Thermal motor protector

Temperature limiter

Thermal cut-out

Applications

- Motors

- Transformers

- Coils

- Electronics, sensors

Benefits

- Small dimensions

- Shock and vibration tested

- Leadframe version

- Various kinds of insulations

13

20

23

Thermal motor protector

Temperature limiter

Thermal cut-out

Applications

- Motors

- Transformers

- Coils

- Electronics, sensors

Benefits

- Small dimensions

- Shock and vibration tested

- Leadframe version

- Various kinds of insulations

13

20

23

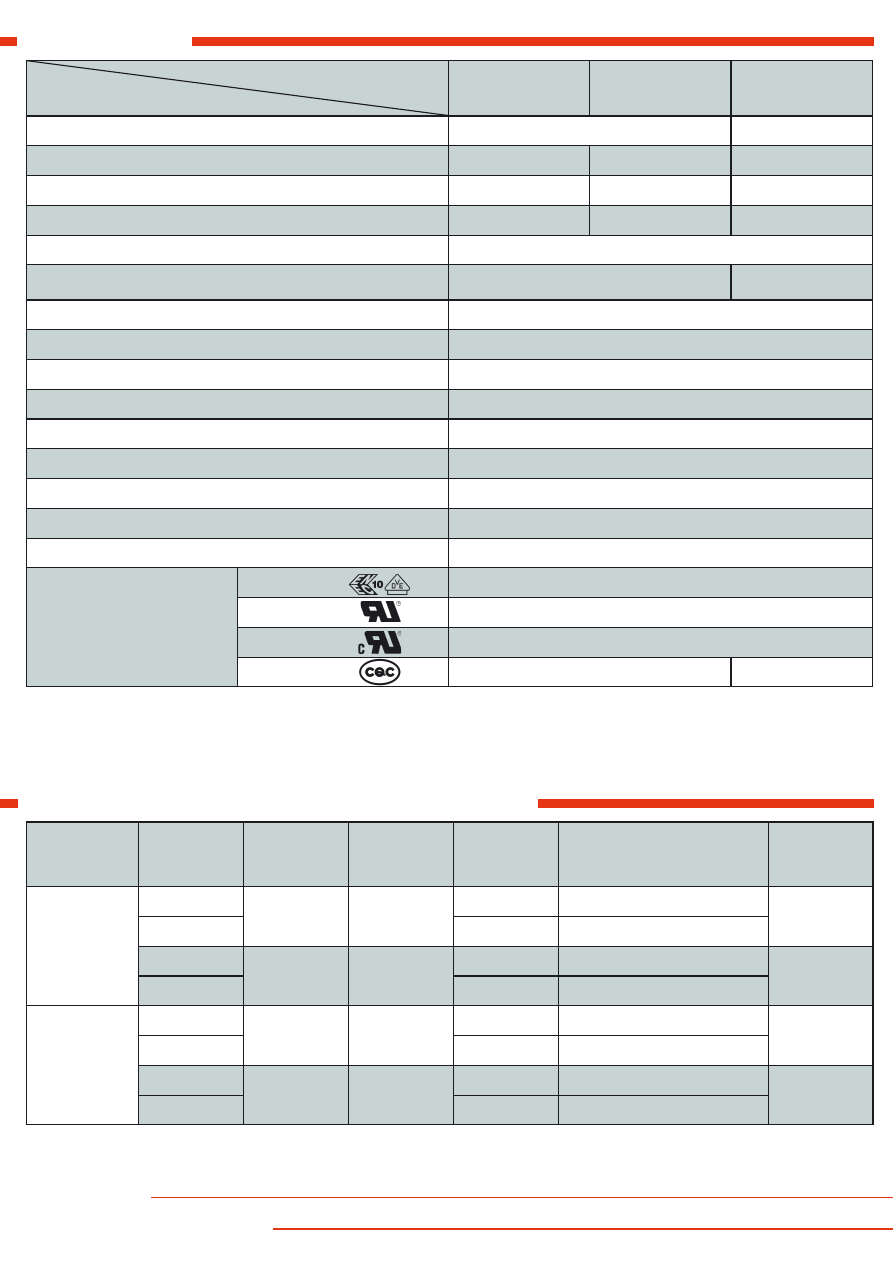

Technical data

Standard wire

( length 100 ± 10 mm, stripped 6 ± 1 mm )

control type

ratings

F13A

F23A / E

F20B / G

version

normally closed

normally open

rated current at 250 V 50/60 Hz ( power factor 0.95 / 0.6 )

3.0 A / 2.5 A

3.0 A / 3.0 A

2.0 A / 1.6 A

switching cycles under rated current

10,000

10,000

7,000

max. current under failure condition at 250 V 50/60 Hz ( power factor 0.95 )

4.0 A

6.0 A

4.0 A

switching cycles under max. current

3,000

temperature rating T

a

( steps in 5 K )

70°C ... 190°C /

... 160°C CQC

70°C ... 185°C

tolerances

standard: ± 5 K

feature of automatic action

2.C, 1.C

contact resistance ( incl. wire of 100 mm )

< 50 mΩ

hysteresis

30 K ± 15 K

2)

dielectric strength ( standard insulation )

2 kV

shock / vibration testing ( similar to EN 50155 )

400 m/s

2

sine half wave / 100 m/s

2

5 Hz ... 2,000 Hz sine

resistances to impregnation

tight against ordinary resins and lacquers

degrees of protection provided by enclosures ( EN 60529 )

IP00

suitable for use in protection category

I, II

approvals

VDE / ENEC

EN 60730-1 / -2-9

UL

UL 2111 / UL 873

1)

cUL

C22.2 No. 77 / C22.2 No. 24

1)

CQC

GB14536.1-2008 / GB14536.10-2008

3)

-

lead

code

temperature

max.

operating

voltage

max.

approx.

diameter

insulation

approx. cross section

diameter

1)

UL

style

stranded

white

L300

150 °C

300 V

1.50 mm

AWG24 / 0.25 mm

2

3398

L310

1.82 mm

AWG20 / 0.50 mm

2

L360

200 °C

600 V

1.20 mm

AWG24 / 0.25 mm

2

10086

L370

1.60 mm

AWG20 / 0.50 mm

2

solid

yellow

L400

150 °C

300 V

1.35 mm

AWG24 / 0.50 mm

3398

L410

1.66 mm

AWG20 / 0.80 mm

L430

200 °C

300 V

1.16 mm

AWG24 / 0.50 mm

1332

L440

1.54 mm

AWG20 / 0.80 mm

1)

AWG24 is recommended

1)

on request

2)

at the T

a

(upper and lower) limits the hysteresis could deviate

3)

different power rating

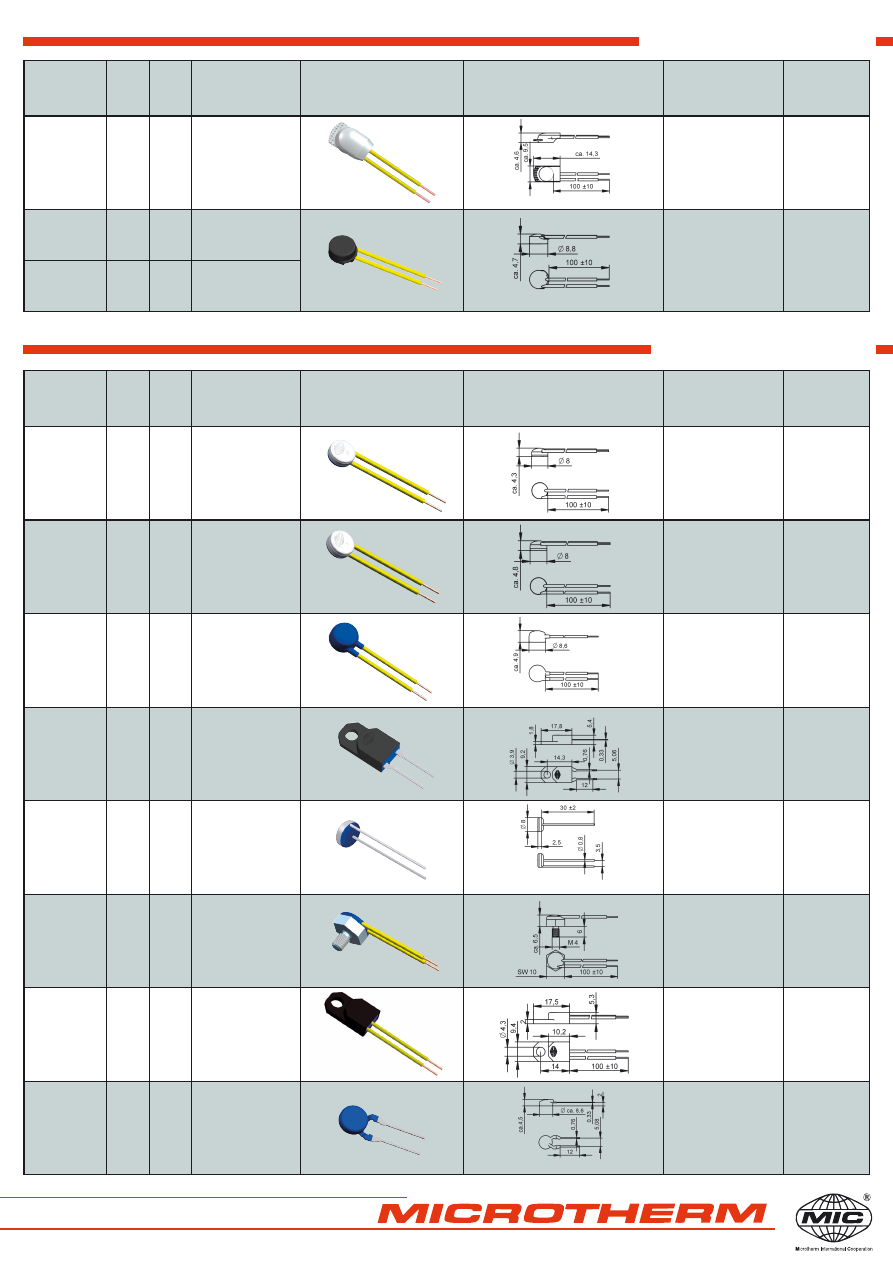

Specific variations

Standard insulation

control

type

nc

normally

closed

no

normally

open

code

illustration

drawing

dimensions ( mm )

technical

specification

approvals

F13

A

not insulated

potted

VDE, UL

cUL

F20

F23

A

B

not insulated

potted

VDE, UL,

cUL

F13

F20

F23

A

A

B

U112

different dimensions for F20, F23

coated

T

a

max. 160 °C

VDE, UL

cUL

F20

F23

A

B

A150 U280

housing of PPS

leadframe leads

grid dimension 5.08

potted

VDE, UL,

cUL

F13

F20

F23

A

A

B

A800

different dimensions for F20, F23

not insulated

potted

VDE, UL

cUL

F20

F23

E

G

G700

alluminium housing

thread M4x6

potted

T

a

max. 150 °C

VDE, UL,

cUL

F13

A

U282

housing of PPS

potted

VDE, UL

cUL

F13

F20

F23

A

A

B

A150 U112

different dimensions for F20, F23

leadframe leads

grid dimension 5.08

coated

T

a

max. 160 °C

VDE, UL,

cUL

control

type

nc

normally

closed

no

normally

open

code

illustration

drawing

dimensions ( mm )

technical

specification

approvals

F13

F20

F23

A

A

B

U254

different dimensions for F20, F23

shrink cap

potted

VDE, UL,

cUL

F13

A

U198

different dimensions for F20, F23

cap of PPS

potted

VDE, UL,

cUL

F20

F23

A

B

U185

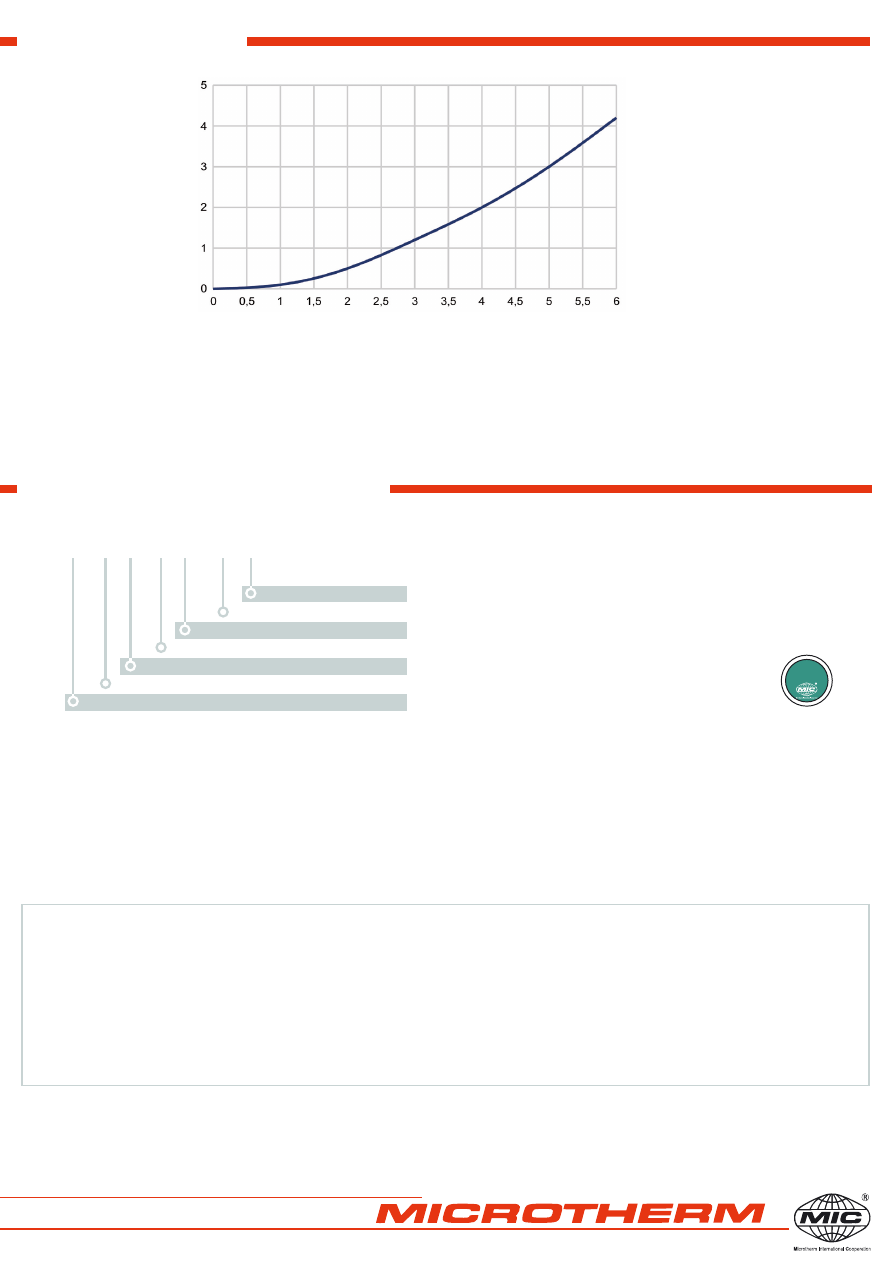

Heating by current

Fon: +49 (0)7231 787-0

Fax : +49 (0)7231 787-155

E-Mail: info@microtherm.de

Internet: www.microtherm.de

Microtherm GmbH

Täschenwaldstraße 3

Postfach 1208

D-75112 Pforzheim

The characteristic curve in the diagram is measured with a thermal control without any insulation in an oil bath.

Attention:

The heating depends on the thermal conduction of the control to the equipment or part which should be

protected.

Ordering example

Marking

shrink cap insulation

length 100 mm

lead wire white, AWG24

tolerance

temperatue

normally closed

type

F13A

type (F13 nc)

12005

response temperature (120°C), tolerance (± 5K)

025D

date of manufacture (February 2015), country (D=Germany)

F13 A 120 05 L300 100 U254

Representation office:

Deviations from standard controls on request.

010.2015 HB Technical subject to change without notice

RoHS

compliant

product

current [A]

self-heating [K]

Ordering and marking example