M

OT

OR

S

Stepper Motors

release November 2012

YOUR CHOICE OUR COMMITMENT

TM

PRODUCT

CATALOG

M

OT

OR

S

Stepper Motors

release November 2012

YOUR CHOICE OUR COMMITMENT

TM

PRODUCT

CATALOG

TABLE OF CONTENTS

3 | Stepper Motor Overview

Size 16 Model HY 200 1607 ....................................................................................4

Size 17 Model HY 200 1713.....................................................................................5

Size 17 Model HY 200 171 .......................................................................................6

Size 17 Model HY 200 1718 ....................................................................................7

Size 17 High Performance Model HS 200 1714 ...........................................8

Size 17 High Performance Model HS 200 1716 ...........................................9

Size 17 High Performance Model HS 200 1720 .........................................10

Size 23 Model HY 200 2215 ..................................................................................11

Size 23 Model HY 200 2220 .................................................................................12

Size 23 Model HY 200 2226 .................................................................................13

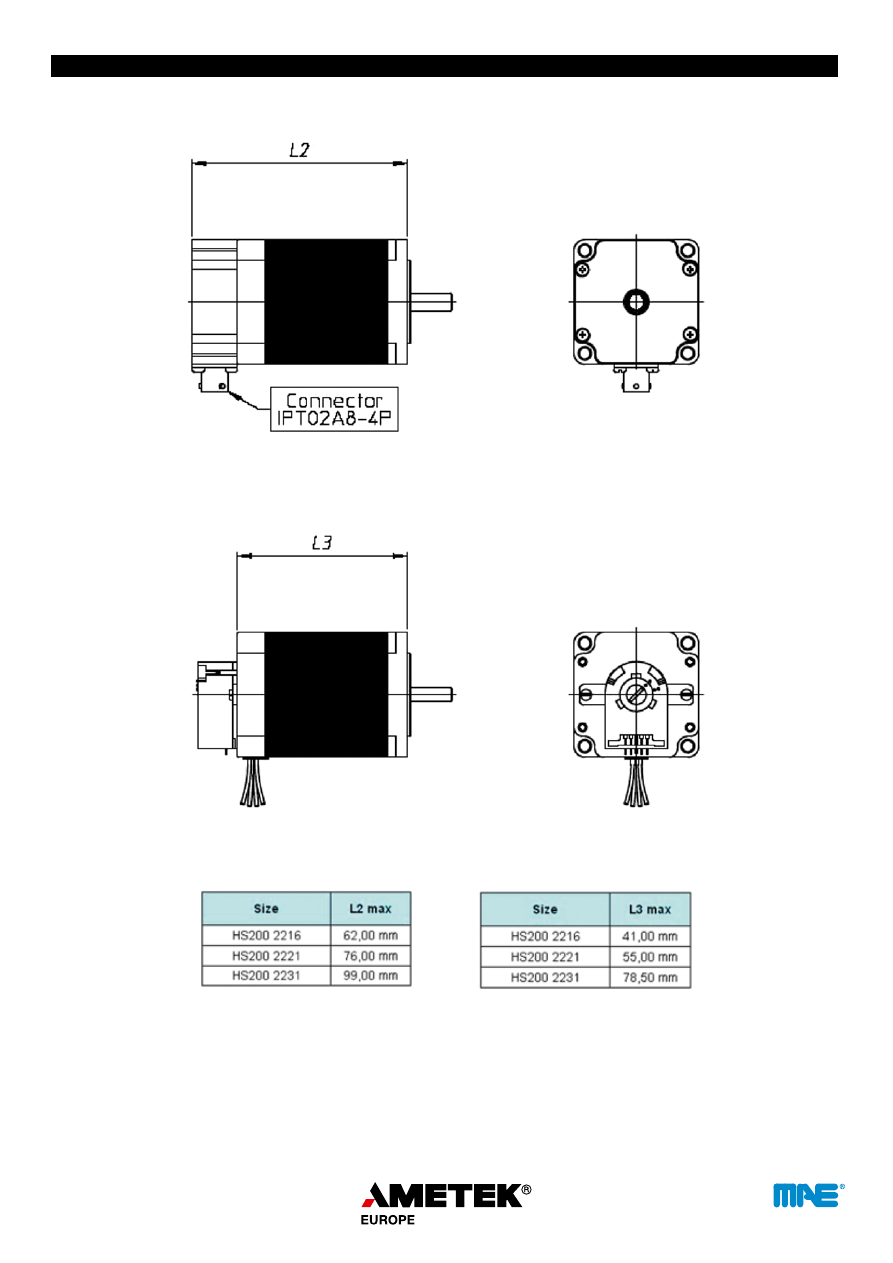

Size 23 High Performance Model HS 200 2216 ........................................14

Size 23 High Performance Model HS 200 2221 ........................................15

Size 23 High Performance Model HS 200 2231 ........................................16

Size 23 High Performance Model HT 200 2220 ........................................17

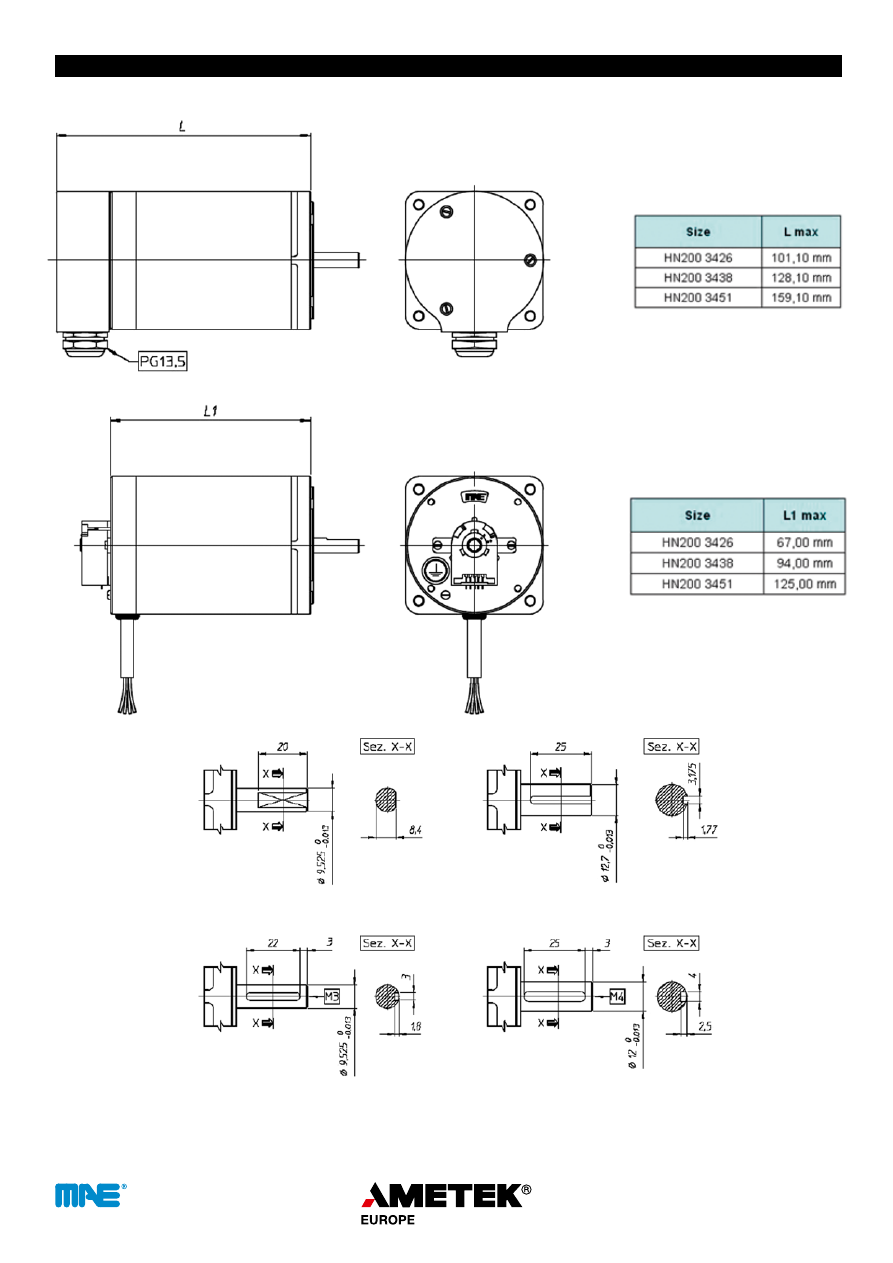

Size 34 Model HN 200 3426 ................................................................................18

Size 34 Model HN 200 3438 ................................................................................19

Size 34 Model HN 200 3451 ................................................................................ 20

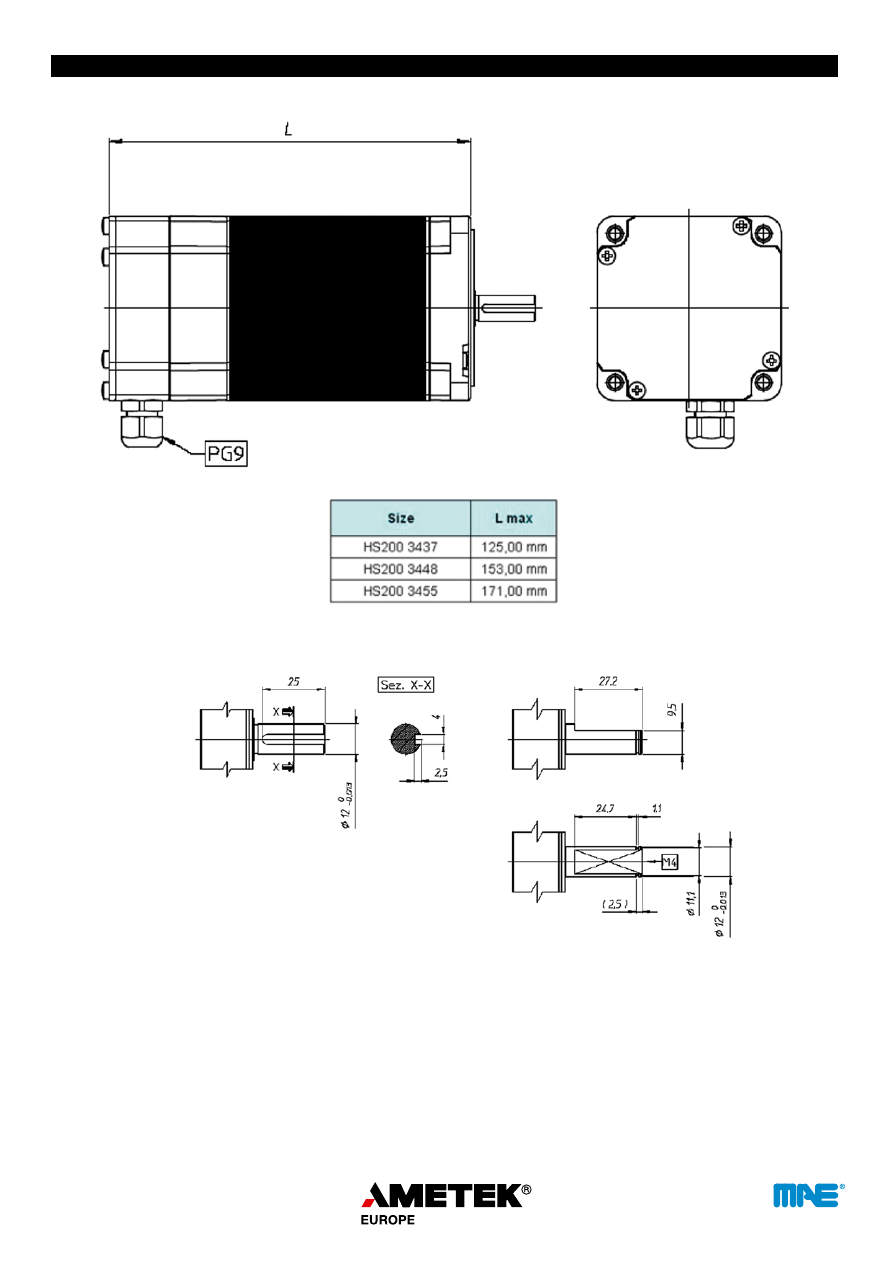

Size 34 High Performance Model HS 200 3437 ........................................21

Size 34 High Performance Model HS 200 3448....................................... 22

Size 34 High Performance Model HS 200 3455 ....................................... 23

Size 34 High Performance Model HS 200 3462 ....................................... 24

Size 34 Synchronous SY 3424 ............................................................................ 25

Size 34 Synchronous SY 3437 ............................................................................ 26

Size 34 Synchronous SY 3450 .............................................................................27

Size 42 Model HY 200 4270 ................................................................................ 28

Size 42 Model HY 200 4288 ................................................................................ 29

30 | Customizations / Options Size 23

31 | Customizations / Options Size 23

32 | Customizations / Options Size 34

33 | Customizations / Options Size 34

34 | Connection Diagrams

34 | Step Sequence

C A T A L O G P A R T N U M B E R D E S C R I P T I O N

H S 2 0 0

1 7 1 3

0 1 0 0

A X 0 4

Motor Type

HY = Hybrid Stepper, Low Rotor Inertia

HN = Hybrid Stepper, Neutral Inertia/Torque

HS = Hybrid Stepper, Superior Torque

Configuration

A = Single Shaft

B = Double Shaft

Custom Designation

X = Catalog Standard

Other = Special

Resolution

200 = 200 Steps/Rev

Winding Phase Current

0100 = 1.00 A/phase

Number of

Leadwires

04 = 4

06 = 6

08 = 8

Length

13 = 1.3”

NEMA Frame Size

17 = NEMA 17 (1.7”)

22 = NEMA 22 (2.3”)

34 = NEMA 34 (3.4”)

42 = NEMA 42 (4.2”)

Stepper Motors

offers a wide range of MAE brand stepper

motor solutions. The HY series hybrid

stepper motors feature low rotor inertia

for maximum possible acceleration. The

HN series hybrid stepper motors offer a

calculated balance between low rotor

inertia and high torque. The HS series

hybrid stepper motors are optimized

for superior torque characteristics.

Additionally, both the HN an HS series

feature low detent torque to holding

torque ratios to provide smooth operation

as well as the fine positioning capability

required for microstep operation.

Motors may be customized with value

added features including but not limited

to: gearboxes, encoders, shaft details,

leadwire-connector assemblies, and

more.

All specifications shown are typical at

20 °C unless otherwise noted.

Shaft extensions

All motors can be supplied with single or

double ended shaft.

Rotation

The motor rotation can run clockwise or

counterclockwise, depending on the

commutation.

Operating temperatre

Ambient operating temperature -20 °C to

+40 °C.

Number of leads

Refer to specifications of individual

models for standard lead wire

configuration. Motors can be supplied

with 4, 6 or 8 leads upon request: however,

rated current and torque may be

reduced.

Angular accuracy

Standard angular accuracy is ±5 %.

Angular accuracy is defined as the

deviation from a theoretical position,

in percentage of one step, after any

number of steps.

Holding torque

The typical values of holding torque of the

different models are indicated in the data

charts. Holding torque is measured with

two phases each supplied at the rated

current.

Specifications and approvals

Motors are manufactured according

to EN 60034-1:1995-02. Motors with drive

voltage higher than or equal to 120 V

are suitable to be fitted on machines

equipped with additional insulation or

when the motor itself has the grounding

through its clamping screws.

Due to thermal considerations, stepper

motors cannot always be operated

continuously in dynamic conditions at the

level of their static rated phased current.

Stepper Motors

• Accurate open loop control for high

performance positioning applications

• Excellent low speed torque

• Simple, rugger construction for high

reliability and long service life

• Smooth, quiet operation

• Standard NEMA frame sizes

• Precision honed stators and ground

rotors for tight air ap and maximum

performance

• EUROPEAN DIRECTIVES

All motors comply with the

requirements of applied European

Directives and related Safety

Standards

MAE

®

Stepper Motors

3

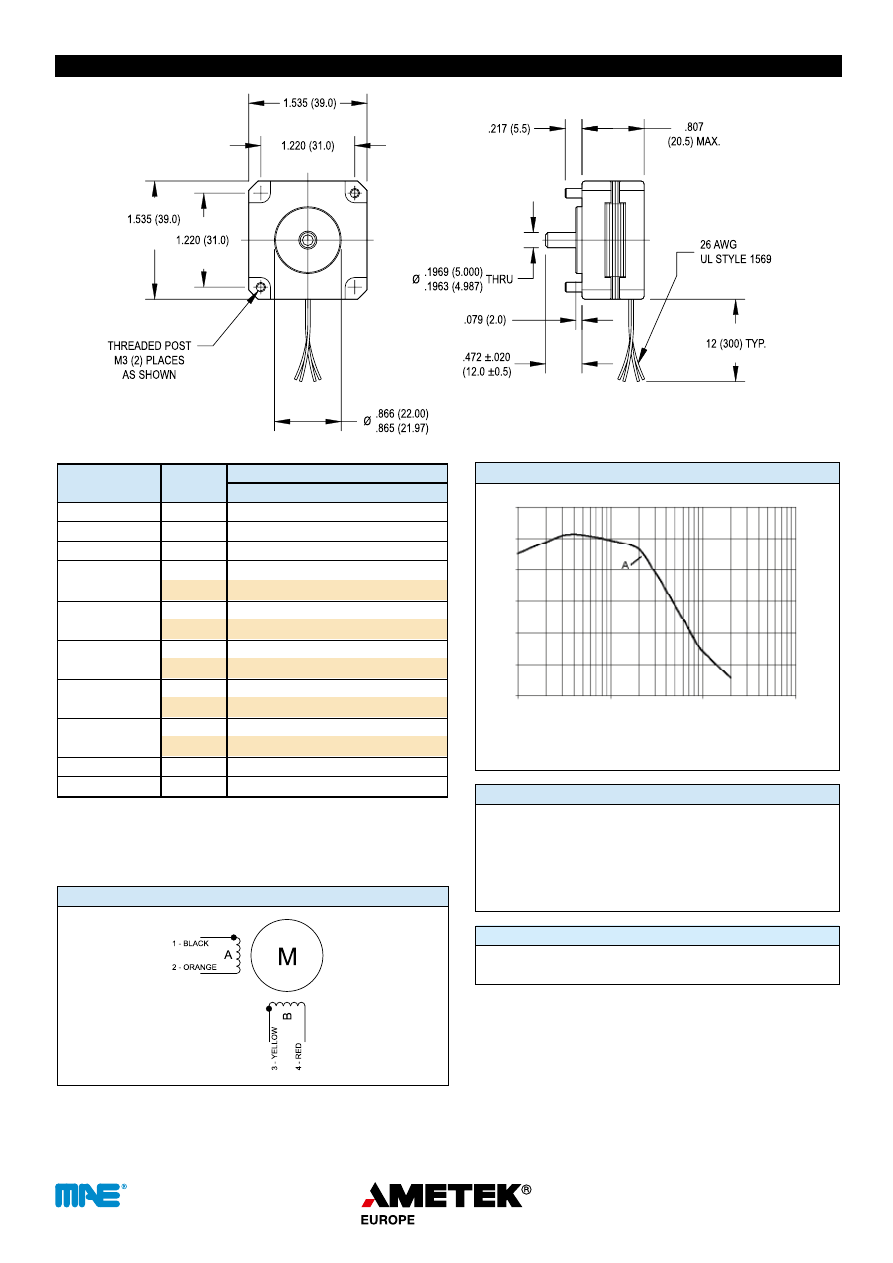

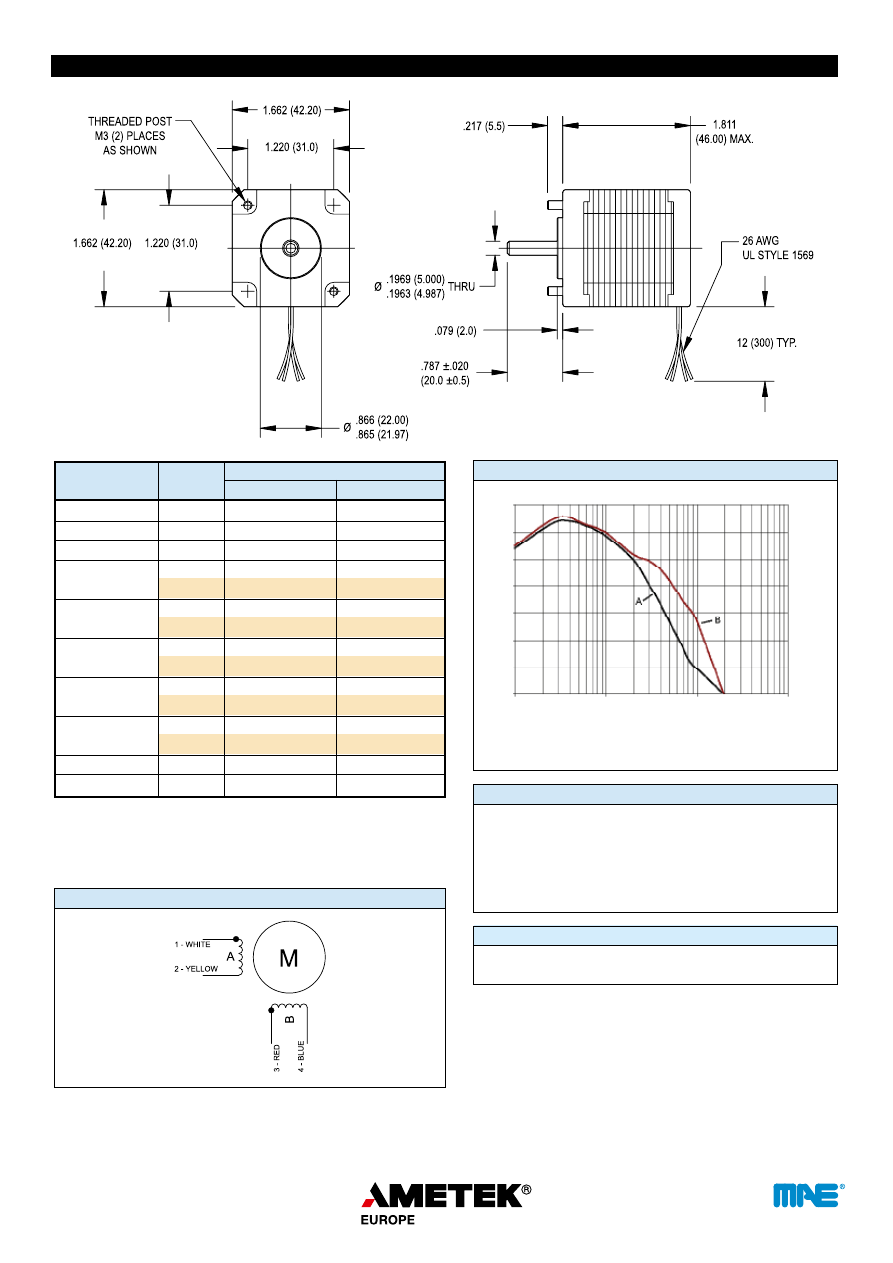

S I Z E 1 6 S T E P P E R M O T O R D A T A

Specification

0060

A

0.60

Ω

6.6

mH

8.5

oz-in

—

Ncm

—

oz-in

12

Bipolar

Ncm

8.7

oz.in

Ncm

oz-in-s

2

–4

g-cm

2

lb

0.33

V

40

—

4

•

•

•

•

•

•

A -

•

•

12

10

8

6

4

2

0

8.5

7.1

5.6

4.2

2.8

1.4

0.0

100

1000

10000

100000

Standard Leadwire Configuration

HY 200 1607

Units

Rated Phase Current

Phase Resistance

Phase Inductance

Holding Torque

Unipolar

Holding Torque

Detent Torque

1.4

1.0

Rotor Inertia

x10

1.6

11

Motor Weight (Mass)

kg

0.15

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

0060, Bipolar chopper, 36V, 0.6A/Phase

Complementary Products

Gearboxes

Encoders

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

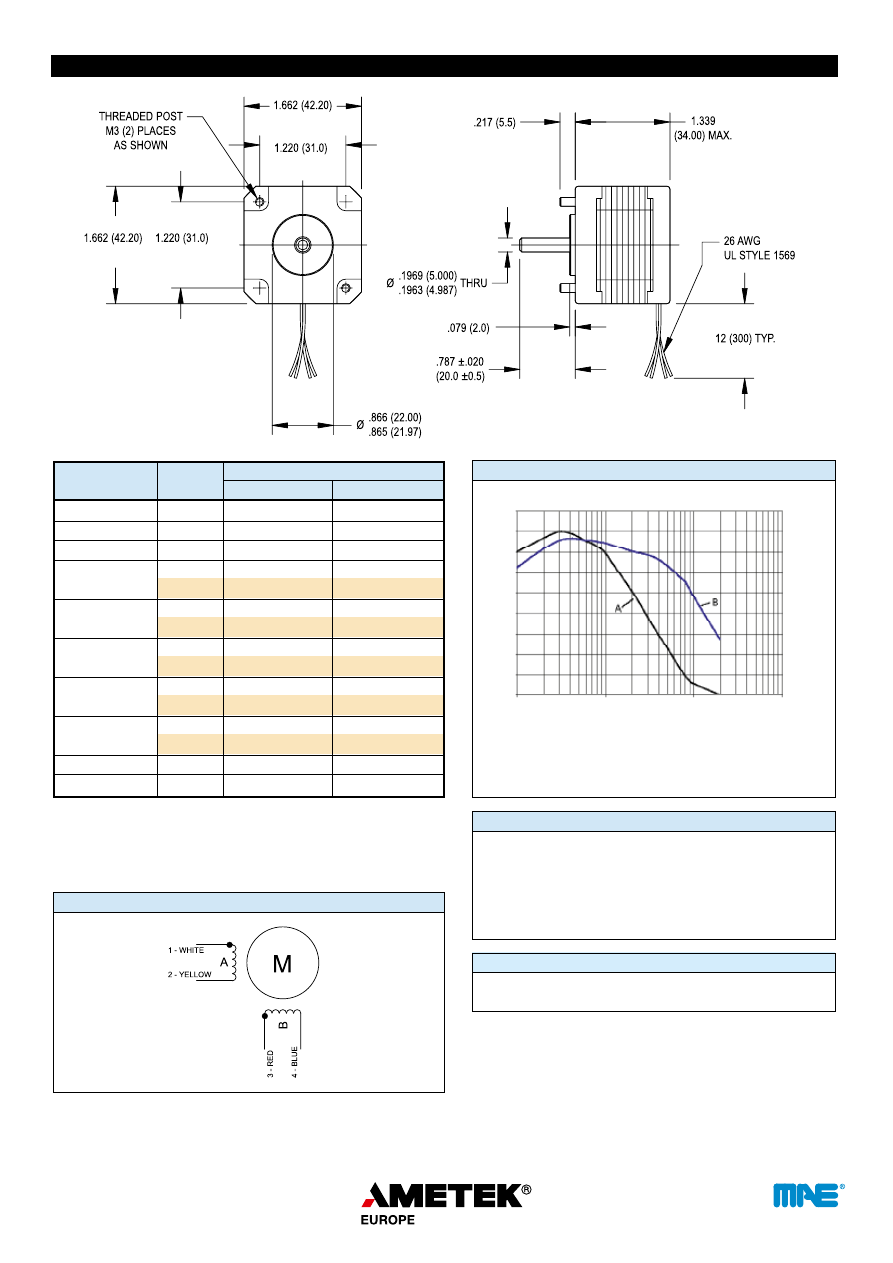

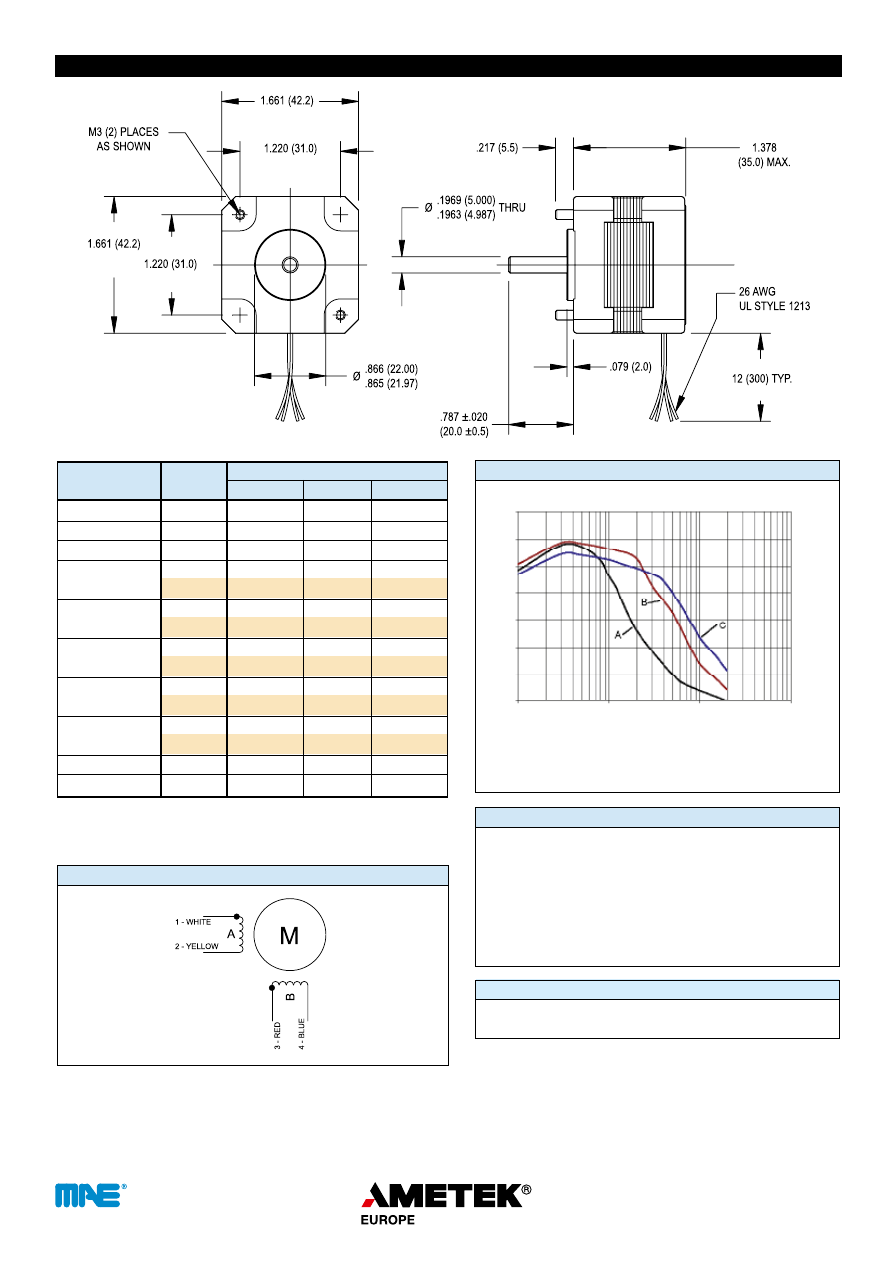

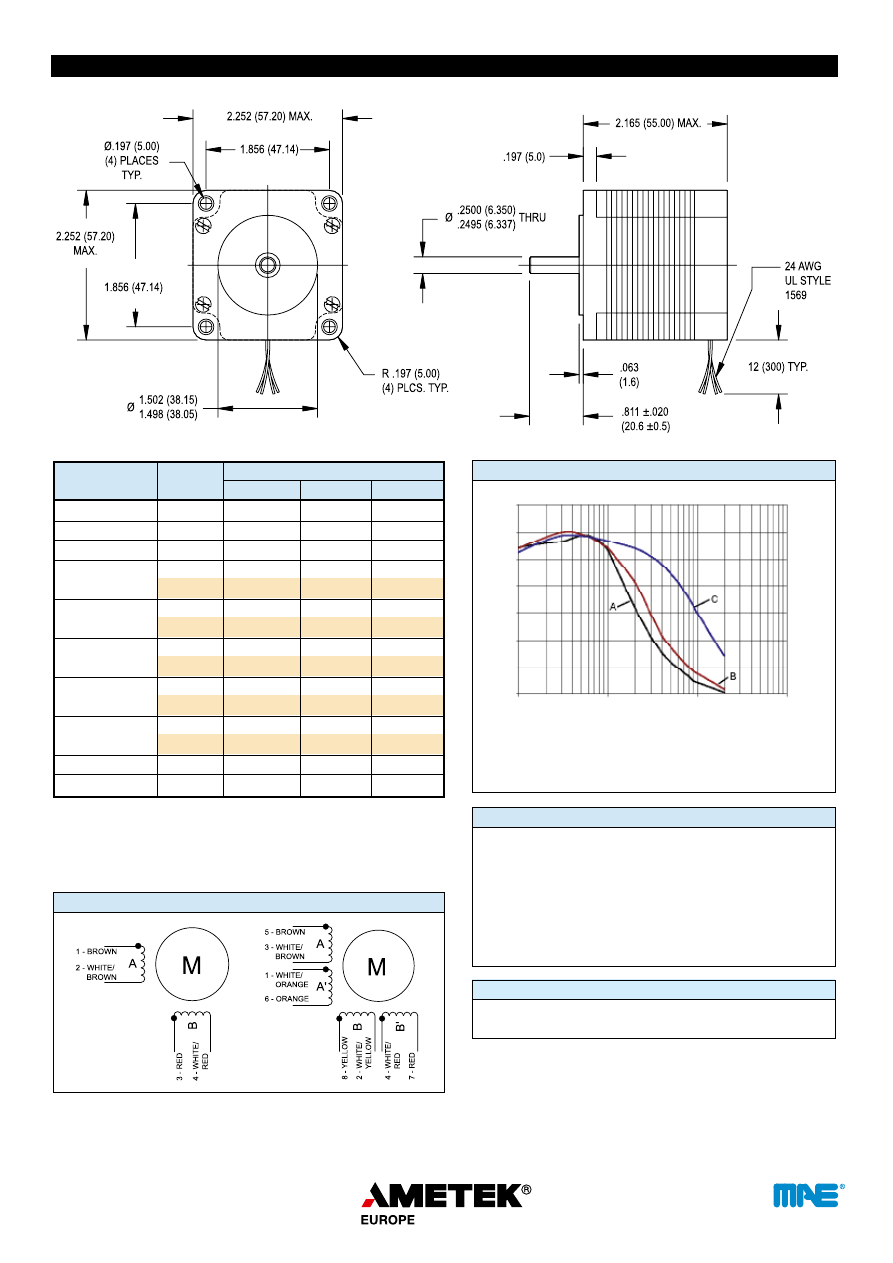

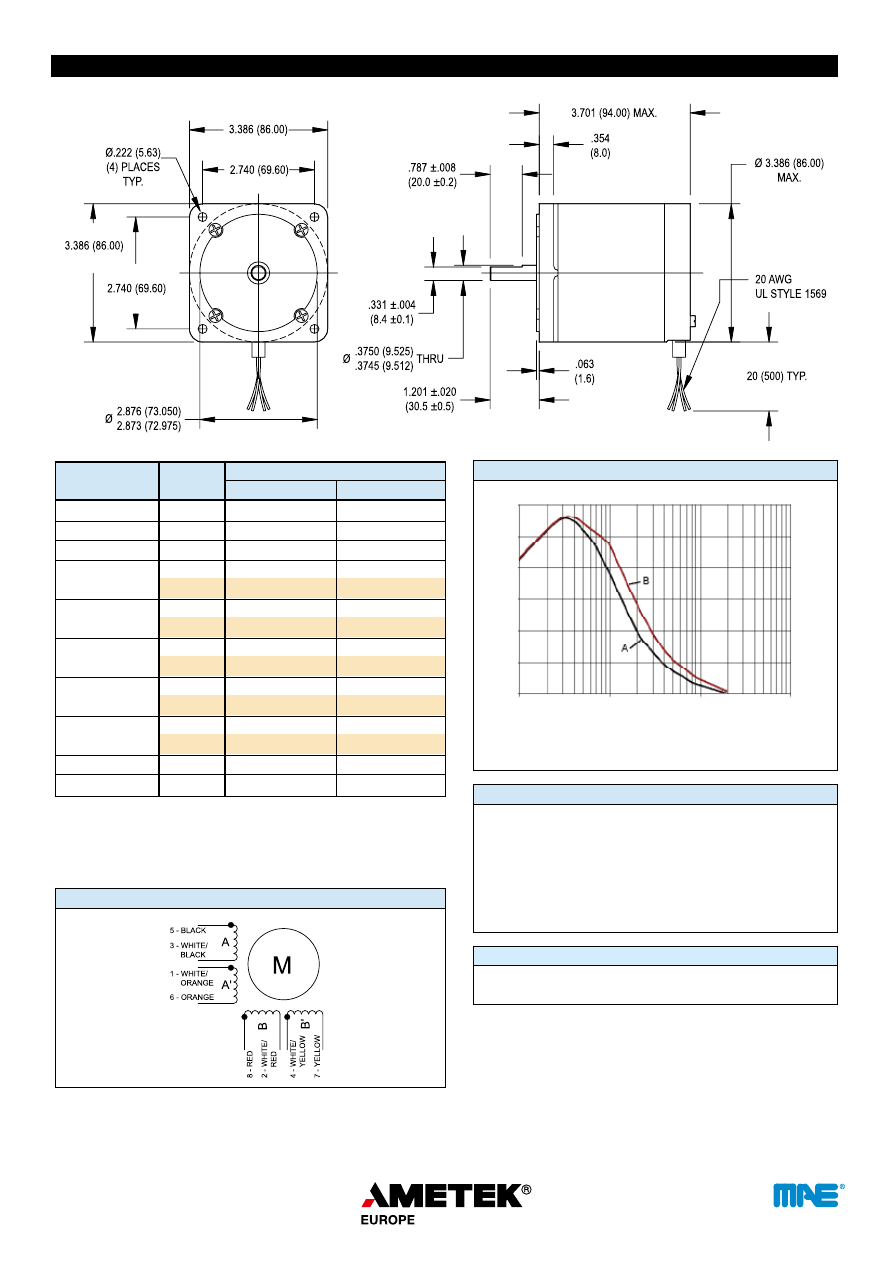

S I Z E 1 7 S T E P P E R M O T O R D A T A

Specification

Units

HY 200 1713

0033

0150

Rated Phase Current

A

0.33

1.50

Phase Resistance

Ω

23.9

1.0

Phase Inductance

mH

28.9

1.2

Holding Torque

Unipolar

oz-in

Ncm

—

—

—

—

Holding Torque

Bipolar

oz-in

Ncm

19.4

13.7

18.4

13.0

oz.in

2.4

2.4

Detent Torque

Ncm

1.7

1.7

oz-in-s

2

x10

–4

2.5

2.5

Rotor Inertia

g-cm

2

18

18

lb

0.4

0.4

Motor Weight (Mass)

kg

0.2

0.2

Maximum Voltage

V

40

40

Std. No. of Leads

—

4

4

Standard Leadwire Configuration

•

•

•

•

•

•

•

•

A -

B -

18

16

14

12

10

8

6

4

2

0

100

1000

10000

100000

12.7

11.3

9.9

8.5

7.1

5.6

4.2

2.8

1.4

0.0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 36V, 0.33A/Phase

0150, Bipolar chopper, 36V, 1.5A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 6 S T E P P E R M O T O R D A T A

4

S I Z E 1 6 S T E P P E R M O T O R D A T A

Specification

0060

A

0.60

Ω

6.6

mH

8.5

oz-in

—

Ncm

—

oz-in

12

Bipolar

Ncm

8.7

oz.in

Ncm

oz-in-s

2

–4

g-cm

2

lb

0.33

V

40

—

4

•

•

•

•

•

•

A -

•

•

12

10

8

6

4

2

0

8.5

7.1

5.6

4.2

2.8

1.4

0.0

100

1000

10000

100000

Standard Leadwire Configuration

HY 200 1607

Units

Rated Phase Current

Phase Resistance

Phase Inductance

Holding Torque

Unipolar

Holding Torque

Detent Torque

1.4

1.0

Rotor Inertia

x10

1.6

11

Motor Weight (Mass)

kg

0.15

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

0060, Bipolar chopper, 36V, 0.6A/Phase

Complementary Products

Gearboxes

Encoders

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 1 7 S T E P P E R M O T O R D A T A

Specification

Units

HY 200 1713

0033

0150

Rated Phase Current

A

0.33

1.50

Phase Resistance

Ω

23.9

1.0

Phase Inductance

mH

28.9

1.2

Holding Torque

Unipolar

oz-in

Ncm

—

—

—

—

Holding Torque

Bipolar

oz-in

Ncm

19.4

13.7

18.4

13.0

oz.in

2.4

2.4

Detent Torque

Ncm

1.7

1.7

oz-in-s

2

x10

–4

2.5

2.5

Rotor Inertia

g-cm

2

18

18

lb

0.4

0.4

Motor Weight (Mass)

kg

0.2

0.2

Maximum Voltage

V

40

40

Std. No. of Leads

—

4

4

Standard Leadwire Configuration

•

•

•

•

•

•

•

•

A -

B -

18

16

14

12

10

8

6

4

2

0

100

1000

10000

100000

12.7

11.3

9.9

8.5

7.1

5.6

4.2

2.8

1.4

0.0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 36V, 0.33A/Phase

0150, Bipolar chopper, 36V, 1.5A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 S T E P P E R M O T O R D A T A

5

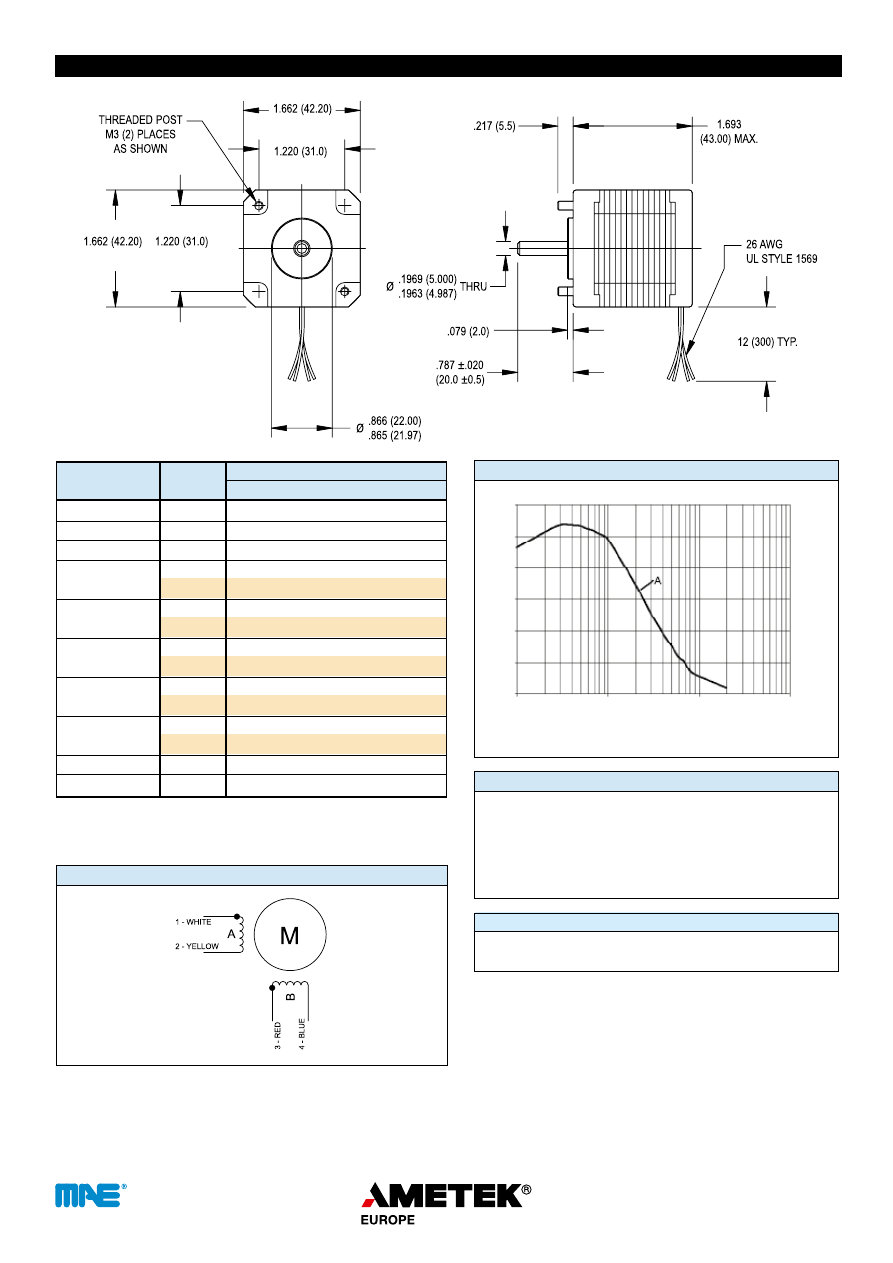

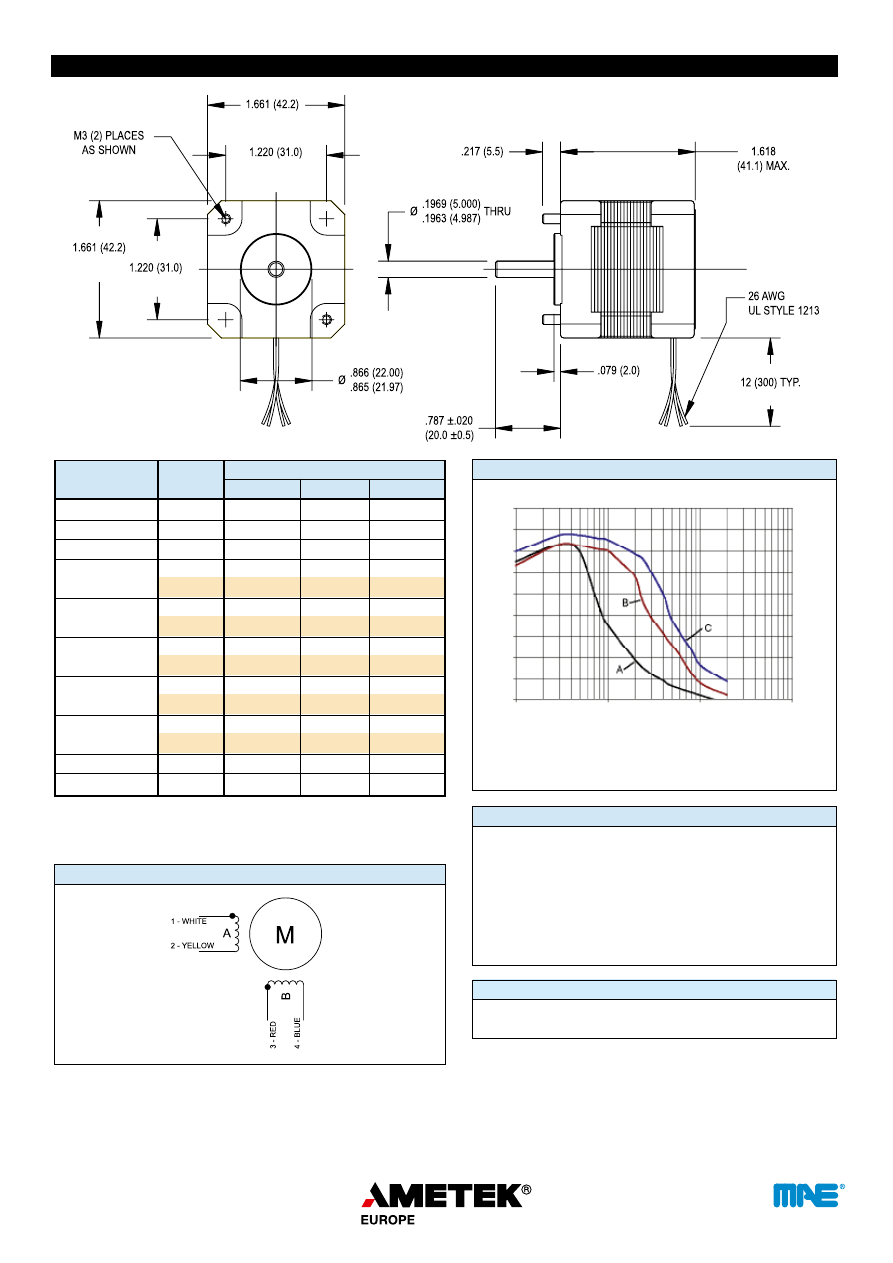

S I Z E 1 7 S T E P P E R M O T O R D A T A

Specification

A

Ω

4.6

mH

oz-in

—

Ncm

—

oz-in

32.7

Bipolar

Ncm

oz.in

2.4

Ncm

oz-in-s

2

–4

4.5

g-cm

2

32

lb

0.7

0.3

V

40

—

4

•

•

•

•

•

•

•

•

A -

30

25

20

15

10

5

0

100

1000

10000

100000

21.2

17.7

14.1

10.6

7.1

3.5

0.0

Standard Leadwire Configuration

HY 200 1717

Units

0100

Rated Phase Current

1.00

Phase Resistance

Phase Inductance

10.6

Holding Torque

Unipolar

Holding Torque

23.1

Detent Torque

1.7

Rotor Inertia

x10

Motor Weight (Mass)

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0100, Bipolar chopper, 36V, 1A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 S T E P P E R M O T O R D A T A

6

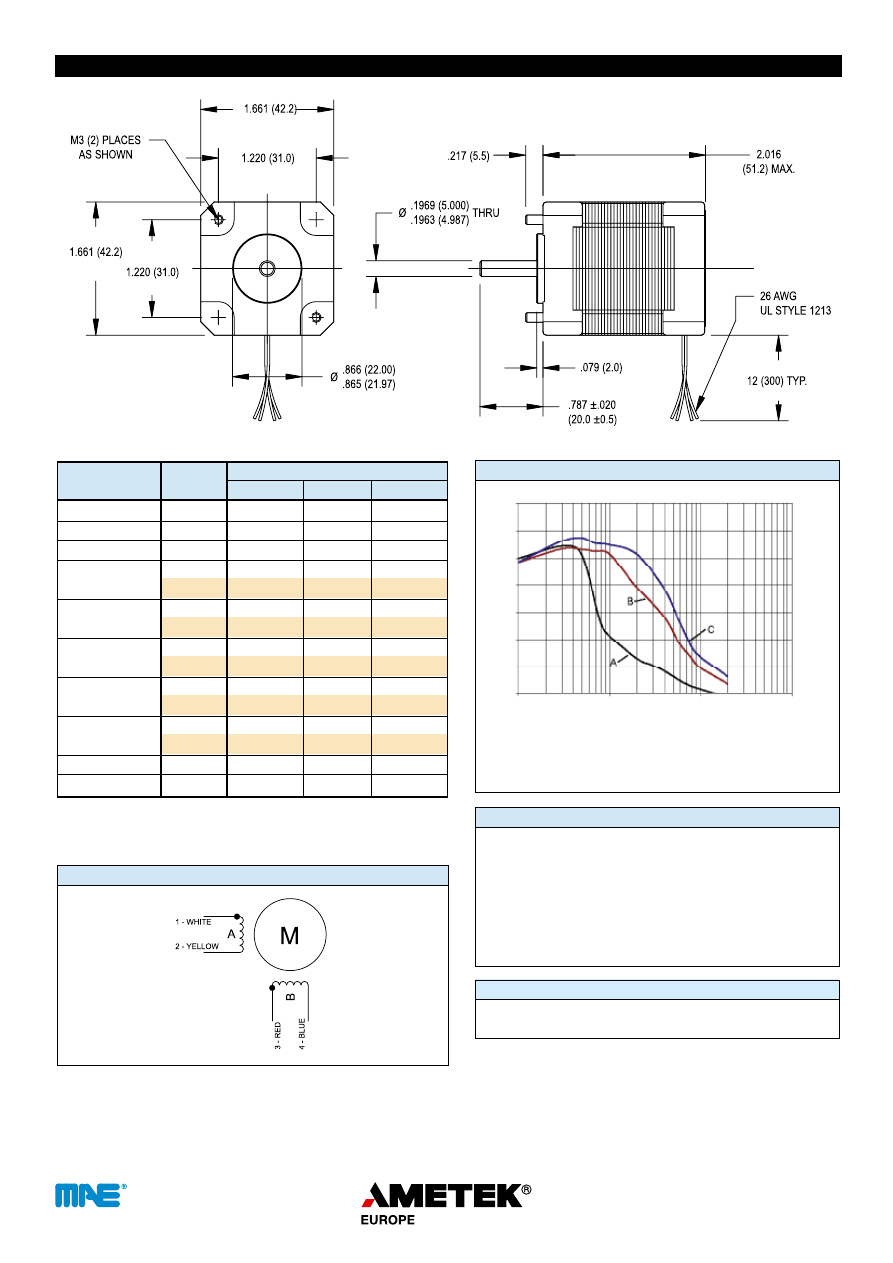

S I Z E 1 7 S T E P P E R M O T O R D A T A

Specification

Units

HY 200 1718

0090

0230

Rated Phase Current

A

0.90

2.30

Phase Resistance

Ω

4.2

0.72

Phase Inductance

mH

5.8

0.83

Holding Torque

Unipolar

oz-in

Ncm

—

—

—

—

Holding Torque

Bipolar

oz-in

Ncm

41.1

29.0

41.1

29.0

oz.in

6.4

6.4

Detent Torque

Ncm

4.5

4.5

oz-in-s

2

x10

–4

5.1

5.1

Rotor Inertia

g-cm

2

36

36

lb

0.7

0.7

Motor Weight (Mass)

kg

0.3

0.3

Maximum Voltage

V

40

40

Std. No. of Leads

—

4

4

Standard Leadwire Configuration

•

•

•

•

•

•

•

•

A -

B -

35

30

25

20

15

10

5

0

100

1000

10000

100000

24.7

21.2

17.7

14.1

10.6

7.1

3.5

0.0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0090, Bipolar chopper, 36V, 0.9A/Phase

0230, Bipolar chopper, 36V, 2.3A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 S T E P P E R M O T O R D A T A

7

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0033

A

0.33

Ω

26.5

2.95

mH

38.8

4.45

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

26

26

26

oz.in

2.3

2.3

2.3

Ncm

oz-in-s

2

–4

6.4

6.4

6.4

g-cm

2

45

45

45

lb

0.23

0.23 0.23

V

40

40

40

—

4

4

4

•

•

•

•

•

•

•

•

•

•

A -

L=75 g cm

2

B -

L=75 g cm

2

C -

L=75 g cm

2

35

30

25

20

15

10

5

0

100

1000

10000

100000

24.7

21.2

17.7

14.1

10.6

7.1

3.5

0.0

Standard Leadwire Configuration

HS 200 1714

Units

0100 0150

Rated Phase Current

1.00 1.50

Phase Resistance

1.25

Phase Inductance

1.80

Holding Torque

Unipolar

Holding Torque

37

37

37

Detent Torque

1.6

1.6

1.6

Rotor Inertia

x10

Motor Weight (Mass)

0.51

0.51 0.51

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 35V, 0.33A/Phase, J

0100, Bipolar chopper, 35V, 1.0A/Phase, J

0150, Bipolar chopper, 35V, 1.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

8

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0033

A

0.33

Ω

26.5

2.95

mH

38.8

4.45

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

26

26

26

oz.in

2.3

2.3

2.3

Ncm

oz-in-s

2

–4

6.4

6.4

6.4

g-cm

2

45

45

45

lb

0.23

0.23 0.23

V

40

40

40

—

4

4

4

•

•

•

•

•

•

•

•

•

•

A -

L=75 g cm

2

B -

L=75 g cm

2

C -

L=75 g cm

2

35

30

25

20

15

10

5

0

100

1000

10000

100000

24.7

21.2

17.7

14.1

10.6

7.1

3.5

0.0

Standard Leadwire Configuration

HS 200 1714

Units

0100 0150

Rated Phase Current

1.00 1.50

Phase Resistance

1.25

Phase Inductance

1.80

Holding Torque

Unipolar

Holding Torque

37

37

37

Detent Torque

1.6

1.6

1.6

Rotor Inertia

x10

Motor Weight (Mass)

0.51

0.51 0.51

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 35V, 0.33A/Phase, J

0100, Bipolar chopper, 35V, 1.0A/Phase, J

0150, Bipolar chopper, 35V, 1.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0033

A

0.33

Ω

2.86

mH

66.7

3.25

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

33

33

33

oz.in

2.3

2.3

2.3

Ncm

oz-in-s

2

–4

9.3

9.3

9.3

g-cm

2

66

66

66

lb

0.66

0.66 0.66

0.30

0.30 0.30

V

40

40

40

—

4

4

4

•

•

•

•

•

•

•

•

A -

L=75 g cm

2

B -

L=75 g cm

2

C -

L=75 g cm

2

45

40

35

30

25

20

15

10

5

0

100

1000

10000

100000

31.8

28.2

24.7

21.2

17.7

14.1

10.6

7.1

3.5

0.0

•

•

Standard Leadwire Configuration

HS 200 1716

Units

0100 0150

Rated Phase Current

1.00 1.50

Phase Resistance

27.2

1.40

Phase Inductance

6.74

Holding Torque

Unipolar

Holding Torque

47

47

47

Detent Torque

1.6

1.6

1.6

Rotor Inertia

x10

Motor Weight (Mass)

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

0033, Bipolar chopper, 35V, 0.33A/Phase, J

0100, Bipolar chopper, 35V, 1.0A/Phase, J

0150, Bipolar chopper, 35V, 1.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

Complementary Products

Gearboxes

Encoders

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

9

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0033

A

0.33

Ω

28.0

3.00

mH

50.0

5.50 2.90

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

50

50

50

oz.in

3.5

3.5

3.5

Ncm

2.5

2.5

2.5

oz-in-s

2

–4

12.7

12.7 12.7

g-cm

2

90

90

90

lb

0.38

0.38 0.38

V

40

40

40

—

4

4

4

•

•

•

•

•

•

•

•

•

•

A -

L=75 g cm

2

B -

L=75 g cm

2

C -

L=75 g cm

2

70

60

50

40

30

20

10

0

100

1000

10000

100000

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

Standard Leadwire Configuration

HS 200 1720

Units

0100 0150

Rated Phase Current

1.00 1.50

Phase Resistance

1.45

Phase Inductance

Holding Torque

Unipolar

Holding Torque

71

71

71

Detent Torque

Rotor Inertia

x10

Motor Weight (Mass)

0.84 0.84 0.84

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 35V, 0.33A/Phase, J

0100, Bipolar chopper, 35V, 1.0A/Phase, J

0150, Bipolar chopper, 35V, 1.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

10

S I Z E 1 7 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0033

A

0.33

Ω

28.0

3.00

mH

50.0

5.50 2.90

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

50

50

50

oz.in

3.5

3.5

3.5

Ncm

2.5

2.5

2.5

oz-in-s

2

–4

12.7

12.7 12.7

g-cm

2

90

90

90

lb

0.38

0.38 0.38

V

40

40

40

—

4

4

4

•

•

•

•

•

•

•

•

•

•

A -

L=75 g cm

2

B -

L=75 g cm

2

C -

L=75 g cm

2

70

60

50

40

30

20

10

0

100

1000

10000

100000

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

Standard Leadwire Configuration

HS 200 1720

Units

0100 0150

Rated Phase Current

1.00 1.50

Phase Resistance

1.45

Phase Inductance

Holding Torque

Unipolar

Holding Torque

71

71

71

Detent Torque

Rotor Inertia

x10

Motor Weight (Mass)

0.84 0.84 0.84

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

NEMA 17 mounting configuration

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 35V, 0.33A/Phase, J

0100, Bipolar chopper, 35V, 1.0A/Phase, J

0150, Bipolar chopper, 35V, 1.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

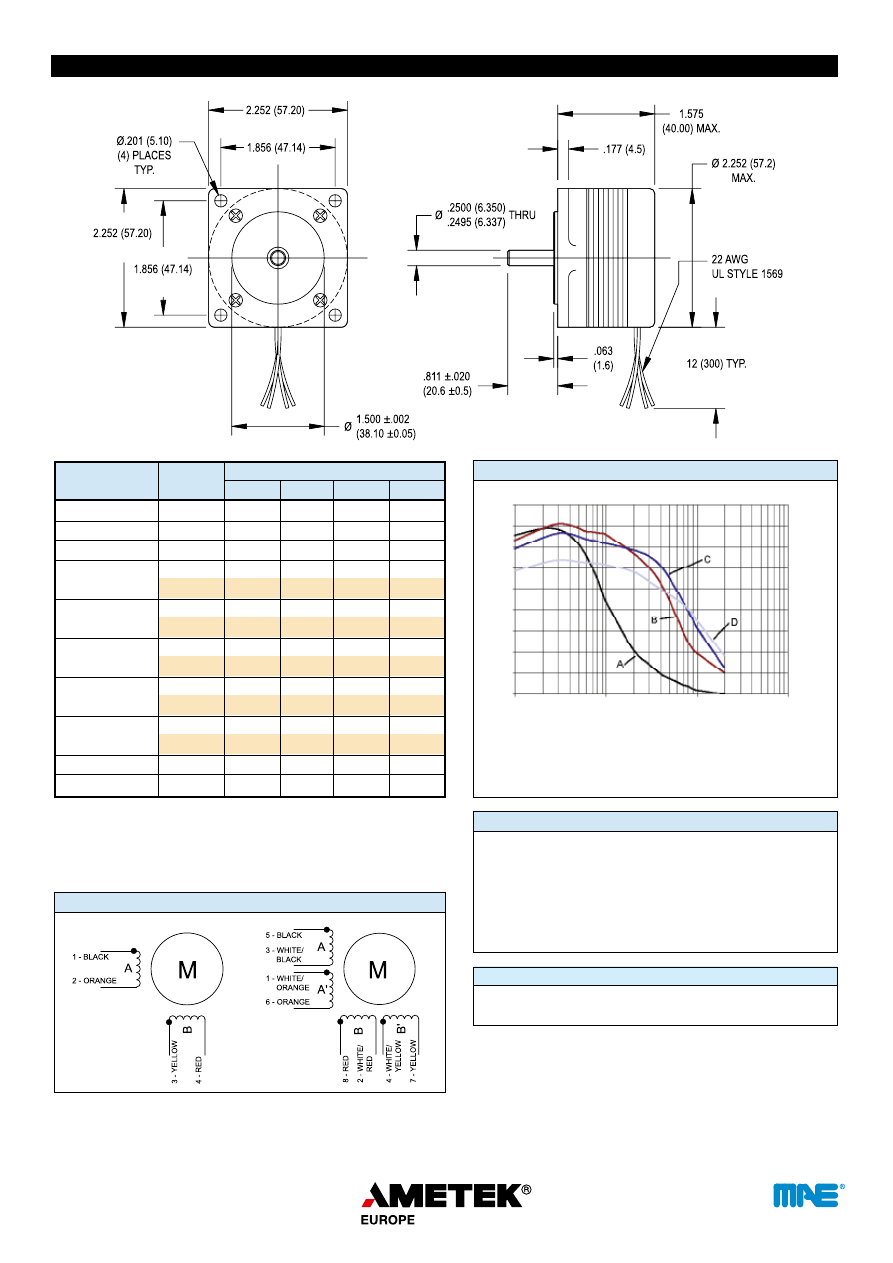

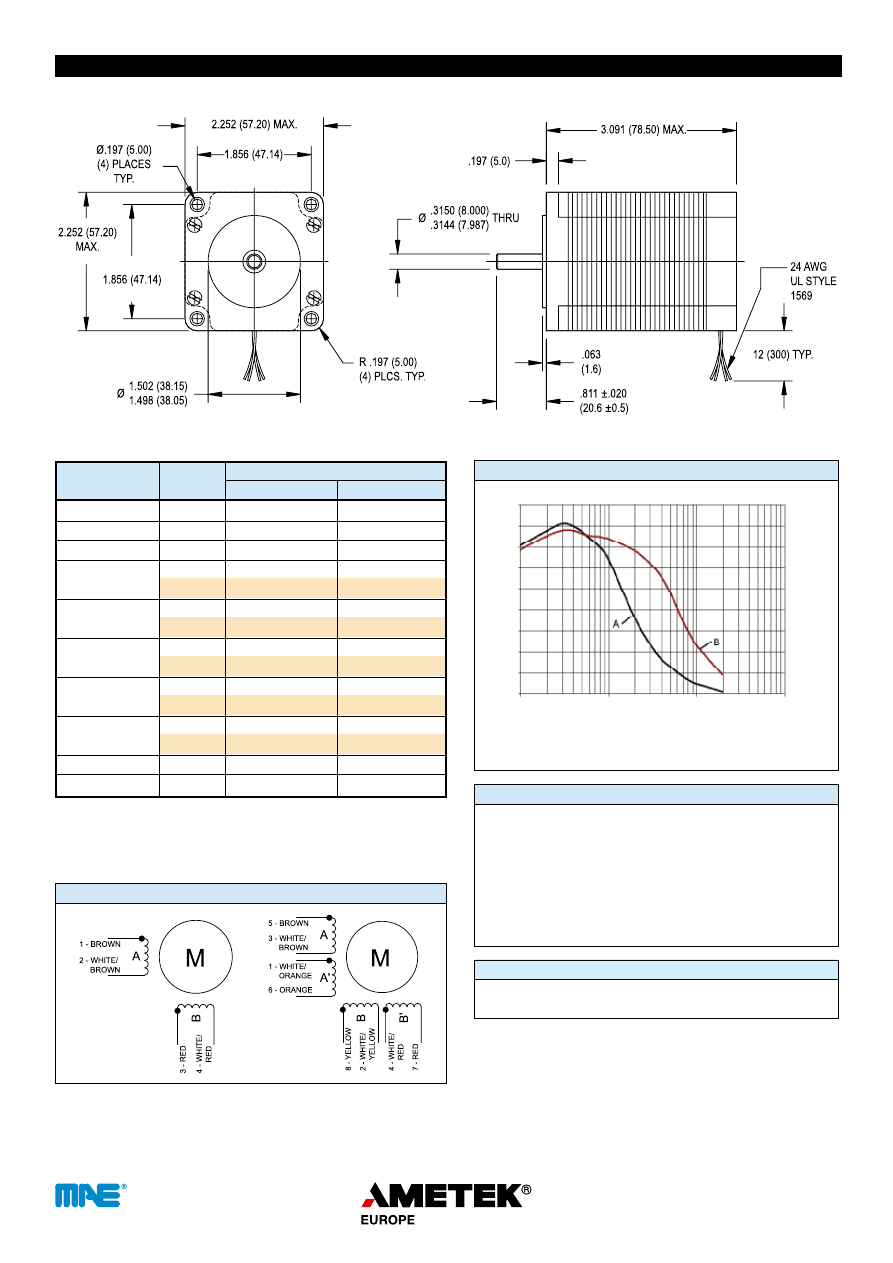

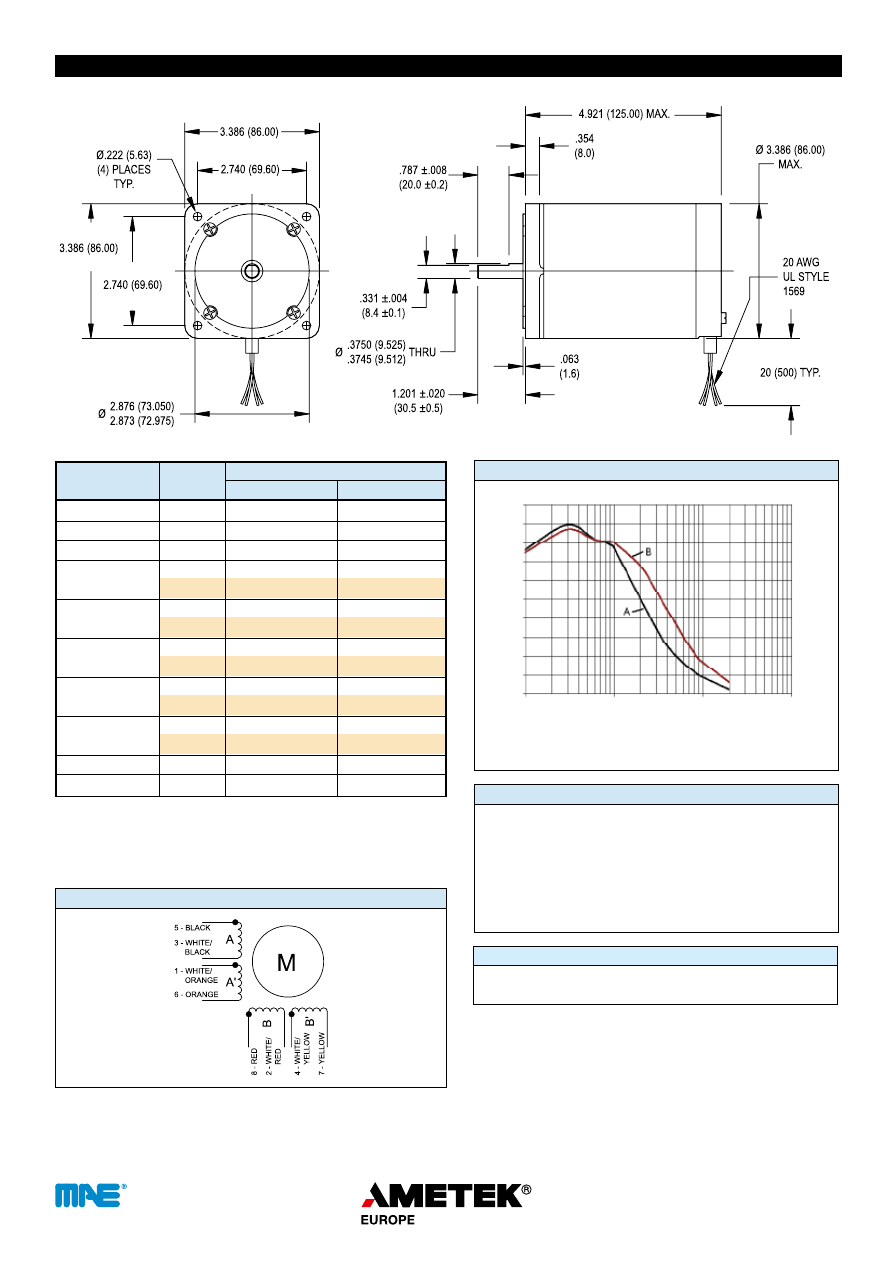

S I Z E 2 3 S T E P P E R M O T O R D A T A

Specification

Units

HY 200 2215

0033 0100 0150

0220

Rated Phase Current

A

0.33

1.00

1.50

2.20

Phase Resistance

Ω

33.8

3.4

1.5

0.7

Phase Inductance

mH

54.6

3.8

1.5

1.2

Holding Torque

Unipolar

oz-in

Ncm

—

—

38

27

35

25

—

—

Holding Torque

Bipolar

oz-in

Ncm

45

32

48

34

47

33

44

31

oz.in 4.8 4.8 4.8 4.8

Detent Torque

Ncm 3.4 3.4 3.4 3.4

oz-in-s

2

x10

–4

7.9

7.9

7.9

7.9

Rotor Inertia

g-cm

2

56 56 56 56

lb

0.75

0.75

0.75

0.75

Motor Weight (Mass)

kg 0.34 0.34 0.34 0.34

Maximum Voltage

V

75

75

75

75

Std. No. of Leads

—

4 8 8 4

Standard Leadwire Configuration

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

D -

31.8

28.2

24.7

21.2

17.7

14.1

10.6

7.1

3.5

0.0

100

1000

10000

100000

45

40

35

30

25

20

15

10

5

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0033, Bipolar chopper, 36V, 0.33A/Phase

0100, Bipolar chopper, Parallel, 48V, 1.5A/Phase

0150, Bipolar chopper, Parallel, 48V, 2.2A/Phase

0220, Bipolar chopper, 48V, 2.2A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 2 3 S T E P P E R M O T O R D A T A

11

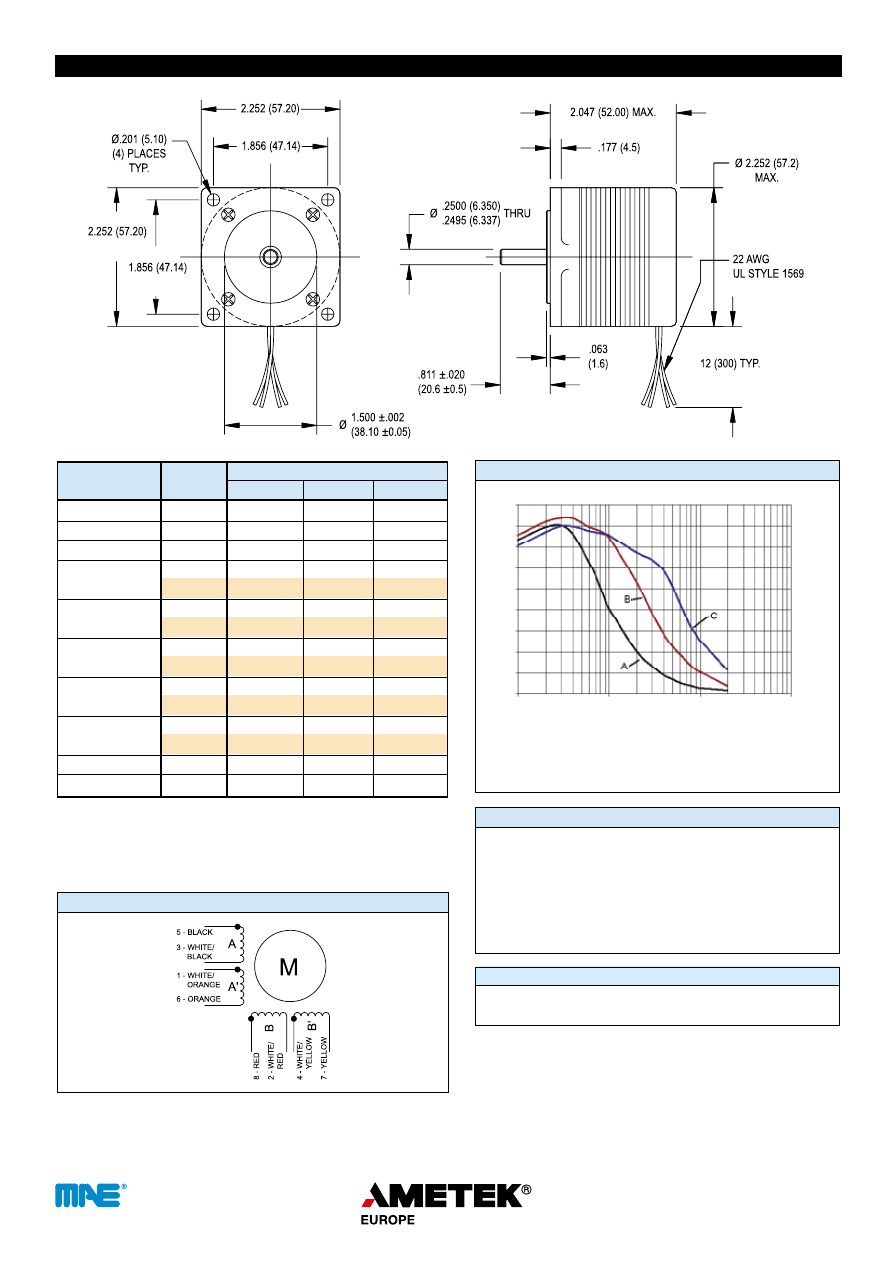

S I Z E 2 3 S T E P P E R M O T O R D A T A

Specification

A

Ω

23.0

5.0

mH

39.2

8.0

oz-in

75

Ncm

52

53

52

oz-in

92

98

Bipolar

Ncm

65

69

oz.in

Ncm

5.3

5.3

5.3

oz-in-s

2

–4

g-cm

2

lb

0.50

0.50 0.50

V

75

75

75

—

8

8

8

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

63.6

56.5

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

100

1000

10000

100000

90

80

70

60

50

40

30

20

10

0

Standard Leadwire Configuration

HY 200 2220

Units

0044 0100 0210

Rated Phase Current

0.44 1.00 2.10

Phase Resistance

1.1

Phase Inductance

1.7

Holding Torque

74

74

Unipolar

Holding Torque

91

64

Detent Torque

7.5

7.5

7.5

Rotor Inertia

x10

17.6

17.6 17.6

124

124 124

Motor Weight (Mass)

1.1

1.1

1.1

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

AINiCo magnets

Additional windings and customization options availabl

Complementary Products

Gearboxes

Encoders

0044, Bipolar chopper, Parallel, 36V, 0.62A/Phase

0100, Bipolar chopper, Parallel, 48V, 1.5A/Phase

0210, Bipolar chopper, Parallel, 48V, 3A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 2 3 S T E P P E R M O T O R D A T A

12

S I Z E 2 3 S T E P P E R M O T O R D A T A

Specification

A

Ω

23.0

5.0

mH

39.2

8.0

oz-in

75

Ncm

52

53

52

oz-in

92

98

Bipolar

Ncm

65

69

oz.in

Ncm

5.3

5.3

5.3

oz-in-s

2

–4

g-cm

2

lb

0.50

0.50 0.50

V

75

75

75

—

8

8

8

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

63.6

56.5

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

100

1000

10000

100000

90

80

70

60

50

40

30

20

10

0

Standard Leadwire Configuration

HY 200 2220

Units

0044 0100 0210

Rated Phase Current

0.44 1.00 2.10

Phase Resistance

1.1

Phase Inductance

1.7

Holding Torque

74

74

Unipolar

Holding Torque

91

64

Detent Torque

7.5

7.5

7.5

Rotor Inertia

x10

17.6

17.6 17.6

124

124 124

Motor Weight (Mass)

1.1

1.1

1.1

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

AINiCo magnets

Additional windings and customization options availabl

Complementary Products

Gearboxes

Encoders

0044, Bipolar chopper, Parallel, 36V, 0.62A/Phase

0100, Bipolar chopper, Parallel, 48V, 1.5A/Phase

0210, Bipolar chopper, Parallel, 48V, 3A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

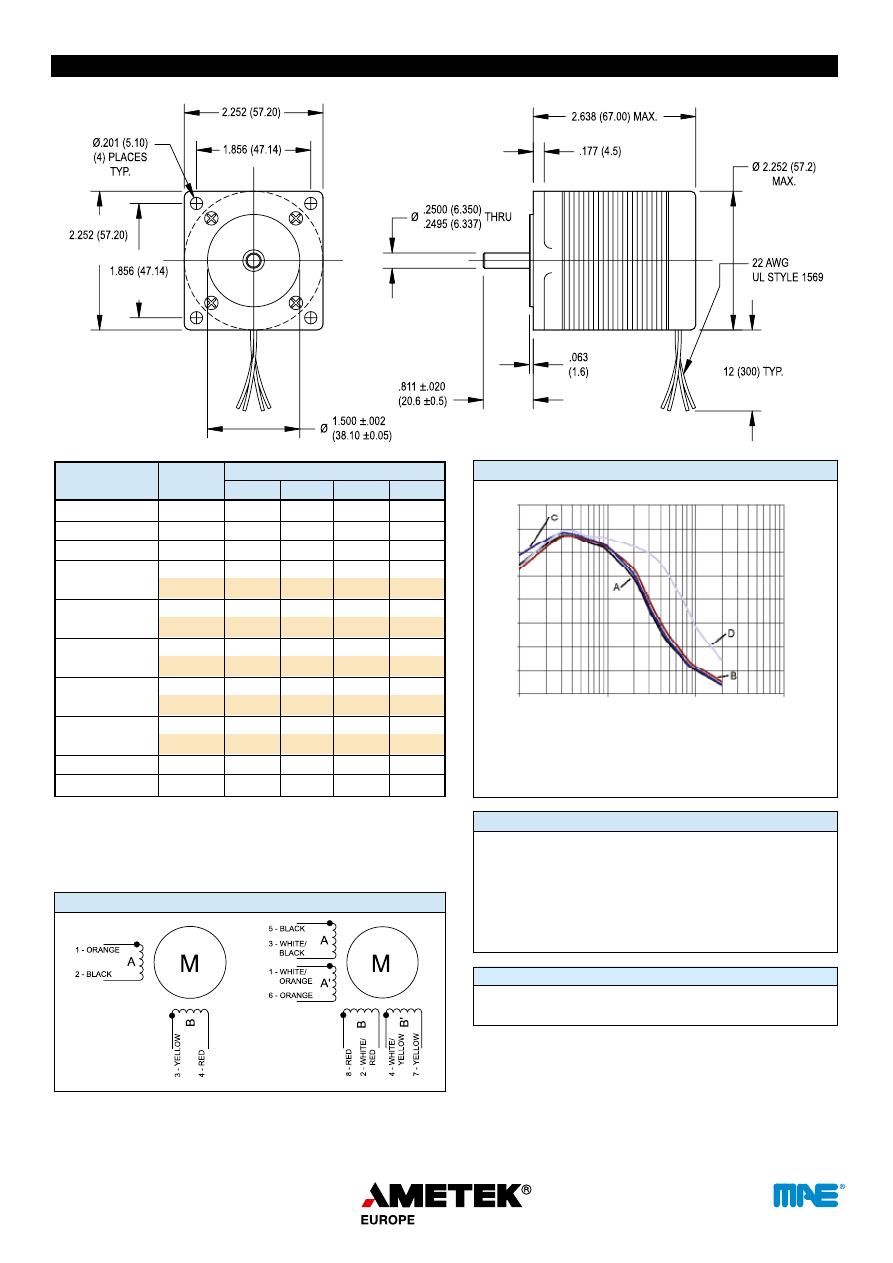

S I Z E 2 3 S T E P P E R M O T O R D A T A

Specification

Units

HY 200 2226

0160 0190 0250 0470

Rated Phase Current

A

1.60

1.90

2.50

4.70

Phase Resistance

Ω

2.6

1.8

1.1

0.33

Phase Inductance

mH

4.7

3.3

4.0

0.5

Holding Torque

Unipolar

oz-in

Ncm

123

87

126

89

—

—

123

87

Holding Torque

Bipolar

oz-in

Ncm

154

109

160

113

161

114

154

109

oz.in 12.0 12.0 12.0 12.0

Detent Torque

Ncm 8.5 8.5 8.5 8.5

oz-in-s

2

x10

–4

28 28 28 28

Rotor Inertia

g-cm

2

200 200 200 200

lb 1.5 1.5 1.5 1.5

Motor Weight (Mass)

kg 0.70 0.70 0.70 0.70

Maximum Voltage

V

75 75 75 75

Std. No. of Leads

—

8 8 4 8

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

D -

113.0

98.9

84.7

70.6

56.5

42.4

28.2

14.1

0.0

100

1000

10000

100000

160

140

120

100

80

60

40

20

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0160, Bipolar chopper, Parallel, 48V, 2.3A/Phase

0190, Bipolar chopper, Parallel, 48V, 2.7A/Phase

0250, Bipolar chopper, 48V, 2.5A/Phase

0470, Bipolar chopper, Parallel, 48V, 6.7A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

Standard Leadwire Configuration

S I Z E 2 3 S T E P P E R M O T O R D A T A

13

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

A

Ω

4.6

mH

4.6

oz-in

52

—

Ncm

—

oz-in

67

67

Bipolar

Ncm

oz.in

3.0

3.0

Ncm

oz-in-s

2

–4

g-cm

2

lb

0.50

0.50

V

75

75

—

8

4

•

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

100

1000

10000

100000

70

60

50

40

30

20

10

0

Standard Leadwire Configuration

HS 200 2216

Units

0100

0210

Rated Phase Current

1.00

2.10

Phase Resistance

1.0

Phase Inductance

2.1

Holding Torque

Unipolar

37

Holding Torque

47

47

Detent Torque

2.1

2.1

Rotor Inertia

x10

11

11

77

77

Motor Weight (Mass)

1.1

1.1

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0100, Bipolar chopper, Parallel, 36V, 1.4A/Phase

0210, Bipolar chopper, 36V, 2.1A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

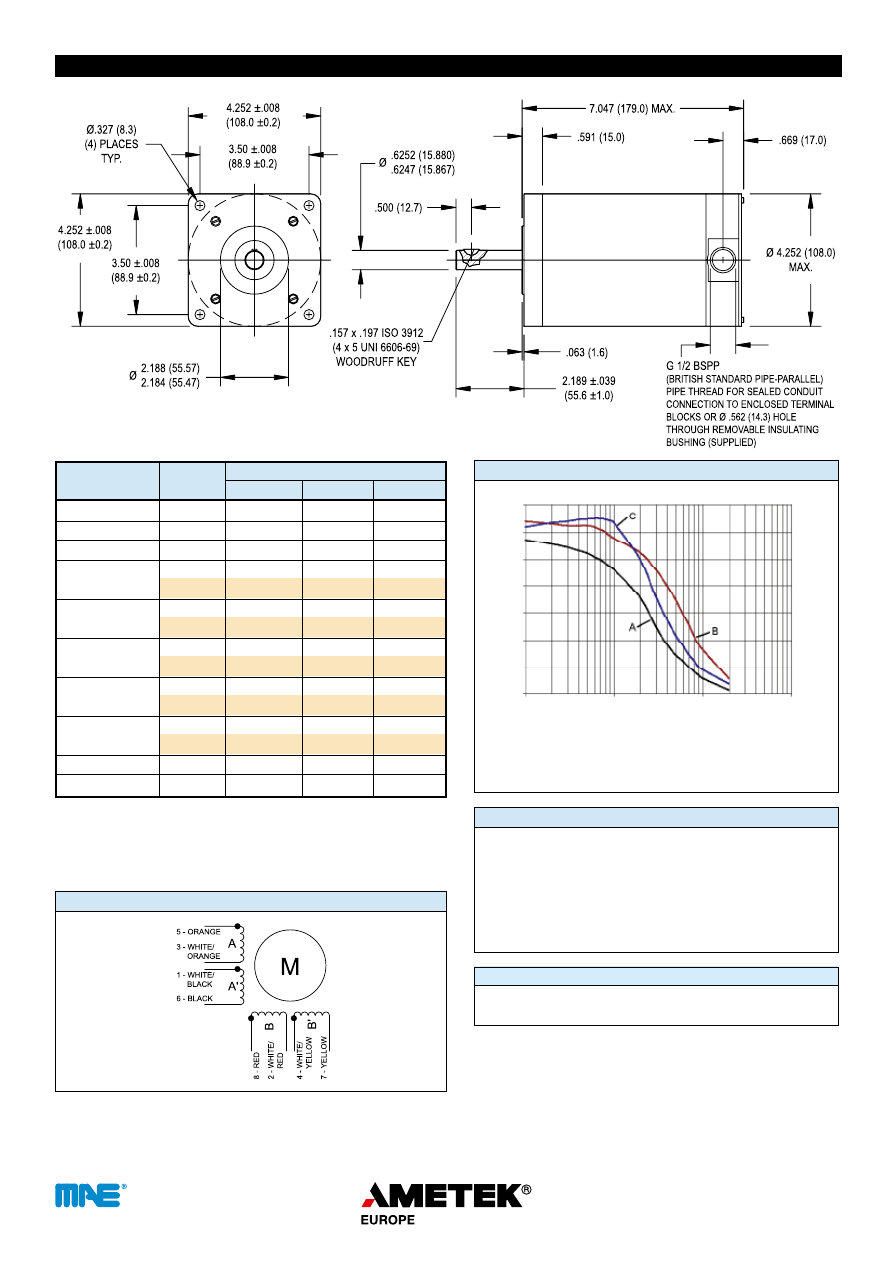

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

Units

HS 200 2221

0100 0210 0300

Rated Phase Current

A

1.00

2.10 3.00

Phase Resistance

Ω

6.2

1.4

0.7

Phase Inductance

mH

8.8

3.9

0.9

Holding Torque

Unipolar

oz-in

Ncm

106

75

—

—

106

75

Holding Torque

Bipolar

oz-in

Ncm

139

98

139

98

139

98

oz.in

5.7

5.7

5.7

Detent Torque

Ncm

4.0

4.0

4.0

oz-in-s

2

x10

–4

31

31

31

Rotor Inertia

g-cm

2

220

220 220

lb

1.5

1.5

1.5

Motor Weight (Mass)

kg

0.70

0.70 0.70

Maximum Voltage

V

75

75

75

Std. No. of Leads

—

8

4

8

Standard Leadwire Configuration

•

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

98.9

84.7

70.6

56.5

42.4

28.2

14.1

0.0

100

1000

10000

100000

140

120

100

80

60

40

20

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0100, Bipolar chopper, Parallel, 36V, 1.4A/Phase

0210, Bipolar chopper, 36V, 2.1A/Phase

0300, Bipolar chopper, Parallel, 60V, 4.2A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

14

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

A

Ω

4.6

mH

4.6

oz-in

52

—

Ncm

—

oz-in

67

67

Bipolar

Ncm

oz.in

3.0

3.0

Ncm

oz-in-s

2

–4

g-cm

2

lb

0.50

0.50

V

75

75

—

8

4

•

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

49.4

42.4

35.3

28.2

21.2

14.1

7.1

0.0

100

1000

10000

100000

70

60

50

40

30

20

10

0

Standard Leadwire Configuration

HS 200 2216

Units

0100

0210

Rated Phase Current

1.00

2.10

Phase Resistance

1.0

Phase Inductance

2.1

Holding Torque

Unipolar

37

Holding Torque

47

47

Detent Torque

2.1

2.1

Rotor Inertia

x10

11

11

77

77

Motor Weight (Mass)

1.1

1.1

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0100, Bipolar chopper, Parallel, 36V, 1.4A/Phase

0210, Bipolar chopper, 36V, 2.1A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

Units

HS 200 2221

0100 0210 0300

Rated Phase Current

A

1.00

2.10 3.00

Phase Resistance

Ω

6.2

1.4

0.7

Phase Inductance

mH

8.8

3.9

0.9

Holding Torque

Unipolar

oz-in

Ncm

106

75

—

—

106

75

Holding Torque

Bipolar

oz-in

Ncm

139

98

139

98

139

98

oz.in

5.7

5.7

5.7

Detent Torque

Ncm

4.0

4.0

4.0

oz-in-s

2

x10

–4

31

31

31

Rotor Inertia

g-cm

2

220

220 220

lb

1.5

1.5

1.5

Motor Weight (Mass)

kg

0.70

0.70 0.70

Maximum Voltage

V

75

75

75

Std. No. of Leads

—

8

4

8

Standard Leadwire Configuration

•

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

C -

98.9

84.7

70.6

56.5

42.4

28.2

14.1

0.0

100

1000

10000

100000

140

120

100

80

60

40

20

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0100, Bipolar chopper, Parallel, 36V, 1.4A/Phase

0210, Bipolar chopper, 36V, 2.1A/Phase

0300, Bipolar chopper, Parallel, 60V, 4.2A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

15

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

•

•

•

•

•

NEMA 23 mounting configuration

•

•

•

•

•

A -

B -

158.9

141.2

123.6

105.9

88.3

70.6

53.0

35.3

17.7

0.0

100

1000

10000

100000

225

200

175

150

125

100

75

50

25

0

Standard Leadwire Configuration

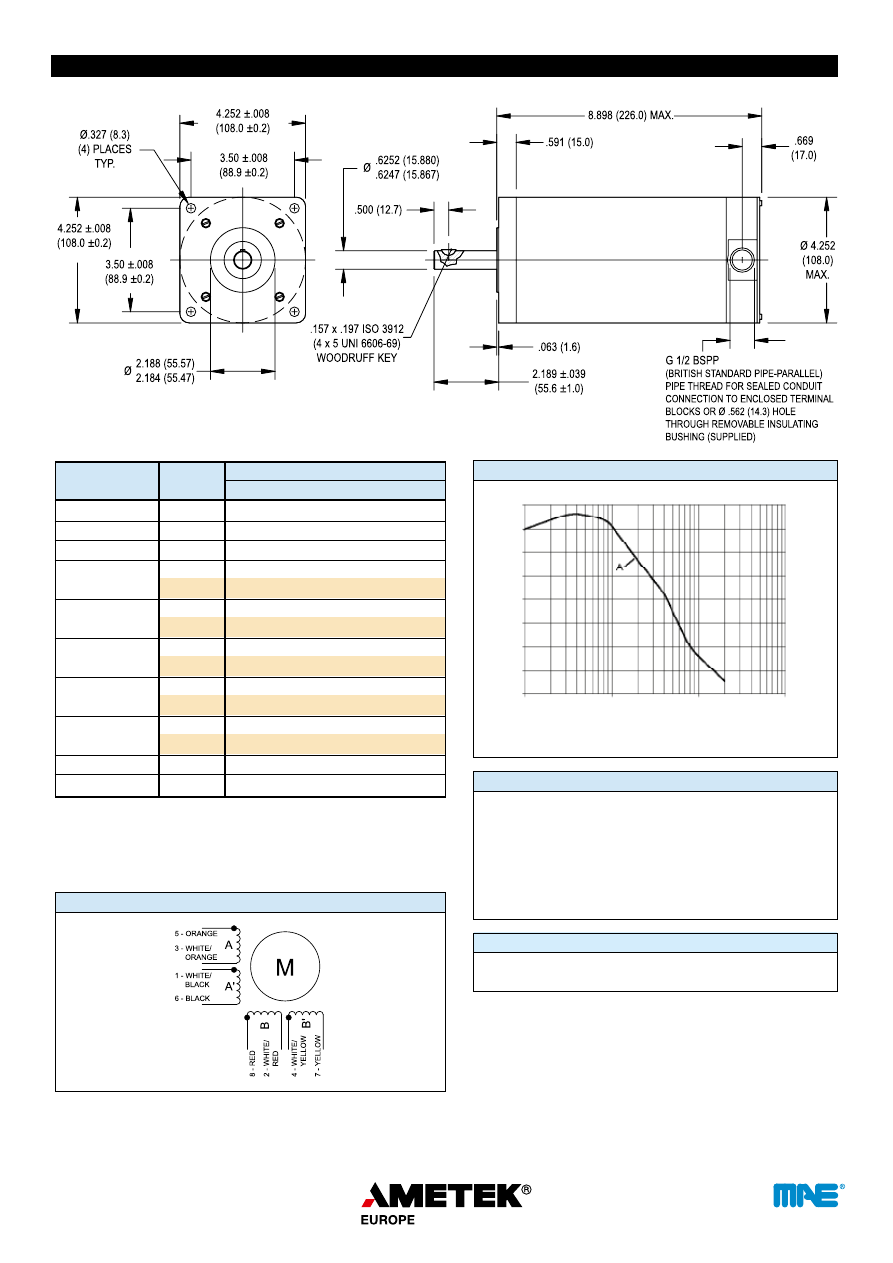

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0210, Bipolar chopper, 36V, 2.1A/Phase

0300, Bipolar chopper, Parallel, 60V, 4.2A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

Specification

Units

HS 200 2231

0210

0300

Rated Phase Current

A

2.10

3.00

Phase Resistance

Ω

2.0

1.1

Phase Inductance

mH

6.5

1.7

Holding Torque

Unipolar

oz-in

Ncm

—

—

177

125

Holding Torque

Bipolar

oz-in

Ncm

228

161

231

163

oz.in

9.6

9.6

Detent Torque

Ncm

6.8

6.8

oz-in-s

2

x10

–4

48

48

Rotor Inertia

g-cm

2

340

340

lb

2.2

2.2

Motor Weight (Mass)

kg

1.0

1.0

Maximum Voltage

V

75

75

Std. No. of Leads

—

4

8

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

16

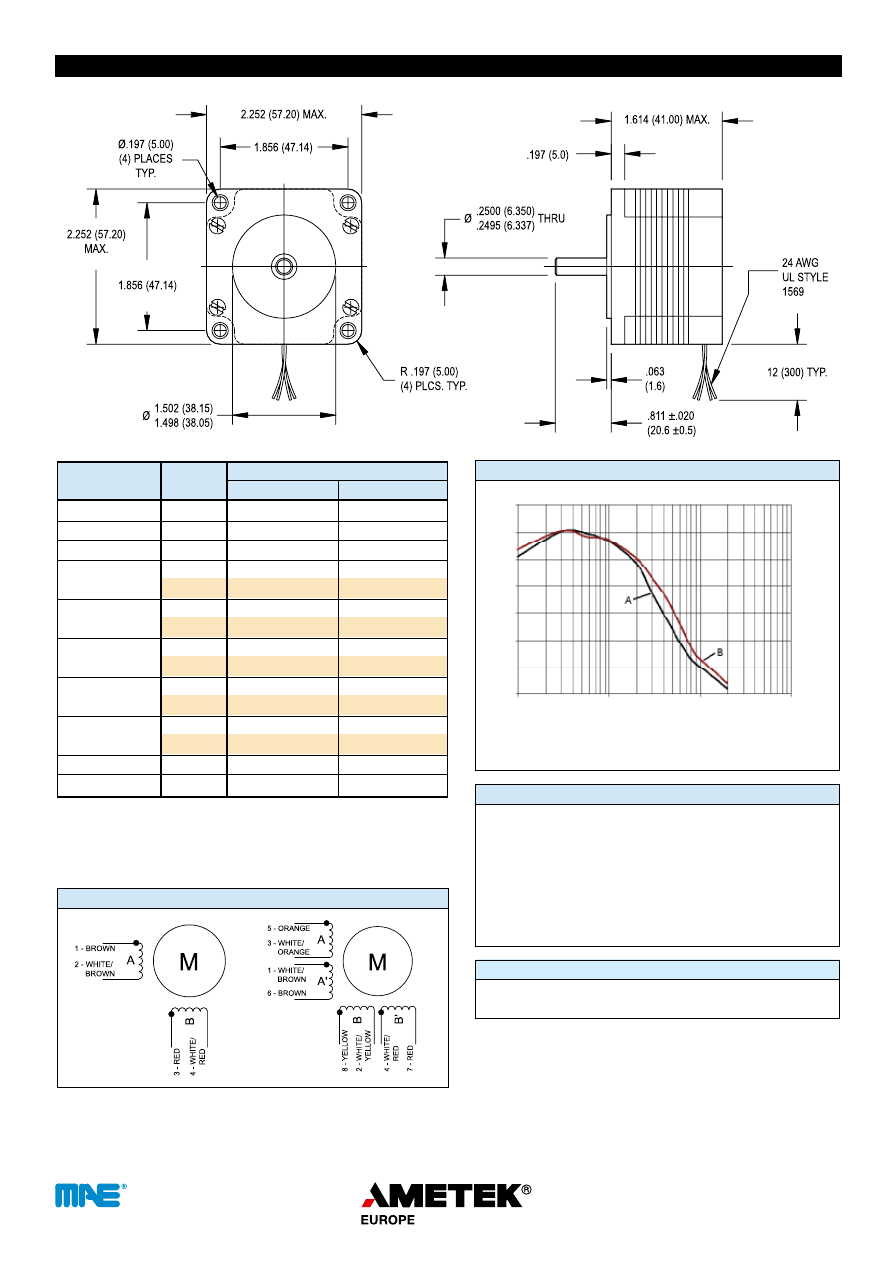

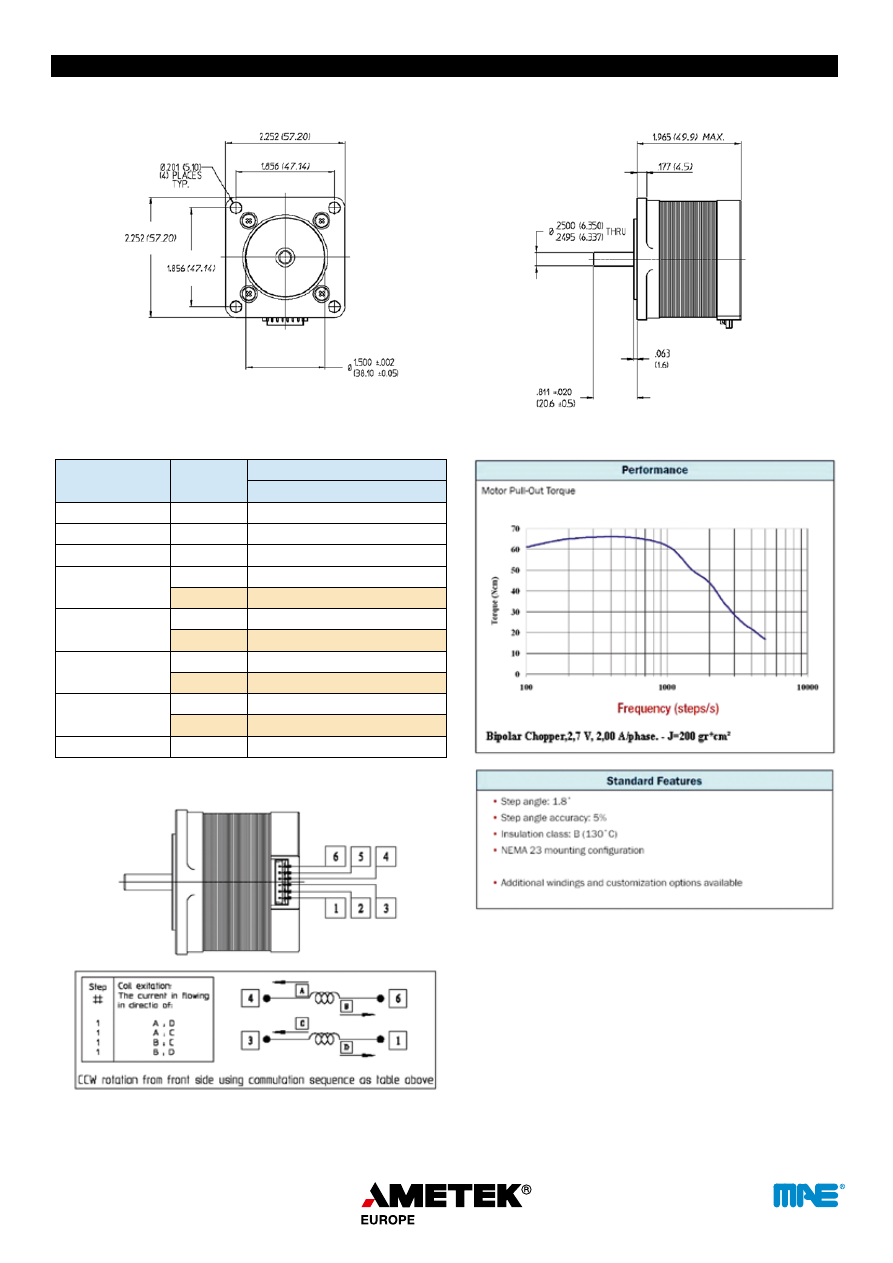

S I Z E 2 3 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

Units

HT 200 2220

0200

Rated Phase Current

A

2.00

Phase Resistance

Ω

1.20

Phase Inductance

mH

3.40

Holding Torque

Bipolar

oz-in

113

Ncm

80

Detent Torque

oz-in

8.5

Ncm

6

Rotor Inertia

oz-in-s

2

x10

-4

18.7

g-cm

2

132

Motor Weight (Mass)

lb

1.1

kg

0.5

Maximum Voltage

V

75

17

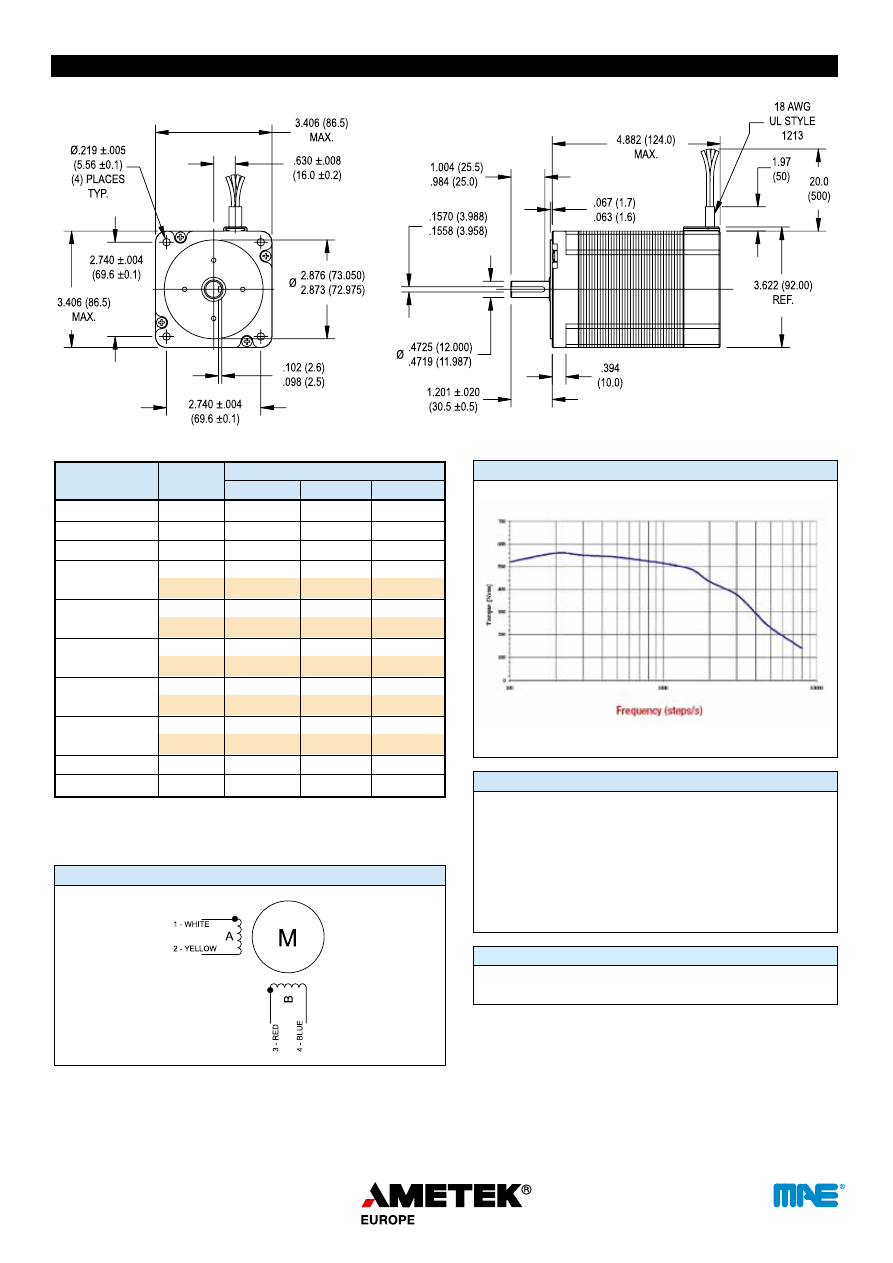

S I Z E 3 4 S T E P P E R M O T O R D A T A

Specification

Units

HN 200 3426

0140 0280 0430

Rated Phase Current

A

1.40

2.80 4.30

Phase Resistance

Ω

5.0

1.3 0.55

Phase Inductance

mH

21

5.1

2.1

Holding Torque

Unipolar

oz-in

Ncm

326

230

326

230

326

230

Holding Torque

Bipolar

oz-in

Ncm

397

280

397

280

397

280

oz.in

12

12

12

Detent Torque

Ncm

8.5

8.5

8.5

oz-in-s

2

x10

–4

93

93

93

Rotor Inertia

g-cm

2

660

660 660

lb

3.5

3.5

3.5

Motor Weight (Mass)

kg

1.6

1.6

1.6

Maximum Voltage

V

90

90

90

Std. No. of Leads

—

8

8

8

Standard Leadwire Configuration

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

B -

C -

247

212

177

141

106

71

35

0

100

1000

10000

100000

350

300

250

200

150

100

50

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0140, Bipolar chopper, Parallel, 60V, 2A/Phase

0280, Bipolar chopper, Parallel, 60V, 4A/Phase

0430, Bipolar chopper, Parallel, 60V, 6A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 3 4 S T E P P E R M O T O R D A T A

18

S I Z E 3 4 S T E P P E R M O T O R D A T A

Specification

0280

A

2.80

4.30

Ω

0.75

mH

3.5

oz-in

538

538

Ncm

380

380

oz-in

680

680

Bipolar

Ncm

480

480

oz.in

Ncm

oz-in-s

2

–4

g-cm

2

1200

1200

lb

5.3

5.3

2.4

2.4

V

90

90

—

8

8

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

B -

424

353

282

212

141

71

0

100

1000

10000

100000

600

500

400

300

200

100

0

Standard Leadwire Configuration

HN 200 3438

Units

0430

Rated Phase Current

Phase Resistance

1.7

Phase Inductance

7.7

Holding Torque

Unipolar

Holding Torque

Detent Torque

18

18

13

13

Rotor Inertia

x10

170

170

Motor Weight (Mass)

kg

Maximum Voltage

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0280, Bipolar chopper, Parallel, 60V, 4A/Phase

0430, Bipolar chopper, Parallel, 60V, 6A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 3 4 S T E P P E R M O T O R D A T A

19

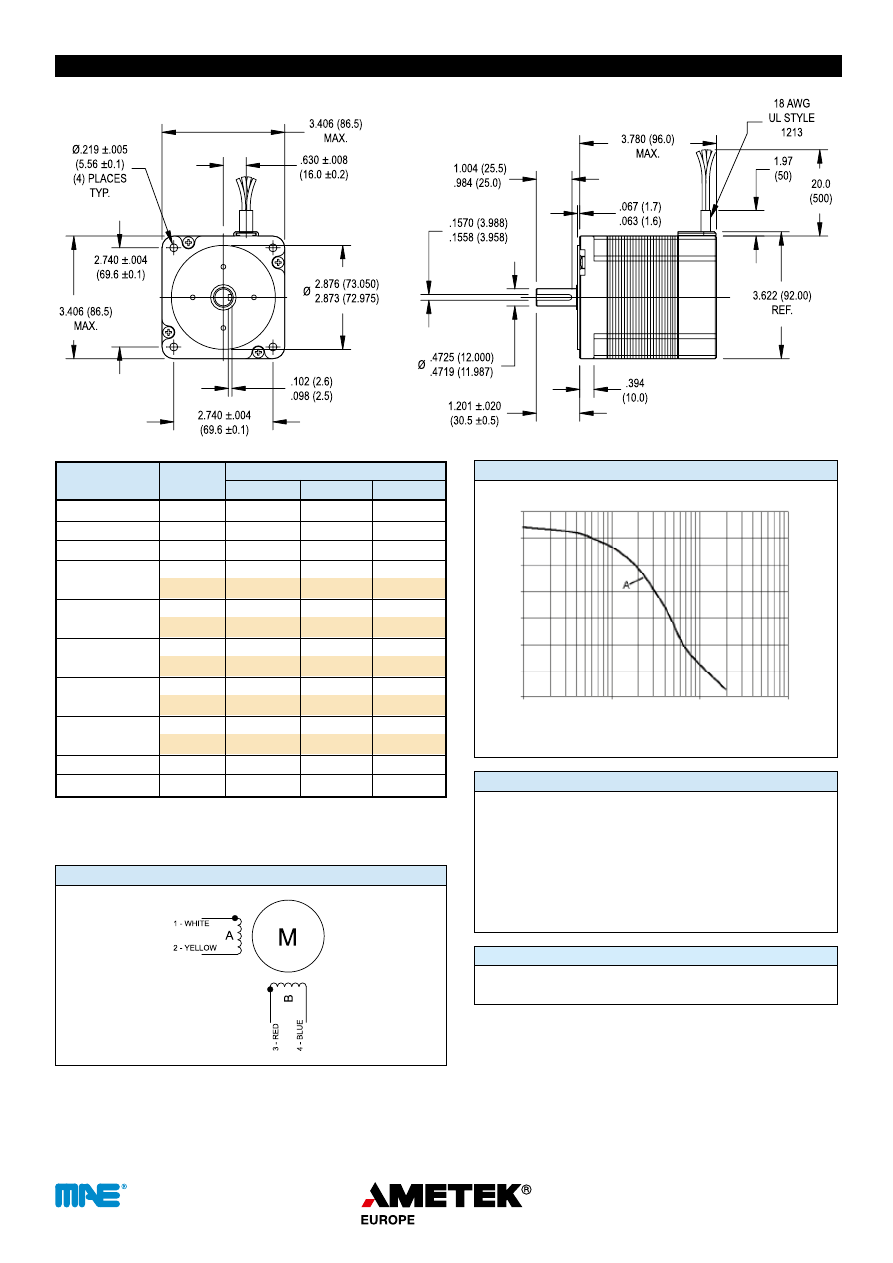

S I Z E 3 4 S T E P P E R M O T O R D A T A

Specification

Units

HN 200 3451

0350

0640

Rated Phase Current

A

3.50

6.40

Phase Resistance

Ω

1.5

0.50

Phase Inductance

mH

8.5

2.5

Holding Torque

Unipolar

oz-in

Ncm

878

620

878

620

Holding Torque

Bipolar

oz-in

Ncm

1076

760

1076

760

oz.in

33

33

Detent Torque

Ncm

23

23

oz-in-s

2

x10

–4

255

255

Rotor Inertia

g-cm

2

1800

1800

lb

7.9

7.9

Motor Weight (Mass)

kg

3.6

3.6

Maximum Voltage

V

140

140

Std. No. of Leads

—

8

8

Standard Leadwire Configuration

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

B -

706

636

565

494

424

353

282

212

141

71

0

100

1000

10000

100000

1000

900

800

700

600

500

400

300

200

100

0

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0350, Bipolar chopper, Parallel, 120V, 5A/Phase

0640, Bipolar chopper, Parallel, 120V, 9A/Phase

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 3 4 S T E P P E R M O T O R D A T A

20

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0300 0550 0800

A

3.00

5.50 8.00

Ω

0.46 0.22

mH

4.0

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm 750 750

750

oz.in

28

28

28

Ncm

20

20

20

oz-in-s

2

–4

548

548

548

g-cm

2

lb

8.8

8.8

8.8

4.0

4.0

4.0

V

—

4

4

4

•

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

L=12000 g cm

2

706

636

565

494

424

353

282

212

141

71

0

100

1000

10000

100000

1000

900

800

700

600

500

400

300

200

100

0

Standard Leadwire Configuration

HS 200 3448

Units

Rated Phase Current

Phase Resistance

1.56

Phase Inductance

14

1.9

Holding Torque

Unipolar

Holding Torque

1062 1062 1062

Detent Torque

Rotor Inertia

x10

3870 3870 3870

Motor Weight (Mass)

kg

Maximum Voltage

160

160

160

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0550, Bipolar chopper, 120V, 5.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

21

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0300 0550 0800

A

3.00

5.50 8.00

Ω

0.55 0.29

mH

20

5.6

2.6

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

oz.in

42

42

42

Ncm

30

30

30

oz-in-s

2

–4

g-cm

2

4900 4900 4900

lb

4.9

4.9

4.9

V

—

4

4

4

•

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

L=12000 g cm

2

B -

L=12000 g cm

2

C -

L=12000 g cm

2

989

847

706

565

424

282

141

0

100

1000

10000

100000

1400

1200

1000

800

600

400

200

0

Standard Leadwire Configuration

HS 200 3455

Units

Rated Phase Current

Phase Resistance

1.70

Phase Inductance

Holding Torque

Unipolar

Holding Torque

1416 1416 1416

1000 1000 1000

Detent Torque

Rotor Inertia

x10

694

694

694

Motor Weight (Mass)

10.8

10.8 10.8

kg

Maximum Voltage

160

160

160

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0300, Bipolar chopper, 120V, 3.0A/Phase, J

0550, Bipolar chopper, 120V, 5.5A/Phase, J

0800, Bipolar chopper, 120V, 8.0A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

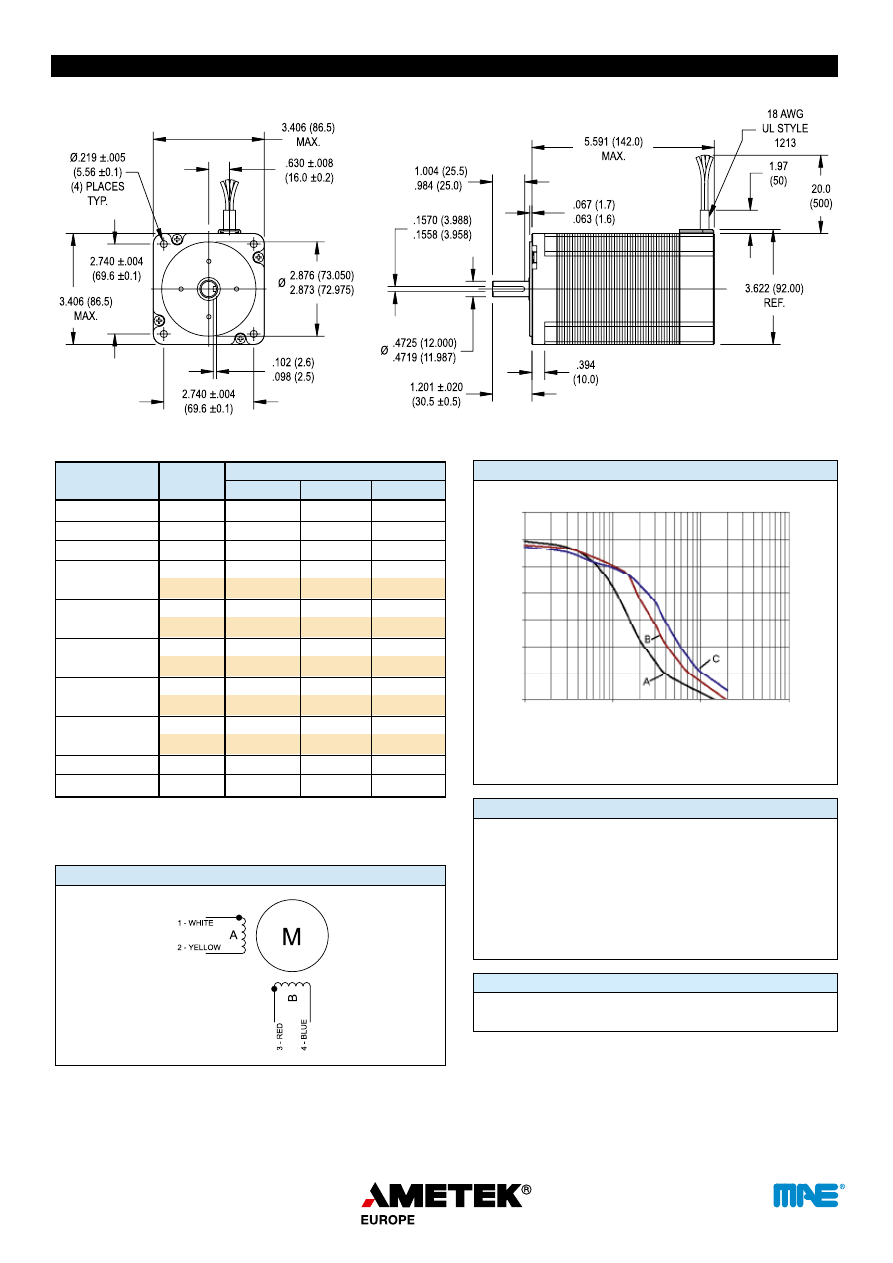

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0300 0550 0800

A

3.00

5.50 8.00

Ω

0.42

mH

3.6

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm 550 550

550

oz.in

28

28

28

Ncm

20

20

20

oz-in-s

2

–4

490

490

490

g-cm

2

3460 3460 3460

lb

6.6

6.6

6.6

3.0

3.0

3.0

V

—

4

4

4

•

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

L=12000 g cm

2

494

424

353

282

212

141

71

0

100

1000

10000 100000

700

600

500

400

300

200

100

0

Standard Leadwire Configuration

HS 200 3437

Units

Rated Phase Current

Phase Resistance

1.37

0.19

Phase Inductance

11

1.6

Holding Torque

Unipolar

Holding Torque

779

779

779

Detent Torque

Rotor Inertia

x10

Motor Weight (Mass)

kg

Maximum Voltage

160

160

160

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0550, Bipolar chopper, 120V, 5.5A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

22

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

Specification

0300 0550 0800

A

3.00

5.50 8.00

Ω

0.55 0.29

mH

20

5.6

2.6

oz-in

—

—

—

Ncm

—

—

—

oz-in

Bipolar

Ncm

oz.in

42

42

42

Ncm

30

30

30

oz-in-s

2

–4

g-cm

2

4900 4900 4900

lb

4.9

4.9

4.9

V

—

4

4

4

•

•

•

•

•

NEMA 34 mounting configuration

•

•

•

•

•

A -

L=12000 g cm

2

B -

L=12000 g cm

2

C -

L=12000 g cm

2

989

847

706

565

424

282

141

0

100

1000

10000

100000

1400

1200

1000

800

600

400

200

0

Standard Leadwire Configuration

HS 200 3455

Units

Rated Phase Current

Phase Resistance

1.70

Phase Inductance

Holding Torque

Unipolar

Holding Torque

1416 1416 1416

1000 1000 1000

Detent Torque

Rotor Inertia

x10

694

694

694

Motor Weight (Mass)

10.8

10.8 10.8

kg

Maximum Voltage

160

160

160

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

Optimized for microstep operation

Neodymium magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0300, Bipolar chopper, 120V, 3.0A/Phase, J

0550, Bipolar chopper, 120V, 5.5A/Phase, J

0800, Bipolar chopper, 120V, 8.0A/Phase, J

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

23

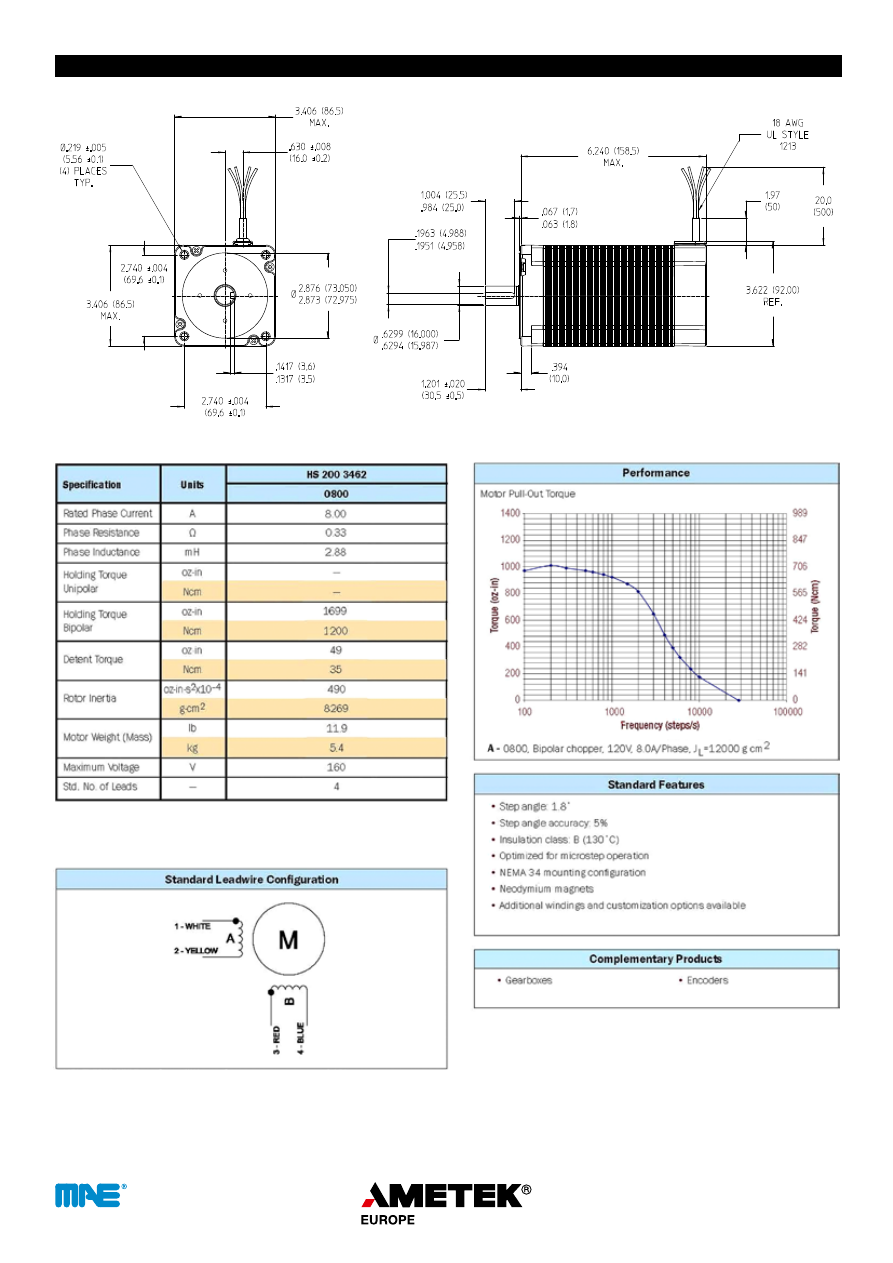

S I Z E 3 4 H I G H P E R F O R M A N C E S T E P P E R M O T O R D A T A

24

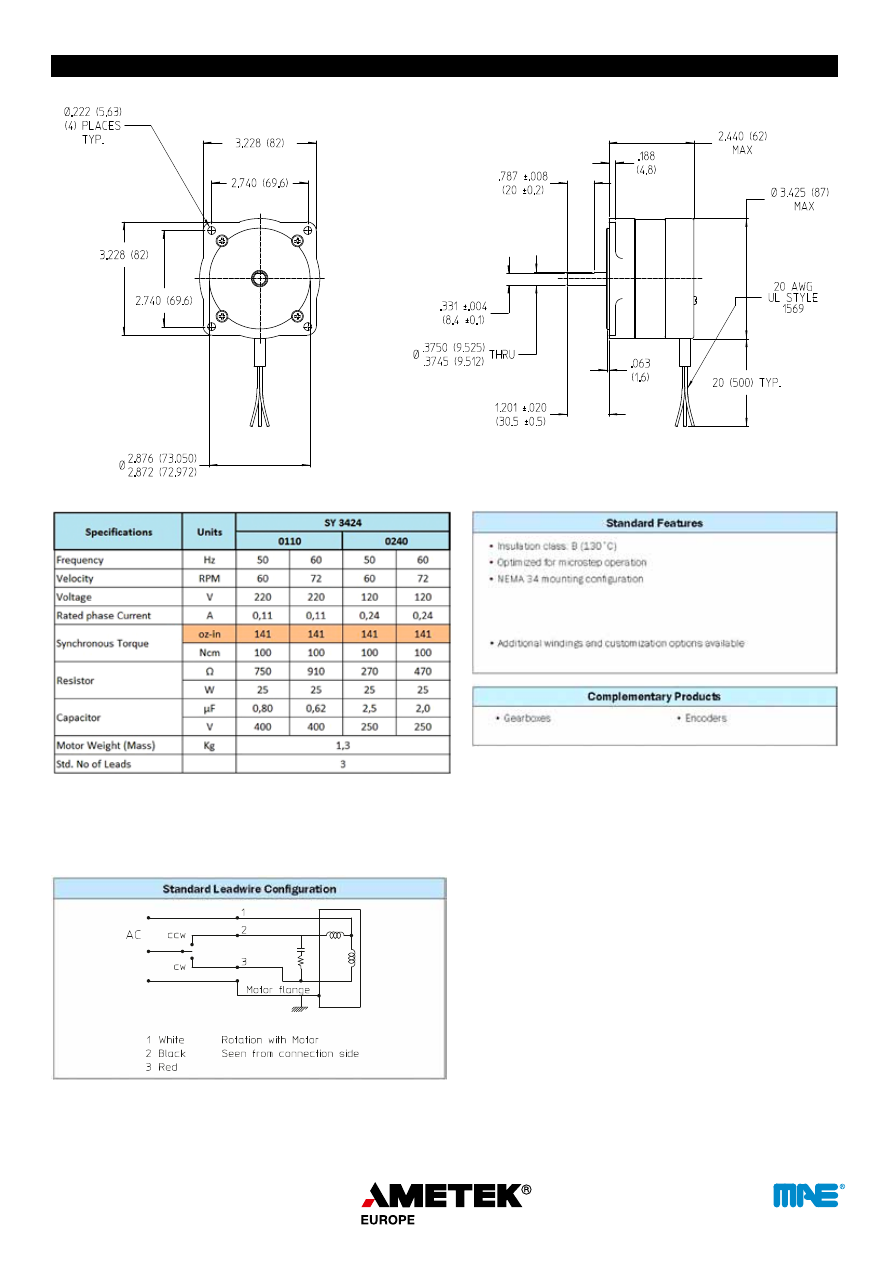

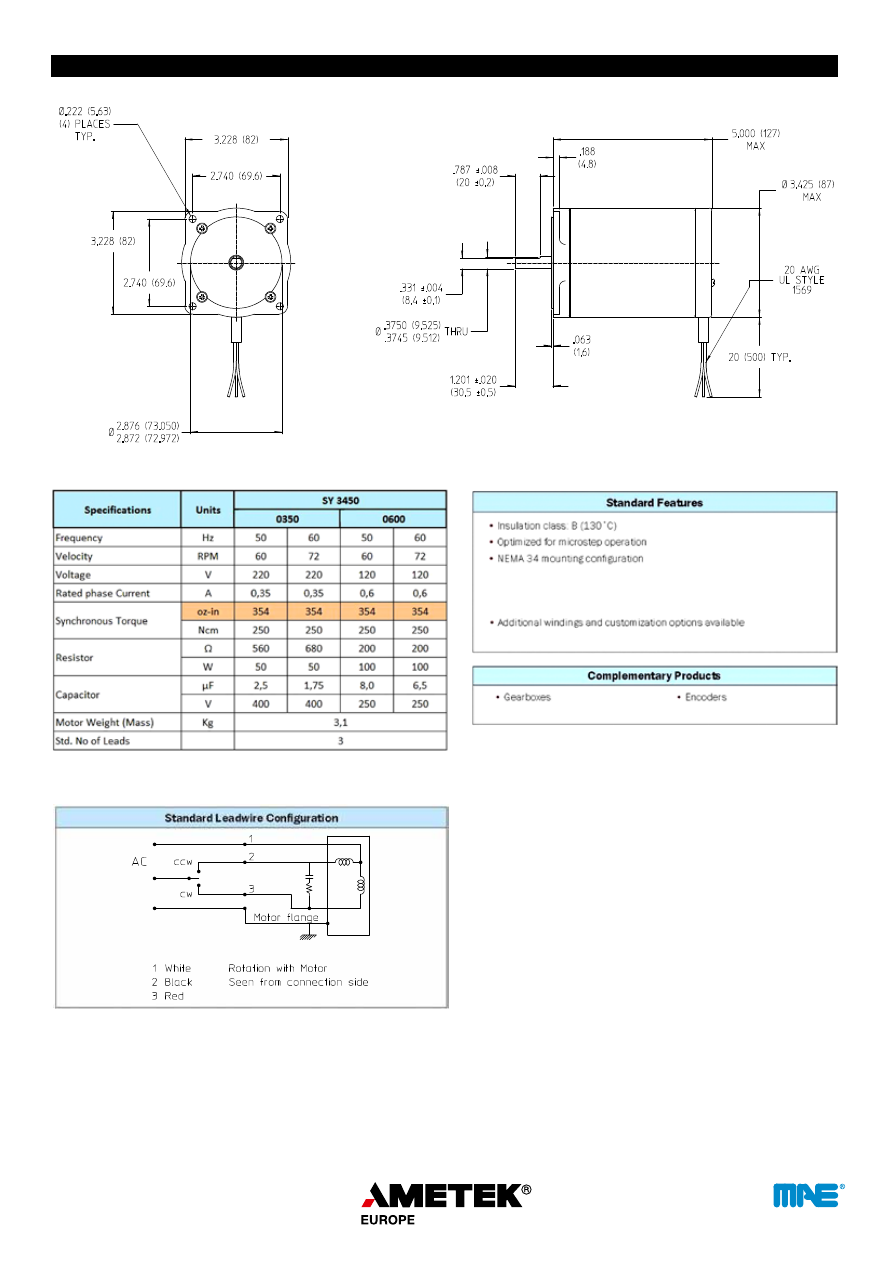

S I Z E 3 4 S Y N C H R O N O U S M O T O R D A T A

25

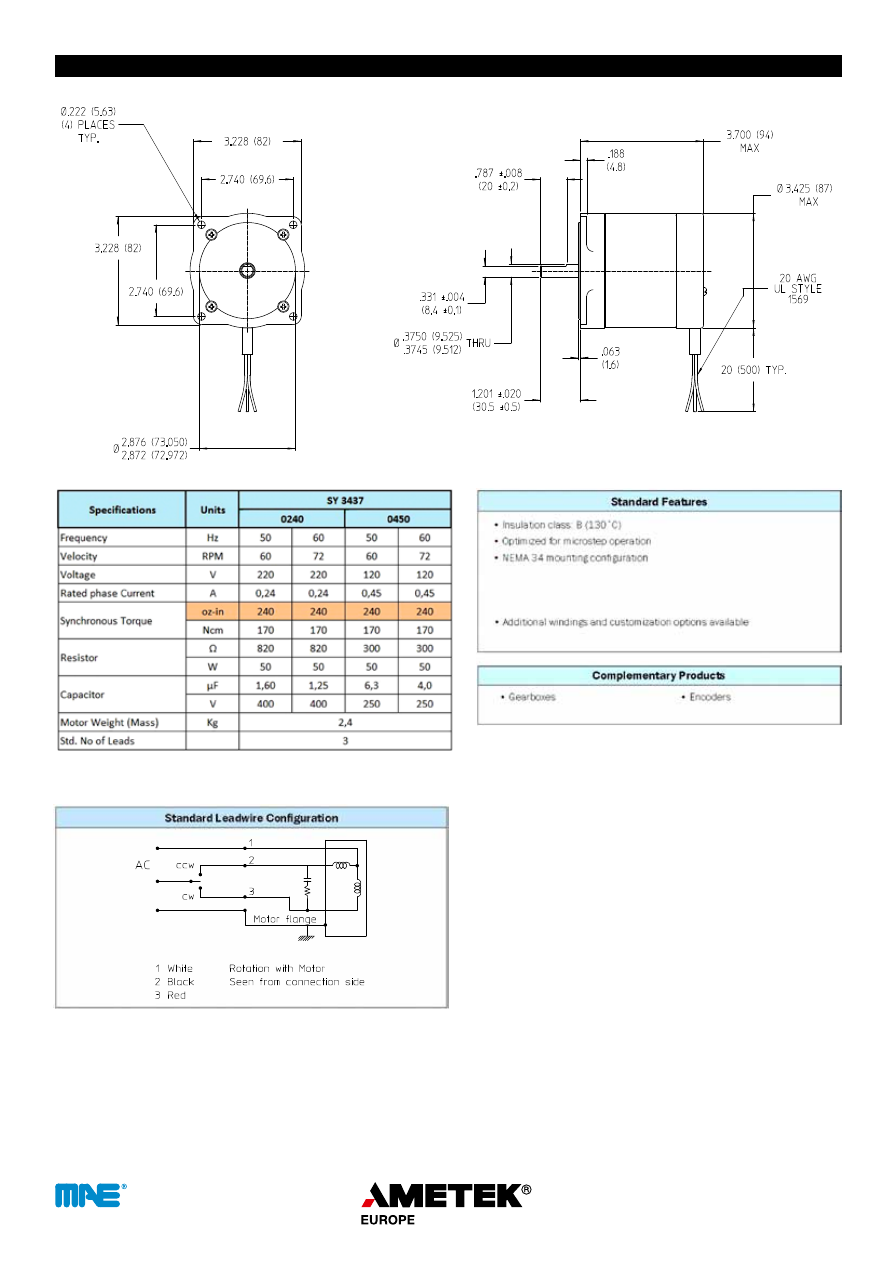

S I Z E 3 4 S Y N C H R O N O U S M O T O R D A T A

26

S I Z E 3 4 S Y N C H R O N O U S M O T O R D A T A

27

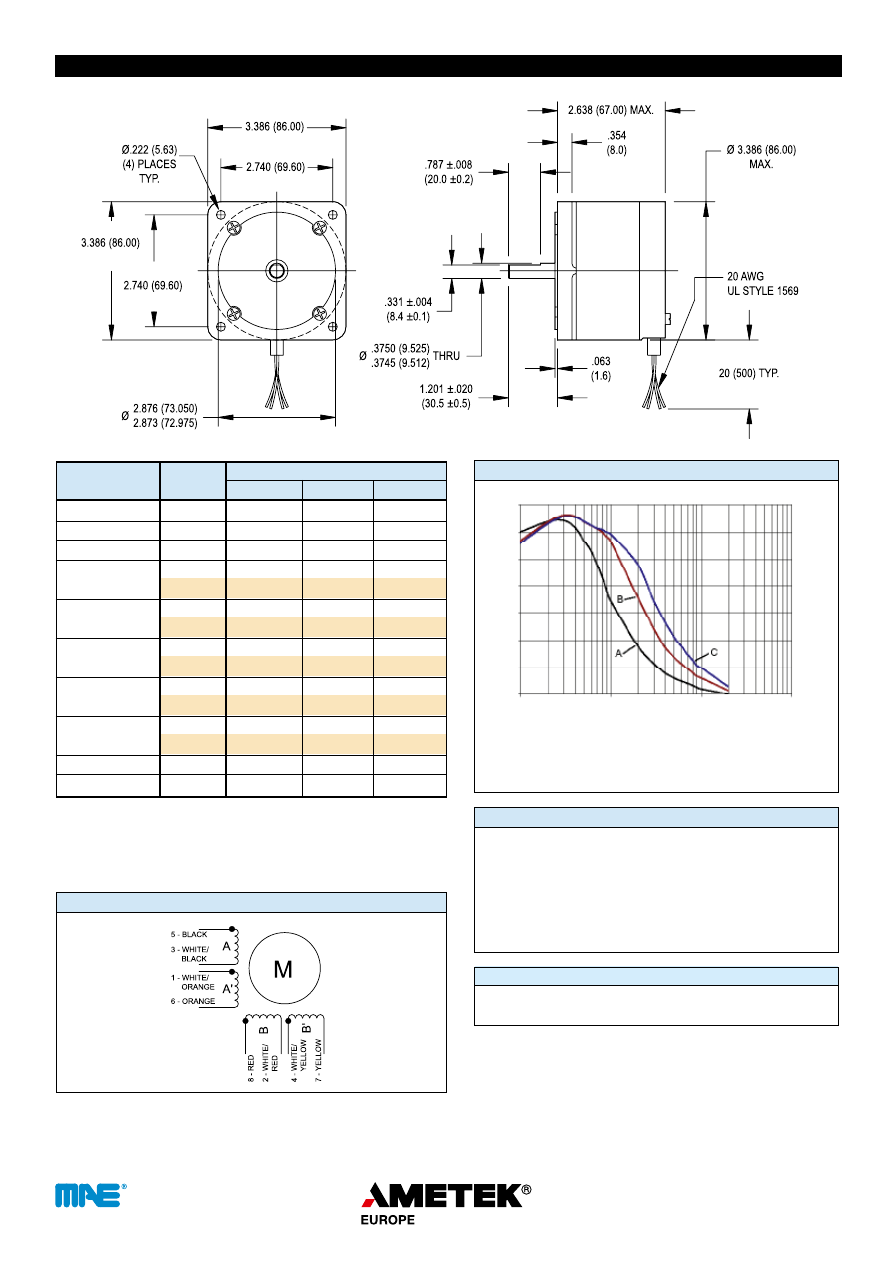

S I Z E 4 2 S T E P P E R M O T O R D A T A

Specification

0340

0900

A

3.40

9.00

Ω

0.30 0.34

mH

6.3

2.0

2.7

oz-in

Ncm

798

830

oz-in

Bipolar

Ncm

990

oz.in

99

99

99

Ncm

70

70

70

oz-in-s

2

–4

g-cm

2

5500 5500 5500

lb

V

—

8

8

8

•

•

•

•

NEMA 42 mounting configuration

•

•

•

•

•

A -

B -

C -

989

847

706

565

424

282

141

0

100

1000

10000

100000

1400

1200

1000

800

600

400

200

0

Standard Leadwire Configuration

HY 200 4270

Units

0710

Rated Phase Current

7.10

Phase Resistance

1.1

Phase Inductance

Holding Torque

1130 1175 1450

Unipolar

1024

Holding Torque

1402 1459 1798

1030 1270

Detent Torque

Rotor Inertia

x10

779

779 779

Motor Weight (Mass)

16

16

16

kg

7.3

7.3

7.3

Maximum Voltage

140

140 140

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0340, Bipolar chopper, Parallel, 120V, 4.8A/Phase

0710, Bipolar chopper, Parallel, 140V, 10A/Phase

0900, Bipolar chopper, Parallel, 140V, 12A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

S I Z E 4 2 S T E P P E R M O T O R D A T A

28

S I Z E 4 2 S T E P P E R M O T O R D A T A

Specification

0890

A

8.90

Ω

mH

2.3

oz-in

Ncm

oz-in

Bipolar

Ncm

oz.in

92

Ncm

65

oz-in-s

2

–4

g-cm

2

8300

lb

23

V

—

8

•

•

•

•

NEMA 42 mounting configuration

•

•

•

•

•

A -

1130

989

847

706

565

424

282

141

0

100

1000

10000

100000

1600

1400

1200

1000

800

600

400

200

0

Standard Leadwire Configuration

HY 200 4288

Units

Rated Phase Current

Phase Resistance

0.31

Phase Inductance

Holding Torque

1614

Unipolar

1140

Holding Torque

2018

1425

Detent Torque

Rotor Inertia

x10

1175

Motor Weight (Mass)

kg

10.5

Maximum Voltage

140

Std. No. of Leads

Performance

Motor Pull-Out Torque

Standard Features

Step angle: 1.8˚

Step angle accuracy: 5%

Insulation class: B (130˚C)

AINiCo magnets

Additional windings and customization options available

Complementary Products

Gearboxes

Encoders

0890, Bipolar chopper, Parallel, 140V, 12A/Phase

Available through the MotionExpress program.

Tor

que (oz-in)

Tor

que (Ncm)

Frequency (steps/s)

TECHNICAL & INDUSTRIAL PRODUCTS

S I Z E 4 2 S T E P P E R M O T O R D A T A

29

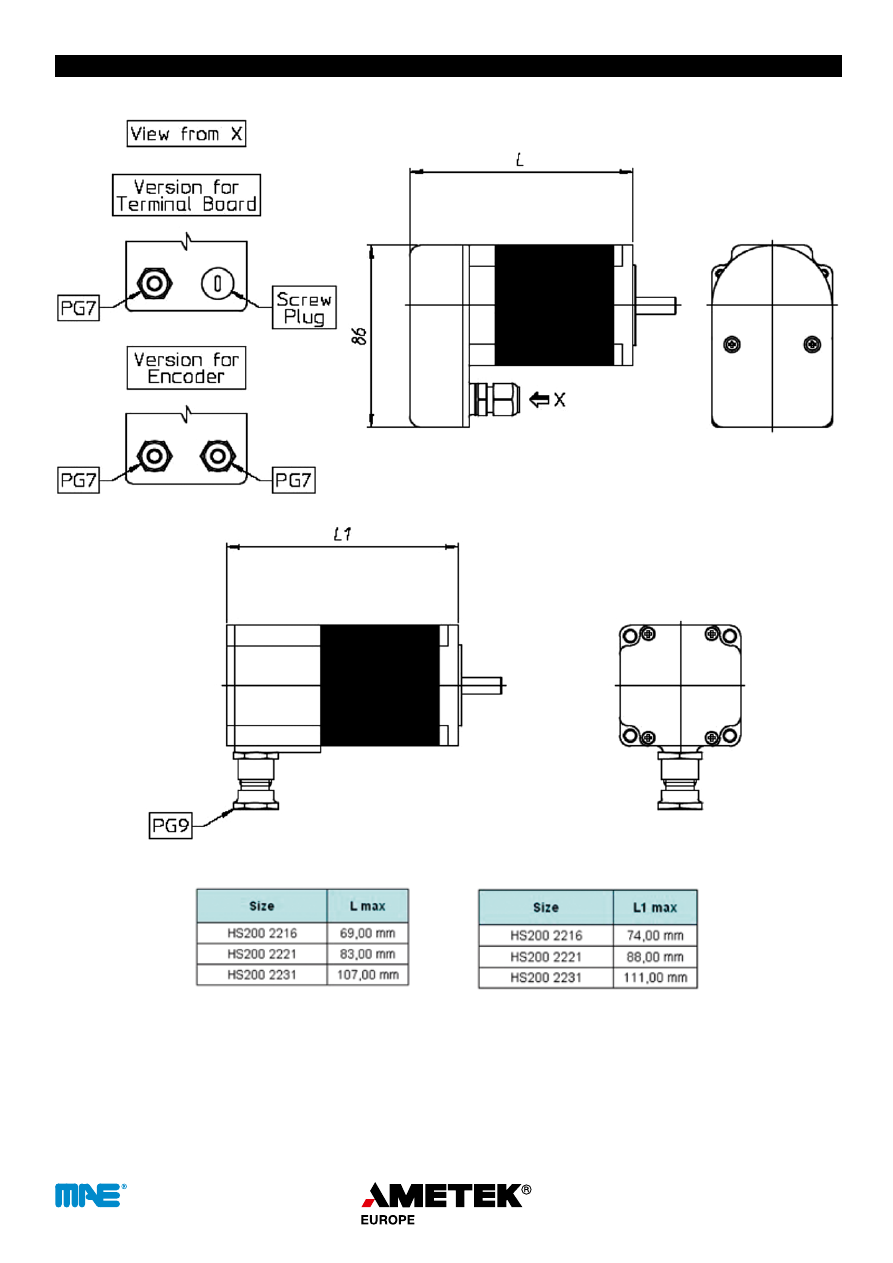

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 2 3

30

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 2 3

31

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 3 4

32

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 3 4

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 3 4

C U S T O M I Z A T I O N S / O P T I O N S S I Z E 3 4

33

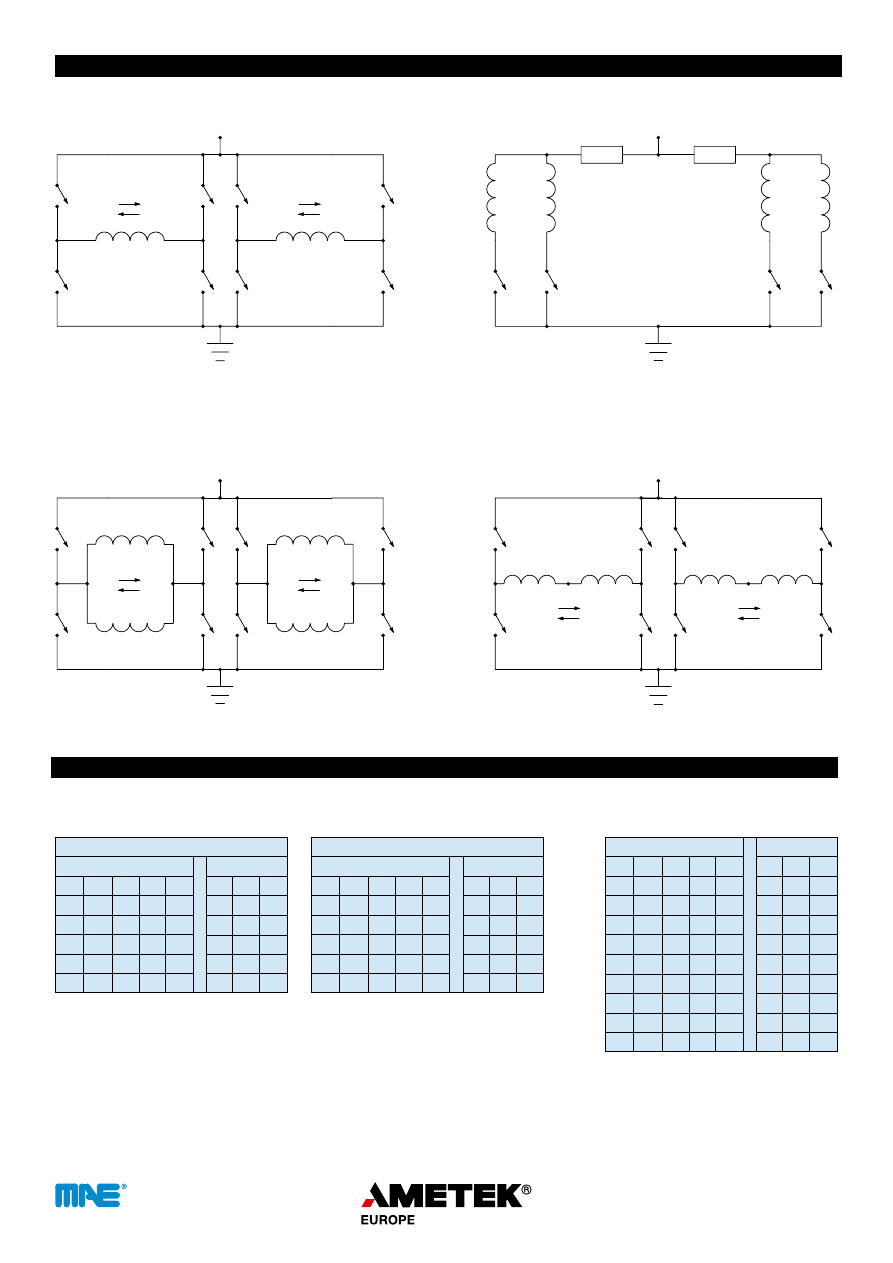

C O N N E C T I O N D I A G R A M S

BIPOLAR

UNIPOLAR

1

2

A

+

3

4

A'

1

5

A

6

4

7

3

8

+

2

B

B'

B

+

-

-

+

-

+

+

-

BIPOLAR (PARALLEL)

5

A'

3

+

A

1

6

Rs

2

B

8

4

7

B'

Rs

BIPOLAR (SERIES)

5

A

+

3 1

6

A'

2

8

B

7

4

B'

+

-

-

+

C O N N E C T I O N D I A G R A M S

S T E P S E Q U E N C E S

FULL STEP OPERATION

HALF STEP OPERATION

One Phase On

Unipolar

Bipolar

A A’ B B’

A B

1 + 0 0 0 1 0 +

2 0 0 + 0 2 – 0

3 0 + 0 0 3 0 –

4 0 0 0 + 4 + 0

1 + 0 0 0 1 0 +

Two Phases On

Unipolar

Bipolar

A A’ B B’

A B

1 + 0 0 + 1 + –

2 + 0 + 0 2 + +

3 0 + + 0 3 – +

4 0 + 0 + 4 – –

1 + 0 0 + 1 + –

Unipolar

Bipolar

A A’ B B’

A B

1 + 0 0 + 1 + +

2 + 0 0 0 2 0 +

3 + 0 + 0 3 – +

4 0 0 + 0 4 – 0

5 0 + + 0 5 – –

6 0 + 0 0 6 0 –

7 0 + 0 + 7 + –

8 0 0 0 + 8 + 0

1 + 0 0 + 1 + +

NOTE:

Following the above steps in sequential order results in clockwise rotation of the shaft when viewed from the

mounting end. Reversing the sequence results in counter-clockwise rotation.

S T E P S E Q U E N C E S

34

Australia & New Zealand:

MOTION SOLUTIONS AUSTRALIA PTY Ltd.

Factory 2, 21-29 Railway Avenue

Huntingdale, 3166

PH: +613 9563 0115

FAX: +613 9568 4667

www.motion-solutions.com.au

Austria & Hungary:

BURISCH ELEKTRONIK BAUTEILE GmbH

Burisch Elektronik Bauteile GmbH

Leopoldauer Straße 29

1210 Wien

Tel.: +43-1-277 20-254

Fax: +43-1-277 20-6

www.beb.co.at

Denmark:

COMPOWER A/S

Smedeholm 13/A

2730 Herlev

Denmark

Phone +45 44 92 66 20

Direct +45 44 50 83 61

Fax +45 44 92 66 02

Mob. +45 26 70 40 82

Finland & Russia:

WEXON O

Juhanilantie 4

FI-01740 Vantaa

Finland

Tel.

+358 9 290 44145 (Direct)

Tel.

+358 9 290 440

Fax: +358 9 290 44100

www.wexon.com

France:

SODIMATEL

Z.l les Amadiers

11,rue des Entrepreneurs – B.P. 168

78421 CARRIERES SUR SEINE CEDEX

France

Tél : +33 (0) 1 39.13.07.70

Fax : +33 (0) 1 39.14.42.87

www.sodimatel.com

ROSIER s.a.

13, rue Sigmund FREUD

69120 VAULX-EN-VELIN

Tél: 04 72 04 68 61

Fax : 04 72 04 37 38

www.rosier.fr

Italy:

PAMOCO S.p.A.

Via Riccardo Lombardi, 19/6

20153 Milano

Tel.

+39 02 3456091

Fax +39 02 33104342

www.pamoco.it

Sweden:

PROMOCO SCANDINAVIA AB

Propellervägen 4A

183 62 Täby

Sweden

Tel.

+46 (0)8 792 91 52

Cell. +46 (0) 70 6633898

www.promoco.se

Netherland & Belgium:

ERIKS bv

Aandrijftechniek Schoonhoven

Broeikweg 25, 2871 RM Schoonhoven

Tel.: +31 (0)182 32 32 38

Fax: +31 (0)182 38 69 20

Mob.: +31 (0)6 539 366 43

www.eriks-at.nl

Spain:

ELMEQ

C/ Vilamarí, 50 - 08015 Barcelona

Tel:

+34 93 292 78 43

Fax: +34 93 432 36 60

www.elmeqmotor.es

United Kingdom:

McLENNAN SERVO SUPPLIES LIMITED

Unit 1, The Royston Centre, Lynchford Lane

Ash Vale, GU12 5PQ

United Kingdom

Direct Line:

+44 (0)8707 700666

Mobile:

+44 (0)7887 532124

Main Line:

+44 (0)8707 700700

Fax:

+44 (0)8707 700699

www.mclennan.co.uk

ASTROSYN INTERNATIONAL TECHNOLOGY Ltd.

The Old Courthouse

New Road Avenue

Chatham

Kent, ME4 6BE

Tel:

+44 (0) 1634 815175

Fax: +44 (0) 1634 826552

www.astrosyn.com

A M E T E K E U R O P E

M A E S T E P P E R M O T O R S D I S T R I B U T O R S

Marketing & Engineerig:

Ametek Italia S.r.l.

Via de Gasperi 18/a

26010 Ripalta Cremasca (CR)

Italy

Tel.: +39 0373 210247

Fax: +39 0373 210295

e-mail: infosteppers@ametek.it

www.ametekfsm.com

Production & Sales:

Ametek elektromotory s.r.o.

Beloveska 318

547 01 Nachod, Czech Republic

Tel.: +420-494-943041

Fax: +420-494-943049

Mobile +420-602-499677

e-mail: infosteppers@ametek.it

www.ametekfsm.com

AMETEK Inc.

is a leading global manufacturer of electronic instruments and electromechanical devices with

annualized sales of $ 3.4 billions.

AMETEK has approximately 13,300 colleagues working at more than 100 manufacturing facilities

and more than 100 sales and service centers in the United States and around the world.