TERMINALS

& TEST

POINTS

59

ALLIGATOR CLIPS

. . . . . . . . . . . . . . . . . . . . . . . . . .62

EDGE CONNECTORS, SMT . . . . . . . . . . . . . . . . .69

i-CLAMP IDC CONNECTORS . . . . . . . . . . . . . . . .72

JUMPERS

THM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

SMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Zero Ohm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

QUICK-FIT TERMINALS

Female, SMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Female, THM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Male, Rivet Mount . . . . . . . . . . . . . . . . . . . . . . . . . .67

Male, SMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Male, THM . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64-66

Male, THM, Continuous Reel . . . . . . . . . . . . . . . .66

SCREW TERMINALS

Slim-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Color Coded, THM . . . . . . . . . . . . . . . . . . . . . . .73-77

SEMS Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Metric Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Swage (Panel) Mount . . . . . . . . . . . . . . . . . . .78-79

Binding Post . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Binding Post, Mini . . . . . . . . . . . . . . . . . . . . . . . . . . .78

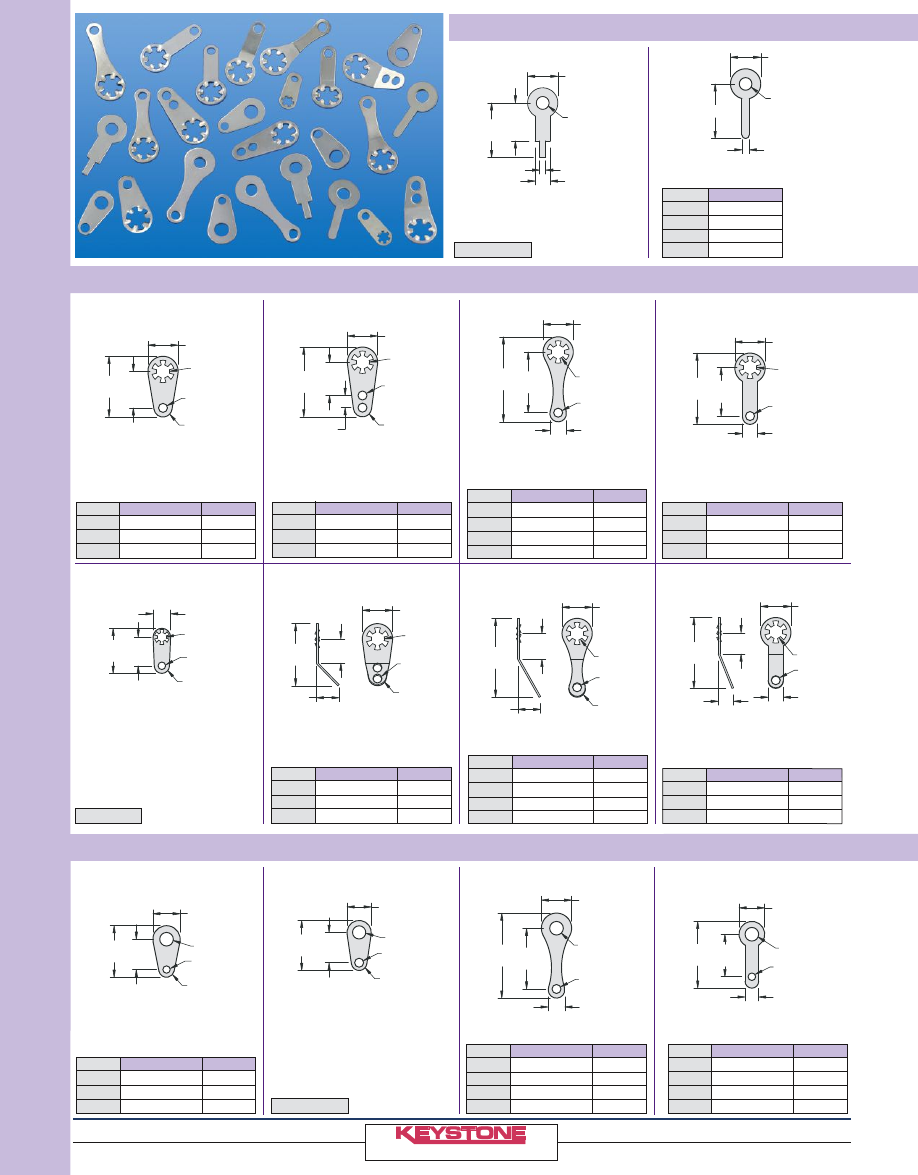

SOLDER LUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

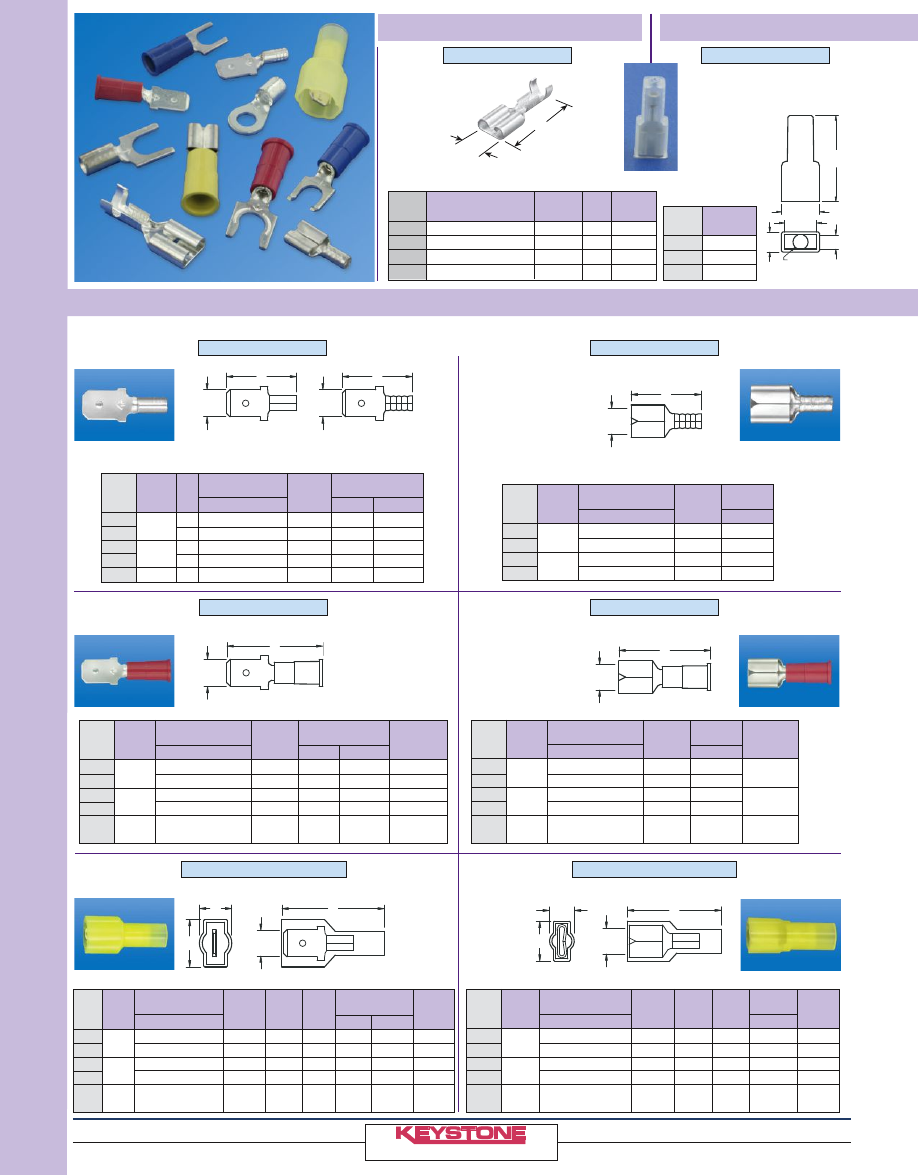

SOLDERLESS (CRIMP) TERMINALS . . .70-71

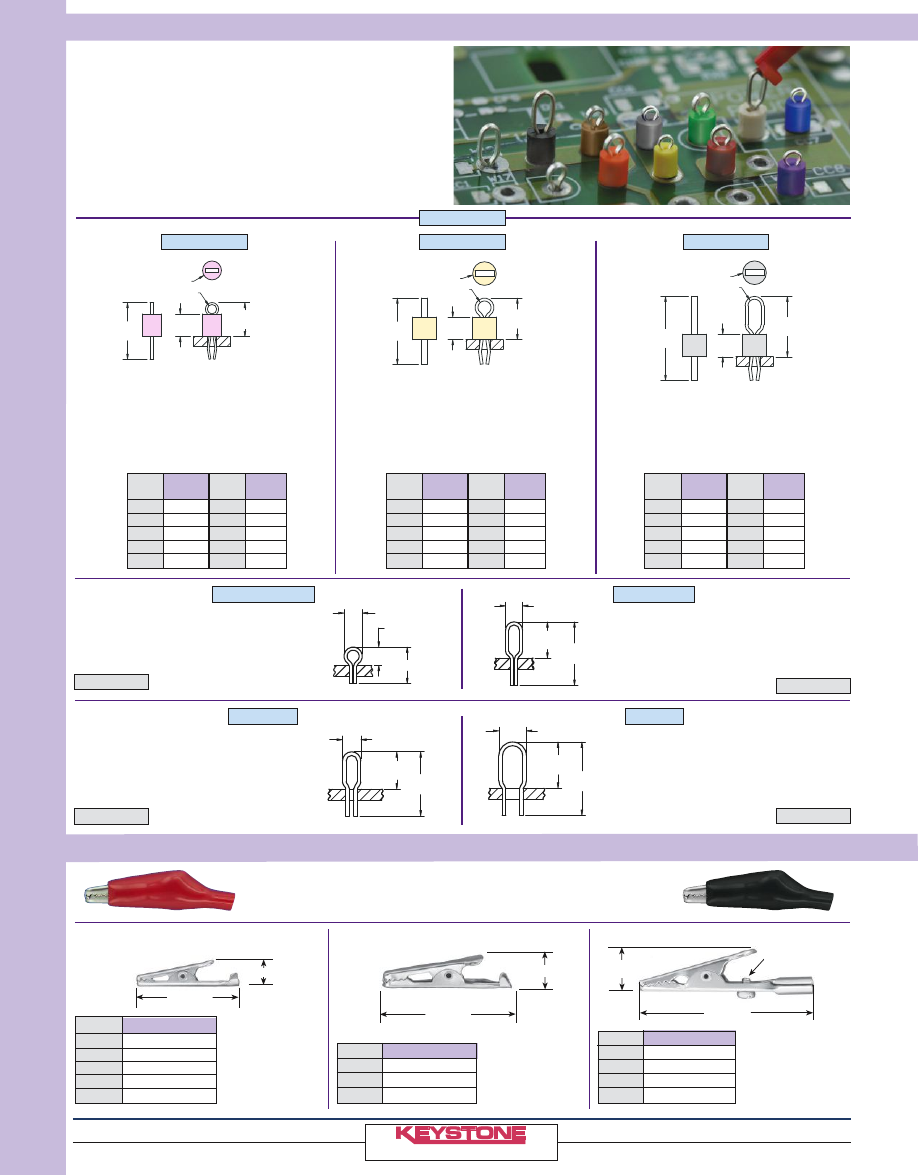

TEST POINTS

Color Coded SMT . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Color Coded THM . . . . . . . . . . . . . . . . . . . . . . . . . . .62

SMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

THM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Slotted & Loop Types (THM) . . . . . . . . . . . . . . . .63

SECTION 3 CONTENTS

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

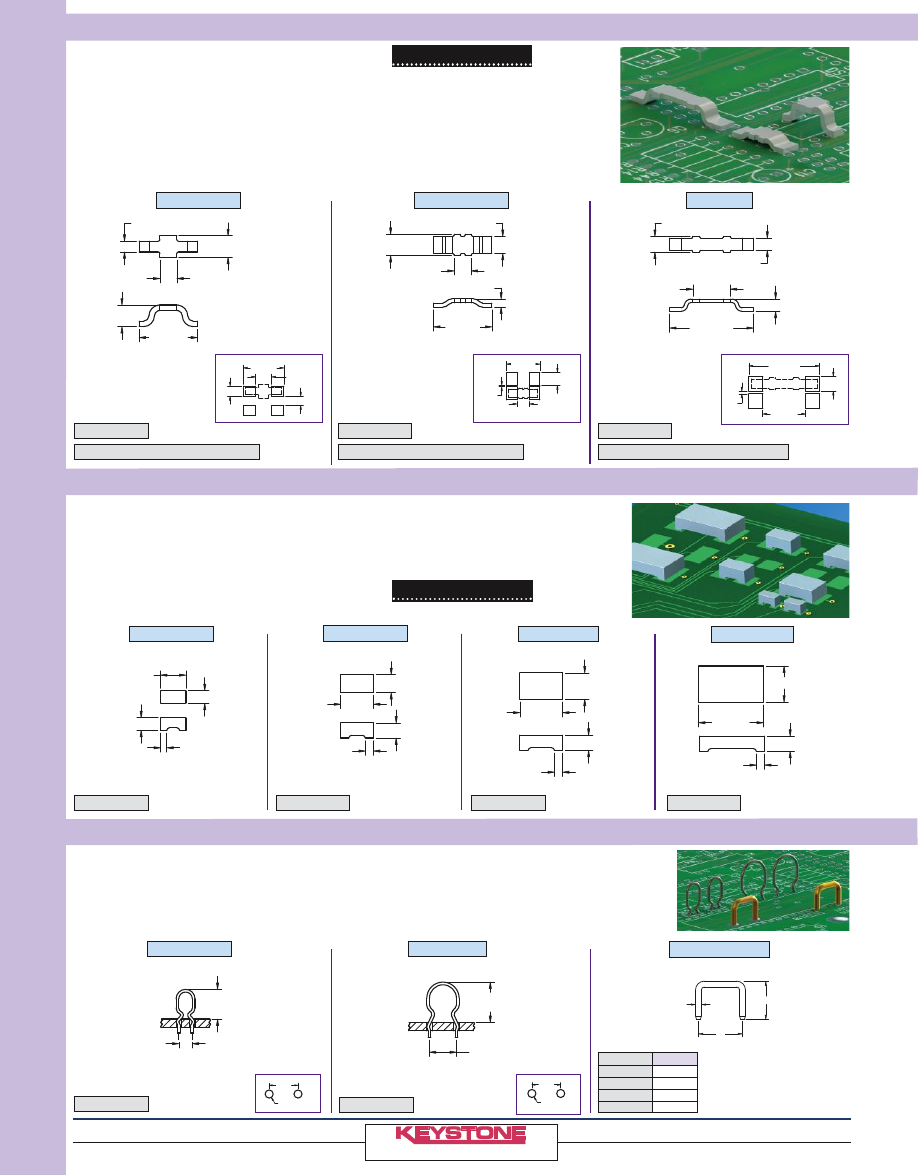

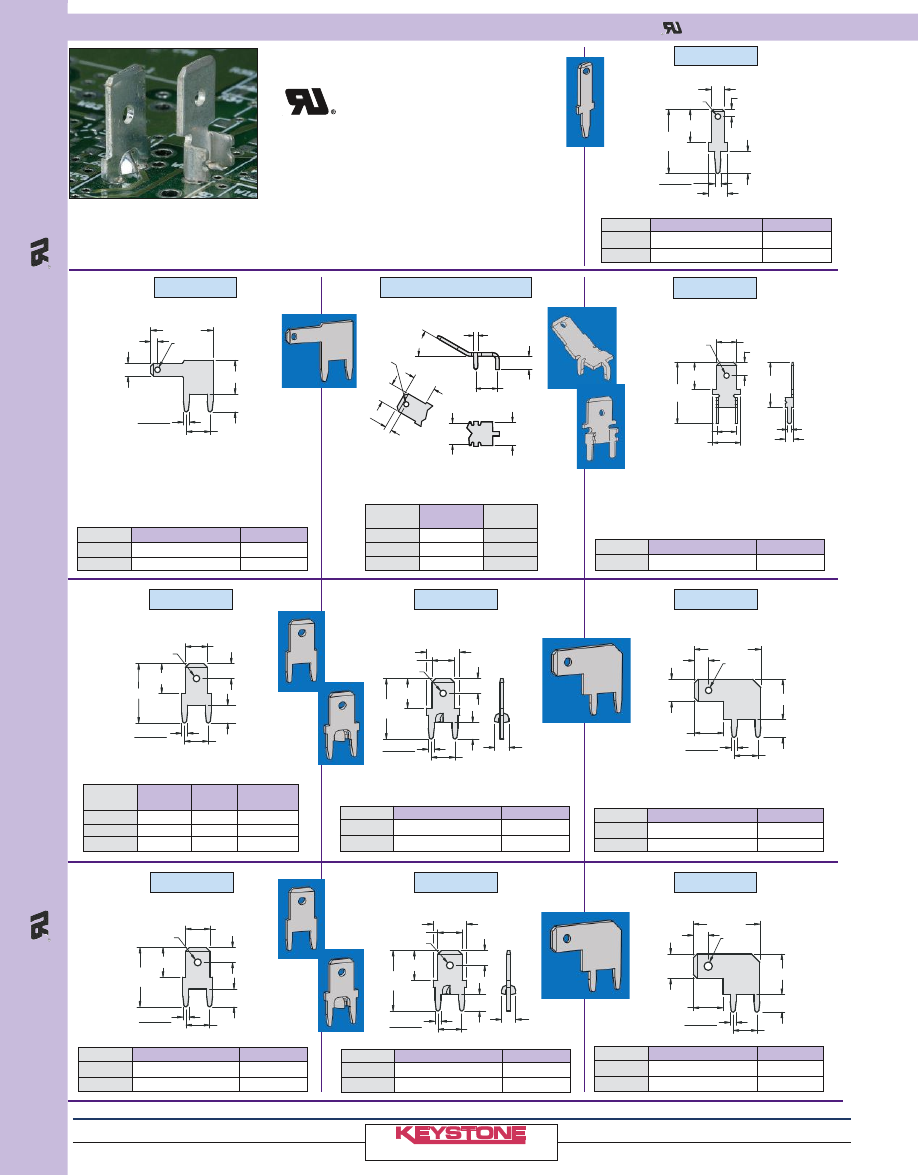

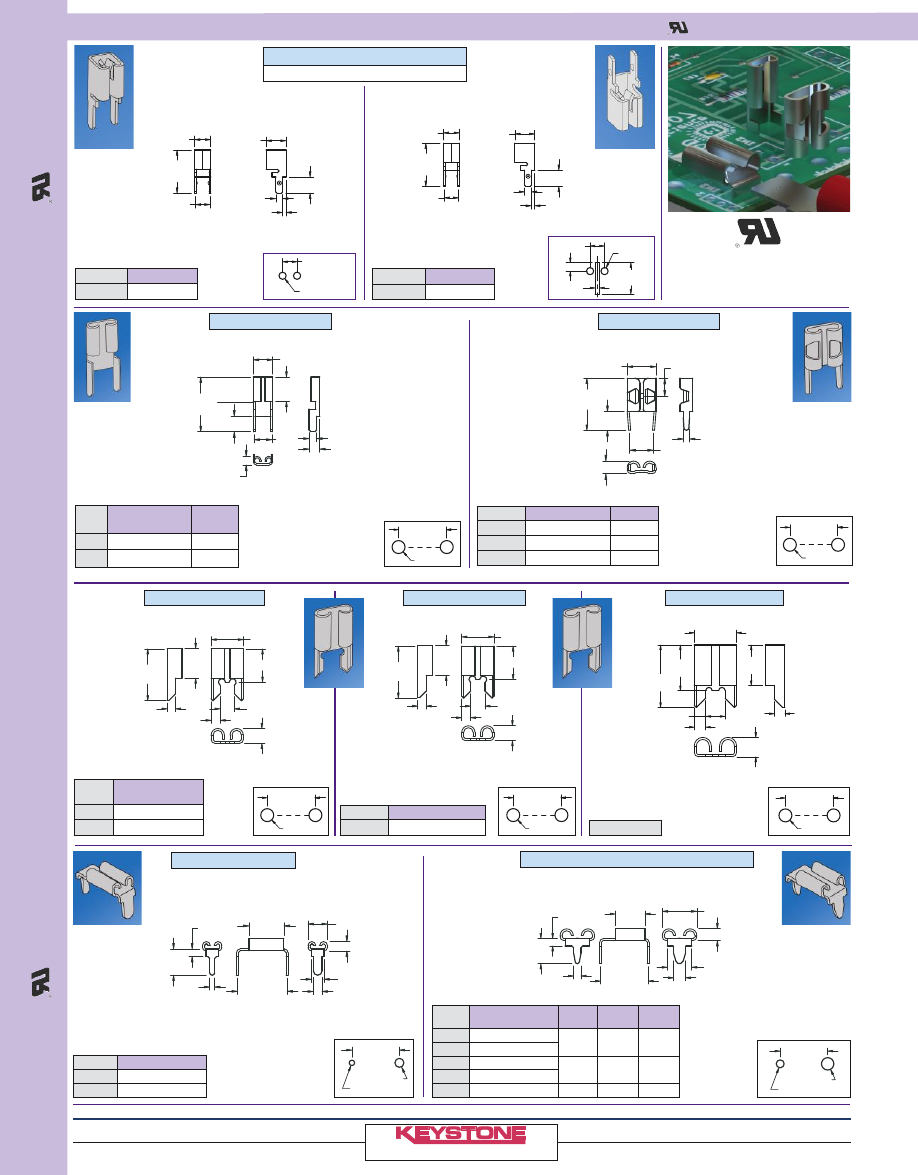

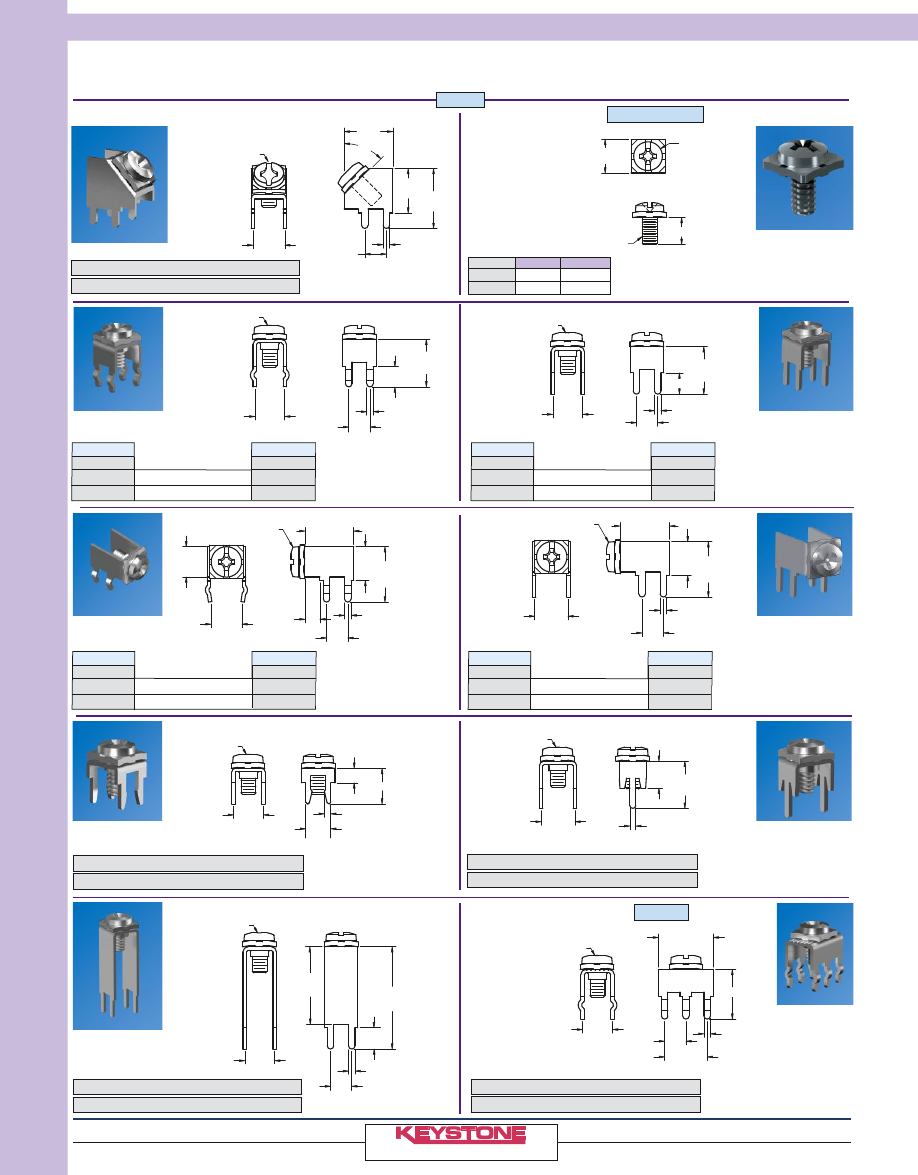

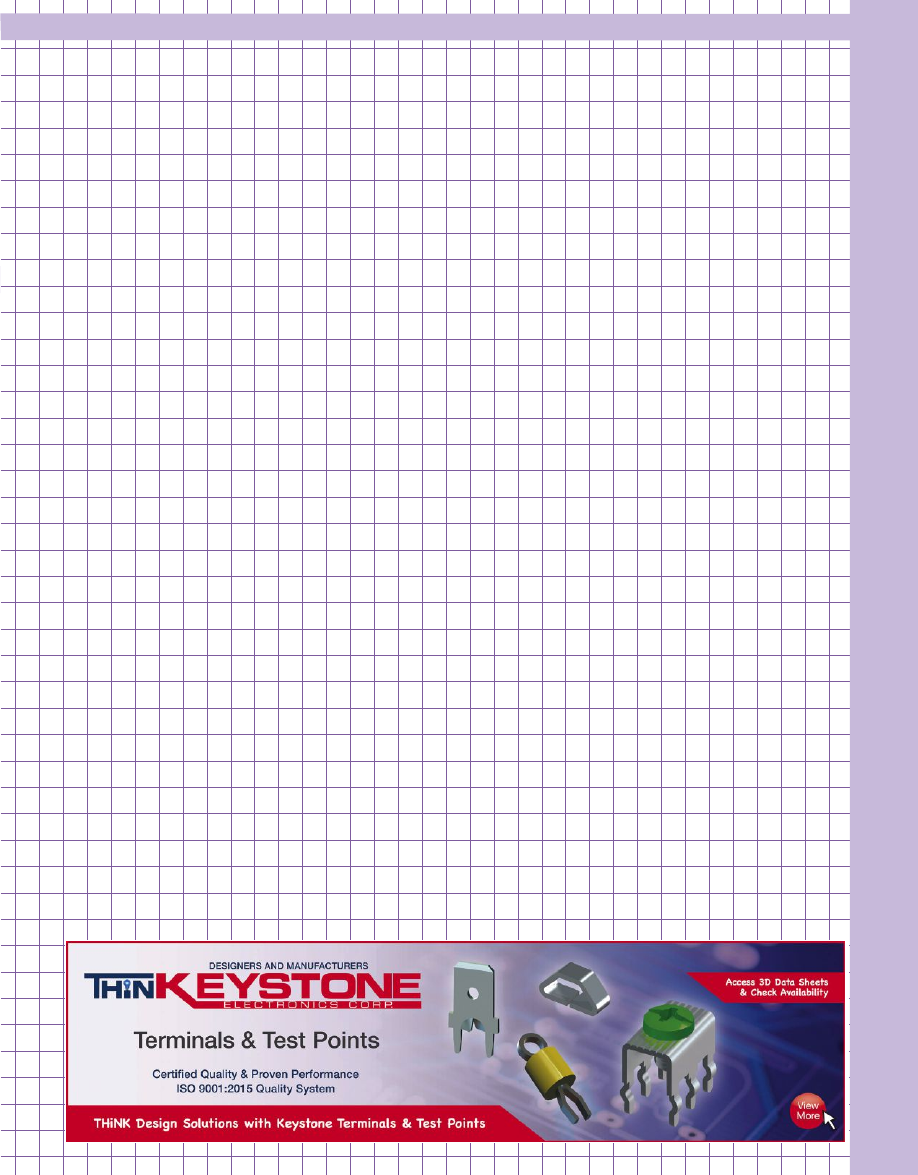

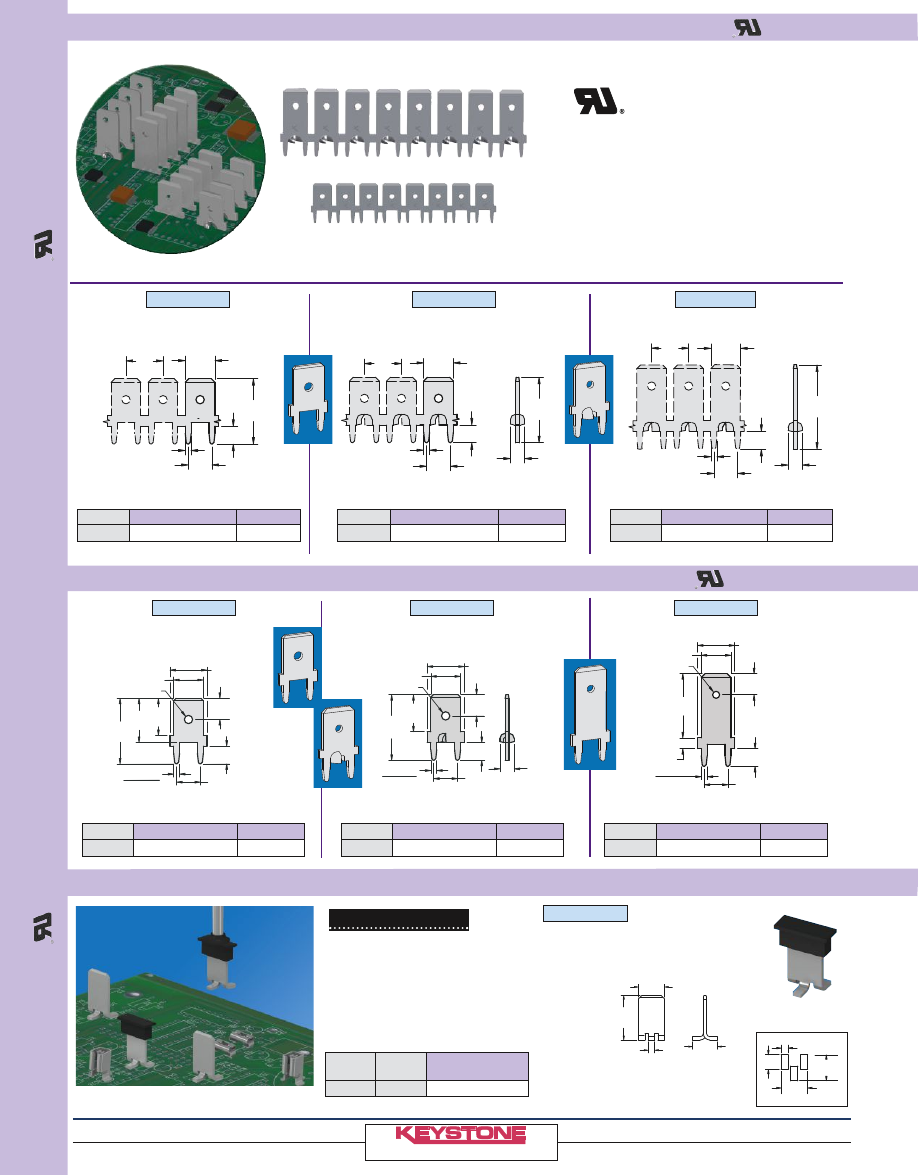

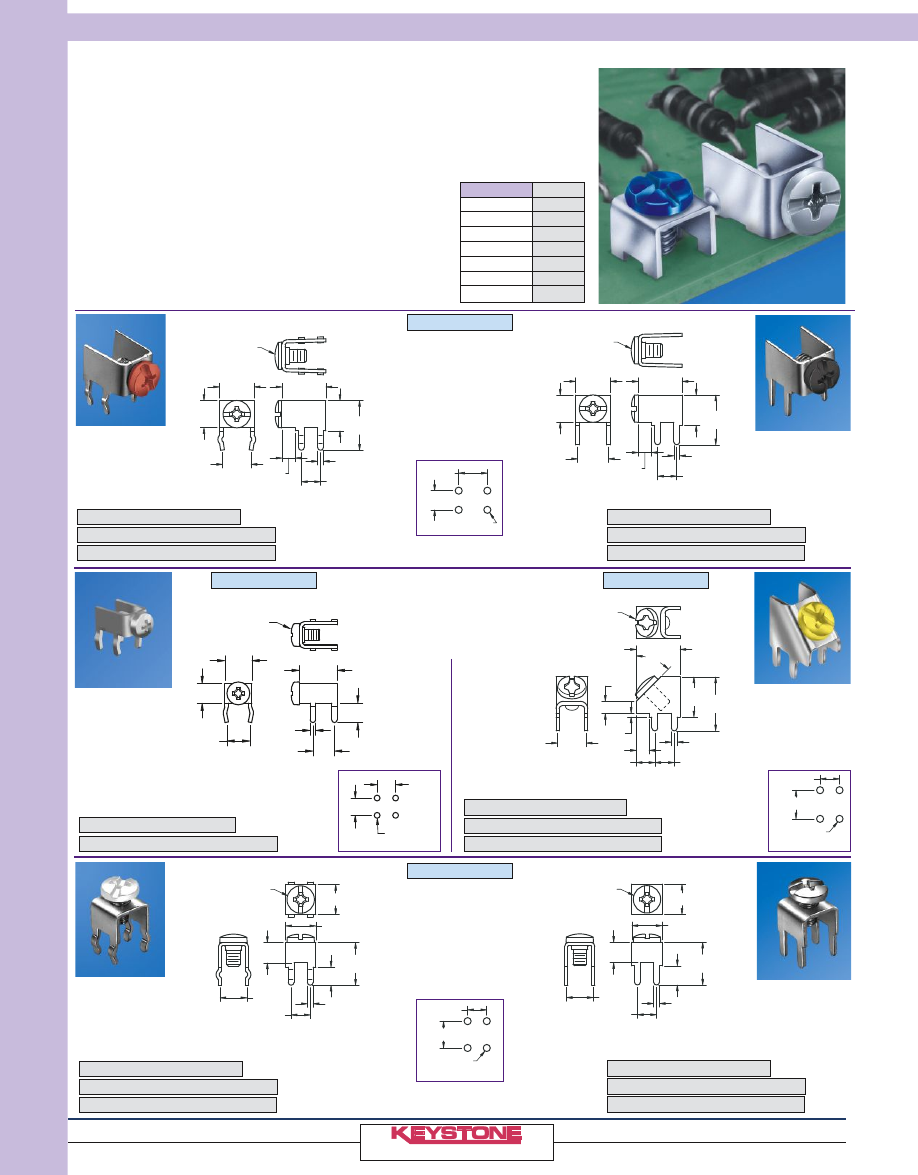

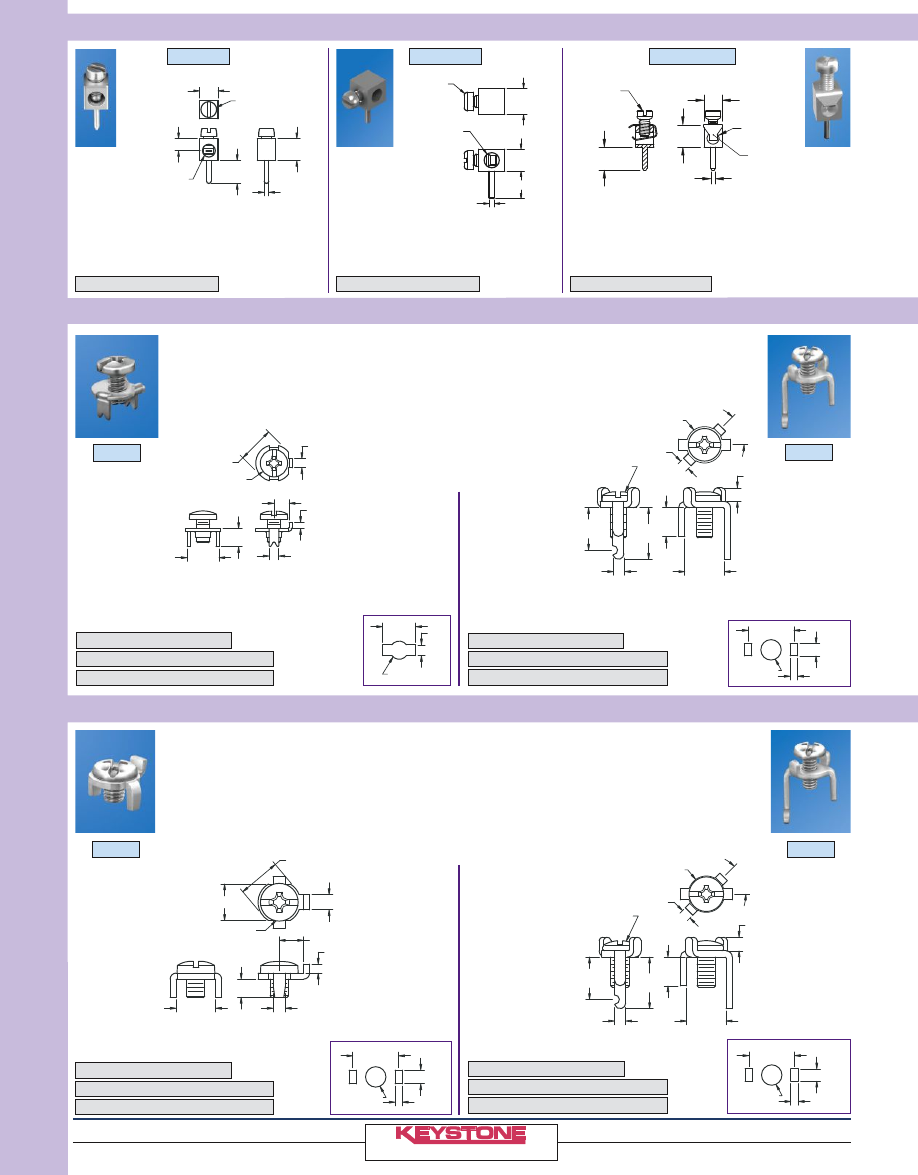

SMT PRINTED CIRCUIT BOARD JUMPERS

•

Designed to link circuit board traces in applications where

thru hole jumpers are not possible

•

All conductive polystyrene carrier meets ANSA/EIA-481 standard

•

Low profile/space saving design

•

Minimal PCB footprint

MATERIAL:

.020 (.50) Dia.

Phospher Bronze, Silver Plate

MATERIAL:

..020 [.50] Dia.

Phospher Bronze, Silver Plate

.200 [5.08]

.300 [7.6]

REF.

SHOWN AS

INSTALLED INTO

TWO .040 [1.02] DIA

MOUNTING HOLE

.100 [2.54]

.200 [5.1]

REF.

SHOWN AS

INSTALLED INTO

TWO .040 [1.02] DIA.

MOUNTING HOLE

SMT

&

THM

JUMPERS

60

CAT. NO. 5025

CAT. NO. 5026

.100 SPACING

.200 SPACING

.040 [1.0] (2) PLS.

.100 [2.5]

Mounting Detail

.200 [5.1]

.040 [1.0] (2) PLS.

Mounting Detail

.040 [1.02]

DIA.

.261 [6.6]

'

A

'

MATERIAL:

Brass, Gold Plate

CAT. NO.

A Dim.

1430-1

.200 (5.1)

1430-2

.250 (6.4)

1430-4

.400 (10.2)

1430-5

.500 (12.7)

MATERIAL:

.020 (.51) Copper, Silver Plate

Power Rating

:

0.5 Watts at 158ºF (70ºC), with a current of 20 Amps

and a connection temperature at 221ºF (105ºC or less)

.270 [6.86]

.100 [2.54]

.079 [2.00]

.100 [2.54]

.050 [1.27] (2) PLS

.039 [1.00]

.079 [2.00] TYP.

.079 [2.00]

.270 [6.85]

.100 [2.54] (2) PLS

.484 [12.30]

.217 [5.50]

.091 [2.30] (2) PLS

.071 [1.80] TYP.

.071 [1.80]

.118 [3.00]

.075 [1.91]

.300 [7.62]

.075 [1.90] MIN.

Mounting Detail

.114 [2.90]

.118 [3.00]

.310 [7.85]

.020

[0.50]

MIN.

Mounting Detail

.020

[0.50]

MIN.

.110 [2.80]

.318 [8.10]

.523 [13.30]

Mounting Detail

HIGH CURRENT “TRUE” ZERO OHM SMT JUMPER

“True” Zero ohm high current SMT Jumpers, designed to replace Zero ohm resistors without changing board designs

or layouts. These new devices are uniquely suited as true zero ohm resistor replacements.

Tape & Reel Spec’s:

12mm Wide, 4mm Pitch, 1,000 pieces

per 7" reel meets ANSI/EIA-481 standards

MATERIAL:

Copper, Silver Plate

Power Rating

:

0.5 Watts at 158ºF (70ºC), with a current of 20 Amps

and a connection temperature at 221ºF (105ºC or less)

.020 [0.50]

.010 [0.25]

(2) PLS

.020 [0.50]

.040 [1.00]

.049 [1.24]

.079 [2.01]

.015 [0.38]

(2) PLS

.028 [0.71]

.015 [0.38]

(2) PLS

.067 [1.70]

.120 [3.05]

.028 [0.71]

THM JUMPERS

•

Unique wave leg design retains jumper in thru hole for

wave soldering

•

May be used as a test point location

•

Shorting Pin may be used in applications that require

precise location of the legs

•

May also be used with micro-jacks (see pages 102-103)

COMPACT

MICRO-MINIATURE

MINIATURE

CAT. NO. 5100TR

- 500 pieces per reel

CAT. NO. 5100

CAT. NO. 5102TR

- 500 pieces per reel

CAT. NO. 5102

CAT. NO. 5104TR

- 2500 pieces per reel

CAT. NO. 5104

CAT. NO. 5112

.028 [0.71]

.061

[1.55]

.033 [0.85]

.015 [0.38]

(2) PLS

CAT. NO. 5110

CAT. NO. 5106

CAT. NO. 5108

0402 JUMPER

0603 JUMPER

0805 JUMPER

1206 JUMPER

.200-.500 SPACING

SUPPLIED ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

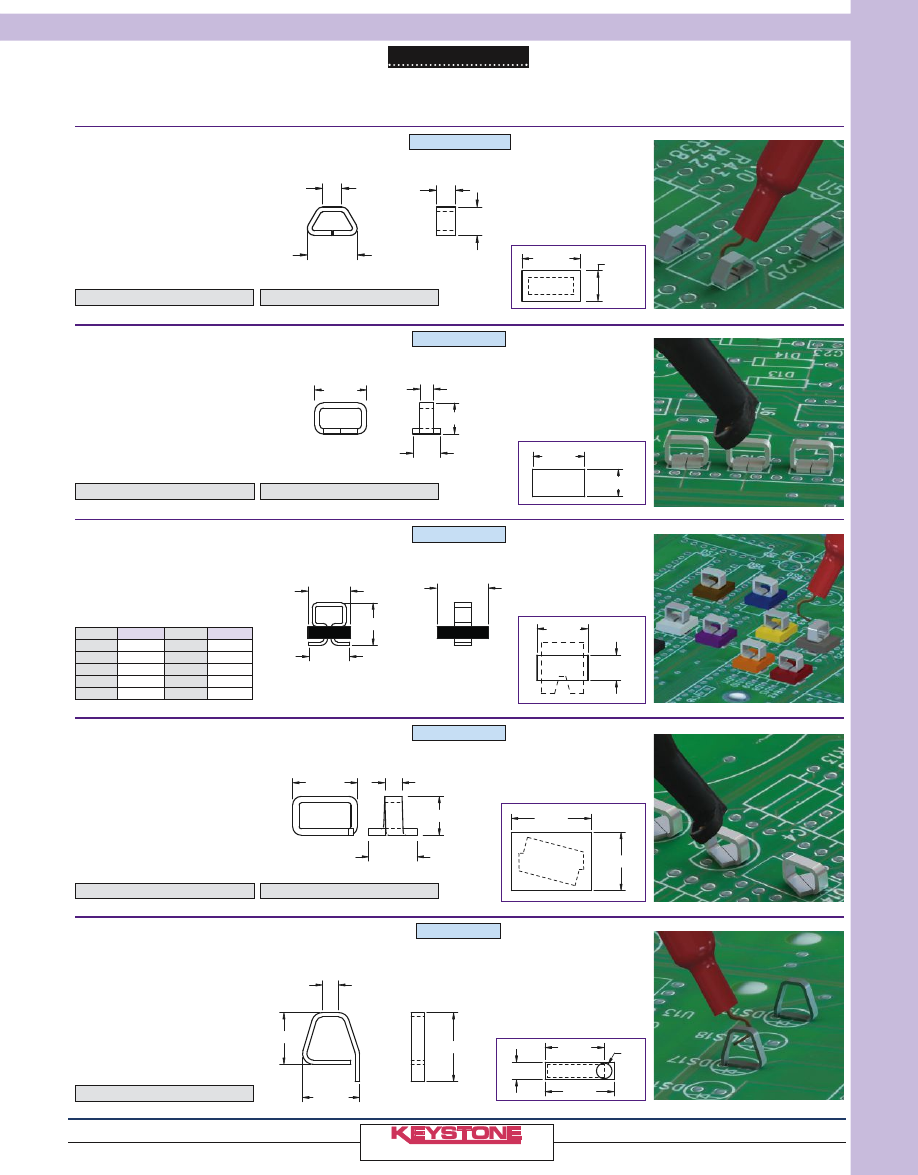

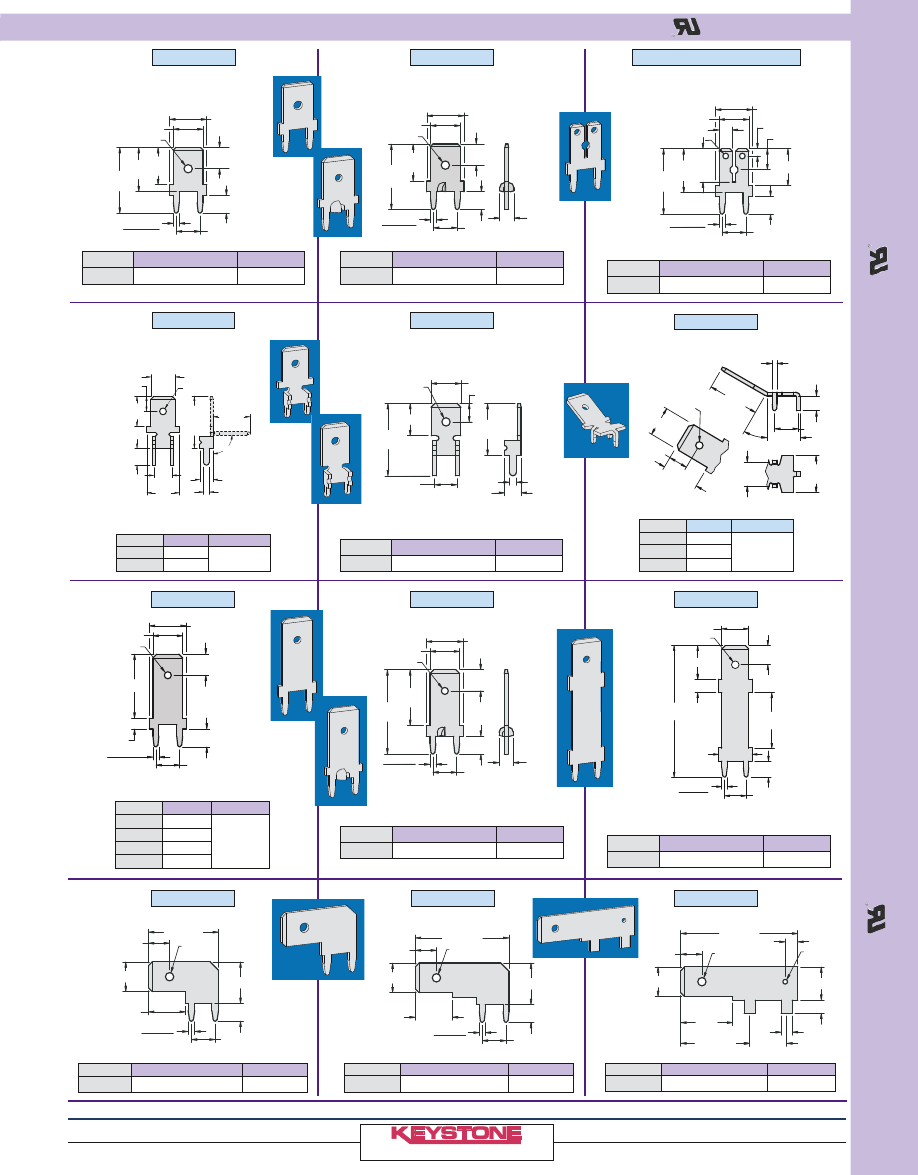

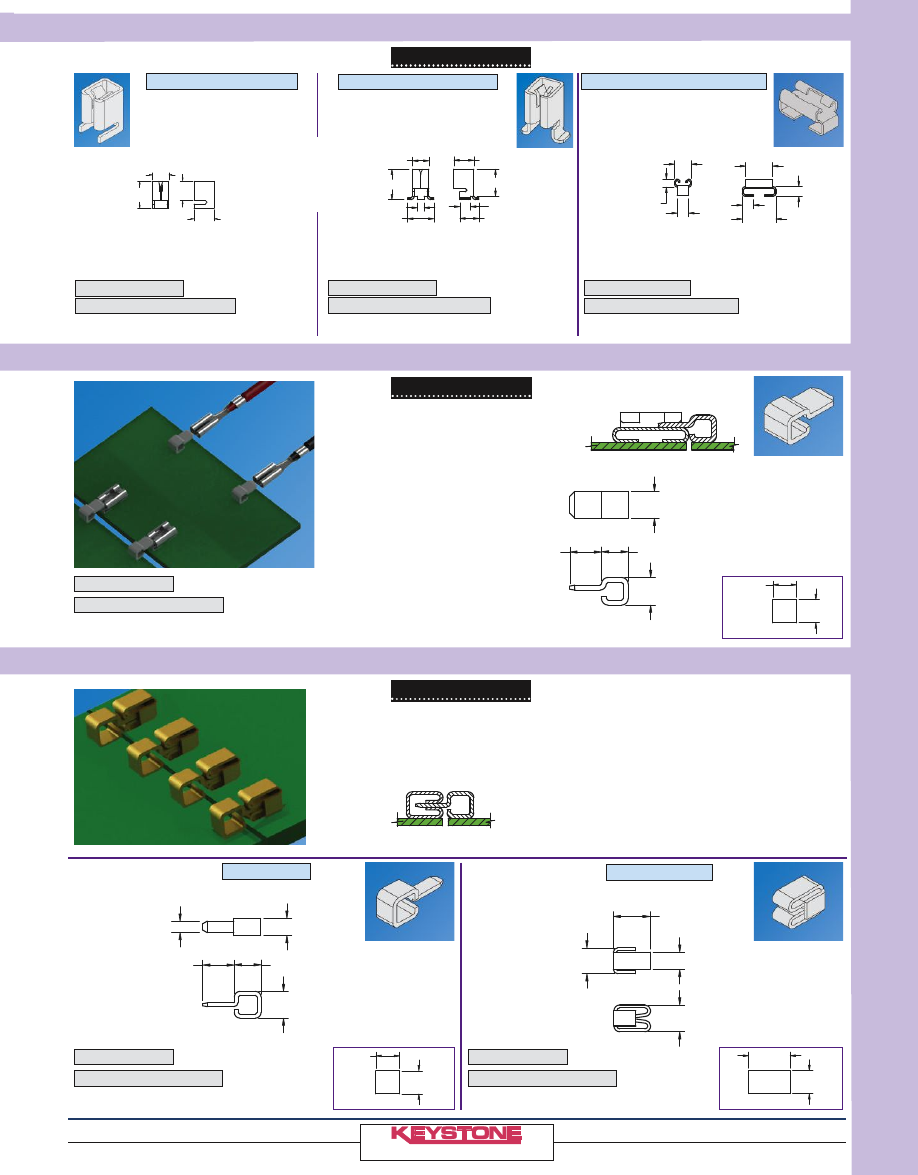

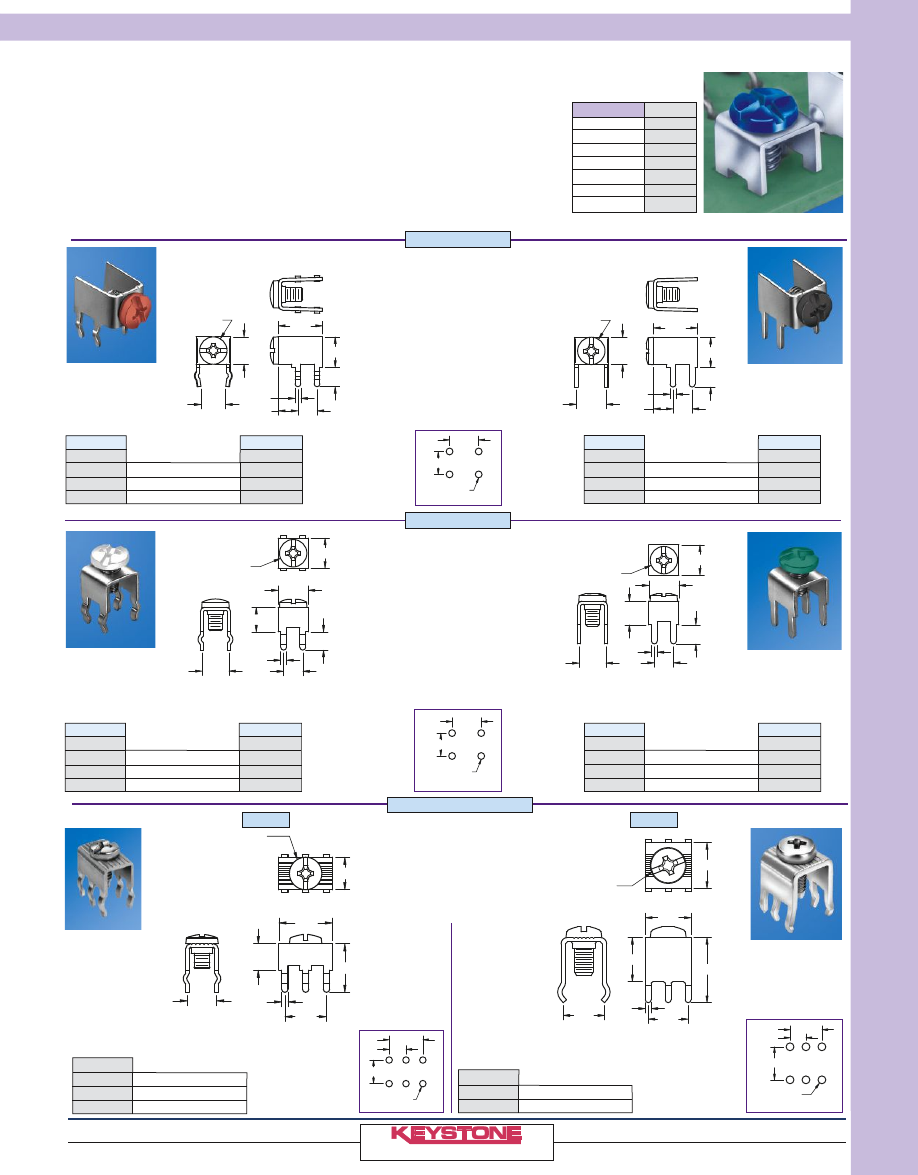

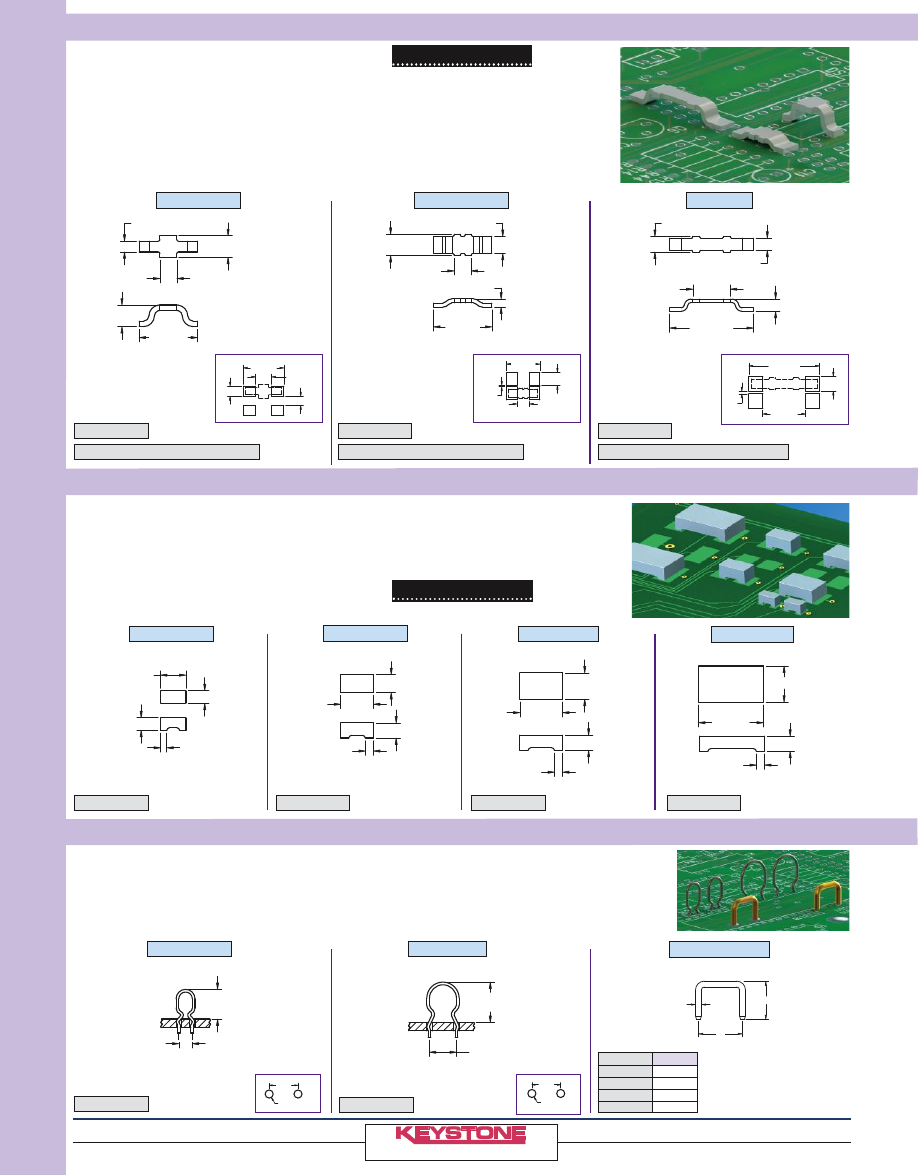

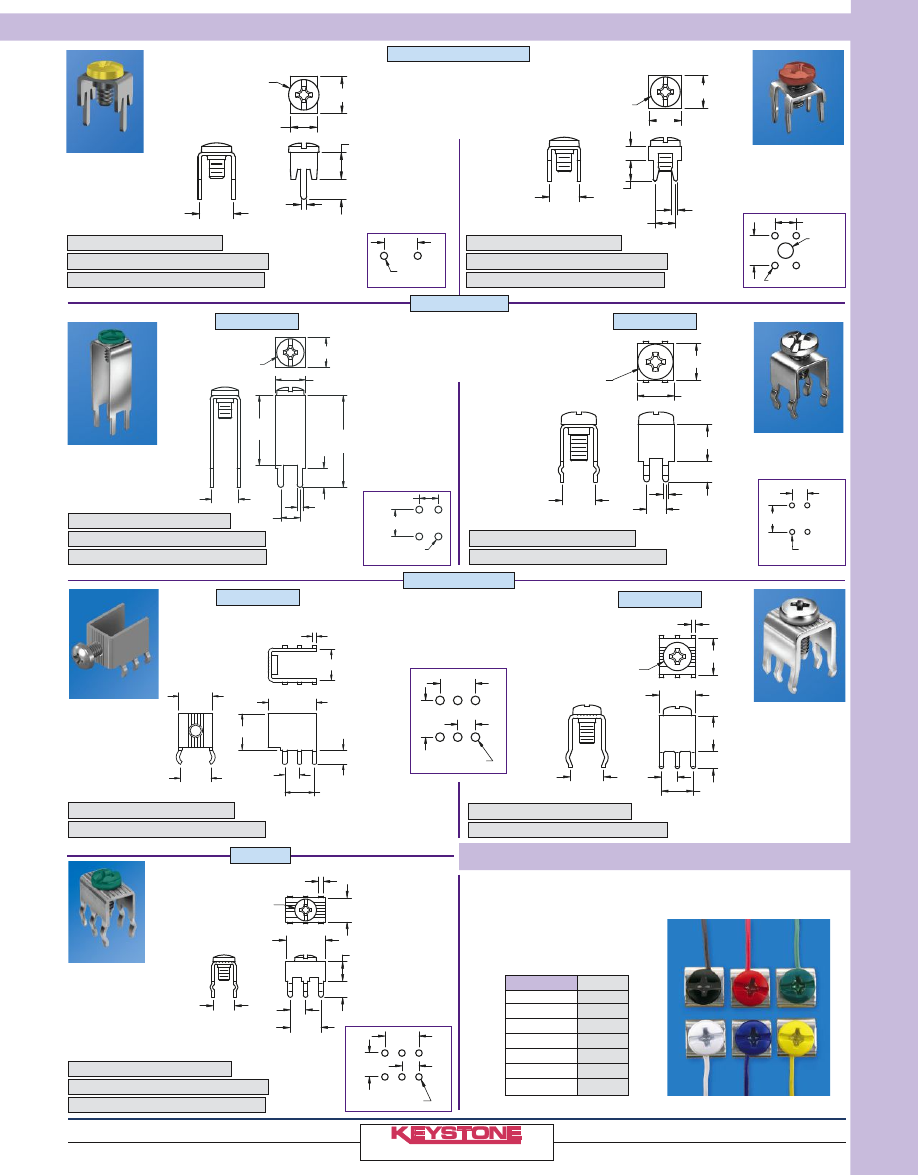

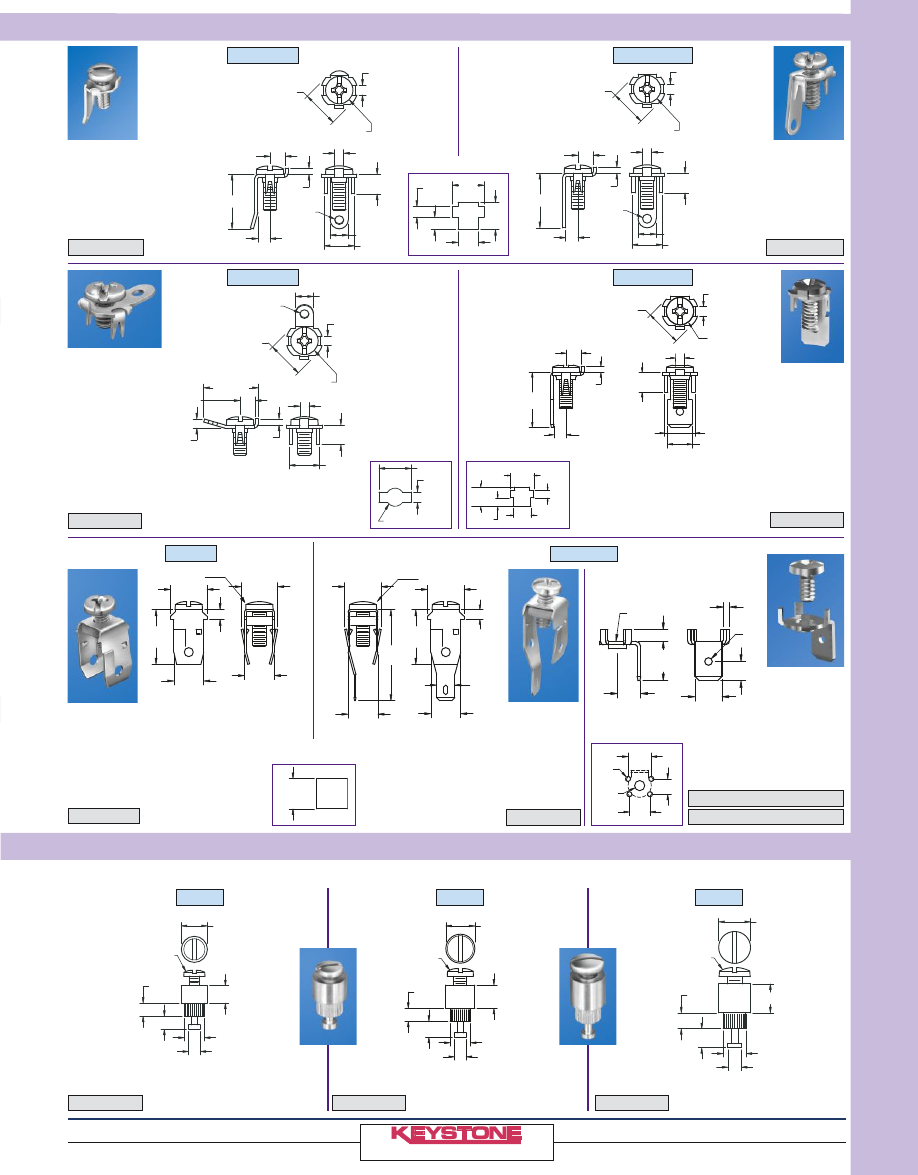

(SMT) SURFACE MOUNT TEST POINTS ON TAPE & REEL

MICRO MINIATURE

HYBRID MOUNT

SPECIFICATIONS

Material:

.010 (.25) Phosphor Bronze, Silver Plate

SPECIFICATIONS

Material:

.010 (.25) Phosphor Bronze, Silver Plate

SPECIFICATIONS

Material:

.015 (.38) Phosphor Bronze, Silver Plate

.064 [1.6]

.120 [3.0]

•

Ideal for use with miniature probes, clips and hooks

•

Ultra low profile, ideal for advanced surface mount

PCB applications

•

Ideal for use with most standard probes, clips and hooks

•

Unique design provides exceptional strength and durability

Pad Layout

Pad Layout

.070 [1.8]

.135 [3.4]

Pad Layout

.137 [3.5]

.040 [1.0]

.160 [4.1]

.036

[.9]

.040 [1.0]

.060 [1.5]

.040 [1.0]

.105 [2.7]

MINIATURE

CAT. NO. 5015

- 1000 pieces per reel

CAT. NO. 5027

- 800 pieces per reel

CAT. NO. 5017

- 5000 pieces per reel

CAT. NO. 5019

- 1000 pieces per reel

CAT. NO. 5029

- 5000 pieces per reel

.032 [.8]

.064

[1.6]

.120 [3.0]

.072 [1.8]

SMT

TEST

POINTS

61

SPECIFICATIONS

Material:

.015 (.38) Phosphor Bronze, Silver Plate

.135 [3.4]

.185 [4.7]

•

Ideal for use with standard probes, clips and hooks

•

Unique design provides exceptional strength

and durability

Pad Layout

COLOR KEYED

CAT. NO. 5016

- 1000 pieces per reel

CAT. NO. 5018

- 5000 pieces per reel

.112 [2.8]

.150 [3.8]

.090 [2.3]

.040 [1.0]

•

Manufactured using flat wire to provide a large mounting surface area

•

Efficient, safe, board level testing

•

Simplifies testing on dense circuit boards

•

Compatible with vacuum and mechanical pick & place assembly systems

•

All conductive polystyrene carrier tape meets ANSA/EIA-481 standards

•

Locating Pin provides positive location during assembly process

•

Increased solder strength

•

Can be used as a SMT test point or when used with a .032 [.81]

board, as a THM test point

.160 [4.1]

.037 [1.0]

.120 [3.0]

.132 [3.3]

Tape & Reel Spec’s:

8mm Wide, 4mm Pitch

Tape & Reel Spec’s:

12mm Wide, 4mm Pitch

Tape & Reel Spec’s:

12mm Wide, 4mm Pitch

Tape & Reel Spec’s:

12mm Wide, 4mm Pitch

COMPACT

•

Ideal for use with most standard probes, clips and hooks

•

Color keyed for visibility and quick identification

MATERIAL

Terminal:

.008 (.20) Phosphor Bronze,

Silver Plate

Base:

LCP UL Rated 94V-0

Tape & Reel Spec’s:

12mm Wide, 4mm Pitch, 1,000 pieces per 7" reel

CAT. NO.

Base Color

CAT. NO.

Base Color

5190TR

RED

5195TR

BROWN

5191TR

BLACK

5196TR

GREEN

5192TR

WHITE

5197TR

BLUE

5193TR

ORANGE

5198TR

GREY

5194TR

YELLOW

5199TR

PURPLE

.118 [3.0]

.059 [1.5]

Pad Layout

.098 [2.5]

.094 [2.4]

.118 [3.0]

.098 [2.5]

AVAILABLE ON TAPE AND REEL

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

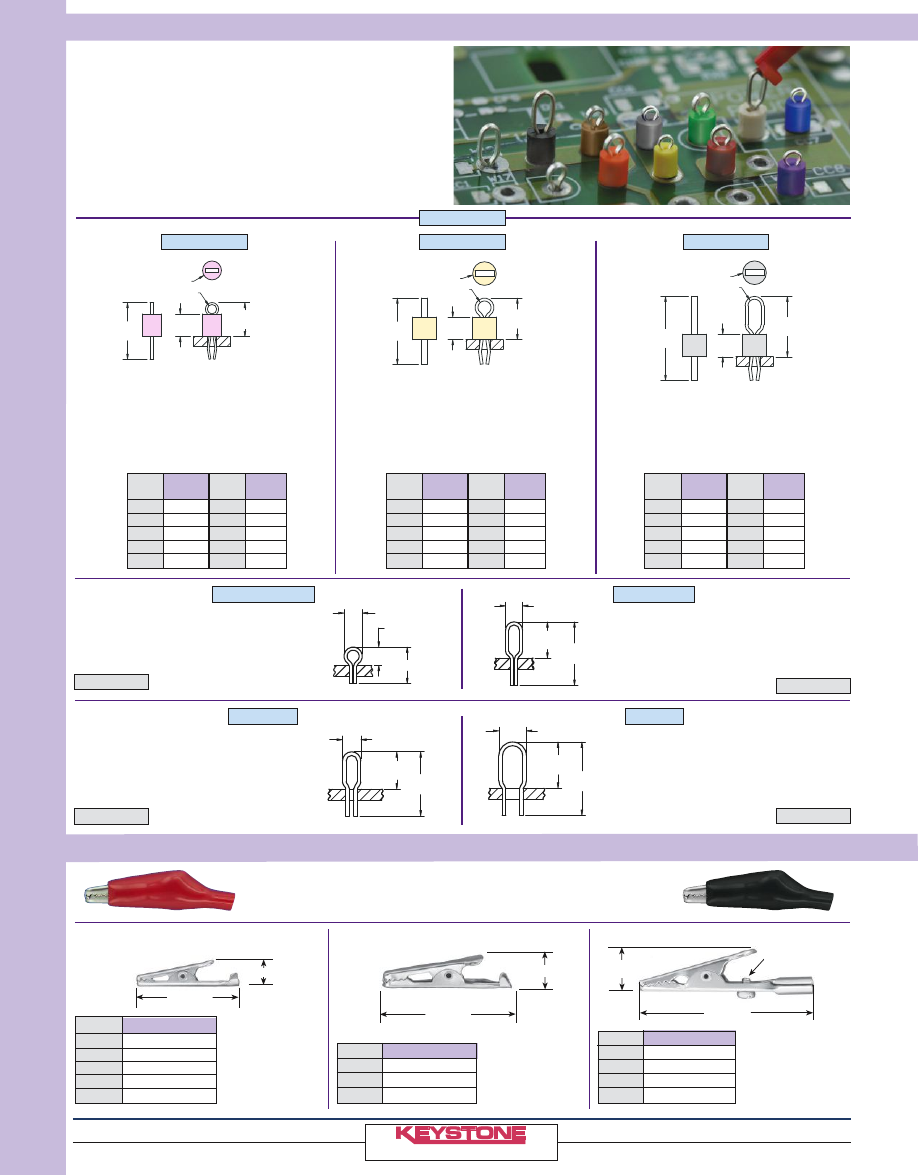

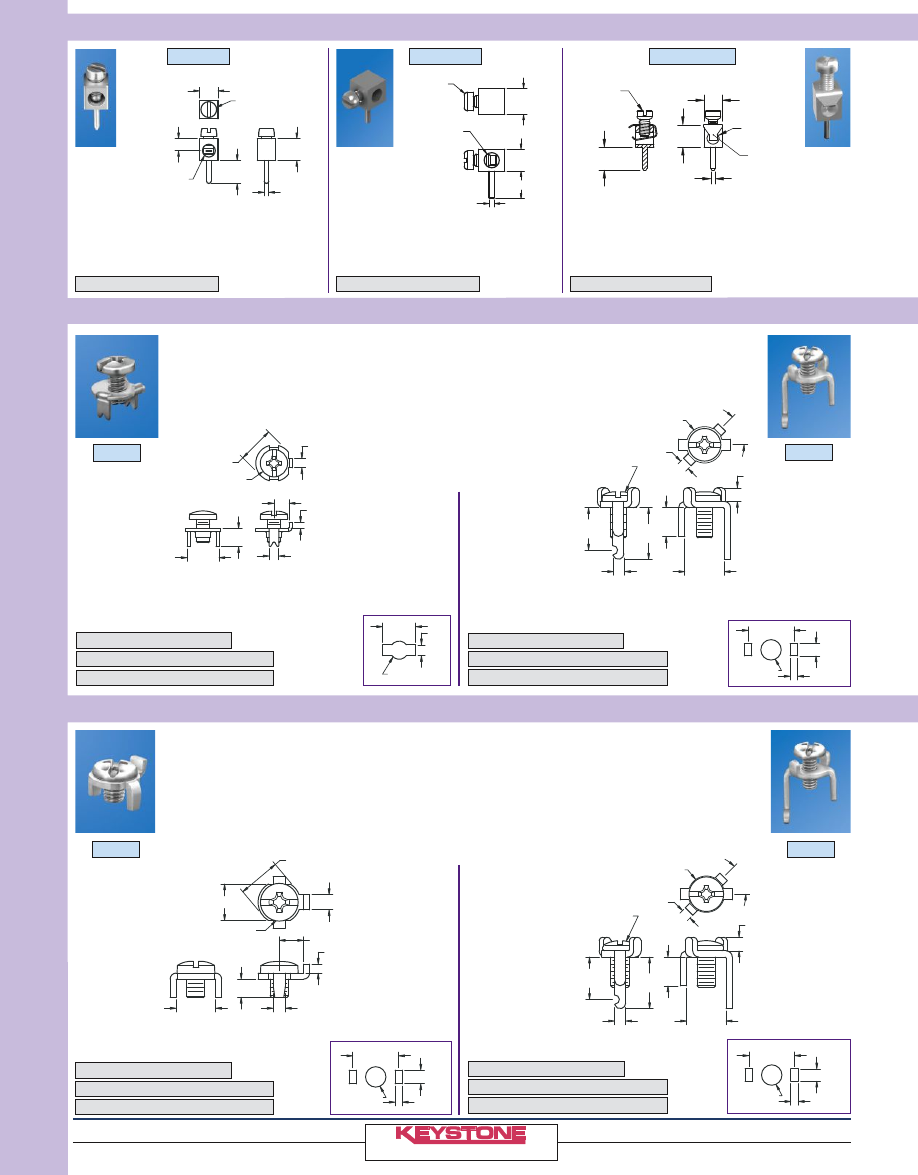

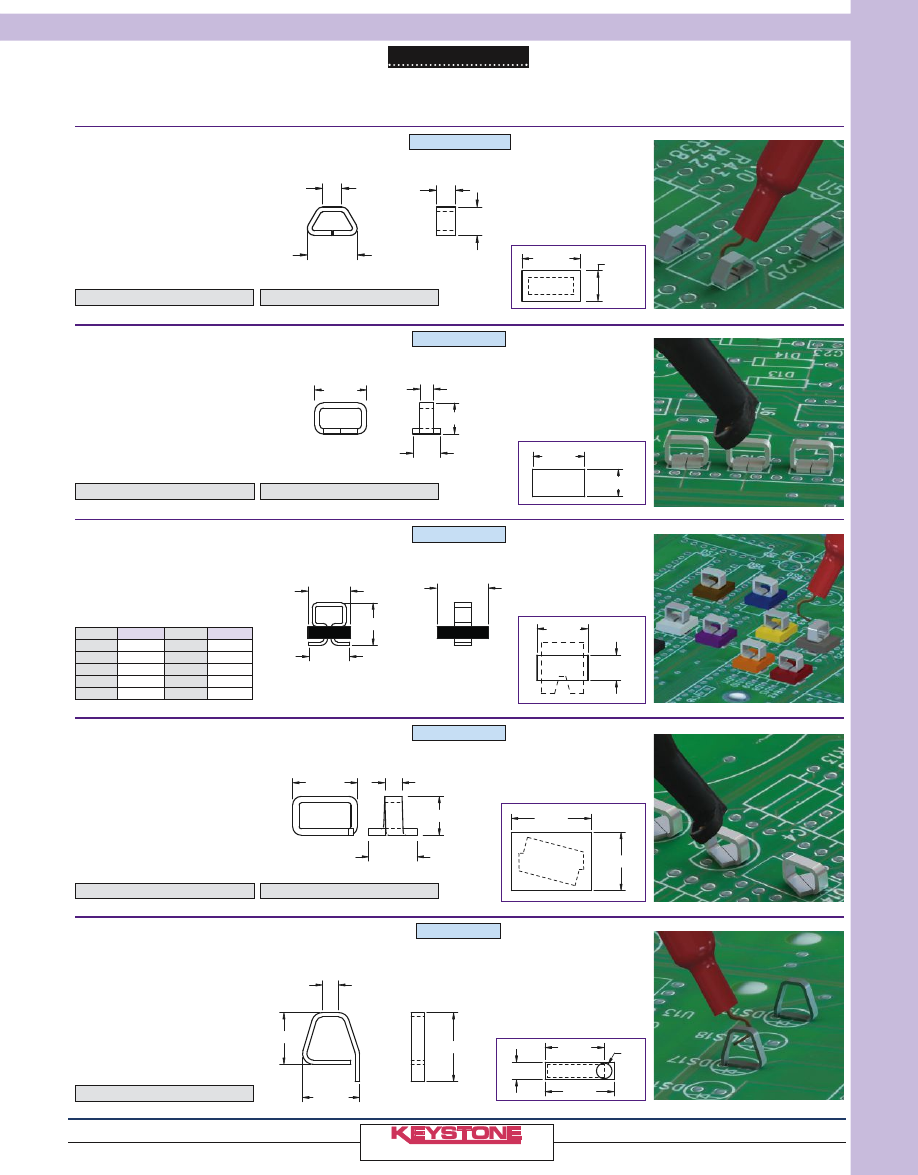

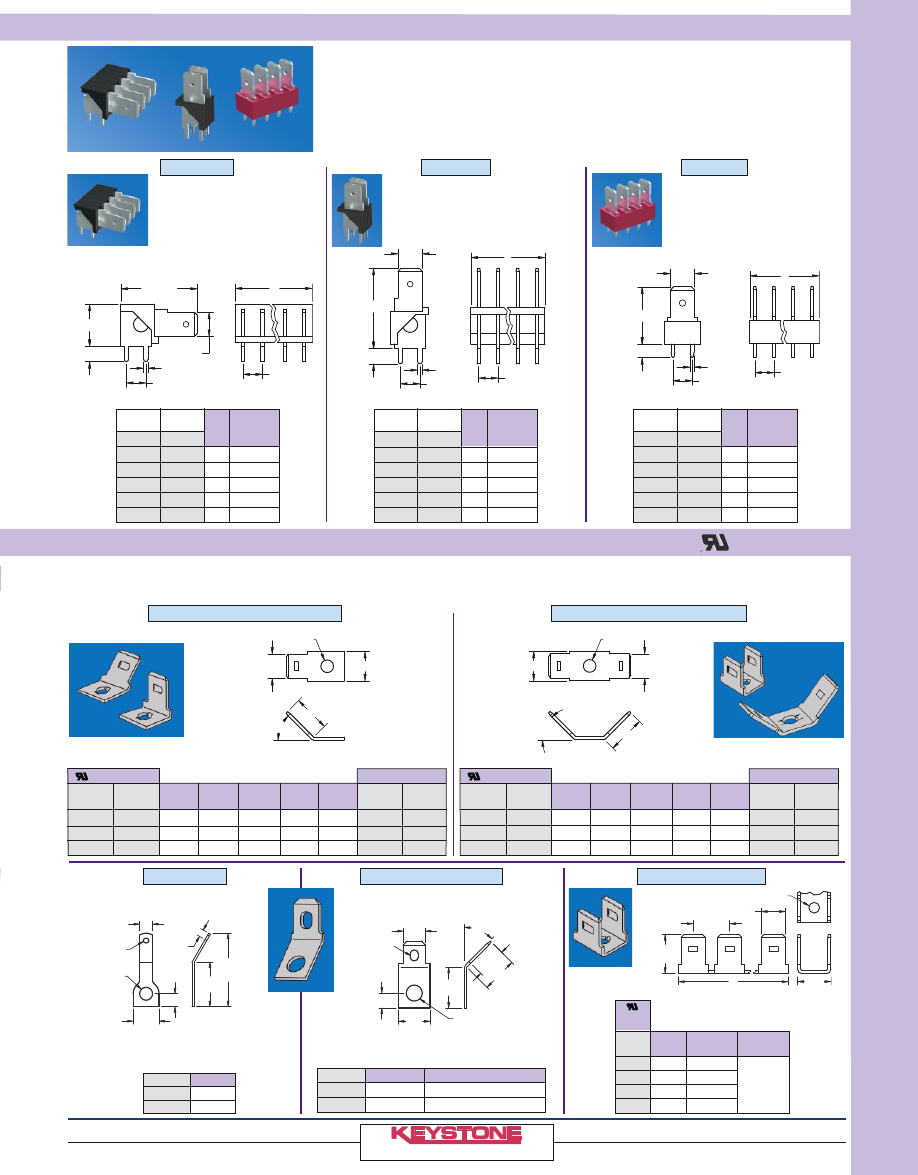

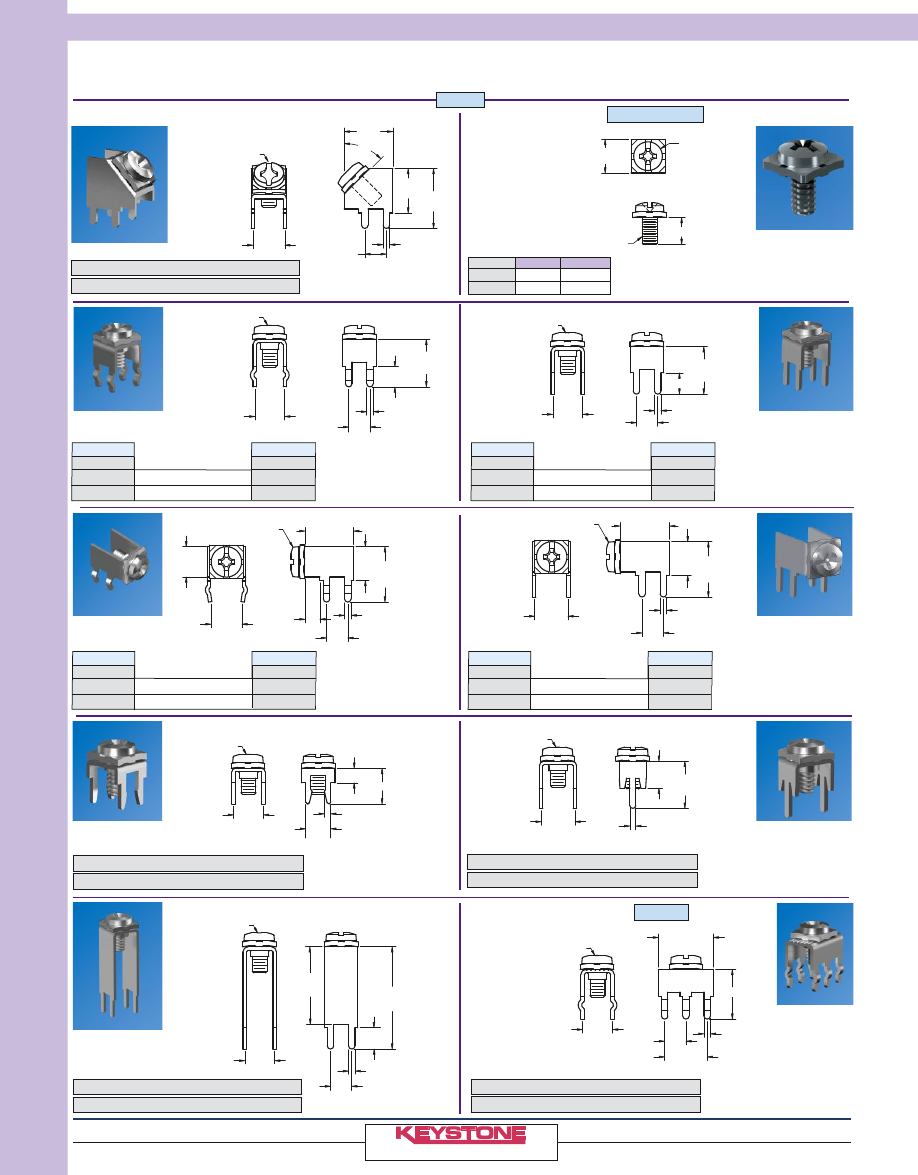

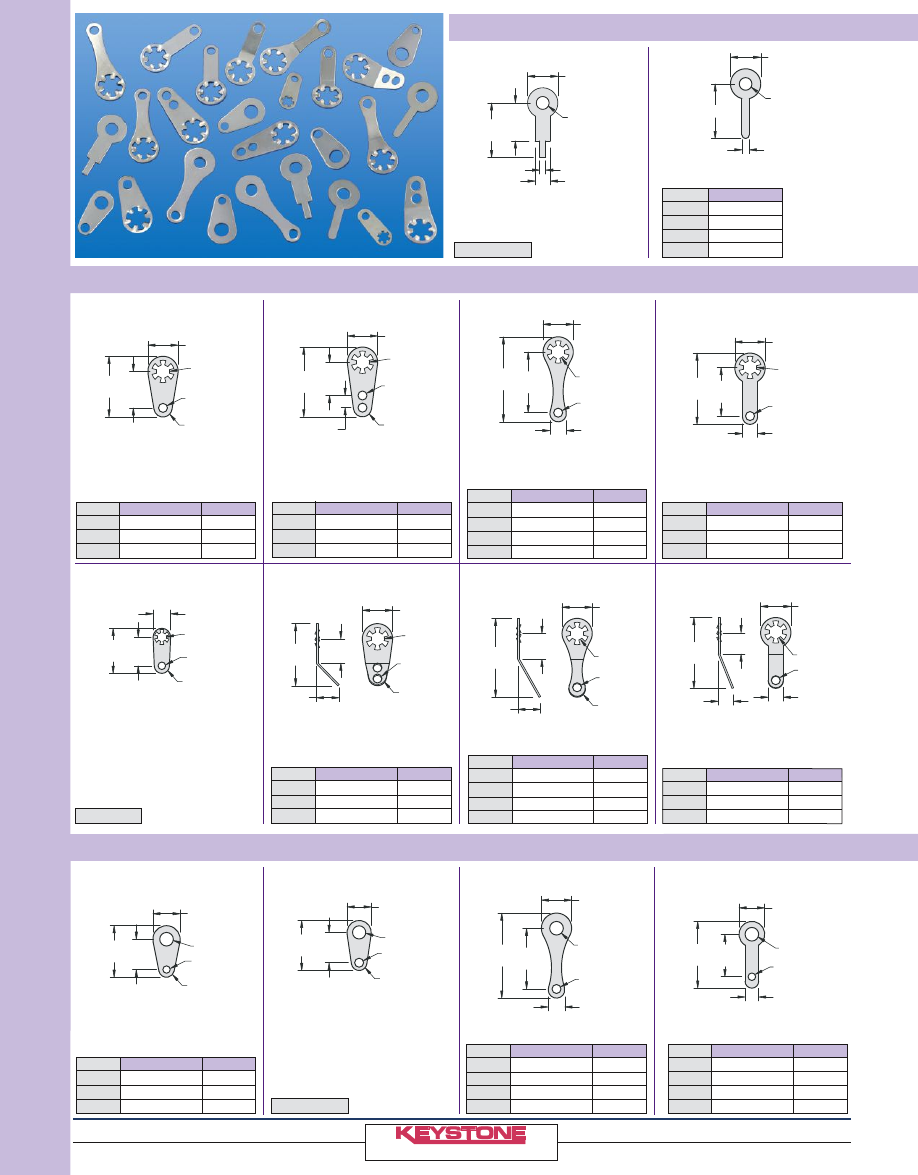

(THM) THRU HOLE MOUNT TEST POINTS - COLOR KEYED

•

Color keyed for visibility and quick identification

•

Economical choice for PC test point terminations

•

Snap-fit mounting provides positive retention for wave soldering

•

Wire form loop for safe, non-slip testing

•

Space saving, ultra low and low profile designs

•

High profile design for difficult to reach applications

•

Suitable for high density packaging on .062 (1.57) and .093 (2.36) PC boards

•

Practical replacement for wire-wrap posts and turrets

•

Secure grip for J hooks, EZ hooks, grabbers, alligator clips, tips or probes

•

High temperature nylon base ideal for reflow soldering

•

Ideal for reliable production testing and field service troubleshooting

SPECIFICATIONS

Terminal:

.010 (.25)

×

.020 (.51) Phosphor Bronze,

Silver Plate

Base:

Nylon 46, UL Rated 94V-0

Mtg. Hole:

.040 (1.0) Diameter

.350

[8.9]

.120

[3.0]

.220

[5.6]

.070 [1.80] I.D.

.125 [3.2] DIA.

COMPACT

COLOR KEYED

MINIATURE

MULTIPURPOSE

SPECIFICATIONS

Terminal:

.015 (.38)

×

.032 (.81) Phosphor Bronze,

Silver Plate

Base:

Nylon 46, UL Rated 94V-0

Mtg. Hole:

.063 (1.6) Diameter

SPECIFICATIONS

Terminal:

.015 (.38)

×

.032 (.81) Phosphor Bronze,

Silver Plate

Base:

Nylon 46, UL Rated 94V-0

Mtg. Hole:

.063 (1.6) Diameter

MATERIAL:

.017 (.43) Dia.

Phosphor Bronze Silver Plate

Mtg Hole:

.040 (1.0)

MATERIAL:

.020 (.50) Dia.

Phosphor Bronze Silver Plate

Mtg Hole:

.073 (1.9)

MATERIAL:

.016 (.40)

×

.028 (.71)

Phosphor Bronze Silver Plate

Mtg Hole:

.040 (1.0)

MATERIAL:

.020 (.50) Dia.

Phosphor Bronze Silver Plate

Mtg Hole:

.114 (2.9)

ULTRA LOW PROFILE

.200 [5.1]

REF.

.350

[8.9]

.094 [2.4] DIA.

SHOWN AS

INSTALLED INTO

.040 [1.02] DIA.

MOUNTING HOLE

.100 [2.5]

REF.

.200 [5.1]

.100 [2.5] DIA.

SHOWN AS

INSTALLED INTO

.040 [1.02] DIA.

MOUNTING HOLE

SHOWN AS

INSTALLED INTO

.112 [2.84] TO .116 [2.95] DIA.

MOUNTING HOLE

.150 [3.8]

.400

[10.2]

.250 [6.4]

REF.

SHOWN AS

INSTALLED INTO

.067 [1.70] TO .078 [1.98] DIA.

MOUNTING HOLE

.100 [2.5]

.350

[8.9]

.200 [5.1]

REF.

LOW PROFILE

.180

[4.6]

.120

[3.0]

.300

[7.6]

.100 [2.5] DIA.

.050 [1.25] I.D.

.445

[11.3]

.120

[3.0]

.320

[8.1]

.070 [1.80] I.D.

.125 [3.2] DIA.

CAT.

BASE

CAT.

BASE

NO.

COLOR

NO.

COLOR

5000

RED

5115

BROWN

5001

BLACK

5116

GREEN

5002

WHITE

5117

BLUE

5003

ORANGE

5118

GREY

5004

YELLOW

5119

PURPLE

CAT.

BASE

CAT.

BASE

NO.

COLOR

NO.

COLOR

5005

RED

5120

BROWN

5006

BLACK

5121

GREEN

5007

WHITE

5122

BLUE

5008

ORANGE

5123

GREY

5009

YELLOW

5124

PURPLE

CAT.

BASE

CAT.

BASE

NO.

COLOR

NO.

COLOR

5010

RED

5125

BROWN

5011

BLACK

5126

GREEN

5012

WHITE

5127

BLUE

5013

ORANGE

5128

GREY

5014

YELLOW

5129

PURPLE

THM

TEST

POINTS

62

CAT. NO. 5021

CAT. NO. 5020

CAT. NO. 5023

CAT. NO. 5024

STANDARD

LARGE

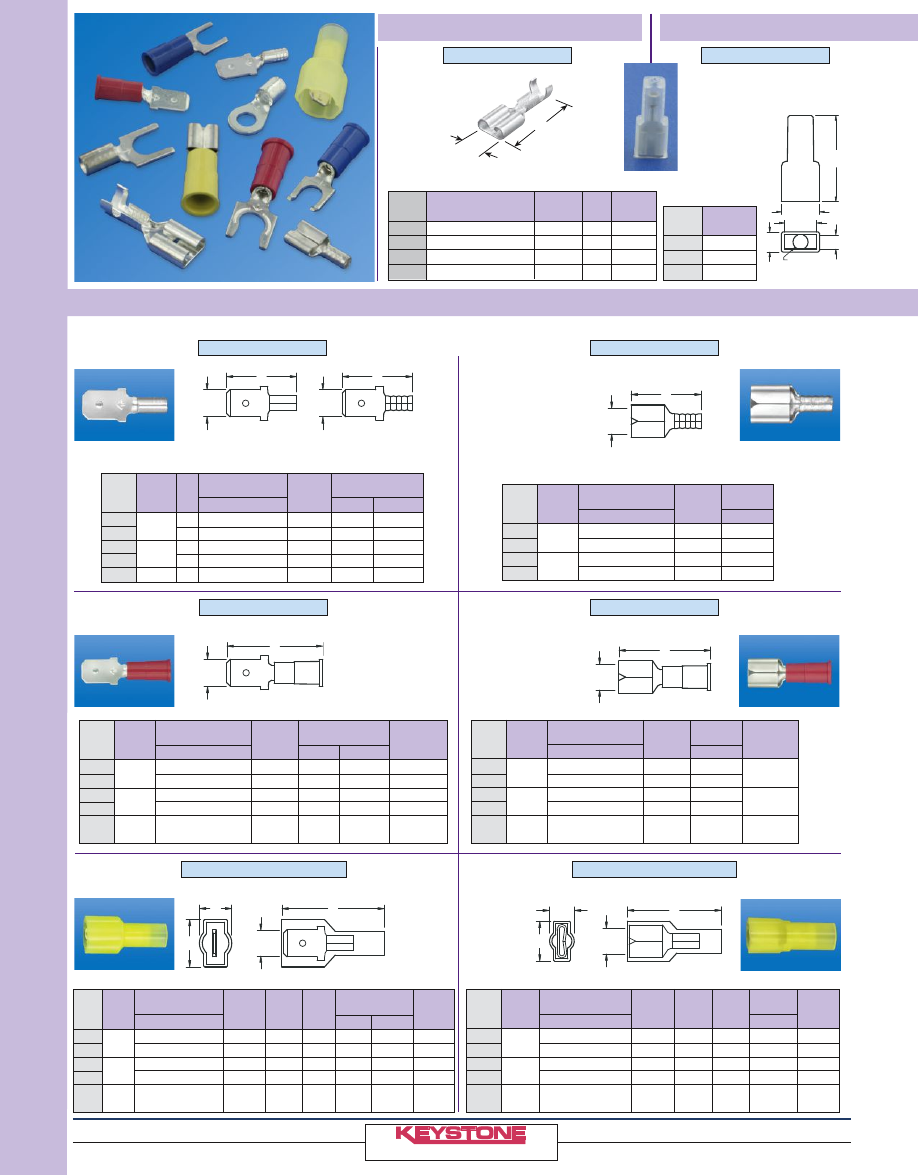

CAT. NO.

INSULATOR

COLOR

5044

NONE

5045

RED

5046

BLACK

5048*

NONE

MATERIAL:

Clip:

Steel, Nickel Plate;

Insulator:

Vinyl

JAW SPREAD

.236 (6.0) max.

JAW SPREAD

.315 (8.0) max.

ALLIGATOR CLIPS

CAT. NO.

INSULATOR

COLOR

5033

NONE

5034

RED

5035

BLACK

5036

GREEN

5037

YELLOW

CAT. NO.

INSULATOR

COLOR

5038

NONE

5039

RED

5040

BLACK

JAW SPREAD

.236 (6.0) max.

1.97 (50.0)

5048 only

.445

(11.3)

1.40 (35.6)

.335 (8.5)

1.06 (27.0)

.295 (7.5)

SMALL CLIP

MEDIUM CLIP

LARGE CLIP

•

Solder connection with strain relief

•

Insulated or non-insulated

•

Large clip also accepts standard banana plug

*with screw

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

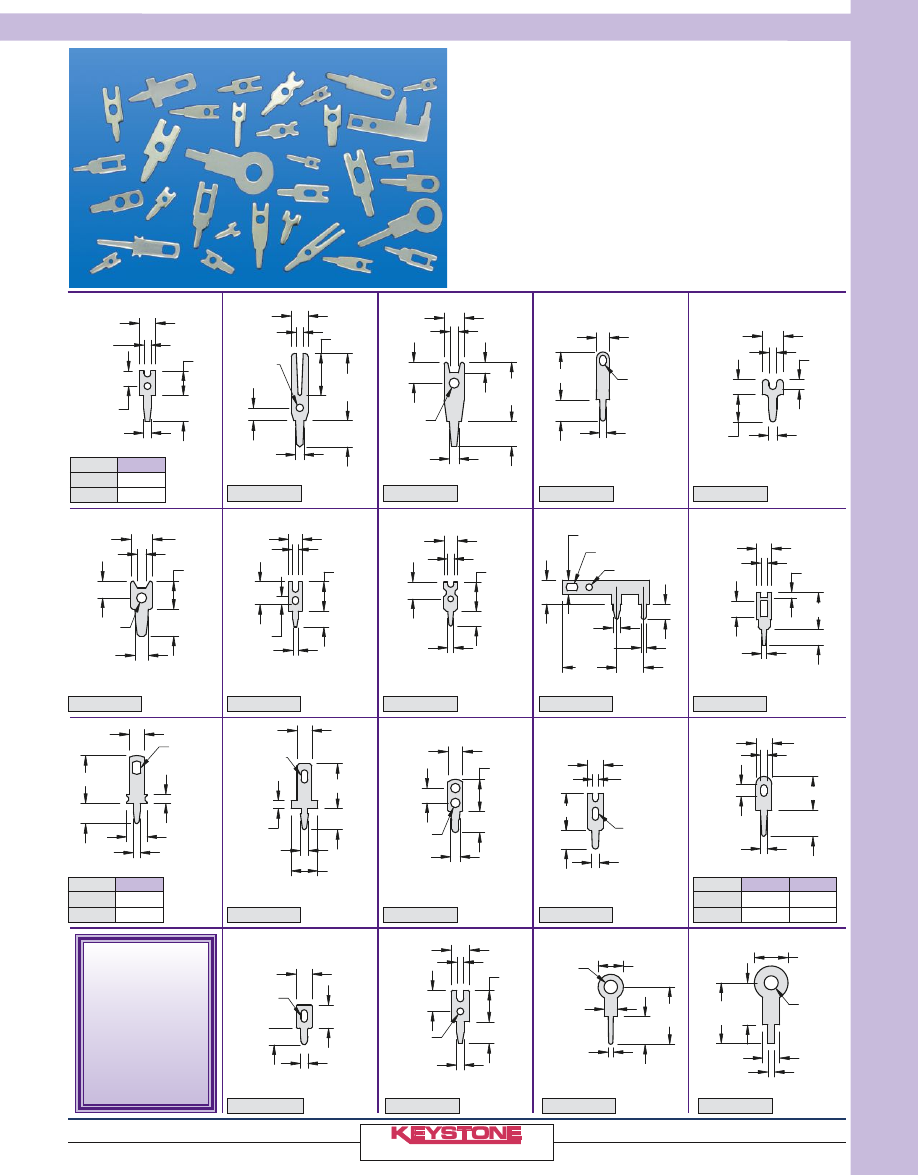

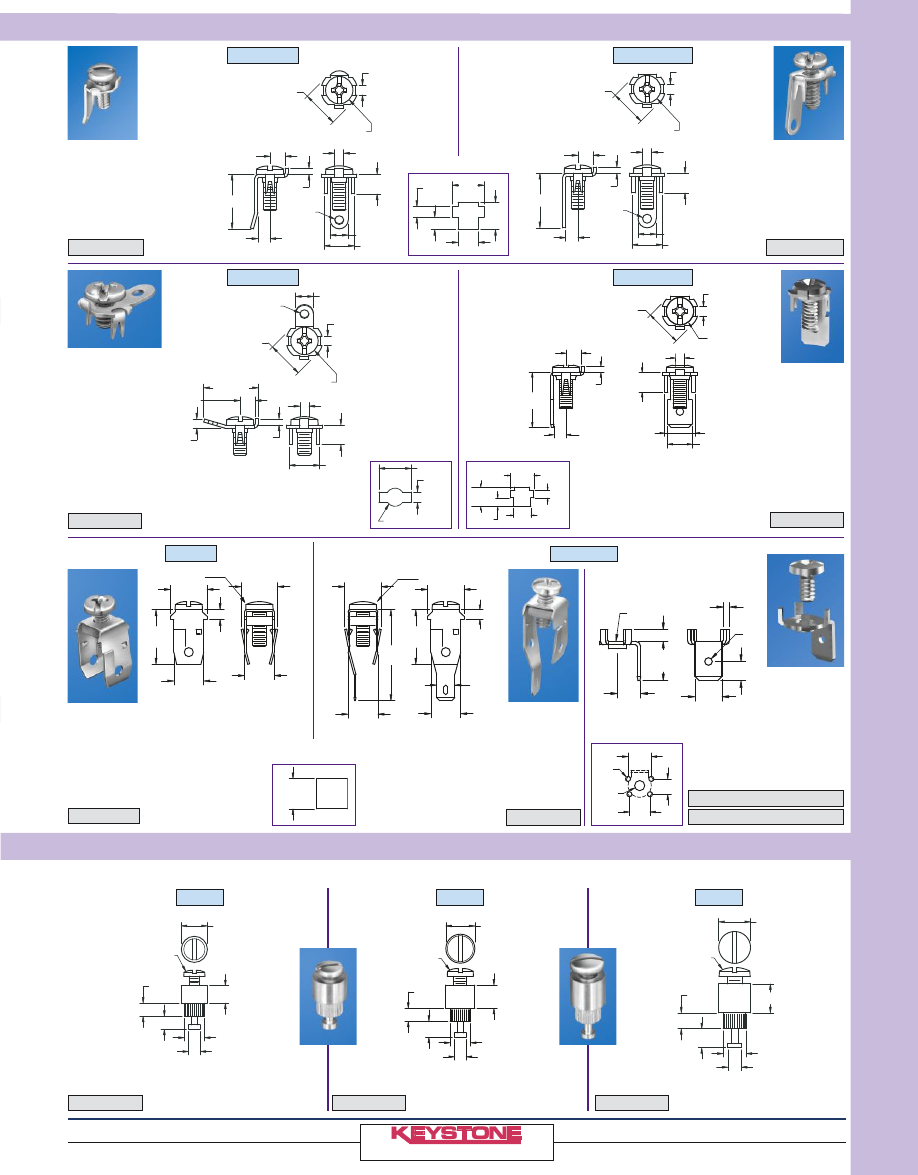

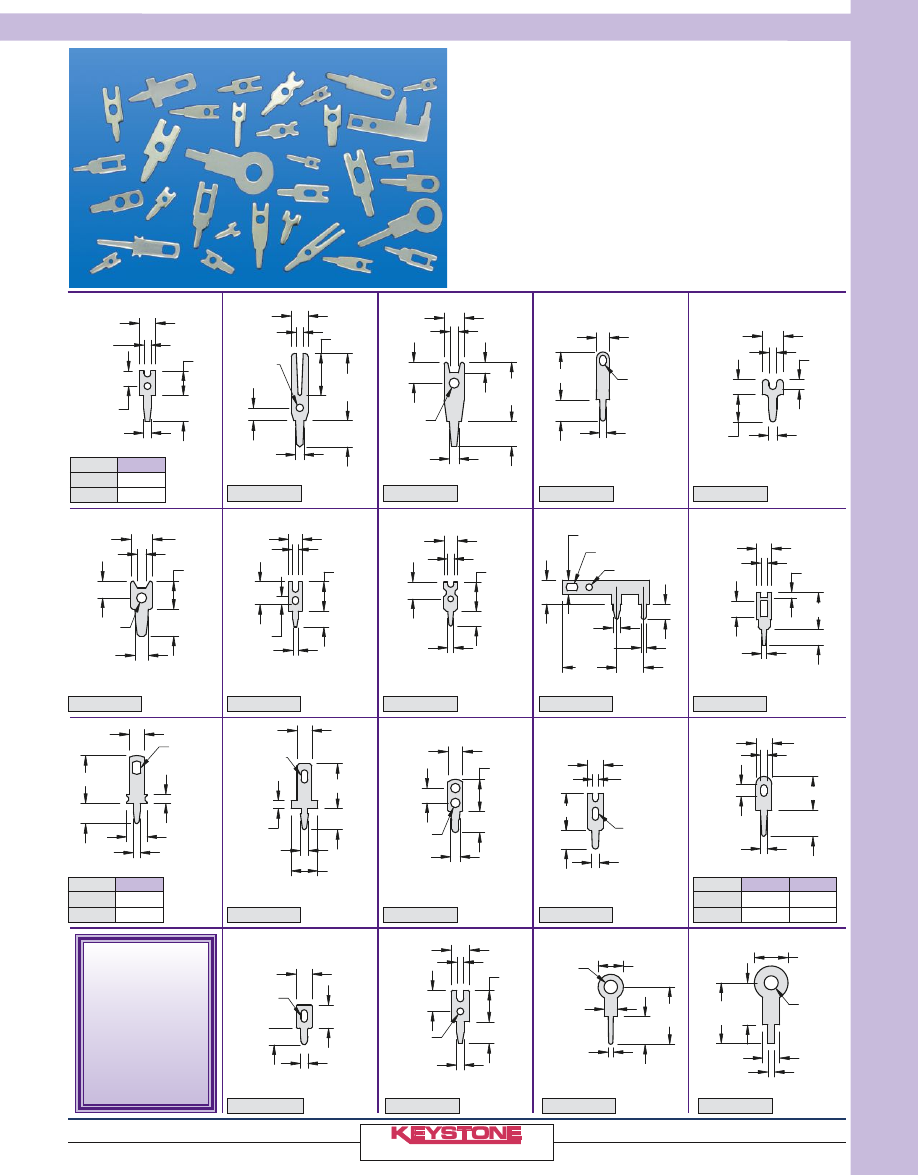

THM TEST POINTS - SLOTTED & LOOP TYPES

THM

TEST

POINT

TERMINALS

63

CAT. NO. 1033

CAT. NO. 680

CAT. NO. 4954

CAT. NO. 1039

CAT. NO. 1045

CAT. NO. 4951

CAT. NO. 1040

CAT. NO. 1034

CAT. NO. 1038

CAT. NO. 1035

CAT. NO. 1250

CAT. NO. 1037

CAT. NO. 1036

CAT. NO. 4953

CAT. NO. 1032

•

Low profile, space saving designs for dense packaging

•

Wide variety of configurations to suit most applications

•

Safe, practical, economical replacement for wire-wrap posts

•

Easy mount design, ideal for wave soldering

•

Re-fit PC boards without need for re-design

•

Provides easy access for production testing and field service troubleshooting

•

Positive grip when using J hooks, EZ hooks, grabbers, clips, tips and probes

•

Custom test point terminals can be manufactured to your specifications

•

Other platings and materials available upon request

.070 [1.78]

L

.032 [.81]

DIA. (2) PLS.

.035 [.89]

.075 [1.90]

.114

[2.9]

.121 [3.1]

.196 [5.0]

.078 [1.98]

.032 [.81]

.312

[7.9]

.035 [.90]

DIA.

.060 [1.52]

.039 [1.00]

CAT. NO. 4950

.047 [1.19]

DIA.

.097 [2.5]

.039 [.99]

.044

[1.12]

.115 [2.9]

.275

[7.0]

.050 [1.27]

.093 [2.4]

.047 [1.19]

DIA.

.130

[3.30]

.078 [1.98]

.039 [1.00]

.125 [3.18]

.100 [2.5]

.062 [1.57]

.039 [1.00]

.117 [3.0]

.218 [5.5]

.169

[4.3]

.060 [1.52]

.100 [2.5]

.047 [1.19]

.218 [5.5]

.047 [1.19]

.110 [2.8]

.100 [2.5]

.043 [1.09]

.125 [3.2]

.105 [2.7]

.039 [1.00]

.177

[4.5]

.050 [1.27]

.055 [1.40] X .087 [2.20]

.055

[1.40]

.200

[5.1]

.400

[10.2]

.114 [2.9]

.039 [1.00]

.115 [2.9]

.275 [7.0]

.040 [1.02]

.118 [3.0]

.047 [1.19]

.110 [2.8]

.098 [2.5]

.035 [.89]

.039

[1.00]

.126

[3.2]

.071 [1.80]

.047

[1.19]

.157 [4.0]

.355 [9.0]

.047 [1.19]

X .078 [1.98]

.094 [2.4]

.047 [1.19]

.060 [1.52] X

.100 [2.5]

.355 [9.0]

.150 [3.8]

.110 [2.8]

L

.067 [1.70]

.063 [1.60]

.197 [5.0]

.050 [1.30] x

.098 [2.50]

.417 [10.6]

.156 [4.0]

.110 [2.8]

.060 [1.52]

.060 [1.52]

.156 [4.0]

.239 [6.1]

.070 [1.78]

DIA (2) PLS.

.110 [2.8]

.110 [2.8]

.069 [1.75]

.047 [1.20] x

.098 [2.5]

.275 [7.0]

.039 [1.00]

.118 [3.0]

.055 [1.40]

.138 [3.5]

.047 [1.19]

.195 [5.0]

.250 [6.4]

.118 [3.0]

W

H

.047 [1.19]

X .093 [2.36]

.054

[1.37]

.125 [3.2]

.171

[4.3]

.118 [3.0]

.064

[1.63] DIA

.234

[5.9]

.055 [1.40]

.160 [4.1]

.156 [4.0]

.051 [1.30]

.138 [3.5]

.125 [3.2]

DIA.

.118 [3.0]

.047 [1.19]

.236 [6.0]

.531

[13.5]

.256

[6.5]

.130 [3.3]

DIA.

.062 [1.57]

.156 [4.0]

.312 [7.9]

.562

[14.3]

.390

[9.9]

CAT. NO.

L

1030

.120 (3.0)

1031

.156 (4.0)

CAT. NO.

L

1041

.275 (7.0)

1046

.150 (3.8)

CAT. NO.

W

H

1249

.047 (1.19) .087 (2.21)

4952

.063 (1.60) .098 (2.49)

CUSTOM

TERMINALS

Custom terminals can be

machined to your exact

specifications. Standard

and special terminals can

be staked onto special

boards. Please email/fax

your

design

to

our

Engineering Department.

MATERIAL:

.025 (.64) Brass

MATERIAL:

.016 (.41) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.020 (.51) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.020 (.51) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.024 (.61) Brass

MATERIAL:

.020 (.51) Brass

MATERIAL:

.020 (.51) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.025 (.64) Brass

MATERIAL:

.020 (.51) Brass

MATERIAL:

.015 (.38) Brass

MATERIAL:

.032 (.81) Brass

MATERIAL:

Brass, Tin Plate

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

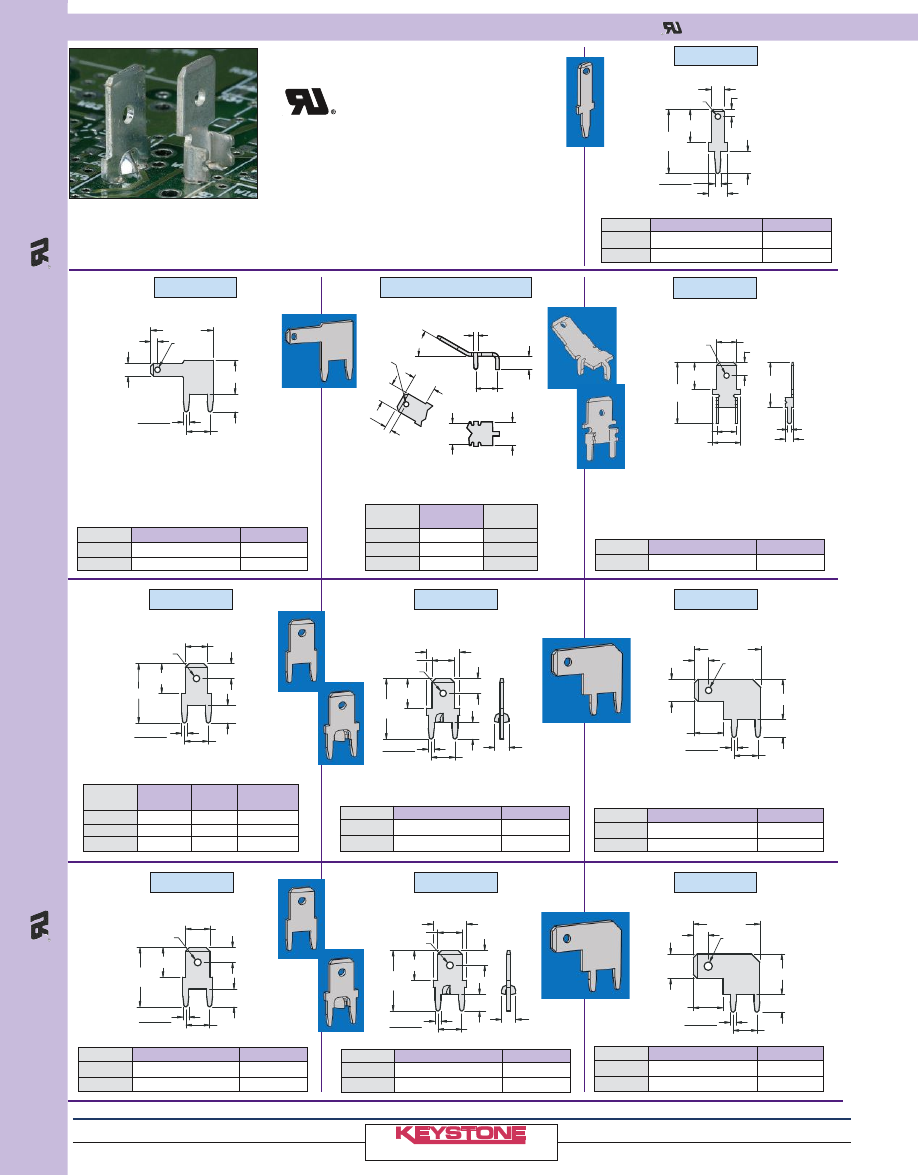

CAT. NO.

MATERIAL

MTG. HOLES

4905*

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

4909*

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1286-ST

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

1213-ST

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1286

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

1213

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

4900

.020 (.50) Brass, Tin Plate

.043 (1.1) Dia.

CAT. NO.

MATERIAL

MTG. HOLE

1267

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

1211

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

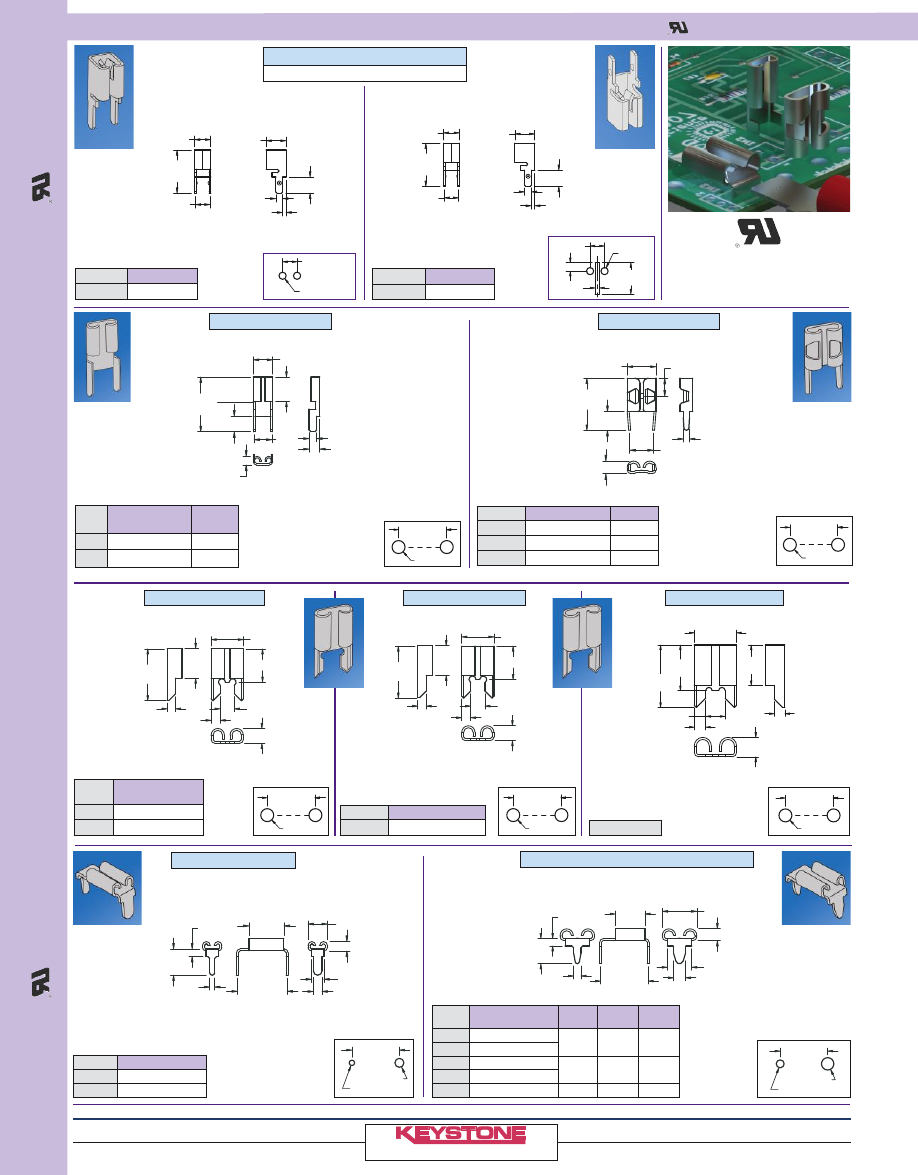

Underwriters Laboratories, Inc.

Recognized Component Program —

UL File Number E201546

UL file number E201546 has been assigned to

Keystone Electronics’ “Quick-Fit” terminals

(Refer to pages 64-68) indicating recognition by

Underwriters Laboratories Inc. that they are in compliance

with their component program.

Underwriters Laboratories Inc. component program

assures that “Quick-Fit” terminals meet the dimensional

and performance requirements of the National Electrical

Manufacturers Association specification number

NEMA2-1982-(1988) and UL310.

PC

QUICK-FIT

MALE

TERMINALS

PC QUICK-FIT MALE TERMINALS

CAT. NO.

MATERIAL

MTG. HOLES

4903

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

4906

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

4904

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

4907

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.187 (4.8) TAB

.187 (4.8) TAB

.187 (4.8) TAB

.110 (2.8) TAB

.205 (5.2) TAB

.205 (5.2) TAB

.187 (4.8) TAB

STURDI-MOUNT

STURDI-MOUNT

STURDI-MOUNT

.125 [3.2]

.205 [5.2]

.150 [3.8]

.500

[12.7]

.250 [6.4]

.200 [5.1]

.045 [1.14]

.050 [1.27]

.070 [1.80] DIA.

.140 [3.6]

.510

[13.0]

.050 [1.27]

.045 [1.14]

.200 [5.1]

.250 [6.4]

.205 [5.2]

.125 [3.2]

.120

[3.1]

REF.

.281 [7.15]

.070 [1.80] DIA.

.250 [6.4]

.570

[14.5]

.187 [4.8]

.256 [6.5]

.177 [4.5]

.040 [1.00]

.080 [2.1]

.416

[10.6]

.125 [3.2]

DIA.

.051 [1.30]

.187 [4.8]

.200 [5.1]

.150 [3.8]

.125 [3.2]

.050 [1.27]

.045 [1.14]

.055 [1.40] DIA.

.250 [6.4]

H

.156 [4.0]

.110 [2.8]

.062 [1.55]

.542

[13.8]

.280 [7.1]

.187 [4.8]

.050 [1.27]

.045 [1.14]

.048 [1.20] DIA.

.110 [2.8]

.285 [7.3]

.150 [3.8]

.057 [1.45]

.525 [13.4]

.048 [1.20]

DIA.

.045 [1.14]

.050 [1.27]

.200 [5.1]

.340 [8.7]

.187 [4.8]

.245 [6.2]

.150 [3.8]

.120 [3.1]

.560 [14.2]

.045 [1.14]

.050 [1.27]

.200 [5.1]

.055

[1.40]

DIA.

CAT. NO.

MATERIAL

MTG. HOLES

1285-ST

.020 (.50) Brass, Tin Plate

.046 (1.2) Dia.

1212-ST

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.205 (5.2) TAB

.205 [5.2]

.250 [6.4]

.150 [3.8]

.340 [8.7]

.560 [14.2]

.125 [3.2]

.200 [5.1]

.050 [1.27]

.045 [1.14]

.070 [1.80]

DIA.

.187 [4.8]

.120

[3.1]

REF.

.125 [3.2]

.200 [5.1]

.281 [7.15]

.140 [3.6]

.045 [1.14]

.050 [1.27]

.510

[13.0]

.055 [1.40] DIA.

.250 [6.4]

.110 (2.8) TAB

.110 (2.8) TAB

A

.187(4.8) TAB

CAT. NO.

ANGLE

CAT. NO

4915*

0°

4918*

4916*

30°

4919*

4917*

60°

4920*

.110 (2.8) & .187 (4.8) TAB

MATL

MTG.

CAT. NO.

H

THICK

HOLES

1285

.500 (12.7)

.020 (.50) .046 (1.2) Dia.

1212

.500 (12.7)

.032 (.81) .052 (1.3) Dia.

1216

.860 (21.8)

.032 (.81) .052 (1.3) Dia.

Material:

Brass, Tin Plate

Material:

.020 (.50) Brass, Tin Plate

Mtg Holes:

.046 (1.2) Dia.

*

Not UL Recognized

.04

8 [1

.2]

DIA

. HO

LE

.06

2 [1

.6]

.125 [3.2]

.220

[5.6]

.200 [5.1]

.040 [1.0]

TAB

.200

[5.1]

A°

.21

5

[5.5

]

64

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

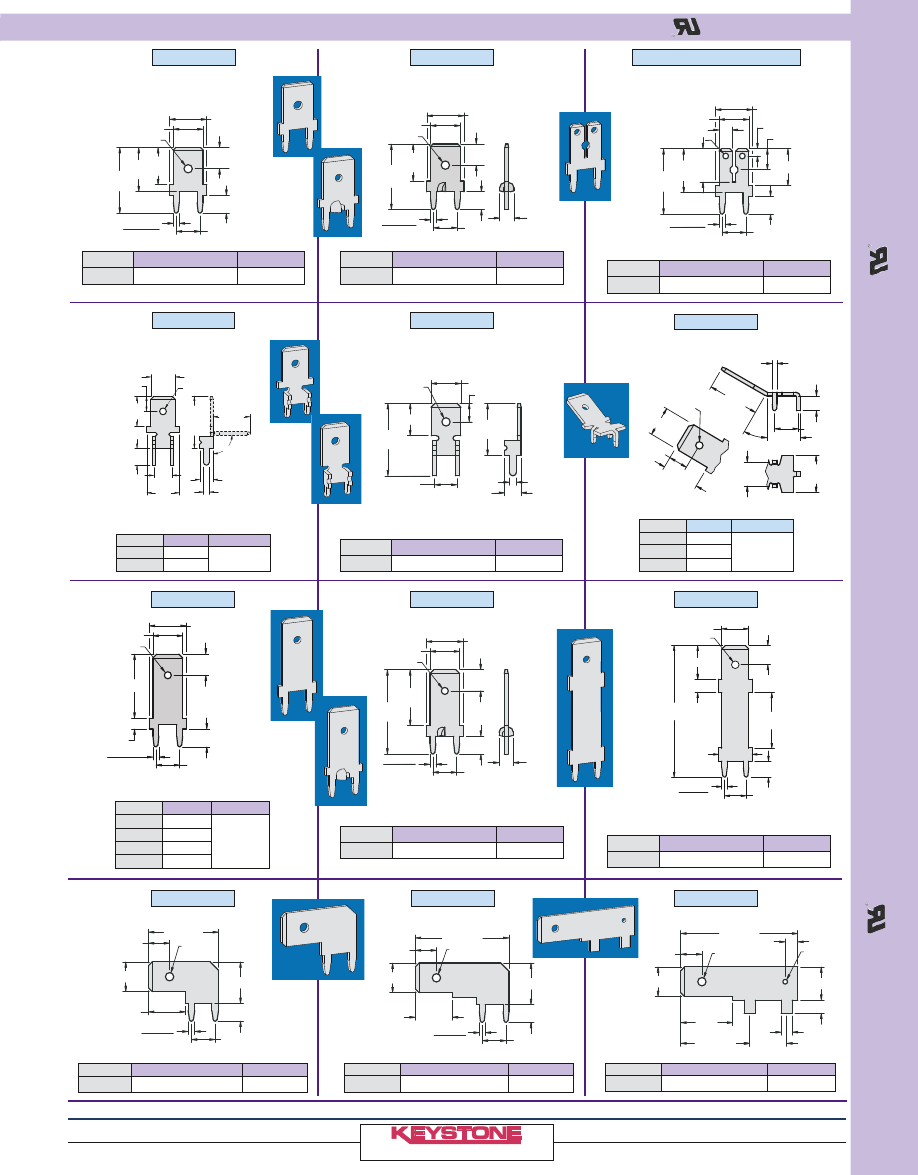

.250 (6.4) PC QUICK-FIT MALE TERMINALS

PC

QUICK-FIT

MALE

TERMINALS

65

.250 (6.4) TAB

.250 (6.4) TAB

.250 (6.4) TAB

CAT. NO.

MATERIAL

MTG. HOLES

1266

.032 (.81) Brass, Tin Plate .052 (1.3) Dia.

.350 [8.9]

.250 [6.4]

.200 [5.1]

.056 [1.42]

.051 [1.30]

.312 [7.9]

.150 [3.8]

.590 [15.0]

.070 [1.80]

DIA.

.178 [4.5]

.789 [20.1]

.312 [7.9]

.250 [6.4]

.178 [4.5]

.350 [8.9]

.150 [3.8]

.045 [1.14]

.050 [1.27]

.200 [5.1]

.070 [1.80] DIA.

.580 [14.8]

.985 [25.0]

.437

[11.1]

.280 [7.1]

.250 [6.4]

.178 [4.5]

.110 [2.8]

.093 [2.4]

.312 [7.9]

.106 [2.7]

.040 [1.00]

DIA.

.070 [1.80] DIA.

CAT. NO.

MATERIAL

MTG. HOLES

4966

.032 (.81) Brass, Tin Plate

.056 (1.4) Dia.

DUAL .110 (2.8)/.250 (6.4) TAB

.250 (6.4) TAB

.250 (6.4) TAB

.250 (6.4) TAB

.250 (6.4) TAB

CAT. NO.

MATERIAL

MTG. HOLES

1287

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1287-ST

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.250 (6.4) TAB

.250 (6.4) TAB

STURDI-MOUNT

STURDI-MOUNT

STURDI-MOUNT

STURDI-MOUNT

STURDI-MOUNT

.250 (6.4) TAB

.250 (6.4) TAB

.156

[4.0]

.138 [3.5]

.335

[8.5]

.172

[4.4]

.060 [1.52]

.312

[7.9]

.537

[13.7]

CAT NO.

4901

.250

[6.4]

.379 [9.7]

CAT NO.

4914

.070 [1.80] DIA.

.187

[4.8]

A

.610

[15.5]

.273 [7.0]

.438

[11.2]

.156 [4.0]

.250 [6.4]

.070 [1.80]

DIA.

.187 [4.8]

.060 [1.52]

.138 [3.5]

.150 [3.8]

.050 [1.27]

.070 [1.80] DIA.

.250 [6.4]

.091 [2.3]

.312 [7.9]

.200 [5.1]

.178 [4.5]

.045 [1.14]

L

/

.710

[18.1]

.470

[12.0]

.120

[3.1]

REF.

.050 [1.27]

.045 [1.14]

.200 [5.1]

.150 [3.8]

.312 [7.9]

.178 [4.5]

.250 [6.4]

.070 [1.80] DIA.

CAT. NO.

MATERIAL

MTG. HOLES

1282

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

4902

.032 (.81) Brass, Tin Plate

.067 (1.7) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1289-ST

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.200 [5.1]

.045 [1.14]

.070 [1.80] DIA.

.371

[9.4]

.552

[14.0]

.312

[7.9]

.250 [6.4]

.178 [4.5]

.050 [1.27]

.150 [3.8]

.312 [7.9]

.120

[3.1]

REF.

.552

[14.0]

.050 [1.27]

.045 [1.14]

.200 [5.1]

.312 [7.9]

.150 [3.8]

.178 [4.5]

.250 [6.4]

.070 [1.80] DIA.

.312

[7.9]

.250 [6.4]

.110 [2.8]

.280

[7.1]

.552

[14.0]

.371

[9.4]

.048 [1.20] DIA.

.312 [7.9]

.062 [1.57]

.178 [4.5]

.150 [3.8]

.200 [5.1]

.045 [1.14]

.050 [1.27]

.312 [7.9]

.312 [7.9]

.150 [3.8]

.312 [7.9]

.125 [3.2]

.200 [5.1]

.045 [1.14]

.050 [1.27]

.178 [4.5]

.070 [1.80] DIA.

.250 [6.4]

.515

[13.1]

1.220

[31.0]

.06

2 [1

.6] D

IA.

.25

0 [6

.4]

.430 [10.9]

.125 [3.2]

.200 [5.1]

A

.040 [1.02](3)

.17

8 [4

.5]

.200

[5.1]

.312

[7.9]

.31

2 [7

.9]

.280 [7.1]

CAT. NO.

ANGLE A

MTG. HOLES

4910

0°

4908

30°

.052 (1.3) Dia.

4912

60°

CAT. NO.

ANGLE A

MTG. HOLES

4901

0°

4914

90°

.067 (1.7) Dia.

MATERIAL:

.032 (.81) Brass, Matte Tin Plate

MATERIAL:

.032 (.81) Brass, Matte Tin Plate

MATERIAL:

.032 (.81) Brass, Matte Tin Plate

CAT. NO.

MATERIAL

MTG. HOLES

1265*

.032 (.81) Brass, Tin Plate

.106 (2.7) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1281

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

*

Not UL Recognized

CAT. NO.

“L”

MTG. HOLES

1289

.540 (13.7)

1203

.657 (16.7)

.052 (1.3) Dia.

1292

.710 (18.0)

1225

1.039 (26.4)

NOTE: see page 66 for continuous reel packaging

NOTE: see page 66 for continuous reel packaging

NOTE: see page 66 for continuous reel packaging

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

REELED .250 (6.4) PC QUICK-FIT MALE TERMINALS

PC

QUICK-FIT

MALE

TERMINALS

66

.250 (6.4) TAB

CAT. NO.

MATERIAL

MTG. HOLES

1287

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1287-ST

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1289

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.250 (6.4) TAB

STURDI-MOUNT

.200 [5.1]

.045 [1.14]

.070 [1.80] DIA.

.371

[9.4]

.552

[14.0]

.312

[7.9]

.250 [6.4]

.178 [4.5]

.050 [1.27]

.150 [3.8]

.312 [7.9]

.120

[3.1]

REF.

.552

[14.0]

.050 [1.27]

.045 [1.14]

.200 [5.1]

.312 [7.9]

.150 [3.8]

.178 [4.5]

.250 [6.4]

.070 [1.80] DIA.

.312

[7.9]

BULK .250 (6.4) PC QUICK-FIT MALE TABS

.250 (6.4) TAB

.250 (6.4) TAB

CAT. NO.

MATERIAL

MTG. HOLES

1287-R

.032 (.81) Brass, Tin Plate .052 (1.3) Dia.

CAT. NO.

MATERIAL

MTG. HOLES

1287-STR

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.250 (6.4) TAB

STURDI-MOUNT

STURDI-MOUNT

CAT. NO.

MATERIAL

MTG. HOLES

1289-STR

.032 (.81) Brass, Tin Plate

.052 (1.3) Dia.

.250

[6.4]

.150 [3.8]

.312

[7.9]

.552

[14.0]

.050 [1.3]

.200

[5.1]

.120

[3.1]

.050 [1.3]

.552

[14.0]

.312

[7.9]

.150 [3.8]

.250

[6.4]

.200

[5.1]

.120

[3.1]

.250

[6.4]

.312

[7.9]

.710

[18.0]

.050 [1.3]

.150 [3.8]

.200

[5.1]

Underwriters Laboratories, Inc.

Recognized Component Program —

UL File Number E201546

UL file number E201546 has been assigned to

Keystone Electronics’ “Quick-Fit” terminals

(Refer to pages 64-68) indicating recognition by

Underwriters Laboratories Inc. that they are in compliance

with their component program.

Underwriters Laboratories Inc. component program

assures that “Quick-Fit” terminals meet the dimensional

and performance requirements of the National Electrical

Manufacturers Association specification number

NEMA2-1982-(1988) and UL310.

•

Supplied in continuous reel for automated pick and place insertion

SMT .250 (6.4) QUICK-FIT TERMINALS

CAT. NO. ON TAPE

BULK

& REEL

MATERIAL

4928*

4928TR*

.032 (.81) Brass, Tin Plate

•

Designed for automated assembly processing

•

Available on tape and reel for automated

assembly. Pick-up cap added to reeled parts to

accommodate vacuum pick and place assembly

•

Reflow solder compatible. Plastic pick-up cap will

survive reflow temperatures

.250 (6.4) TAB

VERTICAL – MALE

.230

[5.8]

.240

[6.1]

.413

[10.5]

.060 [1.5]

(3) PLS

.115

[3.00]

.245

[6.22]

MIN.

.065 [1.65]

MIN. (3) PLS

.240[6.10]

MIN.

Mounting Detail

Tape & Reel Spec’s:

16mm wide, 12mm pitch, 13 inch reel (750 pieces per reel)

.250 (6.4) TAB

.150 [3.8]

.050 [1.27]

.070 [1.80] DIA.

.250 [6.4]

.091 [2.3]

.312 [7.9]

.200 [5.1]

.178 [4.5]

.045 [1.14]

.540

[13.7]

Tape & Reel Spec’s:

12,500 per 15 inch reel

Tape & Reel Spec’s:

15,000 per 24 inch reel

Tape & Reel Spec’s:

15,000 per 24 inch reel

AVAILABLE ON TAPE AND REEL

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

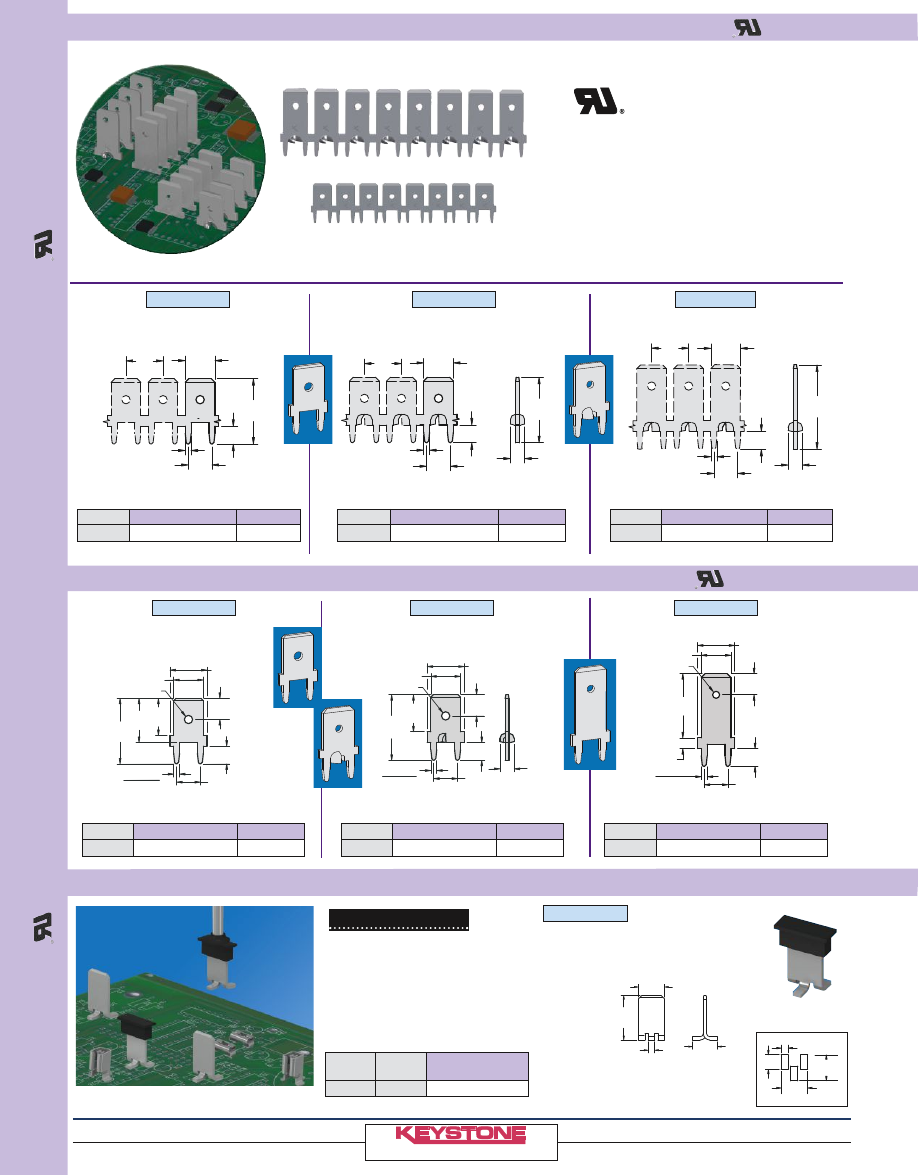

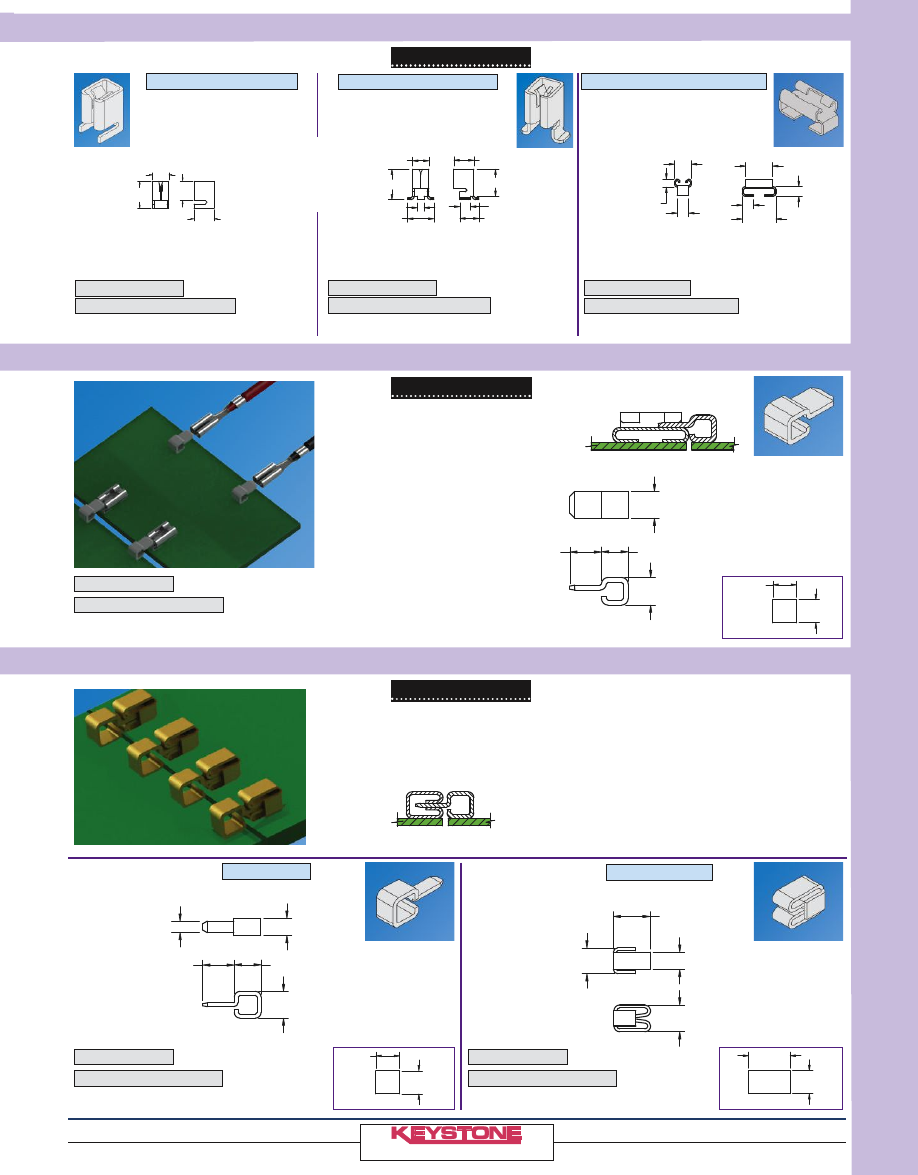

.250 (6.4) “STURDI-MOUNT” PC QUICK-FIT HEADERS

MATERIAL:

.032 (.81) Bright Brass

•

Ideal for rugged multi-insertion applications

•

Pre-assembled header reduces PC assembly costs

•

Increases PC board retention strength

•

Keeps terminals perpendicular

•

Maintains position for wave soldering

SPECIFICATIONS

Material:

.032 (.81) Brass or Steel, Tin Plated

Insulator:

Thermoplastic, UL Rated 94V-0

Current Rating:

15 Amps @ 500V AC

Temperature Rating:

-58°F to +292°F (-50°C to +145°C)

LOW PROFILE

HORIZONTAL

VERTICAL

CAT. NO.

TAB

HOLE

4005

.205 (5.2)

.132 (3.4)

×

.070 (1.78) Slot

4095

.187 (4.7)

.078 (1.98) Dia. Hole

.157 [4.0]

.433 [11.0]

.200 [5.1]

.787 [20.0]

.045 [1.1]

.250 [6.4]

.200 [5.1]

L

L

.157 [4.0]

.200 [5.1]

.045 [1.1]

.200 [5.1]

.827 [21.0]

.250

[6.3]

.197 [5.0]

.039 [1.0]

L

.197 [5.0]

.591 [15.0]

.138 [3.5]

.250

[6.4]

.218

[5.5]

.619

[15.7]

REF.

.110 [2.8]

.109 [2.8]

.375

[9.5]

.062

[1.55]

.109 [2.7]

DIA.

.048 [1.20]

DIA.

.343

[8.7]

HOLE

TAB

.125 [3.2]

45°

.296 [7.5]

.250 [6.4]

.265

[6.7]

.135 [3.4] DIA.

RIVET MOUNT QUICK-FIT TERMINALS

.110 (2.8) - .187(4.8) - .250 (6.4) TABS

MULTIPLE .250 (6.4) TAB

BRASS

STEEL

NO.

TABS

TABS

OF

L

CAT. NO. CAT. NO.

TABS

DIM.

7802

7822

2

.362 (8.2)

7803

7823

3

.562 (14.3)

7804

7824

4

.762 (19.4)

7805

7825

5

.962 (24.4)

7806

7826

6

1.162 (29.5)

AVAILABLE IN BRASS OR STEEL TABS

W

HOLE

A°

L

TAB

A°

L

HOLE

TAB

W

L

.406

[10.3]

.343

[8.7]

.250 [6.4]

.375 [9.5]

.130 [3.3]

MATERIAL:

.020 (.51) Brass, Tin Plate

MATERIAL:

.020 (.51) Brass, Tin Plate

.187 (4.8) - .205 (6.4) TABS

.110 (2.8) TAB

45° TAB

.110 (2.8) - .187 (4.8) - .250 (6.4) TABS

CAT

TAB

NO.

PAIRS

L

SIZE

1005

2

.687 (17.4)

1006

3

1.062 (27.0)

.250 (6.4)

1007

4

1.441 (36.6)

1008

5

1.820 (46.2)

BRIGHT

BRASS

•

UL recognized bright brass Quick-Fit terminals

•

Rivet mount male tab versions meet NEMA 2-E201546 & UL 310 specifications

•

Designed for repeated mating cycles

•

For tabs 0.110 (2.8mm) to 0.250 (6.4mm)

CAT. NO.

ANGLE

1269

0°

1270

30°

MATTE TIN

BRIGHT BRASS

A = 45°

A = 90°

TAB

MAT’L

W

HOLE

A = 45°

A = 90°

CAT. NO. CAT. NO.

SIZE

THICK

TAB

WIDTH

DIA.

CAT. NO. CAT. NO.

2005

2003

.110 (2.8) .020 (.51) .360 (9.1) .180 (4.6) .096 (2.4)

1240

1227

1263

1262

.187 (4.8) .020 (.51) .315 (8.0) .250 (6.4) .100 (2.5)

1241

1228

1258

1257

.250 (6.4) .032 (.81) .400 (10.1) .306 (7.8) .130 (3.3)

1242

1229

MATTE TIN

BRIGHT BRASS

BRASS

STEEL

NO.

TABS

TABS

OF

L

CAT. NO. CAT. NO.

TABS

DIM.

7812

7832

2

.362 (8.2)

7813

7833

3

.562 (14.3)

7814

7834

4

.762 (19.4)

7815

7835

5

.962 (24.4)

7816

7836

6

1.162 (29.5)

BRASS

STEEL

NO.

TABS

TABS

OF

L

CAT. NO. CAT. NO.

TABS

DIM.

7817

7827

2

.320 (.81)

7818

7828

3

.517 (13.1)

7819

7829

4

.713 (18.1)

7820

7830

5

.910 (23.1)

7821

7831

6

1.107 (28.1)

A = 45°

A = 90°

TAB

MAT’L

W

HOLE

A = 45°

A = 90°

CAT. NO. CAT. NO.

SIZE

THICK

TAB

WIDTH

DIA.

CAT. NO. CAT. NO.

2004

2002

.110 (2.8) .020 (.51) .365 (9.3) .180 (4.6) .096 (2.4)

1233

1220

1271

1261

.187 (4.8) .020 (.51) .375 (9.5) .250 (6.4) .100 (2.5)

1234

1221

1280

1256

.250 (6.4) .032 (.81) .406 (10.3) .306 (7.8) .130 (3.3)

1235

1222

QUICK-FIT

MALE

TERMINALS

67

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

PC QUICK-FIT FEMALE TERMINALS

ACCEPTS .110 (2.8) TAB

VERTICAL ENTRY

VERTICAL ENTRY

ACCEPTS .187 (4.8) TAB

VERTICAL ENTRY

ACCEPTS .110 (2.8) TAB

HORIZONTAL ENTRY

ACCEPTS .187 (4.8), .205 (5.2), .250 (6.4) TAB

HORIZONTAL ENTRY

Mounting Detail

MATERIAL:

.012 (.30) Brass, Tin-Nickel Plate

Mounting Detail

MATERIAL:

.016 (.41) Brass, Tin-Nickel Plate

MATERIAL:

Brass, Tin-Nickel Plate

Mounting Detail

Mounting Detail

MATERIAL:

.016 (.41) Brass, Tin-Nickel Plate

CAT.

NO.

ACCEPTS TAB

3525

.205 (5.2)

¥

.020 (.51)

3575*

.205 (5.2)

¥

.032 (.81)

CAT. NO.

ACCEPTS TAB

3528

.250 (6.4)

¥

.032 (.81)

.400 [10.1]

.046 [1.15] DIA.

.076 [1.9] DIA.

.400 [10.1]

.067 [1.70] DIA.

.104 [2.6] DIA.

.146 [3.7]

.232 [5.9]

W (Ref)

.420

[10.7]

.150 [3.8]

.050 [1.25]

.200 [5.1]

.200 [5.1]

.052 [1.30] DIA.

CAT. NO.

ACCEPTS TAB

3545

.110 (2.8)

¥

.020 (.51)

3549

.110 (2.8)

¥

.032 (.81)

.212

[5.4]

.062

[1.55]

.100 [2.5]

.075 [1.90]

.400 [10.2]

.040

[1.00]

.070 [1.80]

.156 [4.0]

.280 [7.1]

.070 [1.80]

.125 [3.2]

.281 [7.1]

.437

[11.1]

.076 [1.90]

.271 [6.9]

.120 [3.0]

.250

[6.3]

Mounting Detail

.200 [5.1]

.100 [2.54] DIA.

Mounting Detail

.200 [5.1]

.089 [2.3]

Mounting Detail

.328 [8.35]

.152 [3.86] DIA.

MATERIAL:

.016 (.41) Brass, Tin-Nickel Plate

ACCEPTS .205 (5.2) TAB

VERTICAL ENTRY

ACCEPTS .250 (6.4) TAB

CAT. NO.

ORIENTATION

3557

top & side entry

MATERIAL:

.016 (.41) Brass, Tin-Nickel Plate

CAT. NO.

ORIENTATION

3577

bottom entry

MATERIAL:

.016 (.41) Brass, Tin-Nickel Plate

MATERIAL:

.020 (.51) Copper, Tin-Nickel Plate

VERTICAL OR HORIZONTAL ENTRY

CAT. NO. 3555

ACCEPTS .312 (7.9) TAB

OVER SIZED

.032 [0.8]

.062 [1.6]

.400

[10.2]

.134 [3.4]

.150 [3.8]

.150 [3.8]

.185 [4.7]

Underwriters Laboratories, Inc.

Recognized Component Program

— UL File Number E201546

CAT.

MATL

NO.

ACCEPTS TAB

“W”

“A”

THICK

3571

.187 (4.8)

¥

.020 (.51)

.222 (5.6) .162 (4.1) .012 (.30)

3572*

.187 (4.8)

¥

.032 (.81)

3546

.205 (5.2)

¥

.020 (.51)

.240 (6.1) .180 (4.6) .012 (.30)

3550

.205 (5.2)

¥

.032 (.81)

3547

.250 (6.4)

¥

.032 (.81) .291 (7.4) .205 (5.2) .016 (.41)

.392 [10.0]

.180 [4.6]

.422

[10.7]

.375

[9.5]

.109

[2.8]

.106 [2.7]

.578

[14.7]

.180 [4.6]

.144 [3.7]

.065 [1.30] DIA.

PC

QUICK-FIT

FEMALE

TERMINALS

68

Mounting Detail

.134 [3.4]

.063 [1.6]

DIA. (2)PLS.

Mounting Detail

.063 [1.6]

DIA. (2)PLS.

TERMINAL

CLEARENCE

.040 [1.0]

.134 [3.4]

.062 [1.6]

.212

[5.4]

.062

[1.55]

W

.100 [2.5]

A

.098 [2.5]

.400 [10.2]

.062

[1.55]

.250

[6.4]

MATERIAL:

.012 (.30) Brass, Tin-Nickel Plate

.050 [1.3]

.125 [3.2]

.281 [7.1]

.437

[11.1]

.091 [2.3]

.291 [7.4]

.110 [2.8]

.250

[6.3]

.086 [2.2]

.062 [1.55]

W (Ref)

.440

[11.2]

.156 [4.0]

.144

[3.7]

.125 [3.2]

.196

[5.0]

CAT.

NO.

ACCEPTS TAB

W

3534

.110 (2.8)

¥

.020 (.51) .070 (1.80)

3544

.110 (2.8)

¥

.032 (.81) .075 (1.92)

†Low insertion force design

CAT. NO.

ACCEPTS TAB

“W”

3548

.187 (4.8)

¥

.020 (.51) .093 (2.36)

3578

†

.187 (4.8)

¥

.020 (.51) .093 (2.36)

3551

.187 (4.8)

¥

.032 (.81) .102 (2.59)

* Not UL Recognized

ACCEPTS ALL TABS

.110 (2.8) TO .250 (6.4)

¥

.020 (.50) TO .032 (.81)

BOTTOM ENTRY

.032 [0.8]

.062 [1.6]

.400

[10.2]

.134 [3.4]

.150 [3.8]

.150 [3.8]

.185 [4.7]

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

SMT LOW PROFILE EDGE CONNECTORS

SMT

EDGE

CONNECTORS

69

SMT QUICK-FIT FEMALE TERMINALS

CAT. NO. 6100TR

(Tape & Reel)

•

Designed to pass signals or power across boards

•

Generous lead-in guide aid in board assembly

•

Gold plating provides superior solderability as well as low contact resistance

•

Compatible with most automated assembly processes

SMT EDGE PIN

SMT EDGE SOCKET

SPECIFICATIONS

Material:

Phosphor Bronze, Gold Plate

Current Rating:

10 Amps

Operating Temperature:

-40°F to +257°F

(-40°C to 125°C)

Life:

100 cycles

CAT. NO. 6100

Bulk

CAT. NO. 6102TR

(Tape & Reel)

CAT. NO. 6102

Bulk

Pad Layout

.071 [1.80]

MIN.

.071 [1.80]

MIN.

Pad Layout

.151[3.84]

MIN.

.071 [1.80]

MIN.

.071 [1.8]

.110 [2.8]

.110 [2.8]

.130 [3.3]

.047 [1.2]

106 [2.7]

.151 [3.8]

REF.

.071 [1.8]

.110 [2.8]

•

Designed to pass signals or voltage across boards

•

Generous lead-in guide aid in board assembly

•

Designed to be used with

Cat. No. 3569

•

.110 tab design also allows standard crimp

terminals to be used, see page 70

•

Compatible with most automated assembly

processes

SPECIFICATIONS

Material:

Brass, Tin Plate

Current Rating:

10 Amps

Operating Temperature:

-40°F to +257°F

(-40°C to 125°C)

Life:

100 cycles

CAT. NO. 3579TR

(Tape & Reel)

CAT. NO. 3579

Bulk

Pad Layout

.110 [2.80]

MIN.

.110 [2.80]

MIN.

.114 [2.9]

.110 [2.8]

.110 [2.8]

.130 [3.3]

Tape & Reel Spec’s:

16mm wide, 8mm pitch,

7 inch reel (500 pieces per reel)

Tape & Reel Spec’s:

12mm wide, 4mm pitch,

7 inch reel (500 pieces per reel)

Tape & Reel Spec’s:

24mm wide, 8mm pitch,

13 inch reel (1000 pieces per reel)

ACCEPTS .110 (2.8)

×

.032 (.81) TAB

HORIZONTAL ENTRY

VERTICAL OR HORIZONTAL ENTRY

.312 [7.9]

.062 [1.6]

.250

[6.4]

.100 [2.54]

.075 [1.9]

.105

[2.7]

.156

[4.0]

.150 [3.8]

.242 [6.2]

.282 [7.2]

.062 [1.6]

.100 [2.5]

.185 [4.7]

.250 [6.4]

.176 [4.5]

SPECIFICATIONS

Material:

.012 (.30) Brass, Matte Tin Plate

Current Rating:

15 Amps @ 500V AC

SPECIFICATIONS

Material:

.016 (.41) Brass, Tin-Nickel Plate

Current Rating:

15 Amps @ 500V AC

Tape & Reel Spec’s:

16mm wide, 12mm

pitch, 13 inch reel (750 pieces per reel)

Tape & Reel Spec’s:

24mm wide, 8mm

pitch, 13 inch reel (2000 pieces per reel)

CAT. NO. 3569

(Bulk)

CAT. NO. 3569TR

(Tape & Reel)

CAT. NO. 3586KTR

(Tape & Reel)

CAT. NO. 3586

(Bulk)

ACCEPTS ALL TABS

VERTICAL OR HORIZONTAL ENTRY

.178

[4.5]

.150

[3.8]

.250

[6.4]

.185

[4.7]

SPECIFICATIONS

Material:

.016 (.41) Brass, Tin-Nickel Plate

Current Rating:

15 Amps @ 500V AC

Tape & Reel Spec’s:

16mm wide, 12mm

pitch, 13 inch reel (750 pieces per reel)

CAT. NO. 3584KTR

(Tape & Reel)

CAT. NO. 3584

(Bulk)

ACCEPTS ALL TABS

SMT .110 (2.8) TAB EDGE CONNECTOR

KTR parts have

Kapton Tape

added to top

surface for

vacuum pick

& place

AVAILABLE ON TAPE AND REEL

Cat. No. 3569

Cat. No.

3579

Cat. No.

6100

Cat. No.

6102

AVAILABLE ON TAPE AND REEL

AVAILABLE ON TAPE AND REEL

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

WIRE

BARREL

MAX.

CAT.

RANGE

MALE TAB

.250 (6.4)

INSUL.

NO.

(AWG)

WIDTH

×

THICK

L

W

D

LENGTH

I.D.

DIA.

8296

22

/

18 .187 (4.8)

×

.020 (.51) .87 (22.1) .37 (9.4) .30 (7.6) .24 (6.1) .080 (2.03) .145 (3.7)

8297

(Red) .250 (6.4)

×

.032 (.81) .95 (24.1) .44 (11.2) .30 (7.6) .25 (6.4) .065 (1.65) .145 (3.7)

8298

16

/

14 .187 (4.8)

×

.020 (.51) .87 (22.1) .37 (9.4) .30 (7.6) .24 (6.1) .080 (2.03) .170 (4.3)

8299

(Blue) .250 (6.4)

×

.032 (.81) .95 (24.1) .44 (11.2) .30 (7.6) .25 (6.4) .085 (2.16) .170 (4.3)

8300

12

/

10

.250 (6.4)

×

.032 (.81) 1.05 (26.7) .47 (11.9) .39 (9.9) .25 (6.4) .150 (3.81) .250 (6.4)

(Yellow)

WIRE

MATES WITH

BARREL

MAX.

CAT.

RANGE

MALE TAB

.250 (6.4)

INSUL.

NO.

(AWG)

WIDTH

×

THICK

L

W

D

I.D.

DIA.

8291

22

/

18

.187 (4.8)

×

.020 (.51) .81 (20.6) .30 (7.6) .23(5.8) .085 (2.16) .145 (3.7)

8292

(Red)

.250 (6.4)

×

.032 (.81) .87 (22.1) .37 (9.4) .23(5.8) .080 (2.03) .145 (3.7)

8293

16

/

14

.187 (4.8)

×

.020 (.51) .81 (20.6) .30 (7.6) .23(5.8) .085 (2.16) .145 (3.7)

8294

(Blue)

.250 (6.4)

×

.032 (.81) .87 (22.1) .37 (9.4) .23(5.8) .080 (2.03) .170 (4.3)

8295

12

/

10

.250 (6.4)

×

.032 (.81) .99 (25.1) .39 (9.9) .32(8.1) .165 (4.19) .250 (6.4)

(Yellow)

CAT.

MATES WITH MALE TAB

AWG

MAT’L

NO.

WIDTH

×

THICK

L

SIZE

THICK

1252

.110 (2.8)

×

.020 (.51)

.606 (15.4) 18-22 .010 (.25)

1264

.187 (4.8)

×

.020 (.51)

.576 (14.6) 16-22 .013 (.33)

4469

.205 (5.2)

×

.020 (.51)

.640 (16.3) 16-20 .013 (.33)

4470

.250 (6.4)

×

.032 (.81)

.750 (19.1) 16-20 .016 (.41)

CAT.

BOOT

NO.

COLOR

4471

CLEAR

4472

RED

4473

BLUE

WIRE

MATES WITH

BARREL

CAT.

RANGE

MALE TAB

.250 (6.4)

NO.

(AWG)

WIDTH

×

THICK

L

I.D.

8272

22

/

18

.187 (4.8)

×

.020 (.51) .58 (14.7)

.085 (2.16)

8273

.250 (6.4)

×

.032 (.81)

.66 (16.8)

.080 (2.03)

8274

16

/

14

.187 (4.8)

×

.020 (.51)

.58 (14.7)

.085 (2.16)

8275

.250 (6.4)

×

.032 (.81)

.66 (16.8)

.080 (2.03)

VINYL BOOT

QUICK-FIT FEMALES

SOLDERLESS QUICK-FIT TERMINALS

MATERIAL:

Tinned Brass

•

Easily slips over terminal

•

Insulates and protects

WIRE

MATES WITH

BARREL

MAX

CAT.

RANGE

MALE TAB

.250 (6.4) INSULATION

NO.

(AWG)

WIDTH

×

THICK

L

I.D.

DIAMETER

8276

22

/

18

.187 (4.8)

×

.020 (.51)

.78 (19.8)

.085 (2.16)

.145 (3.7)

8277

(Red)

.250 (6.4)

×

.032 (.81) .87 (22.1) .080 (2.03)

8278

16

/

14

.187 (4.8)

×

.020 (.51)

.78 (19.8)

.085 (2.16)

.145 (3.7)

8279

(Blue)

.250 (6.4)

×

.032 (.81) .87 (22.1) .080 (2.03)

8280

12

/

10

.250 (6.4)

×

.032 (.81) .96 (24.4)

.165 (4.19)

.250 (6.4)

(Yellow)

WIRE

MAX

CAT.

RANGE

MALE TAB

BARREL

INSULATION

NO.

(AWG)

WIDTH

×

THICK

L

LENGTH

I.D.

DIAMETER

8286

22

/

18 .187 (4.8)

×

.020 (.51)

.85 (21.6) .24 (6.1) .080 (2.03)

.145 (3.7)

8287

(Red)

.250 (6.4)

×

.032 (.81)

.93 (23.6) .25 (6.4) .065 (1.65)

.145 (3.7)

8288

16

/

14 .187 (4.8)

×

.020 (.51)

.85 (21.6) .24 (6.1) .080 (2.03)

.145 (3.7)

8289

(Blue)

.250 (6.4)

×

.032 (.81)

.93 (23.6) .25 (6.4) .085 (2.16)

.170 (4.3)

8290

12

/

10

.250 (6.4)

×

.032 (.81) 1.05 (26.7) .25 (6.4) .150 (3.81)

.250 (6.4)

(Yellow)

L

WIDTH

L

L

WIDTH

WIDTH

L

WIDTH

L

WIDTH

L

D

W

WIDTH

L

D

W

WIDTH

SOLDERLESS

TERMINALS

70

FEMALE NON-INSULATED

For .250 (6.4) QUICK-FITS

FEMALE NON-INSULATED

FEMALE VINYL INSULATED

MALE NON-INSULATED

MALE VINYL INSULATED

FEMALE FULLY INSULATED NYLON

MALE FULLY INSULATED NYLON

Boot and Quick-Fit sold separately

.298 [7.6]

.920

[23.4]

.354 [9.0]

.187

[4.7]

.131 [3.3]

.140 [3.5] DIA.

L

TAB SIZE

WIRE

CAT.

RANGE

MALE TAB

BARREL

NO.

(AWG)

FIG. WIDTH

×

THICK

L

LENGTH

I.D.

8281

22

/

18

2

.187 (4.8)

×

.020 (.51) .64 (16.3) .24 (6.1) .080 (2.03)

8282

1 .250 (6.4)

×

.032 (.81) .73 (18.5) .25 (6.4) .065 (1.65)

8283

16

/

14

2

.187 (4.8)

×

.020 (.51) .64 (16.3) .24 (6.1) .080 (2.03)

8284

1 .250 (6.4)

×

.032 (.81) .73 (18.5) .25 (6.4) .085 (2.16)

8285

12

/

10

1 .250 (6.4)

×

.032 (.81) .75 (19.1) .25 (6.4) .150 (3.81)

FIG. 2

FIG. 1

SPECIFICATIONS:

Terminals:

EPT Copper

Insulation:

Vinyl

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

BARREL

WIRE

FOR

.250 (6.4)

MAX.

CAT.

RANGE STUD

MATL

LONG

INSUL.

NO.

(AWG) SIZE

W

L

E

THICK

I.D.

DIA.

8209

22

/

18

6

.25 (6.4) .80 (20.3) .67 (17.0)

8210

(Red)

8

.33 (8.4) .90 (22.9) .74 (18.8) .030 (.76) .070 (1.78)

.145 (3.7)

8211

10

.33 (8.4) .90 (22.9) .74 (18.8)

8212

16

/

14

6

.25 (6.4) .80 (20.3) .67 (17.0)

8213

(Blue)

8

.33 (8.4) .90 (22.9) .74 (18.8) .030 (.76) .090 (2.29)

.170 (4.3)

8214

10

.33 (8.4) .90 (22.9) .74 (18.8)

8215

12

/

10

6

.28 (7.1) .98 (24.9) .84 (21.3)

8216

(Yellow)

8

.38 (9.7) 1.03 (26.2) .84 (21.3) .040 (1.02) .135 (3.43)

.250 (6.4)

8217

10

.38 (9.7) 1.03 (26.2) .84 (21.3)

WIRE

FOR

FLANGED

CAT.

RANGE STUD

MATL

BARREL

CAT.

NO.

(AWG) SIZE

W

L

E

THICK

I.D.

NO.

8218

6

8236

8219

22/18

8

.30 (7.6) .65 (16.5) .50 (12.7) .030 (.76) .090 (2.29)

8237

8220

10

8238

8221

6

8239

8222

16/14

8

.30 (7.6) .65 (16.5) .50 (12.7) .030 (.76) .090 (2.29)

8240

8223

10

8241

8224

6

8242

8225

12/10

8

.32 (8.1) .73 (18.5) .54 (13.7) .040 (1.02) .135 (3.43)

8243

8226

10

8244

WIRE

FOR

BARREL

CAT.

RANGE

STUD

MATL

NO.

(AWG)

SIZE

W

L

E

THICK

I.D.

8200

6

.25 (6.4) .60 (15.2) .47 (11.9)

8201

22

/

18

8

.33 (8.4) .70 (17.8) .54 (13.7) .030 (.76) .070 (1.78)

8202

10

.33 (8.4) .70 (17.8) .54 (13.7)

8203

6

.25 (6.4) .60 (15.2) .47 (11.9)

8204

16

/

14

8

.33 (8.4) .70 (17.8) .54 (13.7) .030 (.76) .090 (2.29)

8205

10

.33 (8.4) .70 (17.8) .54 (13.7)

8206

6

.28 (7.1) .68 (17.3) .54 (13.7)

8207

12/10

8

.38 (9.7) .73 (18.5).54 (13.7) .040 (1.02).135 (3.43)

8208

10

.38 (9.7) .73 (18.5).54 (13.7)

WIRE

FOR

CAT.

RANGE

STUD

MATL

BARREL

NO.

(AWG)

SIZE

W

L

E

THICK

I.D.

8254

6

.25 (6.4)

8255

22

/

18

8

.30 (7.6) .68 (17.3) .50 (12.7) .030 (.76) .070 (1.78)

8256

10

.32 (8.1)

8257

6

.25 (6.4)

8258

16

/

14

8

.30 (7.6)

.68 (17.3) .50 (12.7) .030 (.76) .090 (2.29)

8259

10

.32 (8.1)

8260

6

.28 (7.1)

8261

12

/

10

8

.32 (8.1) .73 (18.5) .53 (13.5) .040 (1.02) .135 (3.43)

8262

10

.32 (8.1)

BARREL

WIRE

FOR

.250 (6.4)

MAX.

CAT.

RANGE STUD

MATL

LONG

INSUL.

NO.

(AWG) SIZE

W

L

E

THICK

I.D.

DIA.

8263

22

/

18

6

.25 (6.4)

8264

(Red)

8

.30 (7.6)

.88 (22.4) .70 (17.8) .030 (.76)

.070 (1.78) .145 (3.7)

8265

10

.32 (8.1)

8266

16

/

14

6

.25 (6.4)

8267

(Blue)

8

.30 (7.6)

.88 (22.4) .70 (17.8) .030 (.76)

.090 (2.29) .170 (4.3)

8268

10

.32 (8.1)

8269

12

/

10

6

.28 (7.1)

8270

(Yellow)

8

.32 (8.1) 1.03 (26.2) .83 (21.2) .040 (1.02) .135 (3.43) .250 (6.4)

8271

10

.32 (8.1)

L

W

E

.250

[6.4]

E

W

L

E

W

L

.250

[6.4]

L

W

E

E

.250

[6.4]

W

L

L

W

E

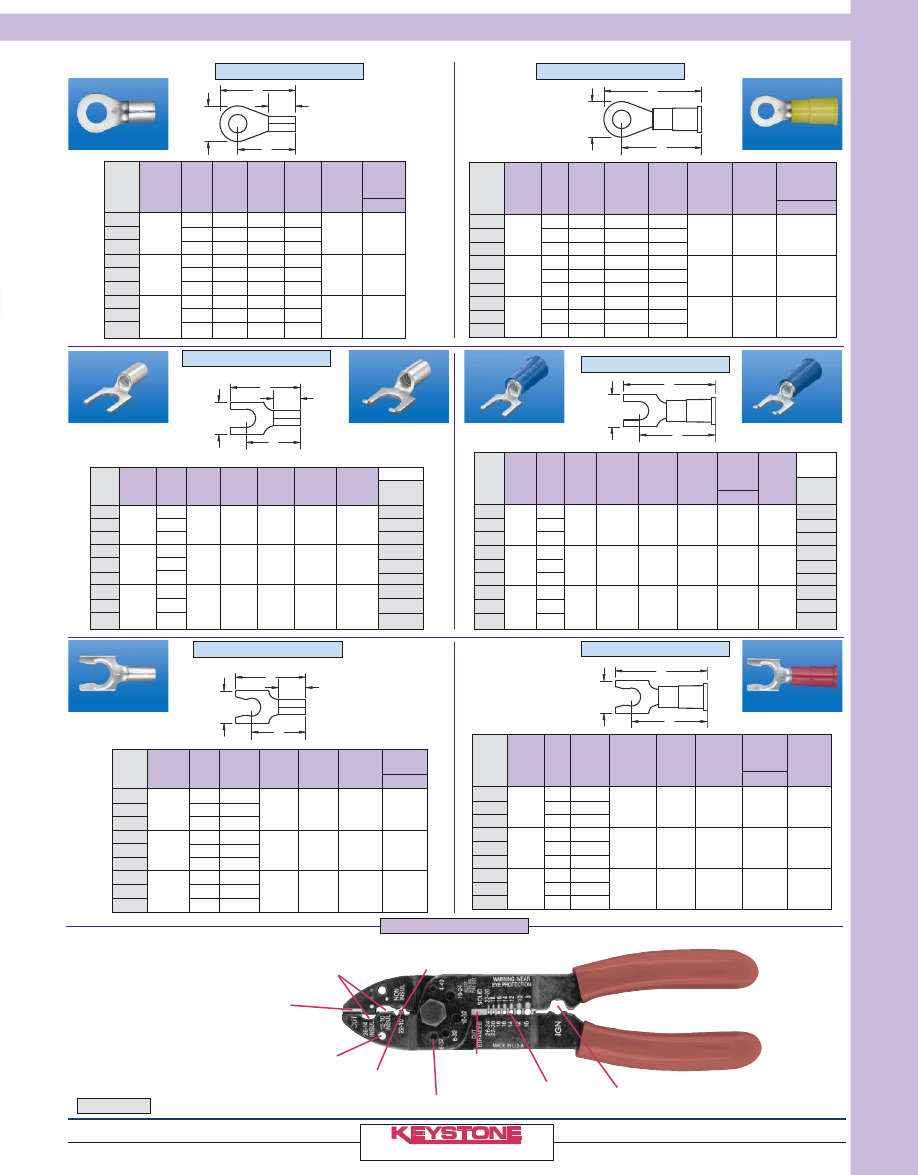

RING TONGUE NON-INSULATED

Flanged

Flanged

SOLDERLESS

TERMINALS

SOLDERLESS TERMINALS

71

RING TONGUE INSULATED

BLOCK SPADE NON-INSULATED

BLOCK SPADE INSULATED

SNAP SPADE NON-INSULATED

SNAP SPADE INSULATED

Slots for looping

solid wire

Confined trapezoid-type crimping

dies for insulated terminals

Indentor-type crimping die

for non-insulated terminals

Anvil-type wire cutter

is precision ground

“F” type crimping die 7-8 mm

for automotive terminals

Wire Stripper is also

handy wire gauge

(#22 thru #8 AWG)

Precision ground

scissors action

wire cutter

Threaded bolt cutter

for five common sizes

Crimping die for

non-insulated terminals

CAT. NO. 1345

BARREL

WIRE FOR

.250 (6.4) MAX. FLANGED

CAT.

RANGE STUD

MATL

LONG

INSUL.

CAT.

NO.

(AWG) SIZE

W

L

E

THICK

I.D.

DIA.

NO.

8227

22

/

18

6

8245

8228

(Red)

8

.30 (7.6) .85 (21.6) .70 (17.8) .030 (.76) .070 (1.78) .145 (3.7)

8246

8229

10

8247

8230

16

/

14

6

8248

8231

(Blue)

8

.30 (7.6) .85 (21.6) .70 (17.8) .030 (.76) .090 (2.29) .175 (4.4)

8249

8232

10

8250

8233

12

/

10

6

8251

8234

(Yellow)

8

.32 (8.1) 1.03 (26.2) .84 (21.3) .040 (1.02) .135 (3.43) .255 (6.5)

8252

—

10

8253

HAND CRIMP TOOL

SPECIFICATIONS:

Terminals:

EPT Copper

Insulation:

Vinyl

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

i-Clamps

–

IDC

CONNECTORS

72

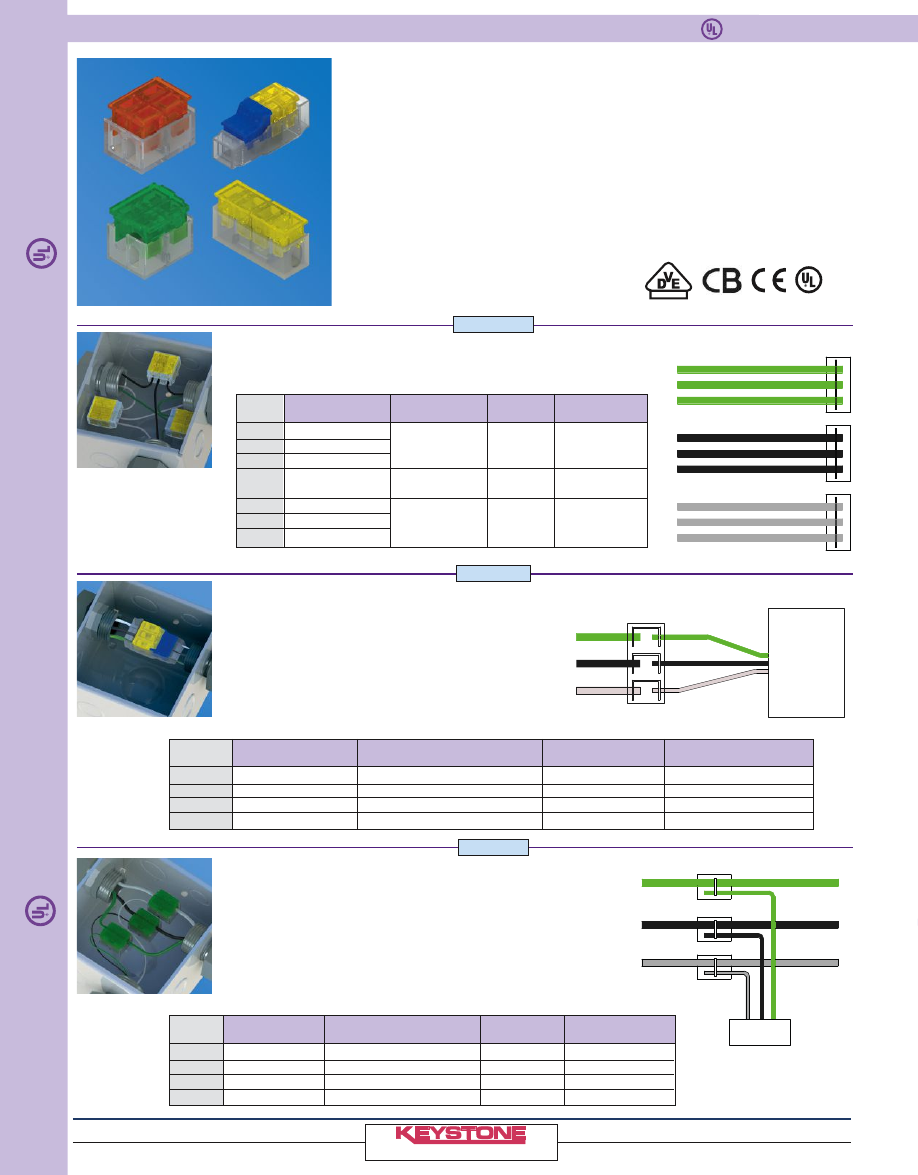

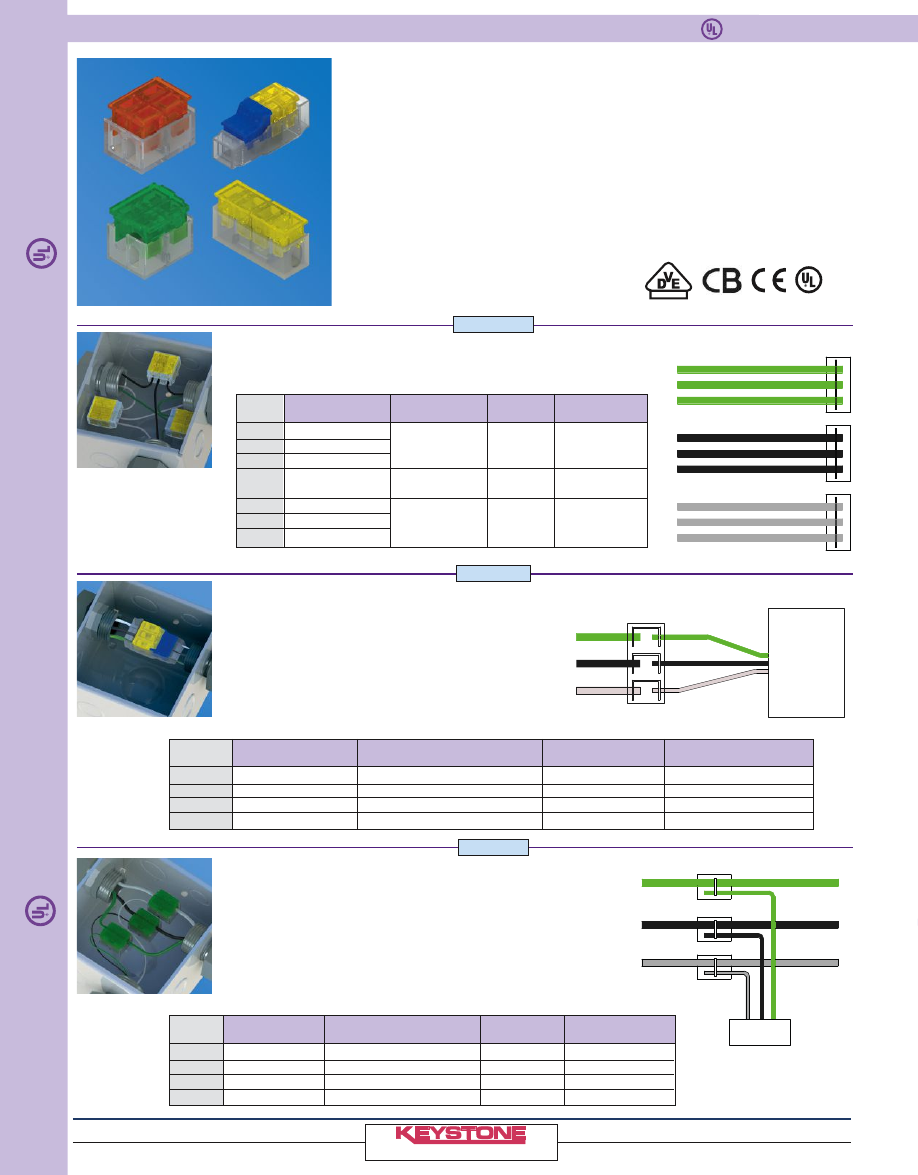

i-Clamps – IDC WIRE-TO-WIRE CONNECTORS

i-Clamp Insulation Displacement wire connectors provide a quick and secure method of connecting wires

and devices. The i-Clamps easily pierces the wire insulation to make a tamper proof and reliable connec-

tion without the need to cut, strip or otherwise secure the wires. Without having to strip or prepare the

wires, installations time is dramatically reduced while connection security is enhanced. i-Clamps are

made from translucent Polycarbonate which makes these devices durable in shock and vibration environ-

ments as well as provide the ability to visually inspect the connections. Once secured, the connection is

permanent and tamper proof without the need to worry about wire exposure or nuts and tape falling off

over time.

One-Way Series

T-Series

Two-Way Series

Quick/easy splice for up to four lines

i-Clamp hinges open to allow main wire to be ran

thru connector without any cuts or stripping

•

Dual wire clamp allows for i-Clamp to be preassembled

onto fixture at factory. Splice can be completed on site

•

Pre-assembly eliminates risk of i-Clamp being lost during

fixture insulation

Specifications:

Housing:

Polycarbonate, UL 94V-0

Contact/Jumper:

High Performance Copper Alloy, Nickel Plate

UL Listed:

E490622/E490623

Voltage Rating:

277 VAC

CAT.

# OF WIRE RUNS/

WIRE RANGE

NO.

TAPS

(IN/OUT)

COLOR CODE

CURRENT RATING

8360

1 Wire

#16-14 AWG (In) / #16-14 AWG (Out)

Yellow

10 Amps @ 277 VAC

8361

2 Wires

#18 AWG (In) / #18 AWG (Out)

Blue

10 Amps @ 277 VAC

8362

2 Wires

#14 AWG (In) / #20-18 AWG (Out)

Yellow / Blue

5 Amps @ 277 VAC

8363

3 Wires

#14 AWG (In) / #20-18 AWG (Out)

Yellow / Blue

5 Amps @ 277 VAC

CAT.

# OF WIRE RUNS/

WIRE RANGE

NO.

TAPS

(IN/OUT)

COLOR CODE

CURRENT RATING

8370

2 Wires

8371

3 Wires

#14 AWG

Yellow

20 Amps @ 277 VAC

8372

4 Wires

8373

4 wire, 2 circuit

#14 AWG

Yellow/Blue

20 Amps @ 277 VAC

8374

2 Wires

8375

3 Wires

#14-12 AWG

Orange

20 Amps @ 277 VAC

8377

4 Wires

INPUT

GROUND

INPUT

HOT

INPUT

NEUTRAL

OUTPUT HOT

OUTPUT NEUTRAL

OUTPUT GROUND

FIXTURE

For Adding Fixtures or Components

GROUND (INPUT/OUTPUT)

HOT (INPUT/OUTPUT)

NEUTRAL (INPUT/OUTPUT)

For Splicing Lines

For Branching a Wire

INPUT GROUND

RUNS THROUGH

INPUT HOT

RUNS THROUGH

INPUT NEUTRAL

RUNS THROUGH

OUTPUT NEUTRAL TAP

OUTPUT HOT TAP

OUTPUT GROUND TAP

FIXTURE

CAT.

# OF WIRE RUNS/

WIRE RANGE

NO.

TAPS

(IN/OUT)

COLOR CODE

CURRENT RATING

8380

1 Run / 1 Tap

#14 AWG (In) / #16 AWG (Out)

Green

15 Amps @ 277 VAC

8381

1 Run / 1 Tap

#12-10 AWG (In) / #16-14 AWG (Out)

Yellow

15 Amps @ 277 VAC

8382

1 Run / 1 Tap

#12-10 AWG (In) / #14-12 AWG (Out)

Orange

20 Amps @ 277 VAC

8383

1 Run / 1 Tap

#16-14 AWG (In) / #22-18 AWG (Out)

Blue

5 Amps @ 277 VAC

Note: Product suitability to your application must be determined prior to use.

All appropriate electrical codes should be followed.

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

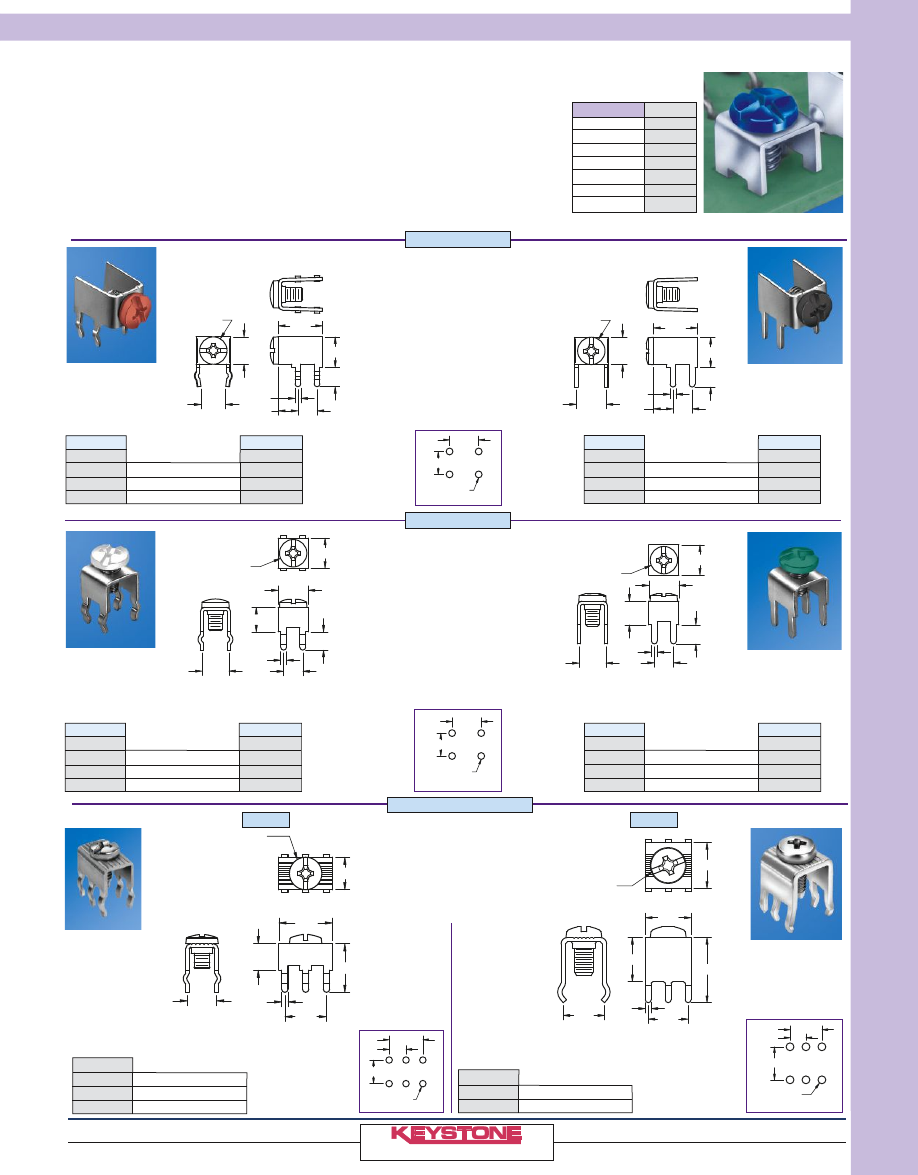

60° Angle

90° Angle

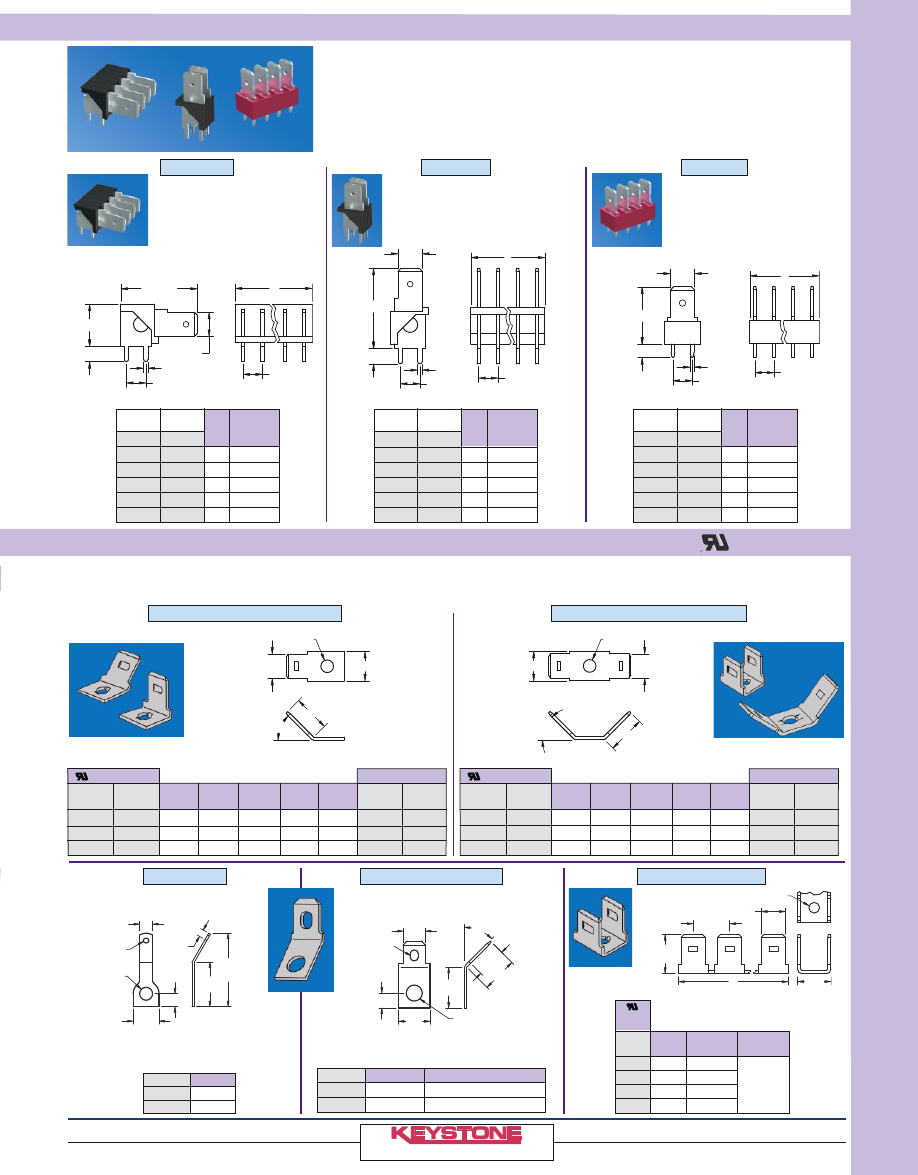

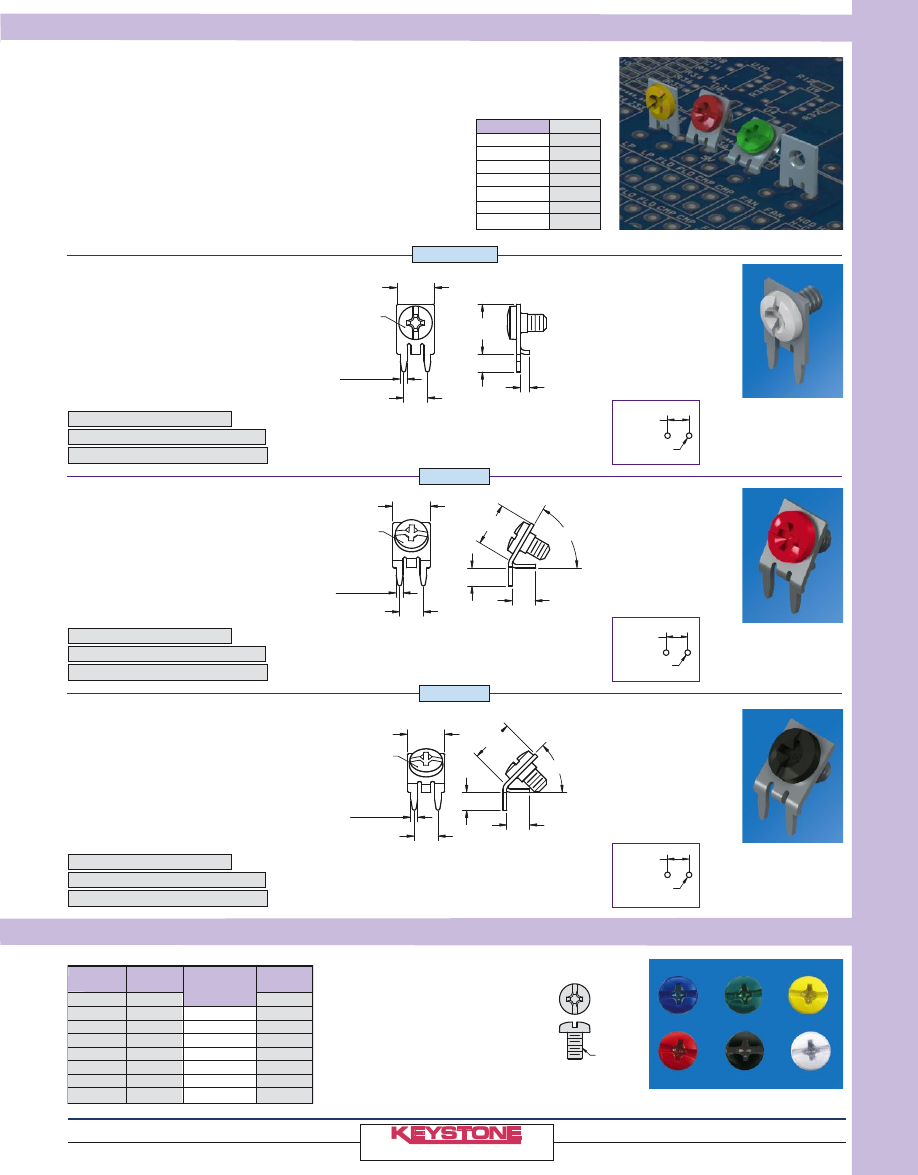

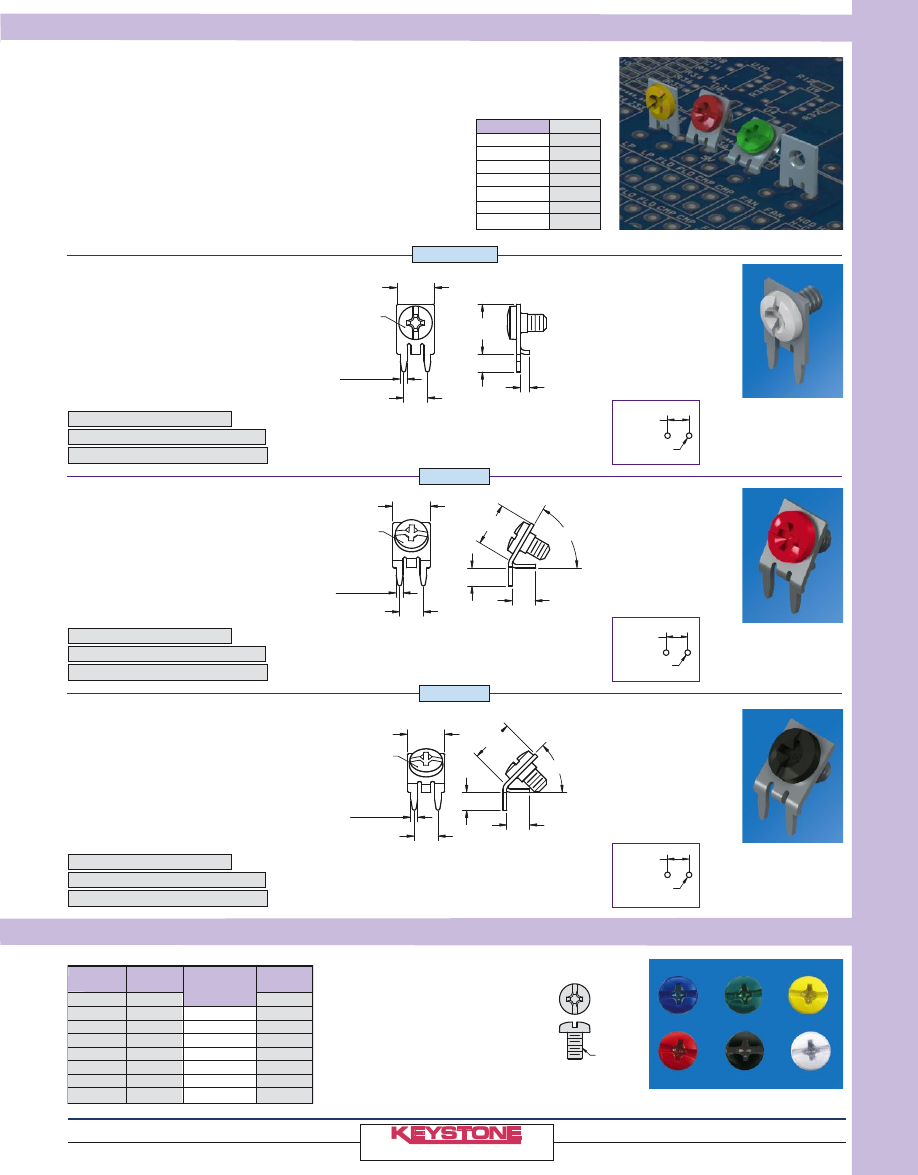

SLIM-LINE PC SCREW TERMINALS

SLIM-LINE

SCREW

TERMINALS

73

HEAD COLOR

SUFFIX

RED

-2

BLACK

-3

WHITE

-4

BLUE

-5

GREEN

-6

YELLOW

-7

NICKEL

none

COLOR SELECTION:

Select desired screw terminal

and add color suffix to the

screw terminal Cat. No.

BINDING HEAD SCREWS – COLORED HEAD

Ideal for quick identification of screw ter-

minal. Reduces errors in wiring of cables.

See pages 73-77 for screw terminals

with colored screws installed. Only head

is painted, provides reliable electrical

contact to terminal.

THREAD

MATERIAL:

Brass, Nickel Plate with Painted Color Head

M4 ×

M3 ×

6-32 ×

6.3mm L

6mm L

.250 (6.3) L

CAT. NO.

CAT. NO.

HEAD COLOR

CAT. NO.

7799-1

7689-1

NICKEL

8190-1

9192-2

9191-2

RED

9190-2

9192-3

9191-3

BLACK

9190-3

9192-4

9191-4

WHITE

9190-4

9192-5

9191-5

BLUE

9190-5

9192-6

9191-6

GREEN

9190-6

9192-7

9191-7

YELLOW

9190-7

These easy to mount multi-purpose screw terminals are a practical low cost alternative to PC edge connectors. Will accept solid

& stranded wire or wire crimp terminals. Supplied unassembled or with screw installed and captivated. These screw terminals

have the same mounting hole pattern as quick fit terminals which allows instant change between quick fit and screw terminals.

Features:

•

Same mounting hole pattern as most quick fit terminals

•

Color coded screws available for quick identification

•

Stable no rock design

•

Accepts #14-22 AWG solid or stranded wire,

crimp terminals or lugs

•

Ideally suited for high density packaging

•

Easy accessible for PC board assembly

and troubleshooting

CAT. NO. 7837

(No Screw Supplied)

CAT. NO. 8183

(Screw Supplied Unassembled)

CAT. NO. 7757

(Screw Installed & Captivated)

Specifications:

Current Rating:

15 Amps

Terminal:

Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

Color coded screws

available (add color

screw suffix to Cat No.)

6-32 SCREW

.150 [3.8]

.050 [1.27]

.045 [1.14]

.315

[8.0]

.421 [10.7]

.078 [2.0]

.200

[5.1]

.052 [1.3] DIA.

.200 [5.1]

Mounting Detail

45° Angle

CAT. NO. 7838

(No Screw Supplied)

CAT. NO. 8184

(Screw Supplied Unassembled)

CAT. NO. 7758

(Screw Installed & Captivated)

Specifications:

Current Rating:

15 Amps

Terminal:

Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

Color coded screws

available (add color

screw suffix to Cat No.)

6-32 SCREW

.050 [1.27]

.045 [1.14]

.315

[8.0]

.150 [3.8]

.197

[5.0]

60°

.360 [9.16]

.200

[5.1]

.052 [1.3] DIA.

.200 [5.1]

Mounting Detail

CAT. NO. 7839

(No Screw Supplied)

CAT. NO. 8185

(Screw Supplied Unassembled)

CAT. NO. 7759

(Screw Installed & Captivated)

Specifications:

Current Rating:

15 Amps

Terminal:

Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

Color coded screws

available (add color

screw suffix to Cat No.)

6-32 SCREW

.200

[5.1]

.050 [1.27]

.045 [1.14]

.197

[5.0]

.315

[8.0]

.150 [3.8]

.360 [9.16]

45°

.200 [5.1]

.052 [1.3] DIA.

Mounting Detail

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

SCREW

TERMINALS

74

Mounting Detail

.073 [1.85] DIA.

(4) PLS

.295 [7.5]

.197 [5.0]

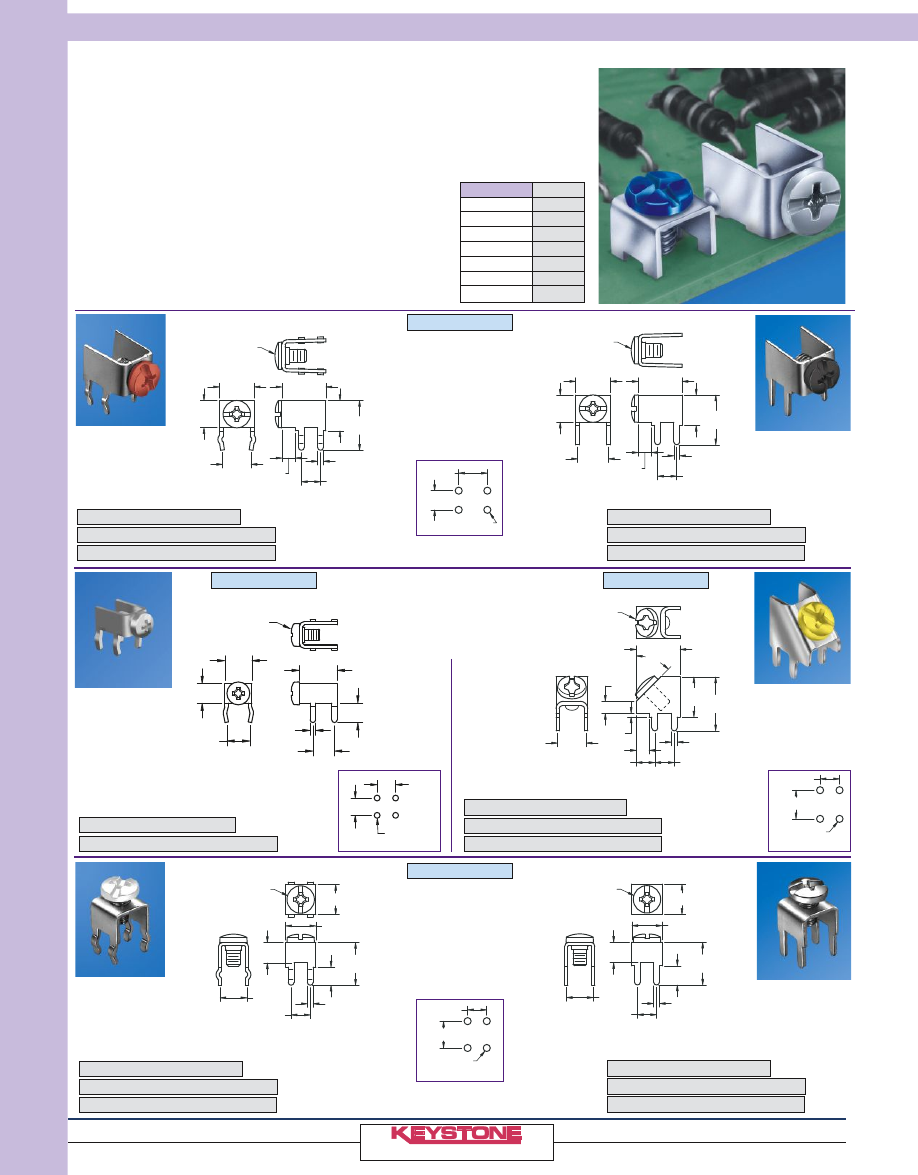

These easy-to-mount, multipurpose screw type terminals are a practical,

low-cost alternative to PC screw type edge connectors, barrier blocks, terminal

boards and terminal strips. Steadfast and easy to install, will accommodate

solid or stranded wire, crimp type terminals or lugs. Multi-placement of these

low-profile terminals make them ideally suited for high density packaging.

Supplied unassembled or with screw installed and captivated.

PRINCIPAL FEATURES

•

Low profile

•

Stable, no-rock design with exclusive anti-rotational feature

•

Easily mounts with four legs into pre-drilled or punched holes

•

Accepts #14-22 AWG solid or stranded wire, crimp type terminals or lugs

•

Ideally suited for high-density packaging

•

Available in horizontal or vertical mounting

•

Space-saving and time saving

•

Easy accessibility for PC board testing

•

Binding screw is positioned above board level to avoid wicking during

wave soldering

•

Terminals are made of Brass with Tin Plate

•

Supplied with a combination drive 6-32 binding head screw

SPECIFICATIONS

Rated:

15 Amps

Terminal:

.032 (.81) Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

.073 [1.85] DIA.

(4) PLS

.197 [5.0]

.276 [7.0]

SPECIFICATIONS

Rated:

15 Amps

Terminal:

.032 (.81) Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

SNAP-IN

PC MOUNT

PC MOUNT

PC MOUNT

SNAP-IN

PC MOUNT

Mounting Detail

.073 [1.85] DIA.

(4) PLS

.200 [5.1]

.295 [7.5]

Mounting Detail

.452 [11.5]

6-32 x .250 [6.3] L.

SCREW

.197 [5.0]

.512

[13.0]

.060 [1.52]

(4) PLS

.312

[7.9]

.138

[3.5]

.327

[8.3]

.280

[7.1]

.295

[7.5]

.312

[7.9]

.060 [1.52]

(4) PLS

.512

[13.0]

.280

[7.1]

.327

[8.3]

.295

[7.5]

.452 [11.5]

.138

[3.5]

.197 [5.0]

6-32 x .250 [6.3] L.

SCREW

.210 [5.4]

.276 [7.0]

.440

[11.2]

.187 [4.8]

.310 [7.9]

.310 [7.9]

6-32 x .250 [6.3] L.

SCREW

.060 [1.52]

(4) PLS

.197 [5.0]

.310 [7.9]

.210 [5.4]

.197 [5.0]

.310 [7.9]

.440

[11.2]

.276 [7.0]

6-32 x .250 [6.3] L.

SCREW

.197 [5.0]

.060 [1.52]

(4) PLS

6-32 x .250 [6.3] L.

SCREW

.295

[7.5]

REF.

.450 [11.5]

.200 [5.1]

45°

.412

[10.5] .555

[14.1]

.190 [4.9]

.037 [1.0]

.130 [3.3]

.125

[3.2]

REF.

.060 [1.52]

(4) PLS

SPECIFICATIONS

Rated:

15 Amps

Terminal:

.032 (.81) Brass, Matte Tin Plate

Binding Head Screw:

Brass, Nickel Plate

PC MOUNT

Color coded screws available

(add color screw suffix to Cat. No.)

Color coded screws available

(add color screw suffix to Cat. No.)

PC SCREW TERMINALS

HORIZONTAL TYPE

VERTICAL TYPE

45°

MINI

CAT. NO. 7780

(No Screw Supplied)

CAT. NO. 7691

(Screw Supplied Unassembled)

CAT. NO. 7693

(Screw Installed & Captivated)

CAT. NO. 7782

(No Screw Supplied)

CAT. NO. 8191

(Screw Supplied Unassembled)

CAT. NO. 7701

(Screw Installed & Captivated)

CAT. NO. 7779

(No Screw Supplied)

CAT. NO. 7690

(Screw Supplied Unassembled)

CAT. NO. 7692

(Screw Installed & Captivated)

CAT. NO. 7781

(No Screw Supplied)

CAT. NO. 8190

(Screw Supplied Unassembled)

CAT. NO. 7700

(Screw Installed & Captivated)

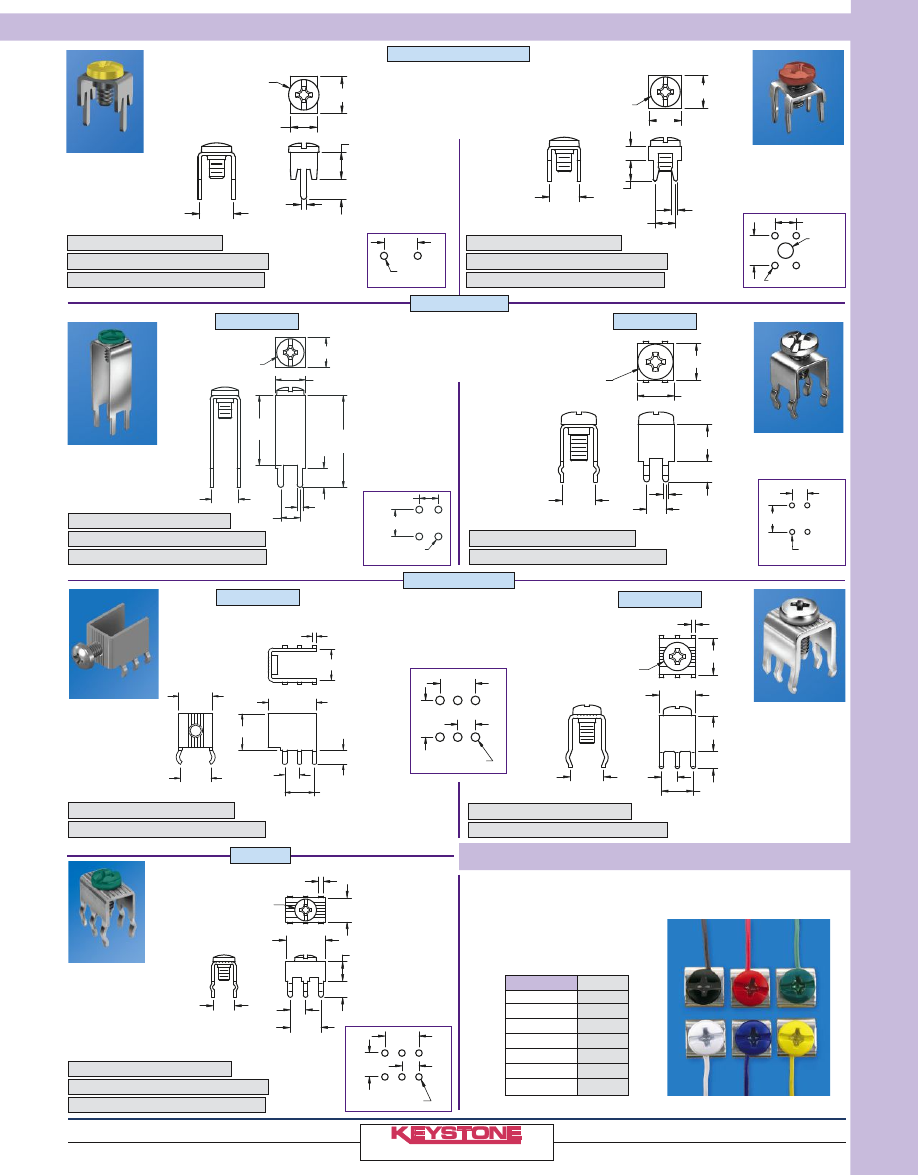

COLOR SELECTION:

Select desired screw terminal

and add color suffix to the

screw terminal Cat. No.

HEAD COLOR

SUFFIX

RED

-2

BLACK

-3

WHITE

-4

BLUE

-5

GREEN

-6

YELLOW

-7

NICKEL

none

7693-5

7700

7700-3

7701

7702-7

CAT. NO. COLOR SUFFIX

Ex:

XXXX

-X

CAT. NO. 7783

(No Screw Supplied)

CAT. NO. 8189

(Screw Supplied Unassembled)

CAT. NO. 7702

(Screw Installed & Captivated)

7693-4

7692-2

•

Color coded screws

available (add color

screw suffix to Cat. No.)

•

Color coded screws

available (add color

screw suffix to Cat. No.)

•

Color coded screws

available (add color

screw suffix to Cat. No.)

•

Color coded screws

available (add color

screw suffix to Cat. No.)

•

Color coded screws

available (add color

screw suffix to Cat. No.)

[5.4]

.200 [5.1]

.214

.062 [1.57] DIA.

(4) PLS

Mounting Detail

.180 [4.6]

.180 [4.6]

.350 [8.9]

[6.4]

.214 [5.4]

.200

[5.1]

.050

[1.3]

(4) PLS

.250

4-40 X .250 [6.3] L.

SCREW

CAT. NO. 7774

(No Screw Supplied)

CAT. NO. 7773

(Screw Supplied Unassembled)

7773

SNAP-IN

PC MOUNT

keystone-Terminals-Test-Points-html.html

Tel (516) 328-7500

•

Fax (516) 328-1080

(800) 221-5510

•

kec@keyelco.com

www.keyelco.com

55 S. Denton Avenue, New Hyde Park, NY 11040

RoHS COMPLIANT

~

ISO 9001 CERTIFIED

®

SCREW

TERMINALS

COLOR CODED GUIDE

PC SCREW TERMINALS

75

.067 [1.7] DIA.