Designers anD Manufacturers

rohs coMpliant

~

iso 9001 certifieD

®

e l e c t r o n i c s c o r p.

interconnect components & hardware

catalog m65

keyelco.com

Designers anD Manufacturers

rohs coMpliant

~

iso 9001 certifieD

®

e l e c t r o n i c s c o r p.

interconnect components & hardware

catalog m65

keyelco.com

Coin Cell Holders & Retainers

pages 2 – 9

Auto-In/EZ-Out Coin Cell Holders

page 4 – 5

Coin Cell Enclosure Contacts

page 8

SMT & THM Battery Holders

page 22 – 25

Li-Ion Battery Holders

page 24 – 25

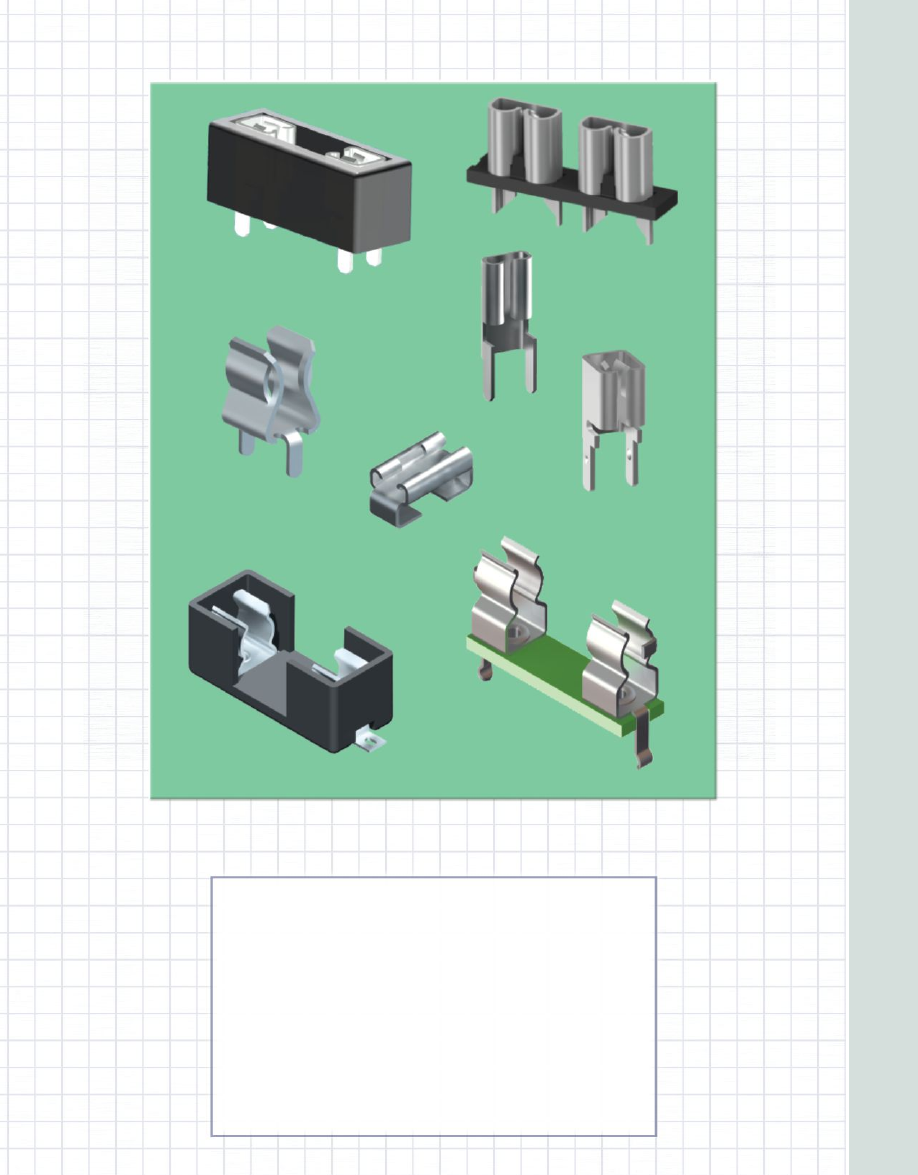

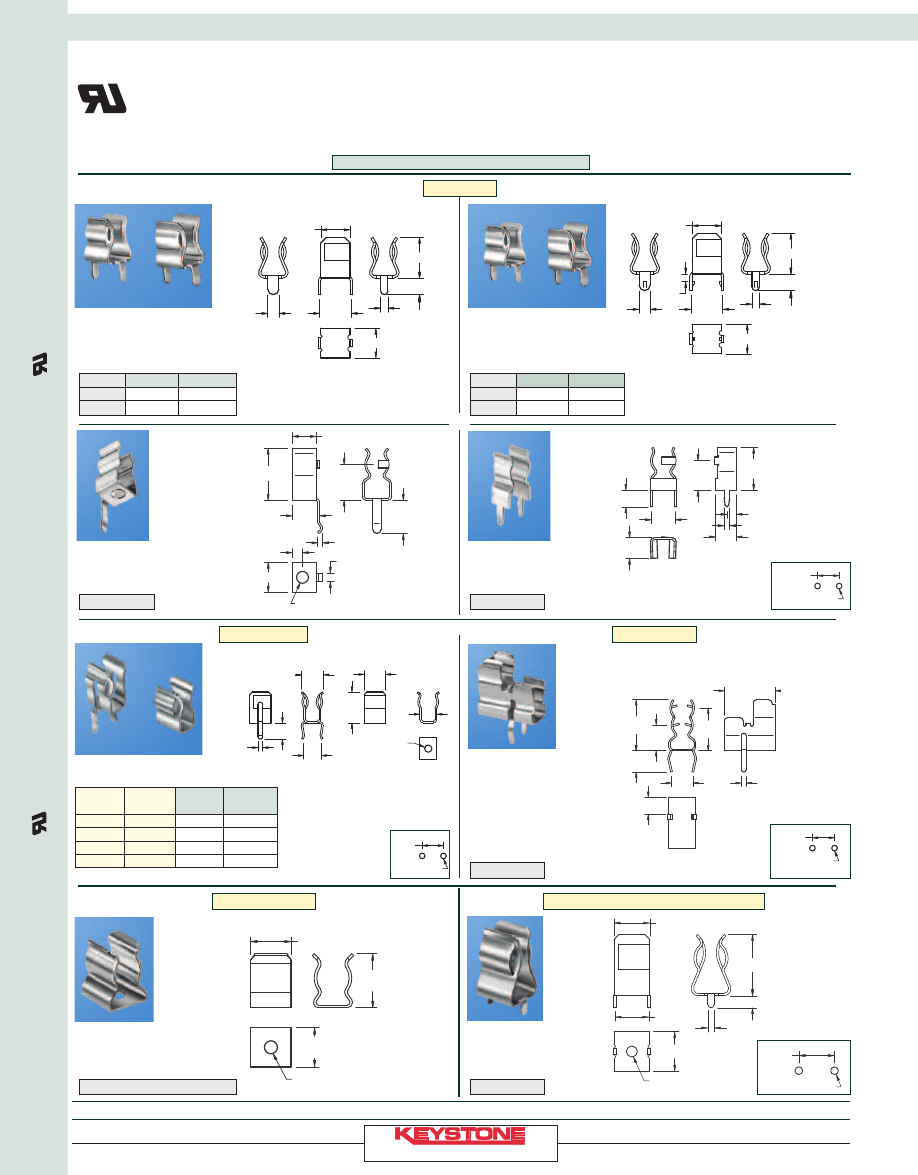

UL Recognized Fuse Clips & Holders

pages 44 – 47

Battery Contacts

pages 10 – 18

UL Recognized Auto Fuse Clips & Holders

page 40 – 43

Jumpers & Zero Ohm Jumpers

page 54

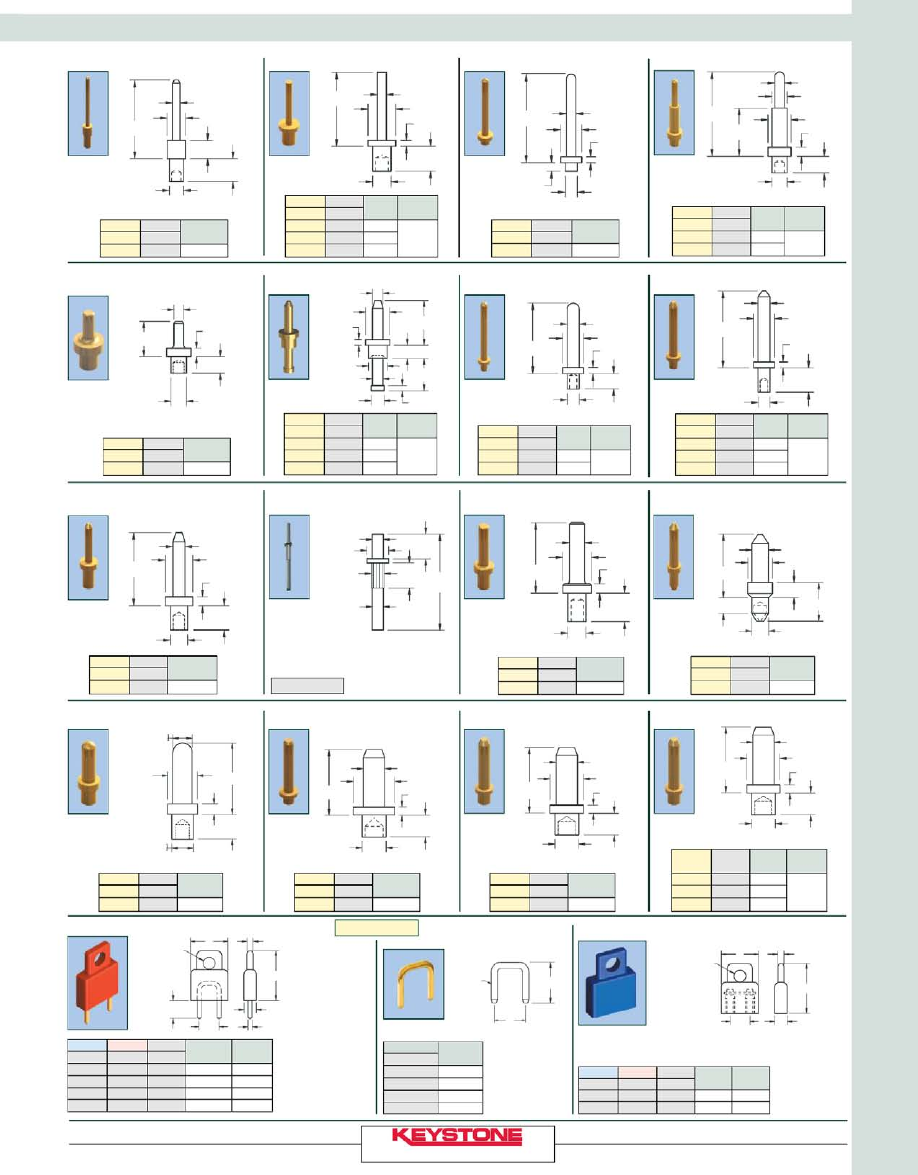

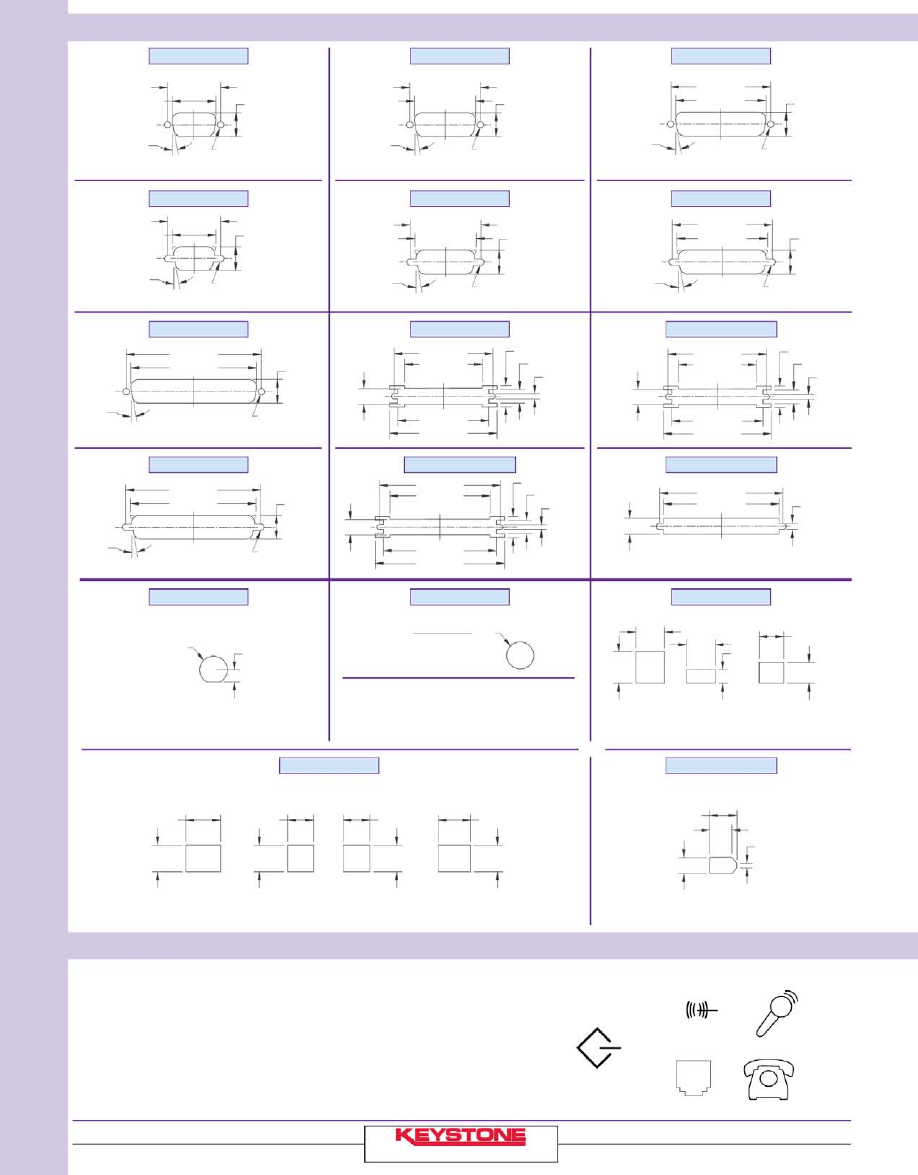

SMT & THM Test Points

page 56

Color Coded & SEMS Screw Terminals

pages 66 – 71

EZ-Out

Tab

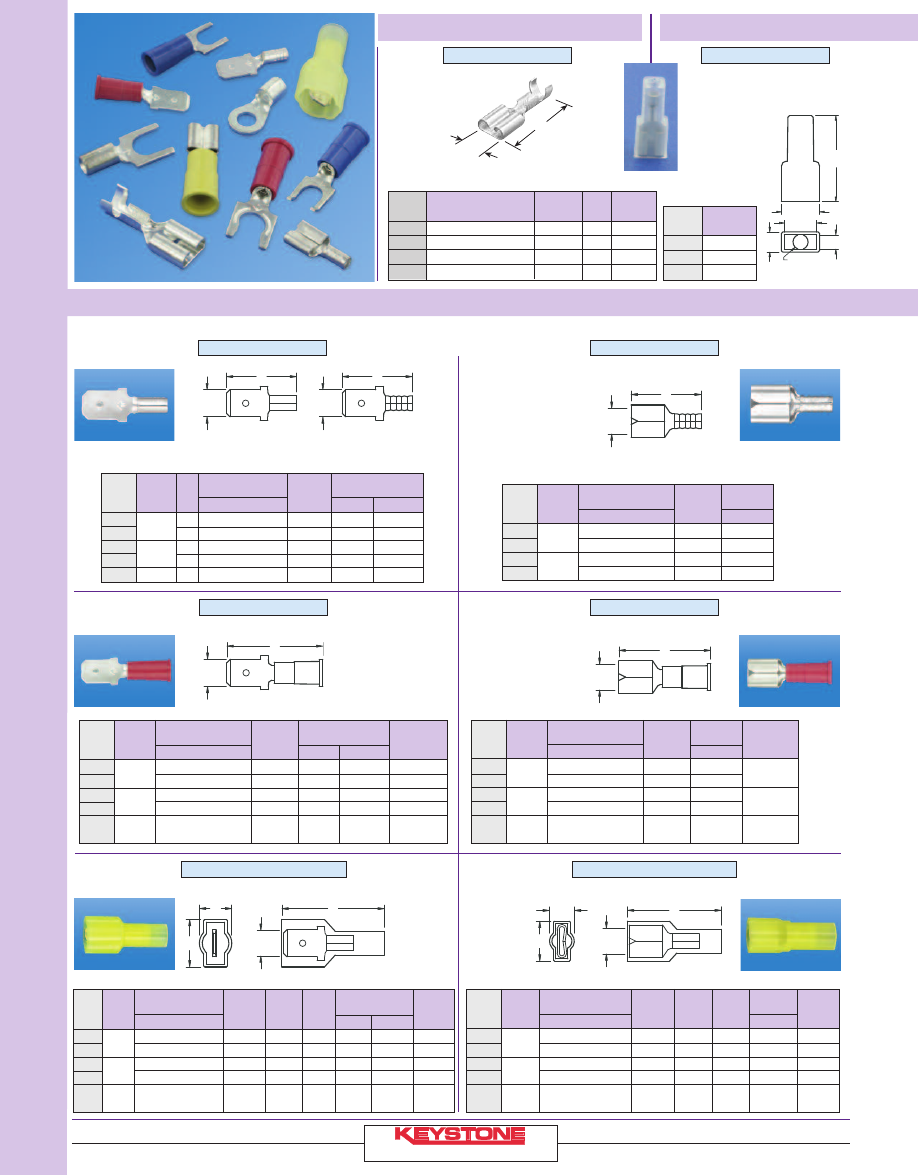

UL Recognized Quick Fit Terminals

pages 58 – 61

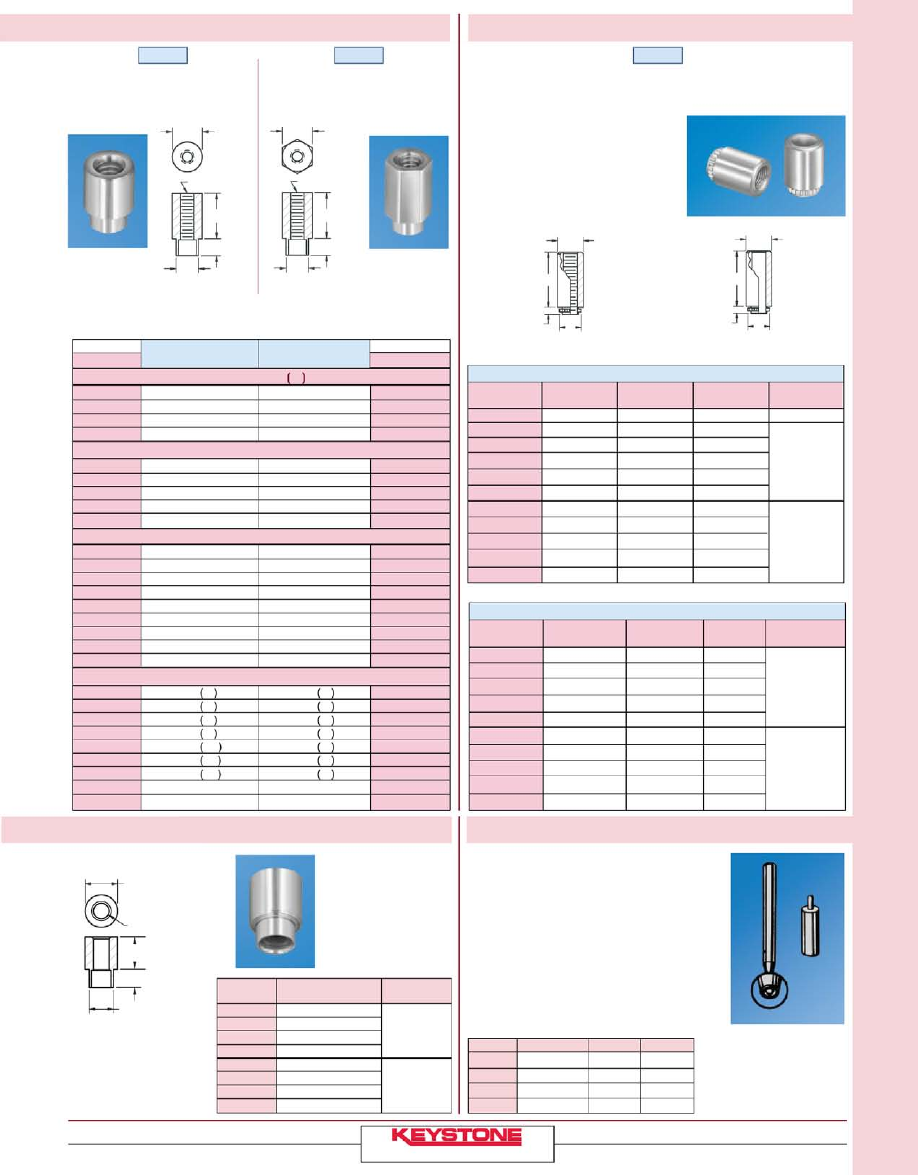

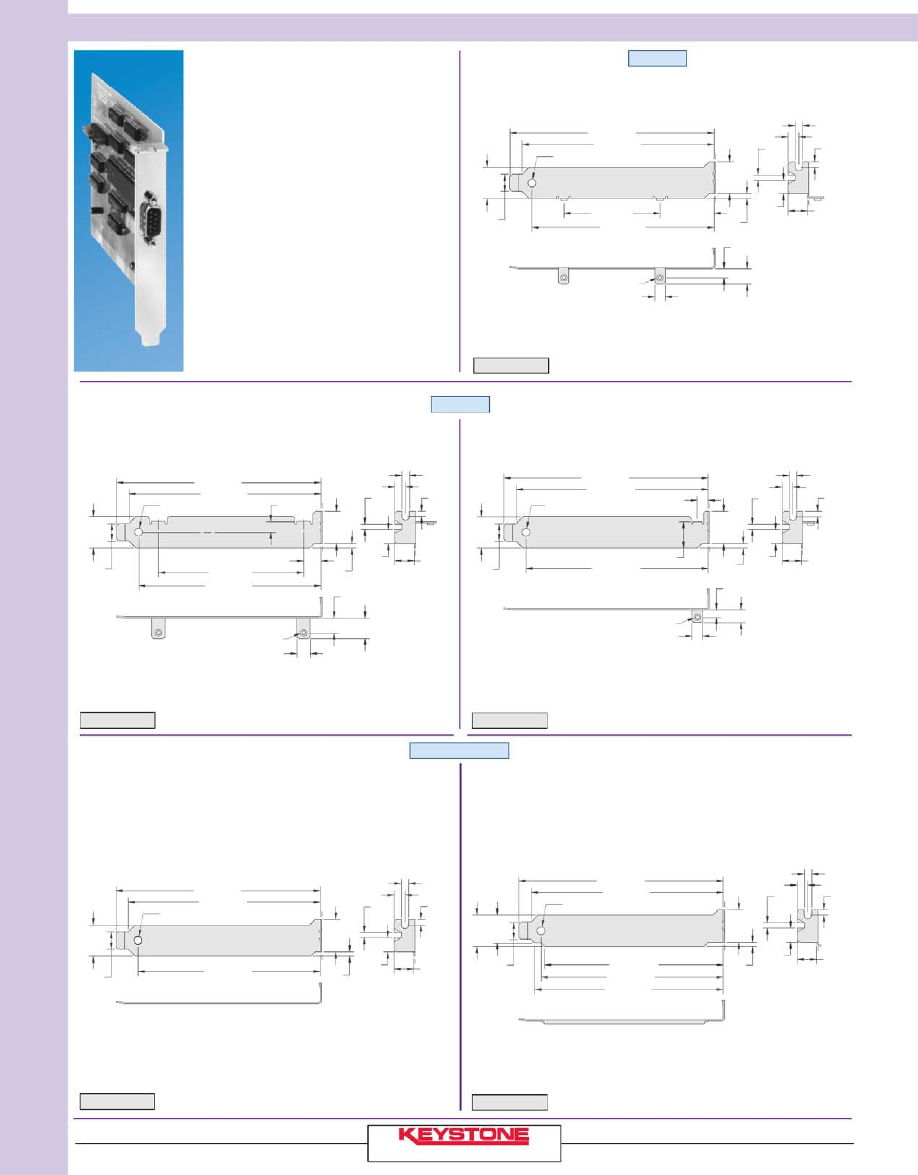

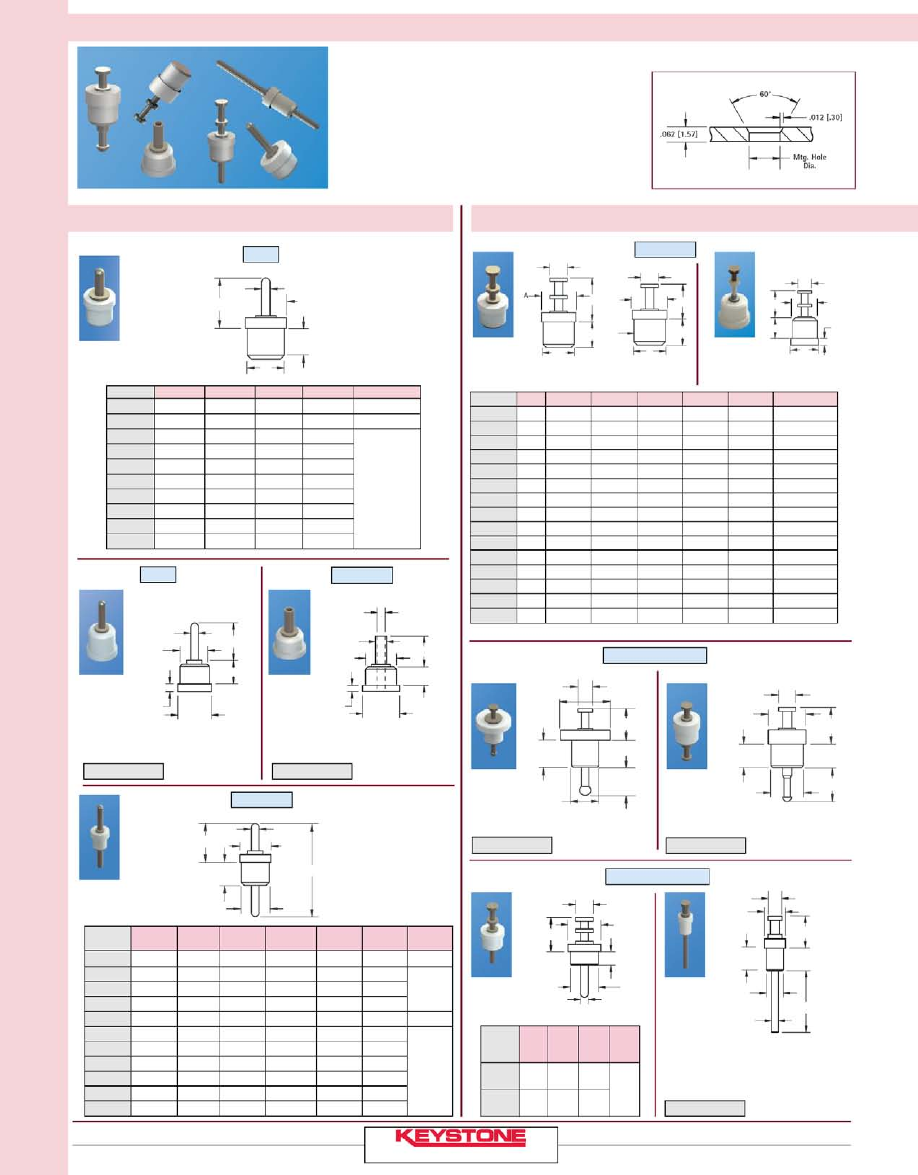

Spacers Supports & Metric Standoffs

page 80 – 83

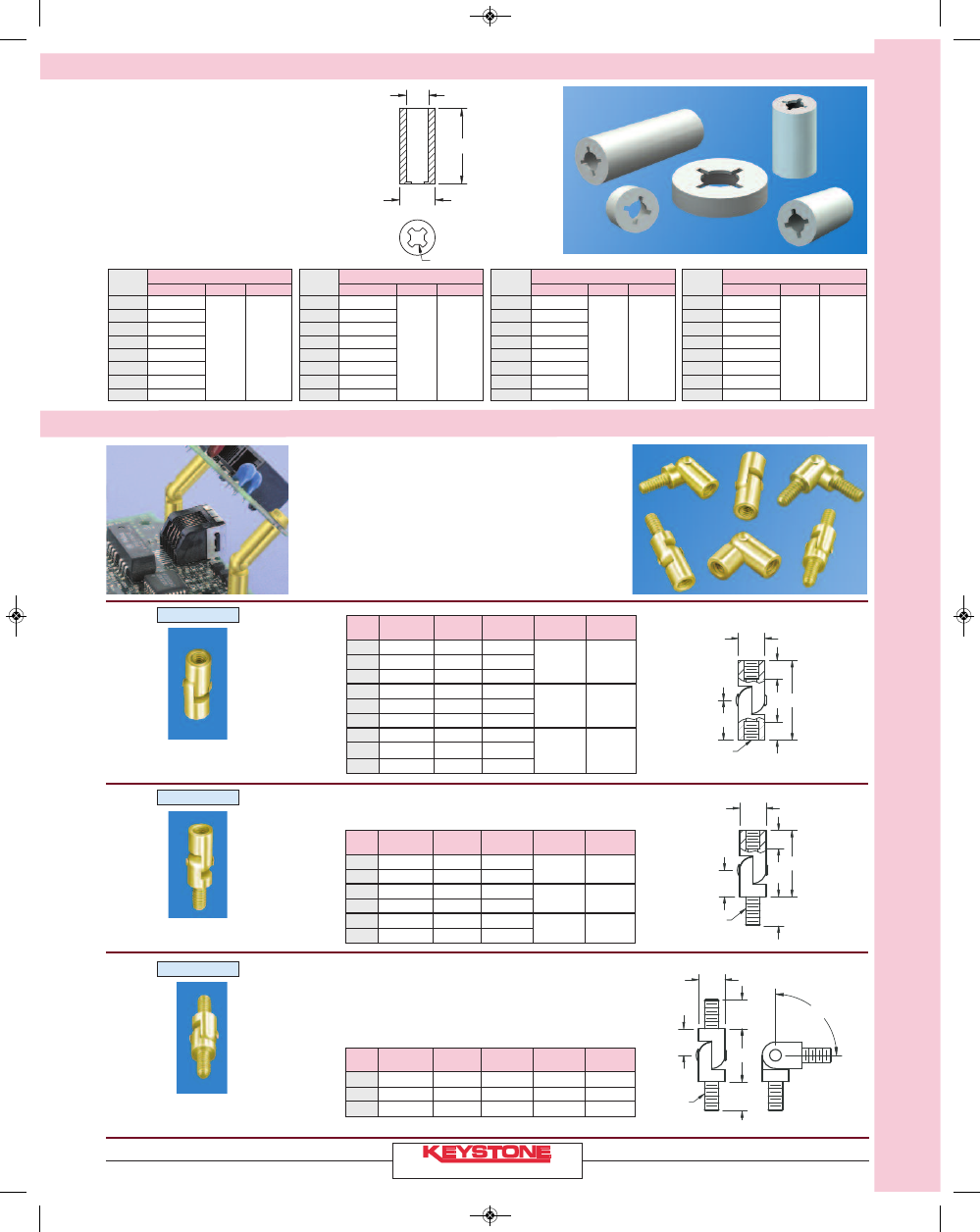

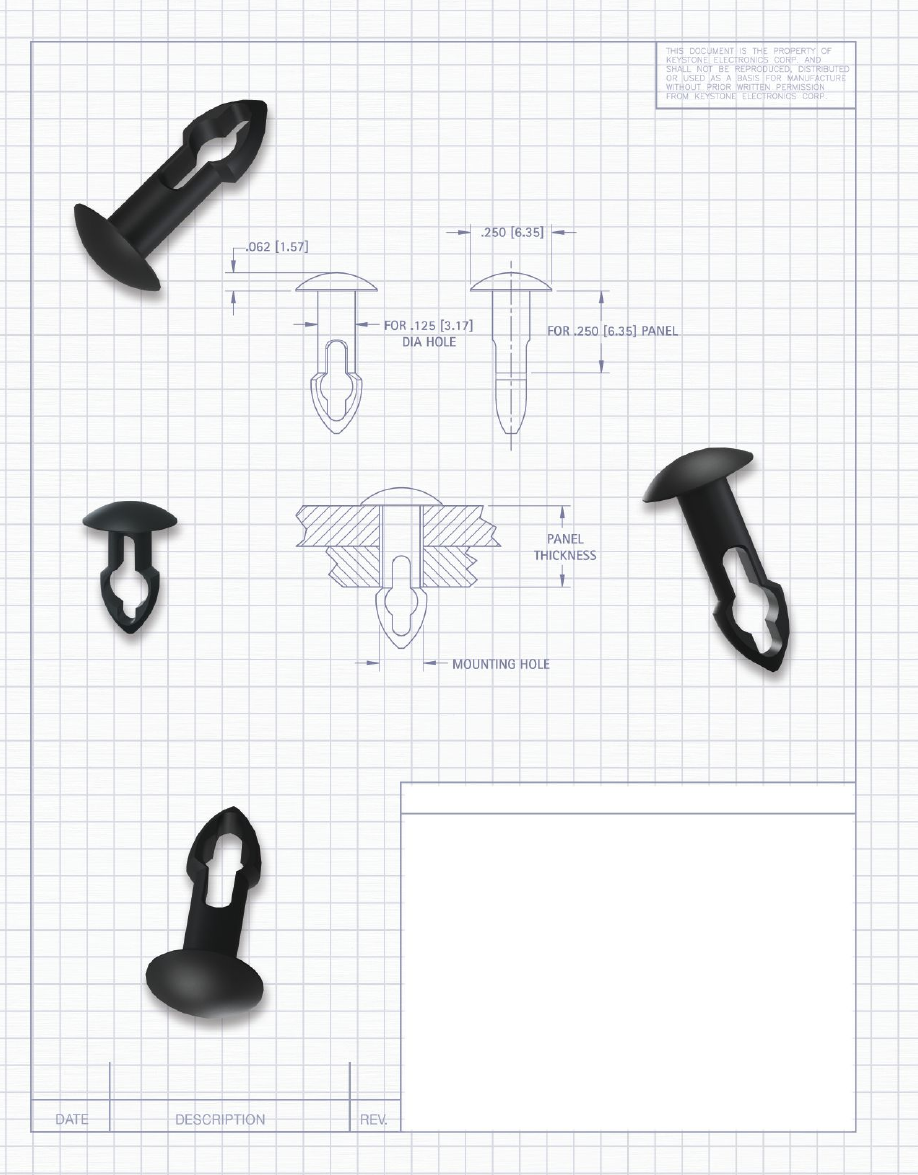

Nylon Self-Retaining Spacers & Washers

pages 79 & 136

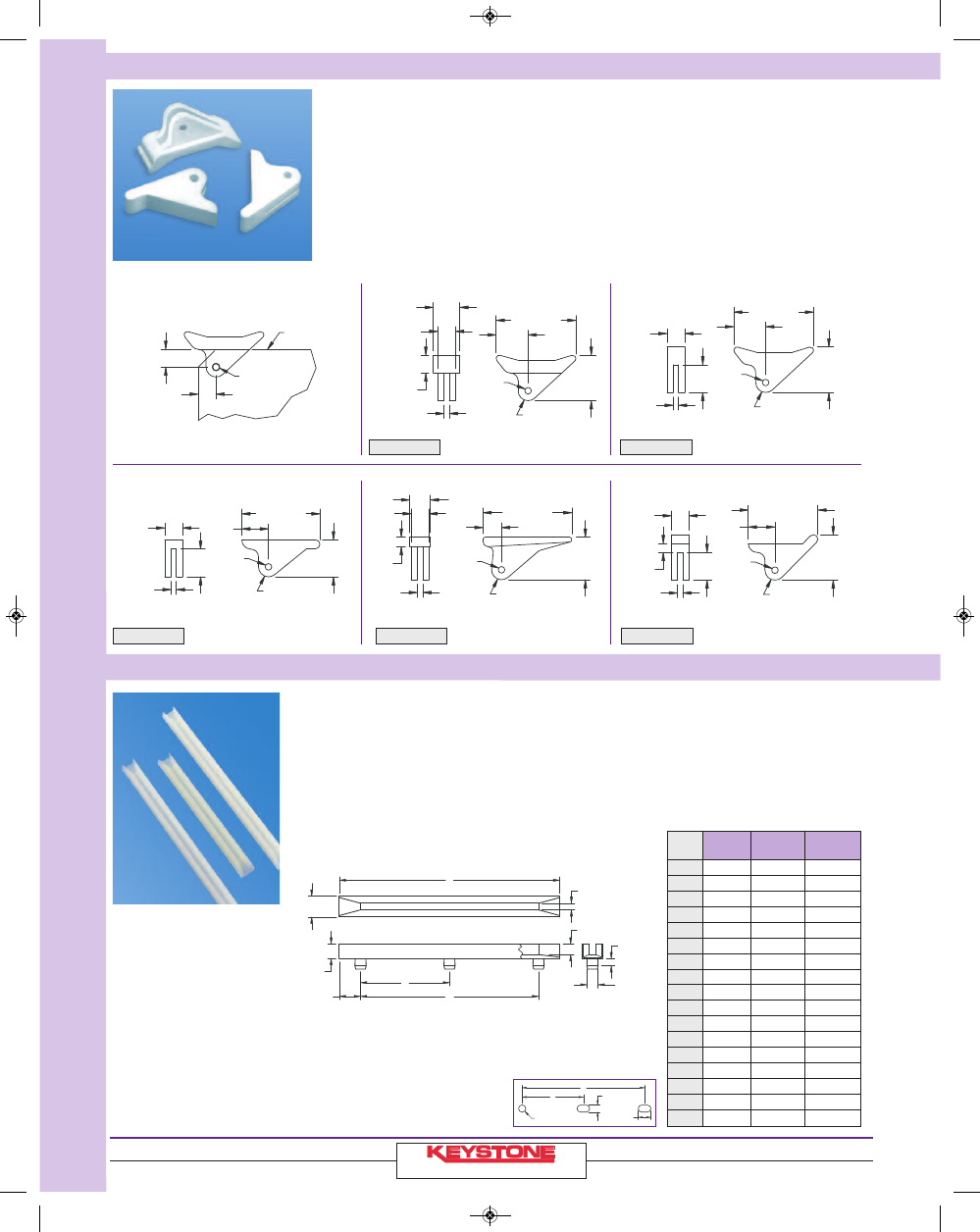

Vertical Card Guides

pages 121

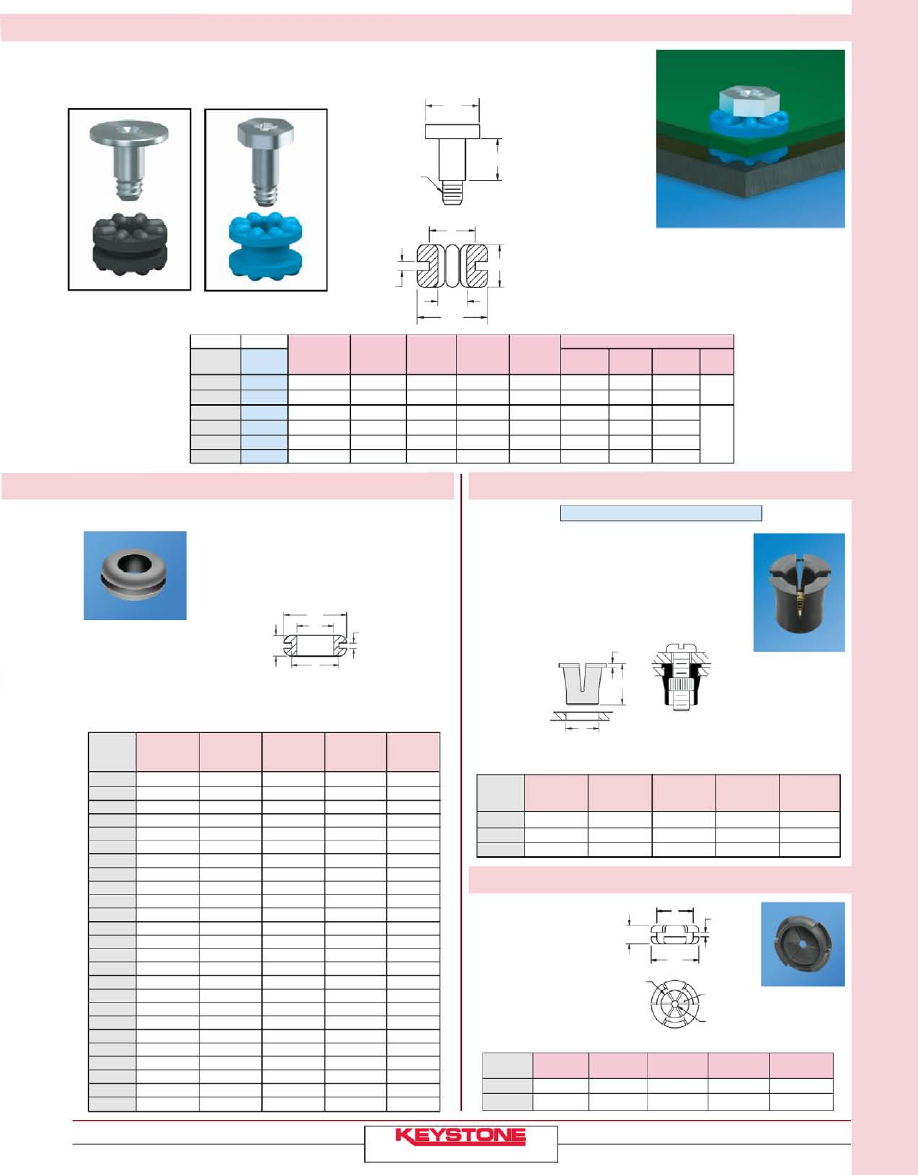

Anti-Vibration Grommets

page 133

Adhesive Bumpers

page 134

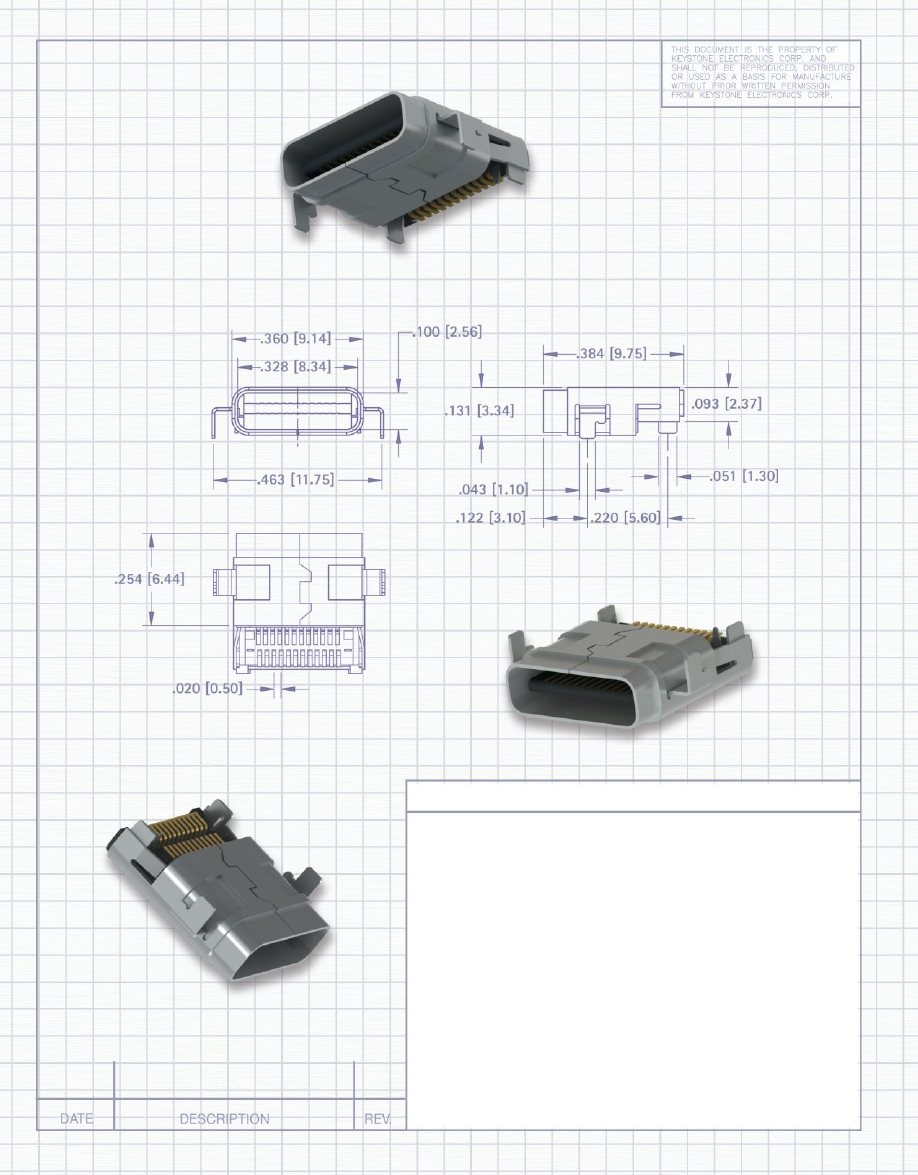

USB 2.0 & 3.0 Plugs & Sockets

pages 98 – 100

PTFE Insulated Terminals & Pins

pages 140 – 142

USB 3.1 Plug & Socket

page 100

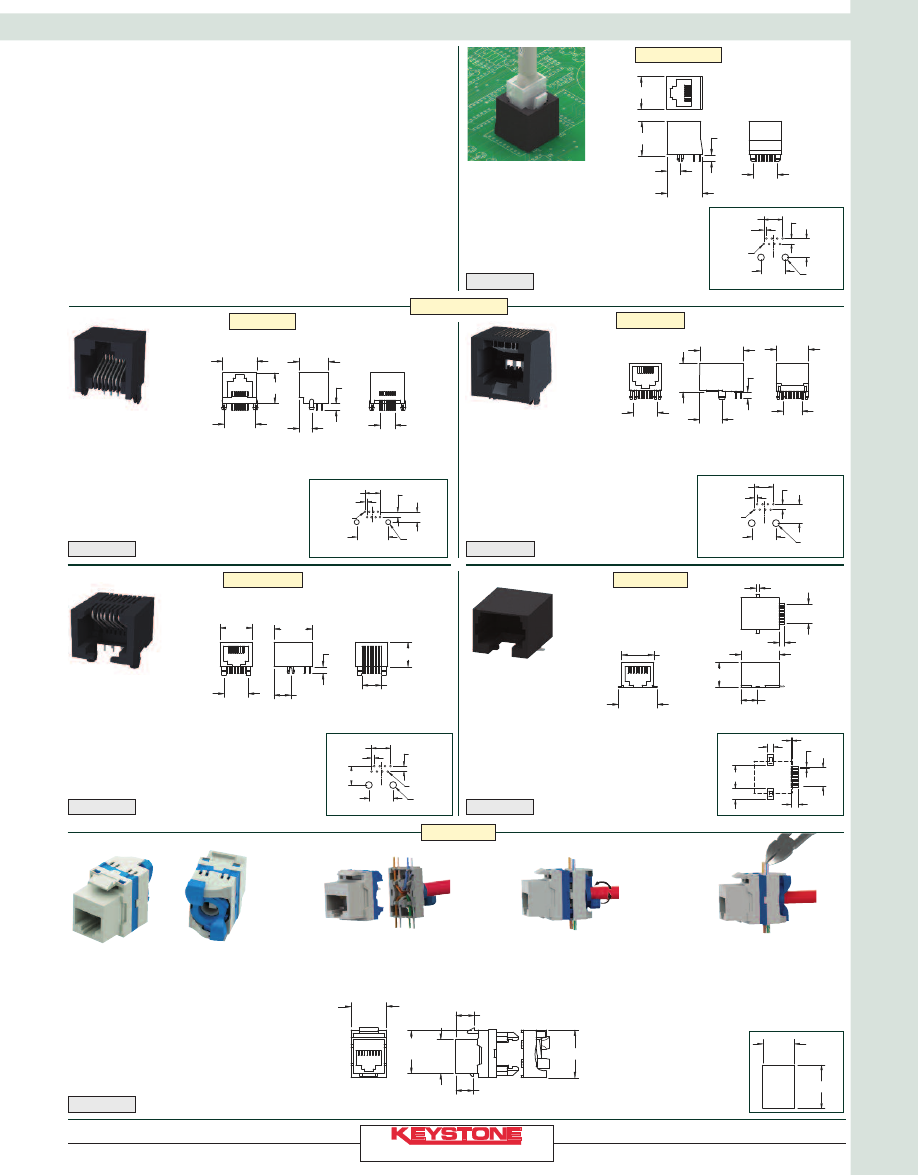

Keystone (RJ45 8P8C) Jacks

pages 101

Micro Pins & Jacks

pages 102 – 105

ADHESIVE BACKED

Bumpers . . . . . . . . . . . . . . . . . . . . 130

PCB Supports . . . . . . . . . . . . . . . . . . 78

ALLIGATOR CLIPS . . . . . . . . . . . . . . . . . 56

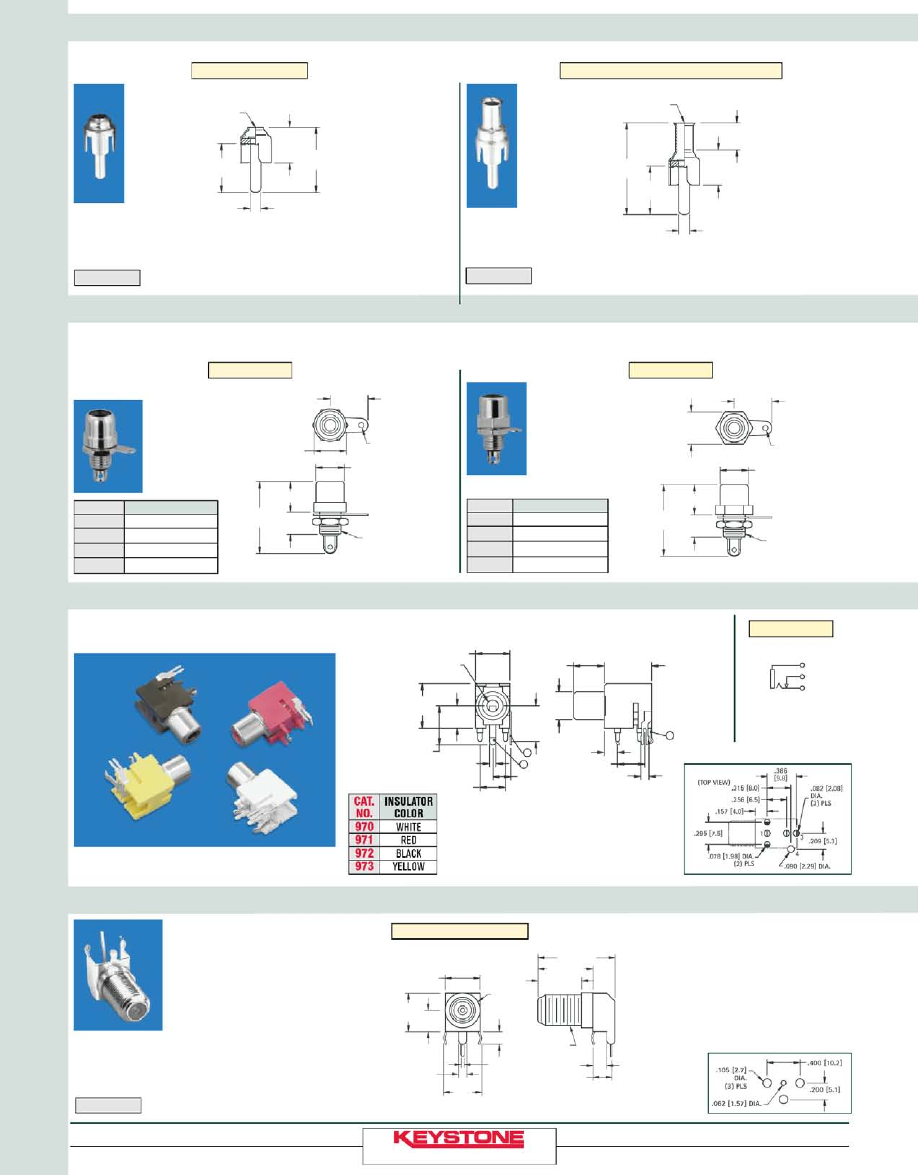

AUDIO JACKS . . . . . . . . . . . . . . . . . . . 112

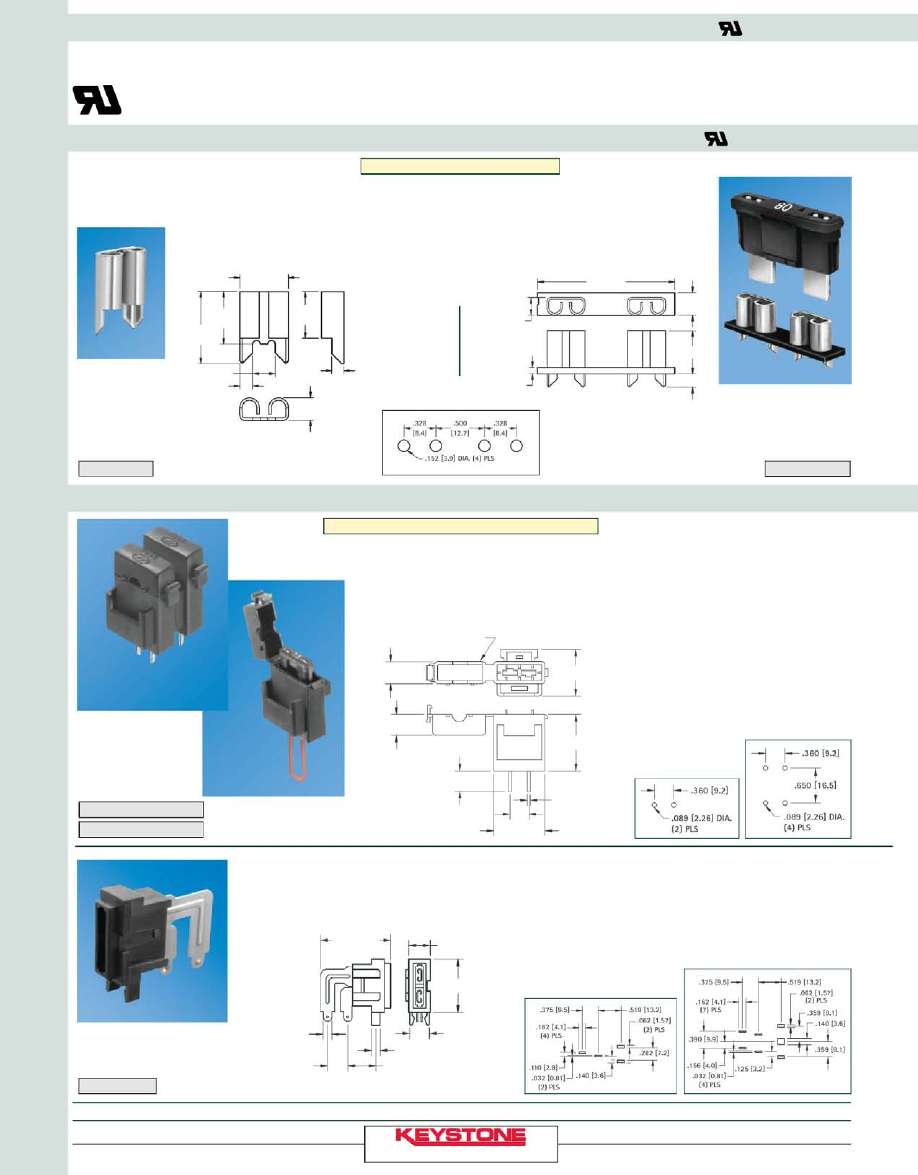

AUTOMOTIVE BLADE FUSE CLIPS

& HOLDERS

Low Profile Auto Fuse. . . . . . . . . . 42-43

MAXI Auto Blade fuse . . . . . . . . . . . . 40

Mini Auto Blade. . . . . . . . . . . . . . 42-43

Standard Auto Blade . . . . . . . . . . 40-41

BATTERY CONTACTS & CLIPS

Button Cell retainers/contacts

(SMT/THM) . . . . . . . . . . . . . . . . . . . 7-8

Clips / Accessories . . . . . . . . . . . 12-13

Coin Cell retainers/contacts

(SMT/THM) . . . . . . . . . . . . . . . . . . . 8-9

Coin Cell retainers, insulated

(SMT/THM). . . . . . . . . . . . . . . . . . . . . 8

Contacts for off board

applications . . . . . . . . . . . . . . . . 14-18

9V Snaps & Contacts . . . . . . . . . . . . 32

BATTERY HOLDERS

Aluminum. . . . . . . . . . . . . . . . . . . . . 19

Coin Cell . . . . . . . . . . . . . . . . . . . . . 2-6

Lithium-Ion . . . . . . . . . . . . . . . . . 22-27

Plastic - ecconomy . . . . . . . . . . . 28-29

Plastic - enclosed . . . . . . . . . . . . . . . 29

Polarized . . . . . . . . . . . . . . . . . . . 24-27

SMT (Surface Mount). . . . . . . . . . 23-27

Steel . . . . . . . . . . . . . . . . . . . . . . . . 21

THM (Thru Hole Mount) . . . . . 22, 24-27

9V Holders . . . . . . . . . . . . . . . . . . . . 33

9V Straps . . . . . . . . . . . . . . . . . . 30-31

BATTERY CONTACTS LAYOUT

& MOUNTING DETAILS . . . . . . . . . . 34-37

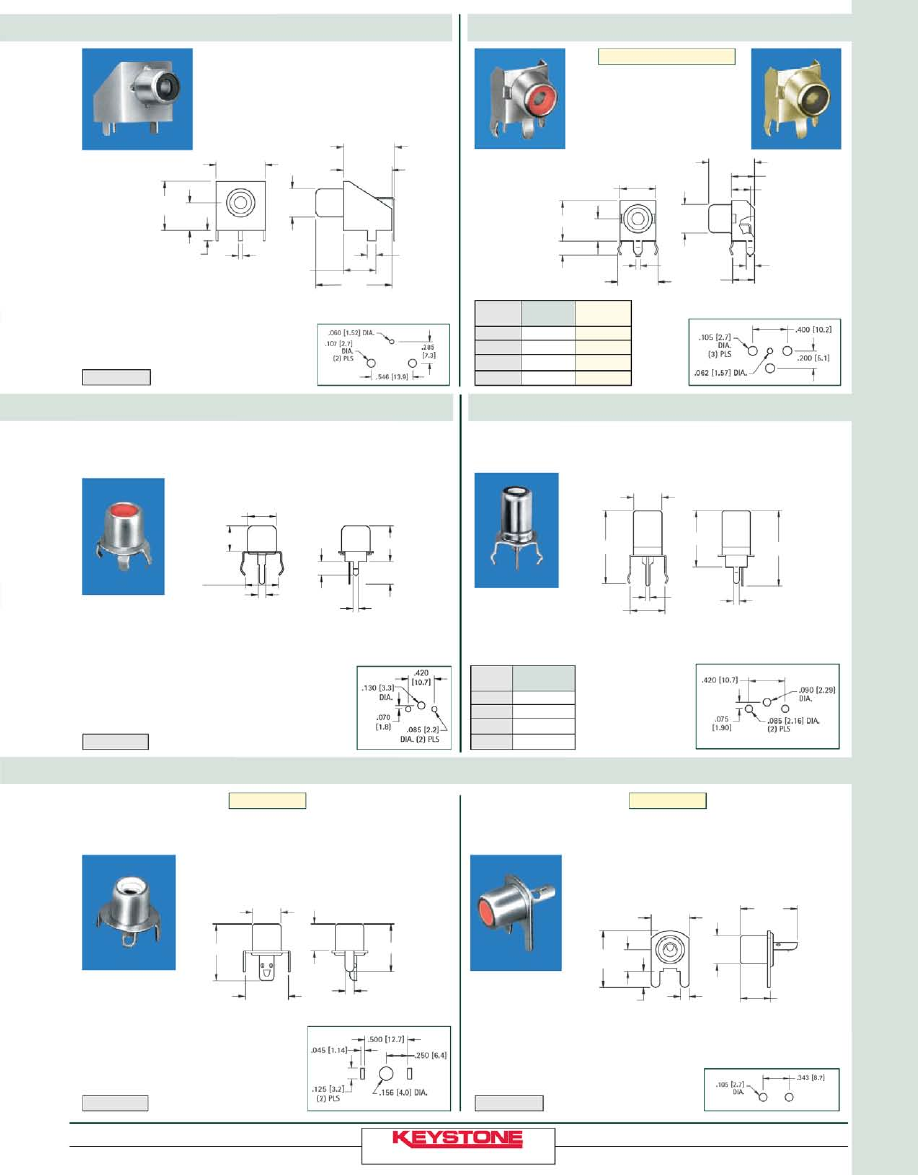

BANANA PLUGS & JACKS . . . . . . . 110-11

BINDING POSTS . . . . . . . . . . . . . . . . . 112

BOARD GUIDES, P.C. . . . . . . . . . . 120-121

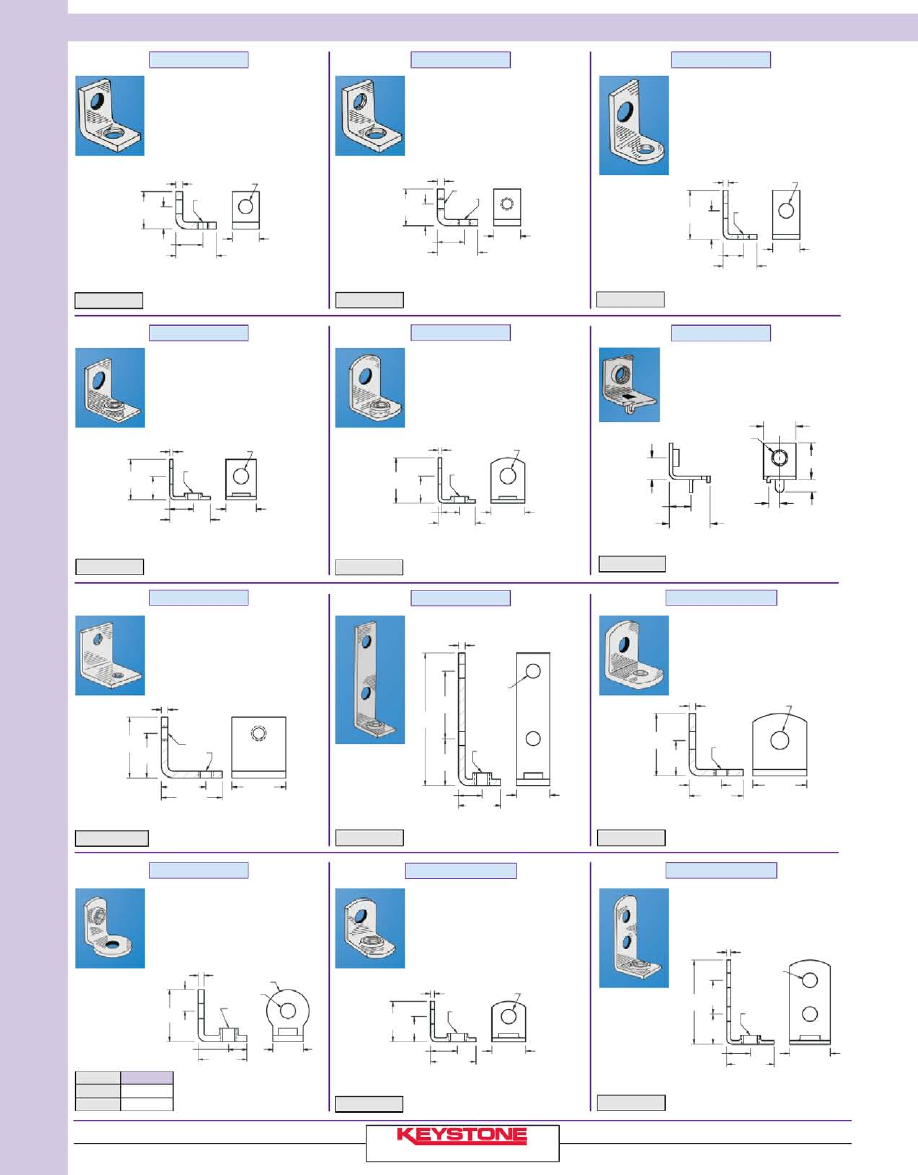

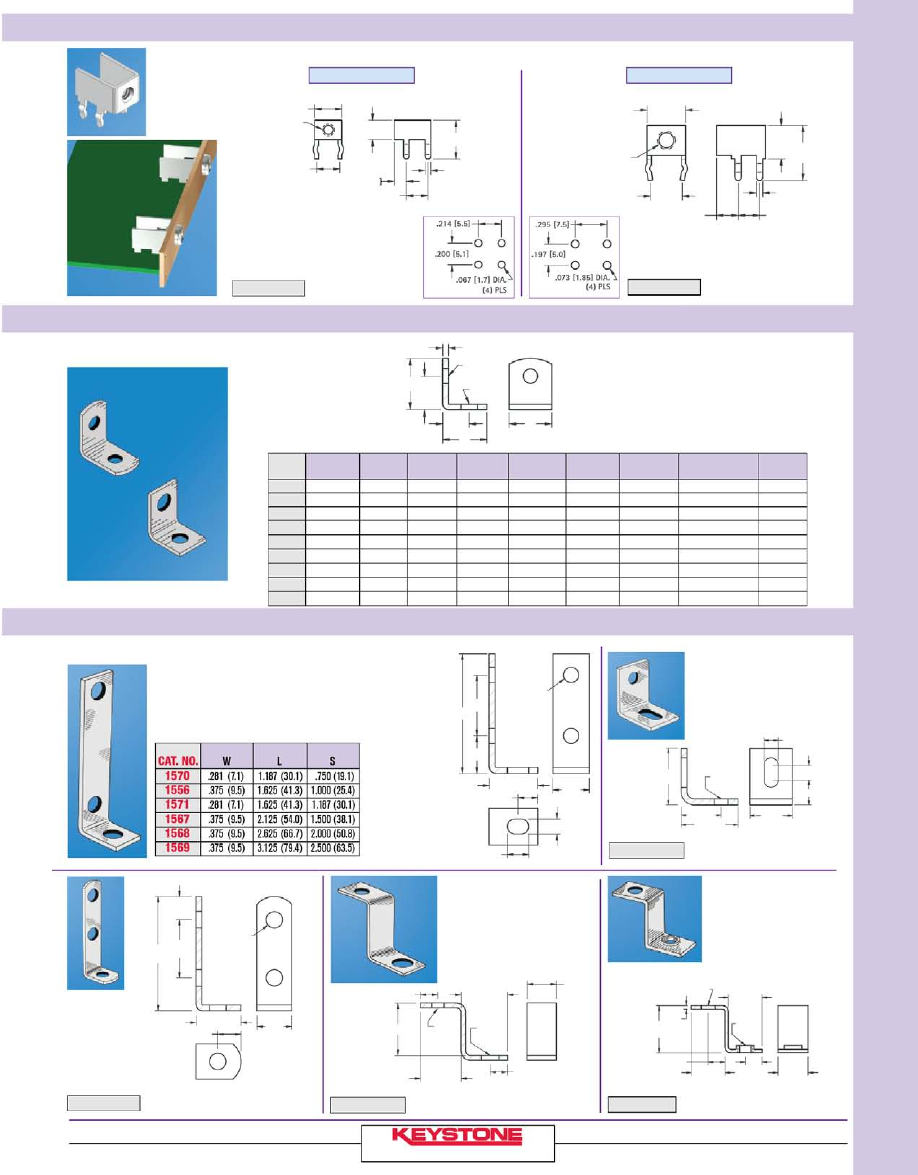

BRACKETS (Mounting). . . . . . . . . 118-119

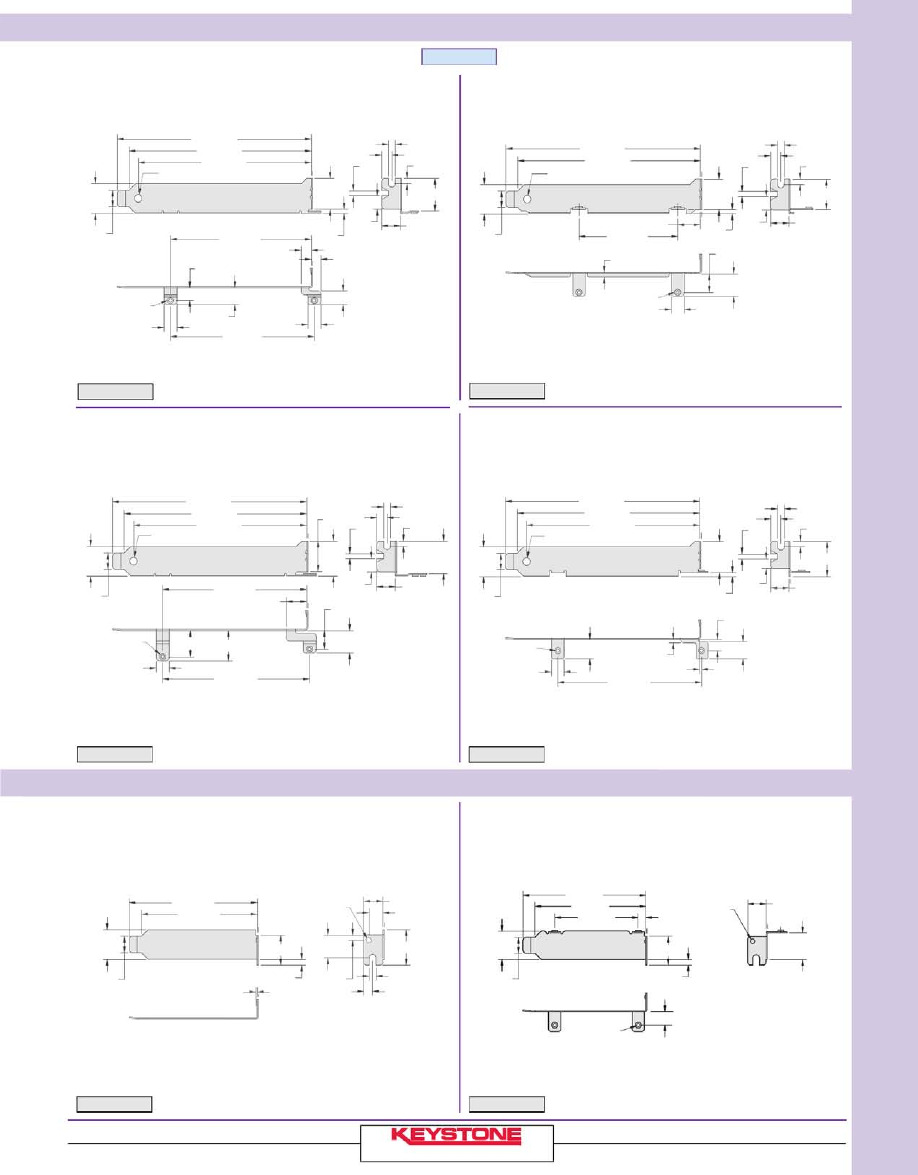

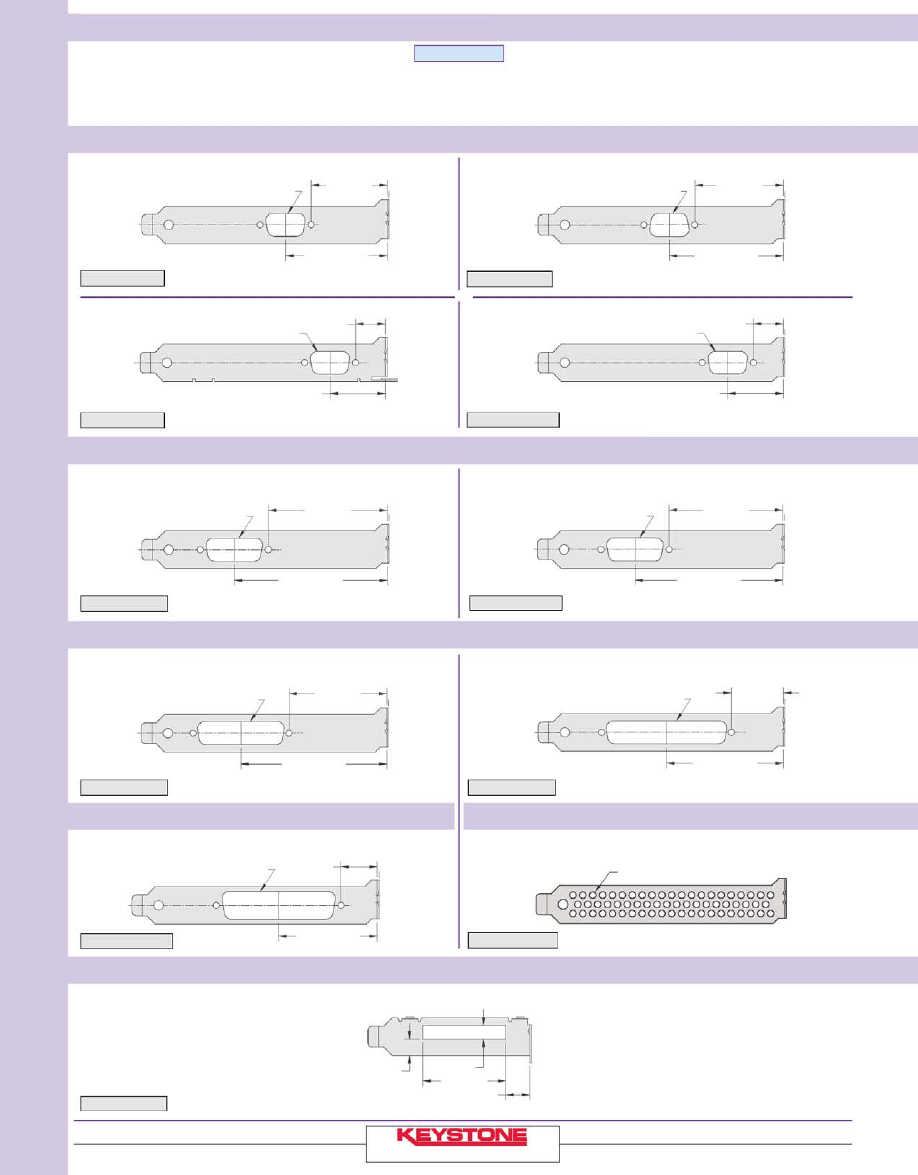

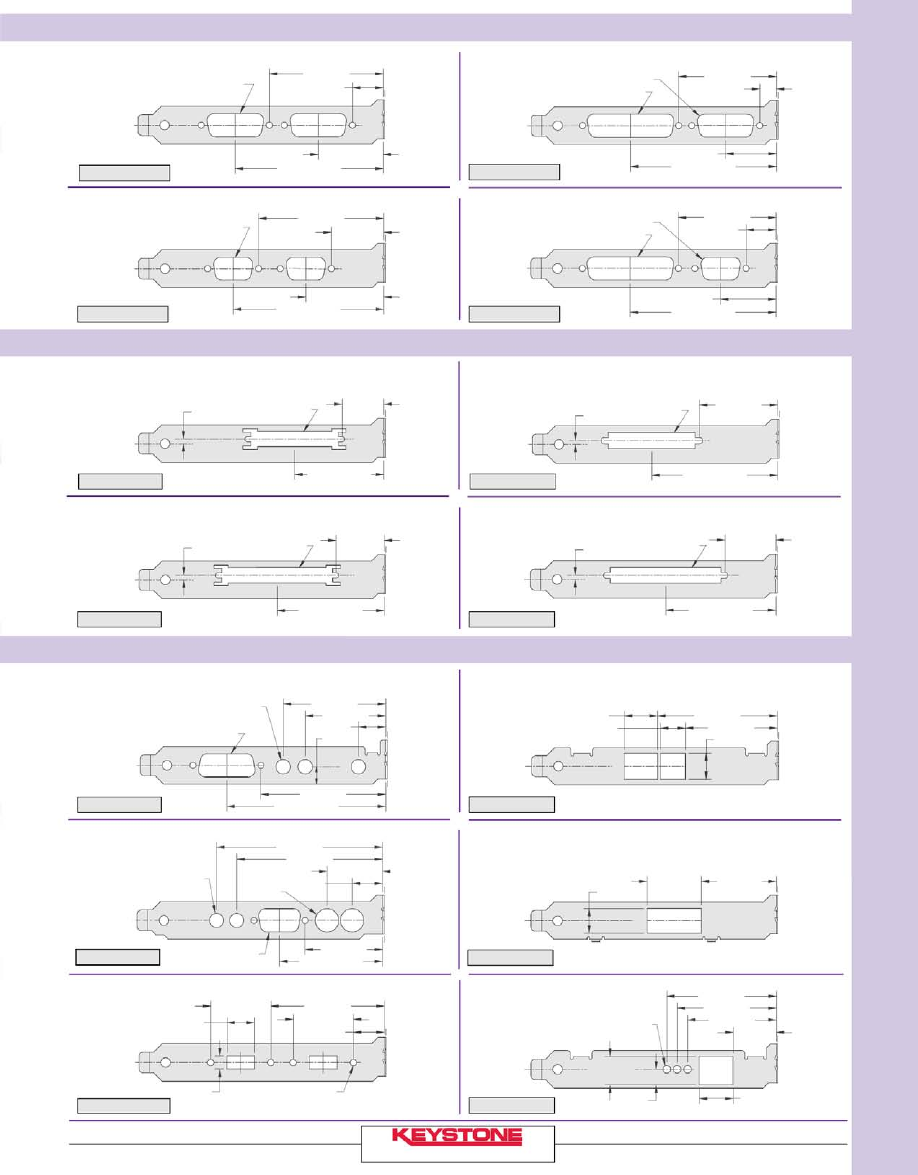

BRACKETS (Computer) . . . . . . . . 122-125

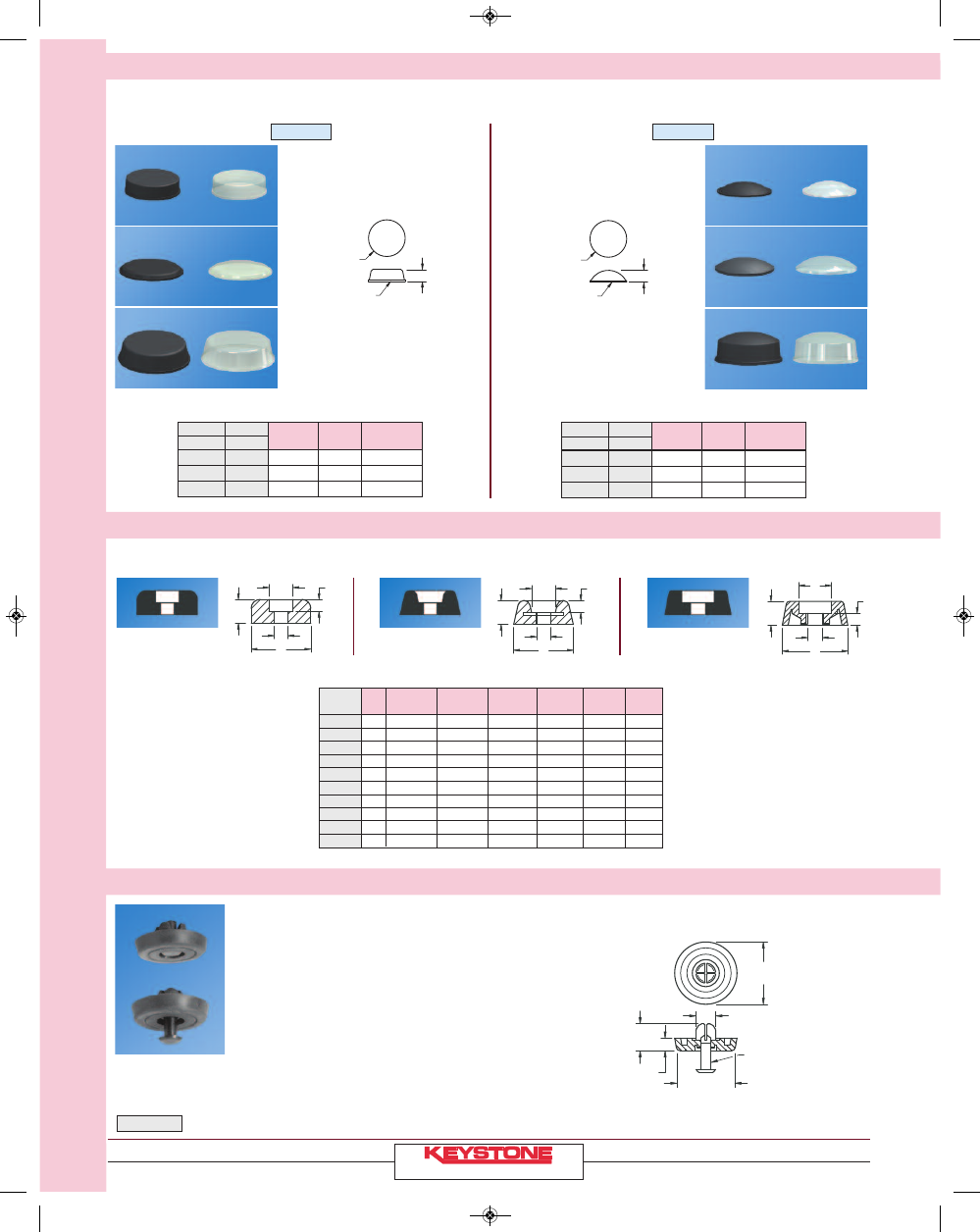

BUMBERS, Adhesive Backed . . . . . . . . 134

BUMPERS, Rubber . . . . . . . . . . . . . . . 134

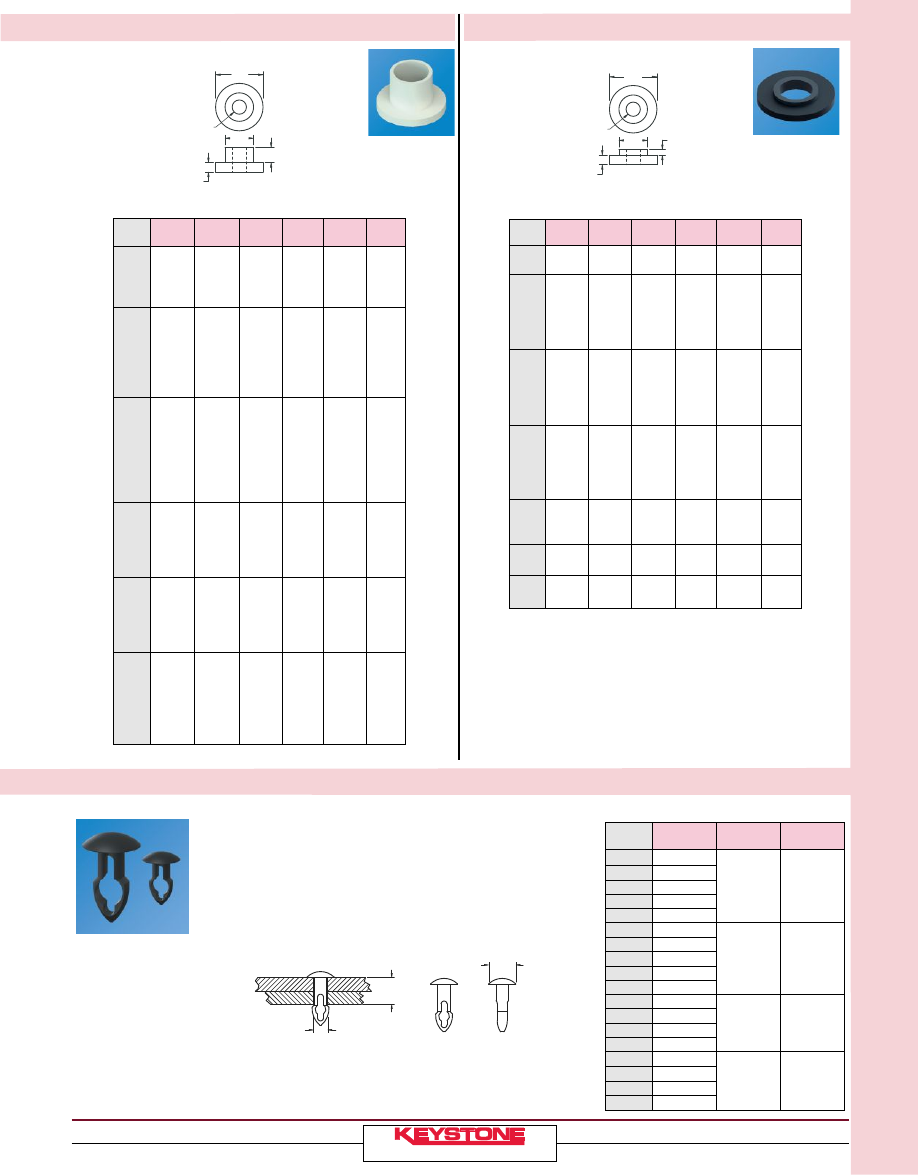

BUSHINGS (Nylon / Rubber). . . . 132-133

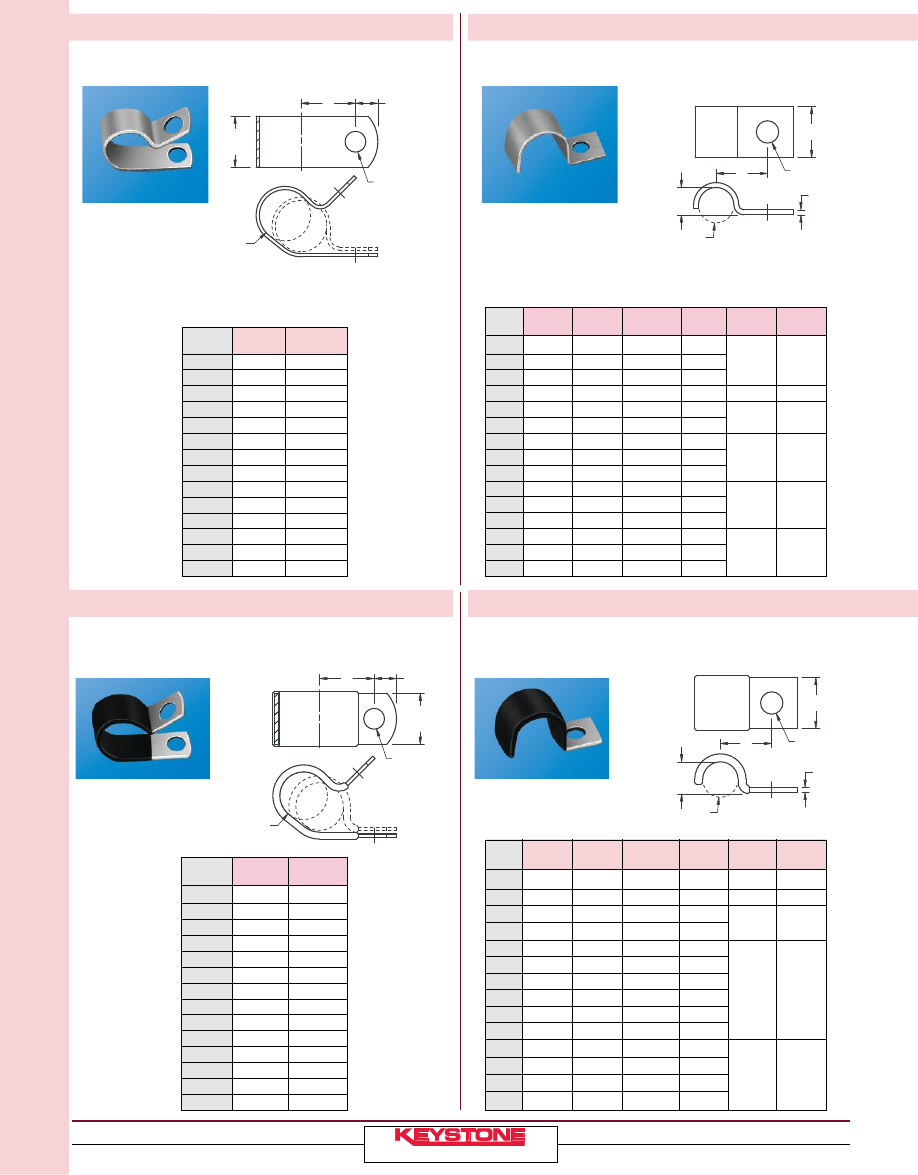

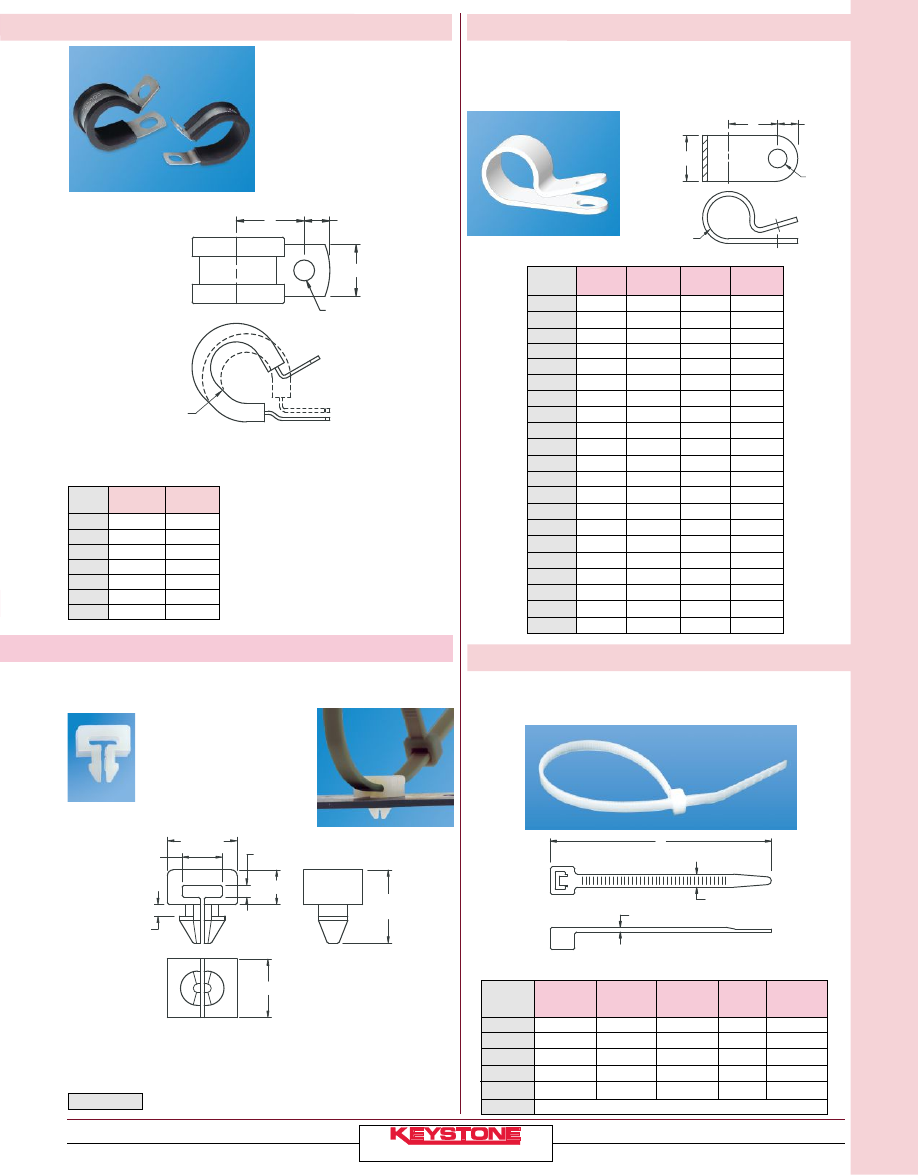

CABLE CLAMPS. . . . . . . . . . . . . . 130-131

CABLE TIES . . . . . . . . . . . . . . . . . . . . 131

CABLE TIE ROUTING CLIP . . . . . . . . . . 131

CARD EJECTORS, PC . . . . . . . . . . . . . . 120

CLIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alligator . . . . . . . . . . . . . . . . . . . . . . . . 56

Battery . . . . . . . . . . . . . . . . . . . . 10-13

Fuse - Auto . . . . . . . . . . . . . . . . . 40-43

Fuse - Cylindrical. . . . . . . . . . . . . 46-47

Key Hole. . . . . . . . . . . . . . . . . . . . . 137

COIN/BUTTON CELL BATTERY . . . . . . . . . .

Contacts (SMT & THM). . . . . . . . . . . 8-9

Holders . . . . . . . . . . . . . . . . . . . . . . 2-6

COMPUTER . . . . . . . . . . . . . . . . . . . . . . . .

Board Guides . . . . . . . . . . . . . 120-121

Card Ejectors . . . . . . . . . . . . . . . . . 120

Jack Screws . . . . . . . . . . . . . . . . . . . 86

Keystone (RJ45) Jacks . . . . . . . . . . 101

Mounting Brackets . . . . . . . . . 118-119

PC/104 Standoffs . . . . . . . . . . . . . . 74

USB Connectors . . . . . . . . . . . . 98-100

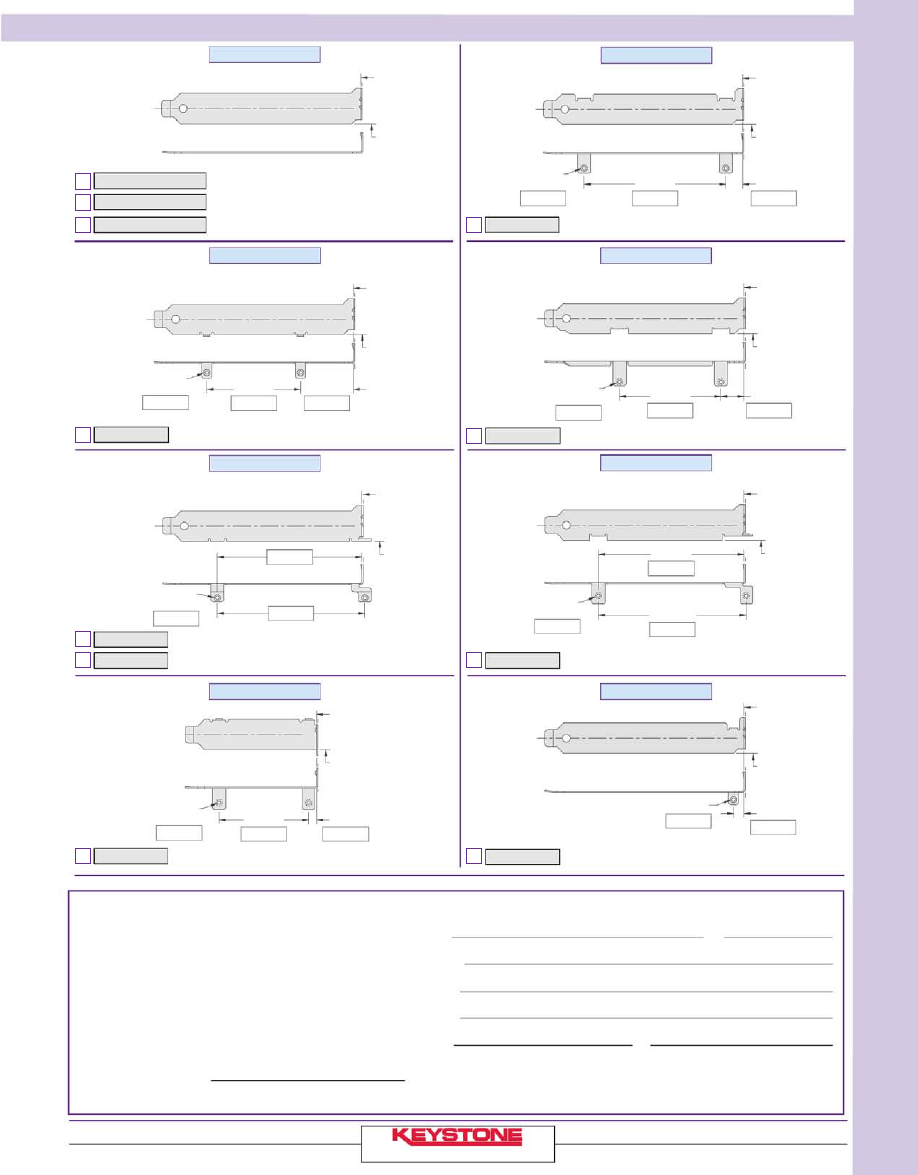

COMPUTER BRACKETS . . . . . . . . . . . . . . .

Blank . . . . . . . . . . . . . . . . . . . 122-123

Standard Computer Brackets . . 124-125

Worksheet (Custom Design) . . . . 126-127

CONNECTORS . . . . . . . . . . . . . . . . . . . . . .

Audio . . . . . . . . . . . . . . . . . . . . . . . 112

Banana Plugs & Jacks. . . . . . . 110-111

“F” 106. . . . . . . . . . . . . . . . . . . . . . . . .

Keystone (RJ45) Jacks . . . . . . . . . . . 101

Micro Jacks & Pins . . . . . . . . . 102-105

Phono Jacks & Plugs. . . . . . . . 106-107

Screw Terminals. . . . . . . . . . . . . . 66-71

USB . . . . . . . . . . . . . . . . . . . . . 98-100

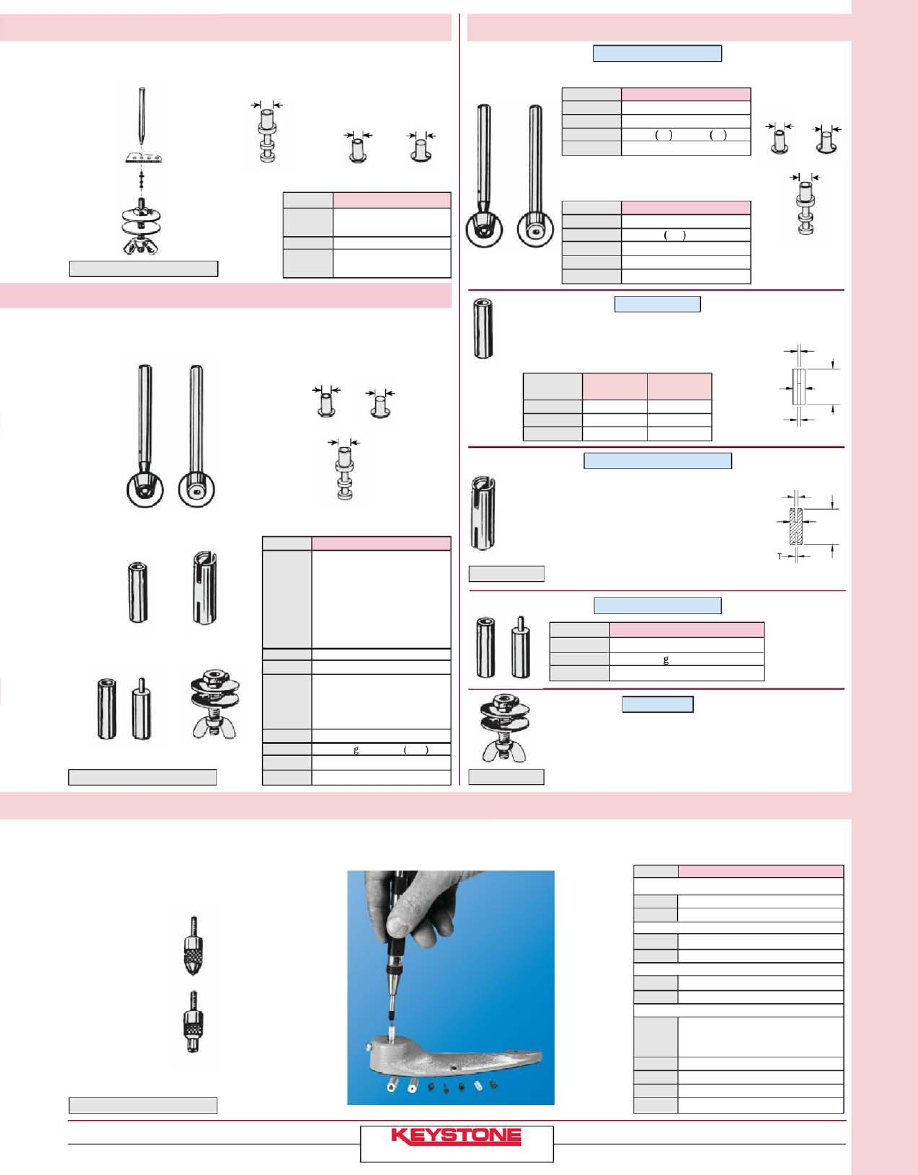

EYELETS . . . . . . . . . . . . . . . . . . . . . . . 138

EYELET STAKING TOOL . . . . . . . . . 138-139

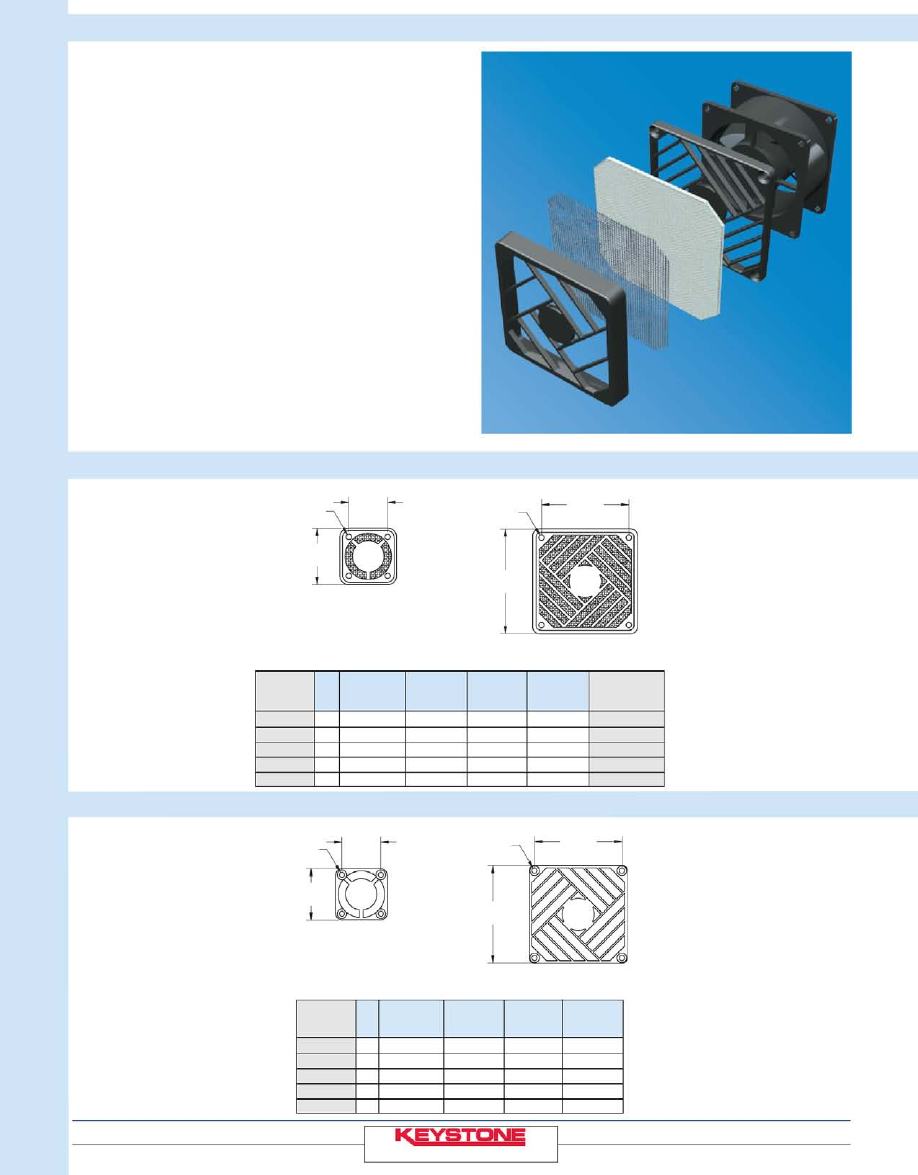

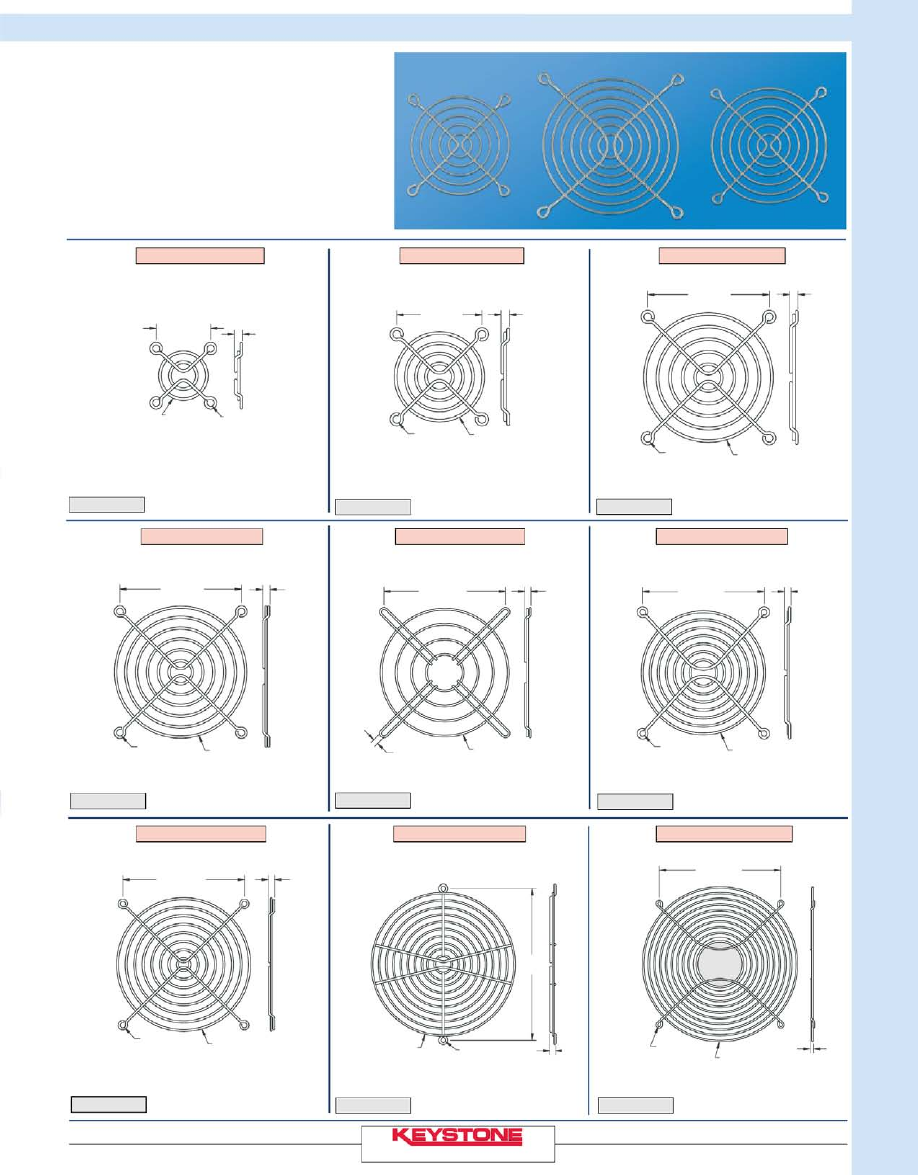

FAN/FINGER GUARDS . . . . . . . . . . . 92-93

FIBER WASHERS

(Flat & Shoulder) . . . . . . . . . . 136-137

FUSE BLOCKS . . . . . . . . . . . . . . . . . . . 45

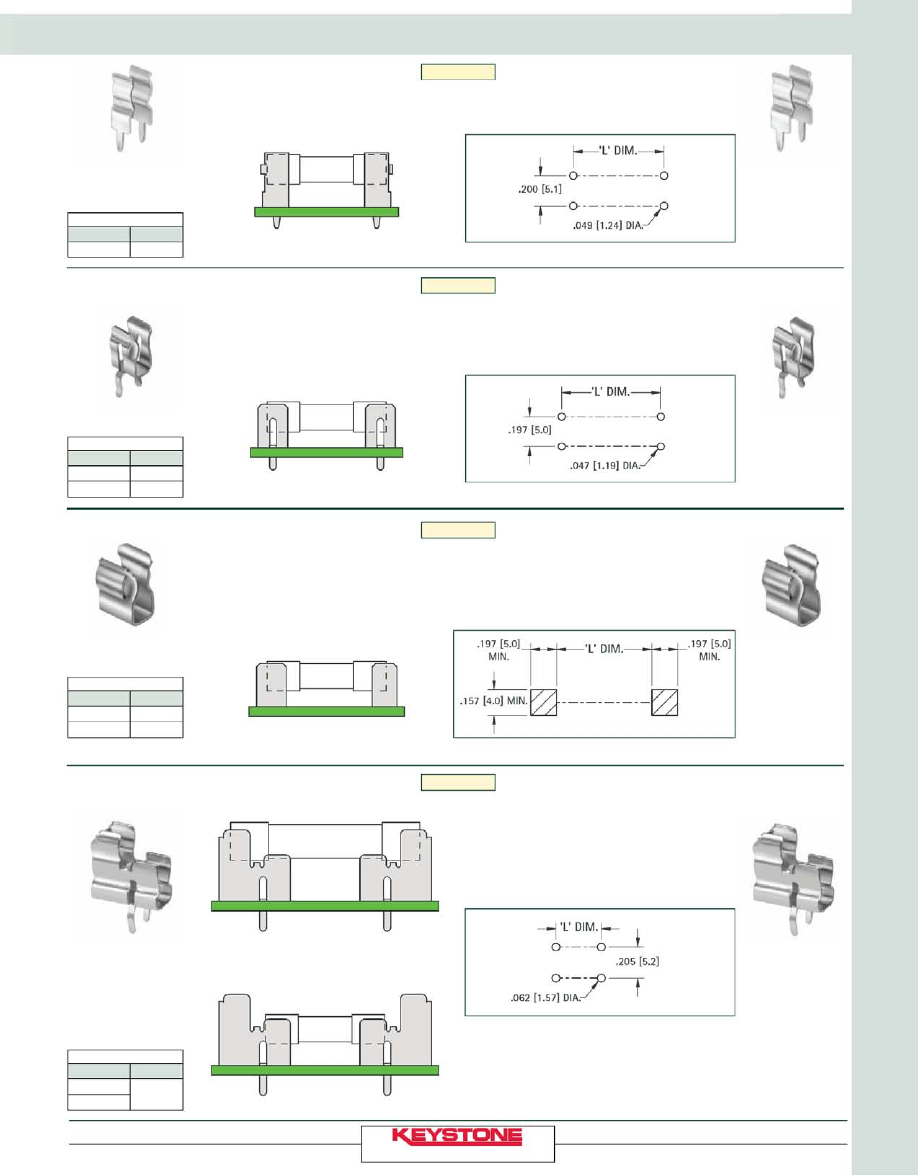

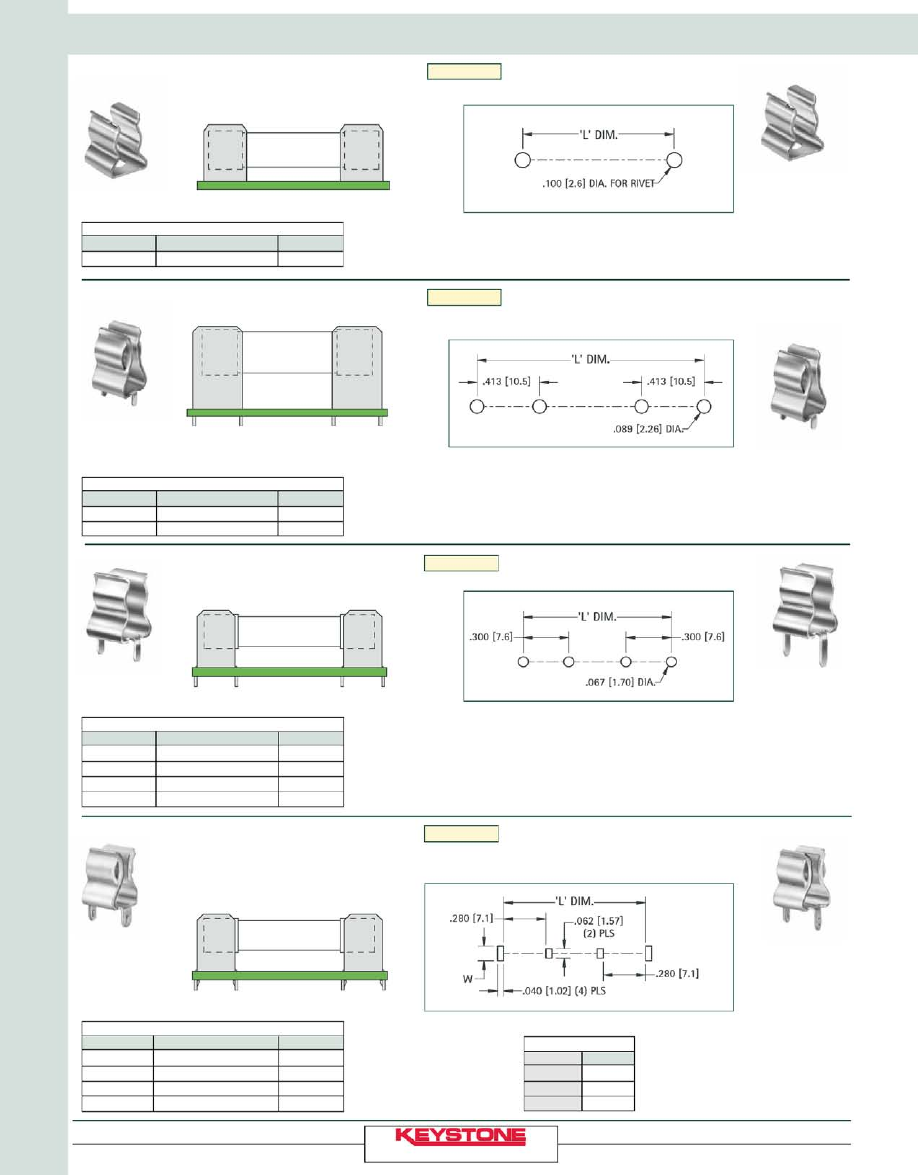

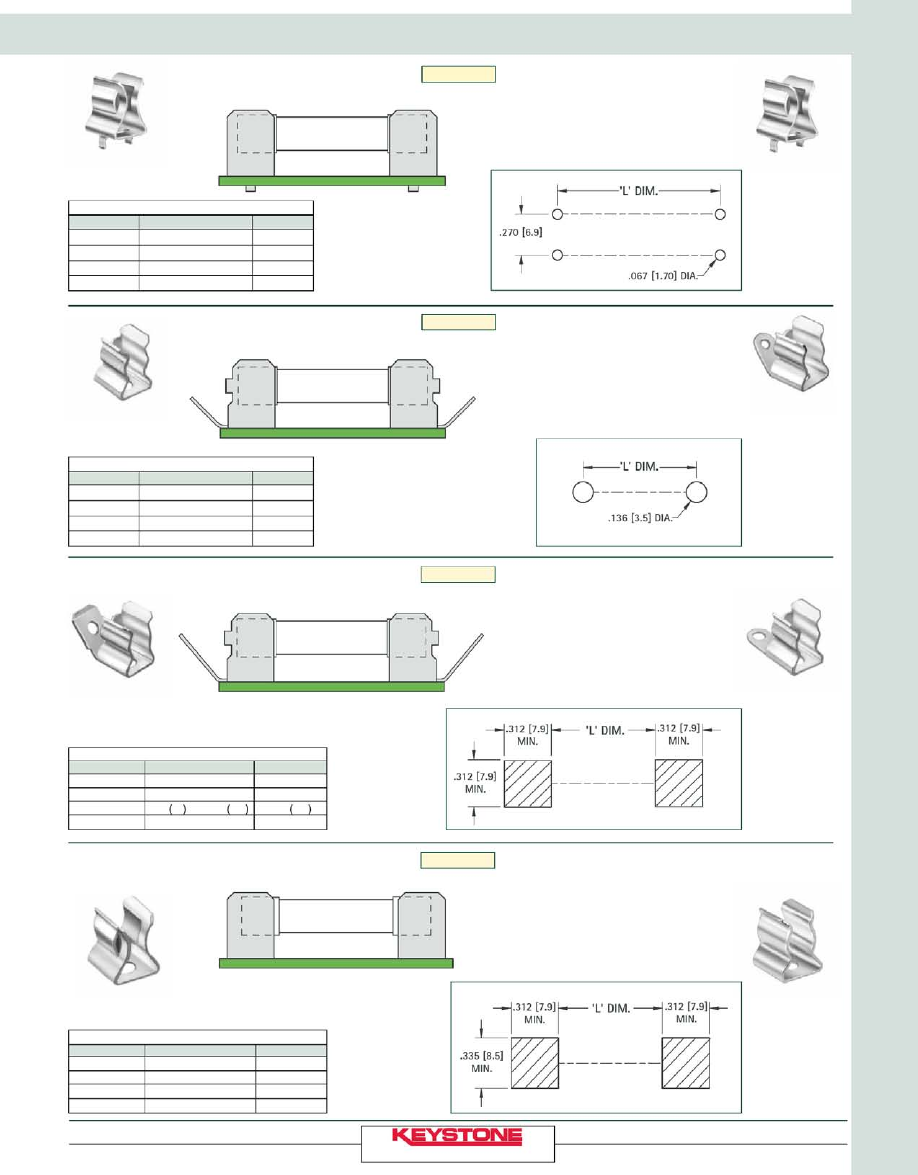

FUSE CLIPS & HOLDERS. . . . . . . . . . . . . .

Automotive Blade clips & Holders 40-43

Cylindrical Clips. . . . . . . . . . . . . . 46-47

Cylindrical Holders (3AG & 5mm) 44-45

Midget (SPF) Clips & Holders . . . . . . 45

Sub-Miniature. . . . . . . . . . . . . . . . . . 45

FUSE CONTACTS LAYOUT

& MOUNTING DETAILS . . . . . . . . . . 48-51

GROMMETS . . . . . . . . . . . . . . . . . . . . . . .

Anti-Vibration . . . . . . . . . . . . . . . . . 129

Rubber . . . . . . . . . . . . . . . . . . 128-129

Universal . . . . . . . . . . . . . . . . . . . . 129

HALOGEN LAMP SOCKET . . . . . . . . . . 114

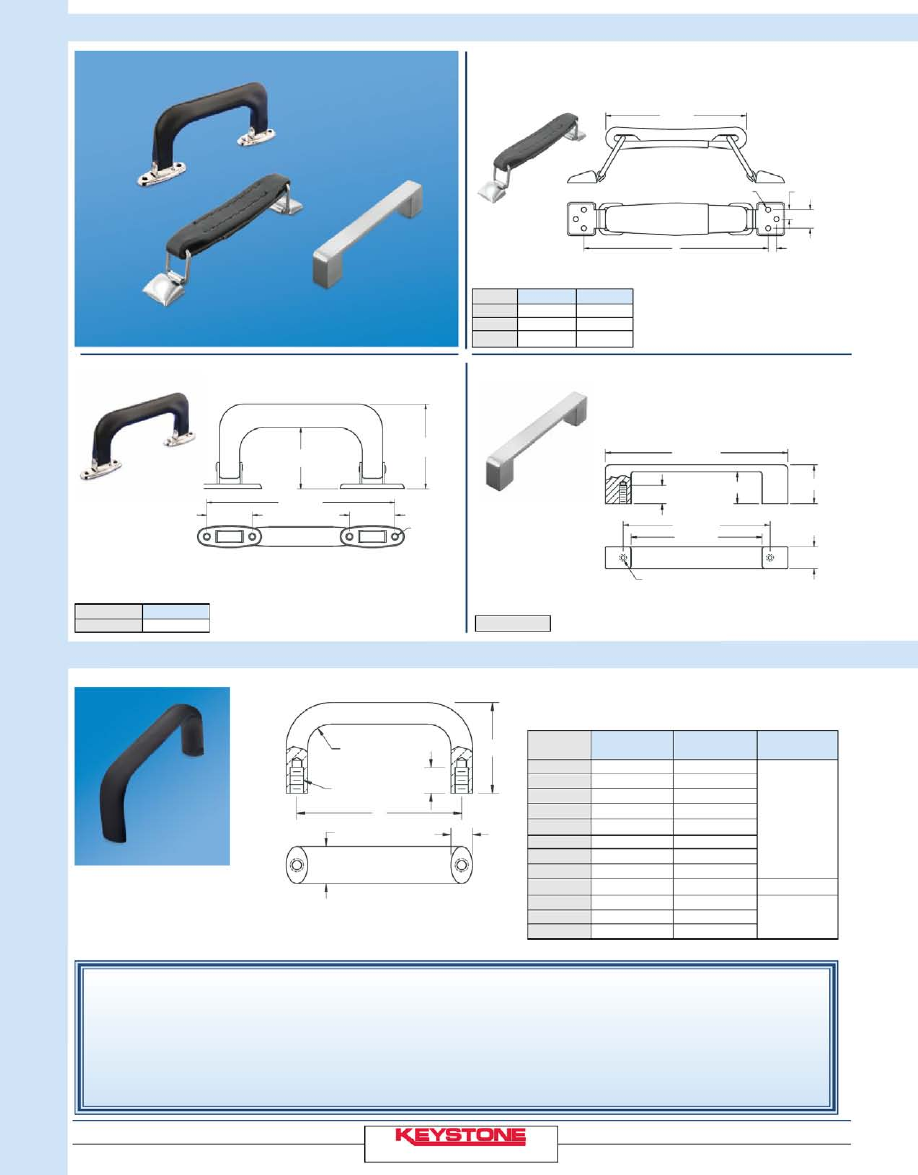

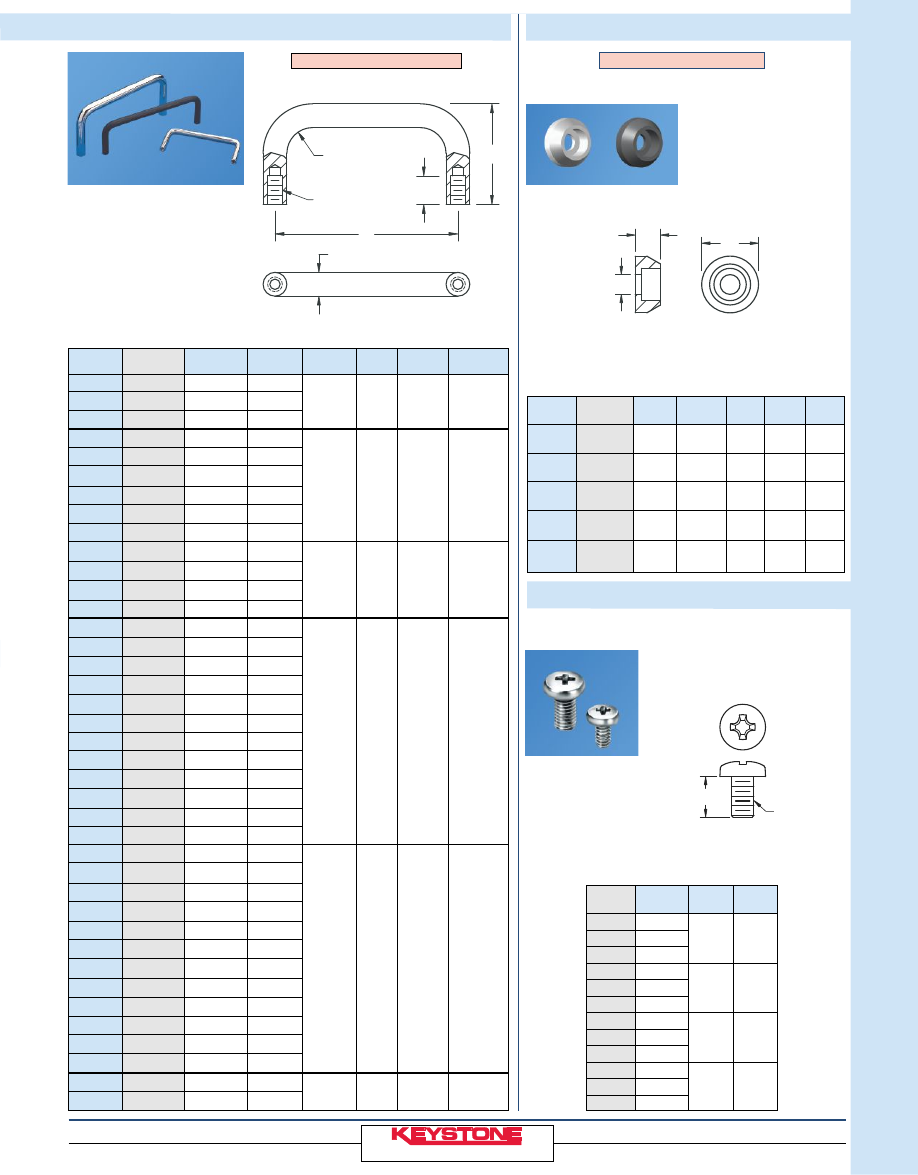

HANDLES, INSTRUMENT . . . . . . . . . 90-91

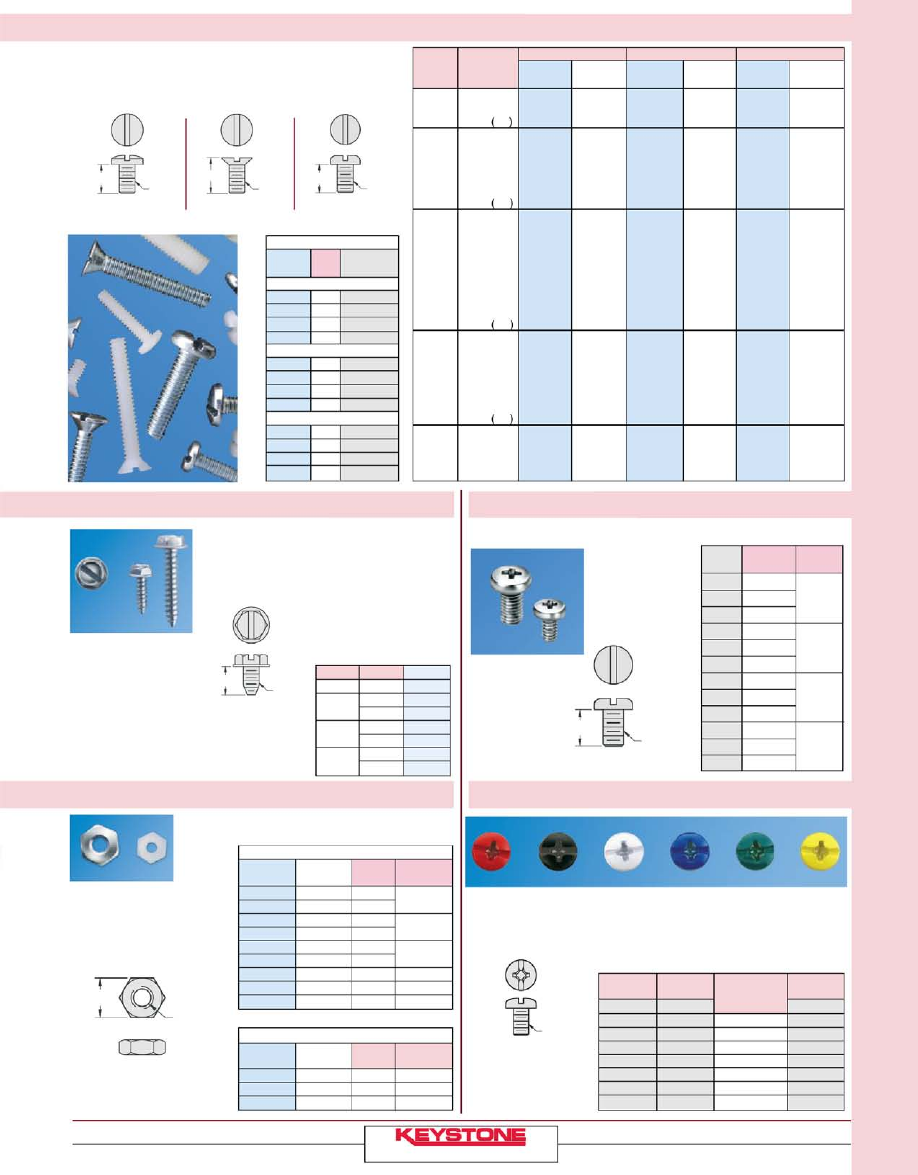

HARDWARE . . . . . . . . . . . . . . . . . . . . . . .

Bumpers . . . . . . . . . . . . . . . . . . . . 134

Captive Nuts. . . . . . . . . . . . . . . . . . 133

Captive Screws . . . . . . . . . . . . . . . . . 87

Cable Ties . . . . . . . . . . . . . . . . . . . 127

Eyelets / Rivets. . . . . . . . . . . . . . . . 138

Jack Screws . . . . . . . . . . . . . . . . . . . 86

Machine Screws & Nuts . . . . . . . . . 135

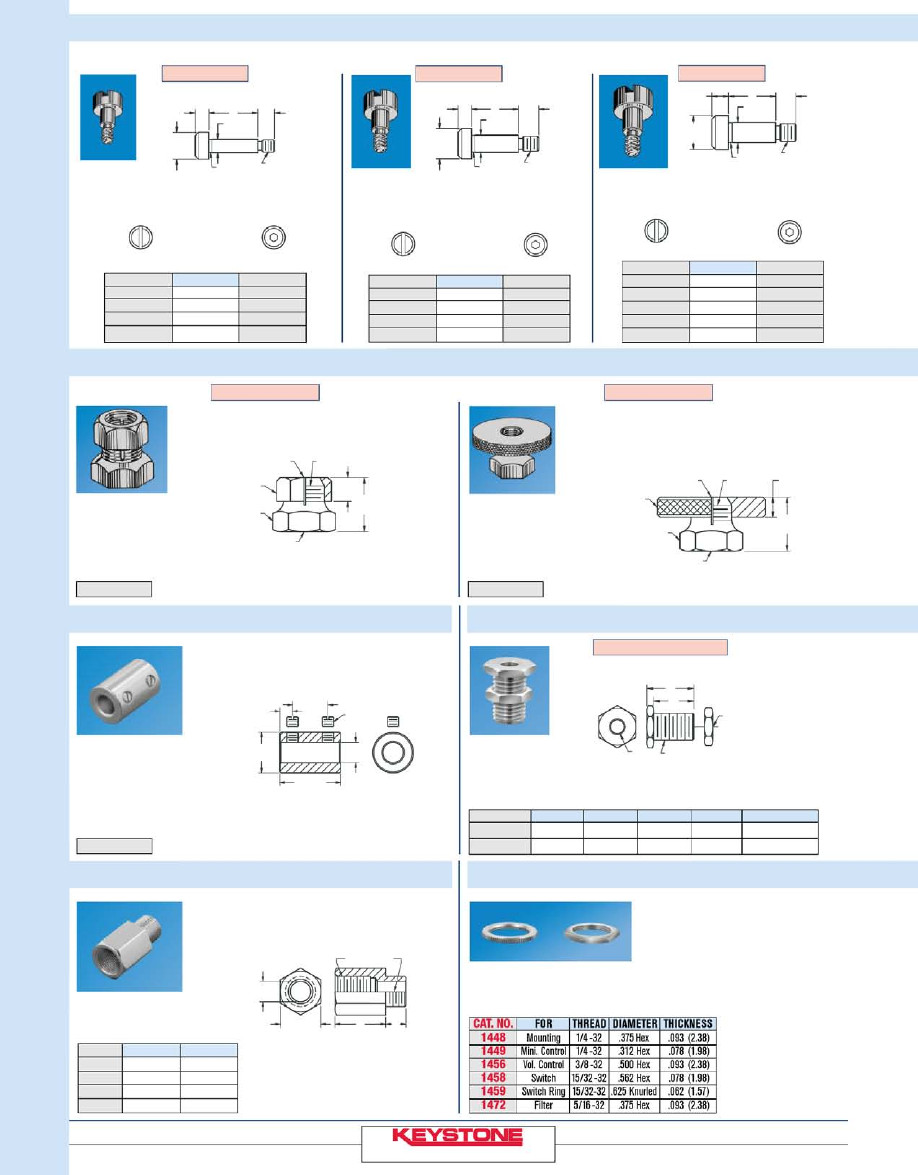

Panel Hardware & Nuts . . . . . . . . . . . 88

Shoulder Screws . . . . . . . . . . . . . . . . 88

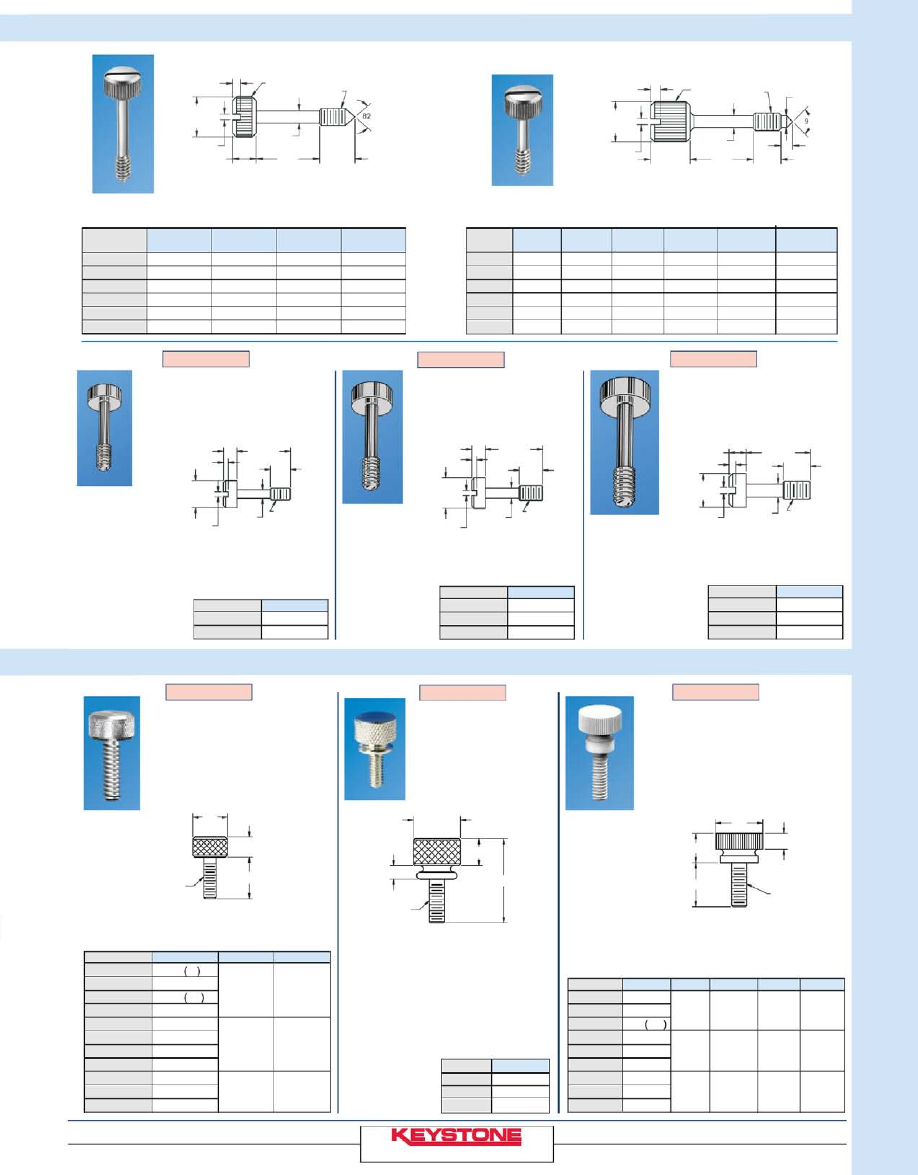

Thumb Screws . . . . . . . . . . . . . . . . . 87

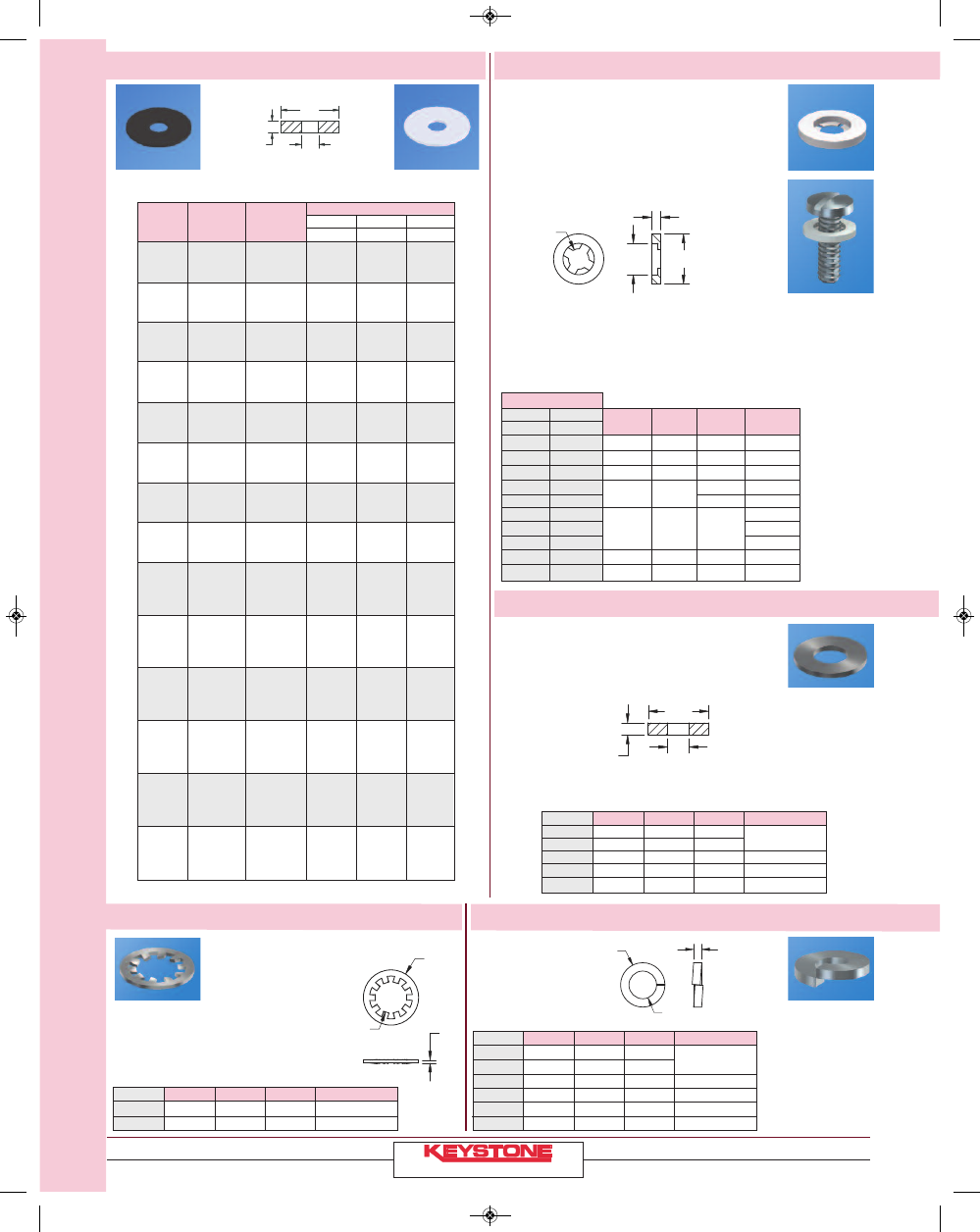

Washers . . . . . . . . . . . . . . . . . 136-137

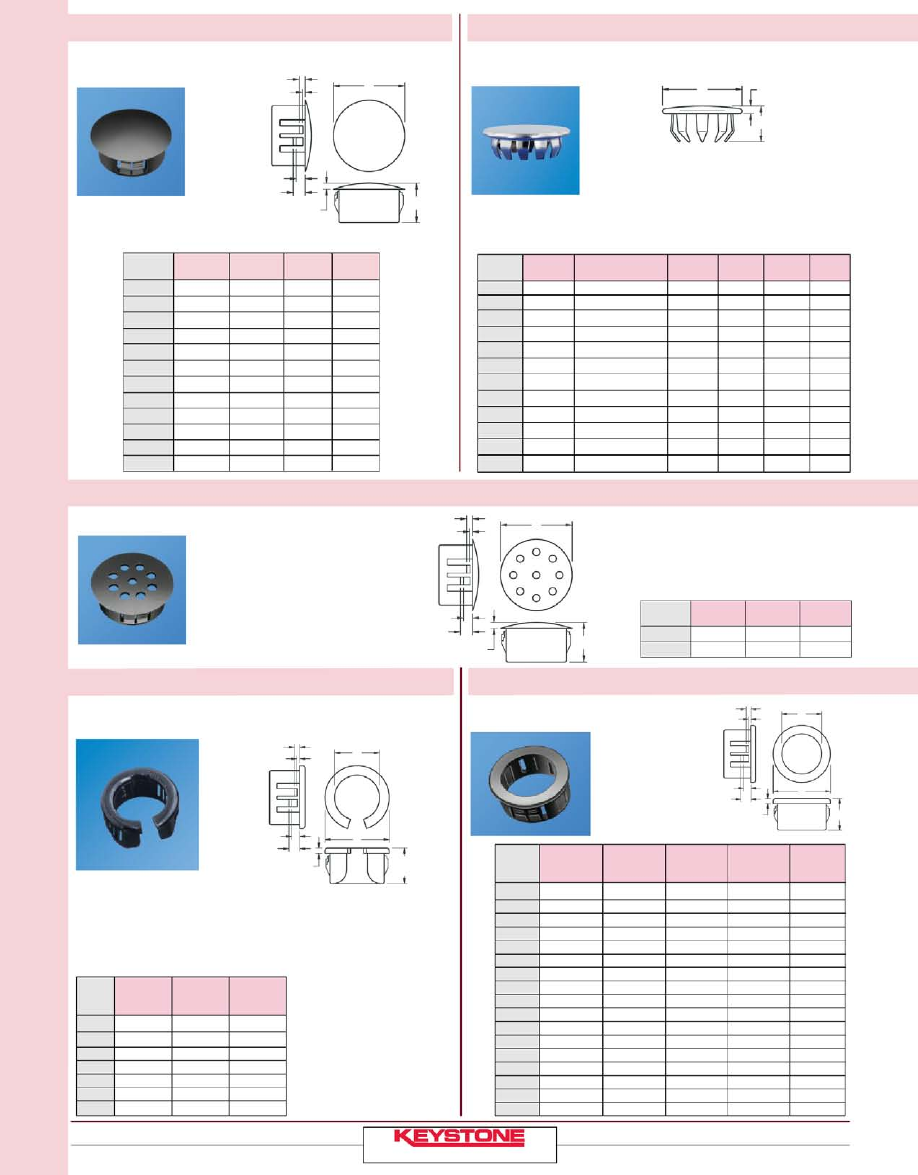

HOLE PLUGS . . . . . . . . . . . . . . . . . . . 132

ISOLATED GROMMETS . . . . . . . . . . . . 133

INSTRUMENTATION CASES . . . . . . . . . . 89

INSULATED COIN CELL RETAINERS . . . . . 8

INSULATED CABLE CLAMPS. . . . . 130-131

INSULATED TERMINALS . . . . . . . . 140-141

INSULATING HARDWARE . . . . . . . . . . . . . .

Bushings. . . . . . . . . . . . . . . . . 132-133

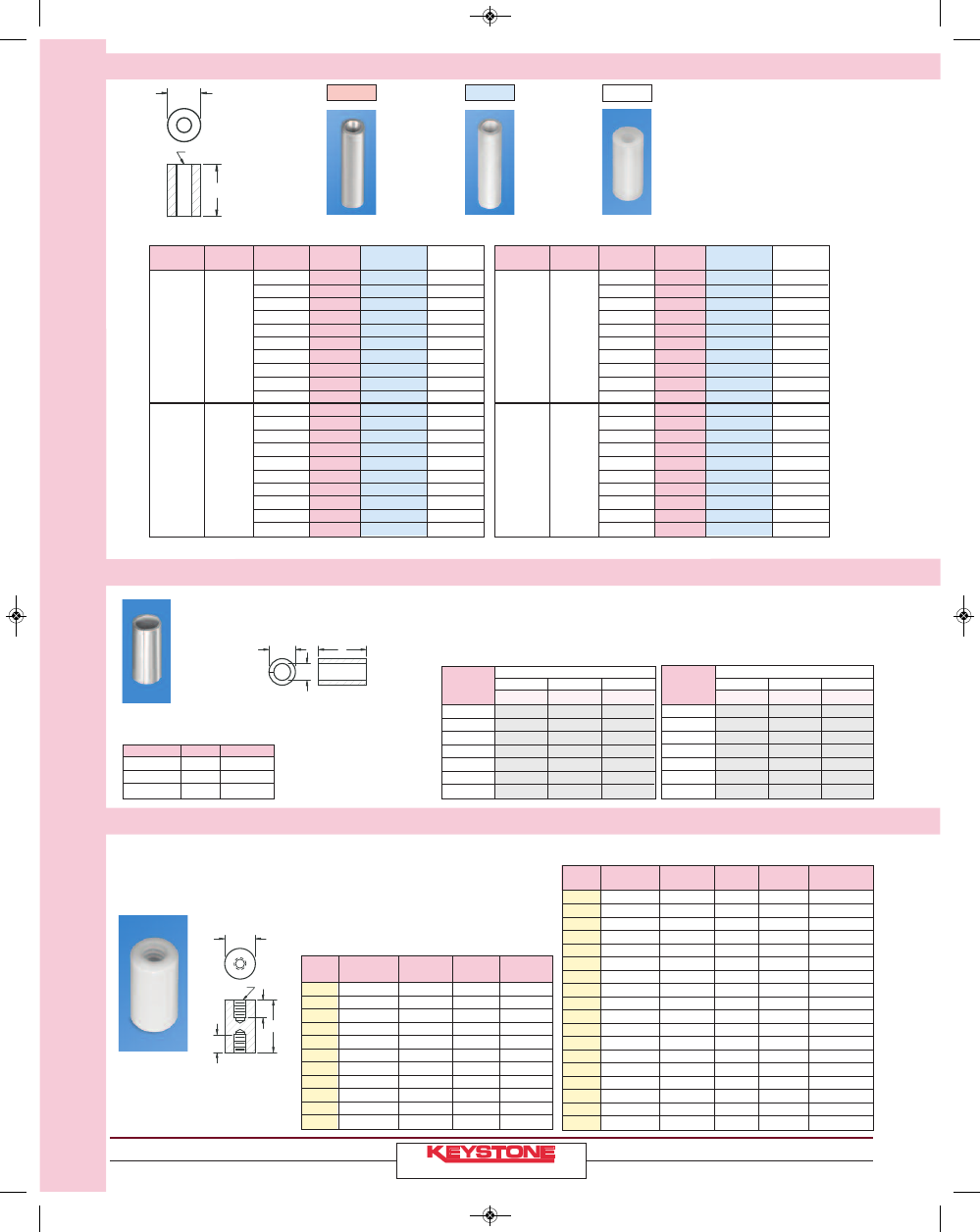

Ceramic Standoffs . . . . . . . . . . . . . . 78

Fiber Washers . . . . . . . . . . . . . 136-137

Mica Insulators . . . . . . . . . . . . . . . . 113

Nylon Spacers . . . . . . . . . . . . . . 78-79

Nylon Washers . . . . . . . . . . . . 136-137

Spacer Supports (Nylon) . . . . . . . 80-82

INSTALLATION TOOLS . . . . . . . . . . . . . . . .

Eyelet . . . . . . . . . . . . . . . . . . . . . . . 138

Rivet. . . . . . . . . . . . . . . . . . . . . . . . 139

Solder Terminal . . . . . . . . . . . . 142-143

Staking. . . . . . . . . . . . . . . . . . . . . . 139

JACKS

Audio . . . . . . . . . . . . . . . . . . . . . . . 112

Banana . . . . . . . . . . . . . . . . . . . . . 111

Insulated . . . . . . . . . . . . . . . . . . . . 109

Keystone (RJ45) . . . . . . . . . . . . . . . 101

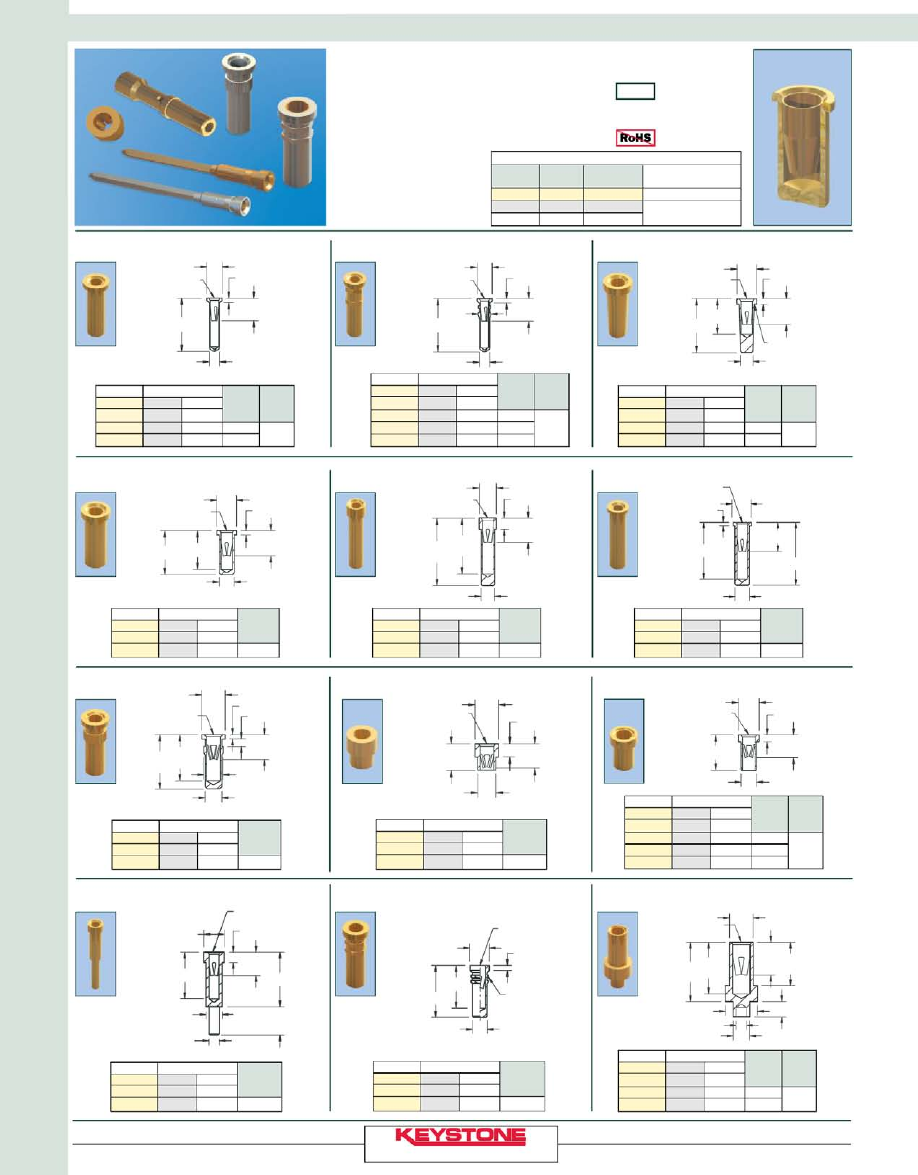

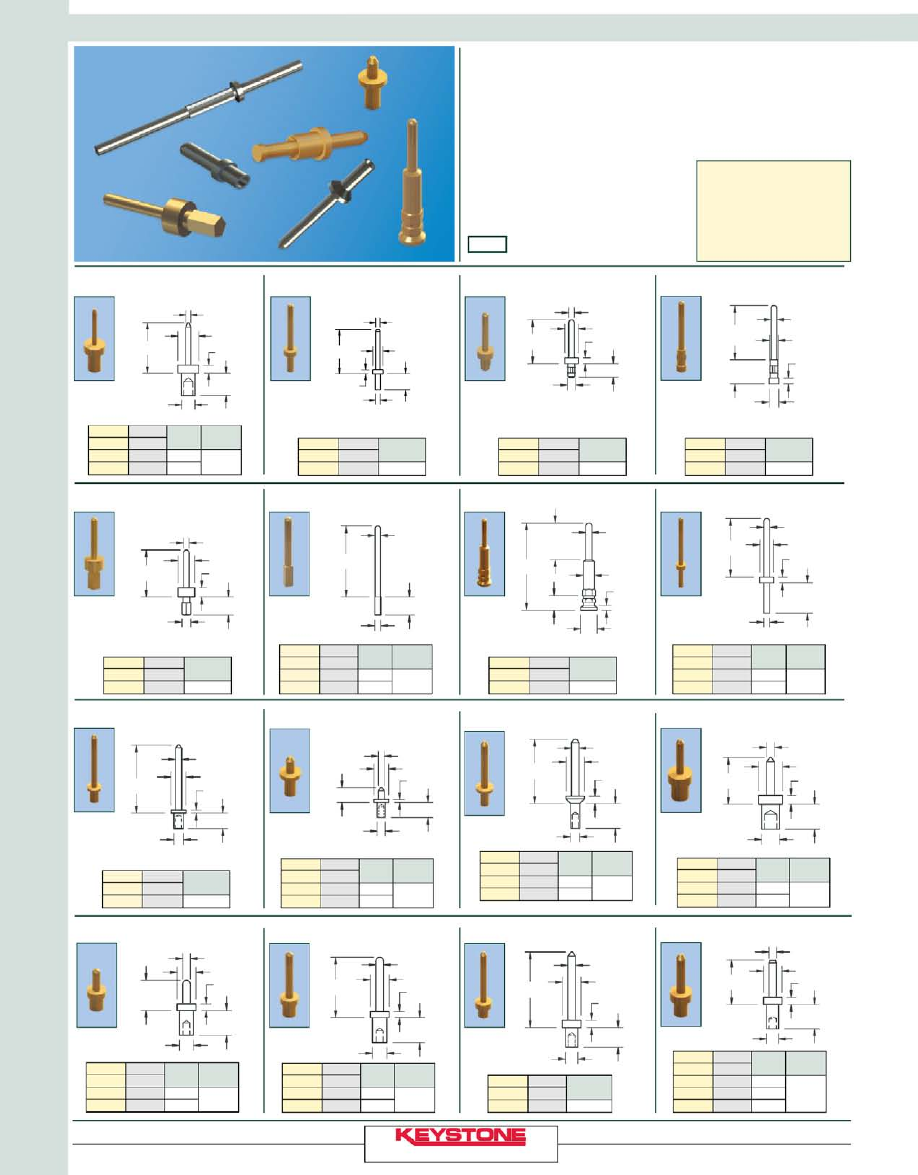

Micro . . . . . . . . . . . . . . . . . . . 102-103

Phono. . . . . . . . . . . . . . . . . . . 106-107

Test. . . . . . . . . . . . . . . . . . . . . 108-109

USB . . . . . . . . . . . . . . . . . . . . . 98-100

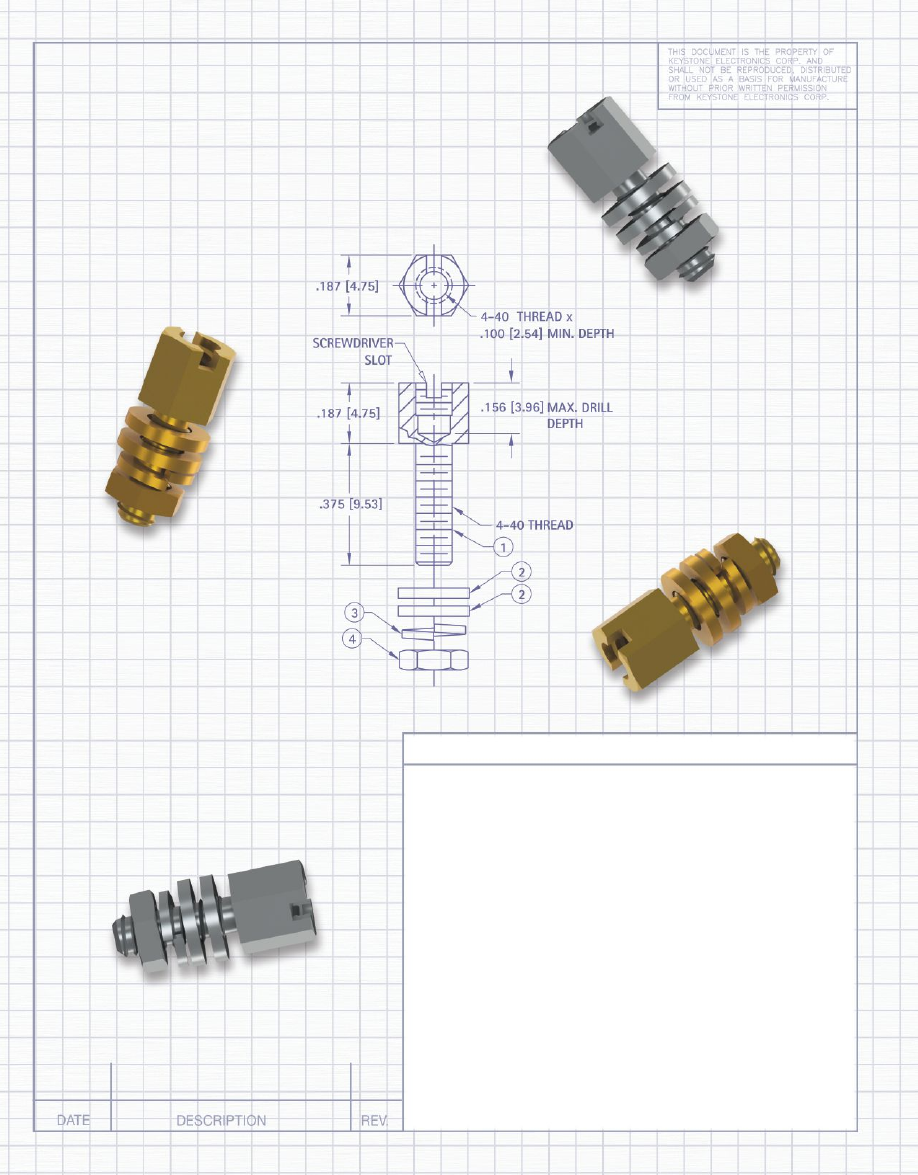

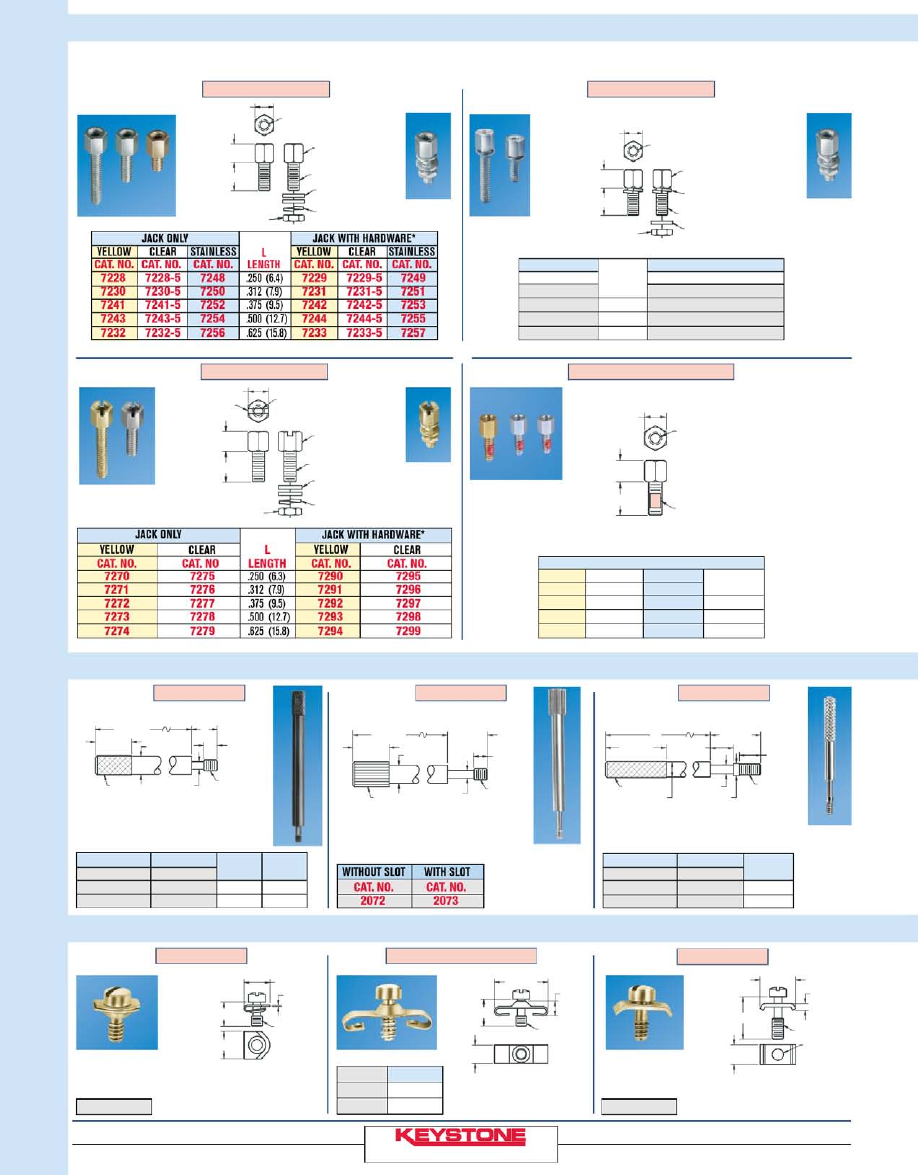

JACK SCREWS

Nylon Patch . . . . . . . . . . . . . . . . . . . 86

Standard - SEMS . . . . . . . . . . . . . . . 86

Turnable . . . . . . . . . . . . . . . . . . . . . . 86

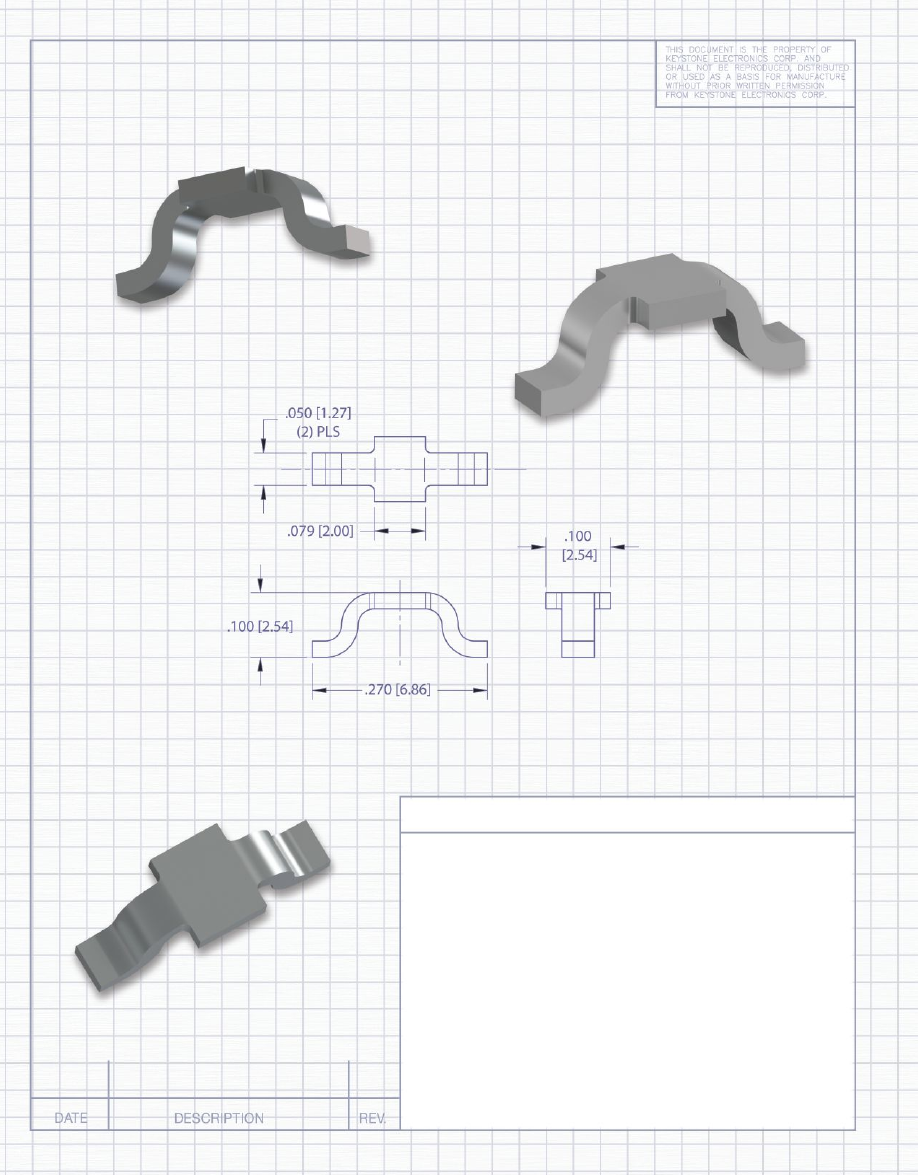

JUMPERS

THM . . . . . . . . . . . . . . . . . . . . . . . . 54

SMT . . . . . . . . . . . . . . . . . . . . . . . . . 54

Zero OHM Chip Resistor Jumper . . . . 54

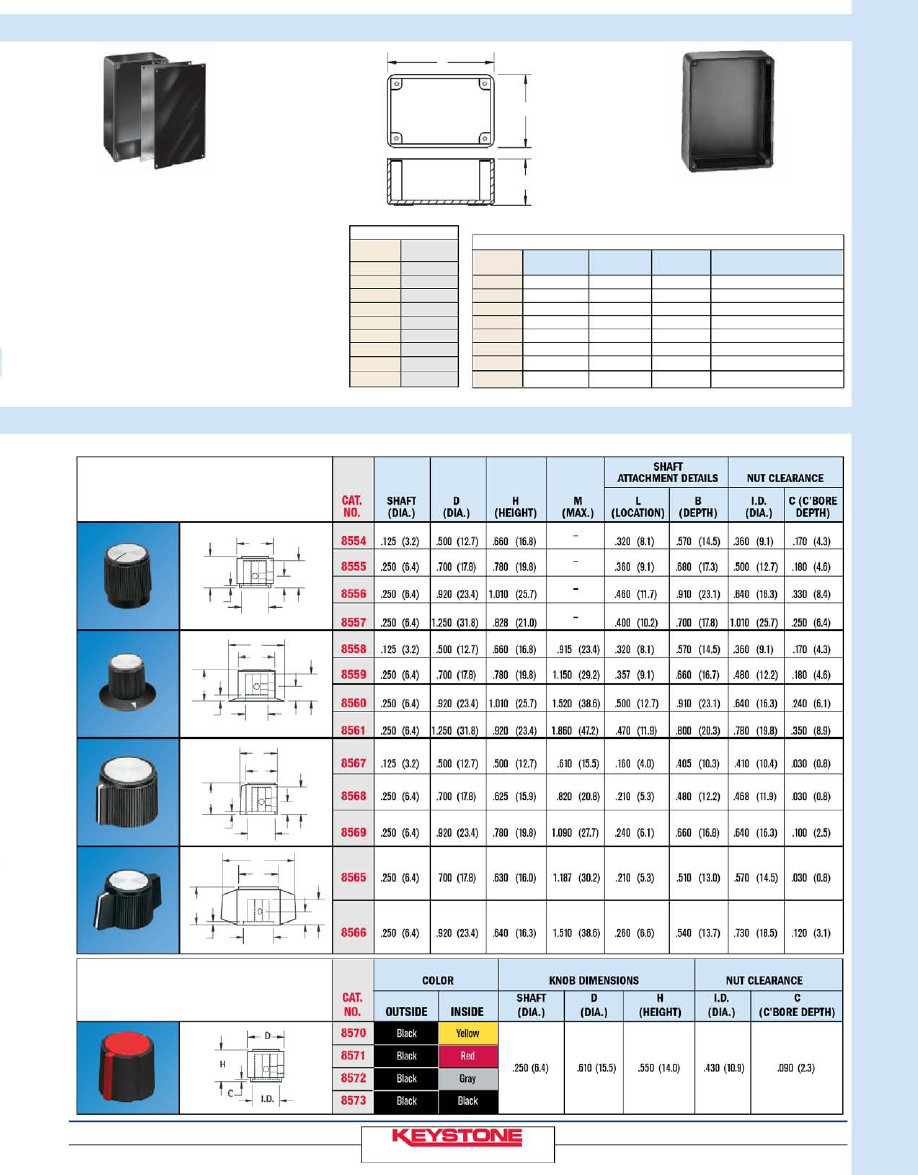

KNOBS. . . . . . . . . . . . . . . . . . . . . . . . . 89

KEY HOLE CLIPS . . . . . . . . . . . . . . . . . 137

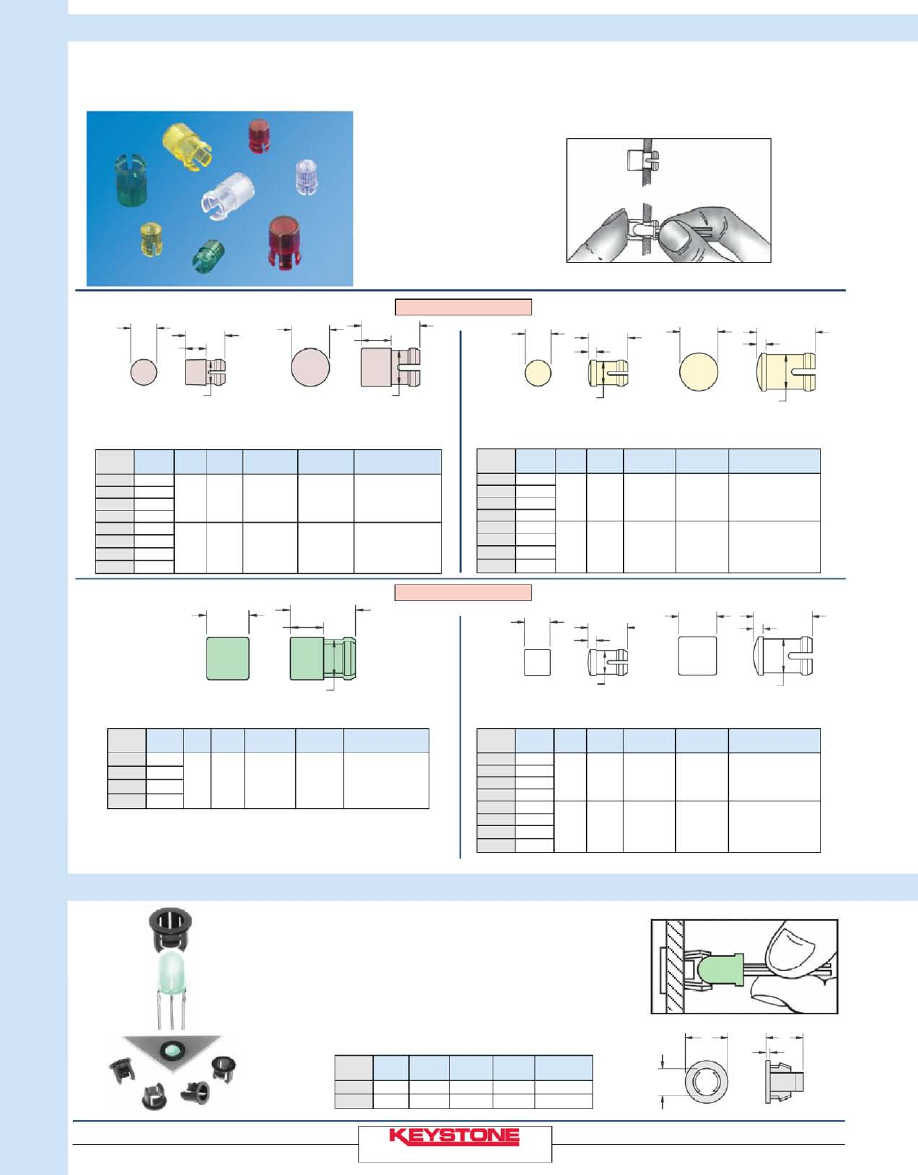

LED HOLDERS . . . . . . . . . . . . . . . . . . . 94

LED LENS CAPS . . . . . . . . . . . . . . . . . . 94

LED SPACER MOUNTS. . . . . . . . . . . . . . 95

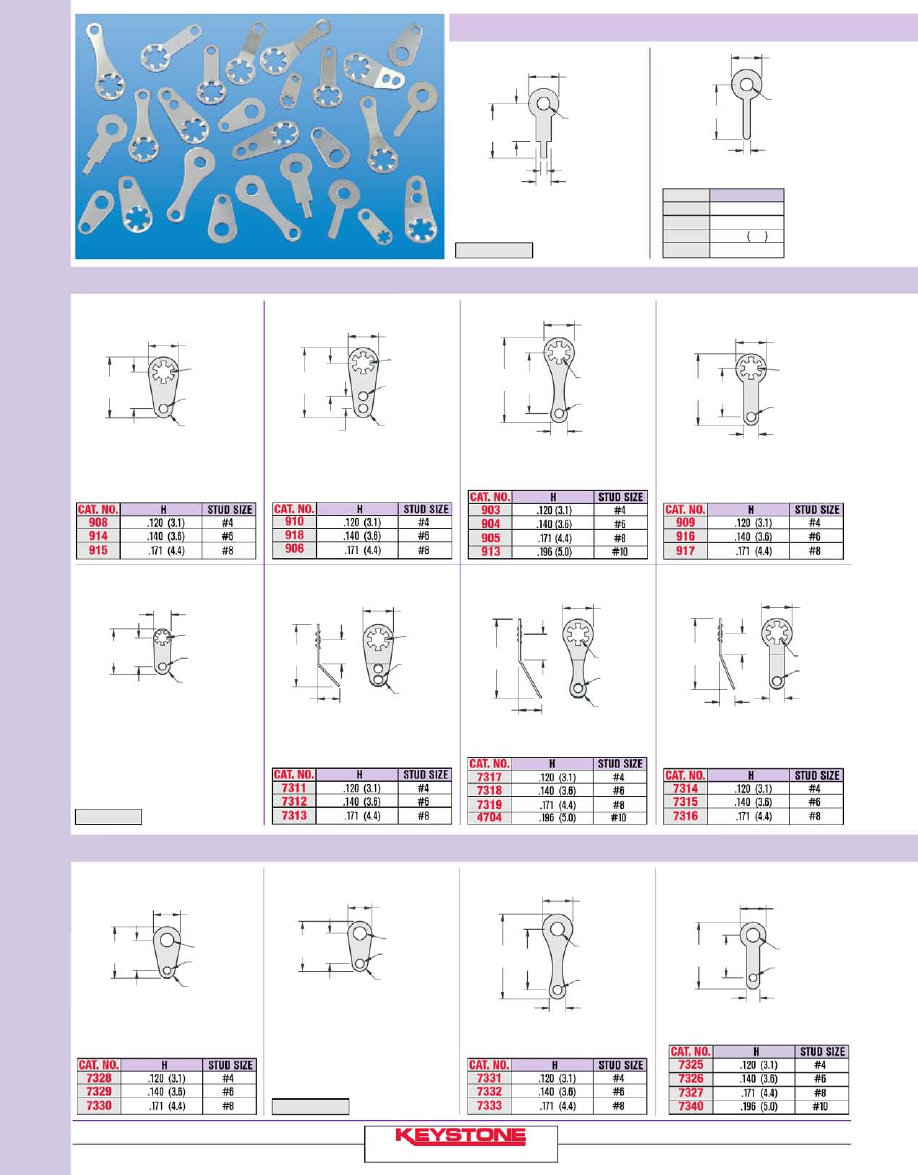

LUGS (SOLDER) . . . . . . . . . . . . . . . . . . 64

MICA TRANSISTOR INSULATORS . . . . . 113

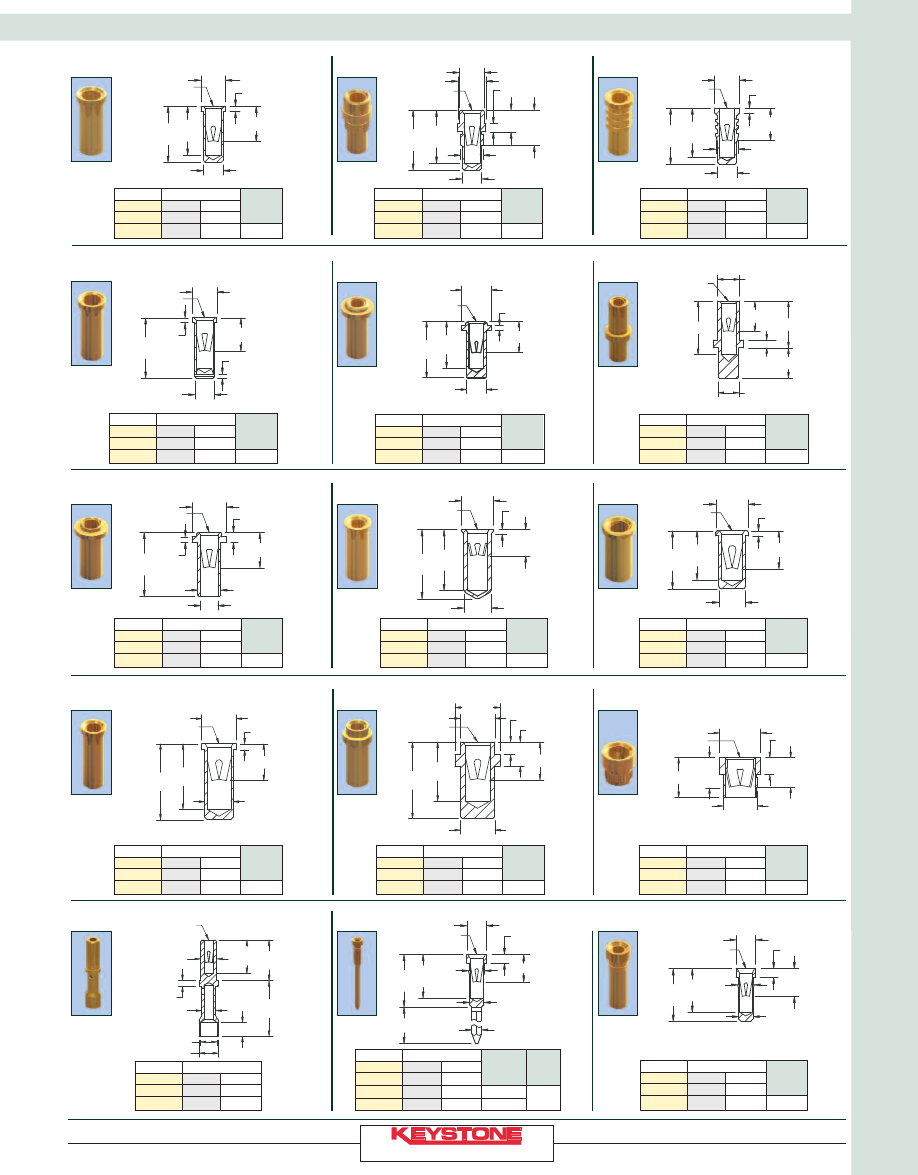

MICRO JACKS . . . . . . . . . . . . . . . 102-103

MICRO PINS . . . . . . . . . . . . . . . . 104-105

MIDGET FUSE HOLDER . . . . . . . . . . . . . 45

MINI / MICRO USB SOCKETS

& PLUGS. . . . . . . . . . . . . . . . . . 99-100

MOUNTING BRACKETS. . . . . . . . . 118-119

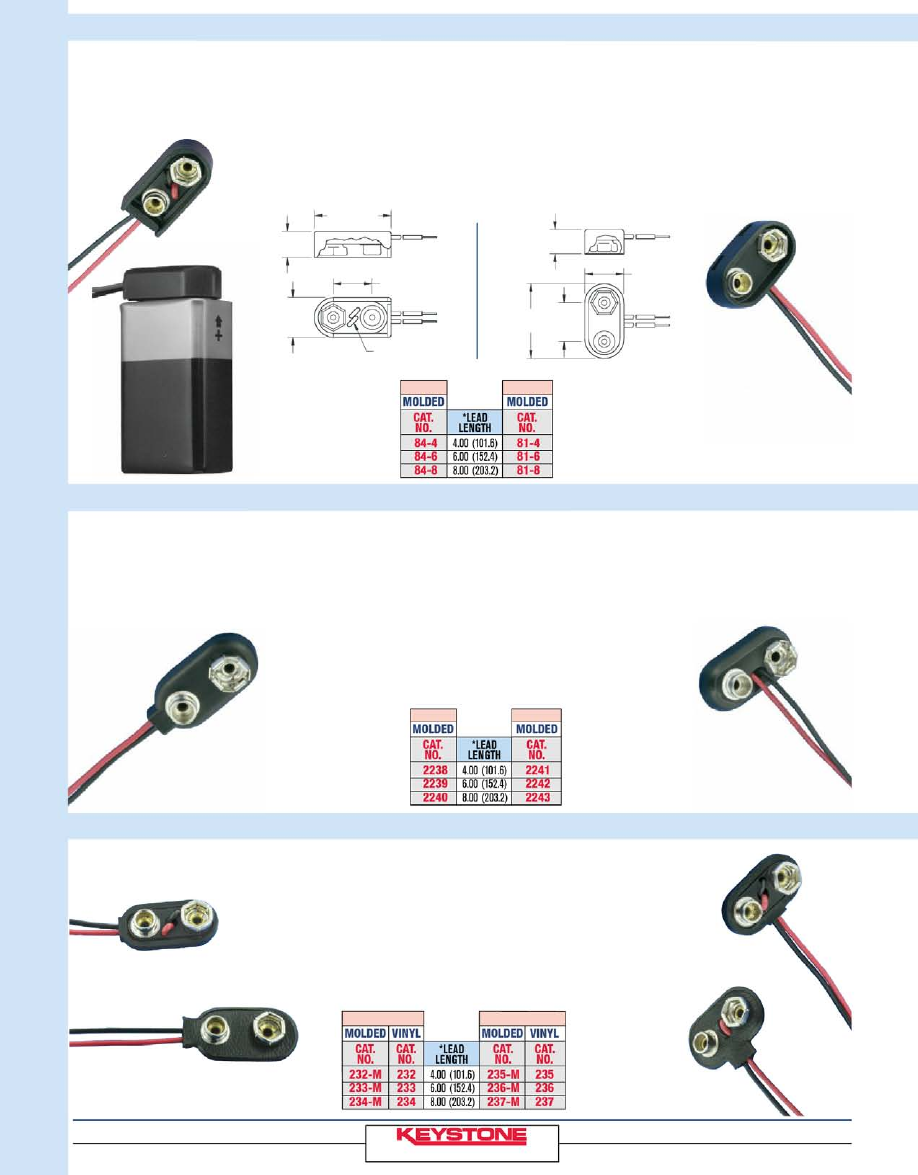

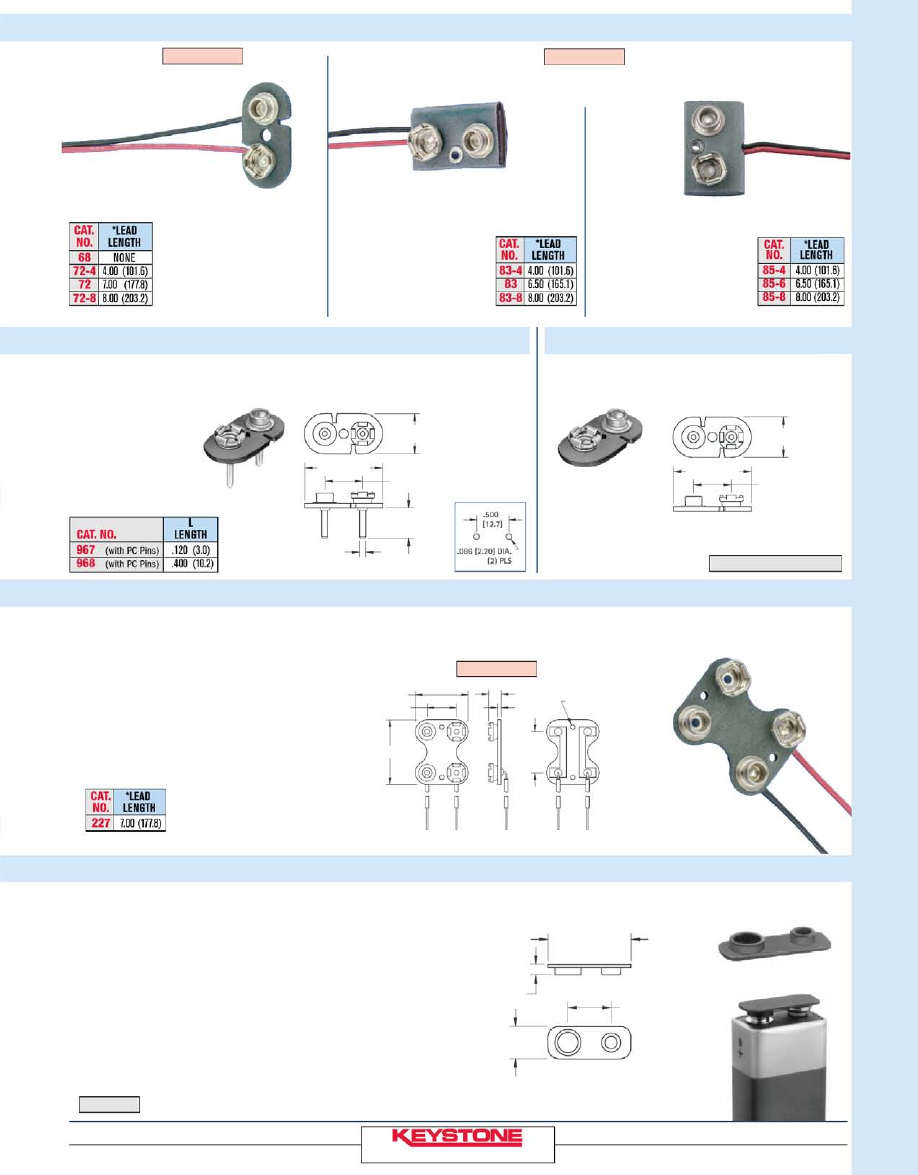

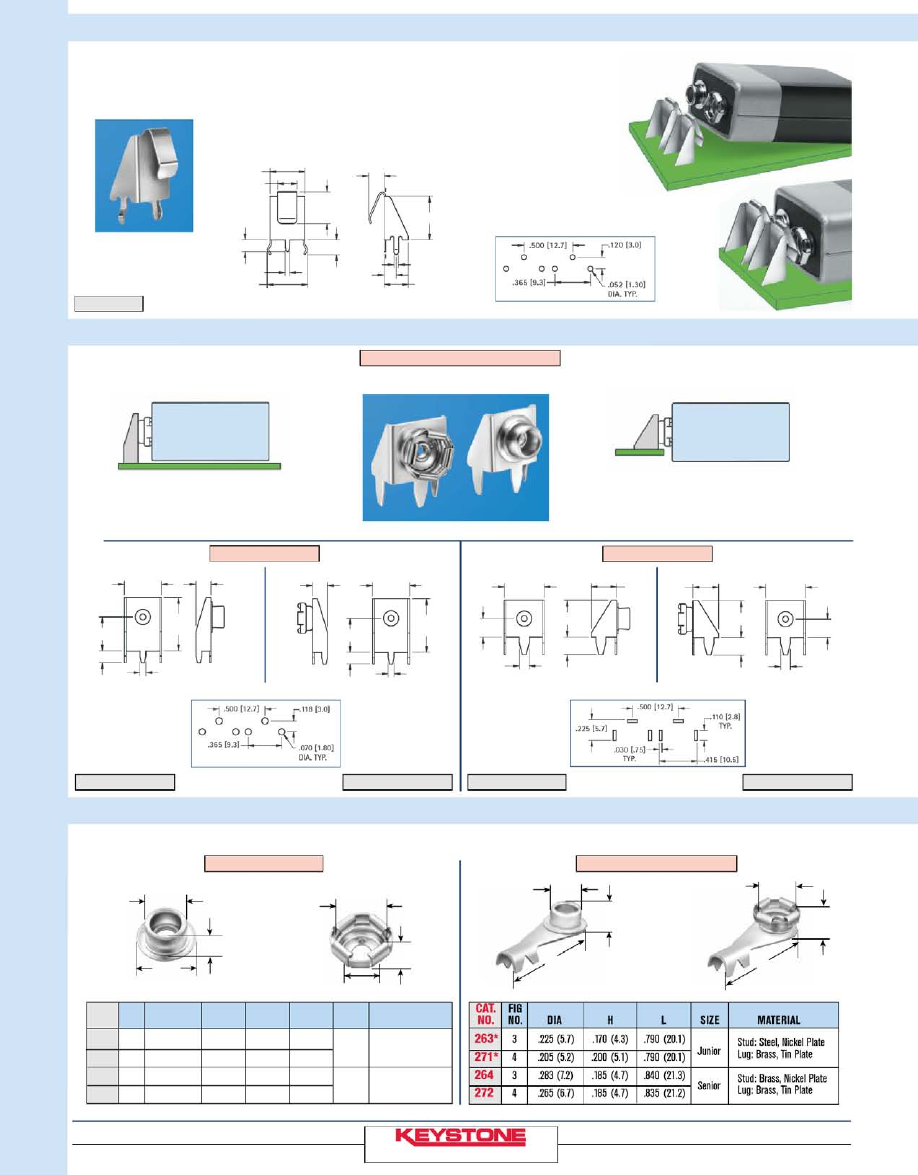

NINE VOLT BATTERY CONTACTS

& STRAPS . . . . . . . . . . . . . . . . . . 30-33

NYLON CABLE CLAMPS . . . . . . . . 130-131

NYLON PC SPACERS/SUPPORTS . . . 80-82

NYLON SCREWS . . . . . . . . . . . . . . . . . 135

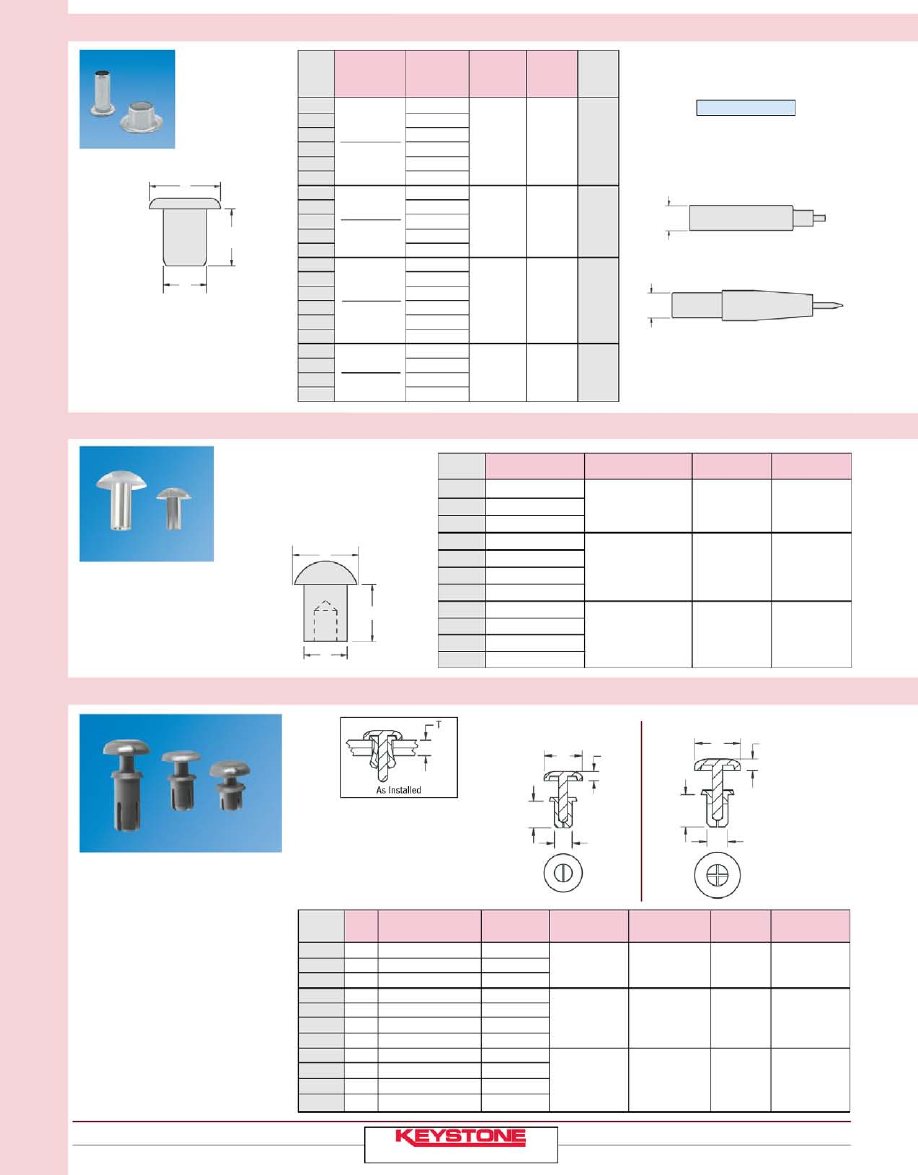

NYLON SNAP RIVETS . . . . . . . . . . . . . 138

NYLON SPACERS . . . . . . . . . . . . . . . 78-79

NYLON STANDOFFS . . . . . . . . . . . . . 74-75

NYLON WASHERS (Flat, Shoulder

& Retaining) . . . . . . . . . . . . . . 136-137

PANEL BEARINGS . . . . . . . . . . . . . . . . . 88

PANEL HARDWARE . . . . . . . . . . . . . . . . . .

Captive Panel Screws . . . . . . . . . 86-87

Panel nuts & Bearings . . . . . . . . . . . 88

Shoulder Screws . . . . . . . . . . . . . . . . 88

Thumb Screws . . . . . . . . . . . . . . . . . 87

PHONO PLUGS & JACKS . . . . . . . 106-107

PINS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact (Seamless) . . . . . . . . . . . . . . . 65

Micro . . . . . . . . . . . . . . . . . . . 104-105

Wire Wrap (.025 Square) . . . . . . . . . 65

PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . .

Banana. . . . . . . . . . . . . . . . . . 110-111

Hole . . . . . . . . . . . . . . . . . . . . . . . . 132

Shorting . . . . . . . . . . . . . . . . . . . . . 105

Solderless . . . . . . . . . . . . . . . . . . 62-63

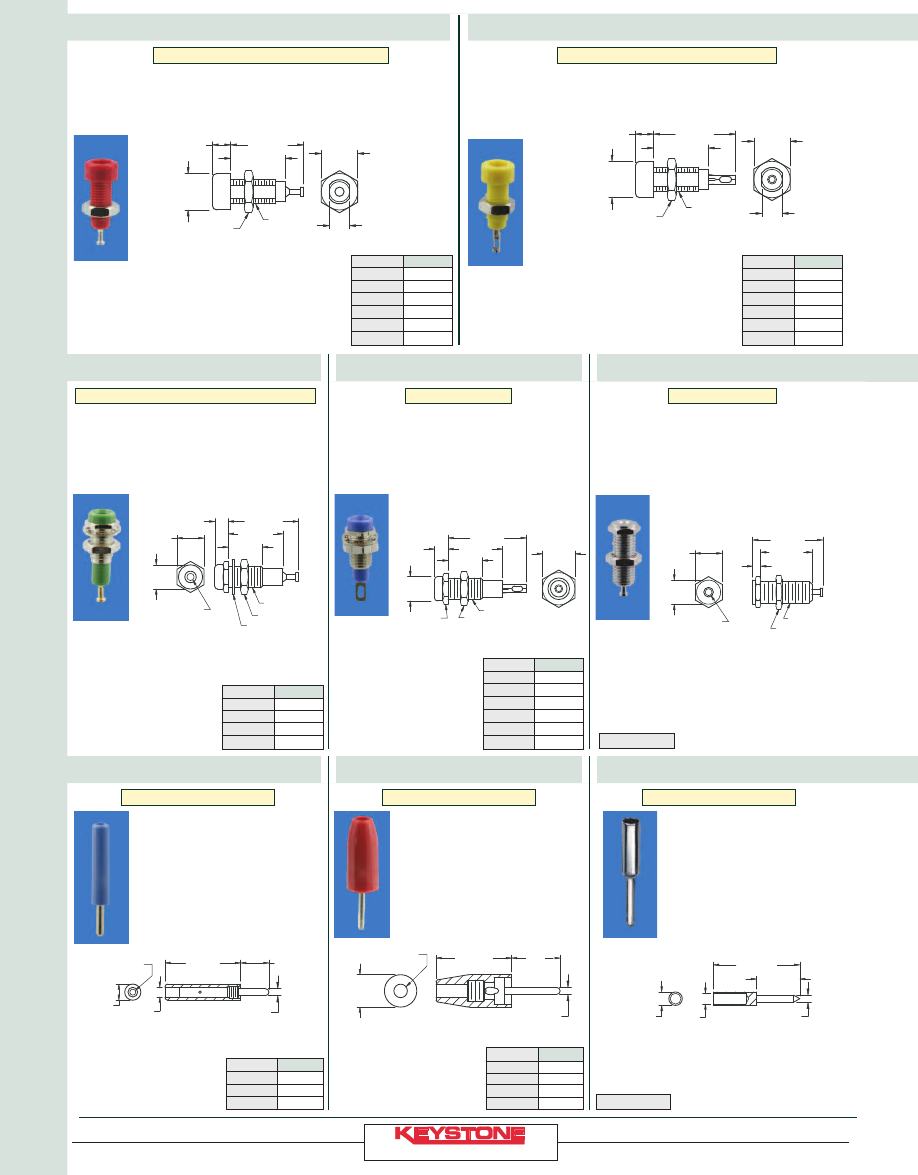

Tips & Plugs . . . . . . . . . . . . . . 108-109

PUSH-IN TERMINALS. . . . . . . . . . . . . . . . .

Flea Clip, Imp, Micro, Solderless . . . . 65

Tubular . . . . . . . . . . . . . . . . . . . . . . . 65

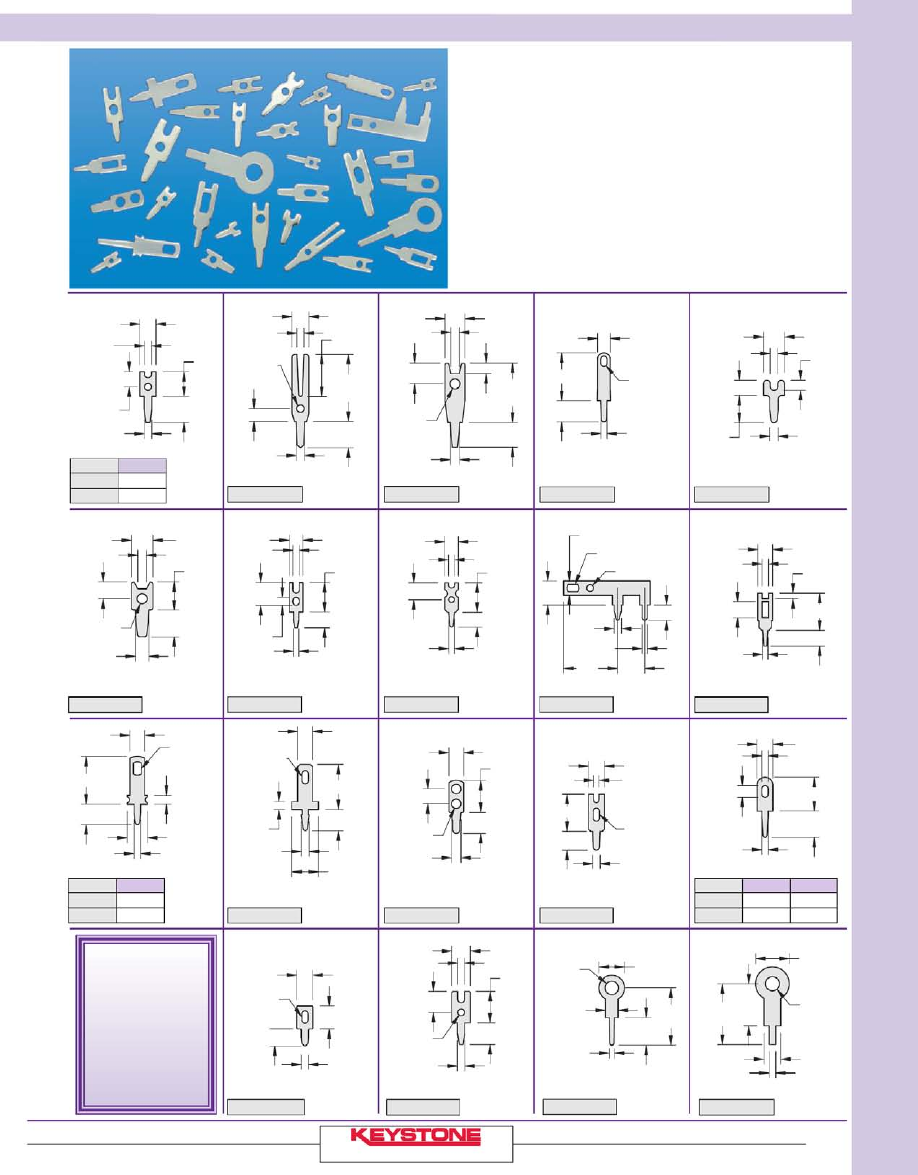

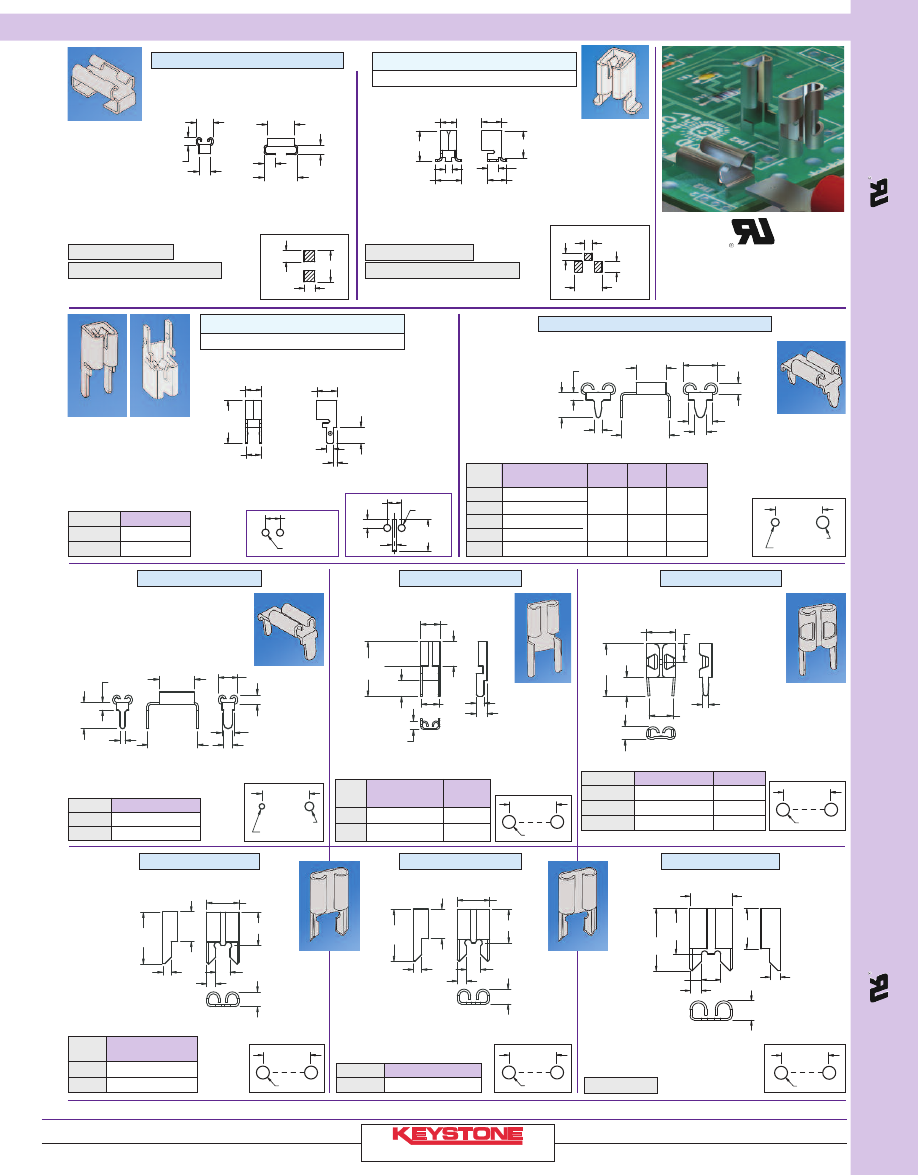

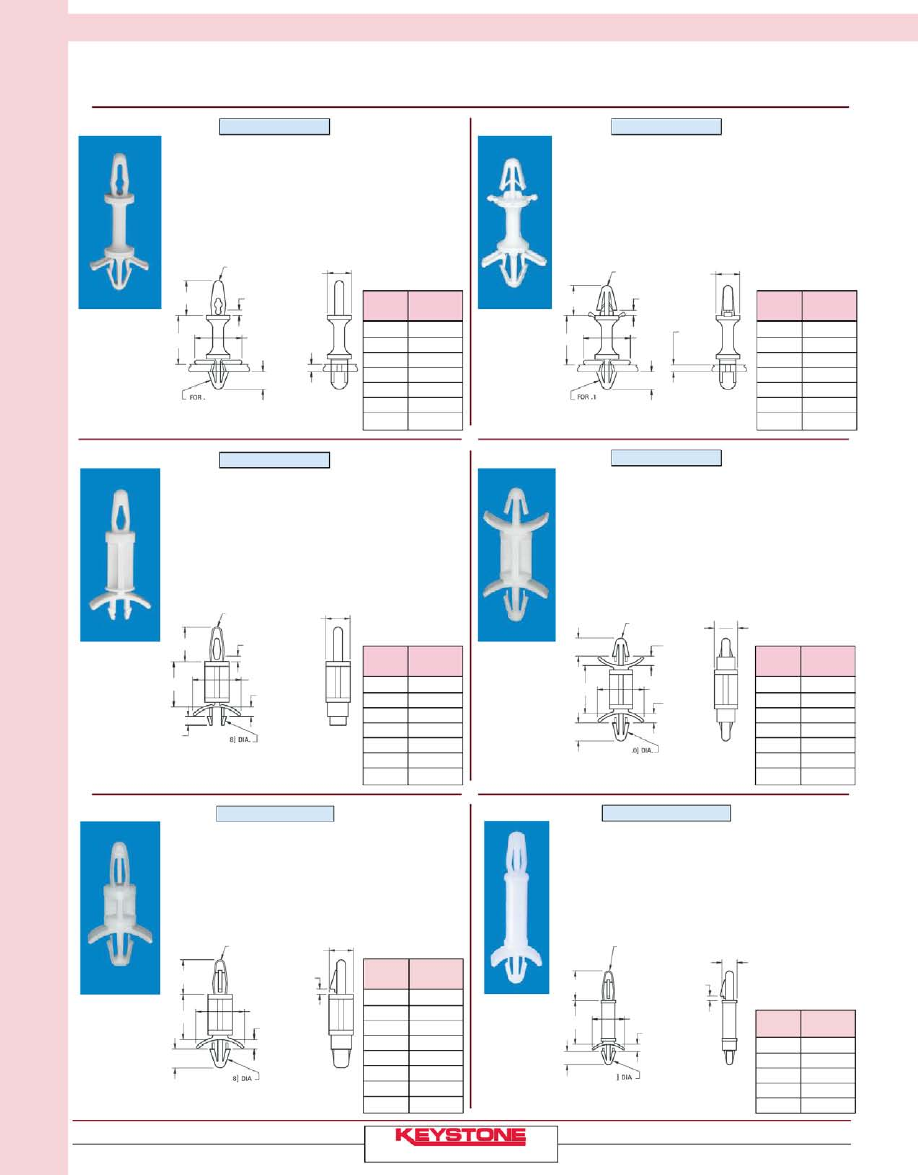

QUICK-FIT COMPONENTS . . . . . . . . . . . . .

Boots . . . . . . . . . . . . . . . . . . . . . . . . 62

Headers . . . . . . . . . . . . . . . . . . . . . . 60

PC Mount Female Terminals . . . . . 58-60

PC Mount Male Terminals . . . . . . . . . 61

Rivet Mount . . . . . . . . . . . . . . . . . . . 60

Surface Mount Female Terminals . . . . 61

RIVETS . . . . . . . . . . . . . . . . . . . . . . . . 138

RJ45 (KEYSTONE) JACKS . . . . . . . . . . 101

RUBBER BUMPERS & GROMMETS132-134

RETAINING SPACERS. . . . . . . . . . . . . . . 79

RETAINING WASHERS . . . . . . . . . . . . . 136

SCREWS. . . . . . . . . . . . . . . . . . . . . . . . . .

Colored Head . . . . . . . . . . . . . . . . . 135

Handle Mounting . . . . . . . . . . . . . . . 91

Jack Screw . . . . . . . . . . . . . . . . . . . . 86

Machine Screw . . . . . . . . . . . . . . . . 135

Metric Screws . . . . . . . . . . . . . . . . . 135

Panel Screw . . . . . . . . . . . . . . . . . . . 87

Self-Tapping . . . . . . . . . . . . . . . . . . 135

Shoulder Screw . . . . . . . . . . . . . . . . 88

Thumb Screw . . . . . . . . . . . . . . . . . . 87

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

A

B

C

H

(cont.)

N

C

(cont.)

E

F

G

H

L

M

Q

R

S

K

J

I

P

BATTERY CLIPS,

CONTACTS

& HOLDERS

PAGE 1

FUSE CLIPS

& HOLDERS

PAGE 39

TERMINALS

& TEST

POINTS

PAGE 53

SPACERS &

STANDOFFS

PAGE 73

PANEL

HARDWARE

PAGE 85

PINS, PLUGS,

JACKS &

SOCKETS

PAGE 97

PC BOARD

HARDWARE

PAGE 117

MULTI-PURPOSE

HARDWARE

PAGE 129

SCREW TERMINALS . . . . . . . . . . . . . 66-71

SHAFT LOCKS / EXTENDERS . . . . . . . . . 88

SHORTING PLUGS & JACKS . . . . . . . . 105

SHOULDER SCREWS. . . . . . . . . . . . . . . 88

SOCKETS . . . . . . . . . . . . . . . . . . . . . . . . .

Halogen . . . . . . . . . . . . . . . . . . . . . 114

Keystone (RJ45) . . . . . . . . . . . . . . . 101

Micro . . . . . . . . . . . . . . . . . . . 102-103

Phono. . . . . . . . . . . . . . . . . . . 106-107

Transistor . . . . . . . . . . . . . . . . 113-115

USB . . . . . . . . . . . . . . . . . . . . . 98-100

SOLDER LUGS & TERMINALS . . . . . . . . 64

SOLDER (TURRET)TERMINALS . . . 142-143

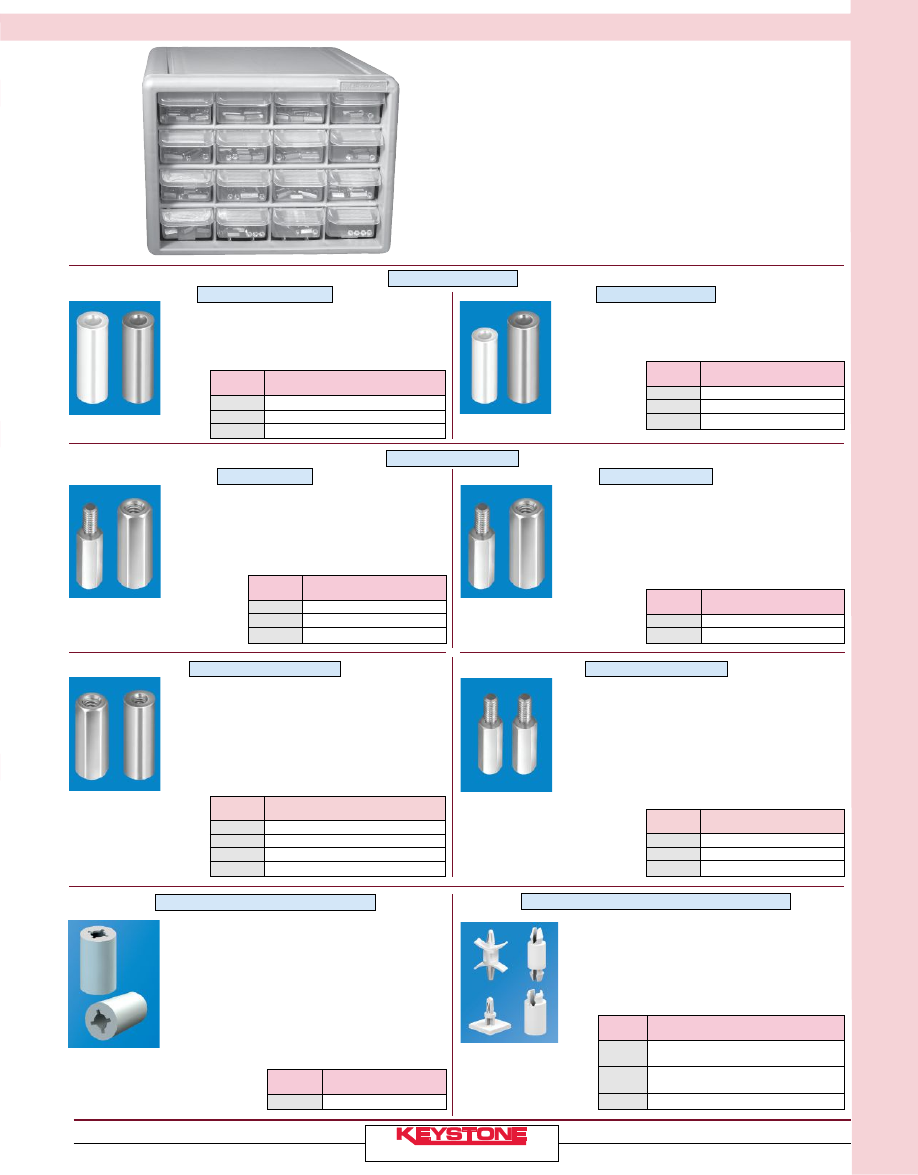

SPACERS . . . . . . . . . . . . . . . . . . . . . . . . .

Aluminum, Brass, Nylon, Phenolic 77-78

Force Fit . . . . . . . . . . . . . . . . . . . . . . 77

LED . . . . . . . . . . . . . . . . . . . . . . . . . 95

Organizer Kits . . . . . . . . . . . . . . . . . . 83

PC Board (Snap In, Adhesive)”. . . 80-82

Self Retaining (Nylon) . . . . . . . . . . . . 80

Swage Mount . . . . . . . . . . . . . . . . . . 77

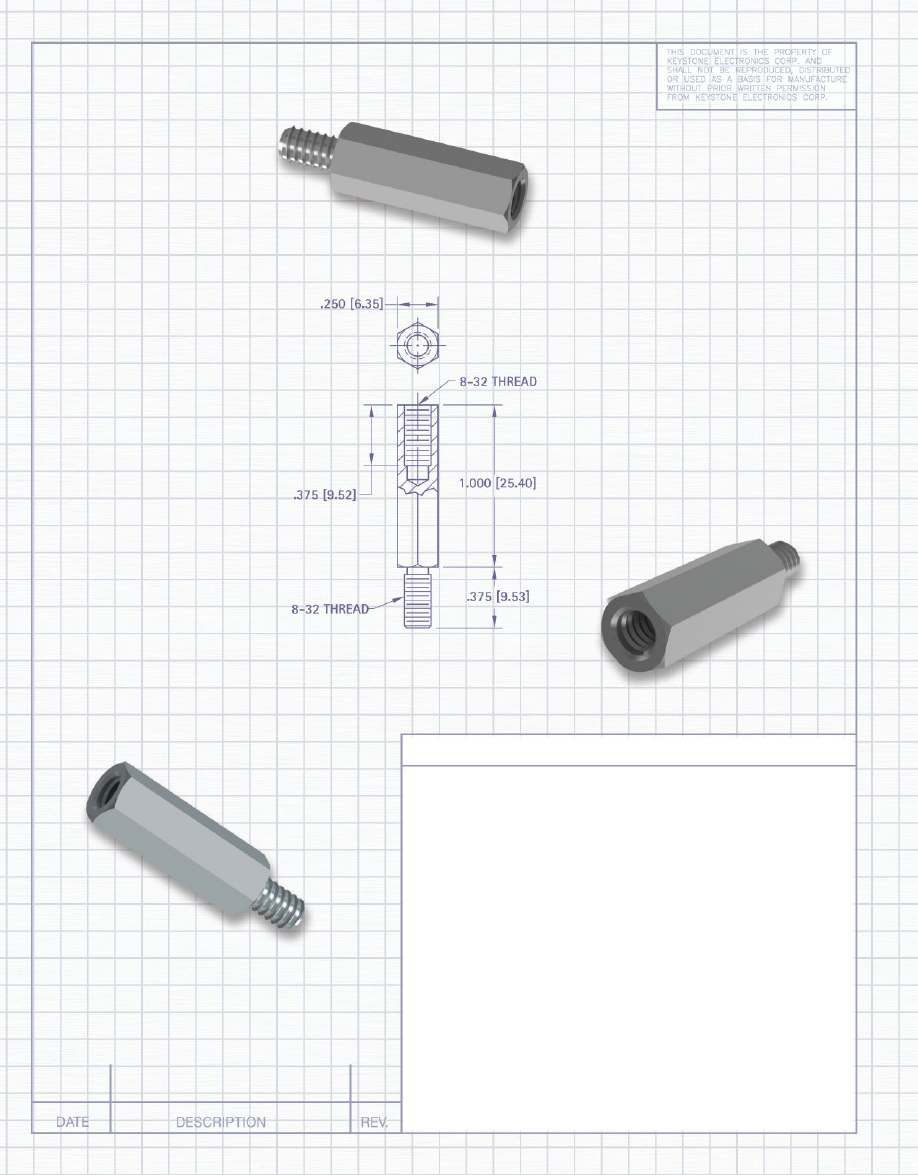

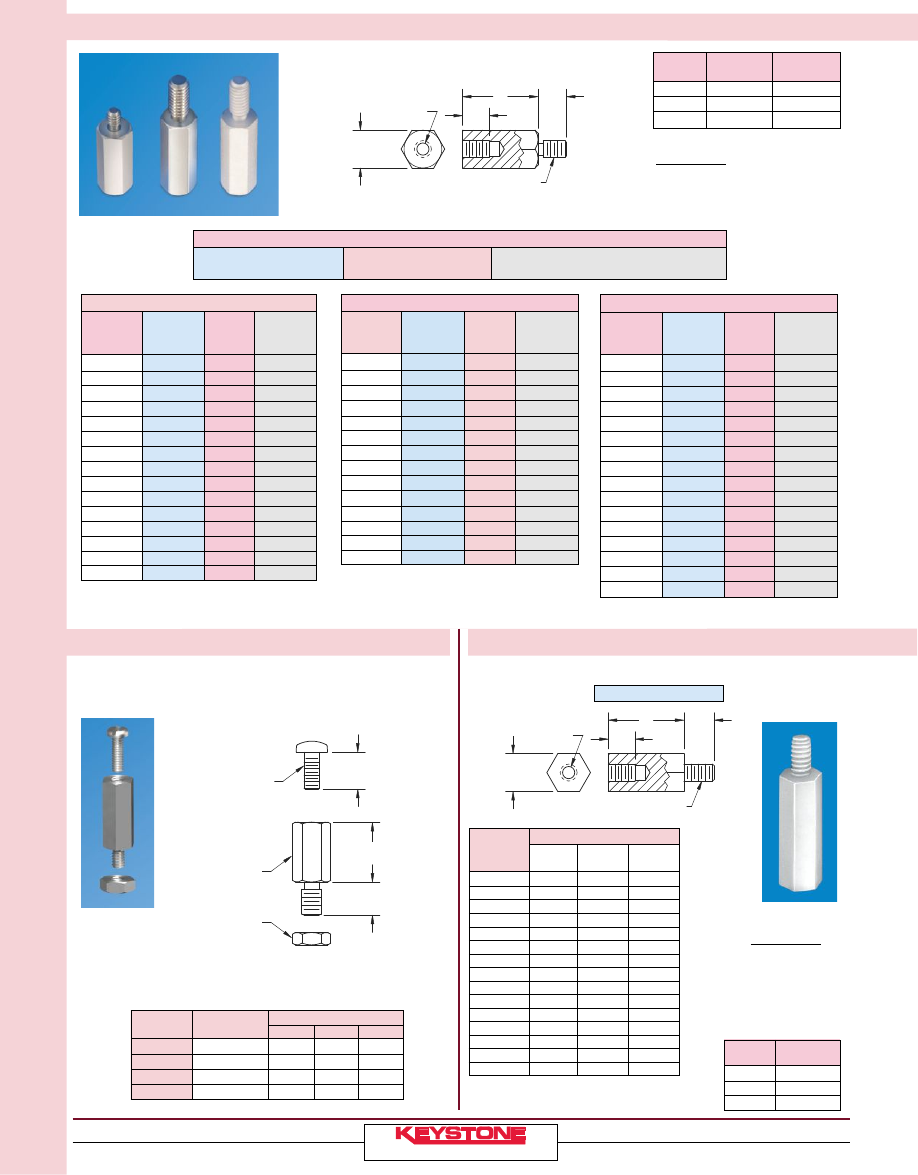

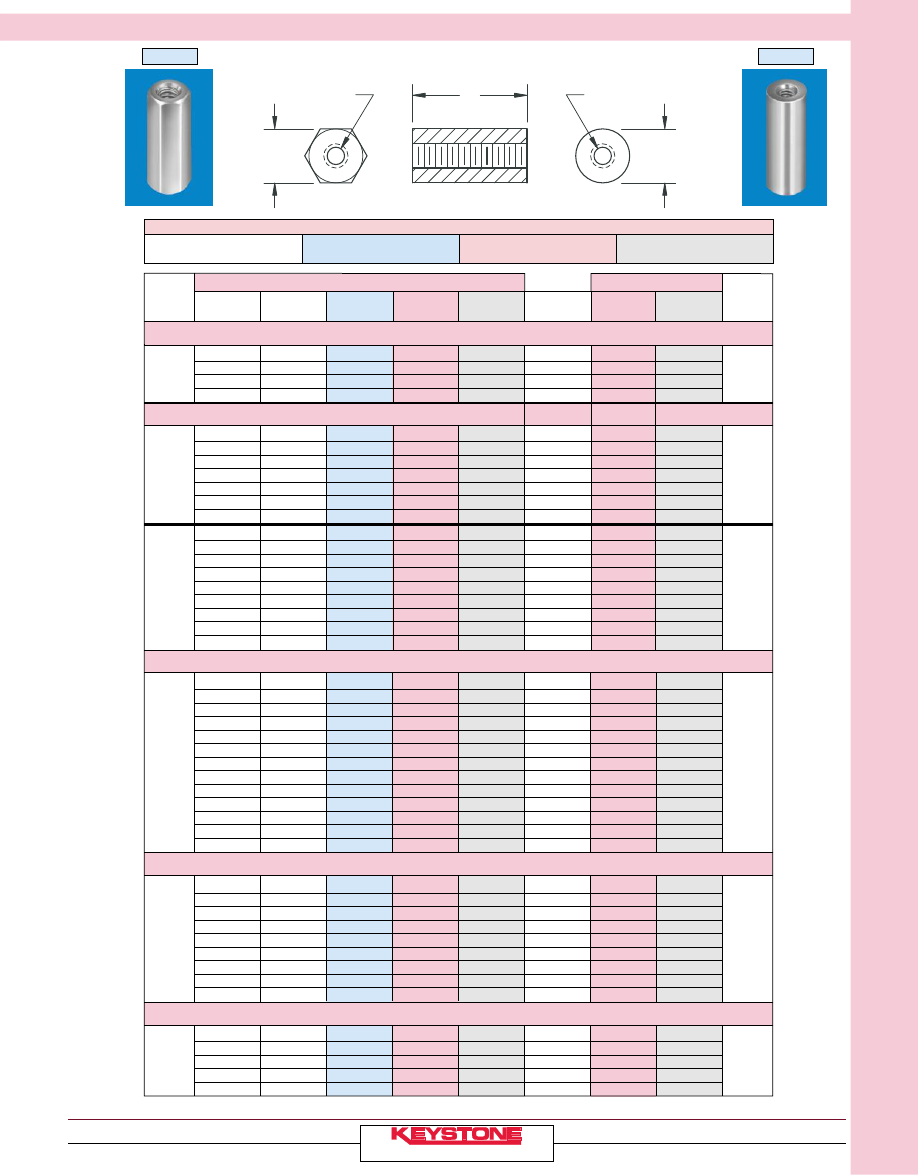

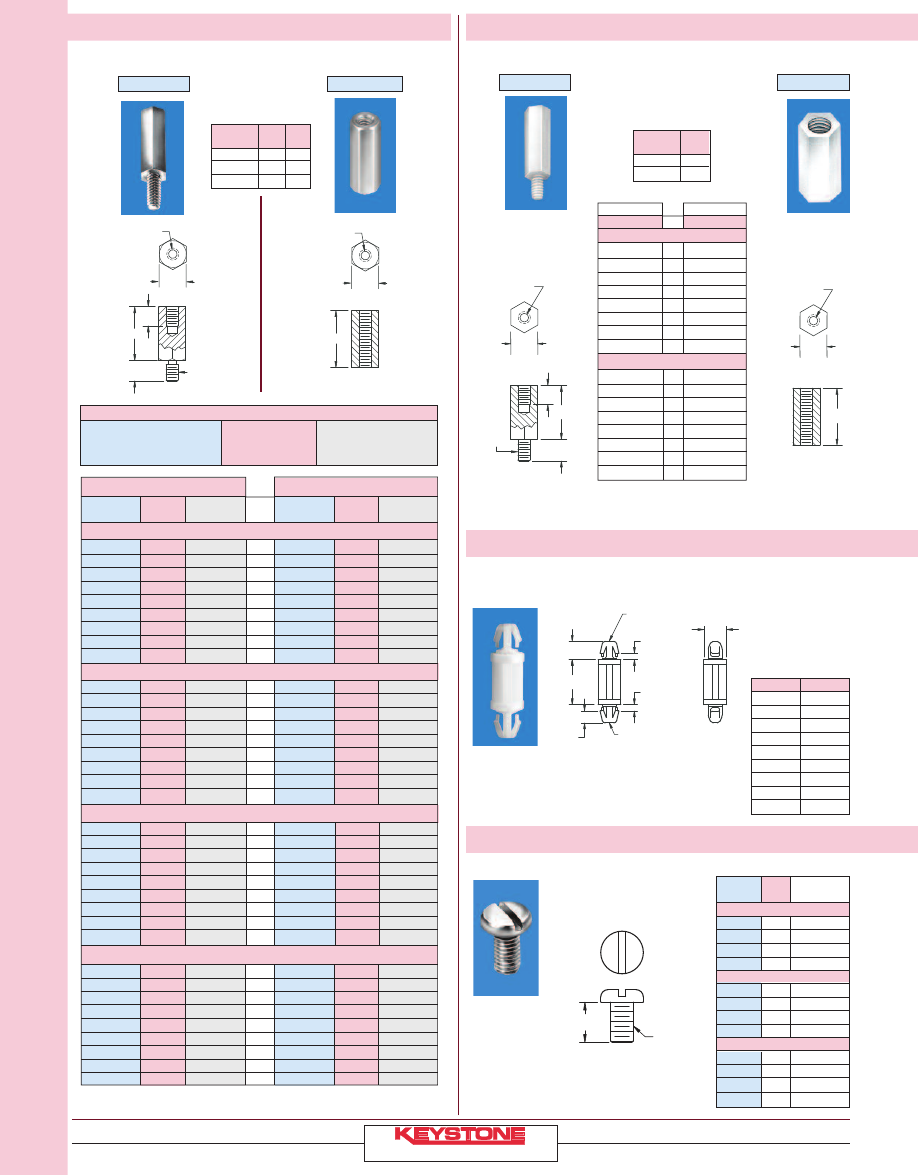

STANDOFFS . . . . . . . . . . . . . . . . . . . . . . .

Aluminum, Brass, Ceramic, Nylon, . . . .

Stainless Steel . . . . . . . . . . . . . . 74-77

Force Fit . . . . . . . . . . . . . . . . . . . . . . 77

Hinged . . . . . . . . . . . . . . . . . . . . . . . 79

Metric. . . . . . . . . . . . . . . . . . . . . . . . 76

Male - Female . . . . . . . . . . . . . . . . . 74

Organizer Kits . . . . . . . . . . . . . . . . . . 83

PC/104 . . . . . . . . . . . . . . . . . . . . . . 74

Swage Mount . . . . . . . . . . . . . . . . . . 77

STURDI-MOUNT

QUICK-FIT TERMINALS . . . . . . . . . 58-59

TAPE & REEL COMPONENTS . . . . . . . . . . .

Audio Jacks . . . . . . . . . . . . . . . . . . 112

Battery Contacts . . . . . . . . . . . . . . 8-10

Coin Cell Holders. . . . . . . . . . . . . . . 2-7

Coin Cell Retainers/Contacts . . . . . . 7-9

Fuse Clips . . . . . . . . . . . . . . . . . . . . 41

Fuse Holders . . . . . . . . . . . . . . . . . . 41

Jumpers . . . . . . . . . . . . . . . . . . . . . 54

Quick-Fit Female Terminals . . . . . . . . 61

Test Points . . . . . . . . . . . . . . . . . . . . 55

USB Plugs & Sockets . . . . . . . . 98-100

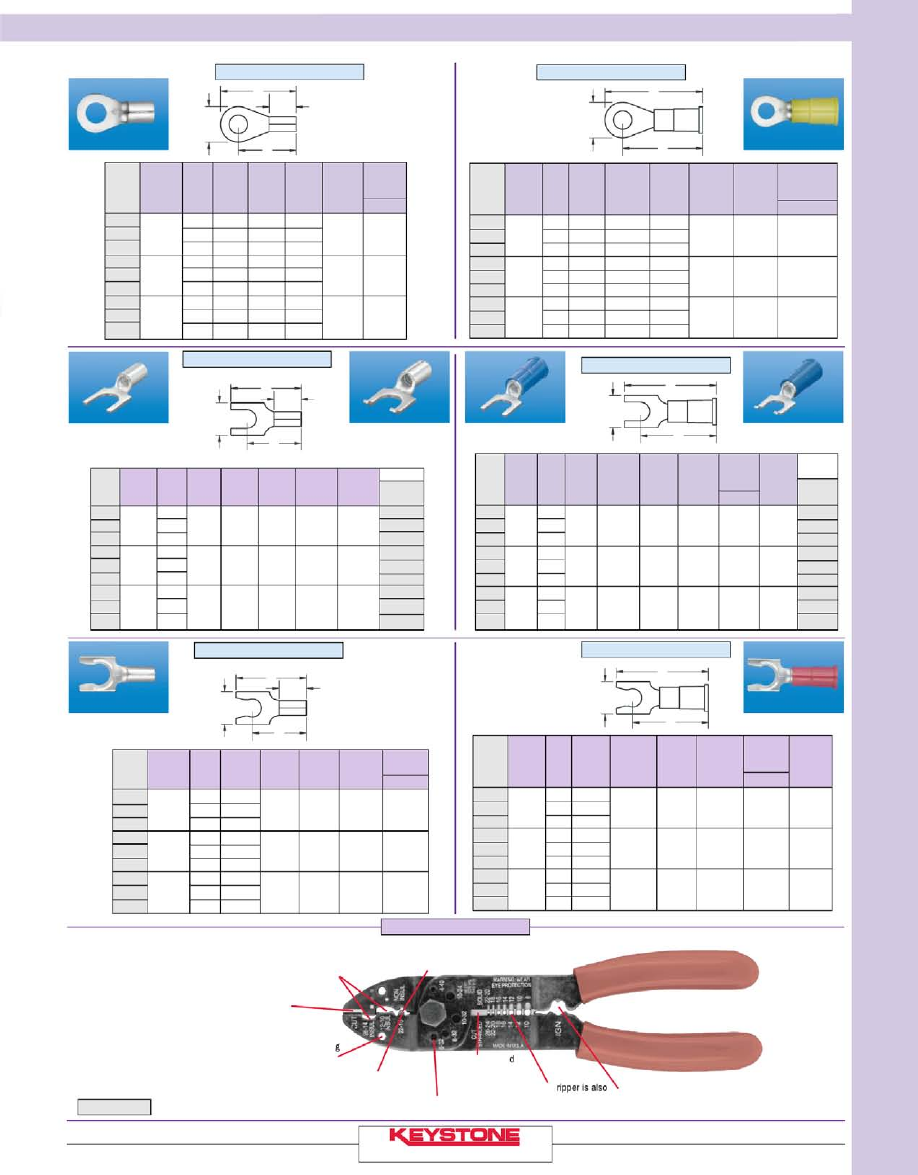

TERMINALS. . . . . . . . . . . . . . . . . . . . . . . .

Binding Post Terminal . . . . . . . . . . . 112

Insulated Solder

(turret) Terminals . . . . . . . . 140-141

Lugs (Solder). . . . . . . . . . . . . . . . 64

Micro Jacks . . . . . . . . . . . . 102-103

Push In . . . . . . . . . . . . . . . . . . . . 65

Quick-Fit . . . . . . . . . . . . . . . . 58-61

Screw Terminals . . . . . . . . . . . 66-71

Solder (Standardized/Turret)142-143

Solderless (Crimp) . . . . . . . . . 62-63

Sturdi-Mount, Quick-Fit . . . . . . 58-59

Test Points . . . . . . . . . . . . . . . 55-57

TEST POINTS. . . . . . . . . . . . . . . . . . . . . . .

Color Keyed . . . . . . . . . . . . . . . . . 56

PC Mount . . . . . . . . . . . . . . . . 56-57

Surface Mount . . . . . . . . . . . . . . . 55

TERMINAL BOARDS. . . . . . . . . . . . . . . 144

TEST TIPS & PLUGS. . . . . . . . . . . 108-109

THUMB SCREWS . . . . . . . . . . . . . . . . . 87

TRANSISTOR COVERS . . . . . . . . . . . . . 114

TRANSISTOR SOCKETS/MOUNTS . 113-115

USB PLUGS & SOCKETS . . . . . . . . 98-100

VERTICAL COIN CELL HOLDERS . . . . . . . . 5

VERTICAL PC BOARD GUIDE . . . . . . . . 121

VIBRATION (ANTI) GROMMETS. . . . . . . 133

WASHERS. . . . . . . . . . . . . . . . . . . . . . . . .

Lock Washers. . . . . . . . . . . . . . . 136

Fibre (Flat & Shoulder). . . . 136-137

Nylon (Flat & Shoulder) . . . 136-137

Self-Retaining . . . . . . . . . . . . . . 136

WORKSHEETS (Custom) . . . . . . . . . . . . . .

Computer Brackets. . . . . . . 126-127

ZERO OHM JUMPERS . . . . . . . . . . . . . . 54

T

S (cont.)

T (cont.)

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

W

Z

U

V

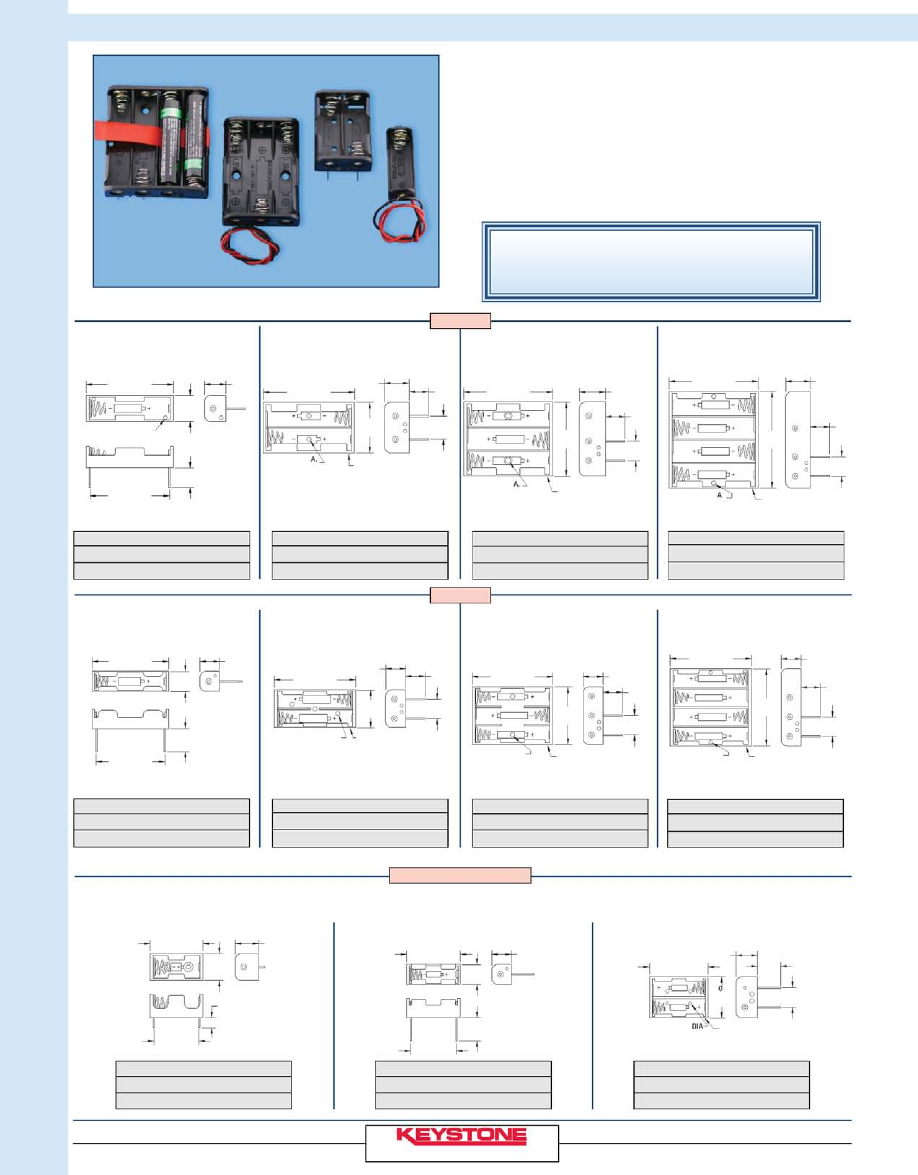

Our battery clips, contacts and holders are designed with leading edge

technology in mind, to accommodate all major manufacturers’ batteries.

Available in a wide range of materials and mounting styles including

surface mount, thru hole and off board, some of the applications include:

•

Telecommunications and Video power back-up

•

Laptop and mobile computing applications

•

Communication system’s power requirements

•

Microcomputer and memory hold

•

Preprogrammed electronic and video games

•

Emergency power systems

•

Industrial and commercial security and alarm systems

•

Miniature battery power devices

•

Computer memory, power transfer and back-up systems

•

Personal medical monitoring devices

Our quality system is ISO 9001:2008 certified. Our products are in

compliance with the RoHS and REACH directives. We provide 3D modeling,

CAD andother application-engineering support for modifications, special

designs or assemblyrequirements to assist you in choosing the right

Keystone product for your application.

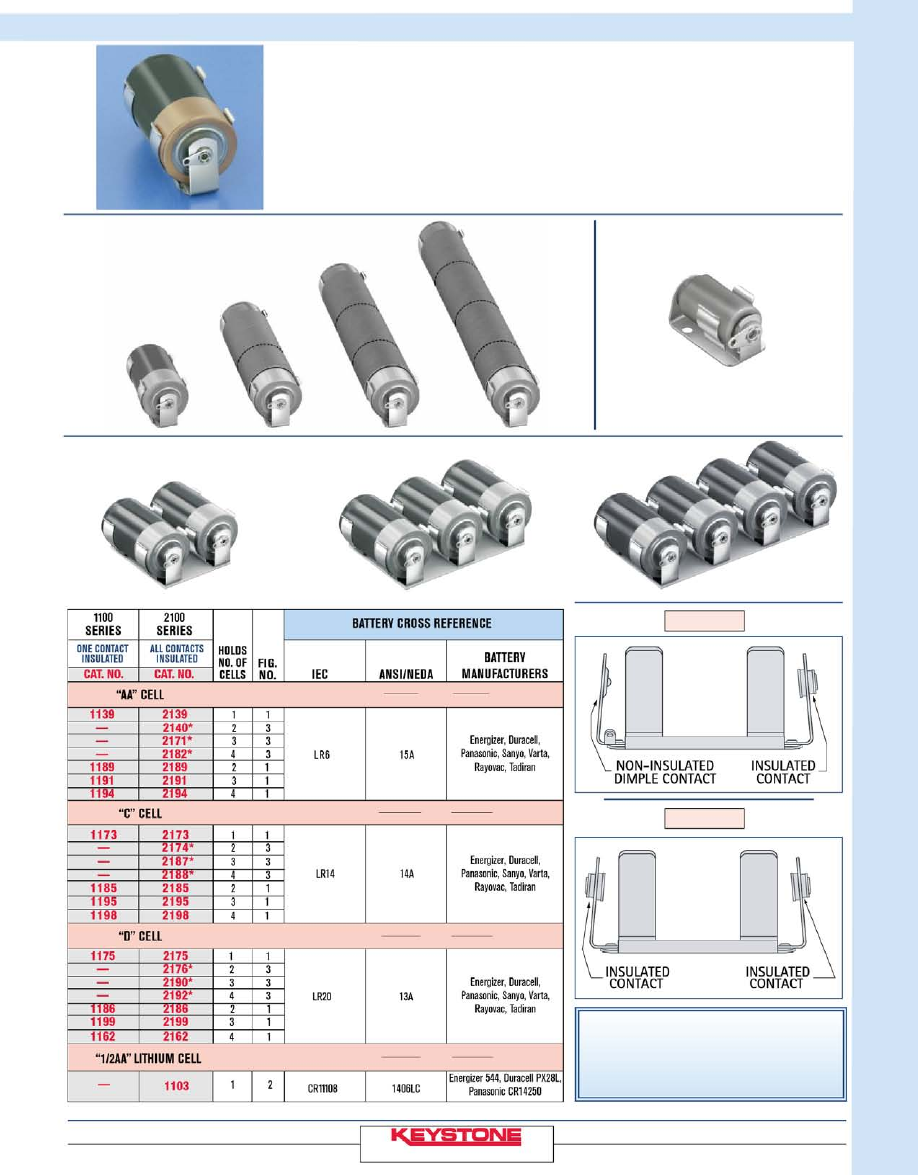

BATTERY CLIPS, CONTACTS & HOLDERS

B

A

TTER

Y

C

LIPS, C

ONT

AC

TS & H

OLDER

S

1

RETAINERS

Button Cell .........................................................

7

Coin Cell .............................................................

9

Insulated ...........................................................

8

Negative Contacts............................................

8

CLIPS/CONTACTS

Alkaline & Lithium, Rivet.................................

12

Alkaline & Lithium, PC ..............................

10-11

Battery Clips (no contact) ............................

13

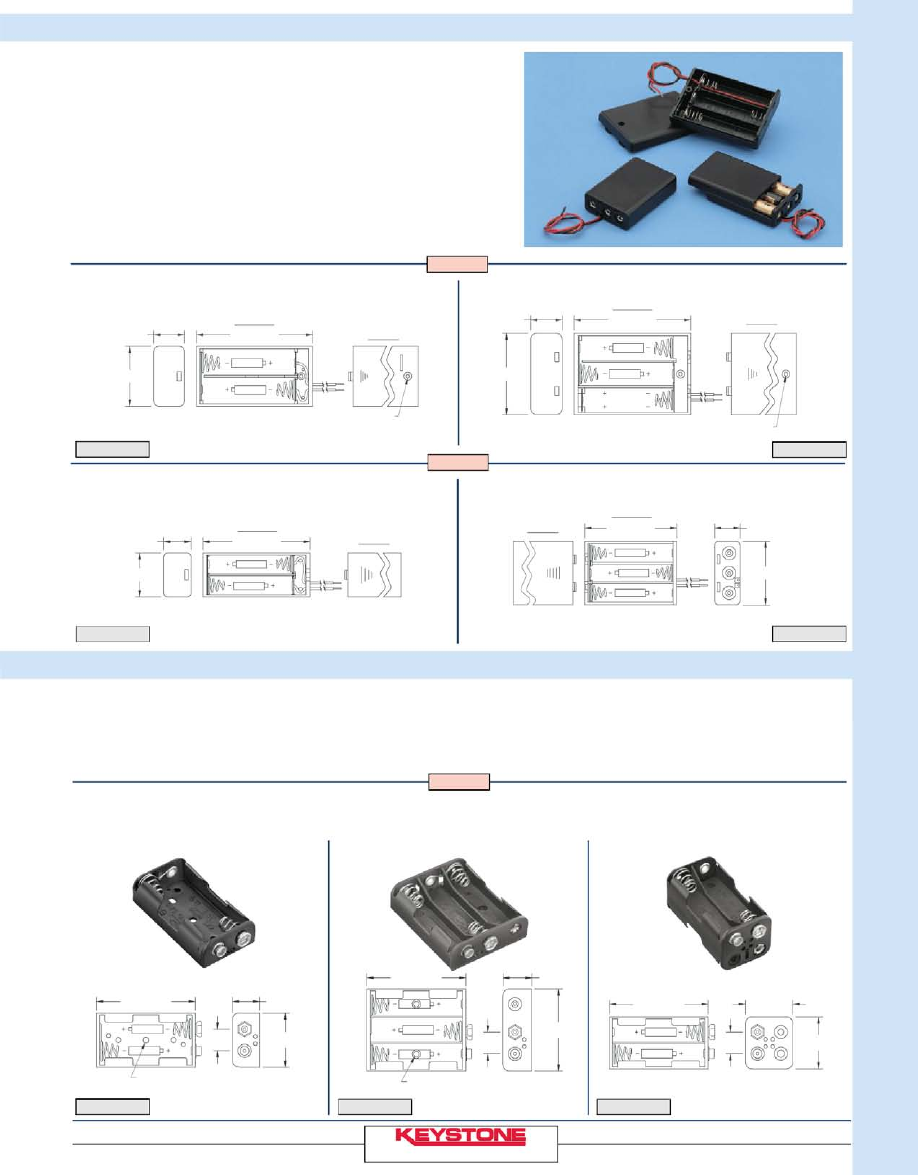

Molded Case ............................................

14-18

9 Volt ..............................................................

32

HOLDERS

Aluminum................................................

19-20

Coin Cell .......................................................

2-6

Lithium Cell ............................................

22-25

PC Mount ...............................................

22-27

Plastic, Economical..............................

28-29

Steel .................................................................

21

9 Volt ..............................................................

33

9 Volt Straps .........................................

30-31

18350, 18650, 26650........................

25-27

MOUNTING DETAILS

..........................

34-37

SECTION CONTENTS

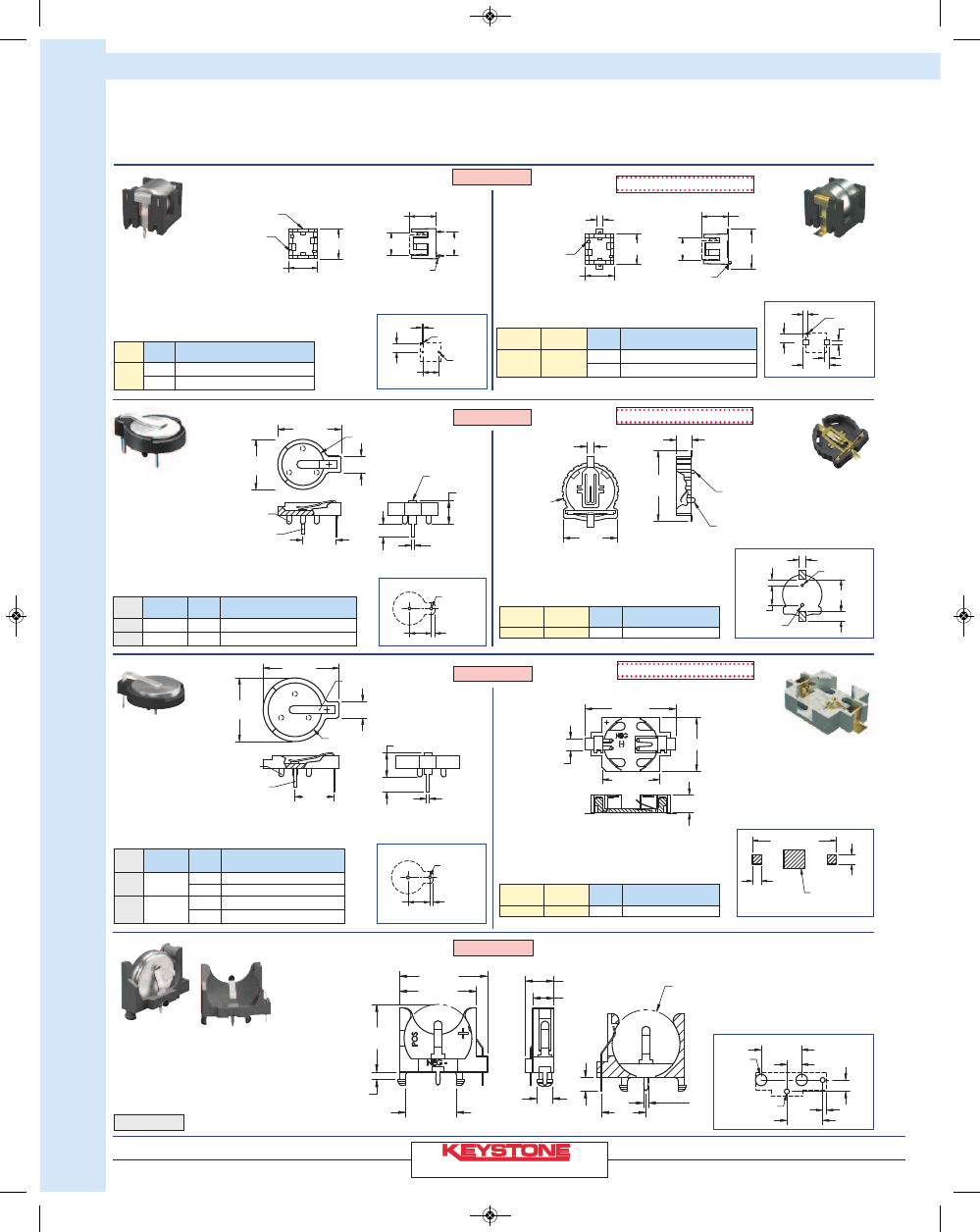

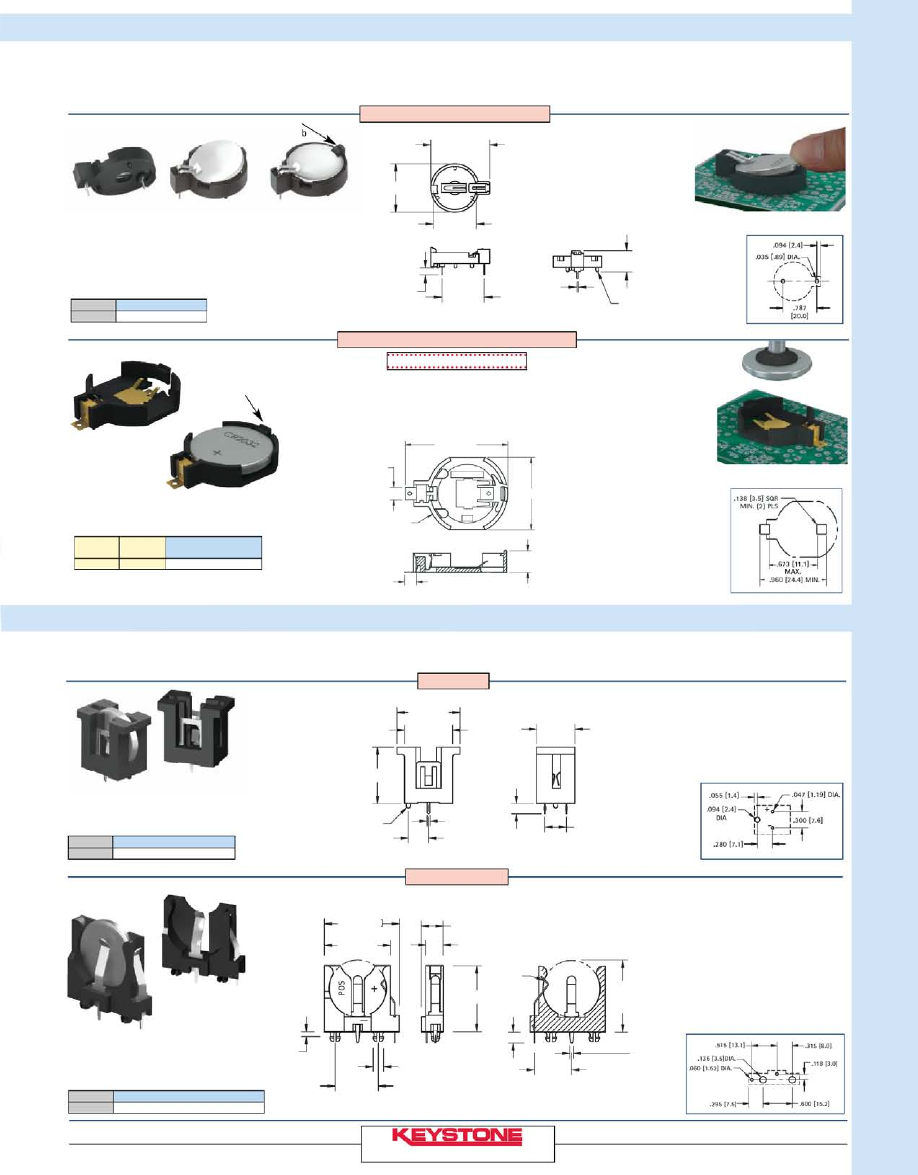

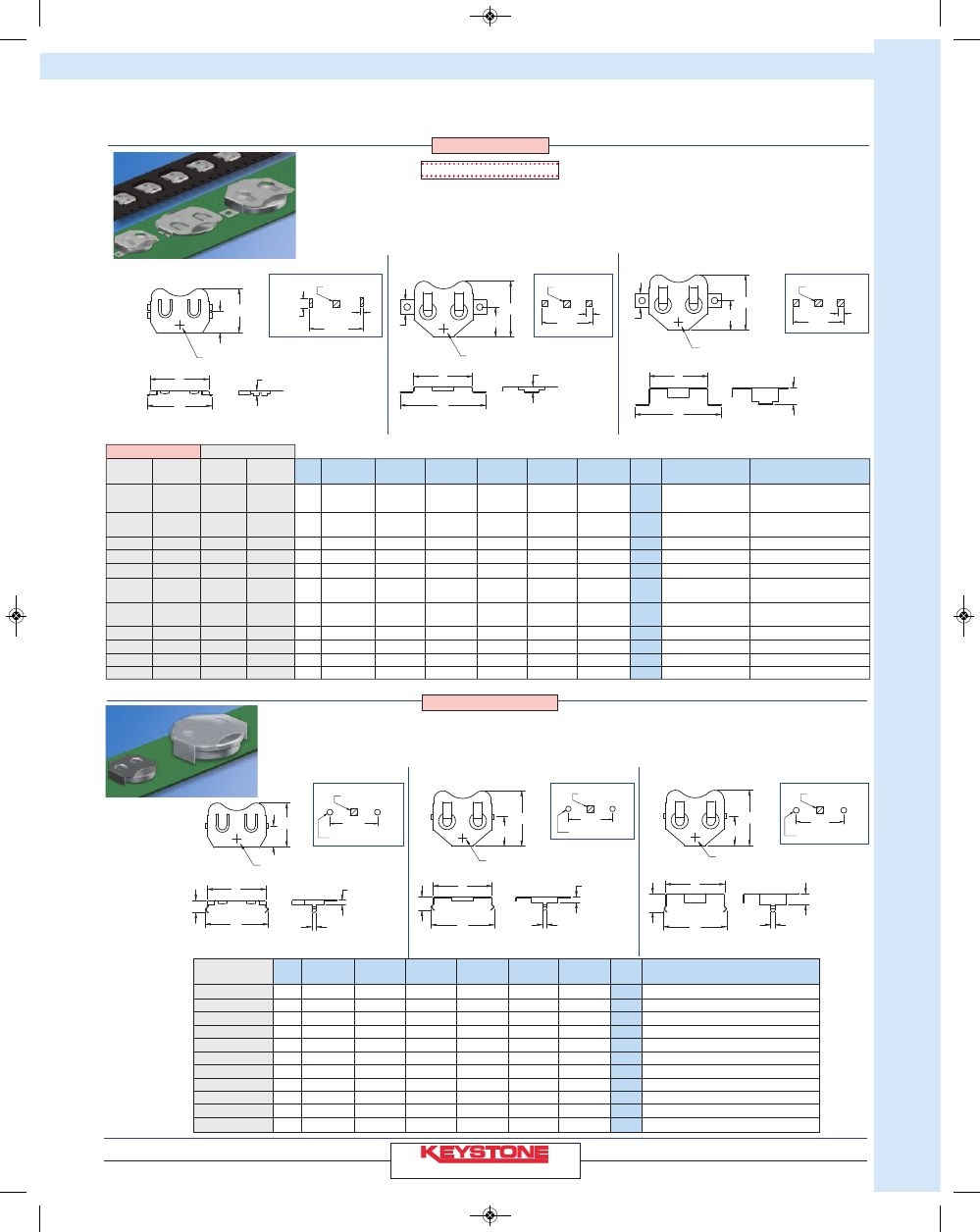

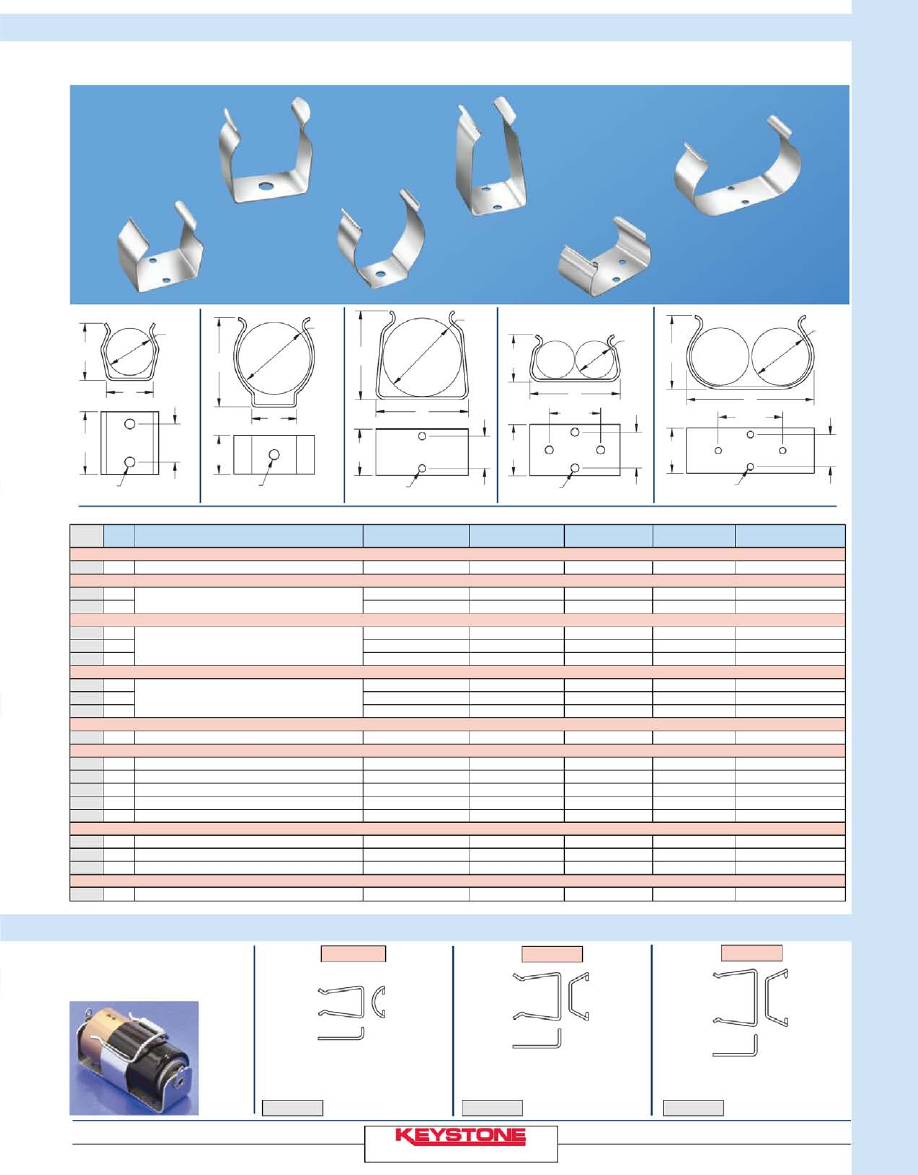

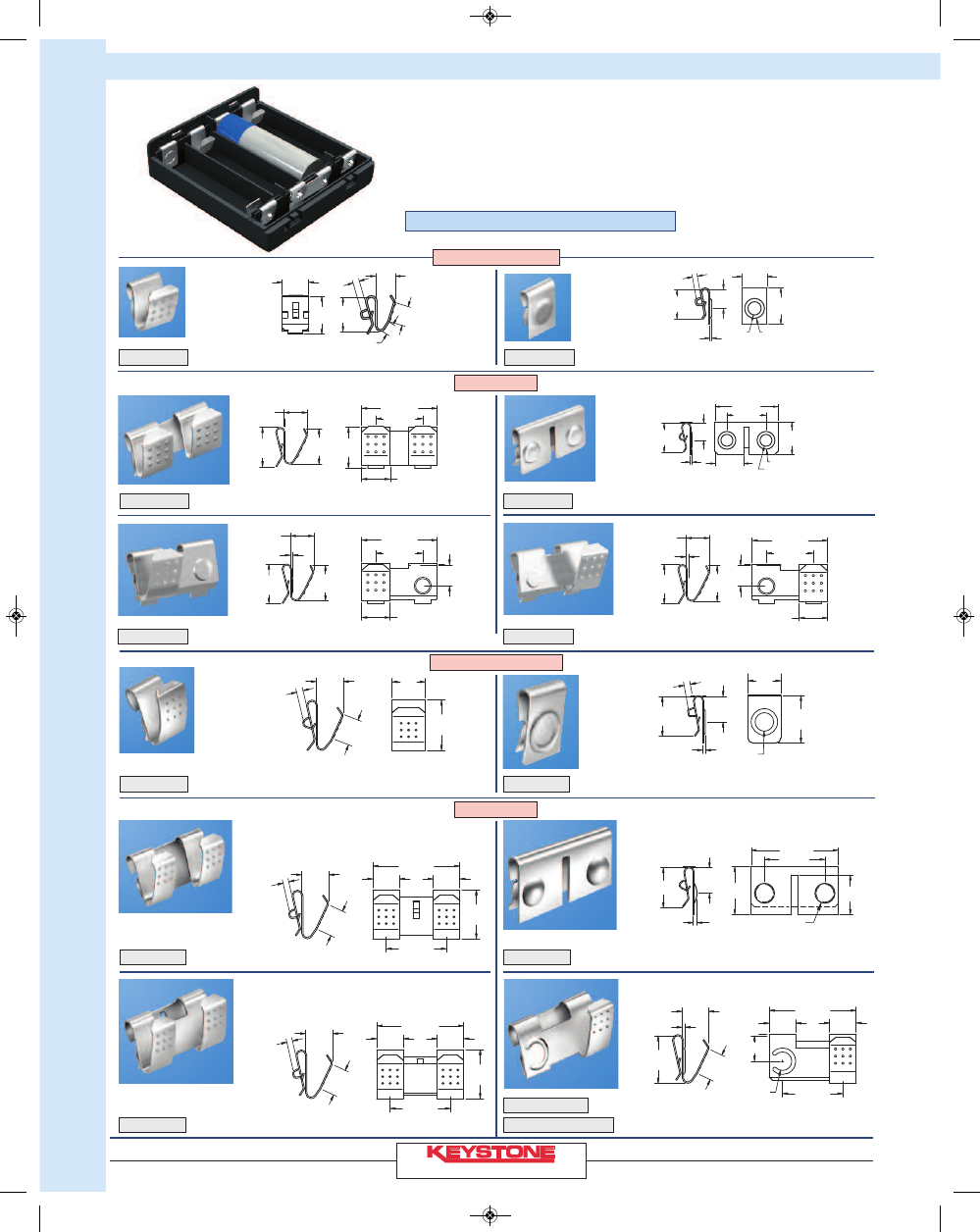

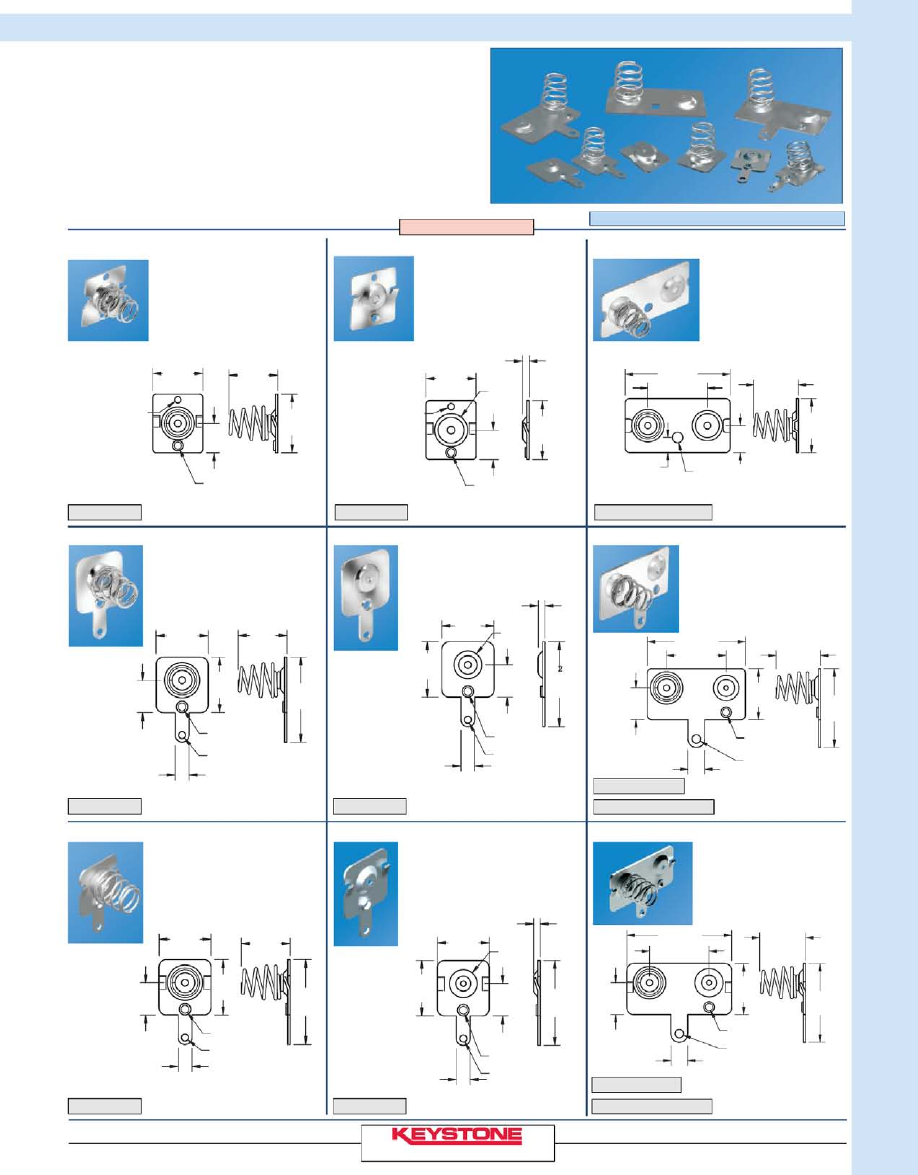

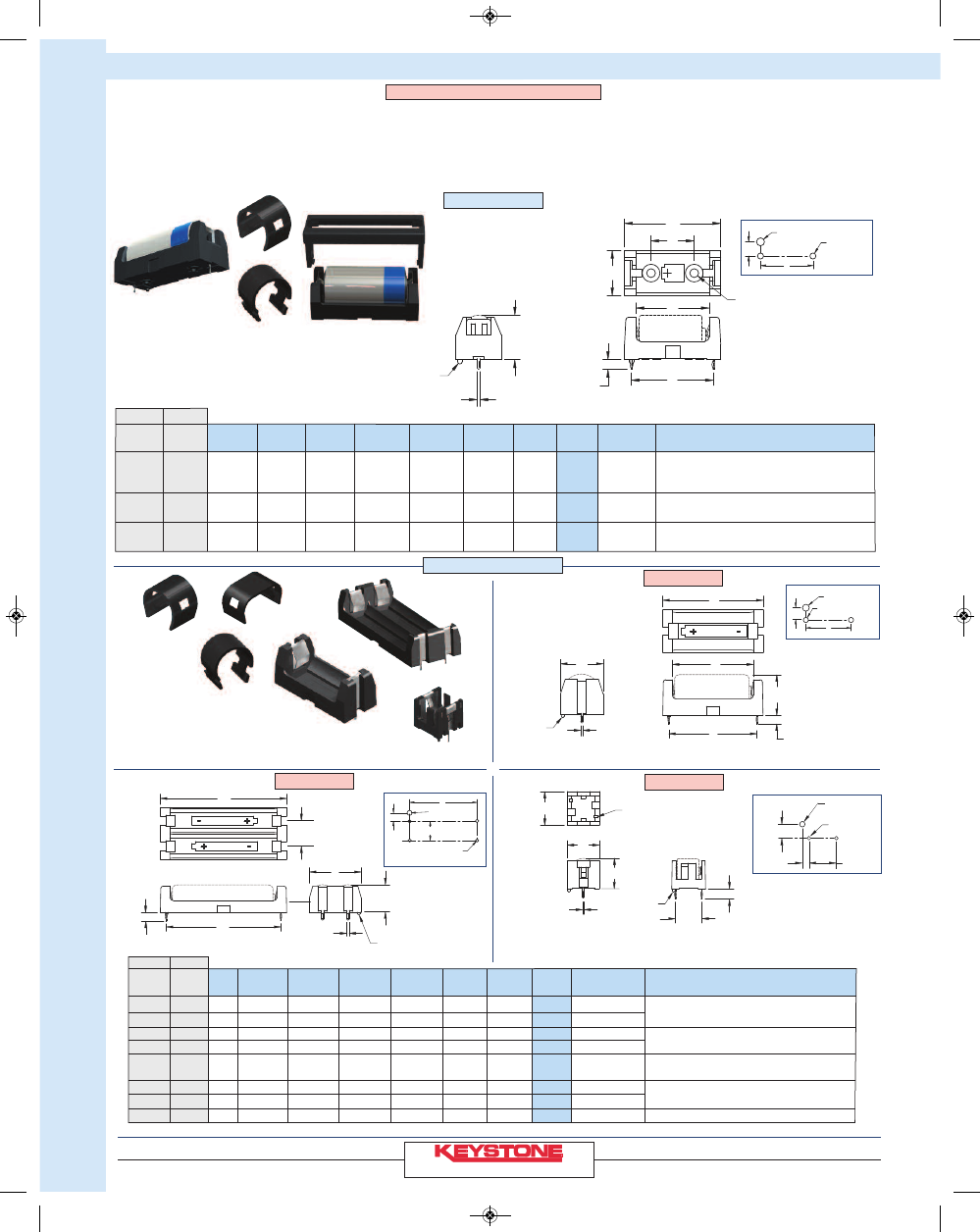

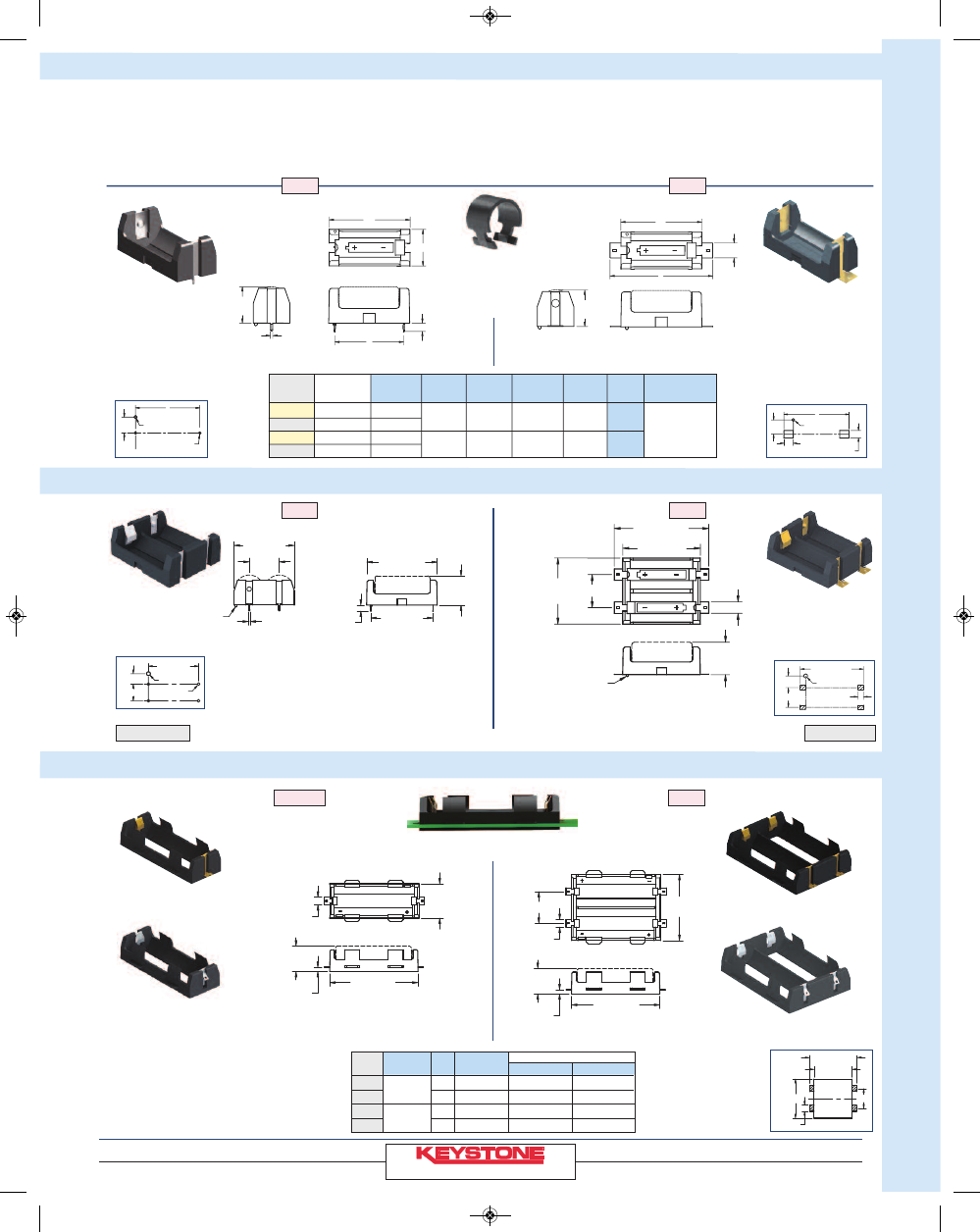

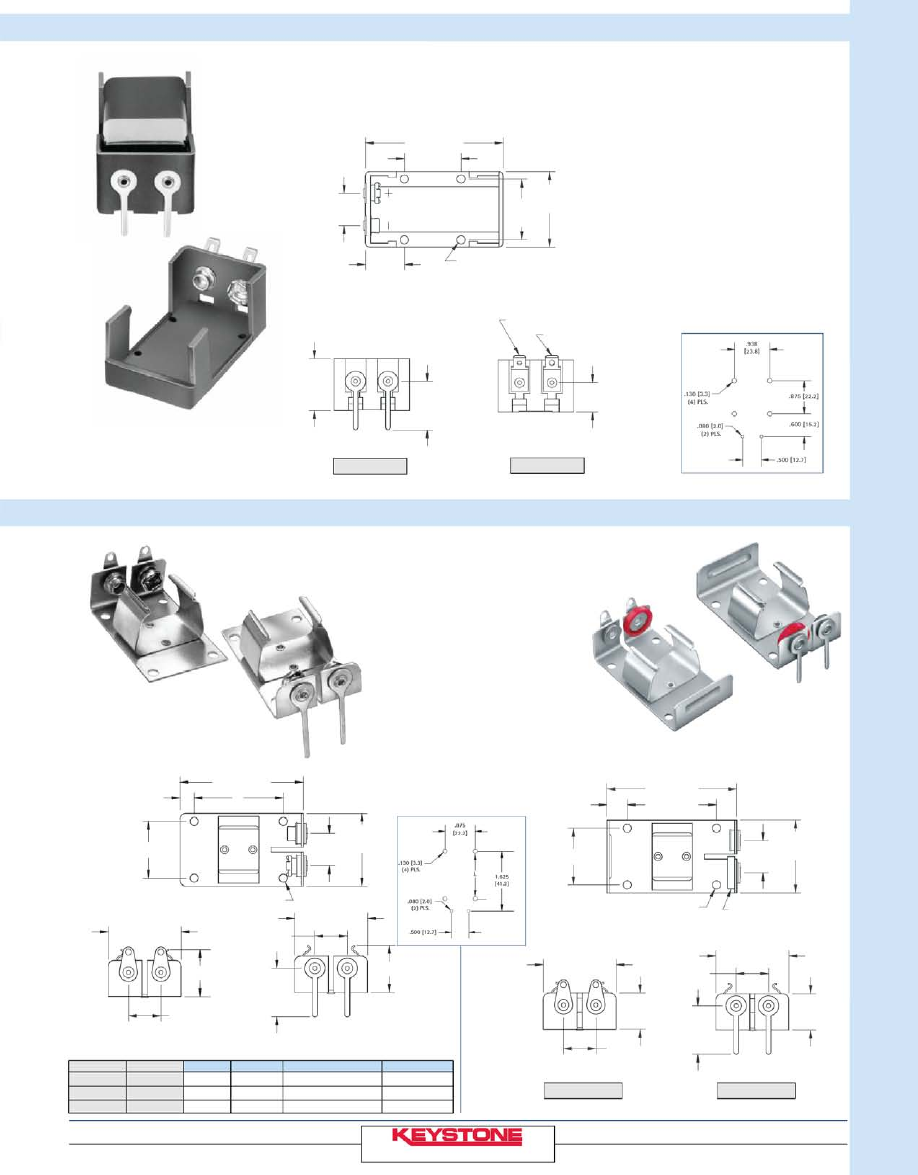

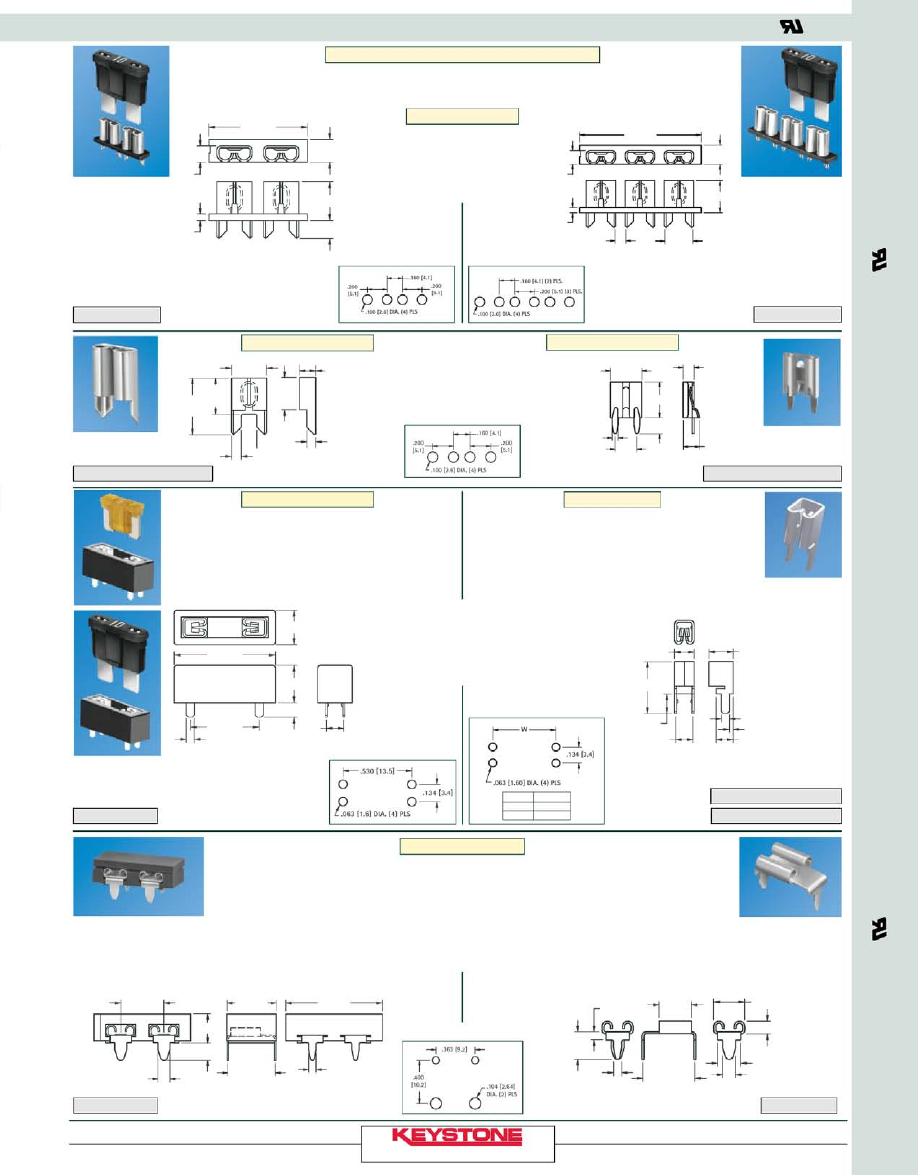

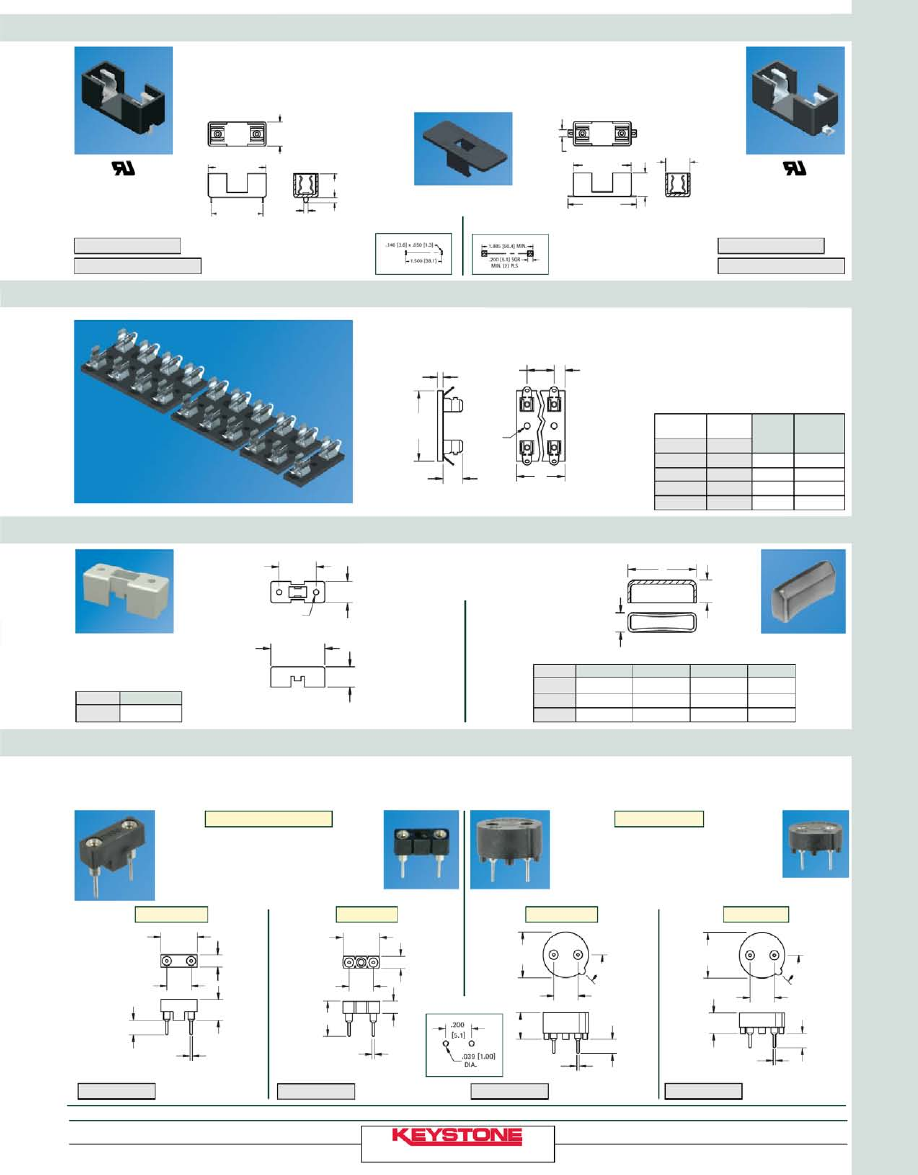

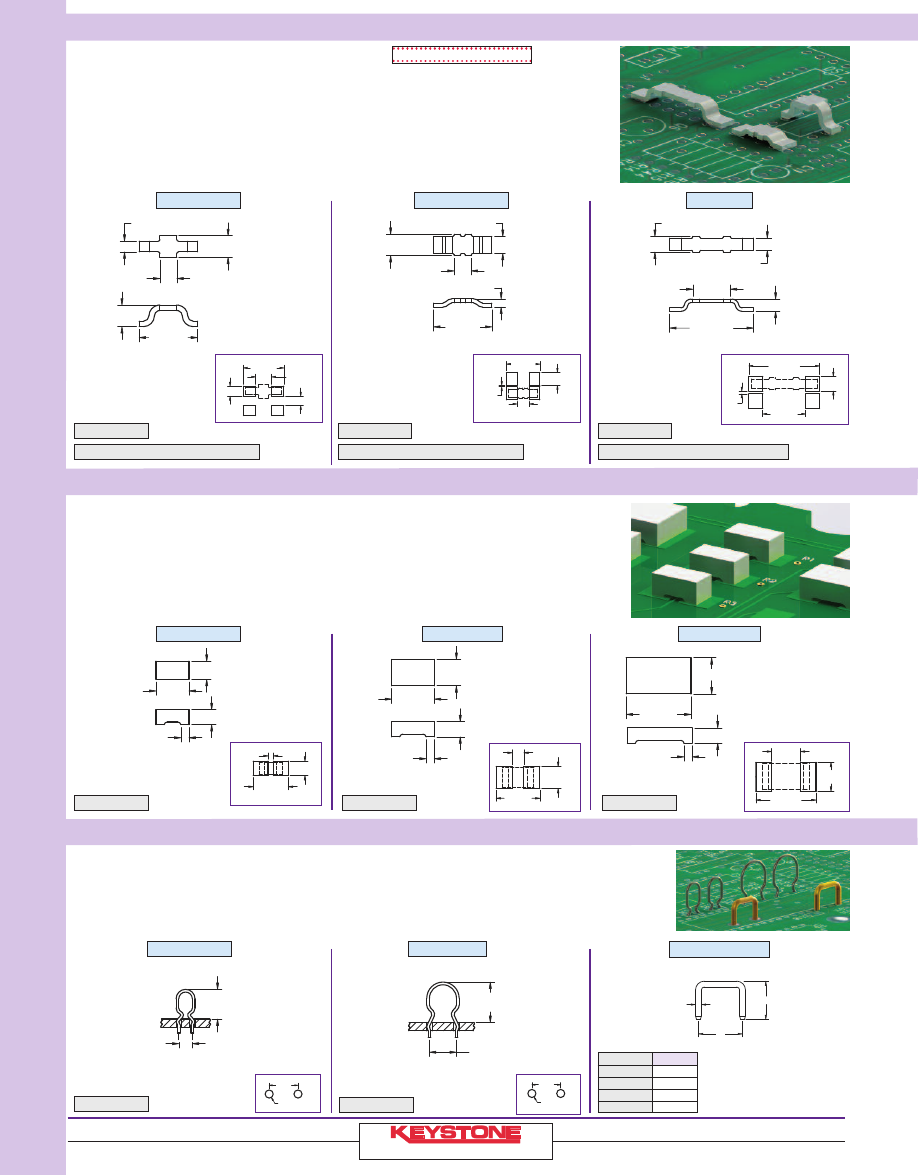

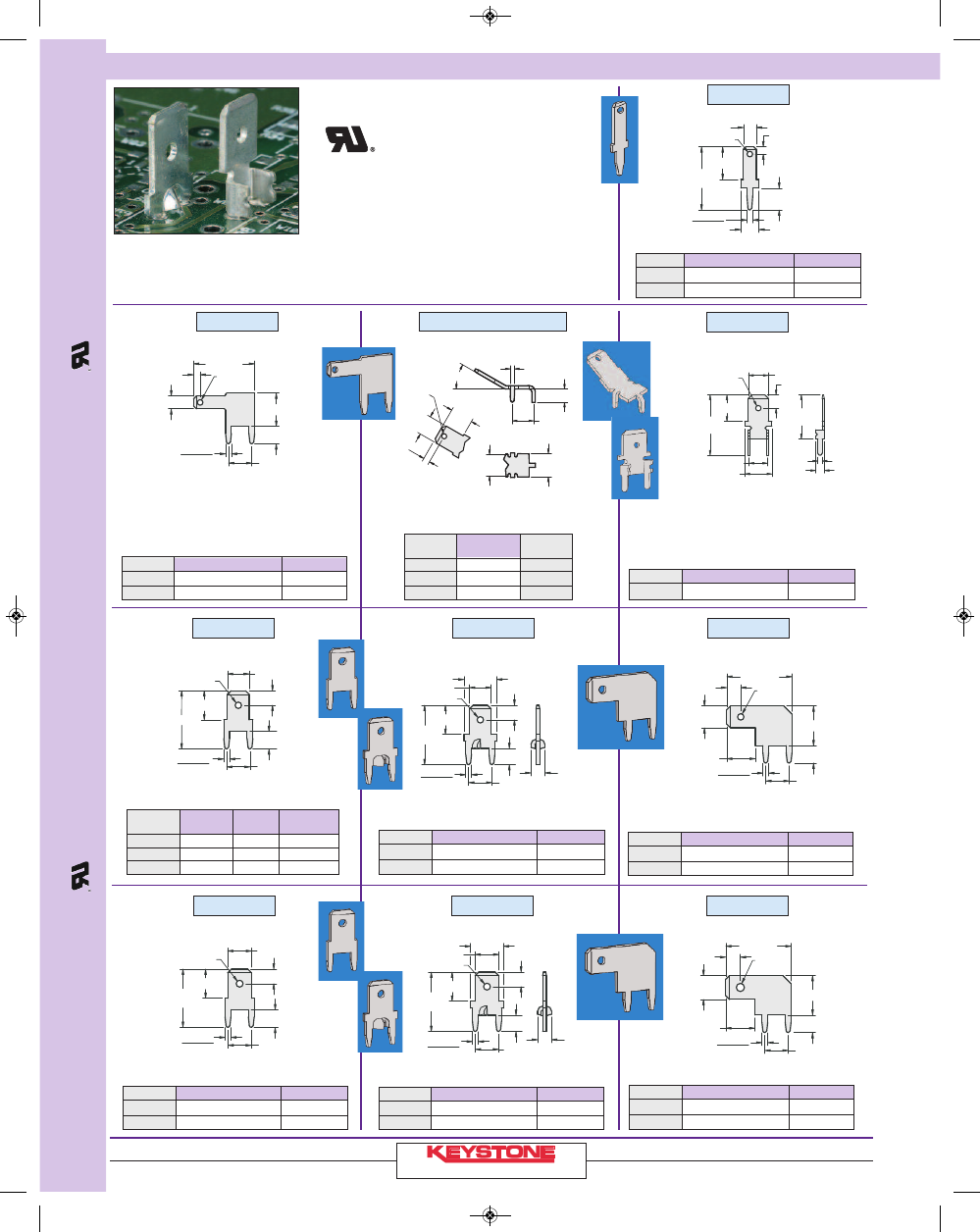

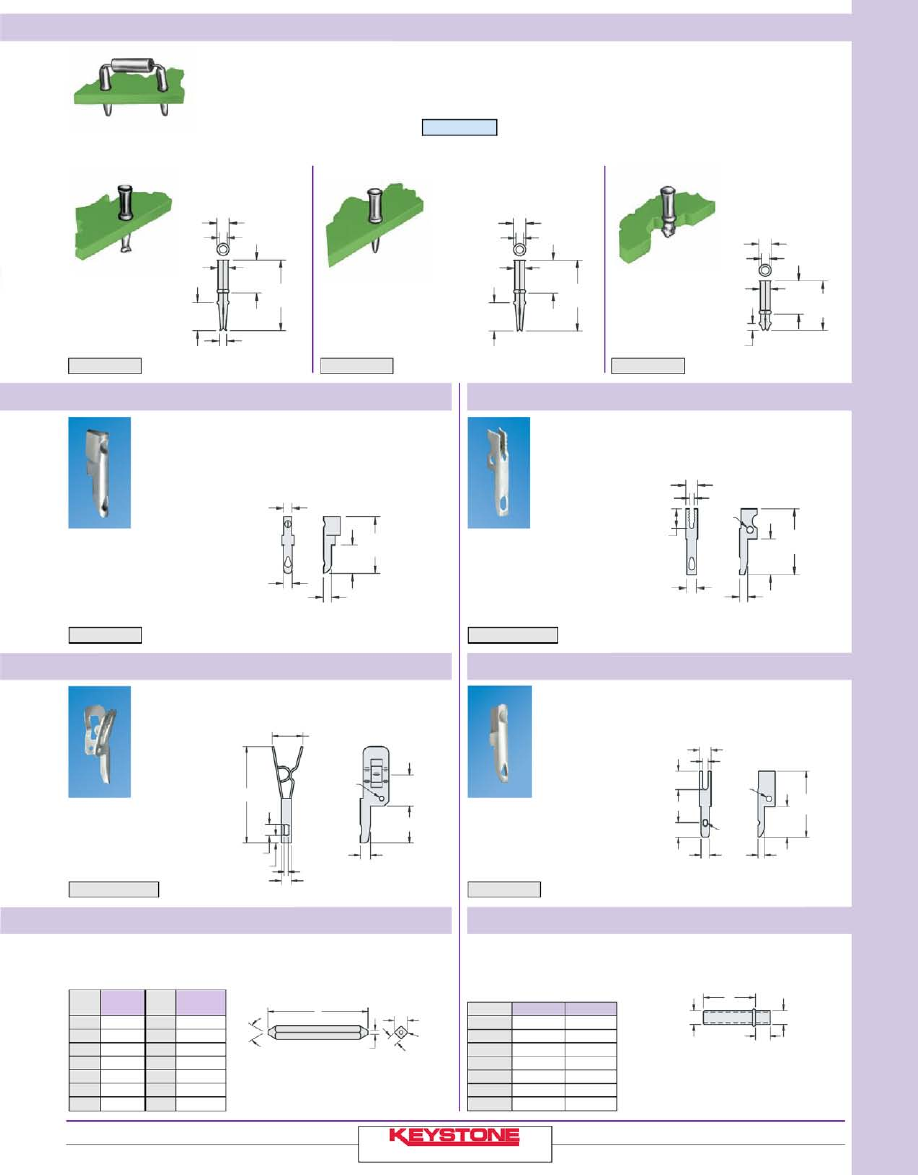

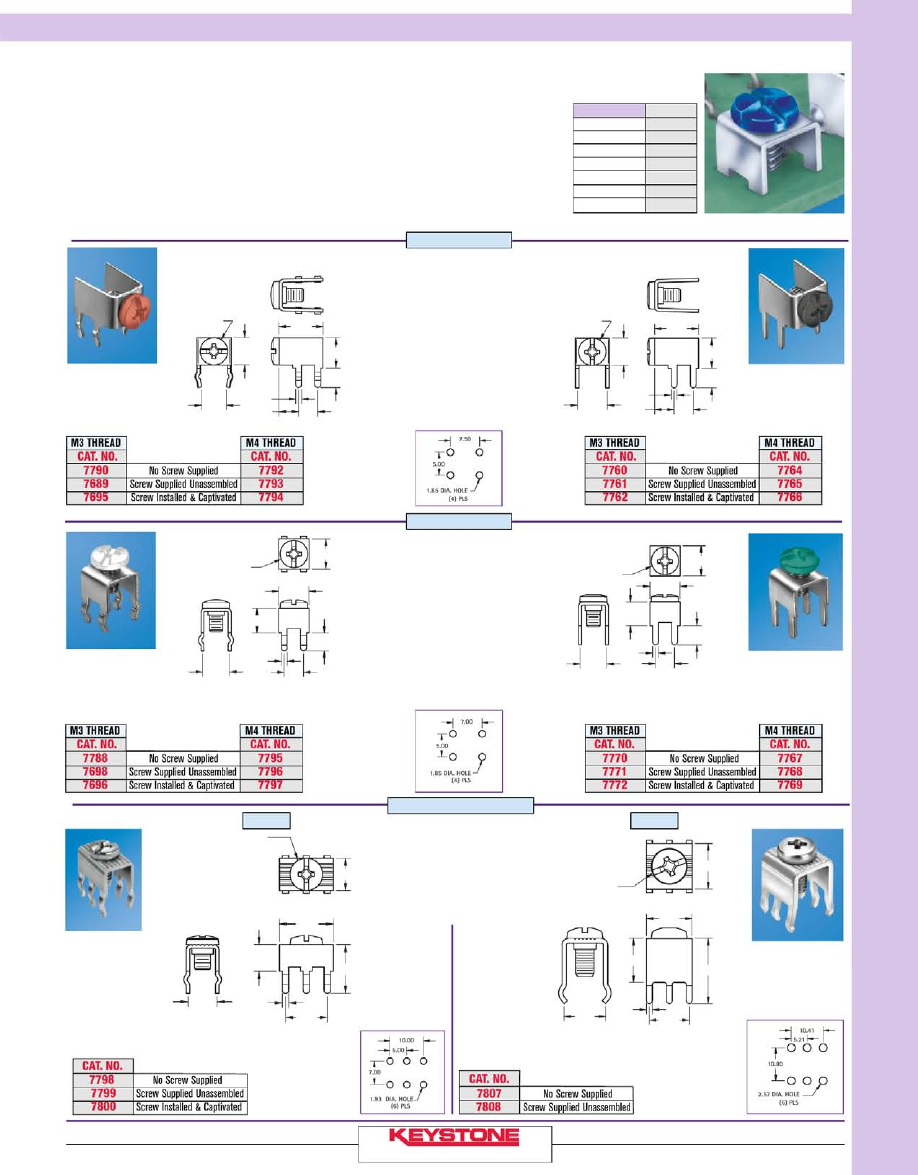

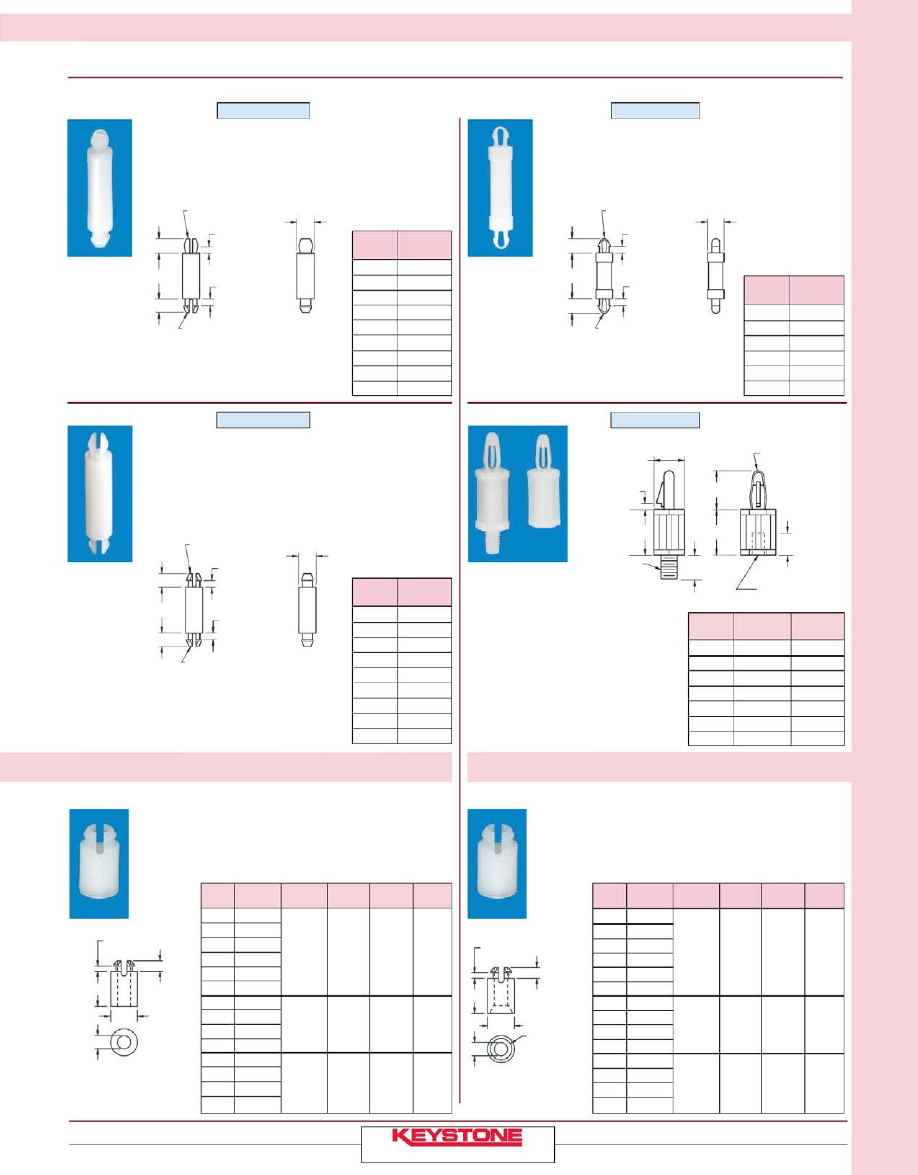

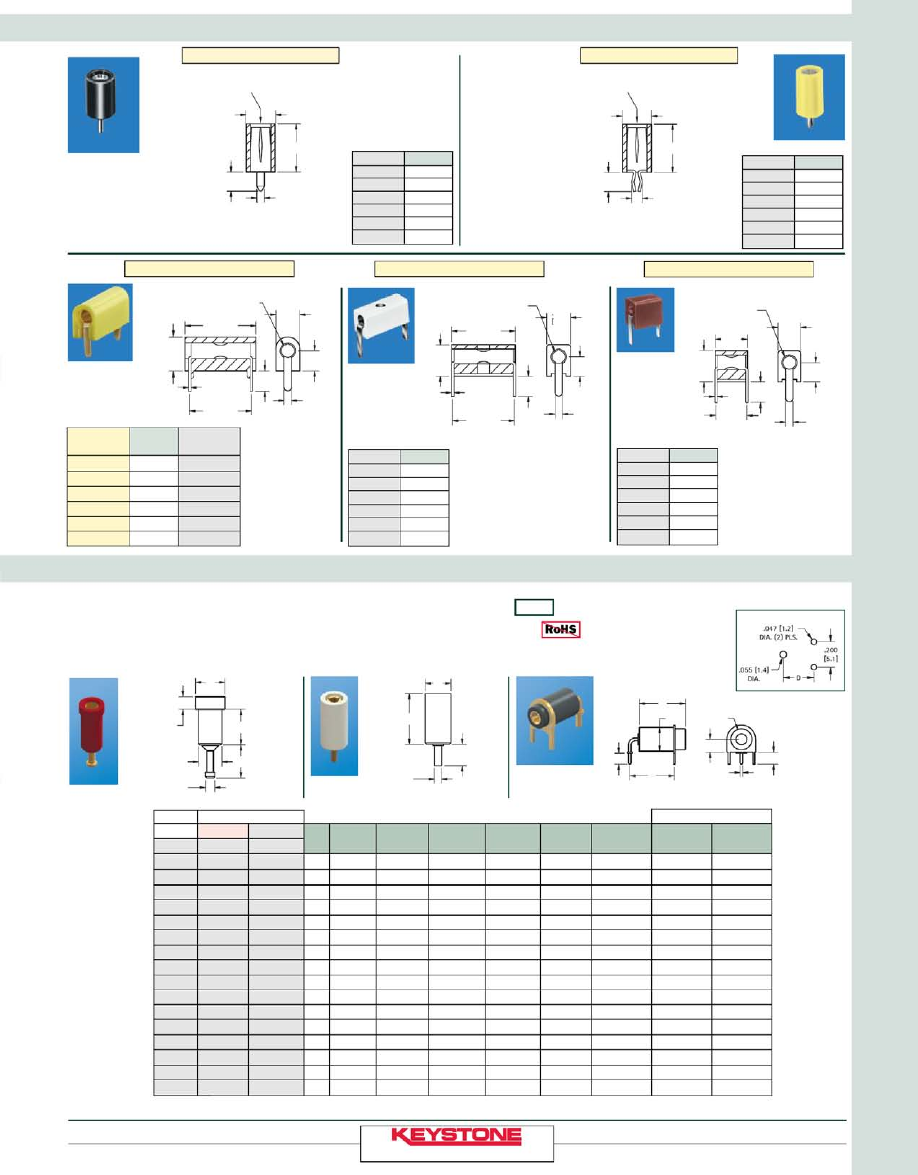

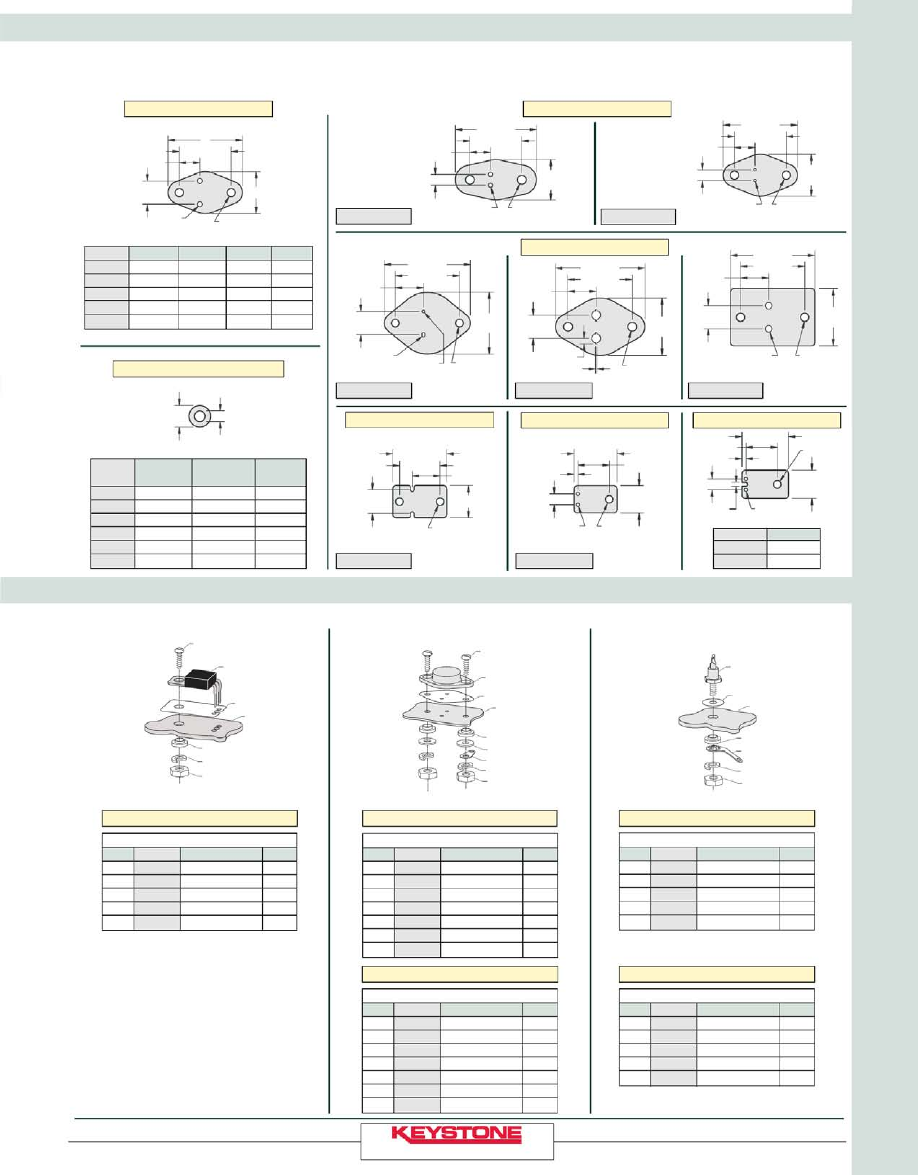

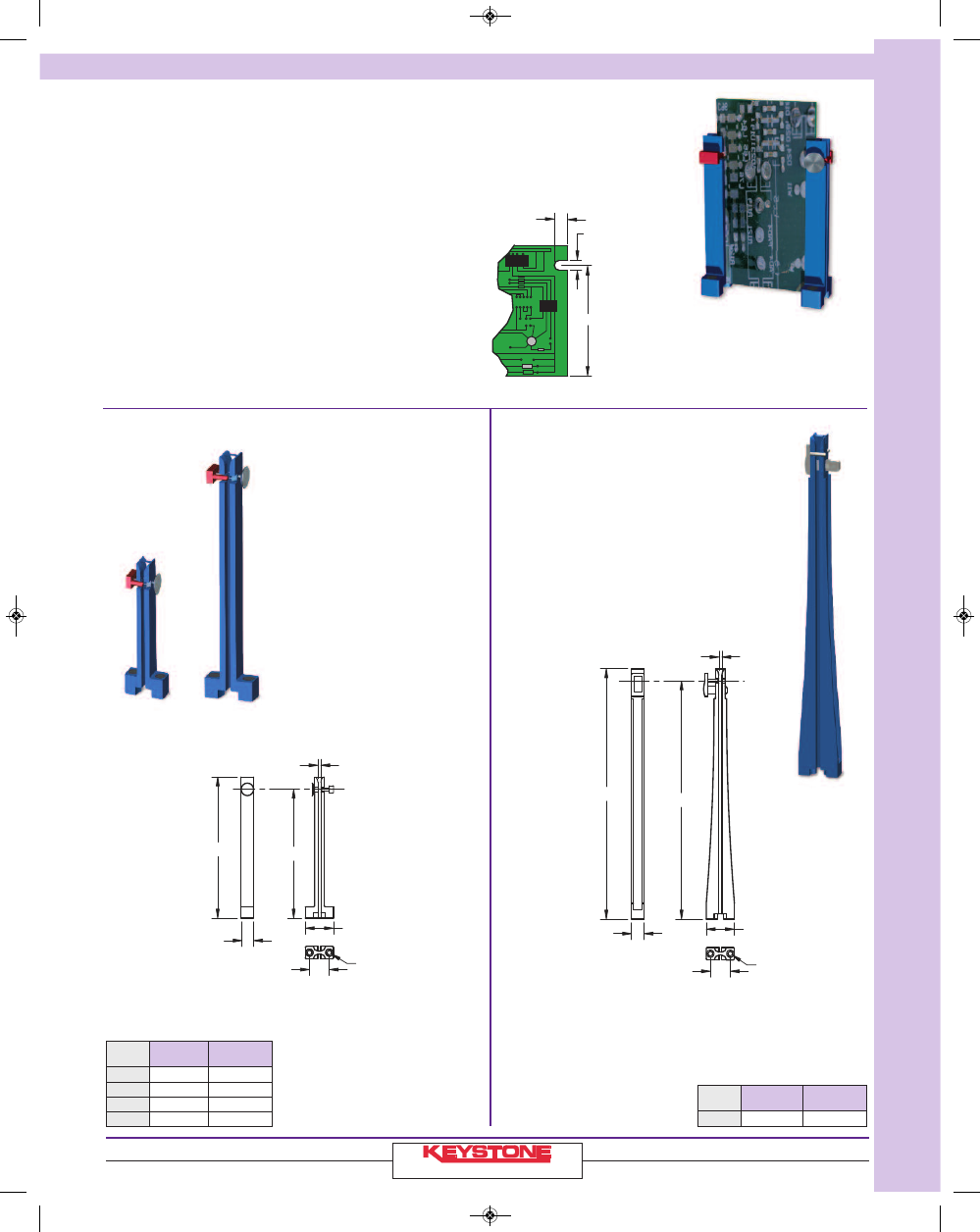

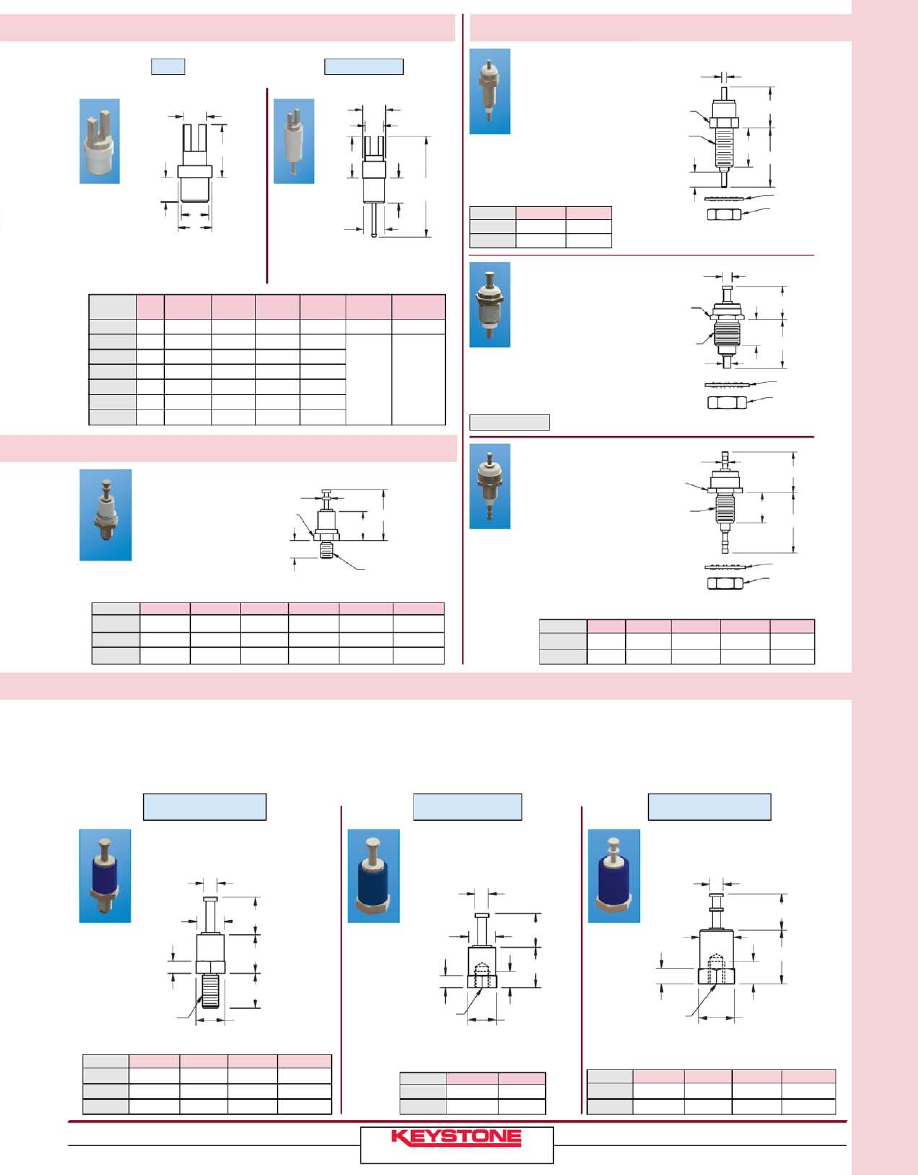

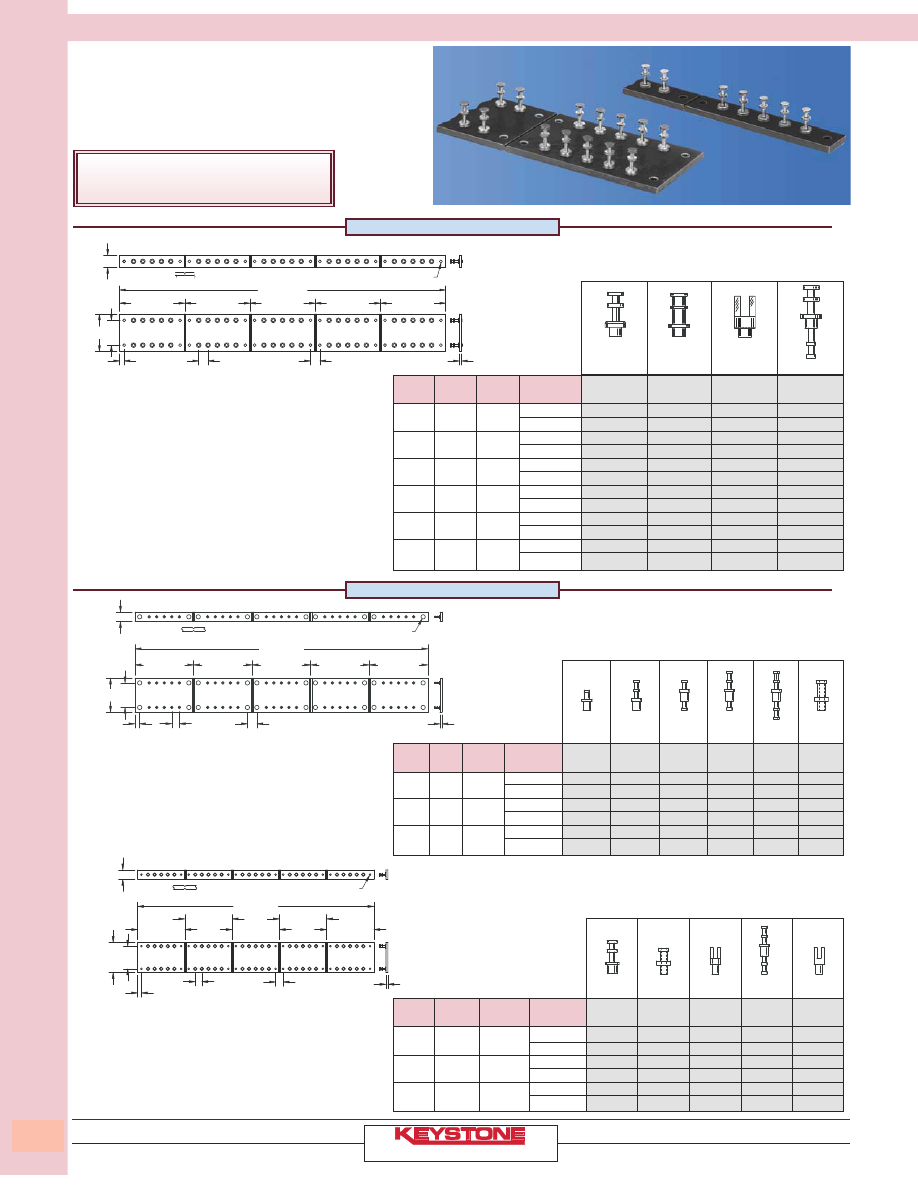

THRU-HOLE (THM) & SURFACE MOUNT (SMT) COIN CELL HOLDERS

1

2

mm

to

1

6

mm

CO

IN

CE

L

L

HO

L

D

E

RS

2

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

DESIGN ADVANTAGES…

•

Reliable spring tension assures low contact resistance

•

Retains battery securely to withstand shock and vibration

•

Base material UL Rated 94V-0. Impervious to most industrial solvents

•

Operating temperature range: -60°F to +293°F (-50°C to +145°C)

IDEALLY SUITED FOR…

•

Computer memory, power transfer and back-up systems

•

Video and telecommunications power back-up

•

Microprocessors and Microcomputer memory hold (desktop and laptop applications)

•

Industrial and commercial security and alarm systems

•

PC/104 application

.048 [1.2] DIA.

x .060 [1.52] L.

.570 [14.5]

.430 [10.9]

.506 [12.9]

REF.

.540 [13.7]

.748 [19.0]

.125 [3.2] TYP.

BATTERY

RELEASE

MATERIAL:

Base:

High Temperature Nylon 46, UL Rated 94V-0

Contacts:

.012 (.30) Phosphor Bronze, Gold Plate (Flash)

Mounting Detail

Pad Layout

.156 [4.0]

.125 [3.2]

.053 [1.3] DIA.

.748

[19.0]

.121 [3.1]

.240 [6.1]

.053 [1.3] DIA.

.031 [0.79]

.047 [1.2]

DIA. (2) PLS

.240 [6.1]

.450 [11.40]

MATERIAL:

Base:

High Temperature Nylon 46, UL Rated 94V-0

Contacts:

.012 (.30) Phosphor Bronze, Gold Plate (Flash)

.038 [.97] WIDE

PIN (2) PLS.

BATTERY

RELEASE

.430 [10.9]

.507 [12.9]

REF.

.048 [1.2] DIA.

x .060 [1.52] L.

.540 [13.7]

.570 [14.5]

.450 [11.4]

Tape & Reel Spec’s:

32mm wide; 20mm pitch; 13 inch reel (500 per reel)

.088

[2.24]

.042 [1.07] DIA.

.295 [7.5]

.480 [12.2]

.144 [3.7]MIN.

.102 [2.6] MIN.

.055 [1.40]

DIA.

Pad Layout

MATERIAL:

Base:

Glass Filled PPS. UL Rated 94V-0

Contacts:

.008 (.20) Phosphor Bronze, Gold Plate (Flash)

.040 [1.0] DIA

(2) PLS.

.393

[10.0]

.061 [1.5]

Mounting Detail

NEGITIVE

.062 [1.57] DIA.

LEG (3) PLS. ON

.375 [2.5] CIR. DIA.

POSITIVE

.497 [12.6] I.D.

.750 [19.1]

.196 [5.0]

.593 [15.1]

O.D.

H

.035 [0.9]

.120 [3.0] MIN.

.393

[10.0]

.036 [0.91]

DIA. LEG

.048 [1.22]

DIA. LEG

.157 [4.0]

.740

[18.8]

.071 [1.8]

(2) PLS

.567

[14.4]

.591

[15.0]

DIA.

MATERIAL:

Base:

PBT, UL Rated 94V-0

Positive Contact:

.015 (.38) Spring Steel, Tin-Nickel Plate

Negative Contact:

.035 (.89) Dia. Steel, Tin-Nickel Plate

Tape & Reel Spec’s:

44mm wide; 24mm pitch; 13 inch reel (450 per reel)

.250 [6.4]

SQUARE ZONE

FOR OPTIONAL

ADHESIVE

1.129 [28.7] MIN.

.138 [3.51]

.111

[2.82]

Pad Layout

MATERIAL:

Base:

Glass Filled LCP, UL Rated 94V-0

Contacts:

.006 (.15) Phosphor Bronze, Gold Plate (Flash)

MATERIAL:

Base:

PBT, UL Rated 94V-0

Contacts:

.010 (.25) Steel, Tin-Nickel Plate

Battery Reference:

(1) cell:

BR1612, CR1616, CL1620,

CR1625, BR1632

CAT. NO. 1069

.061 [1.5]

.463

[11.8]

.040 [1.0] DIA

(2) PLS.

Mounting Detail

NEGITIVE

.062 [1.57] DIA.

LEG (3) PLS. ON

.375 [2.5] CIR. DIA.

POSITIVE

.635 [16.1] I.D.

.120 [3.0] MIN.

H

.196 [5.0]

.750 [19.0]

O.D.

.463

[11.8]

.897 [22.8]

.035 [0.9]

CAT.

HEIGHT

NO.

(H)

CELLS

BATTERY REFERENCE

500

.280 (7.1)

1

BR1212, CR1216, CL1220, CR1225

501

.380 (9.7)

2

BR1212, CR1216, CL1220, CR1225

CAT.

NO.

CELLS

BATTERY REFERENCE

503

1

DL1/3N, K58L, CR1/3N

2

SR44, 357, MS76, G-13, 303, V313, PX76A

CAT. NO.

ON TAPE

BULK

& REEL

CELLS

BATTERY REFERENCE

498

498TR

1

DL1/3N, K58L, CR1/3N

2

SR44, 357, MS76, G-13, 303, V313, PX76A

Tape & Reel Spec’s:

44mm wide; 20mm pitch; 13 inch reel (200 pieces per reel)

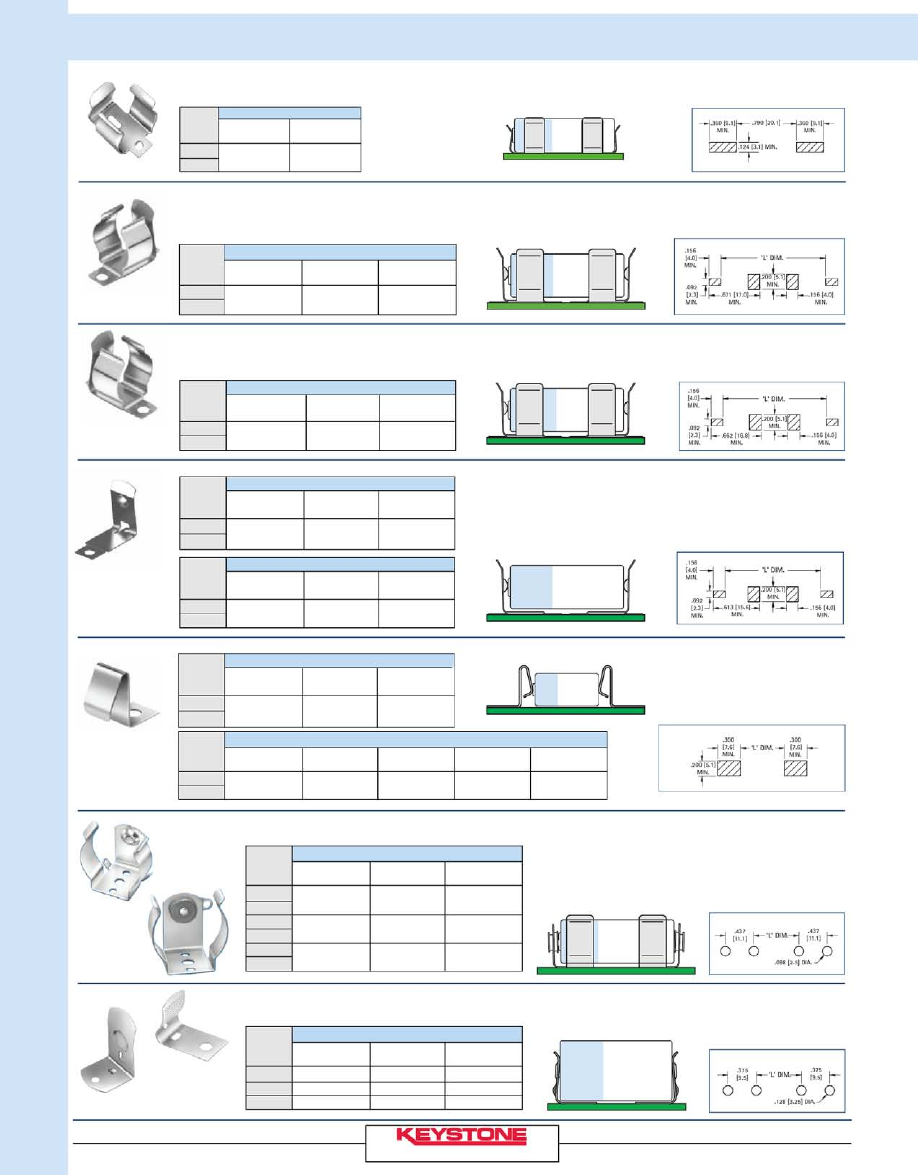

THRU HOLE MOUNT

SURFACE MOUNT

THRU HOLE MOUNT

SURFACE MOUNT

SURFACE MOUNT

THRU HOLE MOUNT

CAT. NO.

ON TAPE

BULK

& REEL

CELLS

BATTERY REFERENCE

504

504TR

1

BR1625, CR1632

CAT. NO.

ON TAPE

BULK

& REEL

CELLS

BATTERY REFERENCE

1056

1056TR

1

CR1220, BR1220

CAT.

HEIGHT

NO.

(H)

CELLS

BATTERY REFERENCE

502

.285 (7.3)

1

CR1612, CL1616, CL1620

2

CR1612

502-3

1

BR1625, CR1632

.330 (8.4)

2

BR1616, CR1620, CL1620

MATERIAL:

Base:

Glass Filled LCP, UL Rated 94V-0

Positive Contact:

.015 (.38) Spring Steel, Tin-Nickel Plate

Negative Contact:

.035 (.89) Dia. Steel, Tin-Nickel Plate

.630 [16.0]

.212 [5.4]

.677 [17.2]

1.129 [28.7]

.138 [3.5]

(2) PLS

.680 [17.3]

REF.

.478 [12.1]

.050 [1.3]

.045 [1.1]

.640

[16.3]

DIA.

.270 [6.9]

.200 [5.1]

.145

[3.7] DIA.

.070

[1.8]

.832 [21.1]

.728 [18.5]

.422

[10.7]

.125

[3.2]

.047 [1.2]

.174 [4.4]

.136 [3.5]

.422 [10.7]

.136 [3.5]

(2) PLS

.060 [1.5]

(2) PLS

.478 [12.1]

+

Pad Layout

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

1/3N

12mm

16mm

16mm VERTICAL

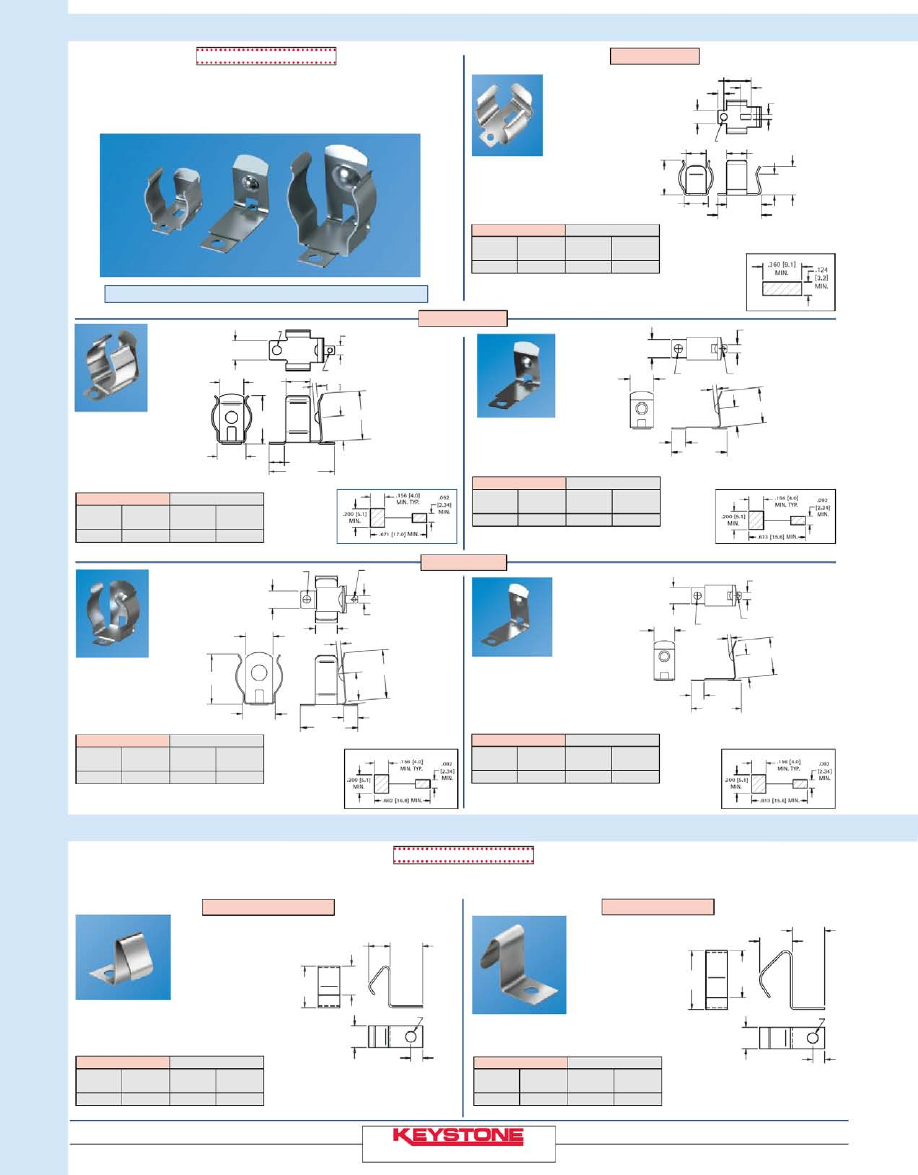

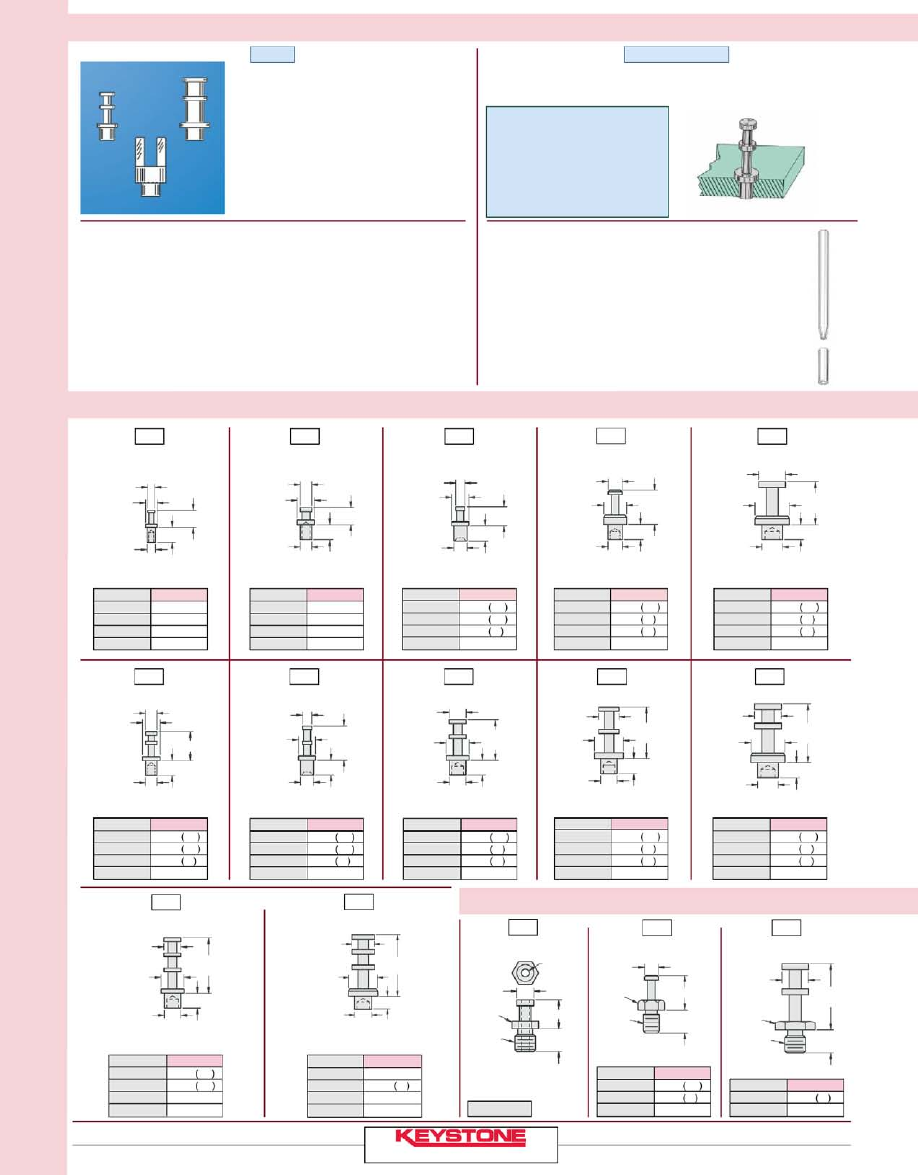

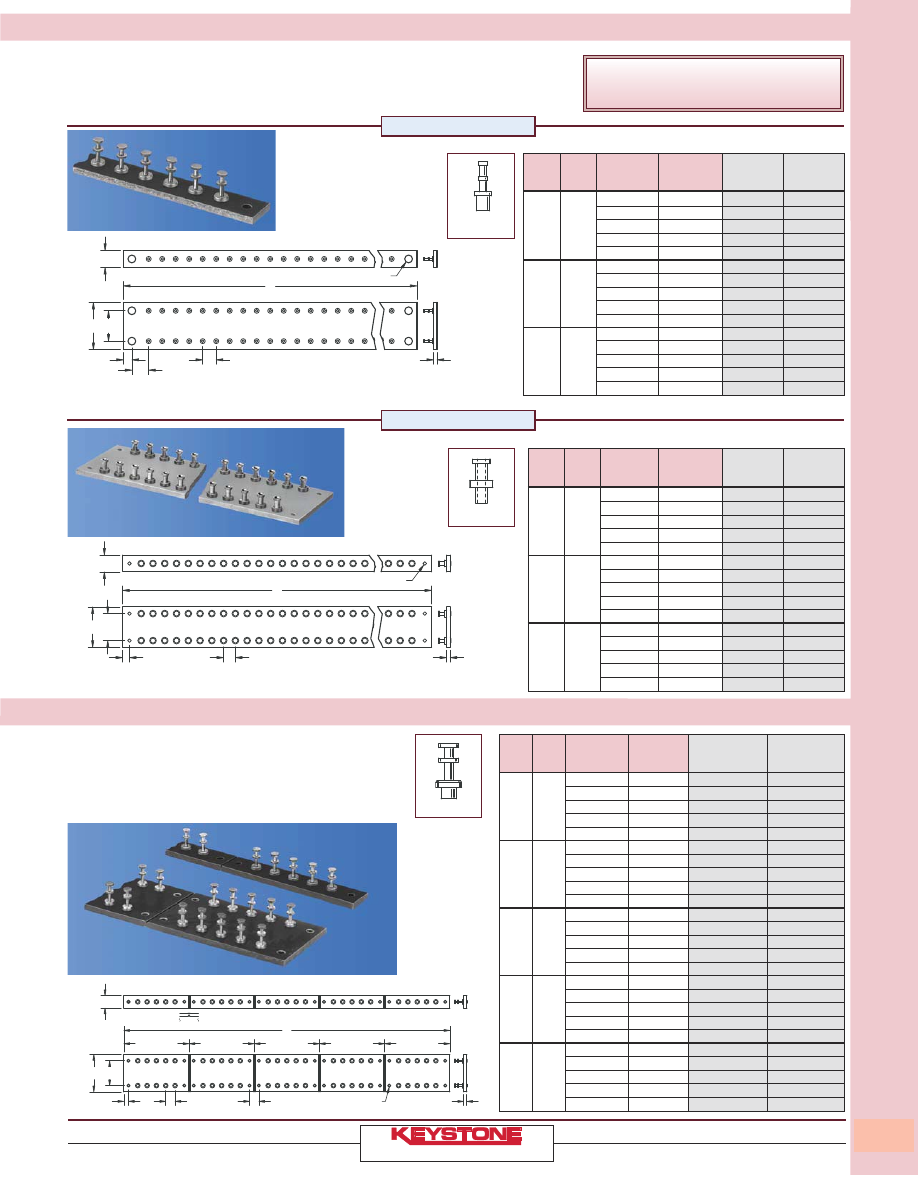

M65.1 S1p2 8/19/15 11:31 AM Page 2

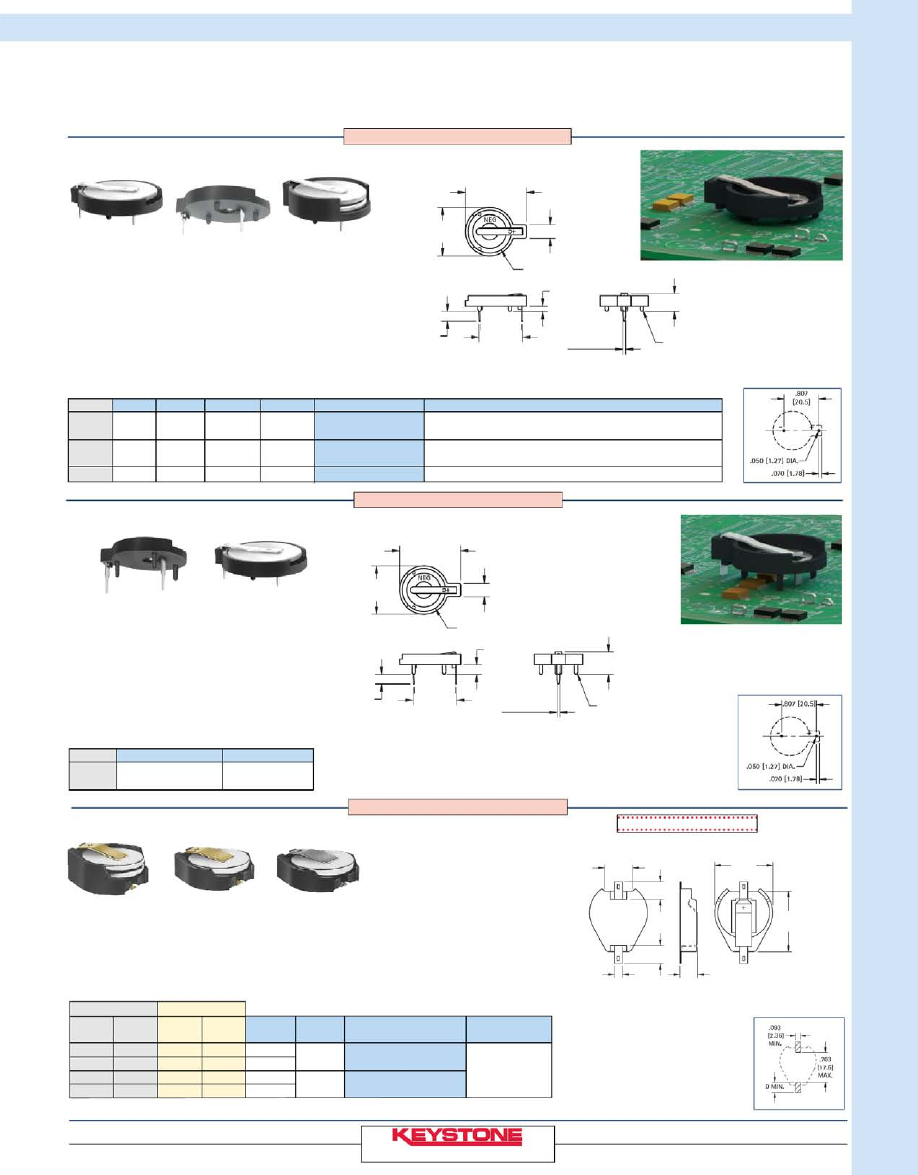

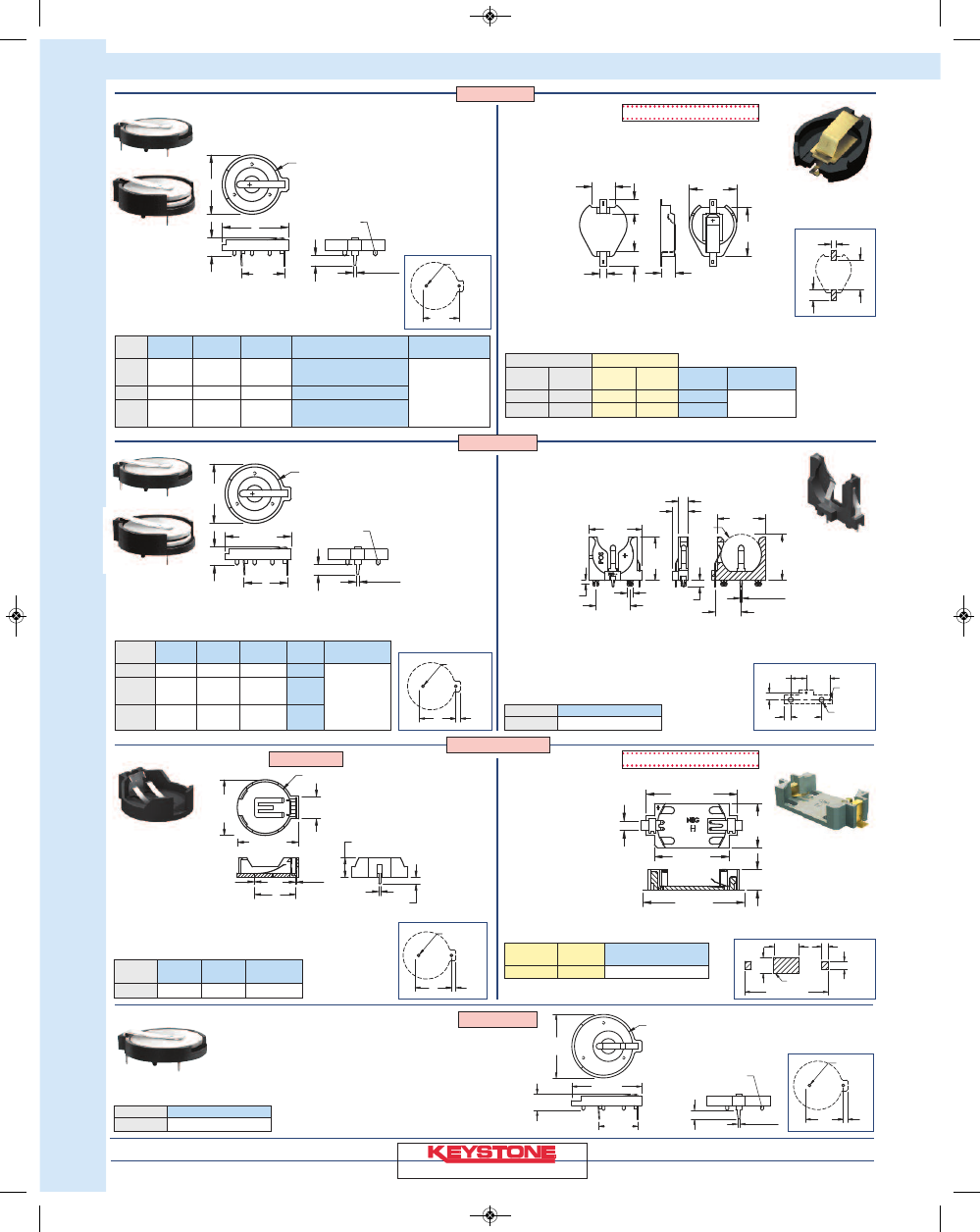

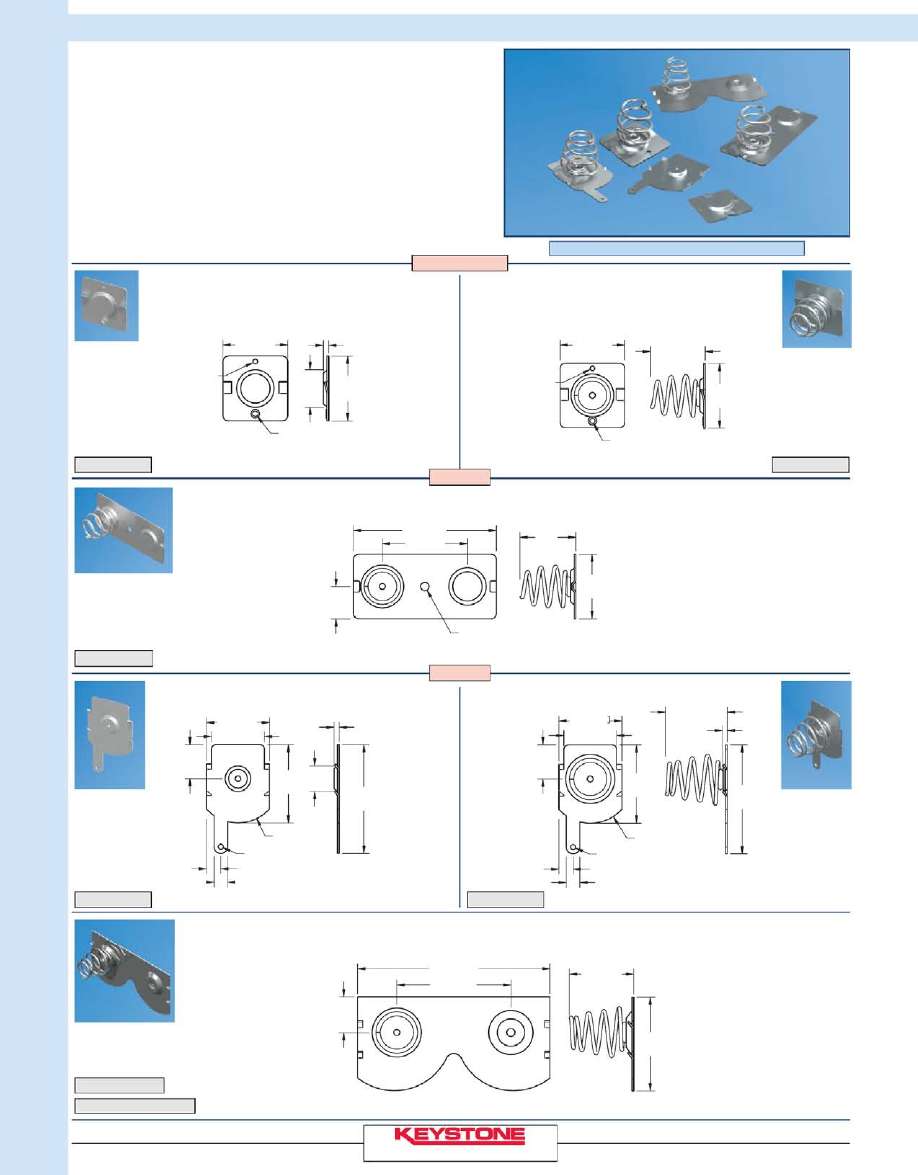

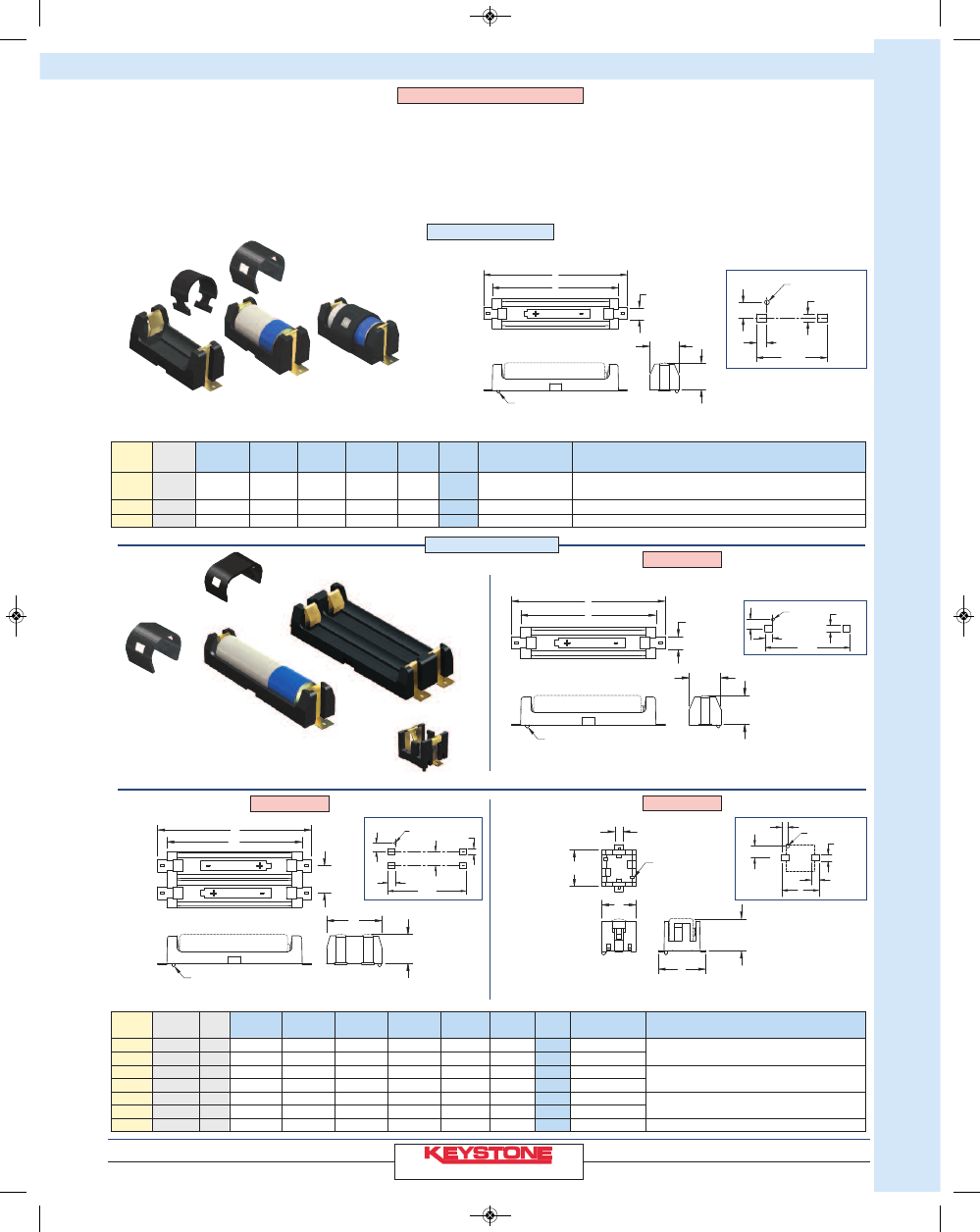

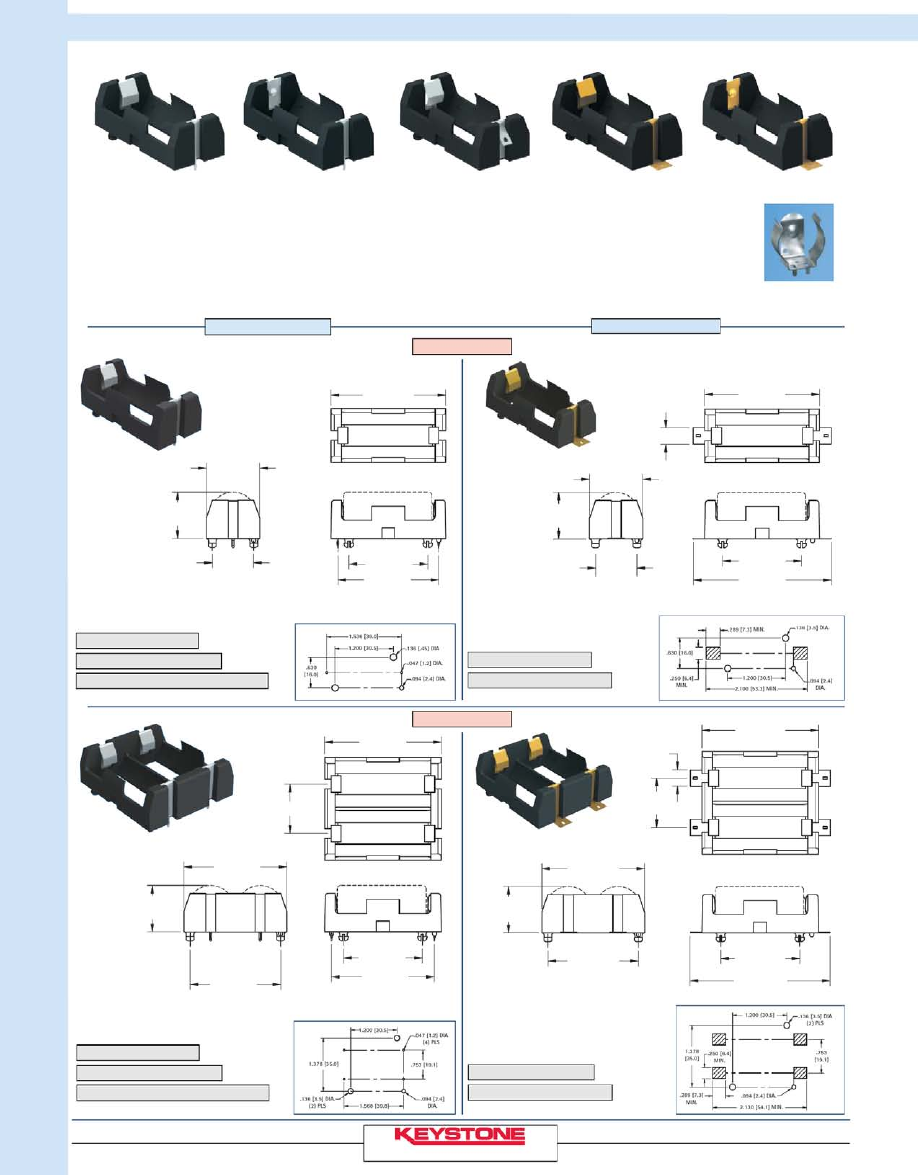

20m

m

C

OIN C

ELL H

OLDER

S

3

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

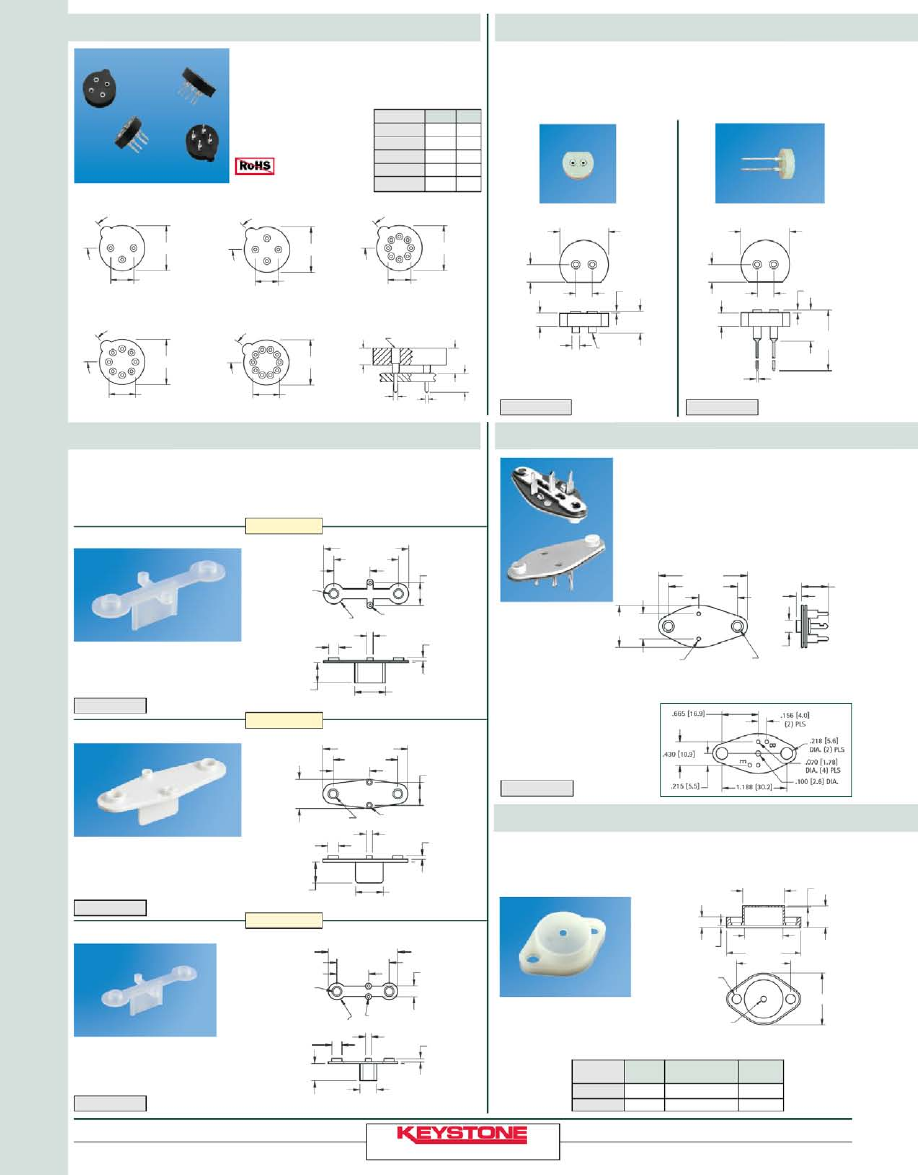

MATERIAL:

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

Mounting Detail

CAT. NO.

G

H

L

O.D.

NO. OF CELLS

BATTERY REFERENCE

103

.100 (2.5) .335 (8.5) 1.130 (28.7)

.896 (22.8)

(1) cell (any 20mm)

BR2012,CR2012, CR2016, CL2016, DL2020, CL2025, BR2025, CR2032, CL2032

(2) 2012, (2) 2016

106

.100 (2.5) .335 (8.5)

1.219 (31.0) 1.093 (27.8)

(1) cell (any 20mm)

BR2012,CR2012, CR2016, CL2016, DL2020, CL2025, BR2025, CR2032, CL2032

(2) 2012, (2) 2016

1026

.100 (2.5) .452 (11.5) 1.219 (31.0) 1.093 (27.8) (2) 2020, (2) 2025, (2) 2032 DL2020, CR2020, CL2025, BR2025, CR2032, CL2032

CAT. NO.

BATTERY REFERENCE

NO. OF CELLS

101

BR2012, CR2016, CL2020,

(1) cell (any 20mm)

CR2025, CR2032

(2) 2012, (2) 2016

.062 [1.57] DIA. LEG (3) PLS.

ON .750 [19.00] CIRCLE DIA.

.050 [1.27]

.045 [1.14]

.807 [20.5]

AT TIP

.796 [20.2] I.D.

.896 [22.8]

O.D.

1.130 [28.7]

H

.179 [4.5]

.179 [4.6]

.250 [6.3]

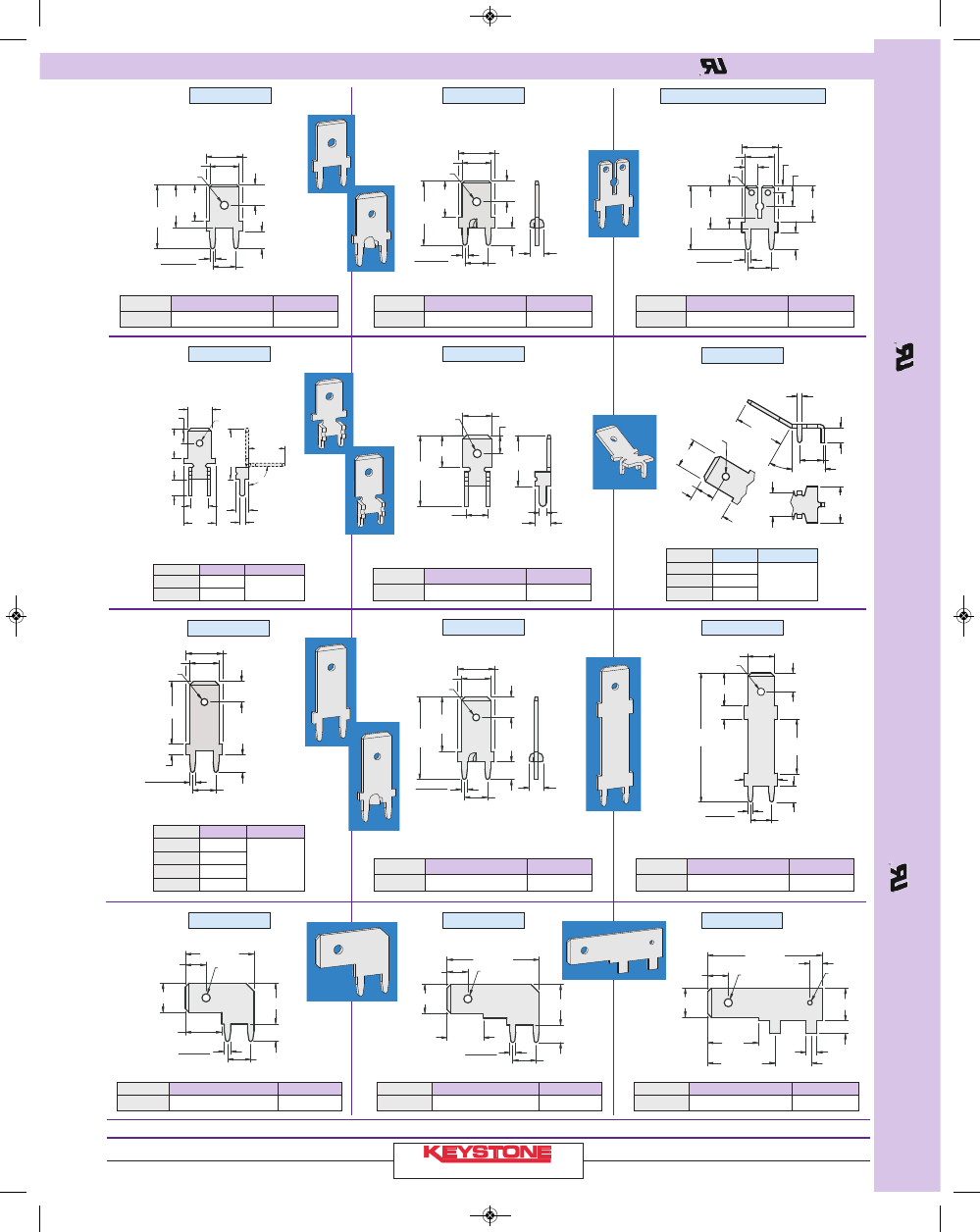

•

Designed to maximize PC Board Capacity

•

Unique raised mounting design allows components to be

placed underneath the holder

•

Ideal when board space is more important than board

height; such as PC/104 applicatons

•

Advanced air-flow design enhances air circulation

around battery

•

Reliable spring tension assures low contact resistance

•

Unique notched slots assure quick and easy battery

insertion and replacement

•

Retains battery securely to withstand shock and vibration

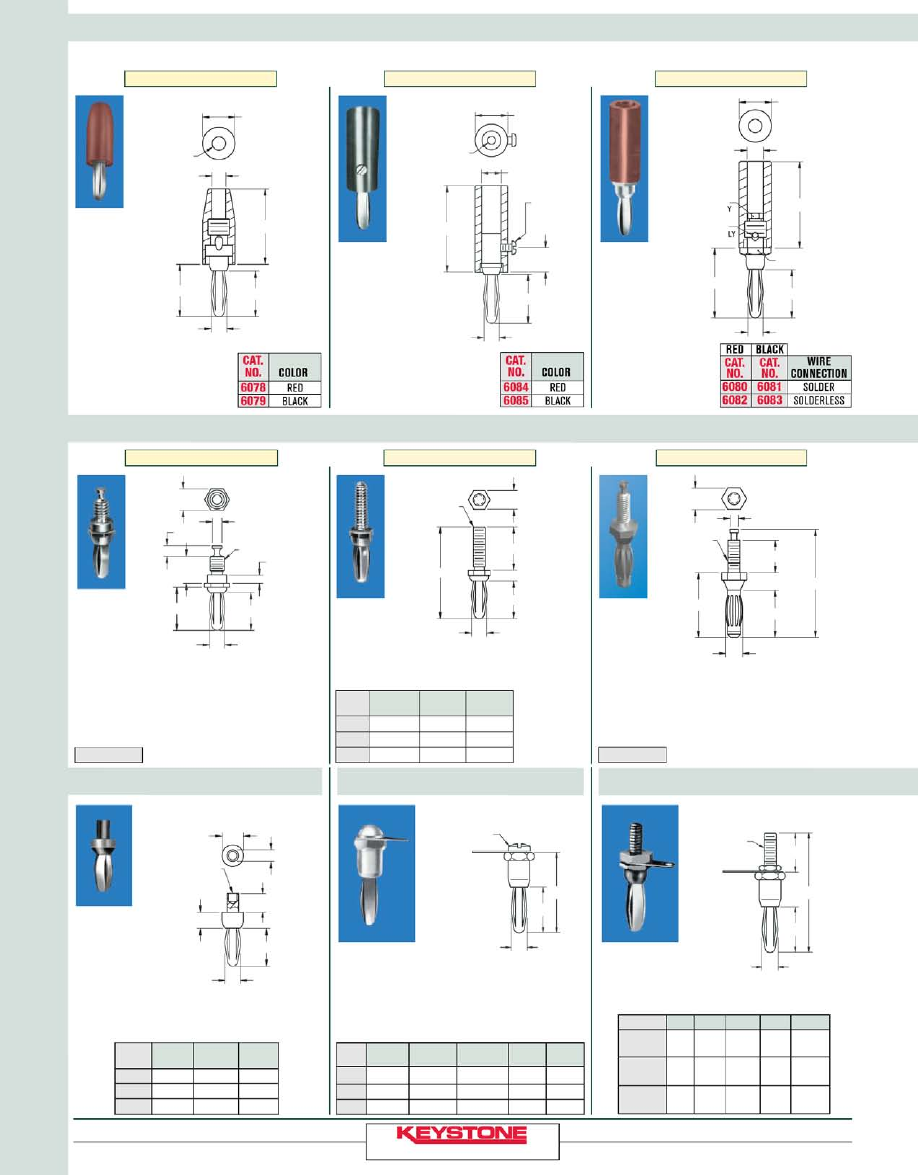

THRU-HOLE (THM) & SURFACE MOUNT (SMT) COIN CELL HOLDERS

MATERIAL:

Contacts:

.015 (.38) Steel

Base:

High Temperature, Nylon 46, UL Rated 94V-0

Pad Layout

NEG

D

D

H

.896

[22.8]

.703

[17.9]

.931

[23.65]

.437

[11.1]

.125

[3.2]

Tin-Nickel Plate

Gold Plate (Flash)

CAT. NO. ON TAPE CAT. NO. ON TAPE

D

H

BATTERY

BULK

& REEL

BULK

& REEL

PAD SIZE

HIEGHT

NO. OF CELLS

REFERENCE

1061

1061TR

1081

1081TR

.156 (4.0)

(1) Cell (any 20mm)

CR2012, CL2016,

1063

1063TR

1093

1093TR

.278 (7.1)

.290 (7.4)

(2) 2012, (2) 2016

BR2020, DL2032

1062

1062TR

1082

1082TR

.156 (4.0)

(2) 2020, (2) 2025, (2) 2032

CR2032

1064

1064TR

1094

1094TR

.278 (7.1)

.391 (9.9)

(3) 2012, (3) 2016

Tape & Reel Spec’s:

44mm wide; 32mm pitch; 13 inch reel (200 pieces per reel)

•

Polarity clearly marked (+)

•

Compatible with vacuum and mechanical

pick & place assembly systems

•

SMT solder tail with “Flow-Hole” design

for increased joint strength

•

Viewable solder tails assures reliable

joint inspection

•

Safe for all soldering & reflow operations

DESIGN ADVANTAGES…

•

Reliable spring tension assures low contact

resistance

•

Retains battery securely to withstand shock

and vibration

•

All conductive polystyrene carrier tape meets

ANSI/EIA - 481 standard

•

Base material UL Rated 94V-0. Impervious

to most industrial solvents

•

Operating temperature range:

-60°F to +293°F (-50°C to +145°C)

IDEALLY SUITED FOR…

•

Computer memory, power transfer and

back-up systems

•

Video and telecommunications power back-up

•

Microprocessors and Microcomputer memory

hold (desktop and laptop applications)

•

Industrial and commercial security and

alarm systems

•

Communications power sources

•

PC/104 applications

AVAILABLE ON TAPE AND REEL

20mm SURFACE MOUNT COIN CELL HOLDER

20mm THRU-HOLE MOUNT CON CELL HOLDER

20mm RAISED MOUNT COIN CELL HOLDER

MATERIAL:

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

.062 [1.57] DIA. LEG (3) PLS.

ON .750 [19.00] CIRCLE DIA.

.050 [1.27]

.045 [1.14]

.807 [20.5]

AT TIP

.796 [20.2] I.D.

.896 [22.8]

O.D.

1.130 [28.7]

.414 [10.5]

.179 [4.5]

.179 [4.6]

.250 [6.3]

Mounting Detail

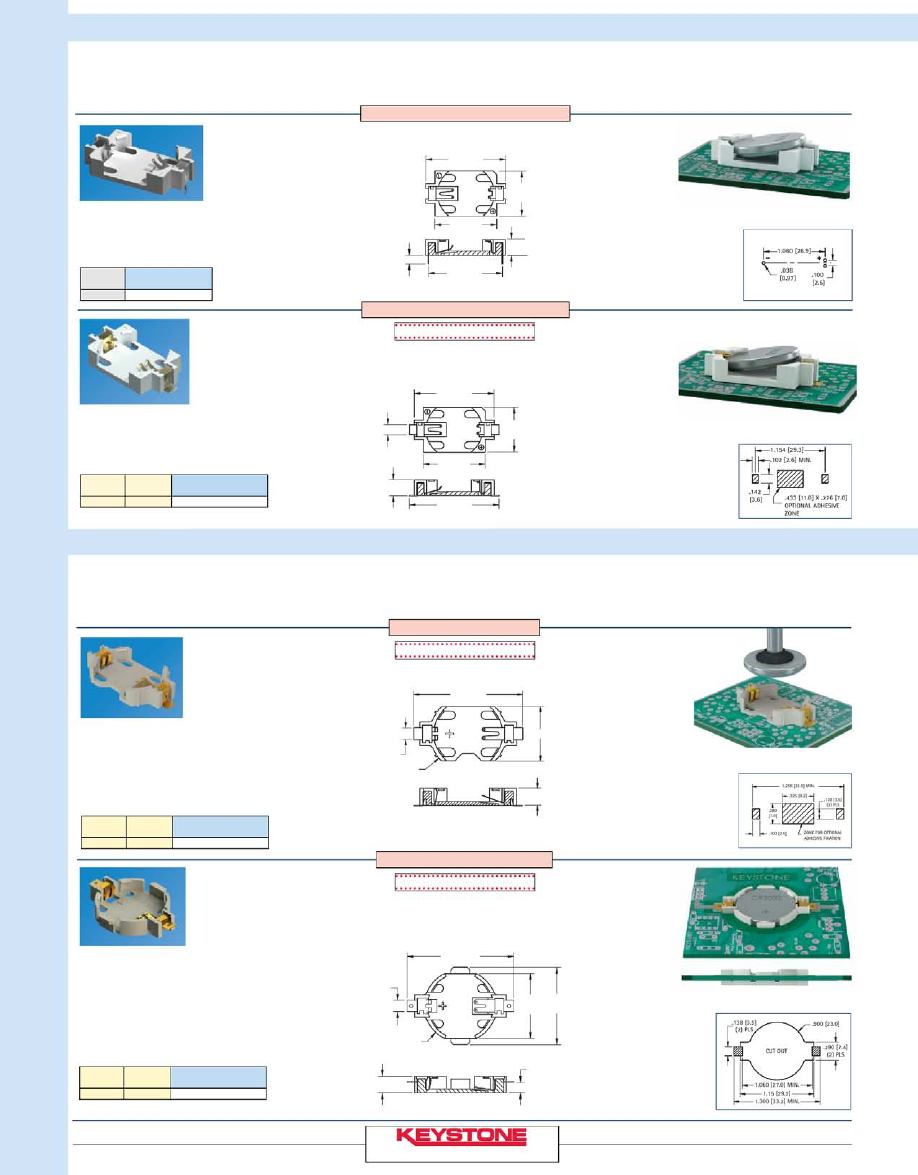

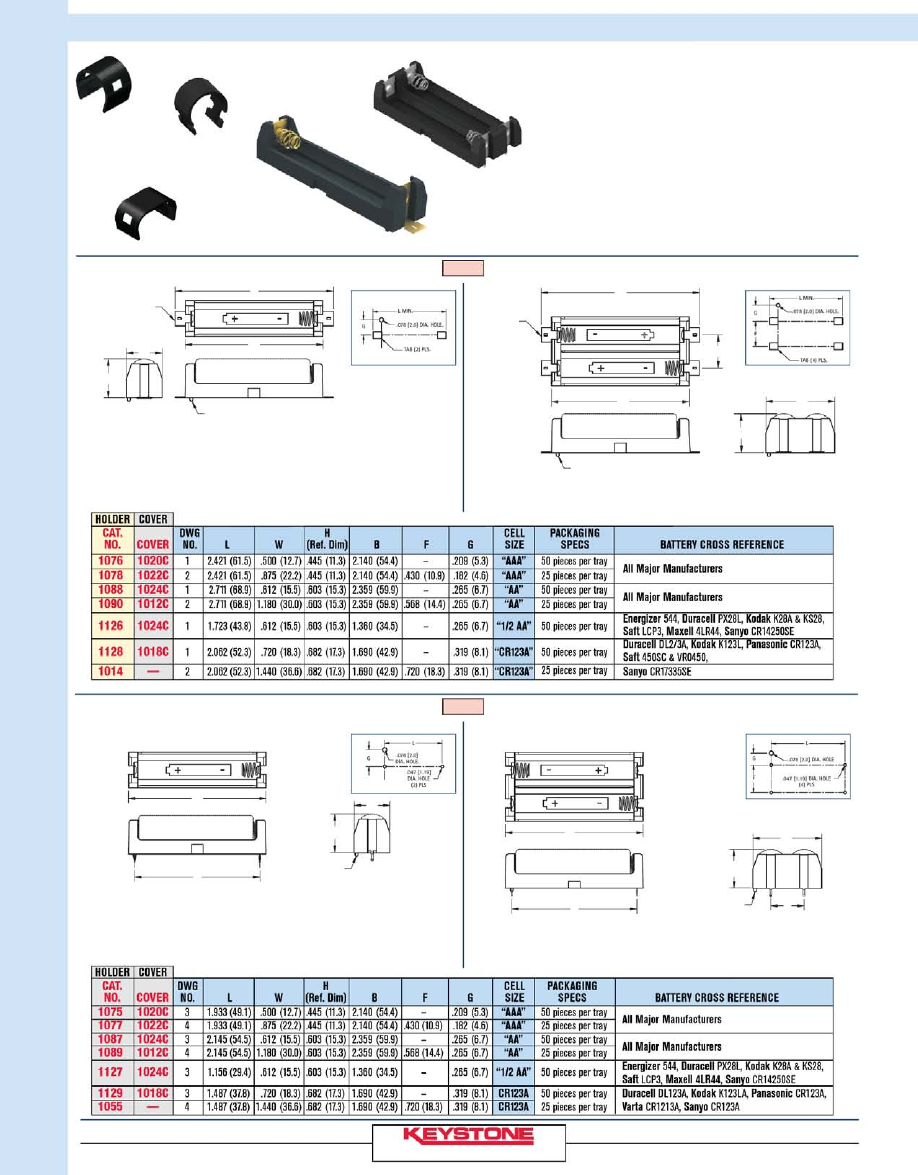

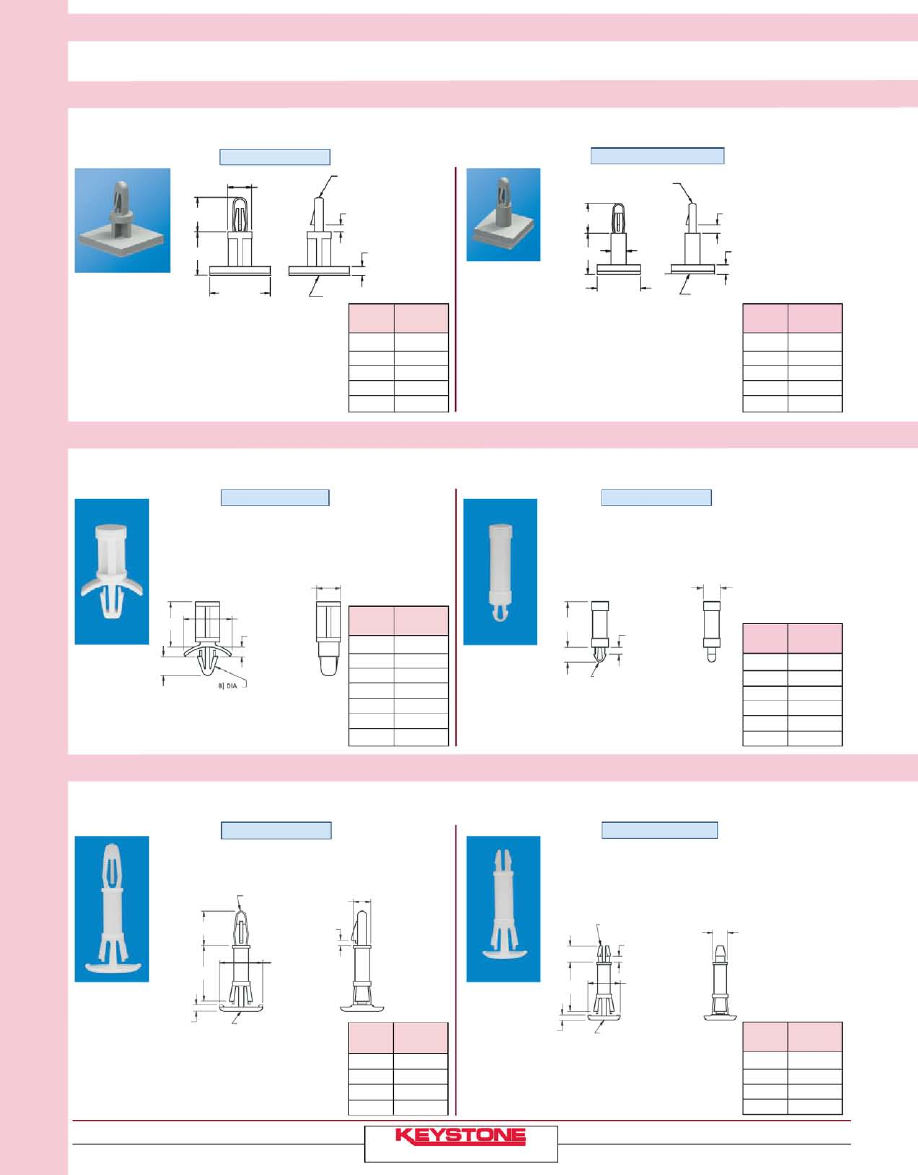

THRU-HOLE (THM) & SURFACE MOUNT (SMT) VIBRA-FIT HOLDERS

20m

m

C

OIN C

ELL H

OLDER

S

4

Tape & Reel Spec’s:

44mm wide; 20mm pitch; 13 inch reel (500 pieces per reel)

Pad Layout

MATERIAL:

Contacts:

.006 (.15) Phosphor Bronze, Gold Plate (Flash)

Base:

Glass Filled LCP, UL Rated 94V-0

•

Extremely rugged, holds battery securely under shock and vibration applications.

•

Polarized holder protects circuit from improper battery insertion.

•

Polarity clearly marked

•

Safe for all soldering and reflow operations

•

Designed for manual insertion of battery

•

Glass Filled LCP base material UL Rated 94V-0

impervious to most industrial solvents.

•

Operating Temperature Range: -60°F to 293°F (-50°C to 146°C)

•

Compatible with vacuum and mechanical pick & place assembly systems

•

All conductive polystyrene carrier tape meets ANSI/EIA-481 standards

•

Viewable solder tails allows for easy solder joint inspection

CAT. NO.

ON TAPE

BULK

& REEL

BATTERY REFERENCE

1060

1060TR

CR2025, DL2032

CAT.

NO.

BATTERY REFERENCE

1059

CR2025, DL2032

MATERIAL:

Contacts:

.006 (.15) Phosphor Bronze, Tin Plate

Base:

Glass Filled LCP, UL Rated 94V-0

Mounting Detail

.130 [3.3]

1.060 [26.9]

.630

[16.0]

1.118 [28.4]

.866 [22.0]

.217 [5.5]

•

Tin plated contacts compatible with wave solder and manual soldering process

1.256 [31.9]

142 [3.6]

.866 [22.0]

1.118 [28.4]

.630

[16.0]

.217 [5.5]

Surface Mount

Thru Hole Mount

2025 / 2032 THRU HOLE MOUNT HOLDER

2025 / 2032 SURFACE MOUNT HOLDER

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

Pad Layout

MATERIAL:

Contacts:

.006 [.15] Phosphor Bronze, Gold Plate (Flash)

Base:

Glass Filled LCP, UL Rated 94V-0

•

Designed for applications where the battery will be

automatically inserted via a vacuum or mechanical

pick-and-place device

•

All conductive polystyrene carrier tape meets ANSI/EIA-481

standards

•

Viewable solder tails allows for easy solder joint inspection

•

Gold plated contacts assure low contact resistance

•

Ideal for retaining cells securely under shock and vibration

•

Compatible with most vacuum and mechanical pick-and-place

assembly systems

KEC

.630 [16.0]

.880 [22.4] DIA.

.138 [3.5]

(2) PLS

1.256 [31.90]

.200 [5.1]

2032 LOW PROFILE HOLDER

CAT. NO.

ON TAPE

BULK

& REEL

BATTERY REFERENCE

1058

1058TR

CR2032

CAT. NO.

ON TAPE

BULK

& REEL

BATTERY REFERENCE

1057

1057TR

CR2032

Surface Mount

2032 ULTRA LOW PROFILE HOLDER

MATERIAL:

Contacts:

.009 (.23) Phosphor Bronze, Gold Plate (Flash)

Base:

Glass filled LCP

,

UL Rated 94V-0

•

Ideal when circuit board height is a critical design parameter

•

Rises only 2mm above the PCB surface by mounting the holder

thru a hole in the PCB, allowing the holder to sit through the PCB

•

Built-in stabilization tabs add mounting security

Pad Layout

1057

KEYSTONE

.200 [5.1]

.138 [3.5]

(2) PLS

1.300 [33.2]

.880 [22.4] DIA.

.128 [3.2]

(2) PLS

.790

[20.1]

.942

[23.9]

Tape & Reel Spec’s:

56mm wide; 32mm pitch; 13 inch reel (400 pieces per reel)

SURFACE MOUNT (SMT) AUTO-IN HOLDERS

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

THRU-HOLE (THM) & SURFACE MOUNT (SMT) 20mm EZ-OUT HOLDERS

20m

m

C

OIN C

ELL H

OLDER

S

5

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

Mounting Detail

Pad Layoutl

Mounting Detail

•

Designed for manual insertion of battery.

•

Mounts securely for wave soldering

•

Accepts all manufactures of 20mm coin cell batteries

•

Retains cells securely, withstands shock and vibration

•

Polarity clearly marked

•

Mounts securely for wave soldering

•

Operating Temperature Range:

-60°F to 293°F (-50°C to 146°C)

MATERIAL:

Contacts:

.016 (.40) Phosphor Bronze, Tin Plate

Base:

Nylon UL Rated 94V-0

Mounting Detail

•

Molded notch prevents improper insertion of 2032 size cells

•

Polarized holder, protects circuit from improper insertion of cells.

MATERIAL:

Contacts:

.016 (.40) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

MATERIAL:

Contacts:

.012 (.30) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

MATERIAL:

Contacts:

.009 (.23) Phosphor Bronze, Gold Plate (Flash)

Base:

High temperature Nylon 4/6, UL Rated 94V-0

.059 [1.50] DIA. LEG (3) PLS.

ON .730 [18.5] CIRCLE DIA.

.023 [.58]

.906 [23.0]

.122 [3.10]

.807 [20.5]

.787

[20.0]

.388 [9.85]

1.089 [27.7]

.060 [1.57] DIA x

.062 [1.57] L. LEG

.038 [1.0]

.875 [22.2]

.300 [7.6]

.140 [3.6]

.785 [19.9]

.670 [17.0]

.280

[7.1]

.531 [13.5]

(2) PLS

NEG

1.000

[25.4]

REF.

.918 [23.3]

.238 [6.0]

.920 [23.4]

1.040 [26.4

.150 [3.8]

.070

[1.8]

.600 [15.2]

.300 [7.6]

.515

[13.1]

.050 [1.3]

.045 [1.14]

.145 [3.7]

.795

[20.2]

DIA.

•

Designed for automatic vertical insertion of battery via a vacuum or

mechanical pick-and-place device

•

Compatible with vacuum and mechanical pick & place assembly systems

•

All conductive polystyrene carrier tape meets ANSI/EIA-481 standards

•

Top loading for compact applications

•

Finger pressure against leaver will release battery

•

No tools required

•

Holds battery securely under shock and vibration applications

•

Nylon base material UL Rated 94V-0, impervious to most

industrial solvents

•

Operating Temperature Range:

-60°F to 293°F (-50°C to 146°C)

CAT. NO.

BATTERY REFERENCE

1065

BR2012, CR2016, DL2020, CL2025, CR2032

CAT. NO.

BATTERY REFERENCE

1067

CR2016, DL2020, CL2025, CR2032

CAT. NO.

BATTERY REFERENCE

1066

BR2025, CR2032

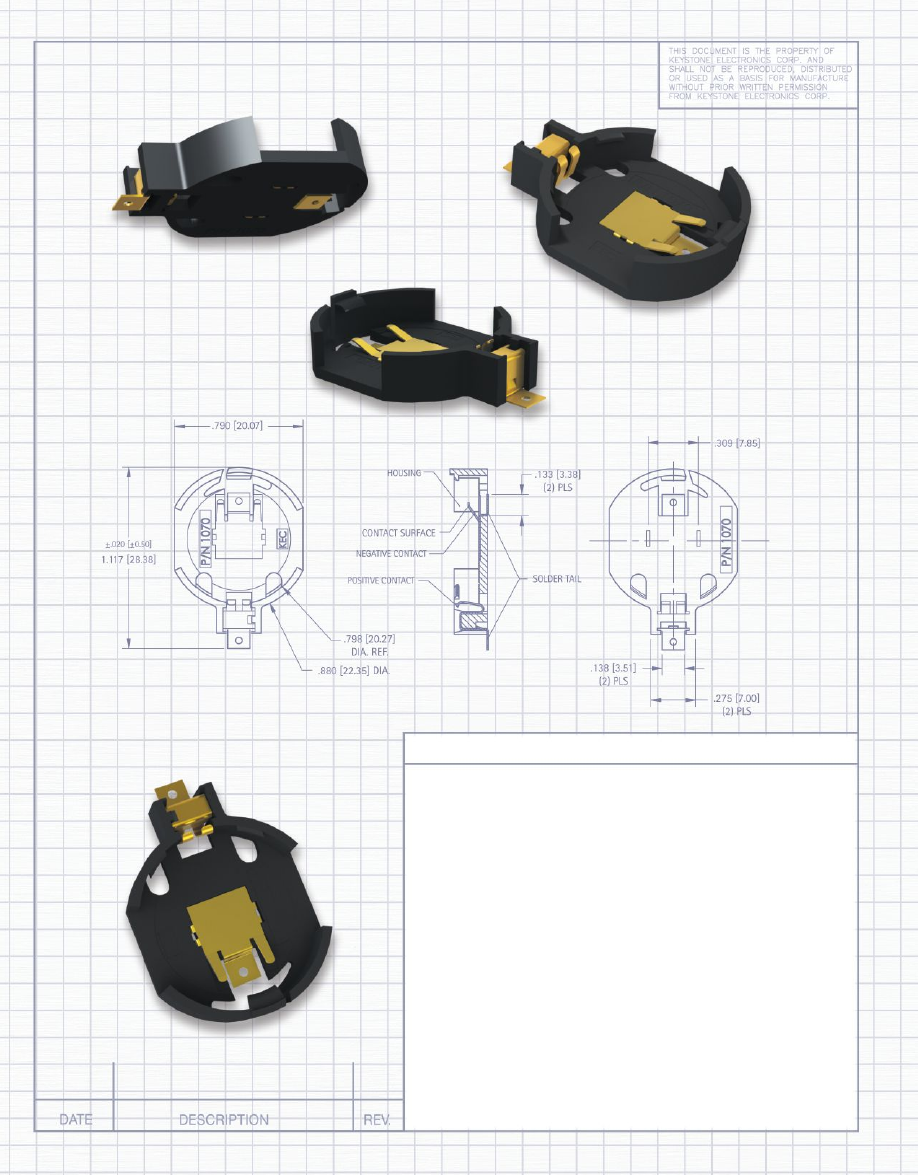

SMT AUTO-IN/EZ-OUT COIN CELL HOLDER

SLIMLINE

THRU-HOLE MOUNT (THM) VERTICAL COIN CELL HOLDERS

Tape & Reel Spec’s:

44mm Wide, 24mm Pitch, 13 inch reel

(400 pieces per reel)

CAT. NO.

ON TAPE

BULK

& REEL

BATTERY REFERENCE

1070

1070TR

CR2032

KEC

P/N 1070

1.117 [28.4]

.790 [20.1]

.235 [6.0]

.133 [3.4]

(2) PLS

.138 [3.5]

(2) PLS

.880 [22.4]

DIA.

THM EZ-OUT COIN CELL HOLDER

COMPACT

EZ-OUT

Release Tab

EZ-OUT

Release Ta

AVAILABLE ON TAPE AND REEL

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

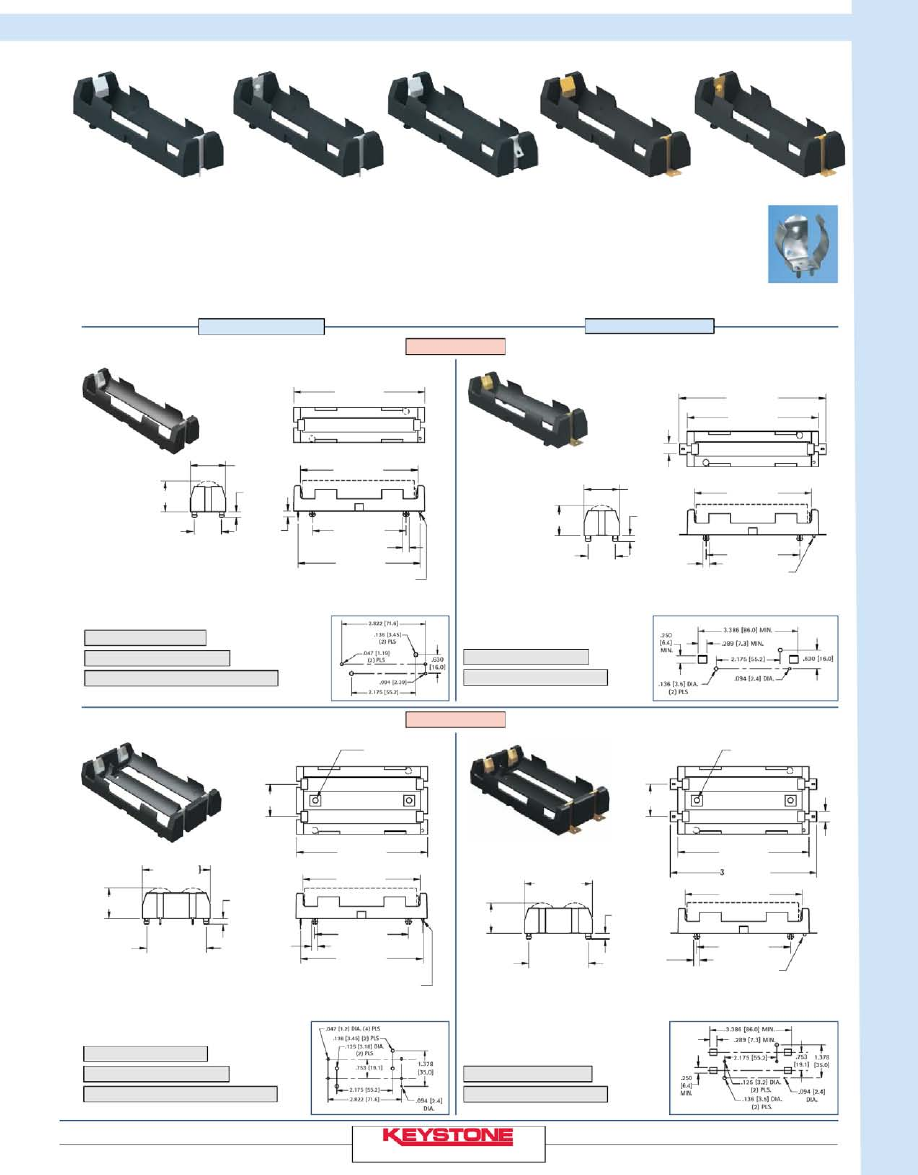

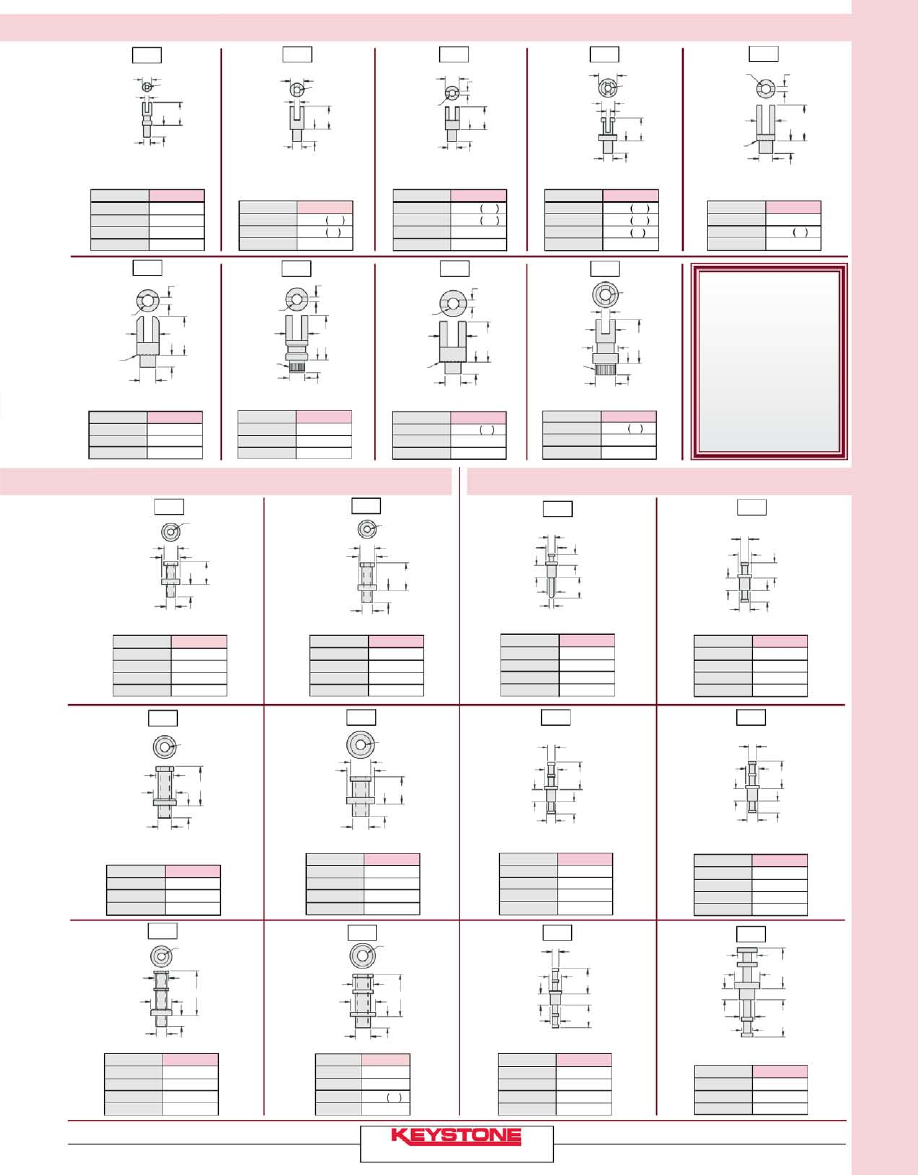

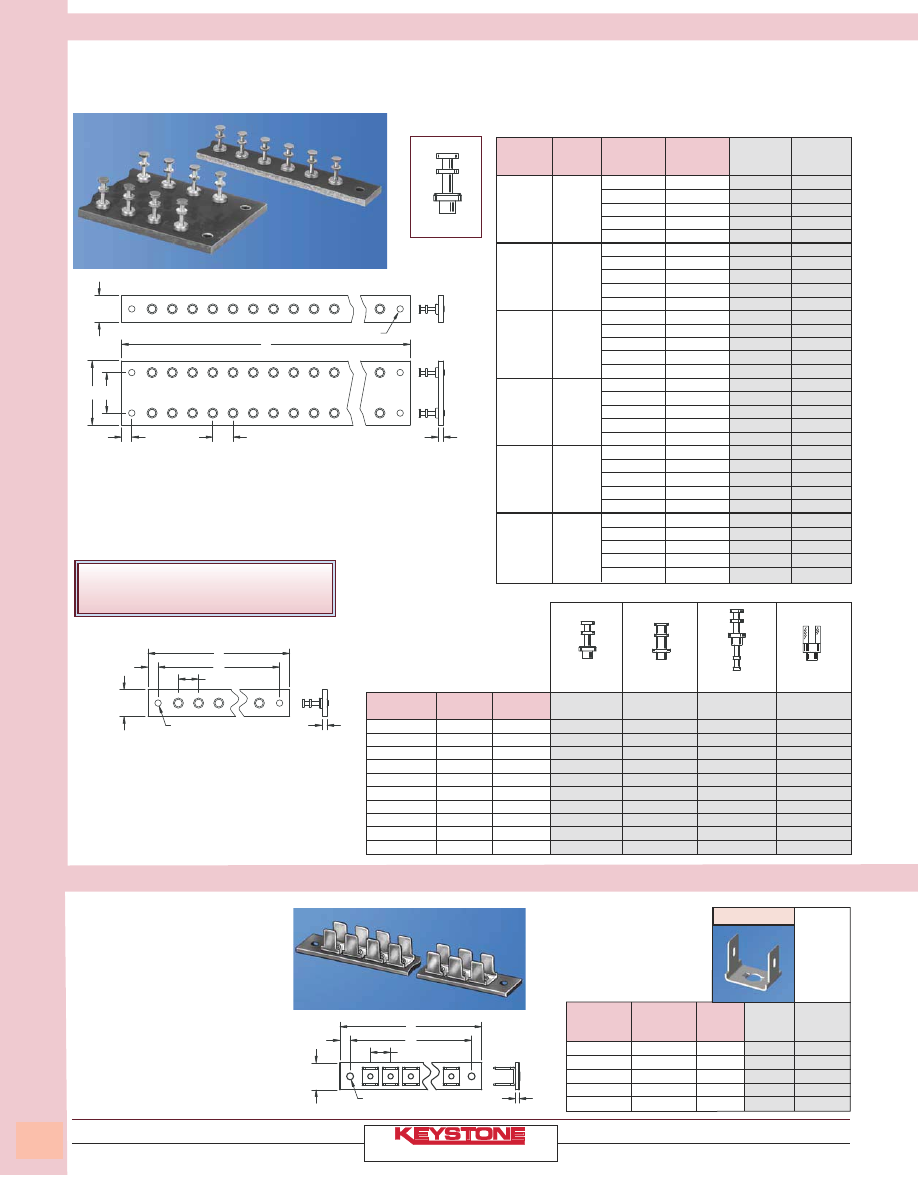

2

3

mm

to

3

0

mm

CO

IN

CE

L

L

HO

L

D

E

RS

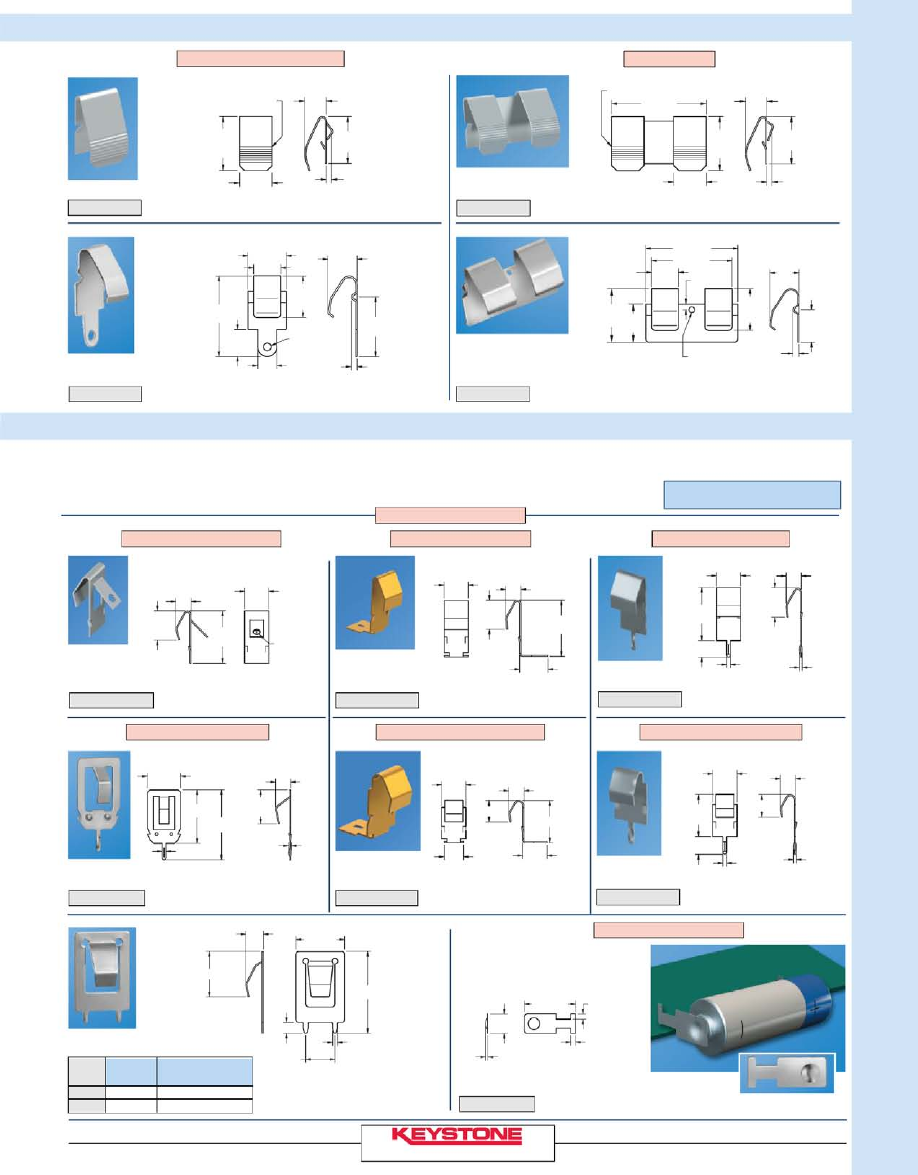

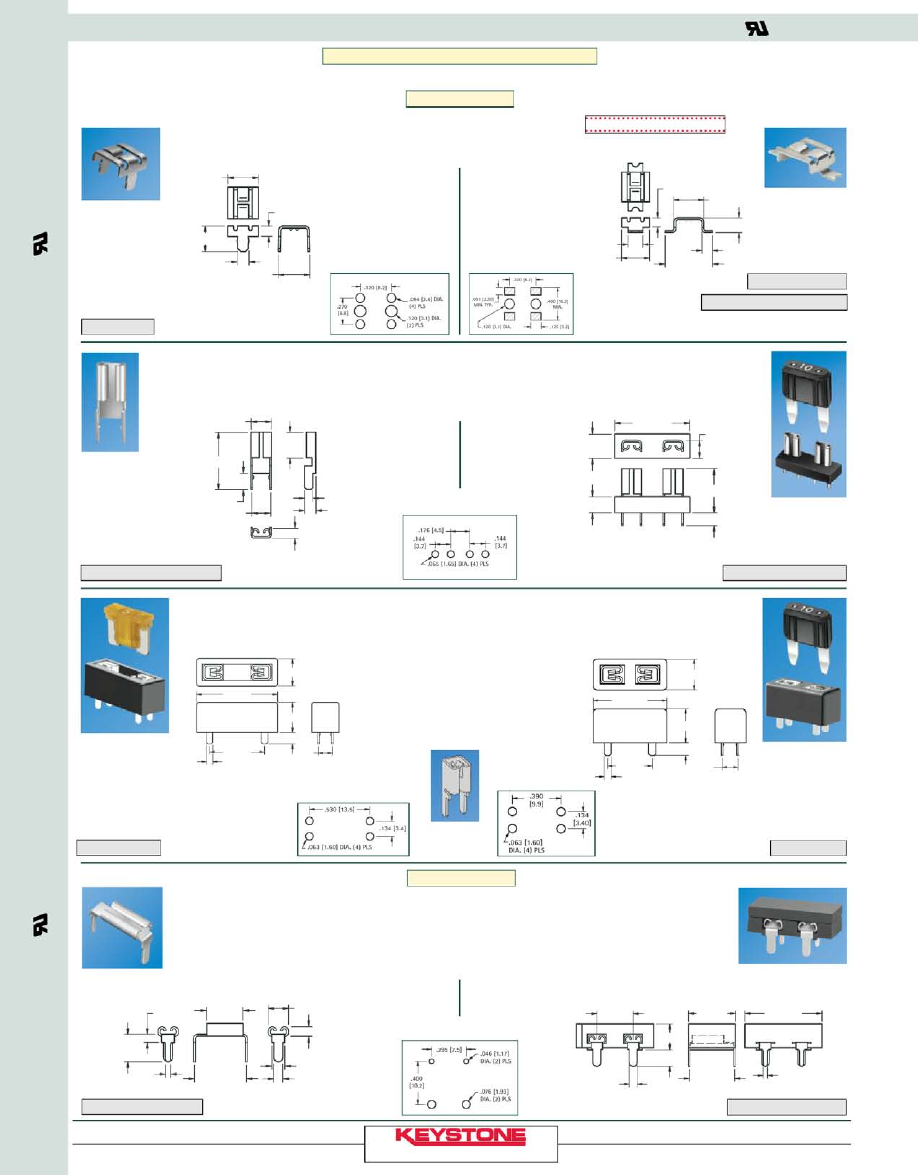

THRU-HOLE (THM) & SURFACE MOUNT (SMT) COIN CELL HOLDERS

•

SMT solder tail with “Flow-Hole” design for increased joint strength

•

Viewable solder tails assures reliable joint inspection

•

All conductive polystyrene carrier tape meets ANSI/EIA - 481 standard

•

Battery “Pop-in”

from Top for automated

assembly

•

No tools required

•

Finger pressure

battery release

•

Polarized holder

•

Low profile for densely

packed PCB’s

•

Compatible with vacuum

and mechanical pick &

place systems

•

Conductive carrier tape

meets ANSA/EIA- 481

standard

NEG

.290

[7.4]

1.000

[25.4]

.931

[23.6]

.125

[3.2]

.437

[11.1]

D

D

.703

[17.9]

D MIN.

.125

[3.2]

MIN.

.703

[17.9]

Pad Layout

.055 [1.4] DIA

(2) PLS.

L

C

Mounting Detail

.055 [1.4] DIA

(2) PLS.

L

C

Mounting Detail

1.433 [36.4] MIN.

OPTIONAL

ADHESIVE ZONE

.138 [3.5] MIN.

.433

[11.0]

.111 [2.8] MIN.

.276

[7.0]

Mounting Detail

.807

[20.5]

.070

[1.77]

.055 [1.4] DIA

(2) PLS.

Mounting Detail

.055 [1.40]

DIA. (2) PLS.

.136 [3.45] DIA.

.162

[4.2]

.405

[10.3]

.185 [4.7]

.620

[15.7]

.810

[20.6]

Mounting Detail

MATERIAL:

Contacts:

.015 (.38) Steel

Base:

High Temp Nylon 46, UL Rated 94V-0

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

MATERIAL:

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

Mounting Detail

.055 [1.4] DIA

(2) PLS.

.807

[20.5]

CAT. NO. ON TAPE CAT. NO. ON TAPE

D

BATTERY

BULK

& REEL

BULK

& REEL

PAD SIZE

REFERENCE

1071

1071TR

1091

1091TR

.156 (4.0) CR2320, CL2325,

1073

1073TR

1083

1083TR

.278 (7.1) DL2330, CR2335

Tin-Nickel Plate

Gold Plate (Flash)

CAT.

NO. OF

BATTERY

NO.

H

L

O.D.

CELLS

REFERENCE

104

.335 (8.5) 1.150 (29.2) 1.000 (25.4)

(1) Cell (Any 23mm)

BR2320, CR2320,

107

.335 (8.5) 1.219 (31.0) 1.093 (27.8)

(1) Cell (Any 23mm)

CL2325, DL2330,

(1) 2354

CL2354, CR2335

1027

.452 (11.5) 1.219 (31.0) 1.093 (27.8)

(2) 2320, (2) 2325, (2) 2330

CAT.

NO. OF

BATTERY

NO.

C

H

L

CELLS

REFERENCE

105

.074 (1.9) .335 (8.5)

.805 (20.5) (1) 2430

1025

.074 (1.9) .452 (11.5) .805 (20.5)

(1) 2450

CR2430, CL2430,

(2) 2430

BR2450, CR2477

1025-7

.074 (1.9) .503 (12.8) .805 (20.5)

(1) 2477

(2) 2430

CAT. NO. ON TAPE

BULK

& REEL

BATTERY REFERENCE

1052

1052TR

(1) CR2450

CAT. NO.

BATTERY REFERENCE

1068

(1) CR2450, (1) CL2450

CAT. NO.

BATTERY REFERENCE

301

BR3032

CAT.

BATTERY

NO.

L

C

REFERENCE

1053

.788 (20.0) .048 (1.2)

(1) CR2450

MATERIAL:

Base:

PBT, UL Rated 94V-0

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

MATERIAL:

Base:

LCP, UL Rated 94V-0

Contacts:

.006 (.15) Phosphor Bronze, Gold Plate (Flash)

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

MATERIAL:

Base:

PBT, UL Rated 94V-0

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

MATERIAL:

Contacts:

Phosphor Bronze, Nickel Plate

Base:

High Temp Nylon 46, UL Rated 94V-0

Operating Temperature:

-60°F to +293°F (-50°C to +145°C)

.187 [4.8]

.050 [1.3]

.045 [1.1]

1.219 [31.0]

.985 [24.0]

I.D.

NEG

1.093

[27.8]

H

L

.062 [1.57] DIA. LEG

(3) PL ON .750 [19.1]

CIRCLE DIA.

1.059 [26.9]

.630

[16.0]

.138 [3.5]

1.433 [36.4]

.294

[7.47]

1.292 [32.8]

.810 [20.6]

.370 [9.4]

1.027

[26.1]

1.255

[31.9]

.070

[1.8]

.232 [5.9]

1.135

[28.9]

.770

[19.6]

DIA.

.150

[3.8]

.145

[3.7]

.050 [1.3]

.045 [1.1]

.620

[15.7]

1.090

[27.7]

REF.

•

Polarized holder

•

Mounts securely for wave soldering

•

Reliable spring tension assures low

contact resistance

•

Advanced air-flow design enhances

air circulation around battery

•

Unique notched slots assure

quick and easy battery insertion

and replacement

NEG

.062 [1.57] DIA. LEG

(3) PL ON .953 [24.2]

CIRCLE DIA.

1.187

[30.1]

I.D.

.335 [8.5]

.050 [1.27]

.045 [1.14]

.187 [4.8]

1.425 [36.2]

1.297

[32.9]

.807 [20.5]

+

Tape & Reel Spec’s:

44mm wide; 32mm pitch; 13 inch reel, (200 pieces per reel)

Tape & Reel Spec’s:

56mm wide; 20mm pitch;

13 inch reel, (400 pieces per reel)

MATERIAL:

Contacts:

.020 (.50) Spring Steel, Tin-Nickel Plate

Base:

PBT, UL Rated 94V-0

Operating Temperature:

-60°F to +293°F

(-50°C to +145°C)

.062 [1.57] DIA. LEG

(3) PL ON .750 [19.1]

CIRCLE DIA.

.807

[20.5]

.050 [1.3]

.045 [1.1]

.187 [4.8]

NEG

.911 [23.1]

I.D.

O.D.

H

L

.008

[0.20]

.974 [24.8] I.D.

.425 [10.8]

.374 [9.5]

1.053

[26.8]

O.D.

.035 [.89]

.016

[0.41]

1.155 [29.4]

.150 [3.2]

MIN

L

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AUTO-IN/EZ-OUT

Surface Mount

Thru Hole Mount

Thru Hole Mount

Thru Hole Mount

Surface Mount

Thru Hole Mount

23mm

24mm

24mm TOP Loading

30mm

Thru Hole Mount

6

•

Advanced air-flow design enhances air circulation around battery

•

Unique notched slots assure quick and easy battery insertion

and replacement

M65.1 S1p6 10/23/15 10:27 AM Page 6

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

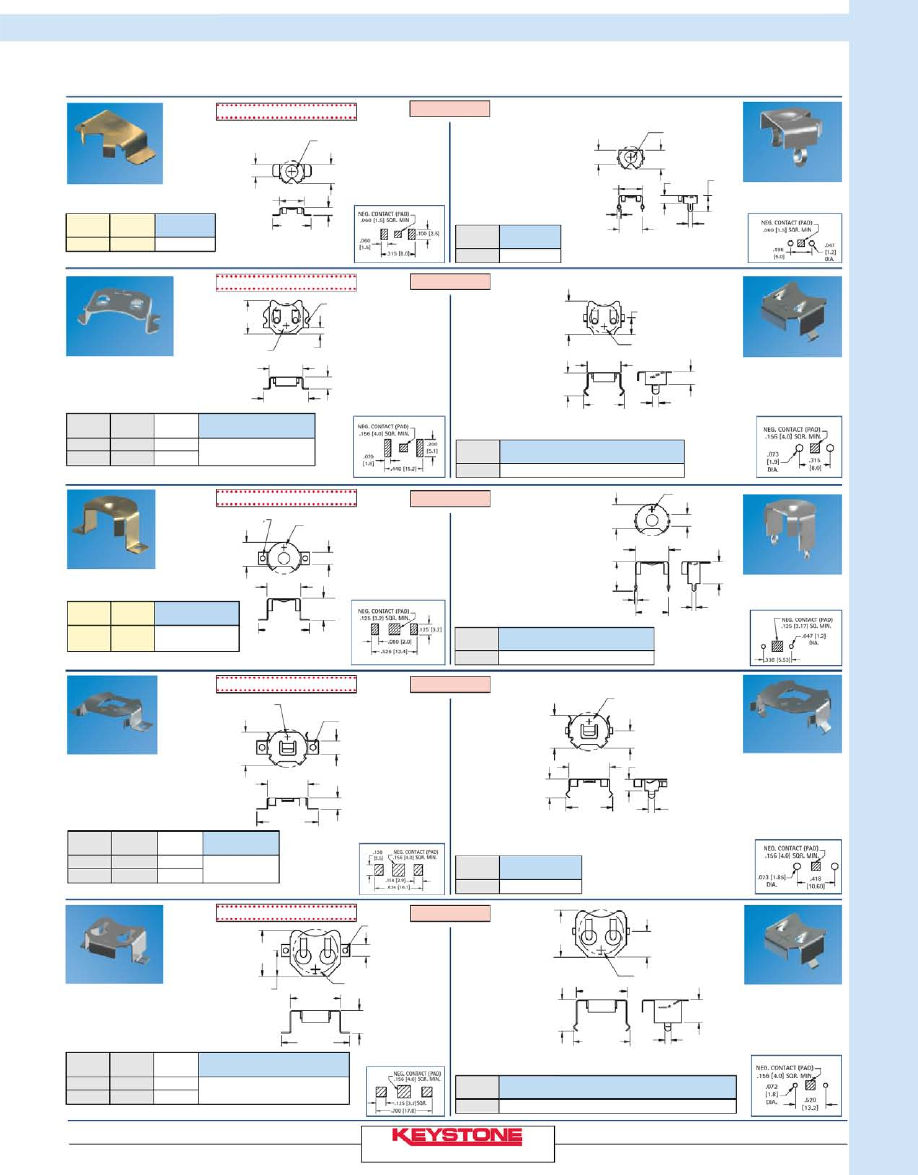

.249

[6.3]

.125 [3.2]

.052 [1.3] DIA

.526 [13.4]

.346 [8.8]

STAMP (+)

AS SHOWN

.225 [5.7]

4

m

m

t

o

12 m

m

B

U

TTON C

ELL R

ET

AINER

S

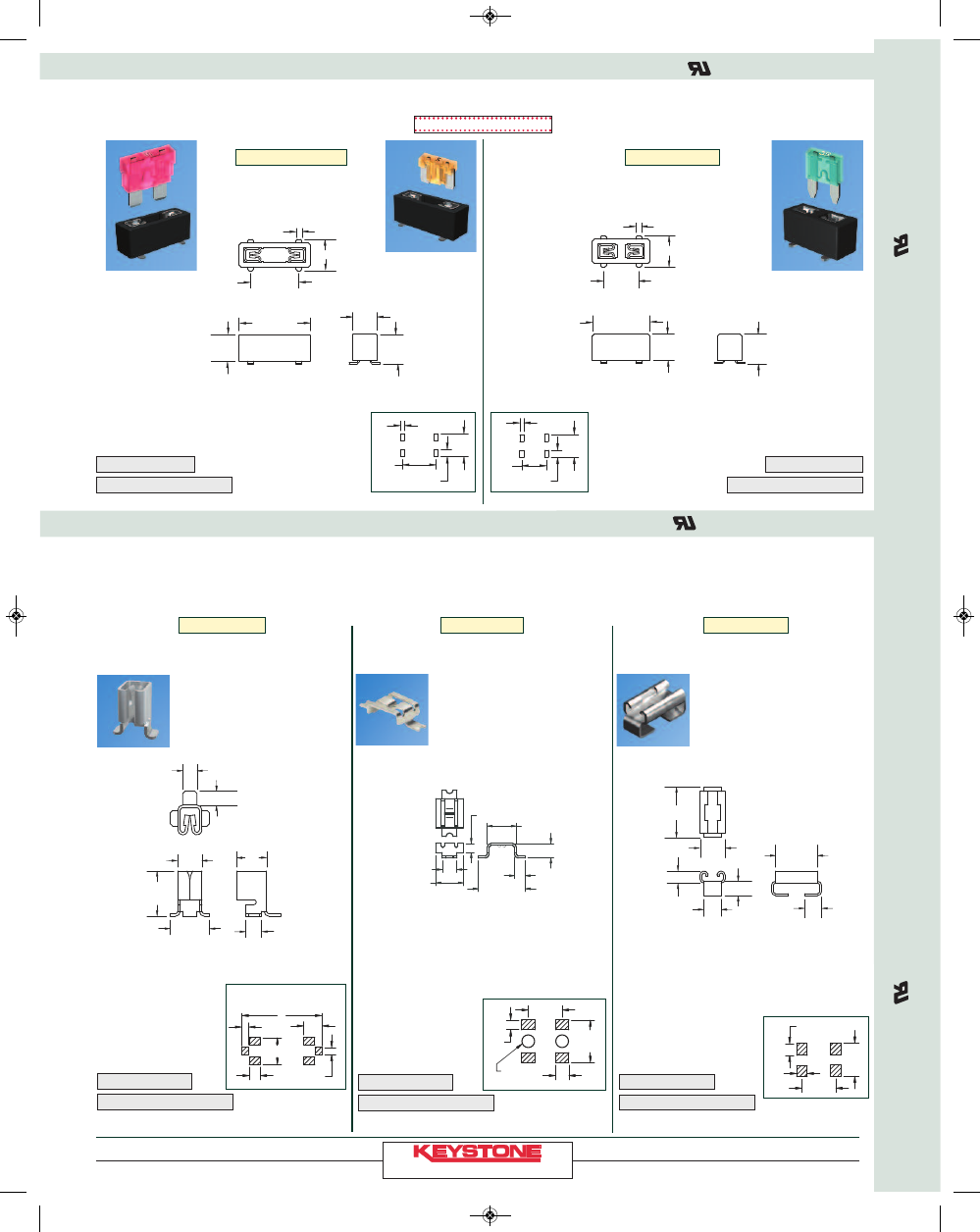

THRU HOLE (THM) & SURFACE MOUNT (SMT) BUTTON CELL RETAINERS

MATERIAL:

.006 (.15) Phosphor Bronze,

Gold Plate (Flash)

MATERIAL:

.010 (.25) Phosphor Bronze

.062

[1.6]

DIA.

.116 [3.0]

.138 [3.5]

.634 [16.1]

.418 [10.6]

.339

[8.6]

STAMP (+)

AS SHOWN

.235

[6.0]

.520 [13.2]

.265

[6.7]

.323

[8.2]

.475

[12.1]

.062

[1.6]

.585 [14.9]

STAMP (+)

AS SHOWN

.062

[1.6]

.116 [3.0]

.180 [4.6]

.339

[8.6]

.195

[5.0]

.482

[12.2]

.418 [10.6]

STAMP (+)

AS SHOWN

•

Available in Thru Hole Mount (THM) or Surface Mount

(SMT) configurations

•

SMT solder tail with “flow-hole” design for increased joint strength

STAMP (+)

AS SHOWN

.315 [8.0]

.125 [3.2]

.158 [4.0]

.315

[8.0]

.215

[5.5]

.062 [1.6]

.380

[9.7]

.336

[8.5]

.320 [8.1]

.030 [0.8]

.346 [8.8]

.225 [5.7]

.038

[1.0]

.249 [6.3]

.125 [3.2]

STAMP (+)

AS SHOWN

R.032

[R0.8]

.120 [3.0]

.315 [8.0]

.315 [8.0]

.060 [1.5]

.421 [10.7]

STAMP (+)

AS SHOWN

.157 [4.0]

.100 [2.5]

.065 [1.7]

.202 [5.1]

.315

[8.0]

STAMP (+)

AS SHOWN

.202 [5.1]

.137

[3.5]

.030

[0.8]

.116 [3.0]

.065 [1.7]

.157 [4.0]

.196

[5.0]

.038

[1.0]

STAMP (+)

AS SHOWN

CAT. NO. ON TAPE

BATTERY

BULK

& REEL

REFERENCE

2994

2994TR

ML414

CAT.

BATTERY

NO.

REFERENCE

2995

ML414

CAT. NO. ON TAPE

BULK

& REEL

FINISH

BATTERY REFERENCE

2998

2998TR

Tin-Nickel

MC621, V364, SC621, DR13H,

3098

3098TR

Matte Tin

DR77, V13AT, 377

Tape & Reel Spec’s:

16mm wide; 8mm pitch; 13 inch reel (1500 pieces per reel)

Tape & Reel Spec’s:

24mm wide; 12mm pitch; 13 inch reel (1000 pieces per reel)

MATERIAL:

.010 (.25)

Phosphor Bronze, Tin-Nickel Plate

MATERIAL:

.010 (.25)

Phosphor Bronze, Tin-Nickel Plate

CAT.

NO.

BATTERY REFERENCE

2999

MC621, V364, SC621, DR13H, DR77, V13AT, 377

CAT.

NO.

BATTERY REFERENCE

2989

Size 13, DA13, AZ13E, 393, SR754, SR48

MATERIAL:

.006 (.15) Phosphor Bronze,

Tin-Nickel Plate

CAT. NO. ON TAPE

BATTERY

BULK

& REEL

FINISH

REFERENCE

3030

3030TR

Tin-Nickel

3050

3050TR

Matte Tin

CR927, CR1025

Tape & Reel Spec’s:

24mm wide; 12mm pitch; 13 inch reel (1500 pieces per reel)

MATERIAL:

.010 (.25) Phosphor Bronze,

Gold Plate (Flash)

CAT. NO. ON TAPE

BATTERY

BULK

& REEL

REFERENCE

2988

2988TR

Size 13, DA13, AZ13E,

393, SR754, SR48

Tape & Reel Spec’s:

24mm wide; 12mm pitch; 13 inch reel (800 pieces per reel)

MATERIAL:

.006 (.15)

Phosphor Bronze, Tin-Nickel Plate

CAT.

BATTERY

NO.

REFERENCE

3031

CR927, CR1025

MATERIAL:

.010 (.25) Phosphor Bronze, Tin-Nickel Plate

CAT.

NO.

BATTERY REFERENCE

2997

SR43, 186, 386, A76, LR44, 357, MS76, PX76A, G-13, 303, V313

MATERIAL:

.010 (.25) Phosphor Bronze

CAT. NO. ON TAPE

BULK

& REEL

FINISH

BATTERY REFERENCE

2996

2996TR

Tin-Nickel

SR43, 186, 386, A76, LR44, 357, MS76,

3096

3096TR

Matte Tin

PX76A, G-13, 303, V313

Tape & Reel Spec’s:

32mm wide; 16mm pitch; 13 inch reel (600 pieces per reel)

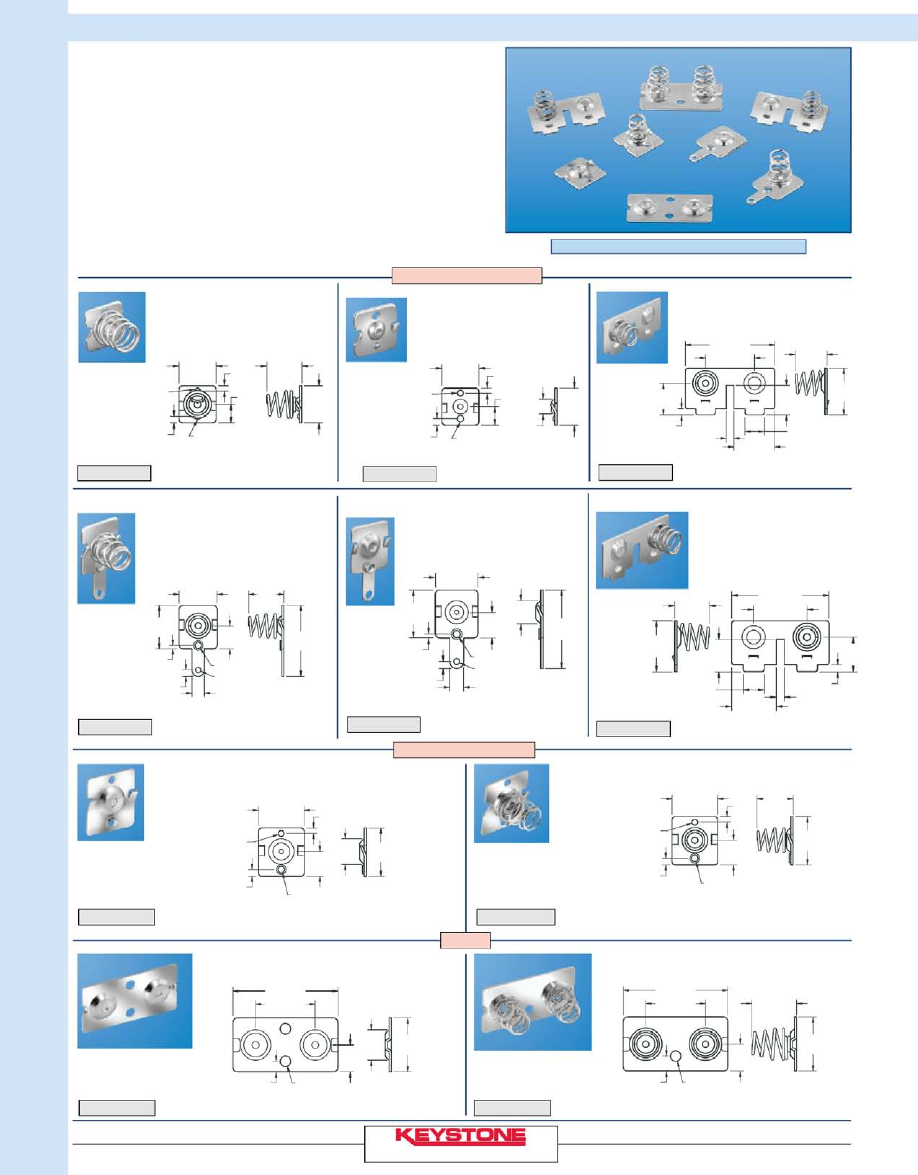

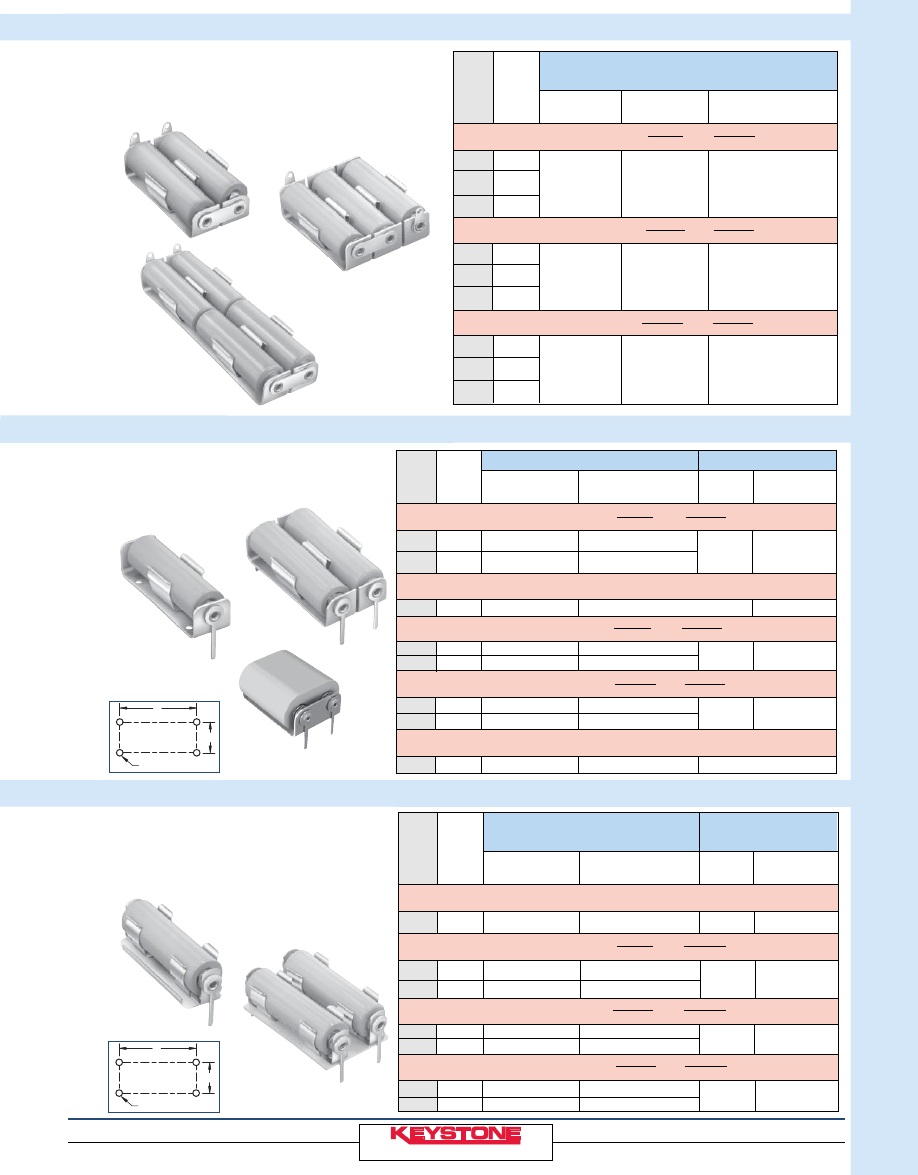

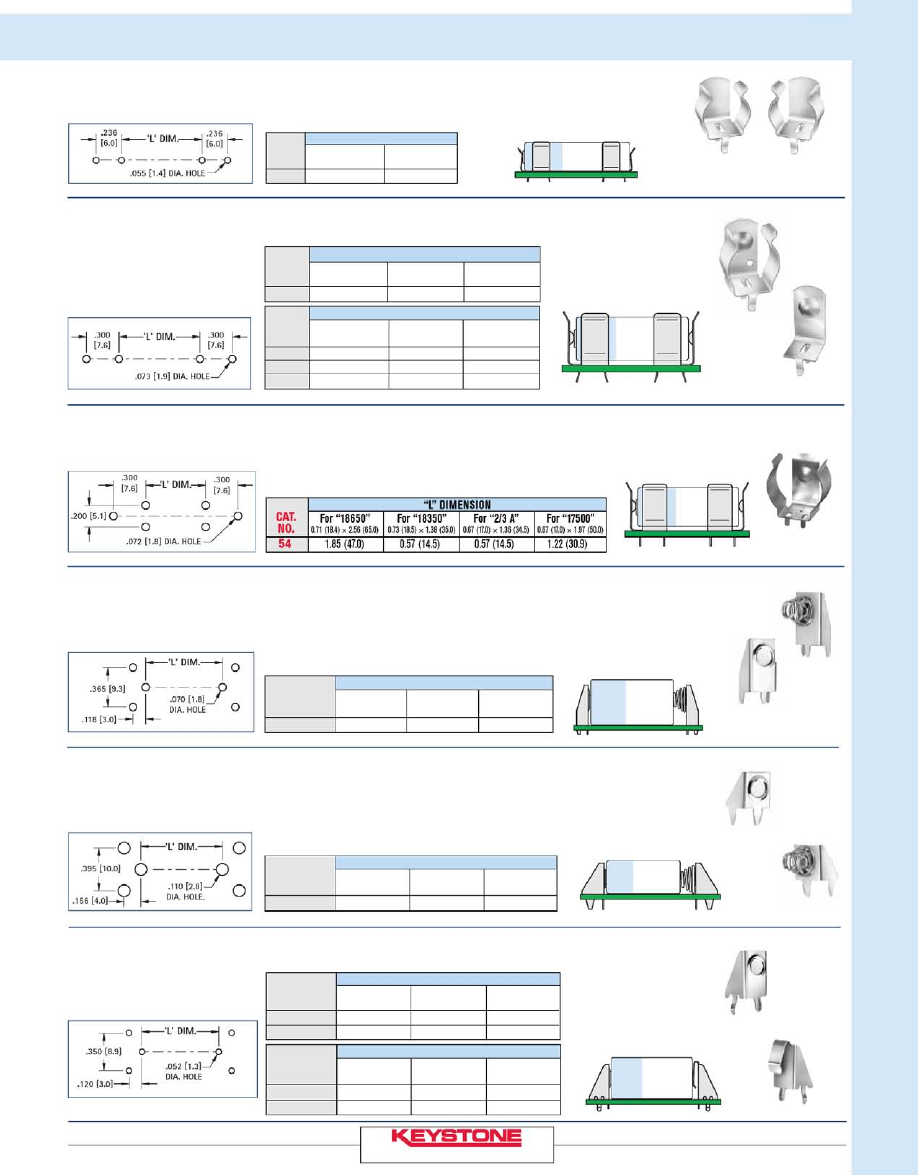

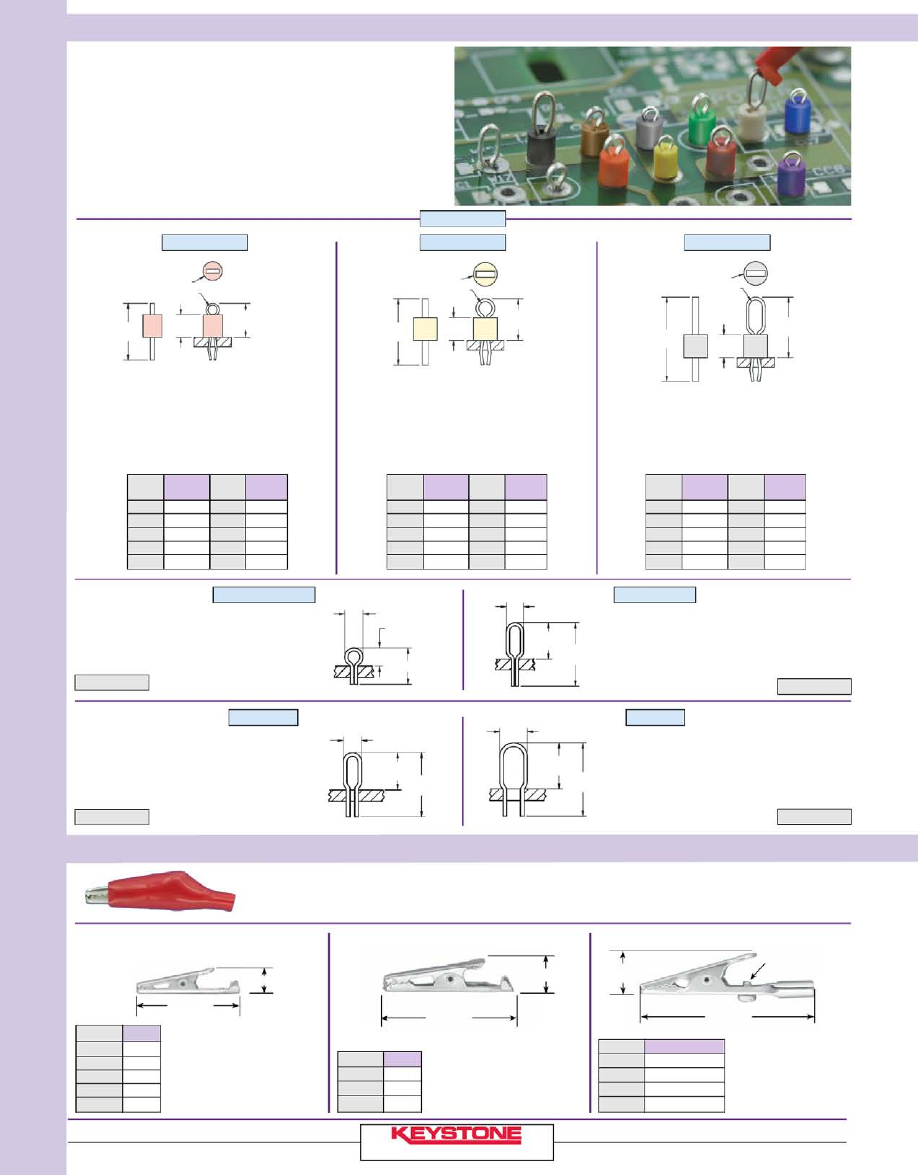

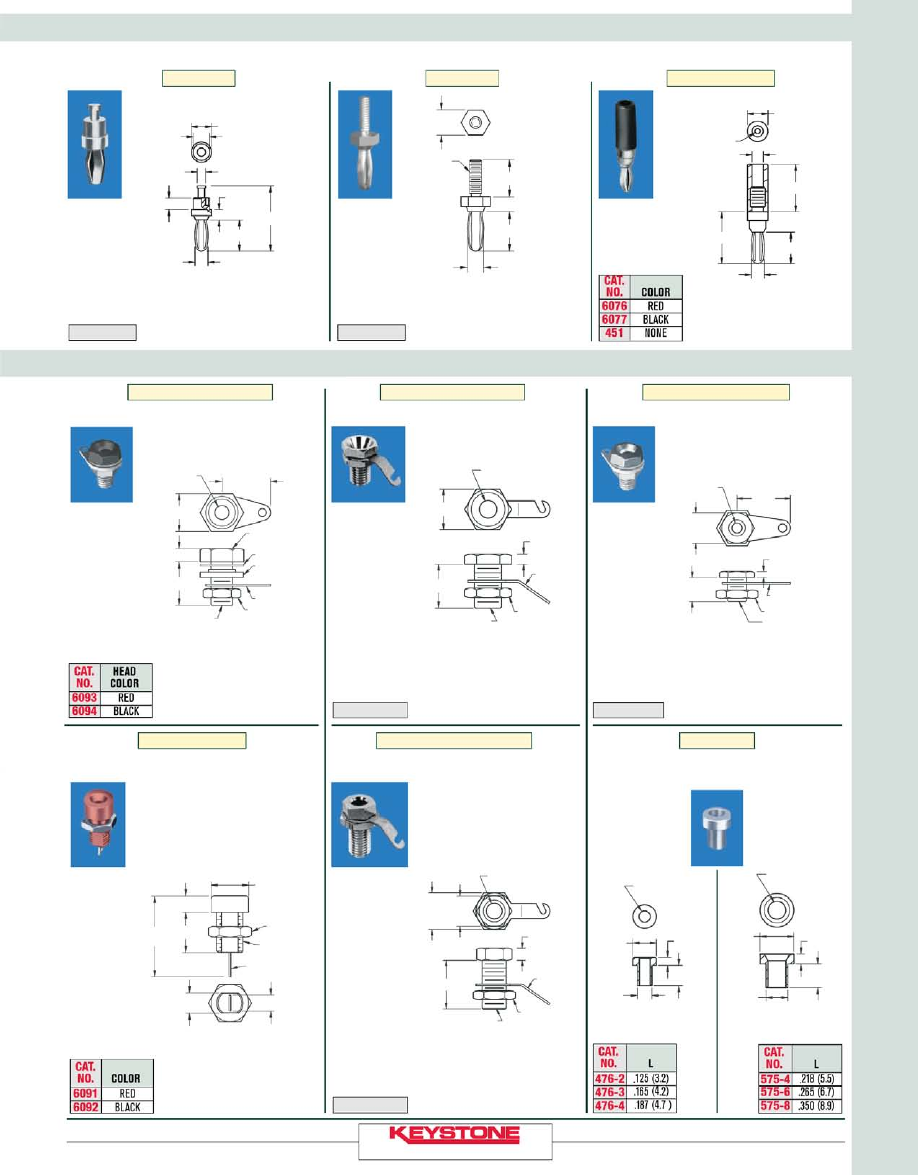

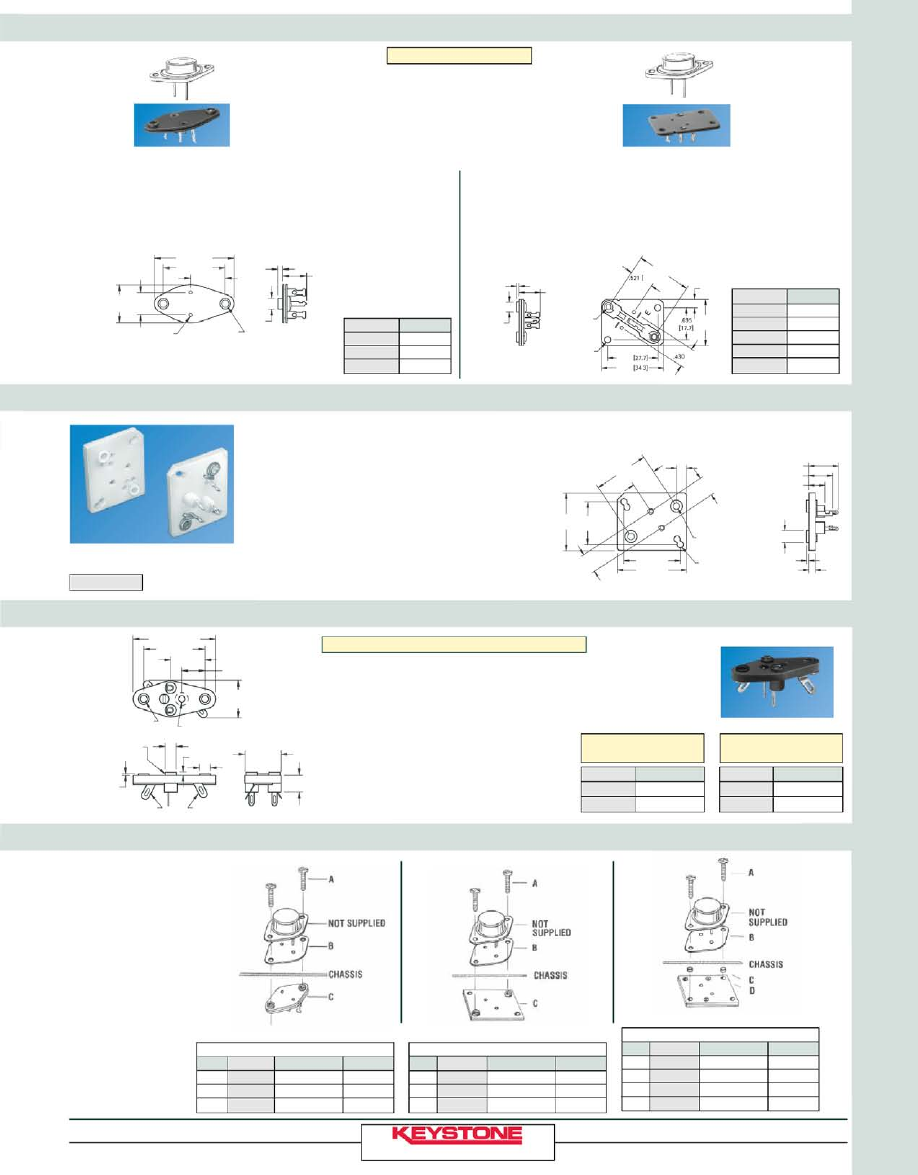

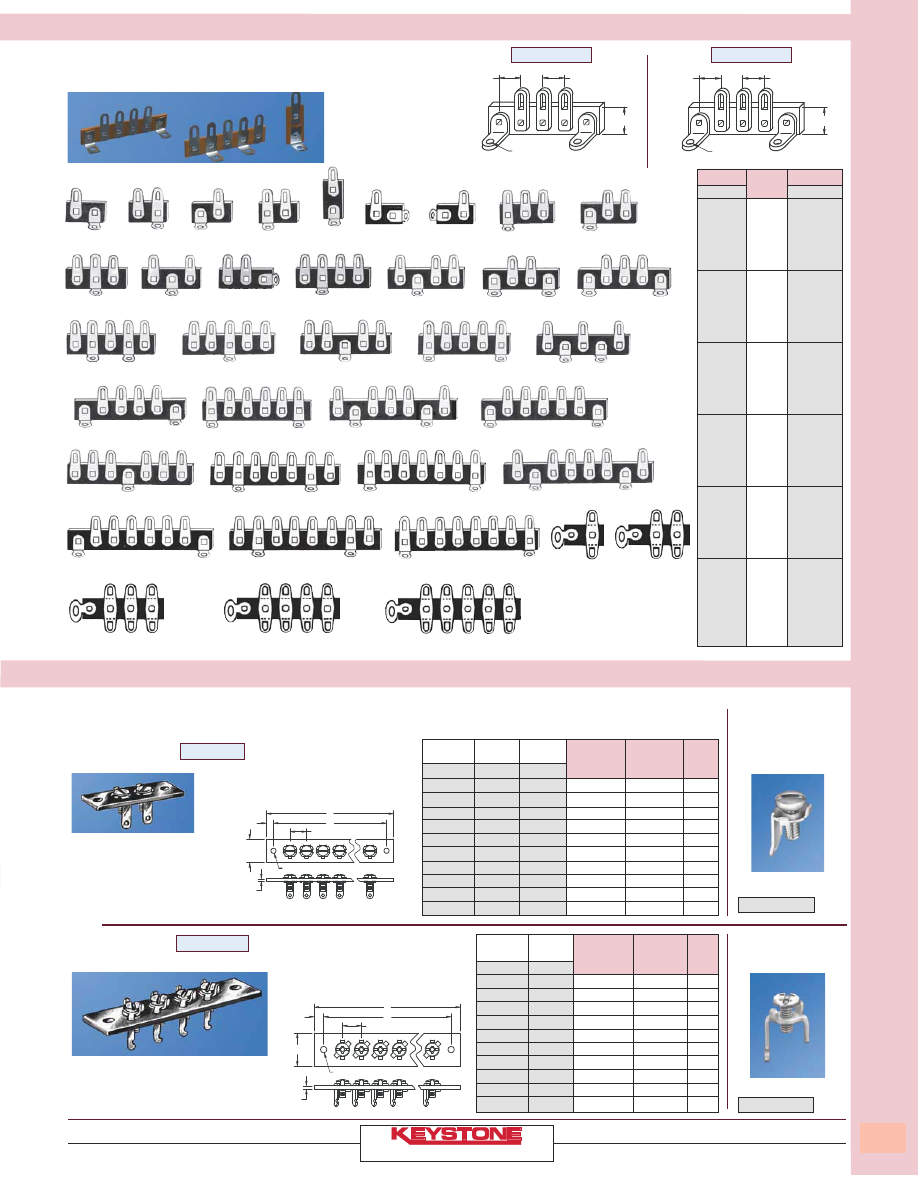

Economical and reliable SMT and THM coin cell retainers specifically designed for miniature electronic applications with limited board space.

.052

[1.3]

DIA.

.125 [3.2]

.235

[6.0]

.700 [17.8]

.520 [13.2]

.475

[12.1]

.265

[6.7]

STAMP (+)

AS SHOWN

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

Mounting Detail

•

THM legs maintain relative position during and after soldering

•

Ideally suited for High Density packaging

•

Reliable spring tension assures low contact resistance

•

Retains battery securely to withstand shock and vibration

•

Solder tail located outside of retainer body which facilitates

visual inspection of the solder joints

Surface Mount

Thru Hole Mount

Thru Hole Mount

Thru Hole Mount

Thru Hole Mount

Thru Hole Mount

Surface Mount

Surface Mount

Surface Mount

Surface Mount

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

Mounting Detail

4.8 mm

6.8 mm

7.9 mm

11.6 mm

9 - 10 mm

MATERIAL:

.006 (.15)

Phosphor Bronze, Tin-Nickel Plate

7

CAT. NO.

ON TAPE

BULK

& REEL

112

112TR

CAT. NO.

ON TAPE

BULK

& REEL

110

110TR

SURFACE MOUNT (SMT) COIN CELL ENCLOSURE CONTACTS

C

OIN C

ELL C

ONT

AC

TS & R

ET

AINER

S

8

.200 [5.1]

1.339 [34.0]

.939 [23.9]

.093 [2.4] DIA.

BATTERY RELEASE

(2) PLS

L

.532

[13.5]

H

MATERIAL:

Contacts:

.010 (.25) Phosphor Bronze

Insulator:

High Temperature,

Nylon 46,

UL Rated 94V-0

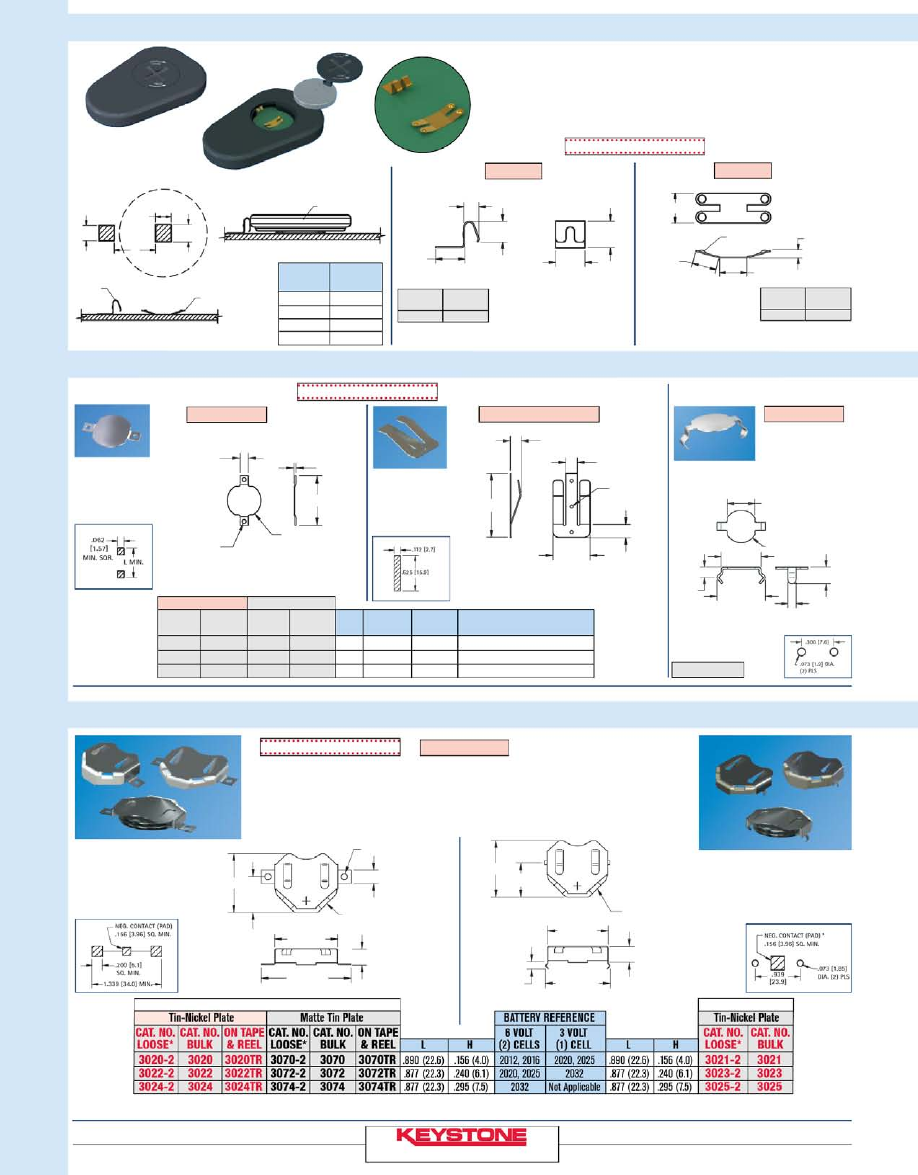

•

Ideal for 6 volt or 3 volt applications

•

Two coin cell batteries can be installed in series

•

Plastic insulator prevents shorting of battery, within

the holder, when installed improperly

•

Low profile

•

Battery release ports for easy battery replacement

•

Refer to pages 7 & 9 for a complete offering of coin

cell retainers

Pad Layout

THRU-HOLE (THM) & SURFACE MOUNT (SMT) INSULATED RETAINERS

Mounting Detail

BATTERY RELEASE

(2) PLS.

.940 [23.9]

1.004 [25.5]

H

L

.110 [2.8]

.535 [13.6]

Surface Mount

Thru Hole Mount

Tape & Reel Spec’s:

56mm wide; 28mm pitch; 13 inch reel:

3020TR, 3070TR

400 pieces per reel;

3022TR, 3072TR

250 pieces per reel;

3024TR, 3074TR

250 pieces per reel

* Supplied Unassembled

AVAILABLE ON TAPE AND REEL

Surface Mount

Thru Hole Mount

20mm CELLS

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

THRU-HOLE (THM) & SURFACE MOUNT (SMT) NEGATIVE BATTERY CONTACTS

L

DIA.

.062 [1.54]

.016 [.41]

.030 [.76] DIA.

.105 [2.7]

.360 [9.1]

.031 [.78] DIA

(3) PLS

.112 [2.8]

.625 [15.9]

.127 [3.2]

Pad Layout

Pad Layout

DWG. 1

MATERIAL:

.

008 (.20) Brass

DWG. 2

MATERIAL

:

.

010 (.25) Phospher Bronze

MATERIAL:

.

008 (.20) Phosphor

Bronze, Tin-Nickel Plate

.308 [7.8]

.373 [9.5]

.128 [3.3]

.062 [1.57]

.212 [5.4]

.250 [6.4] DIA.

.079

[2.01]

Mounting Detail

CAT. NO. 2990

•

Assures proper

contact

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

DWG.

L

DIA.

TAPE & REEL SPECS

2991

2991TR

2981

2981TR

1

.368 (9.4)

.250 (6.4)

16mm wide, 8mm pitch, 1500/7 reel

2992

2992TR

2982

2982TR

1

.289 (7.4)

.186 (4.7)

16mm wide, 12mm pitch, 1000/7 reel

2993

2993TR

2983

2983TR

2

.625 (15.9)

—

24mm wide, 16mm pitch, 1000/13 reel

TIN-NICKEL PLATE

MATTE TIN PLATE

•

Assures proper

contact

•

Assures proper

contact

AVAILABLE ON TAPE AND REEL

SMT SPRING CONTACT*

THM SNAP IN*

SMT COMPACT*

*Note:

Cannot be used with Cat. No. 3028, 3029, 3032, 3038, 3042, 3026, 3078.

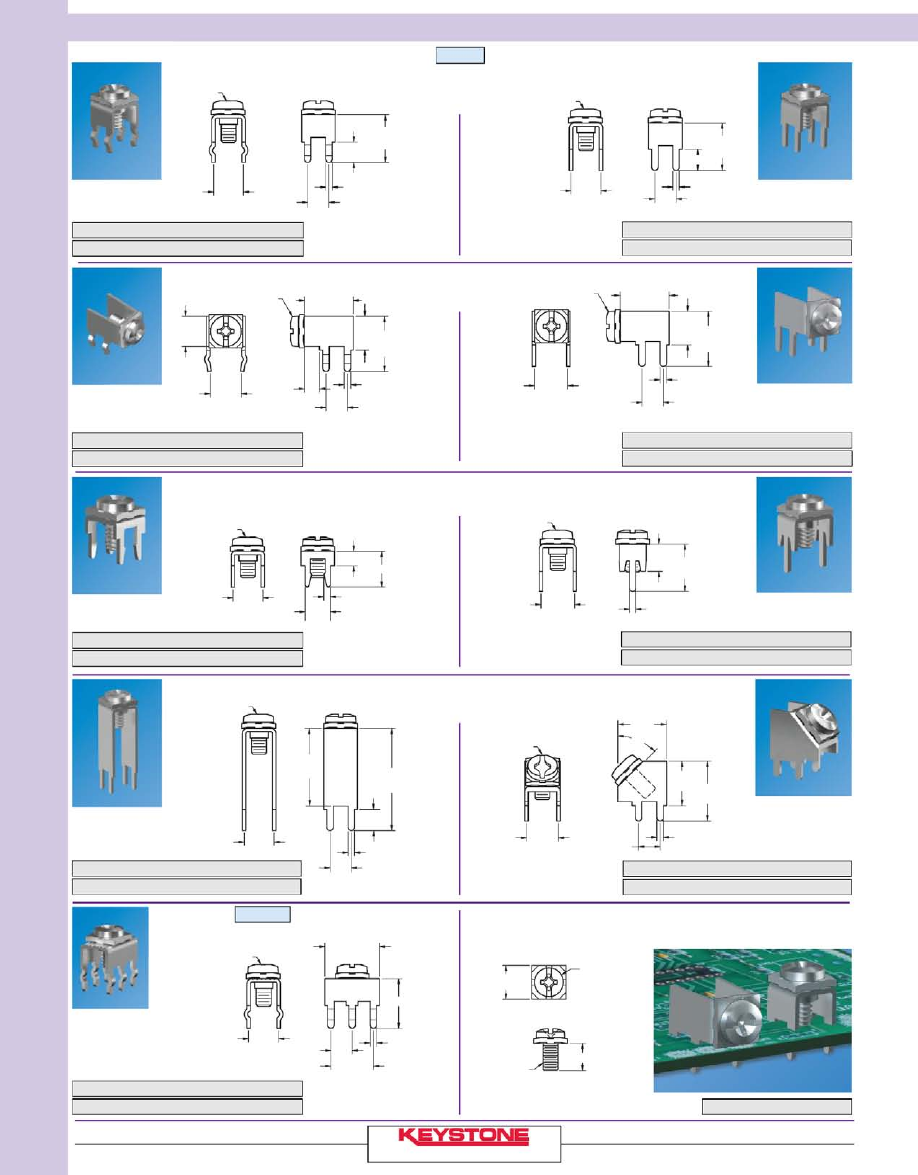

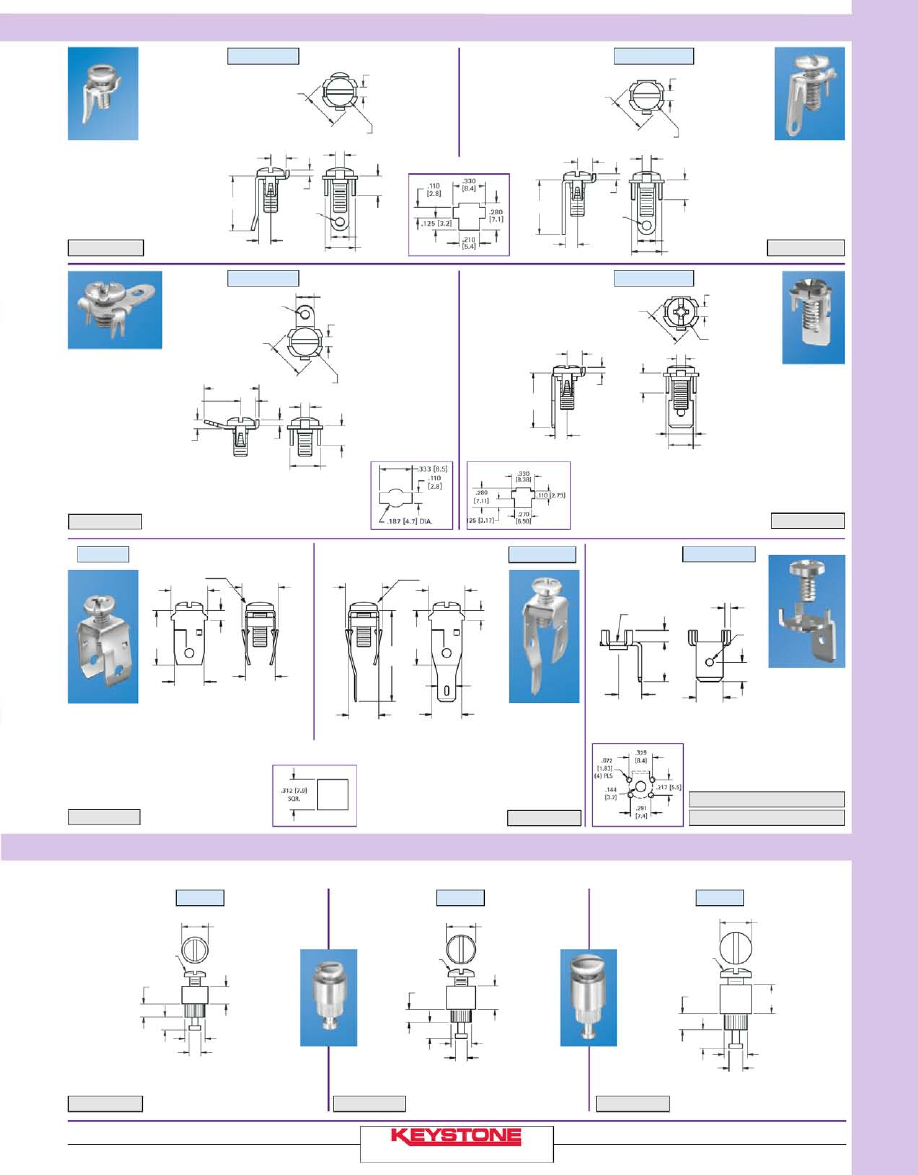

•

Contacts for Enclosure cases with self contained battery compartments

•

Design facilitates easy battery access, removal & installation

•

Suitable for industrial and consumer product applications

•

Spring contacts adjust to variations in battery diameter for a dependable connection

•

Posititve and Negative contacts can be used as a design pair or individually on a PCB

•

Accomodates cell diameters from 16mm to 30mm

.138

[3.5]

.137 [3.5]

.098 [2.5]

.125 [3.2]

.072 [1.8]

Tape & Reel Spec’s:

16mm wide; 8mm pitch; 13 inch reel

(2000 pieces per reel)

Tape & Reel Spec’s:

24mm wide; 8mm pitch; 13 inch reel

(5000 pieces per reel)

.156 [4.0]

DIMPLE (2) PLS

.140 [3.6]

.125 [3.2]

(2) PLS

.041 [1.0] REF.

P/N 112

P/N 110

"L"

.138 [3.5]

SQR MIN.

.140 [3.6]

MIN.

.156 [4.0]

MIN.

COIN CELL

BATTERY

DIA.

L

16mm

.291 (7.4)

20mm

.370 (9.4)

23mm

.429 (10.9)

24mm

.448 (11.4)

Mounting Layout

MATERIAL:

.006 (.15) Stainless steel, Gold plate (flash)

NEGATIVE

POSITIVE

AVAILABLE ON TAPE AND REEL

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

1

2

mm

to

2

4

mm

CO

IN

CE

L

L

RE

T

A

IN

E

RS

9

THRU HOLE (THM) & SURFACE MOUNT (SMT) COIN CELL RETAINERS

•

Compatible with all wave and reflow operations

•

Solder tails located outside of retainer body which facilitates visual inspection of the solder joints

•

Flow-hole solder tail designed for increased joint strength

•

Compatible with most vacuum and mechanical pick & place assembly systems

•

Matte Tin Plate for lower soldering temperatures ideal where other temperature sensitive

components are being used

•

Tin-Nickel plated retainers are ideal for lead free, high temperature soldering applications

•

All conductive polystyrene carrier tape meets ANSI/EIA-481 standards

Pad Layout

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN.

.050 [5.1]

MIN.

W MIN.

.200 [5.1]

MIN.

AVAILABLE ON TAPE AND REEL

MATERIAL:

.010 (.25) Phosphor Bronze

SURFACE MOUNT (SMT)

THRU HOLE MOUNT (THM)

•

All conductive polystyrene carrier tape meets ANSI/EIA-481 standards

MATERIAL:

.010 (.25) Phosphor Bronze, Tin-Nickel Plate

•

Snap-in legs maintain relative position during and after soldering

•

Compatible with wave solder applications

MARKING (+)

POLARITY

H

B

A

L

W

POLARITY

MARKING (+)

F

L

A

B

W

H

POLARITY

MARKING (+)

F

W

A

H

B

L

Pad Layout

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN.

W MIN.

F SQ. MIN.

Pad Layout

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN. *

W MIN.

F SQ. MIN.

FIG. 1 -

Ultra Low

FIG. 2 -

Compact

FIG. 3 -

Low Profile

Mounting Detail

.073 [1.85] DIA (2) PLS.

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN.

A MIN.

POLARITY

MARKING (+)

.062

[1.57]

A

L

W

H

B

E

MARKING (+)

POLARITY

E

W

A

H

L

B

.062

[1.57]

MARKING (+)

POLARITY

E

W

A

L

B

H

.062

[1.57]

Mounting Detail

.073 [1.85] DIA (2) PLS.

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN.

A MIN.

Mounting Detail

NEG. CONTACT (PAD)

.156 [3.96] SQ. MIN. *

.073 [1.85] DIA (2) PLS.

A MIN.

FIG. 4 -

Ultra Low

FIG. 5 -

Compact

FIG. 6 -

Low Profile

*Negative pad can be

relaced with SMT negative

contact. See page 8.

*Negative pad can be

relaced with THM negative

contact. See page 8.

* Nickel Plate

CELL

CAT. NO.

FIG.

A

B

E

H

L

W

DIA.

BATTERY REFERENCE

3001

6

.520 (13.2)

.265 (6.7)

.210 (5.3)

.118 (3.0)

.475 (12.1)

.585 (14.9) 12mm

CR1216, BR1220, DL1225, SR1120, D381, 391, 191

3013

6

.664 (16.9)

.344 (8.7)

.265 (6.7)

.156 (4.0)

.594 (15.1)

.723 (18.4) 16mm

BR1616, CR1612, CR1616, CR1620, CR1632

3029

4

.831 (21.1)

.298 (7.6)

.176 (4.5)

.067 (1.7)

.618 (15.7)

.890 (22.6) 20mm

BR2012, CR2012, DL2012

3027

5

.831 (21.1)

.416 (10.6)

.194 (4.9)

.085 (2.2)

.782 (19.9)

.890 (22.6) 20mm

BR2016, CR2016, DL2016

3035

4

.835 (21.2)

.300 (7.6)

.280 (7.1)

.170 (4.3)

.600 (15.2)

.880 (22.3) 20mm

DL2020, CR2025, CR2032

3003

6

.831 (21.1)

.416 (10.6)

.265 (6.7)

.156 (4.0)

.782 (19.9)

.890 (22.6) 20mm

BR2016, DL2020, CR2025, BR2325, CR0232

3005

6

.939 (23.9)

.475 (12.1)

.265 (6.7)

.156 (4.0)

.832 (21.1) 1.004 (25.5) 23mm

BR2320, CR2320, BR2325, CR2325, DL2325, DL2330

3011

6

.939 (23.9)

.475 (12.1)

.351 (8.9)

.240 (6.1)

.819 (20.8) 1.004 (25.5) 23mm

CR2354, DL2354

3007

5

1.000 (25.4)

.506 (12.9)

.265 (6.7)

.156 (4.0)

.918 (23.3) 1.055 (26.8) 24mm

CR2430, DL2430

3009

6

1.000 (25.4)

.505 (12.8)

.350 (8.9)

.230 (5.8)

.890 (22.6) 1.059 (26.9) 24mm

CR2450, DL2450

3039

6

1.000 (25.4)

.506 (12.9)

.450 (11.4)

.336 (8.5)

.890 (22.5) 1.059 (26.9) 24mm

CR2477, DL2477

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

CELL

BATTERY

BULK

& REEL

BULK

& REEL

FIG.

A

B

F

H

L

W

DIA.

REFERENCE

TAPE & REEL SPEC’S

3000

3000TR

3080

3080TR

3

.520 (13.2)

.265 (6.7)

.125 (3.2)

.125 (3.2)

.475 (12.1)

.745 (18.9)

12mm

CR1216, BR1220, DL1225,

32mm wide; 16mm pitch; 1000/reel

SR1120, D381, 391, 191

3012

3012TR

3092

3092TR

3

.664 (16.9)

.344 (8.7)

.125 (3.2)

.156 (4.0)

.594 (15.1)

.914 (23.2) 16mm

BR1612, CR1616, CR1620,

44mm wide; 24mm pitch; 600/reel

DL1632

3028

3028TR

3038

3038TR

1

.831 (21.1)

.298 (7.6)

—

.067 (1.7)

.618 (15.7)

.911 (23.1) 20mm

BR2012, CR2012, DL2012 44mm wide; 24mm pitch; 1000/reel

3026

3026TR

3078

3078TR

2

.831 (21.1)

.416 (10.6)

.200 (5.1)

.085 (2.2)

.782 (19.9)

1.210 (30.7) 20mm

BR2016, CR2016, DL2016

44mm wide; 24mm pitch; 1000/reel

3034*

3034TR*

3044

3044TR

1

.835 (21.2)

.291 (7.4)

—

.160 (4.1)

.635 (16.1)

0.915 (23.1) 20mm

DL2020, CR2025, CR2032 44mm wide; 24mm pitch; 1000/reel

3002

3002TR

3082

3082TR

3

.831 (21.1)

.416 (10.6)

.200 (5.1)

.156 (4.0)

.782 (19.9)

1.210 (30.7) 20mm

BR2016, DL2020, CR2025,

44mm wide; 24mm pitch; 500/reel

CR2032

3004

3004TR

3084

3084TR

3

.939 (23.9)

.475 (12.1)

.200 (5.1)

.156 (4.0)

.832 (21.1) 1.339 (34.0) 23mm

BR2320, DL2325, CR2330,

56mm wide; 32mm pitch; 400/reel

DL2335

3010

3010TR

3090

3090TR

3

.939 (23.9)

.475 (12.1)

.200 (5.1)

.240 (6.1)

.819 (20.8) 1.339 (34.0) 23mm

CR2354, DL2354

56mm wide; 32mm pitch; 200/reel

3032

3032TR

3042

3042TR

1

1.000 (25.4)

.313 (8.0)

—

.067 (1.7)

.681 (17.3)

1.080 (27.4)

24mm

BR2412, CR2412

44mm wide, 24mm pitch, 1000/reel

3006

3006TR

3086

3086TR

2

1.000 (25.4) .506 (12.9)

.200 (5.1)

.156 (4.0)

.918 (23.3) 1.400 (35.6) 24mm

CR2430, DL2430

56mm wide; 32mm pitch; 400/reel

3008

3008TR

3088

3088TR

3

1.000 (25.4) .506 (12.9)

.200 (5.1)

.230 (5.8)

.890 (22.6) 1.400 (35.6) 24mm

CR2450, DL2450

56mm wide; 32mm pitch; 200/reel

M65.1 S1p9r1 9/29/15 12:53 PM Page 9

.047 [1.19] DIA.

.092 [2.34] DIA.

.662 [16.8]

.250 [6.4]

.050 [1.27]

.369 [9.4]

.312 [7.9]

.200 [5.1]

.092 [2.3]

.593 [15.06]

.359 [9.1]

.569 [14.4]

.156 [4.0] TYP.

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

.200 [5.1]

[2.34]

.040

1.02

.258

[6.6]

.047 [1.19] DIA.

.092 [2.34] DIA.

.156 [4.0]

.671 [17.0]

.497

[12.6]

.296

[7.5]

[6.4]

.092

.250

[6.4]

.250

.498 [12.7]

Pad Layout

Pad Layout

Pad Layout

•

“Flow-Hole” SMT solder tail design for increased joint strength

•

Tin-Nickel plating is ideal for lead free, high temperature soldering

•

Matte Tin Plate for lower soldering temperatures ideal where other temperature

sensitive components are being used

.055 [1.39]

.250 [6.4]

.093 [2.36]

.124 [3.2]

.047

[1.19]

.187 [4.8]

.226 [5.7]

.187 [4.8]

.320 [8.1]

.192

[4.9]

.266

[6.8]

.400 [10.2]

.064 [1.63] DIA.

.320

[8.1]

Tape & Reel Spec’s:

32mm wide; 16mm pitch; 13 inch reel, (300 pieces per reel)

Tape & Reel Spec’s:

32mm wide; 20mm pitch;

13 inch reel, (250 pieces per reel)

.545

.109 [2.8]

[13.8]

.435

[11.0]

REF.

.300 [7.6]

.200

[5.1]

.098 [2.5] DIA.

.300 [7.6]

•

Economical & reliable contacts are ideal for surface mount applications

•

Unique spring tension contacts adjust to variations in battery length

•

Reliable spring tension contacts assure low contact resistance

•

SMT solder tail with “flow-hole” design for increased joint strength

Tape and Reel Spec’s:

24mm wide; 12mm pitch; 13 inch reel (400 pieces per reel)

Tape and Reel Spec’s:

32mm wide; 16mm pitch; 13 inch reel (250 pieces per reel)

[9.9]

.200

[5.1]

.388

.109 [2.8]

.098 [2.5] DIA.

.200 [5.1]

.270

[6.9]

REF.

.300 [7.6]

MATERIAL:

.010 (.25) Spring Steel

MATERIAL:

.010 (.25) Spring Steel

MATERIAL:

.012 (.30) Spring Steel

MATERIAL:

.010 (.25) Spring Steel

MATERIAL:

.010 (.25) Spring Steel

MATERIAL:

.010 (.25) Spring Steel

MATERIAL:

.010 (.25) Spring Steel

AVAILABLE ON TAPE AND REEL

.092 [2.33]

.092 [2.34]

DIA. HOLE

.047 [1.19]

DIA. HOLE

.200 [5.1]

.250 [6.4]

.156 [3.96]

(2) PLS

.613 [15.6]

.040 [1.02]

.396 [10.0]

.215 [5.48]

.250 [6.4]

.092 [.2.34]

DIA. HOLE

.466 [11.8]

.285 [7.2]

.047 [1.19]

DIA. HOLE

.200 [5.1]

.092 [2.33]

.156 [4.0]

(2) PLS

.613 [15.6]

.040 [1.02]

Pad Layout

Pad Layout

Tape & Reel Spec’s:

24mm wide; 16mm pitch;

13 inch reel, (500 pieces per reel)

Tape & Reel Spec’s:

32mm wide; 24mm pitch;

13 inch reel, (150 pieces per reel)

Tape & Reel Spec’s:

32mm wide; 20mm pitch;

13 inch reel, (250 pieces per reel)

AVAILABLE ON TAPE AND REEL

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

50

50TR

550

550TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

55

55TR

555

555TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

56

56TR

556

556TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

53

53TR

553

553TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

57

57TR

557

557TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

5231

5231TR

5331

5331TR

TIN-NICKEL PLATE

MATTE TIN PLATE

CAT. NO. ON TAPE

CAT. NO. ON TAPE

BULK

& REEL

BULK

& REEL

5230

5230TR

5330

5330TR

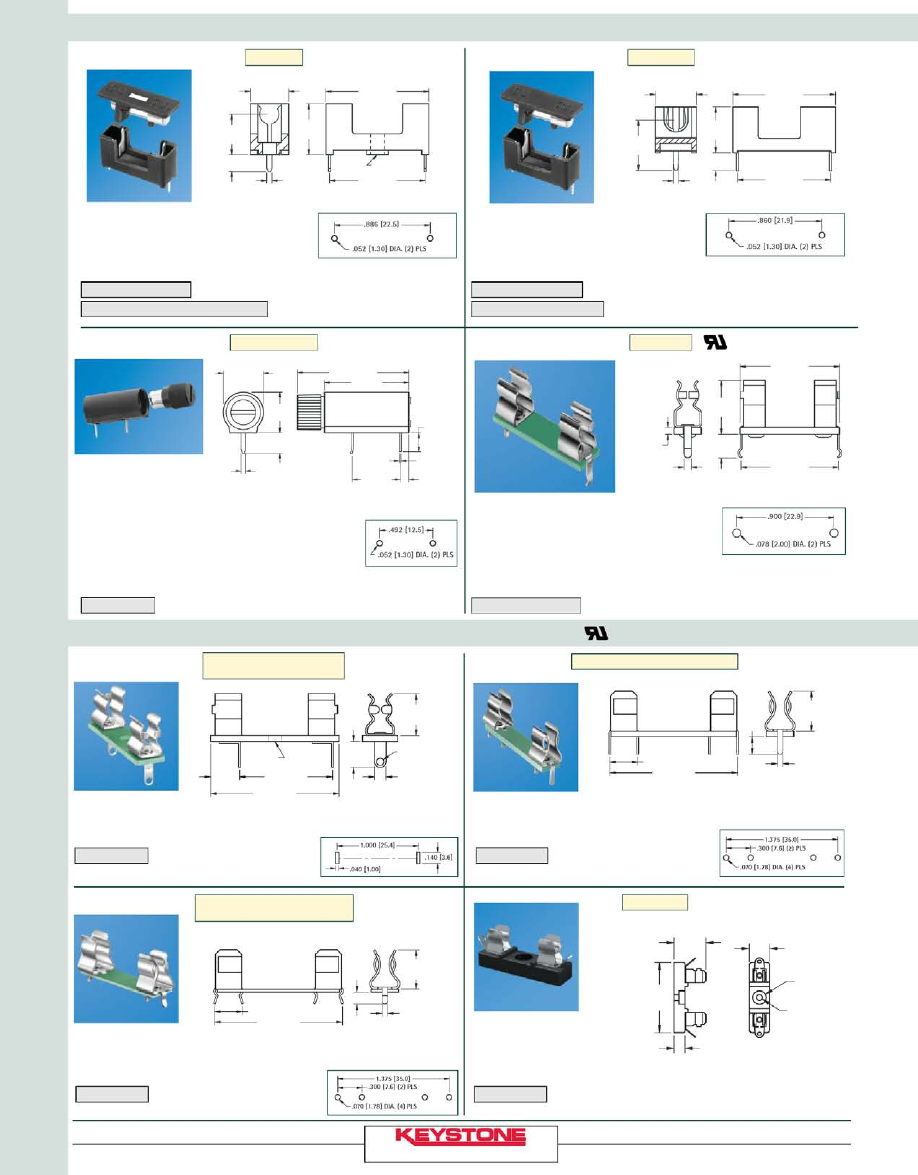

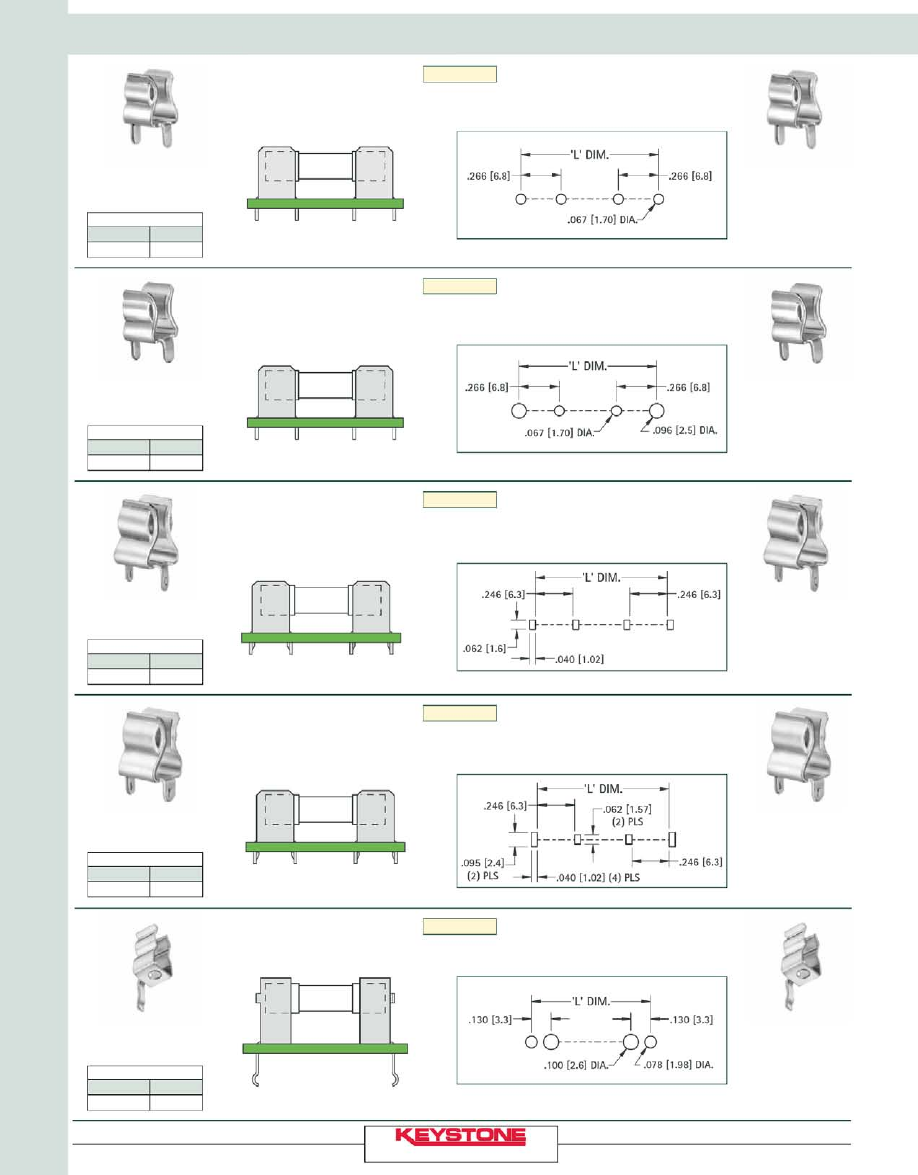

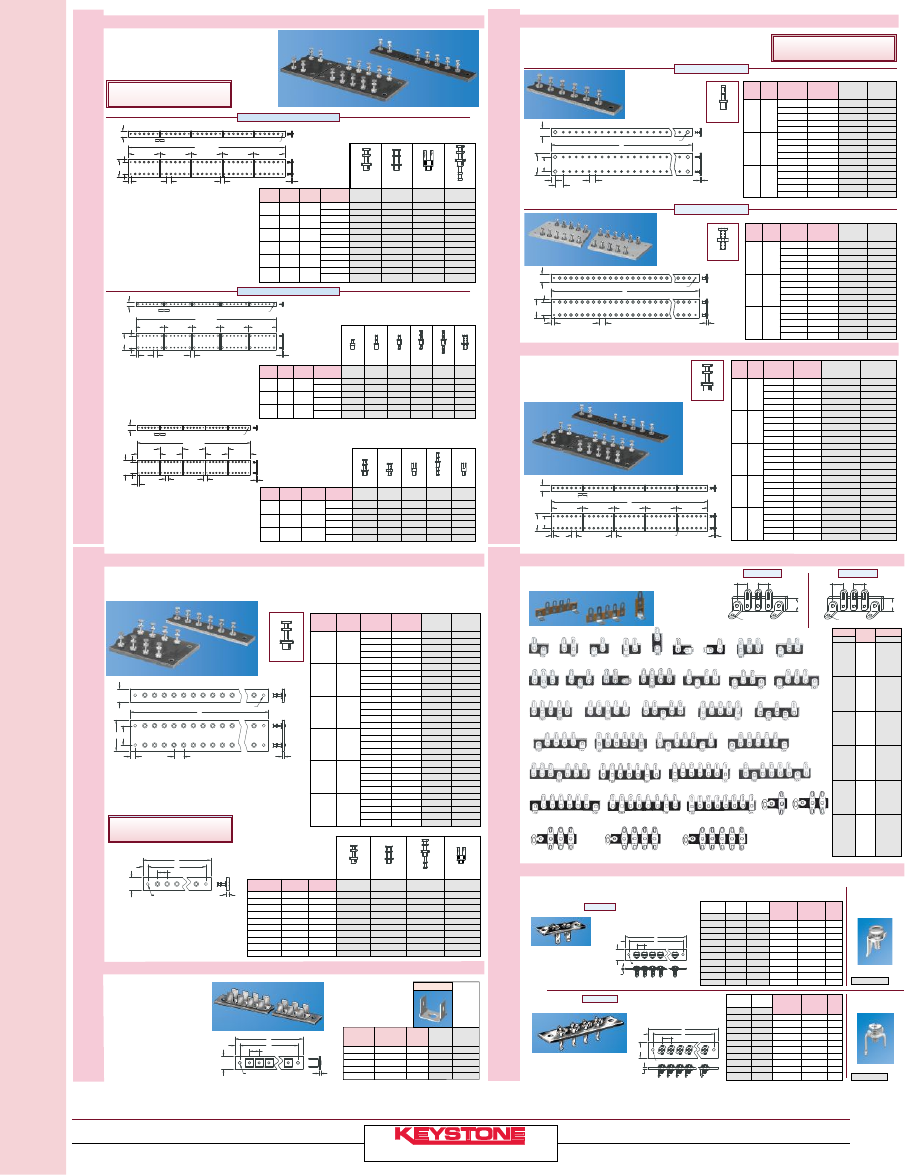

SURFACE MOUNT BATTERY CLIPS/CONTACTS

S

URF

A

CE

M

OU

NT B

A

TTER

Y

C

LIPS & C

ONT

AC

TS

10

Refer to page 34 for Battery Contact Layout & Mounting Details

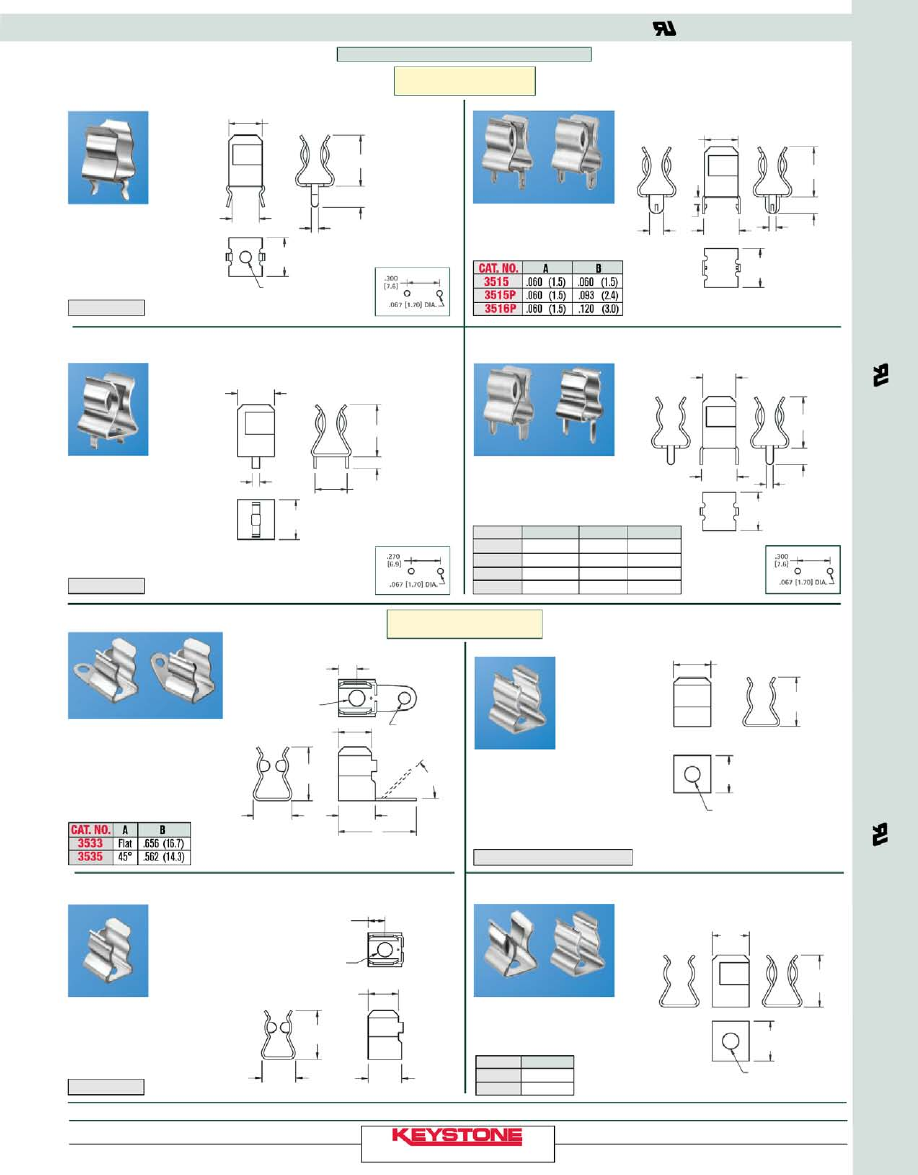

SURFACE MOUNT LEAF-SPRING CONTACTS

“AAAA” • “A27”

“AAA” • “N” • “A23”

“AA” • “CR2” • “A”

“AA” • “CR2” •“A” • “9V”

“AAA” • “AAAA” • “A23” • “N”

Tel (718) 956-8900

•

Fax (718) 956-9040

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

31-07 20th Road – Astoria, NY 11105-2017

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

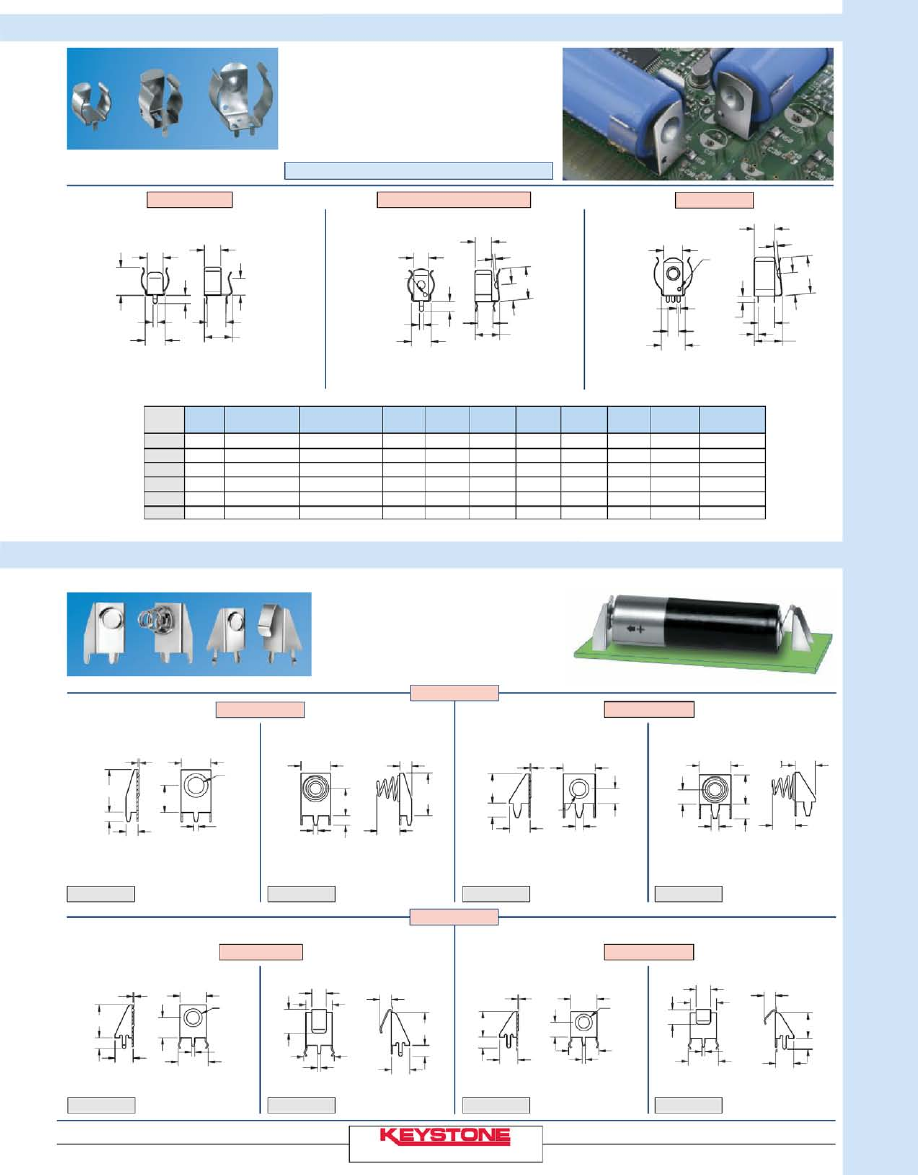

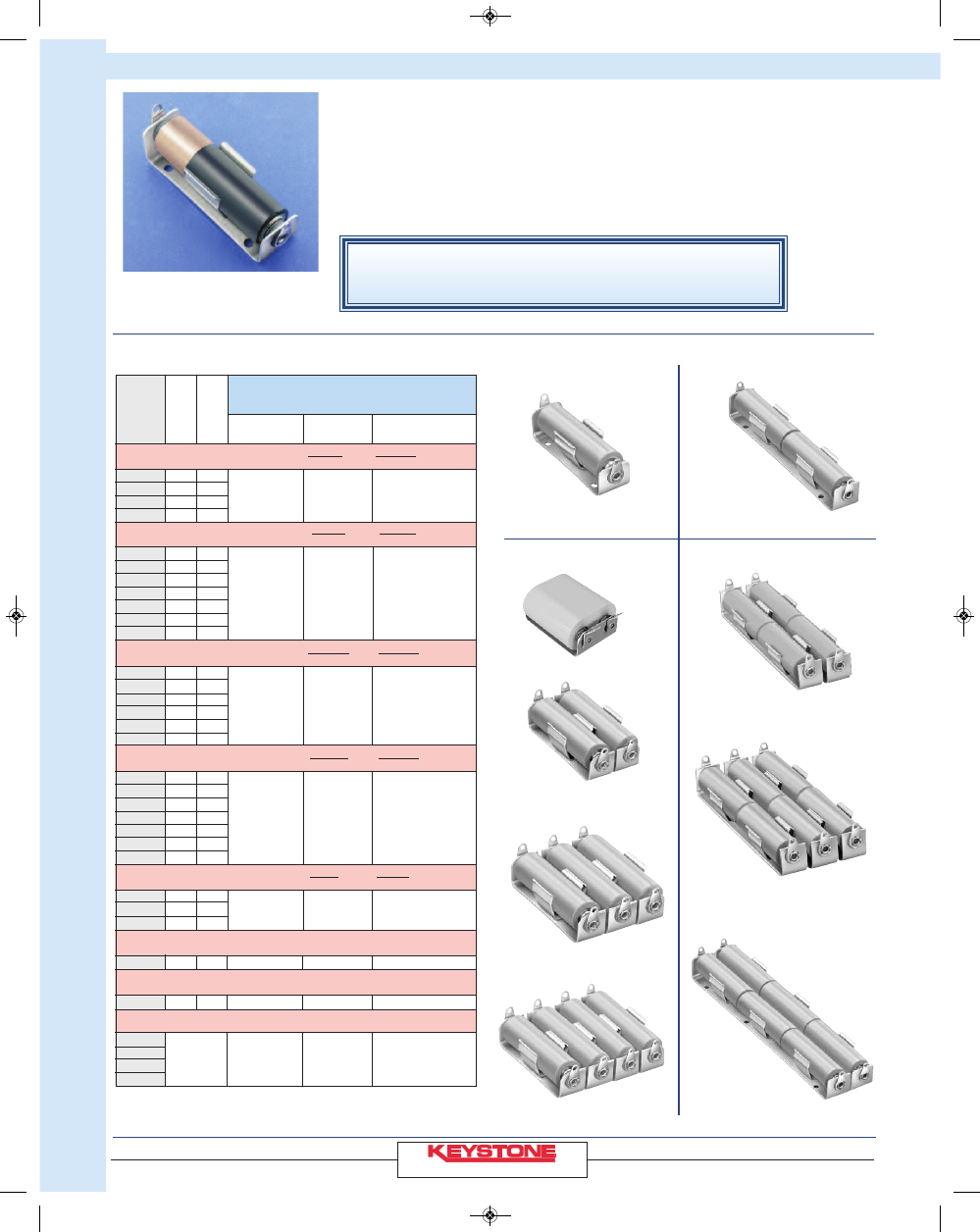

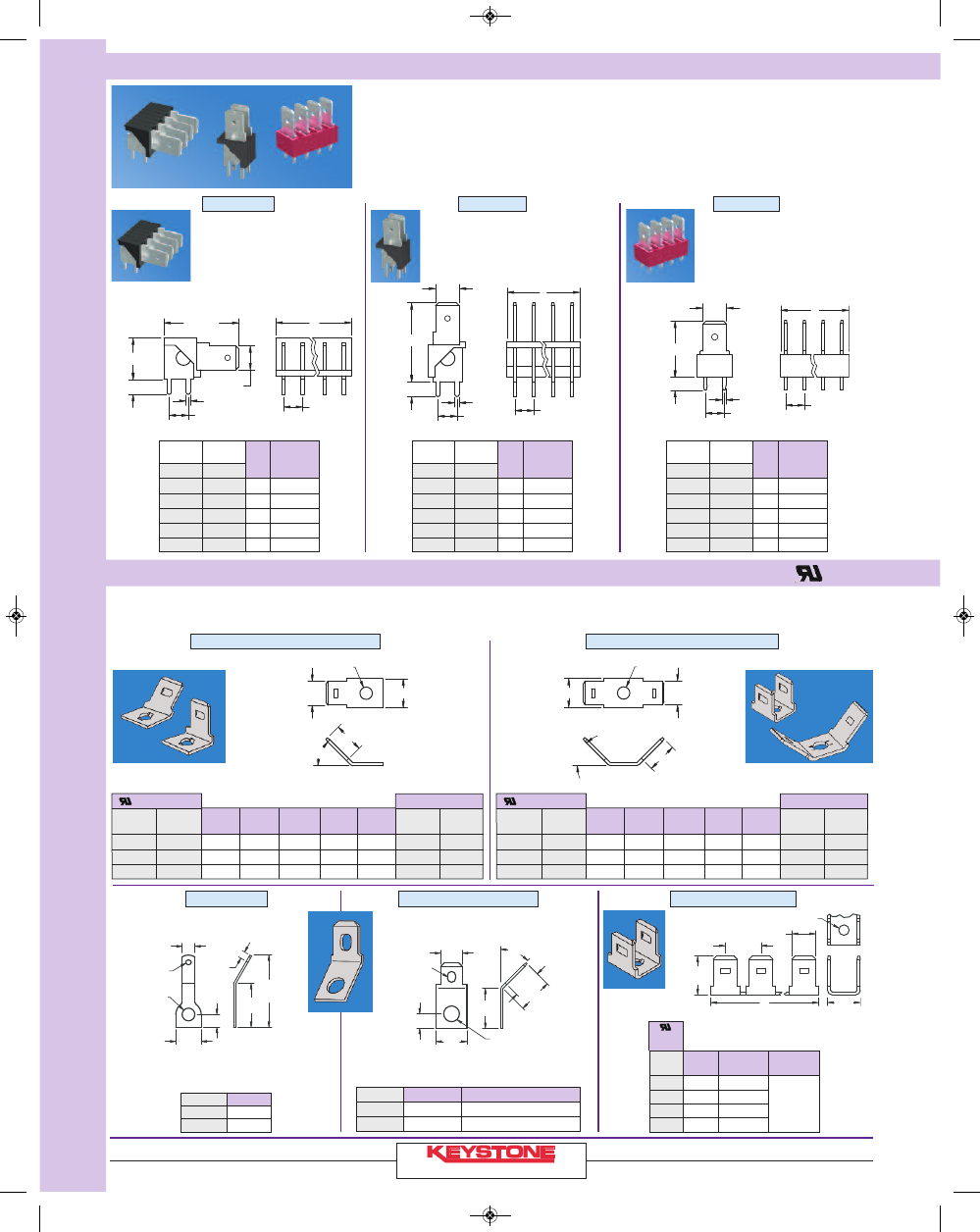

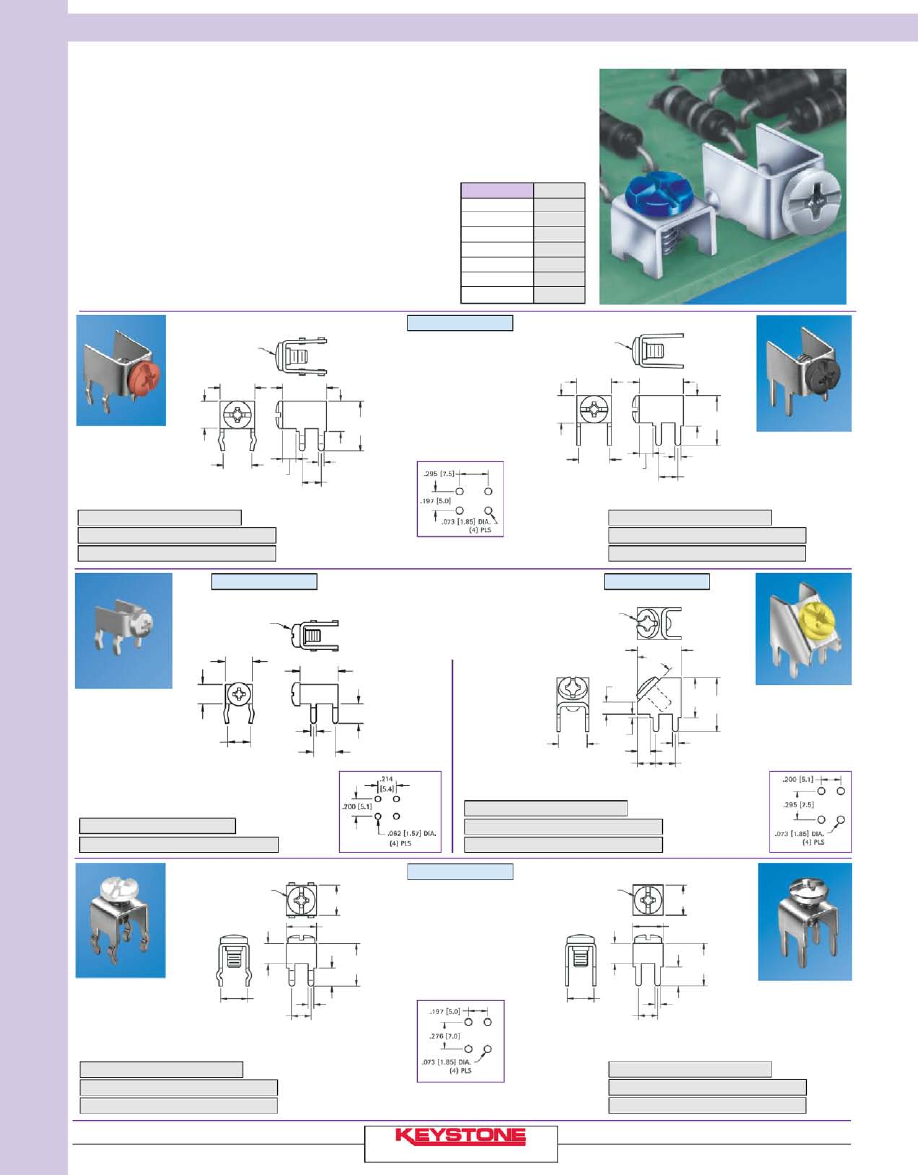

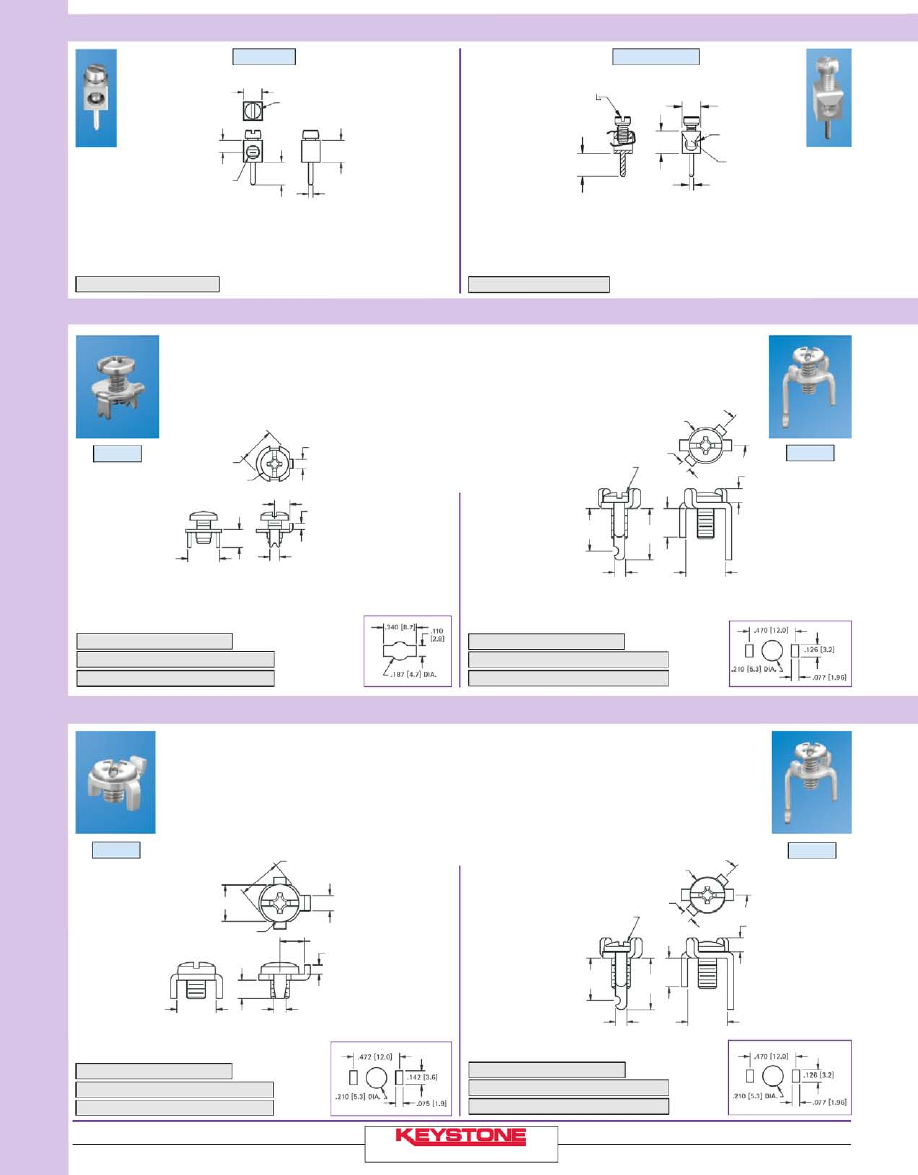

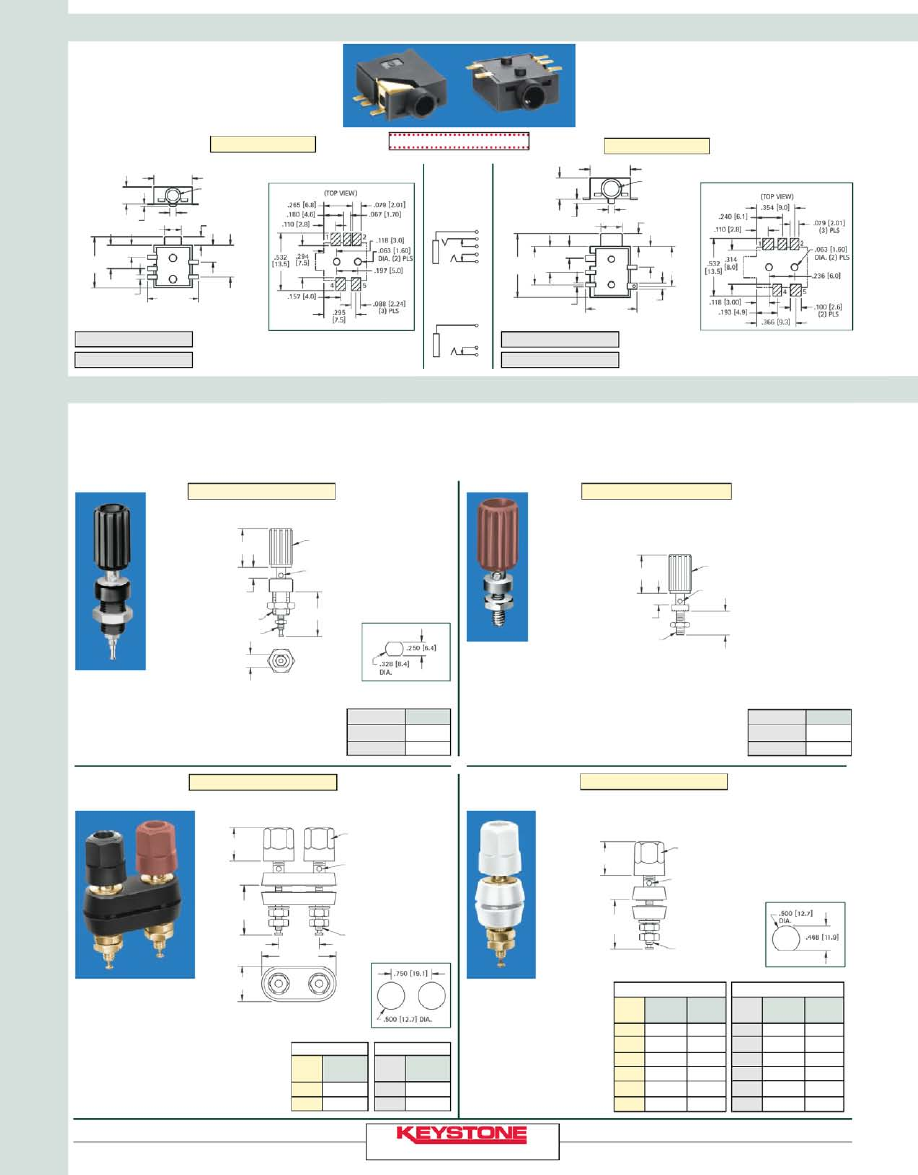

PC BATTERY CLIPS

P.C. BUTTON & SPRING CONTACTS

T

HRU

H

OLE M

OU

NT B

A

TTER

Y

C

ONT

AC

TS

•

Mounts securely to the PC board with advanced “Snap-In”

design for thru hole mounting

•

Reliable spring tension assures low contact resistance

•

Low profile, economical design

•

Retains battery securely to withstand shock and vibration

•

AAAA, AAA, AA, N, 12V, 2/3A, 17-19mm

.320 [8.1]

A

H

C

.047 [1.2]

B

W

.094

[2.4]

L

.200 [5.1]

FRONT LEGS

.062 [1.6]

(3) PLS

.120

[3.0]

.062

[1.6]

DIA.

.070 [1.8]

B

D

.512

[13.0]

A

W

C

H

L

.062

[1.6]

DIA.

H

.062 [1.57]

.375

[9.5]

B

D

A

.155 [3.9]

L

C

W

MATERIAL:

Frame:

.015 (.38)

Steel, Tin-Nickel Plate

MATERIAL:

Frame:

.015 (.38) Steel,

Tin-Nickel Plate

MATERIAL:

Frame:

.015 (.38) Steel,

Matte Tin Plate

MATERIAL:

Frame:

.015 (.38)

Steel,Matte Tin Plate

MATERIAL:

.012 (.30) Spring Steel, Tin-Nickel Plate

.410 [10.4]

.180 [4.6]

.190 [4.8]

.100 [2.5]

(3) PLS

.380 [9.7]

.015 [0.4]

.265

[6.7]

.175

[4.5]

DIA.

.190 [4.8]

.100 [2.5]

(3) PLS

.410

[10.4]

.290

[7.4]

.380 [9.7]

.180 [4.6]

.265 [6.7

.210

[5.3]

DIA.

.015 [0.4]

.380 [9.7]

.062

[1.6]

(3) PLS

.550 [14.0]

.156

[4.0]

.120 [3.0]

.350 [8.9]

.550

[14.0]

.120 [3.0]

.350 [8.9]

.338

[8.6]

.290

[7.4]

.156 [4.0]

.055 [1.4]

(3) PLS

.160 [4.1]

REF.

.200 [5.1]

.450 [11.4]

.360

[9.1]

.250

[6.3]

.416

[10.6]

REF.

.325 [8.2]

REF.

.045 [1.1]

.250

[6.4]

DIA.

.360

[9.1]

.416

[10.6]

REF.

.045 [1.1]

.150 [3.8]

.275 [7.0]

.015 [0.4]

.450 [11.4]

.250

[6.3]

(+) POSITIVE BUTTON

(+) POSITIVE BUTTON

MATERIAL:

.010 (.25) Spring Steel, Tin-Nickel Plate

.232

[5.9]

DIA.

.416

[10.6]

REF.

.360

[9.1]

.350 [8.9]

.045 [1.1]

.150 [3.8]

.015 [0.4]

.200 [5.1]

.250

[6.3]

.350 [8.9]

.160 [4.1]

REF.

.150 [3.8]

.416

[10.6]

REF.

.045 [1.1]

.360 [9.1]

.200 [5.1]

.250

[6.3]

.202 [5.1]

REF.

(-) NEGATIVE SPRING

(-) NEGATIVE SPRING

CAT. NO. 595

CAT. NO. 628

CAT. NO. 637

CAT. NO. 629

CAT. NO. 591

CAT. NO. 597

CAT. NO. 590

CAT. NO. 596

“AA” • “CR2” • “A”

COIL SPRING

LEAF SPRING

11

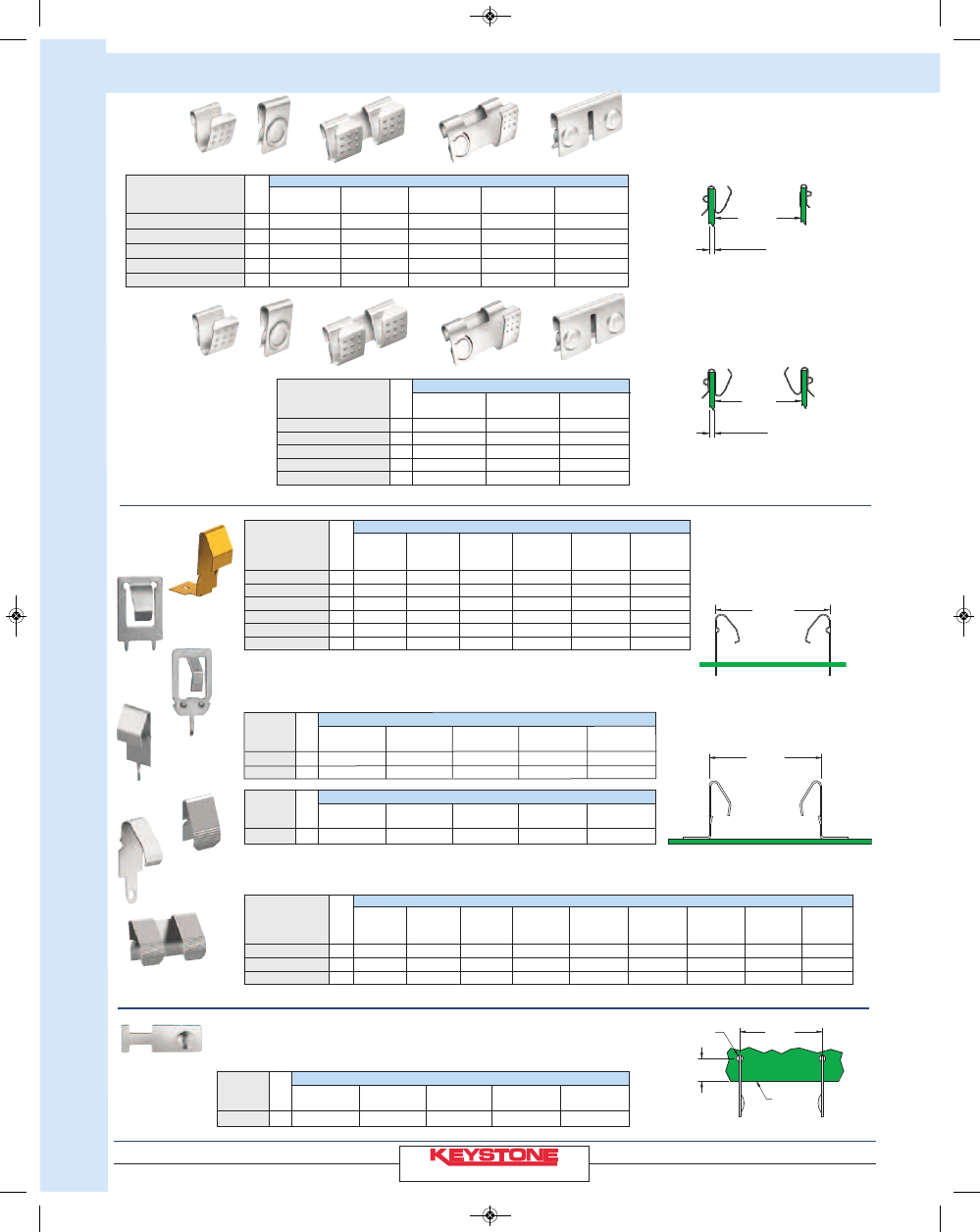

CAT.

BATTERY

BATTERY

MATERIAL

NO.

FIG.

SIZE

DIAMETER

A

B

C

D

H

L

W

THICKNESS

51

1

“AAAA” • “A27”

.300 -.350 (7.6-8.9)

.187 (4.8) .187 (4.8) .194 (4.9)

—

.320 (8.1) .214 (5.4) .226 (5.7)

.010 (.25)

82

2

“AAA”

•

“N”

•

“A23”

.375 -.460 (9.5-11.7) .250 (6.4) .250 (6.4) .280 (7.1) .040 (1.0) .498 (12.7) .228 (5.8) .296 (7.5)

.010 (.25)

52

2

“AA”

•

“CR2”

•

“A”

No Ears.250 (6.4)

—

.280 (7.1) .032 (0.8) .498 (12.7) .228 (5.8) .250 (6.4)

.010 (.25)

92

2

“AA” • “CR2”

.531-.665 (13.5-16.9) .312 (7.9) .250 (6.4) .359 (9.1) .050 (1.3) .593 (15.1) .228 (5.8) .369 (9.4)

.012 (.30)

2915

2

“AA” • “CR2”

.531-.665 (13.5-16.9) .312 (7.9) .250 (6.4) .359 (9.1) .050 (1.3) .593 (15.1) .228 (5.8) .376 (9.5)

.015 (.38)

54

3

“A”• 17-19mm*

.669 -.748 (17.0-19.0) .350 (8.9) .375 (9.5) .385 (9.8) .062 (1.6) .653 (16.6) .300 (7.6) .438 (11.1)

.012 (.30)

*Battery Reference: 2/3A,17335,17450,17500,17650,18500,18650 cells

MATERIAL:

Spring Steel, Tin-Nickel Plate

•

Space saving design installs directly onto the PC board

•

Suitable for .062 (1.57) to .093 (2.36) PC boards

•

Reliable spring tension assures low contact resistance

•

Ideal for self-contained battery compartments

FIG. 1

FIG. 2

FIG. 3

Refer to page 35 for Battery Contact Layout & Mounting Details

*17335, 17450, 17500, 17650, 18600, 18650 cells

“AAA” • “N” • “A23” • “AA” • “CR2”

“AAA” • “N” • “A23”

“AAA” • “N” • “A23”

“AA” • “CR2” • “A”

“A” • 17–19mm*

“AAAA” • “A27”

INSULATED POLARIZING WASHERS

BATTERY SPRING CONTACTS

POLARITY INDICATING LABEL

B

A

TTER

Y

C

LIPS, C

ONT

AC

TS & AC

C

ESSOR

IES

12

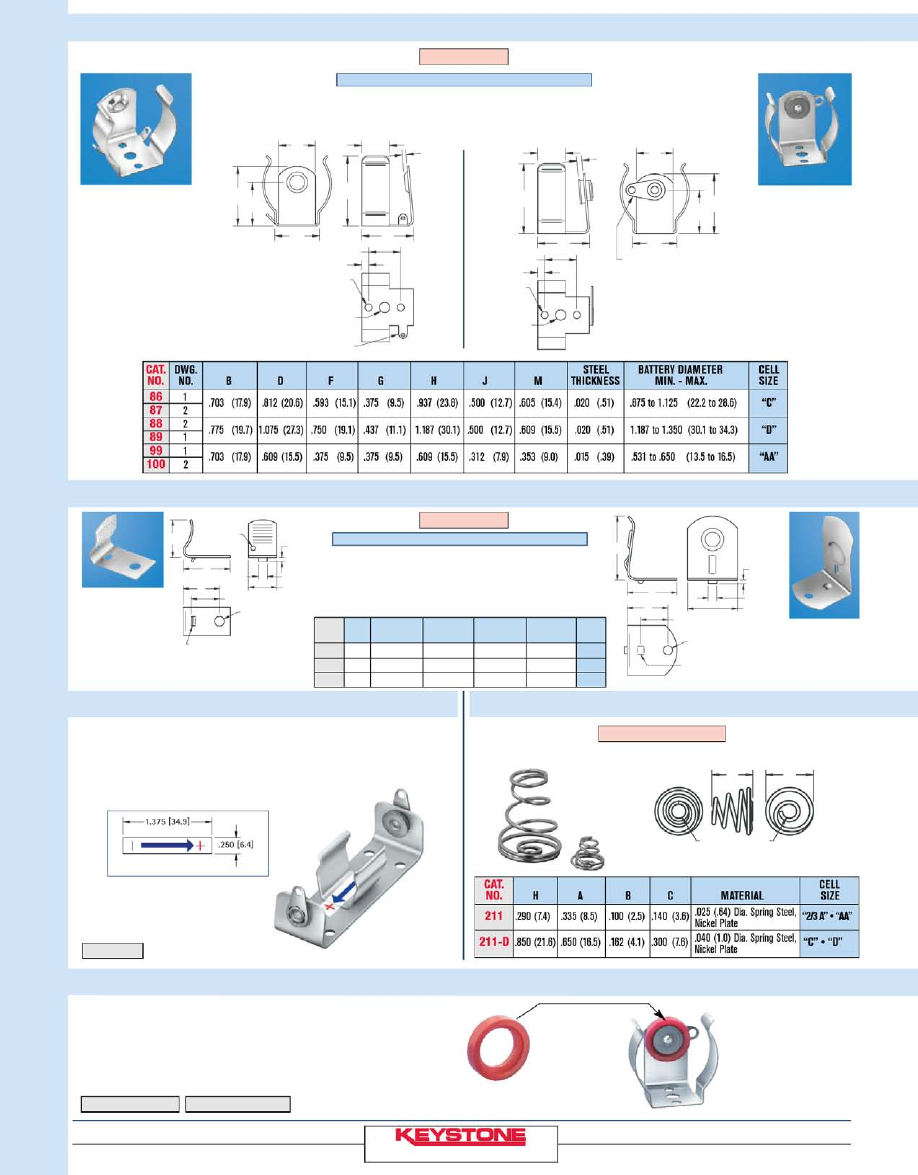

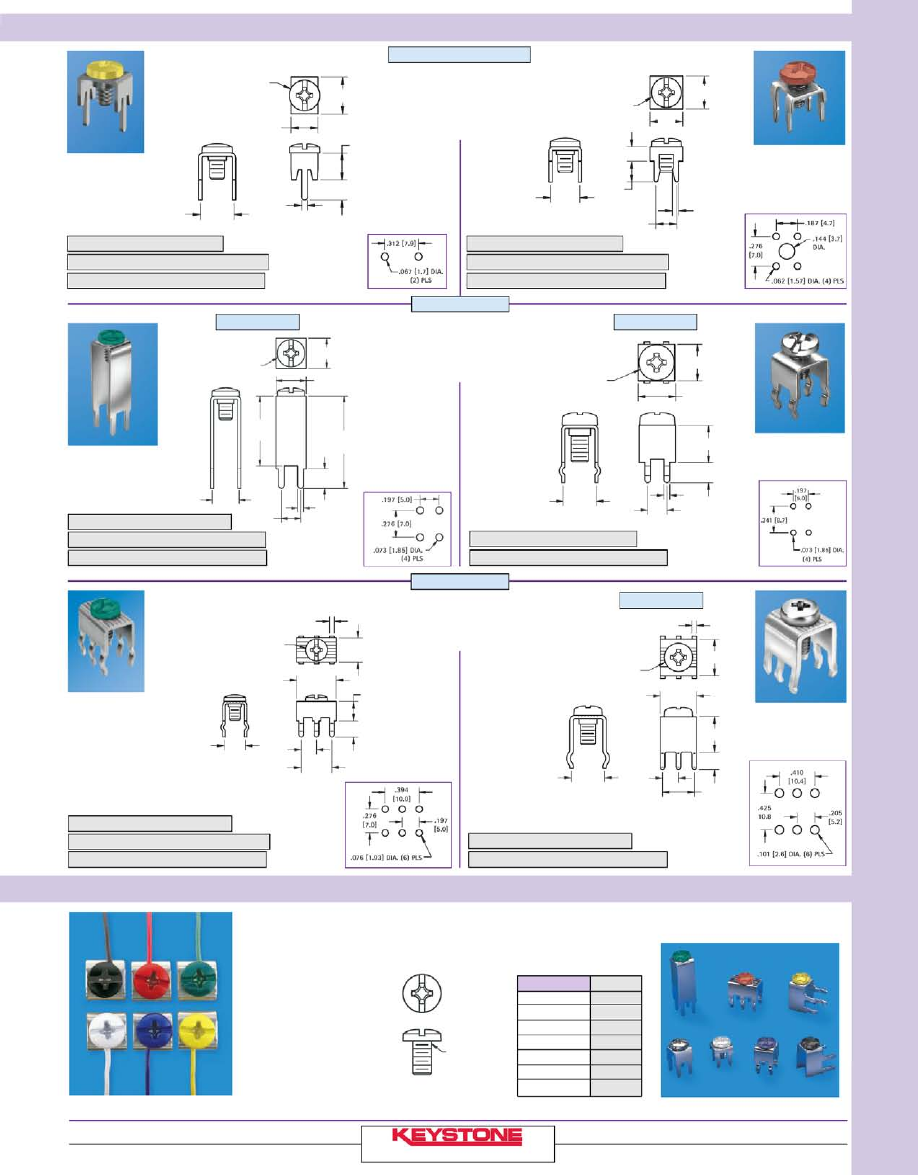

SPECIFICATIONS

Clips:

Spring Steel, Nickel Plate

Contact Eyelets:

Brass, Nickel Plate

Insulating Washers:

Moisture Proof, Resin Impregnated Fibre

Solder Lugs:

Brass, Tin Plate

B

D

F

J

G

H

M

.050

[1.27]

.093 [2.4]

.144 [3.7]

DIA.

.098 [2.5]

DIA. (2) PLS

.437 [11.1]

EAR FOR SOLDERING

RUGGED STEEL BATTERY CLIPS

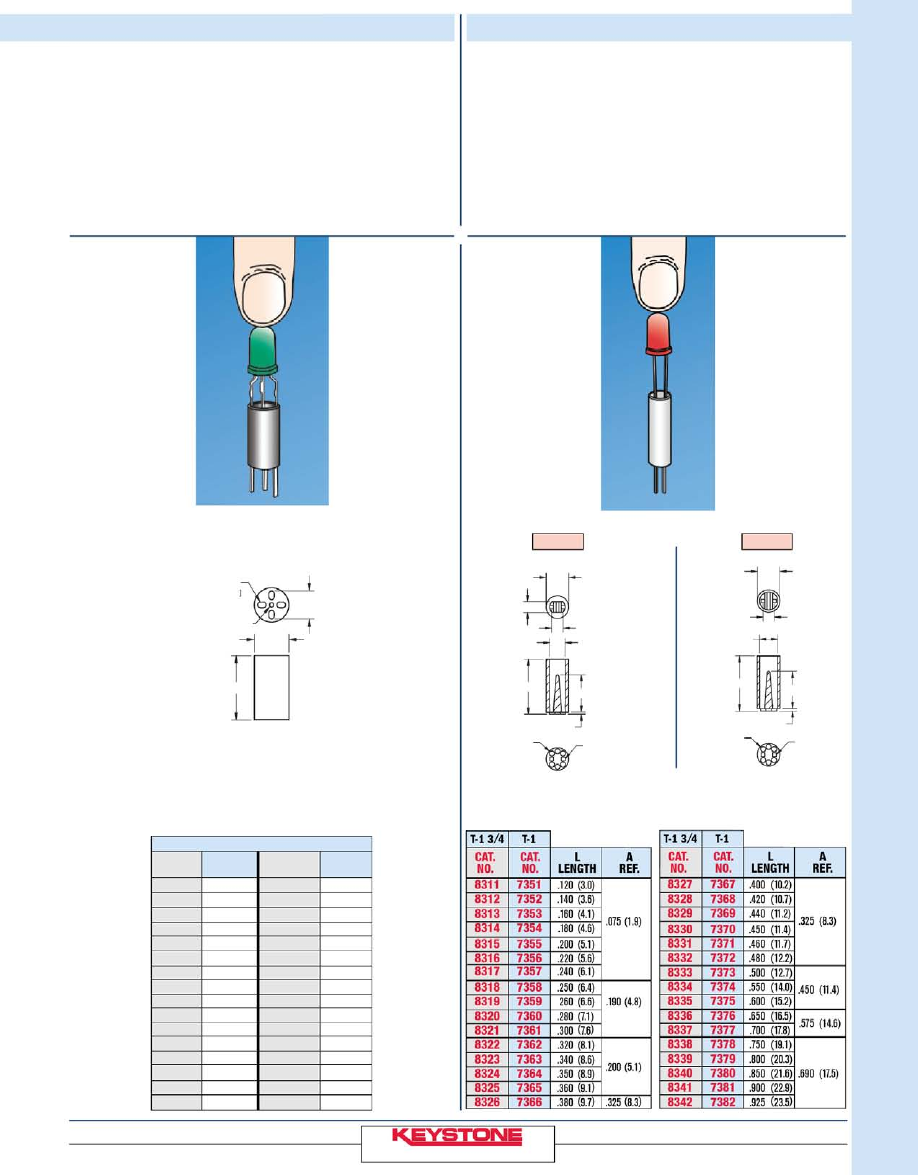

DWG. 1