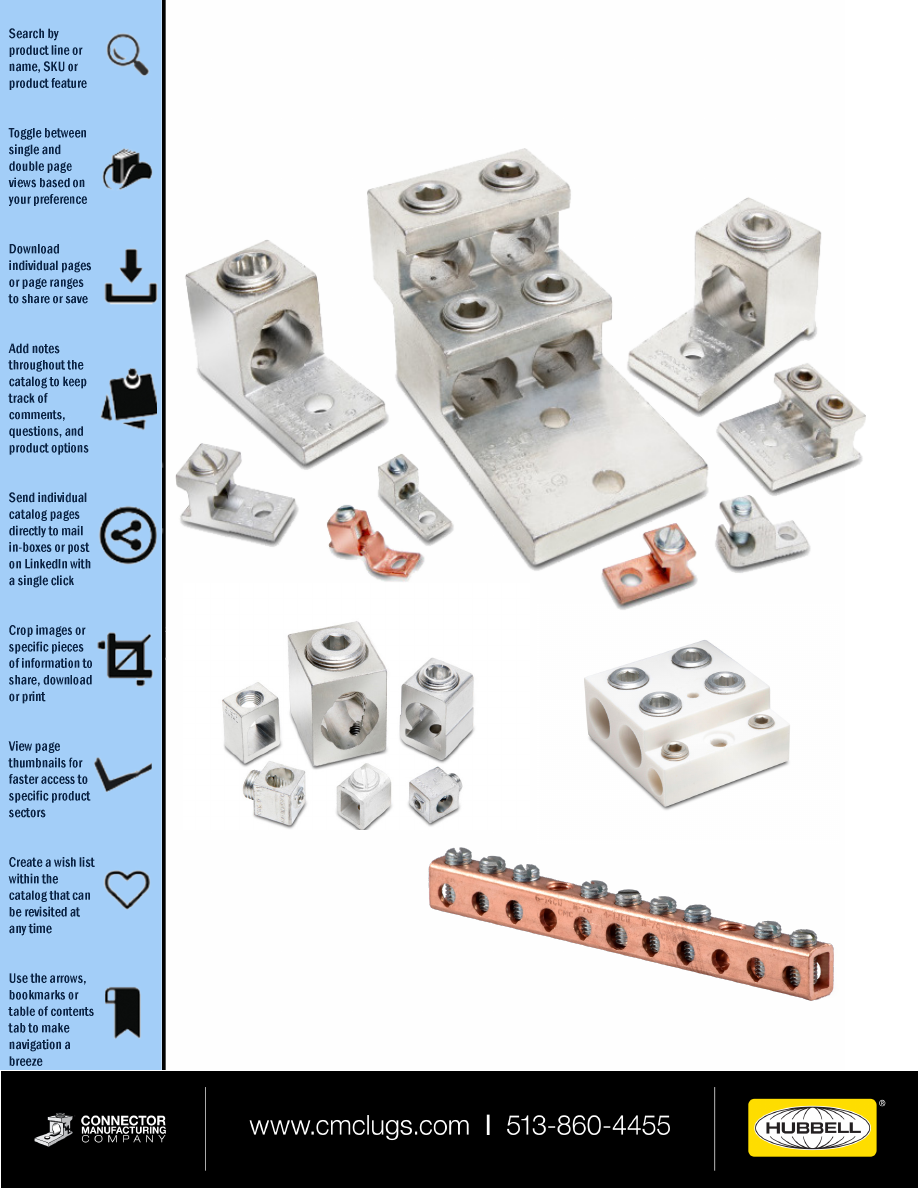

CMC® OEM Products

Connecting Power to Your World

CMC® OEM Products

Connecting Power to Your World

www.cmclugs.com 513.860.4455

CMC® OEM Products

Solutions to Support Original Equipment Manufacturers

Continuous Innovation for the OEM Market

For more than 70 years, Connector Manufacturing Company (CMC®) has been dedicated to

engineering, designing and manufacturing quality products for the OEM industry. Thanks to this long

history, CMC® has a solid understanding of industry challenges and provides the flexibility and

expertise to provide solutions that:

• Improve reliability

• Increase efficiency

• Reduce acquisition and operational costs

Tap our knowledge and you’ll benefit from our wide-reaching capabilities, such as:

• Complete in-house engineering and design

• A certified UL third-party test facility equipped to perform UL, ANSI and CSA test requirements

• Customer service that consistently provides knowledgeable answers to our distributors and end-users

As a result, CMC® provides competitively priced connector and neutral bar solutions

that minimize installation time while ensuring the highest level of quality and safety.

Surpassing Industry Standards

Headquartered in Ohio, CMC® is home to one of the industry’s most comprehensive third-party testing

facilities in the United States. The CMC® lab is qualified under the ISO Guide 17025-2008 certification

requirements for lab accreditation. We have teams of lab technicians at multiple lab facilities to perform

tests that include:

• Electrical (current cycle, fault current, static heat)

• Mechanical (sustained load, pullout, secureness, fatigue)

• Environmental (freeze/thaw, salt spray)

• Metallurgical (grain structure, heat treatment, failure analysis)

www.cmclugs.com 513.860.4455

Thanks to our long history, CMC® has a solid understanding

of industry challenges. We offer a dedicated and specialized engineering team,

masterful in the ability to work with customers from all markets to design,

fabricate, and deliver CUSTOMIZED connectors and SOLUTIONS for your

specific applications. WE’VE GOT YOU!

Here are some examples:

Special Inside-Mounted Connectors

Special Top-Mounted Connectors

Special Styles

Custom Connectors

www.cmclugs.com 513.860.4455

Aluminum Dual Rated Mechanical Connectors

A new generation in mechanical connector performance.

Cool running over 500 heat cycles. Versatile, simple to use and low cost.

Introduction

CMC®

introduces PosiGrip

®

aluminum dual-rated mechanical connectors. The PosiGrip

® line is designed to meet the rigorous

requirements of 486B and CSA 1165A specifications covering connectors for use with aluminum and copper conductors.

The PosiGrip® line is fully listed by Underwriters Laboratories, Inc. and Canadian Standards Association. In addition, these

connectors are EU RoHS compliant.

Low Resistance Design

Low initial contact resistance is the key to long life for any electrical connection and is the major element in meeting the

demanding performance requirements of UL 486B. Connector Manufacturing Company’s engineers have incorporated special

new design concepts into the PosiGrip® line. Uniquely designed I-Beam bodies and conductor hole configuration along

with specially designed and treated screws; minimize high resistance connector failures due to thermal expansion, creep,

and insufficient clamping force. The superior gripping action of the I-Bean design allows the set screw to separate conductor

strands and break down inner stand oxidation even on compressed and compact aluminum conductors. Therefore, superior

performance and long connector life are assured regardless of the type of conductor being used.

Versatility

Each PosiGrip® connector will accommodate a wide range of aluminum or copper conductor sizes of concentric, compressed

or compact configurations. Only eleven connector sizes cover the range from #14 thru 1000 kcmil. In addition, they are UL

listed and CSA certified for use with conductors having thermal insulation ratings of 90

°

C or less. This means greater flexibility

in the type of conductor being used, less inventory to carry and fewer call backs because the installer doesn’t have the right part.

Easy to install; all you need is a screwdriver or an allen wrench.

Quality Assurance

To identify UL 486B connectors, UL requires such connectors to be marked CU9AL when listed for use with 90

° C rated

conductors. To be sure that the connector you buy meets all UL requirements, CMC

®

inspects each lot of PosiGrip® connectors

for integrity of physical dimensions, aluminum properties, set screw and conductor hole alignment, plating, along with screw

and body thread class. Only connector lots meeting industry accepted quality levels are approved for shipment.

PosiGrip

®

Lug Features

1. The unique ridges formed on the bottom of the contact surface are designed to provide positive contact points for an

electrically secure joint of the lowest resistance for current flow. Just as a tri-pod provides tilt free contact on a smooth

surface, this connector is designed to cause specific contact points where current can flow without “hot spots” created when

two flat surfaces are joined together.

2. The screws used to clamp the conductor are designed to extend beyond the barrel sides of the connector to allow a better,

more secure compression of the conductor. This design spreads conductor strands to help dis sipate heat. In addition, this

causes the maximum conductor to spread slightly more than the wire way opening which when installed improves its pull out

safety features and capabilities.

3. The design of the wire way opening allows the conductor to enter the lug at the lowest point possible near the tang of the

lug to provide optimum transfer of current creating a straight line flow through the connec tor for the least possible path of

electrical resistance. A positive wire stop is provided with a step in the connec tor tang.

PosiGrip®

www.cmclugs.com 513.860.4455

A NEW, IMPROVED

PATENTED LUG

DESIGN

New generation of UL-486B Listed CSA Certified 90° C Rated Connectors

Unique body and screw

design minimizes thermal

expansion problems

Listed for use with concentric,

compact and compressed

conductors

Tin-Plated Body

No special tooling required

for installation

No adaptor or

conversion kits required

PosiGrip®

www.cmclugs.com 513.860.4455

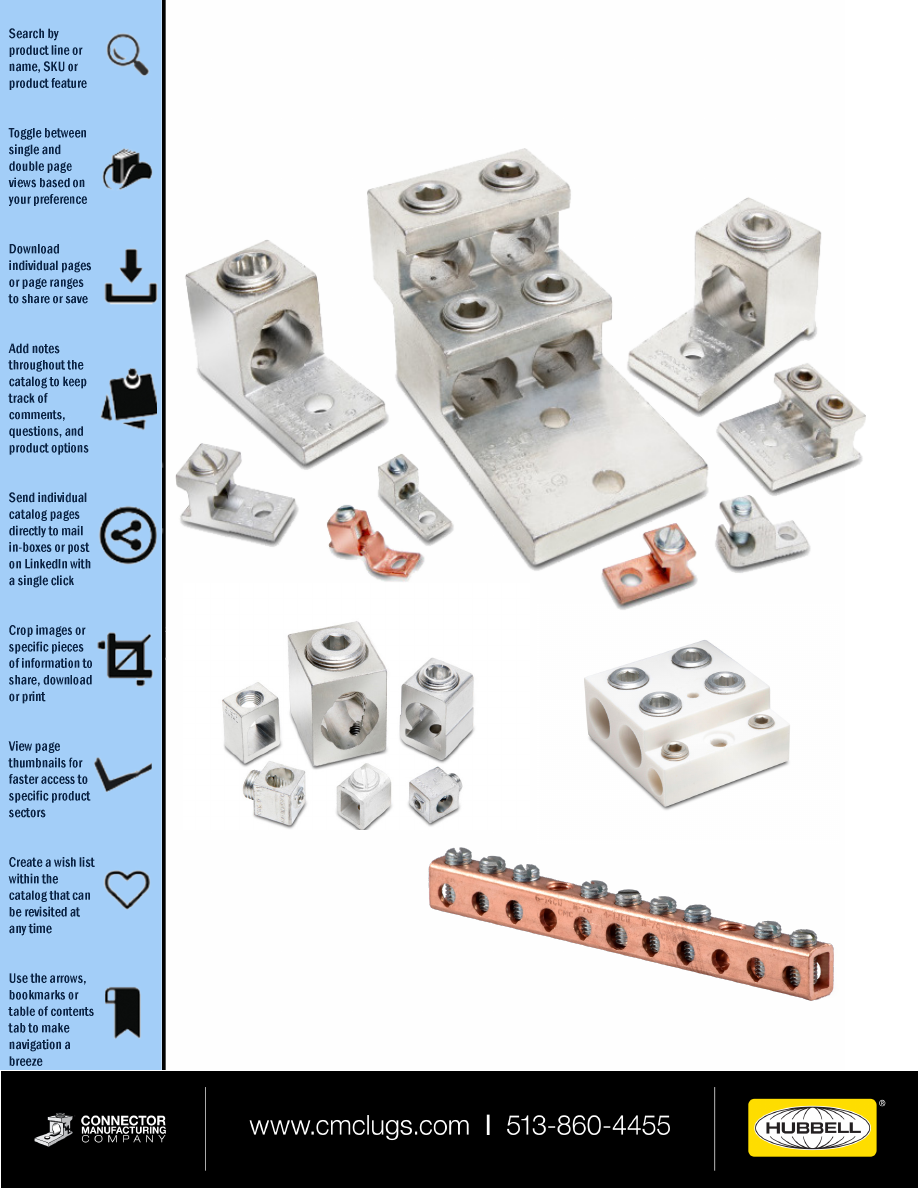

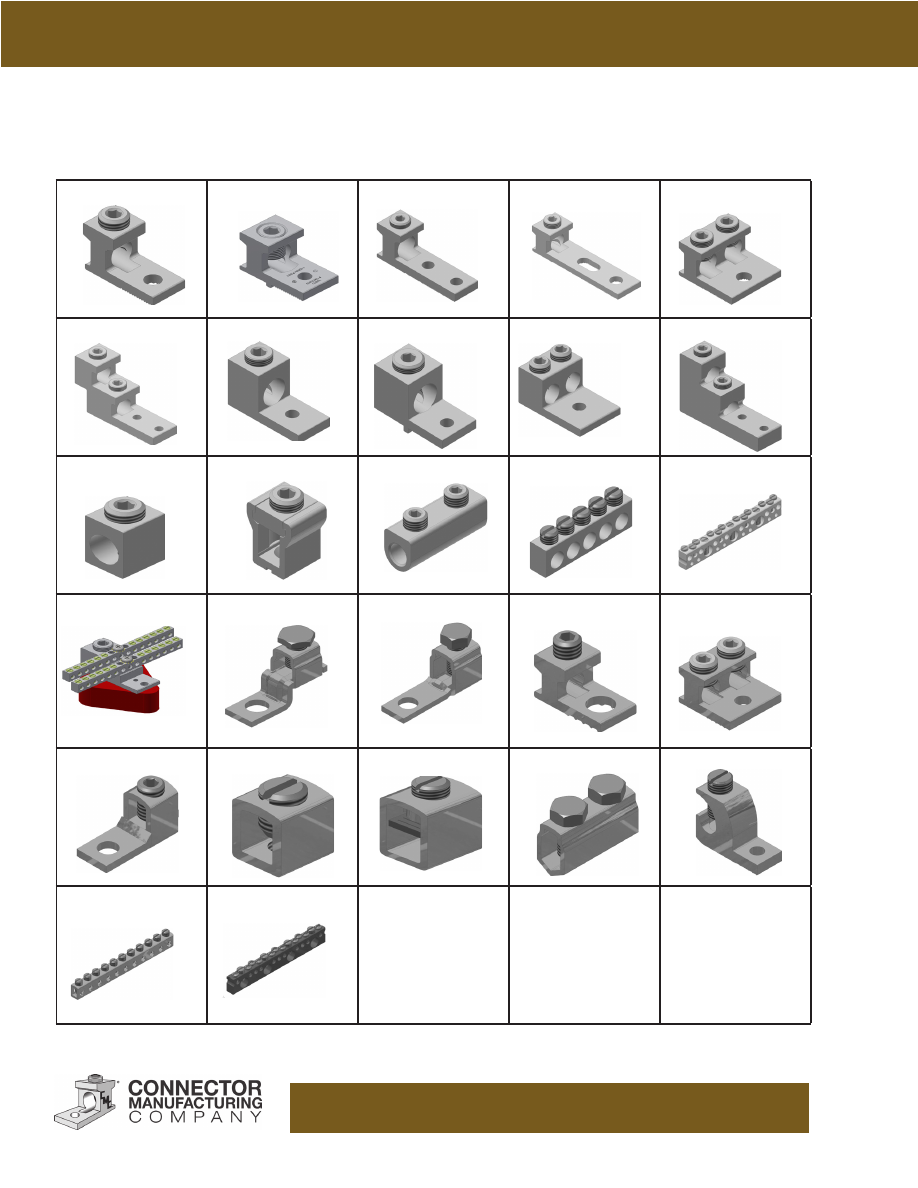

AB

AB Anti-Turn

A1B2

ABSG

2AB

ABV

LA

LA Anti-Turn

DLA

PV

CA

LI

SR

NA

SCB

SNB-350

CF

CFS

BC

2BC

FT

C

CS

C2/C4

CL

N70

LCB

Pictoral Index

Notes

www.cmclugs.com 513.860.4455

CMC® is proud to supply the industry with a line of electrical connectors fabricated from the very best

aluminum alloy, 6061-T6. This choice was predicated upon many design factors to achieve the best

balance between strength and conductivity. Both factors are of extreme importance in connector design

calculations. The aluminum extrusions have almost a two-to-one advantage in yield strength to that of a

sand cast alloy 356 or die cast alloy AXS679, permitting an extra margin of safety while the conductivity

is a most favorable 43% IACS.

The set and socket screw mechanical connectors are designed to utilize the advantages of the 6061-

T6 alloy temper for high yield strength while providing a connector of low stress. Screw pressure is

designed to break through aluminum conductor oxide by cold flow process that ensures a low resistance

connection. Sufficient pressure is maintained on the conductor to prevent the reforming of the aluminum

oxide. The pressure, combined with the high conductivity factor, will result in a connector operating

temperature below that of the conductor.

We therefore, offer these advantages in connector design:

1. Compact design

2. High strength aluminum

3. Relative light weight construction

4. Economic

5. Tested products in accordance with the Underwriters Laboratories and the Canadian Standards

Association requirements for listing.

These factors together with our dedication for the highest quality standards available and an unsurpassed

service level, provide our customers with maximum reliability.

CMC® Aluminum Connectors

www.cmclugs.com 513.860.4455

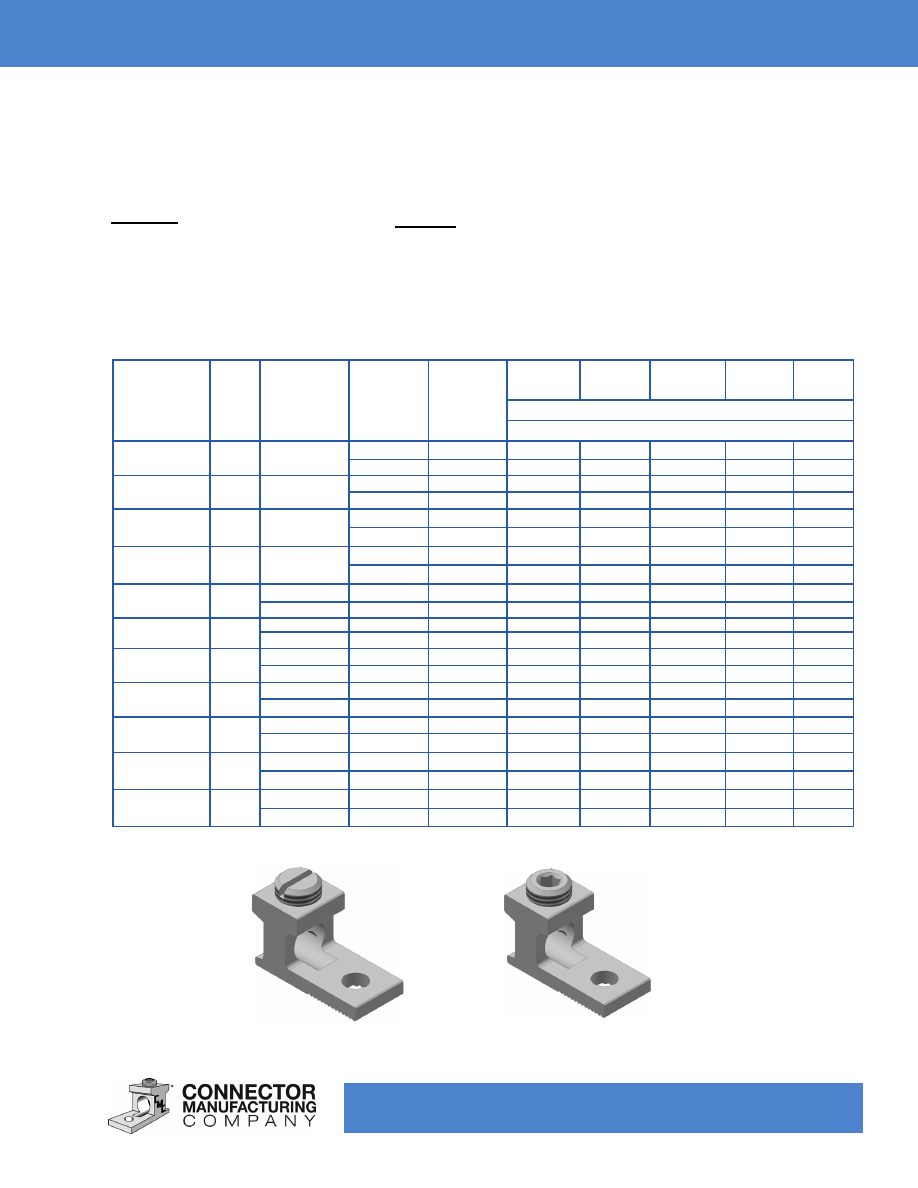

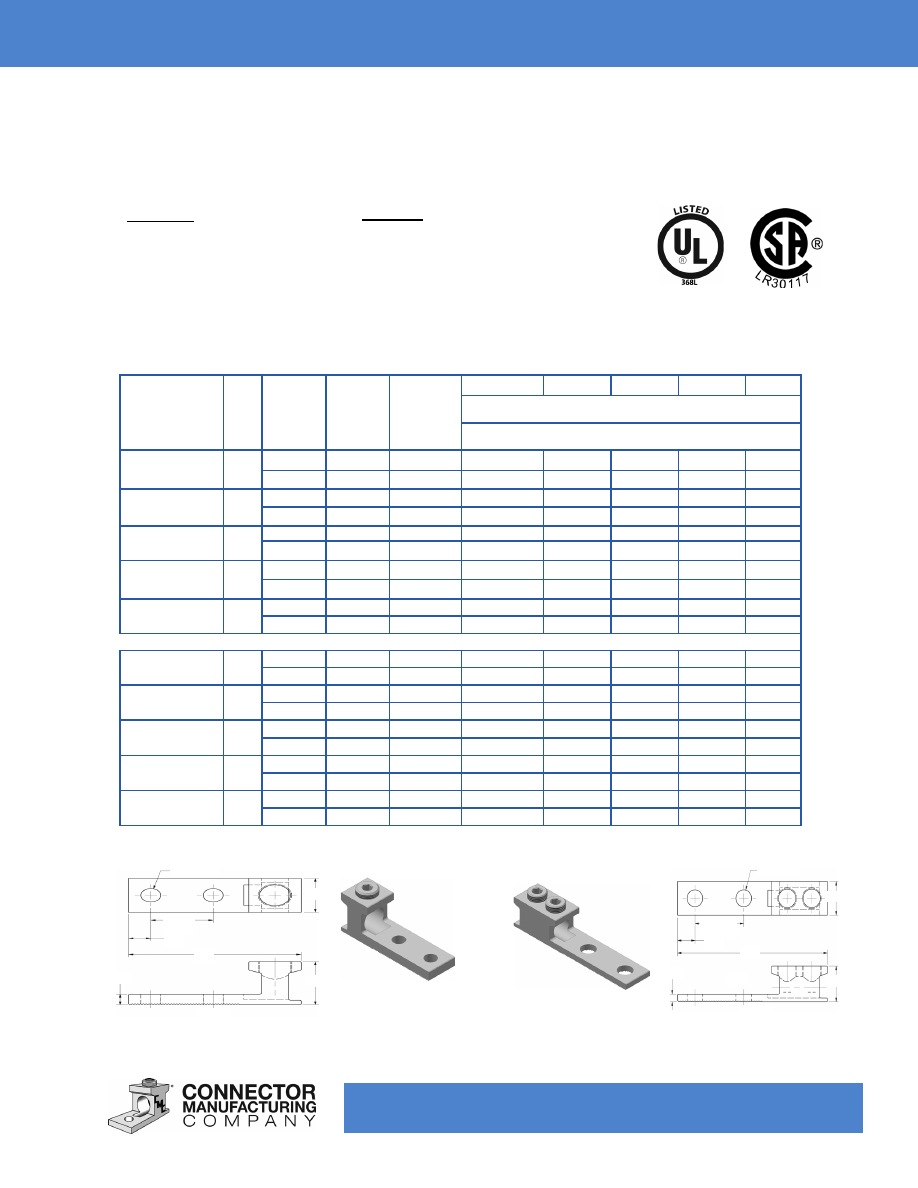

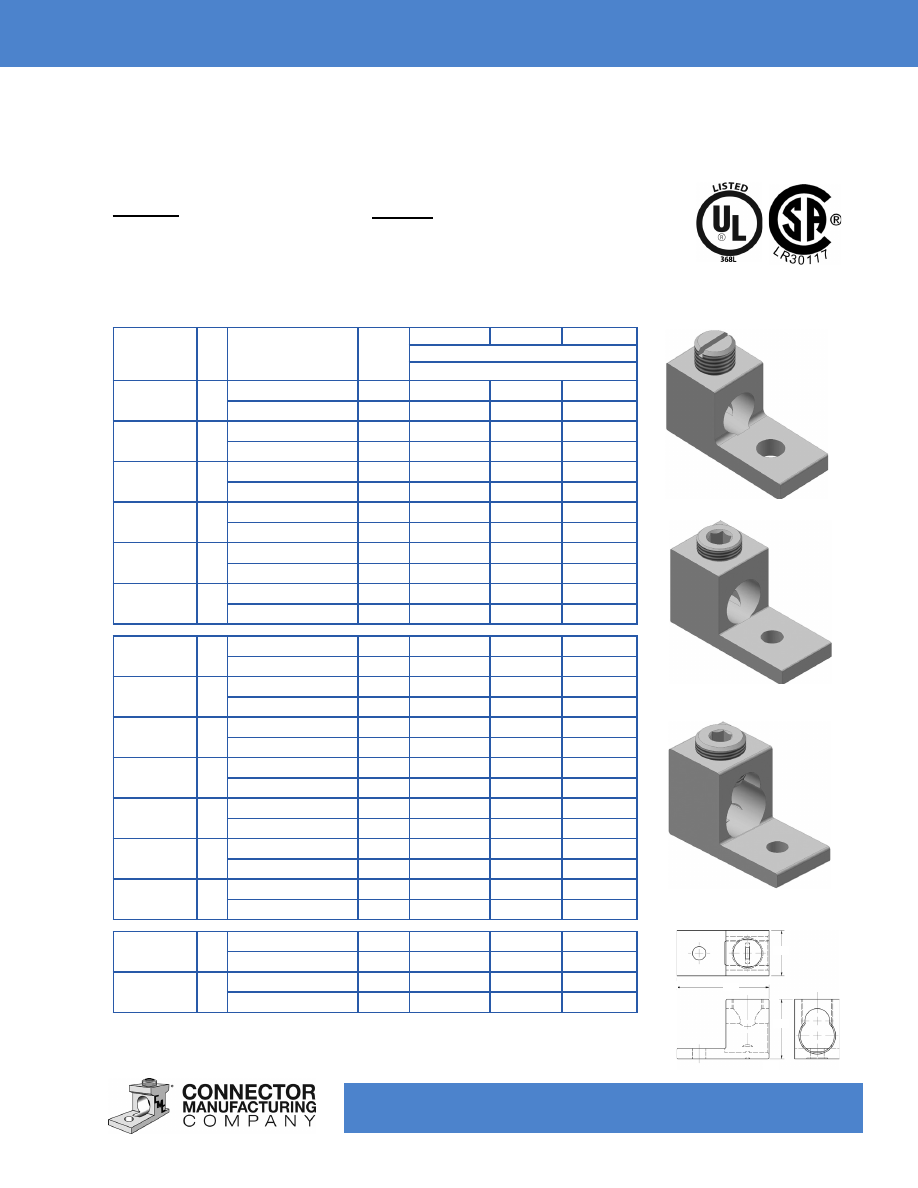

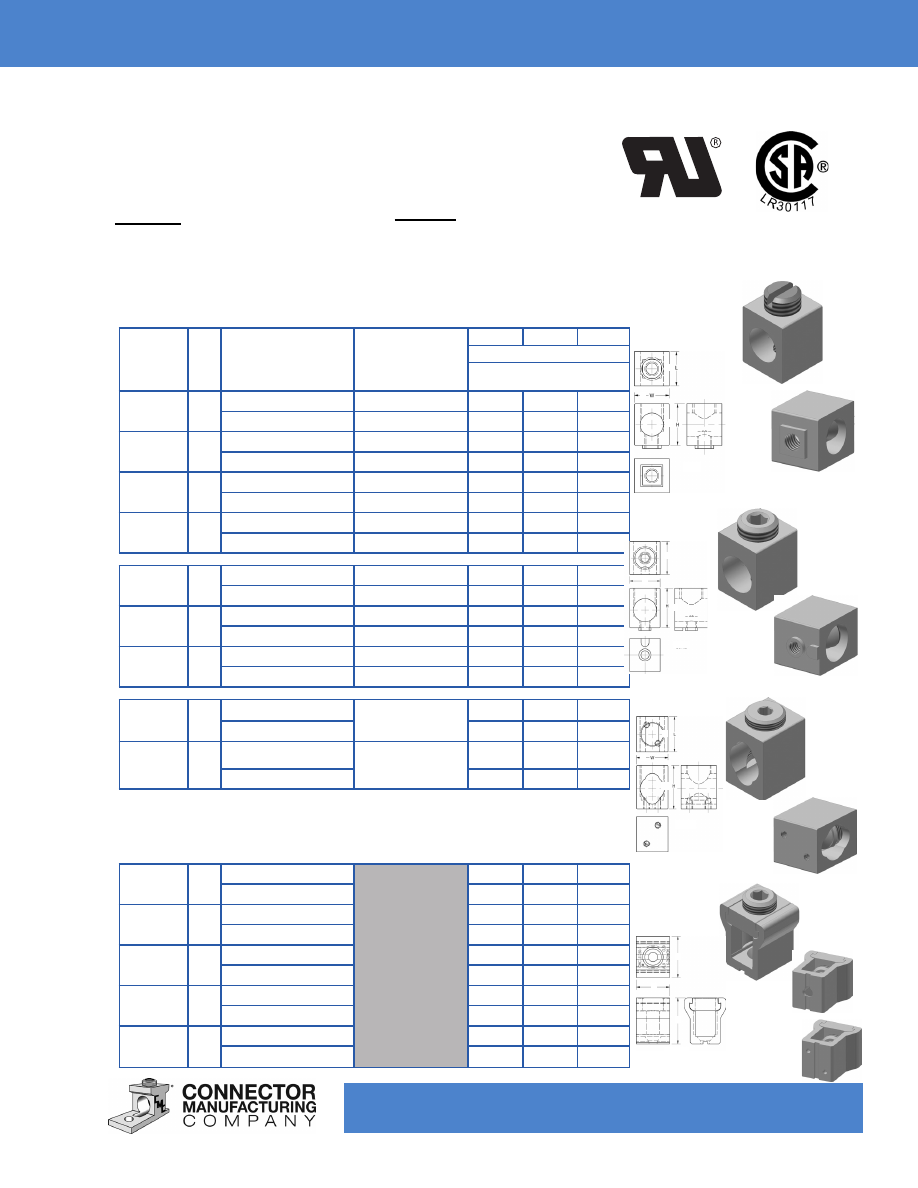

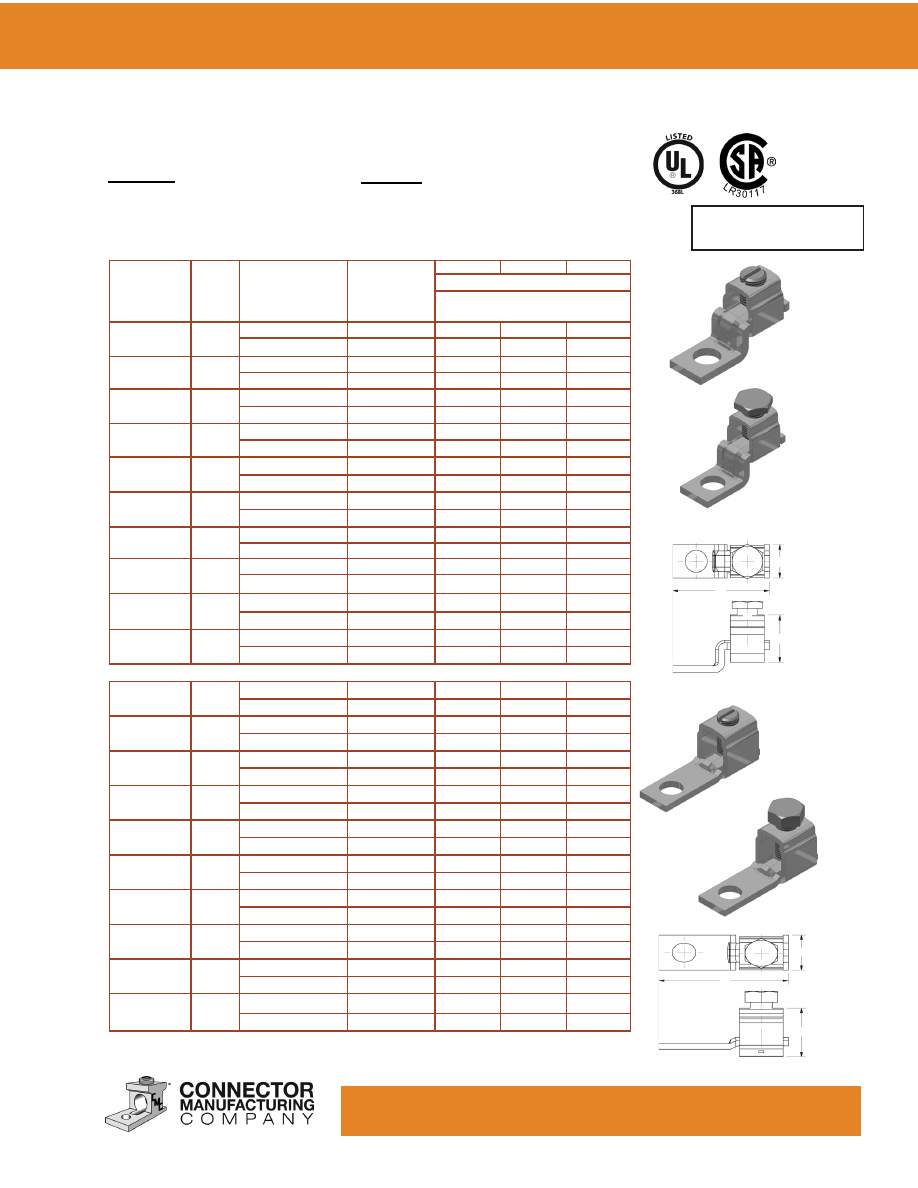

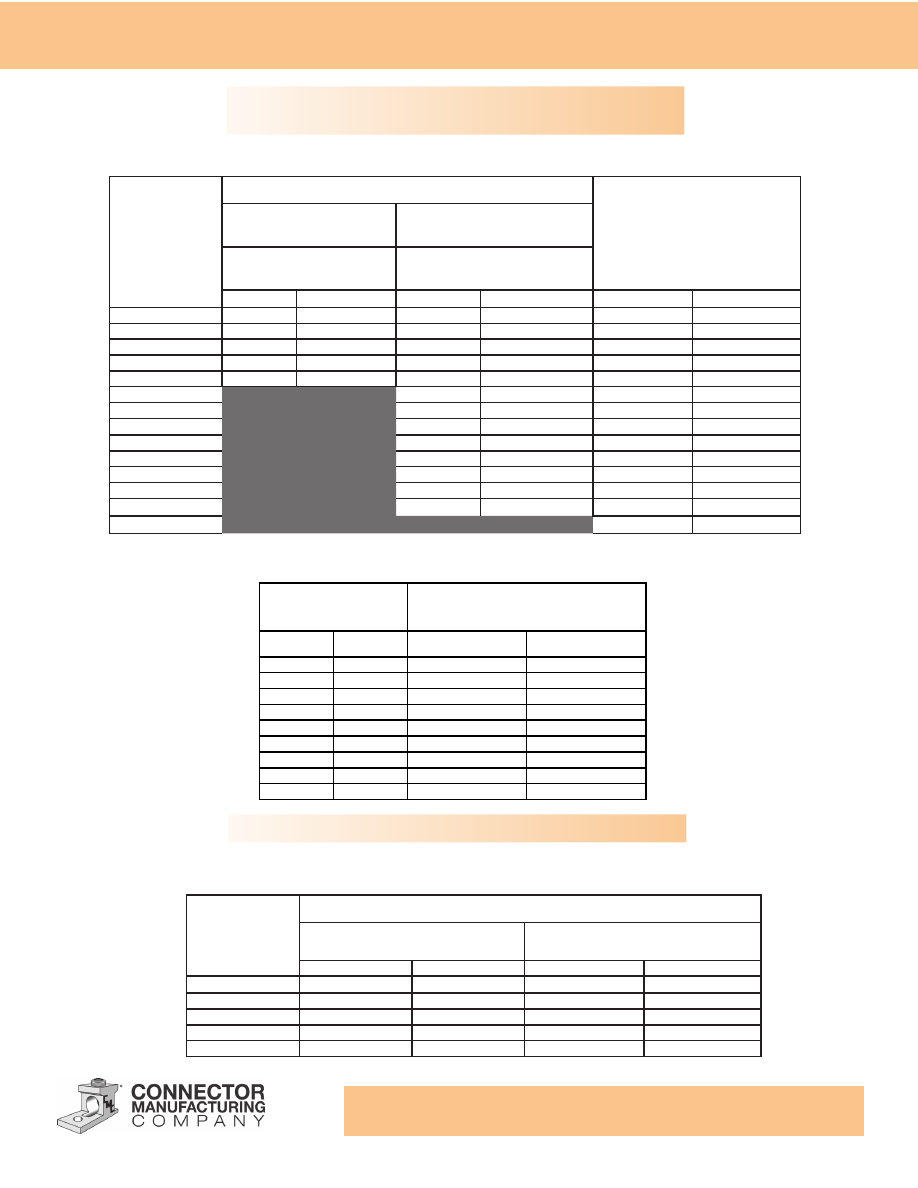

TYPE: AB

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

Single Conductor Solderless Lugs

Catalog

Number

Fig

Screw

Stud Size*

mm

Cond.

Range

mm²

H

W

L

G

T

Dimensions - inches

Dimensions - millimeters

AB-50-S

1

Slot

1/4

6-14

.49

.5

1.06

.31

.09

6.35

16-1.5

12.45

12.70

26.92

7.87

2.29

AB-70-S

1

Slot

1/4

2-14

.55

.50

1.16

.31

.10

6.35

25-1.5

13.97

12.70

29.46

7.87

2.54

AB-112S

1

Slot or Hex

1/4

1/0-14

.78

.62

1.31

.31

.16

6.35

50-1.5

19.81

15.75

33.27

7.87

4.06

AB-125S

1

Slot or Hex

1/4

2/0-14

.78

.63

1.47

.38

.19

6.35

50-1.5

19.81

16.00

37.34

9.65

4.83

AB-250S

2

0.31H

5/16

250-6

1.09

.88

2.00

.44

.22

7.87

7.94

120-16

27.69

22.35

50.80

11.18

5.59

AB-300S

2

.31H

3/8

300-6

1.13

1.00

2.00

.50

.25

7.87

9.53

150-16

28.70

25.40

50.8

12.70

6.35

AB-350S

2

.31H

5/16

350-6

1.19

1.00

2.25

.56

.25

7.87

7.94

185-16

30.23

25.40

57.15

14.22

6.35

AB-500S

2

.38H

3/8

500-4

1.44

1.25

2.63

.63

.31

9.65

9.53

240-16

36.58

31.75

66.80

16.00

7.87

AB-600S

2

.38H

3/8

600-2

1.56

1.43

3.19

.88

.38

9.65

9.53

300-25

39.62

36.32

81.03

22.35

9.65

AB-750S

2

.38H

5/8

750-1/0

1.80

1.43

3.25

.88

.44

9.65

15.88

300-50

45.72

36.32

82.55

22.35

11.18

AB-1000S

2

.50H

1/2

1000-500

1.94

1.62

3.50

.88

.44

12.70

12.7

500-240

49.28

41.15

88.90

22.35

11.18

Fig.1

*This dimension can be altered per customer requirements.

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Custom configurations available upon request.

Fig.2

www.cmclugs.com 513.860.4455

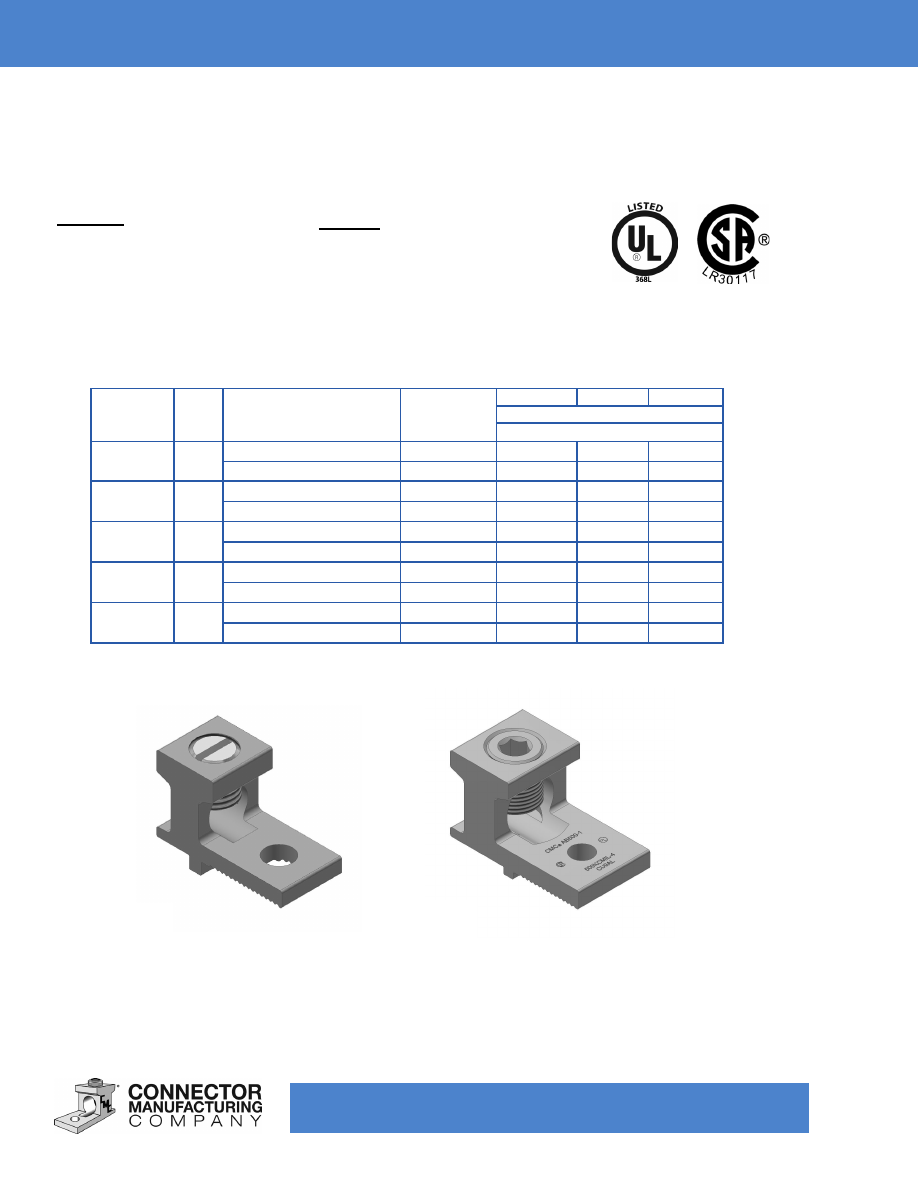

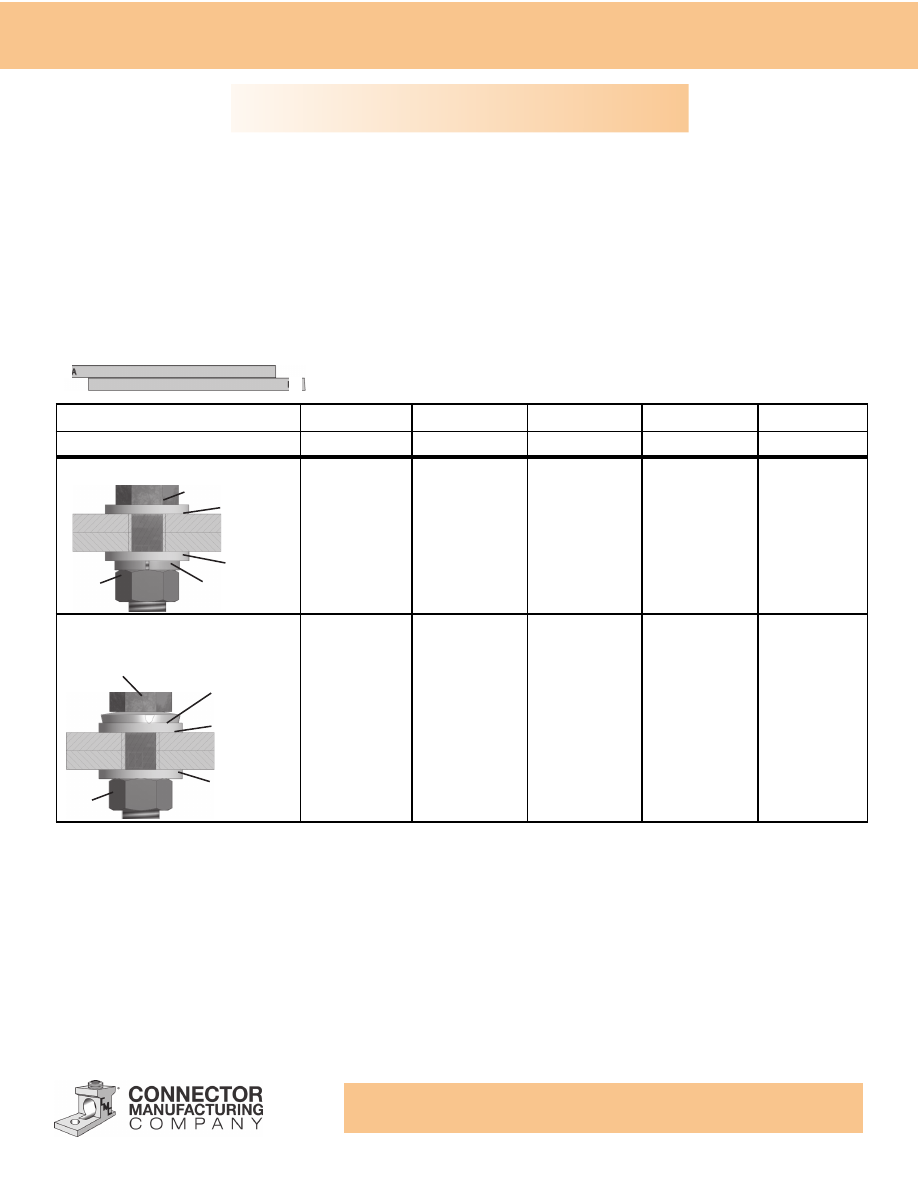

Single Conductor Solderless Lugs

TYPE: AB - Anti-Turn Series

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Catalog

Number

Fig

Cond. Range

AWG

mm²

Stud Size*

mm

H

W

L

Dimensions - inches

Dimensions - millimeters

AB-112-R

1

1/0-14

1/4

.78

.63

1.31

50-1.5

6.35

19.81

16.00

33.27

AB-125-R

1

2/0-14

1/4

.78

.63

1.47

50-1.5

6.35

19.81

16.00

37.34

AB-300-R

1

300-6

1/4

1.13

.88

1.78

150-16

6.35

28.70

22.35

45.21

AB-500-1

2

500-4

3/8

1.44

1.38

2.48

240-16

9.53

36.58

35.05

62.99

AB-600-1

2

600-2

3/8

1.56

1.38

2.75

300-25

9.53

39.62

35.05

69.85

PosiGrip®

90° C Rating (486B Listed)

Custom configurations available upon request.

*This dimension can be altered per customer requirements.

Products marked “-1” use the PosiGrip® Design.

Fig.1

Fig.2

www.cmclugs.com 513.860.4455

Fig. 2

T

L

G

1.7250

(44.45)

H

W

Ø D (2PL.)

Fig. 1

ØD (2PL.)

W

1.750

(44.45)

G

L

H

T

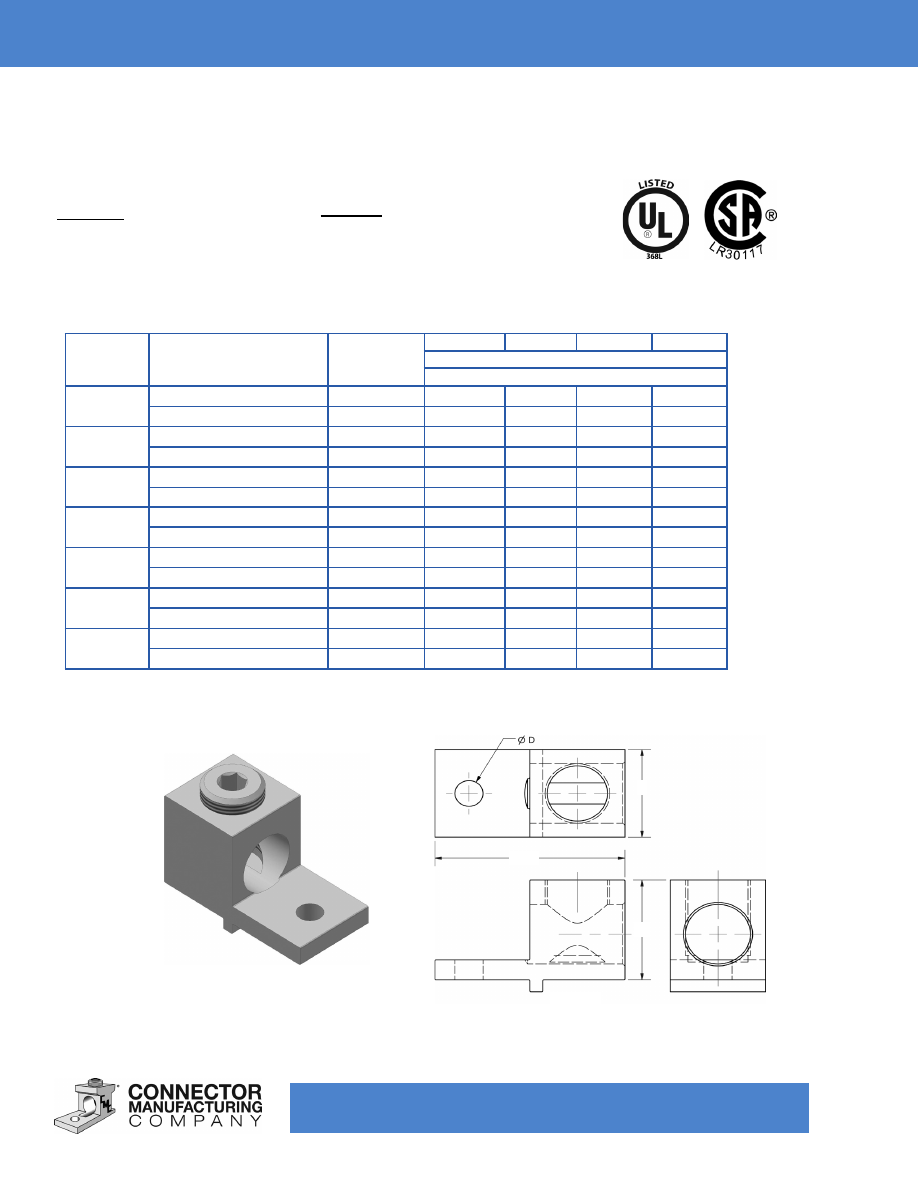

Catalog

Number

Fig

Screw

Type

mm

Stud

Size*

mm

Cond.

Range

AWG

mm²

H

W

L

G

T

Dimensions - inches

Dimensions - millimeters

A1B2-350

1

.31H

1/2

350-6

1.19

1.00

4.25

.63

.25

7.87

12.70

185-16

30.23

25.4

107.95

16.00

6.35

A1B2-500

1

.38H

1/2

500-2

1.56

1.25

4.59

.63

.38

9.65

12.70

240-25

39.62

31.75

116.59

16.00

9.65

A1B2-600

1

.38H

1/2

600-2

1.56

1.25

4.59

.63

.38

9.65

12.70

300-25

39.62

31.75

116.59

16.00

9.65

A1B2-750

1

.38H

1/2

750-1

1.81

1.43

4.84

.63

.44

9.65

12.70

300-35

45.97

36.32

122.94

16.00

11.18

A1B2-1000

1

.50H

1/2

1000-500

1.94

1.63

4.94

.63

.44

12.70

12.70

500-240

49.28

41.40

125.48

16.00

11.18

A1B2-350-2

2

.31H

1/2

350-6

1.19

1.13

5.37

.62

.25

7.87

12.70

185-16

30.23

28.70

136.40

15.75

6.35

A1B2-500-2

2

.38H

1/2

500-4

1.56

1.50

5.62

.63

.38

9.65

12.70

240-16

39.62

38.10

142.75

16.00

9.65

A1B2-600-2

2

.38H

1/2

600-2

1.56

1.50

5.62

.63

.38

9.65

12.70

300-25

39.62

38.10

142.75

16.00

9.65

A1B2-750-2

2

.38H

1/2

750-300

1.94

1.50

6.19

.63

.44

9.65

12.70

300-150

49.28

38.10

157.23

16.00

11.18

A1B2-1000-2

2

.50H

1/2

1000-500

1.94

1.63

6.19

.63

.44

12.70

12.70

500-240

49.28

41.40

157.23

16.00

11.18

Fig. 1

TYPE: A1B2/A1B2-2

Features

•

Made of 6061-T6 Aluminum

Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

Single Conductor Solderless Lugs

PosiGrip®

90° C Rating (486B Listed)

*This dimension can be altered per customer requirements.

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

Catalog

Number

Fig

Screw

Type

mm

Stud

Size*

mm

Cond.

Range

AWG

mm²

H

W

L

G

T

Dimensions - inches

Dimensions - millimeters

ABSG-350

1

.31H

1/2

350-4

1.19

1.25

4.68

.72

.25

7.87

12.70

185-16

30.23

31.75

118.87

18.29

6.35

ABSG-500

1

.38H

1/2

500-400

1.44

1.25

4.68

.72

.31

9.65

12.70

240-185

36.58

31.75

118.87

18.29

7.87

ABSG-750

2

.38H

1/2

750-300

1.94

1.62

6.19

.72

.44

9.65

12.70

300-150

49.28

41.15

157.23

18.29

11.18

ABSG-1000

2

.50H

1/2

1000-300

1.94

1.62

6.19

.72

.44

12.70

12.70

500-150

49.28

41.15

157.23

18.29

11.18

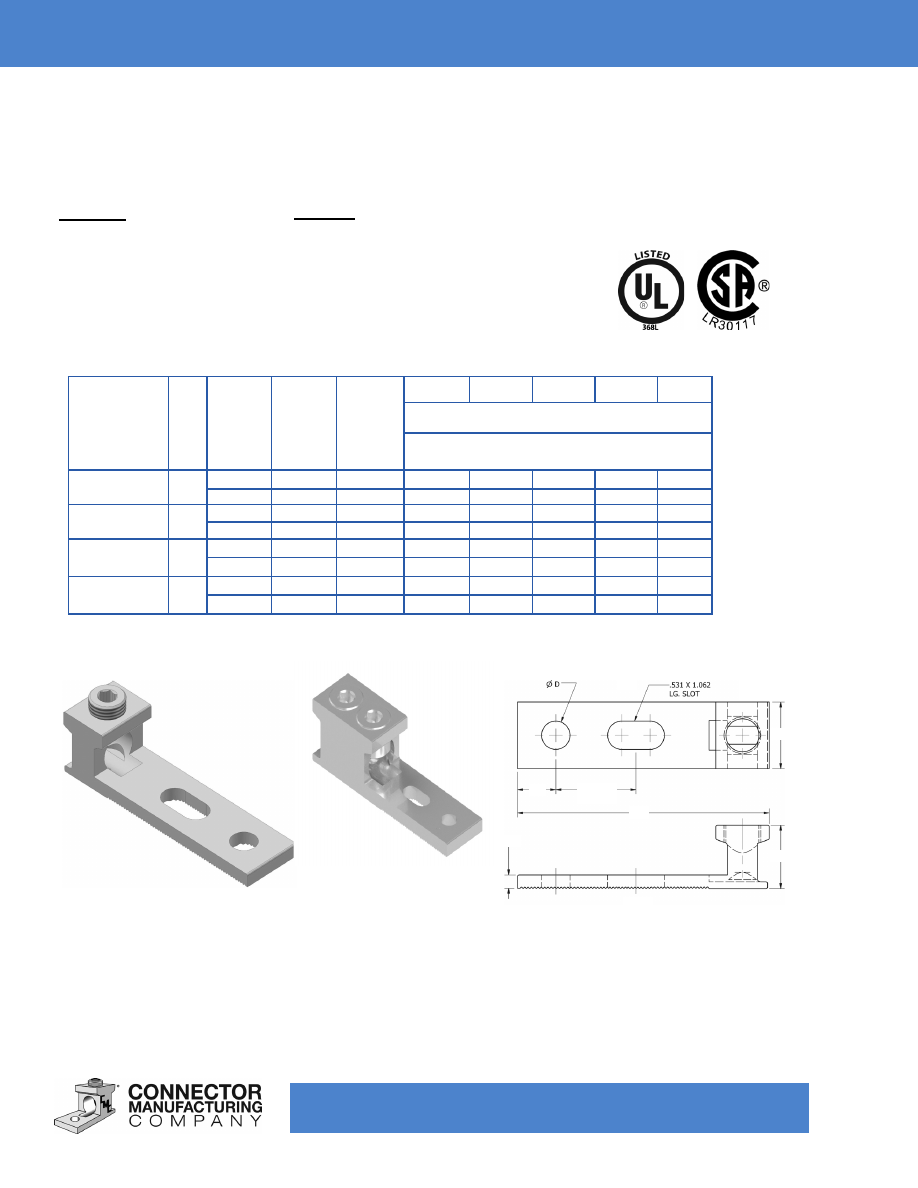

Switchgear Connectors

TYPE: ABSG

Features

•

Made of 6061-T6 Aluminum

Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

PosiGrip®

90° C Rating (486B Listed)

*This dimension can be altered per customer requirements.

Fig. 1

Ø D

.531 X 1.062

LG Slot

W

G

1.500

(38.10)

L

T

H

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Custom configurations available upon request.

Fig. 2

www.cmclugs.com 513.860.4455

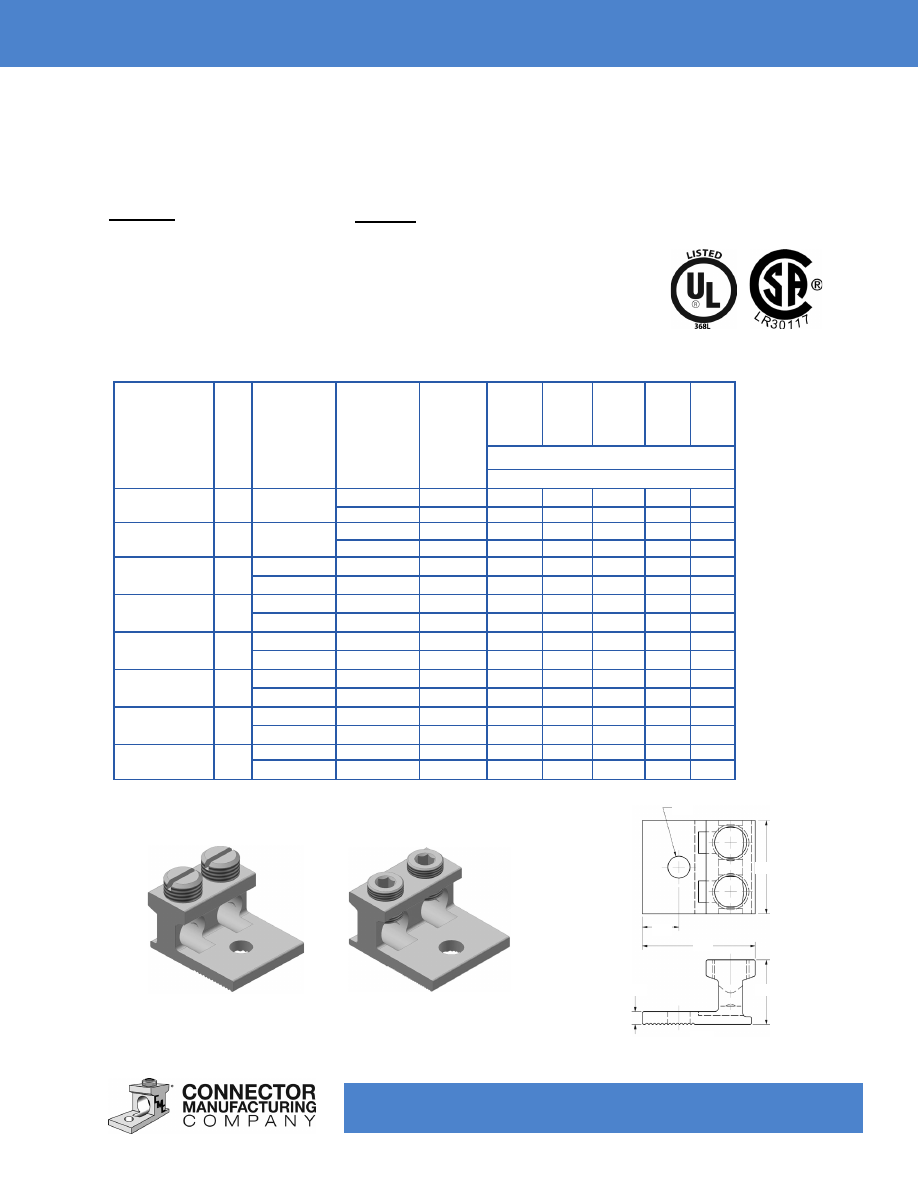

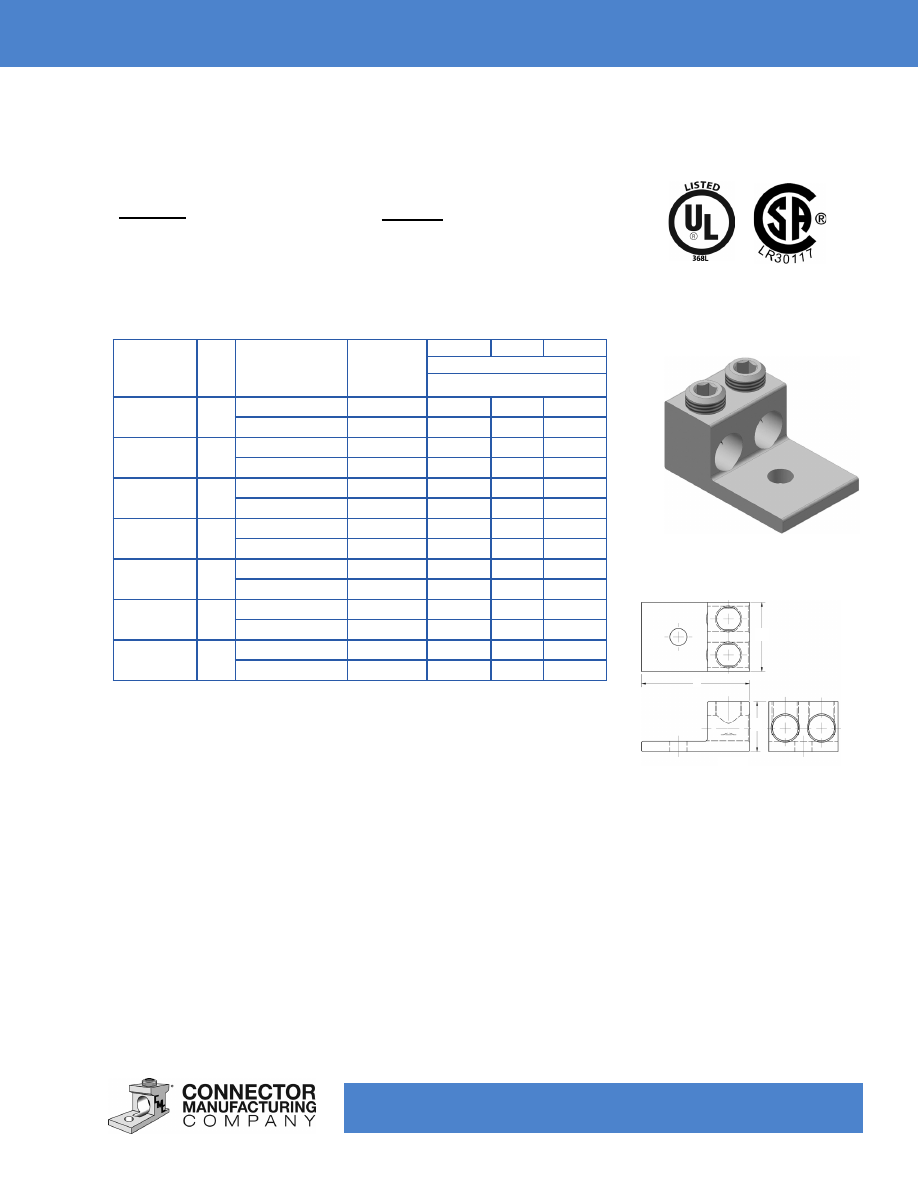

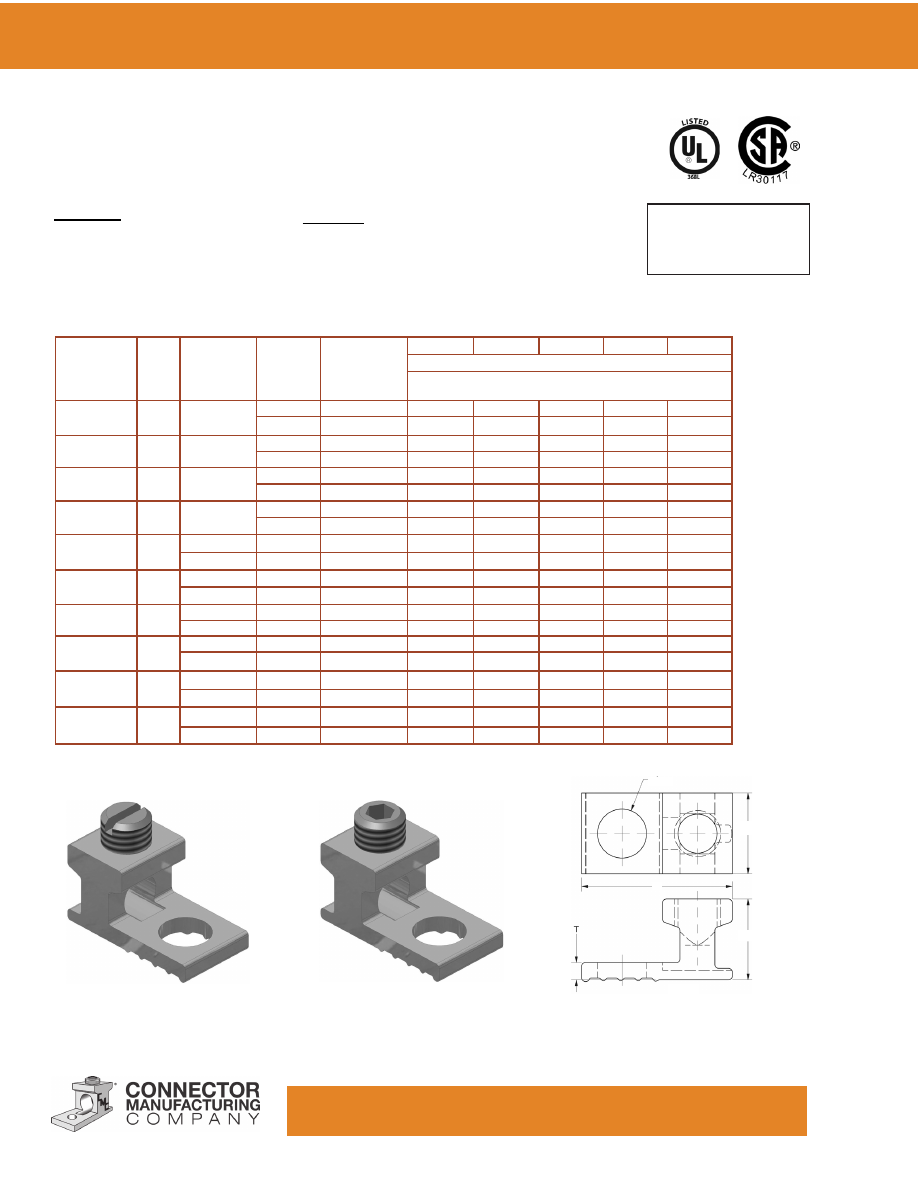

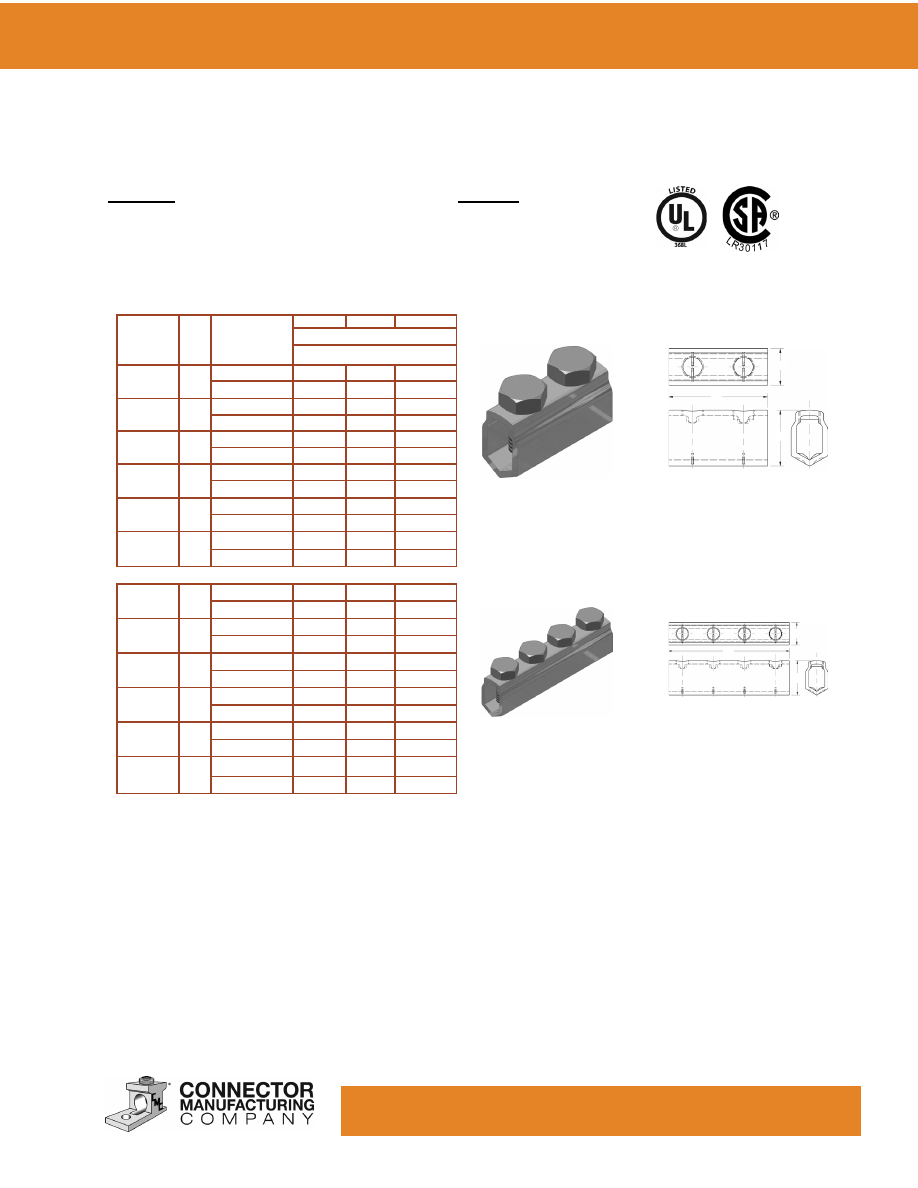

TYPE: 2AB/2AB2

Features

•

Made of 6061-T6 Aluminum

Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

Two Conductor Solderless Lugs

*This dimension can be altered per customer requirements.

Catalog

Number

Fig

Screw

Type

mm

Stud Size*

mm

Cond.

Range

AWG

mm²

H

W

L

G

T

Dimensions - inches

Dimensions - millimeters

2AB-112

1 Slot or Hex

1/4

1/0-14

.78

1.13

1.31

.44

.16

6.35

50-1.5

19.81 28.70 33.27 11.18 4.06

2AB-125

1 Slot or Hex

1/4

2/0-14

.78

1.25

1.47

.42

.19

6.35

50-1.5

19.81 31.75 37.34 10.67 4.83

2AB-250

2

.31H

3/8

250-6

1.09

1.62

2.56

.53

.22

7.87

9.53

120-16 27.69 41.15 65.02 13.46 5.59

2AB-350

2

.31H

3/8

350-6

1.19

1.92

2.88

.63

.25

7.87

9.53

185-16 30.23 48.77 73.15 16.00 6.35

2AB-500

2

.38H

1/2

500-4

1.44

2.41

2.63

.63

.31

9.65

12.70

240-16 36.58 61.21 66.80 16.00 7.87

2AB-600

2

.38H

1/2

600-2

1.56

2.41

3.19

.63

.38

9.65

12.70

300-25 39.62 61.21 81.03 16.00 9.65

2AB-750

2

.38H

1/2

750-1/0

1.81

3.50

3.25

.88

.44

9.65

12.70

300-50 45.97 88.90 82.55 22.35 11.18

2AB-1000

2

.50H

1/2

1000-500 1.94

3.50

3.50

.88

.44

12.70

12.70

500-240 49.28 88.90 88.90 22.35 11.18

Fig 1

Fig 2

Ø D

W

G

L

H

T

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Custom configurations available upon request.

PosiGrip®

90° C Rating (486B Listed)

www.cmclugs.com 513.860.4455

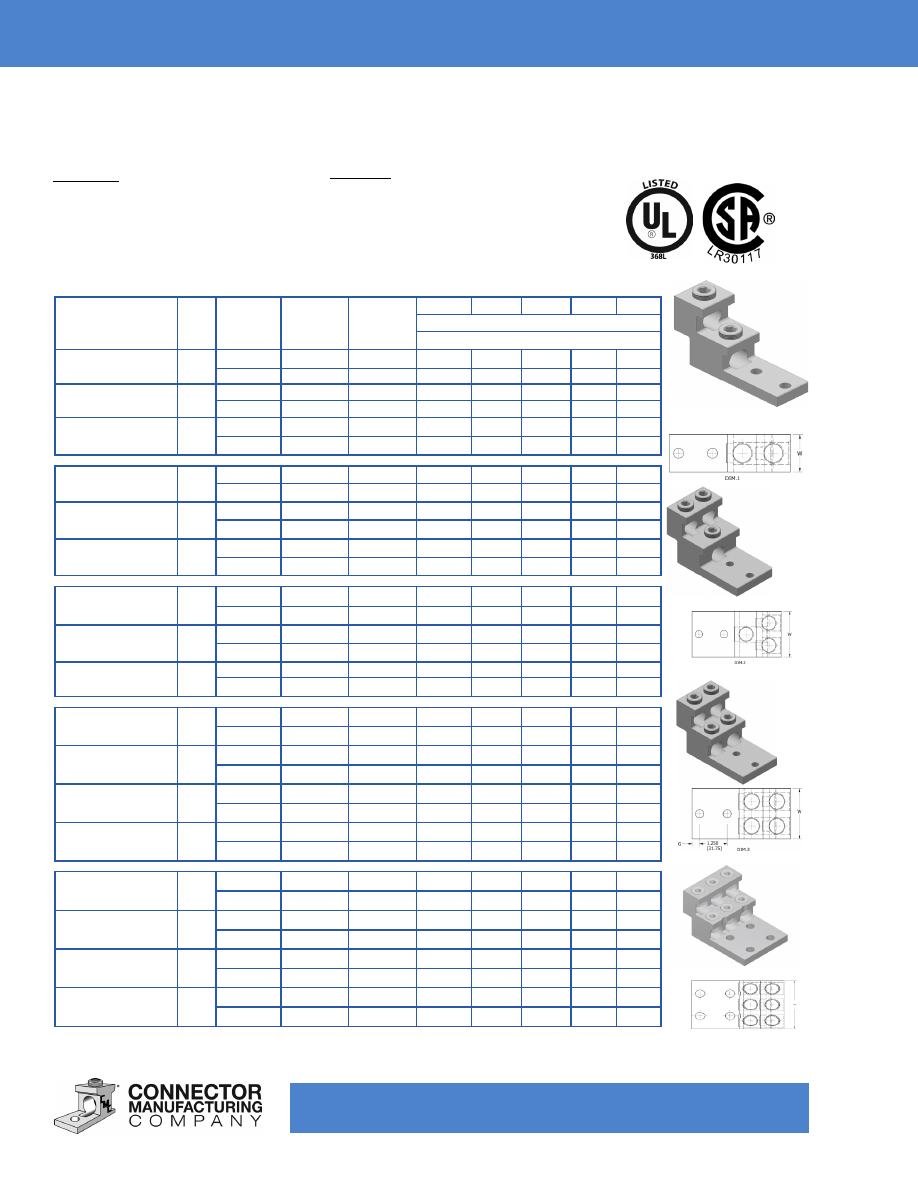

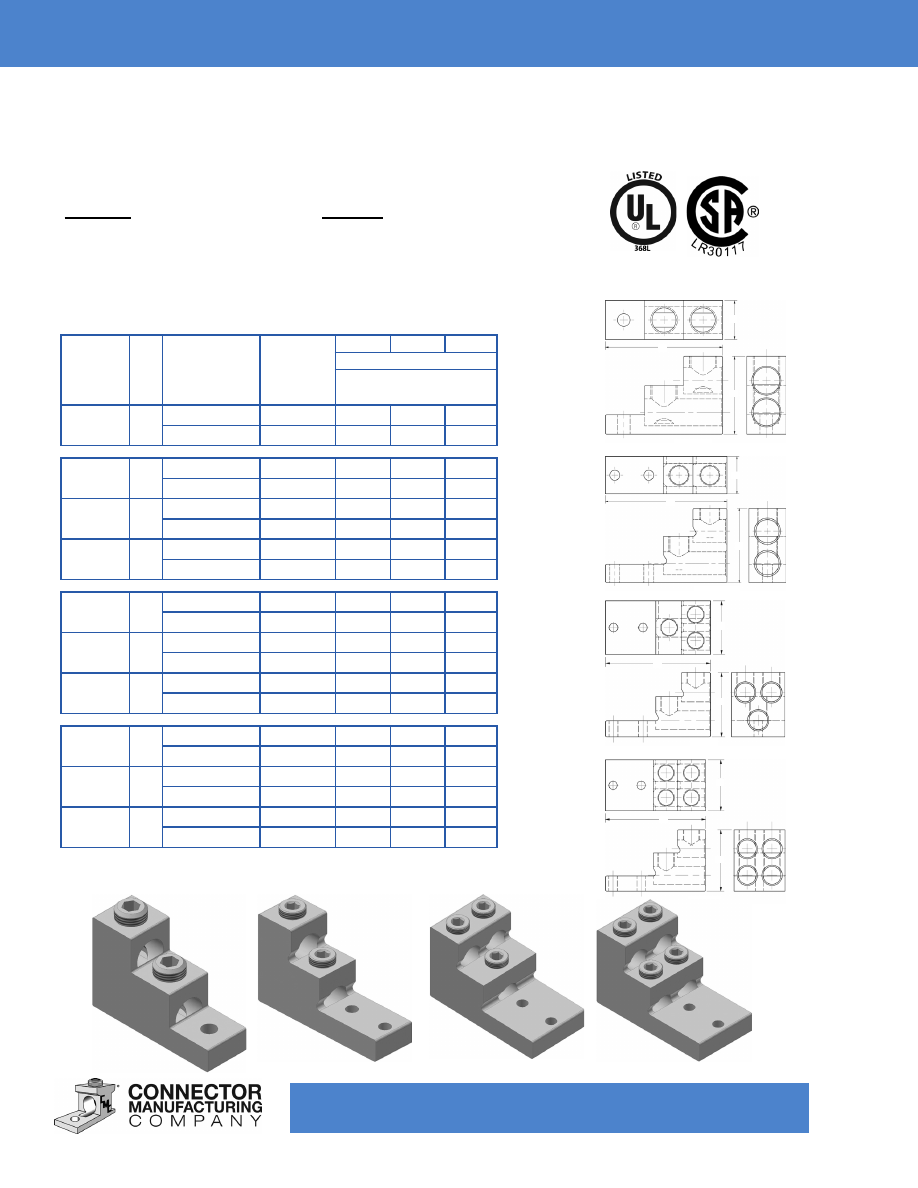

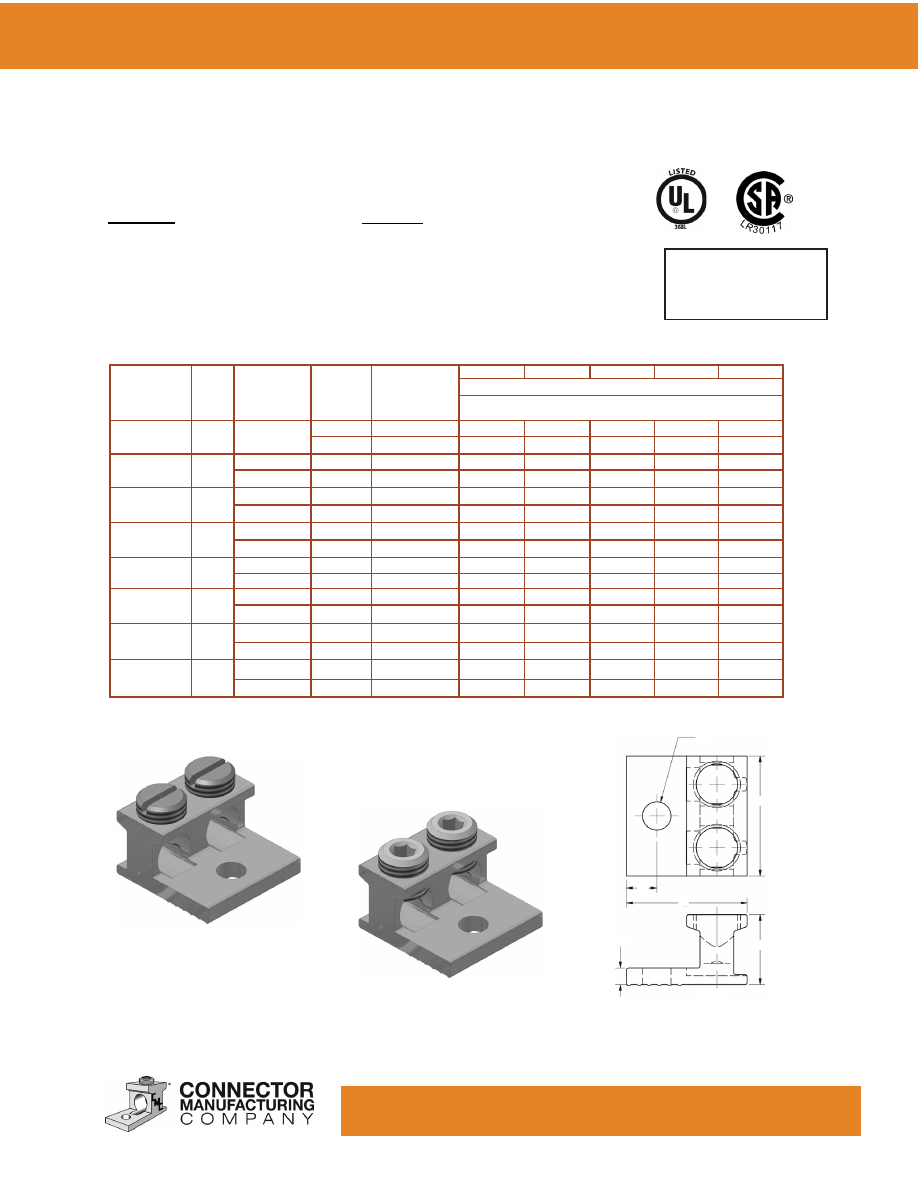

TYPE: ABV / ABV-2N

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Patented PosiGrip® Design

•

Positive Wire Stop

•

Dual-Rated

90° C Rating (486B Listed)

Panelboard Solderless Lugs

*This dimension can be altered per customer requirements.

Fig 1

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

Custom configurations available upon request.

**Products marked “-2N” or “-4N” are NEMA spaced.

Fig 2

Fig 3

Fig 4

PosiGrip®

Catalog

Number

Fig

Screw

Stud

Size*

mm

Cond.

Range

H

W

L

G

T

Dimensions - inches

Dimensions - millimeters

2ABV-500

1

.38H

3/8

500-4

3.00

1.50

4.91

.38

.50

9.65

9.53

240-16 76.20 38.10 124.71 9.65 12.70

2ABV-600

1

.38H

3/8

600-2

3.00

1.50

4.91

.38

.50

9.65

9.53

300-25 76.20 38.10 124.71 9.65 12.70

2ABV-750

1

.38H

3/8

750-1/0

3.00

1.50

4.91

.38

.50

9.65

9.53

300-50 76.20 38.10 124.71 9.65 12.70

3ABV-500

2

.38H

3/8

500-4

3.00

2.50

4.91

.38

.50

9.65

9.53

240-16 76.20 63.50 124.71 9.65 12.70

3ABV-600

2

.38H

3/8

600-2

3.00

2.50

4.91

.38

.50

9.65

9.53

300-25 76.20 63.50 124.71 9.65 12.70

3ABV-750

2

.38H

3/8

750-1/0

3.00

2.50

4.91

.38

.50

9.65

9.53

300-50 76.20 63.50 124.71 9.65 12.70

4ABV-500

3

.38H

3/8

500-4

3.00

2.50

4.91

.38

.50

9.65

9.53

240-16 76.20 63.50 124.71 9.65 12.70

4ABV-600

3

.38H

3/8

600-2

3.00

2.50

4.91

.38

.50

9.65

9.53

300-25 76.20 63.50 124.71 9.65 12.70

4ABV-750

3

.38H

3/8

750-1/0

3.00

2.63

4.91

.38

.50

9.65

9.53

300-50 76.20 66.80 124.71 9.65 12.70

2ABV-600-2N**

1

.38H

1/2

600-2

3.00

1.50

5.34

.63

.50

9.65

12.70

300-25 76.20 38.10 135.74 16.00 12.70

3ABV-600-2N**

2

.38H

1/2

600-2

3.00

2.50

5.34

.63

.50

9.65

12.70

300-25 76.20 63.50 135.74 16.00 12.70

4ABV-600-2N**

3

.38H

1/2

600-2

3.00

2.47

5.34

.63

.50

9.65

12.70

300-25 76.20 62.74 135.74 16.00 12.70

6ABV-600-2N**

4

.38H

1/2

600-2

3.00

3.75

5.34

.63

.50

9.65

12.70

300-25 76.20 95.25 135.74 16.00 12.70

2ABV-750-4N**

1

.38H

1/2

750-1/0

3.00

1.50

5.34

.50

.50

9.65

12.70

300-50 76.20 38.10 135.74 12.70 12.70

3ABV-750-4N**

2

.38H

1/2

750-1/0

3.00

2.50

5.34

.50

.50

9.65

12.70

300-50 76.20 63.50 135.74 12.70 12.70

4ABV-750-4N**

3

.38H

1/2

750-1/0

3.00

2.75

5.34

.50

.50

9.65

12.70

300-50 76.20 69.85 135.74 12.70 12.70

6ABV-750-4N**

4

.38H

1/2

750-1/0

3.00

3.75

5.34

.50

.50

9.65

12.70

300-50 76.20 95.25 135.74 12.70 12.70

www.cmclugs.com 513.860.4455

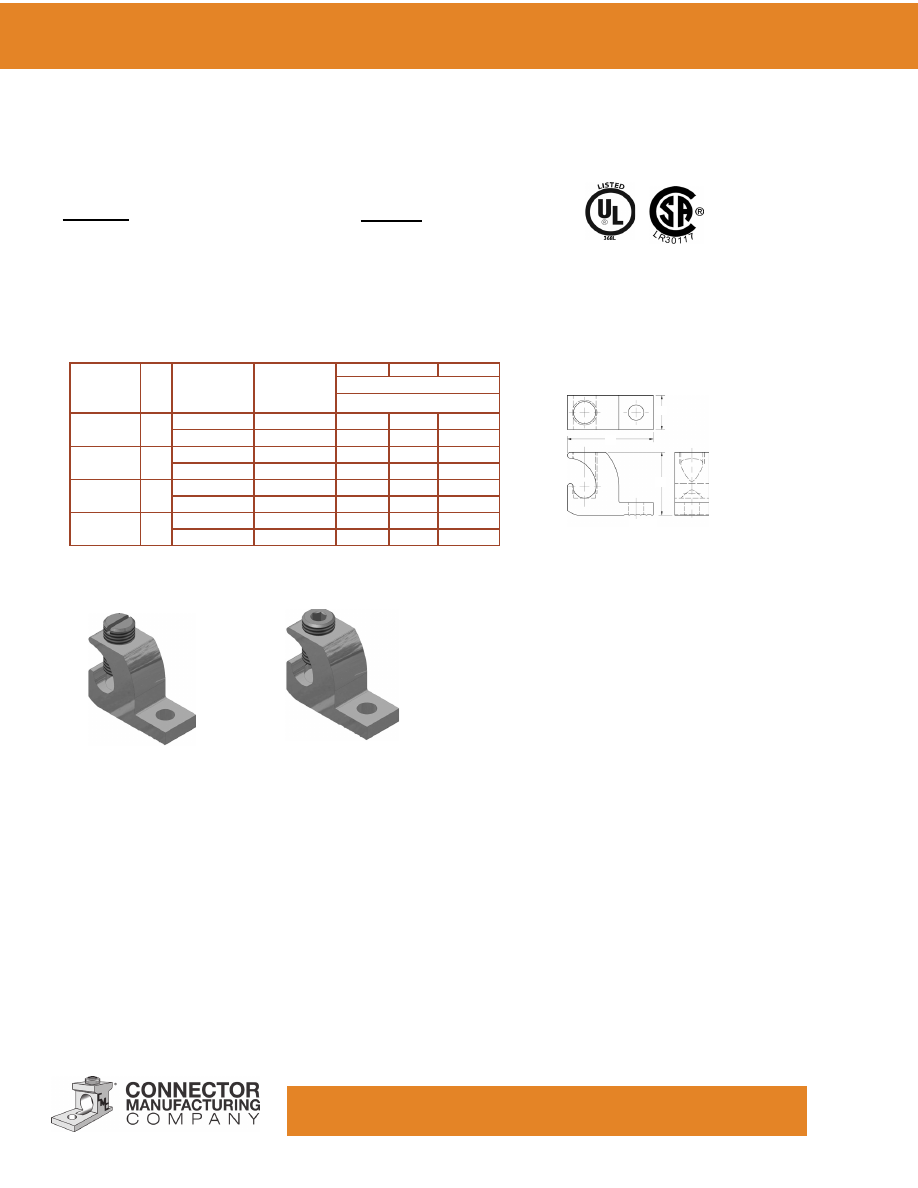

TYPE: LA

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

90° C Rating (486B Listed)

Single Conductor Solderless Lugs

Fig 1

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm

Stud

Size*

mm

H

W

L

Dimensions - inches

Dimensions - millimeters

LA-6-1

1

6-14

15/64

0.50

0.38

1.06

16-1.5

5.85

12.70

9.65

26.92

LA-6

1

6-14

1/2

0.49

0.50

1.06

16-1.5

6.35

12.45

12.70

26.92

LA-6-2

1

4-14

1/2

0.49

0.50

1.06

16-1.5

6.35

12.45

12.70

26.92

LA-2

1

2-14

1/2

0.55

0.50

1.16

25-1.5

6.35

13.97

12.70

29.46

LA-1/0

1

1/0-14

3/8

0.78

0.63

1.47

50-1.5

9.65

19.81

16.00

37.34

LA-2/0

1

2/0-14

1/2

0.78

0.63

1.47

50-1.5

6.35

19.81

16.00

37.34

LA-250

2

250-6

5/16

1.13

1.00

2.00

120-16

7.87

28.70

25.40

50.80

LA-300

2

300-6

5/16

1.13

1.00

2.00

150-16

7.87

28.70

25.40

50.80

LA-350

2

350-6

3/8

1.25

1.13

2.25

185-16

9.65

31.75

28.70

57.15

LA-500

2

500-4

3/8

1.56

1.25

2.81

240-16

9.65

39.62

31.75

71.37

LA-600

2

600-2

3/8

1.56

1.50

3.19

300-25

9.65

39.62

38.10

81.03

LA-800

2

800-300

5/8

1.94

1.75

3.50

400-150

16.00

49.28

44.45

88.90

LA-1000

2

1000-500

5/8

1.94

1.75

3.50

500-240

16.00

49.28

44.45

88.90

LA-630

3

600-4/(2) 250-1/0

3/8

1.81

1.38

2.81

300-16/(2) 120-50 9.65

45.97

35.05

71.37

LA-750

3

750-2 /(2)300-1/0

3/8

1.81

1.38

2.81

300-25/(2)150-50 9.65

45.97

35.05

71.37

Fig 2

Fig 3

*This dimension can be altered per customer requirements.

L

H

W

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: LA - Anti-Turn Series

Features

•

Made of 6061-T6 Aluminum Alloy

•

Anti-Turn Design

•

Electro-Tin Plated

•

Dual-Rated

90° C Rating (486B Listed)

Single Conductor Solderless Lugs

Catalog

Number

Cond. Range

AWG

mm

Stud Size*

mm

H

W

L

R

Dimensions - inches

Dimensions - millimeters

LA-2R

4-14

1/4

.55

.50

1.16

.52

16-1.5

6.35

13.97

12.70

29.46

13.21

LA-1/0R

1/0-14

1/4

.81

.63

1.47

.50

50-1.5

6.35

20.57

16.00

37.34

12.70

LA-2/0R

2/0-14

1/4

.78

.60

1.20

.30

50-1.5

6.35

19.81

15.24

30.48

11.94

LA-300R

300-6

1/4

1.13

.98

2.00

.49

150-16

6.35

28.70

24.89

50.80

12.45

LA-350R

350-6

5/16

1.13

1.00

1.91

.50

185-16

7.87

28.70

25.40

48.51

12.70

LA-625R

(1) 600-2 / (2) 250-1/0

3/8

1.62

1.38

2.62

1.14

(1) 400-25 / (2) 150-50

9.65

39.88

35.05

66.55

22.35

LA-600R

600-2

3/8

1.57

1.38

2.75

.88

300-25

9.65

39.88

35.05

69.85

22.35

W

L

H

*This dimension can be altered per customer requirements.

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: DLA

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

90° C Rating (486B Listed)

Two Conductor Solderless Lugs

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm

Stud Size*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

DLA-112

1

1/0-14 (2)

1/4

.78

1.13

1.47

50-1.5 (2)

6.35

19.81

28.70

37.34

DLA-125

1

2/0-14 (2)

1/4

.78

1.25

1.47

50-1.5 (2)

6.35

19.81

31.75

34.34

DLA-250

1

250-6 (2)

3/8

1.19

1.64

2.56

120-16 (2)

9.65

30.23

41.66

65.02

DLA-350

1

350-6 (2)

1/2

1.25

1.92

2.88

185-16 (2)

12.70

31.75

48.77

73.15

DLA-600

1

600-2 (2)

1/2

1.56

2.41

3.19

300-25 (2)

12.70

39.62

61.21

81.03

DLA-800

1

800-300 (2)

5/8

1.94

3.50

3.50

400-150 (2)

16.00

49.28

88.90

88.90

DLA-1000

1

1000-500 (2)

5/8

1.94

3.50

3.50

500-240

(2)

16.00

49.28

88.90

88.90

Fig. 1

*This dimension can be altered per customer requirements.

H

W

L

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: PV

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

90° C Rating (486B Listed)

Panelboard Solderless Lugs

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Stud Size*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

PV2-300 1

300-6 (2)

5/16

2.00

1.00

3.00

150-16 (2)

7.87

50.80 25.40 76.20

PV2-500 2

500-2 (2)

3/8 (2)

3.00

1.50

4.91

240-25 (2)

9.65 (2)

76.20 38.10 124.71

PV2-600 2

600-2 (2)

3/8 (2)

3.00

1.50

4.91

300-25 (2)

9.65 (2)

76.20 38.10 124.71

PV2-750 2

750-1/0 (2)

3/8 (2)

3.00

1.56

4.91

300-50 (2)

9.65 (2)

76.20 39.62 124.71

PV3-500 3

500-2 (2)

3/8 (2)

3.00

2.50

4.91

240-25 (2)

9.65 (2)

76.20 63.50 124.71

PV3-600 3

600-2 (3)

3/8 (2)

3.00

2.47

4.91

300-25 (3)

9.65 (2)

76.20 62.74 124.71

PV3-750 3

750-1/0 (3)

3/8 (2)

3.00

2.84

4.91

300-50 (3)

9.65 (2)

76.20 72.14 124.71

PV4-500 4

500-2 (2)

3/8 (2)

3.00

2.50

4.91

240-25 (2)

9.65 (2)

76.20 63.50 124.71

PV4-600 4

600-2 (4)

3/8 (2)

3.00

2.47

4.91

300-25 (4)

9.65 (2)

76.20 62.74 124.71

PV4-750 4

750-1/0 (4)

3/8 (2)

3.00

2.84

4.91

300-50 (4)

9.65 (2)

76.20 72.14 124.71

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 1

Fig. 2

Fig. 3

Fig. 4

*This dimension can be altered per customer requirements.

H

H

L

W

L

W

W

H

L

H

L

W

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: CA / LI

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

Rectangular Connectors

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Boss Tap*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

CA-40S

1

4-14

.22 / 10-32

.48

.38

.38

16-1.5

5.59

12.19

9.65

9.65

CA-60S

1

2-14

.22 / 10-32

.56

.47

.47

25-1.5

5.84

14.22 11.94 11.94

CA-110S 1

1/0-14

.22 / 10-32

.61

.53

.62

50-1.5

5.84

15.49 13.46 15.75

CA-150S 1

2/0-14

.22 / 10-32

.76

.58

.63

50-1.5

5.84

19.30 14.73 16.00

CA-210

2

250-6

.29D / 1/4-20

1.00

.81

.94

120-16

7.37D

25.40 20.57 23.88

CA-360

2

300-4

.29D / 1/4-20

1.00

.81

1.00

150-16

7.37D

25.40 20.57 25.40

CA-380

2

350-6

.29D / 1/4-20

1.13

1.00

.94

185-16

7.37D

28.70 25.40 23.88

CA-635

3

600-4 / (2) 250-4

Flat / 1/4-20 (2)

1.69

1.22

1.25

200-16 / (2) 120-16

42.93 30.99 31.75

CA-750

3

750-250 / (2) 250-3/0

Flat / 1/4-20 (2)

2.06

1.38

1.25

300-120 / (2) 120-85

52.32 35.05 31.75

LI-250

4

250-6

1.40

1.25

1.00

120-10

35.56 31.75 25.40

LI-500

4

500-3/0

1.63

1.66

1.50

240-70

41.40 42.16 38.10

LI-501

4

600-2

2.00

1.50

1.25

400-25

50.80 38.10 31.75

LI-750

4

750-1/0

2.50

1.62

1.50

300-50

63.50 41.15 38.10

LI-3501

4

350-6

1.40

1.35

1.00

n/a

n/a

n/a

n/a

Fig. 1

Fig. 2

Fig. 3

Fig. 4

*This dimension can be altered per customer requirements.

Lay-in style collars - Use where lay-in feature is desired.

H

L

W

H

W

L

H

W

L

H

W

L

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

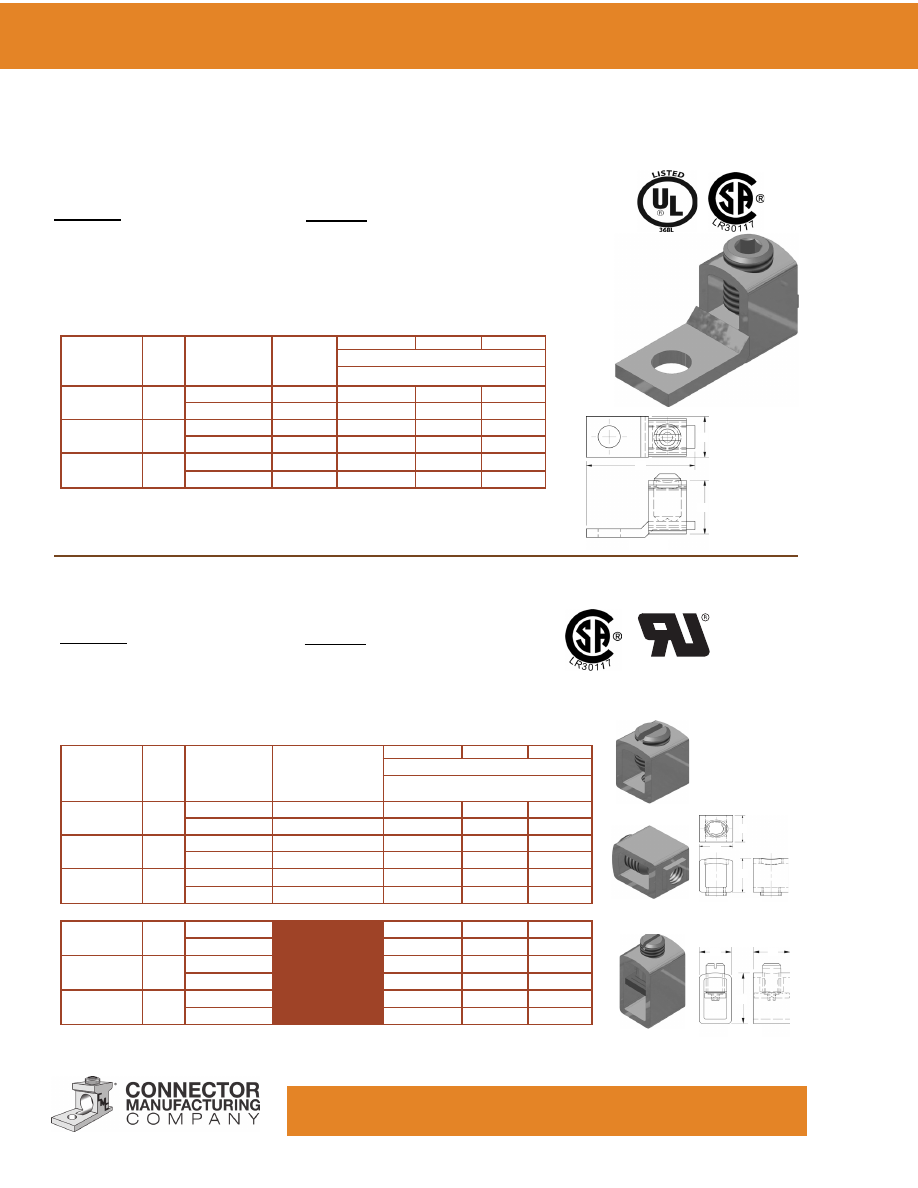

TYPE: SR- Solid Bearers

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

•

Specialized Design

90° C Rating (486B Listed)

Splicers /

Reducers

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Strip

Length

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

SR-2

1

2-14

.63

.56

.50

1.38

25-1.5

16.00

14.22

12.70

35.05

SR-0

1

1/0-14

.88

.75

.75

1.91

50-1.5

22.35

19.05

19.05

48.51

SR-250

2

250-6

.94

1.13

1.00

3.94

120-16

23.88

28.70

25.40

100.08

SR-350

2

350-6

2.06

1.19

1.13

4.19

185-16

52.32

30.23

28.70

106.43

SR-500

2

500-2

2.44

1.50

1.38

5.00

240-25

61.98

38.10

35.05

127.00

SR-750

3

750-250

3.06

1.75

1.63

6.25

300-120

77.72

44.45

41.40

158.75

SR-1000

3

1000-500

3.94

2.00

1.75

8.00

500-240

100.08

50.80

44.45

203.20

Fig. 1

Fig. 3

Fig. 2

H

H

L

L

W

W

A

Benefits

• Easy Installation

•

Center Barrier Prevents Dissimiliar

Metals from Contact

A

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: NA / SCB

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

Aluminum

Neutral Bars

Catalog

Number

Fig.

No.

Conductor

Range

mm²

H

W

Dimensions, inches

Dimensions, millimeters

NA-30

1

6-14

.44

.31

16-1.5

11.18

7.87

NA-35

1

4-14

.50

.31

16-1.5

12.70

7.87

NA-70

1

4-14

.50

.38

16-1.5

12.70

9.65

NA-125

1

1/0-14

.75

.56

50-1.5

19.05

14.22

NA-150

1

2/0-6

.75

.56

50-10

19.05

14.22

NA-250

1

250-6

1.00

.88

120-16

25.40

22.35

Fig. 1

NA-130

2

1/0-14

.75

.56

50-1.5

19.05

14.22

NA-140

2

2/0-14

.75

.56

50-1.5

19.05

14.22

NA-300

2

300-6

1.16

.97

150-16

29.46

24.64

*SCB-1/0

3

1/0-14 / 6-14

.62

.38

50-1.5 / 16-1.5

15.75

9.65

*SCB-2/0

3

2/0-14 / 6-14

.69

.38

50-1.5 / 16-1.5

17.45

9.65

Fig. 3

W

L

H

W

L

H

W

L

H

Fig. 2

Benefits

• Easy Installation

Custom configurations available upon request.

The number of outlets, outlet spacing and mounting hole locations can

be established according to individual requirements.

When ordering

neutral bars please add a suffix to indicate the number of usable

wire ports required. Ex: NA30-8 would result in an NA30 style

neutral bar with eight (8) wire ports.

*This bar is also approved as an equipment ground and is

90° C rated.

www.cmclugs.com 513.860.4455

Aluminum

Neutral Bar Assemblies

Custom configurations available upon request.

Catalog

Number

Fig.

No.

Conductor

Range

mm²

Wire Tap

Range

mm²

H

W

L

Circuit

Holes

Dimensions, inches

Dimensions, millimeters

SNB-350-12

1

350-6

6-14

1.13

2.53

2.17

12

185-16

16-1.5

28.70 64.26 55.12

SNB-350-24

1

350-6

6-14

1.13

2.53

3.43

24

185-16

16-1.5

28.70 64.26 87.12

SNB-350-30

1

350-6

6-14

1.13

2.53

4.06

30

185-16

16-1.5

28.70 64.26 103.12

SNB-350-36

1

350-6

6-14

1.13

2.53

4.77

36

185-16

16-1.5

28.70 64.26 121.16

SNB-350-42

1

350-6

6-14

1.13

2.53

5.27

42

185-16

16-1.5

28.70 64.26 133.86

SNB-350-12

W/SNBI-1

2

350-6

6-14

1.13

2.53

2.17

12

185-16

16-1.5

28.70 64.26 55.12

SNB-350-24

W/SNBI-1

2

350-6

6-14

1.13

2.53

3.43

24

185-16

16-1.5

28.70 64.26 87.12

SNB-350-30

W/SNBI-1

2

350-6

6-14

1.13

2.53

4.06

30

185-16

16-1.5

28.70 64.26 103.12

SNB-350-36

W/SNBI-1

2

350-6

6-14

1.13

2.53

4.77

36

185-16

16-1.5

28.70 64.26 121.16

SNB-350-42

W/SNBI-1

2

350-6

6-14

1.13

2.53

5.27

42

185-16

16-1.5

28.70 64.26 133.86

TYPE: SNB-350

Features

•

Made of 6061-T6 Aluminum Alloy

•

Electro-Tin Plated

•

Dual-Rated

Benefits

• Easy Installation

•

Can Be Used with Insulating Block

Fig. 1

Fig. 2

W

H

L

The number of outlets, outlet spacing and mounting hole locations can be

established according to individual requirements.

www.cmclugs.com 513.860.4455

Connector Manufacturing Company® fabricates the best in electrolytic copper electrical

connectors. Copper connectors are formed from 100% pure electrolytic copper to eliminate the

effects upon conductivity when alloys are utilized to reduce costs.

CMC® copper connectors are either extruded from pure electrolytic copper or formed from copper

tubing carefully shaped to size. They may also be produced from copper strip which is used to

form the tang or bus connection. These light weight connectors will perform better than many of

the heavier, bulkier cast copper alloyed products on the market. This saves the customer the cost of

metal, freight and space, while gaining top conductivity.

We therefore, offer these advantages in connector design:

1. Compact Design.

2. High Strength - low heat rise copper.

3. Relatively light weight construction.

4.

Economy and efficiency.

5. Tested products in accordance with Underwriters Laboratories and the Canadian Standards

Association requirements for listing.

These features together with our dedication for the highest quality standards available and an

unsurpassed service level, provide our customers with maximum reliability.

CMC

®

Copper Connectors

www.cmclugs.com 513.860.4455

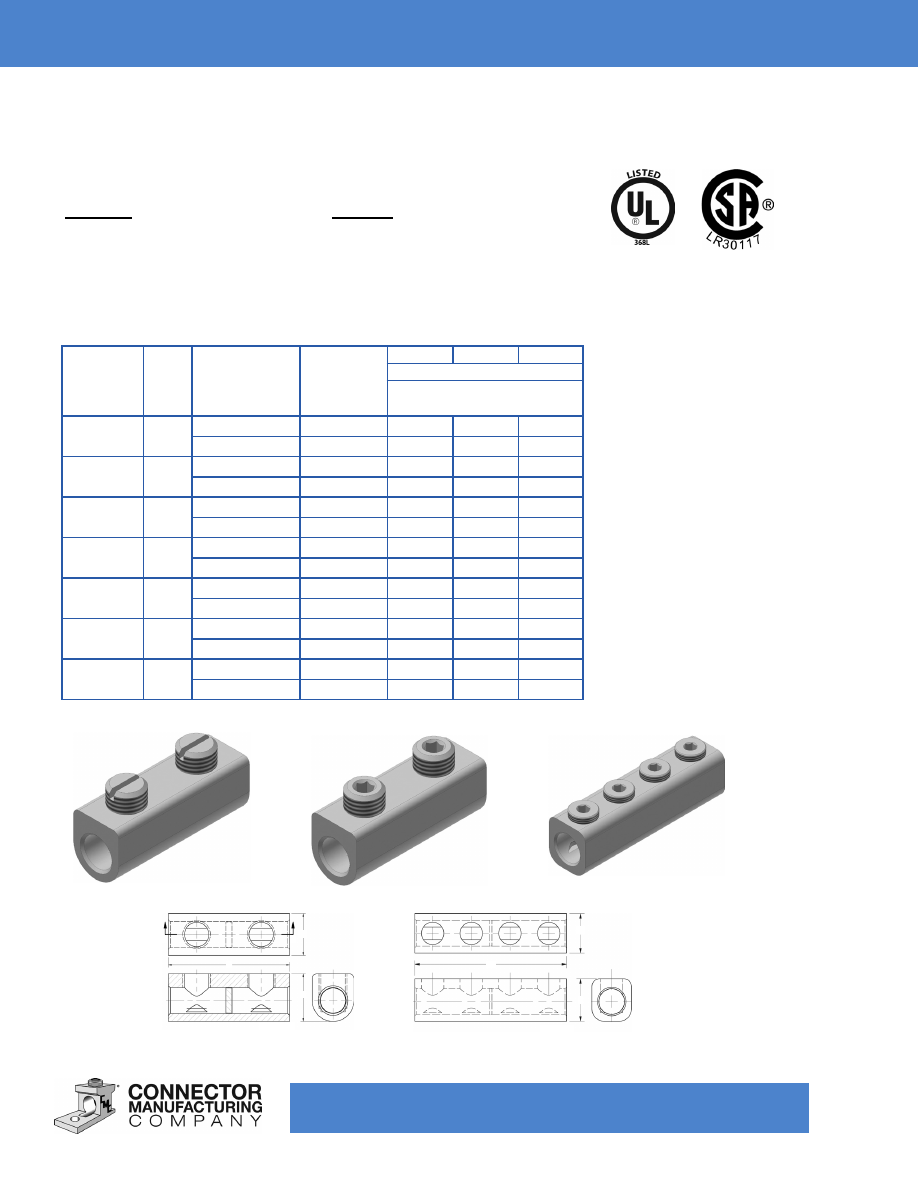

Copper

Solderless Lugs

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Stud Size*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

CF-25

1

10-14

1/8

.37

.31

1.00

4-1.5

3.18

9.40

7.87

25.40

CF-35

1

6-14

3/16

.56

.37

1.09

16-1.5

4.76

14.22

9.40

27.69

CF-70

1

4-14

1/4

.62

.50

1.31

16-1.5

6.35

15.75

12.70

33.27

CF-90

1

2-8

1/4

.72

.50

1.47

25-10

6.35

18.29

12.70

37.34

CF-125

1

1/0-2

3/8

.88

.62

1.79

50-25

9.53

22.35

15.75

45.47

CF-175

2

3/0-4

3/8

1.03

.75

2.05

70-16

9.53

26.16

19.05

52.07

CF-225

2

4/0-2

3/8

1.20

1.00

2.56

95-25

9.53

30.48

25.40

65.02

CF-300

2

350-1/0

3/8

1.41

1.00

3.25

185-50

9.53

35.81

25.40

82.55

CF-400

2

500-1/0

3/8

1.56

1.50

4.31

240-50

9.53

39.62

38.10

109.47

CF-650

2

1000-600

1/2

2.34

2.00

4.75

500-300

12.70

59.44

50.80

120.65

CFS-25

3

10-14

1/8

.37

.31

1.00

4-1.5

3.18

9.40

7.87

25.40

CFS-35

3

6-14

3/16

.56

.38

1.14

16-1.5

4.76

14.22

9.65

28.96

CFS-70

3

4-14

1/4

.63

.50

1.25

16-1.5

6.35

16.00

12.70

31.75

CFS-90

3

2-8

1/4

.71

.50

1.46

25-10

6.35

18.03

12.70

37.08

CFS-125

3

1/0-2

3/8

.88

.62

1.94

50-25

9.53

22.35

15.75

49.28

CSF-175

4

3/0-4

3/8

1.03

.75

2.23

70-16

9.53

26.16

19.05

56.64

CFS-225

4

4/0-2

3/8

1.20

1.00

2.38

95-25

9.53

30.48

25.40

60.45

CFS-300

4

350-1/0

3/8

1.41

1.00

3.25

185-50

9.53

35.81

25.40

82.55

CFS-400

4

500-1/0

3/8

1.56

1.50

3.87

240-50

9.53

39.62

38.10

98.30

CFS-650

4

1000-600

1/2

2.34

2.00

5.00

500-300

12.70

59.44

50.80

127.00

Fig. 1

Fig. 2

Fig. 3

Fig. 4

*This dimension can be altered per customer requirements.

W

L

H

W

L

H

Benefits

• Easy Installation

• Connectors are Reusable

•

Specialized for Copper Conductors ONLY

Custom configurations

available upon request.

TYPE: CF / CFS

Features

• Made of Pure Electrolytic

Copper

• Plain Copper Finish

www.cmclugs.com 513.860.4455

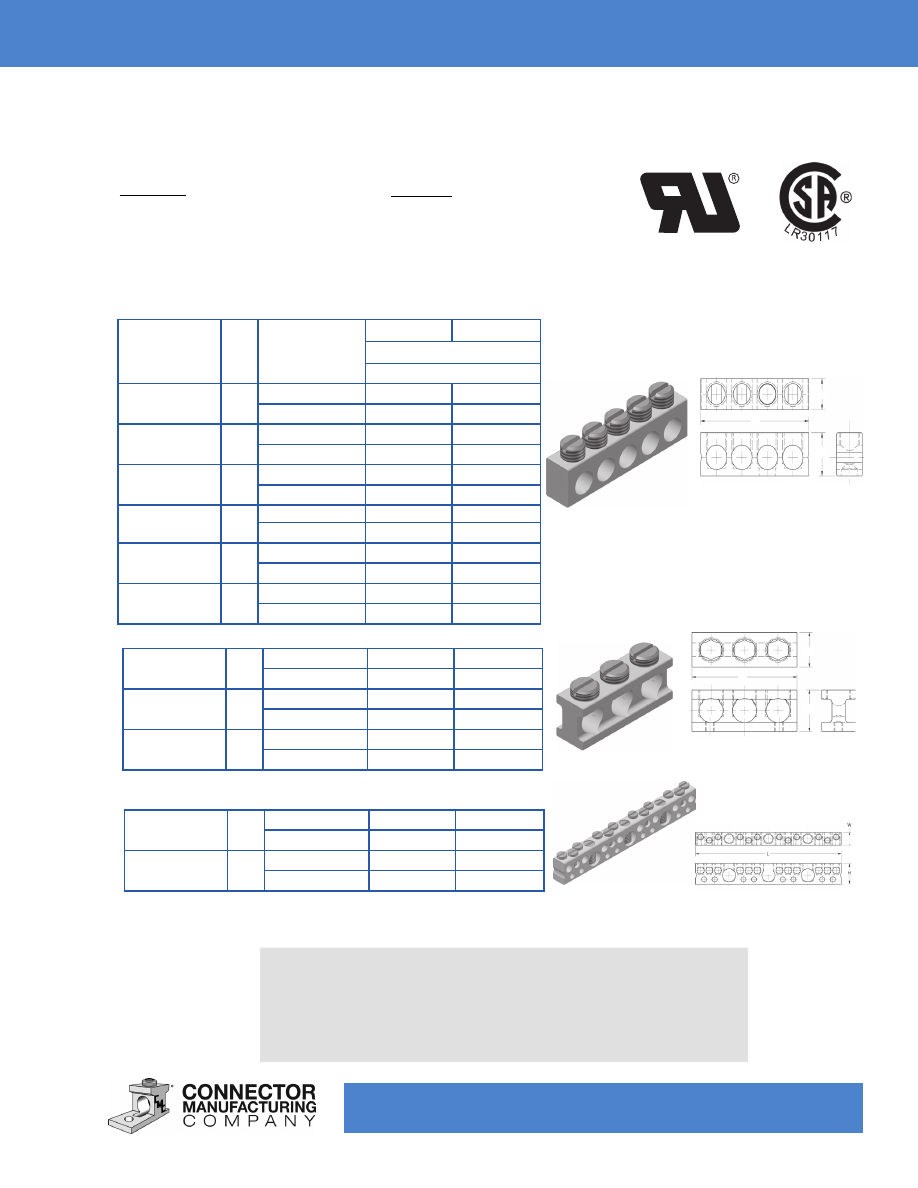

TYPE: BC

Features

• Made of Pure Electrolytic Copper

•

PosiGrip®

•

Unique I-Beam Design

•

Positive Wire Stop

Copper

Solderless Lugs

Catalog

Number

Fig.

No.

Screw

Type

Stud

Size*

mm

Cond. Size

AWG

mm²

H

W

L

G

T

Dimensions, inches

Dimensions, millimeters

BC-50

1

Slot

1/4

6-14

.44

.44

.81

.22

.09

6.35

16-1.5

12.19

12.19

20.57

5.59

2.92

BC-70

1

Slot

1/4

2-14

.50

.50

1.00

.27

.09

6.35

25-1.5

12.70

12.70

25.40

6.86

2.92

BC-112

1

Slot

1/4

1/0-14

.66

.56

1.12

.28

.16

6.35

50-1.5

16.76

14.22

28.45

7.11

4.06

BC-125

1

Slot

1/4

2/0-14

.78

.56

1.25

.31

.19

6.35

50-1.5

19.81

14.22

31.75

7.87

4.83

BC-250

2

.31H

5/16

250-6

.97

.88

1.72

.44

.19

7.87

7.94

120-16

24.64

22.35

43.69

11.18

4.83

BC-350

2

.31H

5/16

350-6

1.13

.94

2.00

.45

.19

7.87

7.94

185-16

28.70

23.88

50.80

11.43

4.83

BC-500

2

.38H

3/8

500-4

1.38

1.25

2.37

.63

.26

9.65

9.53

240-16

35.05

31.75

60.20

16.00

6.60

BC-600

2

.38H

3/8

600-2

1.50

1.19

2.50

.75

.26

9.65

9.53

300-25

38.10

30.23

63.50

19.05

6.60

BC-750

2

.38H

5/8

800-300

1.68

1.38

2.75

.75

.31

9.65

15.88

500-150

42.67

35.05

69.85

19.05

7.87

BC-1000

2

.50H

5/8

1000-500

1.88

1.50

2.87

.75

.31

12.70

15.88

500-240

47.75

38.10

72.70

19.05

7.87

U.S. Patent 4,946,405

U.S. Patent 309,129

U.S. Patent 5,030,131

90° C Rating (486B Listed)

PosiGrip®

*This dimension can be altered per customer requirements.

Fig. 1

Fig. 2

W

L

H

Ø D

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

•

Specialized for Copper Conductors ONLY

Custom configurations available upon request.

G

www.cmclugs.com 513.860.4455

TYPE: 2BC

Features

• Made of Pure Electrolytic Copper

•

PosiGrip®

•

Unique I-Beam Design

•

Positive Wire Stop

Copper

Solderless Lugs

Catalog

Number

Fig.

No.

Screw

Type

Stud

Size*

mm

Cond. Size

AWG

mm²

H

W

L

G

T

Dimensions, inches

Dimensions, millimeters

2BC-112

1

Slot

1/4

1/0-14

.66

1.13

1.12

.28

.16

6.35

50-1.5

16.76

28.70

28.45

7.11

4.06

2BC-125

1

.19H

1/4

2/0-14

.78

1.25

1.25

.31

.19

4.83

6.35

50-1.5

19.81

31.75

31.75

7.87

4.83

2BC-250

2

.31H

3/8

250-6

.97

1.62

1.72

.44

.19

7.87

9.53

120-16

24.64

41.15

43.69

11.18

4.83

2BC-350

2

.31H

1/2

350-6

1.13

1.92

2.00

.50

.19

7.87

12.70

185-16

28.70

48.77

50.80

12.70

4.83

2BC-500

2

.31H

1/2

500-4

1.38

2.41

2.37

.56

.26

7.87

12.70

240-16

35.05

61.21

60.20

14.22

6.60

2BC-600

2

.31H

1/2

600-2

1.50

2.41

2.50

.63

.26

7.87

12.70

300-25

38.10

61.21

63.50

16.00

6.60

2BC-750

2

.31H

5/8

750-300

1.68

3.25

2.75

.75

.31

7.87

15.88

300-150

42.67

82.55

69.85

19.05

7.87

2BC-1000

2

.50H

5/8

1000-500

1.88

3.50

2.87

.75

.31

12.70

15.88

500-300

47.75

88.90

72.90

19.05

7.87

U.S. Patent 4,946,405

U.S. Patent 309,129

U.S. Patent 5,030,131

90° C Rating (486B Listed)

PosiGrip®

*This dimension can be altered per customer requirements.

Fig. 1

Fig. 2

W

H

L

T

G

Ø D

Benefits

• Easy Installation

•

Improved Pull-Out and Safety Features

•

Specialized for Copper Conductors ONLY

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: FT

Features

• Made of Pure Electrolytic Copper

• Plain Copper Finish

Copper

Solderless

Connectors and Collars

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Stud

Size*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

FT-65

1

6-14

1/8

.48

.38

1.00

16-1.5

3.18

12.19

9.65

25.40

FT-70

1

4-14

1/8

.52

.50

1.25

16-1.5

3.18

13.21

12.70

31.75

FT-90

1

1/0-14

3/16

.75

.62

1.26

50-1.5

4.76

19.05

15.75

32.00

90° C Rating (486B Listed)

*This dimension can be altered per customer requirements.

Fig. 1

Fig. 2

TYPE: C / CS

Features

• Made of Pure Electrolytic Copper

• Plain Copper Finish

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Boss Tap*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

C-54-S

2

6-14

.22S / 10-32

.47

.35

.38

16-1.5

5.59

11.94

8.89

9.65

C-58-S

2

4-14

.25S / 10-32

.52

.46

.46

16-1.5

6.35

13.21

11.68

11.68

C-68-S

2

1/0-14

.25S / 12-24

.61

.53

.62

50-1.5

6.35

15.49

13.46

15.75

CS-105

3

1/0-14

.88

.55

.63

50-1.5

22.35

13.97

16.00

CS-175

3

4/0-2

1.09

.75

.88

95-25

27.69

19.05

22.35

CS-200

3

250-6

.88

.81

1.00

120-16

22.35

20.57

25.40

Fig. 3

W

L

H

W

W

H

H

L

L

*This dimension can be altered per customer requirements.

Benefits

• Easy Installation

• Connectors are Reusable

•

Specialized for Copper Conductors ONLY

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

TYPE: C2/C4

Features

• Made of Pure Electrolytic Copper

• Plain Copper Finish

Copper

Splicers

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

H

W

L

Dimensions, inches

Dimensions, millimeters

C2-25

1

8-12

.48

.25

.56

10-2.5

12.19 6.35

14.22

C2-35

1

6

.56

.34

.88

16

14.22 8.64

22.35

C2-50

1

4

.63

.39

.88

16

16.00 9.91

22.35

C2-70

1

2

.72

.50

1.00

25

18.29 12.70 25.40

C2-125 1

2/0-1/0

.88

.59

1.25

70-50

22.35

14.99 31.75

C2-225 1

250-3/0

1.31

.86

2.31

120-70

33.27 21.84 58.67

C4-25

2

8-12

.45

.25

1.63

10-2.5

11.43 6.35

41.40

C4-35

2

6

.69

.33

1.75

16

17.53 8.38

44.45

C4-50

2

4

.75

.38

1.75

16

19.05 9.65

44.45

C4-70

2

2

.91

.47

2.00

25

23.11 11.94 50.80

C4-125 2

2/0-1/0

.88

.59

2.50

70-50

22.35

14.99 63.50

C4-225 2

250-3/0

1.31

.86

4.63

120-70

33.27 21.84 117.60

90° C Rating (486B Listed)

Fig. 1

Fig. 2

W

H

L

W

H

L

Benefits

• Easy Installation

• Connectors are Reusable

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

90° C Rating (486B Listed)

TYPE: CL

Features

• Made of Pure Electrolytic Copper

• Plain Copper Finish

•

Designed for Conduit Grounding Bushings

•

UL Approved for Direct Burial.

*This dimension can be altered per customer requirements.

Catalog

Number

Fig.

No.

Cond. Range

AWG

mm²

Stud Size*

mm

H

W

L

Dimensions, inches

Dimensions, millimeters

CL-50S

1

4-14

3/16

.78

.38

1.07

16-1.5

4.76

19.81 9.65

27.18

CL-112S 1

1/0-14

1/4

1.17

.60

1.50

50-1.5

6.35

29.72 15.24 38.10

CL-200S 2

3/0-6

5/16

1.56

.80

2.00

70-16

7.94

39.62 20.32 50.80

CL-252S 2

250-6

5/16

1.79

.80

2.20

120-16

7.94

45.47 20.32 55.88

Fig. 2

Fig. 1

W

H

L

Benefits

• Easy Installation

• Connectors are Reusable

•

Specialized for Copper Conductors ONLY

Copper

Grounding Connectors

Custom configurations available upon request.

www.cmclugs.com 513.860.4455

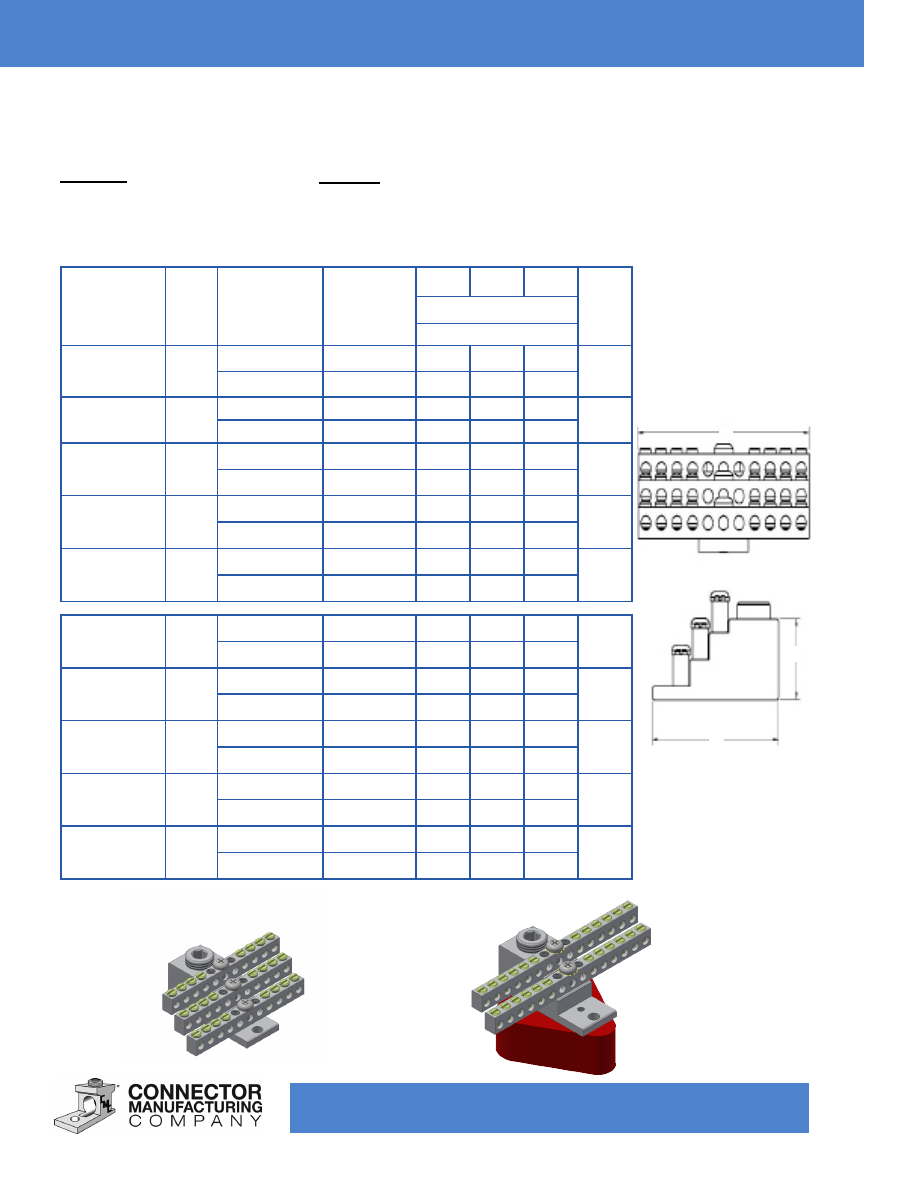

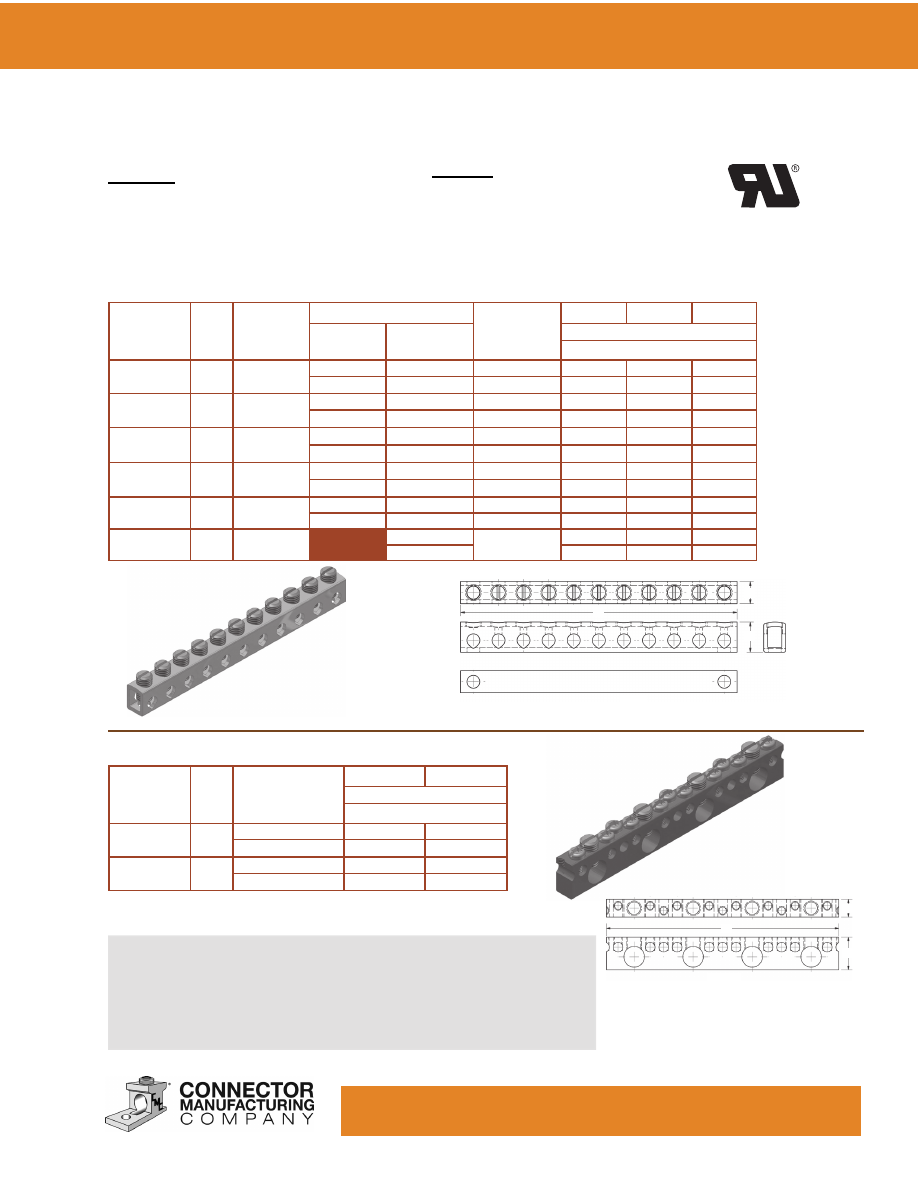

TYPE: N70 / LCB

Features

• Made of Pure Electrolytic Copper

• Plain Copper Finish

Copper

Neutral Bars

Catalog

Number

Fig.

No.

No. of

Taps

Wire Range

Stud Size*

mm

H

W

L

Line

mm

Circuit

mm

Dimensions, inches

Dimensions, millimeters

N70-8-1

1

6

4-14

6-14

3/16 (2)

.48

.35

3.57

16-1.5

16-1.5

4.76 (2)

12.19

8.89

90.68

N70-10-1

1

8

4-14

6-14

3/16 (2)

.48

.35

4.37

16-1.5

16-1.5

4.76 (2)

12.19

8.89

111.00

N70-12-1

1

10

4-14

6-14

3/16 (2)

.48

.35

5.16

16-1.5

16-1.5

4.76 (2)

12.19

8.89

131.06

N70-14-1

1

12

4-14

6-14

3/16 (2)

.48

.35

5.95

16-1.5

16-1.5

4.76 (2)

12.19

8.89

151.13

N70-16-1

1

14

4-14

6-14

3/16 (2)

.48

.35

6.74

16-1.5

16-1.5

4.76 (2)

12.19

8.89

171.20

N70-174

1

174

6-14

None

.47

.34

68.91

16-1.5

11.94

8.64

1750.31

The number of outlets, outlet spacing and mounting hole locations can

be established according to individual requirements.

When ordering

neutral bars please add a suffix to indicate the number of usable

wire ports required. Ex: NA30-8 would result in an NA30 style

neutral bar with eight (8) wire ports.

Fig. 1

Catalog

Number

Fig.

No.

Cond. Range

mm²

H

W

Dimensions, inches

Dimensions, millimeters

*LCB-1/0

2

1/0-14 / 6-14

.63

.38

50-1.5 / 16-1.5

16.00

9.65

*LCB-2/0

2

2/0-14 / 6-14

.69

.38

50-1.5 / 16-1.5

17.45

9.65

Fig. 2

W

H

L

W

H

L

Benefits

• Easy Installation

• Connectors are Reusable

•

Specialized for Copper Conductors ONLY

Custom configurations available upon request.

Custom configurations available upon request.

*This bar is also approved as an equipment ground.

www.cmclugs.com 513.860.4455

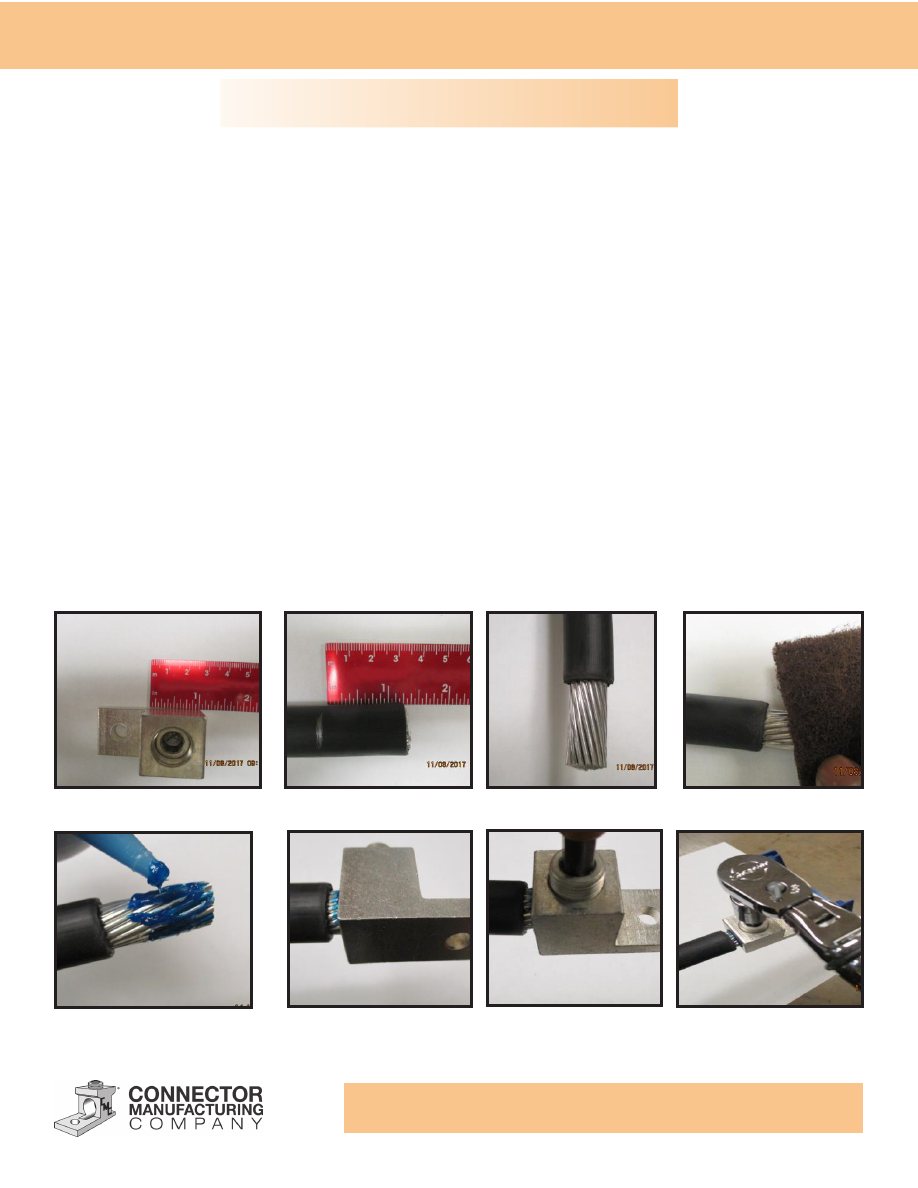

1. Measure the length of the wire hole in the connector, with a measuring device.

2. Measure and mark the conductor cable approximately 1/4” longer than the connector.

3. Strip the insulation from the cable with an appropriate stripping tool; be careful not to damage the

conductor wire while performing this operation.

4. If the wire cable (conductor) is corroded or blemished in any way, clean the exposed end of the cable

with emery cloth or wire brush dependent upon the severity of the corrosion to remove oxides from the

surface of the conductor.

5. Prior to installation of the conductor to the connector, apply a generous amount of oxide inhibitor to the

bare portion of the conductor.

6. Rotate the conductor back and forth to evenly distribute the inhibitor.

7. Install the conductor into the connector leaving approximate 1/4” of exposed conductor visible. Be sure

the installed conductor is equal in length of the wire hole. Snug with an Allen wrench.

8. Torque the set screw to the recommended value with a torque wrench. After a minute, retighten the

screw again to the recommended torque value.

1

3

4

2

8

6

5

7

Installation Instructions

www.cmclugs.com 513.860.4455

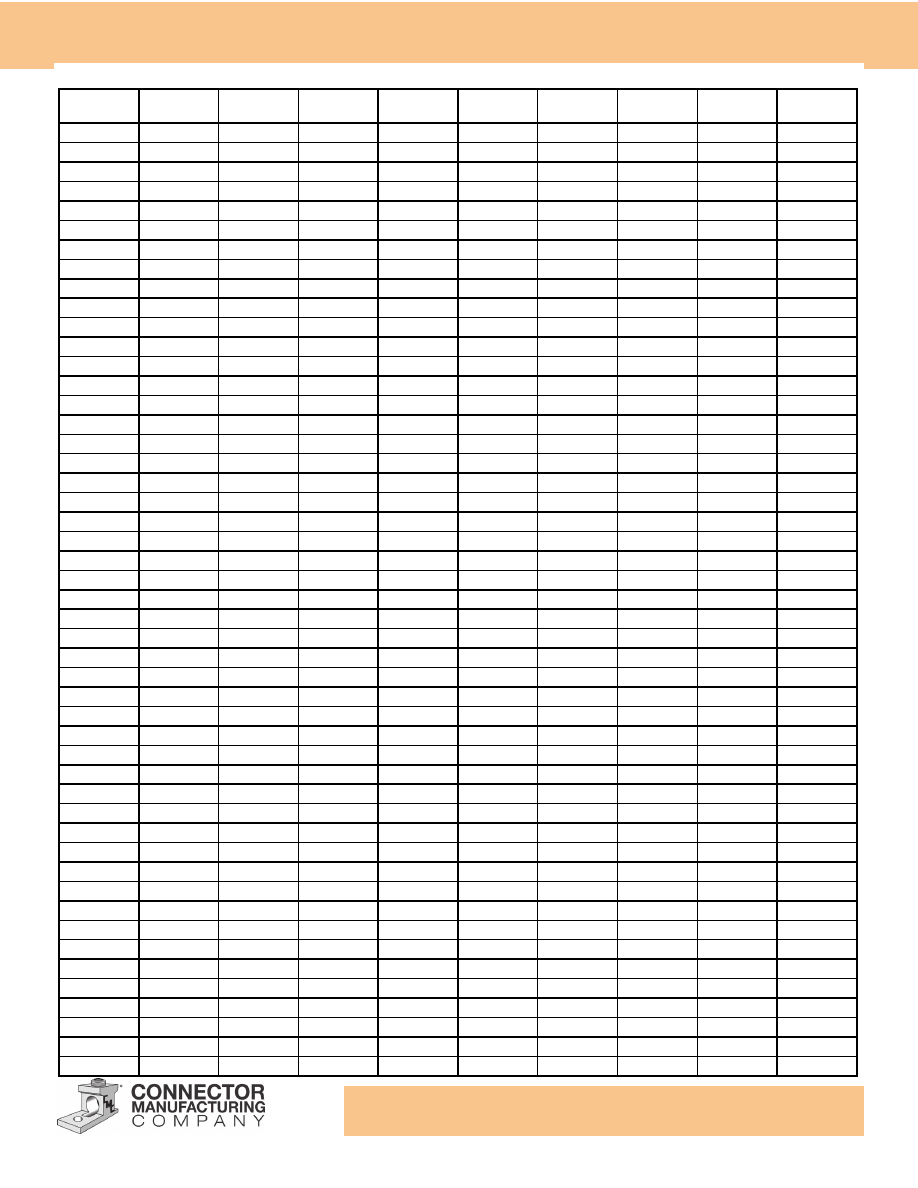

Tightening Torque Values for Mechanical Screw Connectors

Table shows the recommended Tightening torques for silicon bronze, stainless steel, galvanized steel and aluminum

alloy hardware.

Internal Socket Size

Across Flats

Tightening Torque

in

mm

Inch Pounds

Newton Meters

1/8

3.2

45

5.1

5/32

4.0

100

11.3

3/16

4.8

120

13.6

7/32

5.6

150

16.9

1/4

6.4

200

22.6

5/16

7.9

275

31.1

3/8

9.5

375

42.4

1/2

12.7

500

56.5

9/16

14.3

600

67.8

Tightening Torque Values for Socket Head Screw Connectors

Bolt Diameter

Nominal Torque Values

Silicon Bronze, Galvanized or

Stainless Steel

Aluminum Alloy (lubricated)

Ft. - Lbs.

Inch-Lbs.

Ft. - Lbs.

Inch - Lbs.

5/16-18

15

180

-

-

3/8-16

20

240

14

168

1/2-13

40

480

25

300

5/8-11

55

660

40

480

3/4-10

80

960

70

840

AWG.

or Circular

Mill Size

Slotted Head Screws

Hexagonal Head Screw

Slot Width

.047 in (1.2 mm) or less

Slot Width

More than .047 in (1.2 mm)

Slot Length

.25 in (6.4 mm) or less

Slot Length

More than .25 in (6.4 mm)

in-lbf

N-m

in-lbf

N-m

in-lbf

N-m

30-10

20

2.3

35

4.0

75

8.5

8

25

2.8

40

4.5

75

8.5

6-4

35

4.0

45

5.1

110

12.4

3

35

4.0

50

5.6

150

16.9

2

40

4.5

50

5.6

150

16.9

1

50

5.6

150

16.9

1/0 - 2/0

50

5.6

180

20.3

3/0 - 4/0

50

5.6

250

28.2

250-350

50

5.6

325

36.7

400

50

5.6

325

36.7

500

50

5.6

375

42.4

600-750

50

5.6

375

42.4

800-1000

50

5.6

500

56.5

1250-2000

600

67.8

Tightening Torque Values

Additional Torque Information

www.cmclugs.com 513.860.4455

For optimum efficiency, it is necessary that the correct bolt, nut, and washer combination be used with the correct

combination of conductor materials. This table shows acceptable methods of joining different combination of bus bar.

Where different combinations of metals are being joined, a follow-up device such as a conical pressure washer is usually

recommended if one, or both, bus materials are soft drawn aluminum. If both bars are hard drawn, large flat washers will

suffice regardless of the bolt materials.

Other considerations which should be taken into account when selecting hardware are corrosion and vibration. For

example, if severe corrosion is anticipated, non-corrosive materials such as stainless steel or silicon bronze, should be

selected in preference to galvanized steel. If vibration is anticipated, the use of locking washers should be considered.

Methods of Joining Bus Bars

Bar Connections:

The Tang of a compression or mechanical connector is a bus bar, which connects to another bus bar. If you remember the

rule about wire brushing and using joint compound with bare (unplated) aluminum, you cannot go wrong. Plated parts

should be cleaned with a solvent if they are dirty, but never abrade or otherwise disturb the plating! Figure shows a typical

bar connection and the type of hardware used.

Contact surface must be clean. Use a joint compound with bare aluminum. Conical pressure washer is usually

recommended if one, or both, bus materials are soft drawn aluminum.

(1) Denotes preferred hardware usage.

Note: Contact sealant recommended between aluminum to aluminum and alumi-

num to copper connections unless other protective measures are taken.

If “A” Bar is

Copper

Aluminum

Steel

Aluminum

Steel

If “B” Bar is

Copper

Copper

Copper

Aluminum

Aluminum

(1) Silicon Bronze

(2) Stainless Steel

(1) Silicon Bronze

(2) Aluminum

(3) Stainless Steel

(1) Aluminum

(2) Stainless Steel

(1) Aluminum

(2) Stainless Steel

(3) Silicon Bronze,

Plated

(1) Aluminum

(2) Stainless Steel

(1) Silicon Bronze

(2) Stainless Steel

(1) Silicon Bronze

(2) Aluminum

(3) Stainless Steel

(4) Conical Pressure

Washer Plated or

Stainless Steel

(1) Silicon Bronze

(2) Stainless Steel

(1) Aluminum

(2) Stainless Steel

(3) Silicon Bronze

Plated

(4) Conical Pressure

Washer Plated or

Stainless Steel

(1) Aluminum

(2) Stainless Steel

(3) Silicon Bronze

Plated

(4) Conical

Pressure Washer

Plated or Stainless

Steel

Hand drawn bus such as Al Alloy

Bolt

Large Flat

Washer

Large Flat

Washer

Split or Tooth

Lock Washer

Nut

Large Flat

Washer

Large Flat

Washer

Conical Pressure

Washer

Bolt

Nut

Soft drawn bus such as EC-H13 AL

A

B

Additional Torque Information

www.cmclugs.com 513.860.4455

Decimal Equivalents

Drill

Equivalent

Drill

Equivalent

Drill

Equivalent

Drill

Equivalent

Drill

Equivalent

1/16

.0625

53/64

.8281

1 19/32

1.59737

2 3/64

2.3593

3 1/4

3.2500

5/64

.07812

27/32

.8437

1 39/64

1.6093

2 3/8

2.3750

3 9/32

3.2812

3/32

.09375

55/64

.8593

1 5/8

1.6250

2 25/64

2.3906

3 5/16

3.3125

7/64

.10937

7/8

.8750

1 41/64

1.6406

2 13/32

2.4062

3 11/32

3.3437

1/8

.125

57/64

.8906

1 21/32

1.6562

2 27/64

2.4218

3 3/8

3.3750

9/64

.14062

29/32

.9062

1 43/64

1.6718

2 7/16

2.4375

3 13/32

3.4062

5/32

.15625

59/64

.9218

1 11/16

1.6875

2 29/64

2.4531

3 7/16

3.4375

11/64

.17187

15/16

.9375

1 45/64

1.7031

2 15/32

2.4687

3 15/32

3.4687

3/16

.1875

61/64

.9531

1 23/32

1.7187

2 31/64

2.4843

3 1/2

3.5000

13/64

.20312

31/32

.9687

1 47/64

1.7343

2 1/2

2.5000

3 17/32

3.5312

7/32

.21875

63/64

.9843

1 3/4

1.7500

2 33/64

2.5156

3 9/16

3.5625

15/64

.23437

1

1.0000

1 49/64

1.7656

2 17/32

2.5312

3 19/32

3.5937

1/4

.25

1 1/64

1.0156

1 25/32

1.7812

2 35/64

2.5468

3 5/8

3.6250

17/64

.26562

1 1/32

1.0312

1 51/64

1.7968

2 9/16

2.5625

3 21/32

3.6562

9/32

.28125

1 3/64

1.0468

1 13/16

1.8125

2 37/64

2.5781

3 11/16

3.6875

19/64

.29687

1 1/16

1.0625

1 53/64

1.8281

2 19/32

2.5937

3 23/32

3.7187

5/16

.3125

1 5/64

1.0781

1 27/32

1.8437

2 39/64

2.6093

3 3/4

3.7500

21/64

.32812

1 3/32

1.0937

1 55/64

1.8593

2 5/8

2.6250

3 25/32

3.7812

11/32

.34375

1 7/64

1.1093

1 7/8

1.8750

2 41/64

2.6406

3 13/16

3.8125

23/64

.35937

1 1/8

1.1250

1 57/64

1.8906

2 21/32

2.6562

3 27/32

3.8437

3/8

.375

1 9/64

1.1406

1 29/32

1.9062

2 43/64

2.6718

3 7/8

3.8750

25/64

.39062

1 5/32

1.1562

1 59/64

1.9218

2 11/16

2.6875

3 29/32

3.9062

13/32

.40625

1 11/64

1.1718

1 15/16

1.9375

2 45/64

2.7031

3 15/16

3.9375

27/64

.42187

1 3/16

1.1875

1 61/64

1.9531

2 23/32

2.7187

3 31/32

3.9687

7/16

.4375

1 3/64

1.2031

1 31/32

1.9687

2 47/64

2.7343

4

4.0000

29/64

.45312

1 7/32

1.2187

1 63/64

1.9843

2 3/4

2.7500

4 4/16

4.0625

15/32

.46875

1 5/64

1.2343

2

2.0000

2 49/64

2.7656

4 1/8

4.1250

31/64

.48437

1 1/4

1.2500

2 1/64

2.0156

2 25/32

2.7812

4 3/16

4.1875

1/2

.50

1 17/64

1.2656

2 1/32

2.0312

2 51/64

2.7968

4 1/4

4.2500

33/64

.5156

1 9/32

1.2812

2 3/64

1.0468

2 13/16

2.8125

4 15/16

4.3125

17/32

.5312

1 19/64

1.2968

2 1/16

2.0625

2 53/64

2.8281

4 3/8

4.3750

35/64

.5468

1 5/16

1.3125

2 5/64

2.0781

2 27/32

2.8437

4 7/16

4.4375

9/16

.5625

1 21/64

1.3281

2 3/32

2.0937

2 55/64

2.8593

4 1/2

4.5000

37/64

.5781

1 11/32

1.3437

2 7/64

2.1093

2 7/8

2.8750

4 9/16

4.5625

19/32

.5937

1 23/64

1.3593

2 1/8

2.1250

2 57/64

2.8906

5 5/8

4.6250

39/64

.6093

1 3/8

1.3750

2 9/64

2.1406

2 29/32

2.9062

4 11/16

4.6875

5/8

.6250

1 25/64

1.3906

2 5/32

2.1562

2 59/64

2.9218

4 3/4

4.7500

41/64

.6406

1 13/32

1.4062

2 11/64

2.1718

2 15/16

2.9375

4 13/16

4.8125

21/32

.6562

1 27/64

1.4218

2 3/16

2.1875

2 61/64

2.9531

4 7/8

4.8750

43/64

.6718

1 7/16

1.4375

2 13/64

2.2031

2 31/32

2.9687

4 15/16

4.9375

11/16

.6975

1 29/64

1.4531

2 7/32

2.2187

2 63/64

2.9843

5

5.0000

45/64

.7031

1 15/32

1.4687

2 15/64

2.2343

3

3.0000

5 1/8

5.1250

23/32

.7187

1 31/64

1.4843

2 1/4

2.2500

3 1/32

3.0312

5 1/4

5.2500

47/64

.7343

1 1/2

1.5000

2 17/64

2.2656

3 1/16

3.0625

5 3/8

5.3750

3/4

.7500

1 33/64

1.5156

2 9/32

2.2812

3 3/32

3.0937

5 1/2

5.5000

49/64

.7656

1 17/32

1.5312

2 19/64

2.2968

3 1/8

3.1250

5 5/8

5.6250

25/32

.7812

1 35/64

1.5468

2 5/16

2.3125

3 5/32

3.1562

5 3/4

5.7500

51/64

.7968

1 9/16

1.5625

2 21/64

2.3281

3 3/16

3.1875

5 7/8

5.8750

13/16

.8125

1 37/64

1.5781

2 11/32

2.3437

3 7/32

3.2187

6

6.0000

www.cmclugs.com 513.860.4455

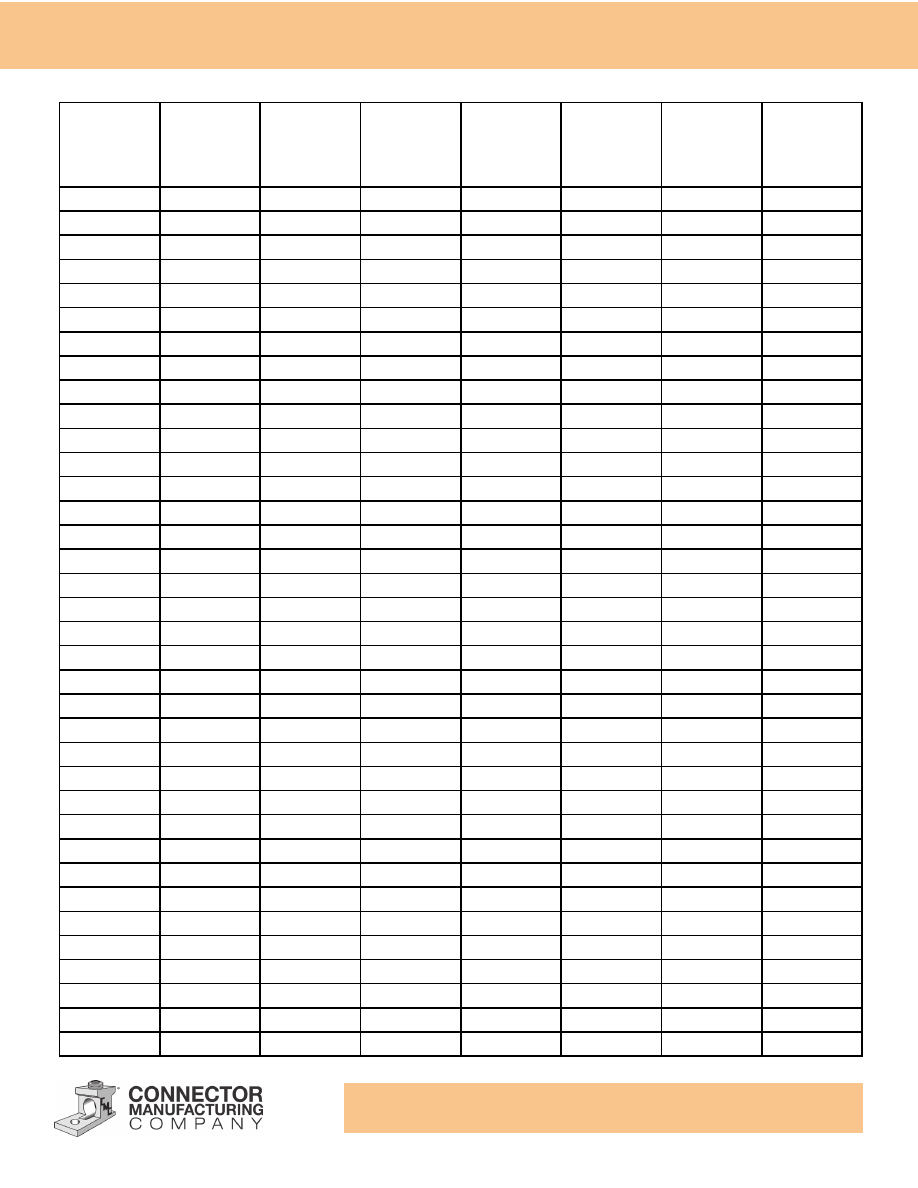

Wire Ranges

Size

AWG-MCM

No. of Wires

Dia. Each

Wire Inches

Dia. Inches

Clearance Drill

Present Clearance

Between

Conductor Dia. &

Hole Dia.

Proposed or

Suggested Drill

Sizes for Wire

Holes

Clearance

Between

Conductor &

Proposed Drill

Sizes

18

Solid

0.0403

0.0403

0.0469

18

7

0.0403

0.0469

16

Solid

0.0508

0.0508

0.0625

16

7

0.0508

0.0625

14

Solid

0.0641

0.0641

0.078

14

7

0.0641

0.078

12

Solid

0.0808

0.0808

0.098

12

7

0.0808

0.098

10

Solid

0.1019

0.1019

0.120

10

7

0.1019

0.120

8

Solid

0.1285

0.1285

0.156

8

7

0.1285

0.156

6

7

0.0612

0.184

0.219

0.035

4

7

0.0772

0.232

0.250

0.018

0.265

0.033

3

7

0.0867

0.260

0.281

0.021

0.296

0.036

2

7

0.0974

0.292

0.312

0.020

0.328

0.036

1

19

0.0664

0.332

0.368

0.036

0

19

0.0745

0.372

0.406

0.034

00

19

0.0837

0.418

0.437

0.019

0.453

0.035

000

19

0.0940

0.470

0.500

0.030

0000

19

0.1055

0.528

0.562

0.034

250

37

0.0822

0.575

0.609

0.034

0.625

0.050

300

37

0.0900

0.630

0.656

0.026

0.687

0.057

350

37

0.0973

0.681

0.719

0.038

0.734

0.053

400

37

0.1040

0.728

0.781

0.053

500

37

0.1162

0.813

0.875

0.062

600

61

0.0992

0.893

0.938

0.045

0.953

0.060

700

61

0.1071

0.964

0.984

0.020

1.035

0.069

750

61

0.1109

0.998

1.035

0.037

1.062

0.064

800

61

0.1145

1.030

1.094

0.064

900

61

0.1215

1.090

1.140

0.050

1.152

0.062

1000

61

0.1280

1.150

1.219

0.069

1.234

0.084

1250

91

0.1172

1.289

1.390

0.101

1.375

0.086

1500

91

0.1284

1.410

1.500

0.090

1750

127

0.1174

1.526

1.593

0.067

1.625

0.099

2000

127

0.1255

1.630

1.697

0.057

1.734

0.104

www.cmclugs.com 513.860.4455

WWW.CMCLUGS.COM

Follow us on Social Media

February 2021

We’re here to support you.

Customer Service - 513-860-4455, press 2

Pricing/Quotations - 513-860-4455, press 3

TO ORDER:

cmcorders@cmclugs.com

02/2021

OEMDCAT0121