RLC

32

Style

K

R470

TP

F

•

Features

1. Most suitable for a detection of current in power source circuits,

motor circuits, etc.

2. Raised Rated dissipation compared with RMC (except 2010,2512 size).

3. Stability Class : 5%

•

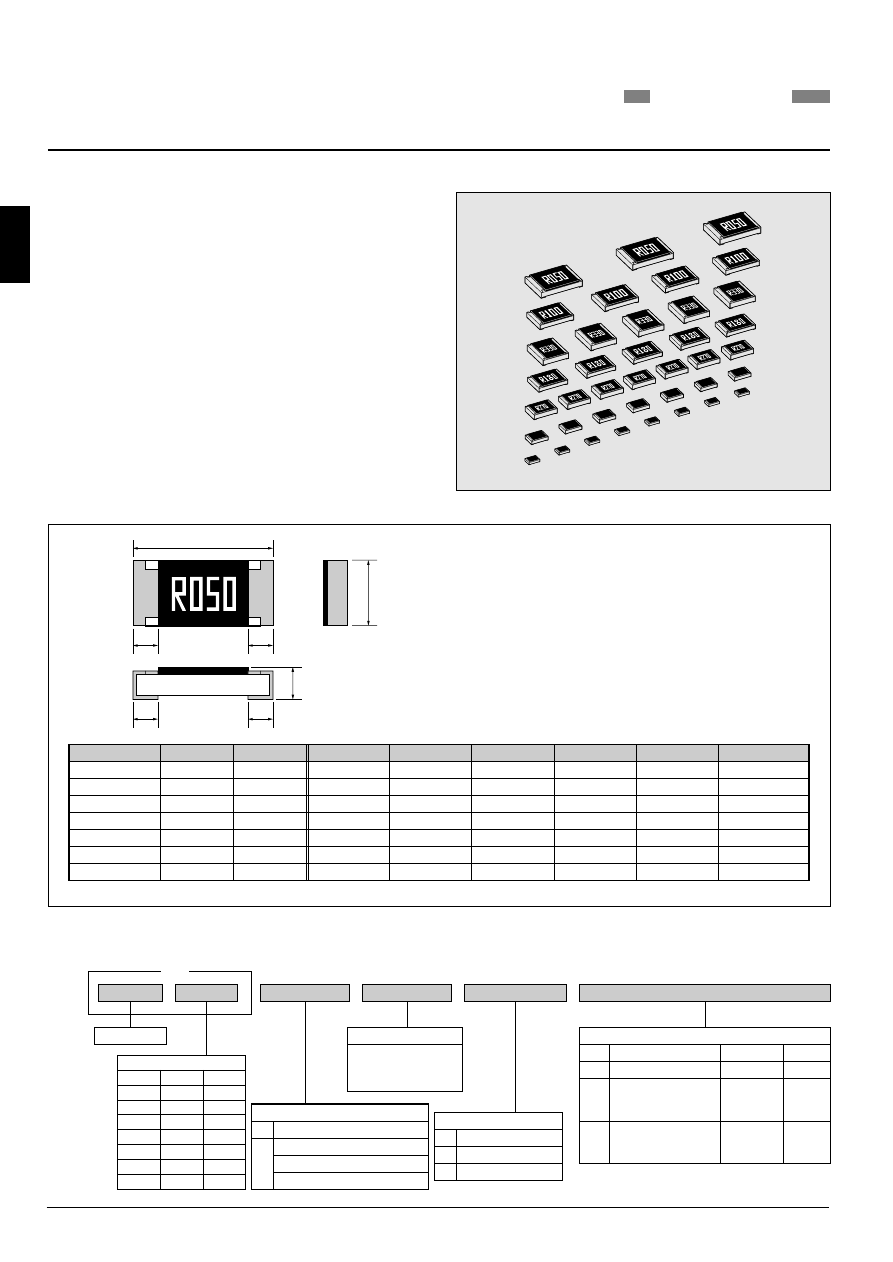

Dimensions

Rated resistance is marked with 4-digit on the over coating. (RLC20~RLC63)

RLC10 : only No marking is available.

Please contact KAMAYA for marking of RLC16.

•

Part Number Description

Example

Product Type

Tolerance on Rated Resistance

F

1%

G

2%

J

5%

e.g.: R050=50m ohm

R100=100m ohm

1R00=1 ohm

* Packaging & Standard Qty. (Min.)

Bulk (Loose Package)

RLC35

RLC50

RLC63

B

Paper Tape

TP

RLC16

RLC20

RLC32

RLC10

Embossed Tape

TE

*Refer to Tape and Packaging information on pages 48 and 49.

All Styles

1,000pcs.

5,000pcs.

Paper Tape(2mm pitch)

TH

10,000pcs.

4,000pcs.

Rated Resistance

Temperature Coefficient of Resistance

–

K

100

10

-6

/

°

C

0

∼

200

10

-6

/

°

C

0

∼

250

10

-6

/

°

C

0

∼

300

10

-6

/

°

C

KAMAYA OHM

RLC

FIXED THICK FILM CHIP RESISTORS; RECTANGULAR TYPE & LOW OHM

RLC32

3.1

0.2

0.1

0.5

0.25

2.0

0.15

0.1

0.4

0.2

3216

W

L

1.25

0.10

0.15

0.15

0805

1206

H

c

0.4

0.2

d

0.2

0.1

0.1

0.3

0.05

0.10

0.25

RLC35

3.1

0.2

0.6

0.15

0.5

0.25

9mg

5mg

16mg

3225

1210

0.2

0.3

1.6

2.5

0.15

RLC50

5.0

0.2

0.6

0.15

0.6

0.2

0.6

0.2

25mg

2.5

0.15

RLC63

6.3

0.2

0.6

0.15

0.6

0.2

0.6

0.2

40mg

3.2

0.6

RLC20

0.05

RLC10

1.0

0.05

0.2

0.1

1mg

0.6

0.05

0.35

RLC16

1.6

0.1

0.3

0.1

0.3

0.1

0.15

0.05

0.8

2mg

0.10

0.45

W

d

d

L

c

c

H

0.5

Unit : mm

*Values for reference

Style

Metric

Inch

*Unit weight/pc.

5025

2010

6332

2512

2012

1005

0402

1608

0603

Code

Metric

Inch

Size

16

1608

10

1005

32

3216

50

5025

20

2012

35

3225

63

6332

0603

0402

1206

2010

0805

1210

2512

16

Product specifications contained in this catalogue are subject to change at any time without notice. Please confirm specifications with your order.

【

RoHS

】

Chip

Resistors

RLC