Top View

Z-1 Foil Ultra High Precision Wrap-around Chip Resistor for

Improved Load Life Stability of 0.0025% (25 ppm) with TCR of

± 0.05 ppm/°C and withstands ESD of 25 KV min

FRSM Series of Precision Chip Resistors

Vishay Foil Resistors

Document Number: 63209

For any questions, contact:

foil@vishaypg.com

www.vishayfoilresistors.com

Revision: 8-Nov-12

1

INTRODUCTION

The FRSM is based on the new generation Z1- technology of

the Bulk Metal® Precision Foil resistor elements by Vishay

Precision Group (VPG), which makes these resistors

virtually insensitive to destabilizing factors. Their element,

based on the new Z-1 Foil is a solid alloy that displays the

desirable bulk properties of its parent material; thus, it is

inherently stable (remarkably improved load life stability of

25 ppm), noise-free and withstands ESD to 25KV or more.

The alloy is matched to the substrate and forms a single

entity with balanced temperature characteristics for an

unusually low and predictable TCR over a wide range from

-55 C° to more than 175C°. Resistance patterns are

photo-etched to permit trimming of resistance values to very

tight tolerances.

Our application engineering department is available to

advise and make recommendations. For non-standard

technical requirements and special applications, please

contact us using the e-mail address in the footer below.

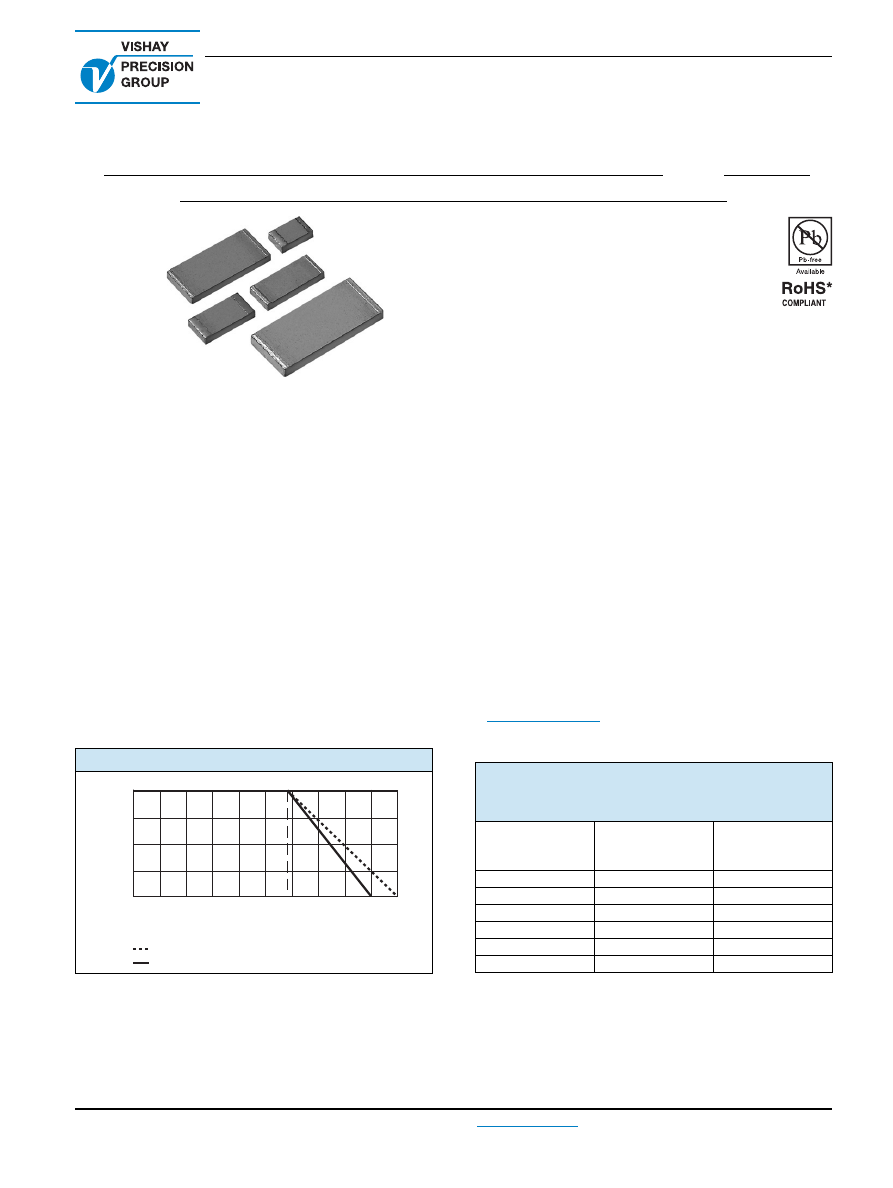

FIGURE 1 - POWER DERATING CURVE

100

75

50

25

0

- 75

- 50

- 25

0

+ 25

+ 50

+ 75 + 100 + 125 + 150 + 175

Ambient Temperature (°C)

Rated Power (%)

+ 70 °C

- 55 °C

Lead (Pb)-free terminals

Tin/lead alloy terminals

FEATURES

Temperature coefficient of resistance (TCR):

0.05 ppm/°C typical (0 °C to + 60 °C)

0.2 ppm/°C typical (- 55 °C to + 125 °C, + 25 °C ref.)

Resistance tolerance: to ± 0.01 %

Power coefficient “

R due to self heating”:

5 ppm at rated power

Power rating: to 750 mW at + 70 °C

Load life stability:

± 0.0025 % at 70 °C, 2000 h at rated power.

± 0.005 % at 70 °C, 10,000 h at rated power.

Resistance Range: 5

to 125 k

(for higher and lower

values, please contact us)

Vishay Foil resistors are not restricted to standard values;

we can supply specific “as required” values at no extra cost

or delivery (e.g. 1K2345 vs. 1K)

Thermal stabilization time < 1 s (nominal value achieved

within 10 ppm of steady state value)

Electrostatic discharge (ESD) at least to 25kV

Short time overload: 0.005 %

Rise time: 1 ns effectively no ringing

Current noise: 0.010 µV

RMS

/V of applied voltage

(< - 40 dB)

Voltage coefficient: 0.1 ppm/V

Non inductive: 0.08 µH

Non hot spot design

Terminal finishes available: lead (Pb)-free, tin/lead alloy

(1)

Matched sets are available on request

Prototype quantities available in just 5 working days

or sooner. For more information, please contact

foil@vishaypg.com

For higher temperature application up to +240 °C and for

better performances, please contact us

TABLE 1 - TOLERANCE AND TCR VS.

RESISTANCE VALUE

(1)

(- 55 °C to + 125 °C, + 25 °C Ref.)

RESISTANCE

VALUE

(

)

TOLERANCE

(%)

TYPICAL TCR AND

MAX. SPREAD

(ppm/°C)

250

to 125K

± 0.01

± 0.2 ± 1.8

100

to < 250

± 0.02

± 0.2 ± 1.8

50

to < 100

± 0.05

± 0.2 ± 2.8

25

to < 50

± 0.1

± 0.2 ± 3.8

10

to < 25

± 0.25

± 0.2 ± 3.8

5

to < 10

± 0.5

± 0.2 ± 7.8

(1)

Pb containing terminations are not RoHS compliant, exemptions may apply

.