500pF, V

b

=5V

60

50

40

30

20

10

0

0

2

4

6

8

10 12

14

16

15

20

25

30

35

40

Motor coil resistance R

m

(

Ω

)

ON time T

ON

( s)

V

CC

=2

4V

V

CC

=36V

Chopping frequency f (kHz)

T

OFF

=12 s

R

S

=1

Ω

L

m

=1~3ms

R

m

= =

r

3

C

1

r

4

C

2

47k

Ω

500pF

µ

µ

Fig. 6 Chopper frequency vs. Motor coil resistance

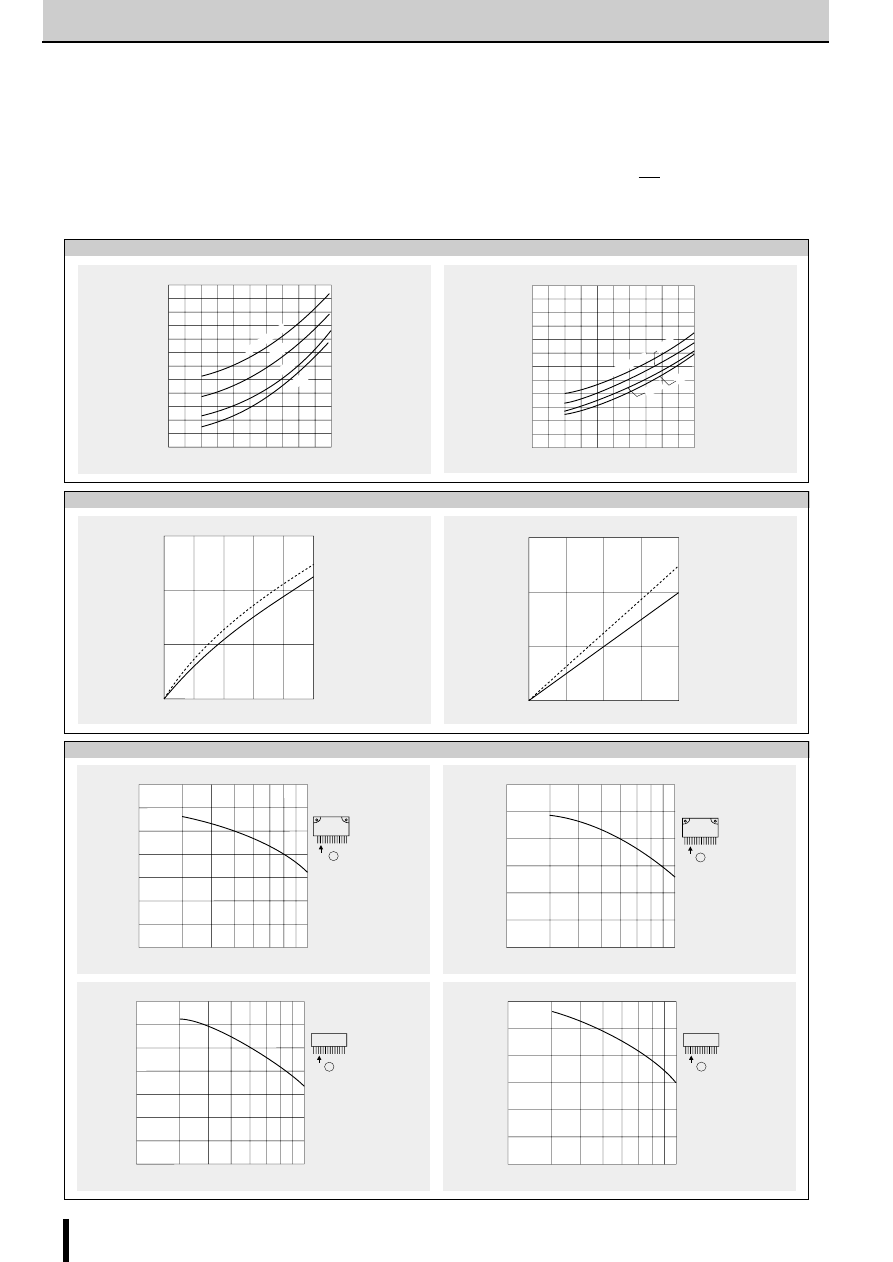

■

Chopper frequency vs. Supply voltage

0

f (kHz)

V

CC

(V)

50

40

30

20

10

0

10

20

30

40

50

Motor : 23LM-C202

I

O

= 0.8A at V

CC

=24V

R

S

=1

Ω

■

Chopper frequency vs. Output current

0

f (kHz)

I

O

(A)

50

40

30

20

10

0

0.2

0.4

0.6

0.8

1.0

Motor : 23LM-C202

V

CC

=24V

R

S

=1

Ω

T

OFF

≅−

r

3

•

C

1 n

(1

−

=

−

r

4

•

C

2

n

(1

−

)

r

r

2

V

b

2

V

b

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

10

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

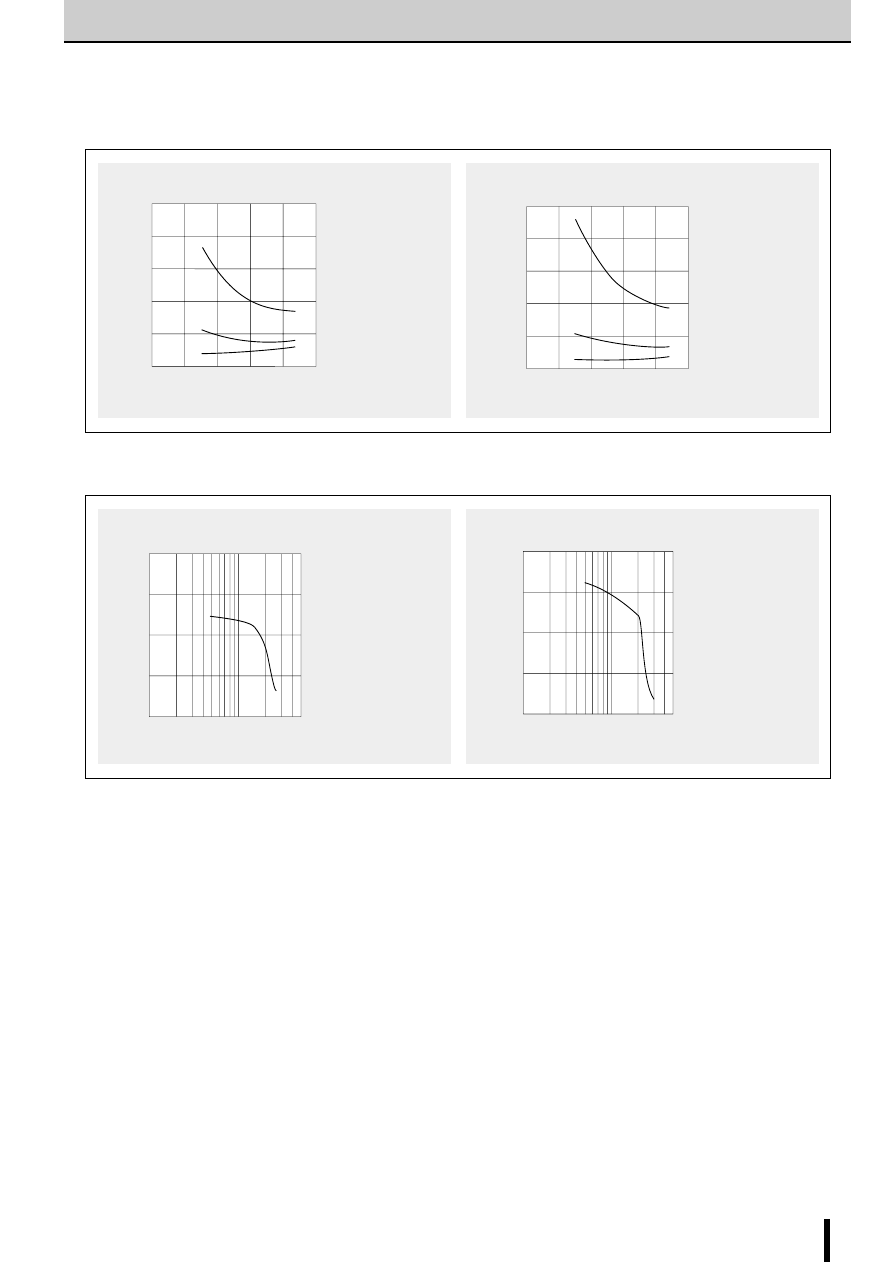

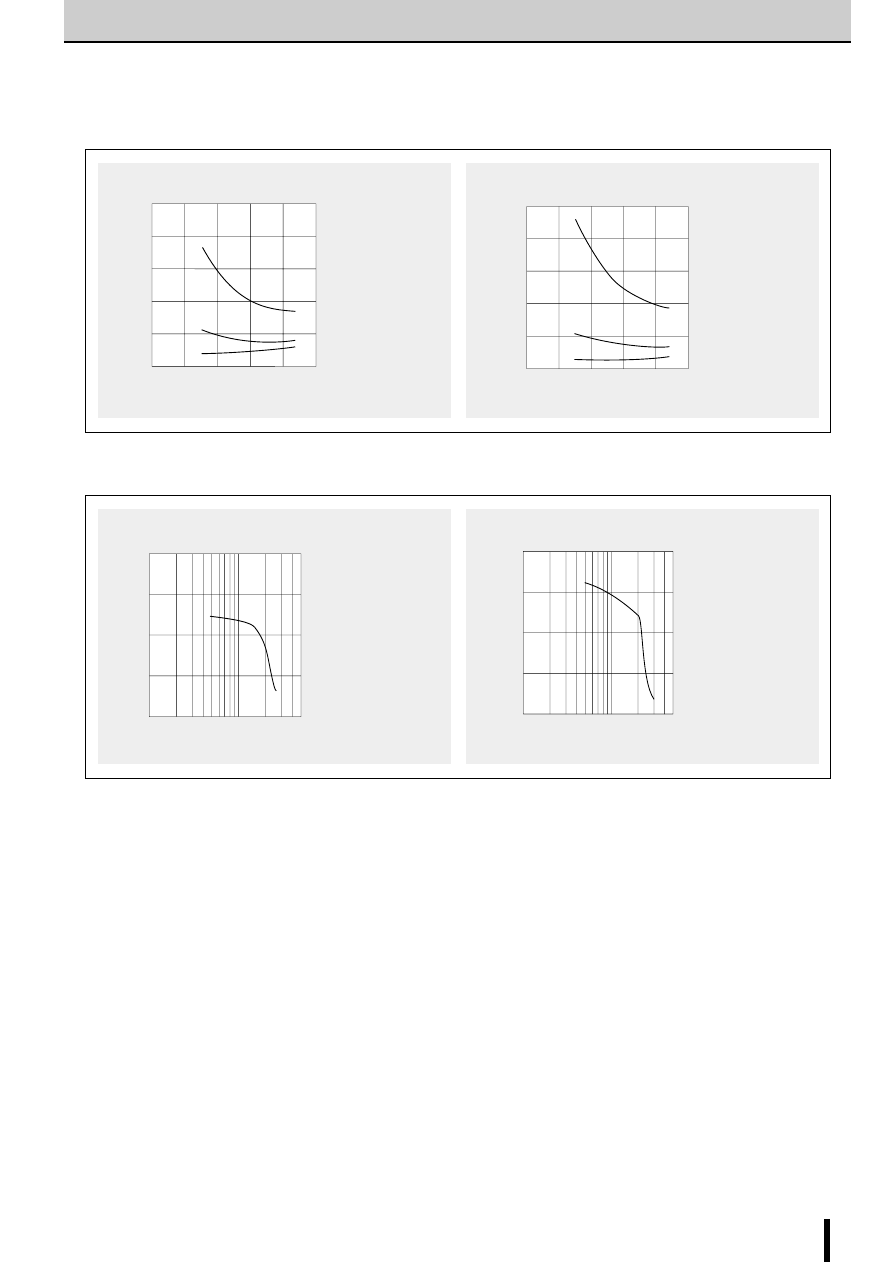

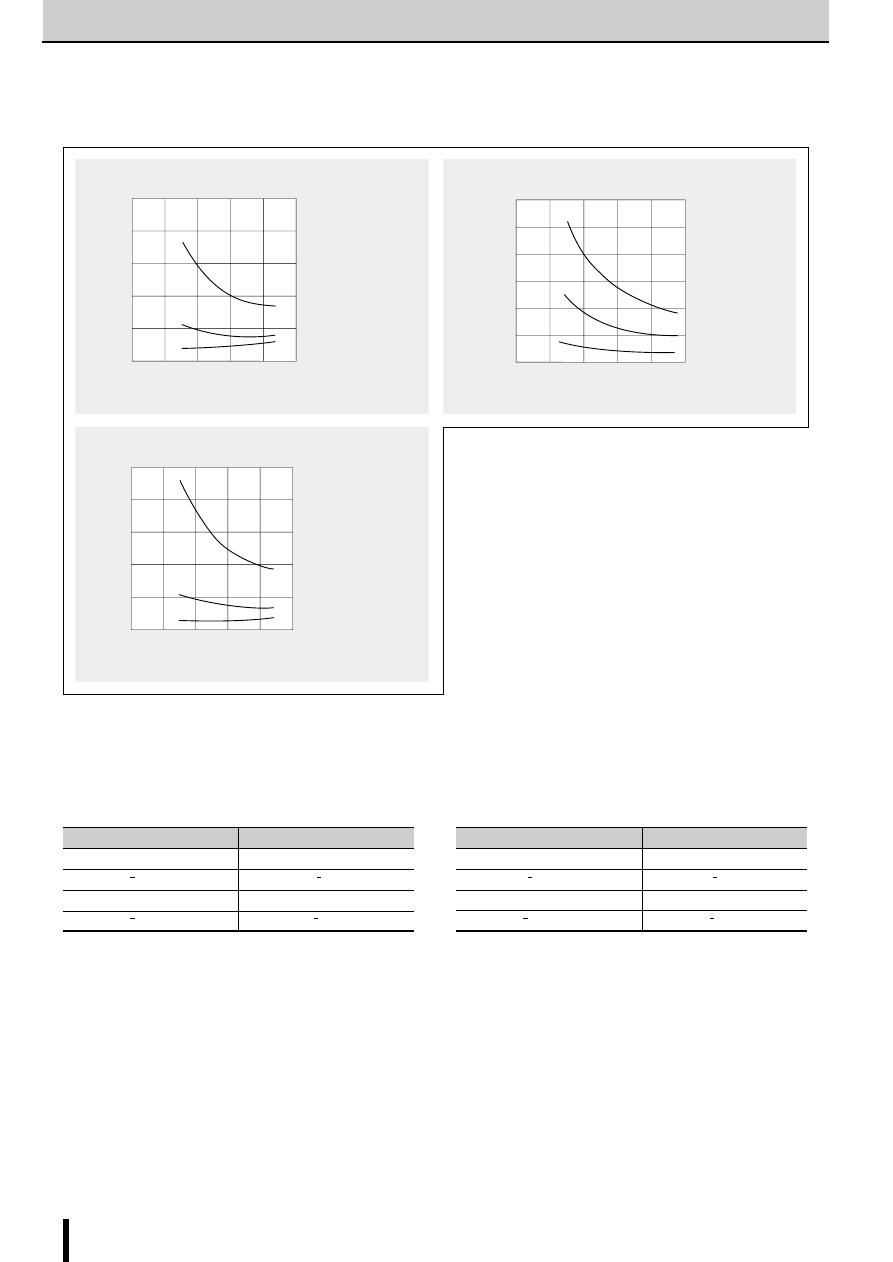

35

30

25

20

15

10

5

0

200

500

1K

Case temperature rise

∆

T

C

–

a

(

°

C)

Motor : PH265-01B

Motor current I

O

=0.8A

T

a

=25

°

C

V

CC

=24V, V

S

=24V

2-phase excitation

Response frequency (pps)

Without heatsink

Natural cooling

T

C

( 4 pin)

30

25

20

15

10

5

0

200

500

1K

Case temperature rise

∆

T

C

–

a

(

°

C)

Motor : PH265-01B

Motor current I

O

=0.8A

T

a

=25

°

C

V

CC

=24V, V

S

=24V

2-phase excitation

Response frequency (pps)

Without heatsink

Natural cooling

T

C

( 4 pin)

35

30

25

20

15

10

5

0

200

500

1K

Case temperature rise

∆

T

C

–

a

(

°

C)

Motor : PH265-01B

Motor current I

O

=0.8A

T

a

=25

°

C

V

CC

=24V, V

S

=24V

2-phase excitation

Response frequency (pps)

Without heatsink

Natural cooling

T

C

( 4 pin)

30

25

20

15

10

5

0

200

500

1K

Case temperature rise

∆

T

C

–

a

(

°

C)

Motor : PH265-01B

Motor current I

O

=0.8A

T

a

=25

°

C

V

CC

=24V, V

S

=24V

2-phase excitation

Response frequency (pps)

Without heatsink

Natural cooling

T

C

( 4 pin)

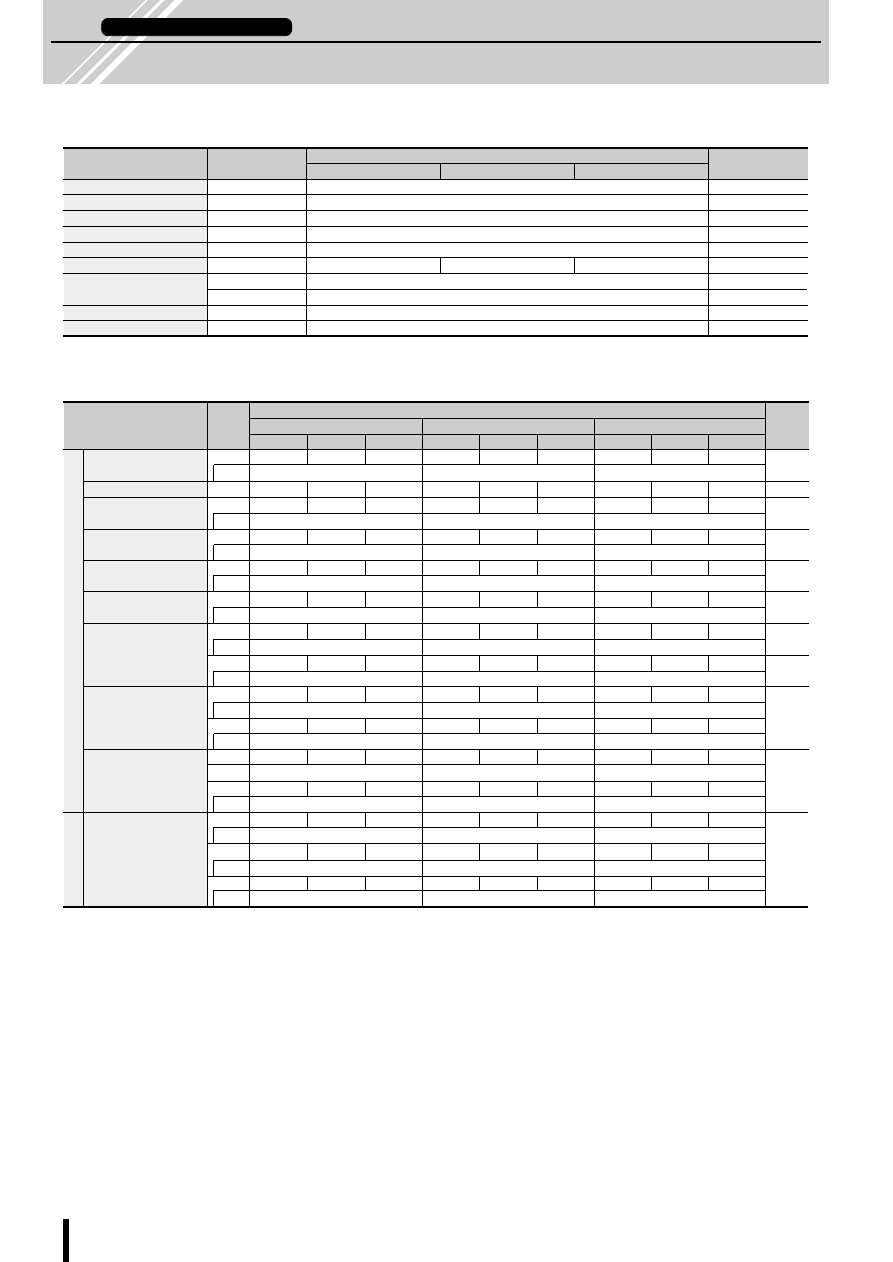

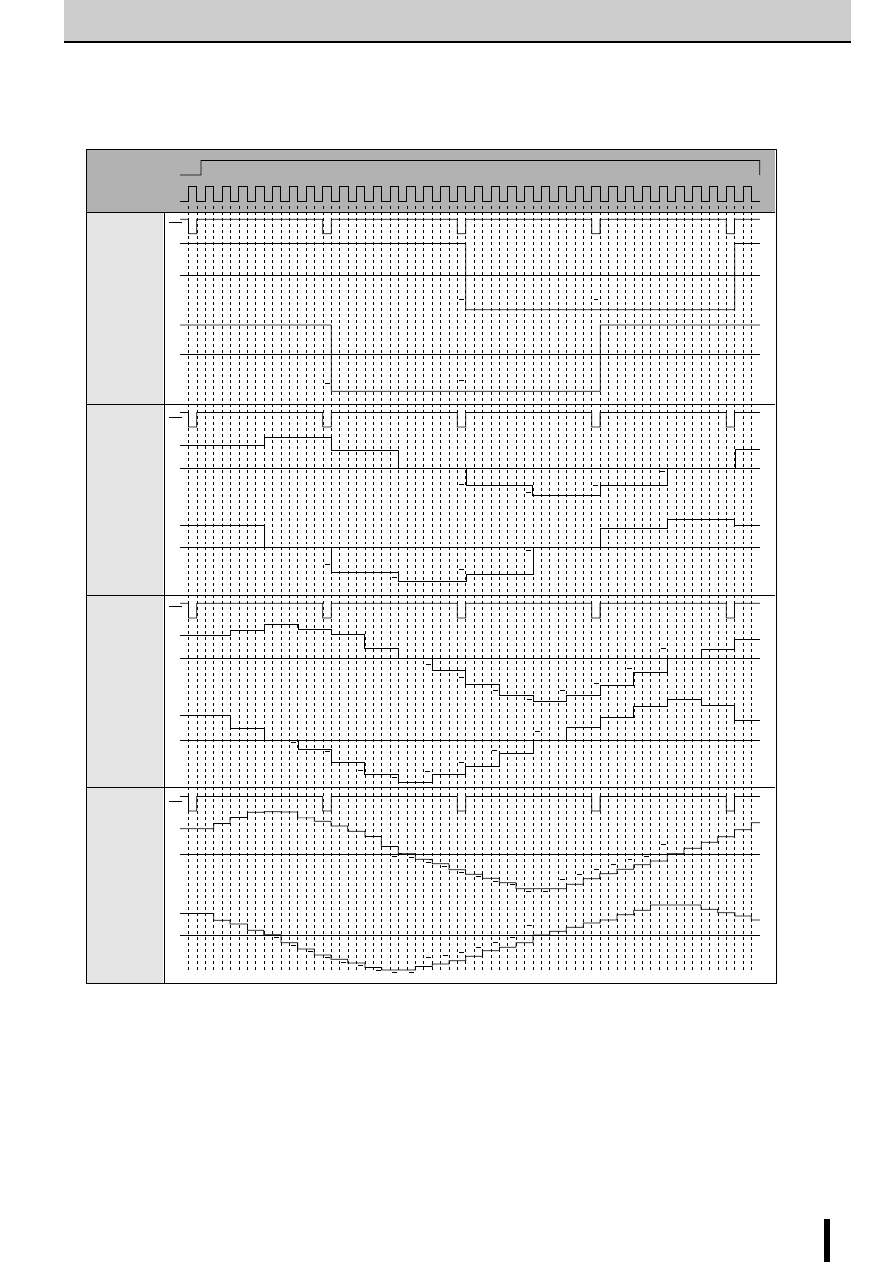

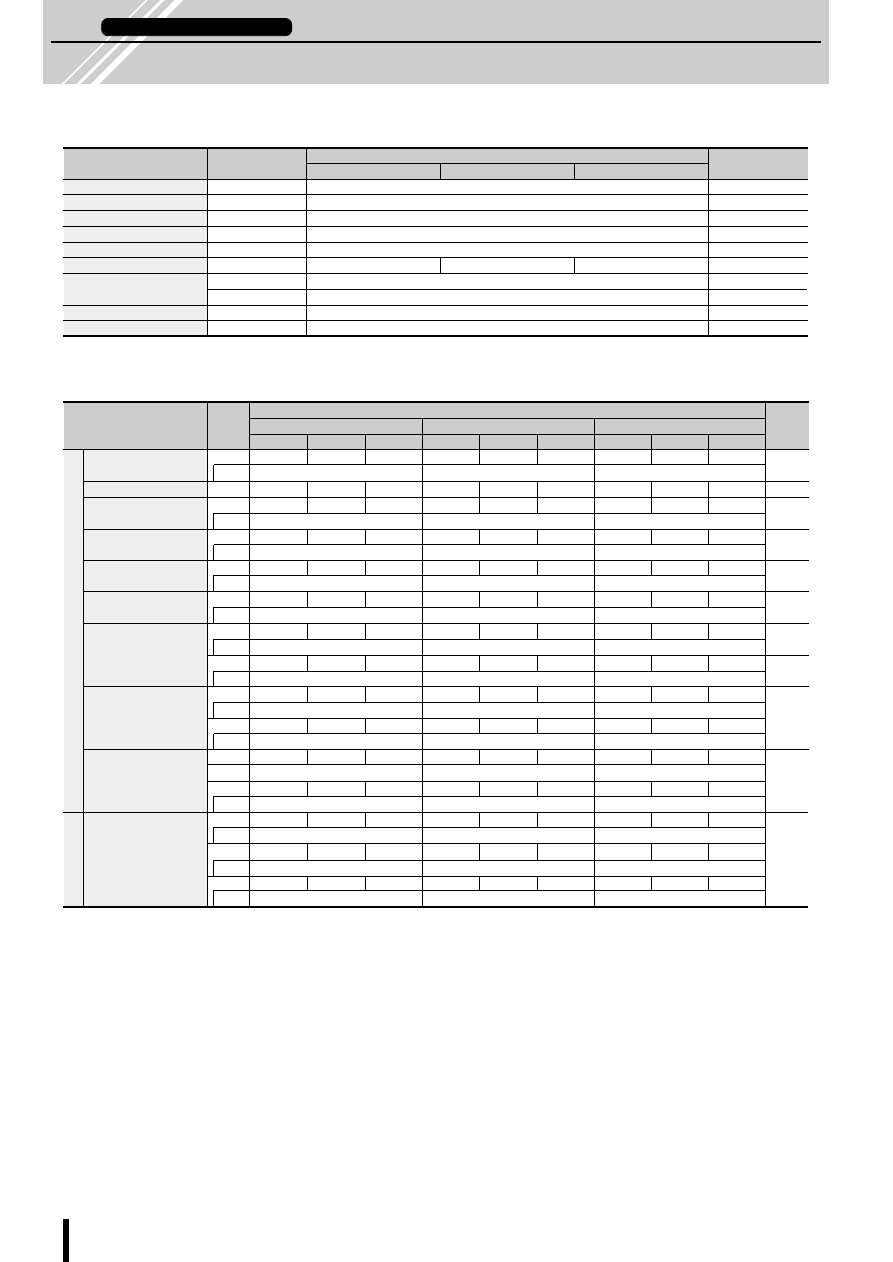

Thermal characteristics

SLA7022MU

SLA7029M

SMA7022MU

SMA7029MU

■

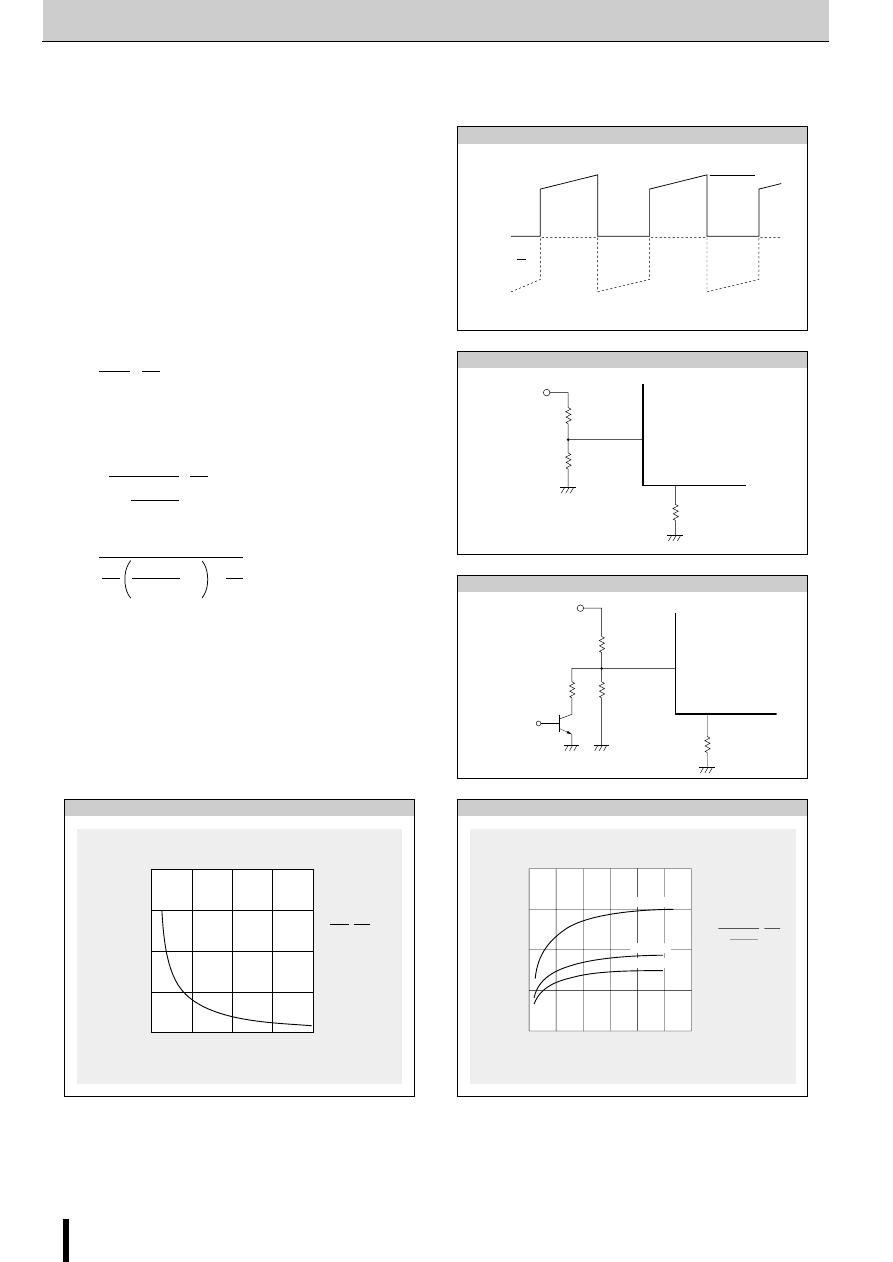

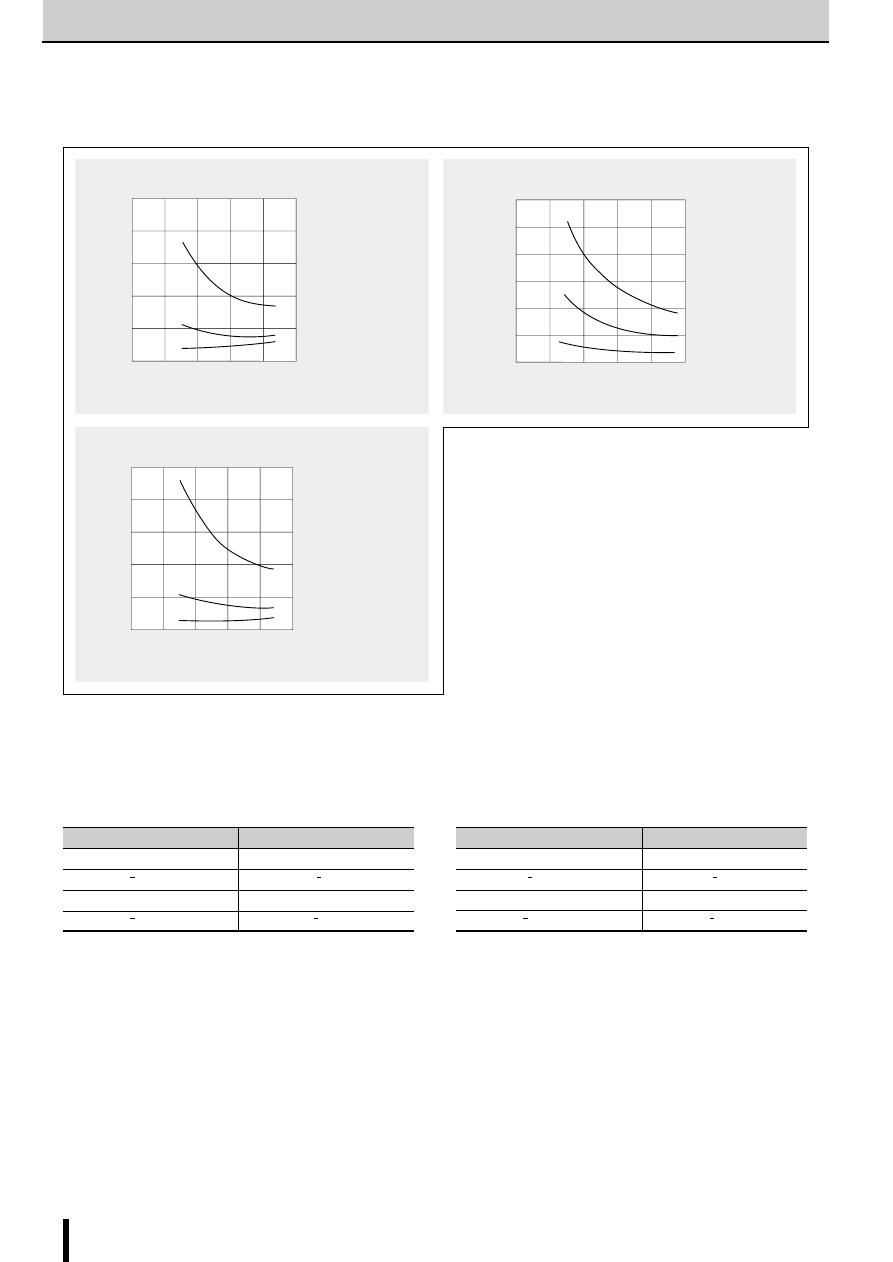

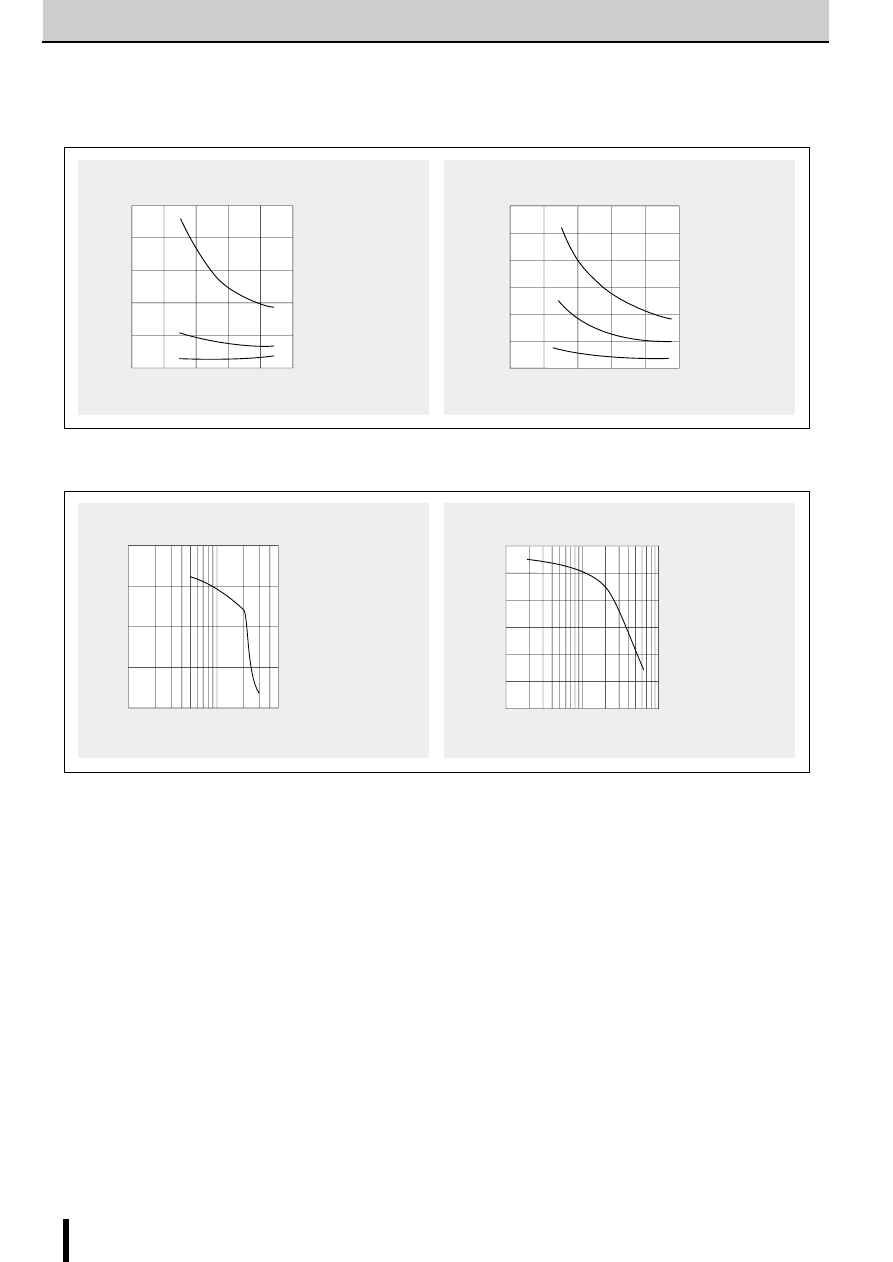

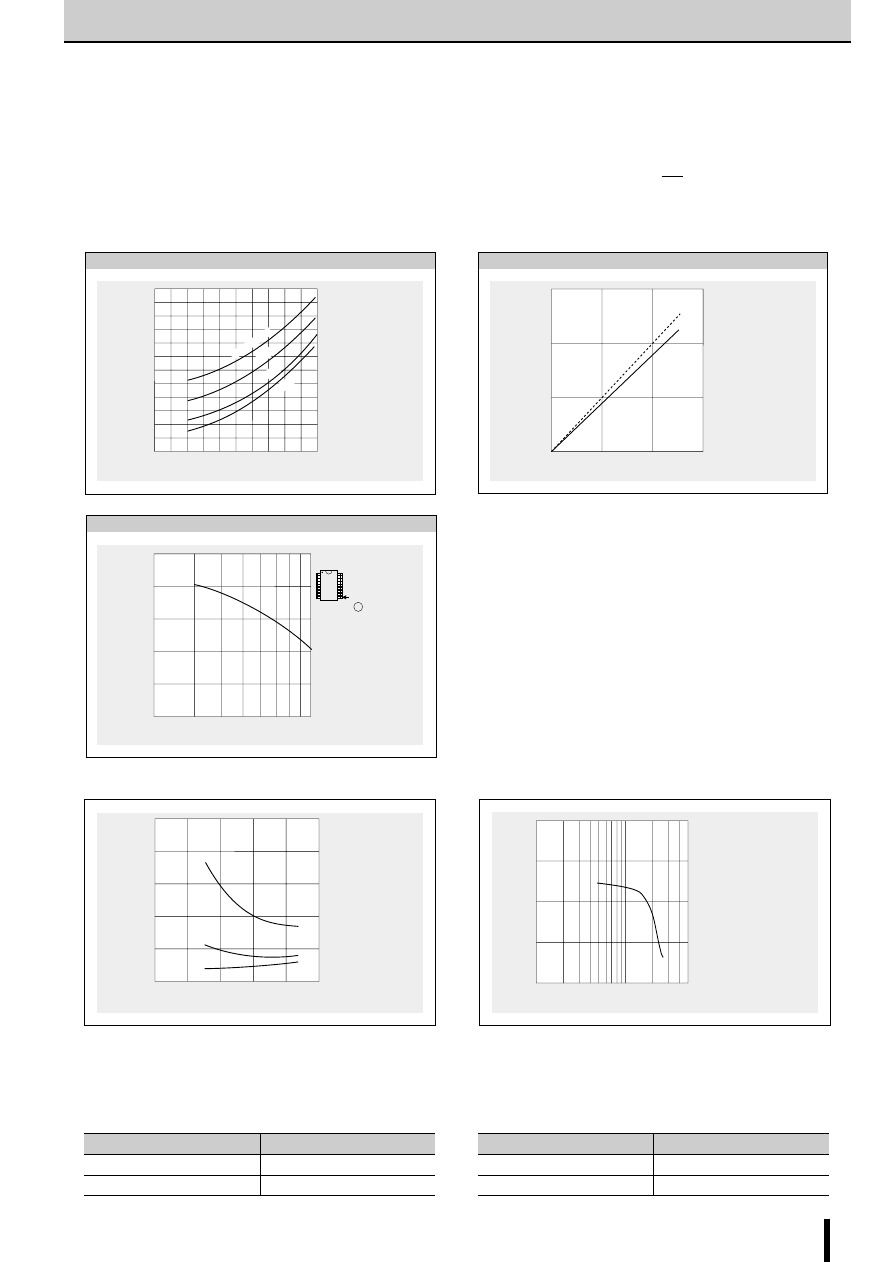

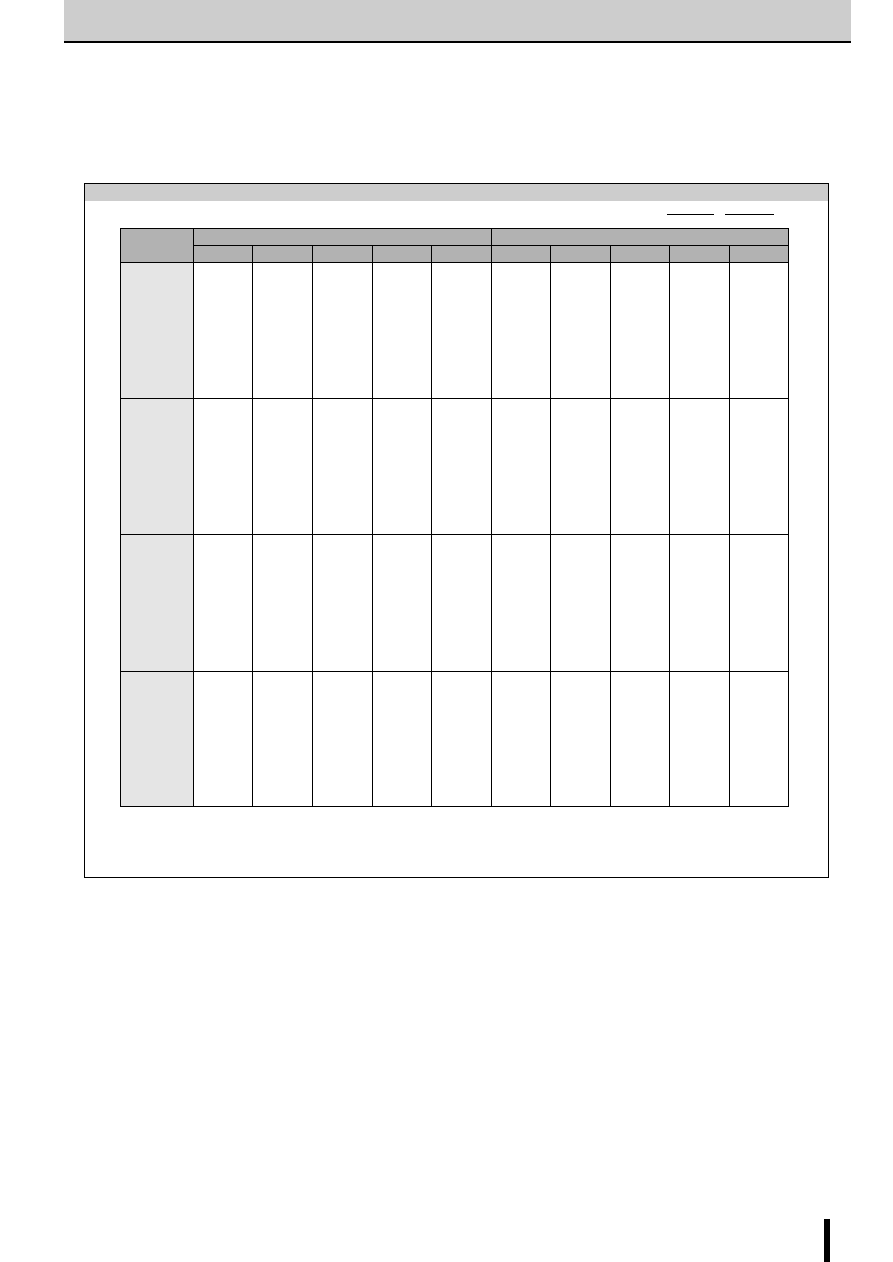

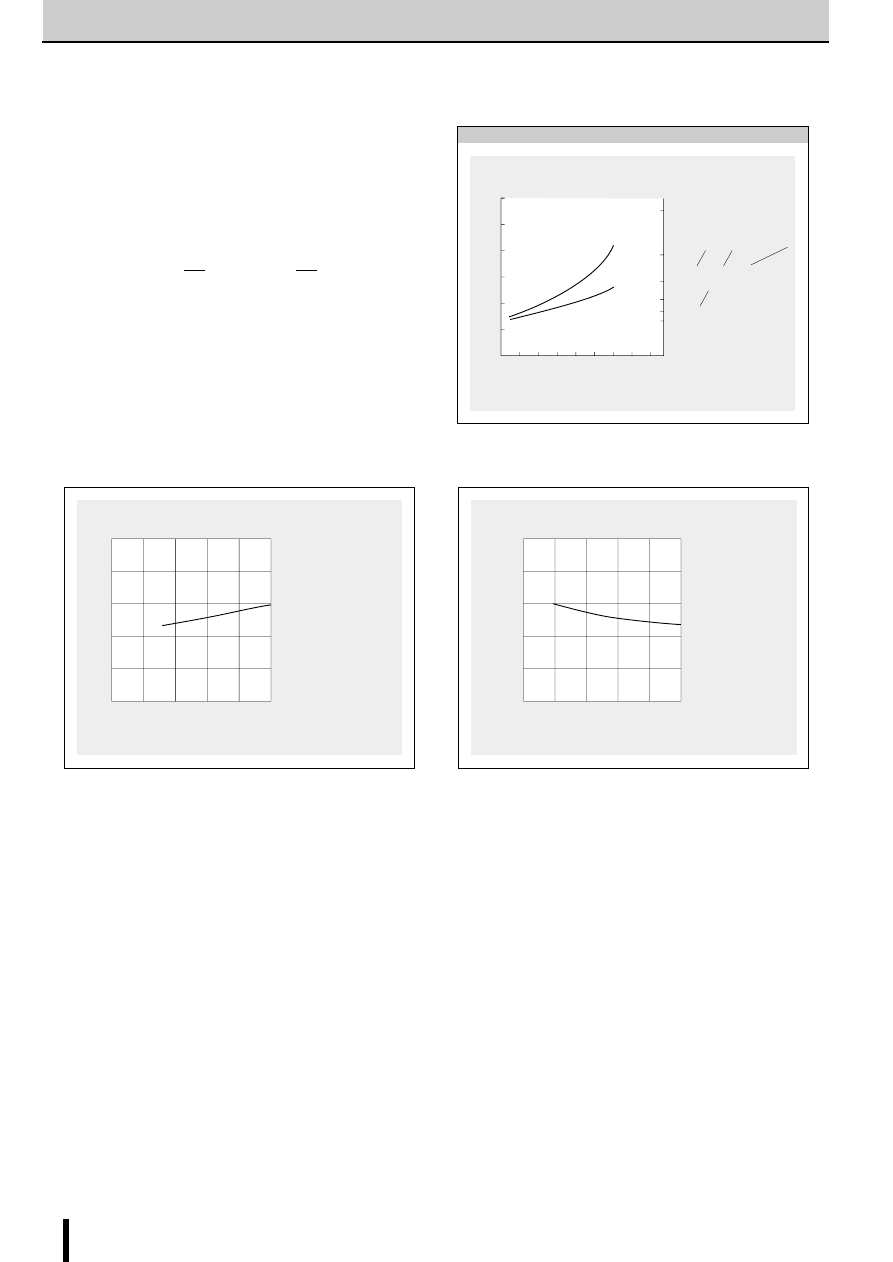

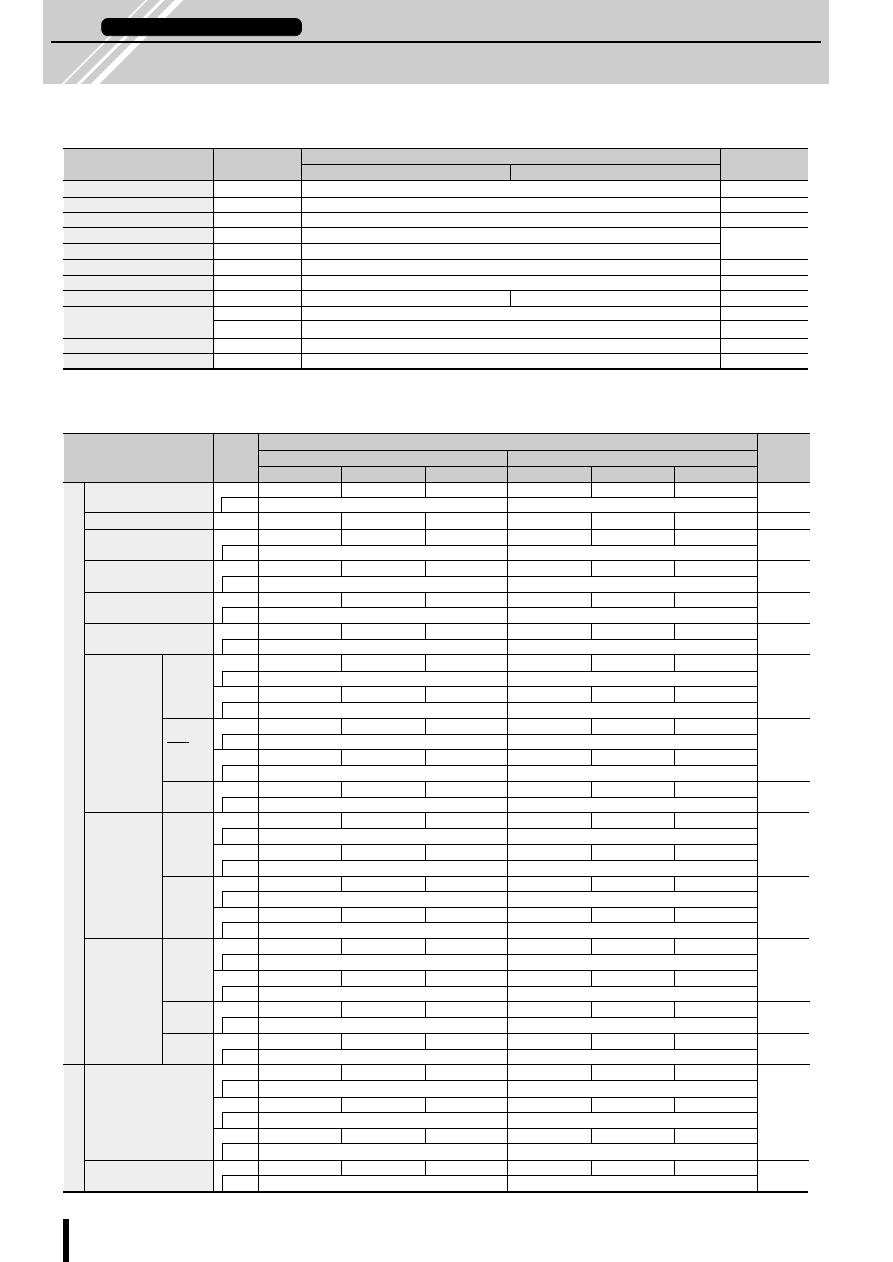

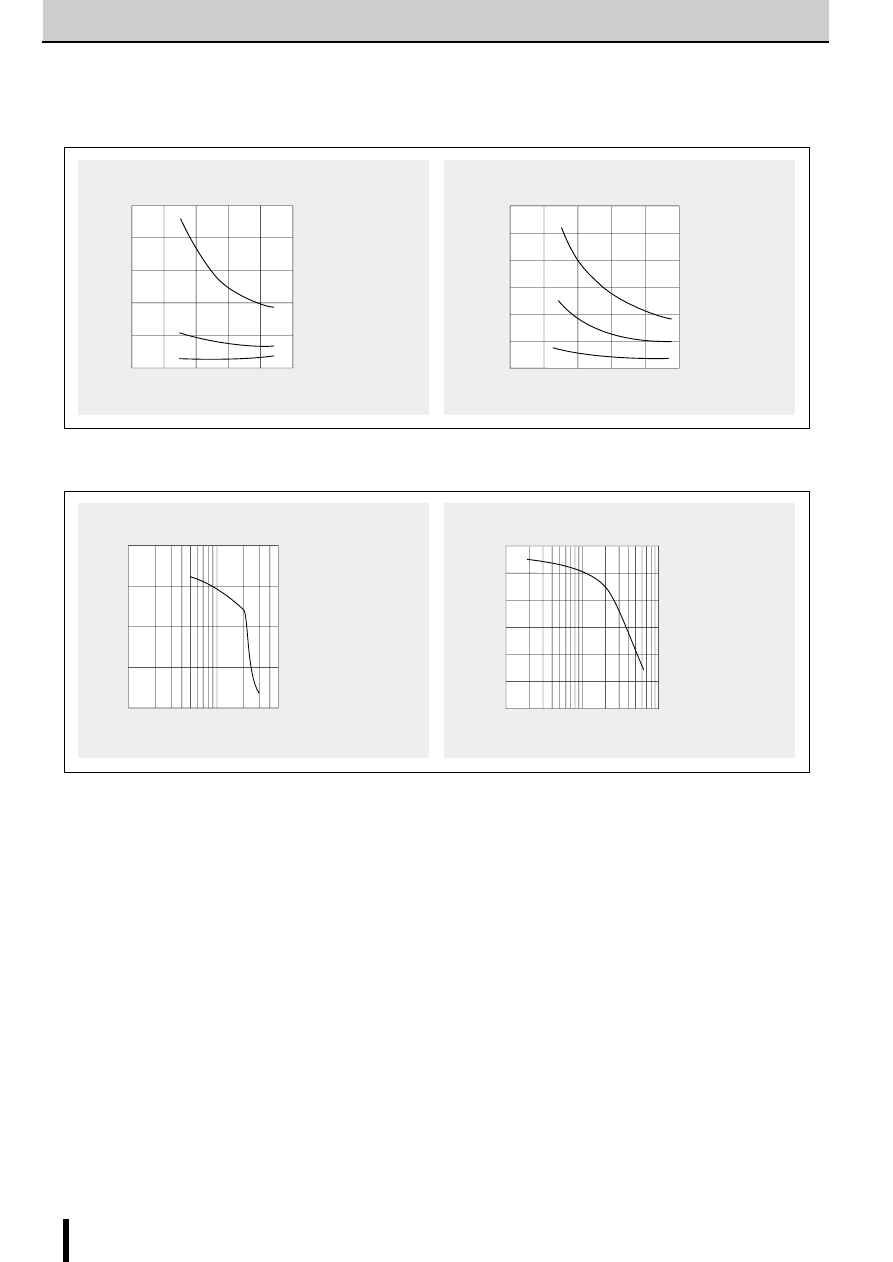

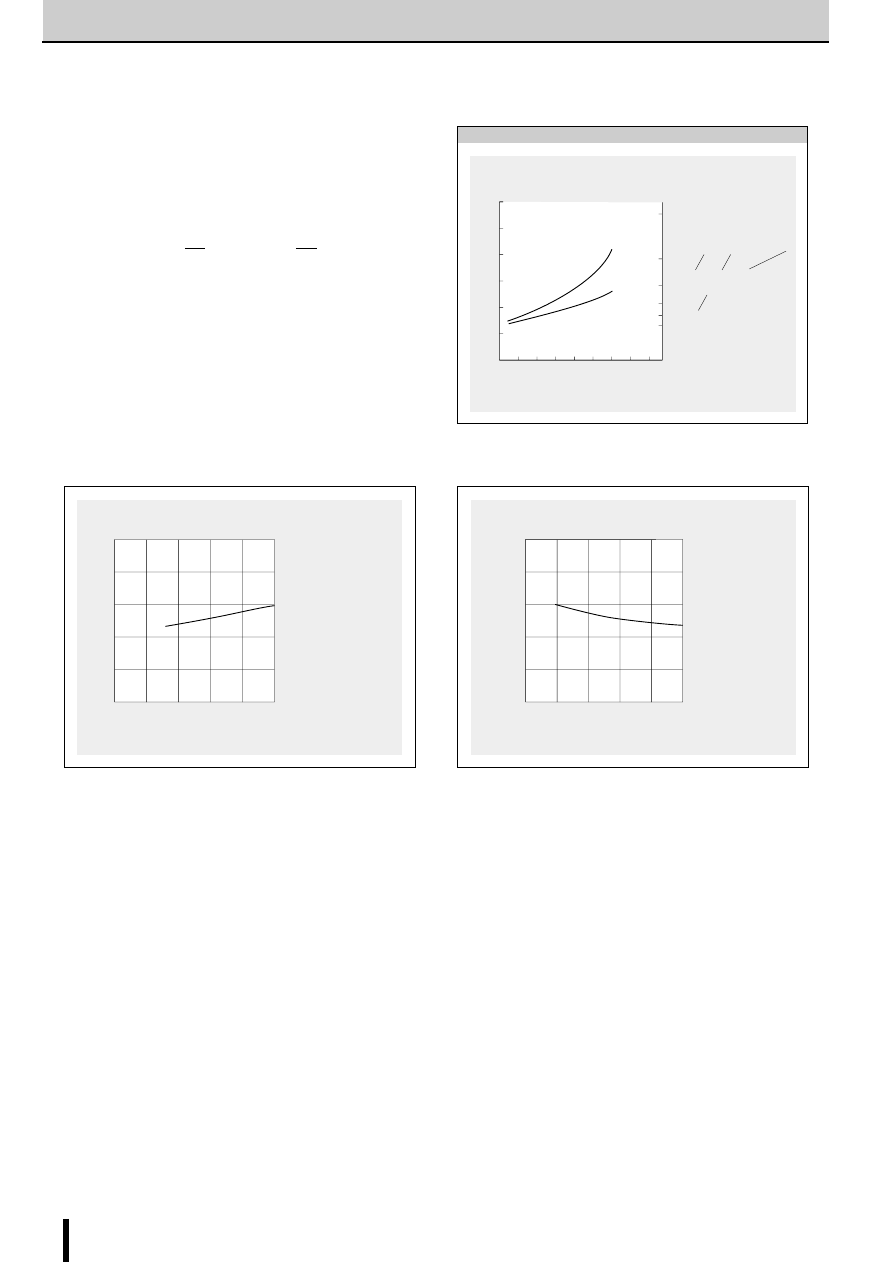

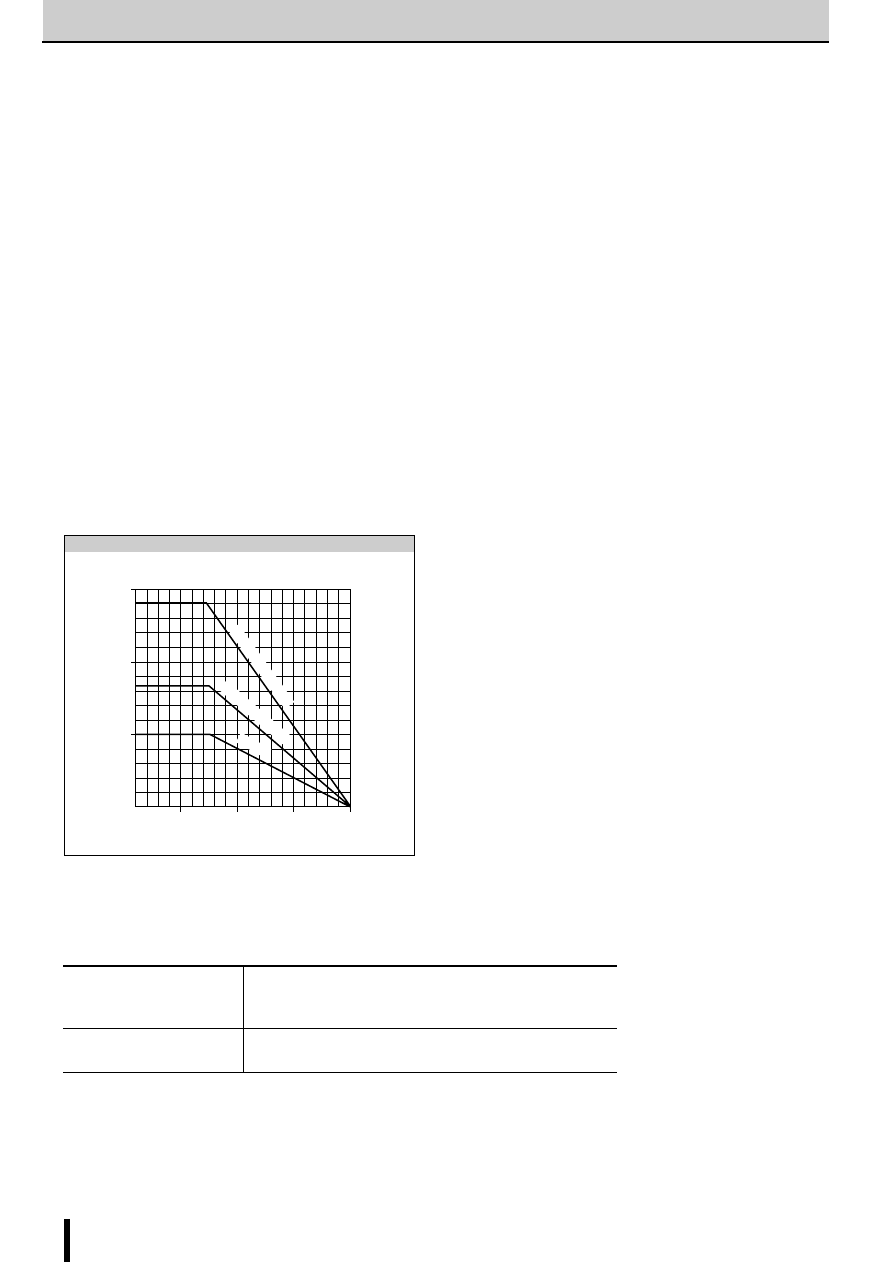

Thermal Design

An outline of the method for calculating heat dissipation is shown below.

(1)Obtain the value of P

H

that corresponds to the motor coil

current I

O

from Fig. 7 "Heat dissipation per phase P

H

vs. Out-

put current I

O

."

Output current I

O

(A)

Heat dissipation per phase P

H

(W)

Motor : 23LM-C004

Holding mode

0

0.2

0.4

0.6

0.8

1.0

1.2

1.0

0.8

0.6

0.4

0.2

0

V

CC

=44V

36V

24V

15V

∆

T

j–

a

∆

T

C

–

a

∆

T

j

1

0

2

3

4

∆

T

C

Natural cooling

Without heatsink

150

100

50

0

Total Power (W)

(

°

C)

Fig. 7 Heat dissipation per phase P

H

vs. Output current I

O

Fig. 8 Temperature rise

(2) The power dissipation P

diss

is obtained using the following formula.

2-phase excitation: P

diss

≅

2P

H

+0.015

×

V

S

(W)

1-2 phase excitation: P

diss

≅

P

H

+0.015

×

V

S

(W)

(3) Obtain the temperature rise that corresponds to the calcu-

lated value of P

diss

from Fig. 8 "Temperature rise."

1.2

1

0.8

0.6

0.4

0.2

0

0

0.2

0.4

0.6

0.8

1.0

Heat dissipation per phase P

H

(W)

Output current I

O

(A)

36V

24V

15V

V

CC

=44V

Motor : 23LM-C202

Holding mode

∆

T

j–

a

∆

T

C

–

a

∆

T

j

1

0

2

3

4

5

∆

T

C

Natural cooling

Without heatsink

150

100

50

0

Total Power (W)

(

°

C)

SLA7022MU, ASMA7022MU

SLA7000M series

SLA7029M, SMA7029M

SMA7000M series

3

2

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

11

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

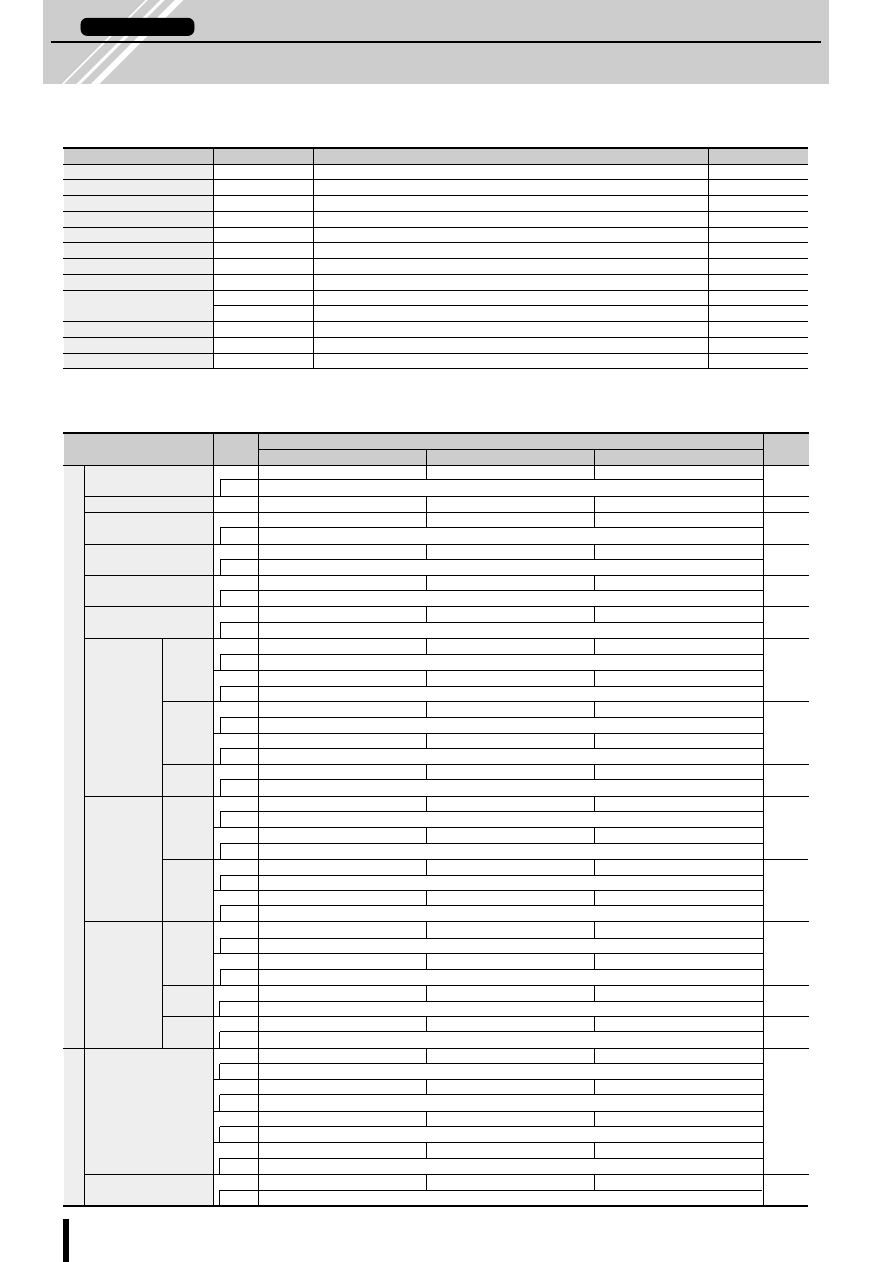

SLA7022MU/SLA7029M/SMA7022MU/SMA7029M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase Excitation)

0

Supply current I

CC

(mA)

Supply voltage V

CC

(V)

500

400

300

200

100

0

10

20

30

40

50

Motor : 23LM-C202

1-phase excitation

Holding mode

I

O

: Output current

I

O

=1A

0.4A

0.2A

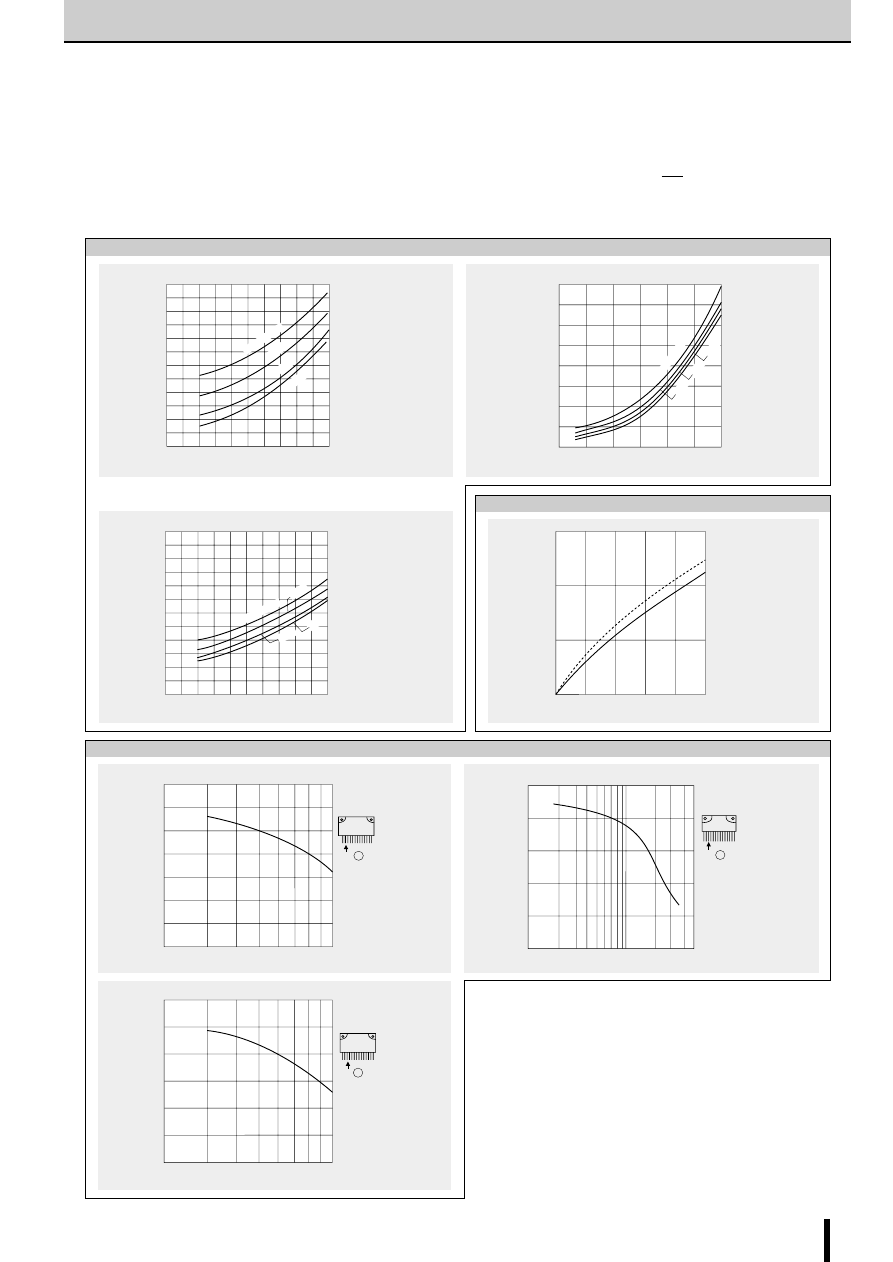

■

Supply Voltage V

CC

vs. Supply Current I

CC

SLA7022MU, SMA7022MU

0

Supply current I

CC

(mA)

Supply voltage V

CC

(V)

500

400

300

200

100

0

10

20

30

40

50

0.2A

0.5A

I

O

=1A

Motor : 23LM-C004

1-phase excitation

Holding mode

I

O

: Output current

SLA7029M, SMA7029M

100

Pull-out torque (kg-cm)

Response frequency (pps)

2.0

1.5

1.0

0.5

0

5K

1K

500

Motor : 23LM-C202

Output current I

O

=0.8A

Motor supply voltage V

CC

=24V

2-phase excitation

■

Torque Characteristics

SLA7029M, SMA7029M

100

Pull-out torque (kg-cm)

Response frequency (pps)

2.0

1.5

1.0

0.5

0

5K

1K

500

Motor : PX244-02

Output current I

O

=0.6A

Motor supply voltage V

CC

=24V

2-phase excitation

SLA7022MU, SMA7022MU

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

12

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC

SMA7036M

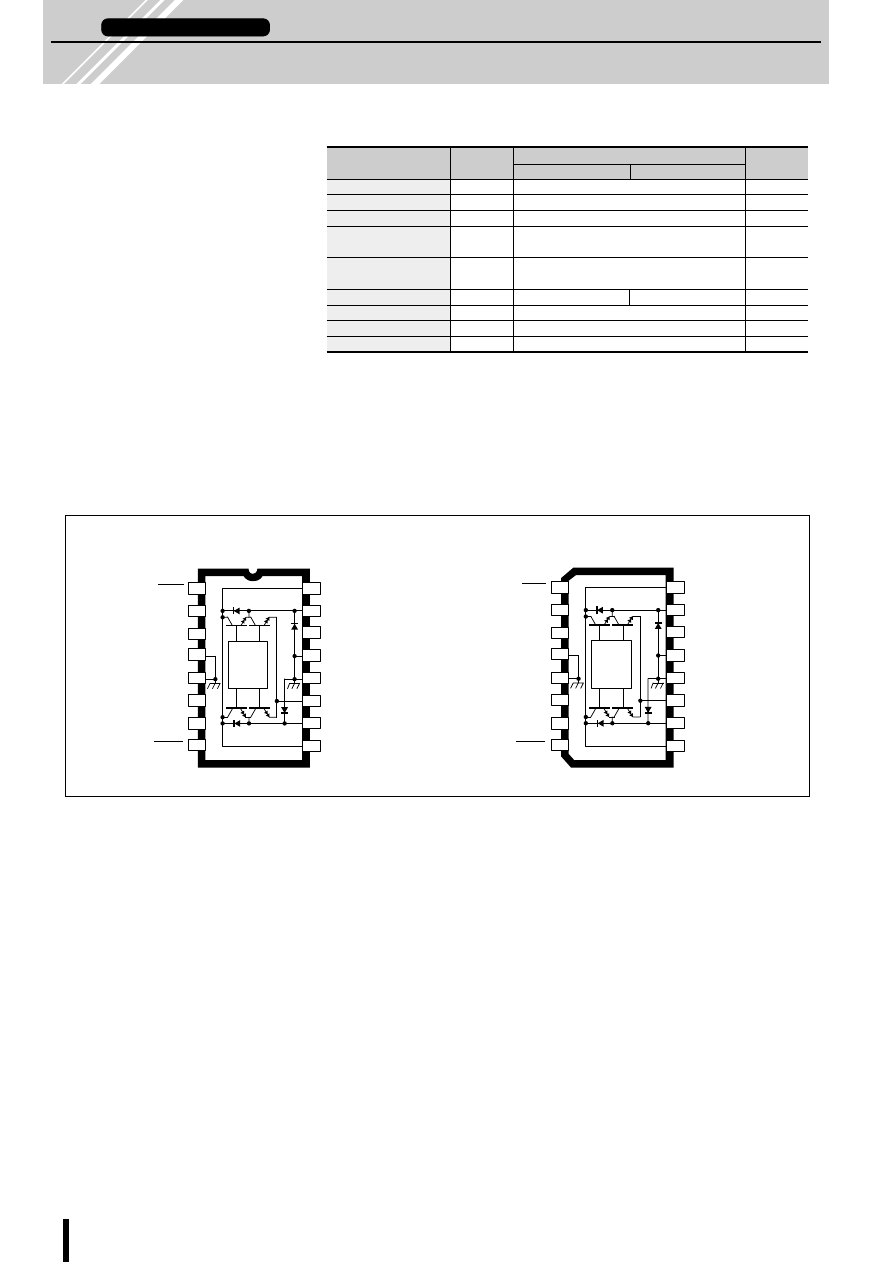

Parameter

Symbol

Ratings

Units

Motor supply voltage

V

CC

46

V

Control supply voltage

V

S

46

V

FET Drain-Source voltage

V

DSS

100

V

TTL input voltage

V

IN

−

0.3 to +7

V

SYNC terminal voltage

V

SYNC

−

0.3 to +7

V

Reference voltage

V

REF

−

0.3 to +7

V

Sense voltage

V

RS

−

5 to +7

V

Output current

I

O

1.5

A

Power dissipation

P

D1

4.0 (T

a

=25

°

C)

W

P

D2

28 (T

c

=25

°

C)

W

Channel temperature

T

ch

150

°

C

Storage temperature

T

stg

−

40 to +150

°

C

Ambient operating temperature

T

a

−

20 to +85

°

C

■

Absolute Maximum Ratings

■

Electrical Characteristics

Parameter

Symbol

Ratings

Units

min

typ

max

Control supply current

I

S

10

15

mA

Condition

V

S

=44V

Control supply voltage

V

S

10

24

44

V

FET Drain-Source

V

DSS

100

V

voltage

Condition

V

S

=44V, I

DSS

=250

µ

A

FET ON voltage

V

DS

0.6

V

Condition

I

D

=1A, V

S

=10V

FET diode forward voltage

V

SD

1.1

V

Condition

I

SD

=1A

FET drain leakage current

I

DSS

250

µ

A

Condition

V

DSS

=100V, V

S

=44V

V

IH

2

Condition

I

D

=1A

V

V

IL

0.8

Condition

V

DSS

=100V

IN terminal

V

IH

2

Condition

V

DSS

=100V

V

V

IL

0.8

Condition

I

D

=1A

I

I

±

1

µ

A

Condition

V

S

=44V, V

I

=0 or 5V

V

SYNC

H

4.0

Condition

Synchronous chopping mode

V

V

SYNC

L

0.8

SYNC terminal

Condition

Asynchronous chopping mode

I

SYNC

H

0.1

Condition

V

S

=44V, V

YS

=5V

mA

I

SYNC

L

−

0.1

Condition

V

S

=44V, V

YS

=0V

V

REF

0

2.0

Condition

Reference voltage input

V

V

REF

4.0

5.5

REF terminal

Condition

Output FET OFF

I

REF

±

1

µ

A

Condition

No synchronous trigger

R

REF

40

Ω

Condition

Resistance between GND and REF terminal at synchronous trigger

T

on

1.5

Condition

V

S

=24V, I

D

=1A

T

r

0.5

Switching time

Condition

V

S

=24V, I

D

=1A

µ

s

T

stg

0.9

Condition

V

S

=24V, I

D

=1A

T

f

0.1

Condition

V

S

=24V, I

D

=1A

Chopping OFF time

T

OFF

12

µ

s

Condition

V

S

=24V

Active H

Active L

Input

current

Input

voltage

Input

current

Input

voltage

Input

current

Internal

resistance

2-Phase Excitation

DC characteristics

AC characteristics

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

13

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

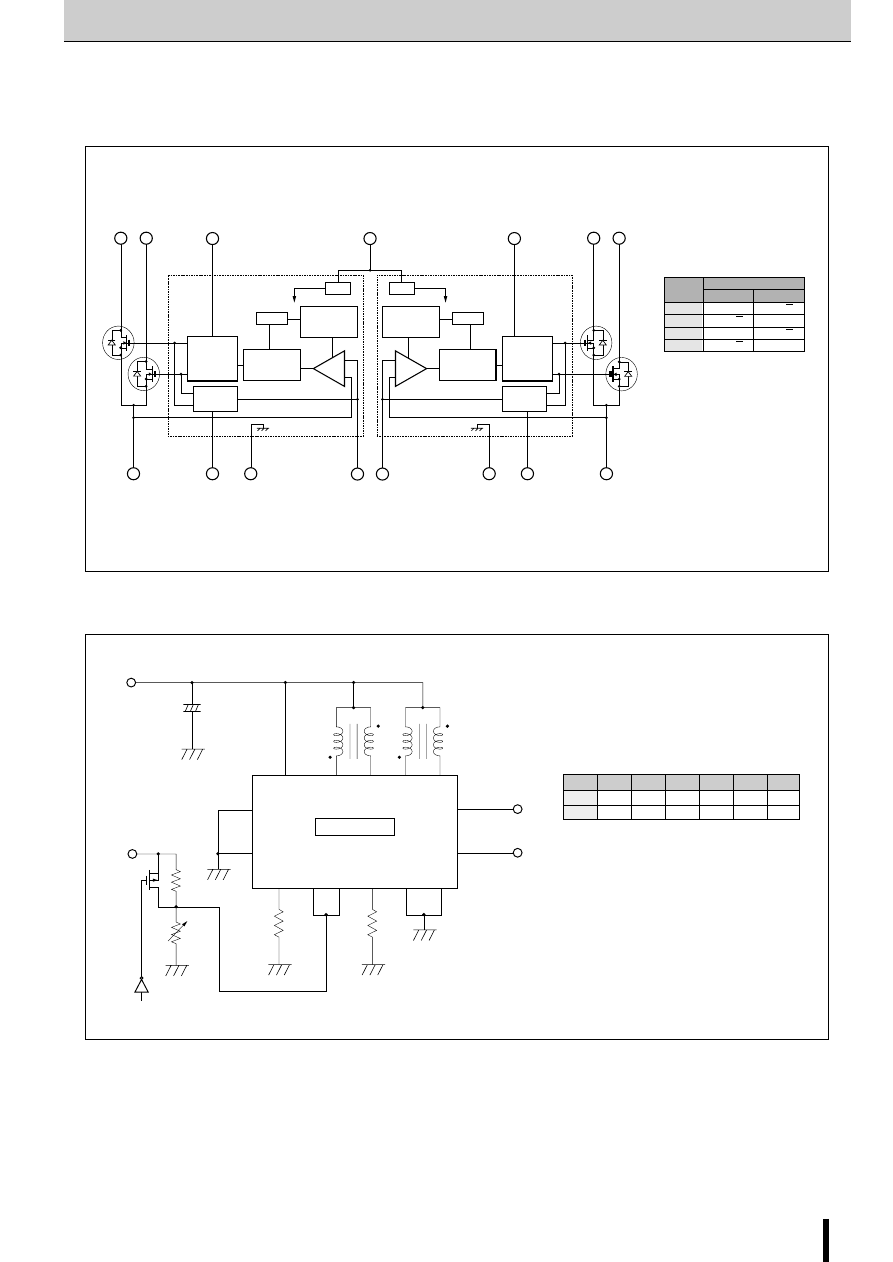

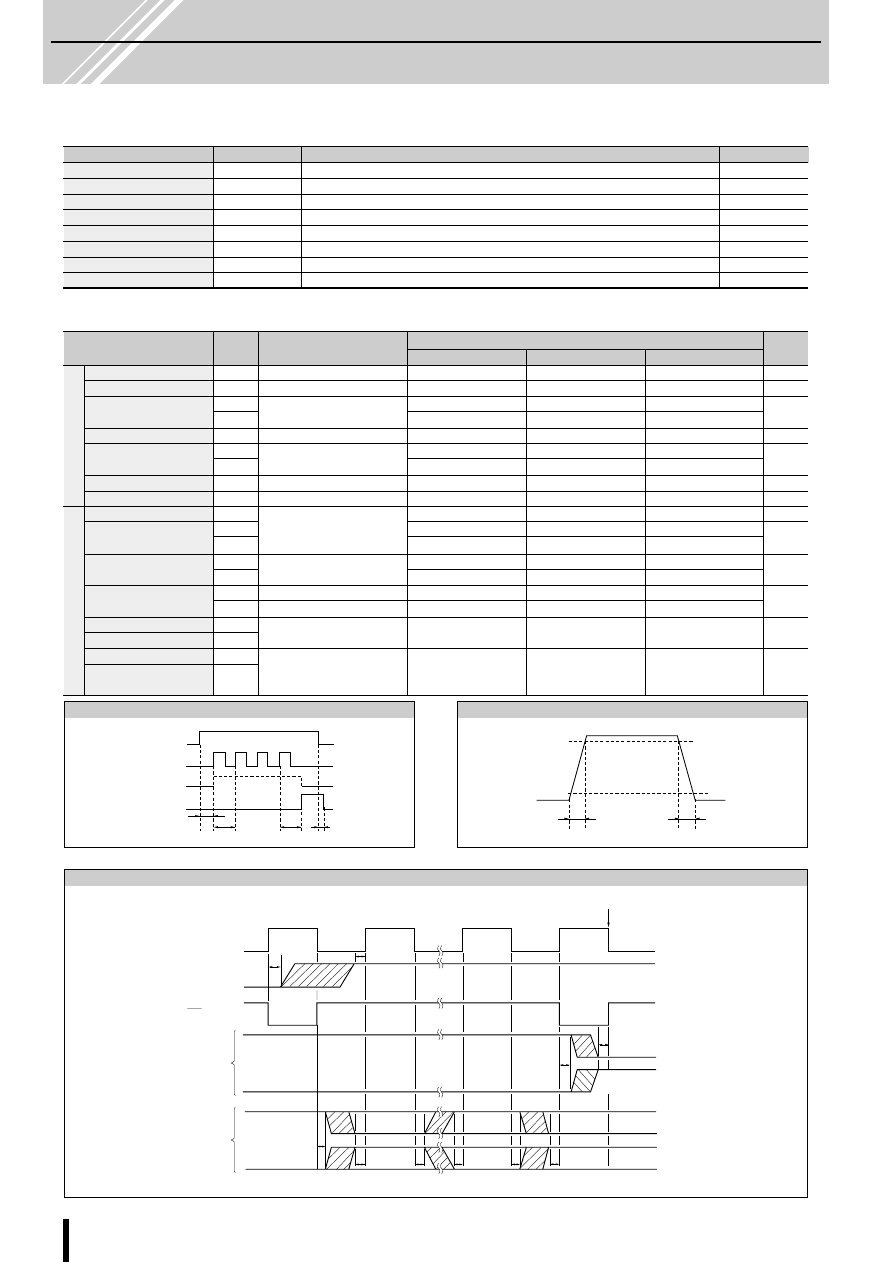

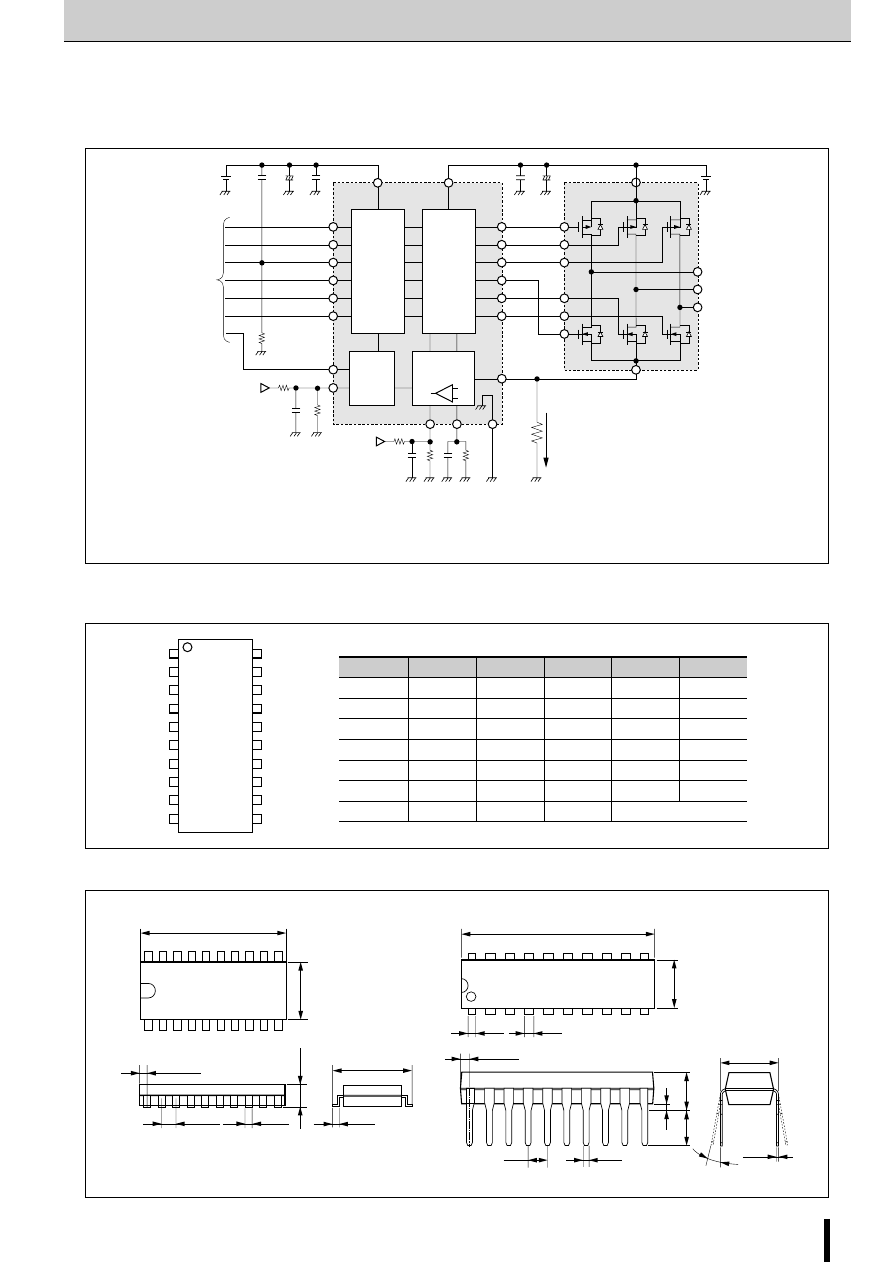

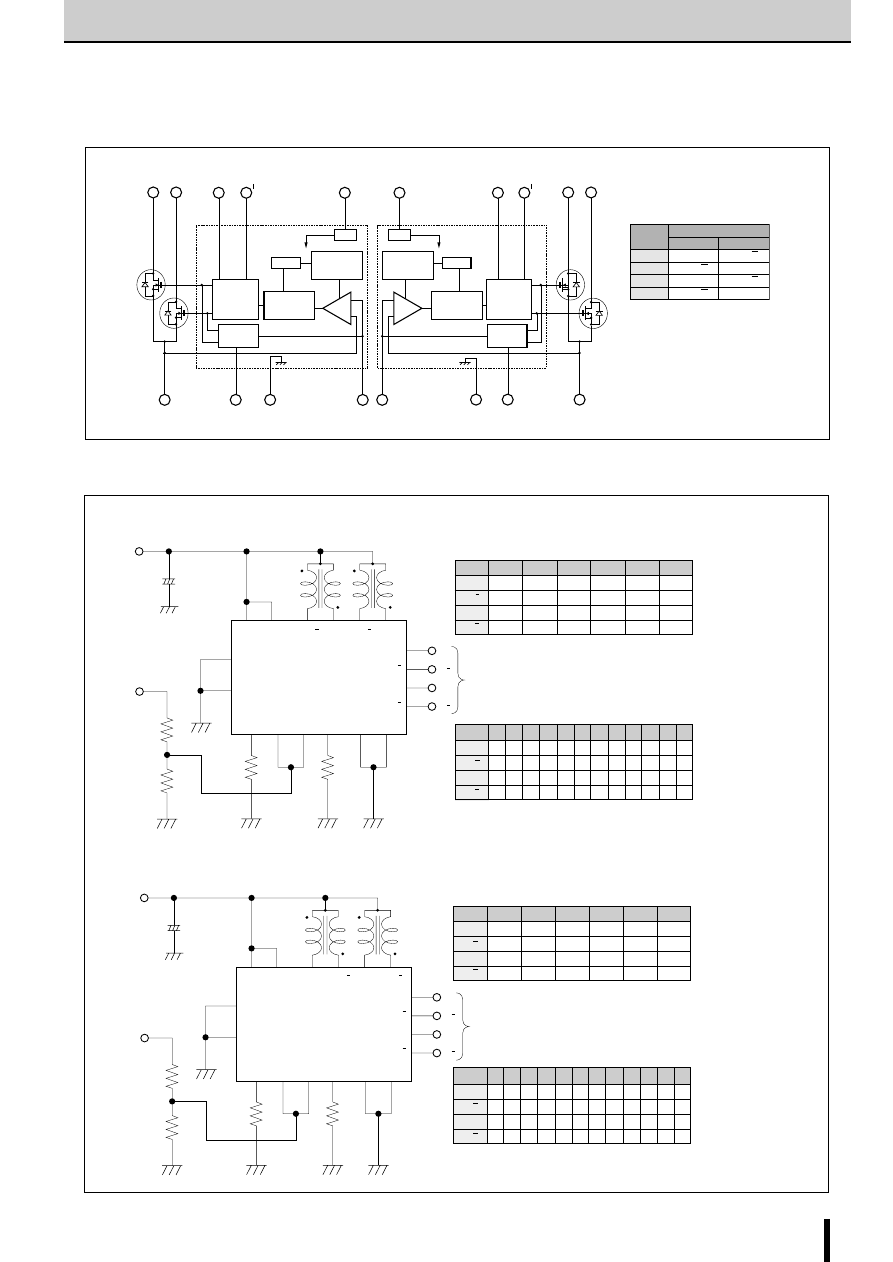

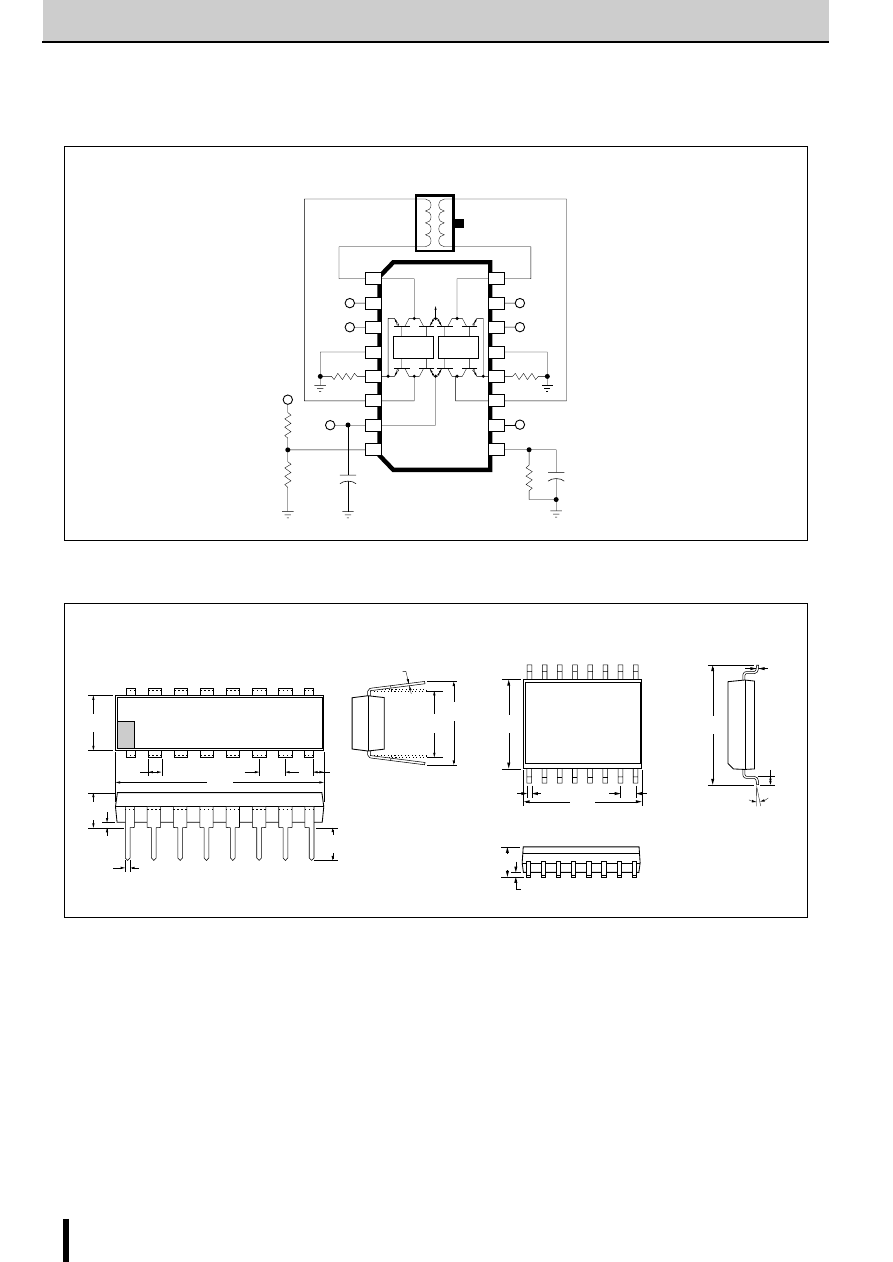

■

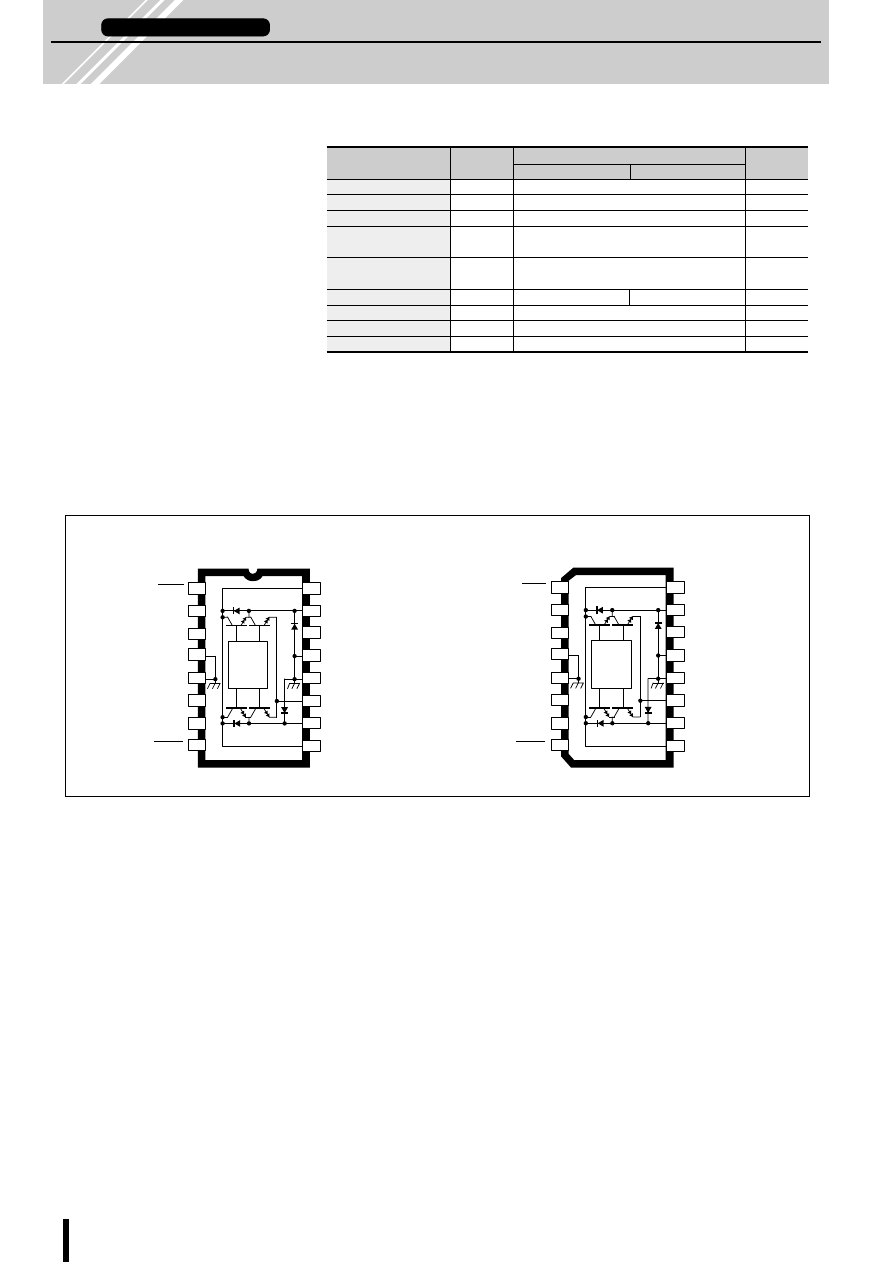

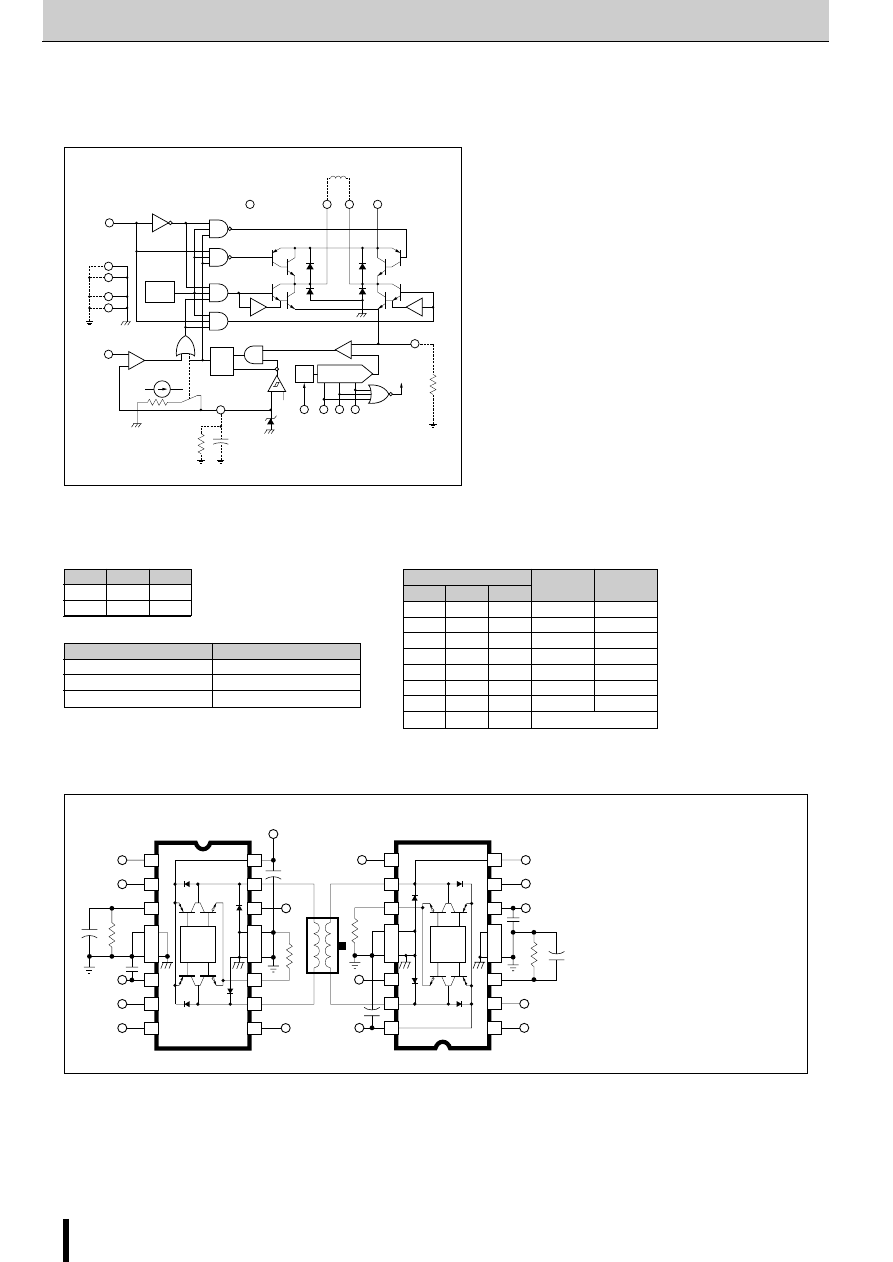

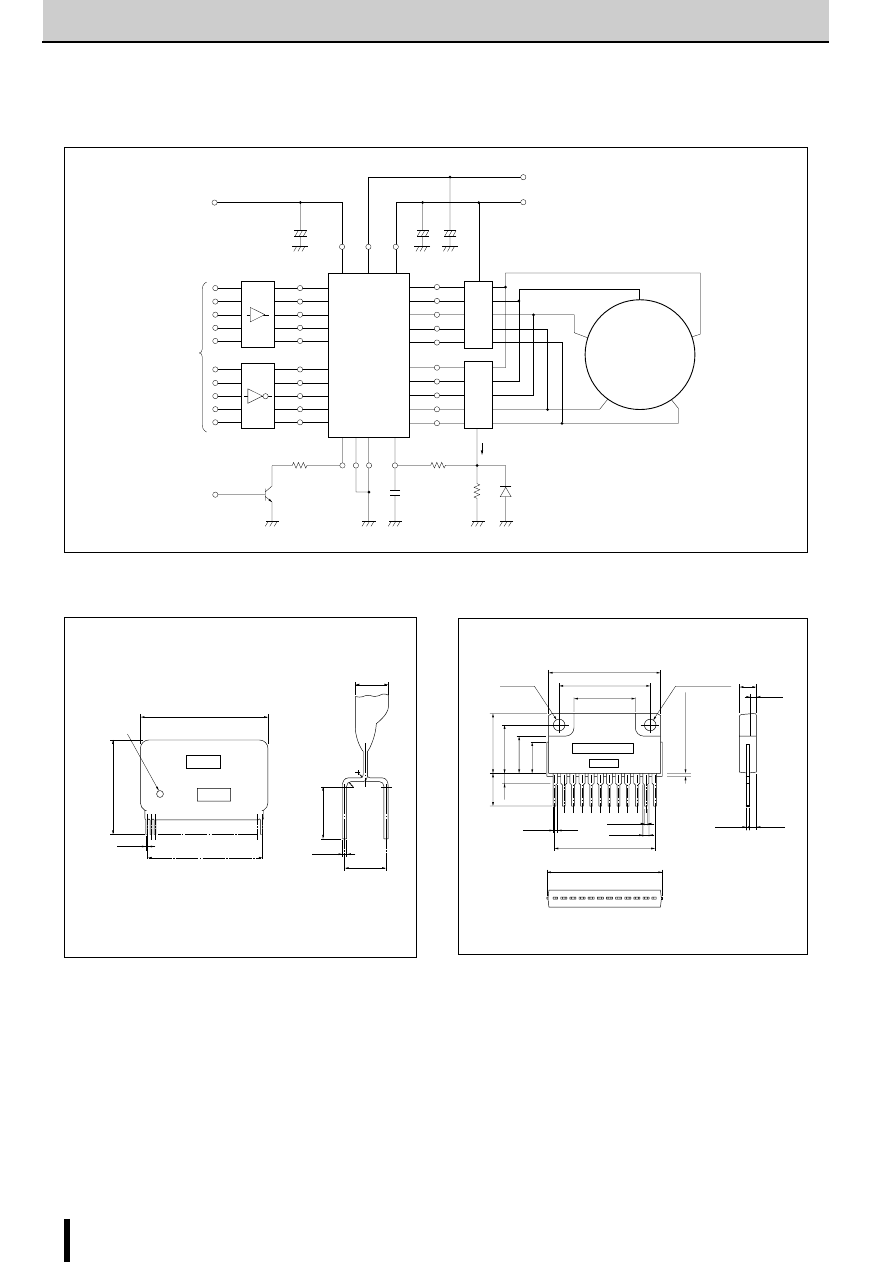

Internal Block Diagram

■

Diagram of Standard External Circuit (Recommended Circuit Constants)

Excitation signal time chart

2-phase excitation

clock

0

1

2

3

0

1

IN

A

H

H

L

L

H

H

IN

B

L

H

H

L

L

H

r

1

: 8k

Ω

r

2

: 2k

Ω

(VR)

R

S

(1 to 2W) : 1

Ω

typ

PchMOS

: HN1J02FU (Toshiba)

Inv

: 7404

5

8

14

10

15

1, 6, 10, 15pin

Description of pins

6

1

7

2

4

3

13

12

11

9

Chopping

blanking timer

(5 s typ)

µ

Chopping

blanking timer

(5 s typ)

Chopping

OFF timer

(12 s typ)

µ

Chopping

OFF timer

(12 s typ)

Synchronous

chopping

circuit

Synchronous

chopping

circuit

MOSFET

gate drive

circuit

MOSFET

gate drive

circuit

IN A

IN B

Vs

Rs A

SYNC A

SYNC B

GND A

REF A

REF B

GND B

Oscillator

Oscillator

Reg.

Reg.

Rs B

+

−

+

−

Excitation input

Active H

OUT A

OUT A

OUT B

OUT B

1pin

6pin

10pin

15pin

Active L

OUT A

OUT A

OUT B

OUT B

µ

µ

Disable (High Active)

Vb (5V)

Vcc (46V max)

PchMOS

2

11

5

14

Inv

r2

7

8

+

1

6

10

15

IN

B

IN

A

Rs

Rs

3

13

12

9

4

r1

SMA7036M

Sync

B

IN

B

IN

A

V

S

Rs

A

G

A

G

B

Rs

B

Ref

A

Ref

B

Sync

A

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

14

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

(Unit: mm)

■

External Dimensions

Forming No. No.1054

31

±

0.2

Part No.

Lot No.

4

±

0.2

2.5

±

0.2

1.45

±

0.15

6.7

±

0.5

(9.7)

(3)

0.55

+0.2

–0.1

4

±

0.7

P2.03

±

0.1

×

14=28.42

0.65

+0.2

–0.1

1 2 3 · · · · · · · 15

12 3 · · · · · · · 15

P2.03

±

0.1

×

14=28.42

1.16

±

0.15

3

±

0.6

0.55

+0.2 –0.1

1.2

±

0.1

(5.9)

(4.6)

1.6

±

0.6

1.16

+0.2

–0.1

30

°

0.62

±

0.1

(7.5)

Epoxy resin package

8.5ma

x

10.2

±

0.2

31.3

+0.2

Forming No. No.1055

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

15

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

■

Outline

SMA7036M is a stepper motor driver IC developed to reduce

the number of external parts required by the conventional

SMA7029M. This IC successfully eliminates the need for some

external parts without sacrificing the features of SMA7029M.

The basic function pins are compatible with those of SMA7029M.

■

Notes on Replacing SMA7029M

SMA7036M is pin-compatible with SMA7029M. When using

the IC on an existing board, the following preparations are nec-

essary:

(1) Remove the resistors and capacitors attached for setting

the chopping OFF time. (r

3

, r

4

, C

1

, and C

2

in the catalog)

(2) Remove the resistors and capacitors attached for preventing

noise in the detection voltage V

RS

from causing malfunction-

ing and short the sections from which the resistors were re-

moved using jumper wires. (r

5

, r

6

, C

3

, and C

4

in the catalog)

(3) Normally, keep pins 2 and 11 grounded because their func-

tions have changed to synchronous and asynchronous

switching (SYNC terminals). For details, see "Circuit for Pre-

venting Abnormal Noise When the Motor Is Not Running (Syn-

chronous circuit)." (Low: asynchronous, High: synchronous)

■

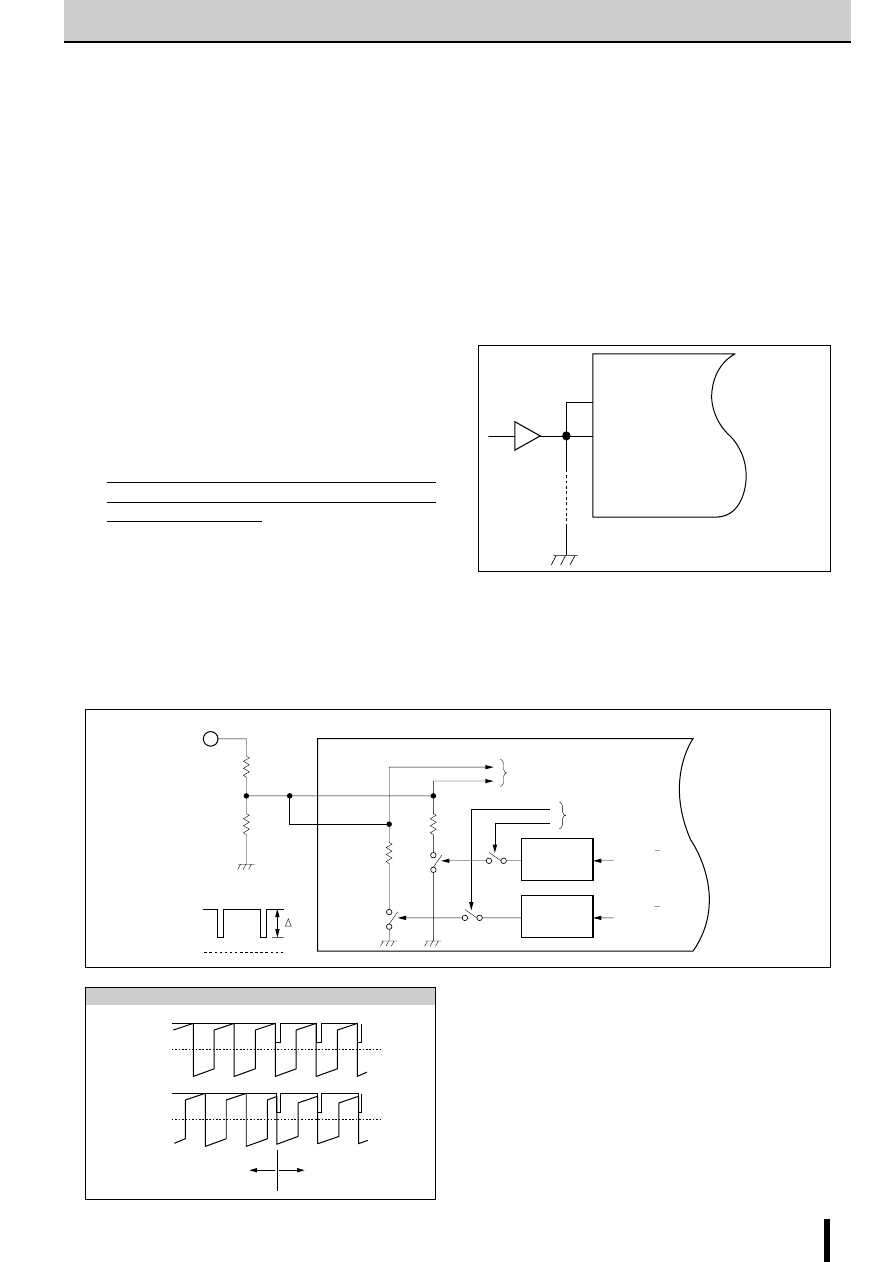

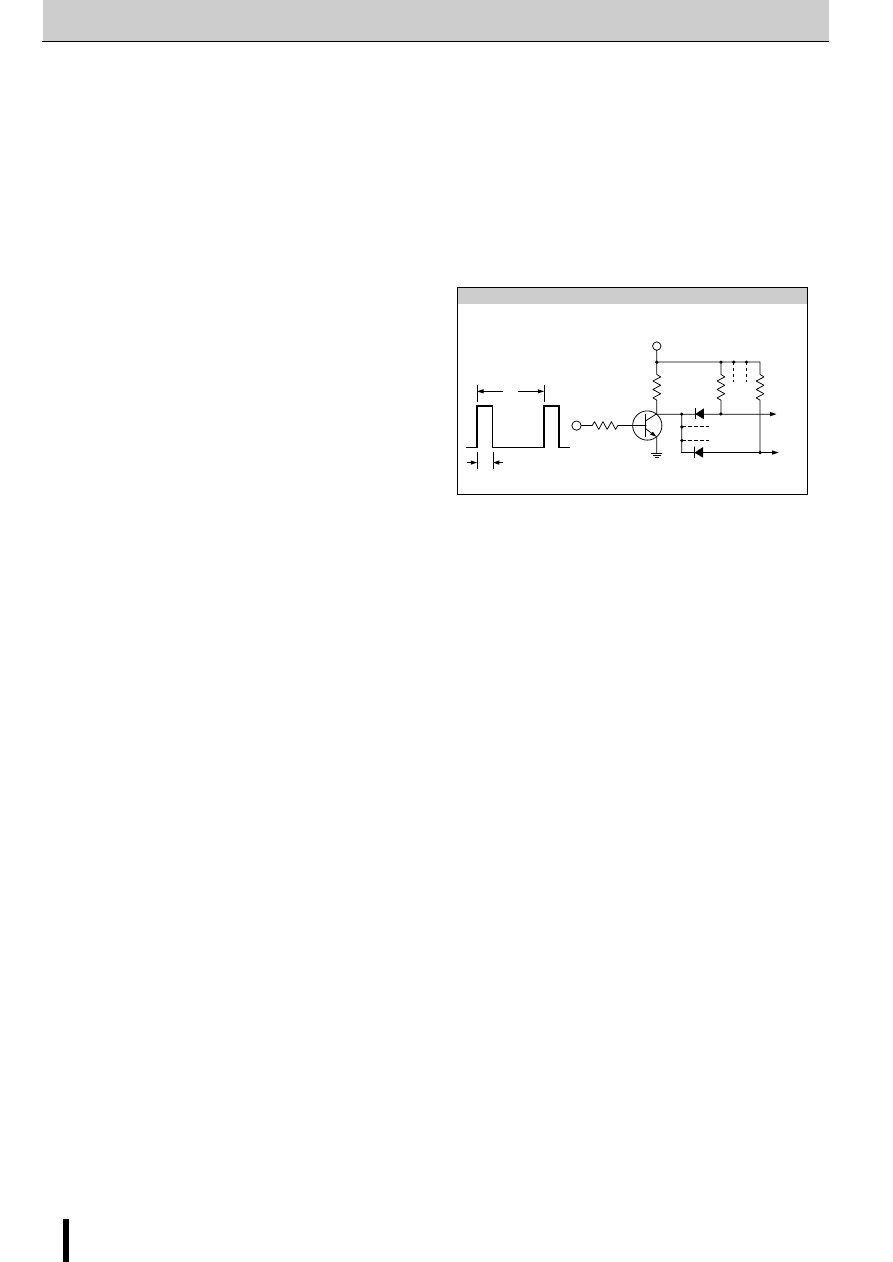

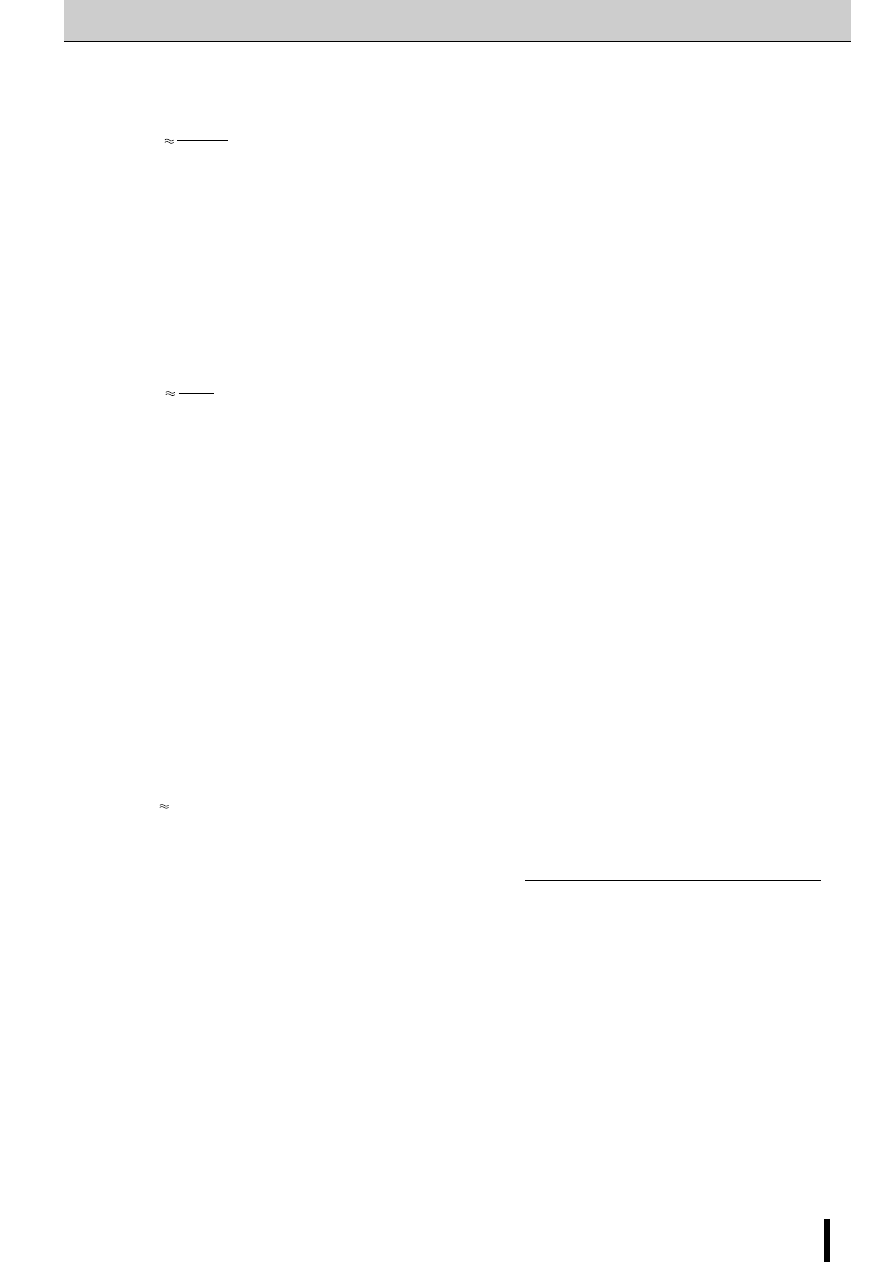

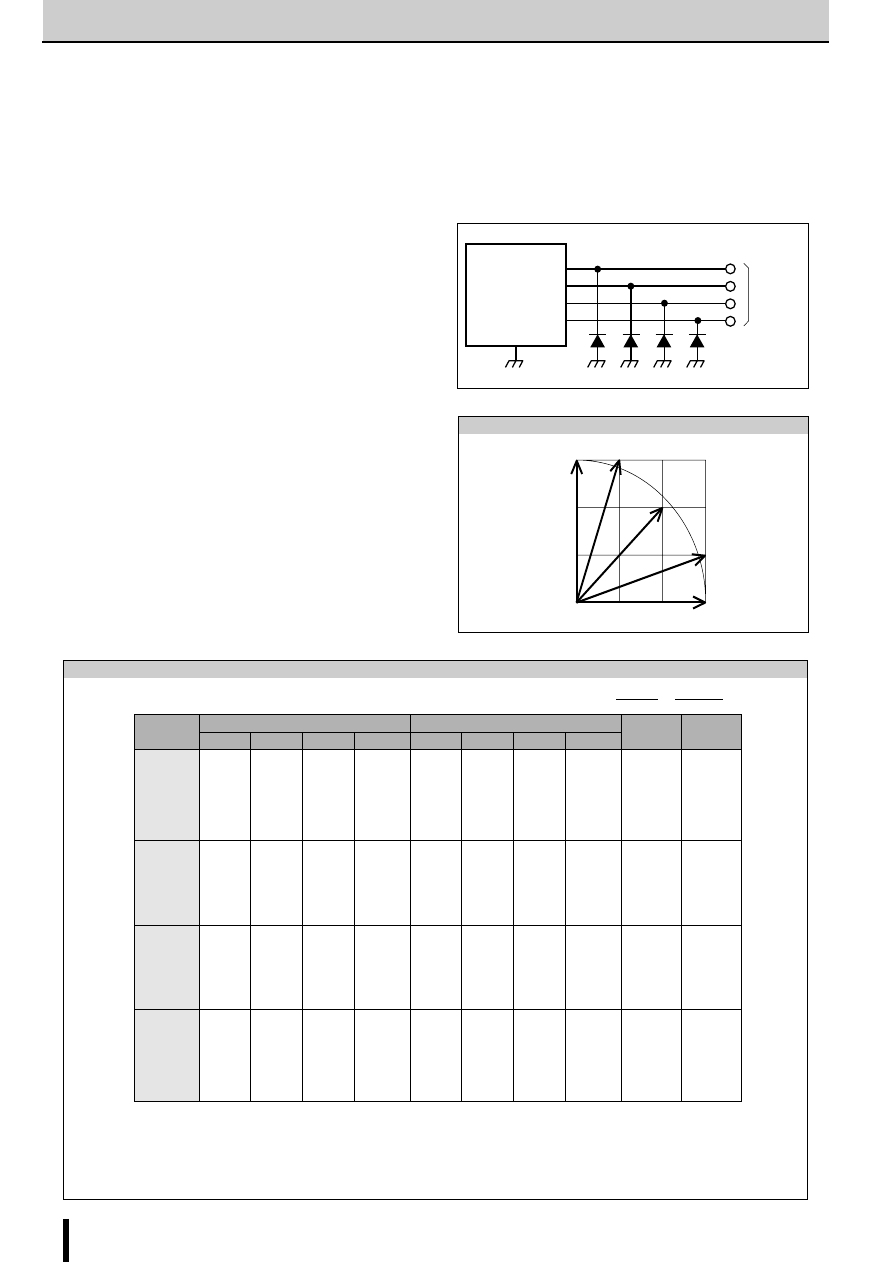

Circuit for Preventing Abnormal Noise When the

Motor Is Not Running (Synchronous Circuit)

A motor may generate abnormal noise when it is not running.

This phenomenon is attributable to asynchronous chopping be-

tween phases A and B. To prevent the phenomenon, SMA7036M

contains a synchronous chopping circuit. Do not leave the SYNC

terminals open because they are for CMOS input.

■

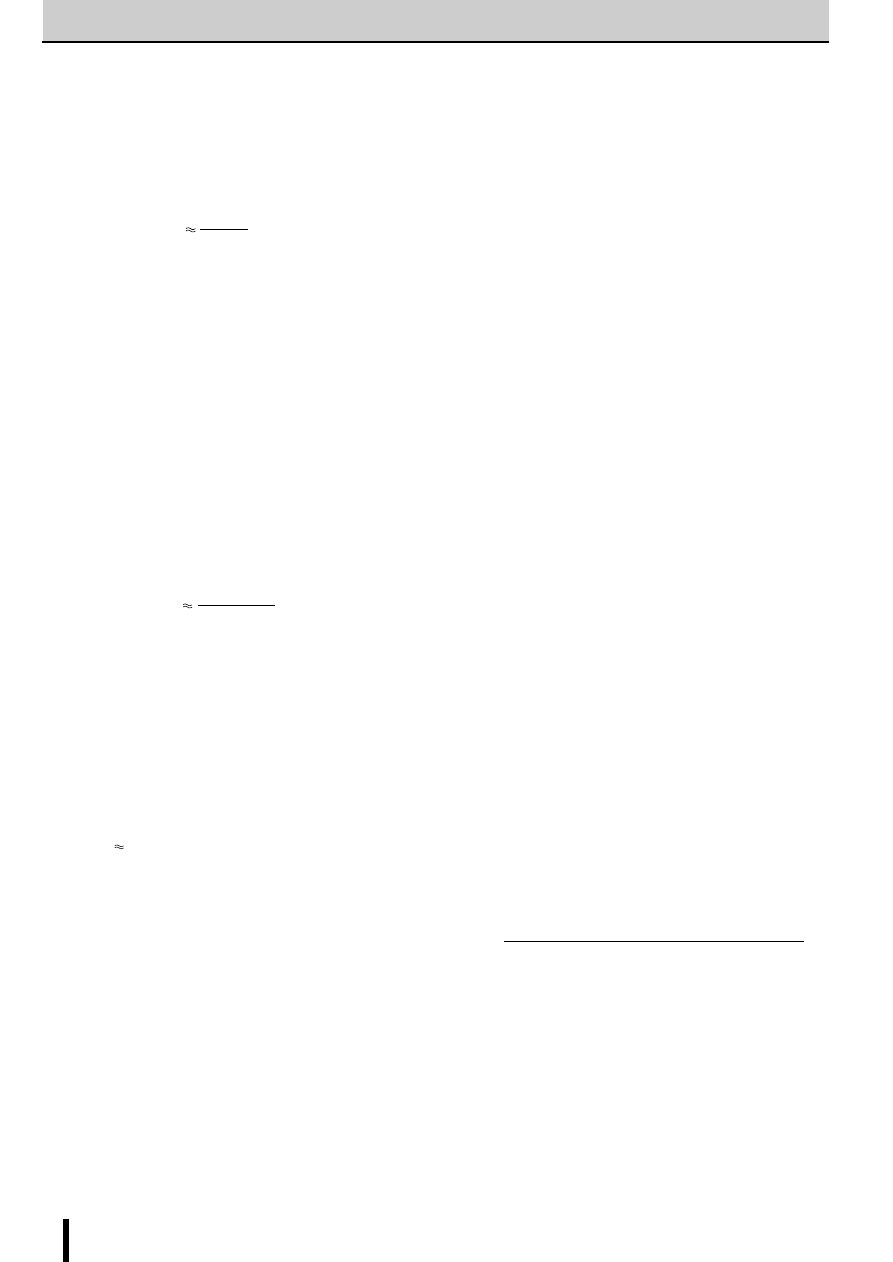

Synchronous circuit operating waveform

SYNC_A

SYNC voltage : Low

SYNC voltage : High

→

Chopping asynchronous

→

Chopping synchronous

TTL, etc.

SYNC_B

SMA7036M

ONE SHOT

(tw=2 S)

Sync/async

switching signal

To comparator

(high impedance)

REF_A

R1

R2

3

5V

REF_B

V

REF

V

REF

waveform

V

REF

0

14

SMA7036M

FET A/A

gate drive signal

40

Ω

(typ.)

40

Ω

(typ.)

FET B/B

gate drive signal

ONE SHOT

(tw=2 S)

µ

µ

V

REF

V

RS

Phase A

0

V

REF

V

RS

Synchronous circuit ON

Synchronous circuit OFF

Phase B

0

Application Notes

Connect TTL or similar to the SYNC terminals and switch the

SYNC terminal level high or low.

When the motor is not running, set the TTL signal high (SYNC

terminal voltage: 4 V or more) to make chopping synchronous.

When the motor is running, set the TTL signal low (SYNC terminal

voltage: 0.8 V or less) to make chopping asynchronous. If chop-

ping is set to synchronous when the motor is running, the motor

torque deteriorates before the coil current reaches the set value.

If no abnormal noise occurs when the motor is not running,

ground the SYNC terminals (TTL not necessary).

The built-in synchronous chopping circuit superimposes a trigger

signal on the REF terminal for synchronization between the two

phases. The figure below shows the internal circuit of the REF

terminal. Since the

∆

V

REF

varies depending on the values of R1

and R2, determine these values for when the motor is not run-

ning within the range where the two phases are synchronized.

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

16

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

0

Phase A

Phase A

I

O

R

S

r

2

r

1

V

b

(5

V

)

7,(9)

3,(13)

R

S

r

2

r

1

V

b

(5

V

)

7,(9)

3,(13)

r

x

T

r

Power down

signal

■

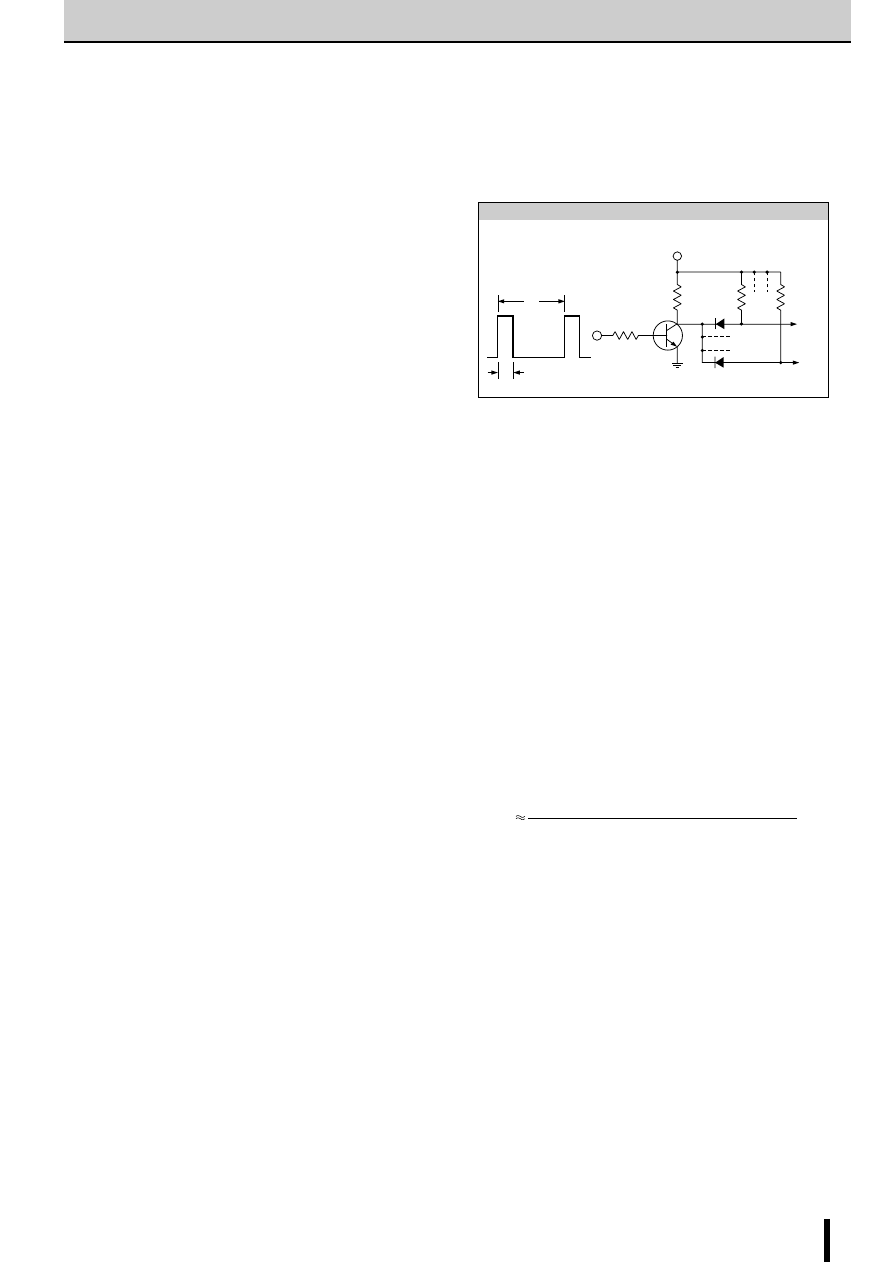

Determining the Output Current

Fig. 1 shows the waveform of the output current (motor coil cur-

rent). The method of determining the peak value of the output

current (I

O

) based on this waveform is shown below.

(Parameters for determining the output current I

O

)

V

b

: Reference supply voltage

r

1

,r

2

: Voltage-divider resistors for the reference supply voltage

R

S

: Current sense resistor

(1) Normal rotation mode

I

O

is determined as follows when current flows at the maximum

level during motor rotation. (See Fig.2.)

(2) Power down mode

The circuit in Fig.3 (r

x

and T

r

) is added in order to decrease the

coil current. I

O

is then determined as follows.

Equation (2) can be modified to obtain equation to determine rx.

Fig. 4 and 5 show the graphs of equations (1) and (2) respec-

tively.

Fig. 2 Normal mode

Fig. 1 Waveform of coil current (Phase A excitation ON)

Fig. 3 Power down mode

4

3

2

1

0

0

1

2

3

4

Current sense resistor R

S

(

Ω

)

Output current I

O

(A)

I

O

=

r

1

+r

2

R

S

r

1

=510

Ω

r

2

=100

Ω

r

x

=

∞

V

b

=5V

r

2

·

V

b

Fig. 4 Output current I

O

vs. Current sense resistor R

S

Fig. 5 Output current I

OPD

vs. Variable current sense resistor rx

2.0

1.5

1.0

0.5

00

200

400

600

800

Variable current sense resistor r

X

(

Ω

)

Output current I

OPD

(A)

1000

1200

R

S

=0.5

Ω

R

S

=0.8

Ω

R

S

=1

Ω

I

OPD

=

1+ R

S

r

1

=510

Ω

r

2

=100

Ω

V

b

=5V

1

·

V

b

r

1

(r

2+

r

X

)

r

2 ·

r

X

r

X

=

1

V

b

R

s

•

I

OPD

1

r

1

−

1

−

1

r

2

................................................................ (1)

I

O

≅

•

r

2

r

1

+r

2

V

b

R

S

......................................................... (2)

I

OPD

≅

•

1

r

1

(r

2

+r

X

)

r

2

•

r

X

V

b

R

S

1+

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

17

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

Output current I

O

(A)

Heat dissipation per phase P

H

(W)

Motor : 23LM-C004

Holding mode

0

0.2

0.4

0.6

0.8

1.0

1.2

1.0

0.8

0.6

0.4

0.2

0

V

CC

=44V

36V

24V

15V

Fig. 6 Heat dissipation per phase P

H

vs. Output current I

O

∆

T

j–

a

∆

T

C

–

a

∆

T

j

1

0

2

3

4

∆

T

C

Natural cooling

Without heatsink

150

100

50

0

Total Power (W)

(

°

C)

Fig. 7 Temperature rise

Thermal characteristics

30

25

20

15

10

5

0

200

500

1K

Case temperature rise

∆

T

C

–

a

(

°

C)

Motor : PH265-01B

Motor current I

O

=0.8A

T

a

=25

°

C

V

CC

=24V, V

S

=24V

2-phase excitation

Response frequency (pps)

Without heatsink

Natural cooling

T

C

( 4 pin)

■

Thermal Design

An outline of the method for calculating heat dissipation is

shown below.

(1) Obtain the value of P

H

that corresponds to the motor coil

current I

O

from Fig. 6 "Heat dissipation per phase P

H

vs. Out-

put current I

O

."

(2) The power dissipation P

diss

is obtained using the following

formula.

2-phase excitation: P

diss

≅

2P

H

+0.015

×

V

S

(W)

1-2 phase excitation: P

diss

≅

P

H

+0.015

×

V

S

(W)

(3) Obtain the temperature rise that corresponds to the calcu-

lated value of P

diss

from Fig. 7 "Temperature rise."

3

2

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

18

SMA7036M

SMA7036M

2-Phase Stepper Motor Unipolar Driver IC (2-Phase Excitation)

■

Handling Precautions

The input terminals of this product use C-MOS circuits. Observe the following precautions.

●

Carefully control the humidity of the room to prevent the buildup of static electricity. Since static electricity is particularly a problem

during the winter, be sure to take sufficient precautions.

●

Take care to make sure that static electricity is not applied to the IC during wiring and assembly. Take precautions such as shorting

the terminals of the printed wiring board to ensure that they are at the same electrical potential.

■

Chopper frequency vs. Supply voltage

■

Chopper frequency vs. Output current

0

f (kHz)

V

CC

(V)

50

40

30

20

10

0

10

20

30

40

50

Motor : 23LM-C202

I

O

= 0.8A at V

CC

=24V

R

S

=1

Ω

0

f (kHz)

I

O

(A)

50

40

30

20

10

0

0.2

0.4

0.6

0.8

1.0

Motor : 23LM-C202

V

CC

=24V

R

S

=1

Ω

■

Supply Voltage V

CC

vs. Supply Current I

CC

0

Supply current I

CC

(mA)

Supply voltage V

CC

(V)

500

400

300

200

100

0

10

20

30

40

50

0.2A

0.5A

I

O

=1A

Motor : 23LM-C004

1-phase excitation

Holding mode

I

O

: Output current

■

Torque Characteristics

100

Pull-out torque (kg-cm)

Response frequency (pps)

2.0

1.5

1.0

0.5

0

5K

1K

500

Motor : 23LM-C202

Output current I

O

=0.8A

Motor supply voltage V

CC

=24V

2-phase excitation

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

19

SMA7036M

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

20

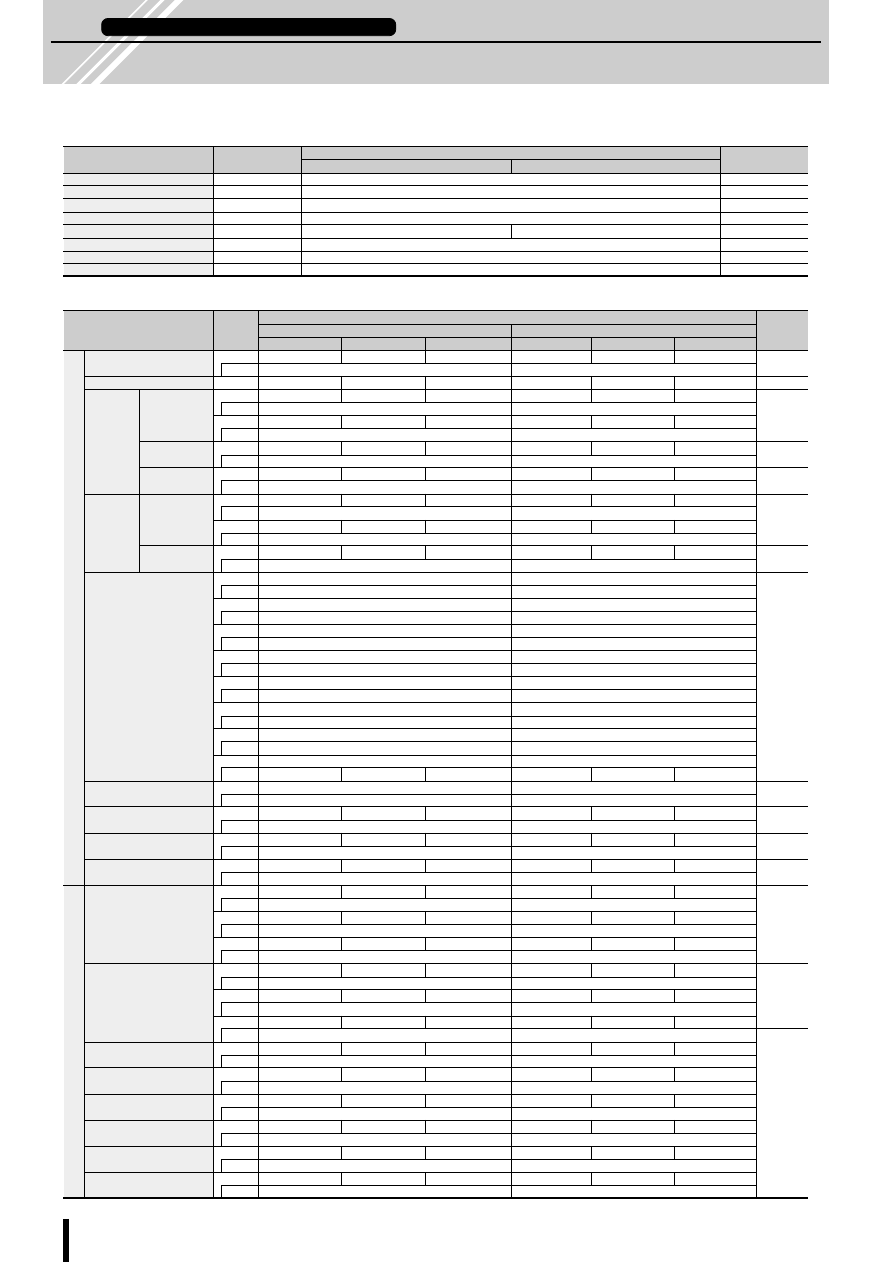

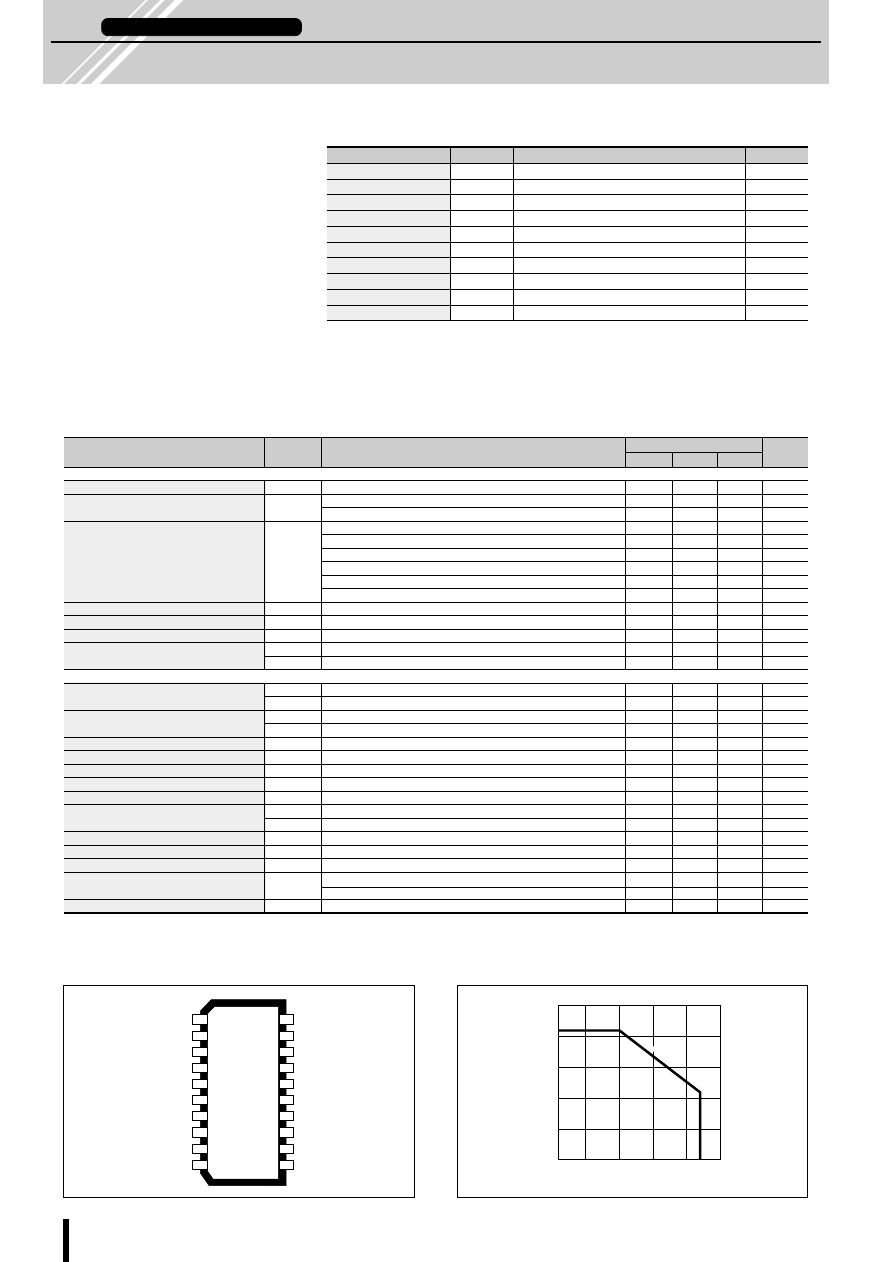

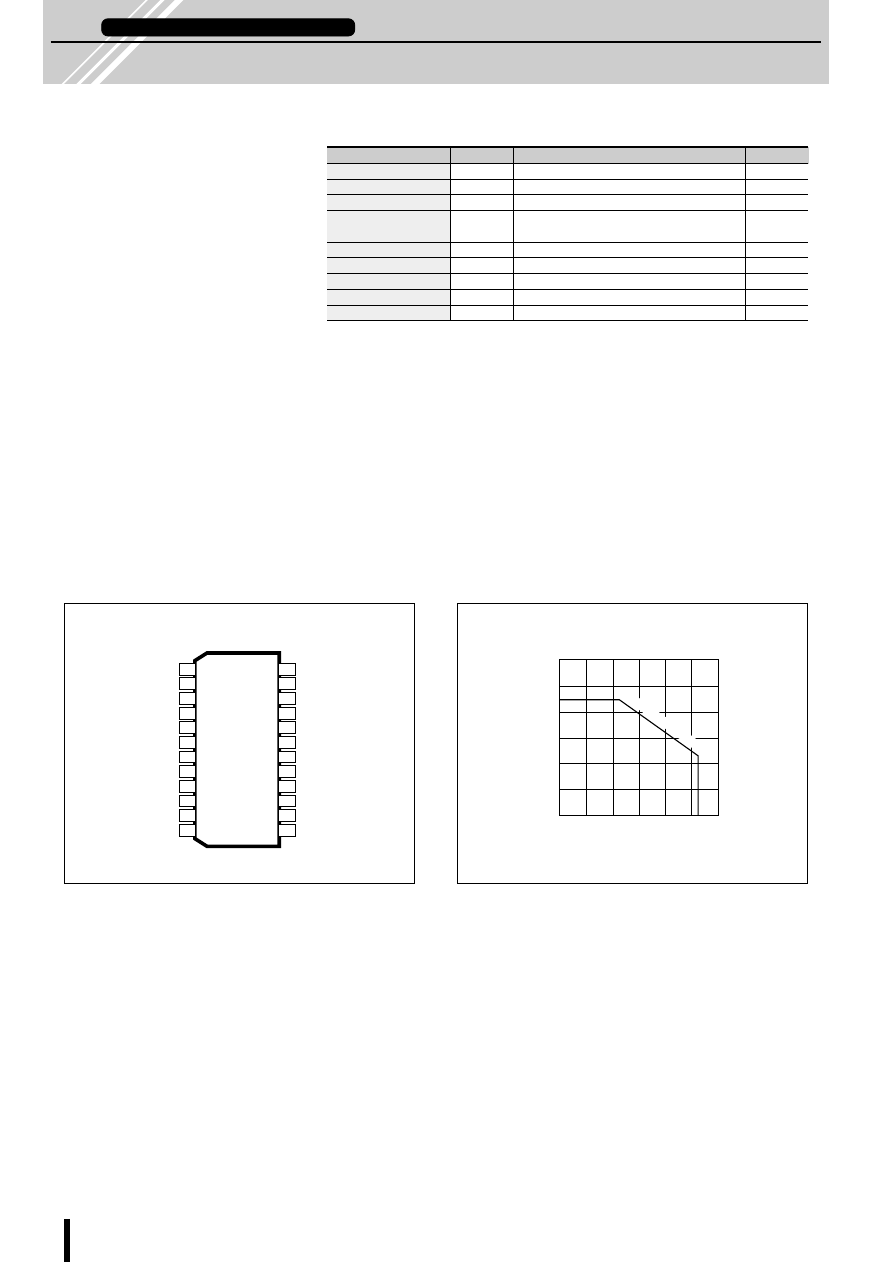

SLA7027MU/SLA7024M/SLA7026M

Parameter

Symbol

Ratings

Units

SLA7027MU

SLA7024M

SLA7026M

Motor supply voltage

V

CC

46

V

FET Drain-Source voltage

V

DSS

100

V

Control supply voltage

V

S

46

V

TTL input voltage

V

IN

7

V

Reference voltage

V

REF

2

V

Output current

I

O

1

1.5

3

A

Power dissipation

P

D1

4.5 (Without Heatsink)

W

P

D2

35 (T

C

=25

°

C)

W

Channel temperature

T

ch

+150

°

C

Storage temperature

T

stg

−

40 to +150

°

C

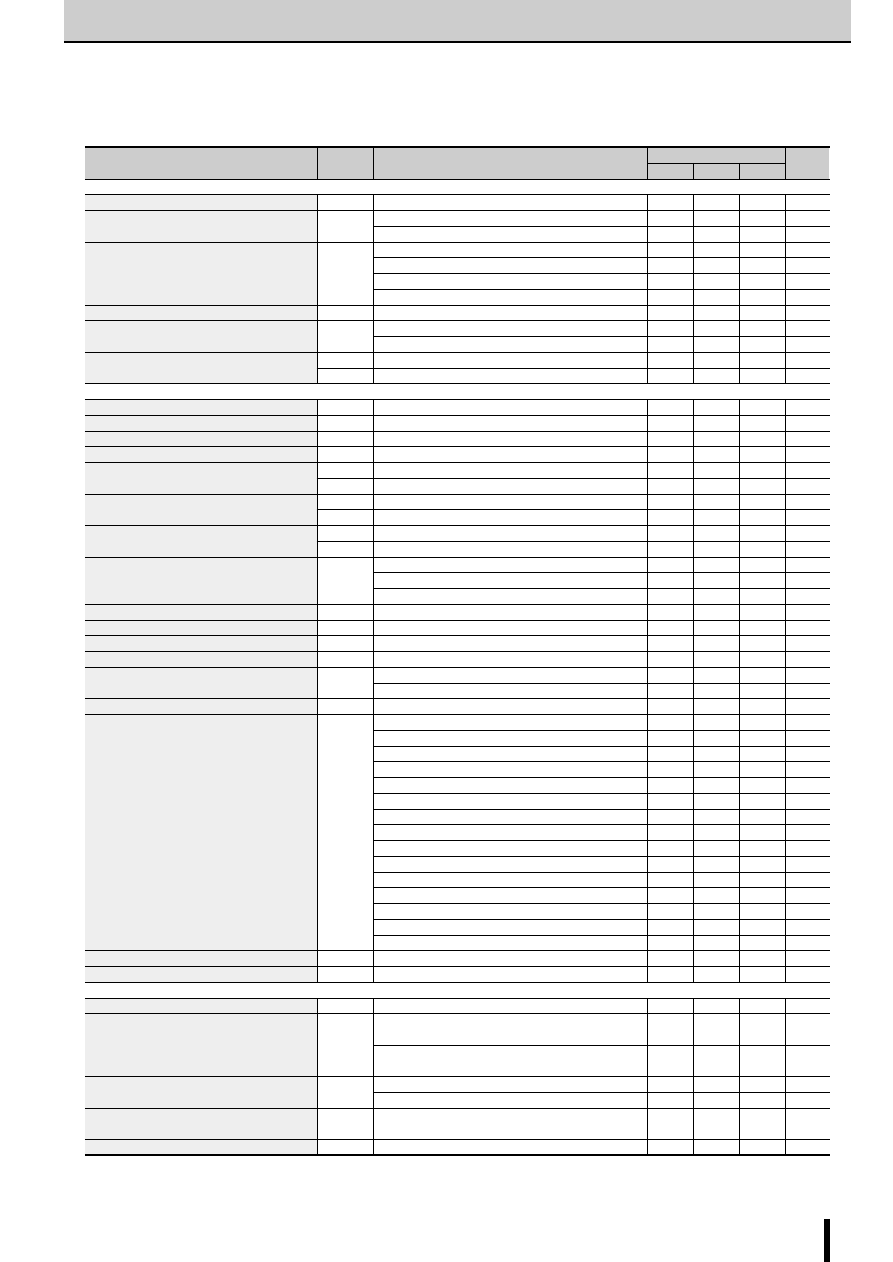

■

Electrical Characteristics

■

Absolute Maximum Ratings

2-Phase Stepper Motor Unipolar Driver ICs

SLA7027MU/SLA7024M/SLA7026M

2-Phase/1-2 Phase Excitation

(Ta=25

°

C)

Ratings

Parameter

Symbol

SLA7027MU

SLA7024M

SLA7026M

Units

min

typ

max

min

typ

max

min

typ

max

Control supply current

I

S

10

15

10

15

10

15

mA

Condition

V

S

=44V

V

S

=44V

V

S

=44V

Control supply voltage

V

S

10

24

44

10

24

44

10

24

44

V

FET Drain-Source voltage

V

DSS

100

100

100

V

Condition

V

S

=44V, I

DSS

=250

µ

A

V

S

=44V, I

DSS

=250

µ

A

V

S

=44V, I

DSS

=250

µ

A

FET ON voltage

V

DS

0.85

0.6

0.85

V

Condition

I

D

=1A, AV

S

=14V

I

D

=1A, V

S

=14V

I

D

=3A, V

S

=14V

FET drain leakage current

I

DSS

4

4

4

mA

Condition

V

DSS

=100V, V

S

=44V

V

DSS

=100V, V

S

=44V

V

DSS

=100V, V

S

=44V

FET diode forward voltage

V

SD

1.2

1.1

2.3

V

Condition

I

D

=1A

I

D

=1A

I

D

=3A

I

IH

40

40

40

µ

A

TTL input current

Condition

V

IH

=2.4V, V

S

=44V

V

IH

=2.4V, V

S

=44V

V

IH

=2.4V, V

S

=44V

I

IL

−

0.8

−

0.8

−

0.8

mA

Condition

V

IL

=0.4V, V

S

=44V

V

IL

=0.4V, V

S

=44V

V

IL

=0.4V, V

S

=44V

V

IH

2

2

2

TTL input voltage

Condition

I

D

=1A

I

D

=1A

I

D

=3A

V

(Active High)

V

IL

0.8

0.8

0.8

Condition

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

IH

2

2

2

TTL input voltage

Condition

V

DSS

=100V

V

DSS

=100V

V

DSS

=100V

V

(Active Low)

V

IL

0.8

0.8

0.8

Condition

I

D

=1A

I

D

=1A

I

D

=3A

T

r

0.5

0.5

0.5

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=1A

Switching time

T

stg

0.7

0.7

0.7

µ

s

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=1A

T

f

0.1

0.1

0.1

Condition

V

S

=24V, I

D

=0.8A

V

S

=24V, I

D

=1A

V

S

=24V, I

D

=1A

DC characteristics

AC characteristics

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

21

SLA7027MU/SLA7024M/SLA7026M

SLA7027MU/SLA7024M/SLA7026M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase/1-2 Phase Excitation)

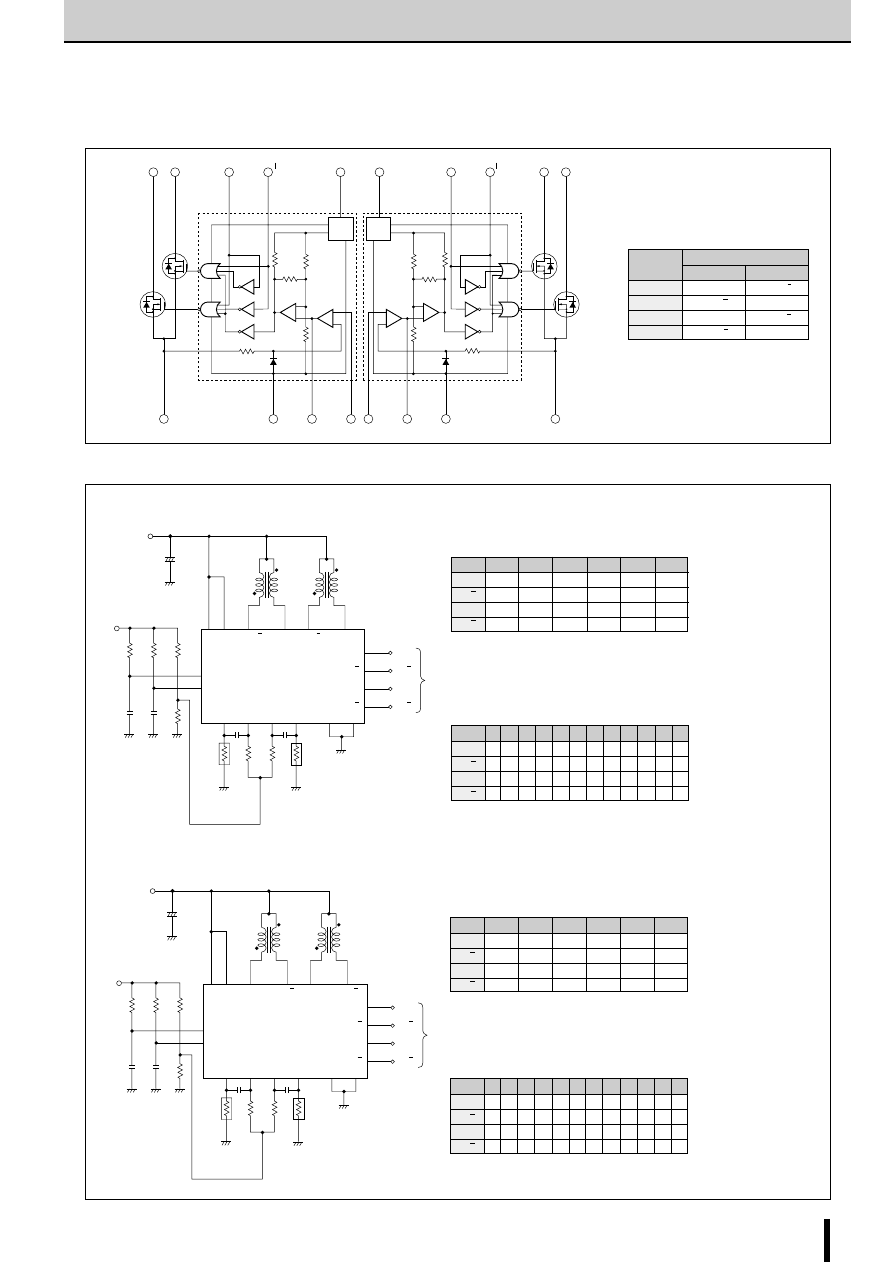

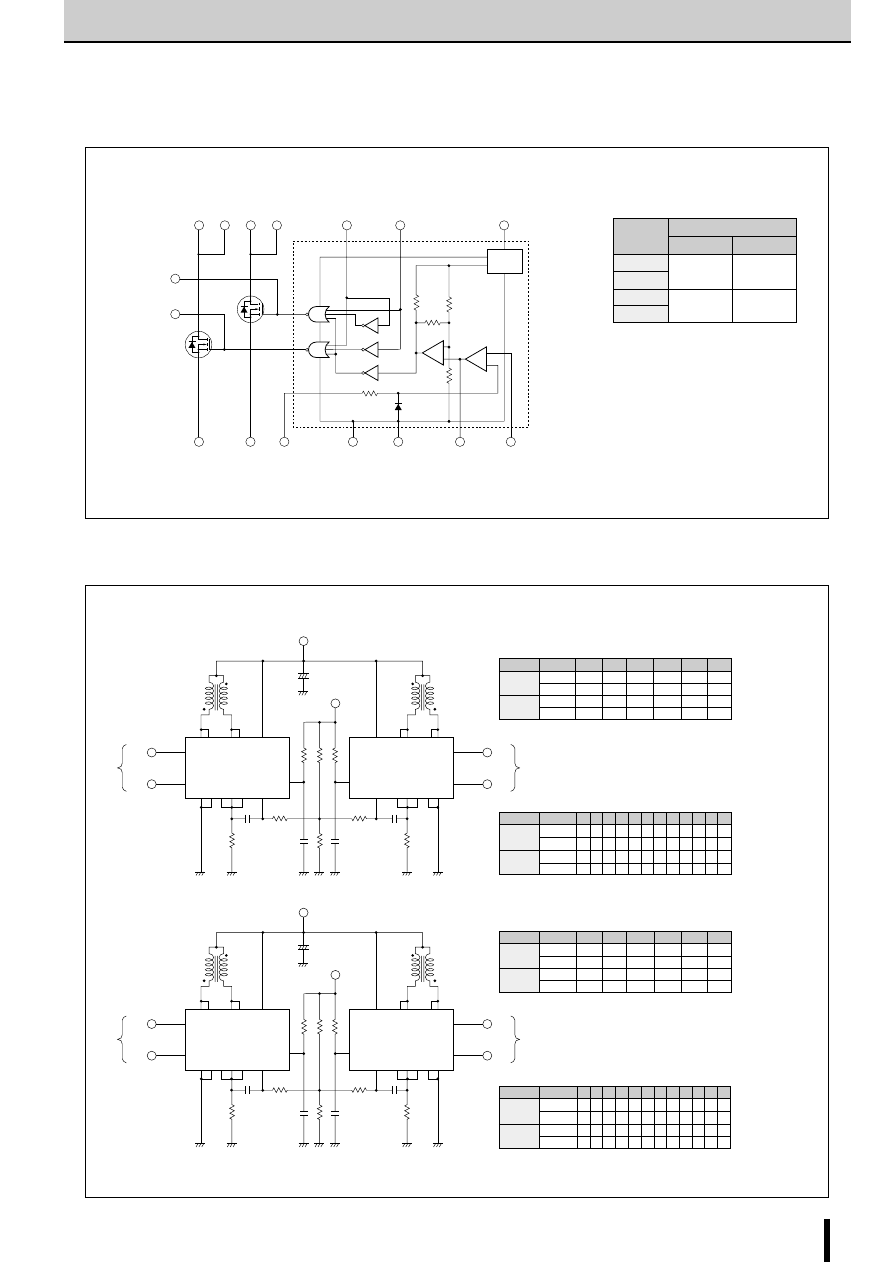

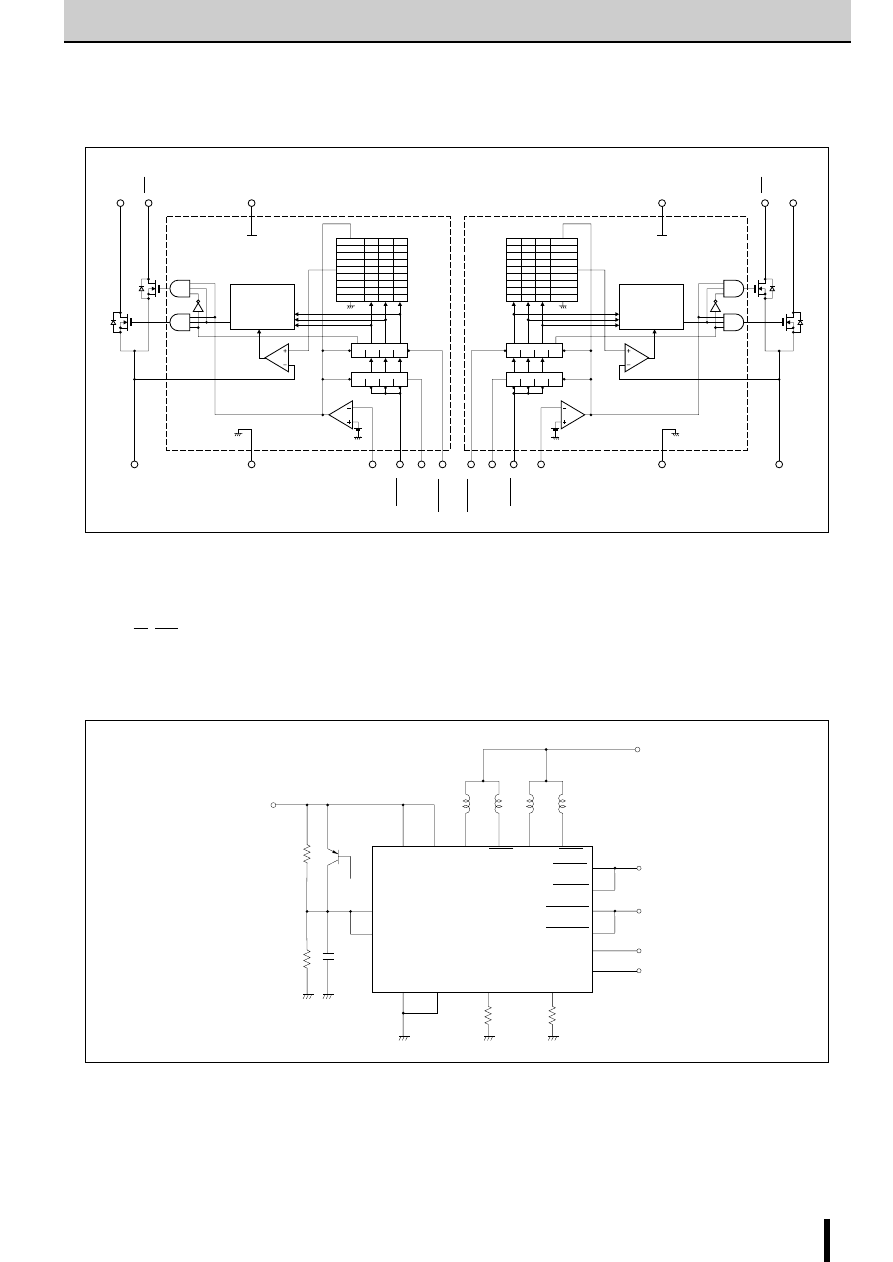

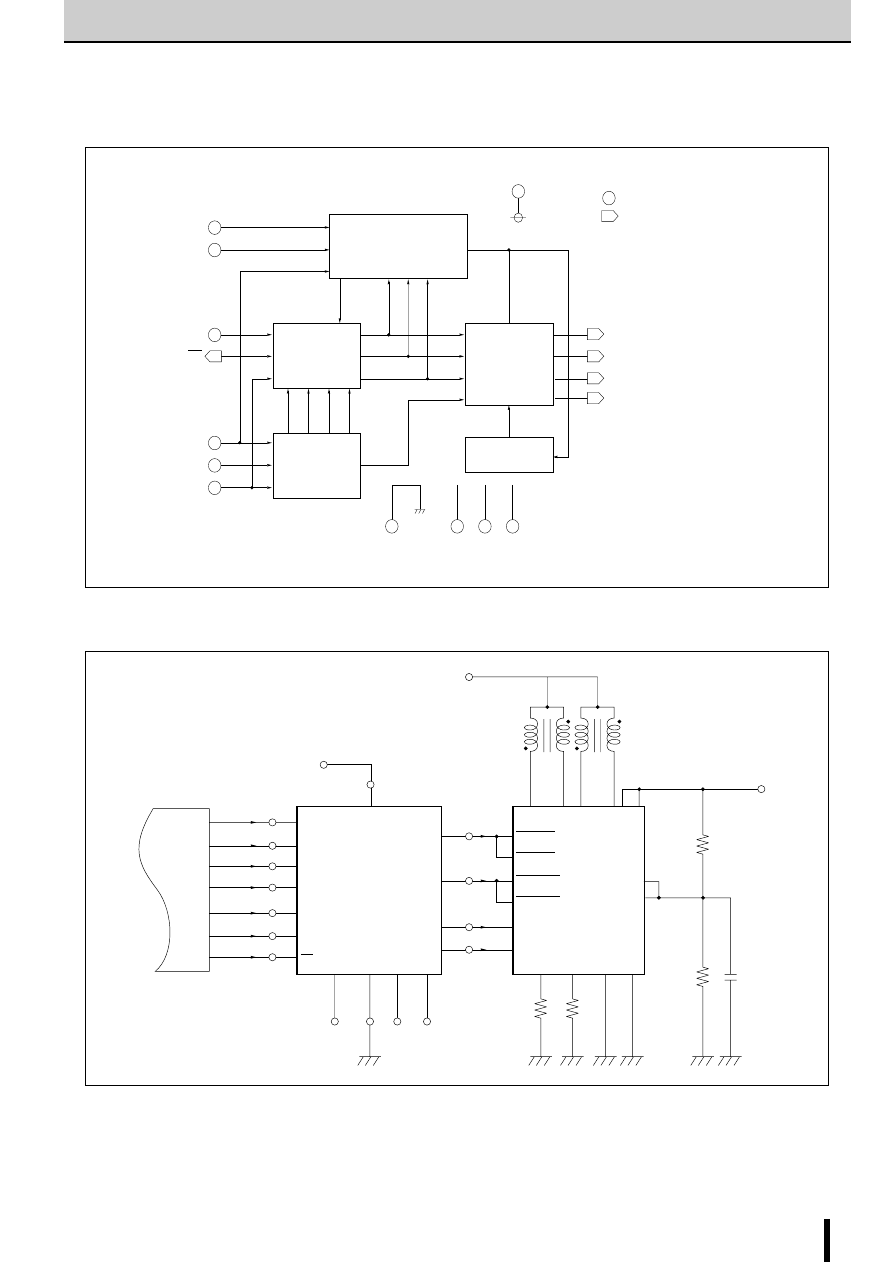

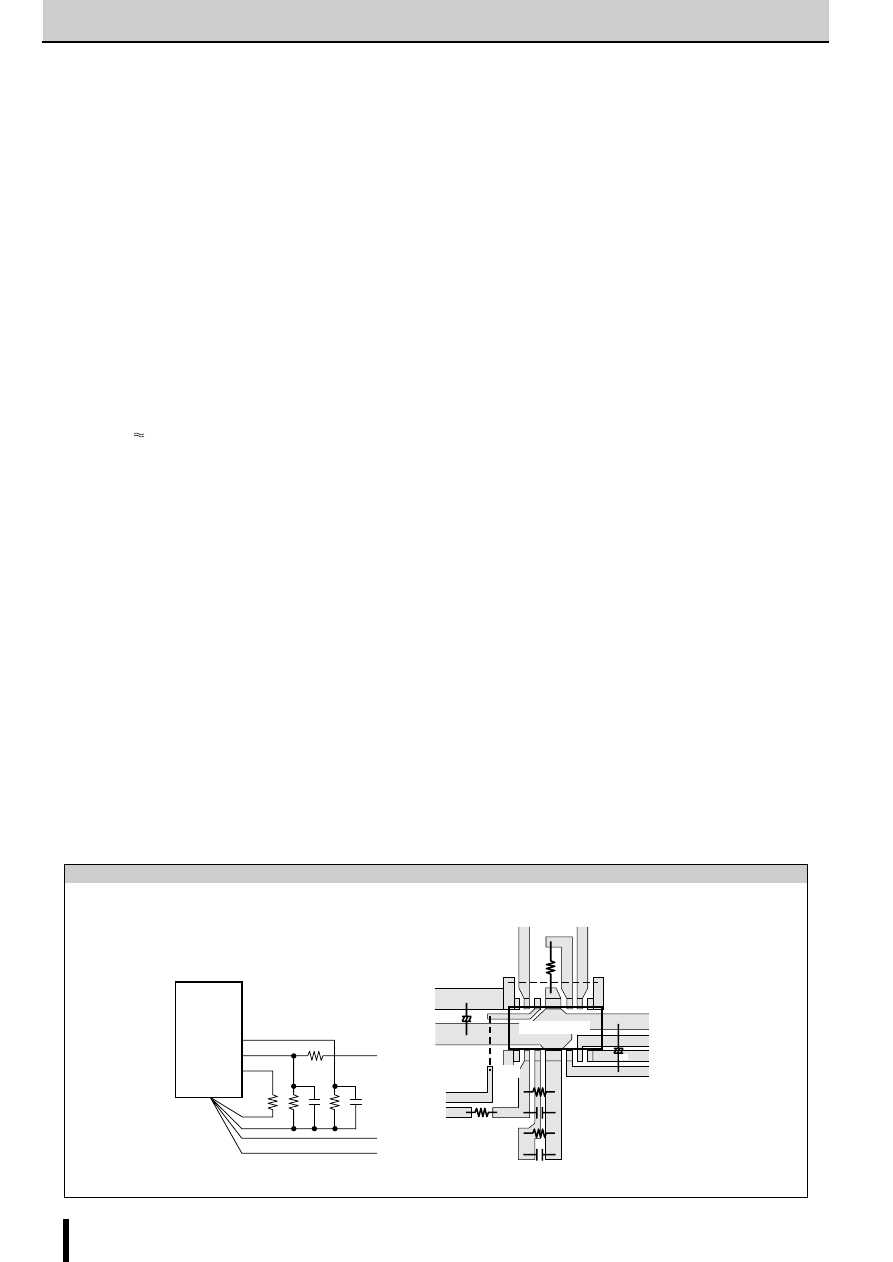

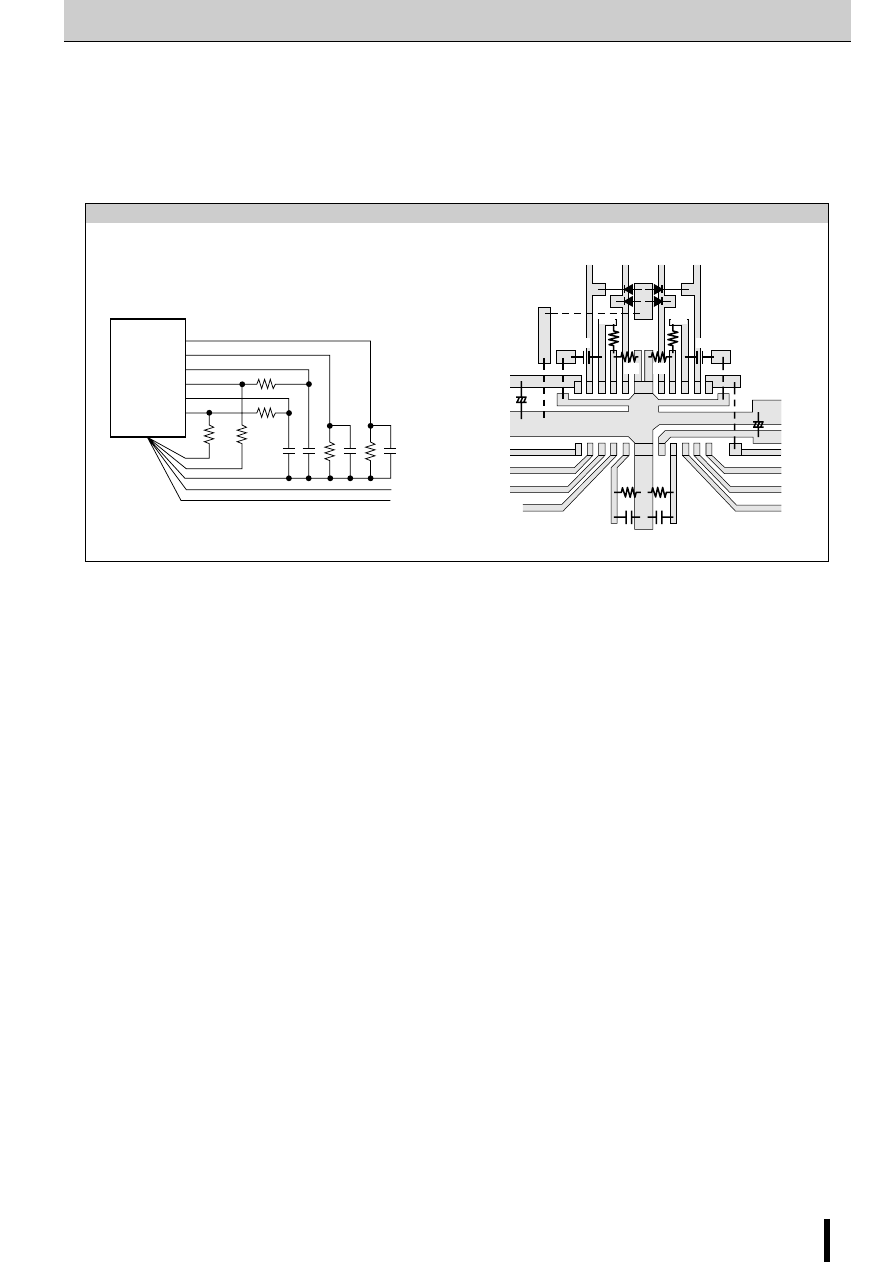

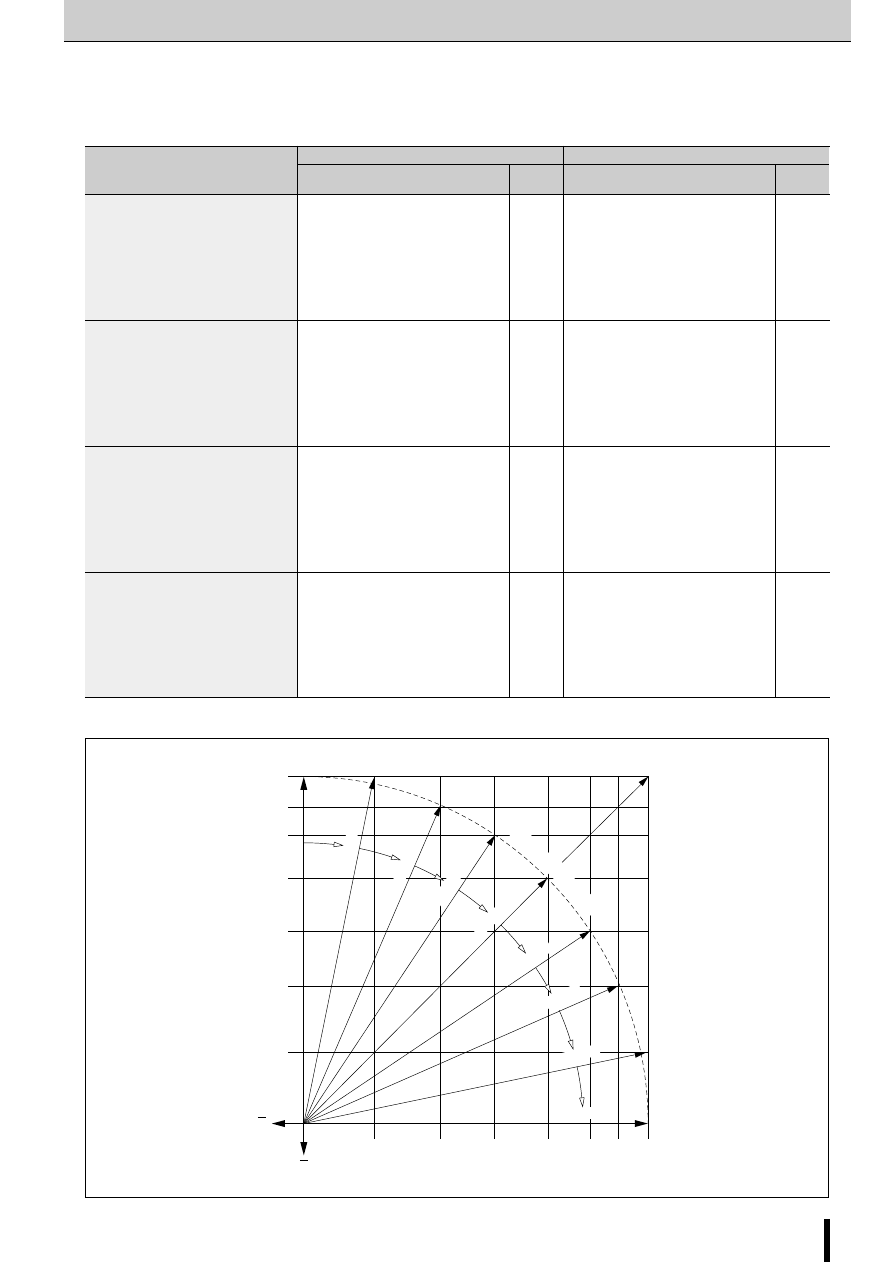

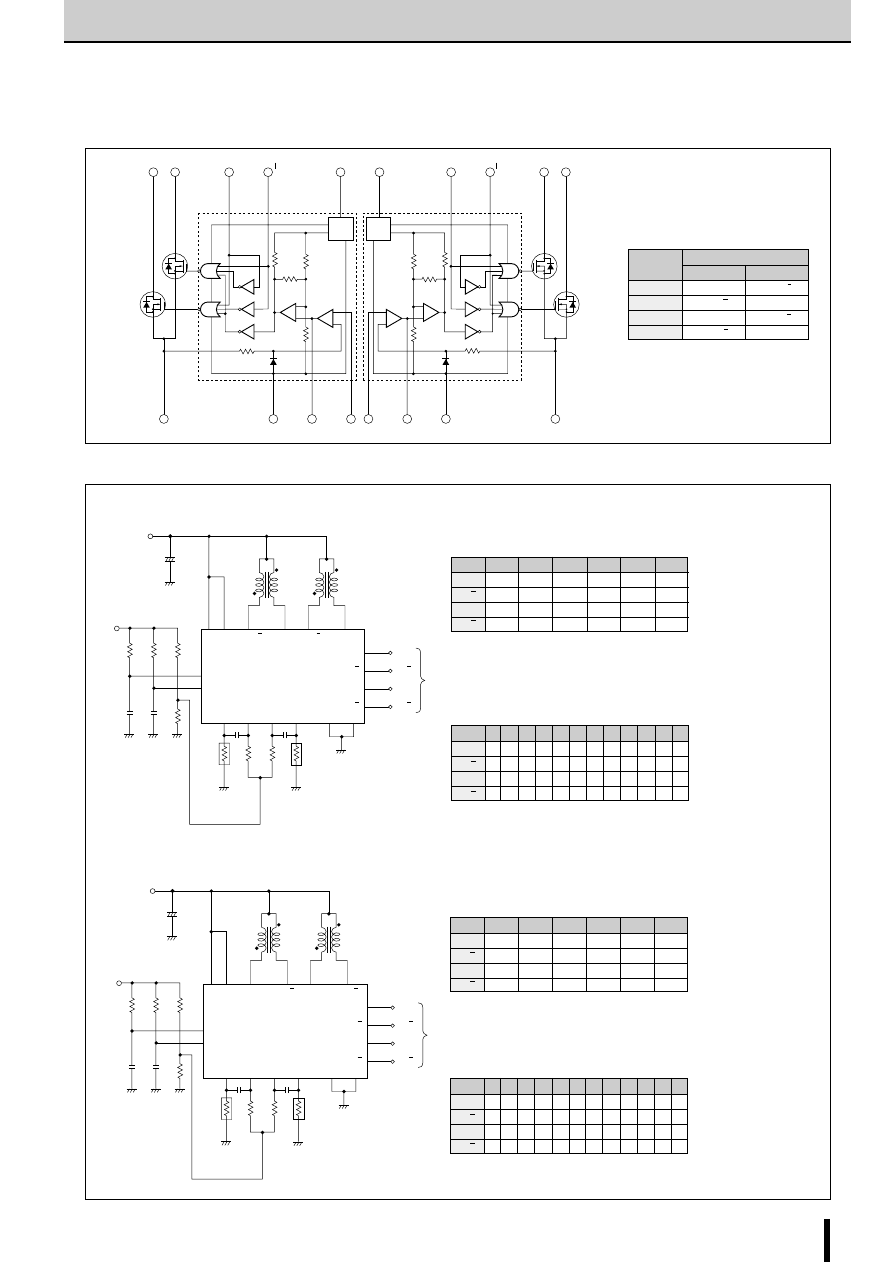

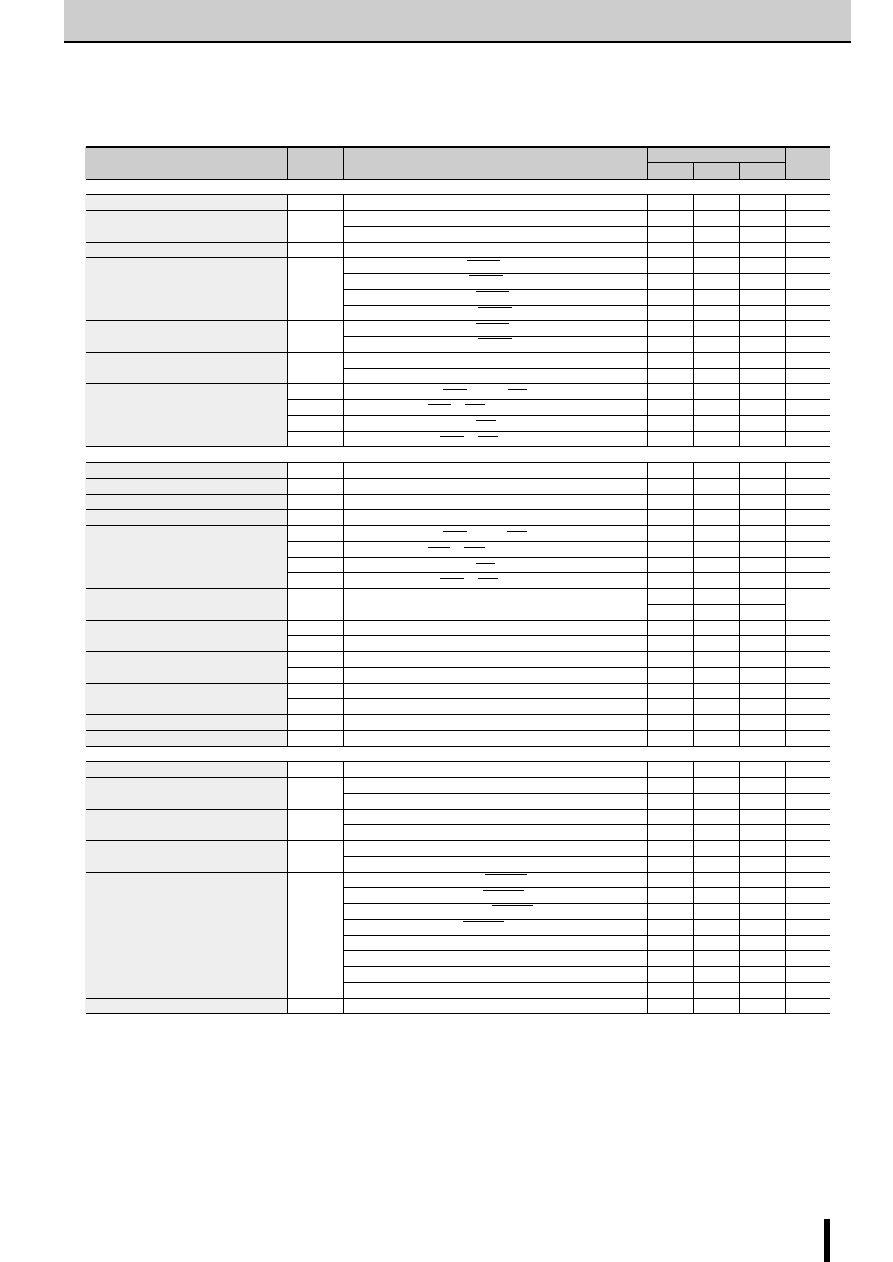

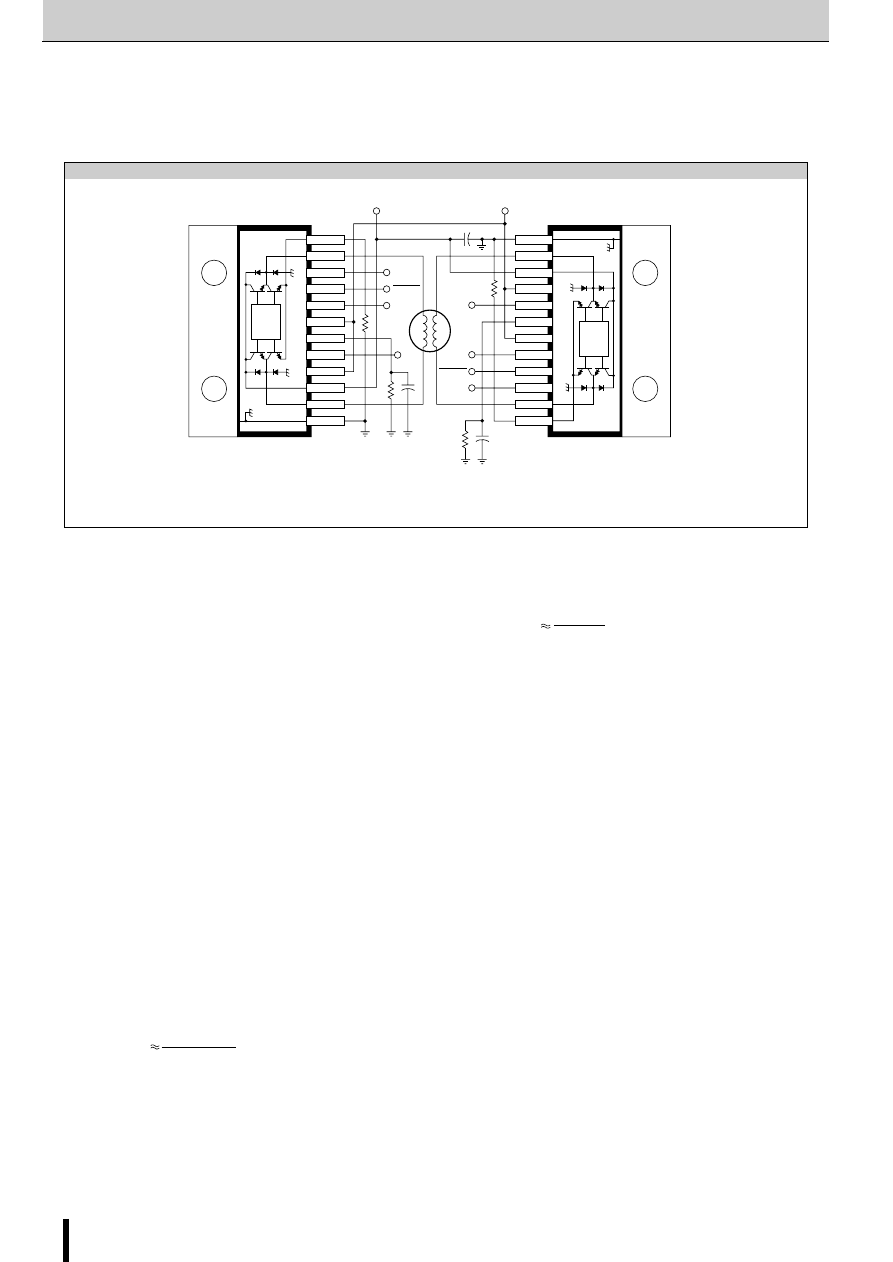

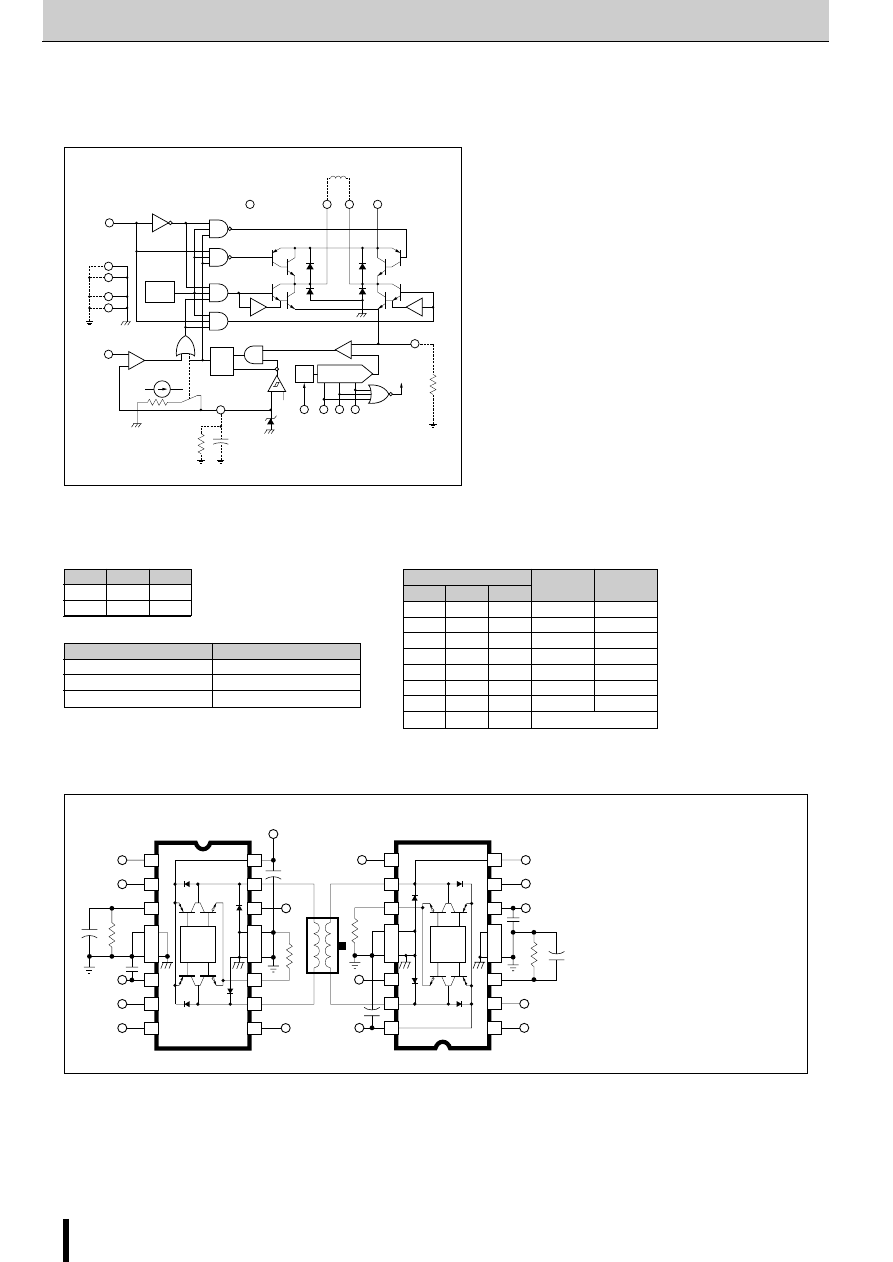

■

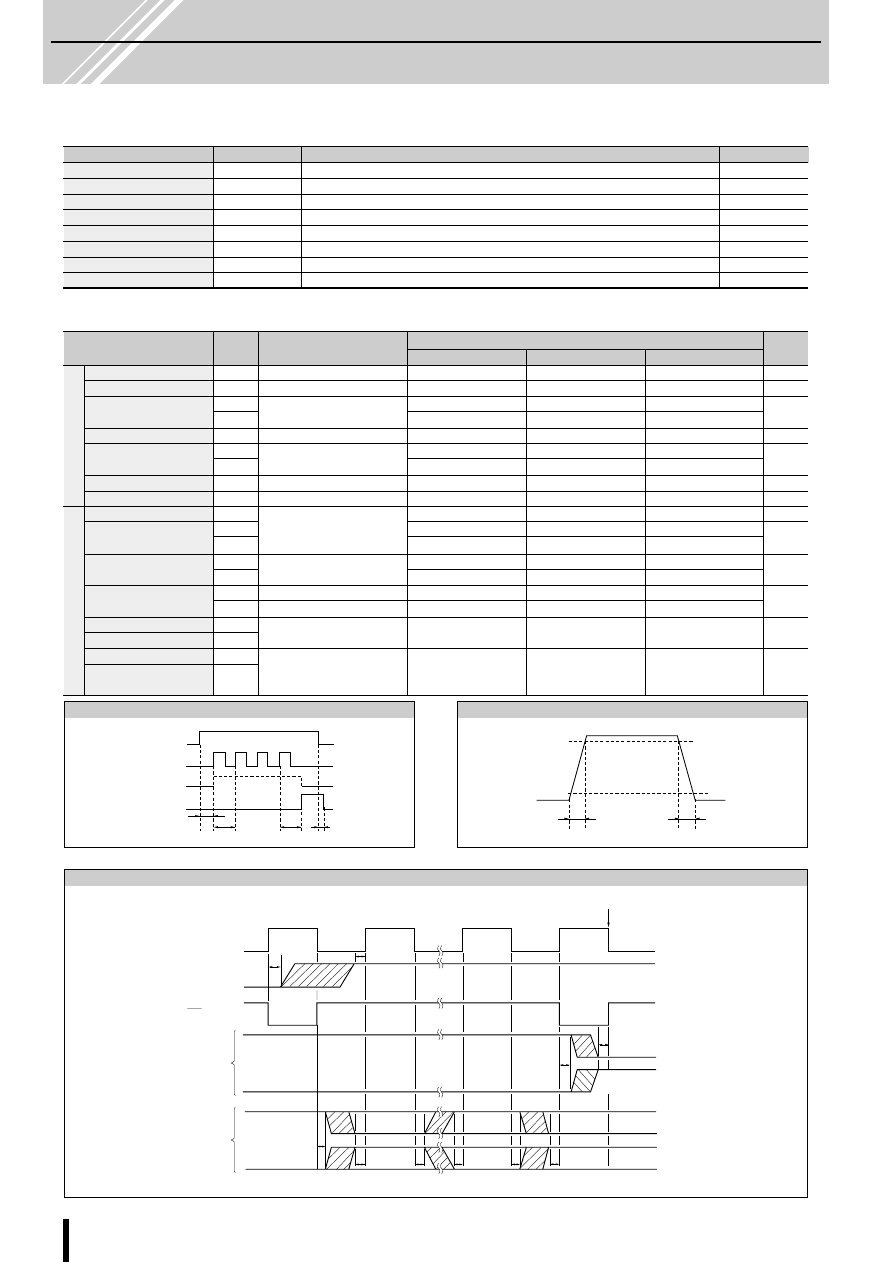

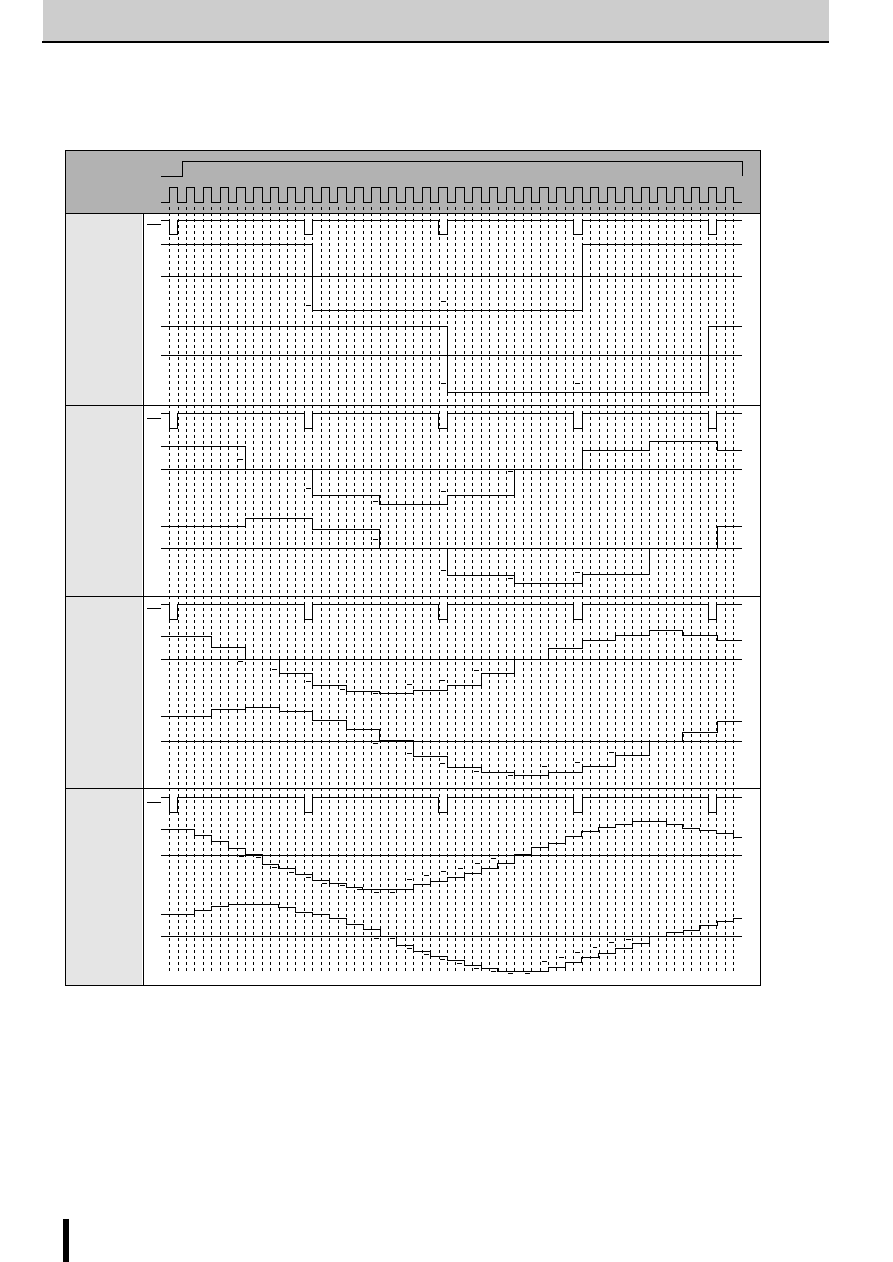

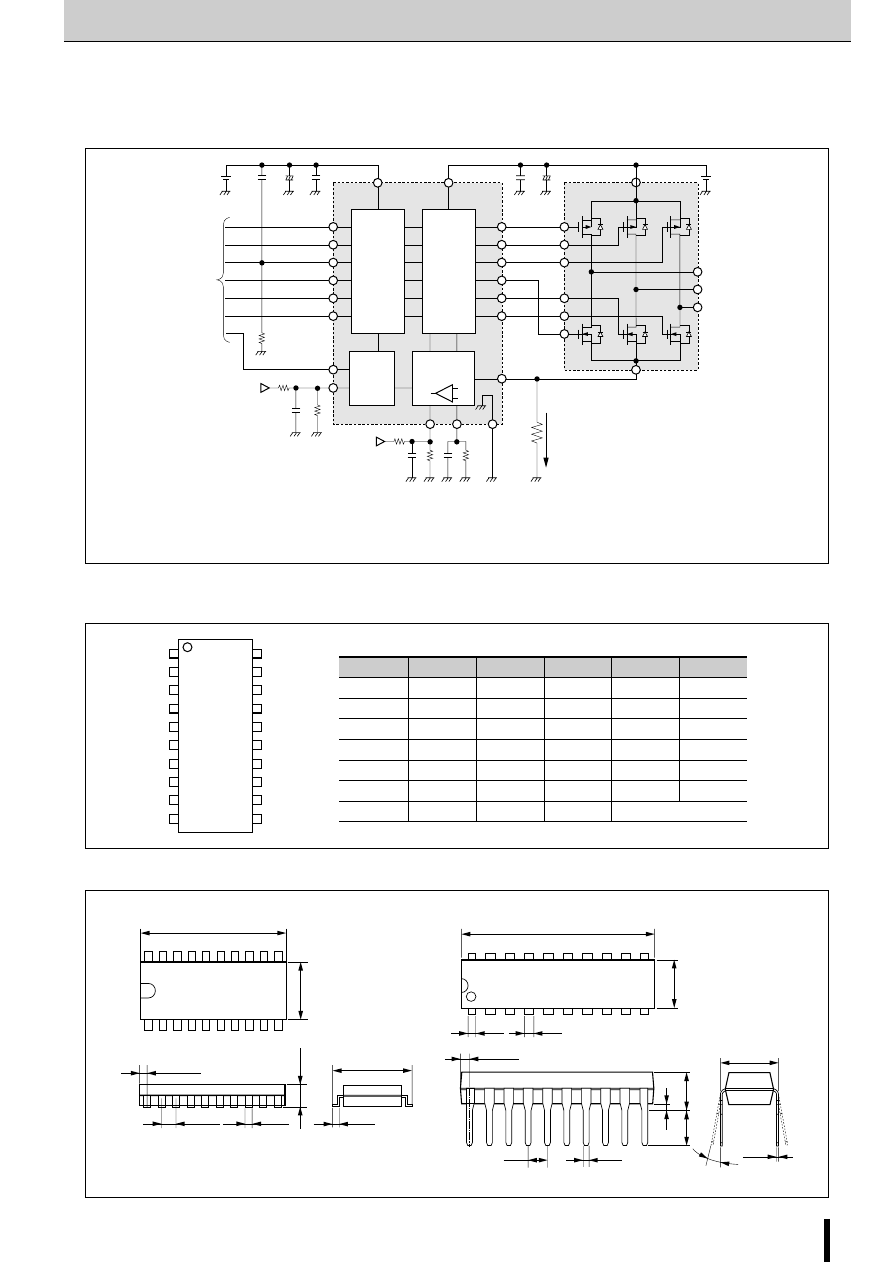

Internal Block Diagram

■

Diagram of Standard External Circuit(Recommended Circuit Constants)

1, 8, 11, 18pin

Description of pins

Excitation input

Active H

Active L

Pin 1

OUT

A

OUT

A

Pin 8

OUT

A

OUT

A

Pin 11

OUT

B

OUT

B

Pin 18

OUT

B

OUT

B

Reg

IN A

V

SA

R

SA

2

3

4

G

A

T

DA

REF

A

9

Reg

IN A

8

1

6

5

7

12

17

16

18

11

IN B

IN B

V

SB

G

B

T

DB

REF

B

R

SB

14

13

15

10

+

–

+

–

+

–

+

–

Active High

7 12

8

1

18

11

V

SA

V

SB

OUT

A

OUT

B

OUT

B

OUT

A

R

SA

REF

A

REF

B

R

SB

G

A

G

B

9

3 14

10

4

15

C

4

r

6

r

5

r

2

r

1

r

4

r

3

C

1

C

2

13

T

dA

T

dB

IN

A

IN

A

IN

B

IN

B

IN

A

IN

A

IN

B

IN

B

6

5

17

16

Active

High

+

V

CC

(46V max)

V

b

(5V)

Rs

Rs

C

3

SLA7024M

7026M

7027MU

2

Active Low

7 12

8

1

18

11

V

SA

V

SB

OUT

A

OUT

B

OUT

B

OUT

A

R

SA

REF

A

REF

B

R

SB

G

A

G

B

9

3 14

10

4

15

C

4

r

6

r

5

r

2

r

1

r

4

r

3

C

1

C

2

13

T

dA

T

dB

IN

A

IN

A

IN

B

IN

B

IN

A

IN

A

IN

B

IN

B

6

5

17

16

Active

Low

+

V

CC

(46V max)

V

b

(5V)

Rs

Rs

C

3

SLA7024M

7026M

7027MU

2

r

1

: 510

Ω

r

2

: 100

Ω

(VR)

r

3

: 47k

Ω

r

4

: 47k

Ω

r

5

: 2.4k

Ω

r

6

: 2.4k

Ω

C

1

: 470pF

C

2

: 470pF

C

3

: 2200pF

C

4

: 2200pF

R

s

: 1

Ω

typ(7024M)

0.68

Ω

typ(7026M)

1.8

Ω

typ(7027MU)

1-2 phase excitation

clock

0

1

2

3

4

5

6

7

0

1

2

3

IN

A

L

L

H H H H H

L

L

L

H H

IN

A

H H H

L

L

L

H H H H H L

IN

B

H

L

L

L

H H H H H

L

L

L

IN

B

H H H H H L

L

L

H H H H

r

1

: 510

Ω

r

2

: 100

Ω

(VR)

r

3

: 47k

Ω

r

4

: 47k

Ω

r

5

: 2.4k

Ω

r

6

: 2.4k

Ω

C

1

: 470pF

C

2

: 470pF

C

3

: 2200pF

C

4

: 2200pF

R

s

: 1

Ω

typ(7024M)

0.68

Ω

typ(7026M)

1.8

Ω

typ(7027MU)

(1 to 2W)

1-2 phase excitation

clock

0

1

2

3

4

5

6

7

0

1

2

3

IN

A

H H L

L

L

L

L

H H H

L

L

IN

A

L

L

L

H H H

L

L

L

L

L

H

IN

B

L

H H H

L

L

L

L

L

H H H

IN

B

L

L

L

L

L

H H H

L

L

L

L

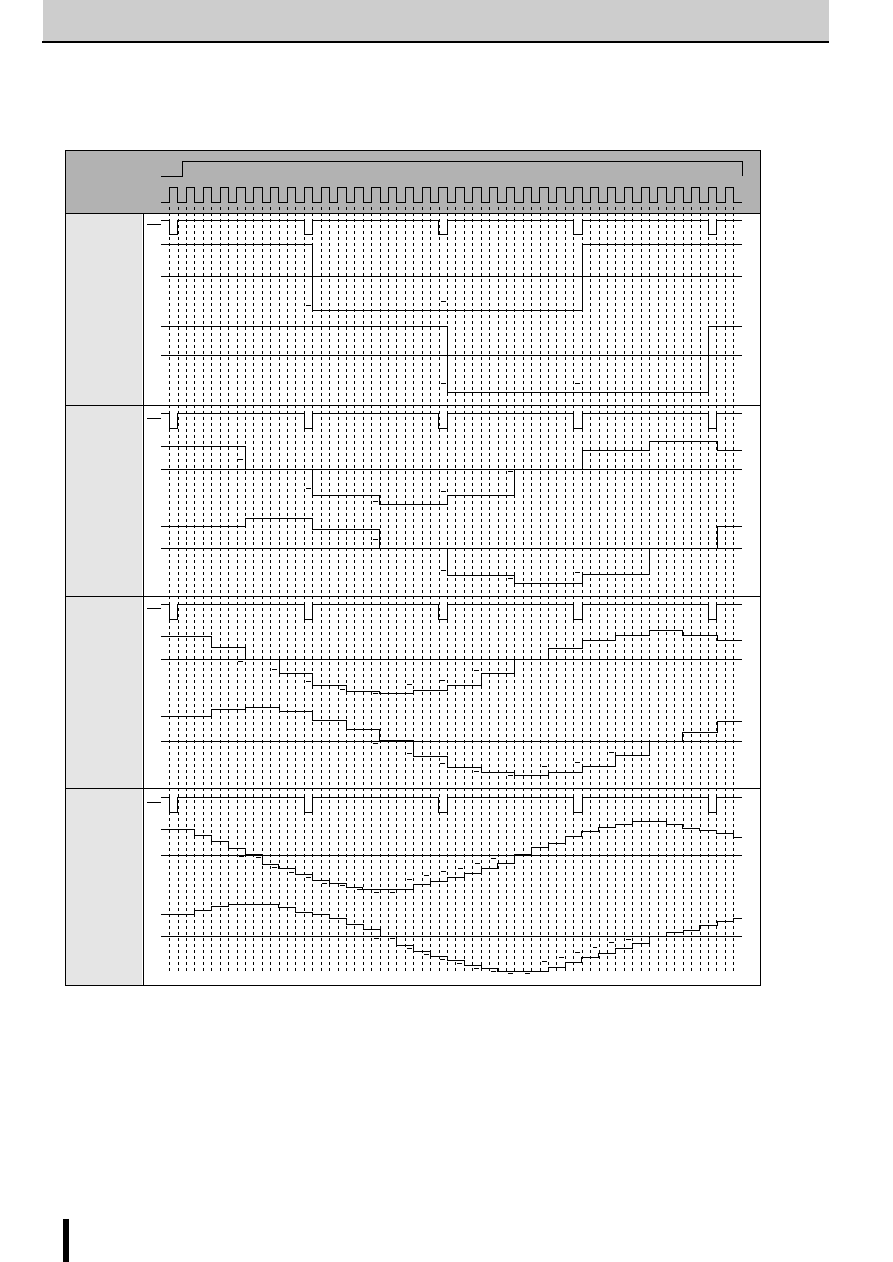

Excitation signal time chart

2-phase excitation

clock

0

1

2

3

0

1

IN

A

H

L

L

H

H

L

IN

A

L

H

H

L

L

H

IN

B

H

H

L

L

H

H

IN

B

L

L

H

H

L

L

Excitation signal time chart

2-phase excitation

clock

0

1

2

3

0

1

IN

A

L

H

H

L

L

H

IN

A

H

L

L

H

H

L

IN

B

L

L

H

H

L

L

IN

B

H

H

L

L

H

H

(1 to 2W)

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

22

SLA7027MU/SLA7024M/SLA7026M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase/1-2 Phase Excitation)

SLA7027MU/SLA7024M/SLA7026M

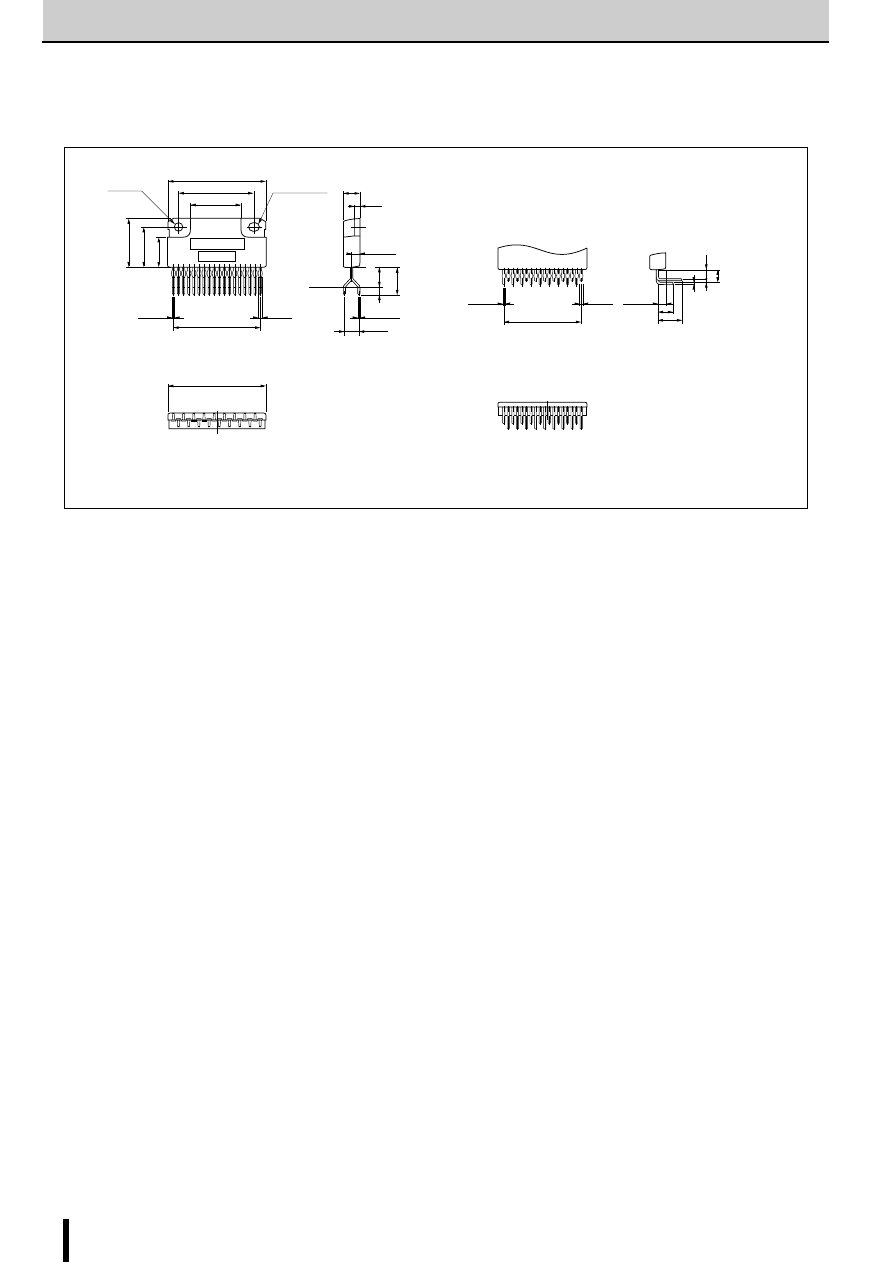

■

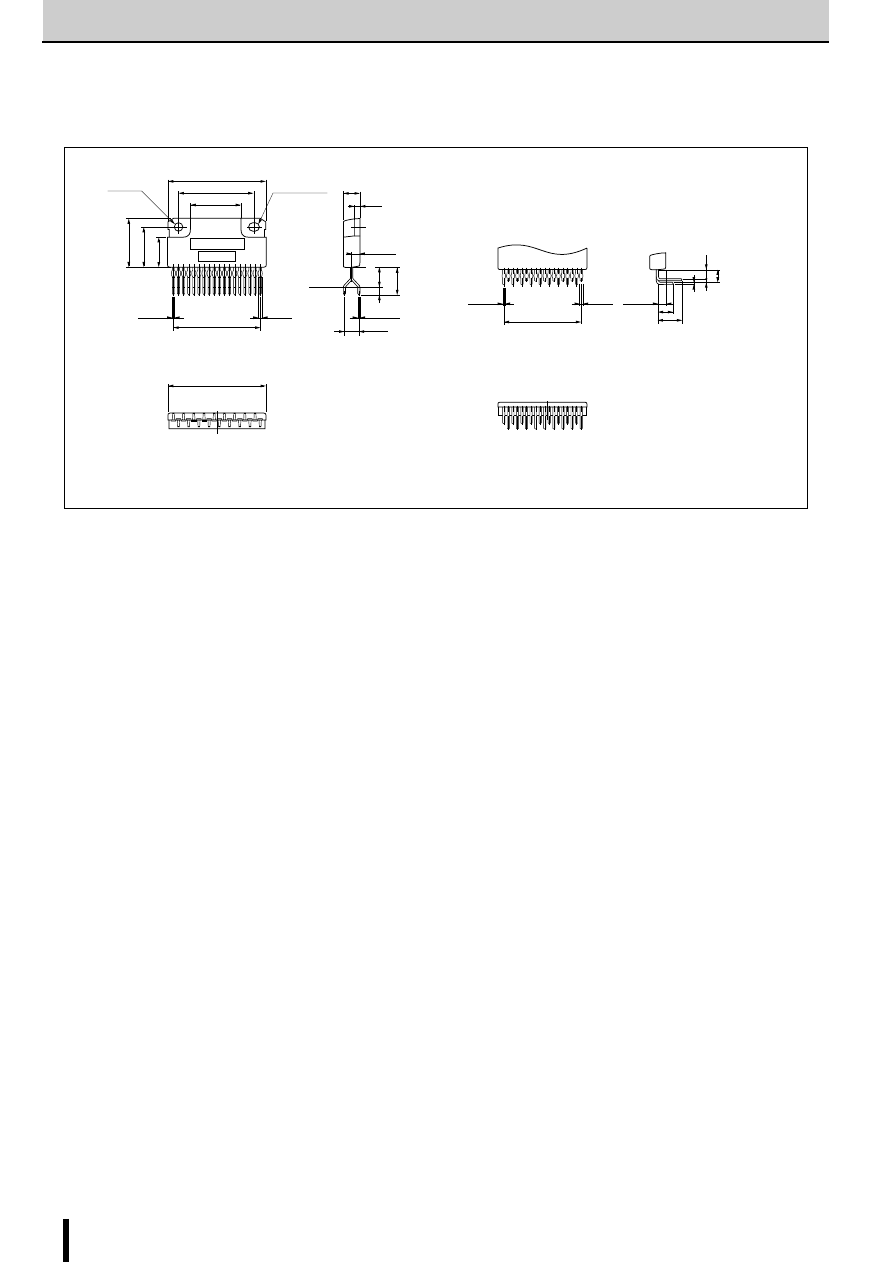

External Dimensions

(Unit: mm)

31

±

0.2

24.4

±

0.2

16.4

±

0.2

3.2

±

0.15

φ

16

±

0.2

13

±

0.2

9.9

±

0.2

Part No.

Lot No.

3.2

±

0.15

×

3.8

φ

4.8

±

0.2

1.7

±

0.1

2.45

±

0.2

R-End

6.7

±

0.5

9.7

+1 –

0.5

(3)

0.55

+0.2

–0.1

4

±

0.7

1

+0.2

–0.1

17

×

P1.68

±

0.4

=28.56

±

1

0.65

+0.2

–0.1

31.3

±

0.2

Forming No. No.871

Forming No. No.872

1 2 3 · · · · · · · 18

123 · · · · · · · 18

17

×

P1.68

±

0.4

=28.56

±

1

0.65

+0.2

–0.1

1

+0.2

–0.1

3

±

0.6

0.55

+0.2 –

0.1

2.2

±

0.6

6

±

0.6

7.5

±

0.6

4.6

±

0.6

1.6

±

0.6

3.

4.

5.

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

23

SLA7027MU/SLA7024M/SLA7026M

SLA7027MU/SLA7024M/SLA7026M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase/1-2 Phase Excitation)

R

S

C

3

r

2

r

1

r

6

r

5

V

b

(5

V

)

9,(10)

3,(14)

C

3

r

2

r

1

r

6

r

5

V

b

(5

V

)

9,(10)

3,(14)

r

X

T

r

Power down

signal

■

Determining the Output Current

Fig. 1 shows the waveform of the output current (motor coil cur-

rent). The method of determining the peak value of the output

current (I

O

) based on this waveform is shown below.

(Parameters for determining the output current I

O

)

V

b

: Reference supply voltage

r

1

,r

2

: Voltage-divider resistors for the reference supply voltage

R

S

: Current sense resistor

(1) Normal rotation mode

I

O

is determined as follows when current flows at the maximum

level during motor rotation. (See Fig.2.)

(2) Power down mode

The circuit in Fig.3 (rx and Tr) is added in order to decrease the

coil current. I

O

is then determined as follows.

Equation (2) can be modified to obtain equation to determine rx.

Fig. 4 and 5 show the graphs of equations (1) and (2) respec-

tively.

(NOTE)

Ringing noise is produced in the current sense resistor R

S

when

the MOSFET is switched ON and OFF by chopping. This noise

is also generated in feedback signals from R

S

which may there-

fore cause the comparator to malfunction. To prevent chopping

malfunctions, r

5

(r

6

) and C

3

(C

4

) are added to act as a noise filter.

Fig. 2 Normal mode

0

Phase A

Phase A

I

O

Fig. 1 Waveform of coil current (Phase A excitation ON)

Fig. 3 Power down mode

4

3

2

1

0

0

1

2

3

4

Current sense resistor R

S

(

Ω

)

Output current I

O

(A)

I

O

=

r

1

+r

2

R

S

r

1

=510

Ω

r

2

=100

Ω

r

x

=

∞

V

b

=5V

r

2

·

V

b

Fig. 4 Output current I

O

vs. Current sense resistor R

S

Fig. 5 Output current I

OPD

vs. Variable current sense resistor rx

2.0

1.5

1.0

0.5

00

200

400

600

800

Variable current sense resistor r

X

(

Ω

)

Output current I

OPD

(A)

1000

1200

R

S

=0.5

Ω

R

S

=0.8

Ω

R

S

=1

Ω

I

OPD

=

1+ R

S

r

1

=510

Ω

r

2

=100

Ω

V

b

=5V

1

·

V

b

r

1

(r

2+

r

X

)

r

2 ·

r

X

Application Notes

r

X

=

1

V

b

R

s

•

I

OPD

1

r

1

−

1

−

1

r

2

However, when the values of these constants are increased,

the response from R

S

to the comparator becomes slow. Hence

the value of the output current I

O

is somewhat higher than the

calculated value.

................................................................ (1)

I

O

≅

•

r

2

r

1

+r

2

V

b

R

S

......................................................... (2)

I

OPD

≅

•

1

r

1

(r

2

+r

X

)

r

2

•

r

X

V

b

R

S

1+

ac/Allegro/Allegro_Motor_Drive_ICs-html.html

24

SLA7027MU/SLA7024M/SLA7026M

2-Phase Stepper Motor Unipolar Driver ICs (2-Phase/1-2 Phase Excitation)

SLA7027MU/SLA7024M/SLA7026M

Fig. 6 Chopper frequency vs. Motor coil resistance

60

50

40

30

20

10

0

0

2

4

6

8

10 12

14

16

15

20

25

30

35

40

Motor coil resistance R

m

(

Ω

)

ON time T

ON

( s)

V

CC

=24V

V

CC

=36V

Chopping frequency f (kHz)

T

OFF

=12 s

R

S

=1

Ω

L

m

=1~3ms

R

m

= =