ETALDOC 591/9

Page 1 of 6

December 2003

PRODUCT DATA SHEET

LOW DISTORTION

P3356

LINE MATCHING TRANSFORMER

Features

Applications

∗

Lead-free (Pb-free)

∗

V.90 and V.92 Modems

∗

Low Distortion

∗

V.34 Modems

∗

12.6mm (0.5”) Seated Height

∗

Fax Machines

∗

Industry Standard Pinout

∗

Instrumentation

∗

IEC 950 and UL 60950 Certified

∗

UL Recognized Component

∗

Environmentally tested to IEC 68

∗

CERT reliability tested

∗

Excellent Frequency Response

∗

Simple Matching

∗

High Thermal Stability

DESCRIPTION

P3356 is intended for V.90 and V.92 (56kbps)

modems and other high-speed applications where

ultra-low distortion at moderate power levels and

very low voiceband frequencies is required at a

most competitive price.

P3356 uses patented design and construction

methods to achieve excellent signal performance

and safety isolation to international standards,

making it the component of choice for high-speed

data applications throughout the world. P3356 is

certified to IEC 950, UL 60950. P3356 is a UL

Recognized Component, and is supported an

IEC CB Test Certificate. The part is completely

lead-free and suitable for lead-free and

conventional processing.

P3356 has exceptionally flat frequency response

from 30Hz to 10kHz, a 3dB bandwidth of over

50kHz and requires only the very simplest of

matching to achieve good return loss and

transhybrid loss across the voiceband, with very

low levels of signal distortion at signal frequencies

as low as 150Hz.

P3356 is a rugged lightweight design that

exhibits stable characteristics over its full

operating temperature range to maximize data

throughput under varying environmental

conditions without the need for modem

retraining.

P3356 has been subjected to relevant

environmental testing according to IEC 68 and

Combined Environmental Reliability Testing

(CERT) beyond normal operational levels and

passed all tests, remaining fully functional.

Patented

line_P3356-html.html

P3356

ETALDOC 591/9

Page 2 of 6

December 2003

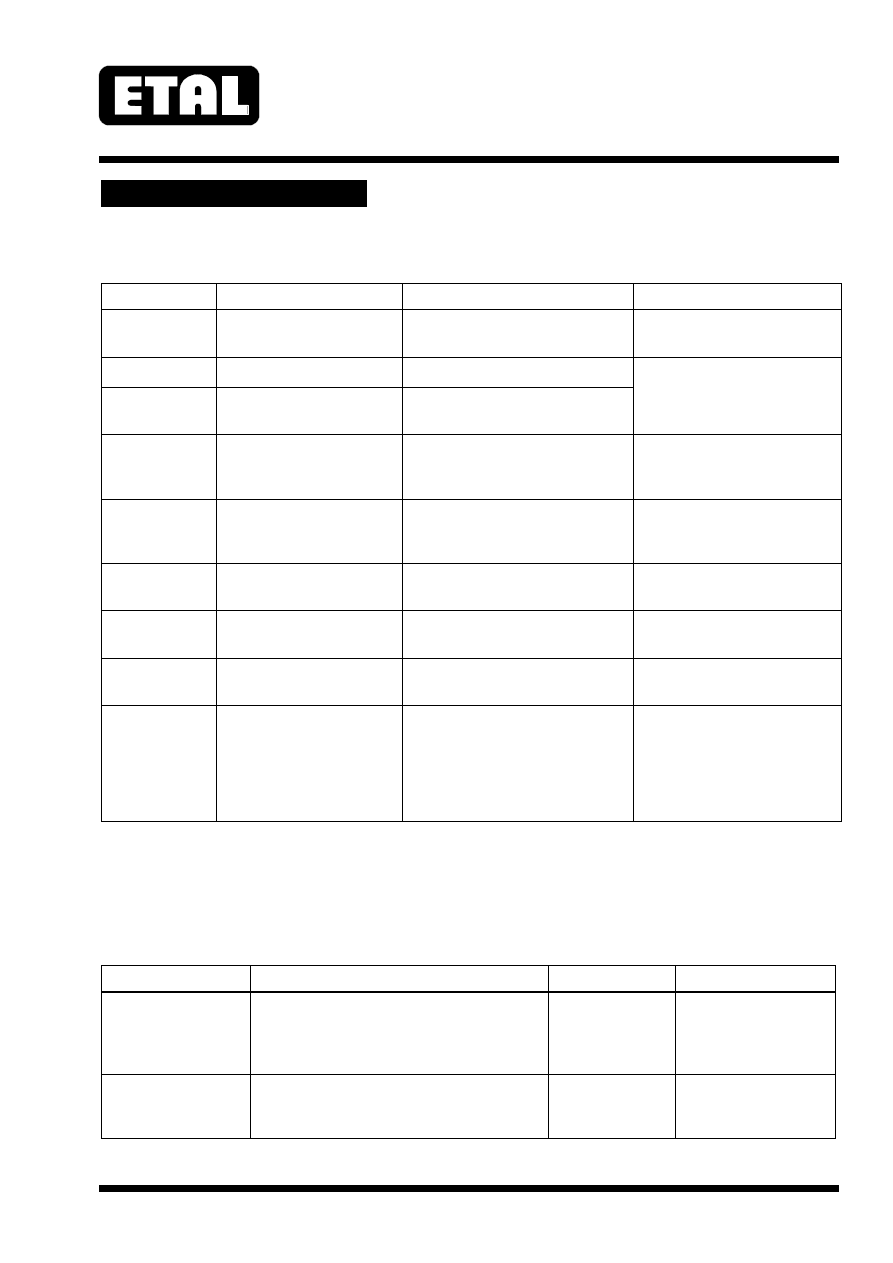

SPECIFICATIONS

Electrical

At T = 25ºC and as circuit Fig. 2 unless otherwise stated.

Parameter

Conditions

Min

Typ

Max

Units

Insertion Loss

f = 2kHz, R

L

= 600

Ω

-

1.5

-

dB

Frequency Response

LF -3dB cutoff

HF -3dB cutoff

100Hz – 4kHz

-

-

-

10

55

-

-

-

±

0.1

Hz

kHz

dB

Return Loss

(5)

200Hz – 4kHz

16

-

-

dB

Transhybrid Loss

(5)

200Hz – 4kHz

20

-

-

dB

Third Harmonic

Distortion

(1)

150Hz -3dBm in line

200Hz -10dBm in line

-

-

-70

-89

-

-

dBm

dBm

Voltage Isolation

(2)

50Hz

DC

2.12

3.0

-

-

-

-

kVrms

kV

Operating Range:

Functional

Storage

0

-40

-

-

+70

+85

ºC

ºC

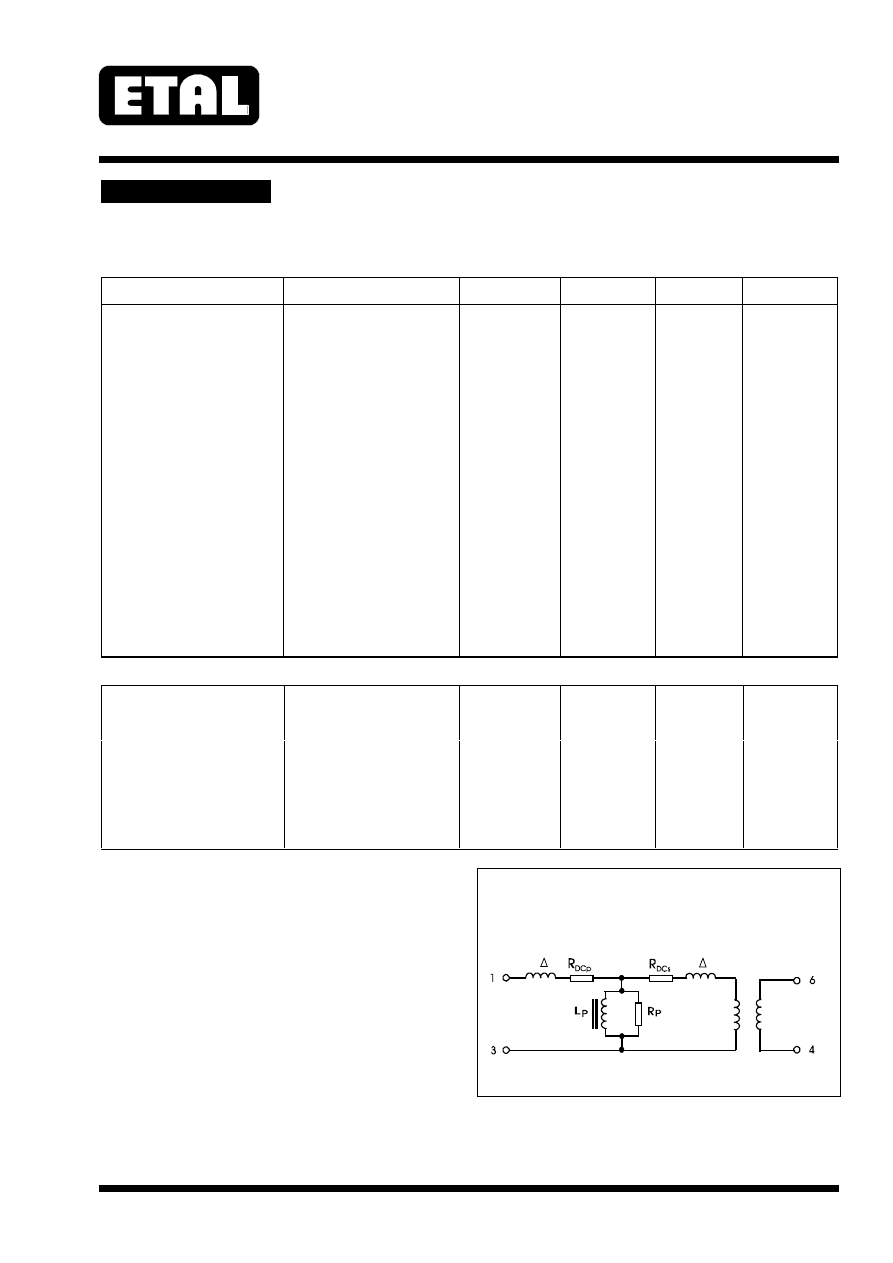

Lumped equivalent circuit parameters as Fig. 1

DC resistance

(3)

Primary resistance R

DCp

Secondary resistance R

DCs

70

95

-

-

87

120

Ω

Ω

Leakage inductance,

∆

L

3

3.9

5

mH

Shunt inductance, Lp

(4)

200Hz, 10mV

6

9

-

H

Shunt loss, Rp

200Hz, 10mV

12

15

-

k

Ω

Notes:

1. Third harmonic typically exceeds other

harmonics by 10dB.

2. Components are 100% tested at 3.25kVDC.

3. Caution: do not pass DC through windings.

Telephone line current must be diverted using

semiconductor line hold circuit or choke.

4. At signal levels greater than 100mV, Lp will

increase and Rp will decrease slightly but the

effect is usually favourable to the return loss

characteristic.

5. Return loss and transhybrid loss can be

improved to 30dB in improved matching circuit.

The values shown relate to the simplest

configuration, Fig. 2.

Equivalent Circuit

Fig. 1

IDEAL

1:1

½ L

½ L

line_P3356-html.html

P3356

ETALDOC 591/9

Page 3 of 6

December 2003

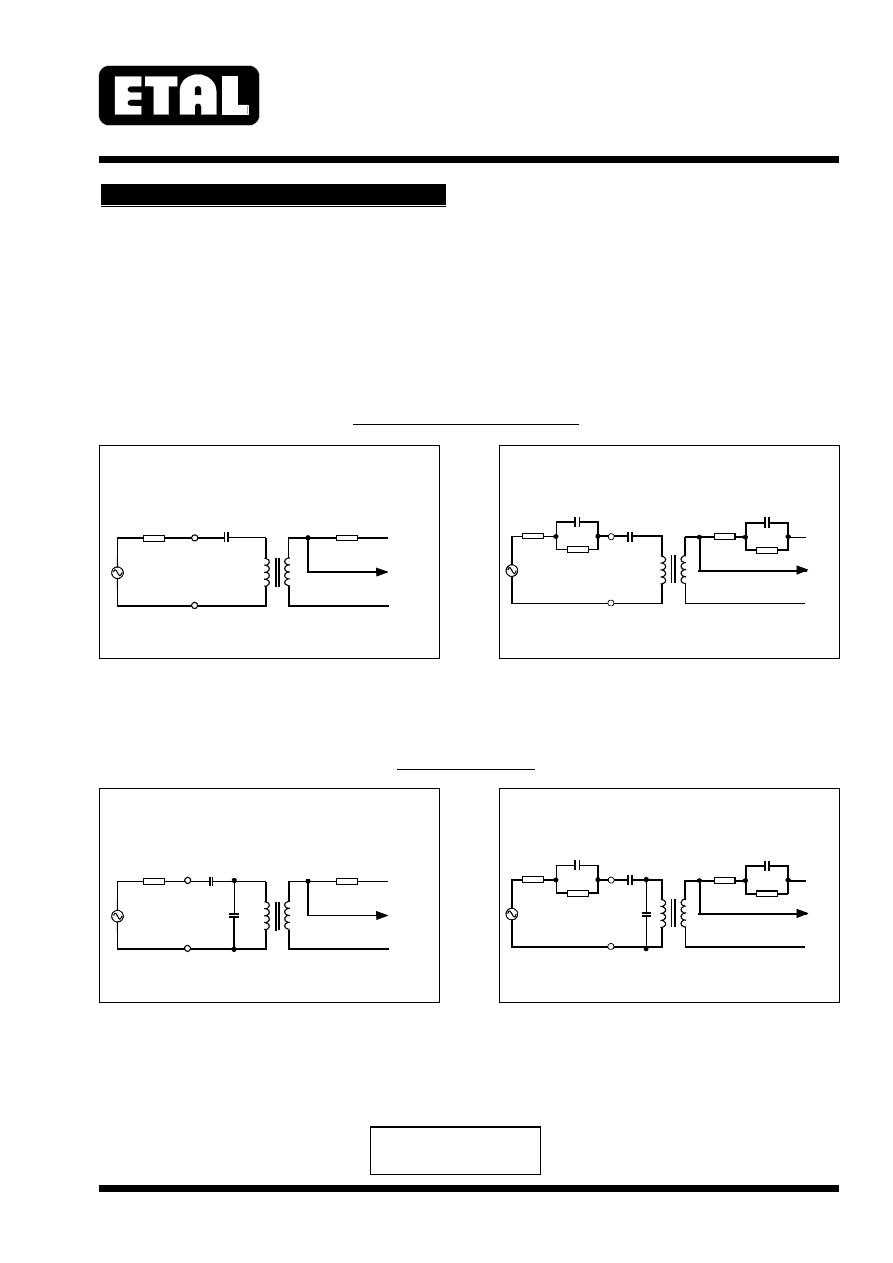

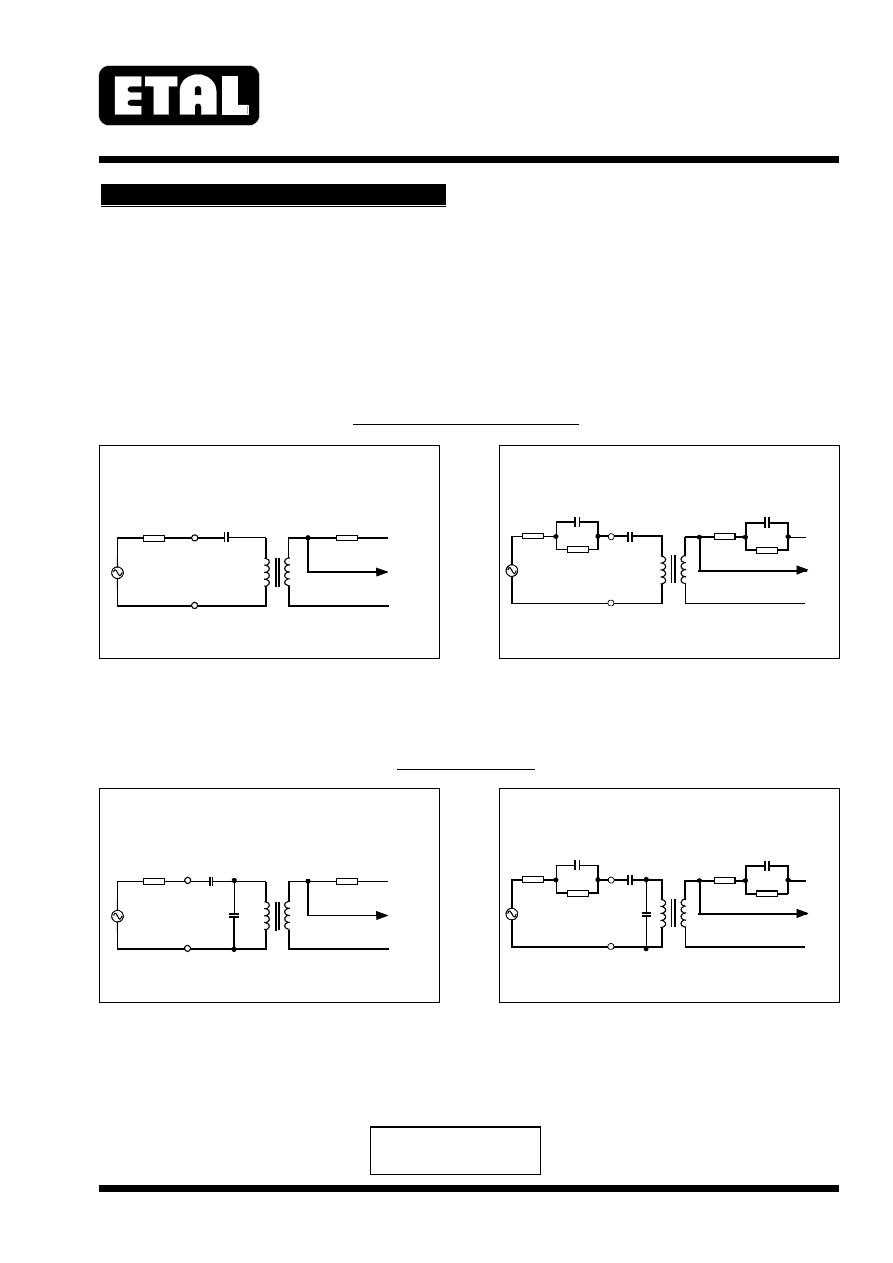

MATCHING RECOMMENDATIONS

The following recommendations start with the simplest implementations and progress to enhanced

performance utilizing additional components. Good performance is achieved even with the simplest

configurations. The implementations assume a low impedance balanced TX drive and a relatively high

impedance RX input, as is commonly available, though use with other TX/RX arrangements is

straightforward. Note that there are no changes to components on the line side, or in the hybrid, whether

600

Ω

or complex reference impedance selected, thus assisting country configuration. For complex

impedance, the matching circuits derived are suitable for reference impedances of the type 270 + 750//150nF

e.g. European CTR21 and 220 + 820//120nF (or 115nF) e.g. Australia, South Africa, etc., and yield similar

performance characteristics. For other impedances, please contact Profec Technologies.

Minimum Cost Implementations

Insertion Loss: 1.8dB @ 2kHz

Frequency Response : ±0.2dB 30Hz – 10kHz

Return Loss: 16dB 200Hz – 4kHz

Transhybrid Loss: 22dB 200Hz – 4kHz

Insertion Loss: 1.0dB @ 2kHz

Frequency Response : ±0.5dB 50Hz – 4kHz

Return Loss: 18dB 200Hz – 4kHz

Transhybrid Loss: 14dB 200Hz – 4kHz

Improved matching

Insertion Loss: 1.8dB @ 2kHz

Frequency Response : ±0.2dB 30Hz – 10kHz

Return Loss: 18dB 200Hz – 4kHz

Transhybrid Loss: 22dB 50Hz – 10kHz

Insertion Loss: 1.0dB @ 2kHz

Frequency Response : ±0.5dB 50Hz – 4kHz

Return Loss: 20dB 200Hz – 4kHz

Transhybrid Loss: 16dB 50Hz – 4kHz

600

Ω

Fig. 4

LINE

600

10nF

560

RXA

TXA2

TXA1

µ

22 F

600

Ω

Fig. 2

LINE

600

560

RXA

TXA2

TXA1

µ

22 F

10nF

LINE

270

(220)

750

(820)

µ

22 F

150nF

(120nF)

750

100nF*

*Note: 100nF capacitor should have a temperature stable dielectric

120

European CTR21/(Australia, etc.)

Fig. 5

RXA

TXA2

TXA1

LINE

270

(220)

750

(820)

150nF

(120nF)

820

100nF*

*Note: 100nF capacitor should have a temperature stable dielectric

100

European CTR21/(Australia, etc.)

Fig. 3

RXA

TXA2

TXA1

µ

22 F

Patented

line_P3356-html.html

P3356

ETALDOC 591/9

Page 4 of 6

December 2003

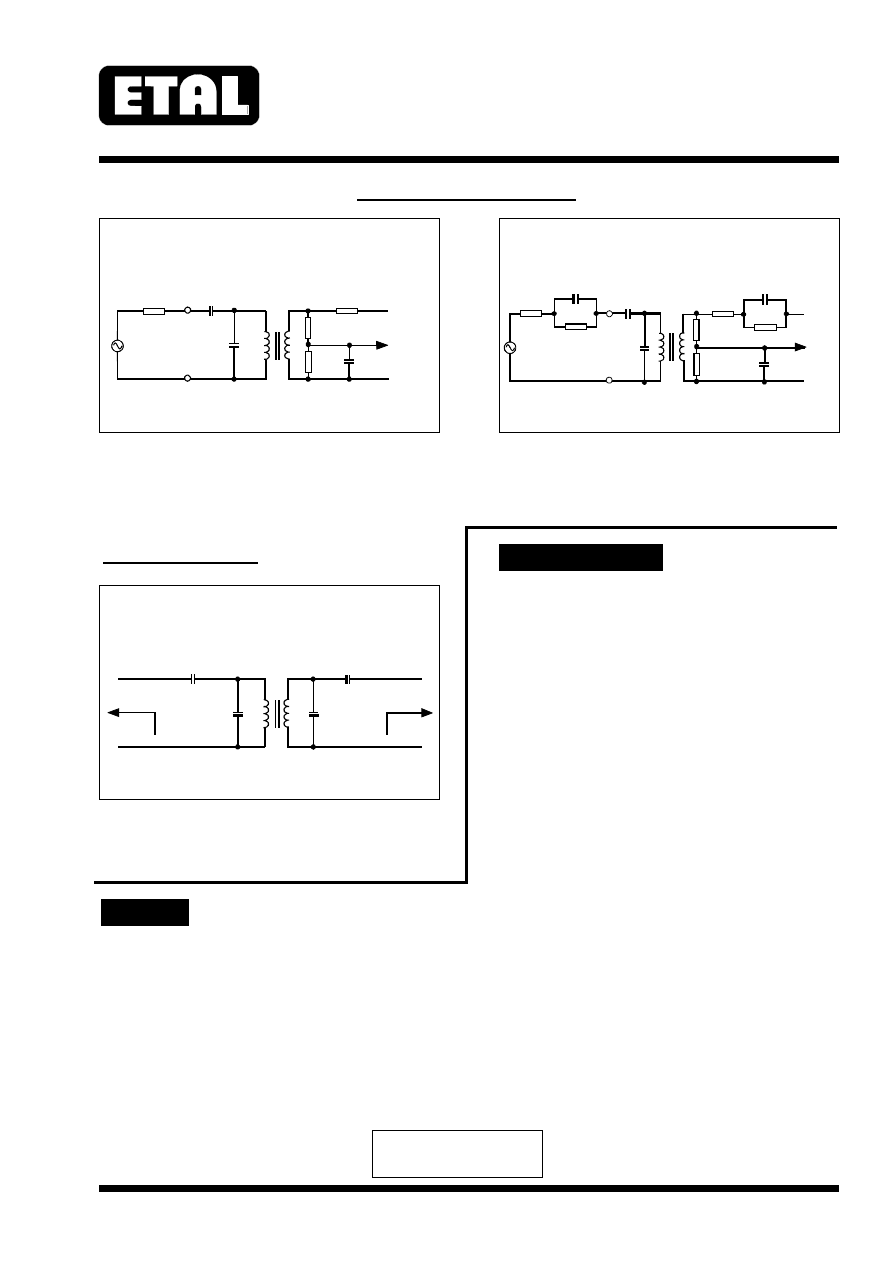

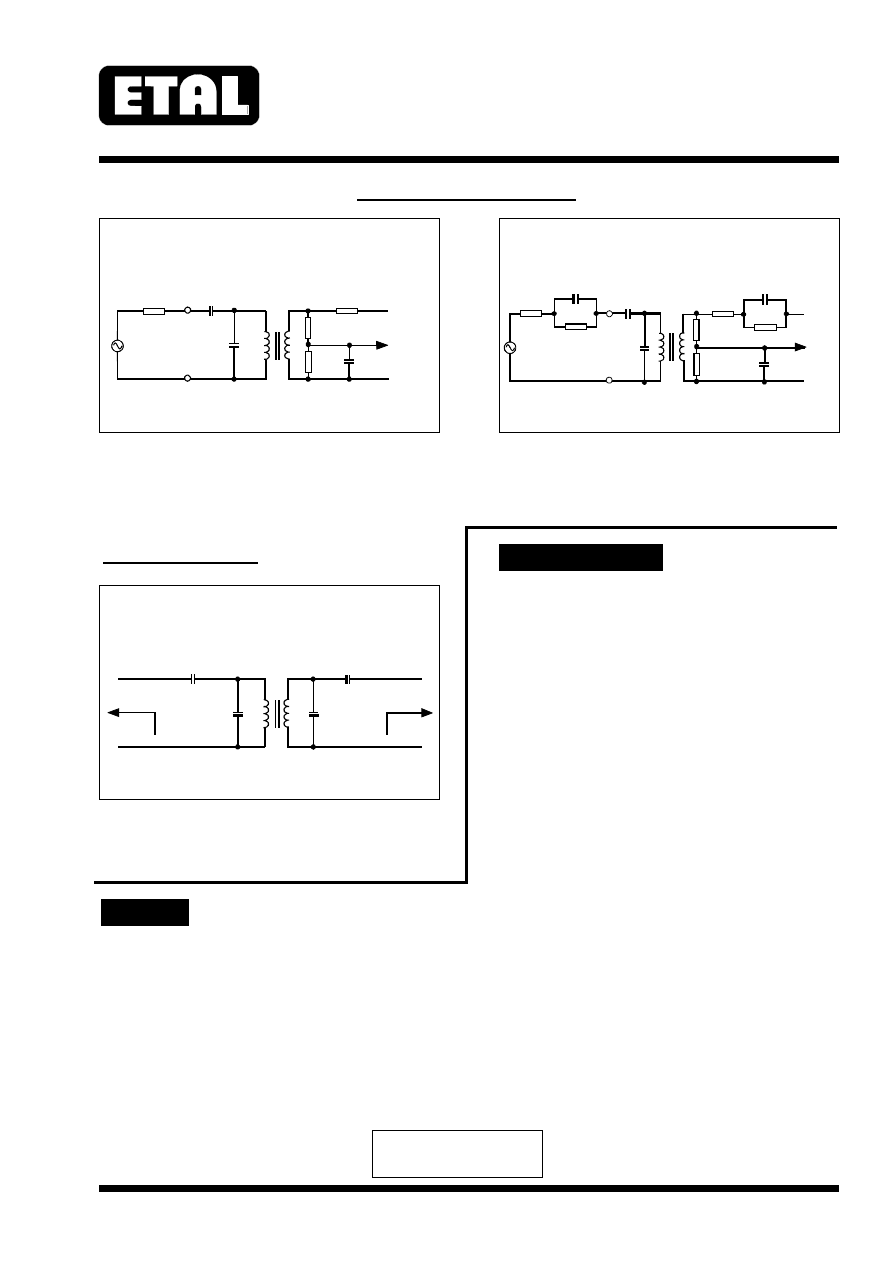

Improved matching and hybrid

Insertion Loss (Line to RXA): 2.8dB @ 2kHz

Frequency Response : ±0.2dB 30Hz – 10kHz

Return Loss: 20dB 200Hz – 4kHz

Transhybrid Loss: 30dB 50Hz – 10kHz

Insertion Loss (Line to RXA): 2.2dB @ 2kHz

Frequency Response : ±0.5dB 50Hz – 4kHz

Return Loss: 20dB 200Hz – 4kHz

Transhybrid Loss: 18dB 200Hz – 4kHz

600

Ω

Ω

Ω

Ω

Instrumentation

CERTIFICATION

Insertion Loss: 1.5dB @ 2kHz

Frequency Response : ±0.2dB 20Hz – 20kHz

Return Loss: 16dB 20Hz – 20kHz

SAFETY

Constructed in accordance with IEC

60950-1,

EN

60950-1, and UL

60950-1, supplementary

insulation, 250Vrms maximum working voltage,

flammability class V-0.

There are no special installation requirements

(beyond attending to usual PCB track separations)

since the integral cover provides supplementary

insulation from its external faces to internal core

and windings.

Certified under the IEC CB scheme (Certificate

GB445W) to IEC 950:1991, up to amendment 4,

sub-clauses 1.5, 1.5.1, 1.5.3, 2.2, 2.2.3, 2.2.4, 2.9.2,

2.9.3, 2.9.4, 4.4, 4.4.3.2 (class V-0) and 5.3 for a

maximum working voltage of 250Vrms, nominal

mains supply voltage not exceeding 300Vrms

and a maximum operating temperature of 70ºC

in Pollution Degree 2 environments.

Recognized under the Component Recognition

Program of Underwriters Laboratories Inc. to US and

Canadian requirements CAN/CSA C22.2

No. 60950-1-03/UL60950-1, First Edition, based on

IEC

60950-1, First Edition, maximum working

voltage 180Vrms (creepage), 420V peak

(clearance), Pollution Degree 2, supplementary

insulation.

UL File number E203175.

Additionally, Profec Technologies certifies all

transformers as providing voltage isolation of

2.12kVrms, 3kV DC minimum. All shipments are

supported by a certificate of conformity to current

applicable safety standards.

600

Ω

Fig. 6

LINE

600

10nF

560

1k

1nF

10k

RXA

TXA2

TXA1

µ

22 F

10nF

1nF

LINE

270

(220)

750

(820)

µ

22 F

150nF

(120nF)

750

100nF*

*Note: 100nF capacitor should have a temperature stable dielectric

120

European CTR21/(Australia, etc.)

Fig. 7

RXA

TXA2

TXA1

1k

10k

µ

µ

47 F*

µ

47 F*

600

Ω

Fig. 8

600

Ω

600

Ω

6.8nF

6.8nF

* If no DC block required, one of these capacitors can be removed and

the other set to 22 F, or, if preferred, both capacitors can be eliminated.

Patented

line_P3356-html.html

P3356

ETALDOC 591/9

Page 5 of 6

December 2003

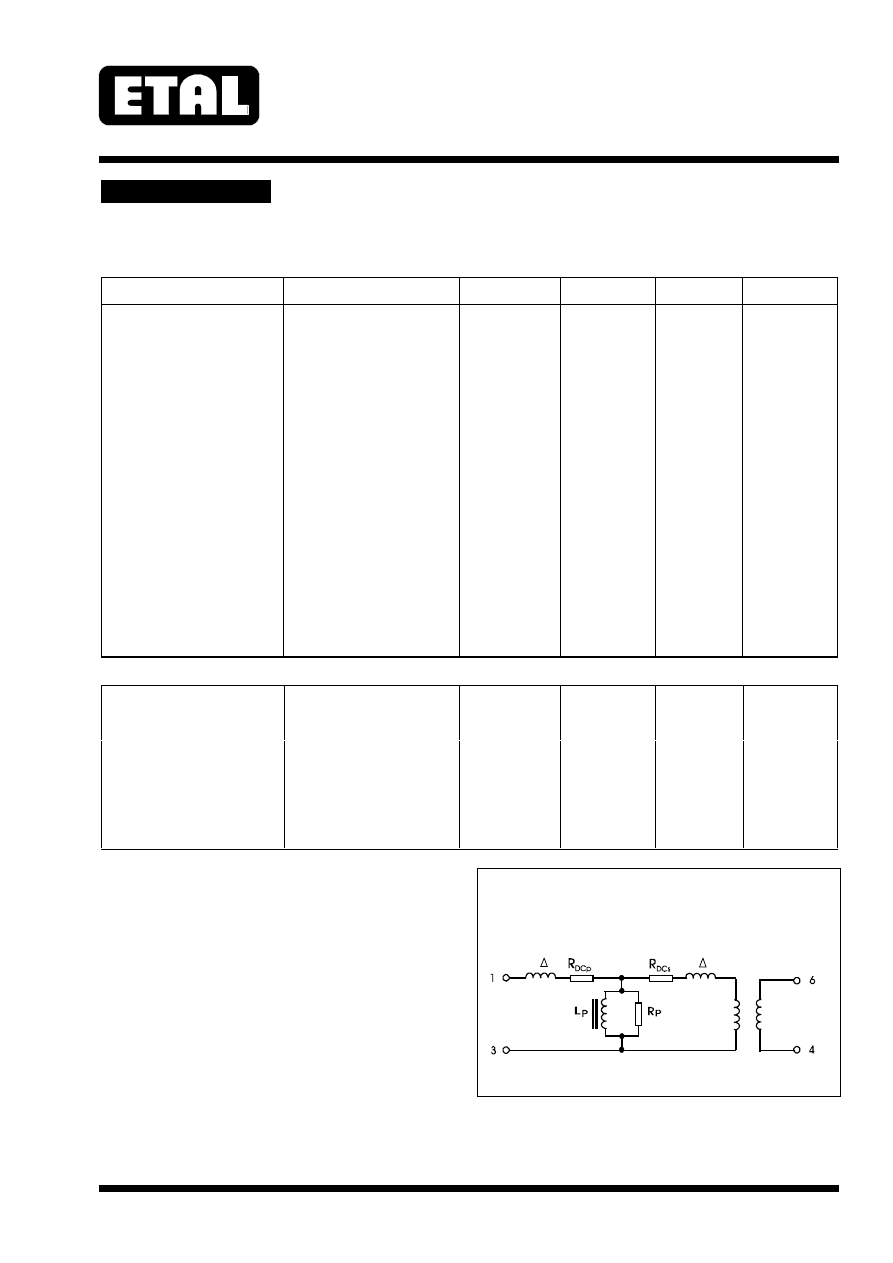

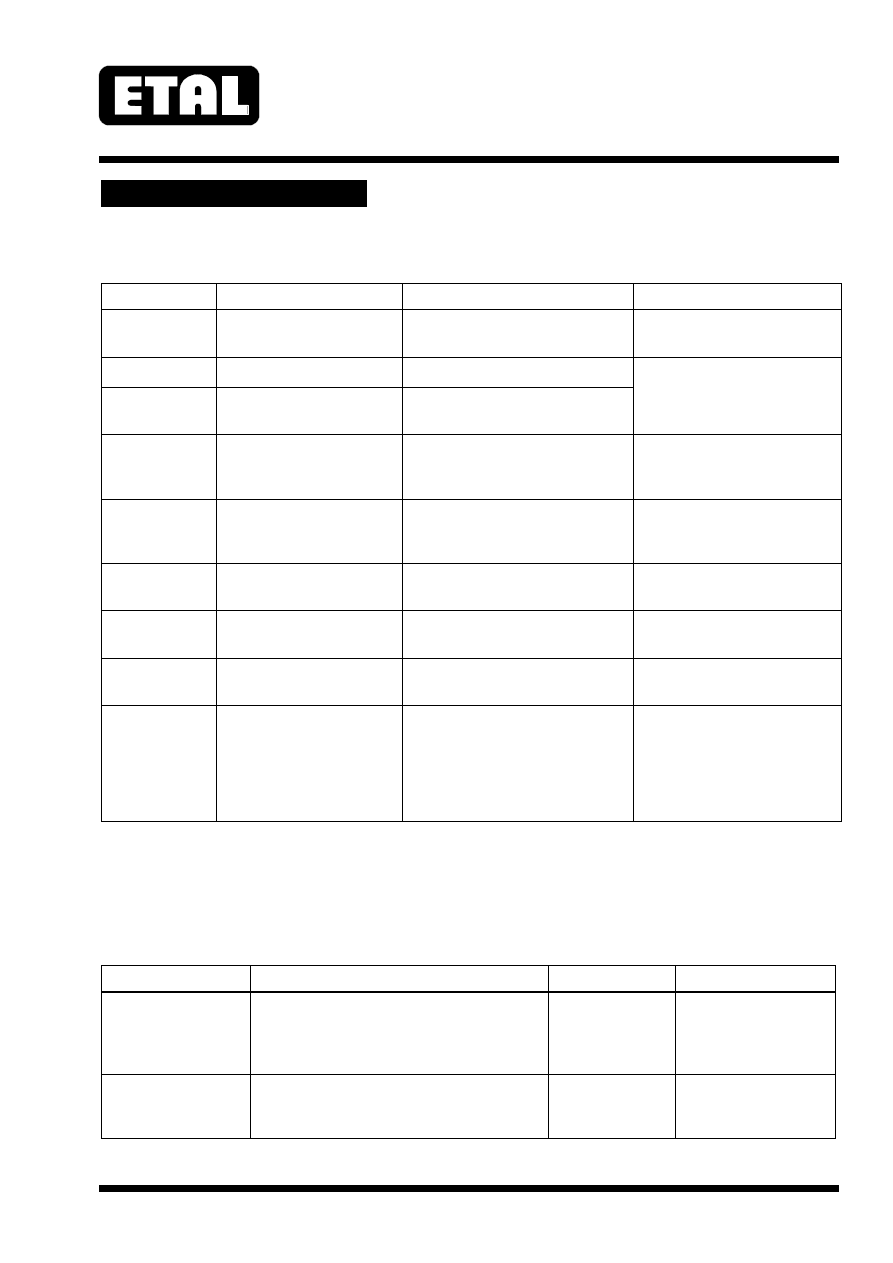

ENVIRONMENTAL TESTING

Reliability testing to IEC 68

Tested to clauses of IEC 68 and compliant with all functional and safety requirements following exposure as follows:

Test description IEC 68 reference

Test details

Result

Robustness of

terminations

68-2-21 Test Ua

1

68-2-21 Test Ua

2

Tensile 5N pull

Thrust 1N push

No impairment

No pin detachment or distortion

Solderability

68-2-20 Test Ta Method 1

Solder bath 235ºC 2s

Resistance to

soldering heat

68-2-20 Test Tb Method 1A

68-2-20 Test Tb Method 2

Solder bath 260ºC 10s

Soldering iron 350ºC 5s

No impairment

Finish smooth, bright and even

Vibration

68-2-6 Test Fc

Sweep 10-55-10Hz in 1 minute

Amplitude 1.5mm pk-pk

Duration 2h per axis, 3 axes

No impairment

Shock

68-2-27 Test Ea

Peak acceleration 1000m/s

2

Duration of pulse 6ms

3 shocks each direction on 3 axes

No impairment

Cold

68-2-1 Test Ab

-25ºC 16h

Recovery to ambient 1-2h

No impairment

Dry heat

68-2-2 Test Bb

125ºC 16h

Recovery to ambient 1-2h

No impairment

Damp heat

68-2-3 Test Ca

40ºC 4 days, RH 93%

Recovery to ambient 1-2h

No impairment

Change of

temperature

68-2-14 Test Na

T

A

–25ºC

T

B

+85ºC

t

1

30 min

2 min

≤

t

2

≤

3 min

Recovery to ambient 1-2h

5 cycles

No impairment

Combined Environmental Reliability Testing (CERT)

Components step stressed at increasing levels of severity using combined stresses to detect potential

weaknesses.

Results are shown for highest levels of stress tested. Compliant with all functional and safety tests following

exposure as follows:

Test description

Test details

Duration

Result

Storage Test

Thermal cycling -30ºC to +100ºC at

11ºC/min

6mm pk 2-9Hz at 1 octave/min

20m/s

2

9-200Hz

20 mins per

plane

No impairment

Transportation Test

Thermal cycling -65ºC to +80ºC

Random vibration 10-200Hz and

200-2000Hz at 57m/s

2

RMS

2 hours per

plane

No impairment

line_P3356-html.html

P3356

ETALDOC 591/9

Page 6 of 6

December 2003

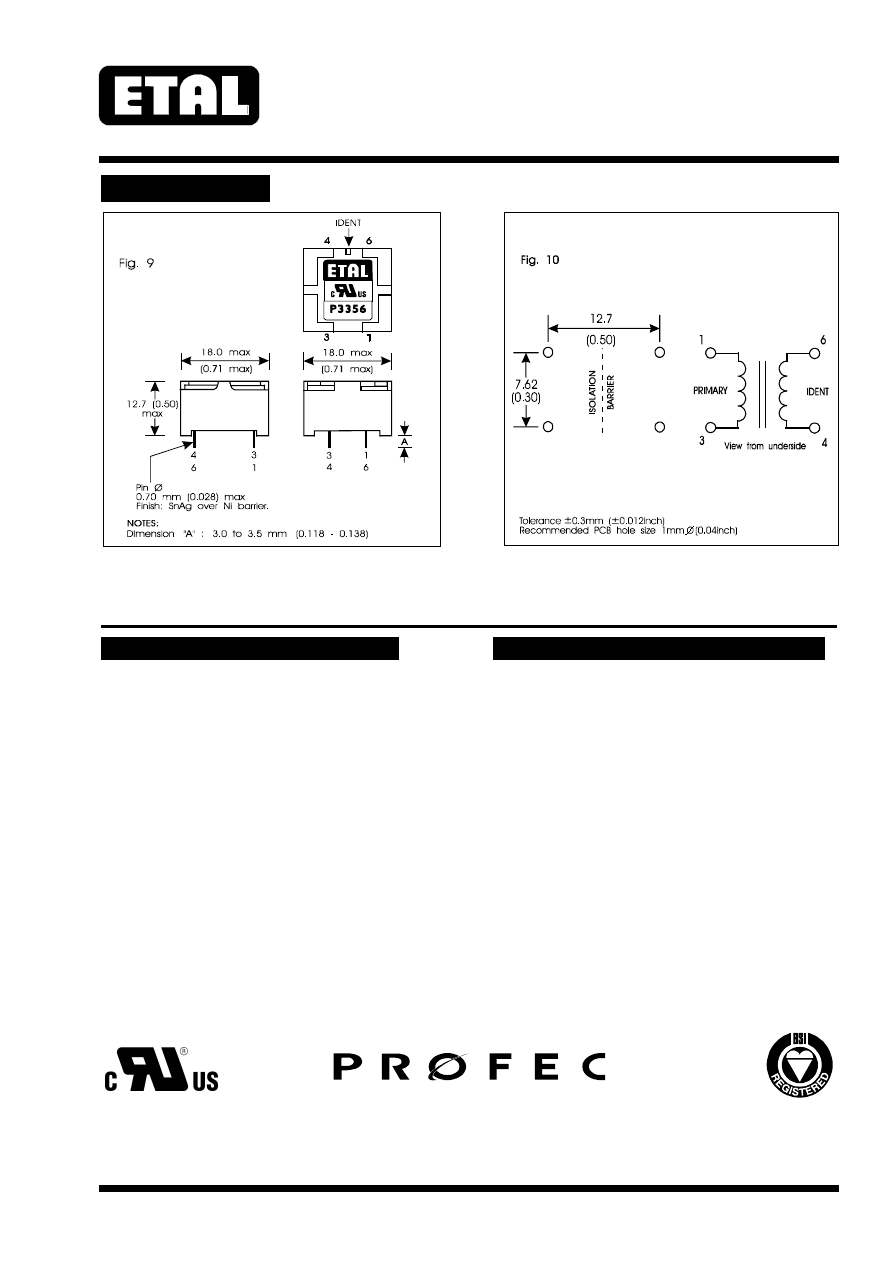

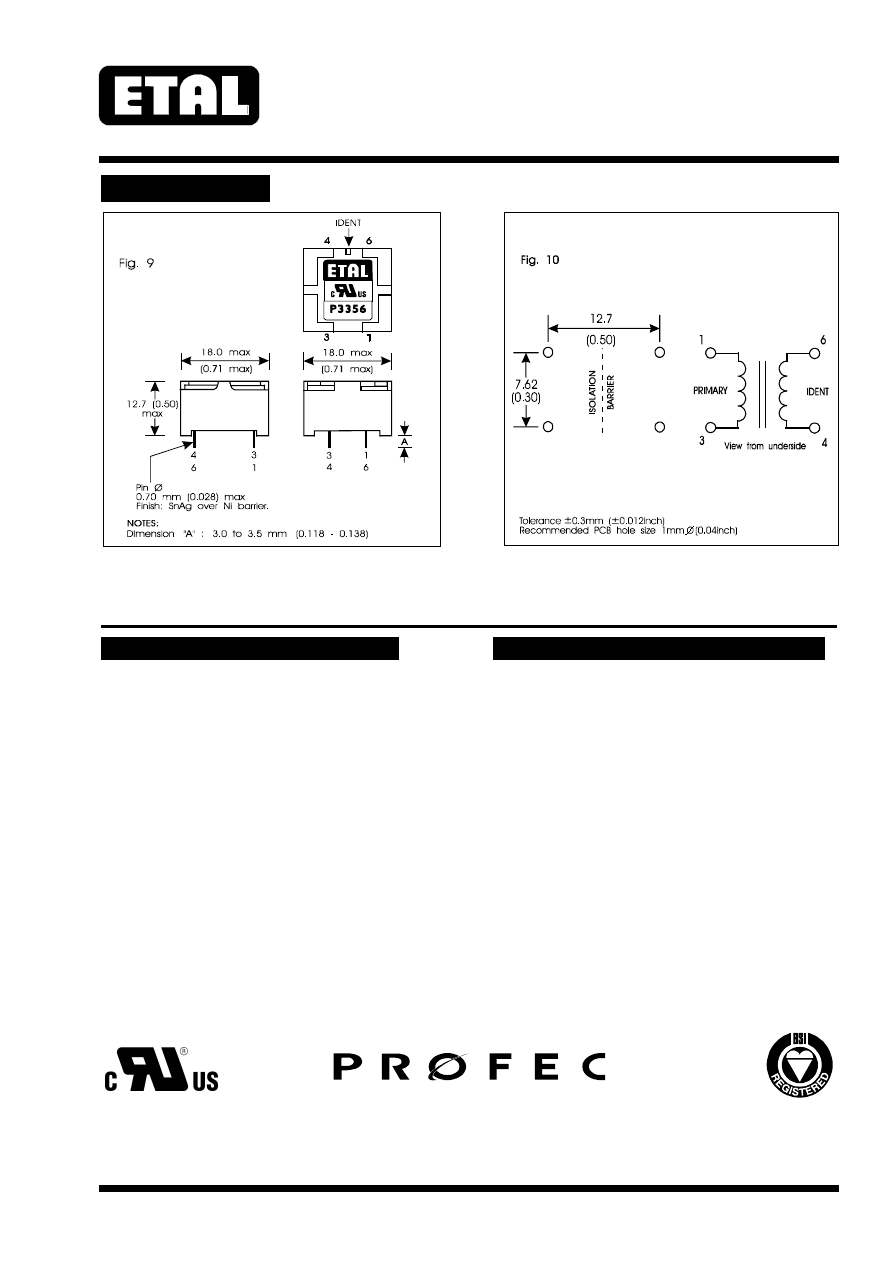

CONSTRUCTION

Dimensions shown are in millimetres (inches).

Geometric centres of outline and pin grid coincide within a tolerance circle of 0.6mmØ.

Windings may be used interchangeably as primary or secondary.

Total weight typically 6.3g.

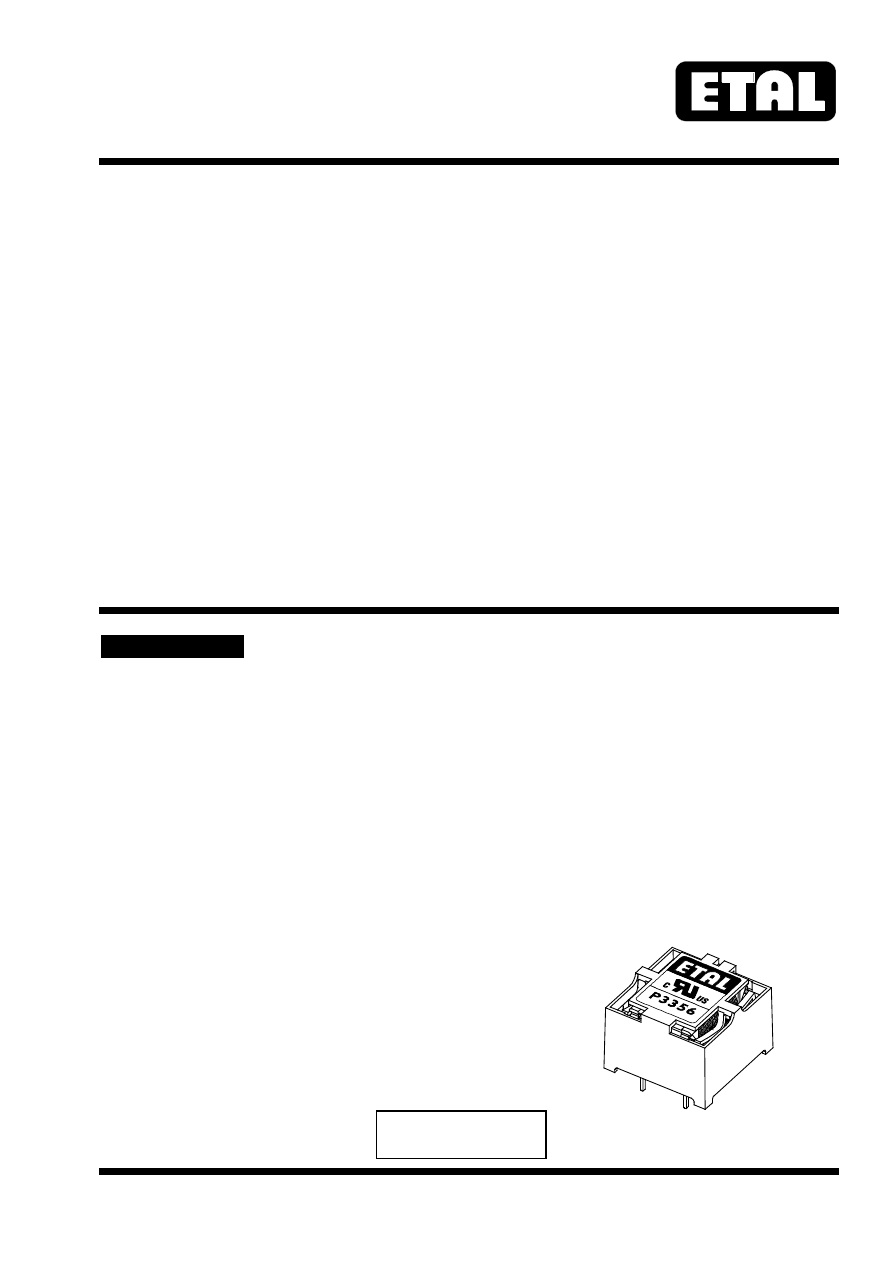

ABSOLUTE MAXIMUM RATINGS

INTELLECTUAL PROPERTY RIGHTS

(Ratings of components independent of circuit).

Short term isolation voltage (1s)

DC current

Storage temperature

Lead temperature, 10s

2.12kVrms,

3.0 kVDC

100

µ

A

-40ºC to

+85ºC

260ºC

ETAL and P3356 are Trade Marks of Profec

Technologies Ltd.

The Trade Mark ETAL is registered at the UK

Trade Marks Registry.

Profec Technologies Ltd. is the owner of the

design right under the Copyright Designs and

Patents Act 1988 and no rights or licences are

hereby granted or implied to any third party.

British Patent Nos. 2333646; 2340667.

USA Patent No. 6, 344, 787

European Patent No. 1082734

Singapore Patent No. 77763

Australia Patent No. 756952

UK Registered Design No. 2077360.

French Registered Design No. 991512.

Germany Registered Design 49902311.0.

United States Registered Design 426, 815.

Mexico Registered Design 12143

Other patents and registered designs pending.

© 1998 - 2003 Profec Technologies Ltd.

Reproduction prohibited.

T R A N S F O R M I N G T H E F U T U R E

Profec Technologies Ltd., 10 Betts Avenue, Martlesham Heath, Ipswich, IP5 3RH, England

Telephone: +44 (0) 1473 611422

Fax: +44 (0) 1473 611919

Website: www.profec.com

Email: info@profec.co.uk sales@profec.com

Connections

Dimensions

FM 25326

ISO 9001

E203175