Please contact ..........

Specifications are subject to change without notice.

ASCTB376E-1 20170

9

-3YKN

Electromechanical Control Business Division

1006, Oaza Kadoma, Kadoma-shi, Osaka 571-8506, Japan

industrial.panasonic.com/ac/e/

©Panasonic Corporation 2017

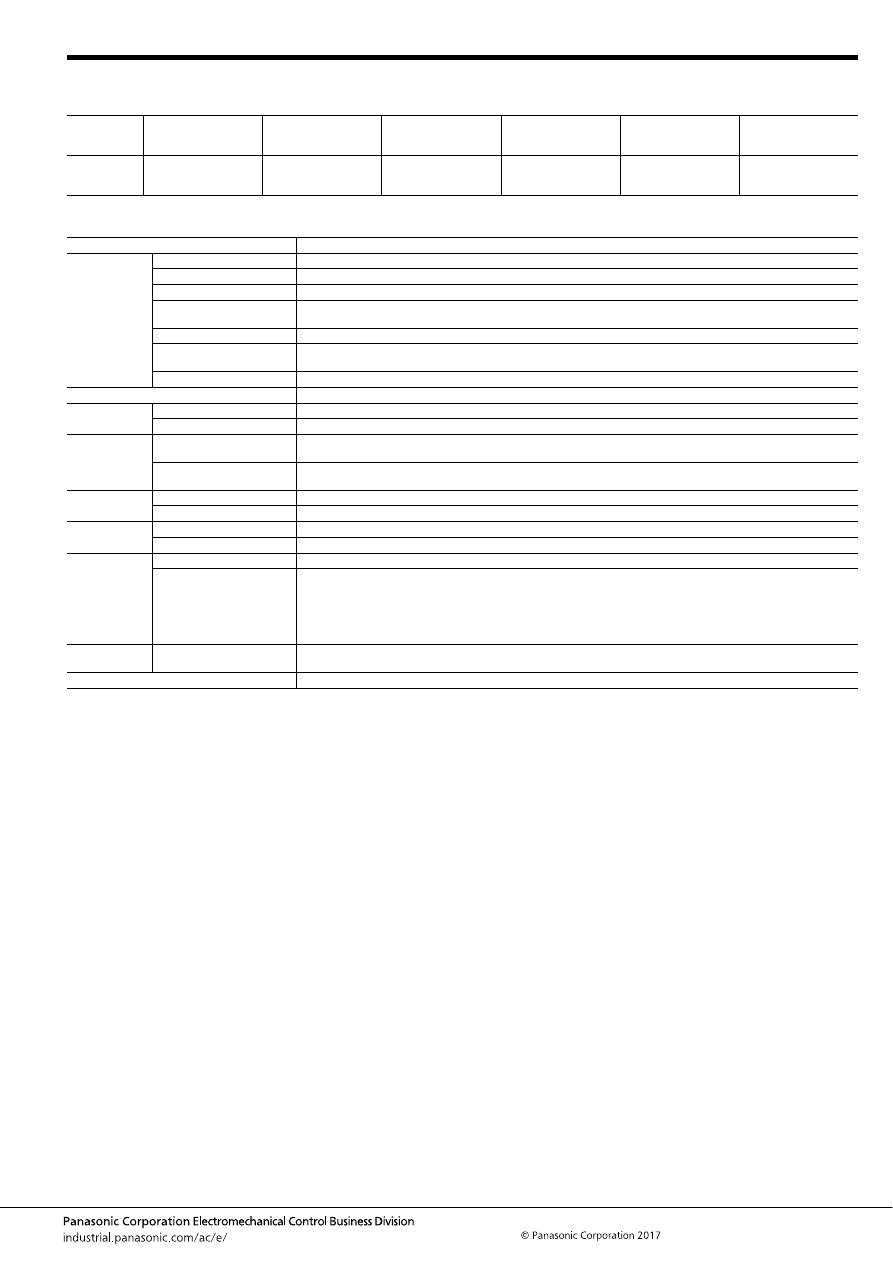

8mm

industrial.panasonic.com/ac/e/

2017-2018

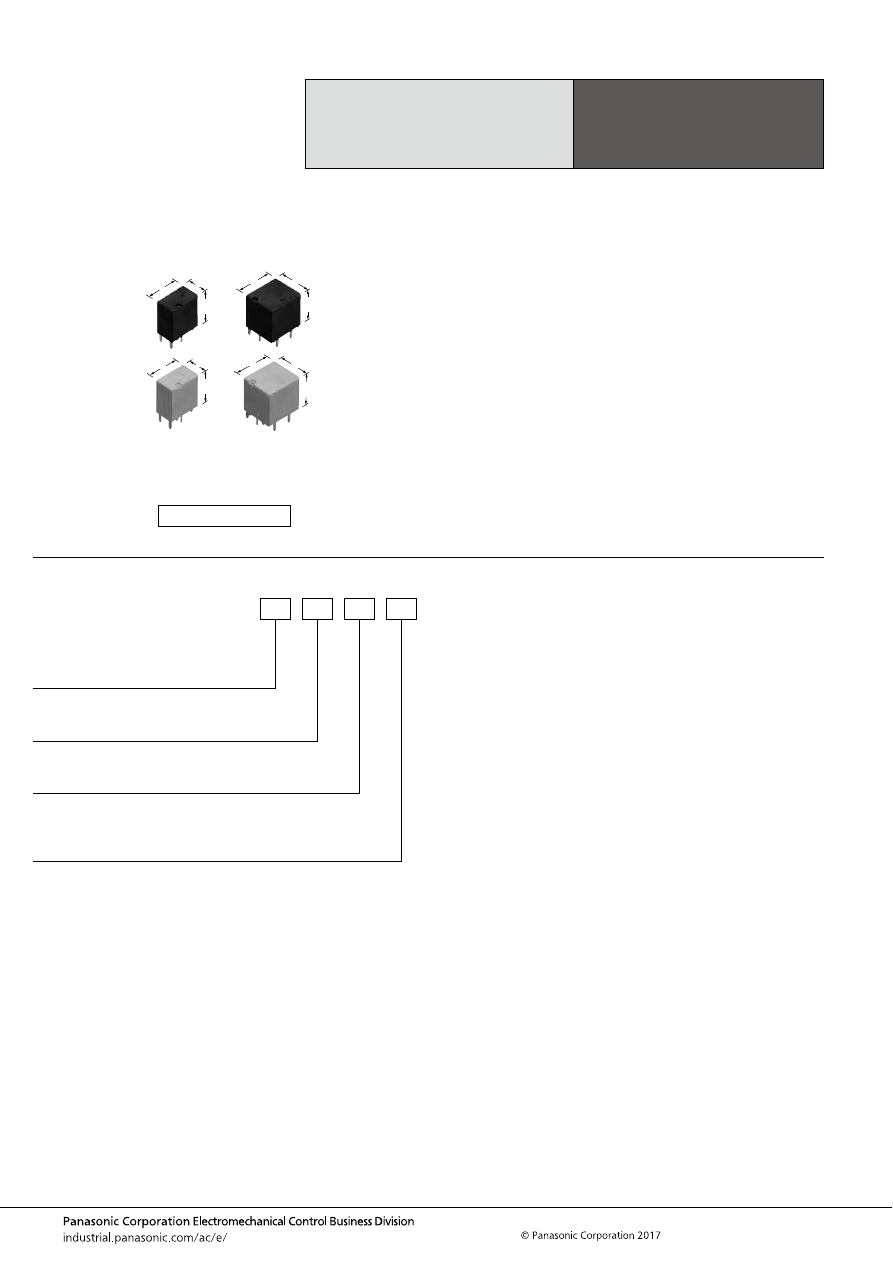

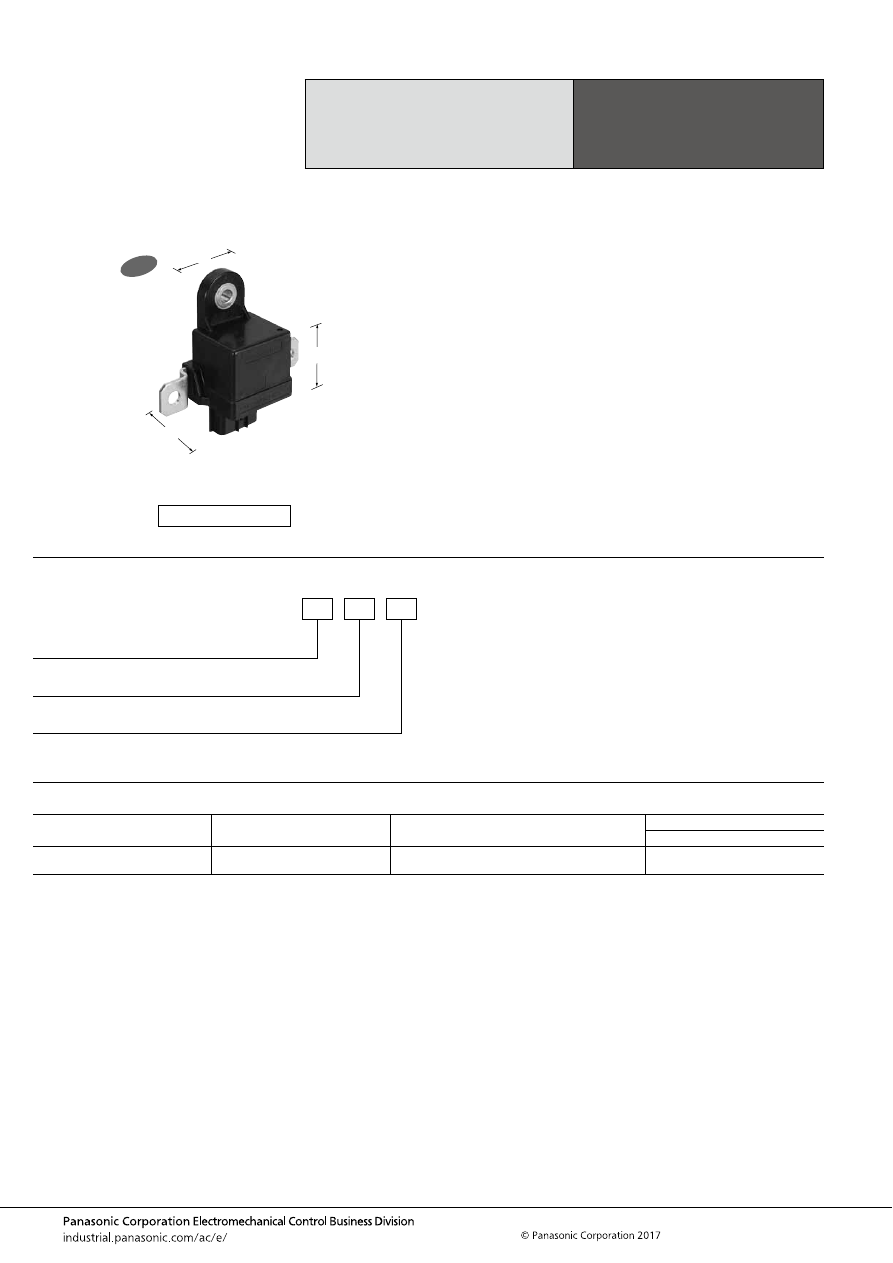

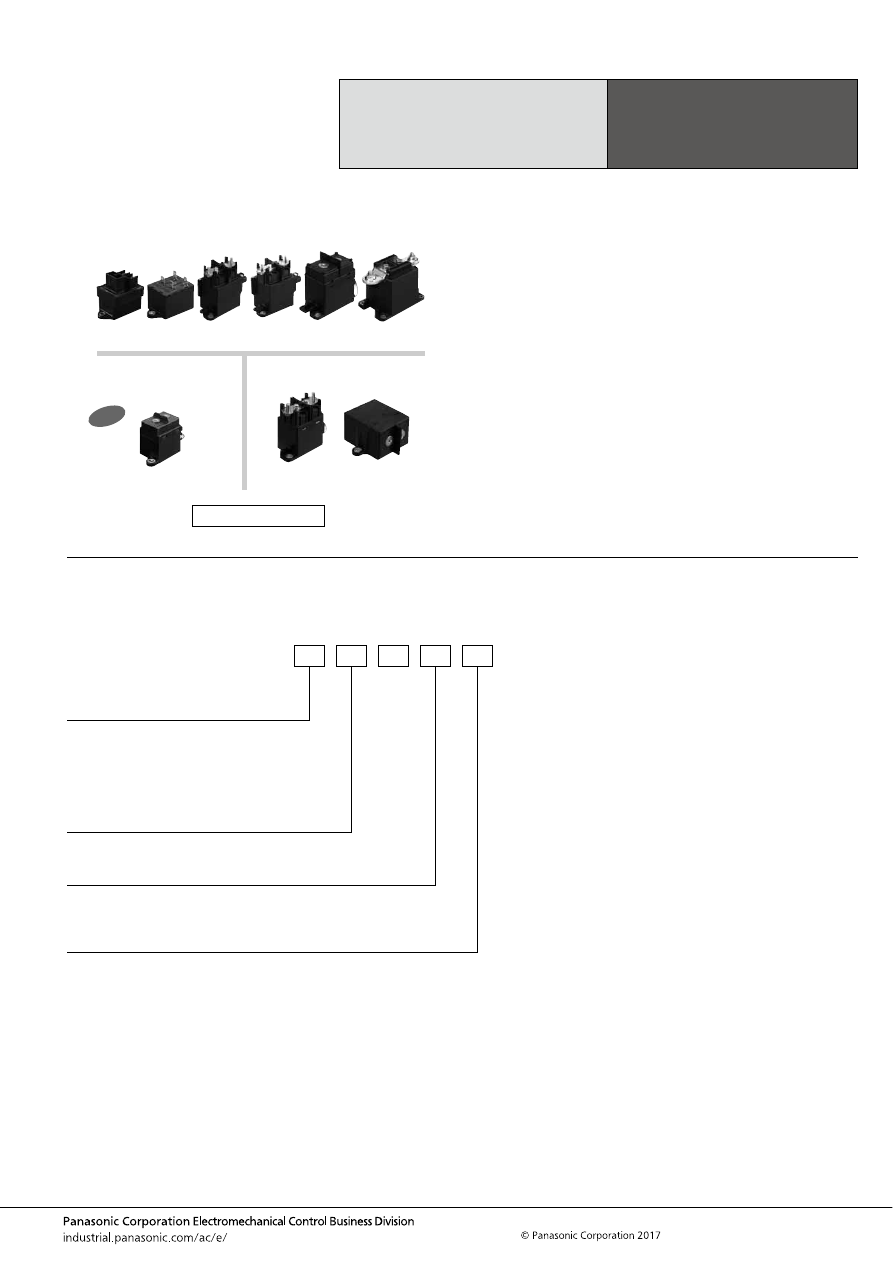

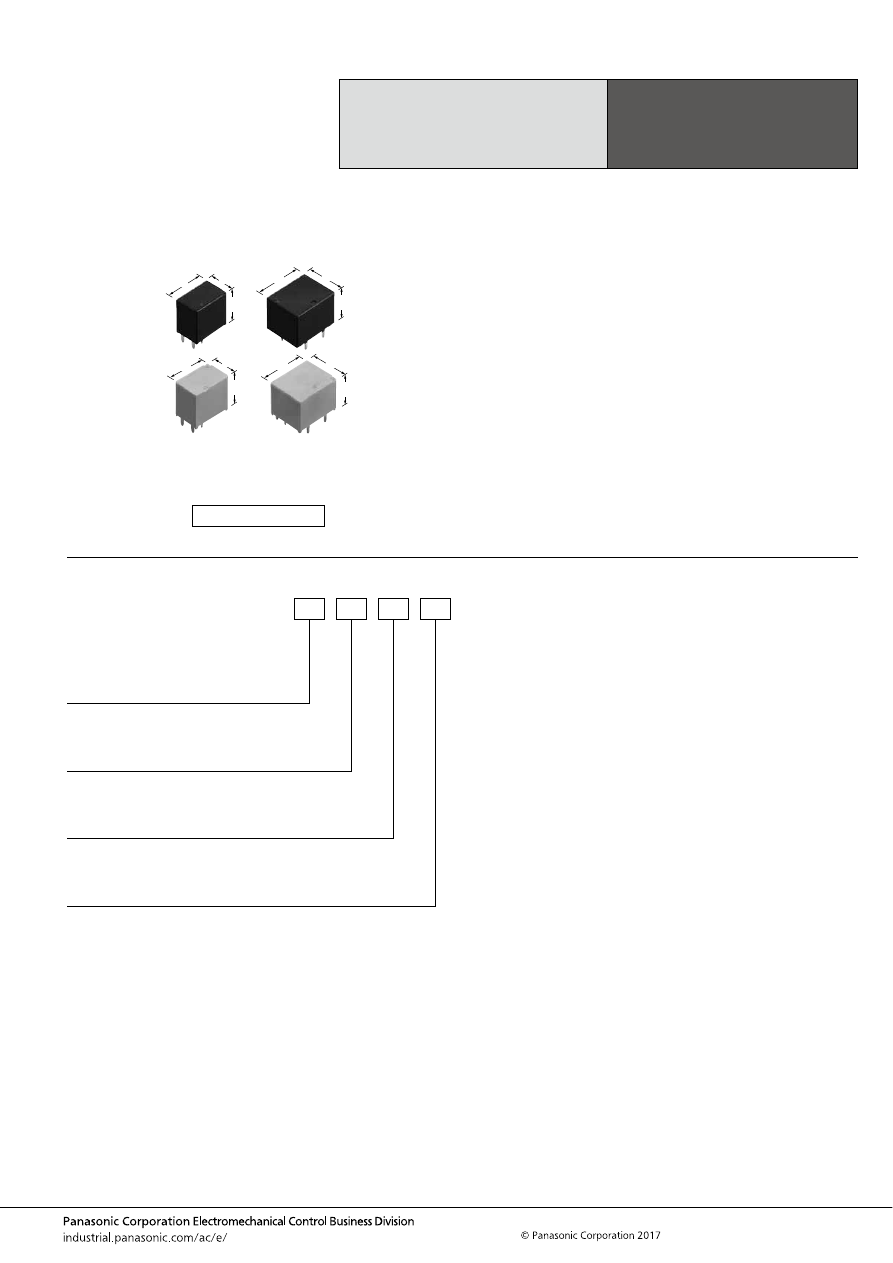

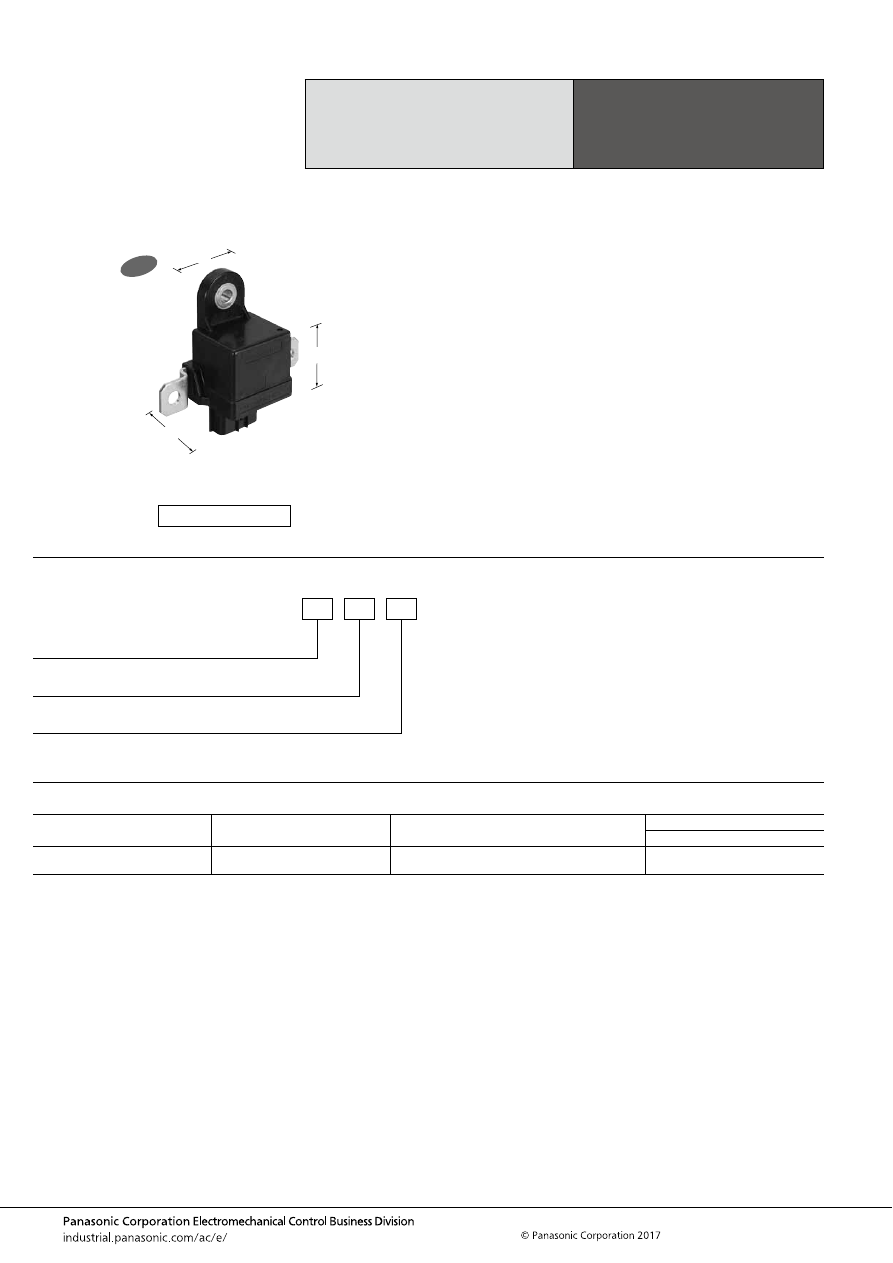

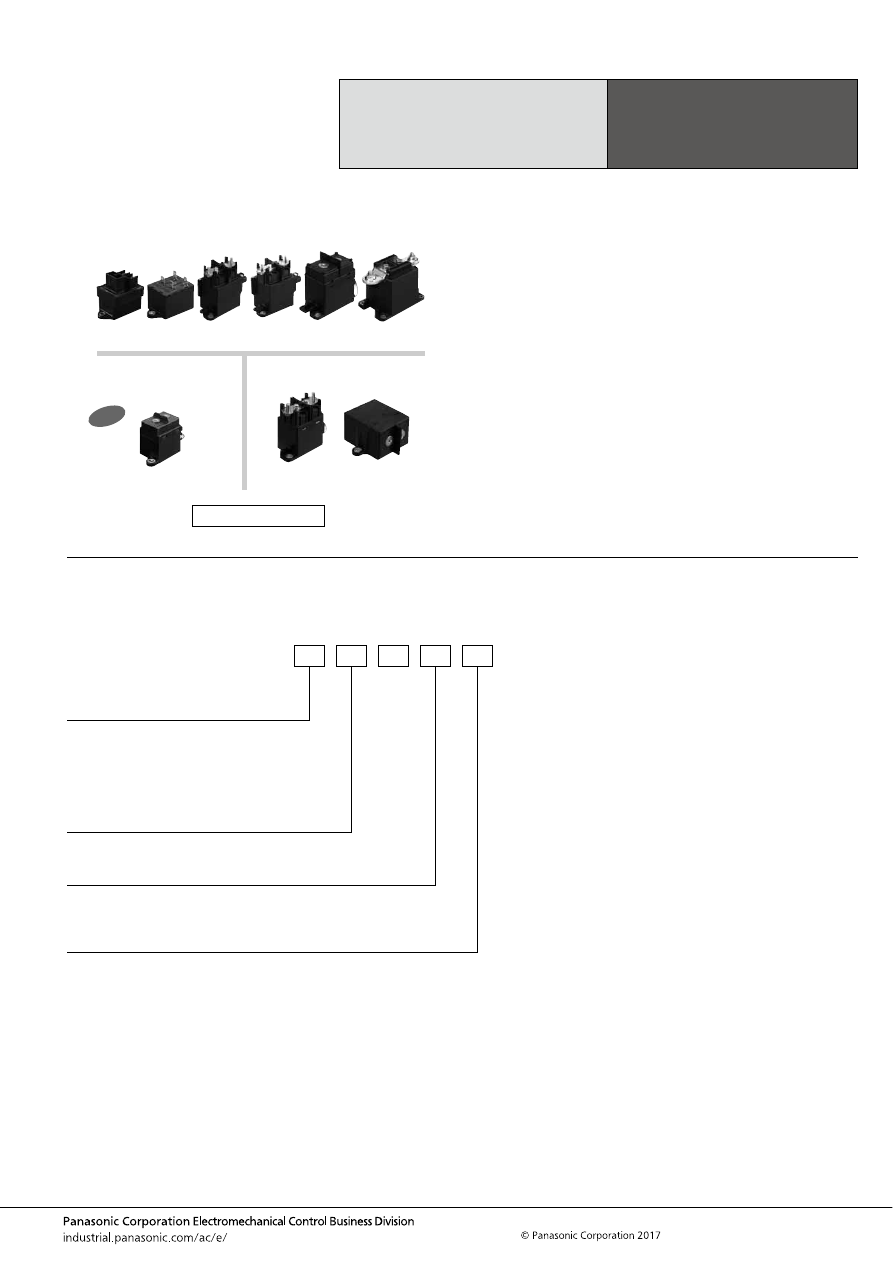

Motorcycle

Commercial Vehicle

Passenger Car

Automotive

Relays

Automation Controls

Group Catalog

Auto

mation Co

ntro

ls Gro

up Catalo

g

2017

-20

18

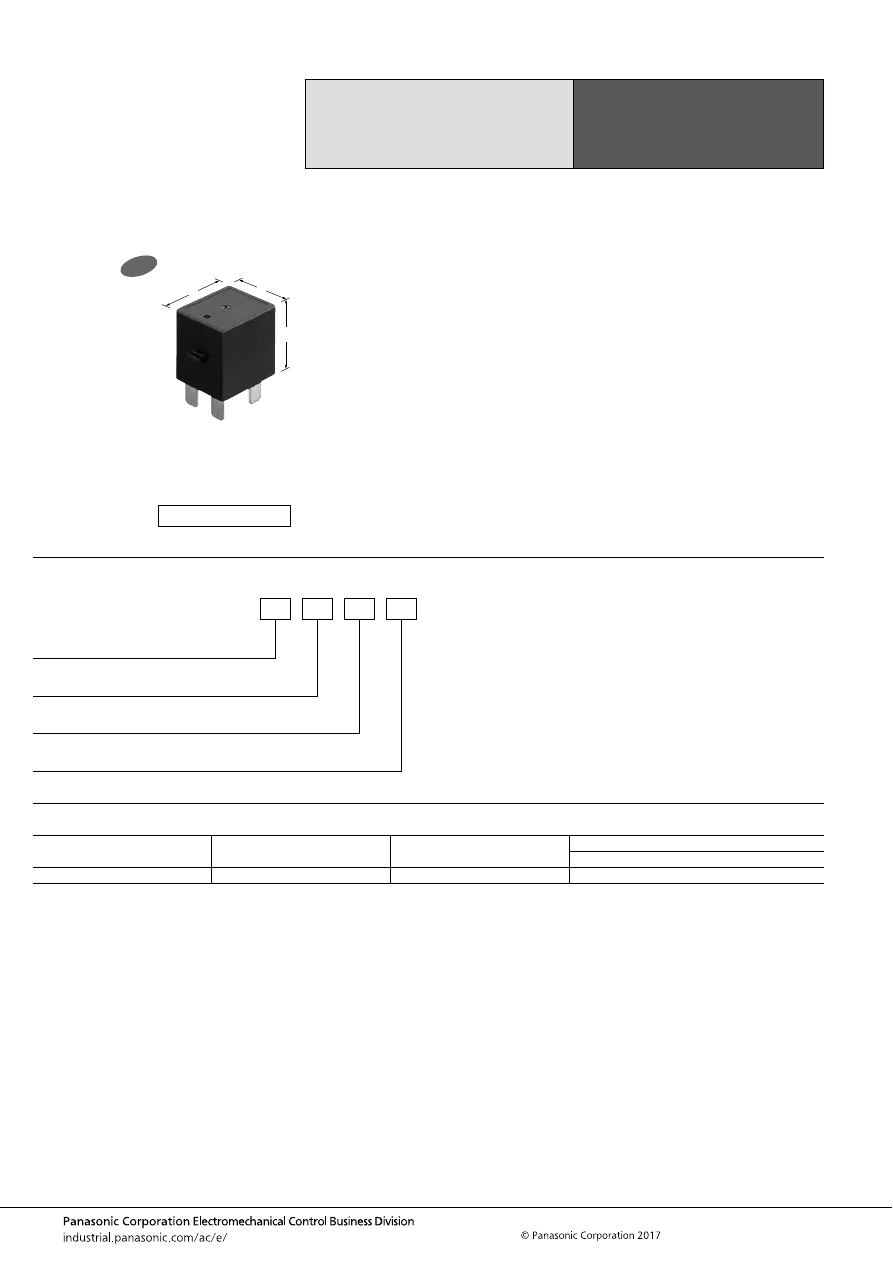

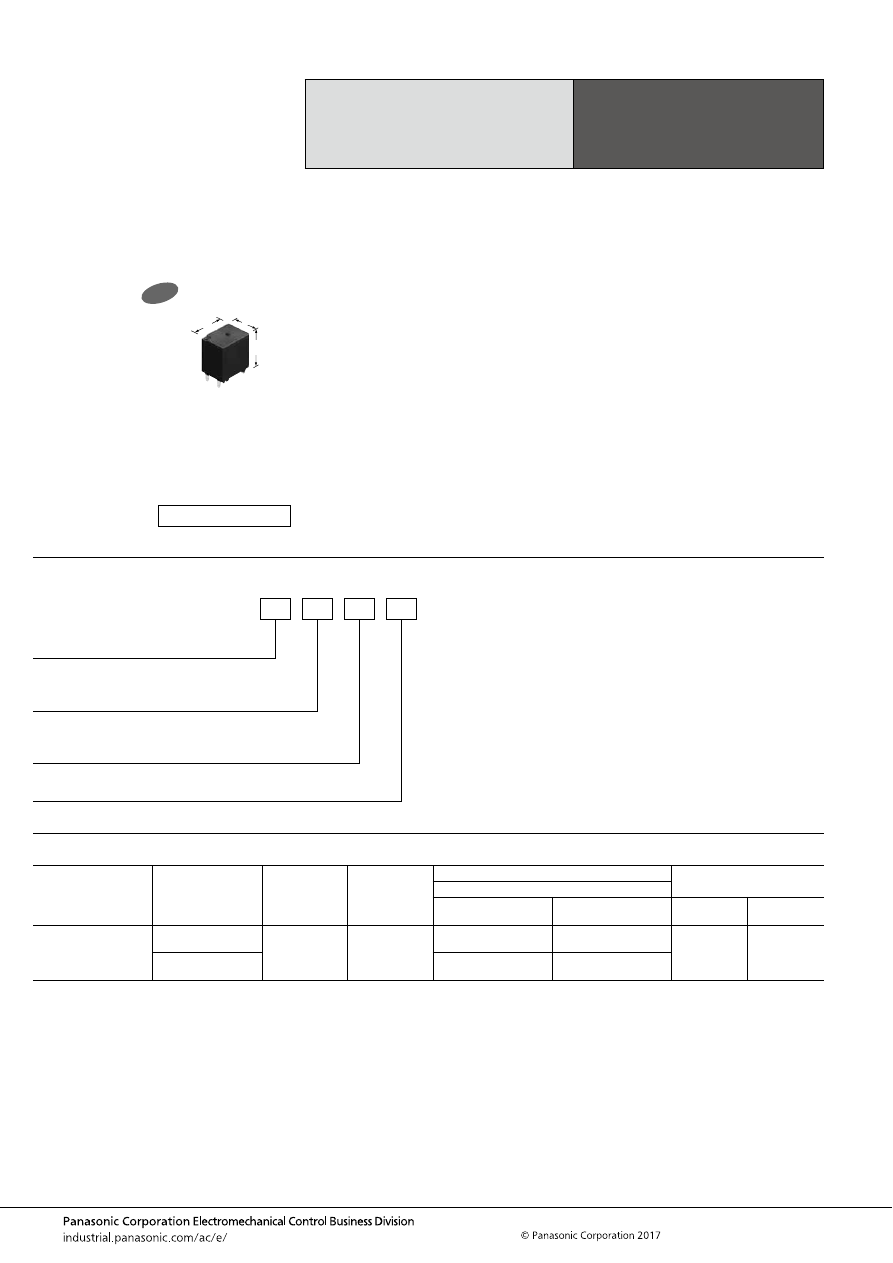

Automotive Relays

automotive-relay_en-html.html

1

ASCTB299E 201709-T

T A B L E O F C O N T E N T S

Page

Line up

......................................................................................2

Application

................................................................................4

Automotive Relays Selector Chart .............................................8

Configuration and Construction................................................19

Definition of Relay Terminology ................................................20

Cautions for Use.......................................................................22

Automotive Relay Users Guide ................................................23

CJ RELAYS ..............................................................................47

CN-H RELAYS .........................................................................55

CN-M RELAYS .........................................................................59

CP RELAYS .............................................................................64

CP RELAYS POWER TYPE.....................................................69

CQ RELAYS .............................................................................73

CT RELAYS..............................................................................77

CT RELAYS POWER TYPE .....................................................83

CW RELAYS ............................................................................88

TA RELAYS ..............................................................................91

TB RELAYS..............................................................................95

TB RELAYS POWER TYPE ...................................................104

TC RELAYS............................................................................109

TE RELAYS............................................................................118

TG RELAYS ...........................................................................126

TH RELAYS............................................................................131

TJ RELAYS ............................................................................136

TL RELAYS ............................................................................140

TM RELAYS ...........................................................................145

CA RELAYS ...........................................................................150

CB RELAYS ...........................................................................157

CM RELAYS ...........................................................................165

CV-N RELAYS ........................................................................170

CN-L RELAYS ........................................................................174

EC-N RELAYS........................................................................178

EV RELAYS............................................................................183

EV SWITCHES ......................................................................201

ISO14001, ISO9001, ISO/TS16949 Certificate of

Approval

................................................................................207

Automation Controls Sales Network

..................................208

automotive-relay_en-html.html

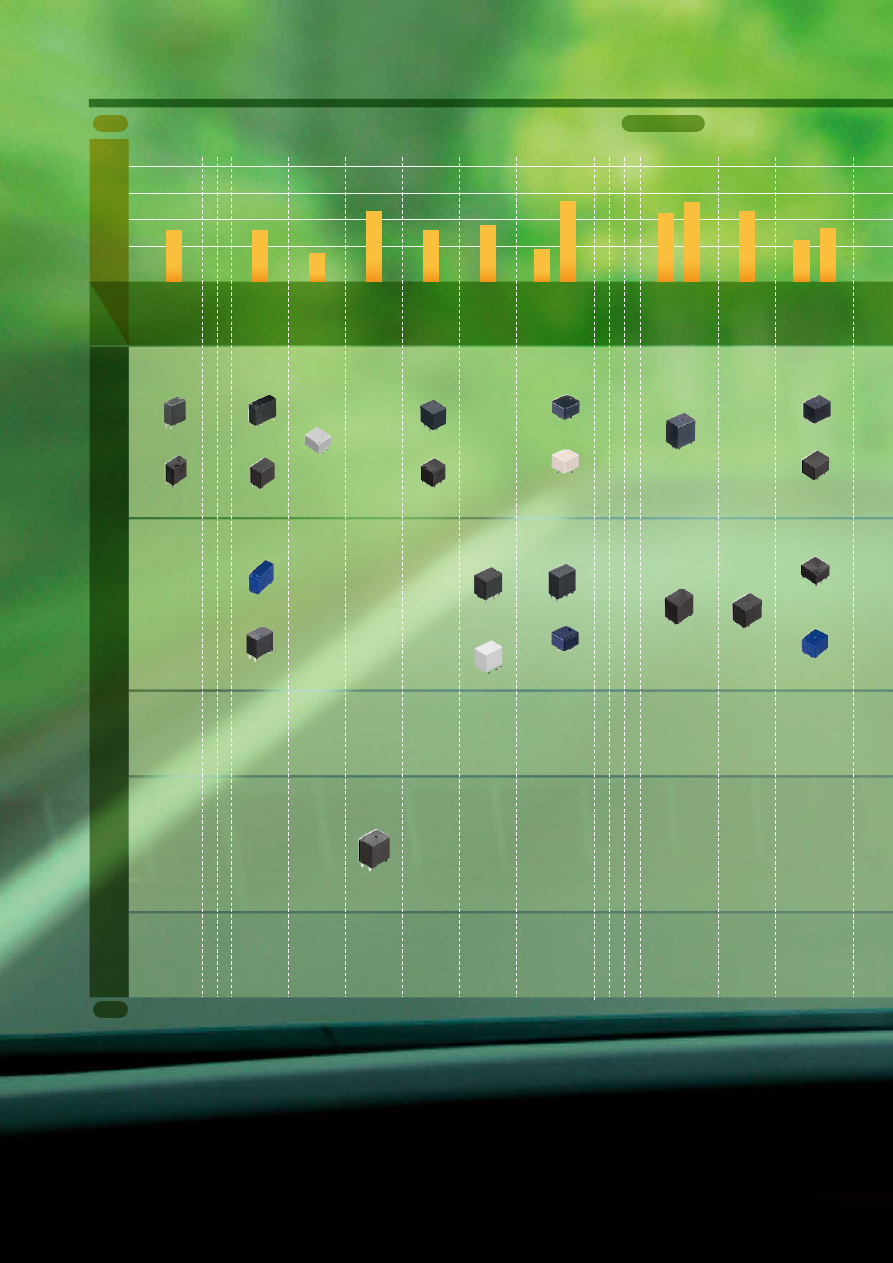

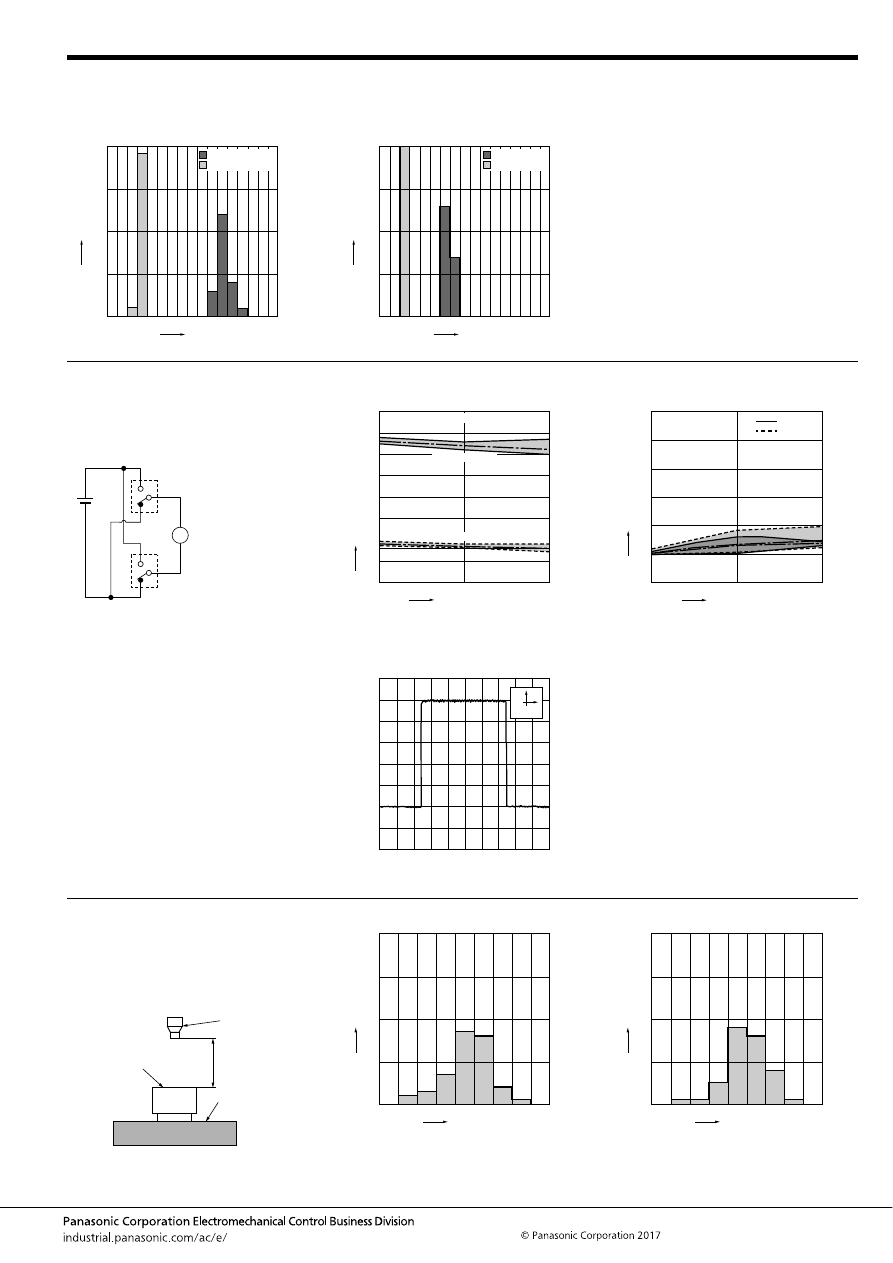

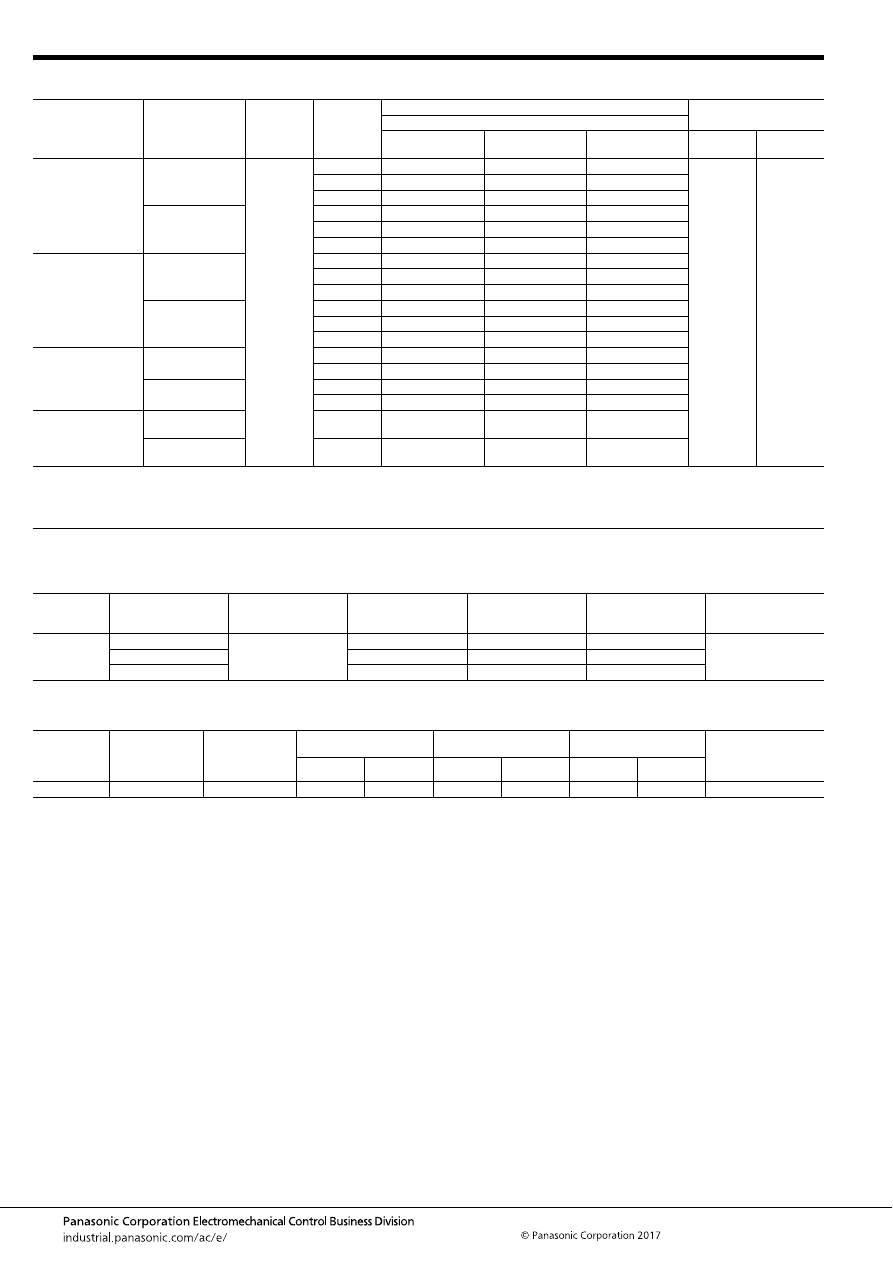

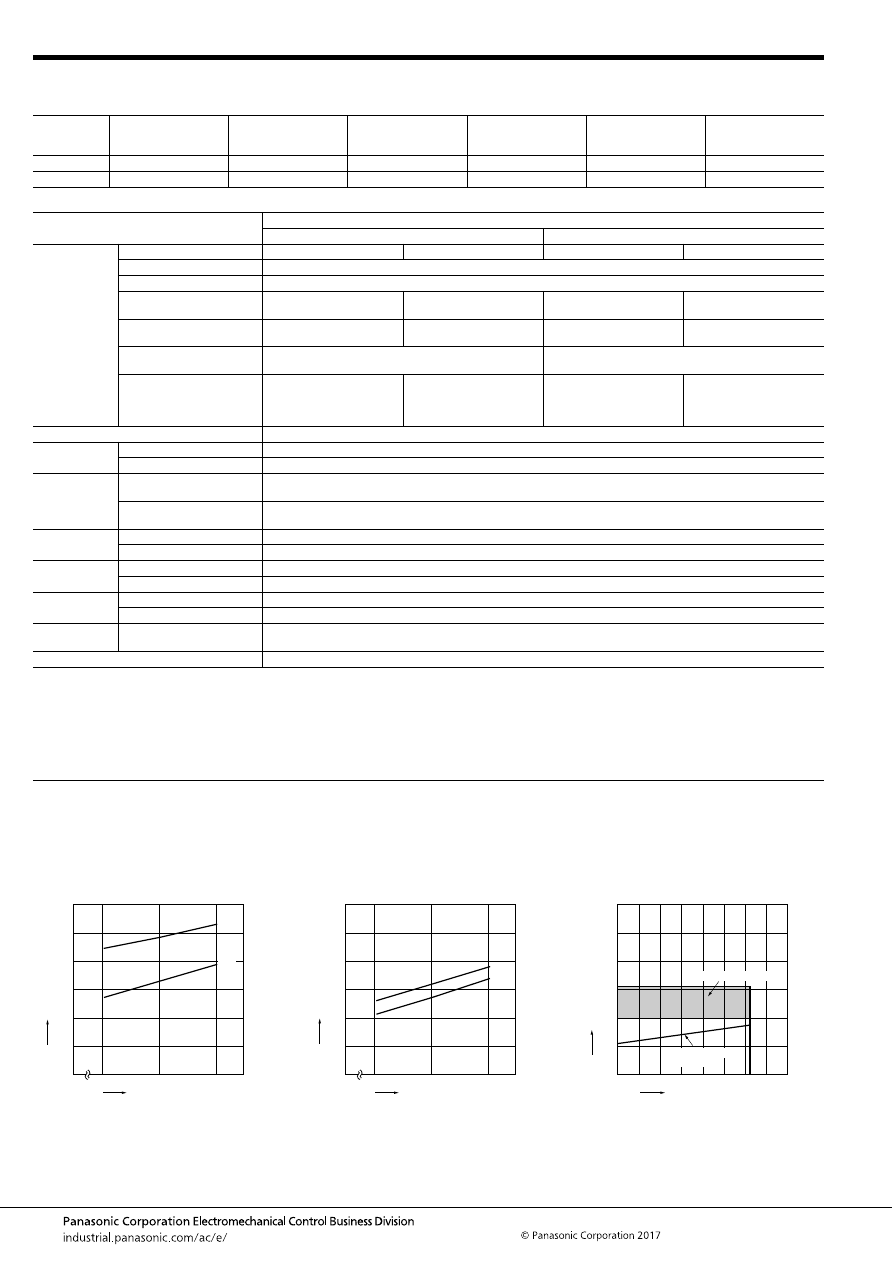

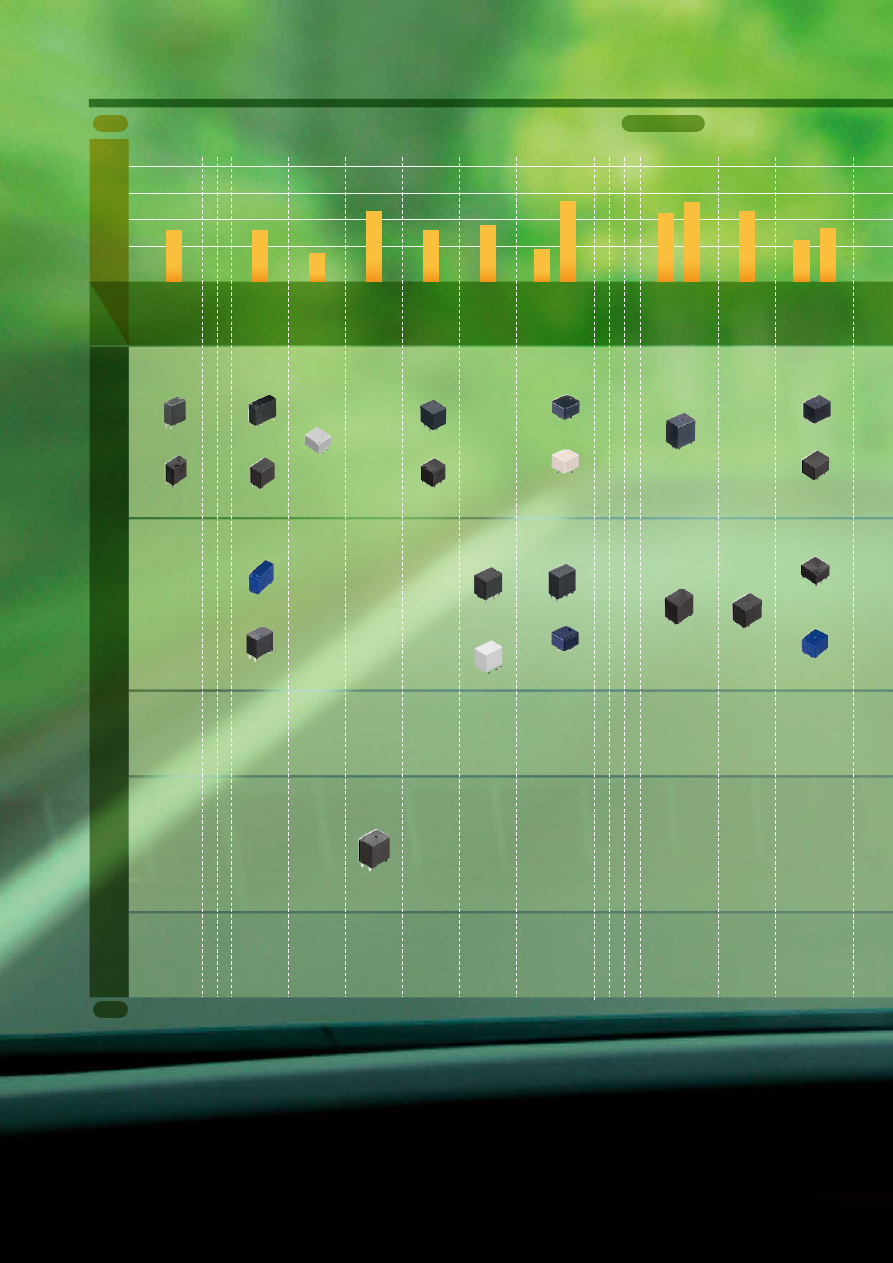

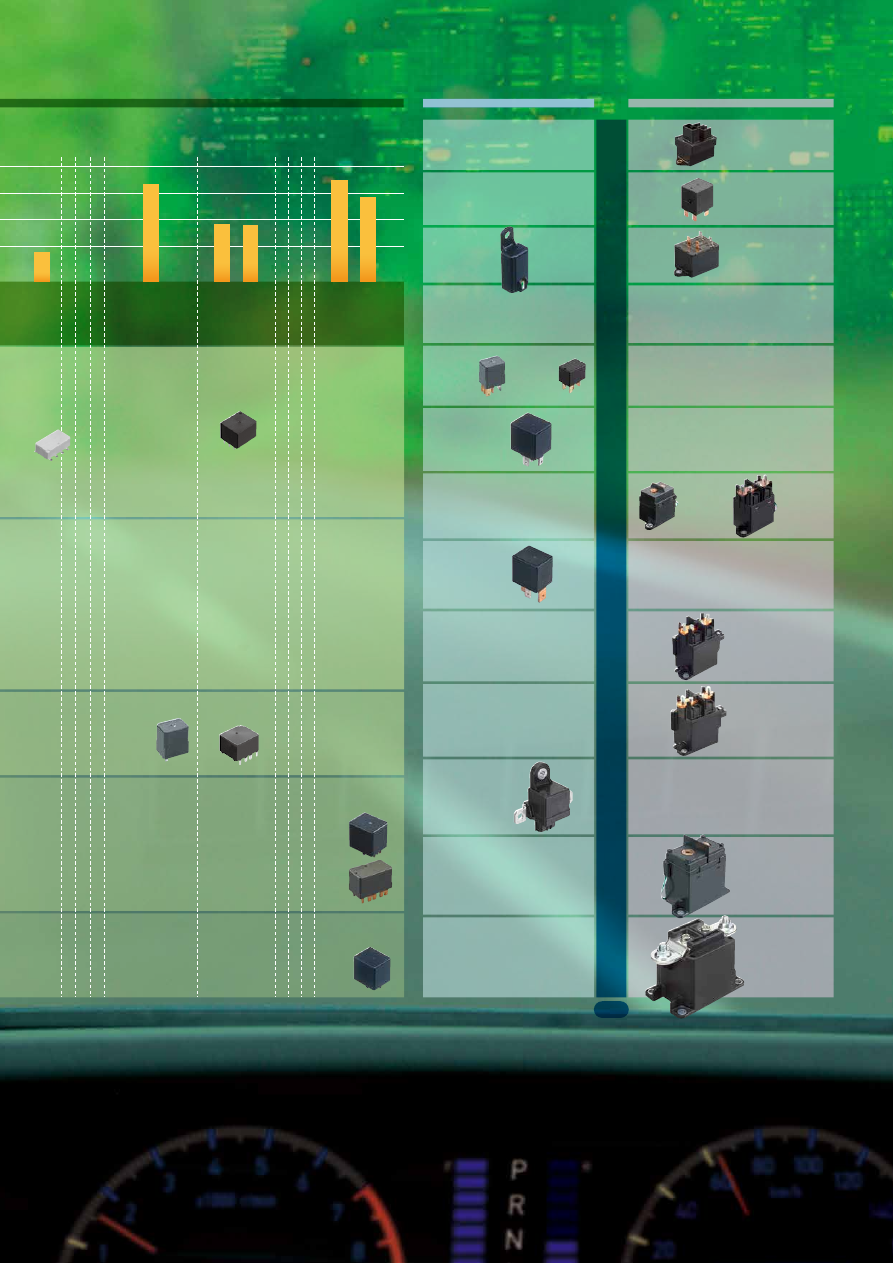

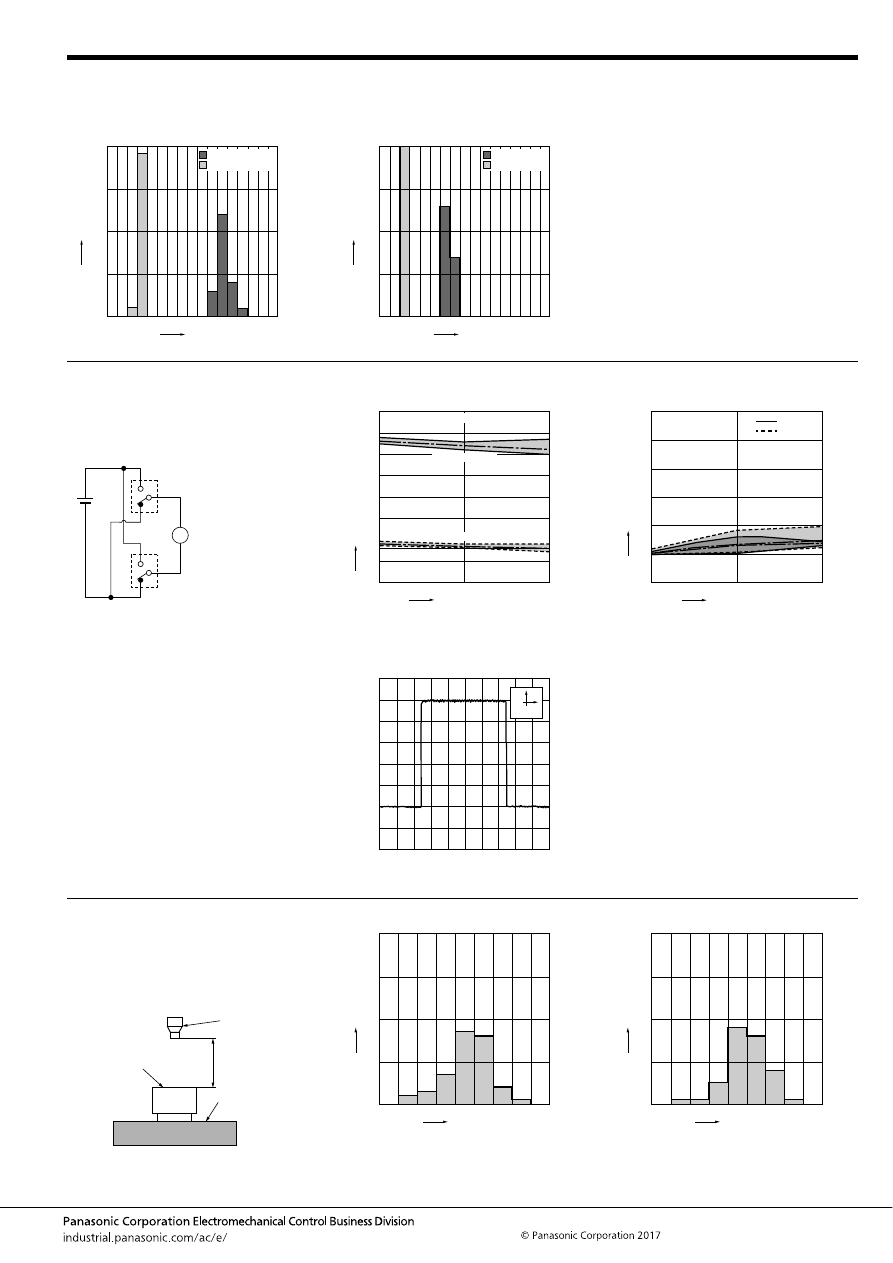

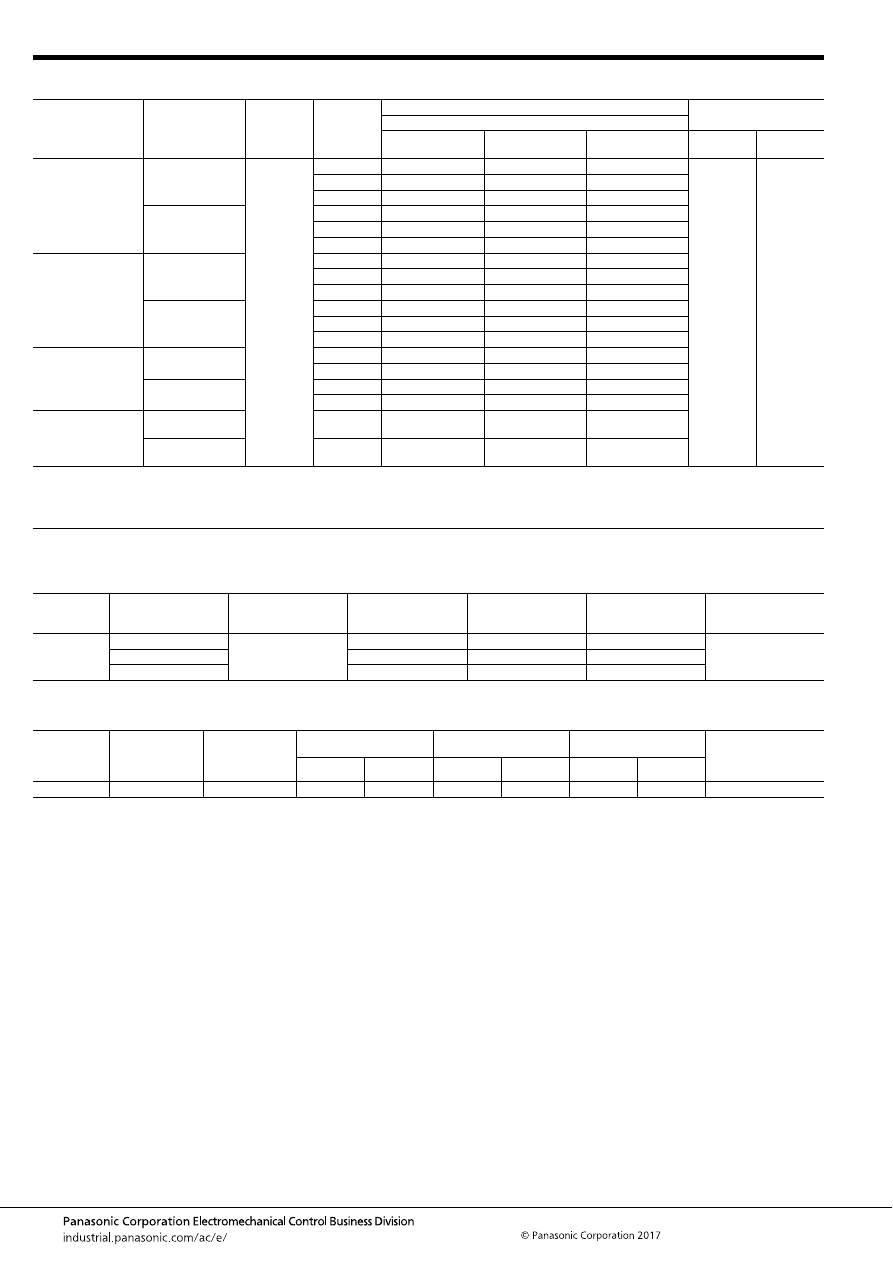

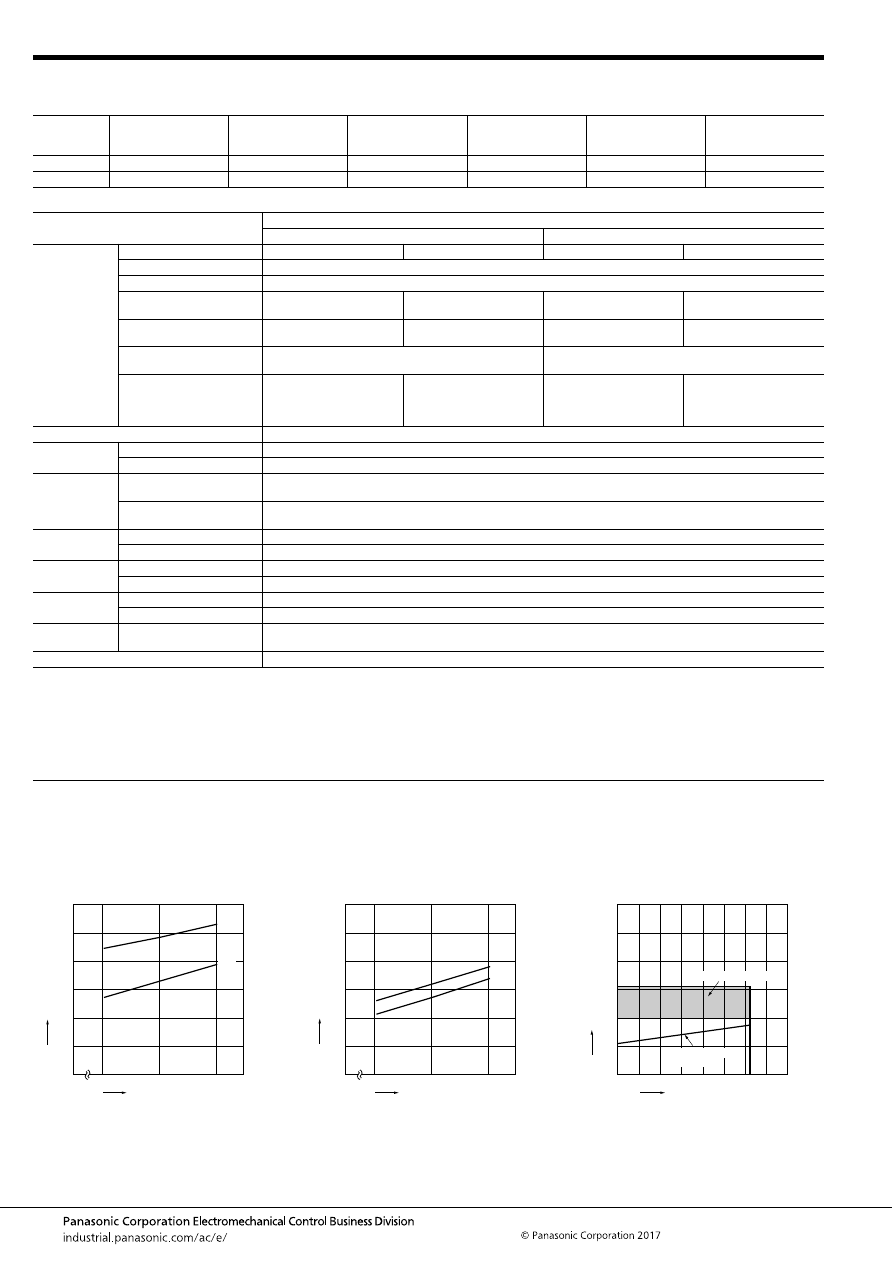

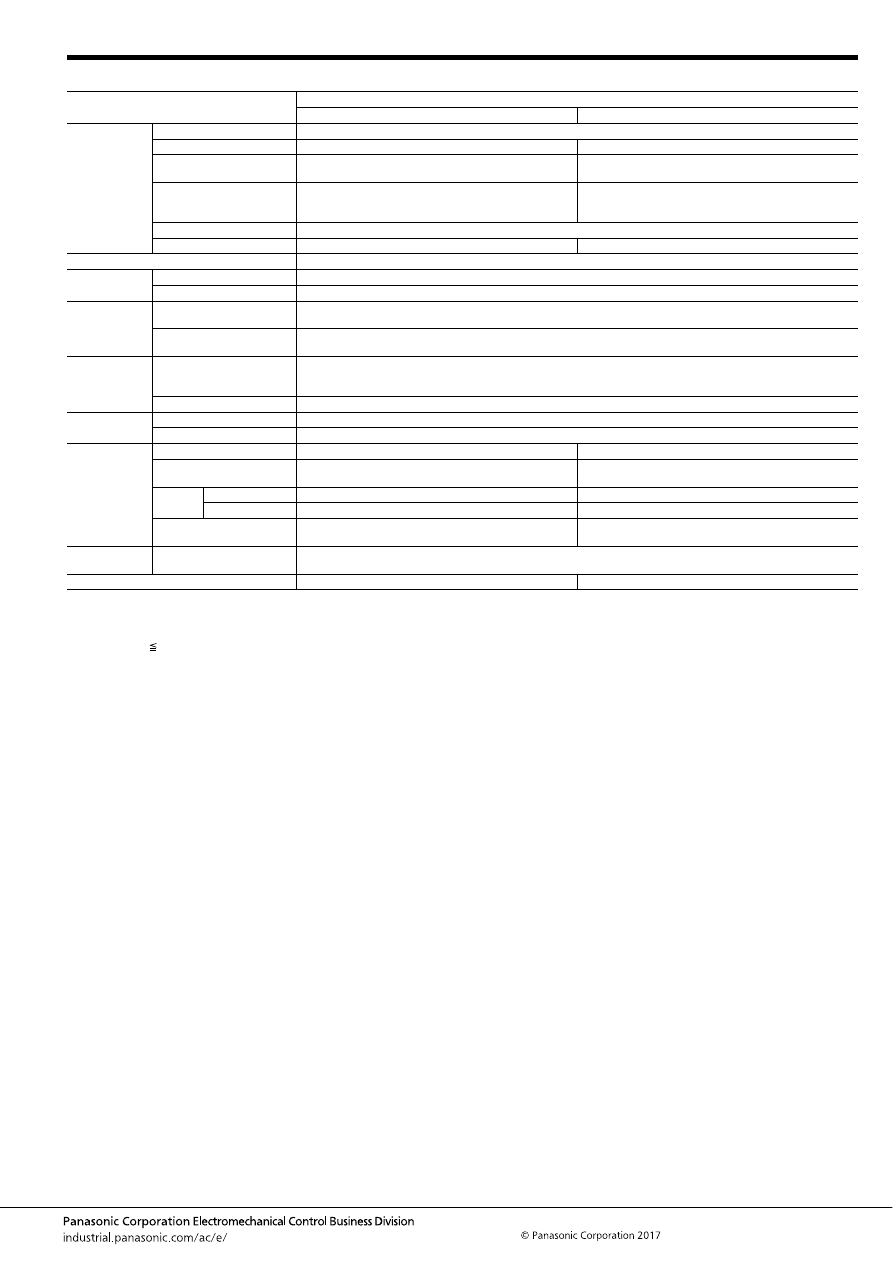

Line up

10A

15A

20A

30A

35A

120A

150A

200A

80A

40A

70A

300A

EV 300A

EV 120A

EV 200A

EV 80A

EV 20A

EV 10A

CB High

capacity

(1a)

Mini ISO

60A

CB Standard

(1a,1c)

Mini ISO

CA

(1a,1b1c)

JIS terminal

CM

(1a,1c)

Micro ISO

EV60A

Quiet type

EV60A

Compact high

short-circuit

capacity type

Foot print

Height

Capacity

Capacity

10mm

100 120

130

140

160

170

180

190

220

240

250

230

260 300

320

340 500

20A

30A

35A

40A

70A

15mm

20mm

30mm

.394inch

.591inch

.787inch

1.181inch

mm

2

PC-BOARD

HIGH-VOLTAGE

PLUG-IN

TE

(1c)

TE

(1c×2)

TG

(1a,1c)

TG

TC

TH

CT

CT-P

TB

CB

CJ

TE

CT

CT-P

TB

TB-P

CP

CP-P

CJ

TE

TJ

TH

TA

CM

TM

CW

CW

TL

CJ

(1c)

CT

(1c)

CT-P

(1c)

TB

(1a,1c)

TB

(1c×2)

TH

(1c)(SMD)

CJ

(1c×2)

CN-H

(1a)

CN-M

(1a,1c)

CN-M

(1a,1c)

(SMD)

TB-P

(1a)

CQ

(1c)

CM

(1a,1c)

Micro ISO

*24V type only

CT

(1c×2)

TH

(1c×2)

(SMD)

CQ

CN-H

CN-M

TC

(1a,1c,2a)

TJ

(1c)

TA

(1c)

CB High

capacity

(1a)

CB Standard

(1a,1c)

Mini ISO

CW

(2a)

CN-L

(1a)

Latching type

CT-P

(1c×2)

CP

(1a,1c)

CP-P

(1a,1c)

CP

(1c)

(SMD)

CV-N

(1a)

Micro ISO

EC-N

(1a)

DC relay

TM

(1a,1c)

TL

(2a)

ASCTB385E 201709-T

2

automotive-relay_en-html.html

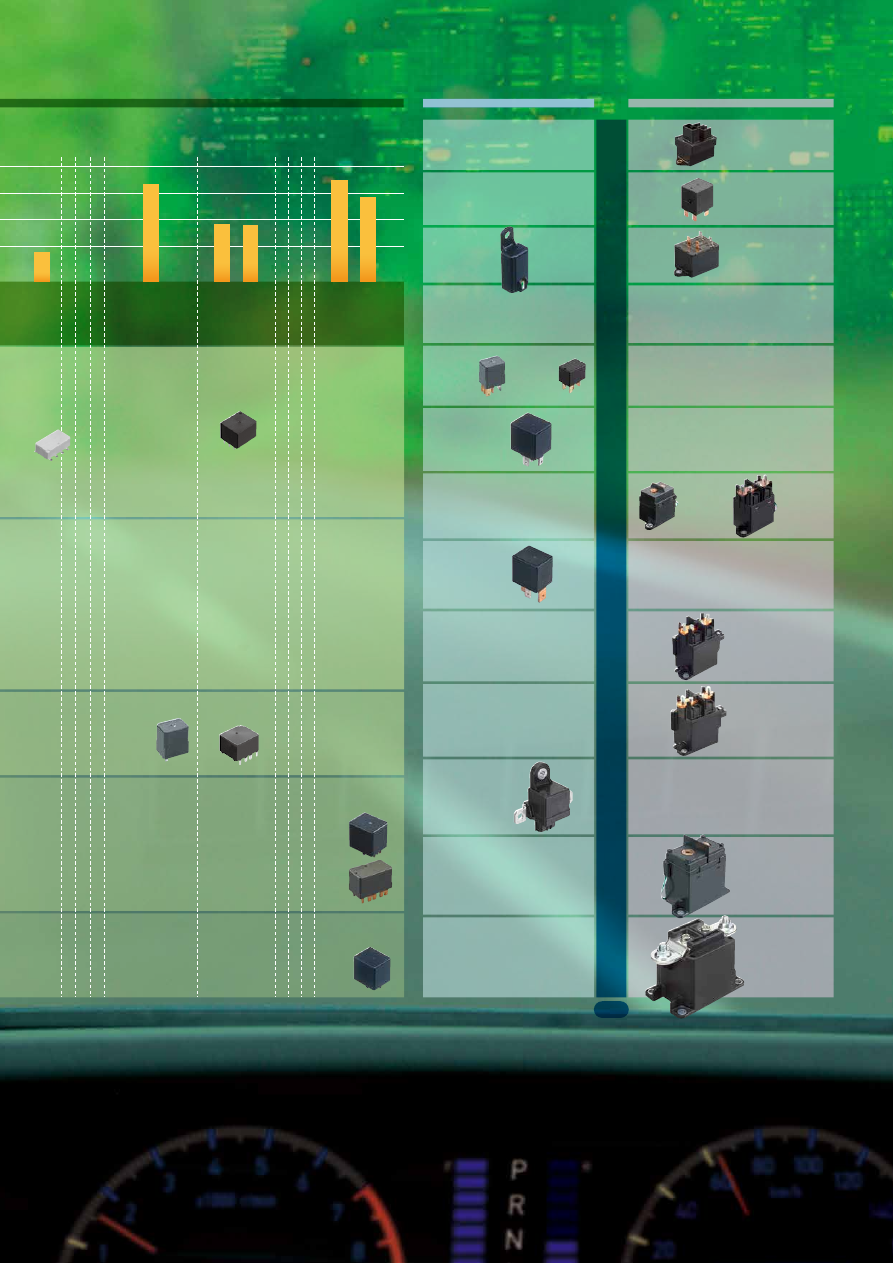

Line up

10A

15A

20A

30A

35A

120A

150A

200A

80A

40A

70A

300A

EV 300A

EV 120A

EV 200A

EV 80A

EV 20A

EV 10A

CB High

capacity

(1a)

Mini ISO

60A

CB Standard

(1a,1c)

Mini ISO

CA

(1a,1b1c)

JIS terminal

CM

(1a,1c)

Micro ISO

EV60A

Quiet type

EV60A

Compact high

short-circuit

capacity type

Foot print

Height

Capacity

Capacity

10mm

100 120

130

140

160

170

180

190

220

240

250

230

260 300

320

340 500

20A

30A

35A

40A

70A

15mm

20mm

30mm

.394inch

.591inch

.787inch

1.181inch

mm

2

PC-BOARD

HIGH-VOLTAGE

PLUG-IN

TE

(1c)

TE

(1c×2)

TG

(1a,1c)

TG

TC

TH

CT

CT-P

TB

CB

CJ

TE

CT

CT-P

TB

TB-P

CP

CP-P

CJ

TE

TJ

TH

TA

CM

TM

CW

CW

TL

CJ

(1c)

CT

(1c)

CT-P

(1c)

TB

(1a,1c)

TB

(1c×2)

TH

(1c)(SMD)

CJ

(1c×2)

CN-H

(1a)

CN-M

(1a,1c)

CN-M

(1a,1c)

(SMD)

TB-P

(1a)

CQ

(1c)

CM

(1a,1c)

Micro ISO

*24V type only

CT

(1c×2)

TH

(1c×2)

(SMD)

CQ

CN-H

CN-M

TC

(1a,1c,2a)

TJ

(1c)

TA

(1c)

CB High

capacity

(1a)

CB Standard

(1a,1c)

Mini ISO

CW

(2a)

CN-L

(1a)

Latching type

CT-P

(1c×2)

CP

(1a,1c)

CP-P

(1a,1c)

CP

(1c)

(SMD)

CV-N

(1a)

Micro ISO

EC-N

(1a)

DC relay

TM

(1a,1c)

TL

(2a)

ASCTB385E 201709-T

3

automotive-relay_en-html.html

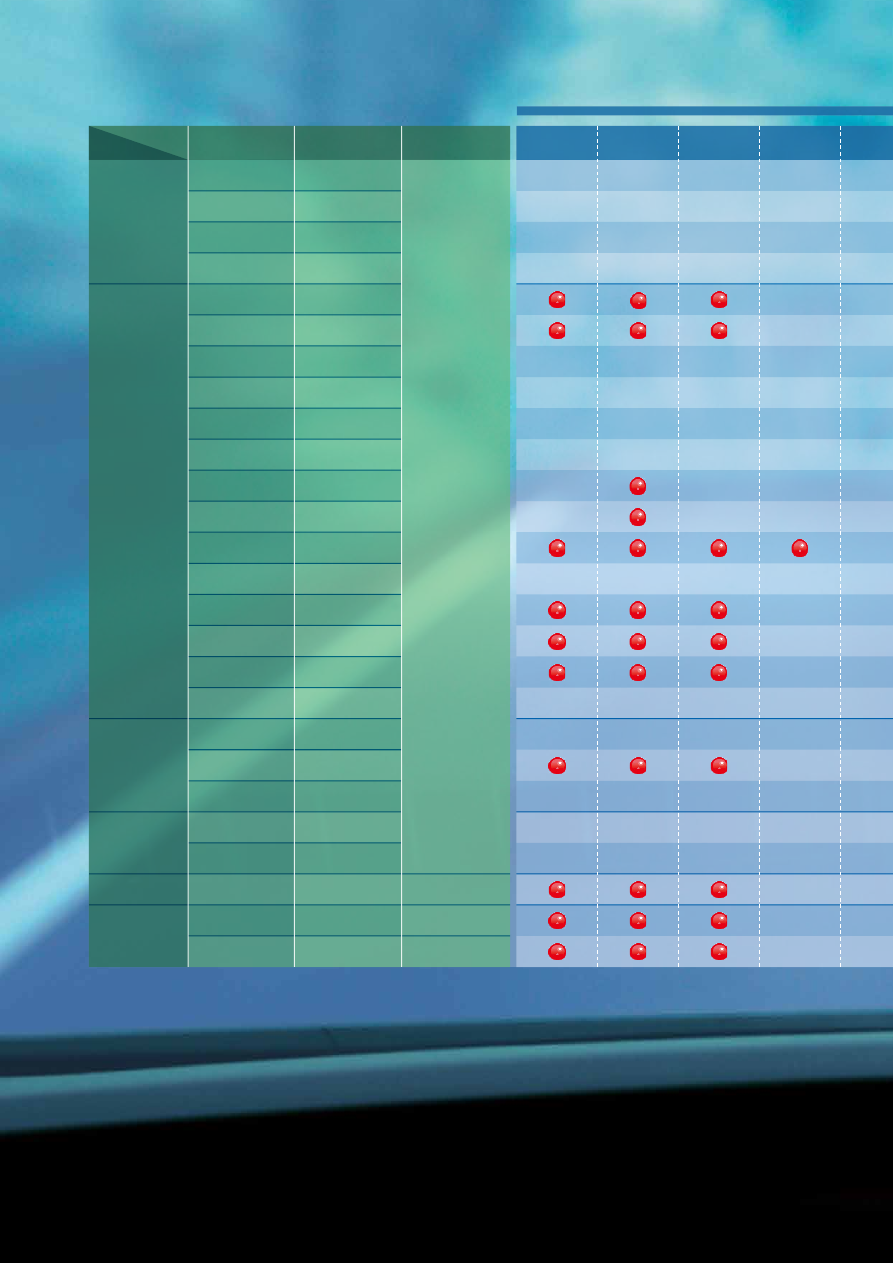

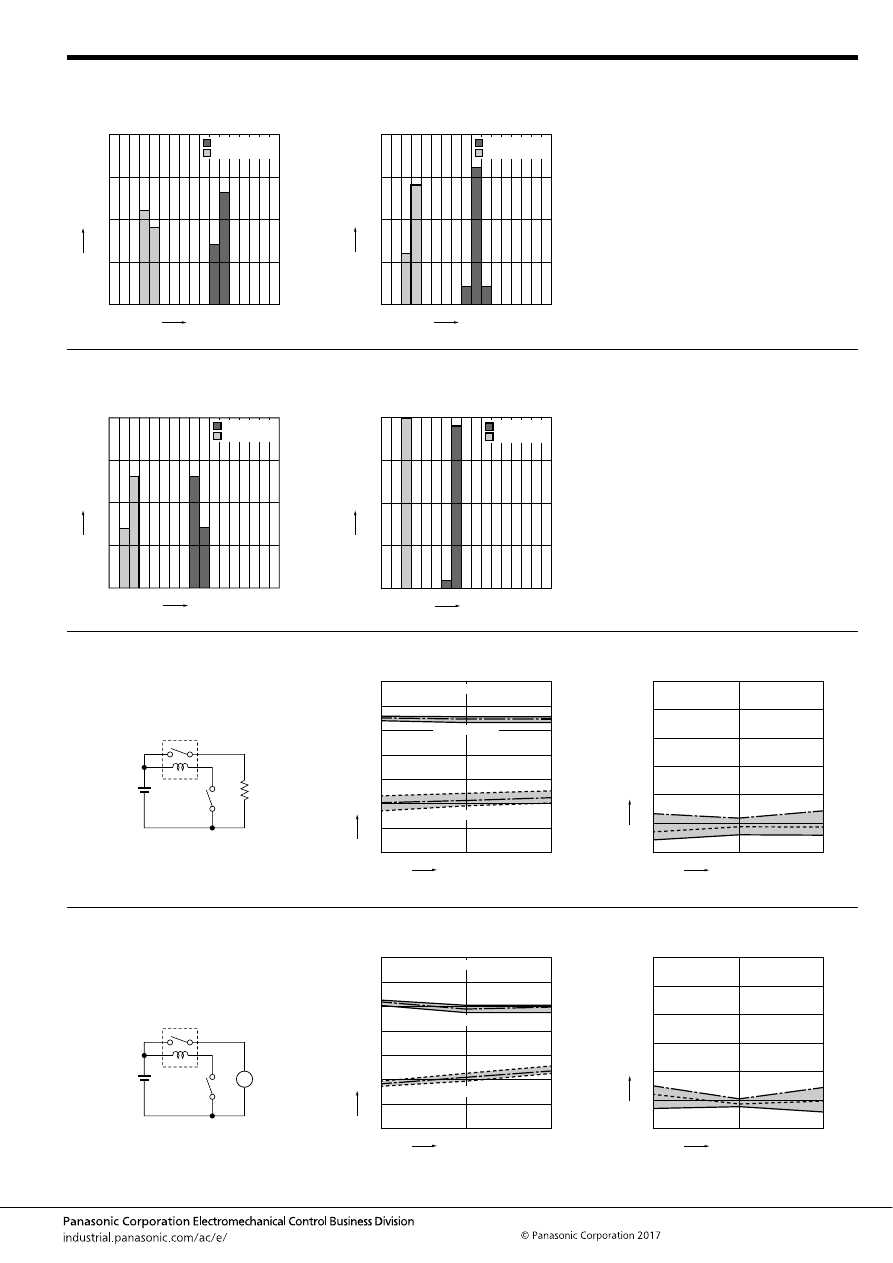

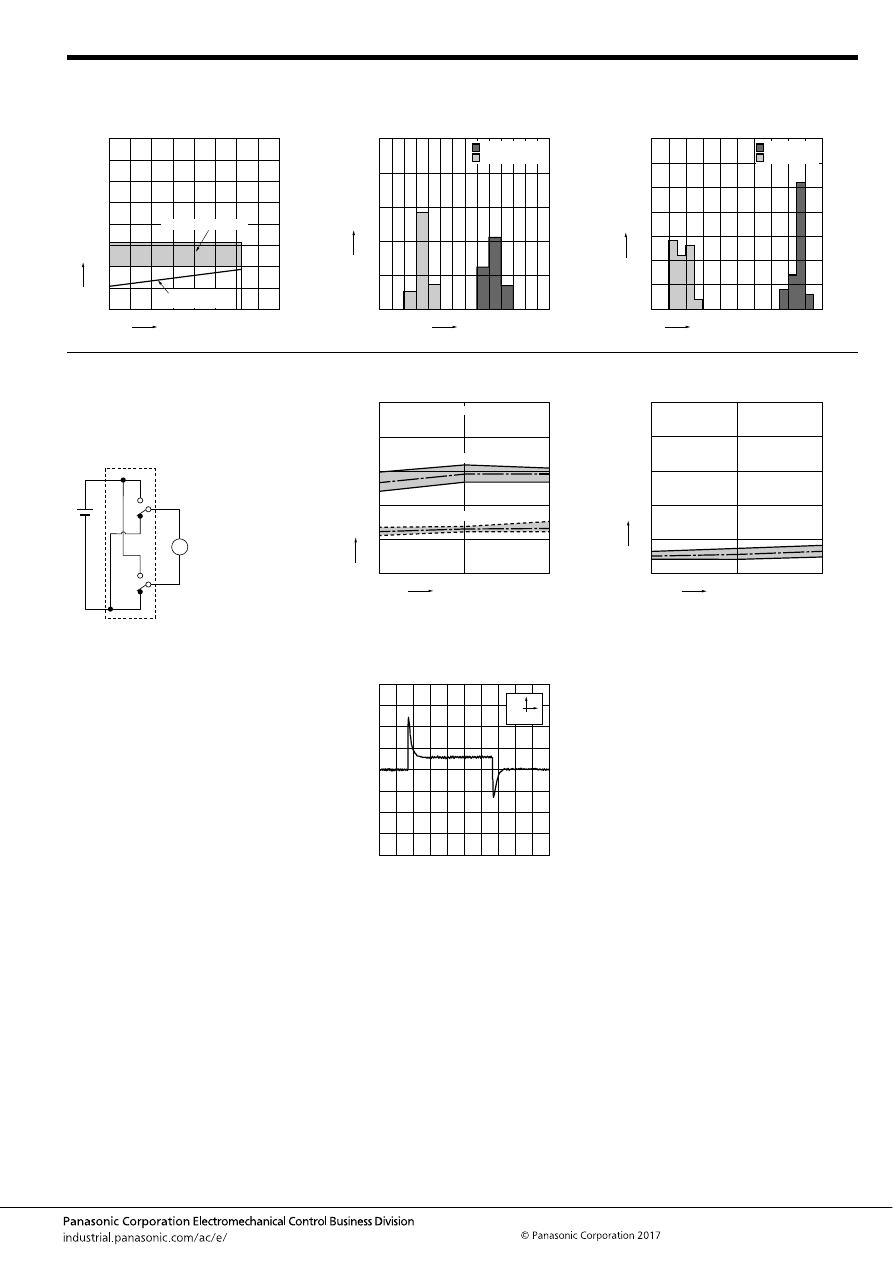

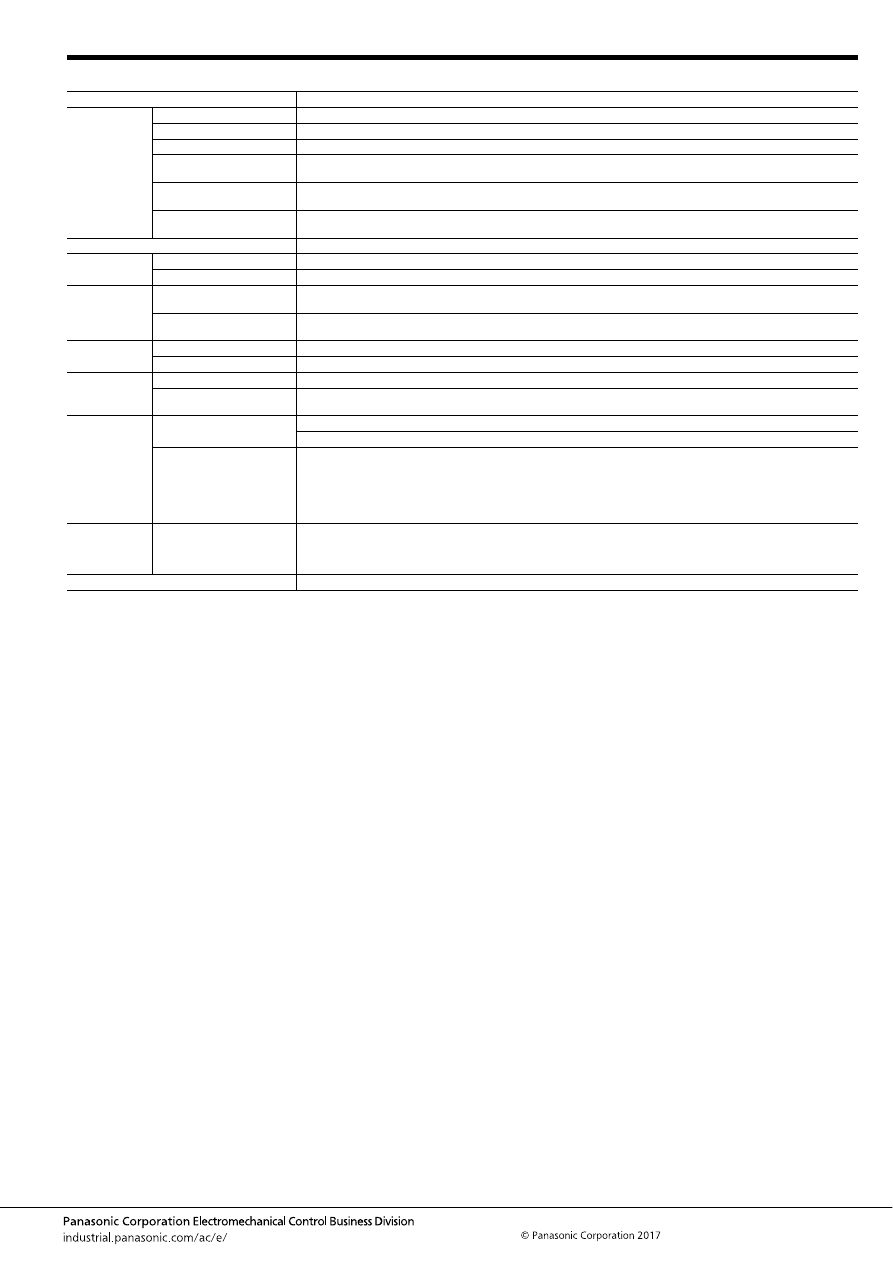

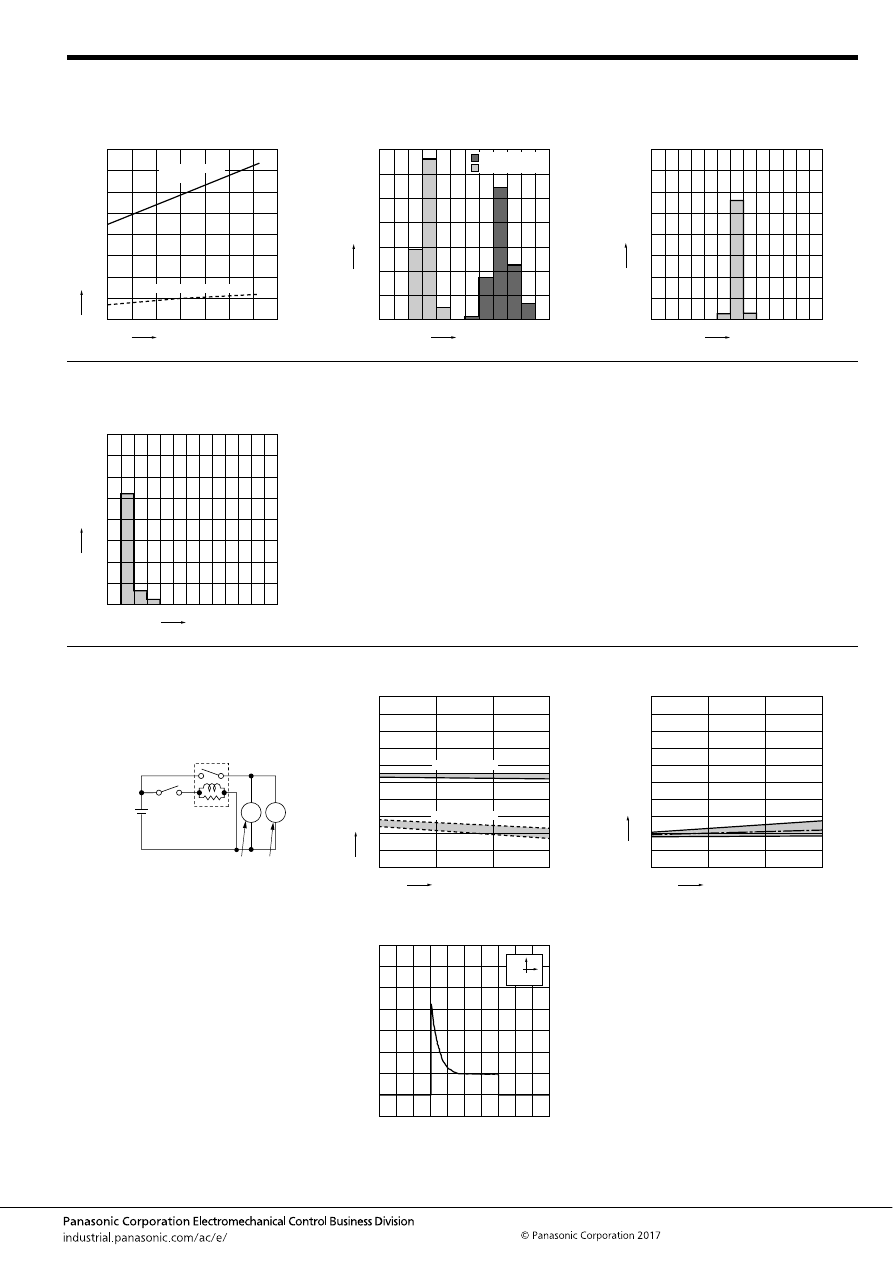

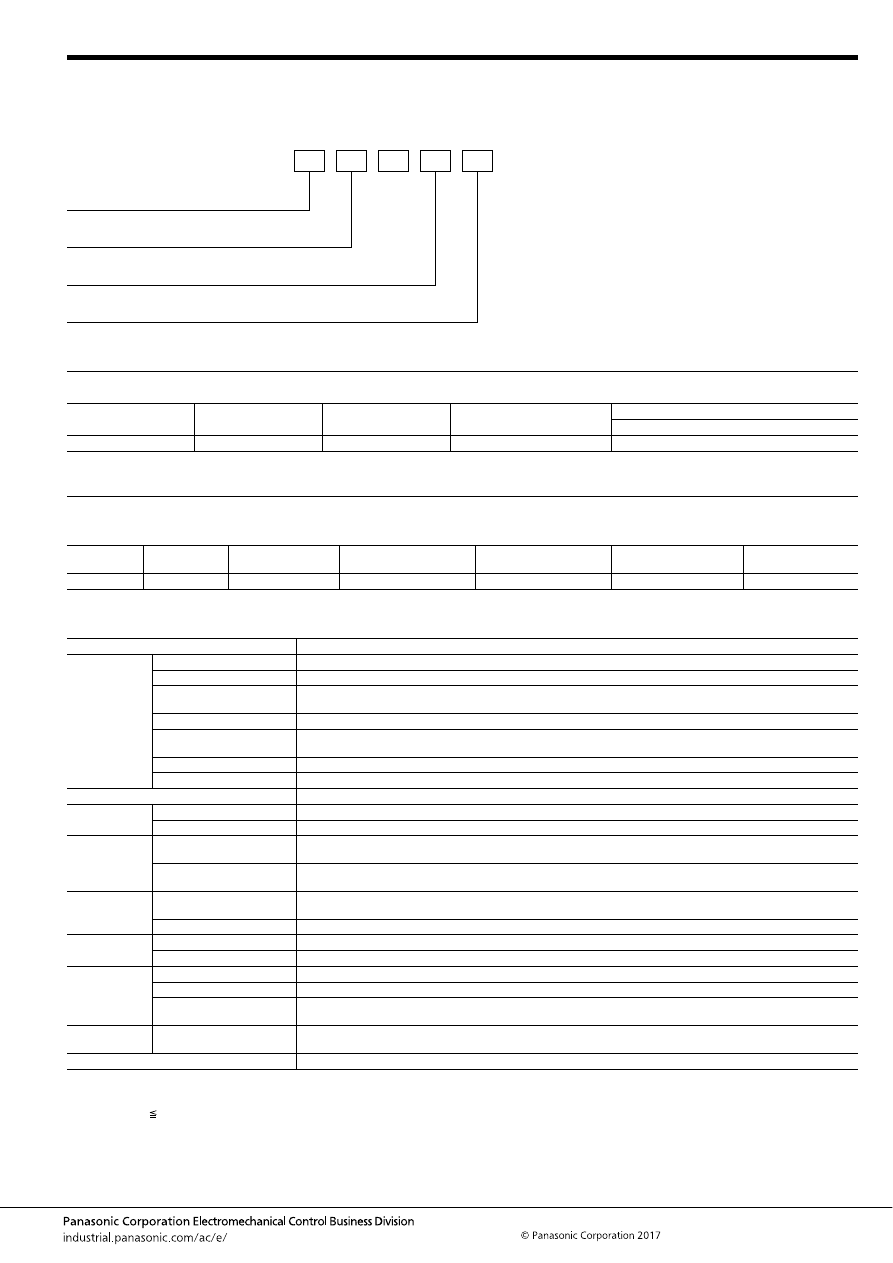

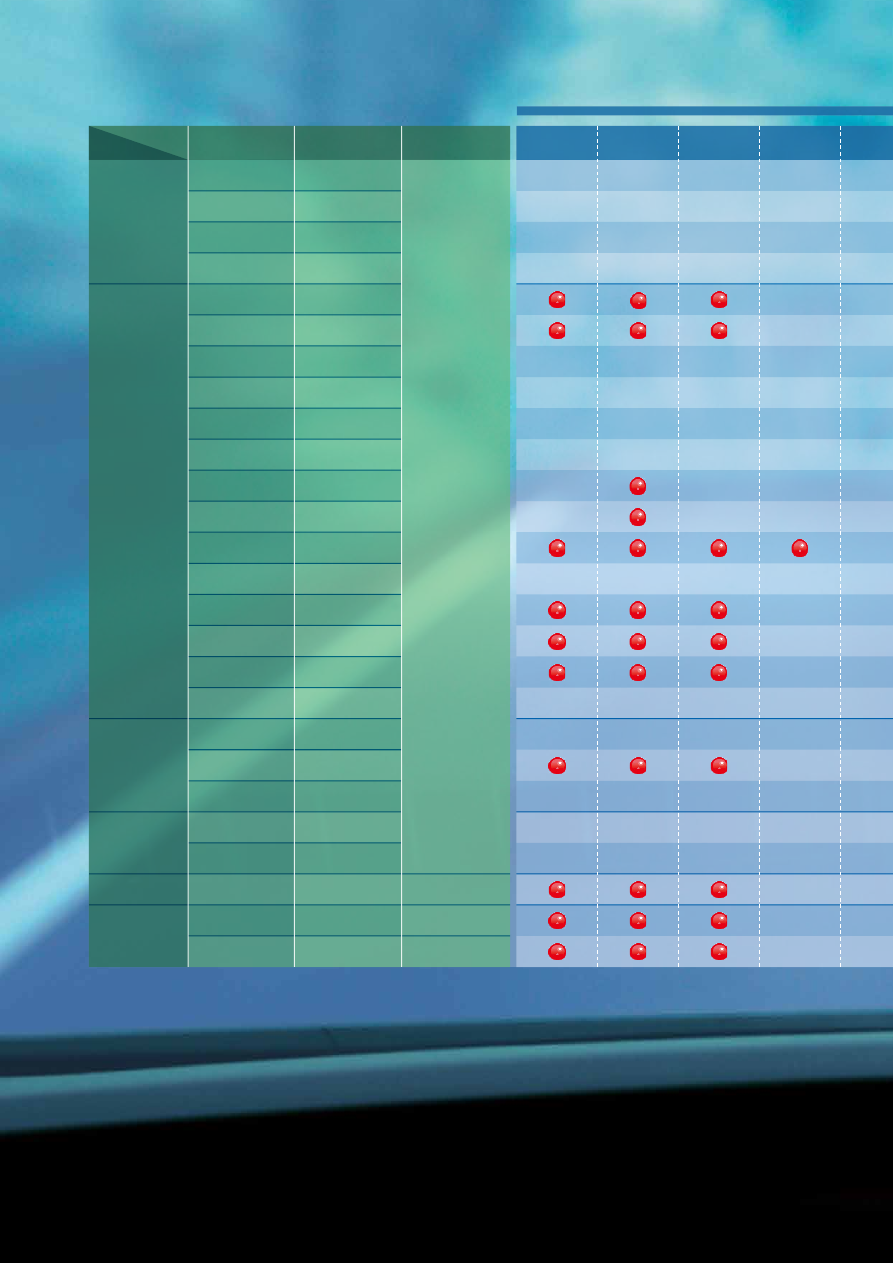

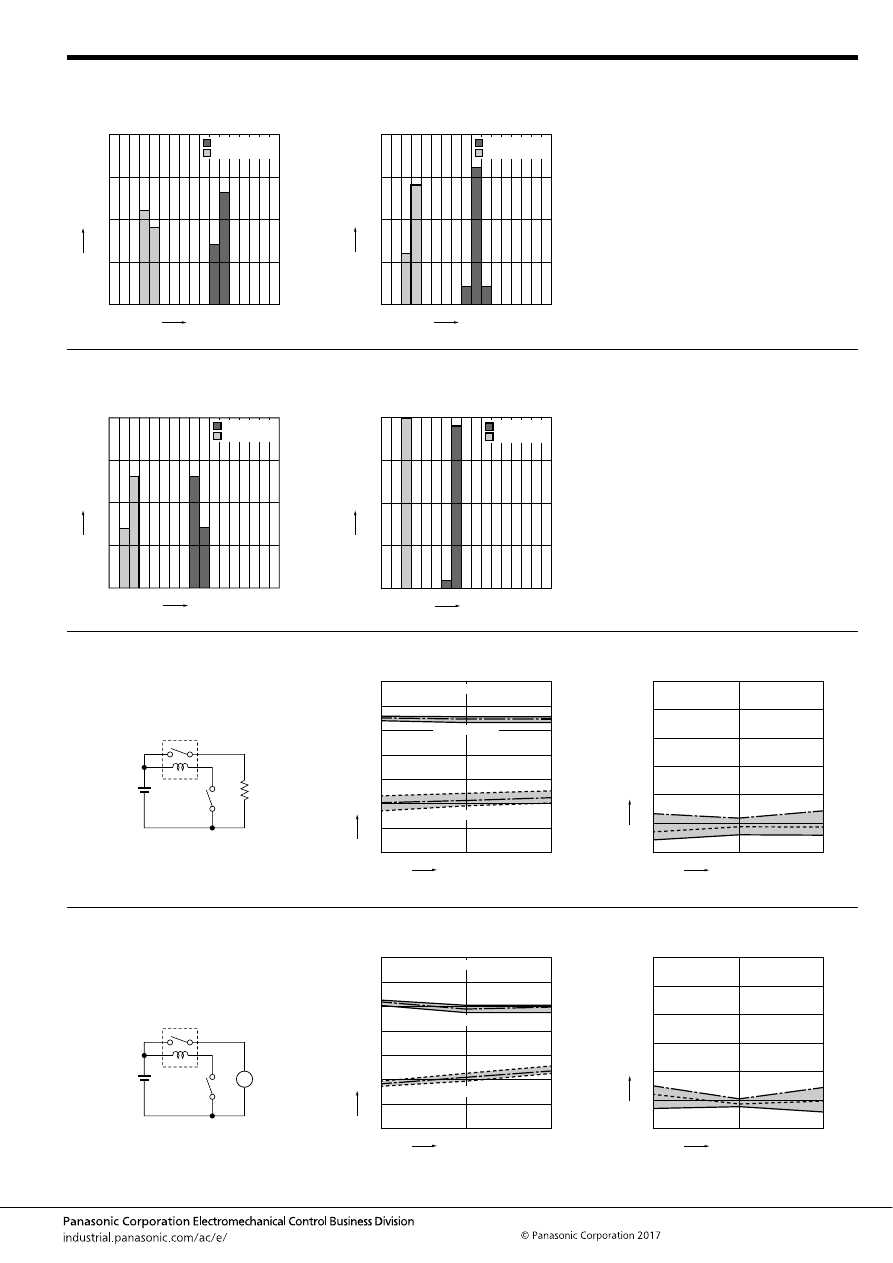

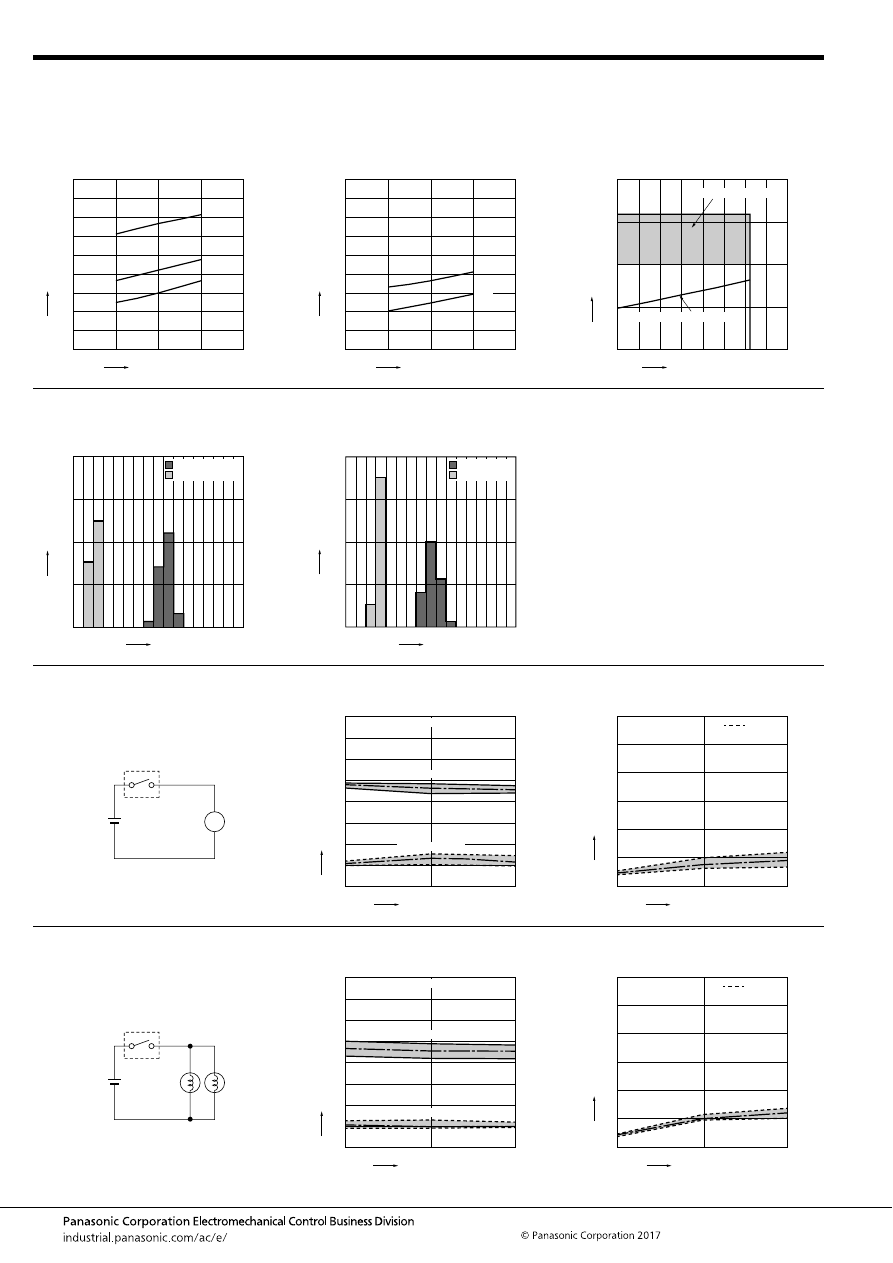

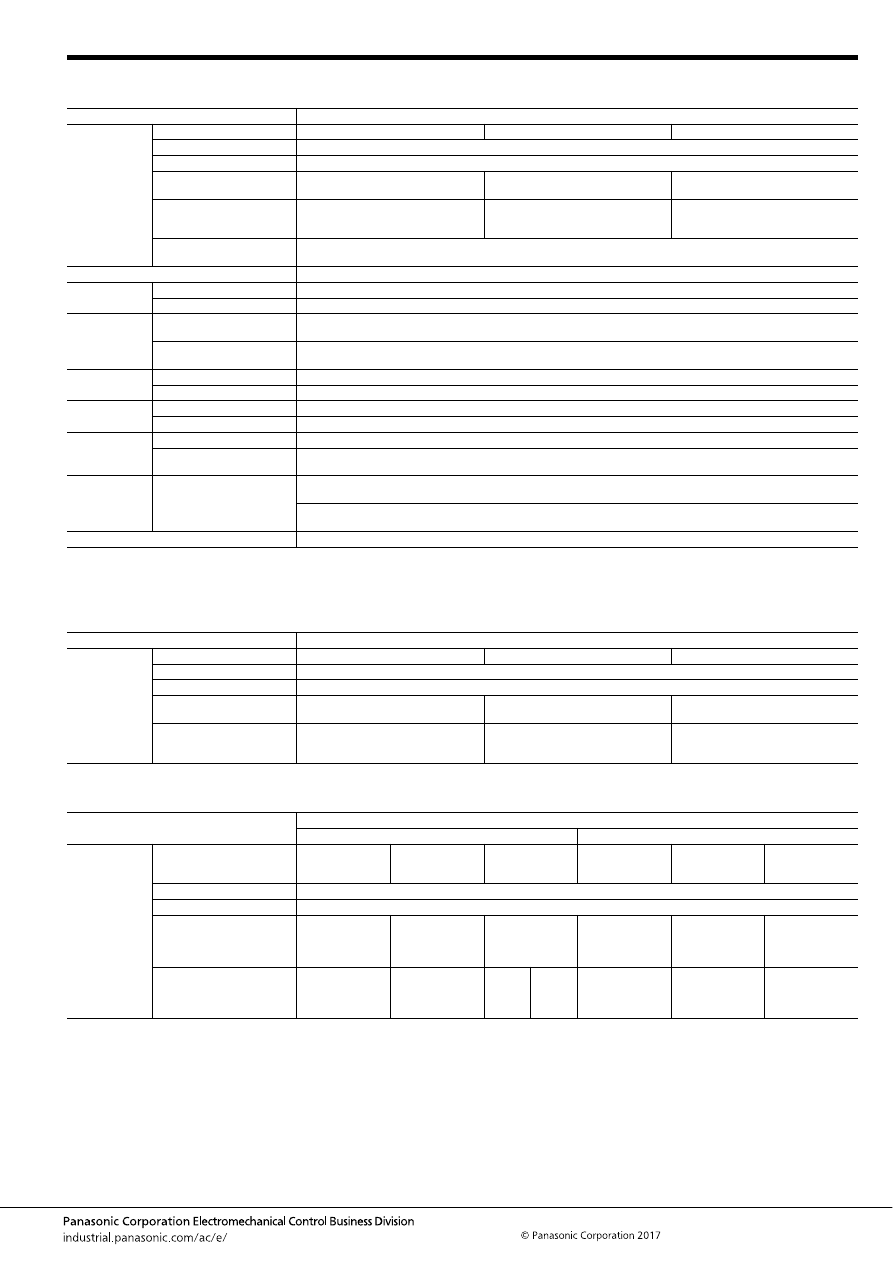

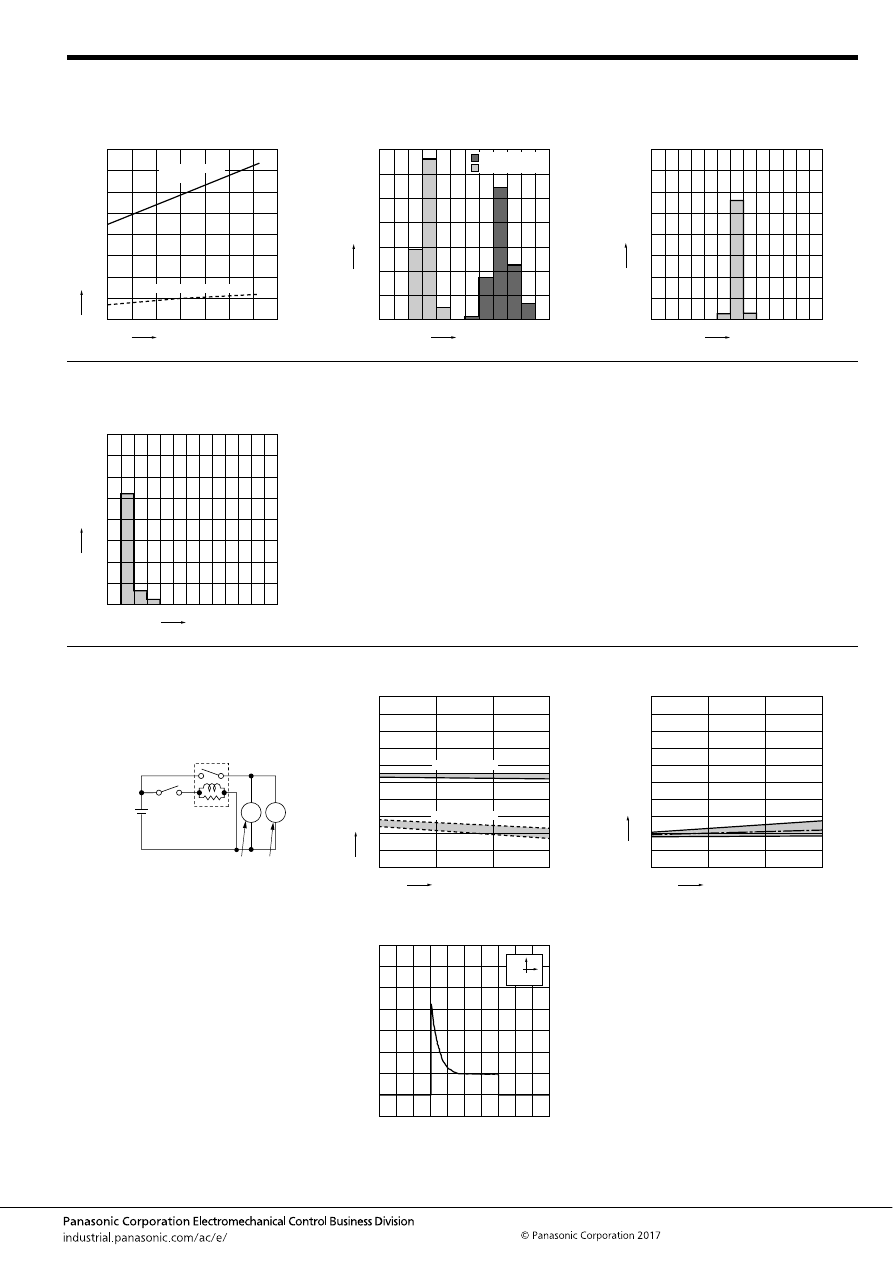

Application :

1

Safety

Power Train Control

Head lights

(incl. HID)

Tail

lamps

Fog lamps

(Front and rear)

Powered mirror

(incl. ones

with heaters)

Washers

Defogger

Blower fan

Engine

starter motor

EPS (Electrical

power steering)

Magnetic

clutch

Page

Radiator

fan motor

Horn

Wipers,

Intermittent

wipers

Flashers

Recommended applications

However, certain operating conditions do not allow the recommended applications

Go to Next Page

Type

Product name

Contact

arrangement

Coil voltage

Twin

SMD

Quiet

Mini ISO

Micro ISO

CT/CT-P

CJ

TB

TE

CN-H

CN-M

CT/CT-P

CJ

CP-P

CP

TB

TB-P

TC

TE

TG

TJ

TL

TM

CP

CN-M

TH

CQ

TA

CB

CM

CV-N

Single

1c × 2

1c × 2

1c × 2

1c × 2

1a

1a, 1c

1c

1c

1a, 1c

1a, 1c

1a, 1c

1a

1c

1a, 1c

1c

1a, 1c

1c

1a, 1c

1c, 1c × 2

1c

1c

1a, 1c

1a, 1c

1a

1a, 1c, Double

make contact 2a

Double make

contact 2a

12V

12V, 24V

12V

Standard: 12V, 24V

1a High capacity: 12V

77/83

47

95

118

55

59

77/83

47

69

64

95

104

109

118

126

136

140

145

64

59

131

73

91

157

165

170

(with Di)

(with Di)

(with Di)

(with Di)

(with Di)

(with Di)

ASCTB385E 201709-T

4

automotive-relay_en-html.html

Application :

1

Safety

Power Train Control

Head lights

(incl. HID)

Tail

lamps

Fog lamps

(Front and rear)

Powered mirror

(incl. ones

with heaters)

Washers

Defogger

Blower fan

Engine

starter motor

EPS (Electrical

power steering)

Magnetic

clutch

Page

Radiator

fan motor

Horn

Wipers,

Intermittent

wipers

Flashers

Recommended applications

However, certain operating conditions do not allow the recommended applications

Go to Next Page

Type

Product name

Contact

arrangement

Coil voltage

Twin

SMD

Quiet

Mini ISO

Micro ISO

CT/CT-P

CJ

TB

TE

CN-H

CN-M

CT/CT-P

CJ

CP-P

CP

TB

TB-P

TC

TE

TG

TJ

TL

TM

CP

CN-M

TH

CQ

TA

CB

CM

CV-N

Single

1c × 2

1c × 2

1c × 2

1c × 2

1a

1a, 1c

1c

1c

1a, 1c

1a, 1c

1a, 1c

1a

1c

1a, 1c

1c

1a, 1c

1c

1a, 1c

1c, 1c × 2

1c

1c

1a, 1c

1a, 1c

1a

1a, 1c, Double

make contact 2a

Double make

contact 2a

12V

12V, 24V

12V

Standard: 12V, 24V

1a High capacity: 12V

77/83

47

95

118

55

59

77/83

47

69

64

95

104

109

118

126

136

140

145

64

59

131

73

91

157

165

170

(with Di)

(with Di)

(with Di)

(with Di)

(with Di)

(with Di)

ASCTB385E 201709-T

5

automotive-relay_en-html.html

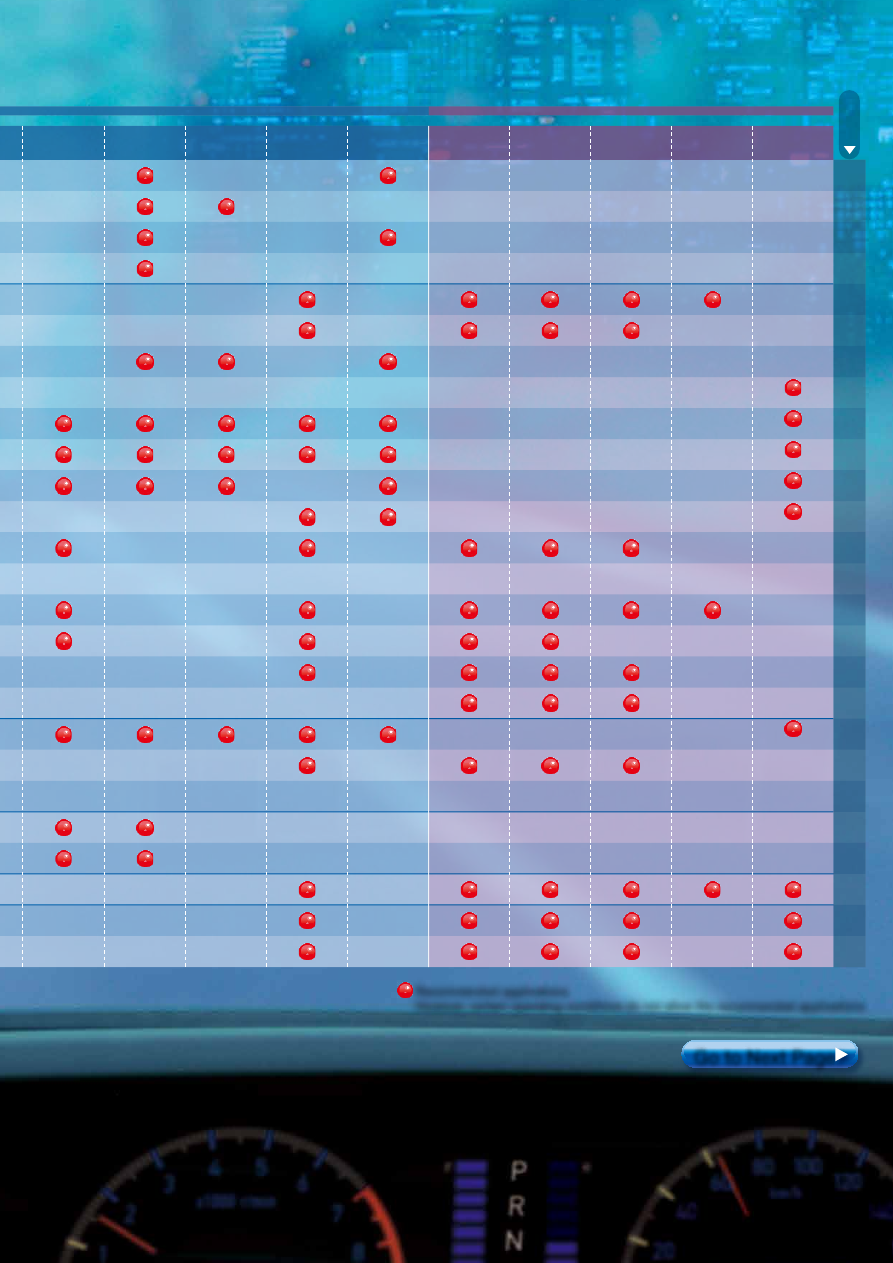

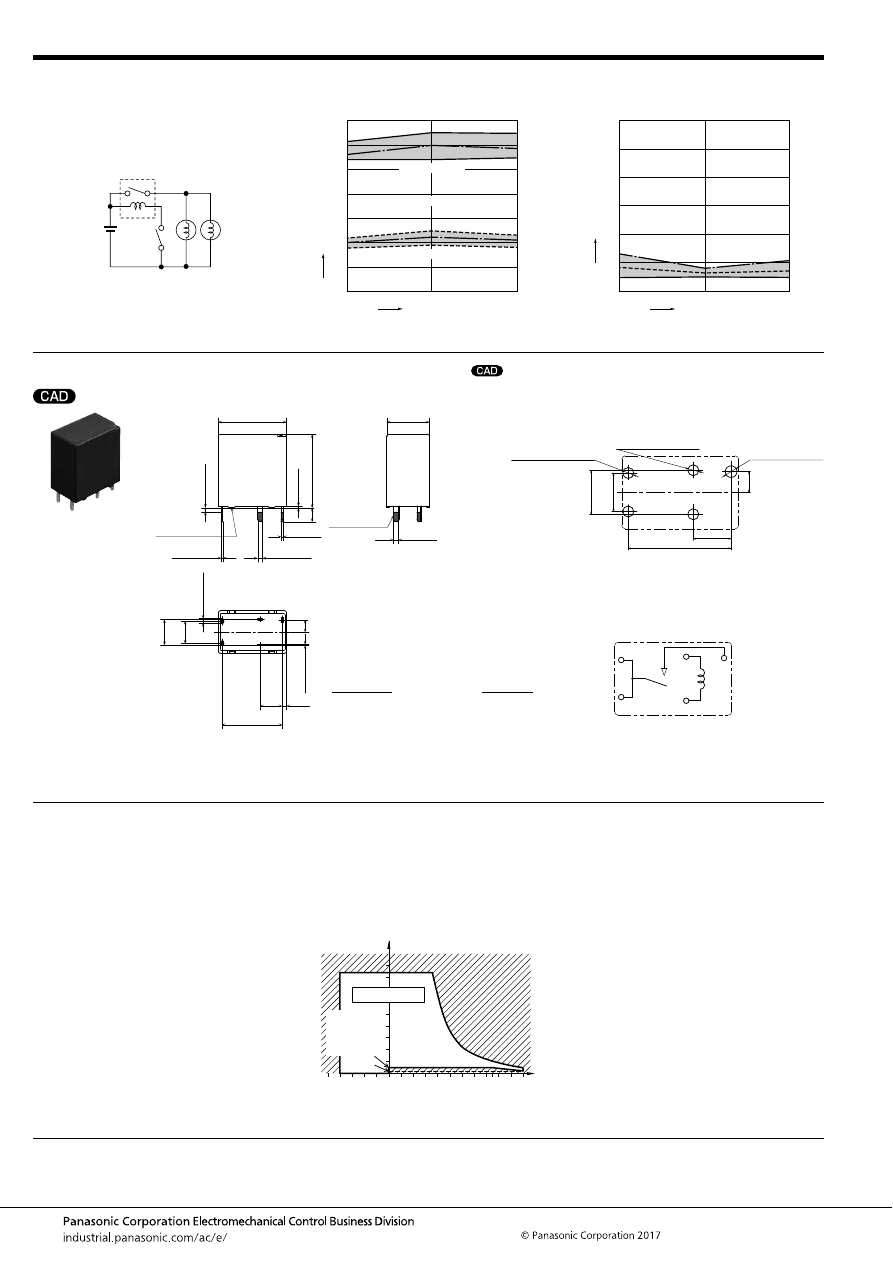

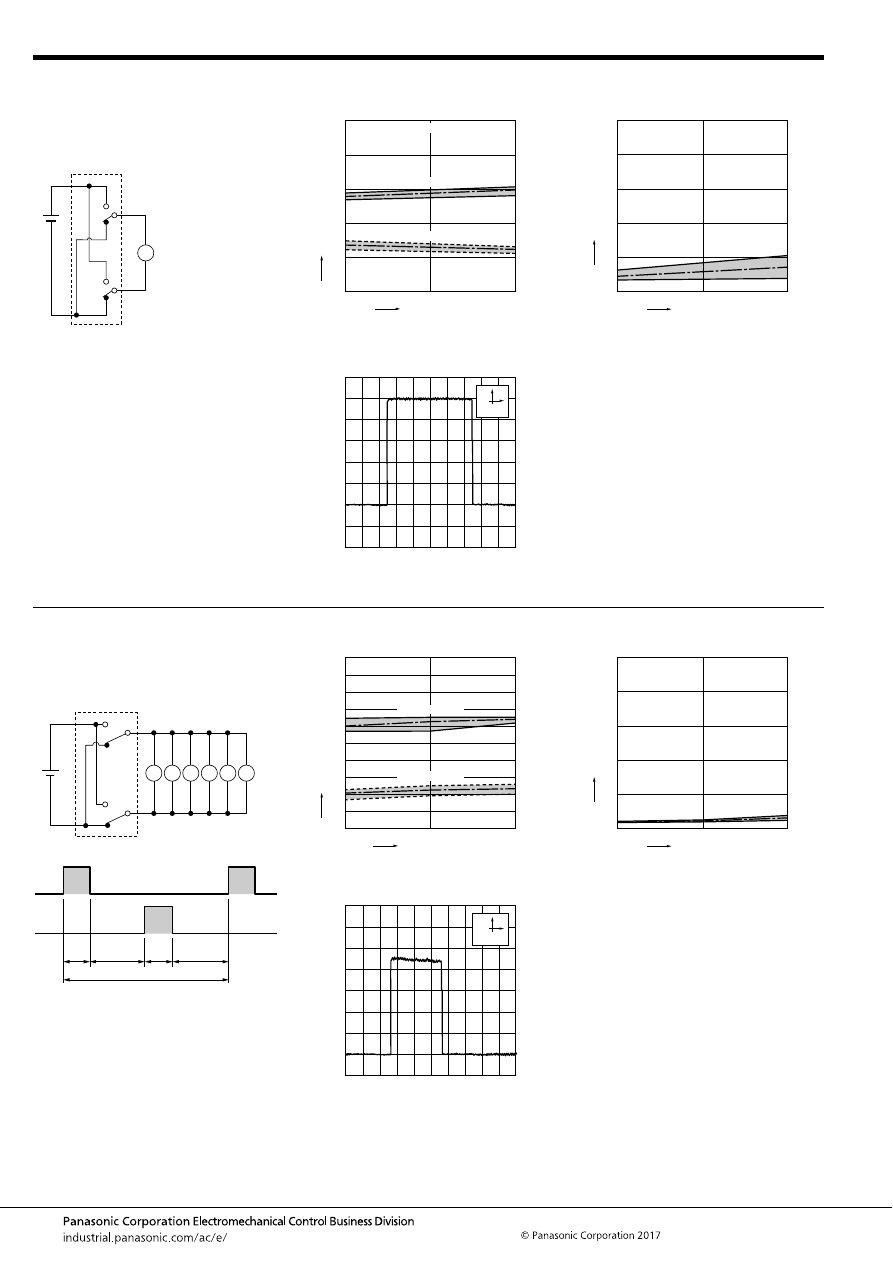

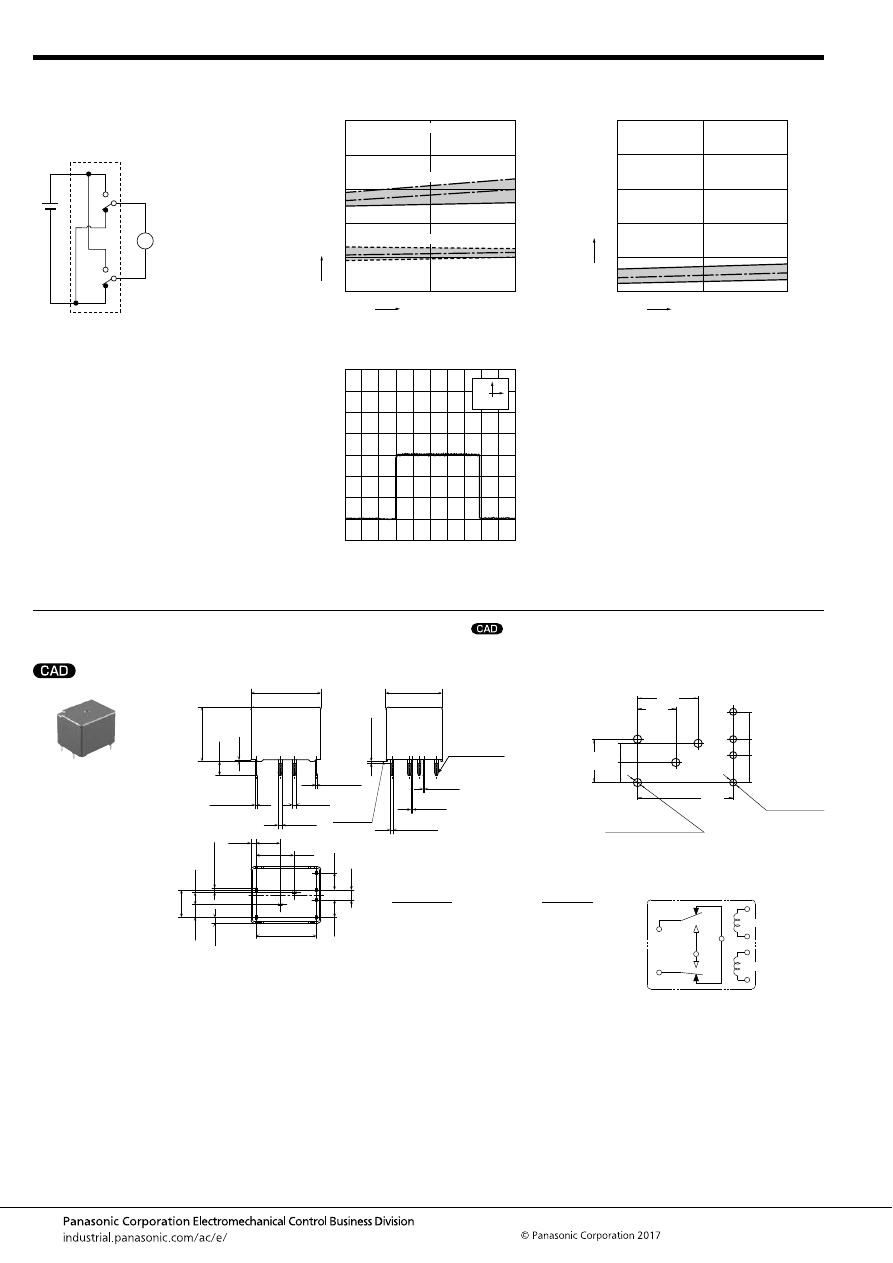

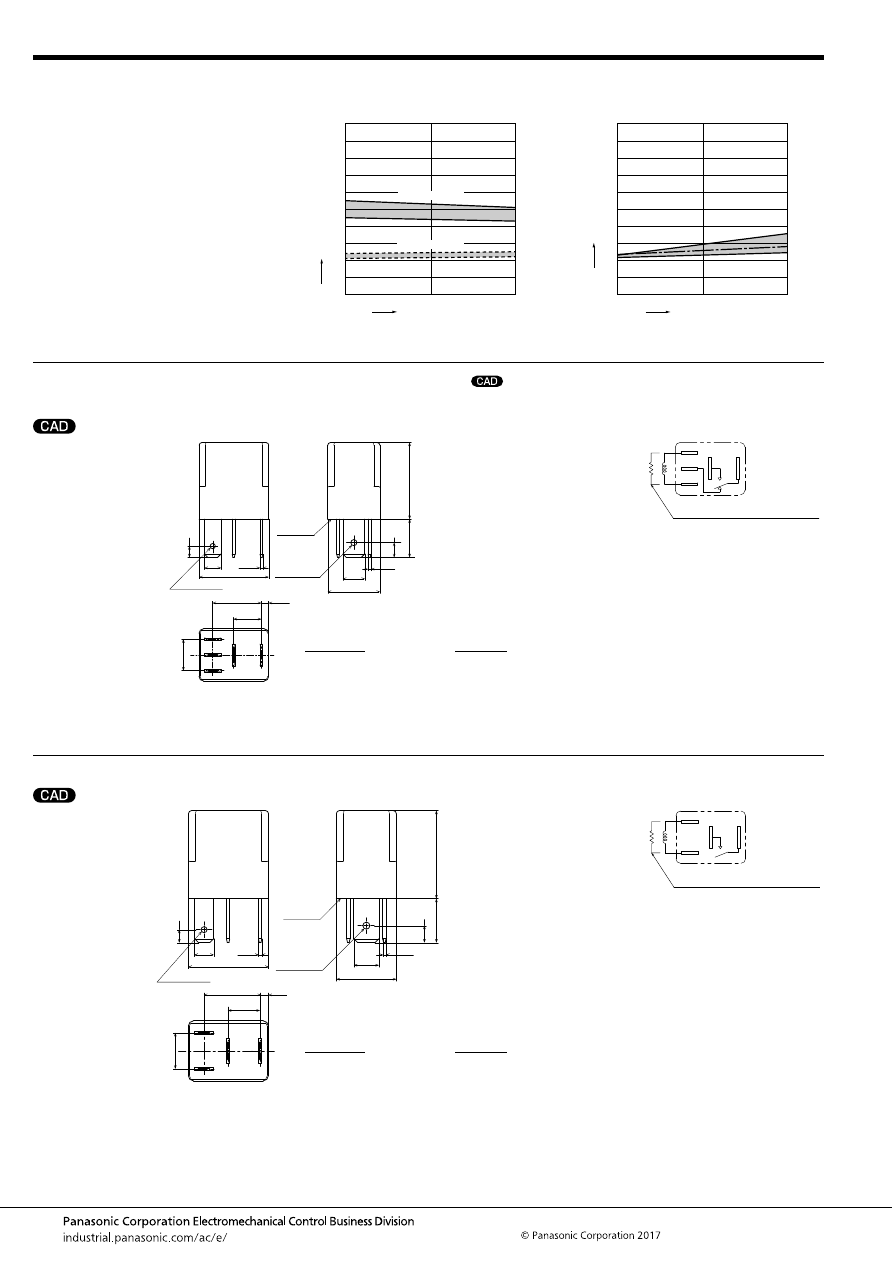

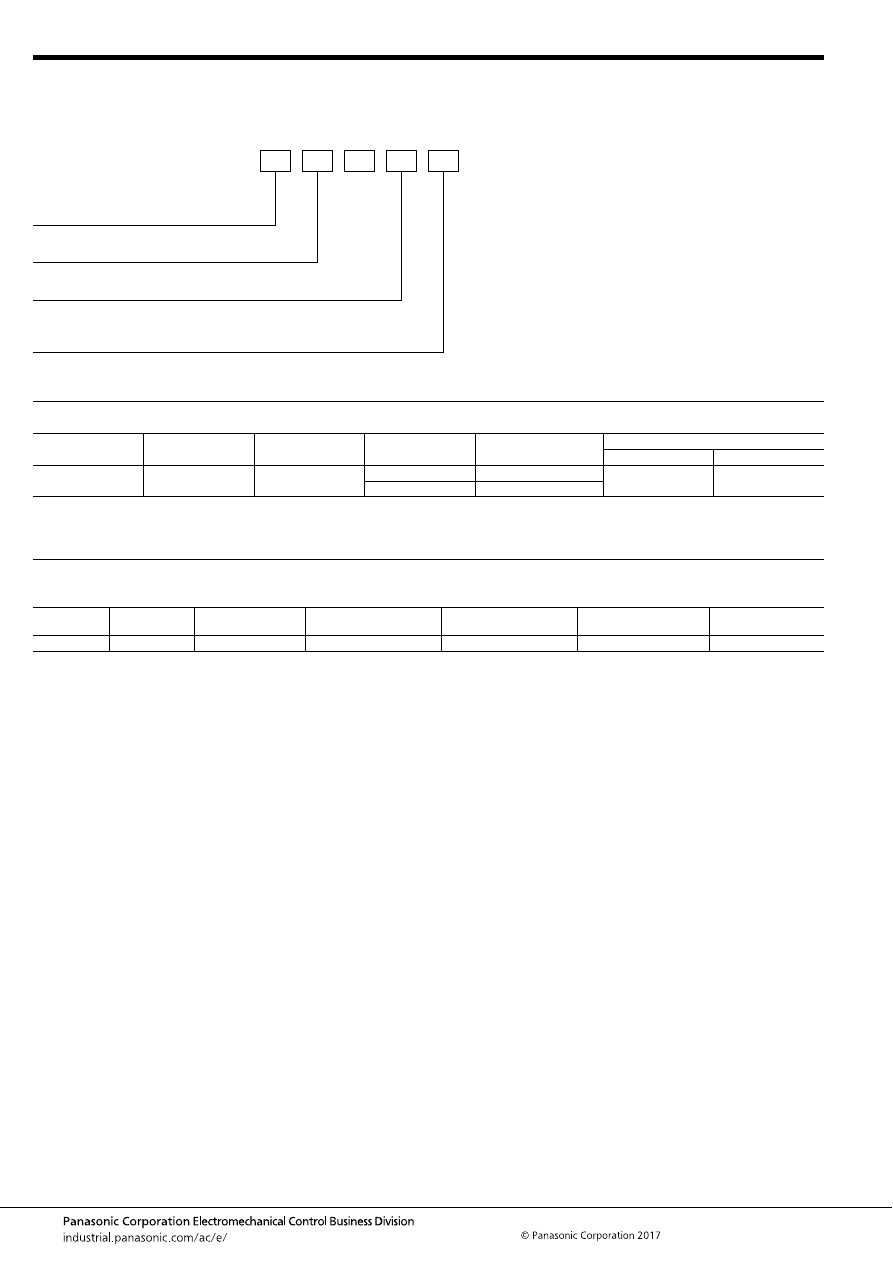

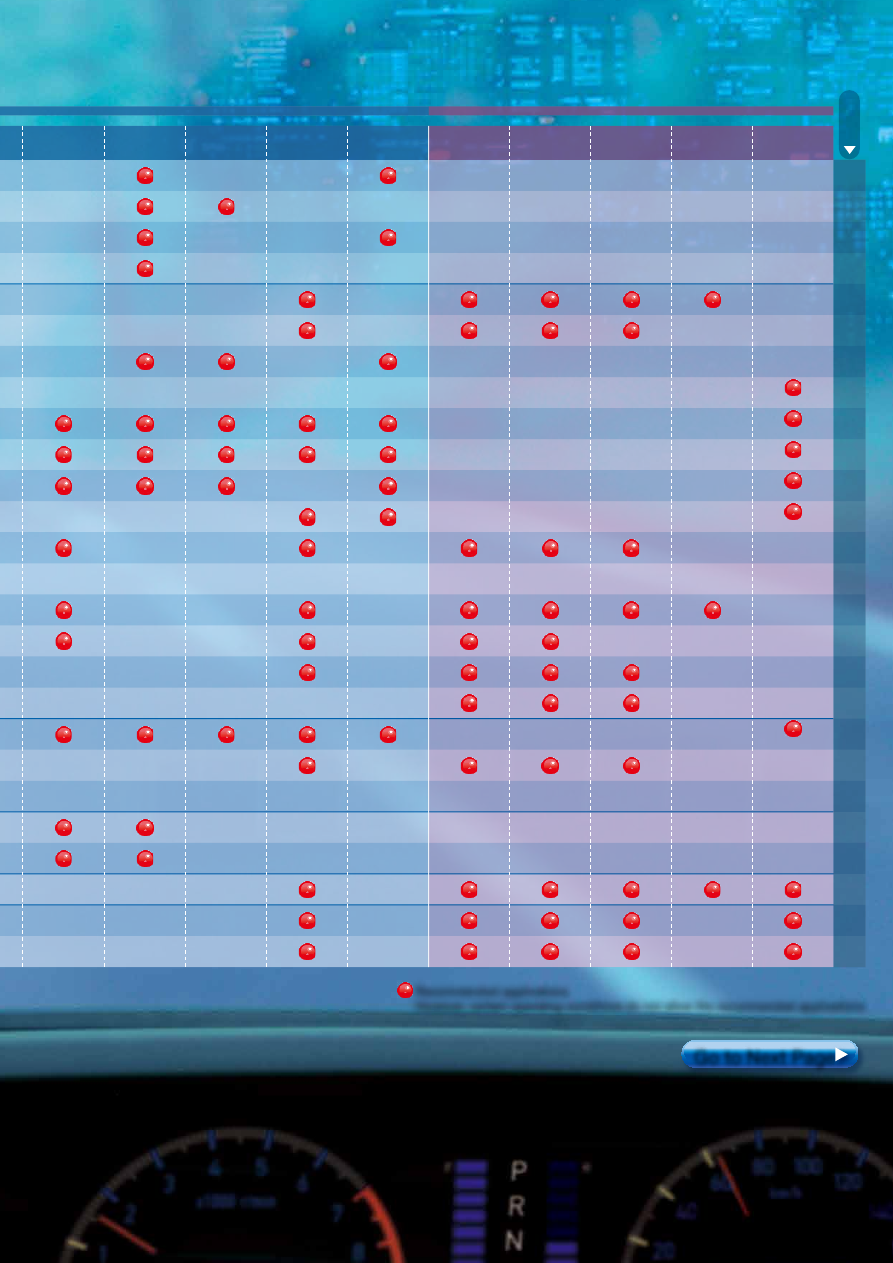

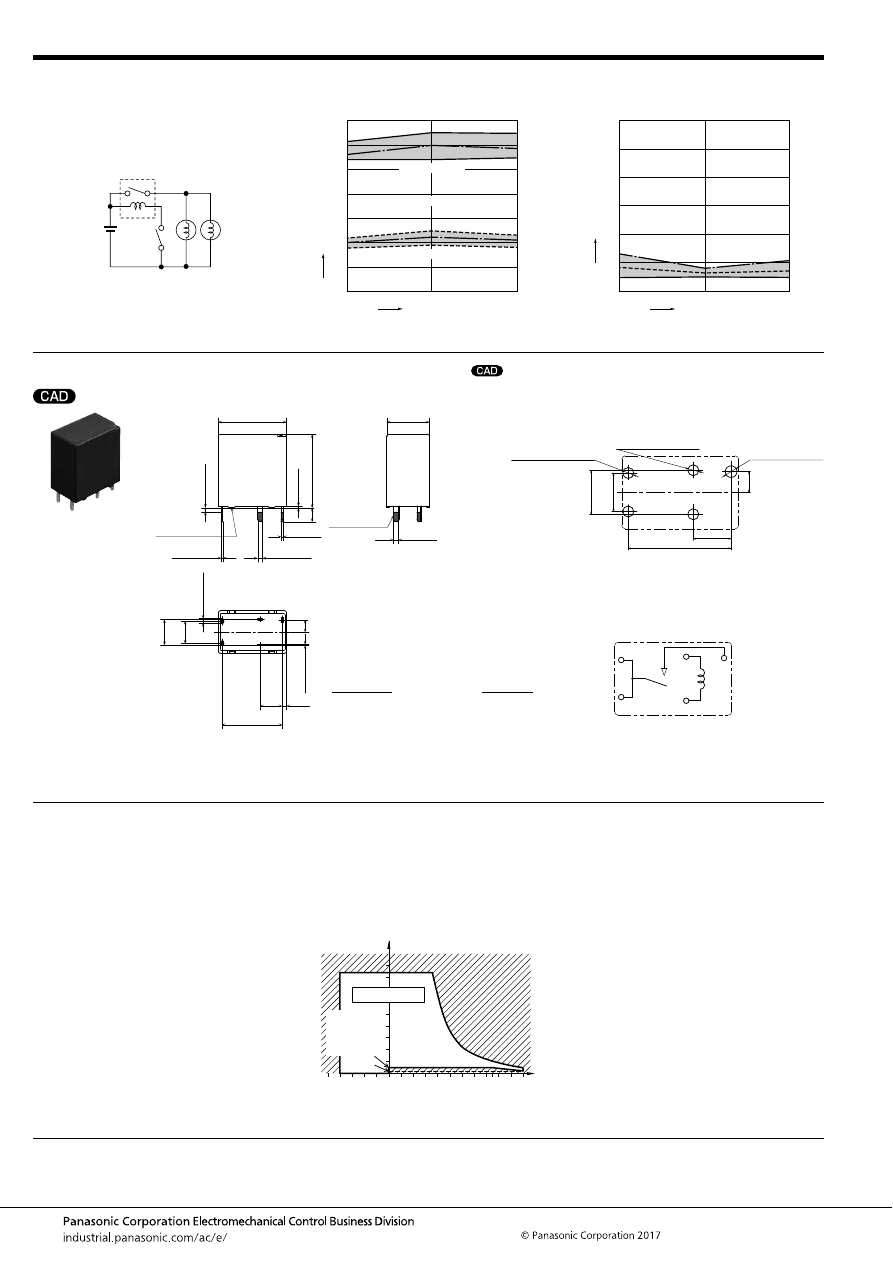

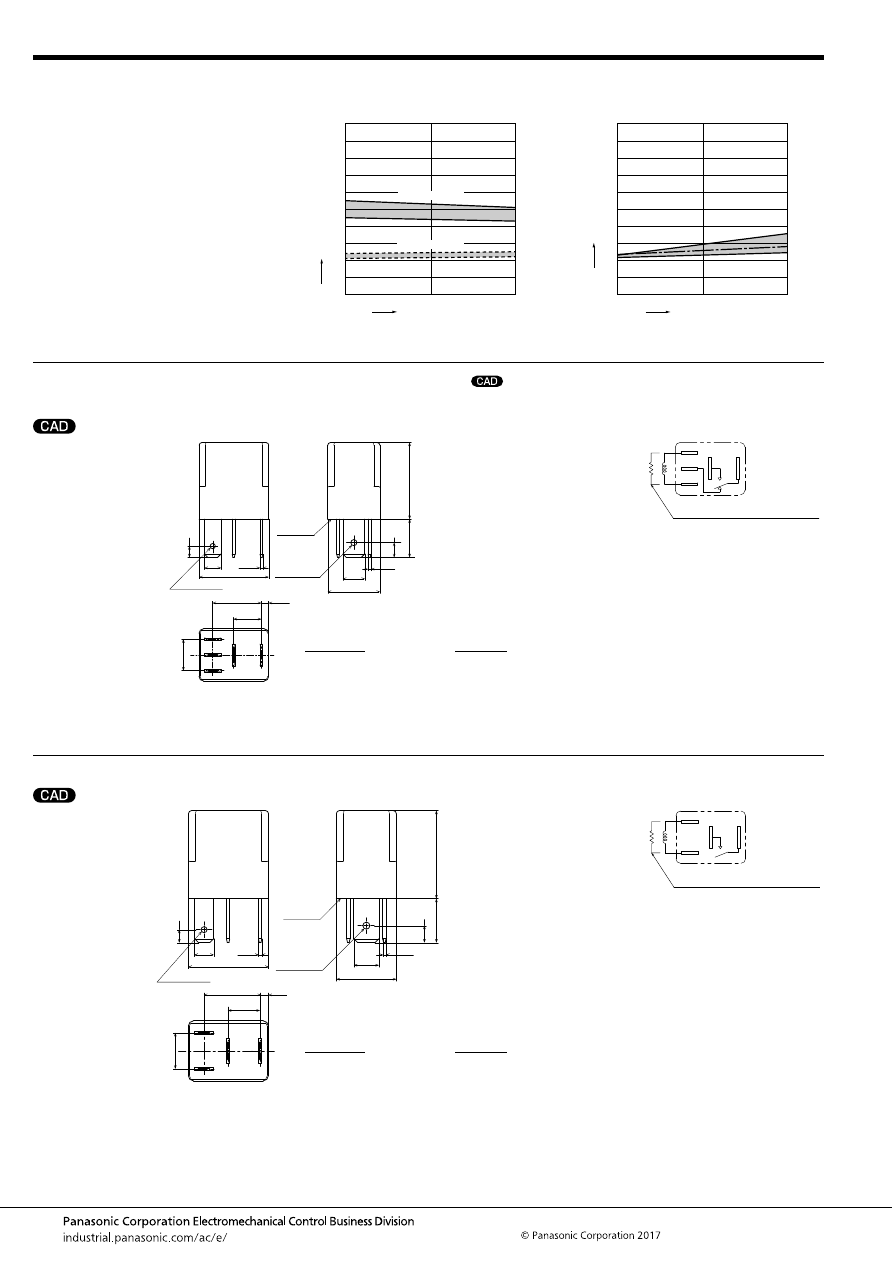

Application :

2

Comfort

Powered

sunroof

Powered seats

Lift gates

Door lock

Slide door

closer

Room lamp

Seat heater

Answerback lamp for

keyless entry

Powered window

motor

77/83

47

95

118

55

59

77/83

47

69

64

95

104

109

118

126

136

140

145

64

59

131

73

91

157

165

170

Twin

SMD

Quiet

Mini ISO

Micro ISO

Type

Product name

CT/CT-P

CJ

TB

TE

CN-H

CN-M

CT/CT-P

CJ

CP-P

CP

TB

TB-P

TC

TE

TG

TJ

TL

TM

CP

CN-M

TH

CQ

TA

CB

CM

CV-N

Single

1c × 2

1c × 2

1c × 2

1c × 2

1a

1a, 1c

1c

1c

1a, 1c

1a, 1c

1a, 1c

1a

1c

1a, 1c

1c

1a, 1c

1c

1a, 1c

1c, 1c × 2

1c

1c

1a, 1c

1a, 1c

1a

Contact

arrangement

Coil voltage

12V

12V, 24V

12V

Standard: 12V, 24V

1a High capacity: 12V

1a, 1c, Double

make contact 2a

Page

Recommended applications

However, certain operating conditions do not allow the recommended applications

Double make

contact 2a

ASCTB385E 201709-T

6

automotive-relay_en-html.html

Application :

2

Comfort

Powered

sunroof

Powered seats

Lift gates

Door lock

Slide door

closer

Room lamp

Seat heater

Answerback lamp for

keyless entry

Powered window

motor

77/83

47

95

118

55

59

77/83

47

69

64

95

104

109

118

126

136

140

145

64

59

131

73

91

157

165

170

Twin

SMD

Quiet

Mini ISO

Micro ISO

Type

Product name

CT/CT-P

CJ

TB

TE

CN-H

CN-M

CT/CT-P

CJ

CP-P

CP

TB

TB-P

TC

TE

TG

TJ

TL

TM

CP

CN-M

TH

CQ

TA

CB

CM

CV-N

Single

1c × 2

1c × 2

1c × 2

1c × 2

1a

1a, 1c

1c

1c

1a, 1c

1a, 1c

1a, 1c

1a

1c

1a, 1c

1c

1a, 1c

1c

1a, 1c

1c, 1c × 2

1c

1c

1a, 1c

1a, 1c

1a

Contact

arrangement

Coil voltage

12V

12V, 24V

12V

Standard: 12V, 24V

1a High capacity: 12V

1a, 1c, Double

make contact 2a

Page

Recommended applications

However, certain operating conditions do not allow the recommended applications

Double make

contact 2a

ASCTB385E 201709-T

7

automotive-relay_en-html.html

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–8–

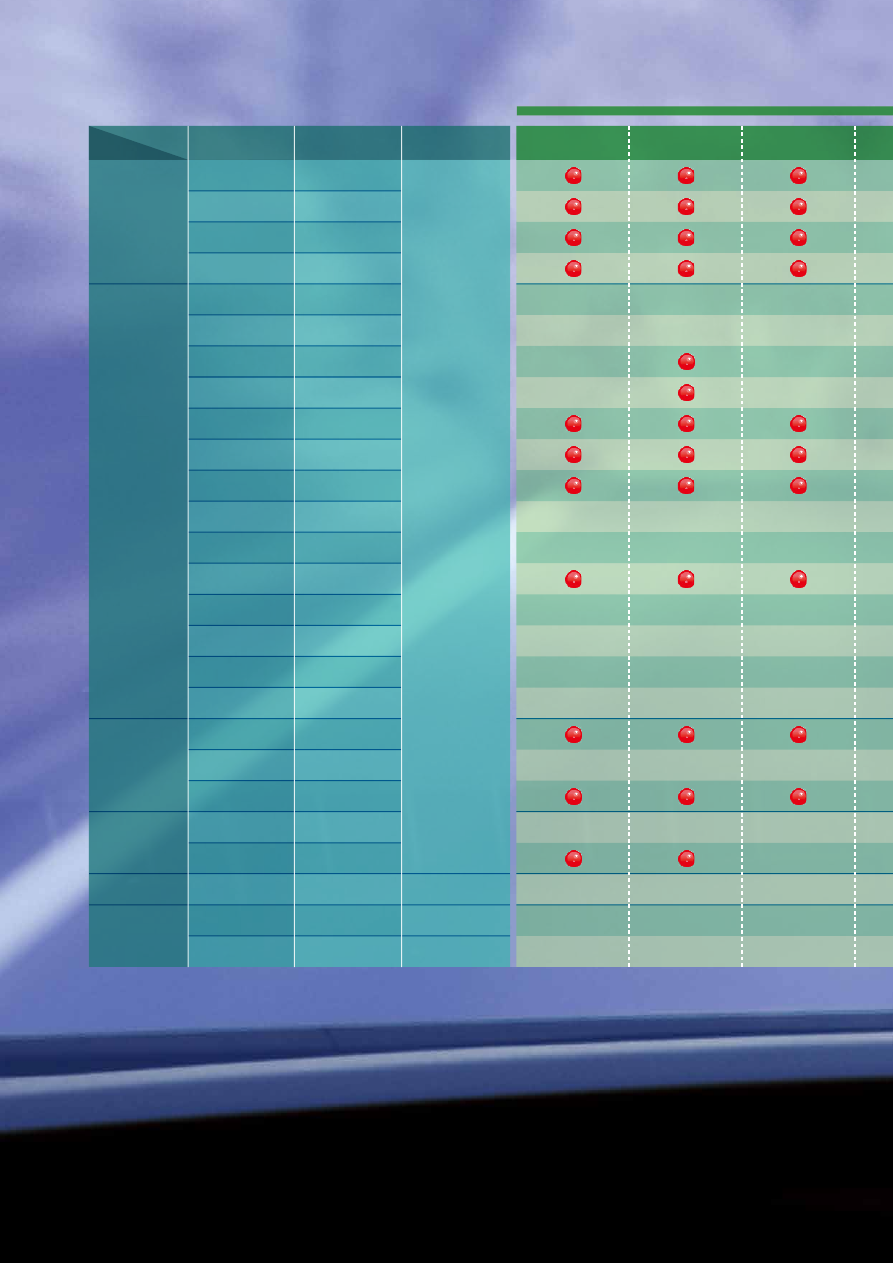

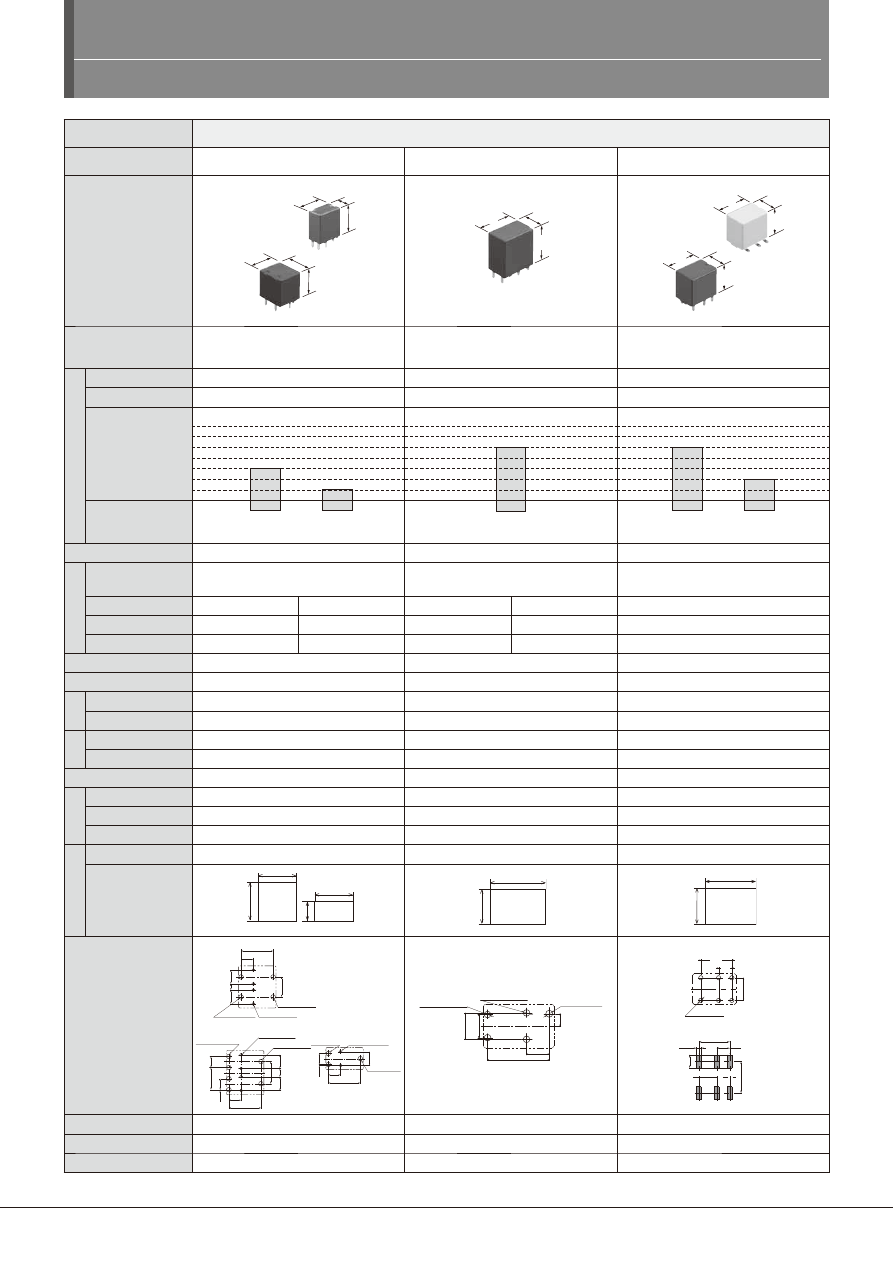

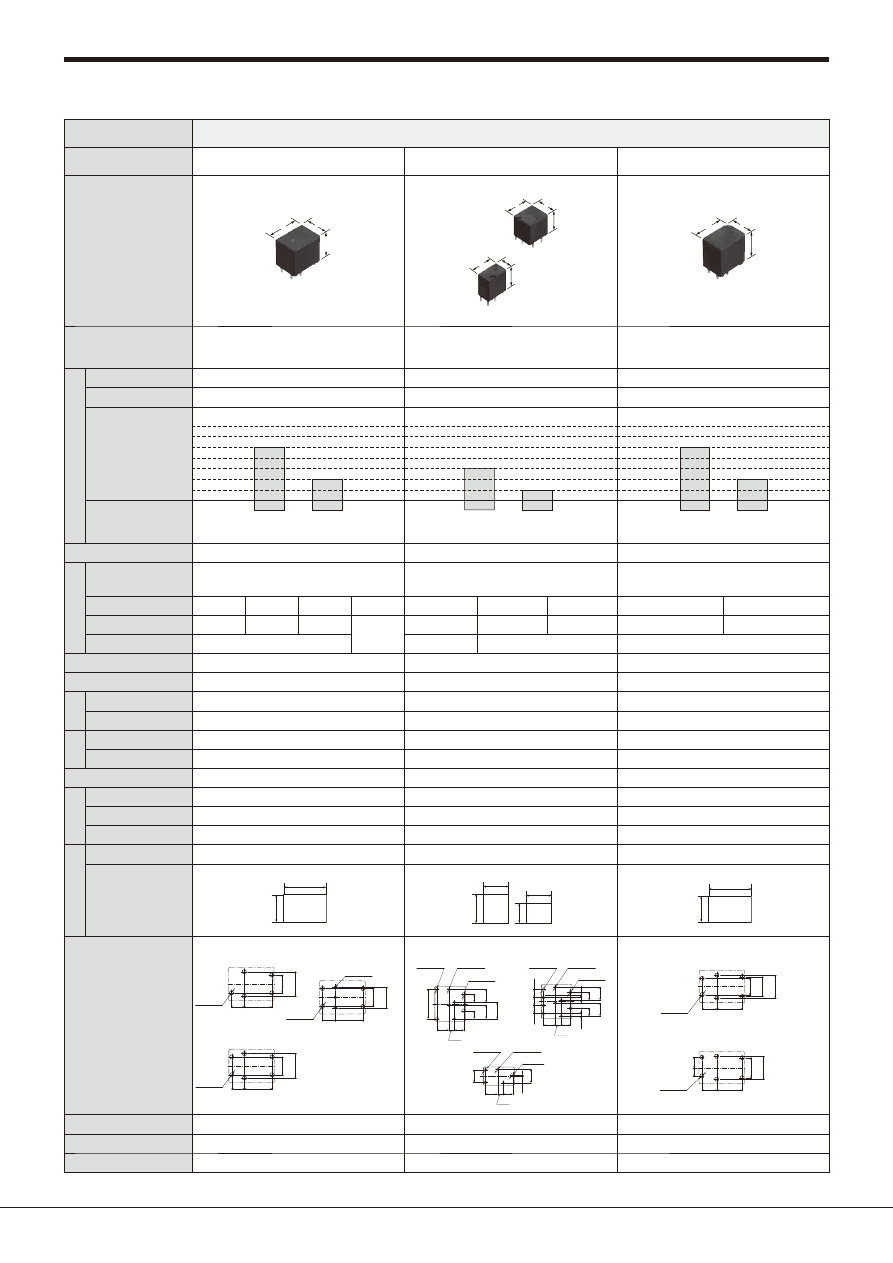

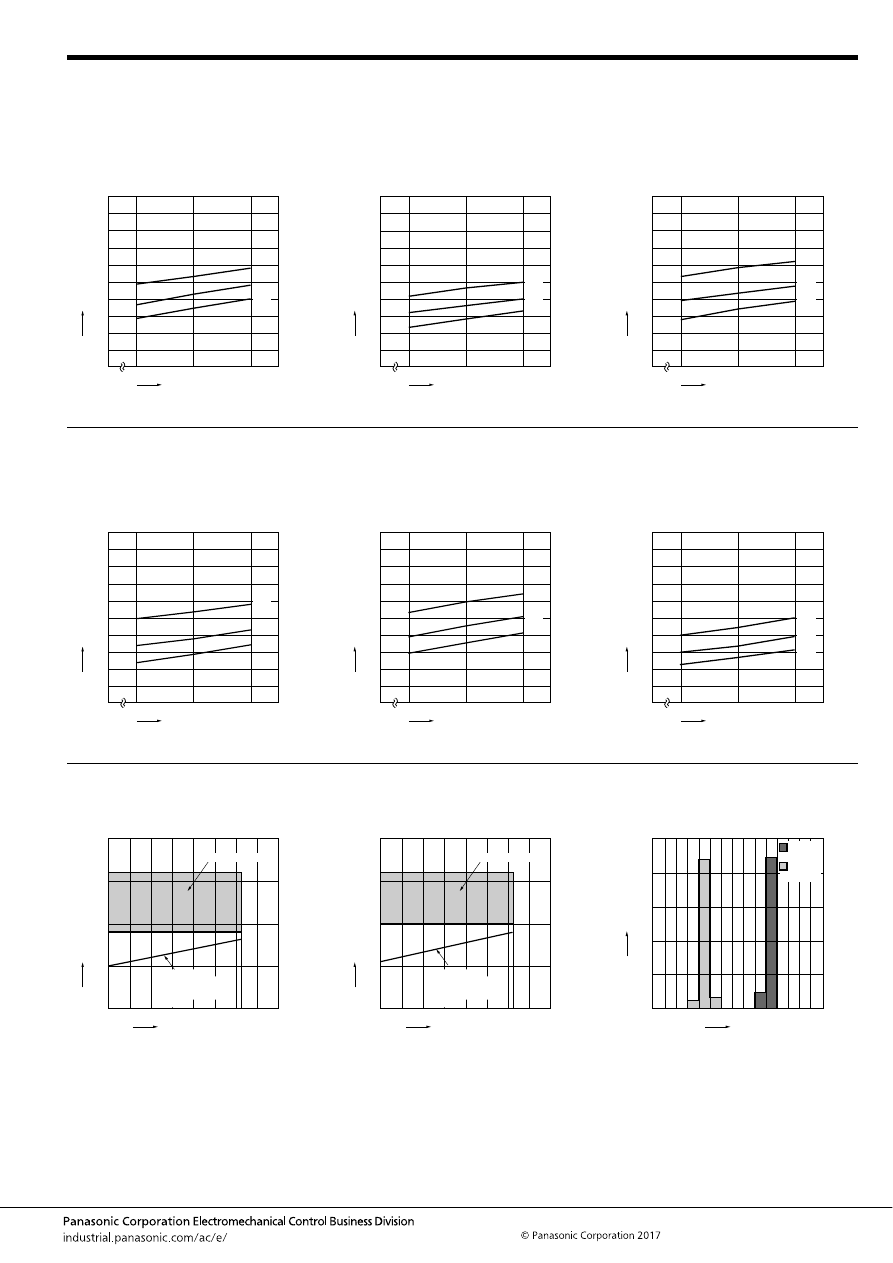

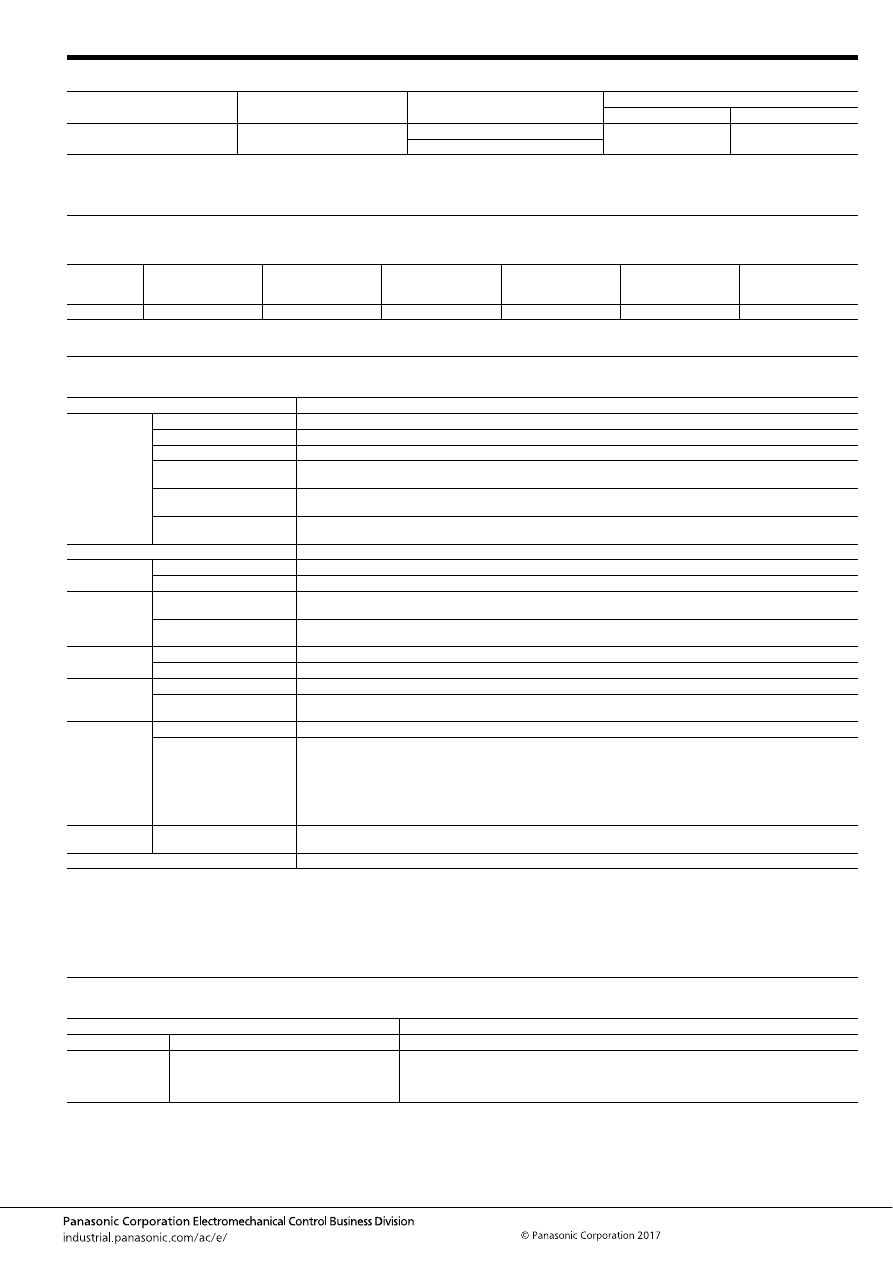

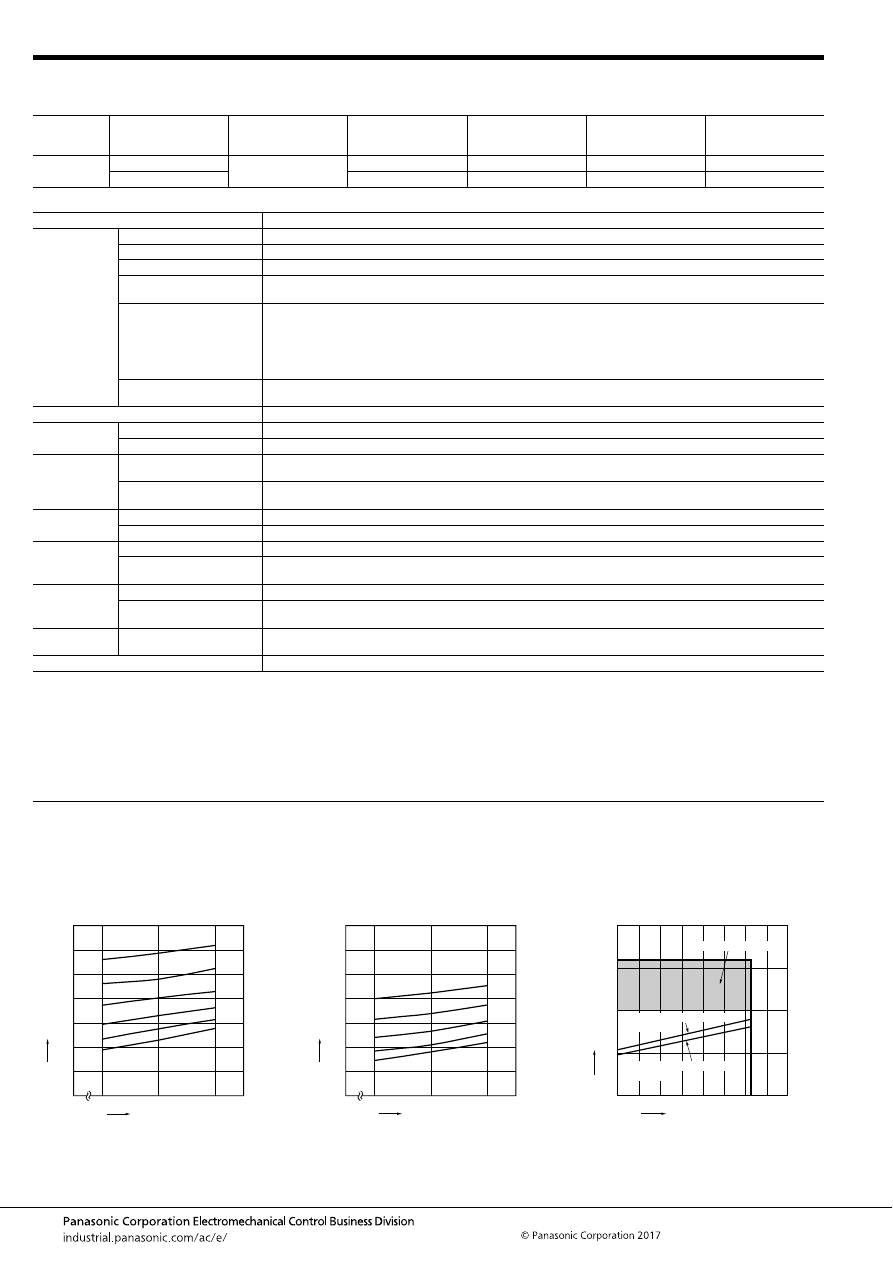

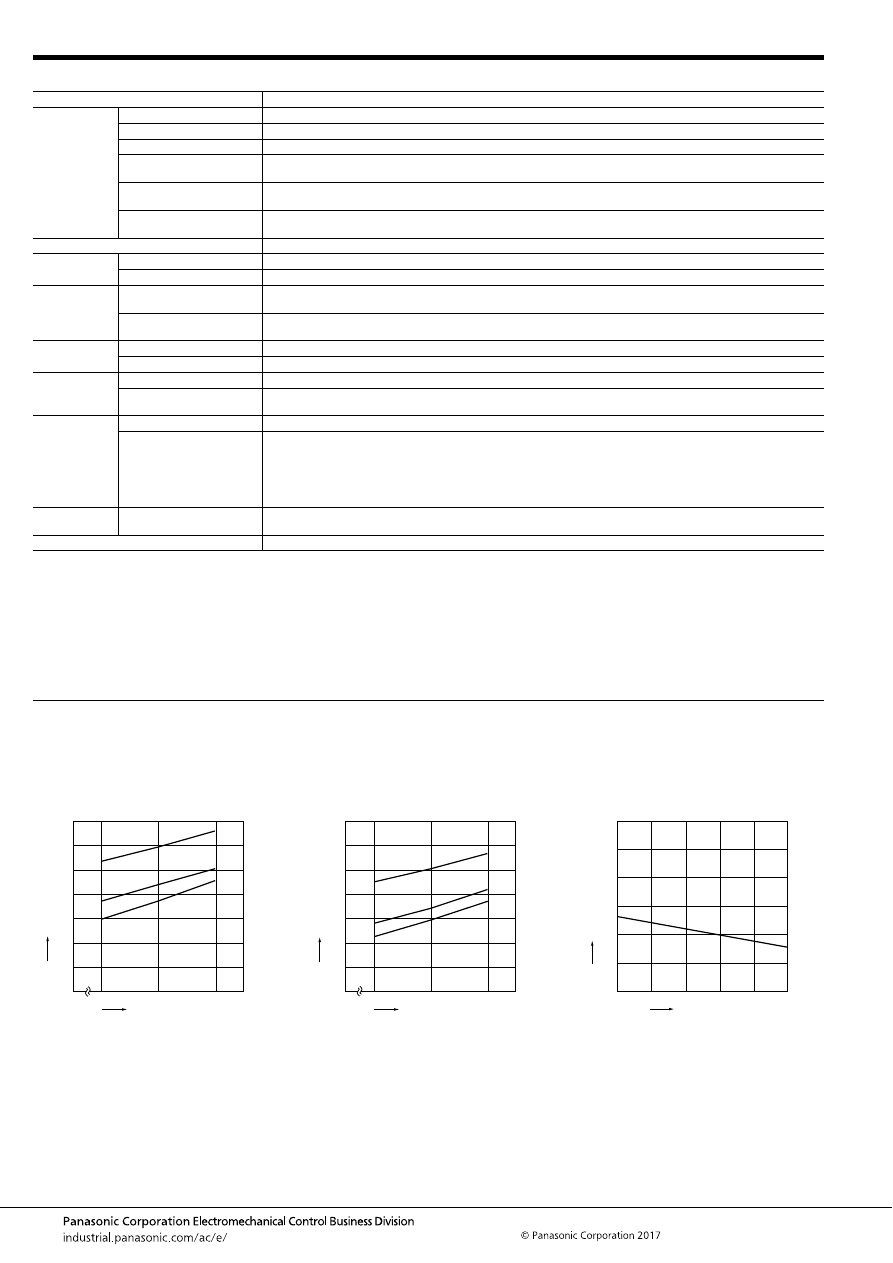

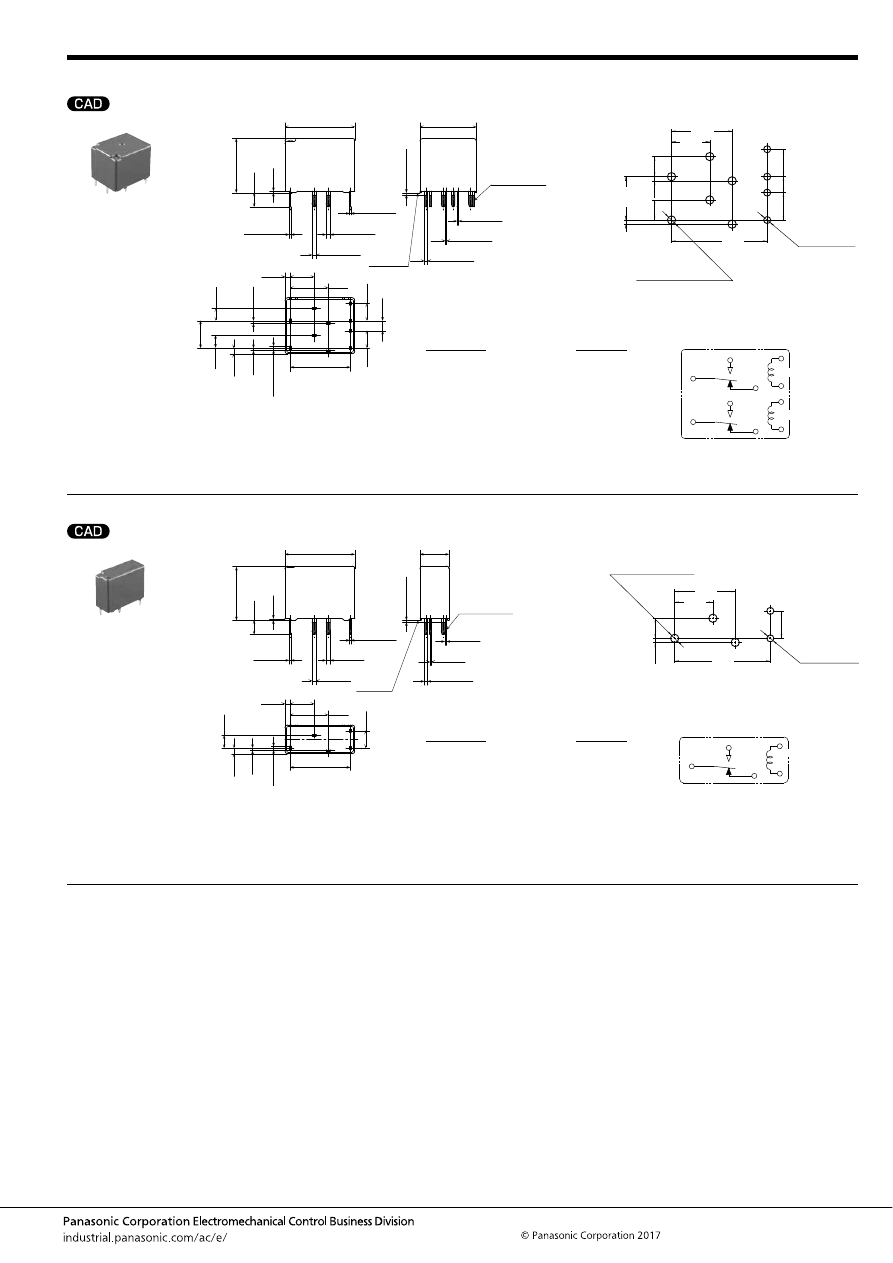

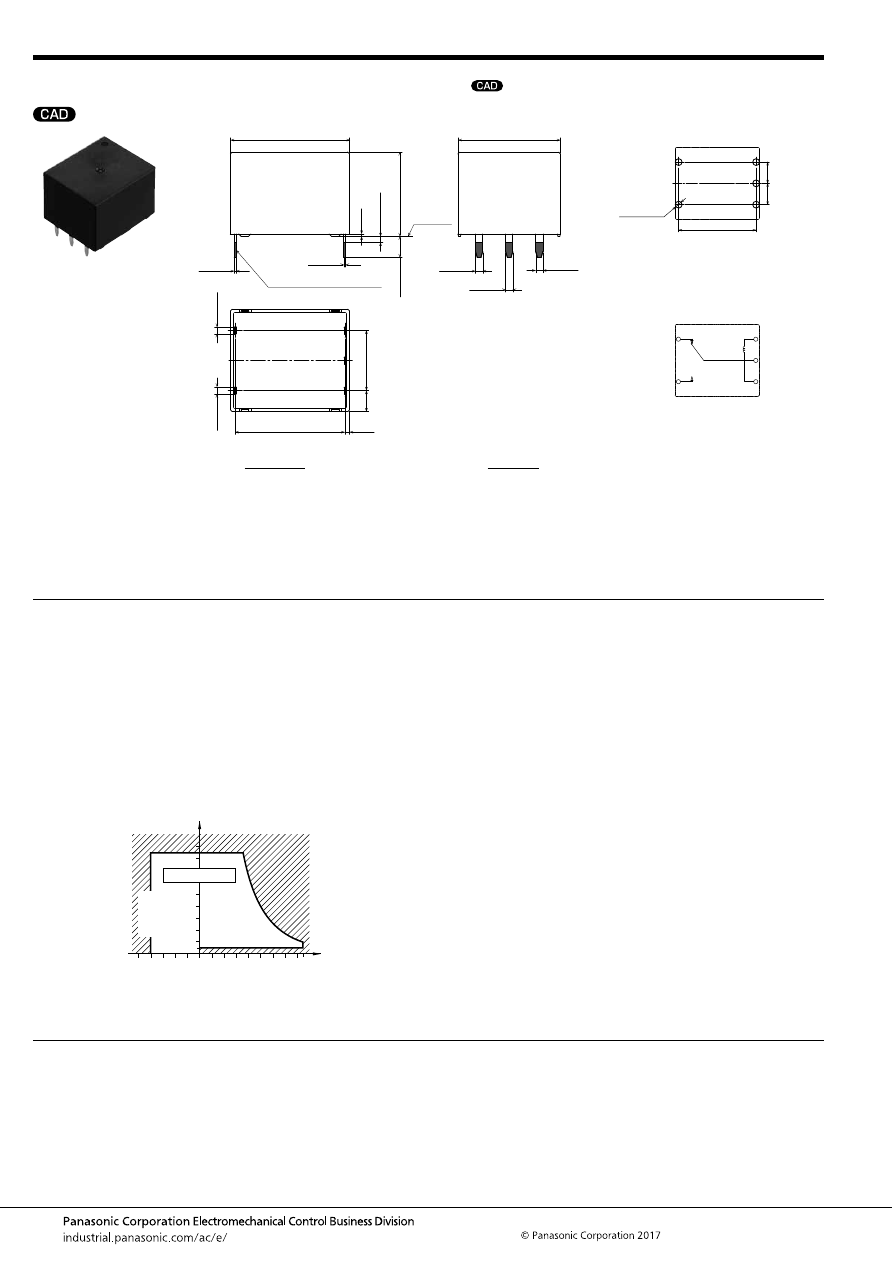

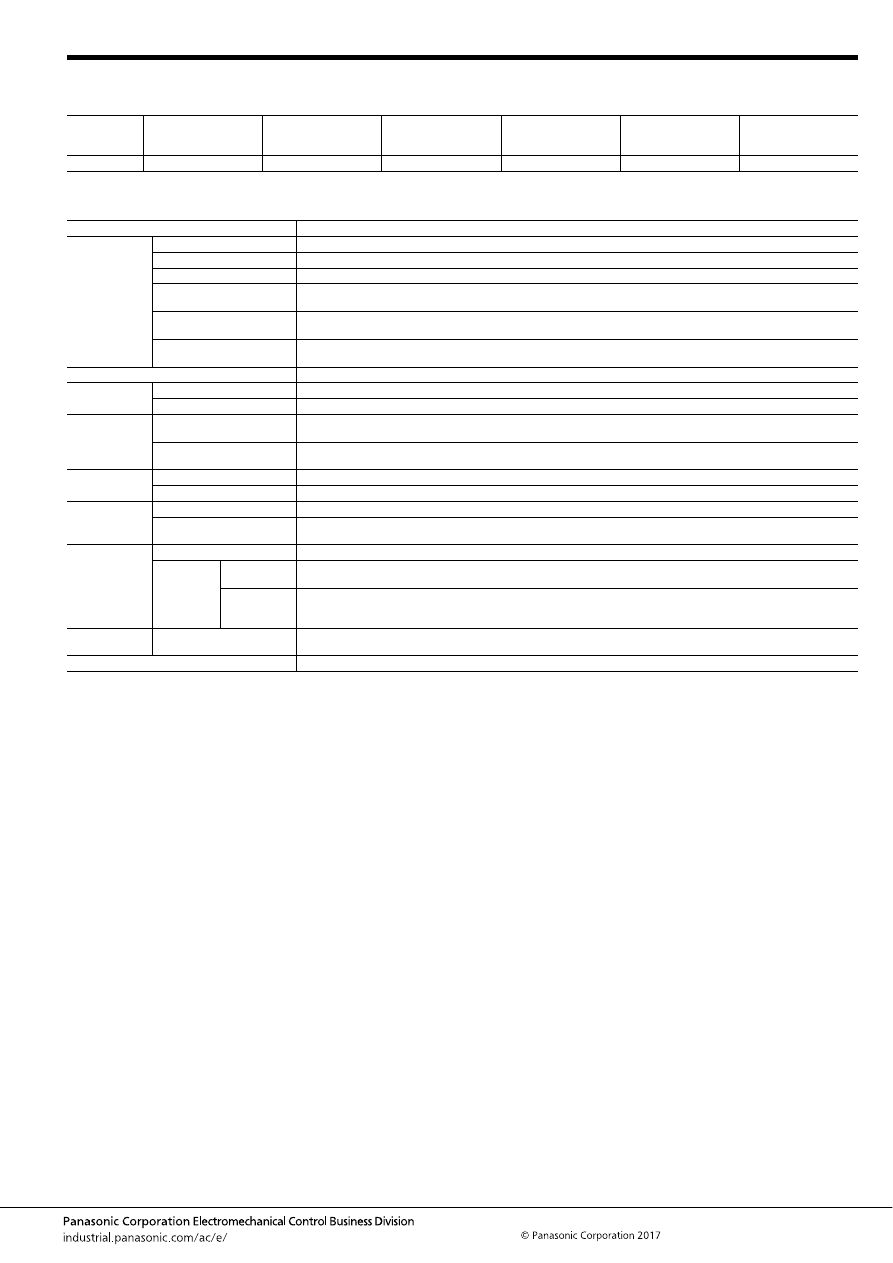

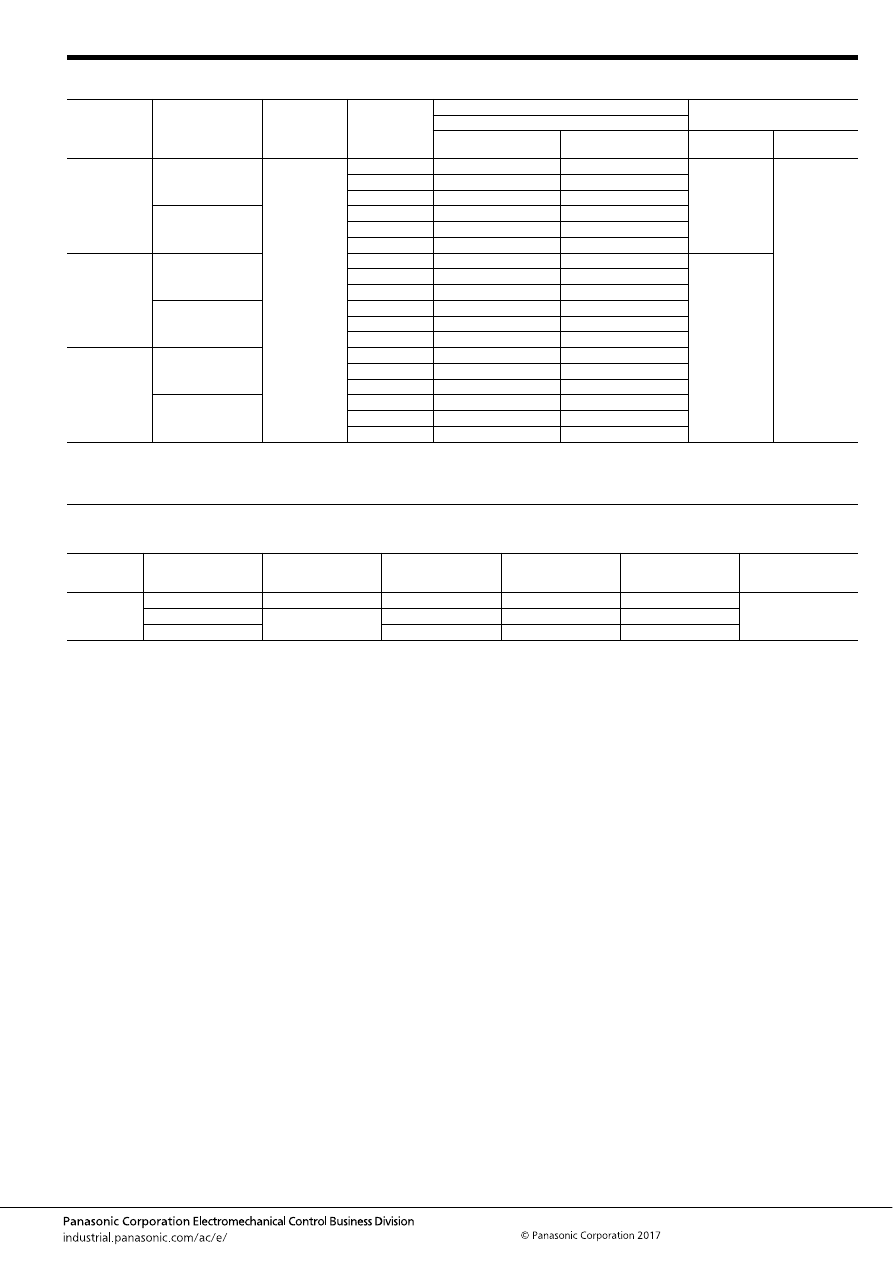

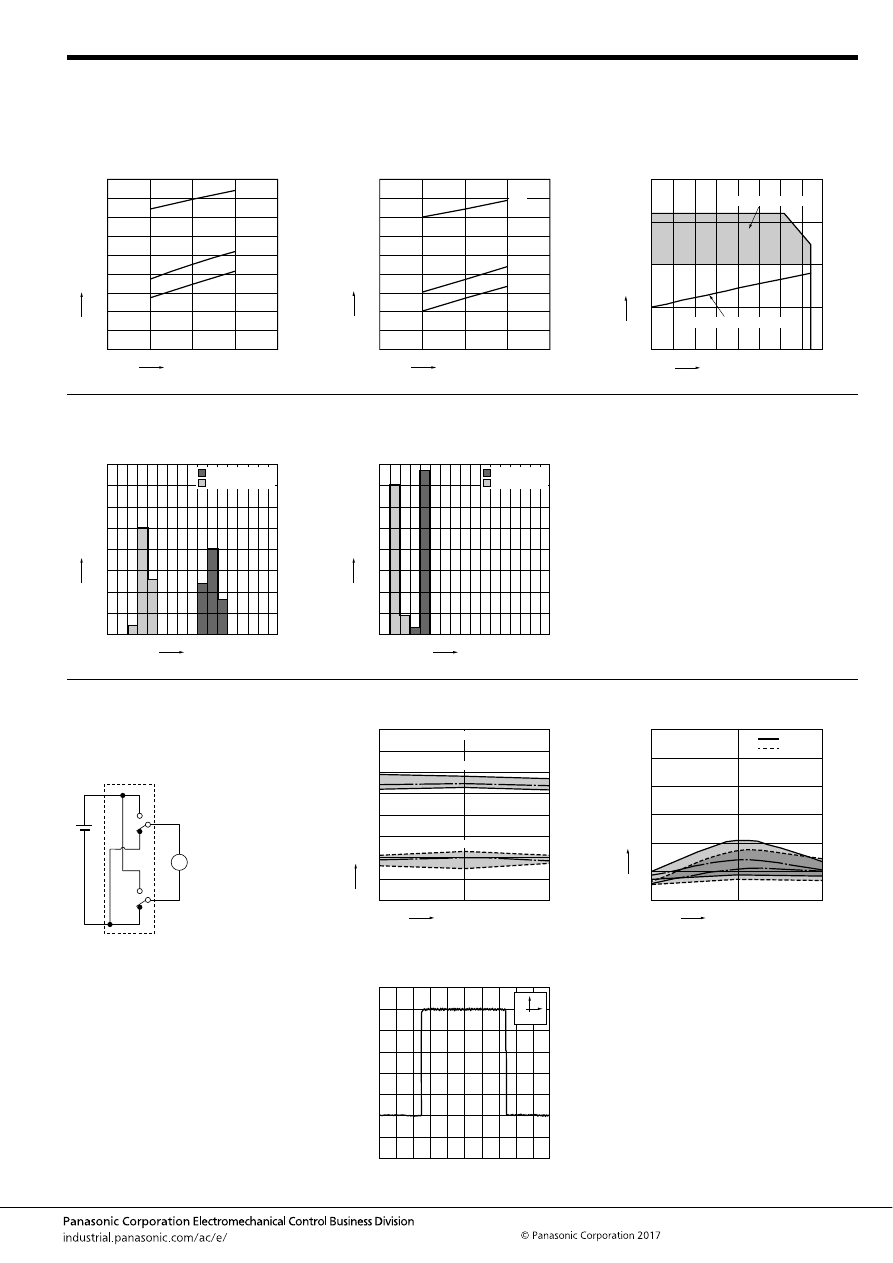

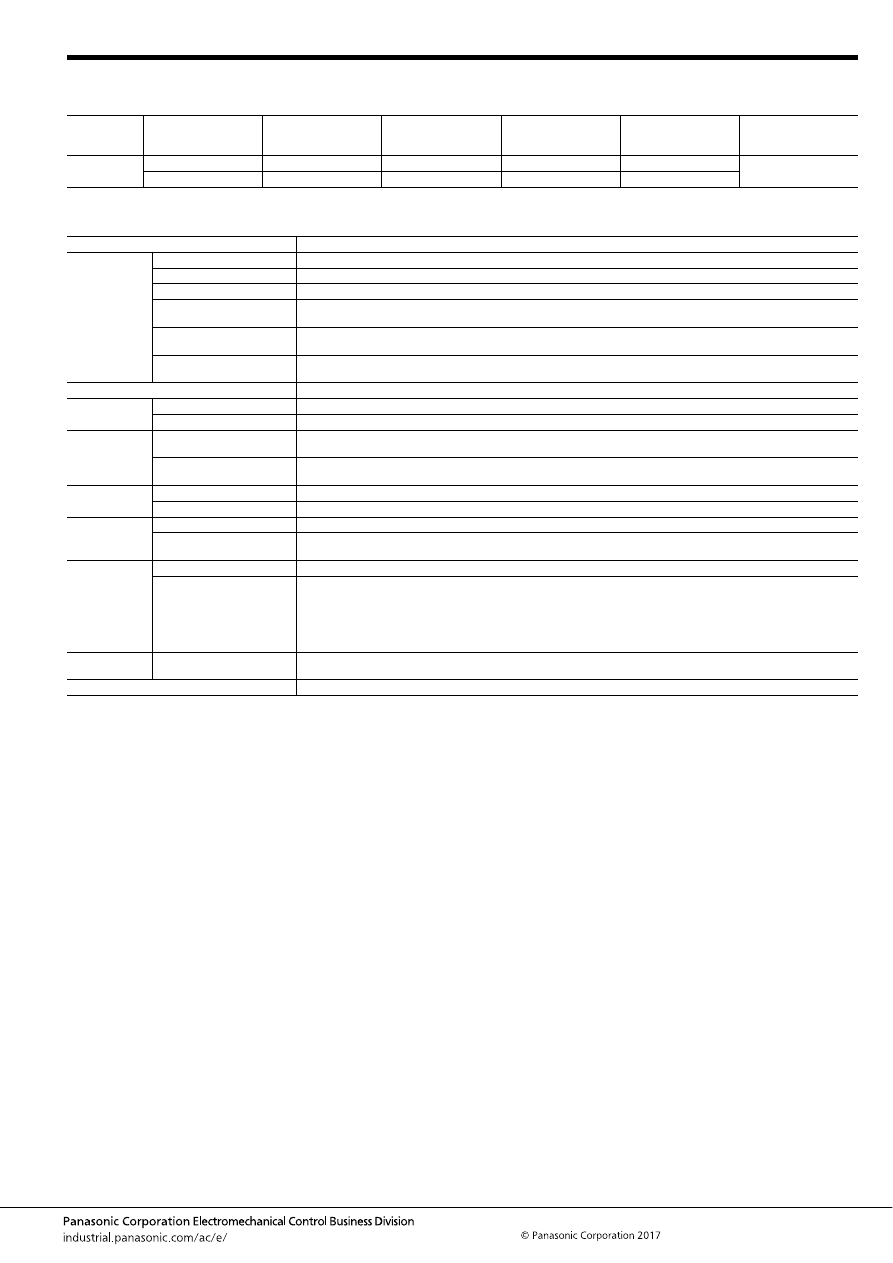

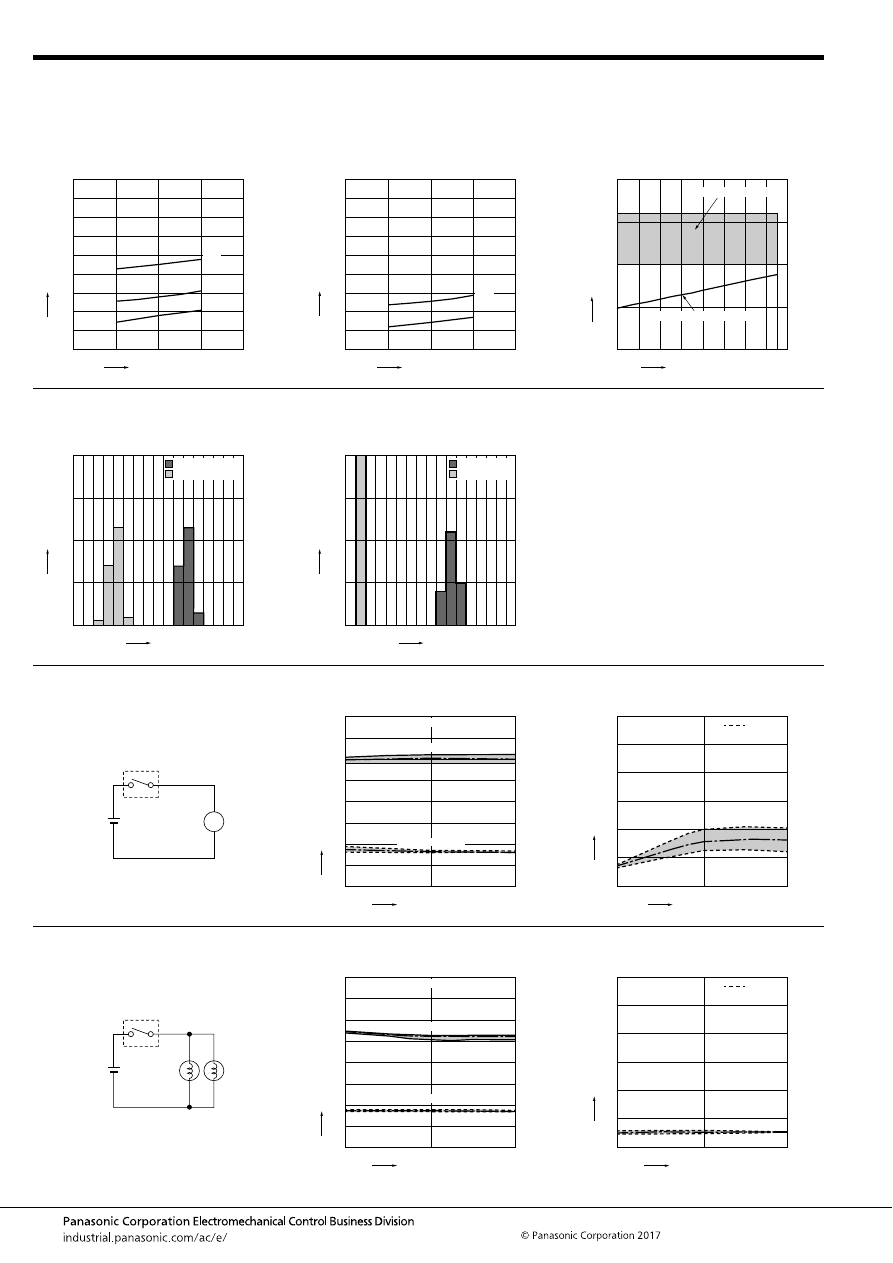

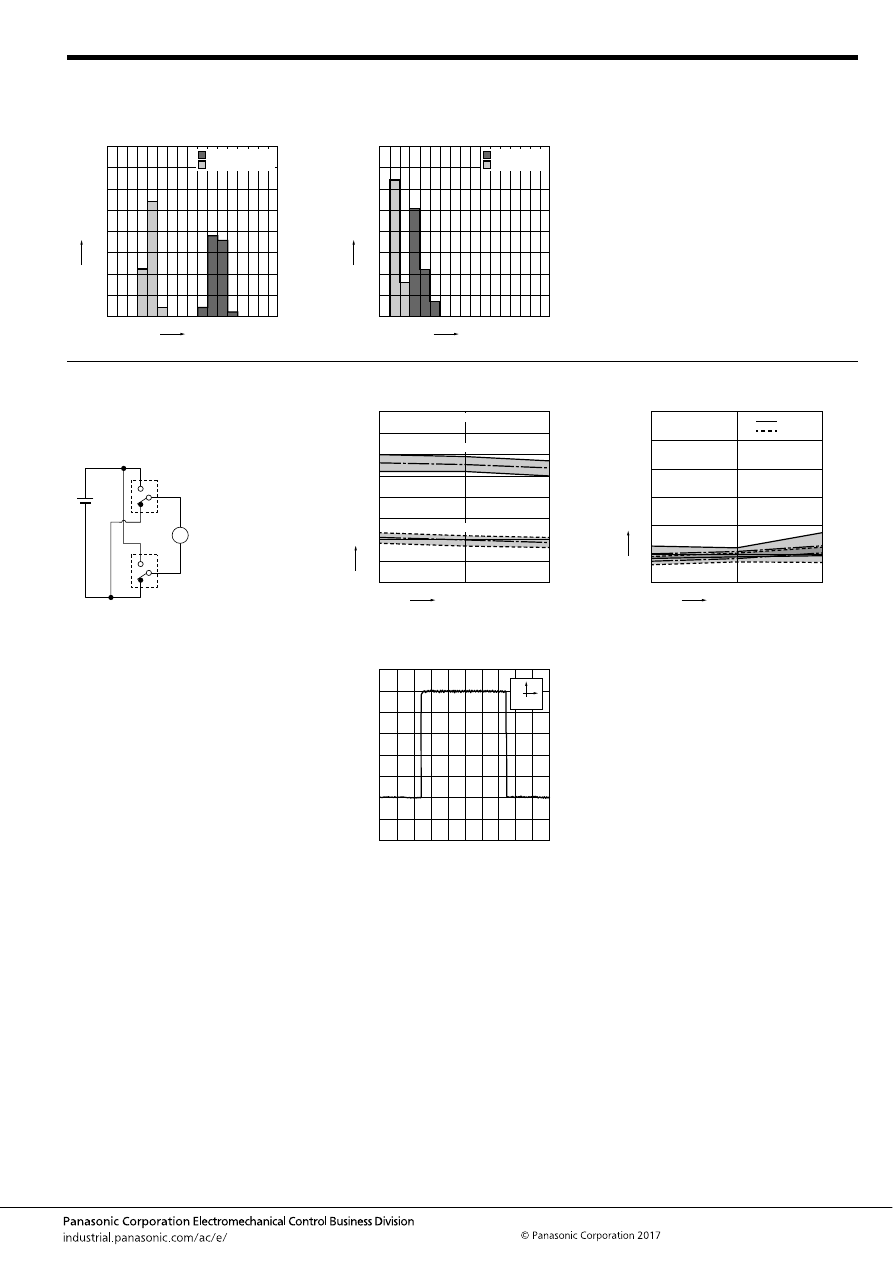

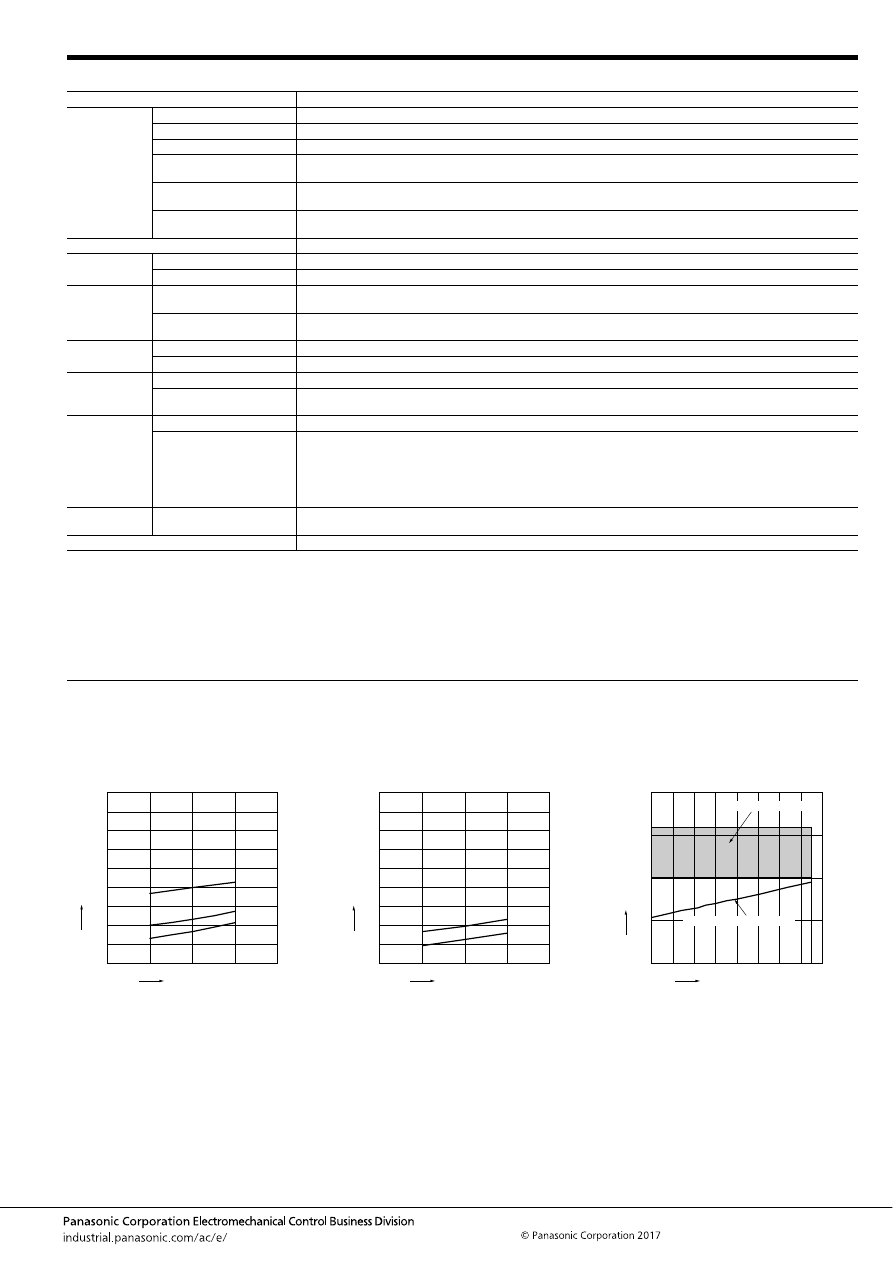

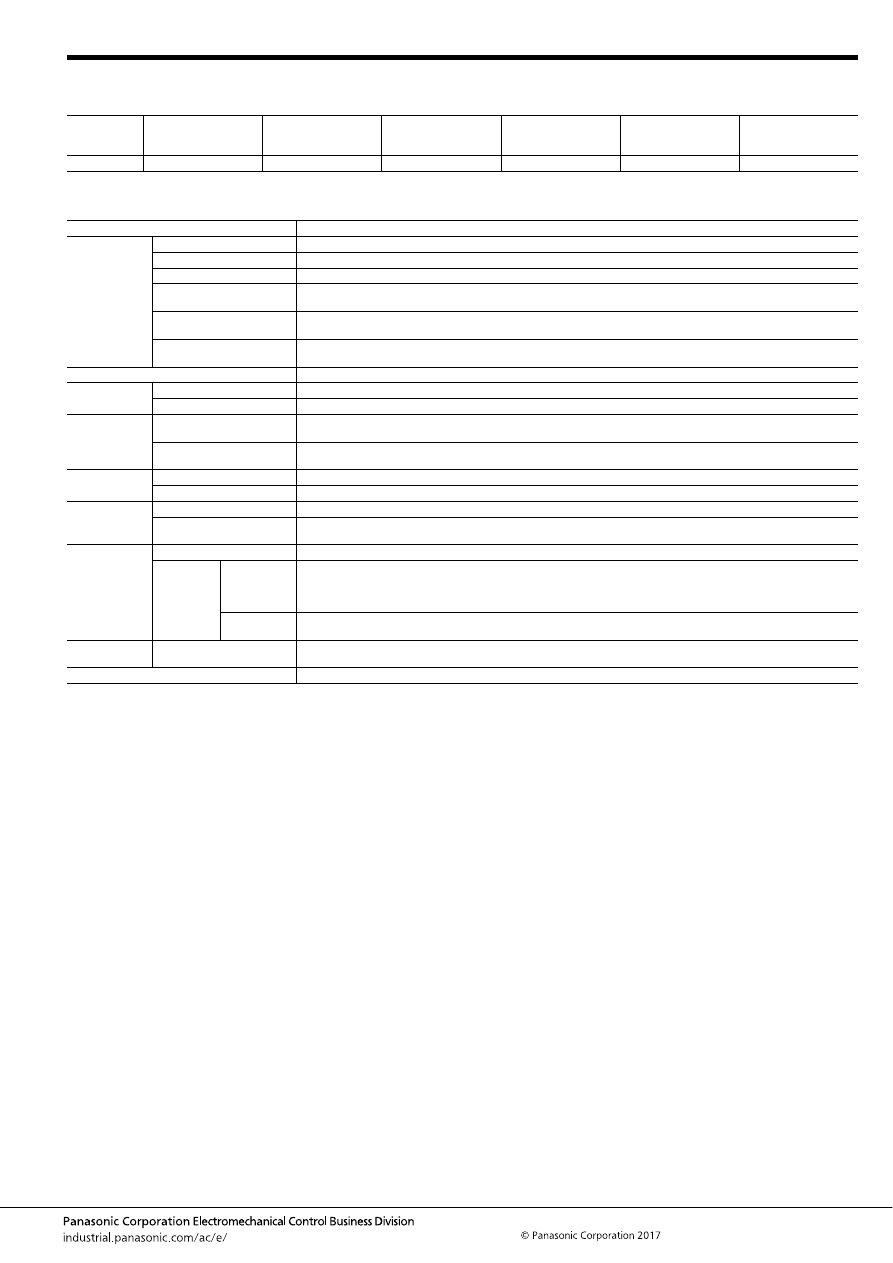

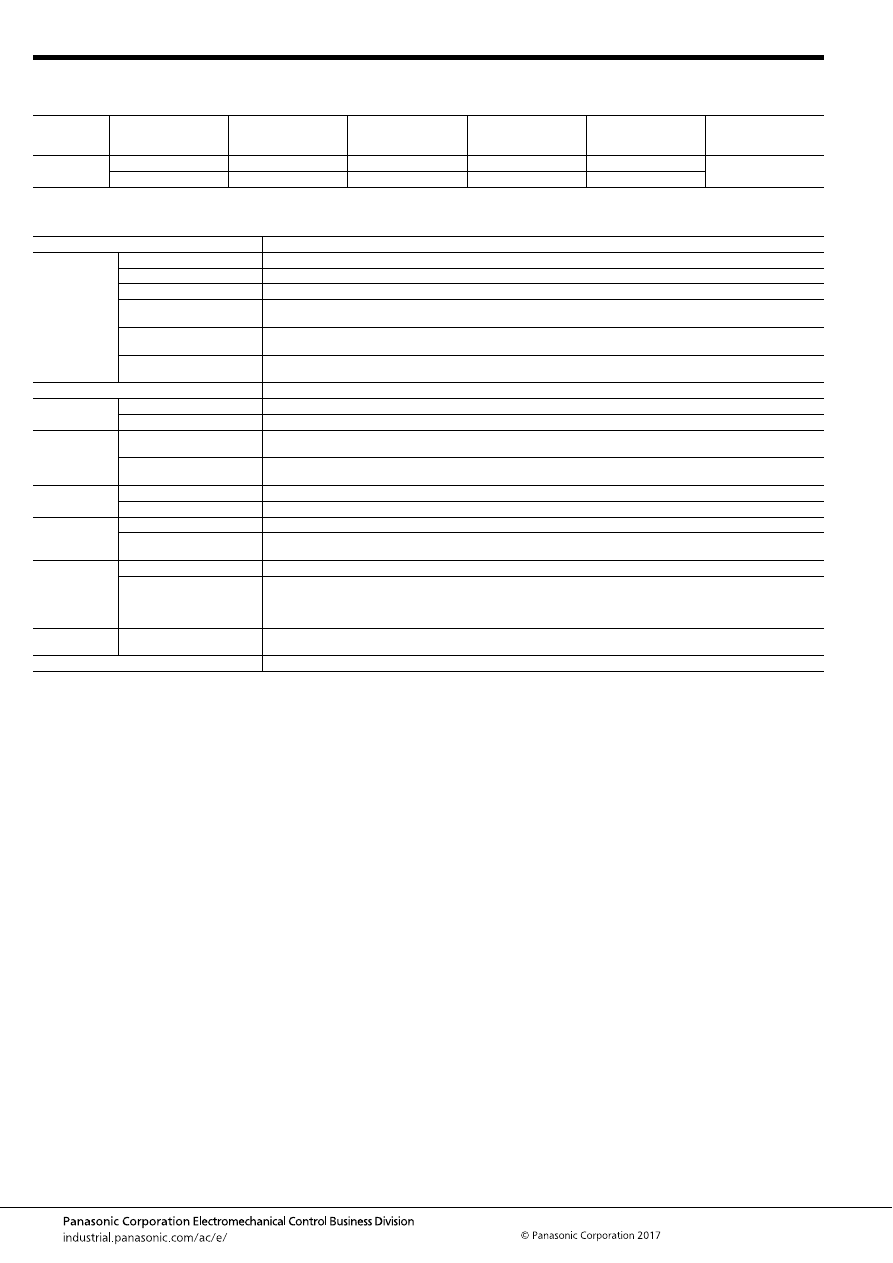

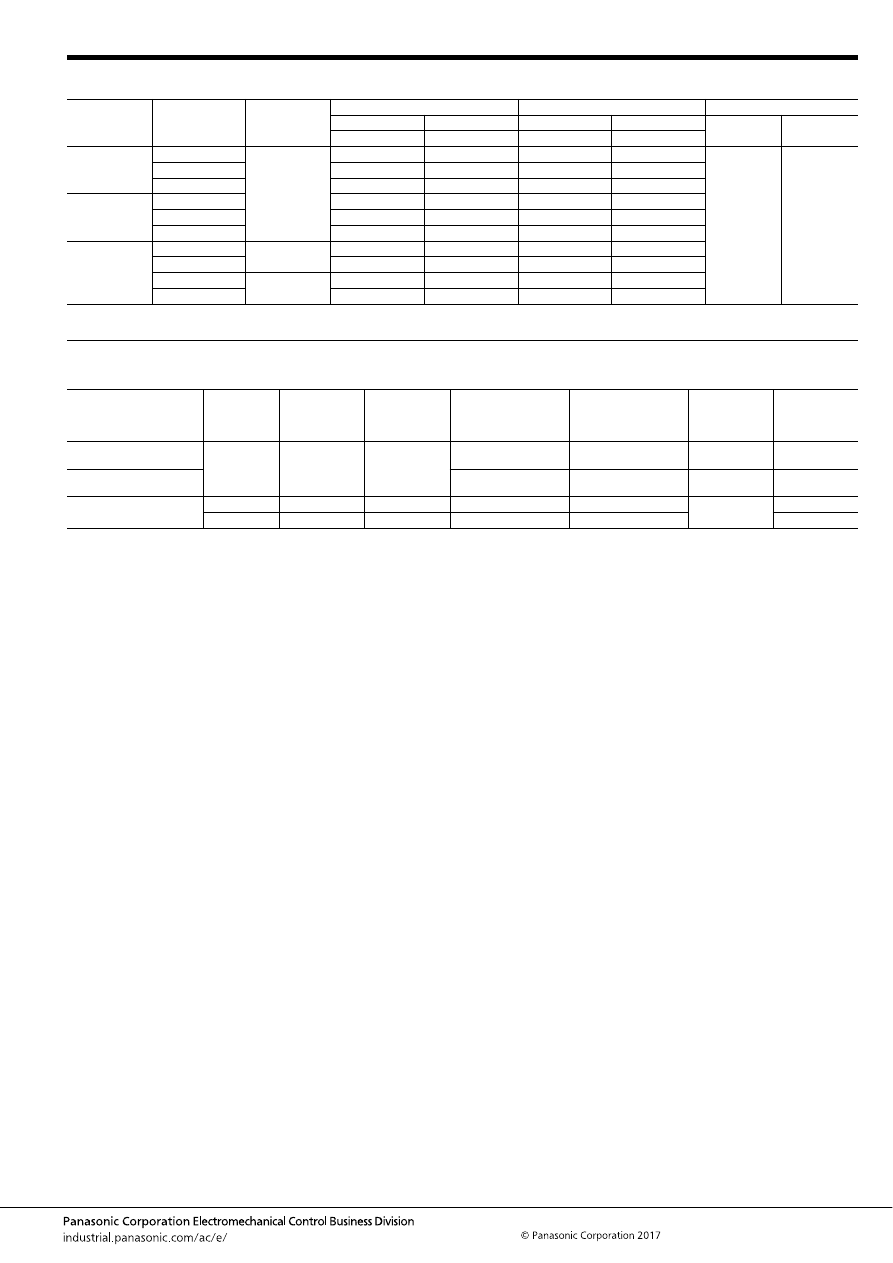

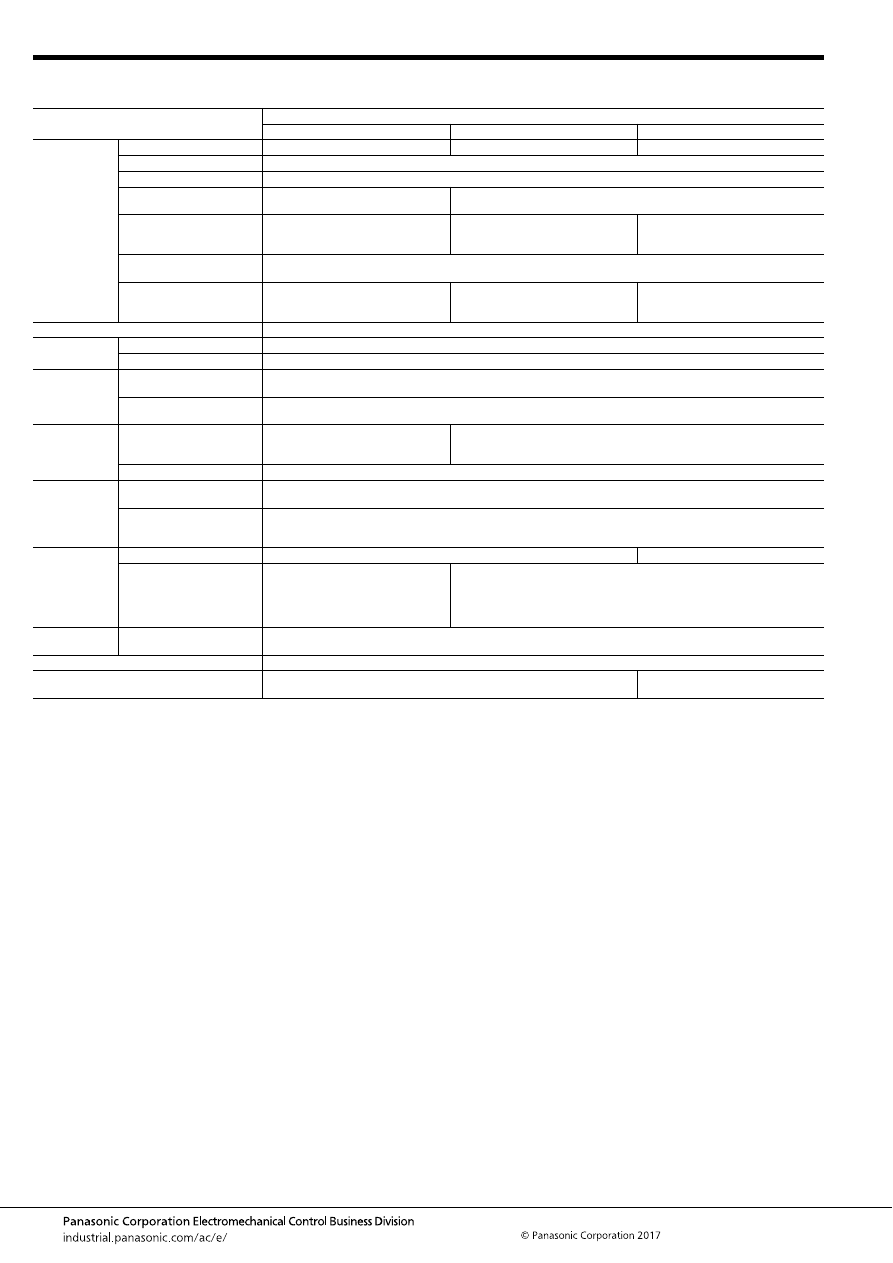

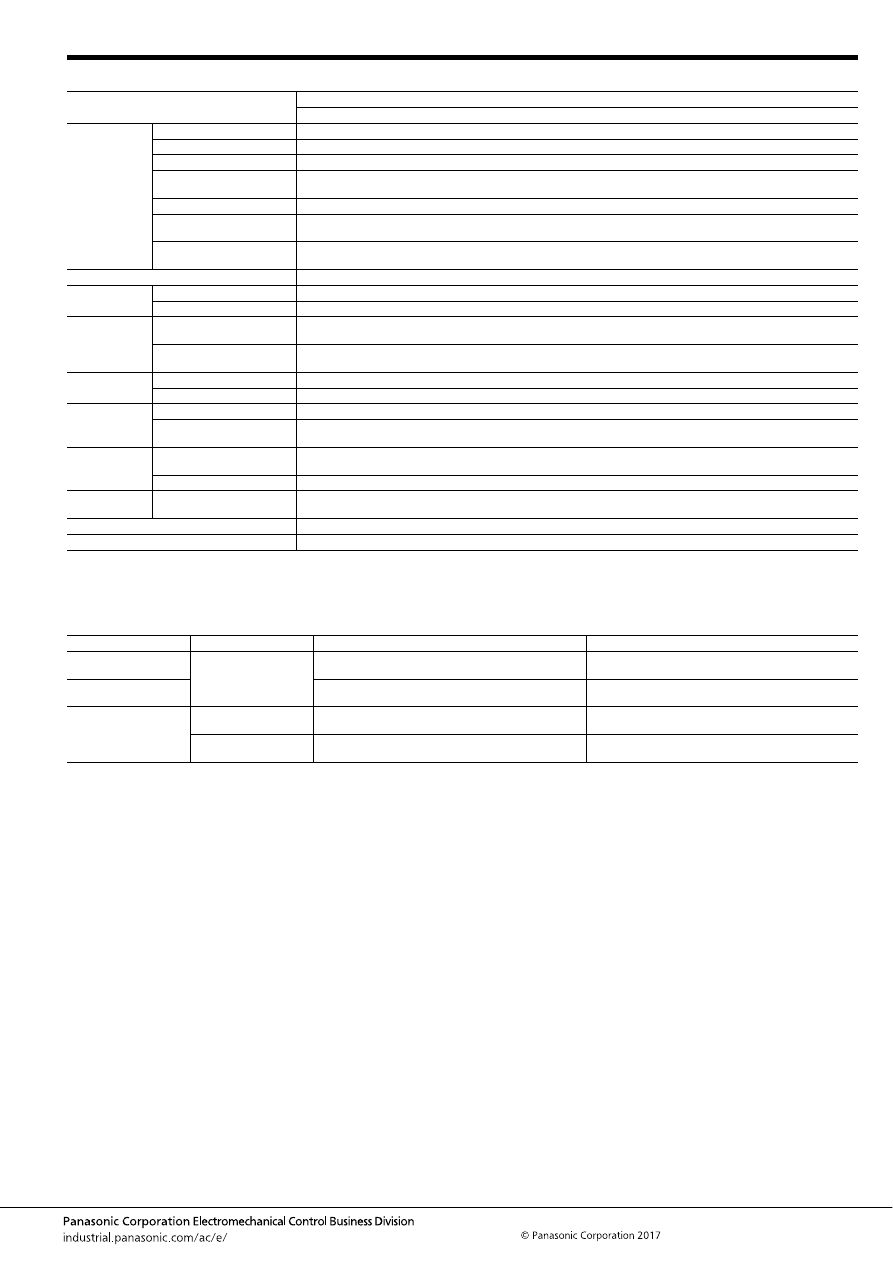

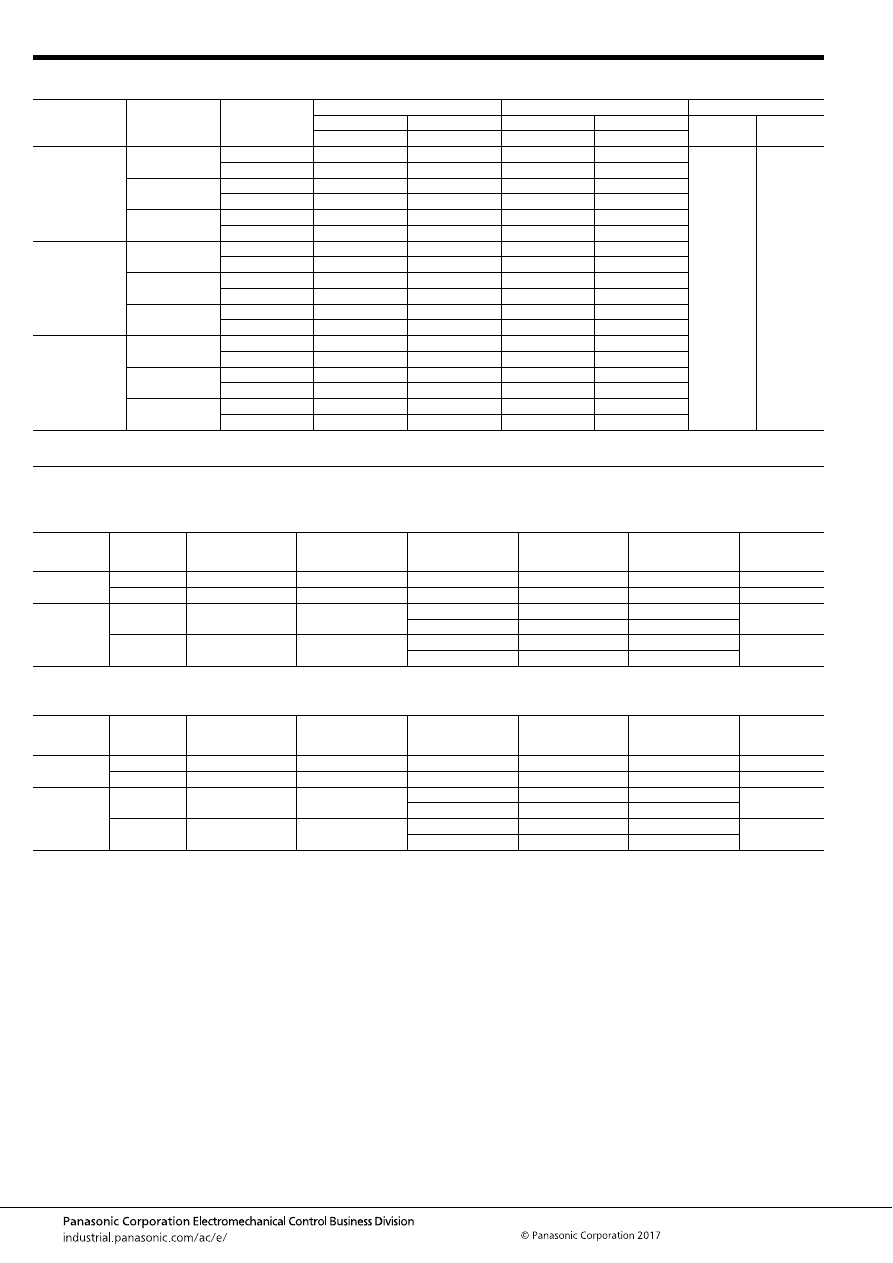

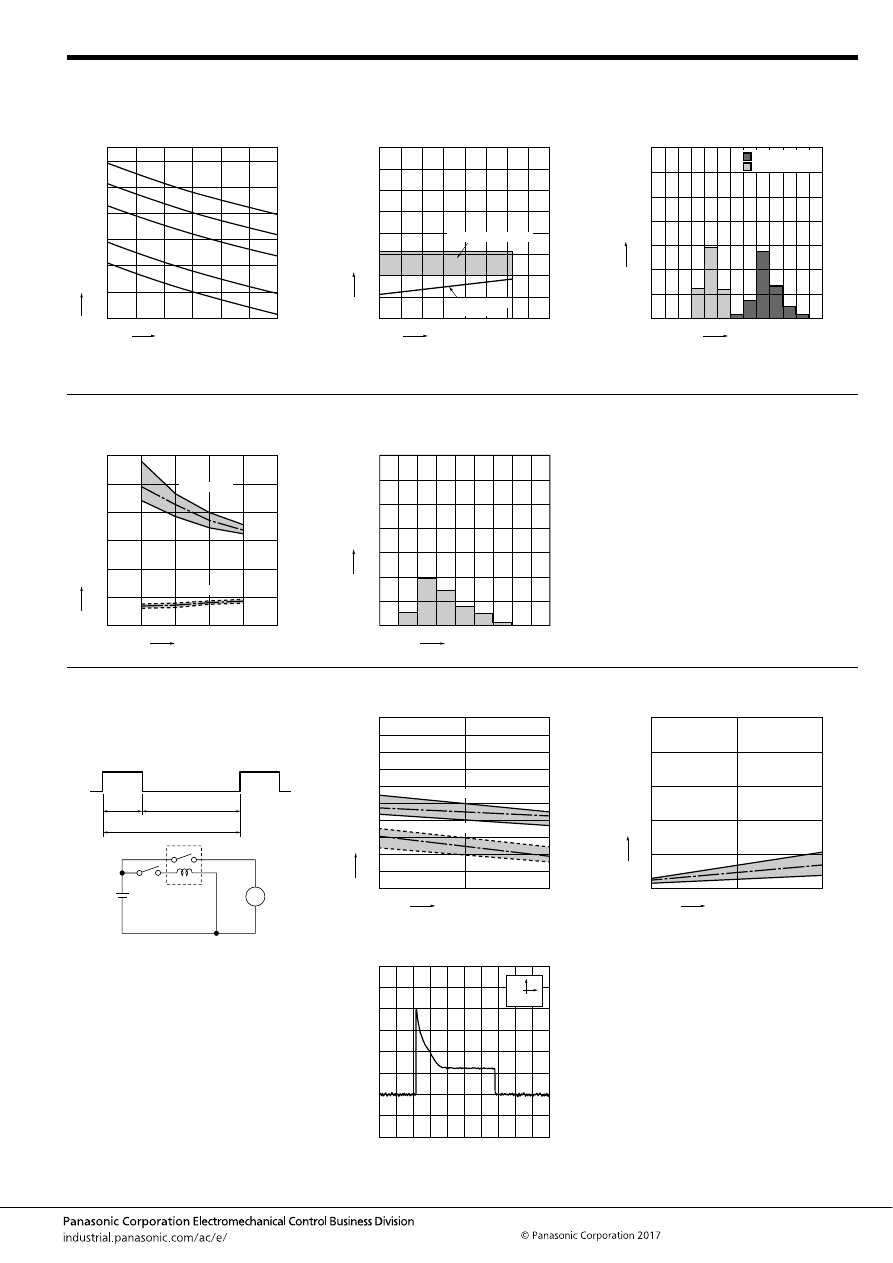

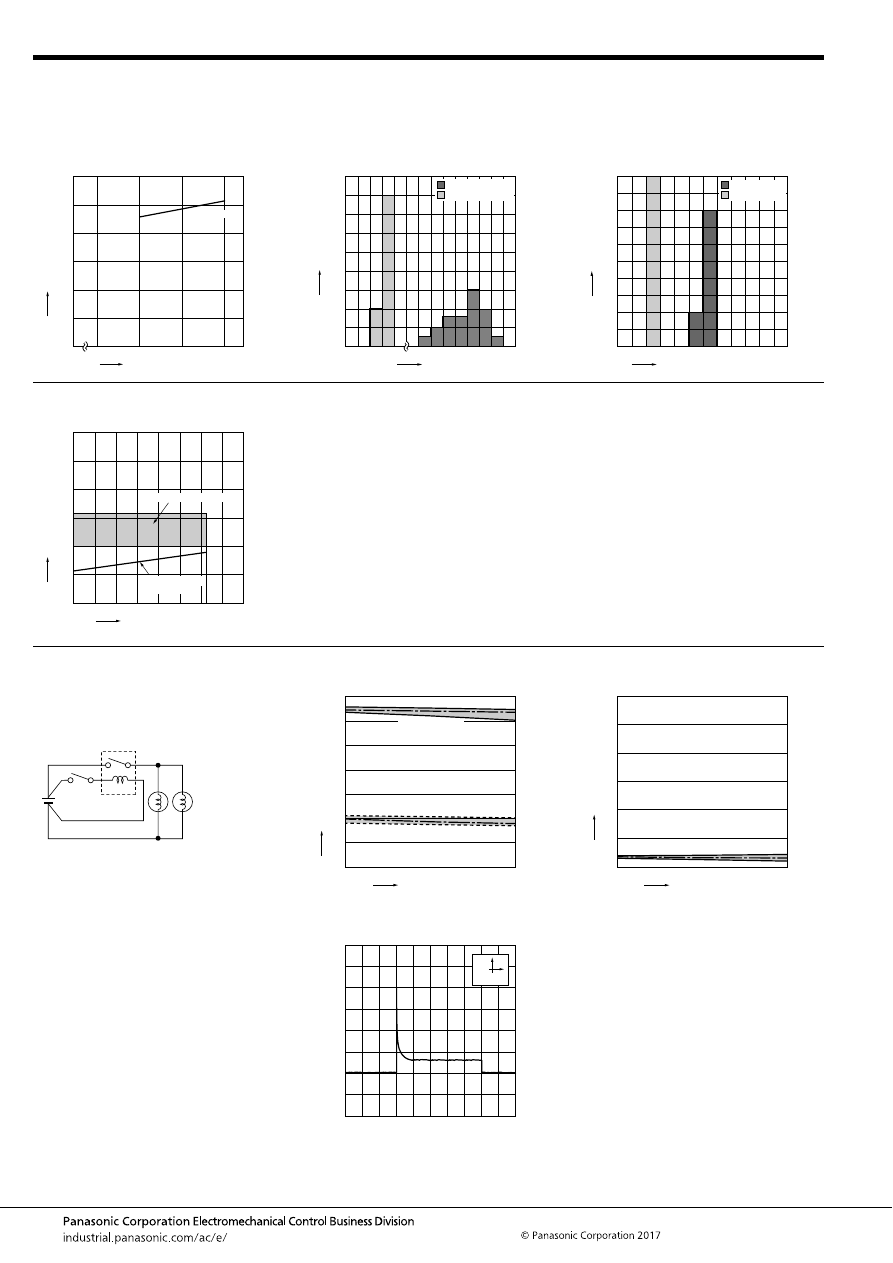

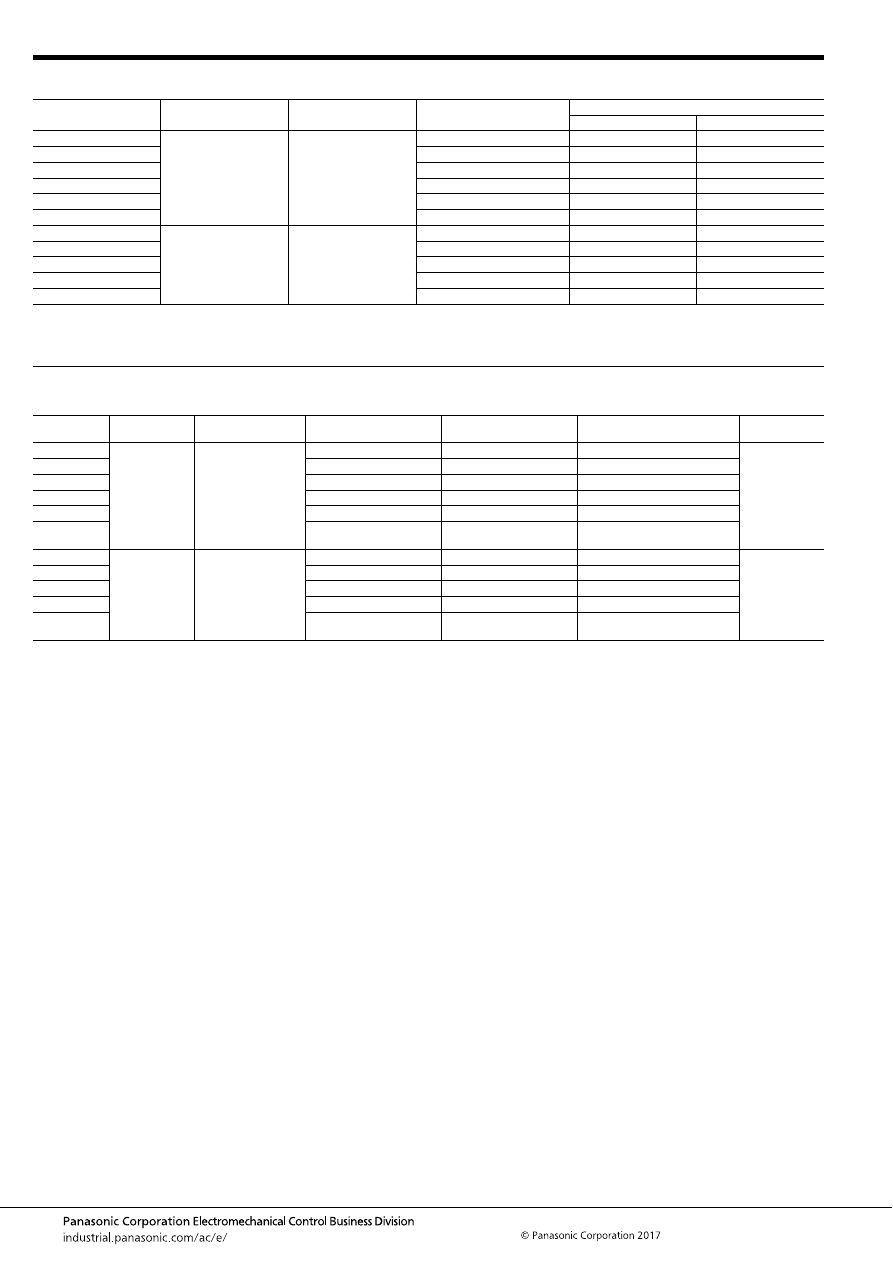

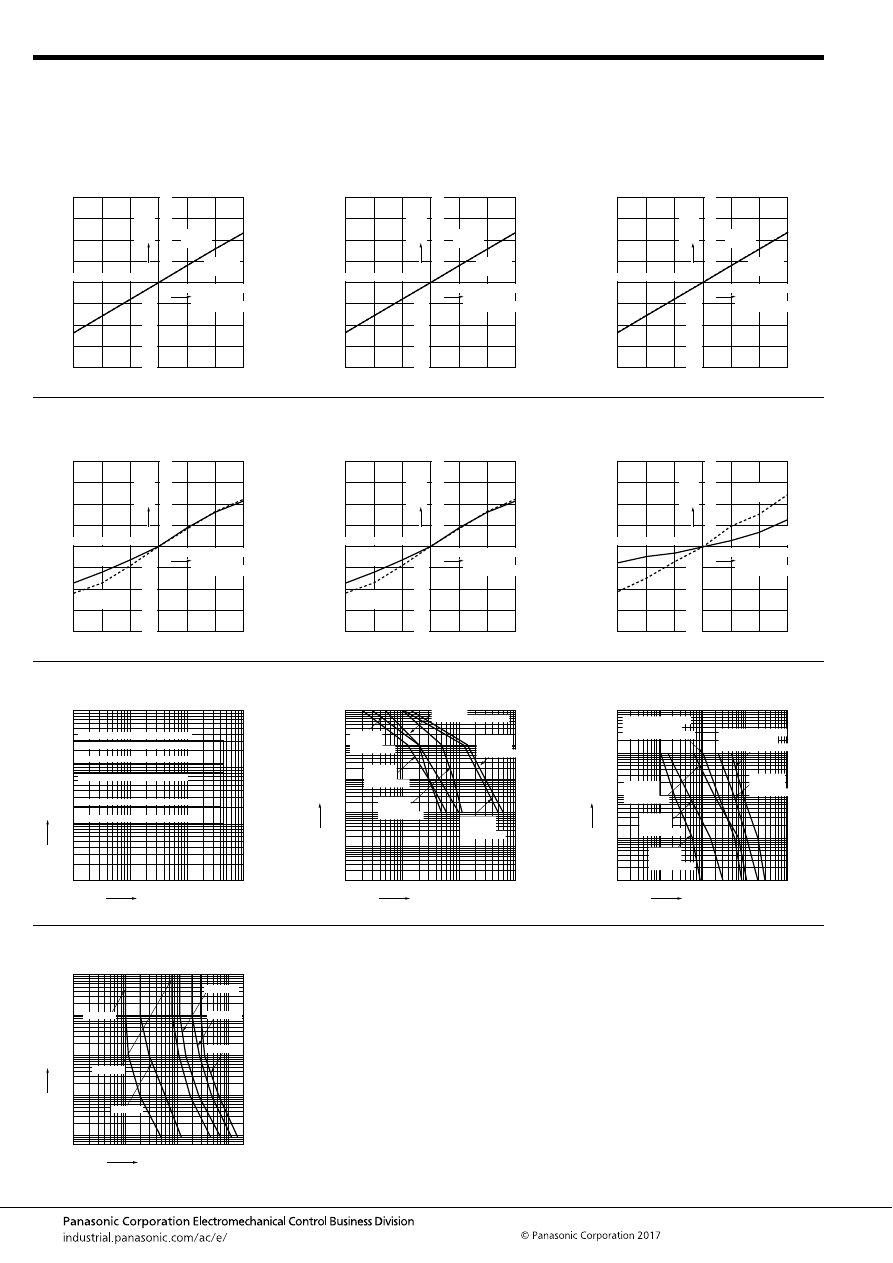

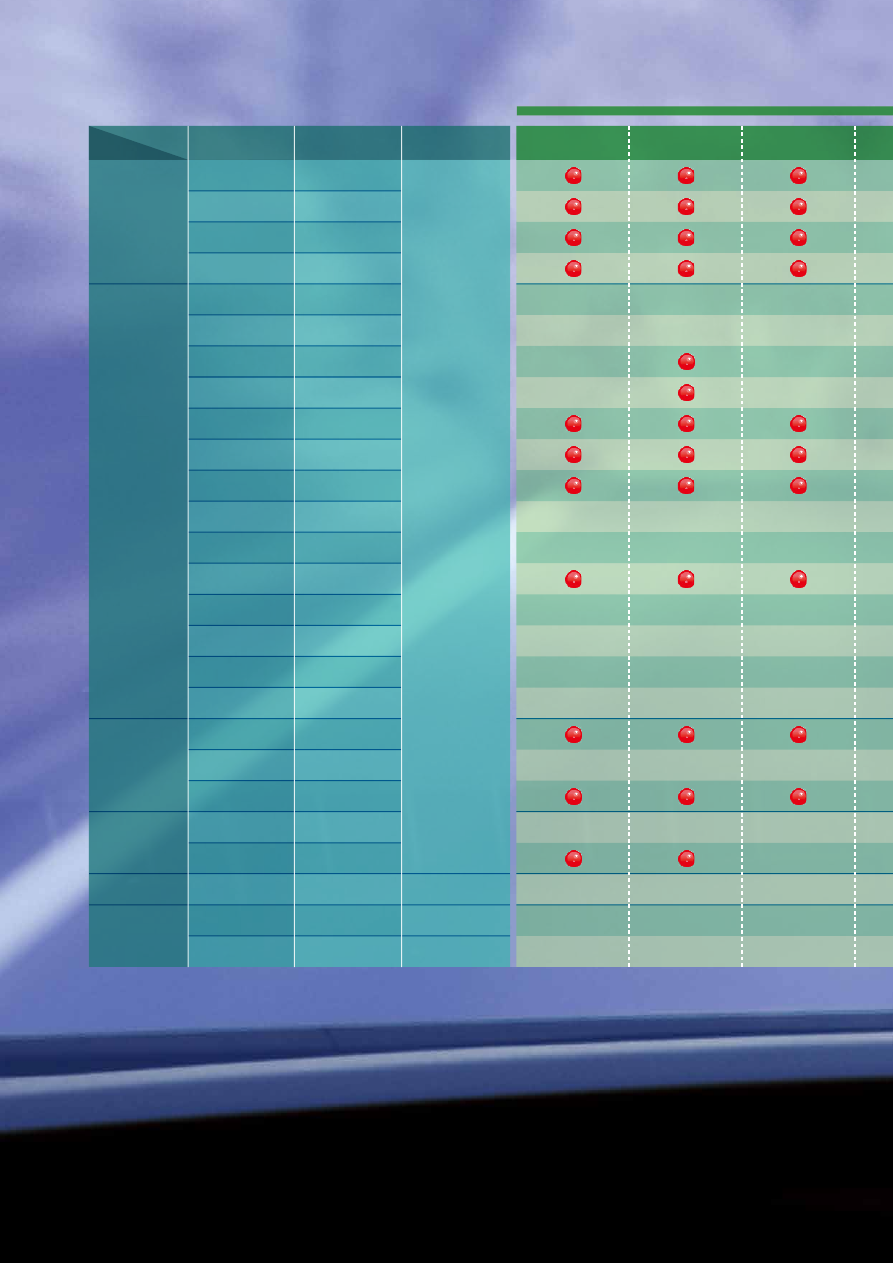

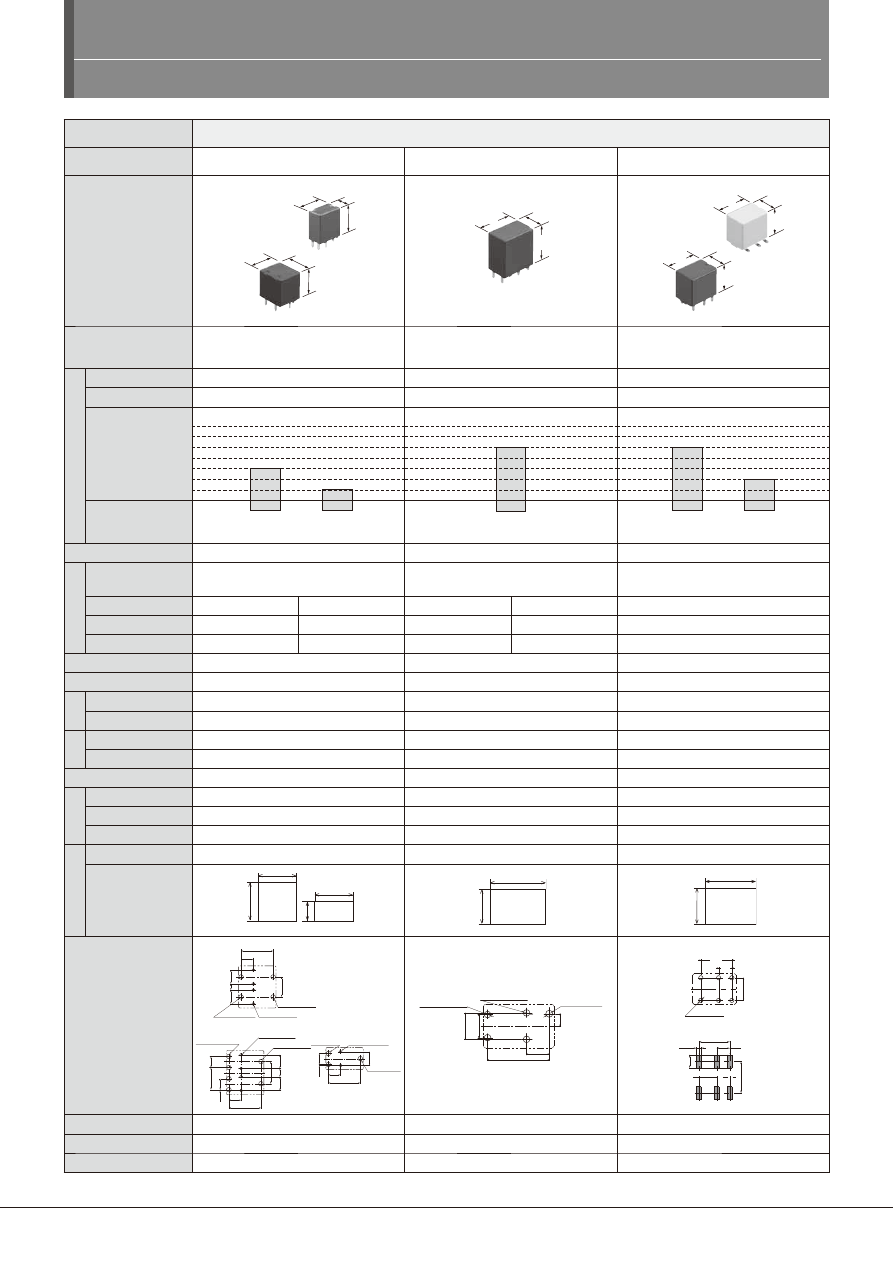

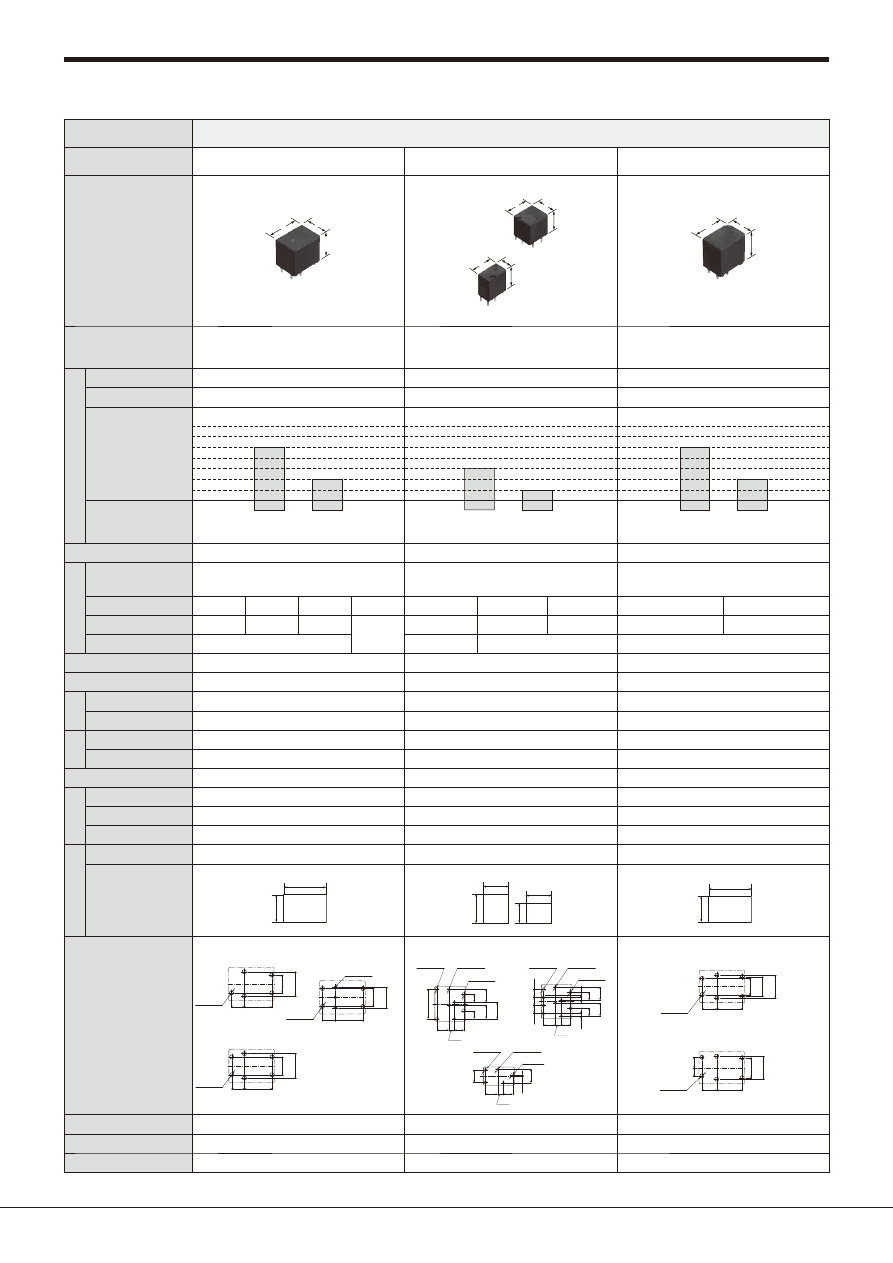

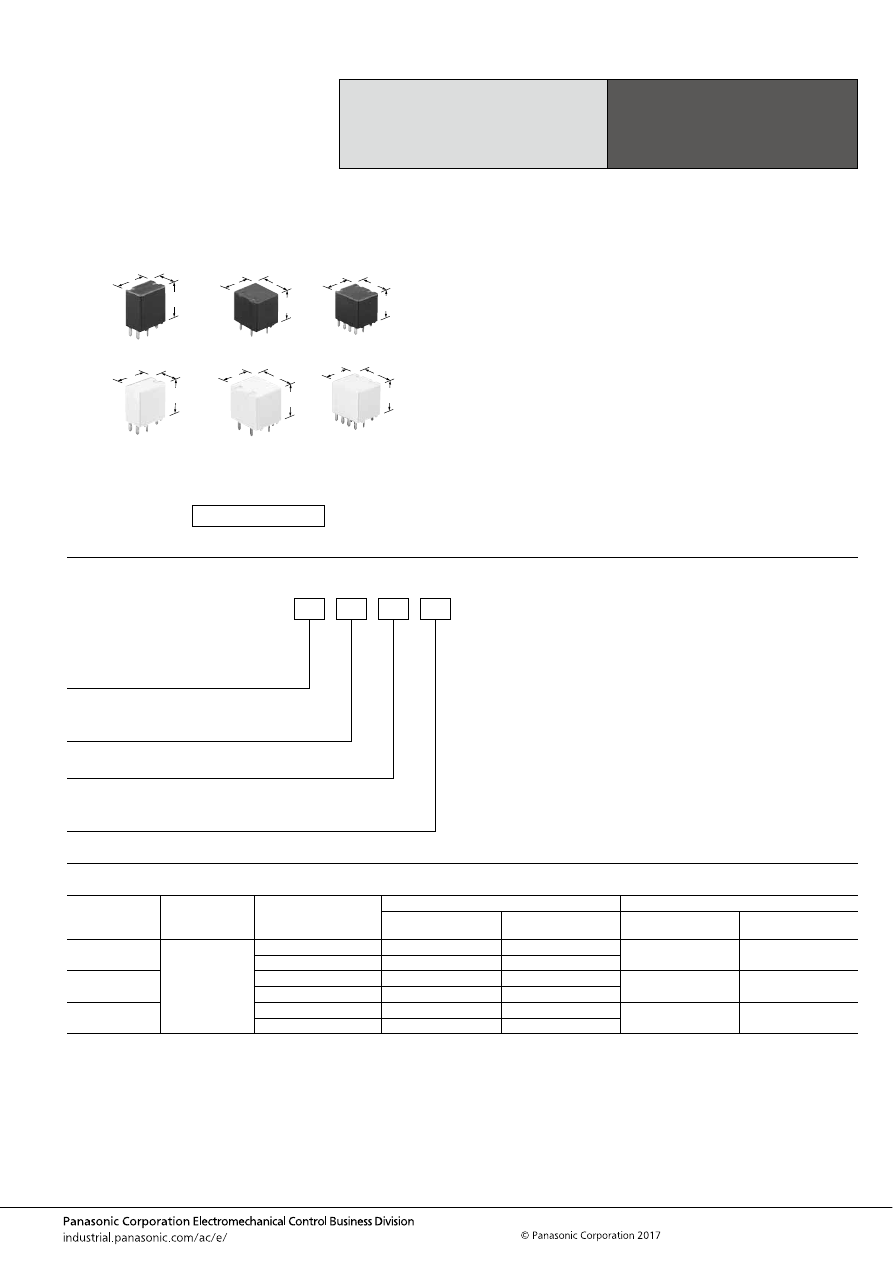

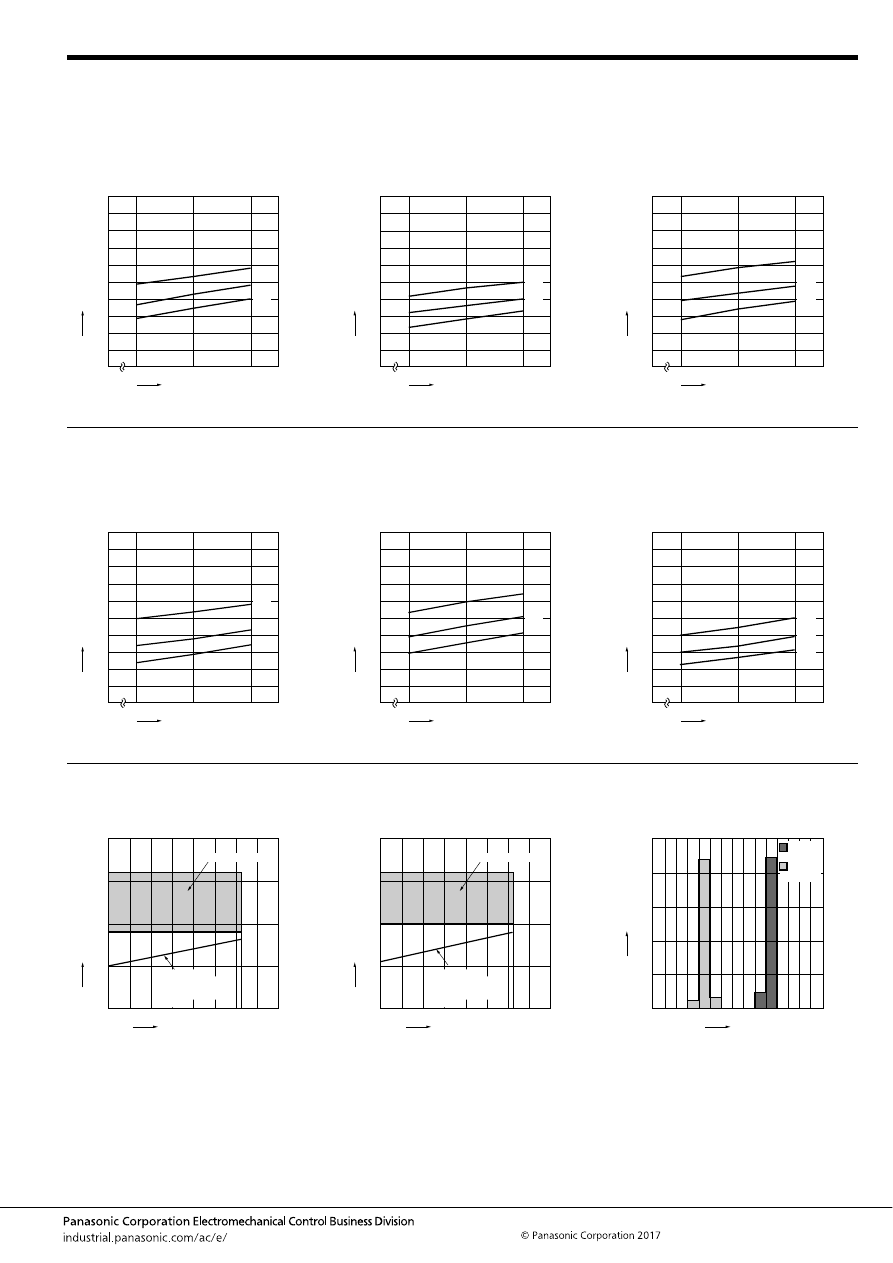

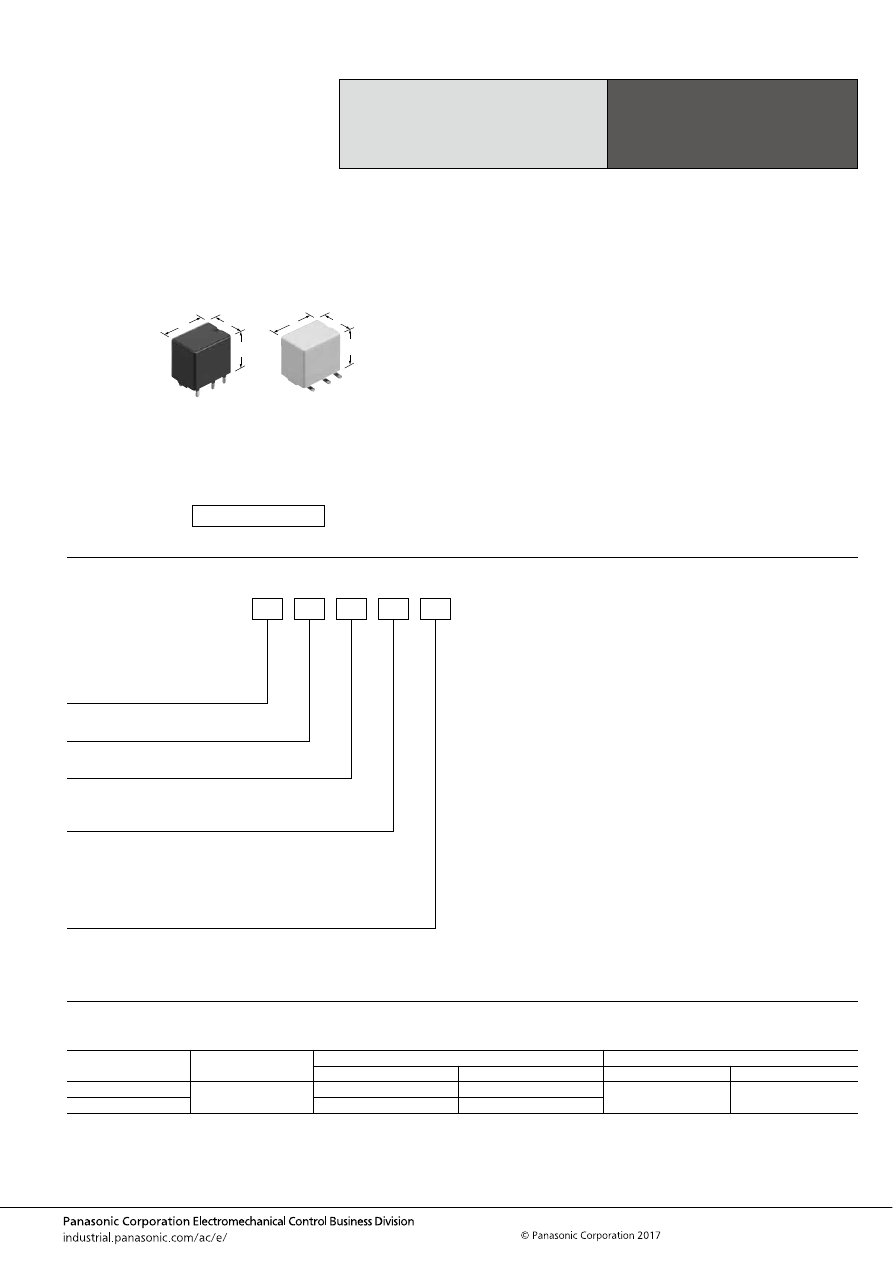

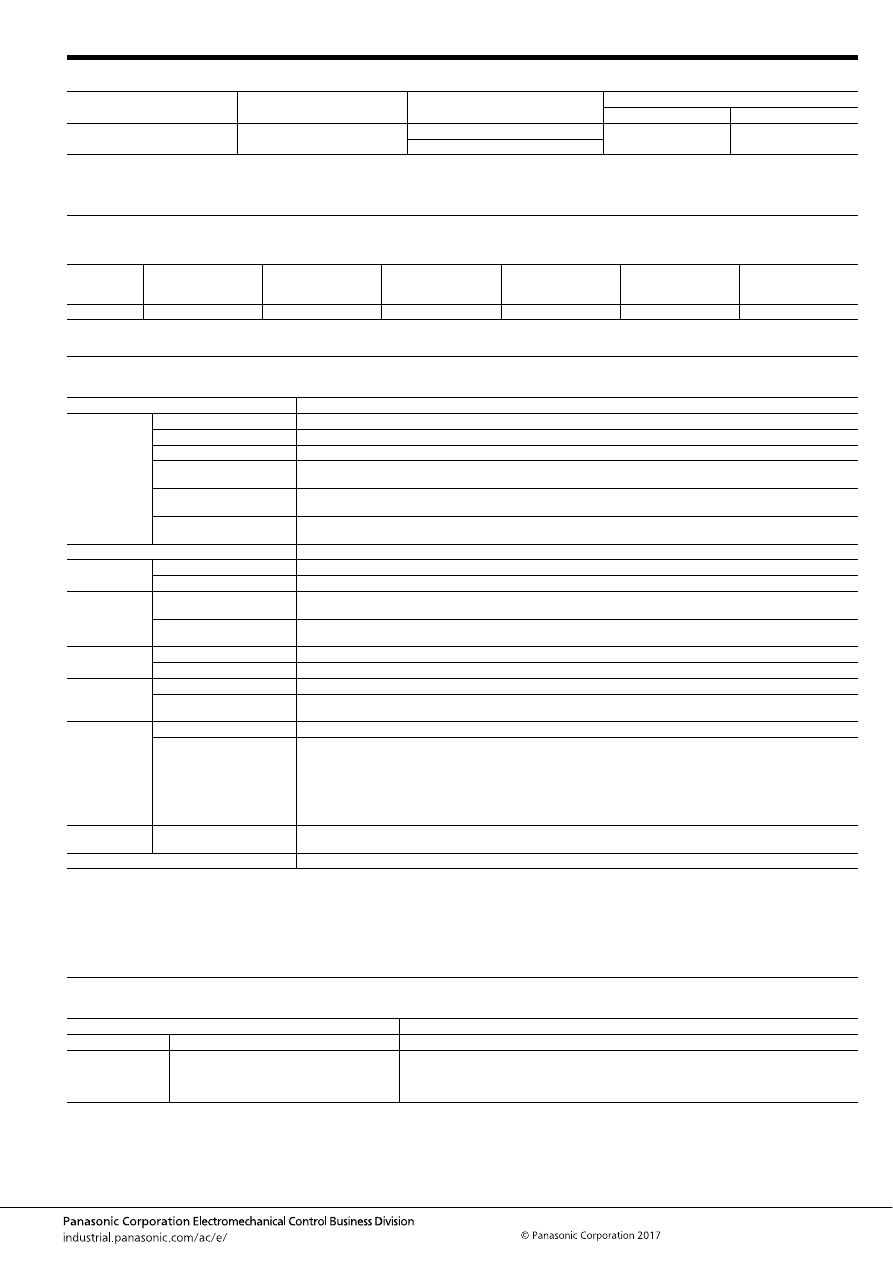

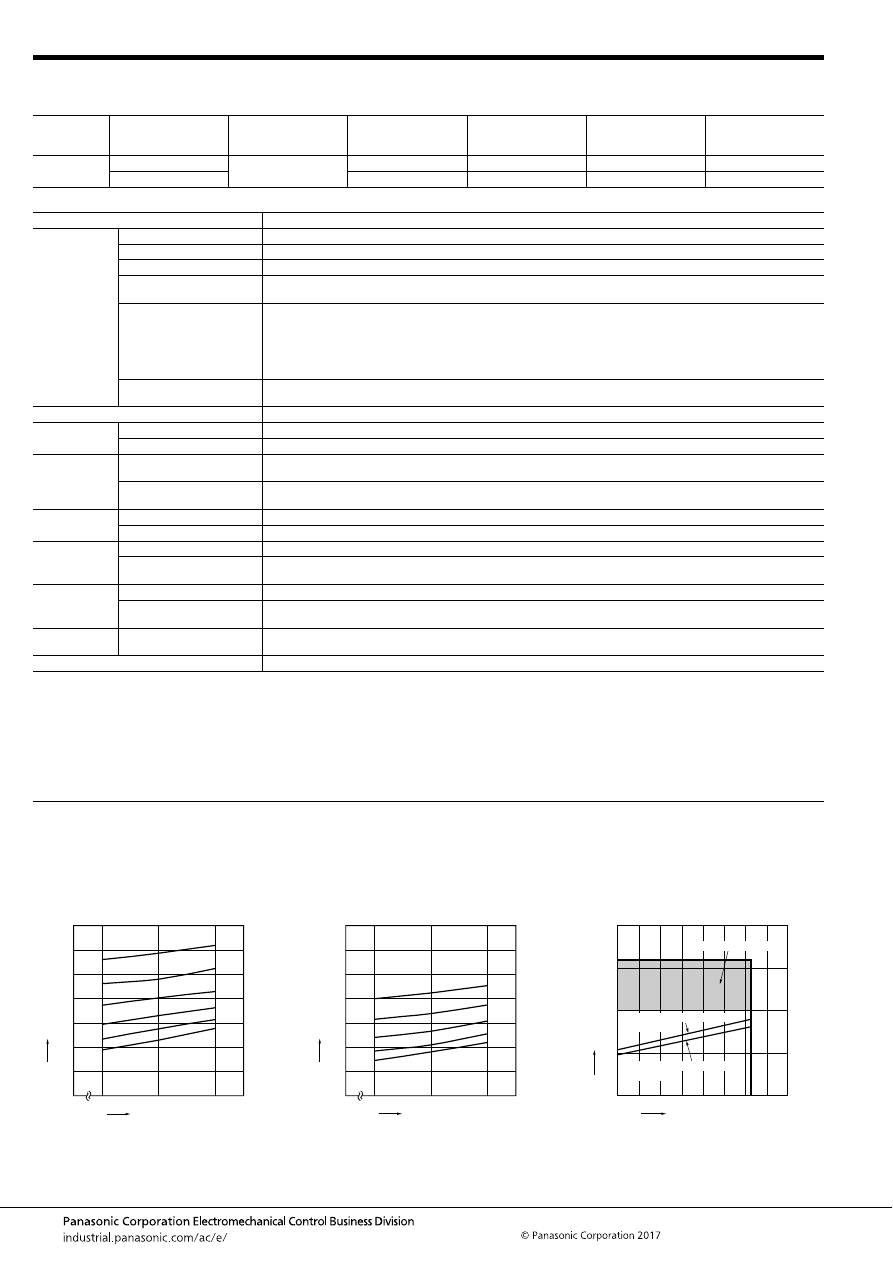

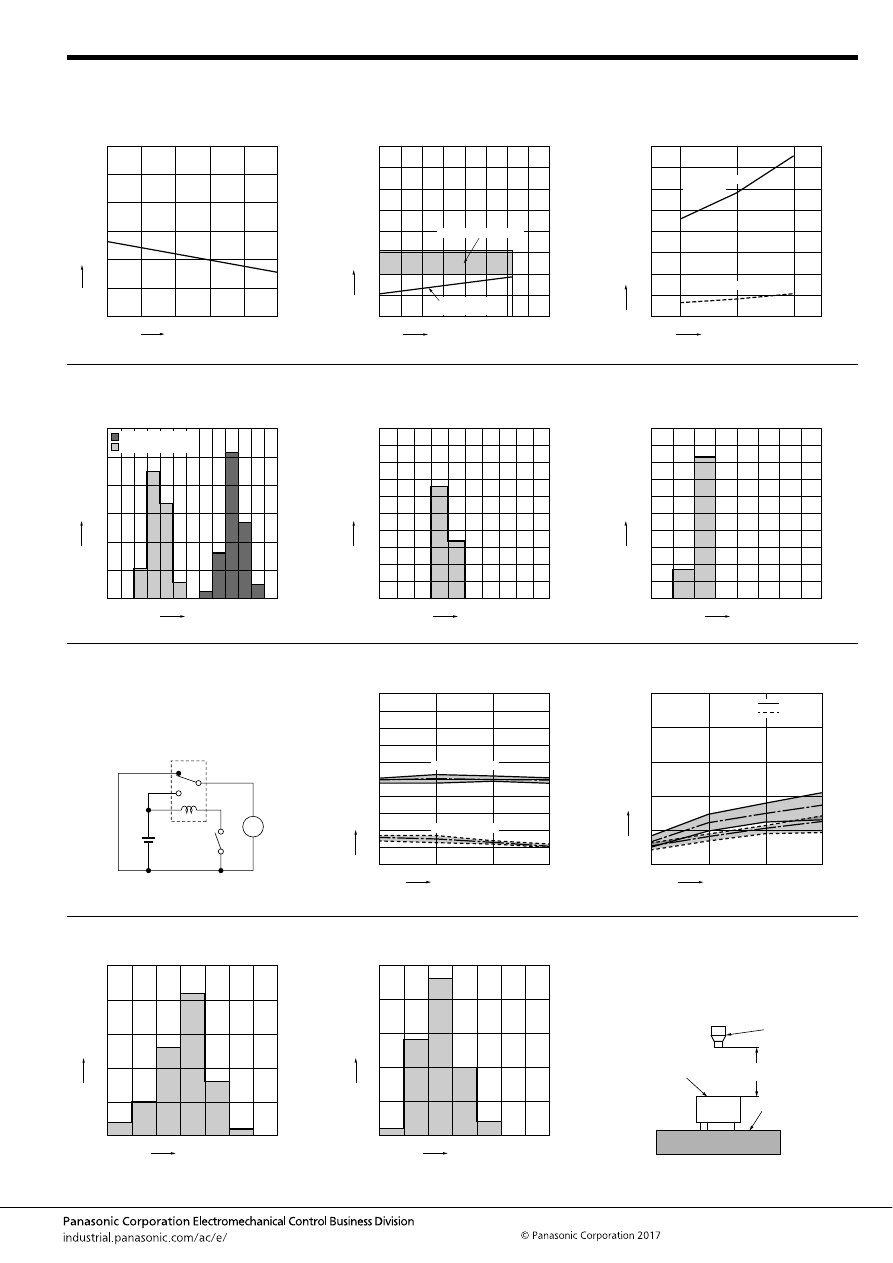

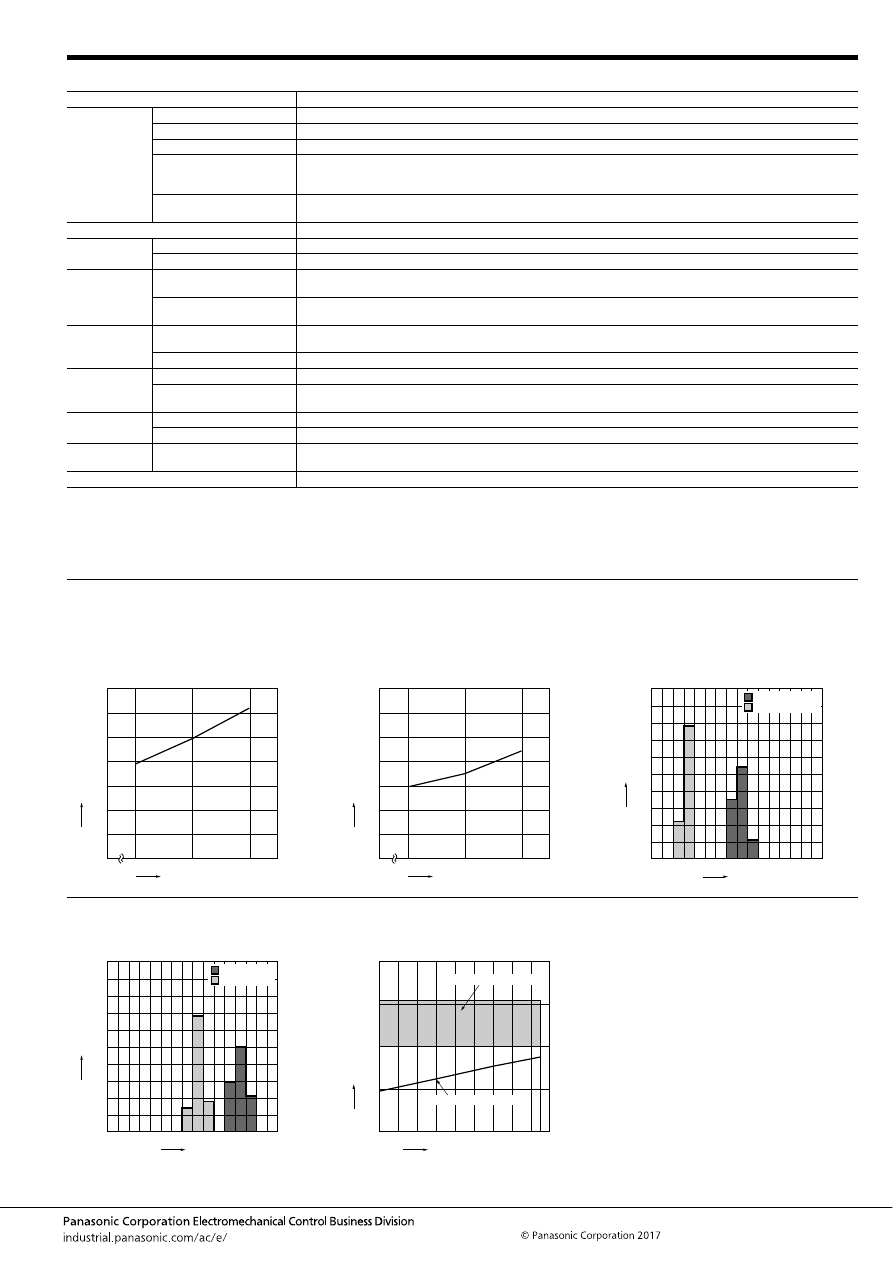

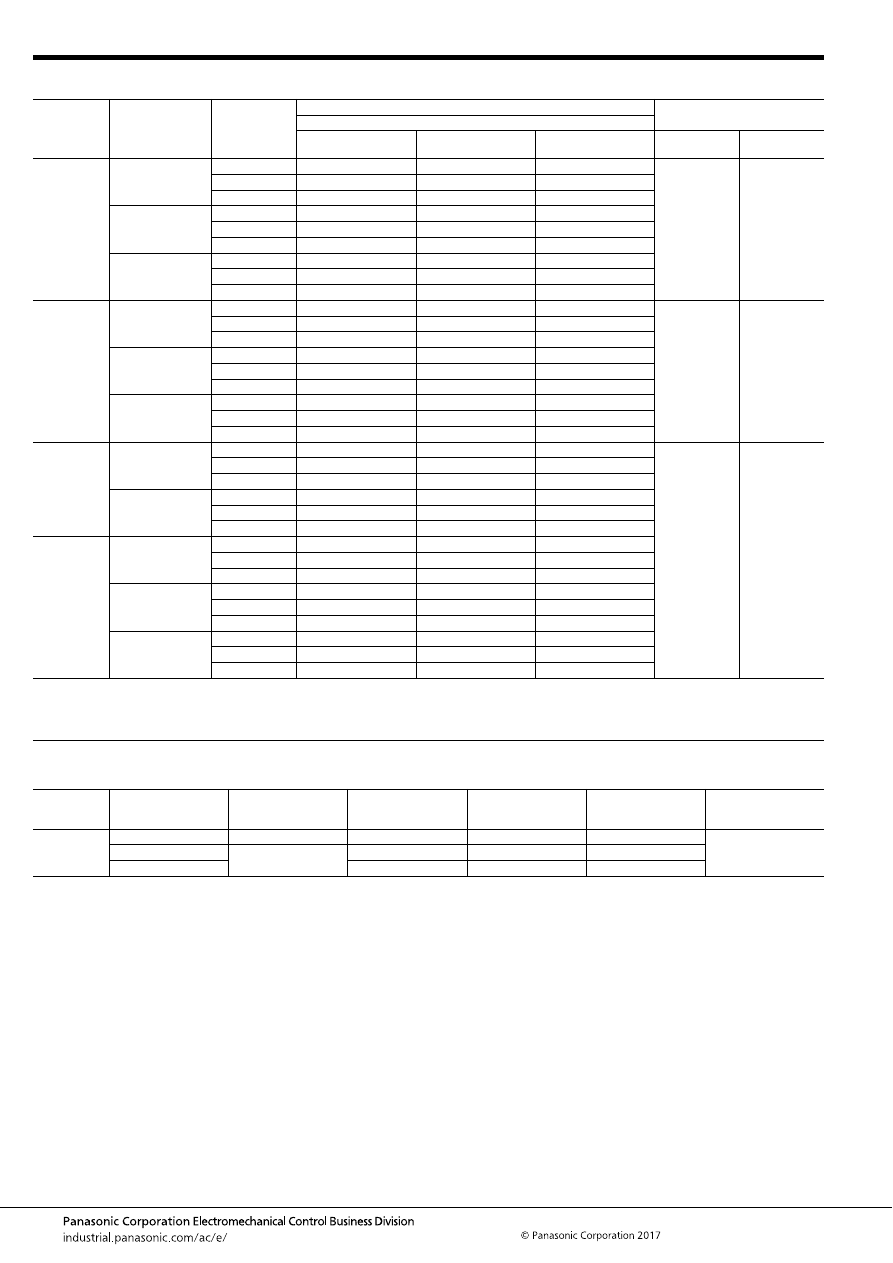

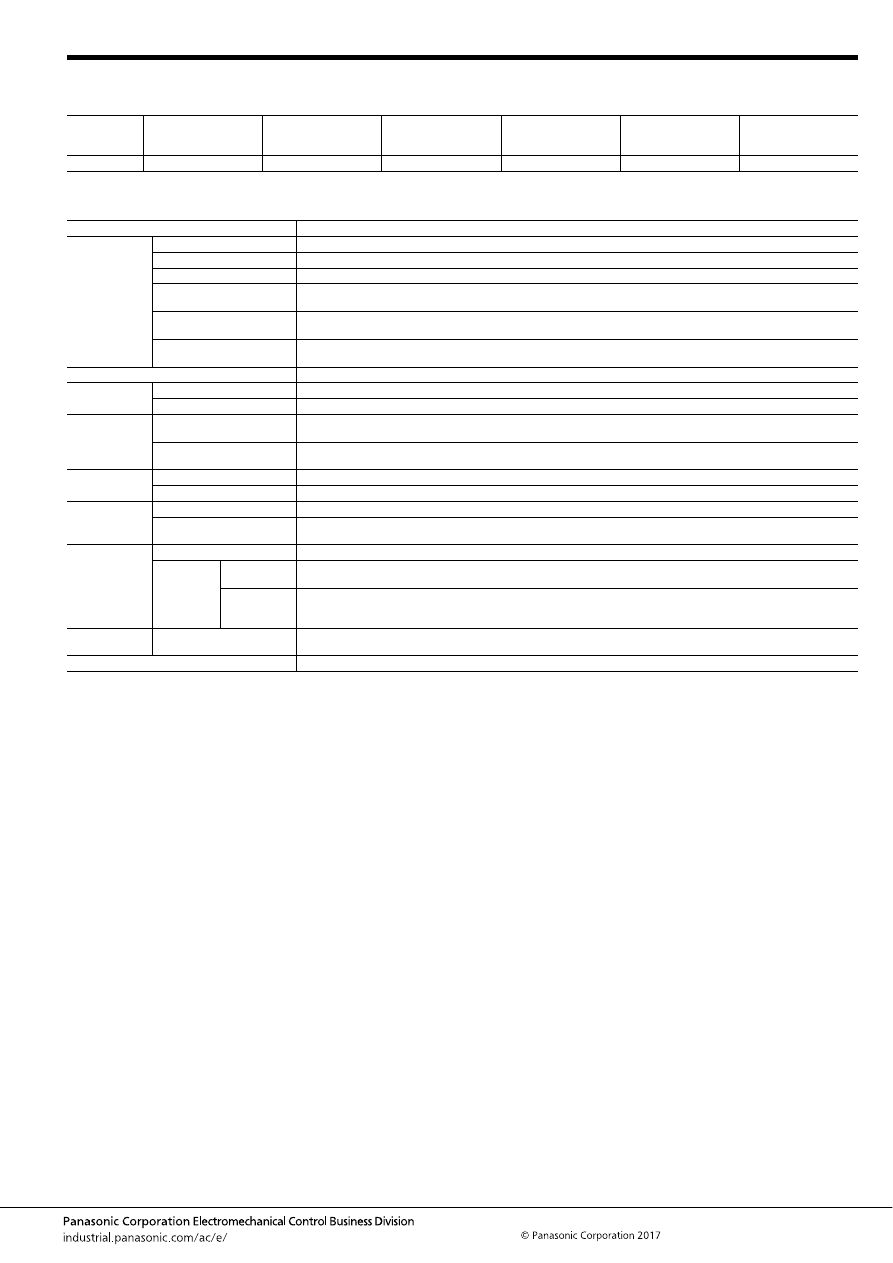

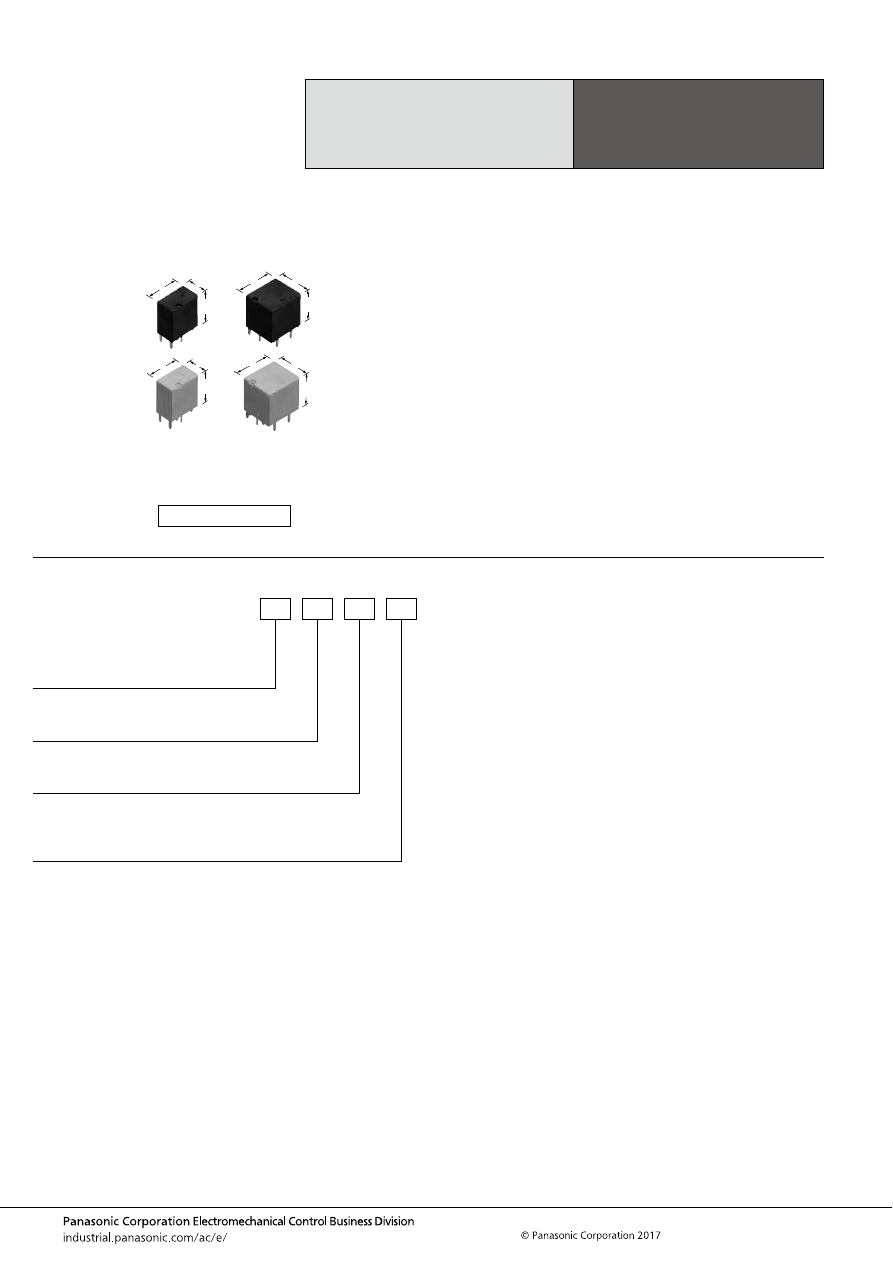

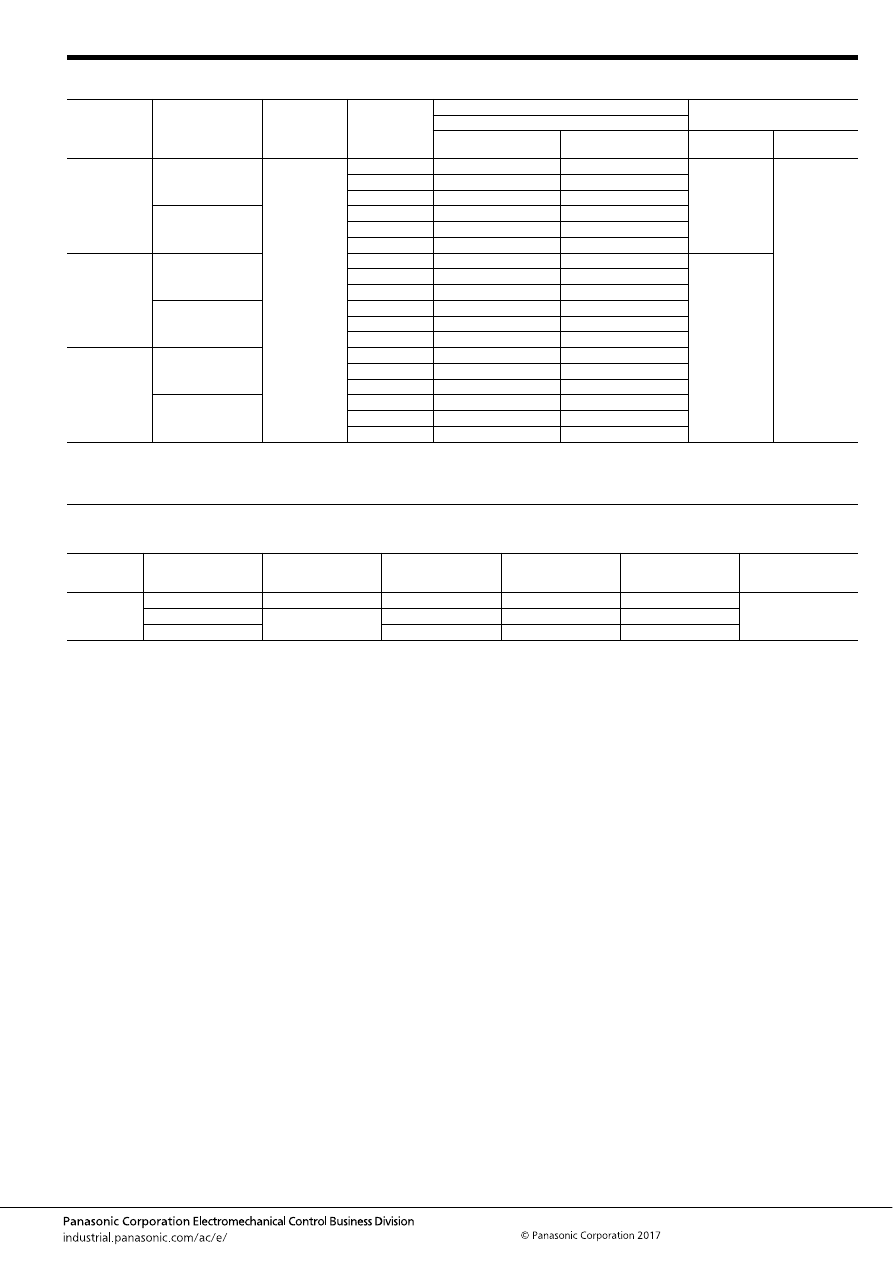

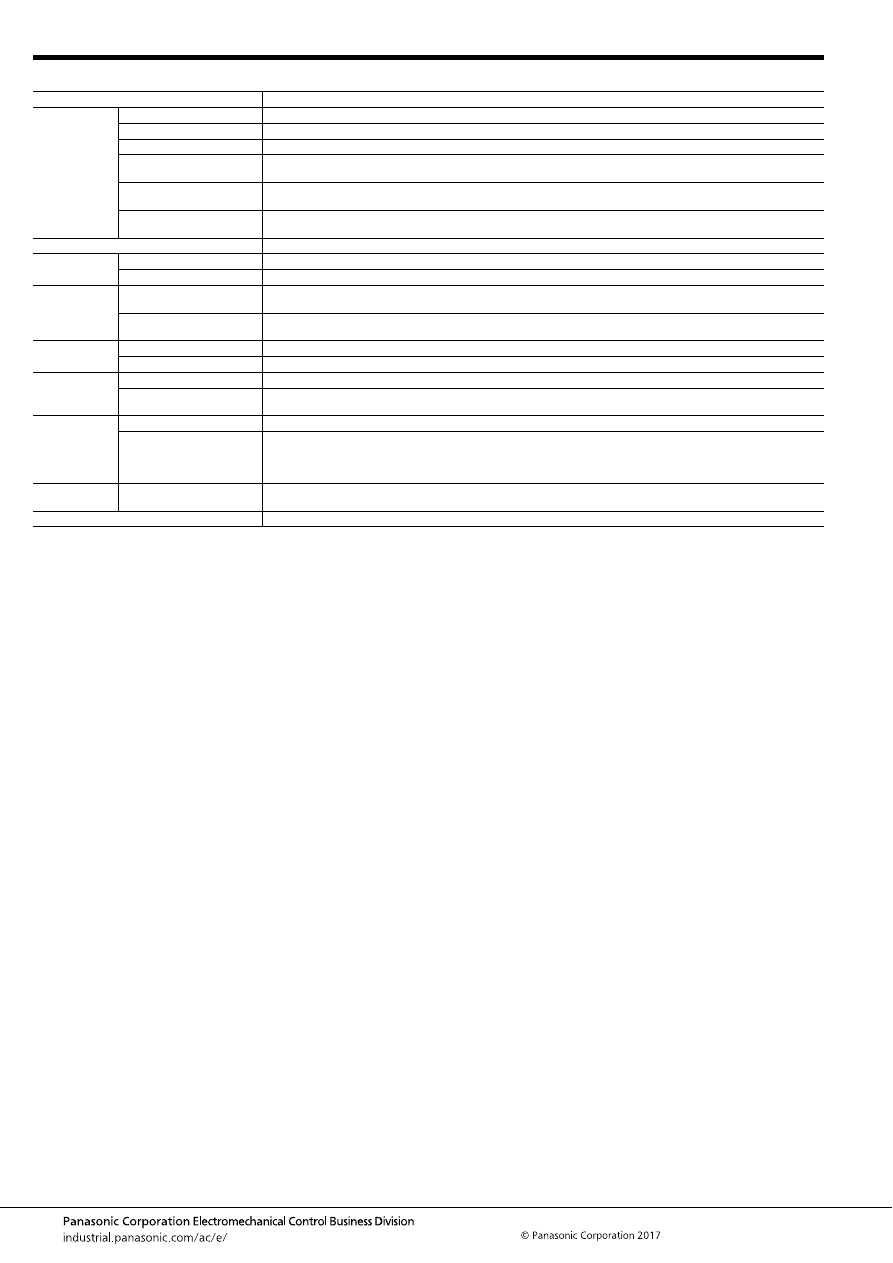

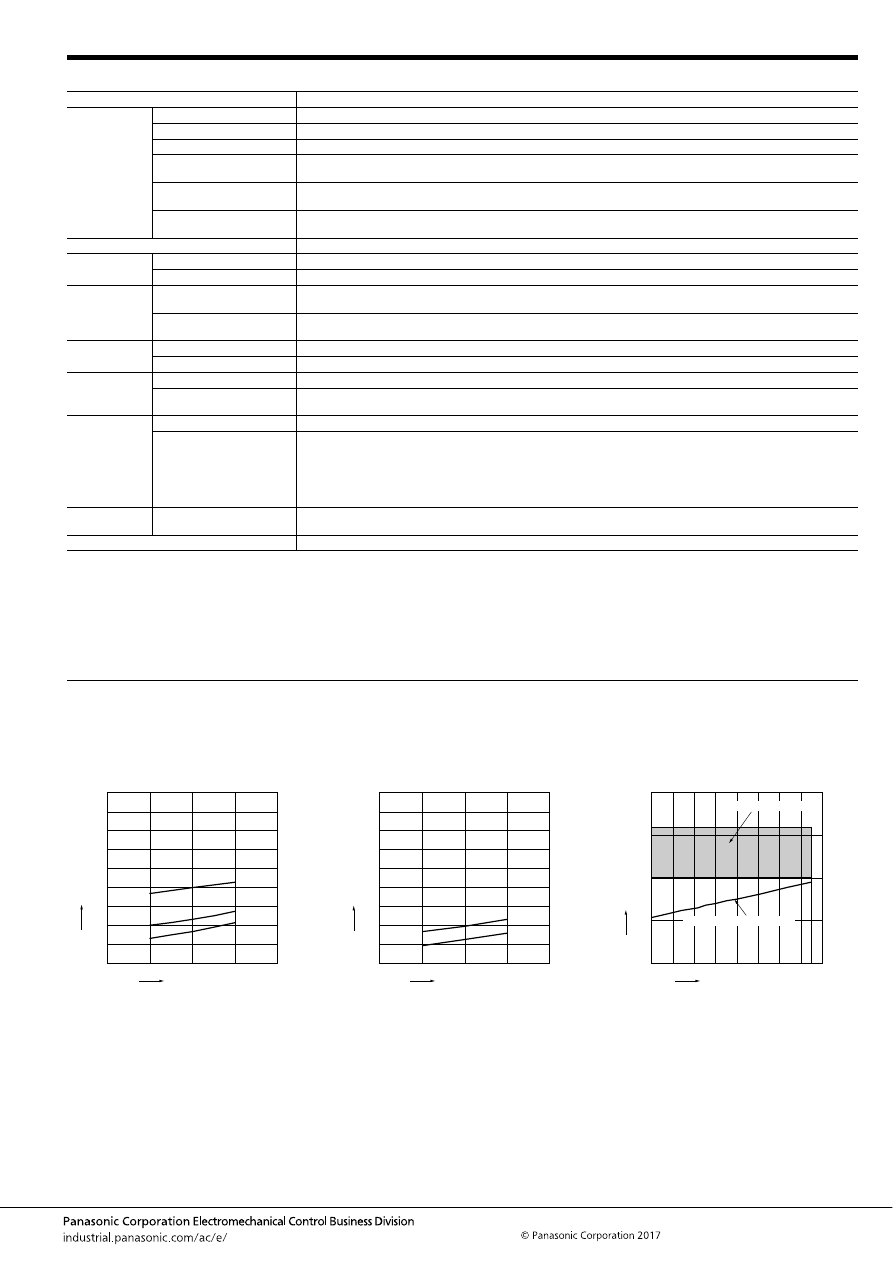

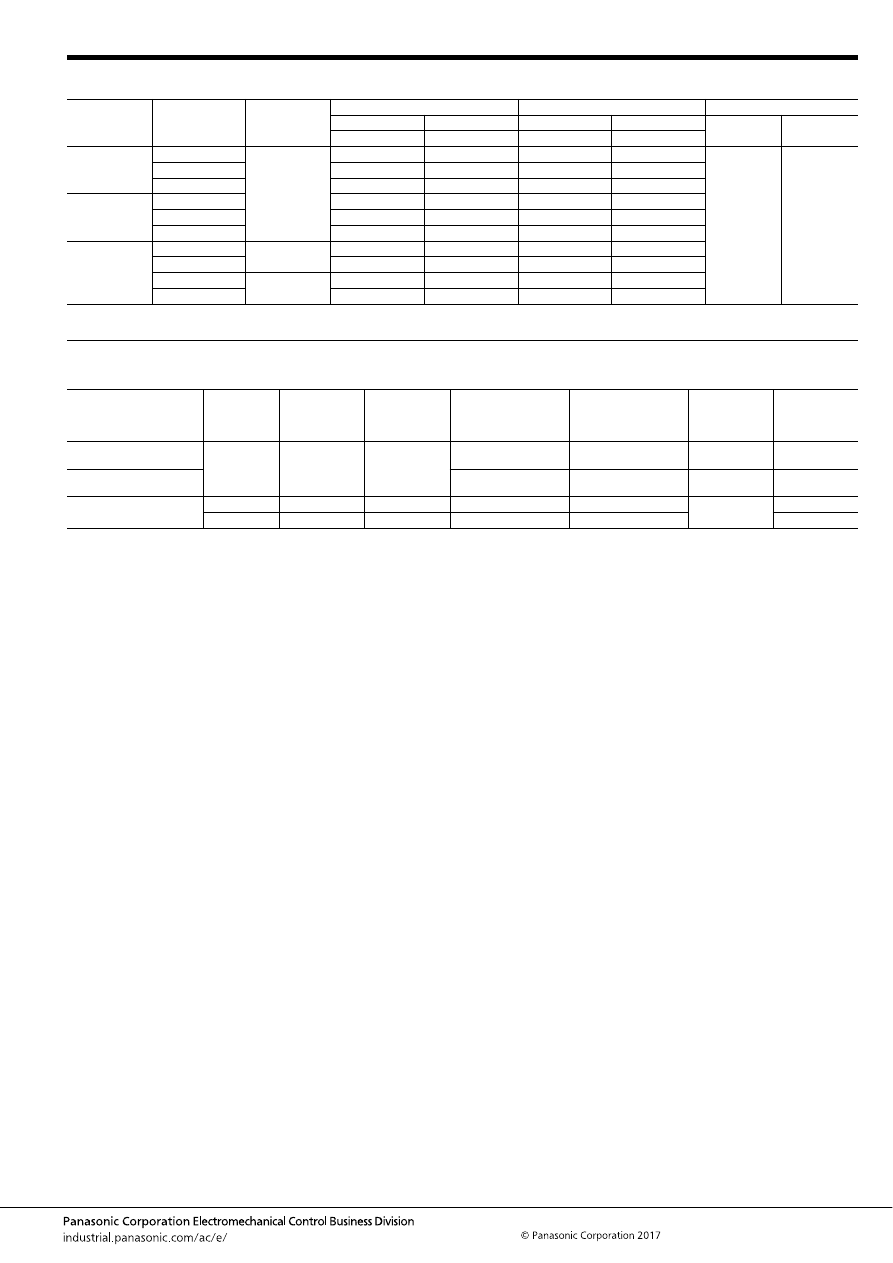

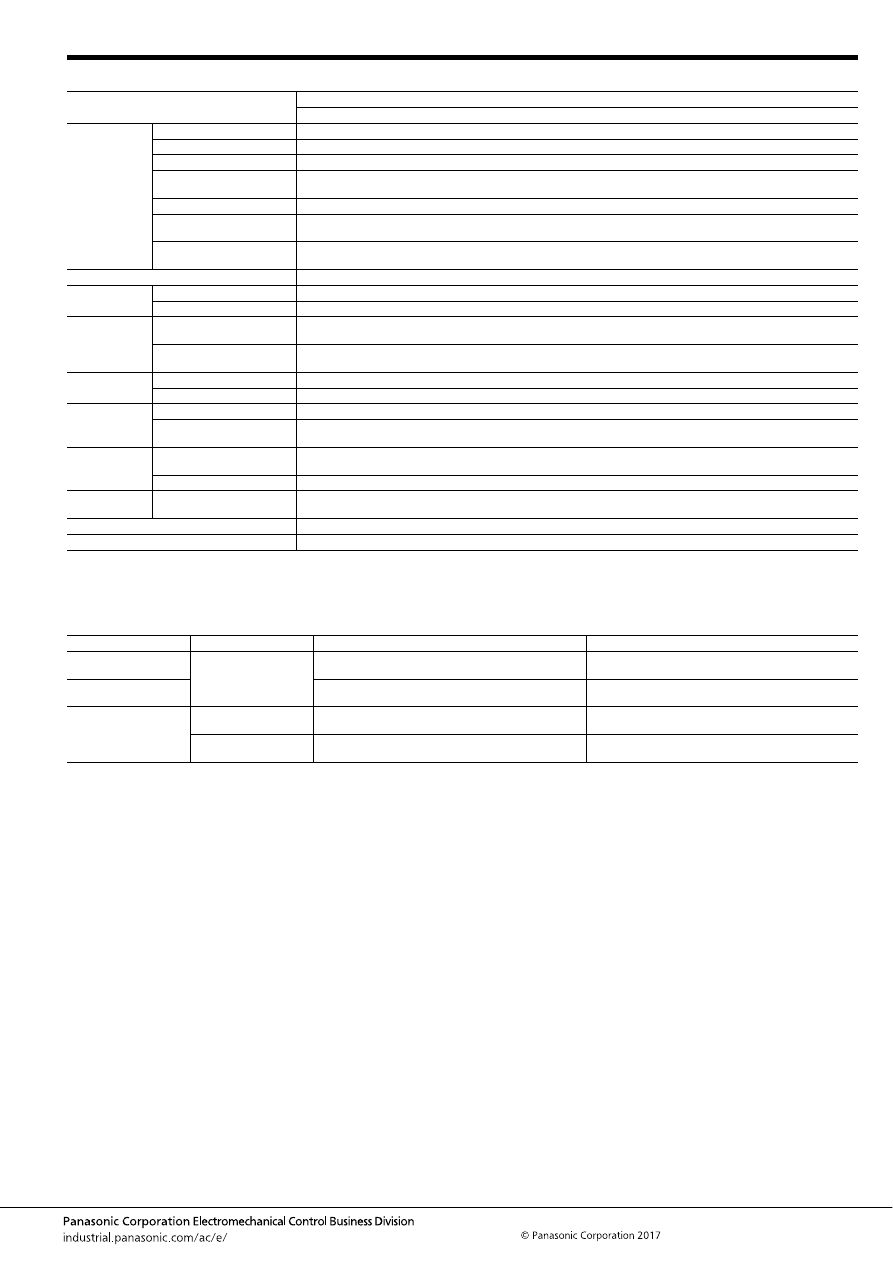

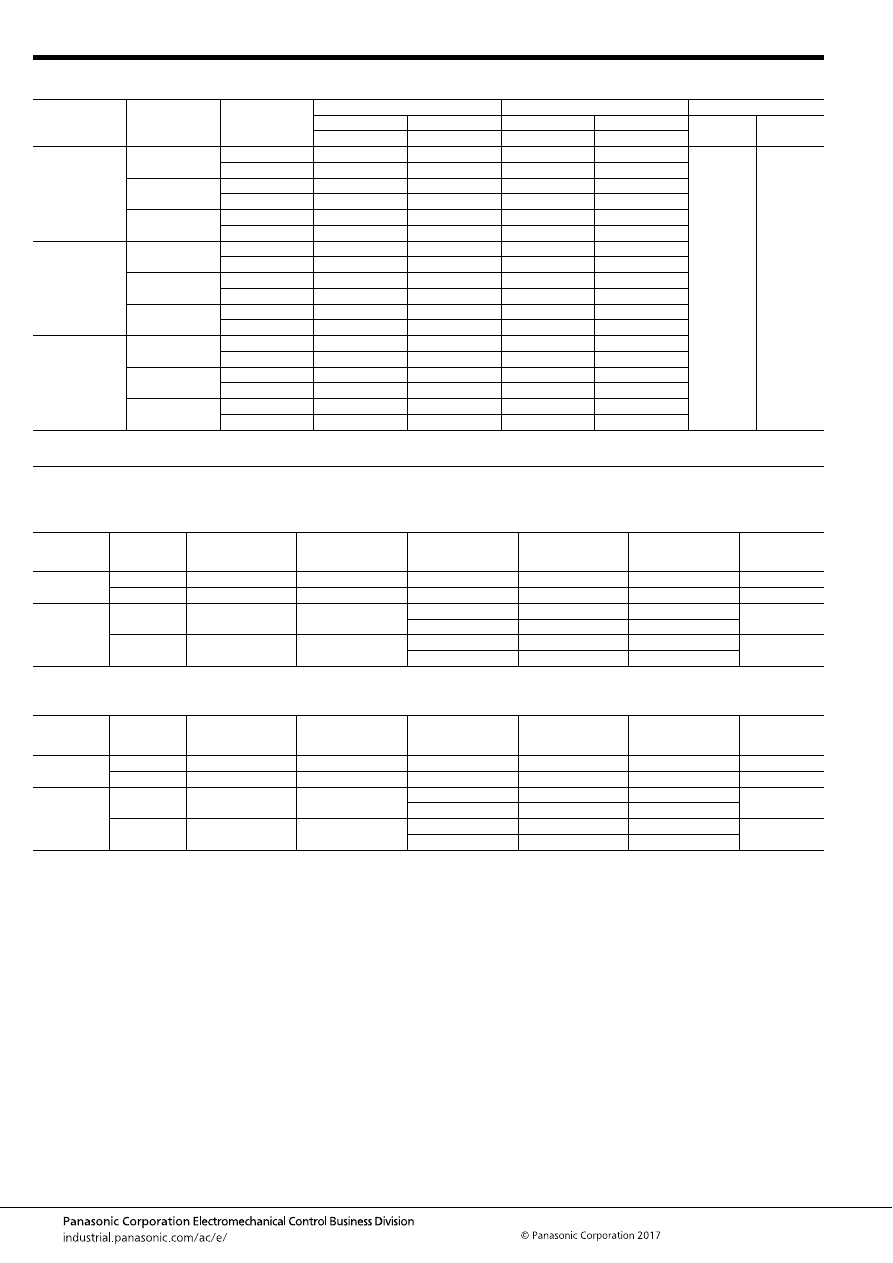

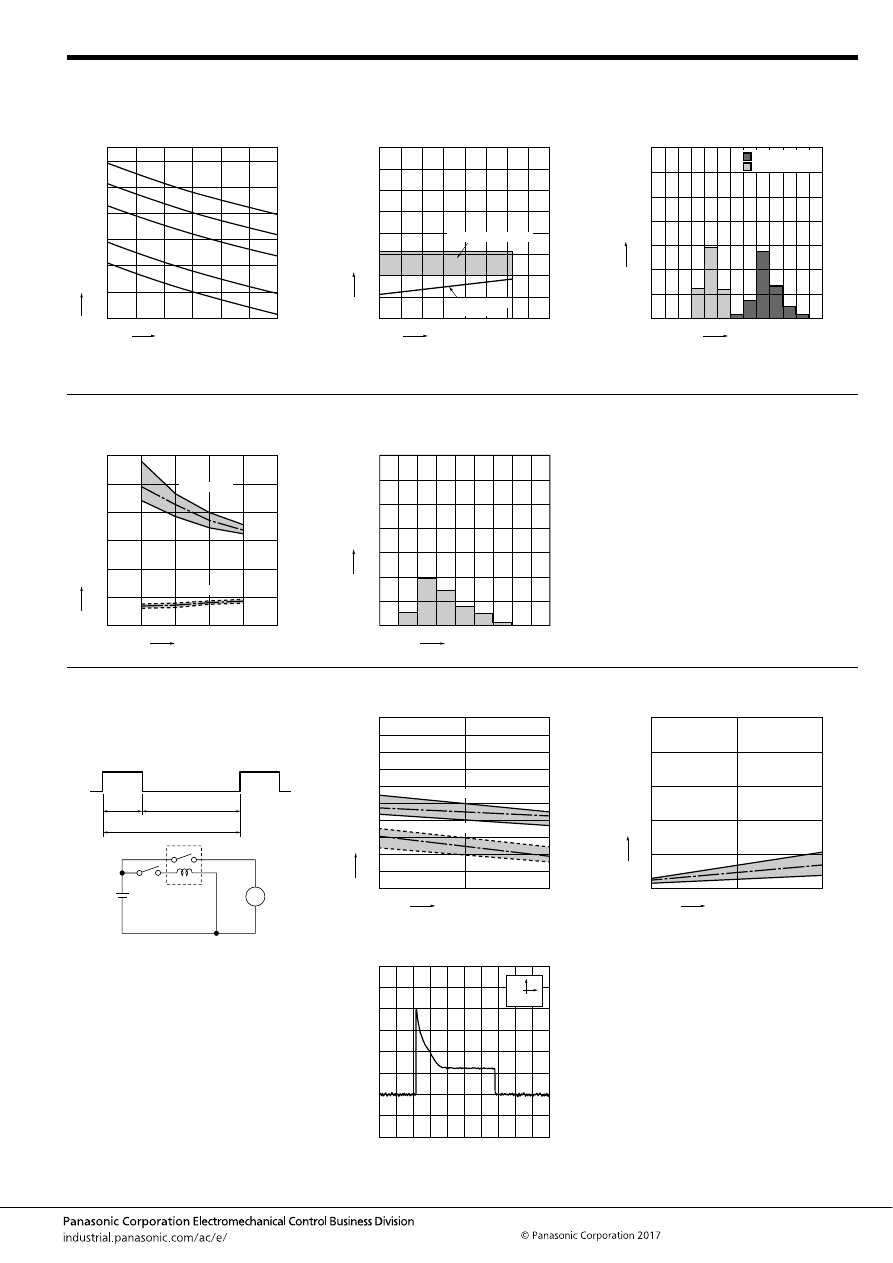

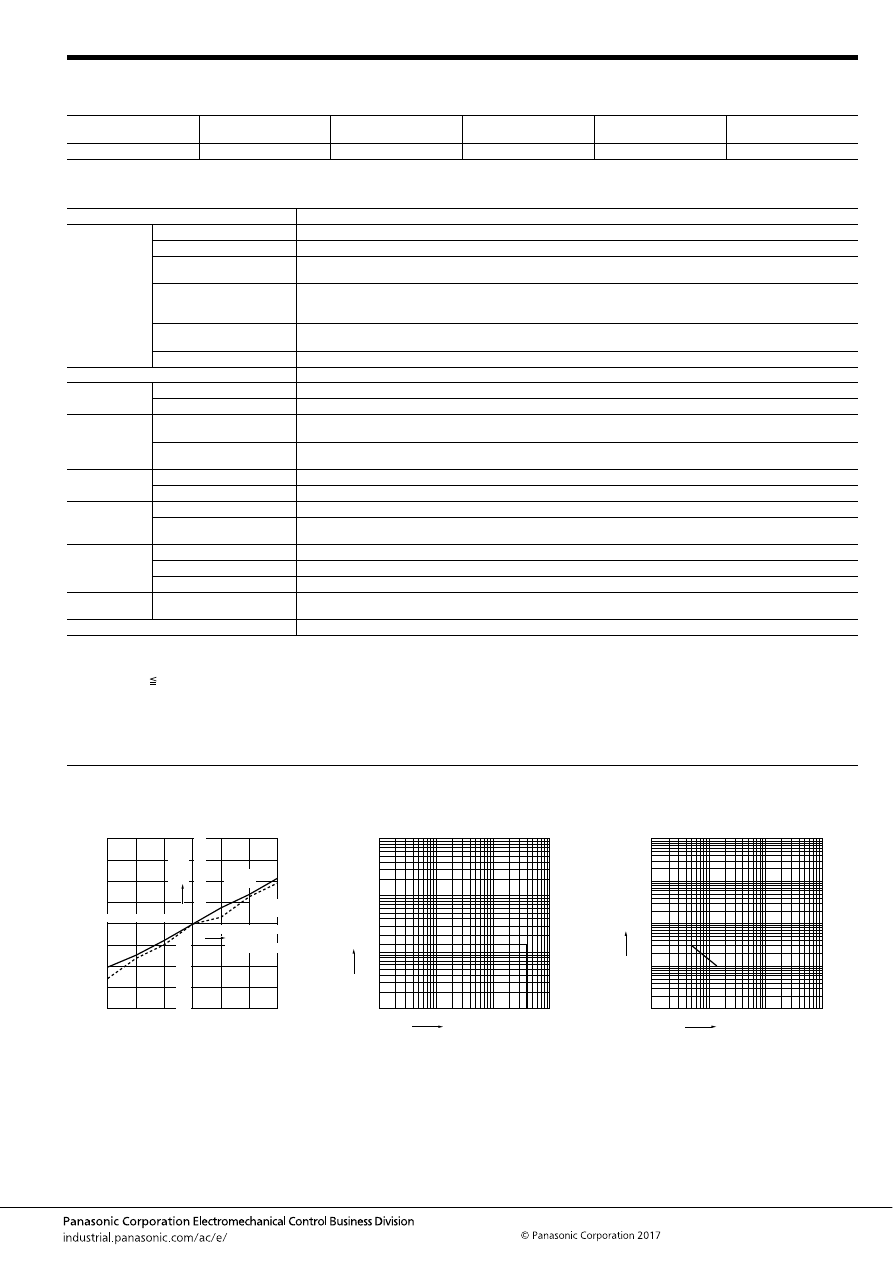

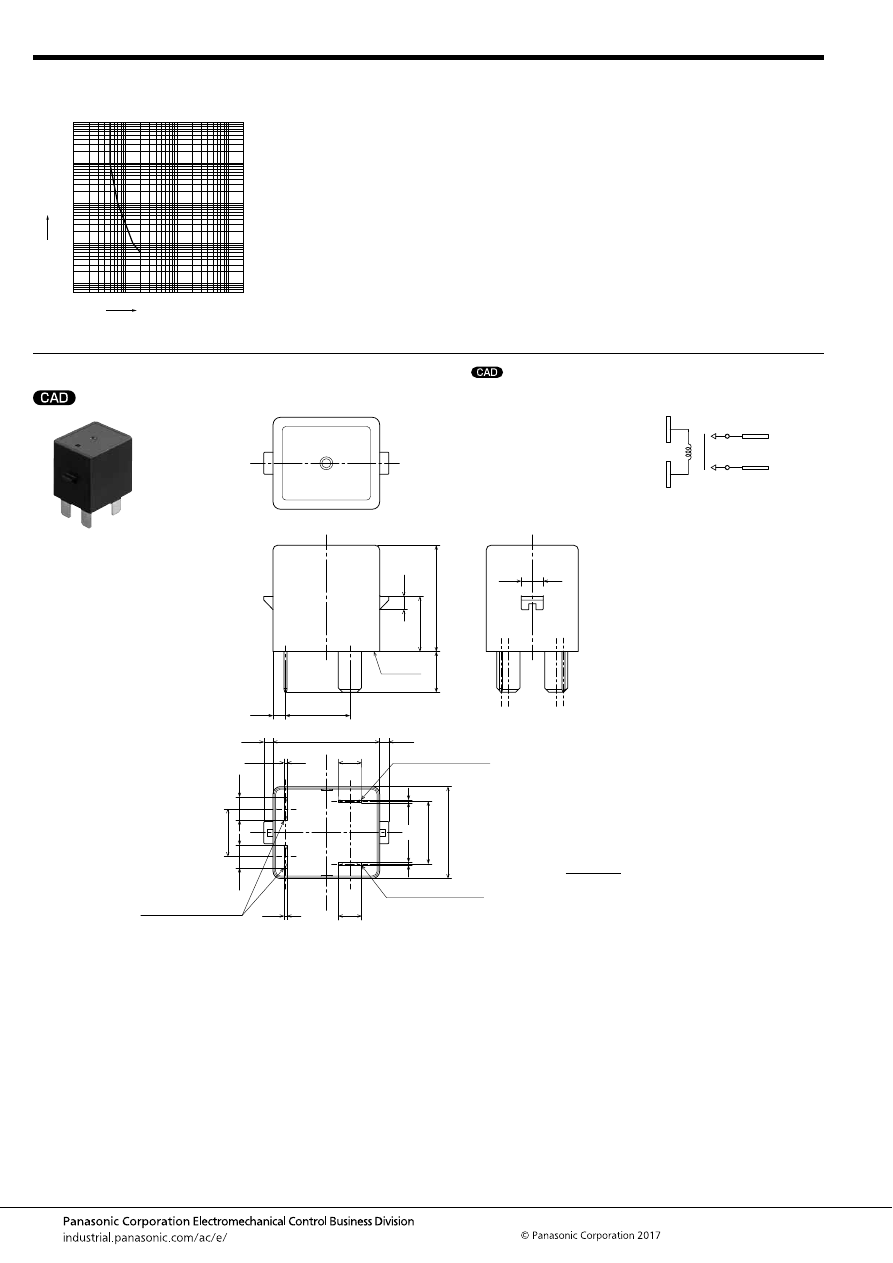

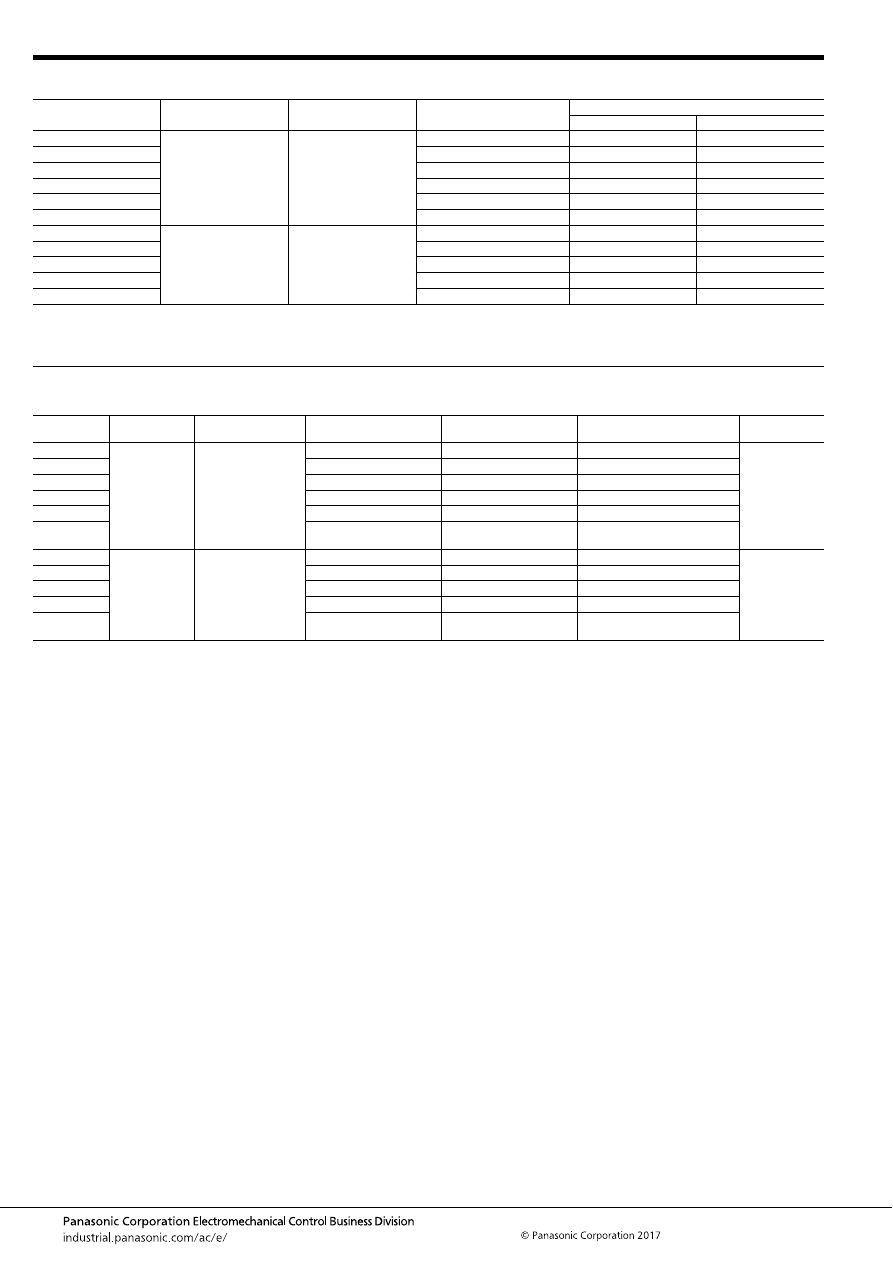

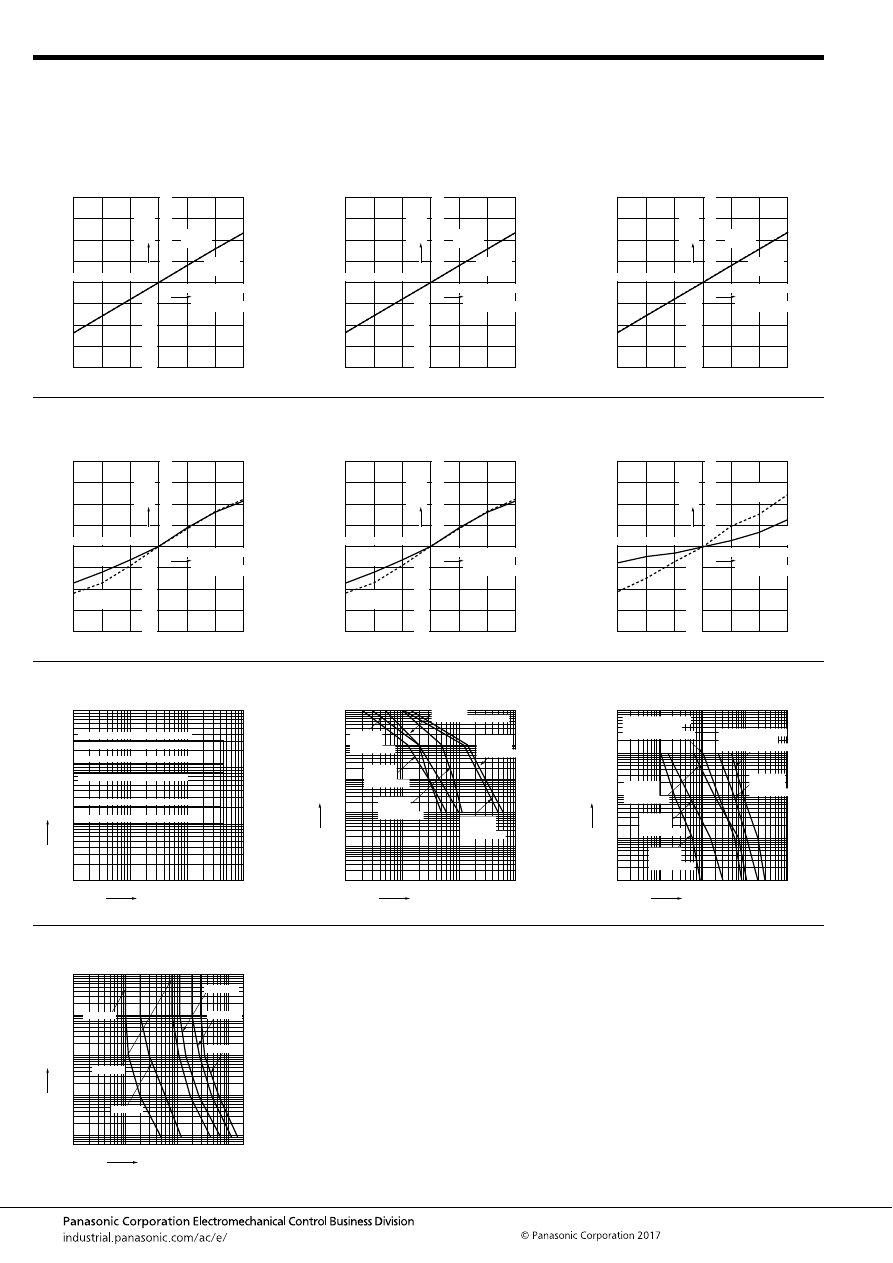

Automotive Relays Selector Chart

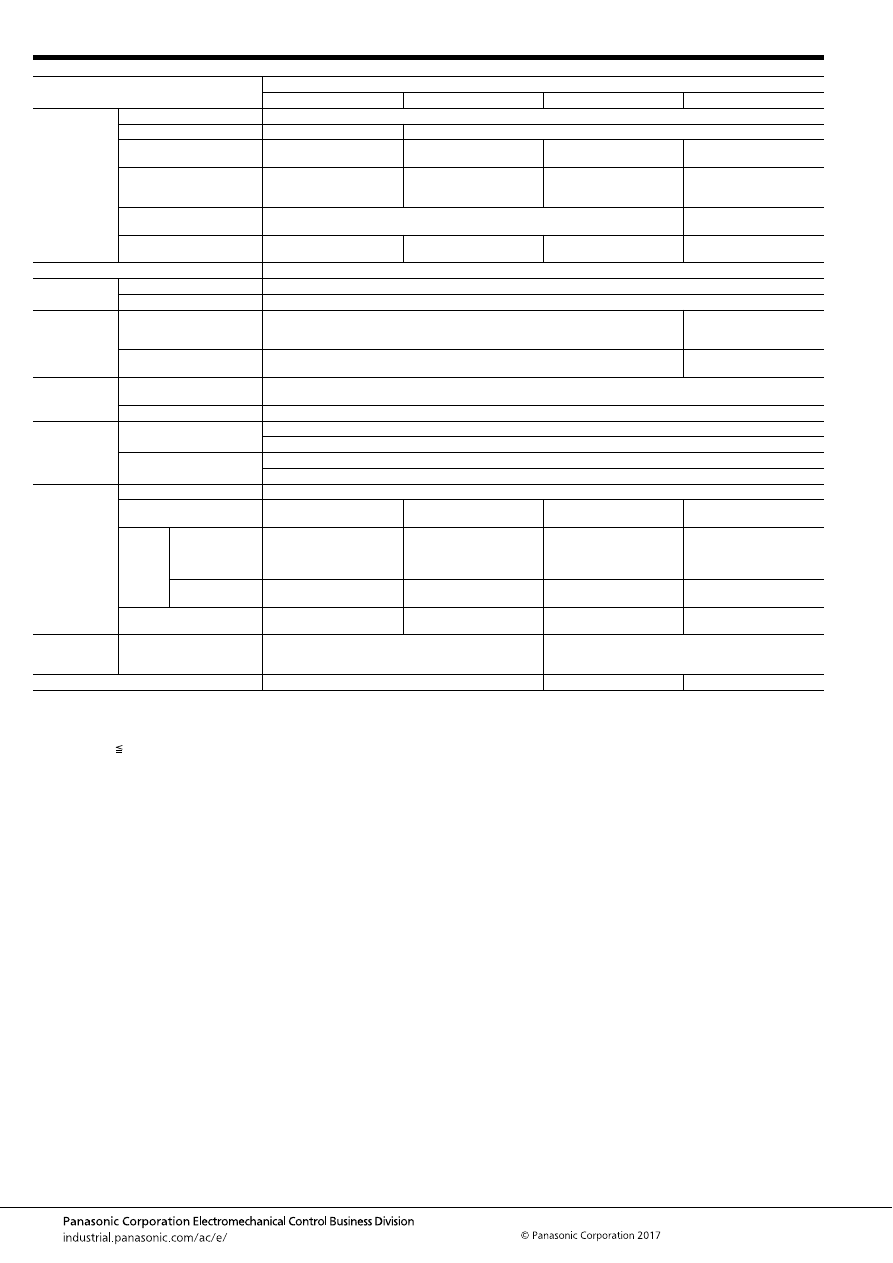

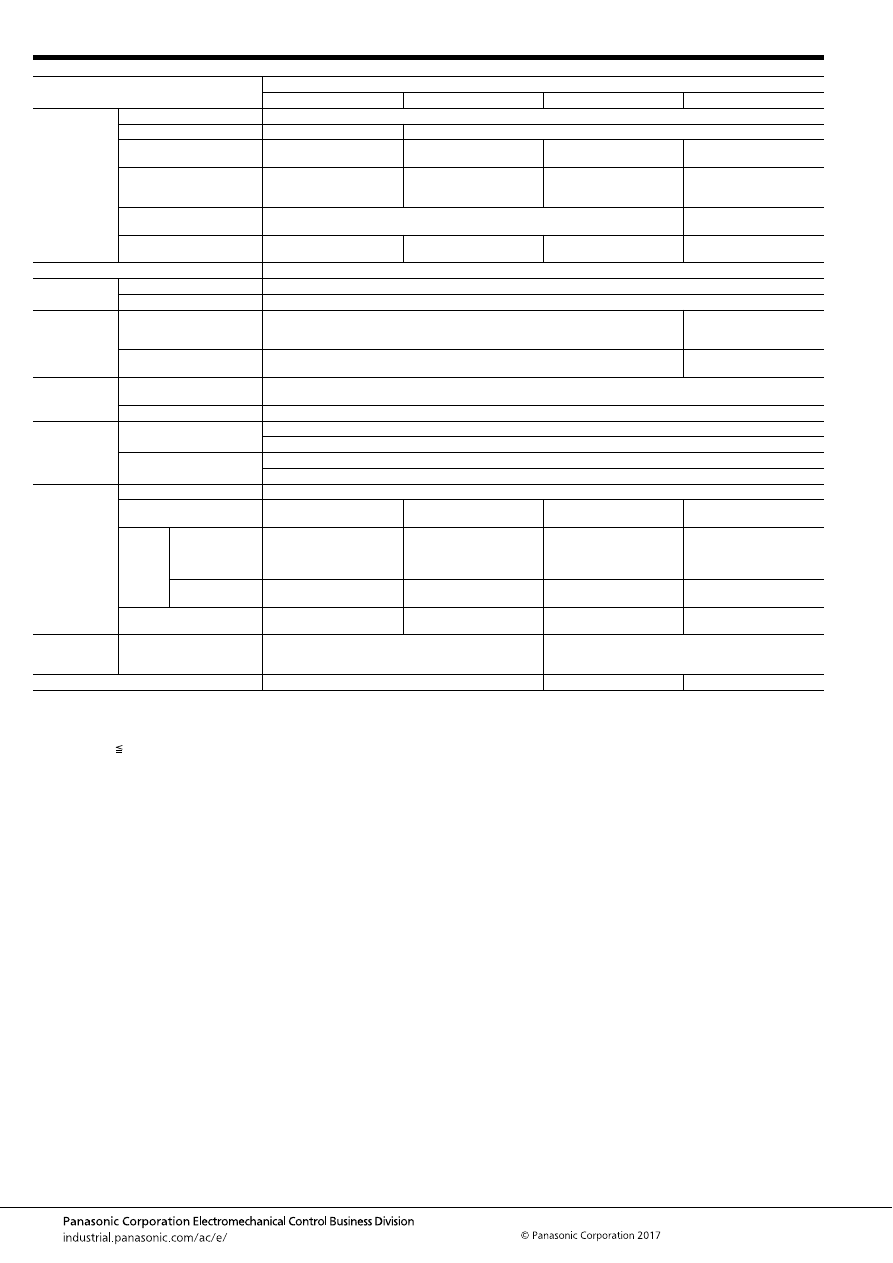

Type

Automotive relays

Product name

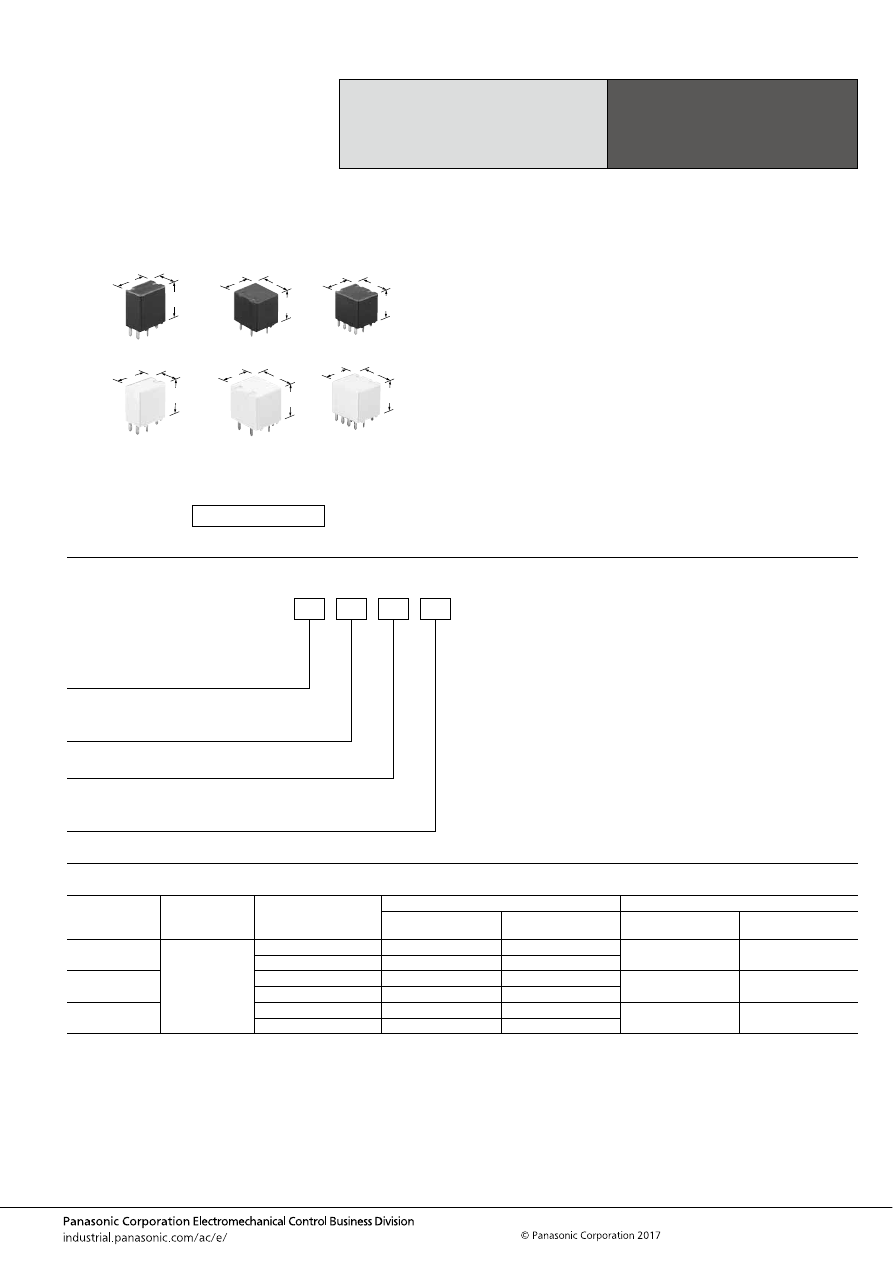

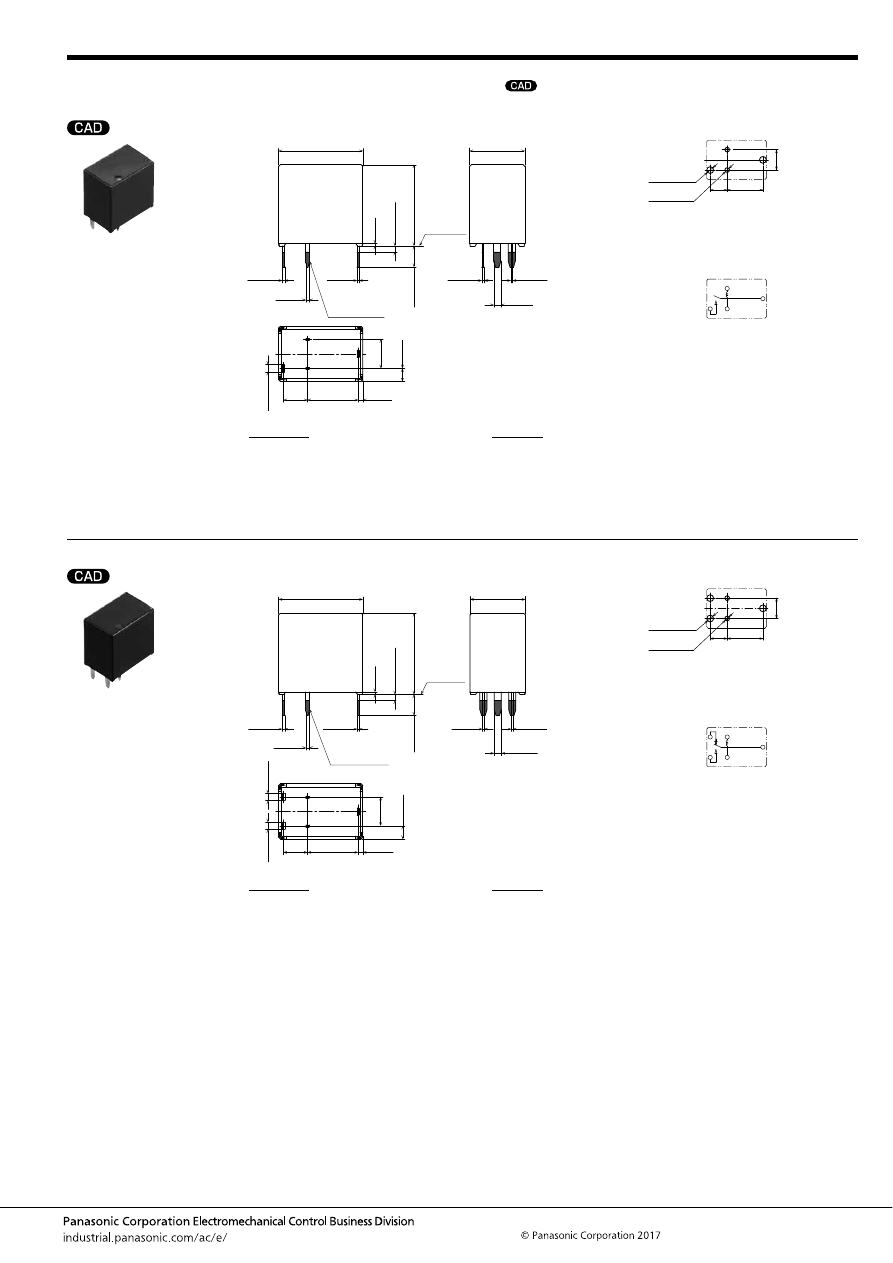

CJ RELAYS

CN-H RELAYS

CN-M RELAYS

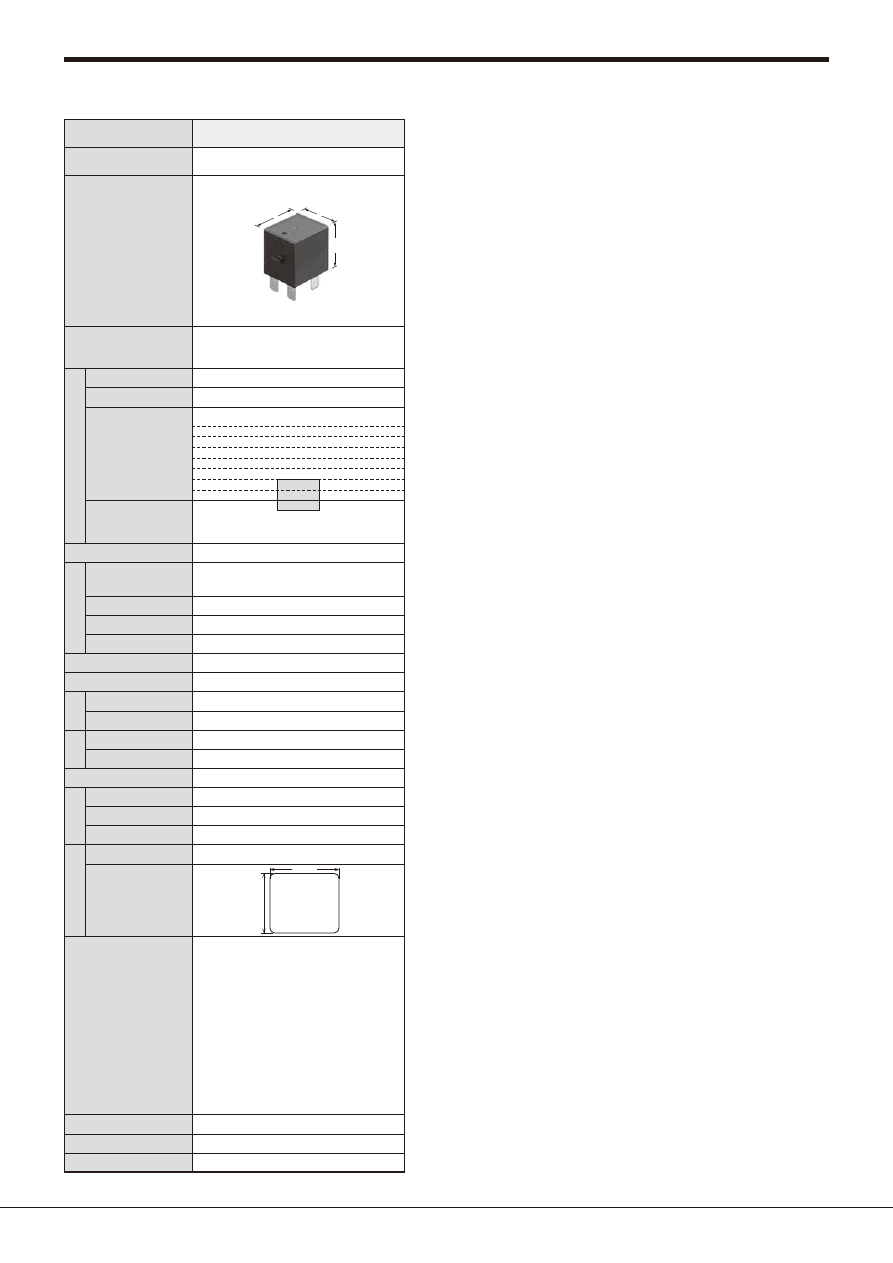

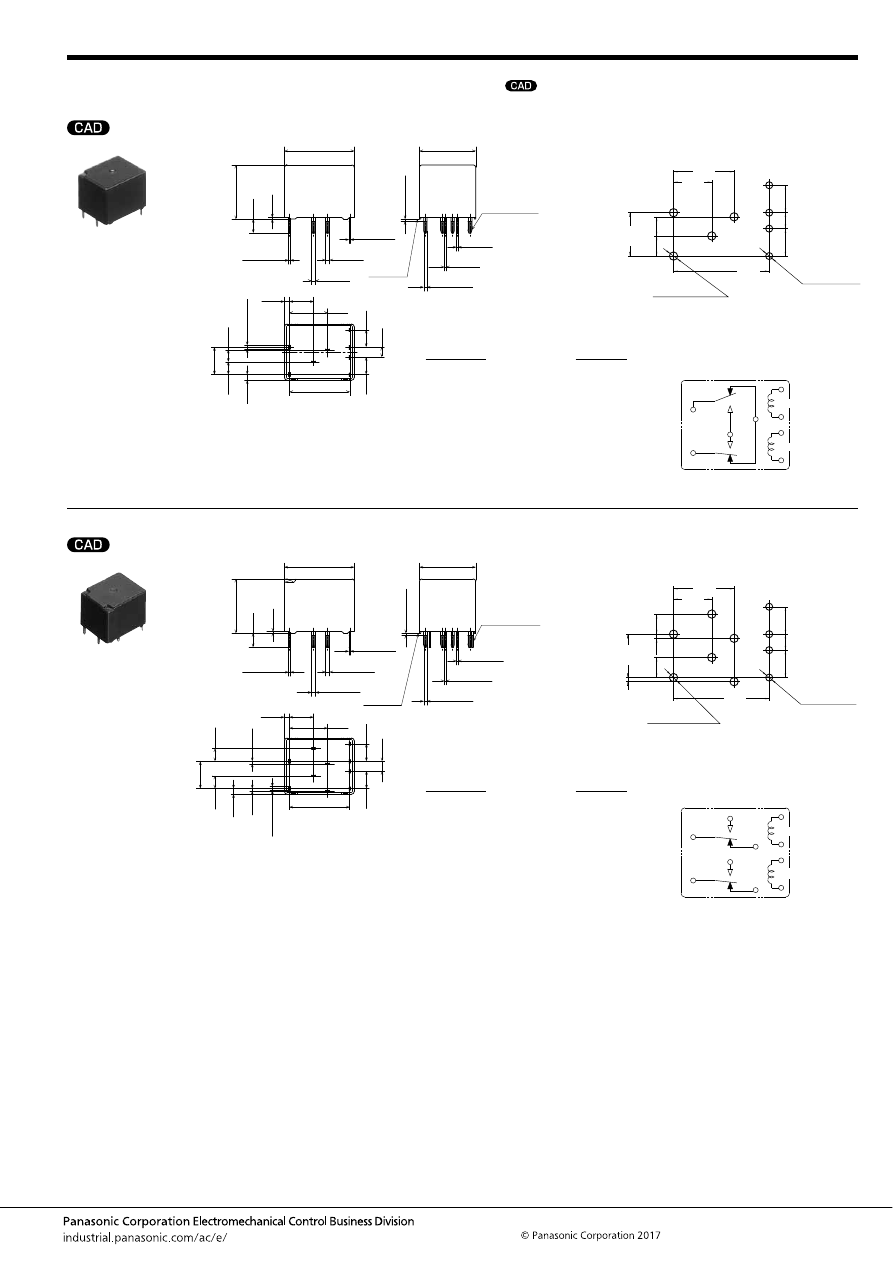

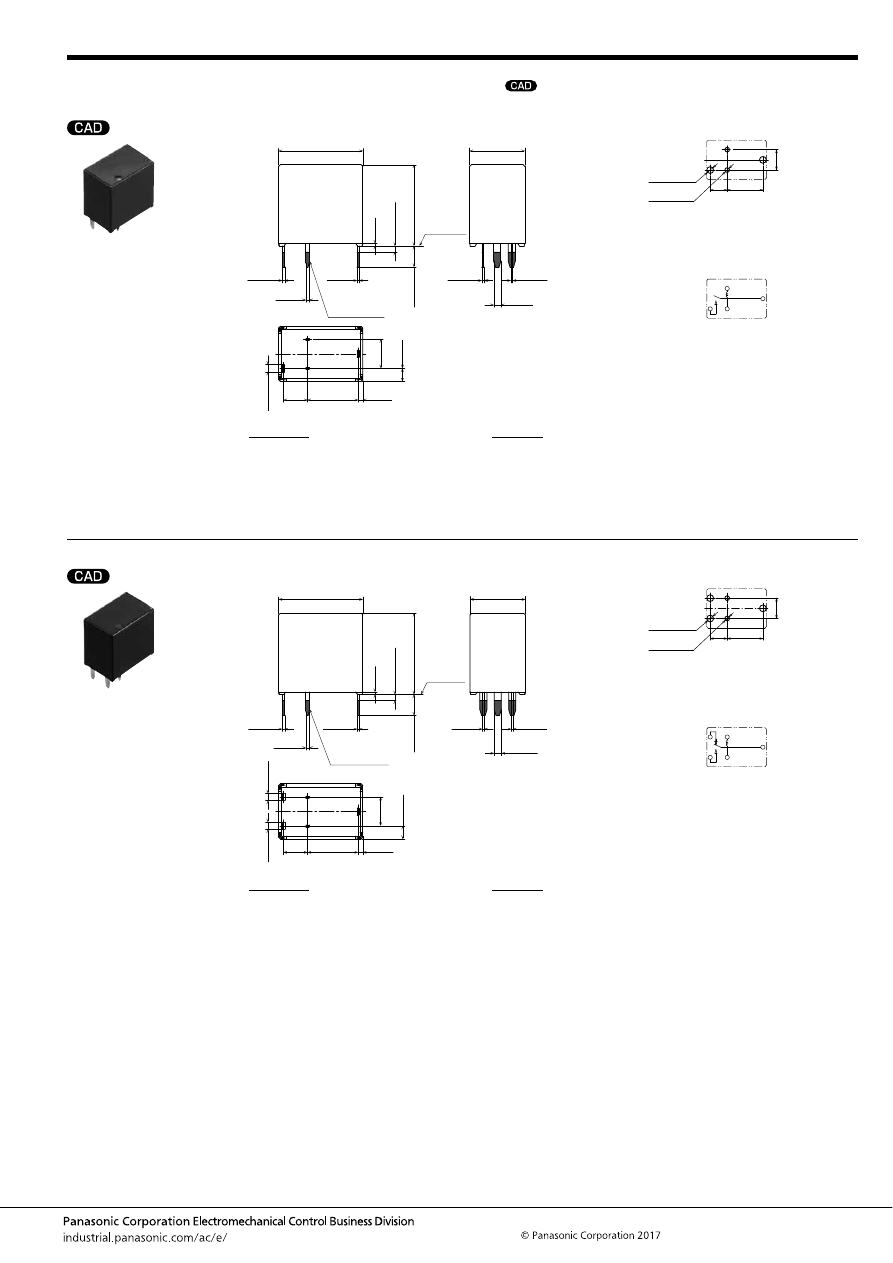

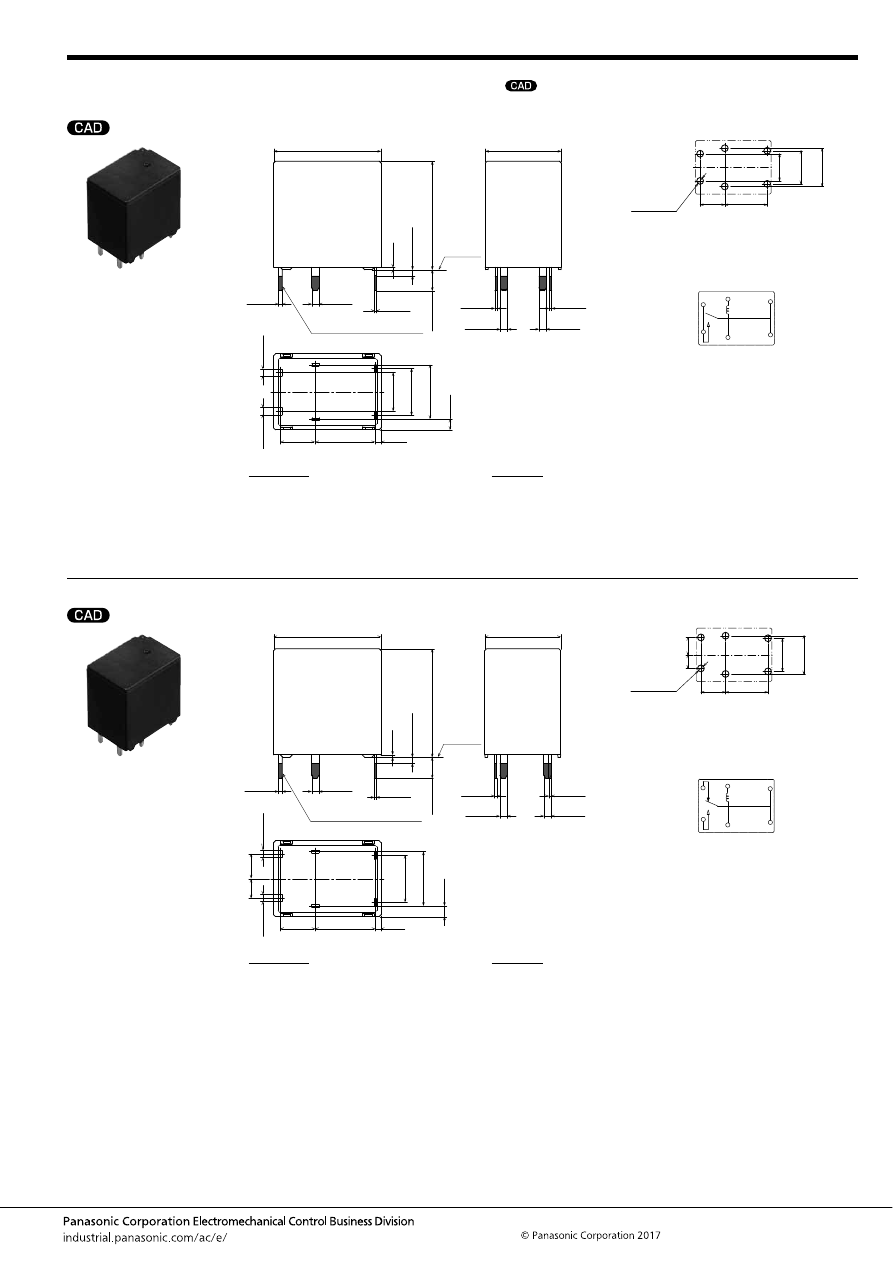

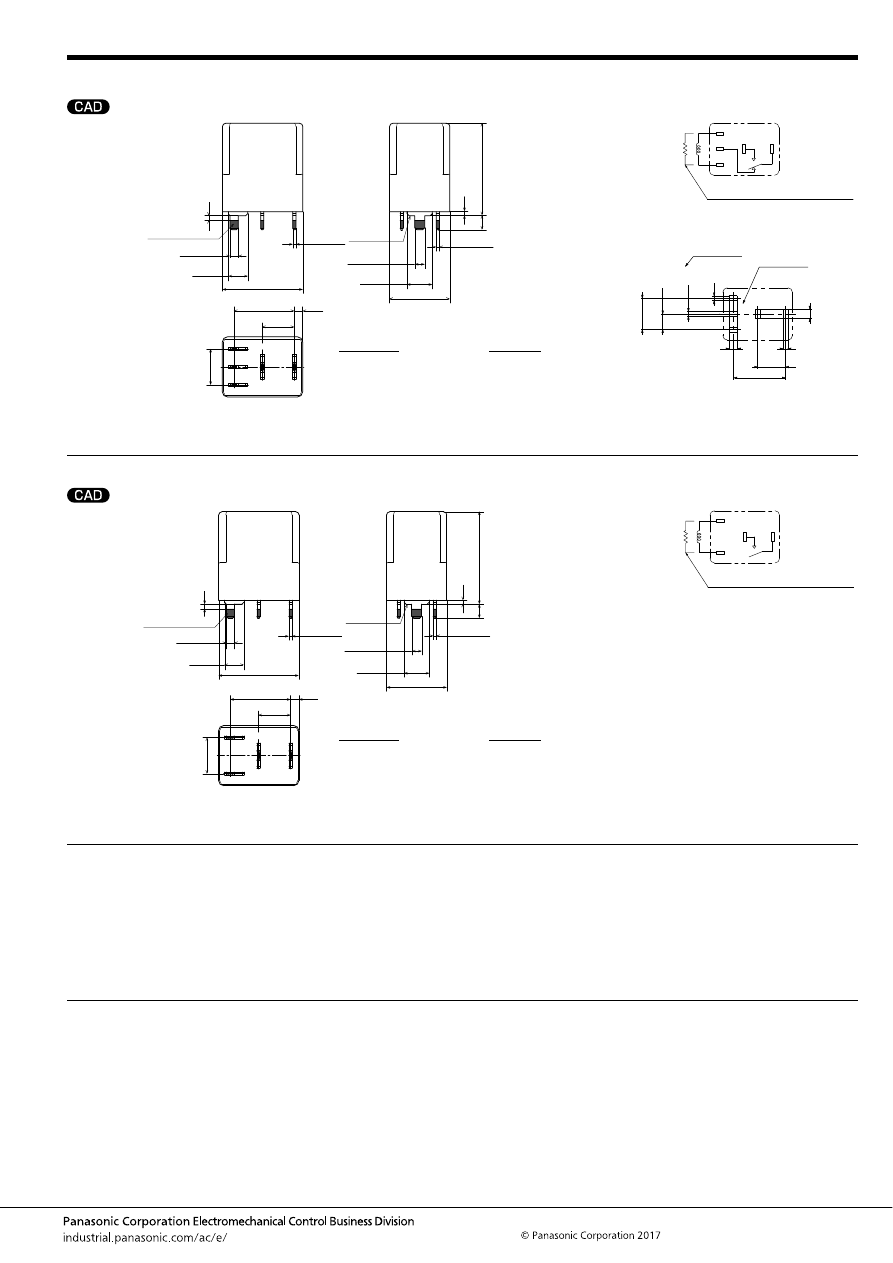

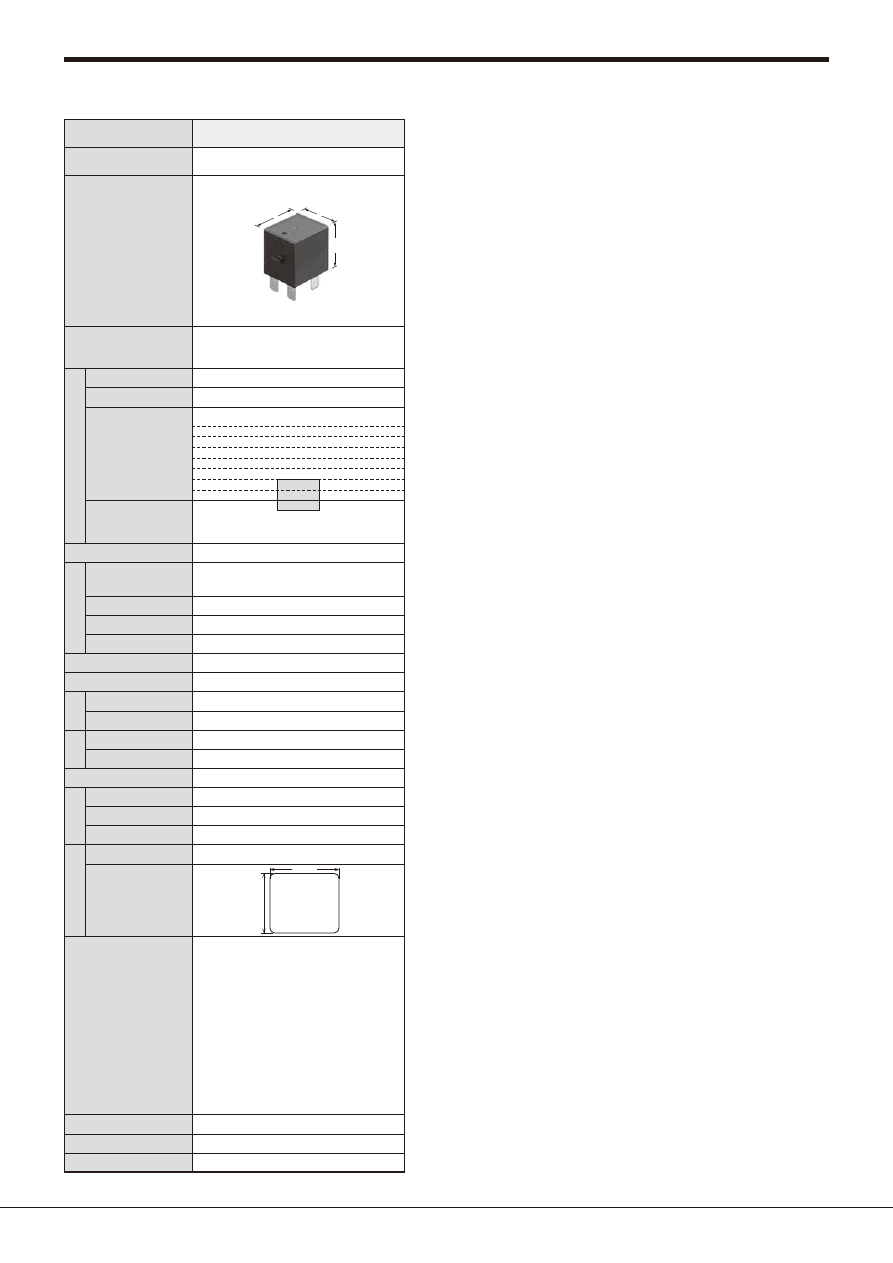

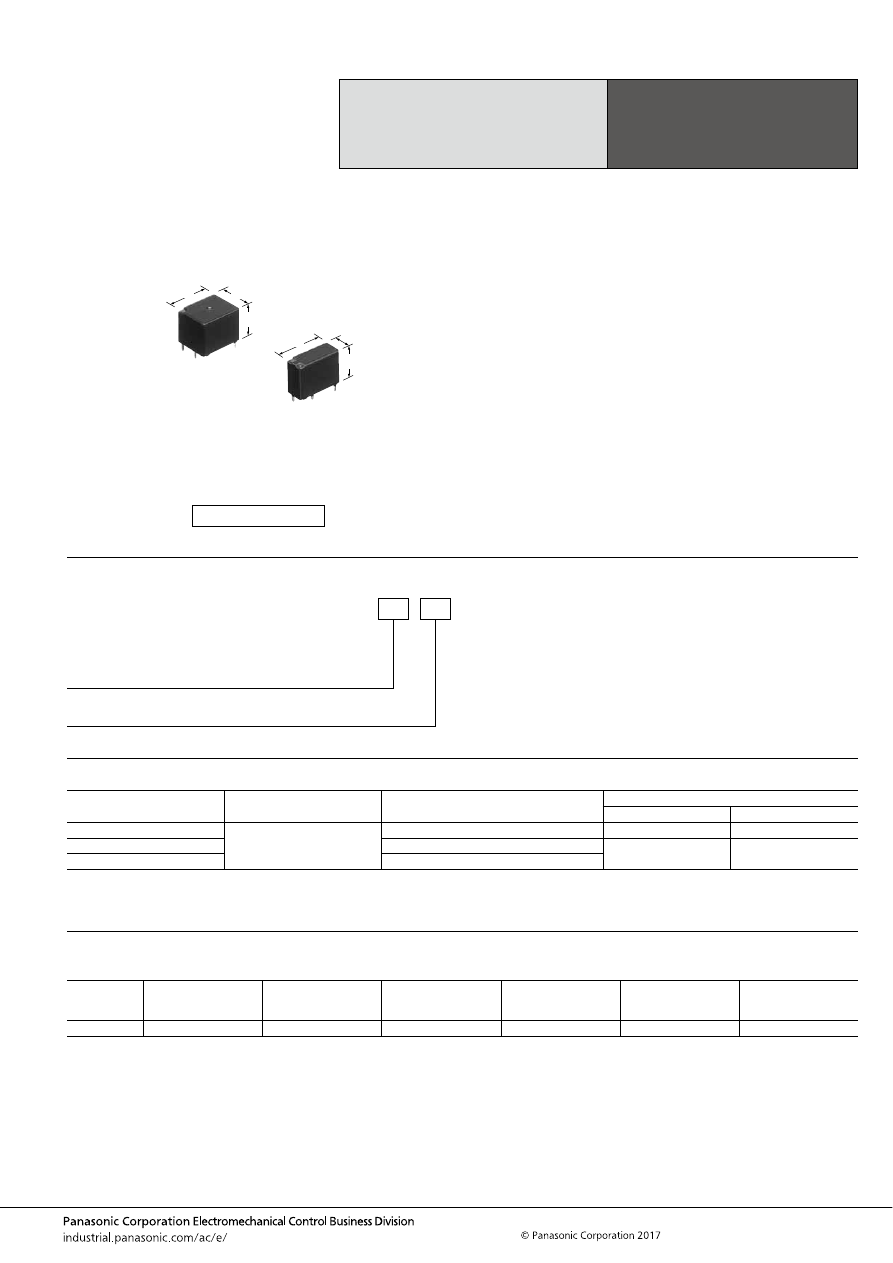

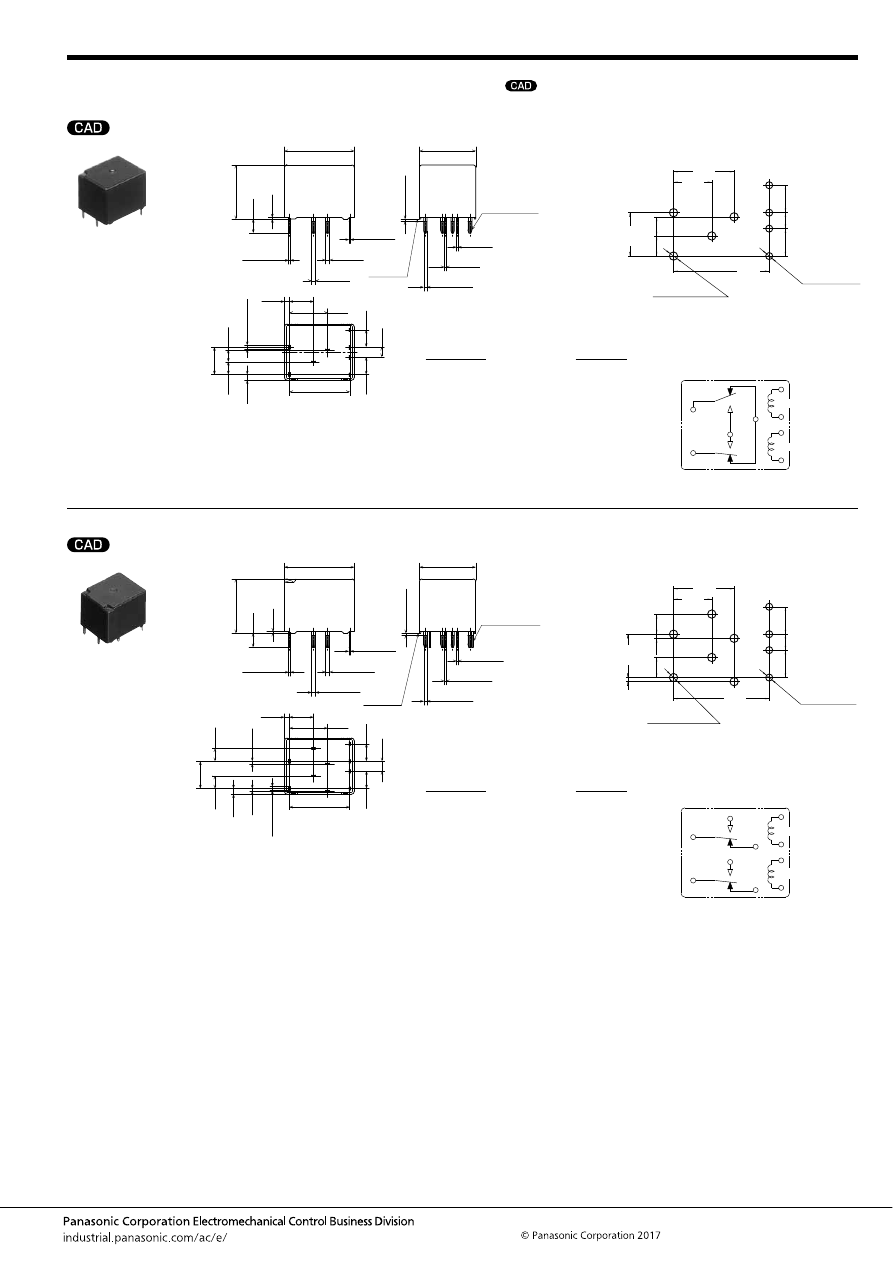

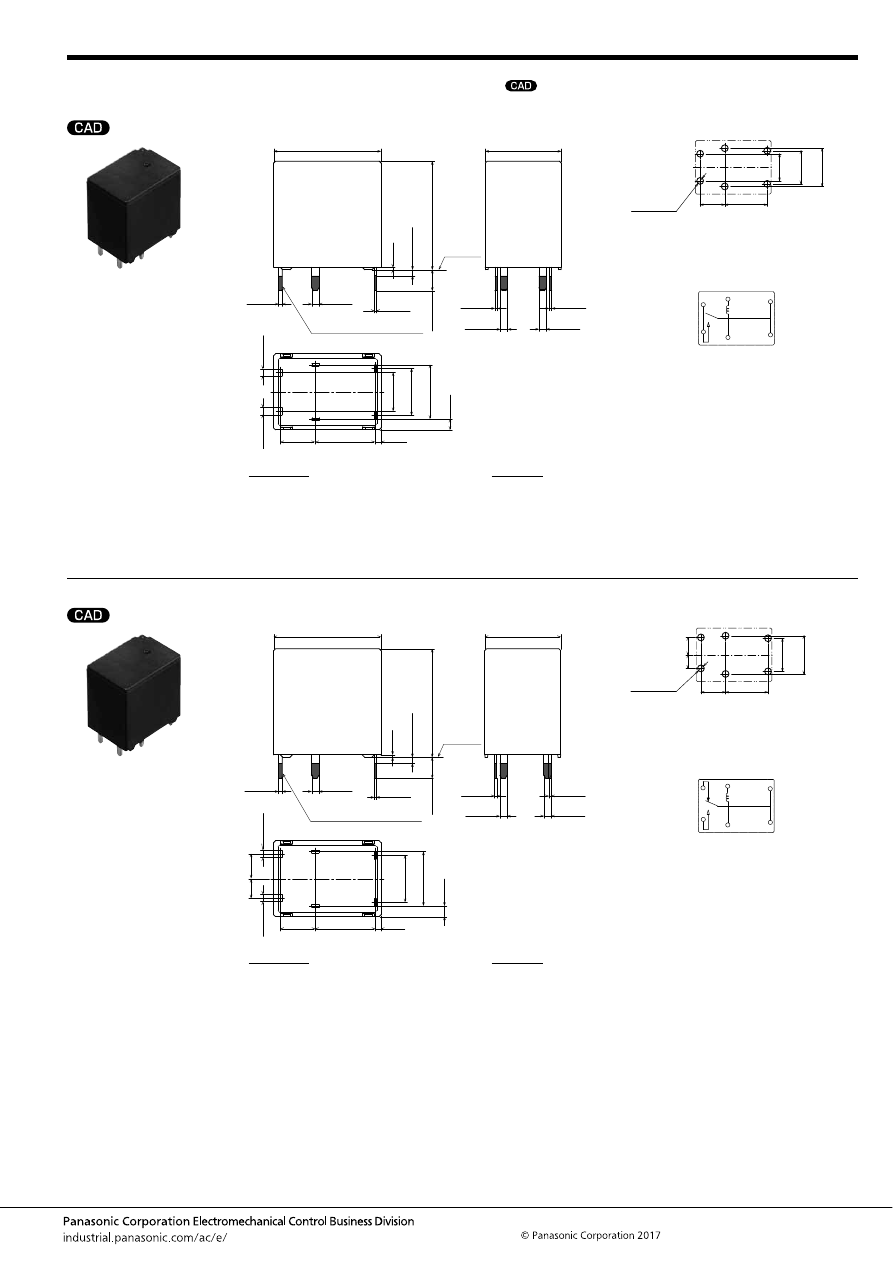

Appearance

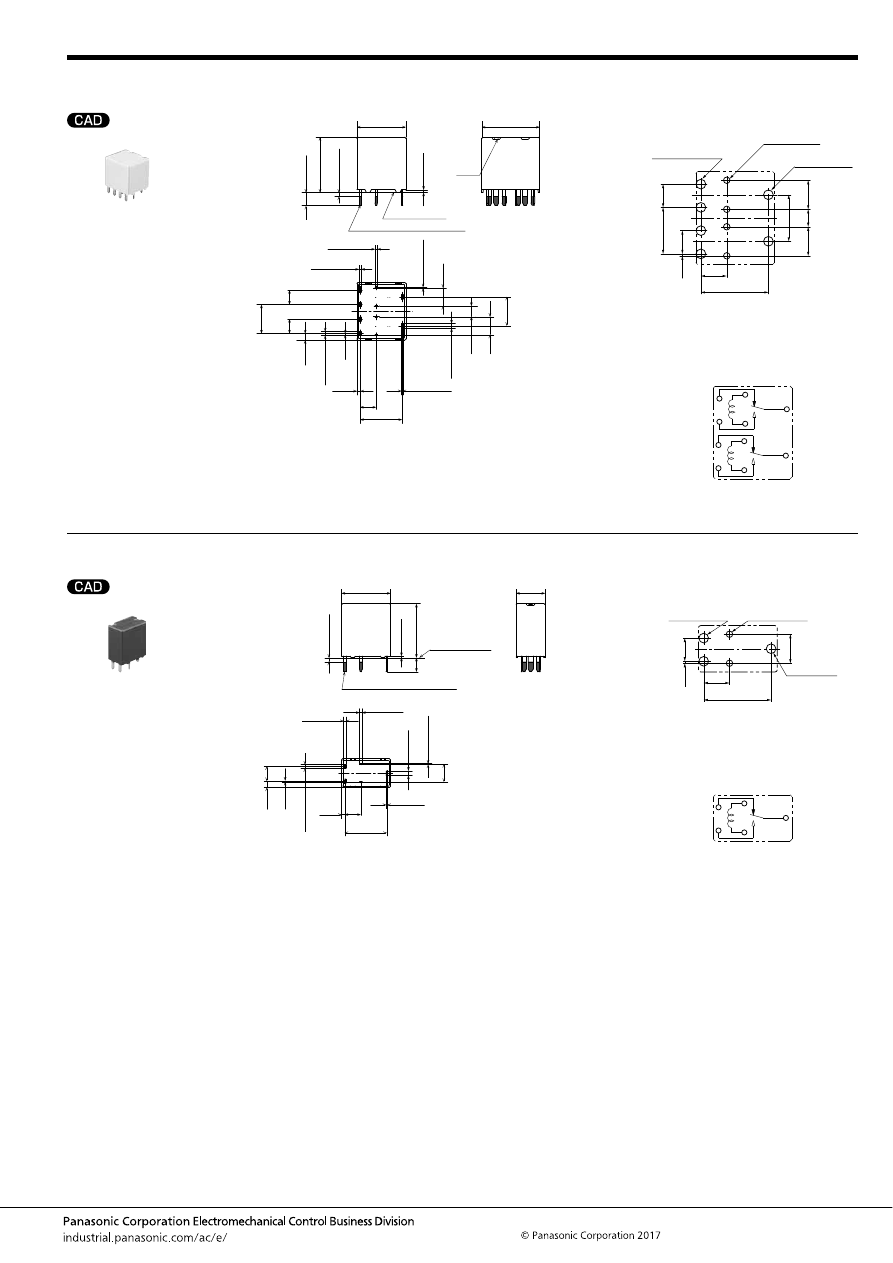

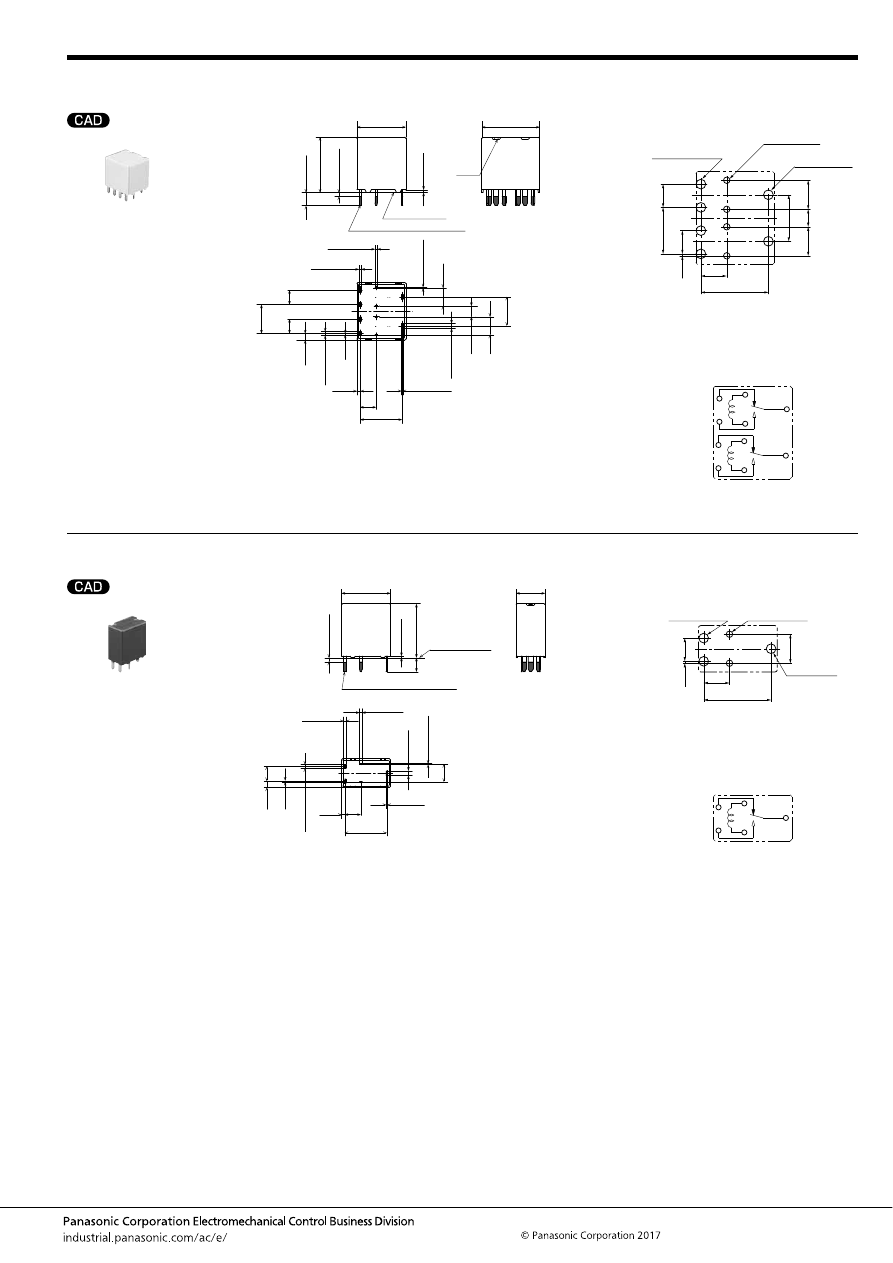

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACJ

(8-pin)

7.2

12.2

13.5

13.7

12.2

13.5

.283

.480

.531

.539

.480

.531

ACNH

10.6

17

18.3

.417

.669

.720

ACNM

11

15.5

14.4

.433

.610

.567

11

15.5

15.1

.433

.610

.594

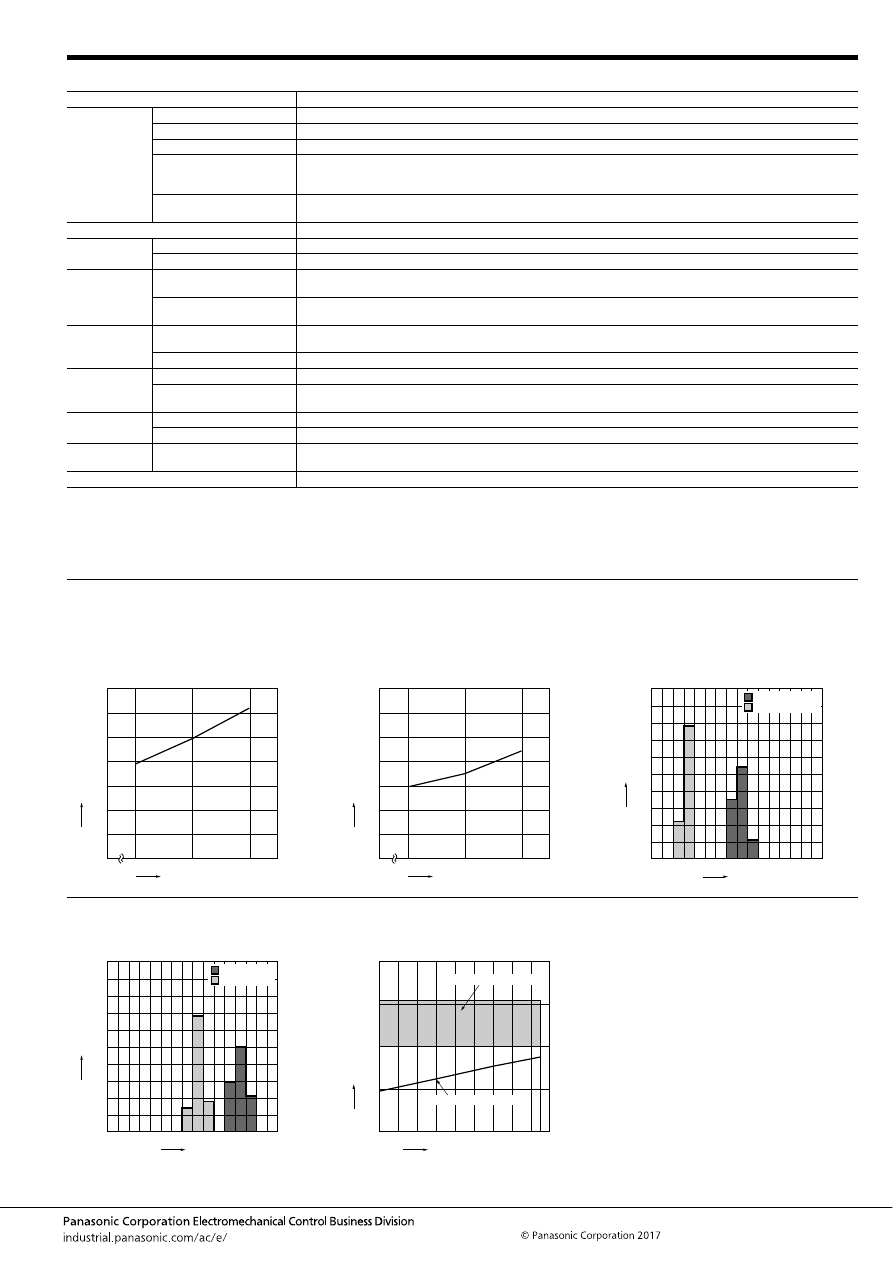

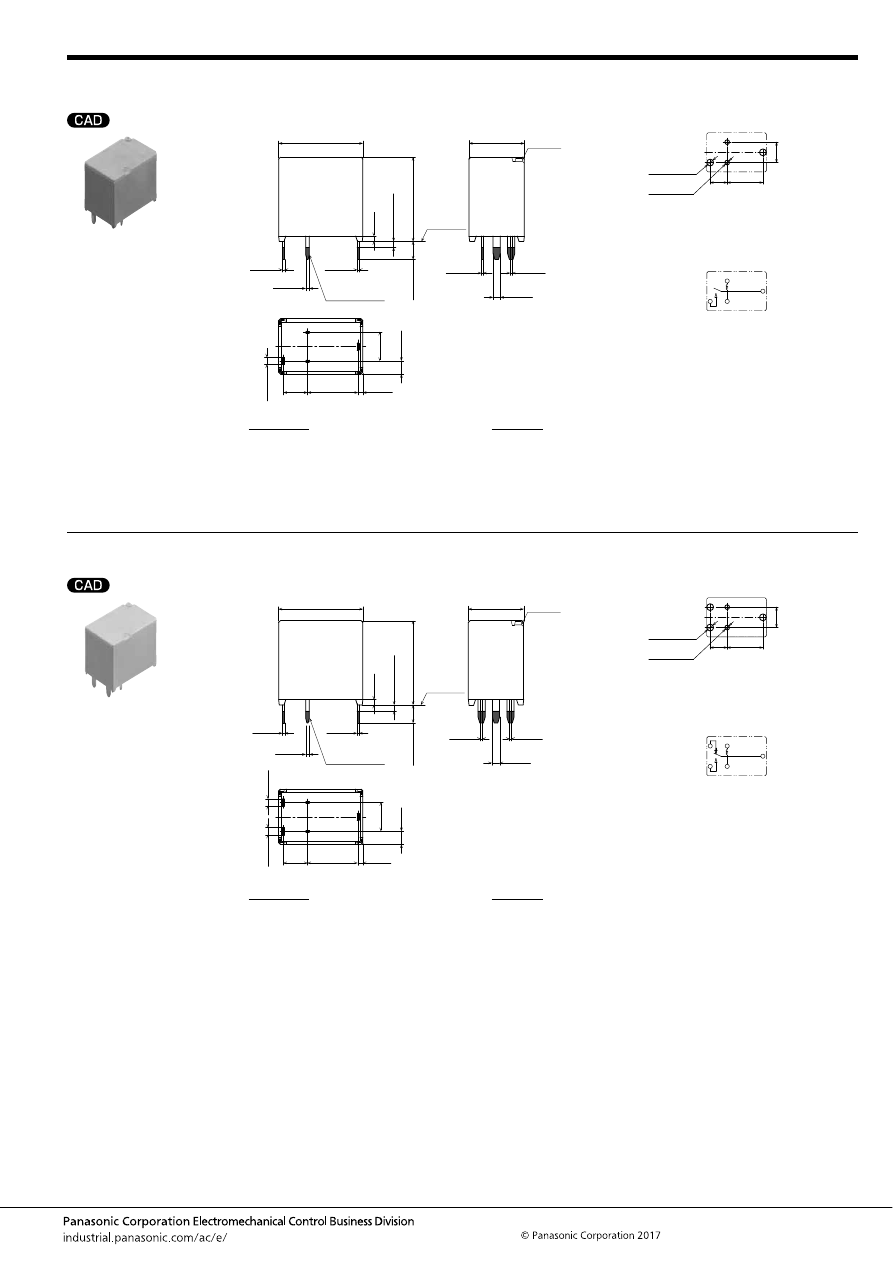

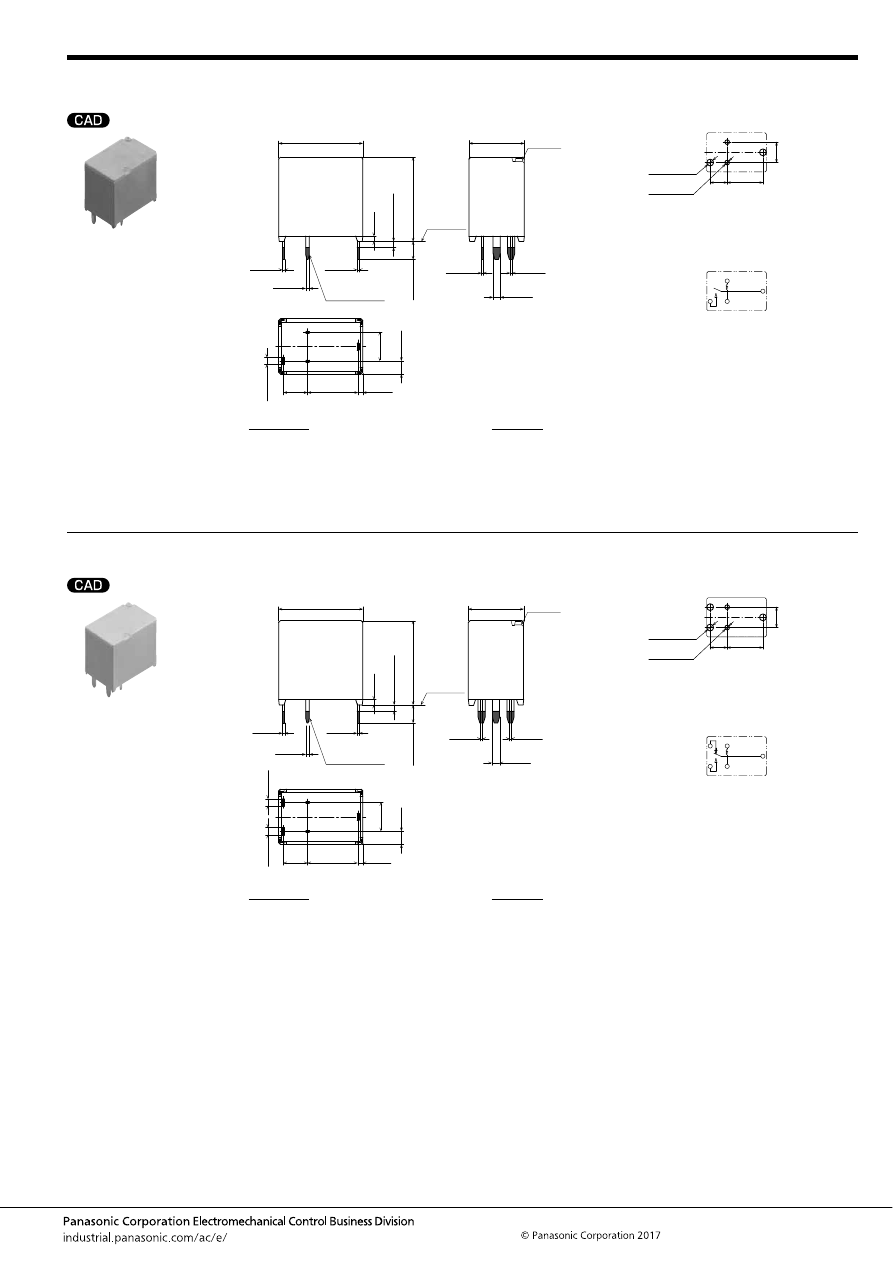

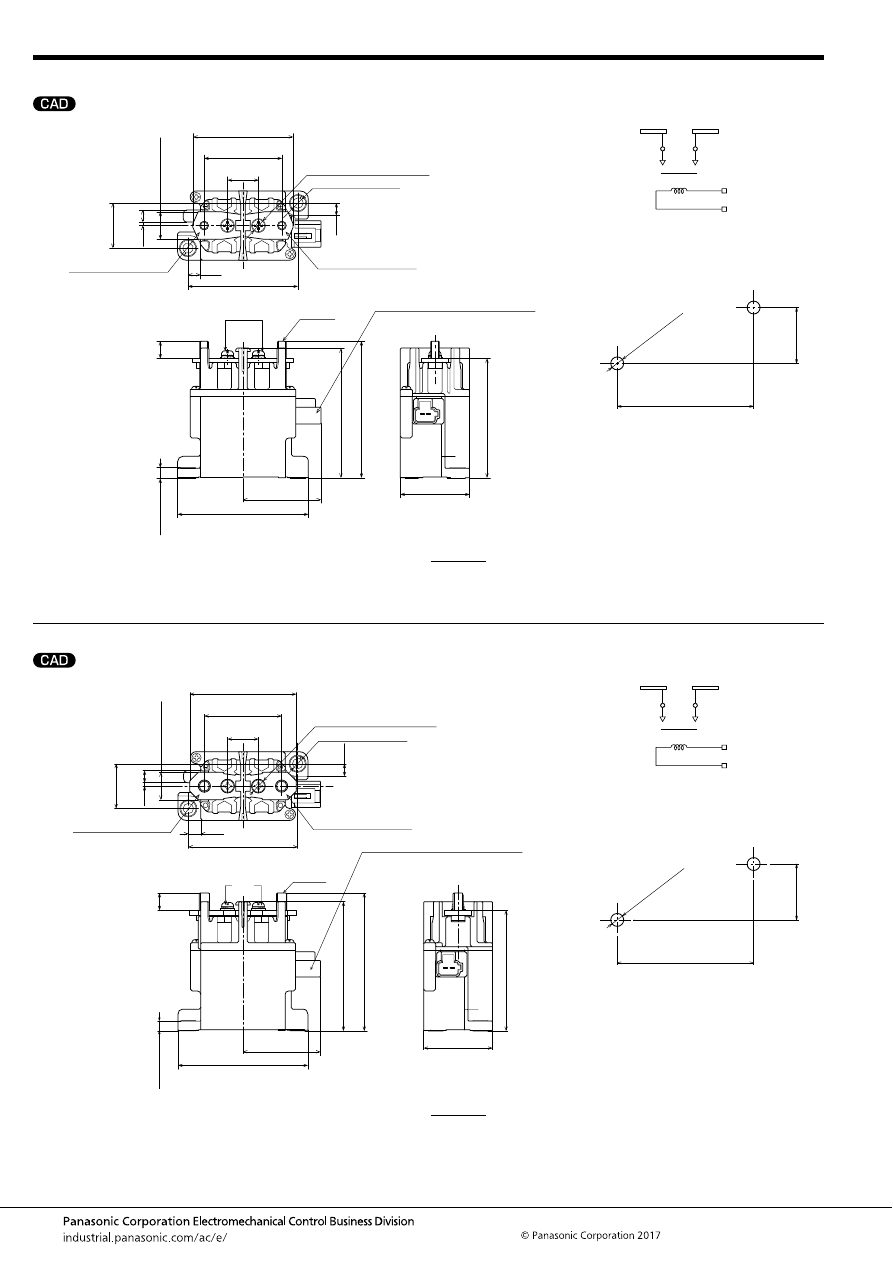

Features

Compact Slim Twin and Single Type

Automotive Relay

High Load Relay for Smart J/B

Middle Load Relay for Smart J/B

Con

tact

data

Contact arrangement 1 Form C, 1 Form C×2 (8 pins), 1 Form C×2 (10 pins)

1 Form A

1 Form A, 1 Form C

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

30A 14V DC

N.O.

30A 14V DC

N.O.

15A 14V DC

N.C.

1A 14V DC

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power

640mW

800mW

450mW

640mW

640mW

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 7.2V DC

Max. 6.5V DC

Max. 6.5V DC

Max. 5.5V DC

Max. 7.2V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 1.0V DC

Min. 0.8V DC

Min. 1.0V DC

Min. 0.8V DC

Min. 1.0V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

7

Min. 10

7

Electrical

Min. 2 × 10

5

(at 14 V DC, inrush: 25 A, steady: 5 A)

Min. 10

5

(at 14 V DC, 25 A Motor lock)

Min. 3 × 10

5

(at 14 V DC, inrush: 84 A, steady: 18 A)

Min. 2 × 10

5

(at 14 V DC, 84 A, steady: 12 A Lamp)

Min. 2 × 10

5

(at 14 V DC, inrush: 80 A, steady: 16 A)

Min. 10

5

(at 14 V DC, 84 A steady: 12 A Lamp)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

–40 to +110°C

–40 to +230°F

Standard type: –40 to +85°C

–40 to +185°F

High heat-resistant type: –40 to +110°C

–40 to +230°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

●

(PIP type)

−

−

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

13.5

.531

/13.8

.543

(PIP type)

18.3

.720

14.4

.567

(Surface-mount: 15.1

.594

)

Foot print (mm

inch

)

13.7

12.2

12.2

.480

.480

7.2

.539

.283

(8-pin)

10.6

.417

17

.669

11

.433

15.5

.610

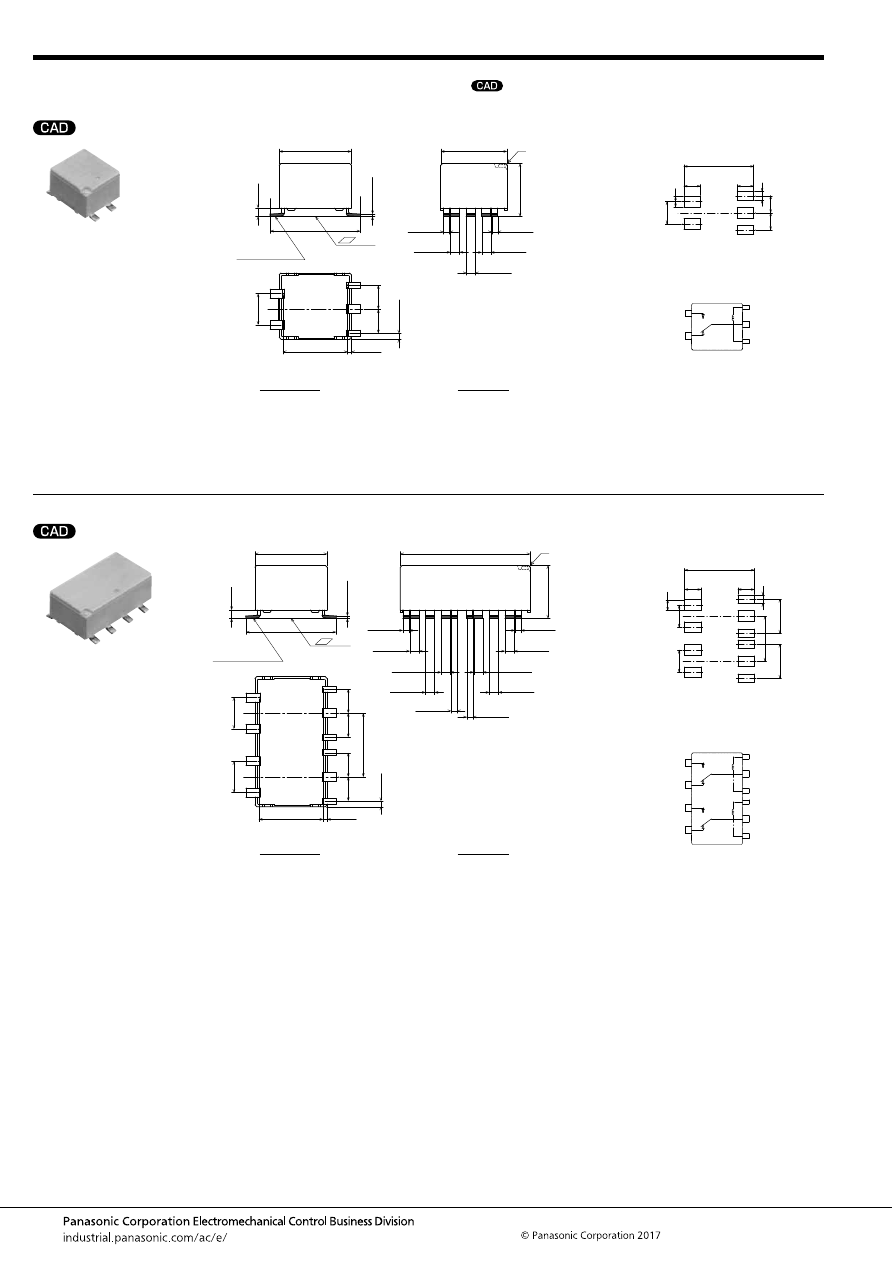

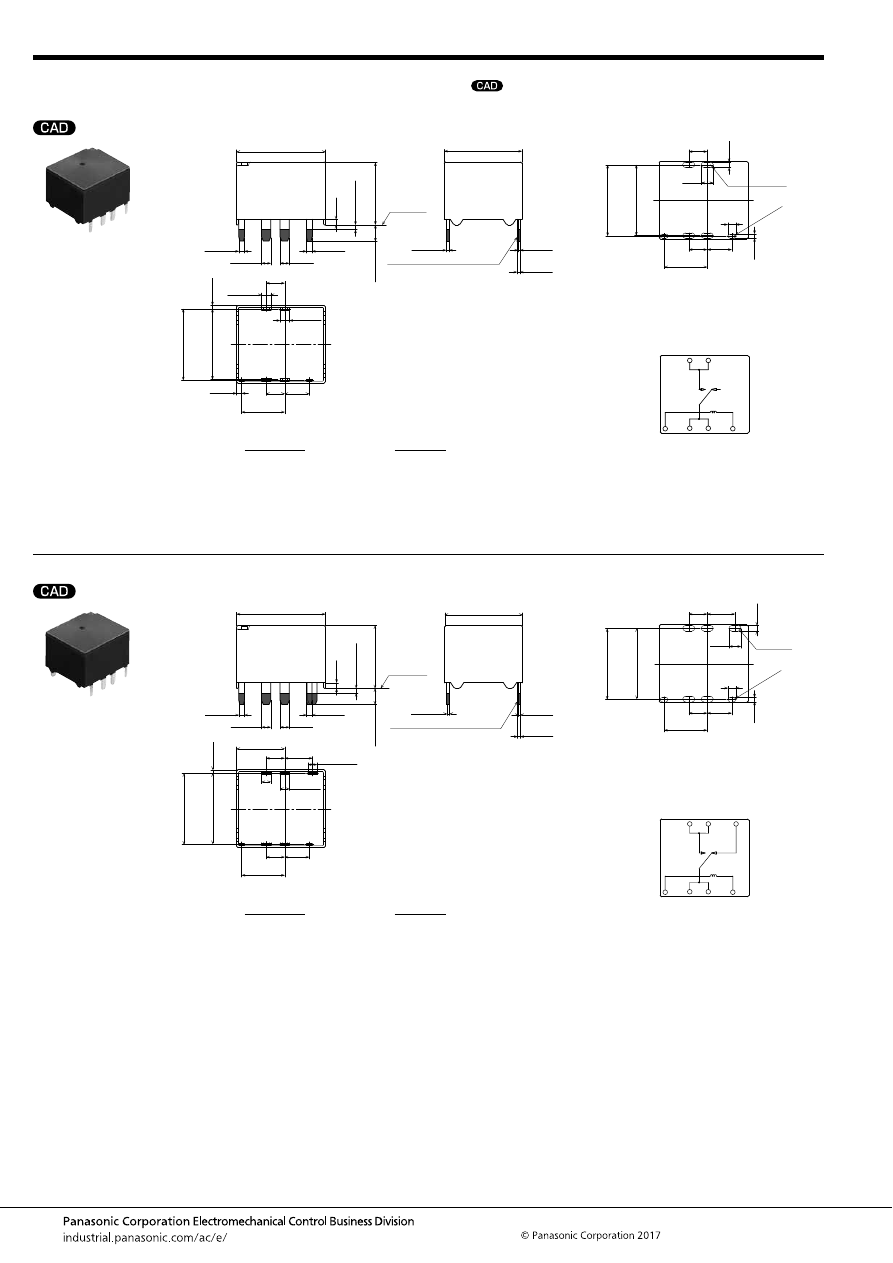

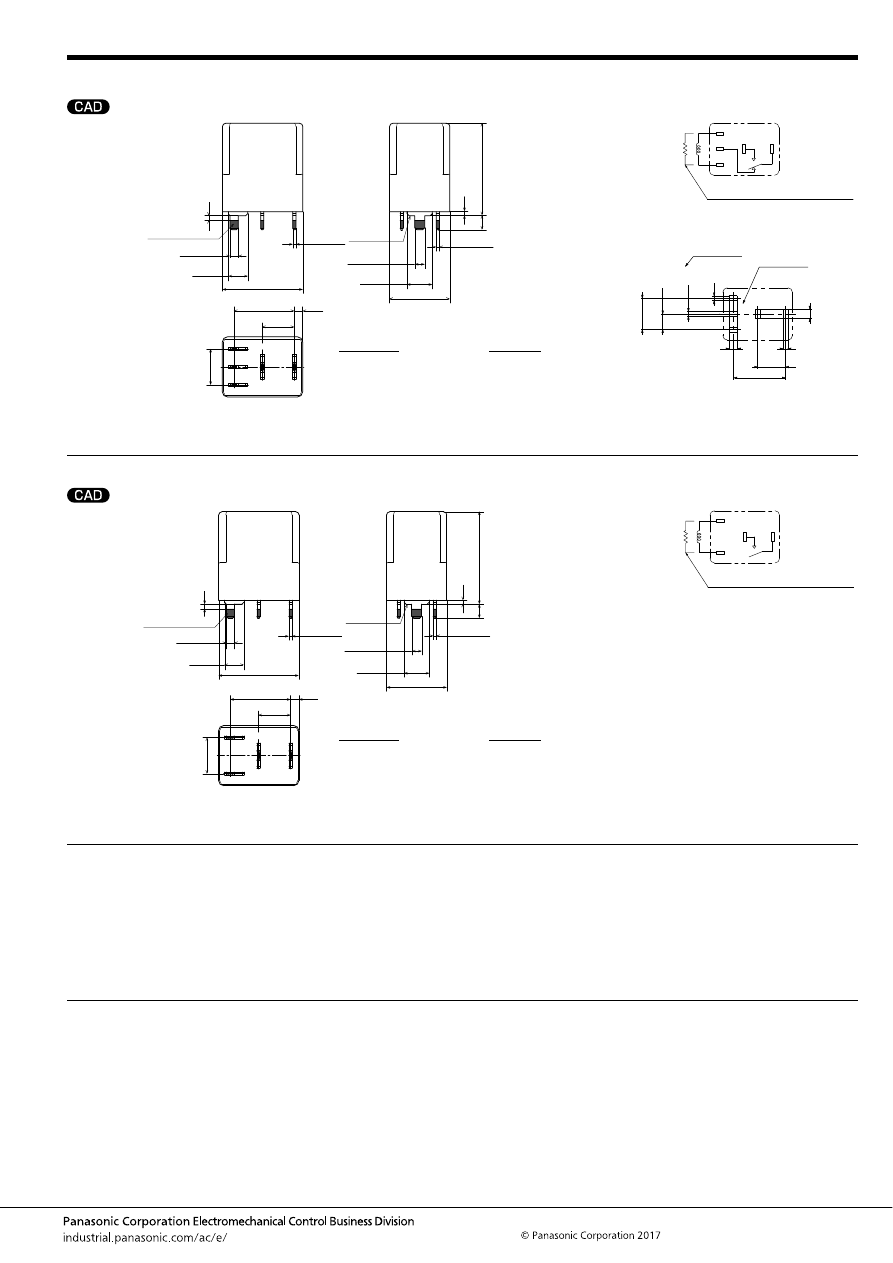

PC board pattern

1 Form C type

Twin type (8-pin)

Twin type (10-pin)

10.45

4.0

.411

.157

6.5

.256

4.5

2.0

4.5

.177

.079

.177

2×1.5

dia. hole

0.1

0

2×.059

dia. hole

.004

0

4×1.0

dia. hole

0.1

0

4×.039

dia. hole

.004

0

2×1.5

dia. hole

0.1

0

2×.059

dia. hole

.004

0

2×1.5

dia. hole

0.1

0

2×.059

dia. hole

.004

0

10.45

4.0

.411

.157

4.5

.177

2.7

.106

7.2

.283

7.2

.283

3.6

.142

3.6

.142

0.3

.012

4.5

.177

4×1.5

dia. hole

0.1

0

4×.059

dia. hole

.004

0

4×1.0

dia. hole

0.1

0

4×.039

dia. hole

.004

0

10.45

4.0

.411

.157

0.3

4.5

.012

3.6

.142

.177

2×1.5

dia. hole

0.1

0

2×.059

dia. hole

.004

0

2×1.0

dia. hole

0.1

0

2×.039

dia. hole

.004

0

1.5

dia. hole

0.1

0

.059

dia. hole

.004

0

1.7

dia. hole

+0.1

0

.067

dia. hole

+.004

0

2×1.6

dia. hole

+0.1

0

2×.063

dia. hole

+.004

0

2×1.6

dia. hole

+0.1

0

2×.063

dia. hole

+.004

0

14.95

.589

5.5

.217

3.0

.118

6.4

.252

5.6

.220

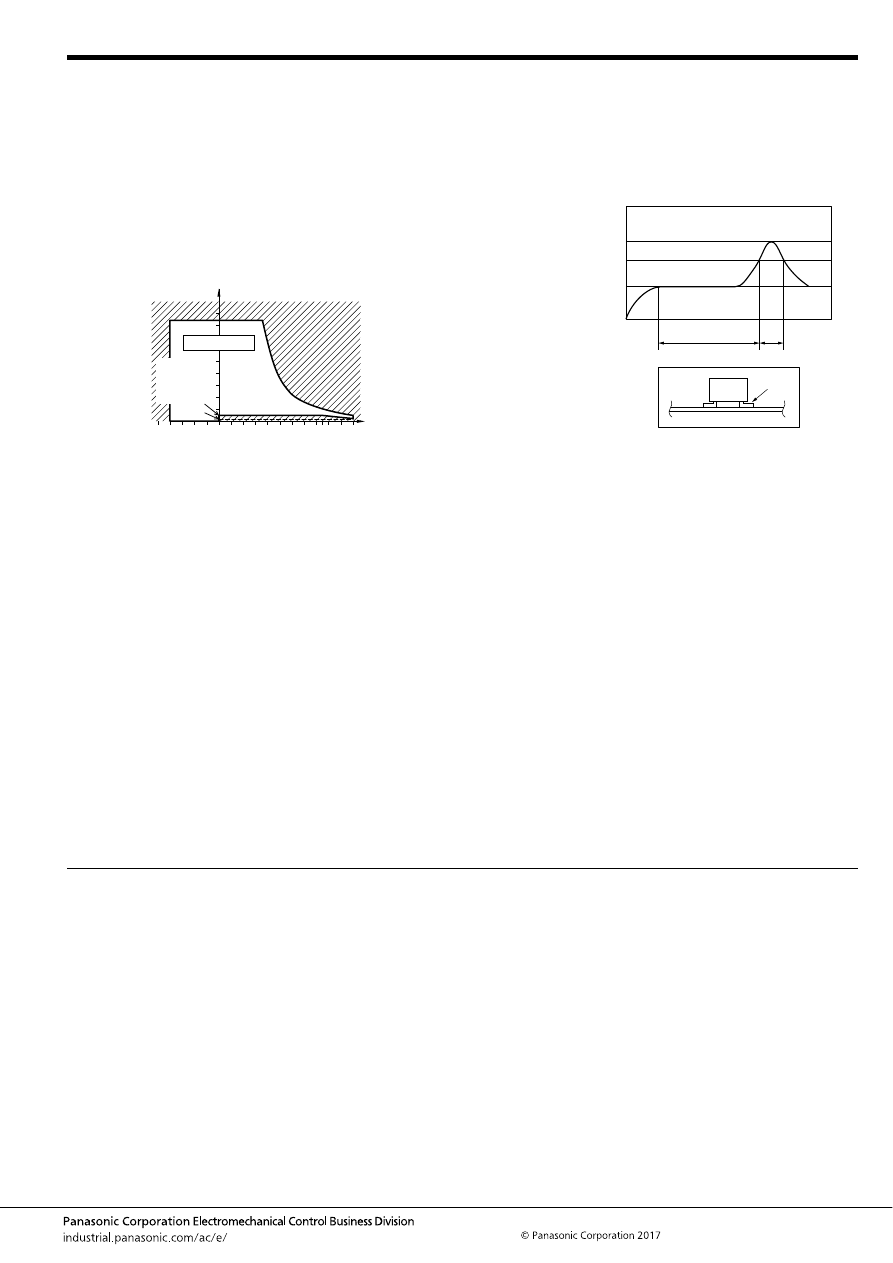

PC board terminal type

1 Form C

1 Form C

Surface-mount terminal type

4.65

.183

10.95

.431

6×1.5

dia.

8

.315

+0.1

0

6×.059

dia.

+.004

0

11.2

4.6

.441

.181

4.65

.183

6×1.7

6×.067

10.95

.431

Weight (approx.)

6.5 g

.23 oz

(Twin type), 3.5 g

.12 oz

(1 Form C type)

9 g

.32 oz

5.5 g

.19 oz

Remarks

10 pins and PIP types available

−

−

Page

47

55

59

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

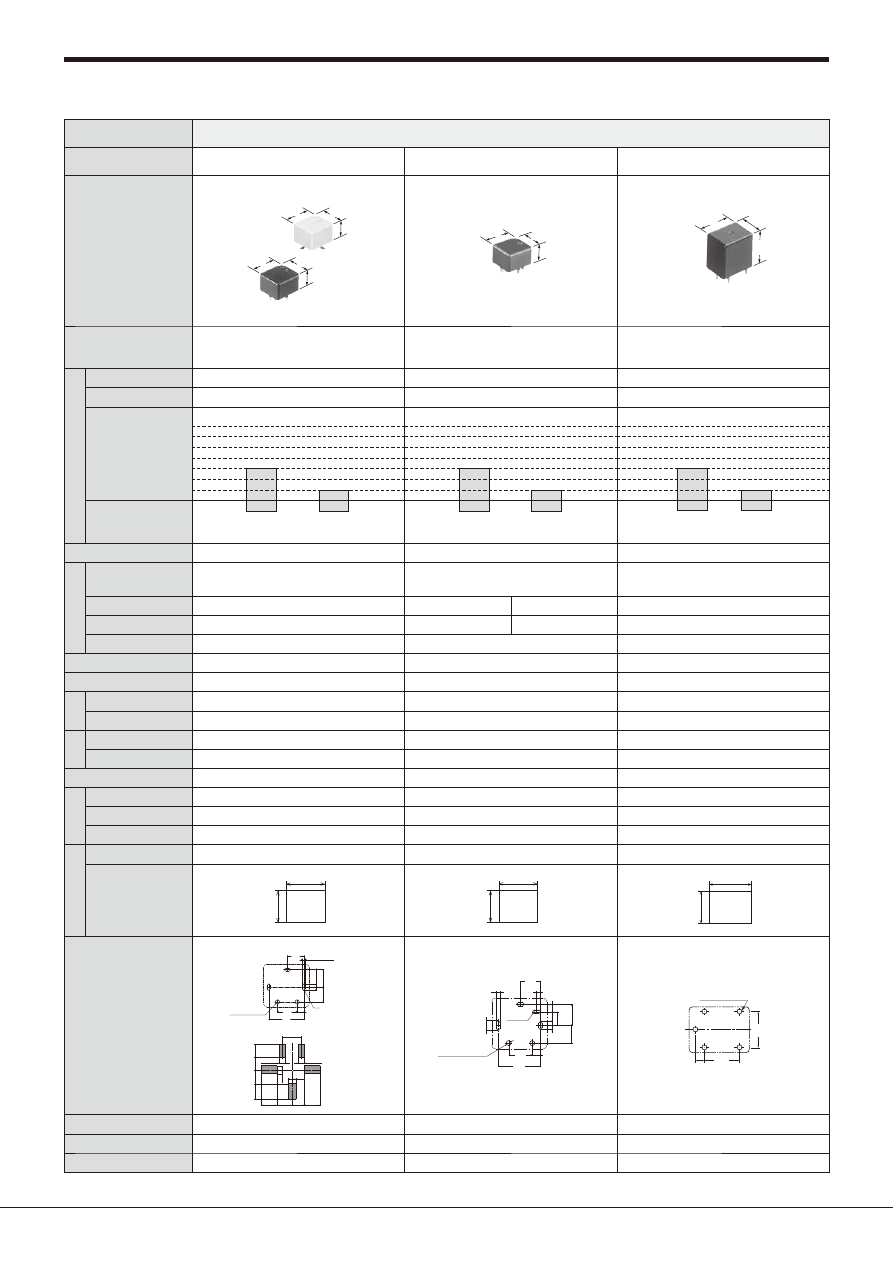

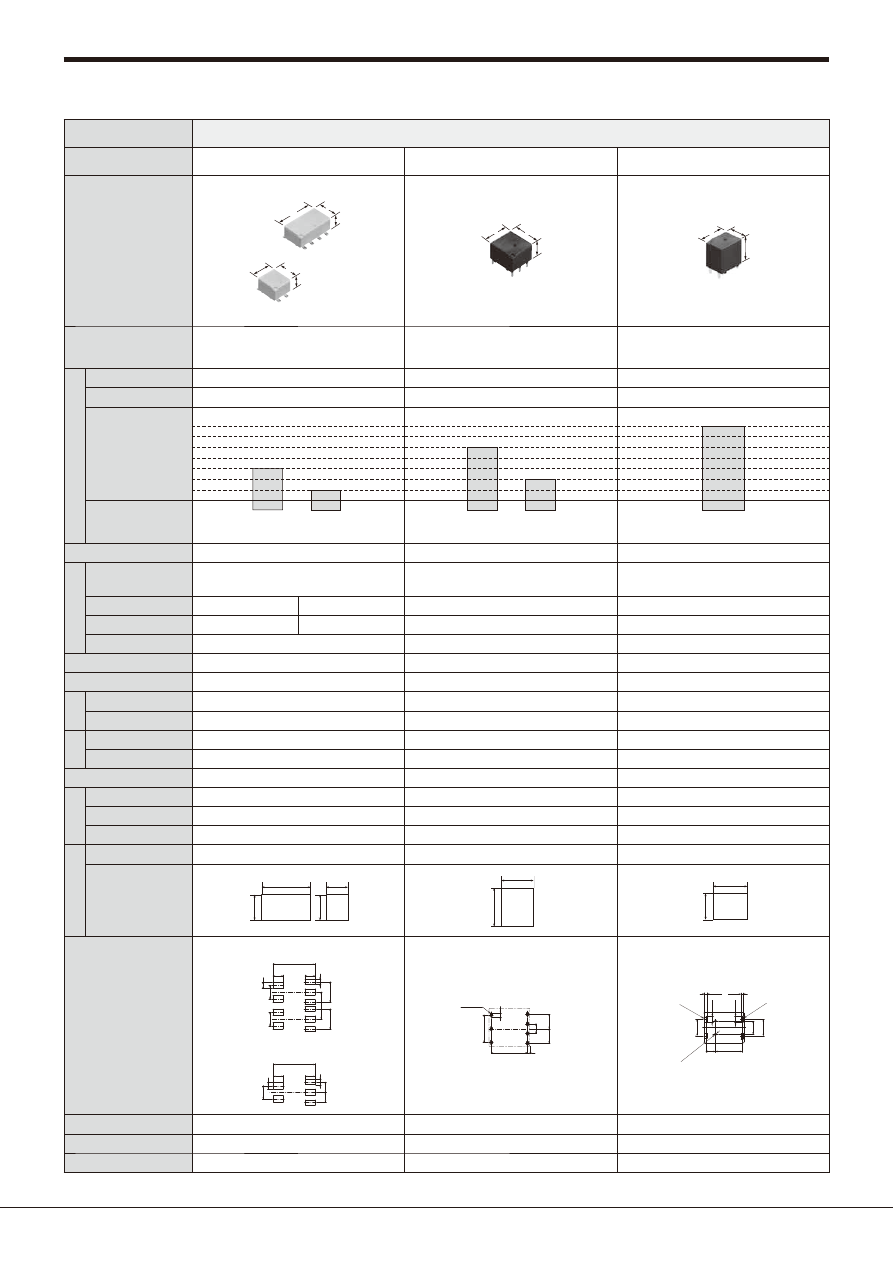

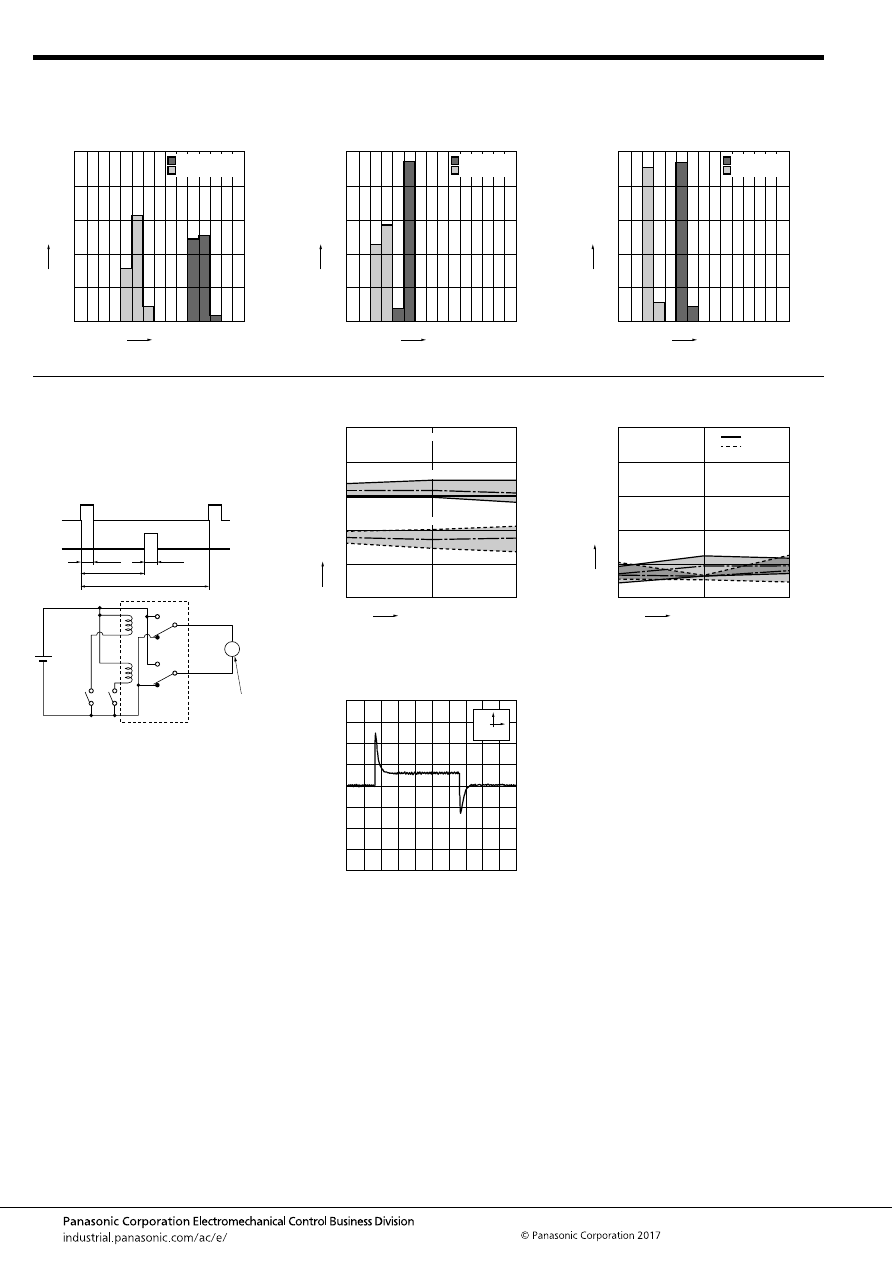

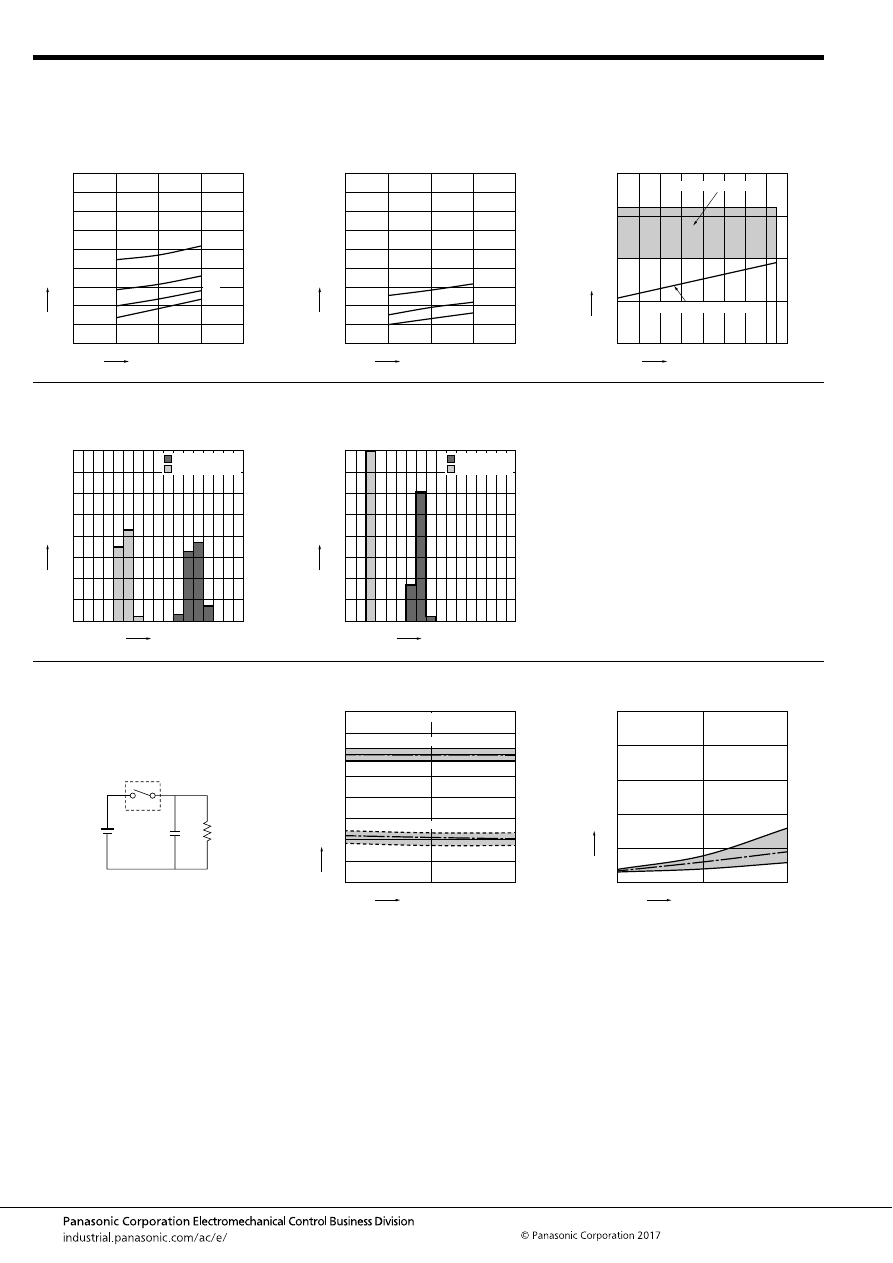

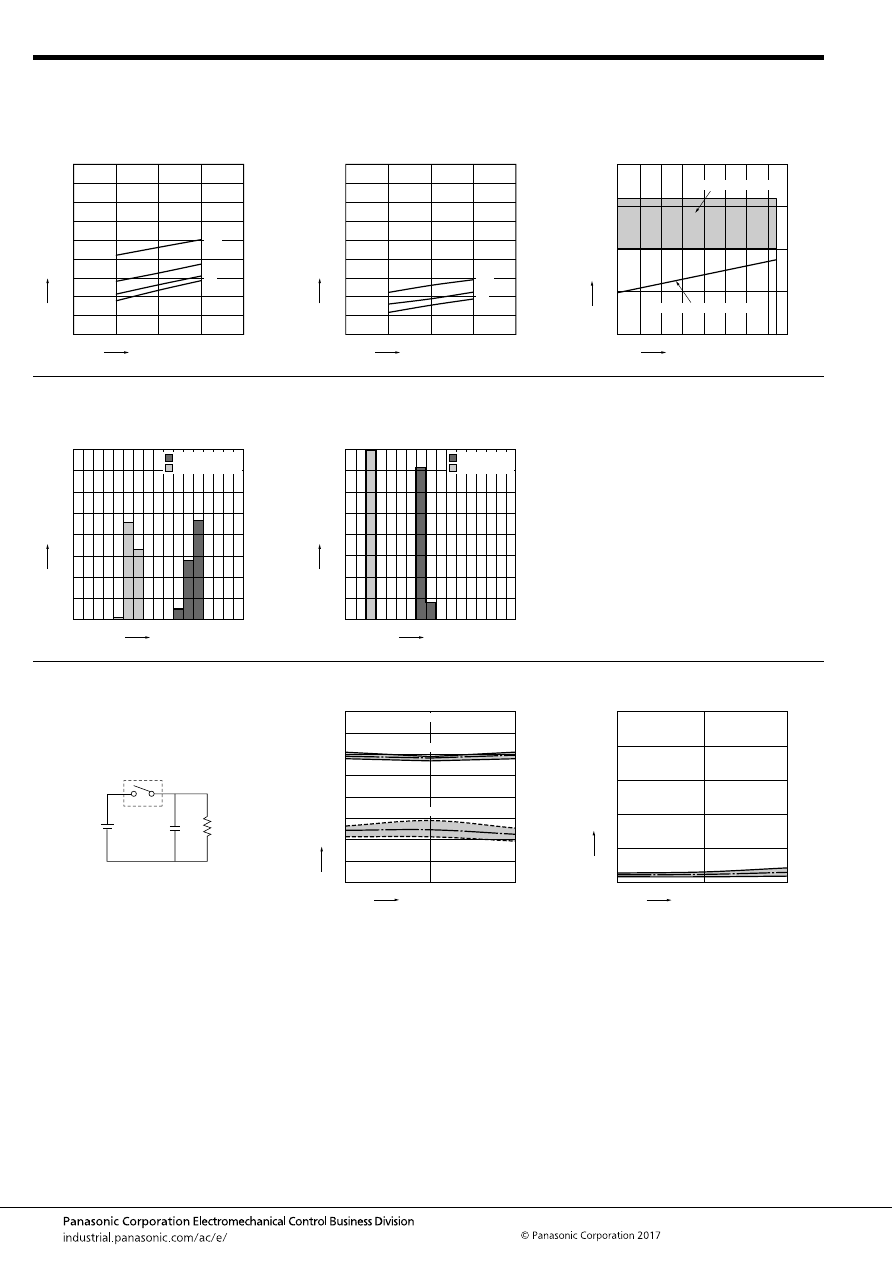

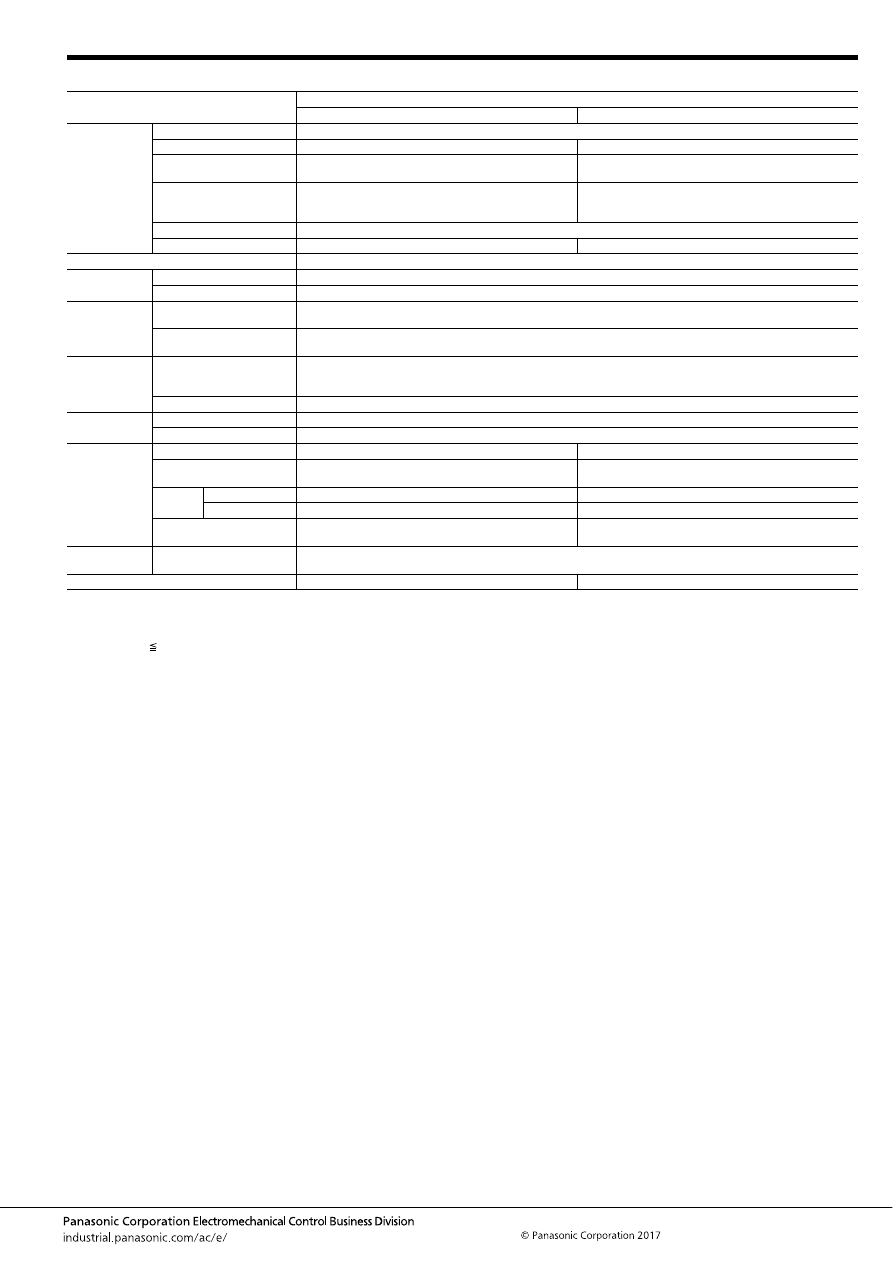

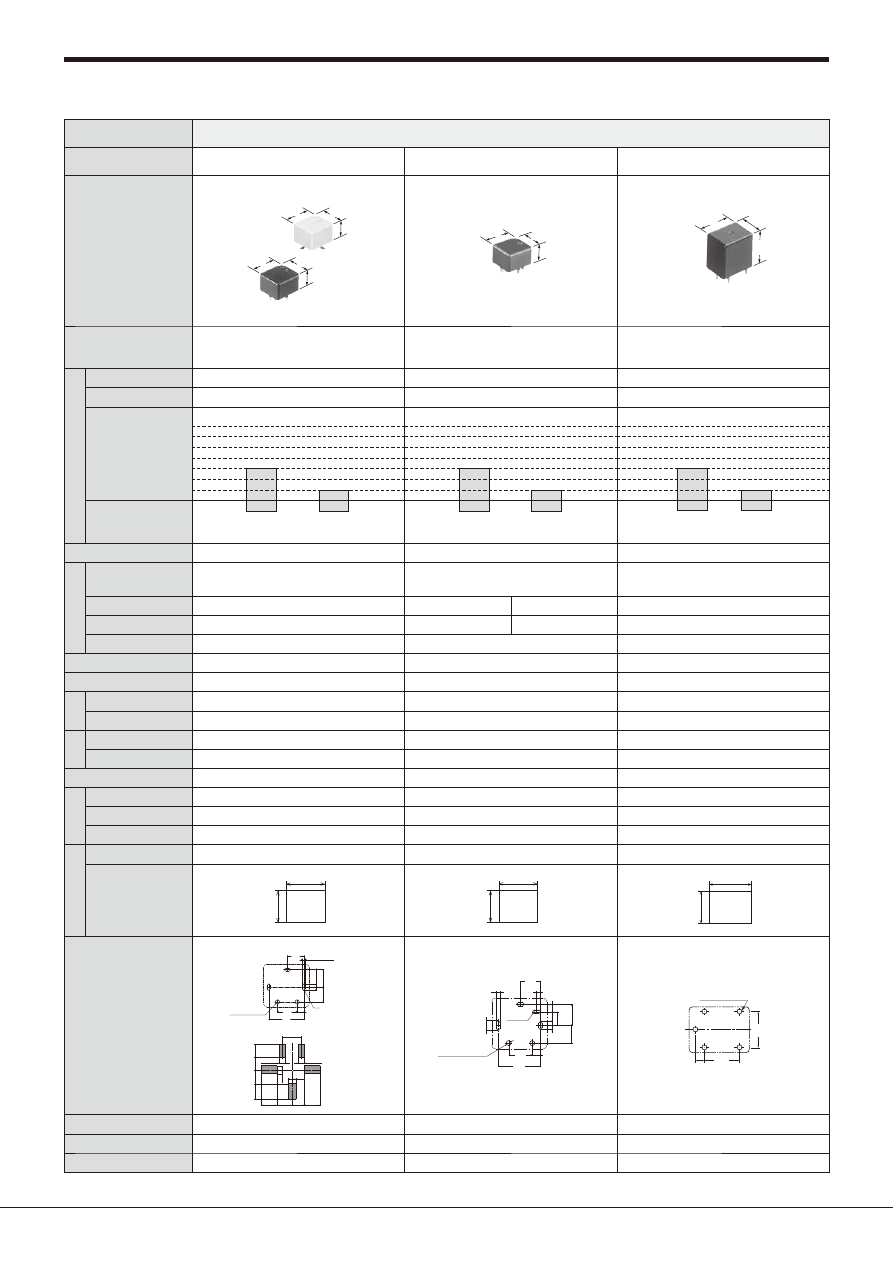

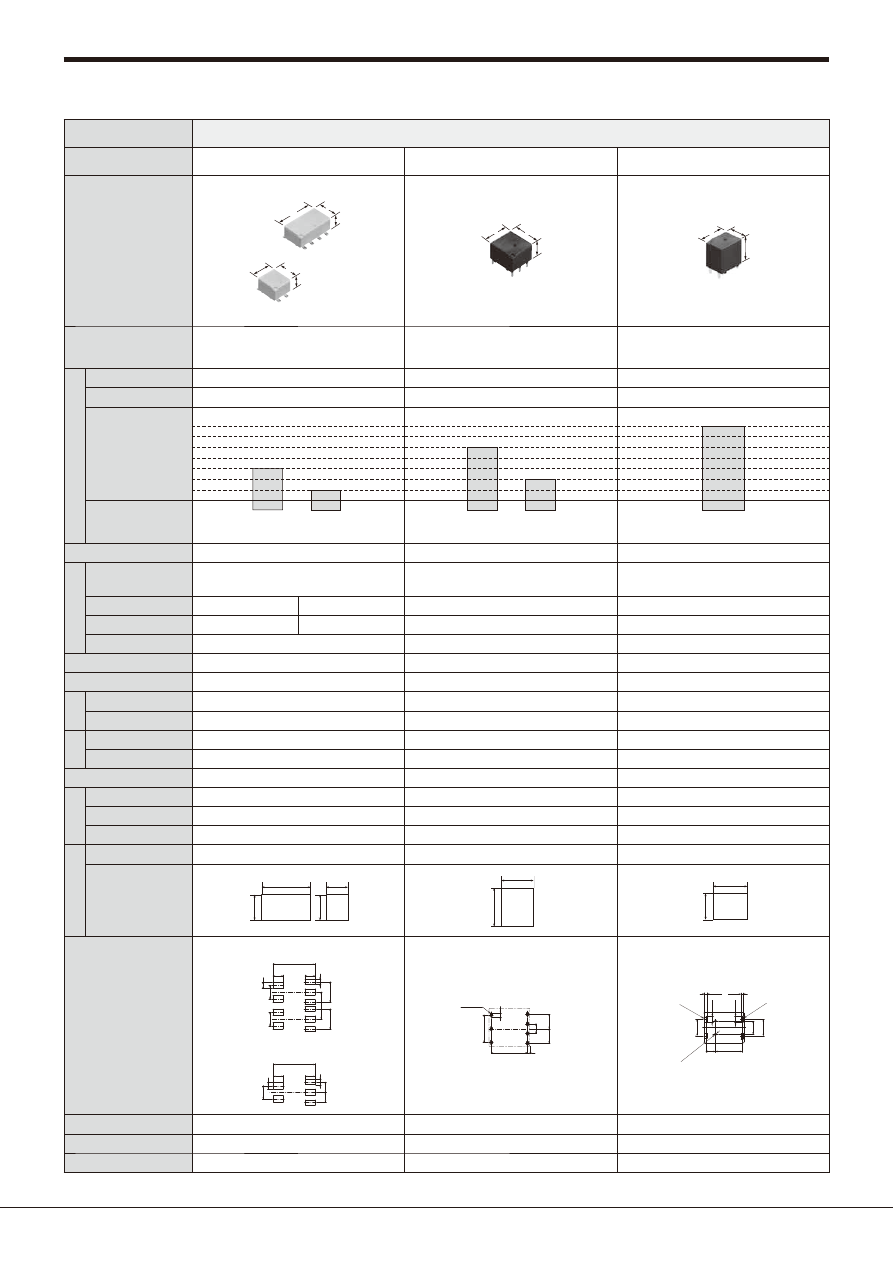

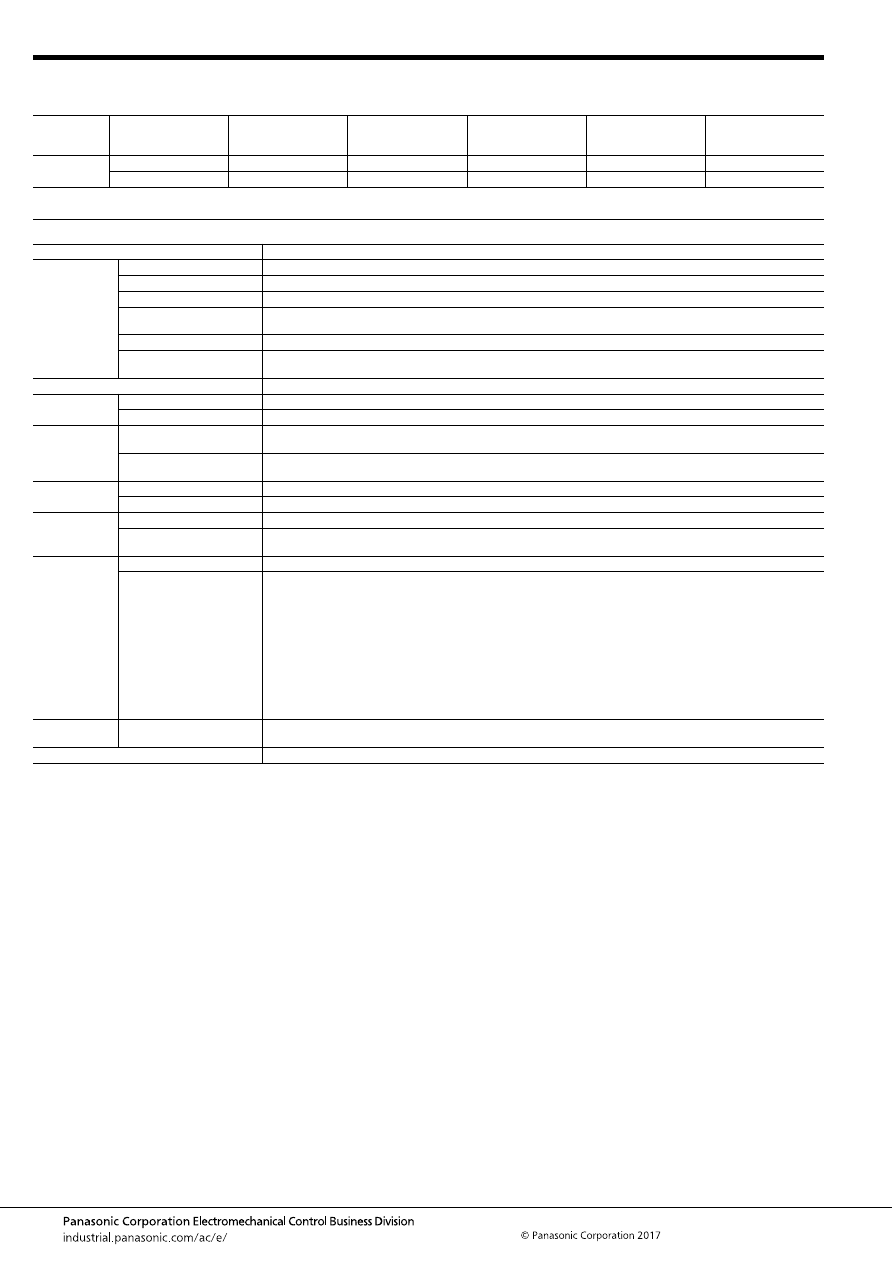

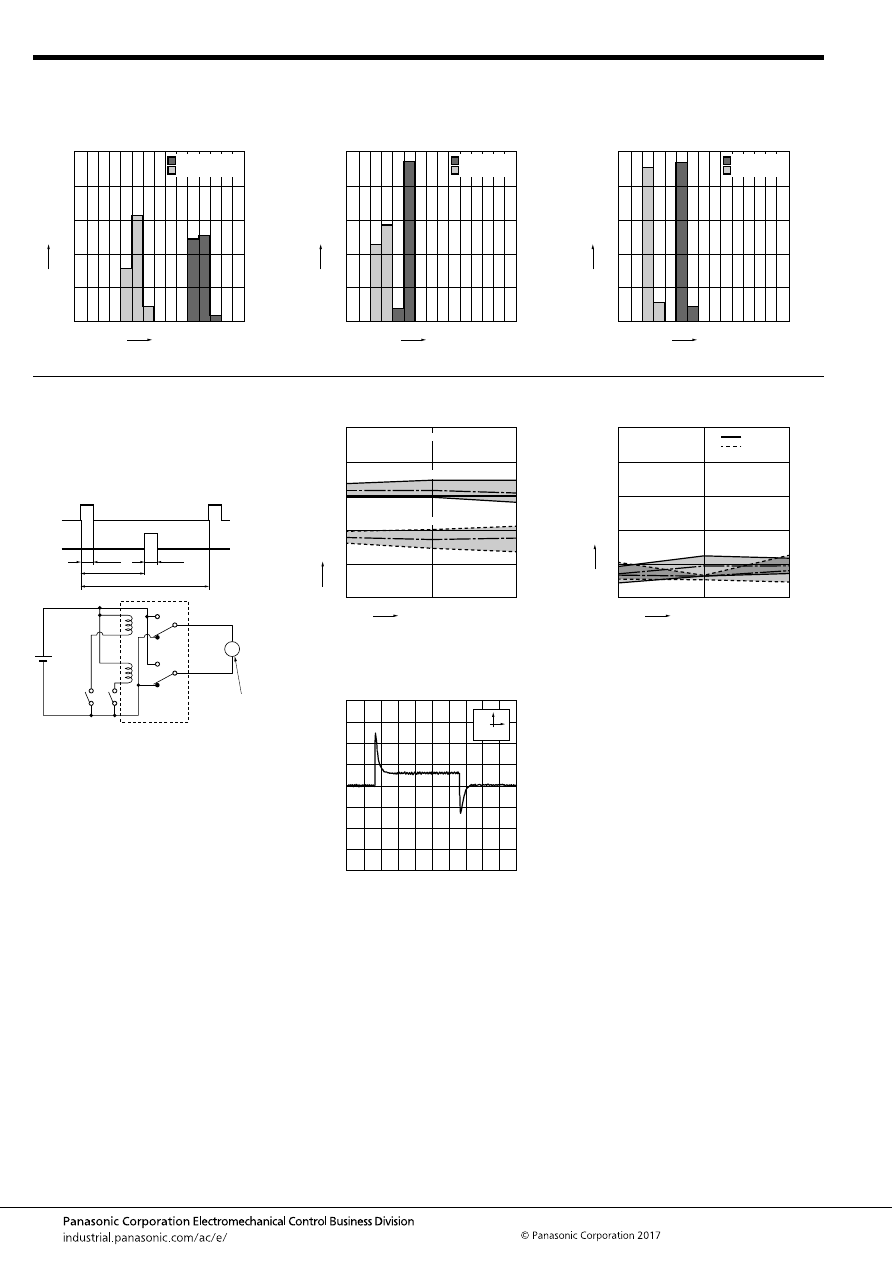

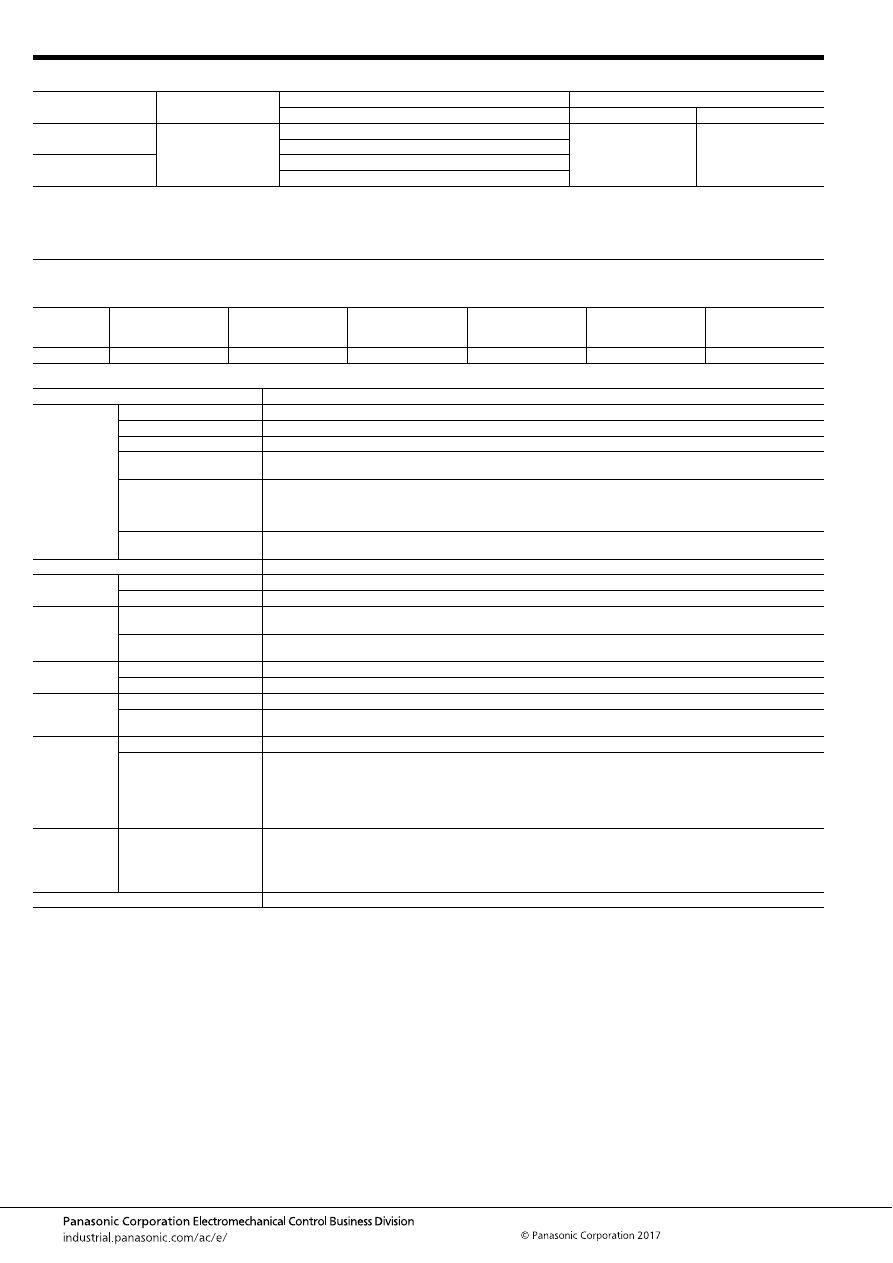

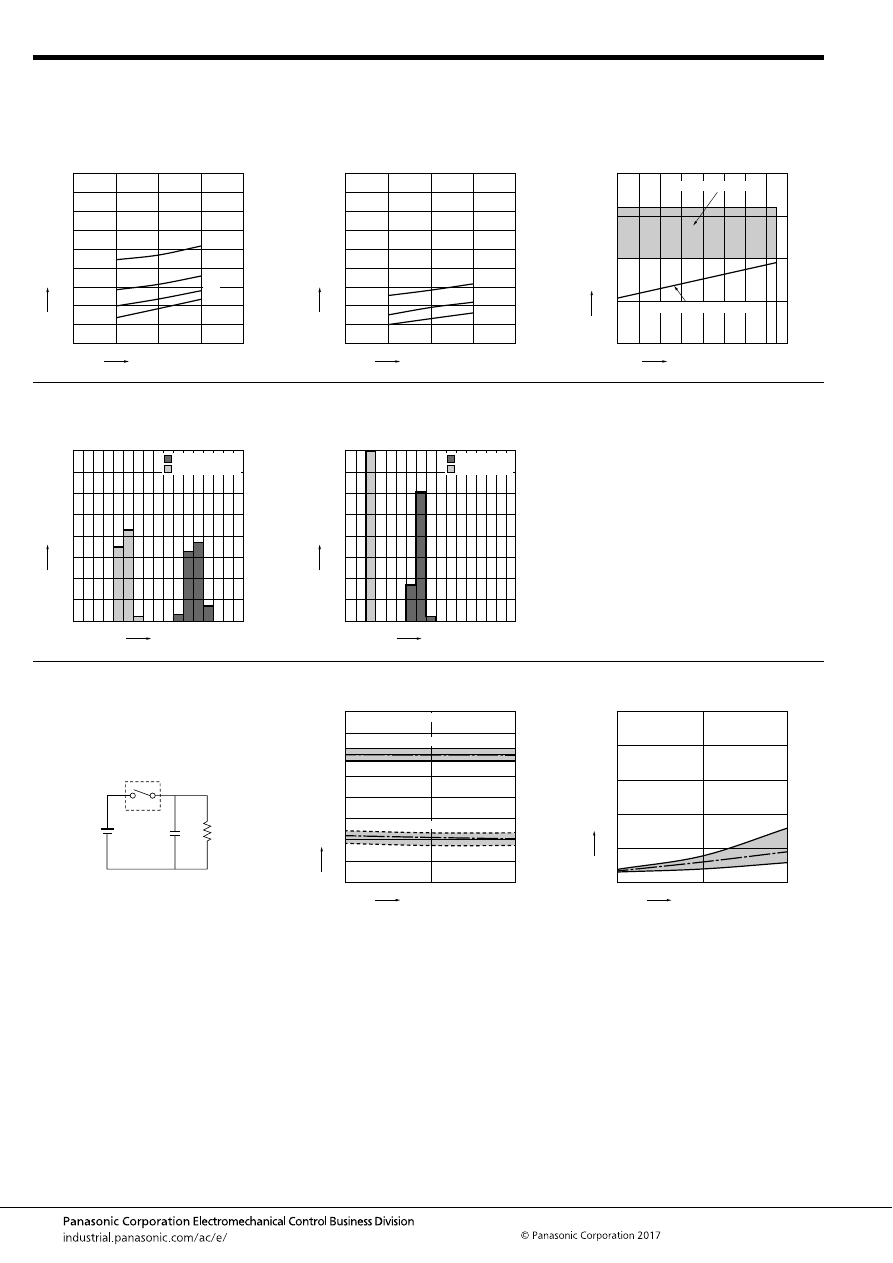

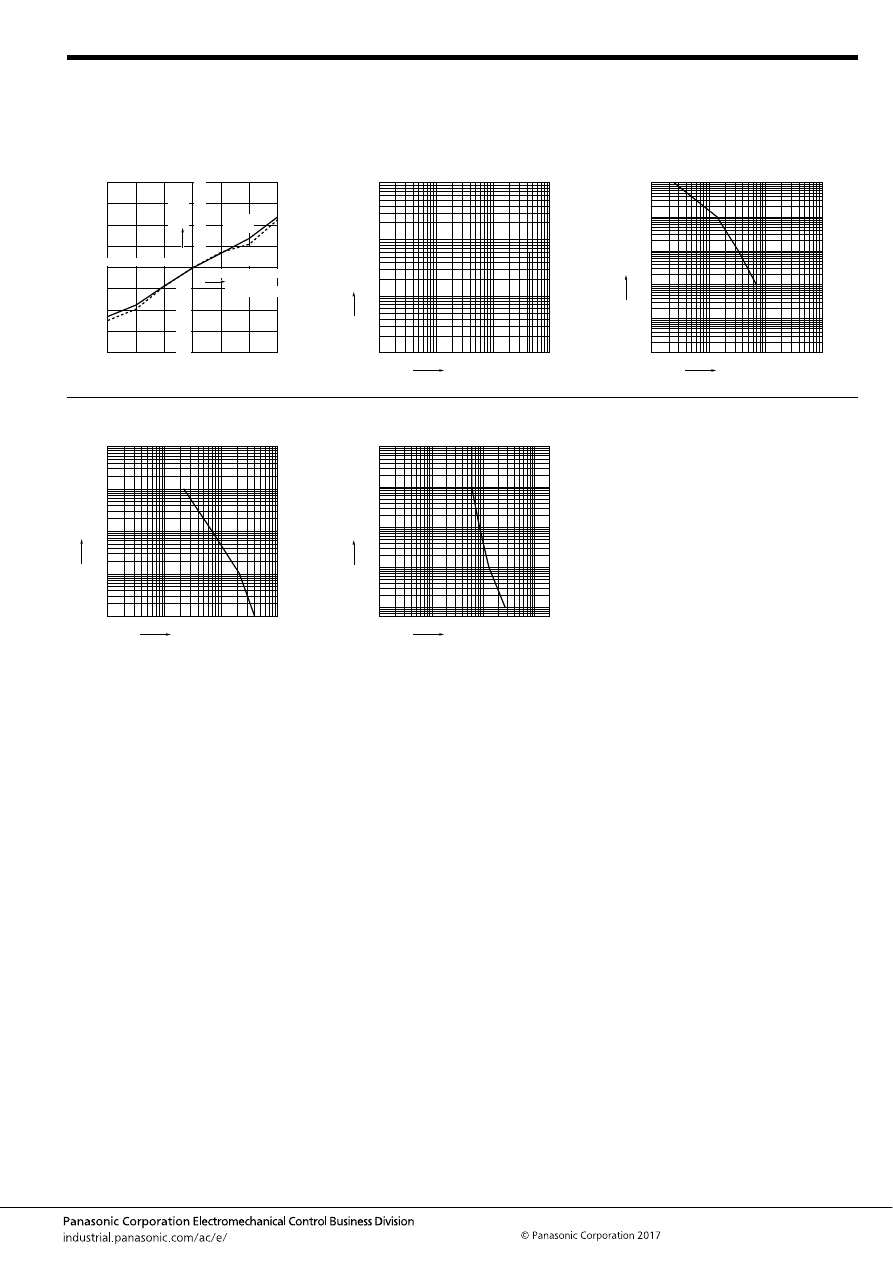

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–9–

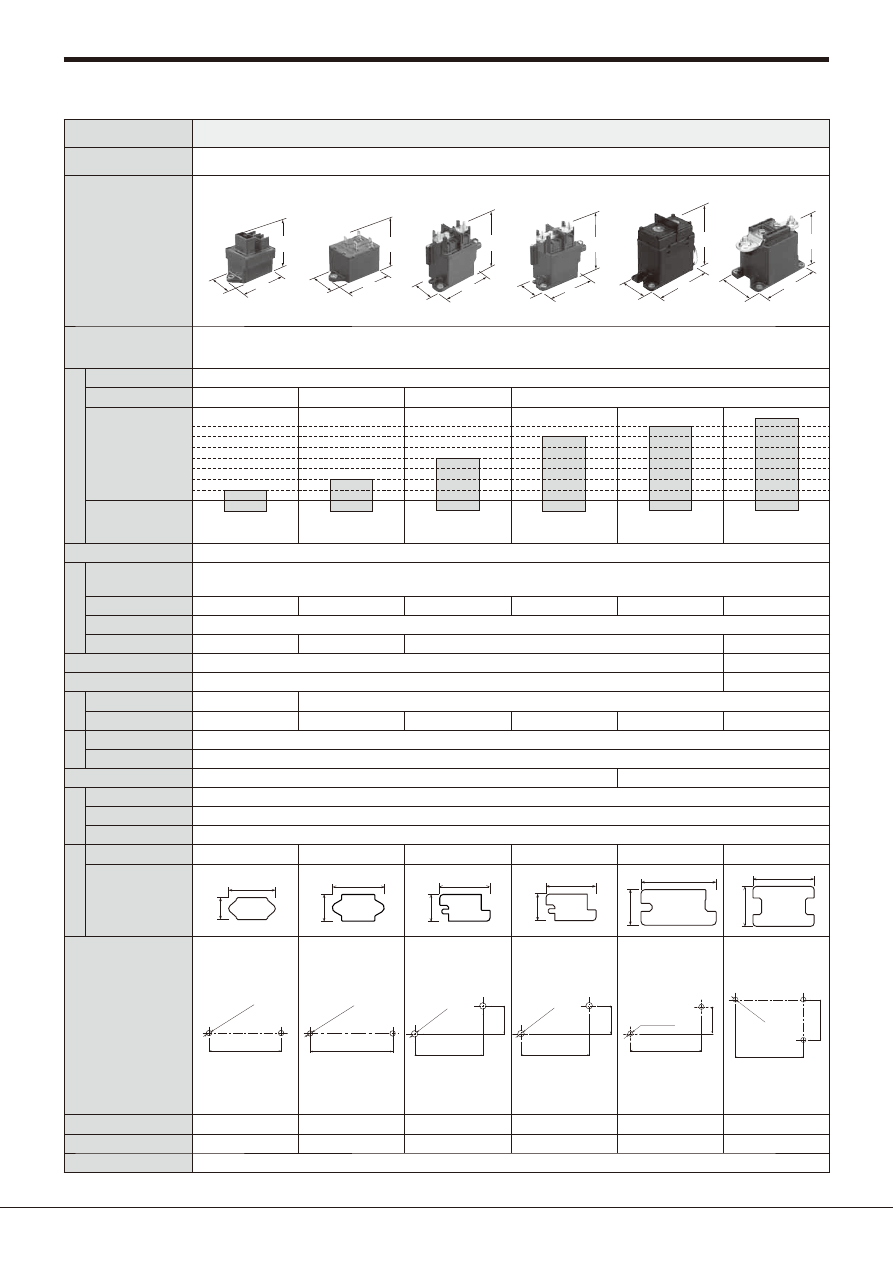

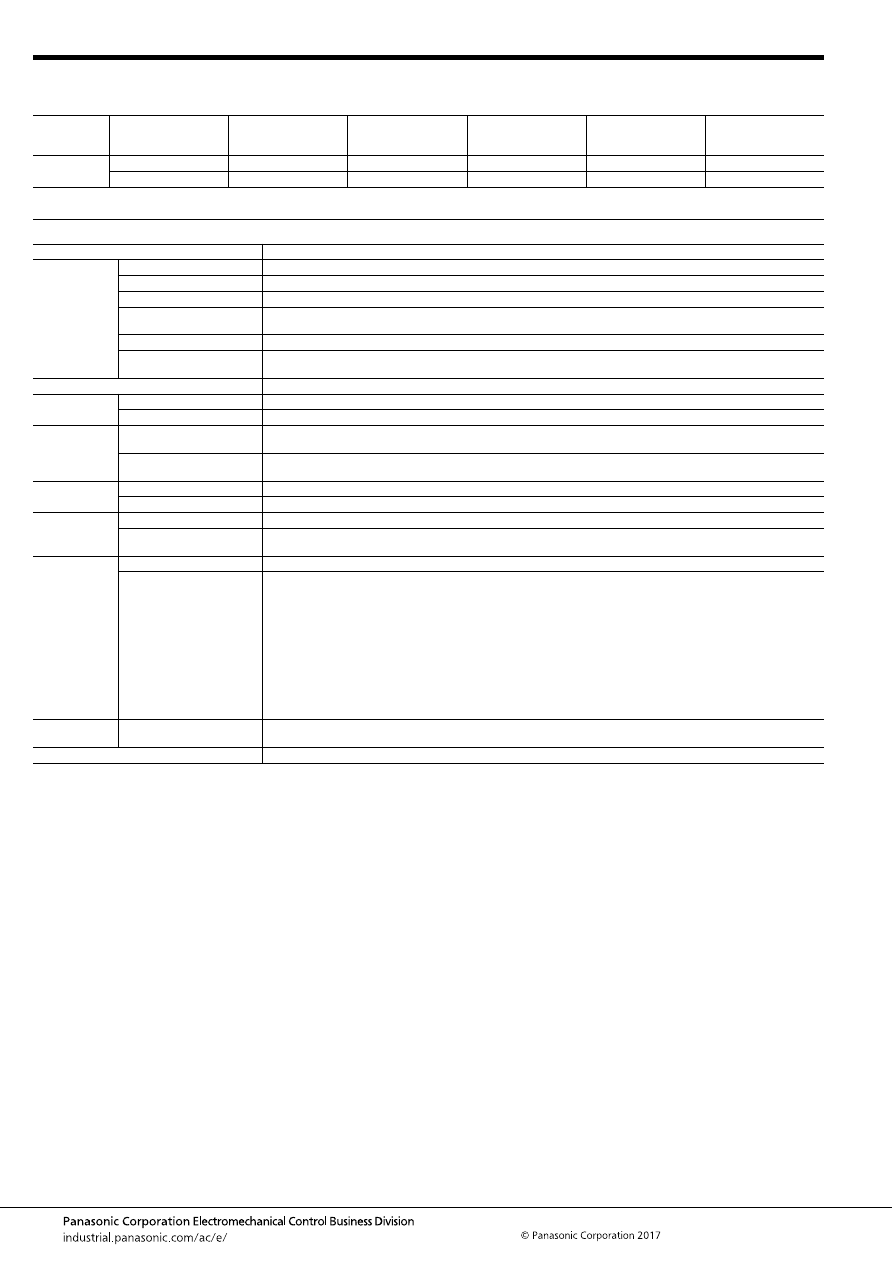

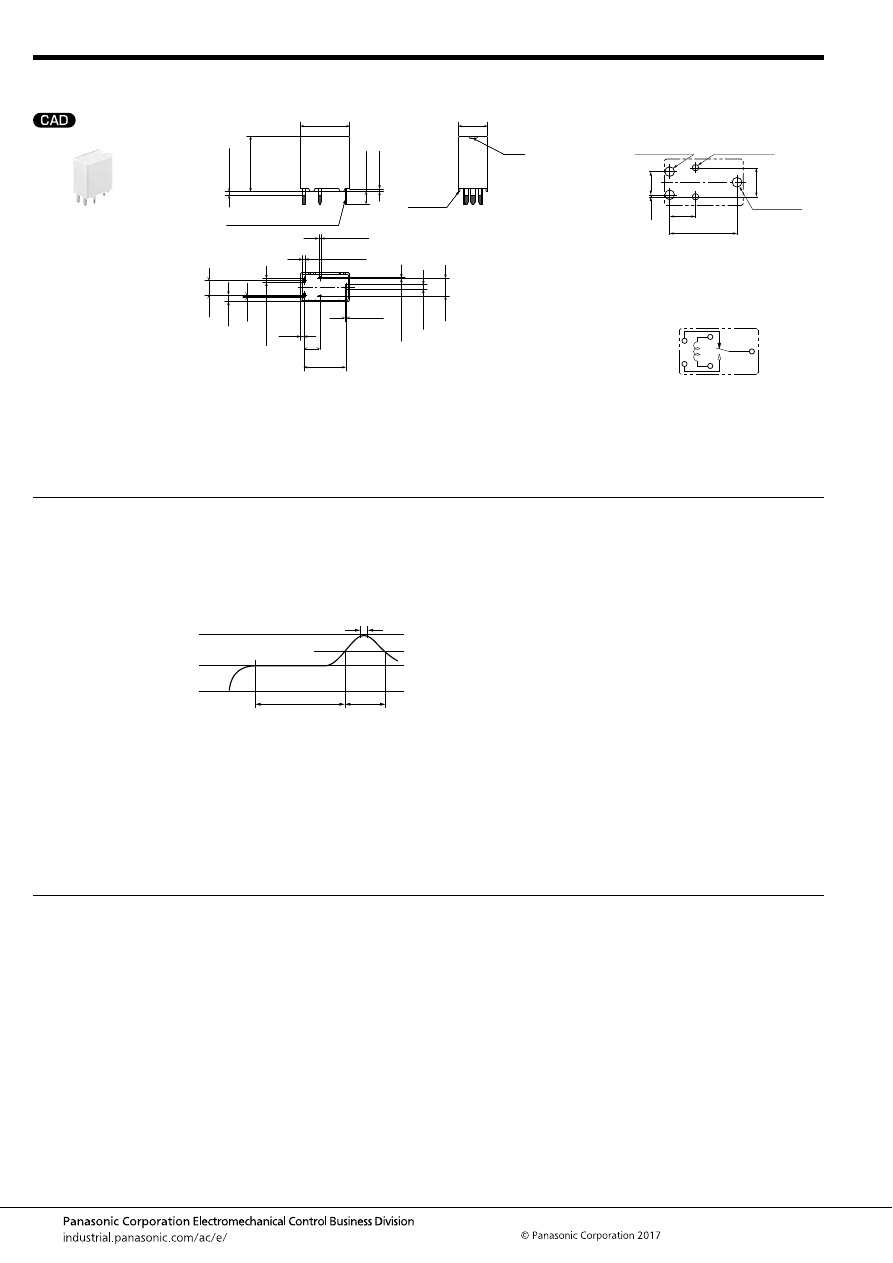

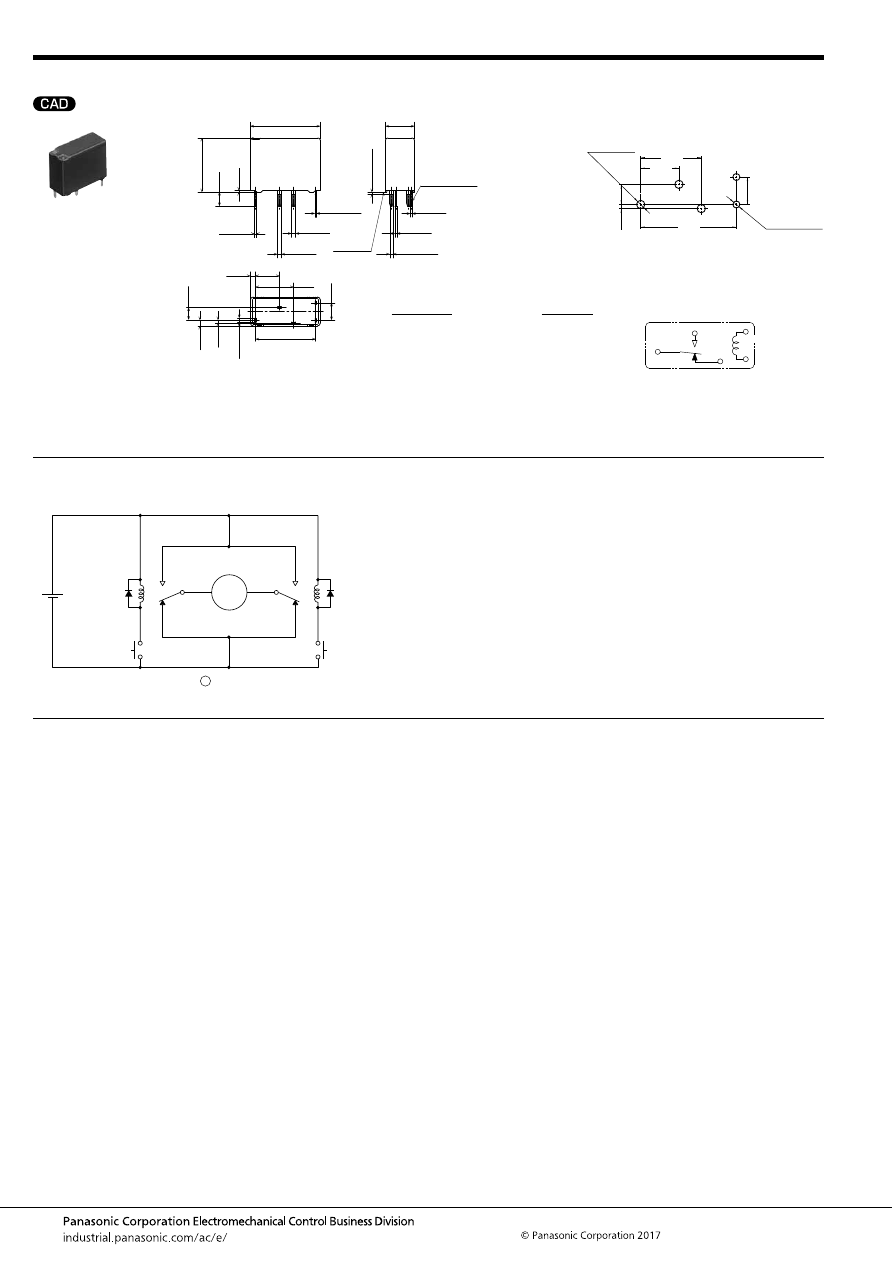

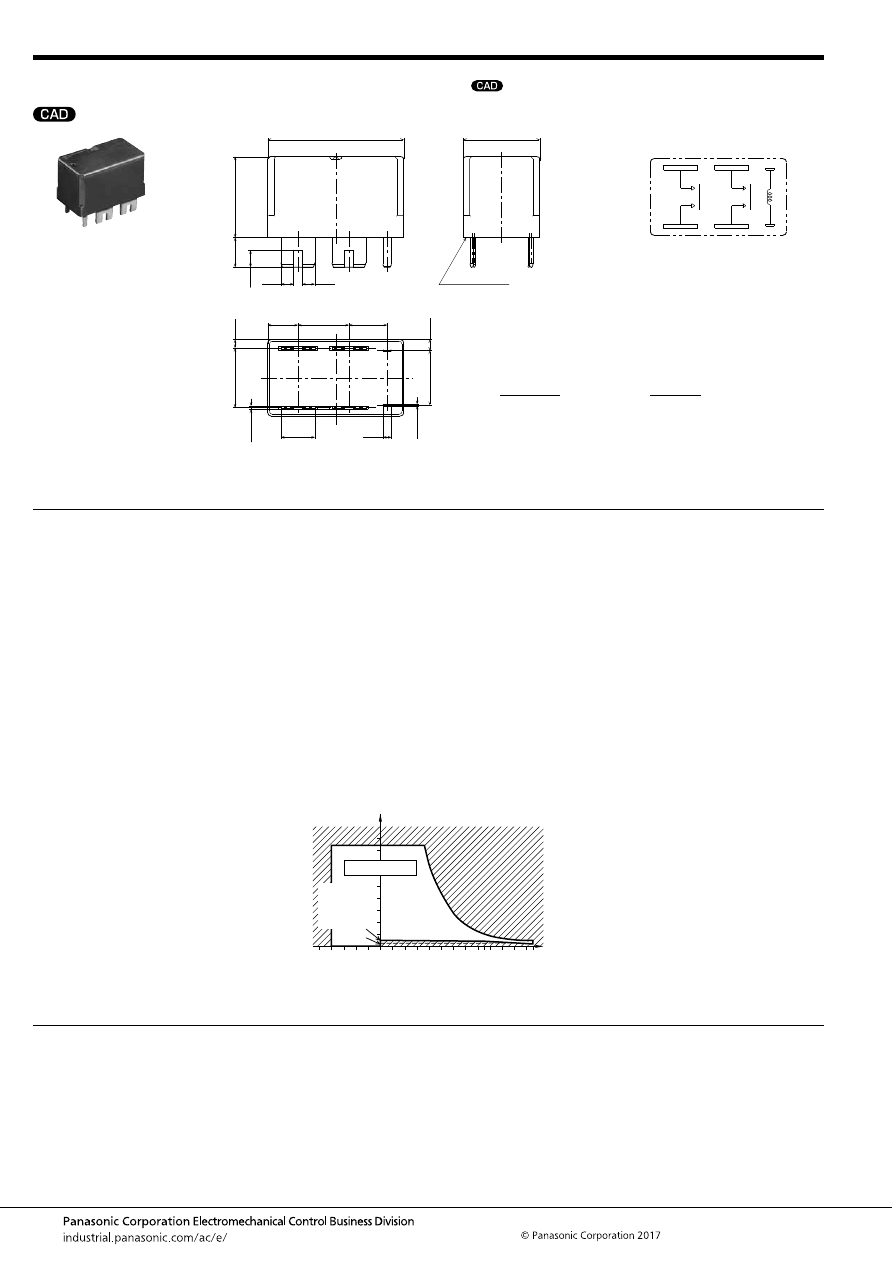

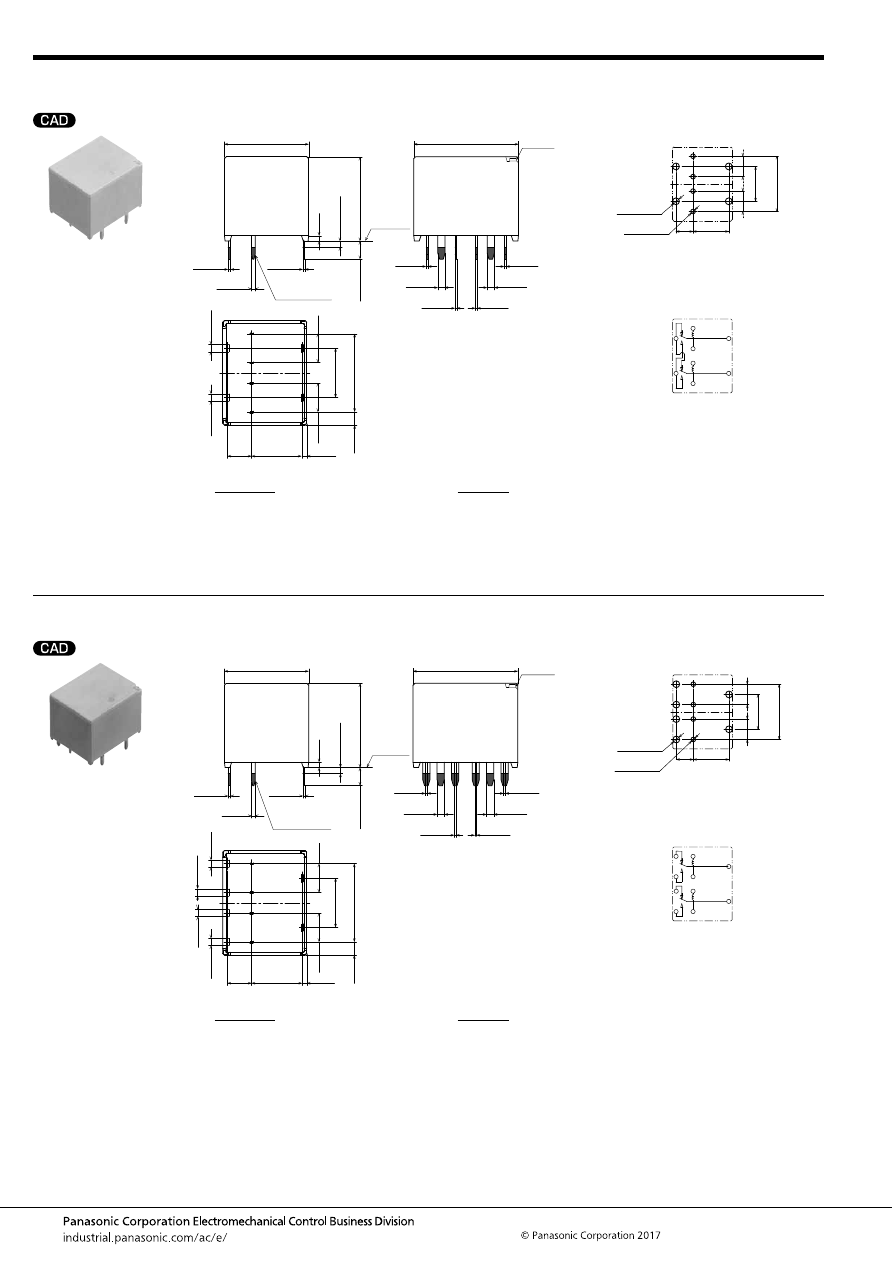

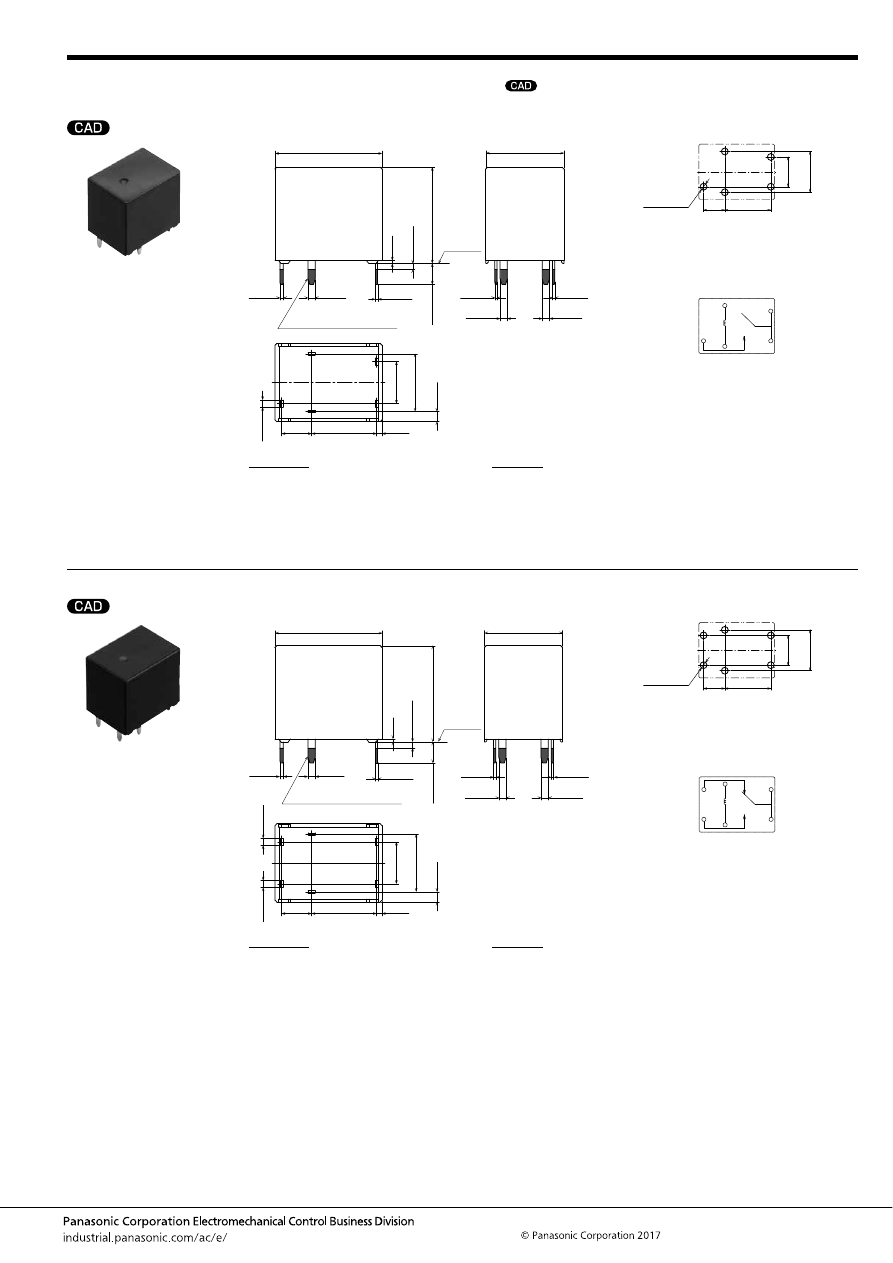

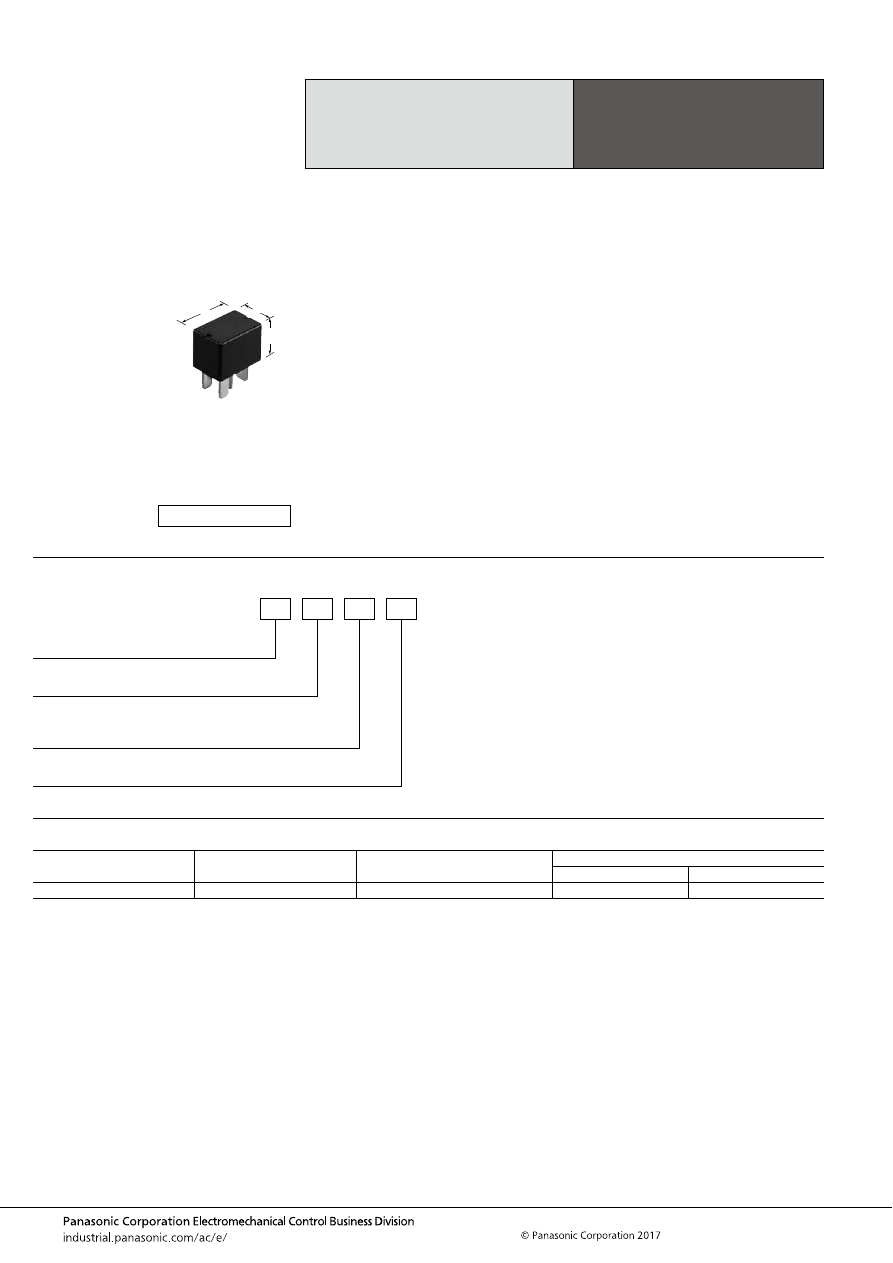

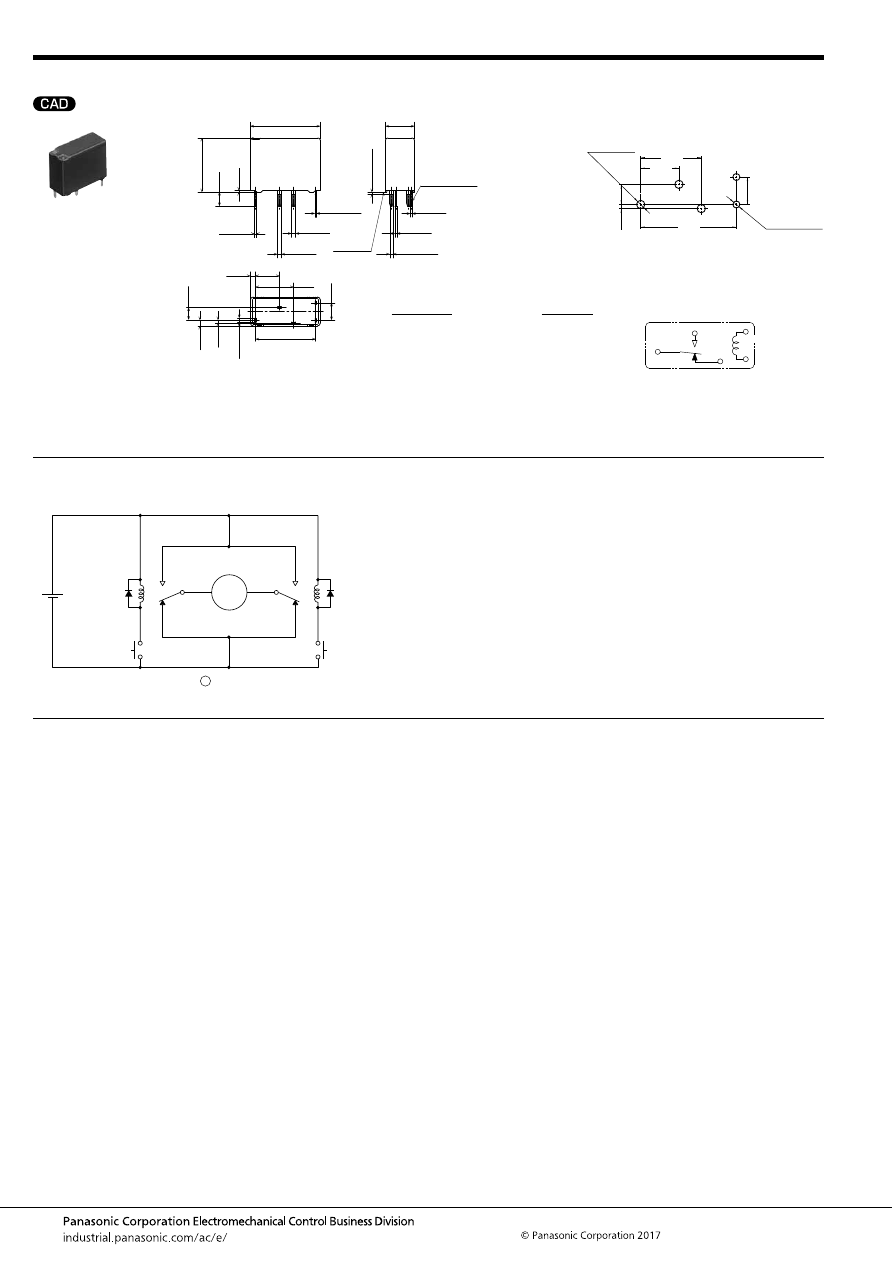

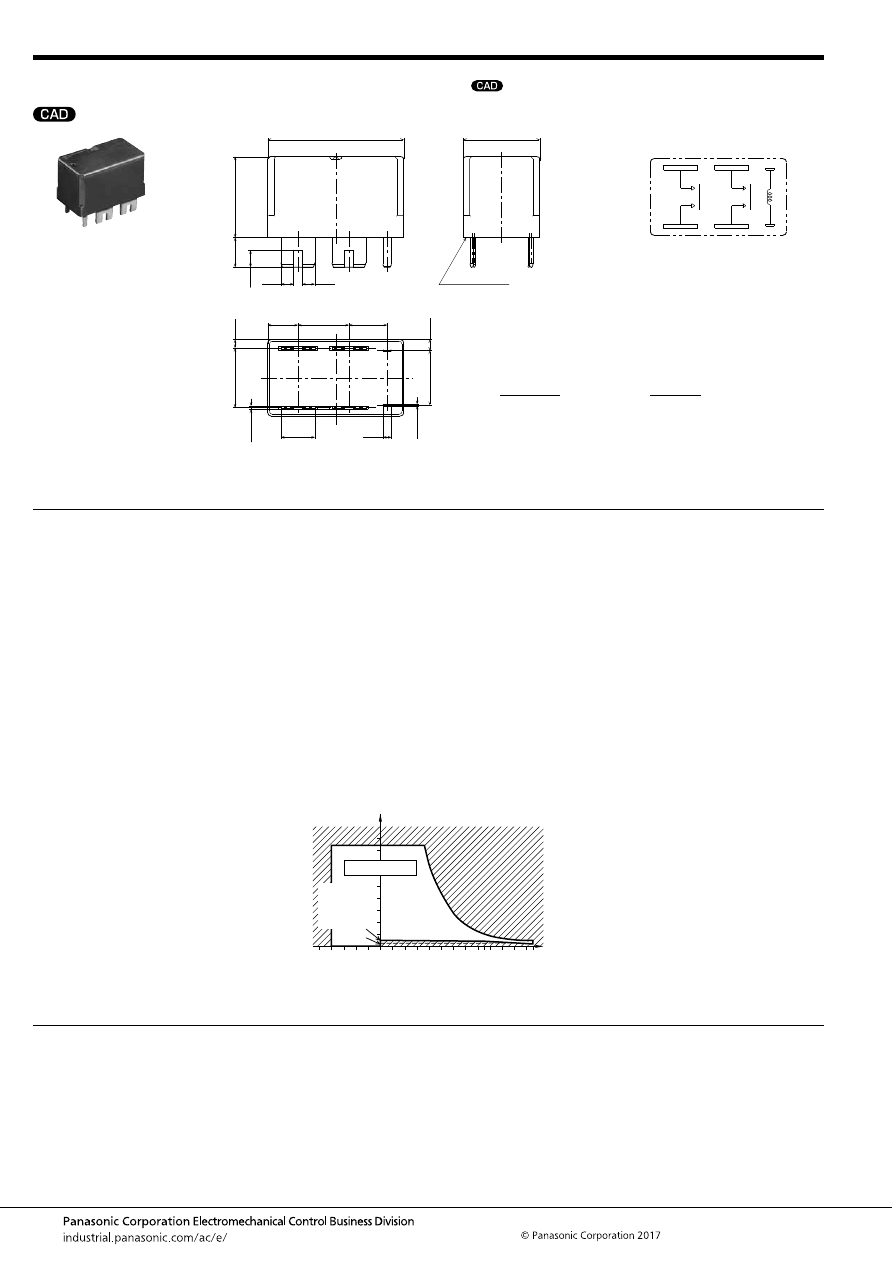

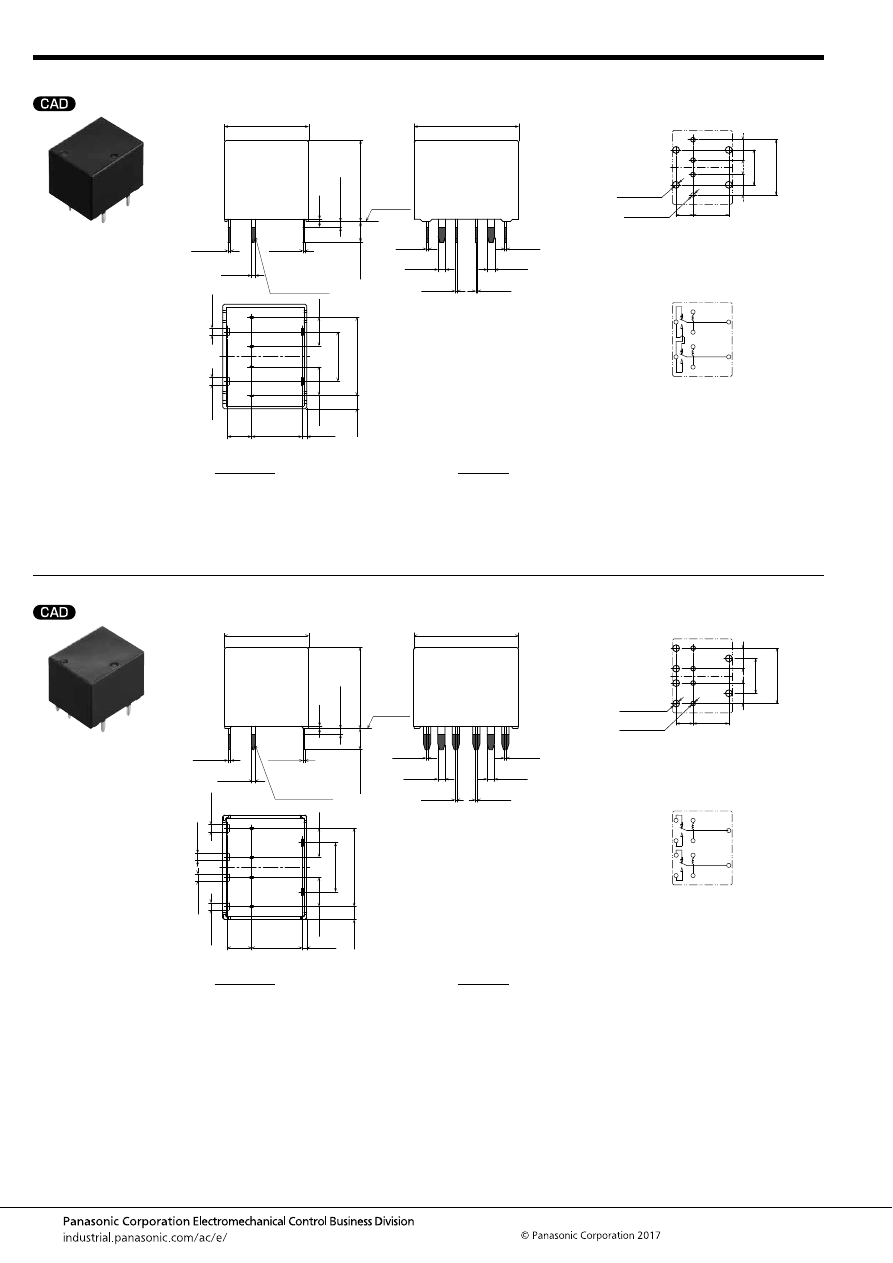

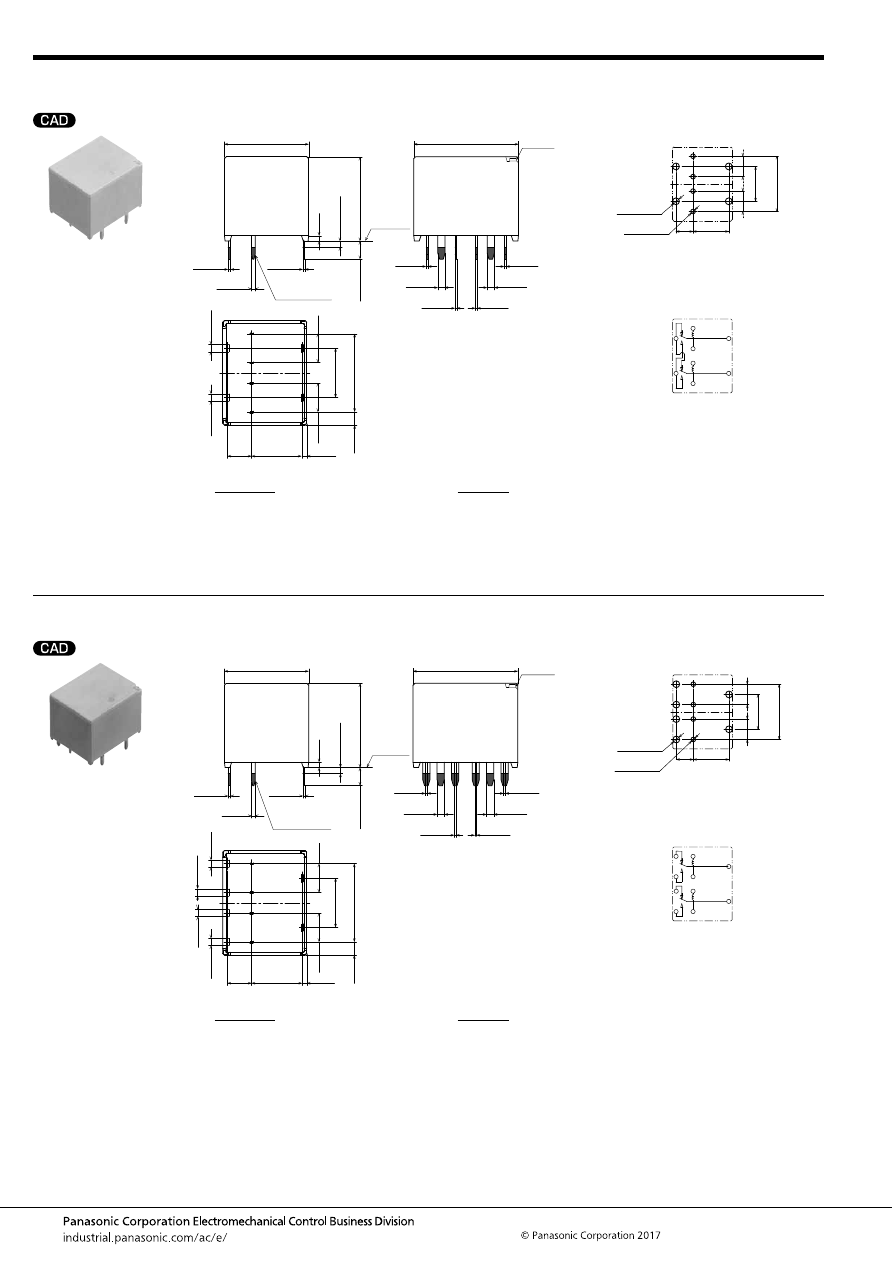

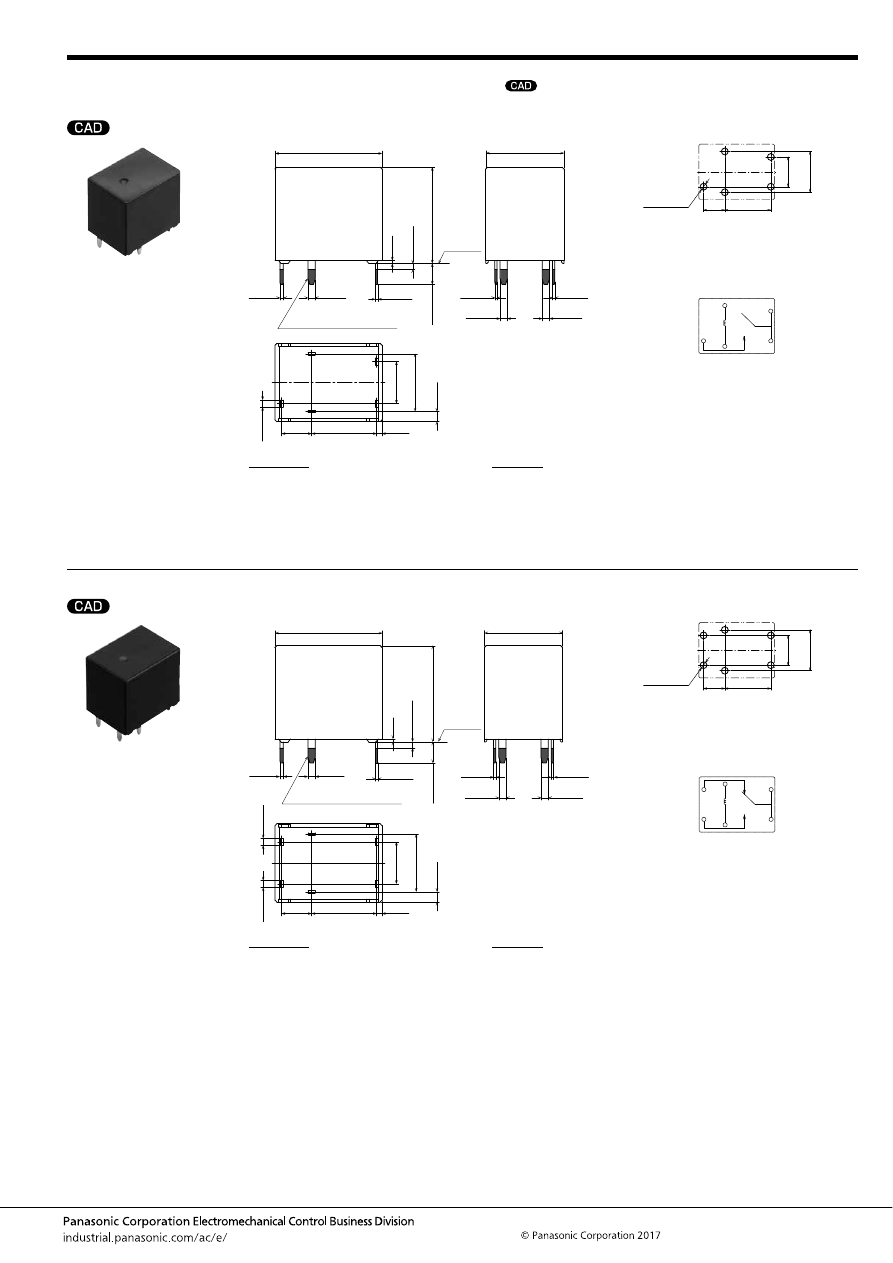

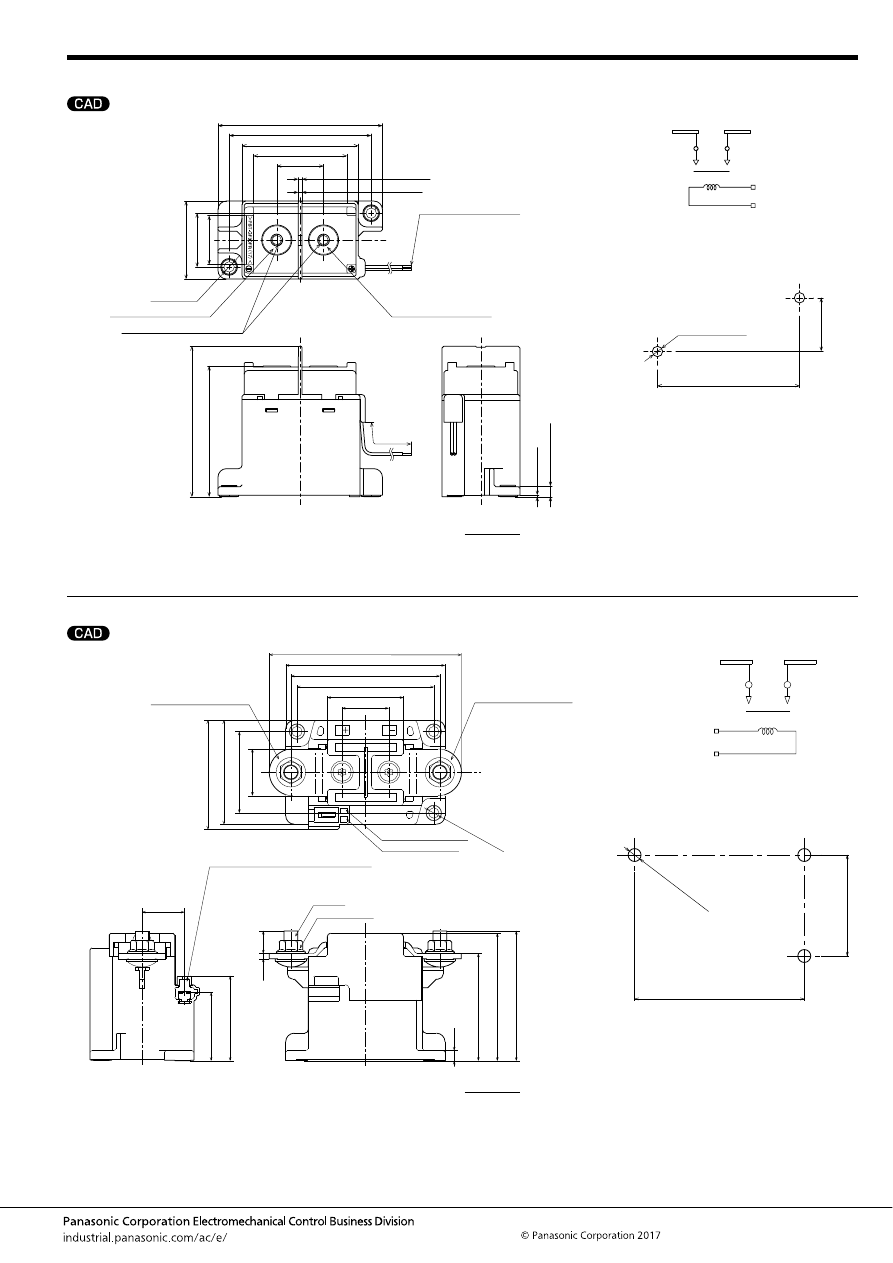

Type

Automotive relays

Product name

CP RELAYS

CP RELAYS POWER TYPE

CQ RELAYS

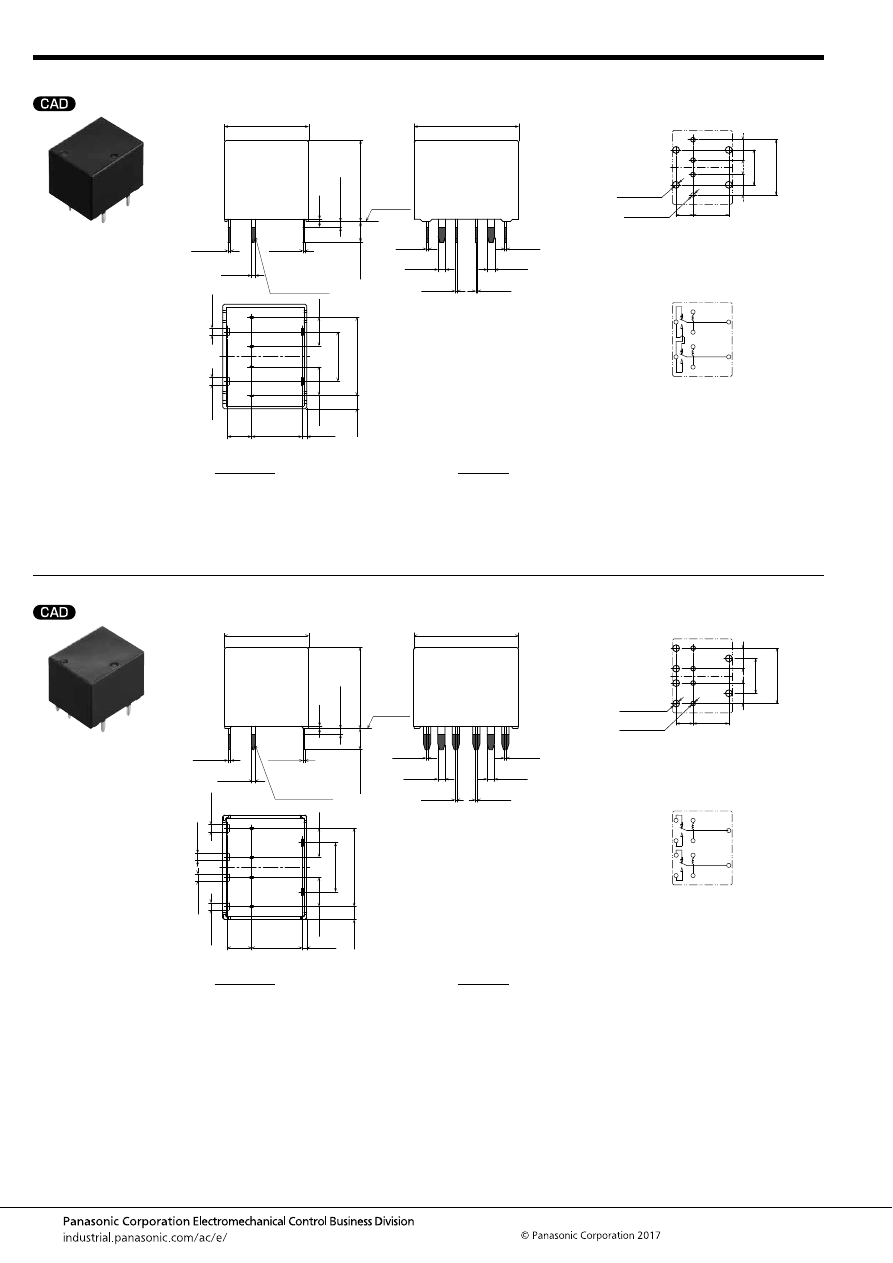

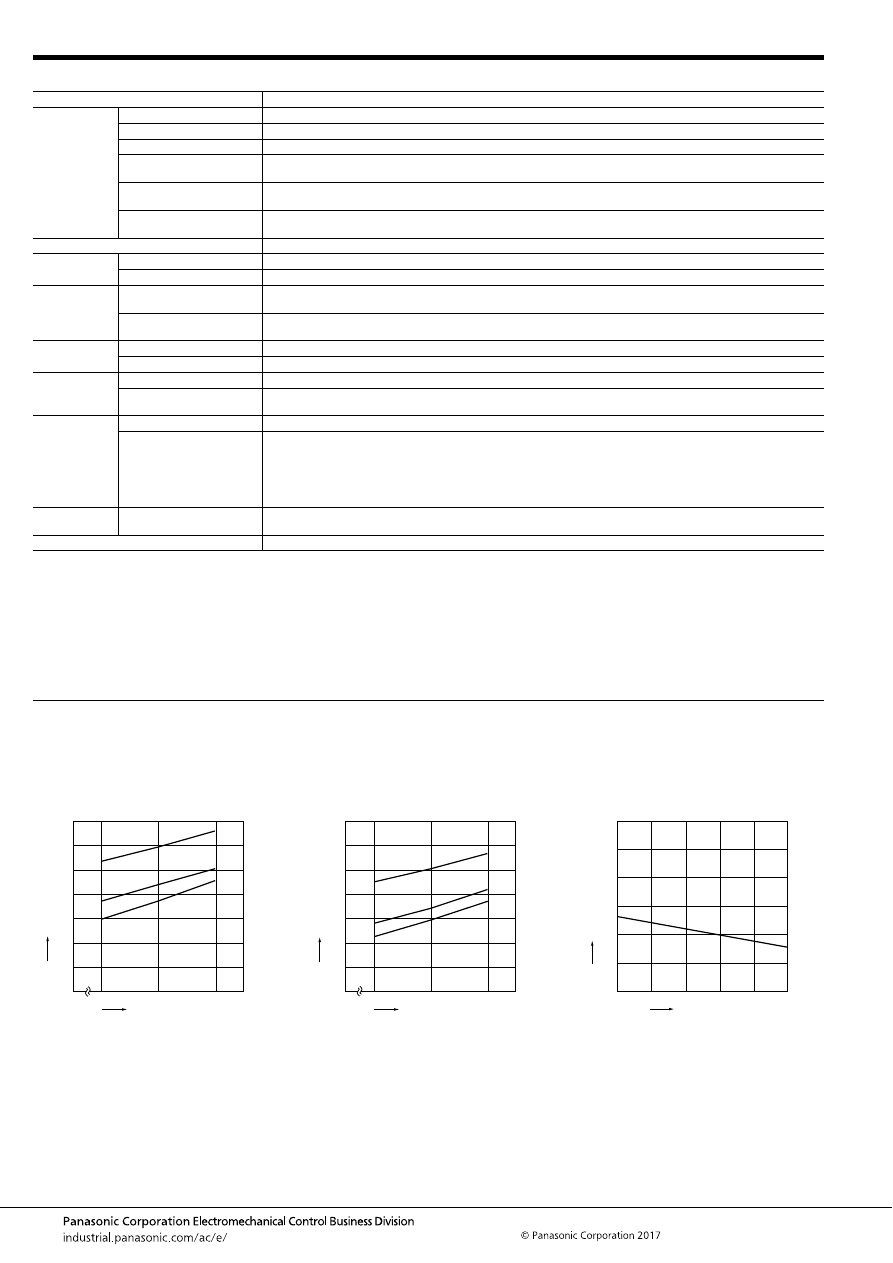

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACP

14

13

9.5

.551

.512

.374

14

13

10.5

.551

.512

.413

ACPP

14

13

9.5

.551

.512

.374

ACQ

13

17

16.6

.512

.669

.654

Features

Compact Flat Size for Automotive Relay

High Carrying Current Type

Miniature Low Profile Automotive Relay

1 Form C Automotive Quiet Relay

Con

tact

data

Contact arrangement

1 Form A, 1 Form C

1 Form A, 1 Form C

1 Form C

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

20A 14V DC

N.O.

10A 14V DC

1A 14V DC

N.C.

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power

640mW

450mW

640mW

640mW

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 7.2 V DC

Max. 7.2V DC

Max. 6.5V DC

Max. 7.2V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 1.0 V DC

Min. 1.0V DC

Min. 1.0V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

7

Min. 10

7

Electrical

Min. 2 × 10

5

(at 14 V DC, inrush: 25 A, steady: 5 A)

Min. 10

5

(Capacitor load)

(at 14 V DC, Inrush 60A, Steady 1A)

Min. 3 x 10

5

(at 14 V DC, Inrush 30A, Steady 5A)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

–40 to +85°C

–40 to +185°F

–40 to +85°C

–40 to +185°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

−

−

−

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

9.5

.374

(Surface mount: 10.5

.413

)

9.5

.374

16.6

.654

Foot print (mm

inch

)

13

.512

14

.551

13

.512

14

.551

13

.512

17

.669

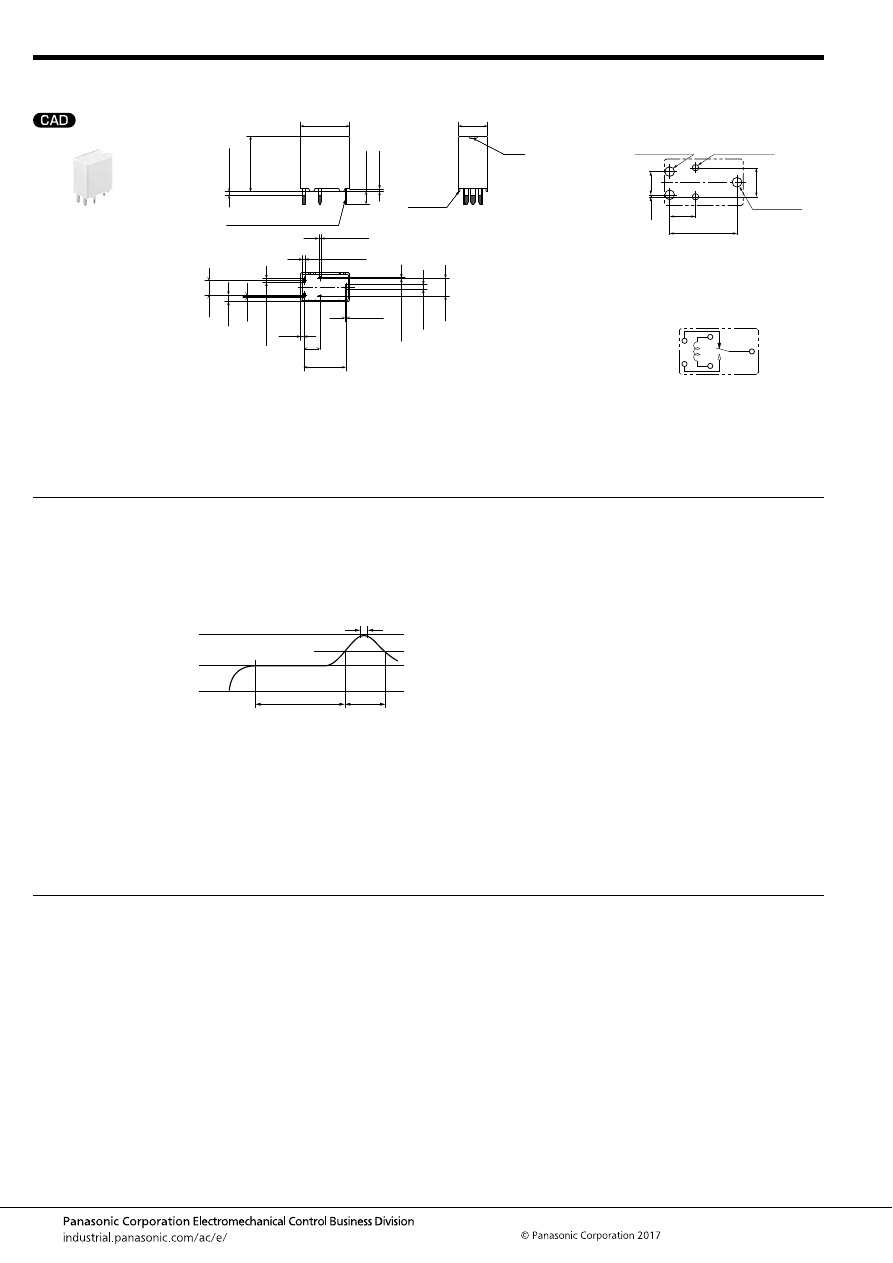

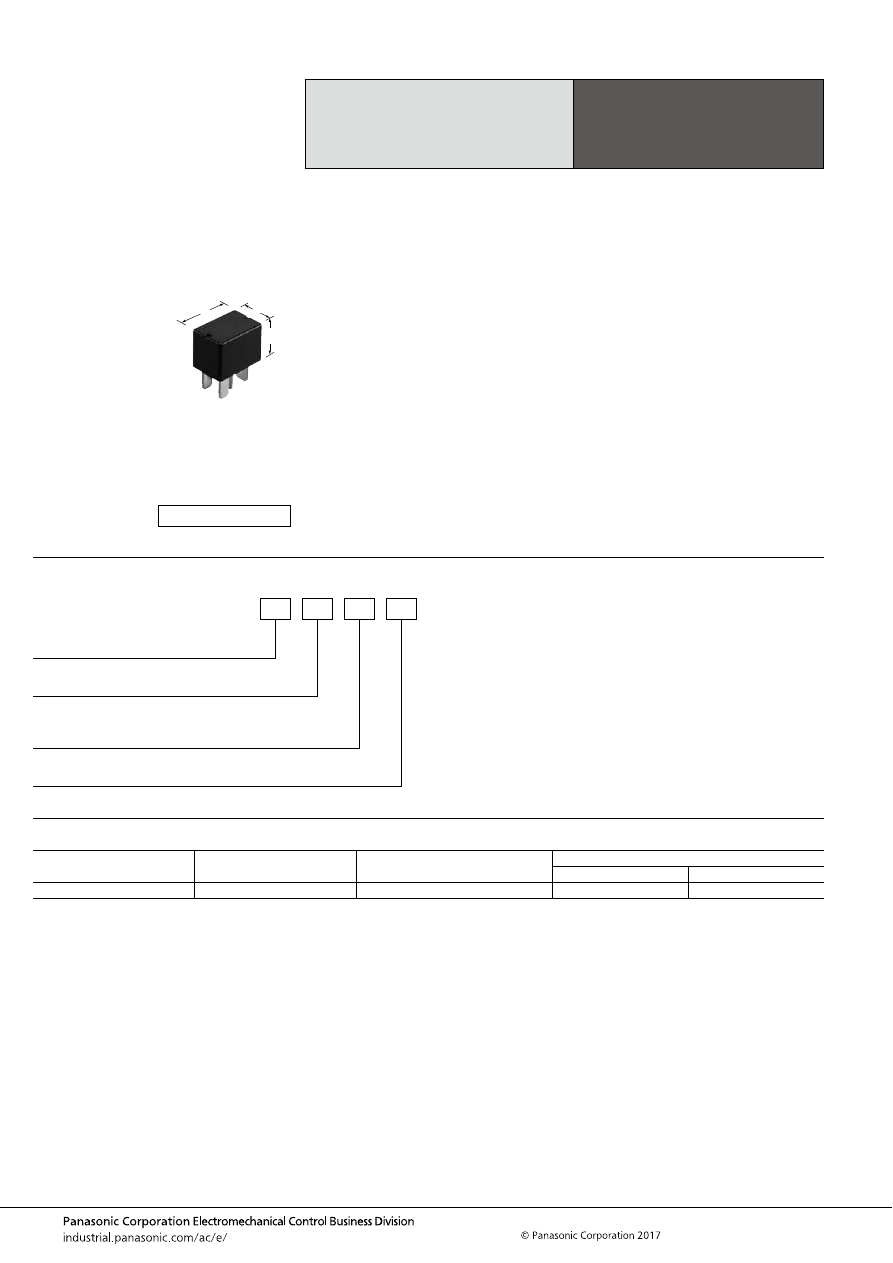

PC board pattern

PC board terminal type

1 From C

1 From C

Surface mount terminal type

4.5

.177

5.4

.213

2.0

.079

(R)

10.7

.421

2×.051

+.004

0

dia. hole

2×1.3

+0.1

0

dia. hole

3×.035

+.004

0

3×.079

+.004

0

3×0.9

+0.1

0

3×2.0

dia.

dia.

dia.

dia.

+0.1

0

6.0

.236

5.0

.197

2.0

2.0

.079

.079

4.8

4.0

4.7

4.8

.189

.157

6.0

.236

2.5

.098

.185

.189

4.2

.165

3.8

.150

4.4

.173

2.5

.098

4.8

.189

1 Form C

0.9

.035

6.0

2.0

.236

5.0

.197

10.7

.421

.079

5.4

.213

4.5

.177

3.5

.138

(R 0.45)

(R .018)

3×.079

+.004

0

3×2.0

+0.1

0

4×.035

+.004

0

4×0.9

+0.1

0

.098

+.004

0

2.5

+0.1

0

2×1.3 dia. (hole)

+0.1

0

2×.051 dia. (hole)

+.004

0

2.5

5×1.5

+0.1

0

10.2

10.0

.098

.402

.394

5×.059

dia. hole

dia. hole

+.004

0

Weight (approx.)

4g

.14 oz

4.5 g

.16 oz

6.5g

.23 oz

Remarks

−

−

−

Page

64

69

73

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

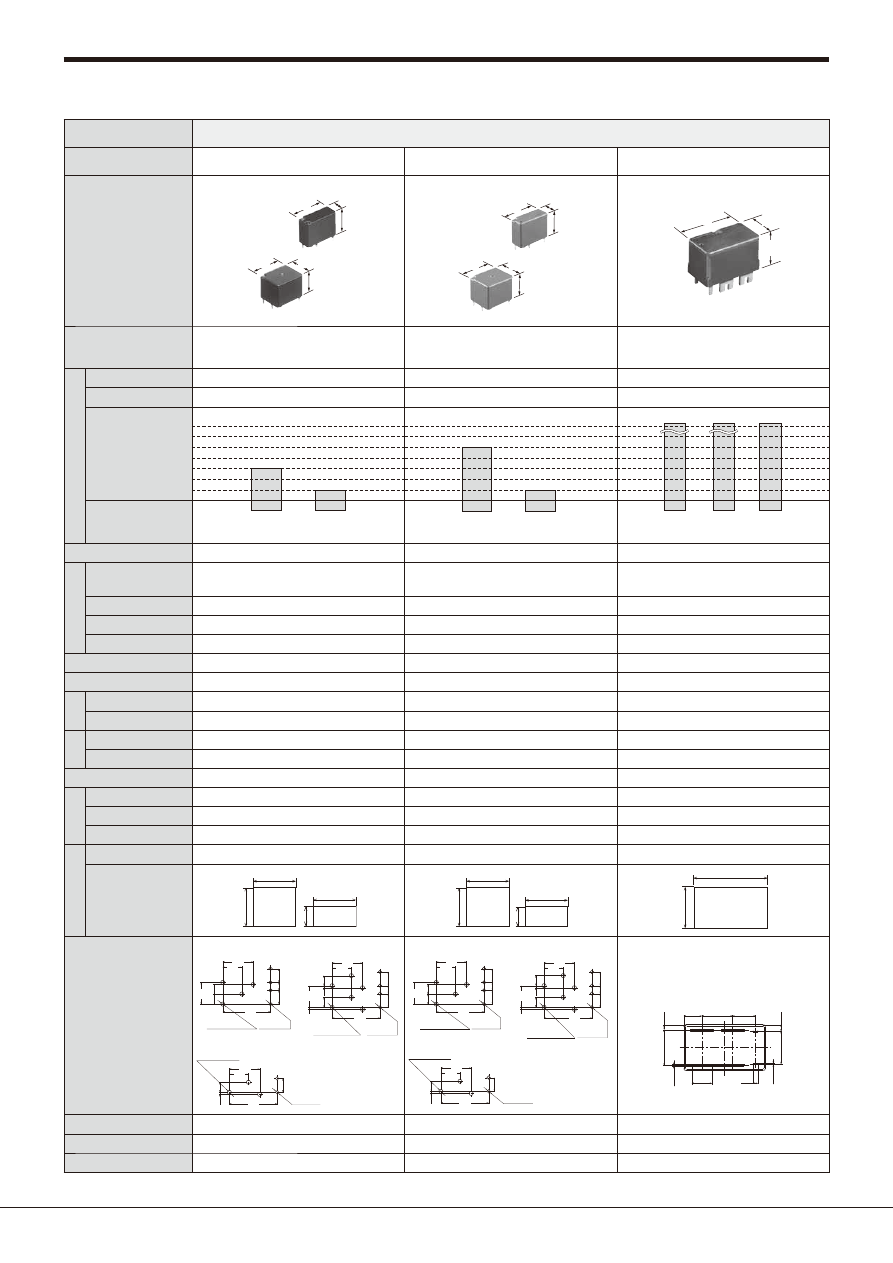

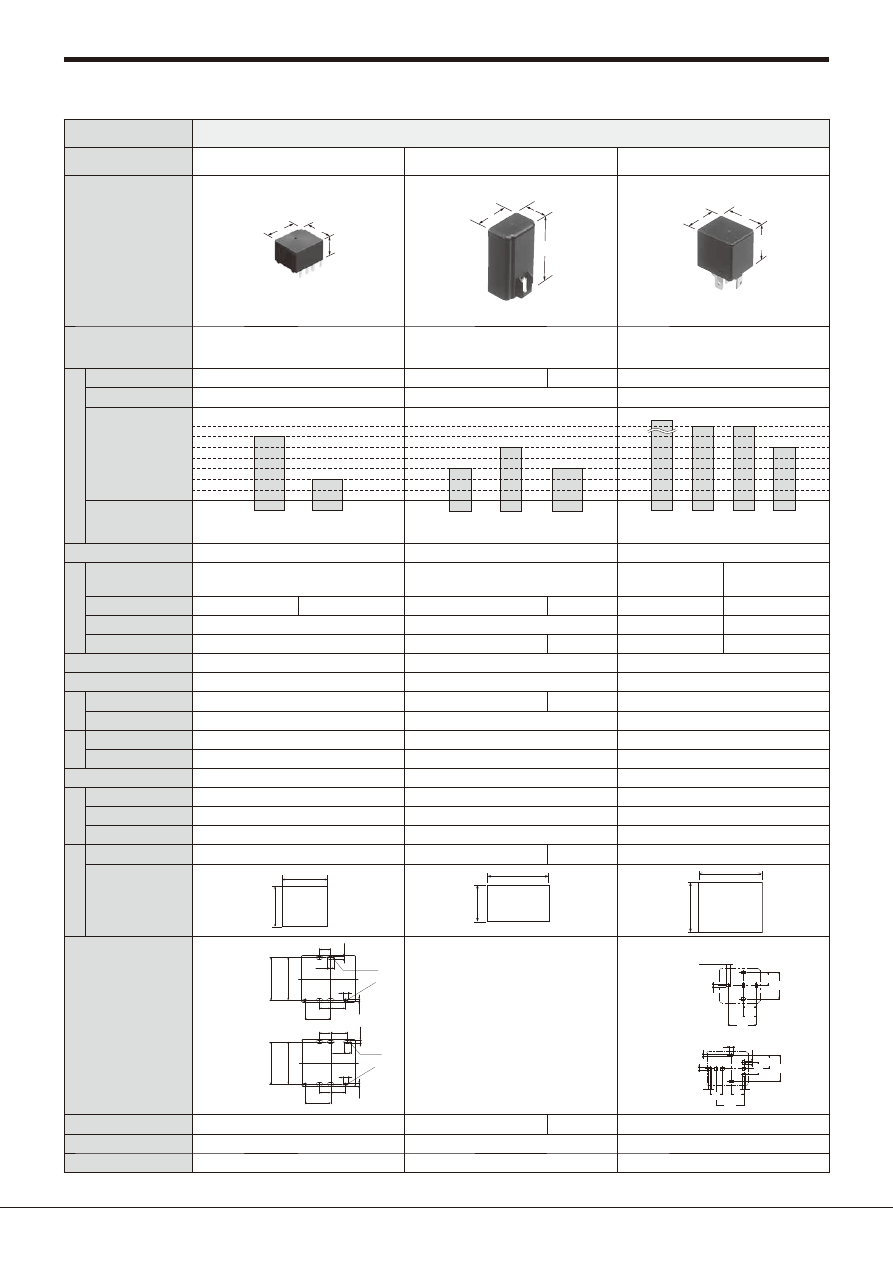

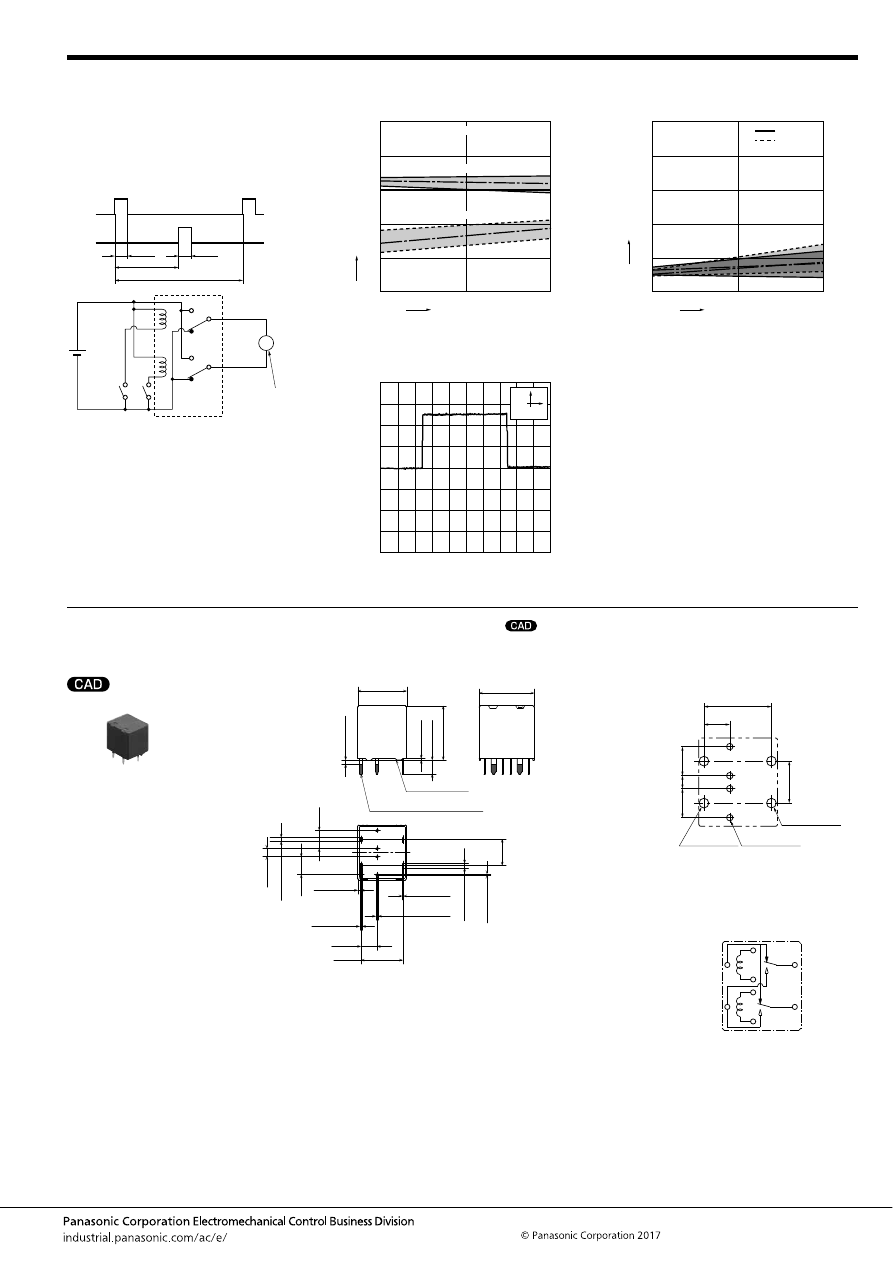

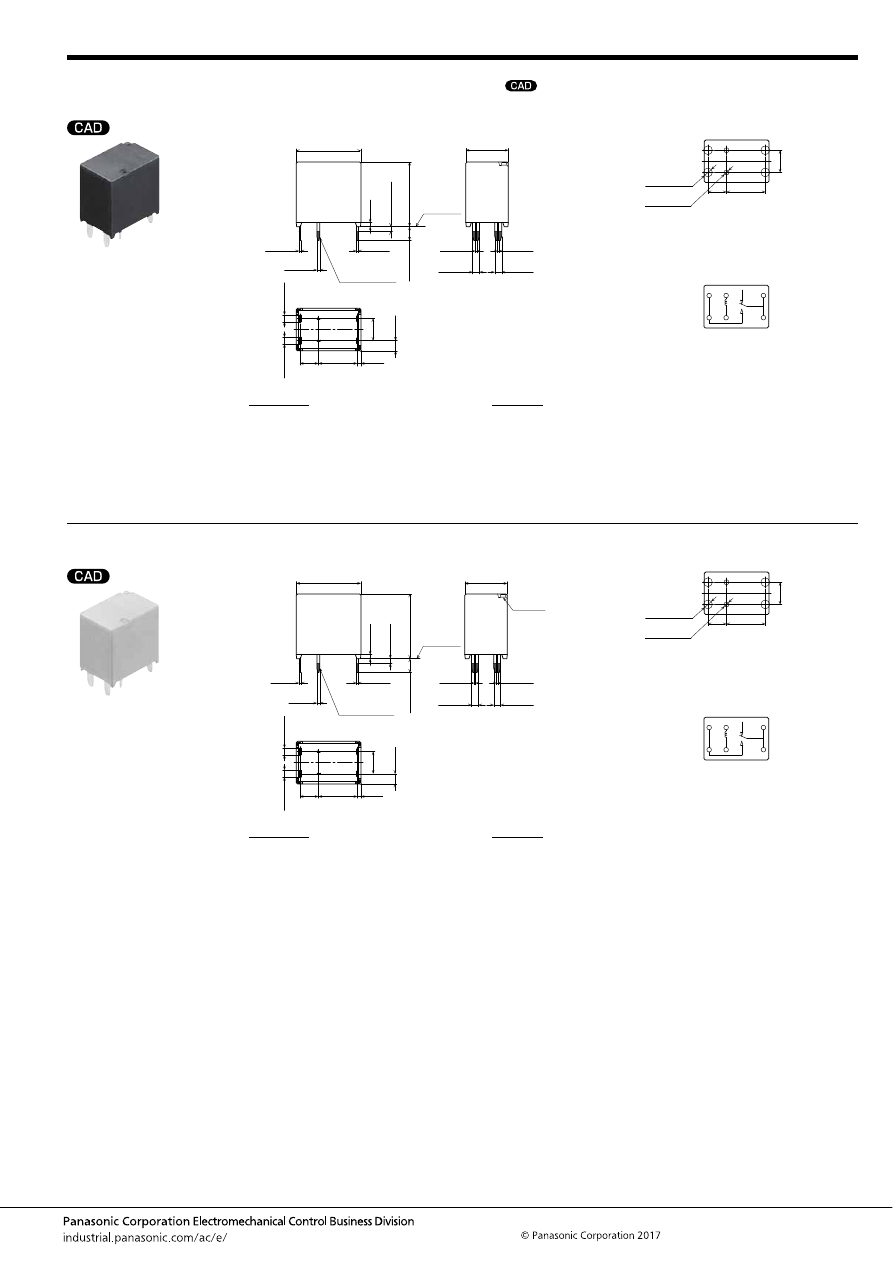

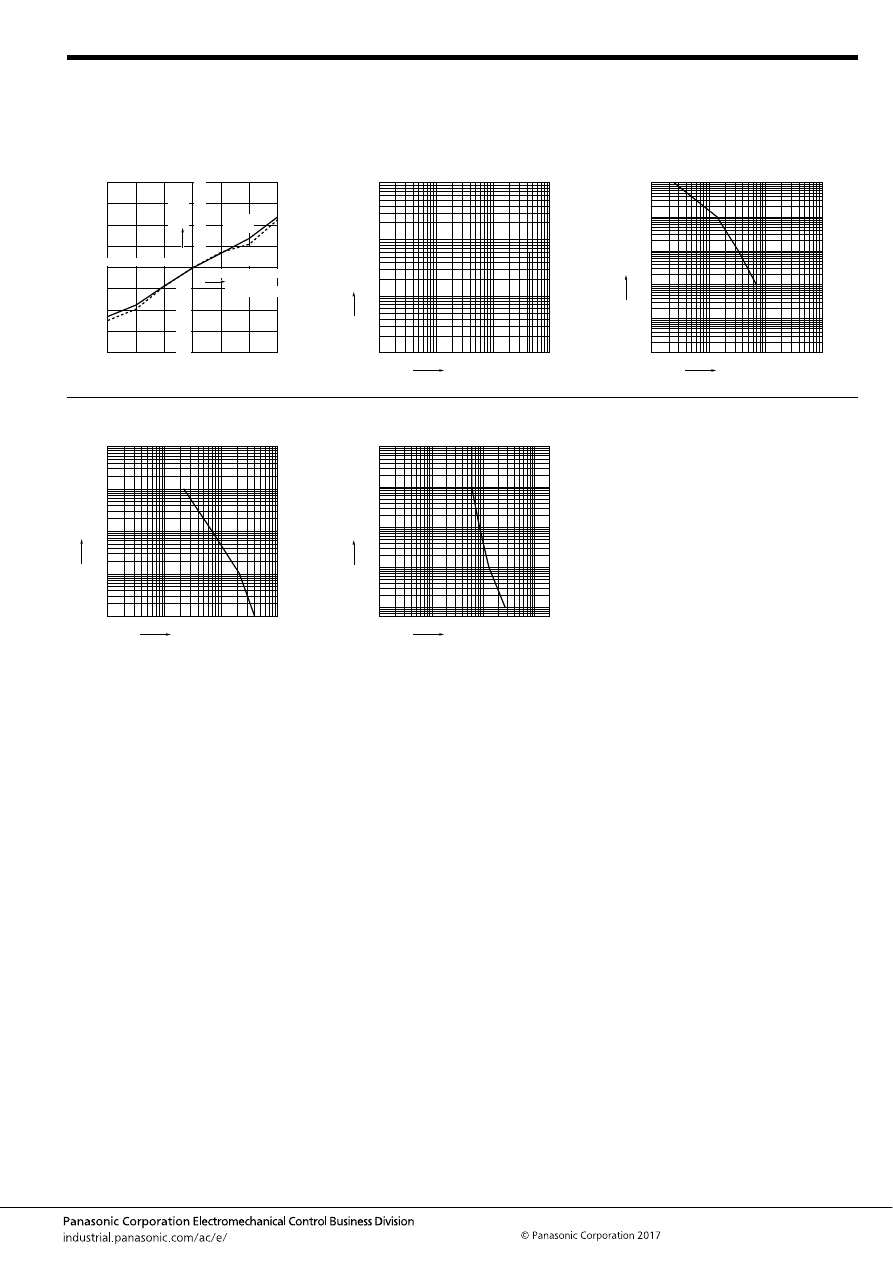

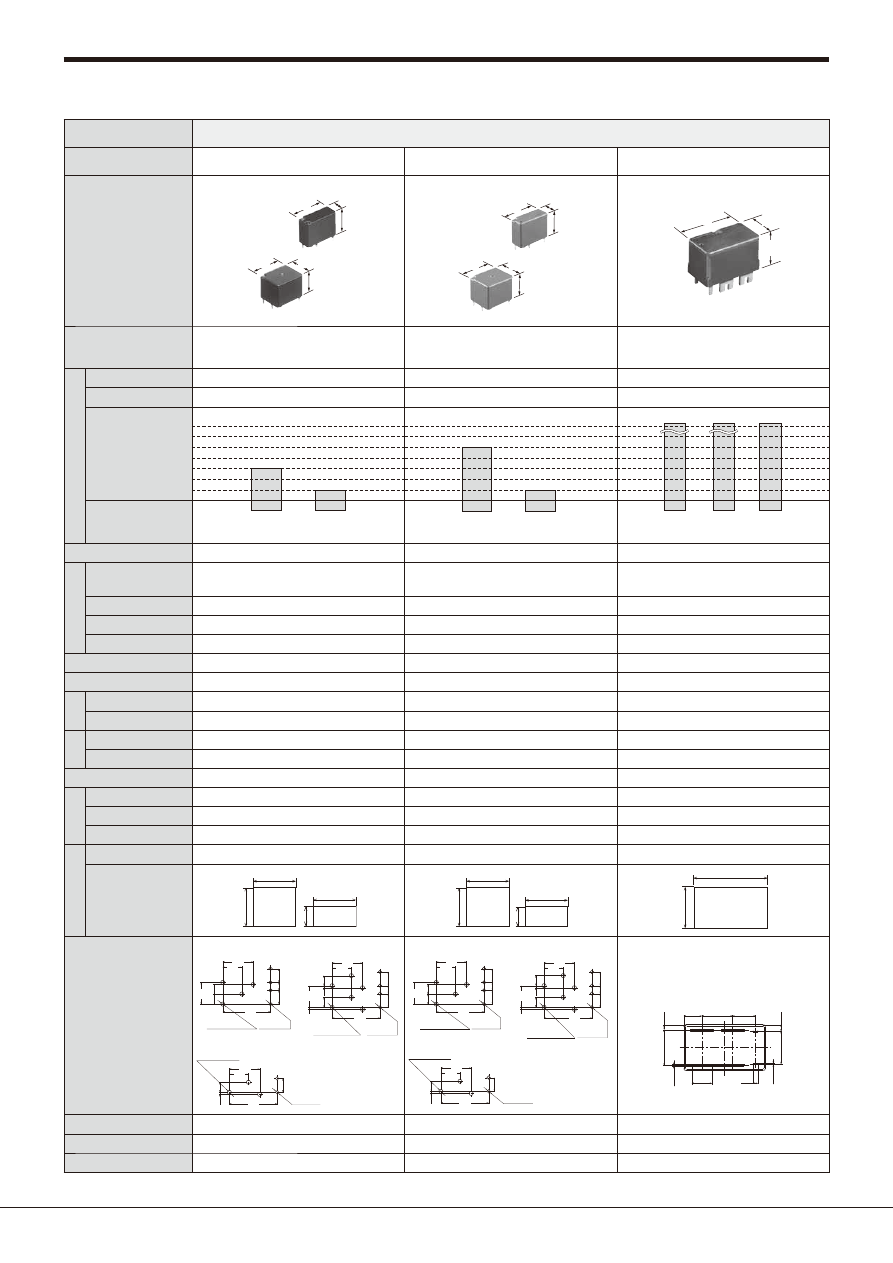

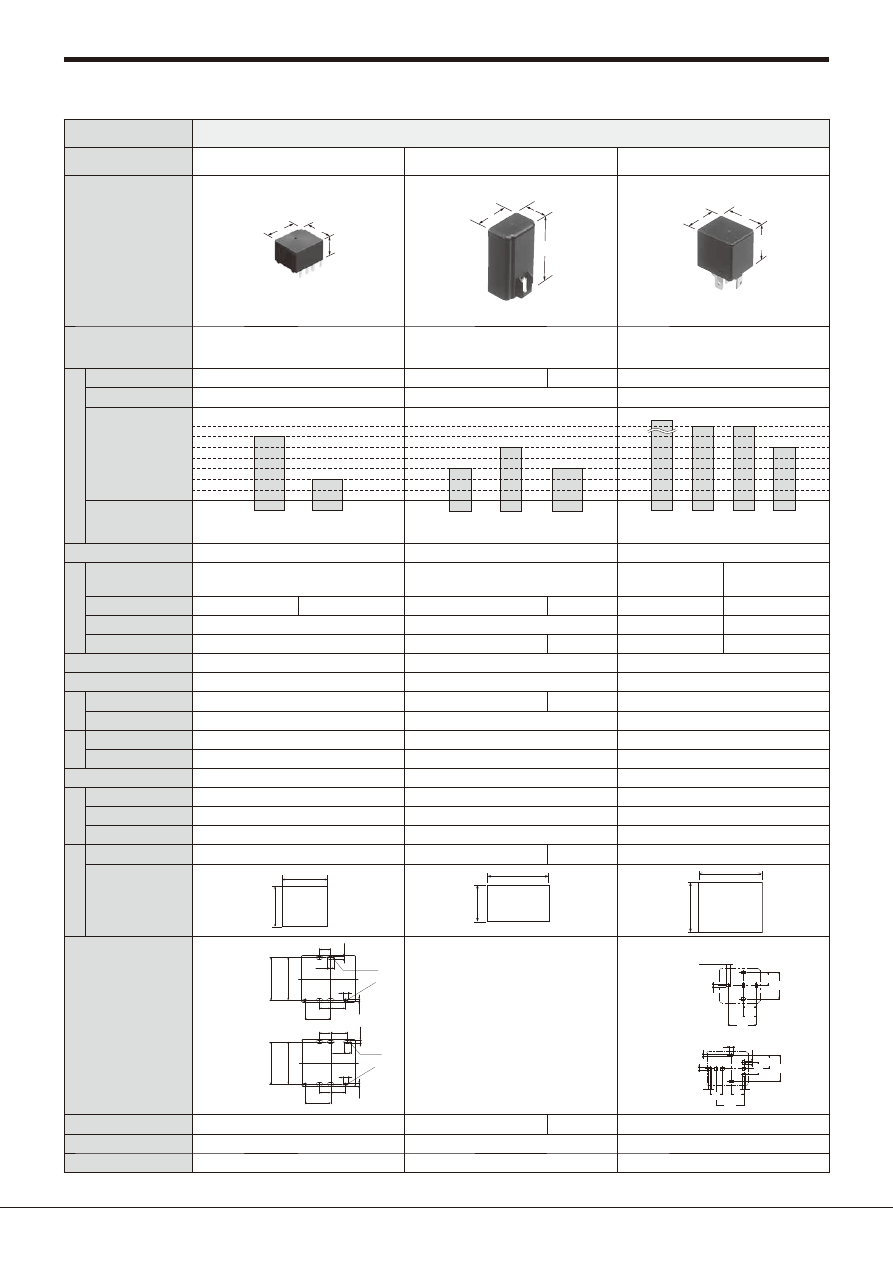

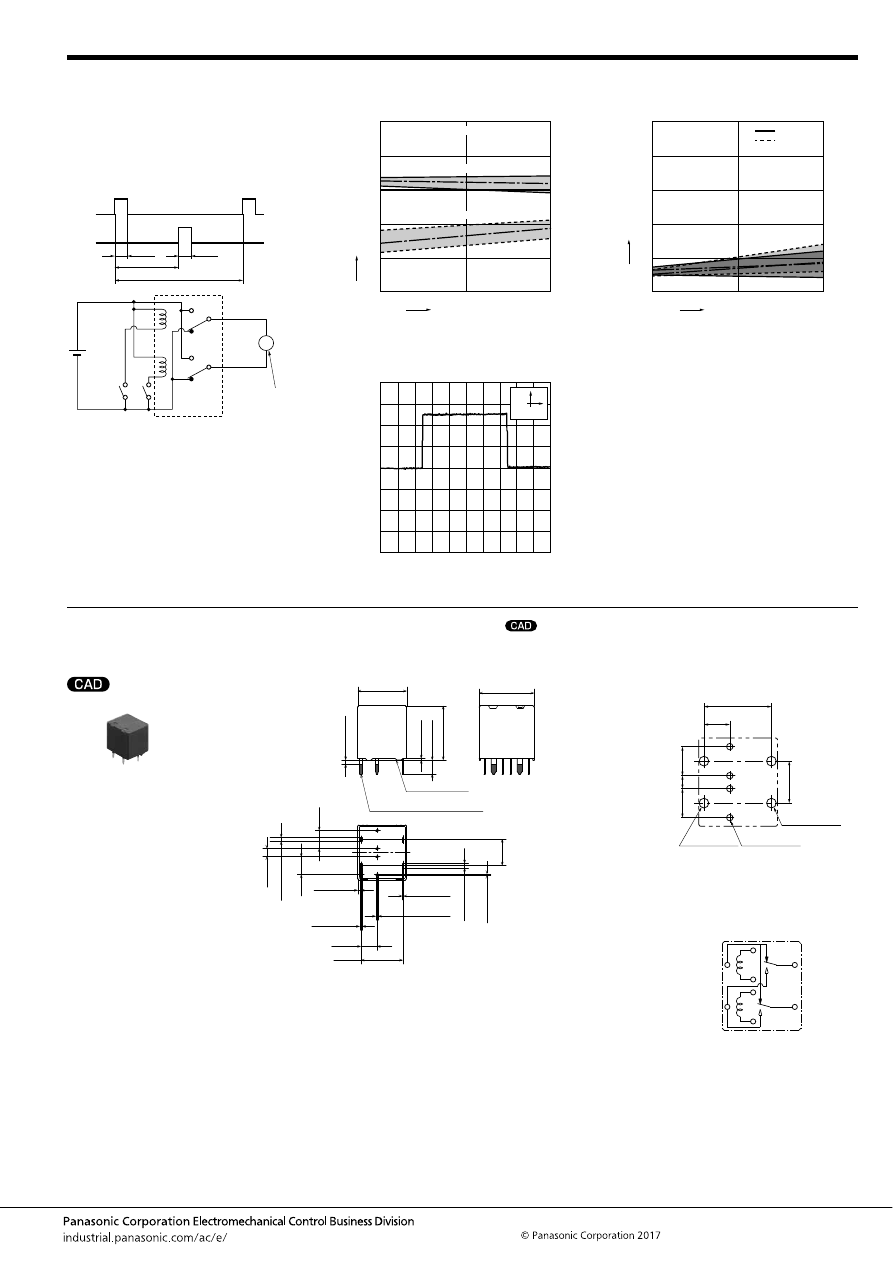

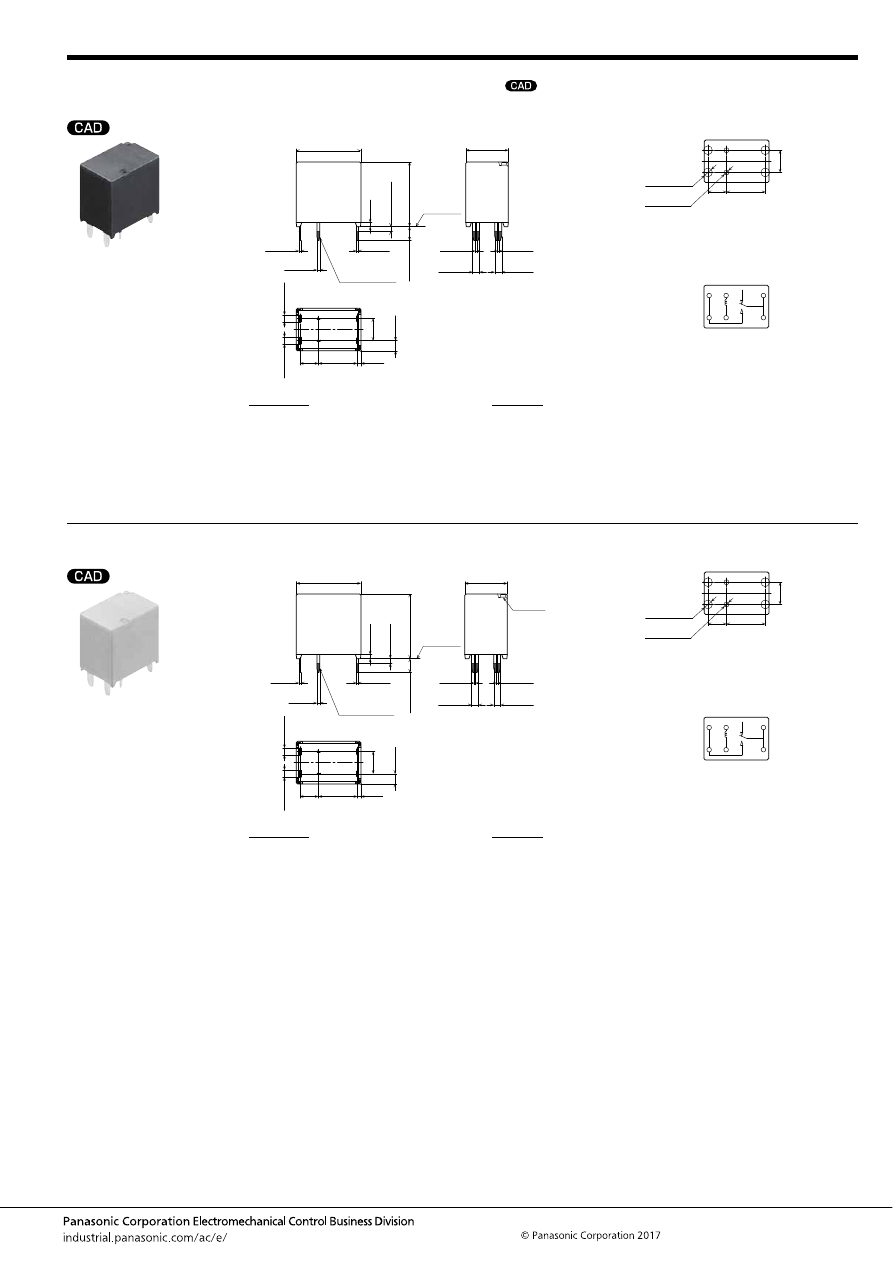

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–10–

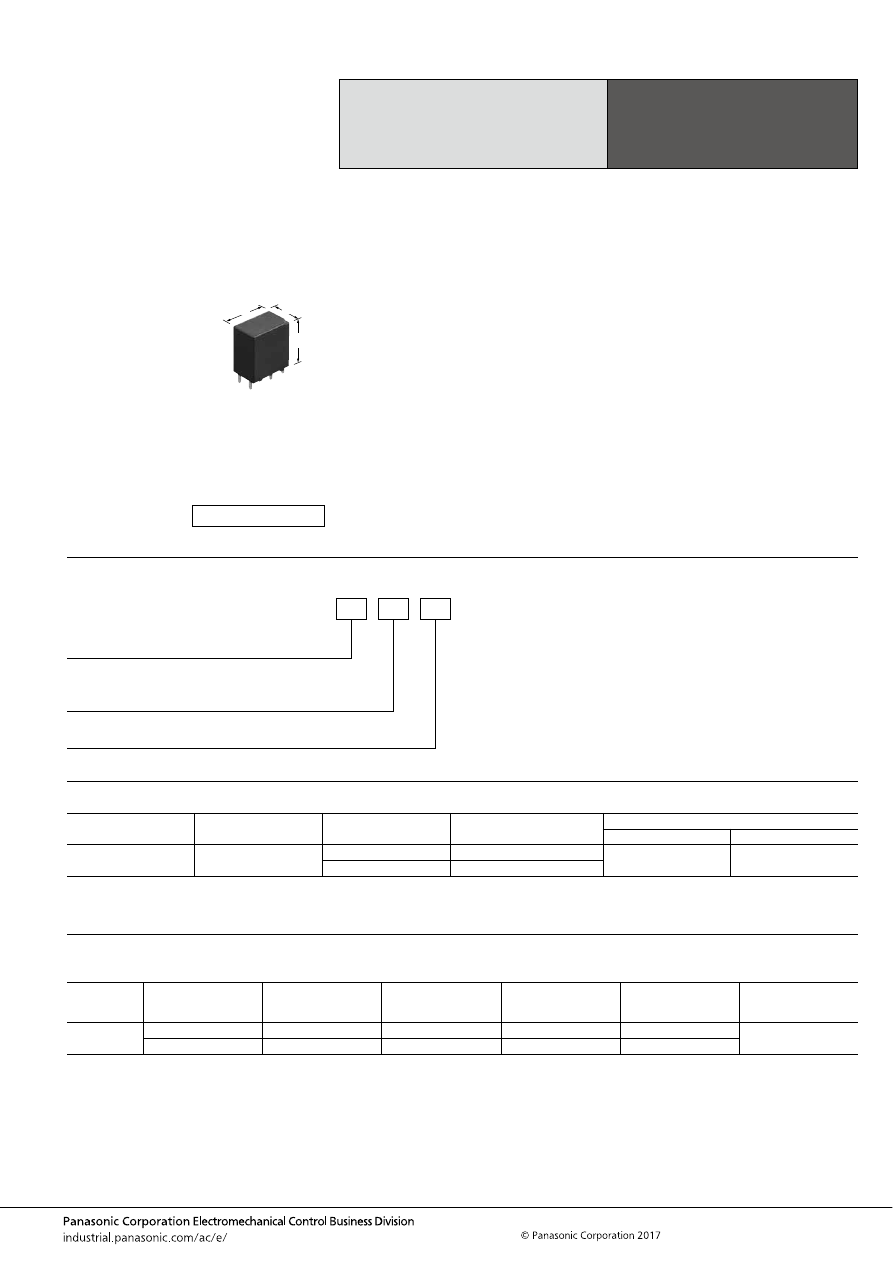

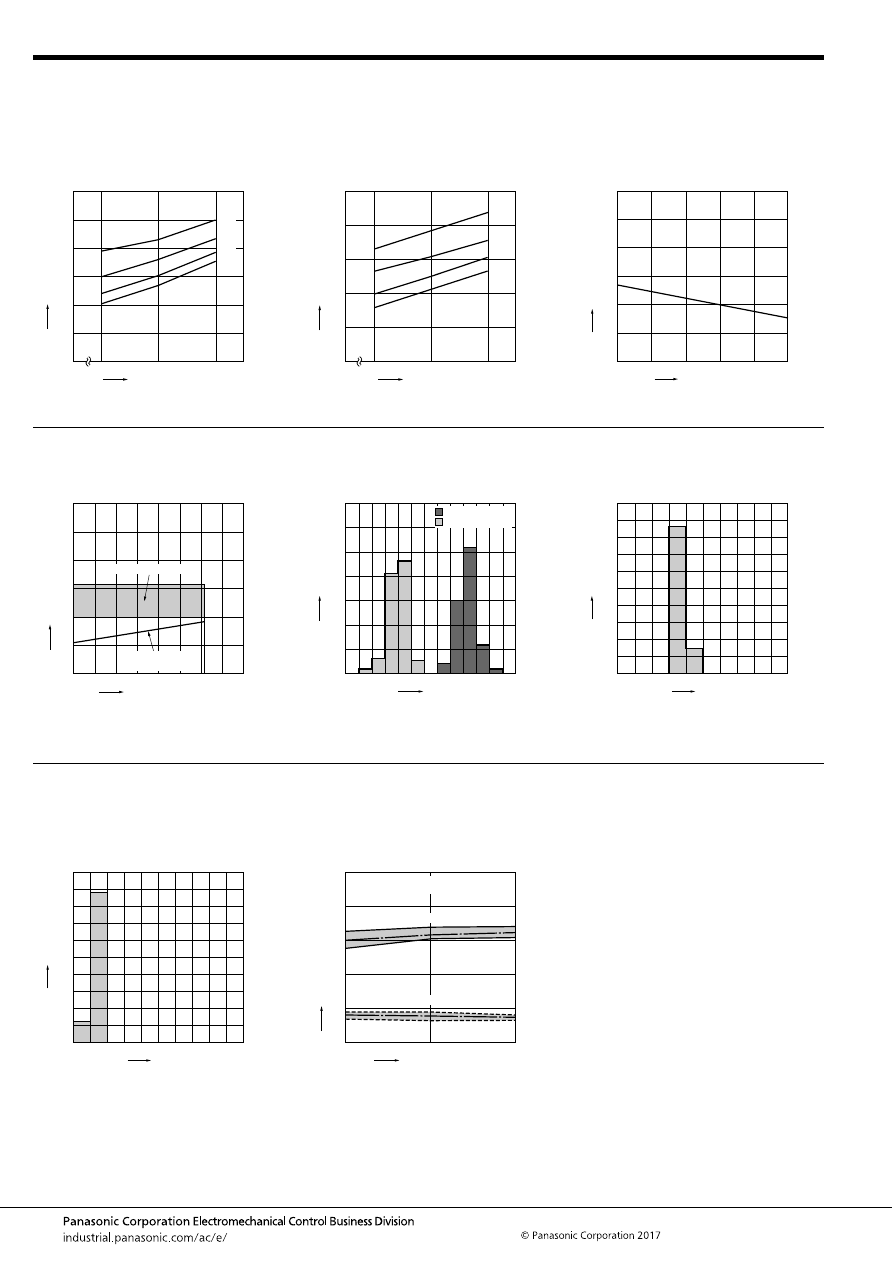

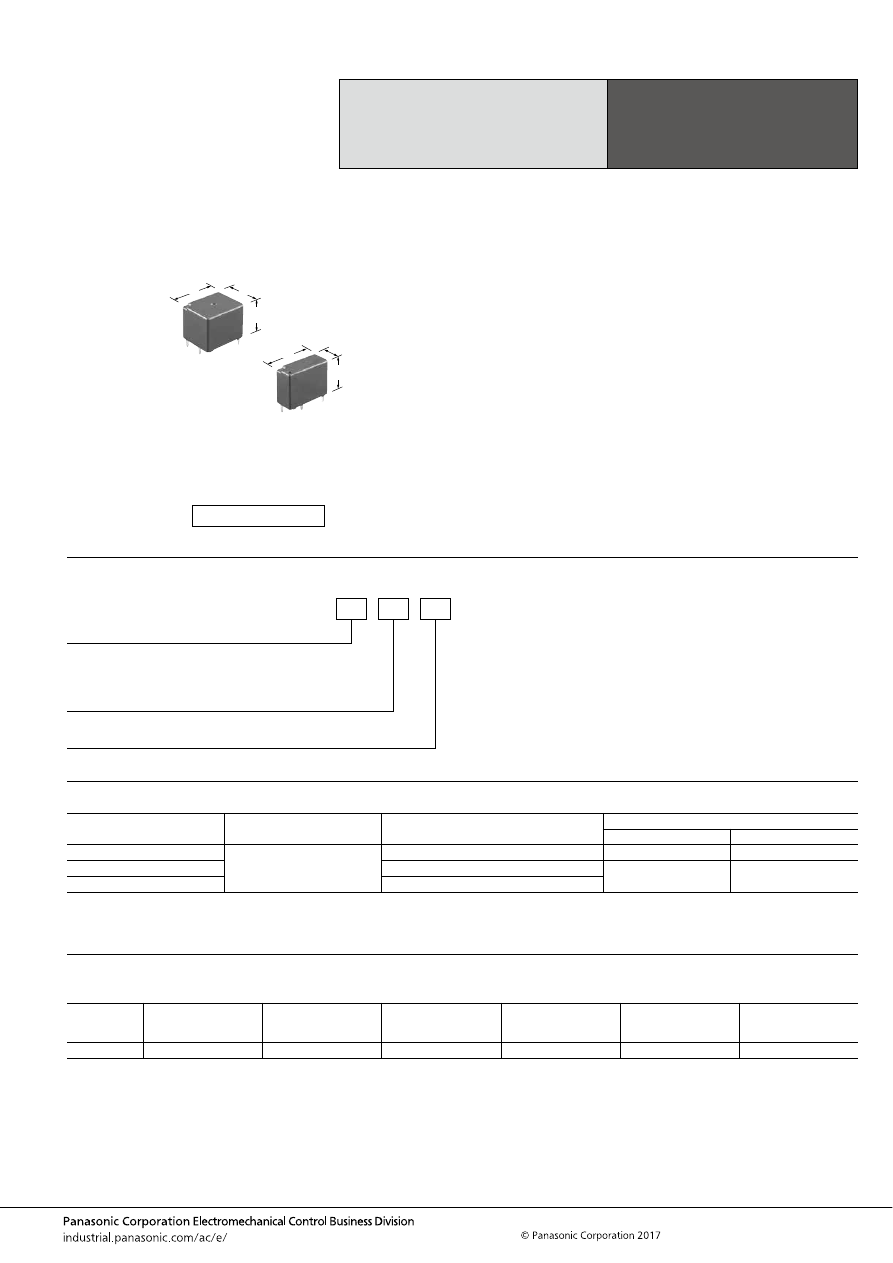

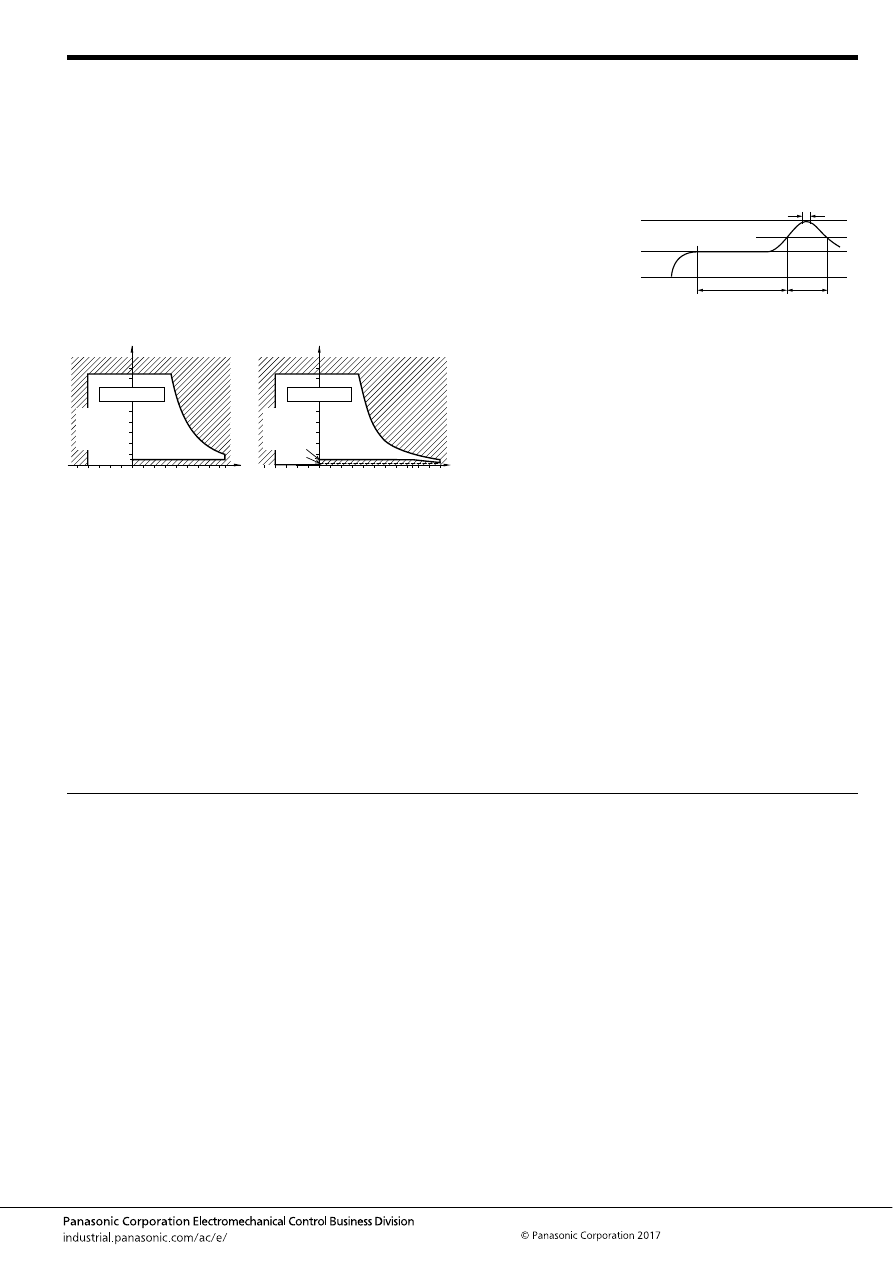

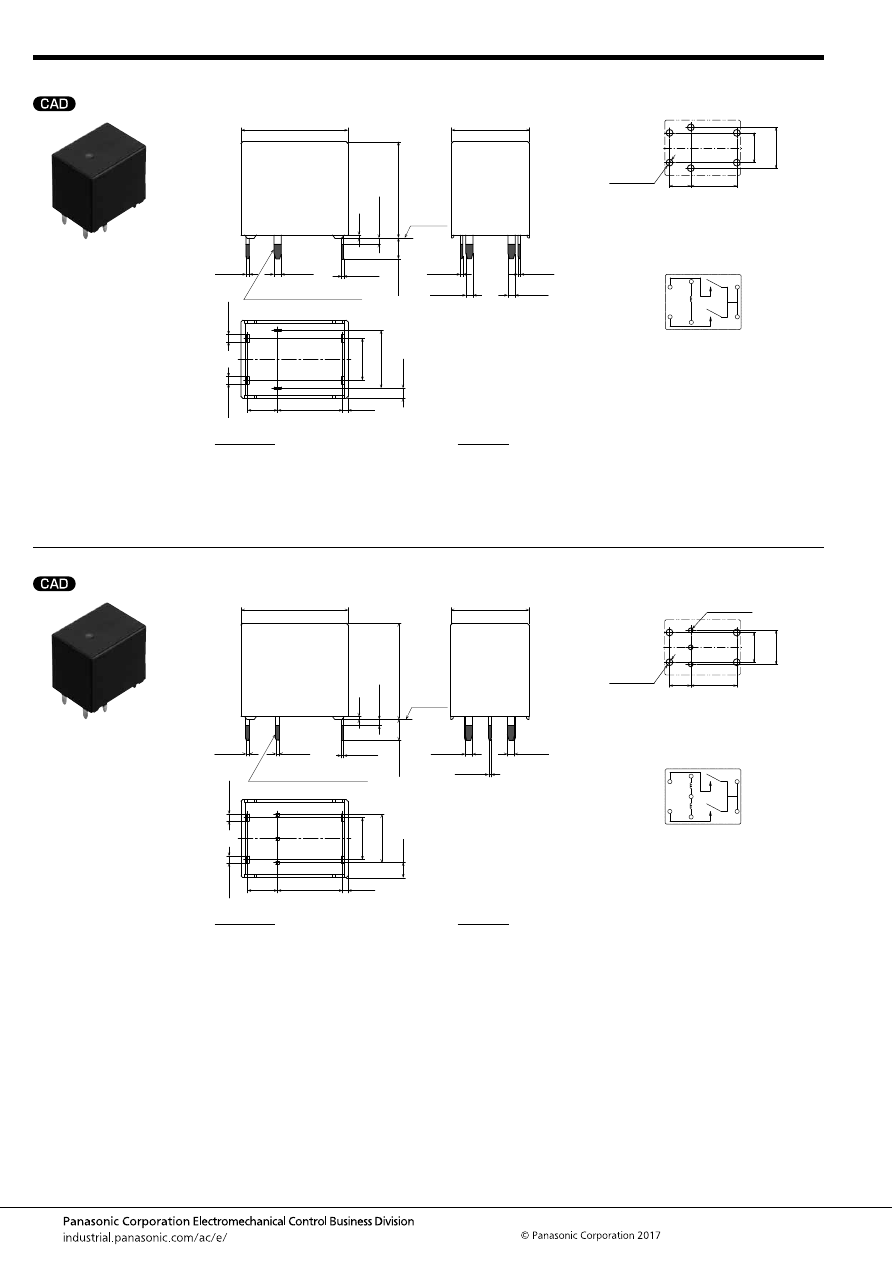

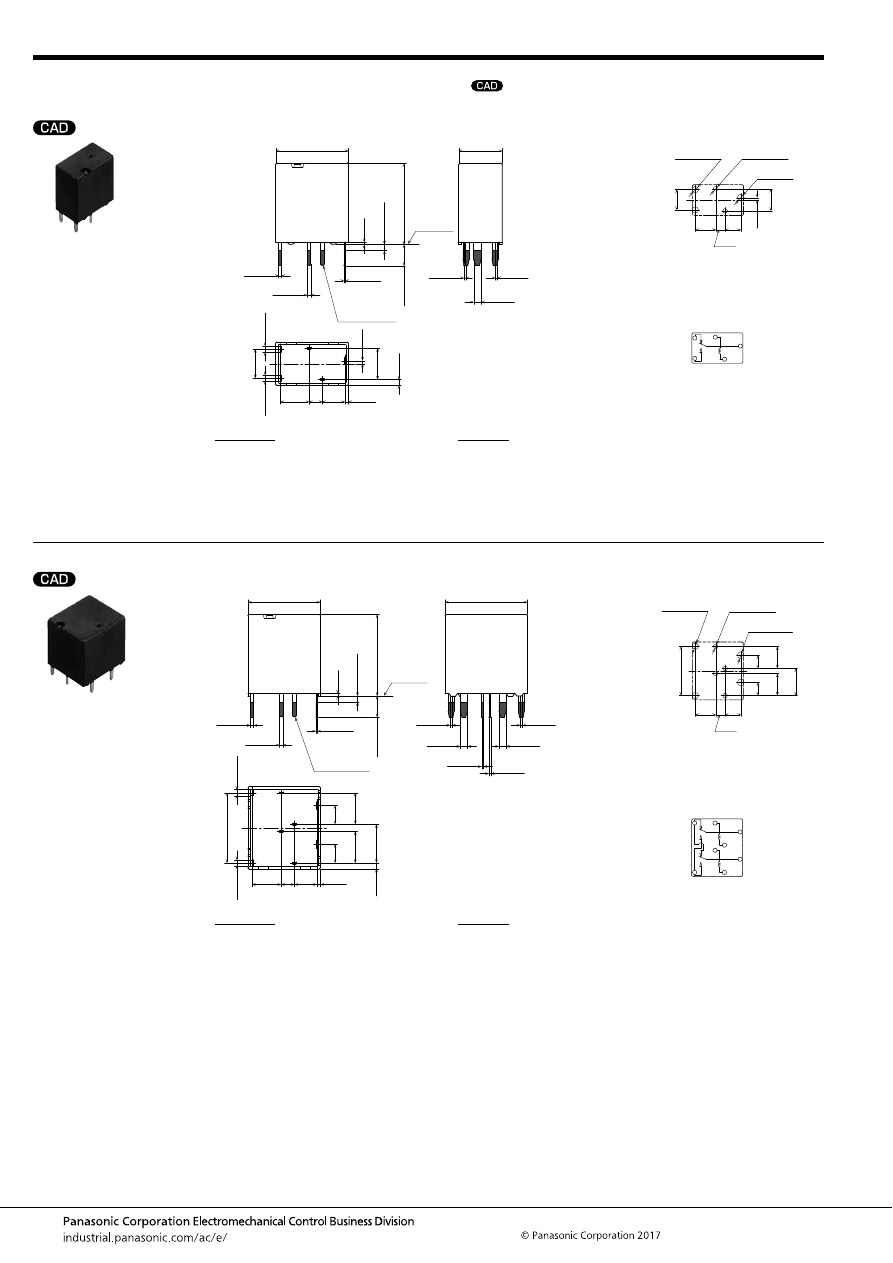

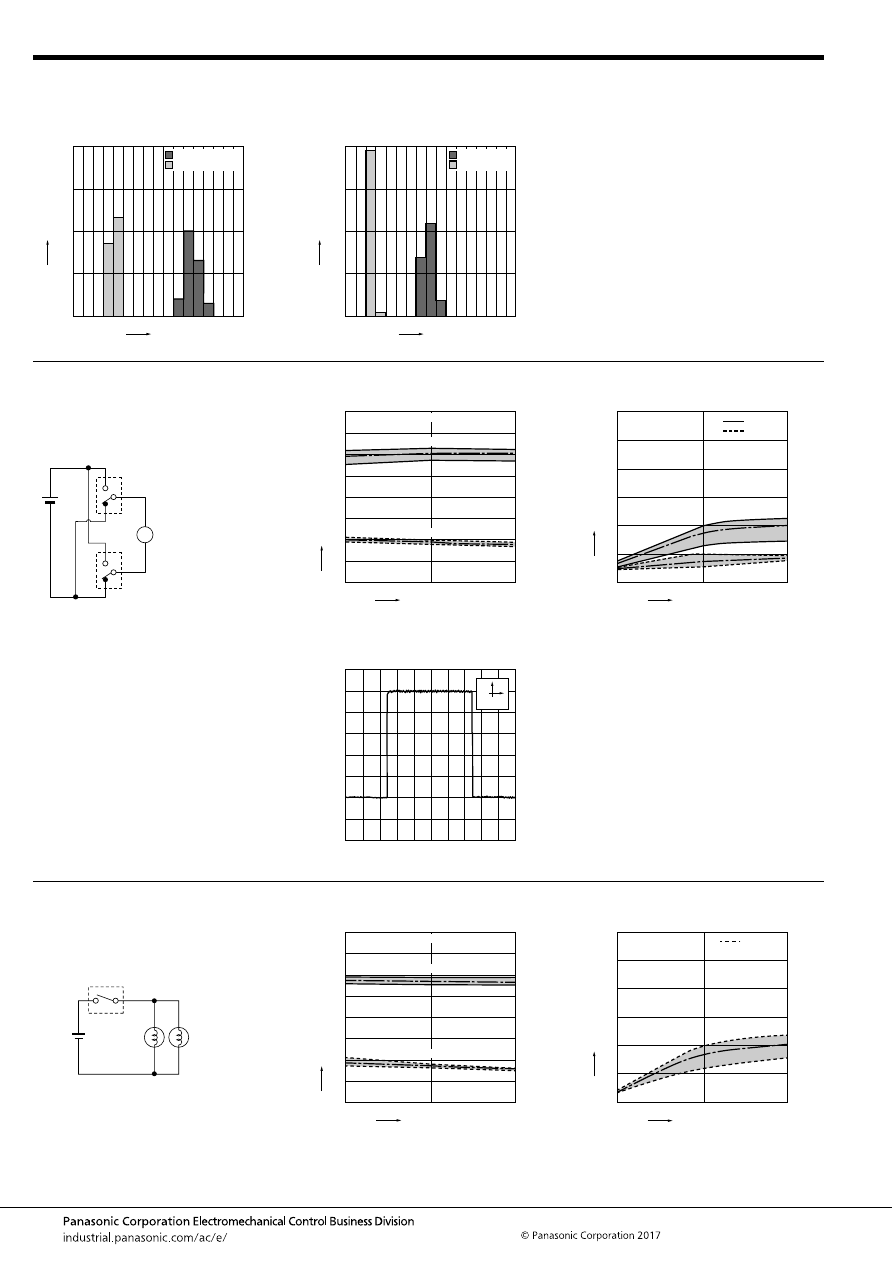

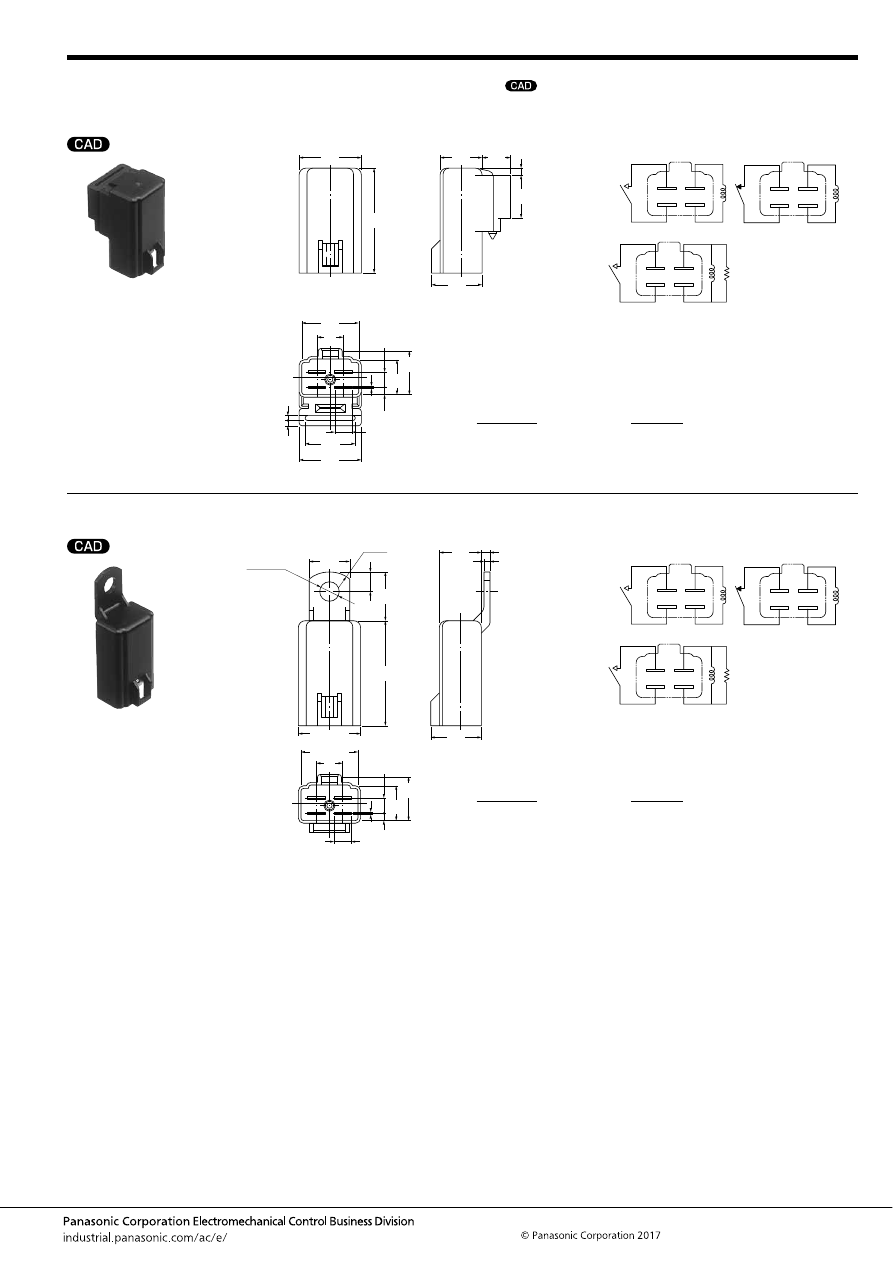

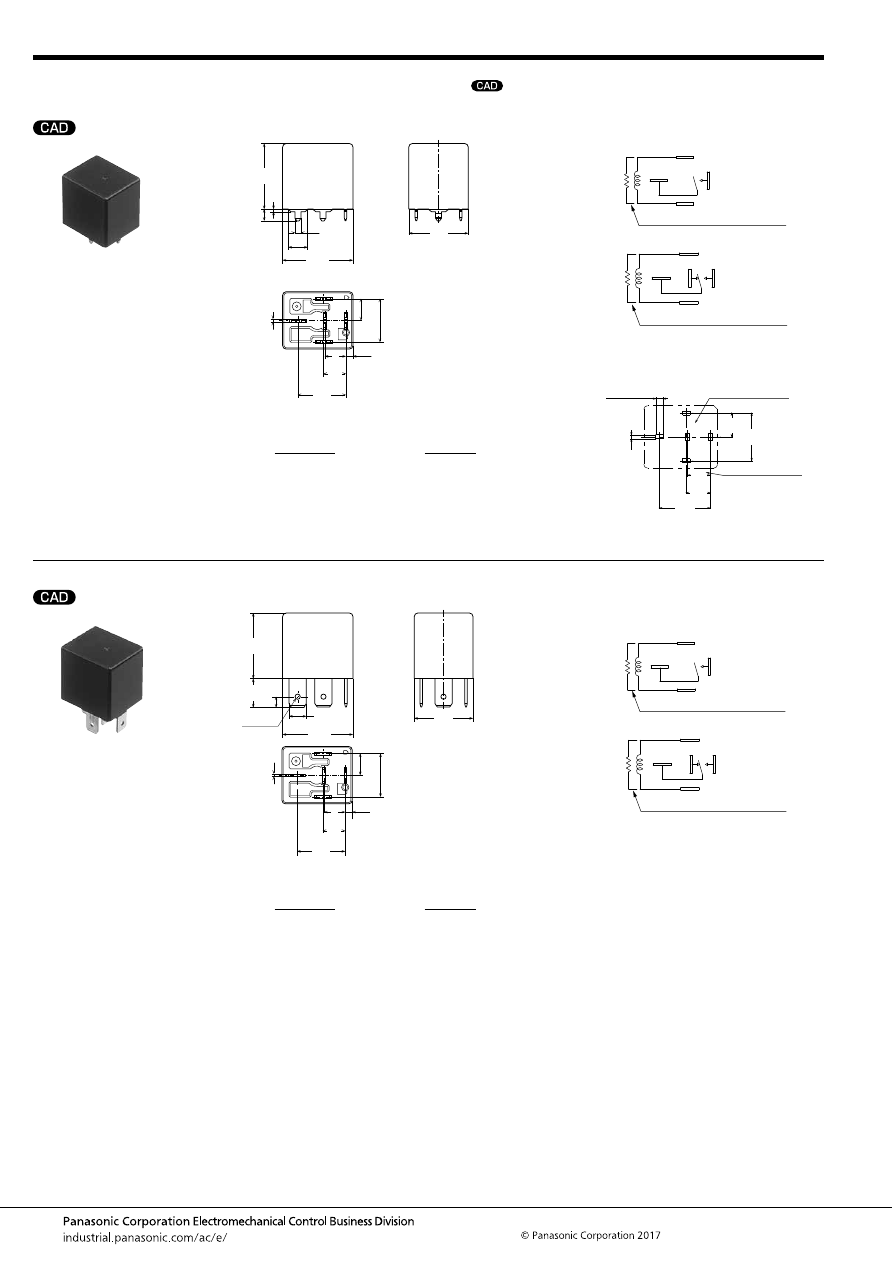

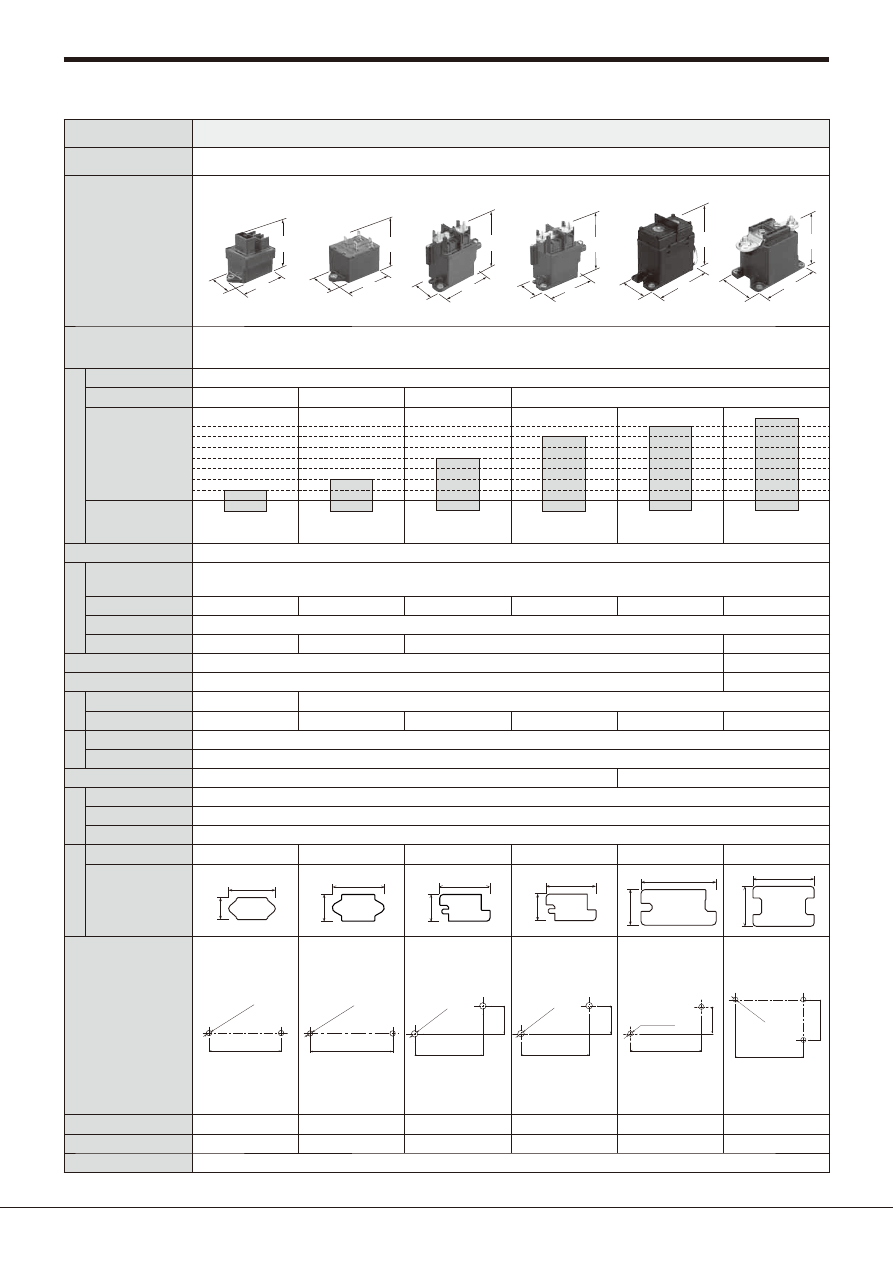

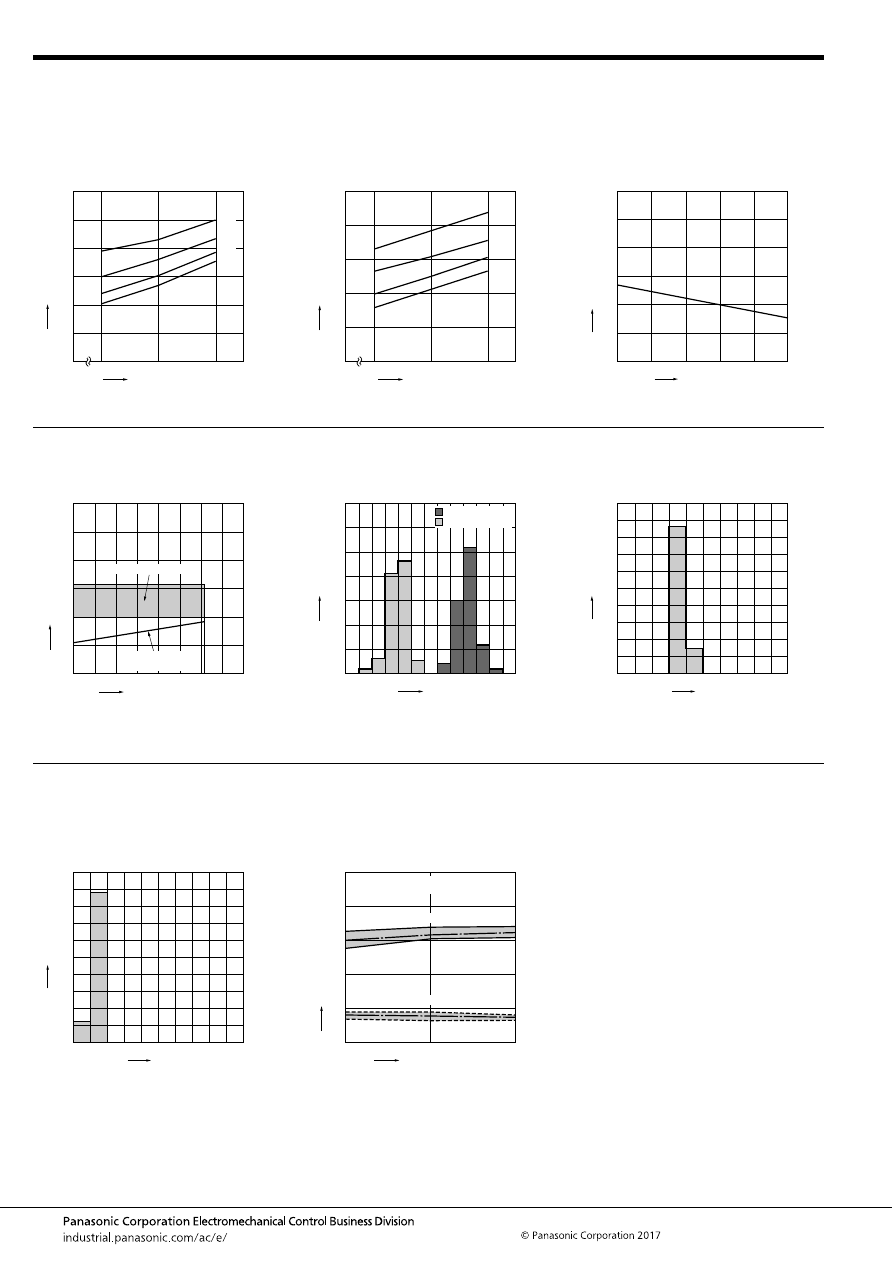

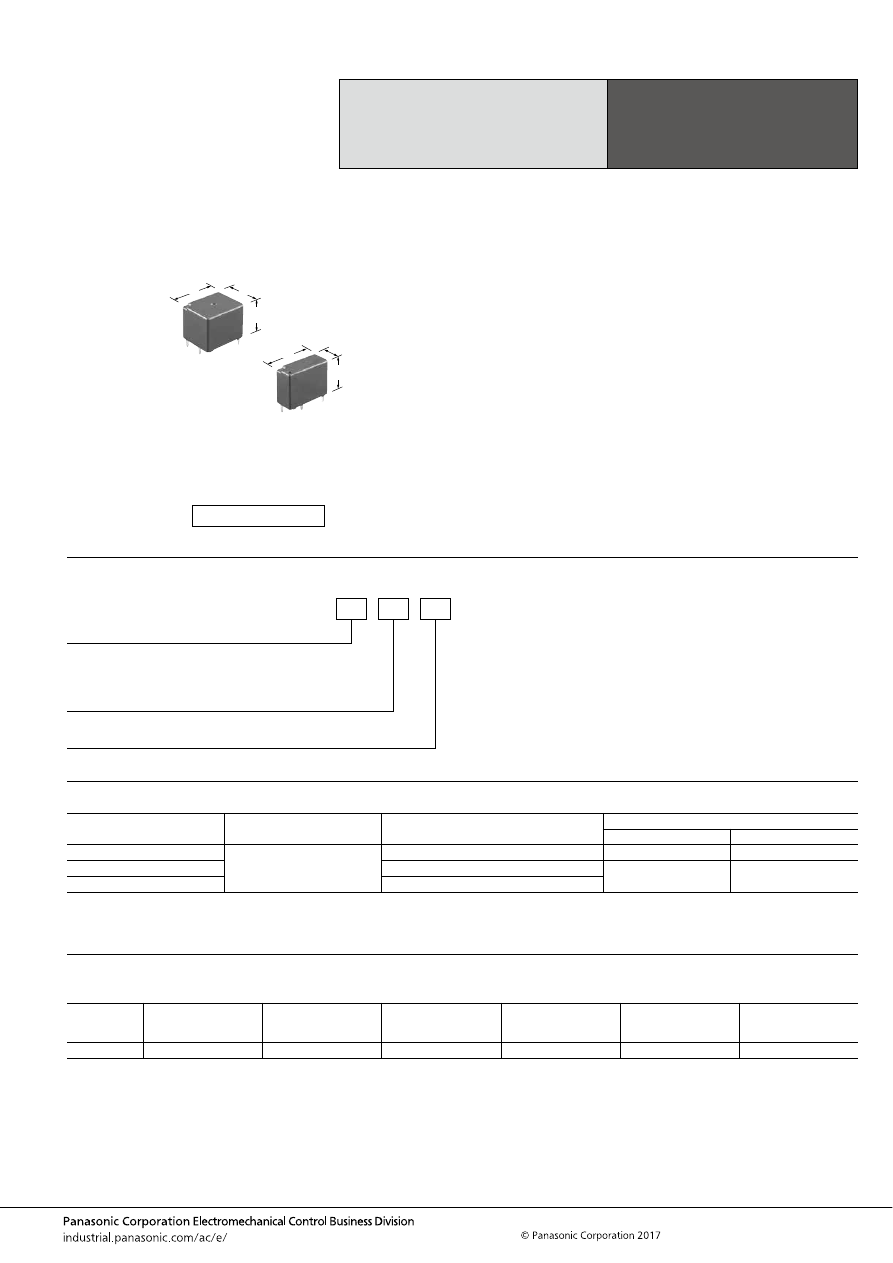

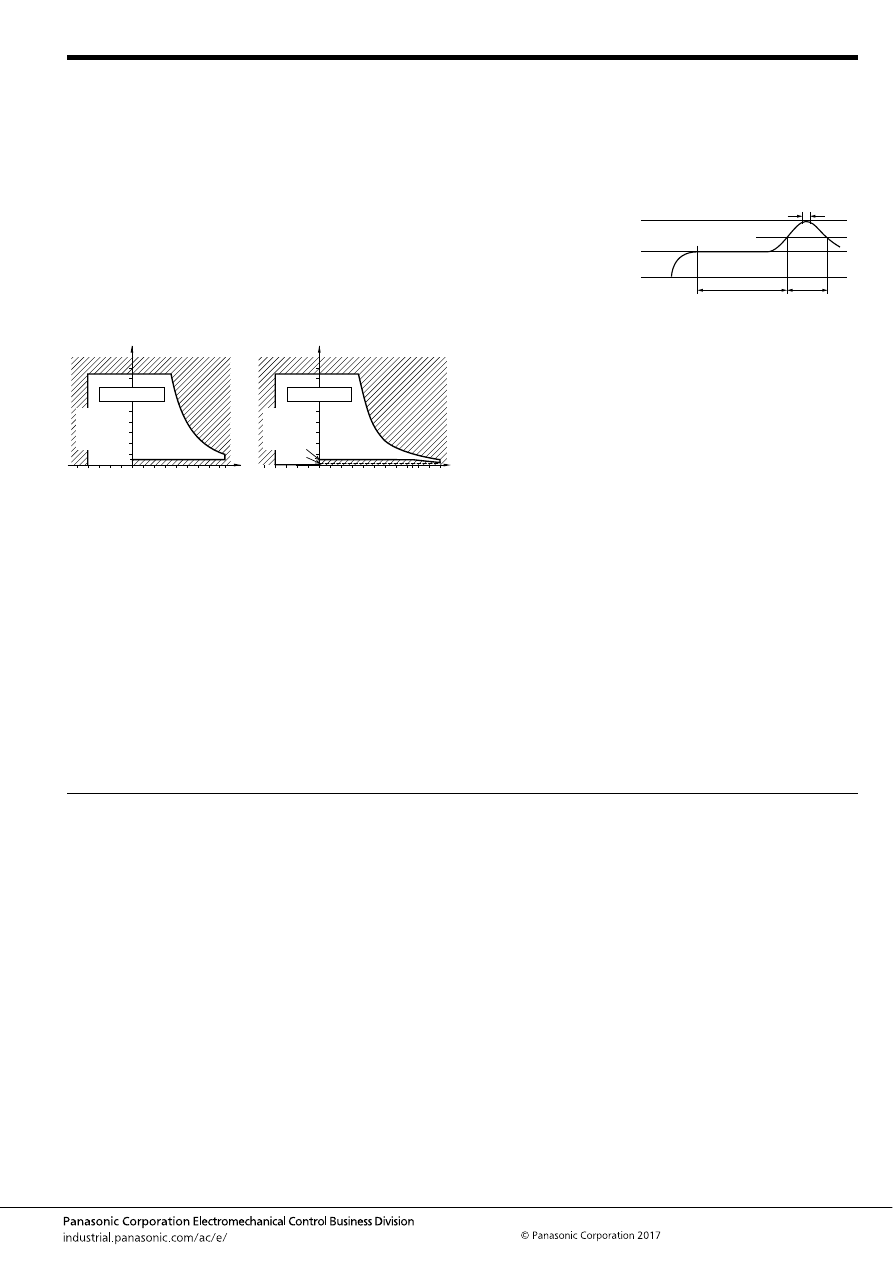

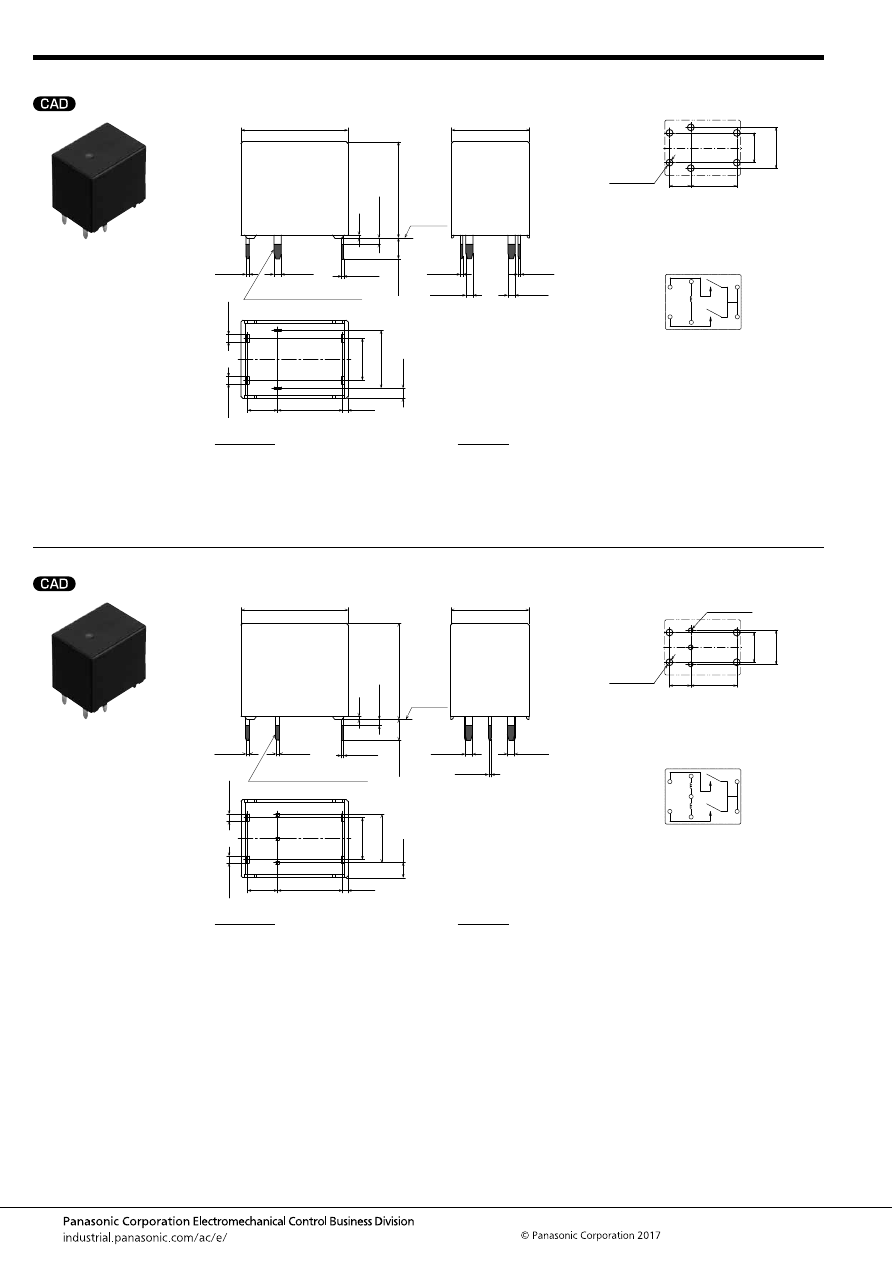

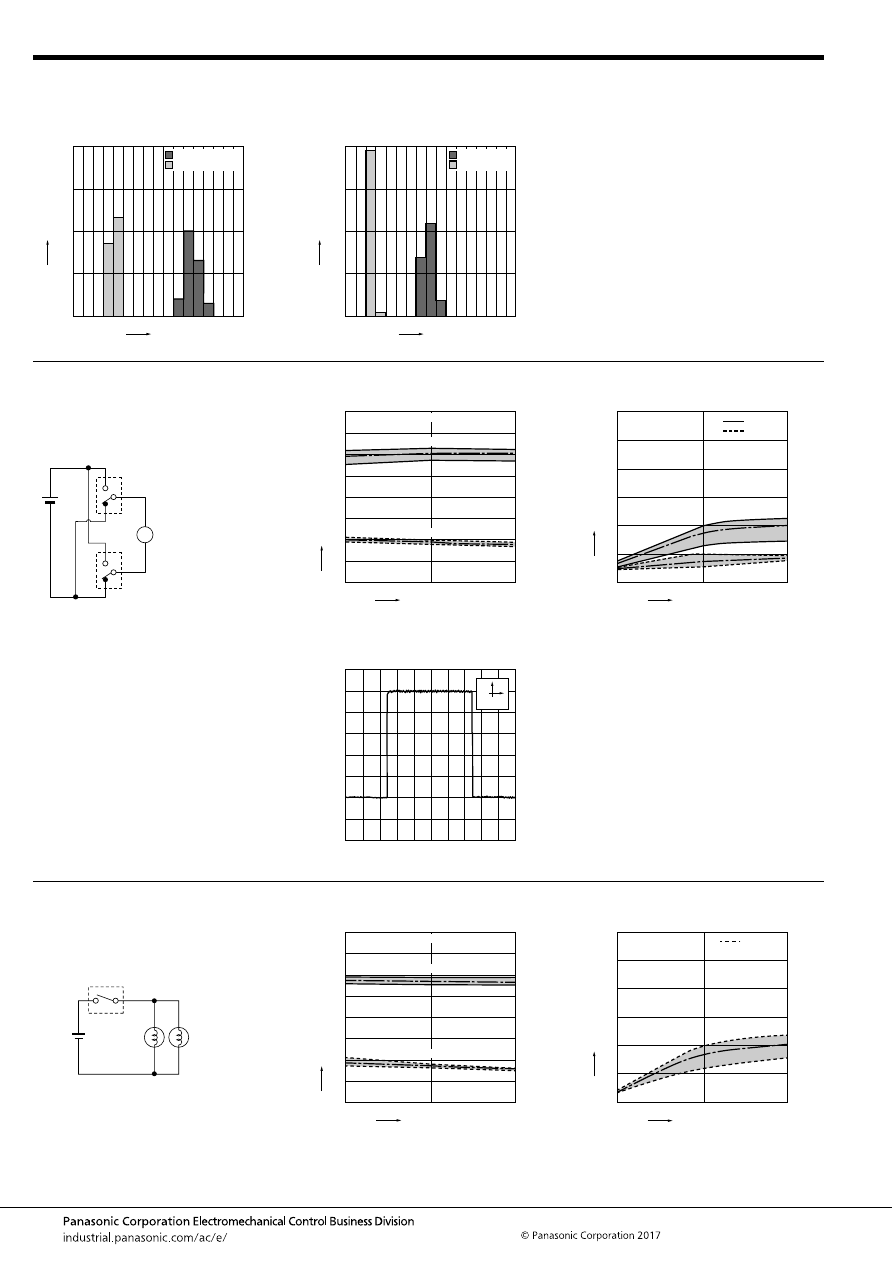

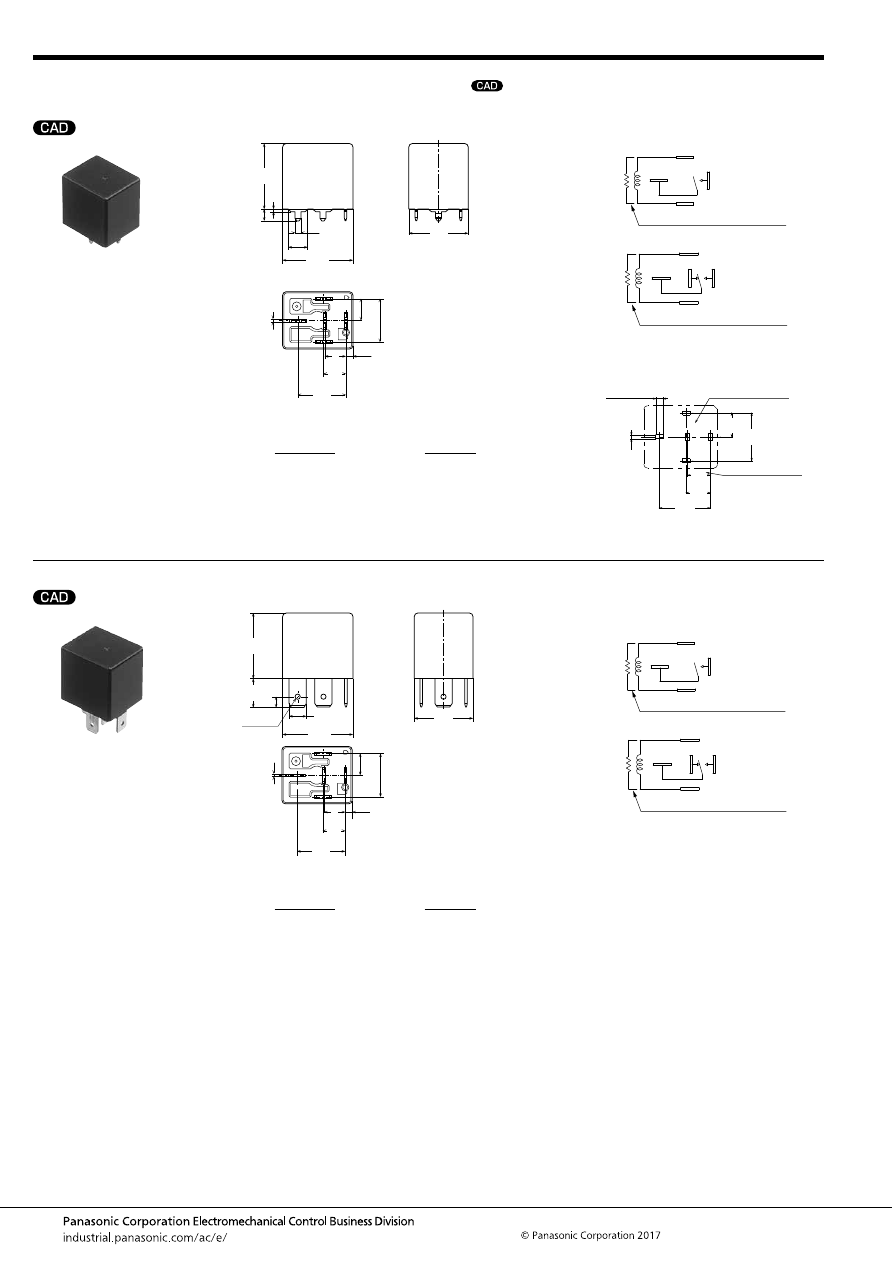

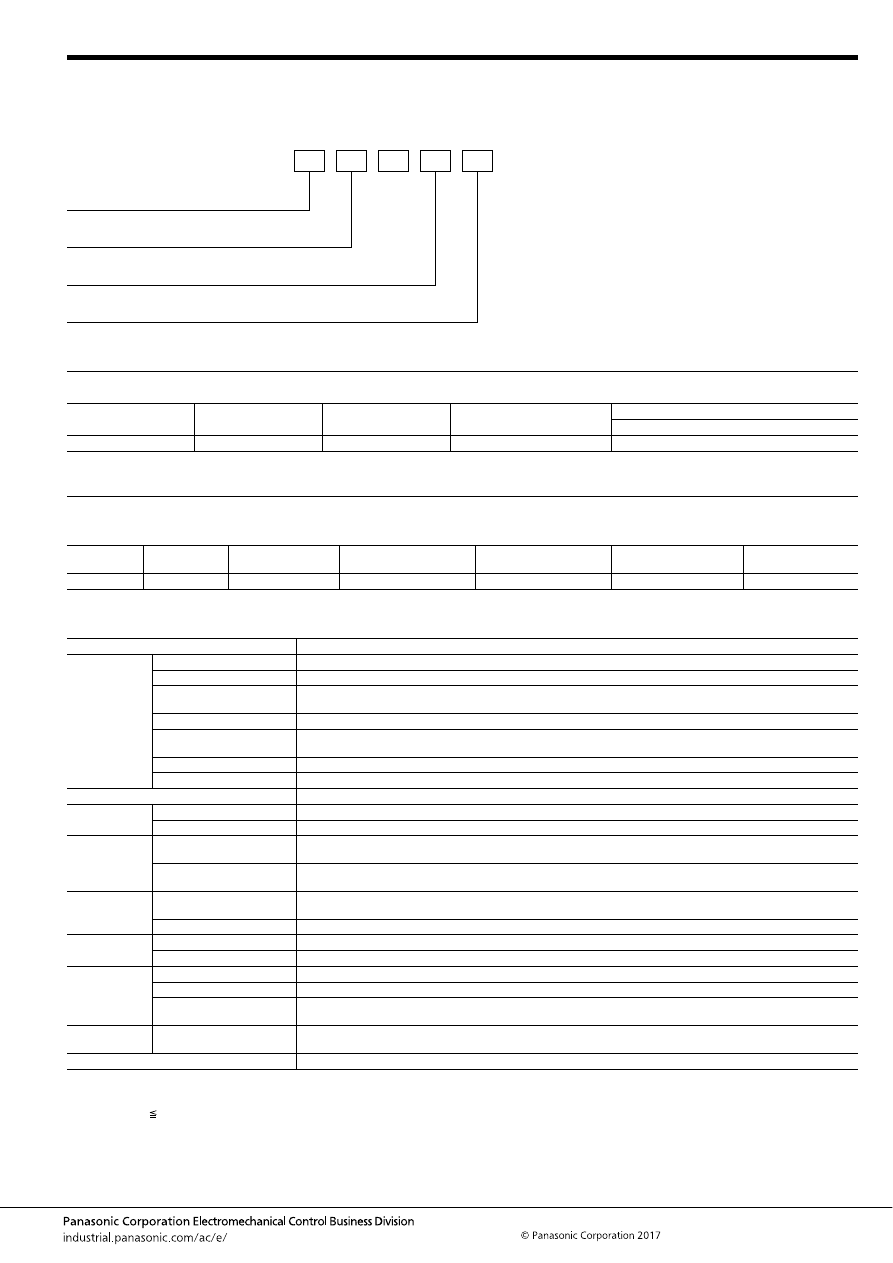

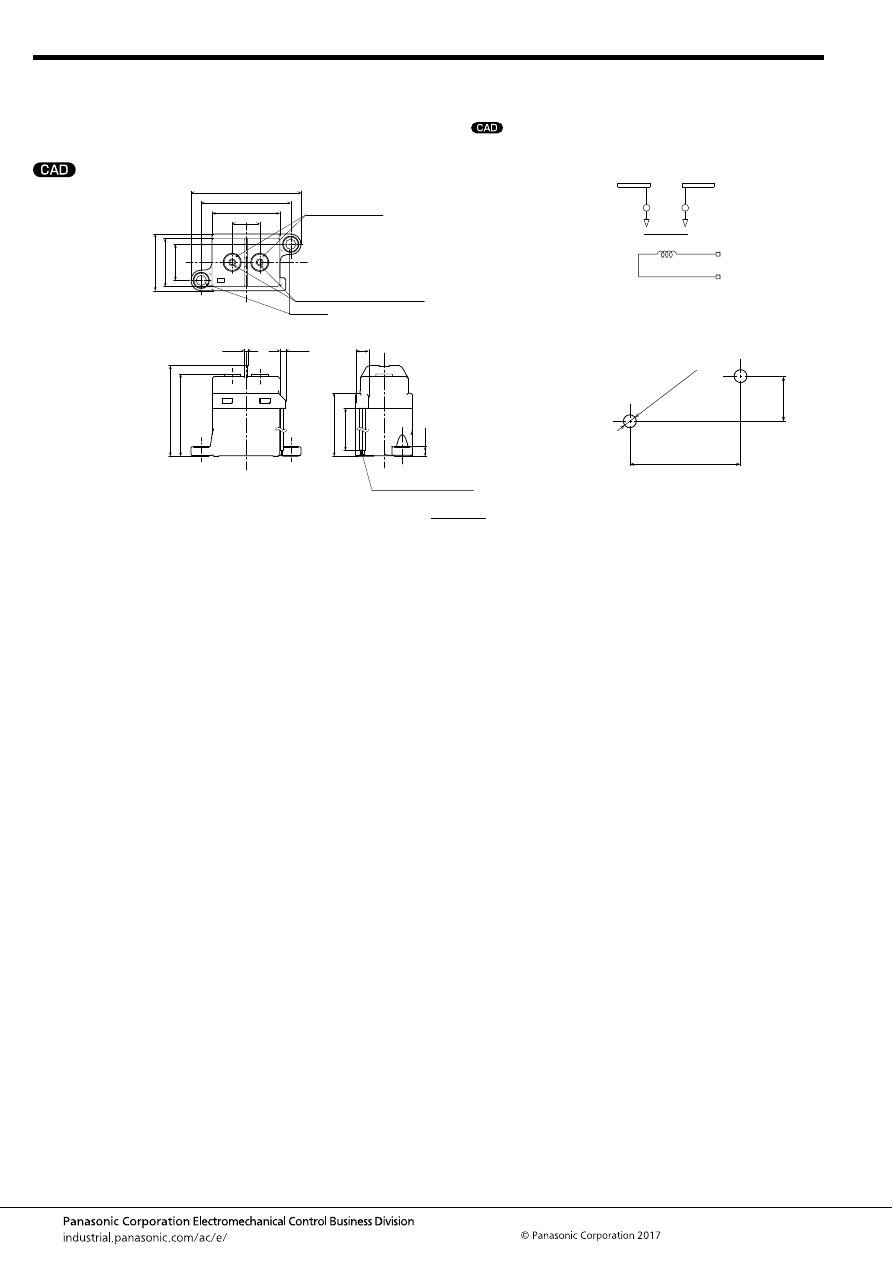

Type

Automotive relays

Product name

CT RELAYS

CT RELAYS POWER TYPE

CW RELAYS

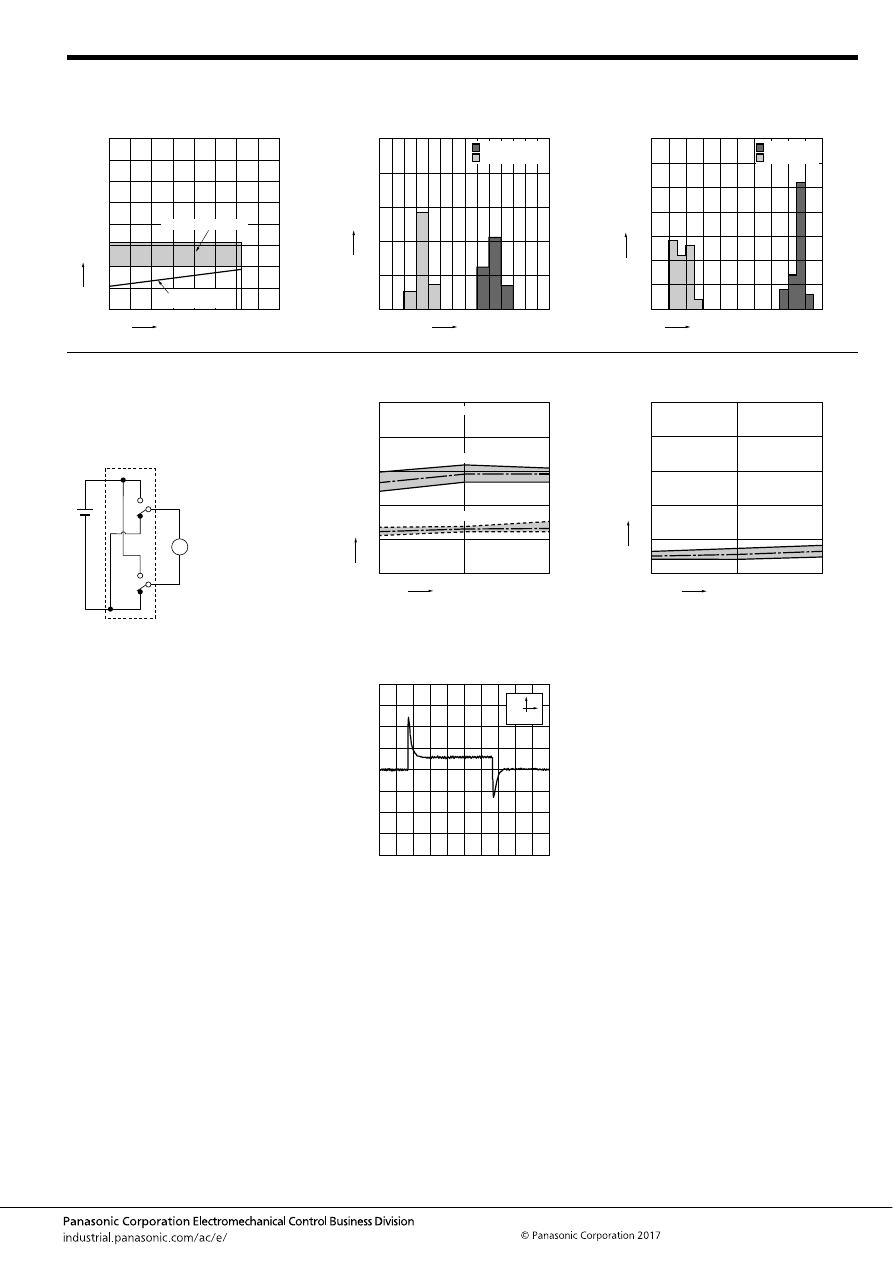

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACT

14

17.4

13.5

.551

7.2

.283

.685

.531

17.4

13.5

.685

.531

ACTP

14

17.4

13.5

.551

7.2

.283

.685

.531

17.4

13.5

.685

.531

ACW

18

32

19

.709

1.260

.748

Features

Small & Slim Twin/1 Form C type

Automotive Relay

High Carrying Current Type Small & Slim

Automotive Relay

Automotive Relay for Failsafe Circuits in

High Output Motors (EPS)

Con

tact

data

Contact arrangement 1 Form C, 1 Form C × 2 (8 pins) and 1 Form C × 2 (10 pins) 1 Form C, 1 Form C × 2 (8 pins) and 1 Form C × 2 (10 pins)

2 Form A

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

30A 14V DC

N.O.

10A 14V DC

N.C.

70A 14V DC

<Max. carrying current>

45A 14V DC

120A 14V DC

1 min.

at 85°C

185°F

Continuous

at 85°C

185°F

5 s

at 20°C

68°F

1A 14V DC

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power

800mW

1,000mW

1.4W

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 7.2V DC

Max. 7.2V DC

Max. 6.2V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 1.0V DC

Min. 1.0V DC

Min. 0.5V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 20ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 20ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

6

Min. 2 x 10

5

Electrical

Min. 2 × 10

5

(at 14 V DC, inrush: 25 A, steady: 5 A)

Min. 10

5

(at 14 V DC, 25 A motor lock condition)

Min. 10

5

(at 14 V DC, inrush: 30 A, steady: 7 A)

Min. 5 x 10

4

(at 14 V DC, 30 A motor lock condition)

−

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

–40 to +85°C

–40 to +185°F

–40 to +125°C

–40 to +257°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

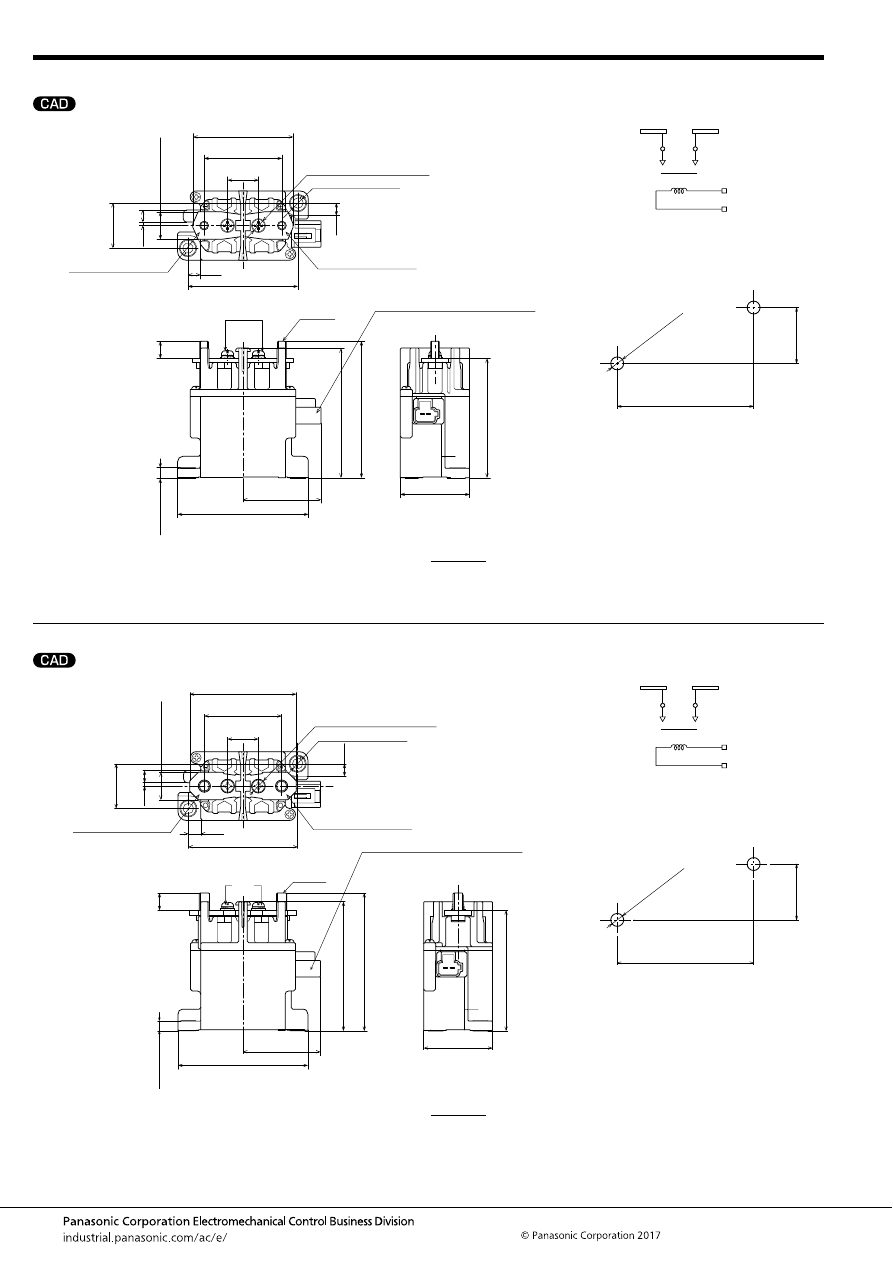

−

−

Flux tight

−

−

−

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

13.5

.531

13.5

.531

19

.748

Foot print (mm

inch

)

14

.551

17.4

.685

7.2

.283

17.4

.685

14

.551

17.4

.685

7.2

.283

17.4

.685

18

0.709

32

1.260

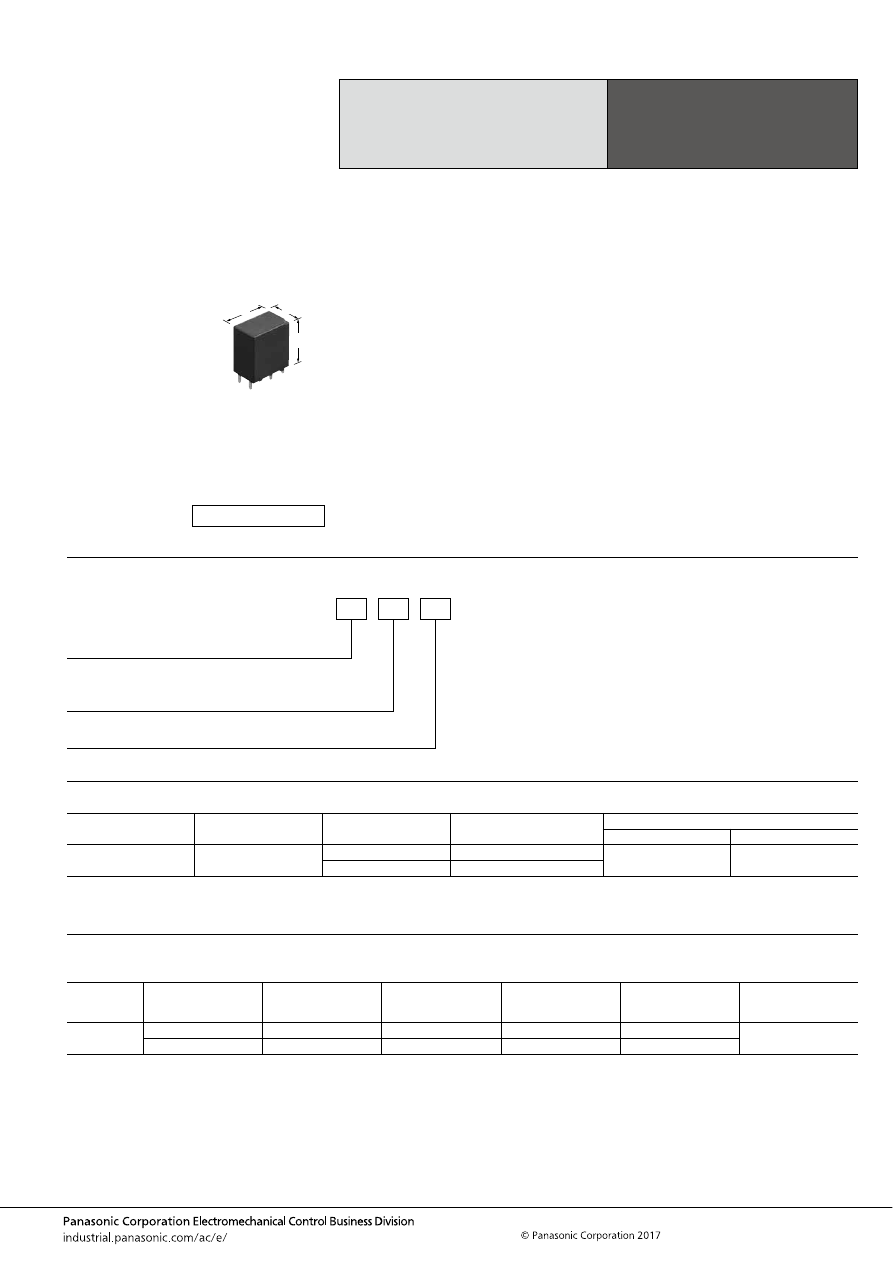

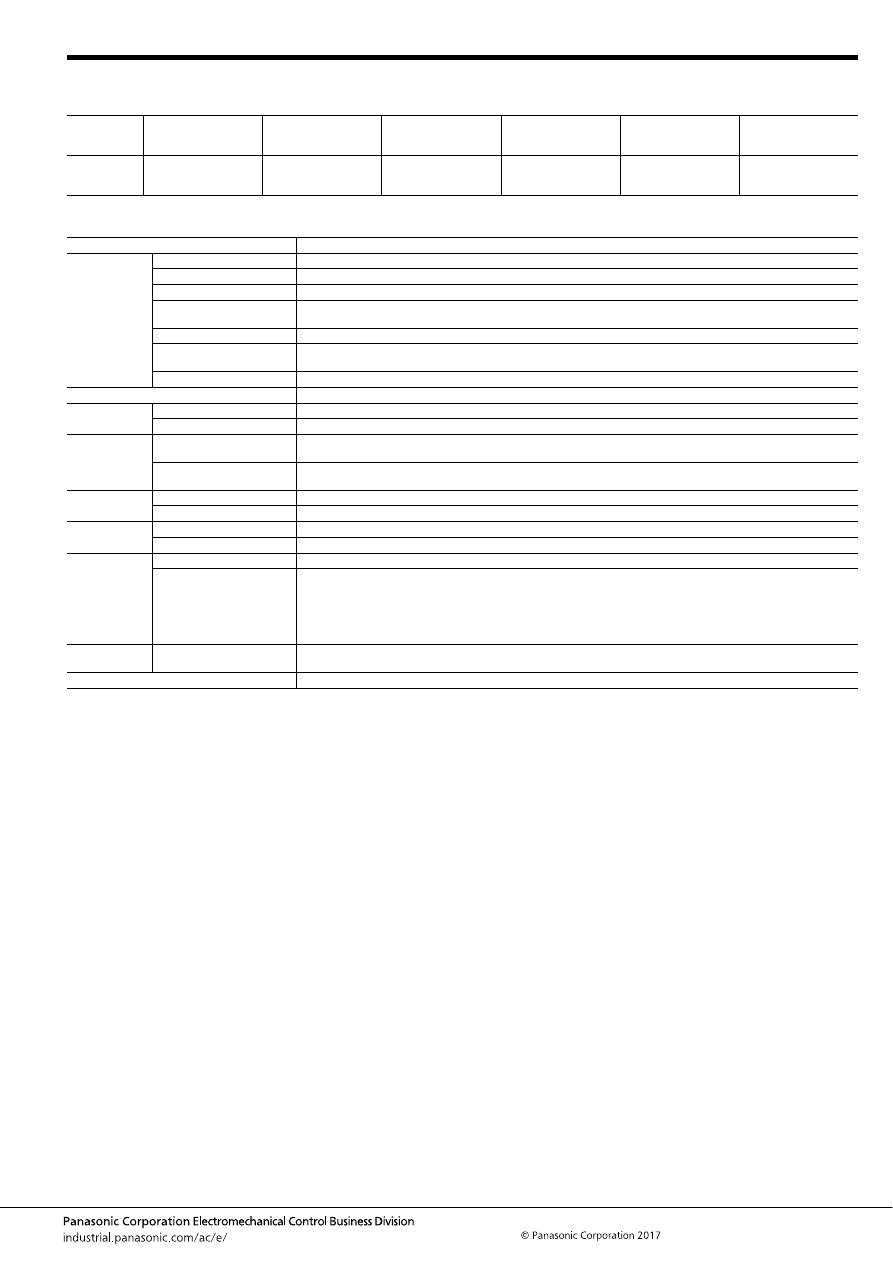

PC board pattern

Twin type (8 pins)

Twin type (10 pins)

1 Form C type

3.15

4.3

4.3

2.5

6.8

4×1.1 dia.

(Coil terminal)

(Coil terminal)

+0.1

0

+0.04

0

9.5

6

3

15

4×1.4 dia.

(Except coil terminal)

(Except coil terminal)

(Coil terminal)

(Except coil terminal)

+0.1

0

+0.04

0

.124

.169

.169

.098

.268

4×.043 dia.

.374

.236

.118

.591

4×.055 dia.

3.15

3.15

0.65

0.65

4.3

4.3

2.5

6.8

9.5

6

15

6×1.4 dia.

+0.1

0

+0.04

0

4×1.1 dia.

+0.1

0

+0.04

0

.124

.124

.026

.026

.169

.169

.098

.268

.374

.236

.591

6×.055 dia.

4×.043 dia.

3.15

4.3

2×1.1 dia.

+0.1

0

+0.04

0

3×1.4 dia.

15

0.65

9.5

6

.124

.169

2×.043 dia.

3×.055 dia.

.591

.026

.374

.236

Twin type (8 pins)

Twin type (10 pins)

1 Form C type

3.15

4.3

4.3

2.5

6.8

4×1.1 dia.

+0.1

0

+0.04

0

9.5

6

3

15

4×1.4 dia.

+0.1

0

+0.04

0

.124

.169

.169

.098

.268

.374

.236

.118

.591

4×.043 dia.

(Coil terminal)

4×.055 dia.

(Except coil terminal)

3.15

3.15

0.65

0.65

4.3

4.3

2.5

6.8

9.5

6

15

6×1.4 dia.

+0.1

0

+0.04

0

4×1.1 dia.

+0.1

0

+0.04

0

.124

.124

.026

.026

.169

.169

.098

.268

.374

.236

.591

6×.055 dia.

(Except coil terminal)

4×.043 dia.

(Coil terminal)

3.15

4.3

2×1.1 dia.

+0.1

0

+0.04

0

15

0.65

9.5

6

3×1.4 dia.

+0.1

0

+0.04

0

.124

.169

.591

.026

.374

.236

2×.043 dia.

(Coil terminal)

3×.055 dia.

(Except coil terminal)

Mounting dimensions

(Bottom view)

*This is not a PCB terminal.

8.0

7.1

r

0.5 12.0

r

0.5

9.0

r

0.5

12.8

2×0.4

2.0

14.0

4×0.8

.315

.280

r

.020.472

r

.020 .354

r

.020

.504

2.6

.102

2×.016

.079

.551

2.0

.079

4×.031

Weight (approx.)

8 g

.28 oz

(Twin type), 4 g

.14 oz

: (1 Form C type) 8 g

.28 oz

(Twin type), 4 g

.14 oz

: (1 Form C type)

26 g

.92 oz

Remarks

10 pins type available

10 pins type available

Welding terminal

Page

77

83

88

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

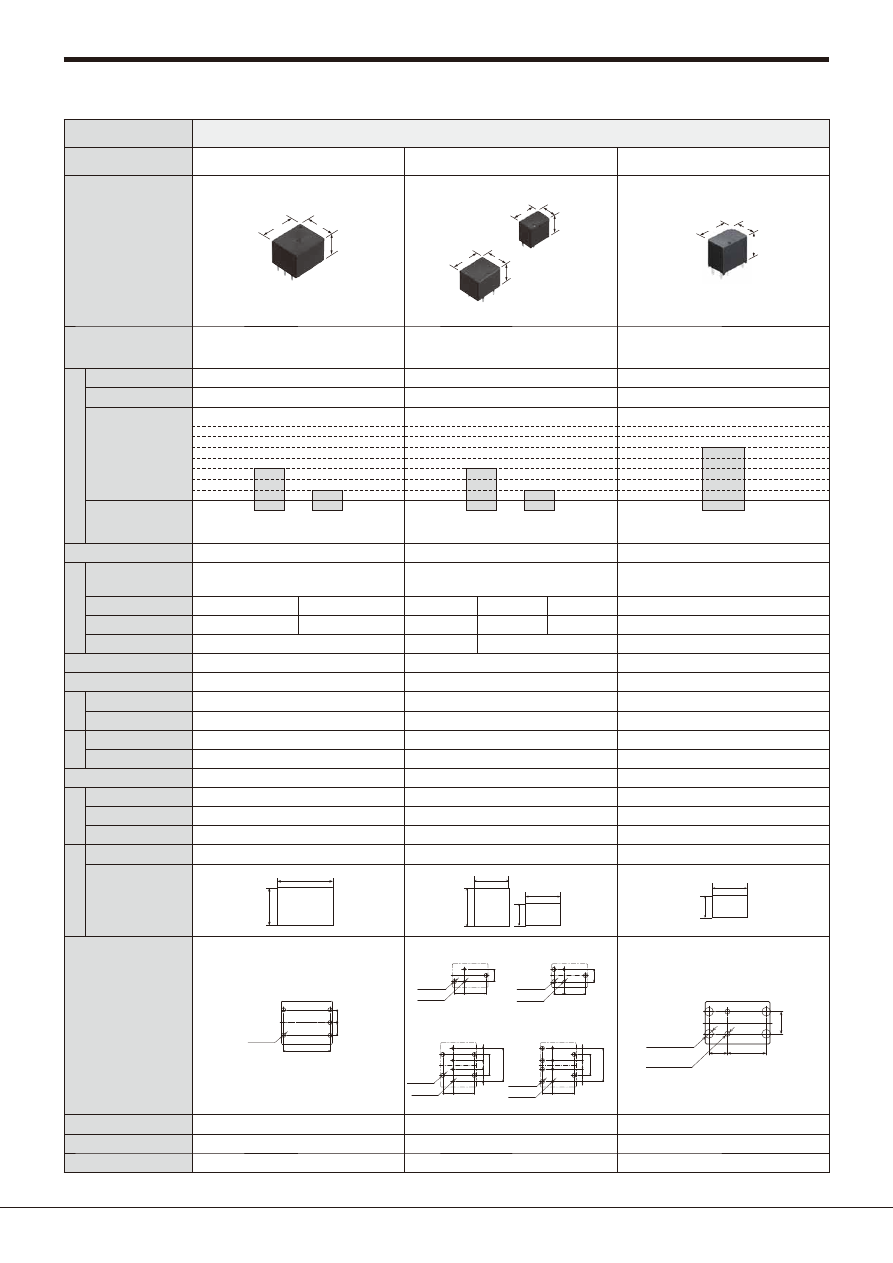

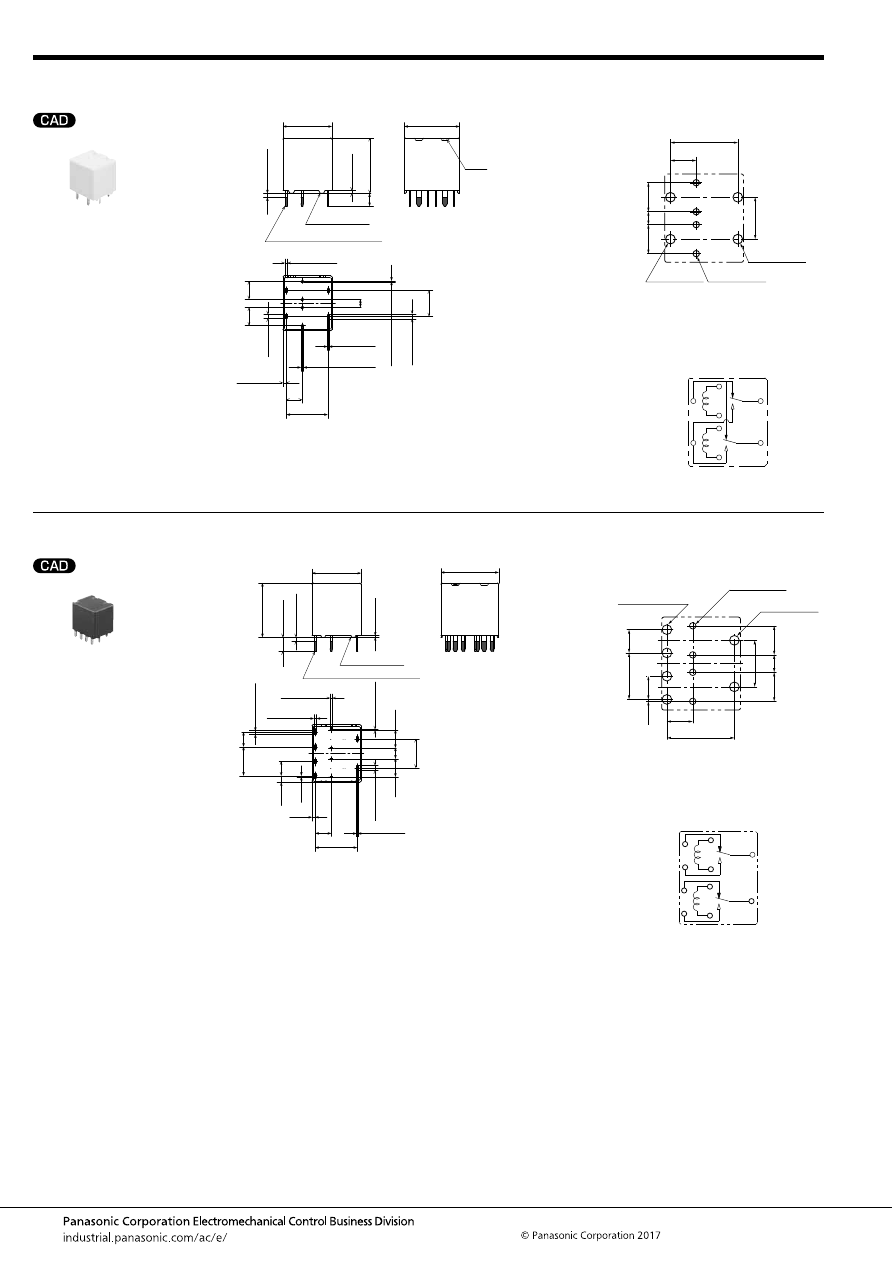

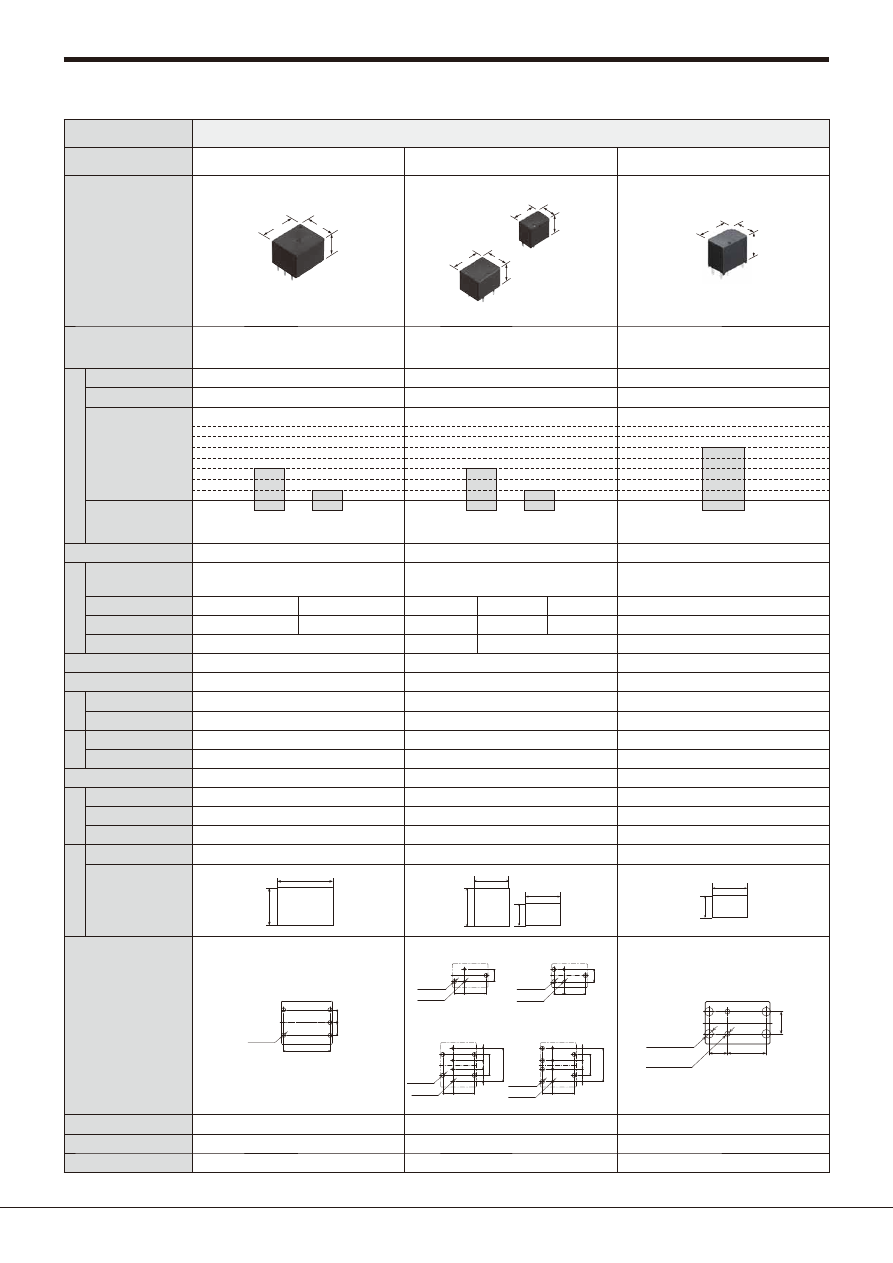

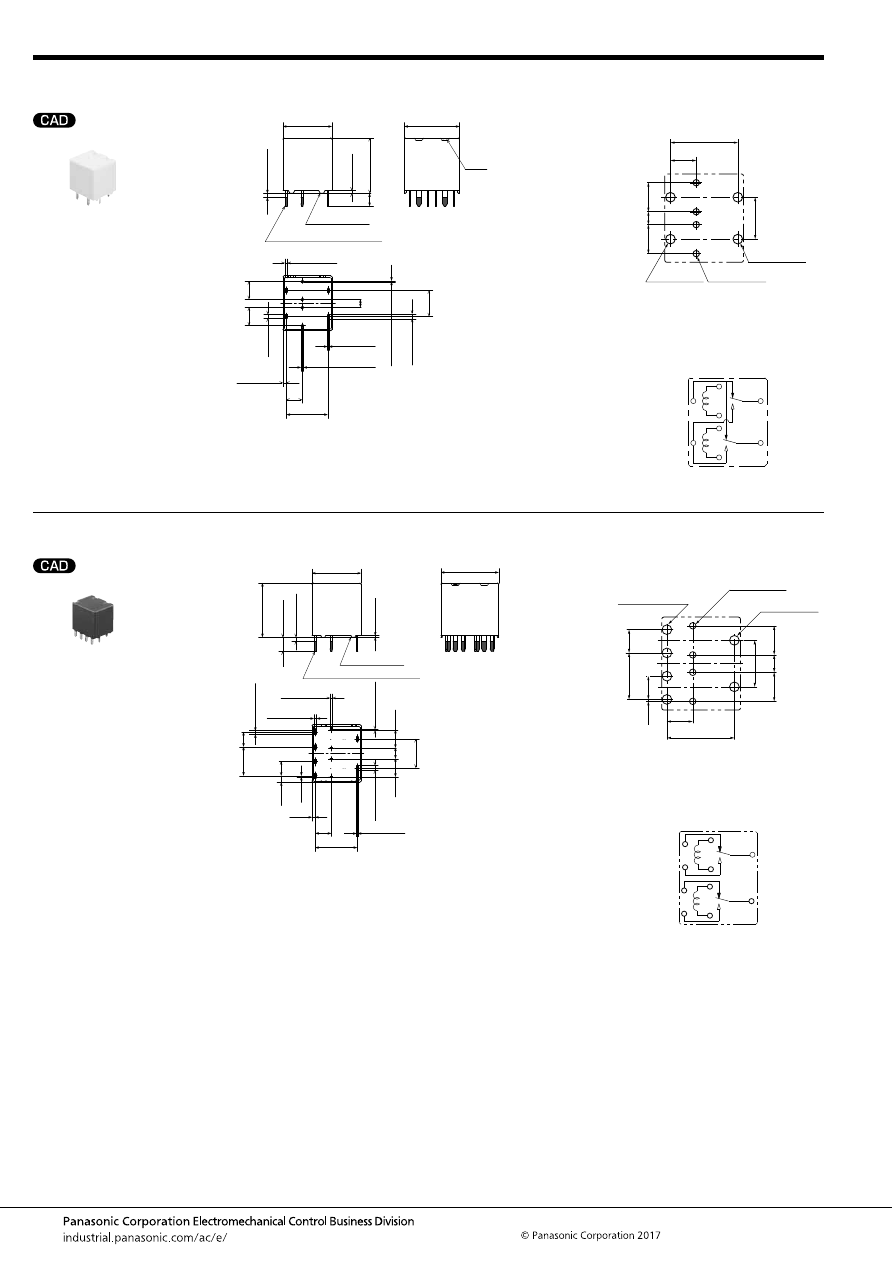

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–11–

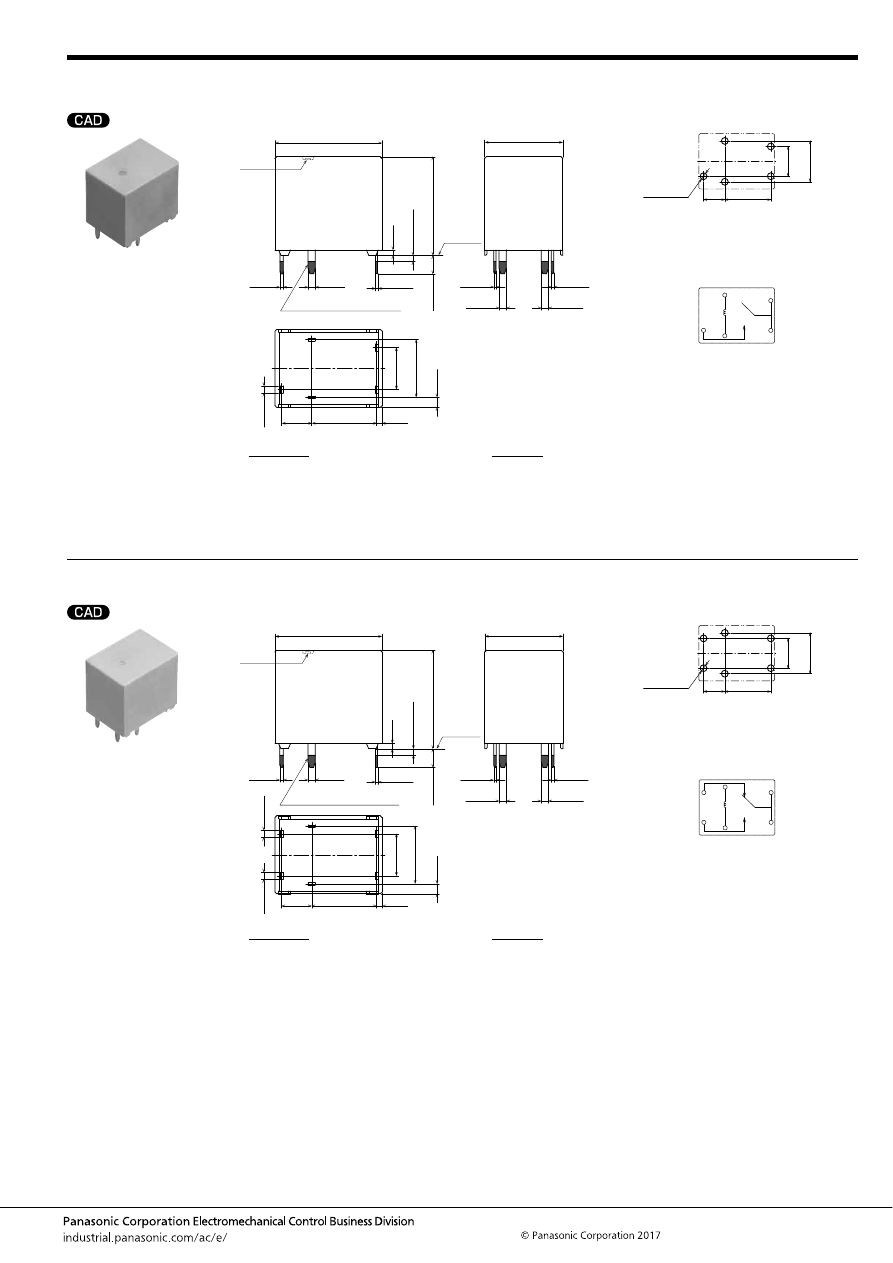

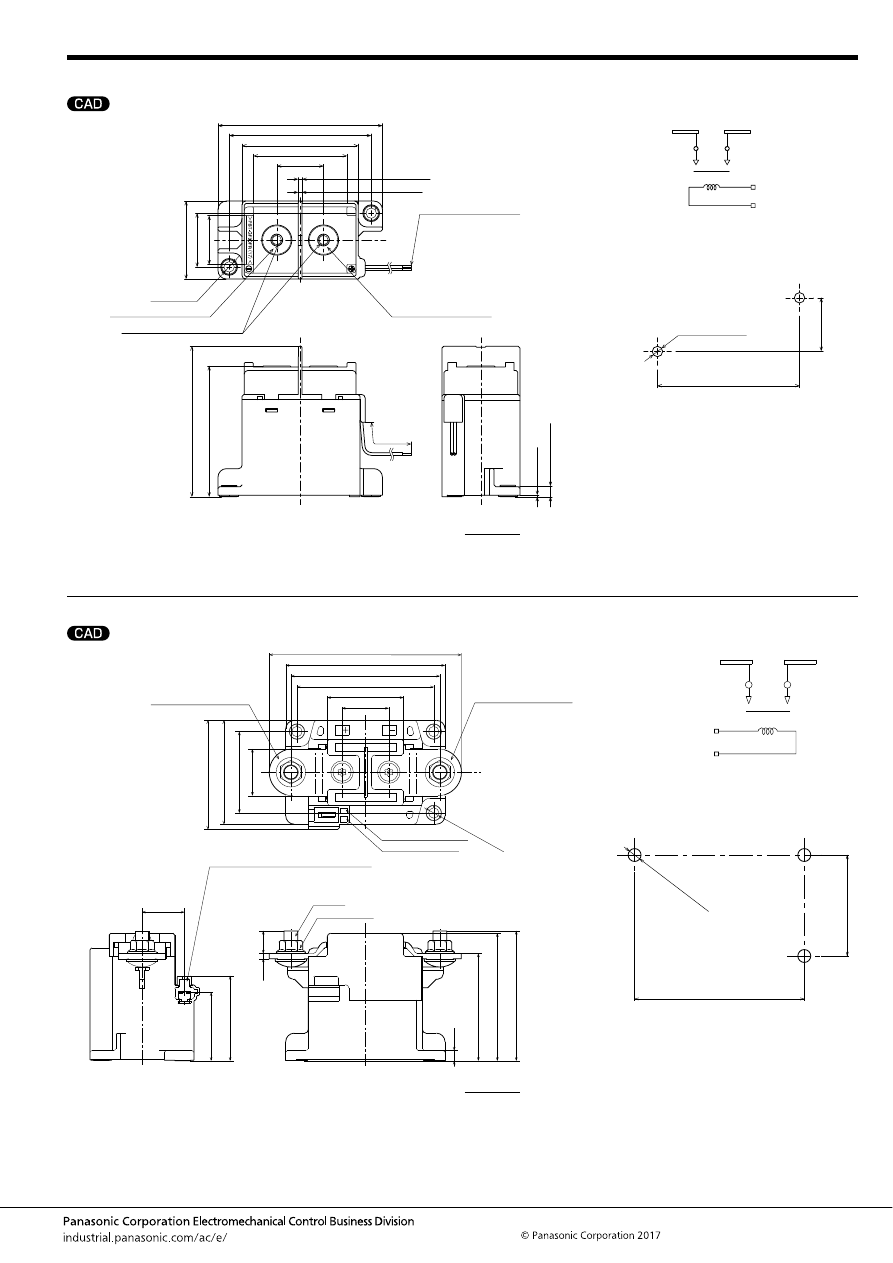

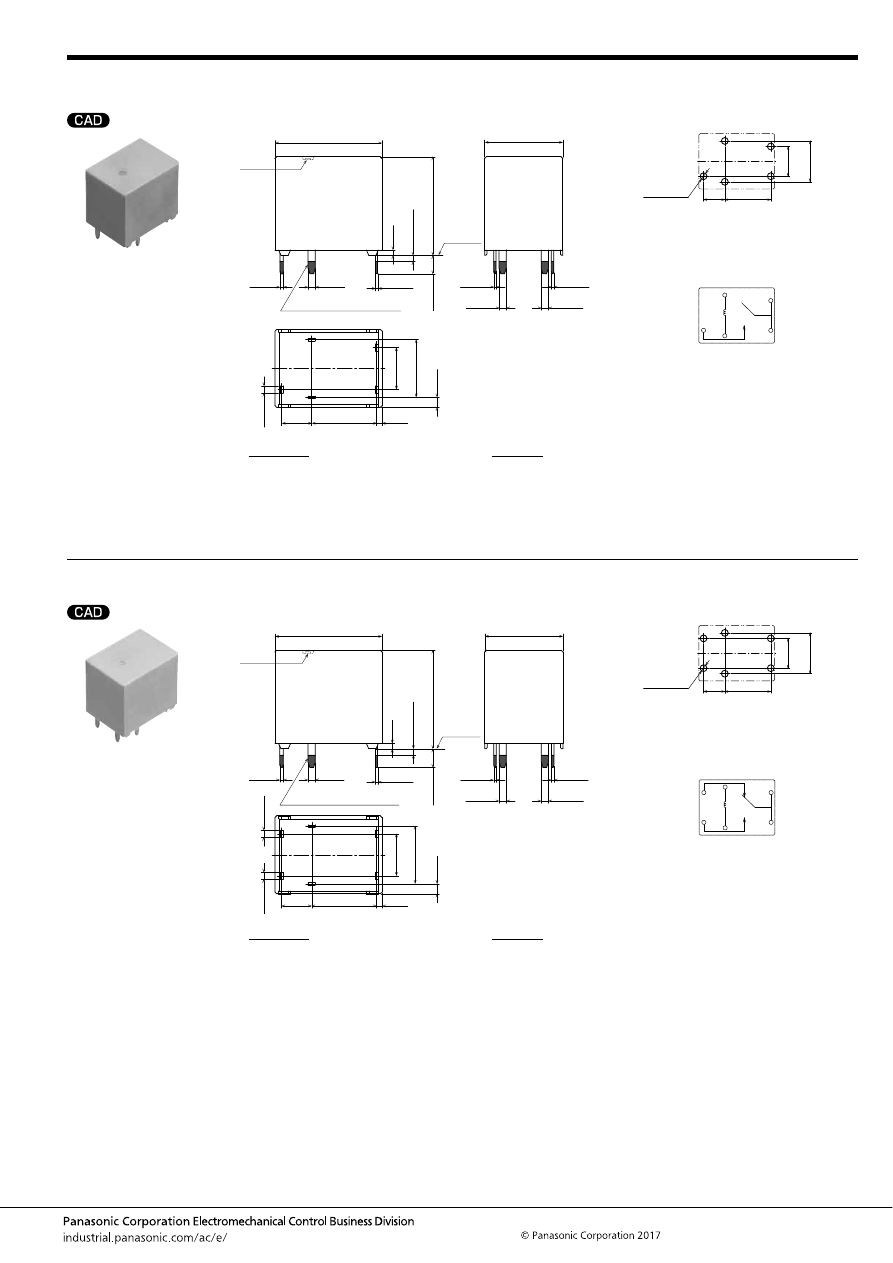

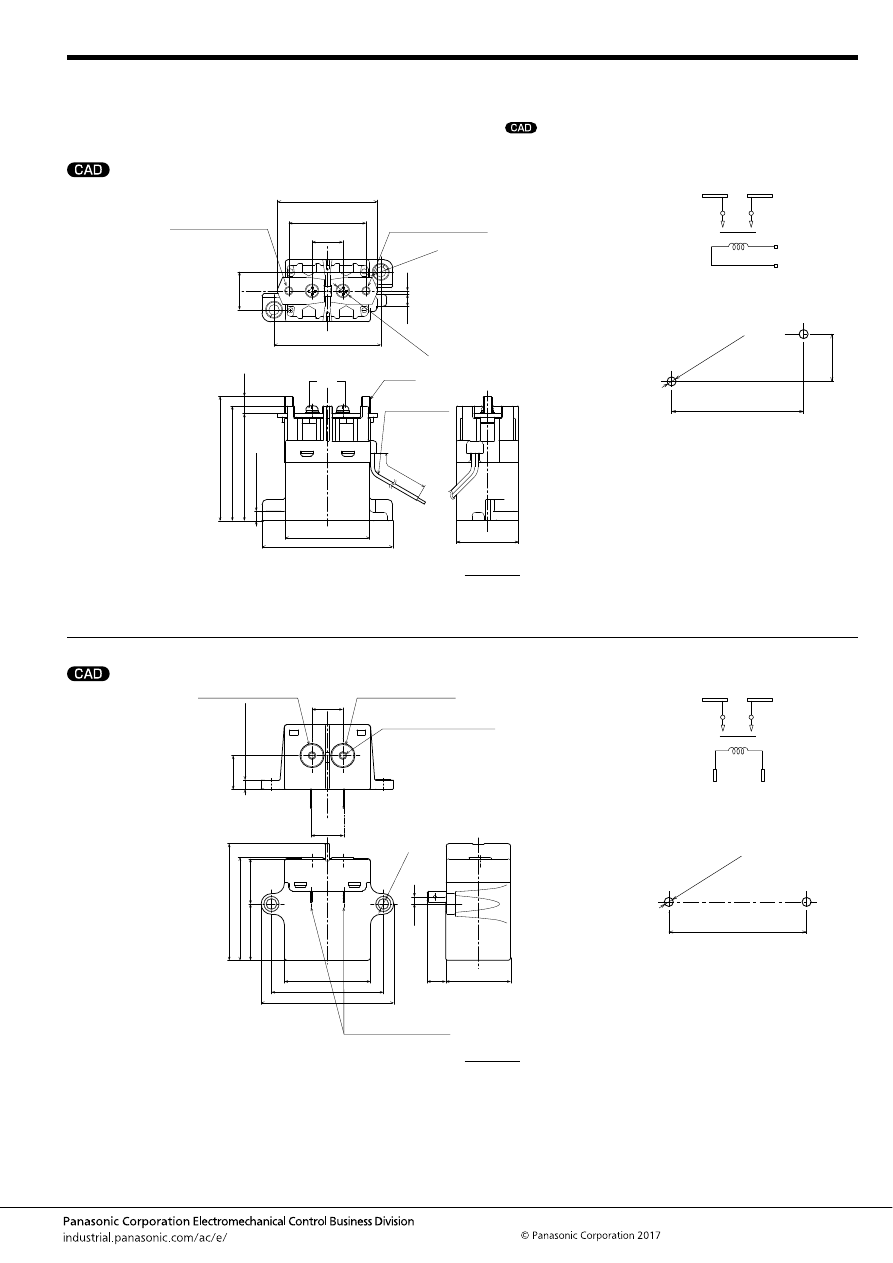

Type

Automotive relays

Product name

TA RELAYS

TB RELAYS

TB RELAYS POWER TYPE

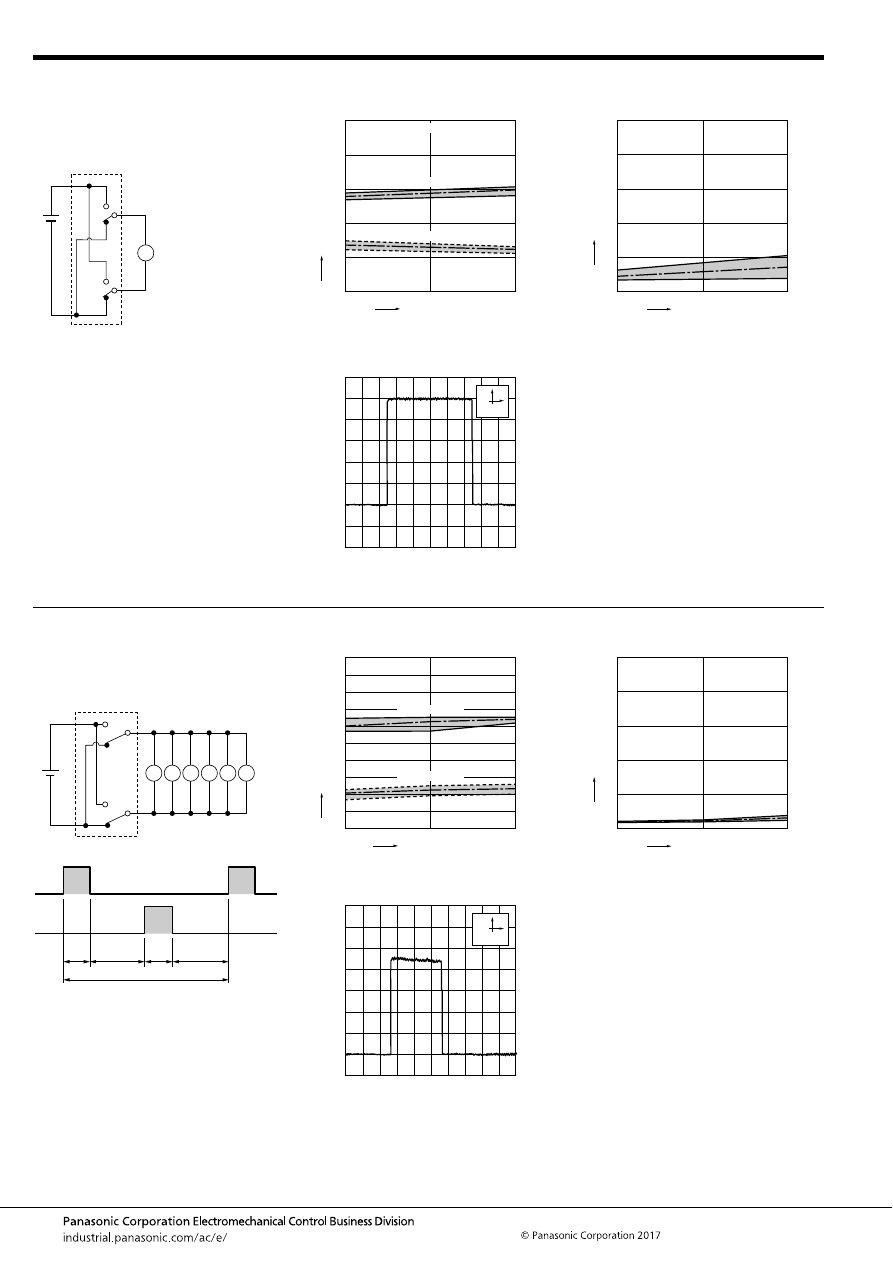

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACTA

17

19.8

14

.669

.780

.551

ACTB

9.2

14

13.5

.362

.551

.531

14

17.4

13.5

.551

.685

.531

ACTBP

9.2

14

14

.362

.551

.551

Features

1 Form C Automotive Quiet Relay

Miniature PC Board, Twin/1 Form C Type

Automotive Relay

High Carrying Current 1 Form A Type Relay

for Miniature PC board

Con

tact

data

Contact arrangement

1 Form C

1 Form A, 1 Form C, 1 Form C × 2 (8 pins) and 1 Form C × 2 (10 pins)

1 Form A

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

30A 14V DC

N.O.

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power

900mW

640mW

1,440mW

900mW

640mW

480mW

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 6.5V DC

Max. 7.7V DC

Max. 5.5V DC Max. 6.5V DC Max. 7.7V DC

Max. 7.0V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 0.8V DC

Min. 0.5V DC

Min. 0.8V DC

Min. 0.5V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

7

Min. 5 x 10

6

Electrical

Min. 10

5

Min. 10

5

Min. 10

5

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

Standard type: –40 to +85°C

–40 to +185°F

High heat-resistant/Pin in Paste compliant type: –40 to +110°C

–40 to +230°F

–40 to +110°C

–40 to +230°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

−

●

(PIP type)

●

(PIP type)

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

14

.551

13.5

.531

/14.0

.551

(PIP type)

14

.551

Foot print (mm

inch

)

17

.669

19.8

.780

14

17.4

.685

14

.551

.551

9.2

.362

14

.551

9.2

.362

PC board pattern

18.2

5×1.6 dia.

5×.063 dia.

5

.197

5

.197

.717

Twin type (8 pins)

1 Form C type

Twin type (10 pins)

1 Form A type

4.8

8.4

.331

4

.157

.189

2×1.6 dia.

2×.063 dia.

2×1.1 dia.

2×.043 dia.

4.8

8.4

.331

4

.157

.189

3×1.6 dia.

3×.063 dia.

2×1.1 dia.

2×.043 dia.

8.4

.331

4

.157

13

.512

8.2

.323

4.8

.189

4.8

.189

4×1.1 dia.

4×.043 dia.

4×1.6 dia.

4×.063 dia.

8.4

.331

4

.157

4.8

.189

4.8

.189

4×1.1 dia.

4×.043 dia.

6×1.6 dia.

6×.063 dia.

13

.512

8.2

.323

1 Form A type

4.8

8.4

.331

4

.157

.189

4×1.9 dia.

4×.075 dia.

2×1.1 dia.

2×.043 dia.

Weight (approx.)

8 g

.28 oz

Single type: 5 g

.176 oz

, Twin type: 9.5 g

.335 oz

5 g

.176 oz

Remarks

−

10 pins type available

−

Page

91

95

104

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

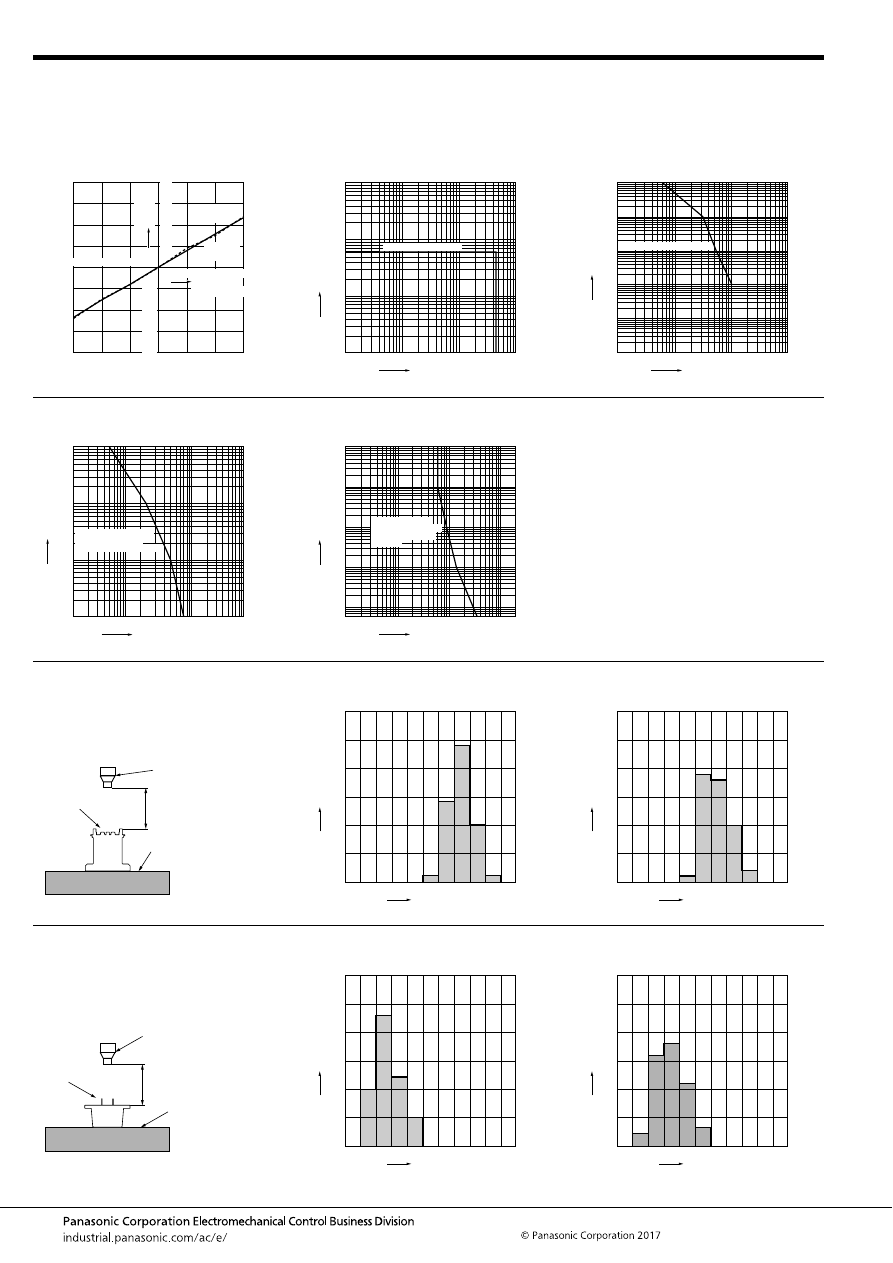

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

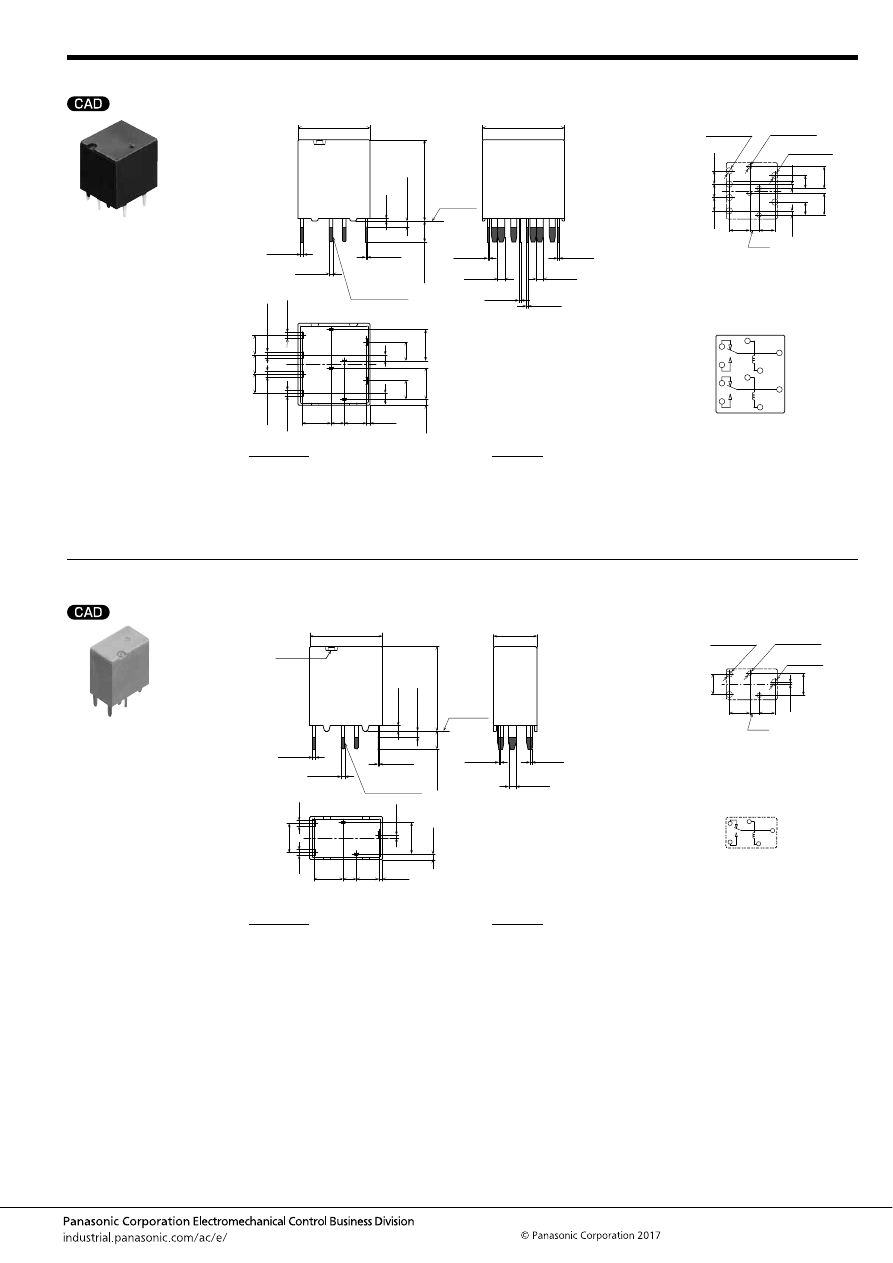

–12–

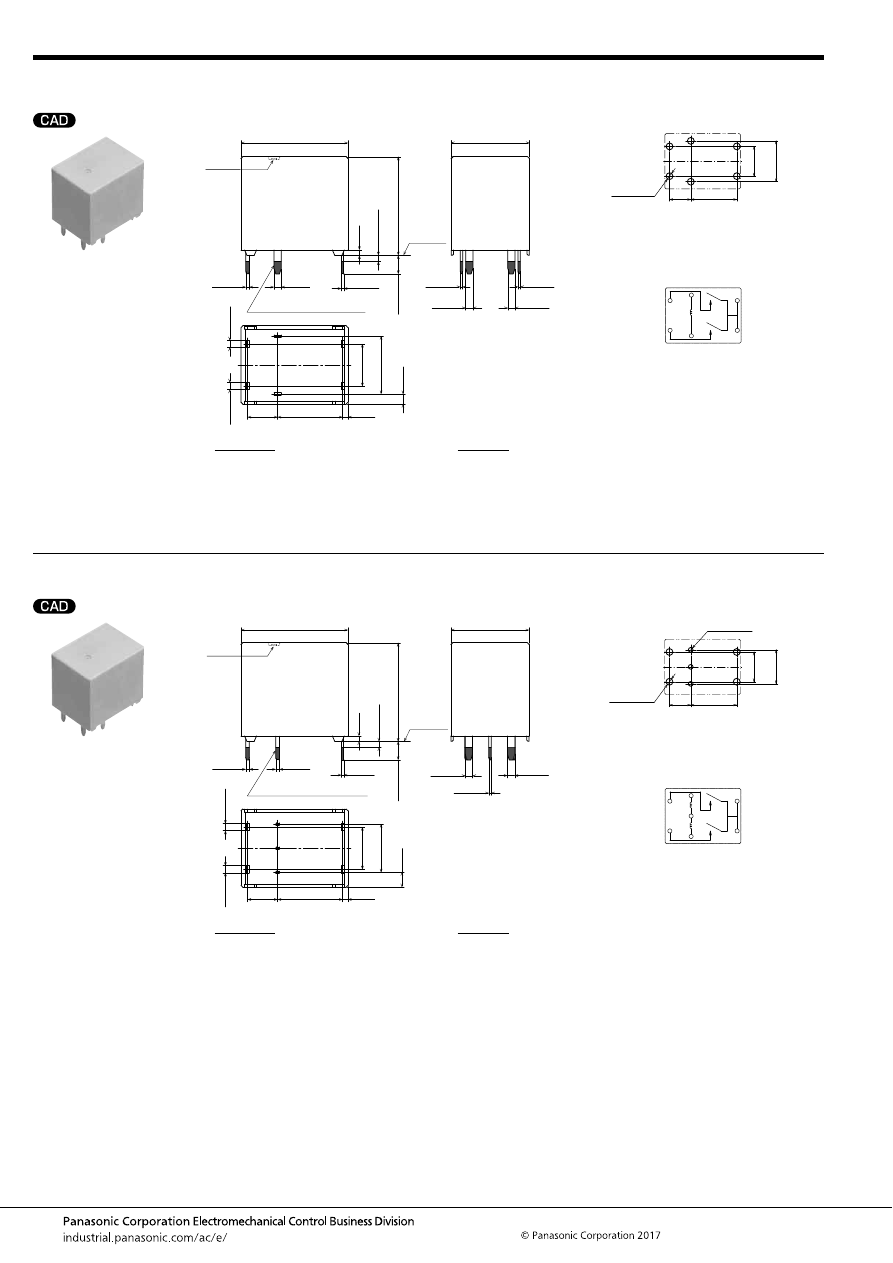

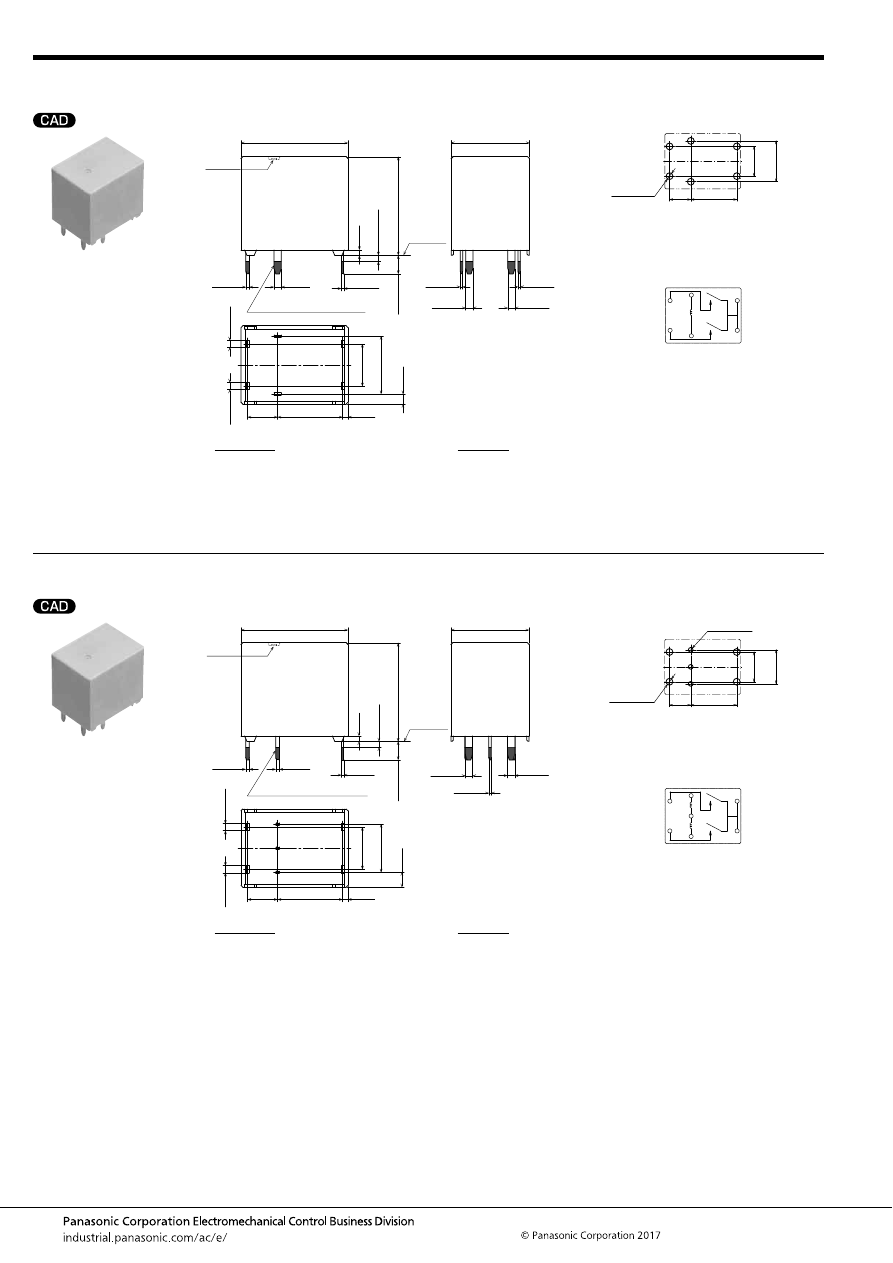

Type

Automotive relays

Product name

TC RELAYS

TE RELAYS

TG RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACTC

13

17.8

16

.512

.701

.630

ACTE

7.2

12

13.5

.283

.472

.531

12

13.6

13.5

.472

.535

.531

ACTG

12.6

17.8

18

.496

.701

.709

Features

High Load Relay for Smart J/B

Miniature PC Board, Twin Type, 1 Form C

Automotive Relay

High Load Relay for Smart J/B

Con

tact

data

Contact arrangement

1 Form A (Standard type), 1 Form C (Standard type), Double make contact 2 Form A

(Standard type) and Double make contact 2 Form A (2 coil latching type)

1 Form C, 1 Form C × 2 (8 pins) and 1 Form C × 2 (10 pins)

1 Form A and 1 Form C

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

30A 14V DC

N.O.

15A 14V DC

N.C.

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

30A 14V DC

N.O.

15A 14V DC

N.C.

Min. switching load

(resistive)

Latching type

●

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power 1,309mW

900mW

640mW

1,920mW

1,309mW

900mW

655mW

640mW

450mW

Operate (Set) voltage at 20°C

68°F

(initial) Max. 6.5 V DC Max. 7.0 V DC Max. 7.5 V DC

Max. 7.5 V DC

Max. 5.5V DC Max. 6.5V DC Max. 7.7V DC

Max. 6.5V DC

Max. 7.0V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 0.5 V DC

Min. 0.6V DC

Min. 0.8V DC

Min. 0.8V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

6

(2 coil latching type)

Min. 10

7

Min. 10

7

Electrical

Min. 10

5

Min. 10

5

Min. 10

5

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

Standard type: –40 to +85°C

–40 to +185°F

High heat-resistant/Pin in Paste compliant type: –40 to +110°C

–40 to +230°F

–40 to +110°C

–40 to +230°F

–40 to +110°C

–40 to +230°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

●

(PIP type)

●

(PIP type)

−

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

16.0

.630

/16.4

.646

(PIP type)

13.5

.531

/14.0

.551

(PIP type)

18.0

.709

Foot print (mm

inch

)

17.8

.701

13

.512

12

13.6

12

.472

.472

7.2

.535

.283

17.8

.701

12.6

.496

PC board pattern

1 Form A type

2 coil latching type

1 Form C type

5×1.6 dia.

9.6

.378

7

10.8

.425

5

.197

.276

5×.063 dia.

9.6

.378

7

10.8

.425

5

.197

.276

6×1.6 dia.

6×.063 dia.

8

.315

7

10.8

.425

5

.197

.276

4×1.6 dia.

4×.063 dia.

3×1.1 dia.

3×.043 dia.

Twin type (8 pins)

1 Form C type

Twin type (10 pins)

4.8

.189

3.7

.146

2.2

.087

0.5

.020

5.2

.205

2×1.5 dia.

2×.059 dia.

2×1.1 dia.

2×.043 dia.

1.6 dia.

.063 dia.

4.8

.189

11.6

.457

6.4

.252

5.2

.205

5.2

.205

2×1.5 dia.

2×.059 dia.

4×1.1 dia.

4×.043 dia.

2×1.6 dia.

2×.063 dia.

3.7

.146

2.2

.087

4.8

.189

3.1

.122

3.1

.122

5.2

.205

5.2

.205

4×1.5 dia.

4×.059 dia.

4×1.1 dia.

4×.043 dia.

2×1.6 dia.

2×.063 dia.

3.7

.146

2.2

.087

4.8

.189

3.1

.122

3.1

.122

3.2

.126

3.2

.126

3.2

.126

1

.039

1

.039

1 Form A type

1 Form C type

6×1.6 dia.

6×.063 dia.

6.4

.252

7.8

.307

9

.354

10

.394

5.8

.228

4.1

.161

3.2

.126

7.8

.307

9

.354

10

.394

5.8

.228

6×1.6 dia.

6×.063 dia.

Weight (approx.)

10 g

.35 oz

Single type: 3.5 g

.12 oz

, Twin type: 6.5 g

.23 oz

12 g

.42 oz

Remarks

−

10 pins type available

−

Page

109

118

126

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–13–

Type

Automotive relays

Product name

TH RELAYS

TJ RELAYS

TL RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACTH

12

11

8.8

.472

.433

.346

12

21.6

8.8

.472

.850

.346

ACTJ

16

15

11.2

.630

.591

.441

ACTL

11

14.4

16

.433

.567

.630

Features

Miniature PC Board, Twin, 1 Form C,

Surface-mount Type Automotive Relay

Middle Load Relay for Smart J/B

High Load Relay for Smart Junction Box

Con

tact

data

Contact arrangement

1 Form C and 1 Form C × 2 (10 pins)

1 Form C

Double make contact 2 Form A

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

20A 14V DC

N.O.

10A 14V DC

N.C.

1A 14V DC

30A 14V DC

N.O.

15A 14V DC

N.C.

1A 14V DC

40A 14V DC

N.O.

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

12V DC

Rated operating power

900mW

655mW

450mW

640mW

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 6.5V DC

Max. 7.7V DC

Max. 7.0V DC

Max. 6.5V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 0.6V DC

Min. 0.8V DC

Min. 0.5V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

7

Min. 10

7

Min. 5 x 10

6

Electrical

Min. 10

5

Min. 10

5

Min. 10

5

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +110°C

–40 to +230°F

–40 to +110°C

–40 to +230°F

–40 to +110°C

–40 to +230°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

●

−

●

(PIP type)

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

Surface mount: 8.8

.346

11.2

.441

16

.630

Foot print (mm

inch

)

21.6

12

11

.850

.433

12

.472

.472

15

.591

16

.630

14.4

.567

11

.433

PC board pattern

Twin type (10 pins)

1 Form C type

2×2

2×.079

3.85

16.4

.646

.152

3.85

.152

3×2.5

3×.098

4

.157

4

.157

5.2

.205

4×2

4×.079

3.85

16.4

.646

.152

3.85

.152

6×2.5

6×.098

10.6

.417

8

.315

8

.315

5.2

.205

5.2

.205

14.3

4×R 0.45

4×R .018

1.7

.067

.563

(0.85)

(.033)

5.7

.224

3.8

.150

5.7

.224

10.8

.425

4.8

6

9.6

.378

3.5

.138

5.9

.189

.236

.232

0.9

2×R1

2×R.039

2.2

1.1

.035

.043

2×R1.1

2×R.043

2.2

.087

.087

2×1.1 dia.

2×.043 dia.

Weight (approx.)

1 Form C type: 3 g

.106 oz

, Twin type: 6 g

.21 oz

7 g

.25 oz

6.5 g

.23 oz

Remarks

−

−

−

Page

131

136

140

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

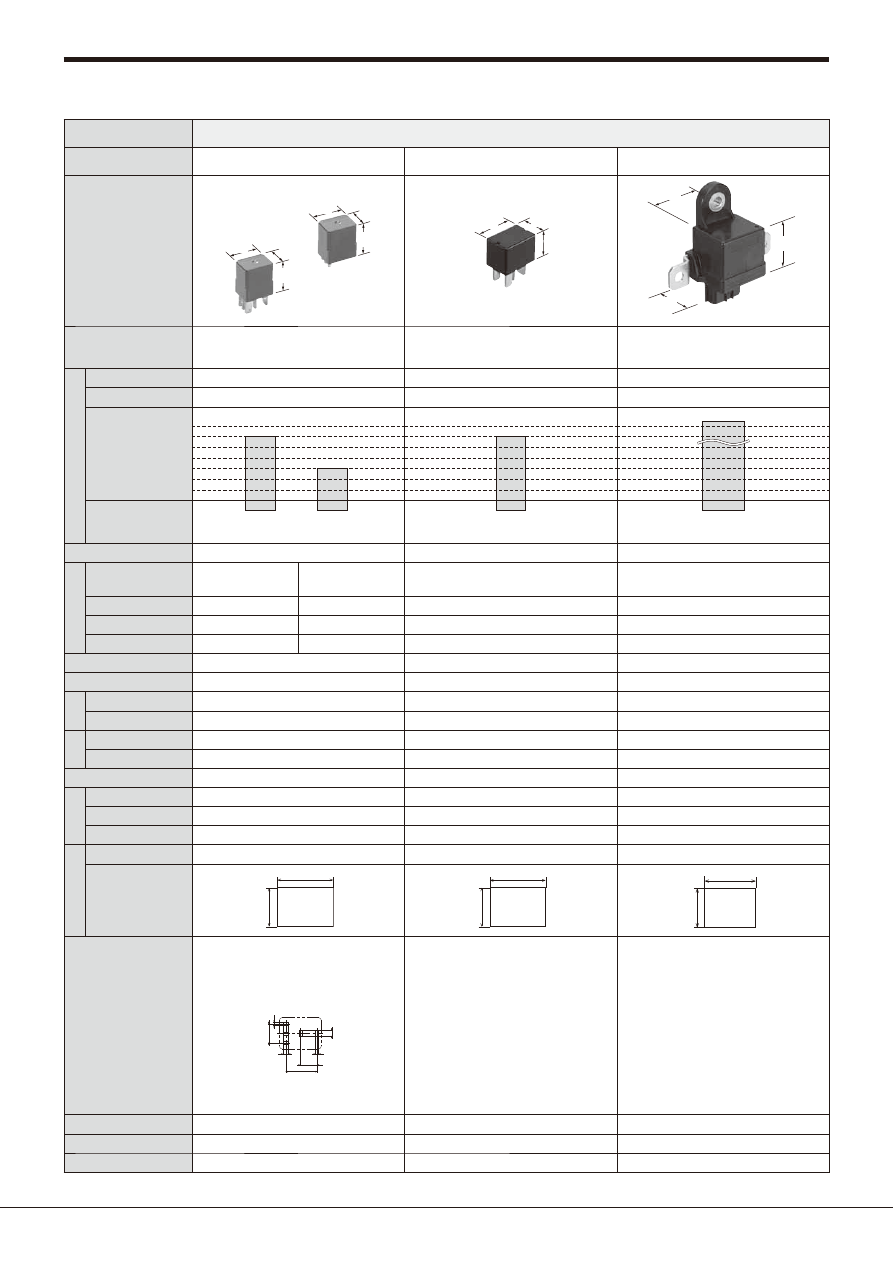

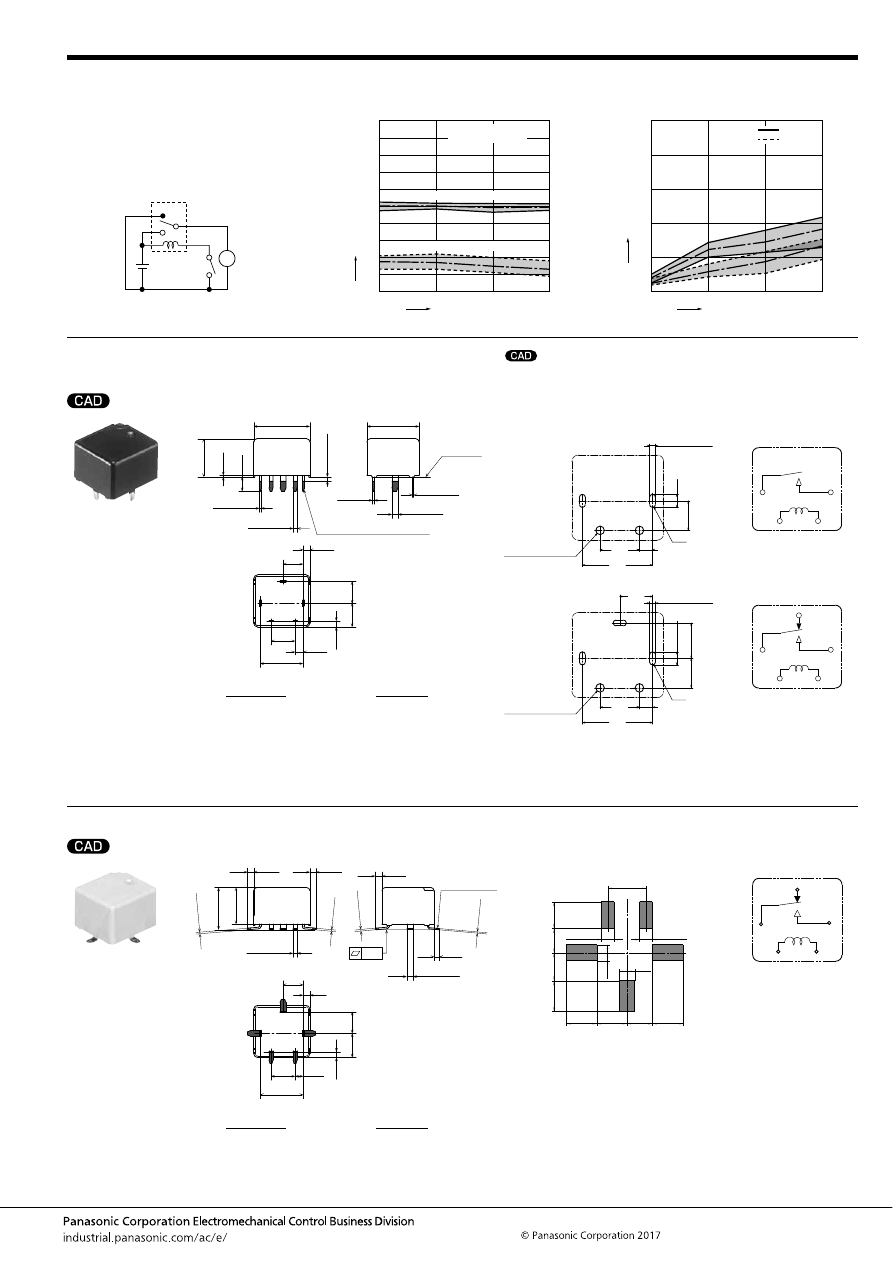

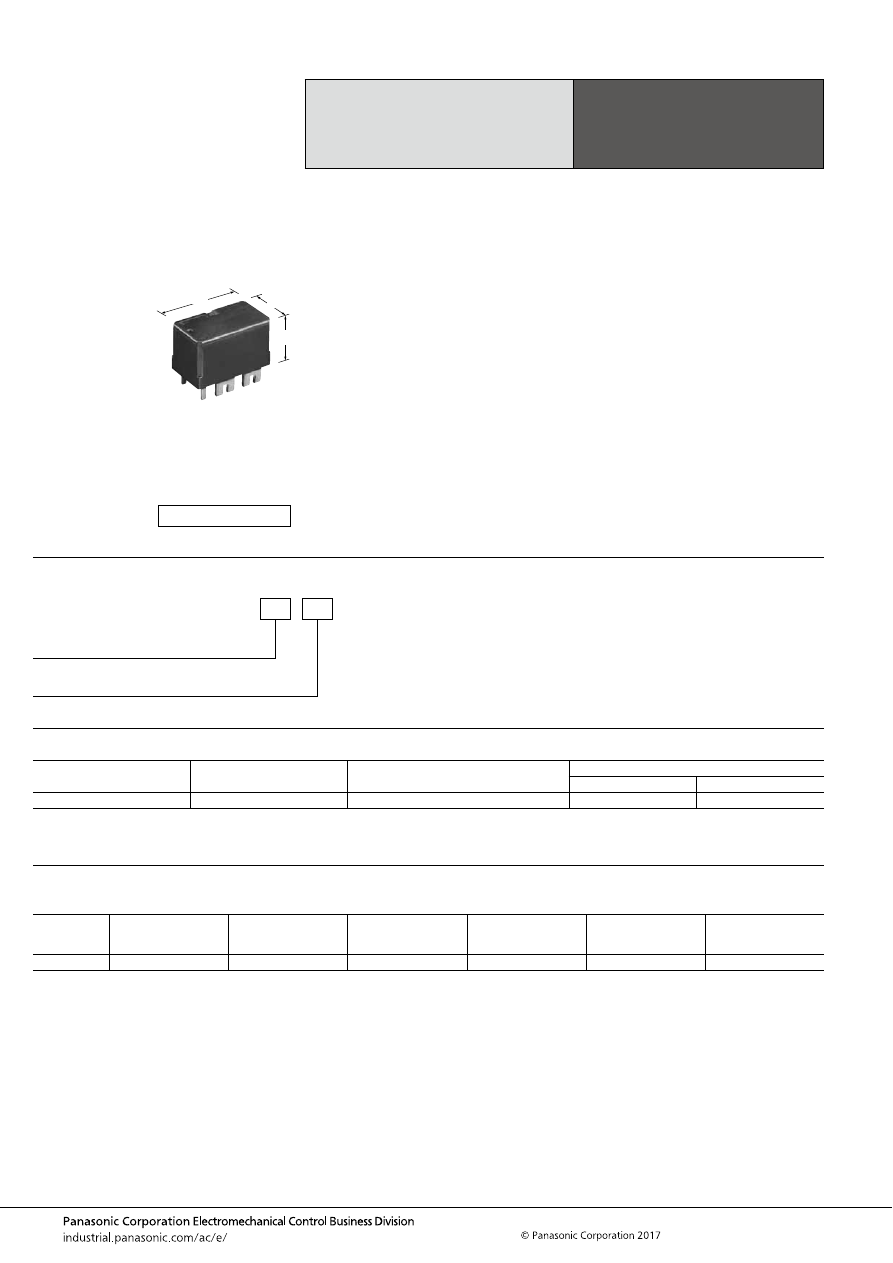

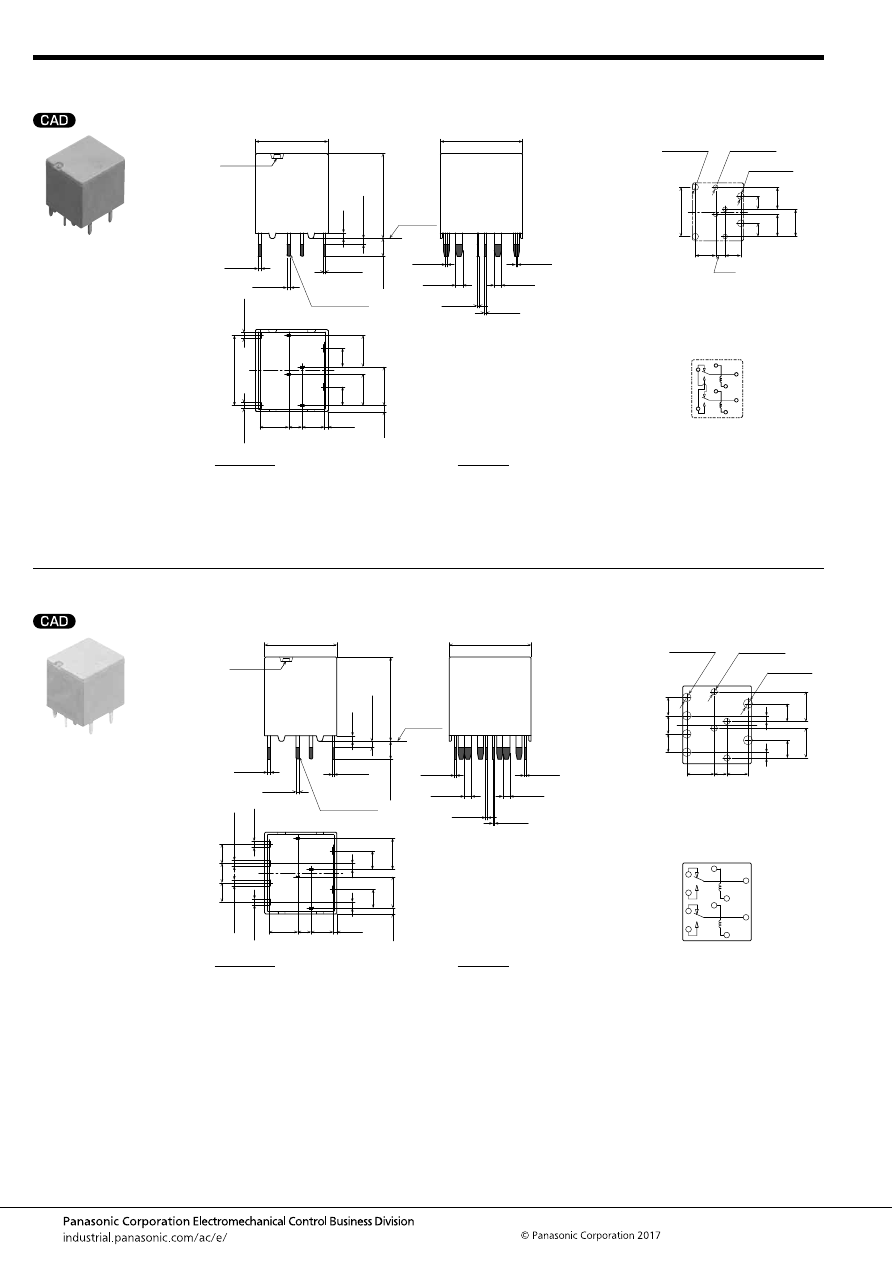

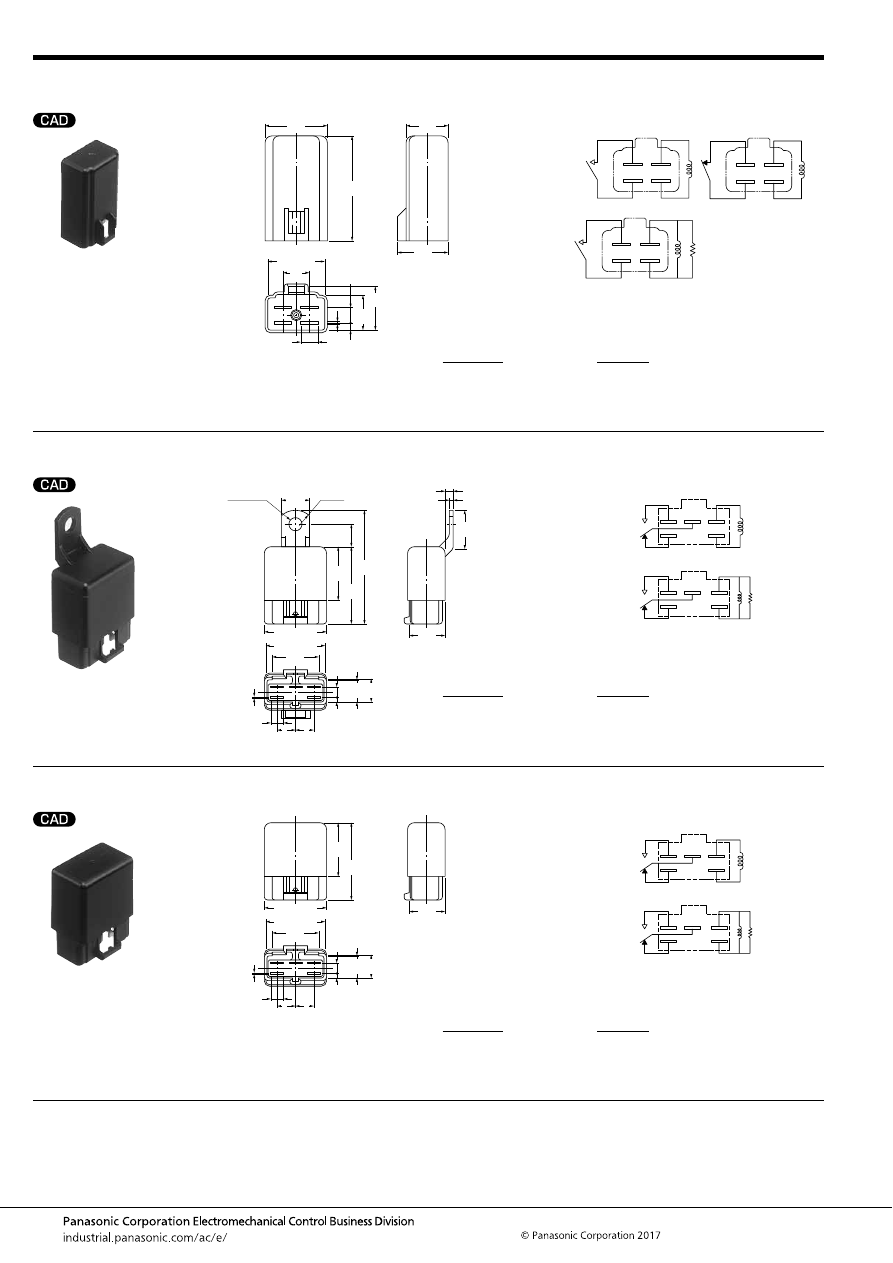

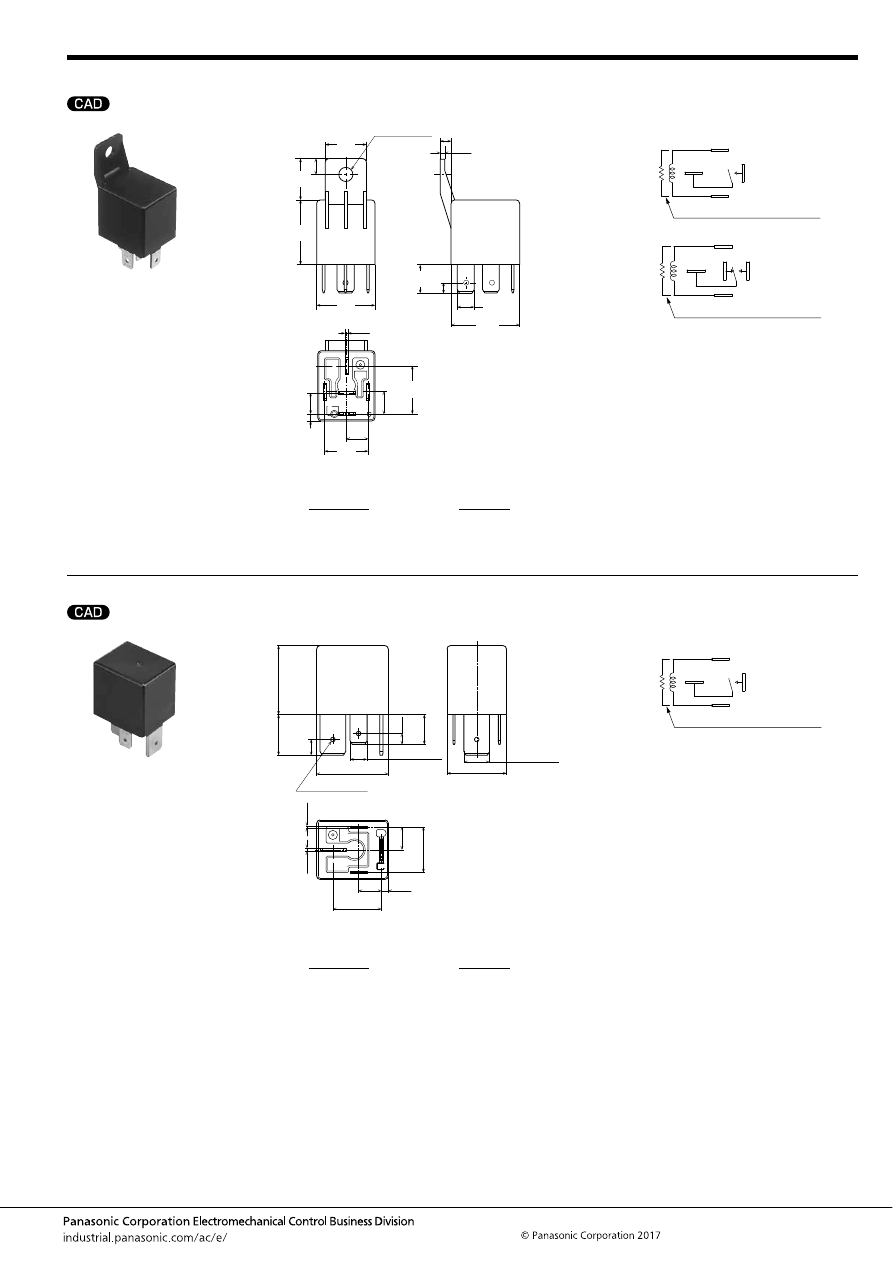

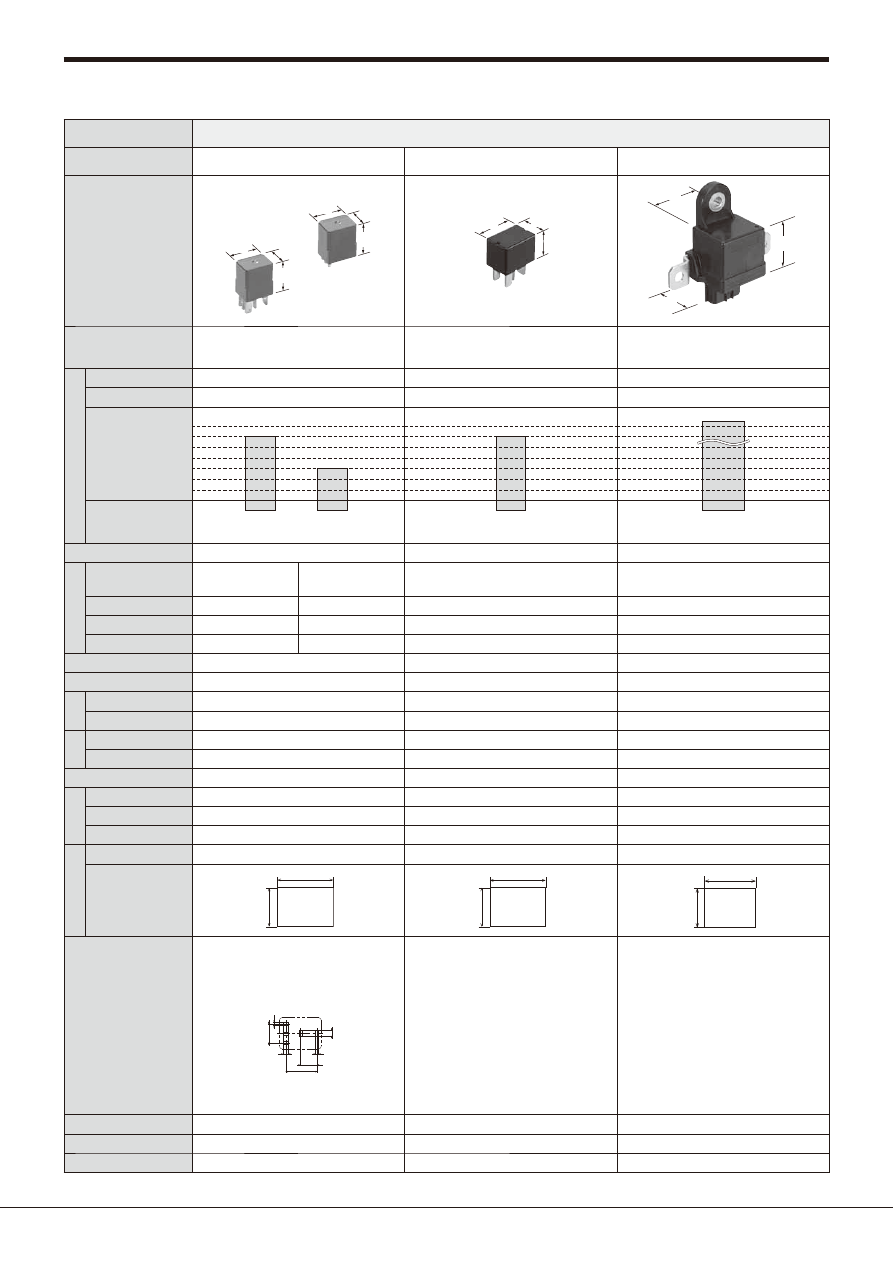

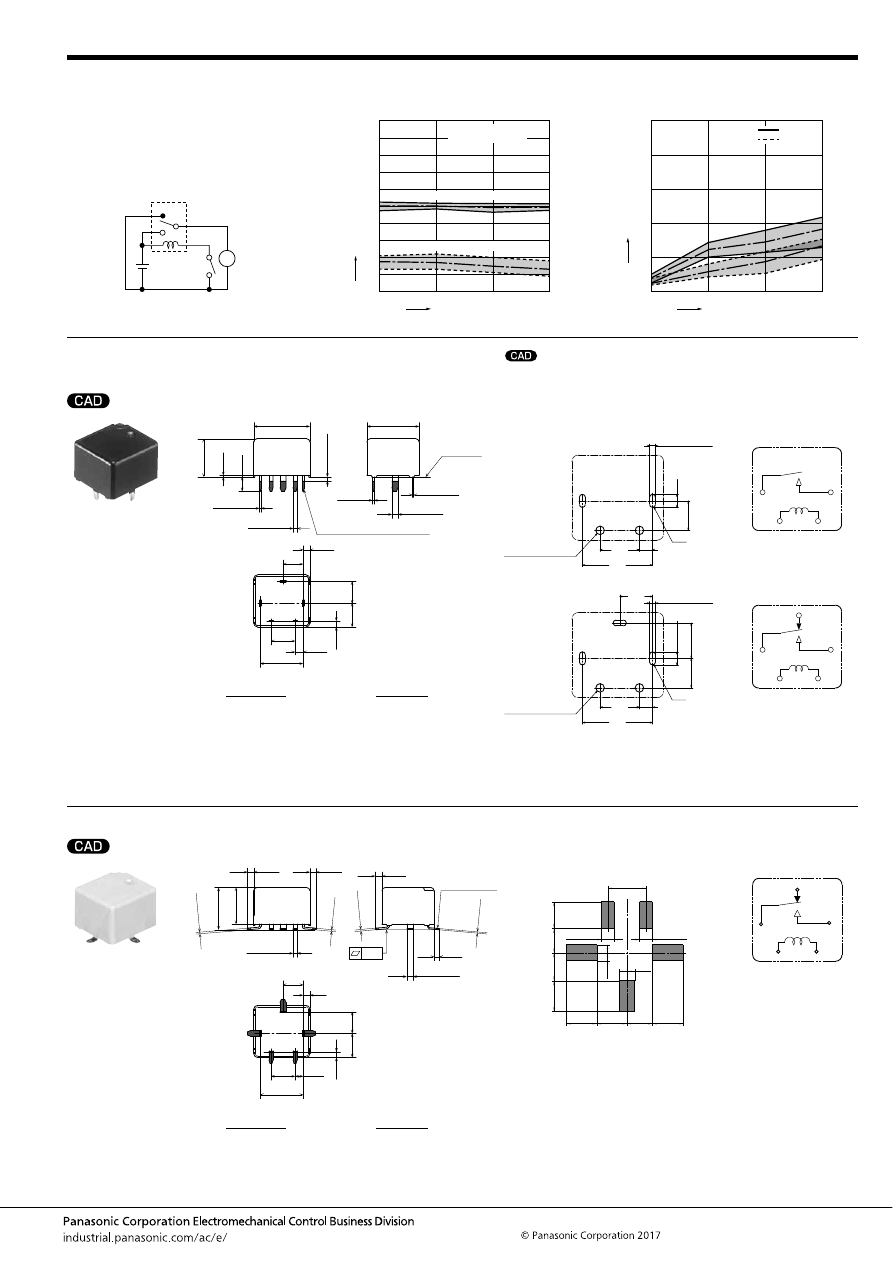

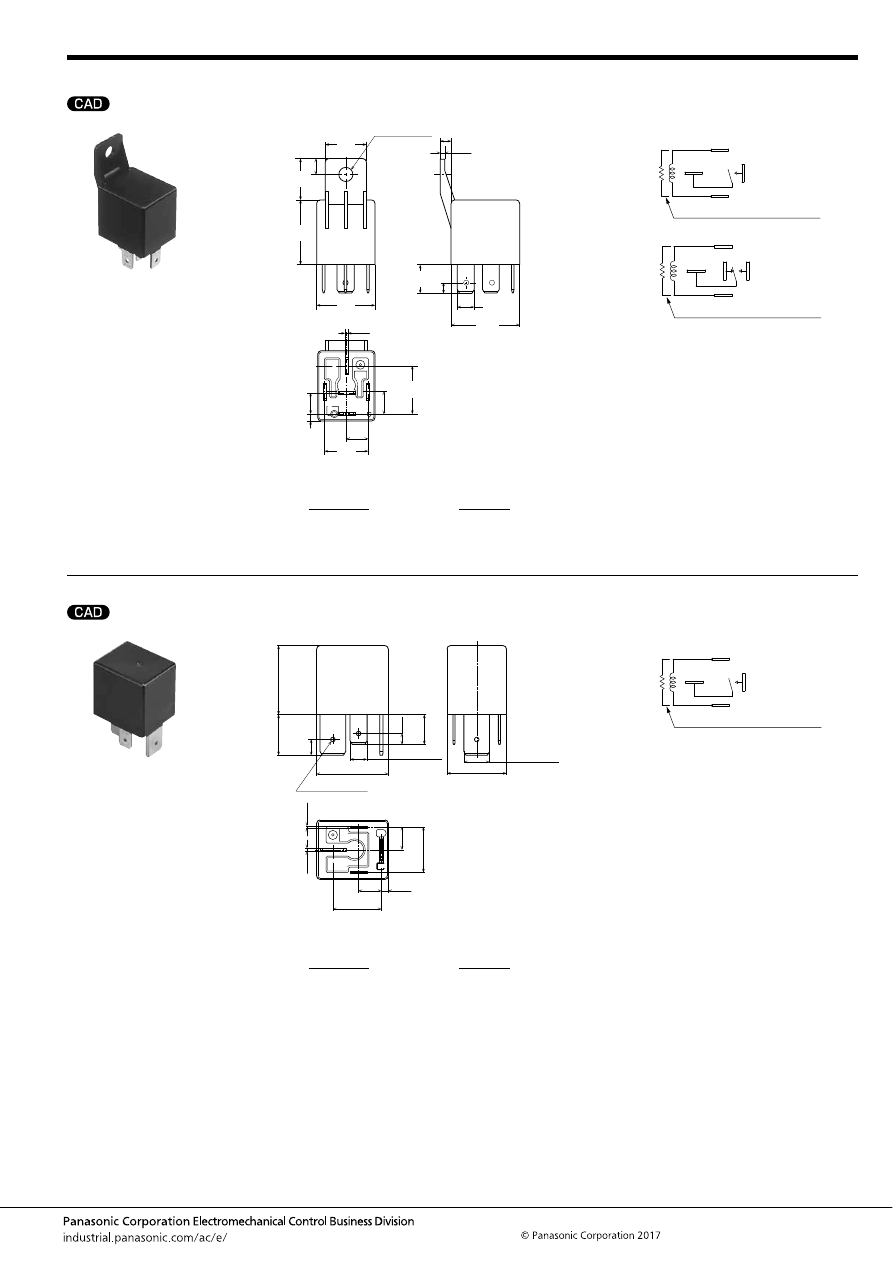

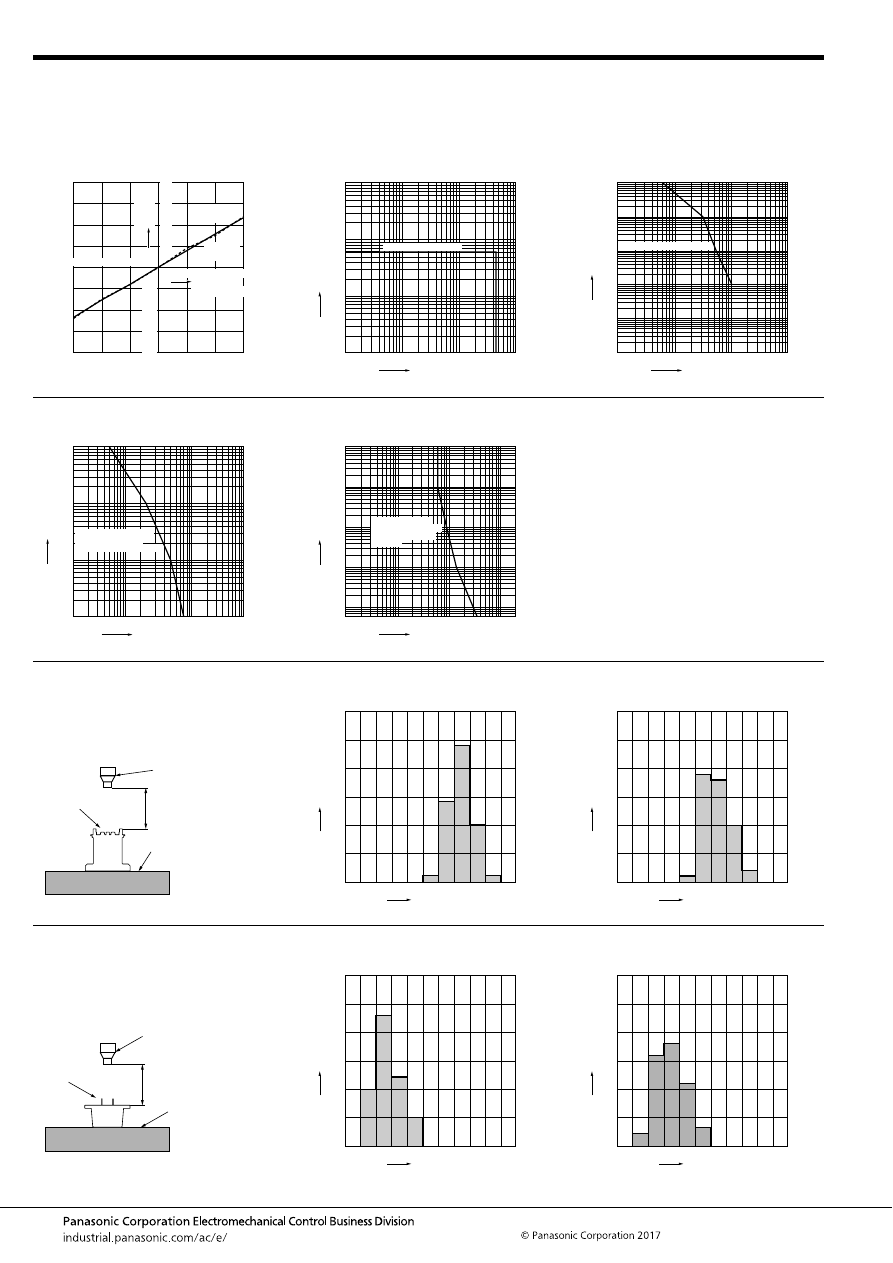

–14–

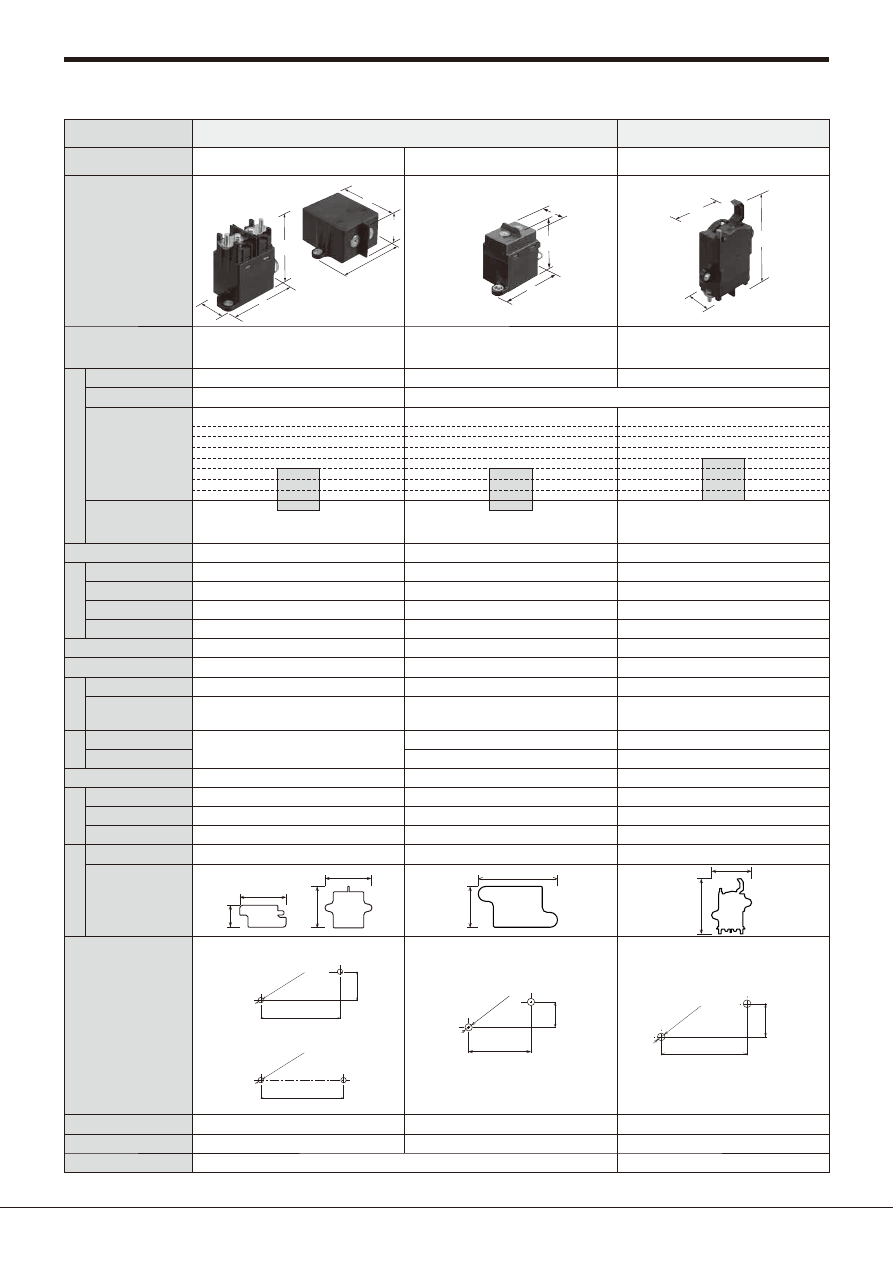

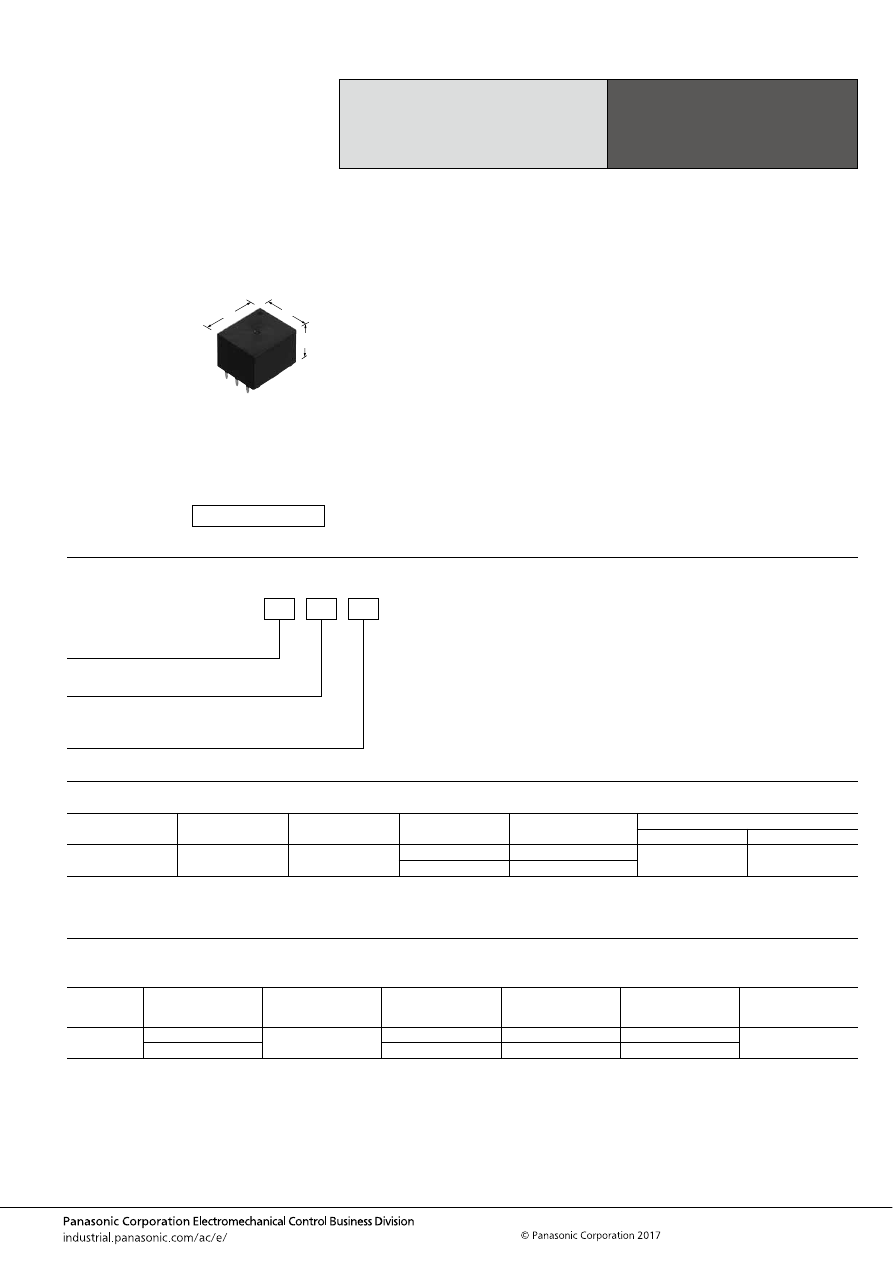

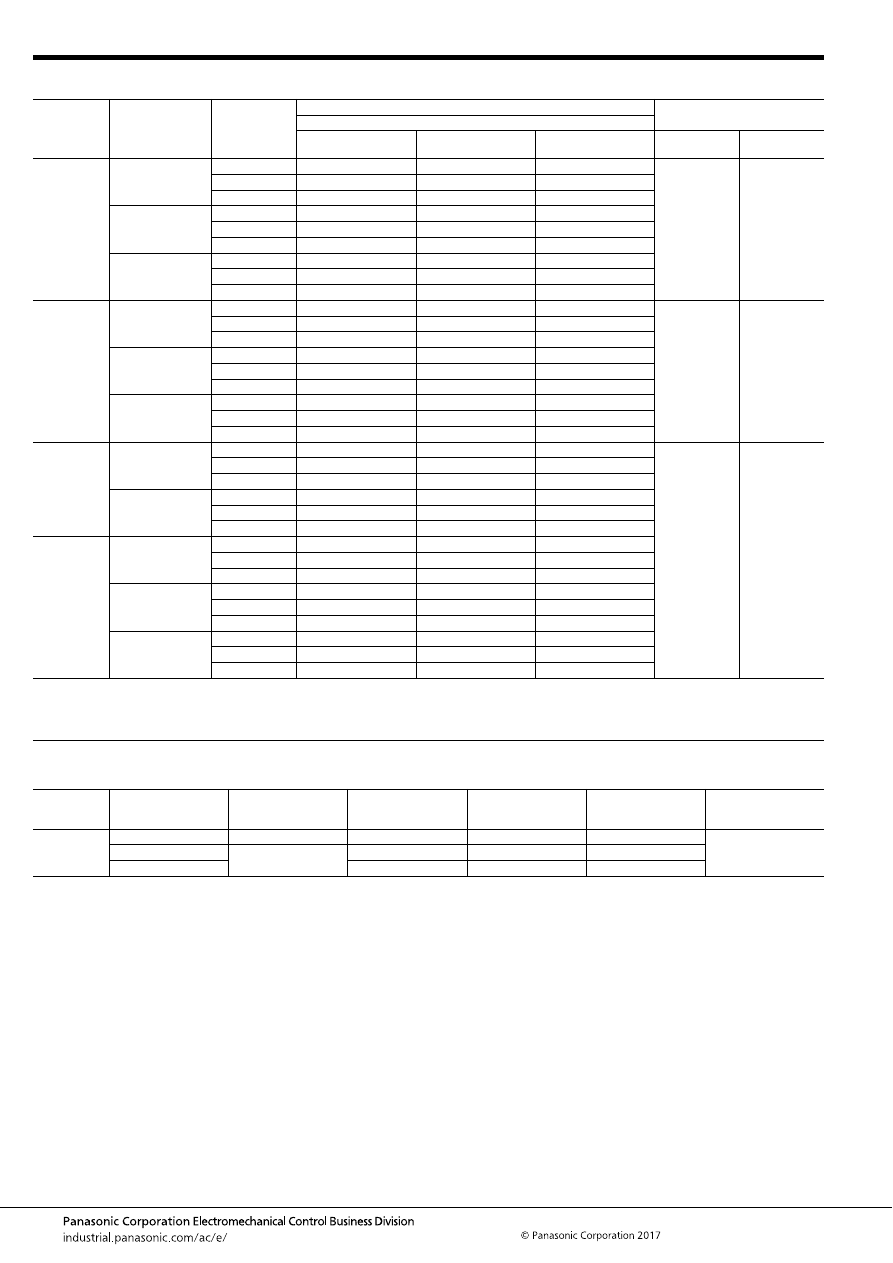

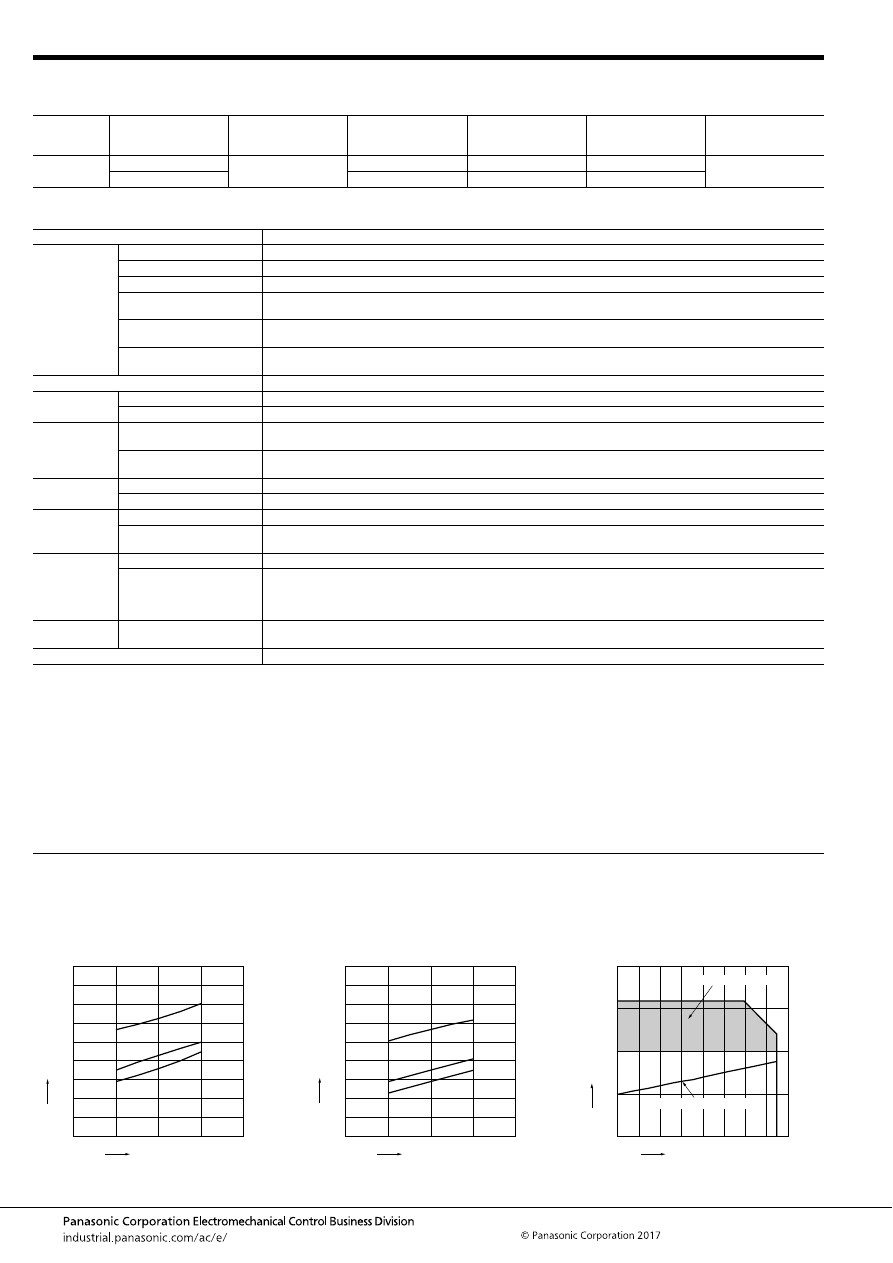

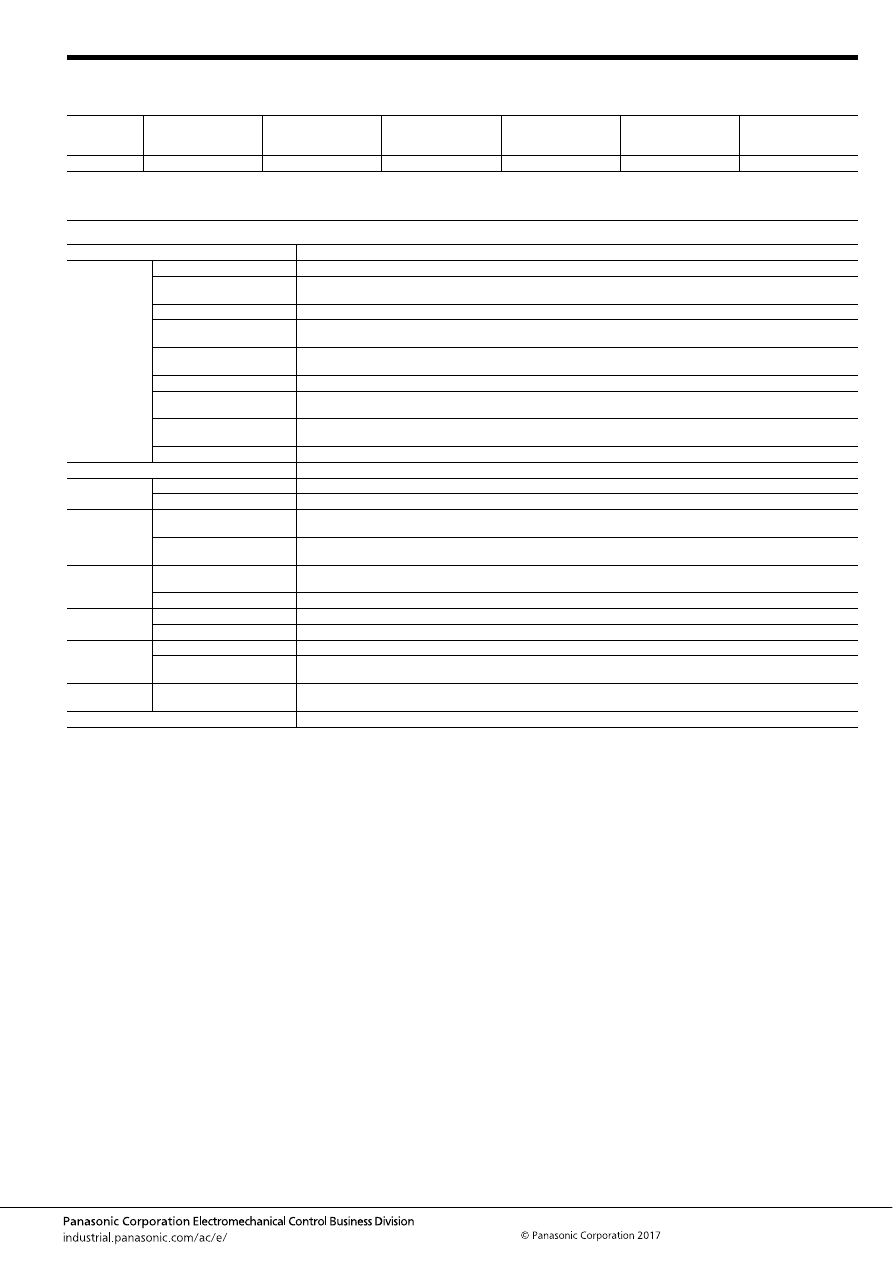

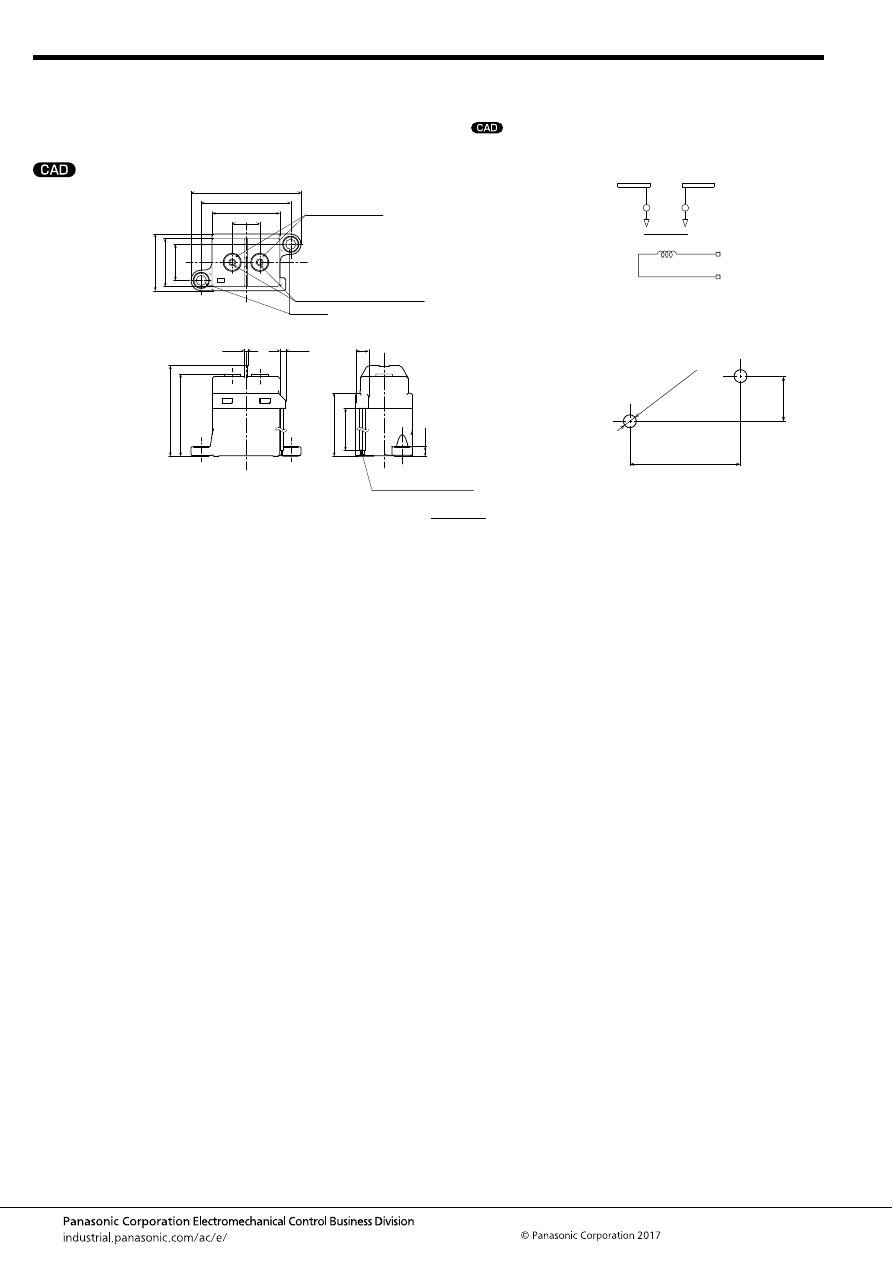

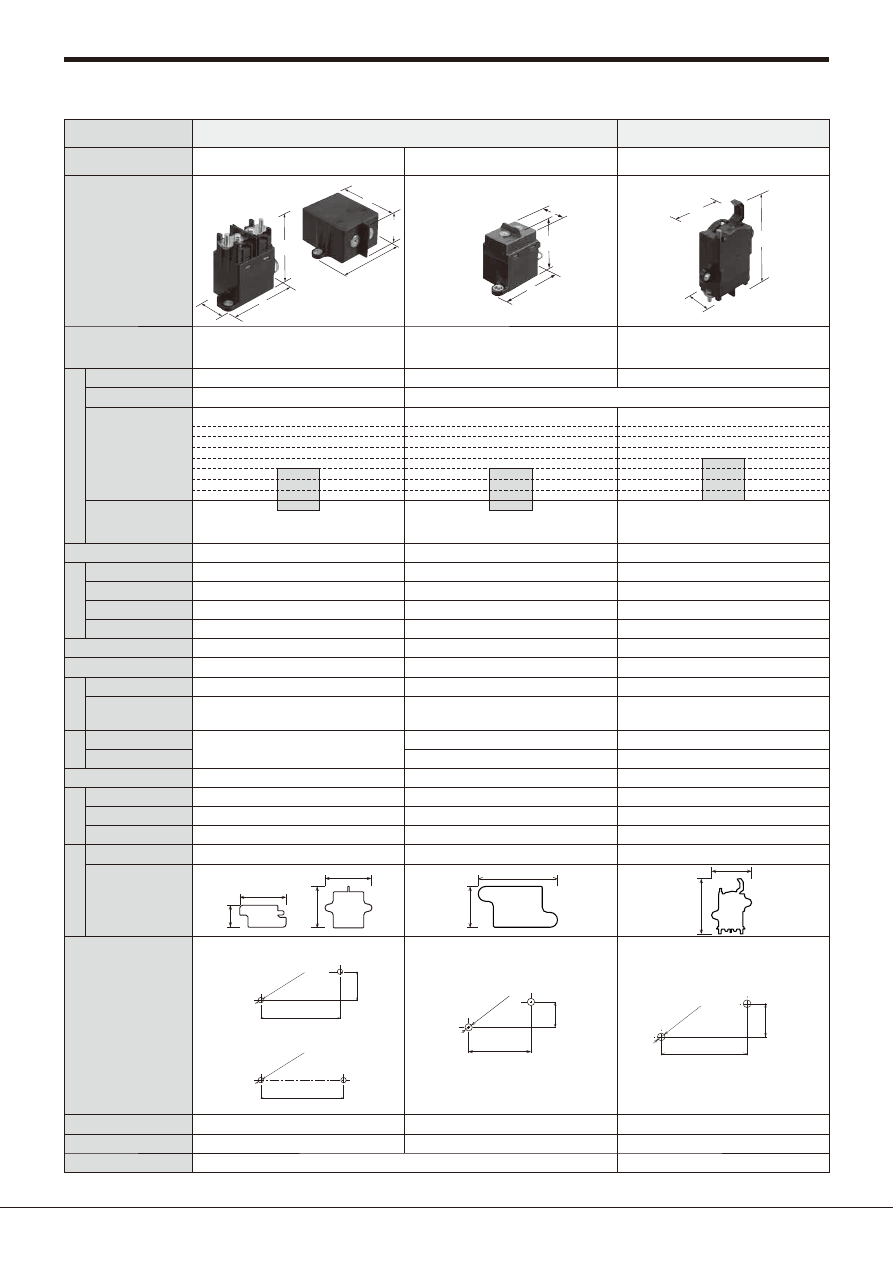

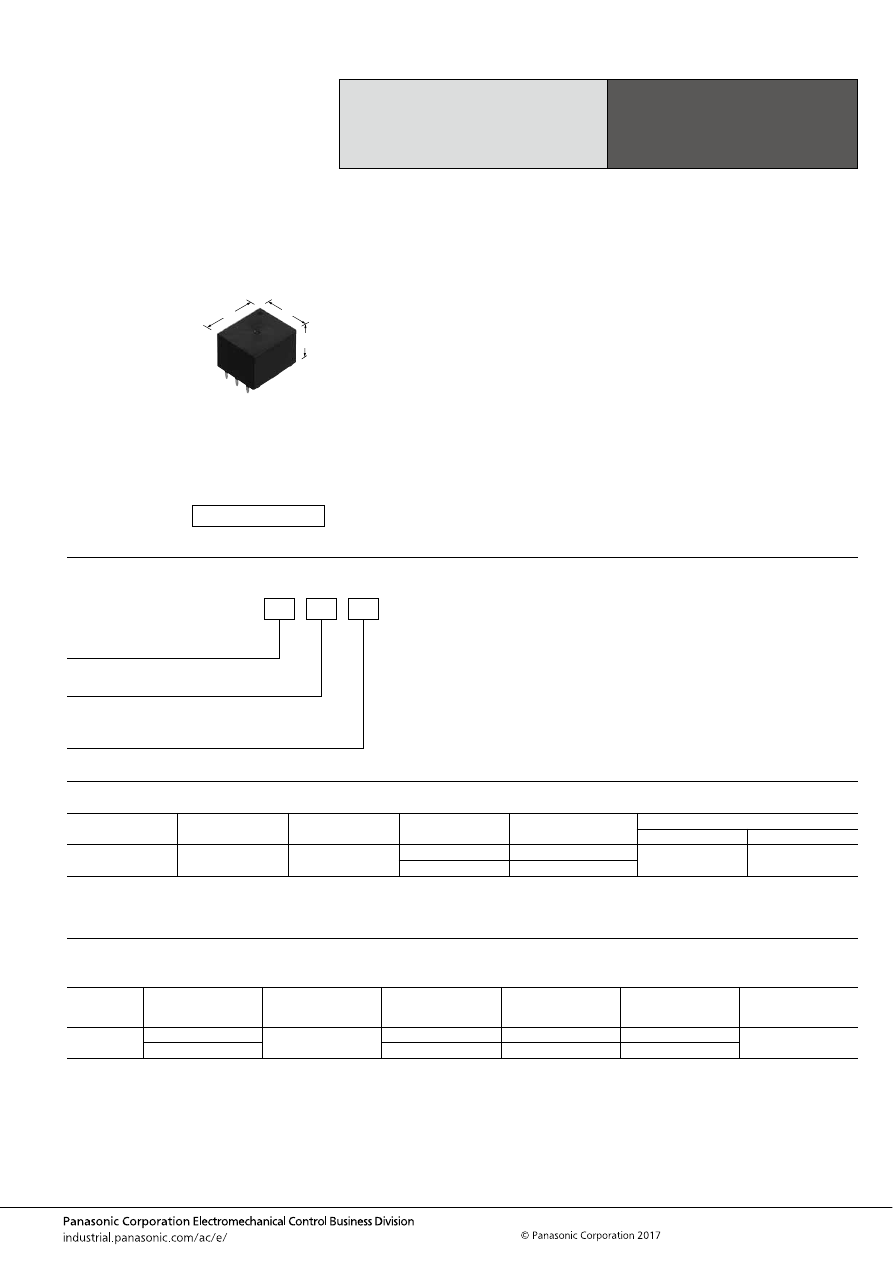

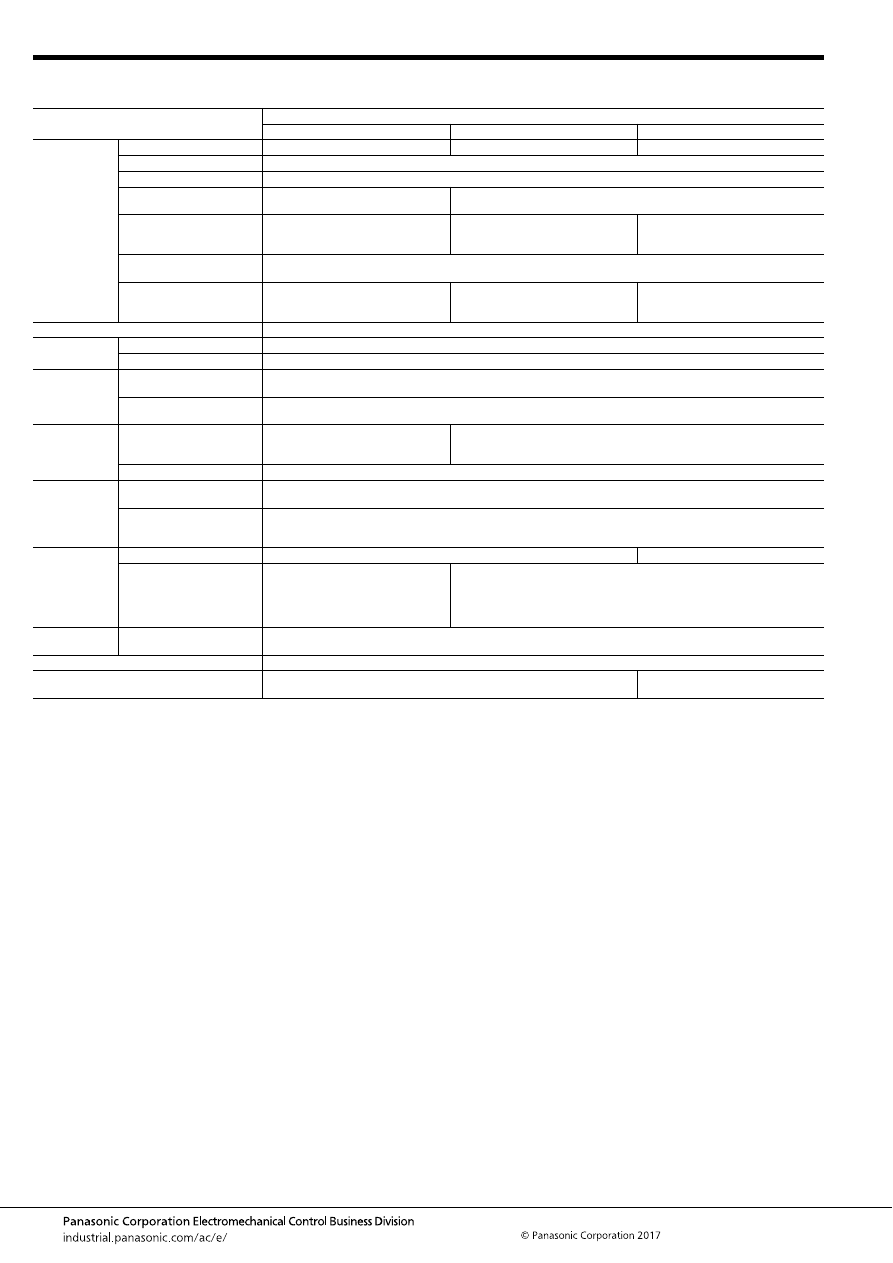

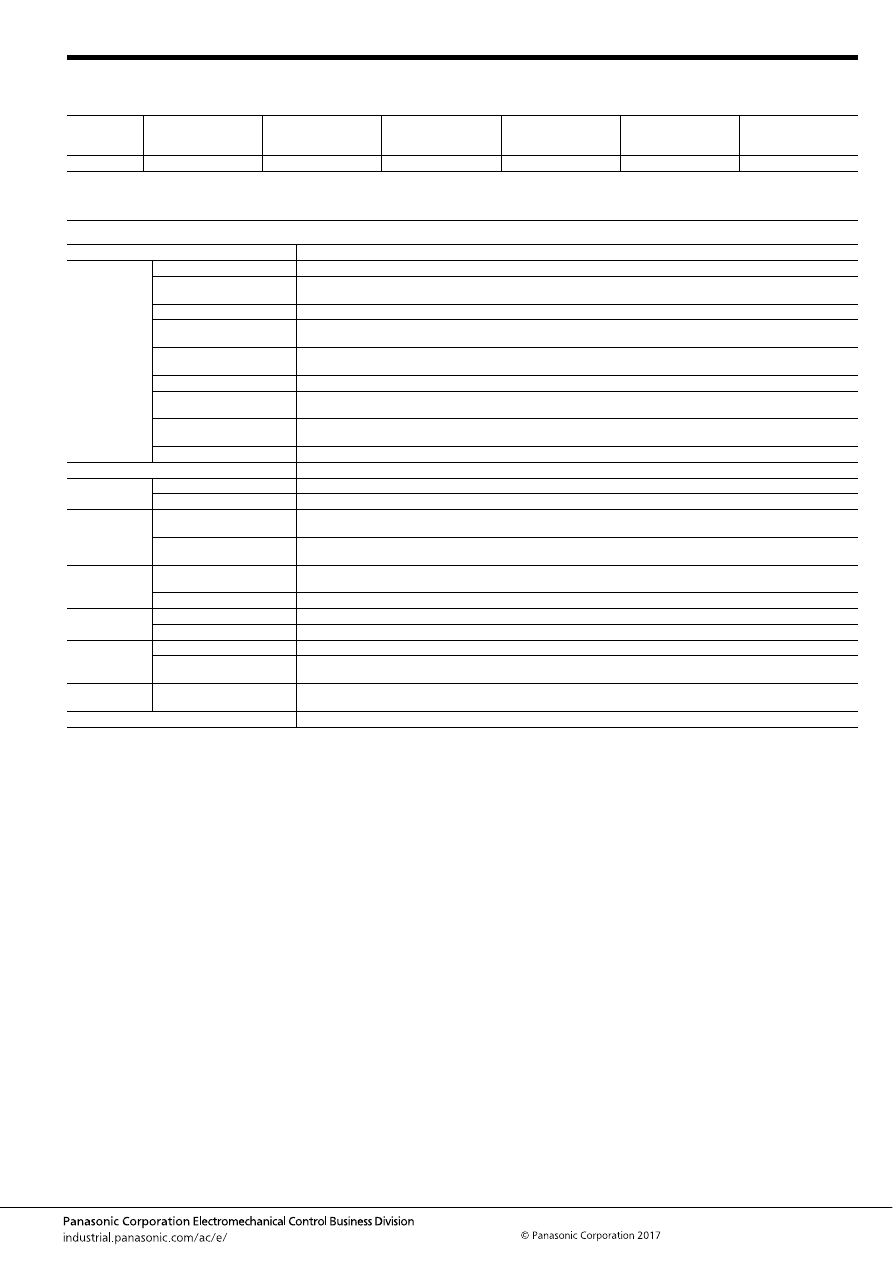

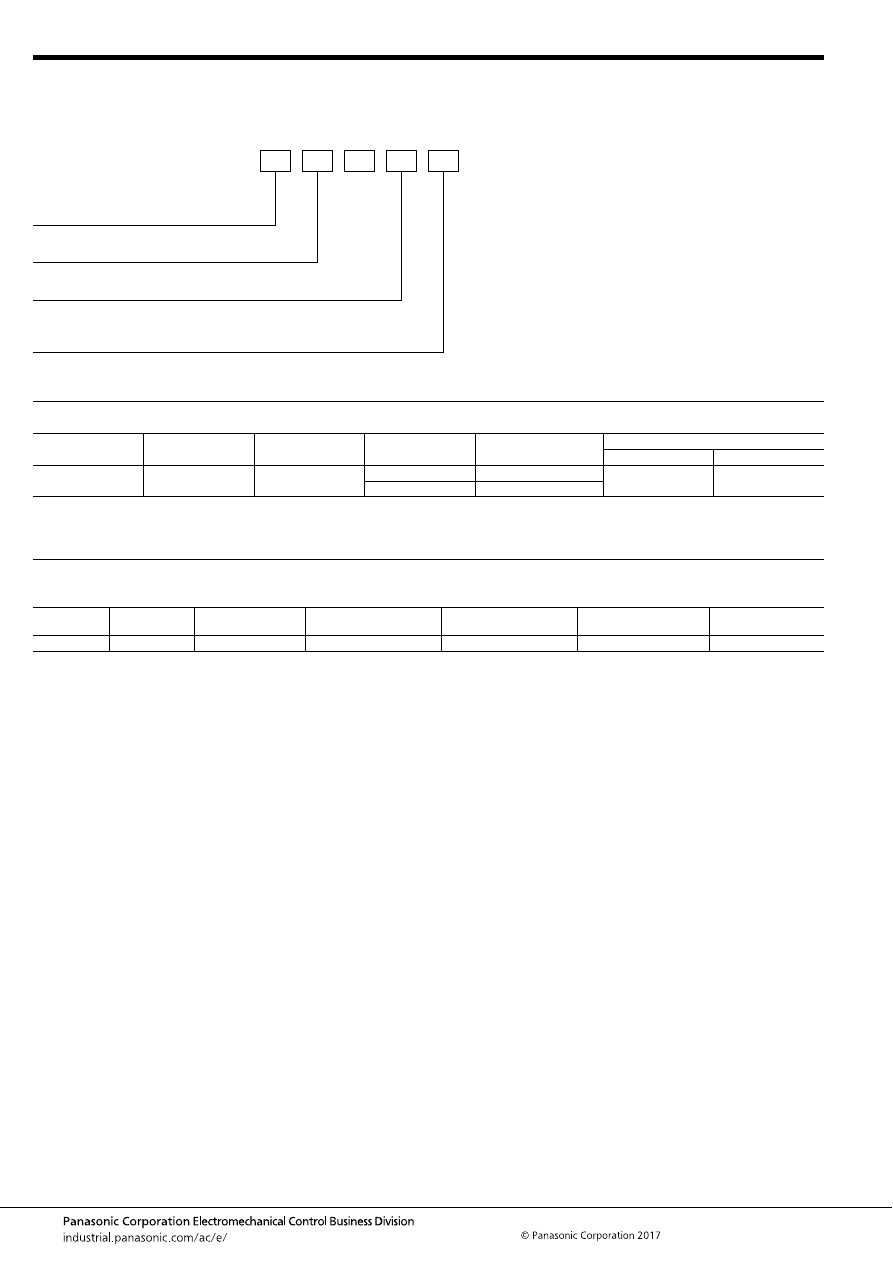

Type

Automotive relays

Product name

TM RELAYS

CA RELAYS

CB RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

ACTM

16.8

19.2

13.6

.661

.756

.535

ACA

21.5

.846

14.4

37

.567

1.457

ACB

26

22

25

1.024

.866

.984

Features

High Capacity Relay for Smart Junction

Box

Small Size, Light Weight Automotive Power

Relays

Mini-ISO Automotive Relay

Con

tact

data

Contact arrangement

1 Form A and 1 Form C

1 Form A and 1 Form B

1 Form C

1 Form A and 1 Form C

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

35A 14V DC

N.O.

15A 14V DC

N.C.

1A 14V DC

30A 12V DC

(1.8 W type)

20A 12V DC

(1.4 W type)

20A 12V DC

1b,1c

1a

1a

30A 14V DC

1c

N.C.

40A 14V DC

1c

N.O.

40A 14V DC

1a

70A 14V DC

High

contact

capacity

1a

1A 14V DC

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12, 24V DC

12V DC

24V DC

Rated operating power

450mW

360mW

1.4W/1.8W

1.8W

Standard: 1.4 W

1 Form A High contact capacity: 1.8 W

1.8W

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 7.0V DC

12V DC: Max. 8.0V DC

24V DC: Max. 16V DC

3.0 to 7.0V DC

6.0 to 14V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 0.5V DC

12V DC: 0.6 to 6.0V DC

24V DC: 1.2 to 12V DC

12V: Min. 0.6V DC

24V: Min. 1.2V DC

1.2 to 4.2V DC

2.4 to 8.4V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 15ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 15ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 5 x 10

6

Min. 10

6

Min. 5 × 10

5

Min. 10

6

Electrical

Min. 10

5

Min. 10

5

1 Form A 1.8 W type: 2 × 10

4

(at 30 A)

Min. 10

5

(Sealed: Min. 5×10

4

)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +110°C

–40 to +230°F

–30 to +80°C

–22 to +176°F

Standard: –40 to +85°C

–40 to +185°F

Heat resistant: –40 to +125°C

–40 to +257°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

●

−

Flux tight

−

−

●

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

13.6

.535

37

1.457

40

1.575

PC board type: 26

1.024

, Plug-in type: 25

.984

Bracket type: 41

1.614

Foot print (mm

inch

)

19.2

.756

16.8

.661

14.4

.567

21.5

.846

1c: 31.2×19.4

1.228×.764

22

.866

26

1.024

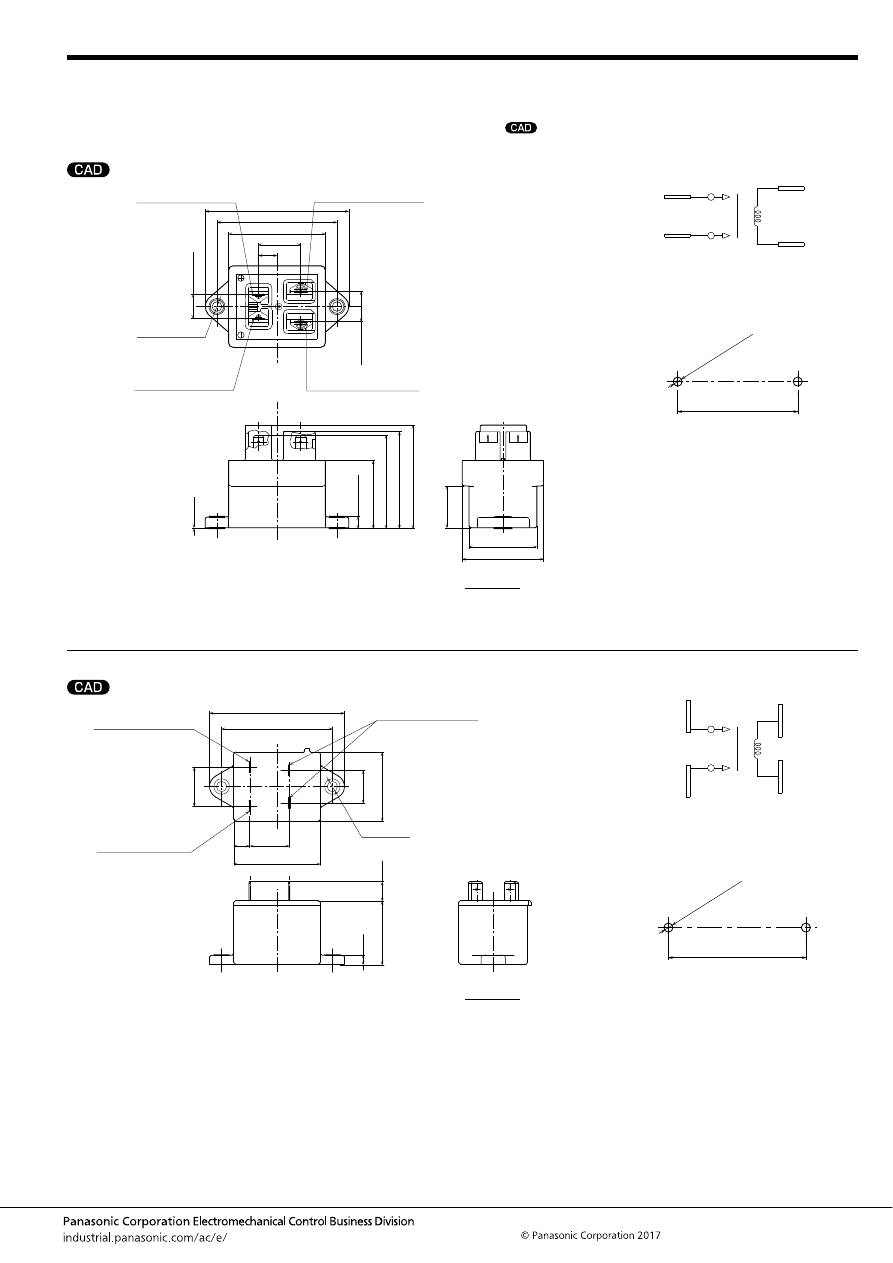

PC board pattern

1 Form A type

1 Form C type

(Coil-N/0 terminal

between centers)

(COM-N/0 terminal

between centers)

.602

.606

15.3

15.4

2×R0.45

2×R.018

2×R0.6

2×R.024

4

.157

4

5.3

.157 .209

9.3

.366

1.2

.047

0.9

.035

2.6

.102

.067

1.7

(Coil-N/0 terminal

between centers)

(COM-N/0 terminal

between centers)

.602

.606

15.3

15.4

2×R0.45

2×R.018

2×R0.6

2×R.024

4

.157

6

.236

4

5.3

.157 .209

9.3

.366

1.2

.047

0.9

.035

2.6

.102

.067

1.7

−

1 Form A High contact capacity

1 Form C

Mini ISO

4(or5)×2.6

30

87a

87

85

86

8.4

16.8

4(or5)×1.4

17.9

8.4

8.0

.331

.661

.705

.331

.315

4(or5)×.102

4(or5)×.055

30

87

85

86

2.6

1.4

3×1.8

3×1.8

3×2.15

3×2.15

16.8

8.4

7.8

8.4

17.9

7.8

.102

.055

3×.071

3×.071

3×.085

3×.085

.661

.331

.307

.331

.705

.307

Weight (approx.)

11.6 g

.41 oz

Rubber bracket A type: 23 g

.81 oz

,

Screw-mounting type: 19 g

.67 oz

31 g

1.09 oz

33 g

1.16 oz

Remarks

−

Rubber bracket type and screw-mounting type available PC board type and bracket type available

Page

145

150

157

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

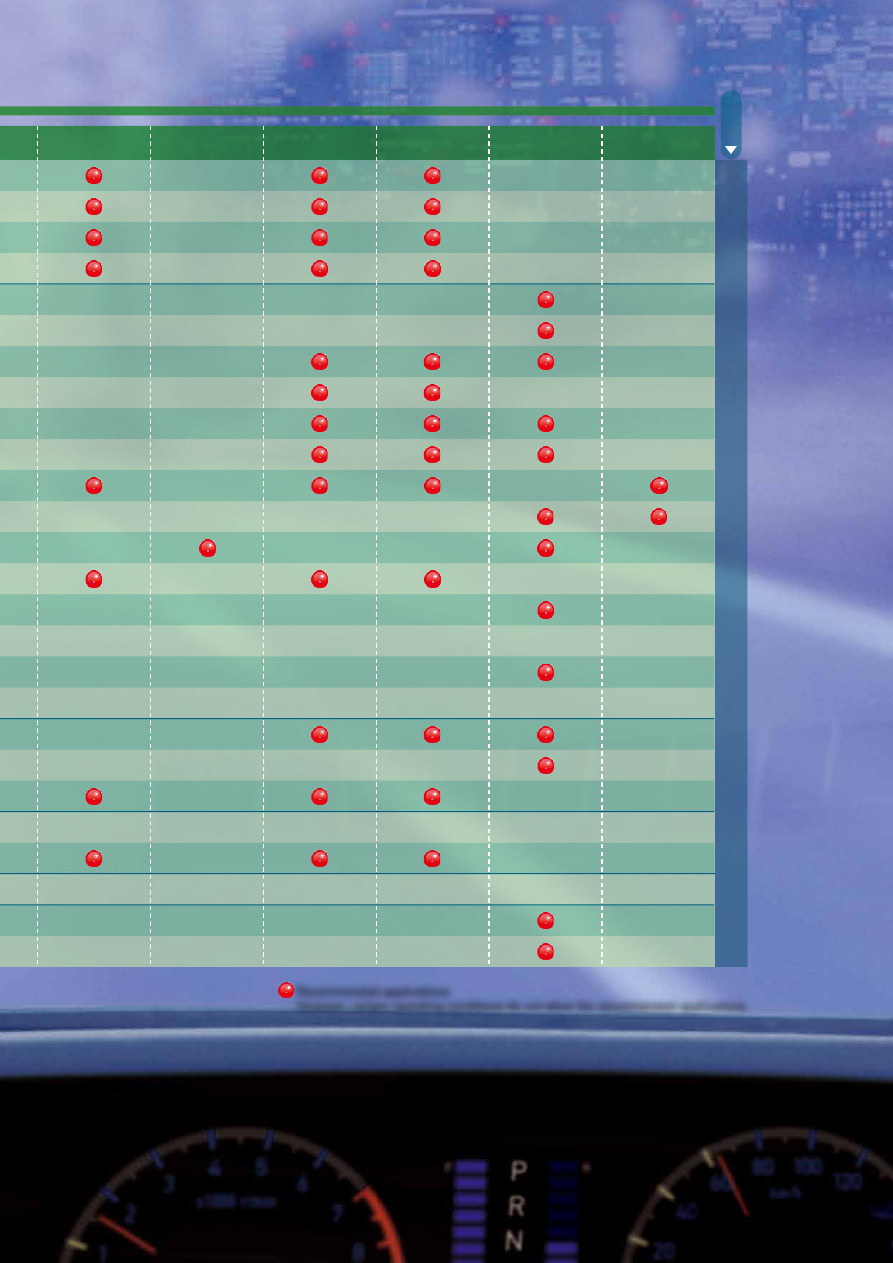

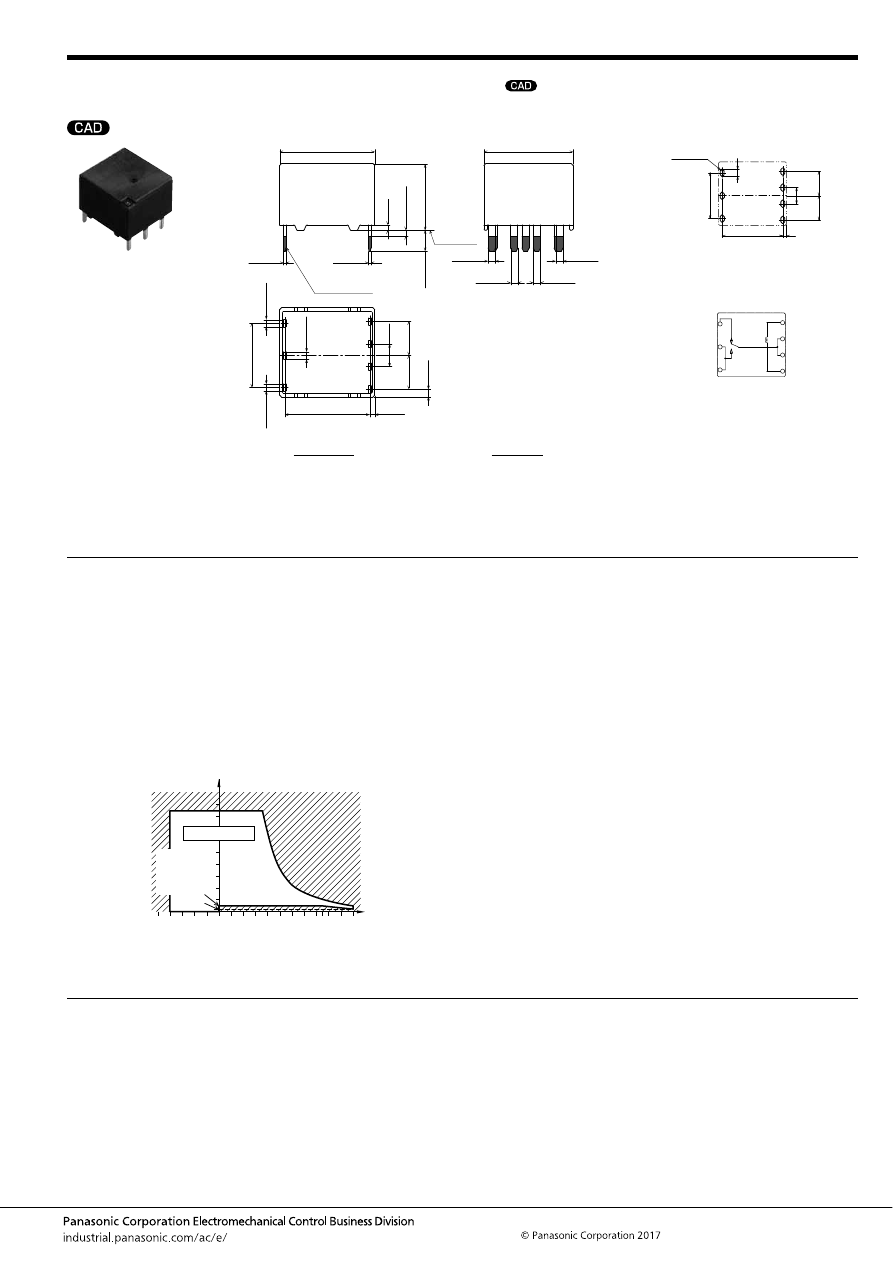

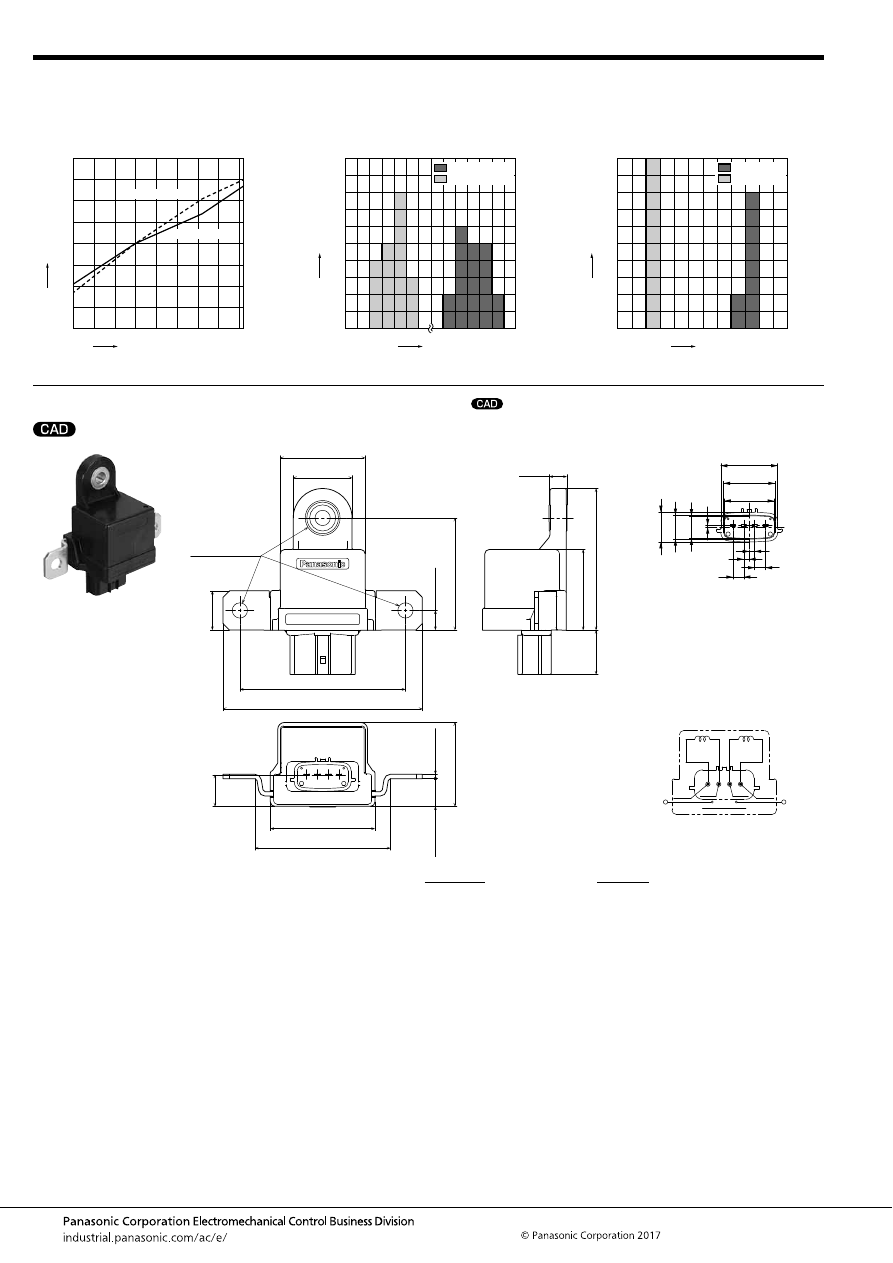

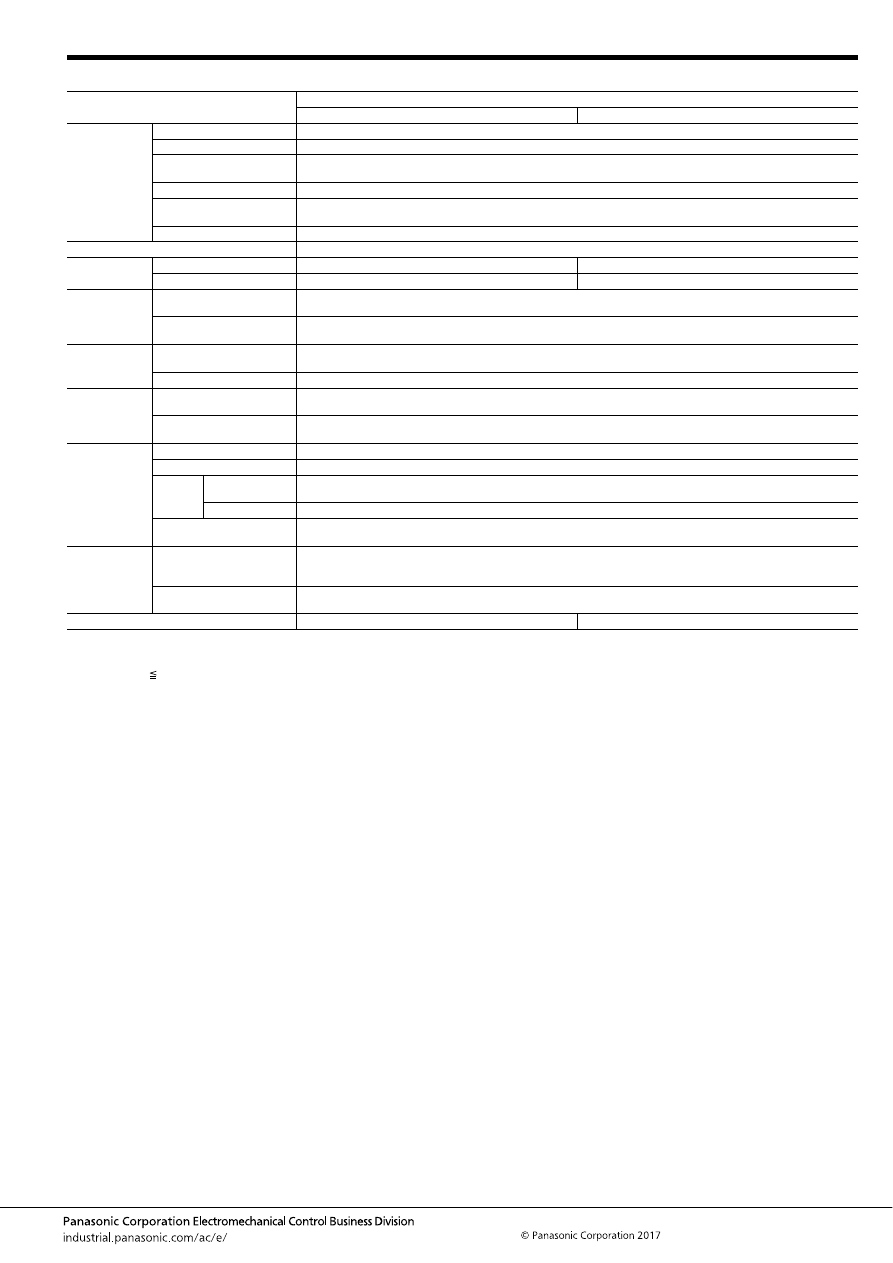

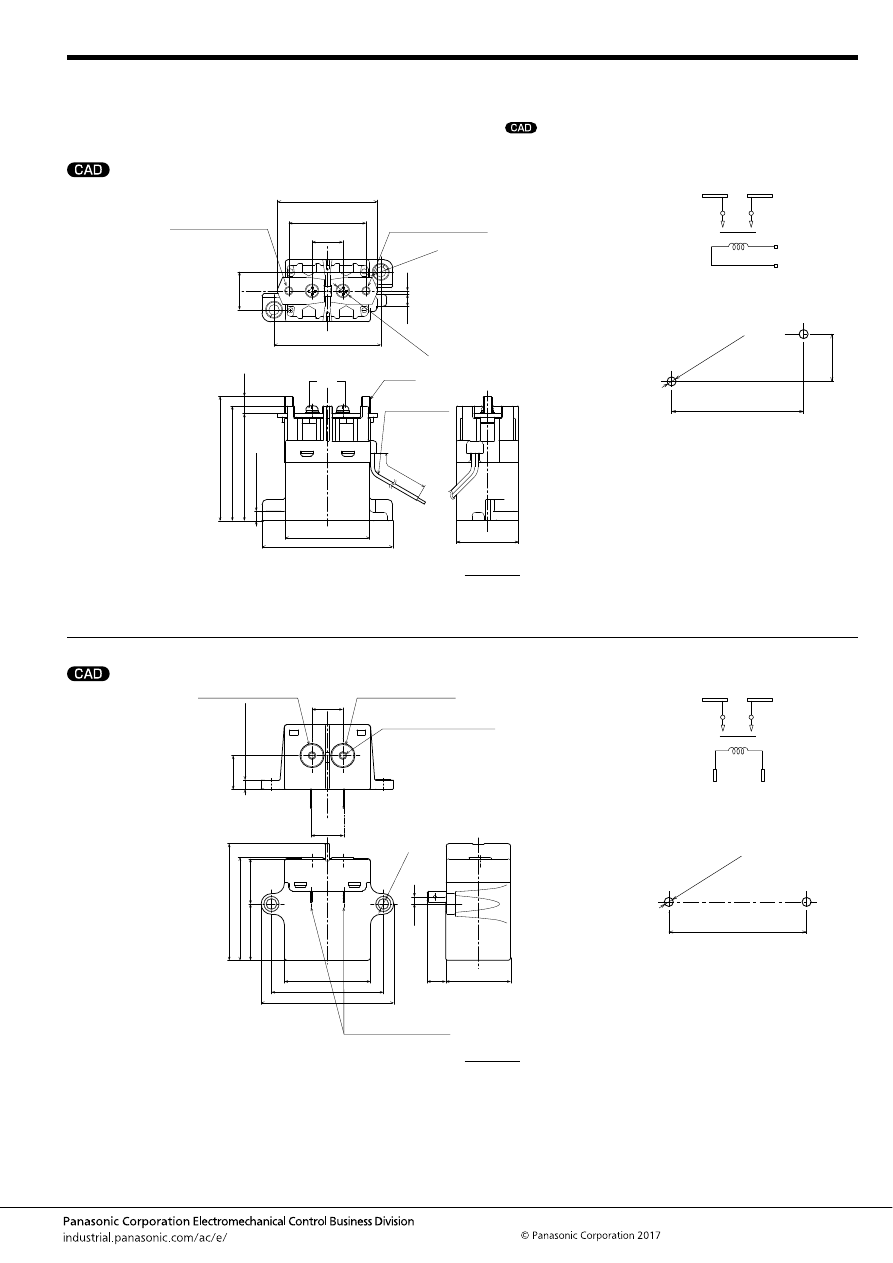

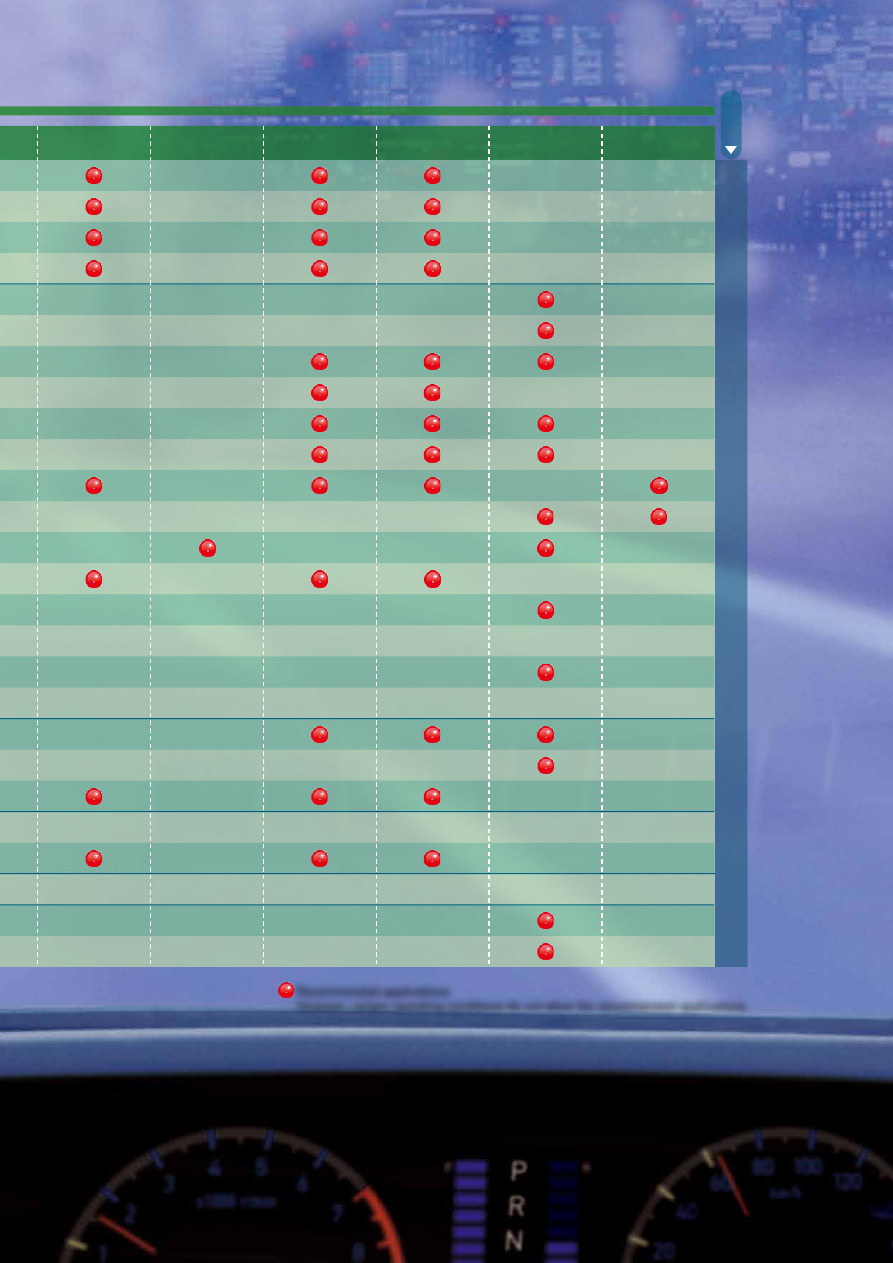

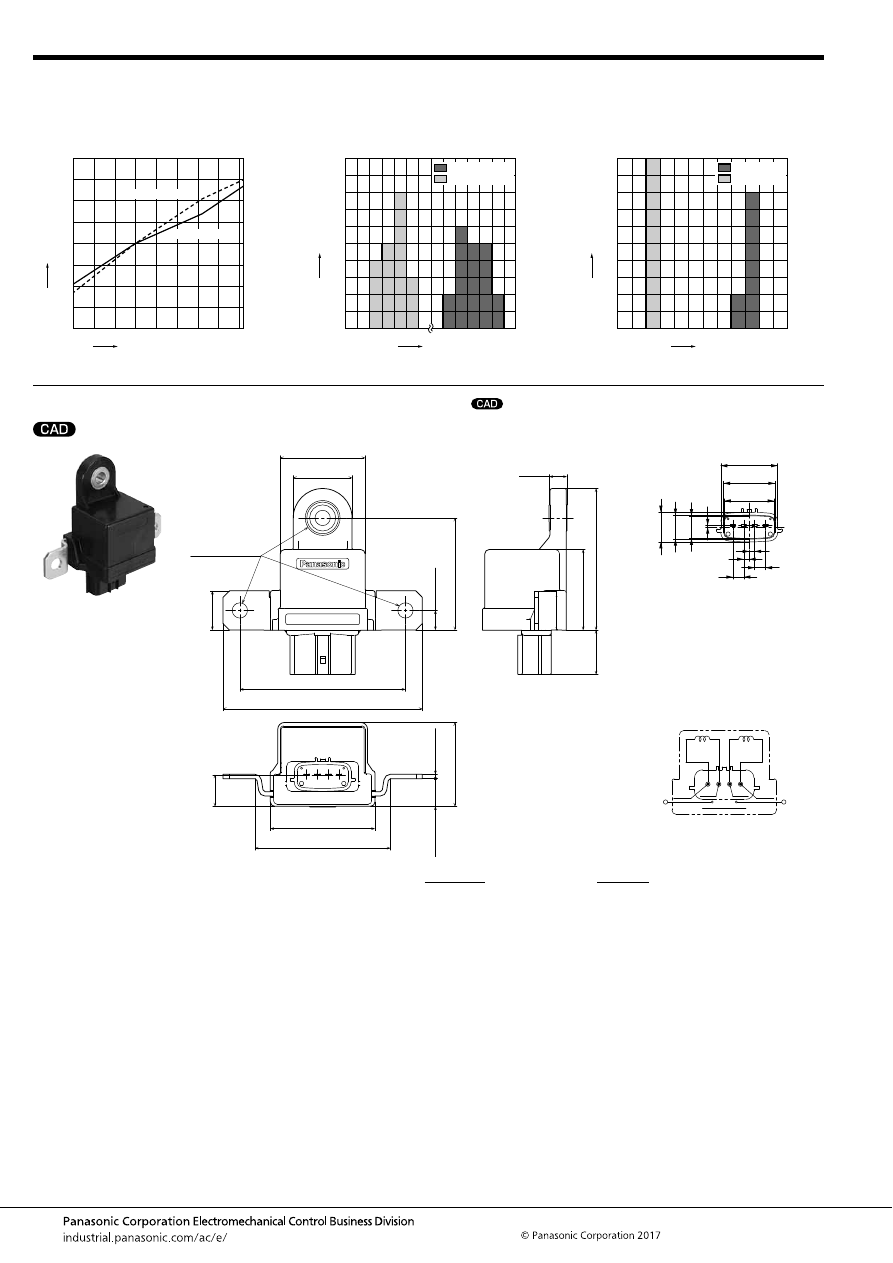

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–15–

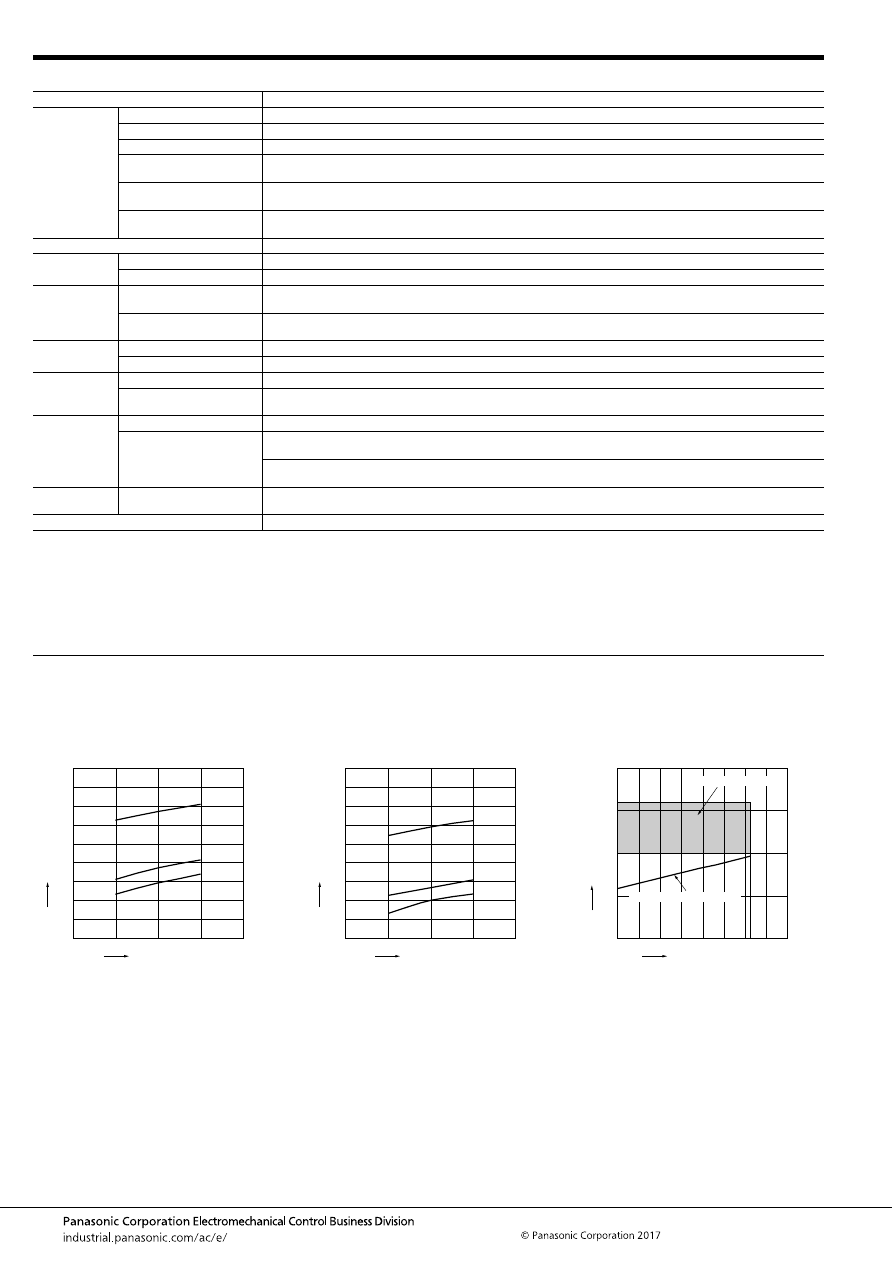

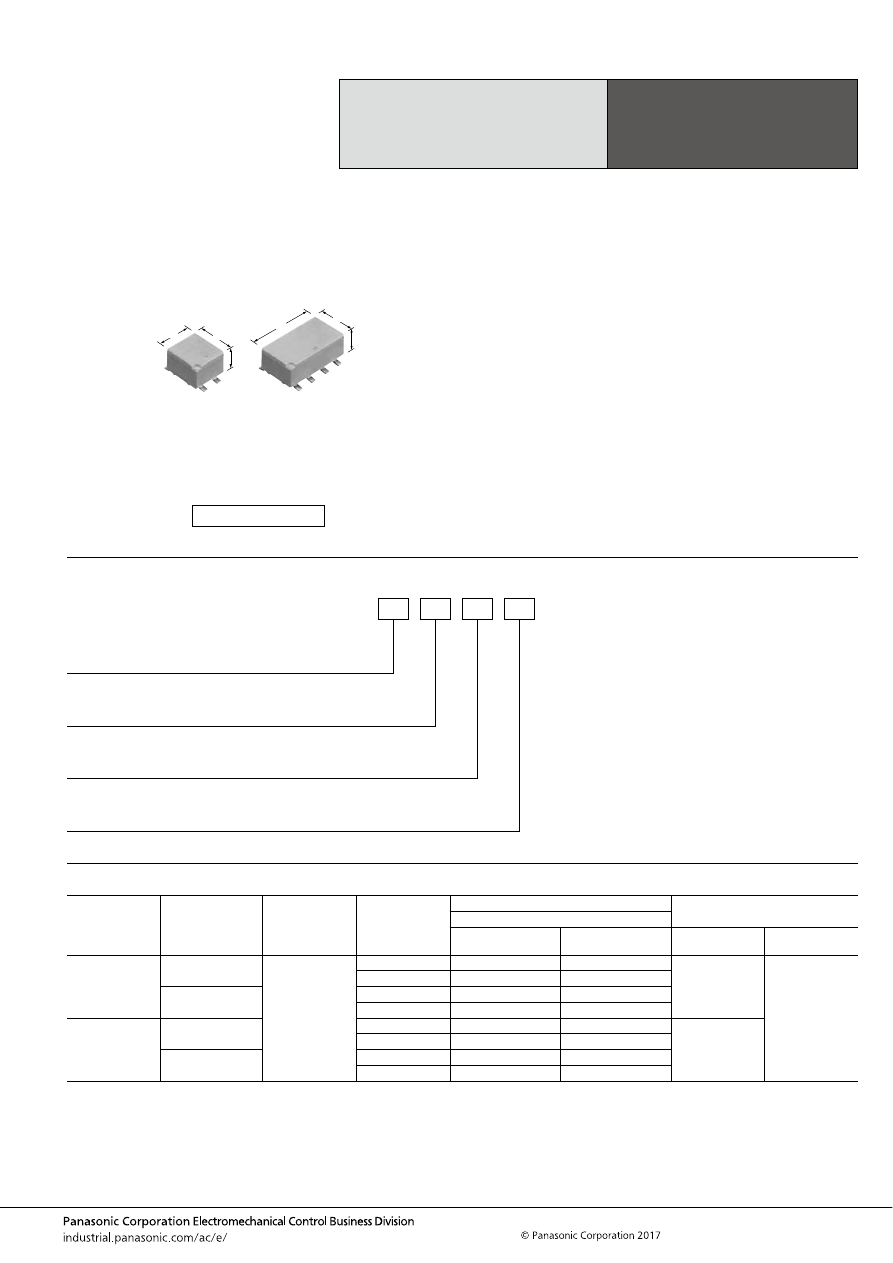

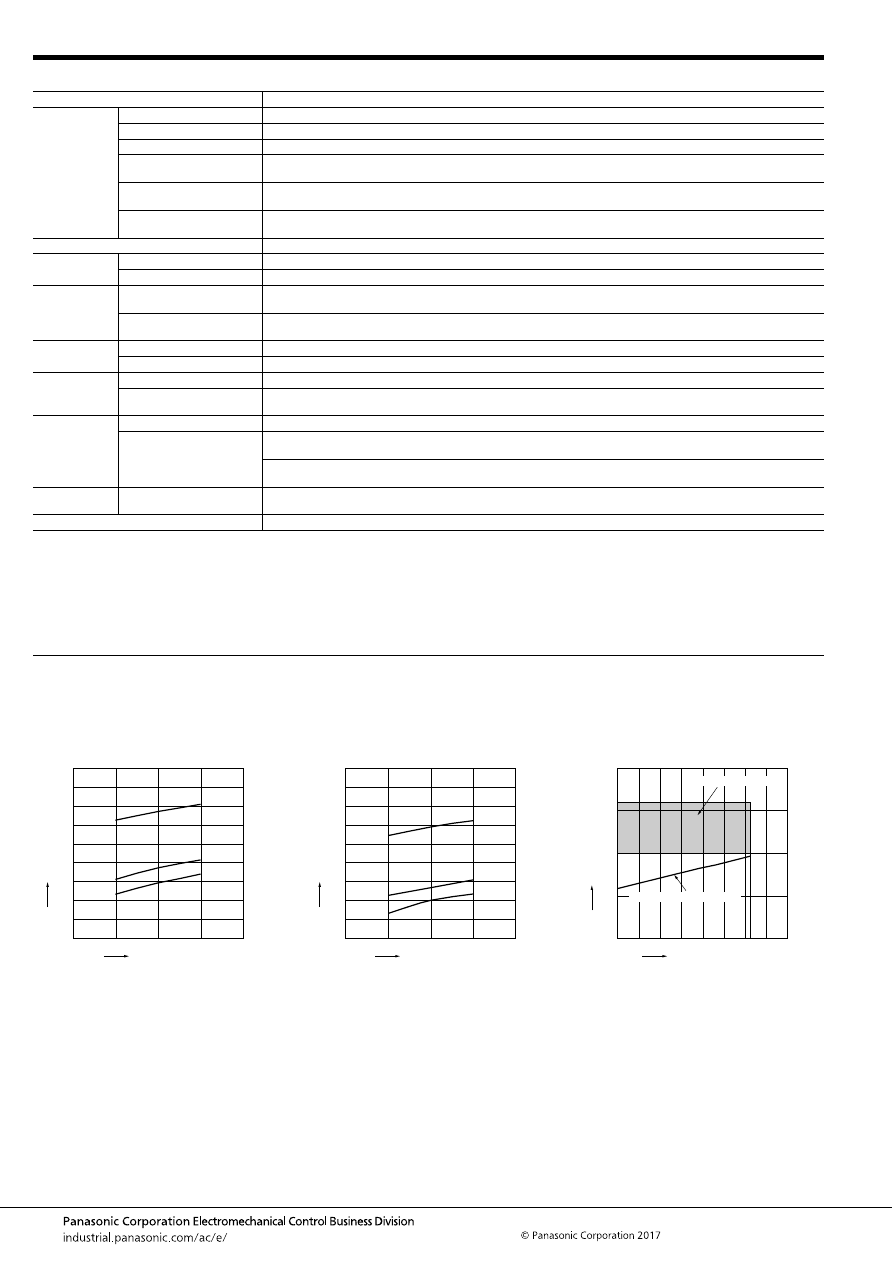

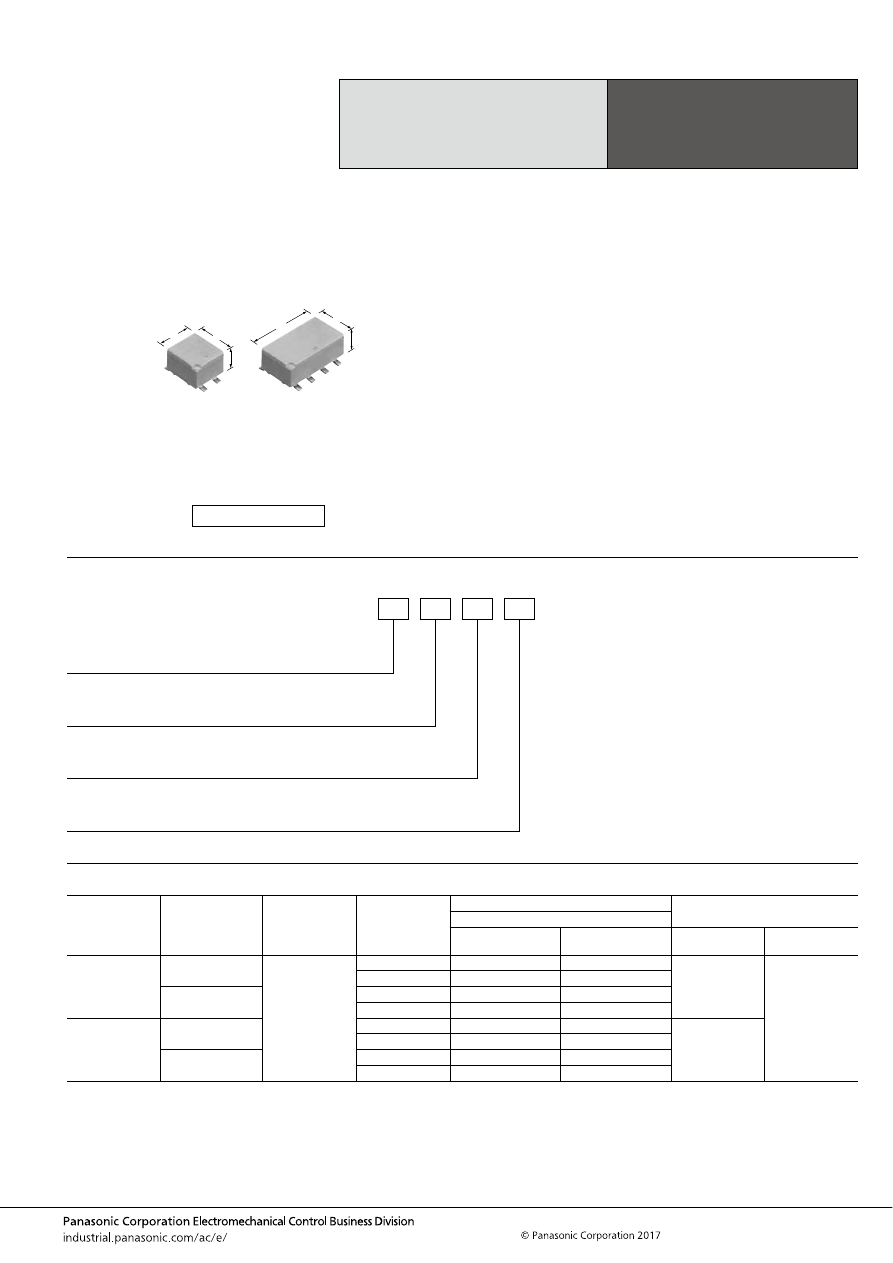

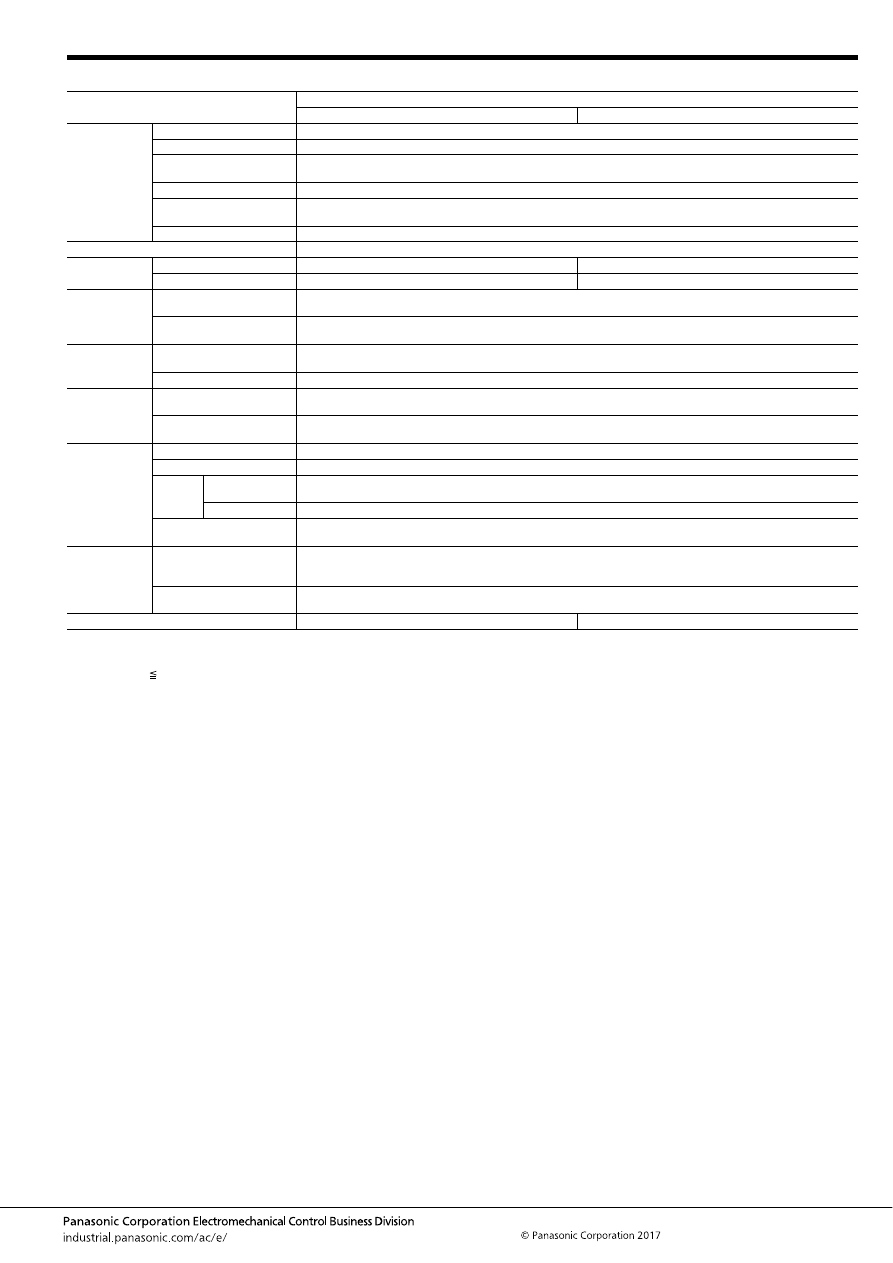

Type

Automotive relays

Product name

CM RELAYS

CV-N RELAYS

CN-L RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

Micro ISO (Plug-in)

Micro ISO (PC board)

*(24V only)

ACM

15

20

22

.591

.787

.866

15

20

23

.591

.787

.906

Micro ISO

ACVN

15

22.5

15.7

.591

.886

.618

ACNL

38.5

48

37

1.516

1.890

1.457

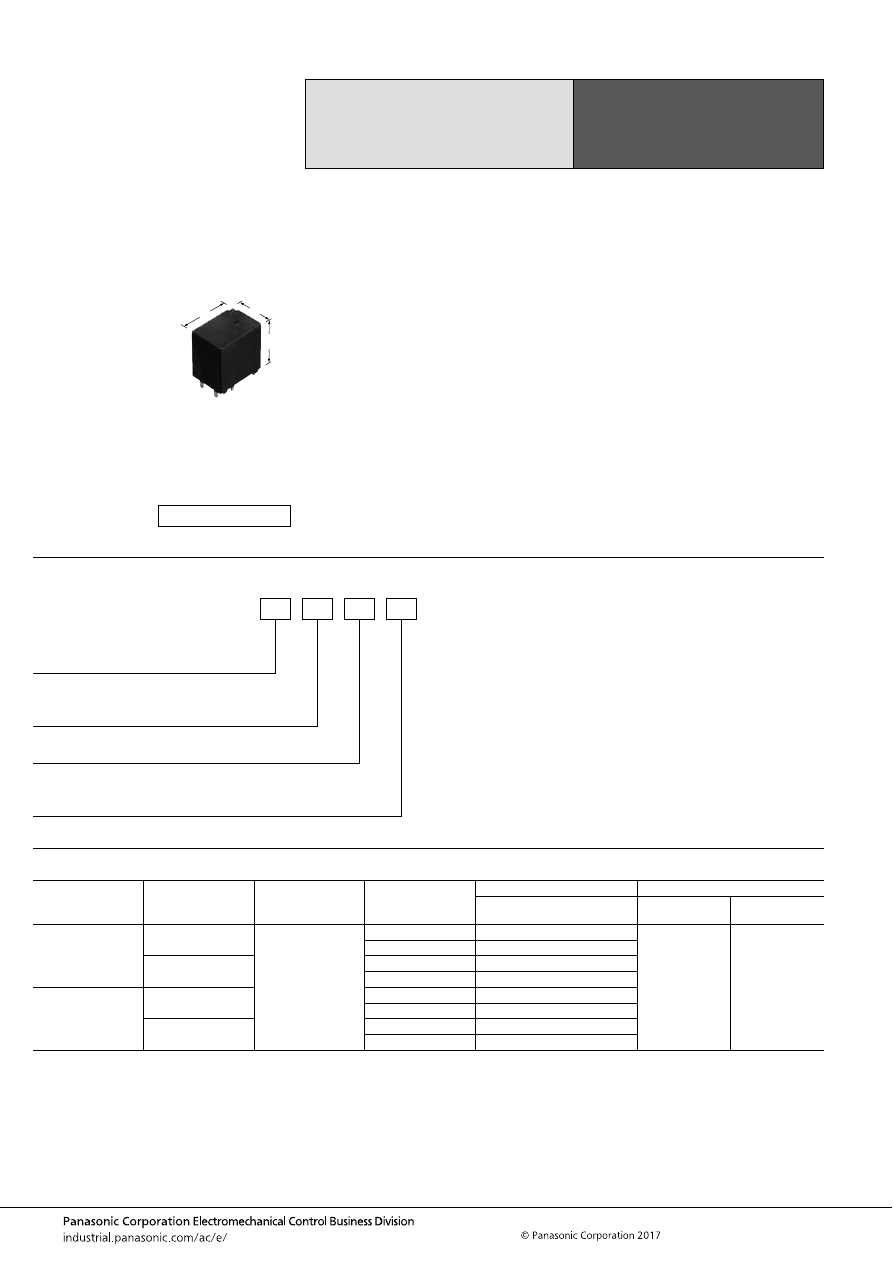

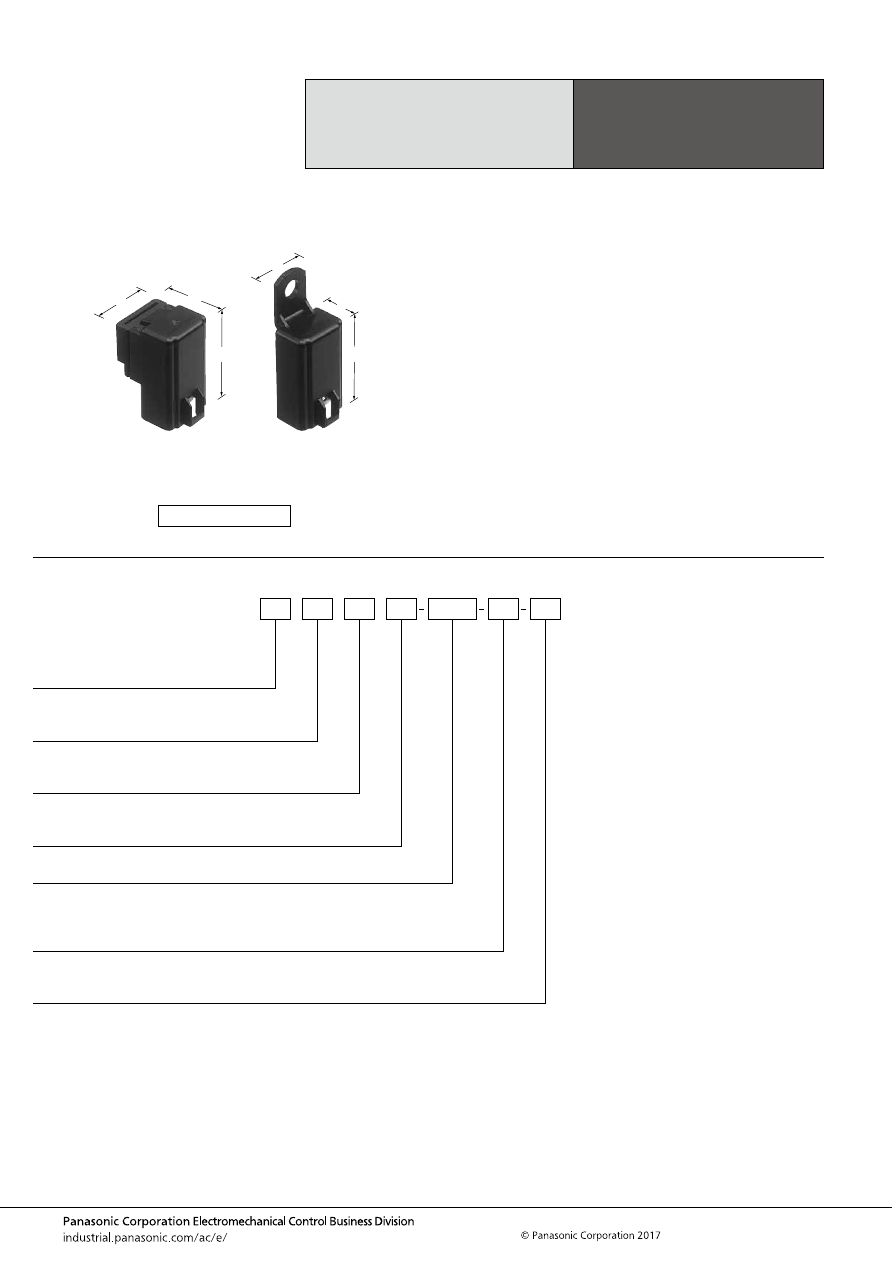

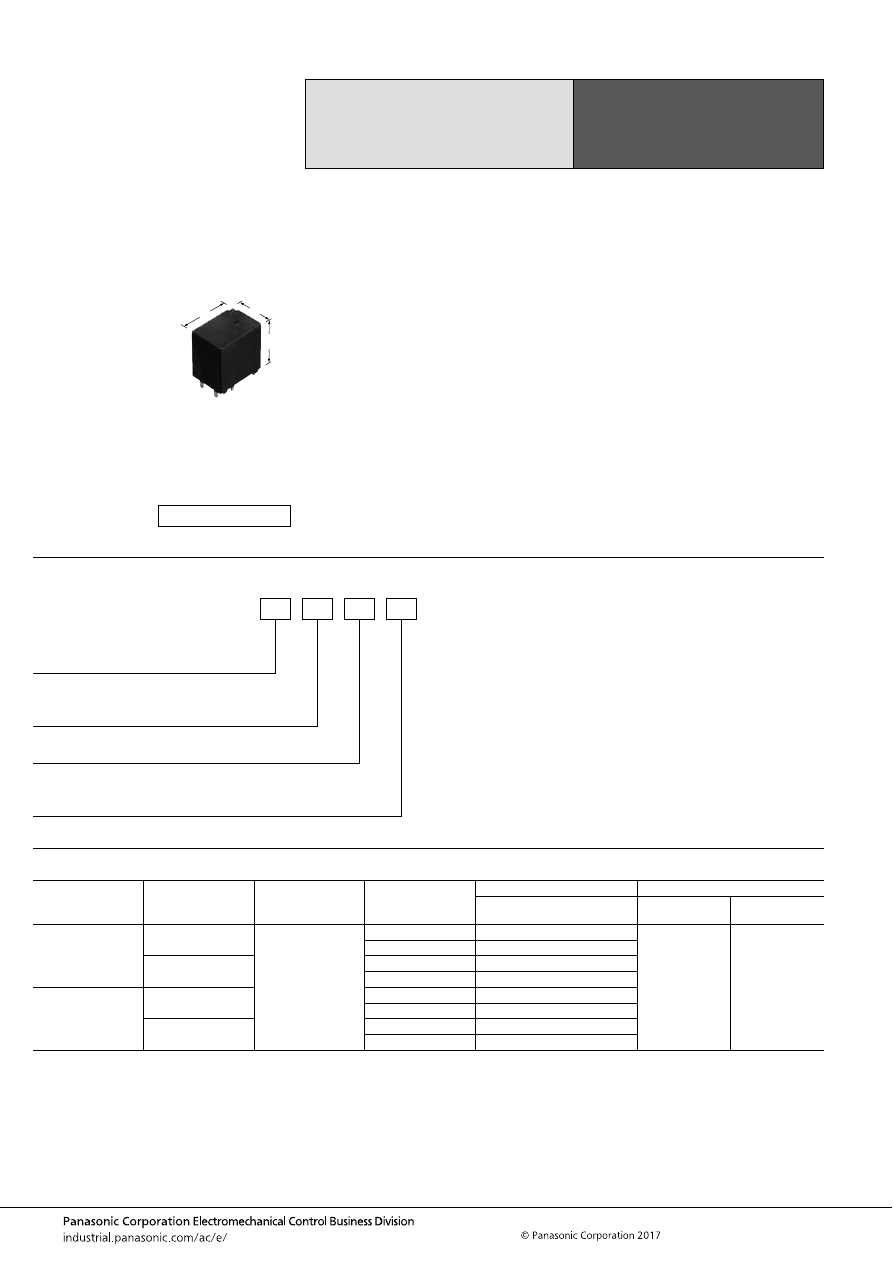

Features

Micro-ISO Automotive Relay

Low Profile Micro-ISO Automotive Relay

Max. 150 A Continuous Carrying

Current Latching Relay

Con

tact

data

Contact arrangement

1 Form A and 1 Form C

1 Form A

1 Form A

Contact material

Ag alloy

Ag alloy

Ag alloy

Rated

switching

capacity

(resistive)

1A 14V DC

For rated coil voltage 12 V DC type

35A 14V DC

N.O.

20A 14V DC

N.C.

1A 14V DC

35A 14V DC

N.O.

1A 14V DC

150A 14V DC

Min. switching load

(resistive)

Latching type

−

−

●

Coi

l data

Rated coil voltage

12V DC

24V DC

12V DC

12V DC

Rated operating power

1.5W

1.8W

800mW

30W

Operate (Set) voltage at 20°C

68°F

(initial)

3.0 to 7.0V DC

6.0 to 14V DC

Max. 7.0V DC

Max. 7.0V DC

Release (Reset) voltage at 20°C

68°F

(initial)

1.2 to 4.2V DC

2.4 to 8.4V DC

Min. 0.5V DC

Max. 7.0V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Max. 10ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode) Max. 10ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

6

(at 120 cpm)

Min. 10

6

(at 120 cpm)

Min. 3 x 10

5

Electrical

Min. 10

5

(resistive)

(Sealed: Min. 5 × 10

4

)

Min. 10

5

(resistive)

Min. 3 x 10

4

Diel

ect

ric st

ren

gth

Between open contacts (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Between contacts and coil (initial)

500 Vrms for 1 min.

500 Vrms for 1 min.

500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

–40 to +85°C

–40 to +185°F

–40 to +125°C

–40 to +257°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

●

−

−

Sealed

●

●

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

PC board type: 23

.906

, Plug-in type: 22

.866

15.7

.618

38.5

1.516

Foot print (mm

inch

)

15

.591

20

.787

15

.591

22.5

.886

48

1.890

38.5

1.516

PC board pattern

Micro-ISO (24V only)

9.0

r

0.05

.354

r

.002

2×1.4

+0.1

0

2×.055

+.004

0

2×2.7

+0.1

0

2×.106

+.004

0

2 (or 3)×1.4

+0.1

0

2 (or 3)×.055

+.004

0

2 (or 3)×2.4

+0.1

0

2 (or 3)×.094

+.004

0

15.0

r

0.05

.591

r

.002

8.0

r

0.05

.315

r

.002

−

−

Weight (approx.)

20 g

.71 oz

12 g

.42 oz

150 g

5.29 oz

Remarks

−

−

−

Page

165

170

174

40A−

35A−

30A−

25A−

20A−

15A−

10A−

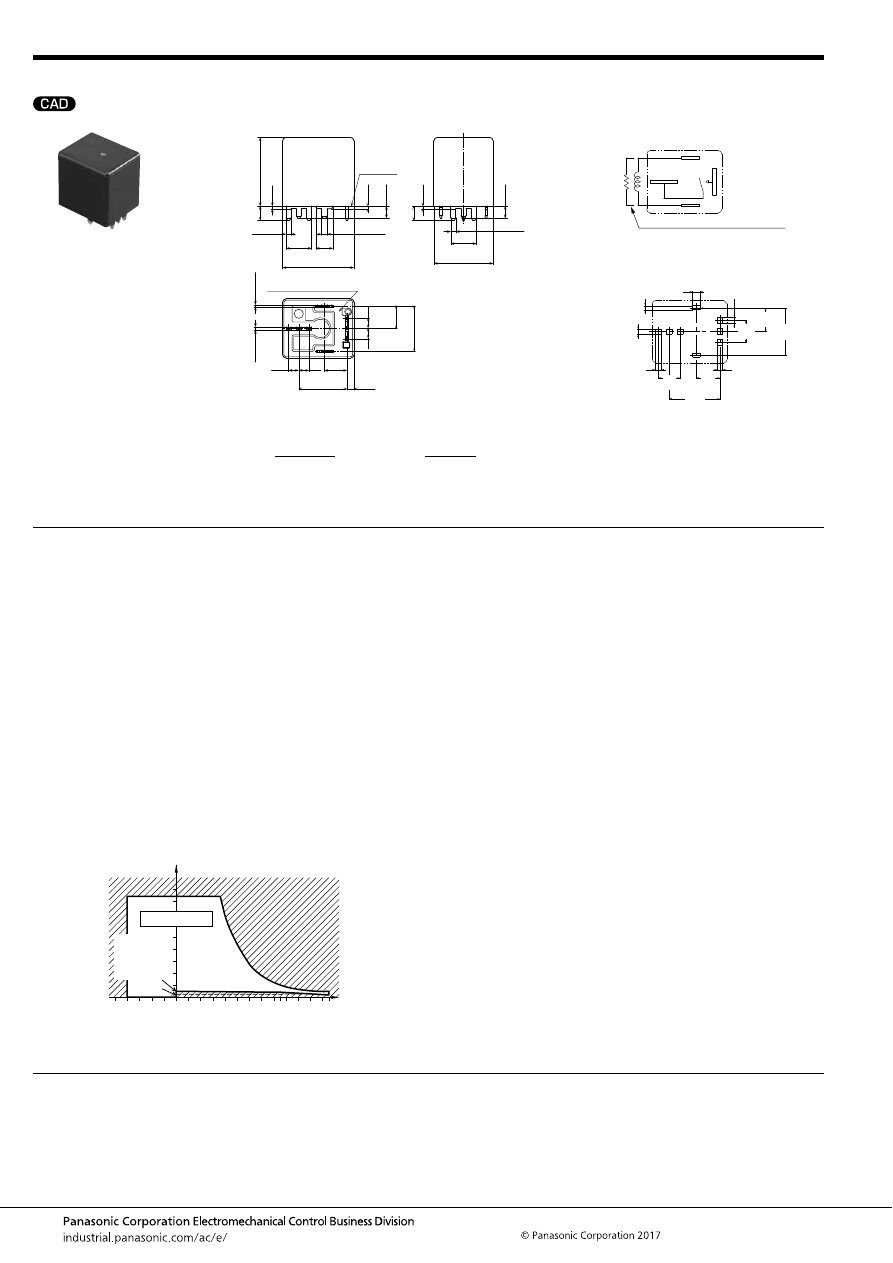

automotive-relay_en-html.html

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–16–

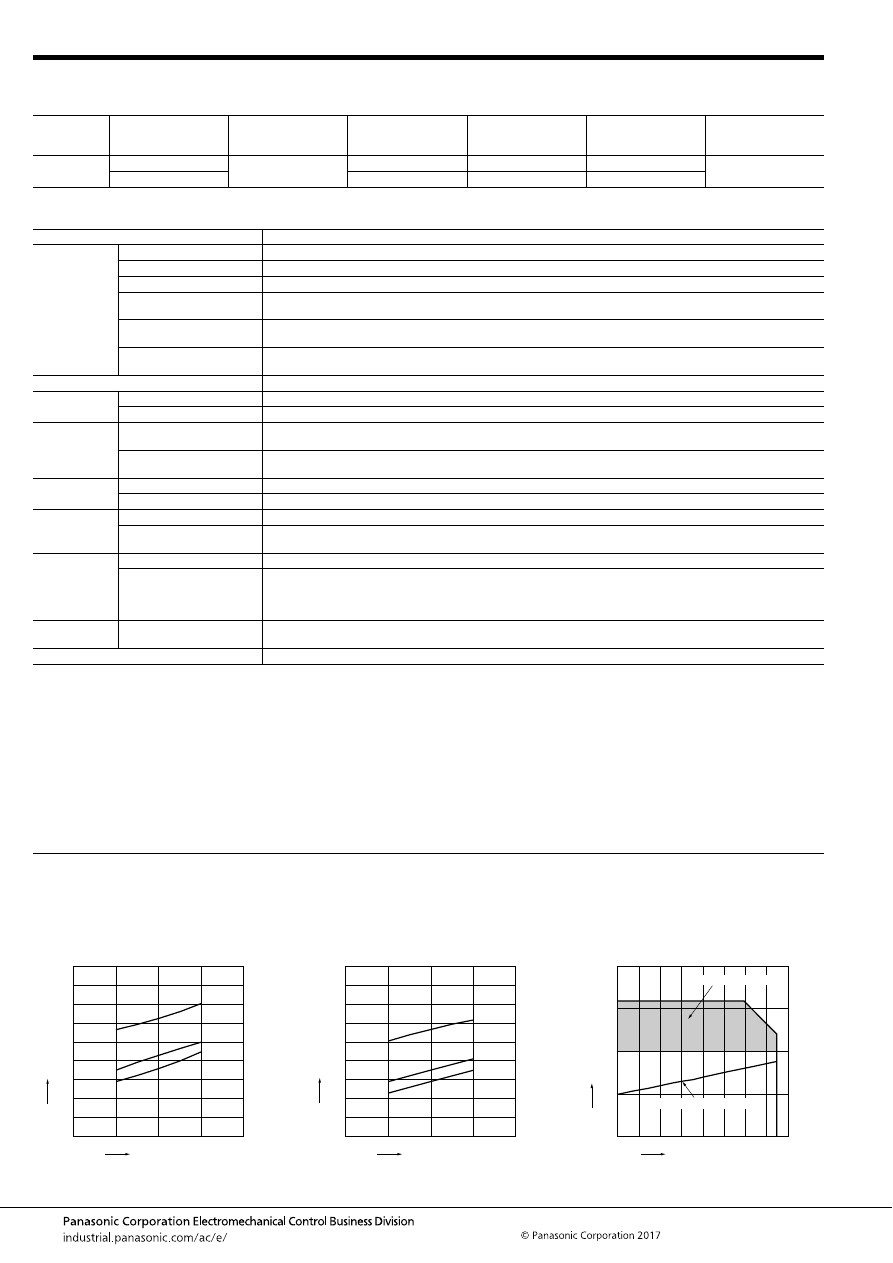

Type

Automotive relays

Product name

EC-N RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

AECN

25

29

28.9

.984

1.142

1.138

Features

Small, High capacity, High voltage DC

Plug in Relay

Con

tact

data

Contact arrangement

1 Form A

Contact material

Ag alloy

Rated

switching

capacity

(resistive)

1A 12V DC

15A 400V DC

Min. switching load

(resistive)

Latching type

−

Coi

l data

Rated coil voltage

12V DC

Rated operating power

1.4

W

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 6.8V DC

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 0.5V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 50ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

) Max. 30ms (without bounce time) (without diode)

Ex

pe

ct

ed

lif

e

Mechanical

Min. 2 x 10

5

Electrical

15A 400V DC, Min. 100,000 cycles (inrush)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

2,500 Vrms for 1 min.

Between contacts and coil (initial)

2,500 Vrms for 1 min.

Ambient temperature

–40 to +85°C

–40 to +185°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

Flux tight

−

Sealed

●

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

28.9

1.138

Foot print (mm

inch

)

25

.984

29

1.142

PC board pattern

−

Weight (approx.)

40 g

1.41 oz

Remarks

−

Page

178

40A−

35A−

30A−

25A−

20A−

15A−

10A−

automotive-relay_en-html.html

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–17–

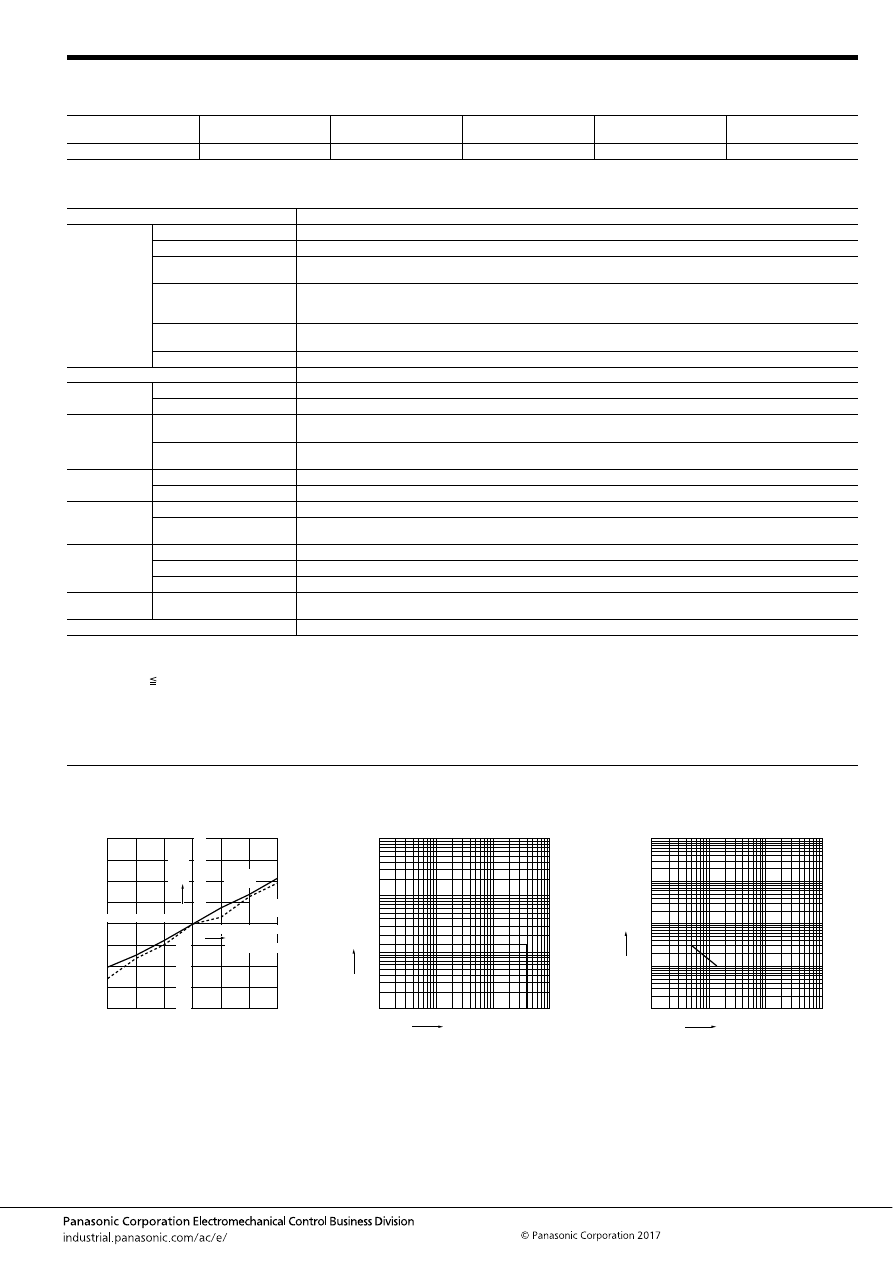

Type

Automotive relays

Product name

EV RELAYS

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

37.9

1.492

10A

80A

40

1.575

300A

120A

40

1.575

20A

40

40

1.575

1.575

AEV

200A

63

63

2.480

2.480

45

45

1.772

1.772

111

111

4.370

4.370

66.8

66.8

2.630

2.630

49.7

49.7

1.957

1.957

48.1

48.1

1.894

1.894

78

78

3.071

3.071

75.5

75.5

2.972

2.972

79

79

3.110

3.110

80

80

3.150

3.150

75.5

75.5

2.972

2.972

86.4

86.4

3.402

3.402

95

95

3.740

3.740

74.7

74.7

2.941

2.941

Features

Compact and High voltage High capacity DC Cut-off Relays using Capsule Contact Mechanism

Con

tact

data

Contact arrangement

1 Form A

Contact material

Molybdenum

Copper alloy

Tungsten and copper

alloy

Copper alloy

Rated

switching

capacity

(resistive)

10A 450V DC

1A 12V DC

20A 400V DC

1A 12V DC

80A 450V DC

1A 12V DC

120A 450V DC

1A 12V DC

1A 12V DC

200A 450V DC

1A 24V DC

300A 450V DC

Min. switching load

(resistive)

Latching type

−

Coi

l data

Rated coil voltage

12, 24V DC

(Please inquire our sales representative for more information about EV20A with nominal coil voltage of 24V DC.)

Rated operating power

1.24W

3.9W

4.2W

4.2W

6.0W

12V: 37.9 W (Inrush), 3.6 W (Stable)

24V: 44.4 W (Inrush), 3.8 W (Stable)

Operate (Set) voltage at 20°C

68°F

(initial)

12V: Max. 9V DC, 24V: Max. 18V DC

Release (Reset) voltage at 20°C

68°F

(initial)

12V: Min. 1.0V DC

24V: Min. 2.0V DC

12V: Min. 0.5V DC

12V: Min. 1.0V DC, 24V: Min. 2.0V DC

12V: Min. 2.0V DC

24V: Min. 4.0V DC

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 50ms (without bounce time)

Max. 30ms (without bounce time)

Release (Reset) time (Rated voltage at 20°C

68°F

)

Max. 30ms

Max. 10ms

Ex

pe

ct

ed

lif

e

Mechanical

Min. 10

5

Min. 2 x 10

5

Electrical

10A 450V DC, Min. 30,000

cycles (resistive)

20A 400V DC, Min. 3,000

cycles (resistive)

80A 450V DC, Min. 1,000

cycles (resistive)

30A 450V DC, Min. 1,000

cycles (resistive)

200A 450V DC, Min. 3,000

cycles (resistive)

300A 450V DC, Min. 1,000

cycles (resistive)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

2,500 Vrms for 1 min.

Between contacts and coil (initial)

2,500 Vrms for 1 min.

Ambient temperature

–40 to +80°C

–40 to +176°F

–40 to +85°C

–40 to +185°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

Flux tight

−

Sealed

●

(Power capsule)

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

49.7

1.957

48.1

1.894

79

3.110

80

3.150

86.4

3.402

74.7

2.941

Foot print (mm

inch

)

31.6

1.244

66.8

2.630

40

1.575

78

3.071

40

1.575

75.5

2.972

40

1.575

75.5

2.972

45

1.772

95

3.740

60

2.362

92

3.622

Mounting dimensions

Mounting hole

2×4.2

r

0.1 dia.

2×.165

r

.004 dia.

55.9

r

0.1

2.201

r

.004

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

64.0

r

0.2

2.520

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

63.5

r

0.2

2.500

r

.008

26.0

r

0.2

1.024

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

63.5

r

0.2

2.500

r

.008

26.0

r

0.2

1.024

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

82

r

0.2

3.228

r

.008

31

r

0.2

1.220

r

.008

Mounting hole

3×6.0

r

0.2 dia.

3×.236

r

.008 dia.

79.0

r

0.2

3.110

r

.008

47.0

r

0.2

1.850

r

.008

Weight (approx.)

90 g

3.17 oz

180 g

6.35 oz

400 g

14.11 oz

400 g

14.11 oz

600 g

21.16 oz

750 g

26.46 oz

Remarks

−

−

−

−

−

−

Page

183

200A−

120A−

100A−

80A−

60A−

20A−

10A−

automotive-relay_en-html.html

Automotive Relays Selector Chart

Panasonic Corporation 2017

©

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

ASCTB283E 201709-T

–18–

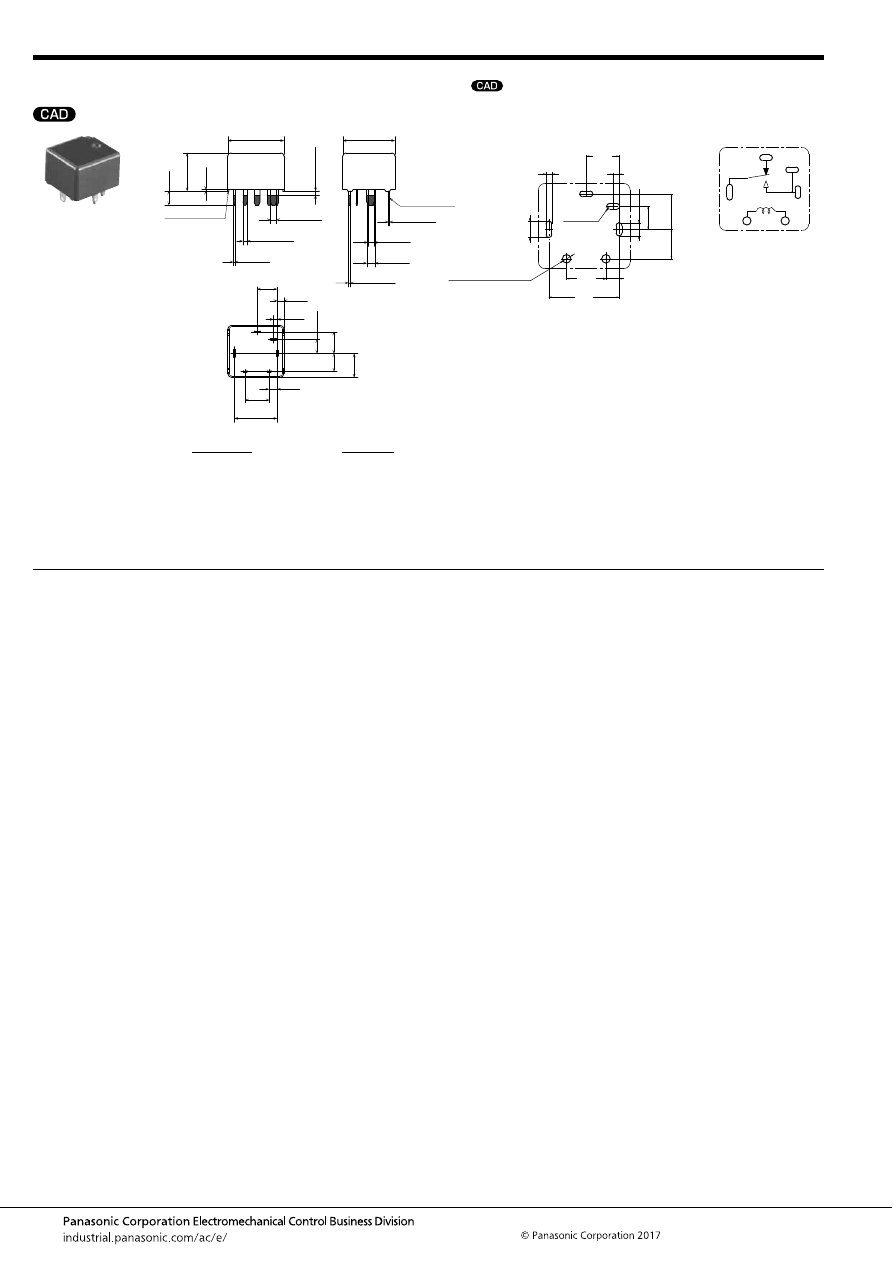

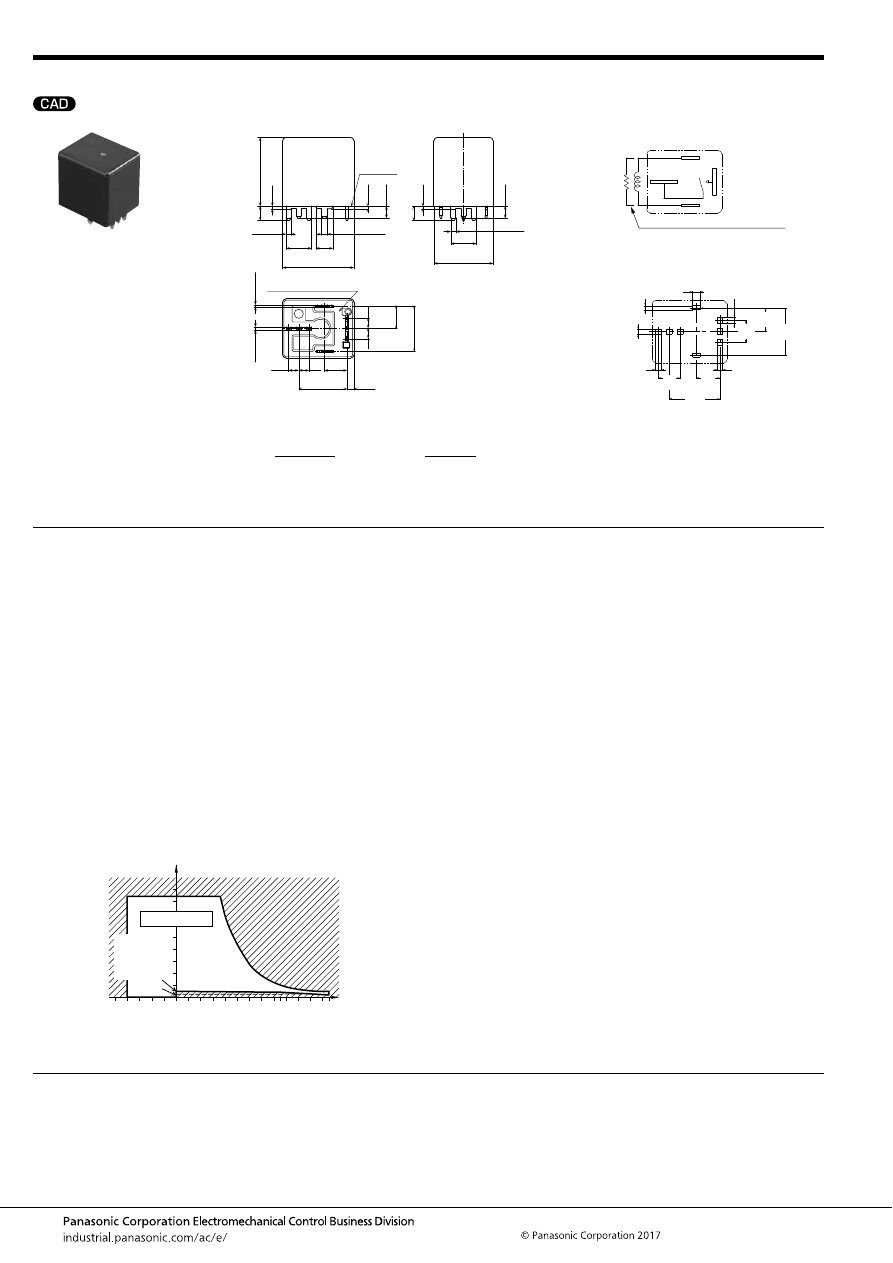

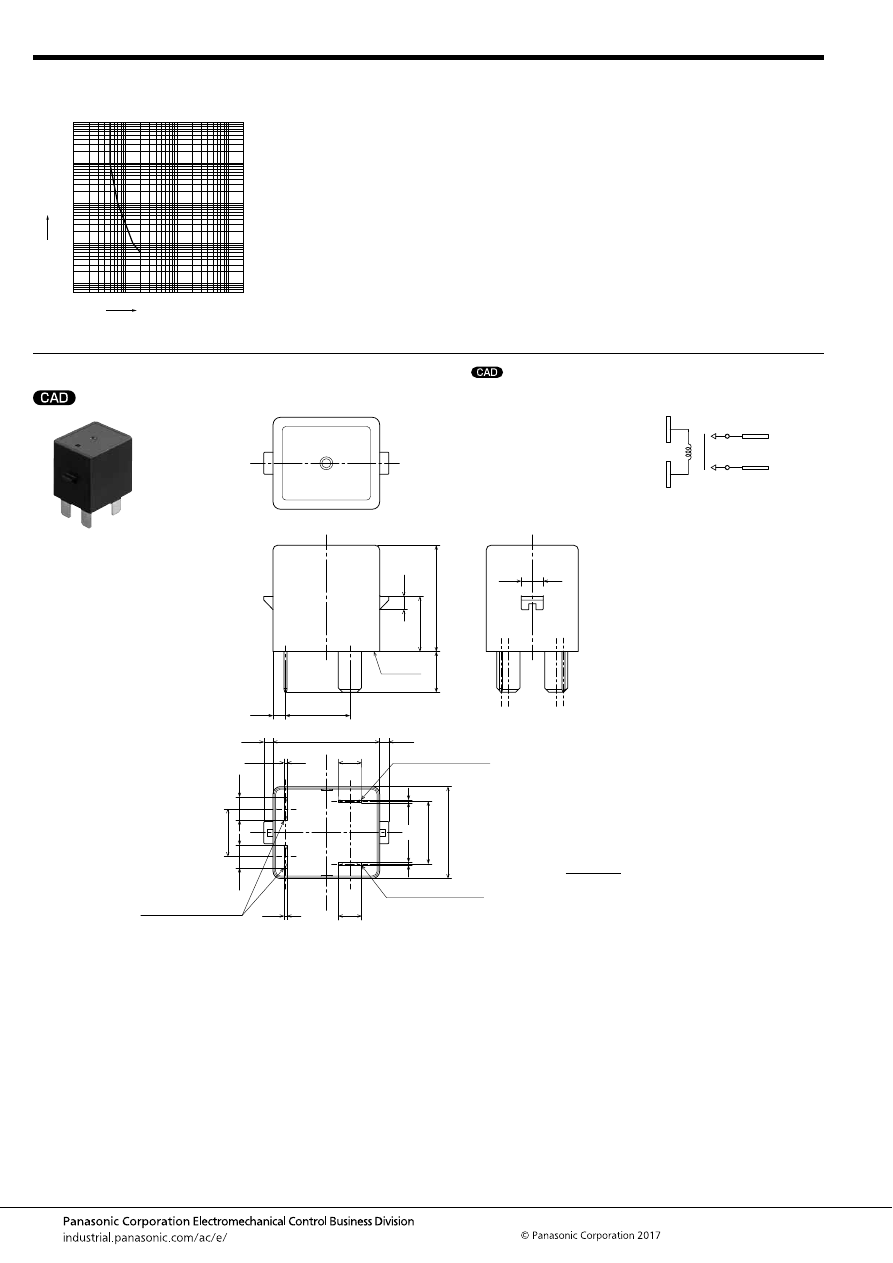

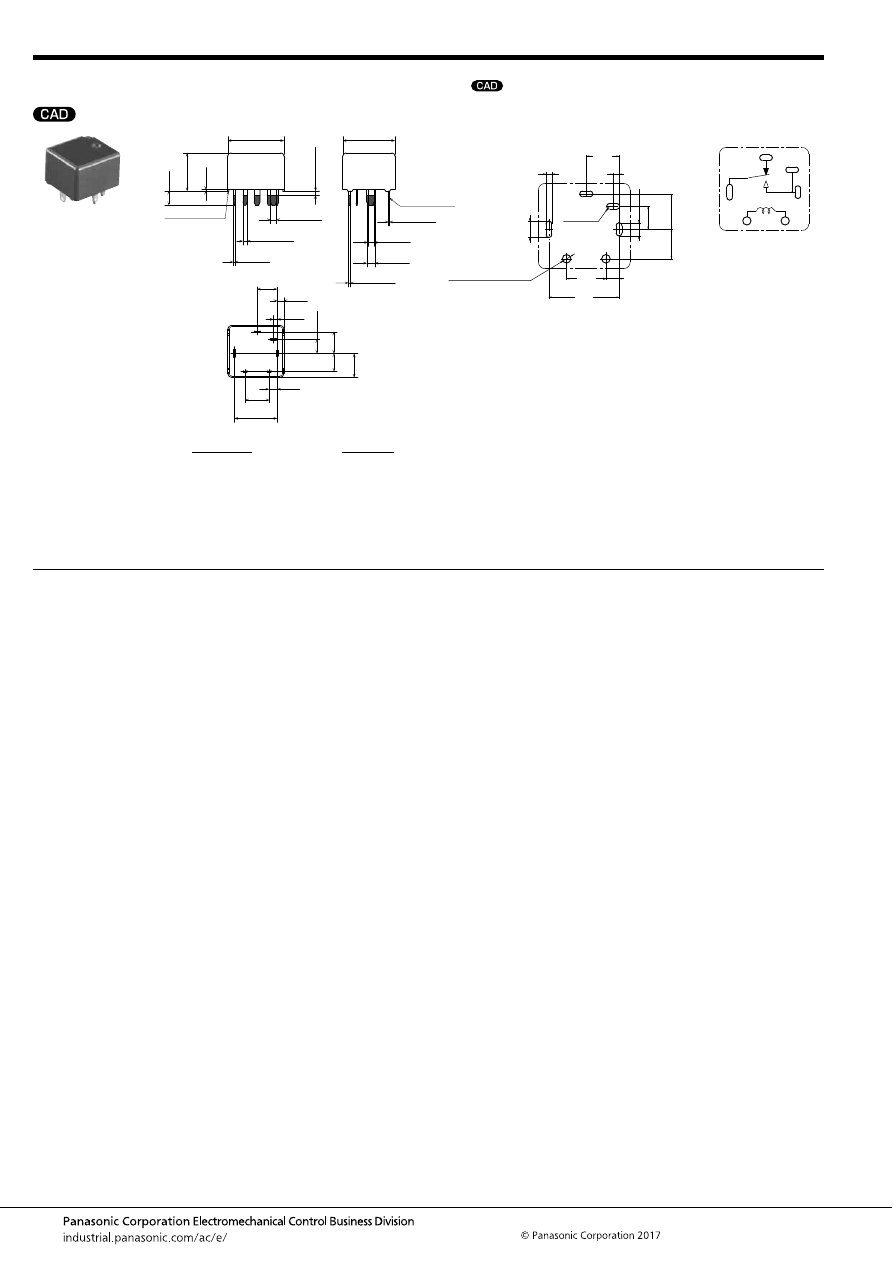

Type

Automotive relays

Automotive safety switches

Product name

EV RELAYS Quiet Type

EV Relay Compact High Short-circuit Capacity Type

EV SWITCHES

Appearance

configuration

(Standoff height included,

Unit: mm

inch

)

Part No.

AEVS

67.8

67.8

36

36

76

76

2.669

2.669

1.417

1.417

2.992

2.992

72.3

72.3

2.846

2.846

37.7

37.7

1.484

1.484

77

77

3.031

3.031

AEVG

64

64

52.8

52.8

2.520

2.520

2.079

2.079

33

1.299

AEVD

82.3

114.3

3.240

34.6

1.362

4.500

Features

Unique Silencing Technology and

Low Operation Noise

Compact and Short Circuit Capacity 4.5kA

High voltage DC Cut-off Switches

using Capsule Contact Mechanism

Con

tact

data

Contact arrangement

1 Form A

1 Form A

1 Form A

Contact material

Tungsten and copper alloy

Copper alloy

Rated

switching

capacity

(resistive)

1A 12V DC

60A 450V DC

60A 450V DC

1A 12V DC

80A 400V DC

Min. switching load

(resistive)

Latching type

−

−

−

Coi

l data

Rated coil voltage

12V DC

12V DC

−

Rated operating power

4.5W

5.2W

−

Operate (Set) voltage at 20°C

68°F

(initial)

Max. 9.0V DC

Max. 9.0V DC

−

Release (Reset) voltage at 20°C

68°F

(initial)

Min. 1.0V DC

Min. 0.5V DC

−

Operate (Set) time (Rated voltage at 20°C

68°F

)

Max. 50ms (without bounce time)

Max. 50ms (without bounce time)

−

Release (Reset) time (Rated voltage at 20°C

68°F

)

Max. 50ms

Max. 30ms

−

Ex

p

ec

te

d l

ife Mechanical

Min. 2 × 10

5

Min. 2 × 10

5

Min. 100

Electrical

60A 450V DC, Min. 800 cycles

(resistive)

30A 450V DC (Inrush resistance),

Min. 70,000 cycles

400A 400V DC, 5 times cut-off (L/R

≦

1ms)

Diel

ect

ric st

ren

gth

Between open contacts (initial)

Vertical type: 2,500 Vrms for 1 min.

Horizontal type: 2,000 Vrms for 1 min.

2,500 Vrms for 1 min.

2,500 Vrms for 1 min. (Between contacts and lever surface)

Between contacts and coil (initial)

2,500 Vrms for 1 min.

−

Ambient temperature

–40 to +80°C

–40 to +176°F

–40 to +80°C

–40 to +176°F

–40 to +80°C

–40 to +176°F

Prot

ec

tiv

e c

on

str

uc

tio

n

Dust cover

−

−

−

Flux tight

−

−

−

Sealed

●

(Power capsule)

●

(Power capsule)

●

(Power capsule)

E

xt

e

rnal

d

imensions

Height (mm

inch

)

Included standoff

Vertical type: 72.3

2.846

Horizontal type: 37.7

1.484

52.8

2.079

34.6

1.362

Foot print (mm

inch

)

76

36

77

2.992

3.031

67.8

1.417

2.669

33

1.299

64

2.520

114.3

4.500

82.3

3.240

Mounting dimensions

Vertical type

Horizontal type

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

62.0

r

0.2

2.441

r

.008

22.0

r

0.2

.866

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

65.0

r

0.2

2.559

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

52.0

r

0.2

2.047

r

.008

21.0

r

0.2

.827

r

.008

67.3

r

0.2

2.650

r

.008

26

r

0.2

1.024

r

.008

Mounting hole

2×6.0

r

0.2 dia.

2×.236

r

.008 dia.

Weight (approx.)

Vertical type: 250 g

8.82 oz

Horizontal type: 240 g

8.47 oz

165 g

5.82 oz

230 g

8.11 oz

Remarks

−

−

−

Page

183

201

200A−

120A−

100A−

80A−

60A−

20A−

10A−

automotive-relay_en-html.html

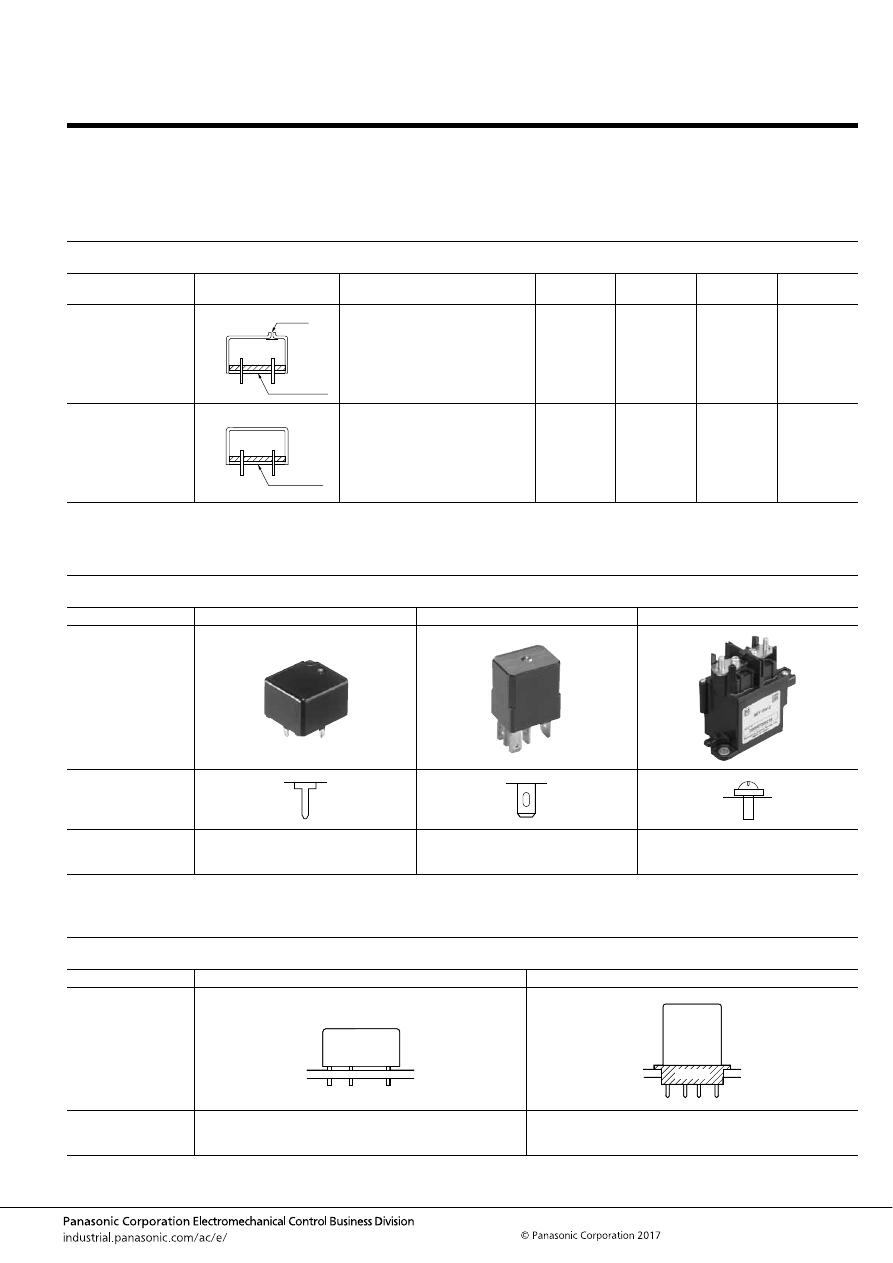

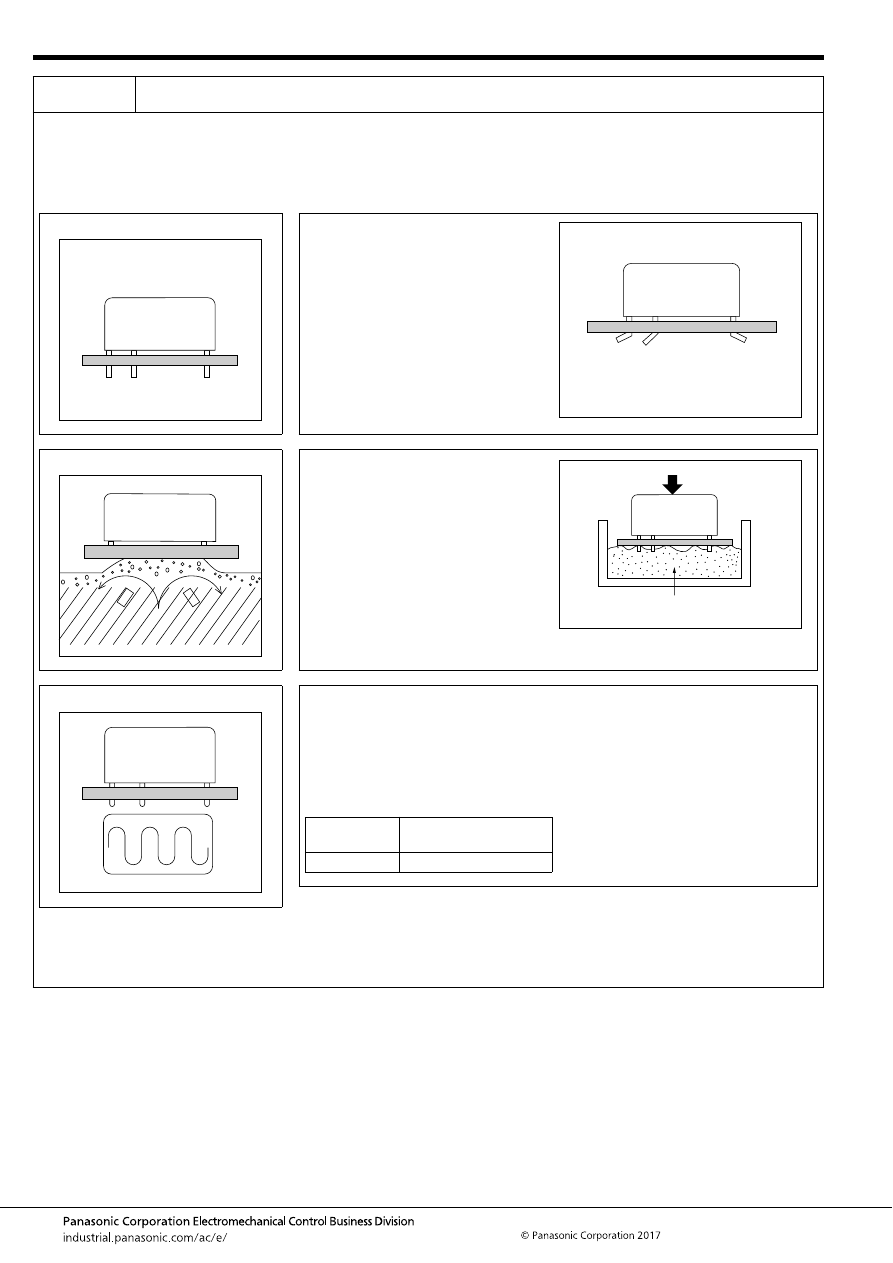

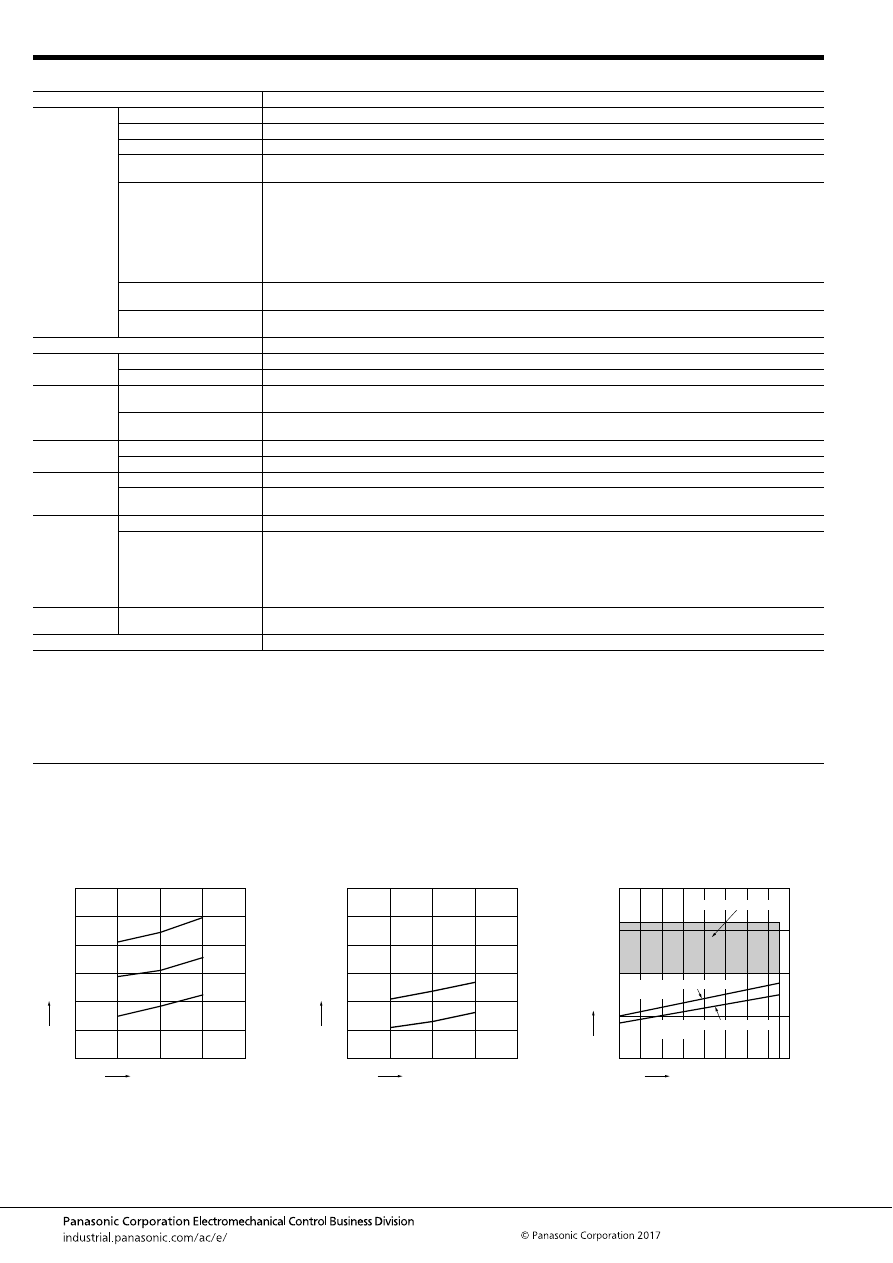

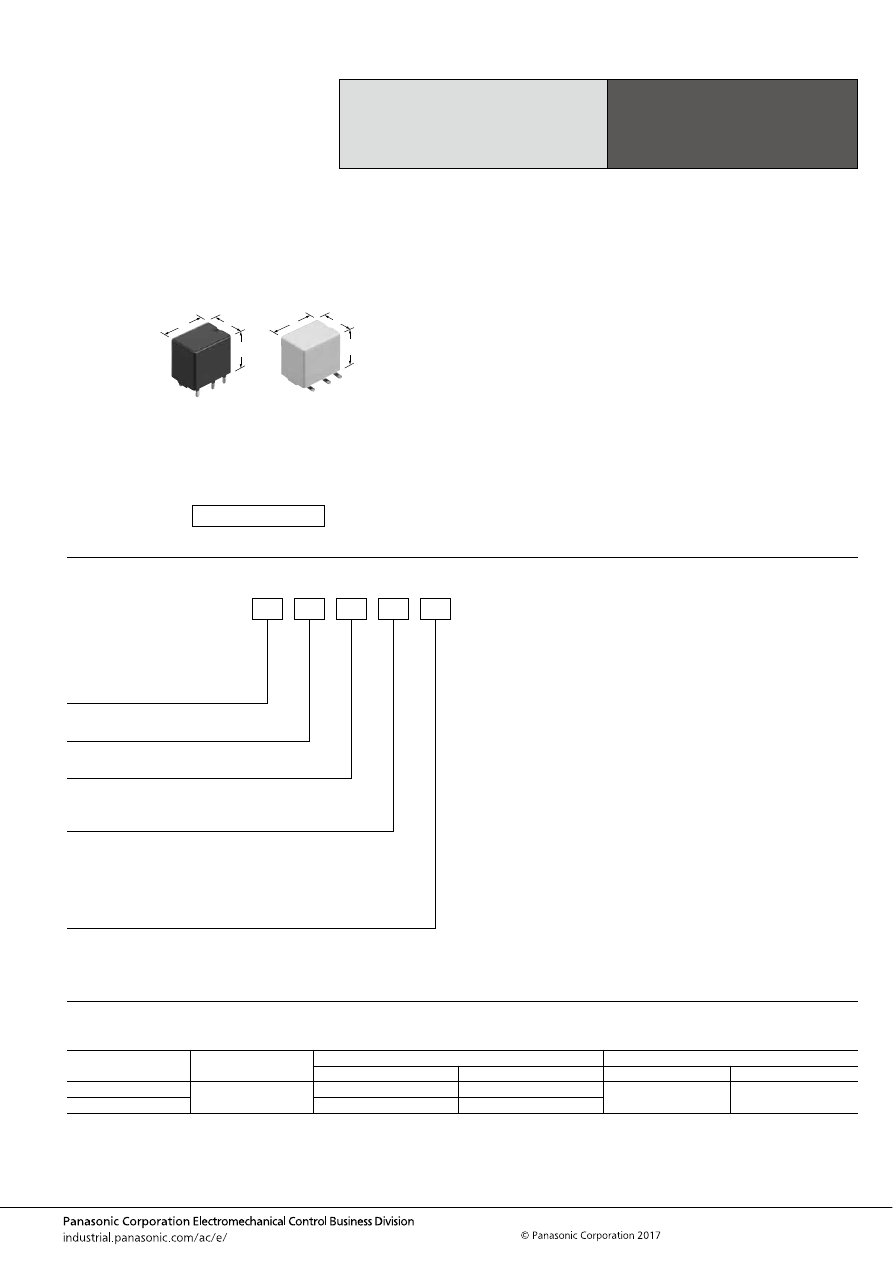

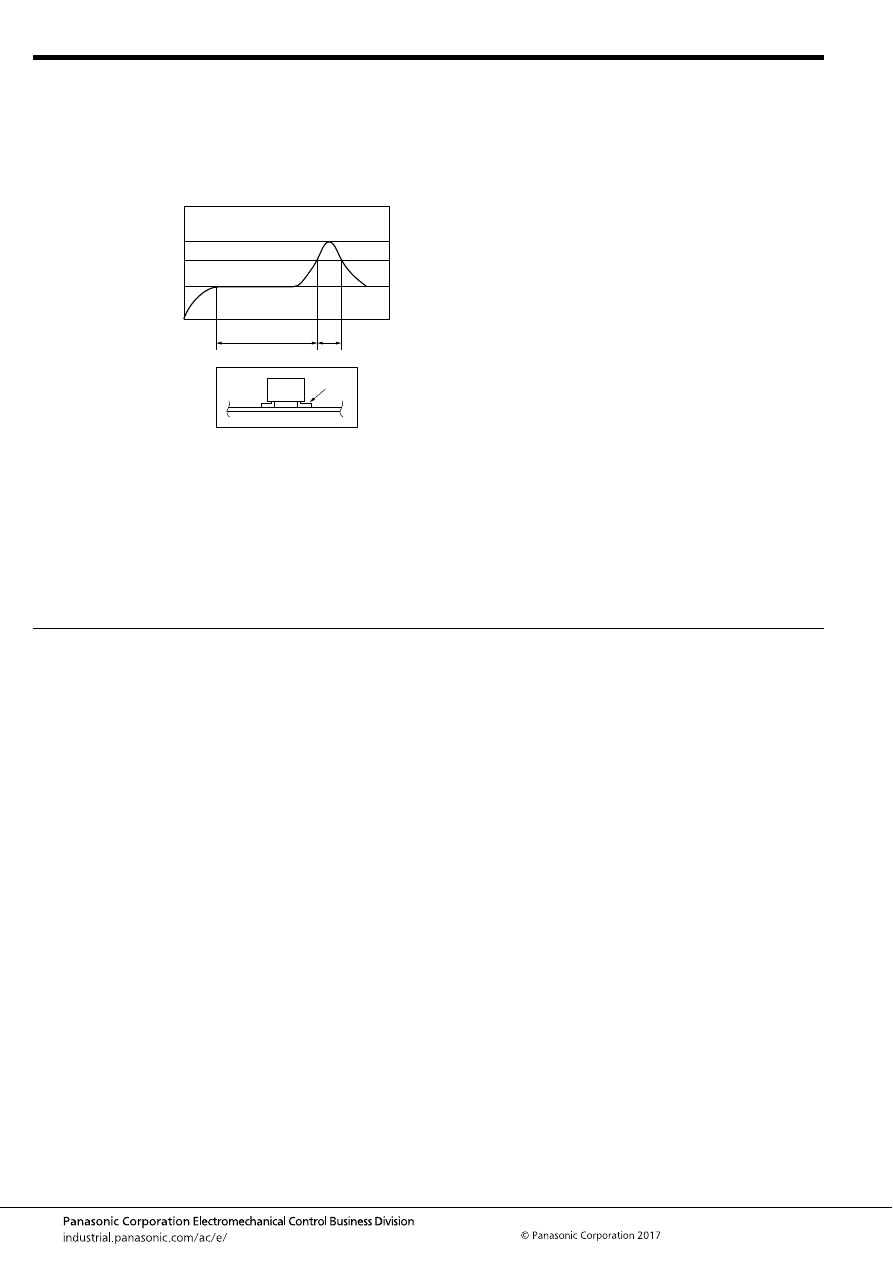

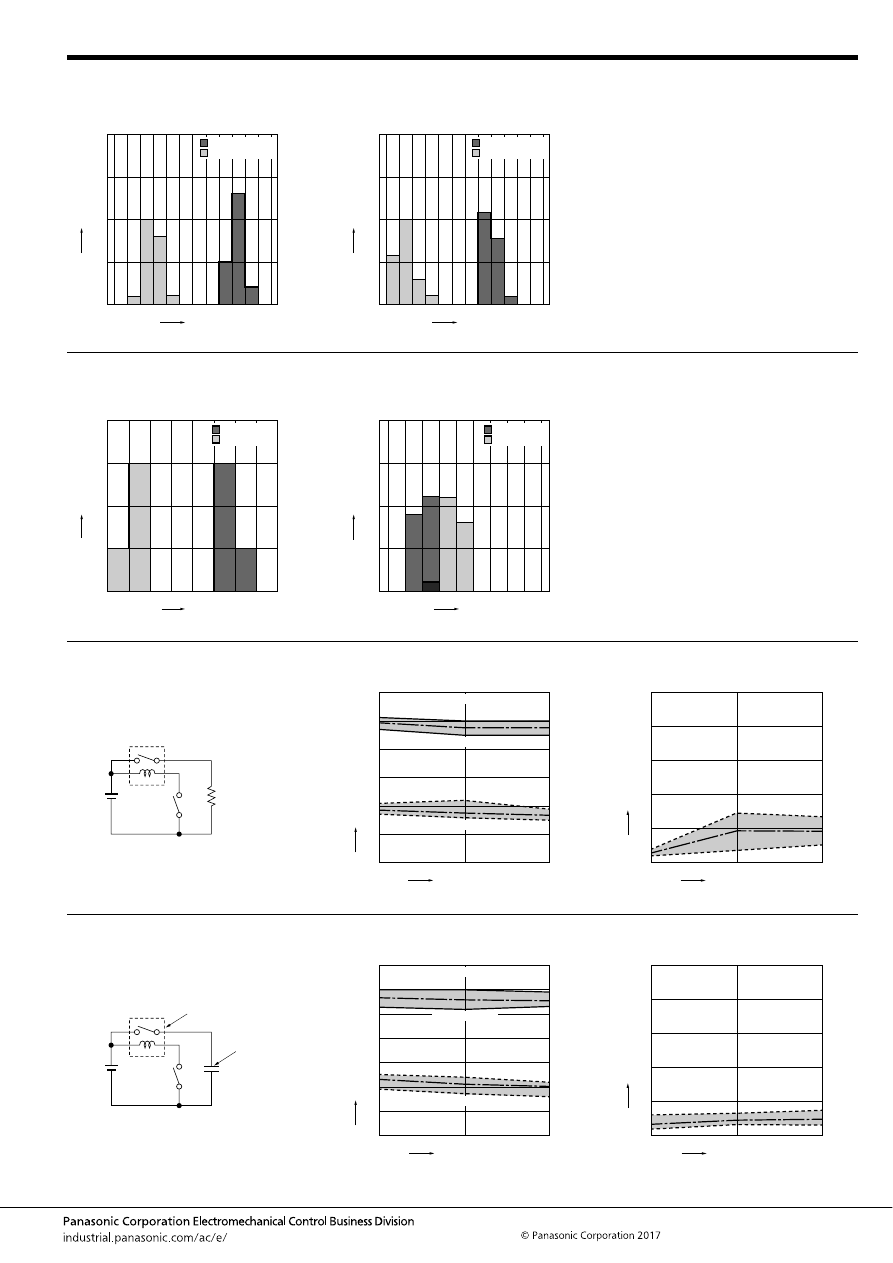

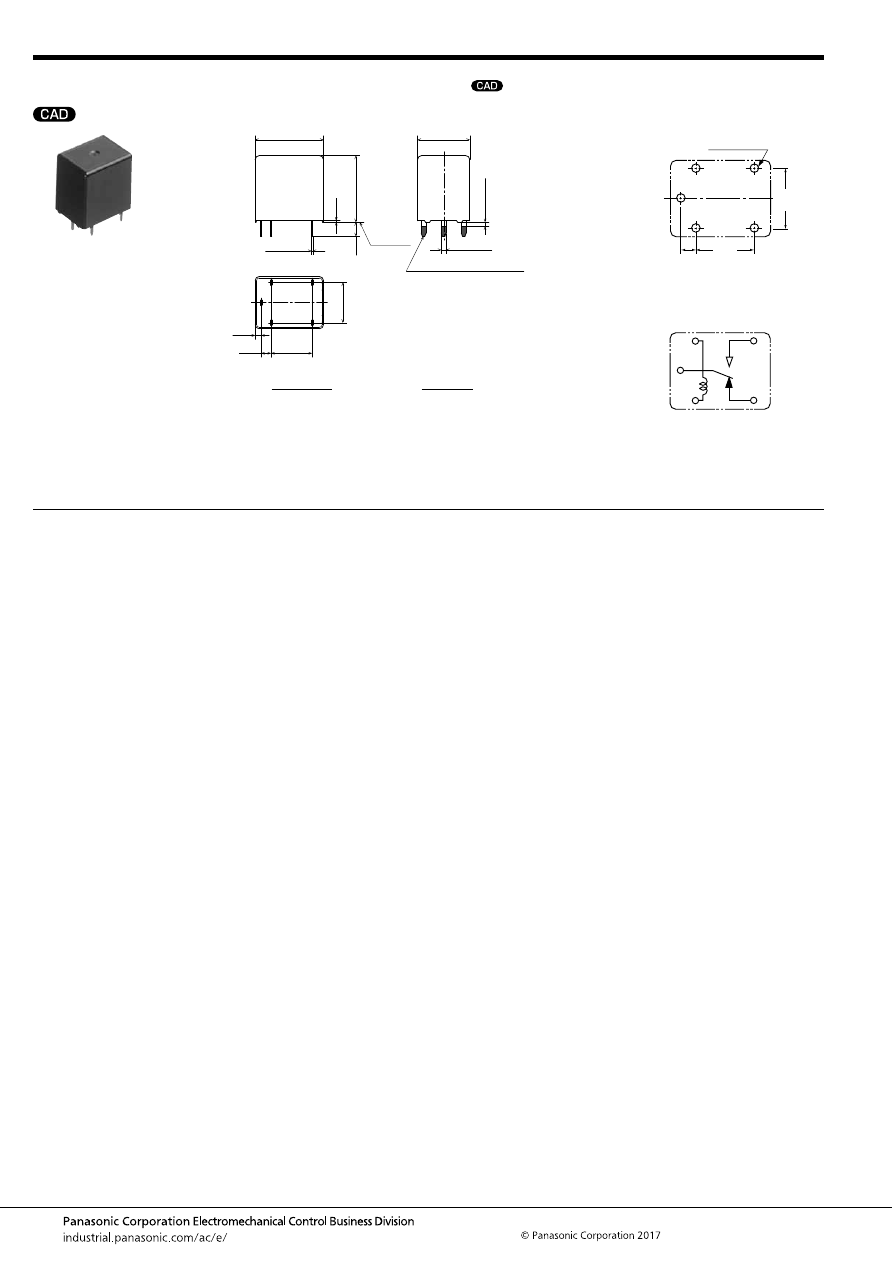

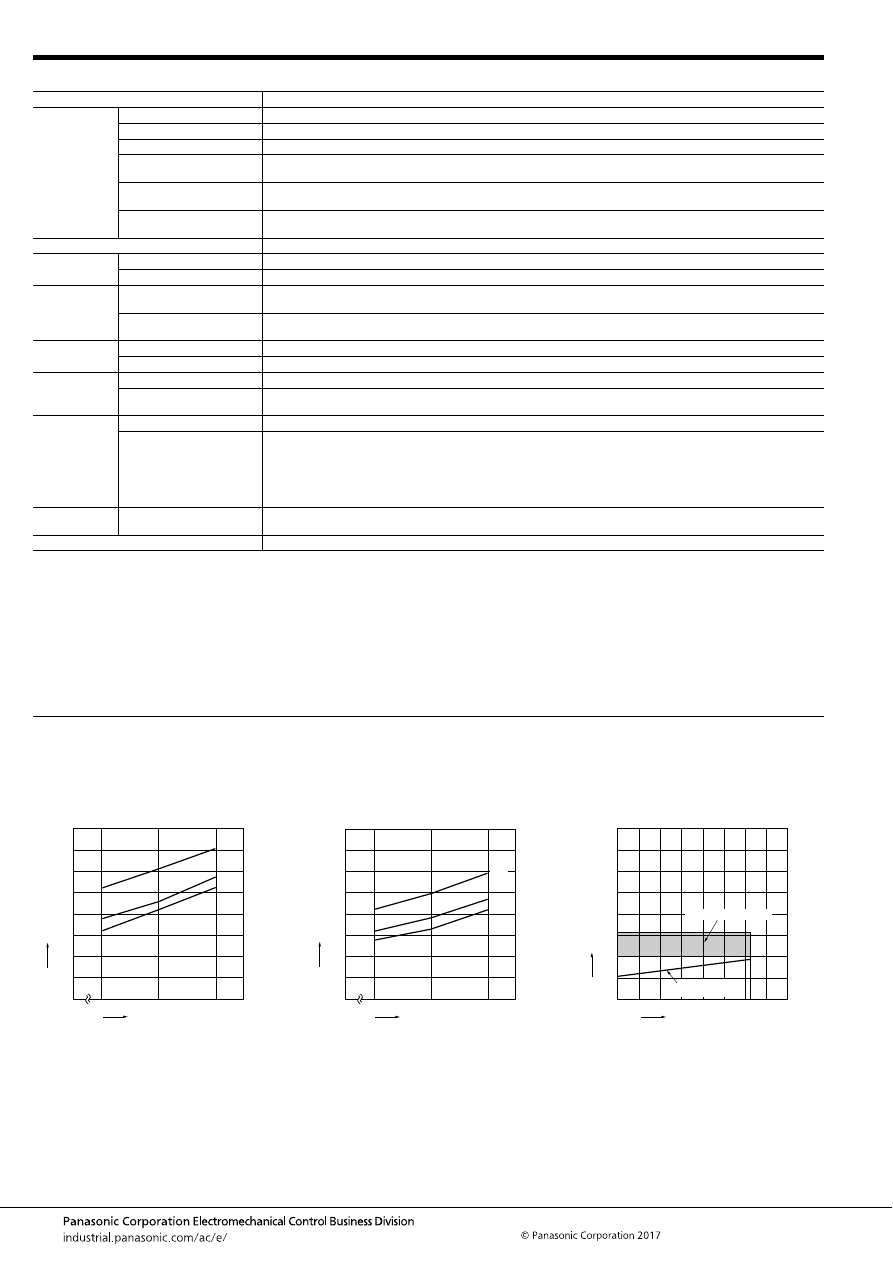

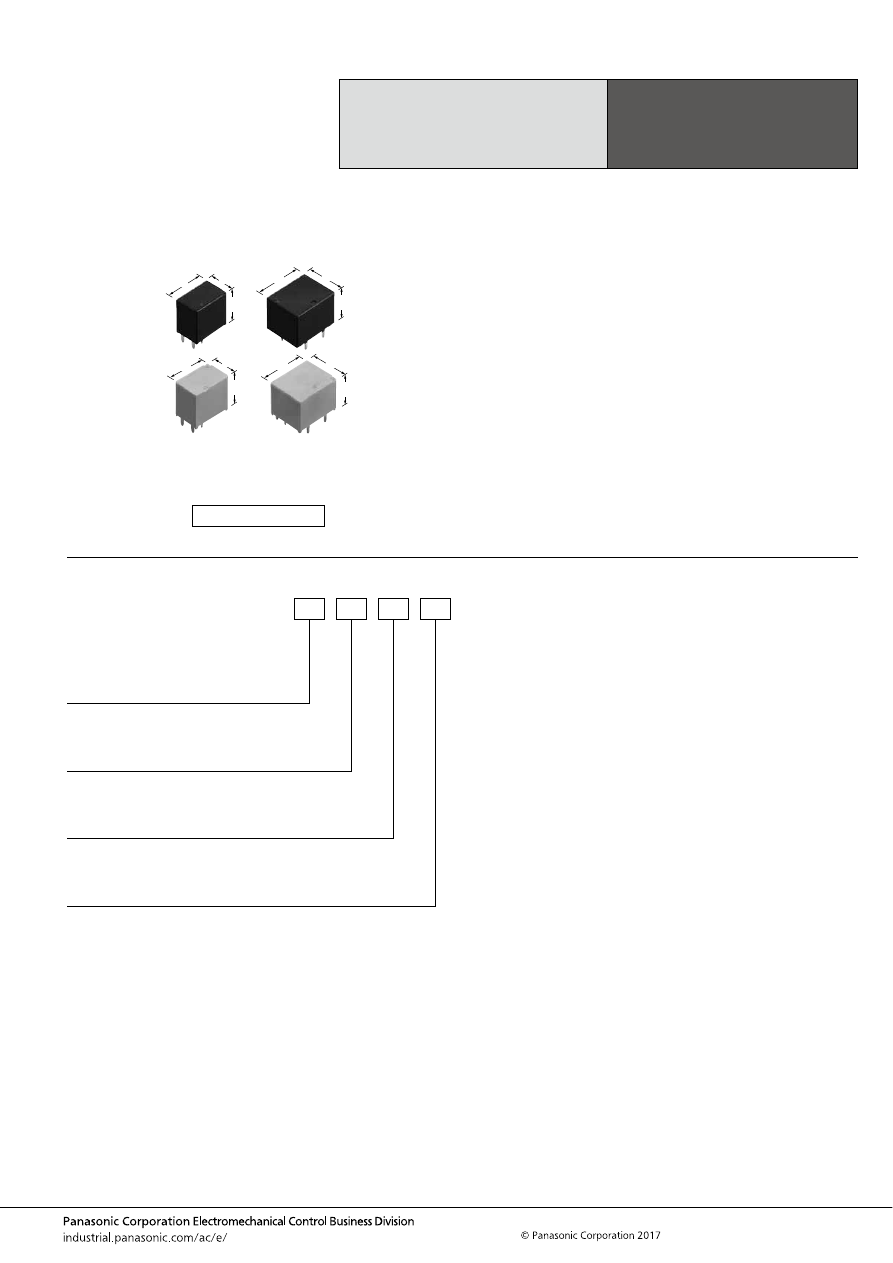

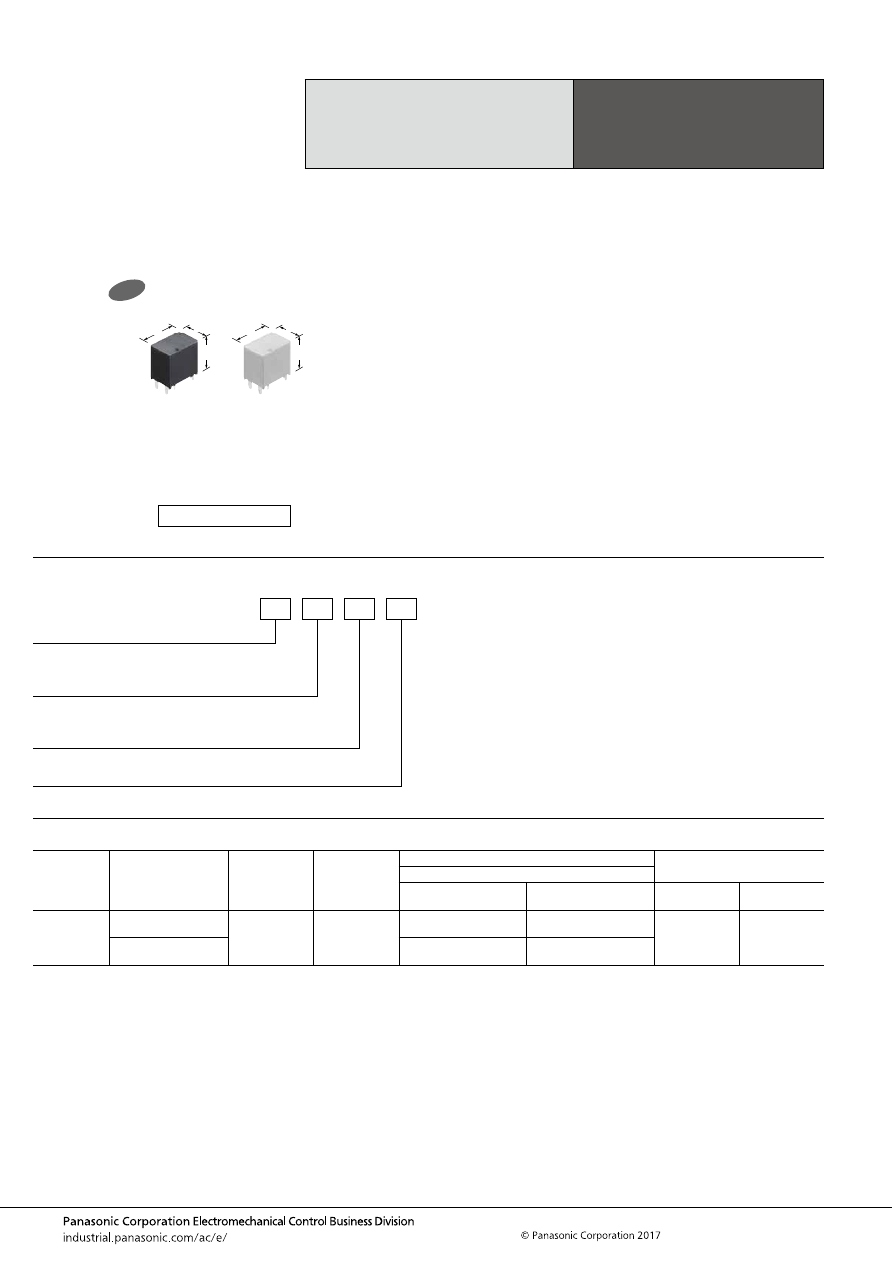

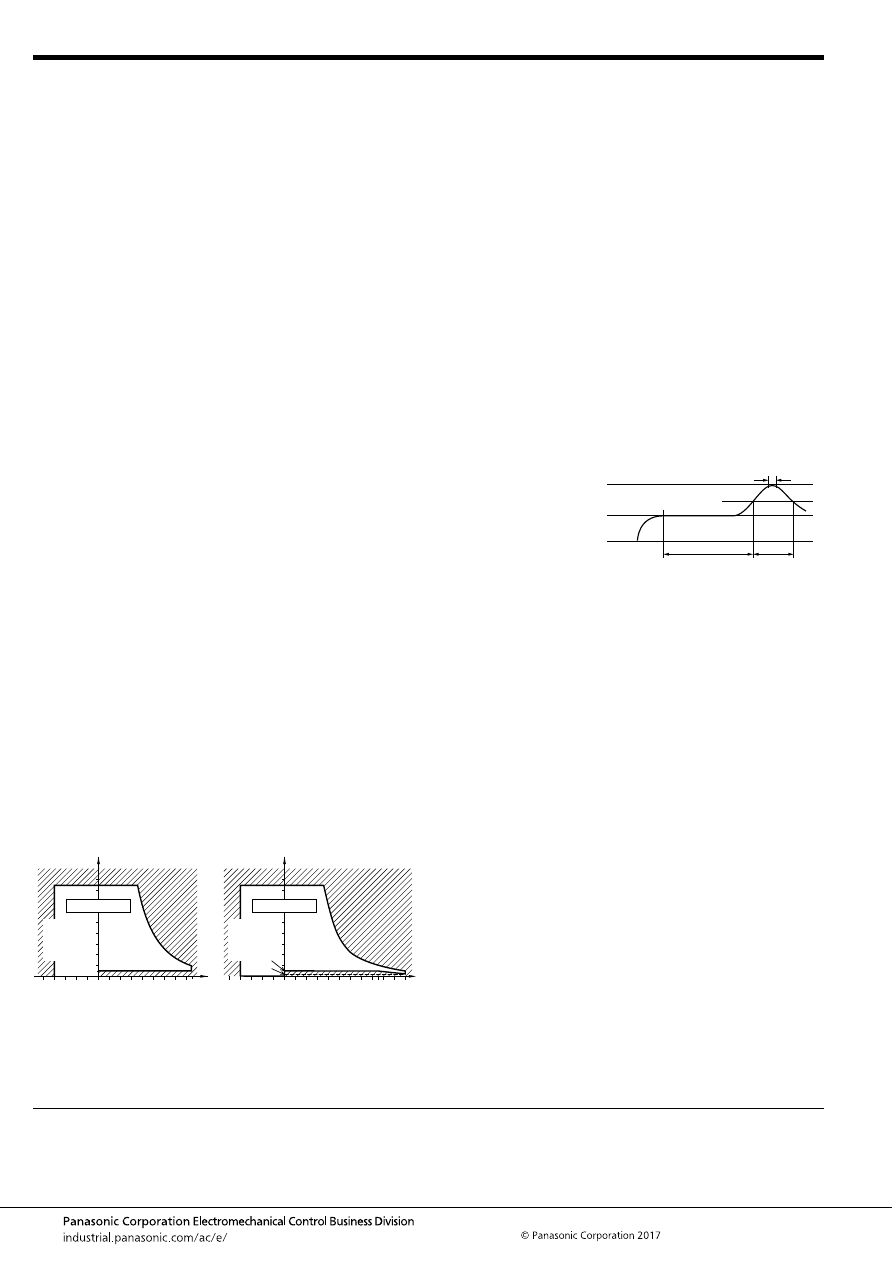

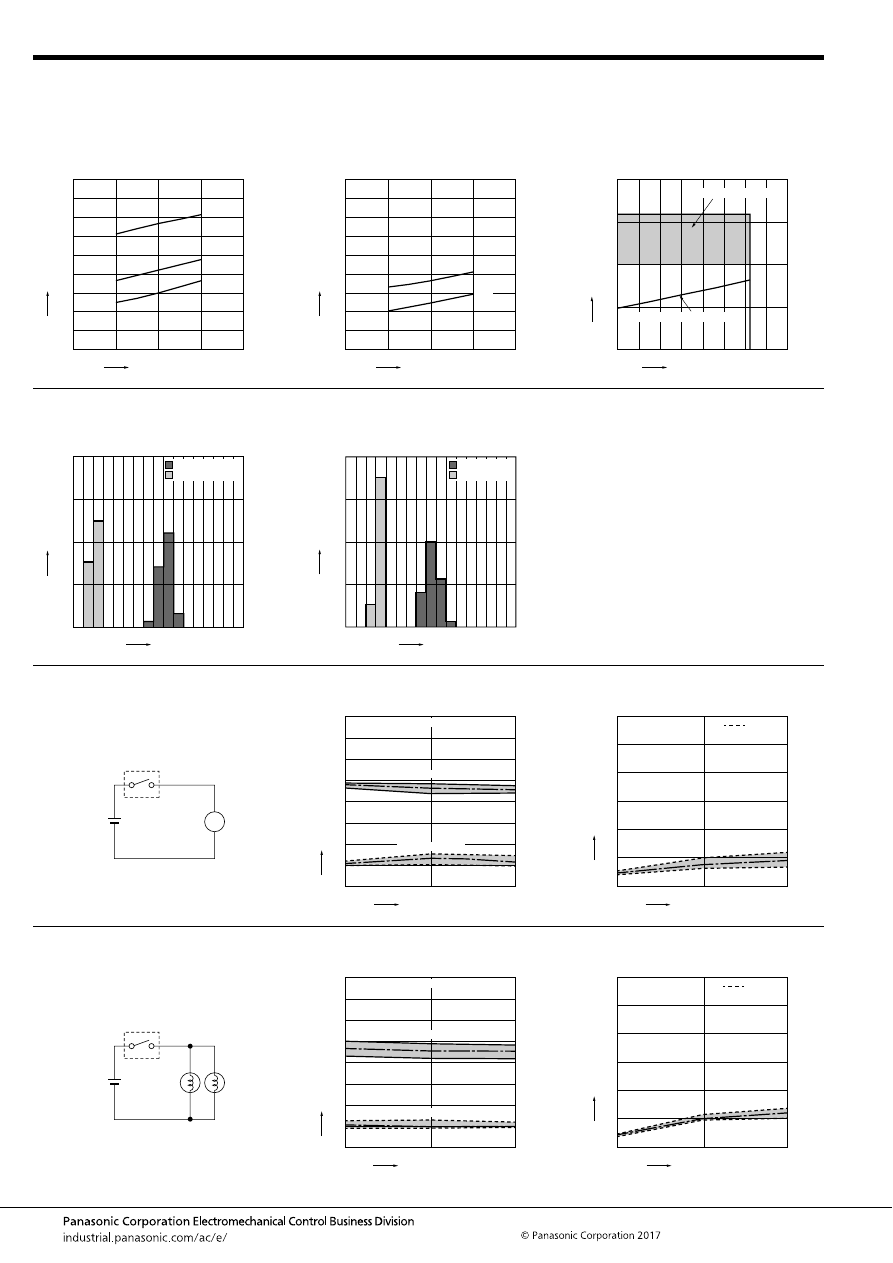

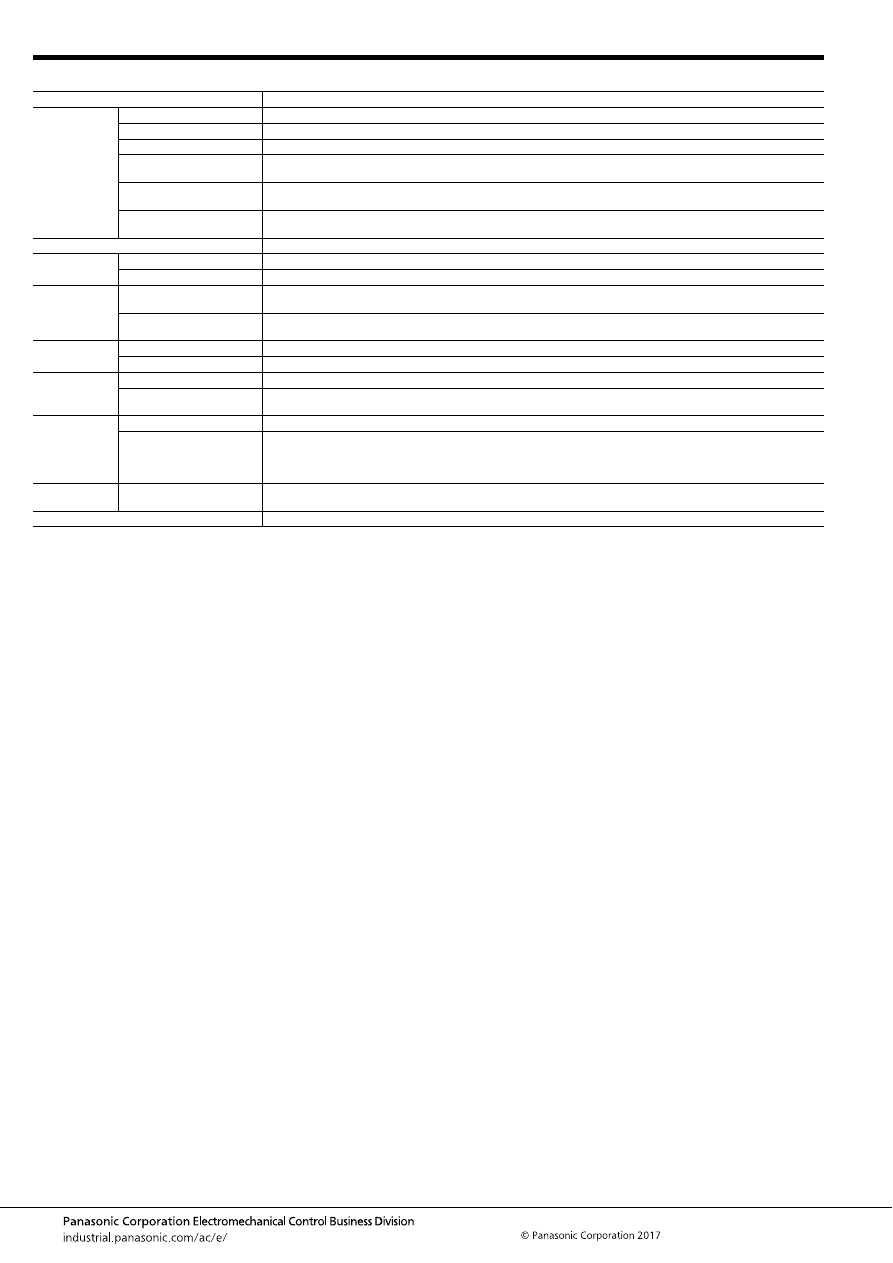

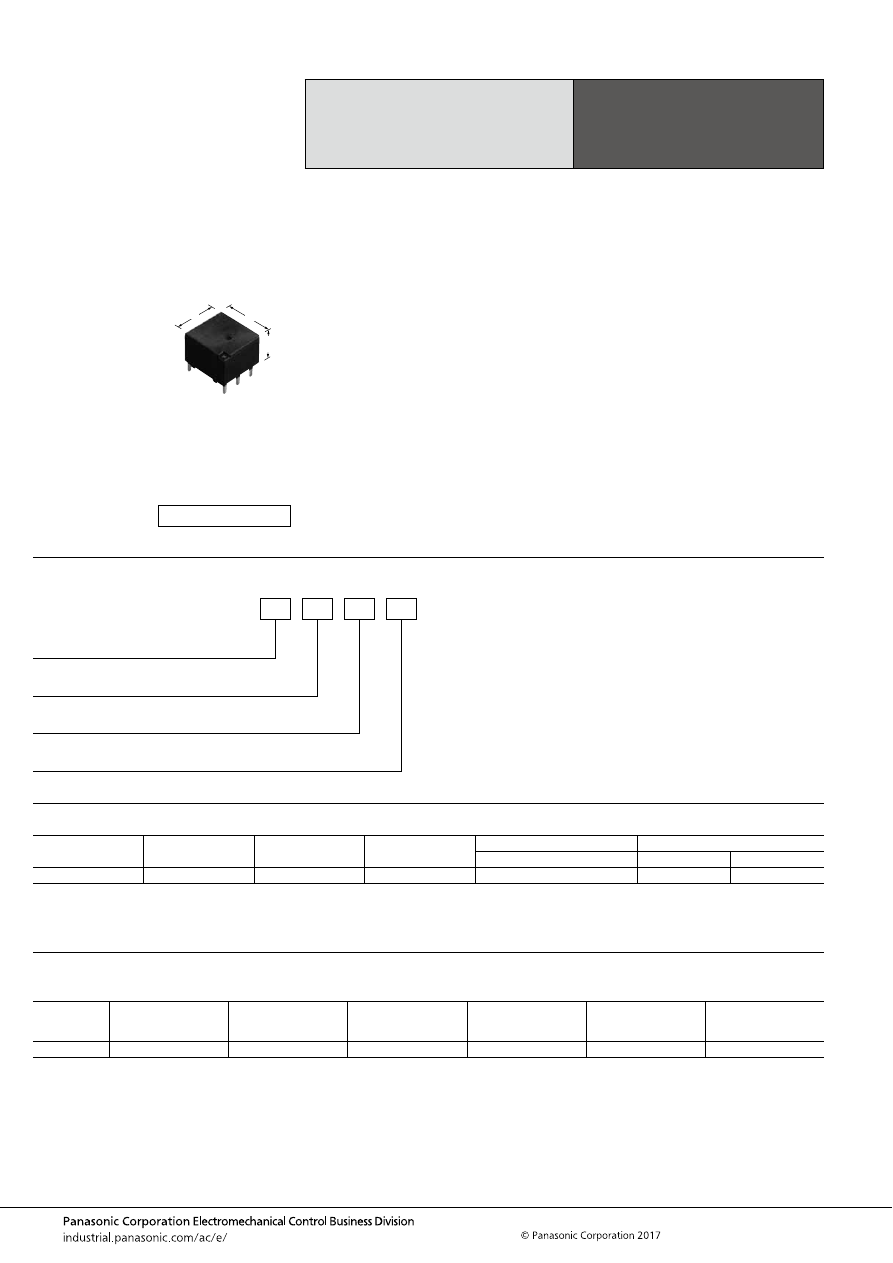

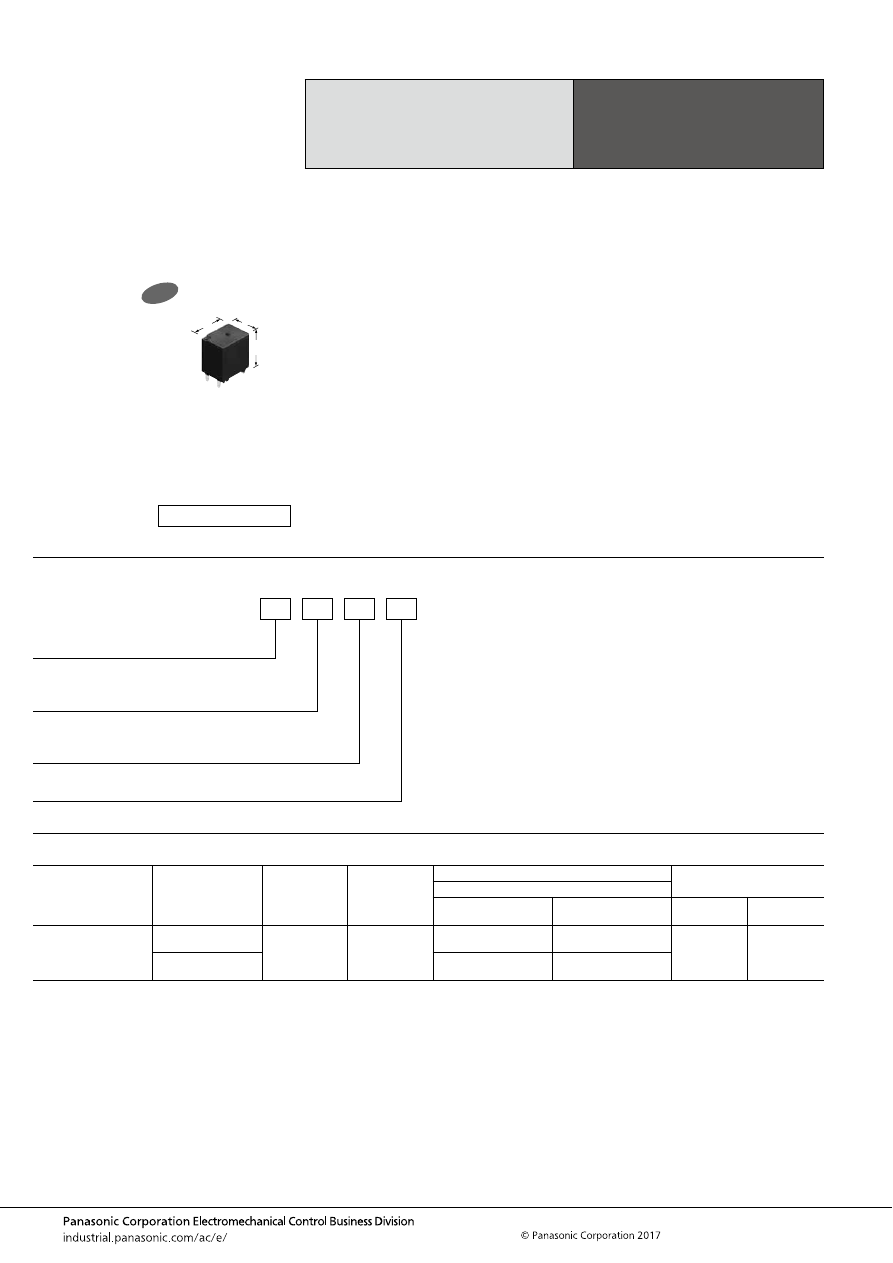

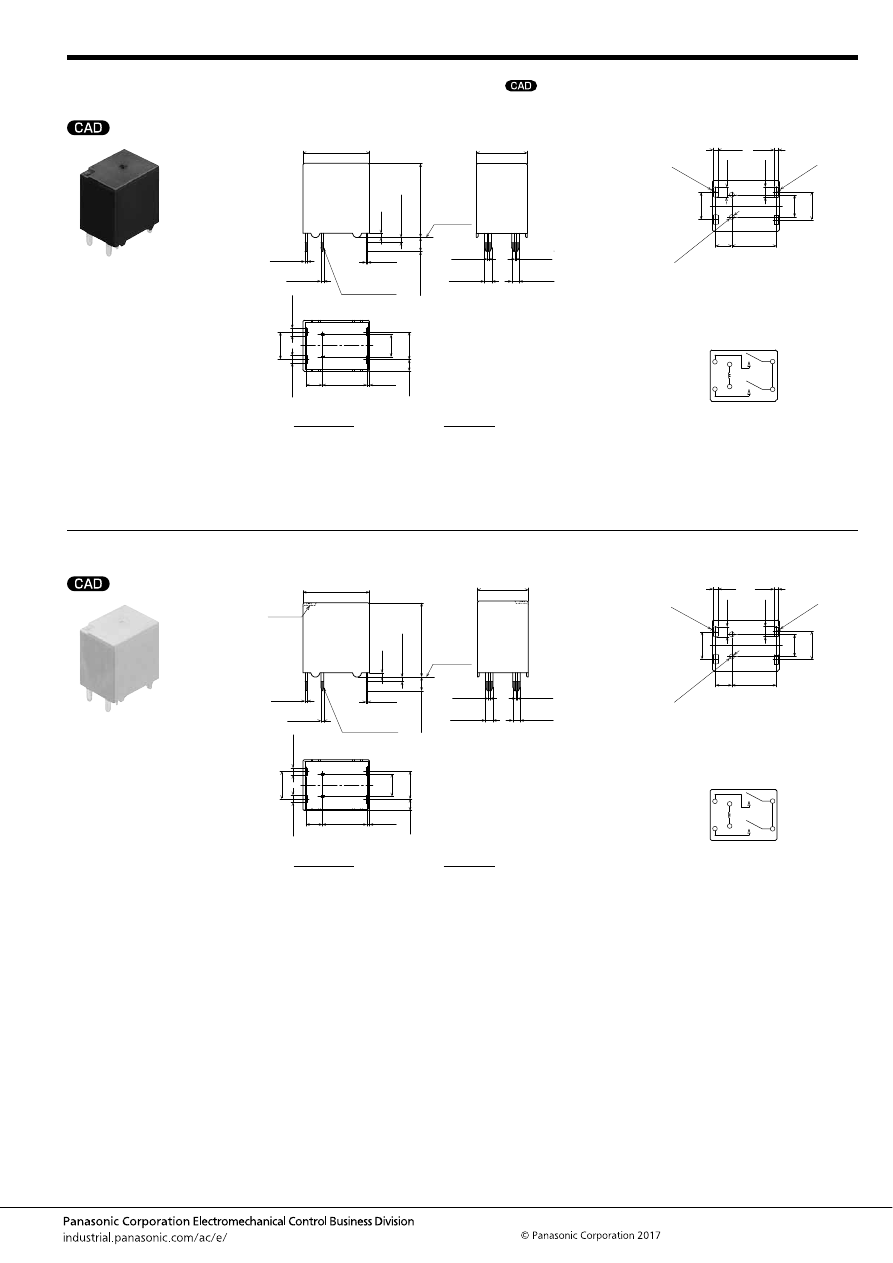

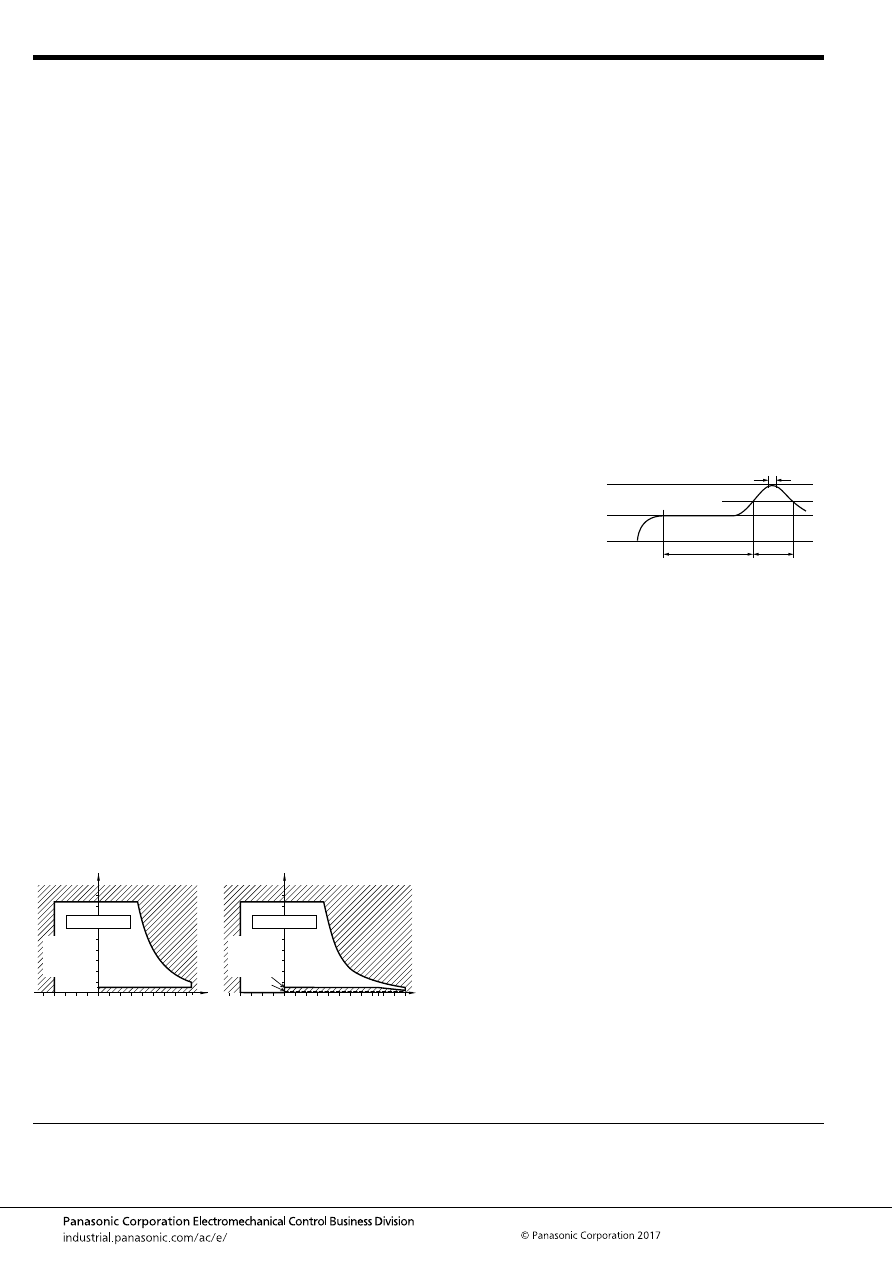

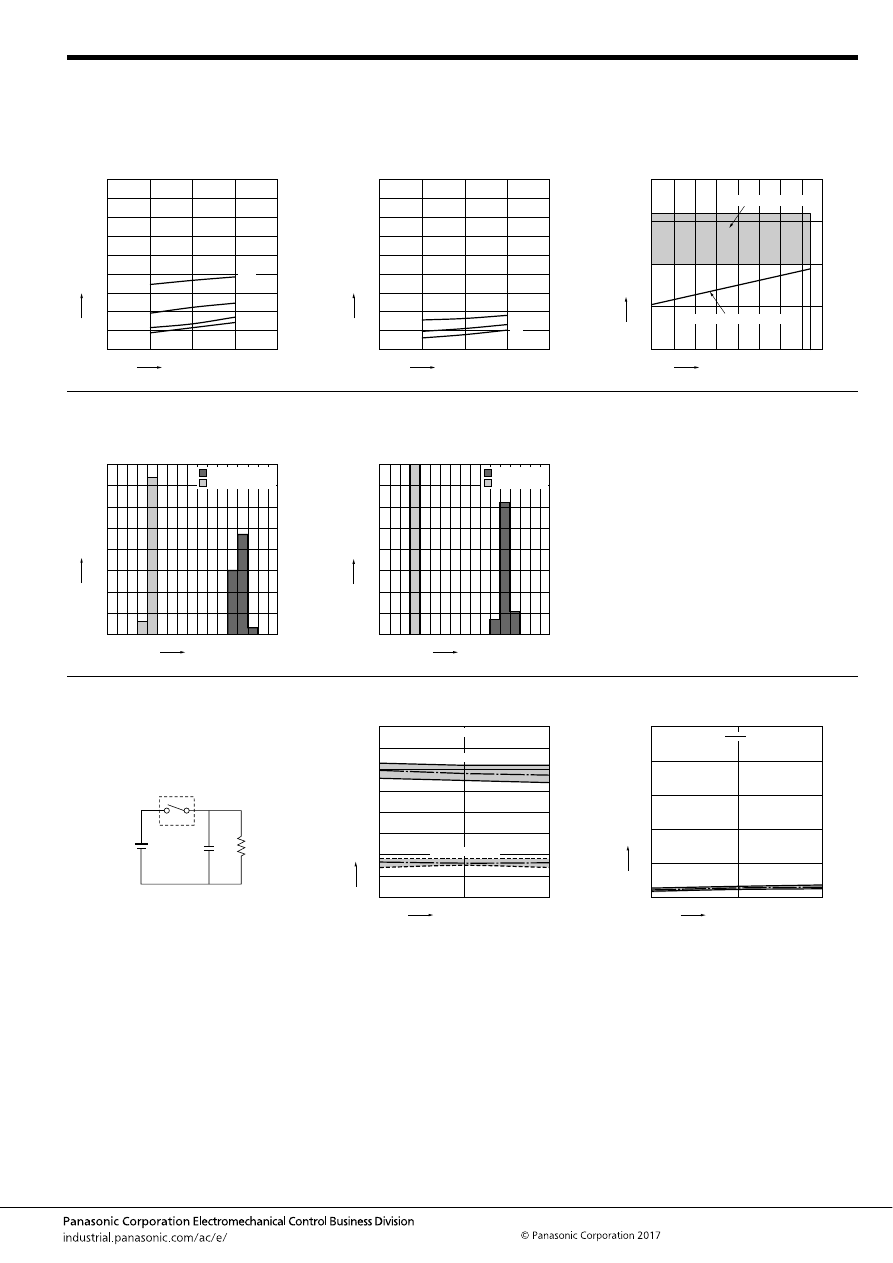

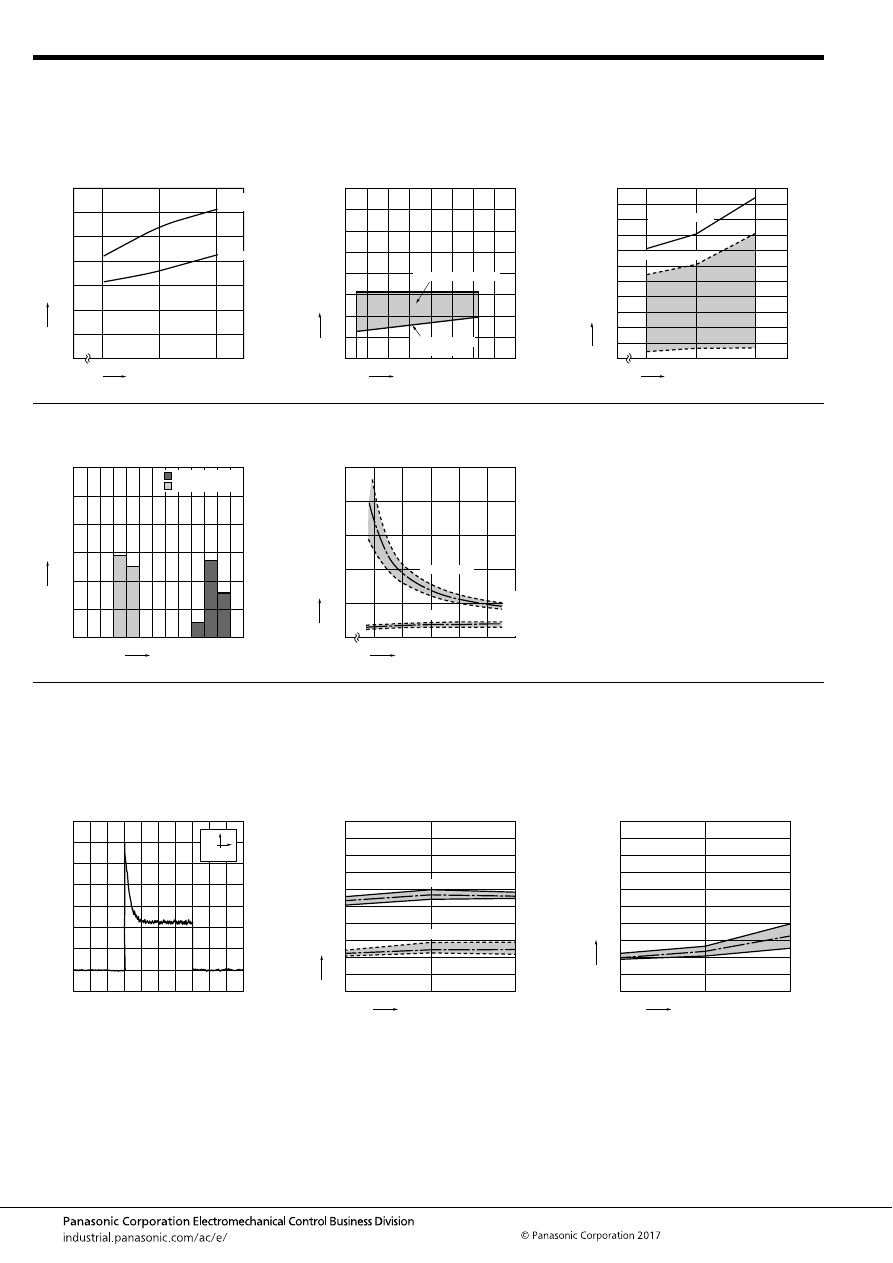

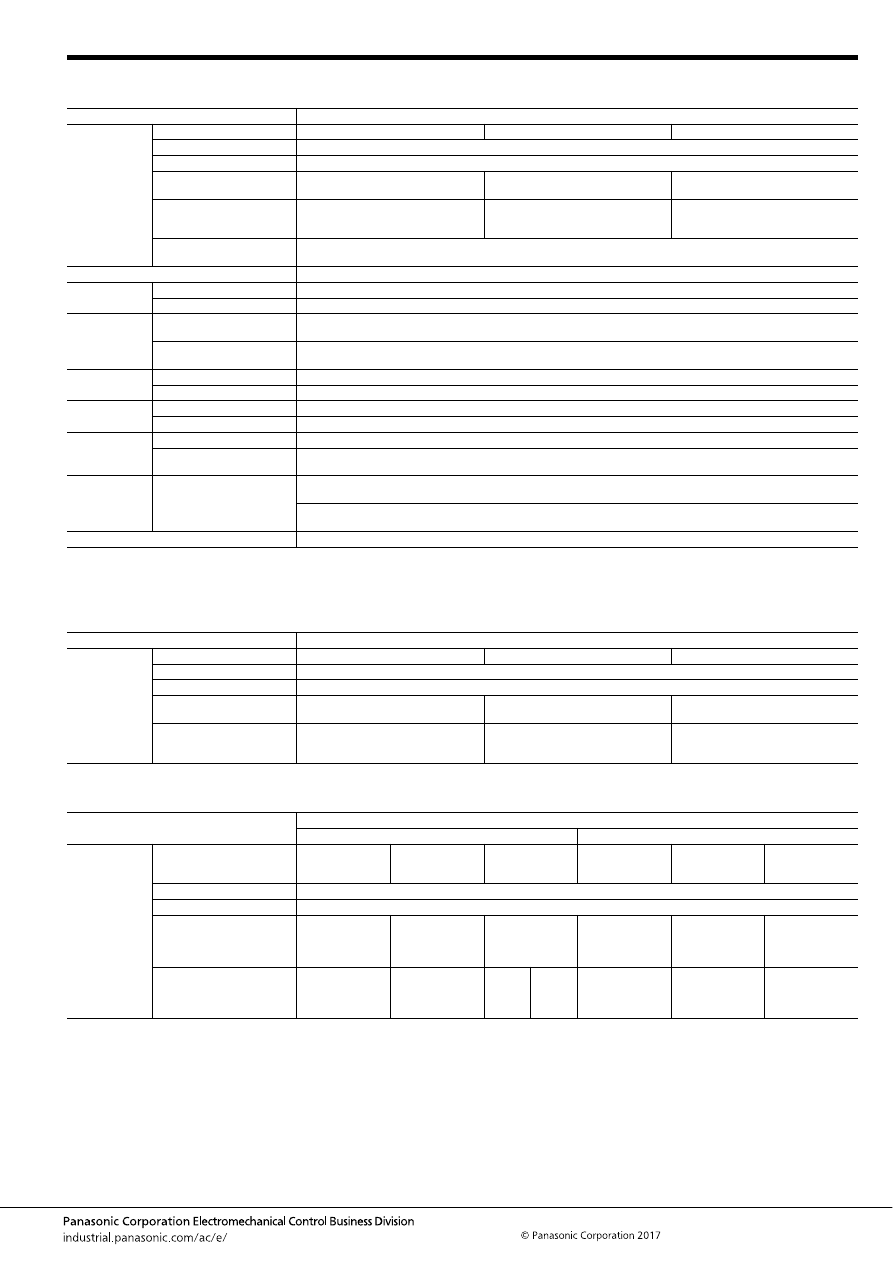

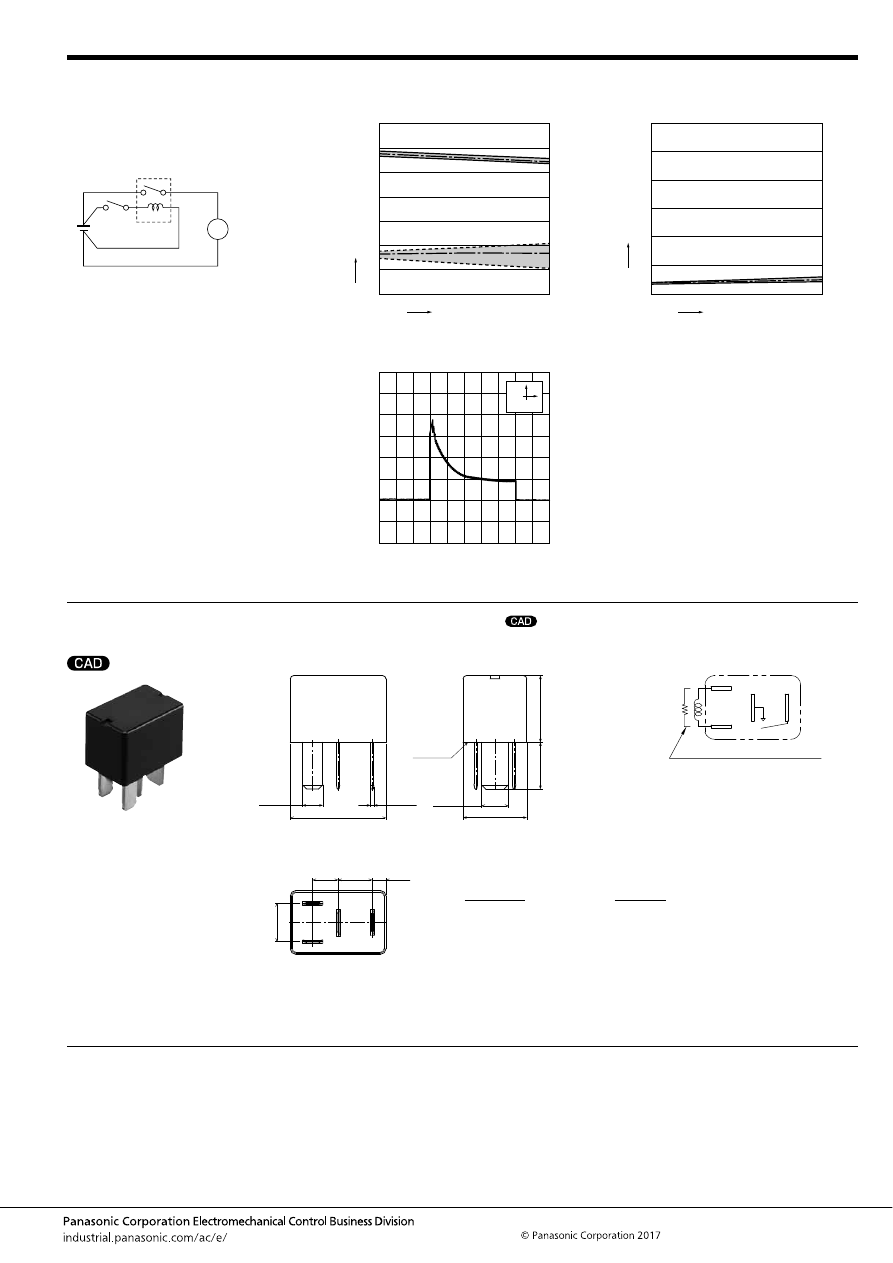

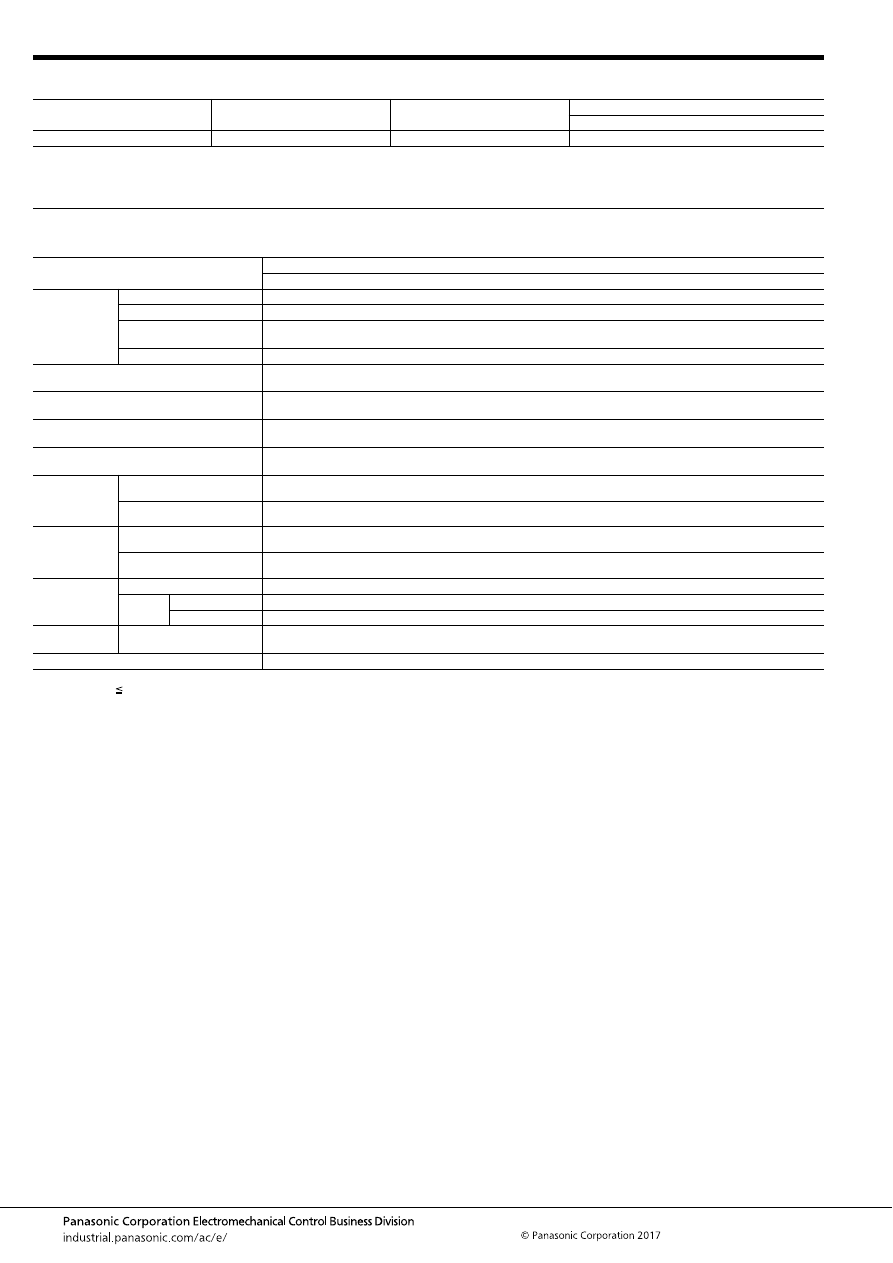

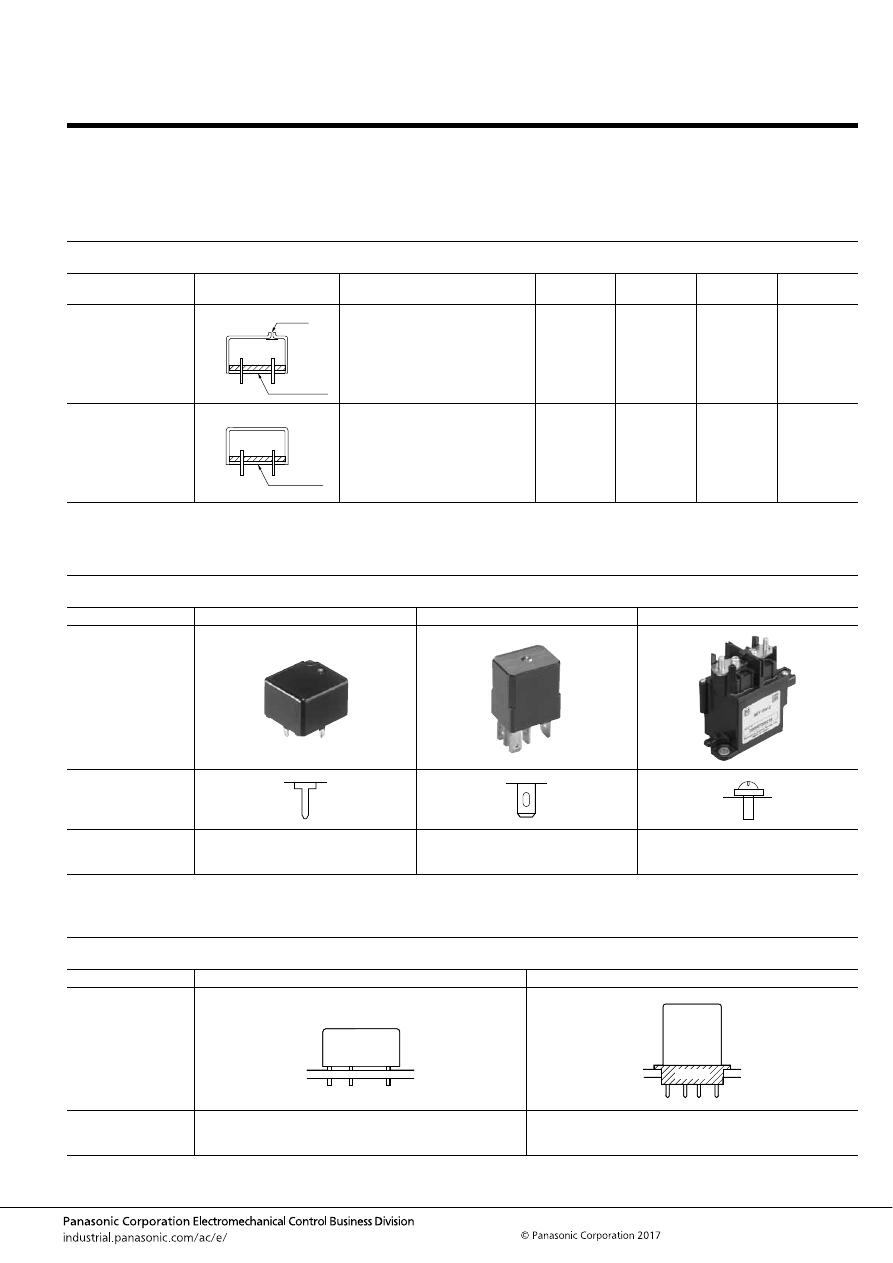

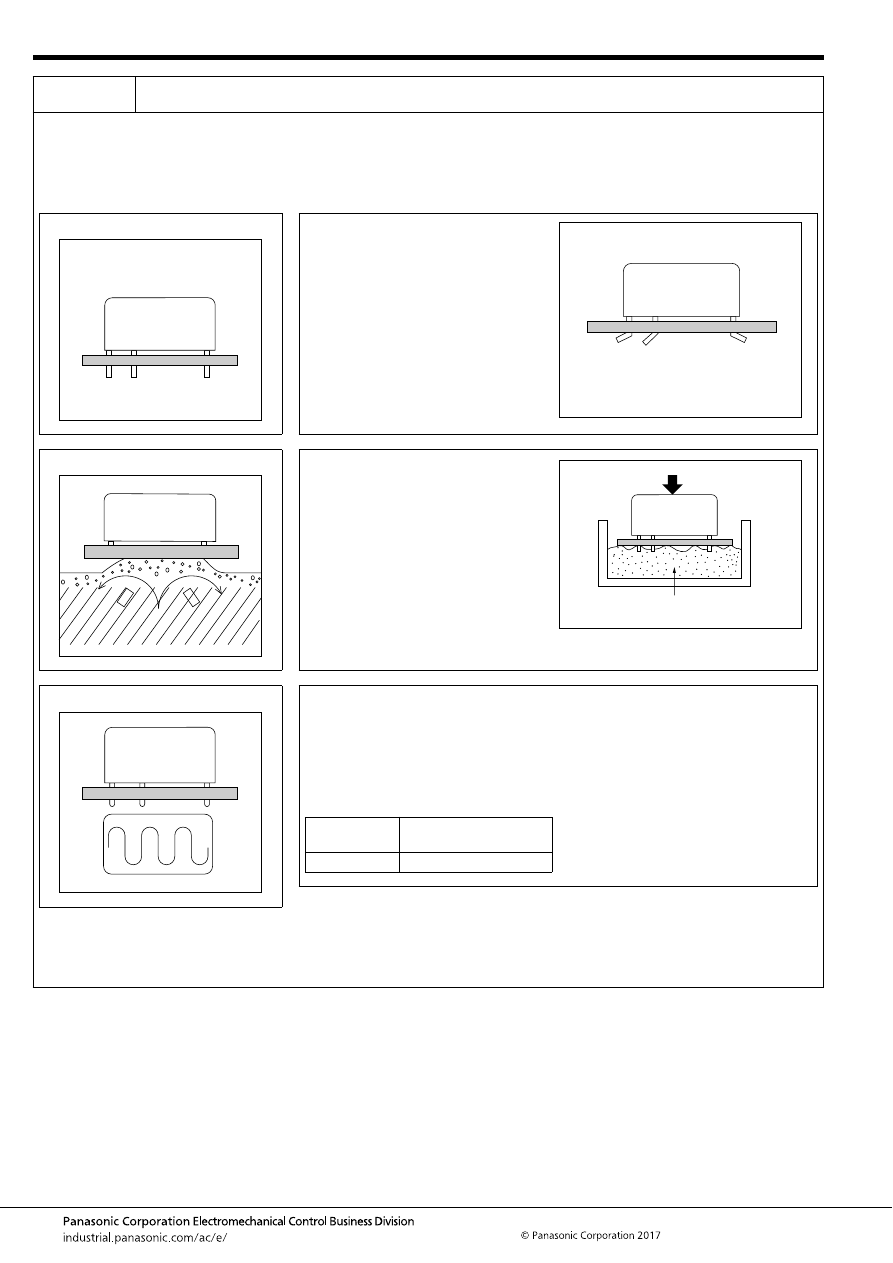

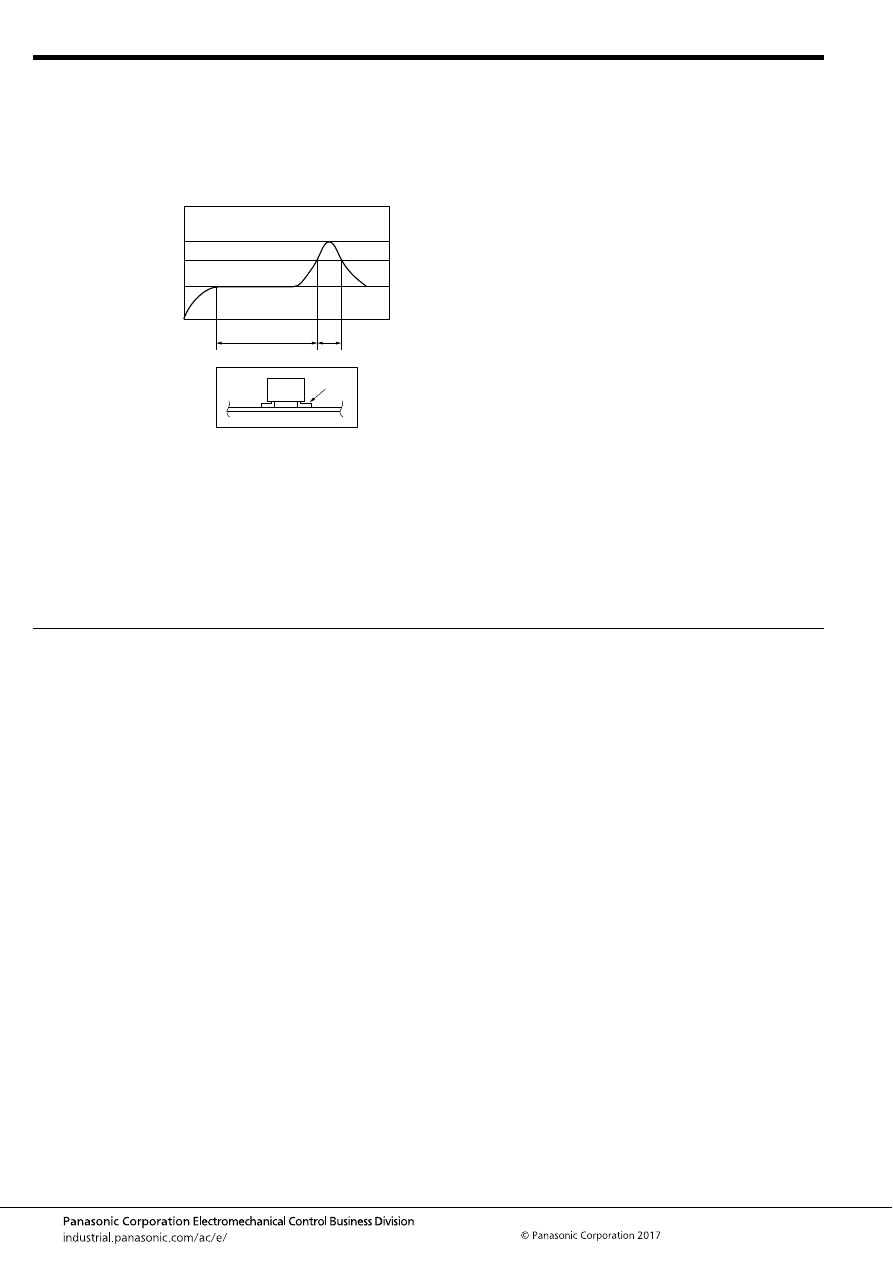

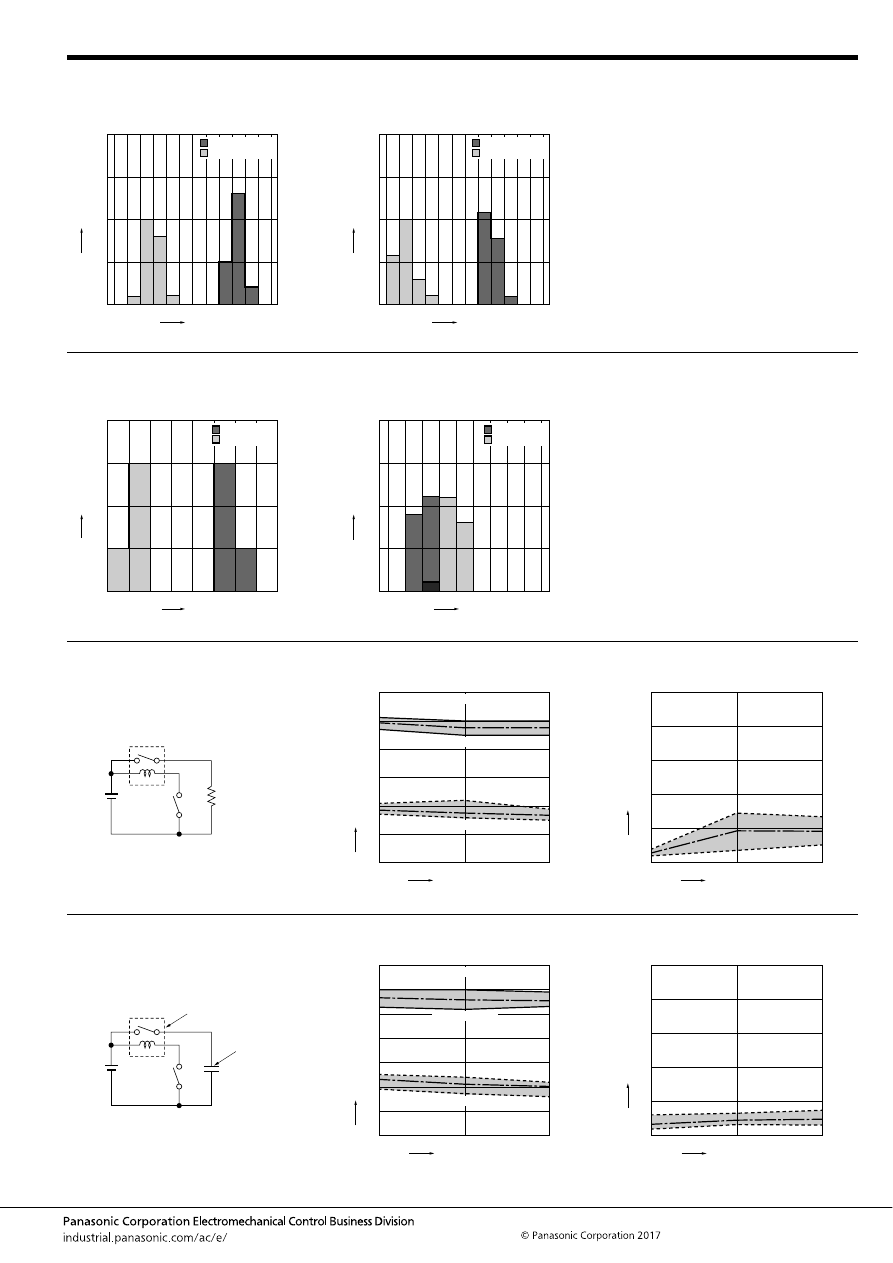

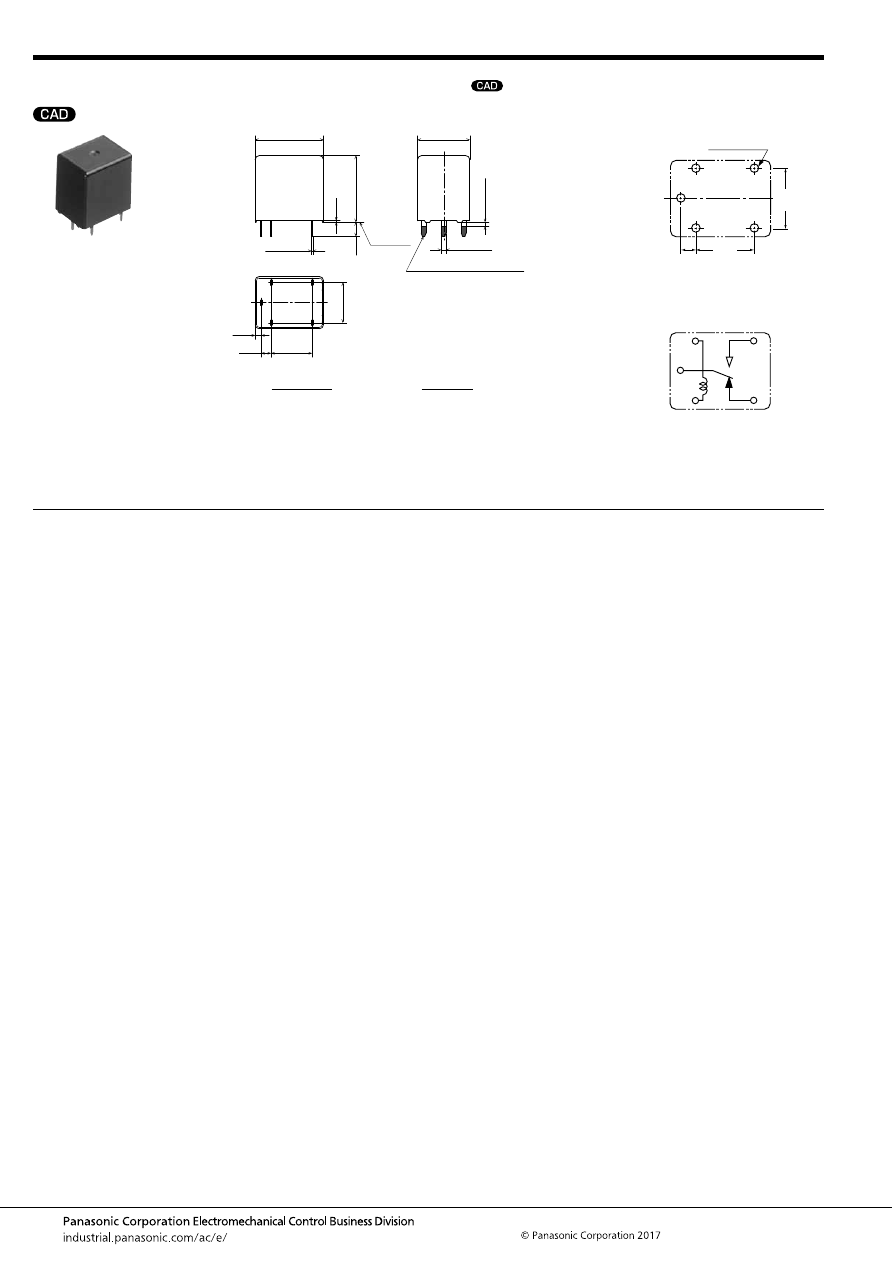

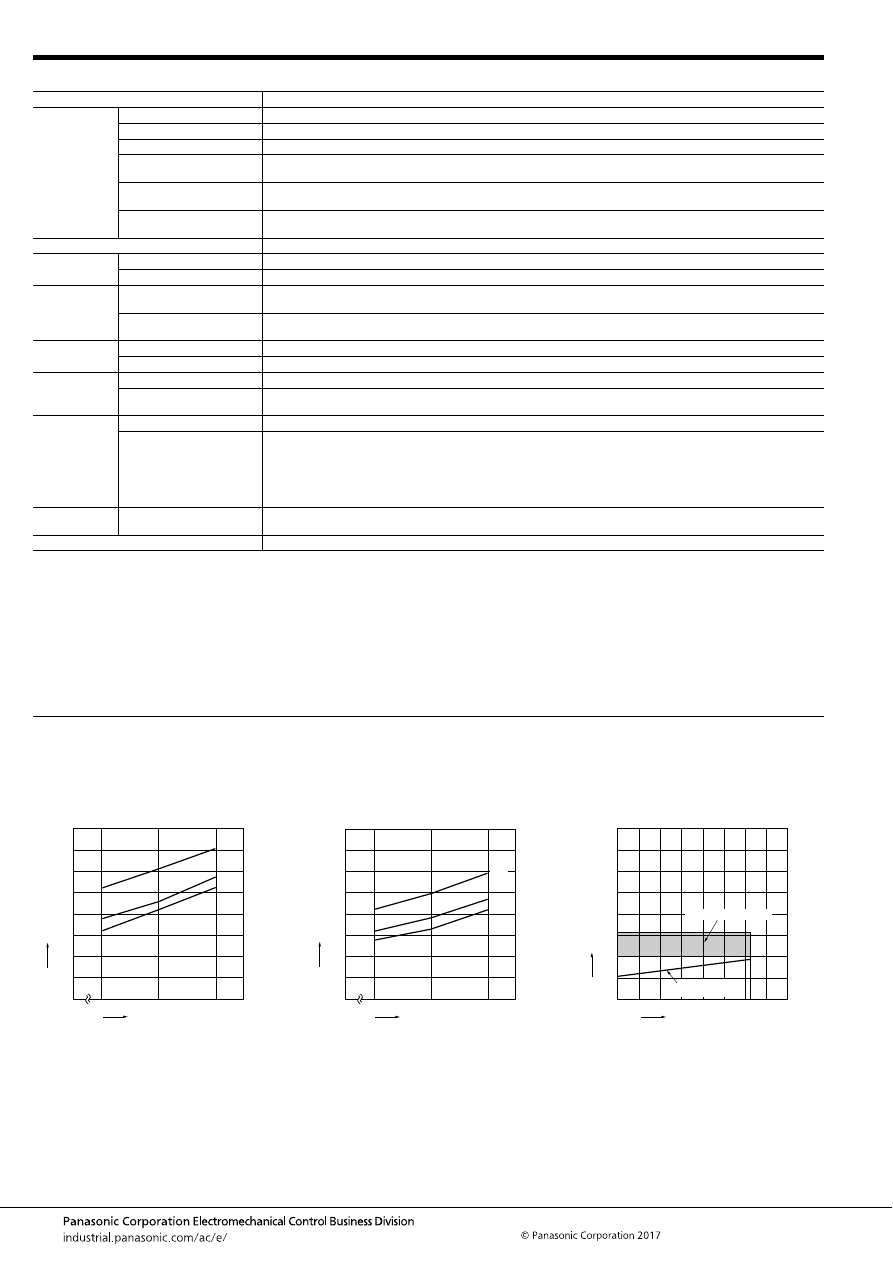

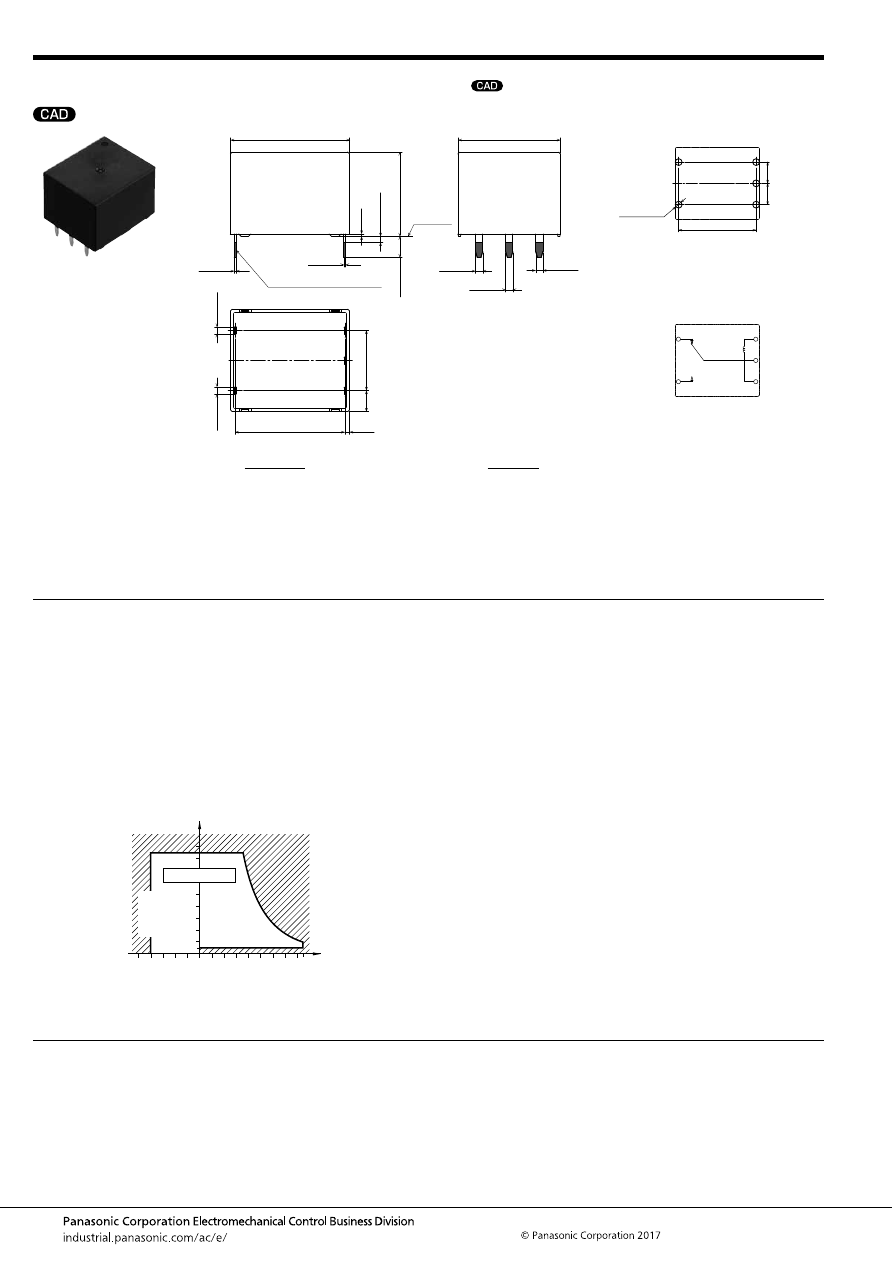

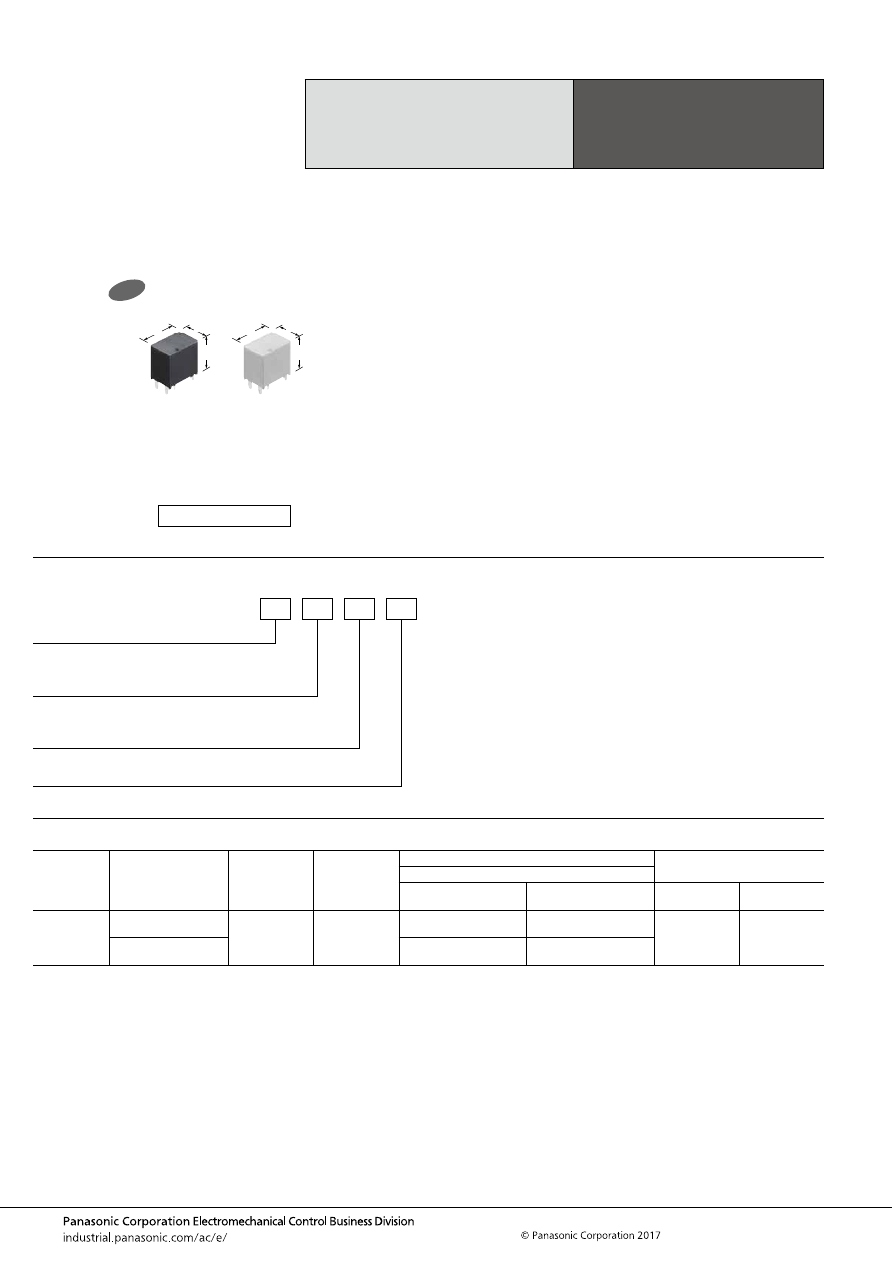

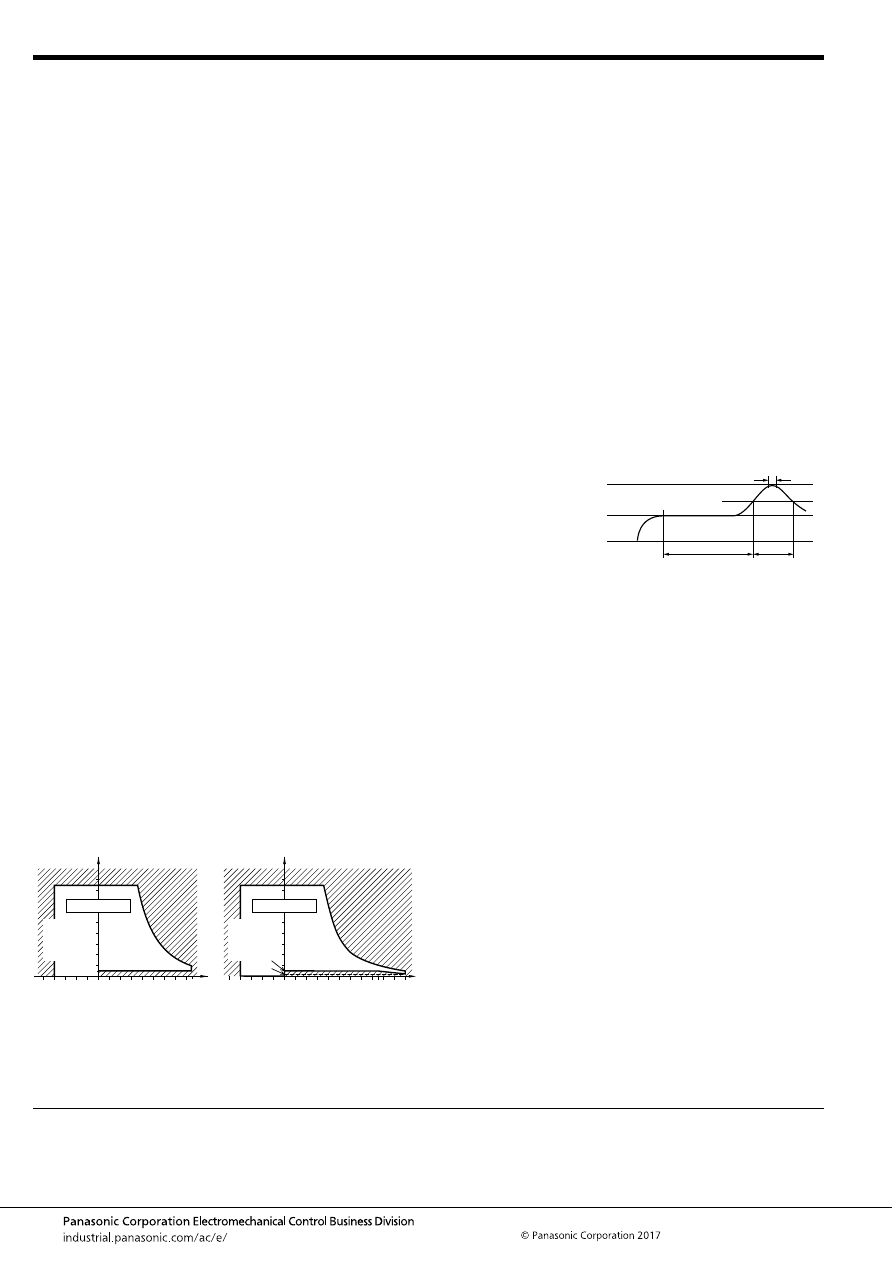

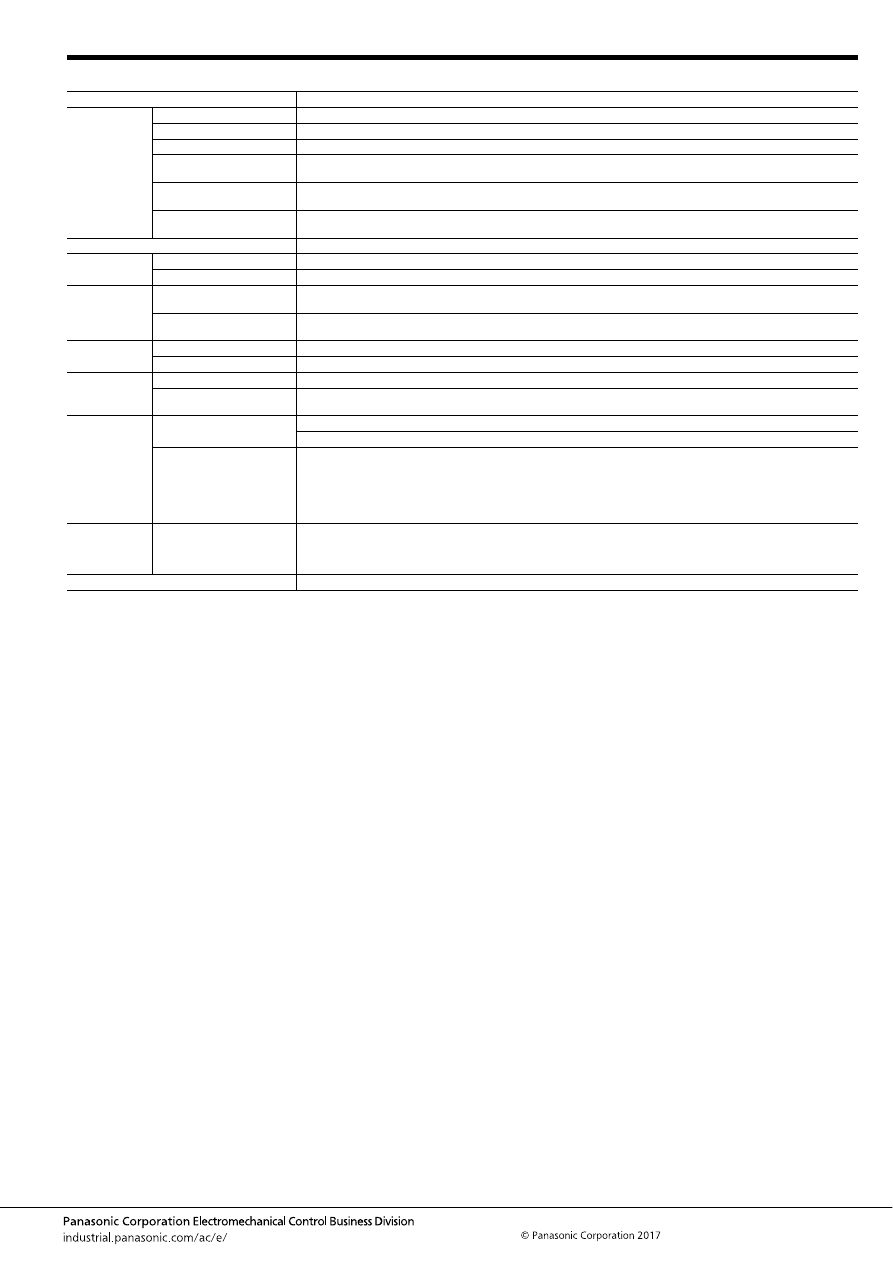

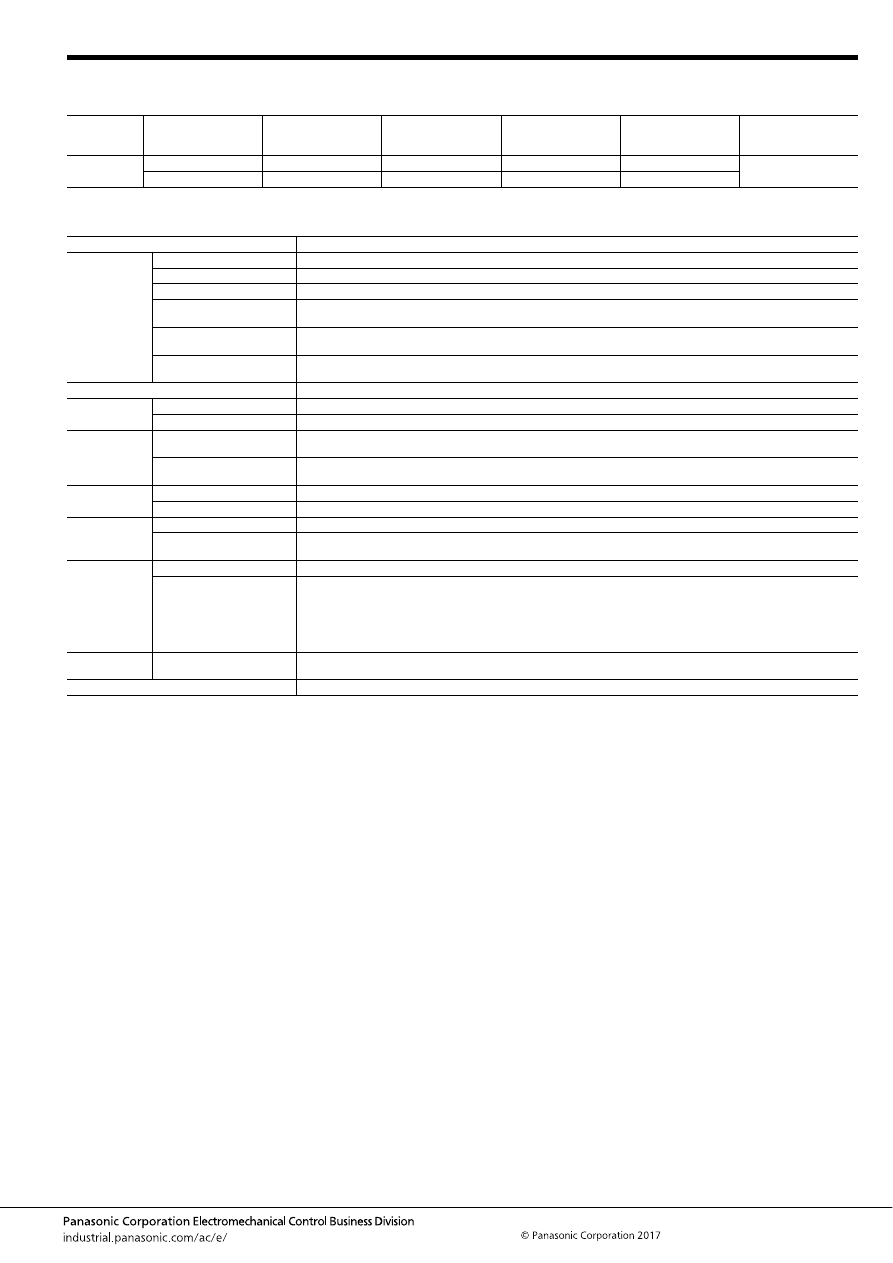

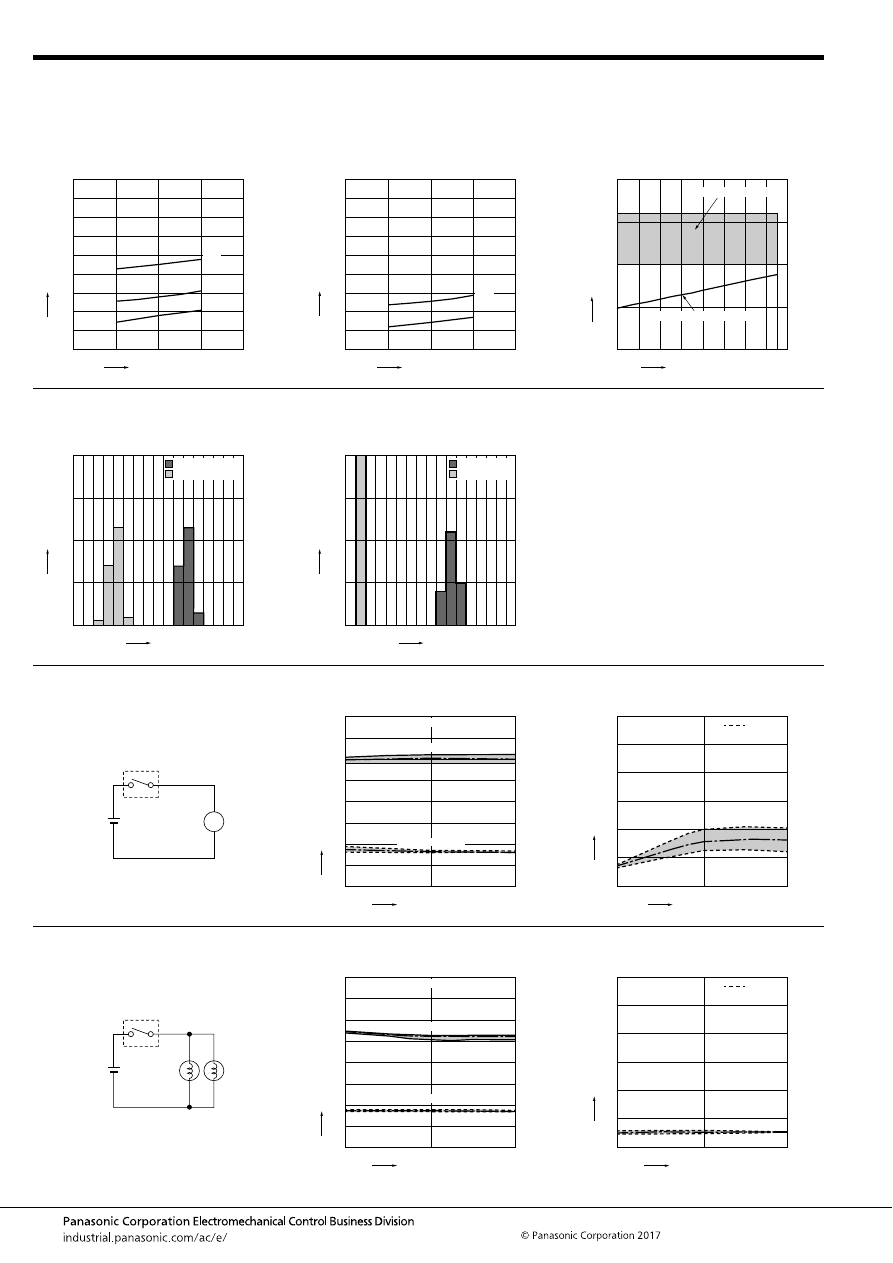

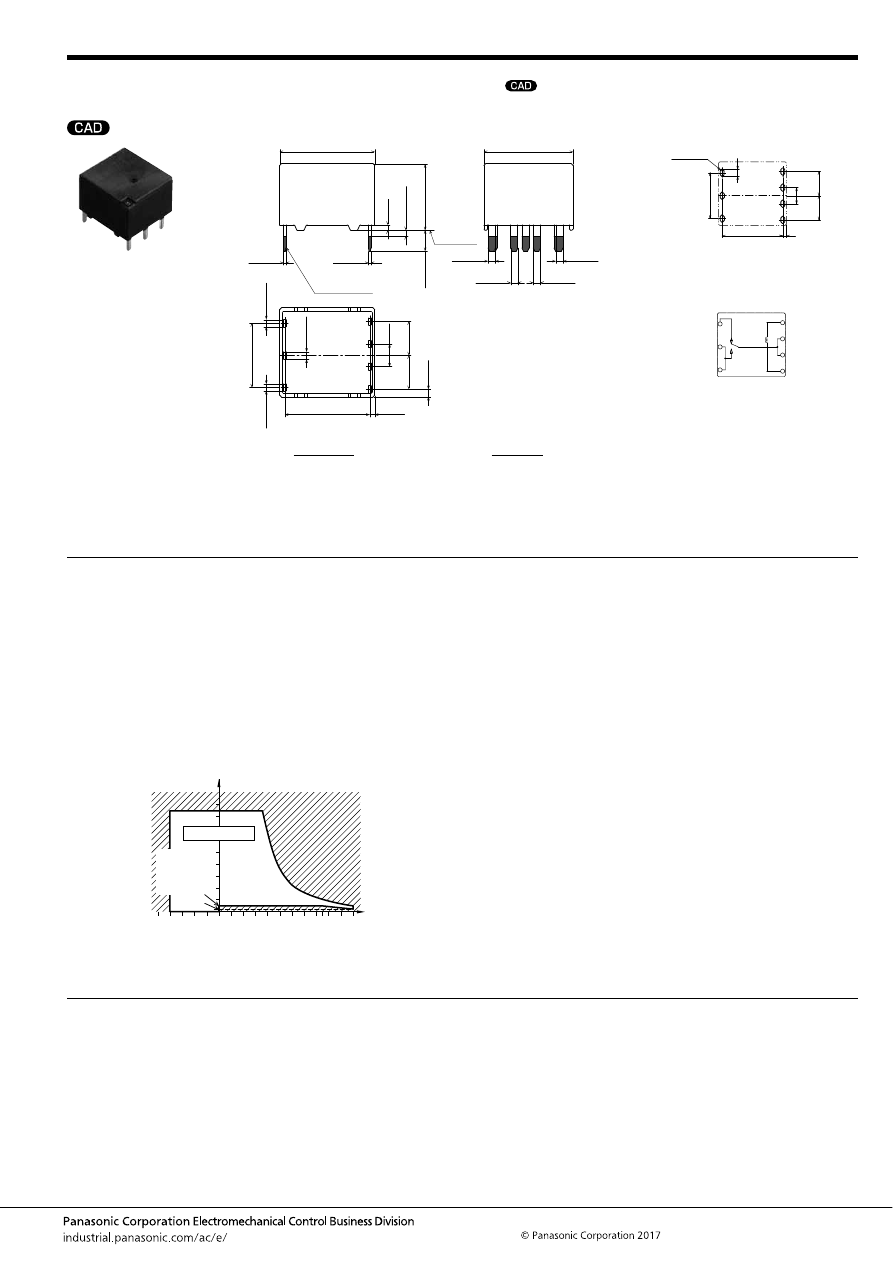

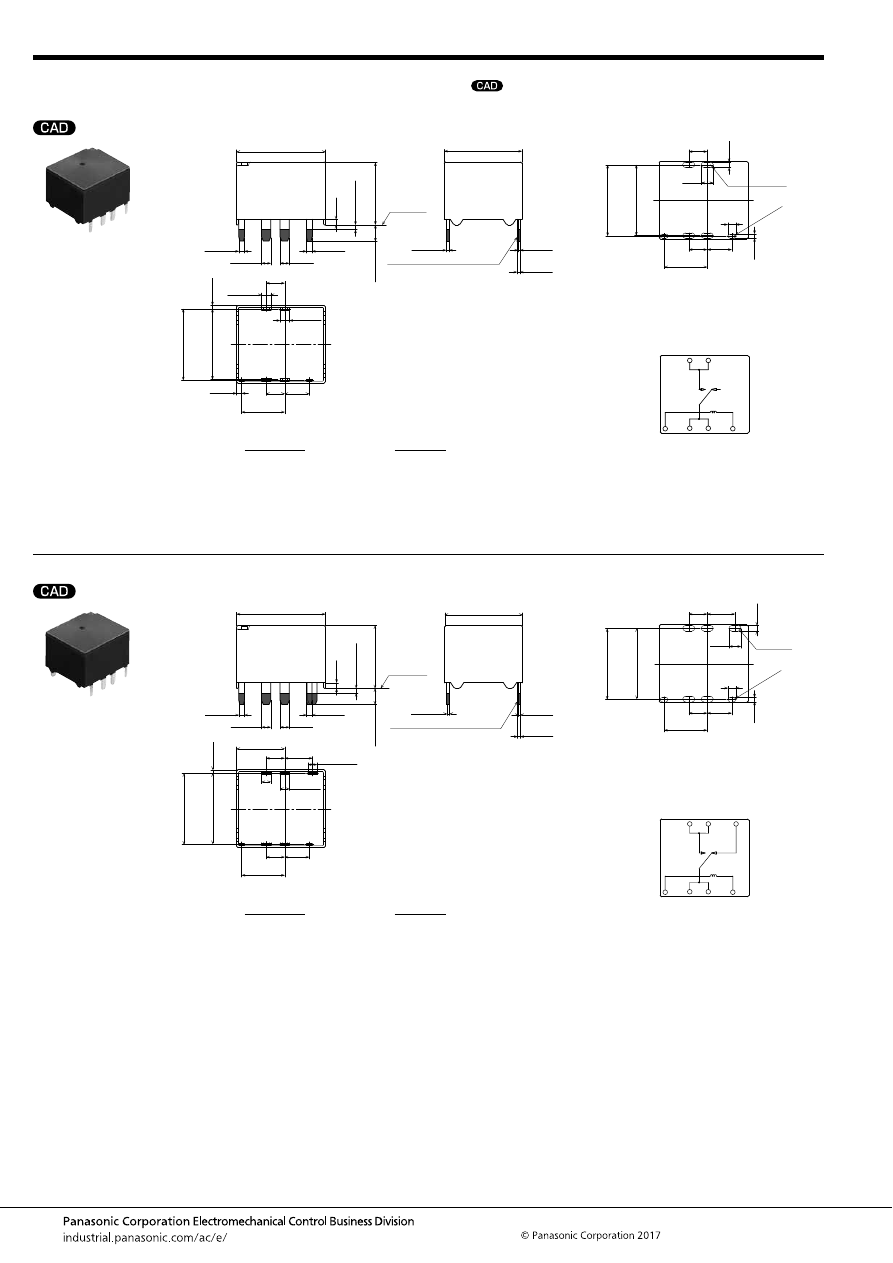

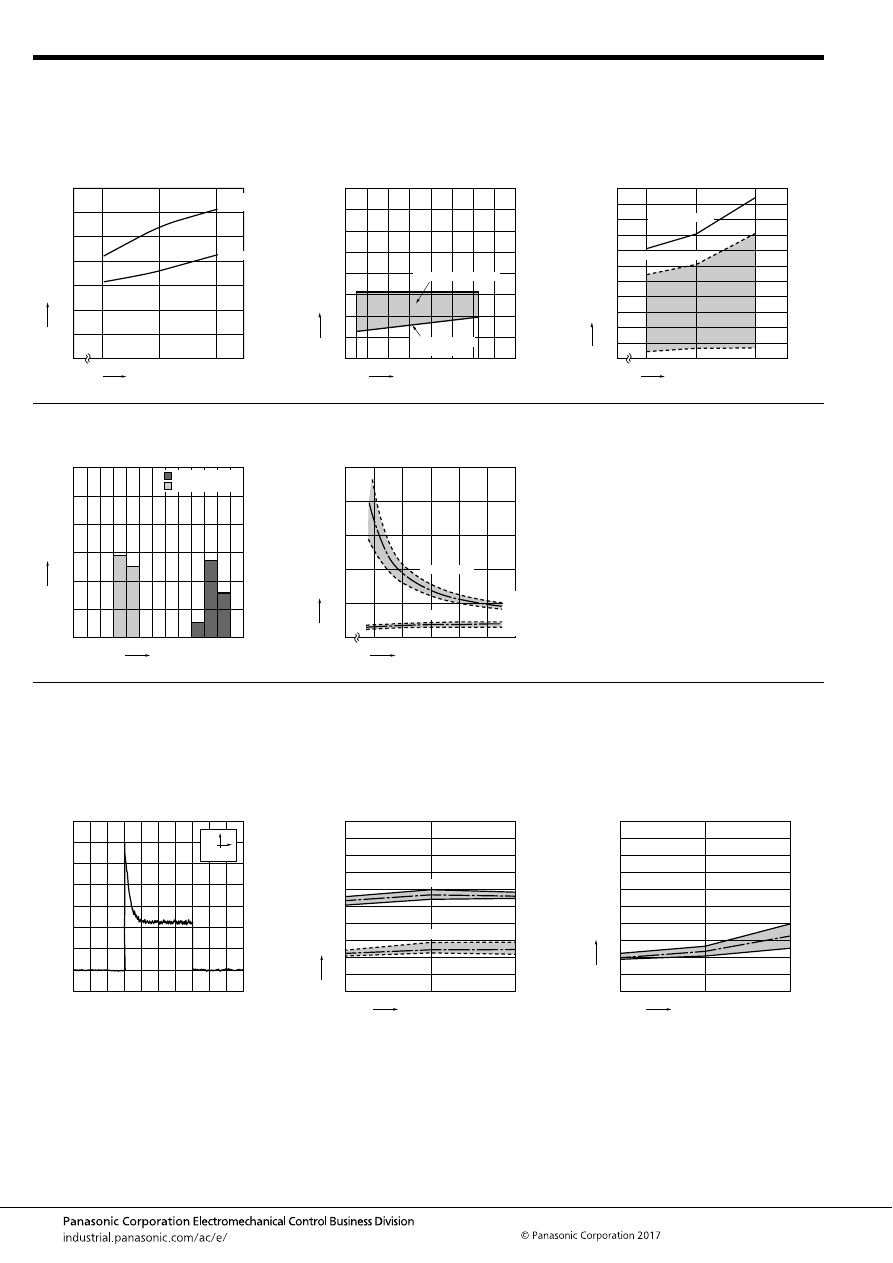

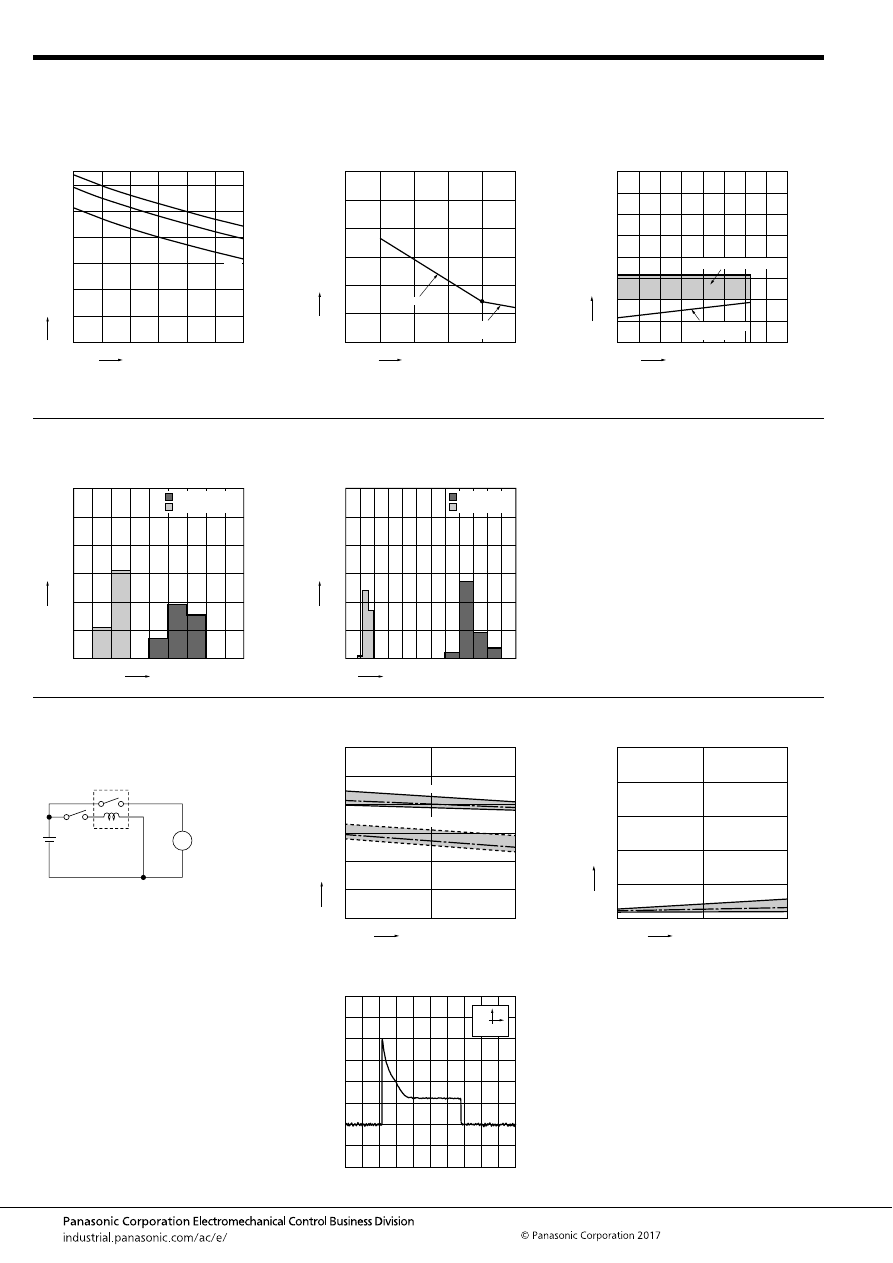

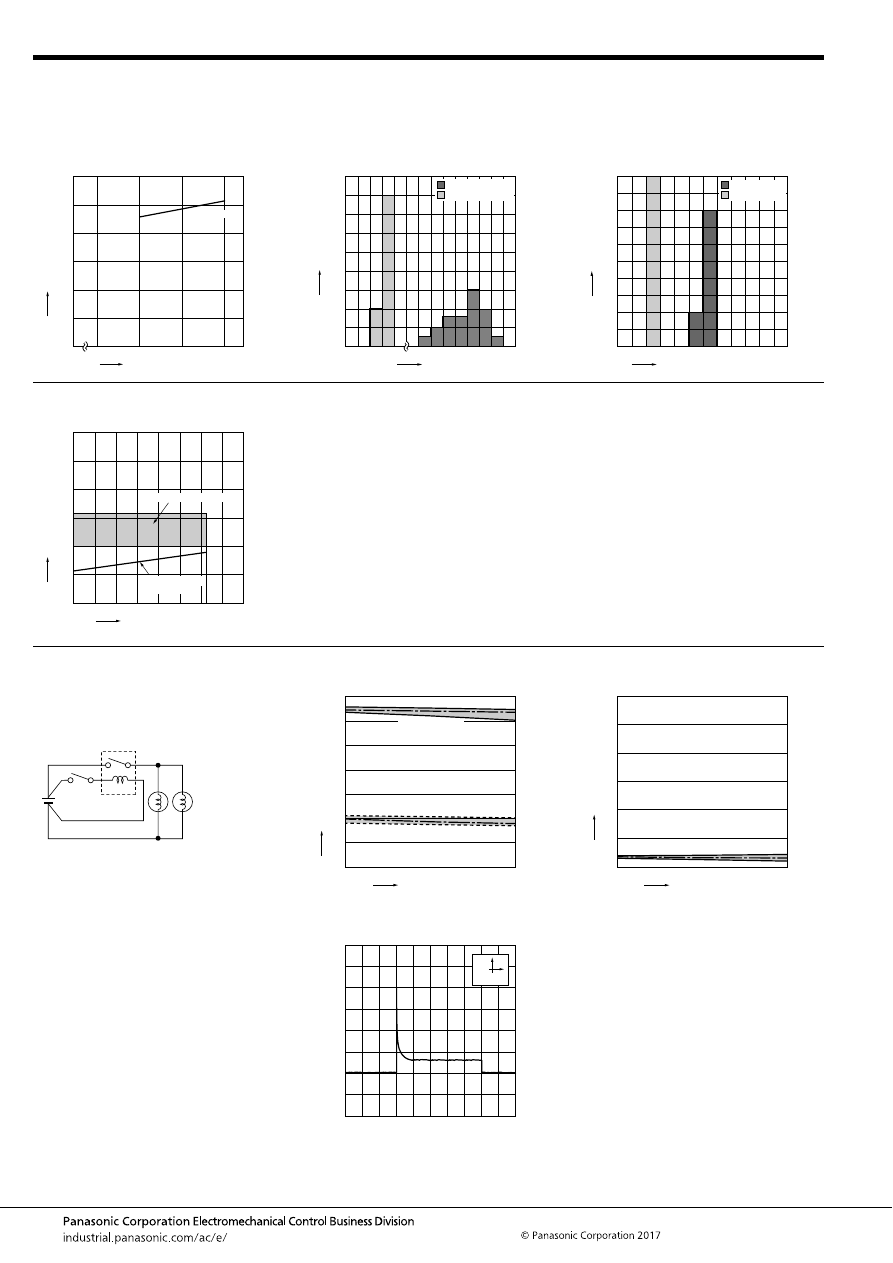

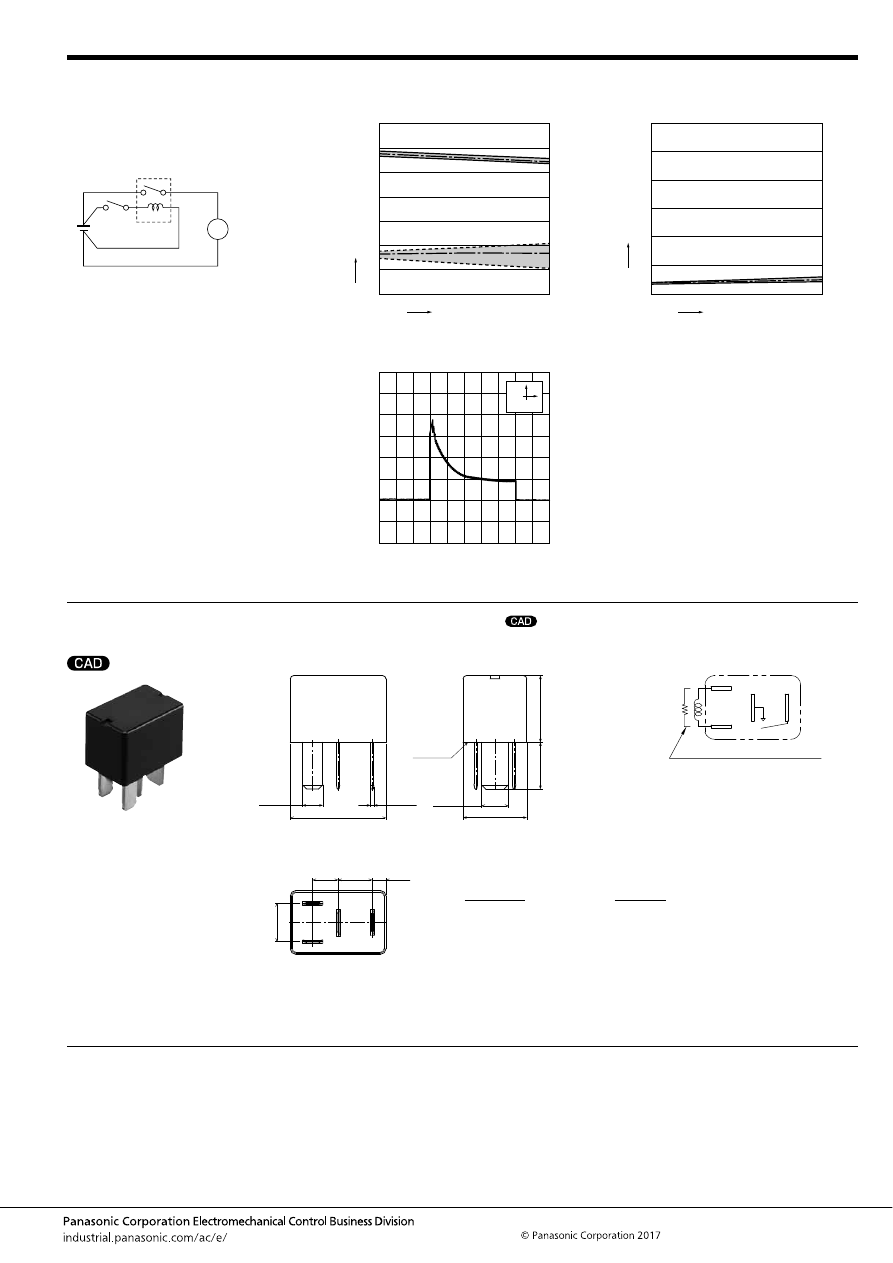

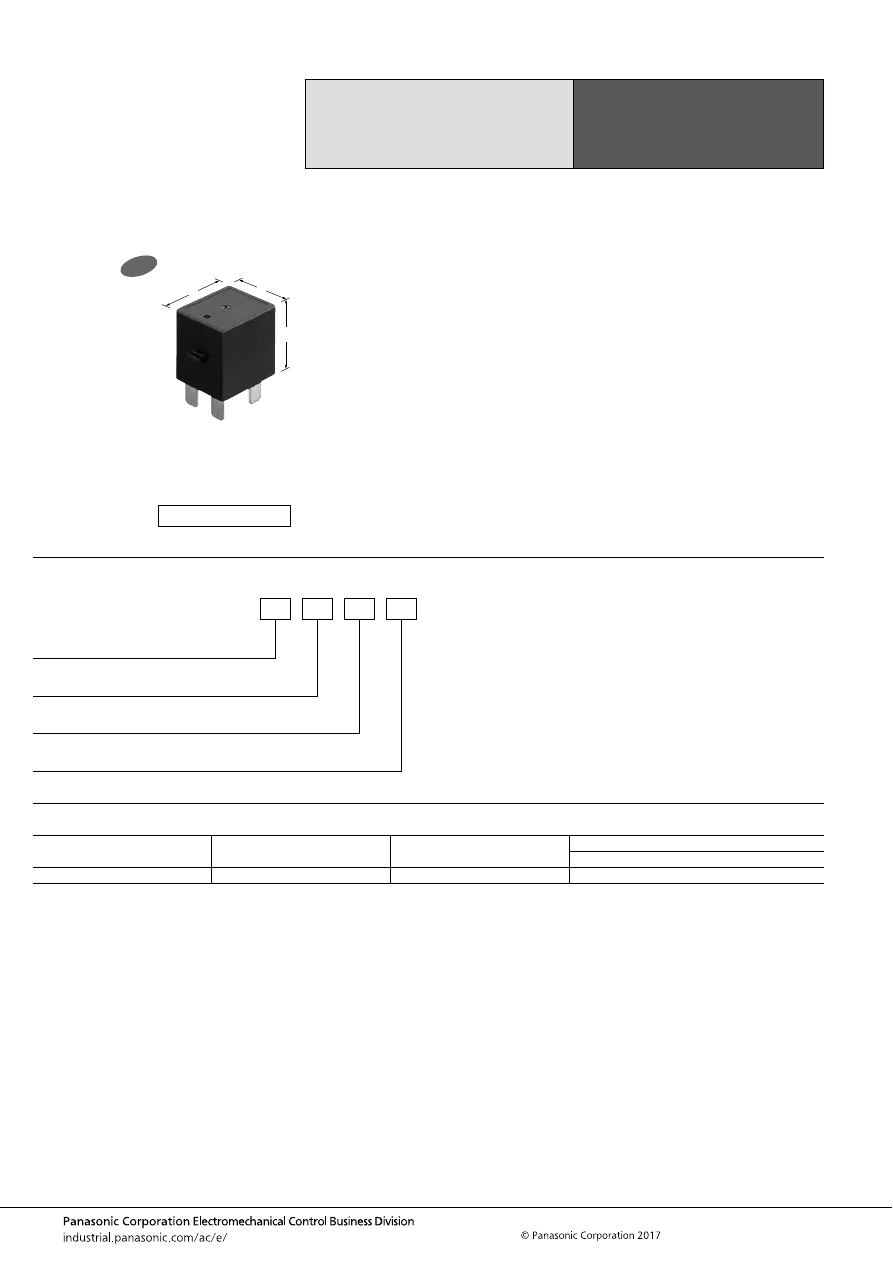

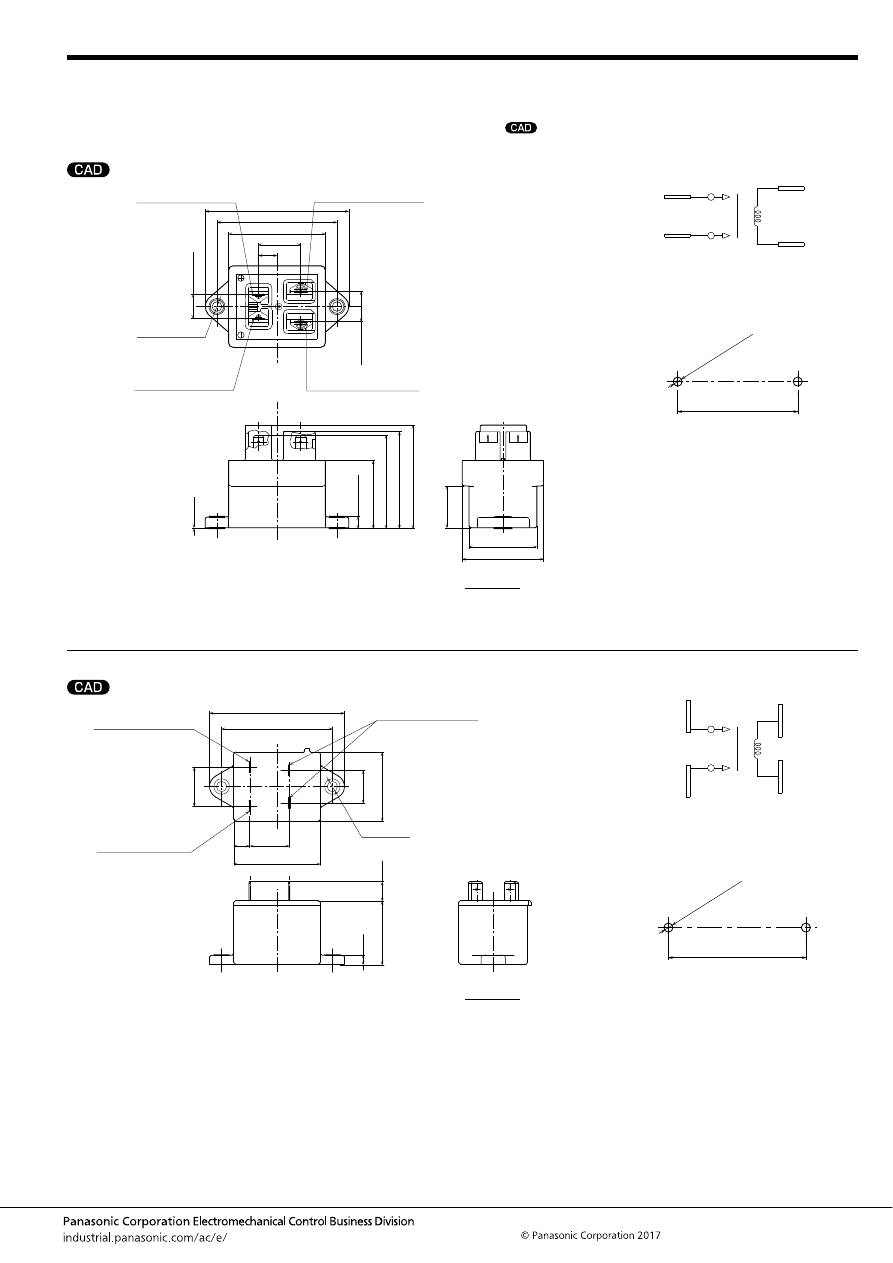

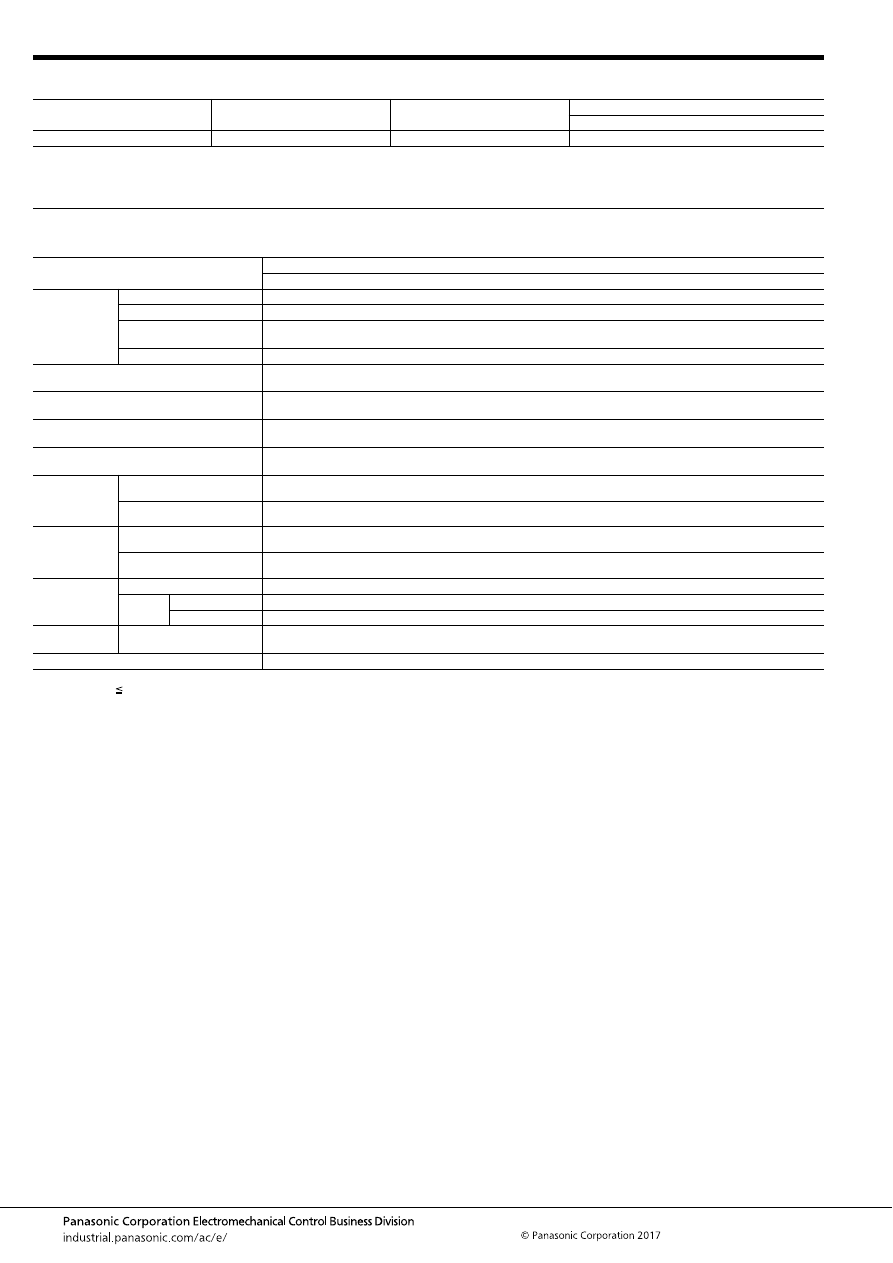

Configuration and Construction

–19–

ASCTB300E 201709-T

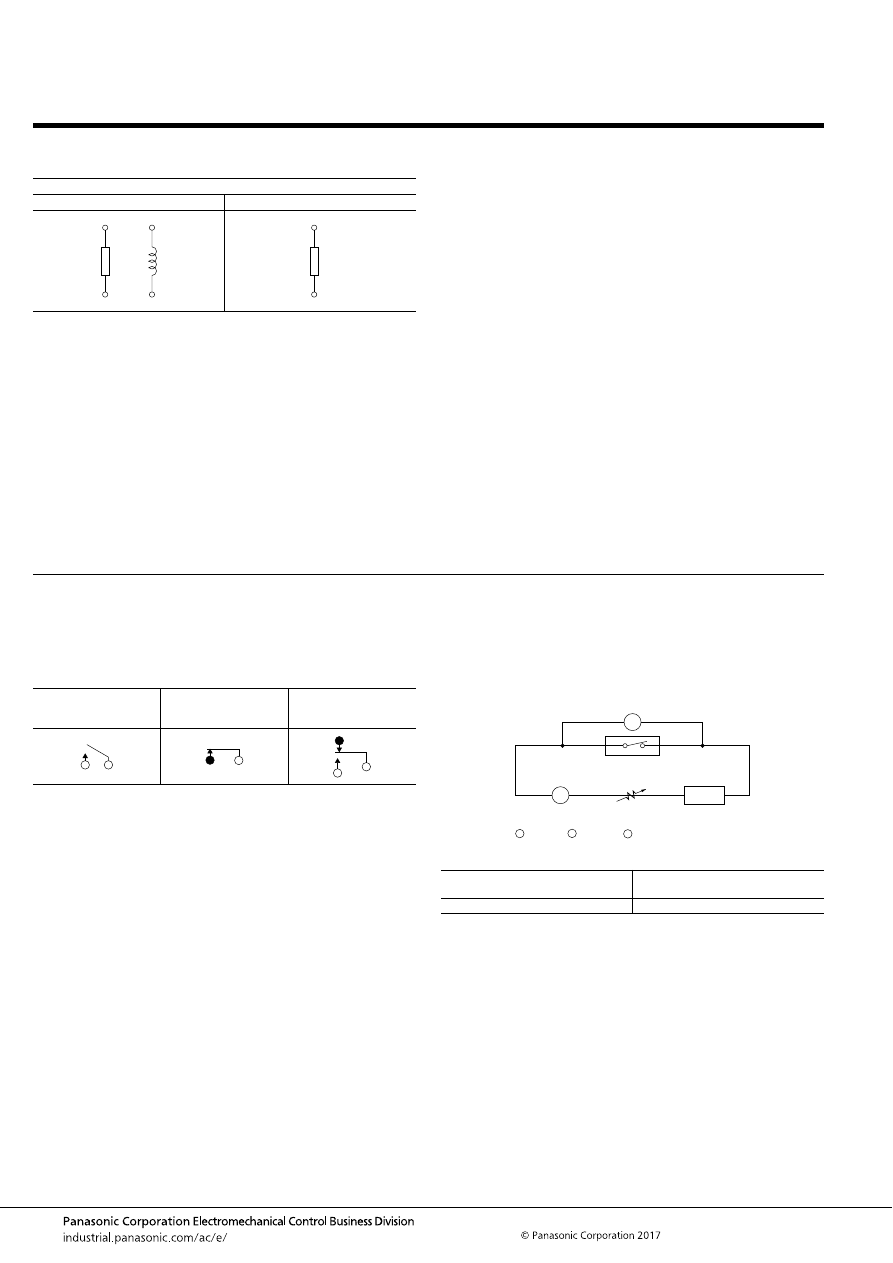

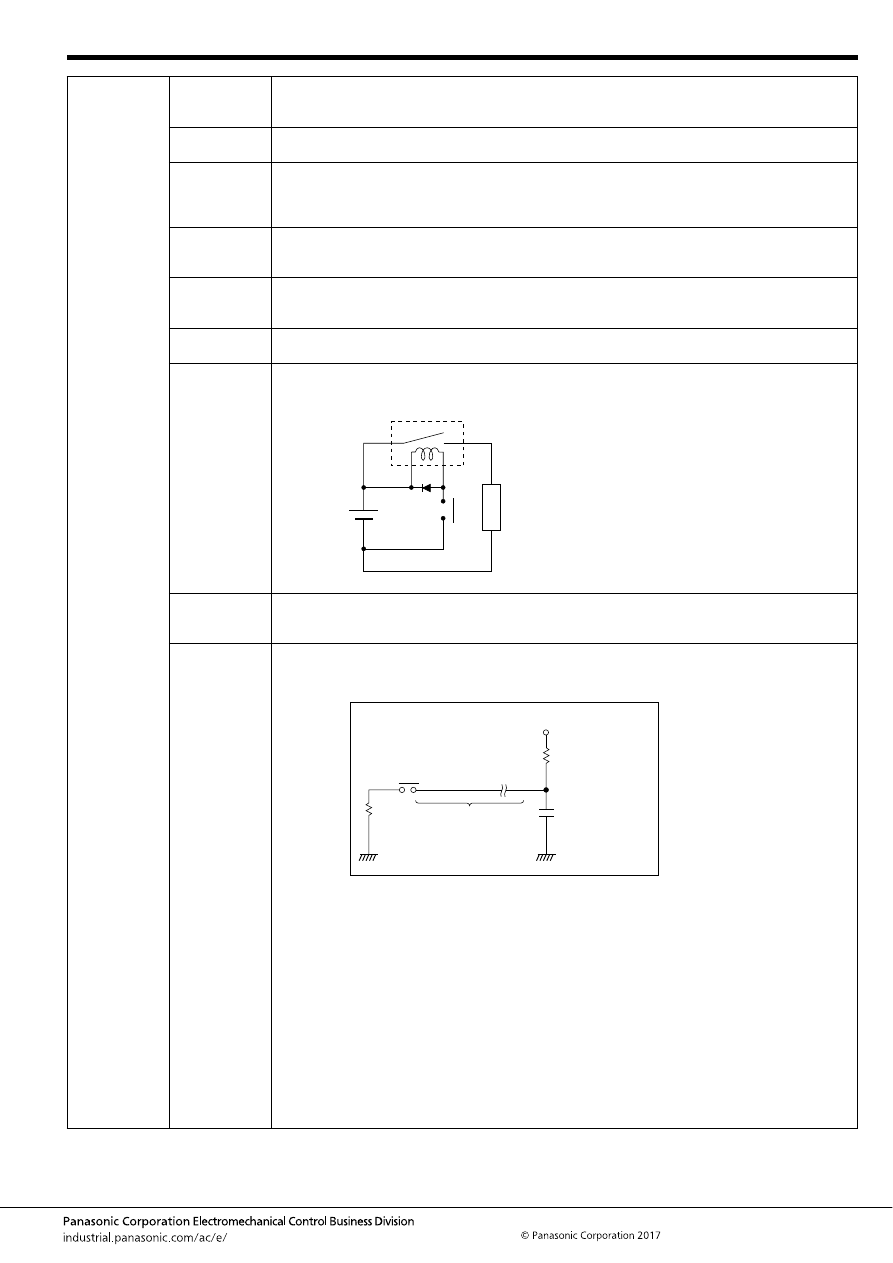

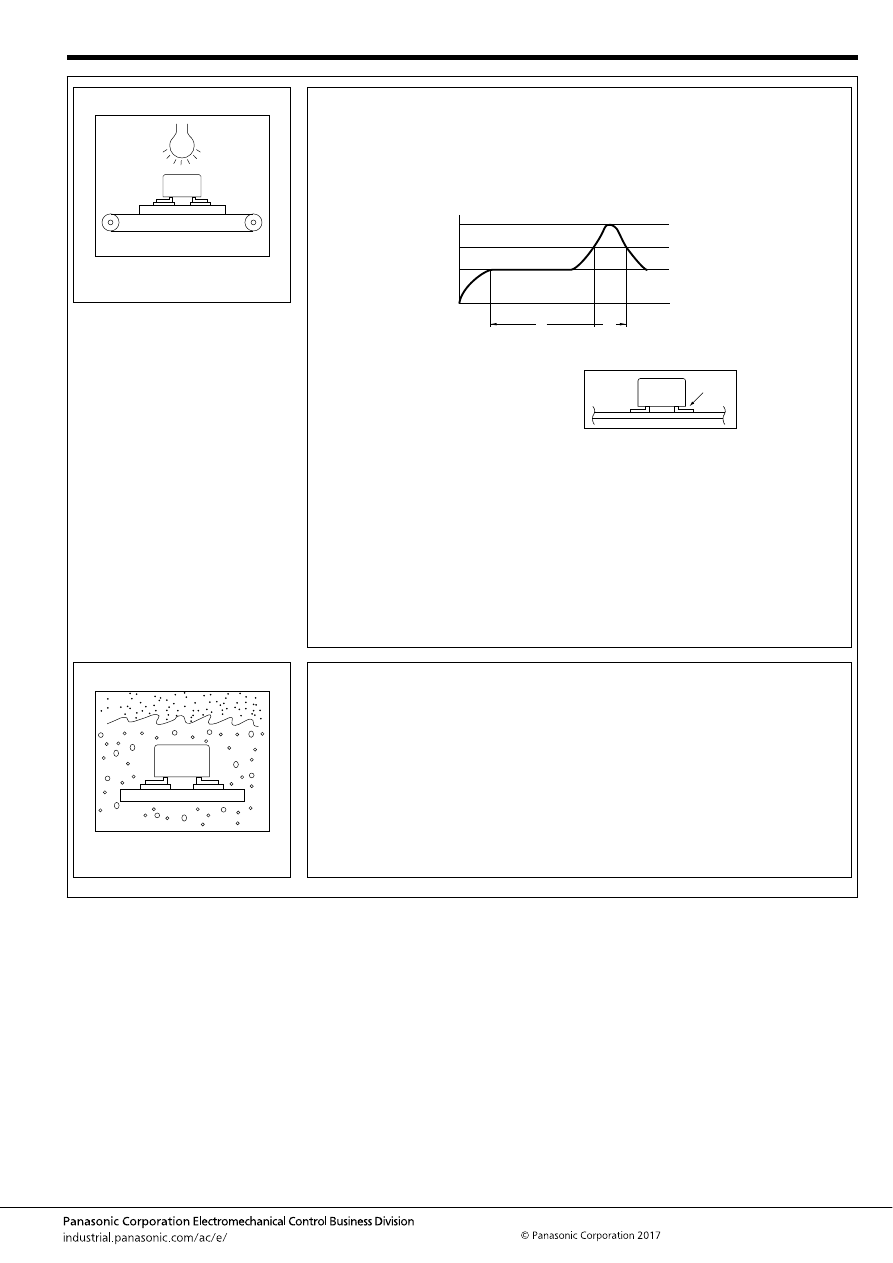

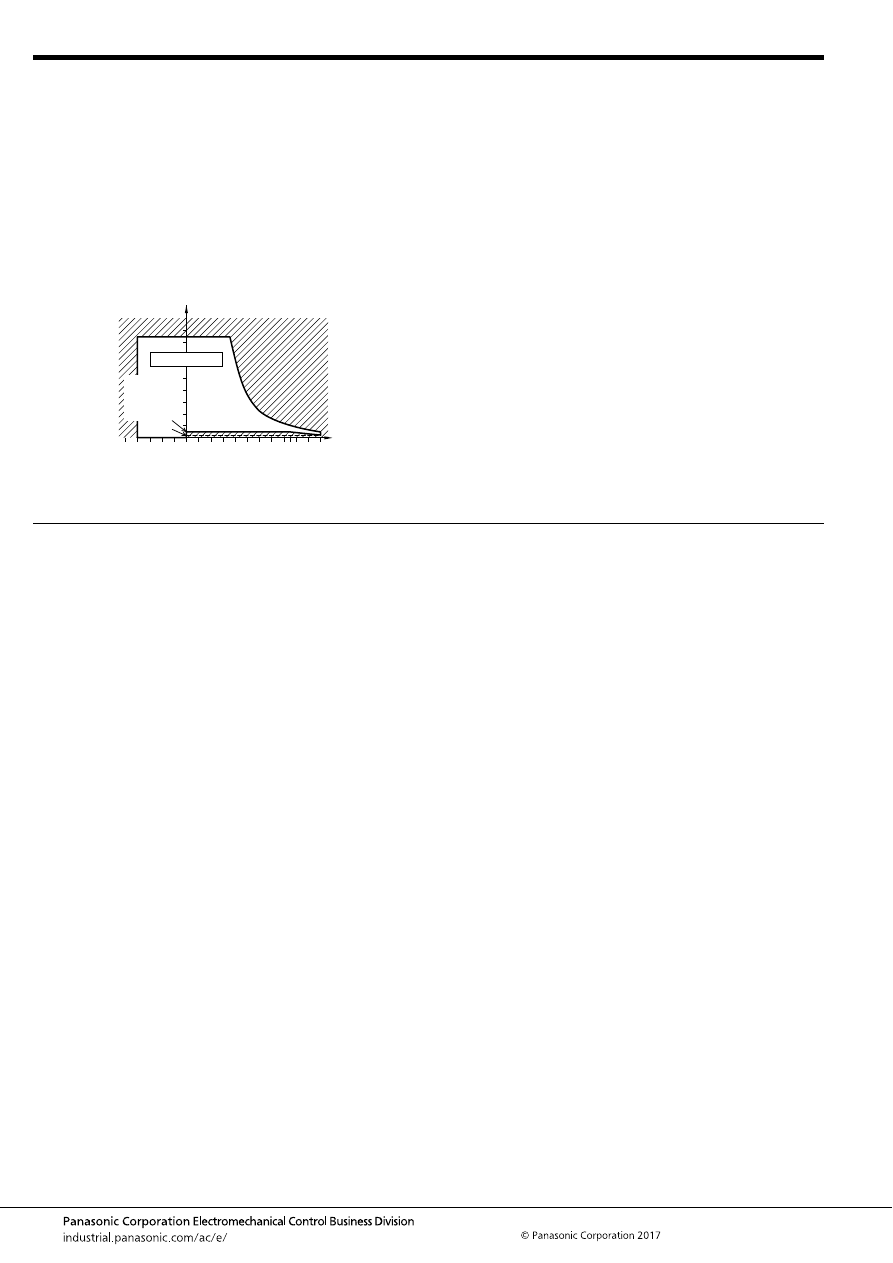

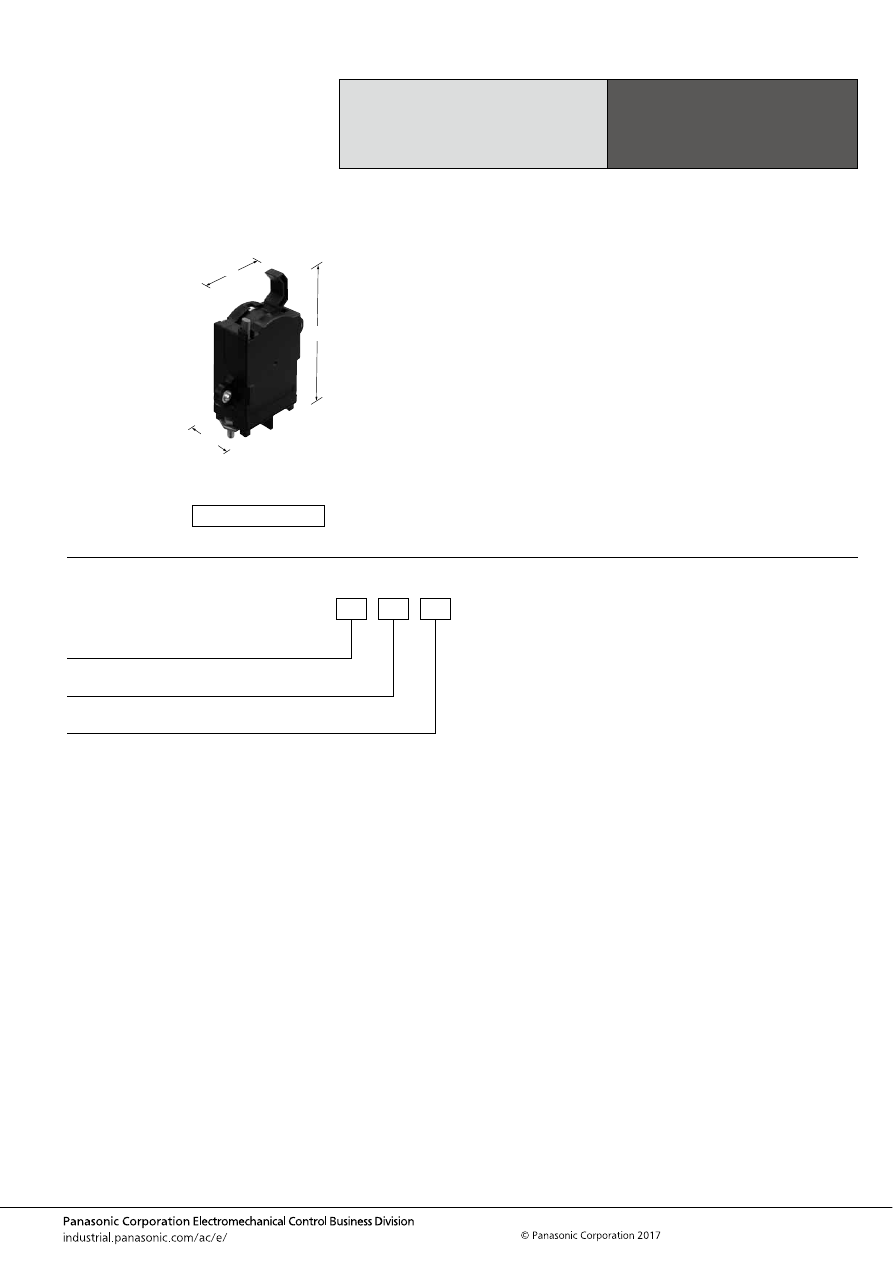

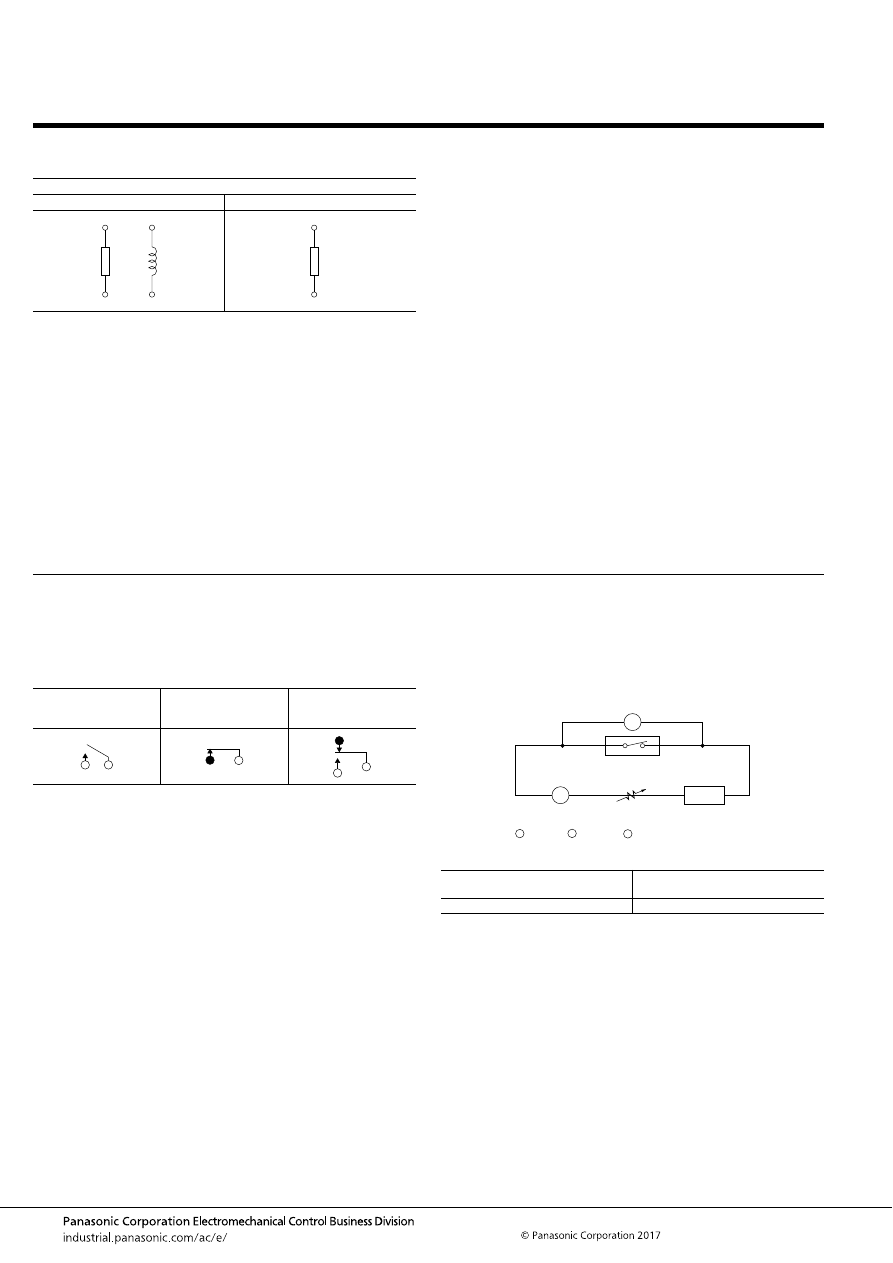

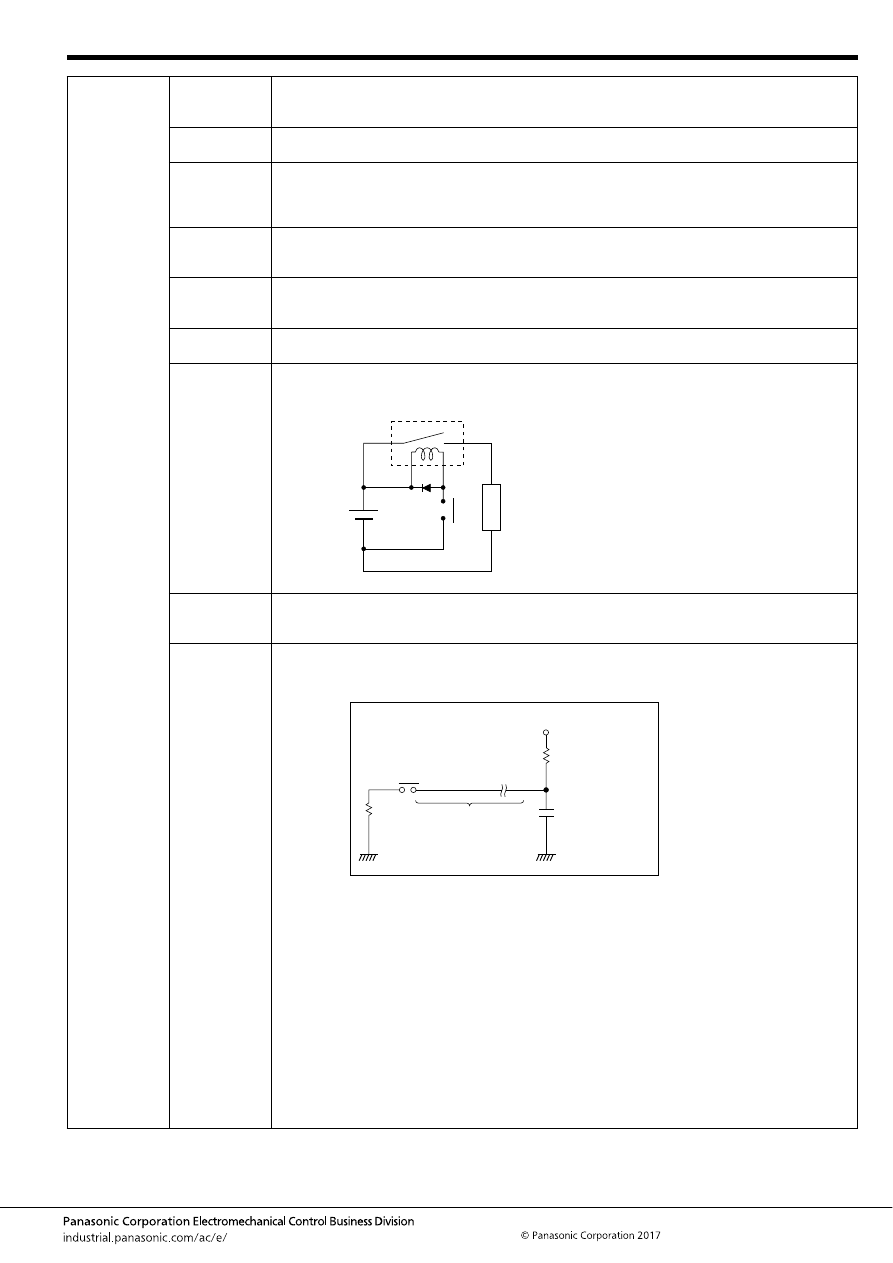

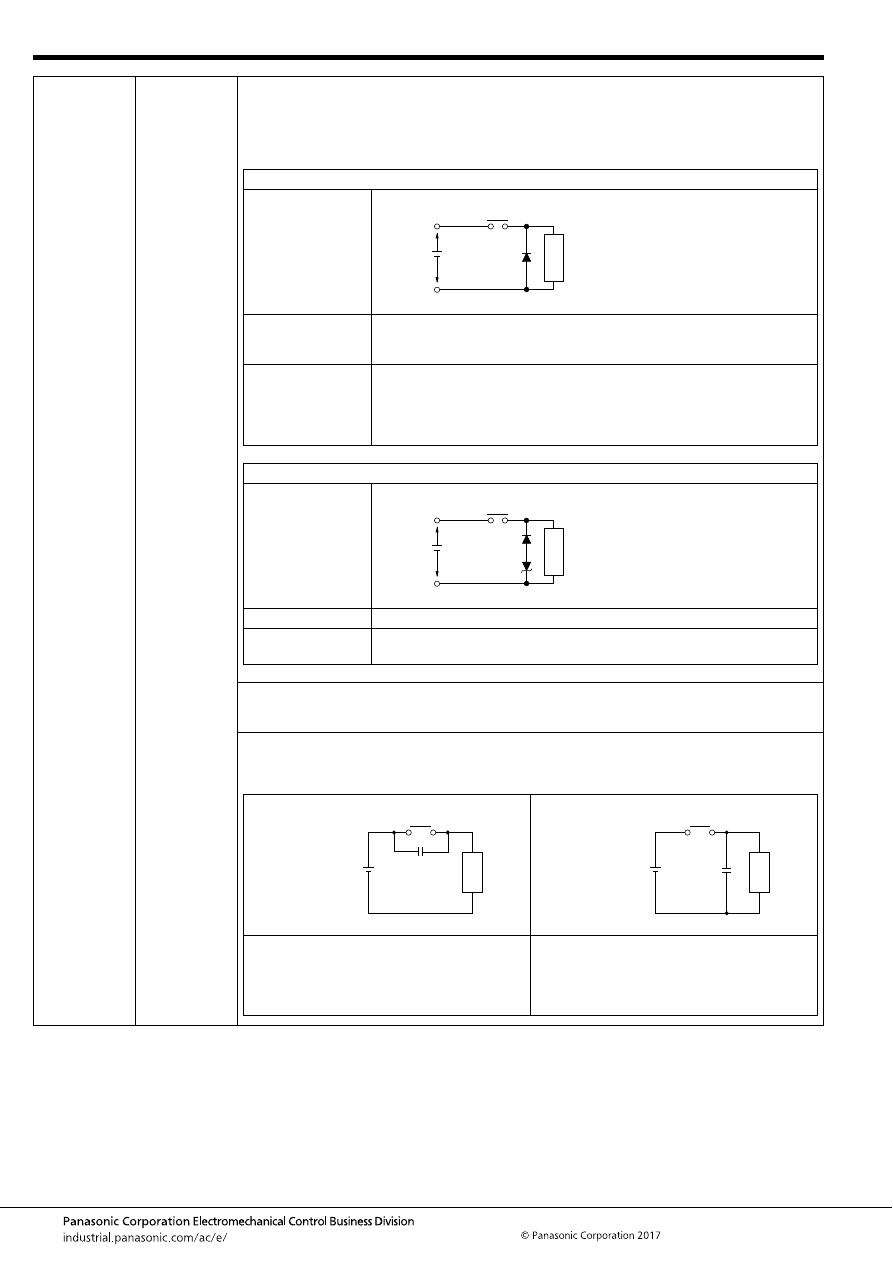

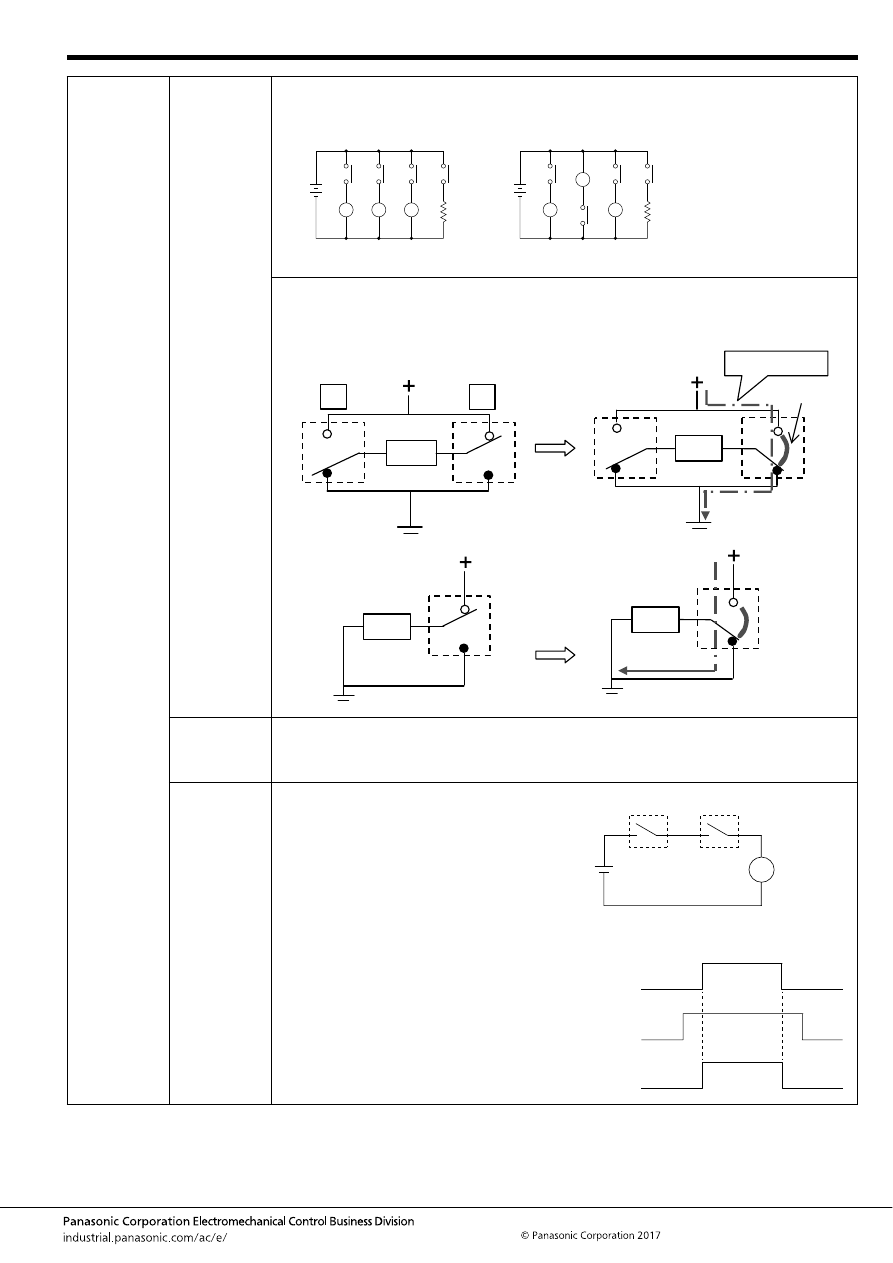

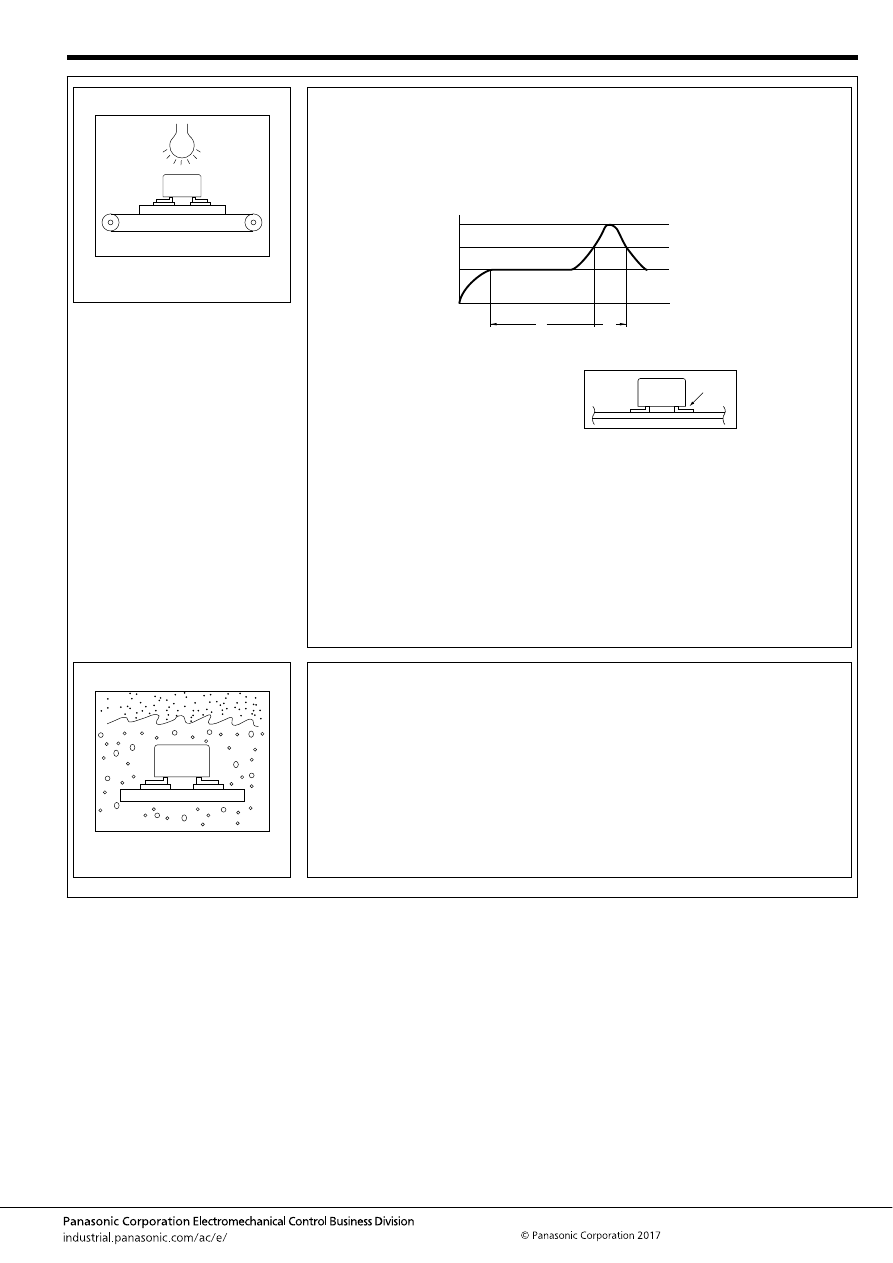

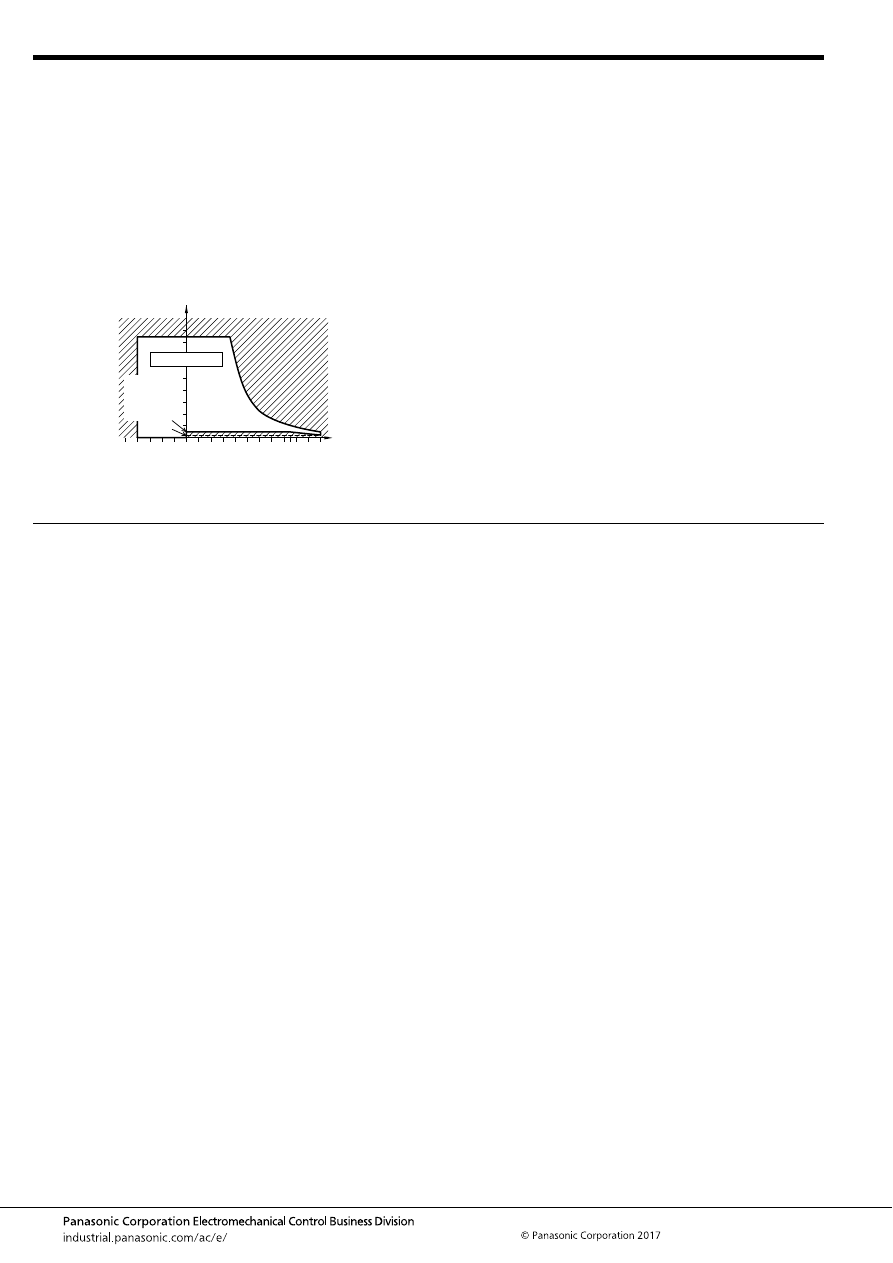

PROTECTIVE CONSTRUCTION

CONSTRUCTION AND CHARACTERISTIC

(

: Yes,

: No,

: Care)

*Since the plastic breathes, please do not use in an atmosphere that contains silicon.

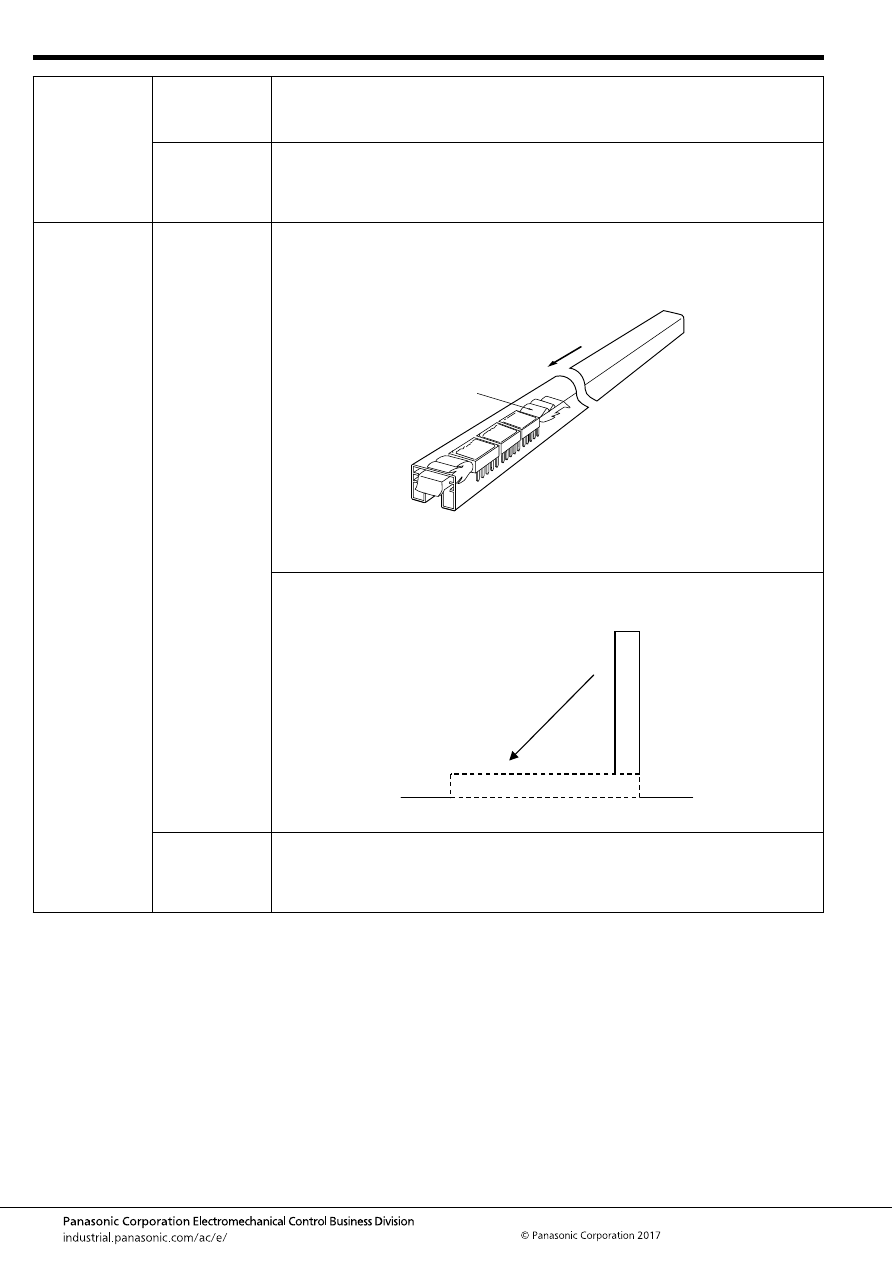

TERMINAL CONFIGURATION

MOUNTING METHOD

Configuration and Construction

Type

Construction

Characteristics

Automatic

Soldering

Automatic

Cleaning

Dust

Resistance

Harmful Gas

Resistance

Flux-Tight

Terminals, case, and base are filled

with sealing resin.

Sealed

Sealed construction with terminals,

case and base sealed shut with

sealing resin.

*

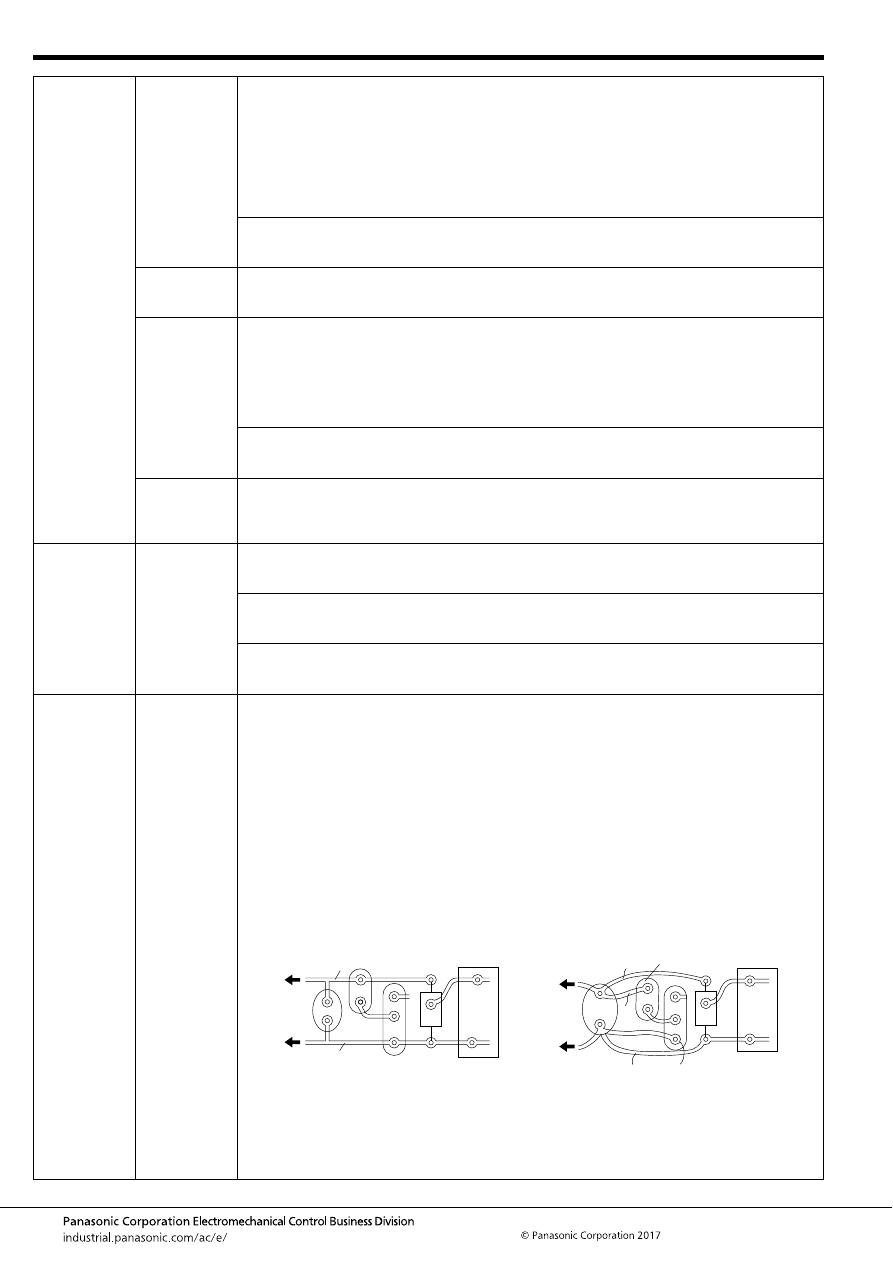

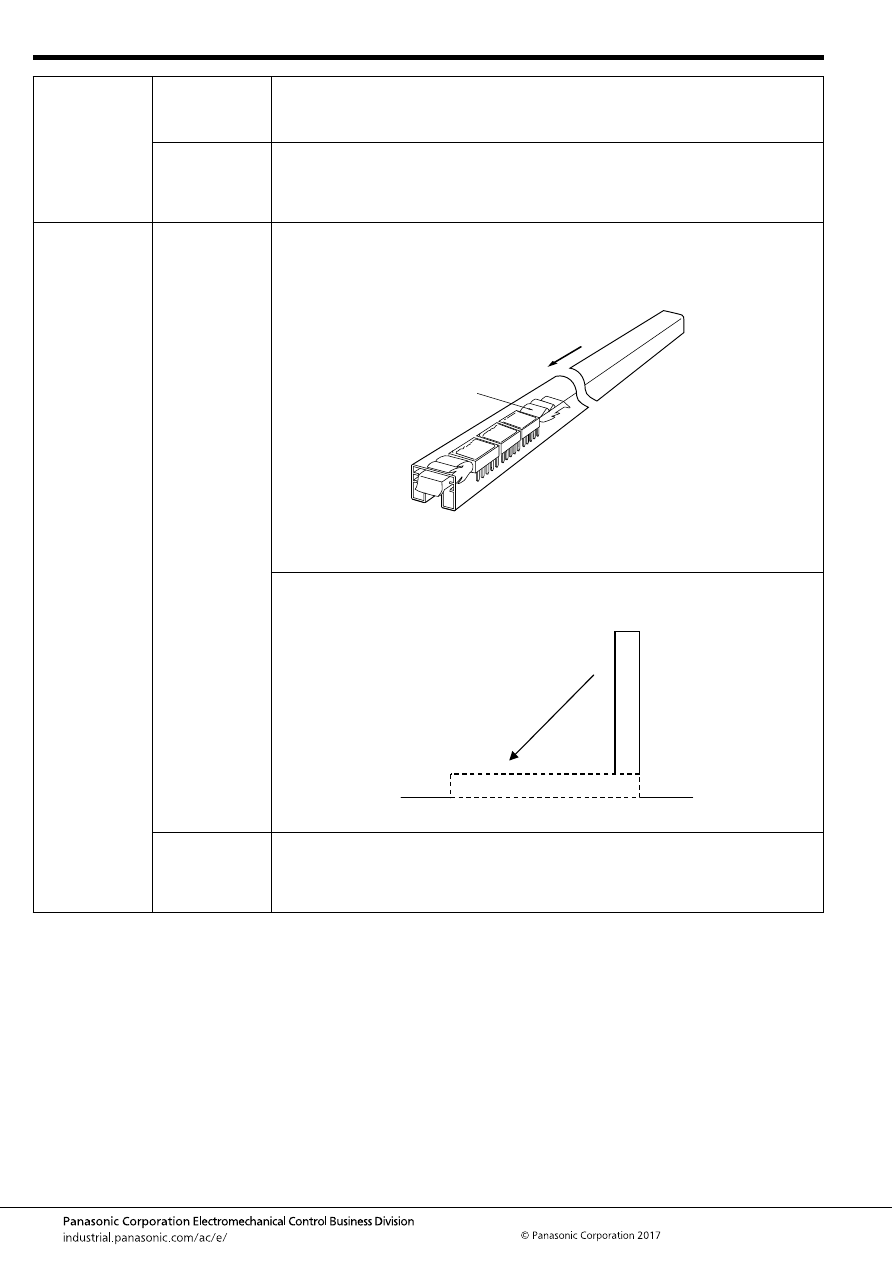

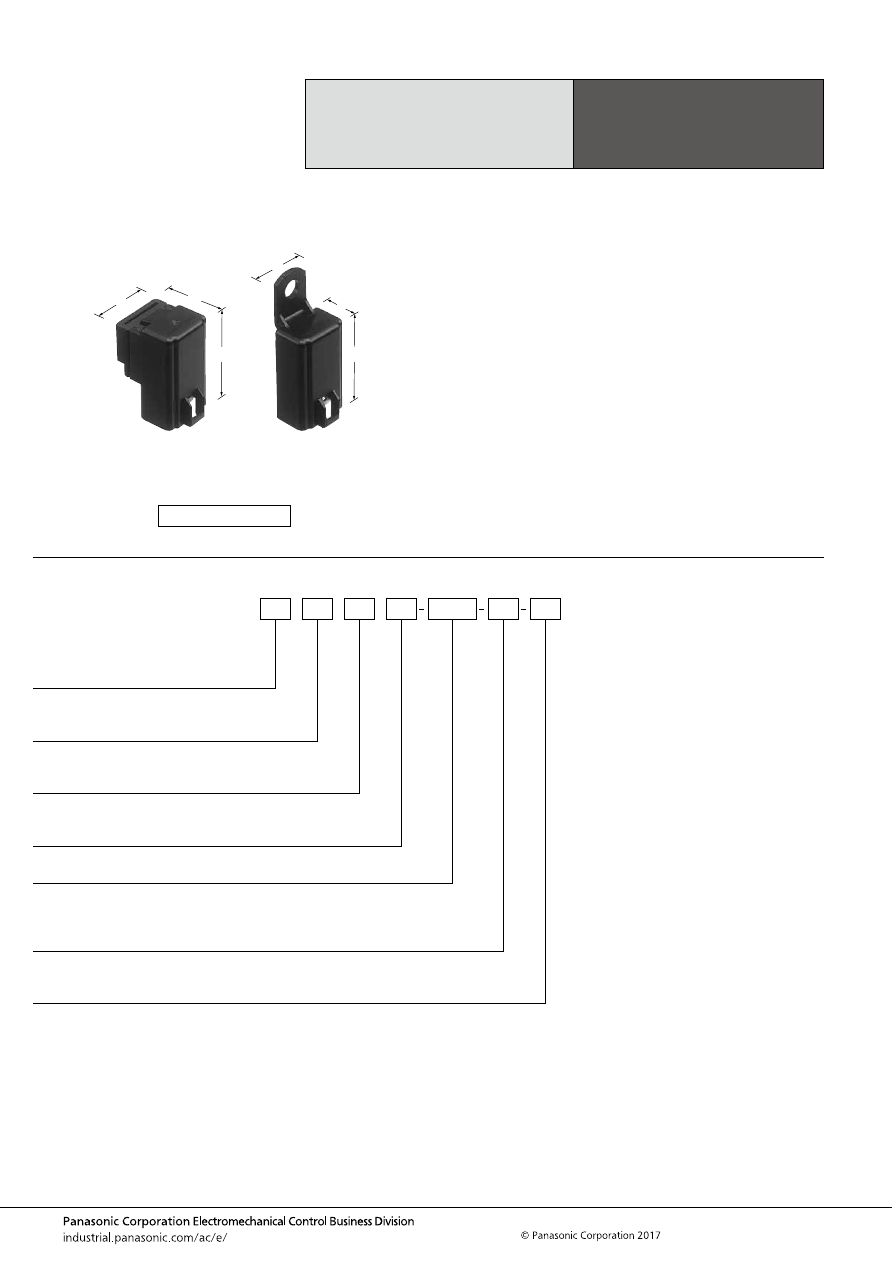

Type

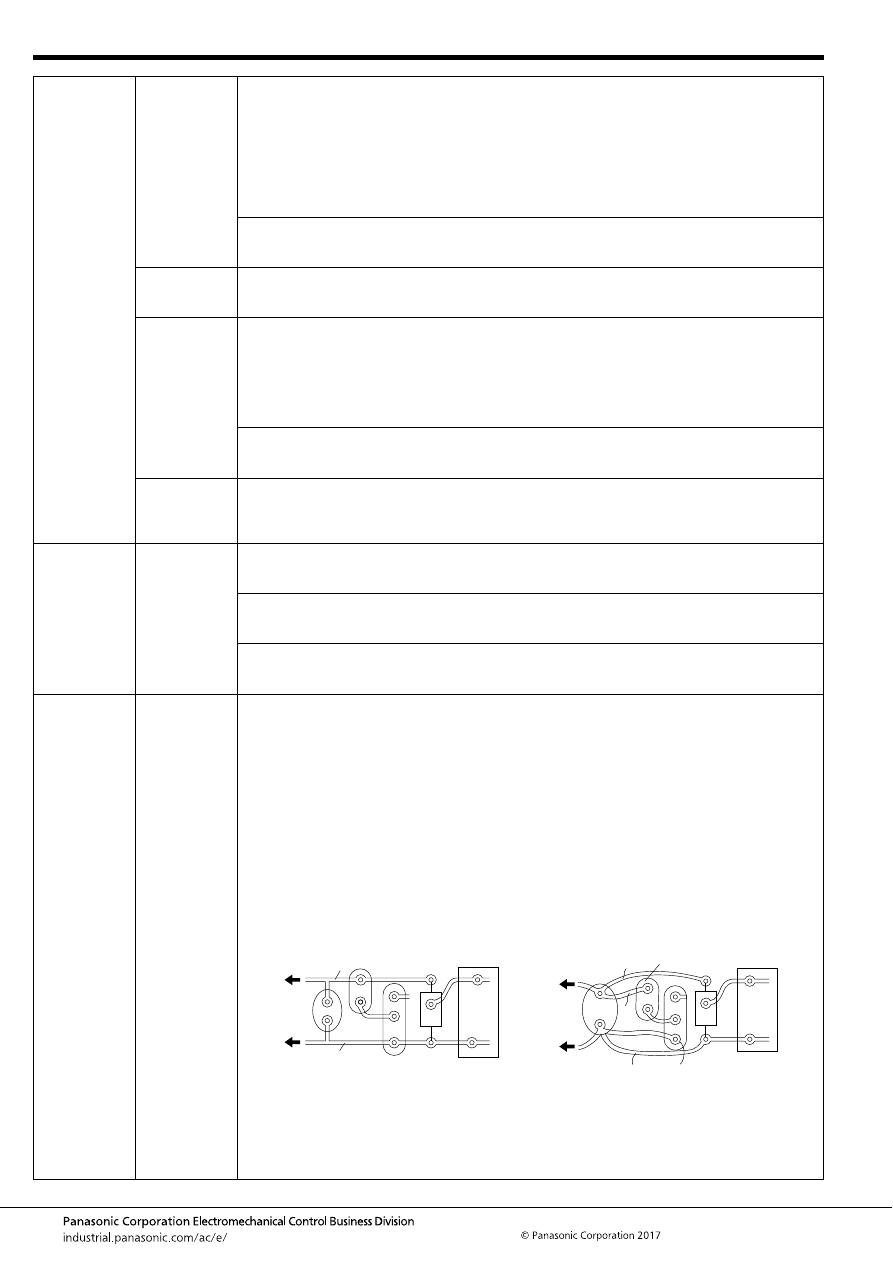

PC board through hole terminal

Plug-in terminal

Screw terminal

Typical relay

Terminal

configuration

Typical relay type

CP relay,

CN-H relay,

TB relay

CM relay,

CB relay,

CV-N relay

EV relay

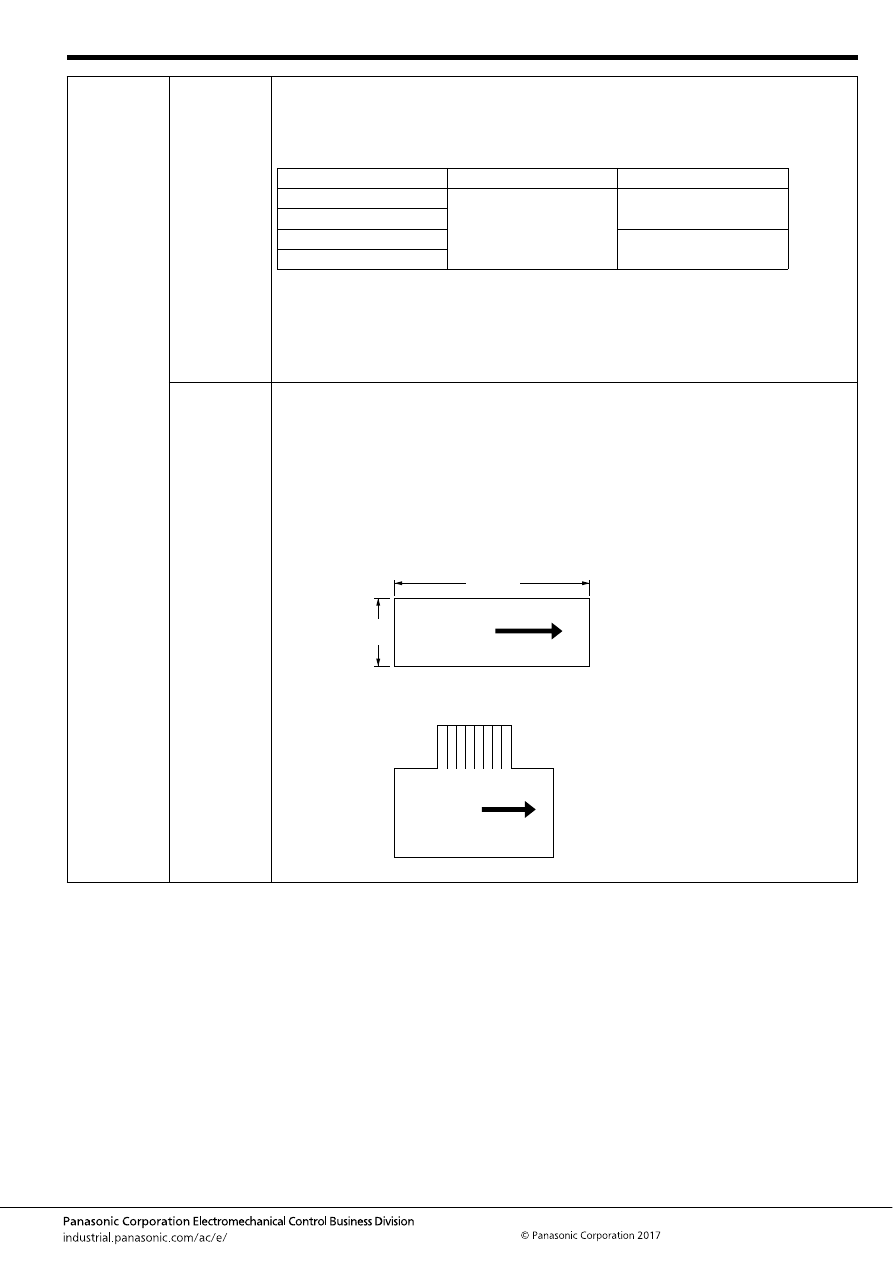

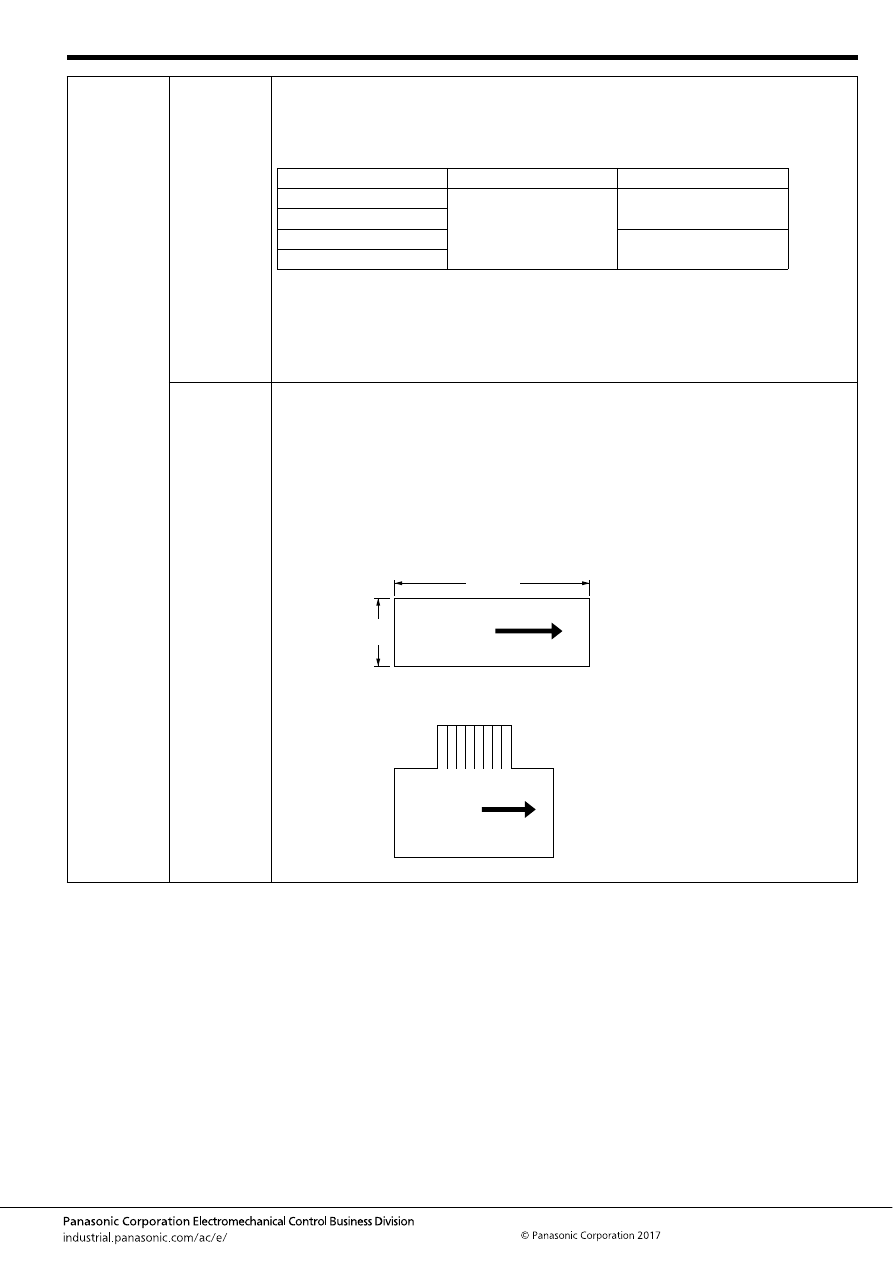

Type

Insertion mount