Components Corporation | ComponentsCorp.com

DIGI-KLIP DRP Series Dual Readout

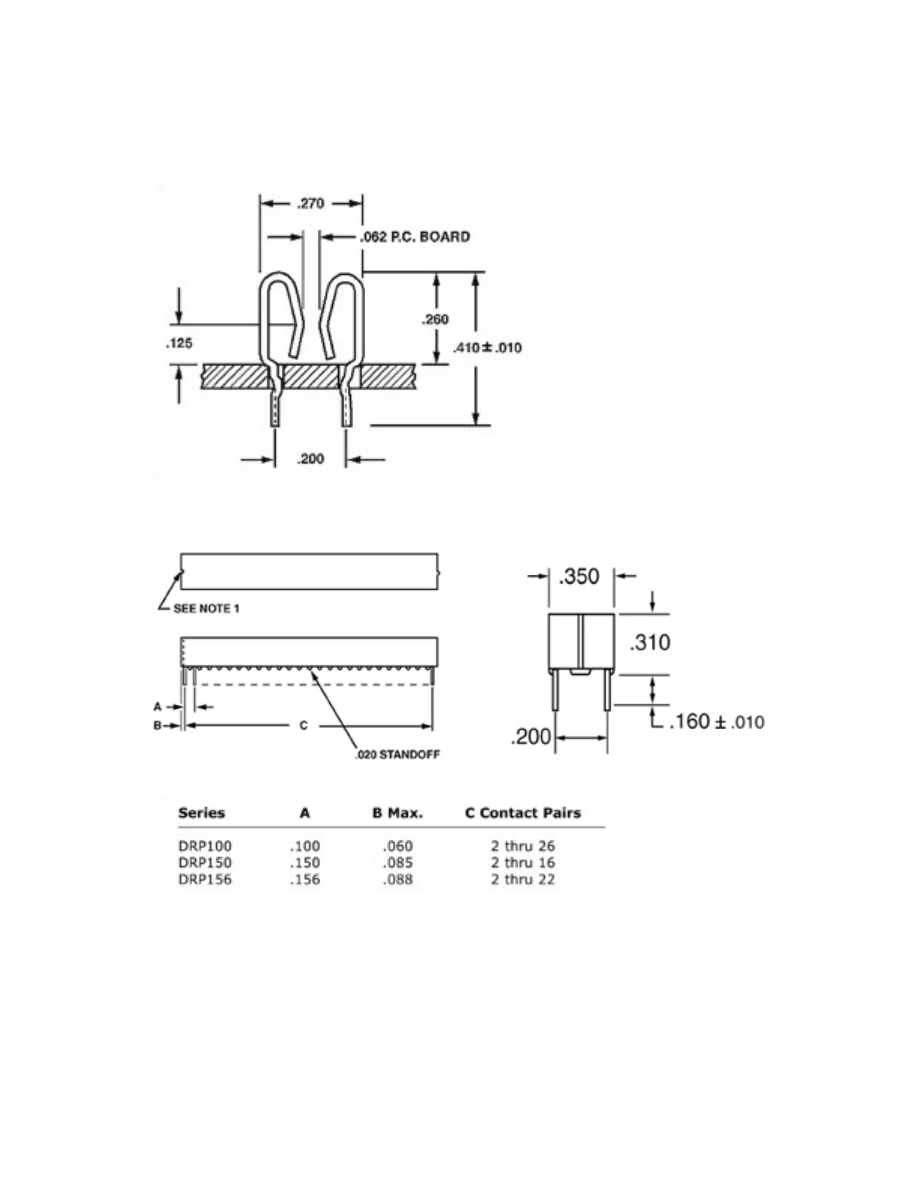

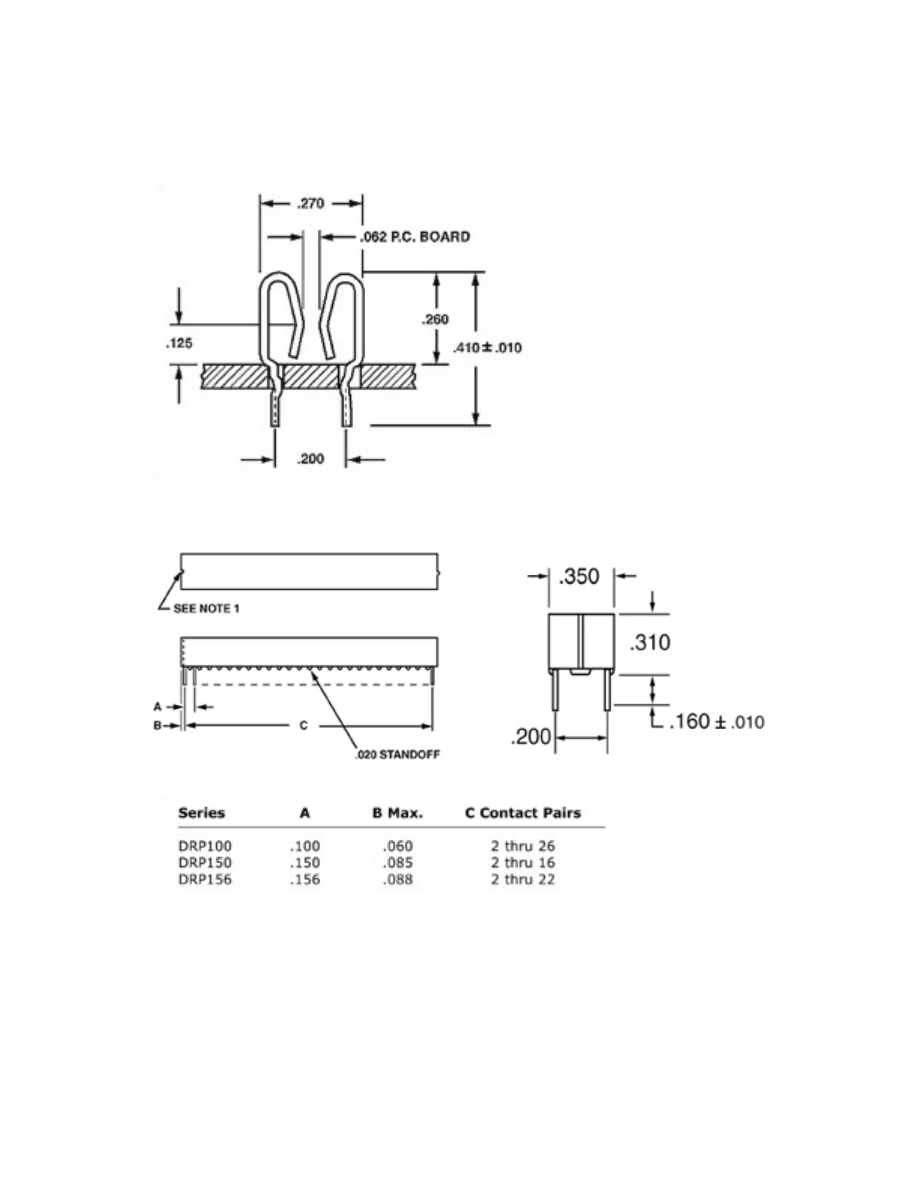

Dual Readout, .200" Row Spacing for .062 PC Board

Specifications

- DRP100: .100" x .200", 26 contact pairs per carrier maximum

- DRP150: .150" x .200", 16 contact pairs per carrier maximum

- DRP156: .156" x .200", 22 contact pairs per carrier maximum

Materials:

Contact Material:

.0201" diameter beryllium copper wire, heat treated after

forming

Mechanical:

Module Board Thickness:

.062" +/- .007"

Carrier Strip Material:

Glass filled polyester, disposable, available in any

combination from two contact pairs to maximum carrier length. Multiple carriers

may be mounted in tandem to achieve any contact configuration.

Insert/Withdrawal Life:

Greater than 5000 cycles without increase in contact

resistance or reduction in contact pressure.

Contact Normal Force:

4.0 oz., typical per contact with .062" nominal PC board

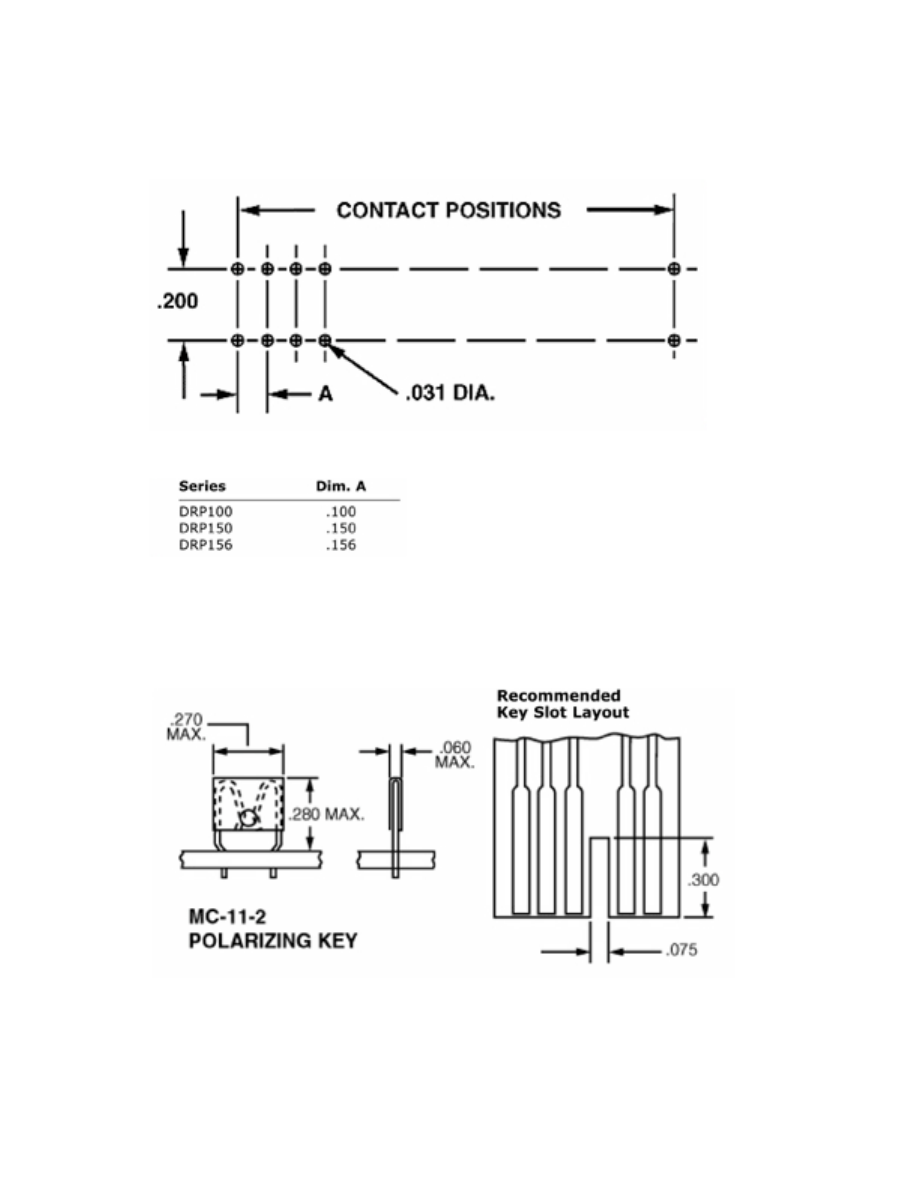

Mounting Holes:

.031" diameter, plated-through

Electrical:

Contact Resistance:

Less than .005 ohm per contact

Maximum Current:

3.0 amperes per contact

Components Corporation | ComponentsCorp.com

DRP Contacts

DRP Carrier Strip

Components Corporation | ComponentsCorp.com

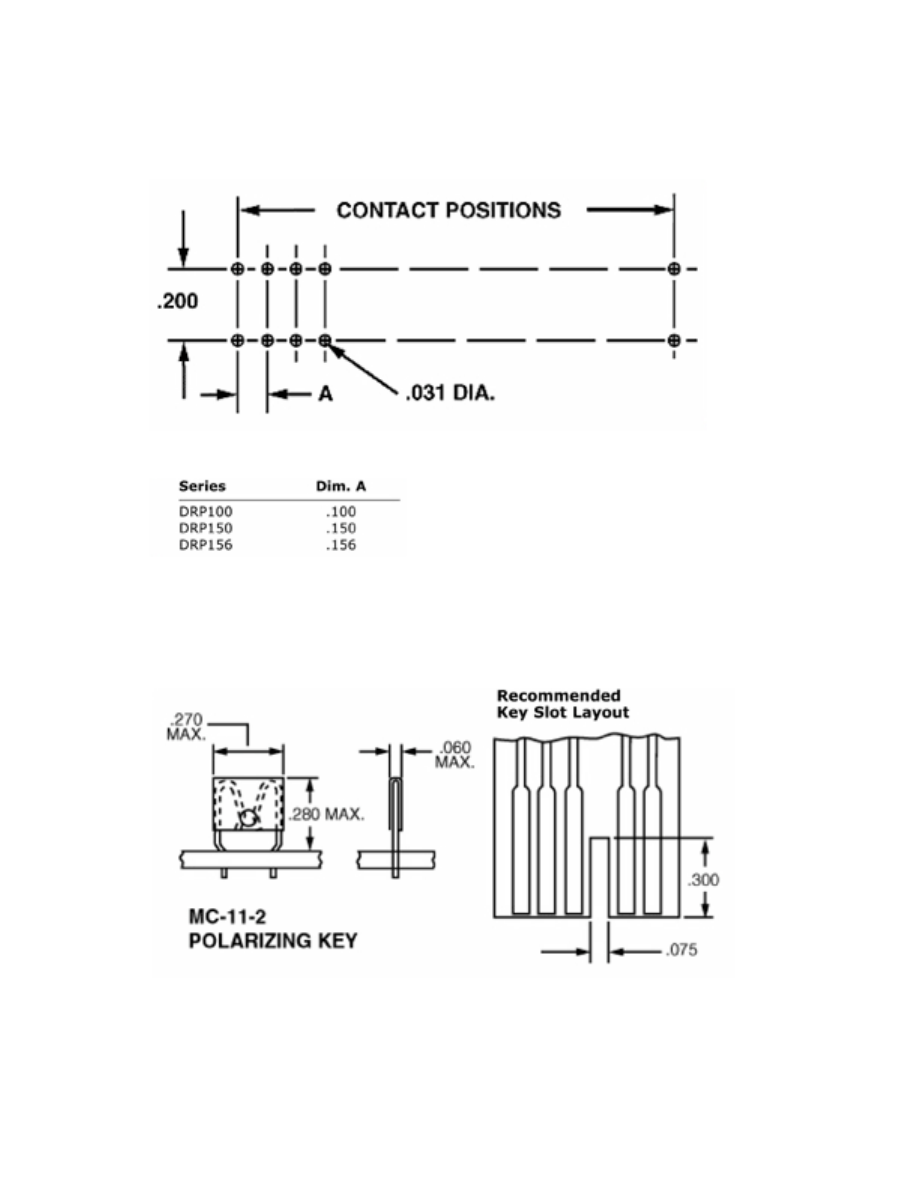

DRP Board Layout

DRP Accessories

Components Corporation | ComponentsCorp.com

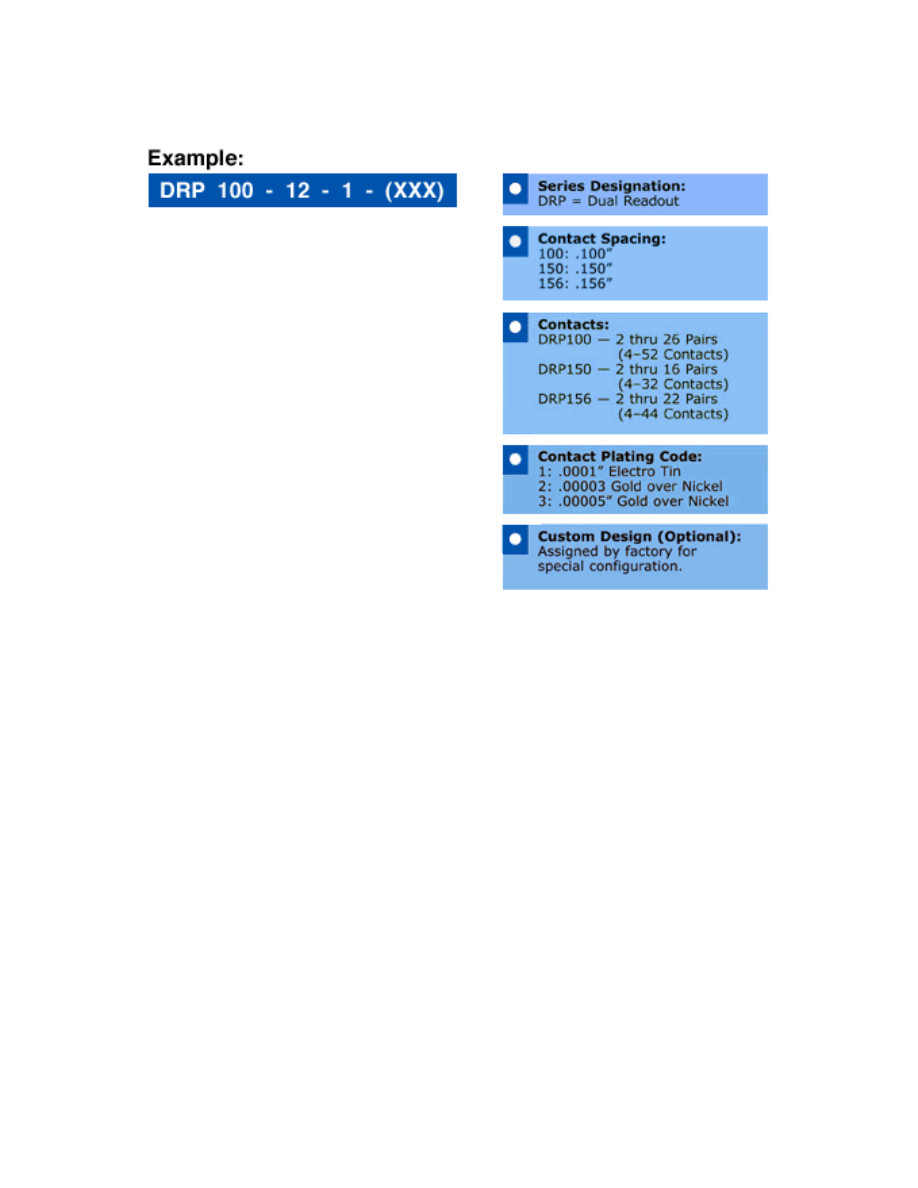

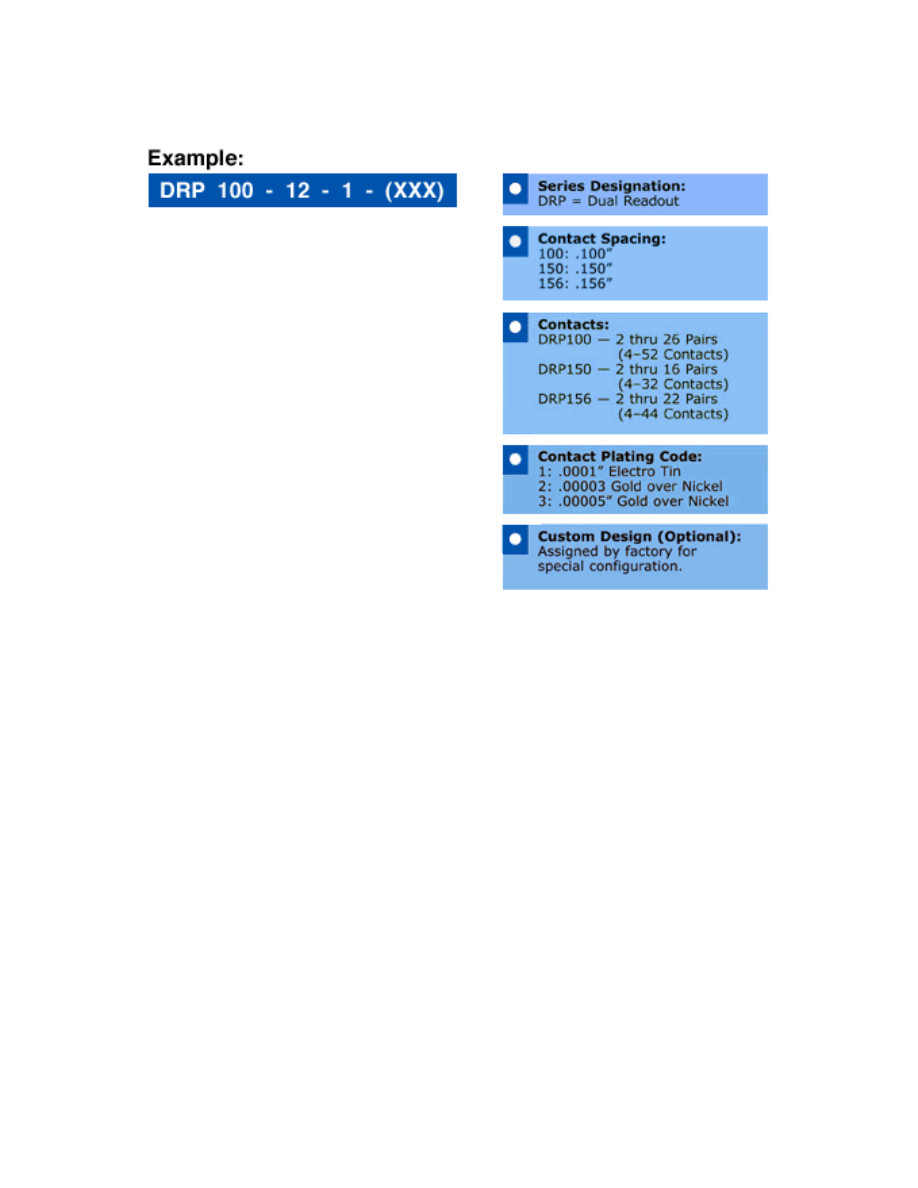

Ordering Information

Product Description

System Description:

The DIGI-KLIP® DRP series of dual readout, free-standing

card edge connectors represents a major advancement in packaging technology

for the reliable mating of printed circuit boards. At the heart of the DRP design is

Components Corporation's proven wire form contact principle, a patented contact

system successfully applied in single readout formats since 1962.

Contact Principle:

The premise is simple: to provide long term and reliable

contact in demanding applications, a card edge contact must be a good spring.

The connector must exhibit no reduction in pressure over years of mated service,

and it must provide a "wiping action." The DRP series contact, successor to the

patented single readout DIGI-KLIP, is manufactured from the highest grade

beryllium copper alloy wire which is heat treated for optimum spring temper after

forming. Because of this design and process, the resulting contact provides a

true wiping action point contact with exceptionally high unit force. This allows for

a "gas tight" mating junction, eliminating the need for precious metal plating in

most applications. Consistent contact normal forces are insured, regardless of

time or multiple insertion/withdrawal cycles.

Components Corporation | ComponentsCorp.com

Design Flexibility:

The DRP series is supplied in disposable, molded carrier

strips to facilitate mounting and positioning during soldering operations. Any

combination of contact pairs may be applied in .100", .150" or .156" increments;

row spacing grid is the popular .200" for all types. Contact pair deletions may be

specified without cost premium. The carrier strips are removed after soldering

and discarded or returned for credit and re-use.

Space Savings:

The DRP presents the lowest profile of any card edge

connector system available today. Total slot depth is .260" and module board

"fingers" may be as short as .130". Overall contact pair width is a mere .270" and

.350" with carrier in place.

Cost Savings:

Since the DIGI-KLIP design is made from a wire form, there is

virtually no scrap material reflected in the cost of the contact. The exclusive, "gas

tight" point contact eliminates the need for precious metal plating on the

connector and the circuit board tab. The versatility of the DRP carrier strip

mounting system, with its unlimited combination of contact pairs, allows the

designer the flexibility to apply only the exact number of terminations necessary;

there is no need to specify a "standard" contact configuration which often results

in unused termination positions.

Industry Compatibility:

The DIGI-KLIP DRP series conforms to the popular

.200" row spacing grid. This standardization allows the designer the confidence

to apply the unique advantages of the DRP series without the concern over sole

sourcing, and many existing products may be re-designed to incorporate this

superior contact system with minimal re-tooling.

Certificate of Compliance with Directive 2002/95/EC RoHS and REACH

Regulations EC 1907/2006

This is to certify that Components Corporation designs, manufactures and

supplies products to our customers that are in compliance with RoHS Directive

2002/95/EC and REACH Regulations EC 1907/2006. This also pertains to

procurement of raw material, component parts and processes.