IMPROVED PRODUCT

Bulk Metal

®

Technology High Precision, Current Sensing, Power Surface

Mount, Metal Strip Resistor with Improved Stability 0.05 %, Resistance

Value from 10 m

Ω

, Rated Power to 1 W and TCR to 0 ± 15 ppm/°C

CSM2512S

Vishay Foil Resistors

Document Number: 63145

For any questions, contact:

foil@vishaypg.com

www.vishayfoilresistors.com

Revision: 3-May-11

1

The CSM’s series of low value current sense resistors

provides power and precision in a four terminal, surface

mount configuration. Its all welded construction is made

up of a Bulk Metal

®

resistive element with plated copper

terminations.

Vishay Foil Resistors’ application engineering department is

available to advise and make recommendations.

For non-standard technical requirements and special

applications, please contact

foil@vishaypg.com

.

FEATURES

•

Temperature coefficient of resistance (TCR):

(- 55 °C to + 125 °C, + 25 °C ref.)

± 15 ppm/°C maximum

± 10 ppm/°C maximum on special request

•

Load life stability to ± 0.05 % (70 °C, 2000 h

at rated power)

•

Power rating: 1 W

•

Resistance tolerance: ± 0.1 %

•

Resistance range: 10 m

Ω

to 100 m

Ω

•

Vishay Foil resistors are not restricted to standard values,

we can supply specific “as required” values at no extra cost

or delivery (e.g. 10.2345 m

Ω

vs. 10 m

Ω

)

•

Short time overload: ± 0.1 % typical

•

Thermal EMF: < 3 µV/°C

•

Maximum current: up to 10 A

•

Surface mount configuration

•

Four terminal (Kelvin) design: allows for precision accurate

measurements

•

Terminal finishes available: lead (Pb)-free, tin/lead alloy

•

Screening in accordance with EEE-INST002 available

(Per MIL-PRF-55342 and MIL-PRF-49465; see

datasheets of 303144 and 303145 )

•

Prototype quantities available in just 5 working days or

sooner. For more information, please contact

foil@vishaypg.com

•

For better performances please contact Application

Engineering

* Pb containing terminations are RoHS compliant, exemptions may apply

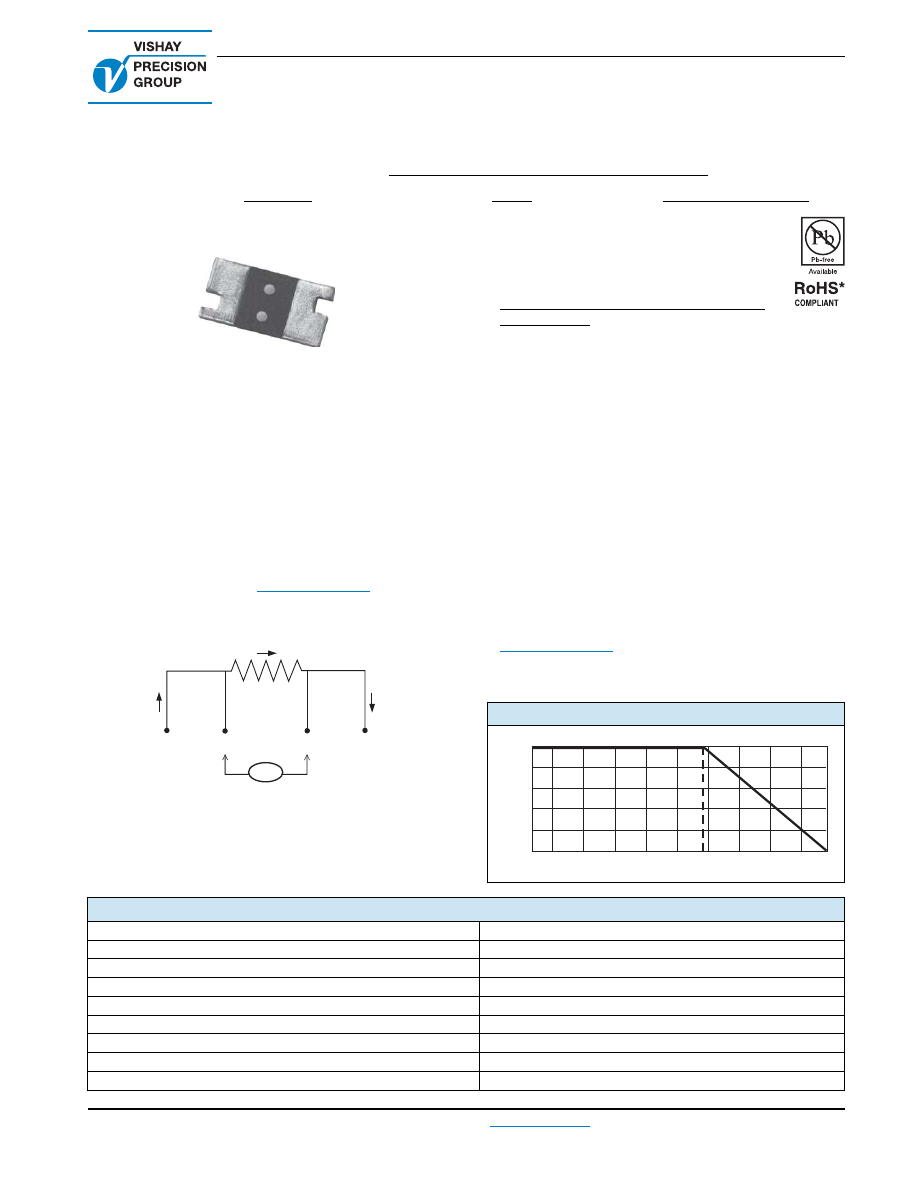

I

A

R

Z

in

I

D

V

=~

∞

B

C

FIGURE 1 - POWER DERATING CURVE

- 65 - 50

- 25

0

25

50

75

100

125

150

170

Ambient Temperature (°C)

100

80

60

40

20

0

Rated Power (%)

+ 70 °C

TABLE 1 - PERFORMANCE SPECIFICATIONS

PARAMETER

CSM2512S

Resistance Range

10 m

Ω

to 100 m

Ω

Power Rating at 70 °C

1 W

Maximum Current

10 A

Maximum Working Voltage

(P x R)

1/2

Tightest Tolerance

± 0.1 %

Temperature Coefficient Maximum (- 55 °C to + 125 °C, + 25 °C ref.)

± 15 ppm/°C, ± 10 ppm/°C is available

Operating Temperature Range

- 65 °C to + 170 °C

Weight (maximum)

0.09 g